FormNo.3362-258RevA

ProCoreSR48,SR54,SR54–S,

SR70,SR70–S,SR72and

SR75–HDAerators

ModelNo.09920—SerialNo.290000001andUp

ModelNo.09921—SerialNo.290000001andUp

ModelNo.09922—SerialNo.290000001andUp

ModelNo.09924—SerialNo.290000001andUp

ModelNo.09925—SerialNo.290000001andUp

ModelNo.09926—SerialNo.290000001andUp

ModelNo.09927—SerialNo.290000001andUp

ToregisteryourproductordownloadanOperator'sManualorPartsCatalogatnocharge,gotowww.T oro.com.OriginalInstructions(EN)

Introduction

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoidinjury

andproductdamage.Youareresponsibleforoperating

theproductproperlyandsafely.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafetyalertsymbol

(Figure2),whichsignalsahazardthatmaycauseserious

injuryordeathifyoudonotfollowtherecommended

precautions.

YoumaycontactTorodirectlyatwww .T oro.comfor

productandaccessoryinformation,helpndinga

dealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready .Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

Figure2

1.Safetyalertsymbol

Thismanualuses2otherwordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Figure1

©2009—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.T oro.com.

2

PrintedintheUSA.

AllRightsReserved

Contents

Introduction.................................................................2

Safety...........................................................................4

SafeOperatingPractices.......................................4

SafetyandInstructionalDecals.............................6

Setup............................................................................8

1ConnectingtheLowerLinkArms......................9

2ConnectingtheHydraulicTopLink

(ModelsSR48,SR54,SR70,SR72and

SR75–HD........................................................9

3ConnectingtheTractorUpperLink(Models

SR54–SandSR70–S)......................................11

4VerifyingtheTopLinkSetUp..........................11

5CheckingthePTOAngle.................................12

6FittingthePTOshaft.......................................12

7InstallingthePTOShield.................................14

8ConnectingthePTOShaft...............................15

9AdjustingtheSwayLinks.................................16

10LevelingtheAeratorSide-to-Side...................17

11InstallingtheTines.........................................17

12RemovingtheStorageStands(Models

SR54,SR54S,SR70andSR70–S).....................18

13RemovingtheStorageStands(Models

SR72).............................................................18

ProductOverview......................................................19

Specications.....................................................19

Attachments/Accessories...................................19

Operation...................................................................20

TractorControls.................................................20

PrinciplesofOperation......................................20

TractorPTOSpeed............................................20

TrainingPeriod...................................................20

BeforeAerating..................................................20

AeratingProcedures...........................................21

OperatingTips...................................................21

SubsoilCultivation.............................................22

HardGround.....................................................22

Longer/LargerTines..........................................22

MultiRowAdapterHeads..................................22

RootZoneLifting..............................................22

AdjustingtheTineAngle....................................22

TransportOperation..........................................23

InspectionandCleanupafterUse........................23

Maintenance...............................................................24

RecommendedMaintenanceSchedule(s)................24

LiftingtheMachine............................................24

GreasingtheBearings.........................................25

CheckingtheGearboxOil..................................25

ChangingtheGearboxOil..................................26

Inspecting/AdjustingtheDriveChain................26

AdjustingthePTOClutch..................................27

CheckingtheCoringHeadFastener

Torque...........................................................27

CheckingtheSprings..........................................28

AdjustingtheHoleSpacing.................................28

RemovingtheAeratorfromtheTractor...............28

TroubleShooting...............................................29

Storage.......................................................................30

3

Safety

Improperuseormaintenancebytheoperatoror

ownercanresultininjury.Toreducethepotential

forinjury,complywiththesesafetyinstructions

andalwayspayattentiontothesafetyalert

symbol,whichmeansCAUTION,WARNING,or

DANGER-"personalsafetyinstruction."Failureto

complywiththeinstructionmayresultinpersonal

injuryordeath.

SafeOperatingPractices

BeforeOperating

•OwnersofthisAeratormustgiveoperatorsand

employeesfulloperationandsafetyinstructions

beforeallowingthemtooperatethismachineandat

leastannuallythereafter.Anoperatorwhohasnot

readandfullyunderstoodalloperatingandsafety

instructionsisnotqualiedtooperatethismachine.

Becomefamiliarwithallcontrolsandknowhowto

stopquickly.

•Donotallowchildrentooperatethemachine.Do

notallowadultstooperatethemachinewithout

properinstruction.

•Removealldebrisorotherobjectsthatmight

interferewithoperation.Keepallbystandersaway

fromtheworkarea.

•Locateandmarkallundergroundobstructionssuch

asirrigationcomponents,electricalortelephone

lines.

•Makesuretractorisinneutralandparkingbrake

appliedbeforestarting.RefertoTractorOperator’s

Manualforsafestartingprocedures.

•Ensurethatyourtractorissuitableforusewithan

implementofthisweightbycheckingwithyour

tractorsupplierormanufacturer.

•Mountingtheaeratortotherearofthetractor

willdecreasetheweightonthetractorfrontaxle.

Toassureadequatesteeringcontrolandstability

itmaybenecessarytoaddballasttothefrontof

thetractor.RefertoTractorOperator’sManualfor

ballastrequirements.

•Keepallshieldsandsafetydevicesinplace.Ifa

shield,safetydeviceordecalisdamaged,repairor

replaceitbeforeoperationiscommenced.Also

tightenanyloosenuts,boltsandscrewstoensure

machineisinsafeoperatingcondition.

•Donotoperatemachinewhilewearingsandals,

tennisshoes,sneakersorshorts.Also,donot

wearloosettingclothingwhichcouldgetcaught

inmovingparts.Alwayswearlongpantsand

substantialshoes.Wearingsafetyglasses,safety

shoes,hearingprotectionandahelmetisadvisable

andmayberequiredbysomelocalordinancesand

insuranceregulations.

WhileOperating

•Neveroperatethetractorinreversewhentheaerator

islowered.

•Keepallbystandersandpetsawayfromthework

area.

•Usingthemachinedemandsattention,andto

preventlossofcontrol:

–Useonlyindaylightorwhenthereisadequate

articiallight.

–Watchforholesorotherhiddenhazards.

–Donotoperatethemachineclosetoasandtrap,

ditch,creekorotherhazard.

–Reducespeedonsidehillsandbeforemaking

sharpturnstopreventtippingorlossofcontrol.

–Lookbehindtheaeratorbeforebackingup.

•Ifthetinesstrikeasolidobjectorthemachine

vibratesabnormally,disengagethePTO ,setthe

parkingbrakeandshuttheengineoff.Removekey

fromignitionswitch.Checkaeratorandtractionunit

fordamage.Repairanydamagebeforerestartingthe

engineandoperatingthetines.Besuretinesarein

goodconditionandallboltsaretight.

•Beforeleavingmachineunattended,disengagepower

toaerator,loweraeratorontostoragestandsandset

parkingbrake.Stopengine.

•Neverdismountwhiletractorisinmotion.Never

getonorofftractorwhileengineisrunningand

PTOdriveshaftisengaged.NeverstepoverPTO

shafttoreachothersideofaerator-walkaround

themachine.

•Whenliftingtheaerator,disengagethePTOwhen

therollerisapproximately5”fromtheground.

•Donotoperatethismachinewithouttherolleron

theground.Neveroperatewiththemachinein

theraisedposition.

•Parktheaeratoronahard,levelsurface,installthe

aeratorstoragestandsbeforedisconnectingfrom

tractor.

•Ifitisnecessarytoprobebelowthesoilsurface,use

anonconductivematerialtopreventelectricalshock

incaseelectricalwiresarepresent.

•Alwayslowertheaeratortothegroundbefore

leavingthetractorunattended.Neverleavethe

aeratorintheraisedpositionwhenitisunattended.

4

Transporting

•Theaeratorisheavy.Whenattachedtoatractor

andintheraisedposition,itsweightwillaffect

stability,brakingandsteering.Exercisecautionwhen

transportingbetweenworkingareas.

•Alwaysmaintainpropertractortirepressure.

•Besureyouareincompliancewithallregulations

beforetransportingequipmentonthepublicroads

andhighways.Makesureallrequiredreectors

andlightsareinplaceandarecleanandvisibleby

overtakingandoncomingtrafc.

•Neverallowpassengerstorideonthemachine

duringtransport.

•Reducespeedonroughroadsandsurfaces

•Independentwheelbrakesshouldalwaysbelocked

togetherwhentransporting.

PTOShaft

•ForallPTOshaftsteelparts(tubes,bearings,joints

etc.)disassemblyorrepairs,itishighlyadvisable

tocontactyourlocalTorodistributor.Removalof

componentsforrepairsandreassemblymaydamage

somepartsifnotperformedwithspecialtoolsby

trainedtechnicians.

•ThePTOshaftmustnotbeusedwithouttheguards

supplied,withpartialprotectionorwithdamaged

guards.OnCEmachines,operationisprohibited

withoutthespecialanti-rotationchainscorrectly

installed,soastopermitthemaximumangleofthe

PTOshaftwithoutbreakingthechains.

•Besurethemachineisinsafeoperatingconditionby

keepingnuts,boltsandscrewstight.Checkthetine

mountingboltsdailytobesuretheyaretightened

tospecication.

•Donotcheckoradjustthechaintensionwhenthe

tractorengineisrunning.

•Besureallguardsarereplacedandthehoodis

securedshutaftermaintainingoradjustingthe

machine.

•Performonlythosemaintenanceinstructions

describedinthismanual.Ifmajorrepairsare

everneededorassistanceisdesired,contactan

AuthorizedToroDistributor.Toensureoptimum

performanceandsafety,alwayspurchasegenuine

Tororeplacementpartsandaccessoriestokeepthe

ToroallToro.Neveruse"will-t"replacementparts

andaccessoriesmadebyothermanufacturers.Look

fortheTorologotoensuregenuineness.Using

unapprovedreplacementpartsandaccessoriescould

voidthewarrantyofTheT oroCompany.

StorageSafety

•Storetheaeratoronthestoragestandspositionedon

armlevelsurface.

•Storetheaeratorawayfromareasofhumanactivity.

•Donotallowchildrentoplayonoraroundthe

storedmachine.

•Makesuretheaeratorispositionedonrmandsolid

groundsoitdoesnotsinkortipover.

•Frictionclutchesmaybecomehotduringuse.Do

nottouch.Toavoidtheriskofre,keepthearea

aroundtheclutchfreeofammablematerialand

avoidprolongedslippingoftheclutch.

Maintenance

•Beforemakingadjustmentsorperforming

maintenanceontheaerator,switchofftheengine,

stopthePTOandapplytheparkingbrakebefore

dismountingfromthetractor.Besuretheaeratoris

onthegroundorloweredontothesafetystands.

•Supportthemachinewiththeblocks,jacksoron

storagestandswhenworkingbeneathit.Never

relyonthetractor’shydraulicstosupportthe

machine.

•Placeallcontrolsinneutral,stoptheengine,apply

parkingbrakeandwaitforallmovingpartsto

stopbeforeservicing,maintaining,adjustingor

unblockingtheaerator.

5

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaof

potentialdanger.Replaceanydecalthatisdamagedorlost.

117–7052

1.ReadtheOperator’sManual,donotoilthechaindrive.

100–3612

1.Entanglementhazard—stayawayfrommovingparts,keep

allguardsandshieldsinplace.

110-4668

1.Entanglementhazard,shaft—stayawayfrommovingparts.

2.PTOspeedandinputdirection.

3.Usecliptosecurelashcablewhennotinuse.Uselash

cabletosupportthepowertake-offwhenthemachineis

disconnectedfromtractor.

117–7051

1.Crushinghazardofhandorfoot—keepbystandersasafe

distancefromthemachine.

117–7050

1.Warning—readtheOperator’sManual.

2.Warning—removetheignitionkeyandreadtheinstructionsbeforeservicingorperformingmaintenance.

3.Warning—donotoperatethismachineunlessyouaretrained.

4.Entanglementhazard,belt—stayawayfrommovingparts,keepallguardsinplace.

5.Crushinghazardofhandorfoot—keepbystandersasafedistancefromthemachine.

6.Crushinghazardofhandandbody—supportmachineonstandwhennotinuse.

7.Fallinghazard—donotcarrypassengers.

6

92–1581

92–1582

7

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

6

7

8

Hitchpin2

Lynchpin2

Hydraulictoplink1

Hydraulichose,3–1/2feet

Hydraulichose,2–1/2feet

Extensionbracket2

Rotationalbracket1

Hosequickcouplings(notincluded)

Springloadedtoplink

Linkpin3

Lynchpin3

Nopartsrequired

Nopartsrequired

PTOshaft

PTOShield

Pin(suppliedwithPTOshaft)

Nut(suppliedwithPTOshaft)

Qty.

Use

ConnectLowerLinkArms

1

1

2

1

–

–

1

1

1

1

ConnectHydraulicT opLink

ConnectUpperLink

Verifythetoplinksetup

CheckingthePTOangle

FittingthePTOshaft

InstallthePTOShield

ConnectPTOShaft

9

10

11

12

13

Nopartsrequired

Level(notsupplied)

Tines

Nopartsrequired

Nopartsrequired

–

1

A/R

–

–

AdjustingSwayLinks

LevelAeratorSide-to-Side

InstalltheTines

RemoveStorageStands

RemoveStorageStands

8

MediaandAdditionalParts

Description

Operator’sManual

PartsCatalog

SpringWires-SR54

SpringWires-SR70

SpringWires-SR72

SpringWires-SR72

Allenwrench1

PTOOperatorsManual

1

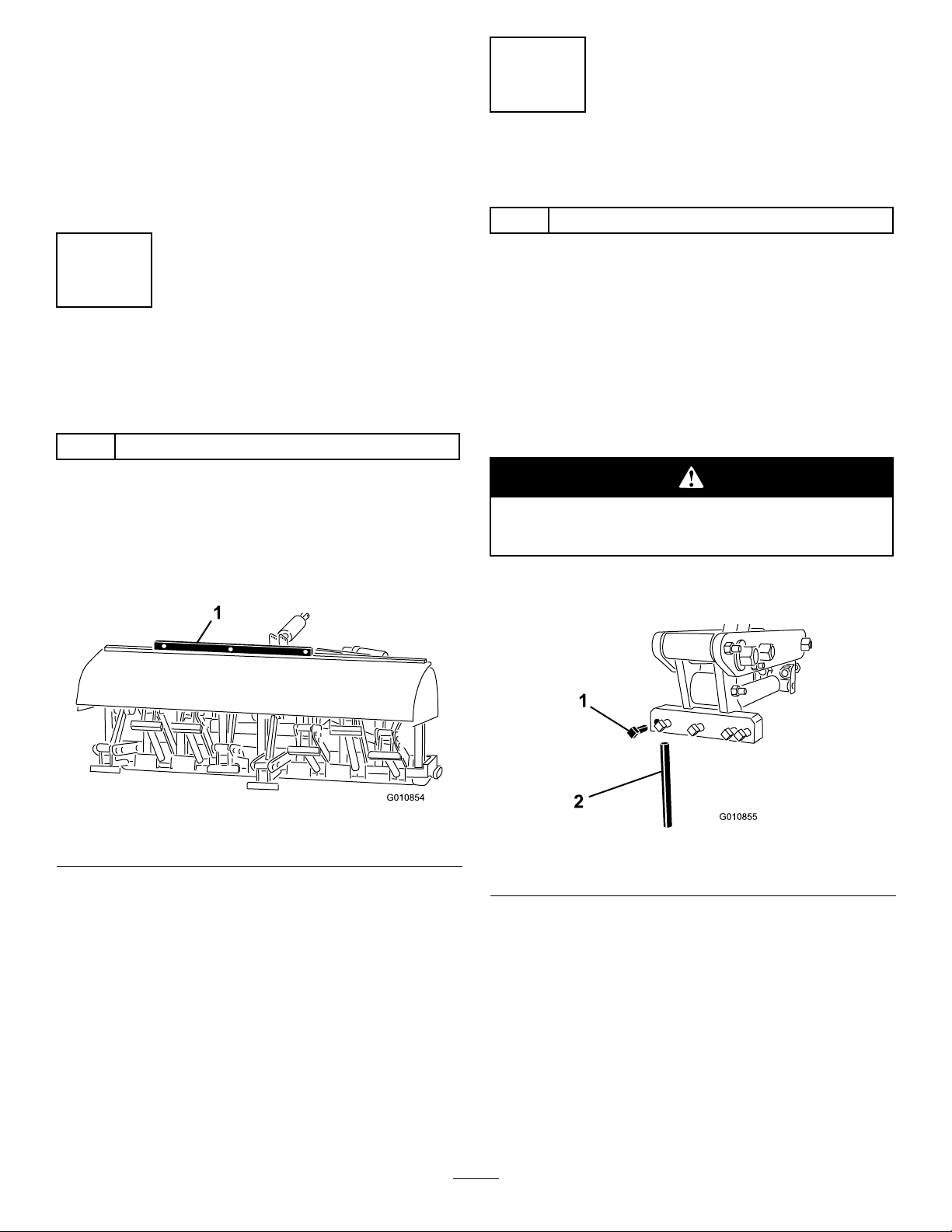

ConnectingtheLowerLink

Arms

Partsneededforthisprocedure:

2Hitchpin

2Lynchpin

Qty.

1

1

6Replacementspringwires

8Replacementspringwires

4Replacementspringwires

2Replacementspringwires

1

Readbeforeoperatingtheaerator

Usetoreferencepartnumbers

TineheadboltwrenchforSR72

Readbeforeoperatingtheaerator

1.Lowerlink2.Lynchpin

Use

Figure3

Procedure

1.Removetheboltssecuringtheaeratorstoragestands

totheshippingpalletandremovetheaeratorfrom

thepallet.

2.Theaeratormustbepositionedonaat,level

surfaceforinstallation.

3.Backthetractorsquarelyuptotheaeratoruntil

thelowerlinkarmsarealignedwiththemounting

brackets.

4.MakesurethePTOisdisengaged.

5.Engagetheparkingbrake,STOPtheengineand

removethekeyfromtheignition.Waitforthe

engineandallmovingpartstoSTOPbeforeleaving

theOperator’sseatonthetractor.

Note:Formaximumgroundclearance,thehitch

pinsshouldbesecuredintheaeratorlowermounting

bracketholes,whensoequipped.Todetermine

whentousetheuppermountingholes,referto

ConnectingthePTOShaft.

6.Securethelowerlinkarmstotheaeratormounting

bracketswitheitherlynchpins(Figure3)orhitch

pinsandlynchpins(Figure4).

Figure4

1.Hitchpin3.Lowerlink

2.Aeratormountingbracket

9

2

Connectingthe

HydraulicTopLink

(ModelsSR48,SR54,SR70,

SR72andSR75–HD

Partsneededforthisprocedure:

1Hydraulictoplink

1

Hydraulichose,3–1/2feet

1

Hydraulichose,2–1/2feet

2Extensionbracket

1Rotationalbracket

2

Hosequickcouplings(notincluded)

Procedure

Figure5

1.Aeratorhitchpin7.Tractorlinkpin

2.Hydraulictoplink

3.Rotationalblock

4.Connectinglink10.3–1/2foothydraulichose

5.3inchextensionblock

6.5inchextensionblock12.Tractorhydraulicports

8.Clevis&lynchpin

9.2–1/2foothydraulichose

11.Hosequickcouplings(not

included)

Thetractormustbeequippedwithadoubleactingspool

valvewithanoperatorcontrolleverandtwo1/2”(12.7

mm)quick-releasecouplingsattherearofthetractor.It

isalsonecessaryforyoutoprovidetwoquickcouplings

tottothehydraulictoplinkhoses(1/2–14NPTF

hoseendthreadsize).

1.Securetheconnectinglinkendofthehydraulictop

linktothetractorwiththepinssuppliedwiththe

tractor(Figure5).Positionthehydraulictoplinkso

therodendistowardtheaerator.Thecylinderports

shouldbepositionedtowardthetractor’sauxiliary

powerhydraulics.

Note:Ifthehydrauliccylindermustbepositioned

withtheportsfacingupward,usetherotational

blockinsteadofthestandardmountingblockto

repositionthecylinder(Figure5).

Installtherotationalblockasfollows:

A.Removethecotterpinandpinsecuring

thestandardconnectinglinktothecylinder

(Figure5).Removetheconnectinglinkfromthe

cylinder.

B.Installtherotationalblocktothecylinderwith

thepinspreviouslyremoved(Figure5).

2.Connectthe3–1/2footlonghydraulichosetothe

hydraulictoplinkportwhichisclosesttotheaerator

Figure5.ApplyTeontapeorpipethreadsealantto

thehosethreadstopreventanyleaks.

3.Connectthe2–1/2footlonghydraulichosetothe

hydraulictoplinkportwhichisclosesttothetractor

(Figure5).ApplyTeontapeorpipethreadsealant

tothehosethreadstopreventanyleaks.

4.Installquickcouplings(notincluded)tothehydraulic

hoses(1/2–14NPTFhoseendthreadsize).

5.Connectthetwohydraulichosequickcouplingsto

theportsprovidedonthetractor.

6.Startthetractorengineandoperatethetractorspool

valvetochecktheextendandretractmotionofthe

hydraulictoplink.

Note:Reversethehoseconnectionsiftheydono

agreewiththetractorcontroloperation.

7.Securetherodendofhydraulictoplinktothemost

forwardholepossibleintheaeratorbracketwithlink

pinandlynchpin(Figure6).

Important:Whensecuringtherodendof

thehydrauliclink,makesuretousethemost

forwardmountingholesinthemountingbracket

sothereisenoughclearanceforthebarrelofthe

cylinderwhenretracted.

10

Figure6

1.Rodendofcylinder4.Aeratorbracket(forward

holes)

2.Lynchpin5.Linkpin

3.Linkpin

Ifthehydrauliccylinderdoesnotreachtheaerator

mountingbracket,useanextensionblockinsteadof

thestandardmountingblocktoconnectthecylinder

tothetractor(Figure5).

3

Connectingthe

TractorUpperLink

(ModelsSR54–SandSR70–S)

Partsneededforthisprocedure:

1

Springloadedtoplink

3Linkpin

3Lynchpin

Procedure

1.Mountthespringloadedtoplinktotheaerator

bracketwithtwolinkpinsandlynchpins(Figure7)

2.Loosenthelocknutonthetractorupperlink.Adjust

theupperlinkuntilitalignswiththeclevisonthe

springloadedtoplinkoftheaerator(Figure7).

Installtheextensionblocksasfollows:

A.Removethecotterpinandpinsecuring

thestandardconnectinglinktothecylinder

(Figure5).Removetheconnectinglinkfromthe

cylinder.

B.Installtherequiredlengthextensionblockto

thecylinderwiththepinspreviouslyremoved

(Figure5).

Figure7

1.Springloadedtoplink

2.Upperlink5.Locknut

3.Linkpin

3.Connectthetractorupperlinktotheclevisonthe

springloadedtoplinkandsecurewithalinkpinand

lynchpin(Figure7).

4.Greasethethreadedsteelupperlinktubes.

5.Measurethelengthofthespringinthetoplink.

6.Rotatetheupperlinkuntilthespringiscompressed

byabout1/2inch(Figure7).

4.Lynchpin

7.Tightenthelocknuttosecuretheupperlinkinto

position.

11

4

VerifyingtheTopLinkSetUp

NoPartsRequired

Procedure

•Extendingthehydrauliccylinderwillincreasethe

tinedepth.

•Fullyextendthehydrauliccylindertodetermine

thelocationofthetineheadsandtoverifyifthey

contacttheground.

Ifthetineheadscontacttheground,turf

damagewilloccur.

Figure8

1.Breakagewilloccurhere

5

CheckingthePTOAngle

Note:Onundulatingturf,theoperatorcanadjust

thecylindertomaintaintinedepth(crestingahill)

butitwillbenecessarytohavethetineheadsset

about2inchesbelowground.

•Ifthetineheadscontacttheground,adjustthe

locationofthecylinderendstomovethetopofthe

aeratorclosertothetractor.

•Ifthetineheadsdonotcontacttheground,

extensionbrackets(includedwithaerator)canbe

installedtothetoplinktomovethetineheadscloser

totheground.

Important:WhenconnectingthePTO,besure

thattheaeratorisnotbeingliftedhigherthanis

necessary.Liftingthemachinetoohighwillcause

thePTOshaftknucklestobreak(Figure8).Never

leavethePTOturningwhentheaeratorislifted.

ThePTOcanbeoperateduptoanangleof25º,but

canneverexceeda35ºanglewhentheaeratoris

atitshighestpositionorsevereshaftdamagemay

occur.

NoPartsRequired

Procedure

Withtheaeratorpositionedonthegroundandlowered

tothedeepestlocation,checktheanglebetweenthe

PTOandtheaerator.Makesurethetinesareremoved

beforeperformingthisoperation.

Lifttheaeratorandfullyretractthehydraulictoplink

cylinder.ChecktheanglebetweenthePTOandthe

aerator.Ifthisangleisgreaterthan35degrees,make

adjustmentstothetractorsothattheaeratorcannotbe

liftedpast35degrees.Thiscanbeaccomplishedby

usingthetractorliftstop(ifsoequipped)ormovingthe

lowerlinkstoahighermountinghole(ifsoequipped).

6

FittingthePTOshaft

Partsneededforthisprocedure:

1

PTOshaft

Procedure

1.Movethetractorandaeratortoalevelsurface.

2.Raisetheaeratorcompletelyandfullyretractthetop

linkcylinderorupperlink(Figure9).

12

Figure9

Figure12

1.Measurehere

3.Measurethedistancefromthereliefontheendof

thetractorPTOshafttothereliefontheaerator

gearboxPTOshaft(Figure10).Recordthisdistance.

Example:26.5inches(67cm).

Figure10

1.Measurehere

4.Lowertheaeratortothegroundandfullyextendthe

toplinkcylinderorupperlink(Figure11).

6.OnthePTOshaft,measurethedistancefromthe

centeroflockingpinballononeendtothecenterof

thelockingpinbuttonontheotherend(Figure13).

Recordthisdistance.Example:32inches(81cm).

Figure13

1.Measurehere

7.Usingthesmallerofthetwomeasurementsin

Figure12andFigure10,subtractthatdistancefrom

thedistanceinFigure13.Example32(81cm)inches

minus26.5inches(67cm)equals5.5inches(14cm).

8.Theexamplemeasurementsshowthattheshaftis

5.5inchestoolong.Nowyouwillneedtoaddan

extra1/2inch(1.2cm)tobesurethatthePTOshaft

willnotbottomoutwhentheaeratorisliftedtoits

highestposition.

Figure11

5.Measurethedistancefromthereliefontheendof

thetractorPTOshafttothereliefontheaerator

gearboxPTOshaft(Figure12).Recordthisdistance.

Example:27.5inches(70cm).

Example:5.50inches(14cm)plus1/2inch(1.2cm)

equals6.00inches(15cm).

9.SlidethePTOshafttubestogetheruntiltheyare

fullycollapsed.V erifythattheinsidetubedoesnot

protrudeintothecrossandbearingsectionofthe

outertube(Figure14).Ifthishappens,cutmoreoff

theinsidetube,tocorrecttheproblem.

13

Figure14

1.Insidetube

10.SeparatethetwohalvesofthePTOshaft(Figure15,

illustration1).

11.Measurethedistancefromtheendofeachtubeto

itssafetyshield(Figure15,illustration1).Record

thedistances.

12.Usingthedimensionsdeterminedinstep8,locate,

markandcutofftheshieldandtubefromeachPTO

half(Figure15,illustrations2&3).

Note:Morewillhavetobecutofftheinsidetube

onlyifitisprotrudingintothecrossandbearing

sectionoftheoutertube.

13.Usingthedimensionsdeterminedinstep11,locate,

markandcutoffjustthesafetyshieldstoexposethe

tubesFigure15—illustrations4&5.

14.Carefullydeburrtheendsofthetubeswithaleand

removeallthelingsfromthetubes.

15.Greasetheinsidetube.

Note:Telescopingtubesmustalwaysoverlapby

1/2oftheirlengthinnormaloperationandatleast

1/3oftheirlengthinallworkingconditions.During

transport,whenthedrivelineisnotrotating,the

telescopingtubesmusthaveasuitableoverlapto

maintainthetubesalignmentandallowthemtoslide

freely.

1.Measurehere

Figure15

7

InstallingthePTOShield

Partsneededforthisprocedure:

1

PTOShield

Procedure

1.Removethe4bolts,lockwashersandatwashers

securedtotherearoftheaeratorgearbox(Figure16).

14

Figure16

1.PTOshield

2.Flatwasher5.Accesspanel

3.Lockwasher

4.Bolt

2.MountthePTOshieldtotheaeratorgearboxwith

thefastenerspreviouslyremoved(Figure16).When

mountingthePTOshield,makesuretheaccess

panel(Figure16)ispositionedtothetoporside

dependingontheaeratorframeconguration.

8

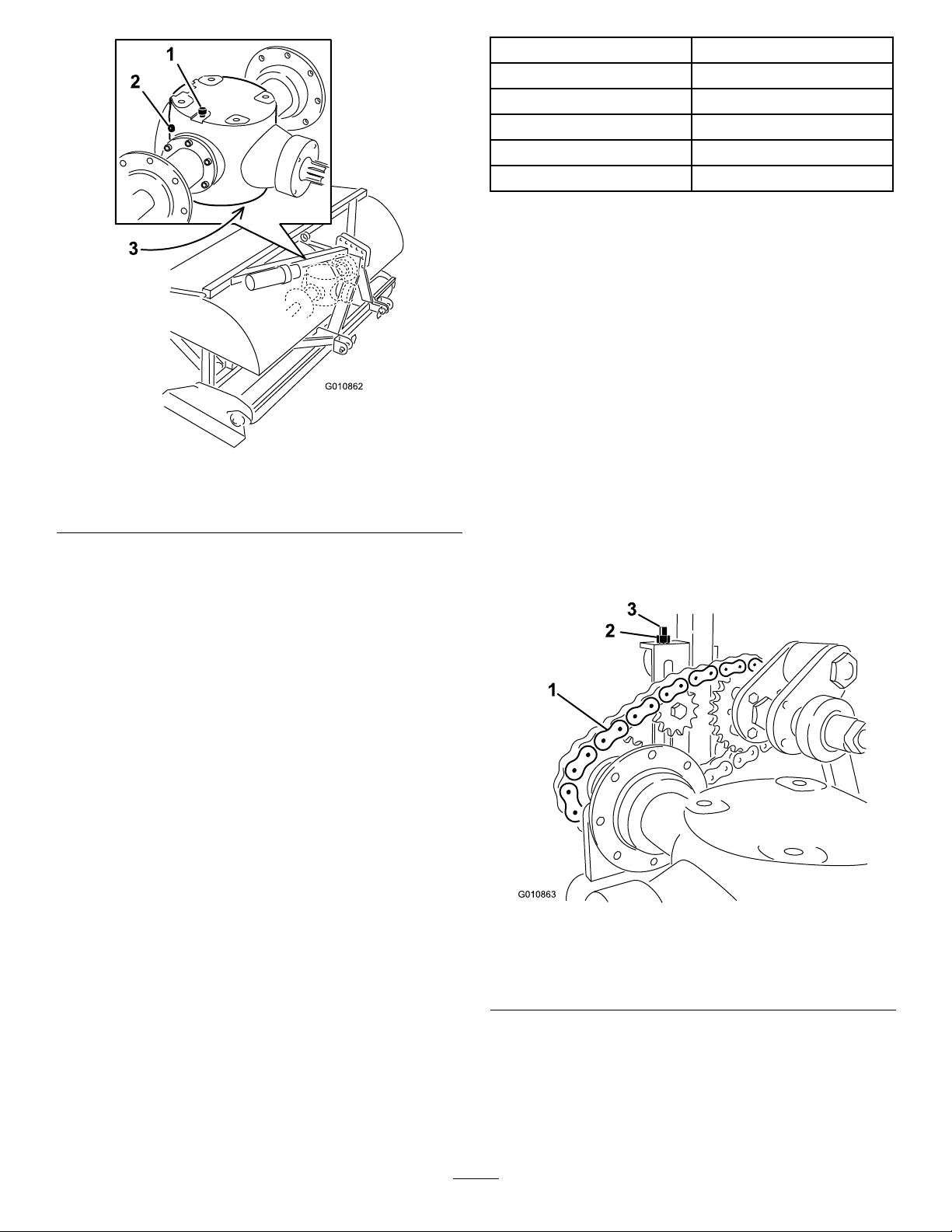

ConnectingthePTOShaft

Partsneededforthisprocedure:

1

Pin(suppliedwithPTOshaft)

1

Nut(suppliedwithPTOshaft)

Figure17

1.Gearboxinputshaft

2.PTOshaftcoupler

3.Pin

4.Nut

Note:MakesuretocloseandlatchthePTOshield

accesspanelifopened.

3.ConnectthePTOshafttothetractorPTOshaft

(Figure18).

Procedure

Note:Theaccesspanel(Figure16)canbeopened

toeasetheremovalandinstallationofthePTOshaft

mountingfasteners.

1.RemovethepinandnutfromthePTOshaft

(Figure17).

2.ConnecttheclutchendofthePTOshaftto

theaeratorgearboxinputshaftwithpinandnut

previouslyremoved(Figure17).Thepincanonly

beinsertedoneway.

Figure18

1.Tractoroutputshaft3.PTOshaft

2.PTOshaftcoupler

4.SlidethePTOshaftforwardasfarasthetractor

allows.

5.PullbackonthelockingcollartosecurethePTO

shaftinplace.SlidethePTOshaftbackandforthto

makesureitisproperlylocked.

6.ConnecttheshieldsafetychainstothePTOshield

andthetractorbracket(Figure19).Makesurethe

chainsremainslackwhentheaeratorisraisedor

lowered.

15

Figure19

1.Safetychains

Note:Toavoidexcesslift,connecttheliftarmsof

thetractorintothetopholesoftheliftbracket,if

soequipped(Figure20).Themaximumangleon

thePTOshaftis35º.

Figure20

1.Topholes

Figure21

1.Breakagewilloccurhere

9

AdjustingtheSwayLinks

NoPartsRequired

Procedure

Theaeratorisdesignedtobecenteredwiththetractor

PTOshaftcenterline.Adjusttheswaylinksasrequired.

ThePTOshaftshouldbeasstraightaspossibletothe

tractorPTOshaft.

Important:WhenconnectingthePTO,be

surethattheaeratorisnotbeingliftedhigher

thanisnecessary.Liftingthemachinetoohigh

willcausethePTOshaftknucklestobreak

(Figure21).NeverleavethePTOturningwhen

theaeratorislifted.ThePTOcanbeoperated

uptoanangleof25º,butcanneverexceeda35º

anglewhentheaeratorisatitshighestposition.

7.VerifythatthePTOshielddoesnotinterferewith

theclutch.

Adjusttheswaylinksonthelowerliftarmstominimize

side-to-sideswaytoamaximumof1inch(25mm)on

eachside(Figure22).

Figure22

1.Swaylink

16

Adjustthelowerlinksinboarduntiltheycontactthe

aeratormountingplates.Thiswillreducethestress

onthepins.Ifthetractorhasswaychainsinsteadof

swaylinks,itisrecommendedthatwashersbeinstalled

betweenthelowerlinkarmandlynchpintoreducethe

overhungloadontheliftpins.

11

InstallingtheTines

Note:RefertothetractorOperator’sManualfor

additionalinstallationandadjustmentprocedures.

10

LevelingtheAerator

Side-to-Side

Partsneededforthisprocedure:

1

Level(notsupplied)

Procedure

1.Parkthetractorandaeratoronalevel,rmsurface.

2.Placealevelontopoftheaeratorframetocheckfor

levelside-to-side(Figure23).

Partsneededforthisprocedure:

A/R

Tines

Procedure

Awideselectionoftinesareavailablefortheaerator.

Choosethetinetype,sizeandspacingsrequiredforthe

job.RefertothePartsCatalogforthelistofaccessories.

1.Makecertaintheaeratorisfullysupportedonthe

ground,standsorsupportblocks.

2.Turnoffthetractorengineandremovethekey .

Avoidstandingtooclosetotherearofthe

machinewheninstallingtines.

3.Loosentheclampingboltsandremovethepreviously

usedtines(Figure24).

Figure23

1.Level

3.Turntheadjustablelinkbody(ifprovided)toraise

orlowerthelinkarmuntiltheaeratorisleveled

side-to-side.

Note:RefertotractorOperator’sManualfor

additionaladjustmentprocedures.

Figure24

1.Clampingbolt

4.Slidethenewtinesintotheholessizedtotthe

tinesselected.Neverusesmalldiametertinesinthe

largediameterholes-thetinesshouldtcloselyin

thehole.Besuretoslidethetineupintothehead

untilitbottomsout.

Note:Hollowcoringtinesshouldbepositioned

withtheejectionslottotherearwhilethesolidtines

shouldhavethetinetipanglefacingthemachine.

5.Tightentheclampingboltsrmlytosecurethetines.

17

2.Tine

6.Setthetineangleforthenewtines.Referto

AdjustingtheTineAngleintheOperationsection.

7.Beforeaeratingformalturfforthersttimeafter

installingtines,testtheaeratoronalessimportant

areasothatyoucantryalternativetractorgearsand

netunetheadjustmenttoachievetheholespacing

andturfappearancedesired.

12

RemovingtheStorageStands

(ModelsSR54,SR54S,SR70

andSR70–S)

NoPartsRequired

Procedure

1.Raisetheaeratorroller(s)3-6inchesoffground.

Placesupportblocksundertheroller(s).

2.Removethebolts,lockwashersandnutssecuringthe

storagestandstoeachendoftheaerator(Figure25).

13

RemovingtheStorageStands

(ModelsSR72)

NoPartsRequired

Procedure

1.Raisetheaeratorroller(s)3-6inchesoffground.

Placesupportblocksundertheroller(s).

2.Removetheboltsandnutssecuringthestorage

standstoeachendoftheaerator(Figure26).

Figure25

1.Bolts3.Nut

2.Lockwasher

3.Removethestoragestands.

4.Usethestoragestandswhenevertheaeratoris

removedfromthetractor.

4.Storagestand

Figure26

1.Bolts3.Nut

2.Lockwasher

3.Removethestoragestands.

4.Usethestoragestandswhenevertheaeratoris

removedfromthetractor.

Note:Whenreinstallingthestoragestands,make

suretheyaremountedtotheinsideoftheroller

platessothelowerframetubewillrestonthetopof

thestands.

4.Storagestand

18

ProductOverview

Specications

Note:Specicationsanddesignaresubjecttochangewithoutnotice.

withPTO&TopLink

WorkingWidth48”

WorkingDepth

(Adjustable)

HoleSpacing

Productivity25,000

Recommended

TractorSize

Recommended

LiftCapacity

Recommended

CounterWeight

Recommended

PTOSpeed

ActualWorking

Speed@400

PTORPM

(Varieswithhole

LiftSystemStd.3–pointStd.3–pointStd.3–pointStd.3–pointStd.3–pointStd.3–pointStd.3–point

ProCore

SR48

Weight

spacing)

1,450lbs.

(655kg)

(1.22m)

1”-14”

(25–300mm)

3”-6”

(75–150mm)

sq.ft./hr.

(2,325

sq.m/hr.)

25HP16–18HP18HP25–35HP25–35HP45HP55+HP

1,800lbs.

(817kg)

300lbs.

(135kg)

400–500rpm400–500rpm400–500rpm400–500rpm400–500rpm400–460rpm400–500rpm

.8–1.3mph1.5–2.5mph1.5–2.5mph1.5–2.5mph1.5–2.5mph.8–1.5mph.8–1.5mph

ProCore

SR54

990lbs.

(450kg)

(1.37m)

1”-10”

(25–250mm

2.5”-4”

(64–102mm)

36,000

sq.ft./hr.

(3,345

sq.m/hr.)

1,200lbs.

(544kg)

150lbs.

(70kg)

ProCore

SR54–S

1,250lbs.

(567kg)

54”

54”

(1.37m)

1”-10”

(25–250mm

2.5”-4”

(64–102mm)

36,000

sq.ft./hr.

(3,345

sq.m/hr.)

1,500lbs.

(680kg)

150lbs.

(70kg)

ProCore

SR70

1,500lbs.

(681kg)

(1.85m)

1”-10”

(25–250mm

2.5”-4”

(64–102mm)

48,000

sq.ft./hr.

(4,460

sq.m/hr.)

1,700lbs.

(771kg)

250lbs.

(115kg)

ProCore

SR70–S

1,655lbs.

(750kg)

73”

73”

(1.85m)

1”-10”

(25–250mm

2.5”-4”

(64–102mm)

48,000

sq.ft./hr.

(4,460

sq.m/hr.)

1,800lbs.

(817kg)

250lbs.

(115kg)

ProCore

SR72

1,985lbs.

(900kg)

(1.83m)

1”-16”

(25–400mm)

3”-6”

(75–150mm)

38,000

sq.ft./hr.

(3,530

sq.m/hr.)

2,800lbs.

(1,270kg)

300–500lbs.

(135–225kg)

ProCore

SR75HD

3,250lbs.

(1,475kg)

72”

78”

(1.98m)

1”-16”

(25–400mm

3”-6”

(75–150mm)

48,000

sq.ft./hr.

(4,460

sq.m/hr.)

4,000lbs.

(1,815kg)

700–900

(315–410kg)

Attachments/Accessories

AselectionofToroapprovedattachmentsand

accessoriesareavailableforusewiththemachineto

enhanceandexpanditscapabilities.Contactyour

AuthorizedServiceDealerorDistributororgoto

www.Toro.comforalistofallapprovedattachments

andaccessories.

19

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

TractorControls

ontherevcounters.SincetheengineandPTOrpms

aredirectlyproportional,youcandeterminetheengine

rpmrequiredfora400rpmPTObycalculatingas

follows:

(Enginerpmat540PTOspeed)x(400÷540)=requiredengine

rpm

Itisnecessarytofamiliarizeyourselfwiththeoperation

ofthefollowingtractorcontrolsbeforeyouareableto

operatetheaerator:

•PTOEngagement

•Engine/PTORpm

•3PointHitch(Raise/Lower)

•AuxiliaryValveOperation

•Clutch

•Throttle

•GearSelection

•Parkingbrake

Note:RefertotractorOperator’sManualfor

operatinginstructions.

PrinciplesofOperation

Thetractor’sthreepointhitchlinkage/hydraulictop

linkliftstheaeratorfortransportandlowersitfor

operation.

Thetractor’spowertakeoff(PTO)poweristransmitted

viashafts,gearboxandO-ringdrivechainstoa

crankshaftwhichdrivesthetineholdingarmsintothe

turfsurface.

AsthetractortravelsforwardwiththePTOengaged

andthemachinelowered,aseriesofholesarecreated

intheturfsurface.

Forexample,iftheenginerpmwere2700foraPTO

speedof540rpm,youwouldget:

2700x(400÷540)=2000rpm

Inthisexample,runningyourtractorat2000rpmnow

providesyouwitha400rpmPTOspeed.

Ifyourtractorindicatessomeotherenginerpmat540

PTOrpm,substitutethatnumberforthe2700thatwas

usedabove.

TrainingPeriod

Beforeusingtheaerator,ndaclearareaandpractice

usingthemachine.Operatethetractoratrecommended

gearsettingsandPTOdrivespeedsandbecome

thoroughlyfamiliarwithmachinehandling.Practice

stoppingandstarting,raisingandloweringtheaerator,

disengagingthePTOdriveandaligningthemachine

withpreviouspasses.Apracticesessionassures

condenceintheperformanceoftheaeratorandhelps

ensureuseofproperoperatingtechniqueswherever

themachineisoperated.

Iftherearesprinklerheads,electricalorcommunication

linesorotherobstructionsintheareatobeaerated,

marktheseitemstoensuretheyarenotdamagedduring

operation.

Thedepthofthetine’spenetrationisdeterminedby

extendingthehydraulictoplinkorsettingthexedtop

linktothedesiredposition.

Note:Donotattempttoadjustaxedtoplinkwhile

themachineisrunning.

Thedistancebetweentheholescreatedisdetermined

bythetractor’sgearratio(orhydrostatictractionpedal

position)andthenumberoftinesineachtinehead.

Simplychangingenginerpmdoesnotchangehole

spacing.

TractorPTOSpeed

TheaeratorisdesignedtooperatewithaPTOspeed

ofupto500rpmdependingonthesize/weightofthe

tines.Mosttractorsindicatea540PTOrpmposition

Toavoidpersonalinjury,neverleavethetractor

seatwithoutrstdisengagingthePTOdrive,

settingtheparkingbrakeandstoppingthe

engine.Neverperformaeratorrepairswithout

rstloweringtheaeratorontothestorage

standorappropriateblockingorjacks.Besure

allsafetydevicesaresecuredinproperplace

beforeresumingoperation.

BeforeAerating

Inspecttheareaofoperationforhazardsthatcould

damagethemachineandremovethem,ifpossible,

orplanhowtoavoidthem.Carryreplacementtines,

springwires,springsandtoolsincasetinesaredamaged

duetocontactwithforeignmaterials.

20

Important:Neveroperatetheaeratorinreverseor

whenitisintheraisedposition.

AeratingProcedures

1.Lowertheaeratorsothatthetinesarenearlytothe

groundatthelowestpartoftheirstroke.

2.Atalowtractorenginerpm,engagethepowertake

off(PTO)clutchtostarttheaeratorworking.

3.Selectagearthatgivesaforwardspeedof

approximately.8-2.5M.P .H.(1to4km/hr.)at

theratedPTOspeedof400–500rpm(refertothe

tractorOperator’sManual).

4.Astheclutchisreleasedandthetractormoves

forward,lowertheaeratorfullyontotheroller(s)

andincreaseenginespeedtogiveamaximumof

400–500rpm(460onmodelSR72)atthePTO .

Important:NeveroperatethetractorPTO

inexcessof500rpmordamagetotheaerator

couldoccur.

Important:Makesurethattherollerison

thegroundatalltimeswhentheaeratoris

operating.

5.Notetheholepattern.Ifyourequiregreaterhole

spacing,increaseforwardthespeedofthetractorby

shiftingupagearorwithahydrostaticdrivetractor,

actuatethehydrostatleverorpedaltogivefaster

speed.Forcloserholespacing,decreasetractor

forwardspeed.Changingenginespeed,whilein

thesamegear,willnotchangetheholepattern.

Important:Lookbehindfrequentlyto

ensurethemachineisoperatingproperlyand

alignmentismaintainedwithpreviouspasses.

6.Usethefronttractorwheelasaguidetomaintain

equallateralholespacingwiththepreviouspass.

7.Attheendoftheaerationpass,raisetheaeratorand

quicklydisengagethePTO.

OperatingTips

1.EngagePTOatlowenginespeed.Increaseengine

speedtoachievethedesiredPTOspeedof400–500

rpm(maximum)andtheloweraerator.Operateat

anenginerpmthattheaeratorrunsmostsmoothly .

Note:Changingtheengine/PTOrpmina

particulartractorgear(orxedhydrostaticpedal

positionontractorswithhydrostatictransmission)

willnotchangeholespacing.

2.Makeverygradualturnswhenaerating.Nevermake

sharpturnswithPTOdriveengaged.Planyour

aerationpathbeforeloweringtheaerator.Making

sharpturnswhileaeratingwilldamagetheaerator

andthetines.

3.Iftractor“bogs”downwhenoperatingonhard

groundorgoinguphill,raiseaeratorslightlyuntil

speedisregained,thenloweraeratoragain.

4.Bestresultsareachievedwhenthetineentryisona

slightinclinetowardtherearofthemachine.Use

cautionwhenextendingthehydraulictoplinkto

keepfromhammeringtheturfwiththetineheads.

Insomecases,youmaynotachievethebestresults

fromusingthepre-setholesinthecamberbrackets.

Especiallywherethegrassrootsareshortorweak.

Youmaywanttoexperimentusinganothercamber

settingthatwillsetthetinesonmoreofanincline

tokeepfrompullingsoiloutofthehole.

5.Donotaerateifthegroundistoohardordry.Best

resultsareobtainedafterarainorwhenturfhas

beenwateredthepreviousday.

Note:Iftherollerridesupoffthegroundwhile

aerating,thegroundistoohardtoachievethe

desireddepth,reducetheaerationdepthuntilthe

rollercontactsthegroundduringoperation.

6.Raiseaeratorpenetration,ifgroundishardpacked.

Cleanupcoresandre-aerateatdeeperpenetration,

preferablyafterwatering.

8.Ifyoubackintoatightarea(likeateebox),

disengagethePTOandraisetheaeratortoits

highestposition.Neverattempttoaerateinreverse.

9.Alwayscleartheareaofalldamagedmachineparts,

suchasbrokentines,etc.,topreventanything

frombeingpickedupbymowersorotherturf

maintenanceequipmentandthrown.

10.Replacebrokentines,inspectandcorrectdamageto

thosestillusable.Repairanyothermachinedamage

beforecontinuingoperation.

Toavoidpersonalinjury,neverleavethetractor

seatwithoutrstdisengagingthePTOdrive,

settingtheparkingbrakeandstoppingthe

engine.Neverperformaeratoradjustments

orrepairswithoutrstloweringtheaerator

ontothesafetystand.Besureallsafetydevices

aresecuredinproperplacebeforeresuming

operation.

7.Lookbehindfrequentlytoensurethemachineis

operatingproperlyandalignmentismaintainedwith

21

previouspasses.Alossofonelineofholesindicates

abentorlosttine.Inspectaftereachpass.

8.Alwayscleartheareaofalldamagedmachine

parts,suchasbrokentines,etc.,topreventthem

frombeingpickedupbymowersorotherturf

maintenanceequipmentandthrown.

9.Replacebrokentines,inspectandcorrectdamageto

thosestillusable.Repairanyothermachinedamage

beforecommencingoperation.

SubsoilCultivation

thePTOspeedisaround400–420rpm.Theforward

spacingisnoteffectedbyreducingtheenginespeed.

Thepushedholecanalsobeaffectedbythepositionof

thecamberbracket.RefertoAdjustingtheTineAngle.

MultiRowAdapterHeads

Whenusingmultirowadapterheads,reducetheengine

speeduntilthePTOspeedisaround400–420rpm.

Theforwardspacingisnoteffectedbyreducingthe

enginespeed.

Subsoilcultivation,fracturingor“heave”iscreatedbya

spadingmotionofthetineinthesoilastheaeratorand

tractormoveforward.Qualityofnishontheplaying

surfaceafteraeratingwilldependonvariousfactors

includingturfcondition,rootgrowthandmoisture

content.

HardGround

Ifthegroundistoormtoobtainthedesiredcoring

depth,thecoringheadcangetintoa“bouncing”

rhythm.Thisisduetothehardpanthetinesare

attemptingtopenetrate.Thisconditioncanbe

correctedbyattemptingoneormoreofthefollowing:

•Bestresultsareobtainedafterarainorwhenturf

hasbeenwateredthepreviousday .

•Reducethenumberoftinesperstomper

arm.Attempttomaintainasymmetricaltine

congurationtoevenlyloadthestomperarms.

•Reduceaeratorpenetration(depthsetting)ifground

ishardpacked.Cleanupcores,waterturf,and

aerateagainatadeeperpenetration.

Aerationofsoiltypesbuiltontopofhardsubsoils

(i.e.sand/soilcapplacedoverrockyground)cancause

undesiredholequality.Thisiscausedwhentheaeration

depthisgreaterthanthesoilcapandthesubsoilis

toohardtopenetrate.Whenthetinescontactthis

subsoiltheaeratormayliftandcausethetopofthe

holestobecomeelongated.Reducetheaerationdepth

sufcientlytoavoidpenetrationintothehardsubsoil.

RootZoneLifting

Usingmulti-tineheadsinconjunctionwithlargercoring

tinesorlargediametersolidtinescaninducesignicant

stressontherootzoneoftheturf.Thisstresscan

fracturetherootzoneandcausealiftingactiontothe

turf.Ifthisdamageoccurstryoneormoreofthe

following:

•Reducetinedensity(removesomeofthetines)

•Decreasecoringdepth(suggestedin1/2inch

increments)

•Increaseforwardholespacing(changetractor

transmissionuponegear)

•Decreasethetinediameter(solidorcoring)

AdjustingtheTineAngle

ModelsSR72

Setthecamberbracket(Figure27)tothecorrect

positionbasedonthelengthoftinestobeused.The

headstopissettooneofvepredeterminedpositions

bychoosingtheholethroughwhichtheadjustmentrod

isbolted.Theseholesarepresetsonly;forinstance,

byusinga10inchtineinthe12inchpositionyou

mayachieveasmoothernish;dependingonthe

application.

1.DisengagethePTOandengagetheparkingbrake.

2.Stoptheengineandremovethekeyfromignition

switch.

Longer/LargerTines

Usinglonger/largertinescanleavethefrontorrearof

theholetuftedorslightlydeformed.Holequalityfor

thiscongurationgenerallyimprovesifthecoringhead

speedisreduced10-15%fromfulloperatingspeed.For

PTOpoweredaeratorsreducetheenginespeeduntil

3.Releasethespringtensiontothetinehead

(Figure27).

4.Removethenutandboltintheadjustmentholesin

thecamberbracket(Figure27).

22

Figure27

1.Camberbracket6.12inchtine(Common)

2.14inchtine7.16inchtine

3.12inchtine(Usethis

positionformorelifting

action)

4.7inchtine

5.10inchtine

8.Tineheadpivotbolt

9.Spring

5.Loosenthetineheadpivotbolt(Figure27).

Figure28

1.Bumperbolt

2.Spring

3.Springpinandclip

4.Removethebumperboltandbumperfromthe

linkagearmandreinsertthemintotheother

adjustmenthole(Figure28).

5.Reconnectthespringtensiontothetinehead.

6.Rotatethecamberbracketuntilitisalignedwiththe

desiredholeinthearmandinstalltheboltandnut.

Note:Makesuretheboltgoesthroughthe

chamberbracketandplate.

7.Torquethetineheadpivotboltto300ft-lb.

8.Reconnectthespringtensiontothetinehead.

ModelsSR54,SR54–S,SR70and

SR70–S

Setthetineangleaccordingtothetinelengthbyusing

oneofthetwoadjustmentholesinthelinkagearm.

Theseholesarepresetsonly.Whenusing7inch(17.77

cm)to10inch(25.4cm)tines,theheadbumpershould

bepositionedclosesttotherearofthetinehead.The

otherposition(theholefarthestfromthehead)maybe

neededduetovariancesofsoilconditions.

1.DisengagethePTOandengagetheparkingbrake.

2.Stoptheengineandremovethekeyfromignition

switch.

TransportOperation

Tobegintransportoperation,raisetheaeratorand

disengagethePTO.Toavoidlossofcontrol,traverse

steepinclinesslowly,approachroughareasatreduced

speedandcrosssevereundulationscarefully.

Important:Donotexceedtransportspeedsof15

m.p.h.(24km/hr.).

InspectionandCleanupafter

Use

Afterdailyuse,thoroughlywashthemachinewith

agardenhosewithoutanozzlesocontamination

andsealandbearingdamageduetoexcessivewater

pressurewillbeavoided.Abrushmaybeusedto

removecaked-onmaterial.Usemilddetergenttoclean

thecovers.Aftercleaning,greasealldrivelinesand

rollerbearings,inspectformachinedamage,oilleakage,

componentandtinewear.DonotoiltheO-ring

drivechain.

3.Releasethespringtensiontothetinehead

(Figure28).

Remove,cleanandoilthetines.Sprayalightoilmist

oncoringheadbearings(crank&damperlinks).

Cleanandcoatthespringswithadrylubricantlike

graphiteorsilicone.

23

Maintenance

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst8hours

Aftertherst50hours

Beforeeachuseordaily

Every50hours

Every500hours

Beforestorage

Yearlyorbeforestorage

MaintenanceProcedure

•Checkthetorqueofallthecoringheadfasteners

•ChangetheGearboxOil

•Inspectthechaintension

•Checkthesprings

•Cleanandlubricatespringsandtinemountingscrews

•InspectthePTOforsignsofwear .

•GreasethebearingsandPTOshaft

•ChecktheGearboxOil

•Inspectthechaintension

•Checkthetorqueofthecrankpinnutsandthehingebolts.

•Inspectbearings

•ChangetheGearboxOil

•Inspectbearingsandreplaceasneeded

•Performall50hourmaintenanceprocedures

•Chippedsurfaces-Paint

•LoosenthePTOclutchbolts

•Removeandcleantines

•Removealldebris

•AdjustthePTOclutch

LiftingtheMachine

Whenchangingattachmentsorperforming

otherservice,usecorrectblocks,hoistsor

jacks.Makesuremachineisparkedonasolid

levelsurfacesuchasaconcreteoor.Priorto

raisingmachine,removeanyattachmentsthat

mayinterferewiththesafeandproperraising

ofthemachine.Alwayschockorblocktow

vehiclewheels.Usestoragestandsorblocksto

supporttheraisedmachine.Ifthemachineis

notproperlysupported,themachinemaymove

orfall,whichmayresultinpersonalinjury.

Note:Ahoistcanbeusedtolifttheaerator.Use

thecoringheadeyeletasahoistattachmentpoint

(Figure29).Makesurethehoisthasenoughliftcapacity.

Refertothespecicationchartforaeratorweights.

Figure29

1.Coringheadeyelet

24

GreasingtheBearings

ServiceInterval:Every50hours

Themainworkingbearingsoftheaeratoraresealedand

requirenomaintenanceorlubrication.Thisdrastically

reducesthemaintenancerequiredandeliminatestherisk

ofgreaseoroilbeingdroppedontotheturf.

Therearegreasettingsthatmustbelubricatedwith

anSAEmultipurpose,high-temperaturegreasewith

highpressure(EP)performanceorSAEmultipurpose

lithiumbasegrease.

Thelubricationpointsare:

PTOShaft(3)(Figure30)

Figure30

Rollerbearings(Qty .2or4,dependingonmodel)

(Figure31)

Thesealedbearingsrequirenolubricationorshortterm

maintenance.Thisminimizesroutineservicerequired

andreducesthepotentialofturfdamageduetogrease

contamination.Thesesealedbearingpackageswill

providegoodperformanceandlifeundernormaluse,

butperiodicinspectionsofbearingconditionandseal

integrityshouldbeconductedtoavoiddowntime.These

bearingsshouldbeinspectedseasonallyandreplacedif

damagedorworn.Bearingsshouldoperatesmoothly

withnodetrimentalcharacteristicssuchashighheat,

noise,loosenessorrustweeping.

Duetotheoperatingconditionsthesebearing/seal

packagesaresubjectto(i.e.sand,turfchemicals,water,

impacts,etc.)theyareconsiderednormalwearitems.

Bearingsthatfailduetootherthandefectsinmaterialsor

workmanshiparetypicallynotcoveredunderwarranty.

Note:Bearinglifecanbenegativelyaffectedby

improperwashdownprocedures.Donotuse

high-pressureorhighvolumespraydirectlyatthe

bearings.

Itiscommonfornewbearingstopurgesomegrease

outthesealsonanewunit.Thispurgedgreasewillturn

blackincolorduetocollectionofdebrisandnotdueto

excessiveheat.Itisgoodpracticetowipethisexcess

greasefromthesealsaftertheinitial8hours.Theremay

alwaysappeartobeawetareaaroundtheseallip.This

isgenerallynotdetrimentaltobearinglife,butkeeps

thesealliplubricated.

Inspectthecoringheadbearingsevery500operating

hoursandreplaceasneeded.

Figure31

O-ringchain—Donotlubricatethechain.

Important:Bearingsrarelyfailfromdefectsin

materialsorworkmanship.Themostcommon

reasonforfailureismoistureandcontamination

workingitswaypasttheprotectiveseals.Bearings

thataregreasedwillrelyuponregularmaintenance

topurgeharmfuldebrisfromthebearingarea.

Sealedbearingsrelyonaninitialllofspecialgrease

andarobustintegralsealtokeepcontaminantsand

moistureoutoftherollingelements.

CheckingtheGearboxOil

ServiceInterval:Every50hours

Thegearboxislledwith80W–90gearoilorequivalent.

Allowthegearboxtocoolbeforecheckingtheoillevel.

1.Cleandebrisfromllplugandcheckplugtoavoid

contamination.

2.Removethecheckplugfromthegearbox(Figure32).

Note:Ifthegearboxhastwocheckplugs,usethe

bottomone.

25

Figure32

1.Vent/Fillplug

2.Checkplug

3.Drainplug

3.Makesureoilisuptothebottomofthecheckplug

holeingearbox(Figure32).

4.Ifoillevelislow ,removevent/llplugfromtopof

gearboxandreplenishoilasrequired.

Model

SR542quarts(1.9liters)

SR54–S2quarts(1.9liters)

SR702quarts(1.9liters)

SR70–S2quarts(1.9liters)

SR724quarts(3.8liters)

GearCaseCapacity

6.Installthevent/llplug.

7.Checktheoillevelandreplenishasrequired.

Inspecting/AdjustingtheDrive

Chain

ServiceInterval:Beforeeachuseordaily

Every50hours

Checkthedrivechainfordamageandcorrect

adjustment.Thechainshouldhaveapproximately1/2

inch(12.7mm)ofoveralldeection(1/4inch[6mm]in

eachdirection).

Chaintensioncanbeadjustedbyslightlylooseningthe

mainjamnutandtighteningthejamrodtodesired

position(Figure33orFigure34).Donotadjustthe

chaintensionwhenthechainishotorwarm.

5.Installplugs.

ChangingtheGearboxOil

ServiceInterval:Aftertherst50hours

Every500hours

Thegearboxislledwith80W–90gearoilorequivalent.

1.Cleandebrisfromvent/llpluganddrainplugto

avoidcontamination(Figure32).

2.Removethevent/llplugtorelieveairdraw.

3.Positionadrainpanunderthedrainplugandremove

theplug.

Note:Thehighviscosityofcooloilwillextendthe

draintime.(approximately30minutes)

4.Aftertheoiliscompletelydrained,reinstallthedrain

plug.

5.Fillthegearboxwithhighquality80W-90gearlube.

Usethefollowingcharttodeterminethegearbox

oilcapacity .

Figure33

Models54,54–S,70,&72

1.Drivechain3.Jamrod

2.Jamnut

26

Figure34

Models72

1.Drivechain3.Jamrod

2.Jamnut

Important:Donotovertightenchains;excess

tighteningofchainscancausegearbox/sprocket

damage.

stoppingthePTO.Turnbackthenutsanadditional

2turns.

Note:Donotallowtheclutchtoslipforan

extendedamountoftime.

3.Iftheclutchcontinuestoslipafterturningbackthe

nuts,tighteneachnutanaddition1/4turnuntilthe

slippingceases.Donotovertightenthenutsasshaft

damagemayoccur.

CheckingtheCoringHead

FastenerTorque

ServiceInterval:Aftertherst8hours

Every50hours

Usingthechartbelow,todeterminethetorqueofthe

crankpinnutsandthehingebolts(Figure36).These

arethetwomostcrucialareasofthemachinewhereloss

oftorquewillcausedamagetothecrankshaftalmost

immediately.

AdjustingthePTOClutch

ServiceInterval:Yearlyorbeforestorage

Frictionclutchesmaybecomehotduringuse.

Do not touch.

theareaaroundtheclutchfreeofammable

materialandavoidprolongedslippingofthe

clutch.

1.Attheendoftheseason,backoffeachoftheclutch

nuts2turns(Figure35).

Toavoidtheriskofre,keep

ModelsSR54,

SR54–S,SR70

&SR72–S

CrankShaftNut950ft-lbs.1200ft-lbs.

CrankPinNut950ft-lbs.950ft-lbs.

HingeBolt

1.Crankshaftnut

2.Crankpinnut

265ft-lbs.300ft-lbs.

Figure36

3.Hingebolts

SR72

Figure35

1.Clutchnut2.Clutch

2.Atthestartofthenewseason,startthePTOand

allowtheclutchtoslipforafewsecondsbefore

27

CheckingtheSprings

ServiceInterval:Beforeeachuseordaily

hosesandtheconnectinglinkfromthetractor.Cap

thehydraulichoses.Storethesecomponentswith

theaerator.

Checkthespringsforcrossedorbrokenwires

(Figure37).Crossedorbrokenspringwireswillcause

anerraticholepatternintheturf.

Figure37

1.Correctspringwires2.Crossedspringwires

Note:Replacementwiresareincludedwiththeaerator.

Thewiresareconsideredaconsumableitem.

AdjustingtheHoleSpacing

10.DisconnectthesafetyshieldchainsfromPTOshaft.

11.Pullbackonthelockcollartodisconnectthepower

shaftfromthetractorPTOshaft.

12.SlidethePTOshaftbackandremovefromtractor.

13.ConnectthePTOsafetychaintotheaeratorto

preventthePTOshaftfromcontactingtheground.

14.Removethepinssecuringthelowerlinkarmstothe

aeratorbrackets.Retainpinswithaerator.

Theforwardholespacingisdeterminedbythetractor’ s

gearratio(orthehydrostatictractionpedal).Changing

theengineRPMdoesnotchangetheforwardhole

spacing.

Thelateralholespacingisdeterminedbythenumber

oftinesinthetineheads.

RemovingtheAeratorfrom

theTractor

1.Stoptheaeratoronalevelsurface,notonaslope.

2.DisengagethePTOandengagetheparkingbrake.

3.Raisetheaeratorroller(s)3-6inchesoffground.

Placesupportblocksundertheroller(s).

4.Stoptheengineandremovethekeyfromignition

switch.

5.BeforeleavingtheOperator’sseatontractor,wait

forengineandallmovingpartstostop.

6.Removethetines.

7.Installthestoragestand.

8.Slowlyloweraeratoruntilstoragestandscontact

ground.

9.Removethepinsecuringthetoplinktotheaerator

bracket.Retainpinwithaerator.Also,onmodels

withahydraulictoplink,disconnectthehydraulic

28

TroubleShooting

Problem

Springsarebreakingornotpullingbackthe

headtonormalposition.

Holesareelongatedorpicking.

Tinesarehittingthegroundwithanerratic

pattern.

PTOclutchslipsexcessively.Adjusttinestoshallowdepth.ReplacePTOclutches.Reviewclutchadjustment

Turfispullingupwithcoringtines.Shallow-rootedturfmayrequiresolidtinesthersttime.

Thesoilistoohardforfullpenetration.

Coringtinesarebreaking.Youaretryingtogettoomuchdepthforthesoilcondition.Seeaboveandaerateto

Tineswillnotstayinthehead.

Tinespullthesoilupwhenthemachineis

raised.

Themachinewillnotturn.

Thetractorhasdifcultyliftingtheaerator.Movetractorliftarms3”(76.19mm)to4”(101.6mm)closertotheaerator.Make

Thehydraulictoplinkcylinderisspongy.(It

“gives”andmovesinandoutashortspan

whenforceisapplied.

Machineisnoisyorknocking.

Thehydraulictoplinkcylindercannotbefully

retracted(PTOshaftjams).

Thetractorisdifculttosteerwhenintransport.•Addweighttothefrontofthetractor.

SlowthePTOspeedofthetractor.Thelongerandheavierthetines,thegreaterthe

centrifugalforceonthehead.Checkforcrossedorbrokenspringwires.

Adjusttheangleofthetineorchangethetractorgroundspeed.Makesurethatthe

aeratorcanbeloweredatleast2inchesbelowatgroundleveltoallowforundulation.

•Checkforcrossedorbrokenspringwires.

•SlowthePTOspeedofthetractor.

procedure.

Aerateatadepththatthemachinecanachieve,waterovernight,andthenincrease

thedepth.Repeatifnecessaryuntilsoilcanbeaeratedatdesireddepth.

ashallowerdepth.

Tightenthetineholderbolts;donotusejamnutsorimpactwrench.Iftheboltwillnot

holdthetine,replaceit.

RaisethemachinepartofthewayoutofthesoilbeforedisengagingthePTO.

MakesurethePTO,driveshaftanddrivechainsareworkingproperly .

surethetractorhasthecapacitytolifttheaerator.

Airisinthecylinderorlinesandmustbebledout.

•Crankpinnuthasvibratedloose.•Chainsaretooloose.

•Boltsonthebottomoftheframeattherearofthemainarmhavevibratedloose.

•Checkoillevelingearbox.

ThePTOshaftistoolongforyourtractorandshouldbecuttothecorrectlength.

•Checktirepressureandadjustasrequired.

Solution

29

Storage

Attheendofanaeratingseasonorwhentheaeratorwill

notbeusedforalongperiod,itisgoodpracticetocarry

outthefollowingpreventativemaintenance.

1.Cleanoffanydirtorgreasethatmayhave

accumulatedontheaeratororanyofthemoving

parts.

2.Removeandcleanouttines.Coattineswithoilto

preventrustingduringstorage.

3.Openthehoodandcleanouttheinsideofthe

machine.

4.Lubricateallgreasettingsandtinefastenerscrew

threads.

5.Storethemachineontheprovidedstoragestandson

ahard,drysurface.

6.LoosenthePTOclutchboltstwoturns.

7.ConnectthePTOsafetychaintotheaeratorinstored

positiontopreventdamageorremovethePTOand

storeunderthehoodtominimizecorrosion.

8.Painttherollerandtouch-upanyotherscratcheson

thepaintedsurfaces.

9.Replaceanymissingordamageddecals.

10.Storetheaeratorinsideadrysecurebuilding.Inside

storagewillreducemaintenance,givealonger

workinglifeandincreasetheresidualvalueofthe

machine.Ifinsidestorageisnotavailable,coverwith

aheavysheetortarpaulinandsecuretightly .

30

Notes:

31

Toro Commercial Aerator Products Warranty

A Two-Year Limited Warranty

Conditions and Products Covered

The Toro Company and its affi liate, Toro Warranty Company,

pursuant to an agreement between them, jointly warrant your Toro

Hydroject or ProCore Aerator (“Product”) to be free from defects in

materials or workmanship for two years or 500 operational hours*,

whichever occurs fi rst. Where a warrantable condition exists, we

will repair the Product at no cost to you including diagnosis, labor,

parts, and transportation. This warranty begins on the date the

Product is delivered to the original retail purchaser.

* Product equipped with hour meter

Instructions for Obtaining Warranty Service

You are responsible for notifying the Commercial Products Distributor or Authorized Commercial Poducts Dealer from whom

you purchased the Product as soon as you believe a warrantable

condition exists. If you need help locating a Commercial Products

Distributor or Authorized Dealer, or if you have questions regarding your warranty rights or responsibilities, you may contact us at:

Toro Commercial Products Service Department

Toro Warranty Company

8111 Lyndale Avenue South

Bloomington, MN 55420-1196

952-888-8801

E-mail: commercial.warranty@toro.com

Owner Responsibilities

As the Product owner, you are responsible for required maintenance and adjustments stated in your Operator’s Manual.

Failure to perform required maintenance and adjustments can be

grounds for disallowing a warranty claim.

Items and Conditions Not Covered

Not all product failures or malfunctions that occur during the

warranty period are defects in materials or workmanship. This

warranty does not cover the following:

Product failures which result from the use of non-Toro

•

replacement parts, or from installation and use of add-on,

or modifi ed non-Toro branded accessories and products. A

seperate warranty may be provided by the manufacturer of

these items.

Product failures which result from failure to perform recom-

•

mended maintenance and/or adjustments. Failure to properly

maintain your Toro product per the Recommended Maintenance listed in the Operator’s Manual can result in claims for

warranty being denied.

Product failures which result from operating the Product in an

•

abusive, negligent or reckless manner.

Parts subject to consumption through use unless found to

•

be defective. Examples of parts which are consumed, or

used up, during normal Product operation include, but are

not limited to, brake pads and linings, clutch linings, blades,

reels, rollers and bearings (sealed or greasable), bedknives,

aerator crankshaft and stomper arm bearings, tines, spark

plugs, castor wheels and bearings, tires, fi lters, belts, and

certain sprayer components such as diaphragms, nozzles,

and check valves, etc.

Failures caused by outside infl uence. Items considered to

•

be outside infl uence include, but are not limited to, weather,

storage practices, contamination, use of unapproved coolants,

lubricants, additives, fertilizers, water, or chemicals, etc.

Normal noise, vibration, wear and tear, and deterioration.

•

Normal “wear and tear” includes, but is not limited to, dam-

•

age to seats due to wear or abrasion, worn painted surfaces,

scratched decals or windows, etc.

Parts

Parts scheduled for replacement as required maintenance are warranted for the period of time up to the scheduled replacement time

for that part. Parts replaced under this warranty are covered for the

duration of the original product warranty and become the property

of Toro. Toro will make the fi nal decision whether to repair any ex-

isting part or assembly or replace it. Toro may use remanufactured

parts for warranty repairs.

Maintenance is at Owner’s Expense

Engine tune-up, lubrication cleaning and polishing, replacement of

fi lters, coolant, and completing Recommended Maintenance are

some of the normal services Toro products require that are at the

owner’s expense.

General Conditions

Repair by an Authorized Toro Distributor or Dealer is your sole

remedy under this warranty.

Neither The Toro Company nor Toro Warranty Company is

liable for indirect, incidental or consequential damages in

connection with the use of the Toro Products covered by this

warranty, including any cost or expense of providing substitute equipment or service during reasonable periods of

malfunction or non-use pending completion of repairs under

this warranty. Except for the Emissions warranty referenced

below, if applicable, there is no other express warranty. All

implied warranties of merchantability and fi tness for use are

limited to the duration of this express warranty.

Some states do not allow exclusions of incidental or consequential

damages, or limitations on how long an implied warranty lasts, so

the above exclusions and limitations may not apply to you. This

warranty gives you specifi c legal rights, and you may also have

other rights which vary from state to state.

Note regarding engine warranty:

The Emissions Control System on your Product may be covered

by a separate warranty meeting requirements established by the

U.S. Environmental Protection Agency (EPA) and/or the California

Air Resources Board (CARB). The hour limitations set forth above

do not apply to the Emissions Control System Warranty. Refer to

the Engine Emission Control Warranty Statement printed in your

Operator’s Manual or contained in the engine manufacturer’s

documentation for details.

Countries Other than the United States or Canada

Customers who have purchased Toro products exported from the United States or Canada should contact their Toro Distributor (Dealer)

to obtain guarantee policies for your country, province, or state. If for any reason you are dissatisfi ed with your Distributor’s service or

have diffi culty obtaining guarantee information, contact the Toro importer.

Part Number 374-0032 Rev. C

Loading...

Loading...