Page 1

FormNo.3392-850RevA

Workman

®

HDX-DUtilityVehicle

withBed

ModelNo.07385—SerialNo.315000001andUp

ModelNo.07385H—SerialNo.315000001andUp

ModelNo.07385TC—SerialNo.315000001andUp

ModelNo.07387—SerialNo.315000001andUp

ModelNo.07387H—SerialNo.315000001andUp

ModelNo.07387TC—SerialNo.315000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3392-850*A

Page 2

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Dieselengineexhaustandsomeofits

constituentsareknowntotheStateof

Californiatocausecancer,birthdefects,

andotherreproductiveharm.

Figure1

1.Modelandserialnumberlocation

Thismachineisautilityvehicleintendedtobeusedby

professional,hiredoperatorsincommercialapplications.It

isprimarilydesignedforthetransportofimplementsusedin

suchapplications.Thisvehicleallowsforthesafetransport

ofanoperatorandonepassengerintheidentiedseats.The

bedofthisvehicleisnotsuitableforanyriders.

ThisproductcomplieswithallrelevantEuropeandirectives;

fordetails,pleaseseetheseparateproductspecicDeclaration

ofConformity(DOC)sheet.

Important:Theengineinthisproductisnotequipped

withasparkarrestedmufer.Itisaviolationof

CaliforniaPublicResourcecodeSection4442touse

oroperatethisengineonanyforest-covered,brush

covered,orgrass-coveredlandasdenedinCPRC4126.

Otherstatesorfederalareasmayhavesimilarlaws.

Introduction

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure2

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

safetyandoperationtrainingmaterials,accessoryinformation,

helpndingadealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready.Figure1identiesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

©2015—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Contents

Safety...........................................................................4

Operation...............................................................4

SoundPressure.......................................................6

Vibration................................................................6

SafetyandInstructionalDecals.................................7

Setup...........................................................................12

1InstallingtheSteeringWheel(TCmodels

only).................................................................12

2InstallingtheRolloverProtectionSystem

(ROPS).............................................................12

3CheckingtheFluidLevels.....................................13

ProductOverview.........................................................14

Controls...............................................................14

Specications........................................................17

Attachments/Accessories........................................17

Operation....................................................................18

OperatingtheCargoBox.........................................18

CheckingtheEngine-oilLevel..................................19

AddingFuel...........................................................20

CheckingtheCoolantLevel.....................................21

CheckingtheTransaxle/Hydraulic-uid

Level.................................................................21

CheckingtheHighFlowHydraulic-uidLevel(TC

modelsonly)......................................................22

CheckingtheFront-differential-oilLevel(4-wheel

drivemodelsonly)...............................................22

CheckingtheTorqueoftheWheelNuts.....................23

CheckingtheTirePressure......................................23

CheckingtheBrake-uidLevel.................................23

StartingtheEngine.................................................24

DrivingtheVehicle.................................................24

StoppingtheMachine.............................................25

StoppingtheEngine...............................................25

BreakinginaNewMachine......................................25

CheckingtheSafety-interlockSystem........................25

EnsuringPassengerSafety.......................................26

EnsuringProperSpeed...........................................26

EnsuringProperTurning.........................................26

EnsuringProperBraking.........................................26

PreventingTipOvers..............................................27

OperatingonHills..................................................27

LoadingandDumping............................................27

UsingtheDifferentialLock......................................28

Using4-wheelDrive(4-wheeldrivemodels

only).................................................................28

TransportingtheMachine........................................28

TowingtheMachine...............................................29

TowingaTrailerwiththeMachine.............................29

UsingtheHydraulicControl....................................29

Maintenance.................................................................32

RecommendedMaintenanceSchedule(s)......................32

OperatinginAdverseConditions..............................33

PremaintenanceProcedures........................................34

UsingtheBedSupport............................................34

RemovingtheFullBed............................................35

InstallingtheFullBed.............................................35

RaisingtheMachine................................................36

RemovingtheHood...............................................37

InstallingtheHood.................................................37

Lubrication...............................................................38

GreasingtheBearingsandBushings..........................38

EngineMaintenance..................................................40

ServicingtheAirCleaner.........................................40

ChangingtheEngineOilandFilter...........................40

FuelSystemMaintenance...........................................41

CheckingtheFuelLinesandConnections..................41

ServicingtheFuelFilter/WaterSeparator...................41

ElectricalSystemMaintenance....................................42

ServicingtheFuses.................................................42

JumpStartingtheMachine.......................................43

ServicingtheBattery...............................................44

DriveSystemMaintenance.........................................44

ChangingtheFront-differentialOil(4-wheeldrive

modelsonly)......................................................44

InspectingtheConstant-velocityBoot(4-wheel

drivemodelsonly)...............................................44

AdjustingtheShiftCables........................................45

AdjustingtheHigh-to-LowCable.............................45

AdjustingDifferential-lockCable..............................45

InspectingtheTires................................................45

CheckingtheFrontWheelAlignment........................46

CoolingSystemMaintenance......................................47

RemovingDebrisfromtheCoolingSystem................47

ChangingtheEngineCoolant...................................47

BrakeMaintenance....................................................48

AdjustingtheParkingBrake.....................................48

AdjustingtheBrakePedal........................................49

BeltMaintenance......................................................50

AdjustingtheAlternatorBelt...................................50

ControlsSystemMaintenance.....................................50

AdjustingtheAcceleratorPedal................................50

AdjustingtheClutchPedal.......................................51

ConvertingtheSpeedometer....................................51

HydraulicSystemMaintenance....................................52

ChangingtheHydraulicuidandCleaningthe

Strainer..............................................................52

ReplacingtheHydraulicFilter..................................52

ChangingtheHigh-owHydraulicuidandFilter

(TCmodelsonly)................................................53

RaisingtheCargoBoxinanEmergency.....................53

Cleaning...................................................................55

WashingtheMachine..............................................55

Storage........................................................................55

3

Page 4

Safety

Improperuseormaintenancebytheoperatororownercan

resultininjury.Toreducethepotentialforinjury,comply

withthesesafetyinstructionsandalwayspayattentionto

thesafetyalertsymbol,whichmeansCaution,Warning,or

Danger—“personalsafetyinstruction.”Failuretocomply

withtheinstructionmayresultinpersonalinjuryordeath.

Operation

•Theoperatorandpassengermustuseseatbeltsand

remainseatedwheneverthemachineisinmotion.The

operatorshouldkeepbothhandsonthesteeringwheel,

wheneverpossible,andthepassengershouldusethehand

holdsprovided.Keeparmsandlegswithinthevehicle

bodyatalltimes.Nevercarrypassengersintheboxor

onattachments.Rememberyourpassengermaynotbe

expectingyoutobrakeorturnandmaynotbeready.

•Neveroverloadyourmachine.Thenameplate(located

underthemiddleofthedash)showstheloadlimitsfor

themachine.Neveroverllattachmentsorexceedthe

machinemaximumgrossvehicleweight(GVW).

•Whenstartingtheengine:

–Sitontheoperator’sseatandensurethattheparking

brakeisengaged.

–DisengagePTO(ifsoequipped)andreturnthehand

throttlelevertotheOffposition(ifsoequipped).

–Makesurethehydraulic-liftleverisinthecenter

position.

–MoveshiftlevertoNeutralandpresstheclutchpedal.

–Keepyourfootoffoftheacceleratorpedal.

–TurnstarterswitchtotheOnposition.Whenthe

glowplugindicatorgoesoff,theengineisreadyto

start.

–TurnthestarterkeytotheStartposition.

Note:Theglow-plugindicatorwillturnon,foran

additional15seconds,whentheswitchreturnstothe

Startposition.

•Usingthemachinedemandsattention.Failuretooperate

machinesafelymayresultinanaccident,tipoverofthe

machine,andseriousinjuryordeath.Drivecarefully.

Topreventtippingorlossofcontrol,takethefollowing

precautions:

–Useextremecaution,reducespeed,andmaintain

asafedistancearoundsandtraps,ditches,creeks,

ramps,anyunfamiliarareas,orotherhazards.

–Watchforholesorotherhiddenhazards.

–Usecautionwhenoperatingthemachineonasteep

slope.Normally,travelstraightupanddownslopes.

Reducespeedwhenmakingsharpturnsorwhen

turningonhillsides.Avoidturningonhillsides

wheneverpossible.

–Useextracautionwhenoperatingthevehicleon

wetsurfaces,athigherspeeds,orwithafullload.

Stoppingtimewillincreasewithafullload.Shiftinto

alowergearbeforestartingupordownahill.

–Whenloadingthebed,distributetheloadevenly.

Useextracautioniftheloadexceedsthedimensions

ofthemachine/bed.Operatethevehiclewithextra

cautionwhenhandlingoff-centerloadsthatcannot

becentered.Keeploadsbalancedandsecureto

preventthemfromshifting.

–Avoidsuddenstopsandstarts.Donotgofrom

reversetoforwardorforwardtoreversewithoutrst

comingtoacompletestop.

–Donotattemptsharpturnsorabruptmaneuversor

otherunsafedrivingactionsthatmaycausealossof

machinecontrol.

–Donotpassanothermachinetravelinginthesame

directionatintersections,blindspots,oratother

dangerouslocations.

–Whendumping,donotletanyonestandbehindthe

machine,anddonotdumptheloadonanyone’sfeet.

Releasethetailgatelatchesfromthesideofbox,not

frombehind.

–Keepallbystandersaway .Beforebackingup,lookto

therearandensurethatnooneisbehindthemachine.

Backupslowly.

–Watchoutfortrafcwhennearorcrossingroads.

Alwaysyieldtherightofwaytopedestriansandother

machines.Thismachineisnotdesignedforuseon

streetsorhighways.Alwayssignalyourturnsorstop

earlyenoughsootherpersonsknowwhatyouplanto

do.Obeyalltrafcrulesandregulations.

–Neveroperatethemachineinornearanareawhere

thereisdustorfumesintheairwhichareexplosive.

Theelectricalandexhaustsystemsofthemachinecan

producesparkscapableofignitingexplosivematerials.

–Alwayswatchoutforandavoidlowoverhangssuch

astreelimbs,doorjambs,overheadwalkways,etc.

Makesurethereisenoughroomoverheadtoeasily

clearthemachineandyourhead.

–Ifeverunsureaboutsafeoperation,stopwork,and

askyoursupervisor.

•Donottouchtheengine,transaxle,radiator,mufer,or

mufermanifoldwhileengineisrunningorsoonafter

ithasstoppedbecausetheseareasmaybehotenough

tocauseburns.

•Ifthemachineevervibratesabnormally,stopimmediately,

turnengineoff,waitforallmotiontostopandinspectfor

damage.Repairalldamagebeforeresumingoperation.

•Beforegettingoffoftheseat:

1.Stopthemovementofthemachine.

2.Settheparkingbrake.

3.TurnthestarterkeytotheOffposition.

4

Page 5

4.Removethestarterkey.

Note:Ifthemachineisonanincline,blockthe

wheelsaftergettingoffofthemachine.

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

Braking

•Slowdownbeforeyouapproachanobstacle.Thisgives

youextratimetostoporturnaway.Hittinganobstacle

caninjureyouandyourpassenger.Inaddition,itcan

damagethemachineanditscontents.

•GrossVehicleWeight(GVW)hasamajorimpactonyour

abilitytostopand/orturn.Heavyloadsandattachments

makethemachinehardertostoporturn.Theheavierthe

load,thelongerittakestostop.

•Decreasethespeedofthemachineifthecargoboxhas

beenremovedandthereisnoattachmentinstalledon

themachine.Thebrakingcharacteristicschangeandfast

stopsmaycausetherearwheelstolockup,whichwill

affectthecontrolofthemachine.

•Turfandpavementaremuchmoreslipperywhentheyare

wet.Itcantake2to4timeslongertostopthemachine

onwetsurfacesasondrysurfaces.Ifyoudrivethrough

deep-standingwaterandgetthebrakeswet,theywill

notworkwelluntiltheyaredry.Afterdrivingthrough

water,youshouldtestthebrakestomakesuretheywork

properly.Iftheydonot,driveslowlyonalevelground

whileputtinglightpressureonthebrakepedal.Thiswill

drythebrakesout.

•Slowthemachinedownbeforestartingupordownahill.

•Iftheenginestallsoryoubegintolosemomentumwhile

climbingahill,graduallyapplythebrakesandslowlyback

themachinestraightdownthehill.

•Turningwhiletravelingupordownhillscanbedangerous.

Ifyouhavetoturnwhileonahill,doitslowlyand

cautiously.Nevermakesharporfastturns.

•Heavyloadsaffectstability.Reducetheweightofthe

loadandyourgroundspeedwhenoperatingonhillsorif

theloadhasahighcenterofgravity.Securetheloadto

thecargoboxofthemachinetopreventtheloadfrom

shifting.Takeextracarewhenhaulingloadsthatshift

easily(liquid,rock,sand,etc.).

•Avoidstoppingonhills,especiallywithaload.Stopping

whilegoingdownahillwilltakelongerthanstopping

onlevelground.Ifthemachinemustbestopped,avoid

suddenspeedchanges,whichmayinitiatetippingor

rollingofthemachine.Donotslamonthebrakes

whenrollingbackward,asthismaycausethemachine

tooverturn.

•Ifyouwillbeusingthemachineonhillyterrain,youcan

installtheoptionalROPSKit.

OperatingonRoughTerrain

Reducethegroundspeedofthemachineandloadcarriedin

themachinewhenoperatingonroughterrain,unevenground,

andnearcurbs,holes,andothersuddenchangesinterrain.

Loadsmayshift,causingthemachinetobecomeunstable.

Ifyouwillbeusingthemachineonroughterrain,youcan

installtheoptionalROPSKit.

OperatingonHills

WARNING

Operatingthemachineonahillmaycausetipping

orrollingofthemachine,ortheenginemaystall

andyoucouldloseheadwayonthehill.Thiscould

resultinpersonalinjury.

•Donotoperatemachineonexcessivelysteep

slopes.

•Donotacceleratequicklyorslamonthebrakes

whenbackingdownahill,especiallywithaload.

•Iftheenginestallsoryouloseheadwayona

hill,slowlybackstraightdownthehill.Never

attempttoturnthemachinearound.

•Operatethemachineslowlyonahillanduse

caution.

•Avoidturningonahill.

•Reduceyourloadandthespeedofthemachine.

•Avoidstoppingonhills,especiallywithaload.

Theseextracautionsneedtobetakenwhenoperatingthe

machineonahill:

WARNING

Suddenchangesinterrainmaycauseabrupt

steeringwheelmovement,possiblyresultingin

handandarminjuries.

•Reduceyourspeedwhenoperatingonrough

terrainandnearcurbs.

•Gripthesteeringwheellooselyaroundthe

perimeterkeepingthumbsupandoutoftheway

ofthesteeringwheelspokes.

LoadingandDumping

Theweightandpositionofcargoandpassengercanaffect

thestabilityandhandlingofthemachine.Beawareofthe

followingconditiontoavoidlosingcontrolofthemachine

ortippingitover:

•Donotexceedtheratedweightcapacityofthemachine

whenoperatingitwithaloadinthecargobox,when

towingatrailer,orboth;refertoSpecications(page17).

•Usecautionwhenoperatingthemachineonahillsideor

onroughterrain,particularlywithaloadinthecargobox

orwhentowingatrailerorboth.

•Usecautionwhencarryingtallloadsinthecargobox.

5

Page 6

•Beawarethatthestabilityandcontrolofthemachine

arereducedwhentheloadinthecargoboxispoorly

distributed.

•Carryingoversizedloadsinthecargoboxchangesthe

stabilityofthemachine.

•Thesteering,braking,andstabilityofthemachineare

affectedwhencarryingaloadwheretheweightofthe

materialcannotbeboundtothemachinesuchasthe

liquidinalargetank.

WARNING

Theweightoftheboxmaybeheavy.Handsor

otherbodypartscouldbecrushed.

–Keephandsandotherbodypartsclearwhen

loweringthebox.

–Donotdumpmaterialsonbystanders.

•Neverdumpaloadedcargoboxwhilethemachineis

sidewaysonahill.Thechangeinweightdistributionmay

causethemachinetooverturn.

•Whenoperatingwithaheavyloadinthecargobox,

reduceyourspeedandallowforsufcientbraking

distance.Donotsuddenlyapplythebrakes.Useextra

cautiononslopes.

WholeBody

•Measuredvibrationlevel=0.3m/s

•UncertaintyValue(K)=0.5m/s

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinEN1032.

2

2

•Beawarethatheavyloadsincreaseyourstoppingdistance

andreduceyourabilitytoturnquicklywithouttipping

over.

•Therearcargospaceisintendedforloadcarrying

purposesonly,notforpassengers.

•Neveroverloadyourmachine.Thenameplate(located

underthemiddleofthedash)showstheloadlimitsfor

themachine.Neveroverllattachmentsorexceedthe

machinemaximumgrossvehicleweight(GVW).

SoundPressure

Thisunithasasoundpressurelevelattheoperator’searof82

dBA,whichincludesanUncertaintyValue(K)of1dBA.

Thesoundpressurelevelwasdeterminedaccordingtothe

proceduresoutlinedinENISO11201.

Vibration

Hand-Arm

•Measuredvibrationlevelforrighthand=0.41m/s

•Measuredvibrationlevelforlefthand=0.2m/s

•UncertaintyValue(K)=0.5m/s

2

2

2

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinEN1032.

6

Page 7

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

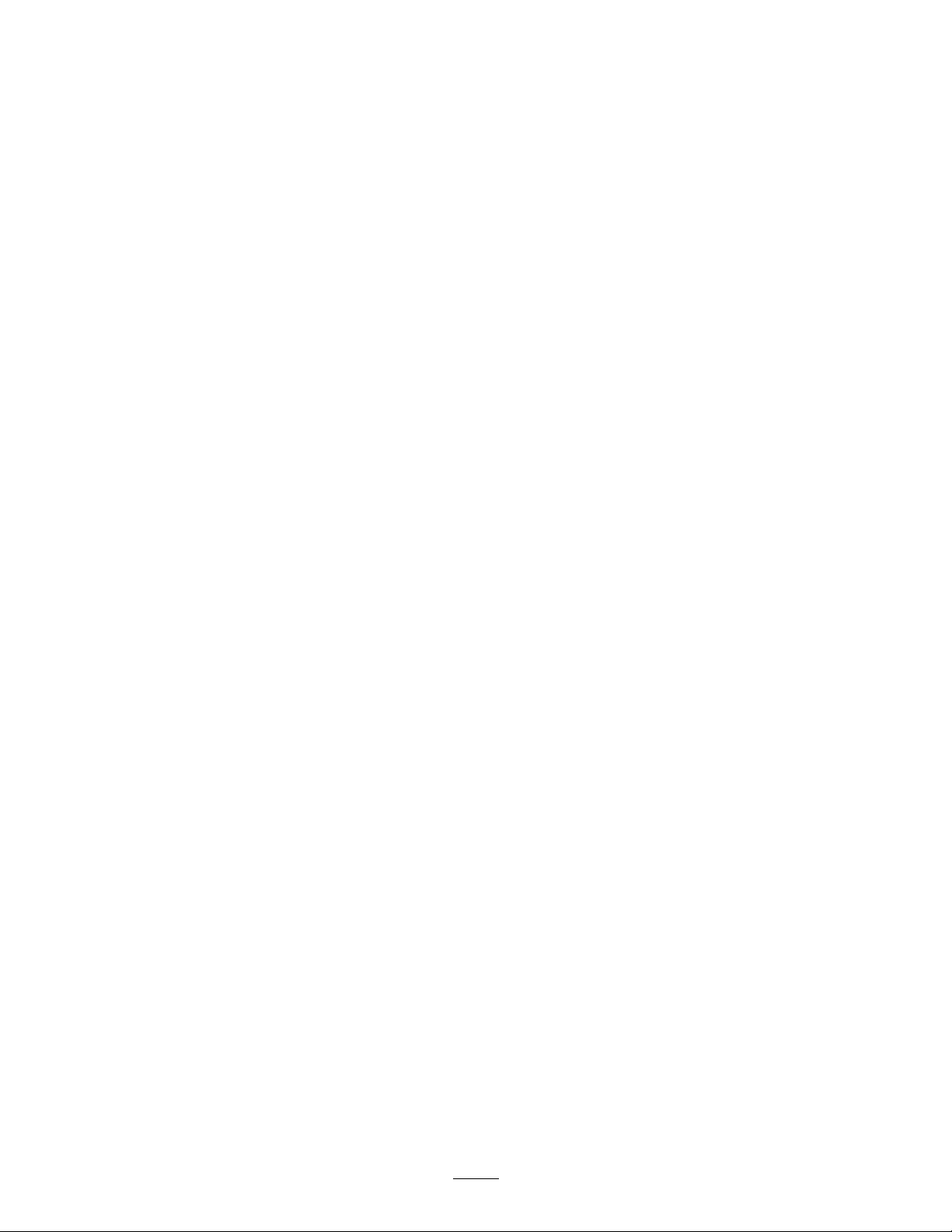

106-6755

1.Enginecoolantunder

pressure.

2.Explosionhazard—read

theOperator'sManual.

115-7813

1.Poweroutlet—10A5.Lights,brake—15A

2.Switchedpower—10A

3.Fuelpump,supervisor

switch—10A

4.Horn,powerpoint—15A

3.Warning—donottouchthe

hotsurface.

4.Warning—readthe

Operator'sManual.

6.Hazard—10A

7.4WD,Transmission—10A

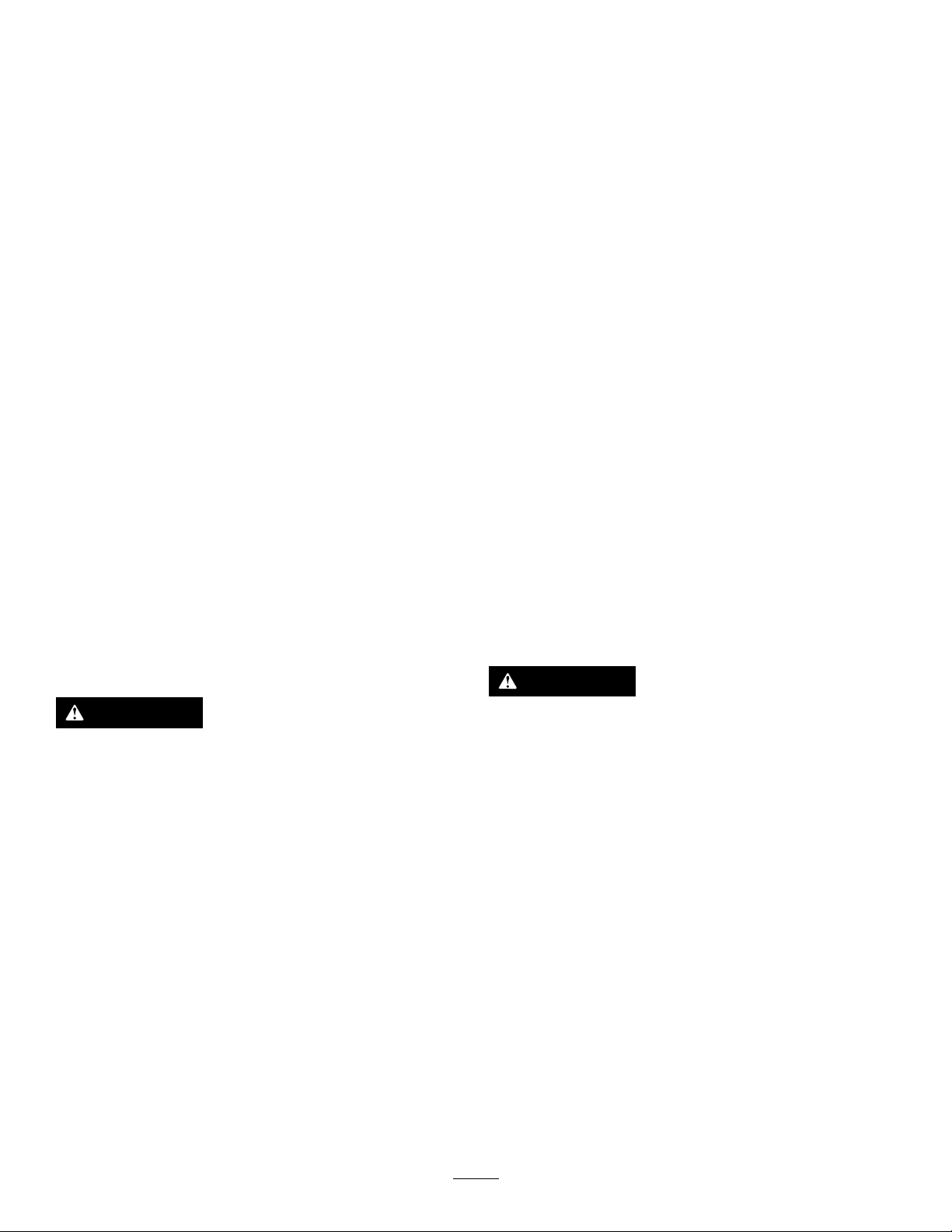

115-7740

1.Warning—maximumtrailerweightis680kg(1500lb),

maximumtongueweightis90kg(200lb).

2.Warning—trailerbrakesarerequiredwhentowinggreater

than680kg(1500lb),maximumtrailerweightwithtrailer

brakesis1591kg(3500lb),maximumtongueweightwith

trailerbrakesis273kg(600lb).

1.Warning—donottouchthehotsurface.

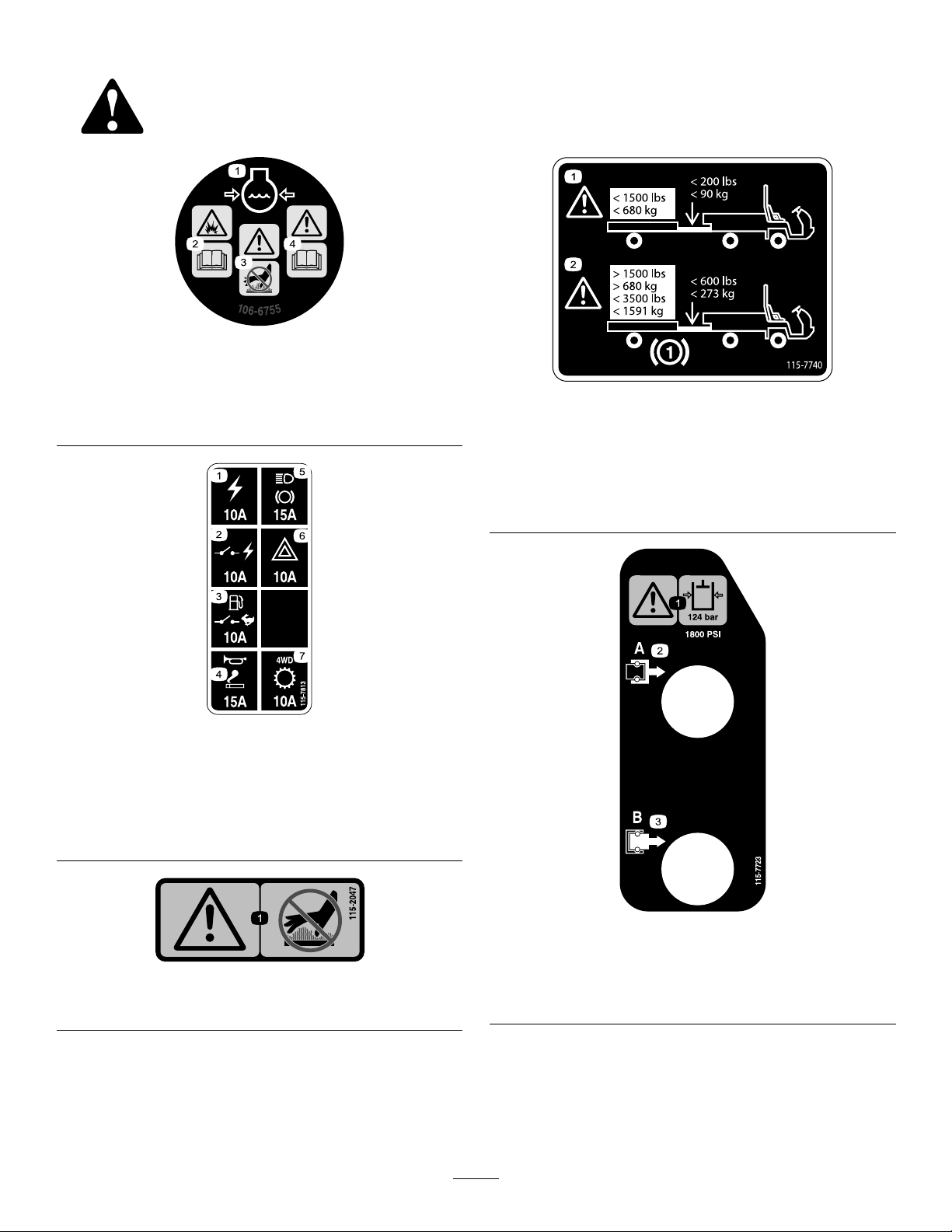

115-7723

1.Warning—thehydraulicoilpressureis124bar(1800psi).

115-2047

2.CouplerA

3.CouplerB

7

Page 8

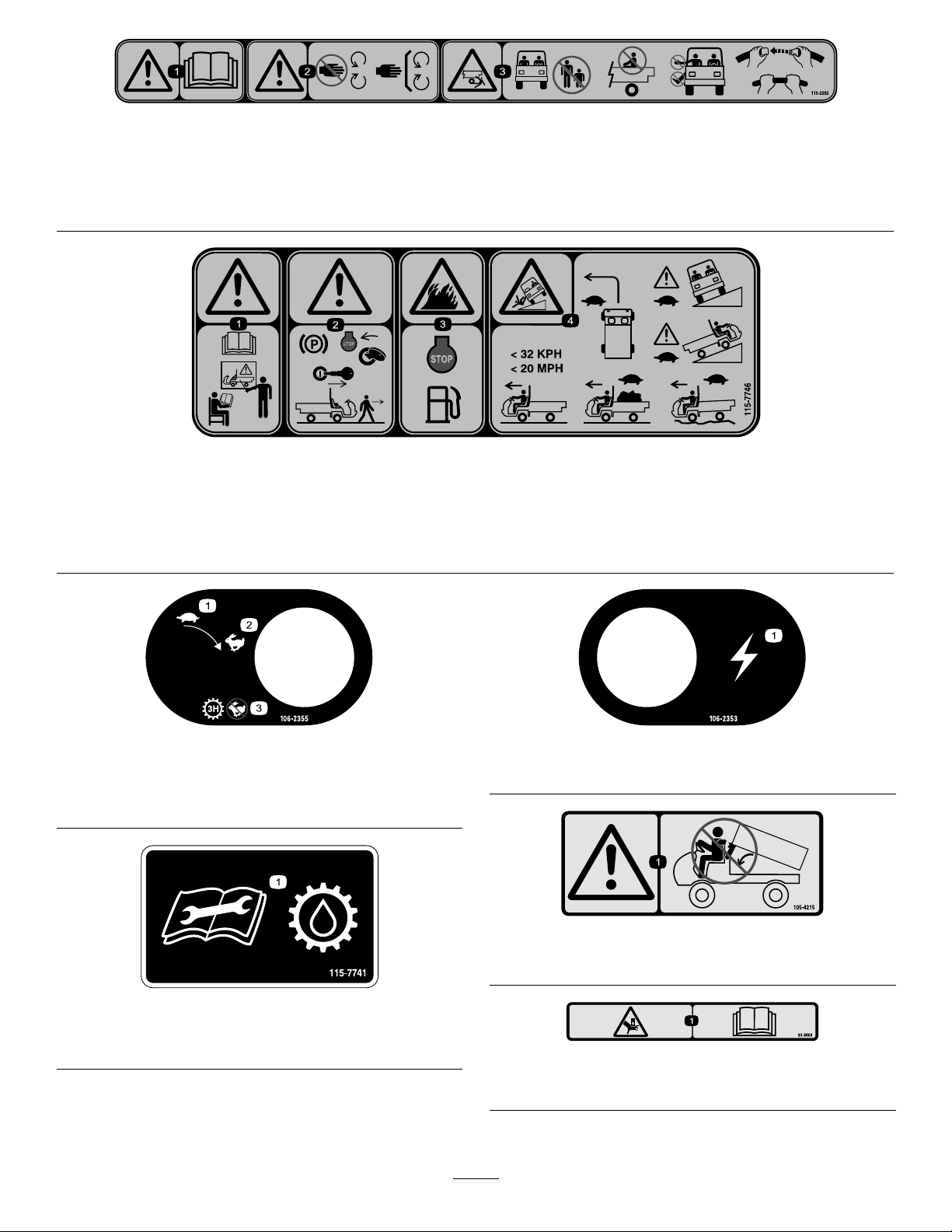

115-2282

1.Warning—readtheOperator'sManual.

2.Warning—stayawayfrommovingparts,keepallguardsandshieldsinplace.

3.Crushing/dismembermenthazardofbystanders—keepbystandersasafedistancefromthevehicle,donotcarrypassengersin

thecargobed,keeparmsandlegsinsideofthevehicleatalltimes,anduseseatbeltsandhandholds.

115-7746

1.Warning—donotoperatethismachineunlessyouaretrained.

2.Warning—locktheparkingbrake,stoptheengine,and

removethestarterkeybeforeleavingthemachine.

106-2355

1.Slow

2.Fast

3.Transmission—thirdhigh;

nofastspeed

3.Firehazard—stoptheenginebeforefueling.

4.Tippinghazard—slowdownandturngradually,usecaution

anddriveslowlywhendrivingonslopes,donotexceed32

kph(20mph),anddriveslowlyoverroughterrainorwhen

carryingafullorheavyload.

106-2353

1.Electricalpowerpoint

115-7741

1.ReadtheOperator’sManualbeforeservicingtransmission

uid.

105-4215

1.Warning—avoidpinchpoints.

93–9868

1.Crushinghazardofhand—readtheOperator’sManual.

8

Page 9

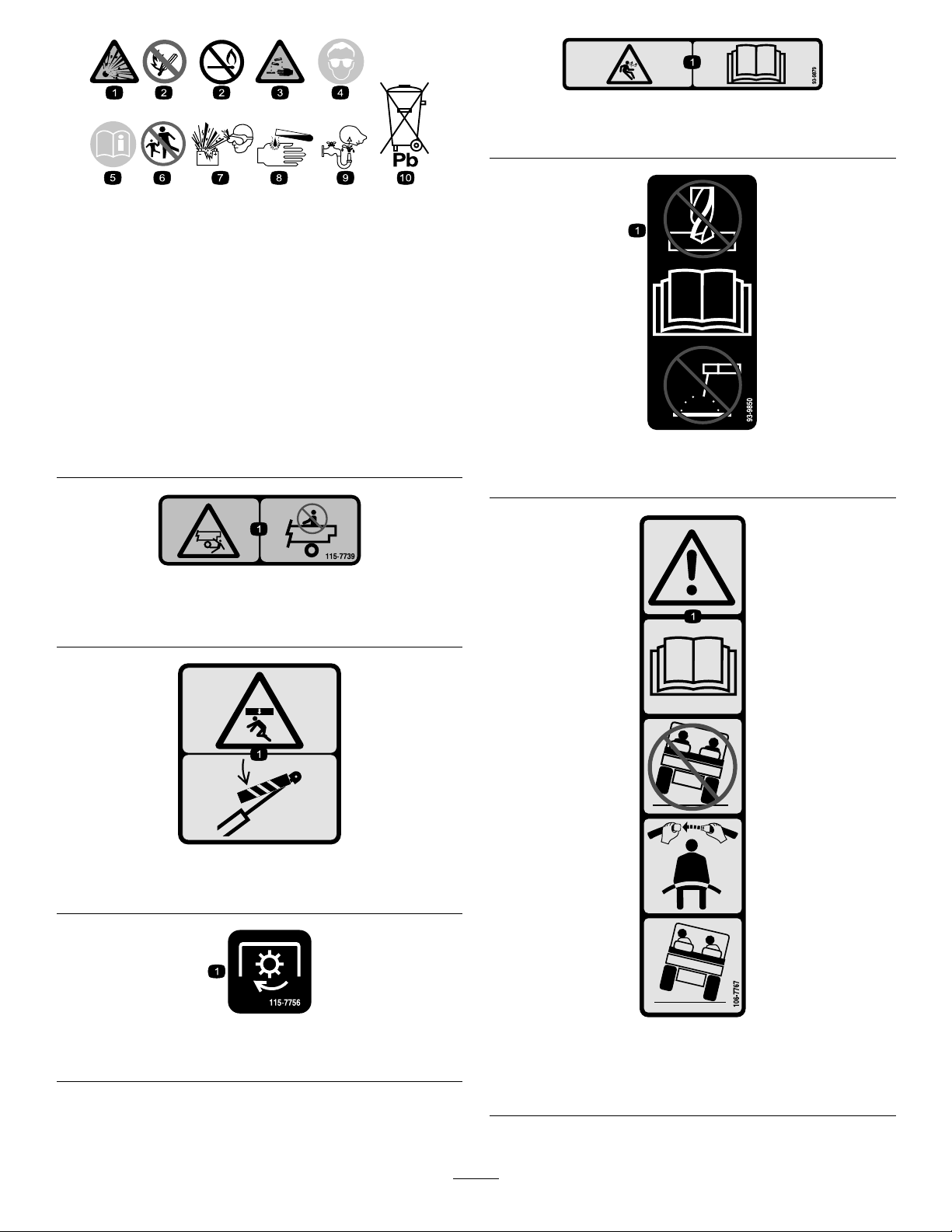

BatterySymbols

93-9899

Someorallofthesesymbolsareonyourbattery

93-9879

1.Storedenergyhazard—readtheOperator'sManual.

1.Explosionhazard

2.Nore,opename,or

smoking.

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

6.Keepbystandersasafe

distancefromthebattery.

7.Weareyeprotection;

explosivegasescan

causeblindnessandother

injuries

8.Batteryacidcancause

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

10.Containslead;donot

discard.

115-7739

1.Falling,crushinghazard,bystanders—noriderson

machine.

93-9850

1.Donotrepairorrevise—readtheOperator'sManual.

93-9899

1.Crushinghazard—installthecylinderlock.

115-7756

1.Highowhydraulics—engaged

106-7767

1.Warning—readtheOperator'sManual;avoidtippingthe

machine;weartheseatbelt;leanawayfromthedirection

themachineistipping.

9

Page 10

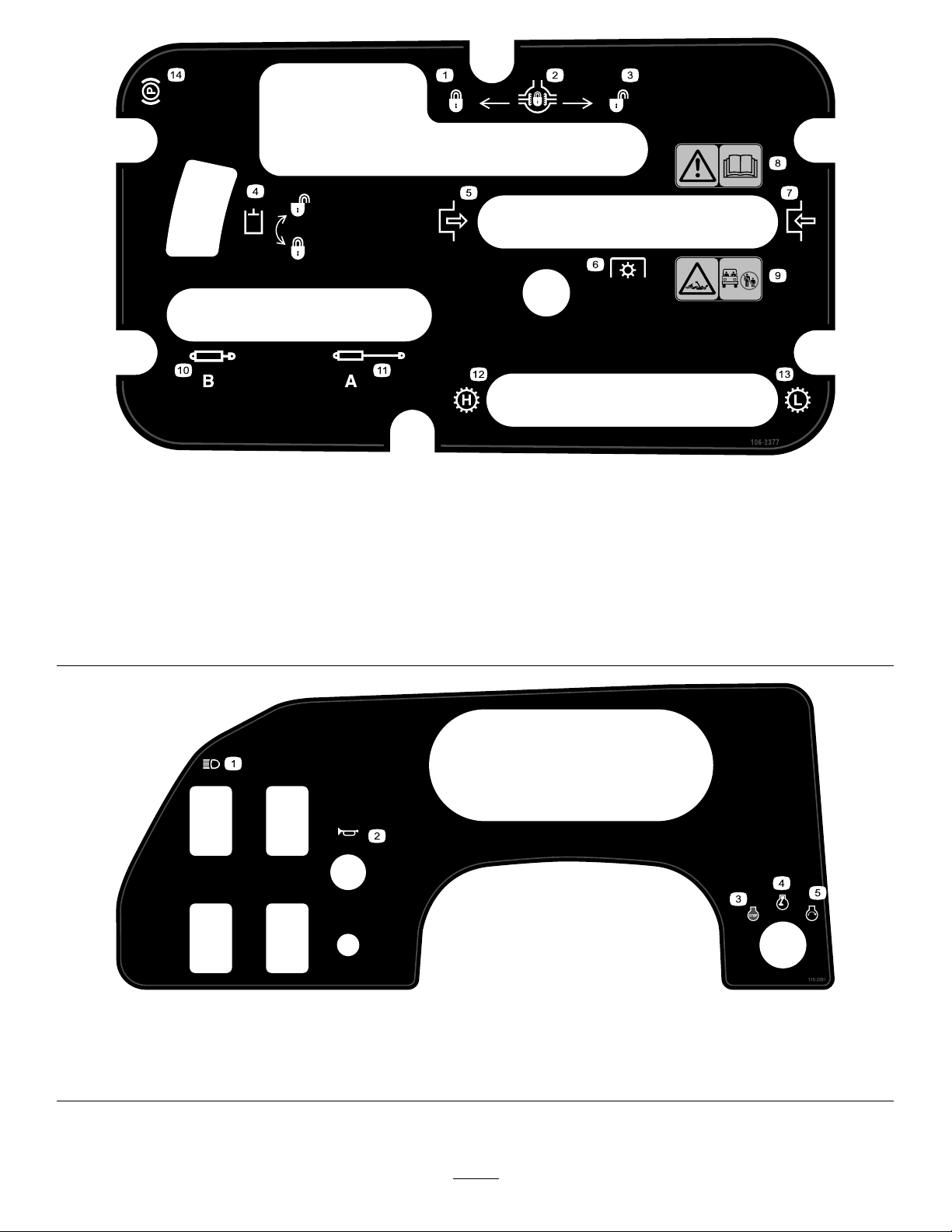

106-2377

1.Locked

2.Differentiallock9.Entanglementhazard,shaft—keepbystander'sasafe

3.Unlocked10.Retracthydraulics

4.Hydrauliclock11.Extendhydraulics

5.Engage12.Transmission—highspeed

6.Powertake-off(PTO)

7.Disengage14.Parkingbrake

8.Warning—readtheOperator'sManual.

distancefromthevehicle.

13.Transmission—lowspeed

1.Headlights4.Engine—run

2.Horn5.Engine—start

3.Engine—stop

115-2281

10

Page 11

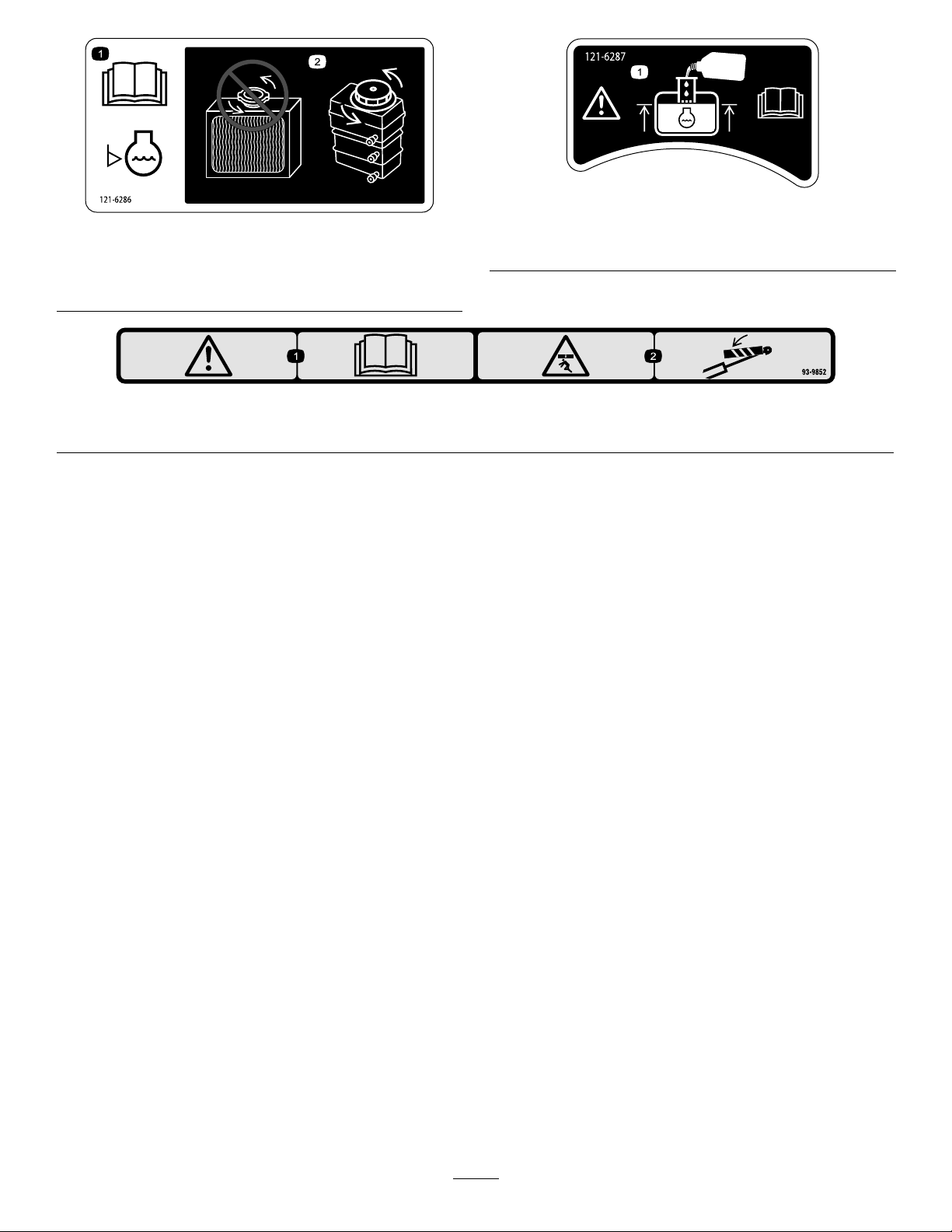

121-6287

1.ReadtheOperator's

Manualbeforechecking

theenginecoolantlevel.

121-6286

2.Donotaddenginecoolant

totheradiator;addengine

coolanttothereservoir,

1.Fillthereservoirwithenginecoolanttothebottomofthe

standpipe.

93-9852

1.Warning—readtheOperator’sManual.2.Crushinghazard—installthecylinderlock.

11

Page 12

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

Note:Determinetheleftandrightsideofthemachinefrom

thenormaloperatingposition.

Steeringwheel

ROPSframe

Bolt(1/2inch)

Nopartsrequired

1

InstallingtheSteeringWheel (TCmodelsonly)

Partsneededforthisprocedure:

Qty.

Use

1

1

6

–

Installthesteeringwheel(TCmodels

only).

MounttheRolloverProtectionSystem

(ROPS).

Checktheengineoil,the

transaxle/hydraulicuid,andthe

brakeuidlevels.

1

Steeringwheel

Procedure

1.Releasethetabsonthebackofthesteeringwheelthat

holdthecentercoverinplace,andremovethecover

fromthehubofthesteeringwheel.

2.Removethelocknutandwasherfromthesteeringshaft.

3.Slidethesteeringwheelandwasherontotheshaft.

Alignthesteeringwheelontheshaftsothatthecross

beamishorizontalwhenthetiresarepointedstraight

aheadandthethickerspokeofthesteeringwheelis

downward.

Note:Thedustcoverispositionontothesteering

shaftatthefactory.

4.Securethesteeringwheeltotheshaftwiththelocknut

(Figure3).Torquethelocknutto24to29N-m(18

to22ft-lb)

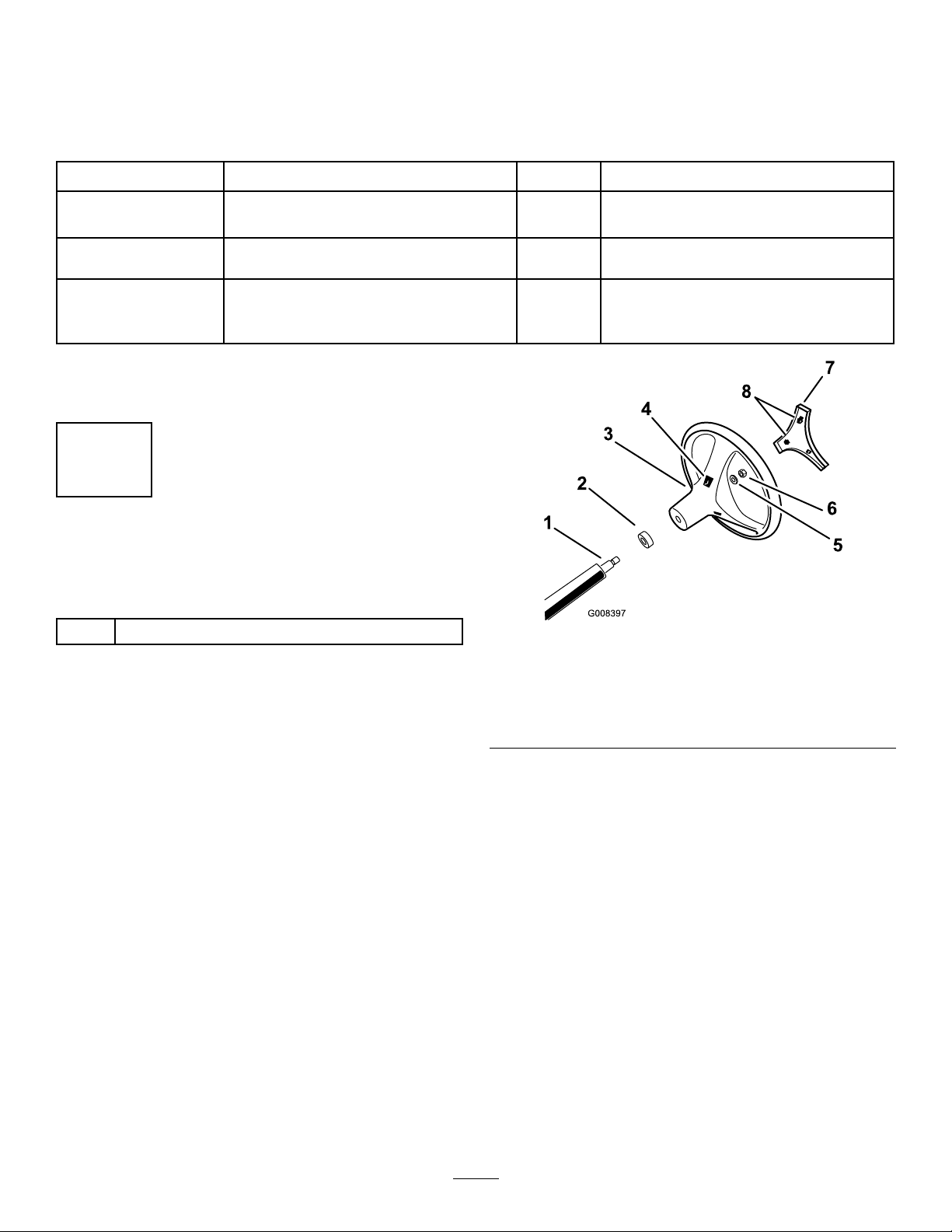

Figure3

1.Steeringshaft

2.Dustcover6.Locknut

3.Steeringwheel7.Cover

4.Tabslotsinwheel8.Tabsincover

5.Alignthetabsofthecoverwiththeslotsinthesteering

wheel,andsnapthecoverontothesteering-wheelhub

(Figure3).

5.Washer

12

Page 13

2

3

InstallingtheRollover

ProtectionSystem(ROPS)

Partsneededforthisprocedure:

1

ROPSframe

6

Bolt(1/2inch)

Procedure

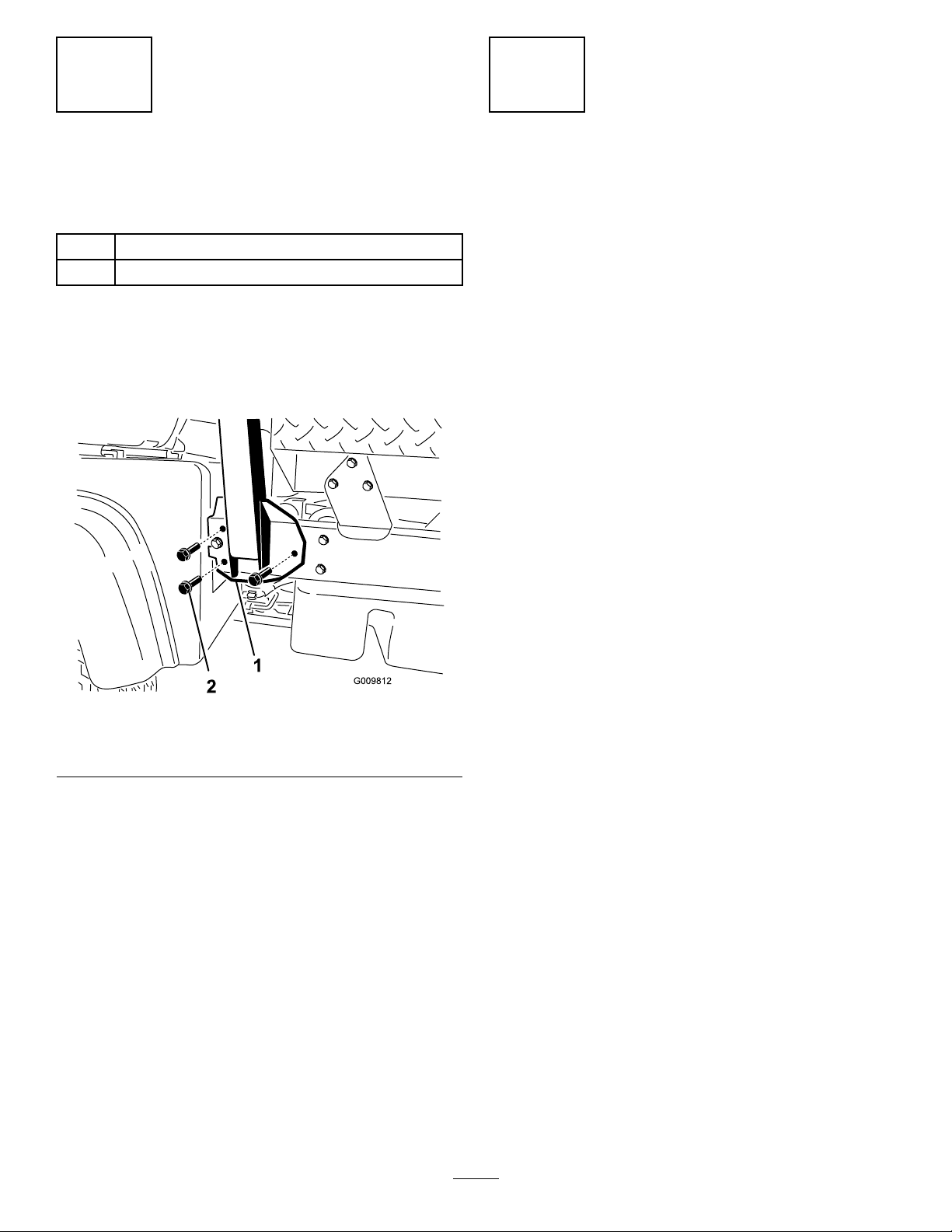

1.AligneachsideoftheROPSwiththemountingholes

intheframeateachsideofthevehicleasshownin

Figure4.

CheckingtheFluidLevels

NoPartsRequired

Procedure

1.Checktheengine-oillevelbeforeandaftertheengine

isrststarted;refertoCheckingtheEngine-oilLevel

(page19).

2.Checkthetransaxle/hydraulic-uidlevelbefore

theengineisrststarted;refertoCheckingthe

Transaxle/Hydraulic-uidLevel(page21).

3.Checkthebrake-uidlevelbeforetheengineisrst

started;refertoCheckingtheBrake-uidLevel(page

23).

Figure4

1.ROPS-mountingbracket2.Flangedbolts(1/2x1-1/4

2.SecureeachsideoftheROPStoframewith3anged

bolts(1/2x1-1/4inch),andtightentheboltsto115

N-m(85ft-lb).

inch)

13

Page 14

ProductOverview

Controls

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

AcceleratorPedal

Theacceleratorpedal(Figure5)givestheoperatortheability

tovarytheengineandgroundspeedofthemachinewhen

thetransmissionisingear.Pressingthepedalincreasesthe

enginerpmandgroundspeed.Releasingthepedaldecreases

theenginerpmandgroundspeedofthemachine.

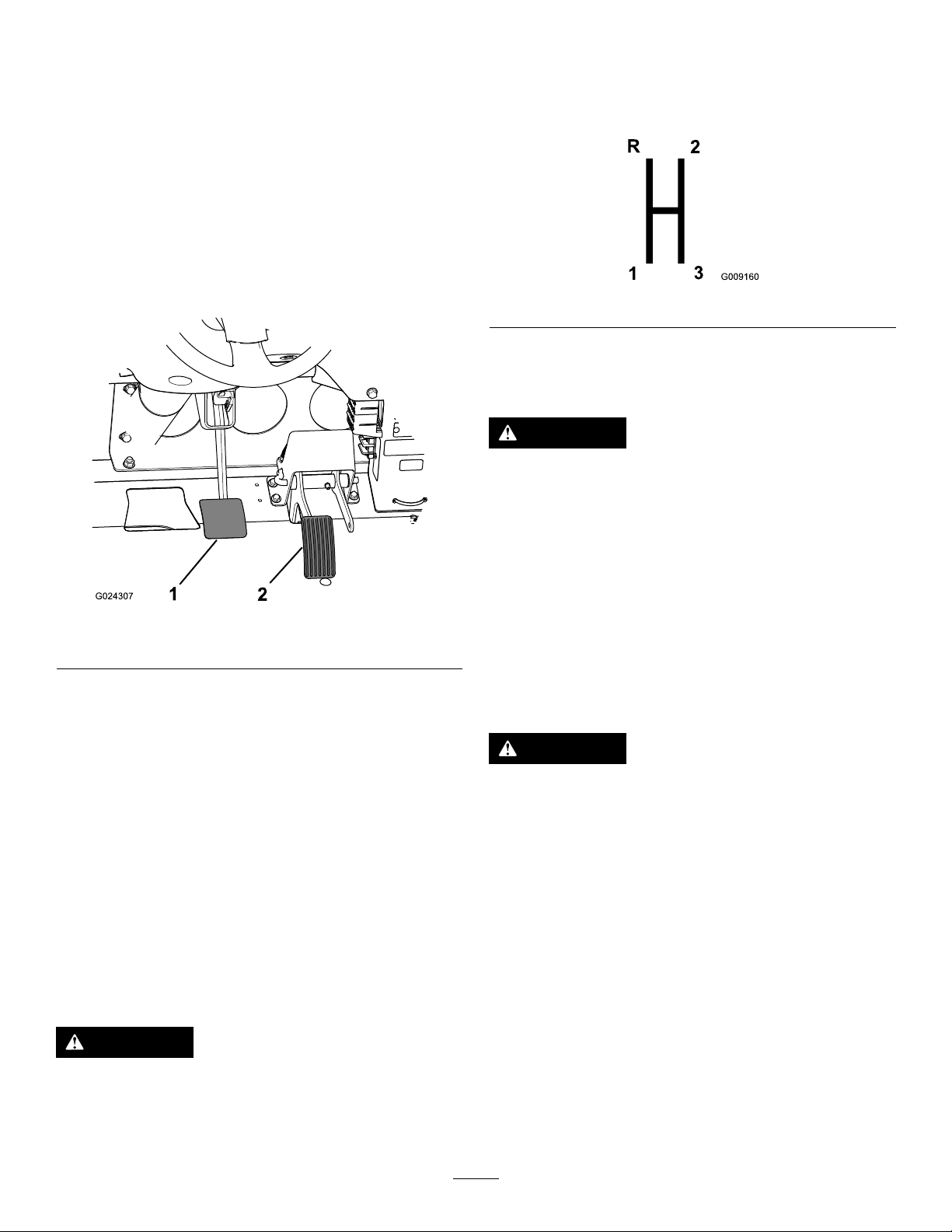

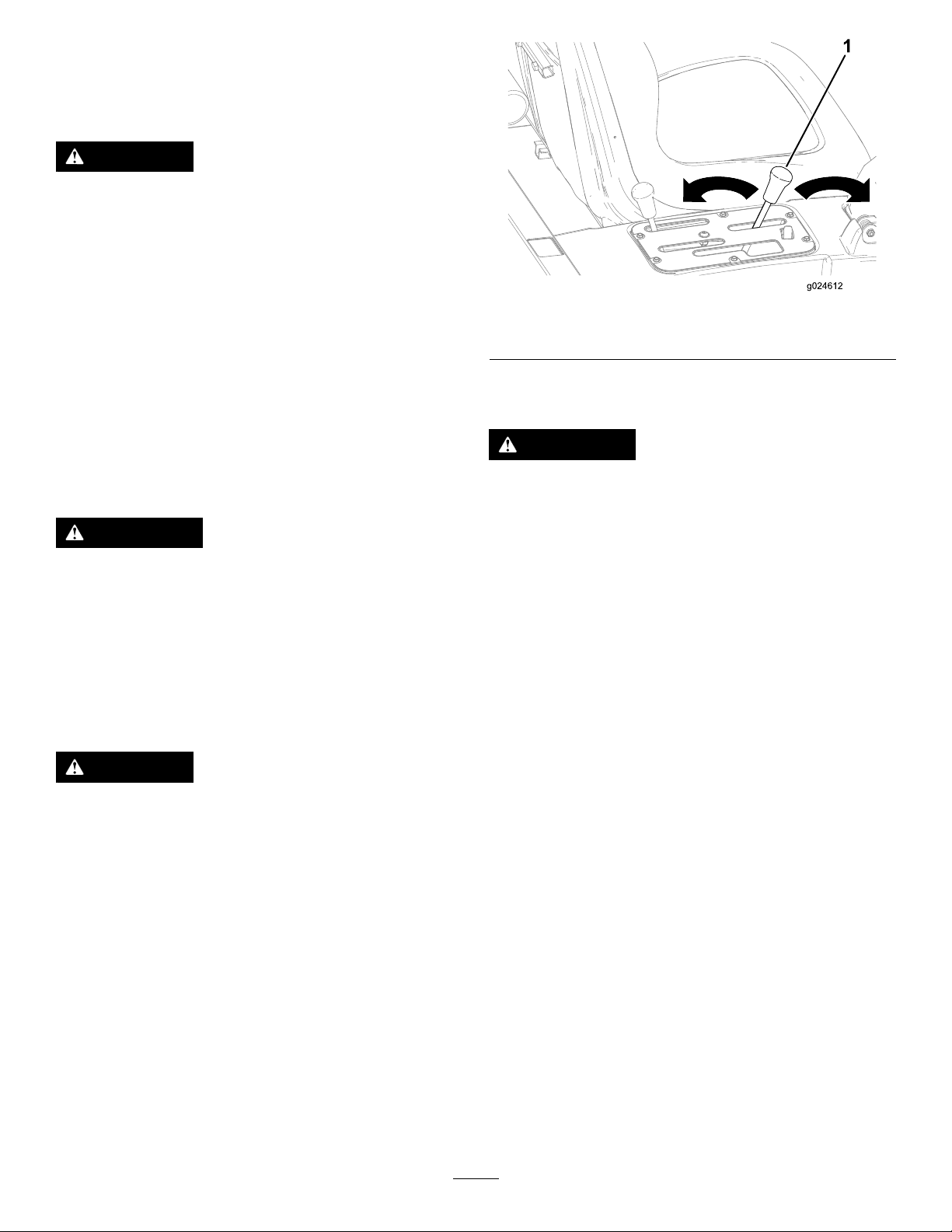

Gear-shiftLever

Fullypresstheclutchpedalandmovetheshiftlever(Figure

6)intothedesiredgearselection.Adiagramoftheshift

patternisshownbelow.

Figure6

Important:Donotshiftthetransaxletothereverseor

forwardgearunlessthevehicleisstandingstill.Damage

tothetransaxlemayoccur.

CAUTION

Downshiftingfromtoohighaspeedcancausethe

rearwheelstoskidresultinginlossofmachine

controlaswellasclutchand/ortransmission

damage.Shiftsmoothlytoavoidgrindinggears.

Figure5

1.Brakepedal2.Acceleratorpedal

ClutchPedal

Theclutchpedal(Figure5)mustbefullypressedtodisengage

clutchwhenstartingtheengineorshiftingtransmissiongears.

Releasethepedalsmoothlywhenthetransmissionisingear

topreventunnecessarywearonthetransmissionandother

relatedparts.

Important:Donotridetheclutchpedalduring

operation.Theclutchpedalmustbefullyoutorthe

clutchwillslipcausingheatandwear.Neverholdthe

vehiclestoppedonahillusingtheclutchpedal.Damage

totheclutchmayoccur.

BrakePedal

Thebrakepedal(Figure5)isusedtoapplyservicebrakes

tostoporslowvehicle.

DifferentialLock

Thedifferentiallockallowsrearaxletobelockedfor

increasedtraction.Thedifferentiallock(Figure7)maybe

engagedwhenthemachineisinmotion.Movethelever

forwardandtotherighttoengagethelock.

Note:Machinemotionplusaslightturnisrequiredto

engageordisengagedifferentiallock.

CAUTION

Turningwiththedifferentiallockoncanresult

inlossofmachinecontrol.Donotoperatewith

differentiallockonwhenmakingsharpturnsorat

highspeeds;refertoUsingtheDifferentialLock

(page28).

CAUTION

Wornormaladjustedbrakesmayresultinpersonal

injury.Ifthebrakepedaltravelstowithin3.8cm

(1-1/2inches)ofthevehicleoorboard,thebrakes

mustbeadjustedorrepaired.

14

Page 15

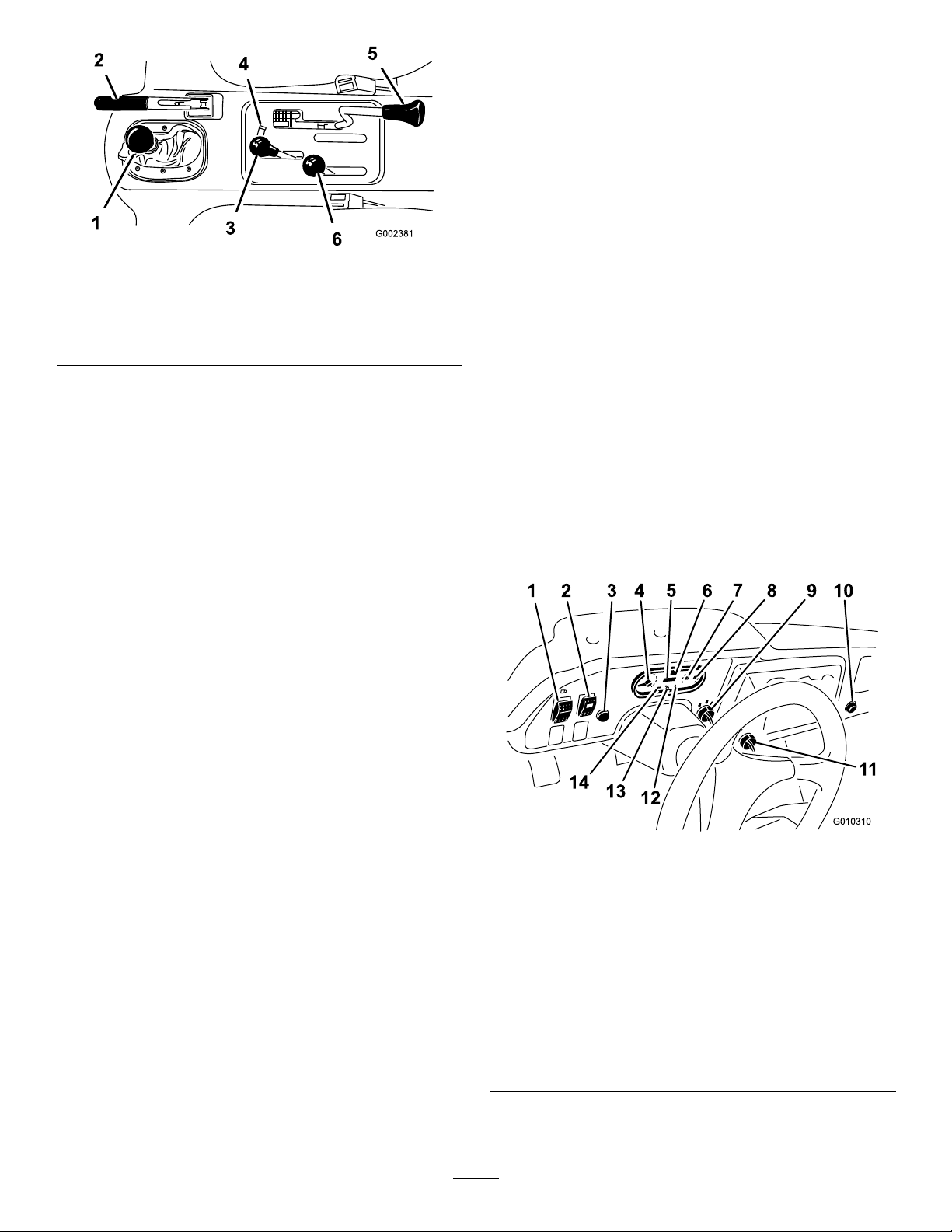

Figure7

1.Gearshiftlever4.Hydraulicliftlock

2.Parkingbrake

3.Hydraulicbedlift6.High–lowrangeshifter

5.Differentiallock

•Presstheclutchpedalfully.

•MovetheleverfullyforwardforHighandfullyrearward

forLow .

Highisforhigherspeeddrivingonlevel,drysurfaceswith

lightloads.

Lowisforlow-speeddriving.Usethisrangewhengreater

thannormalpowerorcontrolisrequired.Forexample,

steepgrades,difcultterrain,heavyloads,slowspeedbut

high-enginespeed(spraying).

Important:ThereisalocationbetweenHighandLow

inwhichthetransaxleisinneitherrange.Donotuse

thispositionasaneutralpositionbecausethevehicle

couldmoveunexpectedlyiftheHigh–Lowshifteris

bumpedandthegear-shiftleverisingear.

StarterSwitch

ParkingBrake

Whenevertheengineisshutoff,settheparkingbrake(Figure

7)inordertopreventthemachinefromaccidentallymoving.

•Tosettheparkingbrake,pullbackonthelever.

•Torelease,pushtheleverforward.

Note:Releasetheparkingbrakebeforemovingthe

machine.

Ifyouparkthemachineonasteepgrade,settheparking

brake,shiftthetransmissionintorstgearonauphillgrade

orreversegearonadownhillgrade,andplacechocksatthe

downhillsideofthewheels.

HydraulicLift

Thehydraulicliftraisesandlowersthebed.Moveitrearward

toraisethebed,andforwardtolowerit(Figure7).

Important:Whenloweringthebed,holdtheleverin

theforwardpositionfor1or2secondsafterthebed

contactstheframetosecureitintheloweredposition.

Donotholdthehydraulicliftineithertheraiseorlower

position,formorethan5seconds,oncethecylinders

havereachedtheendoftheirtravel.

Thestarterswitchislocatedtotherightofthesteering

columnandbelowtheindicatorlightsforthebattery,engine

oilpressure,enginecoolanttemperature,glowplugs(Figure

8).Usethestarterswitchtostartandstoptheengine.The

switchhas3positions:Off,On,andStart.Rotatethekey

clockwisetotheOnpositiontoactivatetheglowplugs.

Whentheglowplugindicatorlightturnsoff,rotatethekey

counterclockwisetotheStartpositiontostarttheengine.

Toshutofftheengine,rotatethekeycounterclockwiseto

theOffposition.

Figure8

Hydraulic-liftLock

Thehydraulic-liftlocklockstheliftlever,sothehydraulic

cylindersdonotoperatewhenthemachineisnotequipped

withabed(Figure7).ItalsolockstheliftleverintheOn

positionwhenusingthehydraulicsforattachments.

High–LowRangeShifter

Thehigh–lowrangeshifteradds3additionalspeedsfor

precisespeedcontrol(Figure7):

•Themachinemustbecompletelystoppedbeforeshifting

betweentheHighandLowrange.

•Shiftonlyonlevelground.

1.Lightswitch8.Fuelgauge

2.High-ow-hydraulics

switch

(TCmodelsonly)

3.Horn

(TCmodelsonly)

4.Tachometer11.3rdhighlockoutswitch

5.Hourmeter

6.Speedometer13.Glow-plugindicator

7.Coolant-temperature

gaugeandlight

9.Ignitionswitch

10.Powerpoint

12.Oilpressurewarninglight

14.Chargeindicator

Note:Removethekeyfromthestarterwhenleavingthe

machine.

15

Page 16

HourMeter

Indicatesthetotalhoursofmachineoperation.Thehour

meter(Figure8)startstofunctionwheneverthekeyswitchis

rotatedtotheOnpositionoriftheengineisrunning.

3rdHighLockoutSwitch

engine,andcheckforpossiblecauses,suchasthealternator

belt(Figure8).

Important:Ifthealternatorbeltislooseorbroken,do

notoperatethemachineuntiladjustmentorrepairis

complete.Failuretoobservethisprecautionmayresult

indamagetotheengine.

Movethe3rd-high-lockoutswitch(Figure8)totheslow

positionandremovethekeytopreventtheuseofthirdgear

whenintheHighrange.Theenginewillshutoffiftheshift

leverismovedtothirdgearwheninHighrange.Thekeyis

removableineitherposition.

LightSwitch

Pushthelightswitch(Figure8)totoggletheheadlightson

oroff.

OilPressureWarningLight

Theoilpressurewarninglightglows(Figure8)ifthe

engine-oilpressuredropsbelowasafelevelwhiletheengine

isrunning.Ifthelightickersorremainson,stopthevehicle,

turnofftheengine,andchecktheoillevel.Iftheoillevelis

low,butaddingoildoesnotcausethelighttogooutwhen

theengineisrestarted,turntheengineoffimmediatelyand

contactyourlocalTorodistributorforassistance.

Checktheoperationofwarninglightsasfollows:

1.Applytheparkingbrake.

2.TurnthestarterkeytotheOn/Preheatposition,but

donotstarttheengine.

Note:Theoilpressurelightshouldglowred.Ifthe

lightdoesnotfunction,eitherabulbisburnedoutor

thereisamalfunctioninthesystemwhichmustbe

repaired.

Note:Ifenginewasjustturnedoff,itmaytake1to

2minutesforthelighttocomeon.

Checktheoperationofwarninglightsasfollows:

•Applytheparkingbrake.

•TurnthestarterkeytotheOn/Preheatposition,butdo

notstarttheengine.Thecoolanttemperature,charge

indicator,andoil-pressurelightsshouldglow.Ifanylight

doesnotfunction,eitherabulbisburnedoutorthereisa

malfunctioninthesystemwhichmustberepaired.

FuelGauge

Thefuelgaugeshowstheamountoffuelinthetank.It

operatesonlywhenstarterswitchisintheOn/Preheat

position(Figure8).Redindicateslowfuellevelandblinking

redindicatesnearempty.

High-owHydraulicsSwitch(TC

modelsonly)

Turnontheswitchtoactivatethehigh-owhydraulics

(Figure8).

HornButton(TCmodelsonly)

Pressingthehornbuttonactivatesthehorn(Figure8).

Tachometer

Thetachometerregistersthespeedoftheengine(Figure8

andFigure9).Whitetriangleindicatesthedesiredrpmfor

PTOoperation(Figure9).

Glow-plugIndicator

Theglow-plugindicator(Figure8)willglowredwhenthe

glowplugsareactivated.

Important:Theglowplugindicatorwillturnon,foran

additional15seconds,whentheswitchreturnstothe

Startposition.

Coolant-temperatureGaugeandLight

Registersthecoolanttemperatureoftheengine.Operates

onlywhenthestarterswitchisinOnposition(Figure8).

Theindicatorlightwillilluminateblinkingrediftheengine

overheats.

ChargeIndicator

Illuminateswhenbatteryisbeingdischarged.Ifthelight

illuminatesduringoperation,stopthemachine,turnoffthe

Figure9

1.Speedoftheengine2.3,300rpmfor540rpm

PTOoperation

16

Page 17

Speedometer

Registersthegroundspeedofthemachine(Figure8).The

speedometerisinmphbutcaneasilyconvertedtokm/h;

refertoConvertingtheSpeedometer(page51).

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

Dimensions

PowerPoint

Usethepowerpoint(Figure8)topoweroptional12volt

electricalaccessories.

PassengerHandHold

Thepassengerhandholdislocatedonthedashboard(Figure

10).

Figure10

OverallWidth160cm(63inches)

Withoutbed:326cm(128inches)

OverallLength

BaseWeight(Dry)

RatedCapacity

(includes91kg(200

lb)operator,91kg

(200lb)passengerand

loadedattachment).

Maximum.Gross

VehicleWeight

TowCapacityTongueweight:272kg(600lb)

GroundClearance18cm(7inches)withnoload

WheelBase

WheelTread(center

linetocenterline)

Height

Withfullbed:331cm(130inches)

With2/3bedinrear-mounting

location:346cm(136inches)

Model07385—887kg(1956lb)

Model07385H—887kg(1956lb)

Model07385TC—924kg(2037lb)

Model07387—914kg(2015lb)

Model07387H—914kg(2015lb)

Model07387TC—951kg(2096lb)

Model07385—1471kg(3244lb)

Model07385TC—1435kg(3163lb)

Model07387—1445kg(3185lb)

Model07387TC—1408kg(3104lb)

2359kg(5200lb)

Maximumtrailerweight:1587kg

(3500lb)

118cm(70inches)

Front:117cm(46inches)

Rear:121cm(48inches)

191cm(75inches)totopofROPS

1.Passengerhandhold

2.Storagecompartment

Seat-adjustingLever

Theseatscanbeadjustedbeforeandafterforoperator

comfort(Figure11).

Figure11

1.Seat-adjustinglever

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesis

availableforusewiththemachinetoenhanceandexpand

itscapabilities.ContactyourAuthorizedServiceDealeror

Distributororgotowww .Toro.comforalistofallapproved

attachmentsandaccessories.

17

Page 18

Operation

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

CAUTION

Beforeservicingormakingadjustmentstothe

machine,stoptheengine,settheparkingbrake,

andremovethekeyfromtheswitch.Removeany

loadmaterialfromthebedorotherattachment

beforeworkingunderaraisedbed.Neverwork

underaraisedbedwithoutpositioningthesafety

supportonafullyextendedcylinderrod.

OperatingtheCargoBox

Figure12

1.Cargoboxlever

Note:Centerloadsinthecargoboxifpossible.

Note:Removeallcargofromtheboxbeforeliftingthebox

uptoservicethemachine.

RaisingtheCargoBox

WARNING

Drivingthemachinewiththecargoboxraisedmay

causethemachinetotiporrolleasier.Thebox

structuremaybecomedamagedifyouoperatethe

machinewiththeboxraised.

•Onlyoperatethemachinewhenthecargobox

isdown.

•Afteremptyingthecargobox,lowerit.

CAUTION

Ifaloadisconcentratednearthebackofthecargo

boxwhenyoureleasethelatches,theboxmay

unexpectedlytipopeninjuringyouorbystanders.

LoweringtheBox

WARNING

Theweightoftheboxmaybeheavy.Handsor

otherbodypartscouldbecrushed.

Keephandsandotherbodypartsclearwhen

loweringthebox.

Movetheleverforwardtolowerthecargobox(Figure12).

OpeningtheTailgate

1.Ensurethatthecargoboxisloweredcompletely.

2.Openthelatchesontheleftandrightsideofthecargo

boxandlowerthetailgate(Figure13).

•Centerloadsinthecargoboxifpossible.

•Holdthecargoboxdownandensurethatno

oneisleaningovertheboxorstandingbehindit

whenreleasingthelatches.

•Removeallcargofromtheboxbeforeliftingthe

boxuptoservicethemachine.

Movetheleverbackwardtoraisethecargobox(Figure12).

18

Page 19

Figure13

1.Latchhandle3.Latchpin

2.Latchgate

enginehasalreadyran,allowtheoiltodrainbackdowntothe

sumpforatleast10minutesbeforechecking.Iftheoillevel

isatorbelowtheAddmarkonthedipstick,addoiltobring

theoilleveltotheFullmark.Donotoverlltheengine

withoil.IftheoillevelisbetweentheFullandAddmarks,

noadditionaloilisrequired.

1.Positionthemachineonalevelsurface.

2.Removethedipstickandwipeitwithacleanrag

(Figure15).

CheckingtheEngine-oilLevel

ServiceInterval:Beforeeachuseordaily

Engineoiltype:DetergentdieselengineoilAPICH-4or

higher

Engine-oilviscosity:Chooseanengine-oilviscosity

accordingtotheambient-airtemperaturetothetablein

Figure14.

Figure15

1.Dipstick

2.Oil-llcap

3.Insertthedipstickintothetubeandmakesurethatit

isseatedfully(Figure15).

4.Removedipstickandchecktheleveloftheoil(Figure

15).

5.Iftheoillevelislow,removetheoil-llcap(Figure15),

andaddenoughoiltoraisetheleveltotheFullmark

onthedipstick.

6.Installthedipstickrmlyinplace(Figure15).

Figure14

Note:Thebesttimetochecktheengineoiliswhenthe

engineiscoolbeforeithasbeenstartedfortheday.Ifthe

19

Page 20

AddingFuel

UsingBiodieselFuel

Fueltankcapacity:22L(5.85USgallons).

Useonlyclean,freshdieselfuelorbiodieselfuelswithlow

(<500ppm)orultralow(<15ppm)sulfurcontent.The

minimumcetaneratingshouldbe40.Purchasefuelin

quantitiesthatcanbeusedwithin180daystoensurefuel

freshness.

•Usesummergradedieselfuel(No.2-D)attemperatures

above-7°C(20°F)andwintergrade(No.1-DorNo.

1-D/2-Dblend)belowthattemperature.

•Useofwintergradefuelatlowertemperaturesprovides

lowerashpointandcoldowcharacteristicswhichwill

easestartingandreducefuellterplugging.

Note:Useofsummergradefuelabove-7°C(20°F)will

contributetowardlongerfuelpumplifeandincreasedpower

comparedtowintergradefuel.

Important:Donotusekeroseneorgasolineinsteadof

dieselfuel.Failuretoobservethiscautionwilldamage

theengine.

WARNING

Fuelisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

•Avoidprolongedbreathingofvapors.

•Keepyourfaceawayfromthenozzleandgas

tankorconditioneropening.

•Keepfuelawayfromyoureyesandskin.

Thismachinecanalsouseabiodieselblendedfuelofup

toB20(20%biodiesel,80%petrodiesel).Thepetrodiesel

portionshouldbeloworultralowsulfur.Observethe

followingprecautions:

•Thebiodieselportionofthefuelmustmeetspecication

ASTMD6751orEN14214.

•TheblendedfuelcompositionshouldmeetASTMD975

orEN590.

•Paintedsurfacesmaybedamagedbybiodieselblends.

•UseB5(biodieselcontentof5%)orlesserblendsincold

weather.

•Monitorseals,hoses,gasketsincontactwithfuelasthey

maybedegradedovertime.

•Fuellterpluggingmaybeexpectedforatimeafter

convertingtobiodieselblends.

•Contactyourdistributorifyouwishformoreinformation

onbiodiesel.

1.Cleantheareaaroundthefuel-tankcap.

2.Removethefuel-tankcap(Figure16).

DANGER

Undercertainconditions,dieselfuelandfuel

vaporsarehighlyammableandexplosive.Are

orexplosionfromfuelcanburnyouandothersand

cancausepropertydamage.

•Beforeremovingthefueltankcap,makesure

thevehicleispositionedonalevelsurface.Open

fueltankcapslowly .

•Useafunnelandllthefueltankoutdoors,in

anopenarea,whentheengineisoffandiscold.

Wipeupanyfuelthatspills.

•Donotllthefueltankcompletelyfull.Addfuel

tothefueltankuntilthelevelis25mm(1inch)

belowthebottomofthellerneck.Thisempty

spaceinthetankallowsthefueltoexpand.

•Neversmokewhenhandlingfuel,andstayaway

fromanopenameorwherefuelfumesmaybe

ignitedbyaspark.

•Storefuelinaclean,safety-approvedcontainer

andkeepthecapinplace.

Figure16

1.Fuel-tankcap

3.Fillthetankslightlybelowthetopofthetank,(bottom

ofthellerneck),theninstallthecap.

Note:Donotoverllthefueltankwithfuel.

4.Wipeupanyfuelthatmayhavespilledtopreventa

rehazard.

20

Page 21

CheckingtheCoolantLevel

ServiceInterval:Beforeeachuseordaily

3.Ifcoolantislow ,removethereservetankcapandadda

50/50mixtureofwaterandpermanentethylene-glycol

antifreeze.

Coolingsystemcapacity:3.7L(4USqt)

Coolanttype:a50/50solutionofwaterandpermanent

ethylene-glycolantifreeze.

CAUTION

Iftheenginehasbeenrunning,thepressurized,hot

coolantcanescapeandcauseburns.

•Donotopentheradiatorcap.

•Allowtheenginetocoolatleast15minutesor

untiltheradiatorcapiscoolenoughtotouch

withoutburningyourhand.

•Usearagwhenopeningthereservetankcap,

andopenthecapslowlytoallowsteamto

escape.

•Donotcheckthecoolantlevelattheradiator;

onlycheckthecoolantlevelatthereservetank.

1.Parkthemachineonalevelsurface.

2.Checkthecoolantlevelinsidethereservetank(Figure

17).

Note:Donotoverllthereservetankwithcoolant.

4.Installthereserve-tankcap.

Checkingthe

Transaxle/Hydraulic-uid

Level

ServiceInterval:Beforeeachuseordaily(checktheuid

levelbeforetheengineisrststartedand

every8hoursordaily ,thereafter.)

Transaxleuidtype:DexronIIIATF

1.Positionthemachineonalevelsurface.

2.Cleantheareaaroundthedipstick(Figure18).

Note:Thecoolantshouldbeuptothebottomofthe

llerneckwhentheengineiscold.

Figure18

1.Dipstick

3.Unscrewthedipstickfromthetopofthetransaxleand

wipeitwithacleanrag.

4.Screwthedipstickintothetransaxleandensurethat

itisfullyseated.

5.Unscrewthedipstickandchecktheuidlevel.

Note:Theuidshouldbeuptotopoftheatportion

ofthedipstick.

6.Ifthelevelislow ,addenoughofthespecieduidto

achievetheproperlevel.

1.Reservetank-cap

2.Reservetank

Figure17

21

Page 22

CheckingtheHighFlow

Hydraulic-uidLevel(TC

modelsonly)

4.Insertthedipstickintothellerneck,thenremoveit

andchecktheuidlevel.

Note:Theuidlevelshouldbebetweenthe2marks

onthedipstick.

ServiceInterval:Beforeeachuseordaily(checkthelevelof

hydraulicuidbeforetheengineisrst

started,anddailythereafter)

Hydraulic-uidtype:T oroPremiumAllSeason

HydraulicFluid(Availablein5gallonpailsor55gallon

drums.SeepartscatalogorTorodistributorforpart

numbers.)

Alternateuids:IftheTorouidisnotavailable,another

conventionalpetroleum–baseduidmaybeusedprovided

itmeetsthefollowingmaterialpropertiesandindustry

specications.Consultwithyourlubricantdistributorto

identifyasatisfactoryproduct.

Note:Torowillnotassumeresponsibilityfordamage

causedbyimpropersubstitutions,souseonlyproducts

fromreputablemanufacturerswhowillstandbehindtheir

recommendation.

HighViscosityIndex/LowPourPointAntiwear

HydraulicFluid,ISOVG46

MaterialProperties:

•Viscosity—ASTMD445cSt@40ºC:44to48/cSt@

100ºC:7.9to8.5

•ViscosityIndex,ASTMD2270—140to152

•PourPoint,ASTMD97—-35ºFto-46ºF

•FZG,Failstage—11orbetter

•Watercontent(newuid)—500ppm(maximum)

IndustrySpecications:

VickersI-286-S,VickersM-2950-S,DenisonHF-0,Vickers

35VQ25(EatonATS373-C)

1.Cleantheareaaroundthellerneckandthecapofthe

hydraulictank(Figure19).

2.Removethecapfromthellerneck.

5.Ifthelevelislow ,addtheappropriateuidtoraise

theleveltotheuppermark;refertoChangingthe

High-owHydraulicuidandFilter(TCmodelsonly)

(page53).

6.Installthedipstickandcapontothellerneck.

7.Starttheengineandturnontheattachment.

Note:Letthemrunforabout2minutestopurgeair

fromthesystem.

Important:Themachinemustberunningbefore

startingthehigh-owhydraulics.

8.Stoptheengineandattachmentandcheckforleaks.

WARNING

Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjury.

•Makesureallhydraulicuidhosesand

linesareingoodconditionandallhydraulic

connectionsandttingsaretightbefore

applyingpressuretothehydraulicsystem.

•Keepyourbodyandhandsawayfrom

pinholeleaksornozzlesthatejecthigh

pressurehydraulicuid.

•Usecardboardorpapertondhydraulic

leaks.

•Safelyrelieveallpressureinthehydraulic

systembeforeperforminganyworkonthe

hydraulicsystem.

•Seekimmediatemedicalattentionifuid

isinjectedintoyourskin.

Figure19

1.Cap

3.Removethedipstick(Figure19)fromthellerneck

andwipeitwithacleanrag.

Checkingthe Front-differential-oilLevel (4-wheeldrivemodelsonly)

ServiceInterval:Every100hours/Monthly(whichever

comesrst)

Differential-oiltype:Mobil424hydraulicoil

1.Positionthemachineonalevelsurface.

2.Cleantheareaaroundthell/checkplugonsideof

thedifferential(Figure20).

22

Page 23

Figure20

CheckingtheTirePressure

ServiceInterval:Beforeeachuseordaily

Theairpressureinthefronttiresis220kPa(32psi)andthe

reartiresis124kPa(18psi).

Checkthetirepressurefrequentlytoensureproperination.

Ifthetiresarenotinatedtothecorrectpressure,thetires

willwearprematurely.

Figure21isanexampleoftirewearcausedbyunderination.

1.Fill/checkplug

3.Removethell/checkplugandcheckthelevelofthe

oil.

Note:Theoilshouldbeuptohole.

4.Iftheoilislow,addspeciedoil.

5.Installthell/checkplug.

2.Drainplug

CheckingtheTorqueofthe WheelNuts

ServiceInterval:Aftertherst2hours

Aftertherst10hours

Every200hours

WARNING

Failuretomaintainpropertorqueofthewheelnuts

couldresultinfailureorlossofawheelandmay

resultinpersonalinjury.

Figure21

1.Under-inatedtire

Figure22isanexampleoftirewearcausedbyoverination.

Figure22

1.Over-inatedtire

Torquethefrontandrearwheelnutsto109to122

N-m(80to90ft-lb)after1to4hoursofoperation

andagainafter10hoursofoperation.T orqueevery

200hoursthereafter.

CheckingtheBrake-uidLevel

ServiceInterval:Beforeeachuseordaily—Checkthe

brake-uidlevel.(Checkthelevelbefore

theengineisrststartedandevery8

hoursordaily,thereafter.)

Every1,000hours/Every2years(whichevercomes

rst)—Changethebrakeuid.

Brakeuidtype:DOT3brakeuid

Thebrake-uidreservoirislocatedunderthedash.

1.Parkthemachineonalevelsurface.

2.TheuidlevelshouldbeuptotheFulllineonthe

reservoir(Figure23).

23

Page 24

Figure23

1.Brake-uidreservoir

3.Iftheuidlevelislow,cleantheareaaroundthecap,

removethereservoircap,andllthereservoirtothe

properlevelwiththespeciedbrakeuid.

Note:Donotoverllthereservoirwithbrakeuid.

Note:Youcanremovethehoodaccesstothereservoirfrom

thefrontofthemachine(Figure24).

5.Keepyourfootoffoftheacceleratorpedal.

6.TurnthestarterswitchtotheOnposition.Whenthe

glowplugindicatorlightgoesoff,theengineisready

tostart.

7.RotatethestarterkeyswitchtotheStartposition.

Releasethekeyimmediatelywhentheenginestartsand

allowittoreturntotheRunposition.

Note:Theglowplugindicatorwillturnonforanadditional

15seconds,whentheswitchreturnstotheRunposition.

Note:Donotrunthestartermotormorethan10secondsat

atimeorprematurestarterfailuremayresult.Ifenginefails

tostartafter10seconds,turnthekeytotheOffposition.

Checkthecontrolsandstartingprocedure,wait10additional

seconds,andrepeatthestartingoperation.

DrivingtheVehicle

1.Releasetheparkingbrake.

2.Fullypresstheclutchpedal.

3.Movethegearshiftlevertorstgear.

Figure24

1.Brake-uidreservoir

StartingtheEngine

1.Sitontheoperator’sseatandengagetheparkingbrake.

2.DisengagethePTOandhighowhydraulics(ifso

equipped)andmovethehandthrottlelevertotheOff

position(ifsoequipped).

3.MovetheshiftlevertotheNeutralpositionandpress

theclutchpedal.

4.Ensurethatthehydraulic-liftleverisinthecenter

position.

4.Releasetheclutchpedalsmoothlywhilepressingthe

acceleratorpedal.

5.Whenthemachinegainsenoughspeed,removeyour

footfromtheacceleratorpedal,fullypresstheclutch

pedal,movethegearshiftlevertothenextgearand

releasetheclutchpedalwhilepressingtheaccelerator

pedal.

6.Repeattheprocedureuntilthedesiredspeedisattained.

Important:Alwaysstopthemachinebefore

shiftingtoreverseaforwardgearortoaforward

gearfromreverse.

Note:Avoidlongperiodsofengineidling.

Usethechartbelowtodeterminethegroundspeedof

thevehicleat3600rpm.

Gear

1L82.83:14.72.9

2L54.52:17.24.5

3L31.56:112.5

1H32.31:112.27.6

2H21.27:118.511.5

3H12.31:131.919.8

RL86.94:14.52.8

RH33.91:111.67.1

RangeRatio

Speed

(kmh)

Important:Donotattempttopushortowthe

machinetogetitstarted.Damagetothedrive

traincouldresult.

Speed

(mph)

7.7

24

Page 25

StoppingtheMachine

CheckingtheSafety-interlock

Tostopthemachine,removeyourfootfromtheaccelerator

pedal,presstheclutchpedal,thenpressthebrakepedal.

StoppingtheEngine

Tostoptheengine,rotatethestarterkeytotheOffposition

andengagetheparkingbrake.Removethekeyfromthe

switchtopreventaccidentalstarting.

BreakinginaNewMachine

Toprovideproperperformanceandlongmachinelife,follow

theseguidelinesfortherst100operatinghours.

•Checktheuidandengineoillevelsregularlyandbealert

forindicationsofoverheatinginanycomponentofthe

machine.

•Afterstartingacoldengine,letitwarmupforabout15

secondsbeforeshiftingintogear.

•Avoidracingtheengine.

•Toensureoptimumperformanceofthebrakesystem,

burnish(break–in)thebrakesbeforeuse.Toburnishthe

brakes,bringthevehicleuptofullspeed,applythebrakes

torapidlystopthevehiclewithoutlockingupthetires.

Repeatthis10times,waiting1minutebetweenstopsto

avoidoverheatingthebrakes.Thisismosteffectiveifthe

machineisloadedwith454kg(1000lb).

•Varythemachinespeedduringoperation.Avoidexcessive

idling.Avoidfaststartsandquickstops.

System

ServiceInterval:Beforeeachuseordaily

Thepurposeofthesafety-interlocksystemistopreventthe

enginefromcrankingorstartingunlesstheclutchpedalis

pressed.

CAUTION

Ifthesafety-interlockswitchesaredisconnectedor

damagedthemachinecouldoperateunexpectedly

causingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlockswitches

dailyandreplaceanydamagedswitchesbefore

operatingthemachine.

Note:RefertoAttachmentOperator’sManualforprocedures

oncheckingtheattachmentinterlocksystem.

VerifyingtheClutchInterlockSwitch

1.Sitontheoperator’sseatandengagetheparkingbrake.

2.MovetheshiftlevertotheNeutralposition.

Note:Theenginewillnotcrankifthehydraulic-lift

leverislockedintheforwardposition.

3.Withoutpressingtheclutchpedal,rotatethekey

clockwisetotheStartposition.

•Abreak–inoilfortheengineisnotrequired.The

originalengineoilisthesametypespeciedforregular

oilchanges.

•RefertotheMaintenancesectionforanyspeciallowhour

checks.

Note:Iftheenginecranksorstarts,thereisa

malfunctionintheinterlocksystemthatmustbe

repairedbeforeoperatingthemachine.

VerifyingtheHydraulic-liftLever

InterlockSwitch

1.Sitontheoperator’sseatandengagetheparkingbrake.

2.MovetheshiftlevertotheNeutralpositionandensure

thatthehydraulic-liftleverisinthecenterposition.

3.Pressclutchpedal.

4.Movethehydraulic-liftleverforwardandrotatethe

startkeyclockwisetothestartposition.

Note:Ifenginecranksorstarts,thereisamalfunction

intheinterlocksystemthatmustberepairedbefore

operatingthemachine.

25

Page 26

EnsuringPassengerSafety

EnsuringProperSpeed

Wheneveryouhaveapassengerridinginthemachine,make

sureheorsheiswearingtheseatbeltandholdingonsecurely .

Driveslowerandturnlesssharplybecauseyourpassenger

doesnotknowwhatyouaregoingtodonextandmaynotbe

preparedforturning,stopping,accelerating,andbumps.

Youandyourpassengershouldremainseatedatalltimes,

keepingarmsandlegsinsidethevehicle.Theoperatorshould

keepbothhandsonsteeringwheel,wheneverpossible,and

thepassengershouldusethehandholdsprovided(Figure

25andFigure26).

Speedisoneofthemostimportantvariablesleadingto

accidents.Drivingtoofastfortheconditionscancauseyou

tolosecontrolandhaveanaccident.Speedcanalsomakea

minoraccidentworse.Drivingheadonintoatreeatslow

speedcancauseinjuryanddamage,but,drivingintoatree

athighspeedcandestroythevehicleandkillyouandyour

passenger.

Neverdrivetoofastfortheconditions.Ifthereisanydoubt

abouthowfasttodrive,slowdown.

Whenusingheavyattachments,morethan454kg(1000lb),

suchassprayers,topdressers,orspreaders,etc.,restrictyour

operatingspeedbymovingthe3rdhighlockoutswitchto

theslowposition.

EnsuringProperTurning

Turningisanotherimportantvariableleadingtoaccidents.

Turningtoosharplyfortheconditionscancausethevehicle

tolosetractionandskid,oreventipover.

Wet,sandy,andslipperysurfacesmaketurningmoredifcult

andrisky .Thefasteryouaregoing,theworsethissituation

becomesso,slowdownbeforeturning.

1.Passenger-handhold

1.Handholdandhiprestraint

Figure25

Figure26

Duringasharpturnathigherspeeds,theinsiderearwheel

mayliftoffoftheground.Thisisnotaawinthedesign,it

happenswithmost4-wheelmachineincludingpassengercars.

Ifthishappens,youareturningtoosharplyforthespeedat

whichyouaretraveling.Slowdown!

2.Storagecompartment

EnsuringProperBraking

Itisgoodpracticetoslowdownbeforeyougetnearan

obstacle.Thisgivesyouextratimetostoporturnaway.

Hittinganobstaclecandamagethemachineanditscontents.

Moreimportant,itcaninjureyouandyourpassenger.Gross

machineweighthasamajorimpactonyourabilitytostop

and/orturn.Heavierloadsandheavierattachmentsmake

avehiclehardertostoporturn.Theheaviertheload,the

longerittakestostop.

Thebrakingcharacteristicsalsochangewithnobedor

attachmentonthemachine.Faststopsmaycausetherear

wheelstolockupbeforethefrontwheelslockup,whichmay

affectthecontrolofthemachine.Itisagoodideatodecrease

machinespeedwithnobedorattachment.

Turfandpavementaremuchslipperierwhentheyarewet.

Itcantake2to4timesaslongtostoponwetsurfacesas

ondrysurfaces.

Neverallowpassengersinthedumpboxoronany

attachments.Thevehicleismeanttohaveonedriverand

onlyonepassenger—nomore.

Ifyoudrivethroughstandingwaterdeepenoughtogetthe

brakeswet,theywillnotworkwelluntiltheyaredry.After

drivingthroughwater,youshouldtestthebrakestomake

suretheyworkproperly.Iftheydonot,driveslowlyinrst

gearwhileputtinglightpressureonthebrakepedal.This

willdrythebrakesout.

26

Page 27

Donotdownshiftforbrakingonicyorslipperysurfaces(wet

grass)orwhilegoingdownahillbecauseenginebraking

maycauseskiddingandlossofcontrol.Shifttoalowergear

beforestartingdownahill.

PreventingTipOvers

Themachineisequippedwitharollbar,hiprestraints,seat

belts,andhandhold.TheRolloverProtectionSystem(ROPS)

usedonthemachinewillreducetheriskofseriousorfatal

injuryintheunlikelyeventofatipover,althoughthesystem

cannotprotecttheoperatorfromallpossibleinjuries.

ReplaceadamagedROPS,donotrepairorrevise.Any

alterationoftheROPSmustbeapprovedbythemanufacturer.

Thebestwaytopreventaccidentsinvolvingutilitymachine

isthroughcontinuoussupervisionandtrainingofoperators

andpayingconstantattentiontotheareainwhichvehicle

isbeingoperated.

Thebestwayforoperatorstopreventseriousinjuryordeath

tothemselvesorothers,istofamiliarizethemselveswiththe

properoperationoftheutilityvehicle,tostayalertandto

avoidactionsorconditionswhichcouldresultinaaccident.

Intheeventofatipover,theriskofseriousinjuryordeath

willbereducediftheoperatorisusingtheROPSsystemand

seatbeltsandisfollowingtheinstructionsprovided.

OperatingonHills

WARNING

Tippingorrollingthemachineonahillcouldcause

seriouspersonalinjury.

•Donotoperatethevehicleonsteepslopes.

•Ifenginestallsoryouloseheadwayonahill,

neverattempttoturnvehiclearound.

•Alwaysbackstraightdownahillinreversegear.

•Neverbackdowninneutralorwiththeclutch

depressed,usingonlythebrakes.

•Neverdriveacrossasteephill,alwaysdrive

straightupordown.

•Avoidturningonahill.

•Don’t“droptheclutch”orslamonthebrakes.

Suddenspeedchangecaninitiateatipover.

andcautiouslyaspossible.Nevermakesharporfastturns

onahill.

Ifyoustallorbegintoloseheadwaywhileclimbingasteep

hill,quicklyapplythebrakes,shifttoneutral,starttheengine

andshifttoreverse.Atidlespeed,theengineandtransaxle

dragwillaidthebrakesincontrollingthevehicleonthehill

andhelpyoubackdownthehillmoresafely.

Reducetheweightoftheloadifitisasteephillorifthe

loadhashighcenterofgravity.Remember,loadscanshift,

securethem.

Note:Themachinehasexcellenthill-climbingability.The

differentiallockwillincreasethisability.Hillclimbingtraction

canalsobeincreasedbyaddingweighttotherearofthe

vehicleinoneofthefollowingways:

•Addingweighttoinsideofbox,makingsureitissecured.

•Mountingwheelweightstorearwheels.

•Addingliquidballast(calciumchloride)toreartires.

•Tractionwillincreasewithnopassengerinfrontseat.

LoadingandDumping

Theweightandpositionofthecargoandpassengercan

changethemachinecenterofgravityandthemachine

handling.Toavoidlossofcontrolresultinginpersonalinjury,

followtheseguidelines:

Donotcarryloadswhichexceedtheloadlimitsdescribed

onthemachineweightlabel.

WARNING

Thebedwilllowerwheneverthedumpleveris

pusheddown,evenwhentheengineisoff.Turning

not

offtheenginewill

lowering.Alwaysplacethesafetysupportonthe

extendedliftcylindertoholdtheboxupifyouare

notgoingtoloweritrightaway.

Themachinehasseveralcombinationsofboxes,platforms,

andattachmentsavailable.Thesecanbeusedinvarious

combinationsthatallowformaximumcapacityandversatility.

Thefullsizedboxis140cm(55inches)wideby165cm(65

inches)longandcanholdupto1360kg(3000lb)ofevenly

distributedcargo.

preventtheboxfrom

Useextracarewhenonhills.Nevergoonhillsthatare

extremelysteep.Stoppingwhilegoingdownahillwilltake

longerthanonlevelground.Turningwhilegoingupordown

ahillismoredangerousthanturningonthelevel.Turnswhile

goingdownhill,especiallywiththebrakeson,and,turning

uphillwhiletraversingahillareparticularlydangerous.Even

ataslowspeedandwithoutaload,tipoversaremorelikelyif

youturnonahill.

Slowdownandshiftintoalowergearbeforestartingupor

downahill.Ifyouhavetoturnwhileonahill,doitasslowly

Loadsvaryinhowtheyaredistributed.Sandspreadsout

evenlyandquitelow .Otheritems,suchasbricks,fertilizeror

landscapetimbers,stackhigherinthebox.

Theheightandweightoftheloadhasasignicantinuence

ontipovers.Thehigheraloadisstacked,themorelikelythe

vehicleistotipover.Youmayndthat1360kg(3000lb)

stackstoohighforsafeoperation.Reducingthetotalweight

isonewaytoreducetheriskofatipover.Distributingthe

loadaslowaspossibleisanotherwaytoreducetheriskof

atipover.

27

Page 28

Iftheloadispositionedtowardoneofthesides,itwillmake

themachinemuchmorelikelytotipoveronthatside.This

isespeciallytruewhenturningiftheloadisontheoutside

oftheturn.

WARNING

Tippingorrollingthemachineonahillwillcause

seriousinjury.

Neverpositionheavyloadsbehindtherearaxle.Iftheloadis

positionedsofartotherearthatitisbehindtherearaxle,it

willreducetheweightonthefrontwheelsandthiswillreduce

steeringtraction.Withtheloadallthewaytotheback,the

frontwheelscanevencomeoffofthegroundwhengoing

overbumpsorupahill.Thiswillresultinalossofsteering

andmayleadtothevehicletippingover.

Asageneralrule,positiontheweightoftheloadevenly

fromfronttorearandevenlyfromsidetoside.

Ifaloadisnotsecured,oryouaretransportingaliquidina

largecontainersuchasasprayer,itcanshift.Thisshifting

happensmostoftenwhileturning,goingupordownhills,

suddenlychangingspeeds,orwhiledrivingoverrough

surfaces.Shiftingloadscanleadtotipovers.Alwayssecure

loadssothattheydonotshift.Neverdumptheloadwhile

thevehicleissidewaysonthehill.

Heavyloadsincreasestoppingdistanceandreduceyour

abilitytoturnquicklywithouttippingover.

Therearcargospaceisintendedforloadcarryingpurposes

only,notforpassengers.

UsingtheDifferentialLock

Thedifferentiallockincreasesthemachinetractionbylocking

therearwheelssoonewheelwillnotspinout.Thiscanhelp

whenyouhaveheavyloadstohaulonwetturforslippery

areas,goinguphills,andonsandysurfaces.Itisimportant

toremember,however,thatthisextratractionisonlyfor

temporarylimiteduse.Itsusedoesnotreplacethesafe

operation,alreadydiscussedconcerningsteephillsandheavy

loads.

Thedifferentiallockcausestherearwheelstospinatthe

samespeed.Whenusingdifferentiallockyourabilitytomake

sharpturnsissomewhatrestrictedandmayscufftheturf.

Usethedifferentiallockonlywhenneeded,atslowerspeeds

andonlyinrstorsecondgear.

•Theextratractionavailablewiththedifferential

lockcanbeenoughtogetyouintodangerous

situationssuchasclimbingslopesthataretoo

steeptoturnaround.Beextracarefulwhen

operatingwiththedifferentiallockon,especially

onsteeperslopes.

•Ifthedifferentiallockisonwhenmakinga

sharpturnatahigherspeedandtheinsiderear

wheelliftsofftheground,theremaybealossof

controlwhichcouldcausevehicletoskid.Use

thedifferentiallockonlyatslowerspeeds.

Using4-wheelDrive(4-wheel drivemodelsonly)

TheAutomaticonDemand4-wheeldrivefeature,onthis

vehicledoesnotrequireoperatoractivation.Thefrontwheel

driveisnotengaged(nopowerdeliveredtofrontwheels)

untiltherearwheelsbegintolosetraction.Thebidirectional

clutchsensestherearwheelsslipping,engagesthefront

wheeldrive,anddeliverspowertothefrontwheels.The4

wheeldrivesystemcontinuestodeliverpowertothefront

wheelsuntiltherearwheelshaveenoughtractiontomove

thevehiclewithoutslipping.Oncethisoccurs,thesystem

stopsdeliveringpowertothefrontwheelsandthehandling

characteristicsbecomesimilartothatofa2-wheeldrive

machine.The4wheeldrivesystemfunctionsinbothfroward

andreverse,however,whenturningtherearwheelswillslip

slightlymorebeforepowerisdeliveredtothefrontwheels.

WARNING

Tippingorrollingthemachineonahillwillcause

seriousinjury.

Theextratractionavailablewiththe4-wheeldrive

featurecanbeenoughtogetyouintodangerous

situationssuchasclimbingslopesthataretoo

steeptoturnaround.Becarefulwhenoperating,

especiallyonsteeperslopes.

TransportingtheMachine

Formovingthemachinelongdistances,useatrailer.Make

surethatthemachineissecuredtothetrailer.RefertoFigure

27andFigure28forthelocationofthetie-downpoints.

Important:Trailersweighingover680kg(1500lb)are

requiredtobeequippedwithtrailerbrakes.

Note:Loadthemachineonthetrailerwiththefrontofthe

machinefacingforward.Ifthatisnotpossible,securethe

machinehoodtotheframewithastrap,orremovethehood

28

Page 29

andtransportandsecureitseparatelyorthehoodmayblow

offduringtransport.

Figure27

1.Eyeholeinframe(eachside)

TowingaTrailerwiththe Machine

Themachineiscapableofpullingtrailersandattachmentsof

greaterweightthanthemachineitself.

Severaltypesoftowhitchesareavailableforthemachine,

dependingonyourapplication.ContactyourAuthorized

ToroDistributorfordetails.

Whenequippedwithatowhitchboltedontotherearaxle

tube,yourmachinecantowtrailersorattachmentswitha

GrossTrailerWeight(GTW)upto1587kg(3500lb).Always

loadatrailerwith60%ofthecargoweightinthefrontof

thetrailer.Thisplacesapproximately10%(272kg(600lb)

max.)oftheGrossTrailerW eight(GTW)onthetowhitchof

themachine.

Trailerbrakesarerequiredwheneveryoutowatrailerover

680kg(1500lb)GTWistowedbehindamachine.

Whenhaulingcargoortowingatrailer(attachment),donot

overloadyourmachineortrailer.Overloadingcancausepoor

performanceordamagetothebrakes,axle,engine,transaxle,

steering,suspension,bodystructure,ortires.

Figure28

1.Axle2.Hitchplate

TowingtheMachine

Incaseofanemergency,thevehiclecanbetowedfora

shortdistance.However,Torodoesnotrecommendthisas

astandardprocedure.

WARNING

Towingatexcessivespeedscouldcausemachine

tolosesteeringcontrol.Nevertowthemachineat

fasterthan8km/h(5mph).

Towingthemachineisa2-personjob.Afxatowlineto

holesinthefrontframemember.MovetheshiftertoNeutral

andreleasetheparkingbrake.Ifthemachinemustbemoved

aconsiderabledistance,transportitonatruckortrailer.

Note:Thepowersteeringwillnotfunction,makingit

difcult(increasedeffort)tosteer.

Important:Toreducepotentialfordrivelinedamage,

uselowrange.

Whentowingfth-wheelattachments,likeafairwayaerator,

alwaysinstallthewheelbar(includedwiththefthwheelkit)

topreventthefrontwheelsfromliftingoffthegroundifthe

towedattachmentsmovementissuddenlyimpaired.

UsingtheHydraulicControl

Thehydrauliccontrolsupplieshydraulicpowerfromthe

machinepumpwhenevertheengineisrunning.Thepower

canbeusedthroughthequickcouplersattherearofthe

machine.

CAUTION

Hydraulicuidescapingunderpressurecanhave

sufcientforcetopenetrateskinanddoserious

damage.Caremustbeusedwhenconnecting

ordisconnectinghydraulicquickcouplers.Stop

theengine,applytheparkingbrake,lowerthe

attachment,andplacetheremotehydraulicvalvein

theoatdetentpositiontorelievehydraulicpressure

beforeconnectingordisconnectingquickcouplers.

Important:Ifmultiplemachinesusethesame

attachment,crosscontaminationofthetransmission

uidmayoccur.Changethetransmissionuidmore

frequently

29

Page 30

UsingtheHydraulic-bedLiftLeverto

ControlHydraulicAttachments

•OffPosition

Thisisthenormalpositionforthecontrolvalvewhenit

isnotbeingused.Inthispositiontheworkportsofthe

controlvalveareblockedandanyloadwillbeheldbythe

checkvalvesinbothdirections.

•Raise(QuickCoupler“ A ”Position)

Thisisthepositionwhichwillliftthebed,rearhitch

attachmentorapplypressuretoquickcouplerA.This

alsoallowshydraulicuidtoreturnfromquickcouplerB

toowbackintothevalveandthenouttothereservoir.

Thisisamomentarypositionandwhentheleveris

releaseditspringreturnstothecenterOffposition.

hydraulicmotor.Thispositionmustonlybeusedon

attachmentswithahydraulicmotorattached.

Important:Ifusedwithahydrauliccylinder

ornoattachment,theOnpositioncausesthe

hydraulic-uidowtogooverareliefvalvewhich

candamagethehydraulicsystem.Usethisposition

onlymomentarilyorwithamotorattached.

Important:Checkhydraulic-uidlevelafter

installationofanattachment.Checktheoperation

oftheattachmentbycyclingtheattachmentseveral

timestopurgeairfromsystem,thenrecheck

hydraulic-uidlevel.Theattachmentcylinderwill

slightlyaffectuidlevelinthetransaxle.Operation

ofvehiclewithlowhydraulic-uidlevelcandamage

thepump,remotehydraulics,powersteering,and

thevehicletransaxle.

ConnectingtheQuickCouplers

Important:Cleandirtfromquickcouplersbefore

connecting.Dirtycouplerscanintroducecontamination

intothehydraulicsystem

Figure29

1.QuickcouplerAposition2.QuickcouplerBposition

•Lower(QuickCouplerBPosition)

Thispositionwilllowerthebed,rearhitchattachment,

orapplypressuretoquickcouplerB.Thisalsoallows

hydraulicuidtoreturnfromquickcouplerAtoow

backintothevalveandthenouttothereservoir.Thisis

amomentarypositionandwhentheleverisreleasedit

springreturnstothecenteroffposition.Momentarily

holdingandthenreleasingthecontrolleverinthis

positionwillprovidehydraulicuidowtoquickcoupler

Bwhichprovidespowerdownontherearhitch.When

released,itwillholdthedownpressureonthehitch.

Important:Ifusedwithahydrauliccylinder,

holdingthecontrolleverinthelowerpositioncauses

thehydraulic-uidowtogooverareliefvalvewhich

candamagethehydraulicsystem.

1.Pullbackthelockingringonthecoupler.

2.Insertthehosenippleintothecoupleruntilitsnaps

intoposition.

Note:Whenattachingremoteequipmenttothequick

couplers,determinewhichsiderequirespressure,thenattach

thathosetoquickcouplerB,whichwillhavepressurewhen

thecontrolleverispushedforwardorlockedintheOn

position.

DisconnectingtheQuickCouplers

Note:Withboththevehicleandattachmentturnedoff,

movetheliftleverbackandforthtoremovethesystem

pressureandeasethedisconnectionofthequickcouplers.

1.Pullbackthelockingringonthecoupler.

2.Pullthehosermlyfromthecoupler.

Important:Cleanandinstallthedustplugand

dustcoverstothequickcouplerendswhennot

inuse.

•OnPosition

ThispositionissimilartoLower(quickcouplerB

position).Italsodirectshydraulicuidtoquickcoupler

Bexceptthattheleverisheldinthispositionbya

detentleverinthecontrolpanel.Thisallowshydraulic

uidtoowcontinuouslytoequipmentthatusesa

30

Page 31

TroubleshootingtheHydraulicControl

•Difcultyinconnectingordisconnectingquickcouplers.

Thepressurenotrelieved(thequickcouplerisunder

pressure).

•Thepowersteeringisturningwithgreatdifcultyorit

isnotturningatall.

–Thehydraulic-uidlevelislow .

–Thehydraulic-uidtemperatureishot.

–Thepumpisnotoperating.

•Therearehydraulicleaks.

–Thettingsareloose.

–Thettingismissingtheo-ring.

•Anattachmentdoesnotfunction.

–Thequickcouplersarenotfullyengaged.

–Thequickcouplersareinterchanged.

•Thereisasquealingnoise.

–RemovethevalveleftintheOndetentposition

causinghydraulicuidtoowoverthereliefvalve.

–Thebeltisloose.

•Theenginewillnotstart.

Thehydraulicleverislockedinforwardposition

31

Page 32

Maintenance

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst2hours

Aftertherst8hours

Aftertherst10hours

Aftertherst50hours

Beforeeachuseordaily

MaintenanceProcedure

•T orquethefrontandrearwheelnuts.

•Checktheconditionandtensionofthealternatorbelt.

•T orquethefrontandrearwheelnuts.

•Checktheadjustmentoftheshiftcables.

•Checktheadjustmentoftheparkingbrake.

•Replacethehydrauliclter.

•Changethehigh-owhydraulicuidlter(TCmodelsonly).

•Changetheengineoilandlter.

•Adjusttheenginevalveclearance.

•Checktheengine-oillevel.

•Checkthelevelofthecoolant.

•Checkthetransaxle/hydraulic-uidlevel.(checktheuidlevelbeforetheengine

isrststartedandevery8hoursordaily,thereafter.)

•Checkthehighowhydraulic-uidlevel(TCmodelsonly).(checkthelevelof

hydraulicuidbeforetheengineisrststarted,anddailythereafter)

•Checkthetirepressure.

•Checkthebrake-uidlevel.(Checkthelevelbeforetheengineisrststartedand

every8hoursordaily ,thereafter.)

•Checktheoperationofthesafety-interlocksystem.

•Checktheairlterserviceindicator.

•Drainwaterorothercontaminantsfromthewaterseparator.

•Removedebrisfromtheengineareaandradiator(cleanmorefrequentlyindirty

conditions).

Every25hours

Every50hours

Every100hours

Every200hours

Every400hours

Every600hours

•Removetheaircleanercover,cleanoutdebris,andchecktheairlterservice

indicator.

•Checkthebattery-uidlevel(every30daysifinstorage).

•Checkthebattery-cableconnections.

•Checktheleveloffrontdifferentialoil(4-wheeldrivemodelsonly).

•Greaseallbearingsandbushings(lubricatemorefrequentlyinheavyduty

applications).

•Changetheengineoilandlter.

•Inspecttheconditionofthetires.

•T orquethefrontandrearwheelnuts.

•Inspecttheconstant-velocitybootforcracks,holes,oralooseclamp.

•Checktheadjustmentoftheshiftcables.

•Checktheadjustmentofthehigh-to-lowcable.

•Checktheadjustmentofthedifferential-lockcable.

•Checktheadjustmentoftheparkingbrake.

•Checktheadjustmentofthebrakepedal.

•Checktheconditionandtensionofthealternatorbelt.

•Checktheadjustmentoftheclutchpedal.

•Inspecttheserviceandparkingbrakes.

•Checkthefuellinesandconnections.

•Replacethefuel-ltercanister .

•Checkthefrontwheelalignment.

•Visuallyinspectthebrakesforwornbrakeshoes.

•Changethesafetyairlter(morefrequentlyindustyordirtyconditions).

•Adjusttheenginevalveclearance.

32

Page 33

MaintenanceService

Interval

Every800hours

Every1,000hours

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

MaintenanceProcedure

•Changethefront-differentialoil.

•Changethehydraulicuidandcleanthestrainer.

•Replacethehydrauliclter.

•Changethehigh-owhydraulicuidandlter(TCmodelsonly).