Page 1

36” Tiller Lift Cable Kit

FORM NO. 3322–562 Rev. A

INSTALLATION

INSTRUCTIONS

Loose

Parts

PART

NO. 100–1591

Note: Use the chart below to identify parts used for assembly.

DESCRIPTION QTY. USE

Cable guide

Cable

Guard extension

Installation Instructions

1

1

2

1

Installation of kit

Read before installing

Description

This kit is designed for use on tillers, Model No.

79375 and Model No. 715704006, to prevent the lift

cable from interfering with the transaxle cooling fan.

In addition, guard extensions are provided to prevent

lift bar interference with the jack shaft pulley.

3

Installing

the Lift Cable

1. If the tiller is mounted on a tractor, park the unit

on a level surface and lower the tiller to the

ground. Turn the ignition to “STOP” to stop the

engine. Remove the ignition key.

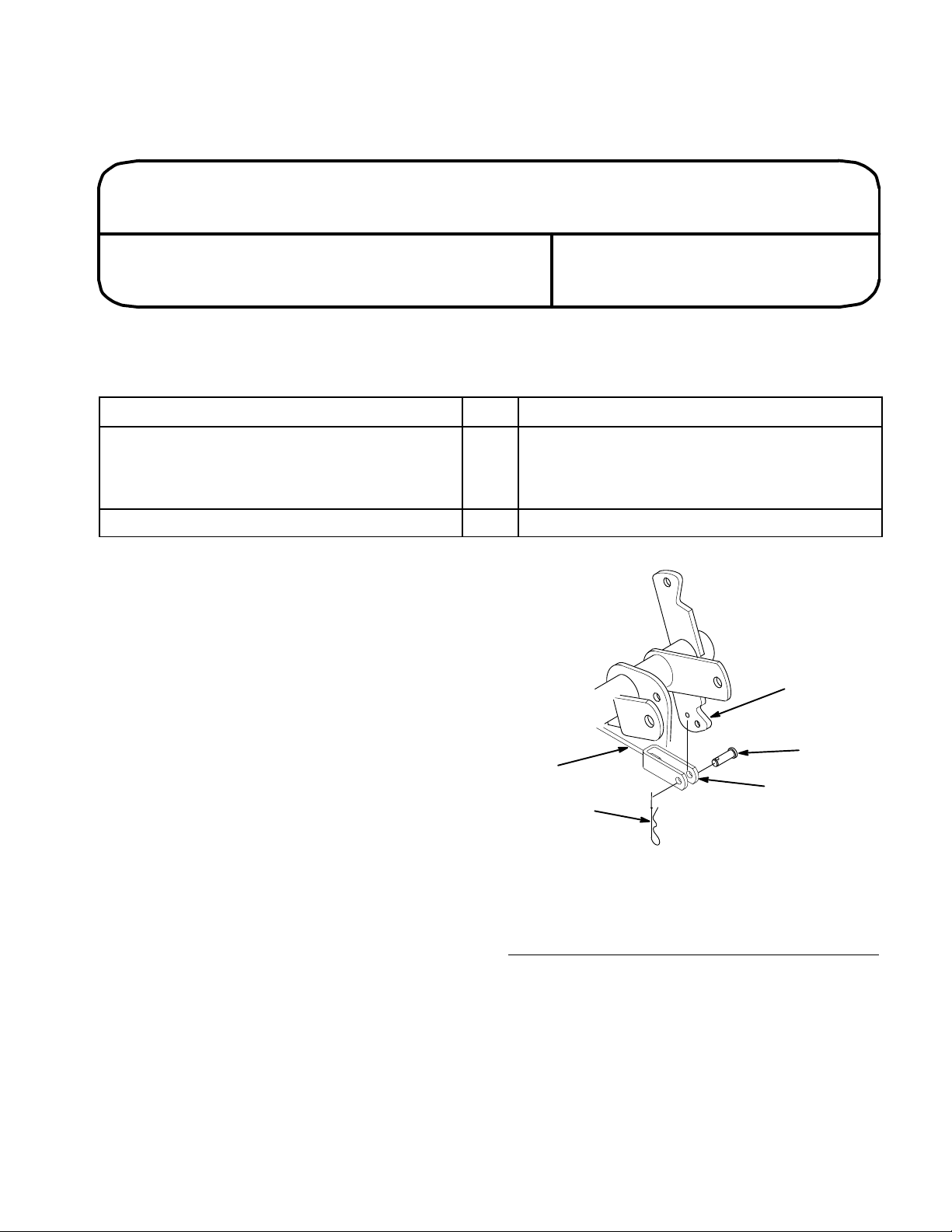

2. Remove the hairpin and clevis pin from the lift

cable at the attachment lift arm (Fig. 1).

Note: Attachment lift arm may be different

than shown in Fig. 1 on some models.

1

1. Lift

cable

2. Clevis

3.

Attachment lift arm

4

2

5

m–3504

Figure 1

4.

Clevis pin 5/16” x 1” (25

mm)

5.

Hairpin cotter

Page 2

Installation

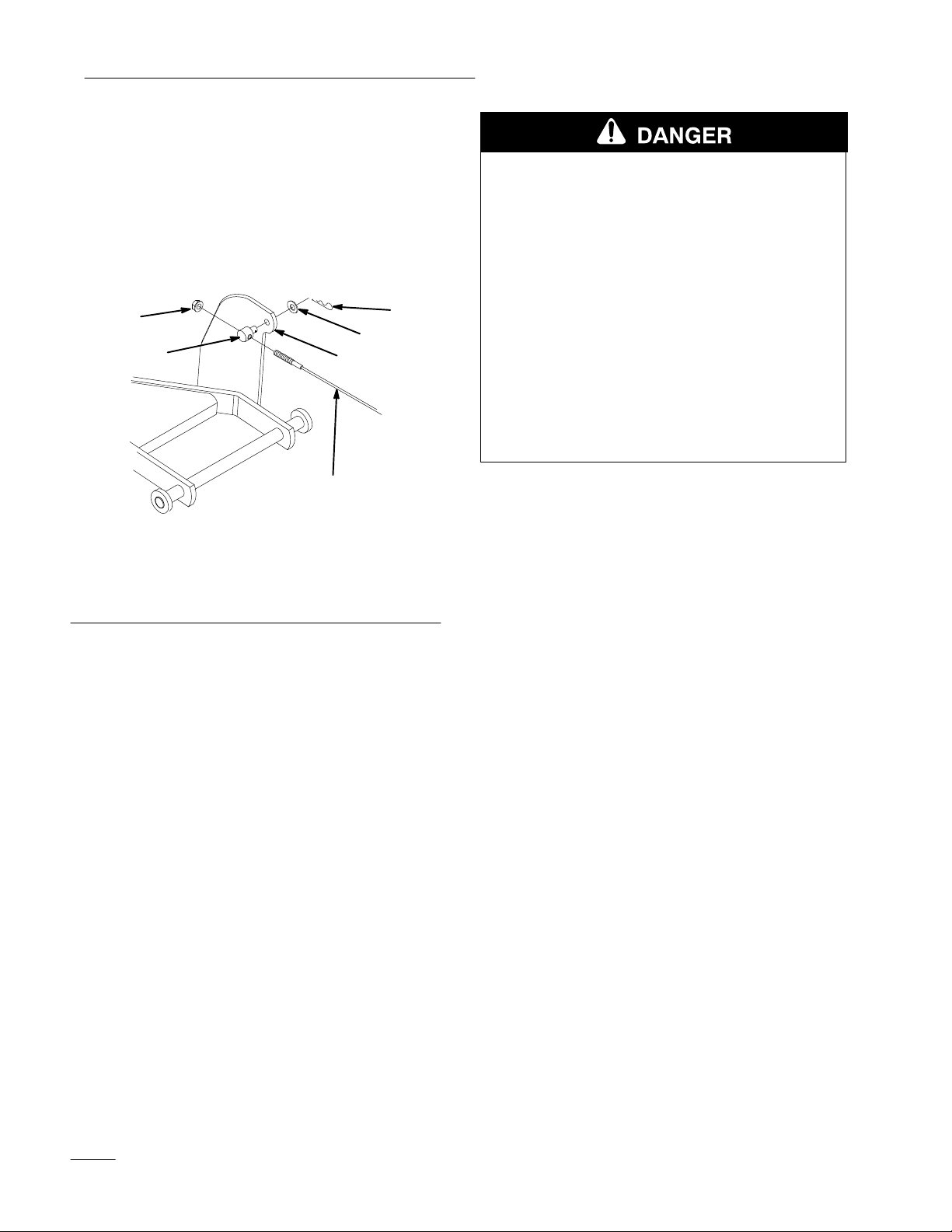

3. Remove the hairpin, washer and trunnion from

the tiller lift mounting bracket on the tiller.

Remove the trunnion and cable assembly

(Fig. 2). Measure and record the distance from

the end of the cable to the trunnion to use as a

reference for installing the trunnion on the new

cable. Unscrew the locknut and trunnion from

the lift cable. Save all parts except the lift cable.

3

2

6

4

5

POTENTIAL HAZARD

• Rotating shaft or cooling fan can cause

injury.

WHAT CAN HAPPEN

• Fingers, hands, feet, hair, etc. can get

caught by shaft or fan.

• Loose clothing can get caught by shaft.

HOW TO AV

OID THE HAZARD

• Do not operate the tractor without the drive

shaft cover in place.

• Keep hands and arms clear of rotating

shaft or fan.

1

m–3503

Figure 2

1. Lift

cable

2. Trunnion

3. Locknut

Installing

the Cable Guide

4. Hairpin

5.

Flat washer

6. T

iller lift mounting bracket

The cable guide can be installed from the underside

of the tractor. For more visibilty, the drive shaft

maintenance cover can be removed to aid in

installation.

1. Remove the two bolts in the plastic fan baffle

(Fig. 3) and remove the baffle.

2. Remove the clip nut from the left side of the

plastic fan baffle and install over the hole in the

bent tab of the cable guide (Fig. 3).

3. Remove the nut from the pivot bolt on the left

hand attachment lift arm (Fig. 3). Leave the bolt

in place.

4. Install the rear hole of the cable guide to the left

hand lift arm pivot bolt and replace the nut

loosely (Fig. 3).

5. Reinstall the plastic fan baffle with one of the

previously removed bolts in the right hand side

only (Fig. 3). Leave the bolt loose.

2

Page 3

Installation Instructions

6. Align the front of the cable guide with the hole

in the left hand side of the plastic fan baffle and

reinstall the other bolt previously removed.

Tighten all bolts and nuts securely.

1

9

8

7

4

2

5

3

3. Replace the drive shaft maintenance cover if it

was removed

Installing

the Guard

Extensions

1. Remove the jack shaft assembly from the tractor,

if installed.

2. Place a guard extension on the top forward edge

of each of the two existing guards (Fig. 4).

Clamp each guard extension tight against the

existing guard and weld in place.

1

2

6

Figure 3

1. Cable

2.

3.

4. Left

5. Plastic

Installing

guide

Clip nut

Fan baf

fle bolt

hand lift arm pivot bolt

nut

fan baf

fle

the New Lift Cable

6.

Right hand attachment lift

arm

7.

Rear of tractor

8.

Pivot bolt

9.

Lift cable

1. Install the trunnion and locknut on the new cable

provided in the kit. Use the measurement taken

in step 3 (Removing the Lift Cable), for locating

the trunnion. Reinstall the trunnion into the

tiller lift mounting bracket using the flat washer

and hairpin previously removed (Fig. 2).

2. Attach the lift cable clevis to the tractor’s

attachment lift arm, as previously installed

(Fig. 1), using the hairpin and clevis pin from

the original installation.

4

3

5

m–4405

Figure 4

1. Guard

2.

3. W

extensions

Existing guards

eld areas

4.

Front of tractor

5.

Jack shaft assembly

3. Add touch–up paint to the welded area when

installation is complete.

3

Page 4

Installation

4

Loading...

Loading...