Page 1

FormNo.3374-948RevB

Workman

®

HDX-DUtilityVehicle

withBed

ModelNo.07385—SerialNo.313000001andUp

ModelNo.07385TC—SerialNo.313000001andUp

ModelNo.07387—SerialNo.313000001andUp

ModelNo.07387TC—SerialNo.313000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3374-948*B

Page 2

Thismachineisautilityvehicleintendedtobeusedby

professional,hiredoperatorsincommercialapplications.Itis

primarilydesignedforthetransportofimplementsusedin

suchapplications.Thisvehicleallowsforthesafetransport

ofanoperatorandonepassengerintheidentiedseats.The

bedofthisvehicleisnotsuitableforanyriders.

ThisproductcomplieswithallrelevantEuropeandirectives,

fordetailspleaseseetheseparateproductspecicDeclaration

ofConformity(DOC)sheet.

WARNING

CALIFORNIA

Proposition65Warning

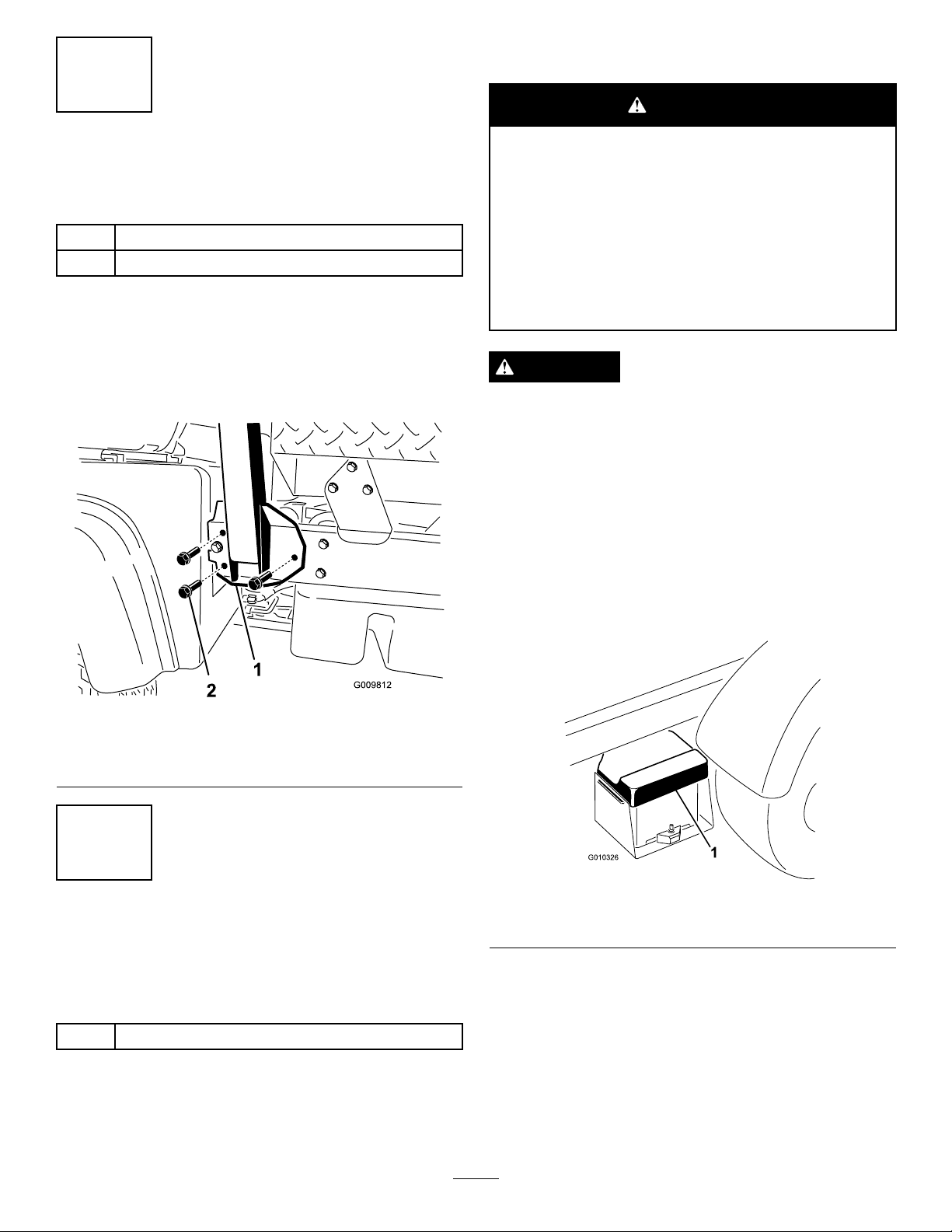

Figure1

1.Modelandserialnumberlocation

ModelNo.

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Dieselengineexhaustandsomeofits

constituentsareknowntotheStateof

Californiatocausecancer,birthdefects,

andotherreproductiveharm.

Important:Theengineinthisproductisnotequipped

withasparkarrestedmufer.Itisaviolationof

CaliforniaPublicResourcecodeSection4442touse

oroperatethisengineonanyforest-covered,brush

covered,orgrass-coveredlandasdenedinCPRC4126.

Otherstatesorfederalareasmayhavesimilarlaws.

Introduction

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Y ouareresponsibleforoperatingthe

productproperlyandsafely.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure2

1.Safetyalertsymbol

Thismanualuses2otherwordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready.Figure1identiesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

©2013—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Contents

Introduction..................................................................2

Safety...........................................................................4

SafeOperatingPractices...........................................4

Supervisor’sResponsibilities.....................................4

BeforeOperating....................................................4

Operation...............................................................5

Maintenance...........................................................6

SoundPressure.......................................................6

Vibration................................................................6

SafetyandInstructionalDecals.................................7

Setup...........................................................................12

1InstallingtheSteeringWheel(TCmodels

only).................................................................12

2InstallingtheROPS(TCmodelsonly)......................12

3ActivatingandChargingtheBattery(TCmodels

only).................................................................13

4CheckingFluidLevels...........................................14

ProductOverview.........................................................15

Controls...............................................................15

Specications........................................................18

Attachments/Accessories........................................18

Operation....................................................................19

CheckingtheEngineOilLevel.................................19

AddingFuel...........................................................19

CheckingtheCoolantLevel.....................................21

CheckingtheTransaxle/HydraulicFluid

Level.................................................................22

CheckingtheHighFlowHydraulicFluid(TC

modelsonly)......................................................22

CheckingtheFrontDifferentialOilLevel

(Four-wheeldrivemodelsonly).............................23

CheckingtheTorqueoftheWheelNuts.....................23

CheckingtheTirePressure......................................23

CheckingtheBrakeFluid.........................................23

Pre–startingChecks................................................24

StartingtheEngine.................................................24

DrivingtheVehicle.................................................24

StoppingtheVehicle...............................................25

StoppingtheEngine...............................................25

NewVehicleBreak–in.............................................25

CheckingtheInterlockSystem.................................25

OperatingCharacteristics........................................25

Passengers.............................................................26

Speed....................................................................27

Turning.................................................................27

Braking.................................................................27

TipOvers..............................................................27

Hills......................................................................27

LoadingandDumping............................................28

UsingTheDifferentialLock....................................28

FourWheelDrive(Four-wheeldrivemodels

only).................................................................29

TransportingtheVehicle.........................................29

TowingtheVehicle.................................................29

TowingaTrailerwiththeVehicle..............................30

HydraulicControl...................................................30

Maintenance.................................................................32

RecommendedMaintenanceSchedule(s)......................32

HeavyDutyOperation............................................33

PremaintenanceProcedures........................................34

UsingtheBedSafetySupport...................................34

RemovingtheFullBed............................................34

InstallingtheFullBed.............................................35

JackingtheVehicle..................................................36

RemovingtheHood...............................................36

Lubrication...............................................................37

GreasingBearingsandBushings...............................37

EngineMaintenance..................................................39

ServicingtheAirCleaner.........................................39

ChangingtheEngineOilAndFilter..........................39

FuelSystemMaintenance...........................................40

FuelLinesandConnections.....................................40

ServicingtheW aterSeparator/FuelFilter...................40

ElectricalSystemMaintenance....................................41

Fuses....................................................................41

JumpStartingtheVehicle.........................................42

ServicingtheBattery...............................................42

DriveSystemMaintenance.........................................43

ChangingtheFrontDifferentialOil(Four-wheel

drivemodelsonly)...............................................43

InspectingtheConstantVelocityBoot(Four-wheel

drivemodelsonly)...............................................43

AdjustingtheShiftCables........................................44

AdjustingtheHigh–LowCable................................44

AdjustingDifferentialLockCable.............................44

InspectingtheTires................................................44

CheckingtheFrontWheelAlignment........................45

CoolingSystemMaintenance......................................46

RemovingDebrisfromtheCoolingSystem................46

ChangingEngineCoolant........................................46

BrakeMaintenance....................................................48

AdjustingtheParkingBrake.....................................48

AdjustingtheBrakePedal........................................48

BeltMaintenance......................................................49

AdjustingBelts.......................................................49

ControlsSystemMaintenance.....................................49

AdjustingtheAcceleratorPedal................................49

AdjustingtheClutchPedal.......................................49

ConvertingtheSpeedometer....................................50

HydraulicSystemMaintenance....................................51

ChangingtheHydraulicFluidandCleaningthe

Strainer..............................................................51

ReplacingtheHydraulicFilter..................................51

ChangingtheHighFlowHydraulicOilandFilter

(TCmodelsonly)................................................52

RaisingtheBoxinanEmergency..............................52

Storage........................................................................54

Schematics...................................................................55

3

Page 4

Safety

ThemachinemeetstherequirementsofSAEJ2258.

Supervisors,operatorsandservicepersonsshouldbefamiliar

withthefollowingstandardsandpublications:(Thematerial

maybeobtainedfromtheaddressshown).

•FlammableandCombustibleLiquidsCode:

ANSI/NFPA30

•NationalFireProtectionAssociation:

ANSI/NFPA#505;PoweredIndustrialTrucks

ADDRESS:

NationalFirePreventionAssociation

BatterymarchPark

Quincy,Massachusetts02169U.S.A

•ANSI/ASMEB56.8PersonalBurdenCarriers

ADDRESS:

AmericanNationalStandardsInstitute,Inc.

25W est43rdStreet

NewYork,NewYork10036U .S.A.

•ANSI/UL558;InternalCombustionEnginePowered

IndustrialTrucks

ADDRESS:

AmericanNationalStandardsInstitute,Inc.

25W est43rdStreet

NewYork,NewYork10036U .S.A.

or

UnderwritersLaboratories

333PngstenRoad

Northbrook,Illinois60062U.S.A.

SafeOperatingPractices

WARNING

TheWorkmanisanoff–highwayvehicleonly,and

isnotdesigned,equipped,ormanufacturedforuse

onpublicstreets,roadsorhighways.

NotalloftheattachmentsthatadapttotheWorkman

arecoveredinthismanual.SeethespecicOperator’ s

Manualprovidedwitheachattachmentforadditionalsafety

instructions.Readthesemanuals.

Toreducethepotentialforinjuryordeath,complywith

thefollowingsafetyinstructions:

Supervisor’sResponsibilities

•Makesureoperatorsarethoroughlytrainedandfamiliar

withtheOperator’sManualandalllabelsonthevehicle.

•Besuretoestablishyourownspecialproceduresand

workrulesforunusualoperatingconditions(e.g.slopes

toosteepforvehicleoperation).Usethe3rdHigh

Lockoutswitchifhighspeedcouldresultinasafetyor

vehicleabusesituation.

BeforeOperating

•Operatethemachineonlyafterreadingandunderstanding

thecontentsofthismanual.Areplacementmanualis

availablebysendingcompletemodelandserialnumber

to:TheToroCompany,8111LyndaleAvenueSouth,

Minneapolis,Minnesota55420.

•Neverallowchildrentooperatethevehicle.Never

allowadultstooperateitwithoutproperinstructions.

Onlytrainedandauthorizedpersonsshouldoperate

thisvehicle.Makesurealloperatorsarephysicallyand

mentallycapableofoperatingthevehicle.

•Thisvehicleisdesignedtocarryonlyyou,theoperator,

andonepassengerintheseatprovidedbythe

manufacturer.Nevercarryanyotherpassengersonthe

vehicle.

•Neveroperatethevehiclewhenundertheinuenceof

drugsoralcohol.

•Becomefamiliarwiththecontrolsandknowhowtostop

theenginequickly .

•Keepallshields,safetydevicesanddecalsinplace.Ifa

shield,safetydeviceordecalismalfunctioning,illegible,

ordamaged,repairorreplaceitbeforeoperatingthe

machine.

TheWorkmanwasdesignedandtestedtooffersafeservice

whenoperatedandmaintainedproperly.Althoughhazard

controlandaccidentpreventionpartiallyaredependent

uponthedesignandcongurationofthemachine,these

factorsarealsodependentupontheawareness,concern,and

propertrainingofthepersonnelinvolvedintheoperation,

maintenanceandstorageofthemachine.Improperuseor

maintenanceofthemachinecanresultininjuryordeath.

Thisisaspecializedutilityvehicledesignedforoff–roaduse

only.Itsrideandhandlingwillhaveadifferentfeelthanwhat

driversexperiencewithpassengercarsortrucks.Sotaketime

tobecomefamiliarwithyourW orkman.

•Alwayswearsubstantialshoes.Donotoperatethe

machinewhilewearingsandals,tennisshoes,orsneakers.

Donotwearloosettingclothingorjewelrywhichcould

getcaughtinmovingpartsandcausepersonalinjury.

•Wearingsafetyglasses,safetyshoes,longpants,anda

helmetisadvisableandrequiredbysomelocalsafetyand

insuranceregulations.

•Keepeveryone,especiallychildrenandpets,awayfrom

theareasofoperation.

•Beforeoperatingthevehicle,alwayscheckallpartsof

thevehicleandanyattachments.Ifsomethingiswrong,

4

Page 5

stopusingvehicle.Makesuretheproblemiscorrected

beforevehicleorattachmentisoperatedagain.

•Sincedieselfuelishighlyammable,handleitcarefully.

–Useanapprovedfuelcontainer.

–Donotremovethecapfromthefueltankwhenthe

engineishotorrunning.

–Donotsmokewhilehandlingfuel.

–Fillthefueltankoutdoorsandtoaboutoneinch

belowthetopoftank(bottomofllerneck).Donot

overll.

–Wipeupanyspilledfuel.

•Operatethevehicleonlyoutdoorsorinawellventilated

area.

•Useonlyanapprovednonmetal,portablefuelcontainer.

Staticelectricdischargecanignitefuelvaporsina

ungroundedfuelcontainer.Removethefuelcontainer

fromthebedofthevehicleandplaceitontheground

awayfromthevehiclebeforelling.Keepthenozzle

incontactwiththecontainerwhilelling.Remove

equipmentfromvehiclebedbeforelling.

•Checkthesafetyinterlocksystemdailyforproper

operation.Ifaswitchshouldmalfunction,replacethe

switchbeforeoperatingmachine.Aftereverytwoyears,

replacetheinterlockswitchesinthesafetysystem,

whethertheyareworkingproperlyornot.

Operation

•Theoperatorandpassengermustuseseatbeltsand

remainseatedwheneverthevehicleisinmotion.The

operatorshouldkeepbothhandsonthesteeringwheel,

wheneverpossible,andthepassengershouldusethehand

holdsprovided.Keeparmsandlegswithinthevehicle

bodyatalltimes.Nevercarrypassengersintheboxor

onattachments.Rememberyourpassengermaynotbe

expectingyoutobrakeorturnandmaynotbeready.

•Neveroverloadyourvehicle.Thenameplate(located

underthemiddleofthedash)showstheloadlimitsfor

thevehicle.Neveroverllattachmentsorexceedthe

vehiclemaximumgrossvehicleweight(GVW).

•Whenstartingtheengine:

–Sitonoperator’sseatandensurethattheparking

brakeisengaged.

–DisengagePTO(ifsoequipped)andreturnthehand

throttlelevertotheOffposition(ifsoequipped).

–Makesurethehydraulicliftleverisinthecenter

position.

–MoveshiftlevertoNeutralandpresstheclutchpedal.

–Keepyourfootoffoftheacceleratorpedal.

–TurnignitionswitchtotheOnposition.Whenthe

glowplugindicatorgoesoff,theengineisreadyto

start.

–TurntheignitionkeytotheStartposition.

Note:Theglowplugindicatorwillturnon,foran

additional15seconds,whentheswitchreturnstothe

Startposition.

•Usingthemachinedemandsattention.Failuretooperate

vehiclesafelymayresultinanaccident,tipoverofthe

vehicle,andseriousinjuryordeath.Drivecarefully .To

preventtippingorlossofcontrol,takethefollowing

precautions:

–Useextremecaution,reducespeed,andmaintain

asafedistancearoundsandtraps,ditches,creeks,

ramps,anyunfamiliarareas,orotherhazards.

–Watchforholesorotherhiddenhazards.

–Usecautionwhenoperatingthevehicleonasteep

slope.Normally,travelstraightupanddownslopes.

Reducespeedwhenmakingsharpturnsorwhen

turningonhillsides.Avoidturningonhillsides

wheneverpossible.

–Useextracautionwhenoperatingthevehicleon

wetsurfaces,athigherspeeds,orwithafullload.

Stoppingtimewillincreasewithafullload.Shiftinto

alowergearbeforestartingupordownahill.

–Whenloadingthebed,distributetheloadevenly.

Useextracautioniftheloadexceedsthedimensions

ofthevehicle/bed.Operatethevehiclewithextra

cautionwhenhandlingoff-centerloadsthatcannot

becentered.Keeploadsbalancedandsecureto

preventthemfromshifting.

–Avoidsuddenstopsandstarts.Donotgofrom

reversetoforwardorforwardtoreversewithoutrst

comingtoacompletestop.

–Donotattemptsharpturnsorabruptmaneuversor

otherunsafedrivingactionsthatmaycausealossof

vehiclecontrol.

–Donotpassanothervehicletravelinginthesame

directionatintersections,blindspots,oratother

dangerouslocations.

–Whendumping,donotletanyonestandbehind

vehicleanddonotdumptheloadonanyone’ sfeet.

Releasethetailgatelatchesfromthesideofbox,not

frombehind.

–Keepallbystandersaway.Beforebackingup,lookto

therearandensurethatnooneisbehindthevehicle.

Backupslowly .

–Watchoutfortrafcwhennearorcrossingroads.

Alwaysyieldtherightofwaytopedestriansandother

vehicles.Thisvehicleisnotdesignedforuseon

streetsorhighways.Alwayssignalyourturnsorstop

earlyenoughsootherpersonsknowwhatyouplanto

do.Obeyalltrafcrulesandregulations.

–Neveroperatethevehicleinornearanareawhere

thereisdustorfumesintheairwhichareexplosive.

Theelectricalandexhaustsystemsofthevehiclecan

producesparkscapableofignitingexplosivematerials.

–Alwayswatchoutforandavoidlowoverhangssuch

astreelimbs,doorjambs,overheadwalkways,etc.

5

Page 6

Makesurethereisenoughroomoverheadtoeasily

clearthevehicleandyourhead.

–Ifeverunsureaboutsafeoperation,stopworkand

askyoursupervisor.

•Donottouchengine,transaxle,radiator,muferor

mufermanifoldwhileengineisrunningorsoonafter

ithasstoppedbecausetheseareasmaybehotenough

tocauseburns.

•Ifthemachineevervibratesabnormally,stopimmediately ,

turnengineoff,waitforallmotiontostopandinspectfor

damage.Repairalldamagebeforeresumingoperation.

•Beforegettingofftheseat:

–Stopmovementofthemachine.

–Lowerbed.

–Shutengineoffandwaitforallmovementtostop.

–Setparkingbrake.

–Removekeyfromignition.

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

•Iftheenginemustberunningtoperformamaintenance

adjustment,keephands,feet,clothing,andanypartsof

thebodyawayfromtheengineandanymovingparts.

Keepeveryoneaway.

•Donotoverspeedtheenginebychangingthegovernor

settings.Themaximumenginespeedis3650RPM.To

ensuresafetyandaccuracy ,haveanAuthorizedToro

Distributorcheckthemaximumenginespeedwitha

tachometer.

•Ifmajorrepairsareeverneededorassistanceisrequired,

contactanAuthorizedT oroDistributor.

•Tobesureofoptimumperformanceandsafety ,

alwayspurchasegenuineTororeplacementpartsand

accessories.Replacementpartsandaccessoriesmadeby

othermanufacturerscouldbedangerous.Alteringthis

vehicleinanymannermayaffectthevehicle’soperation,

performance,durabilityoritsusemayresultininjuryor

death.SuchusecouldvoidtheproductwarrantyofThe

Toro®Company.

•ThisvehicleshouldnotbemodiedwithoutThe

Toro®Company’sauthorization.Directanyinquiries

toTheT oro®Company ,CommercialDivision,V ehicle

EngineeringDept.,8111LyndaleAve.So.,Bloomington,

Minnesota55420–1196.USA

Maintenance

•Beforeservicingormakingadjustmentstothemachine,

stoptheengine,settheparkingbrake,andremovethekey

fromignitiontopreventaccidentalstartingoftheengine.

•Neverworkunderaraisedbedwithoutplacingthebed

safetysupportonthefullyextendedcylinderrod.

•Makesureallhydrauliclineconnectorsaretight,andall

hydraulichosesandlinesareingoodconditionbefore

applyingpressuretothesystem.

•Keepyourbodyandhandsawayfrompinholeleaksor

nozzlesthatejecthydraulicuidunderhighpressure.

Usepaperorcardboard,nothands,tosearchfor

leaks.Hydraulicuidescapingunderpressurecanhave

sufcientforcetopenetrateskinanddoseriousdamage.

Ifuidisinjectedintotheskinitmustbesurgically

removedwithinafewhoursbyadoctorfamiliarwiththis

formofinjuryorgangrenemayresult.

•Beforedisconnectingorperforminganyworkonthe

hydraulicsystem,allpressureinthesystemmustbe

relievedbystoppingtheengine,cyclingthedumpvalve

fromraisetolowerand/orloweringboxandattachments.

Placetheremotehydraulicsleverintheoatposition.

Iftheboxmustbeinraisedposition,secureitwiththe

safetysupport.

•Tomakesuretheentiremachineisingoodcondition,

keepallnuts,bolts,andscrewsproperlytightened.

SoundPressure

Thisunithasasoundpressurelevelattheoperator’searof82

dBA,whichincludesanUncertaintyValue(K)of1dBA.

Thesoundpressurelevelwasdeterminedaccordingtothe

proceduresoutlinedinENISO11201.

Vibration

Hand-Arm

•Measuredvibrationlevelforrighthand=0.41m/s

•Measuredvibrationlevelforlefthand=0.2m/s

•UncertaintyValue(K)=0.5m/s

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinEN1032.

2

WholeBody

•Measuredvibrationlevel=0.3m/s

•UncertaintyValue(K)=0.5m/s

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinEN1032.

2

2

2

2

•Toreducethepotentialrehazard,keeptheenginearea

freeofexcessivegrease,grass,leaves,andaccumulation

ofdirt.

6

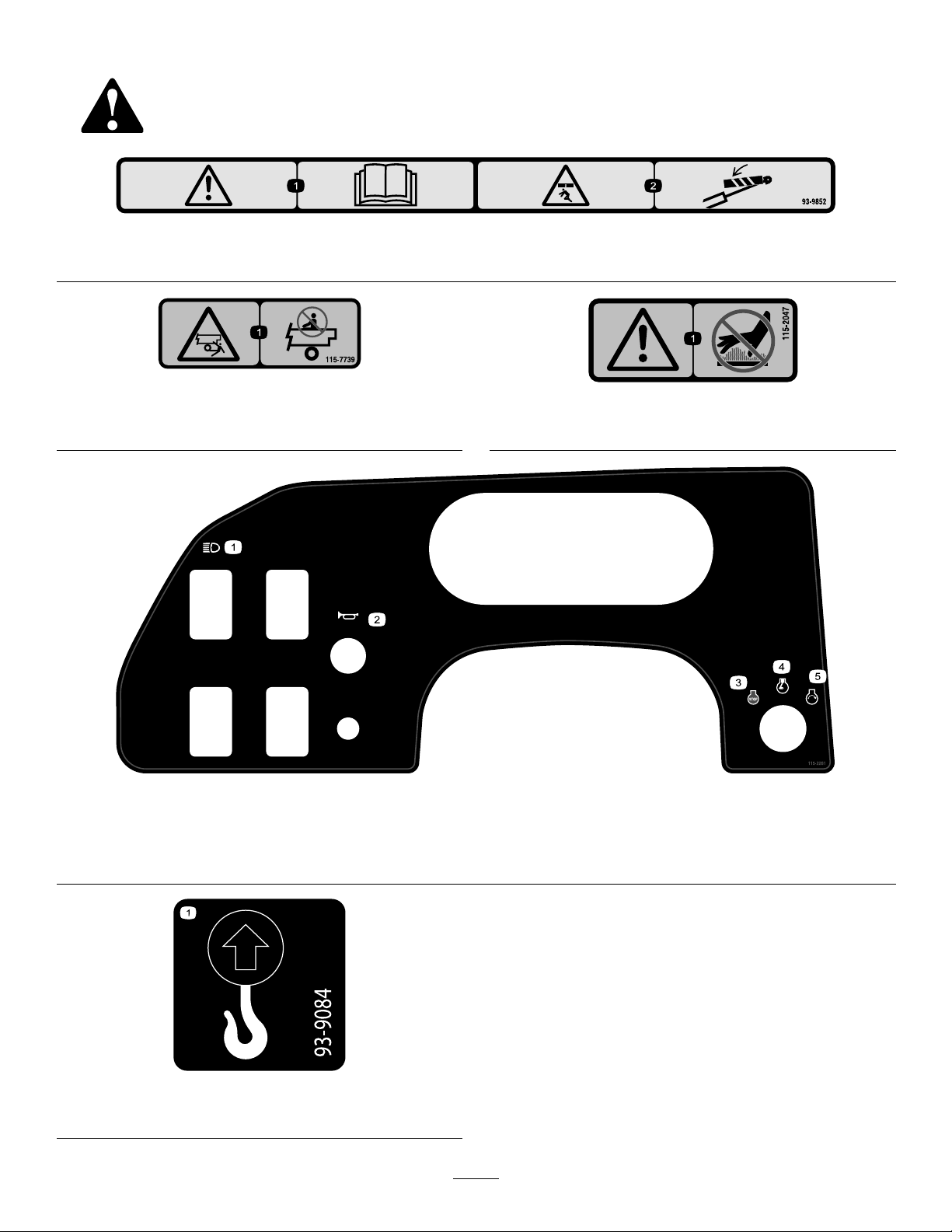

Page 7

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

93-9852

1.Warning—readtheOperator’sManual.2.Crushinghazard—installthecylinderlock.

115-7739

1.Falling,crushinghazard,bystanders—noriderson

machine.

1.Headlights4.Engine—run

2.Horn5.Engine—start

3.Engine—stop

115-2047

1.Warning—donottouchthehotsurface.

115-2281

1.Liftpoint

93-9084

2.Tie-downpoint

7

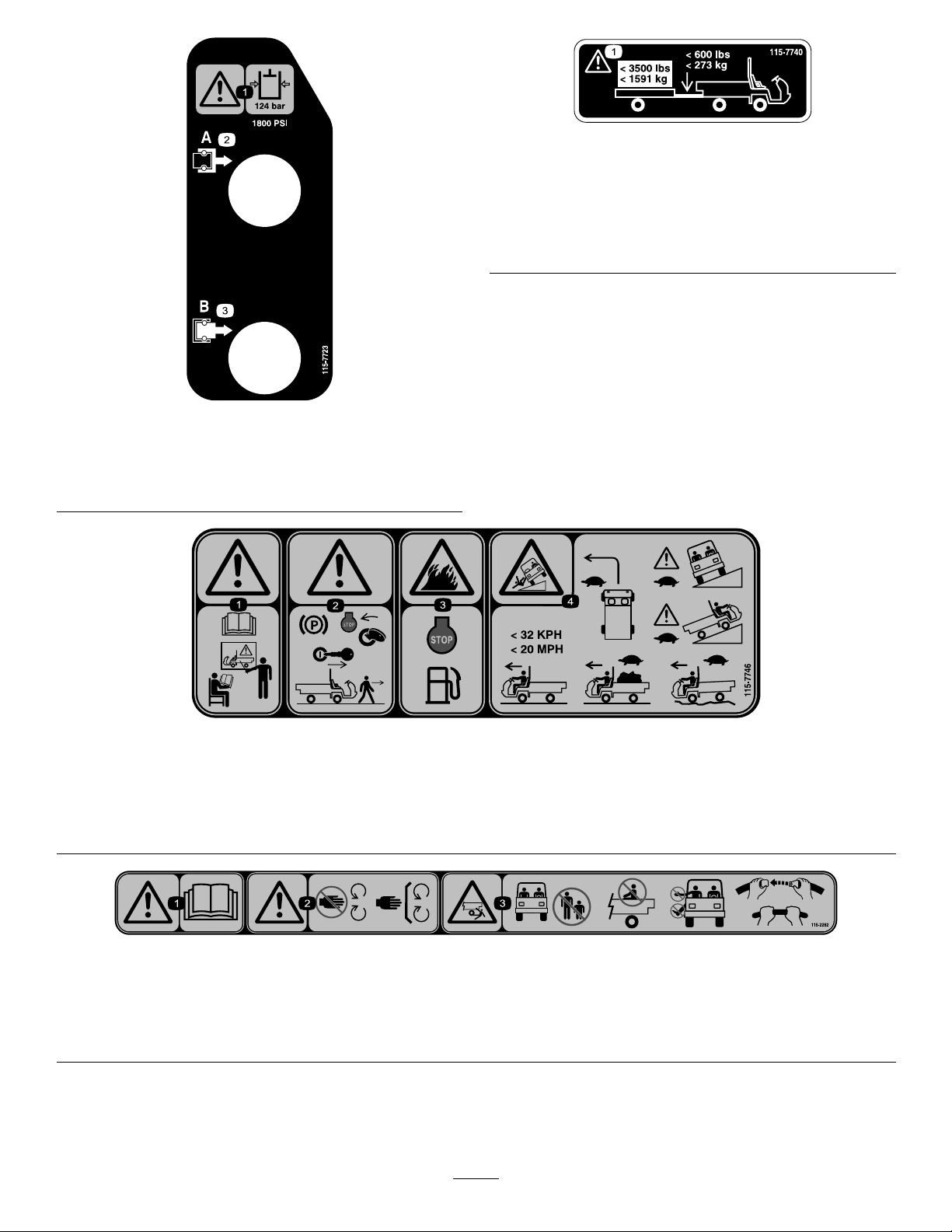

Page 8

115-7723

1.Warning—thehydraulicoilpressureis124bar(1800PSI).

2.CouplerA

3.CouplerB

115-7740

1.Warning—maximumtrailerweightis1500lb(680kg),

maximumtongueweightis200lb(90kg).

2.Warning—trailerbrakesarerequiredwhentowinggreater

than1500lb(680kg),maximumtrailerweightwithtrailer

brakesis3500lb(1591kg),maximumtongueweightwith

trailerbrakesis600lb(273kg).

115-7746

1.Warning—donotoperatethismachineunlessyouaretrained.

2.Warning—locktheparkingbrake,stoptheengine,and

removetheignitionkeybeforeleavingthemachine.

3.Firehazard—stoptheenginebeforefueling.

4.Tippinghazard—slowdownandturngradually,usecaution

anddriveslowlywhendrivingonslopes,donotexceed20

mph(32kph),anddriveslowlyoverroughterrainorwhen

carryingafullorheavyload.

115-2282

1.Warning—readtheOperator'sManual.

2.Warning—stayawayfrommovingparts,keepallguardsandshieldsinplace.

3.Crushing/dismembermenthazardofbystanders—keepbystandersasafedistancefromthevehicle,donotcarrypassengersin

thecargobed,keeparmsandlegsinsideofthevehicleatalltimes,anduseseatbeltsandhandholds.

8

Page 9

93-7814

1.Entanglementhazard,belt—stayawayfrommovingparts.

93–9868

115-7813

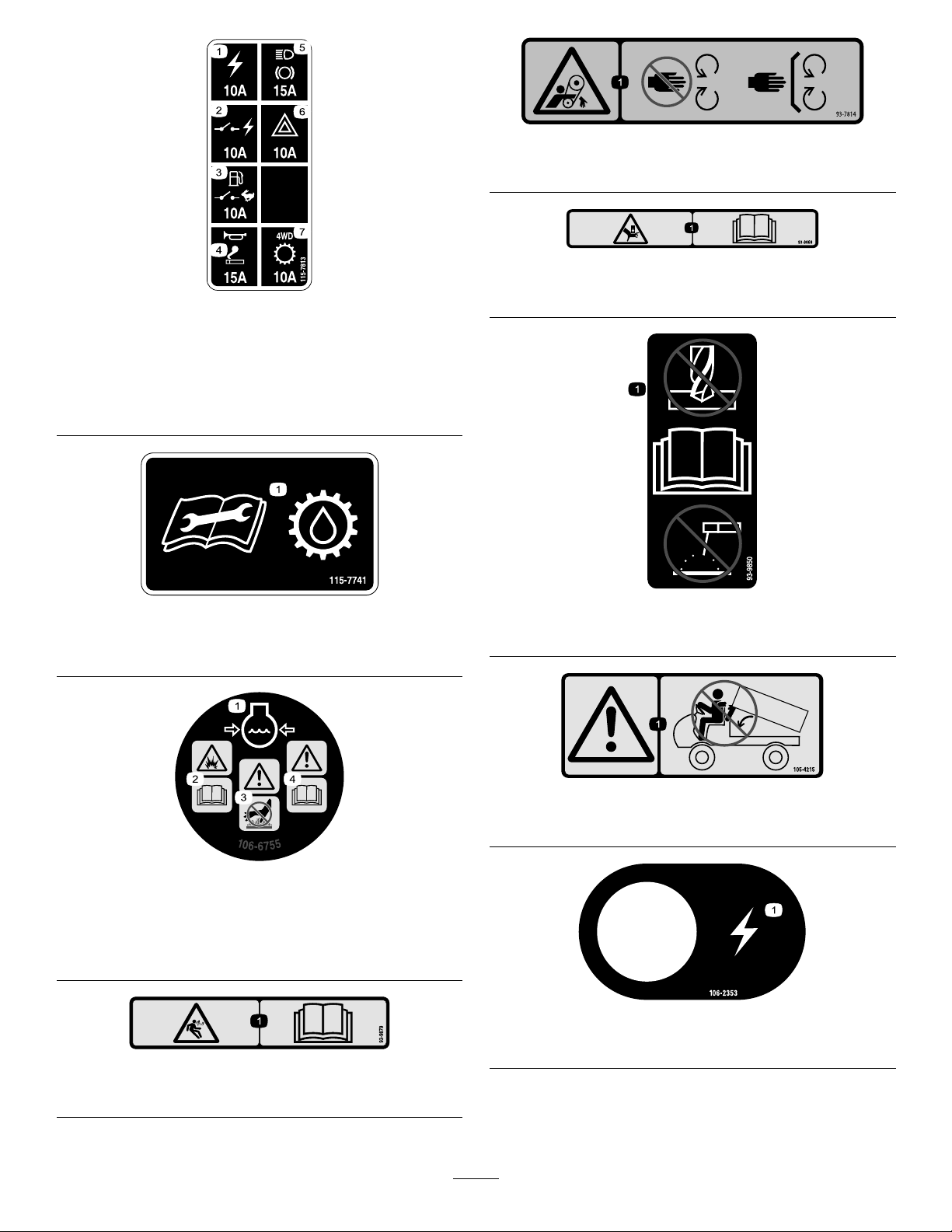

1.Poweroutlet10A5.Lights,brake15A

2.Switchedpower10A

3.Fuelpump,supervisor

switch10A

4.Horn,powerpoint15A

6.Hazard10A

7.4WD,Transmission10A

115-7741

1.ReadtheOperator’sManualbeforeservicingtransmission

uid.

1.Crushinghazardofhand—readtheOperator’sManual.

93-9850

1.Donotrepairorrevise—readtheOperator'sManual.

106-6755

1.Enginecoolantunder

pressure.

2.Explosionhazard—read

theOperator'sManual.

3.Warning—donottouchthe

hotsurface.

4.Warning—readthe

Operator'sManual.

93-9879

1.Storedenergyhazard—readtheOperator'sManual.

105-4215

1.Warning—avoidpinchpoints.

106-2353

1.Electricalpowerpoint

9

Page 10

106-2355

93-9899

1.Slow

2.Fast

3.Transmission—thirdhigh;

nofastspeed

93-9899

1.Crushinghazard—installthecylinderlock.

115-7756

1.Highowhydraulics—engaged

106-7767

1.Warning—readtheOperator'sManual;avoidtippingthe

machine;weartheseatbelt;leanawayfromthedirection

themachineistipping.

10

Page 11

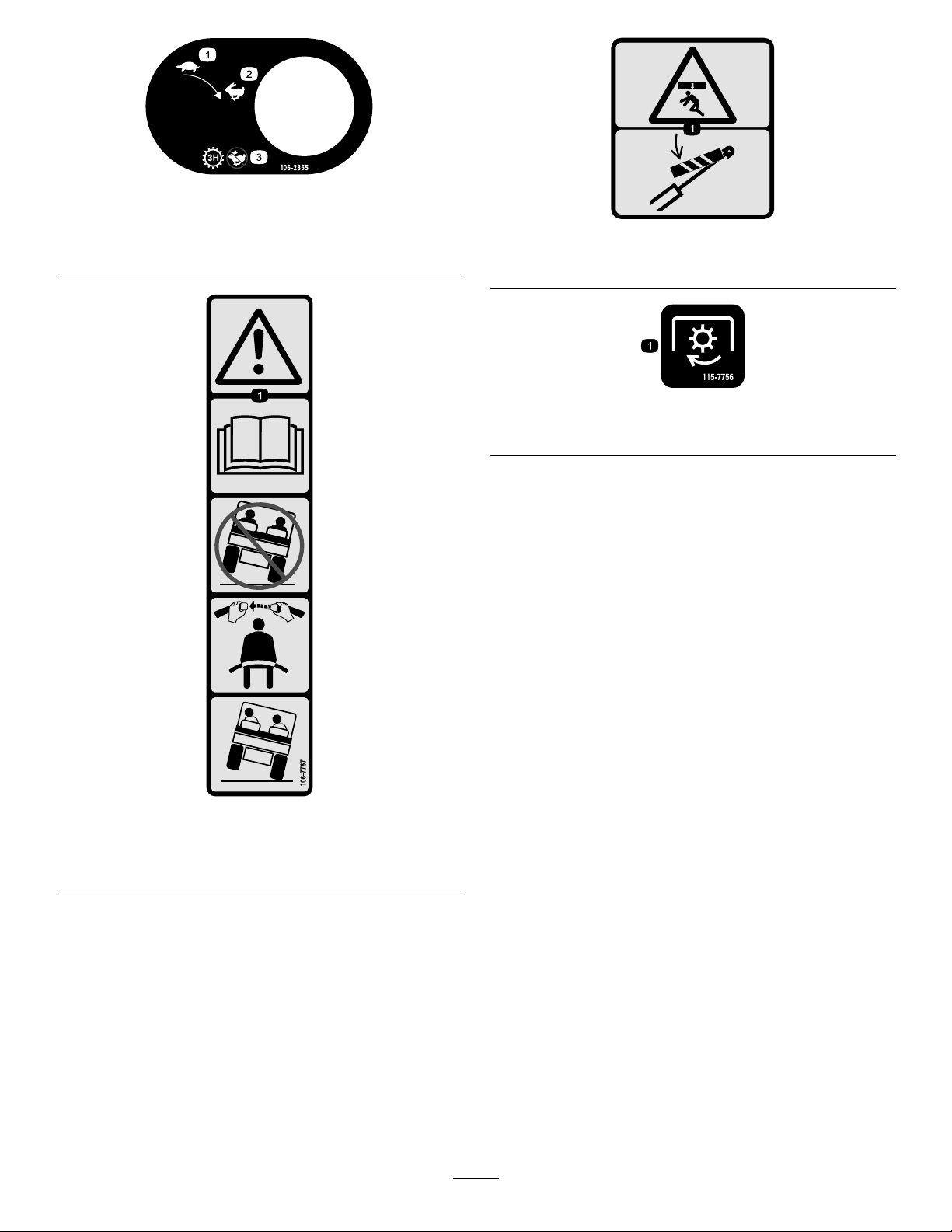

106-2377

1.Locked

2.Differentiallock9.Entanglementhazard,shaft—keepbystander'sasafe

3.Unlocked10.Retracthydraulics

4.Hydrauliclock11.Extendhydraulics

5.Engage12.Transmission—highspeed

6.Powertake-off(PTO)

7.Disengage14.Parkingbrake

8.Warning—readtheOperator'sManual.

distancefromthevehicle.

13.Transmission—lowspeed

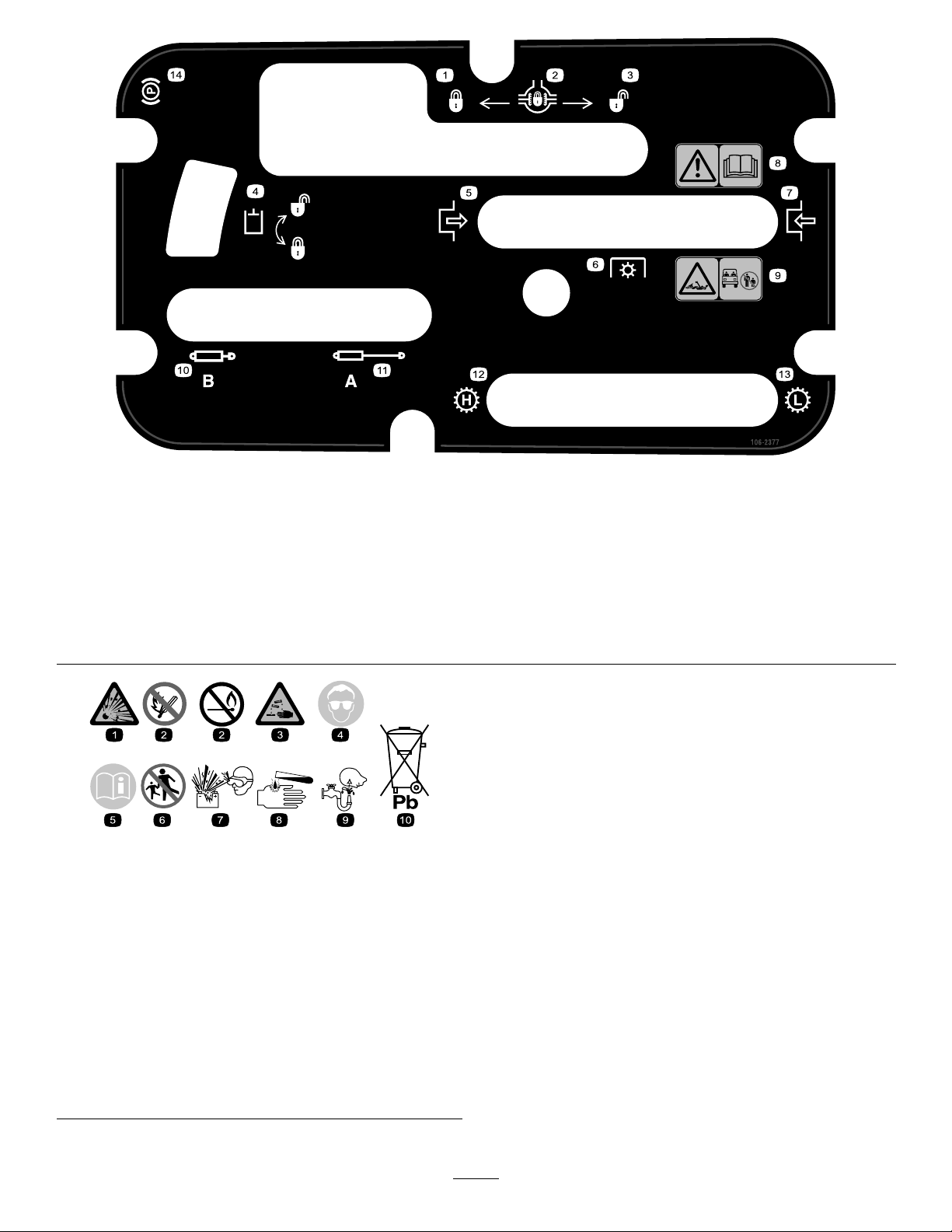

BatterySymbols

Someorallofthesesymbolsareonyourbattery

1.Explosionhazard

2.Nore,opename,or

smoking.

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

6.Keepbystandersasafe

distancefromthebattery.

7.Weareyeprotection;

explosivegasescan

causeblindnessandother

injuries

8.Batteryacidcancause

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

10.Containslead;donot

discard.

11

Page 12

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

Steeringwheel

1

2

3

4

Cap

Washer1

ROPSframe

Bolt,1/2inch

Electrolyte

Nopartsrequired

MediaandAdditionalParts

Description

Operator'sManual

PartsManual1

OperatorTrainingMaterial

Note:Determinetheleftandrightsideofthemachinefrom

thenormaloperatingposition.

Qty.

Qty.

1

1

1

6

A/R

–

1

1

Readbeforeoperatingthevehicle

Usetoreferencepartnumbers

Viewbeforeoperatingmachine

Installthesteeringwheel.

MounttheROPS(RolloverProtection

System).

Activateandchargethebattery.

Checktheengineoil,transaxle/hydraulic

uid,andbrakeuidlevels.

Use

Use

1

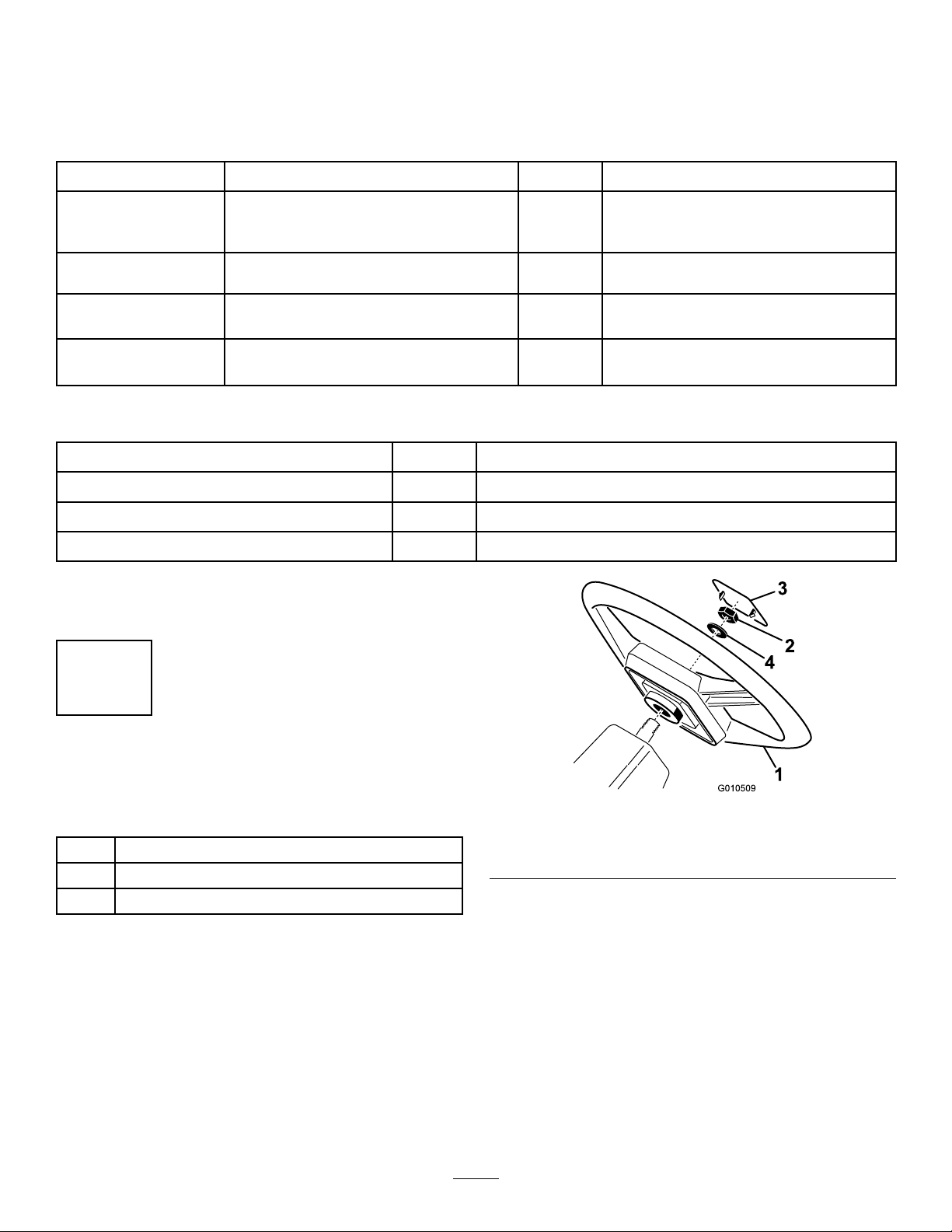

InstallingtheSteeringWheel (TCmodelsonly)

Partsneededforthisprocedure:

1

Steeringwheel

1

Cap

1Washer

Procedure

1.Removethenutfromthesteeringshaft.Slidethe

steeringwheel,andwasherontothesteeringshaft

(

Figure3).

2.Securethesteeringwheeltotheshaftwiththenutand

tightenitto27–34N-m(20-25ft-lb).

3.Installthecaponthesteeringwheel.

Figure3

1.Steeringwheel3.Cap

2.Jamnut4.Washer

12

Page 13

charged.Bulkelectrolytewith1.260specicgravitycanbe

purchasedfromalocalbatterysupplyoutlet.

2

InstallingtheROPS

(TCmodelsonly)

Partsneededforthisprocedure:

1

ROPSframe

6

Bolt,1/2inch

Procedure

1.AligneachsideoftheROPSwiththemountingholes

oneachsideofthevehicleframeasshownin

2.SecureeachsideoftheROPStoframewith3bolts

(1/2inch)andtightenthemto115N-m(85ft-lb).

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

Washhandsafterhandling.

Figure4.

DANGER

Batteryelectrolytecontainssulfuricacidwhichisa

deadlypoisonandcausessevereburns.

•Donotdrinkelectrolyteandavoidcontactwith

skin,eyesorclothing.Wearsafetyglassesto

shieldyoureyesandrubberglovestoprotect

yourhands.

•Fillthebatterywherecleanwaterisalways

availableforushingtheskin.

Figure4

1.ROPS3.ROPScoverplate

2.Mountingbracket

3

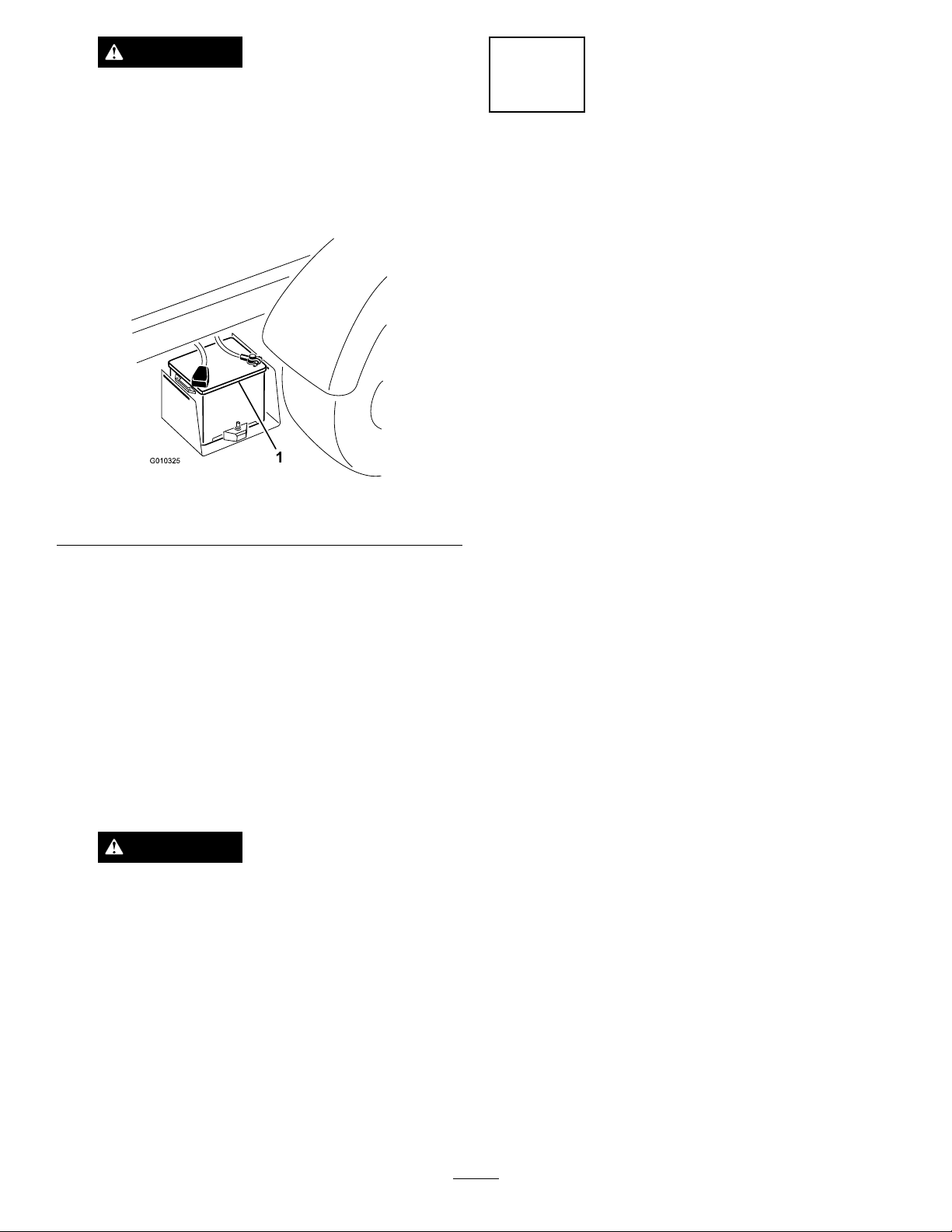

ActivatingandCharging theBattery (TCmodelsonly)

Partsneededforthisprocedure:

A/R

Procedure

Electrolyte

1.Removethebatterycoverfromthebatterycase

(Figure5).

Figure5

1.Batterycover

2.Removethebatteryfromthebatterycase.

3.Removethellercapsfromthebatteryandslowlyll

eachcelluntilelectrolyteisjustabovetheplates.

4.Replacethellercapsandconnecta3to4ampbattery

chargertothebatteryposts.Chargethebatteryata

rateof3to4amperesfor4to8hours.

Ifthebatteryisnotlledwithelectrolyteoractivated,it

mustberemovedfromthevehicle,lledwithelectrolyteand

13

Page 14

WARNING

Chargingthebatteryproducesgassesthatcan

explode.

4

Neversmokenearthebatteryandkeepsparks

andamesawayfrombattery.

5.Whenthebatteryischarged,disconnectthecharger

fromtheelectricaloutletandbatteryposts(Figure6).

Figure6

1.Battery

6.Removethellercaps.Slowlyaddelectrolytetoeach

celluntillevelisuptothellring.Installthellercaps.

CheckingFluidLevels

NoPartsRequired

Procedure

1.Checktheengineoillevelbeforeand

aftertheengineisrststarted,referto

CheckingtheEngineOilLevel(page19).

2.Checkthetransaxle/hydraulicuidlevel

beforetheengineisrststarted,referto

CheckingtheTransaxle/HydraulicFluidLevel(page22).

3.Checkthebrakeuidlevelbeforetheengineisrst

started,refertoCheckingtheBrakeFluid(page23).

Important:Donotoverllthebattery.Electrolyte

willoverowontootherpartsofthevehicleand

severecorrosionanddeteriorationwillresult.

7.Insertthebatteryintothebatterycasesothebattery

terminalsaretowardtheoutsideofthevehicle.

8.Installthepositivecable(red)tothepositive(+)

terminalandthenegativecable(black)tothenegative

(–)terminalofthebatteryandsecurethenwithbolts

andnuts.Slidetherubberbootoverthepositive

terminaltopreventapossibleshort-outfromoccurring.

WARNING

Incorrectbatterycableroutingcoulddamage

themachineandcablescausingsparks.

Sparkscancausethebatterygassesto

explode,resultinginpersonalinjury.

•Alwaysdisconnectthenegative(black)

batterycablebeforedisconnectingthe

positive(red)cable.

•Alwaysconnectthepositive(red)battery

cable

9.Installthebatterycoveronthebatterycase.

14

Page 15

ProductOverview

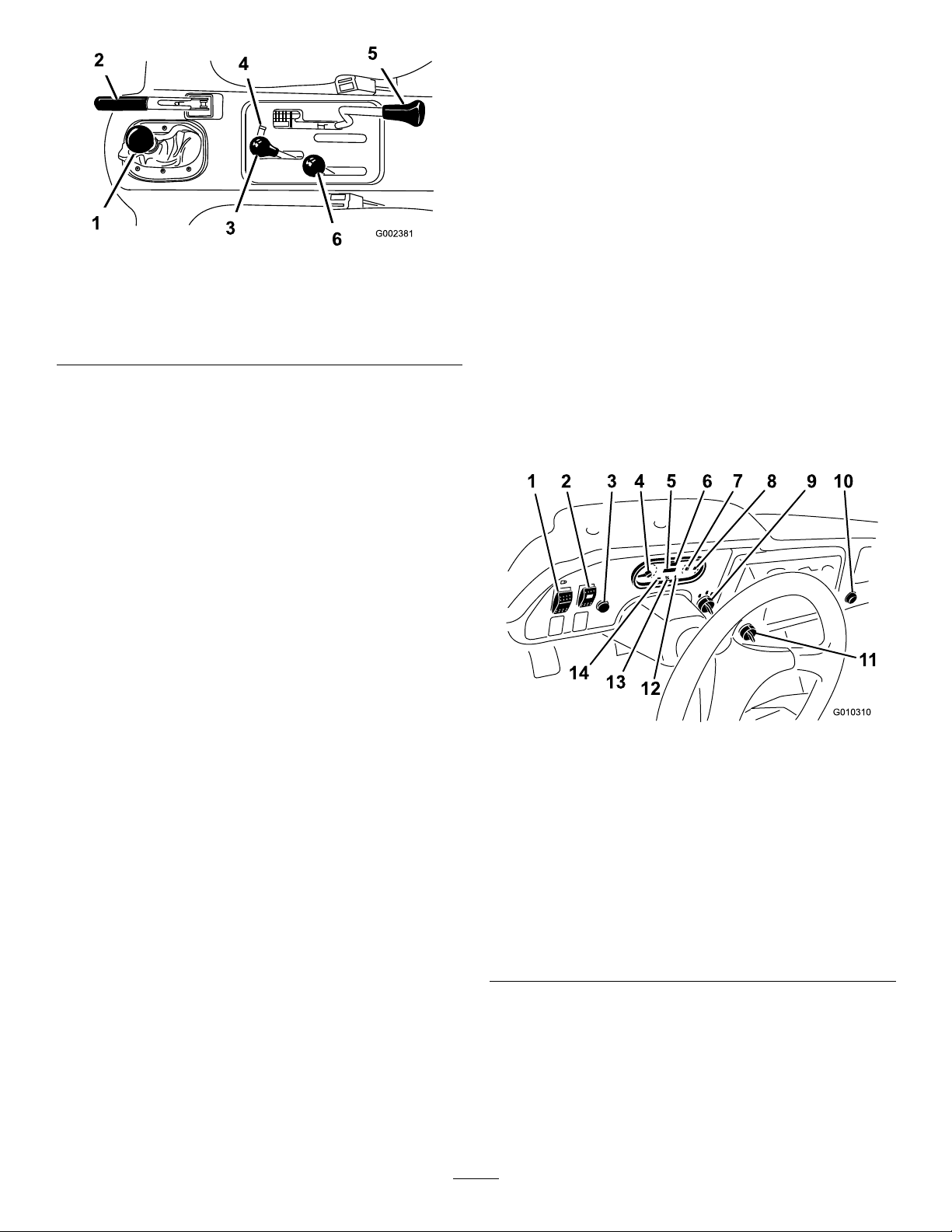

Controls

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

AcceleratorPedal

Theacceleratorpedal(Figure7)givestheoperatortheability

tovarytheengineandgroundspeedofthevehicle,whenthe

transmissionisingear.Pressingthepedalincreasesengine

rpmandgroundspeed.Releasingthepedalwilldecrease

enginerpmandgroundspeedofthemachine.

Figure7

1.Acceleratorpedal3.Brakepedal

2.Clutchpedal

ClutchPedal

Theclutchpedal(Figure7)mustbefullypressedtodisengage

clutchwhenstartingtheengineorshiftingtransmissiongears.

Releasethepedalsmoothlywhenthetransmissionisingear

topreventunnecessarywearonthetransmissionandother

relatedparts.

Important:Donotridetheclutchpedalduring

operation.Theclutchpedalmustbefullyoutorthe

clutchwillslipcausingheatandwear.Neverholdthe

vehiclestoppedonahillusingtheclutchpedal.Damage

totheclutchmayoccur.

GearShiftLever

Fullypresstheclutchpedalandmovetheshiftlever(Figure8)

intothedesiredgearselection.Adiagramoftheshiftpattern

isindicatedbelow .

Figure8

Important:Donotshiftthetransaxletothereverseor

forwardgearunlessthevehicleisstandingstill.Damage

tothetransaxlemayoccur.

CAUTION

Downshiftingfromtoohighaspeedcancause

therearwheelstoskidresultinginlossofvehicle

controlaswellasclutchand/ortransmission

damage.Shiftsmoothlytoavoidgrindinggears.

DifferentialLock

Thedifferentiallockallowsrearaxletobelockedforincreased

traction.Thedifferentiallock(Figure9)maybeengaged

whenthevehicleisinmotion.Movetheleverforwardandto

therighttoengagethelock.

Note:V ehiclemotionplusaslightturnisrequiredtoengage

ordisengagedifferentiallock.

CAUTION

Turningwiththedifferentiallockoncanresult

inlossofvehiclecontrol.Donotoperatewith

differentiallockonwhenmakingsharpturnsorat

highspeeds.Refertousingthedifferentiallock.

BrakePedal

Thebrakepedal(Figure7)isusedtoapplyservicebrakes

tostoporslowvehicle.

CAUTION

Wornormaladjustedbrakesmayresultinpersonal

injury.Ifthebrakepedaltravelstowithin3.8cm

(1-1/2inches)ofthevehicleoorboard,thebrakes

mustbeadjustedorrepaired.

15

Page 16

Figure9

Highisforhigherspeeddrivingonlevel,drysurfaceswith

lightloads.

Lowisforlowspeeddriving.Usethisrangewhengreater

thannormalpowerorcontrolisrequired.Forexample,steep

grades,difcultterrain,heavyloads,slowspeedbuthigh

enginespeed(spraying).

Important:ThereisalocationbetweenHighandLow

inwhichthetransaxleisinneitherrange.Donotuse

thispositionasaneutralpositionbecausethevehicle

couldmoveunexpectedlyiftheHigh–Lowshifteris

bumpedandthegearshiftleverisingear.

1.Gearshiftlever4.Hydraulicliftlock

2.Parkingbrake

3.Hydraulicbedlift6.High–lowrangeshifter

5.Differentiallock

ParkingBrake

Whenevertheengineisshutoff,theparkingbrake(Figure9)

mustbeengagedtopreventaccidentalmovementofthe

vehicle.Toengagetheparkingbrake,pullbackonthelever.

Todisengage,pushtheleverforward.Releasetheparking

brakebeforemovingthevehicle.Ifyouparkthevehicleon

asteepgrade,applytheparking.Also,shiftthetransmission

into1stgearonauphillgradeorreverseonadownhillgrade.

Placechocksatthedownhillsideofthewheels.

HydraulicLift

Thehydraulicliftraisesandlowersbed.Moveitrearwardto

raisethebed,andforwardtolowerit(Figure9).

Important:Whenloweringthebed,holdtheleverin

theforwardpositionfor1or2secondsafterthebed

contactstheframetosecureitintheloweredposition.

Donotholdthehydraulicliftineithertheraiseorlower

position,formorethan5seconds,oncethecylinders

havereachedtheendoftheirtravel.

HydraulicLiftLock

Thehydraulicliftlocklockstheliftleversothehydraulic

cylindersdonotoperatewhenthevehicleisnotequipped

withabed(Figure9).ItalsolockstheliftleverintheOn

positionwhenusingthehydraulicsforattachments.

High–LowRangeShifter

Thehigh–lowrangeshifteraddsthreeadditionalspeedsfor

precisespeedcontrol(Figure9).

•Thevehiclemustbecompletelystoppedbeforeshifting

betweenHighandLowrange.

•Shiftonlyonlevelground.

•Pressclutchpedalfully.

•MovetheleverfullyforwardforHighandfullyrearward

forLow .

IgnitionSwitch

Usetheignitionswitch(Figure10)tostartandstopthe

engine.Ithasthreepositions:Off,On/Preheat,andStart.

RotatethekeyclockwisetotheStartpositiontoengagethe

startermotor.Releasethekeywhentheenginestarts.The

keywillmoveautomaticallytotheOnposition.Toshut

theengineoff,rotatethekeycounterclockwisetotheOff

position.

Figure10

1.Lightswitch8.Fuelgauge

2.Highow

hydraulicsswitch

(TCmodelsonly)

3.Horn

(TCmodelsonly)

4.Tachometer11.3rdhighlockoutswitch

5.Hourmeter

6.Speedometer13.Glowplugindicator

7.Coolanttemperature

gaugeandlight

9.Ignitionswitch

10.Powerpoint

12.Oilpressurewarninglight

14.Chargeindicator

HourMeter

Indicatesthetotalhoursofmachineoperation.Thehour

meter(Figure10)startstofunctionwheneverthekeyswitch

isrotatedtotheOnpositionoriftheengineisrunning.

16

Page 17

3rdHighLockoutSwitch

Movethe3rdhighlockoutswitch(Figure10)totheslow

positionandremovethekeytopreventtheuseofthirdgear

whenintheHighrange.Theenginewillshutoffiftheshift

leverismovedtothirdgearwheninHighrange.Thekeyis

removableineitherposition.

•Applyparkingbrake.

•TurntheignitionkeytotheOn/Preheatposition,butdo

notstarttheengine.Thecoolanttemperature,charge

indicator,andoilpressurelightsshouldglow.Ifanylight

doesnotfunction,eitherabulbisburnedoutorthereisa

malfunctioninthesystemwhichmustberepaired.

LightSwitch

Pushthelightswitch(Figure10)totoggletheheadlightson

oroff.

OilPressureWarningLight

Theoilpressurewarninglightglows(Figure10)iftheengine

oilpressuredropsbelowasafelevelwhiletheengineis

running.Ifthelightickersorremainson,stopthevehicle,

turnofftheengine,andchecktheoillevel.Iftheoillevelwas

low,butaddingoildoesnotcausethelighttogooutwhen

theengineisrestarted,turntheengineoffimmediatelyand

contactyourlocalT orodistributorforassistance.

Checktheoperationofwarninglightsasfollows:

1.Applytheparkingbrake.

2.TurntheignitionkeytotheOn/Preheatposition,but

donotstarttheengine.Theoilpressurelightshould

glowred.Ifthelightdoesnotfunction,eitherabulb

isburnedoutorthereisamalfunctioninthesystem

whichmustberepaired.

Note:Ifenginewasjustturnedoff,itmaytake1to2

minutesforthelighttocomeon.

FuelGauge

Thefuelgaugeshowstheamountoffuelinthetank.It

operatesonlywhenignitionswitchisintheOn/Preheat

position(Figure10).Redindicateslowfuellevelandblinking

redindicatesnearempty.

HighFlowHydraulicsSwitch(TC

modelsonly)

Turnontheswitchtoactivatethehighowhydraulics

(Figure10).

HornButton(TCmodelsonly)

Pressingthehornbuttonactivatesthehorn(Figure10).

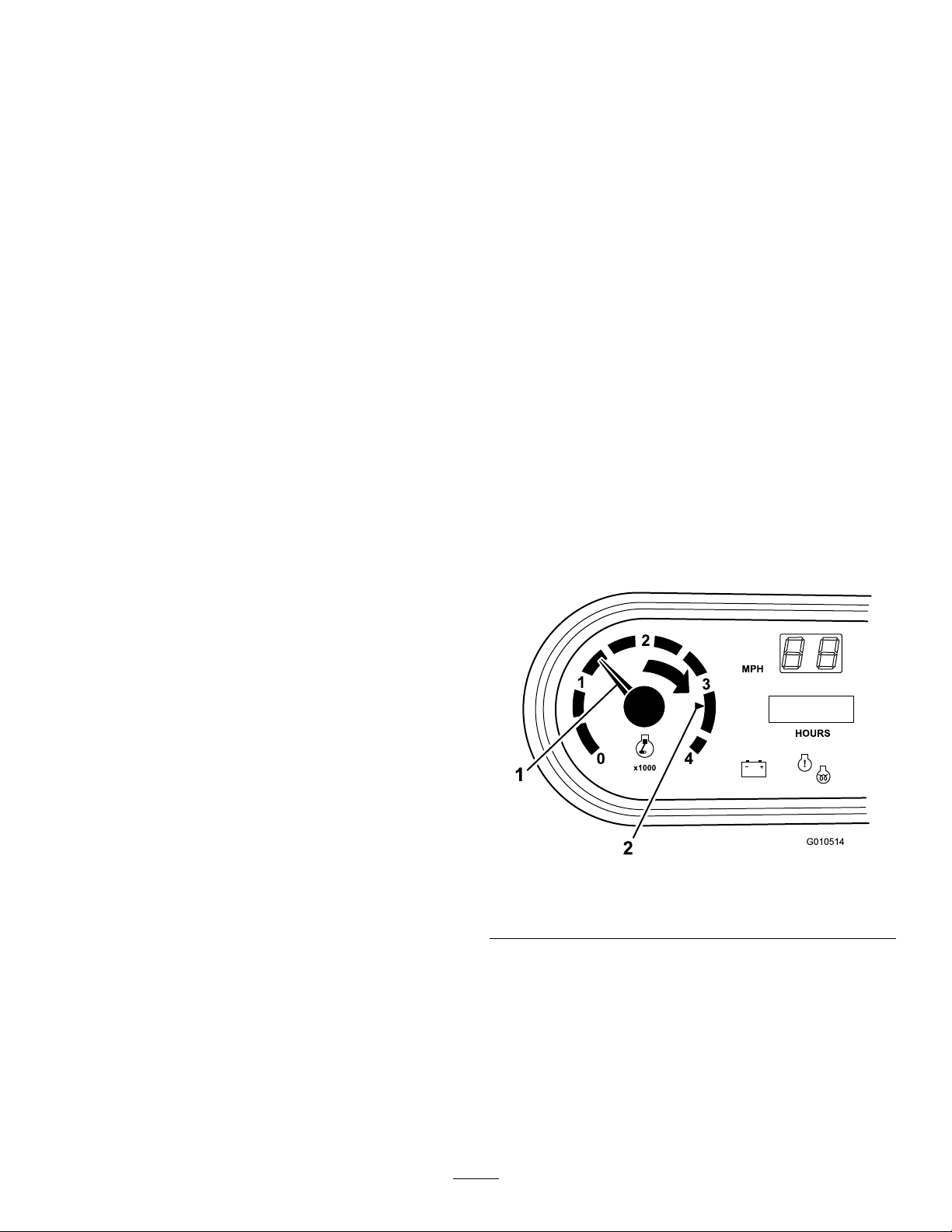

Tachometer

Registersthespeedoftheengine(Figure10&Figure11).

WhitetriangleindicatesdesiredrpmforPTOoperation

(Figure11).

GlowPlugIndicator

Glowplugindicator(Figure10)willglowredwhentheglow

plugsareactivated.

Important:Theglowplugindicatorwillturnon,foran

additional15seconds,whentheswitchreturnstothe

Startposition.

CoolantTemperatureGaugeandLight

Registersthecoolanttemperatureintheengine.Operates

onlywhentheignitionswitchisinOnposition(

Theindicatorlightwillilluminateblinkingrediftheengine

overheats.

Figure10).

ChargeIndicator

Illuminateswhenbatteryisbeingdischarged.Iflight

illuminatesduringoperation,stopvehicle,turnoffengineand

checkforpossiblecauses,suchasalternatorbelt(Figure10).

Important:Ifalternatorbeltislooseorbroken,do

notoperatethevehicleuntiladjustmentorrepairis

complete.Failuretoobservethisprecautionmayresult

indamagetotheengine.

Checktheoperationofwarninglightsasfollows:

Figure11

1.Speedoftheengine2.3,300rpmfor540rpm

PTOoperation

Speedometer

Registersthegroundspeedofthevehicle(Figure10).The

speedometerisinmphbutcaneasilyconvertedtokm/h.

RefertoConvertingtheSpeedometer(page50).

PowerPoint

Usethepowerpoint(Figure10)topoweroptional12volt

electricalaccessories.

17

Page 18

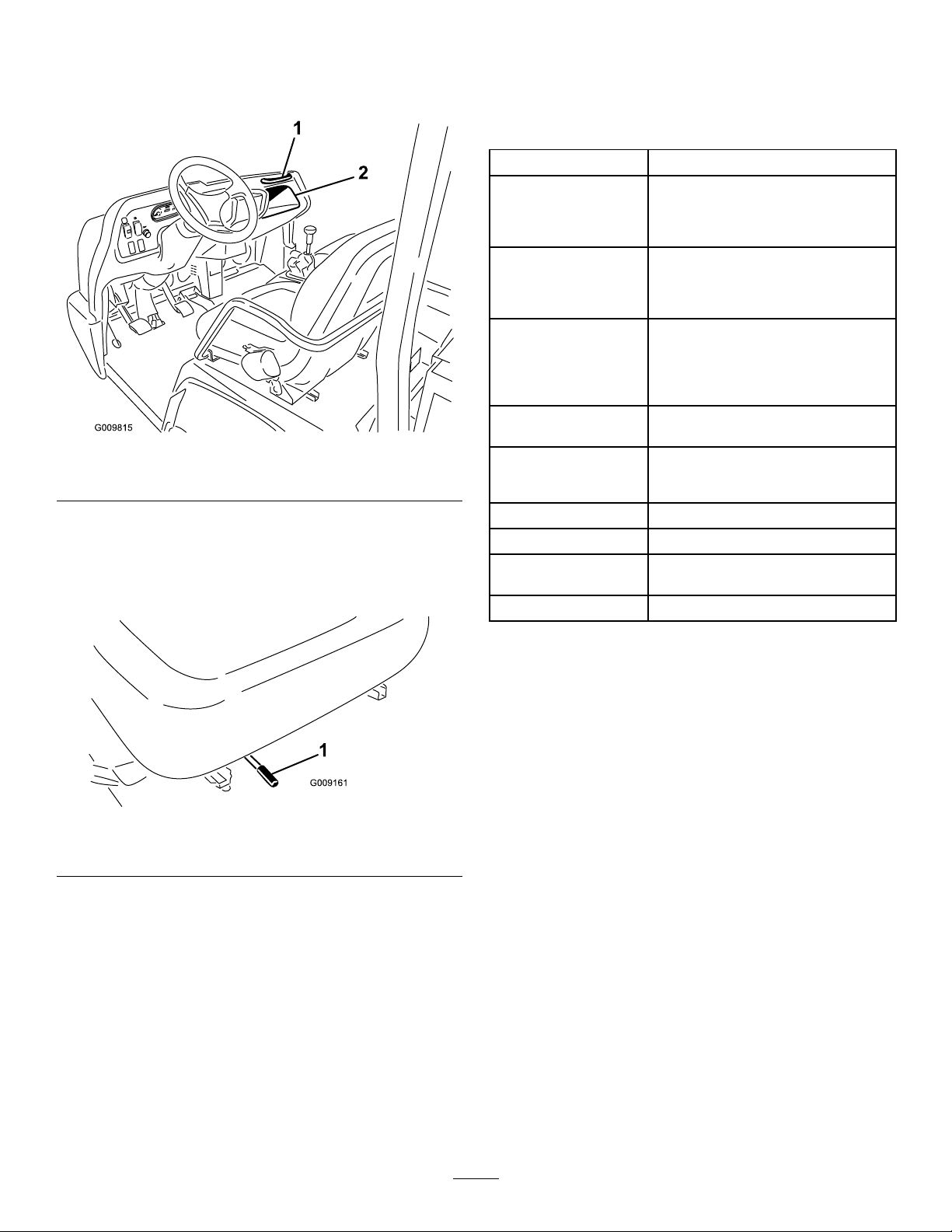

PassengerHandHold

Thepassengerhandholdislocatedonthedashboard

(Figure12).

Figure12

1.Passengerhandhold

2.Storagecompartment

SeatAdjustingLever

Theseatscanbeadjustedforeandaftforoperatorcomfort

(Figure13).

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

Dimensions

OverallWidth160cm(63inches)

w/obed:326cm(128.25inches)

OverallLength

BaseWeight(Dry)

RatedCapacity

(includes91kg(200lb)

operator,91kg(200lb)

passengerandloaded

attachment).

Maximum.Gross

VehicleWeight

TowCapacityT ongueweight:272kg(600lb)

GroundClearance18cm(7inches)w/noload

WheelBase

WheelTread(center

linetocenterline)

Height

w/fullbed:331cm(130.38inches)

w/2/3bedinrearmountinglocation:

346cm(136.38inches)

Model07385—887kg(1,956lb)

Model07385TC—924kg(2,037lb)

Model07387—914kg(2,015lb)

Model07387TC—951kg(2,096lb)

Model07385—1,471kg(3,244lb)

Model07385TC—1,435kg(3,163lb)

Model07387—1,445kg(3,185lb)

Model07387TC—1,408kg(3,104lb)

2,359kg(5,200lb)

Maximumtrailerweight:1,587kg

(3,500lb)

118cm(70inches)

Front:117cm(46inches)

Rear:121cm(47.7inches)

190.5cm(75inches)totopofROPS

1.Seatadjustinglever

Attachments/Accessories

AselectionofT oroapprovedattachmentsandaccessoriesis

availableforusewiththemachinetoenhanceandexpand

itscapabilities.ContactyourAuthorizedServiceDealeror

Distributororgotowww.Toro.comforalistofallapproved

attachmentsandaccessories.

Figure13

18

Page 19

Operation

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

CAUTION

Beforeservicingormakingadjustmentstothe

machine,stoptheengine,settheparkingbrake,

andremovethekeyfromtheswitch.Removeany

loadmaterialfromthebedorotherattachment

beforeworkingunderaraisedbed.Neverwork

underaraisedbedwithoutpositioningthesafety

supportonafullyextendedcylinderrod.

CheckingtheEngineOilLevel

ServiceInterval:Beforeeachuseordaily

Note:Thebesttimetochecktheengineoiliswhenthe

engineiscoolbeforeithasbeenstartedfortheday.Ifithas

alreadybeenrun,allowtheoiltodrainbackdowntothe

sumpforatleast10minutesbeforechecking.Iftheoillevelis

atorbelowtheAddmarkonthedipstick,addoiltobringthe

oilleveltotheFullmark.Donotoverll.Iftheoillevelis

betweentheFullandAddmarks,noadditionaloilisrequired.

TheengineusesanyDetergentdieselengineoil(APIservice

CH-4orhigher).Chooseaviscosityaccordingtothetable

inFigure14.

Figure15

1.Fillercap

4.Installthedipstickrmlyinplace.

AddingFuel

Useonlyclean,freshdieselfuelorbiodieselfuelswithlow

(<500ppm)orultralow(<15ppm)sulfurcontent.The

minimumcetaneratingshouldbe40.Purchasefuelin

quantitiesthatcanbeusedwithin180daystoensurefuel

freshness.

Fueltankcapacity:22l(5.85gallons).

Usesummergradedieselfuel(No.2-D)attemperatures

above-7°C(20°F)andwintergrade(No.1-DorNo.

1-D/2-Dblend)belowthattemperature.Useofwintergrade

fuelatlowertemperaturesprovideslowerashpointand

coldowcharacteristicswhichwilleasestartingandreduce

fuellterplugging.

Useofsummergradefuelabove-7°C(20°F)willcontribute

towardlongerfuelpumplifeandincreasedpowercompared

towintergradefuel.

Figure14

1.Positionthemachineonalevelsurface.

2.Removethedipstickandwipeitwithacleanrag.Insert

thedipstickintothetubeandmakesureitisseated

fully.Removedipstickandchecktheleveloftheoil.

3.Iftheoillevelislow,removethellercap(

andaddenoughoiltoraisetheleveltotheFullmark

onthedipstick.

Figure15)

Important:Donotusekeroseneorgasolineinsteadof

dieselfuel.Failuretoobservethiscautionwilldamage

theengine.

WARNING

Fuelisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

•Avoidprolongedbreathingofvapors.

•Keepyourfaceawayfromthenozzleandgas

tankorconditioneropening.

•Keepfuelawayfromyoureyesandskin.

19

Page 20

DANGER

Undercertainconditions,dieselfuelandfuel

vaporsarehighlyammableandexplosive.Are

orexplosionfromfuelcanburnyouandothersand

cancausepropertydamage.

•Beforeremovingthefueltankcap,makesure

thevehicleispositionedonalevelsurface.Open

fueltankcapslowly .

•Useafunnelandllthefueltankoutdoors,in

anopenarea,whentheengineisoffandiscold.

Wipeupanyfuelthatspills.

•Donotllthefueltankcompletelyfull.Addfuel

tothefueltankuntilthelevelis25mm(1inch)

belowthebottomofthellerneck.Thisempty

spaceinthetankallowsthefueltoexpand.

•Neversmokewhenhandlingfuel,andstayaway

fromanopenameorwherefuelfumesmaybe

ignitedbyaspark.

•Storefuelinaclean,safety-approvedcontainer

andkeepthecapinplace.

BiodieselReady

Figure16

1.Fueltankcap

3.Fillthetanktoaboutoneinchbelowthetopofthe

tank,(bottomofthellerneck),theninstallthecap.

Donotoverll.

4.Wipeupanyfuelthatmayhavespilledtopreventa

rehazard.

Thismachinecanalsouseabiodieselblendedfuelofup

toB20(20%biodiesel,80%petrodiesel).Thepetrodiesel

portionshouldbeloworultralowsulfur.Observethe

followingprecautions:

•Thebiodieselportionofthefuelmustmeetspecication

ASTMD6751orEN14214.

•TheblendedfuelcompositionshouldmeetASTMD975

orEN590.

•Paintedsurfacesmaybedamagedbybiodieselblends.

•UseB5(biodieselcontentof5%)orlesserblendsincold

weather.

•Monitorseals,hoses,gasketsincontactwithfuelasthey

maybedegradedovertime.

•Fuellterpluggingmaybeexpectedforatimeafter

convertingtobiodieselblends.

•Contactyourdistributorifyouwishformoreinformation

onbiodiesel.

1.Cleantheareaaroundthefueltankcap.

2.Removethefueltankcap(Figure16).

20

Page 21

CheckingtheCoolantLevel

1

G019522

ServiceInterval:Beforeeachuseordaily

3.Ifcoolantislow ,removethereservetankcapandadda

50/50mixtureofwaterandpermanentethyleneglycol

antifreeze.Donotoverll.

Coolingsystemcapacity:3.7l(4qt)

Thecoolingsystemislledwitha50/50solutionofwater

andpermanentethyleneglycolantifreeze.

1.Parkthemachineonalevelsurface.

CAUTION

Iftheenginehasbeenrunning,the

pressurized,hotcoolantcanescapeandcause

burns.

•Donotopentheradiatorcap.

•Allowtheenginetocoolatleast15minutes

oruntiltheradiatorcapiscoolenoughto

touchwithoutburningyourhand.

•Usearagwhenopeningthereservetank

cap,andopenthecapslowlytoallow

steamtoescape.

•Donotcheckthecoolantlevelatthe

radiator;onlycheckthecoolantlevelatthe

reservetank.

4.Installthereservetankcap.

2.Checkthecoolantlevelatthereservetank(Figure17).

Thecoolantshouldbeuptothebottomoftheller

neck.

1.Coolantreservetank

Figure17

21

Page 22

Checkingthe Transaxle/HydraulicFluid Level

ServiceInterval:Beforeeachuseordaily

ThetransaxlereservoirislledwithDexronIIIATF .Check

thelevelbeforetheengineisrststartedandevery8hoursor

daily,thereafter.Capacityofsystemis.

Transaxlereservoircapacity:7l(7.5qt).

1.Positionthevehicleonalevelsurface.

2.Cleantheareaaroundthedipstick(

Figure18).

Figure19

1.Cap

2.Removethedipstick(Figure19)fromthellerneck

andwipeitwithacleanrag.Insertthedipstickinto

thellerneck;thenremoveitandchecktheuidlevel.

Theuidlevelshouldbebetweenthetwomarkson

thedipstick.

3.Ifthelevelislow ,addtheappropriateuidto

raisetheleveltotheuppermark.Referto

ChangingtheHighFlowHydraulicOilandFilter(TCmodelsonly)(page52).

4.Installthedipstickandcapontothellerneck.

5.Starttheengineandturnontheattachment.Letthem

runforabouttwominutestopurgeairfromthesystem.

Stoptheengineandattachmentandcheckforleaks.

Figure18

1.Dipstick

3.Unscrewthedipstickfromthetopofthetransaxleand

wipeitwithacleanrag.

4.Screwthedipstickintothetransaxleandensurethat

itisfullyseated.

5.Unscrewthedipstickandchecktheuidlevel.

Theuidshouldbeuptotopoftheatportionof

thedipstick.

6.Ifthelevelislow ,addenoughuidtoachievethe

properlevel.

CheckingtheHighFlow HydraulicFluid(TCmodels only)

ServiceInterval:Beforeeachuseordaily

Thehighowhydraulicsreservoirislledwithapproximately

15l(4gallons)ofhighqualityhydraulicuid.Checkthe

levelofhydraulicuidbeforetheengineisrststarted

anddailythereafter.

1.Cleantheareaaroundthellerneckandthecapof

thehydraulictank(

thellerneck.

Figure19).Removethecapfrom

Important:Thevehiclemustberunningbefore

startingthehighowhydraulics.

WARNING

Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjury.

•Makesureallhydraulicuidhosesand

linesareingoodconditionandallhydraulic

connectionsandttingsaretightbefore

applyingpressuretothehydraulicsystem.

•Keepyourbodyandhandsawayfrom

pinholeleaksornozzlesthatejecthigh

pressurehydraulicuid.

•Usecardboardorpapertondhydraulic

leaks.

•Safelyrelieveallpressureinthehydraulic

systembeforeperforminganyworkonthe

hydraulicsystem.

•Seekimmediatemedicalattentionifuid

isinjectedintoyourskin.

22

Page 23

CheckingtheFrontDifferential

CheckingtheTirePressure

OilLevel(Four-wheeldrive

modelsonly)

ServiceInterval:Every100hours/Monthly(whichever

comesrst)

ThedifferentialislledwithMobil424hydraulicoil.

1.Positionthevehicleonalevelsurface.

2.Cleantheareaaroundthell/checkplugonsideof

thedifferential(Figure20).

ServiceInterval:Beforeeachuseordaily

Theairpressureinthefronttiresis220kPa(32psi)andthe

reartiresis124kPa(18psi).

Checkthetirepressurefrequentlytoensureproperination.

Ifthetiresarenotinatedtothecorrectpressure,thetires

willwearprematurely .

Figure21isanexampleoftirewearcausedbyunderination.

Figure21

1.Underinatedtire

Figure22isanexampleoftirewearcausedbyoverination.

Figure20

1.Fill/checkplug

3.Removethell/checkplugandcheckthelevelofthe

oil.Theoilshouldbeuptohole.Iftheoilislow ,add

Mobil424hydraulicoil.

4.Installthell/checkplug.

2.Drainplug

CheckingtheTorqueofthe WheelNuts

ServiceInterval:Aftertherst2hours

Aftertherst10hours

Every200hours

WARNING

Failuretomaintainpropertorqueofthewheelnuts

couldresultinfailureorlossofawheelandmay

resultinpersonalinjury.

Torquethefrontandrearwheelnutsto109to122

N-m(80to90ft-lb)after1to4hoursofoperation

andagainafter10hoursofoperation.Torqueevery

200hoursthereafter.

Figure22

1.Overinatedtire

CheckingtheBrakeFluid

ServiceInterval:Beforeeachuseordaily—Checkthebrake

uidlevel.

Every1,000hours/Every2years(whichevercomes

rst)—Changethebrakeuid.

Thebrakeuidreservoirisshippedfromthefactorylled

withDOT3brakeuid.Checkthelevelbeforetheengineis

rststartedandevery8hoursordaily,thereafter.

Thebrakeuidreservoirislocatedunderthedash.

1.Parkthemachineonalevelsurface.

2.TheuidlevelshouldbeuptotheFulllineonthe

reservoir(

Figure23).

23

Page 24

1.Brakeuidreservoir

Figure23

•Checkthebrakepedaloperation.

•Checktoseethatthelightsandhornareworking.

•Turnthesteeringwheeltotheleftandrighttocheckthe

steeringresponse.

•Stoptheengineandwitformovingpartstostop,then

checkforoilleaks,looseparts,andanyothernoticeable

malfunctions.

Ifanyoftheaboveitemsarenotcorrect,notifyyourmechanic

orcheckwithyoursupervisorbeforetakingthevehicleout

fortheday.Yoursupervisormaywantyoutocheckother

itemsonadailybasis,soaskwhatyourresponsibilitiesare.

StartingtheEngine

3.Iftheuidlevelislow ,cleantheareaaroundthecap,

removethereservoircap,andllthereservoirtothe

properlevel.Donotoverll.

Note:Youcanremovethehoodaccesstothereservoirfrom

thefrontofthemachine(Figure24).

Figure24

1.Sitontheoperator’sseatandengagetheparkingbrake.

2.DisengagethePTOandhighowhydraulics(ifso

equipped)andmovethehandthrottlelevertotheOff

position(ifsoequipped).

3.MovetheshiftlevertotheNeutralpositionandpress

theclutchpedal.

4.Ensurethatthehydraulicliftleverisinthecenter

position.

5.Keepyourfootoffoftheacceleratorpedal.

6.TurntheignitionswitchtotheOnposition.Whenthe

glowplugindicatorlightgoesoff,theengineisready

tostart.

7.RotatetheignitionkeyswitchtotheStartposition.

Releasethekeyimmediatelywhentheenginestartsand

allowittoreturntotheRunposition.

Note:Theglowplugindicatorwillturnonforanadditional

15seconds,whentheswitchreturnstotheRunposition.

Note:Donotrunthestartermotormorethan10secondsat

atimeorprematurestarterfailuremayresult.Ifenginefails

tostartafter10seconds,turnthekeytotheOffposition.

Checkthecontrolsandstartingprocedure,wait10additional

seconds,andrepeatthestartingoperation.

1.Brakeuidreservoir

Pre–startingChecks

Safeoperationbeginsbeforetakingthevehicleoutforaday’s

work.Youshouldchecktheseitemseachtime:

•Checkthetirepressure.

Note:Thesetiresaredifferentthancartires,theyrequire

lesspressuretominimizeturfcompactionanddamage.

•Checkalluidlevelsandaddtheappropriateamountof

Torospecieduids,ifanyarefoundtobelow .

•Checkthefrontoftheradiator.Removeanydebrisand

cleantheradiatorscreen.

DrivingtheVehicle

1.Releasetheparkingbrake.

2.Fullypresstheclutchpedal.

3.Movethegearshiftleverto1stgear.

4.Releasetheclutchpedalsmoothlywhilepressingthe

acceleratorpedal.

5.Whenthevehiclegainsenoughspeed,removeyour

footfromtheacceleratorpedal,fullypresstheclutch

pedal,movethegearshiftlevertothenextgearand

releasetheclutchpedalwhilepressingtheaccelerator

pedal.Repeattheprocedureuntilthedesiredspeedis

attained.

24

Page 25

Important:Alwaysstopthevehiclebeforeshifting

toreverseaforwardgearortoaforwardgearfrom

reverse.

Note:Avoidlongperiodsofengineidling.

Usethechartbelowtodeterminethegroundspeedof

thevehicleat3600rpm.

Gear

1L82.83:14.72.9

2L54.52:17.24.5

3L31.56:112.5

1H32.31:112.27.6

2H21.27:118.511.5

3H12.31:131.919.8

RL86.94:14.52.8

RH33.91:111.67.1

RangeRatio

Important:Donotattempttopushortowvehicle

togetitstarted.Damagetothedrivetraincould

result.

Speed

(kmh)

•Abreak–inoilfortheengineisnotrequired.The

originalengineoilisthesametypespeciedforregular

oilchanges.

•RefertotheMaintenancesectionforanyspeciallowhour

checks.

Speed

(mph)

7.7

CheckingtheInterlockSystem

ServiceInterval:Beforeeachuseordaily

Thepurposeoftheinterlocksystemistopreventtheengine

fromcrankingorstartingunlesstheclutchpedalispressed.

CAUTION

Ifsafetyinterlockswitchesaredisconnectedor

damagedthemachinecouldoperateunexpectedly

causingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlockswitches

dailyandreplaceanydamagedswitchesbefore

operatingthemachine.

Note:RefertoAttachmentOperator’sManualforprocedures

oncheckingtheattachmentinterlocksystem.

StoppingtheVehicle

Tostopthevehicle,removeyourfootfromtheaccelerator

pedal,presstheclutchpedal,thenpressthebrakepedal.

StoppingtheEngine

Tostoptheengine,rotatetheignitionkeytotheOffposition

andengagetheparkingbrake.Removethekeyfromthe

switchtopreventaccidentalstarting.

NewVehicleBreak–in

YourWorkmanisreadyforwork.Toprovideproper

performanceandlongvehiclelife,followtheseguidelinesfor

therst100operatinghours.

•Checktheuidandengineoillevelsregularlyandbealert

forindicationsofoverheatinginanycomponentofthe

vehicle.

•Afterstartingacoldengine,letitwarmupforabout15

secondsbeforeshiftingintogear.

•Avoidracingtheengine.

•Toensureoptimumperformanceofthebrakesystem,

burnish(break–in)thebrakesbeforeuse.Toburnishthe

brakes,bringthevehicleuptofullspeed,applythebrakes

torapidlystopthevehiclewithoutlockingupthetires.

Repeatthis10times,waiting1minutebetweenstopsto

avoidoverheatingthebrakes.Thisismosteffectiveifthe

vehicleisloadedwith454kg(1000lb).

•Varyvehiclespeedsduringoperation.Avoidexcessive

idling.Avoidfaststartsandquickstops.

VerifyingtheClutchInterlockSwitch

1.Sitontheoperator’sseatandengagetheparkingbrake.

MovetheshiftlevertotheNeutralposition.

Note:Theenginewillnotcrankifthehydrauliclift

leverislockedintheforwardposition.

2.Withoutpressingtheclutchpedal,rotatetheignition

keyclockwisetotheStartposition.

Iftheenginecranksorstarts,thereisamalfunction

intheinterlocksystemthatmustberepairedbefore

operatingthevehicle.

VerifyingtheHydraulicLiftLever

InterlockSwitch

1.Sitontheoperator’sseatandengagetheparkingbrake.

MovetheshiftlevertotheNeutralpositionandensure

thatthehydraulicliftleverisinthecenterposition.

2.Pressclutchpedal.

3.Movethehydraulicliftleverforwardandrotatethe

ignitionkeyclockwisetothestartposition.

Ifenginecranksorstarts,thereisamalfunctioninthe

interlocksystemthatmustberepairedbeforeoperating

vehicle.

OperatingCharacteristics

Thevehicleisdesignedwithsafetyinmind.Ithasfour

wheelsforaddedstability.Itusesfamiliarautomotivestyle

controls,includingthesteeringwheel,brakepedal,clutch

25

Page 26

pedal,acceleratorpedal,andgearshifter.Itisimportantto

remember,however,thatthisvehicleisnotapassengercar.It

isaworkvehicleandisdesignedforoffroaduseonly.

WARNING

TheWorkmanvehicleisanoff–highway

vehicleonly,andisnotdesigned,equipped,or

manufacturedforuseonpublicstreets,roadsor

highways.

Thevehiclehasspecialtires,lowgearratios,alocking

differential,andotherfeaturesthatgiveitextratraction.

Thesefeaturesaddtotheversatilityofthevehiclebut,they

canalsogetyouintodangeroussituations.Youmustkeep

inmindthatthevehicleisnotarecreationvehicle,itis

notanallterrainvehicle,and,itisdenitelynotmeantfor

stuntdrivingorhorsingaround.Itisaworkvehicle,not

aplayvehicle.Childrenshouldnotbeallowedtooperate

thevehicle.Anyonewhooperatesthevehicleshouldhavea

motorvehiclelicense.

Thedriverandpassengershouldalwaysusetheseatbelts.

Ifyouarenotexperiencedatdrivingthevehicle,practice

drivingitinasafeareaawayfromotherpeople.Besure

youarefamiliarwithallthevehicle’scontrols,particularly

thoseusedforbraking,steering,andtransmissionshifting.

Learnhowyourvehiclehandlesondifferentsurfaces.Your

operatingskillswillimprovewithexperience,butasin

operatinganyvehicle,takeiteasyasyoubegin.Besureyou

knowhowtostopquicklyinanemergency.Ifyouneedhelp,

askyoursupervisorforassistance.

Passengers

Wheneveryouhaveapassengerridinginthevehiclemake

sureheorsheiswearingtheseatbeltandholdingonsecurely.

Driveslowerandturnlesssharplybecauseyourpassenger

doesnotknowwhatyouaregoingtodonextandmaynotbe

preparedforturning,stopping,accelerating,andbumps.

Youandyourpassengershouldremainseatedatalltimes,

keepingarmsandlegsinsidethevehicle.Theoperatorshould

keepbothhandsonsteeringwheel,wheneverpossible,

andthepassengershouldusethehandholdsprovided

(

Figure25&Figure26).

Figure25

1.Passengerhandhold

2.Storagecompartment

Manyfactorscontributetoaccidents.Y ouhavecontrolover

severalofthemostimportant.Youractions,suchasdriving

toofastforconditions,brakingtoofast,turningtoosharp,

andcombinationsofthese,arefrequentcauseofaccidents.

Oneofthemajorcausesofaccidentsisfatigue.Besureto

takeoccasionalbreaks.Itisveryimportantthatyoustay

alertatalltimes.

Neveroperatethevehicle,oranyequipment,ifyouareunder

theinuenceofalcoholorotherdrugs.Evenprescription

drugsandcoldmedicinescancausedrowsiness.Readthe

labelonthemedicineorcheckwithyourdoctororpharmacist

ifyouareunsureaboutacertainmedication.

Oneofthemostimportantrulestofollowistogoslowerin

unfamiliarareas.Itissurprisinghowmuchdamageandinjury

commonthingscancause.Treebranches,fences,wires,other

vehicles,treestumps,ditches,sandtraps,streams,andother

thingsfoundinmostparksandgolfcoursescanbehazardous

totheoperatorandpassenger.

Avoiddrivingwhenitisdark,especiallyinunfamiliarareas.If

youmustdrivewhenitisdark,besuretodrivecautiously,use

theheadlights,andevenconsideraddingadditionallights.

Figure26

1.Handhold&hiprestraint

Neveralowpassengersinthedumpboxoronany

attachments.Thevehicleismeanttohaveonedriverand

onlyonepassenger—nomore.

26

Page 27

Speed

Speedisoneofthemostimportantvariablesleadingto

accidents.Drivingtoofastfortheconditionscancauseyou

tolosecontrolandhaveanaccident.Speedcanalsomakea

minoraccidentworse.Drivinghead-onintoatreeatslow

speedcancauseinjuryanddamage,but,drivingintoatree

athighspeedcandestroythevehicleandkillyouandyour

passenger.

Neverdrivetoofastfortheconditions.Ifthereisanydoubt

abouthowfasttodrive,slowdown.

Whenusingheavyattachments,morethan454kg(1000lb),

suchassprayers,topdressers,orspreaders,etc.,restrictyour

operatingspeedbymovingthe3rdhighlockoutswitchto

theslowposition.

Turning

Turningisanotherimportantvariableleadingtoaccidents.

Turningtoosharplyfortheconditionscancausethevehicle

tolosetractionandskid,oreventipover.

Wet,sandy,andslipperysurfacesmaketurningmoredifcult

andrisky.Thefasteryouaregoing,theworsethissituation

becomesso,slowdownbeforeturning.

Duringasharpturnathigherspeeds,theinsiderearwheel

mayliftoffoftheground.Thisisnotaawinthedesign,it

happenswithmostfourwheelvehiclesincludingpassenger

cars.Ifthishappens,youareturningtoosharplyforthespeed

atwhichyouaretraveling.Slowdown!

Donotdownshiftforbrakingonicyorslipperysurfaces(wet

grass)orwhilegoingdownahillbecauseenginebraking

maycauseskiddingandlossofcontrol.Shifttoalowergear

beforestartingdownahill.

TipOvers

Thevehicleisequippedwitharollbar,hiprestraints,seat

belts,andhandhold.TheROPSsystem(RolloverProtection

System)usedonthevehiclewillreducetheriskofseriousor

fatalinjuryintheunlikelyeventofatipover,althoughthe

systemcannotprotecttheoperatorfromallpossibleinjuries.

ReplaceadamagedROPS,donotrepairorrevise.Any

alterationoftheROPSmustbeapprovedbythemanufacturer.

Thebestwaytopreventaccidentsinvolvingutilityvehicles

isthroughcontinuoussupervisionandtrainingofoperators

andpayingconstantattentiontotheareainwhichvehicle

isbeingoperated.

Thebestwayforoperatorstopreventseriousinjuryordeath

tothemselvesorothers,istofamiliarizethemselveswiththe

properoperationoftheutilityvehicle,tostayalertandto

avoidactionsorconditionswhichcouldresultinaaccident.

Intheeventofatipover,theriskofseriousinjuryordeath

willbereducediftheoperatorisusingtheROPSsystemand

seatbeltsandisfollowingtheinstructionsprovided.

Hills

WARNING

Braking

Itisgoodpracticetoslowdownbeforeyougetnearan

obstacle.Thisgivesyouextratimetostoporturnaway .

Hittinganobstaclecandamagethevehicleanditscontents.

Moreimportant,itcaninjureyouandyourpassenger.Gross

vehicleweighthasamajorimpactonyourabilitytostop

and/orturn.Heavierloadsandheavierattachmentsmake

avehiclehardertostoporturn.Theheaviertheload,the

longerittakestostop

Thebrakingcharacteristicsalsochangewithnobedor

attachmentonthevehicle.Faststopsmaycausetherear

wheelstolockupbeforethefrontwheelslockup,whichmay

affectthecontrolofthevehicle.Itisagoodideatodecrease

vehiclespeedwithnobedorattachment.

Turfandpavementaremuchslipperierwhentheyarewet.

Itcantake2to4timesaslongtostoponwetsurfacesas

ondrysurfaces.

Ifyoudrivethroughstandingwaterdeepenoughtogetthe

brakeswet,theywillnotworkwelluntiltheyaredry.After

drivingthroughwater,youshouldtestthebrakestomake

suretheyworkproperly .Iftheydonot,driveslowlyinrst

gearwhileputtinglightpressureonthebrakepedal.This

willdrythebrakesout.

Tippingorrollingthevehicleonahillwillcause

seriouspersonalinjury.

•Donotoperatethevehicleonsteepslopes.

•Ifenginestallsoryouloseheadwayonahill,

neverattempttoturnvehiclearound.

•Alwaysbackstraightdownahillinreversegear.

•Neverbackdowninneutralorwiththeclutch

depressed,usingonlythebrakes.

•Neverdriveacrossasteephill,alwaysdrive

straightupordown.

•Avoidturningonahill.

•Don’t“droptheclutch”orslamonthebrakes.

Suddenspeedchangecaninitiateatipover.

Useextracarewhenonhills.Nevergoonhillsthatare

extremelysteep.Stoppingwhilegoingdownahillwilltake

longerthanonlevelground.Turningwhilegoingupordown

ahillismoredangerousthanturningonthelevel.Turnswhile

goingdownhill,especiallywiththebrakeson,and,turning

uphillwhiletraversingahillareparticularlydangerous.Even

27

Page 28

ataslowspeedandwithoutaload,tipoversaremorelikelyif

youturnonahill.

Slowdownandshiftintoalowergearbeforestartingupor

downahill.Ifyouhavetoturnwhileonahill,doitasslowly

andcautiouslyaspossible.Nevermakesharporfastturns

onahill.

Ifyoustallorbegintoloseheadwaywhileclimbingasteep

hill,quicklyapplythebrakes,shifttoneutral,restartthe

engineandshifttoreverse.Atidlespeed,theengineand

transaxledragwillaidthebrakesincontrollingthevehicleon

thehillandhelpyoubackdownthehillmoresafely.

Reducetheweightoftheloadifitisasteephillorifthe

loadhashighcenterofgravity.Remember,loadscanshift,

securethem.

Note:Thevehiclehasexcellenthillclimbingability.The

differentiallockwillincreasethisability .Hillclimbingtraction

canalsobeincreasedbyaddingweighttotherearofthe

vehicleinoneofthefollowingways:

•Addingweighttoinsideofbox,makingsureitissecured.

•Mountingwheelweightstorearwheels.

•Addingliquidballast(calciumchloride)toreartires.

•Tractionwillincreasewithnopassengerinfrontseat.

vehicleistotipover.Youmayndthat1360kg(3000lb)

stackstoohighforsafeoperation.Reducingthetotalweight

isonewaytoreducetheriskofatipover.Distributingthe

loadaslowaspossibleisanotherwaytoreducetheriskof

atipover.

Iftheloadispositionedtowardoneofthesides,itwillmake

thevehiclemuchmorelikelytotipoveronthatside.Thisis

especiallytruewhenturningiftheloadisontheoutsideof

theturn.

Neverpositionheavyloadsbehindtherearaxle.Iftheloadis

positionedsofartotherearthatitisbehindtherearaxle,it

willreducetheweightonthefrontwheelsandthiswillreduce

steeringtraction.Withtheloadallthewaytotheback,the

frontwheelscanevencomeoffofthegroundwhengoing

overbumpsorupahill.Thiswillresultinalossofsteering

andmayleadtothevehicletippingover.

Asageneralrule,positiontheweightoftheloadevenly

fromfronttorearandevenlyfromsidetoside.

Ifaloadisnotsecured,oryouaretransportingaliquidina

largecontainersuchasasprayer,itcanshift.Thisshifting

happensmostoftenwhileturning,goingupordownhills,

suddenlychangingspeeds,orwhiledrivingoverrough

surfaces.Shiftingloadscanleadtotipovers.Alwayssecure

loadssothattheydonotshift.Neverdumptheloadwhile

thevehicleissidewaysonthehill.

LoadingandDumping

Theweightandpositionofthecargoandpassengercan

changethevehiclecenterofgravityandvehiclehandling.

Toavoidlossofcontrolresultinginpersonalinjury,follow

theseguidelines.

Donotcarryloadswhichexceedtheloadlimitsdescribed

onthevehicleweightlabel.

WARNING

Thebedwilllowerwheneverthedumpleveris

pusheddown,evenwhentheengineisoff.Turning

offtheenginewill

lowering.Alwaysplacethesafetysupportonthe

extendedliftcylindertoholdtheboxupifyouare

notgoingtoloweritrightaway.

Thevehiclehasseveralcombinationsofboxes,platforms,

andattachmentsavailable.Thesecanbeusedinvarious

combinationsthatallowformaximumcapacityandversatility.

Thefullsizedboxis140cm(55inches)wideby165cm(65

inches)longandcanholdupto1360kg(3000lb)ofevenly

distributedcargo.

not

preventtheboxfrom

Heavyloadsincreasestoppingdistanceandreduceyour

abilitytoturnquicklywithouttippingover.

Therearcargospaceisintendedforloadcarryingpurposes

only,notforpassengers.

UsingTheDifferentialLock

Thedifferentiallockincreasesthevehicle’stractionbylocking

therearwheelssoonewheelwillnotspinout.Thiscanhelp

whenyouhaveheavyloadstohaulonwetturforslippery

areas,goinguphills,andonsandysurfaces.Itisimportant

torememberhowever,thatthisextratractionisonlyfor

temporarylimiteduse.Itsusedoesnotreplacethesafe

operation,alreadydiscussedconcerningsteephillsandheavy

loads.

Thedifferentiallockcausestherearwheelstospinatthe

samespeed.Whenusingdifferentiallockyourabilitytomake

sharpturnsissomewhatrestrictedandmayscufftheturf.

Usethedifferentiallockonlywhenneeded,atslowerspeeds

andonlyinrstorsecondgear.

Loadsvaryinhowtheyaredistributed.Sandspreadsout

evenlyandquitelow .Otheritems,suchasbricks,fertilizeror

landscapetimbers,stackhigherinthebox.

Theheightandweightoftheloadhasasignicantinuence

ontipovers.Thehigheraloadisstacked,themorelikelythe

28

Page 29

WARNING

Tippingorrollingthevehicleonahillwillcause

seriousinjury.

•Theextratractionavailablewiththedifferential

lockcanbeenoughtogetyouintodangerous

situationssuchasclimbingslopesthataretoo

steeptoturnaround.Beextracarefulwhen

operatingwiththedifferentiallockon,especially

onsteeperslopes.

•Ifthedifferentiallockisonwhenmakinga

sharpturnatahigherspeedandtheinsiderear

wheelliftsofftheground,theremaybealossof

controlwhichcouldcausevehicletoskid.Use

thedifferentiallockonlyatslowerspeeds.

FourWheelDrive(Four-wheel drivemodelsonly)

TheAutomaticonDemandfourwheeldrivefeature,onthis

vehicledoesnotrequireoperatoractivation.Thefrontwheel

driveisnotengaged(nopowerdeliveredtofrontwheels)until

therearwheelsbegintolosetraction.Thebidirectionalclutch

sensestherearwheelsslipping,engagesthefrontwheeldrive,

anddeliverspowertothefrontwheels.Thefourwheeldrive

systemcontinuestodeliverpowertothefrontwheelsuntilthe

rearwheelshaveenoughtractiontomovethevehiclewithout

slipping.Oncethisoccurs,thesystemstopsdeliveringpower

tothefrontwheelsandthehandlingcharacteristicsbecome

similartothatofatwowheeldrivevehicle.Thefourwheel

drivesystemfunctionsinbothfrowardandreverse,however,

whenturningtherearwheelswillslipslightlymorebefore

powerisdeliveredtothefrontwheels.

vehiclehoodtotheframewithastrap,orremovethehood

andtransportandsecureitseparatelyorthehoodmayblow

offduringtransport.

Figure27

1.Eyeholeinframe(eachside)

Figure28

1.Axle2.Hitchplate

WARNING

Tippingorrollingthevehicleonahillwillcause

seriousinjury.

Theextratractionavailablewiththefourwheeldrive

featurecanbeenoughtogetyouintodangerous

situationssuchasclimbingslopesthataretoo

steeptoturnaround.Becarefulwhenoperating,

especiallyonsteeperslopes.

TransportingtheVehicle

Formovingthevehiclelongdistances,useatrailer.Make

surethevehicleissecuredtothetrailer.RefertoFigure27&

Figure28forthelocationofthetiedownpoints.

Important:Trailersweighingover680kg(1500lb)are

requiredtobeequippedwithtrailerbrakes.

Note:Loadthevehicleonthetrailerwiththefrontofthe

vehiclefacingforward.Ifthatisnotpossible,securethe

TowingtheVehicle

Incaseofanemergency,thevehiclecanbetowedfora

shortdistance.However,Torodoesnotrecommendthisas

astandardprocedure.

WARNING

Towingatexcessivespeedscouldcausevehicleto

losesteeringcontrol.Nevertowvehiclefasterthan

8km/h(5mph).

Towingthevehicleisatwopersonjob.Afxatowlineto

holesinthefrontframemember.MovetheshiftertoNeutral

andreleasetheparkingbrake.Ifthemachinemustbemoved

aconsiderabledistance,transportitonatruckortrailer.

Note:Thepowersteeringwillnotfunction,makingit

difcult(increasedeffort)tosteer.

29

Page 30

TowingaTrailerwiththe Vehicle

TheWorkmaniscapableofpullingtrailersandattachments

ofgreaterweightthanthevehicleitself.

SeveraltypesoftowhitchesareavailablefortheWorkman,

dependingonyourapplication.ContactyourAuthorized

ToroDistributorfordetails.

Whenequippedwithatowhitchboltedontotherearaxle

tube,yourWorkmancantowtrailersorattachmentswitha

GrossTrailerWeight(GTW)upto1587kg(3500lb).Always

loadatrailerwith60%ofthecargoweightinthefrontof

thetrailer.Thisplacesapproximately10%(272kg(600lb)

max.)oftheGrossTrailerWeight(GTW)onthetowhitch

ofthevehicle.

Trailerbrakesarerequiredwheneveryoutowatrailerover

680kg(1500lb)GTWistowedbehindaWorkmanvehicle.

Whenhaulingcargoortowingatrailer(attachment),donot

overloadyourvehicleortrailer.Overloadingcancausepoor

performanceordamagetothebrakes,axle,engine,transaxle,

steering,suspension,bodystructure,ortires.

Important:Toreducepotentialfordrivelinedamage,

uselowrange.

Whentowing5thwheelattachments,likeafairwayaerator,

alwaysinstallthewheelybar(includedwiththe5thwheelkit)

topreventthefrontwheelsfromliftingoffthegroundifthe

towedattachmentsmovementissuddenlyimpaired.

HydraulicControl

Thehydrauliccontrolsupplieshydraulicpowerfromthe

vehiclepumpwhenevertheengineisrunning.Thepowercan

beusedthroughthequickcouplersattherearofthevehicle.

Important:Ifmultiplevehiclesusethesame

attachment,crosscontaminationofthetransmission

uidmayoccur.Changethetransmissionuidmore

frequently

ControlLeverPositions

•OffPosition

Thisisthenormalpositionforthecontrolvalvewhenit

isnotbeingused.Inthispositiontheworkportsofthe

controlvalveareblockedandanyloadwillbeheldbythe

checkvalvesinbothdirections.

•Raise(QuickCoupler“ A ”Position)

Thisisthepositionwhichwillliftthebed,rearhitch

attachmentorapplypressuretoquickcouplerA.This

alsoallowsreturnoilfromquickcouplerBtoowback

intothevalveandthenouttothereservoir.Thisisa

momentarypositionandwhentheleverisreleasedit

springreturnstothecenteroffposition.

Figure29

1.QuickcouplerAposition2.QuickcouplerBposition

•Lower(QuickCouplerBPosition)

Thispositionwilllowerthebed,rearhitchattachment,

orapplypressuretoquickcouplerB.Thisalsoallows

returnoilfromquickcouplerAtoowbackintothe

valveandthenouttothereservoir.Thisisamomentary

positionandwhentheleverisreleaseditspringreturns

tothecenteroffposition.Momentarilyholdingandthen

releasingthecontrolleverinthispositionwillprovide

owtoquickcouplerBwhichprovidespowerdown

ontherearhitch.Whenreleased,itwillholdthedown

pressureonthehitch.

Important:Ifusedwithahydrauliccylinder,

holdingthecontrolleverinthelowerpositioncauses

theoilowtogooverareliefvalvewhichcan

damagethehydraulicsystem.

•OnPosition

ThispositionissimilartoLower(quickcouplerB

position).ItalsodirectsoiltoquickcouplerBexcept

thattheleverisheldinthispositionbyadetentleverin

thecontrolpanel.Thisallowsoiltoowcontinuously

toequipmentthatusesahydraulicmotor.Thisposition

mustonlybeusedonattachmentswithahydraulicmotor

attached.

Important:Ifusedwithahydrauliccylinderorno

attachment,theOnpositioncausestheoilowtogo

overareliefvalvewhichcandamagethehydraulic

system.Usethispositiononlymomentarilyorwitha

motorattached.

Important:Checkhydraulicoillevelafter

installationofanattachment.Checktheoperation

oftheattachmentbycyclingtheattachmentseveral

timestopurgeairfromsystem,thenrecheck

hydraulicoillevel.Theattachmentcylinderwill

slightlyaffecttransaxleoillevel.Operationofvehicle

withlowoillevelcandamagethepump,remote

hydraulics,powersteering,andthevehicletransaxle.

30

Page 31

CAUTION

Hydraulicuidescapingunderpressurecan

havesufcientforcetopenetrateskinanddo

seriousdamage.Caremustbeusedwhen

connectingordisconnectinghydraulicquick

couplers.Stoptheengine,applytheparking

brake,lowertheattachment,andplacethe

remotehydraulicvalveintheoatdetent