Page 1

52” Pulley Kit

For Z–Master Series

FORM NO. 3322-688

Part No. 100–2317

Loose

Note: Use the chart below to identify parts for assembly.

DESCRIPTION QTY. USE

Pulley Assembly

Belt

Idler Arm

Flat W

Removing

1. Stop the engine, set the parking brake, remove

2. Remove the clutch retaining strap from machine

3. Remove the PTO drive belt (Fig. 4).

4. Loosen idler pulley on deck belt. Remove deck

Parts

ashers

Belts

the key and disconnect the spark plug wire(s)

from the spark plug(s).

frame and unplug clutch terminal from wire

harness (Fig. 4).

belt from center spindle pulley.

1

1

1

2

Install Pulleys

Install Idler Arm

Installing

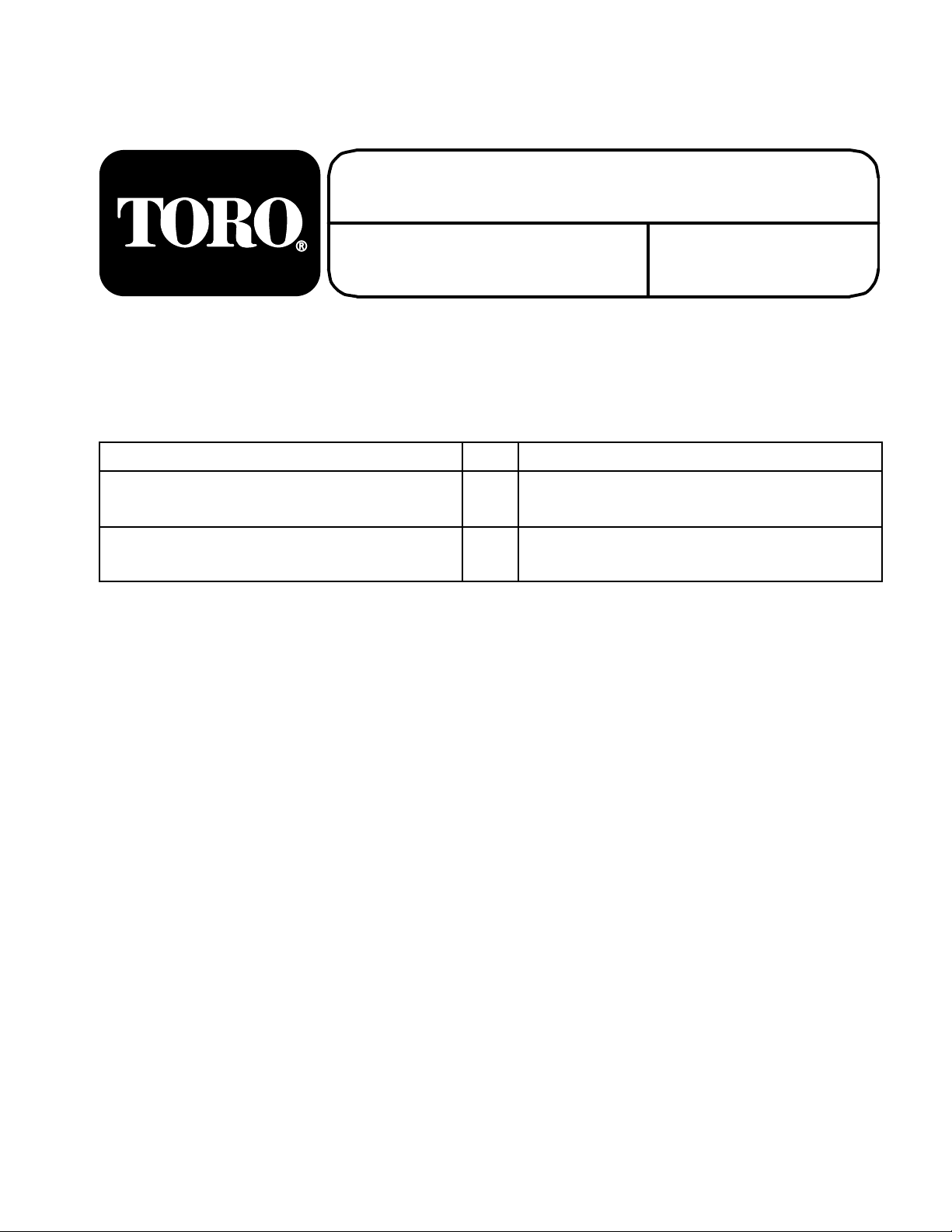

Note: Clean area around pulley before

1. Remove nut and washer on top of center spindle

(Fig. 1). Save the nut and washer.

2. Remove existing pulley assembly (Fig. 1).

3.

Install new pulley assembly. Install it so the

large pulley is on top (Fig. 1).

Pulleys

removing pulley assembly. Hold

spindle up from underneath deck. It

can fall when nut and washer are

removed.

INSTALLATION

INSTRUCTIONS

Printed in USA

The T

oro Company – 1999

All Rights Reserved

4. Reinstall washer and nut. Torque nut to 115

ft–lbs (156 Nm) (Fig. 1).

Page 2

Installation Instructions

5.

Grease spindle.

Installing

New Drive Belt Idler

1

3

1. Nut.

2. Washer

Removing

Figure 1

3. Pulley

4. Spindle

Old Drive Belt Idler

2

4

Assembly

Arm

1. Remove the spring from the old idler arm (Old

idler arm not shown) (Fig. 3).

2. Remove the old idler arm from the machine

frame (Old idler arm not shown) (Fig. 3).

Arm

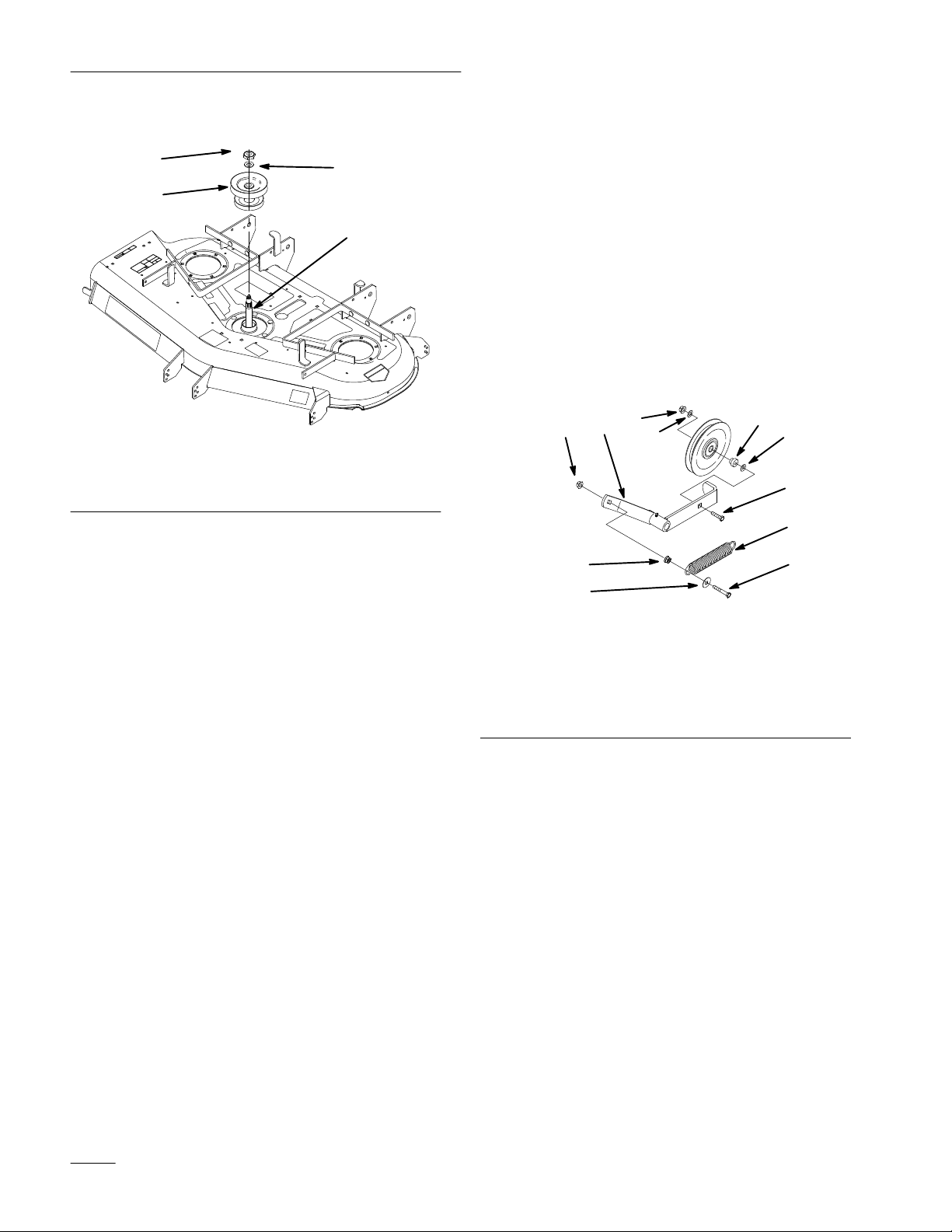

1. Route new belt onto the idler pulley. Install

pulley and belt to new idler arm using existing

hardware (Fig. 2).

2. Install spring to new idler arm. Use existing

hardware and new flat washer included in kit.

(Fig. 2).

Note: New flat washer must be installed

between spring and heat of bolt.

7

6

9

4

5

asher

1. New

2.

3.

4. Spring

5.

Idler Arm

Lock Nut

New Flat W

Bolt (3/8”–16 x 2–1/4”)

asher

2

3

122

6

Figure 2

6.

Flat W

7. Bushing

8.

Idler Pulley

9.

Bolt (3/8”–16 x 1–3/4”)

3. Remove the spring from the machine frame.

Discard old washer (Fig. 3).

4. Remove the pulley, bushing, and hardware from

idler arm. (Old idler arm not shown) (Fig. 2).

2

3. Install new idler arm assembly to machine

frame. Use existing hardware to attach it (Fig.

3).

4. Install spring to machine frame. Use existing

hardware and new flat washer included in kit.

(Fig. 3).

Page 3

Installation Instructions

Note: New flat washer must be installed

between spring and heat of bolt. The

spring must be installed between new

flat washer and spacer (Fig. 3).

8

4

5

1

1. Idler

2.

3.

4.

5.

Arm

Lock Nut

New Flat W

Bolt (3/8”–16 x 3–1/2”)

Flat W

asher

asher

9

376

Figure 3

6. Spacer

Nylon Locknut

7.

8.

Bolt (3/8”–16 x 2–1/4”)

9. Bushing

M-4416

Installing

belts

1. Place deck belt onto new pulley assembly. Route

belt onto outer pulleys and idler pulley.

2. Place new PTO drive belt over clutch, around

rear idler pulley, installed into idler arm

assembly and onto mower top center pulley.

2

Note: Check that belt has only 1/4 twist

between each pulley and idler.

3. Install clutch retaining strap and plug clutch

terminal into main wire harness (Fig. 4).

4

5

3

m–3748

1

2

Figure 4

1. Clutch

2. Clutch

3.

Clutch T

retaining strap

erminal

4. PT

O belt

5.

Machine Frame

4. Check belt tension. The center bolt of spring

loaded idler must be between the two alignment

holes in left support plate (Fig 5).

M-4373

3

Page 4

Installation Instructions

8. To adjust push arms, remove PTO drive belt,

loosen jam nut and rotate ball joint

counterclockwise, one turn at a time. Adjust

each side the same amount (Fig. 7).

2

push arms and decrease tension by

shortening push arms.

Note: Increase tension by lengthening the

3

1

M-4417

1

Figure 5

1. Center

idler

bolt, spring loaded

2.

Alignment hole

5. If adjustment is required, loosen the fixed idler

on right support plate and move up or down in

adjustment slot. To relieve belt tension lift up on

spring loaded idler (Fig. 6).

1. Push

2.

12

Adjusting

arm

15” (381 mm) nominal

Belt Guides

Figure 7

3.

4.

1

2

m–3740

Jam nut

Ball joint

Figure 6

1. Fixed

Idler

2.

Adjustment slot

6. Check belt tension again. The center bolt of

spring loaded idler must be between the two

alignment holes in left support plate (Fig 5).

Adjust, if necessary, and tighten all hardware

securely.

7. If the fixed idler contacts the end of the

adjustment slot and more belt tension is

required, a small change in the length of the

push arms can be made (Fig. 7).

m–3746

1. Loosen belt guide (Fig. 8).

2. Rotate the belt guide, on rear of the mower, so it

is 1/8”–1/4” (3–7 mm) away from the vertical

side of the PTO belt (Fig. 8).

1

3

1. Belt

2. PT

guide

O Drive belt

Figure 8

3.

1/8”–1/4” (3–7 mm)

2

M-4399

4

Loading...

Loading...