Page 1

FormNo.3360-899RevB

HydroJect

ModelNo.09802—SerialNo.280000001andUp

®

3010Aerator

ToregisteryourproductordownloadanOperator'sManualorPartsCatalogatnocharge,gotowww.T oro.com.OriginalInstructions(EN)

Page 2

Introduction

Important:Theengineinthisproductisnot

equippedwithasparkarrestermufer.Itisa

violationofCaliforniaPublicResourceCode

Section4442touseoroperatethisengineonany

forest-covered,brush-covered,orgrass-covered

landasdenedinCPRC4126.Otherstatesor

federalareasmayhavesimilarlaws.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoidinjury

andproductdamage.Youareresponsibleforoperating

theproductproperlyandsafely.

YoumaycontactTorodirectlyatwww .T oro.comfor

productandaccessoryinformation,helpndinga

dealer,ortoregisteryourproduct.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafetyalertsymbol

(Figure1),whichsignalsahazardthatmaycauseserious

injuryordeathifyoudonotfollowtherecommended

precautions.

Figure1

1.Safetyalertsymbol

Thismanualuses2otherwordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Warning

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.Themodel

andserialnumbersareonaplateontheproduct.Write

thenumbersinthespaceprovided.

ModelNo.

SerialNo.

CALIFORNIA

Proposition65Warning

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

ThissparkignitionsystemcomplieswithCanadian

ICES-002.

©2008—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.T oro.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

Contents

Introduction.................................................................2

Safety...........................................................................4

SafeOperatingPractices.......................................4

SafetyandInstructionalDecals.............................6

Setup............................................................................9

1InstallingtheRearWheels..................................9

2ActivatingandChargingtheBattery....................9

3CheckingtheTirePressure...............................11

ProductOverview......................................................12

Controls.............................................................12

Specications.....................................................13

Attachments/Accessories...................................13

DepthsandNozzleCongurations.....................14

..........................................................................14

Operation...................................................................15

ThinkSafetyFirst...............................................15

CheckingtheEngineOil.....................................15

FillingtheGasTank...........................................15

CheckingtheGearCaseFluidLevel....................16

CheckingthePumpCaseOilLevel......................17

WaterSystemAccumulator.................................18

OperatingPrecautions........................................18

StartingandStoppingtheEngine........................18

TrainingPeriod...................................................18

WaterSupply......................................................19

OperatingProcedure..........................................19

CheckingtheInterlockSystem............................20

TransportOperation..........................................21

InspectionandClean-UpAfterUse.....................21

PushingorTowingtheMachine..........................21

Maintenance...............................................................23

RecommendedMaintenanceSchedule(s)................23

WaterSystemAccumulator.................................23

DailyMaintenanceChecklist...............................24

LubricatingtheMachine.....................................25

ServicingthePre-Filter.......................................26

ReplacingtheMainWaterFilter..........................26

ChangingtheEngineOilandFilter.....................27

GeneralAirCleanerMaintenance.......................27

ServicingtheAirCleaner....................................27

CheckingandReplacingtheSparkPlugs..............28

ChangingtheGearCaseOilandFilter.................29

ChangingthePumpCaseOil..............................30

CheckingtheHydraulicLinesandHoses.............30

AdjustingtheTractionPumpBelt.......................30

AdjustingtheTransmissionforNeutral...............31

AdjustingtheAerationSpeed..............................32

AdjustingtheParkingBrake................................32

AdjustingtheRollerSprayWashSystem..............33

ServicingtheSprayWashNozzlesor

Strainers.........................................................33

CaringfortheBattery.........................................33

Storage.......................................................................34

PreparingtheWaterSystem................................34

PreparingtheEngine..........................................34

PreparingtheTractionUnit................................34

Troubleshooting.........................................................35

Schematics.................................................................38

3

Page 4

Safety

Improperuseormaintenancebytheoperatoror

ownercanresultininjury.Toreducethepotential

forinjury,complywiththesesafetyinstructions

andalwayspayattentiontothesafetyalert

symbol,whichmeansCAUTION,WARNING,or

DANGER-"personalsafetyinstruction."Failureto

complywiththeinstructionmayresultinpersonal

injuryordeath.

SafeOperatingPractices

–Neverrefuelordraintheaeratorindoors.

•Checkthattheoperatorpresencecontrols,safety

switchesandshieldsareattachedandfunctioning

properly.Donotoperateunlesstheyarefunctioning

properly.

Operation

•Onlyoperateingoodlight,keepingawayfromholes

andhiddenhazards.

•Besurealldrivesareinneutralandparkingbrakeis

engagedbeforestartingengine.Starttheengineonly

fromtheoperatorsposition.

ThefollowinginstructionsarefromANSIstandard

B71.4-2004.

Training

•ReadtheOperator’sManualandothertraining

material.Iftheoperator(s)ormechanic(s)cannot

readEnglishitistheowner’sresponsibilitytoexplain

thismaterialtothem.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateor

servicetheequipment.Localregulationsmayrestrict

theageoftheoperator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtohimselforherself,

otherpeopleorproperty.

Preparation

•Evaluatetheterraintodeterminewhataccessories

andattachmentsareneededtoproperlyand

safelyperformthejob.Onlyuseaccessoriesand

attachmentsapprovedbythemanufacturer.

•Wearappropriateclothingincludinghardhat,safety

glassesandhearingprotection.Longhair,loose

clothingorjewelrymaygettangledinmovingparts.

•Inspecttheareawheretheequipmentistobeused

andremoveallobjectssuchasrocks,toysandwire

whichcanbecontactedbytheaerator.

•Useextracarewhenhandlinggasolineandother

fuels.Theyareammableandvaporsareexplosive.

–Useonlyanapprovedcontainer.

•Neveroperatewithouttheshields,coversorother

guardssecurelyinplace.Besureallinterlocksare

functioningproperly .

•Keephandsandfeetawayfromthenozzleand

rollerarea.Highvelocitywaterjetscanpenetrate

handsandfeet.Penetrationbythehighvelocity

waterjetscancauseseriouspersonalinjury.If

accidentalpenetrationoccurs,seekmedicalattention

immediately.

•Neverusechemicalsinthewatersupplysystem.

•Donotoperatethewaterinjectionsystem

onconcreteorasphaltbecausewaterjetswill

permanentlydamagethesesurfaces.

•Beforedisconnectingorperforminganyworkon

thewatersystem,allpressureinthesystemmust

berelievedbystoppingtheengineandopeningthe

bleedvalve.Openingthebleedvalveallowsany

trappedwatertoescapefromthesystemandalso

allowstheaccumulatorpistontomovetothebottom

oftheaccumulatorcylinder.

•Donotchangetheenginegovernorsettingor

overspeedtheengine.

•Theaccumulatorinthismachinecontainshigh

pressuredrynitrogen.Accumulatorservicing

requiresspecialtoolsandprecautions.Accumulators

donotcontainuserserviceablecomponents.

Improperaccumulatorservicingcancause

dismembermentordeath.Donotattemptto

disassembleanaccumulator;havethisworkdoneby

anAuthorizedToroDistributor.

•Stoponlevelground,disengagedrives,engage

parkingbrake,shutoffenginebeforeleavingthe

operator’spositionforanyreason.

•Nevercarrypassengersandkeeppetsandbystanders

away.

–Neverremovegascaporaddfuelwithengine

running.Allowenginetocoolbeforerefueling.

Donotsmoke.

•Bealert,slowdownandusecautionwhenmaking

turns.Lookbehindandtothesidebeforechanging

directions.

4

Page 5

•Slowdownandusecautionwhencrossingroads

andsidewalks.

•Donotoperatetheaeratorundertheinuenceof

alcoholordrugs.

•Useextremecarewhenloadingorunloadingthe

aeratorintoatrailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscurevision.

•Alwaysbeawareofobstaclesthatmaybeinthe

areaofoperation.Planyouraerationpathtoavoid

contactwithanyobstaclebyyouorthemachine.

SlopeOperation

•Donotoperateneardrop-offs,ditches,steepbanks

orwater.Wheelsorrollersdroppingoveredgescan

causerollovers,whichmayresultinseriousinjury

ordeath.

•Donotoperateonslopeswhengrassiswet.Slippery

conditionsreducetractionandcouldcausesliding

andlossofcontrol.

•Makesureallhydrauliclineconnectorsaretightand

allhydraulichosesandlinesareingoodcondition

beforeapplyingpressuretothesystem.

•Keepyourbodyandhandsawayfrompinhole

leaksornozzlesthatejecthydraulicuidunder

highpressure.Usepaperorcardboard,notyour

hands,tosearchforleaks.Hydraulicuidescaping

underpressurecanhavesufcientforcetopenetrate

theskinandcauseseriousinjury.Seekimmediate

medicalattentionifuidisinjectedintoskin.

•Beforedisconnectingorperforminganyworkon

thewatersystem,allpressureinthesystemmust

berelievedbystoppingtheengineandopeningthe

bleedvalve.Openingthebleedvalveallowsany

trappedwatertoescapefromthesystemandalso

allowstheaccumulatorpistontomovetothebottom

oftheaccumulatorcylinder.

•Letenginecoolbeforestoringanddonotstorenear

ame.

•Shutofffuelwhilestoringortransportingontrailers.

Donotstorefuelnearamesordrainindoors.

•Donotmakesuddenturnsorrapidspeedchanges.

•Reducespeedanduseextremecautiononslopes.

•Removeormarkobstaclessuchasrocks,treelimbs,

etc.fromtheoperatingarea.Tallgrasscanhide

obstacles.

•Watchforditches,holes,rocks,dips,andrisesthat

changetheoperatingangle,asroughterraincould

overturntheaerator.

•Beawarethatlossoftractionmayoccurgoing

downhill.Weighttransfermaycausedrivewheelto

slipandcauselossofbrakingandsteering.

•Beawarethatlossoftractionmayoccurgoing

downhill.Weighttransfermaycausedrivewheelto

slipandcauselossofbrakingandsteering.

•Alwaysavoidsuddenstartingorstoppingonaslope.

Iftirelosestraction,disengagethewaterinjection

systemandproceedslowlyofftheslope.

MaintenanceandStorage

•Parkmachineonlevel,hardground.Neverallow

untrainedpersonneltoservicemachine.

•Usejackstandsorsafetylatchestosupport

componentswhenrequired.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

•Disconnectbatteryorremovesparkplugwirebefore

makinganyrepairs.Disconnectthenegativeterminal

rstandthepositivelast.Reconnectpositiverst

andnegativelast.

•Keephandsandfeetawayfrommovingparts.If

possible,donotmakeadjustmentswiththeengine

running.

•Chargebatteriesinanopenwellventilatedarea,

awayfromsparkandames.Unplugchargerbefore

connectingordisconnectingfrombattery.W ear

protectiveclothinganduseinsulatedtools.

•Keepallpartsingoodworkingconditionandall

hardwaretightened.Replaceallwornordamaged

decals.

Engineexhaustcontainscarbonmonoxide,

whichisanodorless,deadlypoisonthatcan

killyou.

Donotrunengineindoorsorinanenclosed

area.

•UseonlyToro-approvedattachments.W arrantymay

bevoidedifusedwithunapprovedattachments.

5

Page 6

SoundPressureLevel

VibrationLevel

ThisunithasanequivalentcontinuousA-weighted

soundpressurelevelattheoperatorearof93dBA,based

onmeasurementsofidenticalmachinesperDirective

98/37/ECandamendments.

SoundPowerLevel

Thisunithasaguaranteedsoundpowerlevelof:

108dBA/1pW ,basedonmeasurementsofidentical

machinesperDirective2000/14/ECandamendments.

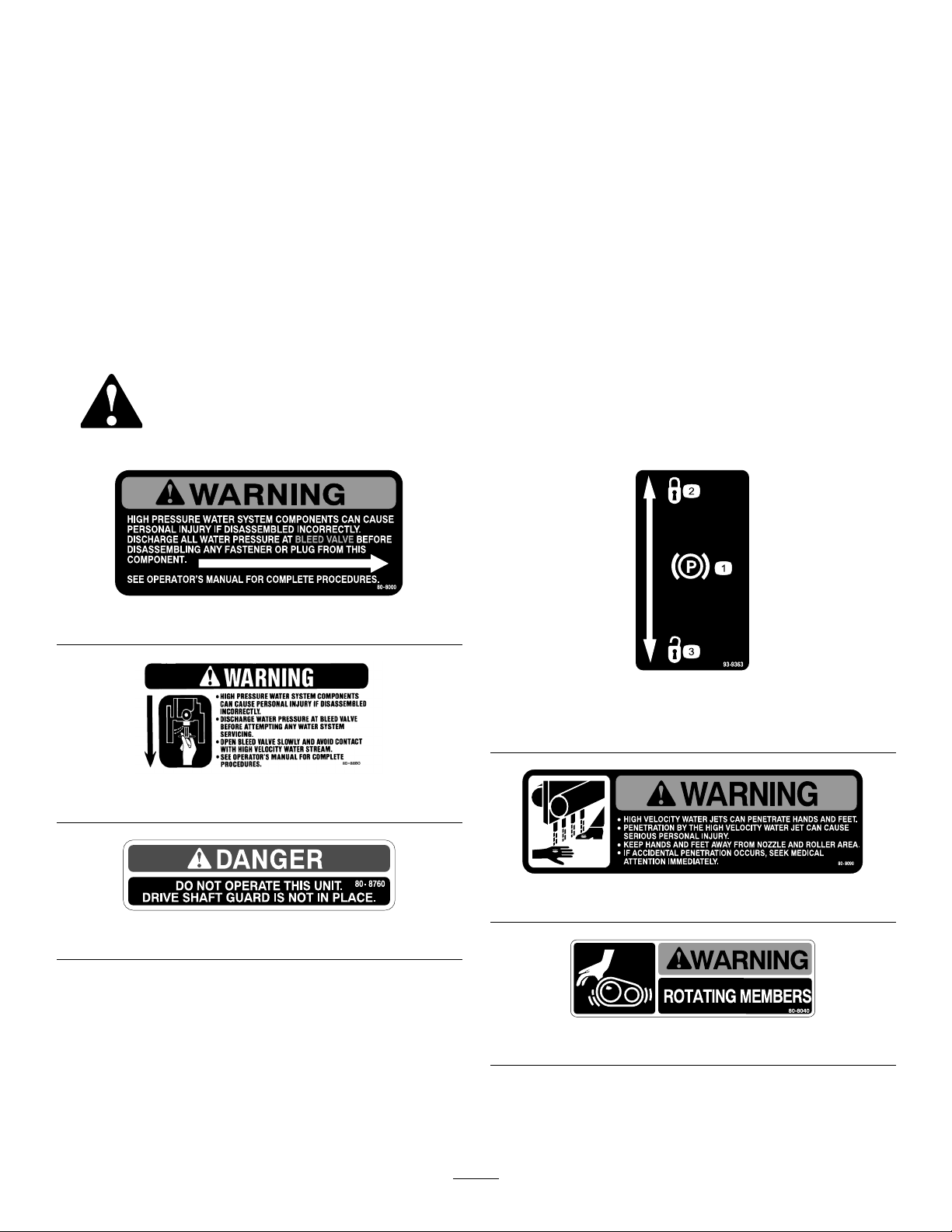

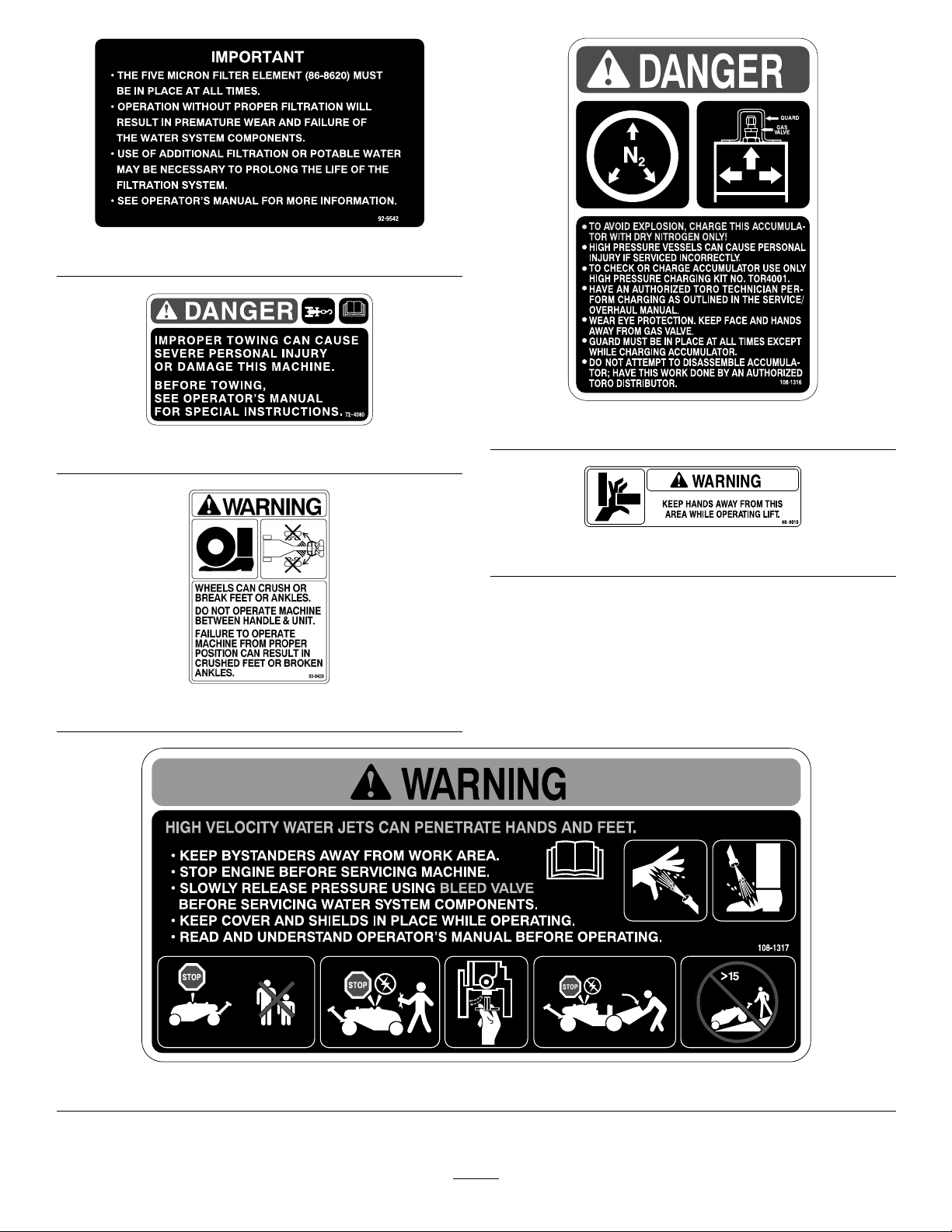

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaof

potentialdanger.Replaceanydecalthatisdamagedorlost.

Thisunitdoesnotexceedavibrationlevelof4.0m/s

thehandsbasedonmeasurementsofidenticalmachines

perISO5349procedures.

2

at

80-8000

93-9363

1.Parkingbrake3.Unlocked

2.Locked

80-8880

80-8090

80-8760

80-8040

6

Page 7

92-9542

108-1316

72-4080

80-8010

93-9429

108-1317

7

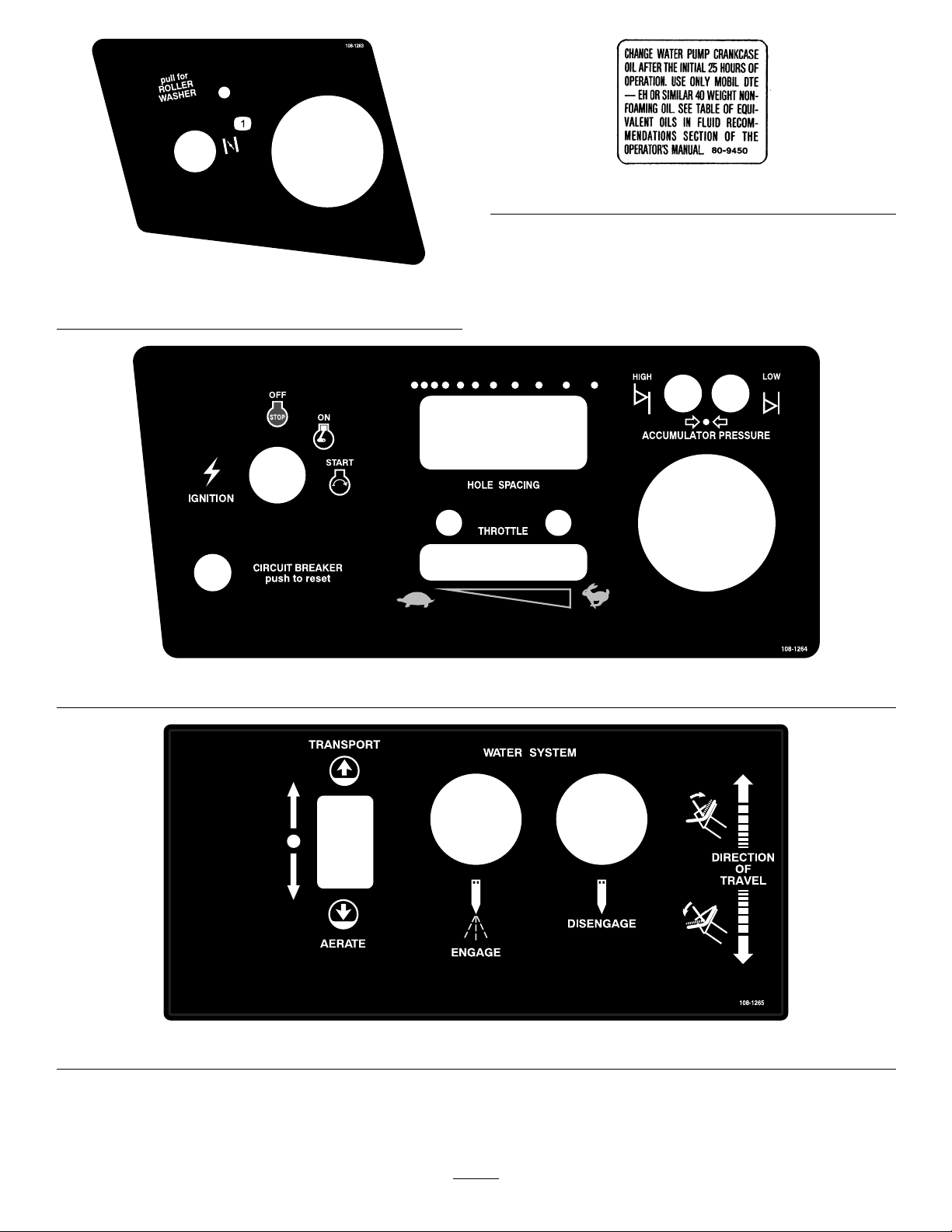

Page 8

80-9450

108-1263

1.Choke

108-1264

108-1265

8

Page 9

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

Wheel3

1

2

3

Lugnut12

Bulkelectrolyte,notsupplied

Nopartsrequired

MediaandAdditionalParts

Description

IgnitionKey1Useinignitionswitch.

HoseAdapter1

SpannerWrench

Operator’sManual

PartsCatalog

Qty.

Mounttoquickcoupleronsideofmachine.

1

1

1

Useforinstallationandremovalofwaterlter.

Readbeforeoperatingtheaerator

Usetoreferencepartnumbers.

Qty.

A/R

Use

Installtherearwheels

Activateandchargethebattery .

–

Checkthetirepressure.

Use

1

InstallingtheRearWheels

Partsneededforthisprocedure:

3Wheel

12Lugnut

Procedure

1.Removethewheelsfromtheshippingpallet.

2.Mountthewheelstothehubswiththelugnuts

(suppliedinlooseparts)(Figure2)andtorquethe

nutsto45-55ft./lb.(61-75N-m).

Figure2

1.Wheel2.Lugnuts

3.Removeanyshippingblocksorbraces,whichmay

obstructmachineremovalfromthepallet.

9

Page 10

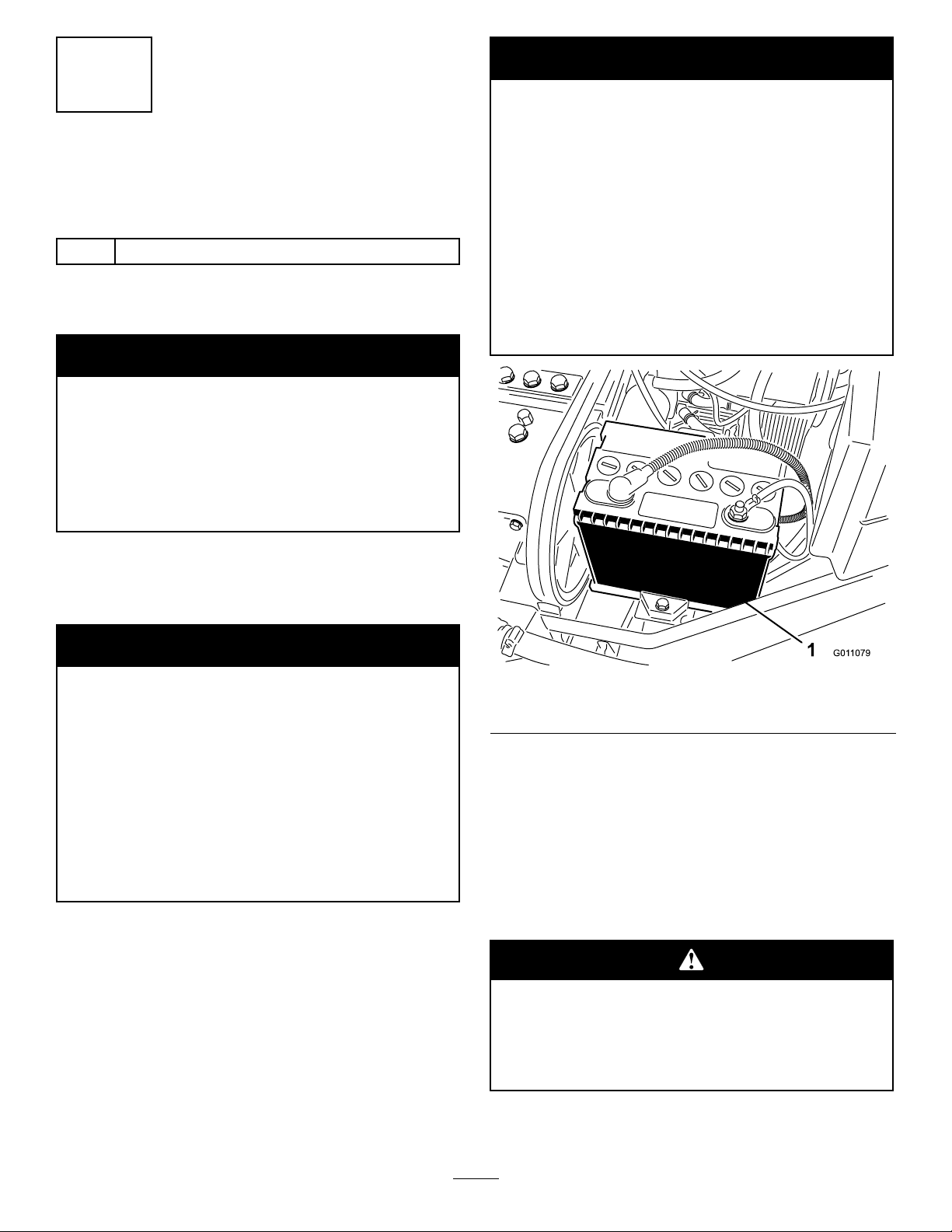

Warning

2

ActivatingandChargingthe

Battery

Partsneededforthisprocedure:

Bulkelectrolyte,notsupplied

A/R

Procedure

Warning

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

Washhandsafterhandling .

CALIFORNIA

Proposition65Warning

Batteryterminalsormetaltoolscouldshort

againstmetaltractorcomponentscausing

sparks.Sparkscancausethebatterygasses

toexplode,resultinginpersonalinjury.

•Whenremovingorinstallingthebattery,

donotallowthebatteryterminalstotouch

anymetalpartsofthetractor.

•Donotallowmetaltoolstoshort

betweenthebatteryterminalsand

metalpartsofthetractor.

1.Sincethebatteryisnotlledwithelectrolyteor

activated,bulkelectrolytewith1.265specicgravity

mustbepurchasedfromalocalbatterysupplyoutlet

Warning

CALIFORNIA

Proposition65Warning

Batteryelectrolytecontainssulfuricacidwhich

isadeadlypoisonandcausessevereburns.

•Donotdrinkelectrolyteandavoidcontact

withskin,eyesorclothing.Wearsafety

glassestoshieldyoureyesandrubber

glovestoprotectyourhands.

•Fillthebatterywherecleanwaterisalways

availableforushingtheskin.

2.Releasethehoodlatchesandraisethehood.

Important:Donotaddelectrolytewhilethe

batteryisinthemachine.Youcouldspillit,

causingcorrosion.

3.Loosenthecapscrewsecuringthebatteryclampto

themachineandremovethebattery(Figure3).

Figure3

1.Battery

4.Cleanthetopofthebatteryandremovethevent

caps.

5.Carefullylleachcellwithelectrolyteuntiltheplates

arecoveredwithabout1/4inch(6mm)ofuid.

6.Allowapproximately20to30minutesforthe

electrolytetosoakintotheplates.Rellasnecessary

tobringtheelectrolytetowithinabout1/4inch(6

mm)ofthebottomofthellwell.

Chargingthebatteryproducesgassesthatcan

explode.

Neversmokenearthebatteryandkeepsparks

andamesawayfrombattery.

7.Connecta3to4ampbatterychargertothebattery

posts.Chargethebatteryatarateof3to4amps

10

Page 11

untilthespecicgravityis1.250orhigherandthe

temperatureisatleast60degreesF(16degreesC)

withallcellsgassingfreely.

8.Whenthebatteryischarged,disconnectthecharger

fromtheelectricaloutletandbatteryposts.

3

CheckingtheTirePressure

Note:Afterthebatteryhasbeenactivated,add

onlydistilledwatertoreplacenormalloss,although

maintenance–freebatteriesshouldnotrequirewater

undernormaloperatingconditions.

9.Installthebatteryandsecureitwiththebattery

clamp.

10.First,installthepositivecable(red)tothepositive

(+)terminalandthenthenegativecable(black)to

thenegative(–)terminalofthebattery.Slidethe

rubberbootoverthepositiveterminaltopreventa

possibleshortfromoccurring.

Warning

CALIFORNIA

Proposition65Warning

Incorrectbatterycableroutingcoulddamage

themachineandcablescausingsparks.Sparks

cancausethebatterygassestoexplode,

resultinginpersonalinjury.

•Alwaysdisconnectthenegative(black)

batterycablebeforedisconnectingthe

positive(red)cable.

NoPartsRequired

Procedure

Thetiresareover–inatedforshipping.Therefore,

releasesomeoftheairtoreducethepressure.Correct

airpressureinfrontandreartiresis8–12psi.

•Alwaysconnectthepositive(red)

batterycablebeforeconnectingthe

negative(black)cable.

Warning

CALIFORNIA

Proposition65Warning

Connectingcablestothewrongpost

coulddamagetheelectricalsystemand

resultinpersonalinjury.

Note:Makesurebatterycablesareroutedaway

fromanysharpedgesormovingparts.

11.Lowerthehoodandsecurethelatches.

11

Page 12

ProductOverview

Controls

HourMeter

Thehourmeter(Figure4)registersaccumulatedhours

ofengineoperation.Usethehourmetertodetermine

intervalsforservicemaintenanceandlubrication.

IgnitionSwitch

Theignitionswitch(Figure4),whichisusedtostart

andstoptheengine,hasthreepositions:OFF ,ON,and

START.

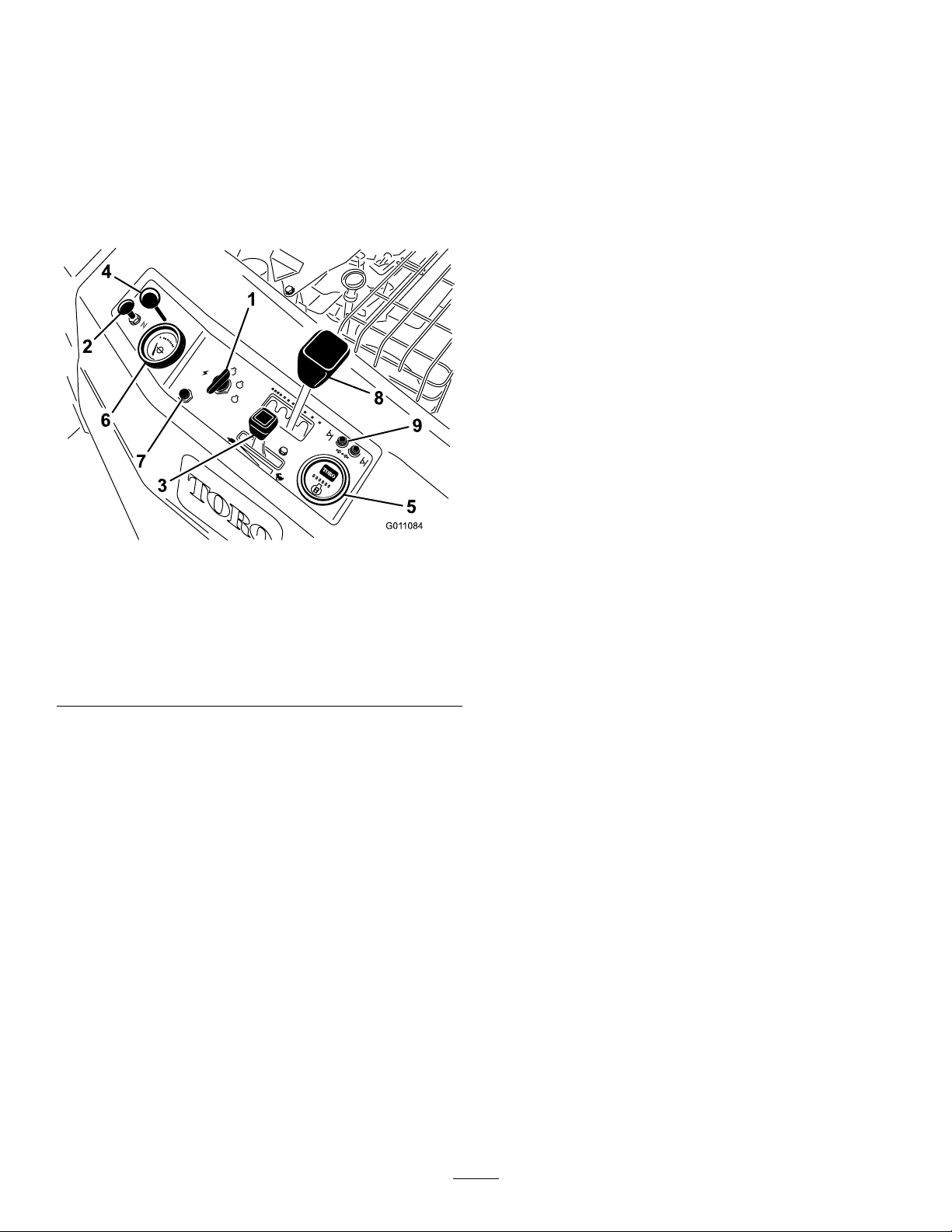

Figure4

1.Ignitionswitch6.Waterpressuregauge

2.Choke7.Circuitbreakerreset

3.Throttle

4.Spraywashcontrol

5.Hourmeter

button

8.Spacingcontrollever

9.Accumulatorpressure

lights

WaterPressureGauge

Thewaterpressuregauge(Figure4)registerssupply

waterpressureinthesystem.Italsoactsasaninterlock

switch,preventingthewaterpumpfromstartingifthe

waterpressureisbelow20-28p.s.i.,orstoppingthewater

pumpifthewaterpressuredropsbelow7-13p.s.i.Check

thegaugefrequentlytomonitorthewaterpressure.

CircuitBreakerResetButton

Pushthebutton(Figure4)toresetthebreakerafter

correctingamalfunctionintheelectricalsystem.The

buttonalsoservesasaswitchtointerruptpowertothe

relays.

SpacingControlLever

Movingthecontrol(Figure4)awayfromthehandle

increasestheaeratinggroundspeedandthedistance

betweenholes.Movingthecontroltowardthehandle

decreasestheaeratinggroundspeedandthedistance

betweenholes.Thesettingwillbeoverriddenwhenthe

machineisshiftedtothetransportposition.

AccumulatorPressureLights

Choke

Tostarttheengine,closethecarburetorchokebypulling

thechokecontrol(Figure4)outwardtotheFULL

position.Aftertheenginestarts,regulatethechoketo

keeptheenginerunningsmoothly.Assoonaspossible,

openthechokebypushingitinwardtotheOFFposition

Throttle

Thethrottle(Figure4)isusedtoregulatetheengine

speed.Movingthethrottleforwardincreasestheengine

speed(FAST);rearwarddecreasestheenginespeed

(SLOW).

SprayWashControl

Pullthehandle(Figure4)upwardtoactivatetheroller

spraywashsystem.Movethecontrolknobupordown

toadjustthesprayratetokeeptherollersfreeofdebris.

Thehighorlowpressurelights(Figure4)willonly

illuminateifahighorlowpressureconditionoccurs

intheaccumulator.Ifalightilluminatesthesystem

willlnotoperateorwillshutdown,ifoperating.Refer

toWaterSystemAccumulatorinformationinthe

Operationsection.

TractionBail

Thetractionbail(Figure5)engagesandregulatesfore

andafttractionoperationofthemachine.Releasingthe

bailstopstractionoperationandwillalsostopwater

injectionin3to4seconds,unlessthebailisre-engaged.

Thetransportspeedisregulatedbytheamountthebail

ismoved.

12

Page 13

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

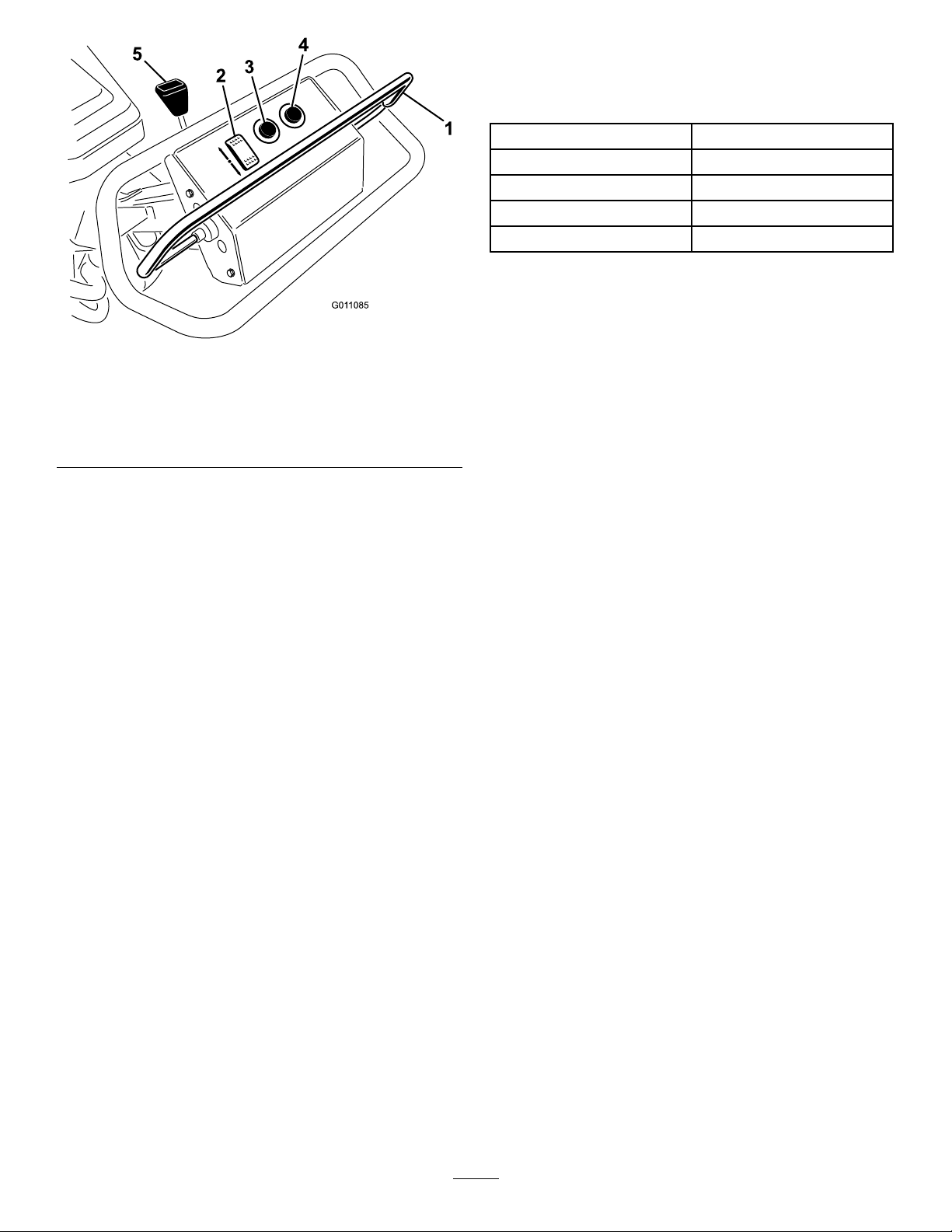

Figure5

1.Tractionbail4.Aerationstopbutton

2.Transport/aeraterocker

switch

3.Aerationengagement

button

5.Parkingbrake

Transport/AerateRockerSwitch

Theswitch(Figure5)lowersmachineontotherollers

tocommenceaeration.Theswitchwilloverridethe

spacingcontrolsettingwhenitismovedtothetransport

position.

Length

Wheelbase

Width

Height

Weight

96.2inches(244cm)

53.2inches(135cm)

63inches(160cm)

38.2inches(97cm

1120lb.(508kg)

Attachments/Accessories

AselectionofToroapprovedattachmentsand

accessoriesareavailableforusewiththemachineto

enhanceandexpanditscapabilities.Contactyour

AuthorizedServiceDealerorDistributororgoto

www.Toro.comforalistofallapprovedattachments

andaccessories.

AerationEngagementButton

Depressingthebutton(Figure5),startsthewater

injectionsystemonlywhenthewaterpressureisabove

28p.s.i.andtherollersareontheground.

AerationStopButton

Theredbutton(Figure5)stopsthewaterinjection

system.Thesystemcontinuesforafewsecondsafter

thebuttonispressed.

ParkingBrake

Pushthelever(Figure5)towardthemachinetoengage

theparkingbrake.Awarningbuzzerwillsoundif

youattempttomovethemachinewithparkingbrake

engaged.

FuelShut-OffValve

Thefuelshut-offvalveislocatedunderthefueltank.

Closethevalvewhenstoringortransporting(trailering)

themachine.

13

Page 14

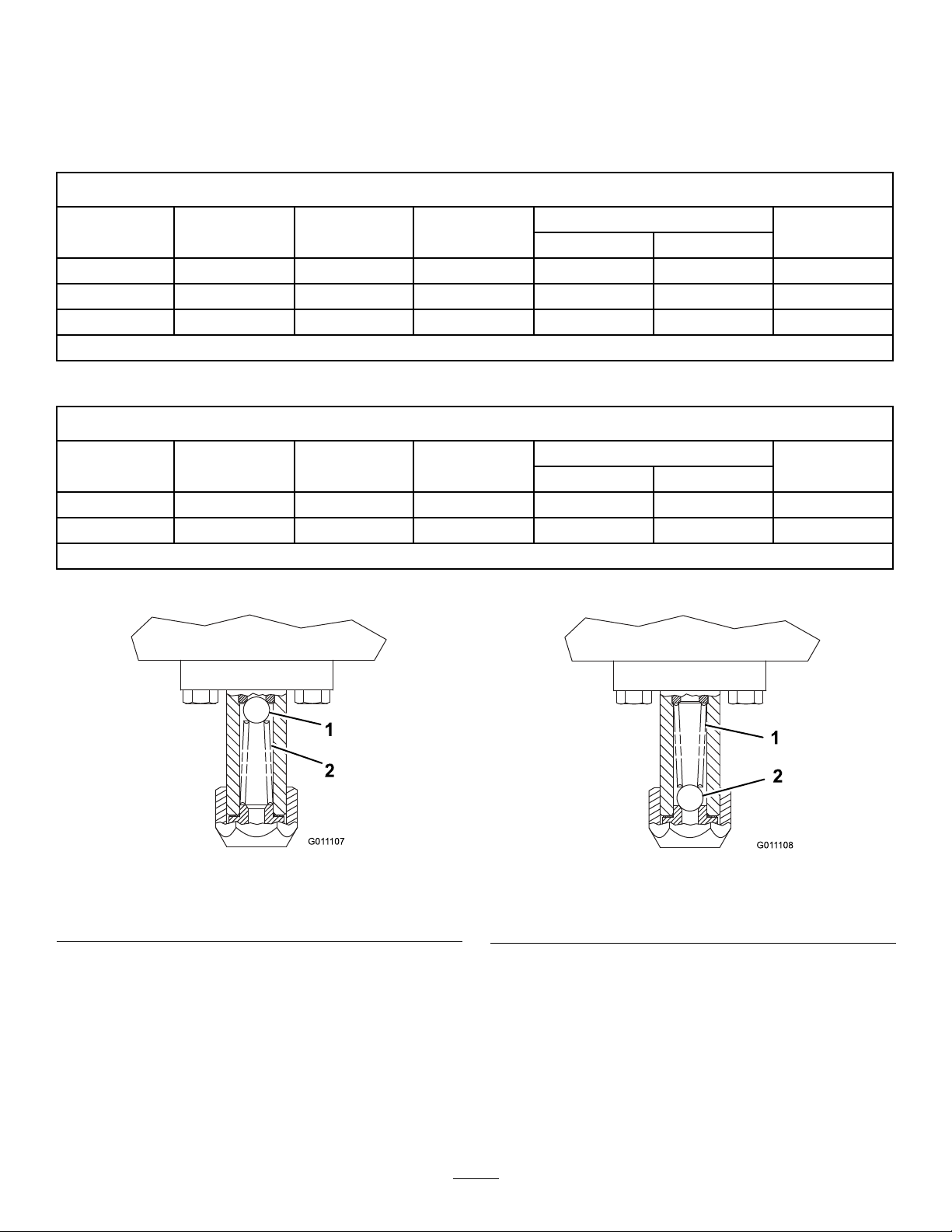

DepthsandNozzleCongurations

Allnozzlesareidentiedwithnumbersindicatingthedrillsizeoftheorice.Thestandardcongurationis11

nozzlesproducingdepthsof4to6inchesdependingonturfconditions.Blockednozzlelocationsareobtainedby

reversingthenozzlecheckvalveballandspring.Seenozzlesizechartandillustrationsbelow:

Important:Useonlynozzlecongurationsshownordamagetothemachinemayoccur.

NozzleSizeandApproximateDepthChart

PartNo.

86-8130

86-8131

86-8133

DrillSize

#56

#53

#46

DecimalSize

(inch)

0.04651.181

0.05951.5111104-6inches

0.0812.0576

*Useonlywithvariedsizecongurations

MetricSize

(mm)

QuantityofNozzles

Open

***

Important:AluminumWasher,ToroPartno.80-6680,isrequiredwithanynozzlechange.

OptionalStaggeredSizeNozzleConguration

PartNo.

86-8130

86-8133

DrillSize

#56

#46

**Additionalnozzlesmaybeblockedtocompensateforpumpwear .

DecimalSize

(inch)

0.04651.1816and

0.0812.057

MetricSize

(mm)

QuantityofNozzles

OpenBlocked**

5

Important:AluminumWasher,ToroPartno.80-6680,isrequiredwithanynozzlechange.

Approximate.

Blocked

5

0**

0**

Depth

6-8inches

Approximate.

Depth

3-4inches

6-8inches

Figure6

OpenNozzle

1.Checkvalveball2.Spring

Figure7

Closed(Blocked)Nozzle

1.Spring2.Checkvalveball

14

Page 15

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

ThinkSafetyFirst

Pleasecarefullyreadallofthesafetyinstructions

andsymbolsinthesafetysection.Knowingthis

informationcouldhelpyouorbystandersavoidinjury.

Theuseofprotectiveequipment,suchasbutnot

limitedto,foreyes,ears,feet,andheadisrecommended.

Figure8

1.Dipstick

2.Oilllcap

Thismachineproducessoundlevelsinexcess

of85dBAattheoperatorsearandcancause

hearinglossthroughextendedperiodsof

exposure.

Wearhearingprotectionwhenoperatingthis

machine.

CheckingtheEngineOil

ServiceInterval:Beforeeachuseordaily—Checkthe

engineoil.

Theengineisshippedwithoilinthecrankcase;

however,theoillevelmustbecheckedbeforeandafter

theengineisrststarted.

Crankcasecapacityisapproximately2qt(1.4l)with

thelter.

Usehigh-qualityengineoilthatmeetsthefollowing

specications:

APIClassicationLevelRequired:SJ,SK,SLorhigher.

Preferredoil:SAE10W–30(above0degreesF)

Alternateoil:SAE5W–30(below32degreesF)

ToroPremiumEngineoilisavailablefromyour

distributorin10W–30viscosity.Seethepartscatalog

forpartnumbers.

1.Parkthemachineonalevelsurface,stoptheengine

andremovethekeyfromtheignitionswitch.

Note:IftheoillevelisattheADDmarkonthe

dipstick,add1quartofoiltoraisetheoillevelto

FULL.Donotoverll.

3.Removethecapfromtheoilll.Pouroilintothe

oillluntilthelevelisattheFULLmarkonthe

dipstick.

Important:Theaeratoroperatesatvery

highengineloads,sochecktheoillevelevery

8operatinghoursordaily.Anewengine

mayconsumesomeoiluntilitisbrokenin.

Initially,changetheoilaftertherst25hoursof

operation;thereafter,undernormalconditions,

changetheoilandlterafterevery100hours

ofoperation.Changetheoilmorefrequently

whentheengineisoperatedinextremelydusty

ordirtyconditions.

FillingtheGasTank

Werecommendtheuseoffresh,clean,unleadedregular

gradegasoline.Unleadedgasolineburnscleaner,

extendsenginelife,andpromotesgoodstartingby

reducingthebuild-upofcombustionchamberdeposits.

Note:Donotmixoilwiththegasoline.Neveruse

methanol,gasolinecontainingmethanol,gasohol,

gasolineadditives,premiumgasoline,orwhitegas

becauseengineandfuelsystemdamagecouldresult.

2.Removethedipstickfromtheoilllerneck

(Figure8)andwipeitwithacleanrag.Insertthe

dipstickintothellerneckandmakesureitisseated

fully.Pullthedipstickfromthellerneckandcheck

theoillevel.Iftheoillevelislow,addenoughoilto

raisetheleveltotheFULLmarkonthedipstick

15

Page 16

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areor

explosionfromgasolinecanburnyouand

othersandcandamageproperty.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupany

gasolinethatspills.

•Donotllthefueltankcompletelyfull.Add

gasolinetothefueltankuntilthelevelis1

in.(25mm)belowthebottomoftheller

neck.Thisemptyspaceinthetankallows

gasolinetoexpand.

•Neversmokewhenhandlinggasoline,and

stayawayfromanopenameorwhere

gasolinefumesmaybeignitedbyaspark.

•Storegasolineinanapprovedcontainerand

keepitoutofthereachofchildren.Never

buymorethana30-daysupplyofgasoline.

•Alwaysplacegasolinecontainersonthe

groundawayfromyourvehiclebeforelling.

•Donotllgasolinecontainersinsidea

vehicleoronatruckortrailerbedbecause

interiorcarpetsorplastictruckbedliners

mayinsulatethecontainerandslowtheloss

ofanystaticcharge.

•Whenpractical,removegas-powered

equipmentfromthetruckortrailerand

refueltheequipmentwithitswheelsonthe

ground

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfroma

portablecontainer,ratherthanfroma

gasolinedispensernozzle.

•Ifagasolinedispensernozzlemustbeused,

keepthenozzleincontactwiththerimof

thefueltankorcontaineropeningatall

timesuntilfuelingiscomplete.

1.Removethecapfromthefueltank(Figure9)and

llthe10gallontanktoabout1inch(25mm)from

thetopoftank(thebottomofthellerneck)with

unleadedgasoline.Installthefueltankcaptightly.

Figure9

1.Fueltankcap

2.Wipeupgasolinethatmayhavespilledtopreventa

rehazard.

CheckingtheGearCaseFluid

Level

ServiceInterval:Beforeeachuseordaily

Themachinesreservoirislledatthefactorywith

approximately4-5quartsofhighqualityhydraulic

uid.Checkthelevelofthehydraulicuid,onthe

sightgauge,beforetheengineisrststartedanddaily

thereafter.Therecommendedreplacementuidis:

MobilDTE26

Alternateuids:Ifthisuidisnotavailable,other

uidsmaybeusedprovidedtheymeetallthefollowing

materialpropertiesandindustryspecications.Wedo

notrecommendtheuseofsyntheticuid.Consult

withyourlubricantdistributortoidentifyasatisfactory

product.

Note:Torowillnotassumeresponsibilityfordamage

causedbyimpropersubstitutions,souseonlyproducts

fromreputablemanufacturerswhowillstandbehind

theirrecommendation.

Anti-wearHydraulicFluid,ISOVG68

MaterialProperties:

Viscosity,ASTMD445cSt@40°C65to71

ViscosityIndexASTM

D2270

PourPoint,ASTMD97-18°Fto-30°F

IndustrySpecications:

VickersI-286-S(QualityLevel),VickersM-2950-S

(QualityLevel),DenisonHF-0

cSt@100°C8.4to8.9

97to107

Note:Manyhydraulicuidsarealmostcolorless,

makingitdifculttospotleaks.Areddyeadditive

16

Page 17

forthehydraulicsystemoilisavailablein2/3oz.(20

ml)bottles.Onebottleissufcientfor4-6gal(15-22

1)ofhydraulicoil.Orderpartno.44-2500fromyour

authorizedTorodistributor.

1.Positionthemachineonalevelsurface.

2.Releasethehoodlatchesandraisethehood.

3.Checkthelevelofhydraulicoilonthesightgauge

(Figure10).Theuidlevelshouldbeuptothe

middleofthegaugewindow .

ShellMorlinaSd150

ChevronAWMachineOil150

ConocoMultipurposeR&O0.1150

ExxonTerresstic150

Philllips

SunSunvis150

76Lubricants

CastrolParadene150R&O

MagnusOil150

TurbineOil150

Important:Theoilmustbechangedimmediately

whenanycontamination,sludge,water,or

condensationappearsintheoil.Determineand

correctanyoilcontaminationproblembefore

restartingtheengineandoperatingthemachine.

1.Positionthemachineonalevelsurface.

2.Releasethehoodlatchesandraisethehood.

3.Removethedipstick/llercapandchecktheoil

levelonthedipstick.Theuidlevelshouldbeupto

theFULLmark(Figure11).

Figure10

1.Sightgauge

2.Fillercap

4.Iftheuidlevelislow ,removethellercapand

addenoughhydraulicoiltobringtheoiluptothe

properlevel.

5.Lowerthehoodandsecurethelatches.

Note:Theoilandltermustbechanged

immediatelywhenanycontamination,sludge,water

orcondensationappearsinoiloronsightgauge.

Determineandcorrectoilcontaminationproblem

beforerestartingengineandoperatingmachine.

CheckingthePumpCaseOil

Level

ServiceInterval:Beforeeachuseordaily

Aftertherst25hours

Every200hours

Figure11

1.Dipstick/llercap

2.Full

4.Iftheuidlevelislow ,addenoughMobilDTE

ExtraHeavyoilorequivalentoiltobringtheoilup

totheproperlevel.Donotoverll.

5.Lowerthehoodandsecurethelatches.

Thepumpcrankcaseislledatthefactorywith

approximately40ouncesofMobilDTEExtraHeavy

oil.Checktheoillevelonthedipstickbeforetheengine

isrststartedanddailythereafter.Changetheoil

initiallyafter25hoursofoperation,thereafterchange

every200hoursofoperation.Seethefollowingchart

forequivalentoils.

17

Page 18

WaterSystemAccumulator

TheHydrojectaccumulatorcontainsahighpressure

nitrogengaspre-charge.Thesafetysystemonthe

aeratorwilldisablethewaterinjectioniftheaccumulator

pressureistoolowortoohigh,andwillilluminateone

oftheaccumulatorpressurelightsontheoperators

console.

Duetotheoperationalrequirementsoftheaccumulator

design,thehighpressureinternalgaspre-chargecan

bleedoutduringperiodsofinactivity.Storingthe

Hydrojectforextendedperiodsoftime(3monthsor

longer)and/orseasonaltemperaturevariancescan

affecttheaccumulatorsabilitytoretainasufcient

pre-chargeandseasonalservicing(recharge)maybe

required.

Ifoneoftheaccumulatorchargeindicatorlamps

illuminates,contactyourauthorizedT oroDistributor

foraccumulatormaintenanceservices.

•Useagood,clean,qualitywatersupplyinthe

system.Ifgoodqualitywaterisnotavailable,

additionalltrationequipmentmayberequired.Do

notusechemicalsinthewatersystem.

•Donotallowthemachinetobesubjecttofreezing

temperatureswithoutdraining,asdamagetothe

systemwilloccur.

StartingandStoppingthe

Engine

1.Makesurethatthewiresareinstalledonthespark

plugsandthefuelshut-offvalveisopen.

2.Makesurethattheparkingbrakeisengaged.

3.PullthechokeleverouttotheFULLpositionand

movethethrottlelevertothehalfthrottleposition.

Note:Whenstartingawarmengine,thechoke

maynotbenecessary,butHALFthrottleis.

OperatingPrecautions

Followtheseprecautionswhenoperatingtheaerator:

•Beforeaerating,inspecttheworkareafordebrisand

obstacles.Determinethebestdirectionandpattern

tooperatethemachine.Alwaysmaintainawareness

ofwhatliesaheadinthedirectionofforwardtravel.

•Ifthemachinestartstovibrateabnormally,shutthe

engineoff.Removethekeyfromtheignitionswitch

topreventthepossibilityofaccidentalstarting.

Checkthemachinefordamagedparts.Repairany

damagebeforerestartingtheengineandoperating

themachine.

•Onlyusetheaeratorindaylightorwhenthereis

goodarticiallight.W atchforholesorotherhidden

hazards.Donottransportthemachineclosetoa

sandtrap,ditch,creek,orotherhazard.

•Topreventrollermarks,alwaysraisethemachineto

thetransportpositionwhenparkedonagreen.

•Donotoperatethewaterinjectionsystem

onconcreteorasphaltbecausewaterjetswill

permanentlydamagethesesurfaces.Donotrun

overthehoseasdamagewilloccur.

•Donotoperatetheaeratorwiththerolleror

injectionsystemovertheedgeofanythingthat

couldbehit,damaged,orinjuredbyhighvelocity

waterblasts.

•Waterjetsfromtheinjectionsystemshouldnot

damageirrigationheadsononepassofthemachine.

Donotallowmultipleshotsfromtheinjection

systemtohitirrigationheadsasdamagewilloccur.

4.Insertthekeyintotheignitionswitchandrotateit

clockwisetostarttheengine.Releasethekeywhen

theenginestarts.Graduallyreturnthechokelever

totheOFFposition(leverallthewayin)afterthe

enginestartsandwarmsup.

Important:T opreventoverheatingofthe

startermotor,donotengagethestarterlonger

than30seconds.After30secondsofcontinuous

cranking,wait2minutesbeforeengagingthe

startermotoragain.

Important:Theengineisequippedwithan

oilpressureinterlockswitchwhichinterrupts

theengineoperationifthereisnotsufcient

oilpressureintheengineduringstartingor

operation.Theenginemaystartbutwillnot

continuetorunduetoalackofoilpressure.

5.Tostoptheengine,movethethrottlecontrol

downwardtotheSLOWpositionandturnthe

ignitionkeytoOFF.Removetheignitionkey.

TrainingPeriod

Beforeaeratingwiththemachine,itissuggestedthat

youndaclearareaandpracticestartingandstopping,

raisingandloweringmachine,turning,etc.Thistraining

periodwillbebenecialtotheoperatoringaining

condenceintheperformanceoftheaerator.

18

Page 19

WaterSupply

Recommendedsourcewith7-8gallonsperminute.

Aminimumpressureof30p.s.i.atthemachineis

requiredforthepumptoengage.Maximumallowable

pressureof200psi.Althoughirrigationwaterpumped

frompondsorefuentholdingpoolscanbeused,not

allconditionscanbehandledbytheltrationsystem.

Additionaloralternativeltrationmayberequired.

OperatingProcedure

1.Makesurethatthewiresareinstalledonthespark

plugsandthefuelshut-offvalveisopen.

2.Uncoilagardenhose,makingsurethatthereareno

kinksorbendsinthehose.Layoutthehosesothat

therearenoobstructionsbetweenthemachineand

theareatobeaerated.Turnonthewatersupplyto

purgeanyairfromthehose.Turnoffthewater.

3.Connectthehoseadapter(Figure12)tothegarden

hose,thenconnecttheadaptertothequickcoupler

onthesideofthemachine.

Figure13

1.Mainwaterlterhead

2.Bleedbutton

6.Reachunderthehoodandopenthebleedvalve

onthemainvalveattherearofthemachine

(Figure14).Bleedthesystemuntilasteadyowof

watercomesfromtheoutlet;thenclosethevalve.

Figure12

1.Hoseadapter

2.Quickcoupler

4.Turnonthewatersupplyandcheckthewater

pressure.Thewaterpressuremustbeatleast30

p.s.i..Ifthesystempressureisnot30p.s.i.,make

surethatthehoseisnotkinkedorobstructed,the

watersupplyisturnedon,andthewaterlterisnot

plugged.

Donotoperatetheenginewhilebleedingthe

lterhead.

5.Reachunderthefueltankandpressthebleed

buttonontopofthewaterlterhead(Figure13).

Holdthebleedbuttondownuntilallairispurged

fromthelterandwatercomesoutoftheopening.

Figure14

1.Mainvalve2.Bleedvalve

7.Ifdesired,thevalveonthepre-lter(Figure15)may

beopenedslightly(cracked)toprovidecontinuous

ushingduringoperationofthemachine.

19

Page 20

Figure15

1.Pre-lter

2.Valve

8.Starttheengine;refertoStartingandStoppingthe

Engine.MovethethrottletotheFASTpositionand

disengagetheparkingbrake.

9.Engagethetractionbailandapproachtheareato

beaerated.Makesurethattherearenoobstructions

betweentheaeratorandwatersupply.Always

maintainawarenessofwhatliesaheadinthe

directionofforwardtravel.

10.Engageandholdthetransport/aeratetoggleswitch

tofullylowerthemachineontotherollers.Release

theswitchwhenthemachineisfullylowered;then

presstheengagementbuttontostartwaterinjection.

Note:Theinjectionoperationstartsapproximately

4-5secondsafterthepumpengages.Also,the

injectionsystemwillautomaticallystopifthe

tractionbailisnotengagedwithin3-4secondsafter

startingthewatersystem.

downtoallowmultipleshotswhilemachineis

stopped.

Important:Holedepthscanreach20inches

ormorewhenstationaryormakingmultiple

shots,sobeawareofwhatisburiedbelowthe

turf.Also,anexcessiveamountofholesand

muddyturfconditionsmayoccurwhenmaking

multipleshots.

14.Tostopwaterinjection,presstheredbutton.The

systemcontinuesforafewsecondsafterthebutton

ispressed.Raisethemachinetothetransport

position,disconnectthesupplyhose,andmoveto

thenextlocation.

CheckingtheInterlockSystem

Ifsafetyinterlockswitchesaredisconnected

ordamagedthemachinecouldoperate

unexpectedly,causingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlock

switchesdailyandreplaceanydamaged

switchesbeforeoperatingthemachine.

Thepurposeofthesafetyinterlocksystemistoprevent

theenginefromcrankingorstartingunlessthetraction

bailisinNEUTRALandpreventsthewatersystem

fromengagingifthemachineisinthetransport(raised)

position.Italsostopsaerationifthetractionbailis

releasedwhileoperatingorifthemachineisraisedto

thetransportposition.

11.Whenaerating,workmovingperpendicularfrom

thewatersupplytoavoidrunningoverthegarden

hose.Usethefrontedgeofthehoodorrearcorner

oftheframetoalignrows,ifdesired.Whenatthe

endofarow,makean“S”maneuverandreversethe

directionoftheaerator.Donotmakesharpturns

onagreenorscufngfromthetiremayoccur.

Alwaysmaintainawarenessofwhatliesaheadinthe

directionofforwardtravel.

12.Regulatetherollerspraywash,ifrequired,to

removedebrisfromtherollers.

Note:Asmallamountofwaterfromtheregulator

bypassmaycomeoutofthespraywashnozzles

evenwiththespraywashintheOFFposition.

13.Inareaswheregreaterholedepthormorefrequent

holesaredesired,theengagebuttoncanbeheld

Todoafunctionalcheckofinterlocksystem:

1.Positionthemachineinaat,openareaonrough

turfandawayfromburiedwires,plumbing,etc.

Stoptheengine.

2.Movethetractionbailupanddownwhiletrying

tostarttheengine.Iftheenginecranks,thereisa

malfunctionintheinterlocksystemthatmustbe

corrected.Iftheenginedoesnotcrank,proceed

tostep3.

3.Connectthewatersupplytothemachine.Turn

onthewatersupplyandbleedallairoutofthe

system.Thewaterpressuremustbe30psiormore.

Starttheengine.Raisethemachinetothetransport

position(upofftherollers).Pushtheaerate

ENGAGEbutton.Ifthewaterpumpengagesand

themachinebeginsaerating,thereisamalfunction

20

Page 21

intheinterlocksystemthatmustbecorrected.Ifthe

machinedoesnotbeginaerating,proceedtostep4.

4.Lowerthemachinetotheaerateposition(on

therollers).Engagethetractionbailtostartthe

machinemoving.Push,thenreleasetheaerate

ENGAGEbutton.Thewaterpumpshould

engageimmediately ,thenthemachineshould

beginaerating5secondsafterthepumpengages.

Releasethetractionbailtotheneutralpositionso

thatthemachinestopsmoving.Thewaterpump

shoulddisengage4secondsafterthetractionbail

returnstoneutral,thenstopaeratingafteranother

3seconds.Ifthemachinedoesnotstopaerating

whenthetractionbailreturnstoneutral,thereisa

malfunctionintheinterlocksystemthatmustbe

corrected.Ifthemachinestopsaerating,proceed

tostep5.

5.Engagethetractionbailtostartthemachine

moving,thenpushtheaerateENGAGEbutton

tobeginaerating.PushtheaerateDISENGAGE

button.Thewaterpumpshoulddisengage

immediately,thenstopaeratingafter3seconds.

Ifthemachinedoesnotstopaerating,thereisa

malfunctionintheinterlocksystemthatmustbe

corrected.

Lights(LED’s)onthecontroller(Figure16)

indicatewhenthefollowinginputsaremadetothe

controller:

Red

GreenAeratestart(engage)switchclosed.Ifthered

Yellow

Transportswitchclosed(tractionbailinneutral)

andyellowlightsareon,thegreenlightwillstay

onuntileithertheredoryellowgoesoff.

Pumpstartlimitswitchclosed(machinelowered

toaerateposition)andwaterpressureswitch

closed(waterpressureofmorethan30psi)and

accumulatorchargepressureswitch(nitrogen

pressuremorethan1800psi).

TransportOperation

Usethetractionbailtoslowthemachinewhilecrossing

undulatingterraintoavoidlossofcontrol.Thesmooth

tiresdonotgripturfverywellsousecautionwhen

transportingthemachine.Alwaysapproachrough

areasatareducedspeedandcrosssevereundulations

carefully.

InspectionandClean-UpAfter

Use

Atthecompletionofoperation,thoroughlywash

themachinewithagardenhosewithoutanozzleso

excessivewaterpressurewillnotcausecontamination

anddamagetosealsandbearings.Aftercleaning,itis

recommendedthemachinebeinspectedforpossible

hydraulicuidorwaterleaksanddamageorwearto

hydraulic,water,andmechanicalcomponents.

PushingorTowingthe

Machine

Inanemergency,themachinecanbepushedor

towedforaveryshortdistance.However,wedonot

recommendthisasstandardprocedure.

Important:Donotpushorthetowmachinefaster

than3MPHbecausepumpdamagemayoccur.

Ifthemachinemustbemovedaconsiderable

distance,transportitonatruckortrailerorpull

itwiththetractionwheelraisedandsecuredtoa

dolly(OptionalHydrototeTrailer,Model09833

available).Wheneverthemachineispushedor

towed,thebypassvalvemustbeopened.Thehook

onthefrontofthehandleisusedasatie-down

only,notahitchpoint.

Figure16

1.Redlight3.Yellowlight

2.Greenlight

1.Unlatchandraisethehood.

2.Locatethebypassvalvecapontheleftsideofthe

hydraulicpump(Figure17).

21

Page 22

Figure17

1.Bypassvalve

3.Rotatethevalvecapcounterclockwise,movethe

machinetothedesiredlocation,andclosethevalve

cap.

4.Lowerthehoodandsecurethelatches.

Important:Donotrunanychemicalsthrough

theHydrojectwatersystem(exceptToro

WettingAgent86-8530).Chemicalscanhave

corrosiveeffectsonmachinecomponentsand

environmentallawsandconcernsexistwhen

injectingchemicalsub-surface.

22

Page 23

Maintenance

Note:Specicationsanddesignaresubjecttochangewithoutnotice.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst25hours

Aftertherst50hours

Beforeeachuseordaily

Every100hours

Every200hours

Every400hours

MaintenanceProcedure

•Changethepumpcaseoil

•Changethehydraulicoilandlter

•Changethepumpoil

•Changetheengineoil

•Checktheengineoil.

•Checkthegearcaseuidlevel

•Checkthepumpcaseoillevel

•Checkthehydrauliclinesandhoses

•Changetheengineoilandlter

•Changethepumpcaseoil

•Servicetheaircleanerelements

•CheckthesparkplugsReplaceasrequired

•Changethehydraulicoilandlter

•Changethepumpoil

•Adjusttheparkingbrake

WaterSystemAccumulator

Duetotheoperationalrequirementsoftheaccumulatordesign,thehighpressureinternalgaspre-chargecanbleed

outduringperiodsofinactivity .StoringtheHydrojectforextendedperiodsoftime(3monthsorlonger)and/or

seasonaltemperaturevariancescanaffecttheaccumulatorsabilitytoretainasufcientpre-chargeandseasonal

servicing(recharge)mayberequired.

Ifoneoftheaccumulatorchargeindicatorlampsilluminates,contactyourauthorizedT oroDistributorfor

accumulatormaintenanceservices.

Contactwithhotsurfacescouldcauseburns.

Waitforthemachinetocoolbeforeservicingormakingadjustmentstothemachine.

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriously

injureyouorotherbystanders.

Removethekeyfromtheignitionanddisconnectthewirefromthesparkplugbeforeyoudoany

maintenance.Setthewireasidesothatitdoesnotaccidentallycontactthesparkplug.

23

Page 24

DailyMaintenanceChecklist

Duplicatethispageforroutineuse.

Fortheweekof:

MaintenanceCheckItem

Checkthesafetyinterlock

operation.

Checkthebrakeoperation.

Checkthefuellevel.

Checktheengineoillevel.

Checktheengineairlter

pre-cleaner

Checktheenginecoolingns

fordebris

Checkthewater

lter/pressure.

Checkthewaterpre-lter.

Checkthegearcaseoillevel.

Checkthepumpcaseoil

level.

Checkforunusualengine

noises

Checkforunusualoperating

noises

Checkhydraulichosesfor

damage

Checkforuidleaks

Checkthetirepressure

Checktheinstrument

operation

Lubricateallthegrease

1

ttings

Touch-upanydamagedpaint

1

=Immediatelyaftereverywashing,regardlessoftheintervallisted

Mon.Tues.Wed.Thurs.Fri.

Sat.Sun.

Important:Refertoyourengine

NotationforAreasofConcern

Inspectionperformedby:

ItemDate

Operator’ s Man ual

foradditionalmaintenanceprocedures.

Information

24

Page 25

LubricatingtheMachine

Theaeratorhas5greasettingsthatmustbelubricated

every50hoursofoperationwithNo.2GeneralPurpose

LithiumBaseGrease.Lubricateallttingsimmediately

aftereverywashing,regardlessoftheintervallisted.

Thebearingsandbushingsthatmustbelubricatedare:

steeringpivotshaft(Figure18),limitswitchhousing

(Figure19)(2)liftarmshaft(Figure19),andneutral

pivotshaft(Figure20).

1.Wipethegreasettingcleansothatforeignmatter

cannotbeforcedintothebearingorbushing.

2.Pumpgreaseintothebearingorbushing.

3.Wipeupexcessgrease.

Figure20

Figure18

Figure19

25

Page 26

ServicingthePre-Filter

Sedimentcanberemovedbyopeningtheballvalve,

withthewatersourceattached,toush(Figure21).The

reusablelterscreenmayberemovedforcleaningby

untwistingtheclearcover(Figure21)fromthelterby

hand.Replacetheclearcoverandhandtightenonly.

Important:Useoftoolswilldamagethelter.

Figure21

1.Body

2.Clearcover

3.Ballvalveforushing

Figure22

1.Filterbody4.Bleedbutton

2.Filtercartridge

3.Filterhead

5.O-ring

3.Unscrewthelterbodyoftheassembly(Figure22)

counterclockwise(asviewedfromthebottom).

Removetheltercartridgeanddiscardit.

Note:T oeasetheremovalofthelterbodyfrom

thelterhead,alterwrenchisavailable.Refer

toPartsCatalogorcontactyourAuthorizedT oro

Distributor.

ReplacingtheMainWater

Filter

Themachineisaprecisionpieceofequipmentand

thequalityorcleanlinessofyourwatersupplyisvery

importantindeterminingthelifeofthemachine.Ifyour

watersupplycontainssilt,sand,orotherdebris,youmay

berequiredtoinstalladditionalltrationorseparation

equipmentbetweenyoursupplysourceandthemachine.

Dependingonthequalityofwater,thefrequencyof

thelterchangewillvarygreatly.Whenthepumpinlet

pressuredecreasesorthewatersystemshutsdown,it

usuallymeansthewaterlterisrestrictedandmustbe

replaced.Neveroperatemachinewithoutawater

lterasseveredamagemayoccur.

1.Positionthemachineonalevelsurfaceandmake

surethattheengineisshutoff.Shutoffthewater

supply.

2.Locatethemainwaterlterassemblymountedbelow

thefueltank.Pressthebleedbutton(Figure22)to

releaseairpressurefromthelterbody.

Thewaterlterbodyisveryheavywhenlled

withwaterandthelter.Usecautionwhen

unscrewingthelterbodyfromthelterhead.

4.Thoroughlyrinseoutthelterbodytoavoid

contaminatingthewatersystem.Makesurethatthe

o-ring(Figure22)isinthegroove.Ifithascome

out,wipeitdry,lubricateitwithalightcoatingof

petroleumjelly,andreplaceitinthegroove.

5.Thoroughlycleanthelterheadmountingsurface

toavoidcontaminatingthewatersystemwhenthe

lterisinstalled.

6.Insertthenewltercartridgeintothelterbody.

7.Threadthelterbodywiththelterontothelter

head.Handtightenthem.

8.Turnonthewatersupplyandpressthebleedbutton

onthetopofthewaterlterhead(Figure22).Hold

thebleedbuttondownuntilallairispurgedfromthe

lterandwatercomesoutoftheopening.

26

Page 27

ChangingtheEngineOiland

Filter

ServiceInterval:Aftertherst50hours

Every100hours

Changetheoilaftertherst50operatinghours.

Thereafter,undernormalconditions,changetheoiland

thelterafterevery100hoursofoperation.However,

anengineoperatedindustyordirtyconditionsrequires

morefrequentoilchanges.Ifpossible,runtheengine

justbeforechangingtheoil.Warmoilowsmorefreely

andcarriesmorecontaminantsthancoldoil.

1.Positionthemachineonalevelsurface.

Figure24

1.Dipstick

2.Oilllcap

2.Disengagethehoodlatchesandopenthehood.

3.Placeanoildrainpanbelowthedrainhoseonthe

sideofthecrankcase(Figure23).

4.Rotatethedrainvalvecounterclockwiseandallow

theoiltoowintoadrainpan.Aftertheoilhas

drained,rotatetheoildrainvalveclockwise.

5.Removetheoillter(Figure23)anddiscardit.

Thoroughlycleantheltermountingsurfaceand

makesurethatanewgasketisinstalledinthenew

lter.

8.Starttheengineandcheckforleaksaroundtheoil

lter.Tightenthelteronlyenoughtoeliminate

leaks.Donotovertighten.

9.Turnofftheengineandallowthemachinetostand

for2minutes.

10.Checktheoilandmakesurethatthelevelisupto

theFULLmarkonthedipstick.Addmoreoilifthe

levelislow;however,donotoverll.

11.Lowerthehoodandsecurethelatches.

GeneralAirCleaner

Maintenance

ServiceInterval:Every200hours

1.Checktheaircleanerbodyfordamagewhichcould

causeanairleak.Replaceifdamaged.Checkthe

wholeintakesystemforleaks,damageorloosehose

clamps.

2.Servicetheaircleanerlterevery200hoursorearlier

ifengineperformancesuffersduetoextremelydusty ,

dirtyconditions.Changingtheairlterbeforeitis

necessaryonlyincreasesthechanceofdirtentering

theenginewhenthelterisremoved.

Figure23

1.Oildrainvalve2.Oillter

6.Applyathinlmofcleanoiltothegasket.Installa

newlterbyhanduntilthegasketjusttouchesthe

mountingsurface,thenturnthelteranadditional

1/2to3/4turn.

7.Removethellercap(Figure24)andpour

approximately2quartsofoilintothellerneck.

3.Besurethecoverisseatedcorrectlyandsealswith

theaircleanerbody.

ServicingtheAirCleaner

Theprimaryaircleanerelementmustbechecked

and/orreplacedafterevery200hoursofengine

operation.However,theaircleanermustbecleaned

morefrequentlyifoperatingconditionsareextremely

dustyorsandy.

1.Releasethelatchessecuringtheaircleanercoverto

theaircleanerbody(Figure25).

27

Page 28

Figure25

1.Aircleanercover2.Latch

Figure27

1.Safetyelement

2.Removethecoverfromtheaircleanerbody.Before

removingthelter(Figure26),uselowpressure

air(40psi,cleananddry)tohelpremovelarge

accumulationsofdebrispackedbetweenoutsideof

primarylterandthecanister.Avoidusinghigh

pressureairwhichcouldforcedirtthroughthelter

intotheintaketract.Thiscleaningprocessprevents

debrisfrommigratingintotheintakewhenthe

primarylterisremoved.

Figure26

1.Primaryelement

3.Removeandreplacetheprimarylter.Cleaningof

theusedelementisnotrecommendedduetothe

possibilityofdamagetotheltermedia.Inspectthe

newlterforshippingdamage,checkingthesealing

endofthelterandthebody.Donotuseadamaged

element.

Important:Donotwashthesafetyelement

orcleanitwithcompressedairasdamagewill

occur.

5.Insertthenewlterbyapplyingpressuretotheouter

rimoftheelementtoseatitinthecanister.Donot

applypressuretotheexiblecenterofthelter.

6.Cleanthedirtejectionportlocatedintheremovable

cover.Removetherubberoutletvalvefromthe

cover,cleanthecavityandreplacetheoutletvalve.

7.Installthecoverorientingtherubberoutletvalvein

adownwardposition-betweenapproximately5:00

to7:00whenviewedfromtheend.

8.Installtheaircleanerandsecurethelatches.

CheckingandReplacingthe

SparkPlugs

ServiceInterval:Every200hoursReplaceasrequired

Sincetheairgapbetweenthecenterandsideelectrodes

increasesgraduallyduringnormalengineoperation,

checkthesparkplugsat200hourintervalsandreplace

asrequired.Thecorrectsparkplugtouseintheengine

isaChampionRC12YCorequivalent.Settheairgap

at.040in.

1.Disengagethehoodlatchesandopenthehood.

2.Cleantheareaaroundthesparkplugs(Figure28)

sothatdirtdoesnotfallintothecylinderwhenthe

plugsareremoved.

4.Inspectthesafetyelement(Figure27)andreplace

itifisdirtyordamaged.

28

Page 29

Figure28

1.Sparkplug

3.Pullthewiresoffofthesparkplugsandremovethe

plugsfromthecylinderhead.

2.Placeadrainpanunderthebottomofthegearcase.

Cleantheareaaroundthedrainplug(Figure29).

Note:Whendrainingtheoil,useafunnelorsome

typeofchanneltodivertthedrainingoilawayfrom

themachinecomponentsandintoadrainpan.

Figure29

1.Drainpluglocation

4.Checktheconditionofthecenterandsideelectrodes

todeterminetheoperatingtemperatureofthe

engine.

•Lightbrowninsulatortipindicatescorrectspark

plugandheatrange.

•Blackoroilyinsulatortipindicatesanexcessively

richfuelmixture,possiblycausedbyadirtyair

cleanerelementoracarburetorthatissettoo

rich.

•Lightgrayorblistered-whiteinsulatorindicates

overheatingcausedbyaleancarburetorsetting

orincorrectsparkplug(heatrangetoohigh).

5.Aftersettingtheairgapat.040in.,installthespark

plugsinthecylinderhead.Tightentheplugsto

18-22ft.-lb.(24-30NVm).Pushthewiresontothe

sparkplugs.

6.Lowerthehoodandsecurethelatches.

ChangingtheGearCaseOil

andFilter

3.Removethedrainplugandallowtheoiltoowinto

adrainpan.Aftertheoilhasdrained,installtheoil

drainplug.

4.Removetheoillter(Figure30),mountedbelow

controlpanelbase,anddiscardthelter.Thoroughly

cleantheltermountingsurfaceandmakesurethat

anewgasketisinstalledinthenewlter.

Figure30

1.Oillter

ServiceInterval:Aftertherst25hours

Every200hours

Changethehydraulicoilandlterinitiallyafter25hours

ofoperation;thereafterchangethemevery200hours

ofoperation.

Important:Thegearcaseoilandltermustbe

changedimmediatelywhenanycontamination,

sludge,waterorcondensationappears.

1.Disengagethehoodlatchesandopenthehood.

5.FillthenewlterwithnewMobilDTE26hydraulic

oilorequivalentoil.Applyathinlmofcleanoil

totheltergasket.

6.Installthenewlterbyhanduntilthegasketjust

touchesthemountingsurface,thenturnitan

additional1/2to3/4turn.

7.Removethellercapandaddapproximately4-5

quartsofMobilDTE26hydraulicoilorequivalent

oiltothegearcasereservoir.Installthellercap.

29

Page 30

8.Checkforleaksaroundtheoillter.Tightenthelter

onlyenoughtoeliminateleaks.Donotovertighten.

9.Lowerthehoodandsecurethelatches.

CheckingtheHydraulicLines

andHoses

ServiceInterval:Beforeeachuseordaily

ChangingthePumpCaseOil

ServiceInterval:Aftertherst25hours

Every200hours

Changethepumpoilinitiallyafter25hoursofoperation;

thereafterchangeitevery200hoursofoperation.

1.Disengagethehoodlatchesandopenthehood.

2.Placeadrainpanunderthepumpcase.Cleanthe

areaaroundthedrainplugonthebottomofthecase

(Figure31).

Note:Whendrainingtheoil,useafunnelorsome

typeofchanneltodivertthedrainingoilawayfrom

themachinecomponentsandintoadrainpan.

Checkthehydrauliclinesandhosesdailyforleaks,kinked

lines,loosemountingsupports,wear,loosettings,

weatherdeterioration,andchemicaldeterioration.Make

allnecessaryrepairsbeforeoperating.

Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjury.

•Makesureallhydraulicuidhosesand

linesareingoodconditionandallhydraulic

connectionsandttingsaretightbefore

applyingpressuretothehydraulicsystem.

•Keepyourbodyandhandsawayfrompin

holeleaksornozzlesthatejecthighpressure

hydraulicuid.

•Usecardboardorpapertondhydraulic

leaks.

•Safelyrelieveallpressureinthehydraulic

systembeforeperforminganyworkonthe

hydraulicsystem.

Figure31

1.Drainpluglocation

3.Removethedrainplugandallowoiltoowintoa

drainpan.Aftertheoilhasdrained,installtheoil

drainplug.

4.Removethedipstick/llercapandadd

approximately40ouncesofMobilDTEExtra

Heavyoilorequivalenttothepumpcase.Installthe

llercap.

5.Checktheoillevel.Iftheuidlevelislow ,add

enoughMobilDTEExtraHeavyoilorequivalentto

bringtheoiluptotheproperlevel.Donotoverll.

6.Checkforpossibleleaks.Lowerthehoodandsecure

thelatches.

•Getimmediatemedicalhelpifuidis

injectedintoskin.

AdjustingtheTractionPump

Belt

Makesurethatthetractionpumpbeltisproperly

tensionedtoensurecorrectoperationoftheunitand

unnecessarywear.Checkthebeltmidwayinthespan

ofthebelt.

1.Disengagethehoodlatchesandopenthehood.

2.Checkthebelttensionbydepressingthebeltmidway

betweenthepulleyswith3lb.offorce.Thebelt

shoulddeect9/64in.(Figure32).

30

Page 31

Figure32

1.Tractionpumpbelt

3.Ifanadjustmentisnecessary,proceedasfollows:

A.Loosenthepivotnutsecuringthepumpmount

tothepumpsupport(Figure33).

AdjustingtheTransmission

forNeutral

Ifthemachinemoveswhentheleverisreleased,an

adjustmenttothetransmissionneutralisrequired.

1.Parkthemachineonalevelsurface,stoptheengine,

andopenthehood.

2.Liftthedrivewheeloffofthegroundusingajack.

Blockthefrontandrearofthewheels.

3.Starttheengineandreleasetheparkingbrake.

4.Slightlyloosenthelocknutonthetopoftheneutral

adjustmentcam(Figure34)androtatethecamhex

untilthetractionwheelstopsrotating.Tightenthe

locknut.

Figure33

1.Pump3.Adjustingnut

2.Pivotnut

B.Loosentheadjustingnutsecuringthepump

andpumpmounttotheslottedpumpsupport

(Figure33).

C.Loosenthe3capscrewssecuringthepulleyguard

brackettothecontrolpanelandpumpsupport.

D.Useaprybartopullthepumptowardtheoutside

ofthemachineuntiltheproperbelttensionis

attained;thentightentheadjustingnutsecuring

thepumpandpumpmounttothepumpsupport

(Figure33).

E.Tightenthepivotnutsecuringthepumpmount

tothepumpsupport(Figure33).

F.Tightenthe3capscrewssecuringthepulleyguard

brackettothecontrolpanelandpumpsupport.

Figure34

1.Neutraladjustmentcam

2.Locknut

3.Switchtab

5.Movethetractionbailcompletelyupanddown.

Releasethehandleandcheckforwheelrotation.If

thewheelcontinuesrotating,repeatstep4.

6.Iftheproblemcontinues,stoptheengine,check

thelinkageforbindingordamage,thendothe

adjustmentprocedureagain.

7.Settheholespacingcontrolinthelowestsetting(to

theleft)andmovethetransport/aerateswitchtothe

aerateposition(transporttiresretracted).Loosen

the2screwsandadjusttheswitchtab(Figure34)

sothattheswitchesareactuatedwhenthepump

controlisinneutralandnotactuatedwhenthepump

isstroked.

8.MovetheignitionswitchtotheONposition,butdo

notstarttheengine.Movethetractionbailinboth

directions;theredtractionlightshouldcomeon.

Repeatstep7ifthelightdoesnotcomeonwhenthe

bailismovedinbothdirections.Thesecondlimit

switchmustsimultaneouslyactivatewhenthered

tractionlightisOFF .Thisswitchenablestheengine

startcircuit.

31

Page 32

AdjustingtheAerationSpeed

AdjustingtheParkingBrake

1.Parkthemachineonalevelsurface,stoptheengine,

andopenthehood.

2.Putthespeedcontrollever(Figure35)intothe

secondslotfromtheleft(whilefacingthecontrol

panel).

Figure35

1.Speedcontrollever

2.Lowercontrolrod

3.Uppercontrolrod

ServiceInterval:Every400hours

1.Removethescrewssecuringthecovertothe

undersideofthehandle(Figure36).Removethe

cover.

Figure36

1.Cover

2.Handle

2.Loosentheupperjamnutsecuringthebrakecable

tothebracket(Figure37).

3.Lowerthemachineintoaeratemodesothatthe

transportwheelsareoffoftheground.

4.Liftthedrivewheeloffofthegroundusingajack.

5.Starttheengineandreleasetheparkingbrake.

6.Operatetheengineatfullspeed.

7.MovethetractionhandleUPtofullspeed.

8.LoosenthejamnutsandadjusttheLOWERspeed

rod(Figure35)untilthetractionwheelrotatesat

20-22RPM.Tightenthejamnuts.

9.MovethetractionhandleDOWNtothefullspeed

position.

10.AdjusttheUPPERspeedrod(Figure35)untilthe

tractionwheelrotatesat20-22RPM.Tightenthe

jamnuts.

Figure37

1.Brakecable

3.Tightenthelowerjamnutuntil25to30poundsof

forcearerequiredtoactuatethebrakelever.Tighten

thejamnut.

4.Installthecovertotheundersideofthehandle.

32

Page 33

AdjustingtheRollerSpray

WashSystem

2.Removethenozzleandstrainerassembly(Figure39).

Cleanorreplacethestrainerandreplaceitinthe

nozzle.

Ifthespraywashsystem(Figure38)ontherollersneeds

tobeadjusted,proceedasfollows:

Figure38

1.Rollerspraywashsystem

1.Loosenthecaponthebottomofthetting

(Figure39).

2.Rotatethenozzlesothattheslotinthetipisparallel

totheroller.

3.Tightenthecapandchecktheadjustment.

3.Looselysecurethenozzleandstrainertothetting

withthecap.

4.Rotatethenozzlesothattheslotinthetipisparallel

totheroller.

5.Tightenthecapandchecktheadjustment.

CaringfortheBattery

Iftheaeratorisstoredinalocationwheretemperatures

areextremelyhigh,thebatterywillrundownmore

rapidlythanifthemachineisstoredinalocationwhere

temperaturesarecool.

Keepthetopofthebatterycleanbywashingit

periodicallywithabrushdippedinammoniaor

bicarbonateofsodasolution.Flushthetopsurfacewith

wateraftercleaning.Donotremovethellcapswhile

cleaning.

Thebatterycablesmustbetightontheterminalsto

providegoodelectricalcontact.

Ifcorrosionoccursattheterminals,disconnectthe

cables,negative(-)cablerst,andscrapetheclampsand

terminalsseparately.Reconnectthecables,positivecable

rst,andcoattheterminalswithpetroleumjelly .

Figure39

1.Fittingcap

2.Nozzle5.Hexnut

3.Fitting

4.Strainer

ServicingtheSprayWash

NozzlesorStrainers

Tocleanorreplacethestrainersinthespraywash

nozzles,proceedasfollows:

1.Loosenandremovethecaponthebottomofthe

tting(Figure39).

Incorrectbatterycableroutingcoulddamage

theaeratorandcablescausingsparks.Sparks

cancausethebatterygassestoexplode,

resultinginpersonalinjury.

•Always

batterycablebeforedisconnectingthe

positive(red)cable.

•Always

cablebeforeconnectingthenegative(black)

cable.

Ifthemachinewillbestoredmorethan30days,remove

thebatteryandplaceitontricklecharge.Eitherstore

itontheshelforonthemachine.Leavethecables

disconnectedifitisstoredonthemachine.Storethe

batteryinacoolatmospheretoavoidquickdeterioration

ofthechargeinthebattery.

disconnect

connect

thenegative(black)

thepositive(red)battery

33

Page 34

Storage

PreparingtheWaterSystem

Note:Itisveryimportantthatthewatersystembe

drainedtoavoidfreezinganddamagingthecomponents.

Drainsystemasfollows:

1.Stoptheengine,removethekeyfromtheignition

switch,andremovethewiresfromthesparkplugs.

2.Removethe2screwssecuringthedriveshieldtothe

frameandremovetheshield.

3.WiththeengineOFFandthekeyremovedfrom

ignition,rotatethedrivecouplingbyhanduntil

resistanceisfelt.Continuetorotatethecoupling

about1/4revolution,openingthecyclingvalve.

4.Usingtheappropriatereducers(NationalPipe

thread),connectasourceofcompressedair

(maximumpressure150psi;minimumpressure90

psi)tothewaterinletsoneithersideofthemachine.

5.Stoptheengine;removethesparkplugs.

6.Pouroneounceofcleanengineoilintothespark

plugholes

7.Withthesparkplugsremoved,cranktheenginewith

thestarterforaleast12revolutionstodistributeoil

inthecylinders.

8.Installthesparkplugs.

9.Drainthegasolinefromthefueltankandfuellines.

Reinstallalllinesandsecureallconnections.

10.Thoroughlycleanandservicetheaircleaner.

11.Checktheoilllercapandfueltankcaptoensure

thattheyaresecurelyinplace.

PreparingtheTractionUnit

1.Thoroughlycleanthemachine.

2.Greaseoroilallttingsandpivotpoints.

3.Checktomakesurethatalltiresareover-inatedto

20-30p.s.i.

Compressedaircanpenetratetheskinand

causephysicalharm.

•Useextremecautionandwearprotective

gogglesandgloveswhenworkingwithhigh

pressureair.

•Getpromptmedicalattentionifaninjury

occurs.

5.Letcompressedairowthroughthemachine

for3minutes.Whilecompressedairisowing,

temporarilyopenthespraywashandhighpressure

drainvalve,purgingwaterfromthespraywashand

highpressuresystem.

6.Disconnectcompressedairandreducers.Installthe

driveshieldpreviouslyremovedandtightentherelief

valvetube.

7.Removeanddrainthewaterltercontainer.Installa

newlterandreplacetheltercontainer.

4.Lightlysandandusetouchuppaintonallareasthat

arescratched,chipped,orrusted.

5.Drainandreplacethehydraulicoilandlteronthe

camgearcase.

6.Drainandreplacetheoilinthewaterpumpcase.

7.Cleanthebattery,terminals,andpostswithawire

brushandbakingsodasolution.Coatthecable

terminalsandbatterypostswithskinovergreaseor

petroleumjelly.Rechargethebattery.

PreparingtheEngine

1.Draintheengineoilfromthecrankcase.

2.Removeanddiscardtheoillter.Installanewlter.

3.Relltheenginewith2qts.ofrecommendedmotor

oil.

4.Starttheengineandrunitatidlespeedfortwo

minutes.Donotrunitforlongerthantwominutes.

34

Page 35

Troubleshooting

Problem

Theunitwillnotmovewhenthetraction

ballisengaged.

Theunitwillnottransportatfullspeed.

Theenginediesduringstartup.

PossibleCauseCorrectiveAction

1.Checkthatmotionoccursatthepump

pivotplatewhenthetractionballis

moved.

2.Theoillevelinthehydraulicreservoir

(gearbox)islow.

3.Bypassvalveisnotfullyclosed.3.Closethevalve.

4.Thetractiondrivebelttensionis

incorrect.

1.Theunitisnotfullyraisedtothe

transportposition.

2.Theoillevelinthehydraulicreservoir

(gearbox)islow.

3.Bypassvalveisnotfullyclosed.3.Closethevalve.

4.Thetractiondrivebelttensionis

incorrect.

5.Checkthatmotionoccursatthepump

pivotplatewhenthetractionballis

moved.

1.Thefuelshut-offvalveisclosed.1.Openthefuelshut-offvalve.

2.Fuelinthefueltankislow .2.Replenish,ifnecessary.

3.Theenginechokeisnotoperating

correctly.

4.Checktheengineoillevel.

5.Startingconditionsarecold(30

degrees).

1.Inspectthetractionpush/pullcable

andoverrideassemblyunderthetiller

handle.

2.Replenish,ifnecessary.

4.Adjustthebelttension.

1.Holdthelifttoggleswitchuntiltheslip

clutchintheactuatorcanbeheard

ratchetingandthespindleliftarmsare

nearlyverticalwiththerearaxlespindle

tippedawayfromtheengine.

2.Replenish,asnecessary.

4.Adjustthebelttension.

5.Inspectthetractionpush/pullcable

andoverrideassemblyunderthetiller

handle.

3.Checkthechokeconnectionsand

operation.Regulatethechokeuntilthe

engineiswarmwhenstartingacold

engine.

4.Theoilpressureswitchisbypassed

duringstart,butmustactivatetoprotect

theenginewhilerunning.

5.Multiplestartattemptsmayberequired

totriptheoilpressureswitch.

Theenginedieswhenthewatersystem

isengaged.

Theenginedoesnotstart(willnotengage

thestarter).

1.Thethrottleisinthewrongoperating

position.

2.Theenginespeedissetincorrectly.

3.Enginepowerislow .3.Fueliscontaminated,thereis

1.Thetractionbailisnotintheneutral

position.

2.Theneutralswitchtabisoutof

adjustment.

3.Thebatteryvoltageislow.

4.Thereisamalfunctionistheelectrical

system.

1.PutthethrottleintheFASTposition

whenaerating.

2.Adjustthecarburetorfastsettingto

3450-3550RPM.

apluggedfuellterorairlter,

orthereisabadsparkplug.

Havethesystemservicedbyan

AuthorizedT oroDistributor .

1.Correctthetractionbailposition.

2.Adjusttheswitchtabuntilthered

tractionlightisOFFinneutral.

3.Checkthebattery.

4.Checkthecircuitbreakerandelectrical

connections.

35

Page 36

Problem

PossibleCauseCorrectiveAction

Theengineisrunningandtheunitisnot

producingaerationholes(thepumpor

watervalvewillnotstart).

Theunitstopsaeratinginonedirectionor

stopsaeratinginthelowestholespacing.

1.Thesupplyhoseiskinked,thereisa

restrictionintheline,orthevalveatthe

watersourceisonlypartiallyopened.

2.Thereisinadequatewaterpressureor

owfromthesource.

3.Checkthewaterpressureatthegauge

whenthepumpisengagedifthewater

pressuredropstolessthan25psi,but

wasinitiallyhigher.

4.Lowaccumulatorpre-chargepressure

(lowpressureindicatorlightison).

5.Highaccumulatorpre-chargepressure

(highpressureindicatorlightison).

1.Thesupplyhoseiskinked,thereisa

restrictionintheline,orthevalveatthe

watersourceisonlypartiallyopened.

2.Thereisinadequatewaterpressureor

owfromthesource.

3.Checkthewaterpressureatthegauge

whenthepumpisengagedifthewater

pressuredropstolessthan25psi,but

wasinitiallyhigher.

4.Theneutralswitchtabisoutof

adjustment.

1.Correctthecondition.

2.Checkthewaterpressure(fromthe

watersource)attheinlet(8gpm-40

psi).

3.Replacethewaterlter.

4.Havethesystemservicedbyan

AuthorizedT oroDistributor .

5.Havethesystemservicedbyan

AuthorizedT oroDistributor .

1.Correctthecondition.

2.Checkthewaterpressure(fromthe

watersource)attheinlet(8gpm-40

psi).

3.Replacethewaterlter.

4.Adjusttheswitchtabuntilthered

tractionlightisONwhilethetraction

bailisactuatedinbothdirections.

TheredtractionlightmustbeOFF,

wheninneutral,toallowtheengine

startinterlocktofunction.

Theunitisnotproducingaerationholes

(thepumpandvalveareoperating

correctly).

Theunitisnotproducingaerationholes

(theinjectionpumpstopsaftertheunit

stopsmoving).

Theholesareshallowortheimproper

depth.

1.Thereisairinthesystem.

2.Anozzle(s)isplugged.

3.Thesoilcompositionishard.

1.Thisisanormalconditionoftheneutral

interlocksystem.

1.Thereisairinthesystem.

2.Iftheholedepthwassatisfactory

earlier,checkthedensityandmoisture

contentofthesoil.

3.Thesoilcompositionishard.

4.Therearetoomanylargenozzles,

causingalossinpressurewhichcould

damagetheaccumulatororotherwater

systemcomponents.

1.Openthemainbleedvalvetopurgeair

fromthesystem.

2.Inspectthenozzles.

3.

Adifferentnozzleconguration

mayberequired.Havethewater

systemcheckedbyanAuthorizedT oro

Distributor.

1.TheoperatormustholdtheEngage

(start)buttontoaeratewithoutmoving.

1.Openthemainbleedvalvetopurgeair

fromthesystem.

2.Adifferentnozzlecongurationmaybe

required.

3.Adifferentnozzlecongurationmaybe

required.

4.Openthebleedvalveandexaminethe

nozzles.Verifythesizeandquantity

pertherecommendationchart.Have

thewatersystemcheckedbyan

AuthorizedT oroDistributor .

36

Page 37

Problem

PossibleCauseCorrectiveAction

Thewaterinjectionsystemismakingan

unusualnoisewhenaerating

1.Thereisairinthesystem.1.Withthewatersupplyon,

2.Anozzleismissingortherearetoo

manylargenozzleinstalled.

3.Therearebrokenspringsinthenozzle

extensioncheckvalve.

4.Thegearboxdriveshaftorcouplers

areworn.

openthebleedvalveunderthe

accumulator/valvebody.Ifmechanical

noisecontinuesduringaeration,stop

theunitandhaveitservicedbyan

AuthorizedT oroDistributor .

2.Openthebleedvalveandexaminethe

nozzles.Verifythesizeandquantity

pertherecommendationchart.

3.Replacethespringsandinspectthe

ballandseat.

4.Removethedriveshaftguardand

repairorreplaceasnecessary .

37

Page 38

Schematics

HydraulicSchematic(Rev.-)

38

Page 39

ElectricalSchematic(Rev.-)

39

Page 40

ElectricalSchematic(Rev.-)

40

Page 41

WaterSystemSchematic(Rev .-)

41

Page 42

Notes:

42

Page 43

Notes:

43

Page 44

Toro Commercial Aerator Products Warranty

A Two-Year Limited Warranty

Conditions and Products Covered

The Toro Company and its affi liate, Toro Warranty Company,

pursuant to an agreement between them, jointly warrant your Toro

Hydroject or ProCore Aerator (“Product”) to be free from defects in

materials or workmanship for two years or 500 operational hours*,

whichever occurs fi rst. Where a warrantable condition exists, we

will repair the Product at no cost to you including diagnosis, labor,

parts, and transportation. This warranty begins on the date the