Page 1

Reel Mower

Basics

PART NO. 09168SL

Page 2

This page is intentionally blank.

Page 3

Reel Mowers 1

Table of Contents

Historical Background......................................................................................................2

Application.......................................................................................................................6

Theory.............................................................................................................................8

Importance of the Operator ...........................................................................................18

Preventive Maintenance................................................................................................19

Set-up and Adjustments................................................................................................21

Quality of Cut and Aftercut Appearance........................................................................30

Sharpening....................................................................................................................34

Bedknives, Rollers and Accessories..............................................................................47

Groomers and Thatchers...............................................................................................52

Toro University Technical Training

Page 4

2 Reel Mowers

Historical Background

The concept of the reel mower goes back to the

1800's. It evolved out of a need for groomed turf

areas being maintained on a regular basis.

The first reel type fairway gang mowers were horse

drawn.

Here is an example of a horse drawn three gang

fairway mower.

Toro University Technical Training

Page 5

Reel Mowers 3

The first tractor drawn gang mower. (Toro “Bull”

Tractor in 1926).

Golf course development during the 1920’s and 30’s

brought about design improvements in engines and

mower drive systems.

These improvements continued, allowing for lighter

weight and easier to use equipment.

Toro University Technical Training

Page 6

4 Reel Mowers

Productivity and quality of cut improved.

The development of hydraulics during the 50's and

60's improved the reliability, safety, operator comfort

and lowered maintenance costs.

With the introduction of the riding greens mower, the

industry reached new heights in the areas of

productivity and efficiency.

Toro University Technical Training

Page 7

Reel Mowers 5

The introduction of hydraulically driven cutting units

greatly reduced wheel slippage and the resulting

turf stress.

Although dramatic improvements have been made

in reel type mowers, some of the same frustrations

that developed working with reel cutting units years

ago are still present today.

Toro University Technical Training

Page 8

6 Reel Mowers

Application

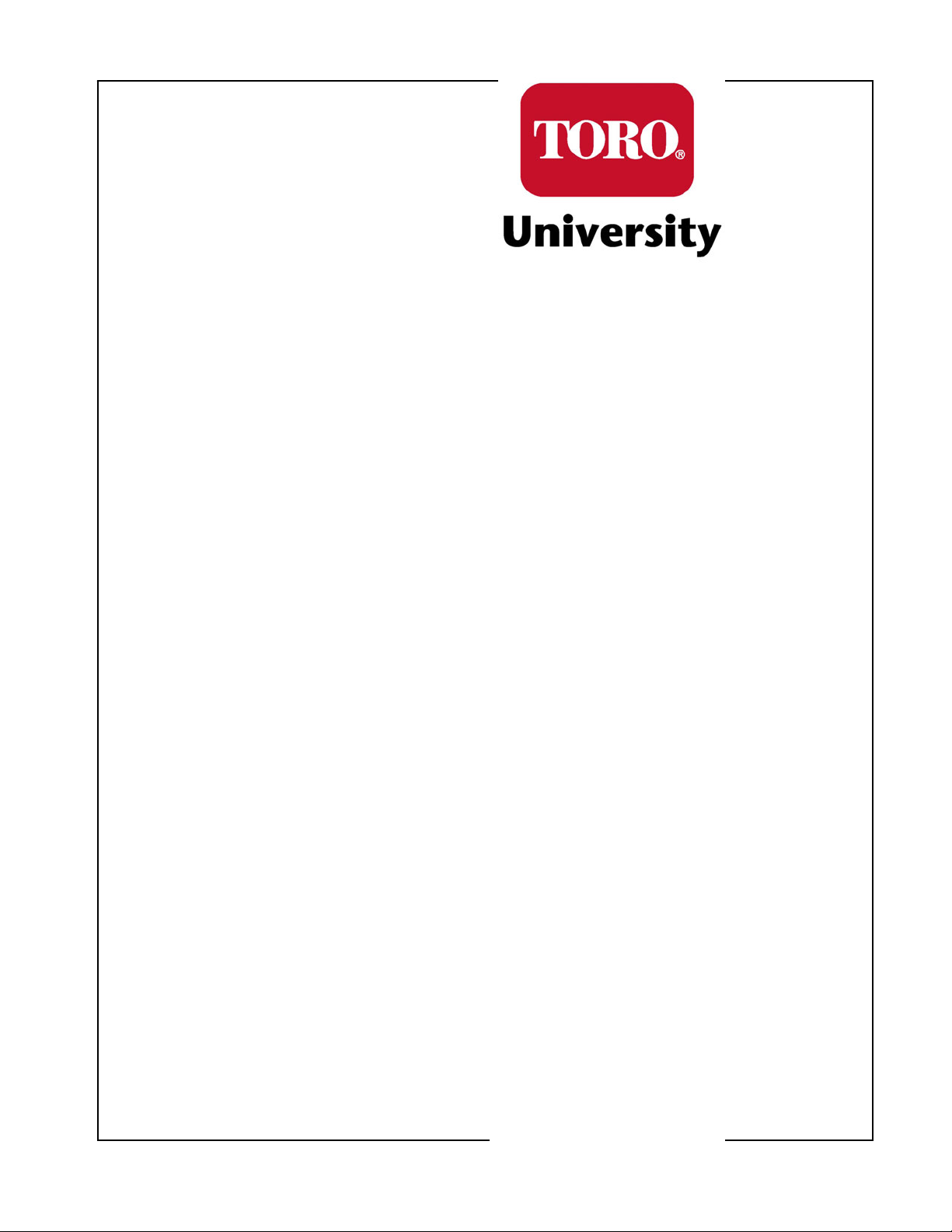

When properly maintained and operated, reel mowers provide superior quality of cut and aftercut

appearance. These mowers are typically dedicated to mowing formal turf areas at low heights of cut. A triplex

riding greens mower is shown here; a Toro Greensmaster 3150 with DPA (Dual Precision Adjust) cutting

units.

Golf course greens are intensely managed, and

Applications

mowed every day, at heights of cut from 1/16 in. –

1/4 in. (2.5 mm – 5 mm).

Greens

Average Height of Cut:

1/16 in. – 1/4 in.

(2.5 mm – 5 mm)

Mowing Frequency:

Daily

Greensmaster

Tees are typically mowed three times per week, at

heights of cut from 3/8 in. – 1/2 in. (9 mm – 12 mm).

Tees

Average Height of Cut:

3/8 in. – 1/2 in.

(9 mm – 12 mm)

Mowing Frequency:

Three times per week

Reelmaster

Greensmaster

Toro University Technical Training

Page 9

Reel Mowers 7

Fairways are typically mowed three times per week,

at heights of cut, from 3/8 in. – 3/4 in. (9 mm – 19

mm). Other areas, such as intermediate / semiroughs and surrounds may also be maintained with

reel mowers.

Reel mowers are also utilized, for mowing elite

sports fields and other finely manicured turf areas.

Fairway

Other Applications

• Sports fields

• Other finely manicured

turf areas

Average Height of Cut:

3/8 in. – 3/4 in.

(9 mm – 19 mm)

Mowing Frequency:

Three times per week

to daily

Reelmaster

Reelmaster

Greensmaster

Toro University Technical Training

Page 10

8 Reel Mowers

Theory

This section will describe the construction, and cutting action of a reel mower cutting unit.

If reel mowers' unique characteristics are not understood and responded to, the end result will be a poor

quality of cut, and expensive down time and repairs.

reel

frame

bedknife

rear roller

front roller

There are three main structural members in a reel cutting unit:

The REEL, consists of several helix shaped blades, mounted to a rotating shaft.

The BEDKNIFE, is attached to the bedbar and the assembly is mounted to the main frame in a manner that

allows for paralleling and adjustment to the reel.

The FRAME, supports the rollers, the bedbar assembly and reel with its drive mechanism, which can be

hydraulic, belt driven, or ground driven.

A reel mower cuts grass with a scissors-like shearing action, as the moving helix shaped blades pass over

the stationary bedknife. The cutting action requires that the bedknife and reel blades, be sharp, matched, and

in close relationship with each other.

Toro University Technical Training

Page 11

Reel Mowers 9

The reel consists of a number of helix shaped

Construction Details

Support

(Spider)

Bedknife Bedbar

Reel

Construction Details

Side Plate

Reel Blade

Shaft

Frame

blades, welded to supports and mounted to a shaft.

This weldment is then ground to be a perfect

cylinder.

The reel is rotated by a drive system, usually a

hydraulic motor.

Below the reel is the bedbar assembly. The

bedknife is held rigidly in position on the bedbar by

screws.

The bedknife is sharpened to be flat and square so

the sharp edge contacts the reel blades across their

entire length.

If the bedknife is not flat, or the reel is not a perfect

cylinder, it is impossible to get the bedknife to

contact along the entire length of the reel.

The reel is supported by precision bearings held

within the side plates.

The side plates are held in place by a frame.

This becomes the reel assembly, and is a precision

cutting tool.

The reel assembly is supported by rollers, and

pulled along the ground by a carrier frame.

Bedbar Assembly

Bedbar Pivot Bolt

Everything comes together, to make a precision

cutting tool.

Toro University Technical Training

Page 12

10 Reel Mowers

Terminology

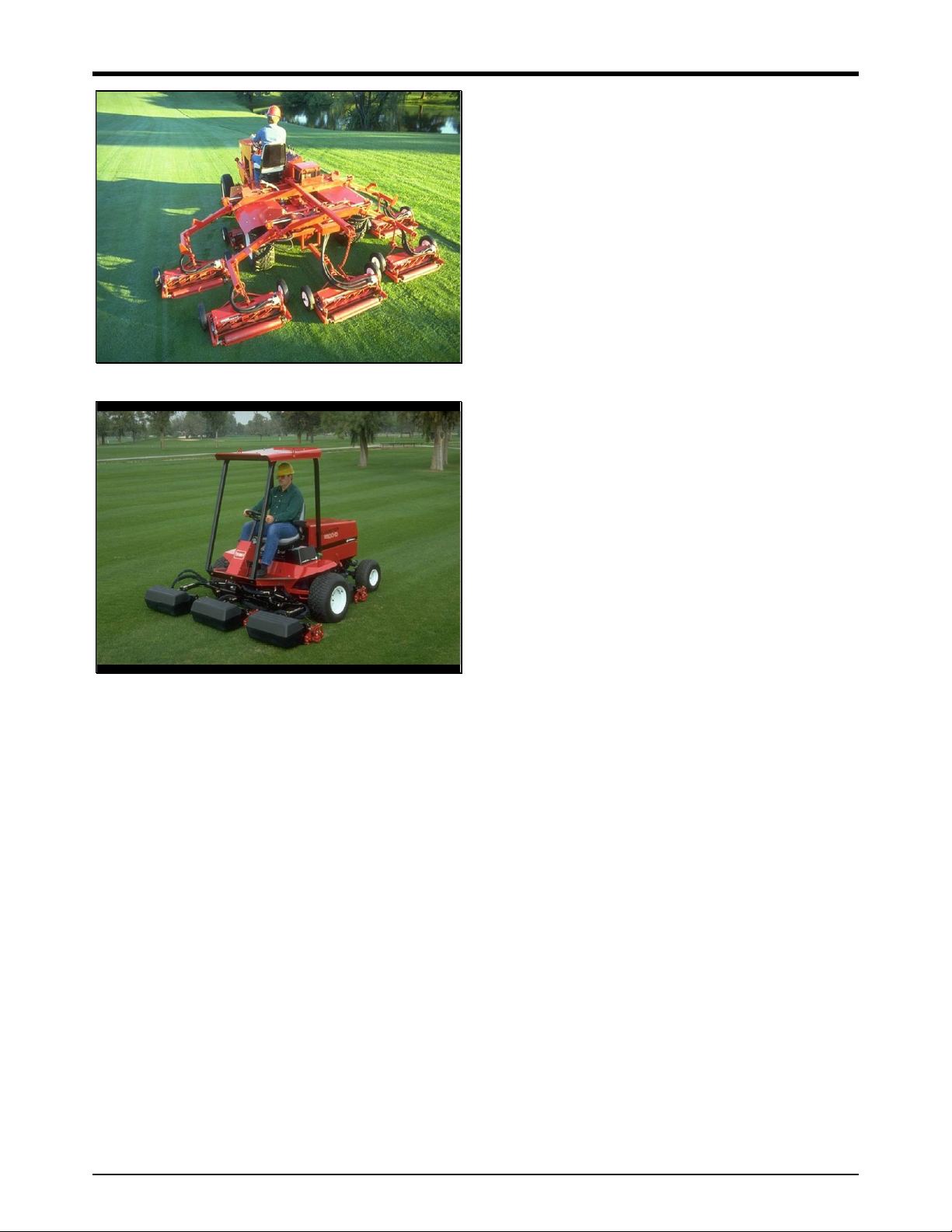

This drawing depicts the common terms used when referring to a reel mower.

We have already discussed the reel, and the bedknife.

The attitude, refers to the angle of the bedknife. This reference is in degree differential from the surface of

the turf, (or the line intersecting the bottom of the rollers).

The shear point, is the point that a reel blade contacts any given point on the bedknife at a specific point in

time.

The reel centerline, is the imaginary line drawn perpendicular to the turf dissecting the reel at its center.

This line is used to find the Behind Center Distance (BCD), this is the distance the shear point lies behind the

centerline.

There are two rollers. The rear roller trails the cutting unit, and is usually a solid roller. The front roller leads

the cutting unit, and due to the forces working on it may be any one of many types. The different types of

rollers will be discussed later in the program.

The Height of Cut (HOC) defines the distance between the roller plane and the shear point. Some cutting

units have a fixed front roller, and the rear roller is used to set the height of cut. Others, such as the newer

DPA design cutting units, have a fixed rear roller, and the front roller is used to set the height of cut.

Toro University Technical Training

Page 13

Reel Mowers 11

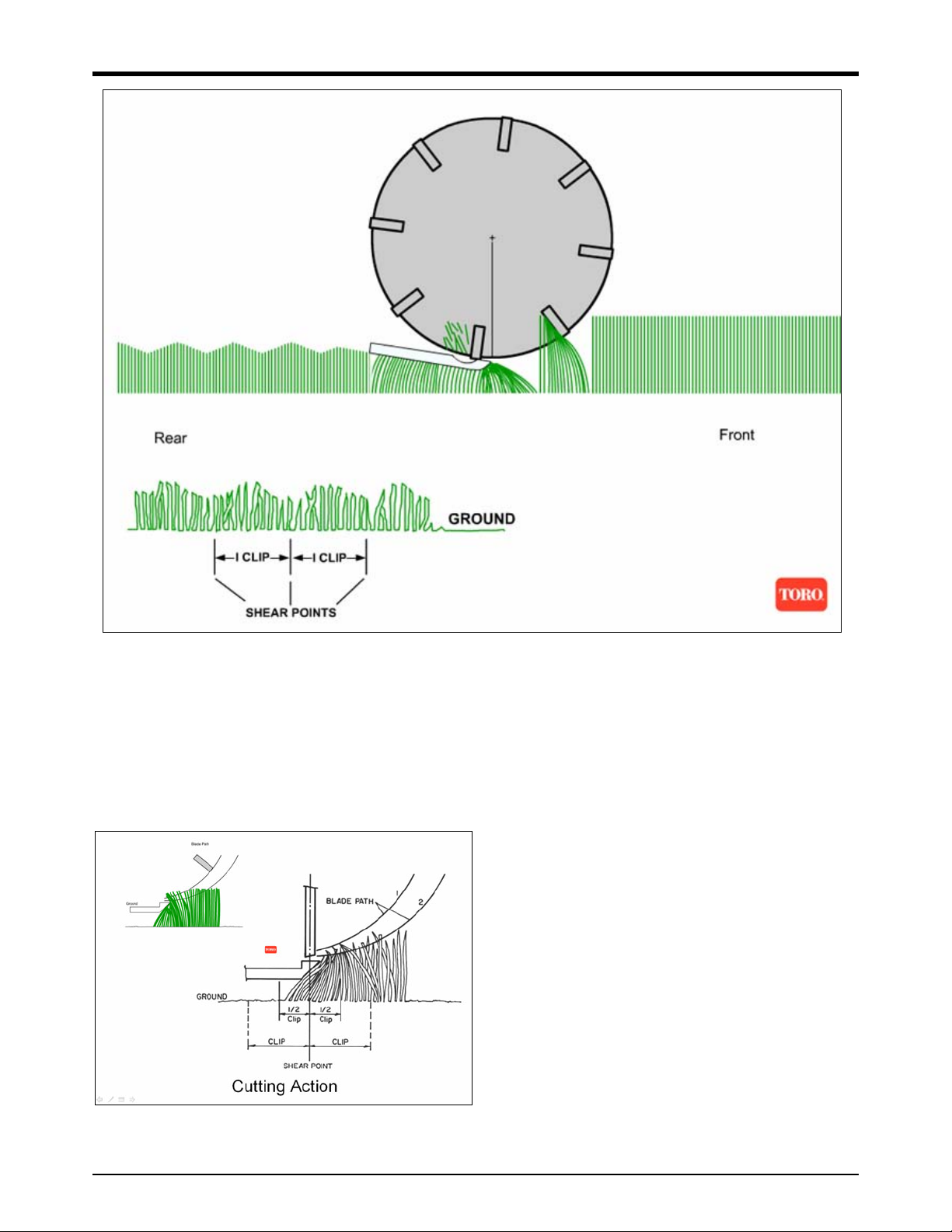

Think of the reel mower cutting action like a

scissors; two blades coming together, with light

contact, to cut the grass. Without sharp reel and

bedknife edges and properly maintained, light

contact, the reel mower will not cut the grass and

give a good quality of cut.

This illustrates the scissors-like cutting action, as

viewed, from turf level, below the cutting unit. Note

how the helix shaped reel blades, move across the

bedknife, to cut the grass.

To understand reel cutting theory, you must

Clip

understand the concept of clip and the shear point.

A shear point is any single point of contact made

between the reel blade and bedknife.

Here we can see the distance between two

successive shear points, one factor that affects the

clip rate.

Toro University Technical Training

Page 14

12 Reel Mowers

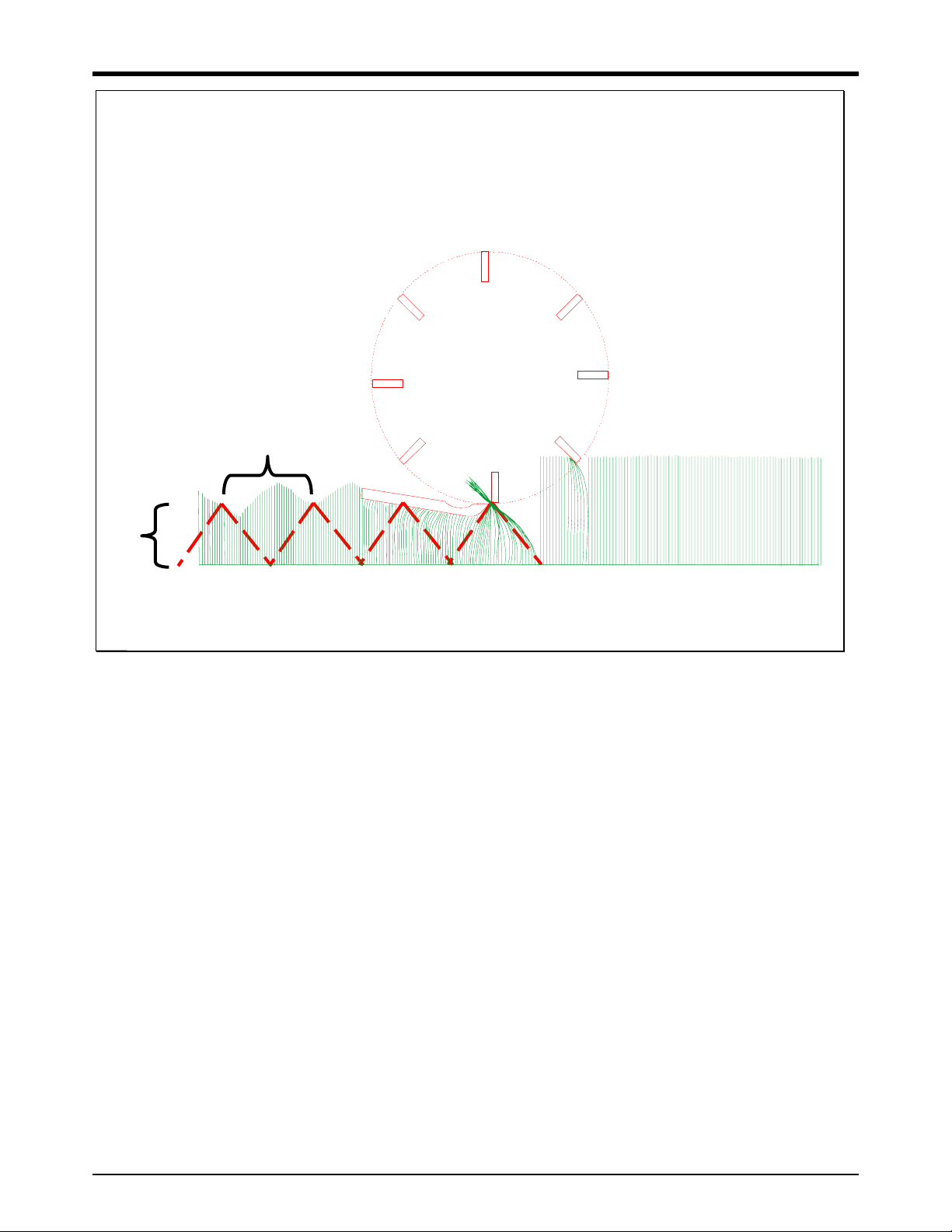

Clip is the forward distance traveled between successive blade contacts at one shear point.

This is viewed as a single contact point on the bedknife.

As the reel travels forward it pushes the grass in front of it, at the same time the reel blade is gathering the

grass it as it moves toward the bedknife.

The opposing forces working on the grass, bunch the grass together at the shear point creating a triangle.

By following the blade path through two “clips” as

the machine moves forward we can illustrate the

actual process of cutting grass. The bedknife

pushes grass toward the shear point, while the reel

blade gathers it in front.

Toro University Technical Training

Page 15

Reel Mowers 13

Factors that affect the clip rate:

• Diameter of reel

• Number of blades

• Speed of reel

• Ground speed

The ideal situation is when H.O.C. = Clip Rate

If we observe multiple clips we get a series of triangles set side by side.

The top of the triangle represents the individual shear point.

The clip rate is therefore, the distance between the tips of the triangles.

The clip rate is critical to the appearance of the cut. Ideally, the clip rate should equal the height of cut.

Factors that affect the Clip Rate are listed in the illustration.

Generally, the lower the height of cut, the more blades are required, or the reel must rotate at a faster speed

to keep the clip range in sync. A greens mower cutting unit, for example, may be available with 8, 11, or even

14 blade cutting units.

Most cutting units have a preferred operating range and all cutting units can be adjusted beyond that

preferred range. Choose a cutting unit where the intended height of cut is in the middle of the height of cut

range

Toro University Technical Training

Page 16

14 Reel Mowers

Here is what the mowing action looks like when the

clip rate is ideal. The bedknife pushes grass

forward, while the reel blade gathers it toward the

bedknife. Optimum clip rate is achieved when the

bedknife and reel blades create small, even

gatherings that are then cut. The result is a small,

unnoticeable clip and an even aftercut appearance.

Toro University Technical Training

Page 17

Reel Mowers 15

If the reel speed is too slow in relation to the ground

speed, there is too much space between cuts,

resulting in visible clip marks and uncut grass.

Visible clip marks in the turf are the result of an

Clip Marks

incorrect clip rate.

NOTE: If you make a large change in height of cut,

you may notice some visible clip marks after the first

mowing. This will go away after the grass is

maintained at this height over a period of time.

If the reel speed is too fast, in relation to ground

speed, the leaves of the grass plants impacted

multiple times before being cut. This can cause leaf

tissue damage, and is detrimental to the long term

health of the turf.

Toro University Technical Training

Page 18

16 Reel Mowers

Reel Speed Chart

The speed of the reel can be adjusted on some machines. As we have discussed, it is important that the reel

speed be matched with the number of reel blades and the forward speed of the tractor.

Factors Affecting Performance

Grass density, and grain, can affect reel mower

Cross section of turf cut at various heights

1/4” 1/2”

(6 mm) (13 mm) (19 mm) (25 mm)

3/4”

1”

cutting results. Grass grows denser at lower heights

of cut. The denser the grass, the easier it is for the

reel mower to cut it with good results.

Toro University Technical Training

Page 19

Reel Mowers 17

These are basic requirements for good performance

Requirements for good performance

of reel mowers:

The cutting edges on the reel blades and bedknife

must be straight and sharp.

The bedknife must be exactly parallel with the reel.

And, the bedknife should be positioned against the

reel with light contact.

When properly maintained and operated, reel

mowers provide superior quality of cut. It cannot be

overstated that reel mowers are precision tools. It is

essential that they be adjusted, and operated with

this in mind.

This illustrates a nice clean cut with all five cutting

units on a fairway mower set-up and adjusted

identically; rollers, bedknife and reel on each cutting

unit, all parallel, bedknife attitude, height of cut, and

bedknife to reel contact, set the same on every

cutting unit.

Toro University Technical Training

Here, the cutting units are not set-up the same, or

have different wear patterns between the individual

cutting units. This can cause a mismatched

appearance across the width of the mower.

Reel mower performance depends on proper set-up

and adjustment procedures. An error of .010 inch or

.25 mm, in height of cut, end to end, or from one

cutting unit to another, can be visible in the turf. In

after-cut appearance terms this is known as, missmatch.

Page 20

18 Reel Mowers

Importance of the Operator

The Operator has a significant influence on the aftercut appearance that a reel mower can deliver.

The large investment in specialized mowing

equipment cannot be jeopardized by unqualified

operators. Before an operator can be considered

qualified to operate a piece of equipment, there

should be a significant effort by the supervisor

towards their training and familiarization with each

piece of equipment.

Make sure the operator reads and understands the

Operator’s Manual. Have the operator watch the

Operator Training Video and take the on-line quiz at

toro.com, Customer Care. You should also take time

to explain the mowing practices used on your

grounds, and have the operator practice with the

equipment in an open area.

A supervisor should play a key role in establishing the

proper attitude and behavior patterns toward

operating turf equipment. A supervisor should not

create the impression that a few minutes orientation

on a piece of equipment will qualify the operator.

Operators and service technicians play a significant

role in determining quality of cut, down time, and life

of mowing equipment. Make a commitment to train

and familiarize staff with each product. Remember,

that each type of mowing equipment will have specific

operating characteristics, and noise qualities.

Operators should become familiar with the product,

and listen for any unusual changes. Concerns should

be reported to the service technician before significant

problems develop.

Toro University Technical Training

Page 21

Reel Mowers 19

Preventive Maintenance

To get the most out of your equipment investment, it is important to have a good preventive maintenance

program.

Doing scheduled maintenance and adjustments will prolong the life of your equipment, help prevent

expensive downtime, and give the best possible quality of cut and performance. Experience has shown that a

high percentage of problems that occur in turf equipment have developed over a period of time and could

have been prevented by adjustment, lubrication, or other required maintenance.

Follow the maintenance and adjustment recommendations listed in the Operator’s Manual. Some products

may also have a Quick Reference maintenance decal on the machine. Recommended maintenance intervals

should be considered minimum requirements. If the equipment is operated in particularly harsh conditions,

such as very hot weather, during the “grow in” period after construction, or on top-dressed greens, these

procedures may have to be performed more often.

Use original Toro parts when doing maintenance or repairs. These parts have been tested and designed for

this specific, very demanding, application. “Will fit” parts may look the same and fit, but they can give totally

different performance. Don’t take a risk on your important equipment investment by saving a little money now

that can cost you expensive repairs or increased maintenance intervals later.

Toro University Technical Training

Page 22

20 Reel Mowers

The maintenance charts and Operator's Manuals

should be used for reference to identify specific

Information

Resources

areas requiring ongoing scheduled maintenance.

Service Manuals and Training Guides are also

available from your Toro Distributor for many models.

Information about Service Education Materials,

Maintenance Schedules, Service Bulletins and more

is also available on the Internet at: www.toro.com.

Mowing equipment is designed for a specific

application and should be operated keeping those

restrictions in mind. Accidents and personal injuries

can be minimized if persons will keep thinking and be

aware in their every day work habits.

Toro University Technical Training

Page 23

Reel Mowers 21

Cutting Unit Setup and Adjustments

The following pages will cover basic requirements for cutting unit set-up and adjustment. Always use the

instructions in the Operator’s Manual or Service Manual when working on a specific model.

Reel mower performance depends on proper set–up, and adjustment procedures. An error of .010 inch or .25

mm in height of cut, end–to–end, or from one cutting unit to another, can be visible as miss-match. Although

there are design variations in cutting units, most require the same basic procedures. A surface plate,

accurate height of cut tools, and proper instruction, are essential for setting up a cutting unit.

Prior to mowing each day there are several items

To Maintain Performance

Check Daily

• Bedknife to reel adjustment

• Edge sharpness

• Height of cut

Check Periodically

• Roller condition

• Reel bearings

• Bedknife attitude

• Roller Parallelism

• General mechanical condition

that should be checked. There are several more

items that should be checked periodically, according

to the mowing conditions and mowing frequency.

Greasing should also be a part of your daily

Lubrication

maintenance routine. Greaseable bearings should be

greased after every use and after any washing. This

not only lubricates, but purges water, which is

responsible for the majority of bearing failures on this

type of equipment.

Toro University Technical Training

Page 24

22 Reel Mowers

Before performing any set–up procedures, it is

critical that the reel and knife cutting edges are

straight, and sharp. Backlap, or grind as necessary.

Adjust as needed, to ensure the knife, and reel,

contact their full length, with LIGHT contact, and free

reel rotation.

Note that different cutting unit models have different

methods of adjusting reel to bedknife contact. The

top illustration shows a four bolt style, adjustment

Bedknife to Reel

Adjustment

Dual Precision Adjustment (DPA)

mechanism. The bottom illustration shows a single

point, adjustment, mechanism. Single point adjust,

cutting units also have an adjustment mechanism on

one end of the bedknife, for adjusting the bedknife

parallel to the reel.

This illustration shows the dual precision adjustment

(DPA) mechanism used on the newer Toro cutting

unit designs. On this Greensmaster DPA cutting unit,

each click of the adjustment screw results in .0007

inch movement of the bedknife; a VERY precise

adjustment. On the Reelmaster DPA cutting unit,

each click results in .0009 inch of movement.

Adjust the bedknife against the reel to EVENLY pinch

one paper thickness across the entire width of the

bedknife. Then cut paper strips to check blade

sharpness.

Toro University Technical Training

Page 25

Reel Mowers 23

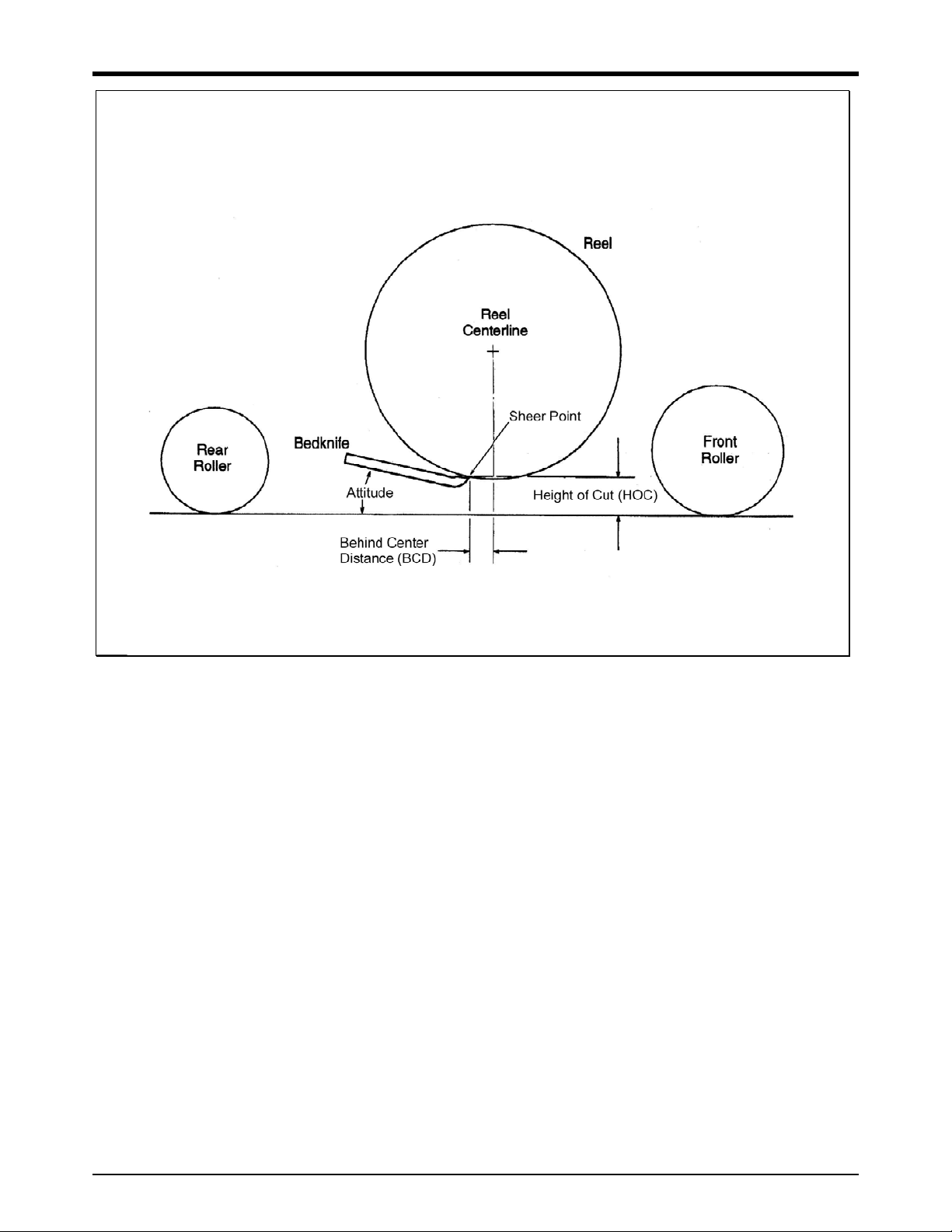

“ Pull, and cut ”:

Parallel, Light Contact and Sharp

When the paper is used as a feeler gauge to set

even contact across the bedknife, it is held parallel to

the bedknife. The reel should pinch with the same

amount of resistance at both ends and the center.

The “feel” of this measurement should be somewhat

the same as pulling the paper between your fingers

while applying moderate pressure with your fingers.

The paper must be held perpendicular to the

bedknife in order to check sharpness by cutting the

paper. If it is not perpendicular it can be pinched

between the reel and the bedknife. This is possible

even if the components are sharp.

Properly adjusting the bedknife to the reel is one of

the most effective preventive maintenance practices

for reel mowers. The amount of contact, and how

frequently it is checked, are major factors in

performance. A light contact adjustment, if

maintained, will help keep cutting edges sharp on the

reel and bedknife. This requires that the adjustment

be checked frequently at a predetermined time

interval. Dulled cutting edges cannot be corrected by

adjustment or over–tightening.

Do not wait until the quality of cut has deteriorated to

check the bedknife to reel adjustment.

If the cutting edges on the reel blades and bedknife

are not straight and sharp the mowing results may

not be acceptable. This is true even if all other set–

Don’t wait until

quality of cut

up procedures are correct.

deteriorates

Toro University Technical Training

Page 26

24 Reel Mowers

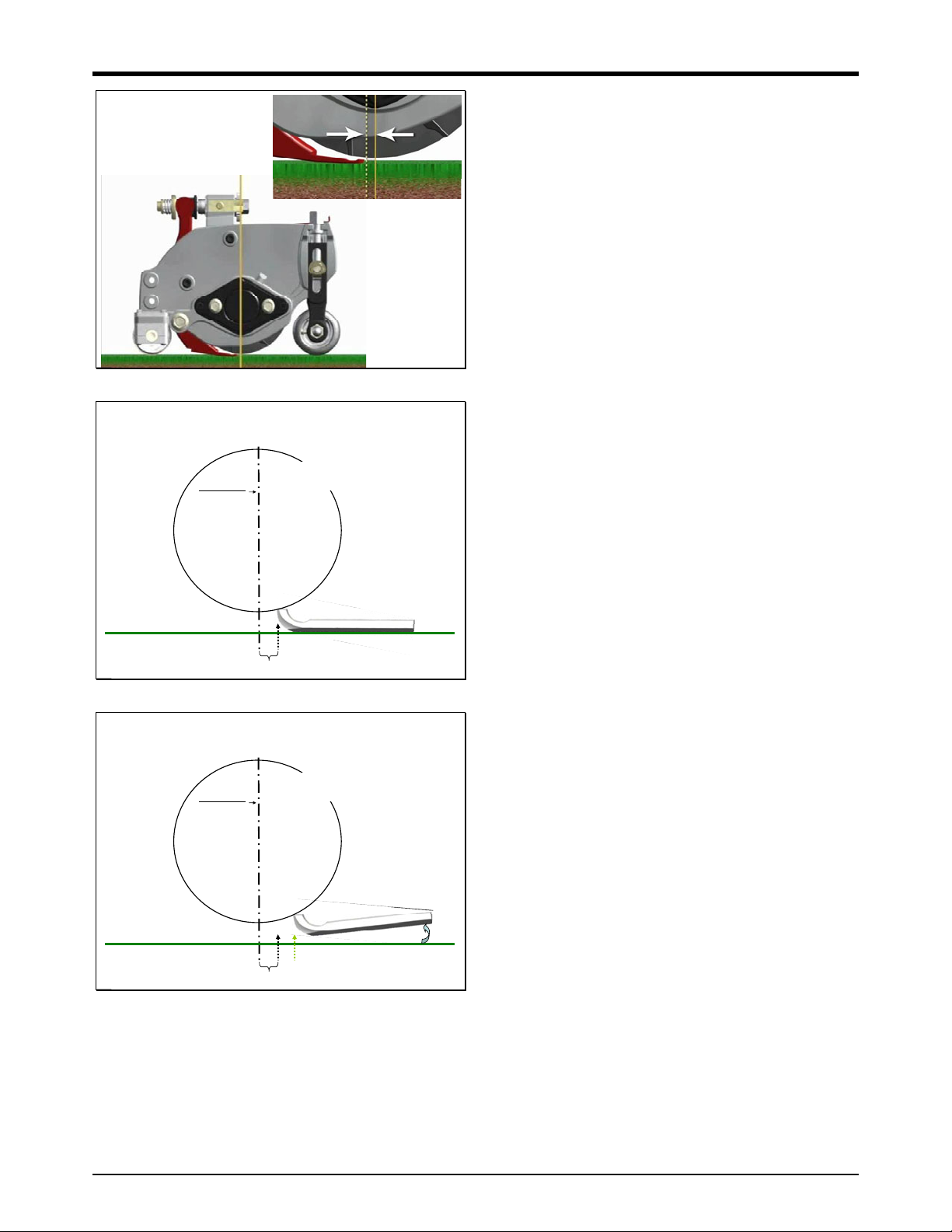

Attitude and Behind Center

Distance (BCD) of Bedknife

The cutting unit attitude is the angle between the bottom of the bedknife and the surface of the turf under the

cutting unit. As the bedknife attitude is changed, it is important to note that the reel to bedknife shear point

changes relative to the center line of the reel. This is known as the Behind Center Distance (BCD). A change

in the behind center distance can change the after cut appearance of the turf. The result may be better or

worse depending on several factors.

Bedknife attitude is adjusted by changing the height of the front, rear, or both rollers depending on the design

of the cutting unit. A height of cut change is not necessarily part of a change to the bedknife attitude. A large

angle is also referred to as an aggressive bedknife attitude. A small angle is also referred to as a less

aggressive bedknife attitude.

The front or the cutting edge must be lower than the back. This prevents the bedbar from contacting the

ground surface in low heights of cut. It will also prevent streaking or ruffling of the turf after it has been cut

and passed over by the bedbar.

Toro University Technical Training

Page 27

Reel Mowers 25

BCD:

Greensmaster

DPA Cutting Unit

Centerline

Behind Center Distance (BCD) has a

positive correlation to Bedknife Angle

This illustrates the bedknife behind center distance

on an actual cutting unit.

The bedknife angle and the behind center distance

have a direct correlation.

When one changes the other changes in the same

direction.

0

0

0

BCD @ 0

As the angle increases to 2 degrees, the behind

center distance has also increased.

0

Centerline

Behind Center Distance (BCD) has a

positive correlation to Bedknife Angle

0

BCD @ 0

2

Toro University Technical Training

Page 28

26 Reel Mowers

At seven degrees the behind center distance is even

greater.

Increasing the behind center distance results in a

more aggressive blade path.

0

An aggressive setting means the bedknife angle is

extreme. The bedknife is further from the centerline

of the reel and the reel blades approach is from an

aggressive angle.

The result can be a crisp, clean cut, however;

differences in up and back appearance, a stripe, is

pronounced. The down side of this aggressive

setting is that any variation in reflections can be very

noticeable and perhaps undesirable.

Centerline

BCD @ 0

Attitude

An aggressive setting is:

•Bedknife angle is extreme

•The bedknife is further from the

centerline of the reel

•The reel blades approach is from an

aggressive angle

The result can be a crisp, clean cut,

however; differences in up and back

appearance, a stripe, is pronounced.

The down side of this aggressive setting

is that any variation in reflections can be

very noticeable and p er ha p s unde si r a bl e .

Behind Center Distance (BCD) has a

positive correlation to Bedknife Angle

7

0

Attitude

A flat setting (less aggressive) is:

•The angle of the bedknife is flat

•The bedknife is closer to the centerline

of the reel

•The reel blade approaches from a

horizontal direc t ion

The result: A diffused appearance.

Reflective variations cannot be seen as

readily. The stripe is less defined. Cut is

prone to stragglers.

With a reduction in behind center distance, the reel

does not gather grass as cleanly; therefore the grass

blades can be different lengths.

This is by definition stragglers, however; the

difference can be negligible and tends to diffuse the

reflective qualities of the cut grass thereby masking

imperfections

Toro University Technical Training

Page 29

Reel Mowers 27

On many cutting unit designs, the bedknife attitude

and behind center distance change as the reel wears

and its diameter get smaller. This can result in a

deteriorating quality of cut, and poor after-cut

appearance, including miss-match between cutting

units.

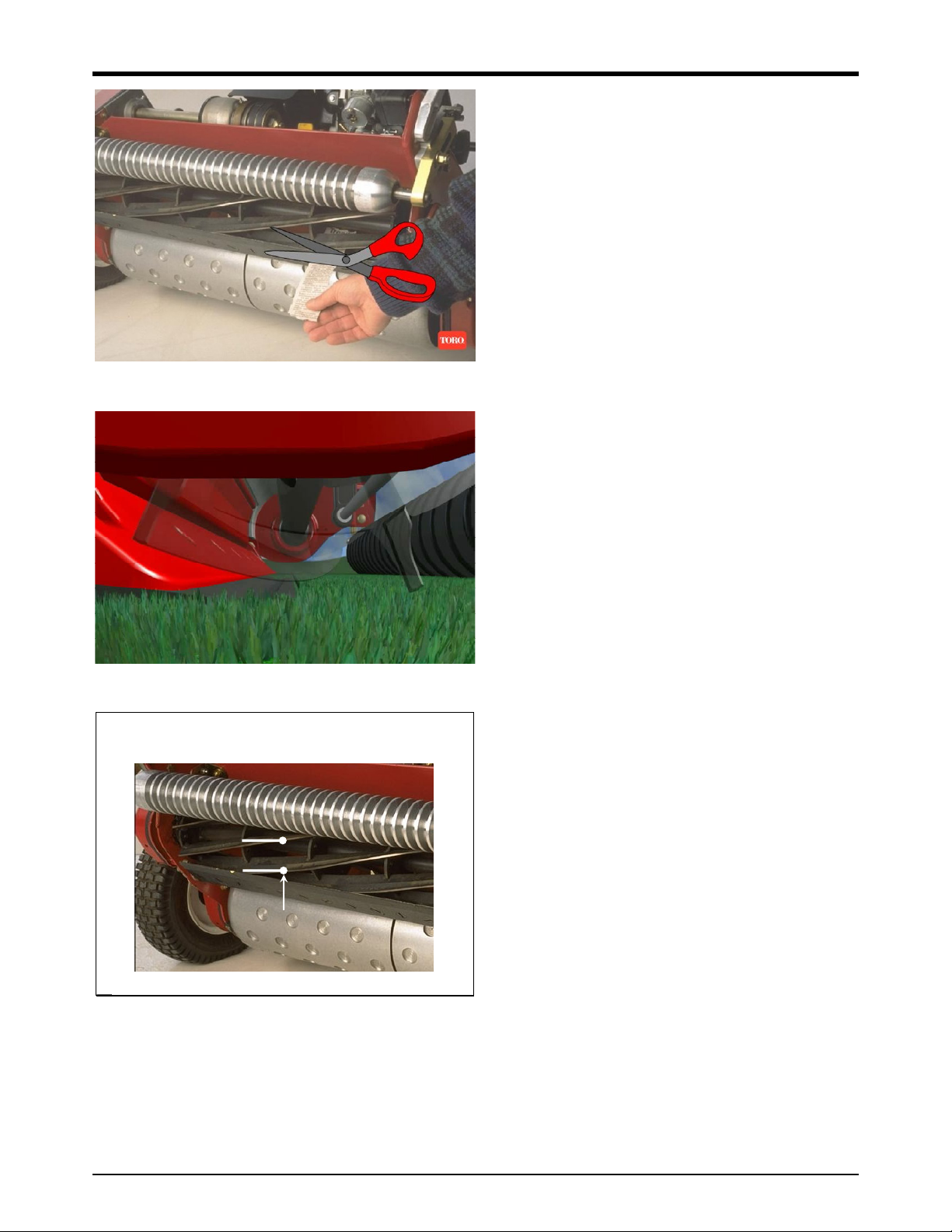

Here is a close up view of the problem. Note the

bedknife angle and behind center distance. This

illustrates how the quality of cut can deteriorate,

when the bedknife angle and behind center distance

change as the reel wears.

Toro University Technical Training

Page 30

28 Reel Mowers

On DPA cutting units, bedknife angle and behind

center distance are maintained as the reel wears.

This keeps the attitude, or aggressiveness,

consistent throughout the life of the bedknife and

reel.

As you can see, the reel diameter gets smaller as the

reel wears. Note that all cutting units have a specified

wear limit diameter for the cutting reel. The reel must

be replaced when this wear limit is reach. A chart,

with this, and other specifications is provided later in

this program.

To achieve an acceptable quality of cut the rollers

must be parallel to the reel. Before adjusting roller

parallelism check for loose roller bearings. Adjust or

replace the bearings as necessary. First parallel the

front, or rear roller, which ever is not used for setting

the height of cut. This paralleling roller is set to match

the reel using a surface plate fixture. With the reel

blades resting on a raised bar on the plate, use a

feeler gauge along the bottom of the roller between

the roller and plate.

Rollers Parallel

to Reel

Newer DPA model cutting units, with a rigid, bolted

frame, normally do not require this procedure.

Height of Cut

(H.O.C.)

Set the height of cut to the desired height using an

accurate tool. This procedure must be done exactly

the same on each cutting unit. Before doing this

adjustment the bedknife and roller, the one not used

for height of cut adjustment, must be parallel to the

reel, as described on previous pages.

As reel cutting unit design and configuration continue

to evolve, height of cut settings may need modifying

to retain visual and playability goals.

Remember, the setting you are making here, the

“bench set height of cut”, is different from the

effective or actual height of cut in the turf

Toro University Technical Training

Page 31

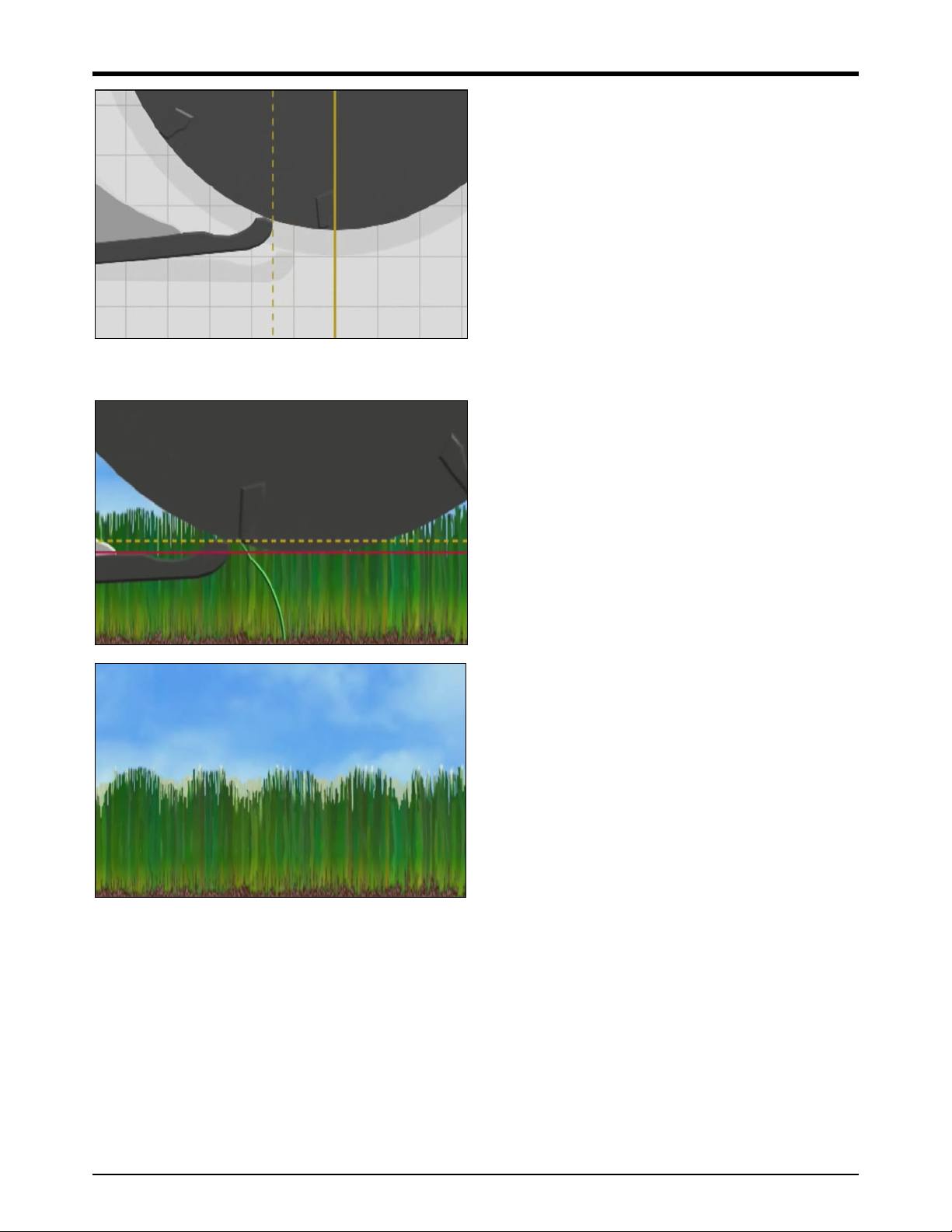

Reel Mowers 29

There can be a significant difference between a

Bench Set vs. Effective H.O.C.

Effective H.O.C.

and Bedknife Selection

HOC

Blade clearance

bench set height of cut and the actual height of cut

when in the turf.

The bench set height of cut, is theoretical, based on

the assumption that the rollers will set at the same

place in the grass and that the turf is firm.

The turf can have varying densities. Different cutting

unit models can weigh more or less and the rollers

do not always set in the grass in the same manner.

In the circle above you see that after the grass is cut,

the remaining grass must make it under the bedknife.

After the grass is cut, the remaining grass must make

it under the bedknife. There is not a lot of room for

that to happen.

If there is too much grass under the bedknife, it can

lift up on the knife causing rifling or the appearance

can vary due to the rollers lifting from the turf as the

bedknife becomes the support and pivot point for the

cutting unit.

On the other hand, if we have too thin of a knife or

the height of cut is set higher; there may not be

enough grass to aid in heat dissipation.

As you can see, selecting the proper bedknife for

your height of cut and turf conditions is important.

Bedknife selection will be discussed in more detail

later in the program

Toro University Technical Training

Page 32

30 Reel Mowers

Quality of Cut and Aftercut Appearance

Aftercut Appearance

This is NOT the same thing as:

Quality of Cut

Turf plant stress increases with:

• Too much tissue removed at one time (infrequent mowing).

Removal of more than 1/3 leaf tissue at one time can stop

root growth from 6 days to 2 weeks depending on the

amount of tissue removed.

• Increased leaf damage (du l l bl ad e, sub - o pt im u m set u p)

• Increased environmental stress in combination with mowing

Ideal is to raise height of cut during periods of turf stress,

such as high heat and/or low moisture

The term Aftercut Appearance, is very specific to

appearance and is not the same thing as Quality of

Cut. Quality of Cut can affect the appearance, but

appearance does not, in itself, affect Quality of Cut.

Quality of Cut refers to how well the individual

leaves of the grass plant are cut. A quality cut

minimizes damage to the leaves of the grass plant.

After cut appearance, refers to the visual effects of

the turf after it has been cut and across the entire

width of the mower.

The standard rule for mowing, is never remove

more than 1/3 of the grass plant leaf. This is true of

all turf cultivars and any type of mowing device.

Leaf damage refers to quality of cut.

In the case of leaf damage, poor quality of cut will

result in poor aftercut appearance.

Raising the height of cut is always an option that will

usually increase both the health and appearance of

the turf.

Toro University Technical Training

Page 33

Reel Mowers 31

Quality of cut can be affected by reel blade

sharpness and contact with the bedknife. There is a

lot of discussion in the industry about the desirability

Related Mowing Quality Issue:

Related Mowing Quality Issue:

Reel mower sharpness and reel-to-bedknife

contact could affect:

• Visual quality

• Plant vigor

• Suscep tibility to disease

Factors that can affect aftercut appearance

• Tire pressure

• Engine governed speed

• Reel bearing

condition/adjustment

• Reel and bedknife

sharpness

• Bedknife parallel to reel

• Bedknife to reel contact

• Bedknife attitude

(angle)

• Roller(s) parallel to reel

• Height of cut (bench set

vs. actual)

• Bedknife selection

• Roller selection

• Cutting unit alignment

and ground following

• Roller and roller bearing

condition

• Reel speed

• Traction speed

• Cutting unit drop speed

and sequence

• Cutting unit

counterbalance or down

pressure setting

of running units with light contact. One camp says

light contact is not necessary while the other says it

is if you want the best quality of cut.

We are interested not only in the effect of these

things on appearance, but the effect of leaf injury

resulting from a less than optimum set-up on plant

vigor and the plants susceptibility to disease. Most

believe that increasing injury increases susceptibility

to disease.

There are many factors that can affect after cut

appearance, including, condition of the mowing

equipment and agronomic factors. Turf conditions,

such as excessive thatch, sponginess, or attempting

to cut off too much grass height may not always be

overcome by adjusting the machine. It is important

to remember that, the lower the height of cut, the

more critical these factors are.

Also, remember that the effective or actual height of

cut depends on many factors, including, cutting unit

weight, cutting unit accessories, and turf conditions.

Effective height of cut will be different than the

bench set height of cut.

Toro University Technical Training

Page 34

32 Reel Mowers

There are published resources available for troubleshooting aftercut appearance issues. The Aftercut

Appearance Troubleshooting Guide is setup with one page dedicated to each issue. At the top is a

description followed by a list of possible causes, then possible corrective actions.

Aftercut Appearance Troubleshooting Guide: Part No. 00076SL

First review the issue and then determine the complaint. Many complaints look very similar but if you have

duplicated the condition, this should be relatively easy to work through. Use the definition to pick out subtle

differences then review the possible causes. Compare to the issue and you can determine if some corrective

actions are easier to try than others. Determine a course of action.

Try one thing and only one thing at a time. Do so in a manner that the results can be watched over a period

of time, at least a week. Give it time to work. Remember that after cutting, the grass needs to heal before the

result will be realized.

While talking with others use the descriptions listed. Not, because it is the only correct description, but

because it has a definition that is identifiable to both of you.

You may download this publication directly from the location you obtained this document, or from toro.com,

customer care, technical reference and education resources web pages, at www.toro.com.

Toro University Technical Training

Page 35

Reel Mowers 33

Some turf discrepancies are subtle and require

closer examination. In these instances, the Turf

Evaluator, grass viewing tool, is helpful. It can assist

turf managers in determining causes for poor reel

mower performance and comparing the effective

height of cut of one mowed surface to another.

Part No.

97931SL

Model 04399

Toro University Technical Training

Page 36

34 Reel Mowers

Sharpening

Sharpening is part of the required maintenance for proper function of a reel mower cutting unit.

How can you tell if sharpening is necessary?

The grass is not cut cleanly.

The color of the grass; it may have a dull appearance or have brown tips.

Streaks.

Stragglers.

The cutting unit is noisy.

One sure way to determine the answer to this is by actually checking the cutting edges of the reel and

bedknife, to see if they are dull!, nicked, bent or being run without light contact against one another.

This profile drawing of the blades shows the result

of wear.

The leading edges are rounded and the angle of the

bedknife has worn to match the circle created by the

blade path.

Reel blades, and the edge of the bedknife, should

be checked for damage visually and by carefully

feeling the edges. Of course, this should only be

done when it is certain that the reel cannot be

started, and never slide your fingers down the

edges lengthwise.

Rounded edges on the reel blades and bedknife will

cause the grass blades to be pinched and torn

rather than sheared off cleanly. When light contact

is not maintained, dull edges will soon result.

Here is light bedknife to reel contact, which gives a

clean cut and helps to maintain a sharp edge.

Toro University Technical Training

Page 37

Reel Mowers 35

If there is no contact (a gap between bedknife and

reel blade) it can result in faster wear of the cutting

edges and more frequent grinding.

No contact results in the leaves of the grass plant

being pinched or torn rather than cleanly cut. This

causes poor quality of cut and can actually

accelerate the wear process of the cutting edges.

The result? deteriorating aftercut appearance and

leaf tissue damage which is detrimental to the long

term health of the turf.

Toro University Technical Training

Page 38

36 Reel Mowers

Sharp vs. Dull Cutting Blades

Cutting units should be kept as sharp as possible. This will:

• Promote growth of healthy grass.

• Optimize cutting unit performance.

• Extend the life of the mower.

• Maximize operator mowing time.

• Allow the tractor to run most efficiently.

• And provide the best possible aftercut appearance of the turf.

Toro University Technical Training

Page 39

Reel Mowers 37

When the cutting unit blades become dull and

quality of cut deteriorates, the tendency is to want to

tighten the bedknife to reel contact, resulting in

heavy contact.

Heavy bedknife to reel contact can cause rifling,

which appears as a grooved or wavy wear pattern

on the reel and or bedknife. This condition can only

be corrected by grinding the reel and bedknife.

BACKLAPPING WILL NOT CORRECT THIS

CONDITION. The bedknife will usually need to be

replaced rather than just ground.

A barrel shaped reel, caused by flexing of the

cutting unit frame will also require grinding to bring

the reel back to a cylindrical shape.

It is more likely that this will occur on cutting units

with welded frames and not on the newer DPA

model cutting units with more rigid bolted frames.

Flexing of the frame can cause uneven wear and

eventually lead to rifling.

If the reel wears unevenly, it becomes difficult to

keep the bedknife parallel across the entire width of

the reel. You may be able to pinch paper in the

middle, but not on the ends, or vice-versa. When

adjusting a cutting unit with this condition, the

tendency is to want to tighten the bedknife to reel

contact, so the paper can be pinched and cut

across the entire bedknife and reel, resulting in

heavy contact.

Grinding will also be required if the reel is cone

shaped or tapered. Reels eventually become

tapered with use. If the reel is not ground to a

cylinder shape again, a mismatch, in the height of

cut between adjacent cutting units can result.

Rifling

pressure

Streaks of uncut grass, will appear on the low

areas of a grooved or wavy (rifled) bedknife

Barrel Shaped Reel

Cone Shaped Reel

Toro University Technical Training

Page 40

38 Reel Mowers

There are several methods that may be used to

Sharpening Methods

• Maintain proper ADJUSTMENT

• BACKLAP the bedknife and reel

• GRIND the reel and bedknife

sharpen a cutting unit. The one that you choose will

depend upon the condition of the cutting unit. It

should also make the most sense for the anticipated

use. For example, if you are about to cut greens that

have been core aerated or top dressed, you may

not want to grind the reels and install new bed

knives.

By backlapping regularly, reel blade and bedknife

sharpness can be maintained longer between

grindings.

Backlapping cannot be used to sharpen a dull reel

or bedknife. Backlapping is an edge maintenance

practice.

As the reel blades run against the bedknife during

backlapping, a slight burr will appear at the front

cutting edge surface the full length of the bedknife.

Run a file or facing grinder across the front edge to

remove this burr.

Backlapping must be done after single blade

grinding. This is done to establish a land area and

to insure a perfect match between the bedknife and

the reel edge.

Backlapping is not intended to be a reconditioning

process to correct severely nicked or rounded

blades, rifling or taper. If, after approximately 5

minutes of lapping, the edge is not restored, it is

time to grind the reel and bedknife.

Backlapping is often a regularly scheduled

maintenance process, particularly with greens

mowers.

Toro University Technical Training

Page 41

Reel Mowers 39

WARNING:

Always use a brush with an extended handle to

apply the lapping compound to the rotating reel.

Using a short handle brush could cause your hand

to be pulled into the reel, and cause serious injury.

Keep your hands, feet and clothing away from

moving parts!

If you use backlapping as a regular maintenance

practice, backlap often, but for a very short time. For

example, five minutes per cutting unit.

BACKLAP OFTEN

but

VERY LITTLE

Approximately

5 Minutes per Cutting Unit

Before a reel can be ground correctly, the reel has

to be cleaned and checked for loose or bent blades.

The reel bearings must be in good condition, with

no end play evident. Make sure the cutting unit

frame and roller brackets are true and not bent or

damaged from impacts with trees, posts or cart path

edges. The cutting unit must be aligned so the

grinding wheel will travel parallel to the reel shaft.

This will result in the reel being ground to the

desired cylinder shape.

Follow the grinder manufacturer’s instructions for

set-up and operation of the grinder.

When grinding, be careful to not overheat the reel

blades. Remove small amounts of material with

each pass of the grinder.

After completing the grinding process, do a

complete set–up and adjustment procedure on each

cutting unit.

Toro University Technical Training

Page 42

40 Reel Mowers

There are several manufacturers of reel grinders.

Grinders

WARNING !

Always wear a face shield or

safety glasses when grinding or

backlapping.

These same manufacturers also produce bedknife

grinders.

Remember to always wear a face shield or safety

glasses when grinding or backlapping.

It is important to understand that Toro reel mowers

are designed and manufactured to optimize

available power from the engine and hydraulic

systems. To help do this, we put a “relief” or back

grind on every reel blade to reduce the width of reel

blade that contacts the bedknife. This has been

proven to reduce power requirements, as well as

allow the machine to operate more efficiently. This

can be very important, depending on the terrain,

type of grass and amount of grass being cut.

Milled Relief (Scalloped Blades)

Toro has two different methods of manufacturing

reel blades with a relief. The reel blades are made

from straight stock steel and then are either relief

ground or the relief is milled in. Either way, there is

a relief on the blade when it is manufactured. A

small, ground relief is also put on milled relief

blades, during manufacture.

Toro greens mowers and DPA fairway cutting units

are manufactured with a milled relief. Other trim,

utility, and fairway mowers have a ground relief.

Toro University Technical Training

Page 43

Reel Mowers 41

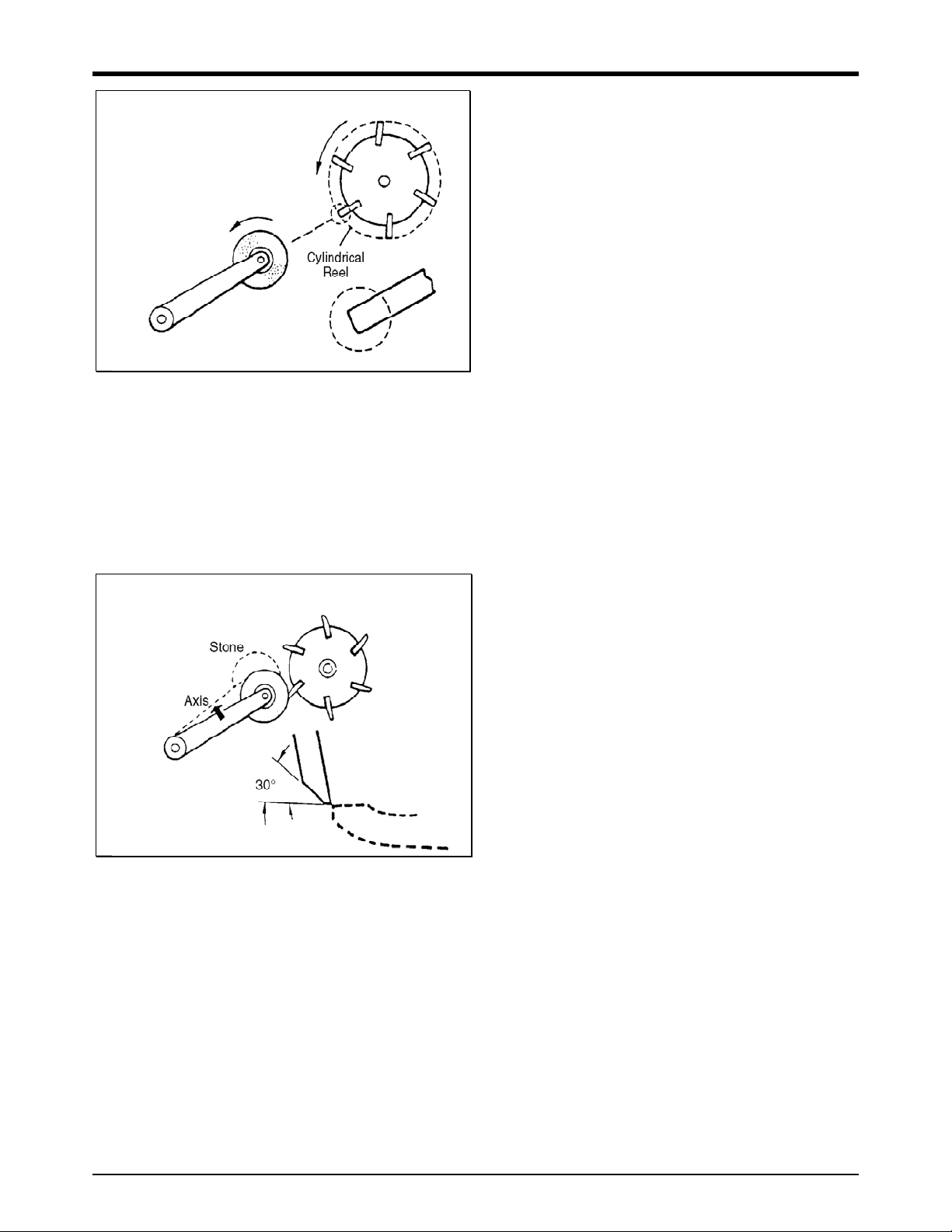

There are two methods of grinding reels. This

Spin Grinding

(Flat Grinding)

Single Blade Grinding

(Relief or Back Grinding)

illustrates Spin Grinding (which is also known as

Flat Grinding).

With this method, both the reel and the grinding

stone are turning as the reel is being sharpened. It

is sometimes stated that backlapping is not required

after spin grinding because the reel is a perfect

cylinder when grinding is completed. This depends

on proper alignment of the reel in the grinder before

sharpening. Also, the bedknife and bedbar must be

straight and perfectly parallel to the reel when it is

mounted. Backlapping will remove burrs and rough

edges, producing a honed edge that will cut grass

evenly.

If using a spin grinder to sharpen straight stock reel

blades (such as on fairway mowers), some or all of

the relief will be ground off. If you are going to

restore the relief that was on the blade when was

manufactured, you will need to also use the other

method of grinding (single blade relief grinding). It is

recommended to do the relief grinding first, then

spin grind to restore the reel to a cylinder shape and

establish the land width.

This illustrates Single Blade Grinding (which is also

know as Relief, Grinding, or Back Grinding.

With modern grinding equipment, spin (or flat)

grinding and single blade grinding are available on

the same machine. Single blade grind if necessary,

to restore the relief or back grind, then spin grind to

sharpen and return the reel to a cylinder shape.

Toro recommends a 30 degree relief angle on each

reel blade. The angle itself is not critical. You can

put as little or as much angle on the blade as you

think is proper. A larger angle will take off more

steel and the reel may have to be replaced sooner.

With a smaller angle, you may have to grind the reel

more often to maintain a relief. See the reel and

bedknife grinding guidelines chart, at the end of this

section, for grinding specifications on each cutting

unit model.

Toro University Technical Training

Page 44

42 Reel Mowers

Whichever grinder you use, be sure to compensate

Reel Grinding

Do Not

A

Grind parallel to the Reel Shaft

grind by equaling the spark pattern on each end

A = B

B

Bedknife Installation

for a cone or barrel shaped condition.

Grind parallel to the Reel Shaft. Do Not

setup the

grinder by simply equaling the spark pattern on

each end. This will not remove the slight cone

shape of the worn reel.

Reels naturally wear more on one end then the

other.

Verify the reel centerline, which is the reel shaft, is

parallel to the grinder stone travel.

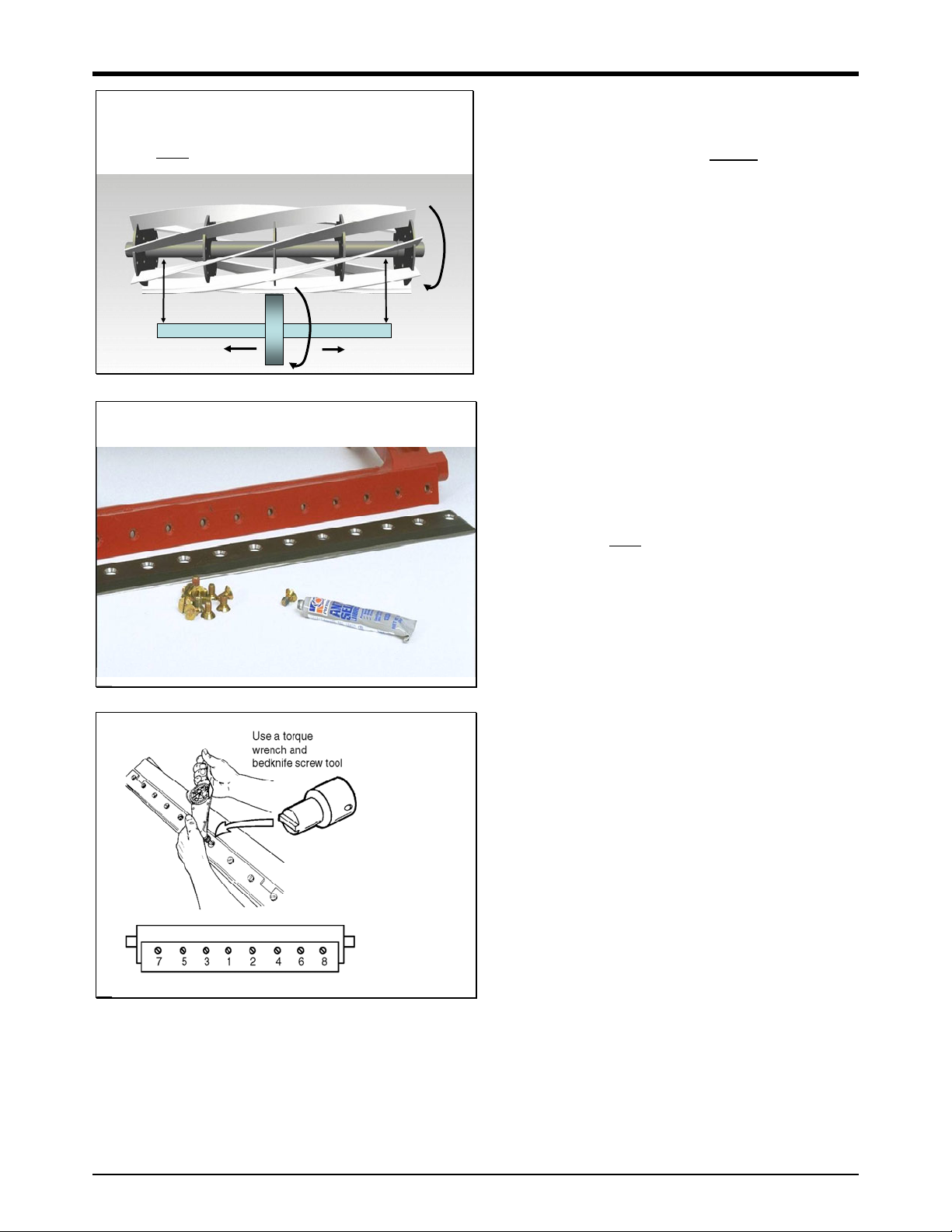

If replacing the bedknife it is important to use the

following procedures:

• Remove all rust, scale and corrosion from

the bedbar surface before installing new

bedknife.

• Make sure the bedbar threads are clean.

• Use new Toro

screws. Apply anti–seize

lubricant to the screw threads before

installing.

Tighten the screws working from the center toward

each end of the bedbar. Do not use an impact

wrench.

Fairway/utility mowers:

250 – 300 in-lb. (288 – 345 KgCm)

Greens mowers:

Fairway and Utility Mowers:

250 – 300 in-lb. (288 - 345 KgCm)

Greens Mowers:

200 – 250 in-lb. (230 - 288 KgCm)

200 - 250 in-lb. (230 - 288 KgCm)

Since there can be variations in the mounting

surface of the bedbar, a new bedknife may not be

perfectly flat after it is installed. Because of this, it is

necessary to backlap or grind a new bedknife after

installing it to the bedbar. Follow the existing angle

that was ground into the bedknife and grind only

enough to make sure the top surface is true.

Toro University Technical Training

Page 45

Reel Mowers 43

This illustrates the characteristics for the bedknife

that are specified in the Toro Reel and Bedknife

Grinding Guidelines, such as Relief Angle and Front

Angle.

When regrinding a bedknife it is important to use the

following procedures:

• Remove the bedbar and bedknife assembly

from the cutting unit before attempting to

grind a used bedknife.

• Keep the bedknife fastened to the bedbar

when grinding.

• When grinding, be careful to not overheat

the bedknife. Remove small amounts of

A lead-in provides a softened entry for the leading

Top View

.050 ± .015

Side View

side of the reel blade helix as it approaches the

bedknife. This helps eliminate rifling caused by

heavy contact and vibration. If the bedknife had the

lead-in originally, be sure to put it there when done

grinding the bedknife and reel.

Example specifications for this lead-in for a fairway

mower knife are as shown. These specifications are

only a suggestion. The idea is to get a grind in place

not to spend a lot of time making sure it is exact.

Using a file to make the lead-in is a perfectly

Lead-in

acceptable method. It is important not to make the

lead-in too long or you will notice that there is a

streak left behind at the edge of the cutting unit as

the reel will not cut well in the area of the grind or

may adversely affect the overlap area.

It is also important that the lead-in make a smooth

transition. Be sure to remove any burr that

develops as a result of making the lead-in. The

lead-in will lessen as a result of bedknife wear and

should be redressed with a file at the same time the

ears are removed.

material with each pass of the grinder.

Toro University Technical Training

Page 46

44 Reel Mowers

• The

EdgeMax

includes a leadi ng edge of

harder steel

• Holds an edge twice as long and

reduces the need for adjustments,

backlappingand grinding

• Set bedknife to reel adjustment as usual

– Light contact while running on the ground

• No special requirements

™ bedknife

Maintaining the EdgeMax Bedknife

• A dull knife must be sharpened

• If backlapping is part of your maintenance practice, be

prepared to backlap for two to three times the amount of

time as compared to a standard bedknife

• Front face grinding is acceptable in moderation

– Any facing or grinding must be done with exacting tolerances.

Do not use a hand held grinder

The Edge Max bedknife includes a leading edge of

harder steel.

The Edge Max bedknife Holds an edge twice as

long as a standard bedknife, and reduces the need

for adjustments, backlapping and grinding.

Set the bedknife to reel adjustment on an Edge Max

bedknife as usual. Light contact while running on

the ground.

There are no other special requirements.

A dull knife must be sharpened.

If backlapping is part of your maintenance practice,

be prepared to backlap for two to three times the

amount of time as compared to a standard bedknife.

Front face grinding is acceptable in moderation.

Any facing or grinding must be done with exacting

tolerances. Do not use a hand held grinder

Sharpening the EdgeMax Bedknife

• No specia l stones required

• Dress the stone more frequently

– Before s tar t ing an d a t least once during grinding

• One pass to dress

– Multiple passes will cause the stone to back up

• When grinding, remove smaller amounts

of material (shallower cut)

• Expect a different spark pattern

Mild Steel: Many orange visible

streaks with few sparks

Tool Steel: Few visible streaks with

noticeable sparks

No special stones required.

Dress the stone more frequently. Before starting,

and at least once during grinding. One pass to

dress. Multiple passes will cause the stone to load

up.

When grinding, remove smaller amounts of material

(a shallower cut).

Expect a different spark pattern.

Toro University Technical Training

Page 47

Reel Mowers 45

This diagram illustrates the characteristics that are specified for the reel in the Toro Reel and Bedknife

Grinding Guidelines, such as the Reel Diameter, Blade Relief Angle, Blade Land Width and Reel Taper.

When regrinding a cutting unit reel or bedknife, use the specifications from the Toro Reel and Bedknife

Grinding Guidelines on the next page. If the reel diameter is less than the service limit shown, it must be

replaced.

Toro University Technical Training

Page 48

46 Reel Mowers

Toro University Technical Training

Page 49

Reel Mowers 47

Bedknives, Rollers and Accessories

Greens Mower Bedknives

C

O

H

)

m

m

5

2

(

in

1

–

)

m

m

5

.

9

Fairway

Low-Cut

Tournament

7

3

.

8

1

.

3

(

n

i

5

2

1

.

(

in

5

8

.

4

(

n

i

8

)

m

m

2

.

Note: High-Cut has similar profile

.313 (8 mm) - 1 i n (25 mm)

5

2

(

n

i

1

-

)

m

m

7

.

2

1

(

n

i

0

0

5

.

–

C

O

H

)

m

m

C

O

H

)

m

m

OC

H

)

m

m

8

.

4

(

n

i

8

8

1

.

-

)

m

Micro-cut

Bedknife design must allow for maximum material to dissipate heat and yet allow the remaining uncut grass

under the bedknife.

Unfortunately, there is no set rule for space left under the knife, nor can there be. This is due primarily to

surface density and turf conditions. There is no measurable plane that works, other than, your mower, in

your turf.

The only thing that is absolute is that while on the bench, the bedknife can not touch the height of cut

adjusting tool. There must be a reasonable space between the bedknife and height of cut adjusting tool.

To look at that in a different manner, place the cutting unit on a table resting on the rollers so as you can look

at the end of the cutting unit. The bedknife can not touch the table top. This is the absolute! Everything else

depends on the agronomic conditions of the turf.

Listed here are popular Greens mower bedknives and their recommended operating range.

0

.

n

i

2

6

m

6

.

1

(

Toro University Technical Training

Page 50

48 Reel Mowers

DPA Fairway Mower Bedknives

EdgeMax ™

38

(

(Original Equipment)

Standard

m

5

.

9

(

n

i

5

7

3

.

m

m

5

.

9

(

n

i

5

7

3

.

m

1

–

)

2

–

)

HD

–

)

m

m

7

.

2

1

(

n

i

0

0

5

.

3

.

-

)

Low-Cut

5

2

.

Due to the height of cut variations on a fairway and the requirements of cutting conditions there is another

line of bedknives for the fairway or higher height of cut ranges.

6

(

in

0

m

m

4

.

n

i

5

.

m

1

5

(

n

i

1

5

(

n

i

2

.

9

(

in

5

7

m

5

m

m

m

m

m

)

H

)

m

)

H

O

)

H

O

C

H

O

C

O

C

C

Toro University Technical Training

Page 51

Reel Mowers 49

The basic groups of ground contacting rollers are

Rollers

Wiehle

Full or Solid

Full Rollers

(Also referred to as solid rollers)

Wiehle Rollers

shown here.

Full rollers provide a stable platform using full width

contact. Some characteristics of full rollers include:

Increases, the effective cutting height.

Rides higher or floats more on the turf.

Can be made heavier or larger to help with cutting

unit control.

Less likely to scuff the turf in turns.

Less likely to damage the turf when lowering onto it.

Narrower rear rollers can help address overlap roller

marks in cool season grasses. Note that the

narrower rollers can reduce the stability of the

cutting unit.

Wiehle (or grooved) rollers also provide a stable

platform with some different characteristics.

Contact line is broken into individual contact points

allowing for greater surface pressure at the contact

point.

Individual contact points allow for better incursion

into the turf canopy.

Allows seed heads to be cut and gathered better.

Note that these rollers can sometimes scuff the turf

in turns.

Toro University Technical Training

Page 52

50 Reel Mowers

Here are some adaptations of the Wiehle roller:

Aluminum lessens contact pressure due to weight

difference.

Cast iron increases cutting unit control by increasing

contact pressure.

Wiehle Rollers

Shouldered Wiehle Rollers

Wider spacing tends to increase incursion into the

canopy due to increased contact pressure while

disturbing less grass.

Narrower spacing tends to lessen incursion into the

canopy acting more as a full roller.

The end of the roller is designed to allow for a clean

transition.

Tapered or wider transitions are less disruptive to

the turf during cutting unit steer.

Disc (flute or Wiehle) design modifies turf

interaction.

The shouldered Wiehle roller offers the same

ground engaging characteristics as a nonshouldered Wiehle roller.

Outermost grooves are filled to help minimize

stripping of grass due to cutting unit overlap in warm

season grasses.

There is an entire array of accessories available for

Accessories

Toro University Technical Training

reel mower cutting units.

Page 53

Reel Mowers 51

Combs and brushes are designed to be mounted

Accessories

Combs and Brushes

Accessories

Roller Scrapers

behind the front.

Generally these devices are used to just make

contact with the grass after the roller has pressed it

down. This is to help stand the grass up for a more

uniform cut.

Brushes may also be in combination with scrapers

on front rollers.

Roller scrapers are designed to do just that, scrape

rollers. This is to keep grass clippings from building

up on the rollers, which can change the height of cut

during mowing.

Scrapers are set with a small clearance from the

roller. Note that affixing the scraper too close or on

the trailing side of rotation will cause them to trap

clippings, cause excessive wear to the roller or

increase rolling resistance binding the roller.

Powered Rear Roller

Brushes

Accessories

Powered rear roller brushes are also intended to

keep the rollers from collecting debris. The

difference is that these brushes help disperse the

debris and do an excellent job of cleaning up the

final appearance.

Toro University Technical Training

Page 54

52 Reel Mowers

Groomers and Thatchers

Groomers are intended to cut stolons, promote

upright growth and stand grass up for a more

uniform cut.

Warm season grasses such as Bermuda grass and

others, but also Creeping Bentgrass, which is

considered a cool season grass, all benefit from the

use of groomers on a regular basis.

One word of caution; groomers are used in a

Groomer

straight line. Turning or engaging the turf with

groomers on cleanup passes can cause some

serious issues.

A new variation is the Broomer. The brush helps to

stand the grass up better than the blades alone,

along with knocking off dew to reduce clumping.

Because of the stoloniferous growth of some

cultivars, the turf tends to be “grainy” as can be

seen in the photo.

Toro University Technical Training

Page 55

Reel Mowers 53

Because of the many leaves that are laying over,

the lie of the ball is quite low and the roll is

inconsistent.

As can be seen in this photo, grooming can greatly

improve the appearance of the turf area.

The precaution is that groomers are to be set just

below the height of cut. Grooming does not contact

the ground or thatch. Doing so can be very

disruptive to the turf, have a negative effect on the

appearance and possibly damage the equipment.

Overly aggressive grooming is detrimental to the

turf.

When grooming is done correctly and regularly it

can have a dramatic effect on the turf and the result

is a better lie. As you can see with a healthier

upright growth, the lie of the ball is much higher on

the turf.

IMPORTANT: Grooming is performed above the soil

level. Grooming promotes vertical growth of the

grass by cutting runners, or stolons, standing grass

blades up and encouraging denser growth and

deeper rooting. This can, in effect, yield a more

even grass with less grain, for faster and truer

action of the golf ball

Toro University Technical Training

Page 56

54 Reel Mowers

Grooming is similar to verti-cutting in its runner

cutting action. Grooming blades however, should

never penetrate the soil like verti-cutting or

dethatching. Groomer blades are spaced closer

together and are used more often than verti-cutters

so that they are more effective in cutting runners

and standing up the grass.

It is difficult to give precise recommendations on

the use of groomers because so many variables

affect the performance of grooming:

• Time of year and

weather pattern

• General condition

of the green

• Frequency of

grooming/cutting

– Number of cuttings per

week and number of

passes per cutting

• Height of cut

• Height of grooming

• How long grooming has

been in use on a green

• Type of grass

on the green

• Overall greens

management program

– Irrigation, fertilizing,

spraying, coring, overseeding

•Traffic

• Stress periods

– Temperature,

humidity, traffic

Thatching Reel

IMPORTANT: Improper use or over-aggressive use

of the grooming reel (such as too deep or too

frequent grooming) may cause unnecessary stress

on the turf, leading to severe damage to the green.

Use the groomer cautiously.

It is important to determine the performance of the

groomer before putting it into regular use on greens.

We strongly suggest that a formal test procedure be

used to determine the proper depth setting for your

conditions.

It is difficult to give precise recommendations on the

use of groomers because so many variables affect

the performance of grooming.

Here is an example of a thatching unit, on a triplex

riding greens mower.

Thatch is the accumulation of organic material at the

soil surface and comes primarily from stolen,

rhizome and root tissue in warm season grasses.

Thatching (vertical mowing) is a mechanical method

of removing excess thatch. Please note that

dethatching is very disruptive to turf. This

mechanical removal does not address the cause of

excess thatch.

Toro University Technical Training

Page 57

Reel Mowers 55

Conclusion

This document has provided you with a basic

knowledge of reel mower operating theory, set-up,

adjustment, and maintenance.

This information will not only help you understand

the how, but also give some insight into why some

operating, adjustment, and maintenance procedures

are so important.

Understanding that reel mowers are precision

machines, requiring regular maintenance and

adjustment, can help achieve attractive, consistent,

aftercut appearance, while reducing downtime and

operating costs.

Toro University Technical Training

Page 58

56 Reel Mowers

Notes:

Toro University Technical Training

Page 59

Page 60

© Copyright – The Toro Company

Loading...

Loading...