Page 1

Rear Baffle Kit

for 60I OFZ Deck

FORM NO. 3323-158

Part No. 100–2439

Loose

Note: Use the chart below to identify parts for assembly.

DESCRIPTION QTY. USE

Baffle

Screw

Lock Nut

Pre–Installation

Parts

1

1

1

Install New Baf

1. Disengage the power take off (PTO), set the

parking brake, and turn the ignition key to

“OFF” to stop the engine. Remove the key.

2. Tilt up deck and lock into vertical position.

fle

INSTALLATION

INSTRUCTIONS

POTENTIAL HAZARD

• Blade is sharp.

WHAT CAN HAPPEN

• Contact with sharp blade can cause serious

personal injury.

HOW TO AV

OID THE HAZARD

• Wear gloves or wrap sharp edges of the

blade with a rag.

3. Thoroughly clean mower deck. All debris must

be removed to ensure baffle will fit properly

against mower deck.

4. Repair all bent or damaged areas of mower deck

and replace any missing parts.

Printed in USA

The T

oro Company – 1999

All Rights Reserved

Page 2

Installation Instructions

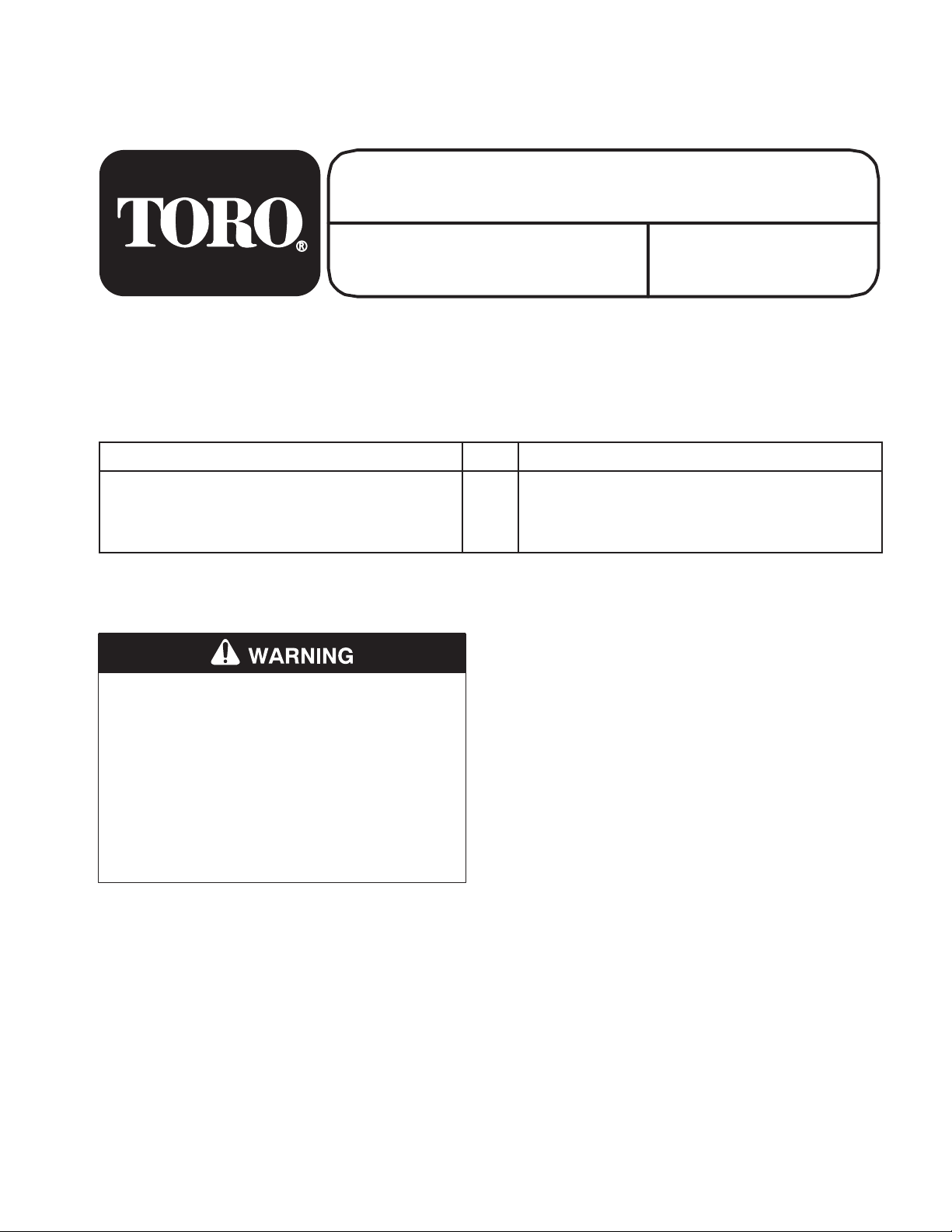

Removing

Existing W

ear Plate

1. Remove existing righthand wear plate under

deck. Save hardware that is removed (Fig. 1).

1

4

1. Deck

2. Bolt

Installing

Figure 1

3. Nut

4. Wear

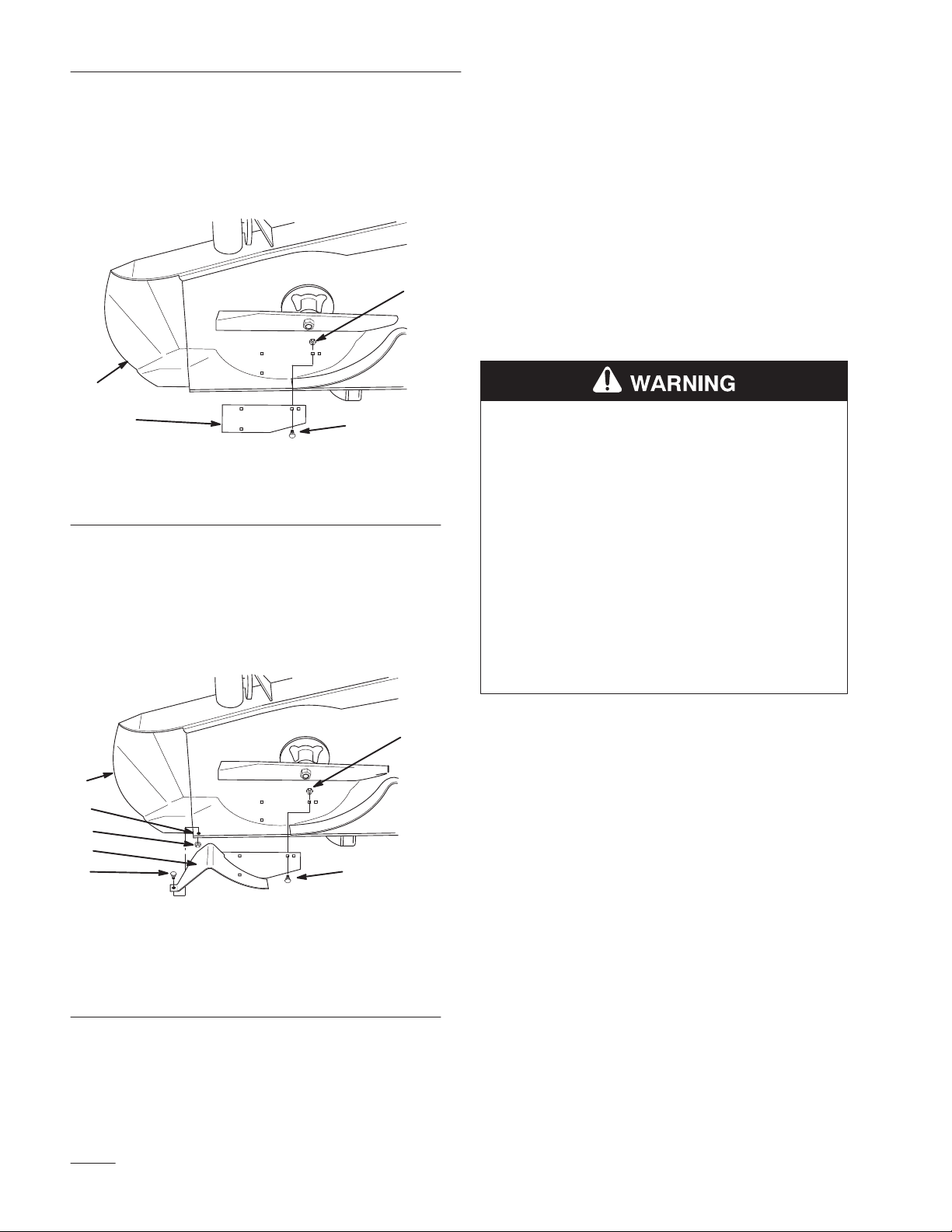

New Baffle

2

Plate

Note: Use existing three holes in which wear

plate was located.

3

M-4512

Note: When installing bolts, the bolt heads

need to be on the inside of cutting

deck.

2. Use the baffle as a template to drill a hole in side

of deck. Mark location and drill a 11/32 in. hole.

(Fig. 2).

3. Install screw and flange nut into deck and baffle.

Torque to 200±25 in–lb.

4. Rotate blade to ensure it does not hit baffle.

POTENTIAL HAZARD

• A blade that is bent or damaged could

break apart and pieces could be thrown at

bystanders or at you as you use the mower.

WHAT CAN HAPPEN

• Pieces of blade that may be thrown could

seriously injure or kill you or bystanders.

HOW TO AV

•

Always r

OID THE HAZARD

eplace bent or damaged blade with

a new blade.

• Never file or create sharp notches in the

edges or surfaces of blade.

3

1

5

7

4

6

1. Deck

2. Bolt

3. Nut

4. Baffle

Figure 2

5. Hole

6. Screw

Flange Nut

7.

2

M-4513

to drill

1. Install new baffle into existing wear plate holes

(Fig. 2).

2

Loading...

Loading...