Page 1

Rotary Mower

Basics

PART NO. 09167SL

Page 2

This page is intentionally blank.

Page 3

Rotary Mowers 1

Table of Contents

Historical Background......................................................................................................2

Theory of Operation.........................................................................................................4

Cutting Action..................................................................................................................6

Equipment Application.....................................................................................................8

Importance of the Operator ...........................................................................................10

Productive Equipment Operation...................................................................................11

Cutting Unit Adjustments...............................................................................................15

Inspection Maintenance and Repairs ............................................................................16

Rotary Blade Inspection and Sharpening ......................................................................20

Toro University Technical Training

Page 4

2 Rotary Mowers

Historical Background

The first practical concept of a rotary type mower

goes back to the 1930's. The concept evolved from

the need for a grass maintenance tool that could cut

long grass acceptably without the cost and

sophistication of a reel mower.

During the 1940's improvements in engines and

material brought about increased use of rotaries but

it wasn't until after World War II that their use

became a common sight.

During the 1960's the bagging concept evolved and

rotary designs incorporated multi- blade

configurations useful for cutting large commercial

type areas.

Toro University Technical Training

Page 5

Rotary Mowers 3

Improvements in engines and drive systems have

resulted in the very effective commercial type rotary

mowers that are presently available.

Toro University Technical Training

Page 6

4 Rotary Mowers

Theory of Operation

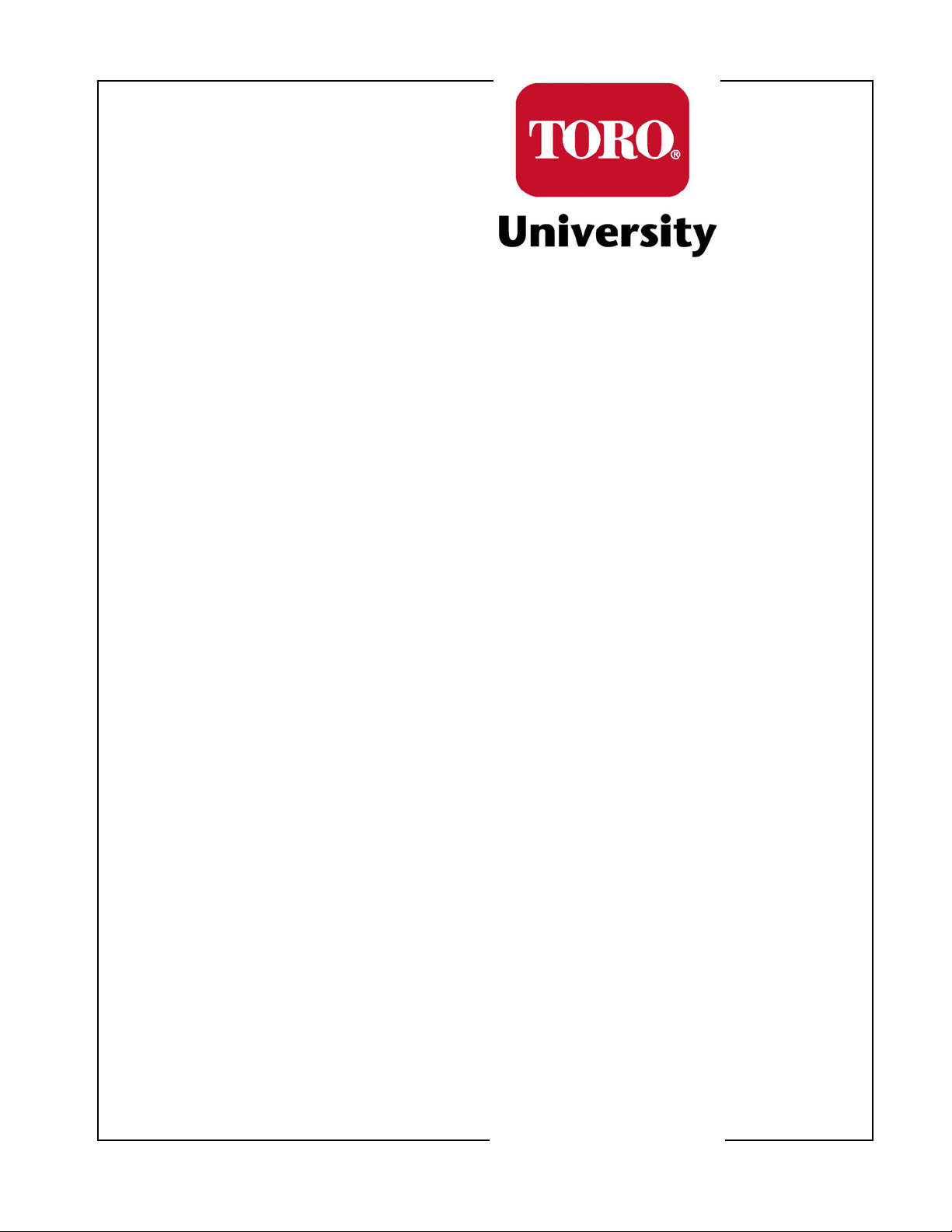

Blade mounting

and drive system

Blade

Deck h ous in g

There are three basic structural members to a rotary cutting unit.

Cutter Deck Housing

The deck housing supports the blade hubs with their drive mechanism and is shaped to carry the cut grass

clippings away from the deck in an effective manner.

Blade mounting and drive system

The blade is normally driven directly by the engine crankshaft, a hydraulic motor or through a belt pulley

system to each blade hub.

The blade

The blade has a sharpened cutting edge at each end with a curved up sail area to create an air flow. This air

flow will whip the grass blades exposing them to the blade cutting edge. The air flow also assists in carrying

the cut grass blades out the discharge.

Toro University Technical Training

Page 7

Rotary Mowers 5

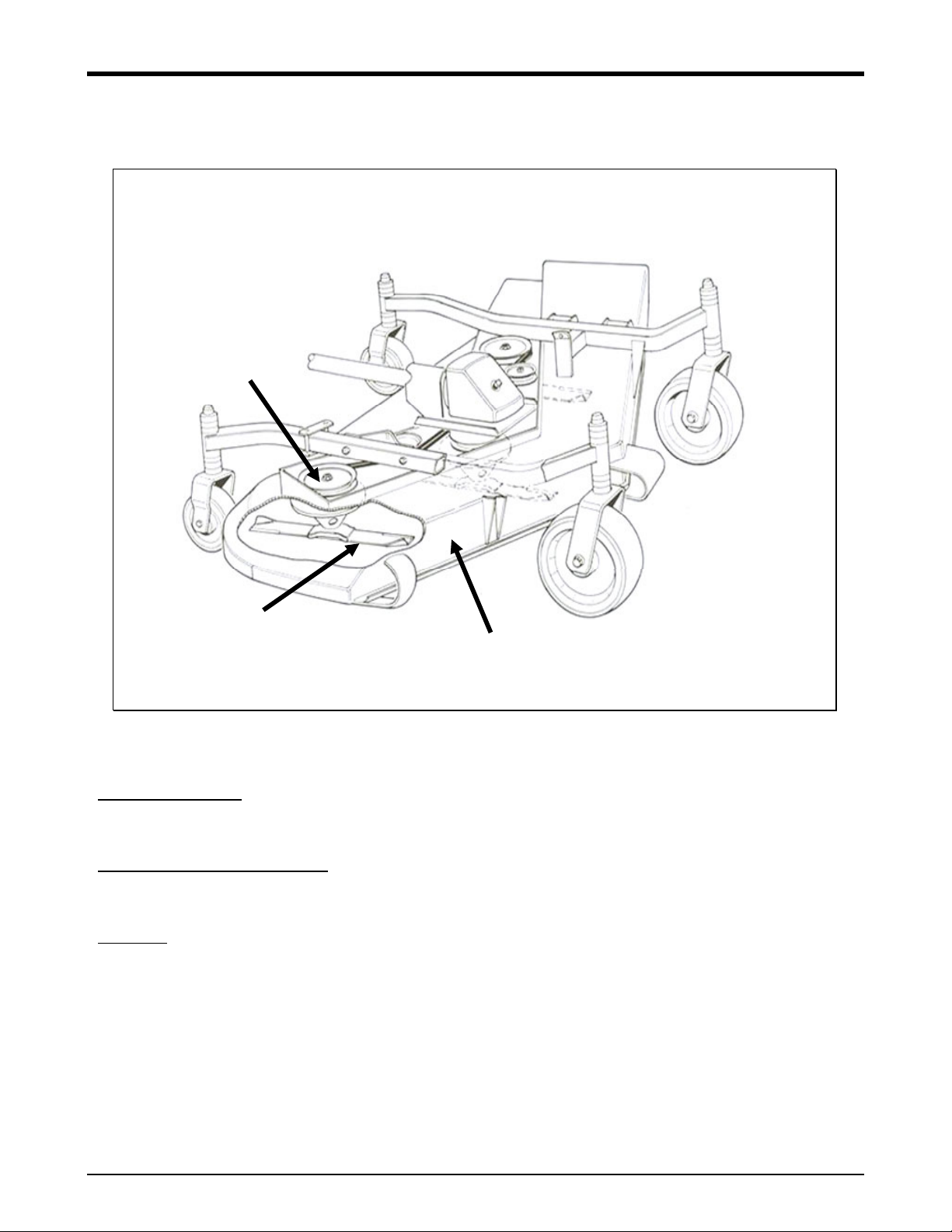

Power transfer from the engine to the blades is

typically done by way of belts and transfer shafts.

Belt drives typically transfer a high percentage of

the available horsepower to the blade and generally

produce much less noise than hydraulic drive

systems.

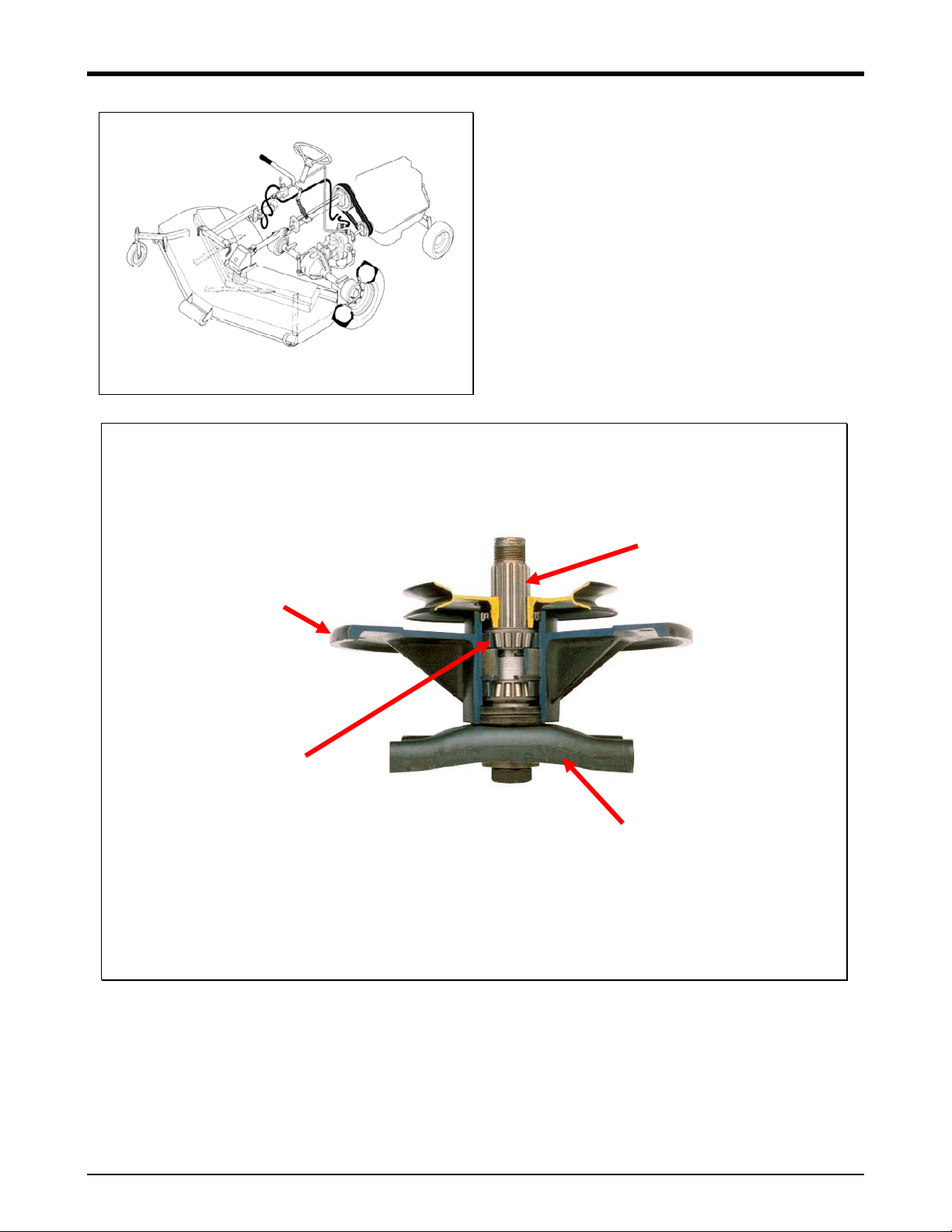

Blade spindle assembly

Large Di a met er

Ductile Cast Iron

Spindle Support

Ductile cast iron,

stronger than

aluminum or

regular cast iron

®

Timken

Roller Bearings

Support spindle

shaft better than

ball bearings

50% mor e load

carryi ng capacity

than b all b eari ngs

Tapered

Solid Cold Finished

Steel Spindle Shaft

Large diameter shaft is

resist ant t o tors i on and

bending failure

Blade Retainer &

Anti-Scalp Cup

Eliminates blade

slippage an d protects

turf from damage

The deck spindles usually run at approximately 2000 to 2500 RPM. They feature tapered roller bearing for

impact resistance and durability. The bearings can be greased, and if done properly can ensure long life

while also purging contaminates from the assembly.

Toro University Technical Training

Page 8

6 Rotary Mowers

Cutting Action

A rotary mower cuts grass by impacting the blade

cutting edge against the grass blades at a very high

velocity. This cutting action requires that the blade

cutting edge is sharp and rotating at an adequate

speed.

Cutting action

Cutting Blade Design

Three types of cutting decks are shown here; a

recycler deck, side discharge and contour deck.

From left to right. Low sail, high sail, medium sail,

recycler sail, and atomic mulching blade. Higher

sails, generate higher lift within the cutting chamber.

The type of blade utilized, depends on cutting deck

design and turf conditions.

Toro University Technical Training

Page 9

Rotary Mowers 7

To understand rotary cutting theory you must

Rotary mower clip

Requirements for

acceptable performance

understand the concept of clip.

Clip can be defined as the forward distance traveled

by the cutting unit during one revolution of the blade.

This distance is divided by the number of blade tips

to arrive at the clip dimension. The dotted lines

represent the cut path by the previous blade tip.

Although the blade cutting edge may be 3" - 4" long

the very tip is the primary contact point with the grass

blades on each pass.

The remaining portion of the cutting edge will tend to

cut off the stragglers from the previous blade pass.

The blade tips are normally lower than the rest of the

blade to avoid any drag on the turf absorbing rotating

horsepower and damaging the grass.

Factors which affect clip:

• Blade speed

• Ground speed

Three basic requirements for acceptable

performance:

The blade must be straight with sharp cutting edges.

The blade must have the proper attitude in relation to

the ground surface.

The blade must rotate at the proper speed with an

accommodating ground speed to get an acceptable

clip.

Toro University Technical Training

Page 10

8 Rotary Mowers

Equipment Application

Rotary mowing equipment is designed for a specific application. The misapplication of rotary mowing

equipment can only result in abuse, poor qualities of cut and costly downtime. The following application

factors will affect the equipment requirements.

Turf areas

maintained with

rotary mowers

Type of terrain

Type of Grass to be cut

Most types of grass can be cut with a rotary mower.

Rotary mowers are generally used for cutting semiformal and rough turf areas at heights of cut 2-inches

and above.

Due to the rotary mower having the capacity to cut

off greater lengths of grass than a reel type, the less

frequent cuttings with a rotary can result in grass

damage due to the excessive length of the grass that

is removed. It is best to cut only about 1/3 of the

grass blade. Cutting more than that is not

recommended unless grass is sparse, or it is late fall

when grass grows more slowly.

Type of Terrain

The type of terrain that would limit a reel mower's

performance would generally apply to rotary mowers

also. Rough and bumpy turf can be cut acceptably

with a rotary due to it’s wider individual width not

being affected by the bumps as readily as a reel

type.

Rotary mowers can be more prone to scalping than

reel type mowers. The shorter individual reel cutting

units conform to uneven terrain better than the wider

rigid individual rotary cutting unit. Contour rotary

mowers with multiple independent cutting decks are

better able to deliver good after cut appearance in

these conditions.

If there are numerous trees and obstacles,

maneuverability and trimability are a prime

importance. Hilly terrain requires a high degree of

stability and traction.

Toro University Technical Training

Page 11

Rotary Mowers 9

Capabilities and

limitations

Mower abuse

and quality of cut

Capabilities and limitations

Rotary mowers will not give the manicured cut

appearance of a reel mower, but will give an

acceptable appearance in more varied and adverse

conditions.

Rotary mowers are capable of cutting much higher

grass than reel mowers. When an excessive amount

of grass is removed, the cut appearance can become

unsightly due to the discharged grass building up in

clumps and ridges. If the grass is allowed to grow

longer than normal, or if it contains a high degree of

moisture, raise the cutting height higher than usual

and cut the grass at this setting. Then, cut the grass

again using the lower, normal setting.

The tolerances within a rotary cutting unit are not

nearly as critical as a reel type cutting unit.

Therefore, a rotary mower can withstand more abuse

than a reel type and maintain an acceptable quality

of cut.

Toro University Technical Training

Page 12

10 Rotary Mowers

The Importance of the Operator and Equipment Manager

The large investment in specialized cutting

equipment cannot be jeopardized by unqualified

operators. Before an operator can be considered

qualified to operate a piece of equipment, there

should be a significant effort by the supervisor

towards their training and familiarization with each

product. All too frequently this procedure is not

followed, with the end result being costly repairs,

down time and a decrease in equipment life. Cost for

these types of repairs far exceeds the cost expanded

in training and familiarization of the operator.

Import an ce of

the supervisor

A supervisor should play a key role in establishing

the proper attitude and behavior patterns towards

operating turf equipment. A supervisor should not

create the impression that a few minutes orientation

on a piece of equipment will qualify the operator.

Toro University Technical Training

Page 13

Rotary Mowers 11

Productive Equipment Operation

Experience has shown that a high percentage of the

problems that develop on turf equipment do not

require an overhaul or disassembly type correction.

In many cases a problem has developed over a

period of time and it could have been corrected by

adjustment, lubrication, or similar required

maintenance. This requires that turf equipment be

checked on a regular basis and not operated until a

major breakdown occurs.

The operator and mechanic should make a thorough

Visually inspect each

day and listen for

abnormal sounds

visual examination of the product each day to include

listening for any abnormal sounds. Equipments

reliability, effectiveness and maintenance costs are

directly affected by how it is operated.

Information

Resources

Toro University Technical Training

The maintenance schedules and owners manuals

should be used for reference to identify specific

areas requiring ongoing maintenance.

The following operating characteristics on rotary

mowers should be made aware to operators and

practiced during their mowing routines.

Page 14

12 Rotary Mowers

Wheel traction

and hill climbing

Wheel traction

Tire pressure in the traction wheels is critical for

maximum traction capability. Over-inflated tire

pressure can cause spinning and tearing out of the

turf in adverse conditions. if lowering the tire

pressure does not correct or stop a spinning

condition, adding liquid to the tires may be required.

Avoid quick acceleration while operating mowing

equipment because a spinning tire can seriously

damage the turf. Try to maintain a constant speed

while going through turns and climbing hills to avoid

a spin out which would damage the turf.

Engine RPM

The correct engine speed is important for the

effective performance of a rotary cutting unit. Most

professional mowing equipment is designed to

operate at full engine RPM. All engine RPM

information is contained in the owner's manual for

each product. The engine speed should be checked

with a tachometer periodically.

Ground Speed

Ground speed

There are three basic problem areas resulting from

too fast a ground speed. It is unsafe, damaging to the

equipment and will result in a poor quality of cut.

The ground speed of a rotary mower must be limited

to a point that the blade can cut and discharge the

grass effectively while maintaining a good quality of

cut. If the cutting unit is becoming overloaded, the

ground speed must be lowered and/or the cutting

width should be reduced so the engine can regain its

normal operating speed.

Toro University Technical Training

Page 15

Rotary Mowers 13

Mowing pa tterns

Mowing patterns

It is normally beneficial to cut a given area in a

pattern that will allow the grass to re discharged onto

the previously cut grass area. If this is not done, the

horsepower requirement increases due to the blade

having to cut the discharged grass again.

Debris on the Turf

All debris should be removed from areas where

rotary mowing equipment is being used to avoid

serious damage to the cutting unit resulting in costly

repairs and downtime. The operator should be

constantly watching for foreign objects in the turf and

when he sees an object, he should stop the mower

and pick it up.

Pick up debris

before mowing

Noise level and condition of equipment

Noise Level

The noise level of equipment is a good indication of

its condition. The operator and mechanic should

continually be aware of changes in noise levels as an

indication of a problem developing.

Toro University Technical Training

Page 16

14 Rotary Mowers

Transporting mowing equipment

Transporting

mowing equipment

Transporting mowing equipment requires discipline

and knowledge to reduce downtime and increase

equipment life. Operating the equipment in an

abusive manner while transporting can only reduce

its mowing efficiency.

Safety

Mowing equipment is designed for a specific

application and should be operated keeping those

restrictions in mind, accidents and personal injuries

can be minimized if persons will think and be aware

in their every day work habits.

Toro University Technical Training

Page 17

Rotary Mowers 15

Cutting Unit Adjustments

Height of cut adjustment and attitude

Height of cut and attitude

Consistent blade height

The height of cut is usually set by the placement of

spacers on the castor wheel shafts or with the height

of the rollers on contour type cutting units. The

effective height of cut can be checked on the turf.

This can be accomplished by inserting a narrow ruler

down into the turf.

Rotary cutting units are normally 1/8" - 1/4" lower at

the front than in the back. This attitude or slope of the

deck cuts down the horsepower requirement to turn

the blades due to the blade only cutting on for the

forward 180° of it’s rotation. If the deck has multiblades and this attitude is too far down at the front

the center will cut lower than the sides due to the

center blade being farther forward.

The attitude can be checked by measuring from a flat

surface up to the forward blade tip. Rotate the

forward tip to the rear and take the measurement at

the back. The difference in dimension is the attitude.

If the cutting unit has multi-blades, the blade tips

should be checked for height to see that they are all

at the same level to avoid mismatch. This can be

accomplished by pointing all the blade tips forward,

measuring up from a flat surface to each blade tip.

Different height readings could be caused by:

Bent or warped blades.

Bent blade spindles.

Height of cut adjustment different on each side.

The attitude or slope of the cutting unit deck being

incorrect.

Toro University Technical Training

Page 18

16 Rotary Mowers

Inspection Maintenance and Repairs

The efficiency of a rotary cutting unit is directly

related to the air flow within the deck.

Cutting efficiency and air flow

The underside of the cutting deck should be

examined periodically. The air flow is significantly

Inspect and

clean out

periodically to

maintain air flow

affected if the deck is not cleaned out periodically.

It is very important that the blade retainer nut/bolt be

Blade Removal and Installation

properly tightened.

If the retainer is not tight enough, the blade may

loosen during operation. If the retainer is too tight,

Impact gun blade removal

only!

Start bolt by

hand and

properly torque.

thread damage may occur and compromise the

integrity of the fastener.

Toro University Technical Training

Page 19

Rotary Mowers 17

The deck spindles usually run at approximately 2000

to 2500 RPM. They feature tapered roller bearing for

impact resistance and durability. The spindles can

be disassembled and repaired, or a complete

assembly may be installed.

The spindle assemblies should be greased as part of

a regularly scheduled maintenance program. If done

properly this will ensure long life while also purging

contaminates from the assembly.

The Spindle Housing.

This component is usually reused when a spindle is

rebuilt unless it was damaged when the spindle

failed.

The Shaft

Running up through the center of the housing is the

shaft. This is the component that runs in the

bearings and the blade is fastened to it. This

component can usually be reused also unless it was

damaged during the failure or is possibly bent by the

blade contacting something. Before reassembling

the spindle assembly, the shaft should be checked to

see if it is bent, the areas on the shaft where the

bearing run needs to be examined, as well as any

areas where seals contact the shaft.

Matched Bearing Set

The matched bearing set includes the bearing races,

bearing cones (Roller bearings) and a set of spacers.

This must be replaced in a set.

Seals

The spindle assembly also includes two seals. The

orientation of these seals is also important to the

overall performance and longevity of the spindle

assembly.

Greasing a bearing after every use and after any

washing not only lubricates, but purges water which

is responsible for the majority of bearing failures on

this type of equipment.

Pulley

Seals

Spacer and

Seal Surface

Spindle assem bly

Matched

Bearing Set

Housing

Shaft

Castor Wheels, Rollers, Lift Arms

Toro University Technical Training

Page 20

18 Rotary Mowers

Periodically inspect drive belts and pulleys. A good

Inspecting drive belts and pulleys

• Oil or grease

contamination

•Debris in pulleys

• Damaged or rusted

pulleys

• Proper installation

and tensioning

time to do this is after cleaning the machine.

• Oil or grease contamination

• Debris in pulleys

• Damaged or rusted pulleys

• Proper installation and tensioning

Drive belt failures

Drive belt failures

The most common causes of belt failures:

• Alignment

• Contamination

• Loading

• Installation Issues

Alignment refers to the alignment of one pulley in

relationship to the other. If this alignment is not

correct the belt may show excessive wear to one of

both sides of the belt. Some of the cords in the belt

may be broken or the belt may actually flip over.

Contamination refers to some other substance

coming in contact with the belt. This may be oil,

grease or other some other foreign object.

Loading refers to excessive loads or shock loading

the drive system.

The last one is installation issues. The belt is

actually damaged during installation.

By inspecting the failed belt the user can get a good

idea as to the cause of the belt failure and can

correct it when the new belt is installed.

Toro University Technical Training

Page 21

Rotary Mowers 19

A belt chirp is a small chirp or squeak that happens

during start-up of an implement. It is caused by

normal slippage an is completely normal. Never

instruct the customer to use belt dressing to prevent

chirps or squeaks. Do not recommend belt dressing

actually for any belt problem. Belt dressing is only a

band-aid and not a fix.

A belt squeal occurs during rapid shaft acceleration

or it can also occur under heavy load conditions. It is

usually caused by insufficient tension. A squealing

belt requires prompt attention because as the belt

squeals an extremely large amount of heat is

generated on the pulley. This heat will very rapidly

damage the belt and the pulley.

There are a few operational problems that the

customer may notice. These include, belt squeal, a

belt chirp or squeak, and vibrations or whipping.

Whipping or vibrations are usually caused by

insufficient belt tension. The belt is too loose and it

will vary it’s position in the pulley groove. To address

this problem adjust the belt according to the

manufacturers guidelines. If this situation is not

addressed, the belt and/or surrounding components

may be damaged.

Belt Chirp

• Chirp occurs on all types of belts.

• Caused by momentary slippage.

• Dust can be a contributing factor.

• Never apply belt dressing.

• Chirps or squeaks will not harm

belts.

Belt Squeal

• Occurs during shaft acceleration.

• Result of insufficient Tension.

• Requires prompt attention.

Belt vibration or whipping

Belt noise

Chirp

Chirp

Belt turnover

Toro University Technical Training

If you ever experiences a belt that flips or turns over

on the pulley, the belt must be replaced. As the belt

flips the cords in the belt will be stretched and the

belt will not want to run true again. The belt will

continuously turn over after that.

Page 22

20 Rotary Mowers

Rotary Blade Inspection and Sharpening

To assure a quality of cut. The cutting edge of the

blade must be kept in a sharp condition. A dull blade

will produce a ragged cut and will require an

excessive amount of engine horsepower to rotate the

blade.

Inspect

the blades

Toro University Technical Training

Page 23

Rotary Mowers 21

The most common causes for rotary mowers not

giving a good quality of cut are due to dull cutting

edges and/or bent blades.

Caution: Check cutter blade daily or before mower is

used or stored and whenever mower is serviced. If

bolt holding blade is loose, tighten it before using

mower.

If the blade is bent, the blade should be replaced. A

bent blade will cause two problems. The most

noticeable problem a increase in horsepower that is

required to operate the mower. This is caused by the

fact that when the grass is cut the at the outer edge

of the blade it is higher then the next area of the

blade. The grass is then cut again and again until

the height is the same as the lowest cutting edge.

The same grass blade could be cut several times.

This can take a considerable amount of power to

repeatedly cut the same grass blade.

The other problem is that this will adversely affect the

quality of cut. In this scenario, a very small amount of

grass is cut from the grass blade frequently. This

can cause the top of the grass blade to fray and it

leaves the grass blade with a unhealthy cut edge.

This will usually show up as a brown die-back from

the top of the grass blade.

In this situation the blade should be replaced.

NEVER straighten a Bent Blade as this could

weaken the blade and cause the blade to break.

Carefully examine cutting ends of blade, especially

where the flat and sail parts of the blade meet. When

mowing in dry or sandy areas, sand and abrasive

material can wear away the metal that joins the sail

and flat part of the blade. For safety, it is important

that when any wear is noticed, the blade must be

replaced. If the condition is not corrected and wear

continues, a slot will form. Eventually a piece of the

sail may break off and be thrown from under the

housing, possibly resulting in serious injury to

yourself or bystander.

Toro University Technical Training

Page 24

22 Rotary Mowers

When discussing rotary blades, keep in mind that

OEM Blades

• Specifically designed for the intended deck.

• Meets all of the requir ed tests .

– Hardness

– Object expulsion

• Meets the mowi ng and qu alit y dem an d s.

• Life expec ta ncy.

Typical Rotary Blade

Cutting Edge

OEM blades are designed specifically to perform on

the intended deck. They have been thoroughly

tested to insure that they are hard enough to provide

the desired life, but not to hard as to be brittle and

risk breakage in the event that they contact a foreign

object. The are specifically designed to insure that a

foreign object that is hit by the blade is not expelled

from the deck in a unsafe manner.

The blades are also designed to insure the best

quality of cut and clippings dispersion from the deck.

The blade sail angle and height is specifically

designed to insure that the mower performs up to the

desired level.

And lastly, while the cost may be slightly higher in

some instances, the increased life expectancy,

coupled with all of the work that has gone into the

safety design of the blade makes original OEM

blades avalue.

Keep the blade cutting edges as sharp as possible. It

is important that the sharpening process be done

correctly. The four items that must be checked if a

blade is removed for sharpening are:

The blade must be checked to assure that it is not

bent and has the correct attitude in relation to the

housing and ground surface.

The blade must be sharpened in the correct manner.

The blade balance must be checked each time the

blade is reground.

It is very important that the blade retaining nut be

sufficiently tightened to assure that it will not loosen

during operation.

Prior to sharpening the blade, it should be checked

for straightness. This can be checked by laying the

blade on a flat surface.

Caution:

Do not try to straighten a blade that is bent, and

never weld a broken or cracked blade. Always use a

new TORO blade to assure continued safety

certification of the product.

Grind the top surface of the blade only, trying to

maintain the original cutting edge angle. Do not grind

the bottom surface or a chisel shape will be the

result.

The lowest portion on the blade that contacts the

grass must be the cutting edge or the grass will not

be cleanly cut and excessive horsepower will be

needed.

Toro University Technical Training

Page 25

Rotary Mowers 23

After the blade has been sharpened the balance

Check blade balance

WARNING !

Always wear a face shield or safety

glasses when grinding or

sharpening.

must be checked. This can best be accomplished

using a commercial balancer. An unbalanced blade

causes vibration damaging to adjoining parts.

Warning: Always wear face shield or safety glasses

when grinding or sharpening is being done.

Turf mowing equipment has unique characteristics

giving it the capability to maintain turf in a well

groomed manner.

Understanding and reacting to these characteristics

will significantly affect the equipments operating

costs, downtime and productivity.

Toro University Technical Training

Page 26

24 Rotary Mowers

Toro University Technical Training

Page 27

Page 28

© Copyright – The Toro Company

Loading...

Loading...