Toro 09715 Operator's Manual

FormNo.3437-560RevD

ProCore

ModelNo.09715—SerialNo.403410001andUp

ModelNo.09716—SerialNo.403410001andUp

®

864and1298Aerators

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3437-560*

ThisproductcomplieswithallrelevantEuropean

directives;fordetails,pleaseseetheseparateproduct

specicDeclarationofConformity(DOC)sheet.

WARNING

CALIFORNIA

Proposition65Warning

Useofthisproductmaycauseexposure

tochemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Introduction

Thismachineisintendedtobeusedbyprofessional,

hiredoperatorsincommercialapplications.It

isdesignedprimarilyforworkinglargeareason

well-maintainedlawnsinparks,golfcourses,sports

elds,andoncommercialgrounds.Usingthisproduct

forpurposesotherthanitsintendedusecouldprove

dangeroustoyouandbystanders.

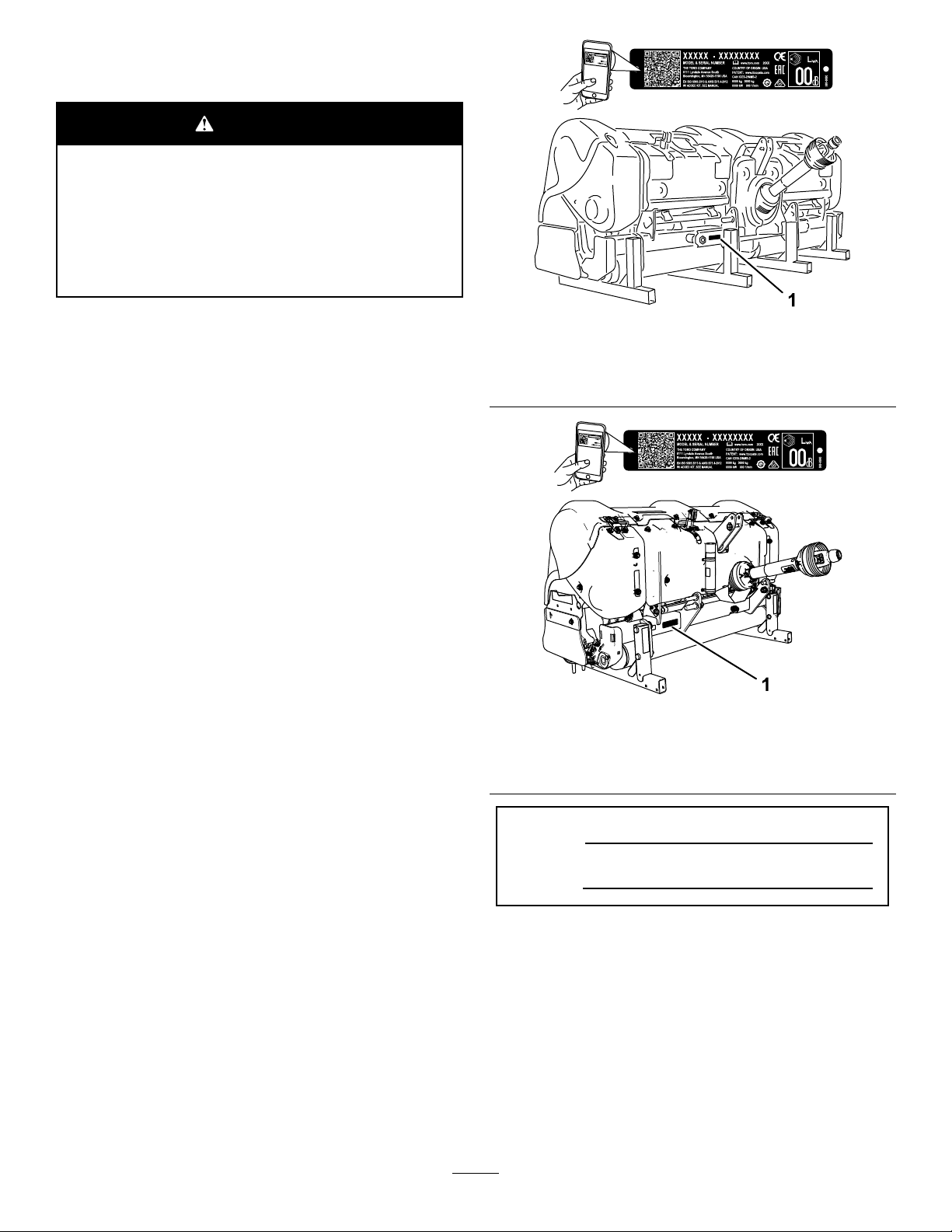

g262223

Figure1

Model09716

1.Modelandserialnumberlocation

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely .

Visitwww.Toro.comformoreinformation,including

safetytips,trainingmaterials,accessoryinformation,

helpndingadealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

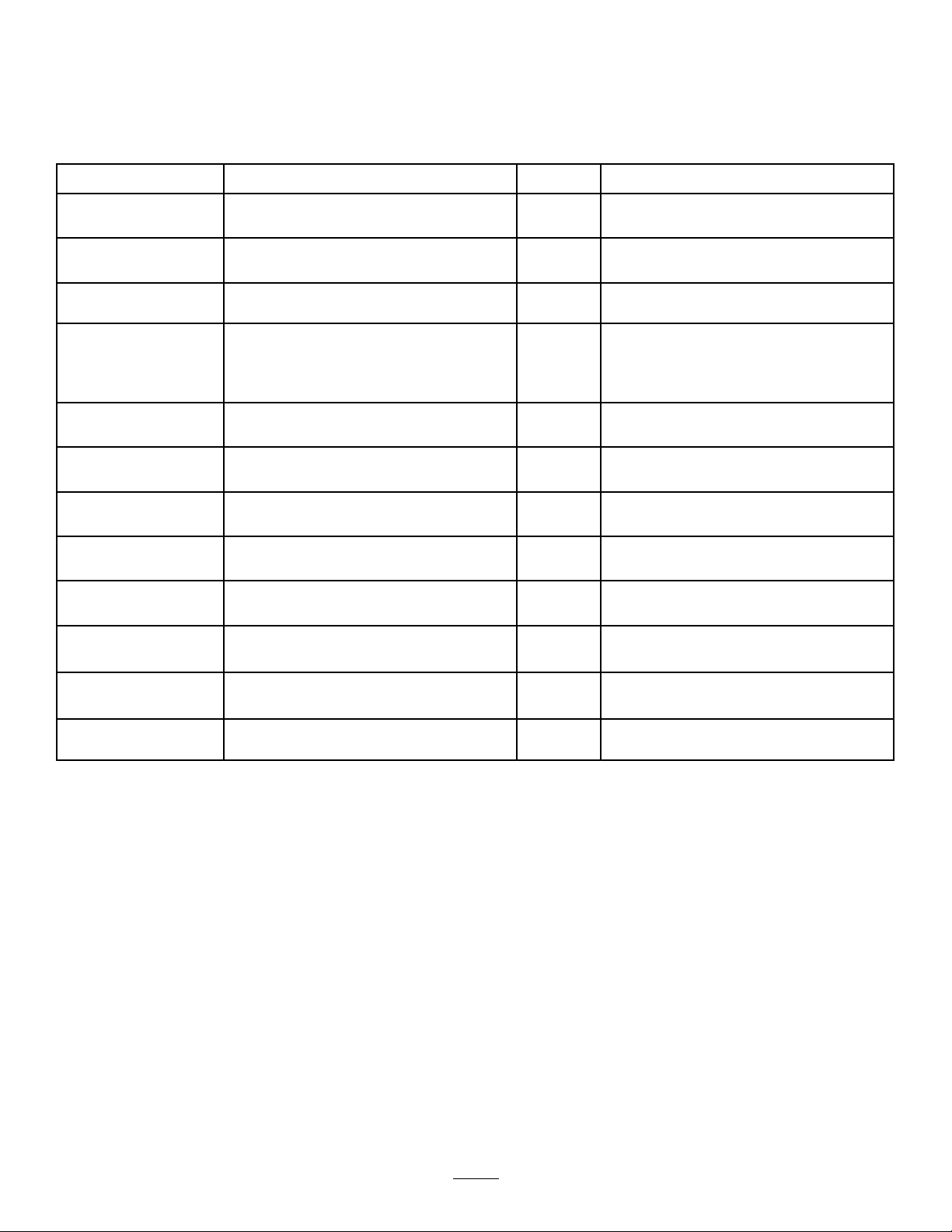

andserialnumbersofyourproductready.Figure1

andFigure2identifythelocationofthemodeland

serialnumbersontheproduct.Writethenumbersin

thespaceprovided.

Important:Withyourmobiledevice,youcan

scantheQRcodeontheserialnumberplate(if

equipped)toaccesswarranty,parts,andother

productinformation.

g262224

Figure2

Model09715

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafetyalertsymbol

(Figure3),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

©2020—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Figure3

Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Contents

Safety.......................................................................4

GeneralSafety...................................................4

SafetyandInstructionalDecals..........................4

Setup........................................................................8

1InspectingtheMachine....................................9

2ConnectingtheLowerLinkArms......................9

3ConnectingtheUpperLink.............................10

4ConnectingthePTODriveshaft.......................11

5AdjustingtheSwayLinks...............................12

6LevelingtheMachineSide-to-Side.................13

7AdjustingtheRollerScraper...........................13

8InstallingtheTineHeadsandthe

Tines.............................................................14

9InstallingtheTurfGuards...............................14

10SecuringtheHoodLatches(CE

only)..............................................................14

11ApplyingtheEntanglementDecal.................15

12RemovingtheStorageStands.....................16

ProductOverview...................................................17

Controls...........................................................17

Specications..................................................17

Attachments/Accessories.................................17

BeforeOperation.................................................21

BeforeOperationSafety...................................21

OutcrossTractionUnitControls........................21

AdjustingtheAerationDepth............................21

UnderstandingtheTractionUnit

Controls........................................................22

UnderstandingthePrinciplesof

Operation......................................................22

PracticingtheOperatingProcedures................22

PreparingtoAerate..........................................23

DuringOperation.................................................23

DuringOperationSafety...................................23

OperatingtheMachine.....................................24

AdjustingtheHoleSpacing...............................25

AeratingHardGround.......................................26

UsingNeedleTines..........................................26

AvoidingRootZoneLifting................................26

AdjustingtheRotalinkAssembly.......................26

OperatingTips.................................................27

AfterOperation....................................................27

AfterOperationSafety......................................27

TransportingtheMachine.................................27

g000502

CleaningtheMachineafterUse........................27

Maintenance...........................................................28

RecommendedMaintenanceSchedule(s)...........28

MaintenanceSafety..........................................28

JackingtheMachine.........................................29

GreasingtheBearingsandBushings................29

CheckingtheGearboxLubrication....................30

ChangingtheGearboxLubrication...................31

CheckingtheCoringHeadFastener

Torque...........................................................31

InspectingtheBelts..........................................31

AdjustingtheBeltT ension.................................31

ReplacingtheDriveBelt...................................32

AdjustingtheSideShield..................................34

ReplacingtheTurfGuards................................34

CoringHeadTiming..........................................34

RemovingtheMachinefromtheTraction

Unit...............................................................35

Storage...................................................................36

StorageSafety..................................................36

StoringtheMachine..........................................36

3

Safety

GeneralSafety

Thisproductiscapableofamputatinghandsand

feetandofthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriouspersonalinjury.

Usingthisproductforpurposesotherthanitsintended

usecouldprovedangeroustoyouandbystanders.

•Readandunderstandthecontentsofthis

Operator’sManualbeforeusingthemachine.

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

•Donotputyourhandsorfeetnearmoving

componentsofthemachine.

SafetyandInstructionalDecals

•Donotoperatethemachinewithoutallguards

andothersafetyprotectivedevicesinplaceand

functioningproperlyonthemachine.

•Keepclearofanydischargeopening.Keep

bystandersandpetsawayfromthemachine.

•Keepbystandersandchildrenoutoftheoperating

area.Neverallowchildrentooperatethemachine.

•Alwaysshutofftheengineofthetractionunit,

removethekey(ifequipped),waitforallmoving

partstostop,andallowthemachinetocool

beforeadjusting,servicing,cleaning,orstoring

themachine.

Improperlyusingormaintainingthismachinecan

resultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandalways

payattentiontothesafety-alertsymbol

meansCaution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeseinstructions

mayresultinpersonalinjuryordeath.

,which

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

93–6696

1.Storedenergyhazard—readtheOperator'sManual.

110-4665

decal93-6696

decal110-4665

1.ReadtheOperator'sManual.

1.Installthepostsinthe

standtotheholesinthe

frame.

4

decal110-4666

110-4666

2.Usepinstosecurethe

frametothestand.

1.Coringdepth

decal110-4668

110-4668

1.Entanglementhazard,shaft—stayawayfrommovingparts.

2.PTOspeedandinputdirection.

3.Usecliptosecurelashcablewhennotinuse.Uselash

cabletosupportthepowertake-offwhenthemachineis

decal110-4678

disconnectedfromtractor.

110-4678

decal110-4667

110-4667

1.Springlength

2.Storedenergyhazard—readtheOperator'sManual.

3.Entanglementhazard,belt—stayawayfrommovingparts.

110-4670

1.Warning—readtheOperator'sManual.

2.Warning—removethekeyandreadtheinstructions.

3.Warning—receivetrainingbeforeoperatingthemachine.7.Crushinghazardofhandandbody—supportmachineon

4.Entanglementhazard,belt—stayawayfrommovingparts.

5.Entanglementhazard,belt—keepallguardsinplace.

6.Crushinghazardofhandorfoot—keepbystandersawayfrom

themachine.

standwhennotinuse.

8.Fallinghazard—donotcarrypassengers.

decal110-4670

5

decal92-1581

92–1581

decal92-1582

92–1582

decal110-4677

110-4677

1.Turnclockwiseto

decreaseaerationdepth.

110-4664

1.ReadtheOperator's

Manual.

2.Wrenchsize4.Torque

2.Turncounterclockwiseto

increaseaerationdepth.

decal110-4664

3.Boltsize

decal106-8856

106-8856

1.ReadtheOperator'sManual.

6

133-8061

138-9038

1.Entanglementhazard—readtheOperator’sManual;stay

awayfrommovingparts;keepallguardsandshieldsin

place.

decal133-8061

decal138-9038

7

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

6

7

8

9

Nopartsrequired

Lynchpin2

Linkpin1

Lynchpin1

Bolt(1/2x3inches)

Nut(1/2inch)

Shortdriveshaft,PartNo.115-2839

(maybeneeded;soldseparately)

Nopartsrequired

Nopartsrequired

Nopartsrequired

Nopartsrequired

Turfguards(notincluded)

Qty.

Use

–

1

1

–

–

–

–

–

–

Inspectthemachine.

Connectthelowerlinkarms.

Connecttheupperlink.

ConnectthePTOdriveshaft.

Adjusttheswaylinks.

Levelthemachineside-to-side.

Adjusttherollerscraper.

Installthetineheadsandthetines.

Installtheturfguards.

CEComplianceKit,PartNo.1 10-4693

10

11

12

(notincluded)

CEentanglementdecal

Lynchpin(ProCore864)

Lynchpin(ProCore1298)

1

4

4

8

Securethehoodlatches(requiredfor

CEonly).

Applytheentanglementdecal—CE

mowers

Removethestoragestands.

8

1

InspectingtheMachine

NoPartsRequired

Procedure

ProCore864

Usethefollowinglistasareference:

•Usea30PTOhorsepowerminimumwhen

aeratinginlighttonormalsoilconditions(sandyto

sandy/loamsoilswithaveragecompaction).

•Usea35PTOhorsepowerminimumwhen

aeratinginnormaltoheavysoilconditions(heavy

loam,clay,androckysoilswithaboveaverage

compaction).

•ThetractionunitmusthaveacategoryIor

II3-pointhitchwithaminimumimplementlift

capacityof714kg(1,575lb).

•ThetractionunitmusthaveaPTOoutput-shaft

speedof540rpm.

•Adequatefront-endweight(ballast)tooffsetthe

weightofthemachine.

•Checkthetireairpressureofthetractionunit.

Adjustthetireairpressureasneeded.

Important:Donotexceedthemaximum

orminimumtireinationpressuresas

recommendedbytiremanufacturer.

ProCore1298

Usethefollowinglistasareference:

•Usea45PTOhorsepowerminimumwhen

aeratinginlighttonormalsoilconditions(sandyto

sandy/loamsoilswithaveragecompaction).

•50PTOhorsepowerminimumwhenaeratingin

normaltoheavysoilconditions(heavyloam,clay ,

androckysoilswithaboveaveragecompaction).

•ThetractionunitmusthaveacategoryII3point

hitchwithaminimumimplementliftcapacityof

1043kg(2,300lb)implement.

•ThetractionunitmusthaveaPTOoutput-shaft

speedof540rpm.

•Adequatefront-endweight(ballast)tooffsetthe

weightofthemachine.

•Checkthetireairpressureofthetractionunit.

Adjustthetireairpressureasneeded.

Important:Donotexceedthemaximum

orminimumtireinationpressuresas

recommendedbytiremanufacturer.

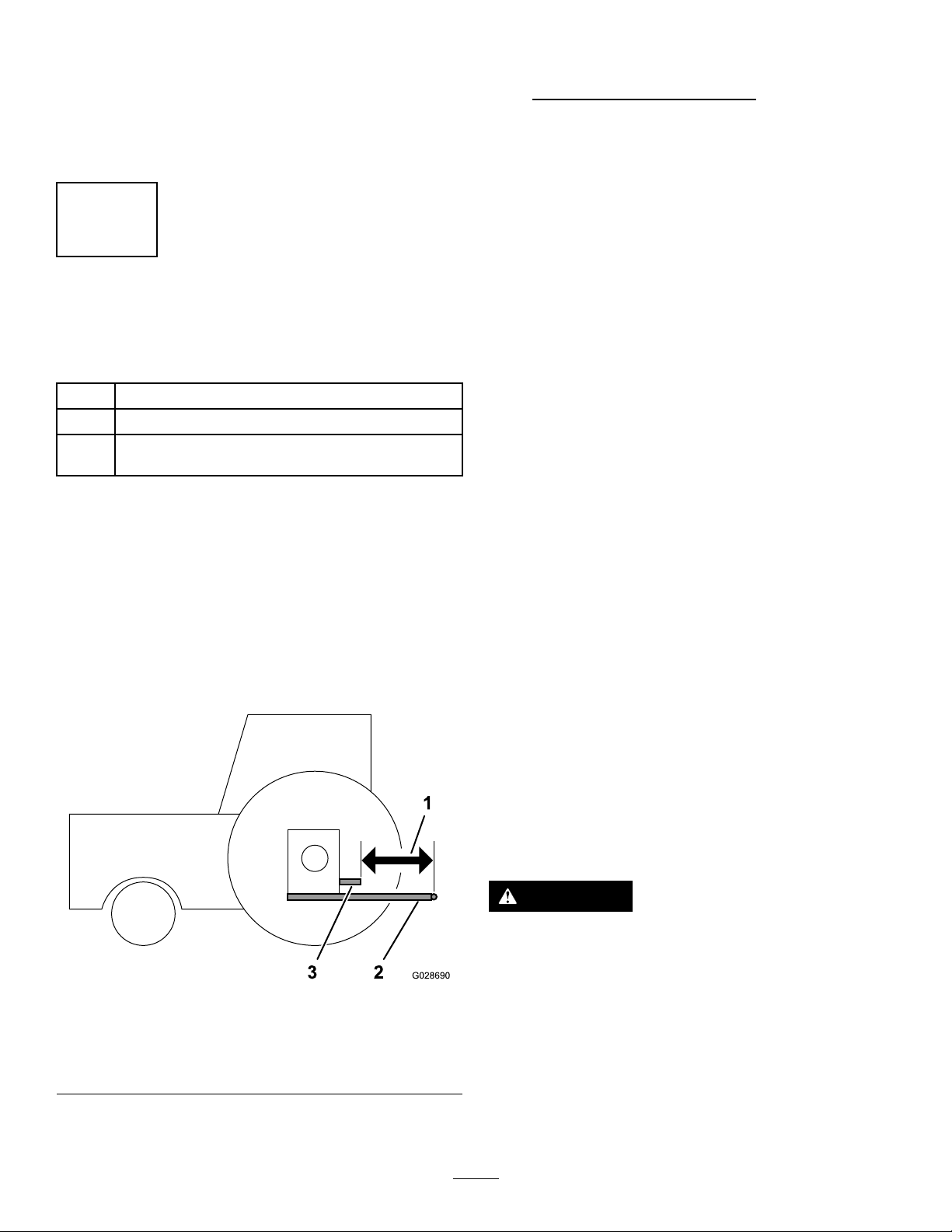

Figure4

3-PointHitchandPTOComponents

1.Lowerlinkarm

2.Upperlinkarm

BallastRequirements

3.PTOdriveshaft

4.Swaylink

WARNING

Mountingthemachinetotherearofthe

tractionunitdecreasestheweightonitsfront

axle.

Failuretoaddrequiredballastmayresultin

anaccidentandsevereinjuryordeath.

•Toensureadequatesteeringcontroland

stabilityyoumayneedtoaddballasttothe

frontofthetractionunit.

•Refertothetractionunitoperator'smanual

forballastrequirements.

2

ConnectingtheLowerLink

Arms

Partsneededforthisprocedure:

2Lynchpin

Procedure

1.Ensurethatthemachineispositionedonalevel

surfaceforinstallation.

2.EnsurethatthePTOisdisengaged.

g007332

9

3.Backthetractionunitsquarelyuptothemachine

untilthelowerlinkarmsarealignedwiththe

hitchpins.

4.Engagetheparkingbrake,shutofftheengine,

andremovethekeyfromtheignition.Waitfor

theengineandallmovingpartstostopbefore

leavingtheoperator'sseat.

Note:Formaximumgroundclearance,install

thehitchpinsinthelowermountingholesof

thehitchplateforthemachine(Figure5).T o

determinewhentousetheuppermounting

holes,refertosetupprocedure4Connectingthe

PTODriveshaft(page11).

3

ConnectingtheUpperLink

Partsneededforthisprocedure:

1Linkpin

1Lynchpin

Procedure

Note:Forbestaerationholequality,alignthefront

ofthemachineverticalwhileoperatingit(Figure7).

Adjusttheupperlinktocontrolthisangle.Referto

OperatingTips(page27)foradditionalinformation.

Figure5

1.Tophole(hitch

plate—machine)

5.Inserttherightandleftlowerlinkarmsontothe

hitchpins(Figure6).

2.Bottomhole(hitch

plate—machine)

Figure6

g028741

g007293

Figure7

1.Connecttheupperlinktothelowerholeinthe

bracketandsecureitwiththelinkpinandthe

lynchpin(Figure8).

g007292

1.Lowerlink2.Lynchpin

6.Securethelowerlinkarmstothehitchpinswith

thelynchpins(Figure6).

g007294

Figure8

1.Upperlink3.Lynchpin

2.Linkpin4.Locknut

10

2.Greasethethreadedsteelupperlinktubes.

3.Rotatetheupperlinktotightenthelink.Adjust

ituntiltheframeatthefrontofthemachineis

vertical(Figure8).

4.Tightenthelocknuttosecuretheupperlinkinto

position.

thelowertrailingarms(Figure9).Recordyour

measurementhere:

Important:ContactyourauthorizedT oro

distributorifyouneedanyassistancewhen

performingthismeasurementandifyou

needtoorderanoptionalshorterPTO

driveshaftassembly.

4

ConnectingthePTO

Driveshaft

Partsneededforthisprocedure:

1

Bolt(1/2x3inches)

1

Nut(1/2inch)

Shortdriveshaft,PartNo.1 15-2839(maybeneeded;

–

soldseparately)

DeterminingtheTrailingArm

LengthandPTODriveshaft

Important:RefertothePTOdriveshaftowner’s

manualforadditionaloperatingandsafety

information.

1.Placeastraightedgeacrosstheendsofthe

trailingarmstohelpyoudeterminethedistance

betweenthemandtheendofthePTOoutput

shaft(Figure9).

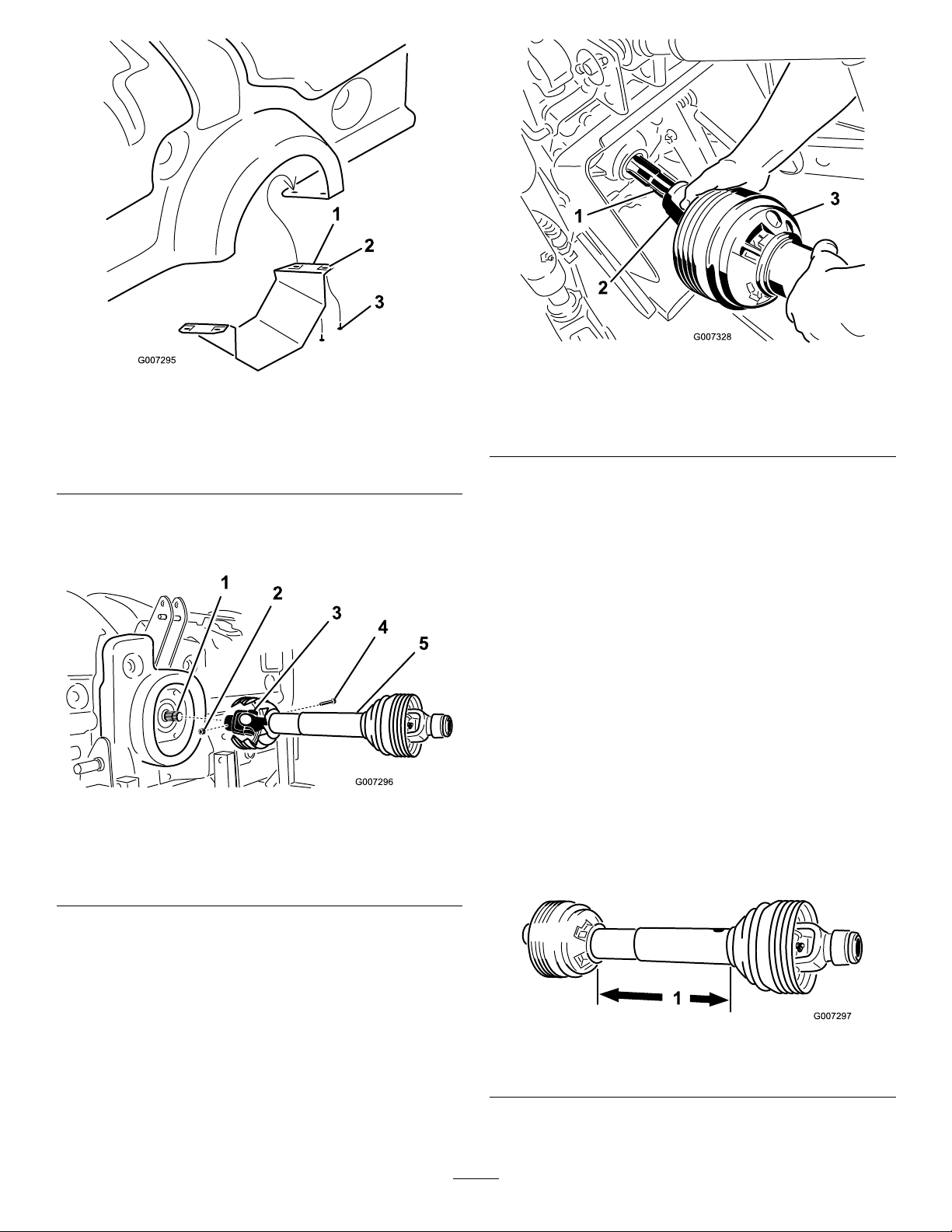

3.Determinewhetheryouneedastandardlength

PTOdriveshaftorashortPTOdriveshaftfrom

thepositionofthePTOoutputshaftonthe

tractionunit,relativetothepositionofthelower

trailingarms.Thisdistanceisdesignatedas“M”

dimension.

•ThestandardPTOdriveshaftincluded

withyourmachinetsatractionunit“M”

dimensionassmallas48.89cm(19.25

inches).

•Ifthe“M”dimensionissmaller,weofferan

optionalshortPTOdriveshaftassembly,

whichtsatractionunit“M”dimensionas

smallas39.37cm(15.50inches);referto

thePartsCatalogforyourmachine.

Important:Ifnecessary ,installthe

shortdriveshaft,PartNo.115-2839(sold

separately).Inmostcases,theshort

driveshaftisnotneeded.

4.Ifyourtractionunitisequippedwithadjustable

trailingarms,changethelengthoftrailingarms

untilthe“M”dimensionmeasures:

Refertotheoperator'smanualforyourtraction

unit.

Figure9

1.“M”dimension3.PTOoutputshaft(traction

unit)

2.Lowertrailingarms

2.Measurethedistancebetweentheendofthe

PTOoutputshaftandtheattachmentpointof

•48.89cm(19.25inches)orlongerforthe

standardPTOshaft

•39.37cm(15.50inches)orlongerforthe

optionalshortPTOshaft

InstallingthePTODriveshaft

CAUTION

OperatingthemachinewithoutthePTO

guardsandshieldsmaycauseinjuryordeath.

g028690

•KeepallPTOguardsandshieldsinplace.

•OnCEmodels,connectthechainsbetween

thePTOdriveshaftguardsandthelink

arms.

1.OntheProCore864only,removethelowerPTO

shield(Figure10).

11

Figure10

ProCore864

1.LowerPTOshield3.Screw

2.Clipnut

2.AssemblethePTOdriveshafttothegearbox

inputshaftofthemachine(Figure11)withabolt

(1/2x3.00inches)andanut(1/2inch).

Figure11

1.Gearboxinputshaft

2.Nut

3.PTOshaftcoupler

4.Bolt

5.PTOdriveshaft

g007328

g007295

1.PTOoutputshaft(traction

unit)

2.PTOshaftcoupler

Figure12

3.PTOdriveshaft

4.SlidethePTOdriveshaftforwardasfarasthe

PTOoutputshaftallows.

5.PullbackonthelockingcollarofthePTOshaft

couplertosecurethePTOdriveshaft.Slidethe

PTOdriveshaftbackandforthtoensurethatit

islockedsecurely.

6.OnCEmodelsonly,connectthesafetychains

fromthedriveshaftguardstotheweldedclipson

thelinkarms.Makesurethatthechainsremain

slackwhenthemachineisraisedorlowered.

7.OntheProCore864,installthelowerPTOshield

tothemachine.

8.Verifythatthetelescopingtubehasaminimum

of76mm(3inches)overlapwhenthemachine

israisedtothemaximumheight.

g007296

Tochecktheoverlap,measurethedistance

betweentheendshields,asshowninFigure

13.Thisdimensionmustnotexceed406mm

(16inches).Ifso,movethelowerliftpinstothe

uppersetofholesbeforeoperatingthemachine.

3.AssemblethePTOdriveshafttothePTOoutput

shaftofthetractionunit.

g007297

Figure13

1.406mm(16inches)

12

Loading...

Loading...