Page 1

Pivot Bracket Kit

for OFZ

FORM NO. 3323-104

Part No. 100–2449

Loose

Note: Use the chart below to identify parts for assembly.

DESCRIPTION QTY. USE

Pivot Bracket

Removing

1. Disengage the power take off (PTO), set the

2. Remove hairpin cotters and clevis pins from

Parts

the Mower

parking brake, and turn the ignition key to

“OFF” to stop the engine. Remove the key.

mower hanger brackets and separate mower from

carrier frame (Fig. 1).

1

Install Pivot Brackets

4. Place a block, approximately 4 inches high,

under the carrier frame. This will raise the frame

vertically.

5. Check to see if tension has been removed from

the spring assemblies. If tension remains add

blocks to raise carrier frame higher.

6. Remove 3/8” x 7/8” (23 mm) shoulder bolts and

3/8” locknuts securing spring end plate

assemblies to carrier frame (Fig. 2).

INSTALLATION

INSTRUCTIONS

3

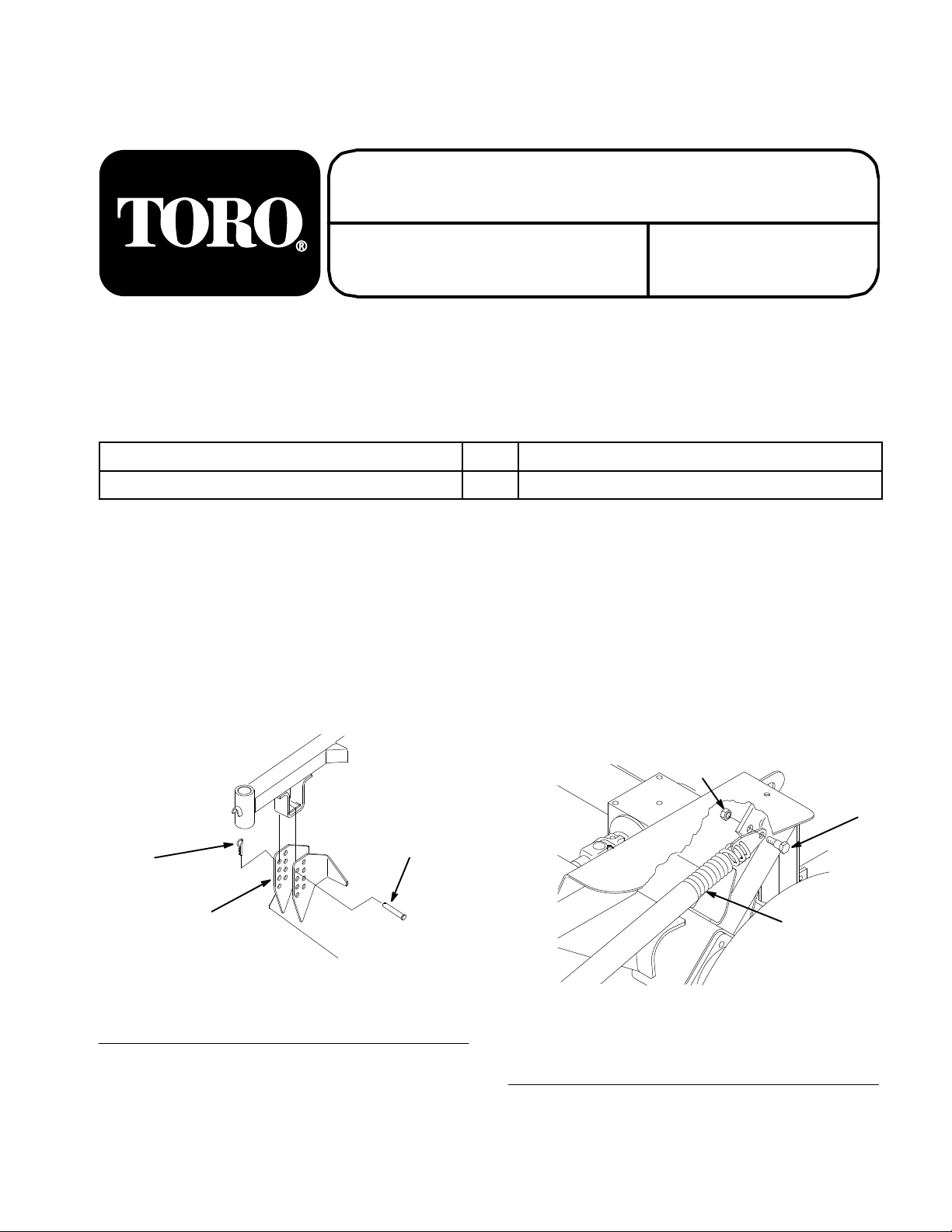

1. Mower

2.

Clevis Pin

1

Hanger Bracket

Figure 1

3.

Hairpin Cotter

2

3. Fold carrier frame into its upright position.

The T

Printed in USA

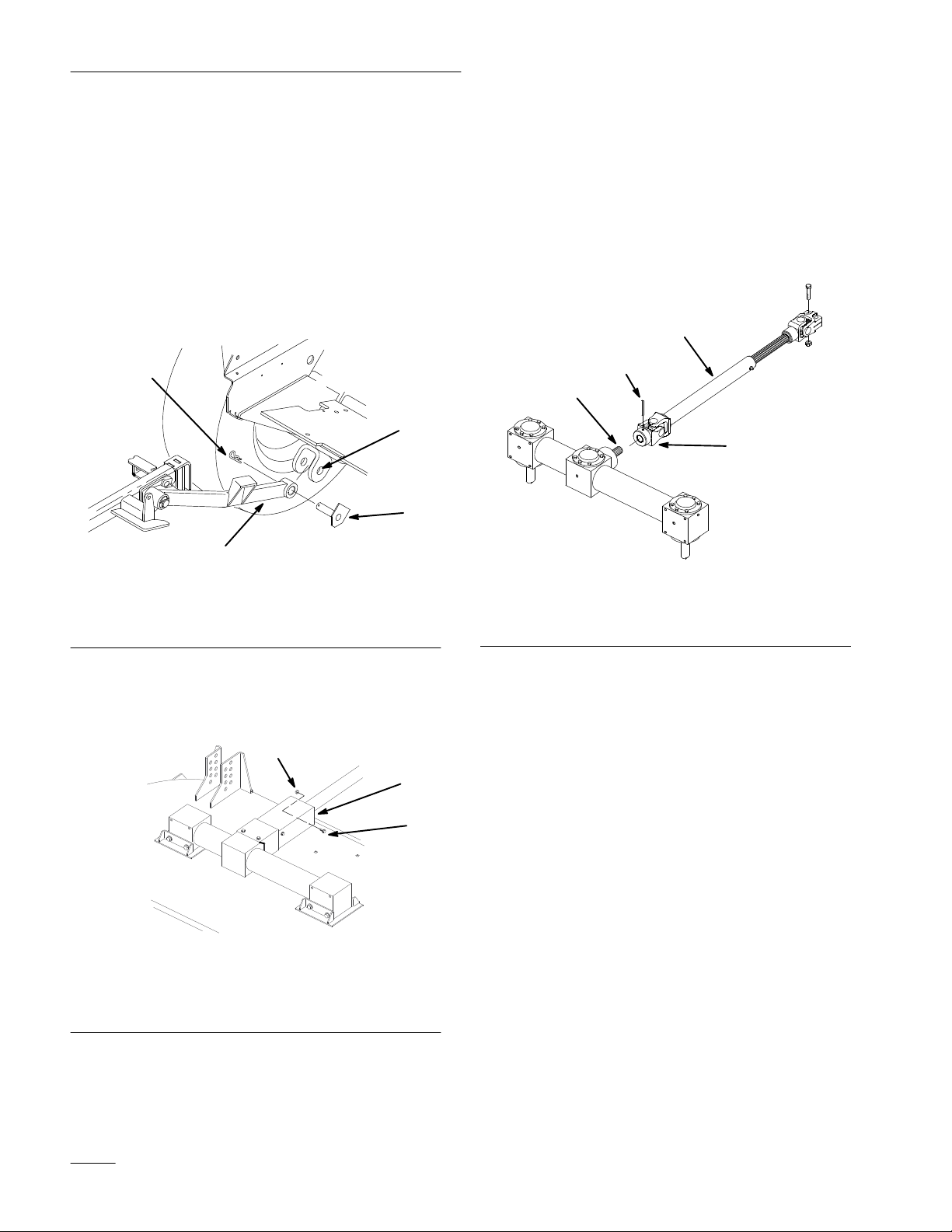

1. Spring

2.

Shoulder Bolt 3/8” x 7/8”

(22 mm)

oro Company – 1999

All Rights Reserved

Assembly

3

Figure 2

3.

Locknut 3/8”

2

1

Page 2

Installation Instructions

7. Remove the block under the carrier frame.

8. Unfold carrier frame.

9. Remove hairpin cotters and pivot pin assemblies

securing push arms to traction unit pivot

brackets (Fig. 3).

Note: Save all hardware for use when

installing mower. Items 3 and 4 are

part of traction unit.

4

1

3

m-3937

1. Pivot

2.

Push Arm

Bracket

2

Figure 3

3.

Pivot Pin Assembly–flat

4.

Hairpin Cotter

11. Drive roll pin through hole in universal joint to

remove PTO drive shaft from gearbox shaft

(Fig. 5).

Note: Drive shaft remains with traction unit.

12. Move deck and carrier frame away from traction

unit.

1

4

3

2

m-3376

Figure 5

1. PTO

2.

Driveshaft

Universal Joint

3.

Gearbox shaft

4.

Roll Pin

10. Remove 5/16–18 x 7/8” (11 mm) shoulder bolt

and 5/16” flange nut holding PTO cover down

(Fig. 4).

3

1

2

m-3718

Figure 4

1. PTO

2.

cover

Shoulder bolt

5/16–18 x 7/8” (1

1 mm)

3.

Flange nut 5/16”

Remove

Existing Pivot

Brackets

1. Jack up machine until the drive wheels are off

the floor. Use jack stands or block the machine

to prevent it from falling accidentally.

2. Remove the drive wheels.

IMPORTANT: Remove all grasss and debris

from wheel motor mounts and area around

them.

3. Remove the existing pivot brackets on the

machine. Remove any welding that exists.

4. Remove paint from areas that will be welded,

including new pivot brackets.

2

Page 3

Installation Instructions

Installing

New Pivot Brackets

The pivot brackets need to be installed with a jig, part

number 100–2444. The jig is available through the

Toro Parts Department.

Note: Apply anti–splatter to jig pins to

prevent weld splatter from sticking to

jig pins (Fig 7). Obtain this locally.

1. Install one of the new pivot brackets onto jig

(Fig 6).

1

3

4

5

2

Figure 6

1. Jig

2. Pivot

3. V

Bracket

ertical Plate (Flush to

side of motor mount)

4.

Base Plate (Flush to

bottom of motor mount)

5.

Bracket surface (Flush to

front of motor mount)

7. Reinstall mower deck.

2

3

5

4

Figure 7

1. OFZ

2.

3.

Frame

Wheel Motor Mount

Right–hand Pivot Bracket

4.

Jig and Left–hand Pivot

Bracket

5. W

eld Here

X

1

2

2. Position the jig and bracket against the wheel

motor mount. (Fig 7).

Note: Position the jig on the inside of the

wheel motor mounts. When positioned

correctly it will be flush to motor

mount (Fig. 6 and 7).

3. Clamp jig and pivot bracket in place (Fig 7).

4. Weld pivot bracket to wheel motor mount.

Lightly tack bracket, opposite jig, to motor

mount. Remove jig and weld along entire length

of both sides (Fig 7).

5. Repeat for pivot bracket on opposite wheel

motor mount.

6. Reinstall the large front tires. Remove jack

stands.

3

Page 4

Installation Instructions

4

Loading...

Loading...