Page 1

Part No. 08160SL (Rev. A)

Service Manual

Preface

The purpose of this publication is to provide the service

technician with information for troubleshooting, testing

and repair of major systems and components on the

Workman MD and Workman MDX.

REFER TO THE OPERATOR’S MANUAL FOR OPERATING, MAINTENANCE AND ADJUSTMENT INSTRUCTIONS. For reference, insert a copy of the

Operator’s Manual and Parts Catalog for your machine

into Chapter 2 of this service manual. Additional copies

of the Operator’s Manual and Parts Catalog are available on the internet at www.Toro.com.

The Toro Company reserves the right to change product

specifications or this publication without notice.

Workman

This safety symbol means DANGER, WARNING,

or CAUTION, PERSONAL SAFETY INSTRUCTION. When you see this symbol, carefully read

the instructions that follow. Failure to obey the

instructions may result in personal injury.

NOTE: A NOTE will give general information about the

correct operation, maintenance, service, testing or repair of the machine.

IMPORTANT: The IMPORTANT notice will give im portant instructions which must be followed to prevent damage to systems or components on the

machine.

MD&MDX

R

E The Toro Company -- 2008, 2011

Page 2

This page is intentionally blank.

Workman MD/MDX

Page 3

Table Of Contents

Chapter 1 -- Safety

Safety Instructions 1 -- 2..........................

Jacking and Other Instructions 1 -- 4...............

Safety and Instruction Decals 1 -- 6................

Chapter 2 -- Product Records and Maintenance

Product Records 2 -- 1...........................

Maintenance 2 -- 1...............................

Equivalents and Conversions 2 -- 2................

Torque Specifications 2 -- 3.......................

Chapter 3 -- Briggs & Stratton Gasoline Engine

General Information 3 -- 2........................

Specifications 3 -- 3..............................

Adjustments 3 -- 4...............................

Service and Repairs 3 -- 5........................

Briggs and Stratton Repair Manual for 4--Cycle, V--Twin

Cylinder, OHV Head Engines

Chapter 4 -- Single Cylinder Gasoline Engine

General Information 4 -- 2........................

Specifications 4 -- 3..............................

Adjustments 4 -- 4...............................

Service and Repairs 4 -- 5........................

Kohler Service Manual for COMMAND PRO CS Series

Engines

Chapter 5 -- Drive Train

General Information 5 -- 1........................

Specifications 5 -- 2..............................

Drive Train Operation 5 -- 3.......................

Special Tools 5 -- 6..............................

Adjustments 5 -- 7...............................

Service and Repairs 5 -- 10.......................

Chapter 6 -- Electrical System

General Information 6 -- 2........................

Electrical Schematics 6 -- 2.......................

Special Tools 6 -- 3..............................

Troubleshooting 6 -- 5............................

Electrical System Quick Checks 6 -- 7..............

Component Testing 6 -- 8.........................

Service and Repairs 6 -- 18.......................

Chapter 7 -- Chassis

General Information 7 -- 1........................

Specifications 7 -- 2..............................

Special Tools 7 -- 2..............................

Troubleshooting 7 -- 3............................

Adjustments 7 -- 6...............................

Service and Repairs 7 -- 9........................

Chapter 8 -- Electrical Drawings

Electrical Schematics 8 -- 3.......................

Circuit Diagrams 8 -- 5...........................

Electrical Harness Drawings 8 -- 7.................

SafetyProduct Records

Briggs & Stratton

Single Cylinder

Drive TrainElectrical

and Maintenance

Gasoline Engine

Gasoline Engine

Workman MD/MDX

Rev. A

Chassis

Electrical

System

Drawings

Page 4

This page is intentionally blank.

Workman MD/MDX

Page 5

Table of Contents

SAFETY INSTRUCTIONS 2......................

Supervisor’s Responsibilities 2.................

Before Operating 2............................

While Operating 3.............................

Maintenance and Service 3....................

JACKING AND OTHER INSTRUCTIONS 4.........

Jack Vehicle 4................................

Transport Vehicle 4...........................

Tow Vehicle 4................................

Transaxle Neutral Position 5....................

SAFETY AND INSTRUCTION DECALS 6..........

Chapter 1

Safety

Safety

Workman MD/MDX Page 1 -- 1 Safety

Page 6

Safety Instructions

The Workman MD and MDX series vehicles are designed and tested to offer safe service when operated

and maintained properly. Although hazard control and

accident prevention partially are dependent upon the

design and configuration of the machine, these factors

are also dependent upon the awareness, concern and

proper training of the personnel involved in the operation, transport, maintenance and storage of the machine. Improper use or maintenance of the machine can

result in injury or death.

Read and understand the contents of the Operator’s

Manual before starting and operating the machine. Become familiar with all controls and know how to stop it

quickly. Additional copies of the Operator’s Manual are

available on the internet at www.Toro.com.

Supervisor’s Responsibilities

The safety alert symbol means

CAUTION, WARNING or DANGER —

“personal safety instruction”. Read

and understand the instruction because it has to

do with safety. Failure to comply with the instruction may result in personal injury.

WARNING

To reduce the potential for injury or death, comply

with the following safety instructions.

WARNING

The Workman is an off-- highway vehicle only. It is

not designed, equipped or manufactured for use

on public streets, roads or highways.

1. Make sure operators are thoroughly trained and familiar with the Operator’s Manual and all labels on the

vehicle.

Before Operating

1. Read and understand the contents of the Operator’s

Manual and Operator’s DVD before starting and operating the vehicle. Become familiar with the controls and

know how to stop the vehicle and engine quickly. Additional copies of the Operator’s Manual are available on

the internet at www.Toro.com.

2. Keep all shields, safety devices and decals in place.

If a shield, safety device or decal is defective, illegible or

damaged, repair or replace it before operating the vehicle. Also, tighten any loose nuts, bolts or screws to ensure vehicle is in safe operating condition.

2. Be sure to establish your own special procedures

and work rules for unusual operating conditions (e.g.

slopes too steep for vehicle operation).

3. Since fuel used in Workman vehicles is highly flammable, handle it carefully:

A. Store fuel in containers specifically designed for

this purpose.

B. Do not remove vehicle fuel tank cap while engine

is hot or running.

C. Do not smoke while handling fuel.

D. Fill fuel tank outdoors and only to within an inch of

the top of the tank, not the filler neck. Do not overfill

the fuel tank.

E. Clean up any spilled fuel.

Workman MD/MDXPage 1 -- 2Safety

Page 7

While Operating

1. Sit on the operator seat when starting and operating

the vehicle.

2. Before starting the engine:

A. Sit on operator’s seat and apply the parking

brake.

B. Turn ignition key to ON.

C. Depress accelerator pedal to startengine and engage drive system.

3. Do not run engine in a confined area without adequate ventilation. Exhaust fumes are hazardous and

could possibly be deadly.

Maintenance and Service

1. Before servicing or making adjustments, turn all accessories off, release pressure from accelerator pedal,

allow engine to stop, set parking brake and remove key

from the ignition switch.

2. Make sure vehicle is in safe operating condition by

keeping all nuts, bolts and screws tight.

3. Never store the vehicle or fuel container inside

where thereis an openflame, such as near a waterheater or furnace.

4. If major repairs are ever needed or assistance is desired, contact an Authorized Toro Distributor.

5. To reduce potential fire hazard, keep engine area

free of excessive grease, grass, leaves and dirt.

6. If engine must be running to perform maintenance or

an adjustment, keep clothing, hands, feet and other

parts of the body away from moving parts. Keep bystanders away.

7. Do not overspeed the engine by changing governor

setting. Toassure safety and accuracy, check maximum

engine speed.

4. Do not touch engine, muffler or exhaust pipe while

engine isrunning or soon after itis stopped. These areas

could be hot enough to cause burns.

Safety

5. Before getting off the seat:

A. Stop movement of the vehicle.

B. Turn ignition key to OFF and wait for all movement to stop.

C. Remove key from ignition switch.

D. Apply parking brake.

E. Do not park on slopesunless wheels are chocked

or blocked.

10.Battery acid is poisonous and can cause burns.

Avoid contact with skin, eyes and clothing. Protect your

face, eyes and clothing when working with a battery.

11. Battery gases can explode. Keep cigarettes, sparks

and flames away from the battery.

12.To assure optimum performance and continued

safety of the vehicle, use genuine Toro replacement

parts and accessories. Replacement parts and accessories made by other manufacturers may result in nonconformance with safety standards, and the warranty

may be voided.

13.When raising the vehicle to change tires or to perform other service, use correct blocks, hoists and jacks.

Make sure vehicle isparked on a solid level surface such

as a concrete floor. Prior to raising the vehicle, remove

any attachments that may interfere with the safe and

proper raising of the vehicle. Always chock or block

wheels. Use appropriate jack stands to support the

raised vehicle. If the vehicle is not properly supported by

jack stands, the vehicle may move or fall, which may result in personal injury (see Jacking Instructions in this

section).

8. Shut engine off before checking or adding oil to the

engine crankcase.

9. Disconnect battery before servicing the vehicle. Disconnect negative (--) battery cable first and positive (+)

cable last. If battery voltage is required for troubleshooting or test procedures, temporarily connect the battery.

Reconnect positive (+) cable first and negative (--) cable

last.

Workman MD/MDX Page 1 -- 3 Safety

Page 8

Jacking and Other Instructions

Jack Vehicle

DANGER

POTENTIAL HAZARD

• A vehicle that is not properly supported

may become unstable.

WHAT CAN HAPPEN

• The vehicle may move or fall. Personal

injury or damage to the machine may result.

HOW TO AVOID THE HAZARD

• Make sure vehicle is parked on a solid level

surface, such as a concrete floor.

• Make sure engine is off and key is removed

from the ignition switch before getting off

the vehicle.

• Before raising the vehicle, remove any

attachments that may interfere with the safe

and proper raising of the vehicle.

• Always chock or block wheels to prevent

the vehicle from rolling.

• Do not start vehicle while it is on jack

stands without placing transaxle in neutral.

• Make sure proper hoists, jacks and jack

stands are used to raise and support the

vehicle.

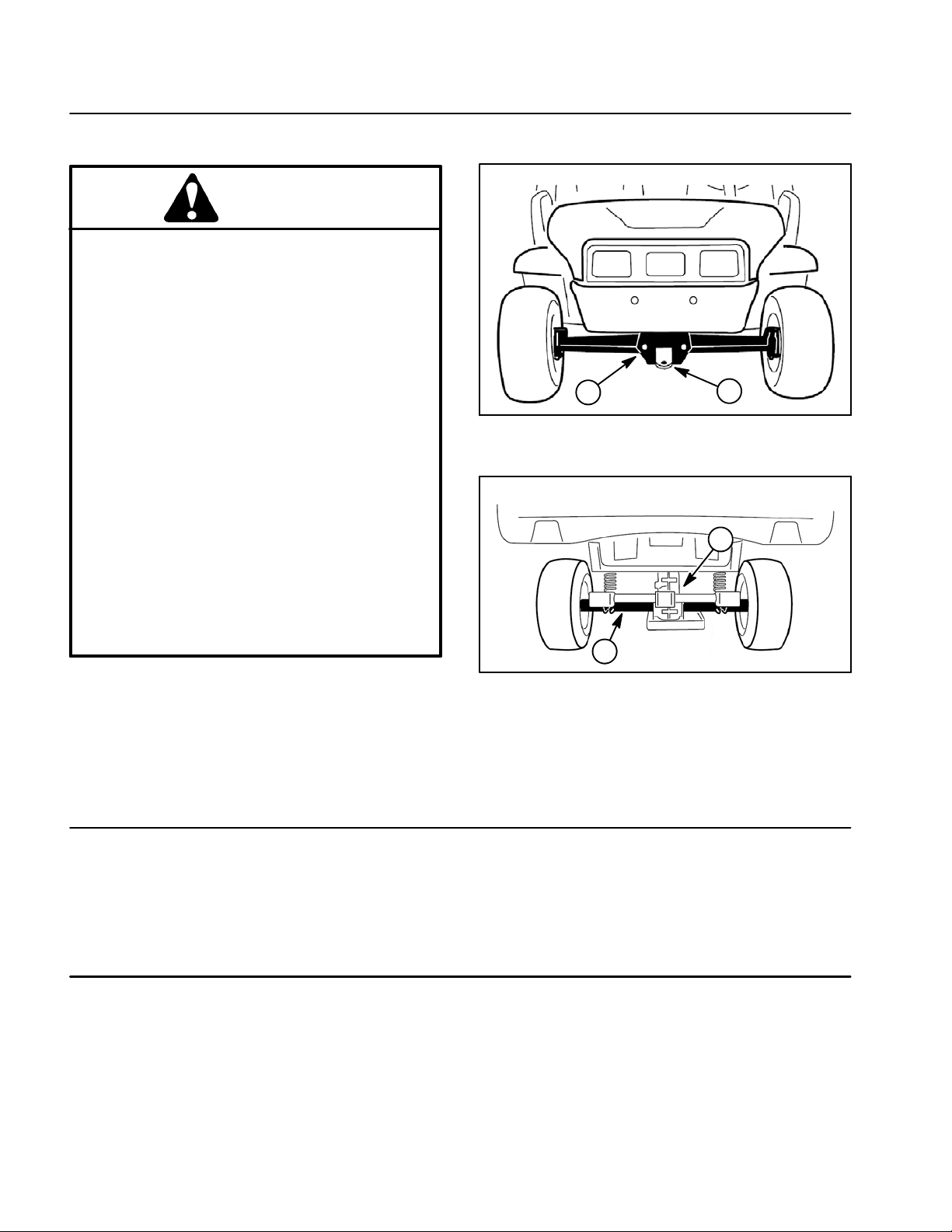

1

Figure 1

1. Front frame 2. Towing tongue

2

2

1

Jacking Locations

1. Jack front of the vehicle on the front of the frame and

behind the towing tongue (Fig. 1).

2. Jack rear of the vehicle under each rear axle tube. Do

not jack vehicle below the transaxle case (Fig. 2).

Transport Vehicle

When moving the vehicle long distances, use a trailer or

flatbed truck. Make sure vehicle is secured to the trailer

properly. Refer to Operator’s Manual for transport information.

Tow Vehicle

IMPORTANT: Frequent or long distance towing of

the Workman is not recommended.

In case of emergency, the vehicle can be towed for a

short distance. Refer to Operator’s Manual for towing

information.

Figure 2

1. Transaxle case 2. Axle tube

IMPORTANT: If vehicle is towed, make sure that

ignition switch is in the OFF position and key is removed from switch.

Workman MD/MDXPage 1 -- 4Safety

Page 9

Transaxle Neutral Position

When performing routine maintenance and/or engine

testing, the transaxle must be shifted into the neutral

position.

1. Park machine on a level surface, stop engine, set

parking brake and remove key from the ignition switch.

2

Safety

2. Move shift lever to the neutral position (Fig. 3).

3. Make sure transaxle is in the neutral position by rotating the driven clutch. The tires should not rotate. If tire

rotation does occur, see Adjust Shift Cables in the Adjustment section of Chapter 5 -- Drive Train.

3

1. Shift lever (in neutral)

2. Forward position

1

Figure 3

3. Reverse position

Workman MD/MDX Page 1 -- 5 Safety

Page 10

Safety and Instruction Decals

Numerous safety and instruction decals are affixed to

your Workman. If any decal becomes illegible or damaged, install a new decal. Part numbers are listed in the

Parts Catalog. Order replacement decals from your Authorized Toro Distributor.

Workman MD/MDXPage 1 -- 6Safety

Page 11

Product Records and Maintenance

Table of Contents

PRODUCT RECORDS 1.........................

MAINTENANCE 1...............................

EQUIVALENTS AND CONVERSIONS 2...........

Decimal and Millimeter Equivalents 2............

U.S. to Metric Conversions 2...................

TORQUE SPECIFICATIONS 3....................

Fastener Identification 3.......................

Standard Torque for Dry, Zinc Plated and

Steel Fasteners (Inch Series). 4...............

Standard Torque for Dry, Zinc Plated and

Steel Fasteners (Metric Fasteners). 5..........

Other Torque Specifications 6..................

Conversion Factors 6..........................

Product Records

Chapter 2

and Maintenance

Product Records

Insert Operator’s Manual and Parts Catalog for your

Workman at the end of this chapter. Additionally, if any

optional equipment or accessories have been installed

to your machine, insert the Installation Instructions, Operator’s Manuals and Parts Catalogs for those options

at the end of this chapter.

Maintenance

Maintenance procedures and recommended service intervals for your Workman are covered in the Operator’s

Manual. Refer to that publication when performing regular equipment maintenance.

Workman MD/MDX Page 2 -- 1 Product Records and Maintenance

Page 12

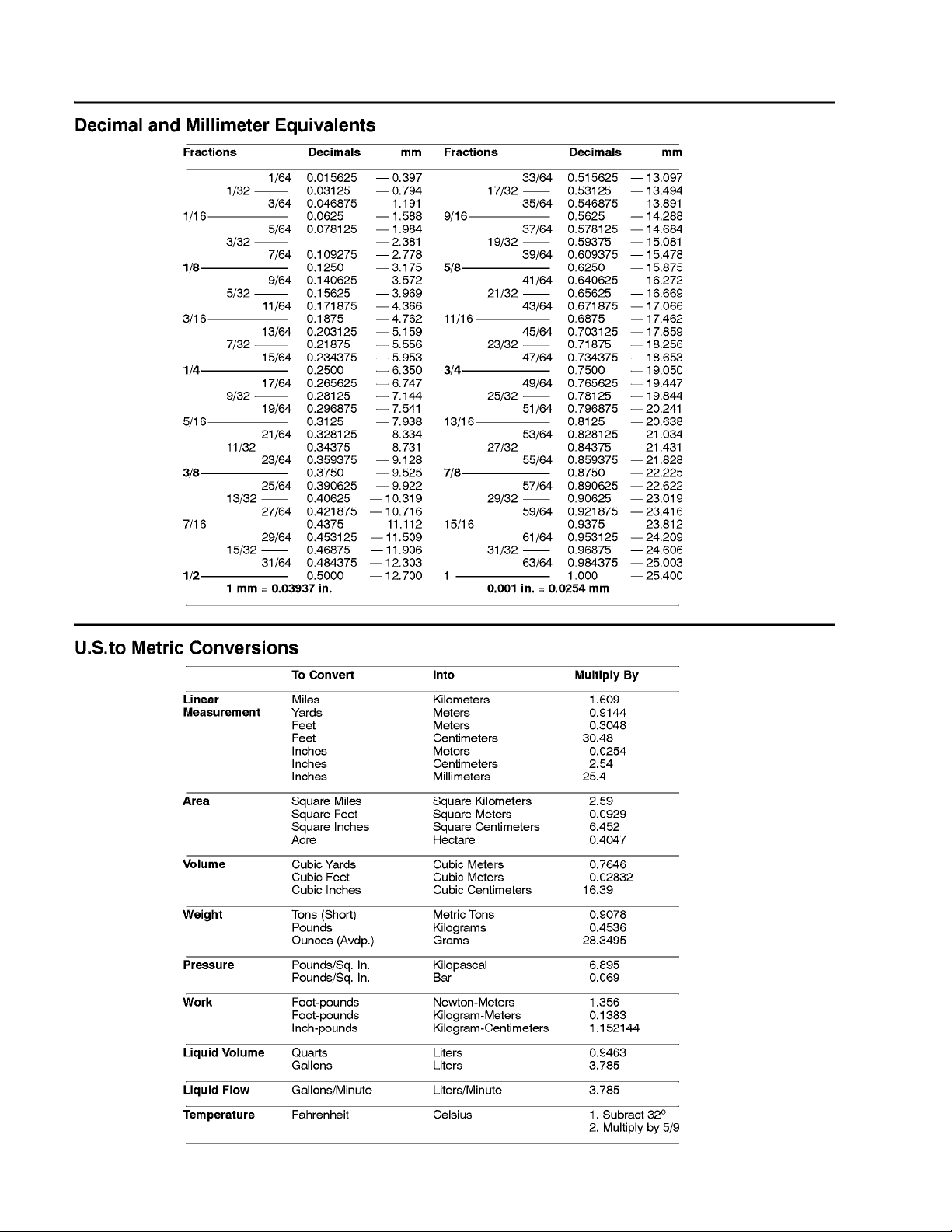

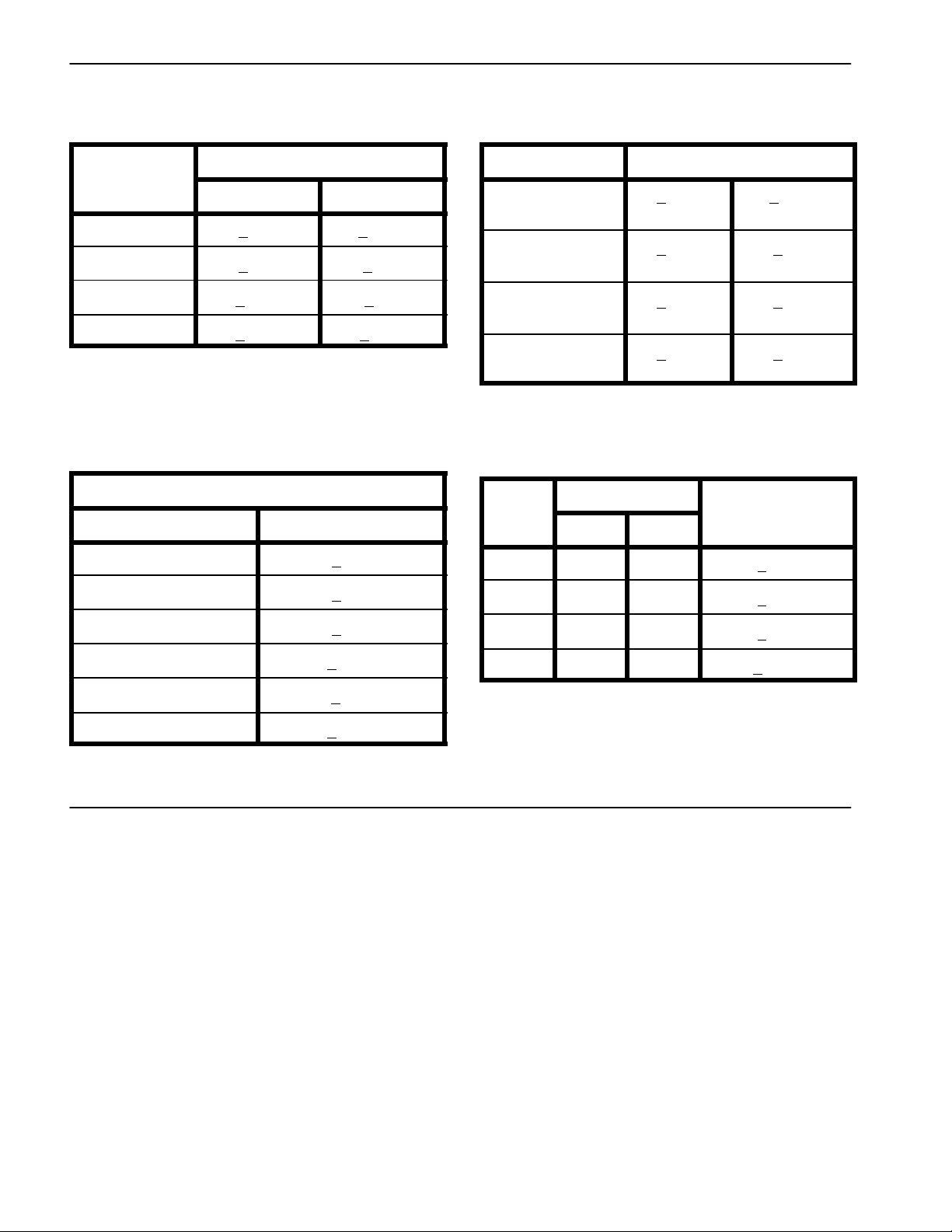

Equivalents and Conversions

0.09375

Workman MD/MDXPage 2 -- 2Product Records and Maintenance

Page 13

Torque Specifications

Recommended fastener torque values are listed in the

following tables. For critical applications, as determined

by Toro, either the recommended torque or a torque that

is unique to the application is clearly identified and specified in this Service Manual.

These Torque Specifications for the installation and

tightening of fasteners s hall apply to all fasteners which

do not have a specific requirement identified in this Service Manual. The following factors shall be considered

when applying torque: cleanliness of the fastener, use

of a thread sealant (e.g. Loctite), degree of lubrication

on the fastener, presence of a prevailing torque feature,

hardness of the surface underneath the fastener’s head

or similar condition which affects the installation.

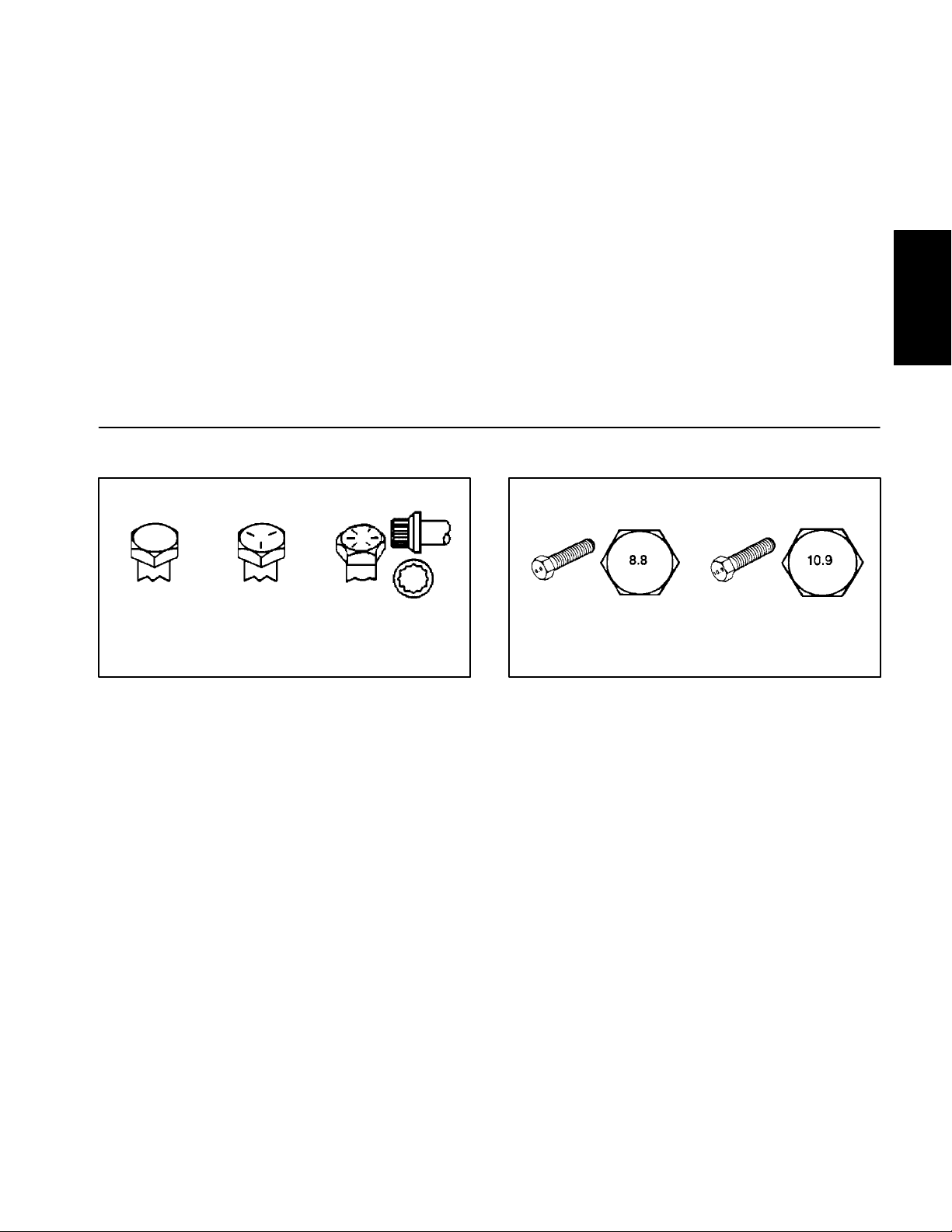

Fastener Identification

As noted in the following tables, torque values should be

reduced by 25% for lubricated fasteners to achieve

the similar stress as a dry fastener. Torque values may

also have to be reduced when the fastener is threaded

into aluminum or brass. The specific torque value

should be determined based on the aluminum or brass

material strength, fastener size, length of thread engagement, etc.

The standard method of verifying torque shall be performed by marking a line on the fastener (head or nut)

and mating part, then back off fastener 1/4 of a turn.

Measure the torque required to tighten the fastener until

the lines match up.

and Maintenance

Product Records

Grade 1 Grade 5 Grade 8

Inch Series Bolts and Screws

Figure 1

Class 8.8 Class 10.9

Metric Bolts and Screws

Figure 2

Workman MD/MDX Page 2 -- 3 Product Records and Maintenance

Page 14

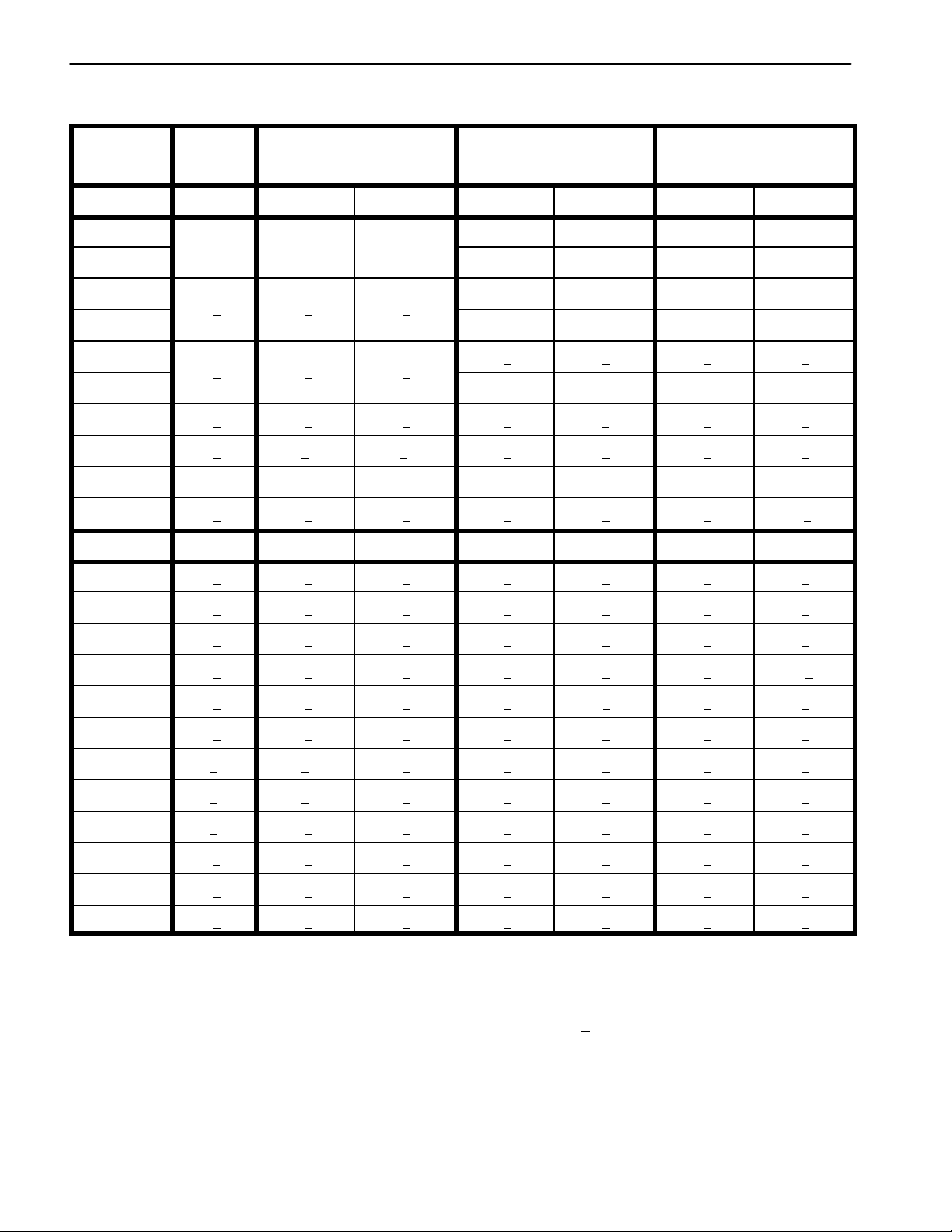

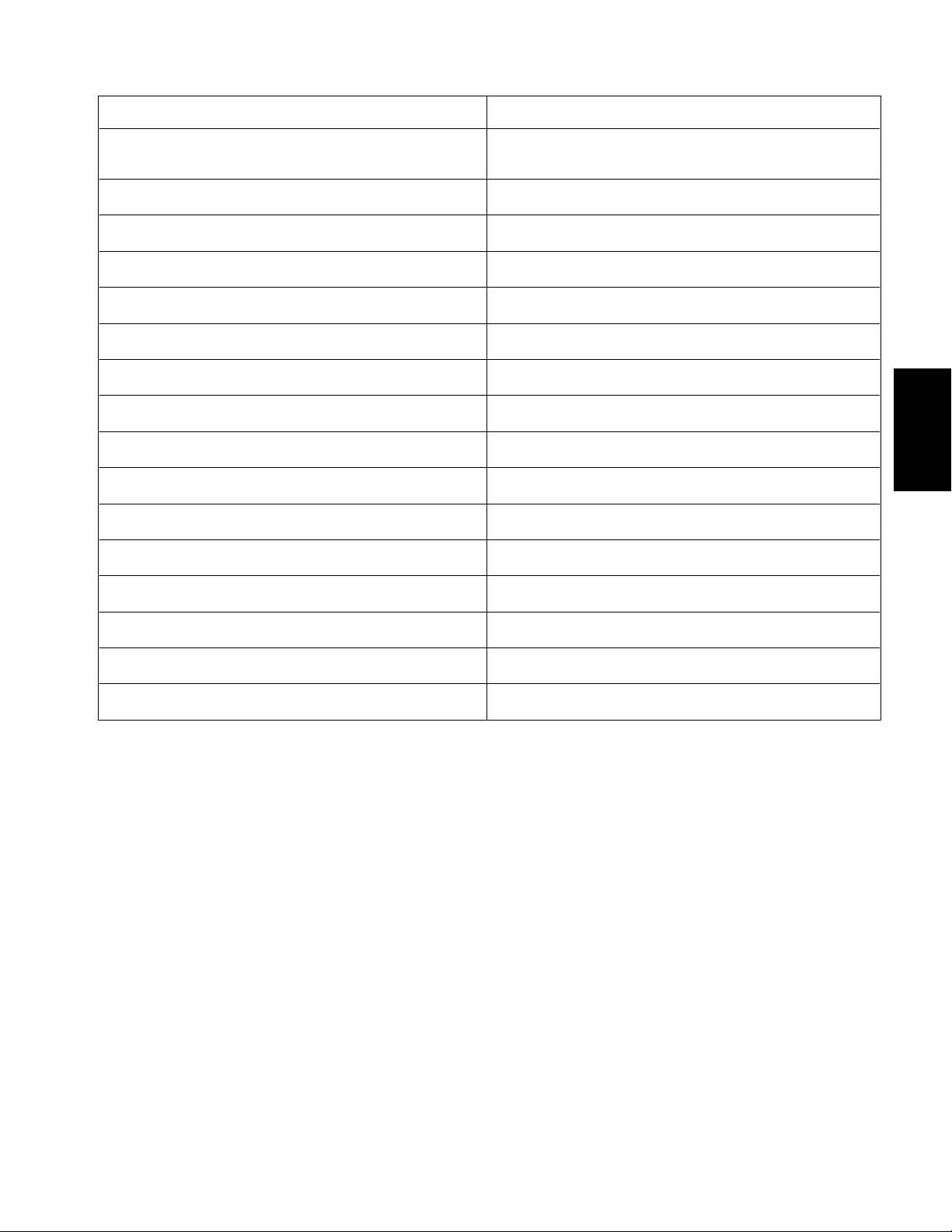

Standard Torque for Dry, Zinc Plated and Steel Fasteners (Inch Series)

Thread Size

# 6 -- 32 UNC

# 6 -- 40 UNF

# 8 -- 32 UNC

# 8 -- 36 UNF

#10--24UNC

#10--32UNF

1/4 -- 20 UNC 48 + 7 53 + 7 599 + 79 100 + 10 1125 + 100 140 + 15 1580 + 170

1/4 -- 28 UNF 53 + 7 65 + 10 734 + 11 3 11 5 + 10 1300 + 100 160 + 15 1800 + 170

5/16 -- 18 UNC 115 + 15 105 + 17 1186 + 169 200 + 25 2250 + 280 300 + 30 3390 + 340

5/16 -- 24 UNF 138 + 17 128 + 17 1446 + 192 225 + 25 2540 + 280 325 + 30 3670 + 340

3/8 -- 16 UNC 16 + 2 16 + 2 22 + 3 30 + 3 41 + 4 43 + 4 58 + 5

Grade 1, 5 &

8withThin

Height Nuts

in--lb in--lb N--cm in-- lb N--cm in-- lb N--cm

10 + 2 13 + 2 147 + 23

13 + 2 25 + 5 282 + 30

18 + 2 30 + 5 339 + 56

ft--lb ft--lb N--m ft--lb N--m ft--lb N--m

SAE Grade 1 Bolts, Screws, Studs &

Sems with Regular Height Nuts

(SAE J995 Grade 2 or Stronger Nuts)

SAE Grade 5 Bolts, Screws, Studs &

Sems with Regular Height Nuts

(SAE J995 Grade 2 or Stronger Nuts)

15 + 2 170 + 20 23 + 2 260 + 20

17 + 2 190 + 20 25 + 2 280 + 20

29 + 3 330 + 30 41 + 4 460 + 45

31 + 3 350 + 30 43 + 4 485 + 45

42 + 4 475 + 45 60 + 6 675 + 70

48 + 4 540 + 45 68 + 6 765 + 70

SAE Grade 8 Bolts, Screws, Studs &

Sems with Regular Height Nuts

(SAE J995 Grade 5 or Stronger Nuts)

3/8 -- 24 UNF 17 + 2 18 + 2 24 + 3 35 + 3 47 + 4 50 + 4 68 + 5

7/16 -- 14 UNC 27 + 3 27 + 3 37 + 4 50 + 5 68 + 7 70 + 7 95 + 9

7/16 -- 20 UNF 29 + 3 29 + 3 39 + 4 55 + 5 75 + 7 77 + 7 104 + 9

1/2 -- 13 UNC 30 + 3 48 + 7 65 + 9 75 + 8 102 + 11 105 + 10 142 + 14

1/2 -- 20 UNF 32 + 3 53 + 7 72 + 9 85 + 8 11 5 + 11 120 + 10 163 + 14

5/8 -- 11 UNC 65 + 10 88 + 12 119 + 16 150 + 15 203 + 20 210 + 20 285 + 27

5/8 -- 18 UNF 75 + 10 95 + 15 129 + 20 170 + 15 230 + 20 240 + 20 325 + 27

3/4 -- 10 UNC 93 + 12 140 + 20 190 + 27 265 + 25 359 + 34 375 + 35 508 + 47

3/4 -- 16 UNF 115 + 15 165 + 25 224 + 34 300 + 25 407 + 34 420 + 35 569 + 47

7/8 -- 9 UNC 140 + 20 225 + 25 305 + 34 430 + 45 583 + 61 600 + 60 813 + 81

7/8 -- 14 UNF 155 + 25 260 + 30 353 + 41 475 + 45 644 + 61 660 + 60 895 + 81

NOTE: Reduce torque values listed in the table above

by 25% for lubricated fasteners. Lubricated fasteners

are defined as threads coated with a lubricant such as

oil, graphite or thread sealant such as Loctite.

NOTE: The nominal torque values listed above for

Grade 5 and 8 fasteners are based on 75% of the minimum proof load specified in SAE J429. The tolerance is

approximately +

10% of the nominal torque value. Thin

height nuts include jam nuts.

NOTE: Torque values may have to be reduced when

installing fasteners into threaded aluminum or brass.

The specific torque value should be determined based

on the fastener size, the aluminum or base material

strength, length of thread engagement, etc.

Workman MD/MDXPage 2 -- 4Product Records and Maintenance

Page 15

Standard Torque for Dry, Zinc Plated and Steel Fasteners (Metric Fasteners)

Class 8.8 Bolts, Screws and Studs with

Thread Size Regular Height Nuts

(Class 8 or Stronger Nuts)

M5 X 0.8 57 + 5in--lb 640 + 60 N--cm 78 + 7in--lb 885 + 80 N--cm

M6 X 1.0 96 + 9in--lb 1018 + 100 N--cm 133 + 13 in--lb 1500 + 150 N --cm

M8 X 1.25 19 + 2ft--lb 26 + 3N--m 27 + 2ft--lb 36 + 3N--m

M10 X 1.5 38 + 4ft--lb 52 + 5N--m 53 + 5ft--lb 72 + 7N--m

M12 X 1.75 66 + 7ft--lb 90 + 10 N--m 92 + 9ft--lb 125 + 12 N--m

M16 X 2.0 166 + 15 ft--lb 225 + 20 N--m 229 + 22 ft--lb 310 + 30 N--m

M20 X 2.5 325 + 33 ft--lb 440 + 45 N--m 450 + 37 ft--lb 610 + 50 N--m

NOTE: Reduce torque values listed in the table above

by 25% for lubricated fasteners. Lubricated fasteners

are defined as threads coated with a lubricant such as

oil, graphite or thread sealant such as Loctite.

NOTE: Torque values may have to be reduced when

installing fasteners into threaded aluminum or brass.

The specific torque value should be determined based

on the fastener size, the aluminum or base material

strength, length of thread engagement, etc.

NOTE: The nominal torque values listed above are

based on 75% of the minimum proof load specified in

SAE J1199. The tolerance is approximately+

nominal torque value.

Class 10.9 Bolts, Screws and Studs with

Regular Height Nuts

(Class 10 or Stronger Nuts)

10% ofthe

and Maintenance

Product Records

Workman MD/MDX Page 2 -- 5 Product Records and Maintenance

Page 16

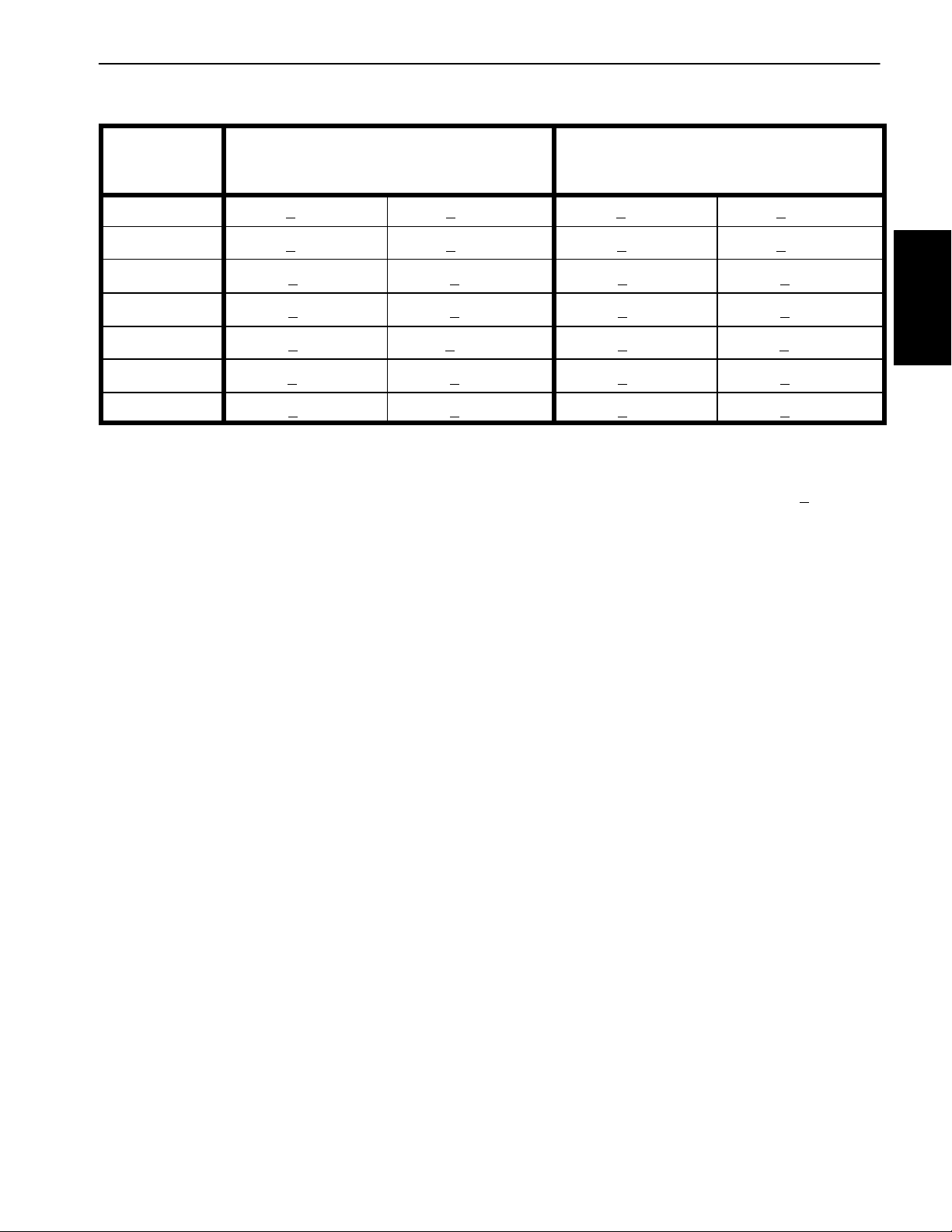

Other Torque Specifications

*

SAE Grade 8 Steel Set Screws

Recommended Torque

Thread Size

Square Head Hex Socket

1/4 -- 20 UNC 140 + 20 in--lb 73 + 12 in--lb

5/16 -- 18 UNC 215 + 35 in--lb 145 + 20 in--lb

3/8 -- 16 UNC 35 + 10 ft--lb 18 + 3ft--lb

1/2 -- 13 UNC 75 + 15 ft--lb 50 + 10 ft--lb

Thread Cutting Screws

(Zinc Plated Steel)

Type 1, Type 23 or Type F

Thread Size Baseline Torque*

No. 6 -- 32 UNC 20 + 5in--lb

Wheel Bolts and Lug Nuts

Thread Size

7/16 -- 20 UNF

Grade 5

1/2 -- 20 UNF

Grade 5

M12 X 1.25

Class 8.8

M12 X 1.5

Class 8.8

** For steel wheels and non--lubricated fasteners.

Thread Cutting Screws

(Zinc Plated Steel)

Thread

Size

No. 6 18 20 20 + 5in--lb

Threads per Inch

Type A Typ e B

Recommended Torque**

65 + 10 ft--lb 88 + 14 N--m

80 + 10 ft--lb 108 + 14 N--m

80 + 10 ft--lb 108 + 14 N--m

80 + 10 ft--lb 108 + 14 N--m

Baseline Torque

No. 8 -- 32 UNC 30 + 5in--lb

No. 10 -- 24 UNC 38 + 7in--lb

1/4 -- 20 UNC 85 + 15 in--lb

5/16 -- 18 UNC 110 + 20 in--lb

3/8 -- 16 UNC 200 + 100 in--lb

Conversion Factors

in--lb X 11.2985 = N--cm N--cm X 0.08851 = in--lb

ft--lb X 1.3558 = N--m N--m X 0.7376 = ft--lb

No. 8 15 18 30 + 5in--lb

No. 10 12 16 38 + 7in--lb

No. 12 11 14 85 + 15 in--lb

* Holesize, material strength, material thickness and finish must be considered when determining specific

torque values. All torque values are based on non--lubricated fasteners.

Workman MD/MDXPage 2 -- 6Product Records and Maintenance

Page 17

Briggs & Stratton Gasoline Engine

Table of Contents

GENERAL INFORMATION 2.....................

Operator’s Manual 2..........................

SPECIFICATIONS 3.............................

ADJUSTMENTS 4..............................

Adjust Throttle Cable 4........................

SERVICE AND REPAIRS 5......................

Cooling System 5.............................

Air Cleaner 6.................................

Exhaust System 8............................

Fuel Tank 10.................................

Oil Filter Assembly 12.........................

Engine 14....................................

Engine Removal 15..........................

Engine Installation 16........................

BRIGGS & STRATTON REPAIR MANUAL FOR

4--CYCLE, V--TWIN CYLINDER, OHV HEAD ENGINES

Chapter 3

Gasoline Engine

Briggs & Stratton

Workman MDX Page 3 -- 1 Briggs & Stratton Gasoline Engine

Page 18

General Information

This Chapter gives information about specifications,

maintenance, troubleshooting, testing and repair of the

V--twin cylinder, gasoline engine used in the Workman

MDX.

Most repairs and adjustments require tools w hich are

commonly available in many service shops. Special

tools are described in the Briggs & Stratton Repair

Manual for 4--Cycle, V--Twin Cylinder, OHV Head En-

Operator’s Manual

The Operator’s Manual provides information regarding

the operation, general maintenance and maintenance

intervals for your Workman MDX vehicle. Refer to the

Operator’s Manual for additional information when servicing the machine.

gines. The use ofsome specialized test equipment isexplained. However, the cost of the test equipment and the

specialized nature of some repairs may dictate that the

work be done at an engine repair facility.

Service and repair parts for Briggs & Stratton engines

are supplied through your local Toro distributor. If no

parts list is available, be sure to provide your distributor

with the Toro model and serial number.

Workman MDXPage 3 -- 2Briggs & Stratton Gasoline Engine

Page 19

Specifications

Item Description

Make / Designation Briggs and Stratton, 4--cycle, V--Twin Cylinder,

OHV, Air Cooled, Gasoline Engine -- Model 303440

Bore x Stroke 2.68” x 2.60” (68 mm x 66 mm)

Total Displacement 29.3 in3(480 cc)

Governor Mechanical Governor

Carburetor Float Feed, Single Barrel

Fuel Pump Pulsating Crankcase Vacuum

Fuel Unleaded, regular grade gasoline

Fuel Tank Capacity 7.0 U.S. gal (26.5 l)

Lubrication System Pressure Lubrication, Gear Driven Geroter Oil Pump

Crankcase Oil Capacity 1.75 U.S. qt (1.66 l) with new filter

Engine Oil See Operator’s Manual

Ignition System Flywheel magneto, twin electronic armatures

Spark Plugs Champion RC 12YC (or equivalent)

Gasoline Engine

Briggs & Stratton

Spark Plug Gap 0.030” (0.76 mm)

Starter/Generator 10.5 VDC 100 Amps/14 VDC and 23 Amps

Dry Weight (approximate) 72 lb (32.4 kg)

Workman MDX Page 3 -- 3 Briggs & Stratton Gasoline Engine

Page 20

Adjustments

Adjust Throttle Cable

NOTE: The Workman MDX is equipped with an engine

governor. Refer to the Briggs & Stratton Repair Manual

at the end of this chapter for governor information on

these machines.

Depressing the accelerator pedal rotates the engine

governor bellcrank which tensions the main governor

spring to increase engine speed. Releasing the accelerator pedal decreases governor spring tension to reduce

engine speed.

1. Park machine on a level surface, stop engine, engage parking brake and remove key from the ignition

switch.

2. Lift cargo box and prop with rod to gain access to the

engine.

3. When the accelerator pedal is fully depressed the

engine governor bellcrank mechanism should have a

gap from 0.030” to 0.080” (0.8 to 2.0 mm) (Fig. 2). If necessary, adjust jam nuts on accelerator cable so that gap

is correct.

2

ACCELERATOR

PEDAL RELEASED

1

Figure 1

1. Throttle cable 2. Governor bellcrank

2

4. After throttle cable adjustment is correct, lower and

secure cargo box.

ACCELERATOR

PEDAL DEPRESSED

1. Throttle cable

2. Governor bellcrank

3

1

Figure 2

3. Gap

Workman MDXPage 3 -- 4Briggs & Stratton Gasoline Engine

Page 21

Service and Repairs

Cooling System

To ensure proper engine cooling, make sure the grass

screen, cooling fins and other external surfaces of the

engine are kept clean at all times.

NOTE: Perform this maintenance procedure at the interval specified in the Operator’s Manual.

IMPORTANT: The engine that powers the Workman

MDX is air--cooled. Operating the engine with dirty

or plugged cooling fins or a plugged or dirty blower

housing w ill result in engine overheating and damage.

1. Park machine on a level surface, stop engine, engage parking brake and remove key from the ignition

switch.

2. Raise cargo box and support with prop rod.

3. Carefully remove spark plug wires from the spark

plugs to prevent the engine from starting unexpectedly.

IMPORTANT: Never clean engine with pressurized

water. Water could enter and contaminate the fuel

system.

4. Clean cooling fins on both cylinder heads (Fig. 3).

5. Clean rotating screen and blower housing of dirt and

debris.

6. If necessary remove rotating screen and blower

housing fromengine for more thorough engine cleaning.

2

1

1

Figure 3

1

Gasoline Engine

Briggs & Stratton

IMPORTANT: Never operate engine without the rotating screen and blower housing installed. Overheating and engine damage will result.

7. Make sure rotating screen and blower housing are

properly installed to the engine if removed.

8. Attach spark plug wires to spark plugs.

9. Lower and secure cargo box.

Workman MDX Page 3 -- 5 Briggs & Stratton Gasoline Engine

1. Rotating screen 2. Blower housing

Figure 4

Page 22

Air Cleaner

18

17

5

4

6

3

2

8

7

9

60 to 65 in-- lb

(6.8 to 7.3 N-- m)

10

1

11

12

19

13

12

14

15

16

17

RIGHT

FRONT

1. Air cleaner assembly

2. Bolt

3. Compression spring

4. Mounting band

5. Nut

6. Flange nut (2 used)

Figure 5

7. Cap screw (2 used)

8. Air cleaner bracket

9. Flange head screw (4 used)

10. Carburetor gasket (2 used)

11. Carburetor adapter

12. Hose clamp

13. Breather hose

14. Adapter gasket

15. Hose clamp

16. Intake hose

17. Hose clamp

18. Intake hose

Workman MDXPage 3 -- 6Briggs & Stratton Gasoline Engine

Page 23

Removal (Fig. 5)

1. Make sure machine is parked on a level surface with

the engine OFF.

2. Raise cargo box and support with prop rod.

3. Thoroughly clean junction of intake hose and carburetor adapter on engine and air cleaner assembly.

4. Remove air cleaner components as needed using

Figure 5 as a guide. Discard any removed gaskets and

clean gasket mating surfaces.

Installation (Fig. 5)

IMPORTANT: Any leaks in the air filter system will

allow dirt into engine and will cause serious engine

damage. Make sure that all air cleaner components

are in good condition and are properly secured during assembly.

1. Assemble all removed air cleaner components using

Figure 5 as a guide.

A. Install new gaskets (items 10 and 14) if they were

removed.

1

1. Air cleaner

2. Carburetor adapter

Figure 6

3. Breather hose

4. Intake hose

2

3

4

Gasoline Engine

Briggs & Stratton

B. If flange head screws ( item 9) were loosened or

removed, torque screws from 60 to 65 in--lb (6.8 to

7.3 N--m).

C. Make sure that air cleaner vacuator valve is

pointed toward ground and slightly toward engine after assembly.

D. Make sure to secure intake hoses with hose

clamps.

2. Lower and secure cargo box.

Workman MDX Page 3 -- 7 Briggs & Stratton Gasoline Engine

Page 24

Exhaust System

RIGHT

FRONT

8

9

4

10

1

2

7

6

5

4

3

1. Muffler

2. Swing arm

3. Cap screw (2 used)

4. Lock washer (6 used)

Figure 7

5. Exhaust coupler

6. Coupler spring (4 used)

7. Exhaust manifold

8. Engine tray

9. Engine

10. Screw (4 used)

Workman MDXPage 3 -- 8Briggs & Stratton Gasoline Engine

Page 25

Removal (Fig. 7)

Installation (Fig. 7)

1. Park machine on a level surface, stop theengine, engage parkingbrake and remove the key from the ignition

switch.

2. Raise cargo box and support with prop rod.

CAUTION

The muffler and exhaust pipe may be hot. To

avoid possible burns, allow engine and exhaust

system to cool before working on the muffler.

3. Remove four (4) coupler springs securing the exhaust coupler to the muffler and exhaust manifold. Remove exhaust coupler.

4. Remove two (2) cap screws and lock washers securing the muffler to the swing arm. Remove muffler from

machine.

5. If exhaust manifold needs to be removed from engine, remove four (4) screws and lock washers securing

the manifold to the engine. Remove exhaust manifold.

Remove exhaust gaskets and clean gasket surfaces of

manifold and engine.

NOTE: Mount all exhaust components loosely before

tightening to ensure a proper fit of exhaust system.

1. If the exhaust manifold was removed from engine,

install manifold to engine with new gaskets. Make sure

that gaskets align with exhaust ports of cylinder heads.

Loosely attach exhaust manifold to the engine with removed fasteners.

2. Position muffler to the machine. Secure muffler

loosely to the swing arm with two (2) cap screws and

lock washers.

3. Position exhaust coupler to the muffler and exhaust

manifold. Secure coupler with four (4) coupler springs.

4. Tighten screws that secure exhaust manifold to the

engine.

5. Tighten cap screws that secure muffler to the swing

arm.

6. Lower and secure cargo box.

Gasoline Engine

Briggs & Stratton

Workman MDX Page 3 -- 9 Briggs & Stratton Gasoline Engine

Page 26

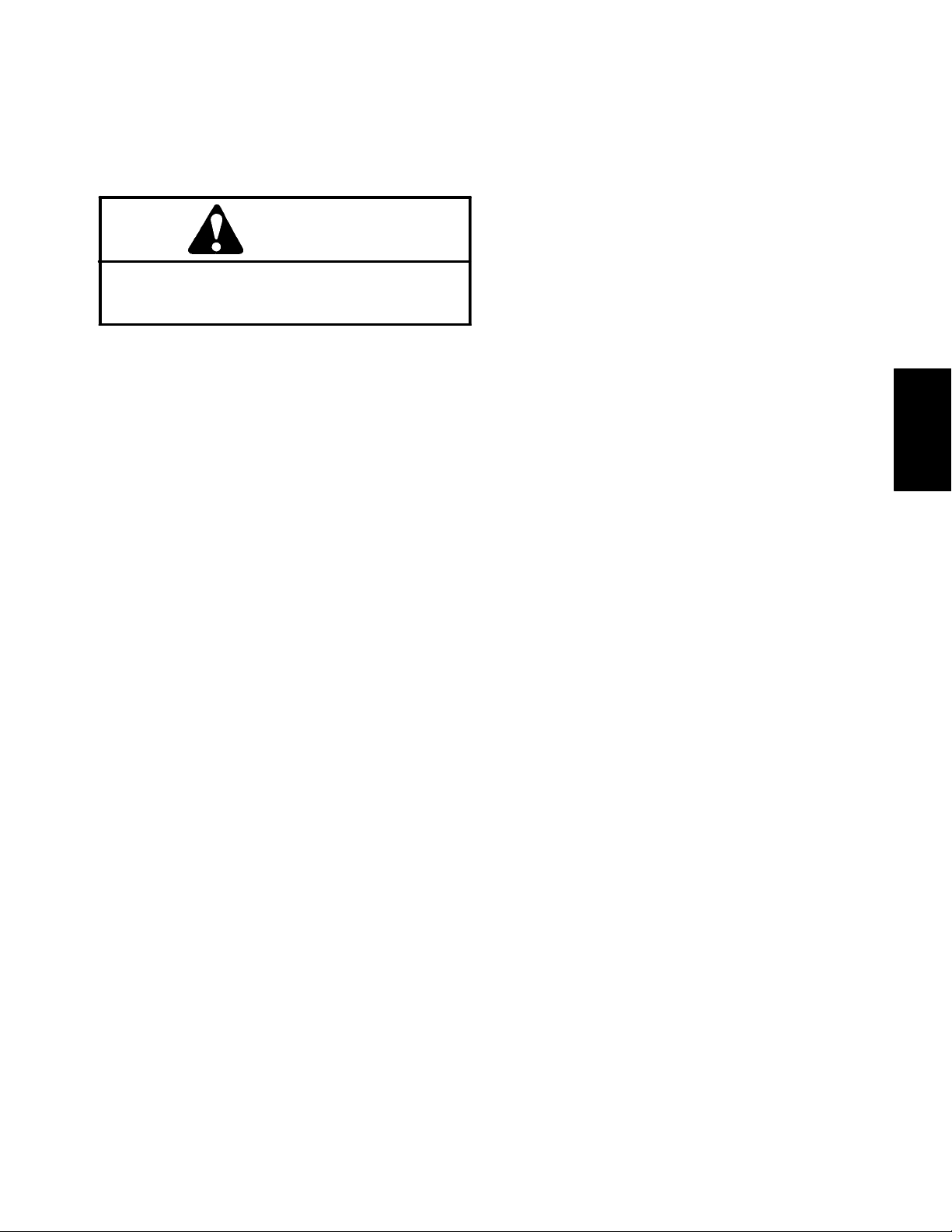

Fuel Tank

RIGHT

FRONT

16

11

15

14

12

13

10

5

1

2

3

9

8

7

6

4

1. Seat

2. Fuel gauge

3. Bushing

4. Gas cap

5. Fuel tank

6. Bushing

7. Stand pipe

Figure 8

8. Hose clamp

9. Fuel hose (to fuel filter)

10. Fuel line conduit

11. Seat base

13

12. Web strapping

13. Hex head flange screw (8 used)

14. Flat washer

15. Parking brake support

16. Shift bracket

Workman MDXPage 3 -- 10Briggs & Stratton Gasoline Engine

Page 27

Fuel Tank Removal (Fig. 10)

CAUTION

Read safety precautions for handling gasoline

before working on the fuel system (see Safety Instructions in Chapter 1 -- Safety).

4

2

5

1. Remove seat base from the frame (see Seat Base

Removal in the Service and Repairs section of Chapter

7 -- Chassis).

2. Use fuel transfer pump to remove gas from fuel tank.

3. Loosen hose clamp and disconnect fuel hose from

the fuel tank stand pipe.

4. Release tank strap that secures fuel tank to frame.

Do not remove strap from floor plate and frame cross

member. Lift tank from frame.

5. If necessary, remove stand pipe, fuel gauge and

bushings from tank.

Fuel Tank Installation (Fig. 10)

1. If removed, install bushings, stand pipe and fuel

gauge to tank.

2. Position fuel tank to frame. Secure tank to frame and

cross member with tank strap.

3. Connect fuel hose to the tank stand pipe and secure

with hose clamp.

4. Install seat base to the frame (see Seat Base Installation in the Service and Repairs section of Chapter 7 -Chassis).

3

1. Shift lever

2. Cap screw (short)

3. Shift plate

1

3

1. Fuel hose

2. Fuel tank

Figure 9

4. Cap screw (long)

5. Choke cable

Figure 10

3. Tank strap

1

Gasoline Engine

Briggs & Stratton

2

5. Fill fuel tank.

Workman MDX Page 3 -- 11 Briggs & Stratton Gasoline Engine

Page 28

Oil Filter Assembly

40 to 50 in-- lb

(4.6 to 5.6 N-- m)

11

RIGHT

FRONT

4

10

1

1

2

3

40 to 50 in-- lb

(4.6 to 5.6 N-- m)

4

3

12

5

6

8

7

8

9

7

1. Hose

2. Elbow fitting

3. Hose

4. Fitting

Figure 11

5. Oil pressure switch

6. Elbow fitting

7. Cap screw (4 used)

8. Flange nut (4 used)

9. Filter bracket

10. Oil filter

11. Oil filter adapter

12. Fitting

Workman MDXPage 3 -- 12Briggs & Stratton Gasoline Engine

Page 29

Removal (Fig. 11)

Installation (Fig. 11)

1. Park machine on a level surface, stop theengine, engage parkingbrake and remove the key from the ignition

switch.

2. Raise cargo box and support with prop rod.

3. To prevent contamination of engine lubrication system duringadapter removal, thoroughly clean exteriorof

filter adapter, hoses and fittings.

4. Remove oil filter adapter components as needed using Figure 11 as a guide.

1. Install removed oil filter adapter components using

Figure 11 as a guide. Torque fittings (items 2, 4 and 6)

from 40 to 50 in--lb (4.6 to 5.6 N--m).

2. Check and adjust engine oil level.

3. Lower and secure cargo box.

Gasoline Engine

Briggs & Stratton

Workman MDX Page 3 -- 13 Briggs & Stratton Gasoline Engine

Page 30

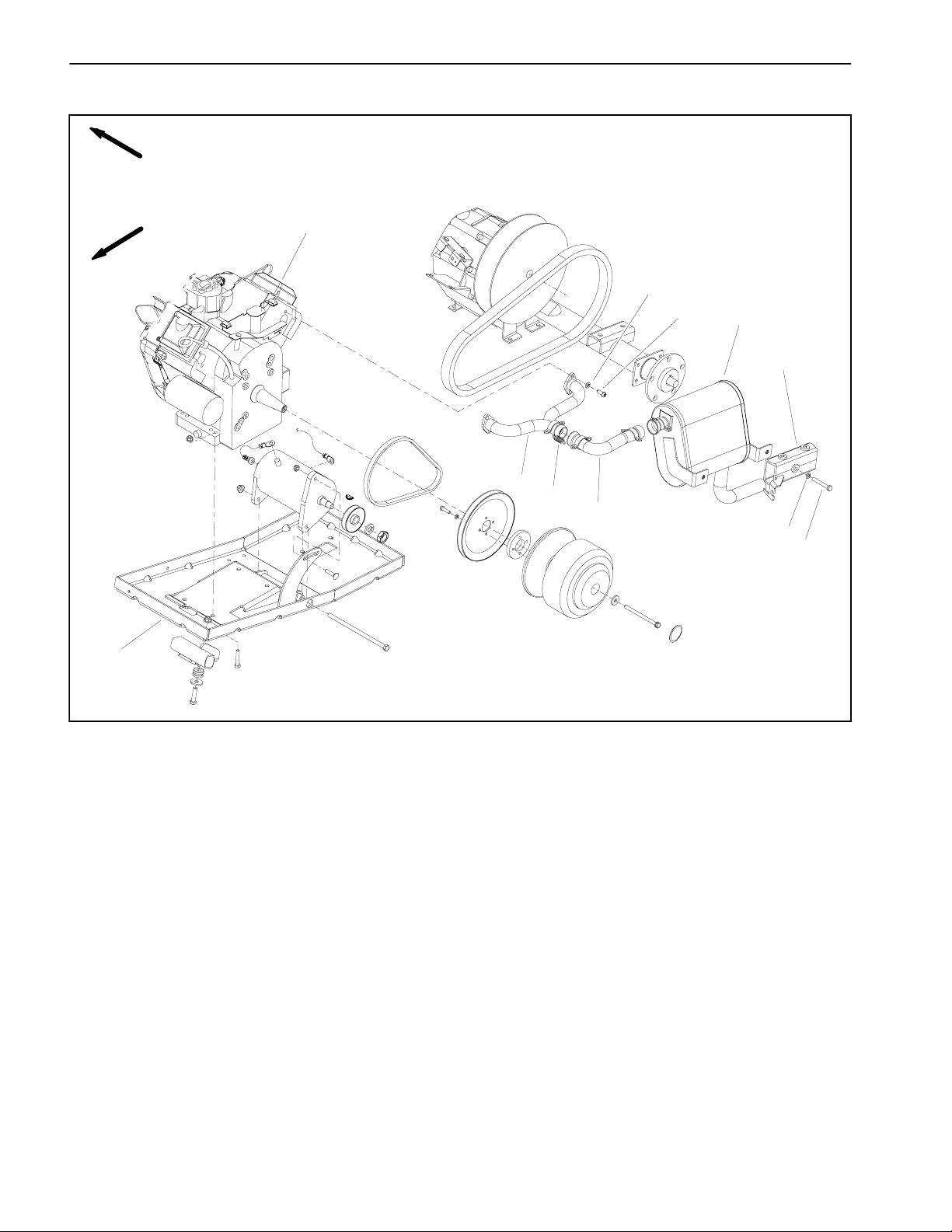

Engine

5

4

3

41

6

40

30

39

RIGHT

FRONT

65 to 85 ft-- lb

(88 to 115 N--m)

8

33

8

31

9

28

10

13

42

Loctite #242

22

38

1

37

1

36

25

1

2

17

29

27

11

43

19

20

14

15

29

7

1. Hose clamp

2. Fuel hose (from tank)

3. Cable bracket

4. Cable clamp

5. Cap screw

6. Threaded insert

7. Swing arm

8. Lock washer (6 used)

9. Cap screw (2 used)

10. Woodruff key

11. Lock washer

12. Nut

13. Starter V-- belt

14. Cap screw (4 used)

15. Lock washer (4 used)

32

26

35

23

34

16. Engine pulley

17. Negative cable

18. Starter spacer

19. Drive clutch

20. Washer

21. Cap screw

22. Flange nut (4 used)

23. Cap screw

24. Carriage screw

25. Engine tray

26. Washer (2 used)

27. Starter/generator pulley

28. Starter/generator

29. Flange nut (3 used)

30. Engine

24

Figure 12

12

16

18

Loctite #242

25 to 30 ft-- lb

(34to40N--m)

31. Engine wire harness

32. Cap screw (2 used)

33. Screw (4 used)

34. Mount (2 used)

35. Cap screw (4 used)

36. Fuel filter

37. Fuel hose

38. Lock nut

39. Cable bracket

40. Ball stud

41. Cable

42. Exhaust manifold

43. Coupler spring (4 used)

44. Plastic cap

21

44

Workman MDXPage 3 -- 14Briggs & Stratton Gasoline Engine

Page 31

Engine Removal (Fig. 12)

1. Park machine on a level surface, stop engine, engage parking brake and remove key from the ignition

switch.

2. Disconnect negative (black) cable from the battery.

Then, disconnect positive (red) cable from the battery.

3. Remove cargo box to gain access to the engine (see

Cargo Box and Tailgate Removal in the Service and Repairs section of Chapter 7 -- Chassis).

3

4

2

4. Depending on needed engine repairs,it may be easier to drain engine oil from engine before engine removal.

IMPORTANT: To prevent contaminants from entering the engine and fuel system, make sure all hoses

and engine openings are covered or plugged after

disconnecting.

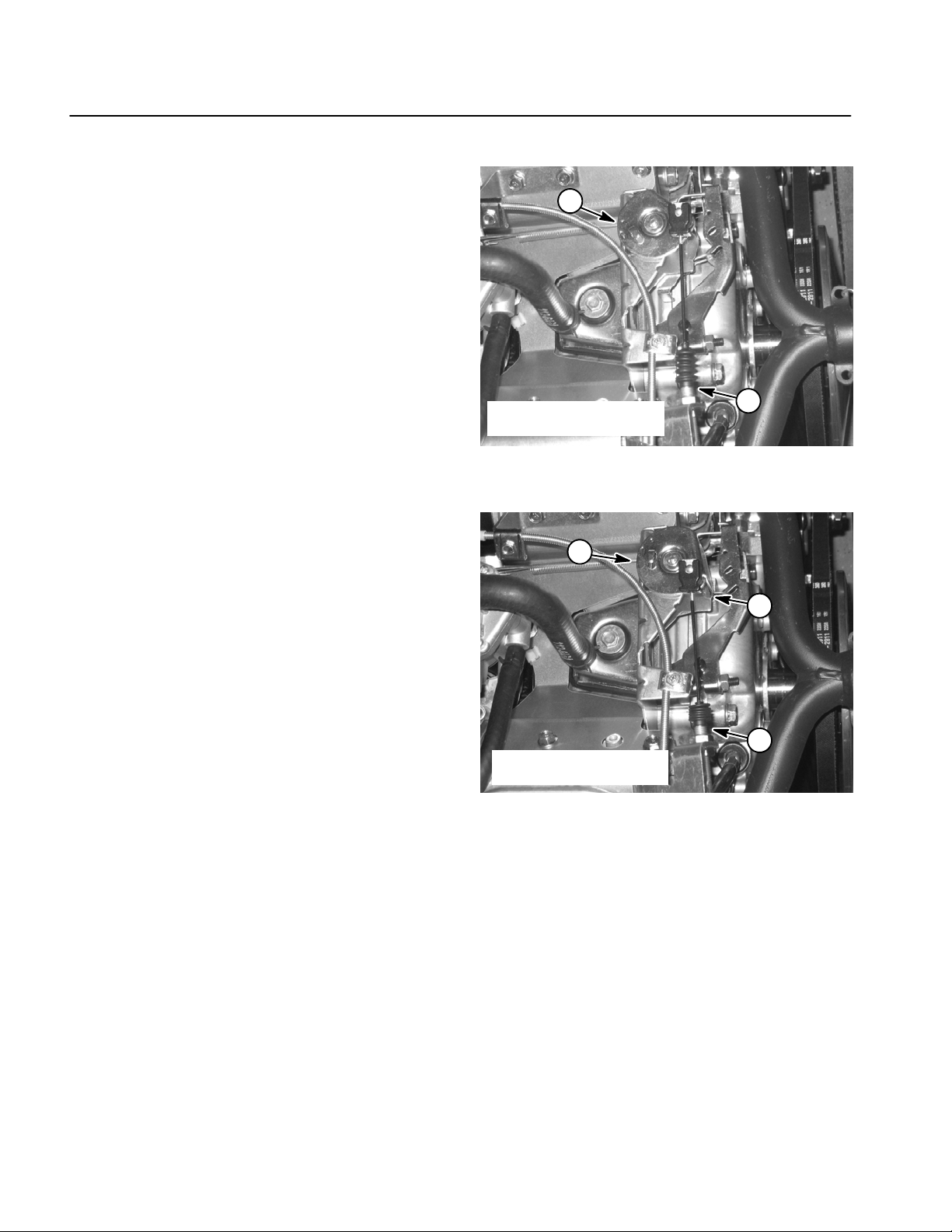

5. Disconnect the following components (Fig. 13):

A. Choke and throttle cables from the c arburetor

and cable brackets.

B. Air intake hose from the air cleaner intake and

machine frame.

CAUTION

Read safety precautions for handling gasoline

before working on the fuel system (see Safety Instructions in Chapter 1 -- Safety).

6. Disconnect fuel inlet hose from the fuel pump (Fig.

13).

7. Remove muffler and exhaust coupler from the machine (see Exhaust System Removal in this section).

1. Throttle cable

2. Choke cable

3. Cable bracket

5

4

2

1. Choke cable

2. Throttle cable

3. Carburetor

5

Figure 13

4. Air intake hose

5. Fuel inlet hose

Figure 14

4. Fuel hose

5. Air intake hose

6. Breather hose

1

6

Gasoline Engine

Briggs & Stratton

3

1

8. Remove drive belt from drive clutch.

9. Loosen fasteners that secure starter/generator. Rotate starter/generator to loosen tension on starter belt

and remove belt from the engine and starter/generator

pulleys.

10.Remove two (2) cap screws and flange nuts that secure oil filter adapter to filter bracket (Fig. 16). Carefully

2

place filter and adapter to allow them to be removed with

engine.

1

Figure 15

1. Starter/Generator ground cable to engine

2. Starter/Generator terminal (A1)

Workman MDX Page 3 -- 15 Briggs & Stratton Gasoline Engine

Page 32

11. Disconnect electrical connections from the following

engine components:

A. Disconnect ground cable to engine at starter/

generator terminal A1 (Fig. 15).

6

B. Disconnect engine harness connector from the

main harness.

12.Remove four (4) flange nuts and cap screws securing the engine to the engine tray.

CAUTION

One person should operate the hoist while the

other person guides the engine out of the frame.

13.Remove engine from the engine tray.

A. Attach a short section of chain between both engine lift tabs.

B. Connect hoist to center of chain.

IMPORTANT: Make sure to not damage the engine, fuel hoses, electrical harness or other parts

while removing the engine.

C. Slowly remove engine from the machine.

5

1

2

3

4

Figure 16

1. Oil filter adapter

2. Oil filter

3. Filter bracket

4. Cap screw

5. Flange nut

6. Engine

3. Install four (4) cap screws and flange nuts to engine

and engine tray. Position engine on engine tray to align

clutch drive pulley and driven pulley on transaxle. Tighten fasteners.

4. Carefully position oil filter assembly to filter bracket

(Fig. 16). Secure filter adapter with two (2) cap screws

and flange nuts.

14.Remove engine parts and attachments as necessary to repair the engine.

Engine Installation (Fig. 12)

1. Install all removed parts and attachments to the engine.

CAUTION

One person should operate the hoist while the

other person guides the engine into the frame.

2. Install engine to the engine tray.

A. Attach a short section of chain between both engine lift tabs.

B. Connect a hoist at the center of the short section

of chain.

IMPORTANT: Make sure to not damage engine,

fuel lines, electrical harness or other parts while

installing the engine.

5. Connect the following electrical components:

A. Connect ground cable from the engine at starter/

generator terminal A1 (Fig. 15).

B. Connect engine harness connector to the main

harness connector.

6. Install starter belt to the engine and starter/generator

pulleys. Tension the belt by rotating the starter/generator away from the engine. Tighten fasteners to secure

starter/generator.

7. Install drive belt to drive clutch.

IMPORTANT: Make sure to remove all plugs and

covers that were placed on hose and engine openings during engine removal.

8. Install muffler and exhaust coupler to the machine

(see Exhaust System Installation in this section).

9. Connect fuel inlet hose to the fuel pump (Fig. 13).

C. Carefully lower engine onto the engine tray.

Workman MDXPage 3 -- 16Briggs & Stratton Gasoline Engine

Page 33

10.Connect the following components (Fig. 13):

A. Choke and throttle cables to the carburetor and

cable bracket.

B. Air intake hose to the air cleaner intake and machine frame.

11. Install cargo box to the frame (see Cargo Box and

Tailgate Installation in the Service and Repairs section

of Chapter 7 -- Chassis).

12.Connect positive (red) cable to the battery. Then,

connect negative (black) cable to the battery.

13.Make sure engine oil level is correct.

Gasoline Engine

Briggs & Stratton

Workman MDX Page 3 -- 17 Briggs & Stratton Gasoline Engine

Page 34

This page is intentionally blank.

Workman MDXPage 3 -- 18Briggs & Stratton Gasoline Engine

Page 35

Single Cylinder Gasoline Engine

Table of Contents

GENERAL INFORMATION 2.....................

Operator’s Manual 2..........................

SPECIFICATIONS 3.............................

ADJUSTMENTS 4..............................

Adjust Throttle Cable 4........................

SERVICE AND REPAIRS 5......................

Cooling System 5.............................

Exhaust System 6............................

Fuel Tank 8..................................

Engine 10....................................

Engine Removal 11..........................

Engine Installation 12........................

KOHLER SERVICE MANUAL FOR COMMAND PRO

CS SERIES ENGINES

Chapter 4

Single Cylinder

Gasoline Engine

Workman MD Single Cylinder Gasoline EnginePage 4 -- 1

Rev. A

Page 36

General Information

This Chapter gives information about specifications,

maintenance, troubleshooting, testing and repair of the

single cylinder gasoline engine used in the Workman

MD.

Workman MD vehicles with serial numbers below

311000000 have an engine that is identified as a Kohler

Command Pro CS engine. Workman MD vehicles with

serial numbers above 311000000 have an engine that

is identified as a YamahaMZ360 engine. From a service

standpoint, these engines are essentially the same. The

Kohler Service Manual for COMMAND PRO CS Series

Engines is included at the end of this chapter and can be

used when servicing either brand of engine.

Operator’s Manual

The Operator’s Manual provides information regarding

the operation, general maintenance and maintenance

intervals for your Workman MD vehicle. Refer to the Operator’s Manual for additional information when servicing the machine.

Most repairs and adjustments require tools which are

commonly available in many service shops. Special

tools are described in the Kohler Service Manual for

COMMAND PRO C S Series Engines and the use of

some specialized test equipment is explained. The cost

of the test equipment and the specialized nature of

some repairs may dictate that engine work be done at

an engine repair facility.

Service and repair parts for theengine used in the Workman MD can be provided by your local Toro distributor.

Rev. A

Workman MDPage 4 -- 2Single Cylinder Gasoline Engine

Page 37

Specifications

Item Description

Make / Designation 4--cycle, Single Cylinder, OHV,

Air Cooled, Gasoline Engine

Bore x Stroke 3.35 in x 2.48 in (85 mm x 63 mm)

Total Displacement 21.8 in3(357 cc)

Governor Transaxle, Ground Speed Governing

Carburetor Float Feed, Single Barrel

Fuel Pump Pulsating Crankcase Vacuum

Fuel Unleaded regular grade gasoline

Fuel Tank Capacity 7.0 U.S. gal (26.5 l)

Lubrication System Splash Lubrication

Crankcase Oil Capacity 1.2U.S.qt(1.1l)

Engine Oil See Operator’s Manual

Spark Plugs Champion RC 14YC (or equivalent)

Spark Plug Gap 0.030 in (0.76 mm)

Single Cylinder

Gasoline Engine

Starter/Generator 10.5 VDC 100 Amps/14 VDC and 23 Amps

Dry Weight (approximate) 70.5 lb (31.9 kg)

Workman MD Single Cylinder Gasoline EnginePage 4 -- 3

Rev. A

Page 38

Adjustments

Adjust Throttle Cable

Releasing theaccelerator pedal should allow thethrottle

cable to close the carburetor throttle control lever so that

the lever touches the adjustment screw. The adjustment

screw keeps the throttle valve inside the carburetor

open slightly to prevent the valve from binding.

1. Park machine on a level surface, stop engine, engage parking brake and remove key from the ignition

switch.

2. Lift cargo box and prop with rod to gain access to the

engine and transaxle.

3. Rotate governor arm on transaxle fully clockwise

(Fig. 1).

4. Make sure of the following:

A. The carburetor throttle lever should be to the fully

open position without contacting the stop (Fig. 2).

B. Adjust governor cable at the transaxle cable

bracket as necessary, so there is no compression of

the cable (Fig. 1). This will allow the throttle lever to

fully close when the accelerator pedal is released.

1

3

1. Governor arm

2. Throttle cable

4

2

Figure 1

3. Governor cable

4. Cable bracket

5. Release the governor arm on transaxle and make

sure that the carburetor throttle lever fully closes.

6. After throttle cable adjustment is correct, lower and

secure cargo box.

3

1. Throttle cable

2. Governor cable

1

2

Figure 2

3. Carb throttle lever

Workman MDPage 4 -- 4Single Cylinder Gasoline Engine

Page 39

Service and Repairs

Cooling System

To ensure proper engine cooling, make sure the grass

screen, cooling fins and other external surfaces of the

engine are kept clean at all times.

NOTE: Perform this maintenance procedure at the interval specified in the Operator’s Manual.

IMPORTANT: The engine that powers the Workman

MD is air--cooled. Operating the engine with dirty or

plugged cooling fins or a plugged or dirty blower

housing w ill result in engine overheating and damage.

1. Park machine on a level surface, stop engine, engage parking brake and remove key from the ignition

switch.

2. Raise bed and support with prop rod.

3. Carefully remove sparkplug wire from the spark plug

to prevent the engine from starting unexpectedly.

1

2

Figure 3

1. Static debris screen 2. Blower housing

IMPORTANT: Never clean engine with pressurized

water. Water could enter and contaminate the fuel

system.

4. Clean cooling fins on cylinder head.

5. Clean static debris screen and blower housing of dirt

and debris. Remove screen and housing if necessary

(Fig. 3).

IMPORTANT: Never operate engine without the

blower housing installed. Overheating and engine

damage will result.

6. Make sure static screen andblower housing are reinstalled to the engine if removed.

7. Attach spark plug wire to spark plug.

8. Lower and secure bed.

Single Cylinder

Gasoline Engine

Workman MD Single Cylinder Gasoline EnginePage 4 -- 5

Page 40

Exhaust System

RIGHT

FRONT

12

3

4

5

2

1

6

7

8

1. Engine

2. Coupler spring (4 used)

3. Exhaust manifold

4. Muffler

Figure 4

5. Exhaust coupler

6. Starter/generator

7. Drive clutch

8. Engine tray

9

10

11

9. Lock washer (2 used)

10. Cap screw (2 used)

11. Swing arm

12. Nut (2 used)

Workman MDPage 4 -- 6Single Cylinder Gasoline Engine

Page 41

Removal (Fig. 4)

1. Park machine on a level surface, stop theengine, engage parking brake and remove the key from the ignition

switch.

2. Raise cargo box and support with prop rod.

CAUTION

The muffler and exhaust pipe may be hot. To

avoid possible burns, allow engine and exhaust

system to cool before working on the muffler.

3

2

1

3

3. Remove four (4) springs securing the exhaust coupler to the muffler and exhaust manifold (Fig. 5).

4. Remove two (2) cap screws and lock washers securing the muffler to the swing arm.

5. Remove exhaust coupler and muffler.

6. If needed, remove exhaust manifold from engine by

removing two (2) nuts. Remove exhaust gasket and

clean gasket surfaces of manifold and engine.

Installation (Fig. 4)

NOTE: Mount all exhaust components loosely before

tightening to ensure a proper fit of exhaust system.

1. If the exhaust manifold was removed from engine,

install manifold to engine with new gasket. Attach exhaust manifold loosely to the engine with removed nuts.

2. Install muffler to the swing arm with two (2) cap

screws and lock washers.

3. Insert exhaust coupler between muffler and manifold. Install springs to attach exhaust coupler to the exhaust manifold and muffler.

1. Exhaust manifold

2. Exhaust coupler

Figure 5

3. Spring

Single Cylinder

Gasoline Engine

4. Tighten all exhaust system fasteners.

5. Lower and secure cargo box.

Workman MD Single Cylinder Gasoline EnginePage 4 -- 7

Page 42

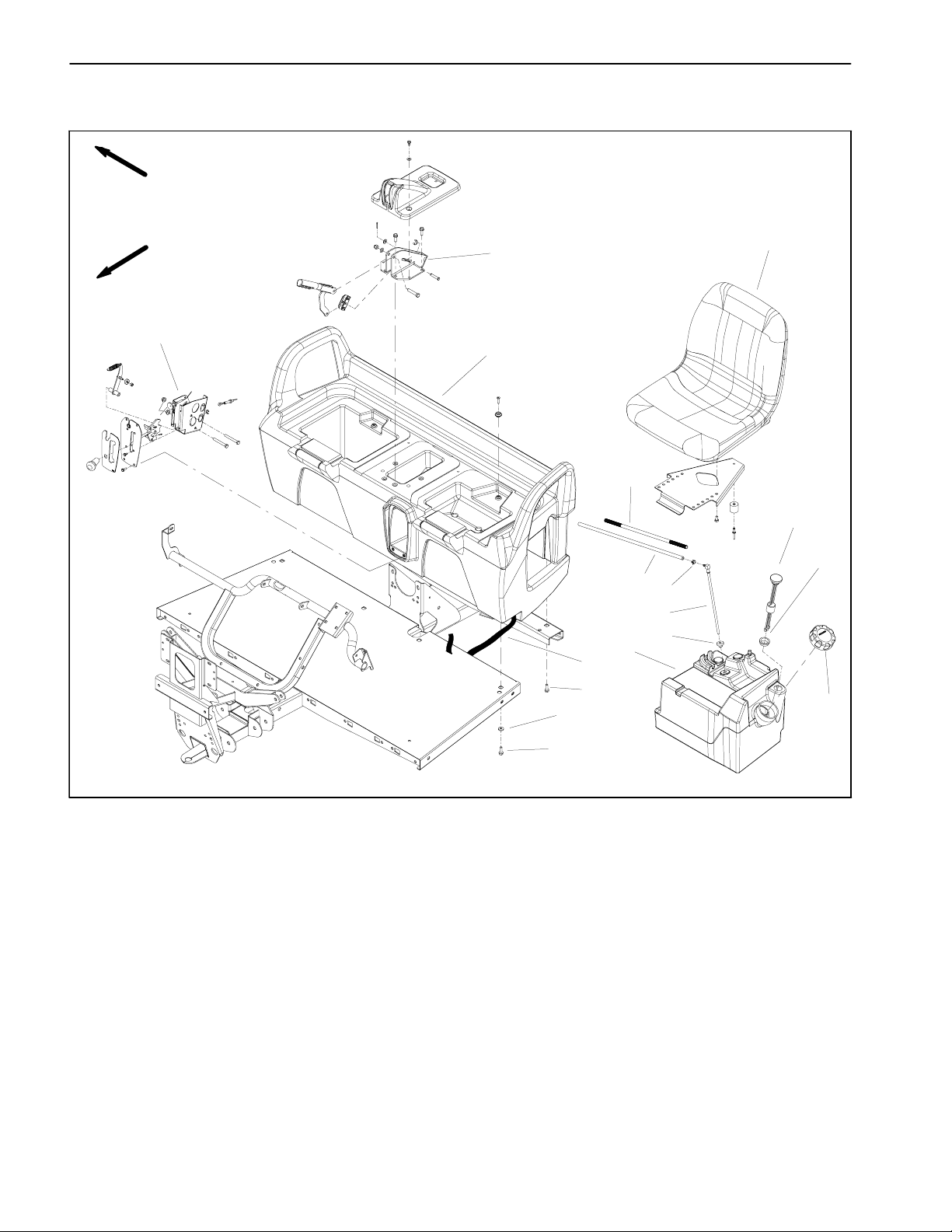

Fuel Tank

RIGHT

FRONT

16

11

15

14

12

13

10

1

2

3

9

8

7

6

5

4

1. Seat

2. Fuel gauge

3. Bushing

4. Gas cap

5. Fuel tank

6. Bushing

7. Stand pipe

Figure 6

8. Hose clamp

9. Fuel hose (to fuel filter)

10. Fuel line conduit

11. Seat base

13

12. Web strapping

13. Hex head flange screw (8 used)

14. Flat washer

15. Parking brake support

16. Shift bracket

Workman MDPage 4 -- 8Single Cylinder Gasoline Engine

Page 43

Fuel Tank Removal (Fig. 6)

CAUTION

Read safety precautions for handling gasoline

before working on the fuel system (see Safety Instructions in Chapter 1 -- Safety).

1. Remove seat base from the frame (see Seat Base

Removal in the Service and Repairs section of Chapter

7 -- Chassis).

2. Use fuel transfer pump to remove gas from fuel tank.

3. Loosen hose clamp and disconnect fuel hose from

the fuel tank stand pipe.

4. Release tankweb strapping from fuel tank.Do not remove strapping from floor plate and frame cross member. Lift tank from frame.

5. If necessary, remove stand pipe, fuel gauge and

bushings from tank.

Fuel Tank Installation (Fig. 6)

1. If removed, install bushings, stand pipe and fuel

gauge to tank.

2. Position fuel tank to frame. Secure tank to frame and

cross member with tank web strapping.

2

3

1. Shift lever

2. Cap screw (short)

3. Shift plate

1

3

Figure 7

4

5

1

4. Cap screw (long)

5. Choke cable

Single Cylinder

2

Gasoline Engine

3. Connect fuel hose to the tank stand pipe and secure

with hose clamp.

4. Install seat base to the frame (see Seat Base Installation in the Service and Repairs section of Chapter 7 -Chassis).

5. Fill fuel tank.

1. Fuel hose

2. Fuel tank

Figure 8

3. Tank web strapping

Workman MD Single Cylinder Gasoline EnginePage 4 -- 9

Page 44

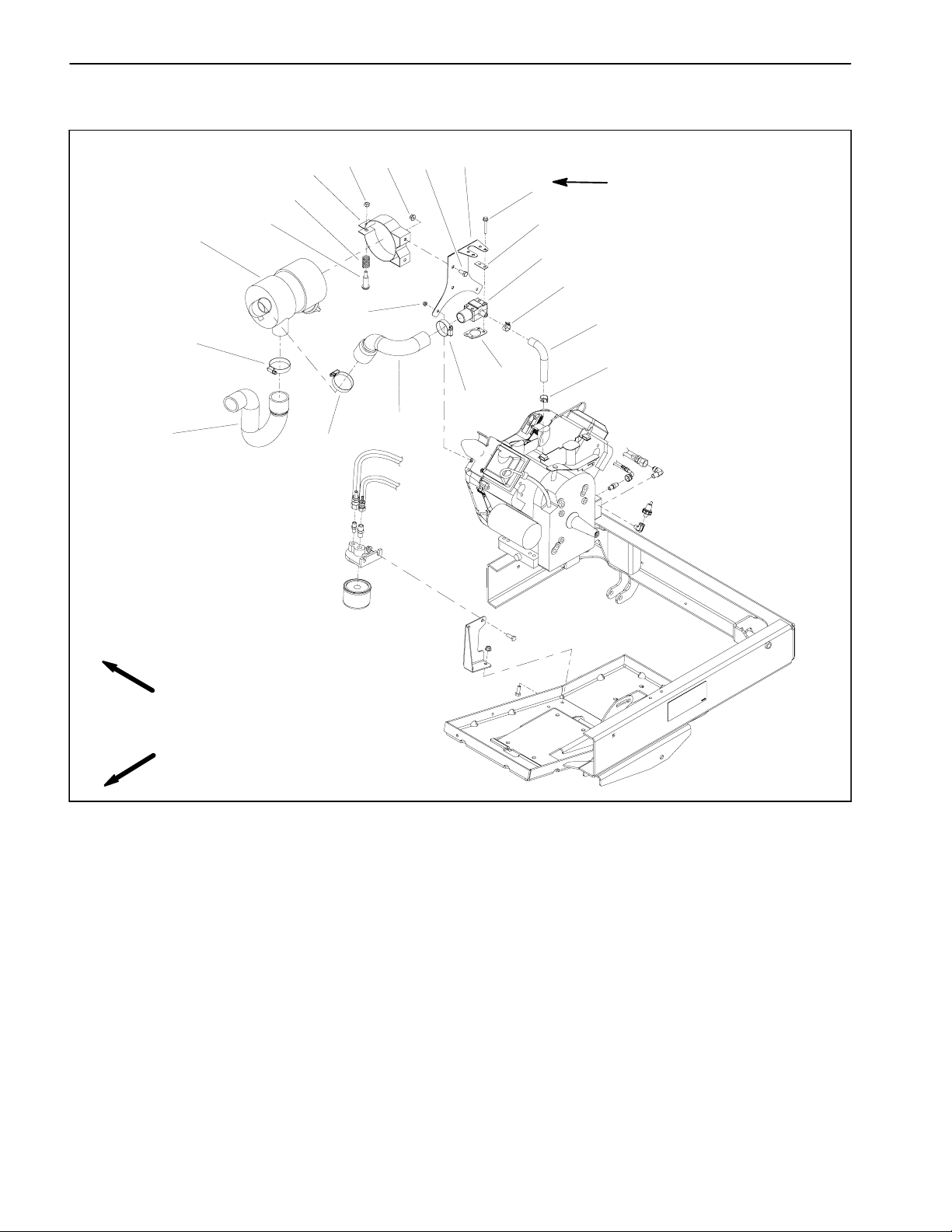

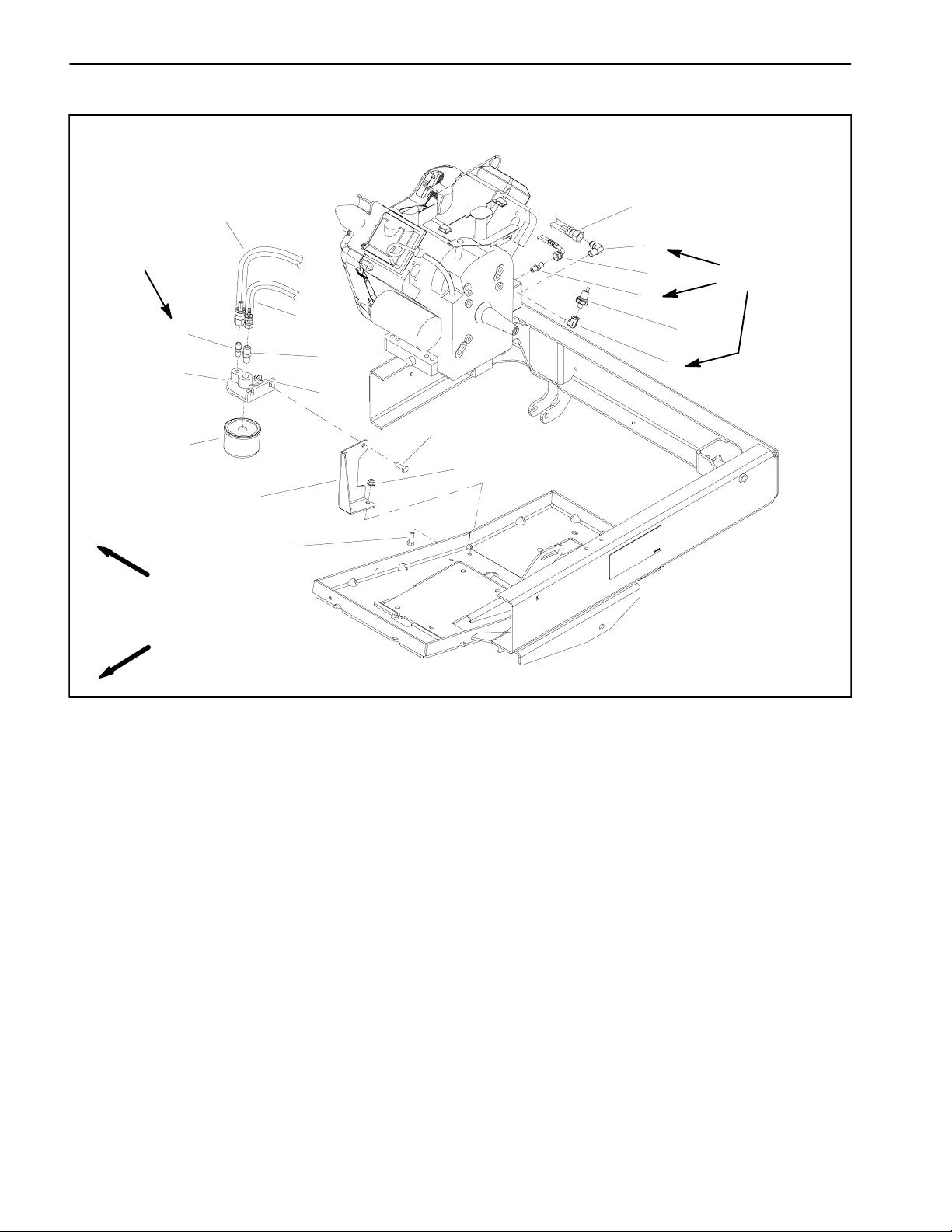

Engine

RIGHT

FRONT

37

48

36

35

52

57

42

40

62

3

4

5

38

52

28

42

40

18

65 to 85 ft-- lb

(88 to 115 N--m)

43

27

Loctite #242

20

17

45

41

16

11

44

55

54

24

27

53

Loctite #242

29

51

8

20

30

15

50

1

22

46

24

49

19

26

39

23

13

25

60

14

58

59

10

21

2

9

25 to 30 ft-- lb

(34to40N--m)

12

32

7

31

Loctite #242

61

47

56

33

24

34

6

1. Kohler engine

2. Coupler spring (4 used)

3. Exhaust manifold

4. Muffler

5. Exhaust coupler

6. Cap screw (2 used)

7. Drive clutch

8. Shift cable (2 used)

9. Starter belt

10. Cap screw

11. Fuel filter

12. Engine pulley spacer

13. Starter/generator

14. Starter pulley

15. Engine pulley

16. Hose clamp (3 used)

17. Fuel hose

18. Fuel hose conduit

19. Air filter mounting band

20. Engine wire harness

21. Engine tray

Figure 9

22. Negative cable

23. Air cleaner bracket

24. Flange nut (7 used)

25. Carriage screw

26. Flange nut (2 used)

27. Hose clamp (2 used)

28. Hose clamp

29. Cap screw (4 used)

30. Lock washer (4 used)

31. Washer

32. Cap screw

33. Mount (2 used)

34. Washer (2 used)

35. Flywheel guard

36. Flat washer (4 used)

37. Flange head screw (4 used)

38. Intake hose

39. Cap screw (2 used)

40. Hose clamp (2 used)

41. Air cleaner assembly

42. Breather hose

43. Intake hose

44. Cap screw (4 used)

45. Fitting

46. Lock nut

47. Lock washer (2 used)

48. R--clamp

49. Cap screw

50. Flat washer

51. R--clamp

52. Cable tie (2 used)

53. Nut

54. Spring

55. Bolt

56. Cap screw (2 used)

57. Governor cable

58. Lock washer

59. Nut

60. Woodruff key

61. Plastic cap

62. Nut (2 used)

Workman MDPage 4 -- 10Single Cylinder Gasoline Engine

Page 45

Engine Removal (Fig. 9)

1. Park machine on a level surface, stop engine, engage parking brake and remove key from the ignition

switch.

2. Disconnect ground (black) cable from the battery.

Then, disconnect positive (red) cable from the battery.

3. Remove cargo box to gain access to the engine (see

Cargo Box and Tailgate Removal in the Service and Repairs section of Chapter 7 -- Chassis).

IMPORTANT: Make sure all hoses and engine openings are plugged after disconnecting. This will prevent contaminants from entering the engine and

fuel system.

9. Remove cap screw (item 49) and flat washer (item

50) that secure r--clamp (item 51) and shift cables (item

8) to engine. Position shift cables away from engine.

10.Disconnect engine electrical harness connector

from the main harness.

11. Remove four (4) flange nuts and cap screws securing the engine to the engine tray.

CAUTION

One person should operate the hoist while a second person guides the engine out of the frame.

4. Disconnect the following components:

A. Choke and governor cables from the carburetor

and cable bracket.

B. Air intake hose (item 38) from the c arburetor.

C. Breather hose (item 42) from the engine valve

cover.

CAUTION

Read safety precautions for handling gasoline

before working on the fuel system (see Safety Instructions in Chapter 1 -- Safety).

5. Disconnect fuel hose from the fuel pump (Fig. 10).

Remove cable tie securing the choke and throttle cables

to the fuel pump bracket.

6. Remove muffler and exhaust coupler (see Muffler

Removal in this section).

7. Remove drive belt from drive clutch.

12.Remove engine from the engine tray.

A. Attach a short section of chain between fuel

pump bracket lift hole and exhaust manifold (Fig.

10).

B. Connect hoist to center of chain.

IMPORTANT: Make sure to not damage the engine, fuel hoses, electrical harness or other parts

while removing the engine.

C. Slowly raise engine and attachments from the

machine.

13.Remove engine parts and attachments as necessary to repair the engine.

2

3

6

4

5

Single Cylinder

Gasoline Engine

8. Loosen fasteners that secure starter/generator. Rotate starter/generator toward engine to loosen tension

on starter belt. Remove belt from the engine and starter/

generator pulleys.

1. Fuel pump bracket

2. Exhaust manifold

3. Fuel line

4. Drive belt

Workman MD Single Cylinder Gasoline EnginePage 4 -- 11

1

7

Figure 10

5. Starter/generator belt

6. Throttle cable

7. Governor cable

Page 46

Engine Installation (Fig. 9)

1. Install all removed engine parts and attachments to

the engine.

6. Install starter belt to the engine and starter/generator

pulleys. Tension the belt by rotating the starter/generator away from the engine. Tighten fasteners to secure

starter/generator.

7. Install drive belt to drive clutch.

CAUTION

One person should operate the hoist while a second person guides the engine into the frame.

2. Install engine to the frame.

A. Attach a short section of chain between fuel

pump bracket lift hole and exhaust manifold (Fig.

10).

B. Connect a hoist at the center of the chain.

IMPORTANT: Make sure to not damage engine,

fuel lines, electrical harness or other parts while

installing the engine.

C. Lower engine onto the engine tray.

3. Install four (4) cap screws and flange nuts to engine

and engine tray. Position engine on engine tray to align

clutch drive pulley and driven pulley on transaxle. Tighten fasteners.

4. Connect engine harness connector to the main electrical harness.

5. Remove cap screw (item 49) and flat washer (item

50) that secure r--clamp (item 51) and shift cables (item

8) to engine. Position r--clamp (item 51) and shift cables

(item 8) to engine. Secure r--clamp to engine with flat

washer (item 50) and cap screw (item 49).

IMPORTANT: Make sure to remove all plugs and

covers that were placed on hose and engine openings during engine removal.

8. Install muffler and exhaust coupler to the exhaust

manifold (see Muffler Installation in this section).

9. Connect fuel hose to the fuel pump (Fig. 10). Make

sure to secure hose with hose clamp.

10.Connect the following components:

A. Choke and throttle cables to the carburetor and

cable bracket.

B. Air intake hose to the carburetor.

C. Breather hose to the engine valve cover.

11. Secure choke and throttle cables to the fuel pump

bracket with cable tie.

12.Install cargo box to the frame (see Cargo Box and

Tailgate Installation in the Service and Repairs section

of Chapter 7 -- Chassis).

13.Connect positive (red) cable to the battery. Then,

connect ground (black) cable to the battery.

14.Make sure engine oil level is correct.

Workman MDPage 4 -- 12Single Cylinder Gasoline Engine

Page 47

Table of Contents

Chapter 5

Drive Train

GENERAL INFORMATION 1.....................

Operator’s Manual 1..........................

SPECIFICATIONS 2.............................

DRIVE TRAIN OPERATION 3....................

Clutch System Operation 3.....................

Drive Clutch Operation 4.......................

Driven Clutch Operation 5......................

SPECIAL TOOLS 6.............................

ADJUSTMENTS 7..............................

Adjust Ground Speed (Workman MD) 7..........

Adjust Ground Speed (Workman MDX) 8.........

Adjust Shift Cables 9..........................

SERVICE AND REPAIRS 10.....................

Drive Clutch 10...............................

Drive Clutch Service (Serial Number

Below 310000000) 12........................

Drive Clutch Service (Serial Number

Above 310000000) 13.3.....................

General Information

Operator’s Manual

Driven Clutch 14..............................

Driven Clutch Service (Serial Number

Below 310000000) 15........................

Driven Clutch Service (Serial Number

Above 310000000) 15.1.....................

Transaxle 16.................................

Removal 16.................................

Installation 18...............................

Transaxle Service 20..........................

Transaxle Disassembly and Inspection 21......

Transaxle Assembly 35.......................

Drive Train

The Operator’s Manual provides information regarding

the operation, general maintenance and maintenance

intervals for your Workman vehicle. Refer to the Operator’s Manual for additional information when servicing

the machine.

Workman MD/MDX Drive TrainPage 5 -- 1

Rev. A

Page 48

Specifications

Item Description

Transaxle

Transaxle Fluid Capacity 1.5 quarts (1.4 liters)

Transaxle Fluid SAE 10W--30 Motor Oil

Clutch System Continuously variable transmission type, torque convertor

Drive Clutch Speed sensing with mechanical fly weights

Driven Clutch Torque sensing with spring loaded cam

Drive Train

Page 5 -- 2

Workman MD/MDX

Page 49

Drive Train Operation

v

Clutch System Operation

3

AB C

6

1

4

7

9

8

5

1. Drive clutch (engine mounted)

2. Driven clutch (transaxle mounted)

3. Moveable sheave (drive clutch)

Power is transferred from the engine to the transaxle by

a variable clutch system that consists of two clutches

connected by a drive belt. The drive clutch responds to

engine speed, and is mounted to the engine drive shaft.

The driven clutch responds to changes inload to the rear

axle, and is mounted to the transaxle input shaft.

4. Fixed sheave (drive clutch)

5. Moveable sheave (driven clutch)

6. Button

Drive Train

2

Figure 1

7. Ramp (fixed cam)

8. Spring

9. Fixed sheave (driven clutch)

The twoclutches work together to automaticallyup--shift

and back--shift as changes in loadand speed occur. This

shifting changes the turning ratio between the drive and

driven clutches and allows the engine to operate at optimum efficiency.

Workman MD/MDX Drive TrainPage 5 -- 3

Rev. A

Page 50

Drive Clutch Operation

The operation of the drive clutch is affected by engine

shaft speed. When the engine is off and not turning, the

drive beltrests low within the drive clutch sheaves asthe

clutch sheaves are spaced apart. As the engine is

started and increases in speed, the clutch weights move

outward as they spin about the engine drive shaft. The

outward movement of the weights against the spider assembly forces the moveable sheave closer to the fixed

sheave. This inward movement of the moveable sheave

engages the drive belt which begins to rotate.

With increasing engine speed, the moveable sheave

continues to move inward. This sheave movement

forces the drive belt to ride towards the outer diameter

of the drive clutch sheaves which increases the drive

belt speed.

When engine speed is decreased, the weights exert

less force on the moveable sheave. The reduced force

causes the moveable sheaveto shift away from thefixed

sheave and slows the drive beltspeed. As engine speed

continues to decrease, the drive belt disengages from

the clutch sheaves.

The drive clutch used on vehicles with serial numbers

below 310000000 (Fig. 2) includes three (3) rollers,

three (3) cam weights and a s pring to control operation

of the moveable sheave.

1

2

6

1. Fixed sheave

2. Moveable sheave

3. Spider assembly

4. Cover

3

4

5

7

Figure 2

5. Spring

6. Cam weight (3 used)

7. Roller (3 used)

The drive clutch used on vehicles with serial numbers

above 310000000 (Fig. 3) controls moveable sheave

operation with six (6) weighted rollers and ramp surfaces in the moveable sheave.

1

1. Fixed sheave

2. Moveable sheave

3. Spider assembly

2

Figure 3

5

4

3

4. Cover

5. Roller (6 used)

Drive Train

Page 5 -- 4

Rev. A

Workman MD/MDX

Page 51

Driven Clutch Operation

The operation of the driven clutch is affected by transaxle load. When the vehicle is stopped, the drive belt is

held at the outer diameter of the driven clutch sheaves

from the pressure of the spring pushing the moveable

sheave against the fixed sheave and away from the

fixed cam.

Once the drive belt starts rotating, the driven clutch also

starts to rotate. With increasing speed of the drive

clutch, the drive belt begins to climb to the outer diameter of the drive clutch sheaves. This increases the tension on the drive belt, and forces the moveable sheave

of the driven clutch to move away from the fixed sheave

against the pressure of the spring. As the belt tightens

and thesheaves open up, the drive belt rides lowerin the

driven clutch sheaves.

With increased load to the transaxle, the fixed c am resists forward movement relative to the moveable

sheave and drive belt. Torque from the drive belt and

spring pressure moves the moveable sheave up the

ramp of the fixed cam. The drive belt becomes positioned closer to the outer diameter of the driven clutch

sheaves.

4

1. Moveable sheave

2. Ramp (fixed cam)

3. Button

1

5

2

3

Figure 4

4. Fixed sheave

5. Spring

On vehicles with a serial number below 310000000,

three (3) sets of buttons on the driven clutch moveable

sheave provide a lowfriction surface on which the moveable sheave can slide on the ramp of the fixed cam (Fig.

4).

On vehicles with a serial number above 310000000, a

fixed cam on the driven clutch moveable sheave rotates

on a pair of rollers in the fixed sheave base to allow low

friction movement of the moveable sheave (Fig. 5).

2

1. Moveable sheave

2. Fixed sheave

3

Drive Train

1

Figure 5

3. Spring

Workman MD/MDX Drive TrainPage 5 -- 5

Rev. A

Page 52

Special Tools

Order special tools from your Toro Distributor.

Drive Clutch Removal Tool (Serial Number Below 310000000)

This tool is required to remove the drive clutch from the

tapered drive shaft of the engine. It is placed in the

threaded hole of the fixed clutch sheave after the clutch

holding cap screw is removed.

Toro Part Number: TOR4094

NOTE: Vehicles witha serial number below 310000000

are equipped with a Comet brand drive clutch.

Figure 6

Drive Clutch Spider Removal Tool Kit (Serial Number Below 310000000)

This kitis required to remove the drive c lutch spider from

the post of the fixed sheave. Kit includes spanner and

clutch holding bar.

Toro Part Number: TOR4098

NOTE: Vehicles witha serial number below 310000000

are equipped with a Comet brand drive clutch.

1

2

1. Holding bar 2. Spanner

Clutch Dry Lubricant (Serial Number Below 310000000)

This lubricant should be used to properly lubricate drive

clutch components on vehicles with serial numbers below 310000000.

Toro Part Number: 104--7011

4

2

3

1

Figure 7

NOTE: Vehicles witha serial number below 310000000

are equipped with a Comet brand drive clutch.

Drive Train

Page 5 -- 6

Rev. A

Figure 8

Workman MD/MDX

Page 53

Drive Clutch Removal Tool (Serial Number Above 310000000)

This tool is required to remove the drive clutch from the

tapered drive shaft of the engine. It is placed in the

threaded hole of the fixed clutch sheave after the clutch

holding cap screw is removed.

Toro Part Number: TOR6013

NOTE: Vehicles with a serial number above

310000000 are equipped with a TEAM brand drive

clutch.

Figure 8.1

Drive Clutch Spider Removal Tool Kit (Serial Number Above 310000000)

This kitis required to remove the drive clutch spider from

the post of the fixed sheave. Kit includes spanner and

clutch holding bar.

Toro Part Number: TOR6016

NOTE: Vehicles with a serial number above

310000000 are equipped with a TEAM brand drive

clutch.

2

Figure 8.2

1. Holding bar 2. Spanner

1

Drive Train

Workman MD/MDX Drive Train

Page 5 --

Rev. A6.1

Page 54

This page is intentionally blank.

Rev. A6.2

Workman MD/MDXDrive Train Page 5 --

Page 55

Adjustments

Adjust Ground Speed (Workman MD)

Workman MD models are equipped with a transaxle

governor. Adjust ground speed using the following procedure.

WARNING

Vehiclesoperating at ground speeds greater than

the recommended speed will require further

distances to fully stop. Do not adjust ground

speed greater than specified.

1. Park machine on a level surface, stop engine and remove key from the ignition switch. Raise and support

cargo box.

WARNING

Before jacking up the machine, review and follow

Jacking Instructions in Chapter 1 -- Safety.

7. Adjust throttle cable (accelerator pedal to transaxle)

at the cable bracket until the correct driven clutch RPM

is obtained with the accelerator pedal fully to the floor

(Fig. 8).

8. Install anti--tamper bracketto the cable bracket using

a new anodized rivet (Toro P/N 99--7122) (Fig. 8).

9. Lower machine to ground. Lower and secure cargo

box.

NOTE: If unable to identifythe driven clutch RPM, analternate method to verify ground speed would be to determine the distance that the vehicle will travel on level

ground in three (3) seconds with the accelerator pedal

to thefloor. The Workman MD should travel 62 feet (18.8

meters) in three seconds. If necessary, adjust ground

speed using steps 6 through 8 above.

1

4

2. Jack up rear of vehicle so both rear wheels are at

least 1 inch (25mm) off the ground. Support the rear axle

tubes on appropriate jack stands.

3. Chock front and rear of both front tires to prevent the

vehicle from moving.

4. Make sure that the shift lever is in the neutral position.

5. Verify ground speed as follows:

A. Start engine and hold accelerator pedal to the

floor.

B. Verify driven clutch RPM with a tachometer. With

the accelerator pedal to the floor, the driven clutch

speed should be from 3550 to 3650 RPM.

6. If ground speed adjustment is necessary, drill out anodized rivet and retain anti--tamper bracket for reinstallation (Fig. 8).

2

1. Anodized rivet

2. Anti--tamper bracket

Figure 8

3. Throttle cable

4. Cable bracket

3

Drive Train

Workman MD/MDX Drive TrainPage 5 -- 7

Page 56

Adjust Ground Speed (Workman MDX)

Workman MDX models use an engine governor for

speed control. Adjust ground speed using the following

procedure.

WARNING

Vehiclesoperating at ground speeds greater than

the recommended speed will require further

distances to fully stop. Do not adjust ground

speed greater than specified.

1. Park machine on a level surface, stop engine, set