Page 1

Hydroject) 3000

Aerator

Model No. 09801—210000001 and Up

Form No. 3325-801 Rev. A

Operator’s Manual

Domestic English (EN)

Page 2

Warning

The engine exhaust from this product contains

chemicals known to the State of California to cause

cancer, birth defects, or other reproductive harm.

This spark ignition system complies with Canadian

ICES-002.

Ce système d’allumage par étincelle de véhicule est

conforme à la norme NMB-002 du Canada.

Contents

Introduction 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Before Operating 3. . . . . . . . . . . . . . . . . . . . . . . . . .

While Operating 3. . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety and Instruction Decals 5. . . . . . . . . . . . . . . . .

Specifications 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Specifications 7. . . . . . . . . . . . . . . . . . . . .

Controls 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Water Injection System 8. . . . . . . . . . . . . . . . . . . . .

Dimensions 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Depths and Nozzle Configurations 9. . . . . . . . . . . .

Fluid Recommendations 10. . . . . . . . . . . . . . . . . . . . .

Setup 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Loose Parts 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing the Rear Wheels 11. . . . . . . . . . . . . . . . . . .

Before Operating 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Activating and Charging the Battery 12. . . . . . . . . . .

Checking the Engine Oil 13. . . . . . . . . . . . . . . . . . . .

Filling the Gas Tank 13. . . . . . . . . . . . . . . . . . . . . . . .

Checking the Gear Case Fluid Level 14. . . . . . . . . . .

Checking the Pump Case Fluid Level 14. . . . . . . . . .

Checking the Tire Pressure 15. . . . . . . . . . . . . . . . . .

Water System Accumulator 15. . . . . . . . . . . . . . . . . .

Operation 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Controls 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Precautions 17. . . . . . . . . . . . . . . . . . . . . .

Starting and Stopping the Engine 17. . . . . . . . . . . . . .

Training Period 17. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Procedure 17. . . . . . . . . . . . . . . . . . . . . . .

Checking the Interlock System 19. . . . . . . . . . . . . . .

Transport Operation 19. . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Clean-Up After Use 19. . . . . . . . . . . .

Pushing or Towing the Machine 20. . . . . . . . . . . . . .

Page

Page

Maintenance 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Recommended Maintenance Schedule 21. . . . . . . . .

Daily Maintenance Checklist 22. . . . . . . . . . . . . . . . .

Lubricating the Machine 23. . . . . . . . . . . . . . . . . . . .

Servicing the Pre-Filter 24. . . . . . . . . . . . . . . . . . . . .

Replacing the Main Water Filter 24. . . . . . . . . . . . . .

Changing the Engine Oil and Filter 25. . . . . . . . . . . .

Servicing the Air Cleaner 26. . . . . . . . . . . . . . . . . . . .

Adjusting the Carburetor 26. . . . . . . . . . . . . . . . . . . .

Checking and Replacing the Spark Plugs 27. . . . . . .

Cleaning the Cylinder Head Fins 28. . . . . . . . . . . . . .

Changing the Gear Case Oil and Filter 28. . . . . . . . .

Changing the Pump Case Oil 28. . . . . . . . . . . . . . . . .

Checking the Hydraulic Lines and Hoses 29. . . . . . .

Adjusting the Traction Pump Belt 29. . . . . . . . . . . . .

Adjusting the Transmission for Neutral 30

Adjusting the Aeration Speed 30. . . . . . . . . . . . . . . .

Adjusting the Parking Brake 31. . . . . . . . . . . . . . . . .

Adjusting the Roller Spray Wash System 31. . . . . . .

Servicing the Spray Wash Nozzles or Strainers 32. . .

Caring for the Battery 32. . . . . . . . . . . . . . . . . . . . . .

Electrical Schematic 33. . . . . . . . . . . . . . . . . . . . . . . .

Water System Schematic 34. . . . . . . . . . . . . . . . . . . .

Hydraulic Schematic 34. . . . . . . . . . . . . . . . . . . . . . .

Seasonal Storage 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preparing the Water System 35. . . . . . . . . . . . . . . . . .

Preparing the Engine 35. . . . . . . . . . . . . . . . . . . . . . .

Preparing the Traction Unit 35. . . . . . . . . . . . . . . . . .

Troubleshooting 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The Toro Aerator Commercial Products Warranty 40. . .

. . . . . . . . .

Introduction

Read this manual carefully to learn how to operate and

maintain your product properly. The information in this

manual can help you and others avoid injury and product

damage. Although Toro designs and produces safe

products, you are responsible for operating the product

properly and safely.

Whenever you need service, genuine Toro parts, or

additional information, contact an Authorized Service

Dealer or Toro Customer Service and have the model and

serial numbers of your product ready. The model and serial

numbers are stamped on a plate which is riveted to the

frame.

W 2001 by The Toro Company

8111 Lyndale Avenue South

Bloomington, MN 55420-1196

All Rights Reserved

Printed in the USA

2

Page 3

Write the product model and serial numbers in the space

below:

Model No.

• Before attempting to start the engine, engage the

parking brake.

• Remove all debris or other objects that might interfere

with operation. Keep all bystanders away from the work

area.

Serial No.

This manual identifies potential hazards and has special

safety messages that help you and others avoid personal

injury and even death. Danger, Warning, and Caution are

signal words used to identify the level of hazard. However,

regardless of the hazard, be extremely careful.

Danger signals an extreme hazard that will cause serious

injury or death if you do not follow the recommended

precautions.

Warning signals a hazard that may cause serious injury or

death if you do not follow the recommended precautions.

Caution signals a hazard that may cause minor or moderate

injury if you do not follow the recommended precautions.

This manual uses two other words to highlight information.

Important calls attention to special mechanical

information and Note: emphasizes general information

worthy of special attention.

Safety

Hazard control and accident prevention are dependent upon

the awareness, concern, and proper training of the

personnel involved in the operation, transport,

maintenance, and storage of the machine. Improper use or

maintenance of the machine can result in injury or death.

To reduce the potential for injury or death, comply with the

following safety instructions.

• Keep all shields and safety devices in place. If a shield,

safety device, or decal is damaged, repair or replace it

before operation is commenced. Also tighten any loose

nuts, bolts, and screws to ensure that the machine is in

safe operating condition.

• Do not operate machine while wearing sandals, tennis

shoes, sneakers, or shorts. Also, do not wear loose

fitting clothing which could get caught in moving parts.

Always wear long pants and substantial shoes. Wearing

safety glasses, safety shoes, ear protection, and a helmet

is advisable and required by some local ordinances and

insurance regulations.

• Fill the fuel tank with gasoline before starting the

engine. Avoid spilling gasoline. Since gasoline is

flammable, handle it carefully.

– Use an approved gasoline container.

– Do not fill the tank while the engine is hot or

running.

– Do not smoke while handling gasoline.

– Fill the fuel tank outdoors and up to about one in.

(25 mm) from the top of the tank, not the filler neck.

– Wipe up any spilled gasoline.

• Check the interlock switches daily for proper operation.

If a switch fails, replace it before operating the

machine. The interlock system is for your protection, so

do not bypass it. Replace all interlock switches every

two years.

Before Operating

• Read and understand the contents of this Operator’s

Manual before operating the machine. Become familiar

with all of the controls and know how to stop quickly. A

free replacement manual is available by sending your

complete Model and Serial Number to:

The Toro Company

8111 Lyndale Avenue South

Bloomington, Minnesota 55420

• Never allow children to operate the machine. Do not

allow adults to operate the machine without proper

instruction. Only trained operators who have read this

manual should operate this machine.

• Never operate the machine when under the influence of

drugs or alcohol.

While Operating

• Do not take an injury risk! When a person or pet

appears unexpectedly in or near the working area, stop

aerating.

• Keep hands and feet away from the nozzle and roller

area. High velocity water jets can penetrate hands and

feet. Penetration by the high velocity water jets can

cause serious personal injury. If accidental penetration

occurs, seek medical attention immediately.

• Never use chemicals in the water supply system.

• Do not operate the water injection system on concrete

or asphalt because water jets will permanently damage

these surfaces.

• Start the engine with the parking brake engaged.

3

Page 4

• Do not run the engine in a confined area without

adequate ventilation. Exhaust fumes are hazardous and

could possibly be deadly.

• Using the machine demands attention. To prevent loss

of control:

– Use only in daylight or when there is good artificial

light.

– Watch for holes or other hidden hazards.

– Do not transport machine close to a sand trap, ditch,

creek, or other hazard.

• If the machine starts to vibrate abnormally, shut the

engine off. Remove the wires from the spark plugs to

prevent possibility of accidental starting. Check the

machine for damaged parts. Repair any damage before

restarting the engine and operating the machine.

search for leaks. Hydraulic fluid or water escaping

under pressure can have sufficient force to penetrate

skin and do serious damage. If either of these fluids are

injected into the skin they must be surgically removed

within a few hours by a doctor familiar with this form

of injury or gangrene may result.

• Before disconnecting or performing any work on the

hydraulic oil system, all pressure in the system must be

relieved by stopping the engine and opening the bypass

valve.

• Before disconnecting or performing any work on the

water system, all pressure in the system must be

relieved by stopping the engine and opening the bleed

valve. Opening the bleed valve allows any trapped

water to escape from the system and also allows the

accumulator piston to move to the bottom of the

accumulator cylinder.

• Do not touch the engine or muffler while the engine is

running or soon after it is stopped. These areas could be

hot enough to cause a burn.

• Before leaving the operator’s position (behind the

handle), engage the parking brake.

• When leaving the machine unattended, engage the

parking brake, shut the engine OFF, and remove the key

from the ignition switch.

Maintenance

• Disconnect the wires from the spark plugs to prevent

accidental starting of the engine when servicing,

adjusting, or storing the machine.

• If the machine must be tipped to perform maintenance

or an adjustment, close the fuel shut-off valve, drain the

gasoline from the fuel tank, the oil from the crankcase,

and remove the battery.

• To reduce the potential for a fire hazard, keep the

engine free of excessive grease, grass, leaves, and

accumulation of dirt.

• Be sure that the machine is in safe operating condition

by keeping nuts, bolts, and screws tight. Check all bolts

and nuts frequently to be sure that they are tightened to

specification.

• If the engine must be running to perform a maintenance

adjustment, keep hands, feet, clothing, and other parts

of the body away from any moving parts.

• Make sure that all hydraulic line connectors are tight

and all hydraulic hoses and lines are in good condition

before applying pressure to the system.

• The accumulator in this machine contains high pressure

dry nitrogen. Accumulator servicing requires special

tools and precautions. Accumulators do not contain user

serviceable components. Improper accumulator

servicing can cause dismemberment or death. Do not

attempt to disassemble a accumulator; have this work

done by an Authorized Toro Distributor.

• Do not overspeed the engine by changing the governor

settings. To be sure of safety and accuracy, have an

Authorized Toro Distributor check the maximum engine

speed with a tachometer.

• The engine must be shut off before checking the oil or

adding oil to the crankcase.

• Allow the engine to cool before storing the machine in

any enclosure such as a garage or storage shed. Make

sure that the fuel tank is empty if the machine is to be

stored in excess of 30 days. Do not store the machine

near any open flame or where gasoline fumes may be

ignited by a spark. Always store gasoline in a safety

approved, red metal container.

• When storing or transporting the machine (trailering),

make sure that the fuel shut-off valve is closed.

• Perform only those maintenance instructions described

in this manual. If major repairs are ever needed or

assistance is desired, contact an Authorized Toro

Distributor. To ensure optimum performance and safety,

always purchase genuine Toro replacement parts and

accessories. Never use “will-fit” replacement parts

and accessories made by other manufacturers. Look for

the Toro logo to ensure genuineness. Using unapproved

replacement parts and accessories could void the

warranty.

• Keep your body and hands away from pin hole leaks or

nozzles that eject water or hydraulic fluid under high

pressure. Use paper or cardboard, not your hands, to

4

Page 5

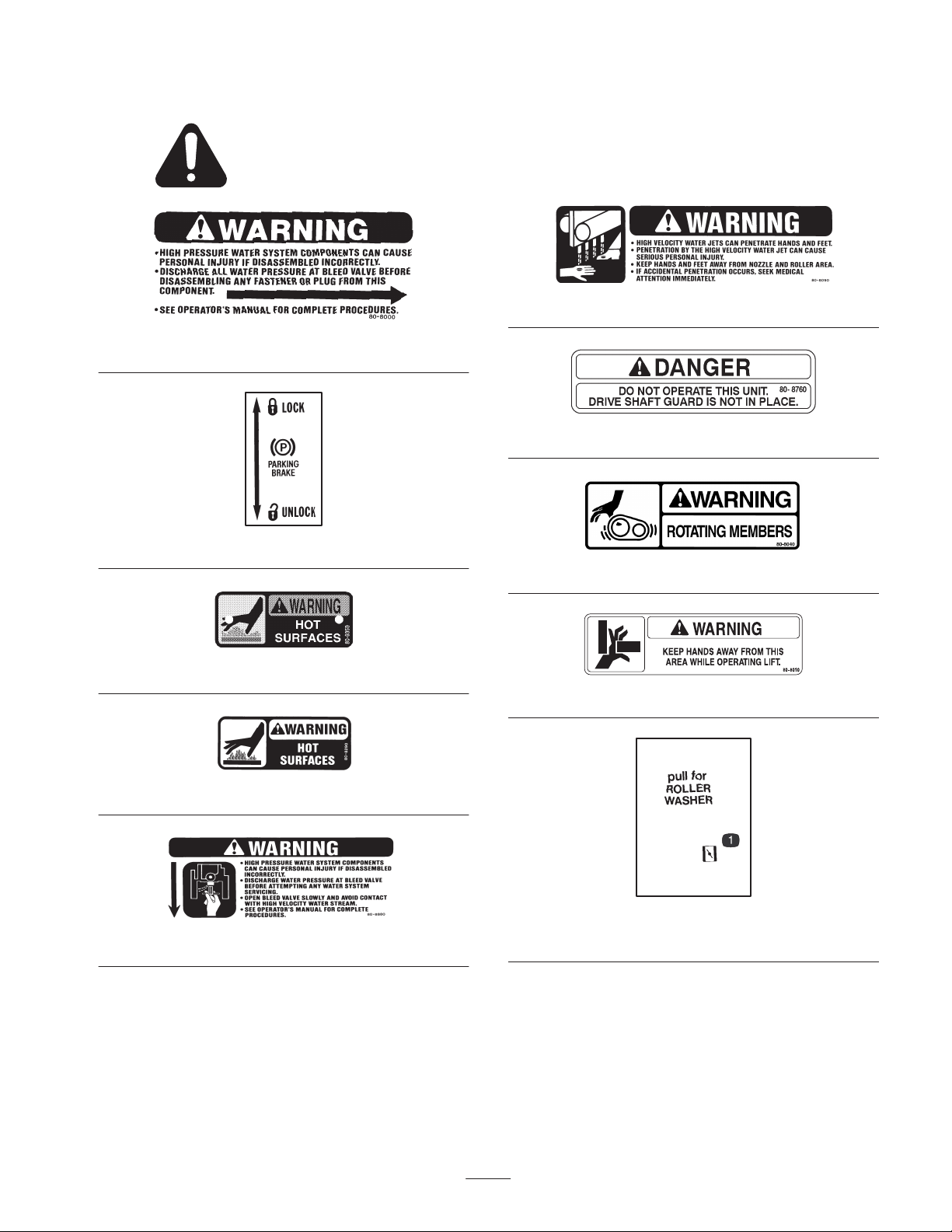

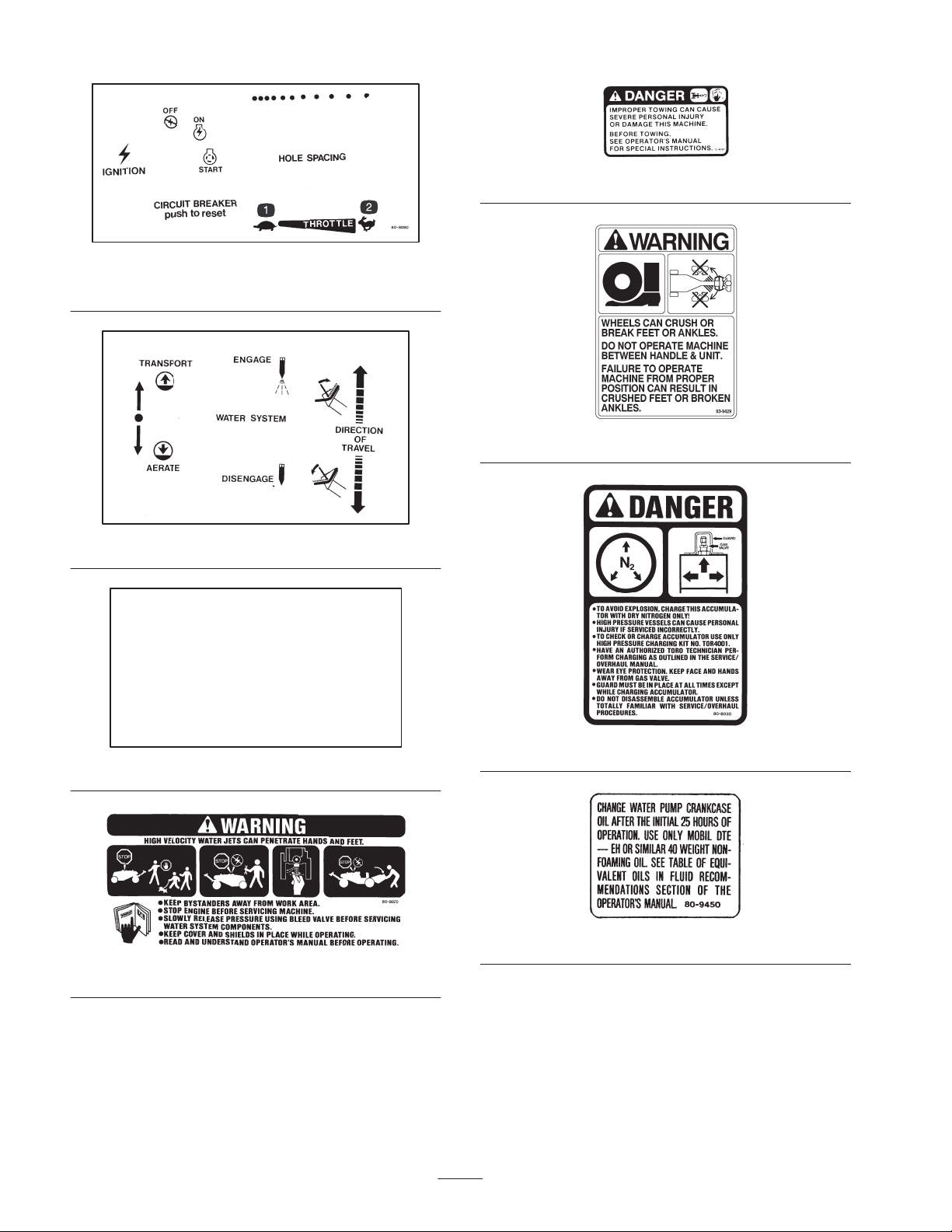

Safety and Instruction Decals

Safety decals and instructions are easily visible to the operator and are located near any area

of potential danger. Replace any decal that is damaged or lost.

80-8000

80-8070

80-8090

80-8760

80-8040

80-9350

80-8290

80-8880

80-8010

80-8150 (Replace control panel)

1. Choke

5

Page 6

80-8110 (Replace control panel)

1. Slow throttle 2. Fast throttle

80-9240

72-4080

93-9429

THE FIVE MICRON FILTER ELEMENT (86-8620) MUST

IMPORTANT

D

BE IN PLACE AT ALL TIMES.

OPERATION WITHOUT PROPER FILTRATION WILL

D

RESULT IN PREMATURE WEAR AND FAILURE OF THE

WATER SYSTEM COMPONENTS.

USE OF ADDITIONAL FILTRATION OR POTABLE WATER

D

MAY BE NECESSARY TO PROLONG THE LIFE OF THE

FILTRATION SYSTEM.

SEE OPERATOR'S MANUAL FOR MORE INFORMATION.D

92-9542

80-8020

80-8030

80-9450

6

Page 7

Specifications

Note: Specifications and design subject to change without notice.

General Specifications

Onan, 4 cycle, opposed twin, air cooled, 24 hp @ 3600 RPM, 60 cu. in (983 cc)

Engine

displacement. Electric start. Heavy duty valve package. Extended service air

cleaner. 3 quart oil capacity. Solid state ignition. Meets California Exhaust Emission

Standard for 1995 Lawn and Garden Equipment.

Clutches

Electrical

Traction Drive

Tires/Wheels

Brake

Transport Lift

Fuel Capacity 10.5 gallons gasoline

Ground Speed

Aeration Width 33 inches with 11 nozzles on 3 inch centers

Aeration Depth 4 to 6 inches depending on turf conditions and nozzle configuration

Hole Pattern

Electromagnetic, dual groove belt drive for water pump and driveshaft flange

brake/clutch for main valve gearbox.

12 volt system with 20 amp circuit breaker protection. Relays for all high current

switching. Electronic controller and sensors for automatic startup and shutdown

sequence of water injection system. Group 28 battery with 525 cold crank amps.

Closed loop hydrostatic drive consisting of Sundstrand variable volume pump and

Parker low speed, high torque wheel motor mounted to steering fork. Hydraulic

system contains 5 quarts with 25 micron suction line filter and gearbox reservoir.

Three, smooth tread 2 ply, 18 x 9.50-8,pneumatic tubeless, tires. Demountable

drop center steel wheels with 4 lug nuts mounted to tapered roller bearing hubs on

transport arms and brake hub on wheel motor. All are interchangeable.

Drum and shoe-type parking brake mounted to wheel motor. Holds unit on a 30%

grade.

12 volt Warner Electric linear screw actuator with 6 inch stroke. Raises and lowers

lift arm/transport tires and activates hole spacing control.

Aerating: 0–2 MPH (both directions)

Transport: 0–4 MPH (both directions)

Variable from 1-1/2 to 6 in. spacing in the direction of travel, and 3 or 6 in.

increments in width

Controls

Engine Panel

Steering Tiller Panel

Electronic Control Module

Throttle, choke, spray wash control, hour meter, water pressure gauge, spacing

control lever, key switch, and circuit breaker reset button

Traction bail, water system engage and disengage buttons, transport/aerate lift

toggle switch, and parking brake with buzzer alarm.

Solid state potted device for sequencing start and stop of water system. Interlocks

for water pressure, transport lift, and traction neutral.

7

Page 8

Water Injection System

Pre-Filter

Supply Filter Replaceable cartridge in plastic housing with air bleed button.

Water Pressure Switch

Pump

Accumulator

Cam and Gearbox

Valve

Rollers

Spin down type with washable cartridge in clear plastic housing and plastic ball

valve for flushing.

Senses for water pressure after filter and turns on when pressure is over 20–28 psi

and turns off when pressure drops below 7–13 psi.

Pump is a Toro exclusive design (patent pending) with cast stainless steel head

and 3 piston plungers. Vee packing seals and Kevlar guides. Forged crankshaft

with plasma sprayed ceramic on stainless steel plungers and cast iron connecting

rods. Nominal performance is 4 gpm @ 5000 psi with 1400 RPM input.

Toro exclusive design with low charge pressure sensor, nitrogen gas charged to a

maximum of 2500psi.

Reduction gear drive for cam that actuates main water valve. Roller cam follower

rides on cam specifically designed (patent pending) to control water injection at 5.3

cycles per second (320 RPM) and store energy in accumulator between injections.

Cast iron case also serves as 4 quart hydraulic reservoir.

Cast stainless steel valve body functions as mounting base for accumulator,

gearbox, and manifold outlet. All high pressure water flows in and out through the

valve body. Pressure balanced valve spool with floating (patent pending), hardened

stainless seat aligns during assembly. Bleed valve in base allows for bleed-off of

high pressure and drain down for cold weather storage. Bolted flanges and

polyurethane o-rings mate all components to valve body.

Pivoting aluminum rollers uniformly smooth the turf and provide protection from the

nozzle discharge. Adjustable flow (0–3 gpm) spray wash system with 6 flood tip

nozzles maintain clean rollers.

Pressure Relief Valve

Manifold and Nozzles

Circle Seal Controls poppet-type valve preset to 5000 psi with corrosion resistant

stainless and brass materials.

Extruded stainless steel manifold with 11 flanged nozzle extensions containing

check valves and hardened stainless discharge orifice. Check valves may be

reversed in housing to block unused nozzles.

Dimensions

Length 96.2 in. (244 cm)

Wheelbase 53.2 in. (135 cm)

Width 63 in. (160 cm)

Height 42.7 in. (108 cm)

Weight 1150 lb. (522 kg)

8

Page 9

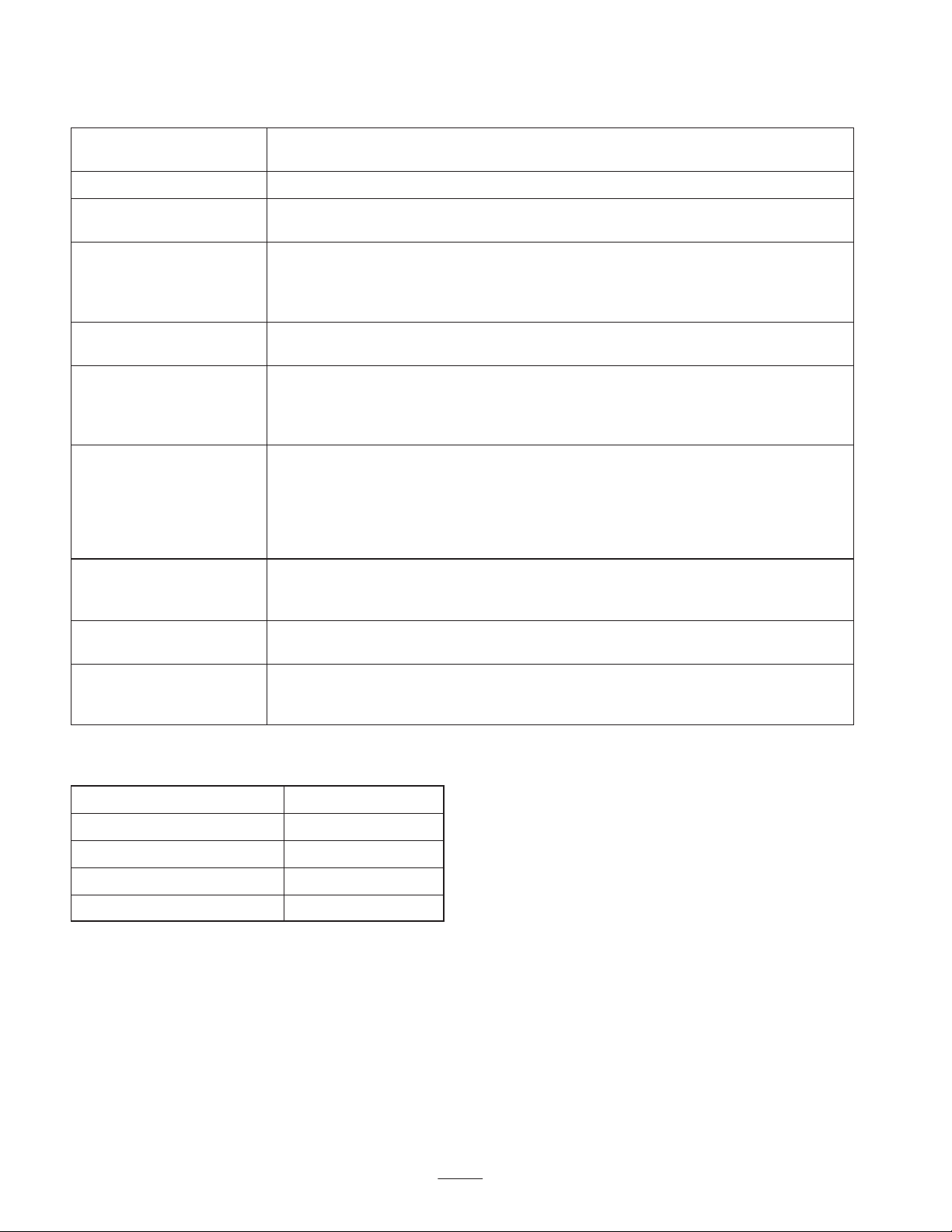

Depths and Nozzle Configurations

Decimal

Metric Size

Approx

Decimal

Metric Size

Approx

All nozzles are identified with numbers indicating the drill size of the orifice. The standard configuration is 11 nozzles

producing depths of 4 to 6 inches depending on turf conditions. Blocked nozzle locations are obtained by reversing the nozzle

check valve ball and spring. See nozzle size chart and illustrations below:

Important Use only nozzle configurations shown or damage to the machine may occur.

Nozzle Size and Approximate Depth Chart

Part No. Drill Size

86-8130 #56 0.0465 1.181 * * *

86-8131 #53 0.0595 1.511 11 0 4–6 in.

86-8133 #46 0.081 2.057 6 5 6–8 in.

* Use only with varied size configurations

Note: Aluminum Washer, Toro Part no. 80-6680, is required with any nozzle change.

Optional Staggered Size Nozzle Configuration

Part No. Drill Size

86-8130 #56 0.0465 1.181 6 and 0** 3–4 in.

86-8133 #46 0.081 2.057 5 0** 6–8 in.

** Additional nozzles may be blocked to compensate for pump wear.

Note: Aluminum Washer, Toro Part no. 80-6680, is required with any nozzle change.

Decimal Metric Size

Size (inch)

Decimal Metric Size

Size (inch)

(mm)

(mm)

Quantity of Nozzles

Quantity of Nozzles

Open Blocked

Open Blocked**

Approx.

Depth

Approx.

Depth

.

.

Check Valve Ball

Spring

Open Nozzle

Spring

Check Valve Ball

Closed (Blocked) Nozzle

9

Page 10

Fluid Recommendations

Fuel

Unleaded regular gasoline recommended to minimize

engine intake valve and combustion chamber deposits.

Standard Energol HLP 150

Sun Sunvis 150

Union Unax RX 150/Turbine Oil 150

Valvoline ETC (R&O) #70

Engine Oil

Service classification API SF, SG, SF/CC or SG/CC in a 30

weight viscosity grade.

Engine Oil Filter

Order Part No. 57-8530

Hydraulic Oil Filter

Order Part No. 67-8110

Hydraulic Oil

Mobil DTE 26 or other interchangeable equivalent. See the

chart below for equivalent oils.

Mobil DTE 26

Shell Tellus 68

Amoco Rykon Oil #68

Conoco Super Hydraulic Oil 68

Exxon Nuto H 68

Kendall Kenoil R&O 68

Pennzoil Penreco 68

Phillips Magnus A 68

Standard Energol HLP 68

Sun Sunvis 831 WR

Union Unax AW 68

Water Supply

Recommended source with 7–8 gallons per minute. A

minimum pressure of 30 psi at the machine is required for

the pump to engage. Maximum allowable pressure of 200

psi. Although irrigation water pumped from ponds or

effluent holding pools can be used, not all conditions can be

handled by the filtration system. Additional or alternative

filtration may be required.

Water Filter Cartridge

Order Part No. 86-8630

Important Do not use chemicals! Concern for

environmental issues and corrosive affects on machine

components.

Water Pump Case Oil

Mobil DTE Extra Heavy or other interchangeable ISO

Grade 150 PE-700-A (Heavy Inhibited Hydraulic &

General Purpose). See the chart below for equivalent oils.

Mobil DTE EH (Extra Heavy)

Shell Turbo 150

Amoco American Ind. Oil 150

Chevron AW Machine Oil 150

Conoco Dectol R & O 150

Exxon Terresstic 150

Kendall Ken-Tran 080

Pennzoil Penreco 150/AW 150

Phillips Magnus Oil 150

10

Page 11

Setup

Note: Determine the left and right sides of the machine from the normal operating position.

Loose Parts

Note: Use this chart as a checklist to ensure that all parts have been received. Without these parts, total setup cannot be

completed.

Description

Wheel

Lug nut

Ignition key 1 Use in ignition switch.

Hose adapter 1 Mount to quick coupler on side of machine.

Spanner wrench 1 Use for installation and removal of water filter.

Parts catalog 1

Operator’s manual 1 Read before operating the machine.

Registration card 1 Fill out and return to Toro.

Qty. Use

3

Installing the rear wheels

12

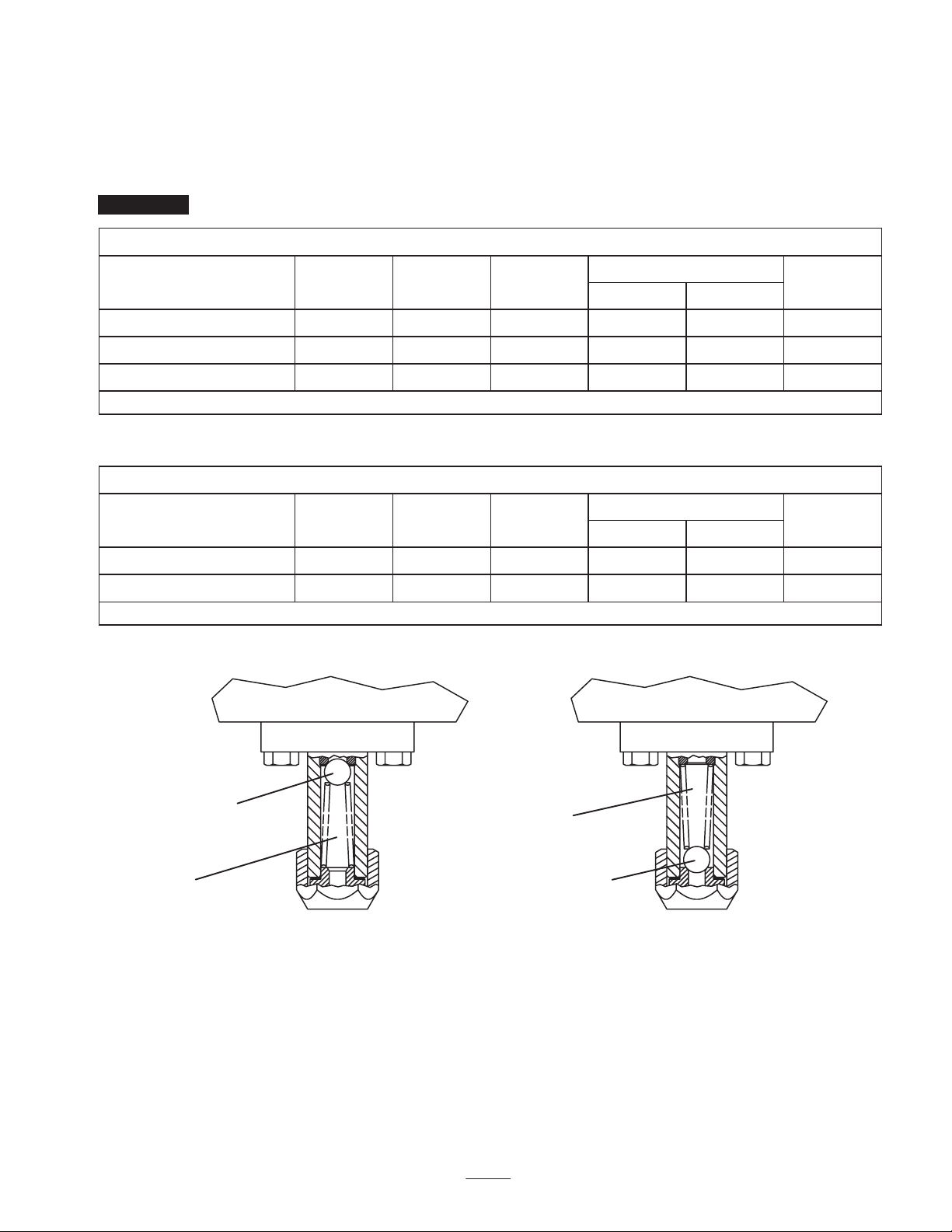

Installing the Rear Wheels

1. Remove the wheels from the shipping pallet.

2. Mount the wheels to the hubs with the lug nuts

(supplied in loose parts) (Fig. 1) and torque the nuts to

45–55 ft.-lb. (61–75 N⋅m).

3. Remove any shipping blocks or braces, which may

obstruct machine removal from the pallet.

Important Refer to the Before Operating section in this

manual, page 12, for instructions on preparing the machine

for operation.

2

1

Figure 1

1. Wheel 2. Lug nuts

11

Page 12

Before Operating

Activating and Charging the

Battery

Warning

Battery posts, terminals, and related accessories

contain lead and lead compounds, chemicals

known to the State of California to cause cancer

and reproductive harm. Wash hands after

handling.

1. Since the battery is not filled with electrolyte or

activated, bulk electrolyte with 1.260 specific gravity

must be purchased from a local battery supply outlet.

Danger

Battery electrolyte contains sulfuric acid which is a

deadly poison and causes severe burns.

• Do not drink electrolyte and avoid contact with

skin, eyes or clothing. Wear safety glasses to

shield your eyes and rubber gloves to protect

your hands.

• Fill the battery where clean water is always

available for flushing the skin.

2. Release the hood latches and raise the hood.

3. Loosen the capscrew securing the battery clamp to the

machine and remove the battery (Fig. 2). Remove the

filler caps from the battery and slowly fill each cell until

electrolyte is just above the plates.

Warning

Battery terminals or metal tools could short

against metal aerator components causing sparks.

Sparks can cause the battery gasses to explode,

resulting in personal injury.

• When removing or installing the battery, do not

allow the battery terminals to touch any metal

parts of the aerator.

• Do not allow metal tools to short between the

battery terminals and metal parts of the aerator.

1

Figure 2

1. Battery

4. Replace the filler caps and connect a 3 to 4 amp battery

charger to the battery posts. Charge the battery at a rate

of 3 to 4 amperes for 4 to 8 hours.

Warning

Charging the battery produces gasses that can

explode.

Never smoke near the battery and keep sparks and

flames away from battery.

5. When the battery is charged, disconnect the charger

from the electrical outlet and battery posts.

6. Remove the filler caps. Slowly add electrolyte to each

cell until the level is up to the fill ring. Install the filler

caps.

Important Do not overfill the battery. Electrolyte will

overflow onto other parts of the machine and severe

corrosion and deterioration will result.

7. Install the battery and secure it with the battery clamp.

Warning

Incorrect battery cable routing could damage the

aerator and cables causing sparks. Sparks can

cause the battery gasses to explode, resulting in

personal injury.

• Always disconnect the negative (black) battery

cable before disconnecting the positive (red)

cable.

• Always connect the positive (red) battery cable

before connecting the negative (black) cable.

12

Page 13

8. Install the positive cable (rubber boot over end) to the

positive (+) terminal and the negative cable (black) to

the negative (–) terminal of the battery and secure them

with capscrews and nuts. Slide the rubber boot over the

positive terminal to prevent a possible short-out from

occurring (Fig. 2).

oil and filter after every 100 hours of operation. Change the

oil more frequently when the engine is operated in

extremely dusty or dirty conditions.

Filling the Gas Tank

9. Lower the hood and secure the latches.

Checking the Engine Oil

The engine is shipped with 3 quarts of oil in the crankcase;

however, the oil level must be checked before and after the

engine is first started.

1. Position the machine on a level surface.

2. Unscrew the dipstick (Fig. 3) and wipe it with a clean

rag. Screw the dipstick into the filler neck and make

sure it is seated fully. Unscrew the dipstick out of the

filler neck and check the oil level. If the oil level is low,

add enough oil to raise the level to the FULL mark on

the dipstick.

1

Figure 3

1. Dipstick

Note: If the oil level is at the ADD mark on the dipstick,

add 1 quart of oil to raise the oil level to FULL. Do not

overfill.

3. Pour oil into the filler neck until the level is at the

FULL mark on the dipstick. The engine uses any

high-quality oil having the American Petroleum

Institute (APl) “service classification” SF or SG. The

recommended viscosity (weight) of oil to use is SAE

30.

Important The aerator operates at very high engine

loads, so check the oil level every 8 operating hours or

daily. A new engine may consume some oil until it is

broken in. Initially, change the oil after the first 25 hours of

operation; thereafter, under normal conditions, change the

We recommend the use of fresh, clean, unleaded regular

grade gasoline. Unleaded gasoline burns cleaner, extends

engine life, and promotes good starting by reducing the

build-up of combustion chamber deposits.

Danger

In certain conditions, gasoline is extremely

flammable and highly explosive. A fire or

explosion from gasoline can burn you and others

and can damage property.

• Fill the fuel tank outdoors, in an open area,

when the engine is cold. Wipe up any gasoline

that spills.

• Do not fill the fuel tank completely full. Add

gasoline to the fuel tank until the level is 1 in.

(25 mm) below the bottom of the filler neck.

This empty space in the tank allows gasoline to

expand.

• Never smoke when handling gasoline, and stay

away from an open flame or where gasoline

fumes may be ignited by a spark.

• Store gasoline in an approved container and

keep it out of the reach of children. Never buy

more than a 30-day supply of gasoline.

• Always place gasoline containers on the ground

away from your vehicle before filling.

• Do not fill gasoline containers inside a vehicle or

on a truck or trailer bed because interior

carpets or plastic truck bed liners may insulate

the container and slow the loss of any static

charge.

• When practical, remove gas-powered equipment

from the truck or trailer and refuel the

equipment with its wheels on the ground.

• If this is not possible, then refuel such

equipment on a truck or trailer from a portable

container, rather than from a gasoline dispenser

nozzle.

• If a gasoline dispenser nozzle must be used, keep

the nozzle in contact with the rim of the fuel

tank or container opening at all times until

fueling is complete.

Note: Do not mix oil with the gasoline. Never use

methanol, gasoline containing methanol, gasohol, gasoline

additives, premium gasoline, or white gas because engine

and fuel system damage could result.

13

Page 14

1. Remove the cap from the fuel tank (Fig. 4) and fill the

10 gallon tank to about 1 inch (25 mm) from the top of

tank (the bottom of the filler neck) with unleaded

gasoline. Install the fuel tank cap tightly.

2. Wipe up gasoline that may have spilled to prevent a fire

hazard.

1

Figure 4

1. Fuel tank cap

2

1

Figure 5

1. Sight gauge 2. Filler cap

4. If the fluid level is low, remove the filler cap and add

enough Mobil DTE 26 hydraulic oil or equivalent oil

(refer to Fluid Recommendations, page 10) to bring the

oil up to the proper level.

5. Lower the hood and secure the latches.

Checking the Gear Case Fluid

Level

The gear case, which acts as the reservoir for the hydraulic

system, is filled at the factory with approximately 4–5

quarts of Mobil DTE 26 hydraulic oil. Check the level of

hydraulic oil on the sight gauge before the engine is first

started and daily thereafter. Change the filter after the first

25 hours of operation; thereafter change the oil and filter

every 250 hours of operation.

Important The oil and filter must be changed

immediately when any contamination, sludge, water or

condensation appears in oil or on sight gauge. Determine

and correct oil contamination problem before restarting

engine and operating machine.

1. Position the machine on a level surface.

2. Release the hood latches and raise the hood.

3. Check the level of hydraulic oil on the sight gauge

(Fig. 5). The fluid level should be up to the middle of

the gauge window.

Checking the Pump Case Fluid

Level

The pump crank case is filled at the factory with

approximately 40 ounces of Mobil DTE Extra Heavy oil.

Check the oil level on the dipstick before the engine is first

started and daily thereafter. Change the oil initially after

25 hours of operation, thereafter change every 200 hours

of operation.

Important The oil must be changed immediately when

any contamination, sludge, water, or condensation appears

in the oil. Determine and correct any oil contamination

problem before restarting the engine and operating the

machine.

1. Position the machine on a level surface.

2. Release the hood latches and raise the hood.

3. Remove the dipstick/filler cap and check the oil level on

the dipstick. The fluid level should be up to the FULL

mark (Fig. 6).

4. If the fluid level is low, add enough Mobil DTE Extra

Heavy oil or equivalent oil (refer to Fluid

Recommendations, page 10) to bring the oil up to the

proper level. Do not overfill.

14

Page 15

5. Lower the hood and secure the latches.

1

FULL

Warning

Charge accumulators contain high pressure

nitrogen. Nitrogen is the only gas to use for

accumulator charging. Installing improper gases in

an accumulator can cause an explosion and death.

Charging requires special tools and precautions.

• Charge the accumulator in a well ventilated

area.

• Have the accumulator checked and charged by

an Authorized Toro Distributor.

• Wear eye protection.

• Keep your hands and face away from the gas

valve.

Figure 6

1. Dipstick/filler cap

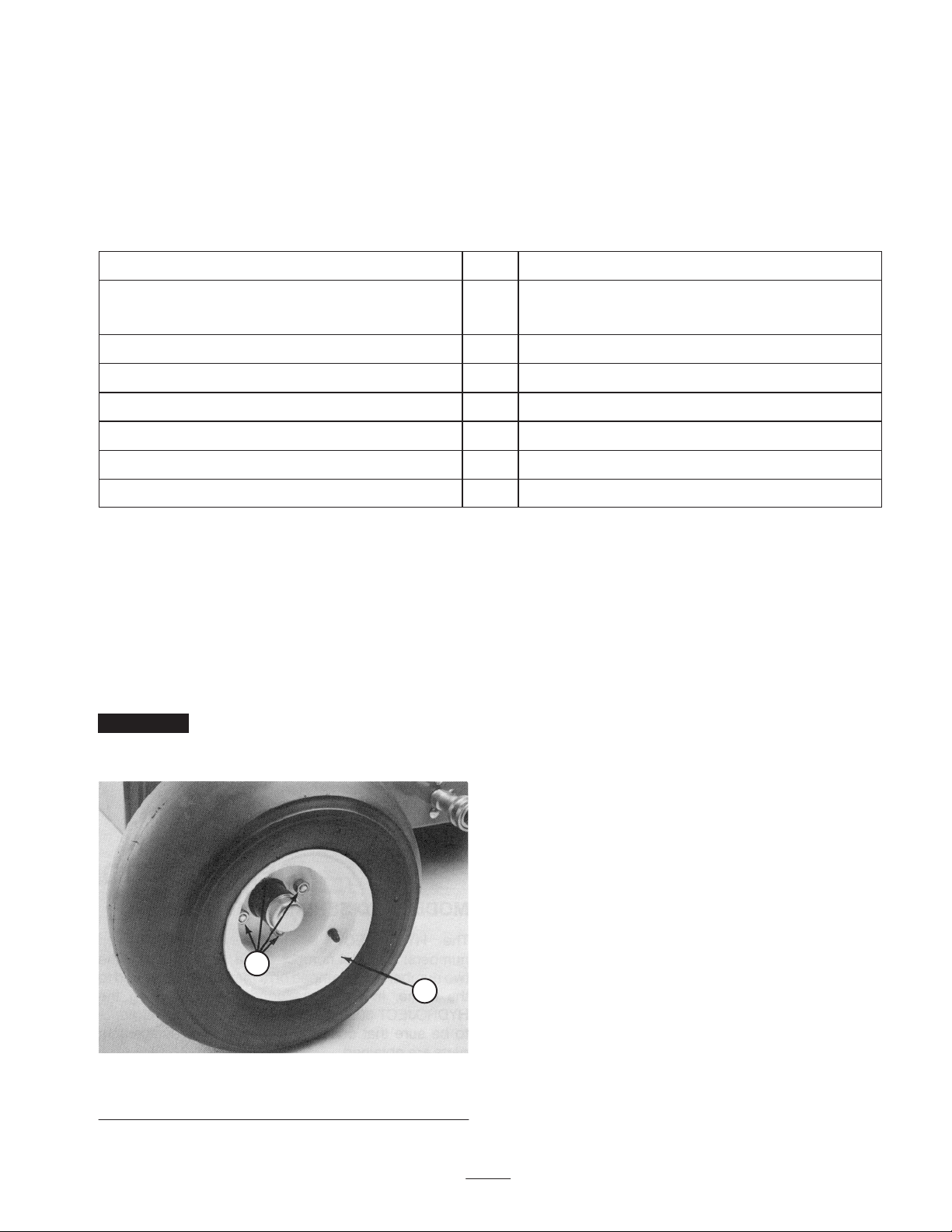

Checking the Tire Pressure

The tires are over inflated for shipping. Make sure that the

front and rear tires are inflated to 8 to 12 p.s.i. (55 to

83 kPa).

Water System Accumulator

The Hydroject accumulator contains a high pressure

nitrogen gas pre–charge. The safety system on the aerator

will disable the water injection if the accumulator pressure

is too low or too high, and will illuminate one of the

accumulator pressure lights on the operators console.

Due to the operational requirements of the accumulator

design, the high pressure internal gas pre–charge can bleed

out during periods of inactivity. Storing the Hydroject for

extended periods of time (3 months or longer) and/or

seasonal temperature variances can affect the accumulators

ability to retain a sufficient pre–charge and seasonal

servicing (recharge) may be required.

If one of the accumulator charge indicator lamps

illuminates, contact your authorized Toro Distributor for

accumulator maintenance services.

Warning

Failure to open the bleed valve before servicing

high pressure water components can cause

personal injury, dismemberment, or death.

Slowly open the high pressure water bleed valve

before servicing any component connected to the

high pressure water system. Opening the high

pressure bleed valve allows any trapped water to

escape from the system and also allows the

accumulator piston to move to the bottom of the

accumulator cylinder.

Note: Charged accumulators cannot be shipped via air

freight.

Operation

Note: Determine the left and right sides of the machine

from the normal operating position.

Controls

Ignition Switch

The ignition switch (Fig. 7), which is used to start and stop

the engine, has three positions: OFF, ON, and START.

15

Page 16

1

4

2 3

6

7

Figure 7

1. Ignition switch

2. Choke

3. Throttle

4. Spray wash control

5. Hour meter

6. Water pressure gauge

7. Circuit breaker reset

button

8. Spacing control lever

8

5

Circuit Breaker Reset Button

Push the button (Fig. 7) to reset the breaker after correcting

a malfunction in the electrical system. The button also

serves as a switch to interrupt power to the relays.

Spacing Control Lever

Moving the control (Fig. 7) away from the handle increases

the aerating ground speed and the distance between holes.

Moving the control toward the handle decreases the

aerating ground speed and the distance between holes. The

setting will be overridden when the machine is shifted to

the transport position.

Traction Bail

The traction bail (Fig. 8) engages and regulates fore and aft

traction operation of the machine. Releasing the bail stops

traction operation and will also stop water injection in 3 to

4 seconds, unless the bail is engaged. The transport speed is

regulated by the amount the bail is moved.

Choke

To start the engine, close the carburetor choke by pulling

the choke control (Fig. 7) outward to the FULL position.

After the engine starts, regulate the choke to keep the

engine running smoothly. As soon as possible, open the

choke by pushing it inward to the OFF position.

Throttle

The throttle (Fig. 7) is used to regulate the engine speed.

Moving the throttle forward increases the engine speed

(FAST); rearward decreases the engine speed (SLOW).

Spray Wash Control

Pull the handle (Fig. 7) upward to activate the roller spray

wash system. Move the control knob up or down to adjust

the spray rate to keep the rollers free of debris.

Hour Meter

The hour meter (Fig. 7) registers accumulated hours of

engine operation. Use the hour meter to determine intervals

for service maintenance and lubrication.

1

23

4

Figure 8

1. Traction bail

2. Transport/aerate toggle

switch

3. Aeration engagement

button

4. Aeration stop button

5. Parking brake

Transport/Aerate Toggle Switch

5

Water Pressure Gauge

The water pressure gauge (Fig. 7) registers supply water

pressure in the system. It also acts as an interlock switch,

preventing the water pump from starting if the water

pressure is below 20–28 p.s.i., or stopping the water pump

if the water pressure drops below 7–13 p.s.i. Check the

gauge frequently to monitor the water pressure.

The switch (Fig. 8) lowers machine onto the rollers to

commence aeration. The switch will override the spacing

control setting when it is moved to the transport position.

Aeration Engagement Button

Depressing the button (Fig. 8), starts the water injection

system only when the water pressure is above 28 p.s.i. and

the rollers are on the ground.

16

Page 17

Aeration Stop Button

The red button (Fig. 8) stops the water injection system.

The system continues for a few seconds after the button is

pressed.

• Do not allow the machine to be subject to freezing

temperatures without draining, as damage to the system

will occur.

Starting and Stopping the

Parking Brake

Push the lever (Fig. 8) toward the machine to engage the

parking brake. A warning buzzer will sound if you attempt

to move the machine with parking brake engaged.

Fuel Shut-Off Valve

The fuel shut-off valve is located under the fuel tank. Close

the valve when storing or transporting (trailering) the

machine.

Operating Precautions

Follow these precautions when operating the aerator:

• Before aerating, inspect the work area for debris and

obstacles. Determine the best direction and pattern to

operate the machine. Always maintain awareness of

what lies ahead in the direction of forward travel.

• If the machine starts to vibrate abnormally, shut the

engine off. Remove the key from the ignition switch to

prevent the possibility of accidental starting. Check the

machine for damaged parts. Repair any damage before

restarting the engine and operating the machine

• Only use the aerator in daylight or when there is good

artificial light. Watch for holes or other hidden hazards.

Do not transport the machine close to a sand trap, ditch,

creek, or other hazard.

Engine

1. Make sure that the wires are installed on the spark plugs

and the fuel shut-off valve is open.

2. Make sure that the parking brake is engaged.

3. Pull the choke lever out to the FULL position and move

the throttle lever to the half throttle position.

Note: When starting a warm engine, the choke may not be

necessary, but HALF throttle is.

4. Insert the key into the ignition switch and rotate it

clockwise to start the engine. Release the key when the

engine starts. Gradually return the choke lever to the

OFF position (lever all the way in) after the engine

starts and warms up.

Important To prevent overheating of the starter motor,

do not engage the starter longer than 30 seconds. After 30

seconds of continuous cranking, wait 2 minutes before

engaging the starter motor again.

Important The engine is equipped with an oil pressure

interlock switch which interrupts the engine operation if

there is not sufficient oil pressure in the engine during

starting or operation. The engine may start but will not

continue to run due to a lack of oil pressure.

5. To stop the engine, move the throttle control downward

to the SLOW position and turn the ignition key to OFF.

Remove the ignition key.

• To prevent roller marks, always raise the machine to the

transport position when parked on a green.

• Do not operate the water injection system on concrete

or asphalt because water jets will permanently damage

these surfaces. Do not run over the hose as damage will

occur.

• Do not operate the aerator with the roller or injection

system over the edge of anything that could be hit,

damaged, or injured by high velocity water blasts.

• Water jets from the injection system should not damage

irrigation heads on one pass of the machine. Do not

allow multiple shots from the injection system to hit

irrigation heads as damage will occur.

• Use a good, clean, quality water supply in the system. If

good quality water is not available, additional filtration

equipment may be required. Do not use chemicals in

the water system.

Training Period

Before aerating with the machine, it is suggested that you

find a clear area and practice starting and stopping, raising

and lowering machine, turning, etc. This training period

will be beneficial to the operator in gaining confidence in

the performance of the aerator.

Operating Procedure

1. Make sure that the wires are installed on the spark plugs

and the fuel shut-off valve is open.

2. Uncoil a garden hose, making sure that there are no

kinks or bends in the hose. Lay out the hose so that

there are no obstructions between the machine and the

area to be aerated. Turn on the water supply to purge

any air from the hose. Turn off the water.

17

Page 18

3. Connect the hose adapter (Fig. 9) to the garden hose,

then connect the adapter to the quick coupler on the side

of the machine.

2

1

1

Figure 9

1. Hose adapter 2. Quick coupler

4. Turn on the water supply and check the water pressure.

The water pressure must be at least 30 p.s.i.. If the

system pressure is not 30 p.s.i., make sure that the hose

is not kinked or obstructed, the water supply is turned

on, and the water filter is not plugged.

5. Reach under the fuel tank and press the bleed button on

top of the water filter head (Fig. 10). Hold the bleed

button down until all air is purged from the filter and

water comes out of the opening.

2

1

2

Figure 11

1. Main valve 2. Bleed valve

7. If desired, the valve on the pre-filter (Fig. 12) may be

opened slightly (cracked) to provide continuous

flushing during operation of the machine.

1

2

Figure 10

1. Main water filter head 2. Bleed button

6. Reach under the hood and open the bleed valve on the

main valve at the rear of the machine (Fig. 11). Bleed

the system until a steady flow of water comes from the

outlet; then close the valve.

Figure 12

1. Pre-filter 2. Valve

8. Start the engine; refer to Starting and Stopping the

Engine, page 17. Move the throttle to the FAST position

and disengage the parking brake.

9. Engage the traction bail and approach the area to be

aerated. Make sure that there are no obstructions

between the aerator and water supply.

10. Engage and hold the transport/aerate toggle switch to

fully lower the machine onto the rollers. Release the

switch when the machine is fully lowered; then press

the engagement button to start water injection.

18

Page 19

Note: The injection operation starts approximately 4–5

seconds after the pump engages. Also, the injection system

will automatically stop if the traction bail is not engaged

within 3–4 seconds after starting the water system.

11. When aerating, work moving perpendicular from the

water supply to avoid running over the garden hose.

Use the front edge of the hood or rear corner of the

frame to align rows, if desired. When at the end of a

row, make an “S” maneuver and reverse the direction of

the aerator. Do not make sharp turns on a green or

scuffing from the tire may occur. Always maintain

awareness of what lies ahead in the direction of forward

travel.

12. Regulate the roller spray wash, if required, to remove

debris from the rollers.

Note: A small amount of water from the regulator bypass

may come out of the spray wash nozzles even with the

spray wash in the “OFF” position.

13. In areas where greater hole depth or more frequent

holes are desired, the engage button can be held down

to allow multiple shots while machine is stopped.

Important Hole depths can reach 20 inches or more

when making multiple shots, so be aware of what is buried

below the turf. Also, an excessive amount of holes and

muddy turf conditions may occur when making multiple

shots.

14. To stop water injection, press the red button. The

system continues for a few seconds after the button is

pressed. Raise the machine to the transport position,

disconnect the supply hose, and move to the next

location.

Checking the Interlock System

Caution

If safety interlock switches are disconnected or

damaged the machine could operate unexpectedly,

causing personal injury.

• Do not tamper with the interlock switches.

• Check the operation of the interlock switches

daily and replace any damaged switches before

operating the machine.

• Replace switches every two years regardless of

whether they are operating properly or not.

To do a functional check of interlock system:

1. Position the machine in a flat, open area on rough turf

and away from buried wires, plumbing, etc. Stop the

engine.

2. Move the traction bail up and down while trying to start

the engine. If the engine cranks, there is a malfunction

in the interlock system that must be corrected. If the

engine does not crank, proceed to step 3.

3. Connect the water supply to the machine. Turn on the

water supply and bleed all air out of the system. The

water pressure must be 30 psi or more. Start the engine.

Raise the machine to the transport position (up off the

rollers). Push the aerate ENGAGE button. If the water

pump engages and the machine begins aerating, there is

a malfunction in the interlock system that must be

corrected. If the machine does not begin aerating,

proceed to step 4.

4. Lower the machine to the aerate position (on the

rollers). Engage the traction bail to start the machine

moving. Push, then release the aerate ENGAGE button.

The water pump should engage immediately, then the

machine should begin aerating 5 seconds after the pump

engages. Release the traction bail to the neutral position

so that the machine stops moving. The water pump

should disengage 4 seconds after the traction bail

returns to neutral, then stop aerating after another 3

seconds. If the machine does not stop aerating when the

traction bail returns to neutral, there is a malfunction in

the interlock system that must be corrected. If the

machine stops aerating, proceed to step 5.

5. Engage the traction bail to start the machine moving,

then push the aerate ENGAGE button to begin aerating.

Push the aerate DISENGAGE button. The water pump

should disengage immediately, then stop aerating after 3

seconds. If the machine does not stop aerating, there is a

malfunction in the interlock system that must be

corrected.

Note: Lights (LED’s) on the controller (Fig. 13) indicate

when the following inputs are made to the controller:

3

2

1

The purpose of the safety interlock system is to prevent the

engine from cranking or starting unless the traction bail is

in NEUTRAL and prevents the water system from

engaging if the machine is in the transport (raised) position.

It also stops aeration if the traction bail is released while

operating or if the machine is raised to the transport

position.

1. Red light

2. Green light

19

Figure 13

3. Yellow light

Red: Transport switch closed (traction bail in neutral)

Page 20

Green: Aerate start (engage) switch closed. If the red

and yellow lights are on, the green light will stay on

until either the red or yellow goes off.

Yellow: Pump start limit switch closed (machine

lowered to aerate position) and water pressure switch

closed (water pressure of more than 30 psi) and

accumulator charge pressure switch (nitrogen pressure

more than 1800 psi).

Transport Operation

1

Use the traction bail to slow the machine while crossing

undulating terrain to avoid loss of control. The smooth tires

do not grip turf very well so use caution when transporting

the machine. Always approach rough areas at a reduced

speed and cross severe undulations carefully.

Inspection and Clean-Up After

Use

At the completion of operation, thoroughly wash the

machine with a garden hose without a nozzle so excessive

water pressure will not cause contamination and damage to

seals and bearings. After cleaning, it is recommended the

machine be inspected for possible hydraulic fluid or water

leaks and damage or wear to hydraulic, water, and

mechanical components.

Pushing or Towing the Machine

In an emergency, the machine can be pushed or towed for a

very short distance. However, we do not recommend this as

standard procedure.

Important Do not push or the tow machine faster than

3 MPH because pump damage may occur. If the machine

must be moved a considerable distance, transport it on a

truck or trailer or pull it with the traction wheel raised and

secured to a dolly. Whenever the machine is pushed or

towed, the bypass valve must be opened. The hook on the

front of the handle is used as a tie-down only, not a hitch

point.

Figure 14

1. Bypass valve

1. Unlatch and raise the hood.

2. Locate the bypass valve cap on the left side of the

hydraulic pump (Fig. 14).

3. Rotate the valve cap counterclockwise, move the

machine to the desired location, and close the valve cap.

4. Lower the hood and secure the latches.

Important Do not run any chemicals through the

Hydroject water system (except Toro Wetting Agent

86–8530). Chemicals can have corrosive effects on

machine components and environmental laws and concerns

exist when injecting chemical sub–surface.

20

Page 21

Maintenance

Note: Determine the left and right sides of the machine from the normal operating position.

Recommended Maintenance Schedule

Maintenance Service

Interval

After first 25 hours

After first 50 hours

Every 50 hours

Every 100 hours

Every 200 hours

Maintenance Procedure

• Change the engine oil and filter.

• Change the gear case oil and filter.

• Change the pump case oil.

• Torque the wheel lug nuts.

• Torque head and adjust the valves.

• Check the engine RPM (idle and full throttle).

• Check the battery fluid level.

• Check the battery cable connections.

• Lubricate all grease fittings.

• Change the engine oil and filter.

• Change the engine pre-cleaner (air filter).

• Replace the air filter element.

• Replace the fuel filter.

• Adjust the water system cam—valve clearance.

• Clean the engine crankcase breather.

• Change the gear case oil and filter.

• Change the pump case oil.

• Torque the wheel lug nuts.

• Adjust the parking brake.

• Calibrate the aeration traction speed.

• Service the injector nozzles and springs.

Every 400 hours

Every 1000 hours or 2

years, whichever occurs

first

• Replace the spark plugs.

• Decarbon the combustion chambers.

• Torque head and adjust the valves.

• Check the engine RPM (idle and full throttle).

• Replace moving hoses.

• Replace safety switches.

• Drain and flush the fuel tank.

• Drain and flush the hydraulic tank.

Water System Accumulator

Due to the operational requirements of the accumulator design, the high pressure internal gas pre–charge can bleed out during

periods of inactivity. Storing the Hydroject for extended periods of time (3 months or longer) and/or seasonal temperature

variances can affect the accumulators ability to retain a sufficient pre–charge and seasonal servicing (recharge) may be

required.

If one of the accumulator charge indicator lamps illuminates, contact your authorized Toro Distributor for accumulator

maintenance services.

21

Page 22

Daily Maintenance Checklist

Duplicate this page for routine use.

For the week of:

Maintenance Check Item

Check safety interlock operation.

Check brake operation.

Check the engine oil level.

Check the engine air filter pre-cleaner.

Check the engine cooling fins for debris.

Check unusual engine noises.

Check unusual operating noises.

Check the water filter/pressure.

Check the water pre-filter.

Check the gear case oil level.

Check the pump case oil level.

Check they hydraulic hoses for damage.

Check for fluid leaks.

Check the tire pressure.

Check instrument operation.

Lubricate all grease fittings.

1

Mon. Tues. Wed. Thurs. Fri. Sat. Sun.

Touch up damaged paint.

1

Immediately after every washing, regardless of the interval listed

Notation for Areas of Concern

Inspection performed by:

Item Date Information

1

2

3

4

5

6

7

8

9

10

11

12

13

22

Page 23

Caution

If you leave the key in the ignition switch, someone

could accidently start the engine and seriously

injure you or other bystanders.

Remove the key from the ignition and disconnect

the wire from the spark plug before you do any

maintenance. Set the wire aside so that it does not

accidentally contact the spark plug.

Caution

Contact with hot surfaces could cause burns.

Wait for the unit to cool before servicing or

making adjustments to the machine.

Lubricating the Machine

The aerator has 5 grease fittings that must be lubricated

every 50 hours of operation with No. 2 General Purpose

Lithium Base Grease. Lubricate all fittings immediately

after every washing, regardless of the interval listed.

The bearings and bushings that must be lubricated are:

steering pivot shaft (Fig. 15), limit switch housing (Fig. 16)

(2) on lift arm shaft (Fig. 16), and neutral pivot shaft

(Fig. 17).

Figure 16

Figure 17

1. Wipe the grease fitting clean so that foreign matter

cannot be forced into the bearing or bushing.

Figure 15

2. Pump grease into the bearing or bushing.

3. Wipe up excess grease.

23

Page 24

Servicing the Pre-Filter

Sediment can be removed by opening the ball valve, with

the water source attached, to flush (Fig. 18). The reusable

filter screen may be removed for cleaning by untwisting the

clear cover (Fig. 18) from the filter by hand. Replace the

clear cover and hand tighten only.

Important Use of tools will damage the filter.

4

3

1

2

3

Figure 18

1. Body

2. Clear cover

3. Ball valve for flushing

Replacing the Main Water Filter

The machine is a precision piece of equipment and the

quality or cleanliness of your water supply is very

important in determining the life of the machine. If your

water supply contains silt, sand, or other debris, you may be

required to install additional filtration or separation

equipment between your supply source and the machine.

Depending on the quality of water, the frequency of the

filter change will vary greatly. When the pump inlet

pressure decreases or the water system shuts down, it

usually means the water filter is restricted and must be

replaced. Never operate machine without a water filter

as severe damage may occur.

1. Position the machine on a level surface and make sure

that the engine is shut off. Shut off the water supply.

2. Locate the main water filter assembly mounted below

the fuel tank. Press the bleed button (Fig. 19) to release

air pressure from the filter body.

2

Figure 19

1. Filter body

2. Filter cartridge

3. Filter head

3. Unscrew the filter body of the assembly (Fig. 19)

counterclockwise (as viewed from the bottom). Remove

the filter cartridge and discard it.

Note: To ease the removal of the filter body from the filter

head, a filter wrench is available. Contact your Authorized

Toro Distributor.

4. Bleed button

5. O-ring

5

1

Caution

The water filter body is very heavy when filled

with water and the filter. Use caution when

unscrewing the filter body from the filter head.

4. Thoroughly rinse out the filter body to avoid

contaminating the water system. Make sure that the

o-ring (Fig. 19) is in the groove. If it has come out,

wipe it dry, lubricate it with a light coating of petroleum

jelly, and replace it in the groove.

5. Thoroughly clean the filter head mounting surface to

avoid contaminating the water system when the filter is

installed.

6. Insert the new filter cartridge into the filter body.

7. Thread the filter body with the filter onto the filter head.

Hand tighten them.

8. Turn on the water supply and press the bleed button on

the top of the water filter head (Fig. 19). Hold the bleed

button down until all air is purged from the filter and

water comes out of the opening.

24

Page 25

Changing the Engine Oil and

Filter

For new engines, change the oil after the first 25 operating

hours. Thereafter, under normal conditions, change the oil

and filter after every 100 hours of operation. However, an

engine operated in dusty or dirty conditions requires more

frequent oil changes. If possible, run the engine just before

changing the oil. Warm oil flows more freely and carries

more contaminants than cold oil.

1. Position the machine on a level surface.

2. Disengage the hood latches and open the hood.

3. Place an oil drain pan below the drain cap on the

bottom of the crankcase (Fig. 20). Clean the area

around the drain cap.

4. Remove the drain cap and allow oil to flow into a drain

pan. After the oil has drained, install the oil drain cap.

1

6. Apply a thin film of clean oil to the gasket. Install a

new filter by hand until the gasket just touches the

mounting surface, then turn the filter an additional 1/2

to 3/4 turn.

7. Remove the filler cap (Fig. 22) and pour approximately

3 quarts of oil having the API “service classification”

SF or SG into the filler neck. The recommended

viscosity (weight) of oil to use is SAE 30.

1

Figure 22

1. Filler cap

Figure 20

1. Drain cap

5. Remove the oil filter (Fig. 21) and discard it.

Thoroughly clean the filter mounting surface and make

sure that a new gasket is installed in the new filter.

1

8. Start the engine and check for leaks around the oil filter.

Tighten the filter only enough to eliminate leaks. Do

not overtighten.

9. Turn off the engine and allow the machine to stand for 2

minutes.

10. Check the oil and make sure that the level is up to the

FULL mark on the dipstick. Add more oil if the level is

low; however, do not overfill.

11. Lower the hood and secure the latches.

1. Oil filter

Figure 21

25

Page 26

Servicing the Air Cleaner

The foam pre-cleaner must be cleaned and oiled after every

100 hours of engine operation. The paper element must be

checked and/or replaced after every 200 hours of engine

operation. However, the air cleaner must be cleaned more

frequently if operating conditions are extremely dusty or

sandy.

4. Wrap the foam pre-cleaner in a clean cloth and squeeze

it dry. Do not wring the pre-cleaner.

5. Add and evenly distribute one tablespoon of engine oil

to the foam pre-cleaner. Squeeze the foam pre-cleaner

to remove excess oil.

6. Inspect the paper element and replace it if is dirty or

damaged.

1. Remove the knob and cover from the air cleaner

(Fig. 23).

3

1

2

Figure 23

1. Air cleaner

2. Air cleaner cover

2. Remove the foam pre-cleaner by sliding it off of the

paper element (Fig. 24).

3. Knob

Important Do not wash the paper element or clean it

with compressed air as damage will occur.

7. Install the pre-cleaner on the paper element.

Note: With the air cleaner disassembled, check the air

cleaner components for damage. Replace them if necessary.

8. Install the paper element with the foam pre-cleaner, air

cleaner element cover, nut, air cleaner cover, and knob.

9. Tighten the knob 1/2 to 1 turn after it contacts the cover.

Do not overtighten.

Adjusting the Carburetor

The carburetor has been adjusted at the factory and should

not have to be reset. Should the carburetor require

adjustment, use the following procedure:

Important Check the fuel filter and air cleaner and

make sure that the choke is operating correctly before the

carburetor is adjusted.

1. Disengage the hood latches and open the hood.

2. Start the engine and let it run for 10 minutes to warm

up. The engine must be warm before making final

adjustments.

1

2

Figure 24

1. Foam pre-cleaner 2. Paper element

3. Wash the foam pre-cleaner in detergent soap and warm

water.

Warning

The engine must be running so adjustment of the

carburetor can be performed.

To guard against possible personal injury, keep

hands, feet, face, and other parts of the body away

from the muffler, hot parts of the engine, and

moving or rotating parts of the engine.

3. Move the throttle control to the SLOW position and

check the low idle speed setting (1500–1800 RPM);

then, move the throttle control to the FAST position and

check the high speed setting (3450–3550 RPM) to

determine if the throttle control linkage is allowing full

travel at the engine. With the throttle control in the

FAST position, the control lever should not be touching

the control panel and the engine mounted throttle lever

26

Page 27

(Fig. 25) should be touching the high speed stop.

Loosen the cable clamp and adjust the cable so that the

lever touches the stop.

8. Move the throttle control to the FAST position. Bend

the high speed stop on the governor so that the engine

runs at 3450–3550 RPM.

9. Repeat step 3, then tighten the cable clamp.

10. Lower the hood and secure the latches.

Checking and Replacing the

Spark Plugs

1

2

Figure 25

1. Throttle stop screw 2. Idle fuel limiter cap

4. Close the idle mixture screw by gently rotating it

clockwise.

Important Do not close the screw too tight because the

screw will likely become damaged.

5. Rotate (open) the screw 1-1/8 turns counterclockwise.

6. With the cable clamp loose, turn the low speed screw on

the governor (Fig. 26) so that the throttle stop screw

(Fig. 25) on the carburetor controls the engine speed.

Adjust the carburetor throttle stop screw for 1000 RPM

idle.

3

4

Since the air gap between the center and side electrodes

increases gradually during normal engine operation, change

the spark plugs at 100 hour intervals. The correct spark

plug to use in the engine is a Champion RS14 YC or

equivalent. Set the air gap at .025 in.

1. Disengage the hood latches and open the hood.

2. Clean the area around the spark plugs (Fig. 27) so that

dirt does not fall into the cylinder when the plugs are

removed.

1

Figure 27

1. Spark plug

2

1

Figure 26

1. Low speed screw

2. High speed stop

7. Adjust the governor low speed stop for 1500–1800

RPM.

3. Throttle lever

4. Cable clamp

3. Pull the wires off of the spark plugs and remove the

plugs from the cylinder head.

4. Check the condition of the center and side electrodes to

determine the operating temperature of the engine.

• Light brown insulator tip indicates correct spark plug

and heat range.

• Black or oily insulator tip indicates an excessively rich

fuel mixture, possibly caused by a dirty air cleaner

element or a carburetor that is set too rich.

• Light gray or blistered-white insulator indicates

overheating caused by a lean carburetor setting or

incorrect spark plug (heat range too high).

Important A cracked, fouled, or dirty spark plug must

be replaced. Do not sandblast, scrape, or clean the

electrodes by using a wire brush because grit may release

from the plug and enter the combustion chamber, resulting

in engine damage.

27

Page 28

5. After setting the air gap at .025 in., install the spark

plugs in the cylinder head. Tighten the plugs to

10–15 ft.-lb. (14–20 N⋅m). Push the wires onto the

spark plugs.

6. Lower the hood and secure the latches.

Cleaning the Cylinder Head

Fins

To avoid overheating and possible engine damage, clean

the cooling fins on the cylinder head every day if necessary.

1. Disengage the hood latches and open the hood.

2. Pull the wires off of the spark plugs.

3. Clean dirt, grass, and chaff from the outside of the

cylinder, the cylinder head fins, and the air intake

screen.

3. Remove the drain plug and allow the oil to flow into a

drain pan. After the oil has drained, install the oil drain

plug.

4. Remove the oil filter (Fig. 29), mounted below control

panel base, and discard the filter. Thoroughly clean the

filter mounting surface and make sure that a new gasket

is installed in the new filter.

1

4. Push the wires onto the spark plugs.

5. Lower the hood and secure the latches.

Changing the Gear Case Oil

and Filter

Change the hydraulic oil and filter initially after 25 hours of

operation; thereafter change them every 200 hours of

operation.

Important The gear case oil and filter must be changed

immediately when any contamination, sludge, water or

condensation appears.

1. Disengage the hood latches and open the hood.

2. Place a drain pan under the bottom of the gear case.

Clean the area around the drain plug (Fig. 28).

Note: When draining the oil, use a funnel or some type of

channel to divert the draining oil away from the machine

components and into a drain pan.

Figure 29

1. Oil filter

5. Fill the new filter with new Mobil DTE 26 hydraulic oil

or equivalent oil (refer to Fluid Recommendations,

page 10). Apply a thin film of clean oil to the filter

gasket.

6. Install the new filter by hand until the gasket just

touches the mounting surface, then turn it an additional

1/2 to 3/4 turn.

7. Remove the filler cap and add approximately 4–5 quarts

of Mobil DTE 26 hydraulic oil or equivalent oil (refer

to Fluid Recommendations, page 10) to the gear case

reservoir. Install the filler cap.

8. Check for leaks around the oil filter. Tighten the filter

only enough to eliminate leaks. Do not overtighten.

9. Lower the hood and secure the latches.

Changing the Pump Case Oil

Change the pump oil initially after 25 hours of operation;

thereafter change it every 200 hours of operation.

1

1. Drain plug location

Figure 28

Important The pump case oil must be changed

immediately when any contamination, sludge, water or

condensation appears.

1. Disengage the hood latches and open the hood.

2. Place a drain pan under the pump case. Clean the area

around the drain plug on the bottom of the case

(Fig. 30).

Note: When draining the oil, use a funnel or some type of

channel to divert the draining oil away from the machine

components and into a drain pan.

28

Page 29

1

Figure 30

1. Drain plug location

3. Remove the drain plug and allow oil to flow into a drain

pan. After the oil has drained, install the oil drain plug.

4. Remove the dipstick/filler cap and add approximately

40 ounces of Mobil DTE Extra Heavy oil or equivalent

oil (refer to Fluid Recommendations, page 10) to the

pump case. Install the filler cap.

5. Check the oil level. If the fluid level is low, add enough

Mobil DTE Extra Heavy oil or equivalent to bring the

oil up to the proper level. Do not overfill.

Checking the Hydraulic Lines

and Hoses

Check the hydraulic lines and hoses daily for leaks, kinked

lines, loose mounting supports, wear, loose fittings, weather

deterioration, and chemical deterioration. Make all

necessary repairs before operating.

Warning

Hydraulic fluid escaping under pressure can

penetrate skin and cause injury.

• Make sure all hydraulic fluid hoses and lines are

in good condition and all hydraulic connections

and fittings are tight before applying pressure to

the hydraulic system.

• Keep your body and hands away from pin hole

leaks or nozzles that eject high pressure

hydraulic fluid.

• Use cardboard or paper to find hydraulic leaks.

• Safely relieve all pressure in the hydraulic

system before performing any work on the

hydraulic system.

• Get immediate medical help if fluid is injected

into skin.

6. Check for possible leaks. Lower the hood and secure

the latches.

Adjusting the Traction Pump

Belt

Make sure that the traction pump belt is properly tensioned

to ensure correct operation of the unit and unnecessary

wear. Check the belt midway in the span of the belt.

1. Disengage the hood latches and open the hood.

2. Check the belt tension by depressing the belt midway

between the pulleys with 3 lb. of force. The belt should

deflect 9/64 in. (Fig. 31).

1

Figure 31

1. Traction pump belt

29

Page 30

3. If an adjustment is necessary, adjust as follows:

A. Loosen the pivot nut securing the pump mount to

the pump support (Fig. 32).

2

3

2

1

3

1

Figure 32

1. Pump

2. Pivot nut

B. Loosen the adjusting nut securing the pump and

pump mount to the slotted pump support (Fig. 32).

C. Loosen the 3 capscrews securing the pulley guard

bracket to the control panel and pump support.

D. Use a pry bar to pull the pump toward the outside of

the machine until the proper belt tension is attained;

then tighten the adjusting nut securing the pump and

pump mount to the pump support (Fig. 32).

E. Tighten the pivot nut securing the pump mount to

the pump support (Fig. 32).

F. Tighten the 3 capscrews securing the pulley guard

bracket to the control panel and pump support.

3. Adjusting nut

Adjusting the Transmission for

Neutral

Figure 33

1. Neutral adjustment cam

2. Locknut

5. Move the traction bail completely up and down. Release

the handle and check for wheel rotation. If the wheel

continues rotating, repeat step 4.

6. If the problem continues, stop the engine, check the

linkage for binding or damage, then do the adjustment

procedure again.

7. Set the hole spacing control in the lowest setting (to the

left) and move the transport/aerate switch to the aerate

position (transport tires retracted). Loosen the 2 screws

and adjust the switch tab (Fig. 33) so that the switches

are actuated when the pump control is in neutral and not

actuated when the pump is stroked.

8. Move the ignition switch to the ON position, but do not