FormNo.3396-642RevA

G023363

SandPro

ModelNo.08706—SerialNo.314000001andUp

ModelNo.08706TC—SerialNo.314000001andUp

®

2040ZTractionUnit

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3396-642*A

ThisproductcomplieswithallrelevantEuropeandirectives.

G023440

1

Fordetails,pleaseseetheseparateproductspecic

DeclarationofConformity(DOC)sheet.

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Introduction

Thismachineisaride-onpieceofutilityequipmentintended

tobeusedbyprofessional,hiredoperatorsincommercial

applications.Itisprimarilydesignedforconditioningsand

trapsonwell-maintainedgolfcoursesandcommercial

grounds.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

ThissparkignitionsystemcomplieswithCanadianICES-002.

Becauseinsomeareastherearelocal,state,orfederal

regulationsrequiringthatasparkarresterbeusedonthe

engineofthismachine,asparkarresterisavailableas

anoption.Ifyourequireasparkarrester,contactyour

AuthorizedToroServiceDealer.

GenuineT orosparkarrestersareapprovedbytheUSDA

ForestryService.

Important:ItisaviolationofCaliforniaPublic

ResourceCodeSection4442touseoroperatetheengine

onanyforest-covered,brush-covered,orgrass-covered

landwithoutasparkarrestermufermaintainedin

workingorder,ortheengineconstricted,equipped,and

maintainedforthepreventionofre.Otherstatesor

federalareasmayhavesimilarlaws.

Theenclosedengineowner'smanualissuppliedfor

informationregardingtheUSEnvironmentalProtection

Agency(EPA)andtheCaliforniaEmissionControl

Regulationofemissionsystems,maintenance,and

warranty.Replacementsmaybeorderedthroughtheengine

manufacturer.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready.Figure1identiesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

©2015—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Contents

Figure2

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Safety...........................................................................4

SafeOperatingPractices...........................................4

SoundPowerLevel..................................................7

SoundPressureLevel...............................................7

VibrationLevel......................................................7

SafetyandInstructionalDecals.................................8

Setup...........................................................................13

1RemovingtheShippingBoard................................14

2InstallinganAttachment.......................................14

3InstallingtheFrontW eights...................................14

ProductOverview.........................................................18

Controls...............................................................18

Specications........................................................20

Attachments/Accessories........................................20

Operation....................................................................20

ThinkSafetyFirst...................................................20

InstallingandRemovingtheWeights.........................21

CheckingtheLeveloftheEngineOil.........................21

FillingtheFuelTank...............................................23

CheckingtheLeveloftheHydraulicFluid..................24

CheckingtheTirePressure......................................25

TorquingtheWheelLugNuts..................................25

UsingtheParkingBrake..........................................25

StartingandStoppingtheEngine..............................26

UsingtheSafetyInterlockSystem.............................26

DrivingtheMachine...............................................27

RakingaSandTrap.................................................28

BreakingintheMachine..........................................29

PushingorTowingtheMachine................................29

TransportingtheMachine........................................30

InstallingaWirelessHourMeter...............................31

OperatingTips......................................................32

Maintenance.................................................................33

RecommendedMaintenanceSchedule(s)......................33

DailyMaintenanceChecklist....................................34

PremaintenanceProcedures........................................35

LiftingtheMachine................................................35

Lubrication...............................................................35

GreasingtheMachine.............................................35

EngineMaintenance..................................................36

ServicingtheEngineOilandFilter............................36

ServicingtheAirCleaner.........................................38

ServicingtheSparkPlugs.........................................39

CheckingandAdjustingtheValveClearance...............39

CleaningandLappingtheValve-Seating

Surface..............................................................39

FuelSystemMaintenance...........................................40

ReplacingtheCarbon-CanisterFilter.........................40

ReplacingtheFuelFilter..........................................40

ElectricalSystemMaintenance....................................41

Jump-StartingtheMachine......................................41

ReplacingtheFuses................................................42

ServicingtheBattery...............................................42

DriveSystemMaintenance.........................................45

AdjustingtheTracking............................................45

3

ReplacingtheDriveBeltandtheTensioner

Pulley................................................................45

ControlsSystemMaintenance.....................................46

AdjustingtheControl-HandlePosition......................46

AdjustingtheControl-HandleLinkage......................47

AdjustingtheControl-HandleDampers....................48

AdjustingtheNeutral-LockResistance......................48

AdjustingtheEngineControls.................................49

HydraulicSystemMaintenance....................................51

CheckingtheHydraulicSystem................................51

ChangingtheHydraulicFluidandFilters....................51

CheckingtheHydraulicLinesandHoses....................53

Cleaning...................................................................54

InspectingandCleaningtheMachine........................54

Storage........................................................................54

StoringtheMachine................................................54

Troubleshooting...........................................................56

Safety

Thismachinehasbeendesignedinaccordance

withANSIB71.4-2012.However,whenyouinstall

attachmentsonthemachine,youmustaddadditional

weighttothemachine,asspecied,tocomplytothe

standards.

Improperlyusingormaintainingthemachinecanresult

ininjury.Toreducethepotentialforinjury,complywith

thesesafetyinstructionsandalwayspayattentiontothe

safetyalertsymbol

Danger—personalsafetyinstruction.Failuretocomply

withtheinstructionmayresultinpersonalinjuryor

death.

SafeOperatingPractices

Training

•ReadtheOperator'sManualandothertrainingmaterial

carefully.Becomefamiliarwiththecontrols,safetysigns,

andtheproperuseoftheequipment.Iftheoperator(s)or

mechanic(s)cannotreadorunderstandtheinformation,

itistheowner'sresponsibilitytoexplainittothem.

•Neverallowchildrenorpeopleunfamiliarwiththese

instructionstouseorservicethemachine.Local

regulationsmayrestricttheageoftheoperator.

•Neveroperatewhilepeople,especiallychildren,orpets

arenearby .

•Keepinmindthattheoperatororuserisresponsiblefor

accidentsorhazardsoccurringtootherpeopleortheir

property.

•Donotcarrypassengers.

•Alldriversandmechanicsshouldseekandobtain

professionalandpracticalinstruction.Theowneris

responsiblefortrainingtheusers.Suchinstructionshould

emphasize:

–theneedforcareandconcentrationwhenworking

withride-onmachines;

–controlofaride-onmachineslidingonaslopewill

notberegainedbytheapplicationofthebrake.The

mainreasonsforlossofcontrolare:

◊insufcientwheelgrip,especiallyonwetgrass;

◊beingdriventoofast;

◊inadequatebraking;

◊thetypeofmachineisunsuitableforthetask;

◊lackofawarenessoftheeffectofground

conditions,especiallyslopes;

◊incorrectattachmentandcounterweight

installation.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtopeopleaswellasdamage

toproperty.

,whichmeansCaution,Warning,or

4

Preparation

•Whileoperatingthemachine,alwayswearsubstantial,

slip-resistantfootwear,longtrousers,hardhat,safety

glasses,andearprotection.Longhair,looseclothing,or

jewelrymaygettangledinmovingparts.Donotoperate

theequipmentwhenbarefootorwearingopensandals.

•Evaluatetheterraintodeterminewhataccessoriesand

attachmentsareneededtoproperlyandsafelyperform

thejob.Useonlyaccessoriesandattachmentsapproved

bythemanufacturer.

•Ensurethattheoperator'spresencecontrols,safety

switches,andshieldsareattachedandfunctioning

properly.Donotoperateunlesstheyarefunctioning

properly.

Operation

•Donotoperatetheengineinaconnedspacewhere

dangerouscarbonmonoxideandotherexhaustgasses

cancollect.

•Operateonlyindaylightoringoodarticiallight.

•Beforeattemptingtostarttheengine,shiftintoneutral,

andengagetheparkingbrake.

•Donotputyourhandsorfeetnearorunderrotating

parts.

•Usingthemachinedemandsattention.T opreventtipping

orlossofcontrol:

–Watchforholesorotherhiddenhazards.

–Usecautionwhenoperatingthemachineonasteep

slope.Reduceyourspeedwhenmakingsharpturns

orwhenturningonhillsides.

–Avoidsuddenstopsandstarts.Donotgofrom

reversetofullforwardwithoutrstcomingtoa

completestop.

–Beforebackingup,looktotherearandensurethat

nooneisbehindthemachine.

–Watchoutfortrafcwhennearorcrossingroads.

Alwaysyieldtherightofway.

•Usecarewhenpullingloadsorusingheavyequipment.

–Useonlyapprovedhitchpoints.

–Limitloadstothosethatyoucansafelycontrol.

–Donotturnsharply.Usecarewhenreversing.

•Neveroperatethemachinewithdamagedguards,shields,

orwithoutprotectivesafetydevicesinplace.Besureall

interlocksareattached,adjustedproperly ,andfunctioning

properly.

•Donotchangetheenginegovernorsettingsoroverspeed

theengine.Operatingtheengineatexcessivespeedmay

increasethehazardofpersonalinjury.

•Beforeleavingtheoperator'sposition:

–stoponlevelground;

–movethecontrolhandlestotheneutralposition;

–settheparkingbrake;

–stoptheengineandremovethekey.

•Raisetheattachmentwhenyoutransportthemachine.

•Stoptheengineinthefollowingsituations:

–beforefuelling;

–beforechecking,cleaning,orworkingonthemachine;

–afterstrikingaforeignobjectorifanabnormal

vibrationoccurs.Inspectthemachinefordamage

andmakerepairsbeforestartingagainandoperating

theequipment.

•Reducethethrottlesettingduringenginerun-out.

•Raisetheattachmentbeforebackingup.

•Lookbehindanddownbeforebackingup,tobesureof

aclearpath.

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalks.

•Donotoperatethemachineundertheinuenceof

alcoholordrugs.

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

•Usecarewhenloadingorunloadingthemachineintoa

trailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,trees,

orotherobjectsthatmayobscurevision.

RolloverProtectionSystem

(ROPS)—UseandMaintenance

•TheROPSisanintegralandeffectivesafetydevice.Keep

afoldingROPSintheraisedandlockedpositionanduse

theseatbeltwhenoperatingthemachine.

•LowerafoldingROPStemporarilyonlywhenabsolutely

necessary.Donotweartheseatbeltwhenfoldeddown.

•Beawarethereisnorolloverprotectionwhenafolded

ROPSisinthedownposition.

•Becertainthattheseatbeltcanbereleasedquicklyin

theeventofanemergency.

•Checktheareatobemowedandneverfolddowna

foldingROPSinareaswherethereareslopes,dropoffs

orwater.

•Checkcarefullyforoverheadclearances(i.e.branches,

doorways,electricalwires)beforedrivingunderany

objectsanddonotcontactthem.

•KeeptheROPSinsafeoperatingconditionby

periodicallythoroughlyinspectingfordamageand

keepingallmountingfastenerstight.

•ReplaceadamagedROPS.Donotrepairorrevise.

•DonotremovetheROPS.

•AnyalterationstoaROPSmustbeapprovedbythe

manufacturer.

5

SafeHandlingofFuels

•Toavoidpersonalinjuryorpropertydamage,use

extremecareinhandlinggasoline.Gasolineisextremely

ammableandthevaporsareexplosive.

•Extinguishallcigarettes,cigars,pipes,andothersources

ofignition.

•Useonlyanapprovedfuelcontainer.

•Neverremovefuelcaporaddfuelwiththeengine

running.

•Allowenginetocoolbeforerefueling.

•Neverrefuelthemachineindoors.

•Neverstorethemachineorfuelcontainerwherethereis

anopename,spark,orpilotlightsuchasonawater

heateroronotherappliances.

•Neverllcontainersinsideavehicleoronatruckor

trailerbedwithaplasticliner.Alwaysplacecontainerson

thegroundawayfromyourvehiclebeforelling.

•Removeequipmentfromthetruckortrailerandrefuelit

ontheground.Ifthisisnotpossible,thenrefuelsuch

equipmentwithaportablecontainer,ratherthanfroma

fueldispensernozzle.

•Keepthenozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilfuelingiscomplete.

•Donotuseanozzlelockopendevice.

•Iffuelisspilledonclothing,changeclothingimmediately.

•Neveroverllfueltank.Replacefuelcapandtighten

securely.

MaintenanceandStorage

•Keepallnuts,bolts,andscrewstighttobesurethatthe

equipmentisinsafeworkingcondition.

•Neverstorethemachinewithfuelinthetankinsidea

buildingwherefumesmayreachanopenameoraspark.

•Allowtheenginetocoolbeforestoringthemachinein

anyenclosure.

•Toreducetherehazard,keeptheengine,mufer,

batteryarea,andfuel-storageareafreeofgrass,leaves,

andexcessivegrease.

•Keepallpartsingoodworkingconditionandallhardware

andhydraulicttingstightened.Replaceallwornor

damagedpartsanddecals.

•Ifthefueltankhastobedrained,dothisoutdoors.

•Becarefulduringadjustmentofthemachine,toprevent

entrapmentofthengersbetweenmovingpartsand

xedpartsofthemachine.

•Disengagedrives,lowertheattachment,settheparking

brake,stoptheengine,andremovethekey .Waitforall

movementtostopbeforeadjusting,cleaning,orrepairing

themachine.

•Usejackstandstosupportcomponentswhenrequired.

•Carefullyreleasepressurefromcomponentswithstored

energy.

•Disconnectthebatteryandremovethespark-plugwires

beforemakinganyrepairs.Disconnectthenegative

batteryterminalrstandthepositiveterminallast.

Connectthepositiveterminalrstandthenegative

terminallast.

•Keephandsandfeetawayfrommovingparts.Ifpossible,

donotmakeadjustmentswiththeenginerunning.

•Chargethebatteryinanopenwell-ventilatedarea,away

fromanysparkandames.Unplugthechargerbefore

connectingordisconnectingitfromthebattery.Wear

protectiveclothing,anduseinsulatedtools.

•Makesurethatallthehydrauliclineconnectorsaretight

andallthehydraulichosesandlinesareingoodcondition

beforeapplyingpressuretothesystem.

•Keepyourbodyandhandsawayfrompinholeleaksor

nozzlesthatejecthydraulicuidunderhighpressure.

Usepaperorcardboard,notyourhands,tosearchfor

leaks.Hydraulicuidescapingunderpressurecanhave

sufcientforcetopenetratetheskinandcauseserious

injury.Seekimmediatemedicalattentionifanyuidis

injectedintotheskin.

•Beforedisconnectingorperforminganyworkonthe

hydraulicsystem,relieveallpressureinthesystemby

stoppingtheengineandloweringtheattachmenttothe

ground.

•Checkallfuellinesfortightnessandwearonaregular

basis.Tightenorrepairthemasneeded.

•Iftheenginemustberunningtoperformamaintenance

adjustment,keephands,feet,clothing,andanypartsof

thebodyawayfromtheattachmentsandanymoving

parts,especiallythescreenatthesideoftheengine.Keep

everyoneaway.

•Toensuresafetyandaccuracy,haveanAuthorizedToro

Distributorcheckthemaximumenginespeedwitha

tachometer.

•Thewarrantymaybevoidedifusedwithunapproved

attachments.

•Ifmajorrepairsareeverneededorifassistanceisdesired,

contactanAuthorizedToroDistributor.

•Tobestprotectyourinvestmentandmaintainoptimal

performanceofyourToroequipment,countonToro

genuineparts.Whenitcomestoreliability ,Torodelivers

replacementpartsdesignedtotheexactengineering

specicationsofourequipment.Forpeaceofmind,insist

onTorogenuineparts.

Hauling

•Usecarewhenloadingorunloadingthemachineintoa

trailerortruck.

•Usefullwidthrampsforloadingmachineintotraileror

truck.

•Tiethemachinedownsecurelyusingstraps,chains,cable,

orropes.Bothfrontandrearstrapsshouldbedirected

downandoutwardfromthemachine.

6

SoundPowerLevel

Thisunithasaguaranteedsoundpowerlevelof99dBA,

whichincludesanUncertaintyValue(K)of1dBA.

Soundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinISO11094.

SoundPressureLevel

Thisunithasasoundpressurelevelattheoperator’searof88

dBA,whichincludesanUncertaintyValue(K)of1dBA.

Soundpressurelevelwasdeterminedaccordingtothe

proceduresoutlinedinENISO11201.

Wearhearingprotection.

VibrationLevel

Hand-Arm

Measuredvibrationlevelforrighthand=1.1m/s

Measuredvibrationlevelforlefthand=0.9m/s

UncertaintyValue(K)=0.6m/s

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinEN1032.

WholeBody

Measuredvibrationlevel=0.39m/s

UncertaintyValue(K)=0.2m/s

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinEN1032.

2

2

2

2

2

7

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

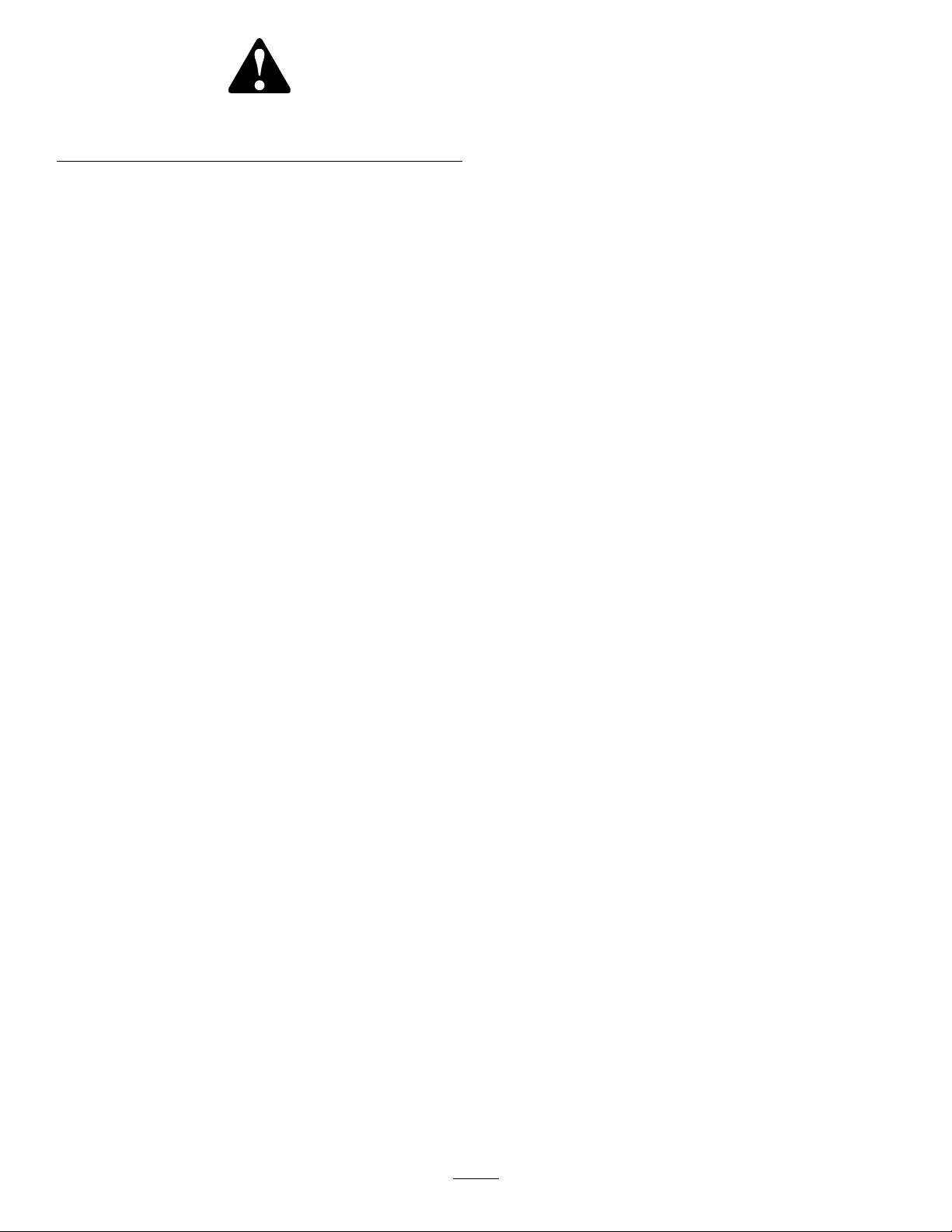

109-7232

1.Fast3.Neutral

2.Slow

4.Reverse

116–5610

1.Hourmeter4.Neutral

2.Powertake-off(PTO)5.Operator-presenceswitch

3.Parkingbrake6.Battery

115-8226

1.Tippinghazard—readtheOperator'smanual;alwayswear

aseatbeltwhenoperating;donotremovetherollover

protectionsystem(ROPS).

116-5944

117–2718

8

125–0214

1.Choke6.Slow

2.Headlight7.Engine—stop

3.Off

4.Headlightandtaillight9.Engine—start

5.Fast

8.Engine—run

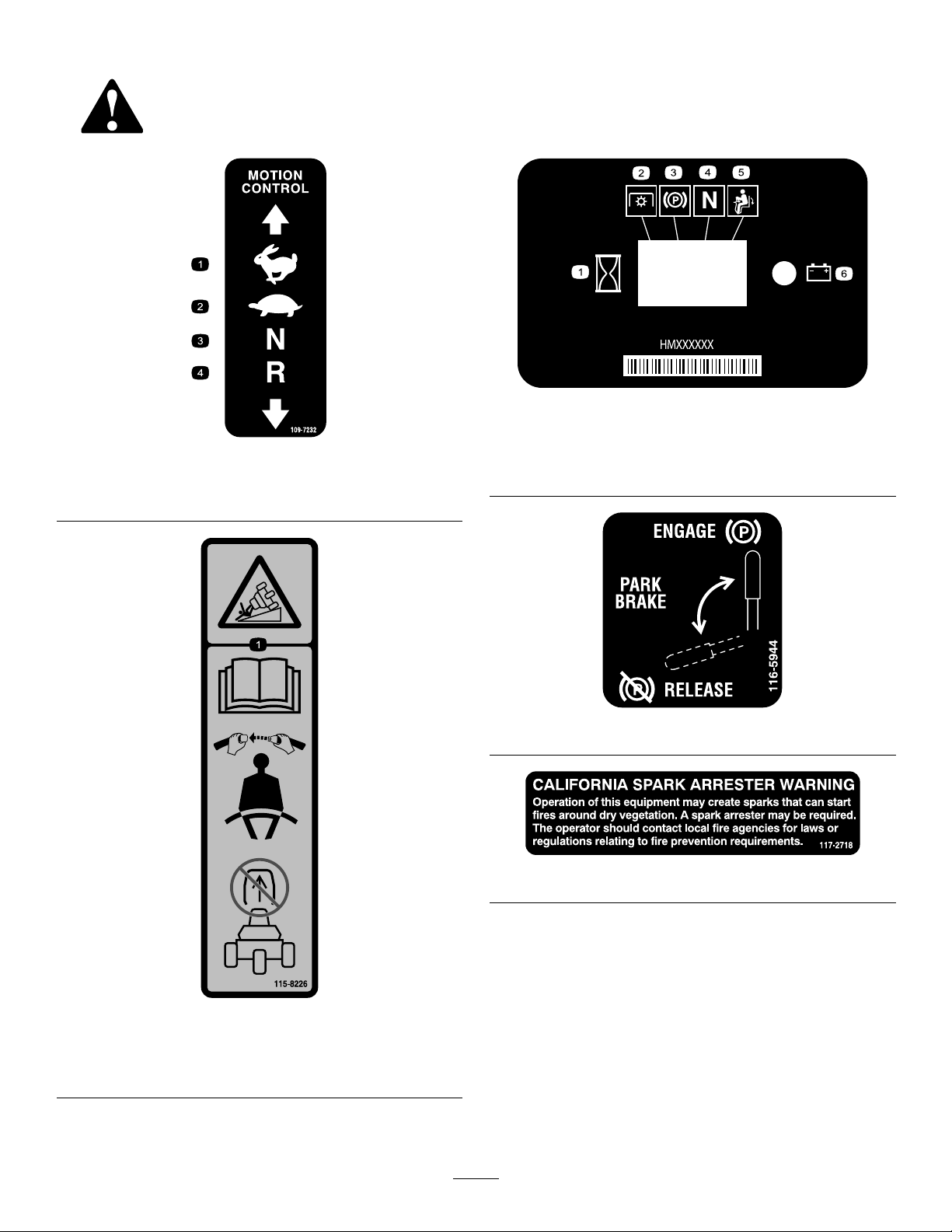

127–0363

1.Warning—readtheOperator’sManual.

2.Warning—donotoperatethemachineunlessyouaretrained.6.Warning—wearaseatbelt.

3.Warning—keepbystandersaway.

4.Warning—keepawayfrommovingparts;keepallguardsand

shieldsinplace.

5.Tippinghazard,slopes—donotturnathighspeed;slowdown

andturngradually.

7.Warning—readtheOperator’sManualbeforeperforming

maintenance;1)Engagetheparkingbrakes,2)Removethe

keyfromtheignitionandremovethewirefromthesparkplug.

9

127–0365

1.Pressuptoraisethe

attachment.

2.Pressdowntolowerthe

attachment.

3.ReadtheOperator’s

Manual.

1.ReadtheOperator’sManualforinformationon

fuses—Headlights15A;Attachment10A;Enginestart25A;

Battery20A.

127–0392

1.Warning—keepawayformhotsurfaces.

127–0371

2.ReadtheOperator’sManual.

10

127–7868

1.Warning—donotoperatethemachinewithoutthe

attachmentinstalled.

130–2620

CEonly

1.ReadtheOperator’sManualforinformationonmaintenance.

2.Checkevery8operatinghours.16.Fueltank/lter

3.Oillevel—engine17.Capacity

4.Oillevel—hydraulictank18.Serviceinterval

5.Neutralinterlockswitch19.Filterpartnumber

6.Airlter20.ReadtheOperator’sManualforinformationon

7.Tirepressure(0.48bar)

8.Wheelnuttorque(61to75N-m)22.Left-handdrivenpulley

9.Battery23.Belttensioner

10.Fuel—gasolineonly24.Drivepulley

11.Seatinterlockswitch

12.Checkevery100operatinghours.26.Belttensioner—partnumber(replaceevery800operating

13.Lubrication

14.Engineoil

15.Hydraulicoil

fuses—Headlights15A;Attachment10A;Enginestart25A;

Battery20A.

21.Beltrouting

25.Right-handdrivenpulley

hours)

27.Belt—partnumber(replaceevery800hours)

11

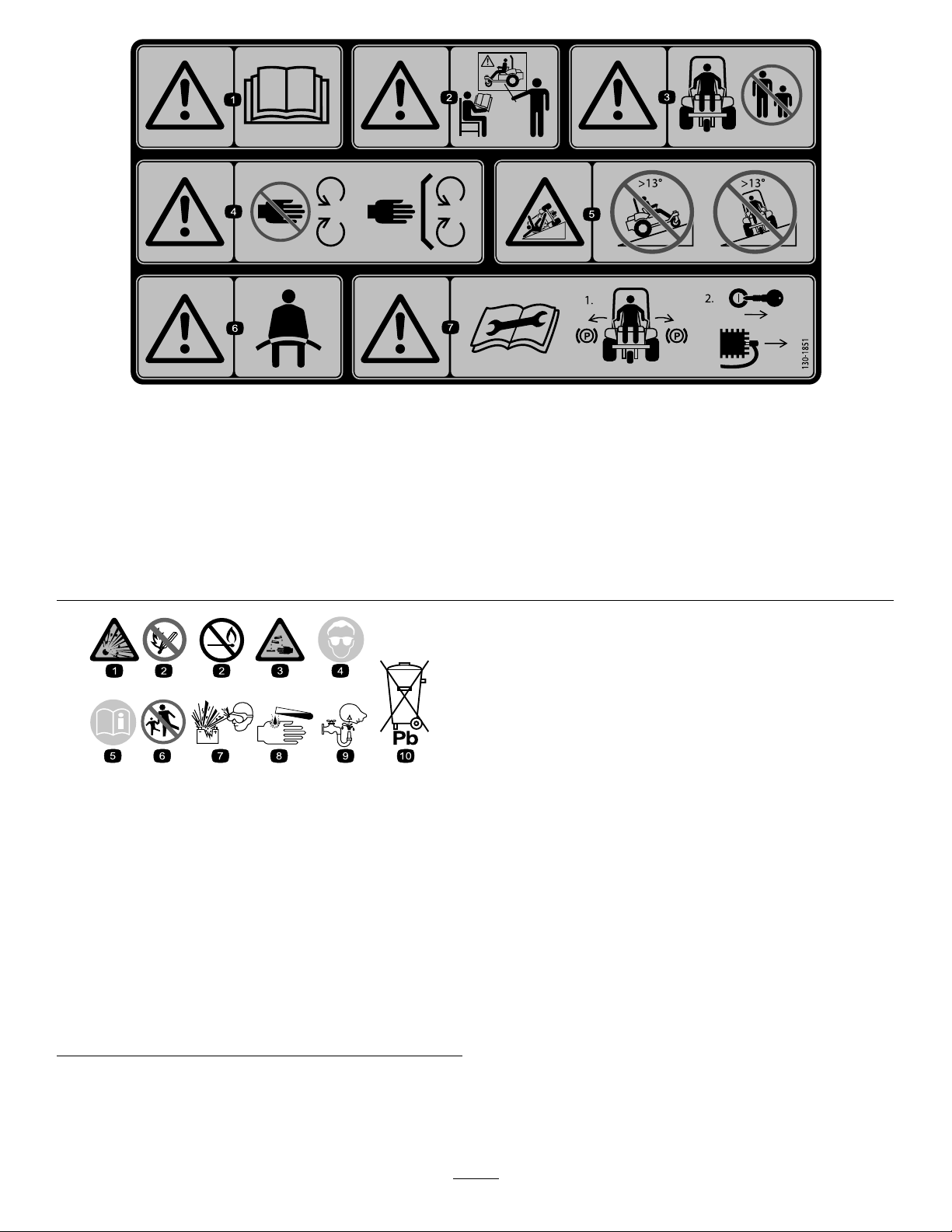

130–1851

CEonly

1.Warning—readtheOperator’sManual.

2.Warning—donotoperatethemachineunlessyouaretrained.6.Warning—wearaseatbelt.

3.Warning—keepbystandersawayfromthemachine.7.Warning—readtheOperator’sManualbeforeperforming

4.Warning—keepawayfrommovingparts;keepallguardsand

shieldsinplace.

5.Tippinghazard—donotdriveupslopesgreaterthan13

degrees;donotdriveacrossslopesgreaterthan13degrees.

maintenance;1)Settheparkingbrake;2)Removethekey

fromtheignitionandremovethewirefromthesparkplug.

BatterySymbols

Someorallofthesesymbolsareonyourbattery

1.Explosionhazard

2.Nore,opename,or

smoking.

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

6.Keepbystandersasafe

distancefromthebattery.

7.Weareyeprotection;

explosivegasescan

causeblindnessandother

injuries

8.Batteryacidcancause

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

10.Containslead;donot

discard.

12

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

6

7

MediaandAdditionalParts

Nopartsrequired

Attachmentandrelatedparts(sold

separately)

Frontweights(asneededper

attachment)

Bolt(5/16x3/4inch)

Nut(5/16inch)

Warningdecal(130-1851)

Servicedecal(130-2620)

Rollbar1

Bolt4

Flangelocknut4

Springwasher

Bracket2

Qty.

Use

–

–

–

1

2

1

1

4

Removetheshippingboard.

Installanattachment.

Installthefrontweights.

Connectthebattery(Model08706TC

only).

ApplytheCEwarningdecal,ifrequired

(Model08706TConly).

ApplytheCEservicedecal,ifrequired

(Model08706TConly).

InstalltheROPS(Model08706TConly).

Description

Operator'sManual

Engineoperator'smanual1

Operatortrainingmaterials

Pre-deliveryinspectionsheet1

PartsCatalog

CerticateofCompliance

Key2

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

Note:Removeanddiscardalltheshippingbracketsandfasteners.

Qty.

1

1

1Usethecatalogtoorderparts.

1

Readthesheetbeforeoperating.

ThecerticateindicatesCEcompliance.

Starttheengine.

Use

13

1

G023667

2

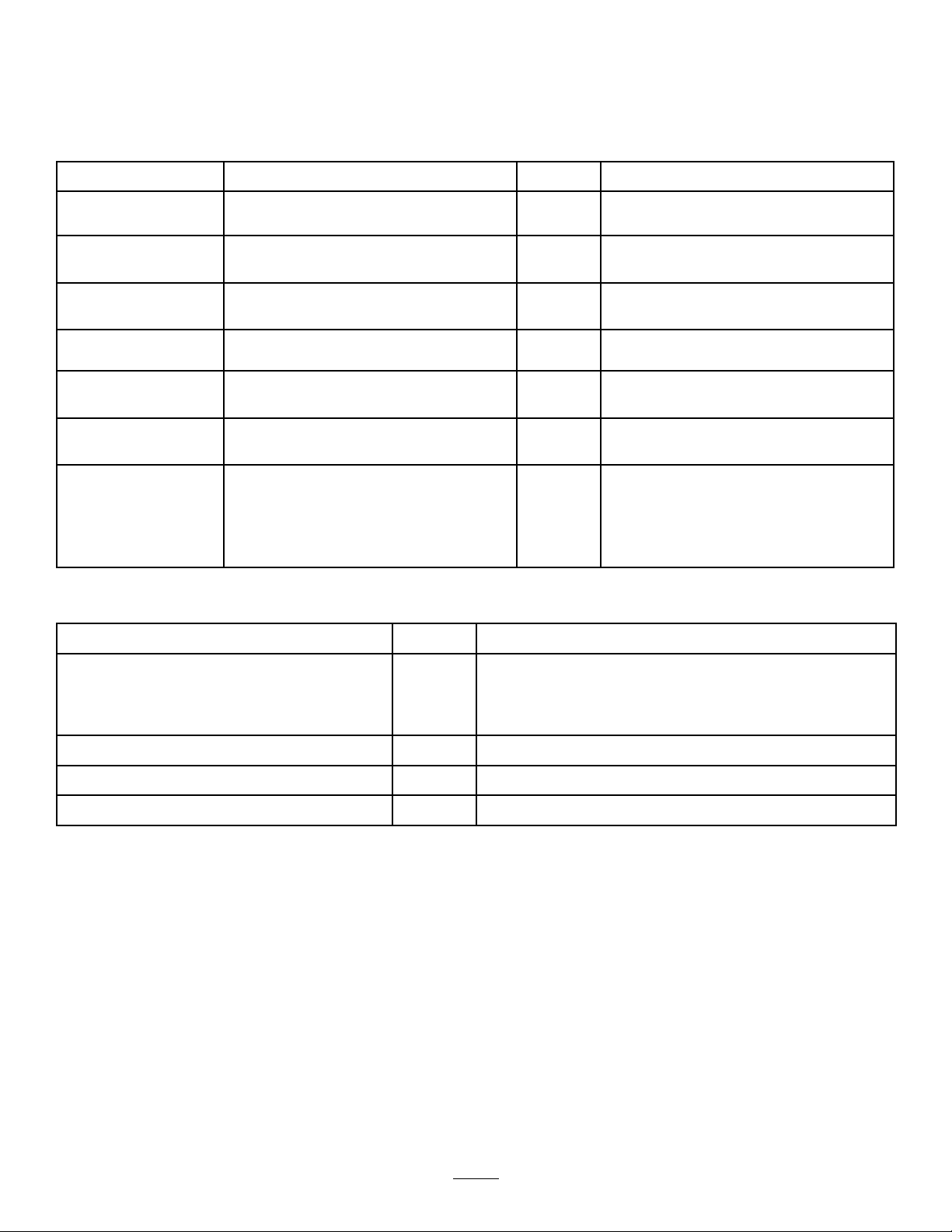

RemovingtheShippingBoard

NoPartsRequired

Procedure

Beforeyoucaninstallanattachmentonthemachine,you

mustremovetheshippingboard.

1.Removethenuts,bolts,andwasherssecuringthe

shippingboardtotherearofthemachine(Figure3).

Figure3

InstallinganAttachment

Partsneededforthisprocedure:

–

Attachmentandrelatedparts(soldseparately)

Procedure

WARNING

Ifyoudrivethemachinewithoutanattachment

installed,itcantipoverandinjuresomeoneor

damageproperty.

Drivethemachineonlyifthereisanapproved

attachmentinstalled.

RefertotheattachmentInstallationInstructionsforinformation

oninstallingtheattachment.

3

2.Discardthefastenersandtheshippingboard.

InstallingtheFrontWeights

Partsneededforthisprocedure:

–

Frontweights(asneededperattachment)

Procedure

ThismachinehasbeendesignedinaccordancewithANSI

B71.4-2012.However,whenyouinstallattachmentsonthe

machine,youmustaddadditionalweighttothemachine,as

specied,tocomplytothestandards.

Usethechartbelowtodeterminetheadditionalweight

required.Themachinecomeswith4weights.Each

attachmentcomeswiththenecessaryadditionalweights,if

required.

Attachment

Flextoothrake4

Flextoothrakewithnishbrush

Naildrag6

Naildragwithnishdragmat

Numberofweightsrequired

6

8

RefertoInstallingandRemovingtheWeights(page21).

14

4

1

G023898

A B

C D

1

4

2

5

3

G023895

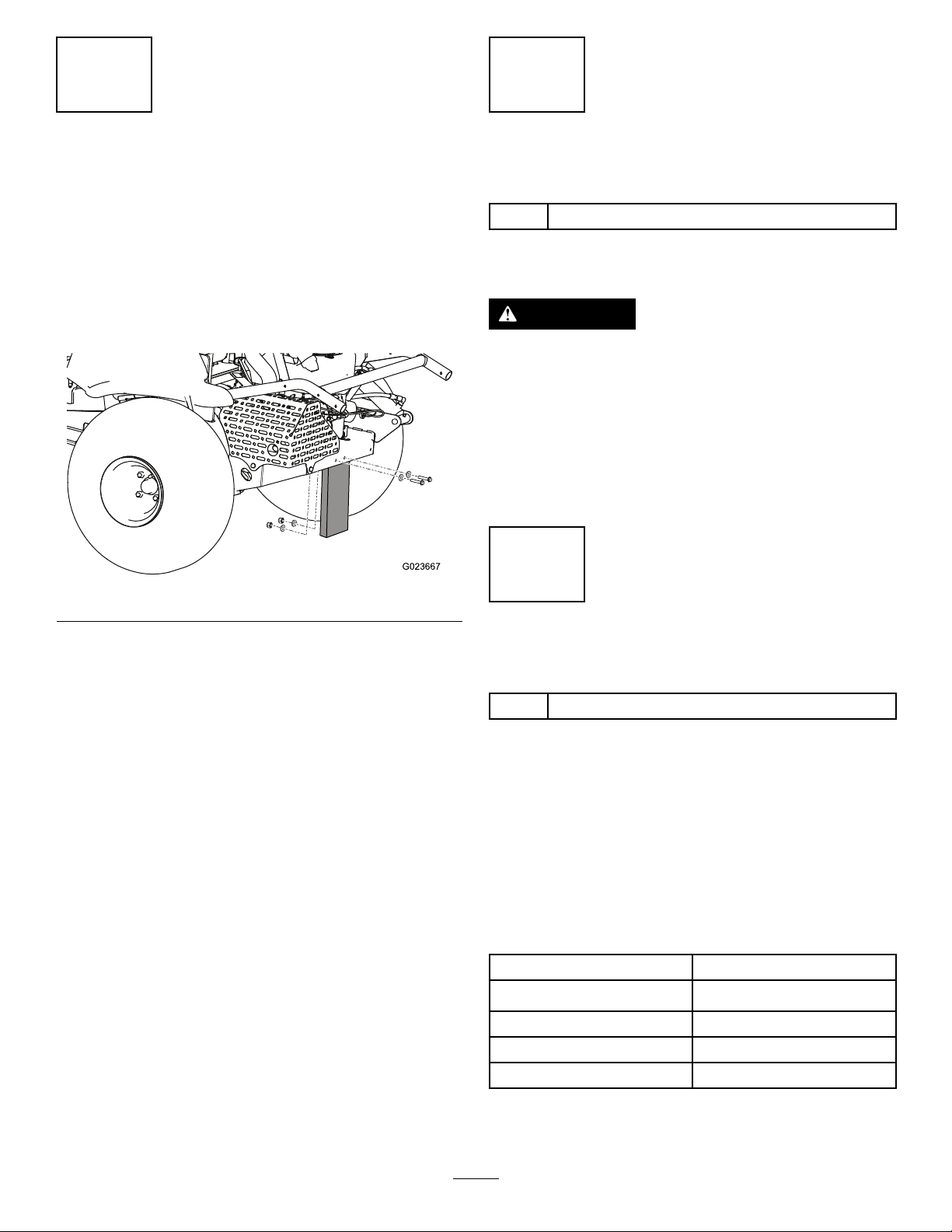

ConnectingtheBattery

Model08706TCOnly

Partsneededforthisprocedure:

1

Bolt(5/16x3/4inch)

2

Nut(5/16inch)

Procedure

1.Cutthecabletiesecuringthebatterycablestothe

frame,anddiscardthecabletie(Figure4).

1.Cabletie

2.Removetheredplasticcoverfromthepositivebattery

terminal(Figure5).

Figure4

Figure5

1.Redcover4.Blackcover

2.Positivecable5.Negativecable

3.Boot

3.Slidetheredbootawayfromtheendofthepositive

batterycable,anduseabolt(5/16x3/4inch)and

anut(5/16inch)tomountthepositivecabletothe

positivebatteryterminal.

4.Slidetheredbootovertheterminalandthefasteners.

5.Removetheblackplasticcoverfromthenegative

batteryterminal.

6.Useabolt(5/16x3/4inch)andanut(5/16inch)

tomountthenegativecabletothenegativebattery

terminal.

15

5

7

ApplyingtheCEWarning

Decal

Model08706TCOnly

Partsneededforthisprocedure:

1

Warningdecal(130-1851)

Procedure

IfthismachinemustbeCEcompliant(Europe),applythe

CEwarningdecal(130-1851)overtheexistingwarningdecal

(127-0363).

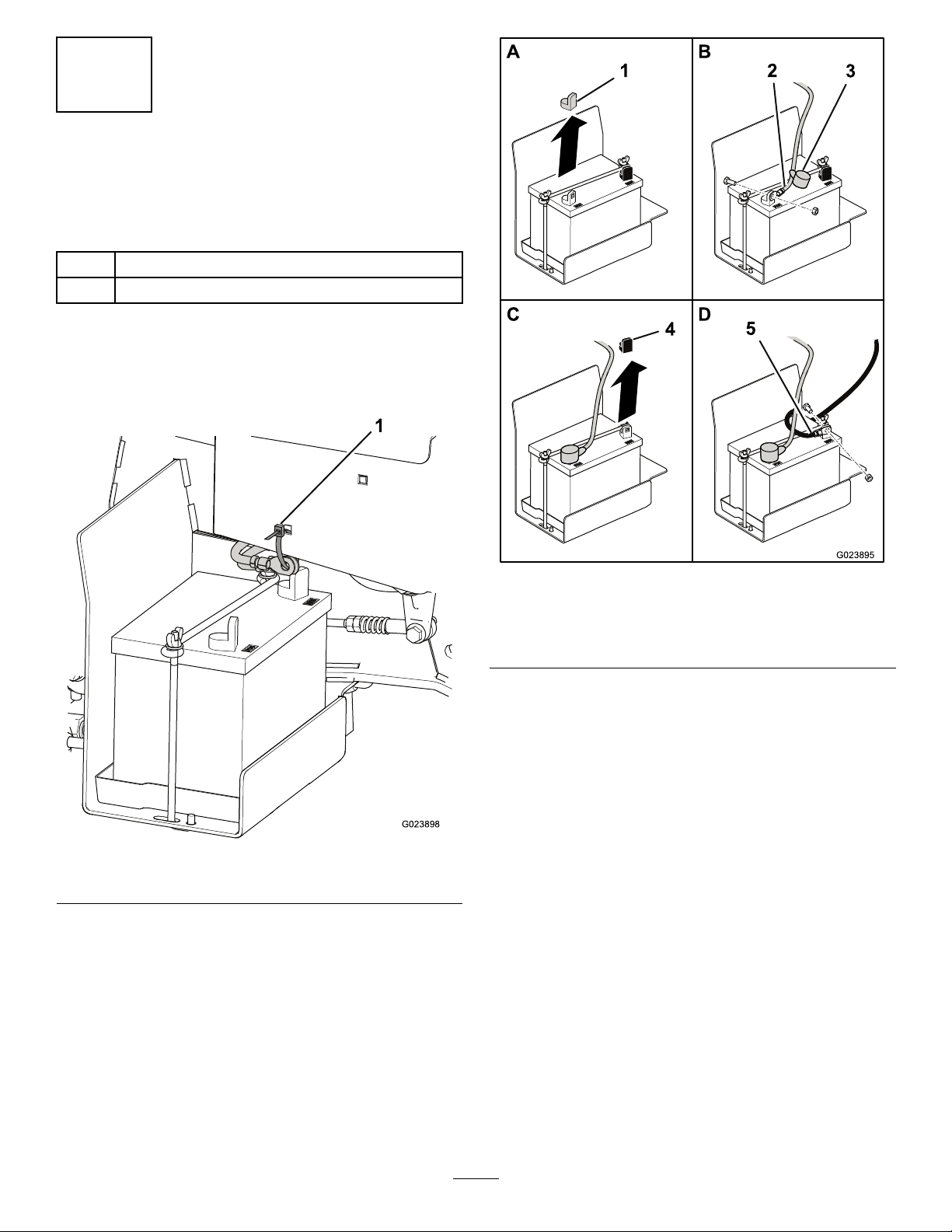

6

ApplyingtheCEServiceDecal

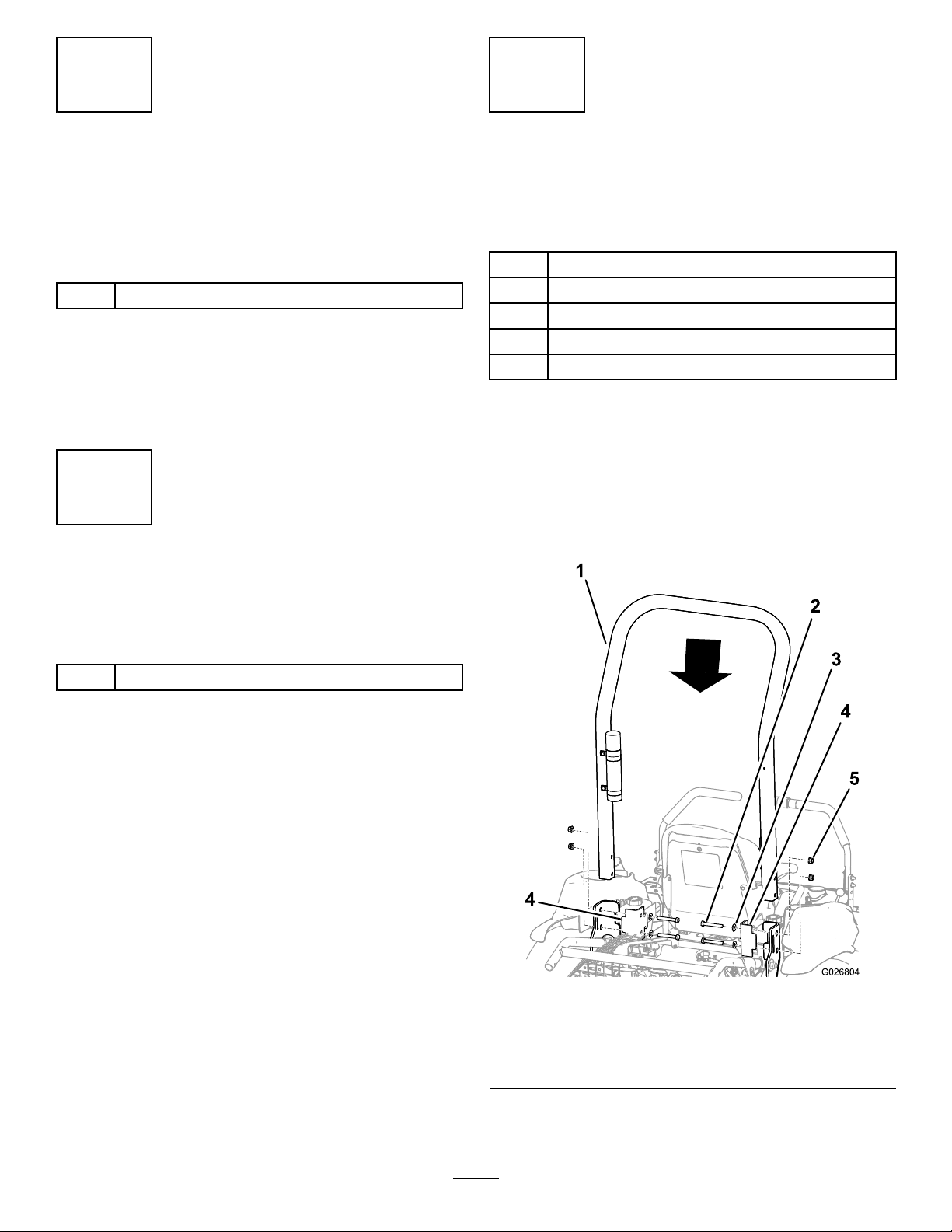

InstallingtheROPS

Model08706TCOnly

Partsneededforthisprocedure:

1Rollbar

4Bolt

4Flangelocknut

4

Springwasher

2Bracket

Procedure

ForModel08706TC,installtheROPSasfollows:

Note:Model08706hastheROPSinstalledatthefactory.

1.Removetherollbarfromthecrate.

2.PlacetherollbaronthemachineasshowninFigure6.

Model08706TCOnly

Partsneededforthisprocedure:

1

Servicedecal(130-2620)

Procedure

IfthismachinemustbeCEcompliant(Europe),applythe

CEservicedecal(130-2620)overtheexistingservicedecal

(127–0371).

Figure6

1.Rollbar

2.Bolt(4)5.Flangelocknut(4)

3.Springwasher(4)

4.Bracket(2)

3.Installthebracketsontheframeofthemachine.

16

Important:Ensurethatthethrottlecableandthe

G023904

chokecableareoutoftheway ,sothattheydonot

getpinchedbytherollbarorabracket.

4.Aligntheholesinthebrackets,therollbar,andthe

frame.

5.Installabolt,withaspringwasher,througheachhole.

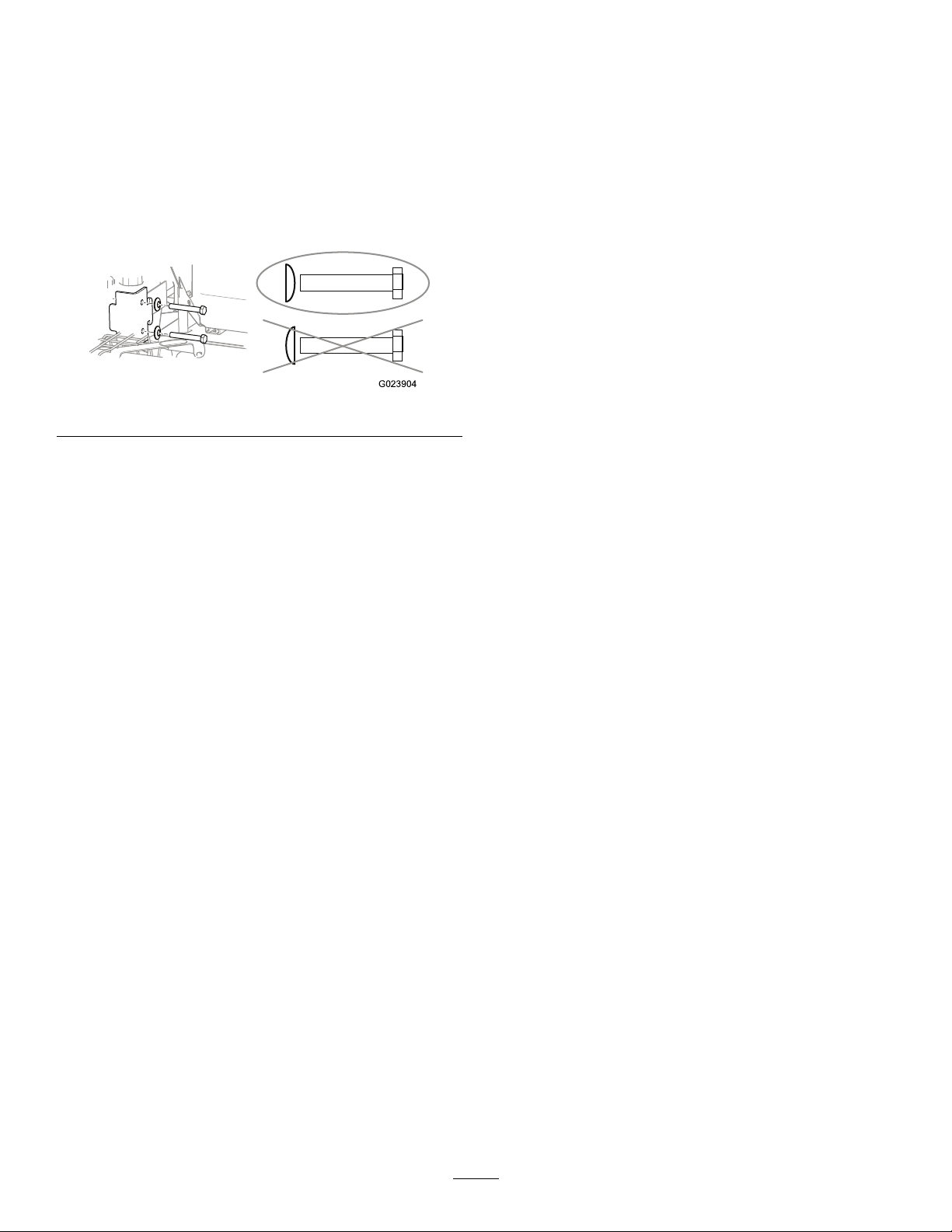

Important:Ensurethateachspringwasheris

positionedsothattheconvexsidefacesthebolt

headasshowninFigure7.

Figure7

6.Installaangelocknutoneachbolt,andtorqueeach

ofthemto102N-m(75ft-lb).

17

ProductOverview

1

2

34

5

6

8

9

7

G023439

1

2

3

4

5

6

G023443

Controls

Figure9

1.Chokecontrol

2.Throttlelever5.Fuses

3.Hourmeter;

safety-interlockdisplay

Figure8

1.Control

handles

2.Raketube5.Battery

3.Fuel-tankcap

4.Attachment

switch

6.Controlpanel

7.Parkingbrake

8.Attachmentlift

9.Engine

ControlHandles

Usethecontrolhandles(Figure8)todrivethemachine

forwardandbackward,andtoturnineitherdirection.

IgnitionSwitch

Theignitionswitch(Figure9),usedtostartandstopthe

engine,has3positions:Off,Run,andStart.Rotatethekey

clockwisetotheStartpositiontostarttheengine.Releasethe

keywhentheenginestarts.Thekeywillmoveautomatically

totheRunposition.Toshuttheengineoff,rotatethekey

counterclockwisetotheOffposition.

ChokeControl

Tostartacoldengine,closethecarburetorchokebypulling

thechokecontrol(Figure9)uptotheClosedposition.After

theenginestarts,regulatethechoketokeeptheengine

runningsmoothly.Assoonaspossible,openthechokeby

pushingthecontroldowntotheOpenposition.

Note:Awarmenginerequireslittleornochoking.

4.Ignitionswitch

6.Attachmentswitch

ThrottleLever

Thethrottlelever(Figure9)controlsthespeedoftheengine.

MovingthethrottleleverforwardtowardtheFastposition

increasestheenginespeed.Movingitbackwardtowardthe

Slowpositiondecreasestheenginespeed.

Note:Thethrottlelevercannotstoptheengine.

18

AttachmentSwitch

1

G020873

G008962

Seat-AdjustmentLever

Toraisetheattachment,presstheupperpartofthe

attachmentswitch(Figure10);tolowertheattachment,press

thelowerpartoftheattachmentswitch.

Whilesittingontheseat,movetheleverinfrontofthe

seat(Figure11)totheleft,andslidetheseattothedesired

position.Releasethelevertolocktheseatintoposition.

Figure11

Figure10

1.Attachmentswitch

Note:Themachinehasadouble-actingliftcylinder.Youcan

applydownpressuretotheattachmentforcertainoperating

conditions.

ParkingBrake

Tosettheparkingbrake(Figure8),pullbackontheleverof

theparkingbrake.Toreleaseit,pushtheleverforward.

HourMeter

Thehourmeter(Figure9)indicatesthetotalhoursof

machineoperation.Thehourmeterrunswheneverthe

ignitionswitchisintheOnposition.

Anoptionalwirelesshourmeterisavailablethroughyour

AuthorizedToroDistributor.Toinstallit,refertoInstallinga

WirelessHourMeter(page31).

19

Specications

Note:Specicationsanddesignaresubjecttochangewithoutnotice.

Machineonly

Weight

Width

Length

Height

Wheelbase

*with4weights,emptyfueltank,andnooperator

**withtheattachmentandweights,emptyfueltank,andnooperator

399kg(880lb)*417kg(920lb)**439kg(970lb)**445kg(980lb)**

147cm(58inches)213cm(84inches)182cm(71.5inches)198cm(78inches)

186cm(73.3inches)226cm(89.0inches)215cm(84.8inches)297cm(1 17inches)

Withextoothrake

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesis

availableforusewiththemachinetoenhanceandexpand

itscapabilities.ContactyourAuthorizedServiceDealeror

Distributororgotowww .Toro.comforalistofallapproved

attachmentsandaccessories.

Tobestprotectyourinvestmentandmaintainoptimal

performanceofyourToroequipment,countonTorogenuine

parts.Whenitcomestoreliability ,Torodeliversreplacement

partsdesignedtotheexactengineeringspecicationofour

equipment.Forpeaceofmind,insistonT orogenuineparts.

WithnaildragWithnaildragand

nishmat

185cm(73inches)

147cm(58inches)

Operation

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

ThinkSafetyFirst

Carefullyreadallsafetyinstructionsandsymbolsinthe

safetysection.Knowingthisinformationcouldhelpyouor

bystandersavoidinjury.

DANGER

Operatingonwetgrassorsteepslopescancause

slidingandlossofcontrol.

Wheelsdroppingoveredgescancauserollovers,

whichmayresultinseriousinjury,death,or

drowning.

Readandfollowtherolloverprotectioninstructions

andwarnings.

Toavoidlossofcontrolandpossibilityofrollover:

•Donotoperateneardrop-offsornearwater.

•Reducespeedanduseextremecautionon

slopes.

•Avoidsuddenturnsorrapidspeedchanges.

CAUTION

Thismachineproducessoundlevelsthatcancause

hearinglossthroughextendedperiodsofexposure.

Wearhearingprotectionwhenoperatingthis

machine.

Theuseofprotectiveequipmentforeyes,ears,hands,feet,

andheadisrecommended.

20

G009027

1

2

Figure12

G023729

1.Wearsafetyglasses.

2.Wearhearingprotection.

InstallingandRemovingthe Weights

ThemachinecomplieswiththeANSIB71.4-2012standards

atthetimeofproduction.However,whenthefollowing

attachmentsareinstalledonthemachine,additionalweight

isrequiredtocomplytothestandards.Usethechartbelow

todeterminetheadditionalweightrequired.Themachine

comeswith4weights.Eachattachmentcomeswiththe

necessaryadditionalweights,ifrequired.

Attachment

Flextoothrake4

Flextoothrakewithnishbrush

Naildrag6

Naildragwithnishdragmat

1.Removethe2boltsand2nutssecuringtheexisting

weightsonthefrontofthemachine(Figure13).

Note:Ifthemachineisequippedwiththelightkit,

removethenutandtheboltsecuringthefrontlightto

themachine.Retainalloftheparts;refertotheLight

KitInstallationInstructions.

Numberofweightsrequired

6

8

Figure13

2.Addorremoveweightsasnecessary.

3.Securetheweightswiththe2boltsandthe2nuts.

•Formostoftheattachments,usetheexistingbolts.

•Thenishdragmatincludes2longerbolts

toaccommodatetheadditionalweightsthatit

requires.

Note:Ifthemachineisequippedwiththelightkit,

installthefrontlightbyinsertingtheboltthroughthe

weightsandsecuringitwiththenut;refertotheLight

KitInstallationInstructions.

CheckingtheLevelofthe EngineOil

ServiceInterval:Beforeeachuseordaily—Checkthelevel

oftheengineoil.

ToroPremiumEngineOilisavailablefromyourAuthorized

ToroDistributor.

CrankcaseCapacity:1.8L(1.7USqt)withlterchange

Use4-cycleengineoilthatmeetsorexceedsthefollowing

requirements:

•APIservicecategory:SJ,SL,SM,orhigher

•Viscosity:SAE30;refertothefollowingchartforother

viscosities(Figure14):

Important:Usingmulti-viscosityoils,suchas

10W-30,increasesoilconsumption.Checktheoil

21

levelmorefrequentlywhenusingthem.

G0 2344 5

-20 0 2 0 40 60 80 100 F

-30 -20 -10 0 10 20 30 4 0 C

o

o

S AE 3 0

S AE 5 W-20

S AE 1 0W-30 / S AE 10W-4 0

S AE 4 0

Figure14

1

G023517

G008792

1

2

5

6

7

3

9

10

4

8

1.Positionthemachineonalevelsurface.

2.Stoptheengineandremovethekey.

3.Removethedipstick(Figure15)andwipeitwitha

cleancloth(Figure16).

1.Dipstick

Figure15

Figure16

4.Insertthedipstickintothelltubewithoutthreading

itintotheport.

5.Removethedipstickfromthetubeandchecktheoil

level.Iftheoillevelislow,slowlypouronlyenoughoil

intothelltubetoraisetheoilleveltotheupper-limit

markonthedipstick

Important:Keeptheengineoillevelbetweenthe

upperandlowerlimitsonthedipstick.Engine

failuremayoccurasaresultofrunningtheengine

withtoomuchortoolittleengineoil.

6.Installthedipstickrmlyinplace.

Important:Thedipstickmustbefullyseatedin

thetubetoprovidepropersealingoftheengine

crankcase.Failuretosealthecrankcasemayresult

inenginedamage.

22

FillingtheFuelTank

1

G023449

DANGER

Fueltankcapacity:17L(4.5USgallons)

RecommendedFuel:

•Forbestresults,useonlyclean,fresh(lessthan30days

old),unleadedgasolinewithanoctaneratingof87or

higher((R+M)/2ratingmethod).

•Ethanol:Gasolinewithupto10%ethanol(gasohol)

or15%MTBE(methyltertiarybutylether)byvolume

isacceptable.EthanolandMTBEarenotthesame.

Gasolinewith15%ethanol(E15)byvolumeisnot

approvedforuse.Neverusegasolinethatcontainsmore

than10%ethanolbyvolume,suchasE15(contains15%

ethanol),E20(contains20%ethanol),orE85(contains

85%ethanol).Usingunapprovedgasolinemaycause

performanceproblemsand/orenginedamagewhichmay

notbecoveredunderwarranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuelcontainers

overthewinterunlessafuelstabilizerisused.

•Donotaddoiltogasoline.

DANGER

Incertainconditionsduringfueling,static

electricitycancauseaspark,whichcanignitethe

fuelvapors.Areorexplosionfromfuelcanburn

youandothersandcandamageproperty.

•Alwaysplacefuelcontainersonthegroundaway

fromyourvehiclebeforelling.

•Donotllfuelcontainersinsideavehicleoron

atruckortrailerbedbecauseinteriorcarpets

orplastictruck-bedlinersmayinsulatethe

containerandslowthelossofanystaticcharge.

•Whenpractical,removefuel-poweredequipment

fromthetruckortrailerandfueltheequipment

withitswheelsontheground.

•Ifthisisnotpossible,thenrefuelsuchequipment

onatruckortrailerfromaportablecontainer,

ratherthanfromafuel-dispensernozzle.

•Ifafueldispensermustbeused,keepthe

nozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilfuelingis

complete.

Incertainconditions,fuelisextremelyammable

andhighlyexplosive.Areorexplosionfromfuel

canburnyouandothersandcandamageproperty.

•Fillthefueltankoutdoors,inanopenarea,when

theengineiscold.Wipeupanyfuelthatspills.

•Neverllthefueltankinsideanenclosedtrailer.

•Donotllthefueltankcompletelyfull.Addfuel

tothefueltankuntilthelevelis25mm(1inch)

belowthebottomofthellerneck.Thisempty

spaceinthetankallowsthefueltoexpand.

•Neversmokewhenhandlingfuel,andstayaway

fromanopenameorwherefuelfumesmaybe

ignitedbyaspark.

•Storefuelinanapprovedcontainerandkeepit

outofthereachofchildren.Donotbuymore

thana30-daysupplyoffuel.

•Donotoperatewithouttheentireexhaust

systeminplaceandinproperworkingcondition.

WARNING

Gasolineisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgastankor

conditioneropening.

•Keepgasawayfromeyesandskin.

1.Cleantheareaaroundthefuel-tankcap(Figure17).

Figure17

1.Fuel-tankcap

2.Removethefuel-tankcap.

23

3.Fillthetanktoabout25mm(1inch)belowthetopof

1

2

3

4

G023450

thetank(bottomofthellerneck).Donotoverll.

4.Installthecap.

5.Wipeupanyfuelthatmayhavespilled,topreventa

rehazard.

Important:Neverusemethanol,gasoline

containingmethanol,orgasoholcontainingmore

than10%ethanol,becausethefuelsystemcould

bedamaged.

Important:Donotmixoilwithfuel.

CheckingtheLevelofthe HydraulicFluid

ServiceInterval:Beforeeachuseordaily—Checkthelevel

ofthehydraulicuid.

Important:Foraccuracy,checkthelevelofthe

hydraulicuidonlywhentheengineandthehydraulic

systemarecold.

Thereservoirsofthemachinearelledatthefactorywith

high-qualityhydraulicuid.Thebesttimetocheckthe

hydraulicuidiswhentheuidiscold.Themachineshould

beinthetransportconguration.Iftheuidlevelisbelow

thetopofthehorizontalpartofthecut-outsightwindowon

therearofthehydraulicreservoirs(Figure18),adduidto

bringtheuidtotheacceptablelevel.Donotoverllthe

reservoirs.Iftheuidlevelisatthetopofthehorizontal

partofthesightwindow,nouidadditionisrequired.The

recommendedreplacementuidis:

MaterialProperties:

Viscosity,ASTMD445cSt@40°C(104°F)55to62

ViscosityIndexASTMD2270

PourPoint,ASTMD97-37°Cto-43°C(-35°Fto-46°F)

IndustrySpecications:

APIGL-4,AGCOPoweruid821XL,FordNewHolland

FNHA-2-C-201.00,KubotaUDT ,JohnDeereJ20C,Vickers

35VQ25,andVolvoWB-101/BM

140to152

Note:Manyhydraulicuidsarealmostcolorless,makingit

difculttospotleaks.Areddyeadditiveforthehydraulic

uidisavailablein20ml(2/3oz)bottles.Onebottleis

sufcientfor15to22L(4to6USgallons)ofhydraulic

uid.Orderpartnumber44-2500fromyourAuthorized

ToroDistributor.

1.Lookattheopeningineachoftheuid-reservoir

brackets,andcheckthelevelofthehydraulicuid.

Note:Theuidlevelshouldbeatthebottomofeach

oftheopenings,asshowninFigure18.

FluidType:ToroPremiumTransmission/HydraulicTractor

FluidorMobiluid

®

424

Capacity:

•Leftside—1.9L(2.0USqt)

•Rightside—2.0L(2.1USqt)

Alternativeuids:Ifthespecieduidisnotavailable,other

universaltractorhydraulicuids(UTHF)maybeused,but

theymustbeonlyconventional,petroleum-basedproducts,

notsyntheticsorbiodegradableuids.Thespecications

mustfallwithinthelistedrangeforallofthefollowing

materialpropertiesandtheuidshouldmeetlistedindustry

standards.Checkwithyouruidsuppliertoseeiftheuid

meetsthesespecications.

Note:Torowillnotassumeresponsibilityfordamage

causedbyimpropersubstitutions,souseonlyproducts

fromreputablemanufacturerswhowillstandbehindtheir

recommendation.

Figure18

1.Hydraulic-uidreservoirs

2.Fluid-reservoircap4.Fluidlevel

3.Bracket

2.Iftheuidlevelislowineitherofthereservoirs,add

uidasfollows:

A.Cleantheareaaroundtheuid-reservoircapsto

preventdebrisfromenteringthesystem(Figure

18).

B.Removethecapsfromthereservoirs.

24

C.Slowlyllthereservoirwiththeappropriate

G016994

1

2

G016995

1

2

hydraulicuiduntilthelevelreachesthebottom

oftheopeningsinthebrackets.

Important:Topreventsystem

contamination,cleanthetopofthe

uidcontainerbeforeopeningit.Ensurethat

thepourspoutandthefunnelareclean.

Important:Donotoverllthereservoirs.

D.Installthereservoircaps.

CheckingtheTirePressure

ServiceInterval:Beforeeachuseordaily

Checkthetirepressurebeforeoperatingthemachine

(Figure19).

Pressure:48kPa(7psi)

SettingtheParkingBrake

WARNING

Theparkingbrakemaynotholdthemachine

parkedonaslopeandcouldcausepersonalinjury

orpropertydamage.

Donotparkonslopesunlessthewheelsare

chockedorblocked.

Tosettheparkingbrake,pullupwardonthehandle(Figure

20).

Figure20

Figure19

1.Valvestem2.Lugnut

TorquingtheWheelLugNuts

ServiceInterval:Aftertherst8hours

Every100hours

Torquethelugsnuts(Figure19)to61to75N-m(45to55

ft-lb).

UsingtheParkingBrake

Alwayssettheparkingbrakewhenyoustopthemachineor

leaveitunattended.

ReleasingtheParkingBrake

Toreleasetheparkingbrake,pushdownwardonthehandle

(Figure21).

Figure21

25

StartingandStoppingthe

1

G023660

Engine

1.Movethecontrolhandlestotheneutral-lockedposition

(Figure22).

5.Tostoptheengine,movethethrottlecontroltothe

Slowposition,andturntheignitionkeytotheOff

position.Removethekeyfromtheswitchtoprevent

accidentalstarting.

Note:Inanemergency,simplyturntheignitionkey

totheOffposition.

UsingtheSafetyInterlock System

CAUTION

Ifthesafetyinterlockswitchesaredisconnectedor

damaged,themachinecouldoperateunexpectedly,

causingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlockswitches

daily,andreplaceanydamagedswitchesbefore

operatingthemachine.

Thesafetyinterlocksystemisdesignedtopreventtheengine

fromstartingunless:

Figure22

1.Controlhandle

(neutral-lockedposition)

2.Center,unlockedposition5.Frontofthemachine

3.Forward

2.Settheparkingbrake;refertoSettingtheParking

Brake(page25).

3.PullthechokecontrolupwardtotheOnposition

(whenstartingacoldengine),andmovethethrottle

levertotheSlowposition.

Important:Whenoperatingthemachinein

temperatureslessthan0°C(32°F)allowthe

machinetimetowarmupbeforeusingit.This

preventsdamagetothehydraulicsystem.

4.Insertthekeyintotheignitionswitchandrotateit

clockwisetostarttheengine.Releasethekeywhenthe

enginestarts.Regulatethechoketokeeptheengine

runningsmoothly.

Important:Topreventoverheatingofthestarter

motor,donotkeeptheignitionkeyintheStart

positionforlongerthan10seconds.After10

secondsofcontinuouscranking,wait60seconds

beforeusingthestartermotoragain.

4.Backward

•Theparkingbrakeisengaged.

•Themotion-controlleversareintheneutral-locked

position

Thesafetyinterlocksystemalsostopstheenginewhenyou

movethecontrolhandlesoutoftheneutral-lockedposition

whileyouareoutoftheseatorwhiletheparkingbrakeisset.

Thehourmeterhassymbolstonotifyyouwhentheinterlock

componentisinthecorrectposition.Whenthecomponentis

inthecorrectposition,atriangleappearsinthecorresponding

location(Figure23).

Figure23

1.Trianglesappearwhentheinterlockcomponentsareinthe

correctposition.

Note:ThePTO(powertake-off)interlockisnotusedon

thismachine.

26

TestingtheSafetyInterlockSystem

ServiceInterval:Beforeeachuseordaily

Ifthesafetyinterlocksystemdoesnotoperateasdescribed

below,haveanAuthorizedT oroDistributorrepairit

immediately.

1.Sitontheseat,movethecontrolhandlestotheneutral

position,andsettheparkingbrake.

2.Starttheengine.

3.Getofftheseatandslowlymoveeachcontrolhandle

forwardandbackward.

Note:Theengineshouldstopin1to3secondsafter

movingeithercontrolhandleineitherdirection.Ifit

doesnot,correcttheproblem.Repeatsteps2and3for

theothercontrolhandle.

4.Sittingontheseat,engagetheparkingbrake.Move

eithercontrolhandleoutoftheneutral-lockedposition.

Trystartingtheengine;theengineshouldnotcrank.

Repeatthisstepfortheothercontrolhandle.

DrivingtheMachine

UsingtheControlHandles

CAUTION

Operatingthemachinedemandsattentionto

preventtippingorlossofcontrol.

•Usecarewhenenteringandleavingsandtraps.

•Useextremecautionaroundditches,creeks,or

otherhazards.

•Usecautionwhenoperatingthemachineona

steepslope.

•Reduceyourspeedwhenmakingsharpturnsor

whenturningonhillsides.

•Avoidsuddenstopsandstarts.

•Donotgofromreversetofullforwardwithout

rstcomingtoacompletestop.

CAUTION

Themachinecanspinveryrapidly.Ifyoumisuse

thecontrolhandles,youmaylosecontrolofthe

machineandinjuresomeoneordamagethe

machineorotherproperty .

Figure24

1.Controlhandle

(neutral-lockedposition)

2.Center,unlockedposition5.Frontofthemachine

3.Forward

4.Backward

DrivingtheMachineForward

Note:Theenginestopsifyoumovethecontrolhandles

whiletheparkingbrakeisset.

1.Releasetheparkingbrake;refertoReleasingthe

ParkingBrake(page25).

2.Movethecontrolhandlestothecenter,unlocked

position.

3.Togoforward,slowlypushthecontrolhandlesforward

(Figure25).

Tostopthemachine,movethecontrolhandlestothe

neutralposition.

•Usecautionwhenmakingturns.

•Slowthemachinedownbeforemakingsharp

turns.

27

G0 2344 1

Figure25

G0 2344 2

DrivingtheMachineBackward

1.Ensurethattheattachmentisinthedesiredposition.

2.Movethecontrolhandlestothecenter,unlocked

position.

3.Togobackward,lookbehindandslowlypullthe

controlhandlesbackward(Figure26).

Figure26

RakingaSandTrap

Readthisentiresectiononrakingbeforerakingasandtrap.

Therearemanyconditionsthatdeterminetheadjustments

necessary.Thetextureanddepthofthesand,moisture

content,weeds,andtheamountofcompactionareallfactors

thatcanvaryfromcoursetocourse,orevenfromtraptotrap

onthesamecourse.Maketheadjustmentsontherakefor

optimumresultsinyourparticulararea.

LearningHowtoRake

Practicerakinginalargeandleveltraponthecourse.Practice

startingandstopping,turning,raisingandloweringtherake,

enteringandleavingthetrap,etc.Practiceatamoderate

enginespeedandaslowgroundspeed.Thistraininghelps

theoperatortogaincondenceintheperformanceofthe

machine.

Therecommendedpatternforrakingatrapisshownin

Figure27.Thispatternavoidsunnecessaryoverlap,keeps

compactiontoaminimum,andleavesaneat,attractive

patternonthesand.Thisisthemostefcientrakingmethod,

however,itisimportanttovarytherakingpatternregularlyto

reducethechanceofcreatingawashboardeffect.

28

1

2

G003409

Figure27

performancecloselysothatyoucannoticeandcorrectminor

difculties,whichcouldleadtomajorproblems.Inspectthe

machinefrequentlyduringthebreak-inperiod,forsignsofoil

leakage,loosefasteners,oranyothermalfunction.

PushingorTowingthe Machine

WARNING

Handsmaybecomeentangledintherotatingdrive

componentsbelowtheenginedeck,whichcould

resultinseriousinjury.

Stoptheengine,removethekey,andallow

allmovingpartstostopbeforeaccessingthe

bypass-valvelevers.

1.Enteratrapstraightinto

thelongdimensionina

levelarea.

Enterthetrapstraightintothelongdimension,wherethe

bankistheleaststeep.Drivethroughthecenterofthetrap

almosttotheend,turntoeitherdirectionassharpasyoucan,

andcomebackrightnexttotherstpass.Spiraloutwardas

showninFigure27,andleavethetrapatarightangleina

levelarea.

Leavesteep,shortbanksandsmallpocketsfortouch-upwith

ahandrake.

2.Exitatrapatarightangle

inalevelarea.

EnteringandLeavingtheTrap

Whenenteringthetrap,donotlowertherakeuntilitis

overthesand.Thisavoidscuttingtheturfordragginggrass

clippingsorotherdebrisintothetrap.Lowertherakewhile

themachineismoving.

Whenleavingthetrap,startraisingtherakewhenthefront

wheelleavesthetrap.Asthemachinemovesout,therakewill

beliftingandwillnotdragsandoutontothegrass.

Throughexperienceandpractice,theoperatorwillsoon

understandtherequiredtimingforenteringandleavingthe

trapproperly.

BreakingintheMachine

Newenginestaketimetodevelopfullpower.Drivesystems

havemorefrictionwhentheyarenew ,placingadditionalload

ontheengine.

WARNING

Theengineandhydrostatictransmissionscan

becomeveryhotandcausesevereburns.

Allowtheengineandhydrostatictransmissionsto

coolcompletelybeforeaccessingthebypass-valve

levers.

Important:Donottowthemachineforlongdistances

orathighspeeds.Doingsocoulddamagethemachine.

Youcantowthemachineslowlyfromthegrooming

surfacetotheon-sitetrailer.

Thebypass-valveleversarelocatedonthetopofeach

hydrostatictransmission.

Important:Makesurethatthebypass-valveleversarein

thefullyforwardpositionwhenoperatingthemachine,

orseveredamagetothehydraulicsystemcanoccur.

1.Stopthemachineonalevelsurfaceandturnthe

ignitionkeytotheOffposition.

2.Movetheleverstotheneutral-lockedposition,setthe

parkingbrake,andremovethekey.

3.Fromunderneaththemachine,rotatethebypass-valve

levers(Figure28andFigure29)sothattheypoint

inward,towardthecenterofthemachine(Figure30),

andreleasetheparkingbrake;refertoReleasingthe

ParkingBrake(page25).

Note:Thisallowsthehydraulicuidtobypassthe

pumps,enablingthewheelstoturnfreely.

Allowtherst8hoursofoperatingtimeforthebreak-in

period.

Sincethersthoursofoperationarecriticaltofuture

dependabilityofthemachine,monitorthefunctionsand

29

1

G023553

1

G023554

G023555

1

2

TransportingtheMachine

Useaheavy-dutytrailerortrucktotransportthemachine.

Ensurethatthetransportvehicle(trailerortruck)hasall

thenecessarybrakes,lighting,andmarkingasrequiredby

law .Carefullyreadandunderstandallthesafetyinstructions.

Knowingthisinformationcouldhelpyou,yourfamily,pets,

orbystandersavoidinjury.

WARNING

Figure28

Leftbypass-valvelever

Figure29

Rightbypass-valvelever

Drivingonthestreetorroadwaywithout

turnsignals,lights,reectivemarkings,ora

slow-moving-vehicleemblemisdangerousandcan

leadtoaccidentscausingpersonalinjury .

Donotdrivethemachineonapublicstreetor

roadway.

Useextremecautionwhenloadingthemachineontothe

transportvehicle.Useafull-widthrampthatiswideenough

toextendbeyondthereartires,insteadofindividualramps

foreachsideofthemachine.Theattachmentservesasastop

fortippingbackward.Usingafull-widthrampprovidesa

largersurfacefortheattachmenttocontactifthemachine

startstotipbackward.

Ensurethattherampislongenoughsothattheangledoes

notexceed13degrees.Asteeperanglemaycausemachine

componentstogetcaughtasthemachinemovesfromthe

ramptothetransportvehicle.Steeperanglesmayalsocause

themachinetotipbackward.Ifloadingonornearaslope,

positionthetransportvehiclesothatitisonthedownside

oftheslopeandtherampextendsuptheslope;thiswill

minimizetherampangle.Thetransportvehicleshouldbeas

levelaspossible.

Figure30

1.Inwardtopushortowthe

machine

4.Whenyouarenishedpushingortowingthemachine,

2.Forwardtodrivethe

machine

rotatethebypass-valveleverssothattheypointtoward

thefrontofthemachine,toallowthemachinetodrive

(Figure30).

30

WARNING

1

G023892

1 2

G023736

Loadingthemachineontoatransportvehicle

increasesthepossibilityoftippingoverandcould

causeseriousinjuryordeath.

•Alignthemachineappropriately,andslowly

drivestraightuptheramp.

•EnsurethattheROPSisinstalledandsecure.

•Ensurethatthereisadequatespaceforthe

machine.

•Donotexceeda13-degreeanglebetweenthe

rampandthegroundorbetweentherampand

thetransportvehicle.

•Avoidsuddenaccelerationwhiledrivingthe

machineuparamp,toavoidtippingbackward.

•Avoidsuddendecelerationwhilebacking

themachinedownaramp,toavoidtipping

backward.

•Ensurethatanattachmentisinstalledandinthe

raisedpositionwhenloadingthemachineonto

atransportvehicle.

Figure32

1.Tie-downpoints

InstallingaWirelessHour Meter

Anoptionalwirelesshourmeterisavailablethroughyour

AuthorizedToroDistributor.

RefertotheWirelessHourmeterSystemguide.

1.Removethecontrolpanel(Figure33).

Figure31

1.Trailer3.Notgreaterthan13

2.Full-widthramp4.Full-widthramp—side

Usethetie-downpointsonthemachine(Figure32)to

securelyfastenthemachinetothetransportvehiclewith

properstraps,chains,cable,orropes.

degrees

view

Figure33

1.Controlpanel2.Screw(4)

2.Locatethewirelesshour-meterjumper.

Note:Thejumperislabeled.

31

3.Attachthewirelesshourmeter.

4.Tiethewirelesshourmetertotheexistingharnessto

preventexcessivemotionintheconsole.

5.Installthecontrolpanel.

OperatingTips

•Ifthesandisdeepenough,youcanrakerightuptothe

edgeofthetrapinlevelareas.

•Ifthesandfeathersouttotheturf,stayfarenoughaway

fromtheedgetoavoiddisturbingtheunderlyingsoil.

•Donotraketooclosetoashort,steepbank.Thesand

willmerelyowdownintothebottomofthetrap.

•Sometouch-upwithahandrakemaybenecessaryon

steepbanks,smallpockets,etc.

32

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriouslyinjure

youorotherbystanders.

Removethekeyfromtheignitionbeforeyoudoanymaintenance.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst8hours

Beforeeachuseordaily

Every100hours

Every200hours

Every300hours

MaintenanceProcedure

•T orquethewheellugnuts.

•Changetheengineoil.

•Changetheengineoillter.

•Changethehydraulicuidandlters.

•Checktheleveloftheengineoil.

•Checkthelevelofthehydraulicuid.

•Checkthetirepressure.

•Checkthesafetyinterlocksystem.

•Checktheconditionofthehydrauliclinesandhoses.

•Inspectandcleanthemachine.

•T orquethewheellugnuts.

•Greasethemachine.

•Changetheengineoil(moreofteninextremelydustyordirtyoperatingconditions).

•Changetheengineoillter(moreofteninextremelydustyordirtyoperating

conditions).

•Servicethesparkplugs.

•Checkthebatterycableconnections.

•Replacetheairlter(moreoftenindustyconditions).

•Replacethecarbon-canisterlter.

•Checkandadjustthevalveclearance.

•Cleanandlapthevalve-seatingsurface.

Every400hours

Every800hours

•Changethehydraulicuidandlters.

•Replacethefuellter.

Important:Refertoyourengineoperator'smanualforadditionalmaintenanceprocedures.

33

DailyMaintenanceChecklist

Duplicatethispageforroutineuse.

Fortheweekof: MaintenanceCheckItem

Mon.Tues.Wed.Thurs.Fri.

Checkthesafetyinterlock

operation.

Checktheparkingbrake

operation.

Checktheoperationofthe

controlhandles.

Checkthefuellevel.

Checktheengineoillevel.

Checktheairltercondition.

Cleantheenginecooling

ns.

Checkunusualengine

noises.

Checkunusualoperating

noises.

Checkthelevelofthe

hydraulicuid.

Checkhydraulichosesfor

damage.

Checkforuidleaks.

Checkthetirepressure.

Checktheinstrument

operation.

Lubricateallgreasettings.

Touch-updamagedpaint.

1.Immediatelyaftereverywashing,regardlessoftheintervallisted.

1

Sat.Sun.

NotationforAreasofConcern

Inspectionperformedby:

ItemDate

Information

34

Premaintenance

2

1

G023550

G023436

Lubrication

Procedures

GreasingtheMachine

LiftingtheMachine

WARNING

Mechanicalorhydraulicjacksmayfailtosupport

themachineandcauseseriousinjury .

Usejackstandswhensupportingthemachine.

RefertoFigure34forthesupportpoints.

ServiceInterval:Every100hours

GreaseType:No.2lithiumgrease

Greaseeachgreasettinglocatedonthefrontwheelhub,the

belttensioner,andtheattachmentliftasfollows:

1.Wipethegreasettingcleansothatforeignmatter

cannotbeforcedintothebearingorbushing.

2.Attachagreaseguntothetting,andpumpgrease

intothetting.

3.Wipeupanyexcessgrease.

•Frontwheelbearing(1)—Figure35

Figure34

1.Supportpoints(rear)2.Supportpoints(front)

Figure35

•Belttensioner(1)—Figure36

35

G023437

Figure36

G023438

G0 2344 5

-20 0 2 0 40 60 80 100 F

-30 -20 -10 0 10 20 30 4 0 C

o

o

S AE 3 0

S AE 5 W-20

S AE 1 0W-30 / S AE 10W-4 0

S AE 4 0

EngineMaintenance

ServicingtheEngineOiland Filter

ChangingtheEngineOil

ServiceInterval:Aftertherst8hours—Changetheengine

oil.

Every100hours—Changetheengineoil(moreoften

inextremelydustyordirtyoperatingconditions).

ToroPremiumEngineOilisavailablefromyourAuthorized

ToroDistributor.

CrankcaseCapacity:1.66L(1.75USqt)withlterchange

Use4-cycleengineoilthatmeetsorexceedsthefollowing

requirements:

•APIservicecategory:SJ,SL,SM,orhigher

•Attachmentlift(4)—Figure37

Figure37

•Viscosity:SAE30;refertothefollowingchartforother

viscosities(Figure38):

Important:Usingmulti-viscosityoils,suchas

10W-30,increasesoilconsumption.Checktheoil

levelmorefrequentlywhenusingthem.

Figure38

1.Runtheengineforafewminutestowarmtheoil.

2.Parkthemachineonalevelsurface,stoptheengine,set

theparkingbrake,andremovethekey.

3.Removethedrainplug(Figure40)andlettheoildrain

intoasuitablecontainer.Whentheoilstopsdraining,

installthedrainplug.

Note:Insertapieceofpaperorlightcardboardinto

thedrainholetochanneltheoilawayfromtheengine

mountingplate(Figure39).

36

Figure39

1

2

3

G023444

G008796

2

3

4

5

6

1

1.Cardboard

2.Drainplug

3.Drainhole

Figure41

5.Pourfreshoilintothelltube.

6.Starttheengineandletitrunforabout3minutes,and

ensurethattherearenoleaks.

7.Stoptheengine.

8.Checktheoillevel,andaddoilifnecessary.

9.Installthedipstick.

10.Disposeoftheusedoilaccordingtolocalcodes.

ChangingtheEngineOilFilter

1.Drainplug3.Dipstick

2.Oillter

4.Removethedipstickandwipeitwithacleancloth

(Figure41).

Figure40

ServiceInterval:Aftertherst8hours—Changetheengine

oillter.

Every100hours—Changetheengineoillter(more

ofteninextremelydustyordirtyoperatingconditions).

1.Runtheengineforafewminutestowarmtheoil.

2.Parkthemachineonalevelsurface,stoptheengine,set

theparkingbrake,andremovethekey.

3.Draintheengineoil;refertoChangingtheEngineOil

(page36).

4.Placeadrainpanundertheoillter,andturnthelter

counterclockwisetoremoveit(Figure42).

37

G008748

3/4

1

2

3

4

5

6

ServicingtheAirCleaner

1

2 3

4

G023446

ReplacingtheAirFilter

ServiceInterval:Every200hours(moreoftenindusty

conditions).

Note:Changingtheairlterbeforeitisnecessaryonly

increasesthechanceofdirtenteringtheenginewhenthe

lterisremoved.

1.Parkthemachineonalevelsurface,stoptheengine,set

theparkingbrake,andremovethekey.

2.Releasethelatchessecuringtheair-cleanercovertothe

air-cleanerbody(Figure43).

Figure42

5.Applyalightcoatofcleanoiltothegasketofthenew

lter.

6.Installthenewlter,turningitbyhanduntilthegasket

contactsthelteradapter;thentightenit3/4turn

more.

Important:Donotovertightenthelter.

7.Checktheoillevel;refertoCheckingtheLevelofthe

EngineOil(page21).

8.Ifnecessary,addoilintothelltube.

9.Starttheengineandletitrunforabout3minutes,and

ensurethattherearenoleaks.

10.Stoptheengine.

11.Checktheoillevel,andaddoilifnecessary.

Note:Thelterholdssomeoil,sotheoillevelmay

decreasewheninstallinganewlter.

12.Installthedipstick.

13.Disposeoftheusedoilaccordingtolocalcodes.

Figure43

1.Latch(2)3.Cover

2.Airlter

3.Removethecoverfromtheair-cleanerbody.

4.Removetheoldlter,andinstallthenewlter.

Note:Inspectthenewlterforshippingdamage,

checkingthesealingendofthelterandthebody .

Donotuseadamagedelement.Insertthenewlter

byapplyingpressuretotheouterrimoftheelement

toseatitinthecanister.Donotapplypressuretothe

exiblecenterofthelter.

Note:Donotcleantheusedelement,becauseitcan

damagetheltermedia.

5.Cleanthedirt-ejectionportlocatedintheremovable

cover.

6.Installthecoversothatthedirt-ejectionportpoints

downward.

4.Dirt-ejectionport

38

7.Securethelatches.

1

G023447

G019300

1 2

4

3

8.Checkthewholeintakesystemforleaks,damage,or

loosehoseclamps.

ServicingtheSparkPlugs

ServiceInterval:Every100hours

Type:NGKBPR4ES(orequivalent)

Gap:0.76mm(0.030inch)

Note:Thesparkplugsusuallylastalongtime;however,you

shouldcheckthemwhenevertheenginemalfunctions.

1.Cleantheareaaroundeachofthesparkplugssothat

foreignmattercannotfallintothecylinderswhenyou

removethesparkplugs.

Figure44

1.Spark-plugwires

2.Disconnectthespark-plugwiresfromthesparkplugs,

andremovetheplugsfromthecylinderheads.

Figure45

1.Sideelectrode

2.Centerelectrode4.0.76mm(0.030inch)gap

3.Insulator

CheckingandAdjustingthe ValveClearance

ServiceInterval:Every300hours

Thisproceduremustbeperformedwiththepropertools.See

yourauthorizedKawasakienginedealerforservice,unless

youhavetheproperequipmentandadequatemechanical

prociency.

CleaningandLappingthe Valve-SeatingSurface

ServiceInterval:Every300hours

Thisproceduremustbeperformedwiththepropertools.See

yourauthorizedKawasakienginedealerforservice,unless

youhavetheproperequipmentandadequatemechanical

prociency.

3.Checktheconditionofthesideelectrode,thecenter

electrode,andtheinsulatortoensurethatthereisno

damage.

Important:Replacethesparkplugsiftheyare

cracked,fouled,dirty,orotherwisemalfunctioning.

Donotcleantheelectrodes,becausegritentering

thecylindermaydamagetheengine.

4.Foreachsparkplug,setthegapbetweenthecenter

electrodeandthesideelectrodeto0.76mm(0.030

inch);refertoFigure45.Installeachofthecorrectly

gappedsparkplugswithagasketseal,andtightenthe

plugsto22N-m(16ft-lb).

39

FuelSystem

G023891

1

2

3

1

G023990

1

G023448

G008963

12

3

Maintenance

ReplacingtheFuelFilter

ServiceInterval:Every800hours

Thefuellinehasanin-linelter.Replaceitasfollows:

ReplacingtheCarbon-Canister Filter

ServiceInterval:Every200hours

1.Removethefastenerssecuringtheseatassemblytothe

machine.

1.Loosenthehoseclamponthecarburetorsideofthe

lter,andremovethefuellinefromthelter(Figure

48andFigure49).

Figure48

1.Fuellter

Figure46

1.Seatassembly3.Washer(4)

2.Bolt(4)

2.Disconnectthelterfromthecarboncanister(Figure

47).

1.Fuellter

Figure47

1.Carbon-canisterlter

3.Connectthenewltertothecarboncanister.

4.Installtheseatsupportplateandtheseat.

2.Hoseclamp(2)

2.Placeadrainpanunderthelter,loosentheremaining

hoseclamp,andremovethelter.

3.Slidethehoseclampsontotheendsofthefuellines.

4.Pushthefuellinesontothenewfuellter,andsecure

themwiththehoseclamps.

Figure49

3.Fuelline

40

Note:Installthenewlterwiththearrowonthelter

bodypointingawayfromthefueltank(towardthe

carburetor).

ElectricalSystem

Maintenance

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

Washhandsafterhandling.

Jump-StartingtheMachine

1.Removeanycorrosionfromthebatteryterminals,

andensurethattheconnectionsaretightbefore

jump-startingthemachine.

Important:Corrosionorlooseconnectionscan

causeunwantedelectricalvoltagespikesatany

timeduringthejump-startingprocedure,which

coulddamagetheengine.

Donotattempttojump-startthemachineifthe

batteryterminalsarelooseorcorroded.

DANGER

Jump-startingaweakbatterythatiscracked

orfrozen,orhasalowelectrolytelevelor

anopen/shortedbatterycell,cancausean

explosionresultinginseriouspersonalinjury.

Donotjump-startaweakbatteryifthese

conditionsexist.

2.Ensurethattheboosterbatteryisagood,fullycharged

lead-acidbatterywithatleast12.6V .Useproperlysized

jumpercableswithshortlengthstoreducethevoltage

dropbetweenthesystems.Makesurethatthecables

arecolorcodedorlabeledforthecorrectpolarity.

Note:Besurethattheventcapsaretightandlevel.

Placeadampcloth,ifavailable,overtheventcapson

eachbattery.Besurethatthemachinesdonottouch

andthatbothelectricalsystemsareturnedoffandhave

thesameratedsystemvoltage.Theseinstructionsare

fornegative-groundsystemsonly .

3.Connectthepositive(+)cabletothepositive(+)

terminalofthedischargedbatterythatiswiredtothe

starterorsolenoidasshowninFigure50.

41

Figure50

g0131 17

1

2

1

2 3 4

G023451

ReplacingtheFuses

Thefuseblock(Figure52)islocatednearthecontrolpanel.

1.Positive(+)cableon

dischargedbattery

2.Positive(+)cableon

boosterbattery

3.Negative(–)cableonthe

boosterbattery

4.Negative(–)cableonthe

engineblock

5.Boosterbattery

6.Dischargedbattery

7.Engineblock

4.Connecttheotherendofthepositivecabletothe

positiveterminaloftheboosterbattery.

5.Connecttheblacknegative(–)cabletotheother

terminal(negative)oftheboosterbattery.

6.Makethenalconnectionontheengineblock(not

onthenegativebatterypost)ofthemachinewiththe

dischargedbattery,awayfromthebattery,andstand

back(Figure51).

Figure52

1.Lights(soldseparately)

2.Attachment—10A

3.Enginestart—25A

4.Battery—20A

Toreplaceafuse,removeitbysimplypullingitoutfromthe

fuseblock,andinstallanewfuse

Important:Alwaysuseafuseofthesametypeand

amperageastheoneyouarereplacing;otherwise,you

coulddamagetheelectricalsystem.Refertothedecal

onthebackoftheseatforthefunctionandamperage

ofeachfuse.

ServicingtheBattery

ChargingtheBattery

WARNING

Chargingthebatteryproducesgasesthatcan

explode,seriouslyinjuringyouorbystanders.

Figure51

1.Engineblock

2.Negative(–)cable

7.Starttheengine,andremovethecablesinthereverse

orderofconnection.

Note:Disconnectthecableconnectedtotheengine

block(blackcable)rst.

Neversmokenearthebattery,andkeepsparksand

amesawayfromthebattery.

Important:Alwayskeepthebatteryfullycharged.This

isespeciallyimportanttopreventbatterydamagewhen

thetemperatureisbelow0°C(32°F).

1.Chargethebatteryfor10to15minutesat25to30

A,or30minutesat10A.

2.Whenthebatteryisfullycharged,unplugthecharger

fromtheelectricaloutlet,anddisconnectthecharger

leadsfromthebatteryposts(Figure53).

3.Installthebatteryinthemachineandconnectthe

batterycables;refertoInstallingtheBattery(page44).

42

Important:Donotrunthemachinewiththe

1 2

43

G023653

batterydisconnected;electricaldamagemay

occur.

Figure53

3.Disconnectthenegative(black)groundcablefromthe

batterypost.

WARNING

Incorrectbatterycableroutingcoulddamage

themachineandcables,causingsparks.

Sparkscancausethebatterygasestoexplode,

resultinginpersonalinjury.

•Alwaysdisconnectthenegative(black)

batterycablebeforedisconnectingthe

positive(red)cable.

•Alwaysconnectthepositive(red)battery

cablebeforeconnectingthenegative

(black)cable.

1.Positivebatterypost

2.Negativebatterypost

Ifthebatterynolongerholdsacharge,replaceit;referto

RemovingtheBattery(page43)andInstallingtheBattery

(page44).

3.Red(+)chargerlead

4.Black(-)chargerlead

RemovingtheBattery

1.Movethemachinetoalevelsurface,settheparking

brake,stoptheengine,andremovethekey.

2.Removethewingnutsandwasherssecuringthebattery

hold-down(Figure54).

WARNING

Batteryterminalsormetaltoolscouldshort

againstmetalmachinecomponents,causing

sparks.Sparkscancausethebatterygasesto

explode,resultinginpersonalinjury.

•Whenremovingorinstallingthebattery,

donotallowthebatteryterminalstotouch

anymetalpartsofthemachine.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsof

themachine.

4.Slidetheredterminalbootoffthepositive(+)battery

terminal,andremovethepositive(red)batterycable.

5.Removethebattery.

Figure54

43

InstallingtheBattery

1 2

43

G023659

1.Placethebatteryinthetray.

Ifcorrosionoccursatthebatteryterminals,disconnectthe

cables,negative(-)cablerst,andscrapetheclampsand

terminalsseparately.Connectthecables,positive(+)cable

rst,andcoattheterminalswithpetroleumjelly.

Figure55

2.Installthepositive(red)batterycabletothepositive

(+)batteryterminal,andtightenthenutontothebolt.

Important:Theredcablemaybecoveredbya

wireloom.Thepositivecableistheonewiththe

redboot.

3.Installthenegative(black)groundcabletothenegative

(-)batteryterminal,andtightenthenutontothebolt.

4.Slidetheredterminalbootontothepositive(+)battery

post.

5.Installthehold-down,andsecureitwiththewingnuts

andwashers.

CheckingandCleaningtheBattery

ServiceInterval:Every100hours—Checkthebatterycable

connections.

Keepthetopofthebatteryclean.Ifthemachineisstoredin

alocationwheretemperaturesareextremelyhigh,thebattery

willdischargemorerapidlythanifthemachineisstoredin

acoolerlocation.

Keepthetopofthebatterycleanbywashingitwithabrush

dippedinammoniaorasolutionofsodiumbicarbonate.

Flushthetopsurfacewithwateraftercleaning.Donot

removethellcapwhilecleaningthebattery.

Thebatterycablesmustbetightontheterminalstoprovide

goodelectricalcontact.

44

DriveSystem

1

2

G023556

2 64 51

G023453

3

Maintenance

AdjustingtheTracking

ReplacingtheDriveBeltand theTensionerPulley

1.Parkthemachineonalevelsurface,stoptheengine,

removethekey ,andwaitforallmovingpartstostop

beforeleavingtheoperatingposition.

1.Drivetoaat,openarea,andmovethecontrolhandles

totheneutral-lockedposition.

2.MovethethrottlemidwaybetweentheFastandSlow

positions.

3.Movebothcontrolhandlesallthewayforwarduntil

theybothhitthestopsintheT-slot.

4.Checkwhichwaythemachinetracks.

•Ifittrackstotheright,loosentheboltsandadjust

theleftstopplaterearwarduntilthemachinetracks

straight(Figure56).

•Ifittrackstotheleft,loosentheboltsandadjust

therightstopplaterearwarduntilthemachine

tracksstraight(Figure56).

2.Raisetherearofthemachineandsupportitwithjack

stands;refertoLiftingtheMachine(page35).

WARNING

Mechanicalorhydraulicjacksmayfailto

supportthemachineandcauseseriousinjury .

Usejackstandswhensupportingthemachine.

3.Usearatchetinthesquareholeinthetensionerarmto

counteractagainstthetensionerspring(Figure57),and

removethebeltfromthetensionerpulley.

Figure56

Leftcontrolhandleshown

1.Bolt(4)2.Stopplate

5.Tightentheboltstosecurethestopplate(Figure56).

Important:Ensurethateachcontrolhandlestops

againstthestopplateandnotagainstthetransmission

internalstop.

Figure57

1.Left-handtransmission

pulley

2.Tensionerspring5.Enginepulley

3.Tensionerarm6.Right-handtransmission

4.Unhookthetensionerspringfromthetensionerarm

andtheframe(Figure57).

5.Removethenutthatsecuresthetensionerassembly

totheframe(Figure58).

4.Tensionerpulley

pulley

45

2

1

G023551

Figure58

1

2

3

4

3

5

G023552

ControlsSystem

Maintenance

AdjustingtheControl-Handle Position

Thereare2heightpositionsforthecontrolhandles;high

andlow .

1.Movethecontrolhandlestotheneutral-locked

position,andsettheparkingbrake.

1.Tensionerassembly2.Nut

6.Removetheboltsecuringtheoldtensionerpulleyto

thetensionerarm,andinstallanewpulley(Figure59).

Figure59

1.Bolt4.Pulley

2.Spacer

3.Seal

5.Tensionerarm

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Loosentheboltsandangenutsthatattachthehandles

tothelevers(Figure60).

Figure60

1.Bolt3.Lever

2.Controlhandle

4.Alignthefront-to-rearpositionofthehandlesby

bringingthemtogethertotheneutralposition,and

slidingthemuntiltheyarealigned(Figure61).

4.Flangenut

7.Removethebeltfromthetransmissionpulleysandthe

enginepulley.

8.Installthenewbeltaroundtheenginepulleyandthe2