Toro 10301, 10307, 10309, 10310, 10311 Service Manual

...

WALK BEHIND POWER

MOWER DRIVE SYSTEMS

SERVICE MANUAL

ABOUT THIS MANUAL

This service manual was written expressly for Toro servicing dealers. The Toro Company has

made every effort to make the information in this manual complete and correct.

This manual was written with the assumption that the reader has basic mechanical knowledge

and skills. This book contains material covering the Toro and Lawn-Boy Walk Behind Mower Drive

Systems models from 1990 through 2006, and may be specifi ed for use on products built after

2006 that are similar in design.

We are hopeful that you will fi nd this manual a valuable addition to your service shop. If you have

any questions or comments regarding this manual, please contact us at the following address:

The Toro Company

LCE Service Training Department

8111 Lyndale Avenue South

Bloomington, MN 55420

The Toro Company reserves the right to change product specifi cations or this manual without

notice.

Copyright© All Rights Reserved

©2006 The Toro Company

THIS PAGE INTENTIONALLY LEFT BLANK.

TABLE OF CONTENTS

QUICK REFERENCE

Transmission Remove and Replace

3 speed transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21” steel & cast deck Personal Pace, Easy Stride transmission . . . . . . . . . . . . . . . .

22” steel deck transmission, Toro and Lawn-Boy . . . . . . . . . . . . . . . . . . . . . .

21” Lawn-Boy Insight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transmission Internal Repair

3 speed transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Spur/Bevel gear transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bevel gear transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wheel Clutch Troubleshooting & Repair

Rocking Key style . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Spring Ratchet style . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Blade Clutch System Troubleshooting & Repair

Blade Brake Clutch System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Blade Override System (Toro - BOS) Blade Clutch System (Lawn-Boy - BCS) . . . . . . . . . . .

4-5

2-3

3-10

3-20

4-6

2-4

3-16

5-2

5-9

6-2

6-28

Handle Disassembly

Toro 2 Bail handle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Personal Pace Easy Stride (Generation 1) . . . . . . . . . . . . . . . . . . . . . . . . .

Personal Pace Easy Stride (Generation 2) . . . . . . . . . . . . . . . . . . . . . . . . .

Lawn-Boy Sens-a-Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Belt Replacement

Mowers with Toro Blade Brake Clutch . . . . . . . . . . . . . . . . . . . . . . . . . .

Mowers with Toro Blade Override System . . . . . . . . . . . . . . . . . . . . . . . . .

Zone start 21” Rear Wheel Drive Toro & Lawn-Boy (except Insight) . . . . . . . . . . . . . . .

Zone start 22” Toro Rear Wheel Drive . . . . . . . . . . . . . . . . . . . . . . . . . .

Zone start 22” Toro Front Wheel Drive . . . . . . . . . . . . . . . . . . . . . . . . . .

Lawn-Boy Insight Zone Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lawn-Boy Insight with Blade Clutch System . . . . . . . . . . . . . . . . . . . . . . . .

7-2

7-3

7-6

7-9

8-3

8-3

8-2

3-10

3-5

3-19

8-3

iWPM Drive Systems Manual

TABLE OF CONTENTS

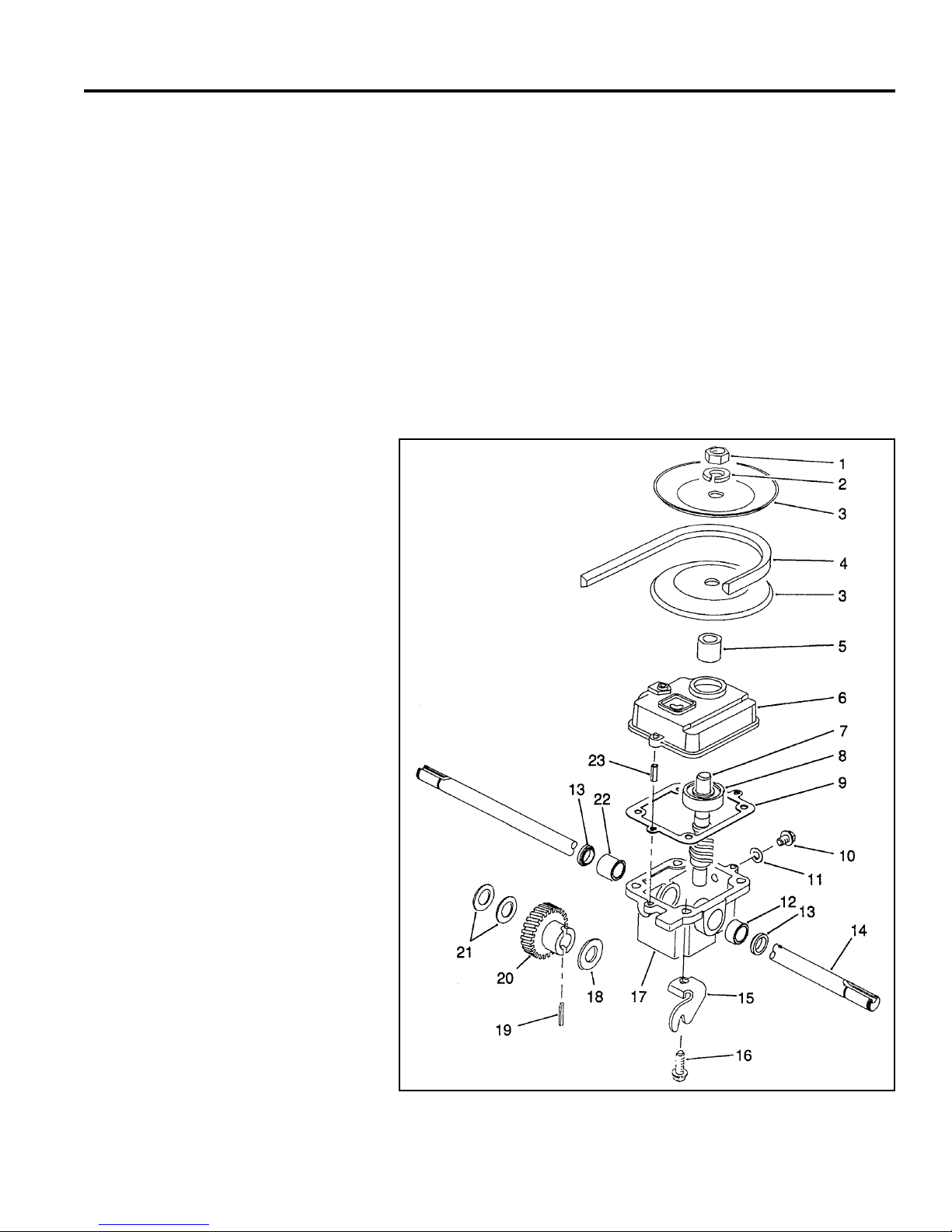

WORM DRIVE TRANSMISSION

GENERAL

INTERNALLY CLUTCHED

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The Shifting Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal & Installation (front wheel drive applications) . . . . . . . . . . . . . . . . . .

Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CONSTANT MESH

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal & Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WHEEL CLUTCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SINGLE SPEED SPUR/BEVEL GEAR TRANSMISSION

GEAR CASE ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transmission Remove & Replace . . . . . . . . . . . . . . . . . . . . . . . . . .

Transmission Internal Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2

1-3

1-3

1-4

1-5

1-7

1-9

1-10

1-11

1-12

1-13

1-14

2-2

2-3

2-3

2-3

2-4

2-5

SINGLE SPEED BEVEL GEAR TRANSMISSION

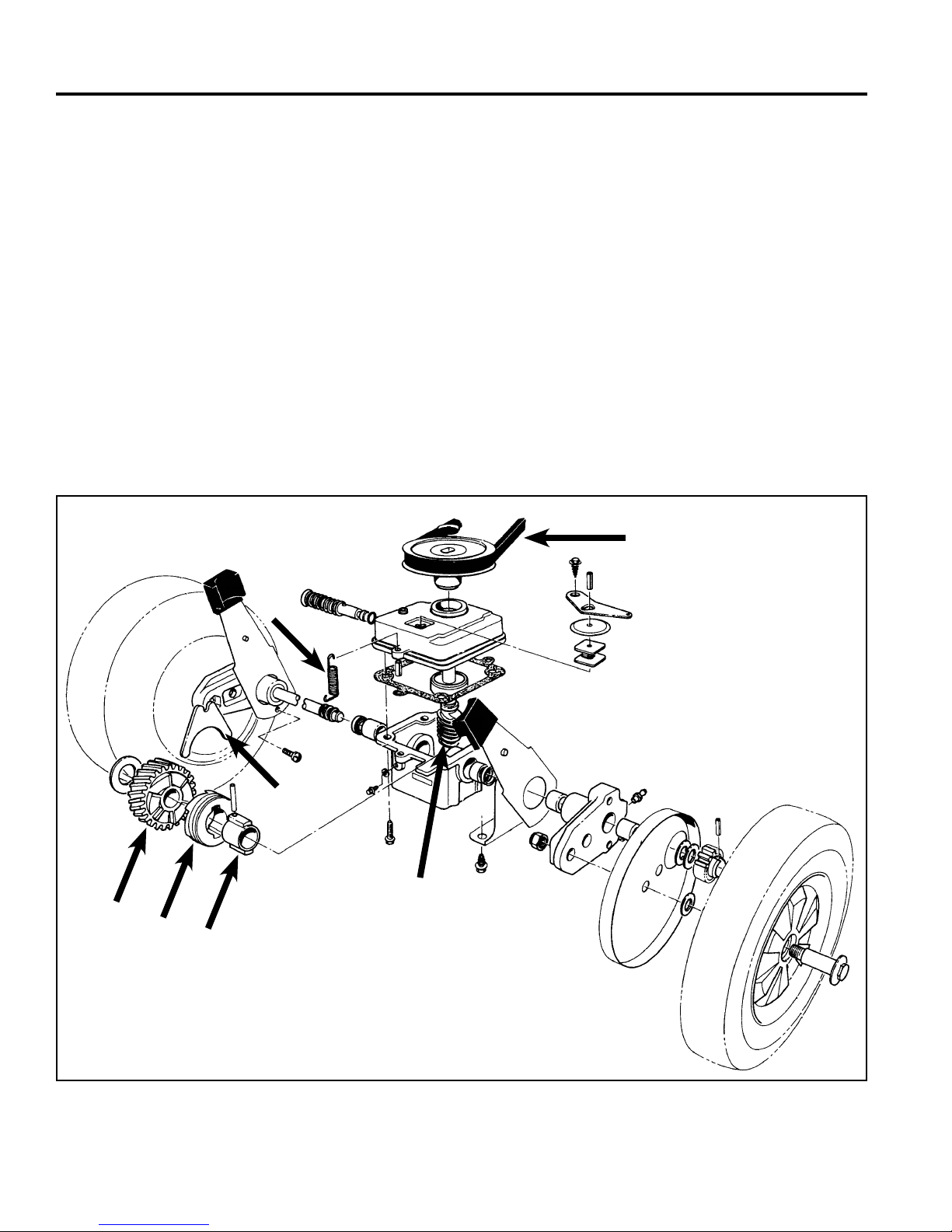

EXPLODED VIEW - SINGLE SPEED BEVEL GEAR TRANSMISSION . . . . . . . . . . . . . .

GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FRONT AXLE & TRANSMISSION ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . .

22” FRONT WHEEL DRIVE MODELS

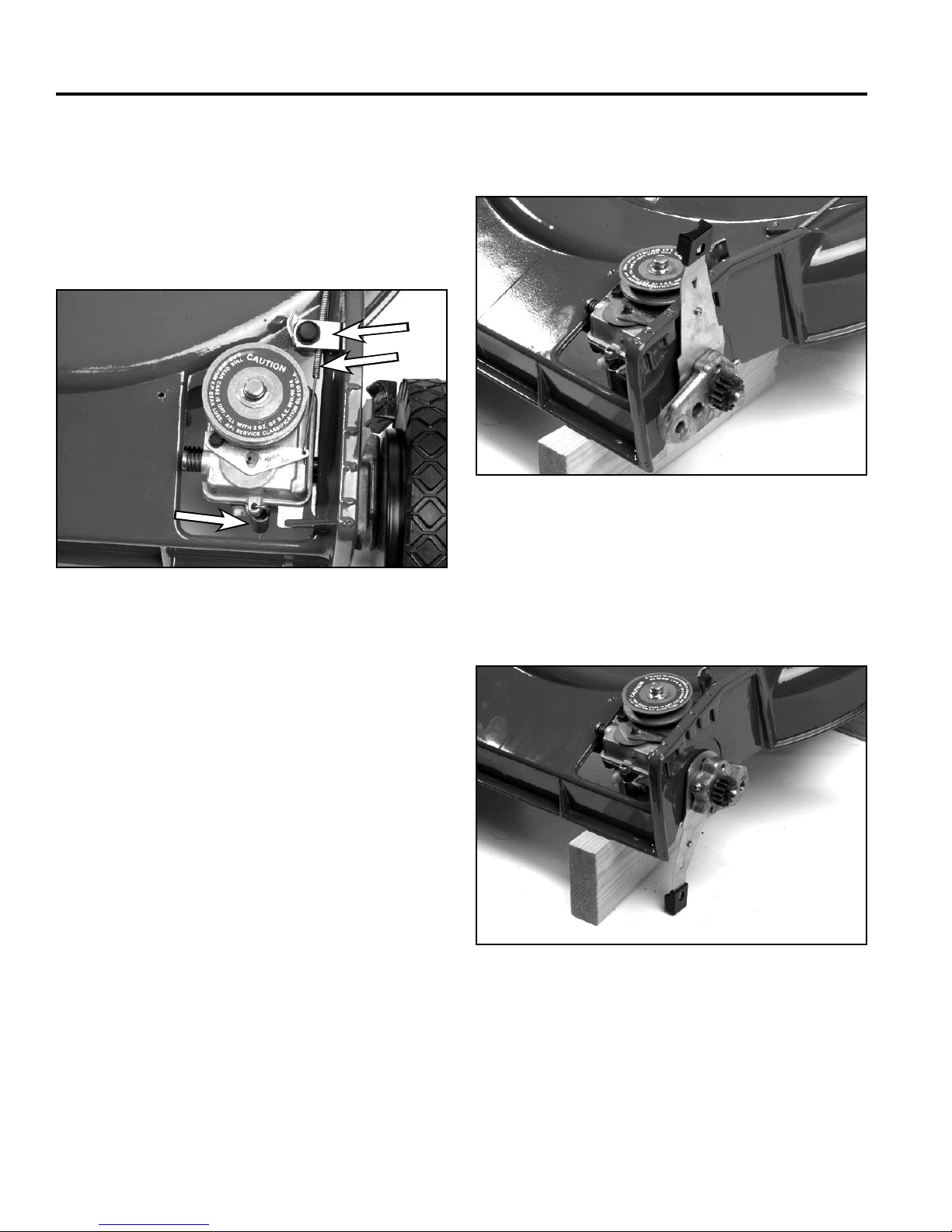

Remove Transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

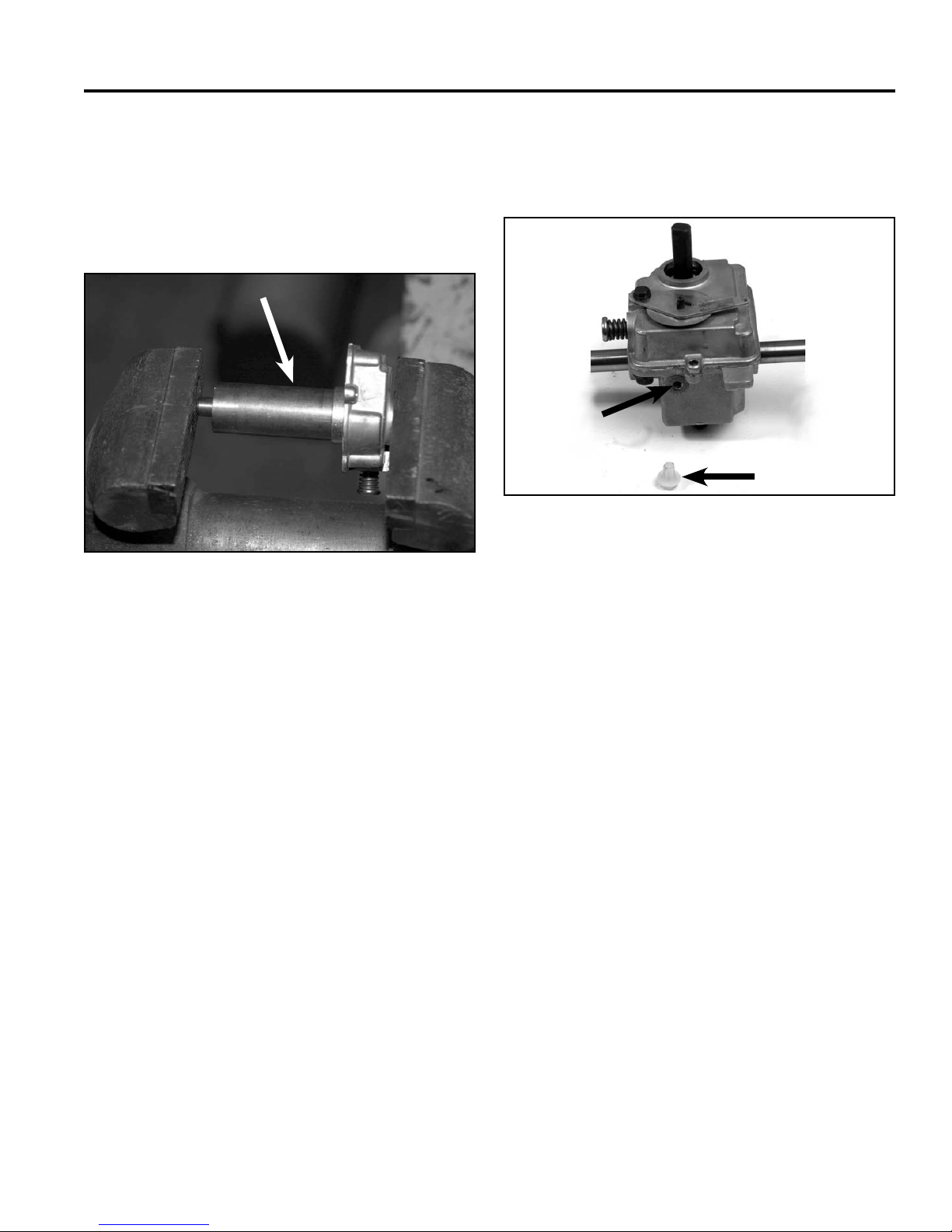

Transmission Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

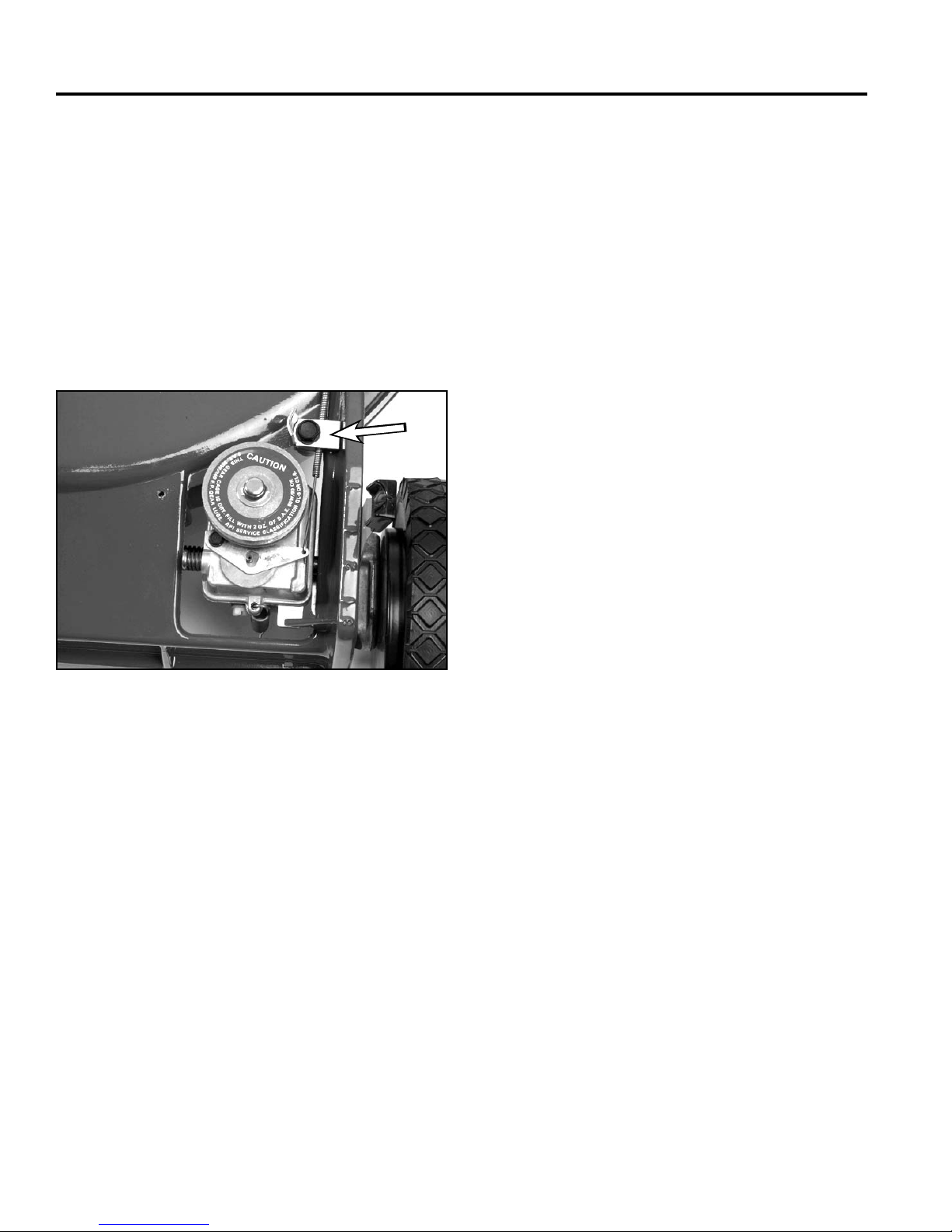

Transmission Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Assembly Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Belt Service - Front Wheel Drive Models . . . . . . . . . . . . . . . . . . . . . . . .

22” TORO & LAWN-BOY REAR WHEEL DRIVE MODELS

Transmission Removal & Belt Replacement . . . . . . . . . . . . . . . . . . . . . .

Rear Axle Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transmission Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transmission Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Axle Assembly Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LAWN-BOY INSIGHT TRANSMISSION REMOVE & REPLACE . . . . . . . . . . . . . . . .

Tranmission Removal & Belt Replacement . . . . . . . . . . . . . . . . . . . . . . .

Transmission Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transmission Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Axle Assembly Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transmission Installation Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . .

THREE SPEED TRANSMISSION

GEAR CASE ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OPERATION

Input System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2

3-3

3-4

3-5

3-7

3-7

3-8

3-9

3-10

3-15

3-16

3-16

3-17

3-19

3-20

3-24

3-24

3-24

3-25

4-2

4-3

ii WPM Drive Systems Manual

TABLE OF CONTENTS

Speed Reduction System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Gear Selection System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal - Toro Vacu Power/Lawn-Boy Medallion Models . . . . . . . . . . . . . . . . .

Removal - Recycler/Rear Bagger Chassis . . . . . . . . . . . . . . . . . . . . . . .

Alternate Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transmission - Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Output Shaft Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Input Shaft Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Intermediate Shaft Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Special Assembly Notes for Toro Vacu Power/Lawn-Boy Medallion . . . . . . . . . . . . .

TROUBLESHOOTING TIPS - 3 SPEED TRANSMISSION

Hard Shifting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Slipping Gears . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

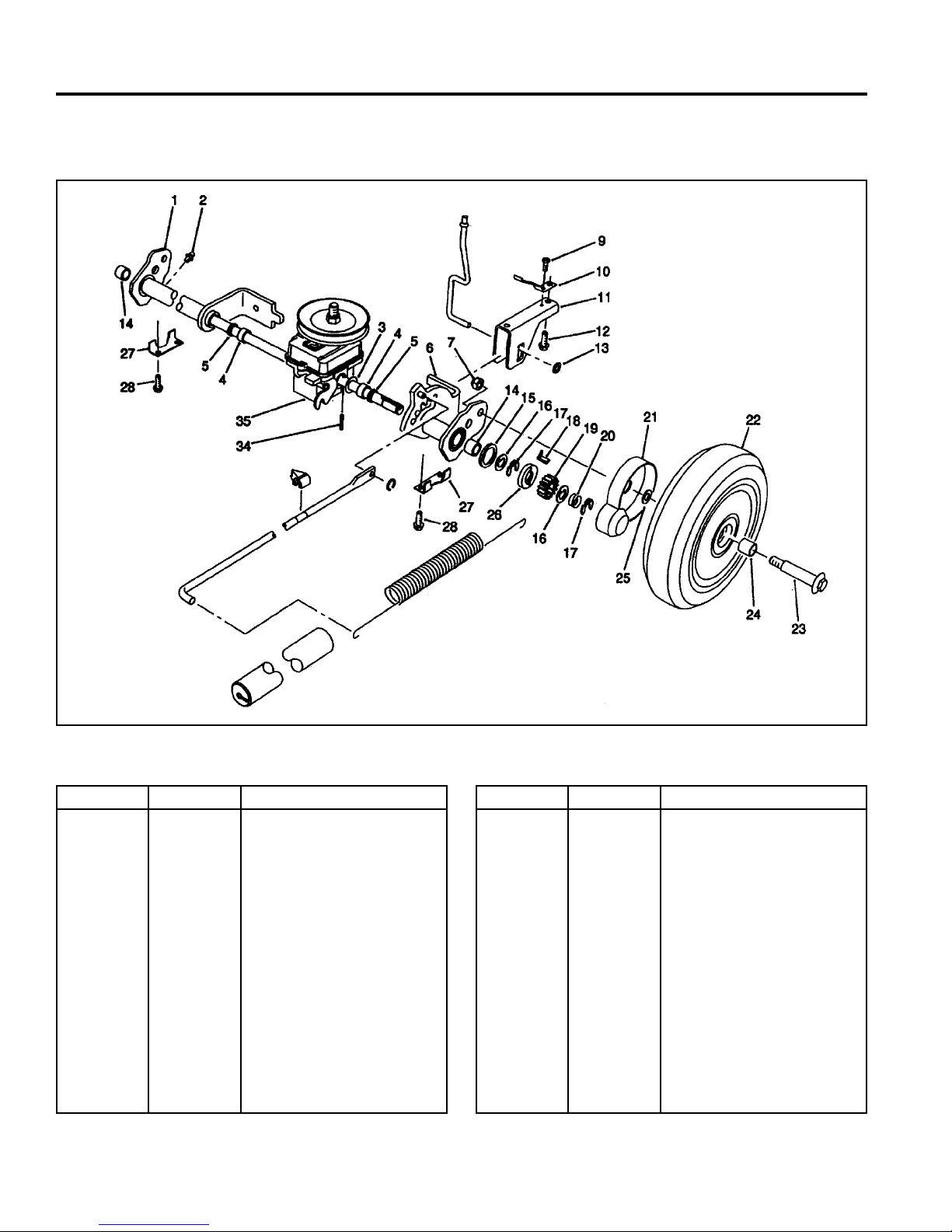

WHEEL PINION CLUTCH

GEAR CASE & WHEEL ASSEMBLY, ROCKING KEY STYLE . . . . . . . . . . . . . . . . .

Wheel Pinion Clutch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Component Defi nitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test for Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Quick Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear Height-of-Cut & Wheel Pinion Clutch - Disassembly . . . . . . . . . . . . . . . . .

Rear Height-of-Cut & Wheel Pinion Clutch - Assembly . . . . . . . . . . . . . . . . . .

GEAR CASE & WHEEL ASSEMBLY SPRING RATCHET STYLE . . . . . . . . . . . . . . . .

Spring Ratchet Key Style . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Servicing the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WHEEL PINION SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-3

4-4

4-5

4-6

4-6

4-6

4-7

4-8

4-9

4-10

4-10

4-11

4-12

4-12

5-2

5-3

5-3

5-4

5-4

5-4

5-5

5-8

5-9

5-9

5-9

BLADE BRAKE CLUTCH SYSTEMS (BBC), BLADE OVERRIDE SYSTEM (BOS),

BLADE CLUTCH SYSTEM (BCS)

BLADE BRAKE CLUTCH SYSTEM

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BBC Clutch Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Box Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Handle Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Box Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Box Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TORO BBC SERVICE GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BLADE BRAKE CLUTCH ASSEMBLY (Toro Vacu Power/Lawn-Boy Medallion) . . . . . . . . . .

TORO VACU POWER/LAWN-BOY MEDALLION BBC . . . . . . . . . . . . . . . . . . . .

Bellcrank System Disassembly (Toro Vacu Power/Lawn-Boy Medallion) . . . . . . . . . . .

Bellcrank System Assembly (Toro Vacu Power/Lawn-Boy Medallion) . . . . . . . . . . . . .

BBC Cover and Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Under Deck Components Disassembly (Toro Vacu Power/Lawn-Boy Medallion) . . . . . . . .

Under Deck Components Assembly (Toro Vacu Power/Lawn-Boy Medallion) . . . . . . . . . .

BBC Cable Removal (Toro Vacu Power/Lawn-Boy Medallion) . . . . . . . . . . . . . . .

BBC Cable Installation (Toro Vacu Power/Lawn-Boy Medallion) . . . . . . . . . . . . . . .

ENGINE & BLADE ASSEMBLY (Toro Recycler/Rear Bagger) . . . . . . . . . . . . . . . . .

TORO RECYCLER/REAR BAGGER BBC . . . . . . . . . . . . . . . . . . . . . . . . .

Idler Arm System Disassembly (Recycler/Rear Bagger) . . . . . . . . . . . . . . . . . .

Idler Arm System Assembly (Recycler/Rear Bagger) . . . . . . . . . . . . . . . . . . .

6-2

6-2

6-2

6-3

6-6

6-7

6-10

6-11

6-12

6-12

6-13

6-14

6-15

6-17

6-19

6-20

6-21

6-22

6-22

6-25

iiiWPM Drive Systems Manual

TABLE OF CONTENTS

BBC Cable Removal (Recycler/Rear Bagger) . . . . . . . . . . . . . . . . . . . . . .

BBC Cable Installation (Recycler/Rear Bagger) . . . . . . . . . . . . . . . . . . . . .

BLADE OVERRIDE SYSTEM (BOS), BLADE CLUTCH SYSTEM (BCS) . . . . . . . . . . . . .

Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Brake Arm Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BOS/BCS System Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HANDLES AND CONTROL CABLES

Toro 2 Bail Handle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Personal Pace Generation 1/Easy Stride Generation 1 . . . . . . . . . . . . . . . . . .

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjusting the Personal Pace Cable . . . . . . . . . . . . . . . . . . . . . . . . . .

Personal Pace Generation 2/Easy Stride Generation 2 . . . . . . . . . . . . . . . . . .

Handle Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjusting the Personal Pace/Easy Stride Cable . . . . . . . . . . . . . . . . . . . . .

Lawn-Boy 2 Bail Handle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lawn-Boy Sens-a-Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Handle Disassembly, Zone Start Models . . . . . . . . . . . . . . . . . . . . . . . .

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cable Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Self-Propel Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Handle Disassembly, Lawn-Boy Blade Clutch System (BCS) Models . . . . . . . . . . . . .

3 Speed Transmission Models . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Speed Control Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BBC Cable Adjustment (Toro Vacu Power/Lawn-Boy Medallion) . . . . . . . . . . . . . . .

Toro BBC Cable Adjustment (Recycler/Rear Bagger) . . . . . . . . . . . . . . . . . . .

Toro BOS Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Toro BOS Control Cable Adjustment . . . . . . . . . . . . . . . . . . . . . . . . .

Lawn-Boy BCS Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lawn-Boy BCS Control Cable Adjustment . . . . . . . . . . . . . . . . . . . . . . .

6-27

6-28

6-28

6-28

6-32

6-33

7-2

7-3

7-3

7-3

7-5

7-6

7-6

7-6

7-8

7-8

7-9

7-9

7-9

7-10

7-11

7-11

7-11

7-13

7-13

7-15

7-16

7-17

7-18

7-18

7-18

SELF-PROPEL BELT REPLACEMENT

Toro 21” Front Wheel Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

22” Front Wheel Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

22” Rear Wheel Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21” Steel & Cast Deck Toro & Lawn-Boy Mowers Belt Replacement . . . . . . . . . . . . .

21” Cast Deck Mowers with 3 Speed Transmission . . . . . . . . . . . . . . . . . . . .

21” Toro & Lawn-Boy Mowers with Blade Brake Clutch . . . . . . . . . . . . . . . . . .

21” Toro Mowers with Blade Override System & Lawn-Boy Mower

with Blade Brake Clutch System . . . . . . . . . . . . . . . . . . . . . . . . .

21” Lawn-Boy Insight Mowers . . . . . . . . . . . . . . . . . . . . . . . . . . . .

iv WPM Drive Systems Manual

8-2

8-2

8-2

8-2

8-2

8-3

8-3

8-3

TABLE OF CONTENTS

Using this manual

Following each model number in the list below are codes identifying the type of

deck material, transmission, wheel pinion clutch, hand controls, and if it has a

blade clutch system. Use this information to select the correct sections of the

service manual for the mower being serviced.

Code List

1B - one bail CDVP - cast deck Vacu Power

2B - two bail ES1 - Easy Stride 1st generation

3S- 3 speed ES2 - Easy Stride 2nd generation

21” stl - 21” steel deck Ins - Insight

22” stl - 22” steel deck PP1 - Personal Pace 1st generation

B- bevel gear PP2 - Personal Pace 2nd generation

BBC - blade brake clutch RK - rocking key

BBC VP - blade brake clutch SB - spur bevel

for Vacu Power SR - spring ratchet

BOS - blade override system SS - Sens-a-Speed

CD - cast deck W - worm

Model Trans Trans Wheel Handle Blade

R&R Internal Pinion Repair Clutch

Repair

10301 CD SB RK 2B None

10302 CD SB RK 2B None

10304 CD SB RK 2B None

10305 CD SB RK 2B None

10307 CD SB RK 2B None

10309 CD SB RK 2B None

10310 CD SB RK 2B None

10311 CD SB RK 2B None

10312 CD SB RK 2B None

10313 CD SB RK 2B None

10314 CD SB RK 2B None

10316 CD SB RK 2B None

10317 CD SB RK 2B None

10318 CD SB RK 2B None

10319 CD SB RK 2B None

10320 CD SB RK 2B None

10321 CD SB RK 2B None

10323 CD SB RK 2B None

10324 CD SB RK 2B None

10324C CD SB RK 2B None

10327 CD SB RK 2B None

10328 CD SB RK 2B None

10329 CD SB RK 2B None

10330 CD SB RK 2B None

vWPM Drive Systems Manual

TABLE OF CONTENTS

1B - one bail CDVP - cast deck Vacu Power

2B - two bail ES1 - Easy Stride 1st generation

3S- 3 speed ES2 - Easy Stride 2nd generation

21” stl - 21” steel deck Ins - Insight

22” stl - 22” steel deck PP1 - Personal Pace 1st generation

B- bevel gear PP2 - Personal Pace 2nd generation

BBC - blade brake clutch RK - rocking key

BBC VP - blade brake clutch SB - spur bevel

for Vacu Power SR - spring ratchet

BOS - blade override system SS - Sens-a-Speed

CD - cast deck W - worm

Model Trans Trans Wheel Handle Blade

R&R Internal Pinion Repair Clutch

Repair

10331 CD SB RK 2B None

10332 CD SB RK 2B None

10334 CD SB RK 2B None

10335 CD SB RK 2B None

10342 CD SB RK 2B None

10343 CD SB RK 2B None

10344 CD SB RK 2B None

10345 CD SB RK 2B None

10356 CD SB RK 2B None

10357 CD SB RK 2B None

10358 CD SB RK 2B None

10359C CD SB RK 2B None

10360 CD SB RK 2B None

10360C CD SB RK 2B None

10361 CD SB RK 2B None

10362 CD SB RK 2B None

10363 CD SB RK 2B None

10515 CD 3S RK 2B None

10516 CD 3S RK 2B None

10517 CD 3S RK 2B None

10518 CD 3S RK 2B None

10519 CD 3S RK 2B None

10520 CD 3S RK 2B None

10521 CD 3S RK 2B None

10522 CD 3S RK 2B None

10523 CD 3S RK 2B None

10524 CD 3S RK 2B None

10525 CD 3S RK 2B None

10527 CD 3S RK 2B None

10528 CD 3S RK 2B None

10533 CD 3S RK BBC BBC VP

10545 CD 3S RK 2B None

Code List

vi WPM Drive Systems Manual

TABLE OF CONTENTS

1B - one bail CDVP - cast deck Vacu Power

2B - two bail ES1 - Easy Stride 1st generation

3S- 3 speed ES2 - Easy Stride 2nd generation

21” stl - 21” steel deck Ins - Insight

22” stl - 22” steel deck PP1 - Personal Pace 1st generation

B- bevel gear PP2 - Personal Pace 2nd generation

BBC - blade brake clutch RK - rocking key

BBC VP - blade brake clutch SB - spur bevel

for Vacu Power SR - spring ratchet

BOS - blade override system SS - Sens-a-Speed

CD - cast deck W - worm

Model Trans Trans Wheel Handle Blade

R&R Internal Pinion Repair Clutch

Repair

10546 CD 3S RK 2B None

10547 CD 3S RK 2B None

10548 CD 3S RK 2B None

10550 CD SB RK ES1 None

10551 CD SB RK ES1 None

10552 CD SB RK ES1 None

10655 22stl B SR ES2 None

10656 22stl B SR ES2 None

10672 Ins B SR SS None

10673 Ins B SR SS None

10682 Ins B SR 2B None

10684 Ins B SR 2B None

10684C Ins B SR 2B None

10685 Ins B SR SS None

10686 Ins B SR SS None

10686C Ins B SR SS None

10687 Ins B SR SS BCS

10695 Ins B SR SS None

10696 Ins B SR SS None

10696C Ins B SR SS None

10697 Ins B SR SS BCS

10910 CD SB RK 2B None

10910B CD SB RK 2B None

10926 CD SB RK 2B None

10927 CD SB RK 2B None

10928 CD 3S RK ? None

10929 CD SB RK 2B None

10995 Ins B SR SS None

10997 CD B SR SS BCS

11001 CD 3S RK 2B None

11001B CD 3S RK 2B None

11003 CD 3S RK 2B None

Code List

viiWPM Drive Systems Manual

TABLE OF CONTENTS

1B - one bail CDVP - cast deck Vacu Power

2B - two bail ES1 - Easy Stride 1st generation

3S- 3 speed ES2 - Easy Stride 2nd generation

21” stl - 21” steel deck Ins - Insight

22” stl - 22” steel deck PP1 - Personal Pace 1st generation

B- bevel gear PP2 - Personal Pace 2nd generation

BBC - blade brake clutch RK - rocking key

BBC VP - blade brake clutch SB - spur bevel

for Vacu Power SR - spring ratchet

BOS - blade override system SS - Sens-a-Speed

CD - cast deck W - worm

Model Trans Trans Wheel Handle Blade

R&R Internal Pinion Repair Clutch

Repair

16212 W Worm None None None

16212B W Wom None None None

16212W W Worm None None None

16212WG W Worm None None None

16401 W Worm None None None

16402 W Worm None None None

16404 W Worm None None None

16411 W Worm None None None

16775 W Worm None None None

16776 W Worm None None None

16785 W Worm None None None

16793 W Worm None None None

20001 22stl B SR 2B None

20003 22stl B SR 2B None

20005 22stl B SR 2B None

20007 22stl B SR 2B None

20011 22stl SB RK 2B None

20012 22stl B SR 2B None

20013 22stl B SR PP2 None

20014 22stl B SR PP2 None

20016 22stl B SR 2B None

20017 22stl B SR PP2 None

20018 22stl B SR PP2 None

20019 22stl B SR 2B None

20020 CD SB RK 2B None

20021 CD SB RK 2B None

20028 CD SB RK 2B None

20031 22stl B SR PP2 None

20036 CD SB RK PP2 None

20037 CD SB RK PP2 None

20038 CD SB RK PP2 None

20039 CD SB RK PP2 None

Code List

viii WPM Drive Systems Manual

TABLE OF CONTENTS

Code List

1B - one bail CDVP - cast deck Vacu Power

2B - two bail ES1 - Easy Stride 1st generation

3S- 3 speed ES2 - Easy Stride 2nd generation

21” stl - 21” steel deck Ins - Insight

22” stl - 22” steel deck PP1 - Personal Pace 1st generation

B- bevel gear PP2 - Personal Pace 2nd generation

BBC - blade brake clutch RK - rocking key

BBC VP - blade brake clutch SB - spur bevel

for Vacu Power SR - spring ratchet

BOS - blade override system SS - Sens-a-Speed

CD - cast deck W - worm

Model Trans Trans Wheel Handle Blade

R&R Internal Pinion Repair Clutch

Repair

20041 22stl B SR PP2 None

20044 CD 3SP RK 1B None

20047 22stl B RK PP2 None

20049 22stl B SR PP2 None

20051 22stl B SR PP2 None

20054 CD SB RK PP2 None

20055 CD SB RK PP2 None

20056 CD SB RK PP2 BOS

20057 CD SB RK PP2 None

20058 CD SB RK PP2 BOS

20070 22stl B SR PP2 None

20079 22stl B SR PP2 None

20106 CD 3SP RK 1B BBC

20107 CD 3SP RK 1B BBC

20210 CD 3SP RK 1B BBC

20211 CD 3SP RK 1B BBC

20214 CD 3SP RK 1B None

20216 CD 3SP RK 1B None

20218 CD 3SP RK 1B None

20219 CD 3SP RK 1B BBC

20320 CD 3SP RK 1B None

20321 CD 3SP RK 1B None

20322 CD 3SP RK 1B None

20324 CD 3SP RK 1BBC BBC

20325 CD 3SP RK BBC BBC

20327B CD 3SP RK 1B None

20328B CD 3SP RK 1B None

20436 CD 3SP RK 1B None

20436WF CD 3SP RK 1B None

20437 CD 3SP RK 1B None

20438 CD 3SP RK BBC BBC

20438WF CD 3SP RK BBC BBC

ixWPM Drive Systems Manual

TABLE OF CONTENTS

1B - one bail CDVP - cast deck Vacu Power

2B - two bail ES1 - Easy Stride 1st generation

3S- 3 speed ES2 - Easy Stride 2nd generation

21” stl - 21” steel deck Ins - Insight

22” stl - 22” steel deck PP1 - Personal Pace 1st generation

B- bevel gear PP2 - Personal Pace 2nd generation

BBC - blade brake clutch RK - rocking key

BBC VP - blade brake clutch SB - spur bevel

for Vacu Power SR - spring ratchet

BOS - blade override system SS - Sens-a-Speed

CD - cast deck W - worm

Model Trans Trans Wheel Handle Blade

R&R Internal Pinion Repair Clutch

Repair

20439 CD 3SP RK BBC BBC

20439WF CD 3SP RK BBC BBC

20462 CD 3SP RK 1B None

20463 CD 3SP RK 1B None

20464 CD 3SP RK 1B None

20465 CD 3SP RK BBC BBC

20466 CD 3SP RK BBC BBC

20470 CD 3SP RK 1B None

20472 CD 3SP RK 1B None

20473 CD 3SP RK 1B None

20474 CD 3SP RK 1B None

20475 CD 3SP RK BBC BBC

20476 CD 3SP RK BBC BBC

20478 CD 3SP RK 1B None

20479 CD 3SP RK 1B None

20480 CD 3SP RK 1B None

20481 CD 3SP RK 1B None

20482 CD 3SP RK BBC BBC

20483 CD 3SP RK BBC BBC

20486 CD 3SP RK 1B None

20487 CD 3SP RK BBC BBC

20488 CD 3SP RK 1B None

20489 CD 3SP RK 1B None

20490 CD 3SP RK BBC BBC

20494 CD 3SP RK 1B None

20495 CD 3SP RK 1B None

20622 CD 3SP RK BBC BBC

20632 CD 3SP RK BBC BBC

20652 21” stl SB RK PP1 None

20654 21” stl SB RK PP2 None

20655 22” stl B SR PP2 None

20656 22” stl B SR PP2 None

Code List

x WPM Drive Systems Manual

TABLE OF CONTENTS

1B - one bail CDVP - cast deck Vacu Power

2B - two bail ES1 - Easy Stride 1st generation

3S- 3 speed ES2 - Easy Stride 2nd generation

21” stl - 21” steel deck Ins - Insight

22” stl - 22” steel deck PP1 - Personal Pace 1st generation

B- bevel gear PP2 - Personal Pace 2nd generation

BBC - blade brake clutch RK - rocking key

BBC VP - blade brake clutch SB - spur bevel

for Vacu Power SR - spring ratchet

BOS - blade override system SS - Sens-a-Speed

CD - cast deck W - worm

Model Trans Trans Wheel Handle Blade

R&R Internal Pinion Repair Clutch

Repair

20666 CD 3SP RK 1B None

20667 CD 3SP RK BBC BBC

20668 CD 3SP RK 1B None

20677 CD 3SP RK 1B None

20680 CD 3SP RK 1B None

20692 CD 3SP RK 1B None

20695 CD 3SP RK BBC BBC

20761B CD 3SP RK 1B None

20763B CD 3SP RK 1B None

20764B CD 3SP RK 1B None

20764BC CD 3SP RK 1B None

20766B CD 3SP RK 1B None

20766BC CD 3SP RK 1B None

20767B CD 3SP RK 1B None

20768B CD 3SP RK 1B None

20776 CD 3SP RK 1B None

20777 CD 3SP RK 1B None

20778 CD 3SP RK 1B None

20781 CD SB RK PP2 None

20783 CD SB RK PP2 None

20784 CD SB RK PP2 None

20786 CD 3SP RK 1B None

20787 CD 3SP RK 1B None

20792 CD SB RK PP2 None

20793 CD SB RK PP2 None

20795 CD SB RK PP2 None

20796 CD SB RK PP2 None

20817 CD SB RK PP2 None

20819 CD SB RK PP2 None

20828 CD SB RK PP2 None

20831 CD SB RK PP2 None

20832 CD SB RK PP2 None

Code List

xiWPM Drive Systems Manual

TABLE OF CONTENTS

1B - one bail CDVP - cast deck Vacu Power

2B - two bail ES1 - Easy Stride 1st generation

3S- 3 speed ES2 - Easy Stride 2nd generation

21” stl - 21” steel deck Ins - Insight

22” stl - 22” steel deck PP1 - Personal Pace 1st generation

B- bevel gear PP2 - Personal Pace 2nd generation

BBC - blade brake clutch RK - rocking key

BBC VP - blade brake clutch SB - spur bevel

for Vacu Power SR - spring ratchet

BOS - blade override system SS - Sens-a-Speed

CD - cast deck W - worm

Model Trans Trans Wheel Handle Blade

R&R Internal Pinion Repair Clutch

Repair

20833 CD SB RK PP2 None

20905 CD Worm RK 1B None

20905B CD Worm RK 1B None

20906B CD Worm RK 1B None

20911B CD Worm RK 1B None

20915 CD Worm RK 1B None

20916B CD Worm RK 1B None

20920 CD Worm RK 1B None

20920B CD Worm RK 1B None

20921B CD Worm RK 1B None

20925 CD Worm RK 1B None

20925B CD Worm RK 1B None

20926B CD Worm RK 1B None

20927B CD Worm RK 1B None

26620B CD VP 3 SP RK 1B None

26620BF CD VP 3 SP RK 1B None

26620BG CD VP 3 SP RK 1B None

26621 CD VP 3 SP RK BBC BBC VP

26621B CD VP 3 SP RK BBC BBC VP

26622 CD VP 3 SP RK BBC BBC VP

26623 CD VP 3 SP RK BBC BBC VP

26624 CD VP 3 SP RK BBC BBC VP

26625B CD VP 3 SP RK 1B None

26625BG CD VP 3 SP RK 1B None

26626 CD VP 3 SP RK BBC BBC VP

26630B CD VP 3 SP RK 1B None

26630BC CD VP 3 SP RK 1B None

26630BG CD VP 3 SP RK 1B None

26631B CD VP 3 SP RK BBC BBC VP

26631BC CD VP 3 SP RK BBC BBC VP

26632 CD VP 3 SP RK 1B None

26632B CD VP 3 SP RK 1B None

Code List

xii WPM Drive Systems Manual

TABLE OF CONTENTS

1B - one bail CDVP - cast deck Vacu Power

2B - two bail ES1 - Easy Stride 1st generation

3S- 3 speed ES2 - Easy Stride 2nd generation

21” stl - 21” steel deck Ins - Insight

22” stl - 22” steel deck PP1 - Personal Pace 1st generation

B- bevel gear PP2 - Personal Pace 2nd generation

BBC - blade brake clutch RK - rocking key

BBC VP - blade brake clutch SB - spur bevel

for Vacu Power SR - spring ratchet

BOS - blade override system SS - Sens-a-Speed

CD - cast deck W - worm

Model Trans Trans Wheel Handle Blade

R&R Internal Pinion Repair Clutch

Repair

26633 CD VP 3 SP RK BBC BBC VP

26633B CD VP 3 SP RK BBC BBC VP

26635B CD VP 3 SP RK 1B None

26635BC CD VP 3 SP RK 1B None

26635BG CD VP 3 SP RK 1B None

26636 CD VP 3 SP RK 1B None

26636B CD VP 3 SP RK 1B None

26637 CD VP 3 SP RK 1B None

26638 CD VP 3 SP RK BBC BBC VP

26639 CD VP 3 SP RK 1B None

26640B CD VP 3 SP RK 1B None

26640BC CD VP 3 SP RK 1B None

26643 CD VP 3 SP RK 1B None

26643B CD VP 3 SP RK 1B None

26680 CD VP 3 SP RK 1B None

26680WG CD VP 3 SP RK 1B None

26682 CD VP 3 SP RK BBC BBC VP

26683 CD VP 3 SP RK BBC BBC VP

27500 CD VP 3 SP RK BBC BBC VP

27501 CD VP 3 SP RK BBC BBC VP

27502 CD VP 3 SP RK BBC BBC VP

20442 CD SB RK 1B None

20444 CD SB RK 1B None

20711 CD SB RK 1B None

Code List

xiiiWPM Drive Systems Manual

TABLE OF CONTENTS

THIS PAGE INTENTIONALLY LEFT BLANK.

xiv WPM Drive Systems Manual

WORM DRIVE TRANSMISSION

Worm Drive Transmission . . . . . . . . . . . . . . . . . . . . . . . .

Single Speed Spur/Bevel Gear Transmission . . . . . . . . . . . . .

Single Speed Bevel Gear Transmission . . . . . . . . . . . . . . . .

Three Speed Transmission . . . . . . . . . . . . . . . . . . . . . . .

Wheel Pinion Clutch . . . . . . . . . . . . . . . . . . . . . . . . . . .

1

2

3

4

5

Blade Brake Clutch Systems (BBC), Blade Override

System (BOS), Blade Clutch Systems (BCS) . . . . . . . . . . . . .

Handles and Control Cables . . . . . . . . . . . . . . . . . . . . . .

Self-Propel Belt Replacement . . . . . . . . . . . . . . . . . . . . . .

6

7

8

1-1WPM Drive Systems Manual

WORM DRIVE TRANSMISSION

GENERAL

There are two versions of the worm drive transmission.

The fi rst is a clutch type and is used on 21” front wheel

drive mowers. The second version is constant mesh and

is used on International 48cm rear wheel drive mowers.

INTERNALLY CLUTCHED

Description

This is a worm and helical gear transmission. The worm

shaft (input shaft) is driven by a belt from the engine

crankshaft. A spring which hooks into the tab on the

front of the transmission (where the roll pin is) and to

the mower housing, pivots the transmission forward to

maintain tension on the belt.

The worm is in constant mesh with the helical gear. The

clutching action is provided by a sliding clutch jaw. A shift

fork moves the clutch jaw to engage and disengage the

transmission. When the clutch jaw engages the helical

gear, power is transferred from the clutch jaw to the

sleeve inside the clutch jaw. The sleeve is pinned to the

axle. The axle then begins to rotate (Fig. 001).

A. Belt E. Shift Fork

B. Spring F. Sleeve

C. Helical Gear G. Input Shaft

D. Clutch Jaw (worm shaft)

A

C

B

E

G

D

F

1-2 WPM Drive Systems Manual

Fig 001 fi g 1

WORM DRIVE TRANSMISSION

Lubrication

This transmission requires 90 wt. gear oil. A variable

weight such as 85w90 is acceptable as long as the

range includes 90 weight. The second part of the

requirement is an EP rating of GL 5 or higher.

The transmission has a fi ll/check plug in the front. With

the transmission level, fi ll until level with the hole. NOTE:

This is equal to about the center of the axle.

Unless the case is cracked, oil can not leak out. Even if

a seal fails, oil will leak out only to the bottom of the seal

on the axle.

If gear failure occurs, the resulting friction can cook the

oil down to a smear in the bottom of the case. This does

not indicate a lack of lubrication.

This type of transmission will last less than 30 minutes

with no lubrication. If a transmission lasts even a few

weeks in consumer use, it had lubrication to start.

The Shifting Process

The upper end of the clutch fork slides over a groove in

a spring loaded rod. This spring pushes the shift fork and

clutch jaw towards the engaged position (Fig. 002).

The shift rod has a roll pin protruding through the top

of the transmission. This pin goes through a latch plate

with an L shaped slot in it. The slot guides the pin in its

travel from engagement to disengagement. Above the

latch plate is a dust fi lter and a dust cover. The shift arm

on top of the transmission holds all these parts in place

(Fig. 003).

G

A

B

C

D

E

F

Fig 003 3428-0165

A. Roll Pin E. Shift Arm

B. Latch Plate F. Screw

C. Dust Filter G. Shift Rod

D. Dust Cover

A

B

Fig 002 3428-0150

A. Shift Rod B. Shift Fork

When the shift arm is pulled to the rear by the shift

cable, the pin moves to the left side of the mower, then

to the rear. This moves the shift pin, the shift fork, and

the clutch jaw to the disengage position.

NOTE: Dirt packed in the latch plate can prevent

disengagement. The dust fi lter and dust

cover help prevent this failure.

When the shift cable is engaged, tension on the shift

arm is released. The spring on the shift rod applies

pressure to the rod, fork, and clutch jaw to engage the

transmission.

1-3WPM Drive Systems Manual

WORM DRIVE TRANSMISSION

C

Removal & Installation (front wheel drive

applications)

1. Remove the belt cover and unhook the spring on

the front of the transmission. Slip the belt off the

transmission pulley (Fig. 004).

A

B

C

Fig 004 3428-0127

A. Cable Clamp C. Spring

B. Shift Cable

4. Remove both front wheels and wheel covers (Fig.

005).

Fig 005 3428-0129

5. Pivot (both) front spring arms forward until they

point straight down. (This removes the tension from

the pivot arms so the roll pin can be removed) (Fig.

006).

2. Raise the front of the mower off the bench and

support it with blocks.

3. Disconnect the shift cable.

Fig 006 3428-0131

1-4 WPM Drive Systems Manual

WORM DRIVE TRANSMISSION

A

6. Place a block of wood under the wheel pinion for

support and drive the roll pin out of the axle (Fig.

007). Repeat the process on the other side.

A

Fig 007 3428-0135

A. Wood Block

8. Remove the transmission from the chassis.

9. Reverse the procedure to install.

NOTE: Support the wheel pinions with the wood

block while driving the roll pins in. This will

prevent the axle from being bent. Fill the

transmission with oil after it is installed in

the mower (Fig. 009).

Note the front of the transmission is identifi ed by the oil

fi ll/check screw and the fl at tab which is part of the lower

case.

7. The wheel pinion, thrust washer, pivot, and spring

arm will now slide off the end of the axle (Fig. 008).

Repeat the process on the other side.

Fig 008 3428-0137

A

C

B

Fig 009 3428-0166

A. Fill/Check C. Tab

B. Plug

Disassembly

1. Cut and discard the push-on retainer on top of the

transmission pulley. Remove the belt and pulley.

1-5WPM Drive Systems Manual

WORM DRIVE TRANSMISSION

2. Drive the roll pins out of the fl anges in the front

and rear of the case. (These pins align the top and

bottom parts of the case) (Fig. 010).

Fig 010 3428-0146

3. Remove the 4 self-tapping screw that connect the

top and bottom cases.

5. Push the worm shaft out of the cover. This may

require a little pressure.

6. To remove the axle, slide the clutch jaw to the side

and drive the roll pin out of the sleeve and axle (Fig.

012).

Fig 012 3428-0151

Note: If you turn this transmission on its side or

upside down, oil may leak out of the top. This

is not a sealed case.

4. Remove the transmission cover. The shift fork may

come with the cover or may fall into the bottom of

the case (Fig. 011).

Fig 011 3428-0148

7. If the axle bearings are to be re-used, clean the end

of the axle before drawing it out of the case.

8. Remove the sleeve, clutch jaw, helical gear, and

thrust washer (Fig. 013)

A

BC

D

Fig 013 3428-0153

A. Helical Gear C. Sleeve

B. Thrust Washer D. Clutch Jaw

1-6 WPM Drive Systems Manual

WORM DRIVE TRANSMISSION

9. Clean the old gasket material from the mating

surfaces of the case and cover.

10. A hook or small screwdriver can be used to pry the

seals out of the case.

11. An arbor press or large vise will be needed when

removing and replacing the bushings.

12. Clean the oil residue and any metal shavings from

the case.

13. Worm and helical gears are sold as a set. Even after

a short run time, they will develop a wear pattern.

Replacing only one gear will result in rapid failure

(Fig. 014).

A

14. Remove the screw from the shift arm and remove

the shift arm, dust cover, and wear plate (Fig. 015). If

the ball bearing is to be replaced, press it out at this

time.

G

A

B

C

D

E

F

Fig 015 3428-0165

A. Roll Pin E. Shift Arm

B. Latch Plate F. Screw

C. Dust Filter G. Shift Rod

D. Dust Cover

B

A. Worm Shaft B. Helical Gear

Fig 014 3428-0157

15. Remove the roll pin and pull shifter rod out of the

cover. Clean the cover.

Assembly

1. Use bushing installation tool P/N 27-0460, to press

in new axle bushings. This tool helps keep the

bushing straight and keeps the inner diameter of the

bushing correctly sized.

1-7WPM Drive Systems Manual

WORM DRIVE TRANSMISSION

Note: The bushings are two different lengths. The

side of the case with the thicker boss uses

a longer busing to support the axle. The

bushings should be fl ush with the inside of

the case (Fig. 016).

A

Fig 016 3428-0158

A. Tool P/N 27-0460

3. Note: Some replacement axles have more than one

hole that can be used to pin the sleeve to the axle.

Refer to the original axle to identify the correct hole

to use. Then drive a roll pin through the sleeve and

axle (Fig. 017).

Fig 017 3428-0151

2. Clean the rust and dirt from the both ends of the

axle. Wipe the inner diameter of the bushings with

a clean cloth. Lightly oil the axle and insert it into

the gearcase. When facing the front of the gearbox,

insert the short end of the axle from left to right.

Install the thrust washer, helical gear, and the sleeve

and clutch jaw. Then push the axle through the other

side of the case.

4. Using a seal protector, slide new seals down each

side of the axle, Install the seal with the lip facing the

transmission. The outer edge of the seal should be

fl ush with the outside of the case. If a seal protector

is not available, wrap a piece of cellophane around

the axle (Fig. 018).

A

B

Fig 018 3428-0170

1-8 WPM Drive Systems Manual

A. Seal protector or B. Seal

Cellophane

WORM DRIVE TRANSMISSION

5. If the bearing in the cover is being replaced, use tool

P/N 27-0490 to press it in place. This bearing only

has one seal. Install the bearing such that the seal

is visible from the top of the cover and the open side

faces the gears. Press the bearing in until it is fully

seated in the case (Fig. 019).

A

Fig 019 3428-0159

9. Fill the transmission with gear oil AFTER it is

installed in the mower. The top of this transmission is

not sealed. It will leak if tipped on its side (Fig. 020).

A

B

Fig 020 3428-0166

A. Fill/Check B. Plug

A. Tool P/N 27-0490

6. Install worm shaft in bearing.

7. Use a new gasket. Install the cover on the bottom

case and start the 4 self-tapping screws. Do not fully

tighten them.

8. Install the front and rear roll pins to align the cover

and case. Then secure the 4 self-tapping screws.

Controls

There are two control cables used with this system. One

cable operates the engine kill switch and fl ywheel brake;

the other controls the transmission.

1-9WPM Drive Systems Manual

WORM DRIVE TRANSMISSION

Adjustment

The transmission cable is a standard lever type. Since

the spring and pin on top of the transmission pushes the

shift fork towards the engaged position, the cable pulls

the shift arm to the rear to disengage the transmission.

The adjustment point is on the mower housing just to

the rear of the transmission. To adjust, pull the control to

the rear (disengage). Go to the cable clamp/adjustment.

Loosen the clamp, pull the cable to the rear until the shift

lever is as far back as it will go. Hold it there and tighten

the clamp (Fig. 021).

A

Fig 021 3428-0127

A. Cable Clamp

1-10 WPM Drive Systems Manual

WORM DRIVE TRANSMISSION

CONSTANT MESH

Description

This transmission is very similar to the “INTERNALLY

CLUTCHED” on page 1 – 1. However, the helical gear

is different as there is no internal clutching (Fig. 022).

Engagement and disengagement is accomplished by

pivoting the transmission to tighten or loosen the belt.

Internal repair procedures are the same, as is the

lubrication requirement, 90 wt. gear oil rated GL-5 or

higher.

1. Jam nut 13. Oil Seal

2. Lock washer 14. Output shaft

3. Half pulley 15. Traction bracket

4. V Belt 16. Thread forming screw

5. Pulley spacer 17. Gearbox case

6. Gearbox cover 18. Thrust washer

7. Shaft & worm 19. Roll pin

8. Ball bearing 20. Helical gear

9. Gearbox gasket 21. Thrust washer

10. Check plug 22. Bushing

11. Gasket check plug 23. Roll pin

12. Bushing

The constant mesh type transmission is used in a 48cm

rear wheel drive application.

Fig 022 fi g 18-A

1-11WPM Drive Systems Manual

WORM DRIVE TRANSMISSION

Removal and Installation

Fig 023 20911B sprearaxleassy

Ref. No. Qty Description

1

2

3

4

5

6

7

9

10

11

12

13

14

15

1-12 WPM Drive Systems Manual

1

2

2

2

2

1

2

1

2

1

2

1

2

2

Rear Pivot Assembly RH

(incl. Ref. #2, 4, 5 & 14)

Grease Fitting

Washer

Sleeve Bushing

Grease Seal

Rear Pivot Assembly LH

(incl. Ref. #3, 4, 5 & 14)

Locknut

Thread Forming Screw

Trigger Return Spring

H.O.C. Saddle

Thread Forming Screw

Push Nut

Needle Bearing

Friction Washer

Ref. No. Qty Description

16

17

18

19

20

21

22

23

24

25

26

27

28

34

35

4

4

1

2

2

2

2

2

4

2

2

2

4

2

1

Keyed Thrust Washer

Retaining Ring

LH Rocking Key

Pinion Gear

Compression Spring

Wheel Cover

Tire & Gear Assy Wheel

(incl. Ref. #24)

Wheel Bolt

Wheel Bushing

Wheel Spacer

Clutch Washer

Rear Suspension Plate

Thread Forming Screw

Roll Pin

Gearbox Assembly

Loading...

Loading...