FormNo.3358-603RevC

ProCore864and1298Aerator

ModelNo.09715—SerialNo.280000001andUp

ModelNo.09716—SerialNo.280000001andUp

Registeratwww.T oro.com.OriginalInstructions(EN)

Contents

Introduction

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoidinjury

andproductdamage.Youareresponsibleforoperating

theproductproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comfor

productandaccessoryinformation,helpndinga

dealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready .Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafetyalertsymbol

(Figure2),whichsignalsahazardthatmaycauseserious

injuryordeathifyoudonotfollowtherecommended

precautions.

Figure2

1.Safetyalertsymbol

Thismanualuses2otherwordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Introduction.................................................................2

Safety...........................................................................3

SafeOperatingPractices.......................................3

SafetyandInstructionalDecals.............................5

Setup............................................................................8

1TractorRequirements........................................9

2ConnectLowerLinkArms.................................9

3ConnectUpperLink........................................10

4ConnectPTOShaft.........................................10

5AdjustingSwayLinks.......................................12

6LevelAeratorSide-to-Side...............................12

7AdjustRollerScraper.......................................13

8InstallTineHeads&Tines...............................13

9InstallTurfGuards..........................................13

10SecureHoodLatches(CEonly)......................14

11RemoveStorageStands..................................14

ProductOverview......................................................16

Controls.............................................................16

Specications.....................................................16

Attachments/Accessories...................................16

Operation...................................................................19

AdjustingAerationDepth..................................19

TractorControls.................................................19

PrinciplesofOperation......................................19

TrainingPeriod...................................................20

BeforeAerating..................................................20

AeratingProcedures...........................................20

OperatingTips...................................................21

HardGround.....................................................21

NeedleTines......................................................21

RootZoneLifting..............................................21

AdjustingtheRotolinkAssembly........................22

TransportOperation..........................................22

InspectionandCleanupafterUse........................22

Maintenance...............................................................23

RecommendedMaintenanceSchedule(s)................23

JackingtheMachine............................................23

GreasingtheBearingsandBushings....................23

CheckingtheGearboxLubrication.....................25

ChangingtheGearboxLubrication.....................25

CheckCoringHeadFastenerT orque...................25

InspectingtheBelts............................................25

AdjustingtheBeltTension..................................25

ReplacingtheDriveBelt.....................................26

AdjustingtheSideShield....................................27

ReplacingtheTurfGuards..................................28

AdjustingHoleSpacing......................................28

CoringHeadTiming...........................................28

RemovingtheAeratorfromtheTractor...............29

Storage.......................................................................30

©2008—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA.

AllRightsReserved

Safety

Improperuseormaintenancebytheoperatoror

ownercanresultininjury.T oreducethepotential

forinjury,complywiththesesafetyinstructions

andalwayspayattentiontothesafetyalert

symbol,whichmeansCAUTION,WARNING,or

DANGER-"personalsafetyinstruction."Failureto

complywiththeinstructionmayresultinpersonal

injuryordeath.

SafeOperatingPractices

BeforeOperating

•OwnersofthisAeratormustgiveoperatorsand

employeesfulloperationandsafetyinstructions

beforeallowingthemtooperatethismachineandat

leastannuallythereafter.Anoperatorwhohasnot

readandfullyunderstoodalloperatingandsafety

instructionsisnotqualiedtooperatethismachine.

Becomefamiliarwithallcontrolsandknowhowto

stopquickly.

•Donotallowchildrentooperatethemachine.Do

notallowadultstooperatethemachinewithout

properinstruction.

•Removealldebrisorotherobjectsthatmight

interferewithoperation.Keepallbystandersaway

fromtheworkarea.

•Locateandmarkallundergroundobstructionssuch

asirrigationcomponents,electricalortelephone

lines.

•Makesuretractorisinneutralandparkingbrake

appliedbeforestarting.RefertoTractorOperator’s

Manualforsafestartingprocedures.

•MountingtheProCoreAeratortotherearofthe

tractorwilldecreasetheweightonthetractorfront

axle.Toassureadequatesteeringcontrolandstability

itmaybenecessarytoaddballasttothefrontof

thetractor.RefertoTractorOperator’sManualfor

ballastrequirements.

•Keepallshieldsandsafetydevicesinplace.Ifa

shield,safetydeviceordecalisdamaged,repairor

replaceitbeforeoperationiscommenced.Also

tightenanyloosenuts,boltsandscrewstoensure

machineisinsafeoperatingcondition.

•Donotoperatemachinewhilewearingsandals,

tennisshoes,sneakersorshorts.Also,donot

wearloosettingclothingwhichcouldgetcaught

inmovingparts.Alwayswearlongpantsand

substantialshoes.Wearingsafetyglasses,safety

shoes,hearingprotectionandahelmetisadvisable

andmayberequiredbysomelocalordinancesand

insuranceregulations.

WhileOperating

•Keepallbystandersandpetsawayfromthework

area.

•Usingthemachinedemandsattention,andto

preventlossofcontrol:

–Useonlyindaylightorwhenthereisgood

articiallight.

–Watchforholesorotherhiddenhazards.

–Donottransportmachineclosetoasandtrap,

ditch,creekorotherhazard.

–Reducespeedonsidehillsandbeforemaking

sharpturnstopreventtippingorlossofcontrol.

–Lookbehindtheaeratorbeforebackingup.

•Ifthetinesstrikeasolidobjectorthemachine

vibratesabnormally,disengagethePTO,setthe

parkingbrakeandshuttheengineoff.Removekey

fromignitionswitch.Checkaeratorandtractionunit

fordamage.Repairanydamagebeforerestartingthe

engineandoperatingthetines.Besuretinesarein

goodconditionandallboltsaretight.

•Beforeleavingmachineunattended,disengagepower

toaerator,loweraeratorandsetparkingbrake.Stop

engine.

•Neverdismountwhiletractorisinmotion.Never

getonorofftractorwhileengineisrunningand

PTOdriveshaftisengaged.NeverstepoverPTO

shafttoreachothersideofaerator-walkaround

themachine.

•Parkaeratoronahard,levelsurface,installaerator

storagestandsbeforedisconnectingfromtractor.

•Ifitisnecessarytoprobebelowthesoilsurface,use

anonconductivematerialtopreventelectricalshock

incaseelectricalwiresarepresent.

Transporting

•Besureyouareincompliancewithallregulations

regardingtransportingequipmentonthepublic

roadsandhighways.

•Ensurethatallreectorsandlightsrequiredarein

placeandarecleanandvisiblebyovertakingand

oncomingtrafc.

•Neverallowanyonetorideonthemachineduring

transport.

•Reducespeedonroughroadsandsurfaces

•Independentbrakesshouldalwaysbelockedtogether

whenontheroad.

3

PTOShaft

StorageSafety

•ForallPTOshaftsteelparts(tubes,bearings,joints

etc.)disassemblyorrepairs,itishighlyadvisable

tocontactyourlocalTorodistributor.Removalof

componentsforrepairsandreassemblymaydamage

somepartsifnotcarriedoutcorrectlyusingspecial

toolsavailableinadistributor’sworkshop.

•ThePTOshaftmustnotbeusedwithouttheguards

supplied,withpartialprotectionorwithdamaged

guard,oronCEmachines,withoutthespecial

anti-rotationchainscorrectlyhooked,soastopermit

themaximumangleofthePTOshaftwithout

breakingthechains.

Maintenance

•Beforemakingadjustmentsorperforming

maintenanceontheaerator,switchofftheengine,

stopthePTOandapplytheparkingbrakebefore

dismountingfromthetractor.Besuretheaeratoris

onthegroundorloweredontothesafetystands.

•Supportthemachinewiththeblocks,jacksoron

storagestandswhenworkingbeneathit.Neverrely

onthetractor’shydraulicstosupportthemachine.

•Storetheaeratoronarmlevelsurface.

•Storeaeratorawayfromareasofhumanactivity.

•Donotallowchildrentoplayonoraroundthe

storedmachine.

•Makesuretheaeratorispositionedonrmandsolid

groundsoitdoesnotsinkortipover.

•Ensurethatthestoragestandlynchpinsaresecured

inplace.

•Placeallcontrolsinneutral,stoptheengine,apply

parkingbrakeandwaitforallmovingpartsto

stopbeforeservicing,maintaining,adjustingor

unblockingtheaerator.

•Besuremachineisinsafeoperatingconditionby

keepingnuts,boltsandscrewstight.Checkthe

tinemountingboltsfrequentlytobesuretheyare

tightenedtospecication.

•Donotcheckoradjustbelttensionwhenthetractor

engineisrunning.

•Besureallguardsarereplacedandthehoodis

securedshutaftermaintainingoradjustingthe

machine.

•Performonlythosemaintenanceinstructions

describedinthismanual.Ifmajorrepairsare

everneededorassistanceisdesired,contactan

AuthorizedToroDistributor.Toensureoptimum

performanceandsafety,alwayspurchasegenuine

Tororeplacementpartsandaccessoriestokeepthe

ToroallToro.Neveruse"will-t"replacementparts

andaccessoriesmadebyothermanufacturers.Look

fortheTorologotoensuregenuineness.Using

unapprovedreplacementpartsandaccessoriescould

voidthewarrantyofTheToroCompany.

4

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaof

potentialdanger.Replaceanydecalthatisdamagedorlost.

93-6696

1.Storedenergyhazard—readtheOperator’sManual.

110-4678

1.Coringdepth

1.ReadtheOperator’sManual.

110-4665

110-4667

1.Springlength

2.Storedenergyhazard—readtheOperator’sManual.

3.Entanglementhazard,belt—stayawayfrommovingparts.

1.Installthepostsinthe

standtotheholesinthe

frame.

110-4666

2.Usepinstosecurethe

frametothestand.

110-4668

1.Entanglementhazard,shaft—stayawayfrommovingparts.

2.PTOspeedandinputdirection.

3.Usecliptosecurelashcablewhennotinuse;uselash

cabletosupportthepowertakeoffwhenthemachineis

disconnectedfromtractor.

5

110-4670

1.Warning—readtheOperator’sManual.

2.Warning—removetheignitionkeyandreadtheinstructions

beforeservicingorperformingmaintenance.

3.Warning—receivetrainingbeforeoperatingthemachine.7.Crushinghazardofhandandbody—supportmachineon

4.Entanglementhazard,belt—stayawayfrommovingparts.

5.Entanglementhazard,belt—keepallguardsinplace.

6.Crushinghazardofhandorfoot—keepbystandersasafe

distancefromthemachine.

standwhennotinuse.

8.Fallinghazard—donotcarrypassengers.

1.Turnclockwiseto

decreaseaerationdepth.

92–1581

92–1582

110-4677

2.Turncounterclockwiseto

increaseaerationdepth.

6

106–8856

1.ReadtheOperator’sManual.

110-4664

1.ReadtheOperator’s

Manual.

2.Wrenchsize4.Torque

3.Boltsize

7

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

6

7

8

9

10

11

Qty.

Nopartsrequired

Lynchpin2

Linkpin1

Lynchpin1

Bolt(1/2x3inches)

Nut(1/2inches)

Nopartsrequired

Nopartsrequired

Nopartsrequired

Nopartsrequired

Turfguards(notincluded)A/RInstallTurfGuards

CEComplianceKit,PartNo.110–4693

(notincluded)

Lynchpin(ProCore864)

Lynchpin(ProCore1298)

–

1

1

–

–

–

–

1

4

8

TractorandballastRequirements

ConnectLowerLinkArms

ConnecttheUpperLink

ConnectPTOShaft

AdjustingSwayLinks

LevelAeratorSide-to-Side

AdjustRollerScraper

InstallTineHeads&Tines

SecureHoodLatches(RequiredforCE

only)

RemoveStorageStands

Use

8

1

TractorRequirements

NoPartsRequired

Procedure

ProCore864

•30PTOhorsepowerminimumwhenusedinlightto

normalconditions(sandytosandy/loamsoilswith

averagecompaction).

•35PTOhorsepowerminimumwhenusedinnormal

toheavyconditions(heavyloam,clayandrockysoils

withaboveaveragecompaction).

•CategoryIorII3pointhitch,ratedtoliftatleasta

1575lb.(714Kg)implement.

TractorComponents(Figure3)

Figure3

1.Lowerlinkarm

2.Upperlinkarm

3.PTOshaft

4.Swaylink

•540rpmtractorPTO˙.

•Adequatefront-endweight(ballast).

•Correcttirepressure.

Donotexceedthemaximumorminimum

tractortireinationpressuresasrecommended

bytiremanufacturer.

ProCore1298

•45PTOhorsepowerminimumwhenusedinlightto

normalconditions(sandytosandy/loamsoilswith

averagecompaction).

•50PTOhorsepowerminimumwhenusedinnormal

toheavyconditions(heavyloam,clayandrockysoils

withaboveaveragecompaction).

•CategoryII3pointhitch,ratedtoliftatleasta2300

lb.(1043Kg)implement.

•540rpmtractorPTO˙.

•Adequatefront-endweight(ballast).

BallastRequirements

MountingtheProCoreaeratortotherearofthe

tractorwilldecreasetheweightonthefront

axle.

•Toassureadequatesteeringcontroland

stabilityitmaybenecessarytoaddballast

tothefrontofthetractor.

•RefertotractorOperator’sManualfor

ballastrequirements.

•Failuretoaddrequiredballastmayresultin

anaccidentandsevereinjuryordeath.

2

ConnectLowerLinkArms

Partsneededforthisprocedure:

•Correcttirepressure.

Donotexceedthemaximumorminimum

tractortireinationpressuresasrecommended

bytiremanufacturer.

2Lynchpin

Procedure

1.Aeratormustbepositionedonaat,levelsurface

forinstallation.

2.Backtractorsquarelyuptoaeratoruntillowerlink

armsarealignedwithhitchpins.

9

3.MakesurePTOisdisengaged.

4.Engageparkingbrake,STOPengineandremovekey

fromignition.Waitforengineandallmovingparts

toSTOPbeforeleavingOperator’sseatontractor.

Note:Formaximumgroundclearancethehitch

pinsshouldbesecuredinthelowermountingholes.

Todeterminewhentousetheuppermountingholes,

refertoConnectingthePTOShaft.

5.Insertrightandleftlowerlinkarmsontohitchpins

(Figure4).

Figure5

1.Connectupperlinktolowerholeinbracketand

securewithlinkpinandlynchpin(Figure6).

Figure4

1.Lowerlink2.Lynchpin

6.Securelowerlinkarmstohitchpinswithlynchpins

(Figure4).

3

ConnectUpperLink

Partsneededforthisprocedure:

1Linkpin

1Lynchpin

Procedure

Note:Thefrontofaeratormustbeverticalwhile

operatingforbestaerationholequality(Figure5).Adjust

upperlinktocontrolthisangle.RefertoOperationfor

additionalinformation.

Figure6

1.Upperlink3.Lynchpin

2.Linkpin4.Locknut

2.Greasethethreadedsteelupperlinktubes.

3.Rotatetheupperlinktotightenthelink.Adjustuntil

frontofaeratorframeis90degreesfromhorizontal

(Figure6).

4.Tightenlocknuttosecureupperlinkintoposition.

10

4

ConnectPTOShaft

Partsneededforthisprocedure:

1

Bolt(1/2x3inches)

1

Nut(1/2inches)

Procedure

1.OntheProCore864only,removethelowerPTO

shield(Figure7).

Figure8

1.Gearboxinputshaft

2.Nut

3.PTOshaftcoupler

4.Bolt

5.PTOshaft

3.ConnectPTOshafttoreartractorPTOshaft.

Figure7

1.LowerPTOshield

(ProCore864only)

2.Tinnermannut

3.Screw

2.ConnectPTOshafttogearboxinputshaftwitha

1/2x3.00inchboltand1/2inchnut(Figure8).

Figure9

1.Tractoroutputshaft3.PTOshaft

2.PTOshaftcoupler

4.SlidePTOshaftforwardasfarasthetractorallows.

5.PullbackonthelockingcollartosecurethePTO

shaftinplace.SlidePTOshaftbackandforthto

makesureitisproperlylocked.

6.OnCEmodelsonly,connecttheshieldsafetychains

frompowershaftsectionstoweldedclipsonlink

arms.Makesurechainsremainslackwhenaerator

israisedorlowered.

Tohelppreventbodilyinjury,keepallPTO

shieldsinplace.OnCEmodels,connectthe

shieldchainstolinkarmstopreventshields

fromrotatingduringoperation.

11

7.OntheProCore864,installthelowerPTOshield

totheaerator.

8.Verifythatthetelescopingtubehasaminimumof

3inches(76mm)overlapwhentheaeratorisraised

toit’ smaximumheight.

Tochecktheoverlap,measurethedistancebetween

theendshields,asshowningureFigure10.This

dimensionmustnotexceed16.00inches(406mm).

Ifso,thelowerliftpinsMUSTbemovedtothe

uppersetofholespriortooperation.

Figure10

1.16.00inches(406mm)

5

Figure11

1.Swaylink

Adjustthelowerlinksinboarduntiltheycontactthe

aeratormountingplates.Thiswillreducethestress

onthepins.Ifthetractorhasswaychainsinsteadof

swaylinks,itisrecommendedthatwashersbeinstalled

betweenthelowerlinkarmandlynchpintoreducethe

overhungloadontheliftpins.

AdjustingSwayLinks

NoPartsRequired

Procedure

TheProCore864isdesignedtobeoffsetfromthe

tractorcenterline.ThePTOshaftisoffset1.57inches

totheleftofcenterandtheaeratorisoffset5.70inches

totherightofthecenterline.Adjusttheswaylinksas

required.

TheProCore1298isdesignedtobecenteredwiththe

tractorcenterline.Adjusttheswaylinksasrequired.

Adjustswaylinksonlowerdraftarmsof3pointhitchto

minimizeside-to-sideswaytoamaximumof1inch(25

mm)oneachside(Figure11).

Note:RefertotractorOperator’sManualforadditional

installationandadjustmentprocedures.

6

LevelAeratorSide-to-Side

NoPartsRequired

Procedure

1.Parktractorandaeratoronalevel,rmsurface.

2.Placelevelontopofaeratorframetocheckforlevel

side-to-side(Figure12).

12

2.Slidetherollerscraperinoroutuntilrequired

positionisattainedandtightenfasteners.

3.OntheProCore864only,thestopboltonthecenter

supportmayalsobeadjustedtoattaintheproper

gap.

Figure12

1.Level

3.Turntheadjustablelinkbody(ifprovided)toraise

orlowerthelinkarmuntiltheaeratorisleveled

side-to-side.

Note:RefertotractorOperator’sManualfor

additionaladjustmentprocedures.

7

AdjustRollerScraper

NoPartsRequired

Procedure

Therollerscrapershouldbeadjustedsothereisagap

ofapproximatelya.06-.09inches(1-2mm)betweenthe

scraperandroller.

1.Loosenfastenerssecuringeachendofscraperto

rollerscrapertab(Figure13).

8

InstallTineHeads&Tines

NoPartsRequired

Procedure

Awideselectionoftinesandtineheadsareavailable

fortheaerator.Choosethetinetype,sizeandspacings

requiredforthejob.Installthetineheadandtinesper

InstallationInstructionssuppliedwitheachtinekit.

Refertothechartsonpages17&18fortheaccessories.

Important:Neveroperatetheaeratorwithout

thetineheadsinstalled.Thearmsmaymove

excessivelyanddamagetheaeratorframe.

9

InstallTurfGuards

Partsneededforthisprocedure:

A/RTurfguards(notincluded)

Figure13

1.Rollerscraper2.Nut

Procedure

Awideselectionofturfguardsareavailableforthe

aerator.Usetheappropriateturfguardsfortheselected

tineheads.

1.Loosennutssecuringturfguardclampstoturfguard

toolbar(Figure14).

13

Figure14

1.Turfguard2.Turfguardclamp

2.Slideappropriateturfguardunderturfguardclamp.

3.Adjusttheturfguards,lefttoright,tomaintain

equaldistancetotineswithineachslot.Tightennuts

securingturfguard.

4.Mountremainingturfguardsandsecureturfguard

clamps.

Important:Fromtherearofthemachine,

checkthatthetineslineupwiththecenterof

thegapsintheturfguards.

10

SecureHoodLatches(CE

only)

Partsneededforthisprocedure:

1

CEComplianceKit,PartNo.110–4693(notincluded)

Procedure

Figure15

1.Tapbolt3.Internallockwasher

2.Lockbracket4.Rearcover

2.OntheProCore1298model,installalockbracket

overalltherearlowerhoodlatchesandtheoutside

upperhoodlatchonbothrightandleftrearcovers

withatapbolt(threepercoringhead,sixtotal)

(Figure15).

3.Usingapliersoradjustablewrench,threadan

internallockwasherontoeachbolt(1-2threads)to

securelatch(Figure15).

11

RemoveStorageStands

Partsneededforthisprocedure:

4

Lynchpin(ProCore864)

8

Lynchpin(ProCore1298)

Note:CECompletionKit,PartNo.110–4693is

requiredtocompletethisstep.

1.OntheProCore864model,installalockbracket

overtheleftandrightrearlowerhoodandupper

hoodlatcheswithatapbolt(fourtotal)(Figure15).

Procedure

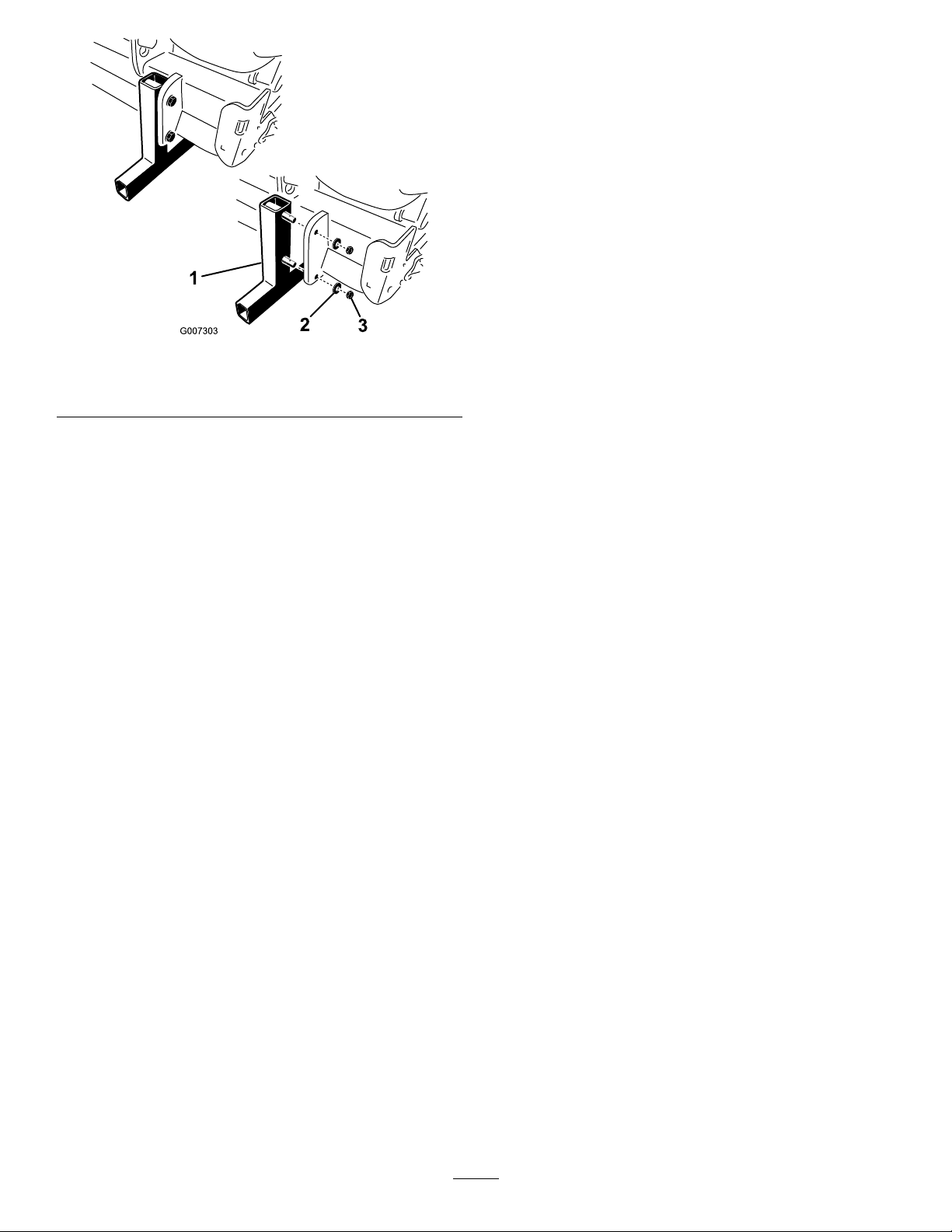

1.Raisetheaerator3-6inchesoffground.

2.Removethenutsandlockwasherssecuringthe

storagestandstotheaerator(Figure16).

14

Figure16

1.Storagestand

2.Lockwasher

3.Nut

3.Removethestoragestands.

4.Insertthelynchpins(includedinlooseparts)into

thestandpinsforstorage(Figure16).

5.Usethestoragestandswhenevertheaeratoris

removedfromthetractor.

15

ProductOverview

Controls

DepthAdjuster

Rotatethedepthadjusterinputshaftclockwise(CW)to

reducetheaerationdepthorrotatecounterclockwise

(CCW)toincreasetheaerationdepth(Figure17).

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

ProCore864Aerator

WorkingWidth

OverallWidth67inches(170cm)

OverallLength35inches(89cm)

OverallHeight38.5inches(98cm)

64inches(163cm)

Figure17

1.Depthadjusterinputshaft

2.Lockingplate4.Depthalignmentmark

3.Depthindicatordecal

Note:Seventeen(17)revolutionsofthedepthadjuster

equalsapproximately1/4inch(6.4mm)depthchange.

Weight

ProCore1298Aerator

WorkingWidth

OverallWidth101inches(257cm)

OverallLength35inches(89cm)

OverallHeight38.5inches(98cm)

Weight

1,575pounds(714Kg)

98inches(249cm)

2300pounds(1043Kg)

Attachments/Accessories

AselectionofToroapprovedattachmentsand

accessoriesareavailableforusewiththemachineto

enhanceandexpanditscapabilities.Contactyour

AuthorizedServiceDealerorDistributororgoto

www.Toro.comforalistofallapprovedattachments

andaccessories.

16

Figure18

17

Figure19

18

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

AdjustingAerationDepth

Adjusttheaerationdepthonlywhenthetractor

isparked,theparkingbrakeisengaged,the

engineisoffandthePTOisdisengaged.

1.Laythedesiredtineontothedepthdecalwhile

aligningthetinetipwiththedesiredaerationdepth

asshowninFigure20.

Figure21

1.Depthadjusterinputshaft

2.Lockingplate4.Depthalignmentmark

4.Pushinonthesocketoruseyourhandtodepress

thelockingplate.

5.Rotatethedepthadjusterclockwise(CW)toreduce

theaerationdepthorrotatecounterclockwise

(CCW)toincreasetheaerationdepth.(Figure21).

6.Rotatethedepthadjusterinputshaftuntilthe

desireddepthisattainedasshownonthedepth

indicatordecal(Figure21).

3.Depthindicatordecal

Figure20

2.Determinethelettersettingalignedwiththe

mountingendoftine(Figure20).Adjustthedepth

controltothecorrespondingletteronthedecal.

3.Inserta9/16”socketw/ratchetontothedepth

adjusterinputshaft(Figure21).

Note:Seventeen(17)revolutionsofthedepth

adjusterinputshaftequalsapproximately1/4inch

(6.4mm)depthchange.

TractorControls

Itisnecessarytofamiliarizeyourselfwiththeoperation

ofthefollowingtractorcontrolsbeforeyouareableto

operatetheaerator:

•PTOEngagement

•3PointHitch(Raise/Lower)

•Clutch

•Throttle

•GearSelection

•Parkingbrake

Note:RefertotractorOperator’sManualfor

operatinginstructions.

PrinciplesofOperation

Thetractor’ sthreepointhitchlinkageliftstheaerator

fortransportandlowersitforoperation.

Thetractor’spowertakeoff(PTO)poweristransmitted

viashafts,gearboxanddrivebeltstoanumberof

crankshaftswhichdrivethetineholdingarmsintothe

turfsurface.

19

AsthetractortravelsforwardwiththePTOengaged

andthemachinelowered,aseriesofholesarecreated

intheturfsurface.

Thedepthofthetine’spenetrationisdeterminedbythe

heightofthedepthcontrol.

Thedistancebetweentheholescreatedisdetermined

bythetractor’sgearratio(orhydrostatictractionpedal

position)andthenumberoftinesineachtinehead.

Simplychangingenginerpmdoesnotchangehole

spacing.

TrainingPeriod

Beforeusingtheaerator,ndaclearareaandpractice

usingthemachine.Operatethetractoratrecommended

gearsettingsandPTOdrivespeedsandbecome

thoroughlyfamiliarwithmachinehandling.Practice

stoppingandstarting,raisingandloweringtheaerator,

disengagingthePTOdriveandaligningthemachine

withpreviouspasses.Apracticesessionassures

condenceintheperformanceoftheaeratorandhelps

ensureuseofproperoperatingtechniqueswherever

themachineisoperated.

Iftherearesprinklerheads,electricalorcommunication

linesorotherobstructionsintheareatobeaerated,

marktheseitemstoensuretheyarenotdamagedduring

operation.

Toavoidpersonalinjury,neverleavethetractor

seatwithoutrstdisengagingthePTOdrive,

settingtheparkingbrakeandstoppingthe

engine.Neverperformaeratorrepairswithout

rstloweringtheaeratorontothestorage

standorappropriateblockingorjacks.Besure

allsafetydevicesaresecuredinproperplace

beforeresumingoperation.

AeratingProcedures

Note:Whenusingneedletineheads,makesuretoread

instructions,includedwithkit,foruniqueoperating

procedure.

1.Lowertheaeratoronthe3pointlinkagesothatthe

tinesarenearlytothegroundatthelowestpartof

theirstroke.

2.Atalowtractorenginerpm,engagethepowertake

off(PTO)clutchtostarttheaeratorworking.

Important:Neveroperatetheaeratorwithout

thetineheadsinstalled

3.Selectagearthatgivesaforwardspeedof

approximately.6-2.5M.P .H.(1to4km/hr.)at

theratedPTOspeedof540(refertothetractor

Operator’sManual).

4.Astheclutchisreleasedandthetractormoves

forward,lowerthemachinefullyintotheturfand

increaseenginespeedtogiveamaximumof540

rpmatthePTO.

Important:NeveroperatethetractorPTO

inexcessof540rpmordamagetotheaerator

couldoccur.

Note:Makesurethattherollerisontheground.

5.Notetheholepattern.Ifyourequiregreaterhole

spacing,increaseforwardthespeedofthetractorby

shiftingupagearorwithahydrostaticdrivetractor,

actuatethehydrostatleverorpedaltogivefaster

speed.Forcloserholespacing,decreasetractor

forwardspeed.Changingenginespeed,ina

particulargear,willnotchangetheholepattern.

Important:Lookbehindfrequentlyto

ensurethemachineisoperatingproperlyand

alignmentismaintainedwithpreviouspasses.

6.Usethefronttractorwheelasaguidetomaintain

equallateralholespacingwiththepreviouspass.

7.Attheendoftheaerationpass,raisetheaeratorand

disengagethePTO.

BeforeAerating

Inspecttheareaofoperationforhazardsthatcould

damagethemachineandremovethem,ifpossible,or

planhowtoavoidthem.Carryreplacementtinesand

toolsincasetinesaredamagedduetocontactwith

foreignmaterials.

8.Ifyoubackintoatightarea(likeateebox),

disengagethePTOandraisetheaeratortoits

highestposition.Usecautionnottocatchtheturf

guardsontheturf.

9.Alwayscleartheareaofalldamagedmachineparts,

suchasbrokentines,etc.,topreventanything

frombeingpickedupbymowersorotherturf

maintenanceequipmentandthrown.

10.Replacebrokentines,inspectandcorrectdamageto

thosestillusable.Repairanyothermachinedamage

beforecommencingoperation.

20

OperatingTips

1.EngagePTOatlowenginespeed.Increaseengine

speedtoachievePTOspeedof540rpm(maximum)

andtheloweraerator.Operateatanenginerpm

thattheaeratorrunsmostsmoothly.

Note:Changingengine/PTOrpminaparticular

tractorgear(orxedhydrostaticpedalposition

ontractorswithhydrostatictransmission)willnot

changeholespacing.

2.Makeverygradualturnswhenaerating.Nevermake

sharpturnswithPTOdriveengaged.Planyour

aerationpathbeforeloweringtheaerator.

frombeingpickedupbymowersorotherturf

maintenanceequipmentandthrown.

10.Replacebrokentines,inspectandcorrectdamageto

thosestillusable.Repairanyothermachinedamage

beforecommencingoperation.

HardGround

Ifthegroundistoormtoobtainthedesiredcoring

depth,thecoringheadcangetintoa“bouncing”

rhythm.Thisisduetothehardpanthetinesare

attemptingtopenetrate.Thisconditioncanbe

correctedbyattemptingoneormoreofthefollowing:

3.Iftractor“bogs”downwhenoperatingonhard

groundorgoinguphill,raiseaeratorslightlyuntil

speedisregained,thenloweraeratoragain.

4.Donotaerateifgroundistoohardordry.Best

resultsareobtainedafterarainorwhenturfhas

beenwateredthepreviousday.

Note:Iftherollerridesupoffthegroundwhile

aerating,thegroundistoohardtoachievethe

desireddepth,reducetheaerationdepthuntilthe

rollercontactsthegroundduringoperation.

5.Raiseaeratorpenetration,ifgroundishardpacked.

Cleanupcoresandre-aerateatdeeperpenetration,

preferablyafterwatering.

6.TheProCore864aeratorisoffsettothetractor’s

rightsidetoallowaeratingwithoutdrivingoverthe

coreswiththetractortires.Wheneverpossible,

aeratewiththelongeroffsettowardstheprevious

aerationpass.

7.Alwayscheck/adjusttoplinkwheneveraeration

depthischanged.Thefrontoftheaeratorshould

bevertical.

Toavoidpersonalinjury,neverleavethetractor

seatwithoutrstdisengagingthePTOdrive,

settingtheparkingbrakeandstoppingthe

engine.Neverperformaeratoradjustments

orrepairswithoutrstloweringtheaerator

ontothesafetystand.Besureallsafetydevices

aresecuredinproperplacebeforeresuming

operation.

•Bestresultsareobtainedafterarainorwhenturf

hasbeenwateredthepreviousday.

•Reducethenumberoftinesperstomper

arm.Attempttomaintainasymmetricaltine

congurationtoevenlyloadthestomperarms.

•Reduceaeratorpenetration(depthsetting)ifground

ishardpacked.Cleanupcores,waterturf,and

aerateagainatadeeperpenetration.

Aerationofsoiltypesbuiltontopofhardsubsoils

(i.e.sand/soilcapplacedoverrockyground)cancause

undesiredholequality.Thisiscausedwhentheaeration

depthisgreaterthanthesoilcapandthesubsoilis

toohardtopenetrate.Whenthetinescontactthis

subsoiltheaeratormayliftandcausethetopofthe

holestobecomeelongated.Reducetheaerationdepth

sufcientlytoavoidpenetrationintothehardsubsoil.

NeedleTines

Longslendertinesusedineitheraneedletinehead

orminitineheadcanleavethefrontorrearofthe

holetuftedorslightlydeformed.Holequalityforthis

congurationgenerallyimprovesifthecoringhead

speedisreduced10-15%fromfulloperatingspeed.For

PTOpoweredaeratorsreducedtheenginespeeduntil

thePTOspeedisaround460–490rpm.Theforward

spacingisnoteffectedbyreducingtheenginespeed.

Thepushedholecanalsobeaffectedbythepositionof

therotalinkdamperassembly.RefertoAdjustingthe

RotolinkAssembly.

RootZoneLifting

8.Lookbehindfrequentlytoensurethemachineis

operatingproperlyandalignmentismaintainedwith

previouspasses.

9.Alwayscleartheareaofalldamagedmachine

parts,suchasbrokentines,etc.,topreventthem

Usingthemini-tineheadsinconjunctionwithlarger

coringtinesorlargediametersolidtinescaninduce

signicantstressontherootzoneoftheturf.This

stresscanfracturetherootzoneandcausealifting

actiontotheturf.Ifthisdamageoccurstryoneor

moreofthefollowing:

21

•Reducetinedensity(removesomeofthetines)

•Decreasecoringdepth(suggestedin1/2inch

increments)

•Increaseforwardholespacing(changetractor

transmissionuponegear)

•Decreasethetinediameter(solidorcoring)

AdjustingtheRotolink

Assembly

Themountingheightoftherotalinkdamperassembly

affectsthereactiveforceappliedtothestomperarm

andgroundengagementduringaeration.Intheevent

ofthefrontoftheholebeingpushed(elongatedor

dimpled),a“stiffer”positioncanhelpresistthispush

andimproveholequality .Intheeventofthebackof

theholebeingpushed(elongatedordimpled)a“softer”

positioncanimprovetheholequality.

Toadjusttherotolinkassembly ,proceedasfollows:

1.Removethe(2)1/2inchlocknutssecuringthe

rotolinkdamperassemblytotheundersideofcoring

headframe(Figure22).

2.Lowerthedamperassemblytoexposethespacers

(Figure22).

3.Moveoneortwospacerspersidefromthedamper

assemblytothetopofthecoringheadframe.Each

spacerisequivalentto1/2inch.Thelowerbumper

spacermustremainondamperassembly.

Toseetheeffectsofthisadjustment,itissuggested

thatonlythreetofourassembliesbeadjustedto

comparetheoriginalpositionandthenewposition

onatrialpass.Whensatisfactoryresultsare

achieved,movetheremainingassembliestothe

sameheightasthedesiredarms.

TransportOperation

Tobegintransportoperation,raisetheaeratorand

disengagethePTO.Toavoidlossofcontrol,traverse

steepinclinesslowly,approachroughareasatreduced

speedandcrosssevereundulationscarefully .

Important:Donotexceedtransportspeedsof15

m.p.h.(24km/hr.).

InspectionandCleanupafter

Use

Afterdailyuse,thoroughlywashthemachinewith

agardenhosewithoutanozzlesocontamination

andsealandbearingdamageduetoexcessivewater

pressurewillbeavoided.Abrushmaybeusedto

removecaked-onmaterial.Usemilddetergenttoclean

thecovers.Aftercleaning,greasealldrivelinesand

rollerbearings,inspectformachinedamage,oilleakage,

componentandtinewear.

Remove,cleanandoilthetines.Sprayalightoilmist

oncoringheadbearings(crank&damperlinks).

Figure22

1.Rotolinkdamperassembly4.Dwasher

2.Lowerbumperspacer5.Locknut

3.Spacer(s)

4.Reassemblethedamperassemblytothecoringhead

frame.Ensurethe“D”washerisinstalledagainst

thecoringheadframeasshowninFigure22.Secure

the(2)locknuts.

22

Maintenance

RecommendedMaintenanceSchedule(s)

MaintenanceService

Aftertherst8hours

Beforeeachuseordaily

Every50hours

Every100hours

Every250hours

Every500hours

Beforestorage

JackingtheMachine

Interval

Yearly

MaintenanceProcedure

•ChangetheGearboxLubrication

•Checkthetorqueofthecoringheadfasteners

•Checkthebelttension

•Checkbelttension

•Greasebearingsandbushings

•Inspectbearings

•Checkgearboxlubrication

•ChangetheGearboxLubrication

•Checkthetorqueofthecoringheadfasteners

•Inspectbearingsandreplaceasneeded

•Performall50hourmaintenanceprocedures

•Chippedsurfaces-Paint

•Removeandcleantines

•Removealldebris

•Inspectthebelts

Whenchangingattachmentsorperforming

otherservice,usecorrectblocks,hoistsor

jacks.Makesuremachineisparkedonasolid

levelsurfacesuchasaconcreteoor.Priorto

raisingmachine,removeanyattachmentsthat

mayinterferewiththesafeandproperraising

ofthemachine.Alwayschockorblocktow

vehiclewheels.Usejackstandsorsolidwood

blockstosupporttheraisedmachine.Ifthe

machineisnotproperlysupportedbyblocks

orjackstands,themachinemaymoveorfall,

whichmayresultinpersonalinjury.

Note:Ifavailable,ahoistcanbeusedtolifttherearof

theProCoreAerator.Useeyeletsincoringheadbearing

housingsashoistattachmentpoints(Figure23)

Figure23

1.Liftingeyelet

GreasingtheBearingsand

Bushings

ServiceInterval:Every50hours

Themainworkingbearingsoftheaeratoraresealed

forlifeandrequirenomaintenanceorlubrication.

Thisdrasticallyreducesthemaintenancerequiredand

eliminatestheriskofgreaseoroilbeingdroppedonto

theturf.

23

Therearegreasettingsthatmustbelubricatedwith

anSAEmultipurpose,high-temperaturegreasewith

highpressure(EP)performanceorSAEmultipurpose

lithiumbasegrease.

Thelubricationpointsare:

PTOShaft(3)(Figure24)

Figure24

Rollerbearings(ProCore864qty.2;ProCore1298qty .

4)(Figure25)

Figure26

Important:Bearingsrarelyfailfromdefectsin

materialsorworkmanship.Themostcommon

reasonforfailureismoistureandcontamination

workingitswaypasttheprotectiveseals.Bearings

thataregreasedwillrelyuponregularmaintenance

topurgeharmfuldebrisfromthebearingarea.

Sealedbearingsrelyonaninitialllofspecialgrease

andarobustintegralsealtokeepcontaminantsand

moistureoutoftherollingelements.

Figure25

Driveshaftbearings(ProCore864qty.1;ProCore1298

qty.2)(Figure26)

Thesealedbearingsrequirenolubricationorshortterm

maintenance.Thisminimizesroutineservicerequired

andreducesthepotentialofturfdamageduetogrease

contamination.Thesesealedbearingpackageswill

providegoodperformanceandlifeundernormaluse,

butperiodicinspectionsofbearingconditionandseal

integrityshouldbeconductedtoavoiddowntime.These

bearingsshouldbeinspectedseasonallyandreplacedif

damagedorworn.Bearingsshouldoperatesmoothly

withnodetrimentalcharacteristicssuchashighheat,

noise,loosenessorrustweeping

Duetotheoperatingconditionsthesebearing/seal

packagesaresubjectto(i.e.sand,turfchemicals,water,

impacts,etc.)theyareconsiderednormalwearitems.

Bearingsthatfailduetootherthandefectsinmaterialsor

workmanshiparetypicallynotcoveredunderwarranty.

Note:Bearinglifecanbenegativelyaffectedby

improperwashdownprocedures.Donotwash

downtheunitwhenitisstillhotandavoiddirecting

high-pressureorhighvolumesprayatthebearings.

Itiscommonfornewbearingstopurgesomegrease

outthesealsonanewunit.Thispurgedgreasewillturn

blackincolorduetocollectionofdebrisandnotdueto

excessiveheat.Itisgoodpracticetowipethisexcess

greasefromthesealsaftertheinitial8hours.Theremay

alwaysappeartobeawetareaaroundtheseallip.This

24

isgenerallynotdetrimentaltobearinglife,butkeeps

thesealliplubricated.

Coringheadbearingreplacementissuggestedat

intervalsof500hours.Abearingservicekitwhich

coversthecompletecoringheadisavailablefromyour

distributor.

CheckingtheGearbox

Lubrication

ServiceInterval:Every100hours

Thegearboxislledwith80W–90gearoilorequivalent.

Allowthegearboxtocoolbeforecheckingthe

lubrication.

1.Cleandebrisfromllplugandcheckplugtoavoid

contamination.

2.Removethecheckplugfromthegearbox(Figure27).

1.Cleandebrisfromllpluganddraincaptoavoid

contamination(Figure27).

2.Removethellplugtorelieveairdraw .

3.Positionadrainpanunderthedraintubeandremove

draincap.

Note:Thehighviscosityofcooloilwillextendthe

draintime.(approximately30minutes)

4.Afteroiliscompletelydrained,reinstallthedraincap.

5.Fillwith56ounces(1650ml)ofhighquality80W -90

gearlube.

6.Installthellplug.

7.Checktheoillevel.

CheckCoringHeadFastener

Torque

ServiceInterval:Aftertherst8hours

Every250hours

Aftertheinitial,eight(8)hoursofuse,checkthecoring

headfastenerstoensurepropertorqueismaintained.

Fastenertorquerequirementsarelistedonthereference

servicedecalbelowandlocatedonthecoringhead.

Figure27

1.Fillplug3.Drainplug

2.Checkplug(rearof

gearbox)

3.Makesureoilisuptothebottomofthecheckplug

holeingearbox(Figure27).

4.Ifoillevelislow,removellplugfromgearboxand

replenishoilasrequired.

5.Installplugs.

ChangingtheGearbox

Lubrication

ServiceInterval:Aftertherst8hours

Every250hours

Thegearboxislledwith80W–90gearoilorequivalent.

Figure28

1.ReadtheOperator’s

Manual.

2.Wrenchsize4.Torque

3.Boltsize

InspectingtheBelts

ServiceInterval:Yearly

Thedrivebelt(s)ontheProCoreAeratorshavebeen

designedtobeverydurable.However,thenormal

exposuretoUVradiation,ozoneorincidentalexposure

tochemicalscandeterioratetherubbercompounding

overtimeandleadtoprematurewearormaterialloss

(i.e.chunking).

Annualbeltinspectionishighlyrecommendedforsigns

ofwear,excessivecushioncracks,orlargeembedded

debriswithreplacementwhenneeded.

AdjustingtheBeltTension

ServiceInterval:Beforeeachuseordaily

25

Makesurebeltsareproperlytensionedtoensurecorrect

operationofunitandunnecessarywear.

1.Properbelttensionisattainedbycompressing

idlerspringtoalengthof5.75inches(146mm)

(Figure29).

Figure31

1.Springretainer2.5.75inches(146mm)

D.Adjustthespringretainertoattainrequired

compressedspringlength(Figure31).

E.Tightenlocknutagainstspringretainertolock

adjustment.

Figure29

2.Toadjustbelttension,proceedasfollows:

A.Removetherearcoringheadcover(Figure30).

Figure30

1.Rearcoringheadcover2.Pulleyshield

F.Reinstallthepulleyshieldandcoringheadcover.

ReplacingtheDriveBelt

Note:Theoutboardstomperarmdoesnotneedtobe

removedtoreplacethedrivebelt.

RemovingtheBelt

1.Removetherearcoringheadcover(Figure32).

B.Removethepulleyshieldmountingboltsand

removetheshield(Figure30).

C.Loosenthelocknutsecuringthespringretainer

(Figure31).

Figure32

1.Rearcoringheadcover2.Pulleyshield

2.Removethepulleyshieldmountingboltsandremove

theshield(Figure32).

3.Removethefastenerssecuringthedirtshieldandthe

lowerbeltshield(Figure33)Removethedirtshield

andthelowerbeltshield.

26

Figure33

1.Lowerbeltshield2.Dirtshield

4.Toreleasetheidlerspringtension,loosenthelock

nutsecuringthespringretainer(Figure34)and

rotatethespringretainer.

Figure34

1.Springretainerlocknut

Figure35

1.Drivebelt4.Washer

2.Rotalinkdamper

3.Nut

5.#1Stomperarm

6.Lowertherotalinkdamperfromthecoringhead

frame.

7.Routethedrivebeltdownthroughthecoringhead

frameandaroundthelowerendofthe#1stomper

armFigure35

InstallingtheBelt

1.Routethenewdrivebeltaroundthelowerendofthe

#1stomperarmandupthroughcoringheadframe.

2.Positionthedrivebeltontothecrankpulley ,under

theidlerassemblyandoverthedrivepulley

3.Raisetherotalinkdamperforthe#1stomperarmto

coringheadframe.Ensurethatthedamperspacers

areinstalledinthesamepositionasinremoval.

4.Securetherotalinkdampertothecoringhead

withthetwo(2)washersandlocknutspreviously

removed.

Springsareundertension,usecautionwhen

adjustingorremoving.

5.Loosenandremovethetwo(2)locknutsand

washerssecuringtherotalinkdamperforthe#1

stomperarm(Figure35).

5.Installandadjustthebeltidlerpulleyandadjustto

theappropriatetension.

6.Installdirtshieldandlowerbeltshield.Adjustlower

shieldtoensureclearancewithbelt.

7.Installpulleyandcoringheadcovers.

AdjustingtheSideShield

Thecoringheadsideshieldsshouldbeadjustedsothe

bottomridesbetween1to1.5inchesfromtheturfwhile

aerating.

1.Loosentheboltsandnutssecuringthesideshieldto

frame(Figure36).

27

1.Sideshield

Figure36

CoringHeadTiming

TheunitizedcoringheaddesignoftheProCoreaerators

providesindustryleadingsmoothoperationwhiletaking

outtheguessworkoftiming.

ProCore864(Figure38)

Thisunithasapatentpendingtimingcongurationthat

makesuseoftheProCore648andProCore1298crank

armcastings.Eachpairofcrankarmsjoinedthrougha

bearinghousingaretimed180degreesapart(i.e.arm

positions1-2,3-4,5-6,7-8).Theadjacentpairsareallset

withthesametimingwherethelaterpairlagsby120

degrees.Thesamepairofcouplingcastingsareused

betweenalladjacentpairs(i.e.couplingpositions2-3,

4-5,6-7).Tofurtherreduceoperatingvibration,two

counterweightsareaddedatthe#1positiononthe

pulleyandthe#8position.

2.Adjustshieldupordownandtightennuts.

ReplacingtheTurfGuards

Allturfguards(Figure37)shouldbereplacedifbroken

orworntolessthan1/4inchthickness.Brokenturf

guardscancatchandtearturfcreatingundesirable

damage.

Figure37

1.Turfguard

Note:Thenumberscastintothecrankarmswillnot

alignwiththeraisedindicatormarkonthebearing

housingsfortheProCore864.

Figure38

ProCore1298(Figure39)

Thisunitiscomprisedoftwoindependentcoringheads

withsixarmseach.Thetimingofeithercoringheadis

notdependentontheadjacentcoringhead.Thetiming

marksareeasilyidentiedbythenumberscastintothe

crankarmcastingsandtheraisedlocatoronthebearing

housings.The#1armalwaysstartswiththedrivepulley.

AdjustingHoleSpacing

Theforwardholespacingisdeterminedbythetractor’s

gearratio(orthehydrostatictractionpedal).Changing

theengineRPMdoesnotchangetheforwardhole

spacing.

Thelateralholespacingisdeterminedbythenumber

oftinesinthetineheads.

28

Figure39

RemovingtheAeratorfrom

1.Lynchpins

Figure40

2.Storagestand

theTractor

1.Stopvehicleonalevelsurface,notonaslope.

2.DisengagethePTOandengagetheparkingbrake.

3.Stoptheengineandremovethekeyfromignition

switch.

4.BeforeleavingtheOperator’sseatontractor,wait

forengineandallmovingpartstostop.

5.Installthestoragestandsandsecuretotheaerator

withlynchpins(Figure40).

Note:Theaeratorcanbestoredonitsoriginal

shippingpallet.

6.Slowlyloweraeratoruntilstoragestandscontact

ground.

7.Loosenlockingnutandrotateupperadjustinglink

toreleasetensionbetweenaeratorandtractor.

8.Removelynchpinandtoplinkpinsecuringcenter

linktobracket.Retainlynchpinandtoplinkpin

withaerator.

9.DisconnectsafetyshieldchainsfromPTOtractor

(CEonly).

10.Pullbackonthelockcollartodisconnectthepower

shaftfromthetractorPTOshaft.

11.SlidePTOshaftbackandremovefromtractor.

12.ConnectthePTOtethertothePTOshieldto

preventthePTOshaftfromcontactingtheground

(Figure41).

29

Figure41

1.PTOtether

13.Removelynchpinsandslidelowerlinkarmsoff

hitchpins.Retainlynchpinswithaerator.

Storage

Attheendofanaeratingseasonorwhentheaeratorwill

notbeusedforalongperiod,itisgoodpracticetocarry

outthefollowingpreventativemaintenance.

1.Cleanoffanydirtorgreasethatmayhave

accumulatedontheaeratororanyofthemoving

parts.

2.Removeandcleanouttines.Coattineswithoilto

preventrustingduringstorage.

3.Openthehoodandcleanouttheinsideofthe

machine.

4.Lubricateallgreasettings.

5.Storethemachineontheprovidedstoragestandson

ahard,drysurface.

6.TetherthePTOshaftinstoredpositiontoprevent

damage.orremovethePTOandstoreunderthe

hoodtominimizecorrosion.

7.Painttherollerandtouch-upanyotherscratcheson

thepaintedsurfaces.

8.Replaceanymissingordamageddecals.

9.Storetheaeratorinsideadrysecurebuilding.Inside

storagewillreducemaintenance,givealonger

workinglifeandincreasetheresidualvalueofthe

machine.Ifinsidestorageisnotavailable,coverwith

aheavysheetortarpaulinandsecuretightly .

30

Notes:

31

The Toro General Commercial Products Warranty

A Two-Year Limited Warranty

Conditions and Products Covered

The Toro Company and its affiliate, Toro Warranty Company,

pursuant to an agreement between them, jointly warrant your Toro

Commercial Product (“Product”) to be free from defects in

materials or workmanship for two years or 1500 operational

hours*, whichever occurs first. Where a warrantable condition

exists, we will repair the Product at no cost to you including

diagnosis, labor, parts, and transportation. This warranty begins

on the date the Product is delivered to the original retail purchaser.

* Product equipped with hour meter

Instructions for Obtaining Warranty Service

You are responsible for notifying the Commercial Products

Distributor or Authorized Commercial Products Dealer from whom

you purchased the Product as soon as you believe a warrantable

condition exists.

If you need help locating a Commercial Products Distributor or

Authorized Dealer, or if you have questions regarding your

warranty rights or responsibilities, you may contact us at:

Toro Commercial Products Service Department

Toro Warranty Company

8111 Lyndale Avenue South

Bloomington, MN 55420-1196

952-888-8801 or 800-982-2740

E-mail: commercial.service@toro.com

Owner Responsibilities

As the Product owner, you are responsible for required maintenance and adjustments stated in your operator’s manual. Failure

to perform required maintenance and adjustments can be grounds

for disallowing a warranty claim.

Items and Conditions Not Covered

Not all product failures or malfunctions that occur during the

warranty period are defects in materials or workmanship. This

express warranty does not cover the following:

• Product failures which result from the use of non-Toro

replacement parts, or from installation and use of add-on,

modified, or unapproved accessories

• Product failures which result from failure to perform required

maintenance and/or adjustments

• Product failures which result from operating the Product in an

abusive, negligent or reckless manner

• Parts subject to consumption through use unless found to be

defective. Examples of parts which are consumed, or used up,

during normal Product operation include, but are not limited to,

blades, reels, bedknives, tines, spark plugs, castor wheels,

tires, filters, belts, and certain sprayer components such as

diaphragms, nozzles, and check valves, etc.

• Failures caused by outside influence. Items considered to be

outside influence include, but are not limited to, weather,

storage practices, contamination, use of unapproved coolants,

lubricants, additives, or chemicals, etc.

• Normal “wear and tear” items. Normal “wear and tear” includes,

but is not limited to, damage to seats due to wear or abrasion,

worn painted surfaces, scratched decals or windows, etc.

Parts

Parts scheduled for replacement as required maintenance are

warranted for the period of time up to the scheduled replacement

time for that part.

Parts replaced under this warranty become the property of Toro.

Toro will make the final decision whether to repair any existing part

or assembly or replace it. Toro may use factory remanufactured

parts rather than new parts for some warranty repairs.

General Conditions

Repair by an Authorized Toro Distributor or Dealer is your sole

remedy under this warranty.

Neither The Toro Company nor Toro Warranty Company is

liable for indirect, incidental or consequential damages in

connection with the use of the Toro Products covered by this

warranty, including any cost or expense of providing substitute equipment or service during reasonable periods of

malfunction or non-use pending completion of repairs under

this warranty. Except for the Emissions warranty referenced

below, if applicable, there is no other express warranty. All

implied warranties of merchantability and fitness for use are

limited to the duration of this express warranty.

Some states do not allow exclusions of incidental or consequential

damages, or limitations on how long an implied warranty lasts, so

the above exclusions and limitations may not apply to you.

This warranty gives you specific legal rights, and you may also

have other rights which vary from state to state.

Note regarding engine warranty: The Emissions Control System

on your Product may be covered by a separate warranty meeting

requirements established by the U.S. Environmental Protection

Agency (EPA) and/or the California Air Resources Board (CARB).

The hour limitations set forth above do not apply to the Emissions

Control System Warranty. Refer to the Engine Emission Control

Warranty Statement printed in your operator’s manual or contained in the engine manufacturer’s documentation for details.

Countries Other than the United States or Canada

Customers who have purchased Toro products exported from the United States or Canada should contact their Toro Distributor (Dealer)

to obtain guarantee policies for your country, province, or state. If for any reason you are dissatisfied with your Distributor’s service or

have difficulty obtaining guarantee information, contact the Toro importer. If all other remedies fail, you may contact us at Toro Warranty

Company.

Part No. 374-0031 Rev. C

Loading...

Loading...