Page 1

FormNo.3368-824RevA

SandPro

ModelNo.08887—SerialNo.311000001andUp

®

2020TractionUnit

ToregisteryourproductordownloadanOperator'sManualorPartsCatalogatnocharge,gotowww.T oro.com.OriginalInstructions(EN)

Page 2

ThisproductcomplieswithallrelevantEuropean

directives,fordetailspleaseseetheseparateproduct

specicDeclarationofConformity(DOC)sheet.

WARNING

CALIFORNIA

Proposition65Warning

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Important:Thisengineisnotequippedwitha

sparkarrestermufer.ItisaviolationofCalifornia

PublicResourceCodeSection4442touseoroperate

theengineonanyforest-covered,brush-covered,or

grass-coveredland.Otherstatesorfederalareas

mayhavesimilarlaws.

ThissparkignitionsystemcomplieswithCanadian

ICES-002.

Introduction

Thismachineisaride-onpieceofutilityequipment

intendedtobeusedbyprofessional,hiredoperators

incommercialapplications.Itisprimarilydesigned

forconditioningsandtrapsandsportseldson

well-maintainedgolfcoursesandcommercialgrounds.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoidinjury

andproductdamage.Youareresponsibleforoperating

theproductproperlyandsafely.

YoumaycontactTorodirectlyatwww .T oro.comfor

productandaccessoryinformation,helpndinga

dealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.These

numbersarestampedintoaplatelocatedontheleft

framerail.Writethenumbersinthespaceprovided.

Theenclosed

Engine Owner’ s Man ual

issupplied

forinformationregardingtheUSEnvironmental

ProtectionAgency(EPA)andtheCalifornia

EmissionControlRegulationofemissionsystems,

maintenance,andwarranty.Replacementsmaybe

orderedthroughtheenginemanufacturer.

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafetyalertsymbol

(Figure1),whichsignalsahazardthatmaycauseserious

injuryordeathifyoudonotfollowtherecommended

precautions.

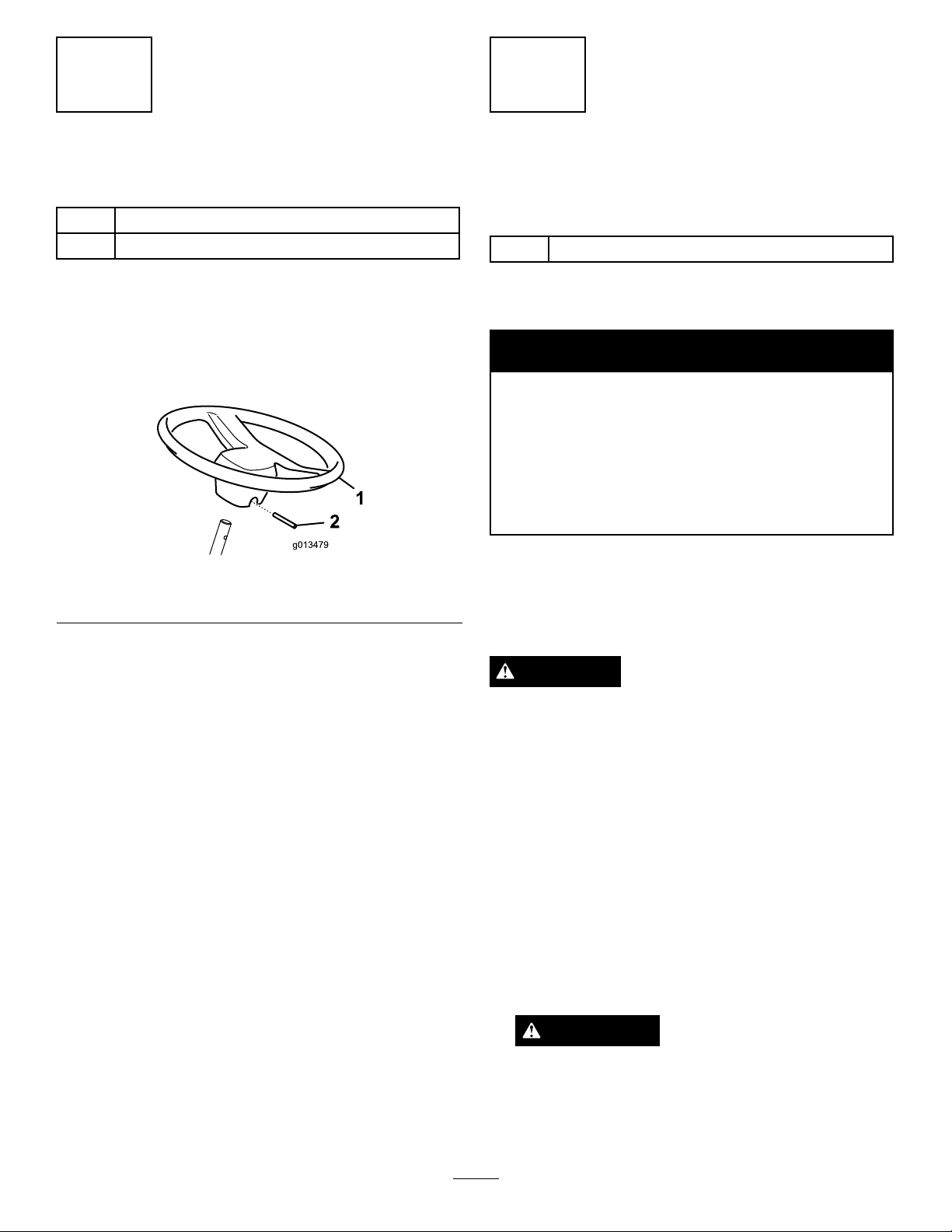

Figure1

1.Safetyalertsymbol

Thismanualuses2otherwordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

©2011—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

Contents

Introduction.................................................................2

Safety...........................................................................4

SafeOperatingPractices.......................................4

SoundPowerLevel...............................................6

SoundPressureLevel...........................................6

VibrationLevel....................................................6

SafetyandInstructionalDecals.............................7

Setup............................................................................9

1InstallingtheSteeringWheel............................10

2ActivatingandChargingtheBattery..................10

3InstallingtheBattery........................................11

4InstallingtheRefuseContainer.........................11

ProductOverview......................................................13

Controls.............................................................13

Specications.....................................................14

Attachments/Accessories...................................14

Operation...................................................................15

CheckingtheEngineOilLevel............................15

FillingtheFuelTank...........................................15

CheckingtheHydraulicFluidLevel.....................16

CheckingtheTirePressure.................................17

TorquetheWheelLugNuts................................17

StartingandStoppingtheEngine........................17

CheckingtheInterlockSystem............................18

TowingtheMachine...........................................18

Break-inPeriod..................................................18

OperatingCharacteristics...................................18

Maintenance...............................................................20

RecommendedMaintenanceSchedule(s)................20

DailyMaintenanceChecklist...............................21

PremaintenanceProcedures....................................21

Lubrication.............................................................22

GreasingtheMachine.........................................22

EngineMaintenance...............................................23

ChangingtheEngineOilandFilter.....................23

ServicingtheRemoteAirCleaner........................23

ReplacingtheSparkPlugs...................................24

CleaningtheCylinderHeadFins.........................24

FuelSystemMaintenance.......................................25

ReplacingtheFuelFilter.....................................25

ElectricalSystemMaintenance................................25

CaringfortheBattery.........................................25

DriveSystemMaintenance.....................................26

AdjustingtheTractionDriveforNeutral.............26

AdjustingtheTractionInterlockSwitch..............27

AdjustingthePedalforForward..........................27

AdjustingtheSteeringChain...............................27

BrakeMaintenance.................................................28

AdjustingtheBrakeInterlockSwitch...................28

AdjustingtheBrakeLinkage...............................28

ControlsSystemMaintenance.................................29

AdjustingtheLiftLever......................................29

AdjustingtheEngineControls............................29

HydraulicSystemMaintenance...............................30

ChangingtheHydraulicSystemOiland

Filter..............................................................30

CheckingtheHydraulicLinesandHoses.............31

ChargingtheHydraulicSystem...........................31

Cleaning.................................................................32

InspectingandCleaningtheMachine..................32

Storage.......................................................................32

TractionUnit......................................................32

Engine...............................................................32

Schematics.................................................................33

3

Page 4

Safety

TheSandProtractionunitcomplieswithANSI

B71.4-2004Standardsatthetimeofproduction.

However,whenattachmentsareinstalledonthe

machineadditionalweightisrequiredtocomplyto

thestandards.

Improperuseormaintenancebytheoperatoror

ownercanresultininjury.Toreducethepotentialfor

injury,complywiththesesafetyinstructionsandalways

payattentiontothesafetyalertsymbol

Caution,Warning,orDanger—“personalsafety

instruction.”Failuretocomplywiththeinstruction

mayresultinpersonalinjuryordeath.

SafeOperatingPractices

ThefollowinginstructionsarefromANSIB71.4-2004.

,whichmeans

◊incorrecthitchingandloaddistribution.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtohimselforherself,

otherpeople,orproperty.

Preparation

•Whileoperating,alwayswearsubstantialfootwear,

longtrousers,hardhat,safetyglasses,andear

protection.Longhair,looseclothing,orjewelrymay

gettangledinmovingparts.Donotoperatethe

equipmentwhenbarefootorwearingopensandals.

•Warning—Fuelishighlyammable.Takethe

followingprecautions:

–Storefuelincontainersspecicallydesignedfor

thispurpose.

–Refueloutdoorsonlyanddonotsmokewhile

refueling.

Training

•Readtheoperator’smanualandothertraining

materialcarefully .Befamiliarwiththecontrols,

safetysigns,andtheproperuseoftheequipment.

•Iftheoperatorormechaniccannotreadthe

languageofistheowner’sresponsibilitytoexplain

thismaterialtothem.

•Neverallowchildrenorpeopleunfamiliarwiththese

instructionstouseorservicethemachine.Local

regulationsmayrestricttheageoftheoperator.

•Neveroperatewhilepeople,especiallychildren,or

petsarenearby .

•Keepinmindthattheoperatororuserisresponsible

foraccidentsorhazardsoccurringtootherpeopleor

theirproperty.

•Donotcarrypassengers.

•Alldriversandmechanicsshouldseekandobtain

professionalandpracticalinstruction.Theowneris

responsiblefortrainingtheusers.Suchinstruction

shouldemphasize:

–theneedforcareandconcentrationwhen

workingwithride-onmachines;

–controlofaride-onmachineslidingonaslope

willnotberegainedbytheapplicationofthe

brake.Themainreasonsforlossofcontrolare:

◊insufcientwheelgrip;

◊beingdriventoofast;

◊inadequatebraking;

◊thetypeofmachineisunsuitableforitstask;

◊lackofawarenessoftheeffectofground

conditions,especiallyslopes;

–Addfuelbeforestartingtheengine.Never

removethecapofthefueltankoraddfuelwhile

theengineisrunningorwhentheengineishot.

–Iffuelisspilled,donotattempttostartthe

enginebutmovethemachineawayfromthe

areaofspillageandavoidcreatinganysourceof

ignitionuntilfuelvaporshavedissipated.

–Replaceallfueltanksandcontainercapssecurely.

•Replacefaultymufers.

•Evaluatetheterraintodeterminewhataccessories

andattachmentsareneededtoproperlyand

safelyperformthejob.Onlyuseaccessoriesand

attachmentsapprovedbythemanufacturer.

•Checkthatoperator’spresencecontrols,safety

switchesandshieldsareattachedandfunctioning

properly.Donotoperateunlesstheyarefunctioning

properly.

Operation

WARNING

Engineexhaustcontainscarbonmonoxide,which

isanodorless,deadlypoisonthatcankillyou.

Donotrunengineindoorsorinanenclosedarea.

•Donotoperatetheengineinaconnedspacewhere

dangerouscarbonmonoxidefumescancollect.

•Operateonlyindaylightoringoodarticiallight.

•Beforeattemptingtostarttheengine,disengage

allattachments,shiftintoneutral,andengagethe

parkingbrake.

4

Page 5

•Donotputhandsorfeetnearorunderrotating

parts.

•Usingthemachinedemandsattention.Toprevent

tippingorlossofcontrol:

–Watchforholesorotherhiddenhazards.

–Usecautionwhenoperatingthemachineona

steepslope.Reduceyourspeedwhenmaking

sharpturnsorwhenturningonhillsides.

–Avoidsuddenstopsandstarts.Donotgofrom

reversetofullforwardwithoutrstcomingtoa

completestop.

–Beforebackingup,looktotherearandensure

thatnooneisbehindthemachine.

–Watchoutfortrafcwhennearofcrossing

roads.Alwaysyieldtherightofway.

•IftheoptionalHitchTowBar,PartNo.110-1375,

isinstalledonthemachine,refertotheattachment

Operator’sManualformaximumhitchload.

•Stayalertforholesintheterrainandotherhidden

hazards.

•Usecarewhenpullingloadsorusingheavy

equipment.

–Useonlyapprovedhitchpoints.

–Limitloadstothoseyoucansafelycontrol.

–Donotturnsharply.Usecarewhenreversing.

•Watchoutfortrafcwhencrossingornearroadways.

•Neveroperatethemachinewithdamagedguards,

shields,orwithoutsafetyprotectivedevicesinplace.

Besureallinterlocksareattached,adjustedproperly,

andfunctioningproperly.

•Donotchangetheenginegovernorsettingsor

overspeedtheengine.Operatingtheengineat

excessivespeedmayincreasethehazardofpersonal

injury.

•Beforeleavingtheoperator’sposition:

–stoponlevelground;

–releasethetractionpedalandlowerthe

attachments;

–settheparkingbrake;

–stoptheengineandremovethekey.

•Disengagedrivetoattachmentswhentransporting

ornotinuse.

•Stoptheengineanddisengagedrivetoattachment

–beforerefuelling;

–beforechecking,cleaningorworkingonthe

machine;

–afterstrikingaforeignobjectorifanabnormal

vibrationoccurs.Inspectthemachinefor

damageandmakerepairsbeforerestartingand

operatingtheequipment.

•Reducethethrottlesettingduringenginerun-out

and,iftheengineisprovidedwithashut-offvalve,

turnthefueloffattheconclusionofoperation.

•Lookbehindanddownbeforebackinguptobesure

ofaclearpath.

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalks.

•Donotoperatethemachineundertheinuenceof

alcoholordrugs.

•Lightningcancausesevereinjuryordeath.If

lightningisseenorthunderisheardinthearea,do

notoperatethemachine;seekshelter.

•Usecarewhenloadingorunloadingthemachine

intoatrailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscurevision.

MaintenanceandStorage

•Keepallnuts,boltsandscrewstighttobesurethe

equipmentisinsafeworkingcondition.

•Neverstoretheequipmentwithfuelinthetank

insideabuildingwherefumesmayreachanopen

ameorspark.

•Allowtheenginetocoolbeforestoringinany

enclosure.

•Toreducetherehazard,keeptheengine,mufer,

batterycompartmentandfuelstorageareafreeof

grass,leaves,orexcessivegrease.

•Keepallpartsingoodworkingconditionandall

hardwareandhydraulicttingstightened.Replaceall

wornordamagedpartsanddecals.

•Ifthefueltankhastobedrained,dothisoutdoors.

•Becarefulduringadjustmentofthemachineto

prevententrapmentofthengersbetweenmoving

partsandxedpartsofthemachine.

•Disengagedrives,lowertheattachment,setparking

brake,stopengineandremovekey .Waitforall

movementtostopbeforeadjusting,cleaningor

repairing.

•Usejackstandstosupportcomponentswhen

required.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

•Disconnectbatteryandremovesparkplugwire

beforemakinganyrepairs.Disconnectthenegative

terminalrstandthepositivelast.Reconnect

positiverstandnegativelast.

5

Page 6

•Keephandsandfeetawayfrommovingparts.If

possible,donotmakeadjustmentswiththeengine

running.

Soundpressurelevelwasdeterminedaccordingtothe

proceduresoutlinedinENISO11201.

•Chargebatteriesinanopenwellventilatedarea,

awayfromsparkandames.Unplugchargerbefore

connectingordisconnectingfrombattery.Wear

protectiveclothinganduseinsulatedtools.

•Makesureallhydrauliclineconnectorsaretightand

allhydraulichosesandlinesareingoodcondition

beforeapplyingpressuretothesystem.

•Keepyourbodyandhandsawayfrompinhole

leaksornozzlesthatejecthydraulicuidunder

highpressure.Usepaperorcardboard,notyour

hands,tosearchforleaks.Hydraulicuidescaping

underpressurecanhavesufcientforcetopenetrate

theskinandcauseseriousinjury.Seekimmediate

medicalattentionifuidisinjectedintoskin.

•Beforedisconnectingorperforminganyworkon

thehydraulicsystem,allpressureinthesystemmust

berelievedbystoppingtheengineandloweringthe

attachmentstotheground.

•Checkallfuellinesfortightnessandwearona

regularbasis.Tightenorrepairthemasneeded.

VibrationLevel

Hand-Arm

Measuredvibrationlevelforrighthand=3.37m/s

Measuredvibrationlevelforlefthand=3.36m/s

UncertaintyValue(K)=0.5m/s

Measuredvaluesweredeterminedaccordingtothe

proceduresoutlinedinEN1032.

WholeBody

Measuredvibrationlevel=0.14m/s

UncertaintyValue(K)=0.5m/s

Measuredvaluesweredeterminedaccordingtothe

proceduresoutlinedinENISO20643.

2

2

2

2

2

•Iftheenginemustberunningtoperforma

maintenanceadjustment,keephands,feet,clothing,

andanypartsofthebodyawayfromtheattachments

andanymovingparts,especiallythescreenatthe

sideoftheengine.Keepeveryoneaway.

•Toensuresafetyandaccuracy,haveanAuthorized

ToroDistributorcheckthemaximumenginespeed

withatachometer.

•Ifmajorrepairsareeverneededorifassistanceis

desired,contactanAuthorizedT oroDistributor.Use

onlyToro-approvedattachmentsandreplacement

parts.Thewarrantymaybevoidedifusedwith

unapprovedattachments.

SoundPowerLevel

Thisunithasaguaranteedsoundpowerlevelof97dBA,

whichincludesanUncertaintyValue(K)of1dBA.

Soundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinISO11094.

SoundPressureLevel

Thisunithasasoundpressurelevelattheoperator’s

earof83dBA,whichincludesanUncertaintyValue(K)

of1dBA.

6

Page 7

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaof

potentialdanger.Replaceanydecalthatisdamagedorlost.

119-2482

1.Warning—readtheOperator’sManual.

2.Warning—readtheOperator’sManual,donotoperatethismachineunlessyouaretrained.

3.Crushinghazard,bystanders—keepbystandersasafedistancefromthemachine.

4.Entanglementhazard,armandbody;hotsurfacehazard—donotoperatewithoutcentershroudinplace.

5.Tippinghazard—slowmachinebeforeturning,donotturnathighspeeds.

6.Warning—donotparkthemachineonaslope;beforeleavingthemachine,putthetractioncontrolpedalinneutral,lowerthe

implement,turntheengineoff,andremovetheignitionkey.

7.Warning—readtheOperator’sManual;donottowthemachine.

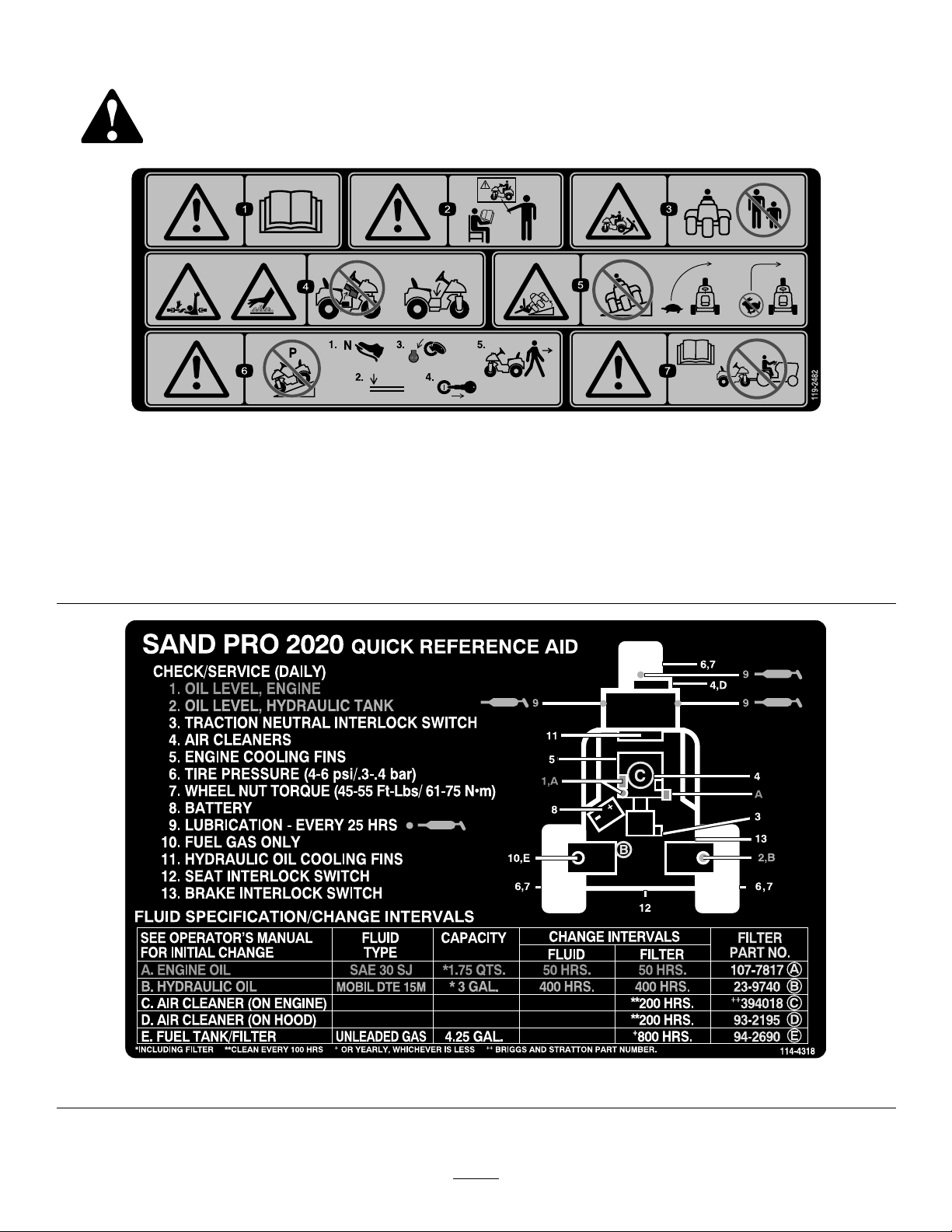

114-4318

7

Page 8

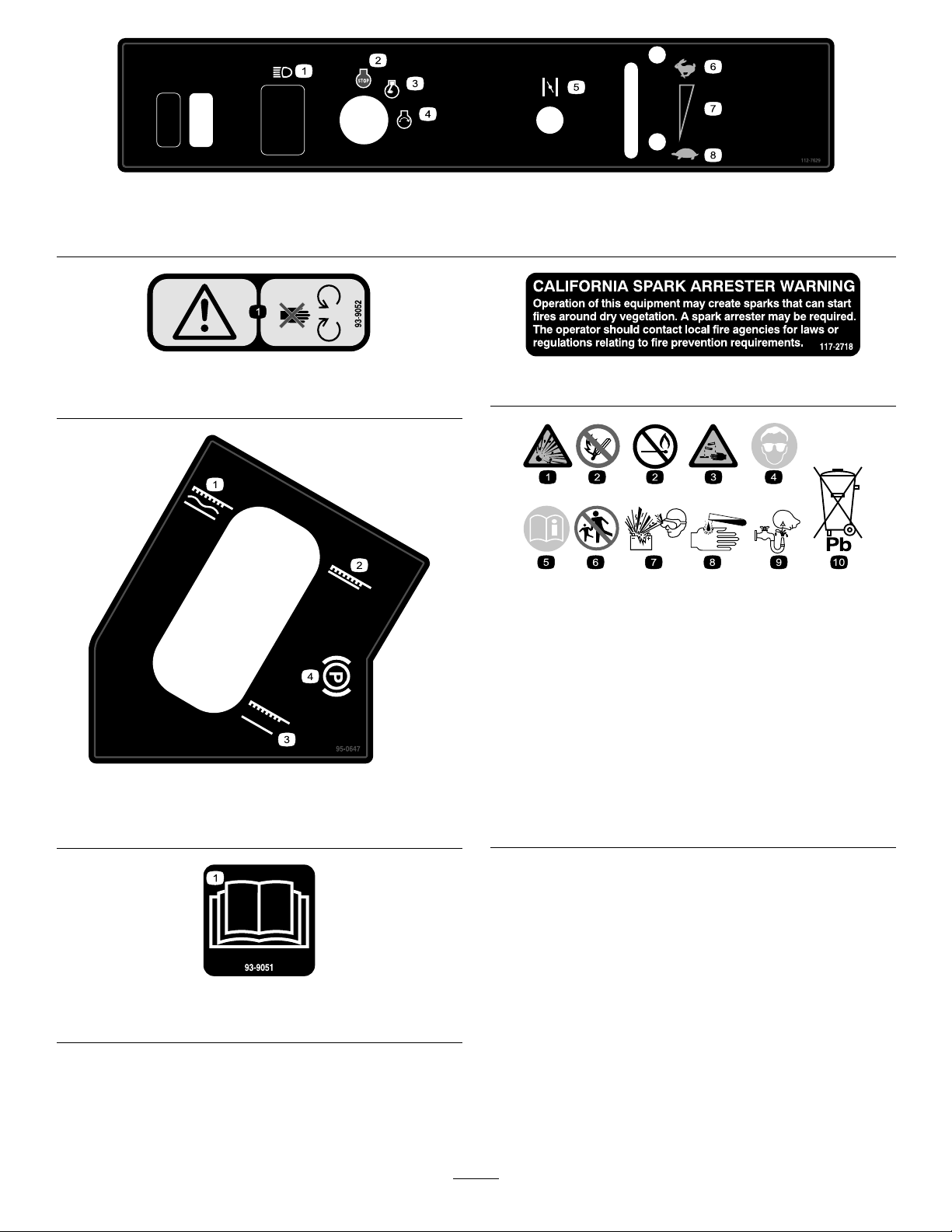

112-7629

1.Headlights3.Engine—run

2.Engine—stop4.Engine—start6.Fast

5.Choke7.Continuousvariablesetting

8.Slow

93-9052

1.Warning—stayawayfrommovingparts.

95-0647

1.Implementoatposition

2.Implementlowerposition4.Parkingbrake

3.Implementraiseposition

117–2718

BatterySymbols

Someorallofthesesymbolsareonyourbattery

1.Explosionhazard

2.Nore,opename,or

smoking.

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection9.Flusheyesimmediately

5.ReadtheOperator’s

Manual.

6.Keepbystandersasafe

7.Weareyeprotection;

8.Batteryacidcancause

10.Containslead;donot

distancefromthebattery .

explosivegasescan

causeblindnessandother

injuries

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

discard.

1.ReadtheOperator’sManual.

93–9051

8

Page 9

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

Steeringwheel

1

2

3

4

Rollpin(1/4x2inch)

Bulkelectrolyte,1.260specicgravity

(notincluded)

Bolt(5/8inch)

Locknut(5/8inch)

Refusecontainer

MediaandAdditionalParts

Description

Capscrew(1/2x1–1/4inch)

Washer(1/2inch)

Cylinderpin

Cotterpin

Operator’sManual

EngineOperator’sManual

PartsCatalog

OperatorTrainingMaterials

Key2

CerticateofCompliance

Qty.

Qty.

1

1

-

2

2

1

4

4

1

2

1

1

1

1

1

Readthemanualsandviewthetrainingmaterialsbefore

operatingthemachine.Usetheremainingpartsforthe

installationofattachments.

Installthesteeringwheel.

Activateandchargethebattery.

Installthebattery

Installtherefusecontainer

Use

Use

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

Note:Removeanddiscardalltheshippingbracketsandfasteners.

9

Page 10

1

2

InstallingtheSteeringWheel

Partsneededforthisprocedure:

1

Steeringwheel

1

Rollpin(1/4x2inch)

Procedure

1.Movethefrontwheelsothatitpointsstraightahead.

2.Slidethesteeringwheelontothesteeringshaft

(Figure2).

Figure2

1.Steeringwheel

3.Securethesteeringwheelinplacewiththerollpin

Figure2).

(

2.Rollpin

ActivatingandChargingthe

Battery

Partsneededforthisprocedure:

-

Bulkelectrolyte,1.260specicgravity(notincluded)

Procedure

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

Washhandsafterhandling.

Ifthebatteryisnotlledwithelectrolyteoractivated,

bulkelectrolytewith1.260specicgravitymustbe

purchasedfromalocalbatterysupplyoutletandadded

tothebattery.

DANGER

Batteryelectrolytecontainssulfuricacidwhichisa

deadlypoisonandcausessevereburns.

•Donotdrinkelectrolyteandavoidcontactwith

skin,eyesorclothing .Wearsafetyglassesto

shieldyoureyesandrubberglovestoprotect

yourhands.

•Fillthebatterywherecleanwaterisalways

availableforushingtheskin.

1.Removethellercapsfromthebatteryandslowly

lleachcelluntilelectrolyteisuptothellline.

2.Replacethellercapsandconnecta3to4amp.

batterychargertothebatteryposts.Chargethe

batteryatarateof3to4amperesfor4to8hours.

WARNING

Chargingthebatteryproducesgassesthatcan

explode.

Neversmokenearthebatteryandkeepsparks

andamesawayfrombattery.

10

Page 11

3.Whenthebatteryischarged,disconnectthecharger

fromtheelectricaloutletandbatteryposts.Allow

thebatterytositfor5-10minutes.

4.Removethellercaps.Slowlyaddelectrolyteto

eachcelluntilthelevelisuptothellline.Install

thellercaps.

Important:Donotoverllthebattery.

Electrolytewilloverowontootherpartsofthe

machineandseverecorrosionanddeterioration

willresult.

WARNING

Incorrectbatterycableroutingcoulddamage

themachineandcablescausingsparks.Sparks

cancausethebatterygassestoexplode,

resultinginpersonalinjury.

•Alwaysdisconnectthenegative(black)

batterycablebeforedisconnectingthe

positive(red)cable.

•Alwaysconnectthepositive(red)battery

cablebeforeconnectingthenegative(black)

cable.

3

InstallingtheBattery

Partsneededforthisprocedure:

2

Bolt(5/8inch)

2

Locknut(5/8inch)

Procedure

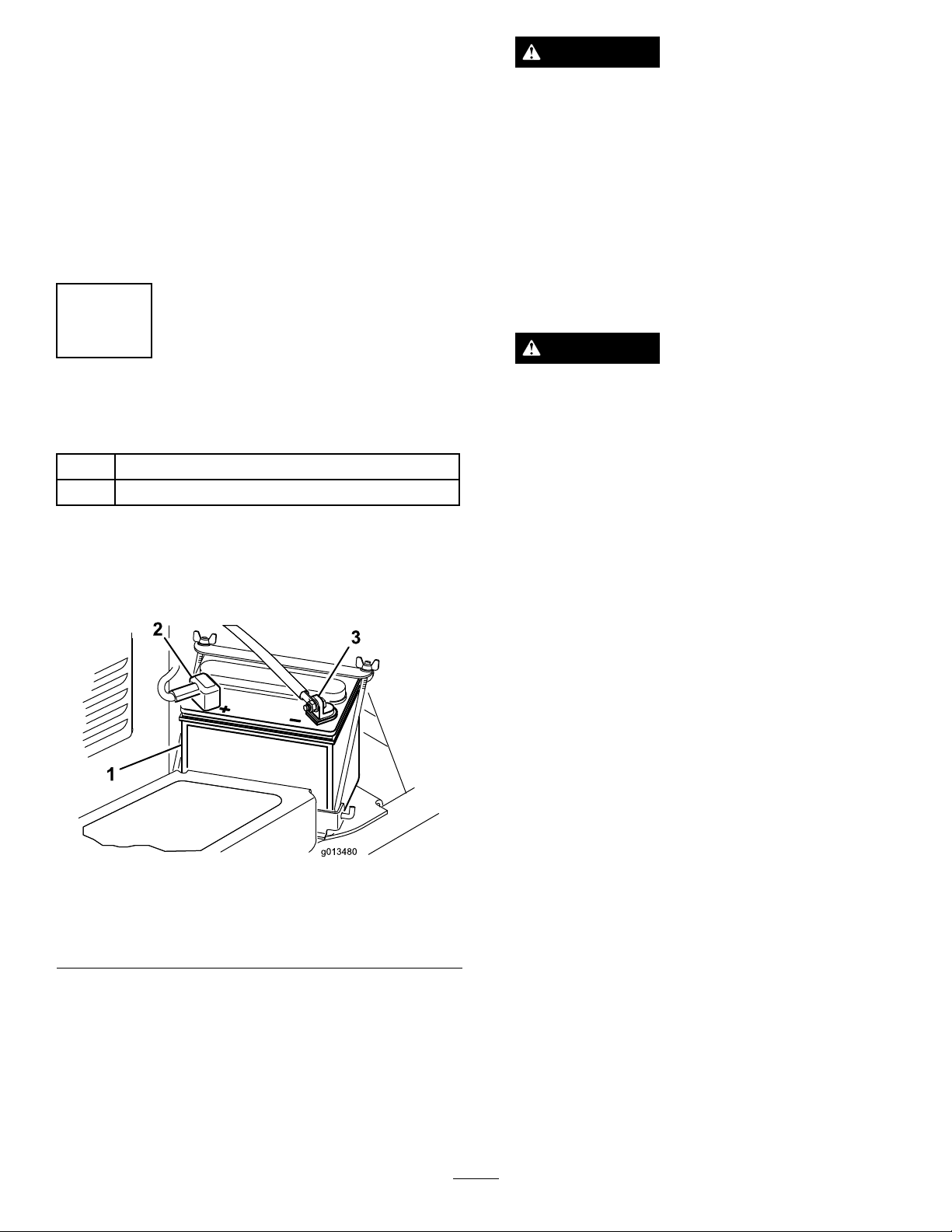

1.Setthebatteryinplace,withthenegativeterminal

positionedtotheoutsideofthemachine(Figure3).

Figure3

1.Battery

2.Positive(+)battery

terminal

3.Negative(-)battery

terminal

WARNING

Batteryterminalsormetaltoolscouldshort

againstmetalmachinecomponentscausing

sparks.Sparkscancausethebatterygassesto

explode,resultinginpersonalinjury.

•Whenremovingorinstallingthebattery,do

notallowthebatteryterminalstotouchany

metalpartsofthemachine.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsofthe

machine.

2.Securethepositivecable(red)tothepositive(+)

terminalwitha5/16x5/8inchboltandlocknut

Figure3).

(

3.Securethesmallblackwireandthenegativecable

(black)tothenegative(-)terminalofthebattery

withabolt(5/16x5/8inch)andlocknut(5/16

inch)(Figure3).

4.Coattheterminalsandmountingfastenerswith

petroleumjellytopreventcorrosion.Slidethe

rubberbootoverthepositive(+)terminaltoprevent

apossibleshortfromoccurring.

5.Installthebatteryclampandsecurethebatterywith

therodsandwingnuts.

11

Page 12

4

InstallingtheRefuseContainer

Partsneededforthisprocedure:

1

Refusecontainer

Procedure

Slidetherefusecontainerontothemountingstudson

thefrontofthefueltank(Figure4).

1.Refusecontainer

Figure4

12

Page 13

ProductOverview

Controls

TractionandStoppingPedal

Thetractionpedal(Figure5)has3functions:tomake

themachinemoveforward,tomoveitbackward,andto

stopthemachine.Usingtheheelandtoeoftheright

foot,depressthetopofthepedaltomoveforwardand

thebottomofpedaltomovebackwardortoassistin

stoppingwhenmovingforward(

thepedaltomoveormoveittotheneutralpositionto

stopthemachine.Foroperatorcomfort,donottherest

heelofthefootonreversewhenoperatingforward.

Figure6).Also,allow

CAUTION

Usethemaximumgroundspeedonlywhendriving

fromoneareatoanother.

Maximumspeedisnotrecommendedwhenusing

amountedortowedattachment.

Important:Donotoperateinreversewiththe

attachmentinthedown(operating)positionorthe

attachmentcouldbeseverelydamaged.

IgnitionSwitch

Theignitionswitch(Figure7),usedtostartandstopthe

engine,hasthreepositions:Off,Run,andStart.Rotate

thekeyclockwisetotheStartpositiontoengagethe

startermotor.Releasethekeywhentheenginestarts.

ThekeywillmoveautomaticallytotheOnposition.To

shuttheengineoff,rotatethekeycounterclockwiseto

theOffposition.

Figure5

1.Tractionandstoppingpedal

Figure6

Groundspeedisproportionatetohowthefartraction

pedalisdepressed.Formaximumgroundspeed,the

pedalmustbefullydepressedwhilethethrottleisin

theFastposition.Togetmaximumpowerorwhen

ascendingahill,havethethrottleintheFastposition

whiledepressingthepedalslightlytokeeptheengine

RPMhigh.WhentheengineRPMbeginstodecrease,

releasethepedalslightlytoallowtheRPMtoincrease.

Important:Formaximumpullingpower,the

throttleshouldbeintheFastpositionandthe

tractionpedaljustbarelydepressed.

Figure7

1.Ignitionkey

2.Chokecontrol6.Lights(optional)

3.Throttlecontrol

4.Hourmeter

5.Fuse(optionlights)

7.Fuse(main)

ChokeControl

Tostartacoldengine,closethecarburetorchokeby

pullingthechokecontrol(Figure7)outtotheOn

position.Aftertheenginestarts,regulatethechoketo

keeptheenginerunningsmoothly.Assoonaspossible,

openthechokebypushingitdownwardtotheOff

position.Awarmenginerequireslittleornochoking.

ThrottleControl

Thethrottlecontrollever(Figure7)connectstoand

operatesthethrottlelinkagetothecarburetor.The

13

Page 14

controlhas2positions:SlowandFast.Theengine

g016653

speedcanbevariedbetweenthe2settings.

Note:Theenginecannotbestoppedbythethrottle

control.

HourMeter

Thehourmeter(Figure7),indicatesthetotalhoursof

machineoperation.Thehourmeterstartstofunction

wheneverthekeyswitchisrotatedtotheOnposition.

LiftLever

Toraisetheattachment,pulltheliftlever(Figure8)

back;tolowertheattachment,pushtheleverforward.

Fortheoatposition,movetheleverintothedetent

position.Whenthedesiredpositionisattained,release

theleveranditwillreturntoneutral.

Figure8

1.Liftlever

2.Parkingbrake

Figure9

1.Fuelshutoffvalve

SeatAdjustment

Movetheleveronthesideoftheseatoutward,slide

theseattothedesiredposition,andreleasetheleverto

locktheseatintoposition.

Anadditional2-1/2inches(64mm)offorward

adjustmentmaybeattainedby,proceedasfollows:

1.Removethe(4)locknutssecuringtheseatslidesto

theseatplate.

2.Movetheseat/slidestotheforwardsetofmounting

holesintheseatplate.

3.Securetheseatslidestotheseatplatewiththe

locknutspreviouslyremoved.

Specications

Note:Themachinehasadouble-actingliftcylinder.

Downpressurecanbeappliedtotheattachmentfor

certainoperatingconditions.

ParkingBrake

Toengagetheparkingbrake(Figure8)pullbackon

theparkingbrakelever.T odisengageit,pushthelever

forward.

FuelShutoffValve

Closethefuelshutoffvalve(Figure9)whenstoringor

traileringthemachine.

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

Widthwithoutattachment

Widthwithrake,modelnumber

08812

Lengthwithoutrake

Height

Wheelbase

Netweight

57–1/2inches(146cm)

75inches(191cm)

76inches(163cm)

45inches(114cm)

42-3/4inches(109cm)

834lb.(378kg)

Attachments/Accessories

AselectionofToroapprovedattachmentsand

accessoriesareavailableforusewiththemachineto

enhanceandexpanditscapabilities.Contactyour

AuthorizedServiceDealerorDistributororgoto

www.Toro.comforalistofallapprovedattachments

andaccessories.

14

Page 15

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

4.Installthedipstickrmlyinplace.

Important:Thedipstickmustbefullyseated

inthetubetoprovidepropersealingofthe

enginecrankcase.Failuretosealthecrankcase

mayresultinenginedamage.

CheckingtheEngineOilLevel

ServiceInterval:Beforeeachuseordaily

Theengineisshippedwithoilinthecrankcase;

however,theoillevelmustbecheckedbeforeandafter

theengineisrststarted.

Crankcasecapacityisapproximately1-3/4USquarts

(1.66l)withthelter.

Usehigh-qualityengineoilthatmeetsthefollowing

specications:

•APIClassicationLevelRequired:SJ,SK,SLor

higher.

•Preferredoil:SAE30(above40degreesF)

1.Positionthemachineonalevelsurface.

2.Pivotseatrearward.

3.Pulloutthedipstick(

cleanrag.Insertthedipstickintothetubeandmake

surethatitisseatedfully .Removethedipstickfrom

thetubeandchecktheoillevel.Iftheoillevelis

low,removethellercapfromthevalvecoverand

addenoughoiltoraisetheleveltotheFullmark

onthedipstick.

Important:Besuretokeeptheengineoillevel

betweentheupperandlowerlimitsontheoil

gauge.Enginefailuremayoccurasaresultof

overllingorunderllingtheengineoil.

Figure10)andwipeitwitha

5.Pivottheseatdown.

Important:Checktheoillevelevery8

operatinghoursordaily.Initially,changethe

oilaftertherst8hoursofoperation;thereafter,

undernormalconditions,changetheoiland

lterevery50hours.However,changetheoil

morefrequentlywhentheengineisoperatedin

extremelydustyordirtyconditions.

FillingtheFuelTank

UseUnleadedregulargasolinesuitableforautomotive

use(87pumpoctaneminimum).Leadedregular

gasolinemaybeusedifunleadedregularisnotavailable.

Fueltankcapacityisapproximately4-1/2gallons

(16.1l).

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupanygasoline

thatspills.

•Neverllthefueltankinsideanenclosedtrailer.

•Donotllthefueltankcompletelyfull.Add

gasolinetothefueltankuntilthelevelis1inch

(25mm)belowthebottomofthellerneck.

Thisemptyspaceinthetankallowsgasoline

toexpand.

•Neversmokewhenhandlinggasoline,andstay

awayfromanopenameorwheregasoline

fumesmaybeignitedbyaspark.

•Storegasolineinanapprovedcontainerand

keepitoutofthereachofchildren.Neverbuy

morethana30-daysupplyofgasoline.

•Donotoperatewithoutentireexhaustsystem

inplaceandinproperworkingcondition.

Figure10

1.Dipstick

2.Oilllcap

15

Page 16

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingasparkwhich

canignitethegasolinevapors.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Alwaysplacegasolinecontainersontheground

awayfromyourvehiclebeforelling.

•Donotllgasolinecontainersinsideavehicle

oronatruckortrailerbedbecauseinterior

carpetsorplastictruckbedlinersmayinsulate

thecontainerandslowthelossofanystatic

charge.

•Whenpractical,removegas-powered

equipmentfromthetruckortrailerandrefuel

theequipmentwithitswheelsontheground.

Figure11

1.Fueltankcap

4.Wipeupanyfuelthatmayhavespilledtopreventa

rehazard.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfromaportable

container,ratherthanfromagasolinedispenser

nozzle.

•Ifagasolinedispensernozzlemustbeused,

keepthenozzleincontactwiththerimofthe

fueltankorcontaineropeningatalltimesuntil

fuelingiscomplete.

WARNING

Gasolineisharmfulorfatalifswallowed.

Long-termexposuretovaporscancauseserious

injuryandillness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgastankor

conditioneropening .

•Keepgasawayfromeyesandskin.

1.Cleantheareaaroundthefueltankcap(Figure11).

2.Removethefueltankcap.

3.Fillthetanktoabout1in.(25mm)belowthetop

ofthetank(bottomofthellerneck).Donot

overll.Installthecap.

Important:Neverusemethanol,gasoline

containingmethanol,orgasoholcontaining

morethan10%ethanolbecausethefuelsystem

couldbedamaged.Donotmixoilwith

gasoline.

CheckingtheHydraulicFluid

Level

ServiceInterval:Beforeeachuseordaily

Thereservoirislledatthefactorywithapproximately

3U.S.gallons(11.4l)ofhighqualityhydraulicuid.

Checkthelevelofthehydraulicuidbeforethe

engineisrststartedanddailythereafter.The

recommendedreplacementuidisasfollows:

ToroPremiumAllSeasonHydraulicFluid(Availablein5

gallonpailsor55gallondrums.SeepartscatalogorT oro

distributorforpartnumbers.)

Alternateuids:IftheT orouidisnotavailable,other

uidsmaybeusedprovidedtheymeetallthefollowing

materialpropertiesandindustryspecications.W edo

notrecommendtheuseofsyntheticuid.Consult

withyourlubricantdistributortoidentifyasatisfactory

product

Note:Torowillnotassumeresponsibilityfordamage

causedbyimpropersubstitutions,souseonlyproducts

fromreputablemanufacturerswhowillstandbehind

theirrecommendation.

16

Page 17

HighViscosityIndex/LowPourPointAntiwear

HydraulicFluid,ISOVG46

MaterialProperties:

Viscosity,ASTMD445cSt@40°C44to48

ViscosityIndexASTM

D2270

PourPoint,ASTMD97-34°Fto-49°F

IndustrySpecications:

VickersI-286-S(QualityLevel),VickersM-2950-S

(QualityLevel),DenisonHF-0

cSt@100°C9.1to9.8

140to160

Note:Manyhydraulicuidsarealmostcolorless,

makingitdifculttospotleaks.Areddyeadditivefor

thehydraulicsystemoilisavailablein2/3oz.(20ml)

bottles.Onebottleissufcientfor4-6gal(15-221)of

hydraulicoil.Orderpartnumber44-2500fromyour

authorizedTorodistributor.

BiodegradableHydraulicFluid-Mobil224H

ToroBiodegradableHydraulicFluid

(Availablein5gallonpailsor55gallondrums.Seeparts

catalogorTorodistributorforpartnumbers.)

Alternateuid:MobilEAL224H

Thisisvegetable-oilbasedbiodegradableoiltestedand

approvedbyToroforthismodel.Thisuidisnotas

resistanttohightemperaturesasstandarduid,somake

suretofollowrecommendeduidchangeintervalswith

thisuid.Contaminationbymineral-basedhydraulic

uidswillchangethebiodegradabilityandtoxicityof

thisoil.Whenchangingfromstandarduidtothe

biodegradabletype,becertaintofollowtheapproved

ushingprocedure.ContactyourlocalToroDistributor

fordetails.

4.Iftheuidlevelislow ,slowlyllthereservoir

withtheappropriatehydraulicuiduntilthelevel

reachestheneckeddownareaonthedipstick.Do

notoverll.

5.Installthereservoircap.

Important:Topreventsystemcontamination,

cleanthetopofthehydraulicoilcontainers

beforepuncturing .Ensurethatthepourspout

andfunnelareclean.

CheckingtheTirePressure

ServiceInterval:Beforeeachuseordaily

Checkthetirepressurebeforeoperatingthemachine

(Figure13).Thecorrectairpressureinthefrontand

reartiresare:

•forTreadedtires4-6psi(0.3-0.4bar)

•forSmoothtires8-10psi(0.5-0.7bar)

1.Cleantheareaaroundthehydraulicoilreservoircap

topreventdebrisfromenteringtank(

Figure12

1.Oilreservoircap

Figure12).

2.Removethecapfromthereservoir.

3.Checktheoillevelinthereservoir.Theoillevel

shouldbeuptothetopoftheconepointonthe

tankscreen.

Figure13

1.Valvestem2.Lugnut

TorquetheWheelLugNuts

ServiceInterval:Aftertherst8hours

Every100hours

Initially,torquethewheellugsaftertherst8hoursof

operation;thereafter,torquethenutsafterevery100

operatinghours.Torquethelugsnutsto45-55ft-lb

(61-75N⋅m).

StartingandStoppingthe

Engine

1.Removeyourfootfromthetractionpedal,make

surethatthepedalisintheneutralposition,and

engagetheparkingbrake.

17

Page 18

2.PullthechokeleverouttotheOnposition(when

startingacoldengine)andthethrottlelevertothe

Slowposition.

Important:Whenoperatingthemachinein

temperatureslessthan32°F(0°C)allowthe

machinetimetowarmupbeforeusing .This

preventsdamagetothehydrostatandthe

tractionloop.

3.Insertthekeyintotheignitionswitchandrotateit

clockwisetostarttheengine.Releasethekeywhen

theenginestarts.Regulatethechoketokeepthe

enginerunningsmoothly.

Important:Topreventoverheatingofthe

startermotor,donotengagethestarterlonger

than10seconds.After10secondsofcontinuous

cranking,wait60secondsbeforeengagingthe

startermotoragain.

Important:Whentheengineisstartedforthe

rsttime,orafteranoverhauloftheengine,

operatethemachineinforwardandreversefor

1to2minutes.Alsooperatetheliftlevertobe

sureofproperoperationofallparts.

2.Sitontheseatandengagetheparkingbrake.

3.Depressthetractionpedalinforwardandreverse

whiletryingtostarttheengine.

4.Iftheenginecranks,theremaybeamalfunctionin

theinterlocksystem.Repairitimmediately.

5.Iftheenginedoesnotcrank,thesystemisoperating

correctly.

6.Withtheoperatorintheseat,tractionpedalin

neutralandparkingbrakeon,theengineshould

start.Liftofftheseatandslowlydepressthe

tractionpedal,theengineshouldstopinoneto

threeseconds.Correctproblemifnotoperating

properly.

7.Withtheoperatorontheseat,theparkingbrake

engagedandtheenginerunning,Depressthe

tractionpedalinforwardandreverse.Theengine

shouldstopwithin2seconds.Iftheenginedoesnot

stop,theremaybeamalfunctionintheinterlock

system.Repairitimmediately.Iftheenginedoes

stop,thesystemisoperatingcorrectly.

TowingtheMachine

4.Tostoptheengine,movethethrottlecontroltothe

SlowpositionandrotatetheignitionkeytoOff.

Engagetheparkingbrakeandremovethekeyfrom

theswitchtopreventaccidentalstarting.

5.Closethefuelshutoffvalvebeforestoringthe

machine.

CAUTION

Shuttheengineoffandwaitforallmoving

partstostopbeforecheckingforoilleaks,loose

parts,andothermalfunctions.

CheckingtheInterlockSystem

CAUTION

Ifsafetyinterlockswitchesaredisconnectedor

damagedthemachinecouldoperateunexpectedly

causingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlockswitches

dailyandreplaceanydamagedswitchesbefore

operatingthemachine.

Thepurposeoftheinterlocksystemistopreventthe

enginefromcrankingorstartingunlessthetraction

pedalisintheneutralposition.

Incaseofemergency,themachinecanbetowedfora

shortdistance.However,wedonotrecommendthis

asastandardprocedure.

Important:Donottowthemachinefasterthan

2–3MPH(3–5km/h)becausethedrivesystem

maybedamaged.Ifthemachinemustbemoved

aconsiderabledistance,transportitonatruck

ortrailer.Thetiresmaylockupifthemachine

istowedtoofast.Ifthisoccurs,stoptowingthe

machineandwaitforthetractioncircuitpressure

tostabilizebeforeresumingtowingataslower

speed.

Break-inPeriod

Only8hoursofoperatingtimeisrequiredforthe

break-inperiod.

Sincethersthoursofoperationarecriticaltofuture

dependabilityofthemachine,monitoritsfunctions

andperformancecloselysothatminordifculties,

whichcouldleadtomajorproblems,arenotedandcan

becorrected.Inspectthemachinefrequentlyduring

break-inforsignsofoilleakage,loosefasteners,orany

othermalfunction.

OperatingCharacteristics

1.Checktheinterlockoperationinawideopenarea

freeofdebrisandbystanders.Stoptheengine.

Refertotheattachmentoperator’ smanualforspecic

operatinginstructionsfortheattachment.

18

Page 19

Practicedrivingthemachinebecauseitsoperating

characteristicsaredifferentthansomeutilityvehicles.

Twopointstoconsiderwhenoperatingthevehicleare

transmissionandenginespeed.

TomaintainsomewhatconstantengineRPM,depress

thetractionpedalslowly.Thisallowstheenginetokeep

upwiththegroundspeedofthevehicle.Bycontrast,

pushingdownquicklyonthetractionpedalwillreduce

engineRPMand,asaresult,therewillnotbeenough

torque-powertomovethevehicle.Therefore,to

transfermaximumpowertotherearwheels,move

thethrottletoFastandslightlydepressthetraction

pedal.Bycomparison,maximumgroundspeedwithno

loadresultswhenthethrottleisintheFastposition

andthetractionpedalisslowlybutfullydepressed.In

summary,alwayskeeptheengineRPMhighenoughto

delivermaximumtorque-powertotherearwheels.

CAUTION

Operatingthemachinedemandsattentionto

preventtippingorlossofcontrol.

•Usecarewhenenteringandleavingsandtraps.

•Useextremecautionaroundditches,creeks,

orotherhazards.

•Usecautionwhenoperatingthemachineon

asteepslope.

•Reduceyourspeedwhenmakingsharpturns

orwhenturningonhillsides.

•Avoidsuddenstopsandstarts.

•Donotgofromreversetofullforwardwithout

rstcomingtoacompletestop.

19

Page 20

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriouslyinjure

youorotherbystanders.

Removethekeyfromtheignitionbeforeyoudoanymaintenance.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst8hours

Beforeeachuseordaily

Every25hours

Every50hours

Every100hours

Every200hours

Every400hours

Every800hours

MaintenanceProcedure

•T orquethewheellugnuts.

•Changetheengineoilandlter.

•Changethehydrauliclter.

•Checktheengineoillevel.

•Checkthehydraulicuidlevel.

•Checkthetirepressure.

•Checktheconditionofthehydrauliclinesandhoses.

•Inspectandcleanthemachine.

•Checkthesafetyinterlockoperation

•Greasethefrontwheelbearings

•Checkthebatteryuidlevelandthecableconnections.

•Changetheengineoilandlter.

•T orquethewheellugnuts.

•Greasethesteeringshaftandsprocket

•Replacetheairlter.

•Changethehydraulicsystemoilandlter.

•Replacethesparkplugs.

•Replacethefuellter.

•Decarbonthecombustionchamber.

•Adjustthevalvesandtorquehead.

•ChecktheengineRPM(atidleandfullthrottle).

•Drainandcleanthefueltank.

Every1,500hours

Important:Refertoyour

•Replacemovinghoses.

•Replacetheneutralandseatinterlockswitches.

Engine Operator’ s Man ual

foradditionalmaintenanceprocedures.

20

Page 21

DailyMaintenanceChecklist

Duplicatethispageforroutineuse.

Fortheweekof: MaintenanceCheckItem

Mon.Tues.Wed.Thurs.Fri.

Checkthesafetyinterlock

operation.

Checkthesteeringoperation.

Checkfuellevel.

Checktheengineoillevel.

Checktheairltercondition.

Cleantheenginecoolingns.

Checkunusualengine

noises.

Checkunusualoperating

noises.

Checkthehydraulicoillevel.

Checkhydraulichosesfor

damage.

Checkforuidleaks.

Checkthetirepressure.

Checktheinstrument

operation.

Touch-updamagedpaint.

Sat.Sun.

NotationforAreasofConcern

Inspectionperformedby:

ItemDate

Premaintenance

Procedures

Important:Thefastenersonthecoversofthis

machinearedesignedtoremainonthecoverafter

removal.Loosenallofthefastenersoneachcovera

fewturnssothatthecoverisloosebutstillattached,

thengobackandloosenthemuntilthecover

Information

comesfree.Thiswillpreventyoufromaccidentally

strippingtheboltsfreeoftheretainers

21

Page 22

Lubrication

GreasingtheMachine

Themachinehasgreasettingsthatmustbelubricated

regularlywithNo.2GeneralPurposeLithiumBase

Grease.Lubricatethefrontwheelbearingsafterevery

25hoursofoperation.Lubricatethesteeringshaftevery

100hours.

Lubricatethefollowingbearingsandbushings:

•Frontwheelbearing(2)(

Figure14)

Figure14

ServiceInterval:Every25hours

Every100hours

1.Wipethegreasettingcleansothatforeignmatter

cannotbeforcedintothebearingorbushing.

2.Pumpgreaseintothebearingorbushing.

3.Wipeupexcessgrease.

•Steeringshaftandsprocket(Figure15)

Figure15

Note:Donotlubricatethesteeringchainunlessit

becomesstiffbecauseofrust.Ifthechainrusts,it

maybelubricatedlightlywithadry-typelubricant.

22

Page 23

EngineMaintenance

necessaryonlyincreasesthechanceofdirtentering

theenginewhenthelterisremoved.

ChangingtheEngineOiland

Filter

ServiceInterval:Aftertherst8hours

Every50hours

Changetheoilandlterinitiallyaftertherst8hoursof

operation;thereafterchangetheoilandthelterevery

50hours.

1.Parkthemachineonalevelsurfaceandturnthe

engineoff.

2.Removethedrainplug(

intoadrainpan.Whentheoilstops,installthedrain

plug.

Figure16)andletoilow

•Besurethecoverisseatedcorrectlyandsealswith

theaircleanerbody .

ReplacingtheAirFilter

ServiceInterval:Every200hours

1.Releasethelatchessecuringtheaircleanercoverto

theaircleanerbody(

1.Aircleanerlatch

2.Dustcap4.Dirtejectionport

Figure17).

Figure17

3.Airlter

Figure16

3.Removetheoillter(Figure16).Applyalightcoat

ofcleanoiltothenewltergasket.

4.Screwthelteronbyhanduntilthegasketcontacts

thelteradapter;thentighten1/2to3/4turn

further.Donotovertighten.

5.Addoiltothecrankcase;refertoCheckingthe

CrankcaseOil.

6.Disposeofusedoilproperly .

ServicingtheRemoteAir

Cleaner

•Checktheaircleanerbodyfordamagewhichcould

causeanairleak.Replaceifdamaged.Checkthe

wholeintakesystemforleaks,damageorloosehose

clamps.

2.Removethecoverfromtheaircleanerbody .Before

removingthelter,uselowpressureair(40psi,

cleananddry)tohelpremovelargeaccumulations

ofdebrispackedbetweenoutsideofprimarylter

andthecanister.

Important:Avoidusinghighpressureairwhich

couldforcedirtthroughthelterintotheintake

tract.Thiscleaningprocesspreventsdebris

frommigratingintotheintakewhentheprimary

lterisremoved.

3.Removeandreplacethelter.

Inspectthenewlterforshippingdamage,checking

thesealingendofthelterandthebody.Donotuse

adamagedelement.Insertthenewlterbyapplying

pressuretotheouterrimoftheelementtoseatitin

thecanister.Donotapplypressuretotheexible

centerofthelter.

Note:Cleaningoftheusedelementisnot

recommendedduetothepossibilityofdamageto

theltermedia.

•Servicetheaircleanerlterevery200hoursorearlier

ifengineperformancesuffersduetoextremelydusty,

dirtyconditions.Changingtheairlterbeforeitis

4.Cleanthedirtejectionportlocatedintheremovable

cover.Removetherubberoutletvalvefromthe

cover,cleanthecavityandreplacetheoutletvalve.

23

Page 24

5.Installthecoverorientingtherubberoutletvalvein

adownwardposition-betweenapproximately5:00

to7:00whenviewedfromtheend.

CleaningtheCylinderHead

Fins

6.Securethelatches.

ReplacingtheSparkPlugs

ServiceInterval:Every800hours

Replacethesparkplugsafterevery800operatinghours

oryearly,whicheveroccursrst.

Type:ChampionRC12YC(orequivalent)

AirGap:0.030in.(0.76mm)

Note:Thesparkplugusuallylastsalongtime;however,

theplugshouldberemovedandcheckedwheneverthe

enginemalfunctions.

1.Cleantheareaaroundthesparkplugssothatforeign

mattercannotfallintothecylinderwhenthespark

plugisremoved.

2.Pullthesparkplugwiresoffofthesparkplugsand

removetheplugsfromthecylinderhead.

3.Checktheconditionofthesideelectrode,center

electrode,andcenterelectrodeinsulatortoensure

thatthereisnodamage.

Toavoidoverheatingandpossibleenginedamage,the

coolingnsonthecylinderheadmustbekeptclean.

Important:Acracked,fouled,dirty,or

otherwisemalfunctioningsparkplugmustbe

replaced.Donotsand-blast,scrape,orclean

theelectrodesbyusingawirebrushbecause

gritmayeventuallyreleasefromtheplugand

fallintothecylinder.Theresultisusuallya

damagedengine.

4.Settheairgapbetweenthecenterandsideofthe

electrodesat0.030in.(0.76mm)(

thecorrectlygappedsparkplugwithgasketseal,and

tightentheplugto200in-lb(23N⋅m).Ifatorque

wrenchisnotused,tightentheplugrmly.

Figure18).Install

Figure18

24

Page 25

FuelSystem

G008963

12

3

ElectricalSystem

Maintenance

ReplacingtheFuelFilter

ServiceInterval:Every800hours

Aninlinelterisincorporatedintothefuelline.Change

thelterevery800hours.Usethefollowingprocedures

whenreplacementbecomesnecessary:

1.Closefuelshutoffvalve,loosenthehoseclampon

thecarburetorsideoflterandremovethefuelline

fromthelter(

Figure19).

Maintenance

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

Washhandsafterhandling.

CaringfortheBattery

ServiceInterval:Every25hours

Thebatteryelectrolytelevelmustbeproperlymaintained

andthetopofthebatterykeptclean.Ifthemachineis

storedinalocationwheretemperaturesareextremely

high,thebatterywillrundownmorerapidlythanif

themachineisstoredinalocationwheretemperatures

arecool.

Figure19

1.Fuellter

2.Hoseclamps

2.Placeadrainpanunderlter,loosentheremaining

hoseclampandremovelter.

3.Installthenewlterwitharrowonthelterbody

pointingawayfromthefueltank(towardcarburetor).

4.Slidethehoseclampsontotheendsofthefuellines.

Pushthefuellinesontothefuellterandsecure

themwiththehoseclamps.Besurethatthearrow

onthesideofthelterpointstowardthecarburetor.

3.Fuelline

DANGER

Batteryelectrolytecontainssulfuricacidwhichisa

deadlypoisonandcausessevereburns.

•Donotdrinkelectrolyteandavoidcontactwith

skin,eyesorclothing .Wearsafetyglassesto

shieldyoureyesandrubberglovestoprotect

yourhands.

•Fillthebatterywherecleanwaterisalways

availableforushingtheskin.

Keepthetopofthebatterycleanbywashingit

periodicallywithabrushdippedinammoniaor

bicarbonateofsodasolution.Flushthetopsurfacewith

wateraftercleaning.Donotremovethellcapwhile

cleaning.

Thebatterycablesmustbetightontheterminalsto

providegoodelectricalcontact.

25

Page 26

WARNING

Incorrectbatterycableroutingcoulddamagethe

machineandcablescausingsparks.Sparkscan

causethebatterygassestoexplode,resultingin

personalinjury.

•Alwaysdisconnectthenegative(black)battery

cablebeforedisconnectingthepositive(red)

cable.

•Alwaysconnectthepositive(red)batterycable

beforeconnectingthenegative(black)cable.

Ifcorrosionoccursatthebatteryterminals,disconnect

thecables,negative(-)cablerst,andscrapetheclamps

andterminalsseparately.Reconnectthecables,positive

(+)cablerst,andcoattheterminalswithpetroleum

jelly.

•Checktheelectrolytelevelevery25operatinghours

or,ifthemachineisinstorage,every30days.

•Maintainthecelllevelwithdistilledordemineralized

water.Donotllthecellsabovethellline.

DriveSystem

Maintenance

AdjustingtheTractionDrive

forNeutral

Ifthemachinemoveswhenthetractionpedalisinthe

neutralposition,thetractioncammustbeadjusted.

1.Parkthemachineonalevelsurfaceandturnthe

engineoff.

2.Pivottheseatupwardandremovetheengineshield.

3.Raiseonerearwheeloffoftheoorandplace

supportblocksundertheframe.

4.Loosenthelocknutonthetractionadjustmentcam

Figure20).

(

Figure20

1.Tractionadjustmentcam

2.Locknut

3.Screw

4.Gap

WARNING

Theenginemustberunningsothatthenal

adjustmentofthetractionadjustmentcamcan

beperformed.Contactwithmovingpartsorhot

surfacesmaycausepersonalinjury.

Keephands,feet,face,andotherbodyparts

awayfromrotatingparts,themufer,andother

hotsurfaces.

5.Starttheengineandrotatethecamhex(Figure20)

inbothdirectionstodeterminethemidpositionof

theneutralspan.

6.Tightenthelocknutsecuringtheadjustment.

7.Stoptheengine.

26

Page 27

8.Installtheengineshieldandlowertheseat.

9.Removethejackstandsandlowerthemachineto

theshopoor.Testdrivethemachinetomakesure

thatitdoesnotmovewhenthetractionpedalisin

neutral.

AdjustingtheTraction

InterlockSwitch

AdjustingtheSteeringChain

Sincethechainandsprocketaresubjectedtosand

thrownupbythefronttire,inspectthemfrequentlyfor

wear.Ifeitherthechainorsprocketiswornbeyond

acceptablelimits,bothshouldbereplaced.

1.Placethefrontwheelinthestraightaheadposition

2.Adjustthelocknutsuntilthechainissnugonboth

sidesofthesprocket(

Figure22).

1.Adjustthetransmissionforneutral;referto

AdjustingtheTractionDriveforNeutral.

2.Activatethepumplevertoensurethatallpartsare

operatingfreelyandseatedproperly .

3.Adjustthescrewuntiltheairgapis.060inches

±.030(1.524mm±.762)(

4.Checkforproperoperation.

Figure20).

AdjustingthePedalfor

Forward

Thepedalmustbeadjustedforforwardifthejam

nutsonthecontrolrodareloosenedorifthepedalis

removed.

1.Parkthemachineonalevelsurface,turntheengine

off,andengagetheparkingbrake.

2.Makesurethatthepumpisinneutral.

3.Loosenthejamnutsonthecontrolrod(

4.Pressdownontherearofthepedaluntilthepedal

contactsthefootrest.

Figure21).

3.Turnthesteeringwheelfullleftandfullrighttobe

surethatthechaindoesnotbindorhangupineither

direction.Adjustasrequired.

Figure22

1.Adjustingnuts

5.Adjustthejamnutstoallowfullstrokeofthepump,

slightlydeectingthecontrolrodwhenthepedal

isatfullstroke.

Figure21

1.Pedal

2.Jamnuts

3.Controlrod

27

Page 28

BrakeMaintenance

7.Engageanddisengagetheparkingbraketomake

sureitdoesnotinterferewiththeswitch.

AdjustingtheBrakeInterlock

Switch

1.Parkthemachineonalevelsurfaceandturnthe

engineoff.

2.Disengagetheparkingbrake.

3.Removetheknobfromtheliftlever(Figure23).

8.Testforproperoperation

9.Installthevalveshroud.

10.Adjusttheliftleverguide.RefertoAdjustingthe

LiftLever.

AdjustingtheBrakeLinkage

Thebrakeshavebeensetatthefactoryforoptimum

performance,butafteruseandwearanadjustmentmay

berequired.

1.Parkthemachineonalevelsurface,turntheengine

off,andblockthewheels.

2.Loosenthejamnutontheactuatorrod(

Removethecotterpinretainingtheactuatorrod.

Increaseordecreasetheactuatorrodlengthby

rotatingtherod.Installtheactuatorrodusinganew

cotterpinandsecurethejamnut.

Figure25).

Figure23

1.Liftleverknob

2.Valveshroudmounting

screws

4.Removethe(3)mountingscrewsandremovethe

valveshroud(

Figure23).

5.Loosenthe(2)nutssecuringbrakeinterlockswitch

tobrakesensorbracket(

Figure24).

6.Adjustthebrakeswitchuntiltheairgapbetweenthe

switchandtheparkingbrakeleverlinkis.060inches

±.030.(1.524mm±.762)(Figure24).Tightenthe

switchmountingnuts.

Figure25

1.Actuatorrod

2.Adjustmentrod(2)4.Cotterpin(3)

3.Jamnut(3)

3.Ifmodifyingtheactuatorrodlengthdoesnot

improvebrakeperformance,adjustboththeleft

andrightadjustmentrodsequallyusingthesame

proceduredescribedinstep2.

1.Brakeswitchmounting

knob

Figure24

2.Valveshroudmounting

screws

28

Page 29

ControlsSystem

Maintenance

AdjustingtheLiftLever

Iftheimplementfailstooatwhentheliftleverisin

thedetentposition,anadjustmenttotheleverguideis

required.

1.Parkthemachineonalevelsurface,turntheengine

off,andengagetheparkingbrake.

2.Disconnecttheimplementfromtheliftcylinderand

extendthecylinderpartway.

3.Loosenthecapscrewsandlocknutssecuringthe

leverguide(

4.Movetheleverguideuntilthecylindermovesfreely

whentheliftleverisinthedetentposition.

5.Tightenthecapscrewsandlocknutslockingthe

adjustment.

1.Liftlever

Figure26)tothevalveshroud.

Figure26

2.Leverguide

Figure27

1.Throttlecasingclamp

screw

2.Throttlecable

3.Swivel6.Chokecable

3.Movetheremotethrottlecontrolleverforwardto

theFastposition.

4.Pullrmlyonthethrottlecableuntilthebackofthe

swivelcontactsthestop(

5.Tightenthecableclampscrewandchecktheengine

RPMsetting:

•HighIdle:3150±50

•LowIdle:1750±50

4.Stop

5.Chokecasingclampscrew

Figure27).

AdjustingtheChokeControl

1.Pivottheseatupwardandremovetheengineshield.

2.Loosenthecableclampscrewsecuringthecableto

theengine(Figure27).

3.Movetheremotechokecontrolleverforwardtothe

Closedposition.

AdjustingtheEngineControls

AdjustingtheThrottleControl

Properthrottleoperationisdependentuponproper

adjustmentofthethrottlecontrol.Beforeadjustingthe

carburetor,ensurethatthethrottlecontrolisoperating

properly.

1.Pivottheseatupwardandremovetheengineshield.

2.Loosenthecableclampscrewsecuringthecableto

theengine(

Figure27).

4.Pullrmlyonthechokecable(

chokebutteryiscompletelyclosed;thentightenthe

cableclampscrew .

Figure27)untilthe

AdjusttheEngineGovernorSpeed

Control

Important:Beforetheenginegovernorspeed

controlisadjusted,thethrottleandchokecontrols

mustbeadjustedproperly.

29

Page 30

WARNING

Theenginemustberunningduringadjustmentof

theenginegovernorspeedcontrol.Contactwith

movingpartsorhotsurfacesmaycausepersonal

injury.

•Ensuretractionpedalisinneutralandengage

theparkingbrakebeforeperformingthis

procedure.

•Keephands,feet,clothing,andotherbodyparts

awayfromanyrotatingparts,themufer,and

otherhotsurfaces.

Note:Toadjustthelowidle,useallthefollowingsteps.

Ifonlythehighidleistobeadjusted,proceeddirectly

tostep5.

HydraulicSystem

Maintenance

ChangingtheHydraulic

SystemOilandFilter

ServiceInterval:Aftertherst8hours

Every400hours

Thehydraulicsystemltermustbechangedinitially,

aftertherst8hoursofoperation,andthereafterevery

400hoursofoperationoryearly ,whicheveroccurs

rst.UseagenuineTorooillterforreplacement.

Thehydraulicoilmustbechangedevery400hoursof

operationoryearly,whicheveroccursrst.

1.Starttheengineandletitrunathalfthrottlefor

approximatelyveminutestowarmup.

2.MovethethrottlecontroltotheSlowsetting.Adjust

theidlestopscrewcounterclockwiseuntilitno

longercontactsthethrottlelever.

3.Bendthegovernedidlespringanchortang

Figure28)toattainanidlespeedof1750±50RPM.

(

Checkthespeedwithatachometer.

Figure28

ShownwithCarbAdapterRemoved

1.Parkthemachineonalevelsurfaceandturnthe

engineoff.

2.Pivottheseatupward.

3.Disconnectthetubefromthebottomttingofthe

reservoirandlettheoilowintoadrainpan.Install

andtightenthetubewhentheoilstopsdraining.

4.Cleantheareaaroundthehydraulicoillter

(Figure29).Removethelterfromthebottomof

thelterhousingandallowtheoiltoowintoa

drainpan.Useabottom-typelterwrench.Dispose

oftheoillterproperly

1.Governedidlespring

anchortag

4.Adjusttheidlestopscrewuntiltheidlespeedis

increased25to50RPMovertheidlespeedsetin

step3.Finalidlespeedmustbe1750±100RPM.

5.MovethethrottlecontroltotheFastposition.Bend

thehighspeedspringanchortang(Figure28)to

attainahighspeedof3150±50RPM.

2.Highspeedspringanchor

tag

Figure29

1.Hydrauliclter

5.Applyalmofoilontheltergasket.Installthe

lterbyhanduntilthegasketcontactsthemounting

head;thentightenthelteranadditional3/4turn.

6.Fillthereservoirtotheproperlevel;referto

CheckingtheHydraulicSystem.

7.Placeallofthecontrolsintheneutralordisengaged

positionandstarttheengine.Runtheengineatthe

lowestpossibleRPMtopurgethesystemofair.

30

Page 31

8.Runtheengineuntiltheliftcylinderextendsand

retractsandforwardandreversewheelmotionis

achieved.

9.Stoptheengineandchecktheoillevelinthe

reservoir.Addoilifnecessary

10.Checkallconnectionsforleaks.

11.Lowertheseat.

12.Disposeofusedoilproperly .

CheckingtheHydraulicLines

andHoses

ServiceInterval:Beforeeachuseordaily

(Figure30),allowingthepumpshaftfreedomto

rotateduringstart-up.

Checkthehydrauliclinesandhosesdailyforleaks,kinked

lines,loosemountingsupports,wear,loosettings,

weatherdeterioration,andchemicaldeterioration.Make

allnecessaryrepairsbeforeoperating.

WARNING

Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjury.

•Makesureallhydraulicuidhosesandlinesare

ingoodconditionandallhydraulicconnections

andttingsaretightbeforeapplyingpressureto

thehydraulicsystem.

•Keepyourbodyandhandsawayfrompin

holeleaksornozzlesthatejecthighpressure

hydraulicuid.

•Usecardboardorpapertondhydraulicleaks.

•Safelyrelieveallpressureinthehydraulicsystem

beforeperforminganyworkonthehydraulic

system.

•Seekimmediatemedicalattentionifuidis

injectedintoskin.

ChargingtheHydraulic

System

Wheneverahydrauliccomponentisrepairedor

replaced,thehydraulicoilltershouldbechangedand

thehydraulicsystemcharged.

Makesurethatthehydraulicreservoirandlterarelled

withoilatalltimeswhenchargingthehydraulicsystem.

1.Parkthemachineonalevelsurfaceandturnthe

engineoff.

2.Pivottheseatupwardandremovetheengineshield.

3.Loosenthelocknutonthespringadjustingpinuntil

thebearingmovesfreelyfromthecamonthelever

Figure30

1.Springadjustingpin3.Cam

2.Bearing

4.Raiseonerearwheeloffoftheoorandplace

supportblocksundertheframe.

5.Starttheengineandsetthethrottletoallowthe

enginetorunatapproximately1800RPM.

6.Actuatetheliftvalveleveruntiltheliftcylinder

rodmovesinandoutseveraltimes.Ifthecylinder

roddoesnotmoveafter10-15secondsorthe

pumpemitsabnormalsounds,shuttheengineoff

immediatelyanddeterminethecauseorproblem.

Inspectforthefollowing:

•Looselterorsuctionlines

•Looseorfaultycoupleronthepump

•Blockedsuctionline

•Faultychargereliefvalve

•Faultychargepump

Ifthecylindermovesin10-15seconds,proceedto

step7.

7.Operatethetractionpedalinforwardandreverse.

Thewheelthatisoffoftheoorshouldrotateinthe

properdirection.Ifthewheelrotatesinthewrong

direction,stoptheengine,removethelinesfromthe

rearofthepumpandreversethelocations.Ifthe

wheelrotatesintheproperdirection,stoptheengine

andadjustthespringadjustingpinlocknut.Adjust

thetractionneutralposition;refertoAdjustingthe

TractionDriveforNeutral.

8.Checktheadjustmentofthetractioninterlock

switch;refertoAdjustingtheTractionInterlock

Switch.

9.Installtheengineshieldandlowertheseat.

31

Page 32

Cleaning

Storage

InspectingandCleaningthe

Machine

ServiceInterval:Beforeeachuseordaily

Atthecompletionofoperation,thoroughlywashthe

machinewithagardenhose-withoutanozzle-sothat

excessivewaterpressurewillnotcausecontamination

anddamagetothesealsandbearings.

Makesurethatthecoolingnsandareaaroundthe

enginecoolingairintakearekeptfreeofdebris.After

cleaning,inspectthemachineforpossiblehydraulic

uidleaks,damage,orweartohydraulicandmechanical

components.

TractionUnit

1.Thoroughlycleanthetractionunit,attachmentsand

theengine.

2.Checkthetirepressure.Refertocheckingthetire

pressure.

3.Checkallfastenersforlooseness;tightenas

necessary.

4.Greaseoroilallgreasettingsandpivotpoints.

Wipeoffanyexcesslubricant.

5.Lightlysandandusetouchuppaintonpaintedareas

thatarescratched,chippedorrusted.

6.Servicethebatteryandcablesasfollows:

A.Removethebatteryterminalsfromthebattery

posts.

B.Cleanthebattery,terminalsandpostswithawire

brushandbakingsodasolution.

C.Coatthecableterminalsandbatterypostswith

Grafo112Xskin-overgrease(ToroPartNo.

505-47),orpetroleumjellytopreventcorrosion.

D.Slowlyrechargethebatteryfor24hoursevery60

daystopreventleadsulfationofthebattery.

Note:Thespecicgravityofafullycharged

batteryis1.250.

Note:Storethebatteryinacoolatmosphereto

avoidquickdeteriorationofthechargeinthebattery.

Topreventthebatteryfromfreezing,makesurethat

itisfullycharged.

Engine

1.Changetheengineoilandlter.RefertoChanging

theEngineOilandFilter.

2.Starttheengineandrunitatidlespeedfortwo

minutes.

3.Thoroughlycleanandservicetheaircleaner

assembly.RefertoServicingtheAirCleaner.

4.Sealtheaircleanerinletandtheexhaustoutletwith

weatherproofmaskingtape.

5.Checktheoilllercap,hydraulicreservoircapand

fueltankcaptoensuretheyaresecurelyinplace.

32

Page 33

Schematics

ElectricalSchematic(Rev.A)

33

Page 34

HydraulicSchematic(Rev.C)

34

Page 35

Notes:

35

Page 36

TheToroTotalCoverageGuarantee

ALimitedWarranty

ConditionsandProductsCovered

TheT oro

toanagreementbetweenthem,jointlywarrantyourT oroCommercial

product(“Product”)tobefreefromdefectsinmaterialsorworkmanship

fortwoyearsor1500operationalhours*,whicheveroccursrst.This

warrantyisapplicabletoallproductswiththeexceptionofAerators

(refertoseparatewarrantystatementsfortheseproducts).Wherea

warrantableconditionexists,wewillrepairtheProductatnocosttoyou

includingdiagnostics,labor,parts,andtransportation.Thiswarranty

beginsonthedatetheProductisdeliveredtotheoriginalretailpurchaser.

*Productequippedwithanhourmeter.

®

Companyanditsafliate,T oroWarrantyCompany,pursuant

InstructionsforObtainingWarrantyService

YouareresponsiblefornotifyingtheCommercialProductsDistributoror

AuthorizedCommercialProductsDealerfromwhomyoupurchasedthe

Productassoonasyoubelieveawarrantableconditionexists.Ifyouneed

helplocatingaCommercialProductsDistributororAuthorizedDealer,or

ifyouhavequestionsregardingyourwarrantyrightsorresponsibilities,

youmaycontactusat:

CommercialProductsServiceDepartment

ToroWarrantyCompany

811 1LyndaleAvenueSouth

Bloomington,MN55420-1196

E-mail:commercial.warranty@toro.com

OwnerResponsibilities

AstheProductowner,youareresponsibleforrequiredmaintenance

andadjustmentsstatedinyourOperator’sManual.Failuretoperform

requiredmaintenanceandadjustmentscanbegroundsfordisallowinga

warrantyclaim.

ItemsandConditionsNotCovered

Notallproductfailuresormalfunctionsthatoccurduringthewarranty

periodaredefectsinmaterialsorworkmanship.Thiswarrantydoesnot

coverthefollowing:

•Productfailureswhichresultfromtheuseofnon-T ororeplacement

parts,orfrominstallationanduseofadd-on,ormodiednon-Toro

brandedaccessoriesandproducts.Aseparatewarrantymaybe

providedbythemanufactureroftheseitems.

•Productfailureswhichresultfromfailuretoperformrecommended

maintenanceand/oradjustments.Failuretoproperlymaintainyour

ToroproductpertheRecommendedMaintenancelistedinthe

Operator’sManualcanresultinclaimsforwarrantybeingdenied.

•ProductfailureswhichresultfromoperatingtheProductinan

abusive,negligentorrecklessmanner.

•Partssubjecttoconsumptionthroughuseunlessfoundtobe

defective.Examplesofpartswhichareconsumed,orusedup,during

normalProductoperationinclude,butarenotlimitedto,brakes

padsandlinings,clutchlinings,blades,reels,bedknives,tines,

sparkplugs,castorwheels,tires,lters,belts,andcertainsprayer

componentssuchasdiaphragms,nozzles,andcheckvalves,etc.

•Failurescausedbyoutsideinuence.Itemsconsideredtobeoutside

inuenceinclude,butarenotlimitedto,weather,storagepractices,

contamination,useofunapprovedcoolants,lubricants,additives,

fertilizers,water,orchemicals,etc.

•Normalnoise,vibration,wearandtear,anddeterioration.

•Normal“wearandtear”includes,butisnotlimitedto,damageto

seatsduetowearorabrasion,wornpaintedsurfaces,scratched

decalsorwindows,etc.

Parts

Partsscheduledforreplacementasrequiredmaintenancearewarranted

fortheperiodoftimeuptothescheduledreplacementtimeforthatpart.

Partsreplacedunderthiswarrantyarecoveredforthedurationofthe

originalproductwarrantyandbecomethepropertyofT oro.Torowill

makethenaldecisionwhethertorepairanyexistingpartorassemblyor

replaceit.T oromayuseremanufacturedpartsforwarrantyrepairs.

NoteRegardingDeepCycleBatteryWarranty:

Deepcyclebatterieshaveaspeciedtotalnumberofkilowatt-hoursthey

candeliverduringtheirlifetime.Operating,recharging,andmaintenance

techniquescanextendorreducetotalbatterylife.Asthebatteriesinthis

productareconsumed,theamountofusefulworkbetweencharging

intervalswillslowlydecreaseuntilthebatteryiscompletelywornout.

Replacementofwornoutbatteries,duetonormalconsumption,isthe

responsibilityoftheproductowner.Batteryreplacementmayberequired

duringthenormalproductwarrantyperiodatowner’sexpense.

MaintenanceisatOwner’sExpense

Enginetune-up,lubricationcleaningandpolishing,replacementof

ItemsandConditionsNotCoveredlters,coolant,andcompleting

RecommendedMaintenancearesomeofthenormalservicesT oro

productsrequirethatareattheowner’sexpense.

GeneralConditions

RepairbyanAuthorizedT oroDistributororDealerisyoursoleremedy

underthiswarranty.

NeitherTheToroCompanynorToroWarrantyCompanyisliablefor

indirect,incidentalorconsequentialdamagesinconnectionwiththe

useoftheT oroProductscoveredbythiswarranty,includingany

costorexpenseofprovidingsubstituteequipmentorserviceduring

reasonableperiodsofmalfunctionornon-usependingcompletion

ofrepairsunderthiswarranty.ExceptfortheEmissionswarranty

referencedbelow,ifapplicable,thereisnootherexpresswarranty.

Allimpliedwarrantiesofmerchantabilityandtnessforusearelimitedto

thedurationofthisexpresswarranty.Somestatesdonotallowexclusions

ofincidentalorconsequentialdamages,orlimitationsonhowlongan

impliedwarrantylasts,sotheaboveexclusionsandlimitationsmaynot

applytoyou.

Thiswarrantygivesyouspeciclegalrights,andyoumayalsohaveother

rightswhichvaryfromstatetostate.

Noteregardingenginewarranty:

TheEmissionsControlSystemonyourProductmaybecoveredby

aseparatewarrantymeetingrequirementsestablishedbytheU.S.

EnvironmentalProtectionAgency(EP A)and/ortheCaliforniaAir

ResourcesBoard(CARB).Thehourlimitationssetforthabovedonot

applytotheEmissionsControlSystemWarranty .RefertotheEngine

EmissionControlW arrantyStatementprintedinyourOperator’sManual

orcontainedintheenginemanufacturer’sdocumentationfordetails

CountriesOtherthantheUnitedStatesorCanada

CustomerswhohavepurchasedT oroproductsexportedfromtheUnitedStatesorCanadashouldcontacttheirT oroDistributor(Dealer)toobtain

guaranteepoliciesforyourcountry ,province,orstate.IfforanyreasonyouaredissatisedwithyourDistributor’sserviceorhavedifcultyobtaining

guaranteeinformation,contacttheT oroimporter.Ifallotherremediesfail,youmaycontactusatT oroWarrantyCompany.

374-0253RevA

Loading...

Loading...