Page 1

FORM NO. 3323-792

Heavy Duty Air Cleaner Kit

for Out Front Z

Part No. 100–2402

Part No. 100–2403

Part No. 100–2404

Loose

Note: Use the chart below to identify parts for assembly.

DESCRIPTION QTY. USE

Carburetor

Adapter Plate

Carburetor Gasket

Air Cleaner Base Gasket

Air Cleaner Adapter Gasket

Adapter

Air Cleaner Bracket

Screws

Parts

1

1

1

1

1

1

1

Install New Carburetor

7

INSTALLATION

INSTRUCTIONS

Plug

Screws

Air Cleaner w/90º Inlet

A/C Bracket

Hood

Nut

T

emplate #1

T

emplate #2

Rubber Grommet

Air Intake Hose

R–Clamp

Screw

Flange Connector

Radiator Clamp

Screws

T

emplate #3

2

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

Cut Holes in Plastic T

Install Air Intake Hose

Install Flange Connector

Drill Holes in Bumper

ank

Printed in USA

The T

oro Company – 1999

All Rights Reserved

Page 2

Installation Instructions

DESCRIPTION USEQTY.

Air Cleaner Bracket

Hex Head Screw

Nuts

Air Cleaner

Hex Head Screw

Nuts

Radiator Clamp

Filter Finder Kit

Filter Guard

Cover Plate

Screws

Nuts

Wing Nut

Carriage bolts

This kit contains a heavy–duty air cleaner, carburetor,

hose adapter

, hoses and mounting hardware. This

creates a complete heavy–duty air cleaner system for

Toro Out Front Z Mowers with Kohler Command

Twin Cylinder Engines.

1

2

2

1

2

2

2

1

1

1

3

3

2

2

Install Air Cleaner Bracket

Install Air Cleaner

Install Hoses to Air Cleaner

Install Filter Finder Kit

Install Guard and Cover

Pre–Installation

1. Disengage the power take off (PTO), set the

parking brake, and turn the ignition key to

“OFF” to stop the engine. Remove spark plug

wire(s) and remove the key.

POTENTIAL HAZARD

• If you leave the key in the ignition switch,

someone could start the engine.

WHAT CAN HAPPEN

• Accidental starting of the engine could

seriously injure you or other bystanders.

HOW TO AV

OID THE HAZARD

• Remove the key from the ignition switch

and pull the wire(s) off the spark plug(s)

before you do any maintenance. Also push

the wire(s) aside so it does not accidentally

contact the spark plug(s).

2. Tilt hopper up remove all grass from hopper.

3. Thoroughly remove all grass and debris from

around the engine and plastic console on left

side.

2

Page 3

Installation Instructions

Removing

Hopper

1. Tilt hopper up.

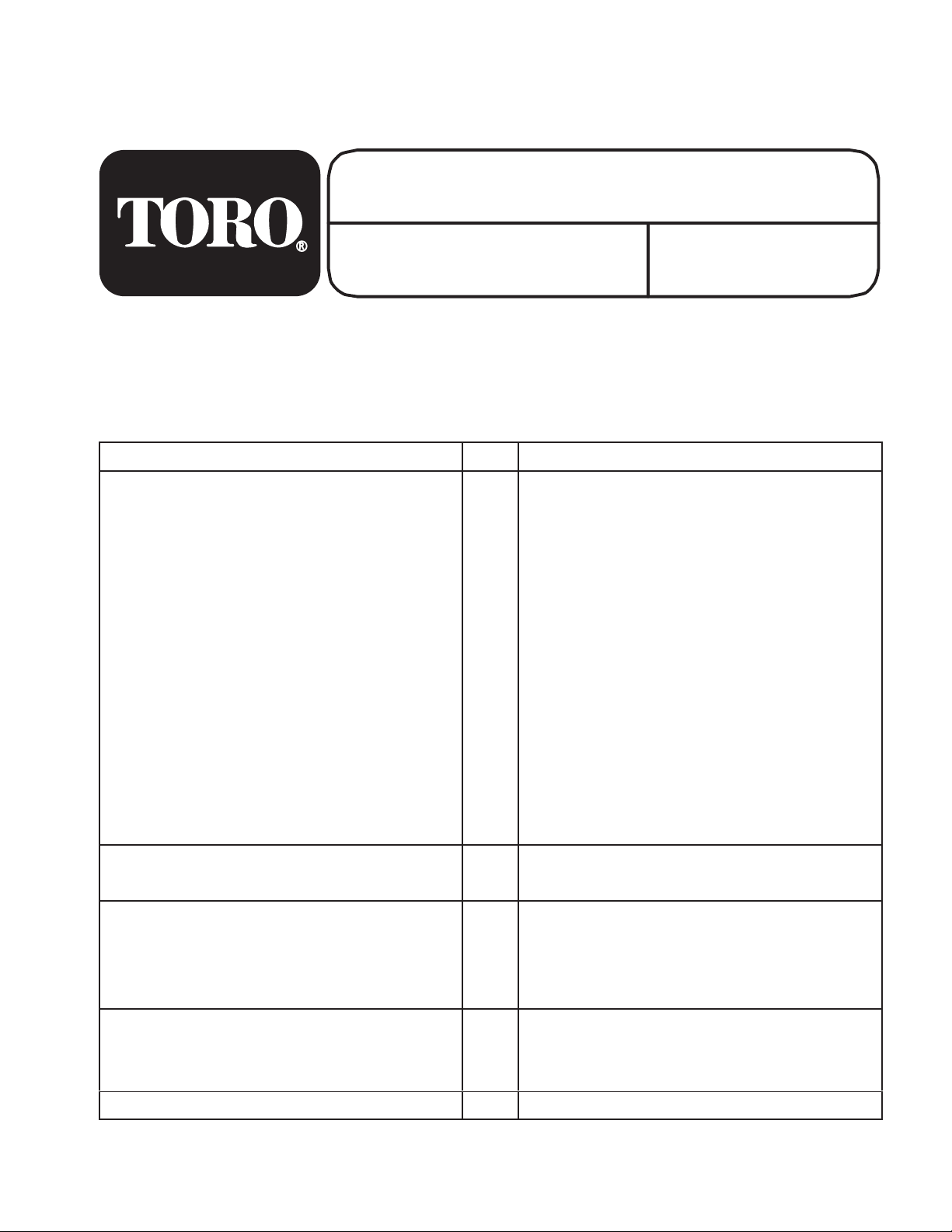

2. Disconnect the wire harnesses along the rear left

side frame as shown in figure 1. Ensure that it is

free of the frame.

3. Remove safety clip from end of gas spring to

hopper. Disconnect gas spring from ball stud

attached to machine frame (Fig. 2). Support

hopper to prevent falling.

4. Lower hopper. Remove both clevis pins from the

rear frame that the hopper pivots on. Remove

hopper. (Fig. 2).

1

M-4582

Figure 1

1. Wire

Harness

Turning

Engine Lift Hook

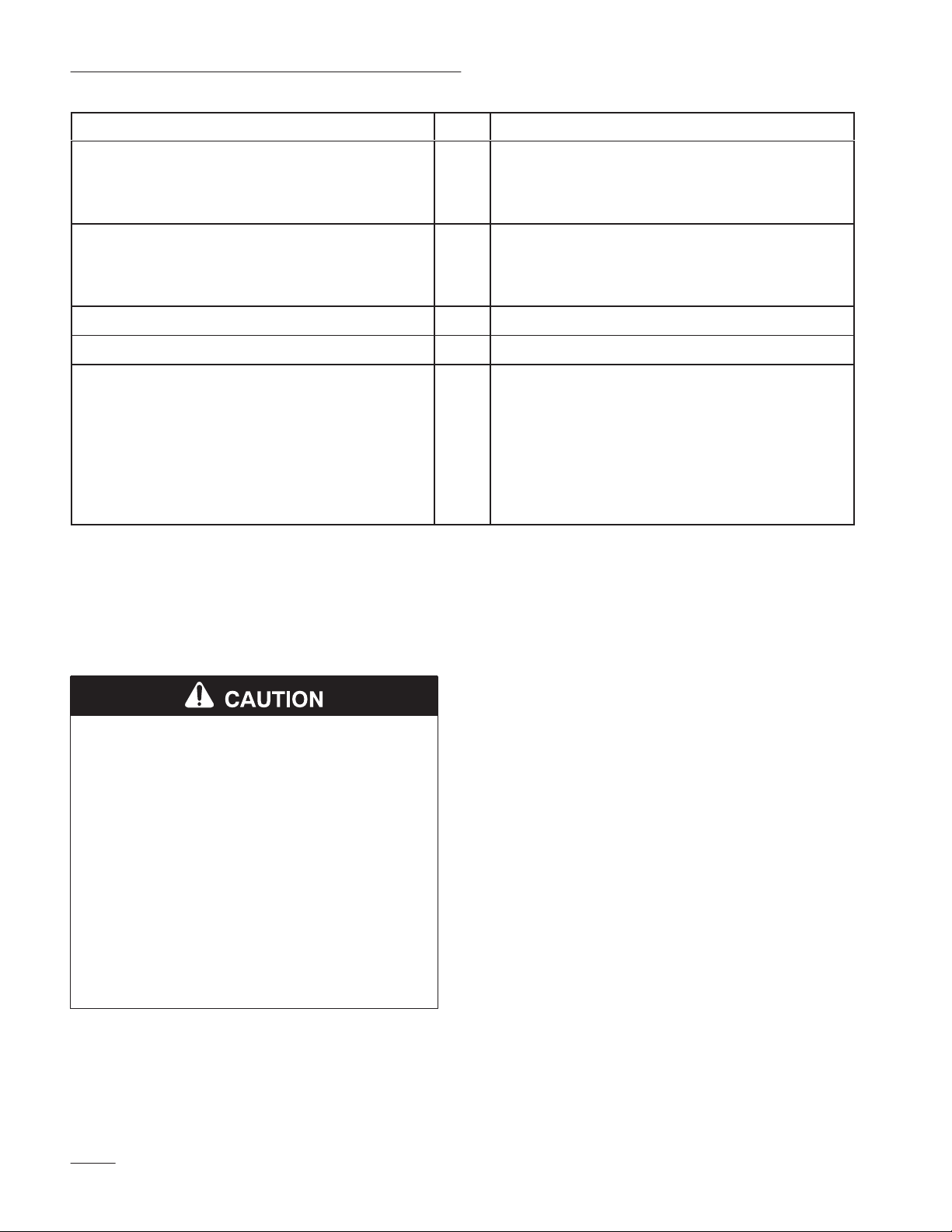

Turning the engine lift hook will allow clearance for

hose installed later in this instruction sheet. Keep the

hook and hardware for future use if needed.

IMPORTANT: Return lift hook to original

position before it is used for to remove engine.

1. Locate on engine the lift hook in figure 3.

2. Remove the lift hook from engine.

3. Rotate lift hook 180 degrees and reinstall.

1

2

M-4583

Figure 3

1. Engine

Lift Hook

2. Screws

1

4

1. Hopper

2. Safety

3.

Gas Spring

Clip

Figure

2

4.

5.

Hair Pin

Clevis pin

Removing

2

1. Remove all existing air cleaner components

Carburetor

attached to the carburetor. Save the three

mounting screws from the air cleaner base plate

and discard everything else.

3

2. Have an appropriate container ready to catch any

5

remaining fuel that might leak out and

disconnect the fuel line from the carburetor.

3. Follow the red lead from the fuel shut–off

solenoid on the front of the carburetor and

disconnect it from the harness plug.

M-4581

4. Remove and save the two carburetor mounting

screws.

3

Page 4

Installation Instructions

5. Lift and pivot the carburetor to unhook the choke

link, throttle link, and throttle dampening spring

attached to the carburetor. Discard the old

carburetor.

6. Remove the carburetor gasket from the intake

manifold and clean off any remaining material

using an aerosol gasket remover.

IMPORTANT: Do not nick or scratch

manifold surface.

Installing

Carburetor

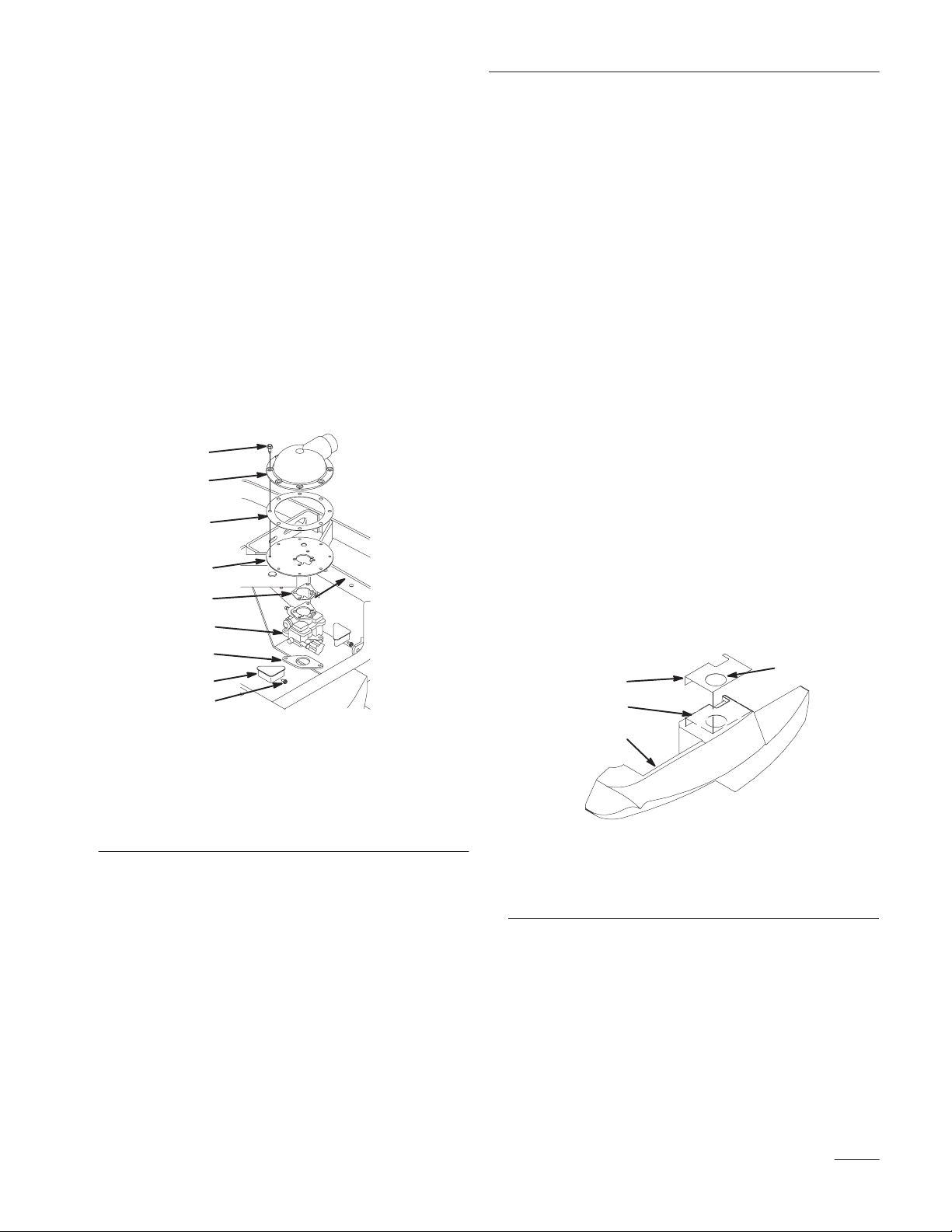

1. Install the two triangular plugs from the kit into

the air ducts on the top of the blower housing.

Start the two thread–forming screws from the kit

into the holes in the front of the air ducts.

Tighten the screws until the plugs are locked into

place (Fig. 5).

2. Install the new carburetor gasket onto the intake

manifold. Make sure all holes are aligned and

open. A dab of gasket adhesive may be used to

keep it in position (Fig. 5).

3. Reconnect the choke link, throttle link, and

throttle dampening spring into the corresponding

levers of the new carburetor (Fig. 5).

6. Check the equipment throttle and choke controls

for proper operation. Be sure the plates in the

carburetor are opening and closing fully with the

movement of the control levers.

7. Connect the lead wire from the fuel shut–off

solenoid.

8. Reconnect the fuel line to the carburetor inlet

and secure with the clamp. Make sure the fuel

line does not interfere with any of the linkages.

9. Place the new air cleaner base gasket from kit on

top of the carburetor (Fig. 5).

10. Position the new adapter plate over the

carburetor gasket and pull the breather tube

through the corresponding hole until the plate is

seated between the flanges. Assemble the new

air cleaner bracket to the top of the new air

cleaner base, inserting the breather tube through

the hole in side of bracket. Make sure the end of

the breather tube points toward the center of

carburetor throat. Install the three mounting

screws removed in step 1 of Removing

Carburetor, page 3. Torque the screws to

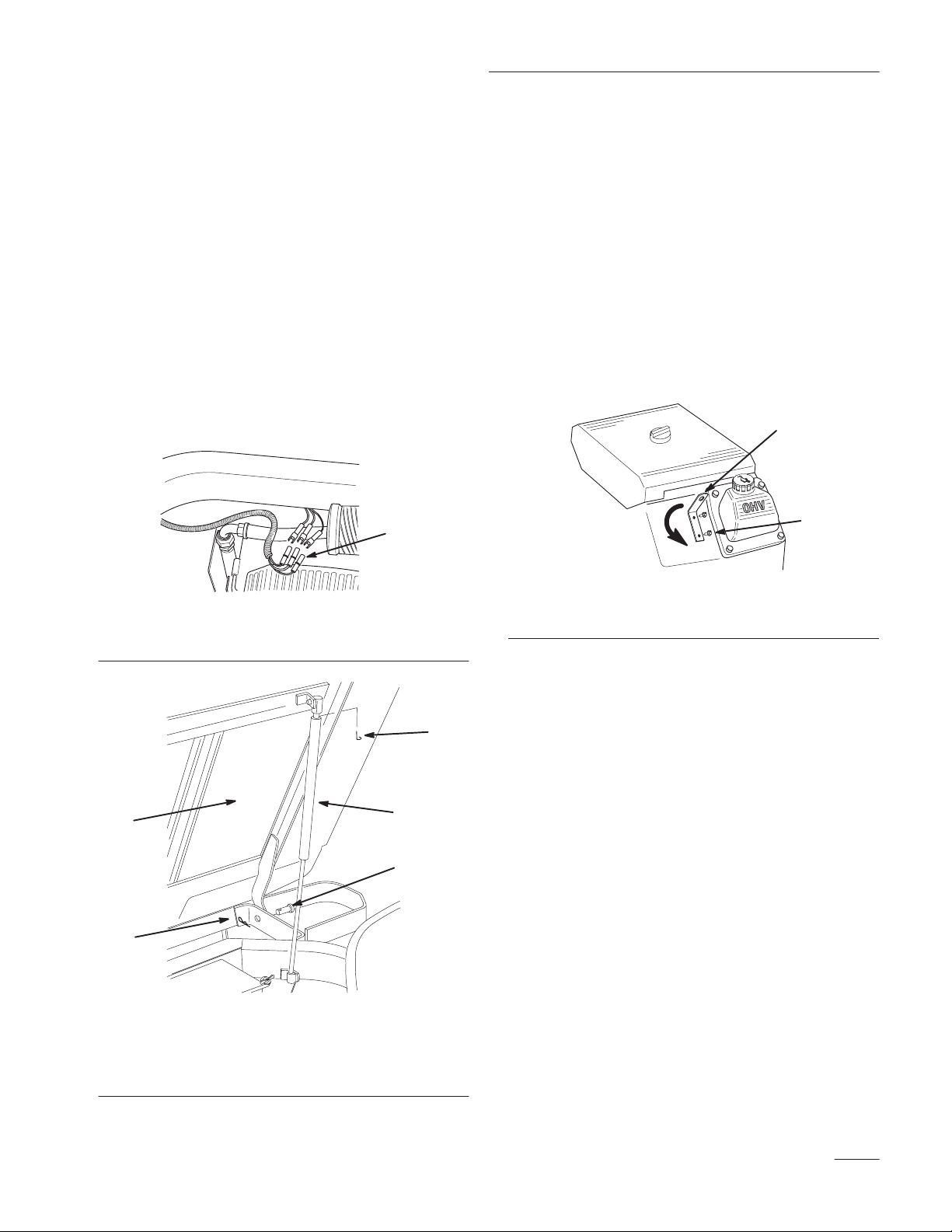

88 in. lb (9.9 N•m). See figure 4.

1

2

4. Set the carburetor into position on the

gasket/intake manifold and install the two

mounting screws saved in step 4 of Removing

Carburetor. Lightly finger tighten the screws

(Fig. 5).

5. Hold the governor lever toward the carburetor as

far as it will go. Check that the throttle plate is

wide open in this position. If the throttle plate is

not wide open, keep pressure against the

governor lever and shift the carburetor until the

plate is wide open. Torque the two mounting

screws to 9.9 NSm (88 in.–lb.).

4

1. Air

Cleaner Bracket

2.

Breather T

ube

3

Figure 4

Mounting Screw

3.

Page 5

Installation Instructions

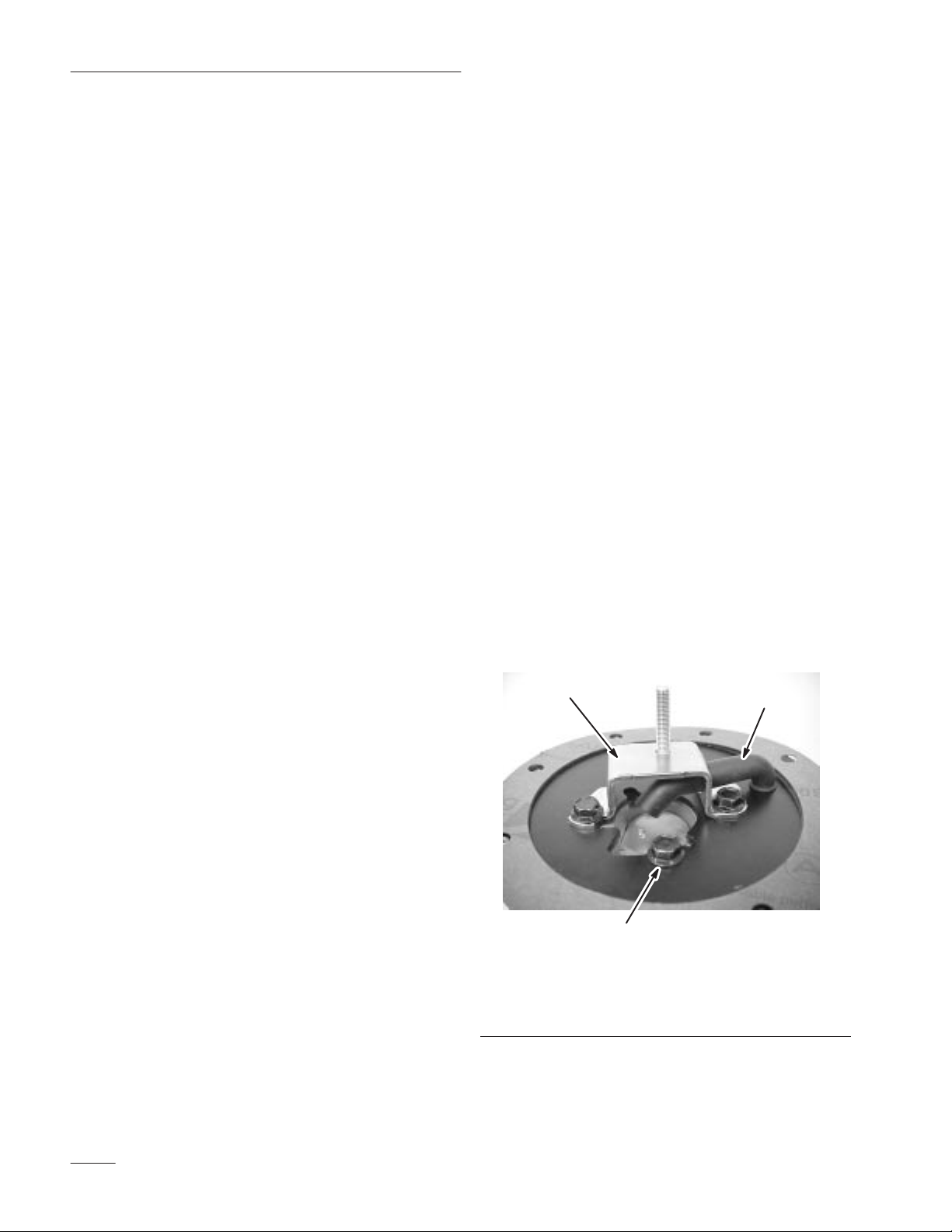

11. Position the new adapter plate over the

carburetor gasket and pull the breather tube

through the corresponding hole until the plate is

seated between the flanges. The end of the

breather hose must point into the carburetor

throat. Install the three mounting screws

removed in step 1 and torque them to 9.9 NSm

(88 in. lb) (Fig. 5).

12. Position the adapter gasket and air intake adapter

onto the adapter plate, so the hose connection

neck is facing straight back in the engine

compartment. Secure with the seven M6

thread–forming screws. Torque the screws to

10.7 NSm (95 in.–lb.) (Fig. 5).

9

8

7

6

Cutting

Holes in Plastic

Console

A 3I and 3–1/2I diameter hole saw is needed to drill

into the left side plastic console.

Note: Templates 1 and 2 must be used to

locate the correct location for holes.

Templates are located in the back of

this instruction sheet.

1. Locate and cut out templates 1 and 2 from the

back of this instruction sheet.

Note: Do not cut out large circles in paper

templates.

2. Take template number one and fold it across the

fold line.

3. Place template number one onto the top of the

plastic console as shown in figure 6. Tape to

plastic console.

5

4

3

1

2

1. Triangular

2.

Plug Screws

3.

Carburetor gasket

4. Carburetor

5.

Air Cleaner Base Gasket

Plugs

Figure 5

3

6.

Adapter Plate

7.

Adapter Gasket

8.

Air Intake Adapter

9. Screws

M-4571

13. Place rag or tape over air intake adapter opening

to prevent debris entering.

4. Using 3I diameter hole saw, cut a hole at the

specified area in template (Fig. 6).

3

m-4573

Diameter Hole to be cut

Leftside console

1. Template

2. T

emplate Position on

console

1

2

4

#1 (Folded)

Figure 6

3. 3”

4.

5. Locate template number two and cut out small

hole. Fold template at the specified fold lines.

6. Place small cut out hole onto bolt head and place

the fold in the bend of metal support. (Fig. 7).

7. Align diagonal line on template with the edge of

metal support. Tape template to plastic console

and metal support (Fig. 7).

5

Page 6

Installation Instructions

9

8. Mark center of 3–1/2” hole. (Fig. 7).

9. Remove bolt that was used when locating

template position (Fig. 7).

10. Using 3–1/2I diameter hole saw, cut a hole at

the specified area in template (Fig. 7).

11. Reinstall bolt. (Fig. 7).

Note: Part of hole will be cut through metal

support. Remove any burrs from the

metal support after hole is cut.

2

4

1. Template

2. T

console

3–1/2” Diameter Hole to

3.

be cut

4. Bottom

#2 (Folded)

emplate Position on

of Leftside console

5

Figure 7

5. Bolt

Head (Remove bolt

after 3–1/2” hole location

is marked.)

6.

Cut out circle (Align onto

bolt head)

7.

Edge of Metal Support

7

1

3

6

m-457

Drilling

Holes into Bumper

Note: Template 3 must be used to locate the

proper location for holes. Template 3 is

located in the back of this instruction

sheet.

1. Locate and cut out template three from the back

of this instruction sheet.

Note: Do not cut out circles in paper

template.

2. Take template number three and fold it across

the fold line.

3. Place template number three onto the top of the

rear bumper as shown in figure 9. Tape to

bumper.

4. Remove the three bolts as shown in figure 8.

Loosen the fourth bolt but do not remove.

1

4

Note: Figure 7 shows machine as if it were

tipped on its side. Do not tip machine

on its side.

6

1. Bolts

2. Nuts

2

3

Figure 8

3. Bumper

4. Bolt

(Loosen)

m-4580

Page 7

Installation Instructions

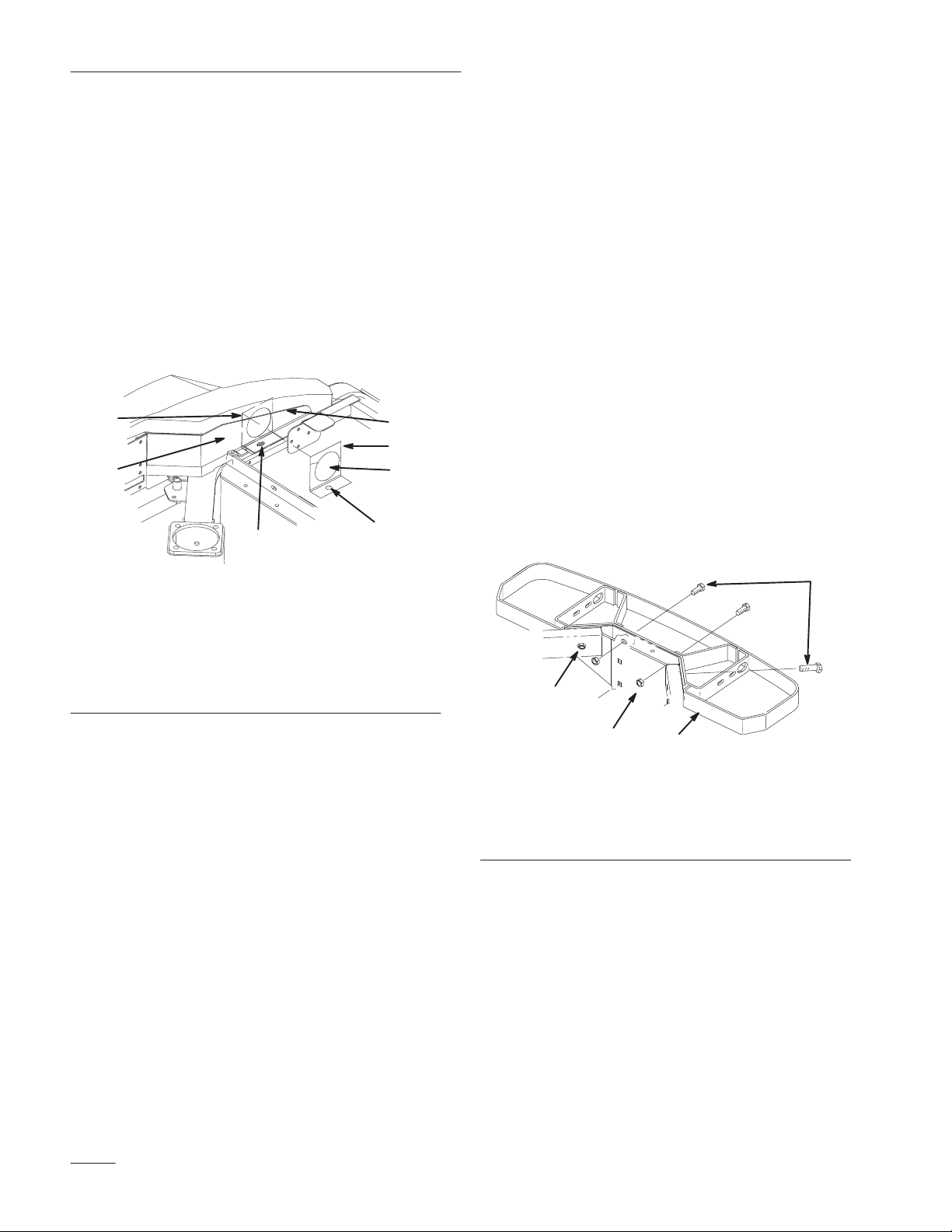

5. Rotate the leftside of bumper up to gain access

to drill holes on front leftside of bumper (Fig. 9).

6. Drill two 11/32” holes onto the front of

bumper (Fig. 9). Remove template.

7. Reinstall the bumper to machine frame.

1

4

2

1. Template

2. T

emplate Position on

Bumper

#3 (Folded)

3

Figure 9

1/32” Diameter Holes to

3. 1

be drilled

4.

Leftside of Bumper

m-4574

Installing

Air Cleaner Bracket

1. Align holes in bracket with holes drilled in the

left front of bumper.

2. Install 5/16I bolts into holes and tighten

(Fig. 10).

Note: Install bolts with heads towards the

rear of the machine.

4

3

1. Air

Cleaner Bracket

2. Bolt

Figure 10

3. Nut

4.

Drilled Holes

M-4569

2

1

7

Page 8

Installation Instructions

5

Installing

IMPORTANT:

Air Cleaner

Ther

e are two types of

bumpers. Figure 11 shows the extended

bumper. Figure 12 shows the recessed

bumper.

Refer to #1 in figures 11 and 12 to determine which

type of bumper you have.

IMPORTANT: Ensure you install bolts in the

correct holes in bracket.

1. Install bolts in the correct holes for which type

of bumper you have. Install bolts with heads

towards the top (Fig. 11 or 12).

2. Tighten bolts.

3

1

3

1

5

4

1. Non–Extended

2. Nut

3. Bolt

Bumper

Figure

TOP VIEW

12

4.

Air Cleaner

5.

Front Bracket Holes

1

2

m-4577

5

4

1. Extended

2. Nut

3. Bolt

Bumper

Figure 1

1

TOP VIEW

1

Air Cleaner

4.

5.

Rear Bracket Holes

Installing

Air Intake Hose

1. Install rubber grommet onto hose. (Fig. 13).

Install grommet into console after hose is

clamped down.

2. Locate and insert air intake hose into the bottom

hole of plastic console. (Fig. 13).

2

m-4576

3. Route hose through plastic console and into the

hole cut in top surface.

2

Figure 13

1

Hole cut into bottom of

3.

plastic console

m–457

1. Air

Intake Hose

2. Grommet

3

8

Page 9

Installation Instructions

4. Locate position for R–clamp by measuring down

6” from top of tube and centered on tube. Mark

center of hole in R–clamp (Fig. 14).

5. Drill a 9/32” hole into the tube.

6. Install R–clamp around air intake hose (Fig. 14).

7. Install screw into R–clamp and tube (Fig. 14).

3

5

1

4

2

Figure 14

1. Air

Intake Hose

2. R–Clamp

3.

6 inches

4. Screw

5. Tube

Installing

Flange Connector

1. Install a hose clamp onto end of air intake hose.

Insert flange connector in to intake hose. Tighten

hose clamp (Fig. 15).

2. Insert flange connector and hose into the top

hole in plastic. Center flange connector into the

top hole.

3. Using flange connector as a template, mark and

drill 3/32I pilot holes into plastic console (Fig.

15).

4. Screw 5/16I x 3/4I (19 mm) screws into the

flange connector and plastic console (Fig. 15).

5. Slide air intake hood onto installed flange

connector.

2

1

4

3

7

65

Figure 15

1. Flange

2.

3.

Connector

Air Intake Hood

Hose Clamp

4. Screw

5. Hose

6.

3/32” Pilot Holes

9

Page 10

Installation Instructions

Installing

Hoses to Air Cleaner

1. Install hose clamps on to the ends of the two

hoses.

2. Install the adapter hose and air intake hose onto

the air cleaner canister and tighten the hose

clamps (Fig. 16).

Note: Ensure that air inlet points straight

down. Adjust by loosening bracket

screw. Tighten bracket screw when

adjustment is done.

3. Install the adapter hose onto the air intake

adapter and tighten the hose clamp (Fig. 16).

3

2

2

5

Figure 16

5.

6.

7.

6

Console Hose

Air Inlet

Bracket Screw

4

1. Air

Cleaner

2.

Hose Clamp

3.

Adapter Hose

4.

Air Intake Adapter

2

4. Install rubber grommet onto hose. (Fig. 13).

Install grommet into console after hose is

clamped down.

Installing

Filter Minder

1. Install the Filter Minder Kit to the air cleaner

housing. Use instructions provided in that kit.

IMPORTANT: Do not discard instructions.

Save for future reference and use.

Using Filter Minder

The plunger inside the gauge canister will rise as the

air cleaner becomes dirty and restricted from use. As

it approaches or reaches the “Change Filter” level, air

cleaner maintenance is required.

1. Start by visually checking the condition of the

paper element. If the element is visually dirty,

replace the paper element. Do not attempt to

clean it.

2. Reset the gauge by depressing the button in the

bottom of the canister until the plunger returns to

1

7

the lowest point.

3. Test run the engine and recheck the gauge. If the

plunger remains in the lower ranges, normal

operation can resume. If the plunger returns to

the “Change Filter” level, the paper element is

restricted and must be replaced, even though it

may not appear to be dirty.

4. The gauge may be reset at any time, however it

will return to the prior position if corrective filter

servicing has not been performed.

10

Page 11

Installation Instructions

7

Test

System

1. Reconnect the spark plug leads. Check the

engine oil level.

2. Perform the final carburetor adjustments as

follows.

Note: The new carburetor installed is a ”fixed

jet, emissions certified” carburetor

designed to deliver the correct

fuel–to–air mixture to the engine under

all operating conditions. The fuel

mixtures are set at the factory and

cannot be adjusted.

Installing

Filter Guard

1. Hold guard up to the bumper so the bottom edge

of hole in guard lines up with the bottom edge of

bumper (Fig. 18). Clamp to bumper.

2. Using the guard as a template, drill three 11/32I

holes into bumper (Fig. 18).

3. Install two 5/16” screws into outside holes (Fig.

18). Do not install bolt in center hole until guard

plate is installed.

4. Install the guard plate using a 5/16” bolt in the

center top hole and carriage bolt and wing nut in

the bottom hole (Fig. 18).

4

2

1

1. Low

Idle Speed Adjusting

Screw

1

Figure 17

m–4540

3. Start the engine and check to be certain that oil

pressure (20 psi or more) is present. Run the

engine for 5–10 minutes to warm up. The engine

must be warm before making final settings.

4. Place the throttle control into the ”idle” or

”slow” position. Turn the low idle speed

adjusting screw in or out, to obtain a low idle

speed of 1400 RPM (±75 RPM). Check the

speed using a tachometer (Fig. 17).

5. Move the throttle control to the

”Fast/Full–Throttle” position. Using a

tachometer, check that the maximum engine

speed does not exceed 3250 RPM (±50 RPM).

Adjust if necessary.

2

1. Align

2. 1

3. Guard

4. Bolt

Bottom Edges

1/32” Holes to drill

4

4

4

3

8

Figure 18

5. Nut

6.

7.

8.

6

Carriage Bolt

Guard Plate

Wing Nut

11

Page 12

Installation Instructions

Servicing

the Air Cleaner

Primary Filter: Clean or replace every 200 operating

hours.

Safety Filter: Replace after every 600 operating

hours.

Note: Service the air cleaner more frequently

if operating conditions are extremely

dusty or sandy.

Removing the Filter

1. Disengage the power take off (PTO), set the

parking brake, and turn the ignition key to

“OFF” to stop the engine. Remove the key.

Remove spark plug wire(s) and remove the key.

2. Release the latches on the air cleaner and pull the

air cleaner cover off of the air cleaner body

(Fig. 19).

3. Clean the inside of the air cleaner cover with

compressed air

.

m–4387

1. Latches

2. Air

cleaner cover

3.

Air filter body

5

2

Figure 19

4.

5.

3

4

1

Primary filter

Safety filter

1

Cleaning the Primary Filter

Blow compressed air from the inside to the outside of

the primary filter.

IMPORTANT: Do not exceed 100 psi and

keep the hose at least 2 inches from the filter.

4. Gently slide the primary filter out of the air

cleaner body (Fig. 19). Avoid knocking the

filter into the side of the body. Do not remove

the safety filter, unless you intend to replace it as

well.

5. Inspect the primary filter for damage by looking

into the filter while shining a bright light on the

outside of the filter. Holes in the filter will

appear as bright spots. If the filter is damaged,

discard it, otherwise clean it.

IMPORTANT: Never attempt to clean the

safety filter. If the safety filter is dirty, then

the primary filter is damaged and you should

replace both filters.

Installing the Filters

1. If installing new filters, check each filter for

shipping damage. Do not use a damaged filter.

2. If the safety filter is being replaced, carefully

slide it into the filter body (Fig. 19).

3. Carefully slide the primary filter over the safety

filter (Fig. 19). Ensure that it is fully seated by

pushing on the outer rim of the filter while

installing it.

IMPORTANT: Do not press on the soft inside

area of the filter.

4. Install the air cleaner cover with the side

indicated as UP facing up and secure the latches

(Fig. 19).

12

Page 13

Installation Instructions

3I DIA. Hole

Template

Do Not cut out

this circle in

paper template.

#1

Fold Line

13

Page 14

Installation Instructions

14

Page 15

Installation Instructions

3–1/2I

DIA.

Template

Align

support edge.

Hole

Do Not cut out

circle in paper

template.

#2

with metal

Cut

Out

Fold Lines

15

Page 16

Installation Instructions

16

Page 17

Installation Instructions

Align to

edge of

bumper

Template

Fold Line

#3

Do Not cut out

these circles in

paper template.

17

Page 18

Installation Instructions

18

Page 19

Installation Instructions

19

Page 20

Installation Instructions

20

Loading...

Loading...