Toro Outcross 9060, 07511BA, 07511CA, 07511AA, 07511DA Service Manual

Outcross9060

Models07511AA/BA/CA/DA

FormNo.18234SLRevB

©2018—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

OriginalInstructions(EN)

Contactusatwww.Toro.com.

AllRightsReserved

RevisionHistory

RevisionDateDescription

A

B

10/2018

InitialRelease

RevisionHistoryPage2

Outcross9060

18234SLRevB

ReaderComments

TheT oroCompanyT echnicalAssistanceCentermaintainsacontinuous

efforttoimprovethequalityandusefulnessofitspublications.T odothis

effectively,weencourageuserfeedback.Pleasecommentonthecompleteness,

accuracy,organization,usability,andreadabilityofthismanualbyane-mail

toservicemanuals@toro.com

orMailto:

TechnicalPublicationManager,Commercial

TheT oroCompany

8111LyndaleAvenueSouth

Bloomington,MN55420-1196

Phone:+1952-887-8495

Outcross9060

18234SLRevB

Page3

ReaderComments

ReaderComments

Page4

Outcross9060

18234SLRevB

Preface

Thepurposeofthispublicationistoprovidetheservicetechnicianwith

informationfortroubleshooting,testing,andrepairingthemajorsystemsand

componentsoftheOutcross9060tractionunit(ModelNo.07511AA,07511BA,

07511CA,and07511DA).

RefertothetractionunitOperator’sManualandaccessoryInstallation

Instructionsforinstallation,operation,maintenance,andadjustmentinformation.

KeepacopyoftheOperator’sManuals,accessoryInstallationInstructionsand

PartsCatalogsforyourmachineanditsaccessorieswiththisServiceManualfor

reference.AdditionalcopiesoftheOperator’sManuals,InstallationInstructions,

PartsCatalogsandthisServiceManualareavailableatwww.toro.com

TheToroCompanyreservestherighttochangetheproductspecicationsor

thispublicationwithoutnotice.

DANGER

Thissafetysymbolmeansdanger.Whenyouseethissymbol,

carefullyreadtheinstructionsthatfollow.Failuretoobeythe

instructionscouldkillorcauseseriouspermanentinjuryordisability .

.

WARNING

Thissafetysymbolmeanswarning.Whenyouseethissymbol,

carefullyreadtheinstructionsthatfollow.Failuretoobeythe

instructionscanresultinseriousinjury.

CAUTION

Thissafetysymbolmeanscaution.Whenyouseethissymbol,

carefullyreadtheinstructionsthatfollow.Failuretoobeythe

instructionscanresultinminortomoderateinjury.

IMPORTANT

TheImportantnoticewillgivetheimportantinstructionswhichyou

mustfollowtopreventdamagetothesystemsorcomponentson

themachine.

Outcross9060

18234SLRevB

Note:ANotewillprovideadditionalinformationaboutthecorrectoperation,

maintenance,service,testing,orrepairofthemachine.

Page5

Preface

ServiceProcedureIcons

ThefollowingiconsappearthroughoutthisServiceManualtobringattentionto

specicimportantdetailsofaserviceprocedure.

CriticalProcess

Thisiconisusedtohighlight:

•installingsafetyequipment(shields,guards,seatbelts,brakesandR.O.P .S.

components)thatmayhavebeenremoved

•dimensionsorsettingsthatmustbemaintainedforpropermachineoperation

•aspecicfastenertighteningsequence

•componentorientationthatmaynotbeobvious

CriticalTorque

Thisiconisusedtohighlightanassemblytorquerequirementthatisdifferentthan

whatisrecommendedintheStandardT orqueTables;refertoStandardTorque

forDry,ZincPlated,andSteelFasteners(InchSeries)(page2–9)orStandard

TorqueforDry,ZincPlated,andSteelFasteners(MetricFasteners)(page2–10).

FluidSpecications

Thisiconisusedtohighlightuidspecicationsandcapacitiesthatareless

common,andmaynotappearonthemachineservicedecalorinthemachine

Operator’sManualoraccessoryInstallationInstructions.

Note:RefertotheservicedecalsonthemachineandthemachineOperator’s

ManualandaccessoryInstallationInstructionsforcommonlyuseduid

specicationsandcapacities.

Preface

Page6

Outcross9060

18234SLRevB

TableofContents

Preface................................................................................................................5

Chapter1:Safety............................................................................................1–1

SafetyInstructions.......................................................................................1–2

JackingInstructions.....................................................................................1–8

SafetyandInstructionalDecals....................................................................1–9

Chapter2:SpecicationsandMaintenance....................................................2–1

Specications...............................................................................................2–2

TorqueSpecications...................................................................................2–6

ShopSupplies............................................................................................2–12

SpecialT ools..............................................................................................2–14

Chapter3:Troubleshooting.............................................................................3–1

GEARS–TheSystematicApproachtoDening,DiagnosingandSolving

Problems......................................................................................................3–2

OperatorAdvisories......................................................................................3–3

MachineandEngineFaults...........................................................................3–6

UsingtheInfoCenterDisplayforTroubleshooting.......................................3–23

GeneralHydraulicSystemProblems..........................................................3–26

TractionSystemProblems..........................................................................3–27

SteeringSystemProblems.........................................................................3–30

PTOSystemProblems................................................................................3–31

3-PointHitchSystemProblems...................................................................3–32

Attachment/LoaderProblems.....................................................................3–33

Chapter4:Engine...........................................................................................4–1

GeneralInformation.....................................................................................4–2

ServiceandRepairs.....................................................................................4–8

Chapter5:HydraulicSystem...........................................................................5–1

GeneralInformation.....................................................................................5–3

HydraulicSchematic...................................................................................5–13

HydraulicFlowDiagrams............................................................................5–14

TestingtheHydraulicSystem......................................................................5–34

Adjustments...............................................................................................5–48

ServiceandRepairs...................................................................................5–49

Chapter6:ElectricalSystem...........................................................................6–1

GeneralInformation.....................................................................................6–3

ElectricalDrawings.....................................................................................6–12

ElectricalSystemQuickChecks..................................................................6–13

ElectricalComponentT esting.....................................................................6–14

ServiceandRepairs...................................................................................6–77

Chapter7:TractionandPTODrive..................................................................7–1

GeneralInformation.....................................................................................7–2

Adjustments.................................................................................................7–3

ServiceandRepairs.....................................................................................7–5

Chapter8:Chassis..........................................................................................8–1

GeneralInformation.....................................................................................8–2

ServiceandRepairs.....................................................................................8–3

Chapter9:OperatorCab.................................................................................9–1

GeneralInformation.....................................................................................9–2

Adjustments.................................................................................................9–5

ServiceandRepairs.....................................................................................9–7

AppendixA......................................................................................................A–1

ElectricalDrawingDesignations....................................................................A–2

HydraulicSchematic.....................................................................................A–3

ElectricalSchematic(part1of3)...................................................................A–4

ElectricalSchematic(part2of3)...................................................................A–5

ElectricalSchematic(part3of3)...................................................................A–6

WireHarnessDrawing–Frame....................................................................A–7

Outcross9060

18234SLRevB

Page7

Preface

AdditionalReferenceMaterials

WireHarnessDiagram–Frame....................................................................A–8

WireHarnessDrawing–Platform.................................................................A–9

WireHarnessDiagram–Platform...............................................................A–10

WireHarnessDiagram–Platform(continued)............................................A–11

WireHarnessDrawing–Engine.................................................................A–12

WireHarnessDiagram–Engine.................................................................A–13

WireHarness–Headlights.........................................................................A–14

WireHarness–CabRooftop......................................................................A–15

WireHarness–CabControlPanel..............................................................A–16

WireHarness–CabHeat/AirConditioning..................................................A–17

WireHarness–InchMode(optional)...........................................................A–18

WireHarness–LoaderSelectorControlV alve(SCV)Switch

(optional).....................................................................................................A–19

WireHarness–LoaderSelectorControlValve(SCV)Valve

(optional).....................................................................................................A–20

WireHarness–RearSelectorControlValve(SCV)Kit(optional)................A–21

WireHarness–CabWorkLightKit(optional)..............................................A–22

WireHarness–DomesticRoadLightKit(optional).....................................A–23

WireHarness–TurnSignal/HazardLights(optional)..................................A–24

WireHarness–InternationalRoadLightKit(optional)................................A–25

YanmarTNV(Tier4)SeriesServiceManual

YanmarTNV(Tier4)SeriesTroubleshootingManual

DanfossH1ClosedCircuitAxialPistonPumpsServiceManual

DanfossH1ClosedCircuitAxialPistonPumpsRepairInstructions

DanfossKandLFrameVariableMotorsServiceManual

DanfossSteeringUnitTypeOSPB,OSPCandOSPFServiceManual

Gresen/ParkerHydraulicsModelV10SectionalBodyDirectionalControlValve

ServiceManual

CarraroDriveTechModel26.09MAxleRepairManual

SandenSDCompressorServiceGuide

Preface

Page8

Outcross9060

18234SLRevB

Chapter1

Safety

TableofContents

SafetyInstructions................................................................................................................................1–2

Supervisor’sResponsibilities.............................................................................................................1–2

BeforeOperatingtheMachine...........................................................................................................1–3

OperatingtheMachine.......................................................................................................................1–4

MaintenanceandService...................................................................................................................1–6

JackingInstructions..............................................................................................................................1–8

RaisingtheFrontoftheMachine........................................................................................................1–8

RaisingtheRearoftheMachine........................................................................................................1–9

SafetyandInstructionalDecals............................................................................................................1–9

Outcross9060

18234SLRevB

Page1–1

Safety

SafetyInstructions

TheOutcross9060machineistestedandcertiedbyT oroforcompliance

withexistingsafetystandardsandspecications.Althoughhazardcontroland

accidentpreventionarepartiallydependentuponthedesignandcongurationof

themachine,hazardcontrolandaccidentpreventionarealsodependentupon

theawareness,concernandpropertrainingofthepersonnelinvolvedinthe

operation,transport,maintenanceandstorageofthemachine.Improperuseor

maintenanceofthemachinecanresultininjuryordeath.T oreducethepotential

forinjuryordeath,complywiththefollowingsafetyinstructions.

WARNING

Toreducethepotentialofinjuryordeath,complywiththefollowing

safetyinstructionsaswellasinformationfoundinthetractionunit

Operator’sManual,accessoryInstallationInstructions,andthe

OperatorandSafetyTrainingVideosfoundonwww.toro.com

Supervisor’sResponsibilities

1.Ensurethatthemachineoperatorsarefullytrainedandfamiliarwiththe

tractionunitOperator’sManual,alloftheoperatingandsafetydecalsonthe

machine,andanyoperationinformationfoundintheInstallationInstructions

foraccessoriesthatareinstalledonthemachine.

.

2.Establishyourownspecialproceduresandworkrulesforunusualoperating

conditions(e.g.,slopestoosteepformachineoperation).Surveythework

sitecompletelytodeterminehillsonwhichyoucanoperatesafely.When

performingthissitesurvey ,alwaysunderstandandtakeintoconsideration

theturfconditionandrolloverrisk.

Safety:SafetyInstructions

Page1–2

Outcross9060

18234SLRevB

BeforeOperatingtheMachine

•ReviewandunderstandthecontentsofthetractionunitOperator’sManual,

alloftheoperatingandsafetydecalsonthemachine,andanyoperation

informationfoundintheInstallationInstructionsforaccessoriesthatare

installedonthemachine.AdditionalcopiesofthetractionunitOperator’s

ManualandaccessoryInstallationInstructionsareavailableatwww.toro.com.

•ViewandunderstandtheOperatorandSafetyTrainingVideosfoundat

www.toro.com

.

•Neverallowchildrentooperatethemachine.Neverallowadultstooperate

themachinewithoutproperinstructions.

•Becomefamiliarwiththecontrolsandknowhowtostopthemachineand

enginequickly.

•Keepalltheshields,safetydevices,anddecalsinplace.Ifashield,safety

device,ordecalisillegibleordamaged,repairorreplaceitbeforeoperating

themachine.

•Alwayswearsubstantialshoes.Donotoperatemachinewhilewearing

sandals,tennisshoesorsneakers.Donotwearloosettingclothingwhich

couldgetcaughtinmovingpartsandcausepersonalinjury.

•Wearingsafetyglasses,safetyshoes,longpantsandahelmetisadvisable

andrequiredbysomelocalsafetyandinsuranceregulations.

•Makesureworkareaisclearofobjectswhichmightbepickedupandthrown

bytheattachments.

•Keepeveryone,especiallychildrenandpets,awayfromtheareaofoperation.

•Ensurethesafetyinterlocksarefunctioningproperly.Adjustorreplace

anymalfunctioningswitchesorinterlockmechanismsbeforeoperatingthe

machine.RefertoCheckingtheOperationoftheInterlockSwitches(page

6–13)foradditionalinformation.

•Dieselfuelishighlyammable;handleitcarefully.

–Storefuelincontainersspecicallydesignedforstoringfuel.

–Donotremovethefueltankcapofthemachinewhiletheengineishot

orrunning.

–Donotsmokewhilehandlingfuel.

–Fillthefueltankoutdoorsandonlytoalevelwithinaninchofthetopof

thetank,notthellerneck.Donotoverllthefueltank.

–Replacethefueltankandfuelcontainercapssecurelyafterrefuelling

themachine.

–Ifyouspillfuel,donotattempttostarttheenginebutmovethemachine

awayfromthespill.Avoidcreatinganysourceofignitionuntilfuelvapors

havedissipated.Wipeupanyspilledfuel.

Outcross9060

18234SLRevB

Page1–3

Safety:SafetyInstructions

OperatingtheMachine

DANGER

Theexhaustfumesarehazardousandhavethepotentialofcausing

injuryordeath.

Donotruntheengineinaconnedareawithoutadequateventilation.

Note:OperatoradvisoriesareautomaticallydisplayedbytheInfoCenterwhen

amachinefunctionispreventedandadditionalactionisrequired.Typically,an

advisorycanbeeliminatedwithachangeinmachinecontrolsbytheoperator.

RefertoOperatorAdvisories(page3–3)foradditionalinformation.

1.Sitontheoperatorseatwhenstartingthemachine.

2.Tostarttheengine:

A.DisengagethePTO(switchindownposition)

B.MovethetransmissionshiftlevertotheNEUTRALposition.

C.Ensurethattheauxiliaryhydraulicleverisinthecenterposition.

D.SettheignitionkeytotheRUNposition.

E.Engagetheparkingbrake(switchilluminated).

F.Keepyourfootofftheacceleratorpedal.

G.TurntheignitionkeytotheSTARTpositionandholduntiltheenginestarts

(nolongerthan20seconds).

3.Usingthemachinedemandsoperatorattention.T opreventlossofmachine

control:

A.Operatemachineattachmentsonlyindaylightorwhenthereisgood

articiallight.

B.Watchforholesorotherhiddenhazards.

C.Donotdriveclosetosandtraps,ditches,creeksorotherhazards.

D.Traverseslopescarefully .Donotstartorstopsuddenlywhentraveling

uphillordownhill.

E.Reducespeedwhenmakingsharpturns.Avoidsuddenstopsandstarts.

F.Beforebackingup,looktothereartobesurenooneisbehindthe

machine.

G.Watchoutfortrafcwhennearorcrossingroads.Alwaysyieldthe

right-of-way.

H.Depressthedeceleratorpedalwhengoingdownhilltokeepforward

speedslowandtomaintaincontrolofthemachine.

4.Keephands,feetandclothingawayfrommovingpartsandthedischarge

areaofanattachment.

5.Raisetheattachmentswhendrivingfromoneworkareatoanother.

6.Donottouchtheengine,muferorexhaustpipewhiletheengineisrunning

orsoonafteritisstoppedbecausetheseareascouldbehotenoughto

causeburns.

7.Ifanattachmentstrikesasolidobjectorvibratesabnormally ,stop

immediately,turntheengineoff,waitforallmotiontostopandinspectfor

damage.Adamagedattachmentmustberepairedorreplacedbefore

operationiscontinued.

8.DON’TTAKEANINJURYRISK!Whenapersonorpetappears

unexpectedlyinorneartheareawhileoperatinganattachment,STOP.

Safety:SafetyInstructions

Page1–4

Outcross9060

18234SLRevB

OperatingtheMachine(continued)

Carelessoperation,combinedwithterrainangles,ricochetsorimproperly

positionedguardscanleadtothrownobjectinjuries.Donotresume

operationuntiltheareaiscleared.

9.Beforegettingofftheseat:

A.Makesureanyattachmentsaredisengaged.

IMPORTANT

Whenanattachmentisloweredtotheground,thepressurein

thehydraulicliftcircuitisreleasedandaccidentallyloweringthe

attachmentisavoided.

B.Loweranyattachmentstotheground.

C.Settheparkingbrakeiftheenginewillbeleftrunning,or,stoptheengine

andremovethekeyfromkeyswitch.

10.WhenusingtheoptionalInchModefeature:

A.Keepbystandersawayfromthemachine.

B.UsetheInchModefeatureonlyonalevelsurface.

C.Whilemovingthemachine,donotstandinfrontoforbehindthemachine.

Outcross9060

18234SLRevB

Page1–5

Safety:SafetyInstructions

MaintenanceandService

Themaintenanceproceduresandrecommendedserviceintervalsforyour

machinearecoveredinthetractionunitOperator’sManualandaccessory

InstallationInstructions.Refertothispublicationwhenperformingregular

equipmentmaintenance.Severalmaintenanceprocedureshavebreak-in

intervalsidentiedinthetractionunitOperator’sManualandaccessory

InstallationInstructions.RefertotheEngineOperator’sManualforadditional

enginespecicmaintenanceprocedures.

•Beforeservicingormakinganyadjustmentstothemachine,lowerany

attachments,shutofftheengine,andremovethekeyfromthekeyswitch.

•Ensurethatthemachineisinsafeoperatingconditionbykeepingallthe

nuts,bolts,andscrewstight.

•Ensurethatallofthehydrauliclineconnectorsaretightandthatallthe

hydraulichosesandlinesareingoodconditionbeforeapplyingpressureto

thehydraulicsystem.

•Useeyeprotectionwhenworkingonthehydraulicsystemandits

components.

•Keepyourbodyandhandsawayfrompin-holeleaksinthehydrauliclines

thatejecthydraulicuidunderhighpressure.Usecardboardorpapertond

hydraulicleaks.Thehydraulicuidescapingunderpressurecanpenetrate

theskinandcauseinjury.Ifhydraulicuidisaccidentallyinjectedintothe

skin,youmusthaveitsurgicallyremovedwithinafewhoursbyadoctor

familiarwiththistypeofinjury .Otherwise,gangrenemayresult.

•Beforedisconnectingorperforminganyworkonthehydraulicsystem,

releaseallthepressureinthesystembyparkingthemachineonalevel

surface,loweringthecuttingdeck(orimplement)completely ,andthen

shuttingofftheengine.

•Toreducepotentialrehazards,keeptheengineareafreeofexcessive

grease,grass,leaves,anddirt.Cleantheprotectivescreenonthemachine

frequently.

•Checkallfuellinesfortightnessandwearonaregularbasis.Tightenor

repairfuellinesasneeded.

•Ifyoumustruntheenginetoperformmaintenanceortomakeanadjustment,

keepyourhands,feet,clothing,andotherpartsofthebodyawayfromany

attachmentsandothermovingparts.Keepbystandersaway.

•Shutofftheenginebeforecheckingoraddingoiltotheenginecrankcase.

•Disconnectthebatterybeforeservicingthemachine.Disconnectthenegative

batterycableandthenthepositivecable.Ifbatteryvoltageisnecessaryfor

troubleshootingortestprocedures,temporarilyconnectthebattery.Connect

thepositivebatterycableandthenthenegativecable.

•Batteryacidispoisonousandcancauseburns.Avoidacidcontactwithskin,

eyes,andclothing.Protectyourface,eyes,andclothingwhenworkingwitha

battery.

•Batterygasescanexplode.Keepcigarettes,sparks,andamesawayfrom

thebattery.

•Ifitisnecessarytoliftthemachinetoperformaserviceprocedure;refer

toJackingInstructions(page1–8).

•Beforeperforminganyweldingonthemachine,turnthekeyswitchto

theOFFposition.T opreventdamagetothemachineelectricalsystem,

disconnecttheground(-)cabletotheframewhenweldingontheframe,or

disconnecttheground(-)cabletotheoperatorplatformwhenweldingon

theoperatorplatform.

•Ifmajorrepairsarenecessary ,contactyourAuthorizedT oroDistributor.

Safety:SafetyInstructions

Page1–6

Outcross9060

18234SLRevB

MaintenanceandService(continued)

•Ensuretodisposeofpotentiallyharmfulwaste(e.g.,fuel,oil,enginecoolant,

lters,battery)inanenvironmentallysafemanner.Followalllocalcodesand

regulationswhenrecyclingordisposingofwaste.

•Atthetimeofmanufacture,themachineconformedtoMachineryDirective

2006/42/EC,ElectromagneticCompatibility(EMC)Directive2014/30/EU,

andISOstandardsforpower,mass,vibration,andsound.T oensurethe

optimumperformanceandcontinuedsafetycerticationofthemachine,use

genuineT ororeplacementpartsandaccessories.Thereplacementpartsand

accessoriesofothermanufacturerscanresultinnon-conformancewiththe

safetystandardsandcanvoidthewarranty.

Outcross9060

18234SLRevB

Page1–7

Safety:SafetyInstructions

JackingInstructions

CAUTION

Failingtoproperlysupportthemachinewithappropriatejackstands

cancausethemachinetomoveorfallandcanresultinpersonal

injury.

Approximateweights:

•Basemodel=2,340kg(5,160lbs)

•Cabmodel=2,640kg(5,820lbs)

Whenchangingtheattachments,tires,orperformingotherservice:

•Beforeyouliftthemachine,removealltheattachmentsthatmay

interferewiththesafeandcorrectliftofthemachine.Removethe

frontloaderattachmentandcounterweightifequipped.

•Parkthemachineonasolidlevelsurface,suchasaconcrete

oor.

•Alwaysblockthewheelswithchocks.

•Usethecorrectblocks,hoists,andjackstoliftthemachine.

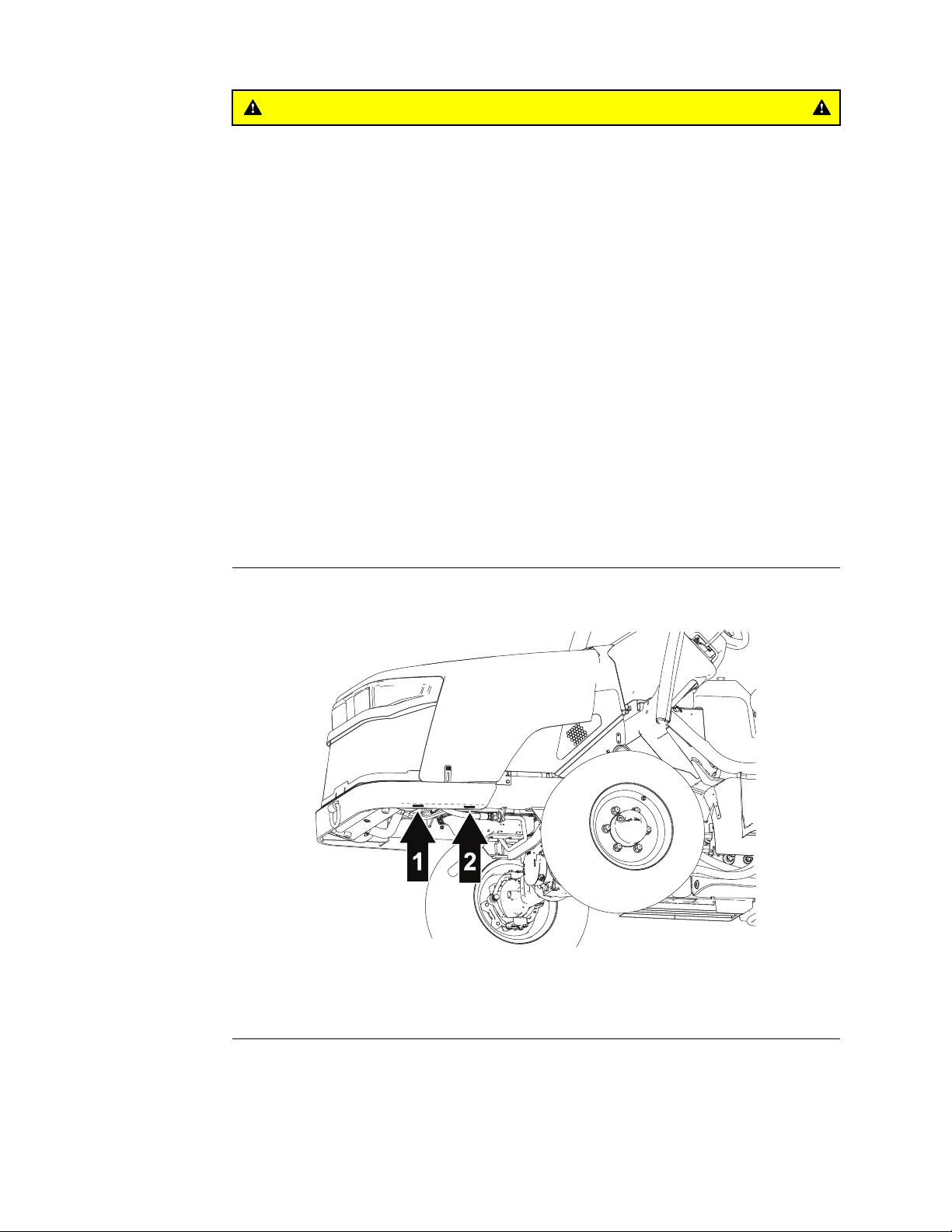

RaisingtheFrontoftheMachine

•Usetheappropriatejackstandstosupporttheraisedmachine.

•DoNotuseanattachmentasajackingpoint.

g232342

Figure1

Safety:JackingInstructions

1.Frontjackpoint(framechannelbehind

sideplate)

1.Blockthe2rearwheelswithchockstopreventthemachinefrommoving.

2.Positionthejacksecurelyunderthedesiredfrontjackingpoint.

3.Afterraisingthefrontofthemachine,useanappropriatejackstandunder

thevehicleframetosupportthemachine.

Page1–8

2.Frontjackstandpoint(framechannel

behindsideplate)

Outcross9060

18234SLRevB

RaisingtheRearoftheMachine

g232344

Figure2

1.Rearjackpoint

1.Blockthe2frontwheelswithchockstopreventthemachinefrommoving.

2.Positionthejacksecurelyunderthedesiredrearjackingpoint.

3.Afterraisingtherearofthemachine,useanappropriatejackstandunderthe

vehicleframetosupportthemachine.

SafetyandInstructionalDecals

Numeroussafetyandinstructiondecalsareafxedtothetractionunitand

attachmentsofyourOutcross9060machine.Ifanydecalbecomesillegible

ordamaged,installanewdecal.DecalpartnumbersarelistedintheParts

Catalog,tractionunitOperator’sManual,andaccessoryInstallationInstructions.

OrderreplacementdecalsfromanAuthorizedT oroDistributor.

2.Rearjackstandpoint(framechannel)

Outcross9060

18234SLRevB

Page1–9

Safety:SafetyandInstructionalDecals

Safety:SafetyandInstructionalDecals

Page1–10

Outcross9060

18234SLRevB

Chapter2

SpecicationsandMaintenance

TableofContents

Specications.......................................................................................................................................2–2

OverallDimensions............................................................................................................................2–2

TractionUnit.......................................................................................................................................2–3

Engine................................................................................................................................................2–3

HydraulicSystem...............................................................................................................................2–4

TractionandPTODrive......................................................................................................................2–4

Chassis..............................................................................................................................................2–5

TorqueSpecications...........................................................................................................................2–6

CalculatingtheT orqueV aluesWhenUsingaDrive-AdapterWrench.................................................2–7

IdentifyingtheFastener......................................................................................................................2–8

StandardT orqueforDry ,ZincPlated,andSteelFasteners(InchSeries)............................................2–9

StandardT orqueforDry,ZincPlated,andSteelFasteners(MetricFasteners).................................2–10

OtherT orqueSpecications.............................................................................................................2–11

ConversionFactors..........................................................................................................................2–11

ShopSupplies....................................................................................................................................2–12

SpecialT ools......................................................................................................................................2–14

Outcross9060

18234SLRevB

Page2–1

SpecicationsandMaintenance

Specications

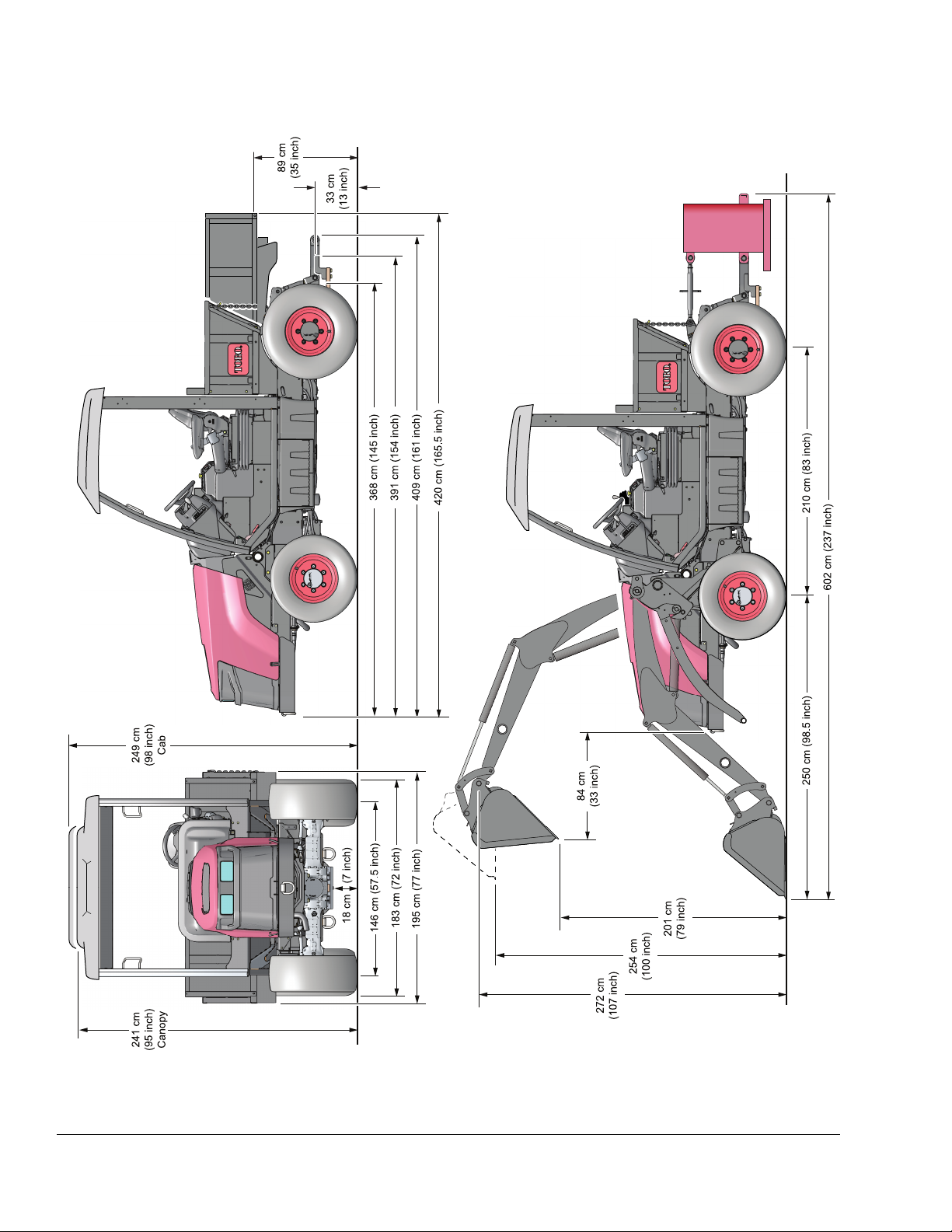

OverallDimensions

g231580

SpecicationsandMaintenance:Specications

Figure3

Outcross9060

Page2–2

Outcross9060

18234SLRevB

TractionUnit

Engine

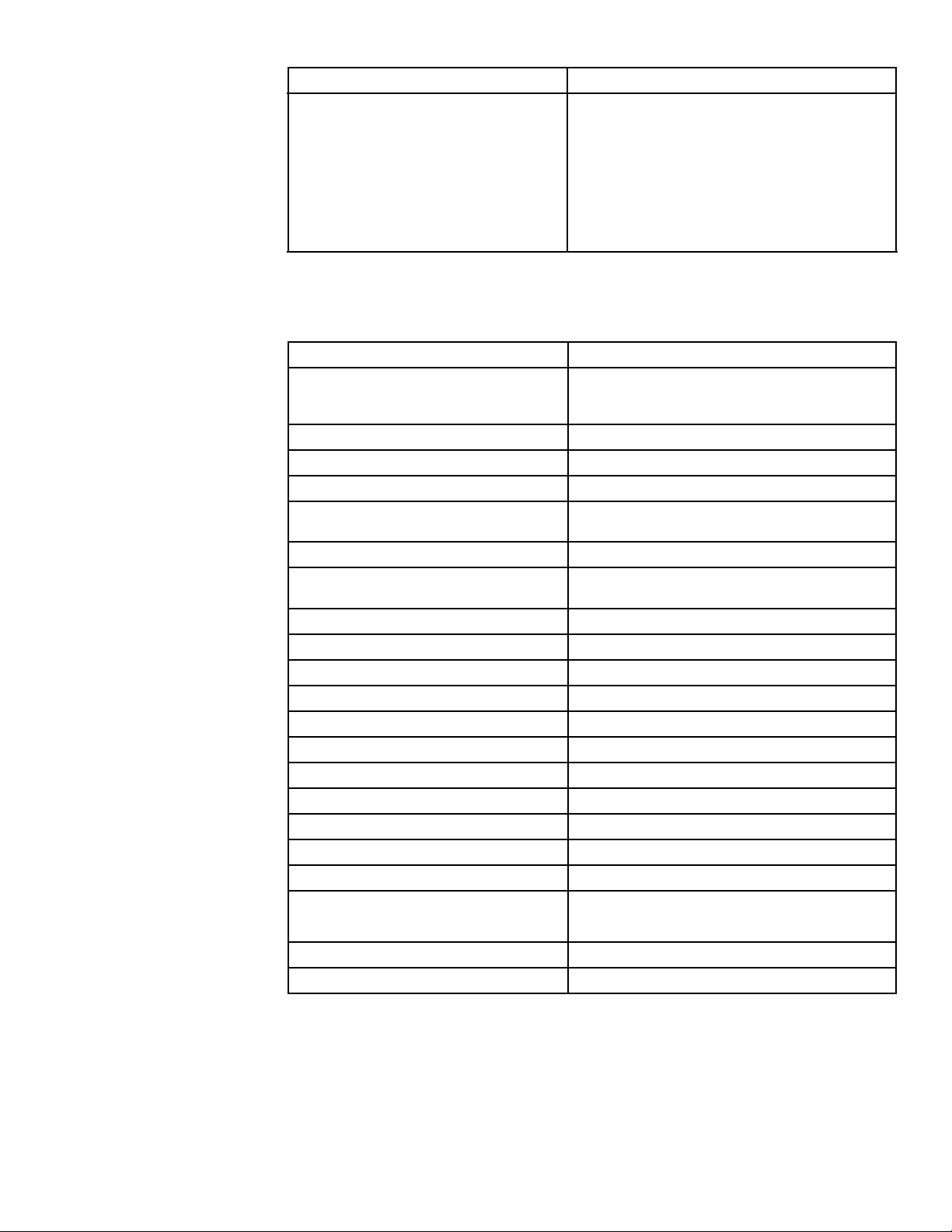

ItemDescription

Weight

Model0751 1AA(basemodel)2,340kg(5,160lb)

Model07511BA(basemodelwith

frontloader*)

Model0751 1CA(cabmodel)2,640kg(5,820lb)

Model0751 1DA(cabmodelwithfront

loader*)

*Frontloaderattachment(bucket)andrearcounterweightnotincluded

ItemDescription

Make/DesignationYanmar4TNV86CT-DTR2:4−Cycle,4

Bore

Stroke90mm(3.54inches)

Totaldisplacement

Firingorder

DirectionofrotationCounterclockwise(viewedfromtheywheel)

Fuel

Fueltankcapacity

FuelpumpYanmarelectricsupplypump

Fuelinjectiontype

GovernorElectronicAllSpeed

Lowidle(noload)1,200+/-100rpm

ECOmode(noload)2,300+/-100rpm

Highidle(noload)3,000+/-100rpm

Engineoil

Engine-oilviscosity

Crankcase-oilcapacity5.7L(6USqt)

Oilpump

CoolantcapacitywithoutOperatorcab7.6L(8USqt)

Alternator/Regulator12VDC,55A

Engineweight(dry)225kg(496lb)

Cylinder,WaterCooled,Turbocharged,EP A

1(closesttotheywheelend)-3-4

DieselorBiodieselfuel(uptoB20)with

Commonrailsystem(EPATier4certied)

APICJ-4,ACEAE-6,JASODH-2

RefertotheOperator’sManual

withOperatorcab8.5L(9USqt)

2,680kg(5,910lb)

2,980kg(6,570lb)

Tier4compliantDiesel

86mm(3.38inches)

2,090cm

(farthestfromywheel)-2

ultra-lowsulfurcontent

53.4L(14.1USgallons)

Yanmartrochoidpump

3

(127.5in3)

Outcross9060

18234SLRevB

Page2–3

SpecicationsandMaintenance:Specications

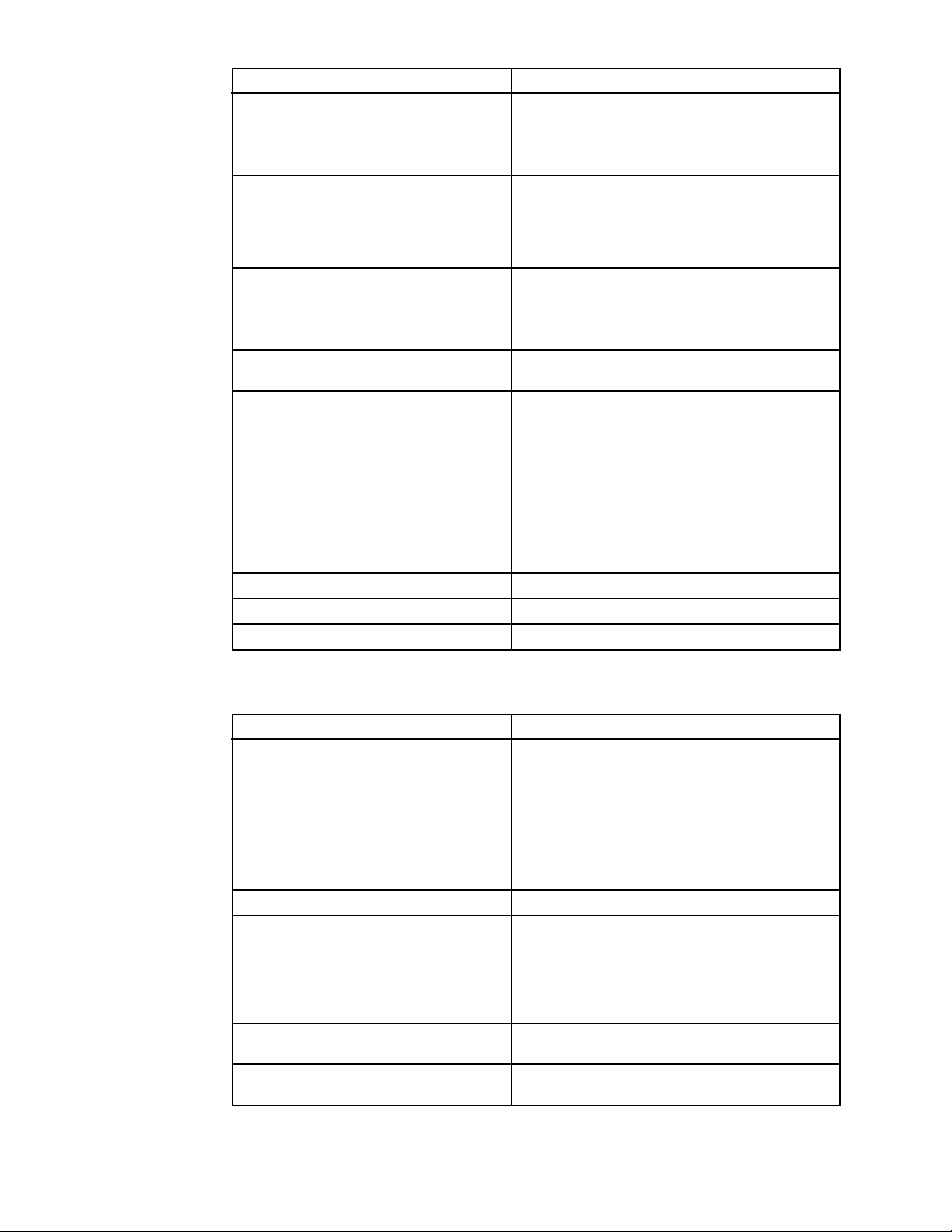

HydraulicSystem

ItemDescription

Piston(traction)pump(P1)and(P2)Danfosstandemvariabledisplacement

Maximumpumpdisplacement(per

pump)

GearpumpCasappa2section,positivedisplacement

Frontsection(P3)displacement16.9cc(1.03in³)perrevolution

RearSection(P4)displacement11cc(0.67in³)perrevolution

Driveaxlemotors

Displacement(perrevolution)38cc(2.32in³)maximum/18.5cc(1.13

SteeringvalveDanfossSteeringUnitTypeOSPCloadsensing

ReliefPressures

Tractioncircuit

Chargecircuit1,999kPa(290psi)

Steering(RV1)20,684kPa(3,000psi)

Hitchlift(RV2)20,684kPa(3,000psi)

Auxiliaryloadvalve

HydrauliclterSpin-oncartridgetype

HydraulicuidRefertothetractionunitOperator'sManual

Hydraulictankcapacity

Danfosspositivedisplacement,2position,axial

37.8cc(2.31in³/rev)perrevolution

pistonmotorwithloopushingvalve

distributorvalvewithrotarymeter

Forward=33,095kPa(4,800psi)

Reverse=33,095kPa(4,800psi)

axialpistonpump

geartypepump

in³)minimum

20,684kPa(3,000psi)

48L(12.75gallons)

TractionandPTODrive

ItemDescription

Tires

Front

Rear

Wheellugnuttorque

Driveaxleuidcapacity

Wheelhub

Axle

RearPTOgearboxuidcapacity1.4L(1.5USqt)Mobil424®multipurpose

BrakeAssemblyuidcapacity160ml(5.4ounces)Mobil424®multipurpose

TurfTread29x12.5–15,6ply@151to

TurfTread29x12.5–15,12ply@413to

TurfTread32x16–15,6ply@151to

380to434N∙m(280to320ft-lb)

0.4L(0.4USqt)Mobil424®multipurpose

9L(9.5USqt)Mobil424®multipurpose

tractorlubricantorequivalent

165kPa(22to24psi)

448kPa(60to65psi)

165kPa(22to24psi)

tractorlubricant

tractorlubricant

tractorlubricant

SpecicationsandMaintenance:Specications

Page2–4

Outcross9060

18234SLRevB

Chassis

ItemDescription

Bedcapacity/volume

Standardbed453kg(1,000lb),0.6cubicmeters(0.8cubicyards)

Cargobed(optional)2,041kg(4,500lb),1cubicmeters(1.3cubicyards)

Outcross9060

18234SLRevB

Page2–5

SpecicationsandMaintenance:Specications

TorqueSpecications

Therecommendedfastenertorquevaluesarelistedinthefollowingtables.For

criticalapplications,asdeterminedbyT oro,eithertherecommendedtorqueora

torquethatisuniquetotheapplicationisclearlyidentiedandspeciedinthis

ServiceManual.

Thesetorquespecicationsfortheinstallationandtighteningofthefastenerswill

applytoallthefastenerswhichdonothaveaspecicrequirementidentiedin

thisServiceManual.Thefollowingfactorsmustbeconsideredwhenapplying

thetorque:cleanlinessofthefastener,useofathreadsealant(e.g.,Loctite),

degreeoflubricationonthefastener,presenceofaprevailingtorquefeature

(e.g.,Nylocknut),hardnessofthesurfaceunderneaththeheadofthefastener,

orsimilarconditionwhichaffectstheinstallation.

Asnotedinthefollowingtables,thetorquevaluesshouldbereducedby25%

forlubricatedfastenersorfastenerswithawetthreadlockingcompound

appliedtoachievethesimilarstressasadryfastener.Thetorquevaluesmust

bereducedwhenthefasteneristhreadedintothealuminumorbrass.The

specictorquevalueshouldbedeterminedbasedonthealuminumorbrass

materialstrength,fastenersize,lengthofthreadengagement,etc.

Thestandardmethodofcheckingthetorquecanbeperformedbymarkingaline

onthefastener(headornut)andmatingpart,thenbackoffthefastener1/4

ofaturn.Measurethetorquenecessarytotightenthefasteneruntilthelines

matchup.

SpecicationsandMaintenance:T orqueSpecications

Page2–6

Outcross9060

18234SLRevB

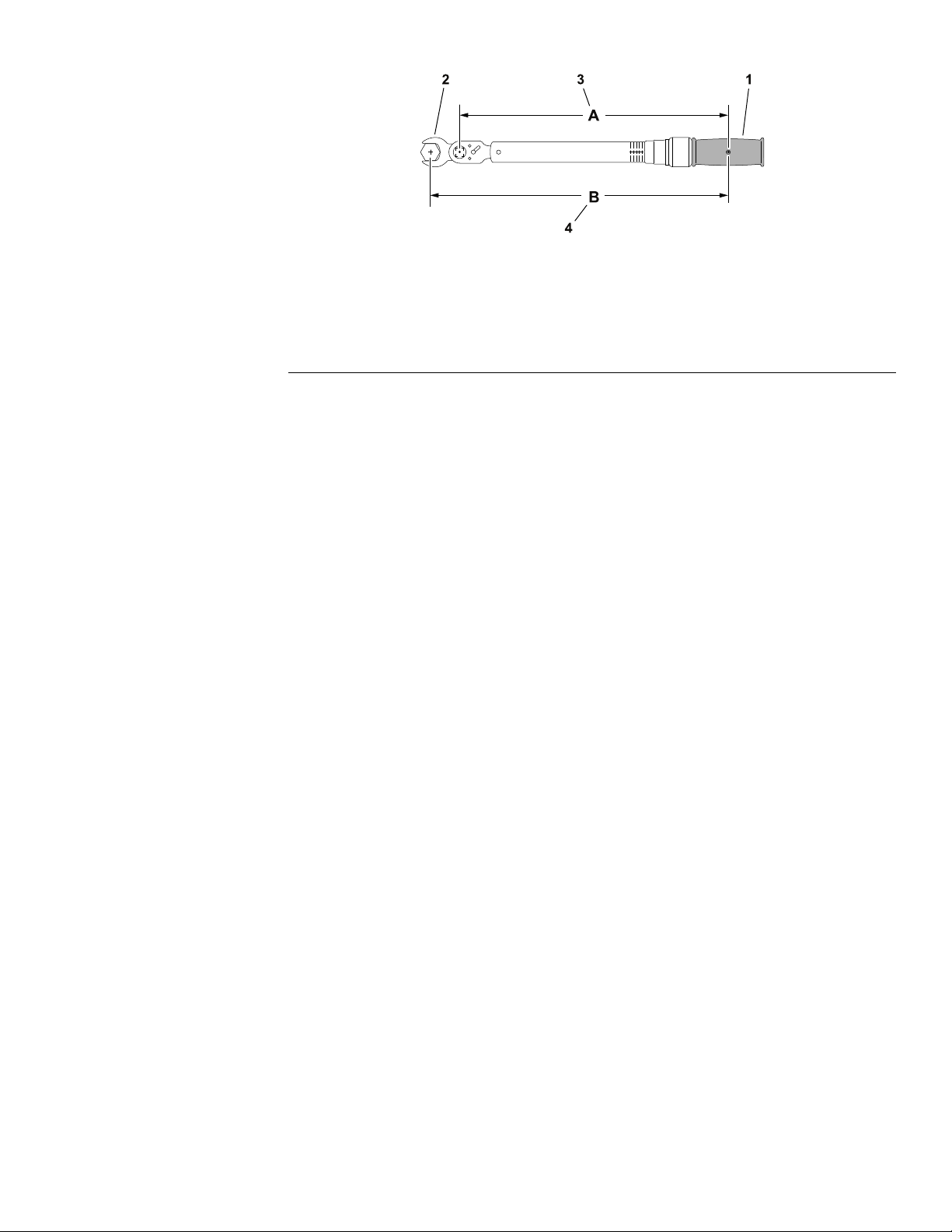

CalculatingtheTorqueValuesWhenUsingaDrive-AdapterWrench

g205924

Figure4

TorqueConversionFactor=A/B

1.Torquewrench

2.Drive-adapterwrench(crowfoot)4.B(effectivelengthoftorquewrenchand

3.A(effectivelengthoftorquewrench)

drive-adapterwrench)

Usingadrive-adapterwrench(e.g.,crowfootwrench)inanypositionotherthan

90°and270°totheframeofthetorquewrenchwillaffectthetorquevalue

measuredbythetorquewrenchbecauseoftheeffectivelength(lever)ofthe

torquewrenchchanges.Whenusingatorquewrenchwithadrive-adapter

wrench,multiplythelistedtorquerecommendationbythecalculatedtorque

conversionfactor(Figure4)todeterminepropertighteningtorque.Whenusinga

torquewrenchwithadrive-adapterwrench,thecalculatedtorquewillbelower

thanthelistedtorquerecommendation.

Example:Themeasuredeffectivelengthofthetorquewrench(distancefrom

thecenterofthehandletothecenterofthesquaredrive)is457mm(18inches).

Themeasuredeffectivelengthofthetorquewrenchwiththedrive-adapter

wrenchinstalled(distancefromthecenterofthehandletothecenterofthe

drive-adapterwrench)is483mm(19inches).

Thecalculatedtorqueconversionfactorforthistorquewrenchwiththis

drive-adapterwrenchwouldbe18/19=0.947.

Ifthelistedtorquerecommendationforafasteneris103to127N∙m(76to94

ft-lb),thepropertorquewhenusingthistorquewrenchwithadrive-adapter

wrenchwouldbe98to121N∙m(72to89ft-lb).

Outcross9060

18234SLRevB

Page2–7

SpecicationsandMaintenance:T orqueSpecications

IdentifyingtheFastener

g206089

Figure5

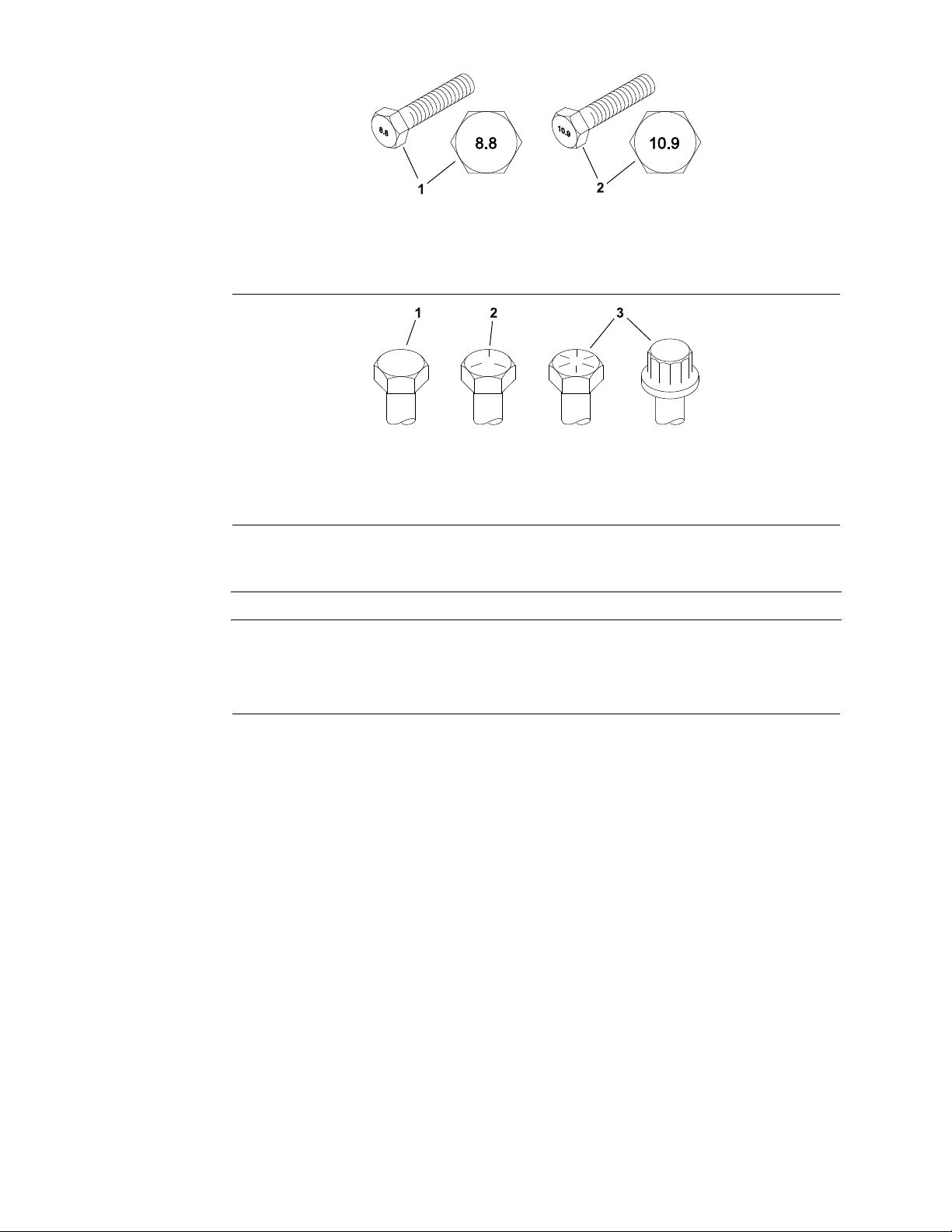

MetricBoltsandScrews

1.Class8.82.Class10.9

g206088

Figure6

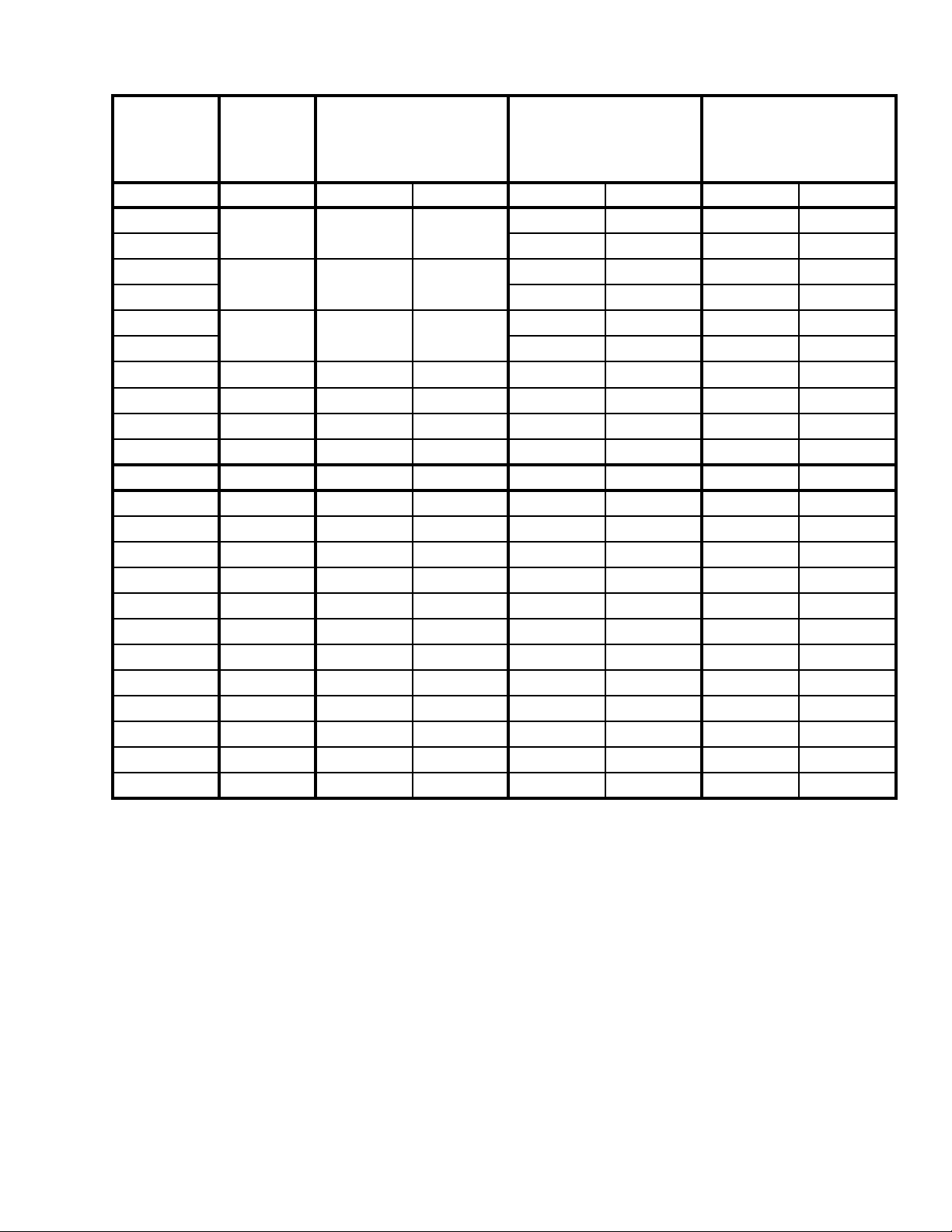

InchSeriesBoltsandScrews

1.Grade12.Grade53.Grade8

FastenerswithaLockingFeature

IMPORTANT

Ifafastenerwithalockingfeatureorpreviouslyappliedthread

lockingcompoundisreused,cleanthefastenerthreadsandapply

newthreadlockertothefastenerduringinstallation.

Lockingfeaturesaredesignedtocreatefrictionandpreventafastenerfrom

loosening.Lockingfeaturescanbefoundonexternallyorinternallythreaded

fasteners.Commonexamplesareplasticinsertsincorporatedintothefastener

andpre-applied“dry”threadlockingcompound.Keepinmind,afastenerwith

alockingfeatureusuallymeanstherewillbefrictionduringinitialinstallation

andduringremoval.

Tororecommendsreplacingfastenerswithalockingfeatureoncetheyhave

beenremovedbecausetheeffectivenessofthelockingfeaturediminisheswith

eachreuse.Ifitisnecessarytoreuseafastenerwithalockingfeature;applya

threadlockingcompound(Loctiteforexample)tothefastenerduringinstallation.

Usetheappropriatestrengthandtypeofthreadlockingcompoundbasedon

application,fastenersizeorinformationfoundintheproductOperatorsManual,

ServiceManualorInstallationInstructions.

SpecicationsandMaintenance:T orqueSpecications

Page2–8

Outcross9060

18234SLRevB

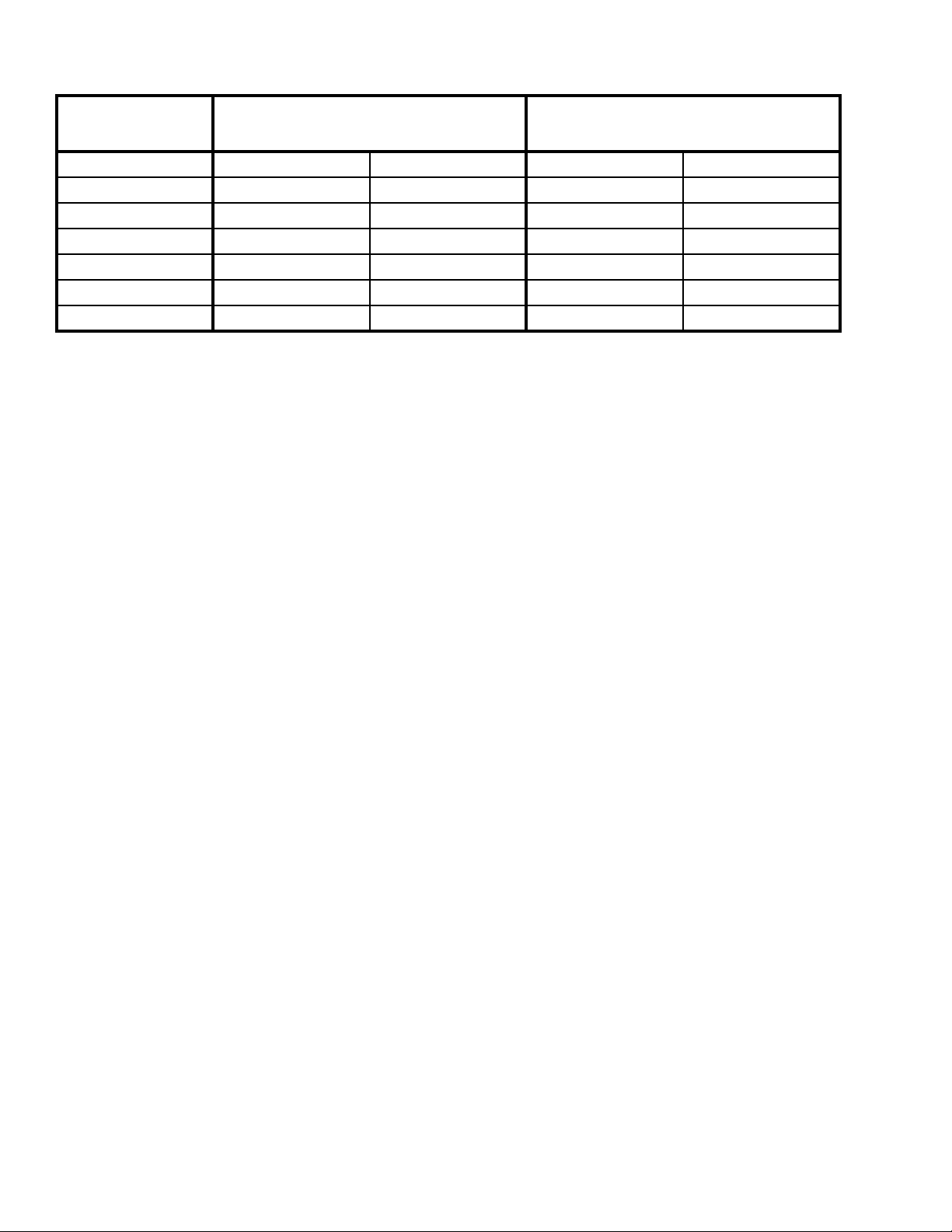

StandardTorqueforDry,ZincPlated,andSteelFasteners(Inch Series)

ThreadSizeGrade1,5

#6-32UNC

#6-40UNF

8-32UNC

#8-36UNF

#10-24UNC

#10-32UNF

1/4-20UNC

1/4-28UNF

5/16-18UNC

5/16-24UNF

3/8-16UNC

3/8-24UNF

7/16-14UNC

7/16-20UNF

1/2-13UNC

1/2-20UNF

5/8-11UNC

5/8-18UNF

3/4-10UNC

3/4-16UNF

7/8-9UNC

7/8-14UNF

and8with

ThinHeight

Nuts

in-lbin-lbN∙cmin-lbN∙cmin-lbN∙cm

10±213±2147±23

13±225±5282±56

18±230±5339±56

48±753±7599±79100±101130±1 13140±151582±169

53±765±10734±1 131 15±121299±136160±171808±192

115±15105±151186±169200±252260±282300±303390±339

138±17128±171146±192225±252542±282325±333672±373

ft-lbft-lb

16±216±222±330±341±443±558±7

17±218±224±335±447±550±668±8

27±327±337±450±568±770±795±9

29±329±339±455±675±877±8104±11

30±348±765±975±8102±11105±11142±15

32±453±772±985±9115±12120±12163±16

65±1088±12119±16150±15203±20210±21285±28

75±1095±15129±20170±18230±24240±24325±33

93±12140±20190±27265±27359±37375±38508±52

115±15165±25224±34300±30407±41420±43569±58

140±20225±25305±34430±45583±61600±60813±81

155±25260±30353±41475±48644±65667±66904±89

SAEGrade1Bolts,

Screws,Studs,andSems

withRegularHeight

Nuts(SAEJ995Grade2

orStrongerNuts)

N∙m

SAEGrade5Bolts,

Screws,Studs,andSems

withRegularHeight

Nuts(SAEJ995Grade2

orStrongerNuts)

15±2169±2323±3262±34

17±2192±2325±3282±34

29±3328±3441±5463±56

31±4350±4543±5486±56

42±5475±5660±6678±68

48±5542±5668±7768±79

ft-lb

N∙m

SAEGrade8Bolts,

Screws,Studs,andSems

withRegularHeight

Nuts(SAEJ995Grade2

orStrongerNuts)

ft-lb

N∙m

Note:Reducethetorquevalueslistedinthetableaboveby25%forlubricatedfasteners.Lubricated

fastenersaredenedasthreadscoatedwithalubricant,suchasengineoil,orathreadsealant,such

asLoctite.

Note:Thetorquevaluesmustbereducedwheninstallingthefastenersintothreadedaluminumor

brass.Thespeciedtorquevalueshouldbedeterminedbasedonthealuminumorbasematerial

strength,fastenersize,lengthofthreadengagement,etc.

Note:ThenominaltorquevalueslistedaboveforGrade5and8fastenersarebasedon75%ofthe

minimumproofloadspeciedinSAEJ429.Thetoleranceisapproximately±10%ofthenominal

torquevalue.Thethinheightnutsincludejamnuts.

Outcross9060

18234SLRevB

Page2–9

SpecicationsandMaintenance:T orqueSpecications

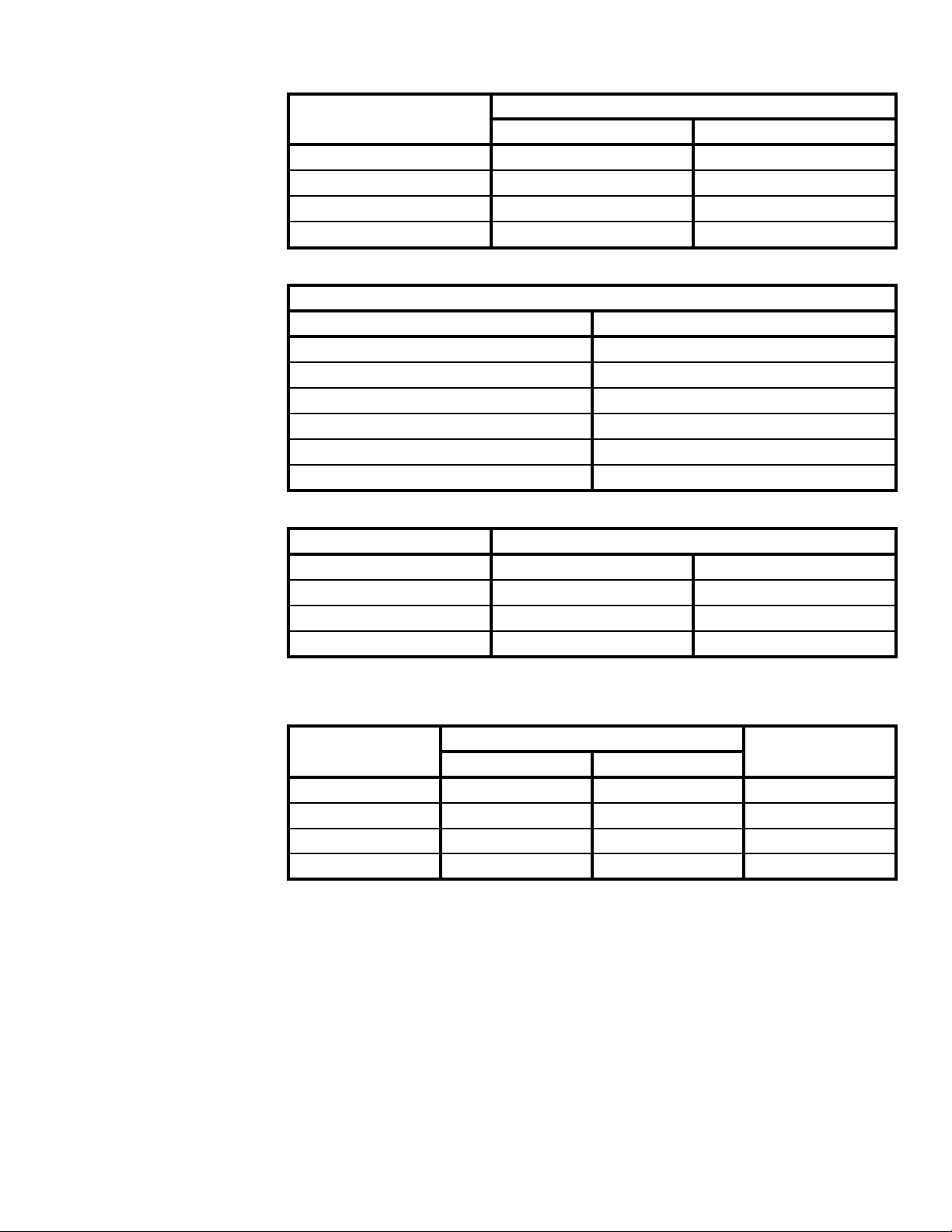

StandardTorqueforDry,ZincPlated,andSteelFasteners(Metric Fasteners)

ThreadSize

M5X0.857±6in-lb644±68N∙cm78±8in-lb881±90N∙cm

M6X1.096±10in-lb1085±113N∙cm133±14in-lb1503±158N∙cm

M8X1.25

M10X1.5

M12X1.75

M16X2.0

M20X2.5

Class8.8Bolts,Screws,andStuds

withRegularHeightNuts(Class8

19±2ft-lb

38±4ft-lb

66±7ft-lb

166±17ft-lb

325±33ft-lb

orStrongerNuts)

26±3N∙m

52±5N∙m

90±10N∙m

225±23N∙m

440±45N∙m

Class10.9Bolts,Screws,andStuds

withRegularHeightNuts(Class10

28±3ft-lb

54±6ft-lb

93±10ft-lb

229±23ft-lb

450±46ft-lb

orStrongerNuts)

38±4N∙m

73±8N∙m

126±14N∙m

310±31N∙m

610±62N∙m

Note:Reducethetorquevalueslistedinthetableaboveby25%forlubricatedfasteners.Lubricated

fastenersaredenedasthreadscoatedwithalubricant,suchasengineoil,orathreadsealant,such

asLoctite.

Note:Thetorquevaluesmustbereducedwheninstallingthefastenersintothreadedaluminumor

brass.Thespeciedtorquevalueshouldbedeterminedbasedonthealuminumorbasematerial

strength,fastenersize,lengthofthreadengagement,etc.

Note:Thenominaltorquevalueslistedabovearebasedon75%oftheminimumproofloadspeciedin

SAEJ1199.Thetoleranceisapproximately±10%ofthenominaltorquevalue.

SpecicationsandMaintenance:T orqueSpecications

Page2–10

Outcross9060

18234SLRevB

OtherTorqueSpecications

SAEGrade8SteelSetScrews

ThreadSize

1/4-20UNC

5/16-18UNC

3/8-16UNC35±10ft-lb18±3ft-lb

1/2-13UNC75±15ft-lb50±10ft-lb

ThreadCuttingScrews(ZincPlatedSteel)

ThreadSizeBaselineTorque**

No.6-32UNC

No.8-32UNC

No.10-24UNC

1/4-20UNC

5/16-18UNC

3/8-16UNC

SquareHeadHexSocket

140±20in-lb73±12in-lb

215±35in-lb145±20in-lb

Type1,Type23orTypeF

RecommendedTorque

20±5in-lb

30±5in-lb

38±7in-lb

85±15in-lb

110±20in-lb

200±100in-lb

WheelBoltsandLugNuts

ThreadSizeRecommendedTorque*

7/16-20UNFGrade565±10ft-lb

1/2-20UNFGrade580±10ft-lb

M12X1.25Class8.880±10ft-lb

M12X1.5Class8.880±10ft-lb

88±14N∙m

108±14N∙m

108±14N∙m

108±14N∙m

*Forsteelwheelsandnon-lubricatedfasteners

ThreadCuttingScrews(ZincPlatedSteel)

ThreadSize

No.6182020±5in-lb

No.8151830±5in-lb

No.10121638±7in-lb

No.12111485±15in-lb

ThreadsperInch

BaselineTorque**

TypeATypeB

**Theholesize,materialstrength,materialthickness,andmaterialnishmustbe

consideredwhendeterminingthespeciedtorquevalues.Allthetorquevalues

arebasedonthenon-lubricatedfasteners.

ConversionFactors

Outcross9060

18234SLRevB

in-lbX11.2985=N∙cmN∙cmX0.08851=in-lb

ft-lbX1.3558=N∙mN∙mX0.7376=ft-lb

Page2–11

SpecicationsandMaintenance:T orqueSpecications

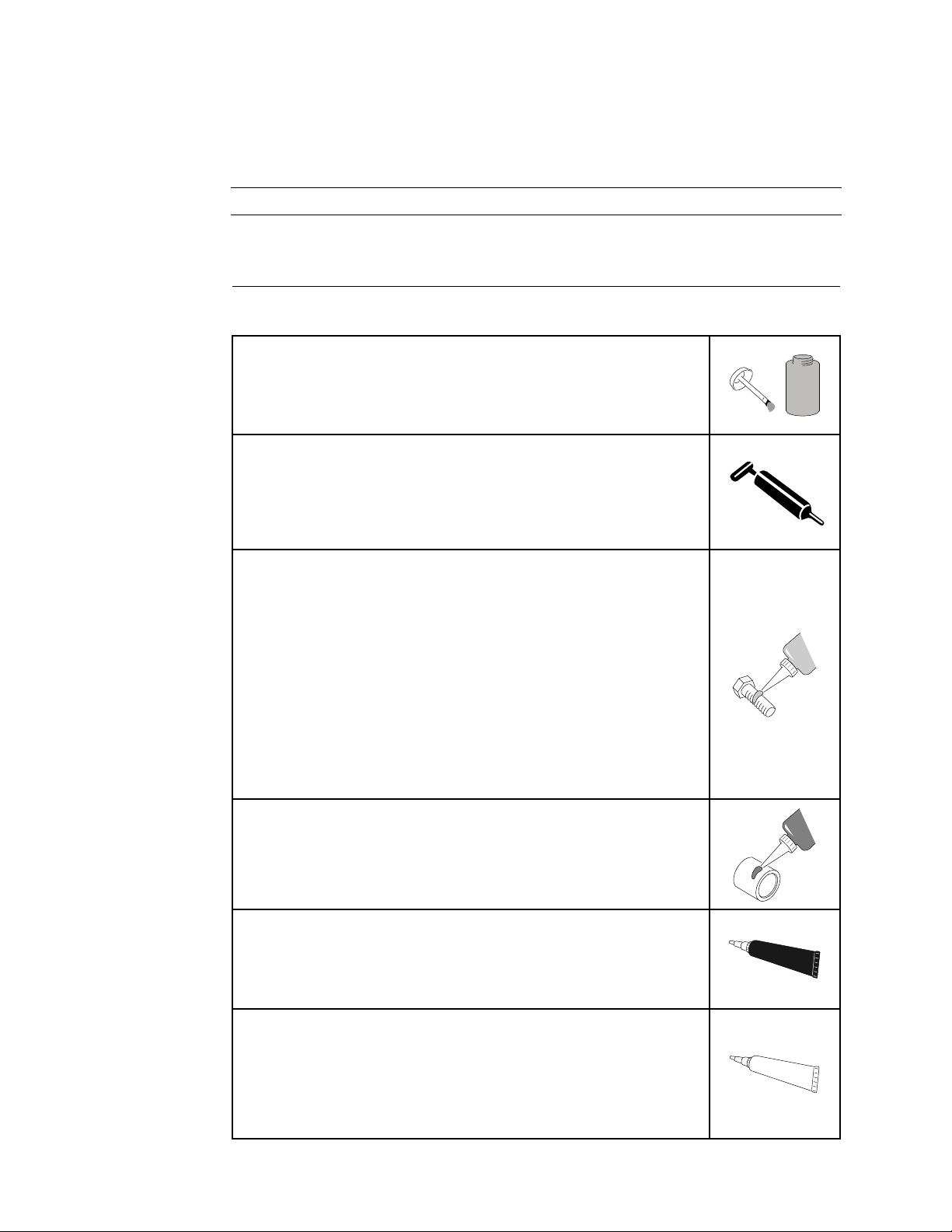

ShopSupplies

TheproceduresfoundinthisServiceManualmayrecommendtheuse

ofcommonlyusedshopsupplies(lubricants,sealantsandadhesives).A

symboldenotingtheuseofashopsupplymayappearinguresthatsupport

aprocedure.Alwaysrefertothewrittenprocedureforspecicinformation

regardingthetypeandtheapplicationofashopsupply .

IMPORTANT

Alwaysfollowmanufacturersinstructionswhenusingorstoring

shopsupplies.

ShopSupplies

ANTI-SEIZELUBRICANT

Usedtopreventcorrosion,gallingandseizurebetweenmetalparts.Most

oftenappliedtoshaftsandboresduringassembly .Unlessotherwise

specied,highviscosityregulargradelithium-graphitebasedanti-seize

lubricantshouldbeused.

GREASE

Canbeusedtopre-ll(pack)bearings,bootsandsealspriortoassembly ,

easeinstallationofcomponentsduringassembly,orllcavitiesbetween

movingpartsthroughgreasettingsafterassembly.Unlessotherwise

noted,refertothemachineOperator’sManualorInstallationInstructions

forgreasespecications.

THREADLOCKINGCOMPOUND(threadLocker)

Usedtolockthreadedfastenersinposition.Availableinlow,mediumand

highstrengthforvarioussizefastenersandapplications.Mostthread

lockingcompoundsareappliedimmediatelypriortofastenerinstallation.

Somethreadlockingcompoundsusea“Wicking”feature,andcanbe

appliedafterfastenerinstallation.Mostthreadlockingcompoundsallow

thefastenertoberemovedwithstandardtoolsoncecured.Highstrength

threadlockingcompoundsmayrequireapplyingheattothefastenerand

thesurroundingareatoallowfastenerremoval.

Note:Somefastenershaveadrythreadlockingcompoundpre-applied

(Patch-Loc)sonoadditionalthreadlockingcompoundisnecessarywhen

installinga“new”fastener.Thesefastenersaredesignedtoberemoved

andre-installedonlyoncebeforeapplyingadditionalthreadlocking

compoundisnecessary .

RETAININGCOMPOUND(bearingsandsleeves)

Anadhesiveusedtosecurebearings,bushingsandcylindricalparts

intohousingsorontoshafts.Whencured,bearingandsleeveretaining

compoundllsthegapbetweenmatingpartswithahardresinthat

increasesloaddistributionandprotectsagainstcorrosion.

ADHESIVE

Usedtosecureavarietyofcomponentsimmediatelypriortoassembly .

Mayberecommendedforinstallingnewcomponentsorwhenreusinga

componentthathadapre-appliedadhesivesuchashoodseals,mouldings

andweather-stripping.

THREADSEALANT

SpecicationsandMaintenance:ShopSupplies

Usedtosealthreadedttingsandsensorsfromair,fuelandoilpressure

leaksandpreventgallingandseizurebetweenthreadedparts.Athread

sealantinpastermispreferredoversealanttape.Thesealantshould

remainsemi-pliabletoallowforcomponentremovalwithstandardtools.

Somethreadsealantsmayrequiretheuseofacleanerorprimerprior

touse.

Page2–12

Outcross9060

18234SLRevB

Loading...

Loading...