Toro 104-8580 Installation Instructions

Electric Starter Kit

Proline Mid–Size Mowers

Part No. 104–8580

Form No. 3350–211

Installation Instructions

This kit can be installed on both Pistol Grip and T–Bar

machines. Follow the instructions that pertain to your type

of machine.

Important This kit can be installed on both 13hp and

15hp Kohler engines only.

Loose Parts

Note: Use the chart below to identify parts for assembly.

Step Description Qty. Use

Removing the existing wire harness

from T–bar machines

Removing the existing wire harness

from pistol grip machines

Installing the starter motor

Installing the ignition switch

1

2

3

4

No parts needed –

No parts needed –

Starter

Screw, 3/8 x 3–1/2 inch

Solenoid cable

Ignition switch, Pistol Grip

Ignition switch, T–Bar

Decal, Pistol Grip

Decal, T–Bar

Nut

Lock washer

Key

1

2

1

1

1

1

1

1

1

1

5

6

7

2003 by The Toro Company

8111 Lyndale Avenue South

Bloomington, MN 55420-1196

Voltage regulator 1 Installing the voltage regulator

Solenoid

Screw

Neutral switch

Tapping screw

Mounting bracket, T–Bar Hydro only

Screw, 1/4 x 1/2 inch, T–Bar Hydro only

Jumper wire

Switch plate

Transmission switch, Pistol Grip Gear

only

1

2

2

4

2

4

2

2

1

1

Installing the solenoid

Installing the neutral switches

Contact us at www.Toro.com

All Rights Reserved

Printed in the USA

Step UseQty.Description

8

9

10

11

Anti skid pad

Battery plate

Screw, 1/2 x 1–3/4 inch

Nut, 1/2 inch

Screw

T–Bar Wire Harness

Relay

Tie strap

Screw

Pistol Grip Wire Harness

Relay

Tie strap

Nut, 1/4 inch

Battery holdown

Battery holdown plate

Nut, 5/16 inch

Battery cable, black

Terminal boot, red

Terminal boot, black

Locknut, 1/4 inch

Screw, 5/16 x 3/4 inch

Battery cable, red

Battery

1

1

2

2

1

1

1

3

1

1

1

3

2

1

3

2

1

1

1

2

2

1

1

Installing the battery holder

Installing the t–bar wire harness

Installing the pistol grip wire harness

Installing battery

Obtain from Dealer

106–0909

2

Step

1

Removing the Existing Wire

Harness from T–Bar Machines

The following instructions are for T–bar machines only.

1. Disconnect the wire harness from the clutch and engine

connectors. Remove the ground wire that is attached to

the engine.

2. Remove the bottom plate of the control panel.

3. Remove the screw and nut securing the relay socket to

the control panel and remove the socket.

4. Unplug the connectors from the interlock module

secured to the bottom of the control panel.

5. Unplug the wire harness connectors from the ignition

switch, clutch switch, neutral switch and the hour meter

if one is installed.

1. Disconnect the wire harness from the clutch and the

engine connectors. Remove the ground wire that is

attached to the engine.

2. Remove the bottom plate of the control panel.

3. Remove the screw and nut securing the relay socket to

the bottom of the control panel and remove the socket.

4. Unplug the connectors from the interlock module

located on the control panel.

5. Unplug the wire harness connectors from the ignition

switch, clutch switch, hour meter (if equipped) and the

control bail switch.

6. Remove the cable ties securing the harness to the handle

and remove the harness.

7. Remove the nut and lock washer securing the ignition

switch to the control panel and remove the switch from

the panel (Fig. 3).

8. Remove the terminals from the upper T–Bar switch

(Figures 21 and 22).

Step

6. Remove the r–clamp and cable ties securing the harness

to the control panel and remove the harness.

7. Remove the nut and lock washer securing the ignition

switch to the control panel and remove the switch from

the panel (Fig. 3).

Step

3

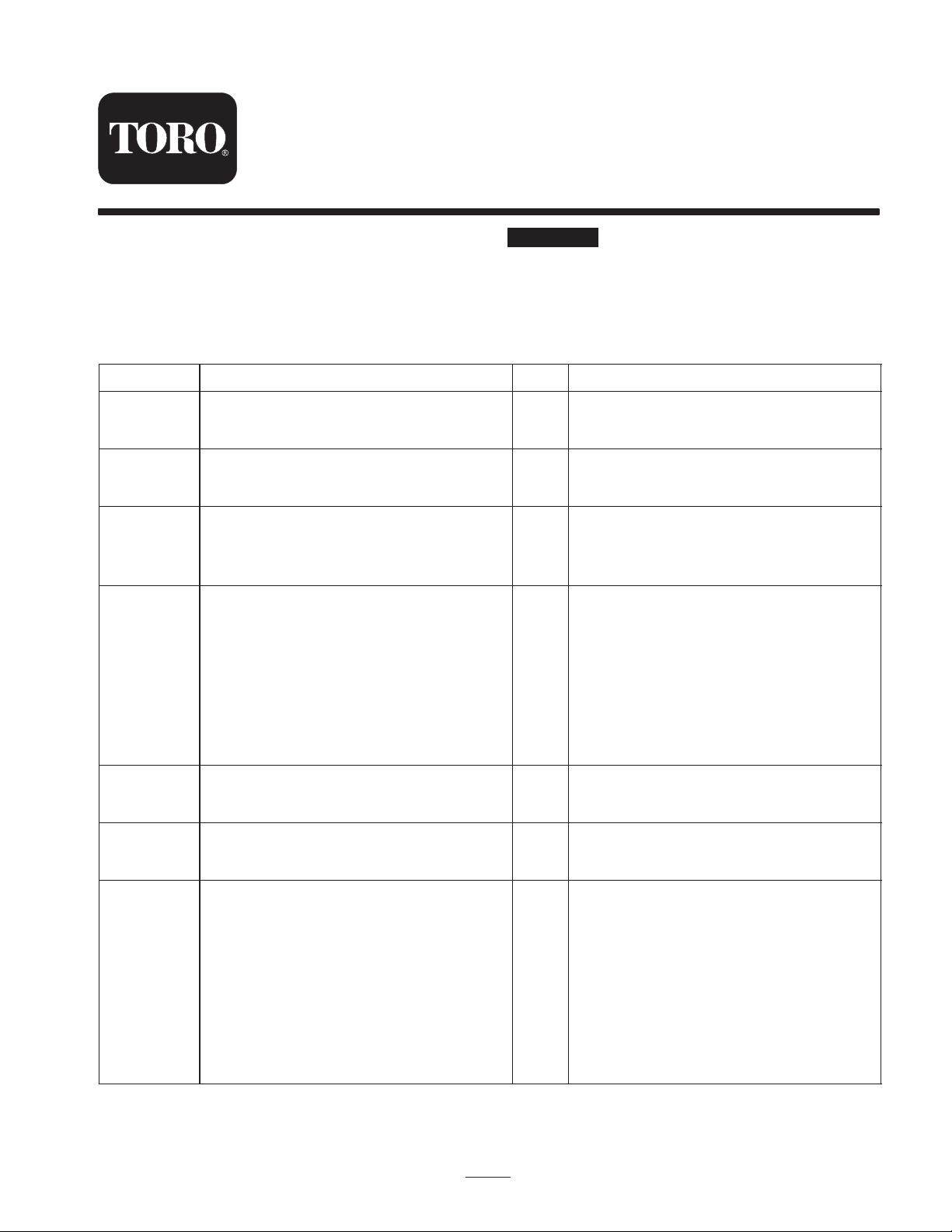

Installing the Starter Motor

Parts needed for this step:

Qty. Part

1 Starter

2 Bolt, 3/8 x 3–1/2 inch

1 Solenoid cable

2

Removing the Existing Wire

Harness from Pistol Grip

Machines

The following instructions are for pistol grip machines

only.

Procedure

1. Install the red battery cable to the bottom of the starter

motor (Fig. 1).

2. Remove the 2 screws securing starter cover to right side

of engine. Retain the screws but discard the cover

(Fig. 1).

3. Mount the starter motor to the engine with 2 flange

head bolts (3/8 x 3–1/2 inch) (Fig. 1).

4. Install the new starter cover to the engine with 2 screws

previously removed (Fig. 1).

3

Procedure

4

2

1

3

5

1. Starter motor

2. New starter cover

3. Red battery cable from

solenoid

Step

Figure 1

5

m–5488

4. Flange head bolt, (3/8 x

3–1/2 inch)

5. Nut

6. Oil filler tube

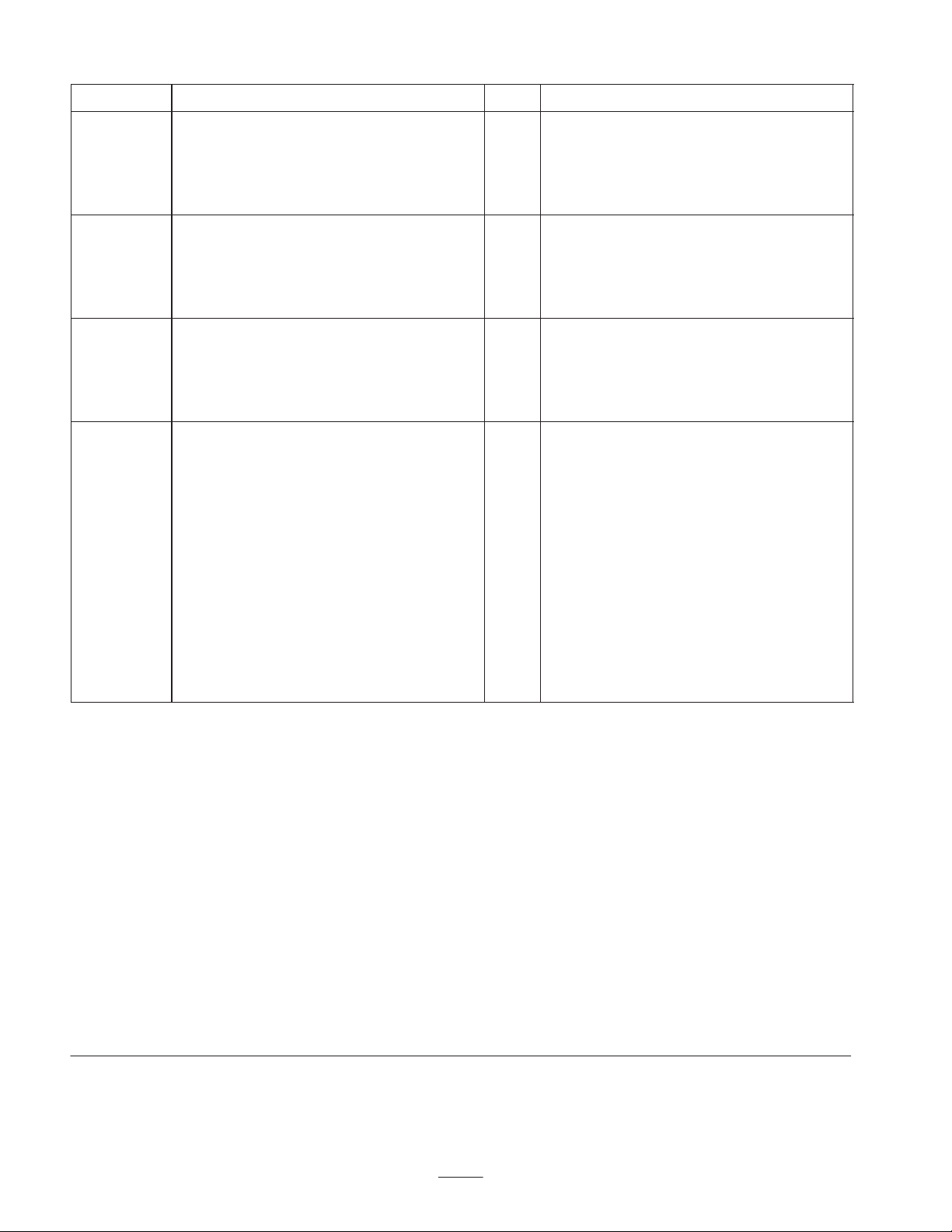

Note: There are two different types of ignition switches.

One is for the Pistol Grip machines and one is for the

T–Bar machines. Use the one that pertains to your machine.

Refer to figure 2.

1

3

2

1. Ignition switch, Pistol Grip

2. Extra terminal, Pistol Grip

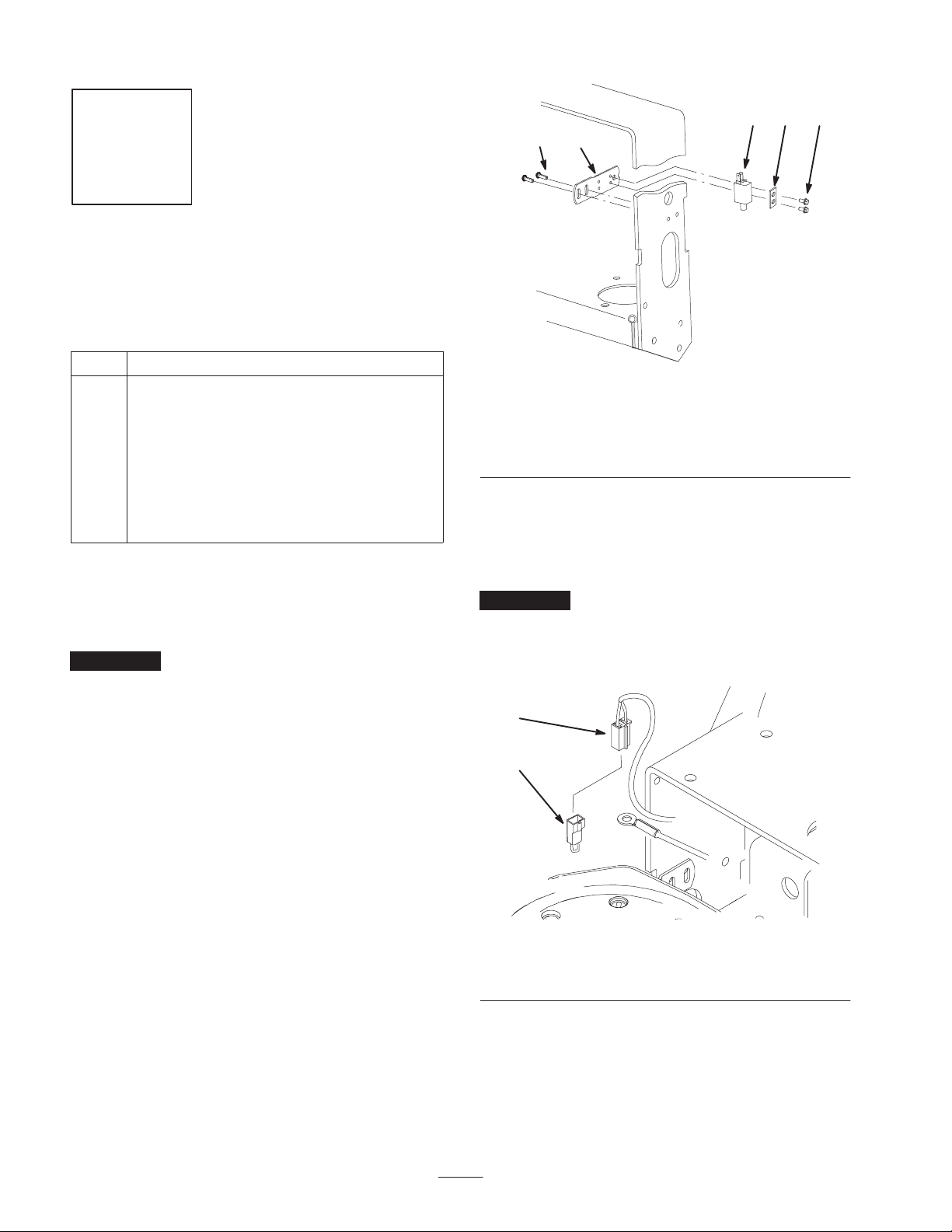

1. Install the new control panel decal over the ignition

switch area, making sure the holes are aligned.

2. Install the new ignition switch to the control panel with

the lock washer and hex nut (Fig. 3).

Bottom View

m–5487

Figure 2

3. Ignition switch, T–Bar

4

Installing Ignition Switch and

Decal

Parts needed for this step:

Qty. Part

1 Ignition switch, Pistol Grip

1 Ignition switch, T–Bar

1 Decal

1 Nut

1 Lock washer

1 Key

4

3

2

5

1

1. Ignition switch

2. Lock washer

3. Nut

m–5474

Figure 3

4. Key

5. Decal

4

Step

Step

5

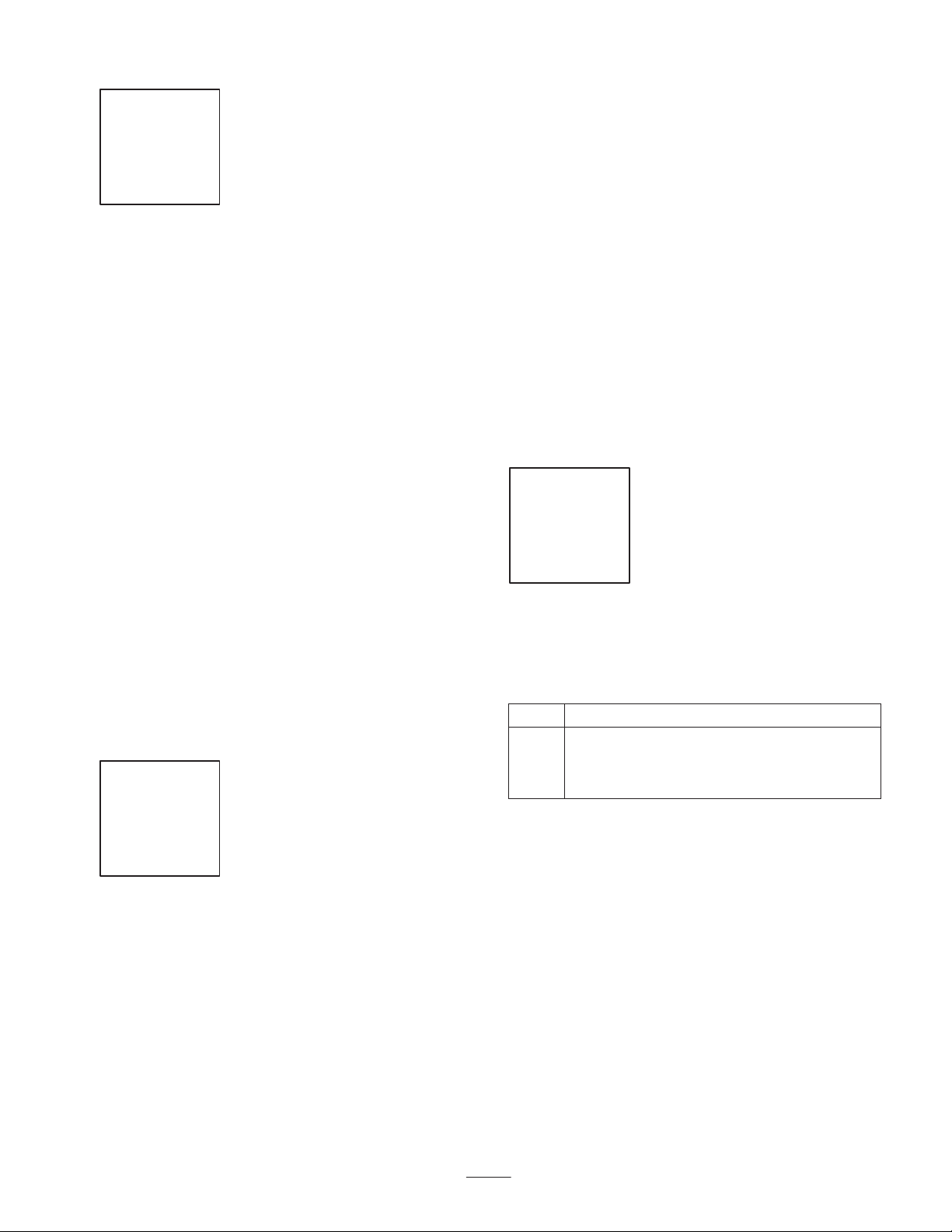

Installing the Voltage Regulator

Parts needed for this step:

Qty. Part

1 Voltage regulator

Procedure

Note: Make note of how the existing voltage regulator is

installed. The new voltage regulator must be install the

same way.

1. Remove the wire connector from the voltage regulator.

2. Remove the existing voltage regulator from the engine

as shown in figure 4. Save the mounting hardware.

3. Install the new voltage regulator to the engine with

existing hardware. Refer to figure 4.

4. Install the wire connector onto the new voltage

regulator (Fig. 4).

1

6

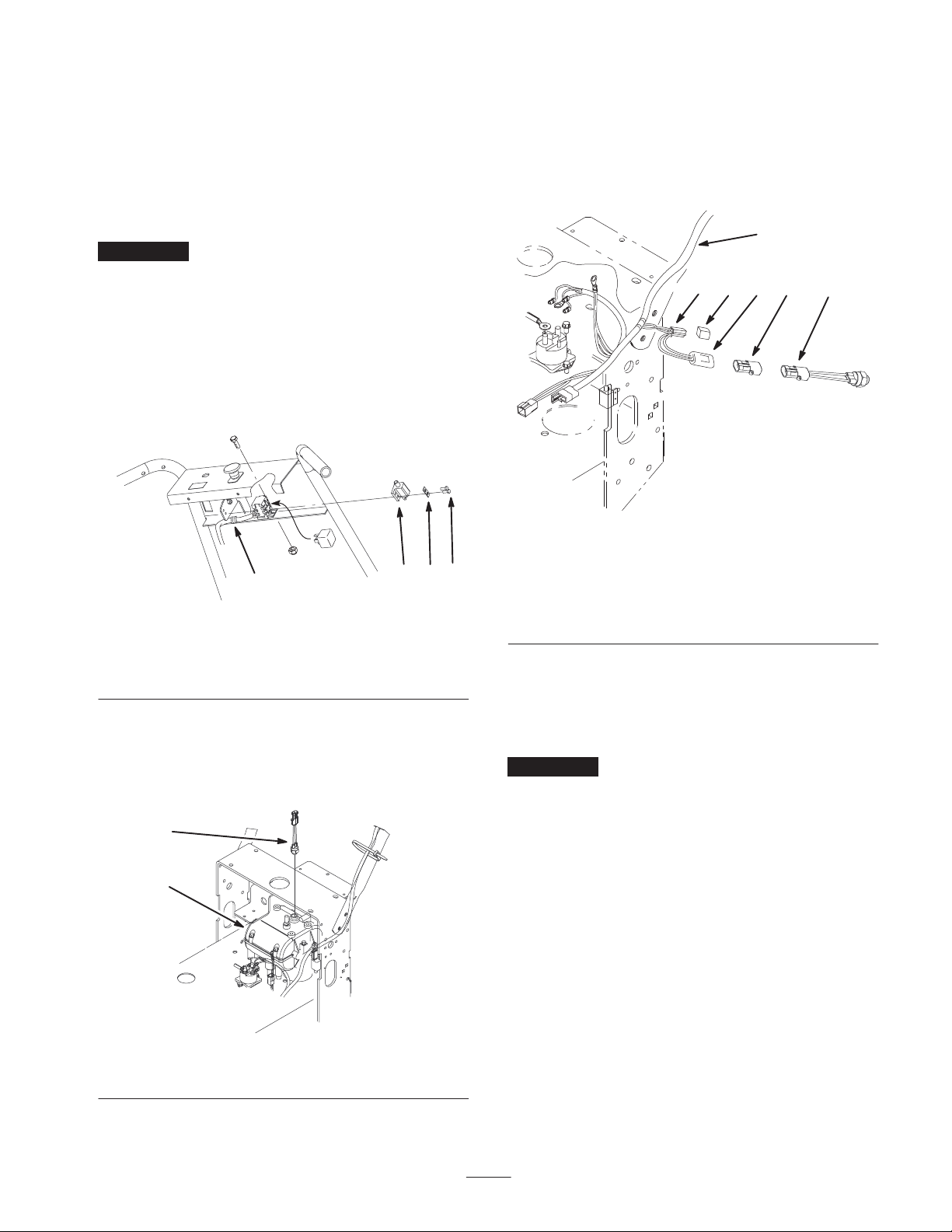

Installing the Solenoid

Parts needed for this step:

Qty. Part

1 Solenoid

2 Bolt

Procedure

1. Install the solenoid to the engine deck with 2 bolts as

shown in figure 5.

Note: Use the existing holes in the engine deck.

1

2

4

1. Voltage regulator

2. Bolt

3. Lock washer

Figure 4

3

5

4. Wire connector

5. Ground wire

3

2

m–5491

Figure 5

1. Solenoid

2. Bolt

3. Engine deck

4. Existing holes

4

m–5493

5

Step

7

Installing the Neutral Switches

for T–Bar Machines

Parts needed for this step:

1

5234

Qty. Part

2 Neutral switch

4 Tapping screw

2 Mounting bracket, T–Bar Hydro only

4 Bolt, 1/4 x 1/2 inch, T–Bar Hydro only

2 Jumper wire

2 Switch plate

1 Transmission switch, Pistol Grip Gear only

T–bar Hydro Drive Machines

Note: The following instructions are for T–bar hydro

machines only.

Important Use the two neutral switches for hydro

machines.

1. Install the neutral switches to the mounting brackets.

Use 4 tapping screws (10–24 x 1/2 in.) (Fig. 6).

2. Install the mounting brackets and the switches to the

inside of the machine frame using 4 bolts

(1/4 x 1/2 inch) (Fig. 6).

Figure 6

1. Neutral switch

2. Mounting bracket

3. Tapping screw,

10–24 x 1/2

4. Bolt, 1/4x 1/2 inch

5. Switch plate

T–bar Gear Drive Machines

Note: The following instructions are for T–bar gear

machines only.

Important No neutral switches are added to the gear

drive machines.

1. Install the jumper wires into both neutral switch

connectors (Figures 7 and 15).

1

2

m–5494

Figure 7

1. Neutral switch connector 2. Jumper wire, right side

shown

6

m–5504

Installing the Neutral Switches

for Pistol Grip Machines

Pistol Grip Gear Drive Machines

Note: The following instructions are for pistol grip gear

drive machines only.

Important One Operator Presence Control (OPC)

switch and one transmission switch are replaced on gear

drive machines.

1. Remove the existing neutral switch under the control

panel (Fig. 8).

2. Install the the Operator Presence Control (OPC) switch

and switch plate to the mounting bracket under the

control panel (Fig. 8). Use 2 tapping screws

(10–24 x 1/2 in.) (Fig. 8).

1

2 3

m–5475

1. Operator Presence

Control (OPC) switch

2. Switch plate

4

Figure 8

3. Tapping screw,

10–24 x 1/2

4. R–clamp

5. Remove the cap off of the transmission switch harness

connector, when installing the harness (Figures 10

and 24).

Note: Do not remove the shrink wrap around the neutral

switch connector for pistol grip hydro drive machines

only (Fig. 10).

6

2

3 4 5

1

m–5507

Figure 10

1. Transmission switch

2. Neutral switch connector

3. Shrink wrap

4. Transmission switch

connector

5. Transmission connector

cap

6. Wire harness

Pistol Grip Hydro Drive Machines

3. Remove the existing transmission switch (Figures 9 and

24).

4. Install new transmission switch into transmission

(Figures 9 and 24).

2

1

m–5482

Figure 9

1. Transmission 2. Transmission Switch

Note: The following instructions are for pistol grip hydro

machines only.

Important One neutral switch and one Operator

Presence Control (OPC) switch are replaced on hydro

machines only.

1. Remove the existing neutral switch under the control

panel (Fig. 8).

2. Install the the Operator Presence Control (OPC) switch

and the switch plate to the mounting bracket under the

control panel (Fig. 8). Use 2 tapping screws

(10–24 x 1/2 in.) (Fig. 8).

3. Remove the existing neutral switch and then install a

grey neutral switch to the left side of frame (Fig. 11).

4. Pull the speed control lever back to neutral.

5. Check to make sure the neutral switch is depressed and

there is a 5/16 inch (8 mm) space between the actuating

tab and the switch (Fig. 11).

6. If needed, adjust the switch location to create the

5/16 in. (8 mm) space (Fig. 11).

7

6

Step

m–5394

Figure 11

1. Actuating tab

2. 5/16 inch (8 mm) space

3. Neutral switch

4. Screw

7. Remove the shrink wrap off the neutral switch

connector (Figures 10 and 24).

Note: Keep the cap on the transmission switch connector

for pistol grip gear drive machines only (Fig. 10).

5. Neutral switch connector,

from wire harness

6. Left side of machine

1

2

8

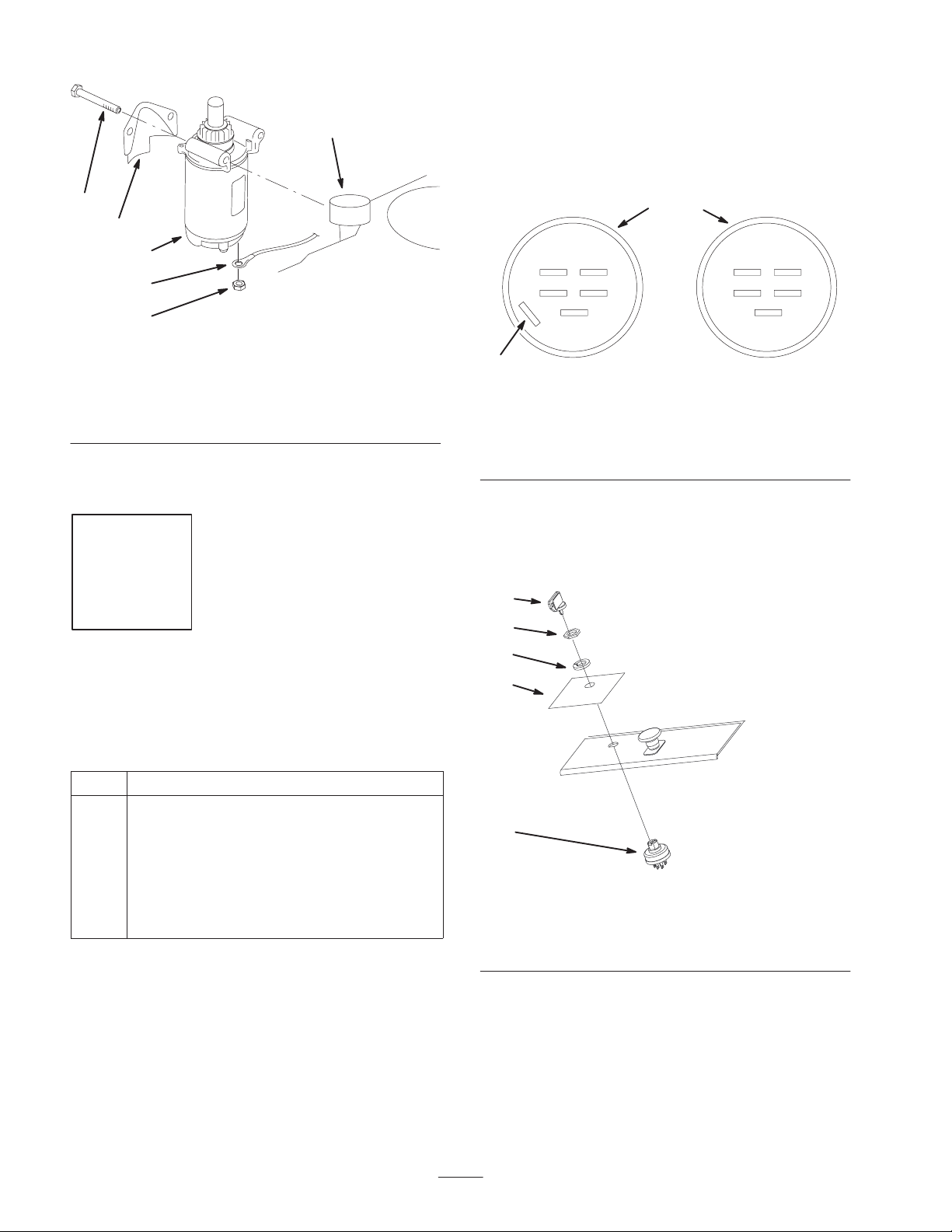

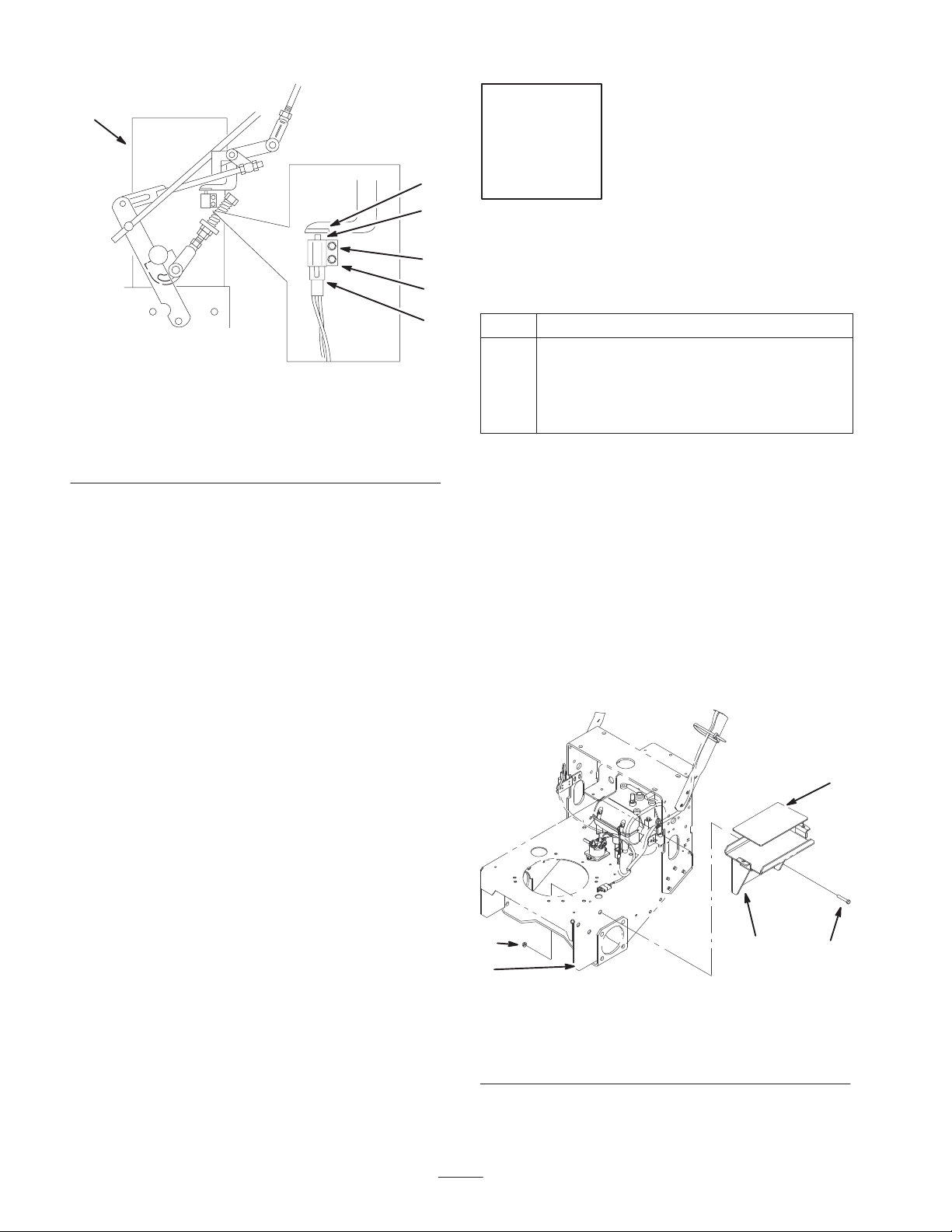

Installing the Battery Holder

4

3

5

Parts needed for this step:

Qty. Part

1 Anti skid pad

1 Battery plate

4 Bolt, 1/2 x 1–3/4 inch

4 Nut, 1/2 inch

Installing the Battery Holder on All

Mowers (Excluding 2002 and Earlier

Pistol Grip Gear Drive Mowers)

1. Remove left drive tire.

2. Mount battery holder to the left side of machine with

2 bolts (1/2 x 1–3/4 inch) and 2 nuts (1/2 inch).

3. Peel off backing from battery pad and affix pad to

battery holder (Fig 12). Rubber battery pad should be

centered on battery holder.

4. Install the left tire.

3

1

1. Left side of machine

2. Bolt, 3/8 x 1–3/4 inch

3. Nut, 1/2 inch

Figure 12

4. Battery holder

5. Battery pad

5

4

2

m–5480

8

Loading...

Loading...