Page 1

252 Series Valves

Valves

Toro® 252 Series valves are built tough and ready to withstand the harshest conditions in any commercial application.

With several confi gurations to choose from, 252 Series valves

are available in electric or hydraulic, 1”, 1.5” and 2” globe/

angle models with fl ow control. Offering the same glass-fi lled

cap and body construction as the 250/260 Series, these valves

are also rated up to 150 PSI. Each valve diaphragm is a single

piece and made with fabric- reinforced rubber for long-term

tear and stretch tolerance. All models are female inlet/outlet

NPT and their durable plastic construction makes them an

economical option for commercial applications.

Features & Benefi ts

Heavy-Duty Toro Solenoid

Provides dependable operation and long life.

High-Grade Construction

Made of durable materials to resist wear.

Globe and Angle Confi gurations

Easy to use in any application.

Fabric-Reinforced Rubber Diaphragm

Provides long-term tear and stretch tolerance.

Water Flow Control Handle

Adjusts the fl ow of each zone on a system.

Robust ABS Material

Ensures the valve will resist heavy pressure and

high fl ows without damage.

Effl uent

Options

Available

Page 2

252 Series Valves

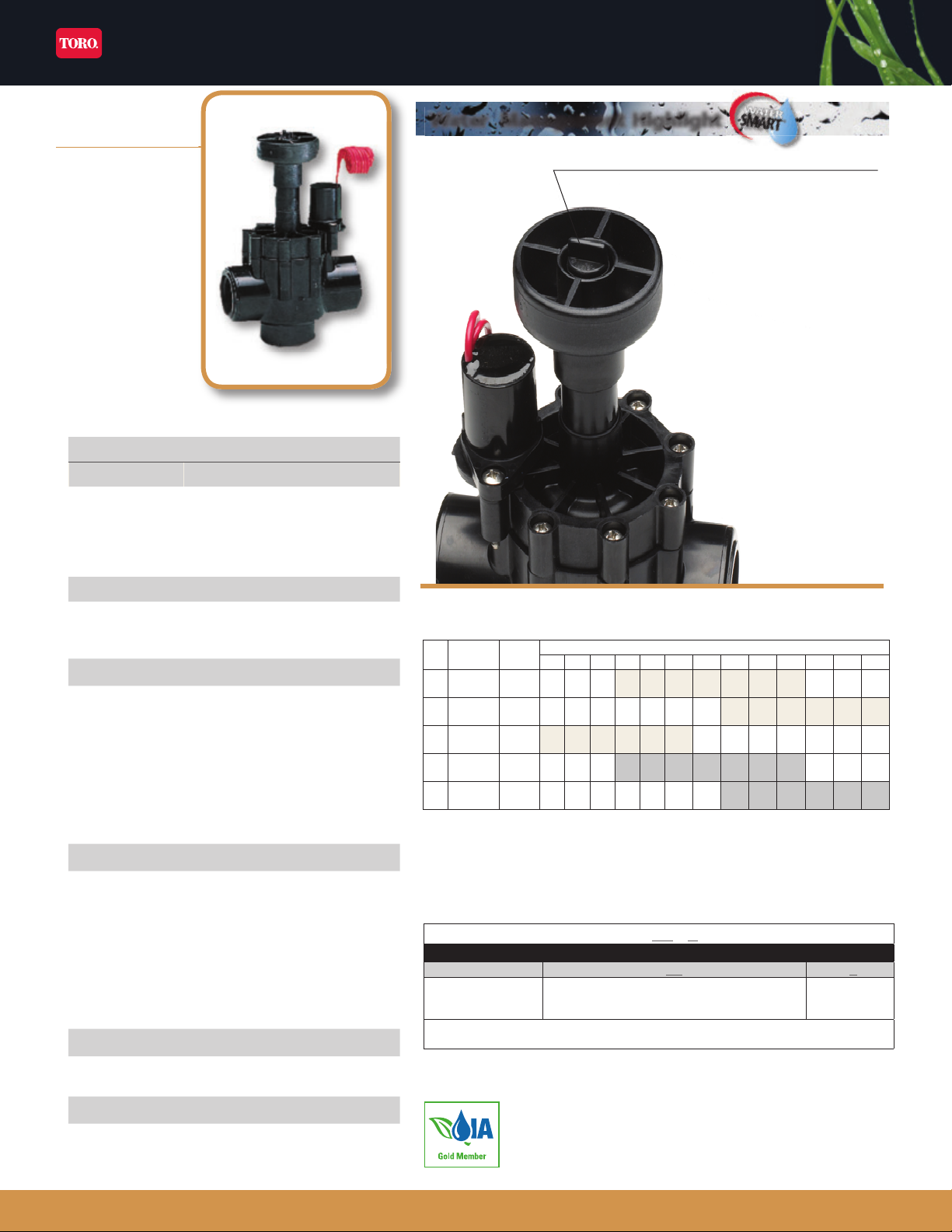

Globe and Angle

In One Valve

The all-in-one globe

and angle configuration of the 252

Series valves allows

flexibility in design

and installation.

Angle installations

allow for less friction loss across the

piping system while

globe configurations are standard

in many irrigation

systems.

Specifi cations

Female NPT In-line/Angle w/Flow Control

Model Description

• 252-06-04

• 252-26-06

• 252-26-08

• 252-21-06

• 252-21-08

Dimensions

• 1” – 6 ¾” H x 4 ½” W

• 1 ½” – 7 ¾” H x 6” W

• 2” – 9 ½” H x 7” W

Operating Specifi cations

• Recommended Flow Range:

– 1” – 5.0 to 20 GPM

– 1 ½” – 25 to 70 GPM

– 2” – 60 to 90 GPM

• Operating Pressure: 20 to 150 psi

• Solenoid: 24 VAC, 50/60 Hz

–Inrush: 0.30 amps, 7.20 VA

–Holding: 0.20 amps, 4.80 VA

• Burst pressure safety rating: 750 psi

Additional Features

• Globe and globe/angle built into one valve

• Manual flow control

• External manual bleed

• 24” lead wires (1 ½” and 2” electric) or

18” lead wires (1” electric)

• Self-cleaning, stainless steel metering pin

(electric)

• Tough, glass-filled bonnet

• Single-piece diaphragm

Options Available

• 89-7855 – Effluent Water Indicator Valve Flow

Control Knob

Warranty

• Two years

1”

1½”

2”

1 ½” Normally Open

2” Normally Open

Water Management HighlightWater Management Highlight

External Bleed

The external bleed allows perfect

manual operation of the valve

without electrically charging the

solenoid. With the ability of

users to bleed the valve to atmosphere, pressure is relieved and

the valve can effectively open

and close. System flushing can

also be accomplished using the

external bleed with debris and

other material being flushed out

of the port.

252 Series Friction Loss Data

Size Type

Hydraulic

1½"

Hydraulic

2"

1"

1½"

2"

Note: For optimum performance when designing a system, be sure to calculate total friction loss to

ensure sufficient downstream pressure.

For optimum regulation performance, size regulating valves toward the higher flow ranges. Flow rates are

recommended not to exceed 5 psi (0,3 bar) loss.

■

= Debris-resistant models

Electric

Electric

Electric

Config.

5 10 20 25 30 40 50 60 70 80 100 120 150

Globe

Angle

Globe

Angle

3.0

2.0

4.0

3.5

Globe

Angle

Globe

Angle

Globe

Angle

5.0

4.5

1.0

1.0

6.0

4.5

1.5

1.5

1.0

1.0

7.0

5.0

1.0

1.0

Specifying Information—252

252-XX-0X

Model Activation Type Size

252 XX 0X

252—252 Series Valve 06—1” Electric

21—Normally Open Hydraulic

1

⁄2” or 2” Electric

26—1

Example: A 11⁄2” electric 252 Series Valve,

would be specified as: 252-26-06

www.toro.com • The Toro Company • Irrigation Division

5825 Jasmine St. • Riverside, CA • 92504 • 877-345-8676

Specifi cations subject to change without notice. For more information,

contact your local Toro distributor. P/N 09-1053-IRC

©2009 The Toro Company. All rights reserved.

GPM Flow

2.0

3.0

4.0

5.5

1.5

1.5

3.0

1.5

1.0

9.5

7.5

2.0

3.0

1.5

4.0

2.0

3.0

2.0

1.0

Note: DC Latching Solenoid not available.

4.0

2.0

1.0

5.0

3.0

2.0

1.0

6.5

5.0

2.0

1.5

7.0

5.0

2.5

2.0

3.5

5.0

2.0

3.0

3.5

5.5

3.0

4.0

4—1”

6—1

8—2”

1

⁄2”

8.0

5.0

8.0

5.0

Loading...

Loading...