Page 1

FormNo.3363-949RevC

Workman

®

HDXUtilityVehicle

ModelNo.07366—SerialNo.310000001andUp

ModelNo.07367—SerialNo.310000001andUp

ModelNo.07367TC—SerialNo.310000001andUp

ModelNo.07370—SerialNo.310000001andUp

ModelNo.07370TC—SerialNo.310000001andUp

ToregisteryourproductordownloadanOperator'sManualorPartsCatalogatnocharge,gotowww.T oro.com.OriginalInstructions(EN)

Page 2

Thismachineisautilityvehicleintendedtobeusedby

professional,hiredoperatorsincommercialapplications.

Itisprimarilydesignedforthetransportofimplements

usedinsuchapplications.Thisvehicleallowsforthe

safetransportofanoperatorandonepassengerinthe

identiedseats.Thebedofthisvehicleisnotsuitable

foranyriders.

ThisproductcomplieswithallrelevantEuropean

directives,fordetailspleaseseetheseparateproduct

specicDeclarationofConformity(DOC)sheet.

WARNING

CALIFORNIA

Proposition65Warning

TheengineexhaustfromthisproductcontainschemicalsknowntothestateofCalifornia

tocausecancer,birthdefects,orotherreproductiveharm.

Important:Theengineinthisproductisnot

equippedwithasparkarrestedmufer.Itis

aviolationofCaliforniaPublicResourcecode

Section4442touseoroperatethisengineonany

forest-covered,brushcovered,orgrass-coveredland

asdenedinCPRC4126.Otherstatesorfederal

areasmayhavesimilarlaws.

Introduction

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoidinjury

andproductdamage.Youareresponsibleforoperating

theproductproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comfor

productandaccessoryinformation,helpndingadealer,

ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,

oradditionalinformation,contactanAuthorized

ServiceDealerorToroCustomerServiceandhave

themodelandserialnumbersofyourproductready.

Figure1identiesthelocationofthemodelandserial

numbersontheproduct.Writethenumbersinthe

spaceprovided.

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjury

ordeathifyoudonotfollowtherecommended

precautions.

Figure2

1.Safetyalertsymbol

Thismanualuses2otherwordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

©2011—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

2

Contactusatwww.Toro.com.

PrintedintheUSA.

AllRightsReserved

Page 3

Contents

Introduction.................................................................2

Safety...........................................................................4

SafeOperatingPractices.......................................4

Supervisor’sResponsibilities.................................5

BeforeOperating.................................................5

Operation.............................................................5

Maintenance.........................................................6

SoundPressure.....................................................7

Vibration..............................................................7

SafetyandInstructionalDecals.............................8

Setup.........................................................................13

1InstalltheSteeringWheel(TCModels

Only)..............................................................13

2InstalltheROPS(RolloverProtection

System)(TCModelsOnly)..............................13

3ActivateandChargetheBattery(TCModels

Only)..............................................................14

4CheckingFluidLevels......................................15

ProductOverview......................................................16

Controls.............................................................16

Specications.....................................................20

Attachments/Accessories...................................20

Operation...................................................................20

CheckingtheEngineOilLevel............................20

AddingFuel.......................................................21

CheckingtheCoolingSystem..............................23

CheckingtheTransaxle/HydraulicFluid

Level..............................................................23

CheckingtheHighFlowHydraulicFluid(TC

modelsonly)...................................................23

CheckingtheFrontDifferentialOilLevel

(FourWheelDriveModelsOnly)....................24

CheckingtheTorqueoftheWheel

Nuts...............................................................24

CheckingtheTirePressure.................................25

CheckingtheBrakeFluid....................................25

Pre–startingChecks............................................25

StartingtheEngine.............................................26

DrivingtheV ehicle.............................................26

StoppingtheVehicle...........................................26

StoppingtheEngine...........................................26

NewVehicleBreak–in........................................26

CheckingtheInterlockSystem............................27

OperatingCharacteristics...................................27

Passengers..........................................................28

Speed.................................................................28

Turning..............................................................29

Braking..............................................................29

TipOvers...........................................................29

Hills...................................................................29

LoadingandDumping........................................30

UsingTheDifferentialLock...............................30

FourWheelDrive(FourWheelDriveModels

Only)..............................................................31

TransportingV ehicle..........................................31

TowingtheVehicle.............................................31

TowingaTrailerwiththeVehicle.........................32

HydraulicControl...............................................32

Maintenance...............................................................34

RecommendedMaintenanceSchedule(s)................34

ServiceIntervalChart.........................................35

HeavyDutyOperation.......................................36

PremaintenanceProcedures....................................36

UsingtheBedSafetySupport..............................36

RemovingtheFullBed.......................................37

InstallingtheFullBed.........................................37

JackingtheVehicle..............................................38

RemovingtheHood...........................................39

Lubrication.............................................................40

GreasingBearingsandBushings.........................40

EngineMaintenance...............................................42

InspectingtheCarbonCanisterAir

Filter..............................................................42

ServicingtheAirCleaner....................................42

ChangingtheEngineOilAndFilter....................42

ReplacingtheSparkPlugs...................................43

FuelSystemMaintenance.......................................44

ReplacingtheFuelFilter.....................................44

FuelLinesandConnections................................44

ElectricalSystemMaintenance................................45

Fuses..................................................................45

JumpStartingtheVehicle....................................45

ServicingtheBattery...........................................46

DriveSystemMaintenance.....................................47

ChangingtheFrontDifferentialOil(Four

WheelDriveModelsOnly).............................47

InspectingtheConstantVelocityBoot(Four

WheelDriveModelsOnly).............................47

AdjustingtheShiftCables...................................47

AdjustingtheHigh–LowCable...........................47

AdjustingDifferentialLockCable.......................47

InspectingtheTires............................................48

CheckingtheFrontWheelAlignment.................48

CoolingSystemMaintenance..................................49

RemovingDebrisfromtheCooling

System............................................................49

ChangingEngineCoolant...................................50

BrakeMaintenance.................................................51

AdjustingtheParkingBrake................................51

AdjustingtheBrakePedal...................................51

BeltMaintenance....................................................52

AdjustingtheAlternatorBelt..............................52

ControlsSystemMaintenance.................................53

AdjustingtheAcceleratorPedal..........................53

AdjustingtheClutchPedal..................................53

3

Page 4

ConvertingtheSpeedometer..............................54

HydraulicSystemMaintenance...............................55

ChangingtheHydraulicFluidandCleaning

theStrainer.....................................................55

ReplacingtheHydraulicFilter.............................55

ChangingtheHighFlowHydraulicOiland

Filter(TCModelsonly)...................................56

RaisingtheBoxinanEmergency........................56

Storage.......................................................................58

Schematics.................................................................60

Safety

ThemachinemeetstherequirementsofSAEJ2258.

Supervisors,operatorsandservicepersonsshouldbe

familiarwiththefollowingstandardsandpublications:

(Thematerialmaybeobtainedfromtheaddressshown).

•FlammableandCombustibleLiquidsCode:

ANSI/NFPA30

•NationalFireProtectionAssociation:

ANSI/NFPA#505;PoweredIndustrialTrucks

ADDRESS:

NationalFirePreventionAssociation

BarrymarchPark

Quincy,Massachusetts02269U.S.A

•ANSI/ASMEB56.8PersonalBurdenCarriers

ADDRESS:

AmericanNationalStandardsInstitute,Inc.

1430Broadway

NewYork,NewYork10018U.S.A.

•ANSI/UL558;InternalCombustionEngine

PoweredIndustrialTrucks

ADDRESS:

AmericanNationalStandardsInstitute,Inc.

1430Broadway

NewYork,NewYork10018U.S.A.

or

UnderwritersLaboratories

333PngstenRoad

Northbrook,Illinois60062U.S.A.

SafeOperatingPractices

WARNING

TheWorkmanisanoff–highwayvehicleonly,and

isnotdesigned,equipped,ormanufacturedforuse

onpublicstreets,roadsorhighways.

TheWorkmanwasdesignedandtestedtooffer

safeservicewhenoperatedandmaintainedproperly.

Althoughhazardcontrolandaccidentprevention

partiallyaredependentuponthedesignand

congurationofthemachine,thesefactorsarealso

dependentupontheawareness,concern,andproper

trainingofthepersonnelinvolvedintheoperation,

maintenanceandstorageofthemachine.Improperuse

ormaintenanceofthemachinecanresultininjuryor

death.

4

Page 5

Thisisaspecializedutilityvehicledesignedforoff–road

useonly .Itsrideandhandlingwillhaveadifferent

feelthanwhatdriversexperiencewithpassengercars

ortrucks.Sotaketimetobecomefamiliarwithyour

Workman.

NotalloftheattachmentsthatadapttotheW orkman

arecoveredinthismanual.SeethespecicOperator’s

Manualprovidedwitheachattachmentforadditional

safetyinstructions.Readthesemanuals.

Toreducethepotentialforinjuryordeath,comply

withthefollowingsafetyinstructions:

Supervisor’sResponsibilities

•Makesureoperatorsarethoroughlytrainedand

familiarwiththeOperator’sManualandalllabelson

thevehicle.

•Besuretoestablishyourownspecialprocedures

andworkrulesforunusualoperatingconditions(e.g.

slopestoosteepforvehicleoperation).Usethe3rd

HighLockoutswitchifhighspeedcouldresultina

safetyorvehicleabusesituation.

BeforeOperating

•Operatethemachineonlyafterreadingand

understandingthecontentsofthismanual.A

replacementmanualisavailablebysendingcomplete

modelandserialnumberto:TheToro®Company ,

8111LyndaleAvenueSouth,Minneapolis,Minnesota

55420.

•Neverallowchildrentooperatethevehicle.Never

allowadultstooperateitwithoutproperinstructions.

Onlytrainedandauthorizedpersonsshouldoperate

thisvehicle.Makesurealloperatorsarephysically

andmentallycapableofoperatingthevehicle.

•Thisvehicleisdesignedtocarryonlyyou,the

operator,andonepassengerintheseatprovidedby

themanufacturer.Nevercarryanyotherpassengers

onthevehicle.

•Neveroperatethevehiclewhenundertheinuence

ofdrugsoralcohol.

•Becomefamiliarwiththecontrolsandknowhowto

stoptheenginequickly.

•Keepallshields,safetydevicesanddecalsinplace.

Ifashield,safetydeviceordecalismalfunctioning,

illegible,ordamaged,repairorreplaceitbefore

operatingthemachine.

•Alwayswearsubstantialshoes.Donotoperate

themachinewhilewearingsandals,tennisshoes,

orsneakers.Donotwearloosettingclothingor

jewelrywhichcouldgetcaughtinmovingpartsand

causepersonalinjury.

•Wearingsafetyglasses,safetyshoes,longpants,anda

helmetisadvisableandrequiredbysomelocalsafety

andinsuranceregulations.

•Keepeveryone,especiallychildrenandpets,away

fromtheareasofoperation.

•Beforeoperatingthevehicle,alwayscheckallparts

ofthevehicleandanyattachments.Ifsomethingis

wrong,stopusingvehicle.Makesuretheproblem

iscorrectedbeforevehicleorattachmentisoperated

again.

•Sincegasolineishighlyammable,handleitcarefully.

–Useanapprovedfuelcontainer.

–Donotremovethecapfromthefueltankwhen

theengineishotorrunning.

–Donotsmokewhilehandlingfuel.

–Fillthefueltankoutdoorsandtoaboutoneinch

belowthetopoftank(bottomofllerneck).Do

notoverll.

–Wipeupanyspilledfuel.

•Operatevehicleonlyoutdoorsorinawellventilated

area.

•Useonlyanapprovednonmetal,portablefuel

container.Staticelectricdischargecanignitefuel

vaporsinaungroundedfuelcontainer.Removethe

fuelcontainerfromthebedofthevehicleandplace

itonthegroundawayfromthevehiclebeforelling.

Keepthenozzleincontactwiththecontainerwhile

lling.Removeequipmentfromvehiclebedbefore

lling.

•Checkthesafetyinterlocksystemdailyforproper

operation.Ifaswitchshouldmalfunction,replace

theswitchbeforeoperatingmachine.

Operation

•Theoperatorandpassengershoulduseseatbelts

andremainseatedwheneverthevehicleisinmotion.

Theoperatorshouldkeepbothhandsonthesteering

wheel,wheneverpossible,andthepassengershould

usethehandholdsprovided.Keeparmsandlegs

withinthevehiclebodyatalltimes.Nevercarry

passengersintheboxoronattachments.Remember

yourpassengermaynotbeexpectingyoutobrakeor

turnandmaynotbeready.

•Neveroverloadyourvehicle.Thenameplate(located

underthemiddleofthedash)showstheloadlimits

5

Page 6

forthevehicle.Neveroverllattachmentsorexceed

thevehiclemaximumgrossvehicleweight(GVW).

•Whenstartingtheengine:

–Sitonoperator’sseatandensurethattheparking

brakeisengaged.

–DisengagePTO(ifsoequipped)andreturnthe

handthrottlelevertotheOffposition(ifso

equipped).

–Makesurethehydraulicliftleverisinthecenter

position.

–MoveshiftlevertoNeutralandpresstheclutch

pedal.

–Keepyourfootoffoftheacceleratorpedal.

–TurntheignitionkeytotheStartposition.

•Usingthemachinedemandsattention.Failureto

operatevehiclesafelymayresultinanaccident,tip

overofthevehicle,andseriousinjuryordeath.Drive

carefully.Topreventtippingorlossofcontrol,take

thefollowingprecautions:

–Useextremecaution,reducespeed,andmaintain

asafedistancearoundsandtraps,ditches,creeks,

ramps,anyunfamiliarareas,orotherhazards.

–Watchforholesorotherhiddenhazards.

–Usecautionwhenoperatingthevehicleona

steepslope.Normally,travelstraightupand

downslopes.Reducespeedwhenmakingsharp

turnsorwhenturningonhillsides.Avoidturning

onhillsideswheneverpossible.

–Useextracautionwhenoperatingthevehicleon

wetsurfaces,athigherspeeds,orwithafullload.

Stoppingtimewillincreasewithafullload.Shift

intoalowergearbeforestartingupordownahill.

–Whenloadingthebed,distributetheload

evenly.Useextracautioniftheloadexceeds

thedimensionsofthevehicle/bed.Operate

thevehiclewithextracautionwhenhandling

off-centerloadsthatcannotbecentered.Keep

loadsbalancedandsecuretopreventthemfrom

shifting.

–Avoidsuddenstopsandstarts.Donotgofrom

reversetoforwardorforwardtoreversewithout

rstcomingtoacompletestop.

–Donotattemptsharpturnsorabruptmaneuvers

orotherunsafedrivingactionsthatmaycausea

lossofvehiclecontrol.

–Donotpassanothervehicletravelinginthesame

directionatintersections,blindspots,oratother

dangerouslocations.

–Whendumping,donotletanyonestandbehind

vehicleanddonotdumptheloadonanyone’s

feet.Releasethetailgatelatchesfromthesideof

box,notfrombehind.

–Keepallbystandersaway.Beforebackingup,

looktotherearandensurethatnooneisbehind

thevehicle.Backupslowly.

–Watchoutfortrafcwhennearorcrossingroads.

Alwaysyieldtherightofwaytopedestriansand

othervehicles.Thisvehicleisnotdesignedfor

useonstreetsorhighways.Alwayssignalyour

turnsorstopearlyenoughsootherpersons

knowwhatyouplantodo.Obeyalltrafcrules

andregulations.

–Neveroperatethevehicleinornearanarea

wherethereisdustorfumesintheairwhichare

explosive.Theelectricalandexhaustsystemsof

thevehiclecanproducesparkscapableofigniting

explosivematerials.

–Alwayswatchoutforandavoidlowoverhangs

suchastreelimbs,doorjambs,overhead

walkways,etc.Makesurethereisenoughroom

overheadtoeasilyclearthevehicleandyour

head.

–Ifeverunsureaboutsafeoperation,stopwork

andaskyoursupervisor.

•Donottouchengine,transaxle,radiator,muferor

mufermanifoldwhileengineisrunningorsoon

afterithasstoppedbecausetheseareasmaybehot

enoughtocauseburns.

•Ifthemachineevervibratesabnormally,stop

immediately,turnengineoff,waitforallmotion

tostopandinspectfordamage.Repairalldamage

beforeresumingoperation.

•Beforegettingofftheseat:

–Stopmovementofthemachine.

–Lowerbed.

–Shutengineoffandwaitforallmovementto

stop.

–Setparkingbrake.

–Removekeyfromignition.

•Lightningcancausesevereinjuryordeath.If

lightningisseenorthunderisheardinthearea,do

notoperatethemachine;seekshelter.

Maintenance

•Beforeservicingormakingadjustmentstothe

machine,stoptheengine,settheparkingbrake,and

removethekeyfromignitiontopreventaccidental

startingoftheengine.

•Neverworkunderaraisedbedwithoutplacingthe

bedsafetysupportonthefullyextendedcylinderrod.

6

Page 7

•Makesureallhydrauliclineconnectorsaretight,and

allhydraulichosesandlinesareingoodcondition

beforeapplyingpressuretothesystem.

•Keepyourbodyandhandsawayfrompinhole

leaksornozzlesthatejecthydraulicuidunder

highpressure.Usepaperorcardboard,nothands,

tosearchforleaks.Hydraulicuidescapingunder

pressurecanhavesufcientforcetopenetrateskin

anddoseriousdamage.Ifuidisinjectedintothe

skinitmustbesurgicallyremovedwithinafew

hoursbyadoctorfamiliarwiththisformofinjury

organgrenemayresult.

•Beforedisconnectingorperforminganyworkonthe

hydraulicsystem,allpressureinthesystemmustbe

relievedbystoppingtheengine,cyclingthedump

valvefromraisetolowerand/orloweringboxand

attachments.Placetheremotehydraulicsleverinthe

oatposition.Iftheboxmustbeinraisedposition,

secureitwiththesafetysupport.

•Tomakesuretheentiremachineisingoodcondition,

keepallnuts,bolts,andscrewsproperlytightened.

•Toreducethepotentialrehazard,keeptheengine

areafreeofexcessivegrease,grass,leaves,and

accumulationofdirt.

•Iftheenginemustberunningtoperforma

maintenanceadjustment,keephands,feet,clothing,

andanypartsofthebodyawayfromtheengineand

anymovingparts.Keepeveryoneaway.

•Donotoverspeedtheenginebychangingthe

governorsettings.Themaximumenginespeedis

3650RPM.Toensuresafetyandaccuracy,havean

AuthorizedToroDistributorcheckthemaximum

enginespeedwithatachometer.

•Ifmajorrepairsareeverneededorassistanceis

required,contactanAuthorizedToroDistributor.

•Tobesureofoptimumperformanceandsafety,

alwayspurchasegenuineTororeplacementpartsand

accessories.Replacementpartsandaccessoriesmade

byothermanufacturerscouldbedangerous.Altering

thisvehicleinanymannermayaffectthevehicle’s

operation,performance,durabilityoritsusemay

resultininjuryordeath.Suchusecouldvoidthe

productwarrantyofTheT oro®Company.

•Thisvehicleshouldnotbemodiedwithout

TheToro®Company’sauthorization.Directany

inquiriestoTheToro®Company ,Commercial

Division,VehicleEngineeringDept.,8111Lyndale

Ave.So.,Bloomington,Minnesota55420–1196.

USA

SoundPressure

Thisunithasasoundpressurelevelattheoperator’ s

earof75dBA,whichincludesanUncertaintyValue(K)

of1dBA.

Thesoundpressurelevelwasdeterminedaccordingto

theproceduresoutlinedinENISO11201.

Vibration

Hand-Arm

•Measuredvibrationlevelforrighthand=0.34m/s

2

•Measuredvibrationlevelforlefthand=0.43m/s

2

•UncertaintyValue(K)=0.5m/s

2

Measuredvaluesweredeterminedaccordingtothe

proceduresoutlinedinEN1032.

WholeBody

•Measuredvibrationlevel=0.33m/s

2

•UncertaintyValue(K)=0.5m/s

2

Measuredvaluesweredeterminedaccordingtothe

proceduresoutlinedinEN1032.

7

Page 8

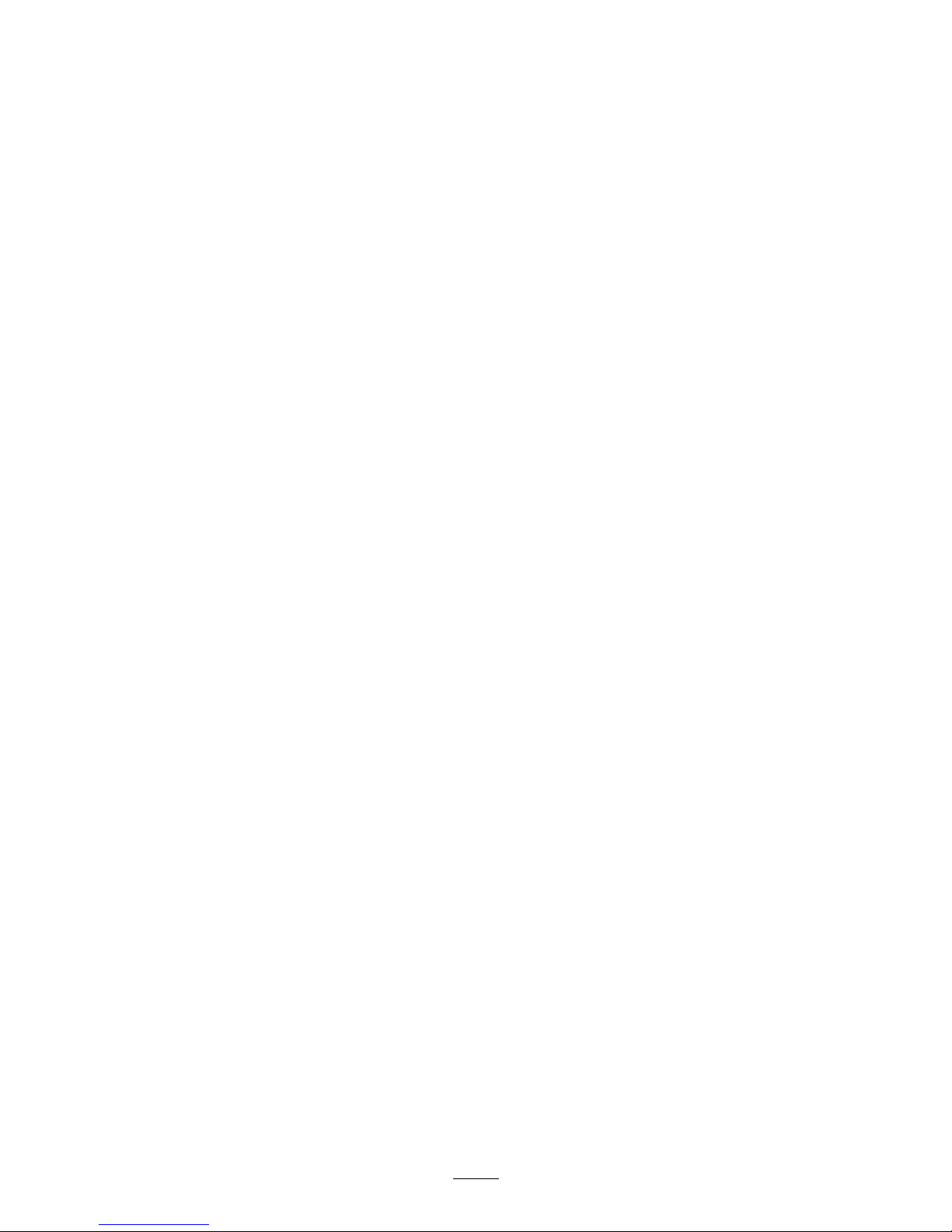

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaof

potentialdanger.Replaceanydecalthatisdamagedorlost.

93-9084

1.Liftpoint

2.Tie-downpoint

106-6755

1.Enginecoolantunder

pressure.

3.Warning—donottouchthe

hotsurface.

2.Explosionhazard—read

theOperator'sManual.

4.Warning—readthe

Operator'sManual.

115-2047

1.Warning—donottouchthehotsurface.

115-7740

1.Warning—maximumtrailerweightis1500lb(680kg),

maximumtongueweightis200lb(90kg).

2.Warning—trailerbrakesarerequiredwhentowinggreater

than1500lb(680kg),maximumtrailerweightwithtrailer

brakesis3500lb(1591kg),maximumtongueweightwith

trailerbrakesis600lb(273kg).

115-7723

1.Warning—thehydraulicoilpressureis124bar(1800PSI).

2.CouplerA

3.CouplerB

93-9879

1.Storedenergyhazard—readtheOperator'sManual.

117–2718

8

Page 9

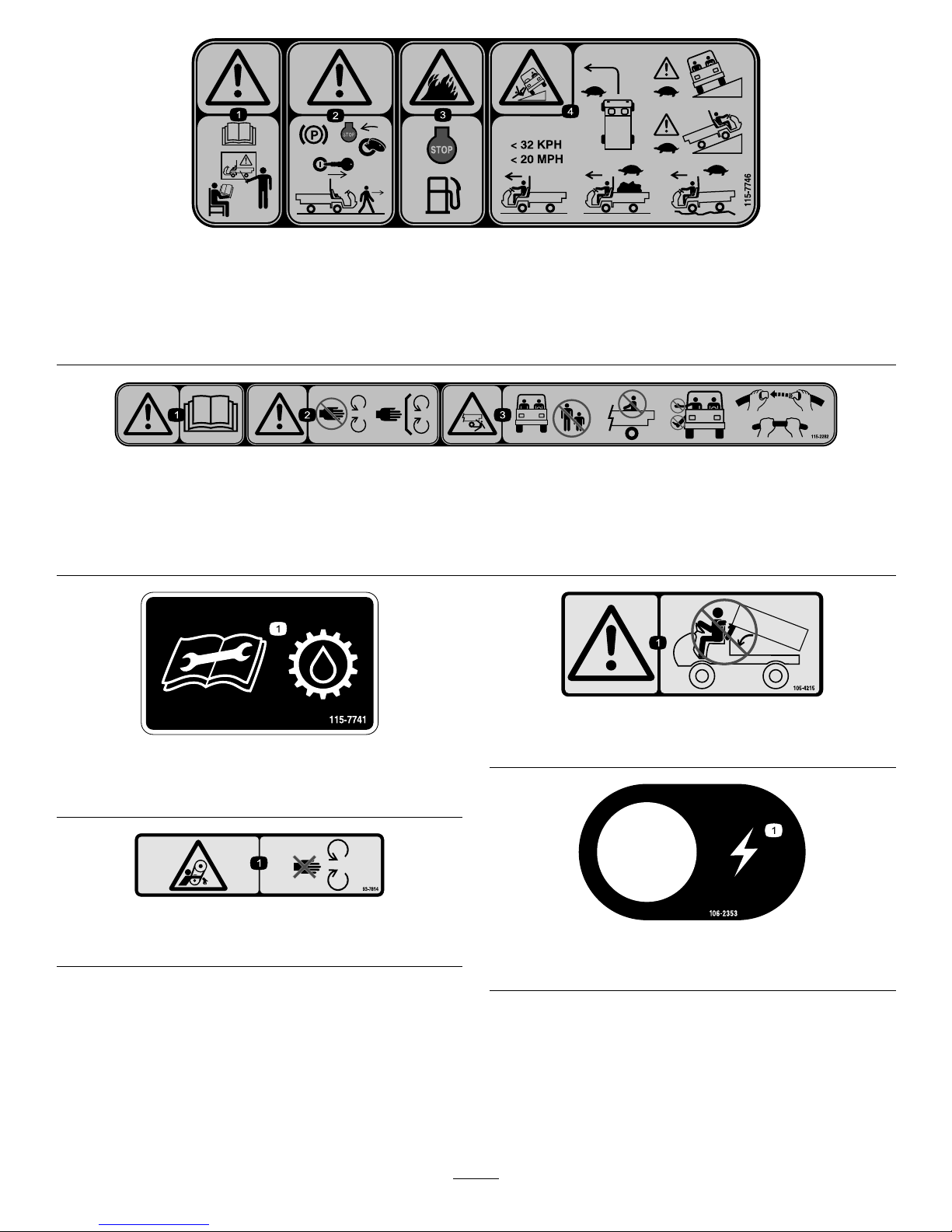

115-7746

1.Warning—donotoperatethismachineunlessyouaretrained.

3.Firehazard—stoptheenginebeforefueling.

2.Warning—locktheparkingbrake,stoptheengine,and

removetheignitionkeybeforeleavingthemachine.

4.Tippinghazard—slowdownandturngradually,usecaution

anddriveslowlywhendrivingonslopes,donotexceed20

mph(32kph),anddriveslowlyoverroughterrainorwhen

carryingafullorheavyload.

115-2282

1.Warning—readtheOperator'sManual.

2.Warning—stayawayfrommovingparts,keepallguardsandshieldsinplace.

3.Crushing/dismembermenthazardofbystanders—keepbystandersasafedistancefromthevehicle,donotcarrypassengersin

thecargobed,keeparmsandlegsinsideofthevehicleatalltimes,anduseseatbeltsandhandholds.

115-7741

1.ReadtheOperator’sManualbeforeservicingtransmission

uid.

93-7814

1.Entanglementhazard,belt—stayawayfrommovingparts.

105-4215

1.Warning—avoidpinchpoints.

106-2353

1.Electricalpowerpoint

9

Page 10

106-2355

1.Slow

3.Transmission—thirdhigh;

nofastspeed

2.Fast

115-7739

1.Falling,crushinghazard,bystanders—noriderson

machine.

93–9868

1.Crushinghazardofhand—readtheOperator’sManual.

BatterySymbols

Someorallofthesesymbolsareonyourbattery

1.Explosionhazard

6.Keepbystandersasafe

distancefromthebattery .

2.Nore,opename,or

smoking.

7.Weareyeprotection;

explosivegasescan

causeblindnessandother

injuries

3.Causticliquid/chemical

burnhazard

8.Batteryacidcancause

blindnessorsevereburns.

4.Weareyeprotection9.Flusheyesimmediately

withwaterandgetmedical

helpfast.

5.ReadtheOperator's

Manual.

10.Containslead;donot

discard.

115-7756

1.Highowhydraulics—engaged

115-7813

1.Poweroutlet10A5.Lights,brake15A

2.Switchedpower10A

6.Hazard10A

3.Fuelpump,supervisor

switch10A

7.4WD,Transmission10A

4.Horn,powerpoint15A

93-9850

1.Donotrepairorrevise—readtheOperator'sManual.

10

Page 11

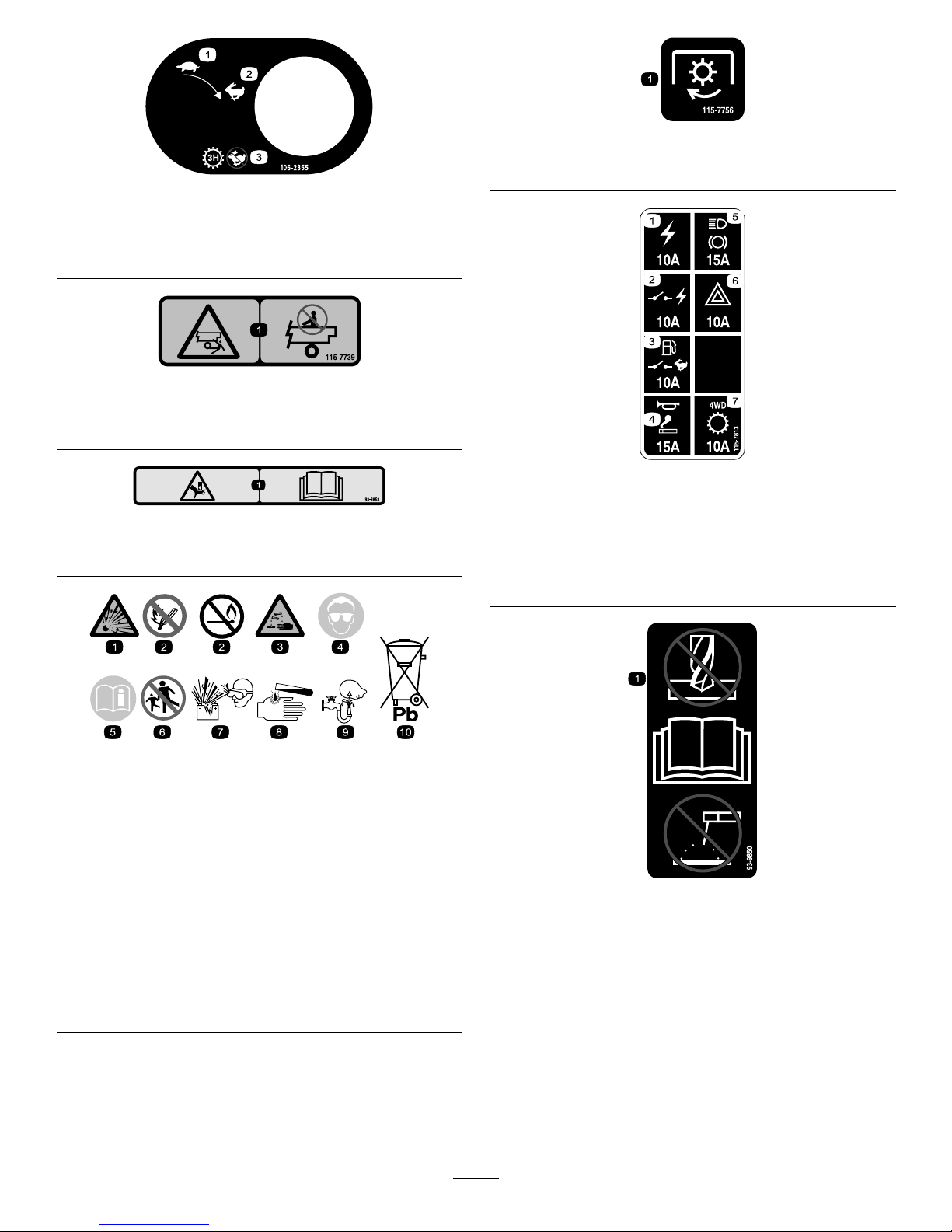

106-2377

1.Locked

8.Warning—readtheOperator'sManual.

2.Differentiallock9.Entanglementhazard,shaft—keepbystander'sasafe

distancefromthevehicle.

3.Unlocked10.Retracthydraulics

4.Hydrauliclock11.Extendhydraulics

5.Engage12.Transmission—highspeed

6.Powertake-off(PTO)

13.Transmission—lowspeed

7.Disengage14.Parkingbrake

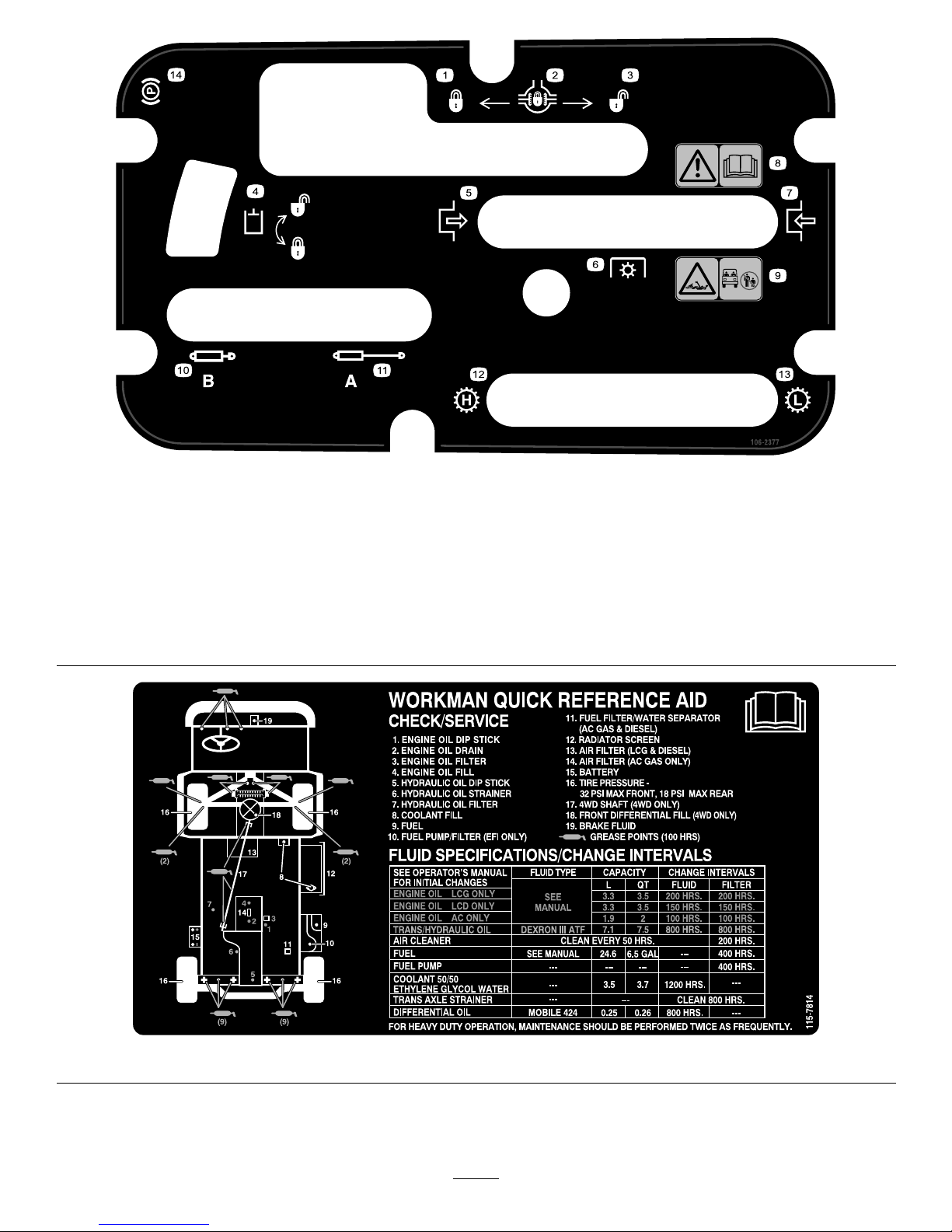

115-7814

11

Page 12

115-2281

1.Headlights4.Engine—run

2.Horn5.Engine—start

3.Engine—stop

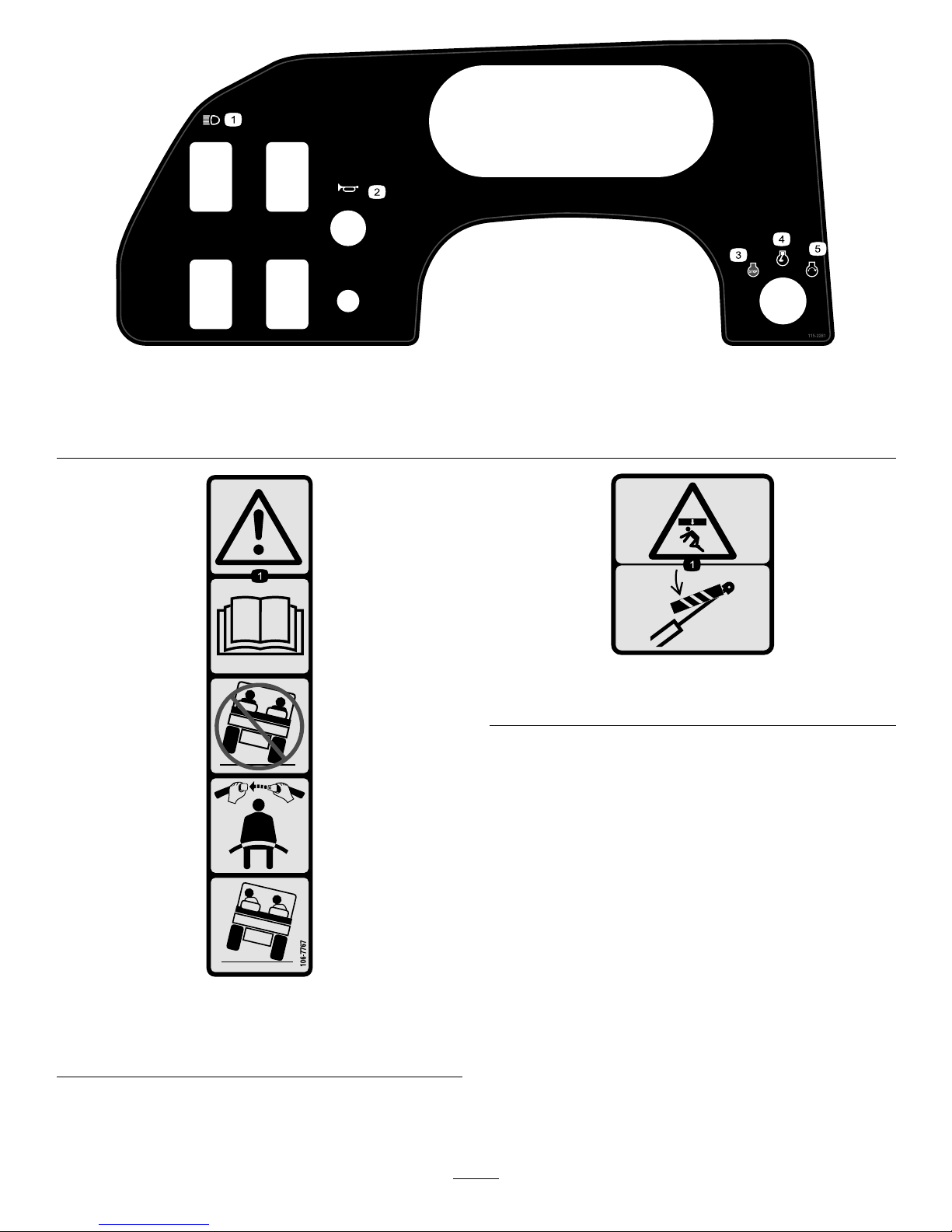

106-7767

1.Warning—readtheOperator'sManual;avoidtippingthe

machine;weartheseatbelt;leanawayfromthedirection

themachineistipping.

93-9899

93-9899

1.Crushinghazard—installthecylinderlock.

12

Page 13

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

Qty.

Use

Steeringwheel

1

Cap

1

1

Washer1

Installthesteeringwheel.

ROPSframe

1

2

Bolt,1/2inch

6

MounttheROPS(RolloverProtection

System)

3

Electrolyte

A/R

Activateandchargethebattery.

4

Nopartsrequired

–

Checktheengineoil,transaxle/hydraulic

uid,andbrakeuidlevels

MediaandAdditionalParts

Description

Qty.

Use

Operator'sManual

1

Readbeforeoperatingthevehicle

PartsManual1

Usetoreferencepartnumbers

OperatorTrainingMaterial

1

Viewbeforeoperatingmachine

Note:Determinetheleftandrightsideofthemachinefromthenormaloperatingposition.

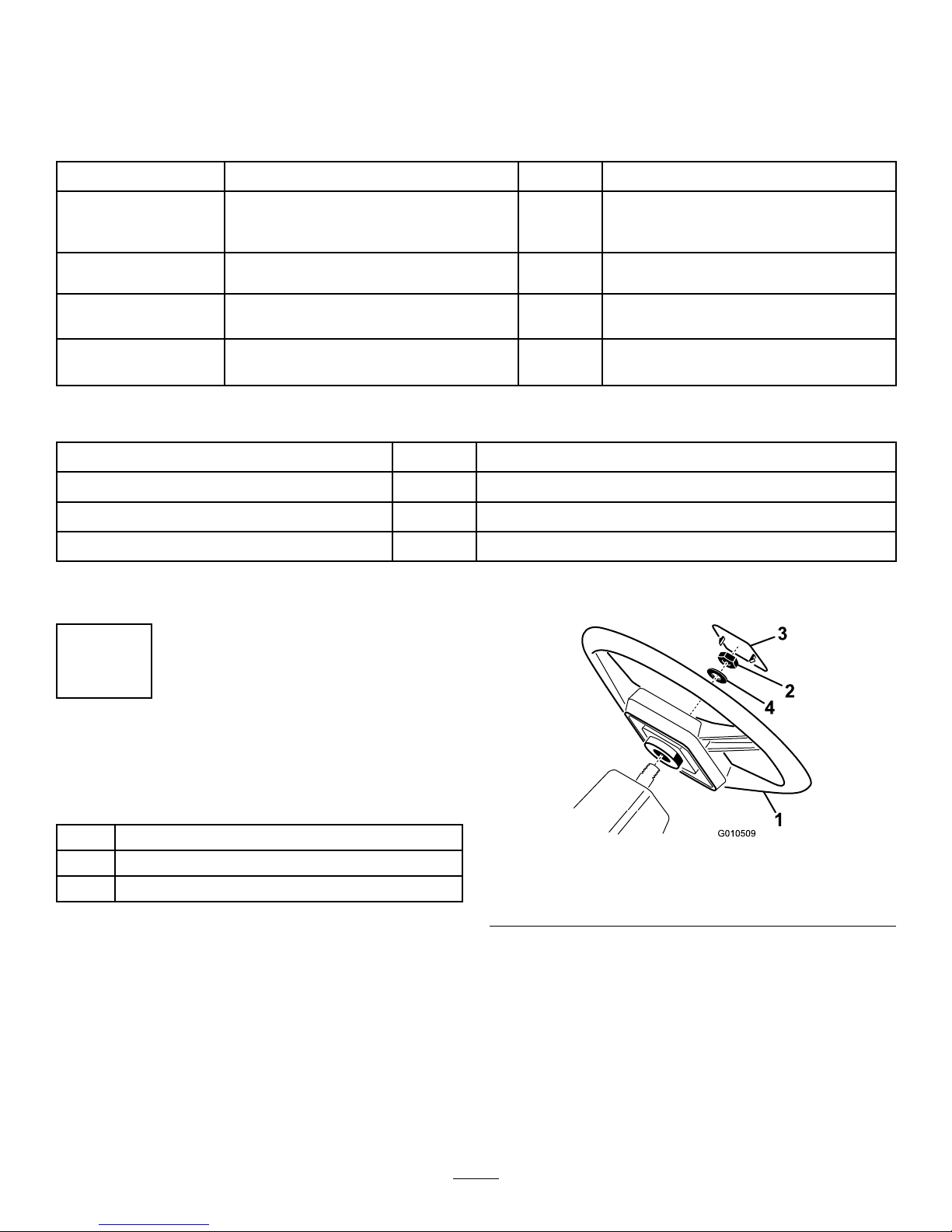

1

InstalltheSteeringWheel

(TCModelsOnly)

Partsneededforthisprocedure:

1

Steeringwheel

1

Cap

1Washer

Procedure

1.Removethenutfromthesteeringshaft.Slidethe

steeringwheelandwasherontothesteeringshaft

(

Figure3).

2.Securethesteeringwheeltotheshaftwiththenut

andtightenitto20-25ft-lb(27–34N-m).

3.Installthecaponthesteeringwheel.

Figure3

1.Steeringwheel3.Cap

2.Nut4.Washer

13

Page 14

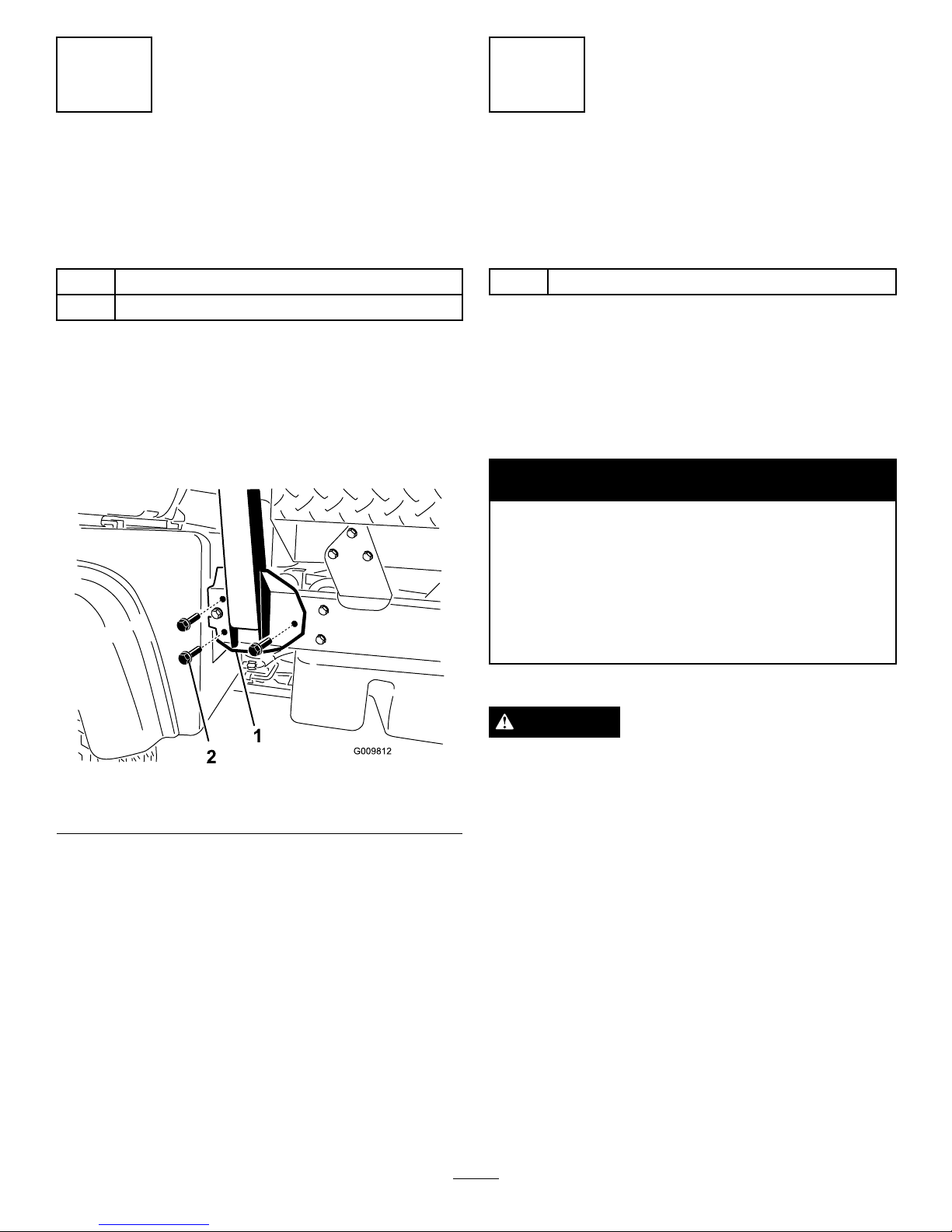

2

InstalltheROPS(Rollover

ProtectionSystem)

(TCModelsOnly)

Partsneededforthisprocedure:

1

ROPSframe

6

Bolt,1/2inch

Procedure

1.AligneachsideoftheROPSwiththemountingholes

oneachsideofvehicleframeasshownin

Figure4.

2.SecureeachsideoftheROPStoframewith3bolts

(1/2inch)andtightenthento85ft-lb(115N-m).

Figure4

1.ROPS

2.Mountingbracket

3

ActivateandChargethe

Battery

(TCModelsOnly)

Partsneededforthisprocedure:

A/R

Electrolyte

Procedure

Ifthebatteryisnotlledwithelectrolyteoractivated,it

mustberemovedfromthevehicle,lledwithelectrolyte

andcharged.Bulkelectrolytewith1.260specicgravity

canbepurchasedfromalocalbatterysupplyoutlet.

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

Washhandsafterhandling.

DANGER

Batteryelectrolytecontainssulfuricacidwhichisa

deadlypoisonandcausessevereburns.

•Donotdrinkelectrolyteandavoidcontactwith

skin,eyesorclothing.Wearsafetyglassesto

shieldyoureyesandrubberglovestoprotect

yourhands.

•Fillthebatterywherecleanwaterisalways

availableforushingtheskin.

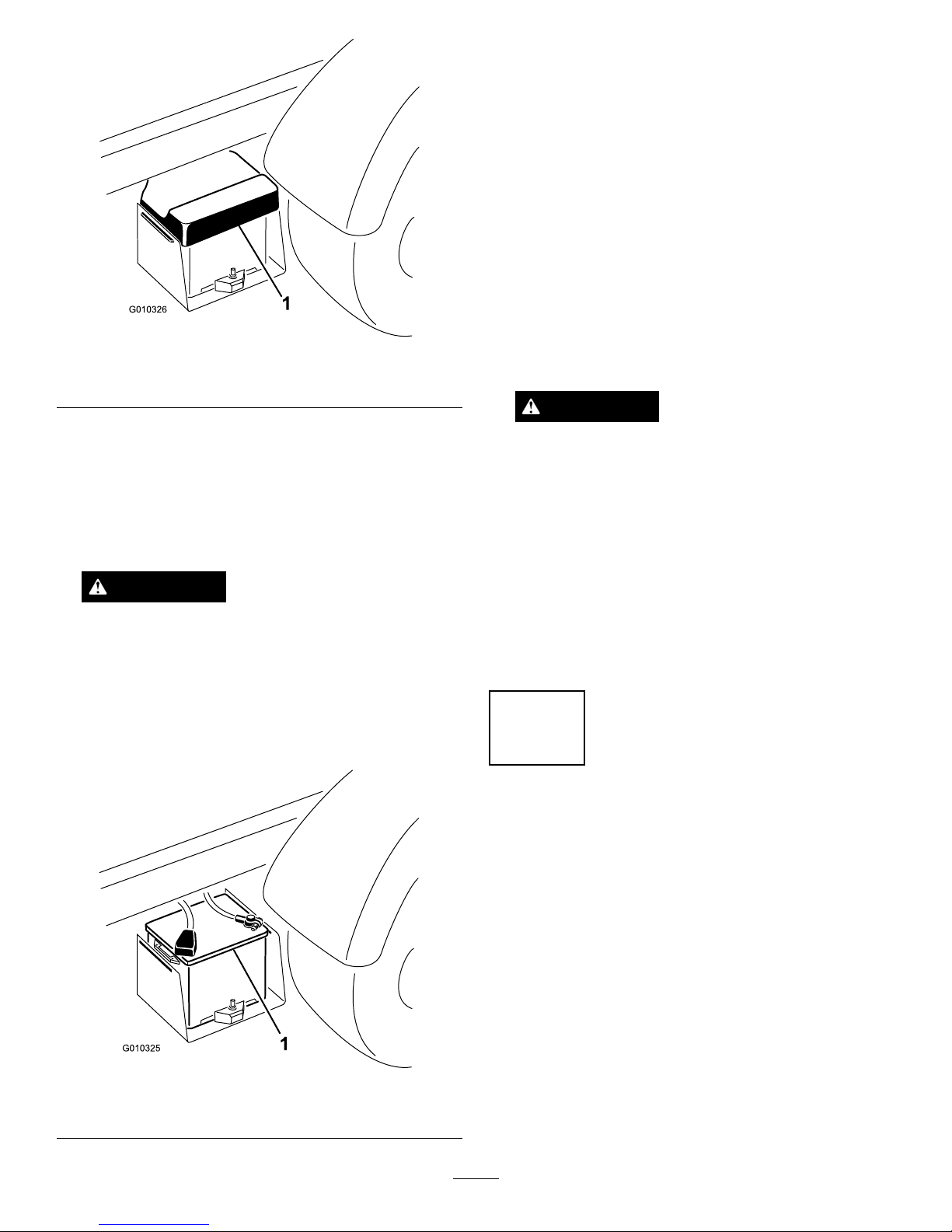

1.Removethebatterycoverfromthebatterycase

(Figure5).

14

Page 15

Figure5

1.Batterycover

2.Removethebatteryfromthebatterycase.

3.Removethellercapsfromthebatteryandslowly

lleachcelluntilelectrolyteisjustabovetheplates.

4.Replacethellercapsandconnecta3to4amp

batterychargertothebatteryposts.Chargethe

batteryatarateof3to4amperesfor4to8hours.

WARNING

Chargingthebatteryproducesgassesthatcan

explode.

Neversmokenearthebatteryandkeepsparks

andamesawayfrombattery.

5.Whenthebatteryischarged,disconnectthecharger

fromtheelectricaloutletandbatteryposts(Figure6).

Figure6

1.Battery

6.Removethellercaps.Slowlyaddelectrolytetoeach

celluntillevelisuptothellring.Installtheller

caps.

Important:Donotoverllthebattery.

Electrolytewilloverowontootherpartsofthe

vehicleandseverecorrosionanddeterioration

willresult.

7.Insertthebatteryintothebatterycasesothebattery

terminalsaretowardtheoutsideofthevehicle.

8.Installthepositivecable(red)tothepositive(+)

terminalandthenegativecable(black)tothe

negative(–)terminalofthebatteryandsecurethen

withboltsandnuts.Slidetherubberbootoverthe

positiveterminaltopreventapossibleshort-out

fromoccurring.

WARNING

Incorrectbatterycableroutingcoulddamage

themachineandcablescausingsparks.Sparks

cancausethebatterygassestoexplode,

resultinginpersonalinjury.

•Alwaysdisconnectthenegative(black)

batterycablebeforedisconnectingthe

positive(red)cable.

•Alwaysconnectthepositive(red)battery

cable

9.Installthebatterycoveronthebatterycase.

4

CheckingFluidLevels

NoPartsRequired

Procedure

1.Checktheengineoillevelbeforeandaftertheengine

isrststarted,refertoCheckingtheEngineOil

LevelinOperation.

2.Checkthetransaxle/hydraulicuidlevelbefore

theengineisrststarted,refertoCheckingthe

Transaxle/HydraulicFluidLevelinOperation.

3.Checkthebrakeuidlevelbeforetheengineisrst

started,refertoCheckingtheBrakeFluidLevelin

Operation.

15

Page 16

ProductOverview

Controls

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

AcceleratorPedal

Theacceleratorpedal(Figure7)givestheoperator

theabilitytovarytheengineandgroundspeedofthe

vehicle,whenthetransmissionisingear.Pressing

thepedalincreasesengineRPMandgroundspeed.

ReleasingthepedalwilldecreaseengineRPMand

groundspeedofthemachine.

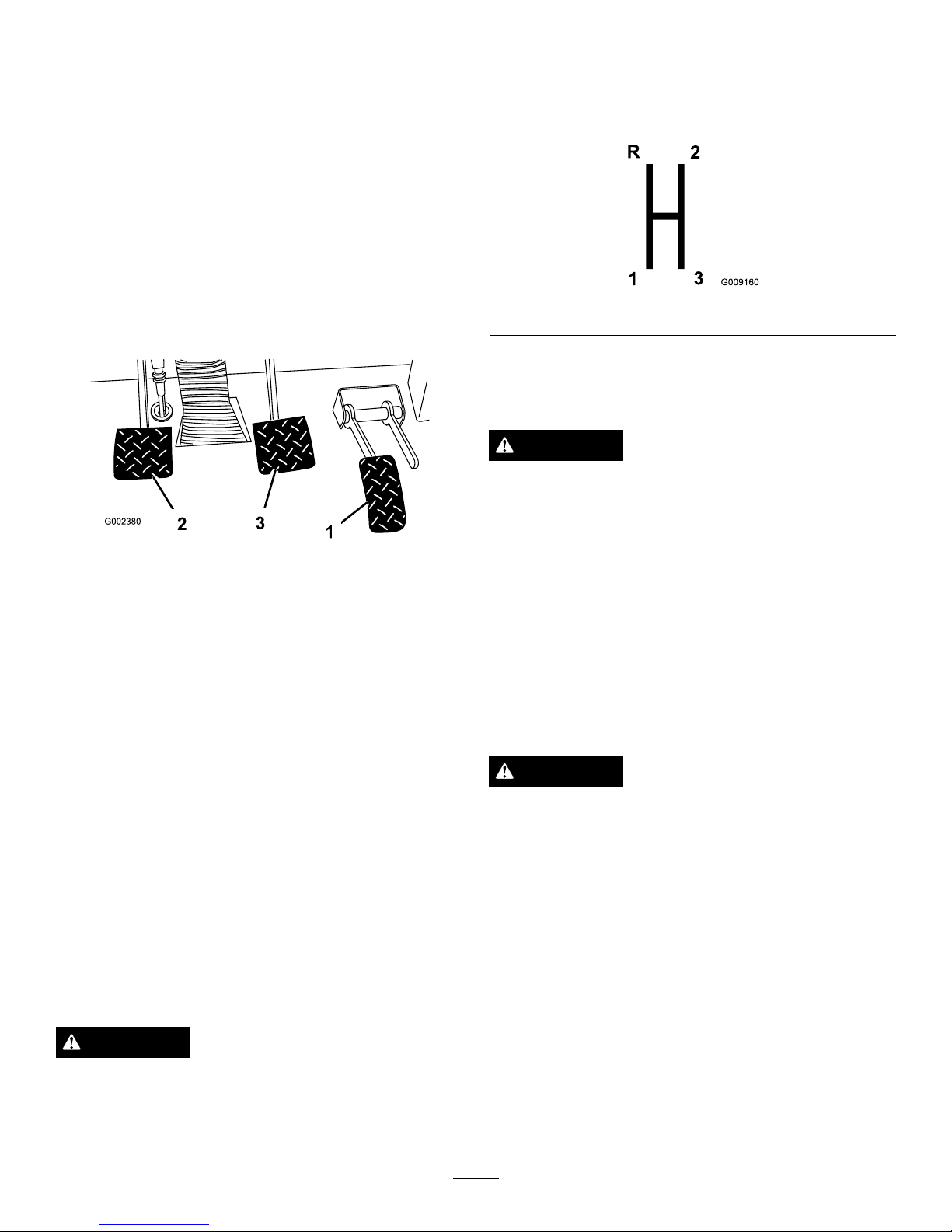

Figure7

1.Acceleratorpedal3.Brakepedal

2.Clutchpedal

ClutchPedal

Theclutchpedal(Figure7)mustbefullypressedto

disengageclutchwhenstartingtheengineorshifting

transmissiongears.Releasethepedalsmoothlywhenthe

transmissionisingeartopreventunnecessarywearon

thetransmissionandotherrelatedparts.

Important:Donotridetheclutchpedalduring

operation.Theclutchpedalmustbefullyoutorthe

clutchwillslipcausingheatandwear.Neverhold

thevehiclestoppedonahillusingtheclutchpedal.

Damagetotheclutchmayoccur.

BrakePedal

Thebrakepedal(Figure7)isusedtoapplyservice

brakestostoporslowvehicle.

CAUTION

Wornormaladjustedbrakesmayresultinpersonal

injury.Ifthebrakepedaltravelstowithin1-1/2

inches(3.8cm)ofthevehicleoorboard,thebrakes

mustbeadjustedorrepaired.

GearShiftLever

Fullypresstheclutchpedalandmovetheshiftlever

(Figure7)intothedesiredgearselection.Adiagramof

theshiftpatternisindicatedinFigure8.

Figure8

Important:Donotshiftthetransaxletothereverse

orforwardgearunlessthevehicleisstandingstill.

Damagetothetransaxlemayoccur.

CAUTION

Downshiftingfromtoohighaspeedcancause

therearwheelstoskidresultinginlossofvehicle

controlaswellasclutchand/ortransmission

damage.Shiftsmoothlytoavoidgrindinggears.

DifferentialLock

Thedifferentiallockallowsrearaxletobelockedfor

increasedtraction.Thedifferentiallock(

Figure9)may

beengagedwhenthevehicleisinmotion.Movethe

leverforwardandtotherighttoengagethelock.

Note:Vehiclemotionplusaslightturnisrequiredto

engageordisengagedifferentiallock.

CAUTION

Turningwiththedifferentiallockoncanresult

inlossofvehiclecontrol.Donotoperatewith

differentiallockonwhenmakingsharpturnsorat

highspeeds.Refertousingthedifferentiallock.

16

Page 17

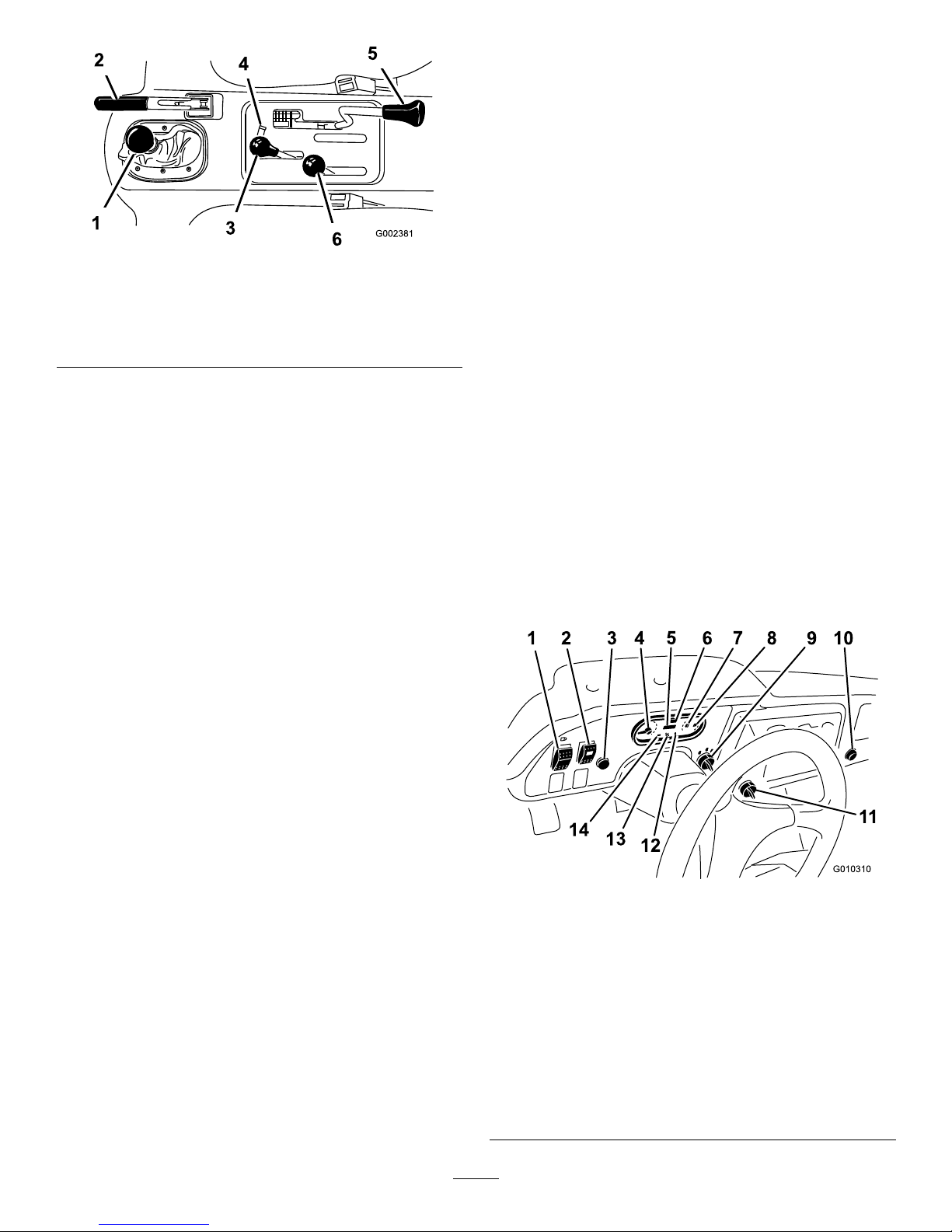

Figure9

1.Gearshiftlever4.Hydraulicliftlock

2.Parkingbrake

5.Differentiallock

3.Hydraulicbedlift6.High–lowrangeshifter

ParkingBrake

Whenevertheengineisshutoff,theparkingbrake

(Figure9)mustbeengagedtopreventaccidental

movementofthevehicle.Toengagetheparkingbrake,

pullbackonthelever.Todisengage,pushthelever

forward.Releasetheparkingbrakebeforemovingthe

vehicle.Ifyouparkthevehicleonasteepgrade,apply

theparking.Also,shiftthetransmissioninto1stgear

onauphillgradeorreverseonadownhillgrade.Place

chocksatthedownhillsideofthewheels.

HydraulicLift

Thehydraulicliftraisesandlowersbed.Moveitrearward

toraisethebed,andforwardtolowerit(Figure9).

Important:Whenloweringthebed,holdthelever

intheforwardpositionfor1or2secondsafterthe

bedcontactstheframetosecureitinthelowered

position.Donotholdthehydraulicliftineitherthe

raiseorlowerposition,formorethan5seconds,

oncethecylindershavereachedtheendoftheir

travel.

HydraulicLiftLock

Thehydraulicliftlocklockstheliftleversothehydraulic

cylindersdonotoperatewhenthevehicleisnot

equippedwithabed(

Figure9).Italsolocksthelift

leverintheOnpositionwhenusingthehydraulicsfor

attachments.

High–LowRangeShifter

Thehigh–lowrangeshifteraddsthreeadditionalspeeds

forprecisespeedcontrol(Figure9).

•Thevehiclemustbecompletelystoppedbefore

shiftingbetweenHighandLowrange.

•Shiftonlyonlevelground.

•Pressclutchpedalfully.

•MovetheleverfullyforwardforHighandfully

rearwardforLow.

Highisforhigherspeeddrivingonlevel,drysurfaces

withlightloads.

Lowisforlowspeeddriving.Usethisrangewhen

greaterthannormalpowerorcontrolisrequired.For

example,steepgrades,difcultterrain,heavyloads,slow

speedbuthighenginespeed(spraying).

Important:ThereisalocationbetweenHighand

Lowinwhichthetransaxleisinneitherrange.

Donotusethispositionasaneutralposition

becausethevehiclecouldmoveunexpectedlyifthe

High–Lowshifterisbumpedandthegearshift

leverisingear.

IgnitionSwitch

Usetheignitionswitch(Figure10)tostartandstop

theengine.Ithasthreepositions:Off,Run,andStart.

RotatethekeyclockwisetotheStartpositiontoengage

thestartermotor.Releasethekeywhentheenginestarts.

ThekeywillmoveautomaticallytotheOnposition.To

shuttheengineoff,rotatethekeycounterclockwiseto

theOffposition.

Figure10

1.Lightswitch8.Fuelgauge

2.Highow

hydraulicsswitch

(TCmodelsonly)

9.Ignitionswitch

3.Horn

(TCmodelsonly)

10.Powerpoint

4.Tachometer11.3rdhighlockoutswitch

5.Speedometer12.Oilpressurewarninglight

6.Hourmeter

13.Checkenginelight

7.Coolanttemperature

gaugeandlight

14.Chargeindicator

17

Page 18

HourMeter

Indicatesthetotalhoursofmachineoperation.The

hourmeter(Figure10)startstofunctionwheneverthe

keyswitchisrotatedtotheOnpositionoriftheengine

isrunning.

3rdHighLockoutSwitch

Movethe3rdhighlockoutswitch(Figure10)totheslow

positionandremovethekeytopreventtheuseofthird

gearwhenintheHighrange.Theenginewillshutoff

iftheshiftleverismovedtothirdgearwheninHigh

range.Thekeyisremovableineitherposition.

LightSwitch

Pushthelightswitch(Figure10)totoggletheheadlights

onoroff.

OilPressureWarningLight

Theoilpressurewarninglightglows(Figure10)ifthe

engineoilpressuredropsbelowasafelevelwhilethe

engineisrunning.Ifthelightickersorremainson,

stopthevehicle,turnofftheengine,andchecktheoil

level.Iftheoillevelwaslow,butaddingoildoesnot

causethelighttogooutwhentheengineisrestarted,

turntheengineoffimmediatelyandcontactyourlocal

Torodistributorforassistance.

Checktheoperationofwarninglightsasfollows:

1.Applytheparkingbrake.

2.TurntheignitionkeytotheOnposition,butdonot

starttheengine.Theoilpressurelightshouldglow

red.Ifthelightdoesnotfunction,eitherabulbis

burnedoutorthereisamalfunctioninthesystem

whichmustberepaired.

Note:Ifenginewasjustturnedoff,itmaytake1to2

minutesforthelighttocomeon.

CoolantTemperatureGaugeandLight

Registersthecoolanttemperatureintheengine.

OperatesonlywhentheignitionswitchisinOnposition

(Figure10).Theindicatorlightwillilluminateblinking

rediftheengineoverheats.

ChargeIndicator

Illuminateswhenbatteryisbeingdischarged.Iflight

illuminatesduringoperation,stopvehicle,turnoff

engineandcheckforpossiblecauses,suchasalternator

belt(Figure10).

Important:Ifalternatorbeltislooseorbroken,do

notoperatethevehicleuntiladjustmentorrepairis

complete.Failuretoobservethisprecautionmay

resultindamagetotheengine.

Checktheoperationofwarninglightsasfollows:

•Applyparkingbrake.

•TurntheignitionkeytotheOnposition,butdonot

starttheengine.Thecoolanttemperature,charge

indicator,andoilpressurelightsshouldglow .Ifany

lightdoesnotfunction,eitherabulbisburnedout

orthereisamalfunctioninthesystemwhichmust

berepaired.

FuelGauge

Thefuelgaugeshowstheamountoffuelinthetank.It

operatesonlywhenignitionswitchisintheOnposition

(

Figure10).Redindicateslowfuellevelandblinking

redindicatesnearempty .

HighFlowHydraulicsSwitch(TC

modelsonly)

Turnontheswitchtoactivatethehighowhydraulics

(Figure10).

HornButton(TCmodelsonly)

Pressingthehornbuttonactivatesthehorn(Figure10).

Tachometer

RegisterstheRPMoftheengine(Figure10&Figure11).

WhitetriangleindicatesdesiredRPMforPTOoperation

(

Figure11).

Figure11

1.RPMoftheengine2.3300RPMfor540RPM

PTOoperation

18

Page 19

CheckEngineLight

Thelight(Figure10)willilluminatetonotifyoperatorof

aenginemalfunction.

Important:Theengineisequippedwithonboard

diagnosticstotroubleshootenginemalfunctions.

RefertotheToroServiceManualforinformation

ontheoperationofthediagnosticsandhowtoread

thecodesofthesystem.

Speedometer

Registersthegroundspeedofthevehicle(Figure10).

ThespeedometerisinMPHbutcaneasilyconvertedto

KPH.RefertoConvertingtheSpeedometerinControls

Maintenance.

PowerPoint

Usethepowerpoint(Figure10)topoweroptional12

voltelectricalaccessories.

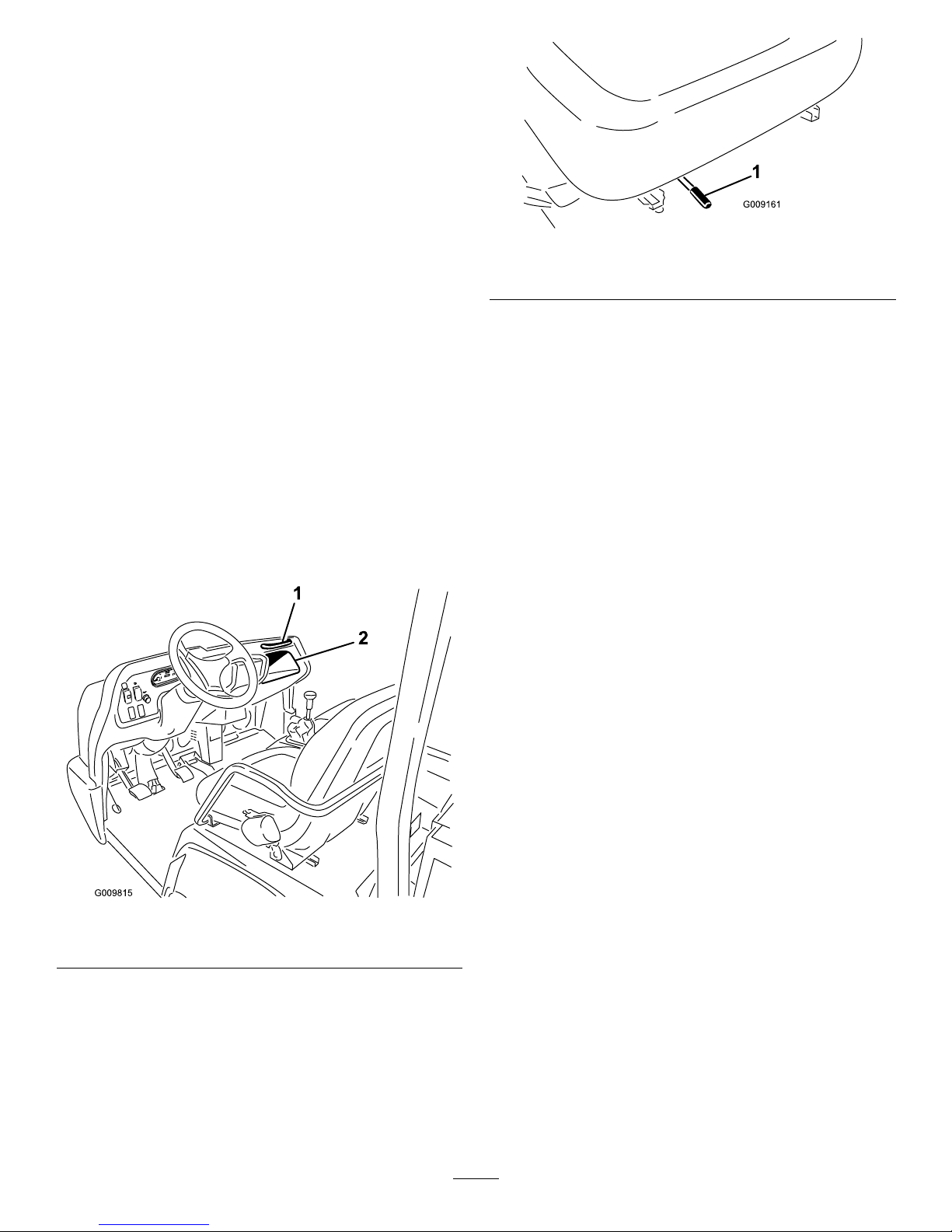

PassengerHandHold

Thepassengerhandholdislocatedonthedashboard

(Figure12).

Figure12

1.Passengerhandhold

2.Storagecompartment

SeatAdjustingLever

Theseatscanbeadjustedforeandaftforoperator

comfort(Figure13).

Figure13

1.Seatadjustinglever

19

Page 20

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

Dimensions

OverallWidth63inches(160cm)

OverallLength

w/obed:128.25inches(326cm)

w/fullbed:130.38inches(331cm)

w/2/3bedinrearmountinglocation:

136.38inches(346cm)

BaseWeight(Dry)

Model07366—1623lb(736kg)

Model07367—1951lb(885kg)

Model07367TC—2032lb(921.6kg)

Model07370—2010lb(912kg)

Model07370TC—2091lb(948kg)

RatedCapacity

(includes200lb.

operator,200lb.

passengerandloaded

attachment).

Model07366—3227lb(1464kg)

Model07367—2899lb(1315kg)

Model07367TC—2818lb(1278kg)

Model07370—2840lb(1288kg)

Model07370TC—2759lb(1251kg)

Maximum.Gross

VehicleWeight

4,850lb(2200kg)

TowCapacityT ongueweight600lb(272kg)

Maximumtrailerweight3,500lb(1587

kg)

GroundClearance7inches(18cm)w/noload

WheelBase

70inches(1 18cm)

WheelTread(center

linetocenterline)

Front:46inches(117cm)

Rear:47.7inches(121cm)

Height

75inches(190.5cm)totopofROPS

Attachments/Accessories

AselectionofToroapprovedattachmentsand

accessoriesareavailableforusewiththemachineto

enhanceandexpanditscapabilities.Contactyour

AuthorizedServiceDealerorDistributororgoto

www.Toro.comforalistofallapprovedattachments

andaccessories.

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

CAUTION

Beforeservicingormakingadjustmentstothe

machine,stoptheengine,settheparkingbrake,

andremovethekeyfromtheswitch.Removeany

loadmaterialfromthebedorotherattachment

beforeworkingunderaraisedbed.Neverwork

underaraisedbedwithoutpositioningthesafety

supportonafullyextendedcylinderrod.

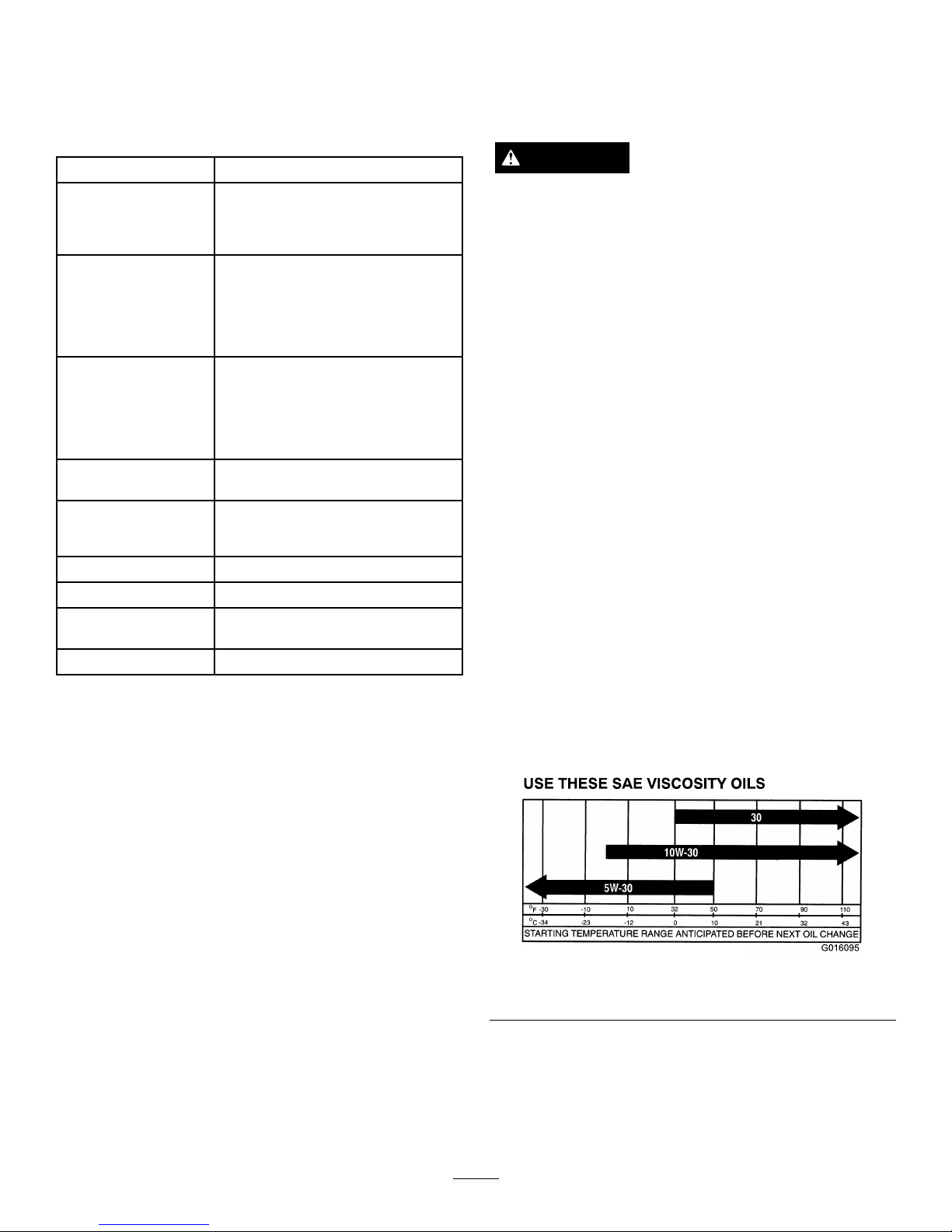

CheckingtheEngineOilLevel

ServiceInterval:Beforeeachuseordaily

Theengineisshippedwithapproximately3.5quarts

(3.3l)(w/lter)ofoilinthecrankcase;however,you

shouldchecktheoillevelbeforeandaftertheengine

isrststarted.

Note:Thebesttimetochecktheengineoiliswhen

theengineiscoolbeforeithasbeenstartedforthe

day.Ifithasalreadybeenrun,allowtheoiltodrain

backdowntothesumpforatleast10minutesbefore

checking.IftheoillevelisatorbelowtheAddmark

onthedipstick,addoiltobringtheoilleveltotheFull

mark.Donotoverll.Iftheoillevelisbetweenthe

FullandAddmarks,noadditionaloilisrequired.

Theengineusesanyhigh-quality10W-30detergentoil

havingtheAmericanPetroleumInstitute(API)service

classicationSJ,SK,SL,SM,orhigher.Choosea

viscosityaccordingtothetablein

Figure14.

G016095

Figure14

1.Positionthemachineonalevelsurface.

2.Removethedipstick(Figure15)andwipeitwitha

cleanrag.Insertthedipstickintothetubeandmake

sureitisseatedfully.Removedipstickandcheck

theleveloftheoil.

20

Page 21

Figure15

1.Fillercap

2.Dipstick

3.Iftheoillevelislow ,removethellercap(Figure15)

andaddenoughoiltoraisetheleveltotheFull

markonthedipstick.

Note:Whenaddingoil,removedipsticktoallow

properventing.Pouroilslowlyandcheckthelevel

oftenduringthisprocess.Donotoverll.

Important:Whenaddingengineoilorlling

oil,theremustbeclearancebetweentheoilll

deviceandtheoilllholeinthevalvecoveras

shownin

Figure16.Thisclearanceisnecessary

topermitventingwhenlling,whichprevents

oilfromoverrunningintothebreather.

Figure16

1.Noteclearance

4.Installthedipstickrmlyinplace.

AddingFuel

TheT oro®Companystronglyrecommendsthe

useoffresh,clean,unleadedregulargradegasoline

inT orogasolinepoweredproducts.Unleaded

gasolineburnscleaner,extendsenginelife,and

promotesgoodstartingbyreducingthebuild–up

ofcombustionchamberdeposits.Useaminimum

octaneratingof87.

Fueltankcapacity:6.5USgallons(25l).

Note:Neverusemethanol,leadedgasoline,

gasolinecontainingmethanol,gasolinecontaining

morethan10%ethanol,gasolineadditives,orwhite

gasbecauseenginefuelsystemdamagecould

result.

21

Page 22

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Beforeremovingthefueltankcap,makesure

thevehicleispositionedonalevelsurface.

Openfueltankcapslowly.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupanygasoline

thatspills.

•Neverllthefueltankinsideanenclosedtrailer.

•Donotllthefueltankcompletelyfull.Add

gasolinetothefueltankuntilthelevelis1inch

(25mm)belowthebottomofthellerneck.

Thisemptyspaceinthetankallowsgasoline

toexpand.

•Neversmokewhenhandlinggasoline,andstay

awayfromanopenameorwheregasoline

fumesmaybeignitedbyaspark.

•Storegasolineinanapprovedcontainerand

keepitoutofthereachofchildren.Neverbuy

morethana30-daysupplyofgasoline.

•Donotoperatewithoutentireexhaustsystem

inplaceandinproperworkingcondition.

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingasparkwhich

canignitethegasolinevapors.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Alwaysplacegasolinecontainersontheground

awayfromyourvehiclebeforelling.

•Donotllgasolinecontainersinsideavehicle

oronatruckortrailerbedbecauseinterior

carpetsorplastictruckbedlinersmayinsulate

thecontainerandslowthelossofanystatic

charge.

•Whenpractical,removegas-powered

equipmentfromthetruckortrailerandrefuel

theequipmentwithitswheelsontheground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfromaportable

container,ratherthanfromagasolinedispenser

nozzle.

•Ifagasolinedispensernozzlemustbeused,

keepthenozzleincontactwiththerimofthe

fueltankorcontaineropeningatalltimesuntil

fuelingiscomplete.

1.Cleantheareaaroundthefueltankcap.

2.Removethefueltankcap(Figure17).

Figure17

1.Fueltankcap

3.Fillthetanktoaboutoneinchbelowthetopofthe

tank,(bottomofthellerneck),theninstallthecap.

Donotoverll.

4.Wipeupanyfuelthatmayhavespilledtopreventa

rehazard.

22

Page 23

CheckingtheCoolingSystem

ServiceInterval:Beforeeachuseordaily

Coolingsystemcapacity:4qt(3.7l)

Thecoolingsystemislledwitha50/50solutionof

waterandpermanentethyleneglycolantifreeze.

1.Parkthemachineonalevelsurface.

CAUTION

Iftheenginehasbeenrunning,thepressurized,

hotcoolantcanescapeandcauseburns.

•Donotopentheradiatorcapwhenthe

engineisrunning.

•Allowtheenginetocoolatleast15minutes

oruntiltheradiatorcapiscoolenoughto

touchwithoutburningyourhand.

•Usearagwhenopeningtheradiatorcap,

andopenthecapslowlytoallowsteamto

escape.

2.Checkthecoolantlevelonthesideofthereserve

tank(Figure18).Thecoolantshouldbeuptothe

Coldline,whenengineiscold.

Figure18

1.Reservetank

3.Coldline

2.Hotline

3.Ifcoolantislow ,removethereservetankcap

andadda50/50mixtureofwaterandpermanent

ethyleneglycolantifreeze.Donotoverll.

4.Installthereservetankcap.

Checkingthe

Transaxle/HydraulicFluid

Level

ServiceInterval:Beforeeachuseordaily

ThetransaxlereservoirislledwithDexronIIIATF.

Checkthelevelbeforetheengineisrststartedand

every8hoursordaily,thereafter.Capacityofsystemis.

Transaxlereservoircapacity:7.5qt(7l).

1.Positionthevehicleonalevelsurface.

2.Cleantheareaaroundthedipstick(

Figure19).

Figure19

1.Dipstick

3.Unscrewthedipstickfromthetopofthetransaxle

andwipeitwithacleanrag.

4.Screwthedipstickintothetransaxleandensurethat

itisfullyseated.

5.Unscrewthedipstickandchecktheuidlevel.

Theuidshouldbeuptotopoftheatportion

ofthedipstick.

6.Ifthelevelislow ,addenoughuidtoachievethe

properlevel.

CheckingtheHighFlow

HydraulicFluid(TCmodels

only)

ServiceInterval:Beforeeachuseordaily

Thehighowhydraulicsreservoirislledwith

approximately4USgallons(15l)ofhighquality

hydraulicuid.Checkthelevelofhydraulic

uidbeforetheengineisrststartedanddaily

thereafter.

1.Cleantheareaaroundthellerneckandthecap

ofthehydraulictank(

Figure20).Removethecap

fromthellerneck.

23

Page 24

Figure20

1.Cap

2.Removethedipstick(Figure20)fromthellerneck

andwipeitwithacleanrag.Insertthedipstickinto

thellerneck;thenremoveitandchecktheuid

level.Theuidlevelshouldbebetweenthetwo

marksonthedipstick.

3.Ifthelevelislow ,addtheappropriateuidtoraise

theleveltotheuppermark.RefertoChangingthe

HighFlowHydraulicFluid.

4.Installthedipstickandcapontothellerneck.

5.Starttheengineandturnontheattachment.Let

themrunforabouttwominutestopurgeairfrom

thesystem.Stoptheengineandattachmentand

checkforleaks.

Important:Thevehiclemustberunning

beforestartingthehighowhydraulics.

WARNING

Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjury.

•Makesureallhydraulicuidhosesand

linesareingoodconditionandallhydraulic

connectionsandttingsaretightbefore

applyingpressuretothehydraulicsystem.

•Keepyourbodyandhandsawayfrompin

holeleaksornozzlesthatejecthighpressure

hydraulicuid.

•Usecardboardorpapertondhydraulic

leaks.

•Safelyrelieveallpressureinthehydraulic

systembeforeperforminganyworkonthe

hydraulicsystem.

•Seekimmediatemedicalattentionifuidis

injectedintoyourskin.

CheckingtheFrontDifferential

OilLevel(FourWheelDrive

ModelsOnly)

ServiceInterval:Every100hours/Monthly(whichever

comesrst)

ThedifferentialislledwithMobil424hydraulicoil.

1.Positionthevehicleonalevelsurface.

2.Cleantheareaaroundthell/checkplugonsideof

thedifferential(

Figure21).

Figure21

1.Fill/checkplug

2.Drainplug

3.Removethell/checkplugandcheckthelevelof

theoil.Theoilshouldbeuptohole.Iftheoilis

low,addMobil424hydraulicoil.

4.Installthell/checkplug.

CheckingtheTorqueofthe

WheelNuts

ServiceInterval:Aftertherst2hours

Aftertherst10hours

Every200hours

WARNING

Failuretomaintainpropertorqueofthewheelnuts

couldresultinfailureorlossofawheelandmay

resultinpersonalinjury.

Torquethefrontandrearwheelnutsto80to90

ft-lb(109to122N-m)after1to4hoursofoperation

andagainafter10hoursofoperation.Torqueevery

200hoursthereafter.

24

Page 25

CheckingtheTirePressure

ServiceInterval:Beforeeachuseordaily

Themaximumairpressureinthefronttiresis32psi

(220kPa)andthereartiresis18psi(124kPa).

Checkthetirepressurefrequentlytoensureproper

ination.Ifthetiresarenotinatedtothecorrect

pressure,thetireswillwearprematurely.

Figure22isanexampleoftirewearcausedbyunder

ination.

Figure22

1.Underinatedtire

Figure23isanexampleoftirewearcausedbyover

ination.

Figure23

1.Overinatedtire

CheckingtheBrakeFluid

ServiceInterval:Beforeeachuseordaily—Checkthe

brakeuidlevel.

Every1,000hours/Every2years

(whichevercomesrst)—Change

thebrakeuid.

Thebrakeuidreservoirisshippedfromthefactory

lledwithDOT3brakeuid.Checkthelevelbefore

theengineisrststartedandevery8hoursordaily,

thereafter.

Thebrakeuidreservoirislocatedunderthedash.

1.Parkthemachineonalevelsurface.

2.TheuidlevelshouldbeuptotheFulllineonthe

reservoir(Figure24).

Figure24

1.Brakeuidreservoir

3.Iftheuidlevelislow,cleantheareaaroundthe

cap,removethereservoircap,andllthereservoir

totheproperlevel.Donotoverll.

Note:Youcanremovethehoodaccesstothereservoir

fromthefrontofthemachine(Figure25).

Figure25

1.Brakeuidreservoir

Pre–startingChecks

Safeoperationbeginsbeforetakingthevehicleoutfor

aday’swork.Youshouldchecktheseitemseachtime:

•Checkthetirepressure.

25

Page 26

Note:Thesetiresaredifferentthancartires,they

requirelesspressuretominimizeturfcompaction

anddamage.

•Checkalluidlevelsandaddtheappropriate

amountofTorospecieduids,ifanyarefound

tobelow .

•Checkthefrontoftheradiator.Removeanydebris

andcleantheradiatorscreen.

•Checkthebrakepedaloperation.

•Checktoseethatthelightsareworking.

•Turnthesteeringwheeltotheleftandrightto

checkthesteeringresponse.

•Stoptheengineandwitformovingpartstostop,

thencheckforoilleaks,looseparts,andanyother

noticeablemalfunctions.

Ifanyoftheaboveitemsarenotcorrect,notifyyour

mechanicorcheckwithyoursupervisorbeforetaking

thevehicleoutfortheday .Yoursupervisormaywant

youtocheckotheritemsonadailybasis,soaskwhat

yourresponsibilitiesare.

StartingtheEngine

1.Sitontheoperator’sseatandengagetheparking

brake.

2.DisengagethePTOandhighowhydraulics(ifso

equipped)andmovethehandthrottlelevertothe

Offposition(ifsoequipped).

3.MovetheshiftlevertotheNeutralpositionand

presstheclutchpedal.

4.Ensurethatthehydraulicliftleverisinthecenter

position.

5.Keepyourfootoffoftheacceleratorpedal.

Note:Iftheengineisooded—fullypressthe

acceleratorpedalandholdittotheooruntilthe

enginestarts.Neverpumptheacceleratorpedal.

6.Insertkeyintoignitionswitchandrotateitclockwise

tostarttheengine.Releasekeywhenenginestarts.

Important:Topreventoverheatingofthe

startermotor,donotengagestarterlongerthan

15seconds.After15secondsofcontinuous

cranking,wait60secondsbeforeengaging

startermotoragain.

DrivingtheVehicle

1.Releasetheparkingbrake.

2.Fullypresstheclutchpedal.

3.Movethegearshiftleverto1stgear.

4.Releasetheclutchpedalsmoothlywhilepressing

theacceleratorpedal.

5.Whenthevehiclegainsenoughspeed,removeyour

footfromtheacceleratorpedal,fullypressthe

clutchpedal,movethegearshiftlevertothenext

gearandreleasetheclutchpedalwhilepressingthe

acceleratorpedal.Repeattheprocedureuntilthe

desiredspeedisattained.

Important:Alwaysstopthevehiclebefore

shiftingtoreverseaforwardgearortoaforward

gearfromreverse.

Note:Avoidlongperiodsofengineidling.

Usethechartbelowtodeterminethegroundspeed

ofthevehicleat3600RPM.

Gear

RangeRatio

Speed

(mph)

Speed

(kmh)

1L82.83:12.94.7

2L54.52:14.57.2

3L31.56:1

7.7

12.5

1H32.31:17.612.2

2H21.27:111.518.5

3H12.31:119.831.9

RL86.94:12.84.5

RH33.91:17.111.6

Note:LeavingignitionswitchintheOnposition

forlongperiodsoftimewithoutrunningtheengine

willdischargethebattery.

Important:Donotattempttopushortow

vehicletogetitstarted.Damagetothedrive

traincouldresult.

StoppingtheVehicle

Tostopthevehicle,removeyourfootfromthe

acceleratorpedal,presstheclutchpedal,thenpressthe

brakepedal.

StoppingtheEngine

Tostoptheengine,rotatetheignitionkeytotheOff

positionandengagetheparkingbrake.Removethekey

fromtheswitchtopreventaccidentalstarting.

NewVehicleBreak–in

YourWorkmanisreadyforwork.Toprovideproper

performanceandlongvehiclelife,followthese

guidelinesfortherst100operatinghours.

26

Page 27

•Checktheuidandengineoillevelsregularly

andbealertforindicationsofoverheatinginany

componentofthevehicle.

•Afterstartingacoldengine,letitwarmupforabout

15secondsbeforeshiftingintogear.

•Avoidracingtheengine.

•Toensureoptimumperformanceofthebrake

system,burnish(break–in)thebrakesbeforeuse.

Toburnishthebrakes,bringthevehicleuptofull

speed,applythebrakestorapidlystopthevehicle

withoutlockingupthetires.Repeatthis10times,

waiting1minutebetweenstopstoavoidoverheating

thebrakes.Thisismosteffectiveifthevehicleis

loadedwith1000lb(454kg).

•Varyvehiclespeedsduringoperation.Avoid

excessiveidling.Avoidfaststartsandquickstops.

•Abreak–inoilfortheengineisnotrequired.The

originalengineoilisthesametypespeciedfor

regularoilchanges.

•RefertotheMaintenancesectionforanyspecial

lowhourchecks.

CheckingtheInterlockSystem

ServiceInterval:Beforeeachuseordaily

Thepurposeoftheinterlocksystemistopreventthe

enginefromcrankingorstartingunlesstheclutchpedal

ispressed.

CAUTION

Ifsafetyinterlockswitchesaredisconnectedor

damagedthemachinecouldoperateunexpectedly

causingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlockswitches

dailyandreplaceanydamagedswitchesbefore

operatingthemachine.

Note:RefertoAttachmentOperator’ sManualfor

proceduresoncheckingtheattachmentinterlock

system.

VerifyingtheClutchInterlockSwitch

1.Sitontheoperator’sseatandengagetheparking

brake.MovetheshiftlevertotheNeutralposition.

Note:Theenginewillnotcrankifthehydrauliclift

leverislockedintheforwardposition.

2.Withoutpressingtheclutchpedal,rotatethe

ignitionkeyclockwisetotheStartposition.

Iftheenginecranksorstarts,thereisamalfunction

intheinterlocksystemthatmustberepairedbefore

operatingthevehicle.

VerifyingtheHydraulicLiftLever

InterlockSwitch

1.Sitontheoperator’sseatandengagetheparking

brake.MovetheshiftlevertotheNeutralposition

andensurethatthehydraulicliftleverisinthe

centerposition.

2.Pressclutchpedal.

3.Movethehydraulicliftleverforwardandrotatethe

ignitionkeyclockwisetothestartposition.

Ifenginecranksorstarts,thereisamalfunctionin

theinterlocksystemthatmustberepairedbefore

operatingvehicle.

OperatingCharacteristics

Thevehicleisdesignedwithsafetyinmind.Ituses

familiarautomotivestylecontrols,includingthesteering

wheel,brakepedal,clutchpedal,acceleratorpedal,and

gearshifter.Itisimportanttoremember,however,that

thisvehicleisnotapassengercar.Itisaworkvehicle

andisdesignedforoffroaduseonly.

WARNING

TheWorkmanvehicleisanoff–highway

vehicleonly,andisnotdesigned,equipped,or

manufacturedforuseonpublicstreets,roadsor

highways.

Thevehiclehasspecialtires,lowgearratios,alocking

differential,andotherfeaturesthatgiveitextratraction.

Thesefeaturesaddtotheversatilityofthevehiclebut,

theycanalsogetyouintodangeroussituations.You

mustkeepinmindthatthevehicleisnotarecreation

vehicle,itisnotanallterrainvehicle,and,itisdenitely

notmeantforstuntdrivingorhorsingaround.Itisa

workvehicle,notaplayvehicle.Childrenshouldnotbe

allowedtooperatethevehicle.Anyonewhooperates

thevehiclemustbeproperlytrained.

Thedriverandpassengershouldalwaysusetheseat

belts.

Ifyouarenotexperiencedatdrivingthevehicle,

practicedrivingitinasafeareaawayfromotherpeople.

Besureyouarefamiliarwithallthevehicle’scontrols,

particularlythoseusedforbraking,steering,and

transmissionshifting.Learnhowyourvehiclehandles

ondifferentsurfaces.Youroperatingskillswillimprove

withexperience,butasinoperatinganyvehicle,take

27

Page 28

iteasyasyoubegin.Besureyouknowhowtostop

quicklyinanemergency.Ifyouneedhelp,askyour

supervisorforassistance.

Manyfactorscontributetoaccidents.Youhavecontrol

overseveralofthemostimportant.Youractions,

suchasdrivingtoofastforconditions,brakingtoo

fast,turningtoosharp,andcombinationsofthese,are

frequentcauseofaccidents.

Oneofthemajorcausesofaccidentsisfatigue.Besure

totakeoccasionalbreaks.Itisveryimportantthatyou

stayalertatalltimes.

Neveroperatethevehicle,oranyequipment,ifyou

areundertheinuenceofalcoholorotherdrugs.

Evenprescriptiondrugsandcoldmedicinescancause

drowsiness.Readthelabelonthemedicineorcheck

withyourdoctororpharmacistifyouareunsureabout

acertainmedication.

Oneofthemostimportantrulestofollowistogo

slowerinunfamiliarareas.Itissurprisinghowmuch

damageandinjurycommonthingscancause.Tree

branches,fences,wires,othervehicles,treestumps,

ditches,sandtraps,streams,andotherthingsfoundin

mostparksandgolfcoursescanbehazardoustothe

operatorandpassenger.

Avoiddrivingwhenitisdark,especiallyinunfamiliar

areas.Ifyoumustdrivewhenitisdark,besuretodrive

cautiously,usetheheadlights,andevenconsideradding

additionallights.

Passengers

Wheneveryouhaveapassengerridinginthevehicle

makesureheorsheiswearingtheseatbeltandholding

onsecurely.Driveslowerandturnlesssharplybecause

yourpassengerdoesnotknowwhatyouaregoingto

donextandmaynotbepreparedforturning,stopping,

accelerating,andbumps.

Youandyourpassengershouldremainseatedatall

times,keepingarmsandlegsinsidethevehicle.The

operatorshouldkeepbothhandsonsteeringwheel,

wheneverpossible,andthepassengershouldusethe

handholdsprovided(

Figure26&Figure27).

Figure26

1.Passengerhandhold

2.Storagecompartment

Figure27

1.Handhold&hiprestraint

Neverallowpassengersinthedumpboxoronany

attachments.Thevehicleismeanttohaveonedriver

andonlyonepassenger—nomore.

Speed

Speedisoneofthemostimportantvariablesleadingto

accidents.Drivingtoofastfortheconditionscancause

youtolosecontrolandhaveanaccident.Speedcan

alsomakeaminoraccidentworse.Drivinghead-on

intoatreeatslowspeedcancauseinjuryanddamage,

but,drivingintoatreeathighspeedcandestroythe

vehicleandkillyouandyourpassenger.

Neverdrivetoofastfortheconditions.Ifthereisany

doubtabouthowfasttodrive,slowdown.

28

Page 29

Whenusingheavyattachments,morethan1000lb(454

kg),suchassprayers,topdressers,orspreaders,etc.,

restrictyouroperatingspeedbymovingthe3rdhigh

lockoutswitchtotheslowposition.

Turning

Turningisanotherimportantvariableleadingto

accidents.Turningtoosharplyfortheconditionscan

causethevehicletolosetractionandskid,oreventip

over.

Wet,sandy,andslipperysurfacesmaketurningmore

difcultandrisky.Thefasteryouaregoing,theworse

thissituationbecomesso,slowdownbeforeturning.

Duringasharpturnathigherspeeds,theinsiderear

wheelmayliftoffoftheground.Thisisnotaawin

thedesign,ithappenswithmostfourwheelvehicles

includingpassengercars.Ifthishappens,youare

turningtoosharplyforthespeedatwhichyouare

traveling.Slowdown!

Braking

Itisgoodpracticetoslowdownbeforeyougetnear

anobstacle.Thisgivesyouextratimetostoporturn

away.Hittinganobstaclecandamagethevehicleandits

contents.Moreimportant,itcaninjureyouandyour

passenger.Grossvehicleweighthasamajorimpact

onyourabilitytostopand/orturn.Heavierloadsand

heavierattachmentsmakeavehiclehardertostopor

turn.Theheaviertheload,thelongerittakestostop

Thebrakingcharacteristicsalsochangewithnobedor

attachmentonthevehicle.Faststopsmaycausetherear

wheelstolockupbeforethefrontwheelslockup,which

mayaffectthecontrolofthevehicle.Itisagoodidea

todecreasevehiclespeedwithnobedorattachment.

Turfandpavementaremuchslipperierwhentheyare

wet.Itcantake2to4timesaslongtostoponwet

surfacesasondrysurfaces.

Ifyoudrivethroughstandingwaterdeepenoughtoget

thebrakeswet,theywillnotworkwelluntiltheyare

dry.Afterdrivingthroughwater,youshouldtestthe

brakestomakesuretheyworkproperly .Iftheydonot,

driveslowlyinrstgearwhileputtinglightpressureon

thebrakepedal.Thiswilldrythebrakesout.

Donotdownshiftforbrakingonicyorslippery

surfaces(wetgrass)orwhilegoingdownahillbecause

enginebrakingmaycauseskiddingandlossofcontrol.

Shifttoalowergearbeforestartingdownahill.

TipOvers

Thevehicleisequippedwitharollbar,hiprestraints,

seatbelts,andhandhold.TheROPSsystem(Rollover

ProtectionSystem)usedonthevehiclewillreduce

theriskofseriousorfatalinjuryintheunlikelyevent

ofatipover,althoughthesystemcannotprotectthe

operatorfromallpossibleinjuries.

ReplaceadamagedROPS,donotrepairorrevise.

AnyalterationoftheROPSmustbeapprovedbythe

manufacturer.

Thebestwaytopreventaccidentsinvolvingutility

vehiclesisthroughcontinuoussupervisionandtraining

ofoperatorsandpayingconstantattentiontothearea

inwhichvehicleisbeingoperated.

Thebestwayforoperatorstopreventseriousinjury

ordeathtothemselvesorothers,istofamiliarize

themselveswiththeproperoperationoftheutility

vehicle,tostayalertandtoavoidactionsorconditions

whichcouldresultinaaccident.Intheeventofatip

over,theriskofseriousinjuryordeathwillbereduced

iftheoperatorisusingtheROPSsystemandseatbelts

andisfollowingtheinstructionsprovided.

Hills

WARNING

Tippingorrollingthevehicleonahillwillcause

seriouspersonalinjury.

•Donotoperatethevehicleonsteepslopes.

•Ifenginestallsoryouloseheadwayonahill,

neverattempttoturnvehiclearound.

•Alwaysbackstraightdownahillinreversegear.

•Neverbackdowninneutralorwiththeclutch

depressed,usingonlythebrakes.

•Neverdriveacrossasteephill,alwaysdrive

straightupordown.

•Avoidturningonahill.

•Don’t“droptheclutch”orslamonthebrakes.

Suddenspeedchangecaninitiateatipover.

Useextracarewhenonhills.Nevergoonhillsthatare

extremelysteep.Stoppingwhilegoingdownahillwill

takelongerthanonlevelground.Turningwhilegoing

upordownahillismoredangerousthanturningon

thelevel.Turnswhilegoingdownhill,especiallywith

thebrakeson,and,turninguphillwhiletraversinga

29

Page 30

hillareparticularlydangerous.Evenataslowspeed

andwithoutaload,tipoversaremorelikelyifyouturn

onahill.

Slowdownandshiftintoalowergearbeforestarting

upordownahill.Ifyouhavetoturnwhileonahill,

doitasslowlyandcautiouslyaspossible.Nevermake

sharporfastturnsonahill.

Ifyoustallorbegintoloseheadwaywhileclimbing

asteephill,quicklyapplythebrakes,shifttoneutral,

restarttheengineandshifttoreverse.Atidlespeed,

theengineandtransaxledragwillaidthebrakesin

controllingthevehicleonthehillandhelpyouback

downthehillmoresafely.

Reducetheweightoftheloadifitisasteephillorifthe

loadhashighcenterofgravity.Remember,loadscan

shift,securethem.

Note:Thevehiclehasexcellenthillclimbingability .

Thedifferentiallockwillincreasethisability .Hill

climbingtractioncanalsobeincreasedbyaddingweight

totherearofthevehicleinoneofthefollowingways:

•Addingweighttoinsideofbox,makingsureitis

secured.

•Mountingwheelweightstorearwheels.

•Addingliquidballast(calciumchloride)toreartires.

•Tractionwillincreasewithnopassengerinfront

seat.

LoadingandDumping

Theweightandpositionofthecargoandpassenger

canchangethevehiclecenterofgravityandvehicle

handling.Toavoidlossofcontrolresultinginpersonal

injury,followtheseguidelines.

Donotcarryloadswhichexceedtheloadlimits

describedonthevehicleweightlabel.

WARNING

Thebedwilllowerwheneverthedumplever

ispusheddown,evenwhentheengineisoff.

Turningofftheenginewill

not

preventthebox

fromlowering.Alwaysplacethesafetysupporton

theextendedliftcylindertoholdtheboxupifyou

arenotgoingtoloweritrightaway.

Thevehiclehasseveralcombinationsofboxes,

platforms,andattachmentsavailable.Thesecanbe

usedinvariouscombinationsthatallowformaximum

capacityandversatility .Thefullsizedboxis55inches

(140cm)wideby65inches(165cm)longandcanhold

upto3000lb(1360kg)ofevenlydistributedcargo.

Loadsvaryinhowtheyaredistributed.Sandspreads

outevenlyandquitelow .Otheritems,suchasbricks,

fertilizerorlandscapetimbers,stackhigherinthebox.

Theheightandweightoftheloadhasasignicant

inuenceontipovers.Thehigheraloadisstacked,the

morelikelythevehicleistotipover.Y oumayndthat

3000lb(1360kg)stackstoohighforsafeoperation.

Reducingthetotalweightisonewaytoreducetherisk

ofatipover.Distributingtheloadaslowaspossibleis

anotherwaytoreducetheriskofatipover.

Iftheloadispositionedtowardoneofthesides,itwill

makethevehiclemuchmorelikelytotipoveronthat

side.Thisisespeciallytruewhenturningiftheloadis

ontheoutsideoftheturn.

Neverpositionheavyloadsbehindtherearaxle.Ifthe

loadispositionedsofartotherearthatitisbehindthe

rearaxle,itwillreducetheweightonthefrontwheels

andthiswillreducesteeringtraction.Withtheloadall

thewaytotheback,thefrontwheelscanevencome

offofthegroundwhengoingoverbumpsorupahill.

Thiswillresultinalossofsteeringandmayleadtothe

vehicletippingover.

Asageneralrule,positiontheweightoftheload

evenlyfromfronttorearandevenlyfromsideto

side.

Ifaloadisnotsecured,oryouaretransportingaliquid

inalargecontainersuchasasprayer,itcanshift.This

shiftinghappensmostoftenwhileturning,goingupor

downhills,suddenlychangingspeeds,orwhiledriving

overroughsurfaces.Shiftingloadscanleadtotipovers.

Alwayssecureloadssothattheydonotshift.Never

dumptheloadwhilethevehicleissidewaysonthehill.

Heavyloadsincreasestoppingdistanceandreduceyour

abilitytoturnquicklywithouttippingover.

Therearcargospaceisintendedforloadcarrying

purposesonly ,notforpassengers.

UsingTheDifferentialLock

Thedifferentiallockincreasesthevehicle’stractionby

lockingtherearwheelssoonewheelwillnotspinout.

Thiscanhelpwhenyouhaveheavyloadstohaulon

wetturforslipperyareas,goinguphills,andonsandy

surfaces.Itisimportanttorememberhowever,thatthis

extratractionisonlyfortemporarylimiteduse.Itsuse

doesnotreplacethesafeoperation,alreadydiscussed

concerningsteephillsandheavyloads.

Thedifferentiallockcausestherearwheelstospinatthe

samespeed.Whenusingdifferentiallockyourabilityto

makesharpturnsissomewhatrestrictedandmayscuff

30

Page 31

theturf.Usethedifferentiallockonlywhenneeded,at

slowerspeedsandonlyinrstorsecondgear.

WARNING

Tippingorrollingthevehicleonahillwillcause

seriousinjury.

•Theextratractionavailablewiththedifferential

lockcanbeenoughtogetyouintodangerous

situationssuchasclimbingslopesthatare

toosteeptoturnaround.Beextracareful

whenoperatingwiththedifferentiallockon,

especiallyonsteeperslopes.

•Ifthedifferentiallockisonwhenmakinga

sharpturnatahigherspeedandtheinsiderear

wheelliftsofftheground,theremaybealossof

controlwhichcouldcausevehicletoskid.Use

thedifferentiallockonlyatslowerspeeds.

FourWheelDrive(FourWheel

DriveModelsOnly)

TheAutomaticonDemandfourwheeldrivefeature,on

thisvehicledoesnotrequireoperatoractivation.The

frontwheeldriveisnotengaged(nopowerdelivered

tofrontwheels)untiltherearwheelsbegintolose

traction.Thebidirectionalclutchsensestherearwheels

slipping,engagesthefrontwheeldrive,anddelivers

powertothefrontwheels.Thefourwheeldrivesystem

continuestodeliverpowertothefrontwheelsuntilthe

rearwheelshaveenoughtractiontomovethevehicle

withoutslipping.Oncethisoccurs,thesystemstops

deliveringpowertothefrontwheelsandthehandling

characteristicsbecomesimilartothatofatwowheel

drivevehicle.Thefourwheeldrivesystemfunctions

inbothfrowardandreverse,however,whenturning

therearwheelswillslipslightlymorebeforepoweris

deliveredtothefrontwheels.

WARNING

Tippingorrollingthevehicleonahillwillcause

seriousinjury.

Theextratractionavailablewiththefourwheel

drivefeaturecanbeenoughtogetyouinto

dangeroussituationssuchasclimbingslopesthat

aretoosteeptoturnaround.Becarefulwhen

operating,especiallyonsteeperslopes.

TransportingVehicle

Formovingthevehiclelongdistances,useatrailer.

Makesurethevehicleissecuredtothetrailer.Refer

toFigure28andFigure29forthelocationofthetie

downpoints.

Important:Trailersweighingover1500lb(680kg)

arerequiredtobeequippedwithtrailerbrakes.

Note:Loadthevehicleonthetrailerwiththefrontof

thevehiclefacingforward.Ifthatisnotpossible,secure

thevehiclehoodtotheframewithastrap,orremove

thehoodandtransportandsecureitseparatelyorthe

hoodmayblowoffduringtransport.

Figure28

1.Eyeholeinframe(eachside)

Figure29

1.Axle2.Hitchplate

TowingtheVehicle

Incaseofanemergency,thevehiclecanbetowedfor

ashortdistance.However,Torodoesnotrecommend

thisasastandardprocedure.

WARNING

Towingatexcessivespeedscouldcausevehicleto

losesteeringcontrol.Nevertowvehiclefasterthan

5mph(8kph).

Towingthevehicleisatwopersonjob.Afxatowline

toholesinthefrontframemember.Movetheshifterto

31

Page 32

Neutralandreleasetheparkingbrake.Ifthemachine

mustbemovedaconsiderabledistance,transportiton

atruckortrailer.

Note:Thepowersteeringwillnotfunction,

makingitdifcult(increasedeffort)tosteer.

TowingaTrailerwiththe

Vehicle

TheWorkmaniscapableofpullingtrailersand

attachmentsofgreaterweightthanthevehicleitself.

Severaltypesoftowhitchesareavailableforthe

Workman,dependingonyourapplication.Contact

yourAuthorizedToroDistributorfordetails.

Whenequippedwithatowhitchboltedontotherear

axletube,yourWorkmancantowtrailersorattachments

withaGrossTrailerWeight(GTW)upto3500lb(1587

kg).Alwaysloadatrailerwith60%ofthecargoweight

inthefrontofthetrailer.Thisplacesapproximately

10%(600lb(272kg)max.)oftheGrossTrailerWeight

(GTW)onthetowhitchofthevehicle.

Trailerbrakesarerequiredwheneveryoutowatrailer

over1500lb(680kg)GTWistowedbehindaWorkman

vehicle.

Whenhaulingcargoortowingatrailer(attachment),do

notoverloadyourvehicleortrailer.Overloadingcan

causepoorperformanceordamagetothebrakes,axle,

engine,transaxle,steering,suspension,bodystructure,

ortires.

Important:Toreducepotentialfordriveline

damage,uselowrange.

Whentowing5thwheelattachments,likeafairway

aerator,alwaysinstallthewheelybar(includedwiththe

5thwheelkit)topreventthefrontwheelsfromlifting

offthegroundifthetowedattachmentsmovementis

suddenlyimpaired.

HydraulicControl

Thehydrauliccontrolsupplieshydraulicpowerfrom

thevehiclepumpwhenevertheengineisrunning.The

powercanbeusedthroughthequickcouplersatthe

rearofthevehicle.

Important:Ifmultiplevehiclesusethe

sameattachment,crosscontaminationofthe

transmissionuidmayoccur.Changethe

transmissionuidmorefrequently

ControlLeverPositions

•OffPosition

Thisisthenormalpositionforthecontrolvalve

whenitisnotbeingused.Inthispositionthework

portsofthecontrolvalveareblockedandanyload

willbeheldbythecheckvalvesinbothdirections.

•Raise(QuickCoupler“ A ”Position)

Thisisthepositionwhichwillliftthebed,rear

hitchattachmentorapplypressuretoquickcoupler

A.Thisalsoallowsreturnoilfromquickcoupler

Btoowbackintothevalveandthenouttothe

reservoir.Thisisamomentarypositionandwhen

theleverisreleaseditspringreturnstothecenter

offposition.

Figure30

1.QuickcouplerAposition2.QuickcouplerBposition

•Lower(QuickCouplerBPosition)

Thispositionwilllowerthebed,rearhitch

attachment,orapplypressuretoquickcouplerB.

ThisalsoallowsreturnoilfromquickcouplerA

toowbackintothevalveandthenouttothe

reservoir.Thisisamomentarypositionandwhen

theleverisreleaseditspringreturnstothecenteroff

position.Momentarilyholdingandthenreleasing

thecontrolleverinthispositionwillprovideow

toquickcouplerBwhichprovidespowerdownon

therearhitch.Whenreleased,itwillholdthedown

pressureonthehitch.

Important:Ifusedwithahydrauliccylinder,

holdingthecontrolleverinthelowerposition

causestheoilowtogooverareliefvalvewhich

candamagethehydraulicsystem.

•OnPosition

ThispositionissimilartoLower(quickcoupler

Bposition).Italsodirectsoiltoquickcoupler

32

Page 33

Bexceptthattheleverisheldinthispositionby

adetentleverinthecontrolpanel.Thisallows

oiltoowcontinuouslytoequipmentthatusesa

hydraulicmotor.Thispositionmustonlybeused

onattachmentswithahydraulicmotorattached.

Important:Ifusedwithahydrauliccylinderor

noattachment,theOnpositioncausestheoil

owtogooverareliefvalvewhichcandamage