Page 1

FormNo.3368-805RevC

ProCoreSR48,SR54,SR54–S,

SR70,SR70–S,SR72andSR75

Aerators

ModelNo.09930—SerialNo.311000001andUp

ModelNo.09931—SerialNo.311000001andUp

ModelNo.09932—SerialNo.311000001andUp

ModelNo.09933—SerialNo.311000001andUp

ModelNo.09934—SerialNo.311000001andUp

ModelNo.09935—SerialNo.311000001andUp

ModelNo.09936—SerialNo.311000001andUp

ToregisteryourproductordownloadanOperator'sManualorPartsCatalogatnocharge,gotowww.Toro.com.OriginalInstructions(EN)

Page 2

Introduction

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoidinjury

andproductdamage.Youareresponsibleforoperating

theproductproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comfor

productandaccessoryinformation,helpndingadealer,

ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,

oradditionalinformation,contactanAuthorized

ServiceDealerorToroCustomerServiceandhave

themodelandserialnumbersofyourproductready .

Figure1identiesthelocationofthemodelandserial

numbersontheproduct.Writethenumbersinthe

spaceprovided.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjury

ordeathifyoudonotfollowtherecommended

precautions.

Figure2

1.Safetyalertsymbol

Thismanualuses2otherwordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

©2011—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Figure1

Contactusatwww.Toro.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

Contents

Introduction.................................................................2

Safety...........................................................................4

SafeOperatingPractices.......................................4

SafetyandInstructionalDecals.............................6

Setup...........................................................................8

1RemovingtheAeratorfromtheCrating..............9

2ConnectingtheLowerLinkArms......................9

3ConnectingtheHydraulicTopLink

(ModelsSR48,SR54,SR70,SR72and

SR75).............................................................10

4ConnectingtheTractorUpperLink(Models

SR54–SandSR70–S)......................................12

5VerifyingtheHydraulicTopLinkSet

Up..................................................................12

6CheckingthePTOAngle.................................13

7FittingthePTOshaft.......................................14

8InstallingthePTOShield.................................15

9ConnectingthePTOShaft...............................16

10AdjustingtheSwayLinks................................17

11LevelingtheAeratorSide-to-Side...................18

12InstallingtheTines.........................................18

13SettingtheTineDepth(ModelsSR54–S

andSR70–S)...................................................18

14InstallingtheRearGuard................................19

15InstallingtheLatchLock................................20

16RemovingtheStorageStands(ModelsSR54

andSR70)......................................................20

17RemovingtheStorageStands(ModelsSR48

andSR72).......................................................21

ProductOverview......................................................22

Specications.....................................................22

Attachments/Accessories...................................22

Operation...................................................................23

TractorControls.................................................23

PrinciplesofOperation......................................23

TractorPTOSpeed............................................23

TrainingPeriod...................................................23

BeforeAerating..................................................23

AeratingProcedures...........................................24

OperatingTips...................................................24

SubsoilCultivation.............................................25

HardGround.....................................................25

Longer/LargerTines..........................................25

MultiRowAdapterHeads..................................25

RootZoneLifting..............................................25

UsingtheHoodPropRodsModelSR75

only................................................................25

AdjustingtheTineAngle....................................26

AdjustingtheTineDepth(ModelsSR54–S

andSR70–S)...................................................27

TransportOperation..........................................27

InspectionandCleanupafterUse........................28

Maintenance...............................................................29

RecommendedMaintenanceSchedule(s)................29

LiftingtheMachine............................................29

GreasingtheBearings.........................................30

CheckingtheGearboxOil..................................30

ChangingtheGearboxOil..................................31

Inspecting/AdjustingtheDriveChain................31

AdjustingthePTOClutch..................................32

FastenerTorqueSpecications............................32

CheckingtheSprings..........................................33

AdjustingtheHoleSpacing.................................33

RemovingtheAeratorfromtheTractor...............33

TroubleShooting...............................................34

Storage.......................................................................35

3

Page 4

Safety

Improperuseormaintenancebytheoperatoror

ownercanresultininjury.Toreducethepotential

forinjury,complywiththesesafetyinstructions

andalwayspayattentiontothesafetyalert

symbol,whichmeansCAUTION,WARNING,or

DANGER-"personalsafetyinstruction."Failureto

complywiththeinstructionmayresultinpersonal

injuryordeath.

SafeOperatingPractices

BeforeOperating

•OwnersofthisAeratormustgiveoperatorsand

employeesfulloperationandsafetyinstructions

beforeallowingthemtooperatethismachineandat

leastannuallythereafter.Anoperatorwhohasnot

readandfullyunderstoodalloperatingandsafety

instructionsisnotqualiedtooperatethismachine.

Becomefamiliarwithallcontrolsandknowhowto

stopquickly.

•Donotallowchildrentooperatethemachine.Do

notallowadultstooperatethemachinewithout

properinstruction.

•Removealldebrisorotherobjectsthatmight

interferewithoperation.Keepallbystandersaway

fromtheworkarea.

•Locateandmarkallundergroundobstructionssuch

asirrigationcomponents,electricalortelephone

lines.

•Makesuretractorisinneutralandparkingbrake

appliedbeforestarting.RefertoTractorOperator's

Manualforsafestartingprocedures.

•Ensurethatyourtractorissuitableforusewithan

implementofthisweightbycheckingwithyour

tractorsupplierormanufacturer.

•Mountingtheaeratortotherearofthetractorwill

decreasetheweightonthetractorfrontaxle.To

assureadequatesteeringcontrolandstabilityitmay

benecessarytoaddballasttothefrontofthetractor.

RefertoTractorOperator'sManualforballast

requirements.

•Keepallshieldsandsafetydevicesinplace.Ifa

shield,safetydeviceordecalisdamaged,repairor

replaceitbeforeoperationiscommenced.Also

tightenanyloosenuts,boltsandscrewstoensure

machineisinsafeoperatingcondition.

•Donotoperatemachinewhilewearingsandals,

tennisshoes,sneakersorshorts.Also,donotwear

loosettingclothingwhichcouldgetcaughtin

movingparts.Alwayswearlongpantsandsubstantial

shoes.W earingsafetyglasses,safetyshoes,hearing

protectionandahelmetisadvisableandmaybe

requiredbysomelocalordinancesandinsurance

regulations.

WhileOperating

•Neveroperatethetractorinreversewhentheaerator

islowered.

•Keepallbystandersandpetsawayfromthework

area.

•Usingthemachinedemandsattention,andto

preventlossofcontrol:

–Useonlyindaylightorwhenthereisadequate

articiallight.

–Watchforholesorotherhiddenhazards.

–Donotoperatethemachineclosetoasandtrap,

ditch,creekorotherhazard.

–Reducespeedonsidehillsandbeforemaking

sharpturnstopreventtippingorlossofcontrol.

–Lookbehindtheaeratorbeforebackingup.

•Ifthetinesstrikeasolidobjectorthemachine

vibratesabnormally,disengagethePTO ,setthe

parkingbrakeandshuttheengineoff.Removekey

fromignitionswitch.Checkaeratorandtractionunit

fordamage.Repairanydamagebeforerestartingthe

engineandoperatingthetines.Besuretinesarein

goodconditionandallboltsaretight.

•Beforeleavingmachineunattended,disengagepower

toaerator,loweraeratorontostoragestandsandset

parkingbrake.Stopengine.

•Neverdismountwhiletractorisinmotion.Never

getonorofftractorwhileengineisrunningand

PTOdriveshaftisengaged.NeverstepoverPTO

shafttoreachothersideofaerator-walkaround

themachine.

•Whenliftingtheaerator,disengagethePTOwhen

therollerisapproximately5inchesfromtheground.

•Donotoperatethismachinewithouttherolleron

theground.Neveroperatewiththemachinein

theraisedposition.

•Parktheaeratoronahard,levelsurface,installthe

aeratorstoragestandsbeforedisconnectingfrom

tractor.

•Ifitisnecessarytoprobebelowthesoilsurface,use

anonconductivematerialtopreventelectricalshock

incaseelectricalwiresarepresent.

•Alwayslowertheaeratortothegroundbefore

leavingthetractorunattended.Neverleavethe

aeratorintheraisedpositionwhenitisunattended.

4

Page 5

Transporting

•Theaeratorisheavy.Whenattachedtoatractor

andintheraisedposition,itsweightwillaffect

stability,brakingandsteering.Exercisecautionwhen

transportingbetweenworkingareas.

•Alwaysmaintainpropertractortirepressure.

•Besureyouareincompliancewithallregulations

beforetransportingequipmentonthepublicroads

andhighways.Makesureallrequiredreectors

andlightsareinplaceandarecleanandvisibleby

overtakingandoncomingtrafc.

•Neverallowpassengerstorideonthemachine

duringtransport.

•Reducespeedonroughroadsandsurfaces

•Independentwheelbrakesshouldalwaysbelocked

togetherwhentransporting.

PTOShaft

•ForallPTOshaftsteelparts(tubes,bearings,joints

etc.)disassemblyorrepairs,itishighlyadvisable

tocontactyourlocalTorodistributor.Removalof

componentsforrepairsandreassemblymaydamage

somepartsifnotperformedwithspecialtoolsby

trainedtechnicians.

•ThePTOshaftmustnotbeusedwithouttheguards

supplied,withpartialprotectionorwithdamaged

guards.OnCEmachines,operationisprohibited

withoutthespecialanti-rotationchainscorrectly

installed,soastopermitthemaximumangleofthe

PTOshaftwithoutbreakingthechains.

•Besurethemachineisinsafeoperatingconditionby

keepingnuts,boltsandscrewstight.Checkthetine

mountingboltsdailytobesuretheyaretightened

tospecication.

•Donotcheckoradjustthechaintensionwhenthe

tractorengineisrunning.

•Besureallguardsarereplacedandthehoodis

securedshutaftermaintainingoradjustingthe

machine.

•Performonlythosemaintenanceinstructions

describedinthismanual.Ifmajorrepairsare

everneededorassistanceisdesired,contactan

AuthorizedToroDistributor.Toensureoptimum

performanceandsafety,alwayspurchasegenuine

Tororeplacementpartsandaccessoriestokeepthe

ToroallT oro.Neveruse"will-t"replacementparts

andaccessoriesmadebyothermanufacturers.Look

fortheTorologotoensuregenuineness.Using

unapprovedreplacementpartsandaccessoriescould

voidthewarrantyofTheToroCompany .

StorageSafety

•Storetheaeratoronthestoragestandspositionedon

armlevelsurface.

•Storetheaeratorawayfromareasofhumanactivity.

•Donotallowchildrentoplayonoraroundthe

storedmachine.

•Makesuretheaeratorispositionedonrmandsolid

groundsoitdoesnotsinkortipover.

•Frictionclutchesmaybecomehotduringuse.Do

nottouch.Toavoidtheriskofre,keepthearea

aroundtheclutchfreeofammablematerialand

avoidprolongedslippingoftheclutch.

Maintenance

•Beforemakingadjustmentsorperforming

maintenanceontheaerator,switchofftheengine,

stopthePTOandapplytheparkingbrakebefore

dismountingfromthetractor.Besuretheaeratoris

onthegroundorloweredontothesafetystands.

•Supportthemachinewiththeblocks,jacksoron

storagestandswhenworkingbeneathit.Never

relyonthetractor'shydraulicstosupportthe

machine.

•Placeallcontrolsinneutral,stoptheengine,apply

parkingbrakeandwaitforallmovingpartsto

stopbeforeservicing,maintaining,adjustingor

unblockingtheaerator.

5

Page 6

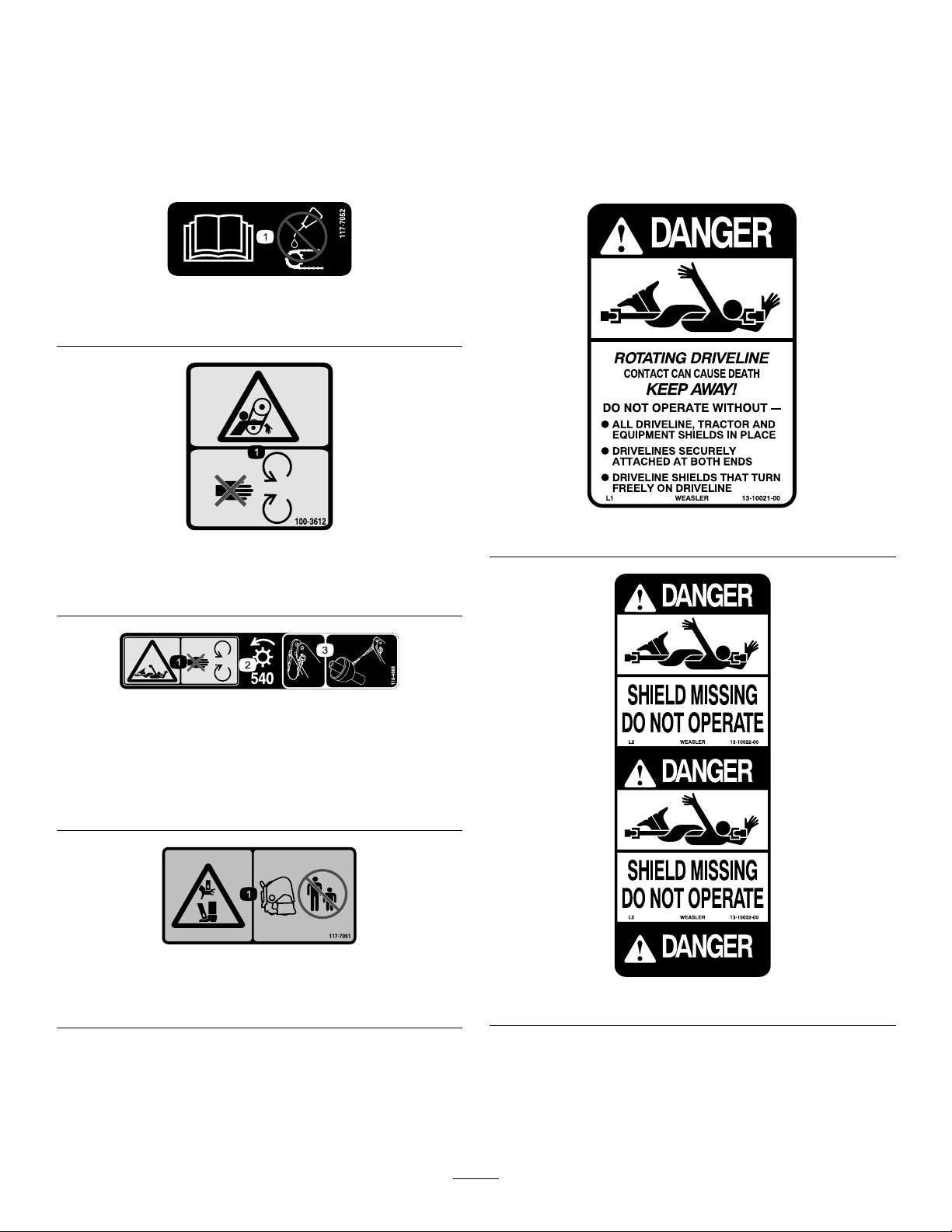

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaof

potentialdanger.Replaceanydecalthatisdamagedorlost.

117–7052

1.ReadtheOperator’sManual,donotoilthechaindrive.

100–3612

1.Entanglementhazard—stayawayfrommovingparts,keep

allguardsandshieldsinplace.

110-4668

1.Entanglementhazard,shaft—stayawayfrommovingparts.

2.PTOspeedandinputdirection.

3.Usecliptosecurelashcablewhennotinuse.Uselash

cabletosupportthepowertake-offwhenthemachineis

disconnectedfromtractor.

117–7051

92–1581

1.Crushinghazardofhandorfoot—keepbystandersasafe

distancefromthemachine.

92–1582

6

Page 7

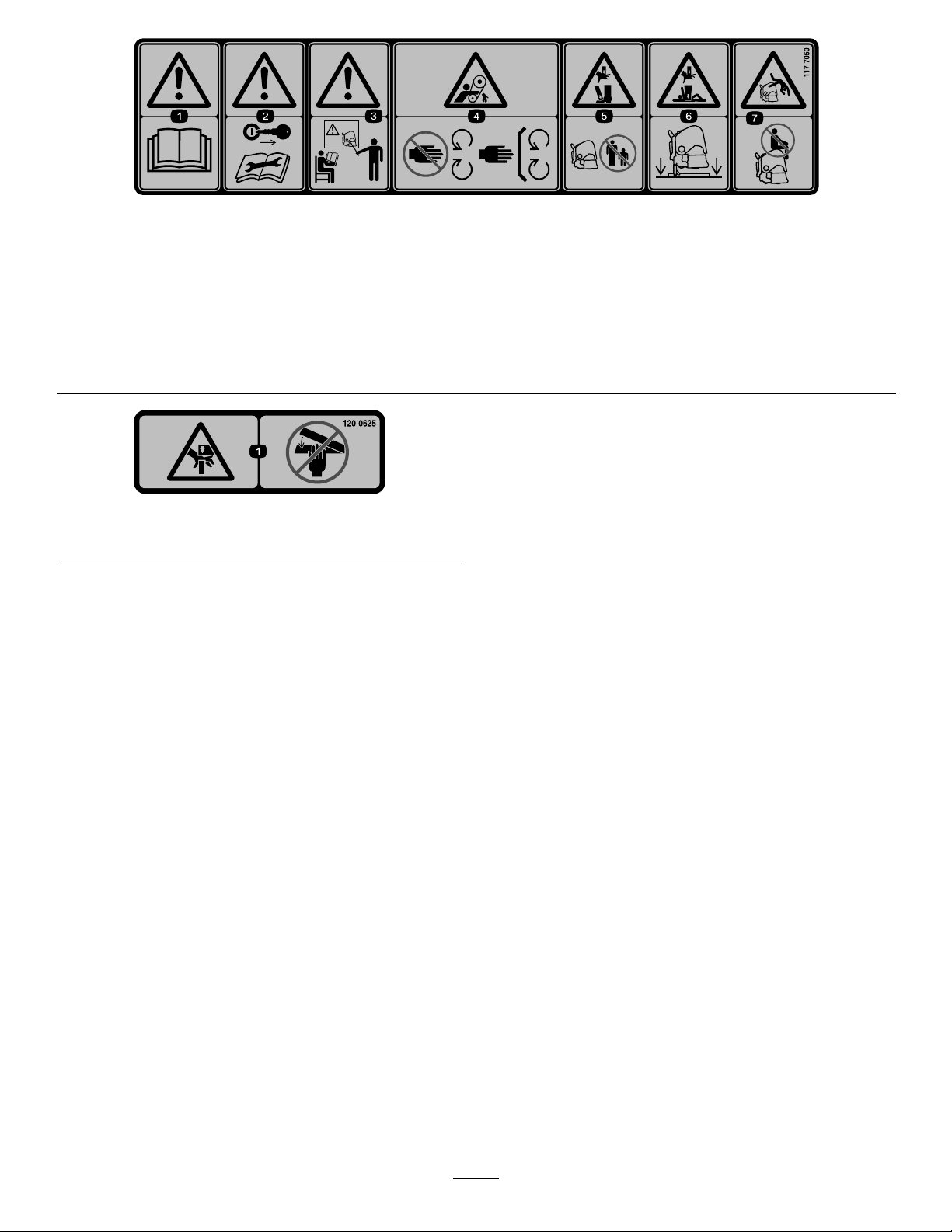

117–7050

1.Warning—readtheOperator'sManual.

2.Warning—removetheignitionkeyandreadtheinstructionsbeforeservicingorperformingmaintenance.

3.Warning—donotoperatethismachineunlessyouaretrained.

4.Entanglementhazard,belt—stayawayfrommovingparts,keepallguardsinplace.

5.Crushinghazardofhandorfoot—keepbystandersasafedistancefromthemachine.

6.Crushinghazardofhandandbody—supportmachineonstandwhennotinuse.

7.Fallinghazard—donotcarrypassengers.

120-0625

1.Pinchpoint,hand—keephandsaway.

7

Page 8

Setup

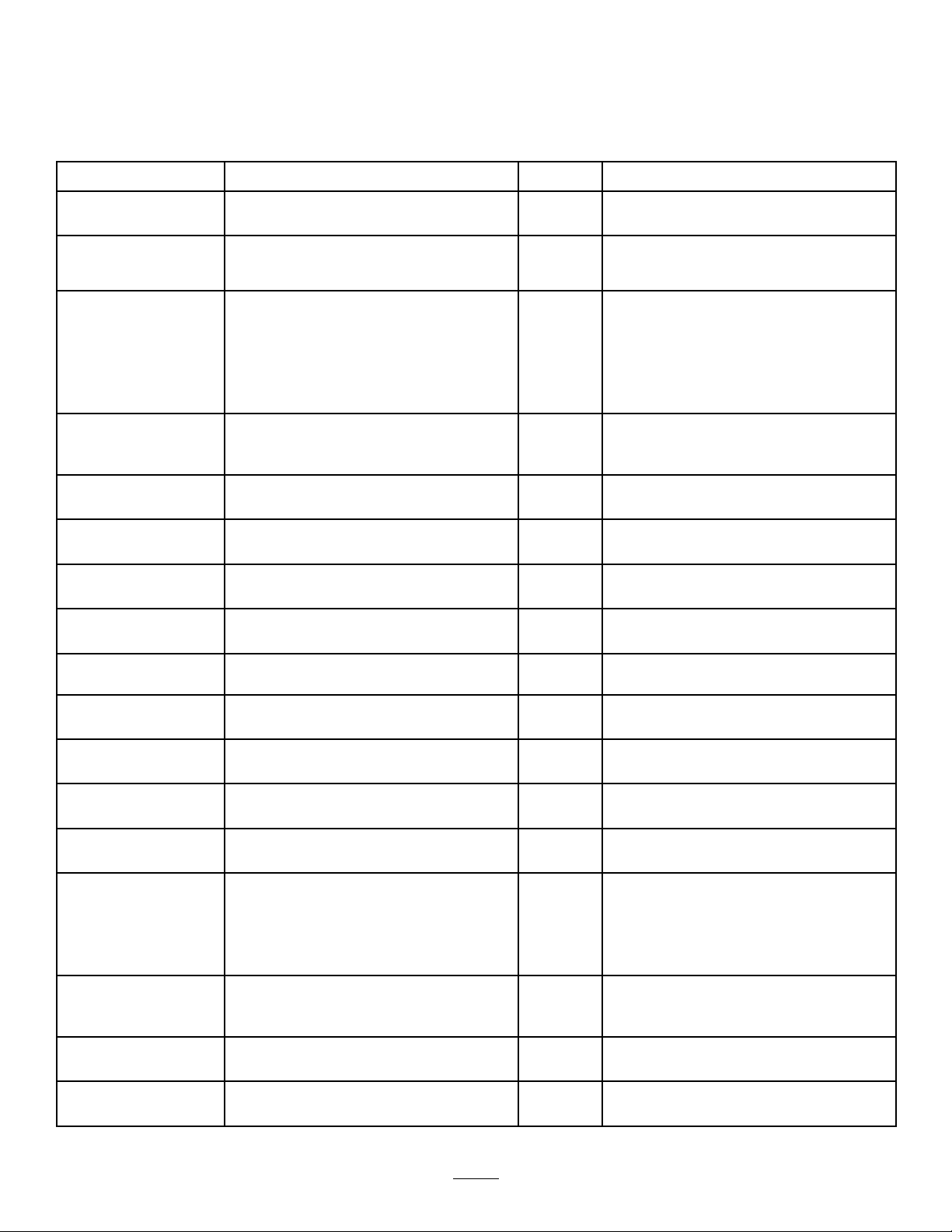

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

6

7

Nopartsrequired

Hitchpin2

Lynchpin2

Hydraulictoplink1

Hydraulichose,3–1/2feet

Hydraulichose,2–1/2feet

Extensionbracket2

Rotationalbracket1

Hosequickcouplings2

Springloadedtoplink

Linkpin3

Lynchpin3

Nopartsrequired

Nopartsrequired

PTOshaft

Qty.

Use

–

1

1

1

–

–

1

Removetheaeratorfromthecrating

Connectlowerlinkarms(Hitchpinsand

lynchpinsareshippedinstalledonthe

SR54andSR54-SAerators)

ConnectHydraulicT opLink(Models

SR48,SR54,SR70,SR72andSR75)

ConnectUpperLink(ModelsSR54–S

andSR70–S)

Verifythetoplinksetup

CheckingthePTOangle

FittingthePTOshaft

8

9

10

11

12

13

14

15

16

PTOShield

Pin(suppliedwithPTOshaft)

Nut(suppliedwithPTOshaft)

Nopartsrequired

Level(notsupplied)

Tines

Nopartsrequired

Rearguard1

Screw,3/8x3–1/4inch

Flatwasher,.438x1.00inch12

Locknut4

Endcap2

Lockplate2

Tapbolt2

Retainingring2

Nopartsrequired

1

1

1

–

1

A/R

–

4

–

InstallthePTOShield

ConnectPTOShaft

AdjustingSwayLinks

LevelAeratorSide-to-Side

InstalltheTines

Setthetinedepth

Installtherearguard

Installthelatchlock

RemoveStorageStands

17

Nopartsrequired

8

–

RemoveStorageStands

Page 9

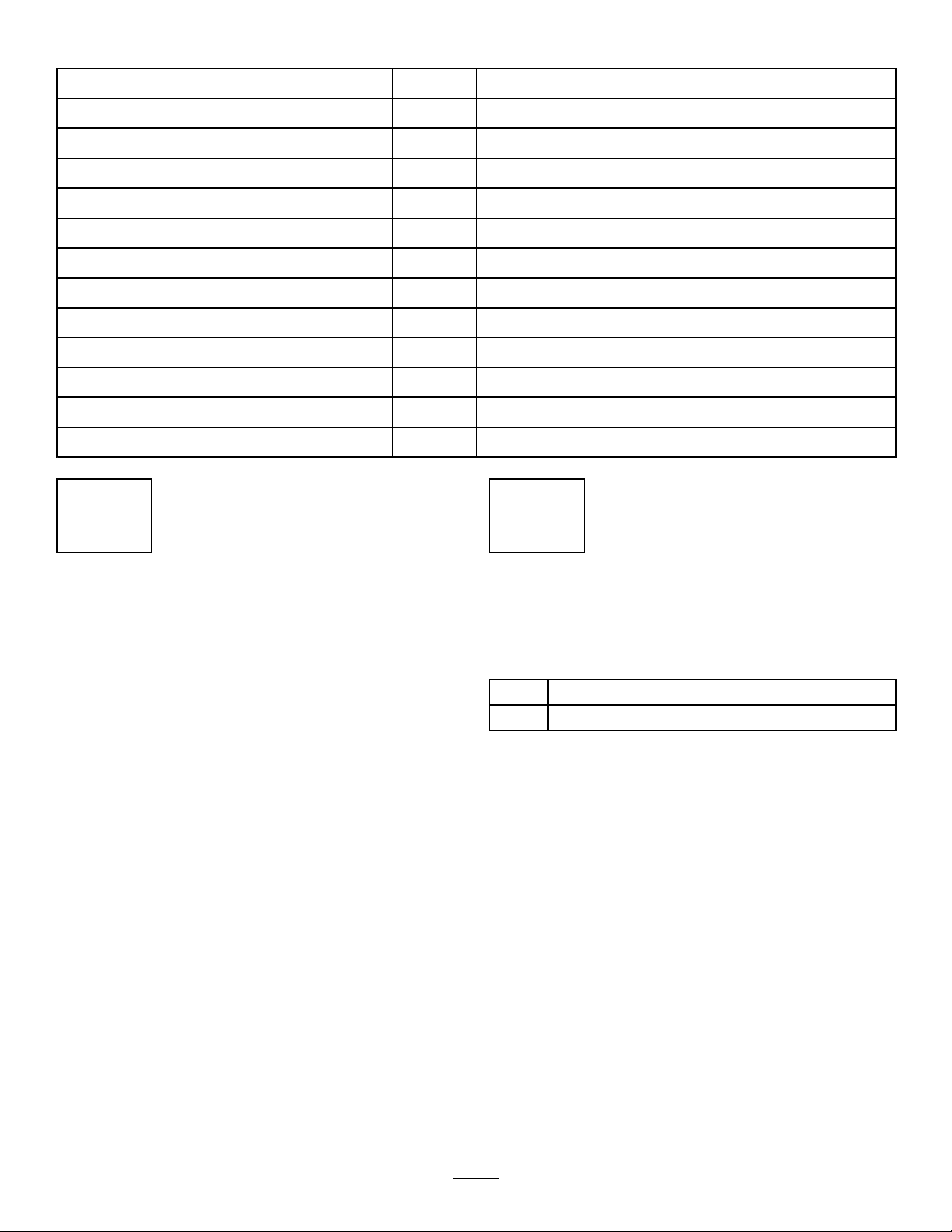

MediaandAdditionalParts

Operator'sManual

PartsCatalog

SpringWires-SR48

SpringWires-SR48

SpringWires-SR54&SR54-S

SpringWires-SR70&SR70-S

SpringWires-SR72

SpringWires-SR72

SpringWires-SR75

SpringWires-SR75

Operatortrainingmaterials

PTOOperatorsManual

Description

Qty.

1

1

4Replacementspringwires

2Replacementspringwires

6Replacementspringwires

8Replacementspringwires

4Replacementspringwires

2Replacementspringwires

4Replacementspringwires

2Replacementspringwires

1

1

Readbeforeoperatingtheaerator

Usetoreferencepartnumbers

Viewbeforeoperatingtheaerator

Readbeforeoperatingtheaerator

Use

1

RemovingtheAeratorfrom

theCrating

NoPartsRequired

Procedure

1.Removetheaeratorfromthecrating.

2.Removetheboltssecuringtheaeratorstoragestands

totheshippingpalletandremovetheaeratorfrom

thepallet.

3.Removethestoragestandsfromtheaerator.Retain

themforstorageuse.

Note:TheSR54-SandtheSR70-Sdonothave

shippingstands.

4.Placetheaeratoronaat,levelsurfacewiththe

frontrolleronthegroundanda2x4positioned

undertheheads.

2

ConnectingtheLowerLink

Arms

Partsneededforthisprocedure:

2Hitchpin

2Lynchpin

Procedure

1.Backthetractorsquarelyuptotheaeratoruntil

thelowerlinkarmsarealignedwiththemounting

brackets.

Note:Theaeratorgearboxshaftshouldbeinline

withthetractorPTOshaft(centeredonthetractor).

Iftheyarenotinline,adjustthelowerlinkarms,

fromsidetosideuntiltheshaftsarealigned.

2.MakesurethePTOisdisengaged.

3.Engagetheparkingbrake,STOPtheengineand

removethekeyfromtheignition.Waitforthe

engineandallmovingpartstoSTOPbeforeleaving

theOperator'sseatonthetractor.

Note:Formaximumgroundclearance,thehitch

pinsshouldbesecuredintheaeratorlowermounting

bracketholes,whensoequipped.Todetermine

9

Page 10

whentousetheuppermountingholes,referto

ConnectingthePTOShaft.

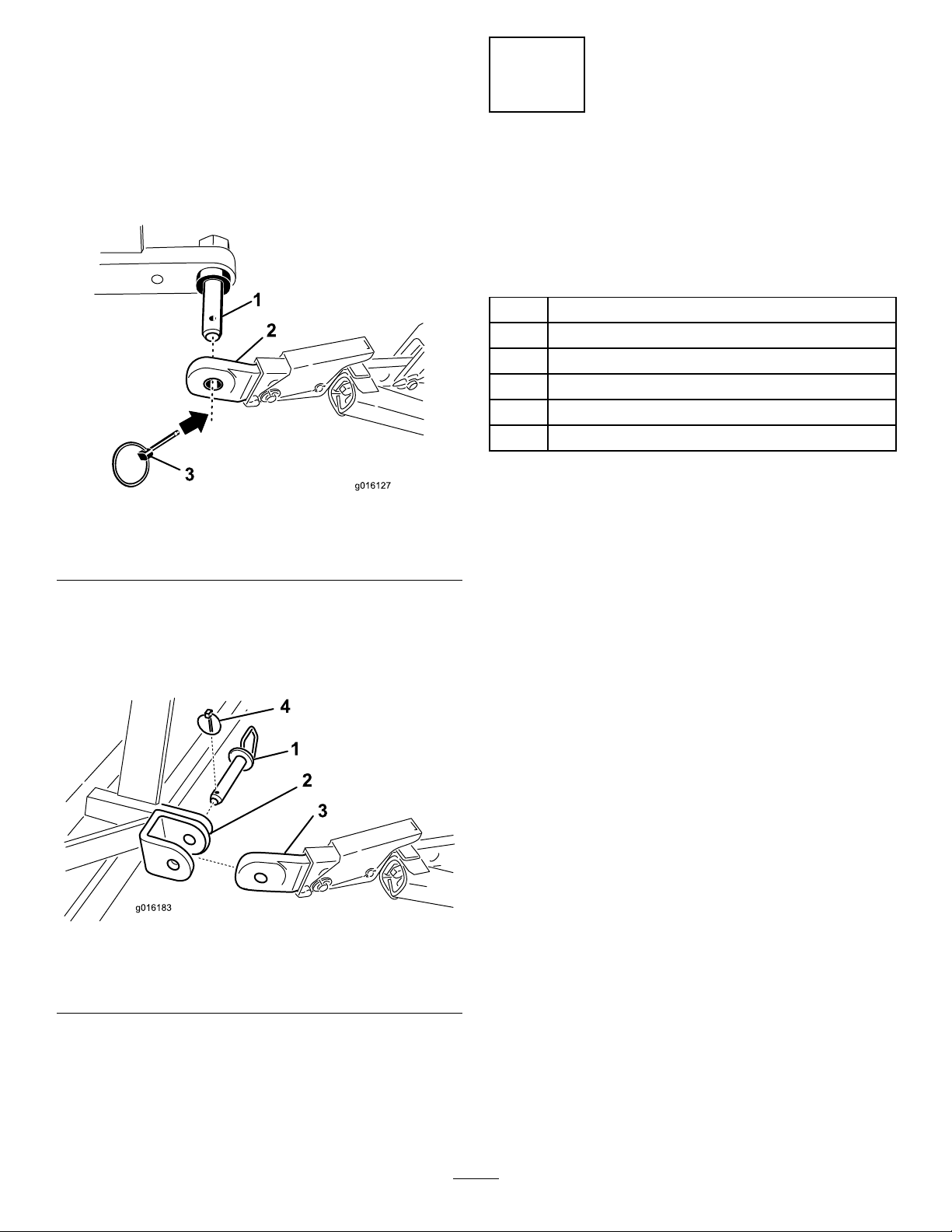

SR54andSR54-SAeratorsonly

Note:Thehitchpinsandlynchpinsareshipped

installedontheSR54andSR54-SAerators.

4.Securethelowerlinkarmstotheaeratormounting

pinswithlynchpins(

1.Aeratormountingpin3.Lynchpin

2.Lowerlink

Figure3).

Figure3

3

Connectingthe

HydraulicTopLink

(ModelsSR48,SR54,SR70,

SR72andSR75)

Partsneededforthisprocedure:

1Hydraulictoplink

1

Hydraulichose,3–1/2feet

1

Hydraulichose,2–1/2feet

2Extensionbracket

1Rotationalbracket

2Hosequickcouplings

Procedure

Note:Makesurethesuppliedcouplingsarecorrectfor

thetractor.Ifnot,itwillbenecessarytocontactthe

tractormanufacturertoobtainthecorrectcouplings.

SR48,SR70,SR70-S,SR72andSR75Aerators

only

5.Securethelowerlinkarmstotheaeratormounting

bracketswithhitchpinsandlynchpins(

Figure4

1.Hitchpin3.Lowerlink

2.Aeratormountingbracket4.Lynchpin

Figure4).

Thetractormustbeequippedwithadoubleactingspool

valvewithanoperatorcontrolleverandtwo1/2inch

(12.7mm)quick-releasecouplingsattherearofthe

tractor.Twoquickcouplingshavebeenprovidedtot

tothehydraulictoplinkhoses(1/2–14NPTFhoseend

threadsize).

Thissectionwillbeusedtoinstallthehosesand

determinetheneedfortheextensionorrotationblocks.

Thisinformationwillhelptodeterminethedepthrange

oftheaerator.

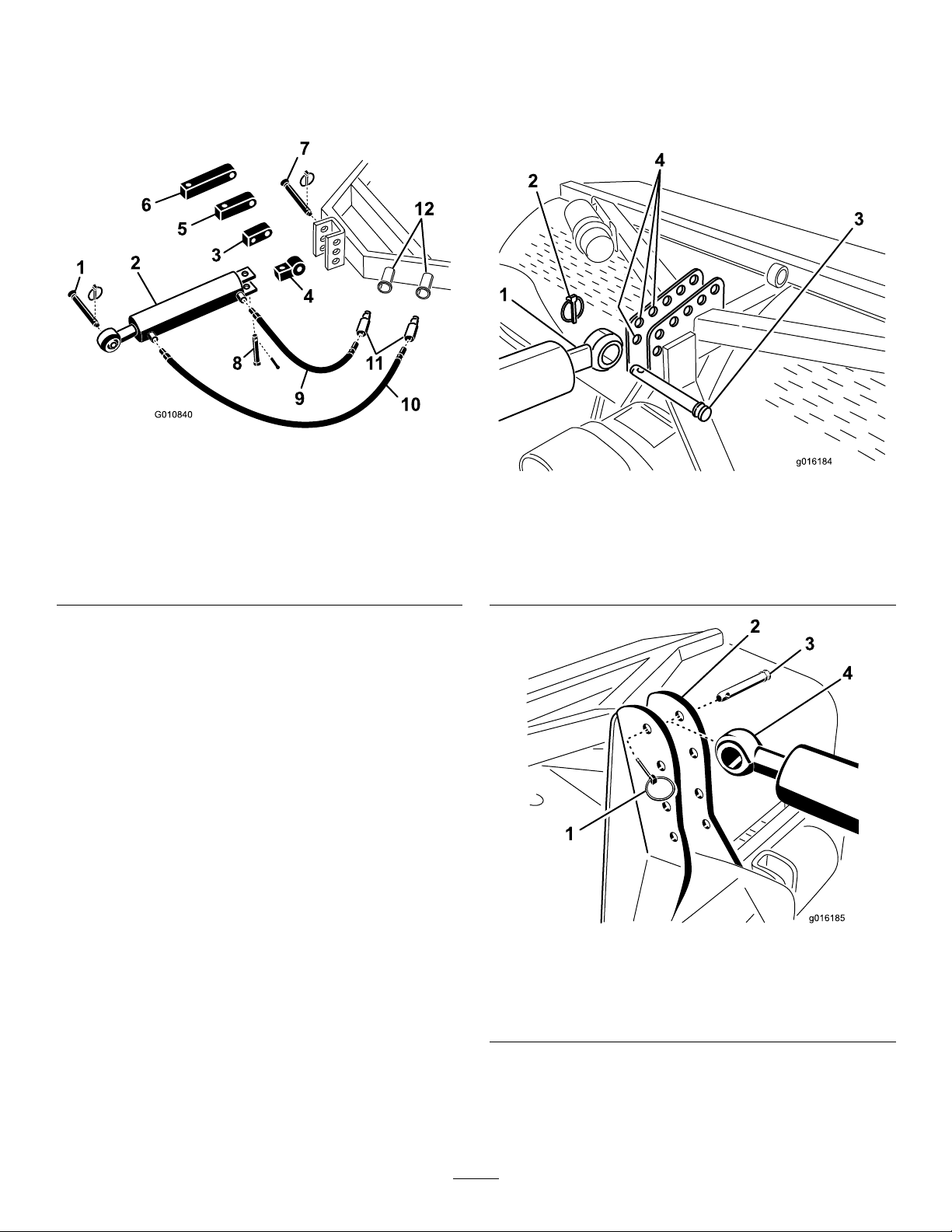

1.Securetheconnectinglinkendofthehydraulictop

linktothetractorwiththepinssuppliedwiththe

tractor(

therodendistowardtheaerator.Thecylinderports

shouldbepositionedtowardthetractor'sauxiliary

powerhydraulics.

Note:Ifthehydrauliccylindermustbepositioned

withtheportsfacingupward,usetherotationalblock

insteadofthestandardmountingblocktoreposition

thecylinder(

maybeusedinsteadoftherotationalblock(ttings

arenotsupplied).

Figure5).Positionthehydraulictoplinkso

Figure5).A90degreehydraulictting

Installtherotationalblockasfollows:

A.Removethecotterpinandpinsecuring

thestandardconnectinglinktothecylinder

10

Page 11

(Figure5).Removetheconnectinglinkfromthe

cylinder.

B.Installtherotationalblocktothecylinderwith

thepinspreviouslyremoved(

Figure5

Figure5).

Important:Whensecuringtherodendof

thehydrauliclink,makesuretousethemost

forwardmountingholesinthemountingbracket

sothereisenoughclearanceforthebarrelofthe

cylinderwhenretracted.

1.Aeratorhitchpin7.Tractorlinkpin

2.Hydraulictoplink

3.Rotationalblock

4.Connectinglink10.3–1/2foothydraulichose

5.3inchextensionblock11.Hosequickcouplings

6.5inchextensionblock12.Tractorhydraulicports

8.Clevis&lynchpin

9.2–1/2foothydraulichose

2.Connectthe3–1/2footlonghydraulichosetothe

hydraulictoplinkportwhichisclosesttotheaerator

Figure5.ApplyTeontapeorpipethreadsealantto

thehosethreadstopreventanyleaks.

3.Connectthe2–1/2footlonghydraulichosetothe

hydraulictoplinkportwhichisclosesttothetractor

Figure5).ApplyTeontapeorpipethreadsealant

(

tothehosethreadstopreventanyleaks.

4.Installquickcouplingstothehydraulichoses

(1/2–14NPTFhoseendthreadsize).ApplyTeon

tapeorpipethreadsealanttothehosethreadsto

preventanyleaks.

5.Connectthetwohydraulichosequickcouplingsto

theportsprovidedonthetractor.

6.Startthetractorengineandoperatethetractorspool

valvetochecktheextendandretractmotionofthe

hydraulictoplink.

Note:Reversethehoseconnections,atthetractor,

iftheydonoagreewiththetractorcontroloperation.

Figure6

SR54andSR70mountingshown

1.Rodendofcylinder

2.Lynchpin

SR48andSR72mountingshown

1.Lynchpin3.Linkpin

2.Aeratorbracket

3.Linkpin

4.Aeratorbracket(forward

Figure7

4.Rodendofcylinder

holes)

7.Securetherodendofhydraulictoplinktothemost

forwardholepossibleintheaeratorbracketwithlink

pinandlynchpin(

Figure6,Figure7orFigure8).

11

Page 12

Figure8

SR75mountingshown

1.Linkpin

2.Aeratorbracket4.Lynchpin

Ifthehydrauliccylinderdoesnotreachtheaerator

mountingbracket,useanextensionblockinsteadof

thestandardmountingblocktoconnectthecylinder

tothetractor(Figure5).

3.Rodendofcylinder

4

Connectingthe

TractorUpperLink

(ModelsSR54–SandSR70–S)

Partsneededforthisprocedure:

1

Springloadedtoplink

3Linkpin

3Lynchpin

Procedure

1.Mountthespringloadedtoplinktotheaerator

bracketwithtwolinkpinsandlynchpins(

2.Loosenthelocknutonthetractorupperlink.Adjust

theupperlinklengthuntilitalignswiththeclevison

thespringloadedtoplinkoftheaerator(Figure9).

Figure9)

Note:Ifanextensionblockisinstalledandthe

cylinderneedstoberetractedtobeinstalled,the

aeratortineheadswillgetclosertotheground.

Installtheextensionblocksasfollows:

A.Removethecotterpinandpinsecuring

thestandardconnectinglinktothecylinder

Figure5).Removetheconnectinglinkfromthe

(

cylinder.

B.Installtherequiredlengthextensionblockto

thecylinderwiththepinspreviouslyremoved

Figure5).

(

Figure9

1.Springloadedtoplink

2.Upperlink5.Locknut

3.Linkpin

3.Connectthetractorupperlinktotheclevisonthe

springloadedtoplinkandsecurewithalinkpinand

lynchpin(

4.Greasethethreadedsteelupperlinktubes.

5.Measurethelengthofthespringinthetoplink.

Figure9).

4.Lynchpin

6.Rotatetheupperlinkuntilthespringiscompressed

byabout1/2inch(

7.Tightenthelocknuttosecuretheupperlinkinto

position.

12

Figure9).

Page 13

5

VerifyingtheHydraulicTop

LinkSetUp

NoPartsRequired

Procedure

•Extendingthehydrauliccylinderwillincreasethe

tinedepth.

•Fullyextendthehydrauliccylindertodetermine

thelocationofthetineheadsandtoverifyifthey

contacttheground.

CAUTION

Ifthetineheadscontacttheground,turf

damagemayoccur.

Note:Onundulatingturf,theoperatorcanadjust

thecylindertomaintaintinedepth(crestingahill)

butitwillbenecessarytohavethetineheadsset

about2inchesbelowground.

•Ifthetineheadscontacttheground,adjustthe

locationofthecylinderendstomovethetopofthe

aeratorclosertothetractor.

•Ifthetineheadsdonotcontacttheground,

extensionbrackets(includedwithaerator)canbe

installedtothetoplinktomovethetineheadscloser

totheground.

Important:WhenconnectingthePTO,besure

thattheaeratorisnotbeingliftedhigherthanis

necessary.Liftingthemachinetoohighwillcause

thePTOshaftknucklestobreak(

leavethePTOturningwhentheaeratorislifted.

ThePTOcanbeoperateduptoanangleof25º,but

canneverexceeda35ºanglewhentheaeratoris

atitshighestpositionorsevereshaftdamagemay

occur.

Figure10).Never

Figure10

1.Breakagewilloccurhere

6

CheckingthePTOAngle

NoPartsRequired

Procedure

Important:Makesurethetinesareremovedbefore

performingthisoperation.

Withtheaeratorpositionedonthegroundandlowered

tothedeepestlocation,checktheanglebetweenthe

PTOandtheaerator.

Lifttheaeratorandfullyretractthehydraulictoplink

cylinder.Usinganangleindictor,checktheangle

betweenthePTOandtheaerator.Ifthisangleisgreater

than35degrees,makeadjustmentstothetractorso

thattheaeratorcannotbeliftedpast35degrees.This

canbeaccomplishedbyusingthetractorliftstop(if

soequipped)ormovingthelowerlinkstoahigher

mountinghole(ifsoequipped).

13

Page 14

7

FittingthePTOshaft

Partsneededforthisprocedure:

1

PTOshaft

Procedure

1.Movethetractorandaeratortoalevelsurface.

2.Raisetheaeratorcompletelyandfullyretractthe

hydraulictoplinkcylinderorupperlink(

Figure11

3.Measurethedistancefromthelockinggrooveonthe

endofthetractorPTOshafttothelockinggroove

ontheaeratorgearboxPTOshaft(Figure12).

Recordthisdistance.Example:26.5inches(67cm).

Figure11).

Figure13

5.Measurethedistancefromthelockinggrooveonthe

endofthetractorPTOshafttothelockinggroove

ontheaeratorgearboxPTOshaft(

Recordthisdistance.Example:27.5inches(70cm).

Figure14

1.Measurehere2.Lockinggroove

6.OnthePTOshaft,measurethedistancefromthe

centeroflockingpinballononeendtothecenterof

thelockingpinontheotherend(Figure15).Record

thisdistance.Example:32inches(81cm).

Figure14).

Figure12

1.Measurehere2.Lockinggroove

4.Lowertheaeratortothegroundandfullyextendthe

hydraulictoplinkcylinderorupperlink(Figure13).

Figure15

1.Measurehere

7.Usingthesmallerofthetwomeasurementsin

Figure14andFigure12,subtractthatdistancefrom

thedistanceinFigure15.Example32(81cm)inches

minus26.5inches(67cm)equals5.5inches(14cm).

8.Theexamplemeasurementsshowthattheshaftis

5.5inchestoolong.Addanextra1/2inch(1.2cm)

tobesurethatthePTOshaftwillnotbottomout

whentheaeratorisliftedtoitshighestposition.

Example:5.50inches(14cm)plus1/2inch(1.2cm)

equals6.00inches(15cm).

14

Page 15

9.SlidethePTOshafttubestogetheruntiltheyare

fullycollapsed.V erifythattheinsidetubedoesnot

protrudeintothecrossandbearingsectionofthe

outertube(

havetobecutofftheinsidetube,tocorrectthe

problem.Proceedtonextstep.

10.Measurethedistancetheinsidetubeprotrudesinto

thecrossandbearingsectionoftheoutertube

Figure16).Addthisdistancetothedimension

(

attainedinstep8.

Figure16).Ifthishappens,morewill

telescopingtubesmusthaveasuitableoverlapto

maintainthetubesalignmentandallowthemtoslide

freely.

Figure16

1.Cutoff

11.SeparatethetwohalvesofthePTOshaft(Figure17,

illustration1).

12.Measurethedistancefromtheendofeachtubeto

itssafetyshield(Figure17,illustration1).Record

thedistances.

13.Usingthedimensionsdeterminedinstep8,locate,

markandcutofftheshieldandtubefromeachPTO

half(Figure17,illustrations2&3).

Note:Morewillhavetobecutofftheinsidetubeif

itwasprotrudingintothecrossandbearingsection

oftheoutertube.

14.Usingthedimensionsdeterminedinstep11,locate,

markandcutoffjustthesafetyshieldstoexposethe

tubesFigure17,illustrations4&5.

15.Carefullydeburrtheendsofthetubeswithaleand

removeallthelingsfromthetubes.

16.Greasetheinsidetube.

Note:Telescopingtubesmustalwaysoverlapby

1/2oftheirlengthinnormaloperationandatleast

1/3oftheirlengthinallworkingconditions.During

transport,whenthedrivelineisnotrotating,the

2.Insidetube

Figure17

1.Measurehere

8

InstallingthePTOShield

Partsneededforthisprocedure:

1

PTOShield

Procedure

1.Removethe4bolts,lockwashersandatwashers

securedtotherearoftheaeratorgearbox(

Figure18).

15

Page 16

Figure18

1.PTOshield

2.Flatwasher5.Accesspanel

3.Lockwasher

4.Bolt

2.MountthePTOshieldtotheaeratorgearboxwith

thefastenerspreviouslyremoved(Figure18).When

mountingthePTOshield,makesuretheaccess

panel(

Figure18)ispositionedtothetoporside

dependingontheaeratorframeconguration.

9

ConnectingthePTOShaft

Partsneededforthisprocedure:

1

Pin(suppliedwithPTOshaft)

1

Nut(suppliedwithPTOshaft)

Figure19

1.Gearboxinputshaft

2.PTOshaftcoupler

3.Pin

4.Nut

Note:MakesuretocloseandlatchthePTOshield

accesspanelifopened.

Note:Makesurethepinisfullyinsertedintothe

yokeofthePTO.

3.ConnectthePTOshafttothetractorPTOshaft

(Figure20).

Procedure

Note:Theaccesspanel(Figure18)canbeopened

toeasetheremovalandinstallationofthePTOshaft

mountingfasteners.

1.RemovethepinandnutfromthePTOshaft

Figure19).

(

2.ConnecttheclutchendofthePTOshafttothe

aeratorgearboxinputshaftwithpinandnut

previouslyremoved(

beinsertedoneway .

Figure19).Thepincanonly

Figure20

1.Tractoroutputshaft3.PTOshaft

2.PTOshaftcoupler

4.SlidethePTOshaftforwardasfarasthetractor

allows.

5.PullbackonthelockingcollartosecurethePTO

shaftinplace.SlidethePTOshaftbackandforthto

makesureitisproperlylocked.

6.ConnecttheshieldsafetychainstothePTOshield

andthetractorbracket(

Figure21).Makesurethe

chainsremainslackwhentheaeratorisraisedor

lowered.

16

Page 17

Figure21

1.Safetychains

Note:Toavoidexcesslift,connecttheliftarmsof

thetractorintothetopholesoftheliftbracket,if

soequipped(

thePTOshaftis35º.

1.Topholes

Figure22).Themaximumangleon

Figure22

Figure23

1.Breakagewilloccurhere

10

AdjustingtheSwayLinks

NoPartsRequired

Procedure

Theaeratorisdesignedtobecenteredwiththetractor

PTOshaftcenterline.Adjusttheswaylinksasrequired.

ThePTOshaftshouldbeasstraightaspossibletothe

tractorPTOshaft.

Important:WhenconnectingthePTO,be

surethattheaeratorisnotbeingliftedhigher

thanisnecessary.Liftingthemachinetoohigh

willcausethePTOshaftknucklestobreak

Figure23).NeverleavethePTOturningwhen

(

theaeratorislifted.ThePTOcanbeoperated

uptoanangleof25º,butcanneverexceeda35º

anglewhentheaeratorisatitshighestposition.

7.VerifythatthePTOshielddoesnotinterferewith

theclutch.

Adjusttheswaylinksonthelowerliftarmstominimize

side-to-sideswaytoamaximumof1inch(25mm)on

eachside(

1.Swaylink

Figure24).

Figure24

17

Page 18

Adjustthelowerlinksinboarduntiltheycontactthe

aeratormountingplates.Thiswillreducethestress

onthepins.Ifthetractorhasswaychainsinsteadof

swaylinks,itisrecommendedthatwashersbeinstalled

betweenthelowerlinkarmandlynchpintoreducethe

overhungloadontheliftpins.

12

InstallingtheTines

Note:RefertothetractorOperator'sManualfor

additionalinstallationandadjustmentprocedures.

11

LevelingtheAerator

Side-to-Side

Partsneededforthisprocedure:

1

Level(notsupplied)

Procedure

1.Parkthetractorandaeratoronalevel,rmsurface.

2.Placealevelontopoftheaeratorframetocheckfor

levelside-to-side(

Figure25).

Partsneededforthisprocedure:

Tines

A/R

Procedure

Awideselectionoftinesareavailablefortheaerator.

Choosethetinetype,sizeandspacingsrequiredforthe

job.RefertothePartsCatalogforthelistofaccessories.

1.Makecertaintheaeratorisfullysupportedonthe

standsorsupportblocks.

2.Turnoffthetractorengineandremovethekey.

3.Loosentheclampingboltsandremovethepreviously

usedtines(Figure26).

Figure25

1.Level

3.Turntheadjustablelinkbody(ifprovided)toraise

orlowerthelinkarmuntiltheaeratorisleveled

side-to-side.

Note:RefertotractorOperator'sManualfor

additionaladjustmentprocedures.

Figure26

1.Tine

4.Slidethenewtinesintotheholessizedtotthetines

selected.Neverusesmalldiametertinesinthelarge

diameterholes-thetinesshouldtcloselyinthe

hole.Besuretoslidethetineupintotheheaduntil

itbottomsout.

Note:Hollowcoringtinesshouldbepositioned

withtheejectionslottotherearwhilethesolidtines

shouldhavethetinetipanglefacingthemachine

Figure26).

(

5.Tightentheclampingboltsrmlytosecurethetines.

6.Setthetineangleforthenewtines.Referto

AdjustingtheTineAngleintheOperationsection.

7.Beforeaeratingformalturfforthersttimeafter

installingtines,testtheaeratoronalessimportant

areasothatyoucantryalternativetractorgearsand

netunetheadjustmenttoachievetheholespacing

andturfappearancedesired.

2.Clampingbolt

18

Page 19

13

14

SettingtheTineDepth

(ModelsSR54–SandSR70–S)

NoPartsRequired

Procedure

Thetinedepthcanbechangedbyraisingorloweringthe

rearroller.Therollerheightisadjustedbymovingthe

rolleradjustingboltstothedesiredposition.

Note:TheaeratorisshippedinPositionA.

InstallingtheRearGuard

Partsneededforthisprocedure:

1Rearguard

4

Screw,3/8x3–1/4inch

12Flatwasher ,.438x1.00inch

4Locknut

2Endcap

Procedure

1.Inserttheendcapsintotheendsoftherearguard

tubes(

Figure28).

Figure27

•PositionA-Maximumdepth

•PositionB-Depthisdecreased1–1/2inchesfrom

PositionA

•PositionC-Depthisdecreased3inchesfrom

PositionA

Figure28

1.Rearguard3.Uppermountinghole

2.Endcap4.Lowermountinghole

2.Aligntheholesintherearguardmountingtubes

withtheholesintheaeratorsideplates(Figure28).

Note:OnSR54–SandSR70–Smodels,mountthe

endsofthetubestothelowersideplatemounting

holesiftheaeratortinedepthissetinPositionA

(

Figure29).Usetheuppermountingholesfordepth

settingPositionsBorC.

19

Page 20

Figure29

3.Securetheguardmountingtubestothesideplates

with(4)screws,atwashersandnuts(

Note:Usetheremainingwashers,asrequired,toll

anygapbetweenthetubesandtheaeratorsideplates.

Figure28).

15

Figure30

1.Retainingring3.Latchplate

2.Mountinghole4.Tapbolt

2.Securethelatchplatetothesideplatewithatapbolt

andaretainingring(Figure30).

InstallingtheLatchLock

Partsneededforthisprocedure:

2Lockplate

2Tapbolt

2Retainingring

Procedure

1.Positionthelatchplateoverthehoodlatchwhile

aligningthemountingholewiththeholeintheside

Figure30).

plate(

3.Repeattheprocedureontheotherhoodlatch.

16

RemovingtheStorageStands

(ModelsSR54andSR70)

NoPartsRequired

Procedure

1.Raisetheaeratorroller(s)3-6inchesoffground.

Placesupportblocksundertheroller(s).

2.Removethebolts,lockwashersandnutssecuringthe

storagestandstoeachendoftheaerator(

Figure31).

20

Page 21

Figure31

1.Bolts3.Nut

2.Lockwasher

3.Removethestoragestands.

4.Usethestoragestandswhenevertheaeratoris

removedfromthetractor.

4.Storagestand

3.Removethestoragestands.

4.Usethestoragestandswhenevertheaeratoris

removedfromthetractor.

Note:Whenreinstallingthestoragestands,make

suretheyaremountedtotheinsideoftheroller

platessothelowerframetubewillrestonthetopof

thestands.

Note:TheSR75shippingstandisalsothestorage

standandtheSR54-SandtheSR70-Sdonothave

shippingstands.

17

RemovingtheStorageStands

(ModelsSR48andSR72)

NoPartsRequired

Procedure

1.Raisetheaeratorroller(s)3-6inchesoffground.

Placesupportblocksundertheroller(s).

2.Removetheboltsandnutssecuringthestorage

standstoeachendoftheaerator(

Figure32).

Figure32

1.Bolts3.Nut

2.Lockwasher

4.Storagestand

21

Page 22

ProductOverview

Specications

Note:Specicationsanddesignaresubjecttochangewithoutnotice.

withPTO&TopLink

WorkingWidth48”

WorkingDepth

(Adjustable)

HoleSpacing

Productivity25,000

Recommended

TractorSize

Recommended

LiftCapacity

Recommended

CounterWeight

Recommended

PTOSpeed

ActualWorking

Speed@400

PTORPM

(Varieswithhole

LiftSystemStd.3–pointStd.3–pointStd.3–pointStd.3–pointStd.3–pointStd.3–pointStd.3–point

ProCore

SR48

Weight

spacing)

1,530lbs.

(694kg)

(1.22m)

1”-14”

(25–300mm)

3”-6”

(75–150mm)

sq.ft./hr.

(2,325

sq.m/hr.)

25HP16–18HP18HP25–35HP25–35HP45HP55+HP

1,800lbs.

(817kg)

300lbs.

(135kg)

400–500rpm400–500rpm400–500rpm400–500rpm400–500rpm400–460rpm400–500rpm

.8–1.3mph1.5–2.5mph1.5–2.5mph1.5–2.5mph1.5–2.5mph.8–1.5mph.8–1.5mph

ProCore

SR54

1165lbs.

(528kg)

(1.37m)

1”-10”

(25–250mm

2.5”-4”

(64–102mm)

36,000

sq.ft./hr.

(3,345

sq.m/hr.)

1,200lbs.

(544kg)

150lbs.

(70kg)

ProCore

SR54–S

1,242lbs.

(563kg)

54”

54”

(1.37m)

1”-10”

(25–250mm

2.5”-4”

(64–102mm)

36,000

sq.ft./hr.

(3,345

sq.m/hr.)

1,500lbs.

(680kg)

150lbs.

(70kg)

ProCore

SR70

1,373lbs.

(623kg)

(1.85m)

1”-10”

(25–250mm

2.5”-4”

(64–102mm)

48,000

sq.ft./hr.

(4,460

sq.m/hr.)

1,700lbs.

(771kg)

250lbs.

(115kg)

ProCore

SR70–S

1,498lbs.

(679kg)

73”

73”

(1.85m)

1”-10”

(25–250mm

2.5”-4”

(64–102mm)

48,000

sq.ft./hr.

(4,460

sq.m/hr.)

1,800lbs.

(817kg)

250lbs.

(115kg)

ProCore

SR72

2,091lbs.

(948kg)

(1.83m)

1”-16”

(25–400mm)

3”-6”

(75–150mm)

38,000

sq.ft./hr.

(3,530

sq.m/hr.)

2,800lbs.

(1,270kg)

300–500lbs.

(135–225kg)

ProCore

SR75

3,100lbs.

(1,406kg)

72”

78”

(1.98m)

1”-16”

(25–400mm

3”-6”

(75–150mm)

48,000

sq.ft./hr.

(4,460

sq.m/hr.)

4,000lbs.

(1,815kg)

700–900

(315–410kg)

Attachments/Accessories

AselectionofToroapprovedattachmentsand

accessoriesareavailableforusewiththemachineto

enhanceandexpanditscapabilities.Contactyour

AuthorizedServiceDealerorDistributororgoto

www.Toro.comforalistofallapprovedattachments

andaccessories.

22

Page 23

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

ontherevcounters.SincetheengineandPTOrpmsare

directlyproportional,youcandeterminetheenginerpm

requiredfora400rpmPTObycalculatingasfollows:

(Enginerpmat540PTOspeed)x(400÷540)=requiredengine

rpm

TractorControls

Itisnecessarytofamiliarizeyourselfwiththeoperation

ofthefollowingtractorcontrolsbeforeyouareableto

operatetheaerator:

•PTOEngagement

•Engine/PTORpm

•3PointHitch(Raise/Lower)

•AuxiliaryValveOperation

•Clutch

•Throttle

•GearSelection

•Parkingbrake

Note:RefertotractorOperator'sManualfor

operatinginstructions.

PrinciplesofOperation

Thetractor'sthreepointhitchlinkage/hydraulictop

linkliftstheaeratorfortransportandlowersitfor

operation.

Thetractor'spowertakeoff(PTO)poweristransmitted

viashafts,gearboxandO-ringdrivechainstoa

crankshaftwhichdrivesthetineholdingarmsintothe

turfsurface.

AsthetractortravelsforwardwiththePTOengaged

andthemachinelowered,aseriesofholesarecreated

intheturfsurface.

Thedepthofthetine'spenetrationisdeterminedby

extendingthehydraulictoplinkorsettingthexedtop

linktothedesiredposition.

Note:Donotattempttoadjustaxedtoplinkwhile

themachineisrunning.

Thedistancebetweentheholescreatedisdetermined

bythetractor'sgearratio(orhydrostatictractionpedal

position)andthenumberoftinesineachtinehead.

Simplychangingenginerpmdoesnotchangehole

spacing.

Forexample,iftheenginerpmwere2700foraPTO

speedof540rpm,youwouldget:

2700x(400÷540)=2000rpm

Inthisexample,runningyourtractorat2000rpmnow

providesyouwitha400rpmPTOspeed.

Ifyourtractorindicatessomeotherenginerpmat540

PTOrpm,substitutethatnumberforthe2700thatwas

usedabove.

Note:TherecommendedPTOspeedfor10inchtines

andshorteris460rpmand425rpmfortineslonger

than10inches.

TrainingPeriod

Beforeusingtheaerator,ndaclearareaandpractice

usingthemachine.Operatethetractoratrecommended

gearsettingsandPTOdrivespeedsandbecome

thoroughlyfamiliarwithmachinehandling.Practice

stoppingandstarting,raisingandloweringtheaerator,

disengagingthePTOdriveandaligningthemachine

withpreviouspasses.Apracticesessionassures

condenceintheperformanceoftheaeratorandhelps

ensureuseofproperoperatingtechniqueswherever

themachineisoperated.

Iftherearesprinklerheads,electricalorcommunication

linesorotherobstructionsintheareatobeaerated,

marktheseitemstoensuretheyarenotdamagedduring

operation.

CAUTION

Toavoidpersonalinjury,neverleavethetractorseat

withoutrstdisengagingthePTOdrive,setting

theparkingbrakeandstoppingtheengine.Never

performaeratorrepairswithoutrstlowering

theaeratorontothestoragestandorappropriate

blockingorjacks.Besureallsafetydevicesare

securedinproperplacebeforeresumingoperation.

BeforeAerating

TractorPTOSpeed

TheaeratorisdesignedtooperatewithaPTOspeed

ofupto500rpmdependingonthesize/weightofthe

tines.Mosttractorsindicatea540PTOrpmposition

Inspecttheareaofoperationforhazardsthatcould

damagethemachineandremovethem,ifpossible,

orplanhowtoavoidthem.Carryreplacementtines,

springwires,springsandtoolsincasetinesaredamaged

duetocontactwithforeignmaterials.

23

Page 24

Important:Neveroperatetheaeratorinreverseor

whenitisintheraisedposition.

AeratingProcedures

Important:Iftheaeratorhasbeenstoredforan

extendedperiod,checktomakesurethePTOslip

isoperational.RefertoAdjustingthePTOClutch

intheMaintenanceSection.

1.Lowertheaeratorsothatthetinesarenearlytothe

groundatthelowestpartoftheirstroke.

2.Atalowtractorenginerpm,engagethepowertake

off(PTO)clutchtostarttheaeratorworking.

3.Selectagearthatgivesaforwardspeedof

approximately.8-2.5M.P .H.(1to4km/hr.)at

theratedPTOspeedof400–500rpm(refertothe

tractorOperator'sManual).

4.Astheclutchisreleasedandthetractormoves

forward,lowertheaeratorfullyontotheroller(s)

andincreaseenginespeedtogiveamaximumof

400–500rpm(460onmodelSR72)atthePTO .

Important:NeveroperatethetractorPTO

inexcessof500rpmordamagetotheaerator

couldoccur.

Important:Makesurethattherollerison

thegroundatalltimeswhentheaeratoris

operating.

5.Notetheholepattern.Ifyourequiregreaterhole

spacing,increaseforwardthespeedofthetractorby

shiftingupagearorwithahydrostaticdrivetractor,

actuatethehydrostatleverorpedaltogivefaster

speed.Forcloserholespacing,decreasetractor

forwardspeed.Changingenginespeed,whilein

thesamegear,willnotchangetheholepattern.

Important:Lookbehindfrequentlyto

ensurethemachineisoperatingproperlyand

alignmentismaintainedwithpreviouspasses.

6.Usethefronttractorwheelasaguidetomaintain

equallateralholespacingwiththepreviouspass.

7.Attheendoftheaerationpass,raisetheaeratorand

quicklydisengagethePTO.

8.Ifyoubackintoatightarea(likeateebox),

disengagethePTOandraisetheaeratortoits

highestposition.Neverattempttoaerateinreverse.

frombeingpickedupbymowersorotherturf

maintenanceequipmentandthrown.

10.Replacebrokentines,inspectandcorrectdamageto

thosestillusable.Repairanyothermachinedamage

beforecontinuingoperation.

OperatingTips

1.EngagePTOatlowenginespeed.Increaseengine

speedtoachievethedesiredPTOspeedof400–500

rpm(maximum)andtheloweraerator.Operateat

anenginerpmthattheaeratorrunsmostsmoothly .

Note:Changingtheengine/PTOrpmina

particulartractorgear(orxedhydrostaticpedal

positionontractorswithhydrostatictransmission)

willnotchangeholespacing.

2.Makeverygradualturnswhenaerating.Nevermake

sharpturnswithPTOdriveengaged.Planyour

aerationpathbeforeloweringtheaerator.Making

sharpturnswhileaeratingwilldamagetheaerator

andthetines.

3.Iftractor“bogs”downwhenoperatingonhard

groundorgoinguphill,raiseaeratorslightlyuntil

speedisregained,thenloweraeratoragain.

4.Bestresultsareachievedwhenthetineentryisona

slightinclinetowardtherearofthemachine.Use

cautionwhenextendingthehydraulictoplinkto

keepfromhammeringtheturfwiththetineheads.

Insomecases,youmaynotachievethebestresults

fromusingthepre-setholesinthecamberbrackets.

Especiallywherethegrassrootsareshortorweak.

Youmaywanttoexperimentusinganothercamber

settingthatwillsetthetinesonmoreofanincline

tokeepfrompullingsoiloutofthehole.

5.Donotaerateifthegroundistoohardordry.Best

resultsareobtainedafterarainorwhenturfhas

beenwateredthepreviousday .

Note:Iftherollerridesupoffthegroundwhile

aerating,thegroundistoohardtoachievethe

desireddepth,reducetheaerationdepthuntilthe

rollercontactsthegroundduringoperation.

6.Raiseaeratorpenetration,ifgroundishardpacked.

Cleanupcoresandre-aerateatdeeperpenetration,

preferablyafterwatering.

9.Alwayscleartheareaofalldamagedmachineparts,

suchasbrokentines,etc.,topreventanything

24

Page 25

CAUTION

Toavoidpersonalinjury,neverleavethetractor

seatwithoutrstdisengagingthePTOdrive,

settingtheparkingbrakeandstoppingthe

engine.Neverperformaeratoradjustmentsor

repairswithoutrstloweringtheaeratoronto

thesafetystand.Besureallsafetydevices

aresecuredinproperplacebeforeresuming

operation.

7.Lookbehindfrequentlytoensurethemachineis

operatingproperlyandalignmentismaintainedwith

previouspasses.Alossofonelineofholesindicates

abentorlosttine.Inspectaftereachpass.

8.Alwayscleartheareaofalldamagedmachine

parts,suchasbrokentines,etc.,topreventthem

frombeingpickedupbymowersorotherturf

maintenanceequipmentandthrown.

toohardtopenetrate.Whenthetinescontactthis

subsoiltheaeratormayliftandcausethetopofthe

holestobecomeelongated.Reducetheaerationdepth

sufcientlytoavoidpenetrationintothehardsubsoil.

Longer/LargerTines

Usinglonger/largertinescanleavethefrontorrearof

theholetuftedorslightlydeformed.Holequalityfor

thiscongurationgenerallyimprovesifthecoringhead

speedisreduced10-15%fromfulloperatingspeed.For

PTOpoweredaeratorsreducetheenginespeeduntil

thePTOspeedisaround400–420rpm.Theforward

spacingisnoteffectedbyreducingtheenginespeed.

Thepushedholecanalsobeaffectedbythepositionof

thecamberbracket.RefertoAdjustingtheTineAngle.

MultiRowAdapterHeads

9.Replacebrokentines,inspectandcorrectdamageto

thosestillusable.Repairanyothermachinedamage

beforecommencingoperation.

SubsoilCultivation

Subsoilcultivation,fracturingor“heave”iscreatedbya

spadingmotionofthetineinthesoilastheaeratorand

tractormoveforward.Qualityofnishontheplaying

surfaceafteraeratingwilldependonvariousfactors

includingturfcondition,rootgrowthandmoisture

content.

HardGround

Ifthegroundistoormtoobtainthedesiredaeration

depth,thecoringheadcangetintoa“bouncing”

rhythm.Thisisduetothehardpanthetinesare

attemptingtopenetrate.Thisconditioncanbe

correctedbyattemptingoneormoreofthefollowing:

•Bestresultsareobtainedafterarainorwhenturf

hasbeenwateredthepreviousday.

•Reducethenumberoftinesperstomper

arm.Attempttomaintainasymmetricaltine

congurationtoevenlyloadthestomperarms.

•Reduceaeratorpenetration(depthsetting)ifground

ishardpacked.Cleanupcores,waterturf,and

aerateagainatadeeperpenetration.

Aerationofsoiltypesbuiltontopofhardsubsoils

(i.e.sand/soilcapplacedoverrockyground)cancause

undesiredholequality.Thisiscausedwhentheaeration

depthisgreaterthanthesoilcapandthesubsoilis

Whenusingmultirowadapterheads,reducetheengine

speeduntilthePTOspeedisaround400–420rpm.

Theforwardspacingisnoteffectedbyreducingthe

enginespeed.

RootZoneLifting

Usingmulti-tineheadsinconjunctionwithlargercoring

tinesorlargediametersolidtinescaninducesignicant

stressontherootzoneoftheturf.Thisstresscan

fracturetherootzoneandcausealiftingactiontothe

turf.Ifthisdamageoccurstryoneormoreofthe

following:

•Reducetinedensity(removesomeofthetines)

•Decreasecoringdepth(suggestedin1/2inch

increments)

•Increaseforwardholespacing(changetractor

transmissionuponegear)

•Decreasethetinediameter(solidorcoring)

UsingtheHoodPropRods

ModelSR75only

1.Releasethelatchoneachsideoftheaeratorhood.

2.Raisethehood.

3.Oneachsideofthehood,pivottheproproddown

frommagneticstoragebracketandinsertitintothe

proprodcatch(Figure33).

25

Page 26

g017489

1

2

3

Figure34

Figure33

1.Proprodcatch3.Magneticstoragebracket

2.Proprod

4.Whenloweringthehood,returntheproprodsto

themagneticstoragebrackets.

AdjustingtheTineAngle

ModelSR72

Setthecamberbracket(Figure34)tothecorrect

positionbasedonthelengthoftinestobeused.The

headstopissettooneofvepredeterminedpositions

bychoosingtheholethroughwhichtheadjustmentrod

isbolted.Theseholesarepresetsonly;forinstance,by

usinga10inchtineinthe12inchpositionyoumay

achieveasmoothernish;dependingontheapplication.

1.DisengagethePTOandengagetheparkingbrake.

2.Stoptheengineandremovethekeyfromignition

switch.

3.Releasethespringtensiontothetinehead

Figure34).

(

4.Removethenutandboltintheadjustmentholesin

thecamberbracket(Figure34).

1.Camberbracket

2.16inchtine6.14inchtine

3.12inchtine7.Tineheadpivotbolt

4.7inchtine

5.10inchtine

8.Spring

5.Rotatethecamberbracketuntilitisalignedwiththe

desiredholeinthearmandinstalltheboltandnut.

Note:Makesuretheboltgoesthroughthe

chamberbracketandplate.

6.Reconnectthespringtensiontothetinehead.

ModelsSR54,SR54–S,SR70and

SR70–S

Setthetineangleaccordingtothetinelengthbyusing

oneofthetwoadjustmentholesinthelinkagearm.

Theseholesarepresetsonly .Whenusing7inch(17.77

cm)to10inch(25.4cm)tines,theheadbumpershould

bepositionedclosesttotherearofthetinehead.The

otherposition(theholefarthestfromthehead)maybe

neededduetovariancesofsoilconditions.

1.DisengagethePTOandengagetheparkingbrake.

2.Stoptheengineandremovethekeyfromignition

switch.

3.Releasethespringtensiontothetinehead

Figure35).

(

26

Page 27

4.Removethenutandboltintheadjustmentholesin

thecamberbracket(Figure36).

5.Rotatethecamberbracketuntilitisalignedwith

thedesiredholeinthearmandinstalltheboltand

Figure36).

nut(

Note:Makesuretheboltgoesthroughthe

chamberbracketandplate.

6.Reconnectthespringtensiontothetinehead.

Figure35

1.Spring3.Springpinandclip

2.Bumperbolt

4.Removethebumperboltandbumperfromthe

linkagearmandreinsertthemintotheother

adjustmenthole(Figure35).

5.Reconnectthespringtensiontothetinehead.

ModelSR75

Setthecamberbracket(Figure36)tothecorrect

positionbasedonthelengthoftinestobeused.The

headstopissettooneofvepredeterminedpositions

bychoosingtheholethroughwhichtheadjustmentrod

isbolted.Theseholesarepresetsonly;forinstance,by

usinga10inchtineinthe12inchpositionyoumay

achieveasmoothernish;dependingontheapplication.

1.DisengagethePTOandengagetheparkingbrake.

2.Stoptheengineandremovethekeyfromignition

switch.

3.Releasethespringtensiontothetinehead

(Figure36).

AdjustingtheTineDepth

(ModelsSR54–SandSR70–S)

Thetinedepthcanbechangedbyraisingorlowering

therearroller.Therollerheightisadjustedbymoving

therolleradjustingboltstothedesiredposition.

Note:TheaeratorisshippedinPositionA.

Figure37

•PositionA-Maximumdepth

•PositionB-Depthisdecreased1–1/2inchesfrom

PositionA

Figure36

1.10inchtine

2.7inchtine6.Tineheadpivotbolt

3.12inchtine7.14inchtine

4.16inchtine

5.Camberbracket

8.Spring

•PositionC-Depthisdecreased3inchesfrom

PositionA

TransportOperation

Tobegintransportoperation,raisetheaeratorand

disengagethePTO.Toavoidlossofcontrol,traverse

steepinclinesslowly,approachroughareasatreduced

speedandcrosssevereundulationscarefully.

Important:Donotexceedtransportspeedsof15

m.p.h.(24km/hr.).

27

Page 28

InspectionandCleanupafter

Use

Afterdailyuse,thoroughlywashthemachinewitha

gardenhosewithoutanozzlesocontaminationandseal

andbearingdamageduetoexcessivewaterpressurewill

beavoided.Abrushmaybeusedtoremovecaked-on

material.Usemilddetergenttocleanthecovers.After

cleaning,greasealldrivelinesandrollerbearings,

inspectformachinedamage,oilleakage,component

andtinewear.DonotoiltheO-ringdrivechain.

Remove,cleanandoilthetines.Sprayalightoilmiston

coringheadbearings(crank&damperlinks).

Cleanandcoatthespringswithadrylubricantlike

graphiteorsilicone.

28

Page 29

Maintenance

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst50hours

Beforeeachuseordaily

Every50hours

Every500hours

Beforestorage

Yearly

MaintenanceProcedure

•ChangetheGearboxOil

•Inspectthechaintension

•Checkthesprings

•Cleanandlubricatespringsandtinemountingscrews

•InspectthePTOforsignsofwear.

•GreasethebearingsandPTOshaft

•ChecktheGearboxOil

•Inspectthechaintension

•Inspectbearings

•ChangetheGearboxOil

•Inspectbearingsandreplaceasneeded

•Oiltineholderfasteners

•Performall50hourmaintenanceprocedures

•Chippedsurfaces-Paint

•LoosenthePTOclutchbolts

•Removeandcleantines

•Removealldebris

•AdjustthePTOclutchBeforeandafterstorage

LiftingtheMachine

CAUTION

Whenchangingattachmentsorperformingother

service,usecorrectblocks,hoistsorjacks.Make

suremachineisparkedonasolidlevelsurface

suchasaconcreteoor.Priortoraisingmachine,

removeanyattachmentsthatmayinterferewith

thesafeandproperraisingofthemachine.Always

chockorblocktowvehiclewheels.Usestorage

standsorblockstosupporttheraisedmachine.If

themachineisnotproperlysupported,themachine

maymoveorfall,whichmayresultinpersonal

injury.

Note:Ahoistcanbeusedtolifttheaerator.Use

thecoringheadeyeletasahoistattachmentpoint

(Figure38).Makesurethehoisthasenoughliftcapacity.

Refertothespecicationchartforaeratorweights.

Figure38

1.Coringheadeyelet

29

Page 30

GreasingtheBearings

ServiceInterval:Every50hours

Themainworkingbearingsoftheaeratoraresealedand

requirenomaintenanceorlubrication.Thisdrastically

reducesthemaintenancerequiredandeliminatestherisk

ofgreaseoroilbeingdroppedontotheturf.

Therearegreasettingsthatmustbelubricatedwith

anSAEmultipurpose,high-temperaturegreasewith

highpressure(EP)performanceorSAEmultipurpose

lithiumbasegrease.

Thelubricationpointsare:

PTOShaft(3)(

Rollerbearings(Qty .2or4,dependingonmodel)

(Figure40)

Figure39)

Figure39

Thesealedbearingsrequirenolubricationorshortterm

maintenance.Thisminimizesroutineservicerequired

andreducesthepotentialofturfdamageduetogrease

contamination.Thesesealedbearingpackageswill

providegoodperformanceandlifeundernormaluse,

butperiodicinspectionsofbearingconditionandseal

integrityshouldbeconductedtoavoiddowntime.These

bearingsshouldbeinspectedseasonallyandreplacedif

damagedorworn.Bearingsshouldoperatesmoothly

withnodetrimentalcharacteristicssuchashighheat,

noise,loosenessorrustweeping.

Duetotheoperatingconditionsthesebearing/seal

packagesaresubjectto(i.e.sand,turfchemicals,water,

impacts,etc.)theyareconsiderednormalwearitems.

Bearingsthatfailduetootherthandefectsinmaterialsor

workmanshiparetypicallynotcoveredunderwarranty.

Note:Bearinglifecanbenegativelyaffectedby

improperwashdownprocedures.Donotuse

high-pressureorhighvolumespraydirectlyatthe

bearings.

Itiscommonfornewbearingstopurgesomegreaseout

thesealsonanewunit.Thispurgedgreasewillturn

blackincolorduetocollectionofdebrisandnotdueto

excessiveheat.Itisgoodpracticetowipethisexcess

greasefromthesealsaftertheinitial8hours.Theremay

alwaysappeartobeawetareaaroundtheseallip.This

isgenerallynotdetrimentaltobearinglife,butkeeps

thesealliplubricated.

Inspectthecoringheadbearingsevery500operating

hoursandreplaceasneeded.

Figure40

O-ringchain—Donotlubricatethechain.

Important:Bearingsrarelyfailfromdefectsin

materialsorworkmanship.Themostcommon

reasonforfailureismoistureandcontamination

workingitswaypasttheprotectiveseals.Bearings

thataregreasedwillrelyuponregularmaintenance

topurgeharmfuldebrisfromthebearingarea.

Sealedbearingsrelyonaninitialllofspecialgrease

andarobustintegralsealtokeepcontaminantsand

moistureoutoftherollingelements.

CheckingtheGearboxOil

ServiceInterval:Every50hours

Thegearboxislledwith80W–90gearoilorequivalent.

Allowthegearboxtocoolbeforecheckingtheoillevel.

1.Cleandebrisfromllplugandcheckplugtoavoid

contamination.

2.Removethecheckplugfromthegearbox(

Note:Ifthegearboxhastwocheckplugs,usethe

bottomone.

Figure41).

30

Page 31

Model

SR482quarts(1.9liters)

SR542quarts(1.9liters)

SR54–S2quarts(1.9liters)

SR702quarts(1.9liters)

SR70–S2quarts(1.9liters)

SR724quarts(3.8liters)

SR754quarts(3.8liters)

GearCaseCapacity

6.Installthevent/llplug.

7.Checktheoillevelandreplenishasrequired.

Inspecting/AdjustingtheDrive

Chain

ServiceInterval:Beforeeachuseordaily

Figure41

1.Vent/Fillplug

2.Checkplug

3.Drainplug

3.Makesureoilisuptothebottomofthecheckplug

holeingearbox(Figure41).

4.Ifoillevelislow ,removevent/llplugfromtopof

gearboxandreplenishoilasrequired.

5.Installplugs.

ChangingtheGearboxOil

ServiceInterval:Aftertherst50hours

Every500hours

Thegearboxislledwith80W–90gearoilorequivalent.

1.Cleandebrisfromvent/llpluganddrainplugto

avoidcontamination(

2.Removethevent/llplugtorelieveairdraw .

Figure41).

Every50hours

Checkthedrivechainfordamageandcorrect

adjustment.Thechainshouldhaveapproximately1/2

inch(12.7mm)ofoveralldeection(1/4inch[6mm]in

eachdirection).

Chaintensioncanbeadjustedbyslightlylooseningthe

mainjamnutandtighteningthejamrodtodesired

position(

Figure42orFigure43).Donotadjustthe

chaintensionwhenthechainishotorwarm.

3.Positionadrainpanunderthedrainplugandremove

theplug.

Note:Thehighviscosityofcooloilwillextendthe

draintime.(approximately30minutes)

4.Aftertheoiliscompletelydrained,reinstallthedrain

plug.

5.Fillthegearboxwithhighquality80W -90gearlube.

Usethefollowingcharttodeterminethegearbox

oilcapacity .

Figure42

ModelsSR54,SR54–S,SR70,&SR72

1.Drivechain3.Jamrod

2.Jamnut

31

Page 32

Note:Donotallowtheclutchtoslipforan

extendedamountoftime.

3.Iftheclutchcontinuestoslipafterturningbackthe

nuts,tighteneachnutanaddition1/4turnuntilthe

slippingceases.Donotovertightenthenutsasshaft

damagemayoccur.

FastenerTorque

Specications

Figure43

ModelSR72

1.Drivechain3.Jamrod

2.Jamnut

Important:Donotovertightenchains;excess

tighteningofchainscancausegearbox/sprocket

damage.

AdjustingthePTOClutch

ServiceInterval:YearlyBeforeandafterstorage

WARNING

Frictionclutchesmaybecomehotduringuse.

not touch.

aroundtheclutchfreeofammablematerialand

avoidprolongedslippingoftheclutch.

Toavoidtheriskofre,keepthearea

ModelsSR54,

SR54–S,

SR70&

SR70–S

CrankShaft

Nut

CrankPinNut950ft-lbs.950ft-lbs.1100ft-lbs.

HingeBolt

950ft-lbs.1200ft-lbs.1100ft-lbs.

265ft-lbs.300ft-lbs.800ft-lbs.

SR48&SR72SR75

Do

1.Attheendoftheseason,backoffeachoftheclutch

nuts2turns(Figure44).

Figure44

1.Clutchnut2.Clutch

2.Atthestartofthenewseason,startthePTOand

allowtheclutchtoslipforafewsecondsbefore

stoppingthePTO.Turnbackthenutsanadditional

2turns.

1.Crankshaftnut

2.Crankpinnut

Figure45

3.Hingebolts

32

Page 33

CheckingtheSprings

ServiceInterval:Beforeeachuseordaily

Checkthespringsforcrossedorbrokenwires

(Figure46).Crossedorbrokenspringwireswillcause

anerraticholepatternintheturf.

Figure46

1.Correctspringwires2.Crossedspringwires

Note:Replacementwiresareincludedwiththeaerator.

Thewiresareconsideredaconsumableitem.

hosesandtheconnectinglinkfromthetractor.Cap

thehydraulichoses.Storethesecomponentswith

theaerator.

10.DisconnectthesafetyshieldchainsfromPTOshaft.

11.Pullbackonthelockcollartodisconnectthepower

shaftfromthetractorPTOshaft.

12.SlidethePTOshaftbackandremovefromtractor.

13.ConnectthePTOsafetychaintotheaeratorto

preventthePTOshaftfromcontactingtheground.

14.Removethepinssecuringthelowerlinkarmstothe

aeratorbrackets.Retainpinswithaerator.

AdjustingtheHoleSpacing

Theforwardholespacingisdeterminedbythetractor's

gearratio(orthehydrostatictractionpedal).Changing

theengineRPMdoesnotchangetheforwardhole

spacing.

Thelateralholespacingisdeterminedbythenumber

oftinesinthetineheads.

RemovingtheAeratorfrom

theTractor

1.Stoptheaeratoronalevelsurface,notonaslope.

2.DisengagethePTOandengagetheparkingbrake.

3.Raisetheaeratorroller(s)3-6inchesoffground.

Placesupportblocksundertheroller(s).

4.Stoptheengineandremovethekeyfromignition

switch.

5.BeforeleavingtheOperator'sseatontractor,wait

forengineandallmovingpartstostop.

6.Removethetines.

7.Installthestoragestand.

8.Slowlyloweraeratoruntilstoragestandscontact

ground.

9.Removethepinsecuringthetoplinktotheaerator

bracket.Retainpinwithaerator.Also,onmodels

withahydraulictoplink,disconnectthehydraulic

33

Page 34

TroubleShooting

Problem

Springsarebreakingornotpullingbackthe

headtonormalposition.

Holesareelongatedorpicking.

Tinesarehittingthegroundwithanerratic

pattern.

PTOclutchslipsexcessively.

Turfispullingupwithcoringtines.Shallow-rootedturfmayrequiresolidtinesthersttime.

Thesoilistoohardforfullpenetration.

Coringtinesarebreaking.Youaretryingtogettoomuchdepthforthesoilcondition.Seeaboveandaerateto

Tineswillnotstayinthehead.

Tinespullthesoilupwhenthemachineis

raised.

Themachinewillnotturn.

Thetractorhasdifcultyliftingtheaerator.Movetractorliftarms3”(76.19mm)to4”(101.6mm)closertotheaerator.Make

Thehydraulictoplinkcylinderisspongy.(It

“gives”andmovesinandoutashortspan

whenforceisapplied.

Machineisnoisyorknocking.

Thehydraulictoplinkcylindercannotbefully

retracted(PTOshaftjams).

Thetractorisdifculttosteerwhenintransport.•Addweighttothefrontofthetractor.

Camberbracketdamage

SlowthePTOspeedofthetractor.Thelongerandheavierthetines,thegreaterthe

centrifugalforceonthehead.Checkforcrossedorbrokenspringwires.

Adjusttheangleofthetineorchangethetractorgroundspeed.Makesurethatthe

aeratorcanbeloweredatleast2inchesbelowatgroundleveltoallowforundulation.

•Checkforcrossedorbrokenspringwires.

•SlowthePTOspeedofthetractor.

Adjusttinestoashallowerdepth.Reviewclutchadjustmentprocedure.Replace

PTOclutches.

Aerateatadepththatthemachinecanachieve,waterovernight,andthenincrease

thedepth.Repeatifnecessaryuntilsoilcanbeaeratedatdesireddepth.

ashallowerdepth.

Tightenthetineholderbolts;donotusejamnutsorimpactwrench.Iftheboltwillnot

holdthetine,replaceit.

RaisethemachinepartofthewayoutofthesoilbeforedisengagingthePTO.

MakesurethePTO,driveshaftanddrivechainsareworkingproperly .

surethetractorhasthecapacitytolifttheaerator.

Airisinthecylinderorlinesandmustbebledout.

•Crankpinnuthasvibratedloose.

•Chainsaretooloose.

•Boltsonthebottomoftheframeattherearofthemainarmhavevibratedloose.

•Checkoillevelingearbox.

ThePTOshaftistoolongforyourtractorandshouldbecuttothecorrectlength.

•Checktirepressureandadjustasrequired.

•Donotstoretheaerator,ontheground,withtinesinstalled.

•Donotrunthecoringhead,foranextendedtimeathighRPM,whenthetines

areoutoftheground.

Solution

34

Page 35

Storage

Attheendofanaeratingseasonorwhentheaeratorwill

notbeusedforalongperiod,itisgoodpracticetocarry

outthefollowingpreventativemaintenance.

1.Cleanoffanydirtorgreasethatmayhave

accumulatedontheaeratororanyofthemoving

parts.

2.Removeandcleanouttines.Coattinesandtine

fastenerswithoiltopreventrustingduringstorage.

3.Openthehoodandcleanouttheinsideofthe

machine.

4.Lubricateallgreasettingsandtinefastenerscrew

threads.

5.Storethemachineontheprovidedstoragestandson

ahard,drysurface.

6.LoosenthePTOclutchboltstwoturns.

7.ConnectthePTOsafetychaintotheaeratorinstored

positiontopreventdamageorremovethePTOand

storeunderthehoodtominimizecorrosion.

8.Painttherollerandtouch-upanyotherscratcheson

thepaintedsurfaces.

9.Replaceanymissingordamageddecals.

10.Storetheaeratorinsideadrysecurebuilding.Inside

storagewillreducemaintenance,givealonger

workinglifeandincreasetheresidualvalueofthe

machine.Ifinsidestorageisnotavailable,coverwith

aheavysheetortarpaulinandsecuretightly.

35

Page 36

ToroCommercialAeratorProductsWarranty

Atwo-YearLimitedWarranty

ConditionsandProductsCovered

TheToroCompanyanditsafliate,ToroWarrantyCompany,pursuant

toanagreementbetweenthem,jointlywarrantyourT oroHydroject

orProCoreAerator(“Product”)tobefreefromdefectsinmaterialsor

workmanshipfortwoyearsor500operationalhours*,whicheveroccurs

rst.Thiswarrantyisapplicabletoallproductswiththeexceptionof

Aerators(refertoseparatewarrantystatementsfortheseproducts).

Whereawarrantableconditionexists,wewillrepairtheProductatnocost

toyouincludingdiagnostics,labor,parts,andtransportation.Thiswarranty

beginsonthedatetheProductisdeliveredtotheoriginalretailpurchaser.

*Productequippedwithanhourmeter.

InstructionsforObtainingWarrantyService

YouareresponsiblefornotifyingtheCommercialProductsDistributoror

AuthorizedCommercialProductsDealerfromwhomyoupurchasedthe

Productassoonasyoubelieveawarrantableconditionexists.Ifyouneed

helplocatingaCommercialProductsDistributororAuthorizedDealer,or

ifyouhavequestionsregardingyourwarrantyrightsorresponsibilities,

youmaycontactusat:

CommercialProductsServiceDepartment

ToroWarrantyCompany

811 1LyndaleAvenueSouth

Bloomington,MN55420-1196

952–888–8801or800–952–2740

E-mail:commercial.warranty@toro.com

OwnerResponsibilities

AstheProductowner,youareresponsibleforrequiredmaintenance

andadjustmentsstatedinyourOperator’sManual.Failuretoperform

requiredmaintenanceandadjustmentscanbegroundsfordisallowinga

warrantyclaim.

ItemsandConditionsNotCovered

Notallproductfailuresormalfunctionsthatoccurduringthewarranty

periodaredefectsinmaterialsorworkmanship.Thiswarrantydoesnot

coverthefollowing:

•Productfailureswhichresultfromtheuseofnon-Tororeplacement

parts,orfrominstallationanduseofadd-on,ormodiednon-T oro

brandedaccessoriesandproducts.Aseparatewarrantymaybe

providedbythemanufactureroftheseitems.

•Productfailureswhichresultfromfailuretoperformrecommended

maintenanceand/oradjustments.Failuretoproperlymaintain

yourToroproductpertherecommendedmaintenancelistedinthe

Operator’sManualcanresultinclaimsforwarrantybeingdenied.

•ProductfailureswhichresultfromoperatingtheProductinan

abusive,negligentorrecklessmanner.

•Partssubjecttoconsumptionthroughuseunlessfoundtobe

defective.Examplesofpartswhichareconsumed,orusedup,during

normalProductoperationinclude,butarenotlimitedto,brakes

padsandlinings,clutchlinings,blades,reels,bedknives,tines,

sparkplugs,castorwheels,tires,lters,belts,andcertainsprayer

componentssuchasdiaphragms,nozzles,andcheckvalves,etc.

•Failurescausedbyoutsideinuence.Itemsconsideredtobeoutside

inuenceinclude,butarenotlimitedto,weather,storagepractices,

contamination,useofunapprovedcoolants,lubricants,additives,

fertilizers,water,orchemicals,etc.

•Normalnoise,vibration,wearandtear ,anddeterioration.

•Normal“wearandtear”includes,butisnotlimitedto,damageto

seatsduetowearorabrasion,wornpaintedsurfaces,scratched

decalsorwindows,etc.

Parts

Partsscheduledforreplacementasrequiredmaintenancearewarranted

fortheperiodoftimeuptothescheduledreplacementtimeforthatpart.

Partsreplacedunderthiswarrantyarecoveredforthedurationofthe

originalproductwarrantyandbecomethepropertyofToro.T orowill

makethenaldecisionwhethertorepairanyexistingpartorassemblyor

replaceit.T oromayuseremanufacturedpartsforwarrantyrepairs.

MaintenanceisatOwner’sExpense

Enginetune-up,lubricationcleaningandpolishing,replacementof

ItemsandConditionsNotCovered,lters,coolant,andcompleting

recommendedmaintenancearesomeofthenormalservicesToro

productsrequirethatareattheowner’sexpense.

GeneralConditions

RepairbyanAuthorizedT oroDistributororDealerisyoursoleremedy

underthiswarranty .

NeitherTheToroCompanynorToroWarrantyCompanyisliablefor

indirect,incidentalorconsequentialdamagesinconnectionwiththe

useoftheT oroProductscoveredbythiswarranty,includingany

costorexpenseofprovidingsubstituteequipmentorserviceduring

reasonableperiodsofmalfunctionornon-usependingcompletion

ofrepairsunderthiswarranty.ExceptfortheEmissionswarranty

referencedbelow,ifapplicable,thereisnootherexpresswarranty.

Allimpliedwarrantiesofmerchantabilityandtnessforusearelimitedto

thedurationofthisexpresswarranty.Somestatesdonotallowexclusions

ofincidentalorconsequentialdamages,orlimitationsonhowlongan

impliedwarrantylasts,sotheaboveexclusionsandlimitationsmaynot

applytoyou.

Thiswarrantygivesyouspeciclegalrights,andyoumayalsohaveother

rightswhichvaryfromstatetostate.

Noteregardingenginewarranty:

TheEmissionsControlSystemonyourProductmaybecoveredby

aseparatewarrantymeetingrequirementsestablishedbytheU.S.

EnvironmentalProtectionAgency(EP A)and/ortheCaliforniaAir

ResourcesBoard(CARB).Thehourlimitationssetforthabovedonot

applytotheEmissionsControlSystemWarranty.RefertotheEngine

EmissionControlWarrantyStatementprintedinyourOperator’sManual

orcontainedintheenginemanufacturer’sdocumentationfordetails

CountriesOtherthantheUnitedStatesorCanada

CustomerswhohavepurchasedT oroproductsexportedfromtheUnitedStatesorCanadashouldcontacttheirToroDistributor(Dealer)toobtain

guaranteepoliciesforyourcountry ,province,orstate.IfforanyreasonyouaredissatisedwithyourDistributor'sserviceorhavedifcultyobtaining

guaranteeinformation,contacttheToroimporter.Ifallotherremediesfail,youmaycontactusatT oroWarrantyCompany.

374-0270RevA

Loading...

Loading...