Toro 07390 Workman HDX-Auto, 07390H Workman HDX-Auto, 07390TC Workman HDX-Auto Operator's Manual

Page 1

FormNo.3392-863RevB

Workman

®

HDX-AutoUtility

Vehicle

ModelNo.07390—SerialNo.315000001andUp

ModelNo.07390H—SerialNo.315000001andUp

ModelNo.07390TC—SerialNo.315000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3392-863*B

Page 2

ThisproductcomplieswithallrelevantEuropeandirectives.

Fordetails,pleaseseetheseparateproductspecic

DeclarationofConformity(DOC)sheet.

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Figure1

1.Modelandserialnumberlocation

Important:Theengineinthisproductisnotequipped

withasparkarrestedmufer.Itisaviolationof

CaliforniaPublicResourcecodeSection4442touse

oroperatethisengineonanyforest-covered,brush

covered,orgrass-coveredlandasdenedinCPRC4126.

Otherstatesorfederalareasmayhavesimilarlaws.

Introduction

Thismachineisautilityvehicleintendedtobeusedby

professional,hiredoperatorsincommercialapplications.It

isprimarilydesignedforthetransportofimplementsusedin

suchapplications.Thisvehicleallowsforthesafetransport

ofanoperatorandonepassengerintheidentiedseats.The

bedofthisvehicleisnotsuitableforanyriders.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

safetyandoperationtrainingmaterials,accessoryinformation,

helpndingadealer,ortoregisteryourproduct.

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure2

1.Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready.Figure1identiesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

©2015—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Contents

Safety...........................................................................4

SafeOperatingPractices...........................................4

Supervisor’sResponsibilities.....................................4

BeforeOperating....................................................4

SafeHandlingofFuels.............................................4

Operation...............................................................5

Maintenance...........................................................6

RolloverProtectionSystem(ROPS)-Useand

Maintenance.......................................................6

Hauling..................................................................6

SoundPressure.......................................................7

Vibration................................................................7

SafetyandInstructionalDecals.................................7

Setup...........................................................................12

1InstallingtheSteeringWheel(TCandHModels

only).................................................................12

2InstallingtheROPS..............................................13

3ConnectingtheBattery(TCandHModels

only).................................................................13

4ConnectingtheCVTIntakeDuct(TCandH

Modelsonly)......................................................14

5CheckingtheFluidLevels.....................................15

ProductOverview.........................................................15

Controls...............................................................15

DashboardSwitches............................................17

InstrumentCluster..............................................17

Specications........................................................19

Attachments/Accessories........................................19

Operation....................................................................19

OperatingtheCargoBox.........................................19

CheckingtheFluidLevels........................................20

CheckingtheOilPressureWarningLight...................24

AddingFuel...........................................................25

CheckingtheTirePressure......................................26

RemovingDebrisfromtheCoolingSystem................26

PreformingPre-startChecks....................................26

StartingtheEngine.................................................27

DrivingtheVehicle.................................................27

StoppingtheVehicle...............................................27

StoppingtheEngine...............................................27

UsingtheSpeed-rangeControl................................27

UsingtheDifferentialLock......................................28

BreakinginaNewMachine......................................28

CheckingtheInterlockSystem.................................29

TransportingtheMachine........................................29

TowingtheMachine...............................................30

TowingaTrailerwiththeMachine.............................30

UsingtheHydraulicControl....................................30

OperatingTips......................................................31

Maintenance.................................................................34

RecommendedMaintenanceSchedule(s)......................34

HeavyDutyOperation............................................35

PremaintenanceProcedures........................................35

UsingtheBedSafetySupport...................................36

RemovingtheFullBed............................................36

InstallingtheFullBed.............................................37

JackingtheMachine................................................37

RemovingandInstallingtheHood............................38

Lubrication...............................................................39

GreasingtheBearingsandtheBushings.....................39

EngineMaintenance..................................................40

ServicingtheAirFilter............................................40

ChangingtheEngineOilandFilter...........................41

ReplacingtheSparkPlug.........................................42

FuelSystemMaintenance...........................................42

ReplacingtheFuelFilter..........................................42

InspectingtheCarbonCanisterAirFilter...................43

InspectingtheFuelLinesandConnections.................43

ElectricalSystemMaintenance....................................43

ServicingtheFuses.................................................43

Jump-StartingtheMachine......................................44

ServicingtheBattery...............................................45

DriveSystemMaintenance.........................................45

MaintainingtheTires,Wheels,and

Suspension........................................................45

MaintainingtheTransmission..................................47

MaintainingtheDifferentialandAxles.......................50

CoolingSystemMaintenance......................................51

ChangingtheEngineCoolant...................................51

BrakeMaintenance....................................................52

AdjustingtheParkingBrake.....................................52

AdjustingtheBrakePedal........................................53

ControlsSystemMaintenance.....................................54

ConvertingtheSpeedometer....................................54

AdjustingtheAcceleratorPedal................................54

HydraulicSystemMaintenance....................................57

ReplacingtheHydraulicFilter..................................57

ChangingtheHydraulicFluid...................................57

RaisingtheBoxinanEmergency..............................58

Storage........................................................................59

Troubleshooting...........................................................61

3

Page 4

Safety

ThemachinemeetstherequirementsofSAEJ2258.

SafeOperatingPractices

Important:Themachineisdesignedprimarilyasan

off-roadvehicleandisnotintendedforextensiveuse

onpublicroads.

Whenusingthemachineonpublicroads,followall

trafcregulationsanduseanyadditionalaccessories

thatmayberequiredbylaw,suchaslights,turnsignals,

slowmovingvehicle(SMV)sign,andothersasrequired.

TheW orkmanwasdesignedandtestedtooffersafeservice

whenoperatedandmaintainedproperly.Althoughhazard

controlandaccidentpreventionpartiallyaredependent

uponthedesignandcongurationofthemachine,these

factorsarealsodependentupontheawareness,concern,and

propertrainingofthepersonnelinvolvedintheoperation,

maintenanceandstorageofthemachine.Improperuseor

maintenanceofthemachinecanresultininjuryordeath.

Thisisaspecializedutilityvehicledesignedforoff–roaduse

only.Itsrideandhandlingwillhaveadifferentfeelthanwhat

driversexperiencewithpassengercarsortrucks.Sotaketime

tobecomefamiliarwithyourmachine.

Notalloftheattachmentsthatadapttothemachine

arecoveredinthismanual.SeethespecicOperator’s

Manualprovidedwitheachattachmentforadditionalsafety

instructions.Readthesemanuals.

Toreducethepotentialforinjuryordeath,complywith

thefollowingsafetyinstructions:

Supervisor’sResponsibilities

•Makesureoperatorsarethoroughlytrainedandfamiliar

withtheOperator’ sManualandalllabelsonthevehicle.

•Besuretoestablishyourownspecialproceduresand

workrulesforunusualoperatingconditions(e.g.slopes

toosteepforthesafeoperationofthemachine).

BeforeOperating

•Operatethemachineonlyafterreadingandunderstanding

thecontentsofthismanual.Areplacementmanualis

availablebysendingcompletemodelandserialnumber

to:TheToro®Company,8111LyndaleAvenueSouth,

Minneapolis,Minnesota55420.

•Thismachineisdesignedtocarryonlyyou,the

operator,andonepassengerintheseatprovidedbythe

manufacturer.Nevercarryanyotherpassengersonthe

vehicle.

•Becomefamiliarwiththecontrolsandknowhowtostop

theenginequickly.

•Neveroperatethemachinewhenundertheinuence

ofdrugsoralcohol.

•Alwayswearsubstantialshoes.Donotoperatethe

machinewhilewearingsandals,tennisshoes,orsneakers.

Donotwearloosettingclothingorjewelrywhichcould

getcaughtinmovingpartsandcausepersonalinjury.

•Wearingsafetyglasses,substantialsafetyshoes,long

pants,andahelmetisadvisableandrequiredbysome

localsafetyandinsuranceregulations.

•Neverallowchildrentooperatethemachine.Never

allowadultstooperateitwithoutproperinstructions.

Onlytrainedandauthorizedpersonsshouldoperate

thismachine.Makesurealloperatorsarephysicallyand

mentallycapableofoperatingthemachine.

•Keepeveryone,especiallychildrenandpets,awayfrom

theareasofoperation.

•Checkthesafetyinterlocksystemdailyforproper

operation.Ifaswitchshouldmalfunction,replacethe

switchbeforeoperatingmachine.

•Keepallshields,safetydevicesanddecalsinplace.Ifa

shield,safetydeviceordecalismalfunctioning,illegible,

ordamaged,repairorreplaceitbeforeoperatingthe

machine.

•Beforeoperatingthevehicle,alwayscheckallpartsof

thevehicleandanyattachments.Ifsomethingiswrong,

stopusingvehicle.Makesuretheproblemiscorrected

beforevehicleorattachmentisoperatedagain.

•Useonlyanapprovednonmetal,portablefuelcontainer.

Staticelectricdischargecanignitefuelvaporsinafuel

containerthatisnotgrounded.Removethefuelcontainer

fromthebedofthemachineandplaceitontheground

andawayfromthevehiclebeforelling.Keepthe

nozzleincontactwiththecontainerwhilellingthefuel

container.Removeequipmentfrombedofthemachine

beforefuelingit.

•Operatethemachineonlyoutdoorsorinawellventilated

area.

SafeHandlingofFuels

•Toavoidpersonalinjuryorpropertydamage,use

extremecareinhandlinggasoline.Gasolineisextremely

ammableandthevaporsareexplosive.

•Extinguishallcigarettes,cigars,pipes,andothersources

ofignition.

•Useonlyanapprovedfuelcontainer.

•Neverremovefuelcaporaddfuelwiththeengine

running.

•Allowenginetocoolbeforerefueling.

•Neverrefuelthemachineindoors.

•Neverstorethemachineorfuelcontainerwherethereis

anopename,spark,orpilotlightsuchasonawater

heateroronotherappliances.

•Neverllcontainersinsideavehicleoronatruckor

trailerbedwithaplasticliner.Alwaysplacecontainerson

thegroundawayfromyourvehiclebeforelling.

4

Page 5

•Removeequipmentfromthetruckortrailerandrefuelit

ontheground.Ifthisisnotpossible,thenrefuelsuch

equipmentwithaportablecontainer,ratherthanfroma

fueldispensernozzle.

•Keepthenozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilfuelingiscomplete.

Donotuseanozzlelockopendevice.

•Iffuelisspilledonclothing,changeclothingimmediately.

•Neveroverllfueltank.Replacefuelcapandtighten

securely.

Operation

•Theoperatorandpassengershouldremainseatedand

usetheseatbeltswheneverthevehicleisinmotion.The

operatorshouldkeepbothhandsonthesteeringwheel,

wheneverpossible,andthepassengershouldusethehand

holdsprovided.Keeparmsandlegswithinthevehicle

bodyatalltimes.Nevercarrypassengersintheboxor

onattachments.Rememberyourpassengermaynotbe

expectingyoutobrakeorturnandmaynotbeready.

•Neveroverloadyourvehicle.Thenameplate(located

underthemiddleofthedash)showstheloadlimitsfor

thevehicle.Neveroverllattachmentsorexceedthe

vehiclemaximumgrossvehicleweight(GVW).

•Whenstartingtheengine:

–Sitonoperator’sseatandensurethattheparking

brakeisengaged.

–DisengagePTO(ifsoequipped)andreturnthehand

throttlelevertotheOffposition(ifsoequipped).

–Makesurethehydraulicliftleverisinthecenter

position.

–Pressinthebrakepedal.

–Keepyourfootoffoftheacceleratorpedal.

–TurntheignitionkeytotheStartposition.

•Usingthemachinedemandsattention.Failuretooperate

machinesafelymayresultinanaccident,tipoverofthe

machine,andseriousinjuryordeath.Drivecarefully.

Topreventtippingorlossofcontrol,takethefollowing

precautions:

–Useextremecaution,reducespeed,andmaintain

asafedistancearoundsandtraps,ditches,creeks,

ramps,anyunfamiliarareas,orotherhazards.

–Watchforholesorotherhiddenhazards.

–Usecautionwhenoperatingthevehicleonasteep

slope.Normally,travelstraightupanddownslopes.

Reducespeedwhenmakingsharpturnsorwhen

turningonhillsides.Avoidturningonhillsides

wheneverpossible.

–Useextracautionwhenoperatingthemachineon

wetsurfaces,athigherspeeds,orwithafullload.

Stoppingtimewillincreasewithafullload.

–Whenloadingthebed,distributetheloadevenly.

Useextracautioniftheloadexceedsthedimensions

ofthevehicle/bed.Operatethemachinewithextra

cautionwhenhandlingoff-centerloadsthatcannot

becentered.Keeploadsbalancedandsecureto

preventthemfromshifting.

–Avoidsuddenstopsandstarts.Donotgofrom

reversetoforwardorforwardtoreversewithoutrst

comingtoacompletestop.

–Donotattemptsharpturnsorabruptmaneuversor

otherunsafedrivingactionsthatmaycausealossof

controlofthemachine.

–Donotpassanothermachinetravelinginthesame

directionatintersections,blindspots,oratother

dangerouslocations.

–Whendumping,donotletanyonestandbehind

machineanddonotdumptheloadonanyone’sfeet.

Releasethetailgatelatchesfromthesideofbox,not

frombehind.

–Keepallbystandersaway .Beforebackingup,lookto

therearandensurethatnooneisbehindthevehicle.

Backupslowly.

–Watchoutfortrafcwhennearorcrossingroads.

Alwaysyieldtherightofwaytopedestriansand

othervehicles.Alwayssignalyourturnsorstopearly

enoughsootherpersonsknowwhatyouplantodo.

Obeyalltrafcrulesandregulations.

–Neveroperatethemachineinornearanareawhere

thereisdustorfumesintheairwhichareexplosive.

Theelectricalandexhaustsystemsofthemachinecan

producesparkscapableofignitingexplosivematerials.

–Alwayswatchoutforandavoidlowoverhangssuch

astreelimbs,doorjambs,overheadwalkways,etc.

Makesurethereisenoughroomoverheadtoeasily

clearthemachineandyourhead.

–Ifyouareeverunsureaboutthesafeoperationofthe

machine,stopyourworkandaskyoursupervisor.

•Beforegettingofftheseat:

–Stopmovementofthemachine.

–Lowerbed.

–Shutengineoffandwaitforallmovementtostop.

–Setparkingbrake.

–Removekeyfromignition.

•Donottouchengine,transmission,radiator,muferor

mufermanifoldwhileengineisrunningorsoonafter

ithasstoppedbecausetheseareasmaybehotenough

tocauseburns.

•Ifthemachineevervibratesabnormally,stopthemachine

immediately,turnengineoff,waitforallmotionto

stopandinspectfordamage.Repairalldamagebefore

resumingoperation.

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

5

Page 6

Maintenance

•Beforeservicingormakingadjustmentstothemachine,

movethemachinetoalevelsurface,stoptheengine,set

theparkingbrake,andremovethekeyfromignitionto

preventaccidentalstartingoftheengine.

•Neverworkunderaraisedbedwithoutplacingthe

bed-safetysupportontothefullyextendedbed-actuator

rod.

•Makesureallhydraulicttingsaretight,andallhydraulic

hosesandlinesareingoodconditionbeforeapplying

pressuretothesystem.

inquiriestoTheToro®Company,CommercialDivision,

VehicleEngineeringDept.,8111LyndaleAve.So.,

Bloomington,Minnesota55420–1196USA.

RolloverProtectionSystem (ROPS)-UseandMaintenance

•TheROPSisanintegralandeffectivesafetydevice.Use

theseatbeltwhenoperatingthemachinewithROPS.

•Becertainthattheseatbeltcanbereleasedquicklyin

theeventofanemergency.

•Keepyourbodyandhandsawayfrompinholeleaksor

nozzlesthatejecthydraulicuidunderhighpressure.

Usepaperorcardboard,notyourhands,tosearch

forleaks.Hydraulicuidescapingunderpressurecan

havesufcientforcetopenetrateskinandcauseserious

damagetoyourbody.Ifuidisinjectedintotheskin,it

mustbesurgicallyremovedwithinafewhoursbyadoctor

familiarwiththisformofinjury,organgrenemayresult.

•Beforedisconnectingorperforminganyworkonthe

hydraulicsystem,allpressureinthehydraulicsystem

mustberelievedbystoppingtheengineandcyclingthe

hydrauliccontrolvalveforthebedliftfromraisetolower

and/orloweringboxandattachments.Ifequipped,

placetheremote-hydraulicsleverintheoatposition.

Iftheboxmustbeinraisedposition,secureitwiththe

bed-safetysupport.

•Tomakesuretheentiremachineisingoodcondition,

keepallnuts,bolts,andscrewsproperlytightened.

•Toreducethepotentialrehazard,keeptheenginearea

freeofexcessivegrease,grass,leaves,andaccumulation

ofdirt.

•Iftheenginemustberunningtoperformamaintenance

adjustment,keephands,feet,clothing,andanypartsof

thebodyawayfromtheengineandanymovingparts.

Keepeveryoneaway.

•Checkcarefullyforoverheadclearances(i.e.branches,

doorways,electricalwires)beforedrivingunderany

objectsanddonotcontactthem.

•KeeptheROPSinsafeoperatingconditionby

periodicallythoroughlyinspectingfordamageand

keepingallmountingfastenerstight.

•ReplaceadamagedROPS.Donotrepairorrevise.

•DonotremovetheROPS.

•AnyalterationstoaROPSmustbeapprovedbythe

manufacturer.

Hauling

•Usecarewhenloadingorunloadingthemachineintoa

trailerortruck.

•Usefullwidthrampsforloadingmachineintotraileror

truck.

•Tiethemachinedownsecurelyusingstraps,chains,cable,

orropes.Bothfrontandrearstrapsshouldbedirected

downandoutwardfromthemachine.

•Donotoverspeedtheenginebychangingthegovernor

settings.Themaximumenginespeedis3650rpm.To

ensuresafetyandaccuracy,haveanAuthorizedToro

Distributorcheckthemaximumenginespeedwitha

tachometer.

•Ifmajorrepairsareeverneededorassistanceisrequired,

contactanAuthorizedToroDistributor.

•Tobesureofoptimumperformanceandsafety,always

purchasegenuineTororeplacementpartsandaccessories.

Replacementpartsandaccessoriesmadebyother

manufacturerscouldbedangerous.Alteringthismachine

inanymannermayaffecttheoperation,performance,

durabilityofthemachine,oritsusemayresultininjury

ordeath.Suchusecouldvoidtheproductwarrantyof

TheToro®Company.

•Thismachineshouldnotbemodiedwithout

authorizationfromTheToro®Company.Directany

6

Page 7

SoundPressure

Thisunithasasoundpressurelevelattheoperator’searof79

dBA,whichincludesanUncertaintyValue(K)of1dBA.

Thesoundpressurelevelwasdeterminedaccordingtothe

proceduresoutlinedinENISO11201.

Vibration

Hand-Arm

•Measuredvibrationlevelforrighthand=0.3m/s

2

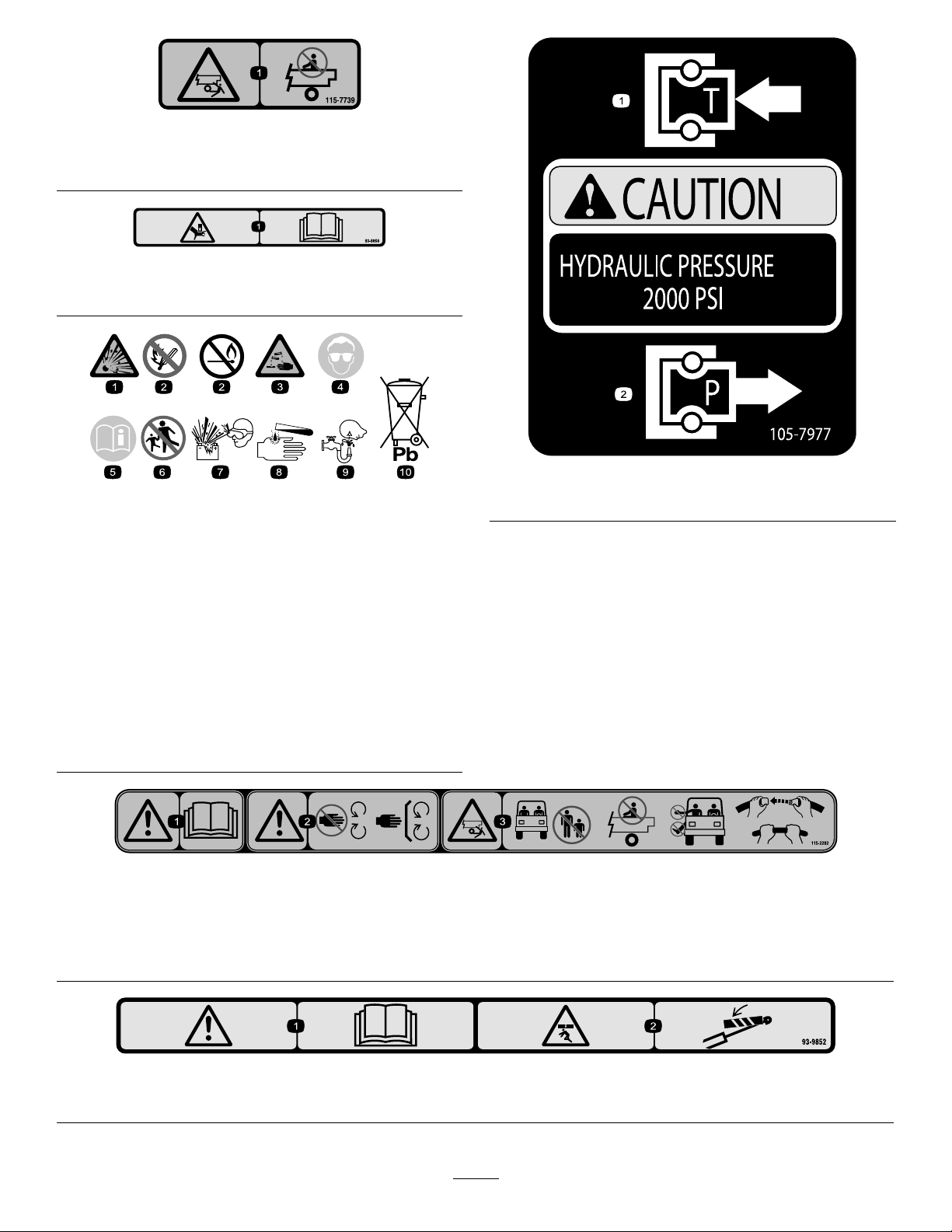

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

•Measuredvibrationlevelforlefthand=0.4m/s

•UncertaintyValue(K)=0.2m/s

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinENISO20643.

2

WholeBody

•Measuredvibrationlevel=0.18m/s

•UncertaintyValue(K)=0.09m/s

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinEN1032.

2

2

2

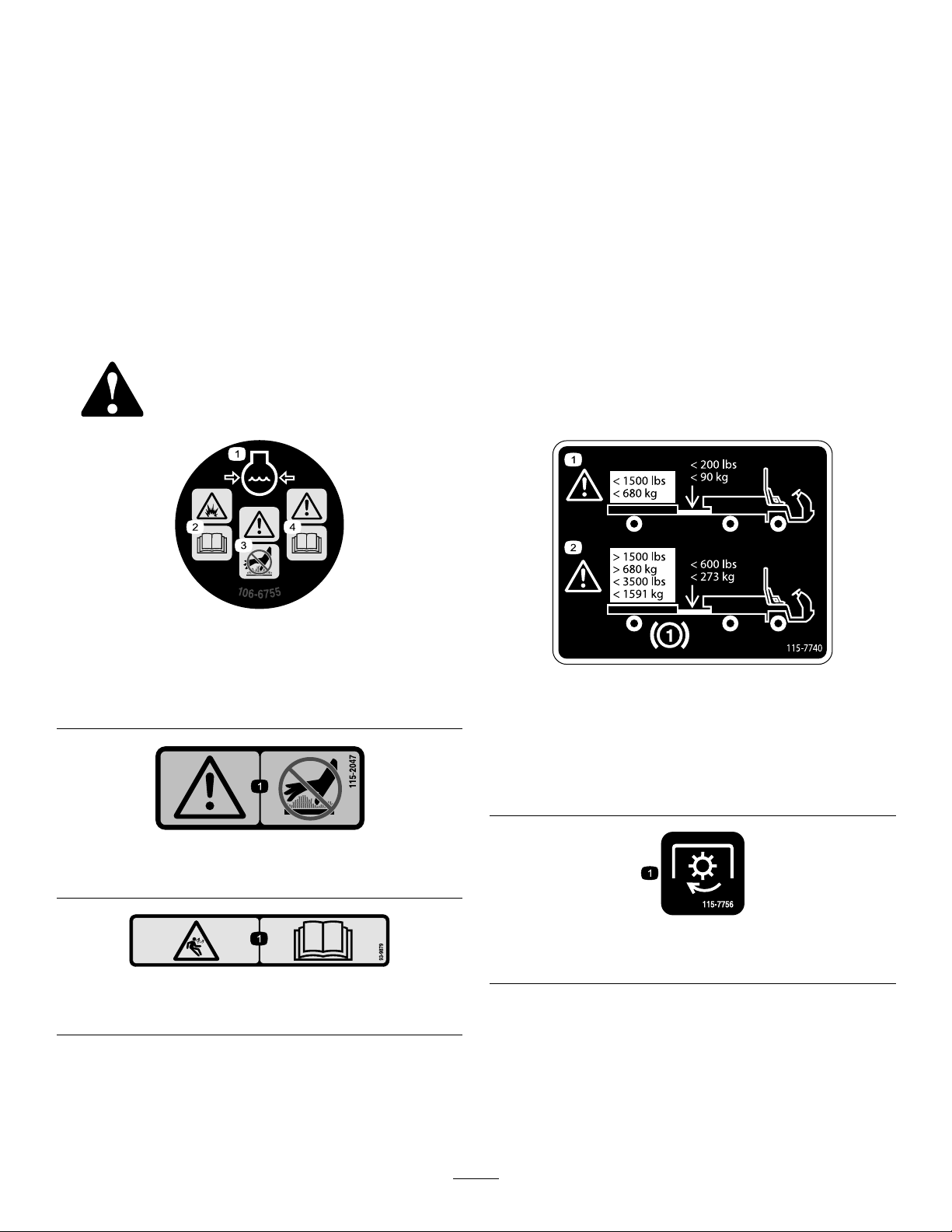

106-6755

1.Enginecoolantunder

pressure.

2.Explosionhazard—read

theOperator'sManual.

1.Warning—donottouchthehotsurface.

1.Storedenergyhazard—readtheOperator'sManual.

3.Warning—donottouchthe

hotsurface.

4.Warning—readthe

Operator'sManual.

115-2047

93-9879

115-7740

1.Warning—maximumtrailerweightis680kg(1500lb);

maximumtongueweightis90kg(200lb).

2.Warning—trailerbrakesarerequiredwhentowinggreater

than680kg(1500lb).Maximumtrailerweightwithtrailer

brakesis1591kg(3500lb)maximumtongueweightwith

trailerbrakesis273kg(600lb).

115-7756

1.Highowhydraulics—engaged

7

Page 8

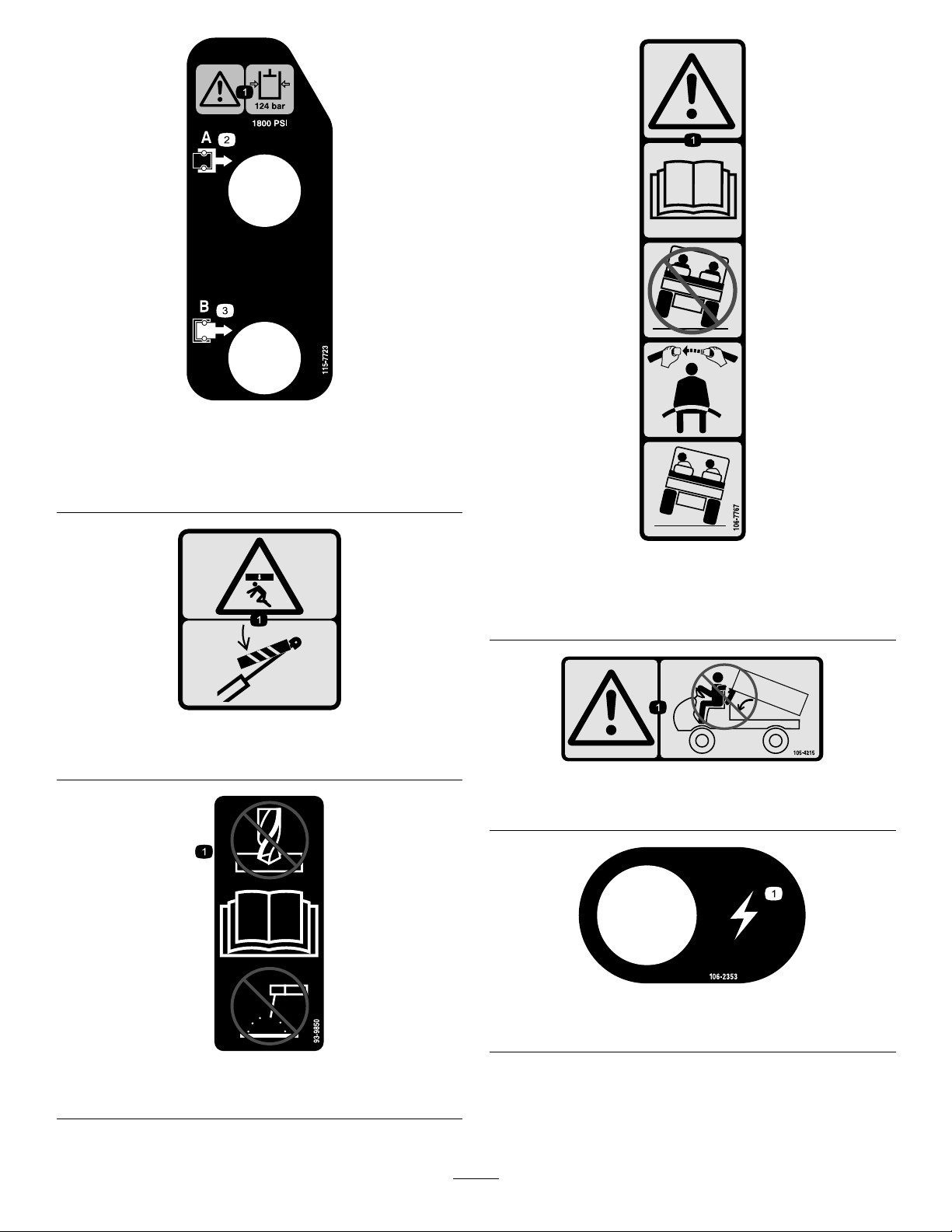

115-7723

93-9899

1.Warning—thehydraulicoilpressureis124bar(1800psi).

2.CouplerA

3.CouplerB

93-9899

1.Crushinghazard—installthecylinderlock.

106-7767

1.Warning—readtheOperator'sManual;avoidtippingthe

machine;weartheseatbelt;leanawayfromthedirection

themachineistipping.

105-4215

1.Warning—avoidpinchpoints.

93-9850

1.Donotrepairorrevise—readtheOperator'sManual.

106-2353

1.Electricalpowerpoint

8

Page 9

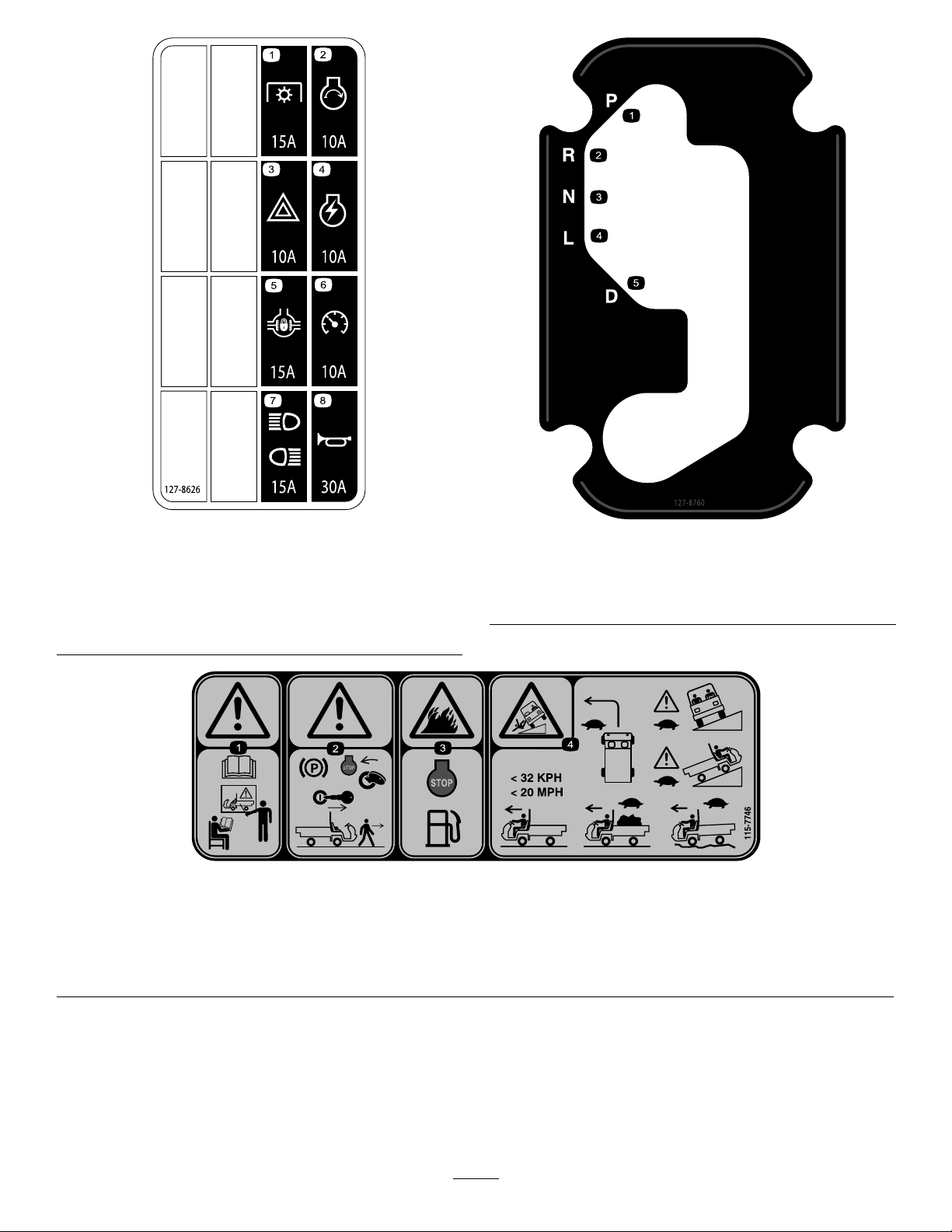

115-7739

1.Falling,crushinghazard,bystanders—noriderson

machine.

93–9868

1.Crushinghazardofhand—readtheOperator’sManual.

BatterySymbols

Someorallofthesesymbolsareonyourbattery .

105–7977

1.Tank2.Pressure

1.Explosionhazard

2.Nore,opename,or

smoking.

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

6.Keepbystandersasafe

distancefromthebattery.

7.Weareyeprotection;

explosivegasescan

causeblindnessandother

injuries

8.Batteryacidcancause

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

10.Containslead;donot

discard.

115-2282

1.Warning—readtheOperator'sManual.

2.Warning—stayawayfrommovingpartsandkeepallguardsandshieldsinplace.

3.Crushing/dismembermenthazardofbystanders—keepbystandersasafedistancefromthevehicle,donotcarrypassengersin

thecargobed,keeparmsandlegsinsideofthevehicleatalltimes,anduseseatbeltsandhandholds.

93-9852

1.Warning—readtheOperator’sManual.2.Crushinghazard—installthecylinderlock.

9

Page 10

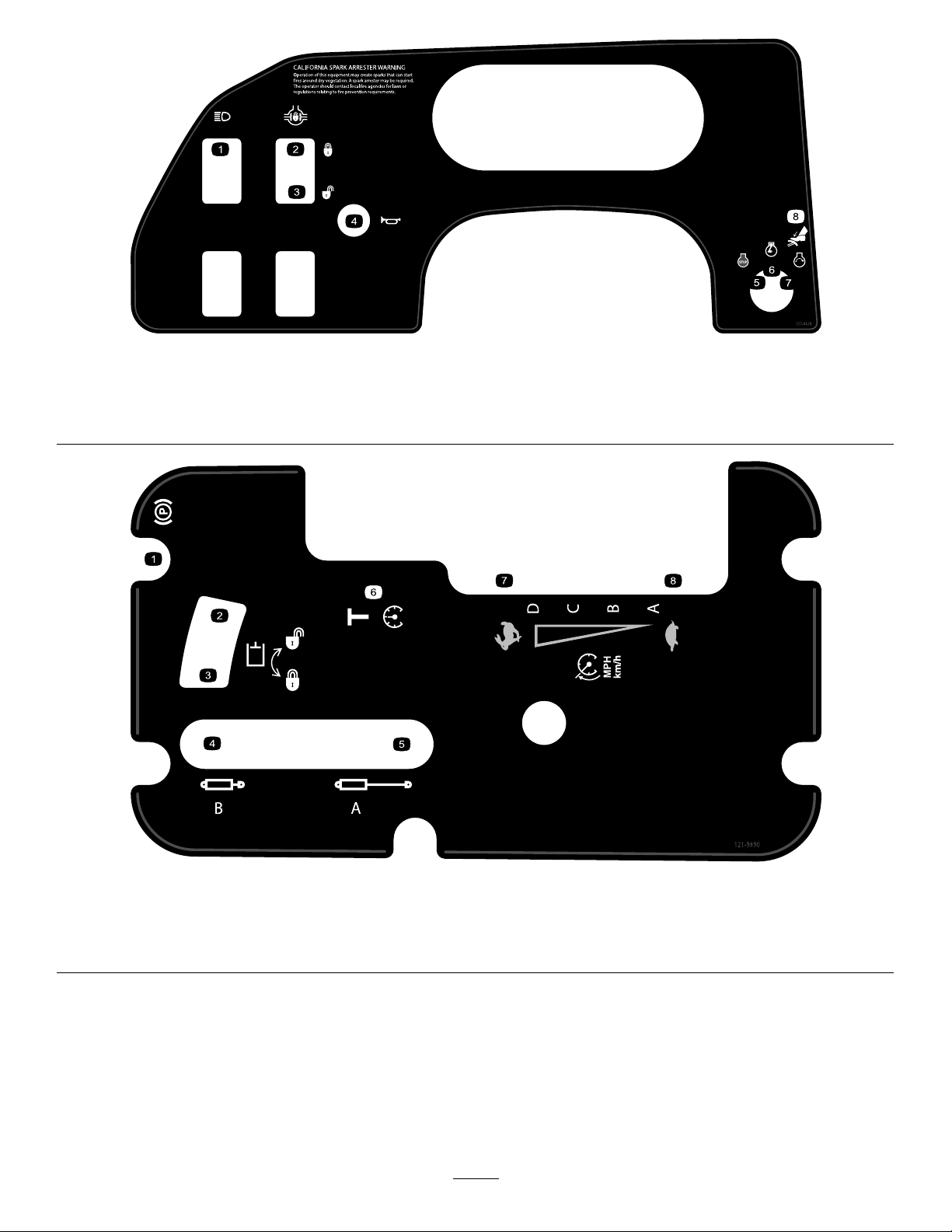

127–8626

1.Powertake-off—15A5.Differentiallock—15A

2.Enginestart—10A

3.Hazards—10A7.Headlightsandrear

4.Engineignition—10A8.Horn—30A

6.Speedometer—10A

lights—15A

127–8760

1.Park4.Lowgear

2.Reverse5.Drive

3.Neutral

115-7746

1.Warning—donotoperatethismachineunlessyouaretrained.

2.Warning—locktheparkingbrake,stoptheengine,and

removetheignitionkeybeforeleavingthemachine.

3.Firehazard—stoptheenginebeforefueling.

4.Tippinghazard—slowdownandturngradually,usecaution

anddriveslowlywhendrivingonslopes,donotexceed32

kph(20mph),anddriveslowlyoverroughterrainorwhen

carryingafullorheavyload.

10

Page 11

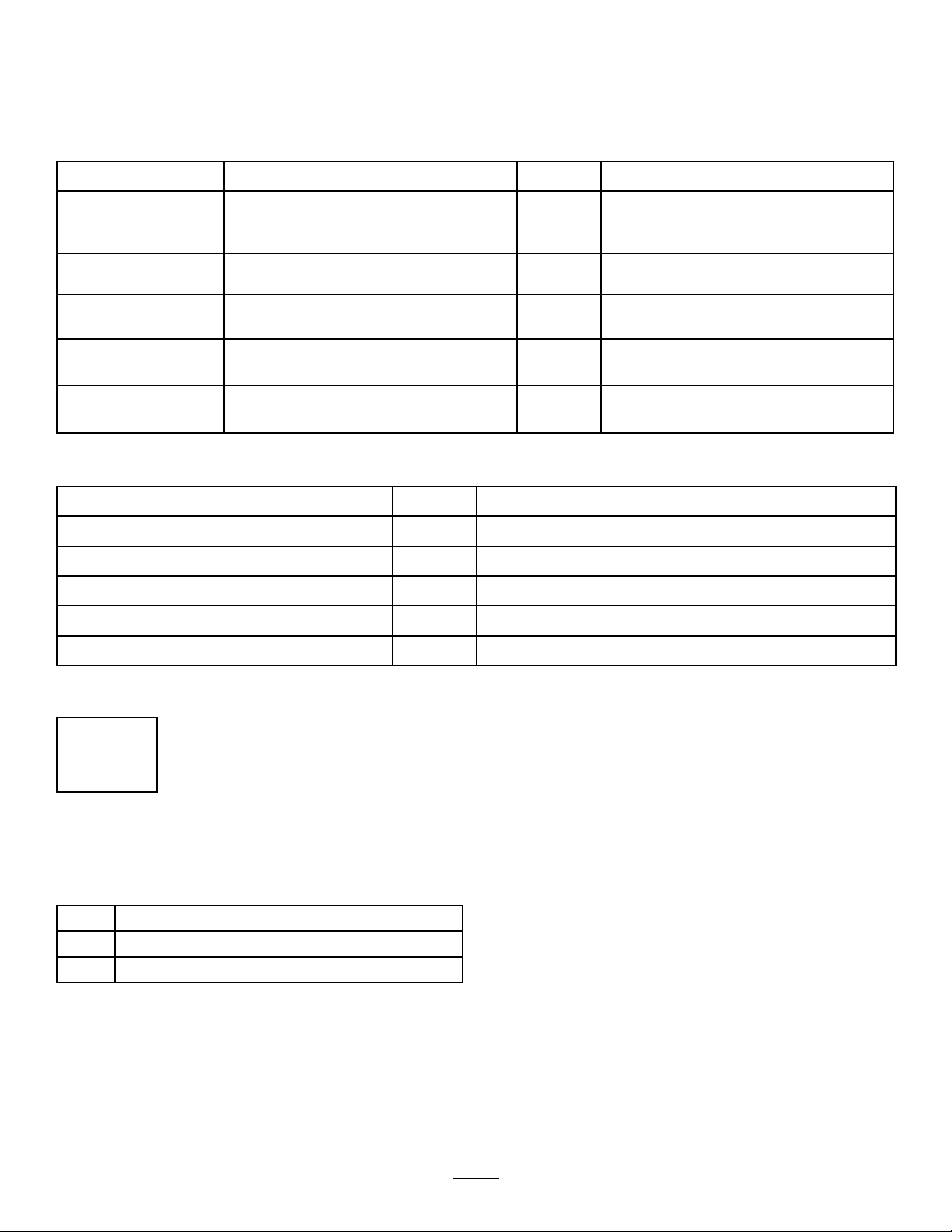

127-8620

1.Headlights4.Horn7.Engine—start

2.Differentiallock—lock

3.Differentiallock—unlock

5.Engine—stop8.Brake

6.Engine—run

1.Parkingbrake

2.Unlock—hydraulicsystem

3.Lock—hydraulicsystem6.Transport

121-9890

4.Cylinderretract

5.Cylinderextend8.Slow

11

7.Fast

Page 12

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

Steeringwheel

1

2

3

4

5

Cover

Washer(5/8inch)

ROPSframe

Flange-headbolt(1/2x1-1/4inch)

Nopartsrequired

Nopartsrequired

Nopartsrequired

MediaandAdditionalParts

Description

Operator'sManual

PartsManual1

OperatorTrainingMaterial

CVTKit121-9853

Qty.

Qty.

1

1

1

1

6

–

–

–

1

1

1

Readbeforeoperatingthevehicle.

Usetoreferencepartnumbers.

Viewbeforeoperatingthemachine.

ConnectingtheCVTIntakeDuct(TCandHModelsOnly)

Installthesteeringwheel.

MounttheROPS(RolloverProtection

System).

Connectthebattery.

Connectthecontinuouslyvariable

transmissionintakeduct.

Checktheengineoil,transaxle/hydraulic

uid,coolant,andbrakeuidlevels.

Use

Use

CVTAdapter127-8750

Note:Determinetheleftandrightsideofthemachinefromthenormaloperatingposition.

1

1

ConnectingtheCVTIntakeDuct(TCandHModelsOnly)

4.Securethesteeringwheeltotheshaftwiththenutand

tightenitto27–34N-m(20-25ft-lb).

5.Installthecoveronthesteeringwheel(Figure3).

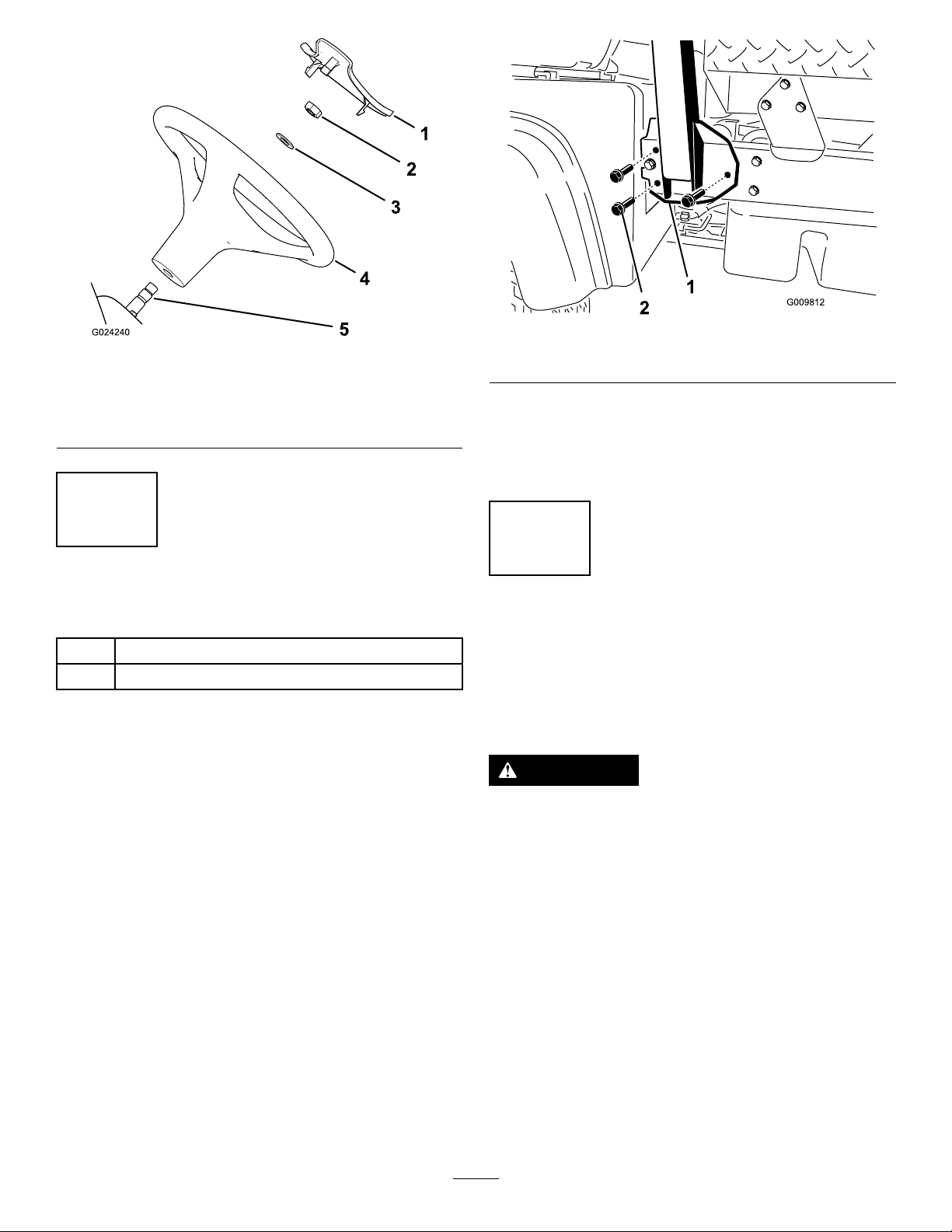

InstallingtheSteeringWheel (TCandHModelsonly)

Partsneededforthisprocedure:

1

Steeringwheel

1

Cover

1

Washer(5/8inch)

Procedure

1.Ifthecoverisinstalled,removetheitfromthehubof

thesteeringwheel(Figure3).

2.Removethenutfromthesteeringshaft(Figure3).

3.Slidethesteeringwheelandwasherontothesteering

shaft(Figure3).

12

Page 13

Figure3

1.Cover4.Steeringwheel

2.Nut

3.Washer(5/8inch)

5.Steeringshaft

2

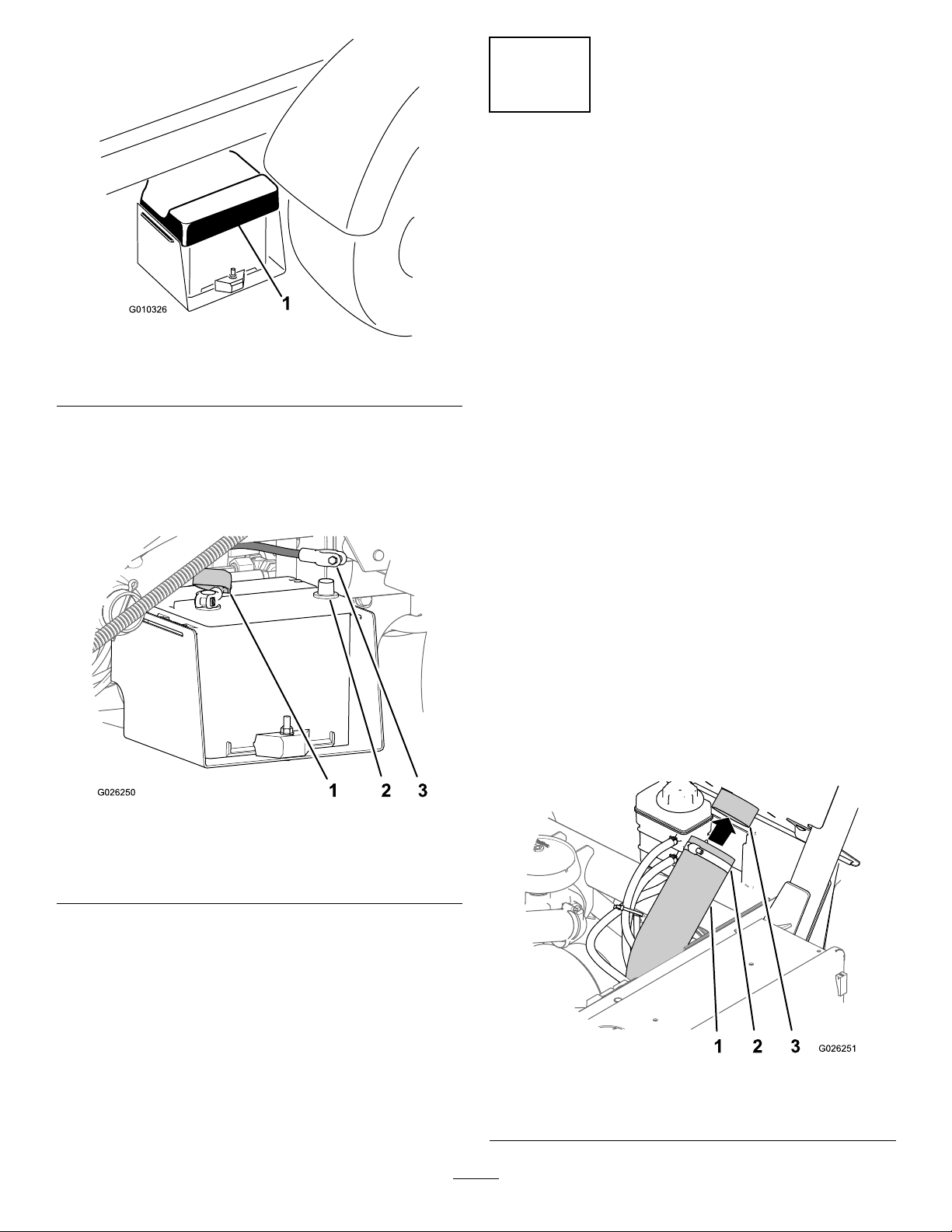

Figure4

1.ROPSmountingbracket

3.SecureeachsideoftheROPSmountingbracketto

frameofthemachinewith3ange-headbolt(1/2x

1-1/4inch).

4.Torquetheange-headboltsto115N-m(85ft-lb).

2.Flange-headbolt

InstallingtheROPS

Partsneededforthisprocedure:

1

ROPSframe

6

Flange-headbolt(1/2x1-1/4inch)

Procedure

1.Applymedium-grade(service-removable)thread

lockingcompoundtothethreadsofthe6ange-head

bolts(1/2x1-1/4inch).

2.AligneachsideoftheROPSwiththemountingholes

oneachsideofframeofthemachineasshownin

Figure4.

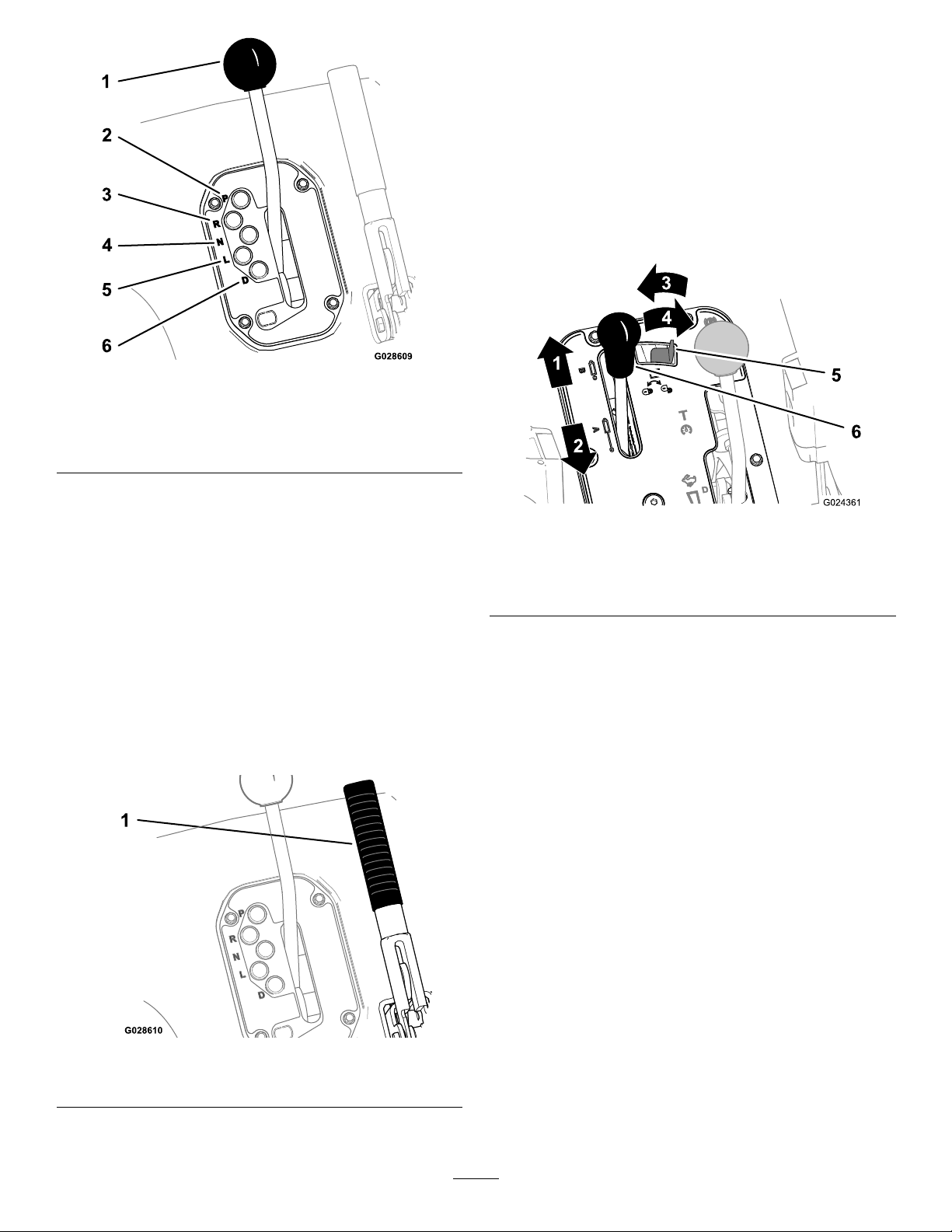

3

ConnectingtheBattery(TC andHModelsonly)

NoPartsRequired

Procedure

WARNING

Incorrectbatterycableroutingcoulddamagethe

machineandcablescausingsparks.Sparkscan

causethebatterygassestoexplode,resultingin

personalinjury.

•Alwaysdisconnectthenegative(black)battery

cablebeforedisconnectingthepositive(red)

cable.

•Alwaysconnectthepositive(red)batterycable

rst.

1.Squeezethebatterycovertoreleasethetabsfromthe

batterybase(Figure5).

13

Page 14

1.Batterycover

Figure5

4

ConnectingtheCVTIntake Duct(TCandHModelsonly)

NoPartsRequired

Procedure

Important:Removetheplasticbagcoveringtheendof

theCVTductbeforestartingtheengineofthemachine.

TheCVTkit121-9853andadapterkit127-8750isrequired

forthisprocedure.

1.Loosenthehoseclampsecuringtheplasticbagatthe

endoftheCVTintakehoseandremovethebag.

2.Removethebatterycoverfromthebatterybase(Figure

5).

3.Installthepositive-batterycable(red)ontothepositive

(+)terminalofthebatteryandsecurethecablewith

theboltsandnuts(Figure6).

Figure6

1.Insulatorboot

(positive-batterycable)

2.Negative-batterypost

3.Negative-batterycable

Note:Discardplasticbag.

2.Raisethecargoboxbyperformingthefollowing:

A.Settheparkingbrake;refertoParkingBrake

(page16).

B.Starttheengine;refertoStartingtheEngine(page

27).

C.Movethehydraulic-liftleverbackwardtoraisethe

cargobox;refertoHydraulicLiftLever(page16).

D.Shutofftheengine;refertoStoppingtheEngine

(page27).

E.Removethebedsupportfromthestoragebrackets

onbackoftheROPSpanelandinstallthesupport

ontothecylinderrodofthebedliftcylinder;refer

toUsingtheBedSafetySupport(page36).

3.AligntheCVTintakehoseontotheintake-tube

connectoratthebacksideoftheROPSpaneland

tightenthehoseclamp(Figure7).

4.Slidetheinsulatorbootoverthepositiveterminal.

Note:Theinsulatorbootisusedtopreventapossible

short-to-groundfromoccurring.

5.Installthenegative-batterycable(black)ontothe

negative(–)terminalofthebatteryandsecurethecable

withboltsandnuts.

6.Alignthebatterycovertothebatterybase(Figure5).

7.Squeezethebatterycover,alignthetabstothebattery

base,andreleasethebatterycover(Figure5).

14

1.CVTintakehose

2.Hoseclamp

Figure7

3.Intake-tubeconnector

Page 15

4.Removethebedsupport,lowerthebed,shutoffthe

engine,andremovethekeyfromtheignitionswitch.

5

ProductOverview

Controls

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

CheckingtheFluidLevels

NoPartsRequired

Procedure

1.Checktheengineoillevelbeforeandaftertheengineis

rstoperated;refertoCheckingtheEngine-oilLevel

(page21).

2.Checkthetransmission-uidlevelbeforetheengineis

rstoperated;refertoCheckingtheTransmission-uid

Level(page47).

3.Checktheengine-coolantlevelbeforetheengineisrst

operated;referto(page).

4.Checkthebrakeuidlevelbeforetheengineisrst

operated;refertoCheckingtheBrakeFluid(page24).

AcceleratorPedal

Theacceleratorpedal(Figure8)givestheoperatortheability

tovarytheengineandgroundspeedofthevehiclewhenthe

transmissionisingear.Pressingthepedalincreasestheengine

speedandgroundspeed.Releasingthepedaldecreasesthe

enginespeedandgroundspeedofthemachine.

Figure8

1.Brakepedal2.Acceleratorpedal

BrakePedal

Usethebrakepedal(Figure8)toapplytheservicebrakes

tostoporslowthemachine.

CAUTION

Brakesthatarewornornotcorrectlyadjustedmay

resultinpersonalinjury.Ifthebrakepedaltravels

towithin3.8cm(1-1/2inches)ofthemachineoor

board,adjustorrepairthebrakes.

TransmissionLever

Usethetransmissionlever(Figure9)toshiftthetransmission

betweenP(park),R(reverse),N(neutral),L(lowforward),

andD(drive)groundoperation.

Important:DonotshiftthetransmissiontotheReverse,

Low,orDrivegearunlessthevehicleisstandingstilland

theengineisatlowidle.Otherwiseyoumaydamage

thetransmission.

15

Page 16

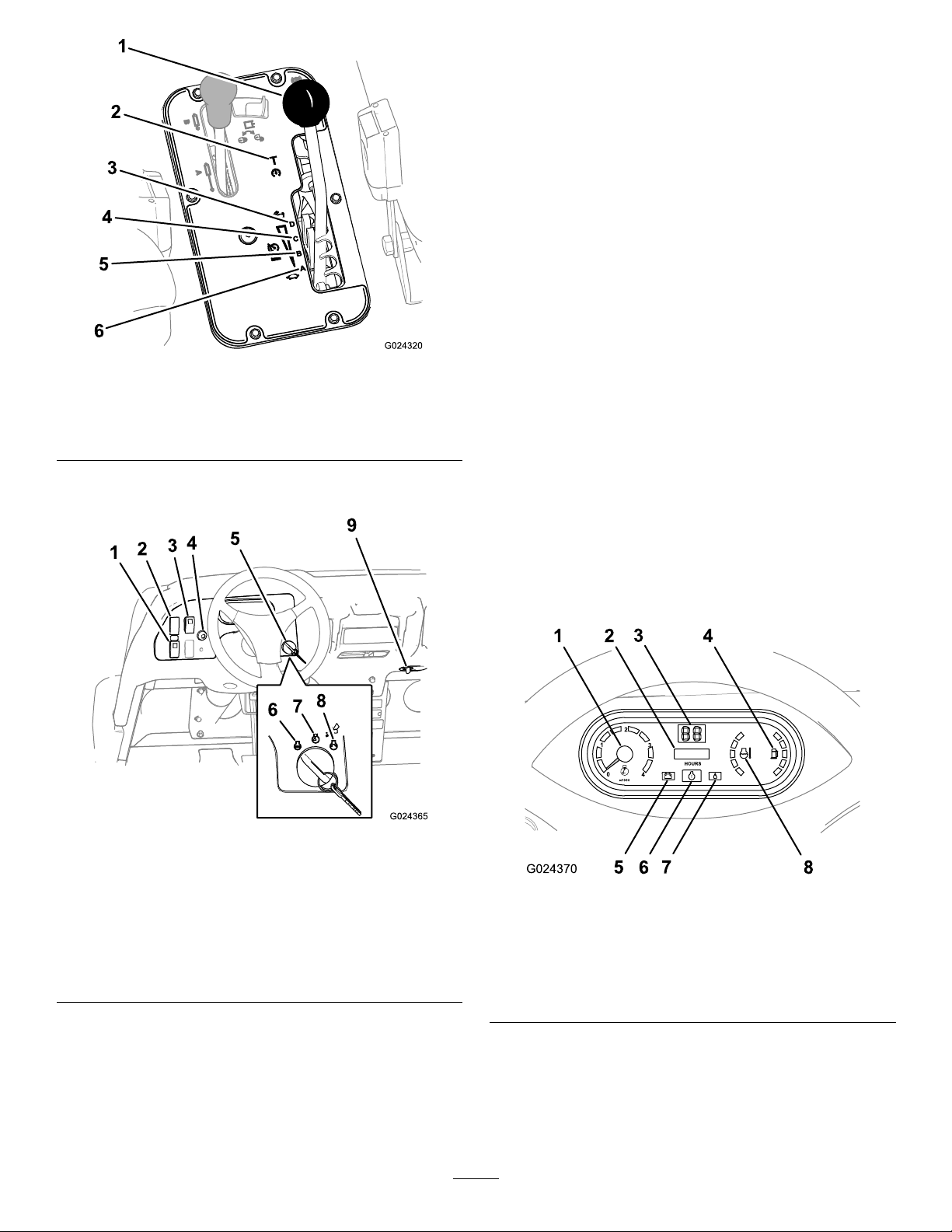

Figure9

HydraulicLiftLever

Thehydraulicliftraisesandlowersthebed.Movethe

hydraulicliftleverrearwardtoraisethebed,andforwardto

lowerit(Figure11).

Important:Whenloweringthebed,holdtheleverinthe

forwardpositionfor1or2secondsafterthebedcontacts

theframetosecureitintheloweredposition.Donot

holdthehydraulicliftineithertheraiseorlowerposition

formorethan5secondsoncethecylindershavereached

theendoftheirtravel.

1.Transmissionlever

2.P(park)5.L(lowforward)

3.R(reverse)6.D(drive)

4.N(neutral)

ParkingBrake

Whenevertheengineisshutoff,settheparkingbrake(Figure

10)topreventaccidentalmovementofthevehicle.

•Tosettheparkingbrake,pullbackontheparking-brake

lever.

•Toreleasetheparkingbrake,pushtheleverforward.

Note:Releasetheparkingbrakebeforemovingthe

vehicle.

•Ifyouparkthevehicleonasteepuphillordownhillgrade,

shiftthetransmissionintoP(park)andsettheparking

brake.Placechocksatthedownhillsideofthewheels.

Figure11

1.Lowerthebed4.Unlocked

2.Raisethebed

3.Locked

5.Hydraulic-liftlock

6.Hydraulic-liftlever

Hydraulic-liftLock

Thehydraulic-liftlocklockstheliftleversothatthehydraulic

cylindersdonotoperatewhenthevehicleisnotequipped

withabed(Figure11).ItalsolockstheliftleverintheOn

positionwhenusingthehydraulicsforattachments.

Speed-rangeLever

Usethespeed-rangelever(Figure12)toselect1of

the4work-speedrangesforprecisecontrolofthe

maximum-groundspeedoratransport-speedrangethatisfor

movingthemachinebetweenjobsites.

1.Parking-brakelever

Figure10

16

Page 17

LightSwitch

Pushthelightswitchdowntotoggletheheadlightsonorpush

thelightswitchuptotoggletheheadlightsoff(Figure13).

Differential-lockSwitch

Thedifferential-lockswitchallowsyoutolocktherearaxle

forincreasedtraction.Pushthedifferential-lockswitch

(Figure13)totogglethedifferentiallockonoroff.

Note:Youmaylockandunlockthedifferentialwhilethe

vehicleisinmotion.

HornButton(TCmodelsonly)

Pressingthehornbuttonactivatesthehorn(Figure13).

Figure12

1.Speed-rangelever4.C(mid-highrange)

2.T(transportrange)5.B(mid-lowrange)

3.D(highrange)6.A(lowrange)

DashboardSwitches

IgnitionSwitch

Usetheignitionswitch(Figure13)tostartandstopthe

engine.Ithas3positions:Off,Run,andStart.Rotatethekey

clockwisetotheStartpositiontoengagethestartermotor.

Releasethekeywhentheenginestarts.Thekeywillmove

automaticallytotheOnposition.Toshuttheengineoff,

rotatethekeycounterclockwisetotheOffposition.

PowerPoint

Usethepowerpointsocket(Figure13)topoweroptional

12-voltelectricalaccessories.

InstrumentCluster

Figure13

1.Highowhydraulicsswitch

(TCmodelsonly)

2.Lightswitch

3.Differentialswitch8.Start

4.Hornbutton(TCmodels

only)

5.Ignitionswitch

HighFlowHydraulicsSwitch(TCmodelsonly)

6.Off

7.On

9.Powerpoint

Pushtheswitchdowntostartthehighowhydraulicsand

pushtheswitchuptoshutoffthehydraulics(Figure13).

Note:Youmustsetthehighowhydraulicsswitchtothe

Offpositioninordertostarttheengine.

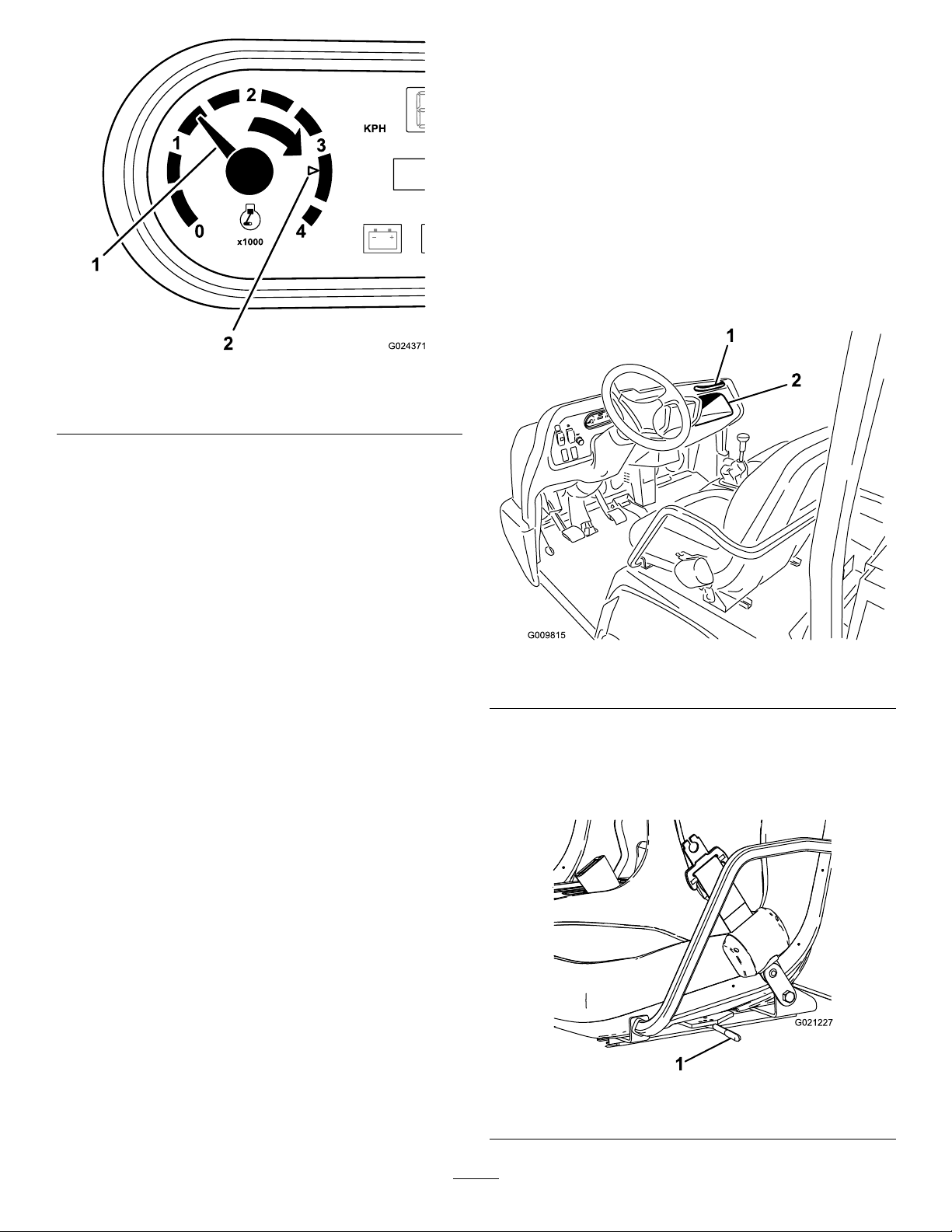

Figure14

1.Tachometer

2.Hourmeter

3.Speedometer

4.Fuelgauge

Tachometer

5.Charge-indicatorlight

6.Check-enginelight

7.Low-oilpressurelight

8.Coolant-temperature

gauge

Thetachometerdisplaysthespeedoftheengine(Figure14).

Note:Thewhitetriangleindicatesthedesiredenginespeed

for540rpmPTOoperation.

17

Page 18

Figure15

temperaturelightwillilluminateredandashiftheengine

overheats.

FuelGauge

Thefuelgaugeshowstheamountoffuelinthetank.It

displaysonlywhenignitionswitchisintheOnposition

(Figure14).Theredsegmentofthedisplayindicateslow

fuellevelandtheashing-redlightindicatesthatthefuelin

thetankisnearempty .

PassengerHandHold

Thepassengerhandholdislocatedonthedashboard(Figure

16).

1.Enginespeed(inrpm)2.3300rpmfor540rpmPTO

operation

HourMeter

Thehourmeterindicatesthetotalhoursofmachine

operation.Thehourmeter(Figure14)startstofunction

wheneverthekeyswitchisrotatedtotheOnpositionorif

theengineisrunning.

Speedometer

Thespeedometerregistersthegroundspeedofthevehicle

(Figure14).Thespeedometerisinmph,butyoucaneasily

convertedthespeedometertokm/h.RefertoConverting

theSpeedometer(page54).

CheckEngineLight

Thecheckenginelight(Figure14)willilluminatetonotify

operatorofaenginemalfunction.

ContactyourauthorizedToroservicedealer.

OilPressureWarningLight

Figure16

1.Passengerhandhold

2.Storagecompartment

SeatAdjustingLever

Usetheseatadjustmentlevertoadjusttheseatforwardor

backwardforoperatorcomfort(Figure17).

Theoilpressurewarninglightilluminates(Figure14)ifthe

engineoilpressuredropsbelowasafelevelwhiletheengine

isrunning.

Important:Ifthelightickersorremainson,stopthe

vehicle,turnofftheengine,andchecktheoillevel.Ifthe

oillevelwaslow,butaddingoildoesnotcausethelight

togooutwhentheengineisstarted,turntheengine

offimmediatelyandcontactyourAuthorizedService

Distributorforassistance.

CoolantT emperatureGaugeandLight

Thecoolanttemperaturegaugedisplaysthecoolant

temperatureoftheengine.Thelightoperatesonlywhenthe

ignitionswitchisinOnposition(Figure14).Thecoolant

Figure17

1.Seat-adjustinglever

18

Page 19

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

Dimensions

OverallWidth160cm(63inches)

withoutbed—326cm(128inches);

OverallLength

BaseWeight(Dry)

RatedCapacity

(includes91kg(200

lb)operator,91kg

(200lb)passengerand

loadedattachment)

MaximumGross

VehicleWeight

TowCapacityTongueweight:272kg(600lb);

GroundClearance18cm(7inches)withnoload

WheelBase

WheelTread(center

linetocenterline)

Height

withfullbed—331cm(130inches);

with2/3bedinrearmounting

location—346cm(136inches)

Model07390—866kg(1905lb);

Model07390H—866kg(1905lb);

Model07390TC—887kg(1951lb)

Model07390—1498kg(3295lb);

Model07390TC—1477kg(3249lb);

Model07090H—1498kg(3298lb)

2363kg(5210lb)

Maximumtrailerweight:1587kg

(3,500lb)

118cm(70inches)

Front:117cm(46inches);Rear:121

cm(48inches)

191cm(75inches)totopofROPS

Operation

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

CAUTION

Youmaybeinjuredorkillediftheraisedbedofthe

machinefallsonyou.

Beforeworkingunderaraisedbed,removeany

cargoandpositionthesafetysupportonthefully

extendedcylinderrod.

OperatingtheCargoBox

RaisingtheCargoBox

WARNING

Drivingthevehiclewiththecargoboxraisedmay

causethevehicletotiporrolleasier.Thebox

structuremaybecomedamagedifyouoperatethe

vehiclewiththeboxraised.

•Onlyoperatethevehiclewhenthecargoboxis

down.

•Afterdumpingaload,lowerthecargobox.

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesis

availableforusewiththemachinetoenhanceandexpand

itscapabilities.ContactyourAuthorizedServiceDealeror

Distributororgotowww .Toro.comforalistofallapproved

attachmentsandaccessories.

CAUTION

Ifaloadisconcentratednearthebackofthecargo

boxwhenyoureleasethelatches,thetailgatemay

unexpectedlytipopen,injuringyouorbystanders.

•Centertheloadinthecargobox,ifpossible.

•Ensurethatnooneisleaningovertheboxor

standingbehinditwhenreleasingthetailgate

latches.

•Removeallcargofromtheboxbeforeliftingthe

boxuptoservicethemachine.

1.Settheparkingbrake;refertoParkingBrake(page16).

2.Starttheengine;refertoStartingtheEngine(page27).

3.Movetheleverbackwardtoraisethecargoboxtothe

desiredposition.(Figure18).

Note:Ifyouaremaintainingthemachineandneedto

havetheboxraised,securetheboxwiththebedsafety

support;refertoUsingtheBedSafetySupport(page

36).

19

Page 20

Figure18

1.Cargo-boxlever

LoweringtheBox

WARNING

Theweightoftheboxmaybeheavy.Handsor

otherbodypartscouldbecrushed.

Keephandsandotherbodypartsclearwhen

loweringthebox.

Figure19

1.Latchhandle3.Latchpin

2.Latchgate

1.Ensurethattheparkingbrakeisset;refertoParking

Brake(page16).

2.Ifthebedsupportisinstalled,removetheit;referto

UsingtheBedSafetySupport(page36).

3.Starttheengine;refertoStartingtheEngine(page27).

4.Movetheleverforwardtolowerthecargobox(Figure

18).

OpeningtheTailgate

1.Ensurethatthecargoboxisdownandlatched.

2.Openthelatchesontheleftandrightsideofthecargo

box(Figure19)andlowerthetailgate.

CheckingtheFluidLevels

PreparingtoChecktheFluidLevels

1.Movethemachinetoalevelsurface.

2.ShiftthetransmissiontotheParkposition,shutoff

theengine,settheparkingbrake,andremovethekey

fromtheignitionswitch.

3.Allowthemachinetocoolbeforeyouchecktheuid

levelsofthemachine.

4.Checkthefollowing:

Note:Checkingtheengineoil,hydraulicuidlevel,or

coolantlevelrequiresraisingandloweringthecargo

boxofthemachine;refertoOperatingtheCargoBox

(page19).

•CheckingtheEngine-oilLevel(page21)

•CheckingtheHydraulicFluid(page22)

•(page)

•CheckingtheBrakeFluid(page24)

20

Page 21

CheckingtheEngine-oilLevel

G016095

ServiceInterval:Beforeeachuseordaily—Checkthe

engine-oillevel.(Checktheoillevel

beforeandaftertheengineisrststarted

anddailythereafter.)

3.Removedipstickandchecktheleveloftheoil(Figure

21).

4.Iftheoillevelislow,removethellercap(Figure21)

andaddenoughoiltoraisetheleveltotheFullmark

onthedipstick.

OilType:ahigh-quality10W-30APIserviceclassication

SJorhigher.

RefertothetableinFigure20foroilviscosityaccording

ambientairtemperature.

Figure20

Note:Theengineisshippedwithapproximately2.0L(2.1

qt)ofoilinthecrankcase(includingtheoillter).

Note:Thebesttimetochecktheengineoiliswhenthe

engineiscoolbeforeithasbeenstartedfortheday.Ifthe

enginehasalreadybeenrun,shutitoffandwaitforatleast

10minutesbeforecheckingtheoillevel.

1.Removethedipstick(Figure21)andwipeitwitha

cleanrag.

Note:Whenaddingoil,removedipsticktoallow

properventing.Slowlypourtheoilintothellerneck,

andchecktheleveloftenduringthisprocess.Donot

overlltheenginewithoil.

Figure22

1.Notetheclearancebetweenthelldeviceandtheoilll

neck

Important:Whenaddingengineoilorllingoil,

theremustbeclearancebetweentheoillldevice

andtheoilllneckinthevalvecoverasshownin

Figure22.Thisclearanceisnecessarytopermit

ventingwhenaddingoil.

Figure21

1.Dipsticktube3.Fillercap

2.Fillerneck4.Dipstick

2.Insertthedipstickintothetubeandmakesurethat

itisseatedfully.

5.Installthellercapontothellerneck(Figure21).

6.Firmlyinstallthedipstickintothedipsticktube(Figure

21).

21

Page 22

CheckingtheHydraulicFluid

ServiceInterval:Beforeeachuseordaily(Checkthelevelof

hydraulicuidbeforetheengineisrst

startedanddailythereafter.)

HydraulicFluidType:MobilM15

HydraulicFluidCapacity:(Non-TCmodel):7.5l(2US

gallons)

HydraulicFluidCapacity:(Non-TCmodelwiththeHigh

FlowHydraulicKit(option)orTCModel):15.1l(4US

gallons)

WARNING

Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjury.

•Makesurethatallhydraulicuidhosesand

linesareingoodconditionandallhydraulic

connectionsandttingsaretightbefore

applyingpressuretothehydraulicsystem.

•Keepyourbodyandhandsawayfrompinhole

leaksornozzlesthatejecthighpressure

hydraulicuid.

Figure23

HydraulicFluidLevel(Non-TCmodels)

1.Cap

2.Dipstick3.Fillerneck

•Usecardboardorpapertondhydraulicleaks.

•Safelyrelieveallpressureinthehydraulicsystem

beforeperforminganyworkonthehydraulic

system.

•Seekimmediatemedicalattentionifuidis

injectedintoyourskin.

1.Cleantheareaaroundthellerneckandthecapofthe

hydraulicreservoir(Figure23andFigure24).

Figure24

HydraulicFluidLevel(Non-TCmodelwiththeHighFlow

HydraulicKit(option)orTCmodel)

1.Cap

22

2.Dipstick3.Fillerneck

Page 23

2.Removethecapanddipstickfromthellerneckofthe

1

G019522

reservoirandwipethedipstickcleanwitharag(Figure

23andFigure24).

3.Insertthedipstickintothellerneck;thenremoveit

andchecktheuidlevel(Figure23andFigure24).

•Non-TCmodel:theuidlevelshouldbebetween

thelowerindentedareaonthedipstick.

•Non-TCmodelwiththeHighFlowHydraulic

Kit(option)orTCmodel:theuidlevelshould

bebetweentheupperindentedareaonthedipstick.

4.Ifthelevelislow ,addthespeciedhydraulicuidinto

thereservoirtoraisetheleveltothemiddleofthe

indentedareaonthedipstick(Figure23andFigure24).

5.Installthedipstickandcaptothellerneckofthe

reservoir(Figure23andFigure24).

CheckingtheCoolantLevel

ServiceInterval:BeforeeachuseordailyChecktheCoolant

levelattheoverowreservoironly.Do

Notremovetheradiatorcap.(Checkthe

coolantlevelbeforetheengineisrst

startedanddailythereafter.)

Figure25

1.Coolantreservetank

Coolanttype:a50/50solutionofwaterandpermanent

ethyleneglycolantifreeze

1.Parkthemachineonalevelsurface.

CAUTION

Iftheenginehasbeenrunning,the

pressurized,hotcoolantcanescapeandcause

burns.

•Donotopentheradiatorcap.

•Allowtheenginetocoolatleast15minutes

oruntiltheradiatorcapiscoolenoughto

touchwithoutburningyourhand.

•Usearagwhenopeningthereservetank

cap,andopenthecapslowlytoallow

steamtoescape.

•Donotcheckthecoolantlevelatthe

radiator;checkthecoolantlevelonlyatthe

reservetank.

2.Checkthecoolantlevelatthereservetank(Figure25).

3.Ifcoolantislow ,removethereservetankcapandadda

50/50mixtureofwaterandpermanentethylene-glycol

antifreeze.

Note:Donotoverll.

4.Installthereserve-tankcap.

Note:Thecoolantshouldbeuptothebottomof

thellerneck.

23

Page 24

CheckingtheBrakeFluid

ServiceInterval:Beforeeachuseordaily—Checkthebrake

uidlevel.(Checkthelevelbeforethe

engineisrststartedanddailythereafter.)

Every1,000hours/Every2years(whichevercomes

rst)—Changethebrakeuid.

Brakeuidtype:DOT3brakeuid

Note:Thebrake-uidreservoirisshippedfromthefactory

lledwithDOT3brakeuid.

Thebrake-uidreservoirislocatedunderthehoodandbelow

thedash.

1.Parkthemachineonalevelsurface.

2.Removethehood;refertoRemovingtheHood(page

38).

3.Checktheuidlevelinthebrake-uidreservoir(Figure

26andFigure27).

Note:TheuidlevelshouldbeuptotheFullline

onthereservoir.

Figure27

1.Brake-uidreservoir

4.Iftheuidlevelislow,performthefollowing:

A.Cleantheareaaroundthecapforthereservoir

(Figure27).

B.Removethereservoircap(Figure27).

C.AddthespeciedbrakeuidtotheFulllineon

thereservoir(Figure27).

Note:Donotoverllthebrake-uidreservoir.

D.Installthecap(Figure27).

5.Installthehood;refertoRemovingtheHood(page38).

CheckingtheOilPressure WarningLight

ServiceInterval:Beforeeachuseordaily

Note:Ifyoujuststoppedtheengine,itmaytake1to2

minutesforthelighttocomeon.

1.Brake-uidreservoir

1.Applytheparkingbrake.

2.TurntheignitionkeytotheOnposition,butdonot

starttheengine.

Note:Theoilpressurelightshouldglowred.

Figure26

Note:Ifthelightdoesnotfunction,eitherabulb

isburnedoutorthereisamalfunctioninthesystem

whichmustberepaired.

24

Page 25

AddingFuel

DANGER

Fueltankcapacity:25L(6.5USgallons).

•Forbestresults,useonlyclean,fresh(lessthan30days

old),unleadedgasolinewithanoctaneratingof87or

higher((R+M)/2ratingmethod).

•ETHANOL:Gasolinewithupto10%ethanol(gasohol)

or15%MTBE(methyltertiarybutylether)byvolume

isacceptable.EthanolandMTBEarenotthesame.

Gasolinewith15%ethanol(E15)byvolumeisnot

approvedforuse.Neverusegasolinethatcontainsmore

than10%ethanolbyvolume,suchasE15(contains15%

ethanol),E20(contains20%ethanol),orE85(contains

upto85%ethanol).Usingunapprovedgasolinemay

causeperformanceproblemsand/orenginedamage

whichmaynotbecoveredunderwarranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuelcontainers

overthewinterunlessafuelstabilizerisused.

•Donotaddoiltogasoline.

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Beforeremovingthefueltankcap,makesure

thatthevehicleispositionedonalevelsurface.

Openthefueltankcapslowly.

Incertainconditionsduringfueling,static

electricitycanbereleased,causingaspark,which

canignitethegasolinevapors.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Alwaysplacegasolinecontainersontheground

awayfromyourvehiclebeforelling.

•Donotllgasolinecontainersinsideavehicleor

onatruckortrailerbed,becauseinteriorcarpets

orplastictruckbedlinersmayinsulatethe

containerandslowthelossofanystaticcharge.

•Whenpractical,removegas-poweredequipment

fromthetruckortrailerandrefueltheequipment

withitswheelsontheground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfromaportable

container,ratherthanfromagasolinedispenser

nozzle.

•Ifyoumustuseagasolinedispensernozzle,,

keepthenozzleincontactwiththerimofthe

fueltankorcontaineropeningatalltimesuntil

fuelingiscomplete.

1.Cleantheareaaroundthefuel-tankcap(Figure28).

2.Removethefuel-tankcap(Figure28).

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupanygasoline

thatspills.

•Neverllthefueltankinsideanenclosedtrailer.

•Donotllthefueltankcompletelyfull.Add

gasolinetothefueltankuntilthelevelis25mm

(1inch)belowthebottomofthellerneck.This

emptyspaceinthetankallowsthegasolineto

expand.

•Neversmokewhenhandlinggasoline,andstay

awayfromanopenameorwheregasoline

fumesmaybeignitedbyaspark.

•Storegasolineinanapprovedcontainerand

keepitoutofthereachofchildren.Neverbuy

morethana30-daysupplyofgasoline.

•Donotoperatethemachinewithouttheentire

exhaustsysteminplaceandinproperworking

condition.

Figure28

1.Fuel-tankcap

3.Fillthetanktoabout1inchbelowthetopofthetank,

(bottomofthellerneck),theninstallthecap.

Note:Donotoverllthefueltankwithfuel.

4.Wipeupanyfuelthatmayhavespilledtopreventa

rehazard.

25

Page 26

CheckingtheTirePressure

ServiceInterval:Beforeeachuseordaily

Themaximumairpressureinthefronttiresis220kPa(32

psi)andthereartiresis124kPa(18psi).

Checkthetirepressurefrequentlytoensureproperination.

Ifthetiresarenotinatedtothecorrectpressure,thetread

willwearprematurely.

Figure29showsanexampleoftirewearcausedbyunder

ination.

Figure29

1.Under-inatedtire

Figure30showsanexampleoftirewearcausedbyover

ination.

Figure31

1.Radiatorscreen

2.Latch

4.Ifsoequipped,rotatethelatchesandpivottheoil

coolerawayfromtheradiator(Figure32).

Figure32

1.Radiatorhousing3.Latches

2.Oilcooler

Figure30

1.Over-inatedtire

RemovingDebrisfromthe CoolingSystem

ServiceInterval:Beforeeachuseordaily(Cleanitmore

frequentlyindirtyconditions.)

1.Shutofftheengine.

2.Cleantheengineareathoroughlyofalldebris.

3.Unlatchandremovetheradiatorscreenfromthefront

oftheradiator(Figure31).

5.Cleantheradiator,oilcooler,andscreenthoroughly

withcompressedair.

Note:Blowdebrisawayfromtheradiator.

6.Installthecoolerandscreentotheradiator.

PreformingPre-startChecks

Safeoperationbeginsbeforetakingthevehicleoutforaday’ s

work.Y oushouldchecktheseitemseachtime:

•Checkthetirepressure.

Note:Thesetiresaredifferentthancartires,theyrequire

lesspressuretominimizeturfcompactionanddamage.

•Checkalluidlevelsandaddtheappropriateamountof

Torospecieduids,ifanyarefoundtobelow.

•Checkthefrontoftheradiator.Removeanydebrisand

cleantheradiatorscreen.

•Checkthebrakepedaloperation.

•Checktheoilpressurewarninglight.

•Checktoseethatthelightsareworking.

26

Page 27

•Turnthesteeringwheeltotheleftandrighttocheckthe

steeringresponse.

•Stoptheengineandwaitformovingpartstostop,then

checkforoilleaks,looseparts,andanyothernoticeable

malfunctions.

GearSpeed(kmh)Speed(mph)

R(reverse)

L(lowforward)

D(Drive)

0to210to13

0to180to11

0to320to20

Ifanyoftheaboveitemsarenotcorrect,notifyyourmechanic

orcheckwithyoursupervisorbeforetakingthevehicleout

fortheday.Yoursupervisormaywantyoutocheckother

itemsonadailybasis,soaskwhatyourresponsibilitiesare.

StartingtheEngine

Important:Donotattempttopushortowvehicletoget

itstarted.Damagetothedrivetraincouldresult.

Note:Referto(page).

1.Sitontheoperatorseatandengagetheparkingbrake.

2.DisengagethePTOandhighowhydraulics(ifso

equipped)andmovethehandthrottlelevertotheOff

position(ifsoequipped).

3.MovethetransmissionlevertotheP(park)position.

4.Ensurethatthehydraulic-liftleverisintheOffposition

(center).

5.Pressthebrakepedal.

Note:Keepyourfootofftheacceleratorpedal.

6.Insertkeyintoignitionswitchandrotateitclockwise

tostarttheengine.

Note:Avoidlongperiodsofengineidling.

Note:LeavingignitionswitchintheOnpositionfor

longperiodsoftimewithoutrunningtheenginewill

dischargethebattery.

StoppingtheVehicle

Note:Referto(page).

Tostopthevehicle,removeyourfootfromtheaccelerator

pedal,thenpressthebrakepedal.

StoppingtheEngine

Note:Referto(page).

1.Ensurethatthemachineisstopped.

2.MovethetransmissionlevertotheP(Park)position.

3.Settheparkingbrake.

4.RotatetheignitionkeytotheOffpositionandremove

thekeyfromtheswitch.

Note:Releasekeywhenenginestarts.

Note:Theengineoilpressurewarninglightshould

turnoff.

Important:Topreventoverheatingofthestarter

motor,donotengagestarterlongerthan15

seconds.After15secondsofcontinuouscranking,

wait60secondsbeforeengagingstartermotor

again.

DrivingtheVehicle

Note:Referto(page).

1.Pressthebrakepedal.

2.Releasetheparkingbrake.

3.Movethetransmissionlevertothedesiredgear.

4.Releasetheservicebrakeandgraduallypressinthe

acceleratorpedal.

Important:Alwaysstopthevehiclebeforeshifting

toreverseaforwardgearortoaforwardgearfrom

reverse.

Usethechartbelowtodeterminethegroundspeed

ofeachgearwhenoperatingthemachinewiththe

speed-rangecontrolintheT(transport)position.

UsingtheSpeed-rangeControl

Usetheleverofthespeed-rangecontroltolimitthe

maximumgroundspeedofthemachineforoperationsthat

requireaconstantspeedlikesprayingandtopdressing.The

speed-rangelever(Figure33)isusedtoselect1ofthe4

work-speedrangesthatareusedtolimitmaximumground

speedoratransport-speedrangethatisusedwhenyoumove

themachinebetweenjobsites.

Note:Youmustreleasetheacceleratorpedalinorderto

shiftbetweenspeedranges,butyoudonotneedtostopthe

machineinordertoshift.

•Movethespeed-rangeleverintothedetentfor

speedrangesA,B,C,andDwhenprecisecontrolof

maximum-groundspeedisdesired.

•Movethespeed-rangelevertotransportpositionby

movingthespeed-rangeleveroutofthedetentforrange

A,B ,C,orD,thenforwardtotheTposition.

Note:Usethespeed-rangecontroltolimitthe

maximum-groundspeedineachrangeby4to18kmh(2.5to

11mph)withthetransmissionleverintheLlow(forward)

positionor8to32kmh(5to20mph)withthetransmission

leverintheintheDdriveposition.

27

Page 28

Figure33

1.Speed-rangelever4.C(mid-highrange)

2.T(transportrange)5.B(mid-lowrange)

3.D(highrange)6.A(lowrange)

Thedifferentiallockcausestherearwheelstospinatthe

samespeed.Whenusingdifferentiallockyourabilitytomake

sharpturnsissomewhatrestrictedandmayscufftheturf.Use

thedifferentiallockonlywhenneededandatslowerspeeds.

Note:Vehiclemotionplusaslightturnisrequiredtoengage

ordisengagedifferentiallock.

•Pressthedifferential-lockswitchuptolockthedifferential

(Figure34).

Note:Thelightinthedifferential-lockswitchwill

illuminatewhentheswitchisinthelockposition.

•Pressthedifferential-lockswitchuptounlockthe

differential(Figure34).

UsingtheDifferentialLock

WARNING

Tippingorrollingthevehicleonahillcancausea

seriousinjury.

•Theextratractionavailablewiththedifferential

lockcanbeenoughtogetyouintodangerous

situationssuchasclimbingslopesthataretoo

steeptoturnaround.Beextracarefulwhen

operatingwiththedifferentiallockon,especially

onsteeperslopes.

•Ifthedifferentiallockisonwhenmakinga

sharpturnatahigherspeedandtheinsiderear

wheelliftsofftheground,theremaybealossof

controlwhichcouldcausevehicletoskid.Use

thedifferentiallockonlyatslowerspeeds.

CAUTION

Turningwiththedifferentiallockoncanresult

inlossofvehiclecontrol.Donotoperatewith

differentiallockonwhenmakingsharpturnsorat

highspeeds.

Thedifferentiallockincreasesthetractionofthevehicleby

lockingtherearwheelssothat1wheelwillnotspinout.

Thiscanhelpwhenyouhaveheavyloadstohaulonwet

turforslipperyareas,goinguphills,andonsandysurfaces.

Itisimportanttorememberthatthisextratractionisonly

fortemporarylimiteduse.Itsusedoesnotreplacethesafe

operationalreadydiscussedconcerningsteephillsandheavy

loads.

Figure34

1.Lockposition

(differential-lockswitch)

2.Unlockposition

(differential-lockswitch)

BreakinginaNewMachine

ServiceInterval:Aftertherst100hours

•Checktheuidandengineoillevelsregularlyandbealert

forindicationsofoverheatinginanycomponentofthe

vehicle.

•Afterstartingacoldengine,letitwarmupforabout15

secondsbeforeshiftingintogear.

Note:Allowmoretimetowarm-uptheenginewhen

operatingincoldambienttemperatures.

•Avoidracingtheengine.

•Toensureoptimumperformanceofthebrakesystem,

burnish(break–in)thebrakesbeforeuse.Toburnishthe

brakes,bringthevehicleuptofullspeed,applythebrakes

torapidlystopthevehiclewithoutlockingupthetires.

Repeatthis10times,waiting1minutebetweenstopsto

avoidoverheatingthebrakes.Thisismosteffectiveifthe

vehicleisloadedwith454kg(1000lb).

•Varyvehiclespeedsduringoperation.Avoidexcessive

idling.Avoidfaststartsandquickstops.

•Abreak–inoilfortheengineisnotrequired.The

originalengineoilisthesametypespeciedforregular

oilchanges.

•RefertoHeavyDutyOperation(page35)foranyspecial

low-hourchecks.

28

Page 29

CheckingtheInterlockSystem

ServiceInterval:Beforeeachuseordaily

Thepurposeoftheinterlocksystemistopreventtheengine

fromcrankingorstartingunlessthebrakepedalispressed

andthehydraulicliftleverintheNeutralposition.

1.Sitontheoperator’sseatandengagetheparkingbrake.

2.MovetheshiftlevertotheNeutralpositionandensure

thatthehydraulicliftleverisinthecenterposition.

3.SetthehighowhydraulicswitchtotheOnposition.

4.Pressbrakepedal.

CAUTION

Ifsafetyinterlockswitchesaredisconnectedor

damaged,themachinecouldoperateunexpectedly

causingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlockswitches

dailyandreplaceanydamagedswitchesbefore

operatingthemachine.

Note:RefertoAttachmentOperator’sManualforprocedures

oncheckingtheattachmentinterlocksystem.

VerifyingtheHydraulicLiftLever

InterlockSwitch

1.Sitontheoperator’ sseatandsettheparkingbrake.

2.MovetheshiftlevertotheNeutralposition,ensure

thatthehydraulicliftleverisinthecenterposition.

3.IfNon-TCmodelwiththeHighFlowHydraulicKit

(option)orTCmodel,setthehighowhydraulic

switchtotheOffposition.

4.Pressbrakepedal.

5.Movethehydraulicliftleverforwardandrotatethe

ignitionkeyclockwisetothestartposition.

5.Rotatetheignitionkeyclockwisetothestartposition.

Ifenginecranksorstarts,thereisamalfunctioninthe

interlocksystemthatmustberepairedbeforeoperating

vehicle.

TransportingtheMachine

Formovingthemachinelongdistances,useatrailer.Make

surethatthemachineissecuredtothetrailer.RefertoFigure

35andFigure36forthelocationofthetie-downpoints.

Important:Trailersweighingover680kg(1500lb)are

requiredtobeequippedwithtrailerbrakes.

Note:Loadthemachineonthetrailerwiththefrontofthe

machinefacingforward.Ifthatisnotpossible,securethe

hoodofthemachinetotheframewithastraporremovethe

hoodandtransportandsecureitseparately,otherwisethe

hoodmayblowoffduringtransport.

Ifenginecranksorstarts,thereisamalfunctioninthe

interlocksystemthatmustberepairedbeforeoperating

vehicle.

VerifyingtheBrakePedalInterlock

Switch

1.Sitontheoperator’ sseatandsettheparkingbrake.

2.MovetheshiftlevertotheNeutralposition,ensure

thatthehydraulicliftleverisinthecenterposition.

3.IfNon-TCmodelwiththeHighFlowHydraulicKit

(option)orTCmodel,setthehighowhydraulic

switchtotheOffposition.

4.Rotatetheignitionkeyclockwisetothestartposition.

Note:Donotpressthebrakepedal

Ifenginecranksorstarts,thereisamalfunctioninthe

interlocksystemthatmustberepairedbeforeoperating

vehicle.

VerifyingtheHighFlowSwitchInterlock

Non-TCmodelwiththeHighFlowHydraulicKit(option)

orTCmodel

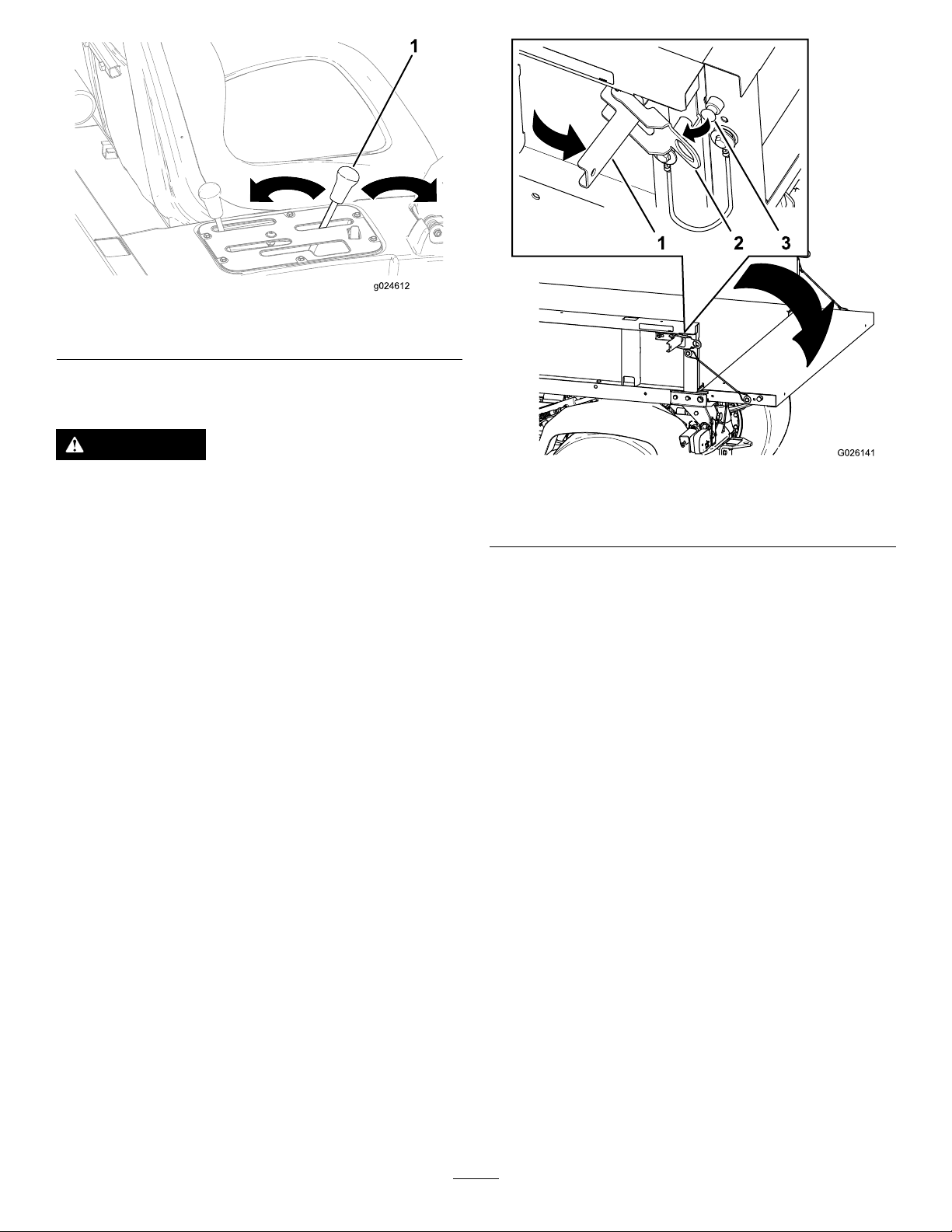

Figure35

1.Eyeholeinframe(eachside)

Figure36

1.Axle2.Hitchplate

29

Page 30

TowingtheMachine

Incaseofanemergency ,themachinecanbetowedfora

shortdistance.However,Torodoesnotrecommendthisas

astandardprocedure.

Important:Ifmultiplevehiclesusethesame

attachment,crosscontaminationofthehydraulicuid

mayoccur.Changethehydraulicuidmorefrequently.

HydraulicControlPositions

WARNING

Towingatexcessivespeedscouldcausemachine

tolosesteeringcontrol.Nevertowmachinefaster

than8kph(5mph).

Towingthemachineisa2-personjob.Afxatowlineto

holesinthefrontframemember.MovetheshiftertoNeutral

andreleasetheparkingbrake.Ifthemachinemustbemoved

aconsiderabledistance,transportitonatruckortrailer.

Note:Thepowersteeringwillnotfunction,makingit

difculttosteer.

TowingaTrailerwiththe Machine

Thismachineiscapableofpullingtrailersandattachmentsof

greaterweightthanthemachineitself.

Severaltypesoftowhitchesareavailableforthismachine,

dependingonyourapplication.ContactyourAuthorized

Distributorfordetails.

•OffPosition

Thisisthenormalpositionforthecontrolvalvewhenit

isnotbeingused.Inthispositiontheworkportsofthe

controlvalveareblockedandanyloadwillbeheldbythe

checkvalvesinbothdirections.

•Raise(QuickCouplerAposition)

Thishydraulicliftleverpositionliftsthebedcylindersora

rearhitchattachmentbyapplyingRaisehydraulicpressure

throughquickcouplerA.Thisalsoallowsthereturnoilto

owthroughquickcouplerB,backthroughthecontrol

valve,andthenintothereservoir.Thisisamomentary

position;whenthehydraulicliftleverisreleased,aspring

returnsthelevertotheCenterOffposition.

Whenequippedwithatowhitchboltedontotherearaxle,

yourmachinecantowtrailersorattachmentswithagross

trailerweight(GTW)upto1587kg(3500lb).Alwaysloada

trailerwith60%ofthecargoweightinthefrontofthetrailer.

Thisplacesapproximately10%(272kg(600lb)max.)ofthe

grosstrailerweight(GTW)onthetowhitchofthemachine.

Trailerbrakesarerequiredwheneveryoutowatrailerover

680kg(1500lb)GTWistowedbehindthismachine.

Whenhaulingcargoortowingatrailer(attachment),donot

overloadyourmachineortrailer.Overloadingcancausepoor

performanceordamagetothebrakes,axle,engine,transaxle,

steering,suspension,bodystructure,ortires.

Important:Toreducepotentialfordrivelinedamage,

uselowrange.

Whentowing5thwheelattachments,likeafairwayaerator,

alwaysinstallthewheelybar(includedwiththefthwheelkit)

topreventthefrontwheelsfromliftingoffthegroundifthe

towedattachmentsmovementissuddenlyimpaired.

UsingtheHydraulicControl

Thehydrauliccontrolsupplieshydraulicpowerfromthe

machinepumpwhenevertheengineisrunning.Usethe

quickcouplersattherearofthemachinetoprovidehydraulic

powerforrearhitchattachments.

Figure37

1.QuickcouplerAposition2.QuickcouplerBposition

•Lower(QuickCouplerBposition)

Thispositionlowersthebedorarearhitchattachmentby

applyingLowerhydraulicpressurethroughquickcoupler

B.Thisalsoallowsthereturnoiltoowthroughquick

couplerA,backthroughthecontrolvalve,andtheninto

thereservoir.Thisisamomentaryposition;whenthe

hydraulicliftleverisreleased,aspringreturnsthecontrol

levertotheCenterOffposition.Momentarilyholding

andthenreleasingthehydraulicliftleverinthisposition

willprovideowtothequickcouplerB,whichprovides

Lowerhydraulicpressuretothebedcylindersorarear

hitchattachment.Whenthehydraulicliftleverisreleased,

theLowerhydraulicpressuretothebedcylindersora

rearhitchattachmentishydraulicallylocked.

Important:Ifusedwithahydrauliccylinder,

holdingthehydraulicliftleverintheLowerposition

30

Page 31

causestheoilowtogooverareliefvalve,whichcan

damagethehydraulicsystem.

•Onposition

ThispositionissimilartoLower(quickcouplerB

position).Italsodirectshydraulicoiltoquickcoupler

Bexceptthattheleverisheldinthispositionbythe

hydraulic-liftlockinthecontrolpanel.Thisallowsoil

toowcontinuouslytoequipmentthatusesahydraulic

motor.Usethispositiononlywhenyouareoperatingthe

machinewithanattachmentwithahydraulicmotor.

Important:Ifyouareusingthemachinewitha

hydrauliccylinderornoattachment,theOnposition

causestheoilowtogooverareliefvalve,whichcan

damagethehydraulicsystem.Usethispositiononly

momentarilyorwithamotorattached.

Important:Checkthehydraulicoillevelafter

installinganattachment.Checktheoperationof

theattachmentbycyclingitseveraltimestopurge

airfromsystem,thencheckthehydraulicoillevel.

Theattachmentcylinderwillslightlyaffecttransaxle

oillevel.Operatingthemachinewithlowoillevel

candamagethepump,remotehydraulics,power

steering,andthemachinetransaxle.

CAUTION

Hydraulicuidescapingunderpressurecan

havesufcientforcetopenetrateskinanddo

seriousdamage.Caremustbeusedwhen

connectingordisconnectinghydraulicquick

couplers.Stoptheengine,applytheparking

brake,lowertheattachment,andplacethe

remotehydraulicvalveintheoatdetent

positiontorelievehydraulicpressurebefore

connectingordisconnectingquickcouplers.

2.Pullthehosermlyfromthecoupler.

Important:Cleanandinstallthedustplugand

dustcoverstothequickcouplerendswhennot

inuse.

OperatingTips

OperatingCharacteristics

Themachineisdesignedwithsafetyinmind.Itusesfamiliar

automotivestylecontrols,includingthesteeringwheel,brake

pedal,andacceleratorpedal,.Itisimportanttoremember,

however,thatthismachineisnotapassengercar.Itisawork

vehicleandisdesignedforoffroaduseonly.

WARNING

Themachineisdesignedprimarilyasanoff-road

vehicleandisnotintendedforextensiveuseon

publicroads.

Occasionaluseonpublicroadwaysshouldonlybe

undertakenwithrespecttolocaltrafcregulations

andusinganyadditionalaccessoriesthatmaybe

requiredbylocallaw(includingbutnotlimitedto

lights,turnsignals,slowmovingvehicle(SMV)

sign,etc).

Themachinehasspecialtires,lowgearratios,alocking

differential,andotherfeaturesthatgiveitextratraction.

Thesefeaturesaddtotheversatilityofthevehiclebut,they

canalsogetyouintodangeroussituations.Youmustkeepin

mindthatthevehicleisnotarecreationvehicle,itisnotanall

terrainvehicle,and,itisdenitelynotmeantforstuntdriving

orhorsingaround.Itisaworkvehicle,notaplayvehicle.

Childrenshouldnotbeallowedtooperatethemachine.

Anyonewhooperatesthemachinemustbeproperlytrained.

ConnectingtheQuickCouplers

Important:Cleandirtfromquickcouplersbefore

connecting.Dirtycouplerscanintroducecontamination

intothehydraulicsystem.

1.Pullbackthelockingringonthecoupler.

2.Insertthehosenippleintothecoupleruntilitsnaps

intoposition.

Note:Whenattachingremoteequipmenttothequick

couplers,determinewhichsiderequirespressure,thenattach

thathosetoquickcouplerBwhichwillhavepressurewhen

thecontrolleverispushedforwardorlockedintheOn

position.

DisconnectingtheQuickCouplers

Note:Withboththemachineandattachmentturnedoff,

movetheliftleverbackandforthtoremovethesystem

pressureandtomakedisconnectingthequickcouplerseasier.

1.Pullbackthelockingringonthecoupler.

Thedriverandpassengershouldalwaysusetheseatbelts.

Ifyouarenotexperiencedatdrivingthemachine,practice

drivingitinasafeareaawayfromotherpeople.Besure

youarefamiliarwithallthemachine’scontrols,particularly

thoseusedforbraking,steering,andtransmissionshifting.

Learnhowyourmachinehandlesondifferentsurfaces.

Youroperatingskillswillimprovewithexperience,butasin

operatinganyvehicle,takeiteasyasyoubegin.Besureyou

knowhowtostopquicklyinanemergency.Ifyouneedhelp,

askyoursupervisorforassistance.

Manyfactorscontributetoaccidents.Youhavecontrolover

severalofthemostimportant.Youractions,suchasdriving

toofastforconditions,brakingtoofast,turningtoosharp,

andcombinationsofthese,arefrequentcauseofaccidents.

Oneofthemajorcausesofaccidentsisfatigue.Besureto

takeoccasionalbreaks.Itisveryimportantthatyoustay

alertatalltimes.

Neveroperatethemachine,oranyequipment,ifyou

areundertheinuenceofalcoholorotherdrugs.Even

31

Page 32

prescriptiondrugsandcoldmedicinescancausedrowsiness.

Readthelabelonthemedicineorcheckwithyourdoctoror

pharmacistifyouareunsureaboutacertainmedication.

Oneofthemostimportantrulestofollowistogoslowerin

unfamiliarareas.Itissurprisinghowmuchdamageandinjury

commonthingscancause.Treebranches,fences,wires,other

vehicles,treestumps,ditches,sandtraps,streams,andother

thingsfoundinmostparksandgolfcoursescanbehazardous

totheoperatorandpassenger.

Avoiddrivingwhenitisdark,especiallyinunfamiliarareas.If

youmustdrivewhenitisdark,besuretodrivecautiously,use

theheadlights,andevenconsideraddingadditionallights.

CarryingPassengers

Wheneveryouhaveapassengerridinginthemachinemake

sureheorsheiswearingtheseatbeltandholdingonsecurely .

Driveslowerandturnlesssharplybecauseyourpassenger

doesnotknowwhatyouaregoingtodonextandmaynotbe

preparedforturning,stopping,accelerating,andbumps.

Youandyourpassengershouldremainseatedatalltimes,

keepingarmsandlegsinsidethemachine.Theoperator

shouldkeepbothhandsonsteeringwheel,wheneverpossible,

andthepassengershouldusethehandholdsprovided(Figure

38andFigure39).

Figure39

1.Handholdandhiprestraint

Neverallowpassengersinthedumpboxoronany

attachments.Themachineismeanttohave1driverandonly

1passenger—nomore.

ControllingtheSpeedoftheVehicle

Speedisoneofthemostimportantvariablesleadingto

accidents.Drivingtoofastfortheconditionscancauseyou

tolosecontrolandhaveanaccident.Speedcanalsomakea

minoraccidentworse.Drivinghead-onintoatreeatslow

speedcancauseinjuryanddamage,but,drivingintoatreeat

highspeedcandestroythemachineandkillyouandyour

passenger.

Neverdrivetoofastfortheconditions.Ifthereisanydoubt

abouthowfasttodrive,slowdown.

Whenusingheavyattachments,morethan454kg(1000lb),

suchassprayers,topdressers,orspreaders,etc.,restrictyour

operatingspeedbyselectinglowrange.

1.Passengerhandhold

Figure38

EnsuringProperTurning

Turningisanotherimportantvariableleadingtoaccidents.

Turningtoosharplyfortheconditionscancausethemachine

tolosetractionandskid,oreventipover.

Wet,sandy,andslipperysurfacesmaketurningmoredifcult

2.Storagecompartment

andrisky .Thefasteryouaregoing,theworsethissituation

becomesso,slowdownbeforeturning.

Duringasharpturnathigherspeeds,theinsiderearwheel

mayliftofftheground.Thisisnotaawinthedesign,it

happenswithmostfourwheelmachinesincludingpassenger

cars.Ifthishappens,youareturningtoosharplyforthespeed

atwhichyouaretraveling.Slowdown!

EnsuringProperBraking

Itisgoodpracticetoslowdownbeforeyougetnearan

obstacle.Thisgivesyouextratimetostoporturnaway.

Hittinganobstaclecandamagethemachineanditscontents.

32

Page 33

Moreimportant,itcaninjureyouandyourpassenger.Gross

machineweighthasamajorimpactonyourabilitytostopor

turn.Heavierloadsandheavierattachmentsmakeamachine

hardertostoporturn.Theheaviertheload,thelongerit

takestostop.

Thebrakingcharacteristicsalsochangewithnobedor

attachmentonthemachine.Faststopsmaycausetherear

wheelstolockupbeforethefrontwheelslockup,whichmay

affectthecontrolofthemachine.Itisagoodideatodecrease

machinespeedwithnobedorattachment.

Turfandpavementaremuchslipperierwhentheyarewet.

Itcantake2to4timesaslongtostoponwetsurfacesas

ondrysurfaces.

OperatingtheMachineonHills

WARNING

Tippingorrollingthemachineonahillwillcause

seriouspersonalinjury.

•Donotoperatethemachineonsteepslopes.

•Ifenginestallsoryouloseheadwayonahill,

neverattempttoturnmachinearound.

•AlwaysbackstraightdownahillinReverse.

•NeverbackdowninNeutralusingonlythe

brakes.

Ifyoudrivethroughstandingwaterdeepenoughtogetthe

brakeswet,theywillnotworkwelluntiltheyaredry.After

drivingthroughwater,youshouldtestthebrakestomake

surethattheyworkproperly.Iftheydonot,driveslowly

whileputtinglightpressureonthebrakepedal.Thiswilldry

outthebrakes.

PreventingTipOvers

Themachineisequippedwitharollbar,hiprestraints,seat

belts,andhandhold.TheROPSsystem(RolloverProtection

System)usedonthemachinewillreducetheriskofserious

orfatalinjuryintheunlikelyeventofatipover,althoughthe

systemcannotprotecttheoperatorfromallpossibleinjuries.

ReplaceadamagedROPS,donotrepairit.Anyalterationof

theROPSmustbeapprovedbythemanufacturer.

Thebestwaytopreventaccidentsinvolvingutilitymachines

isthroughcontinuoussupervisionandtrainingofoperators

andpayingconstantattentiontotheareainwhichmachine

isbeingoperated.

Thebestwayforoperatorstopreventseriousinjuryordeath

tothemselvesorothers,istofamiliarizethemselveswiththe

properoperationoftheutilitymachine,tostayalertandto

avoidactionsorconditionswhichcouldresultinaaccident.

Intheeventofatipover,theriskofseriousinjuryordeath

willbereducediftheoperatorisusingtheROPSsystemand

seatbeltsandisfollowingtheinstructionsprovided.

•Neverdriveacrossasteephill,alwaysdrive

straightupordown.

•Avoidturningonahill.

•Don’tslamonthebrakes.Asuddenspeed

changecaninitiateatipover.

Useextracarewhenonhills.Nevergoonhillsthatare

extremelysteep.Stoppingwhilegoingdownahillwilltake

longerthanonlevelground.Turningwhilegoingupor

downahillismoredangerousthanturningonthelevel.

Makingturnswhilegoingdownhill,especiallywiththebrakes

on,andturninguphillwhiletraversingahillareparticularly

dangerous.Evenataslowspeedandwithoutaload,tipovers