Page 1

FORM NO. 3326–335

Parking Brake Kit

Proline Mid–Size Hydro Mowers

Part No. 105–0898

Safety

To comply with ANSI B71.4 1999 Standard, this

parking brake kit must be added to this machine.

Note: The addition of attachments made by

other manufacturers that do not meet

American National Standards Institute

certification will cause noncompliance

of this machine.

Loose Parts

Note: Use the chart below to identify parts for assembly.

INSTALLATION

INSTRUCTIONS

Safe Operation

• Be sure all drives are in neutral and parking brake is

engaged before starting engine.

• Stop on level ground, disengage drives, engage

parking brake, shut off engine before leaving the

operator ’s position for any reason including emptying

the catchers or unclogging the chute.

• Check brake operation frequently. Adjust and service

as required.

DESCRIPTION QTY. USE

Grip

Handle

Upper bracket

Bushing

Bolt, 3/8 x 2.50 in.

Washer, 7/16 in.

Lock Nut, 3/8 in.

Bracket Assembly

Bolt, 5/16 x 3–1/4 in., T–bar machines only

Lock Nut, 5/16 in.

Bolt, 1/4 x 7/8 in.

Lock Nut, 1/4 in.

Bolt, 5/16 x 7/8 in., Pistol grip machines only

1

1

1

1

1

2

1

1

1

1

1

1

1

Assemble handle and bracket

Installing Upper Bracket

The Toro Company – 2001

Printed in USA

All Rights Reserved

Page 2

Installation Instructions

DESCRIPTION USEQTY.

Brake Assembly

Bolt, 3/8 x 1–1/4 in.

Lock Nut, 3/8 in.

Bolt, 3/8 x 1–3/4 in.

Jam Nut, 3/8 in.

Flange Nut, 5/16 in.

Bolt, 5/16 x 1–1/4 in.

Spring

Flange Nut, 3/8 in.

Brake Rod

Clevis Pin

Hair pin cotter

Yoke

Cotter Pin

Kit Installation

1

3

3

1

1

2

1

1

1

1

1

1

1

1

Installing Brake Assembly

Installing Brake Rod

3

4

1

2

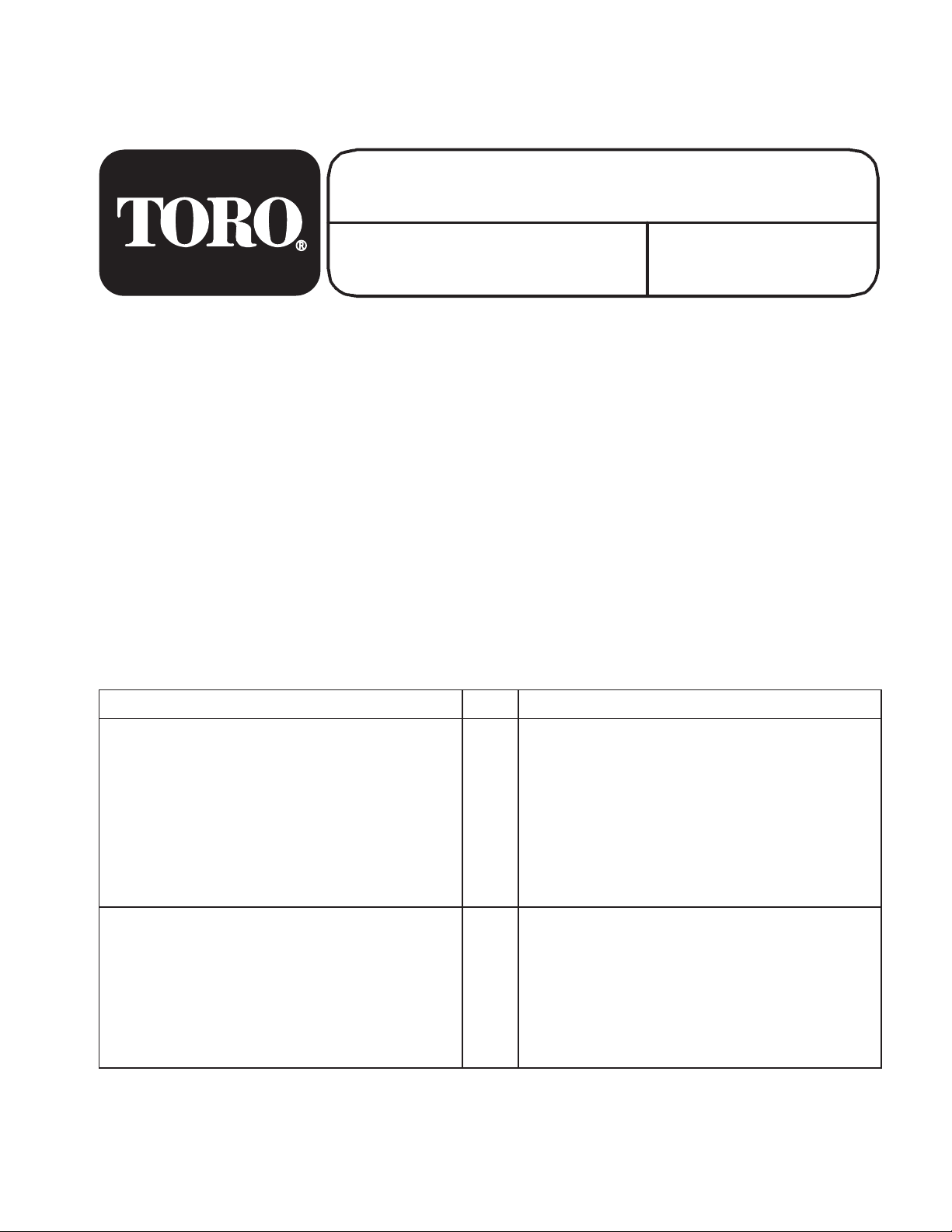

Remove Bolts

1. Remove long bolt from the rightside bracket as

shown in figure 1. Discard this bolt and nut.

2. Remove the one short bolt that holds the bearing

to the bracket as shown in figure 1. Discard this

bolt and nut.

Note: Save the spacer used on T–bar

machines.

m–5452

Figure 1

1. Long bolt

2. Short bolt

3. Nut

4. Rightside bracket

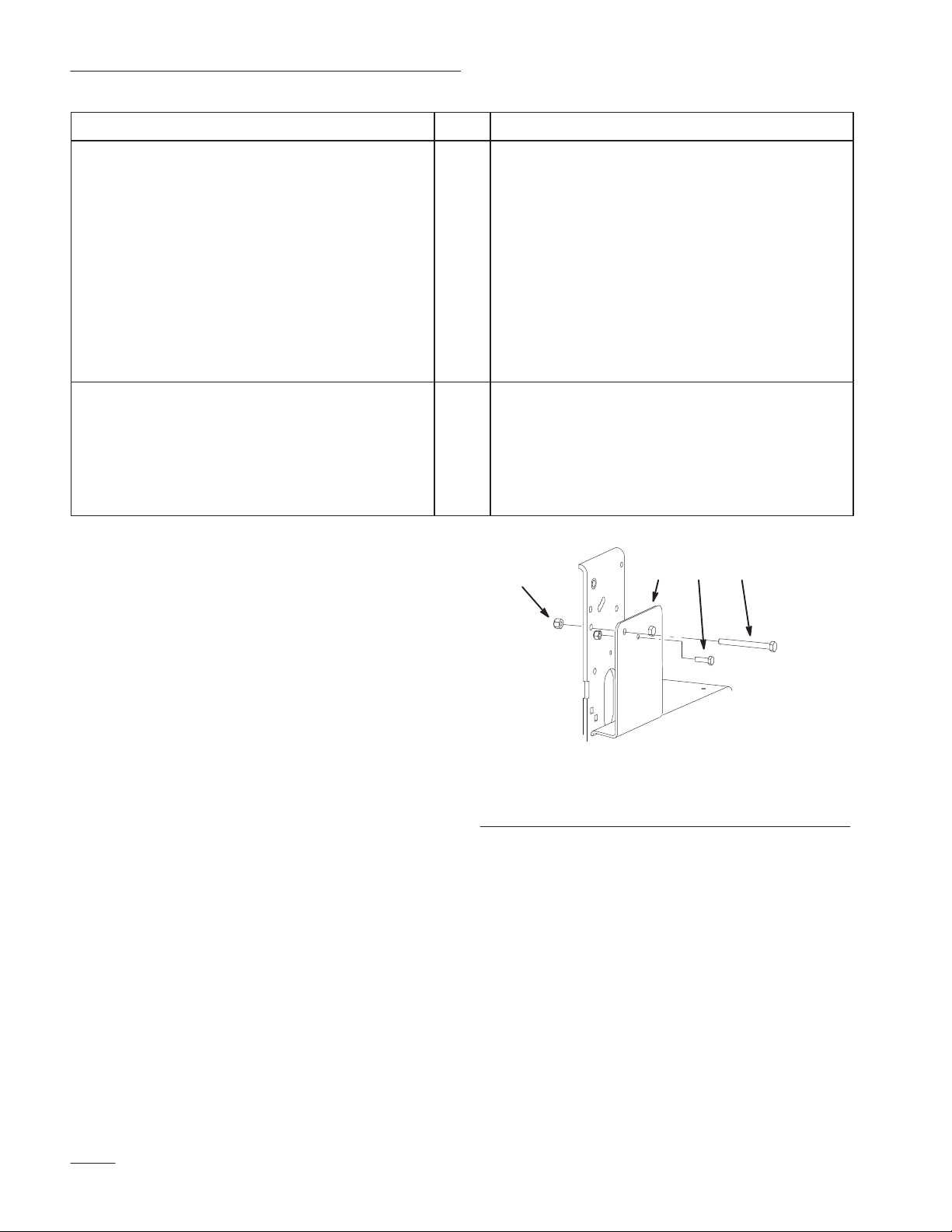

Assemble Handle and Bracket

1. Install grip onto handle (Fig. 2).

2. Install bushing into the upper bracket (Fig. 2).

3. Install the handle to bracket with a bolt

(3/8 x 2.50 in.), 2 washers (7/16 in.) and a

locknut (3/8 in.) (Fig. 2).

2

Page 3

Installation Instructions

1

65

1

6245

7

3

4 3

m–5448

Figure 2

1. Upper bracket

2. Bushing

3. Bolt, 3/8 x 2–1/2 in.

4. Washer, 7/16 in.

5. Locknut. 3/8 in.

6. Handle

7. Grip

Install Upper Bracket

IMPORTANT: Use the correct bolt in step 1

according to the style of machine you have.

Use a 5/16 x 7/8 in. bolt for a pistol grip

machine.

Use a 5/16 x 3–1/4 in. bolt for a T–bar

machine.

1. Install upper bracket to the machine frame with a

bolt (5/16 x 3–1/4 in. or 5/16 x 7/8 in.) and

locknut (Fig. 3). Install spacer on T–bar units.

2. Install upper bracket to the side plate and bearing

with a bolt (5/16 x 7/8 in.) and locknut (Fig. 3).

7

24

8

m–5450

Figure 3

1. Bracket assembly

2. Bolt, 5/16 x 3–1/4 in., for

T–bar

3. Locknut. 5/16 in.

4. Bolt, 1/4 x 7/8 in.

5. Machine frame

6. Side plate

7. Locknut. 1/4 in.

8. Bolt, 5/16 x 7/8 in., for

Pistol grip

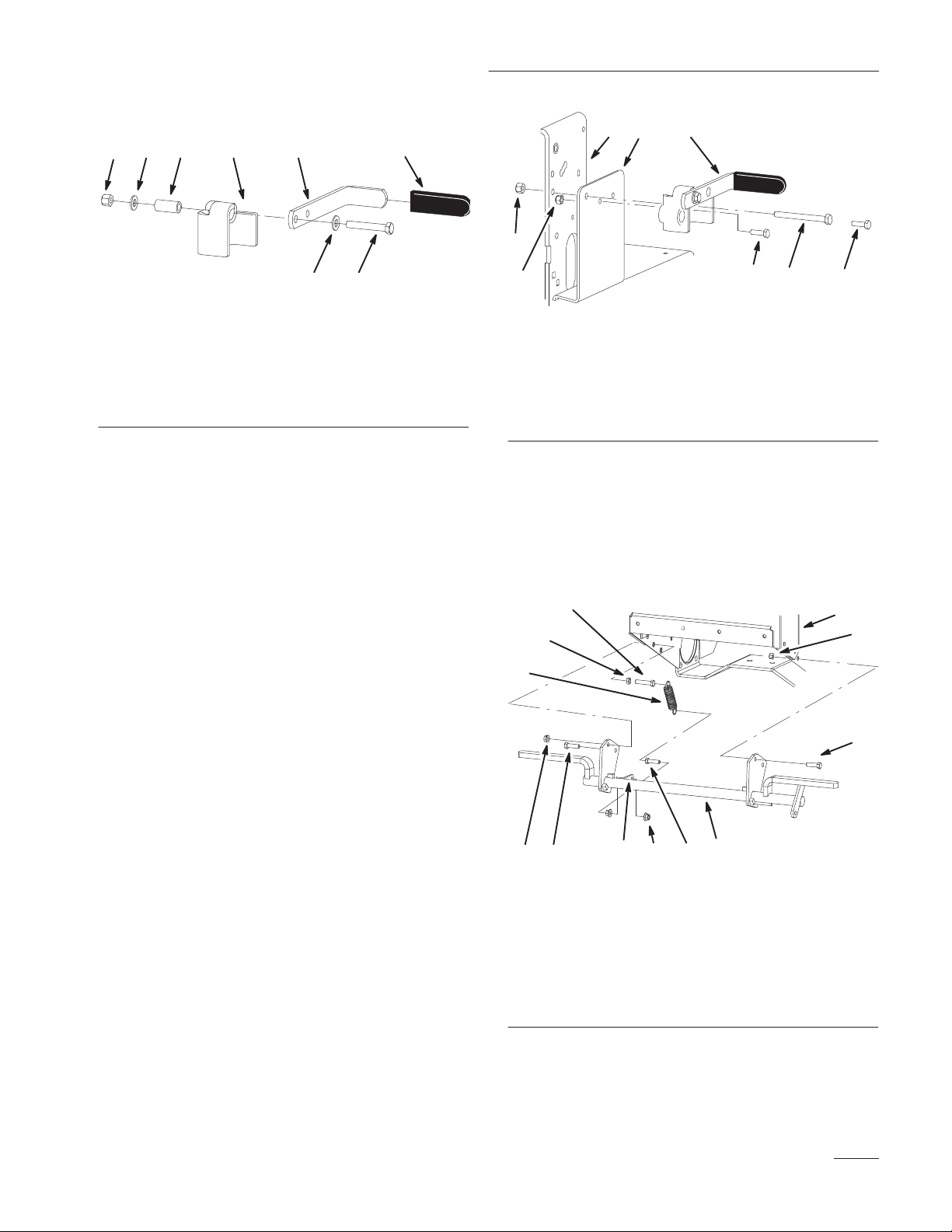

Install Brake Assembly

1. Install brake assembly to machine frame with 3

bolts (3/8 x 1–1/4 in.) and 3 locknuts (3/8 in.)

(Fig. 4).

4

5

7

9

3

2

28

11

m–5447

10 1

6

Figure 4

1. Brake assembly

2. Bolt, 3/8 x 1–1/4 in.

3. Lock Nut, 3/8 in.

4. Upper bolt, 3/8 x 1–3/4 in.

5. Jam Nut, 3/8 in.

6. Flange Nut, 5/16 in.

7. Spring

8. Flange Nut, 3/8 in.

9. Machine frame

10. Lower bolt, 5/16 x

1–1/4 in.

11. Tab

2. Install lower bolt (5/16 x 1–1/4 in.) in the brake

assembly using two flange nuts (5/16 in.) on

both sides of the tab (Fig. 4 and 5).

3

Page 4

Installation Instructions

Note: Install bolt so 2 or 3 threads show out

of the flange nut (Fig. 4 and 5).

3. Install spring onto upper bolt (3/8 x 1–3/4 in.) as

shown in figures 4 and 5.

4. Install upper bolt (3/8 x 1–3/4 in.) in the brake

assembly and machine frame using a flange nut

(5/16 in.) and jam nut (5/16 in.) on both sides of

the tab (Fig. 4 and 5).

Note: Install bolt so 2 or 3 threads show out

of the flange nut (Fig. 4 and 5).

5. Install spring onto lower bolt (5/16 x 1–1/4 in.)

as shown in figures 4 and 5.

9

8

5

6

9

2

7

3

4

10

Topview

1

2. Install yoke onto the brake assembly with a

clevis pin and a hairpin cotter.

3. Install the “L” shaped end into brake handle.

with a cotter pin.

6

5 2

2

4

7

3

5

1. Yoke

2. Brake rod

3. Clevis pin

4. Brake assembly

Figure 6

5. Hairpin cotter

6. Handle

7. 1–1/4 in.

1

m–5451

m–5455

Figure 5

1. Brake assembly

2. Upper bolt, 3/8 x 1–3/4 in.

3. Jam Nut, 3/8 in.

4. Flange Nut, 5/16 in.

5. Spring

6. Flange Nut, 3/8 in.

7. Machine frame

8. Lower bolt, 5/16 x

1–1/4 in.

9. Two or three threads

showing

10. Tab

Install Brake Rod

1. Install yoke onto brake rod, 1–1/4 in. from the

top of threads.

Check Operation of Brake

1. Check brake for proper operation as described

below.

2. Refer to Brake Service if adjustment is needed

on page 5.

Parking Brake Operation

Always set the parking brake when you stop the machine

or leave it unattended. Before each use, check brake for

proper operation.

If the parking brake does not hold securely, an adjustment

is required. Refer to Brake Service on page 5.

4

Page 5

Caution

Children or bystanders may be injured if they

move or attempt to operate the machine while it is

unattended.

Always remove the ignition key and set the

parking brake when leaving the machine

unattended, even if just for a few minutes.

Installation Instructions

3. To set the parking brake, it should take a reasonable

amount of force. If it engages too hard or easily,

adjustment is required. Refer to Adjusting the Brake

on page 5.

Note: When the brake is engaged, the brake handle

should be close to the 11 o’clock position.

4. If there is a reasonable amount of force, no adjustment

is required.

Adjusting the Brake

Setting the Parking Brake

1. Pull the brake handle rearward (Fig. 7).

Releasing the Parking Brake

1. Push the brake handle forward (Fig. 7).

Figure 7

1. Parking brake lever

(released position)

The brake handle is on the right side of machine (Fig. 8).

If the parking brake does not hold securely, an adjustment

is required.

1. Check the brake before you adjust it; refer to Checking

the Brake, page 5.

2. Release the parking brake; refer to Releasing the

Parking Brake, page 5.

1

3. To adjust the brake, remove the hair pin cotter and

clevis pin from the lower brake lever (Fig. 8).

4. Rotate the yoke in to tighten the brake and rotate out

to loosen the brake (Fig. 8).

5. Secure yoke to lower brake lever with the hair pin

cotter and clevis pin (Fig. 8).

6. Check the brake operation again; refer to Checking the

Brake, page 5.

m–5383

2

Brake Service

Service Interval/Specification

Before each use, check brake for proper operation.

Always set the parking brake when you stop the machine

or leave it unattended. If the parking brake does not hold

securely, an adjustment is required.

Checking the Brake

1. Set the parking brake (Fig. 8).

2. Park the machine on a level surface, disengage the

power take off (PTO) and turn the ignition key to

“OFF” to stop the engine. Remove the key.

1

3

14

1. Yoke

2. Parking brake lever

(released position)

m–5384

Figure 8

3. Clevis pin

4. Hairpin cotter

5

Page 6

Installation Instructions

6

Page 7

Installation Instructions

7

Page 8

Installation Instructions

8

Loading...

Loading...