Page 1

FormNo.3359-781RevB

Workman

®

3300–D&4300–D

LiquidCooledDieselUtilityVehicle

ModelNo.07362—SerialNo.280000001andUp

ModelNo.07362TC—SerialNo.280000001andUp

ModelNo.07364—SerialNo.280000001andUp

ModelNo.07364TC—SerialNo.280000001andUp

Registeratwww.T oro.com.OriginalInstructions(EN)

Page 2

Introduction

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoidinjury

andproductdamage.Youareresponsibleforoperating

theproductproperlyandsafely.

YoumaycontactT orodirectlyatwww .Toro.comfor

productandaccessoryinformation,helpndinga

dealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

Thismanualuses2otherwordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafetyalertsymbol

(Figure2),whichsignalsahazardthatmaycauseserious

injuryordeathifyoudonotfollowtherecommended

precautions.

Figure2

1.Safetyalertsymbol

©2007—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

Contents

Introduction.................................................................2

Safety...........................................................................4

SafeOperatingPractices.......................................4

Supervisor’sResponsibilities.................................5

BeforeOperating.................................................5

WhileOperating...................................................5

Maintenance.........................................................7

SoundPowerLevel...............................................7

SoundPressureLevel...........................................7

VibrationLevel.....................................................7

SafetyandInstructionalDecals.............................8

Setup..........................................................................13

1InstalltheRearFenders....................................13

2InstalltheWheels............................................14

3InstalltheSteeringWheel.................................14

4InstalltheFrontFenders..................................15

5InstallROPS....................................................15

6ActivateandChargetheBattery........................16

7FullBedRemoval.............................................17

8Re-InstalltheFullBed......................................18

ProductOverview......................................................19

Controls.............................................................19

Specications.....................................................22

Attachments/Accessories...................................23

Operation...................................................................23

CheckCrankcaseOil..........................................23

FillFuelTank.....................................................24

CheckCoolingSystem........................................25

CheckTransaxle/HydraulicFluid......................25

CheckFrontDifferentialOil...............................26

CheckTorqueOfWheelNuts.............................26

CheckTirePressure............................................26

CheckBrakeFluid..............................................26

CheckFanBeltTension......................................27

Pre–startingChecks............................................27

StartingEngine...................................................27

DrivingVehicle..................................................28

StoppingVehicle................................................28

StoppingEngine.................................................28

NewVehicleBreak–in........................................28

CheckInterlockSystem......................................28

OperatingCharacteristics...................................29

Passengers..........................................................29

Speed.................................................................30

Turning..............................................................30

Braking..............................................................30

Tipovers.............................................................30

Hills...................................................................31

LoadingAndDumping.......................................31

UsingTheDifferentialLock...............................32

FourWheelDrive...............................................32

TransportingVehicle..........................................33

TowingVehicle...................................................33

TrailerT owing....................................................33

HydraulicControl...............................................34

Maintenance...............................................................36

RecommendedMaintenanceSchedule(s)................36

ServiceIntervalChart.........................................37

HeavyDutyOperation.......................................37

PremaintenanceProcedures....................................38

UsingBedSafetySupport...................................38

JackingVehicle...................................................39

Lubrication.............................................................40

GreasingBearingsandBushings.........................40

EngineMaintenance...............................................41

GeneralAirCleanerMaintenance

Practices.........................................................41

ServicingAirCleaner..........................................41

ChangingEngineOilAndFilter..........................42

CylinderHeadBolts...........................................42

EngineValveClearance......................................42

FuelSystemMaintenance.......................................43

FuelSystem........................................................43

BleedingAirFromInjectors...............................43

ElectricalSystemMaintenance................................44

Fuses..................................................................44

JumpStartingVehicle.........................................44

BatteryCare.......................................................44

DriveSystemMaintenance.....................................45

ChangeFrontDifferentialOil.............................45

InspectConstantVelocityBoot...........................45

AdjustingShiftCables........................................45

AdjustingHigh–lowCable..................................46

InspectTires......................................................46

FrontWheelToe................................................46

CoolingSystemMaintenance..................................47

RemovingDebrisFromEngineCooling

System............................................................47

ChangingEngineCoolant...................................47

BrakeMaintenance.................................................49

InspectBrakes....................................................49

BeltMaintenance....................................................49

AdjustingBelts...................................................49

ControlsSystemMaintenance.................................50

AdjustingAcceleratorPedal................................50

AdjustingBrakePedal.........................................51

AdjustingClutchPedal.......................................51

AdjustingParkingBrake.....................................52

HydraulicSystemMaintenance...............................53

ChangingTransaxle/HydraulicFluid.................53

ReplacingHydraulicFilter...................................53

CleaningHydraulicStrainer................................54

EmergencyBoxRaising......................................54

Storage.......................................................................56

BatteryStorage...................................................56

3

Page 4

Schematics.................................................................57

Safety

TheTOROWORKMANmeetstherequirementsof

SAEJ2258.

Supervisors,operatorsandservicepersonsshouldbe

familiarwiththefollowingstandardsandpublications:

(Thematerialmaybeobtainedfromtheaddressshown).

•FlammableandCombustibleLiquidsCode:

ANSI/NFPA30

•NationalFireProtectionAssociation:

ANSI/NFPA#505;PoweredIndustrialTrucks

ADDRESS:

NationalFirePreventionAssociation

BarrymarchPark

Quincy,Massachusetts02269U .S.A

•ANSI/ASMEB56.8PersonalBurdenCarriers

ADDRESS:

AmericanNationalStandardsInstitute,Inc.

1430Broadway

NewYork,NewYork10018U.S.A.

•ANSI/UL558;InternalCombustionEngine

PoweredIndustrialTrucks

TrucksADDRESS:

AmericanNationalStandardsInstitute,Inc.

1430Broadway

NewYork,NewYork10018U.S.A.

OR

UnderwritersLaboratories

333PngstenRoad

Northbrook,Illinois60062U.S.A.

SafeOperatingPractices

TheWorkmanisanoff–highwayvehicleonly,

andisnotdesigned,equipped,ormanufactured

foruseonpublicstreets,roadsorhighways.

TheWorkmanwasdesignedandtestedtooffersafe

servicewhenoperatedandmaintainedproperly .

Althoughhazardcontrolandaccidentprevention

partiallyaredependentuponthedesignand

congurationofthemachine,thesefactorsarealso

4

Page 5

dependentupontheawareness,concern,andproper

trainingofthepersonnelinvolvedintheoperation,

maintenanceandstorageofthemachine.Improperuse

ormaintenanceofthemachinecanresultininjuryor

death.

Thisisaspecializedutilityvehicledesignedforoff–road

useonly .itsrideandhandlingwillhaveadifferent

feelthanwhatdriversexperiencewithpassengercars

ortrucks.Sotaketimetobecomefamiliarwithyour

Workman.

NotalloftheattachmentsthatadapttotheW orkman

arecoveredinthismanual.SeethespecicOperator’s

Manualprovidedwithattachmentforadditionalsafety

instructions.Readthesemanuals.

Toreducethepotentialforinjuryordeath,comply

withthefollowingsafetyinstructions:

illegible,ordamaged,repairorreplaceitbefore

operatingthemachine.

•Alwayswearsubstantialshoes.Donotoperate

machinewhilewearingsandals,tennisshoesor

sneakers.Donotwearloosettingclothingor

jewelrywhichcouldgetcaughtinmovingpartsand

causepersonalinjury.

•Wearingsafetyglasses,safetyshoes,longpantsanda

helmetisadvisableandrequiredbysomelocalsafety

andinsuranceregulations.

•Keepeveryone,especiallychildrenandpets,away

fromtheareasofoperation.

•Beforeoperatingthevehicle,alwayscheckallparts

ofthevehicleandanyattachments.Ifsomethingis

wrong,stopusingvehicle.Makesureproblemis

correctedbeforevehicleorattachmentisoperated

again.

Supervisor’sResponsibilities

•Makesureoperatorsarethoroughlytrainedand

familiarwiththeOperator’ sManualandalllabels

onthevehicle.

•Besuretoestablishyourownspecialproceduresand

workrulesforunusualoperatingconditions(e.g.

slopestoosteepforvehicleoperation).Usethe3rd

HighLockoutswitchifhighspeedcouldresultina

safetyorvehicleabusesituation.

BeforeOperating

•Operatethemachineonlyafterreadingand

understandingthecontentsofthismanual.A

replacementmanualisavailablebysendingcomplete

modelandserialnumberto:TheToroCompany,

8111LyndaleAvenueSouth,Minneapolis,Minnesota

55420.

•Neverallowchildrentooperatethevehicle.Never

allowadultstooperateitwithoutproperinstructions.

Onlytrainedandauthorizedpersonsshouldoperate

thisvehicle.Makesurealloperatorsarephysically

andmentallycapableofoperatingthevehicle.

•Thisvehicleisdesignedtocarryonlyyou,the

operator,andonepassengerintheseatprovidedby

themanufacturer.Nevercarryanyotherpassengers

onthevehicle.

•Sincedieselfuelishighlyammable,handleit

carefully.

–Useanapprovedfuelcontainer.

–Donotremovecapfromfueltankwhenengine

ishotorrunning.

–Donotsmokewhilehandlingfuel.

–Fillfueltankoutdoorsandtoaboutoneinch

belowtopoftank(bottomofllerneck).Do

notoverll.

–Wipeupanyspilledfuel.

•Operatethevehicleonlyoutdoorsorinawell

ventilatedarea.

•Useonlyanapprovednon–metal,portablefuel

container.Staticelectricdischargecanignitefuel

vaporsinaungroundedfuelcontainer.Removethe

fuelcontainerfromthebedofthevehicleandplace

onthegroundawayfromthevehiclebeforelling.

Keepnozzleincontactwithcontainerwhilelling.

Removeequipmentfromvehiclebedbeforelling.

•Checkthesafetyinterlocksystemdailyforproper

operation.Ifaswitchshouldmalfunction,replace

theswitchbeforeoperatingmachine.Afterevery

twoyears,replacetheinterlockswitchesinthesafety

system,whethertheyareworkingproperlyornot.

•Neveroperatethevehiclewhenundertheinuence

ofdrugsoralcohol.

•Becomefamiliarwiththecontrolsandknowhowto

stoptheenginequickly.

•Keepallshields,safetydevicesanddecalsinplace.

Ifashield,safetydeviceordecalismalfunctioning,

WhileOperating

•Operatorandpassengershoulduseseatbeltsand

remainseatedwheneverthevehicleisinmotion.

Operatorshouldkeepbothhandsonsteeringwheel,

wheneverpossibleandpassengershouldusehand

holdsprovided.Keeparmsandlegswithinthe

5

Page 6

vehiclebodyatalltimes.Nevercarrypassengers

intheboxoronattachments.Rememberyour

passengermaynotbeexpectingyoutobrakeorturn

andmaynotbeready.

•Neveroverloadyourvehicle.Nameplate(located

undermiddleofdash)showsloadlimitsforvehicle.

Neveroverllattachmentsorexceedthevehicle

maximumGVW .

•Whenstartingtheengine:

–Sitonoperator’ sseatandensureparkingbrake

isengaged.

–DisengagePTO(ifsoequipped)andreturnhand

throttlelevertoOFFposition(ifsoequipped).

–Makesurethehydraulicliftleverisinthecenter

position.

–MoveshiftlevertoNEUTRALanddepress

clutchpedal.

–Keepfootoffacceleratorpedal.

–TurnignitionswitchtoONposition.When

glowplugindicatorgoesoff,engineisreadyto

START.

–TurnignitionkeytoSTART.

Note:Theglowplugindicatorwillturnon,foran

additional15seconds,whentheswitchreturnsto

theSTARTposition.

•Usingthemachinedemandsattention.Failureto

operatevehiclesafelymayresultinanaccident,tip

overofvehicleandseriousinjuryordeath.Drive

carefully.Topreventtippingorlossofcontrol:

–Useextremecaution,reducespeedandmaintain

asafedistancearoundsandtraps,ditches,creeks,

ramps,anyunfamiliarareasorotherhazards.

–Watchforholesorotherhiddenhazards.

–Usecautionwhenoperatingvehicleonasteep

slope.Normallytravelstraightupanddown

slopes.Reducespeedwhenmakingsharpturns

orwhenturningonhillsides.Avoidturningon

hillsideswheneverpossible.

–Useextracautionwhenoperatingvehicleonwet

surfaces,athigherspeedsorwithafullload.

Stoppingtimewillincreasewithafullload.Shift

intoalowergearbeforestartingupordowna

hill.

–Whenloadingbed,distributeloadevenly .Use

extracautioniftheloadexceedsthedimensions

ofthevehicle/bed.Operatevehiclewithextra

cautionwhenhandlingoff–centerloadsthat

cannotbecentered.Keeploadsbalancedand

securetopreventthemfromshifting.

–Avoidsuddenstopsandstarts.Donotgofrom

reversetoforwardorforwardtoreversewithout

rstcomingtoacompletestop.

–Donotattemptsharpturnsorabruptmaneuvers

orotherunsafedrivingactionsthatmaycausea

lossofvehiclecontrol.

–Donotpassanothervehicletravelinginthesame

directionatintersections,blindspots,oratother

dangerouslocations.

–Whendumping,donotletanyonestandbehind

vehicleanddonotdumploadonanyone’sfeet.

Releasetailgatelatchesfromsideofbox,not

frombehind.

–Keepallbystandersaway.Beforebackingup,

looktotherearandassurenooneisbehindthe

vehicle.Backupslowly.

–Watchoutfortrafcwhennearorcrossingroads.

Alwaysyieldtherightofwaytopedestriansand

othervehicles.Thisvehicleisnotdesignedfor

useonstreetsorhighways.Alwayssignalyour

turnsorstopearlyenoughsootherpersons

knowwhatyouplantodo.Obeyalltrafcrules

andregulations.

–Neveroperatevehicleinornearanareawhere

thereisdustorfumesintheairwhichare

explosive.Theelectricalandexhaustsystems

ofthevehiclecanproducesparkscapableof

ignitingexplosivematerials.

–Alwayswatchoutforandavoidlowoverhangs

suchastreelimbs,doorjambs,overhead

walkways,etc.Makesurethereisenoughroom

overheadtoeasilyclearthevehicleandyour

head.

–Ifeverunsureaboutsafeoperation,STOP

WORKandaskyoursupervisor.

•Donottouchengine,transaxle,radiator,muferor

mufermanifoldwhileengineisrunningorsoon

afterithasstoppedbecausetheseareasmaybehot

enoughtocauseburns.

•Ifthemachineevervibratesabnormally,stop

immediately,turnengineoff,waitforallmotion

tostopandinspectfordamage.Repairalldamage

beforeresumingoperation.

•Beforegettingofftheseat:

–Stopmovementofthemachine.

–Lowerbed.

–Shutengineoffandwaitforallmovementto

stop.

–Setparkingbrake.

6

Page 7

–Removekeyfromignition.

Maintenance

•Beforeservicingormakingadjustmentstothe

machine,stopengine,setparkingbrakeandremove

keyfromignitiontopreventaccidentalstartingof

theengine.

•Neverworkunderaraisedbedwithoutplacingbed

safetysupportonfullyextendedcylinderrod.

•Makesureallhydrauliclineconnectorsaretight,and

allhydraulichosesandlinesareingoodcondition

beforeapplyingpressuretothesystem.

•Keepbodyandhandsawayfrompinholeleaksor

nozzlesthatejecthydraulicuidunderhighpressure.

Usepaperorcardboard,nothands,tosearchfor

leaks.Hydraulicuidescapingunderpressurecan

havesufcientforcetopenetrateskinanddoserious

damage.Ifuidisinjectedintotheskinitmustbe

surgicallyremovedwithinafewhoursbyadoctor

familiarwiththisformofinjuryorgangrenemay

result.

•Beforedisconnectingorperforminganyworkon

thehydraulicsystem,allpressureinsystemmust

berelievedbystoppingengine,cyclingdump

valvefromraisetolowerand/orloweringboxand

attachments.Placetheremotehydraulicsleverin

theoatposition.Ifboxmustbeinraisedposition,

securewithsafetysupport.

•Tomakesureentiremachineisingoodcondition,

keepallnuts,boltsandscrewsproperlytightened.

Alteringthisvehicleinanymannermayaffectthe

vehicle’soperation,performance,durabilityoritsuse

mayresultininjuryordeath.Suchusecouldvoid

theproductwarrantyofTheTOROCompany.

•Thisvehicleshouldnotbemodiedwithoutthe

TOROCompany’sauthorization.Directany

inquiriestoTheTOROCompany,Commercial

Division,VehicleEngineeringDept.,8111Lyndale

Ave.So.,Bloomington,Minnesota55420–1196.

USA

SoundPowerLevel

Thisunithasaguaranteedsoundpowerlevelof

100dBA/1pW ,basedonmeasurementsofidentical

machinesperDirective2000/14/ECandamendments.

SoundPressureLevel

ThisunithasanequivalentcontinuousA-weighted

soundpressureattheoperatorearof:88dB(A),based

onmeasurementsofidenticalmachinesperDirective

98/37/ECandamendments.

VibrationLevel

Hand-Arm

Thisunitdoesnotexceedavibrationlevelof2.5m/s2at

thehandsbasedonmeasurementsofidenticalmachines

perISO5349procedures.

•Toreducepotentialrehazard,keeptheengine

areafreeofexcessivegrease,grass,leavesand

accumulationofdirt.

•Iftheenginemustberunningtoperforma

maintenanceadjustment,keephands,feet,clothing,

andanypartsofthebodyawayfromtheengineand

anymovingparts.Keepeveryoneaway.

•Donotoverspeedenginebychanginggovernor

settings.Maximumenginespeedis3650rpm.To

assuresafetyandaccuracy ,haveanAuthorized

TORODistributorcheckmaximumenginespeed

withatachometer.

•Ifmajorrepairsareeverneededorassistanceis

required,contactanAuthorizedT oroDistributor.

•Tobesureofoptimumperformanceandsafety,

alwayspurchasegenuineTOROreplacementparts

andaccessories.Replacementpartsandaccessories

madebyothermanufacturerscouldbedangerous.

WholeBody

Thisunitdoesnotexceedavibrationlevelof0.5m/s2

attheposterior,basedonmeasurementsofidentical

machinesperISO2631procedures.

7

Page 8

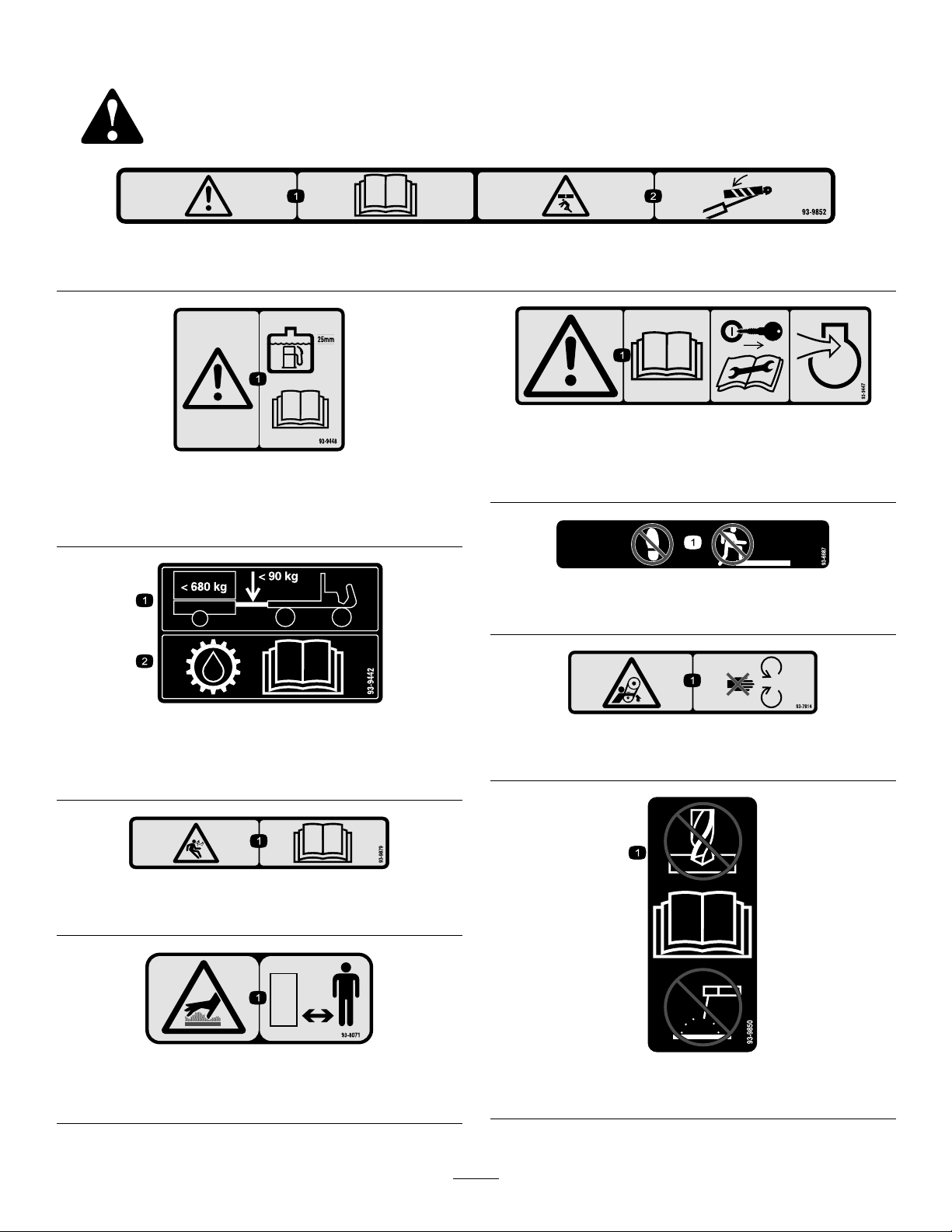

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaof

potentialdanger.Replaceanydecalthatisdamagedorlost.

93-9852

1.Warning—readtheOperator’sManual.2.Crushinghazard—installthecylinderlock.

93-9447

1.Warning—readtheOperator’sManual;removetheignition

93-9448

1.Warning—whenaddingfueltothetank,leave25mm

betweenthefuelandthetopofthetank;readtheOperator’s

Manual.

keybeforeservicingorperformingmaintenanceonthe

engineairintakesystem.

93-9442

1.Maximumtongueweight

is90kg;maximumtrailer

weightis680kg.

2.Forinformationon

transmissionuid,read

theOperator’sManual.

93-9879

1.Storedenergyhazard—readtheOperator’sManual.

93-6687

1.Donotstephere.

93-7814

1.Entanglementhazard,belt—stayawayfrommovingparts.

93-8071

1.Hotsurface/burnhazard—stayasafedistancefromthe

hotsurface.

93-9850

1.Donotrepairorrevise—readtheOperator’sManual.

8

Page 9

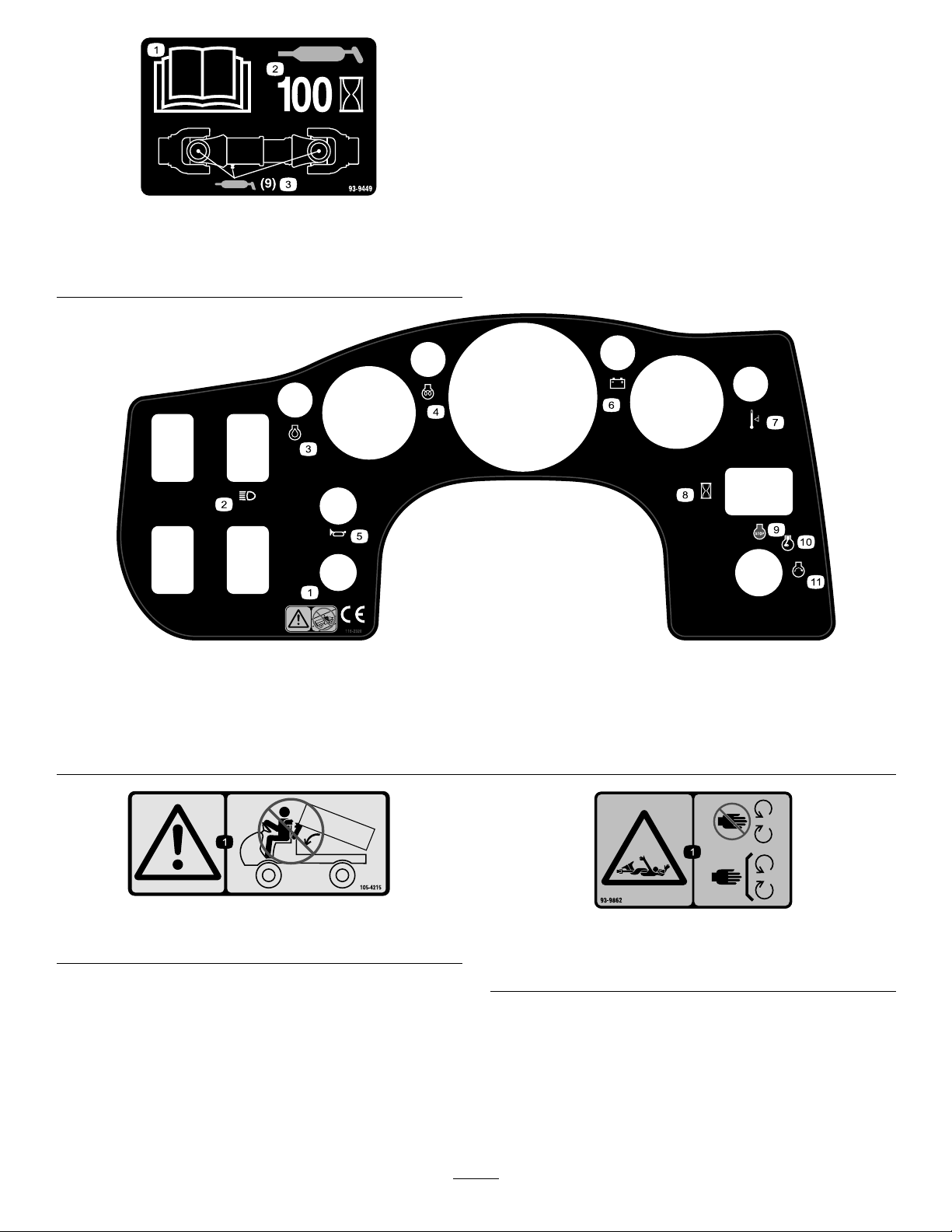

93-9449

1.ReadtheOperator’s

Manual.

2.Greaseevery100hours.

3.Addgrease(9grease

points).

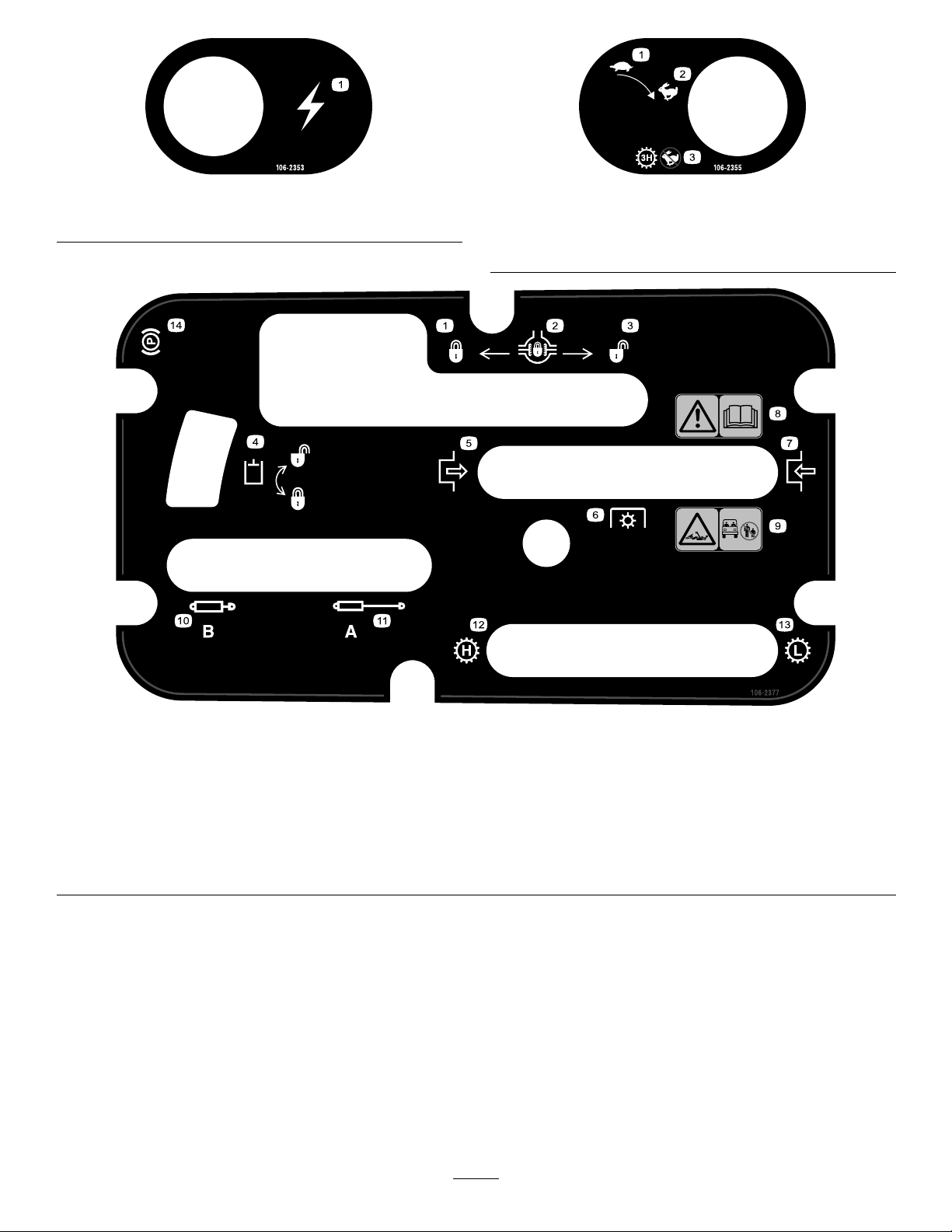

115-2320

1.Warning—donotoperate

thevehicleonpublic

streets,roads,orhighways.

2.Headlights5.Horn8.Hourmeter11.Engine—start

3.Engine—oil6.Battery9.Engine—stop

4.Engine—preheat7.Temperaturelevel10.Engine—run

1.Warning—avoidpinchpoints.

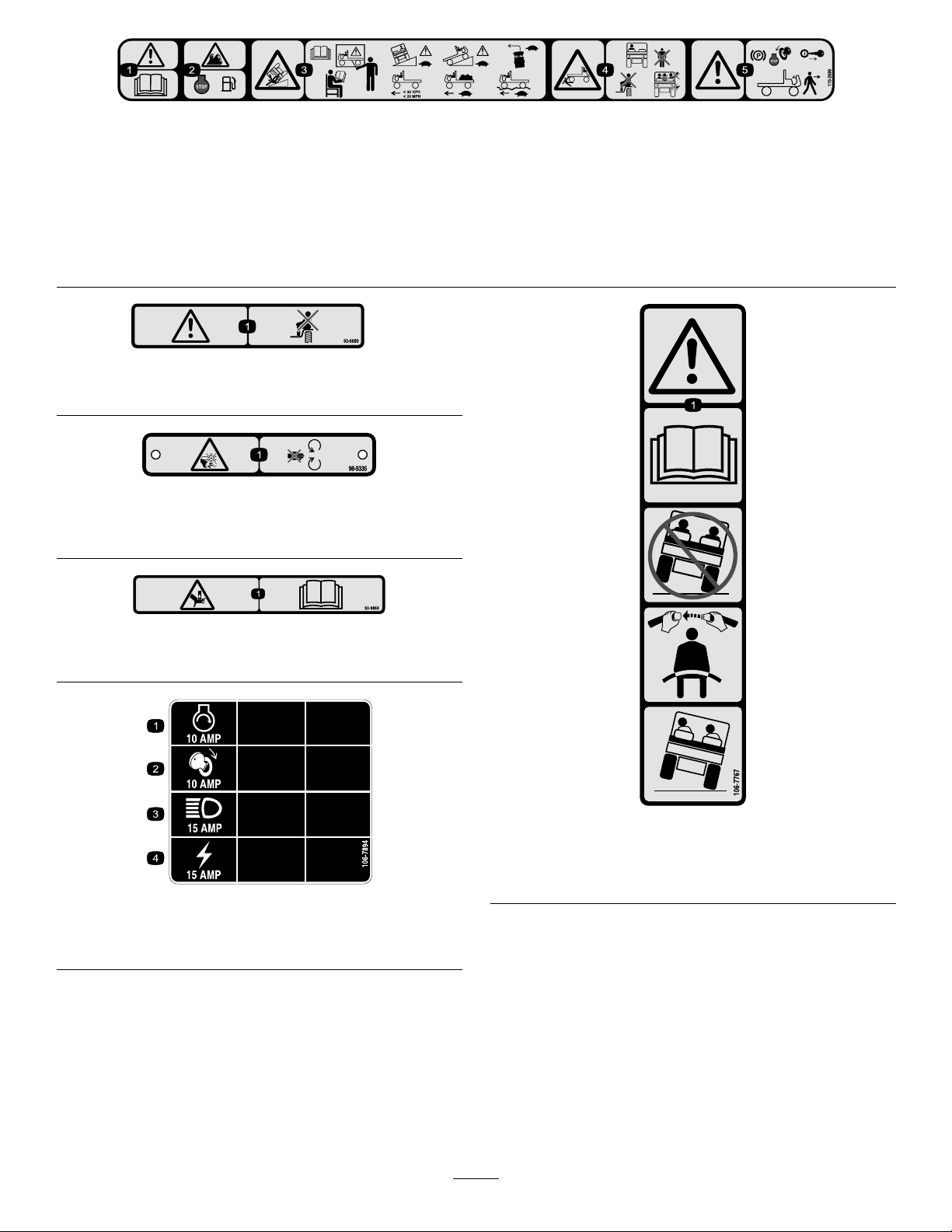

105-4215

1.Entanglementhazard,shaft—stayawayfrommovingparts,

keepallguardsandshieldsinplace.

93-9862

9

Page 10

1.Electricalpowerpoint

106-2353

1.Slow

2.Fast

106-2355

3.Transmission—thirdhigh;

nofastspeed

106-2377

1.Locked

2.Differentiallock9.Entanglementhazard,shaft—keepbystander’sasafe

3.Unlocked10.Retracthydraulics

4.Hydrauliclock11.Extendhydraulics

5.Engage12.Transmission—highspeed

6.Powertake-off(PTO)

7.Disengage14.Parkingbrake

8.Warning—readtheOperator’sManual.

distancefromthevehicle.

13.Transmission—lowspeed

10

Page 11

110-2599

1.Warning—readtheOperator’sManual.

2.Firehazard—stoptheenginebeforefueling.

3.Tippinghazard—readtheOperator’sManual,donotoperatethismachineunlessyouaretrained,usecautionanddriveslowly

whendrivingonslopes,slowdownandturngradually ,donotexceed20mph(32kph),anddriveslowlyoverroughterrainor

whencarryingafullorheavyload.

4.Crushing/dismembermenthazardofbystanders—keepbystandersasafedistancefromthevehicle,donotcarrypassengersin

thecargobed,andkeeparmsandlegsinsideofthevehicleatalltimes.

5.Warning—stoptheengineandremovetheignitionkeybeforeleavingthevehicle.

93-6689

1.Warning—donotcarrypassengers.

98-9335

1.Cutting/dismembermenthazard,fan—stayawayfrom

movingparts.

93–9868

1.Crushinghazardofhand—readtheOperator’sManual.

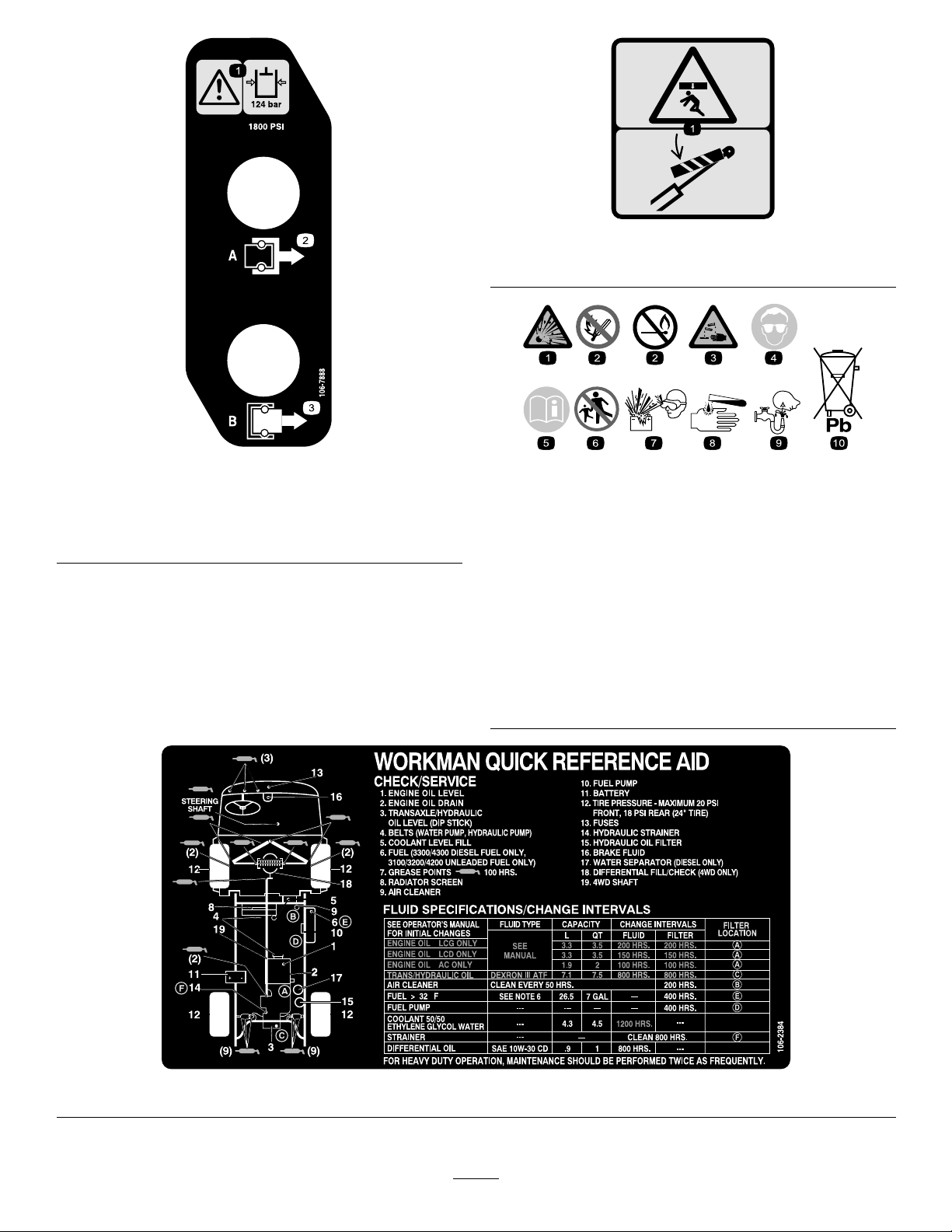

106-7894

1.Engine—start3.Headlights

2.Ignition4.Powerpoint

106-7767

1.Warning—readtheOperator’sManual;avoidtippingthe

machine;weartheseatbelt;leanawayfromthedirection

themachineistipping.

11

Page 12

93-9899

93-9899

1.Crushinghazard—installthecylinderlock.

1.Warning—readthe

hydraulicoilpressure

is124bar(1800psi)

2.CouplerA

106-7888

3.CouplerB

BatterySymbols

Someorallofthesesymbolsareonyourbattery

1.Explosionhazard

2.Nore,opename,or

smoking.

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection9.Flusheyesimmediately

5.ReadtheOperator’s

Manual.

6.Keepbystandersasafe

7.Weareyeprotection;

8.Batteryacidcancause

10.Containslead;donot

distancefromthebattery.

explosivegasescan

causeblindnessandother

injuries

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

discard.

106-2384

12

Page 13

Setup

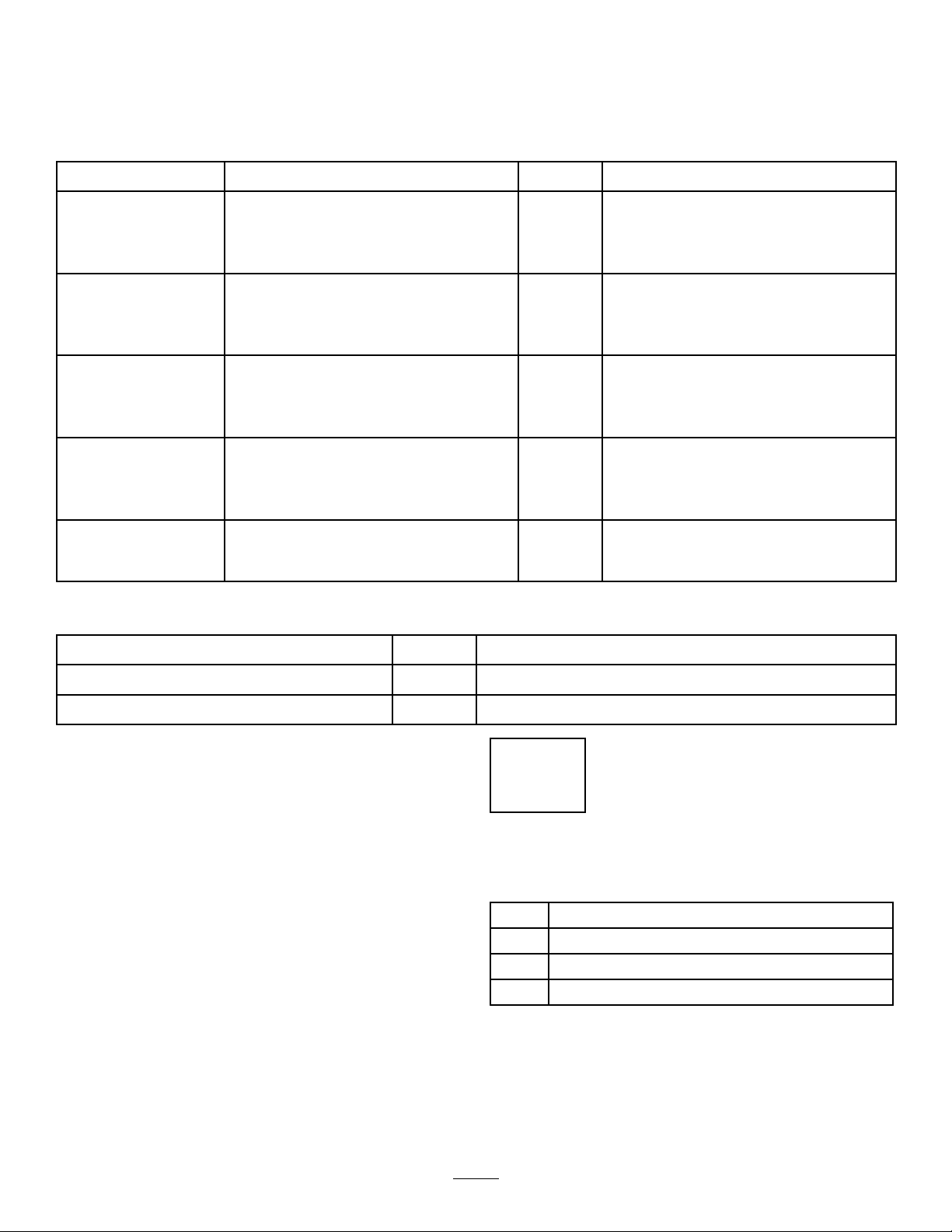

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

MediaandAdditionalParts

Rearfender

Bolts,3/8x1–1/4in

Locknut,3/8

Supportplate

Wheelnut10

Frontwheel2

Wheelnut10

Rearwheel2

Steeringwheel

Cap

Washer1

Foamseal1

Frontfender

Sockethexheadbolt,#10x3/4”in.

Washer,.210I.D.20

Locknut,#10

ROPSframe

bolt1/2x3”in.

Locknuts1/2

Qty.

10

10

10

Use

2

2

2

1

1

2

1

4

4

Mounttherearfenders.

Mountthewheels.

Installthesteeringwheel.

Installthefrontfenders.

MounttheROPS(RolloverProtection

System)

Description

Operator’sManual

PartsManual1

Note:Determinetheleftandrightsideofthemachine

fromthenormaloperatingposition.

Qty.

Use

1

Readbeforeoperatingthevehicle

Usetoreferencepartnumbers

1

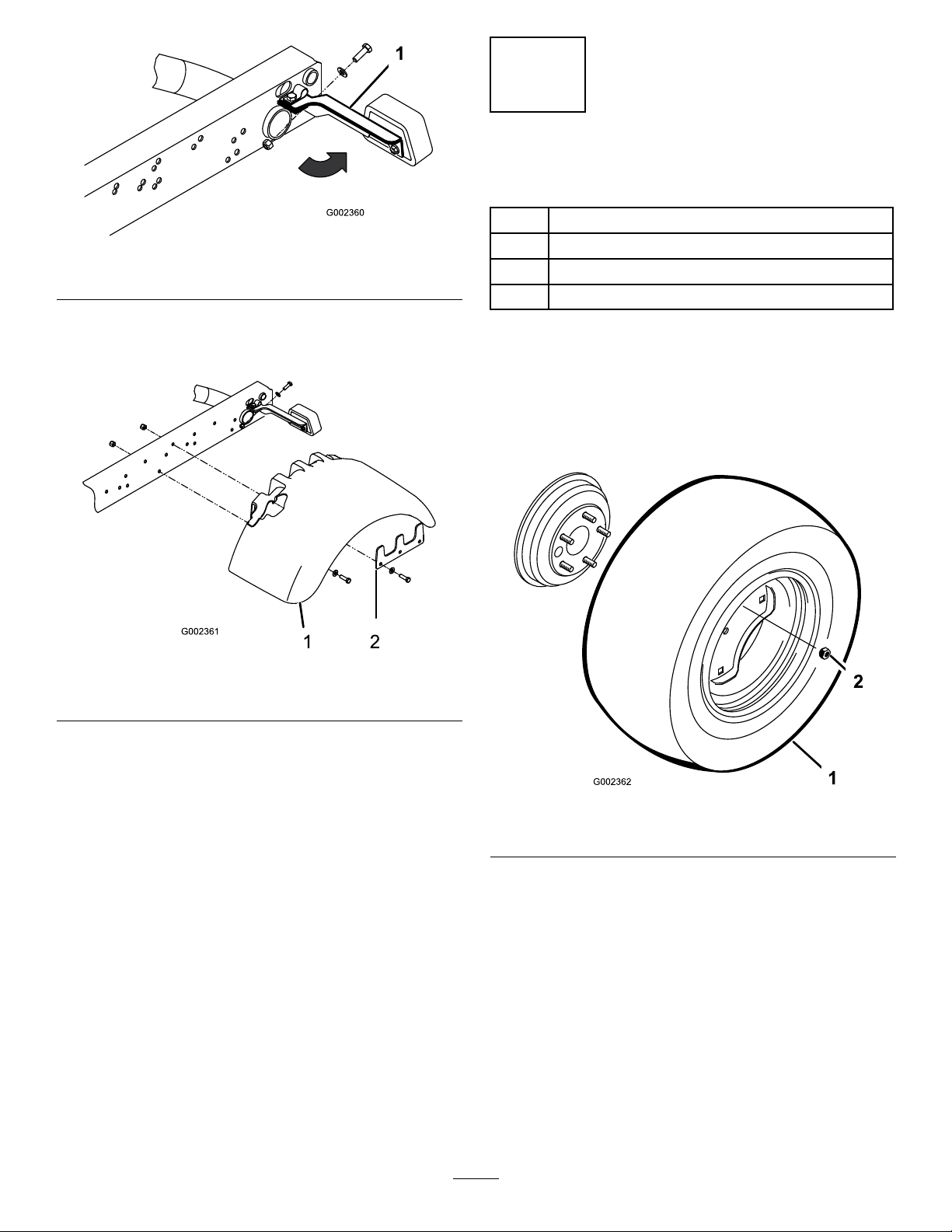

InstalltheRearFenders

Partsneededforthisprocedure:

2

Rearfender

10

Bolts,3/8x1–1/4in

2

Locknut,3/8

2

Supportplate

Procedure

1.Loosenthelocknutsandboltssecuringtaillight

bracketstorightandleftframebrackets(Figure3).

2.Pivottaillightbracketsrearwardandtightenbolts

andlocknuts.

13

Page 14

Figure3

1.Fender

3.Securerearofeachtaillightbrackettorearof

framebracketswitha5/16x1in.bolt,.344”I.D .

atwasherandlocknut,asshowninFigure3.

2

InstalltheWheels

Partsneededforthisprocedure:

10Wheelnut

2Frontwheel

10Wheelnut

2Rearwheel

Procedure

1.Removelugnutssecuringwheelstowheelbrackets.

Retainlugnuts.

2.Mountwheelsandinstalllugnuts.T orquelugnuts

to45–65ft-lb.

Figure4

1.Fender

4.Looselysecureafendertoeachsideofframewith

asupportplate,(5)3/8x1–1/4in.bolts,anda

locknutasshowninFigure4.

Note:Weldnutsareinplacetosecure(4)ofthe

bolts.

5.Tightenallfasteners.

2.Supportplate

Figure5

1.Wheel2.Wheelnut

14

Page 15

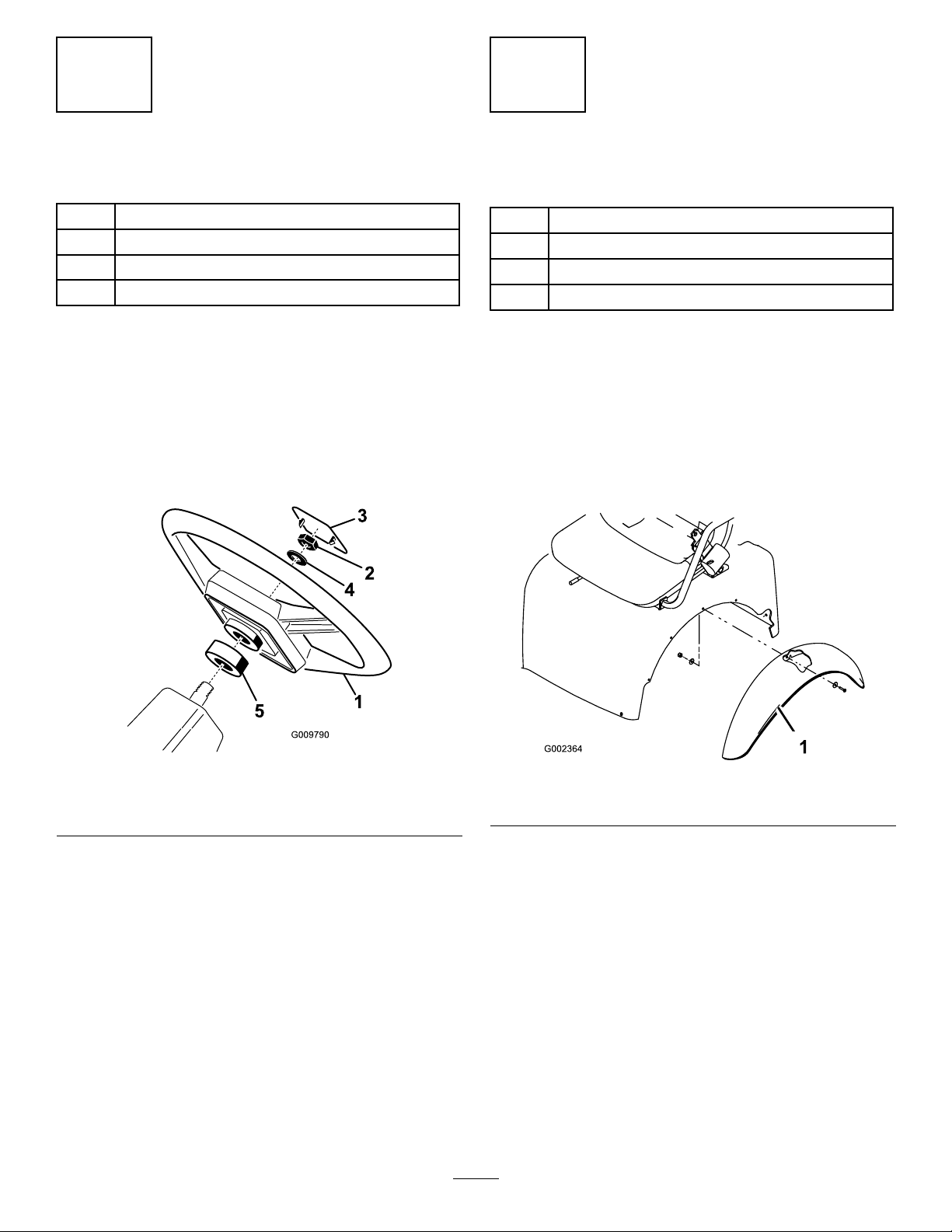

3

4

InstalltheSteeringWheel

Partsneededforthisprocedure:

1

Steeringwheel

1

Cap

1Washer

1Foamseal

Procedure

1.Removethejamnutfromthesteeringshaft.Slide

thefoamseal,steeringwheelandwasheronto

steeringshaft(Figure6).

2.Securesteeringwheeltoshaftwithjamnutand

tightenitto10-15ft-lb.

3.Installcaptosteeringwheel.

InstalltheFrontFenders

Partsneededforthisprocedure:

2

Frontfender

10

Sockethexheadbolt,#10x3/4”in.

20Washer,.210I.D.

10

Locknut,#10

Procedure

1.Alignthevefendermountingholeswiththeholes

ineachsideofbody(Figure7).

2.Mountafendertoeachsideofbodywith(5)#10x

3/4in.socketheadbolts,(10)atwashersand(5)

#10locknuts.Positionawashernexttobolthead

andlocknut.

Figure6

1.Steeringwheel3.Cap

2.Jamnut4.Washer

Figure7

1.Fender

15

Page 16

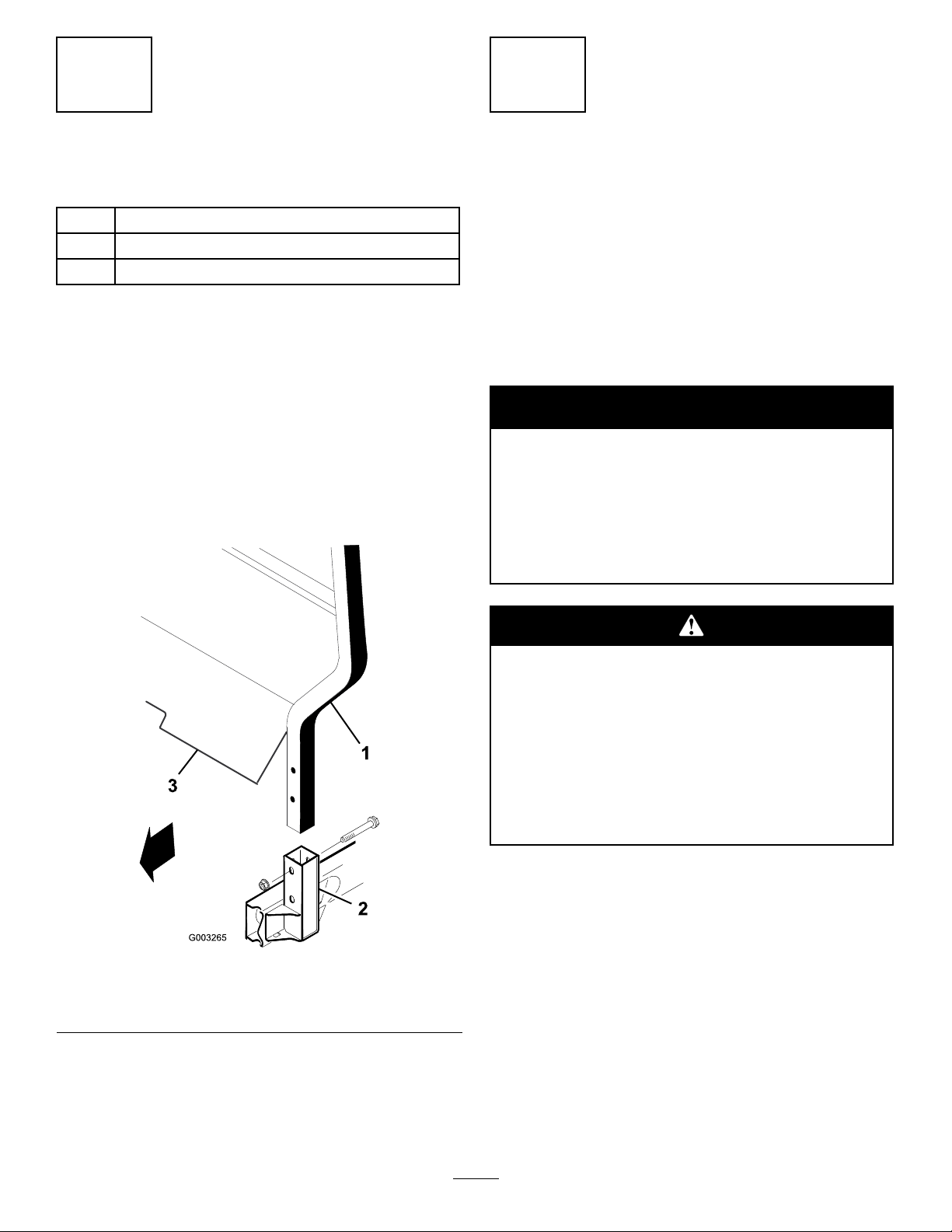

5

6

InstallROPS

Partsneededforthisprocedure:

1

ROPSframe

4

bolt1/2x3”in.

4

Locknuts1/2

Procedure

1.InserteachsideofROPSintomountingbracket

oneachsideofvehicleframe,positioningROPSas

showninFigure8.

Note:TheROPScoverplatemountingboltsmay

havetobeloosenedtoinserttheROPSintothe

mountingbrackets.

2.SecureeachsideofROPStomountingbracketswith

(2)1/2–13x3”lg.boltsandlocknuts.

ActivateandChargethe

Battery

NoPartsRequired

Procedure

Ifbatteryisnotlledwithelectrolyteoractivated,it

mustberemovedfromvehicle,lledwithelectrolyte

andcharged.Bulkelectrolytewith1.260specicgravity

canbepurchasedfromalocalbatterysupplyoutlet.

Warning

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

Washhandsafterhandling.

Figure8

1.ROPS3.ROPScoverplate

2.Mountingbracket

Batteryelectrolytecontainssulfuricacidwhich

isadeadlypoisonandcausessevereburns.

•Donotdrinkelectrolyteandavoidcontact

withskin,eyesorclothing.Wearsafety

glassestoshieldyoureyesandrubbergloves

toprotectyourhands.

•Fillthebatterywherecleanwaterisalways

availableforushingtheskin.

1.Loosenknobssecuringbatterycovertobatterybase

andslidecoveroff.

16

Page 17

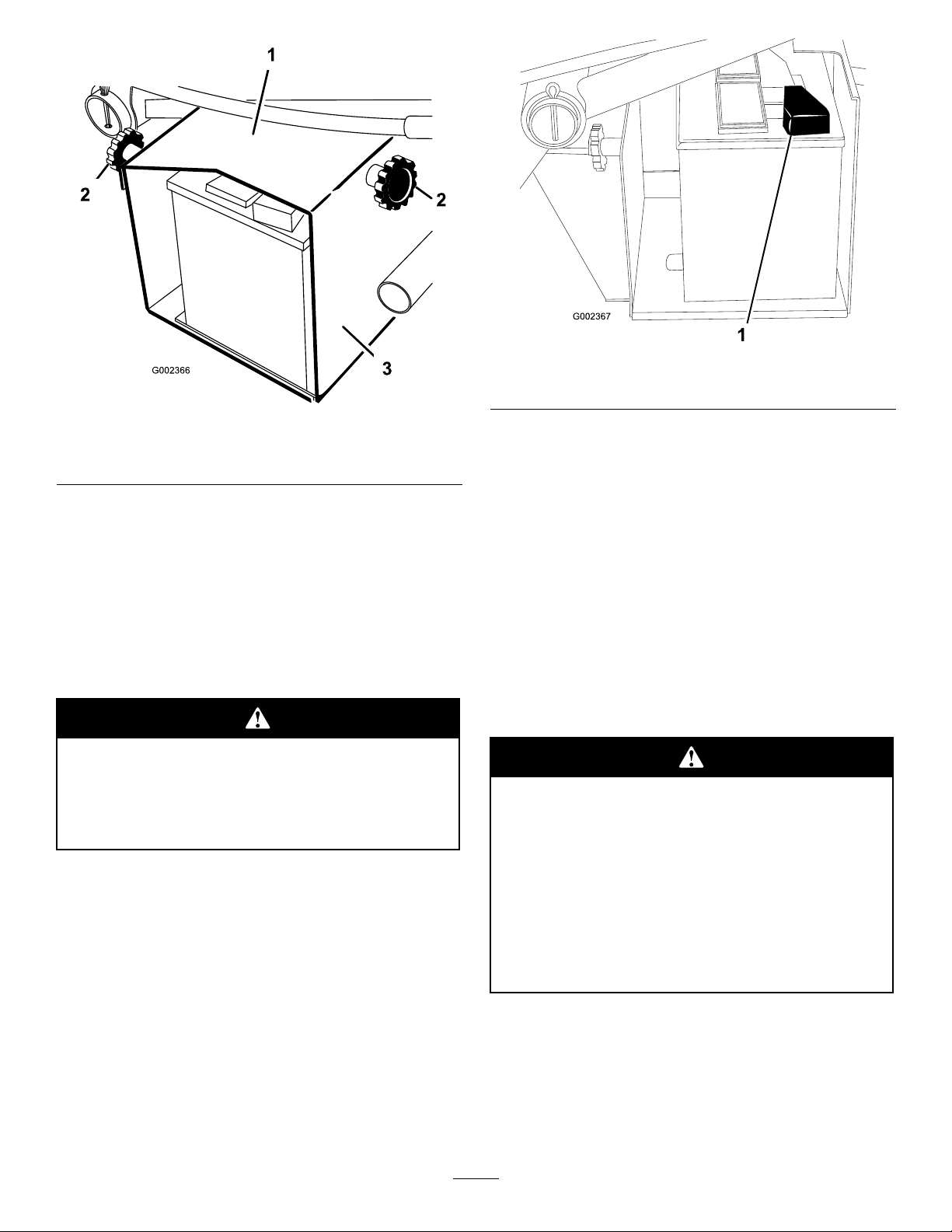

Figure9

1.Batterycover3.Batterybase

2.Knob

2.Removebolt,washersandlocknutsecuringbattery

holddowntobatterybase.Removeholddownand

slidebatteryoutofbatterybase.

3.Removellercapsfrombatteryandslowlylleach

celluntilelectrolyteisjustabovetheplates.

4.Replacellercapsandconnecta3to4ampbattery

chargertothebatteryposts.Chargethebatteryata

rateof3to4amperesfor4to8hours.

Chargingthebatteryproducesgassesthatcan

explode.

Neversmokenearthebatteryandkeepsparks

andamesawayfrombattery.

5.Whenbatteryischarged,disconnectchargerfrom

electricaloutletandbatteryposts.

Figure10

1.Positive(+)cable

6.Removellercaps.Slowlyaddelectrolytetoeach

celluntillevelisuptollring.Installllercaps.

Important:Donotoverllbattery.Electrolyte

willoverowontootherpartsofthevehicleand

severecorrosionanddeteriorationwillresult.

7.Slidebatteryintobatterybasesobatteryterminals

aretowardtherearofthevehicle.

8.Installthepositivecable(red)tothepositive(+)

terminalandthenegativecable(black)tothe

negative(—)terminalofthebatteryandsecure

withboltsandnuts.Slidetherubberbootoverthe

positiveterminaltopreventpossibleshort–outfrom

occurring.

Incorrectbatterycableroutingcoulddamage

themachineandcablescausingsparks.Sparks

cancausethebatterygassestoexplode,

resultinginpersonalinjury.

•Alwaysdisconnectthenegative(black)

batterycablebeforedisconnectingthe

positive(red)cable.

•Alwaysconnectthepositive(red)battery

cable

9.Installbatteryholddownandsecuretobasewith

bolt,washersandlocknut.

10.Reinstallbatterycovertobatterybaseandtighten

knobs.

17

Page 18

7

FullBedRemoval

Thefullbedweighsapproximately325pounds,

sodonottrytoinstallorremoveitbyyourself.

Useanoverheadhoistorgetthehelpoftwoor

threeotherpeople.

NoPartsRequired

Procedure

1.Startengine.Engagehydraulicliftleverandlower

beduntilcylindersarelooseinslots.Releaseliftlever

andturnoffengine.

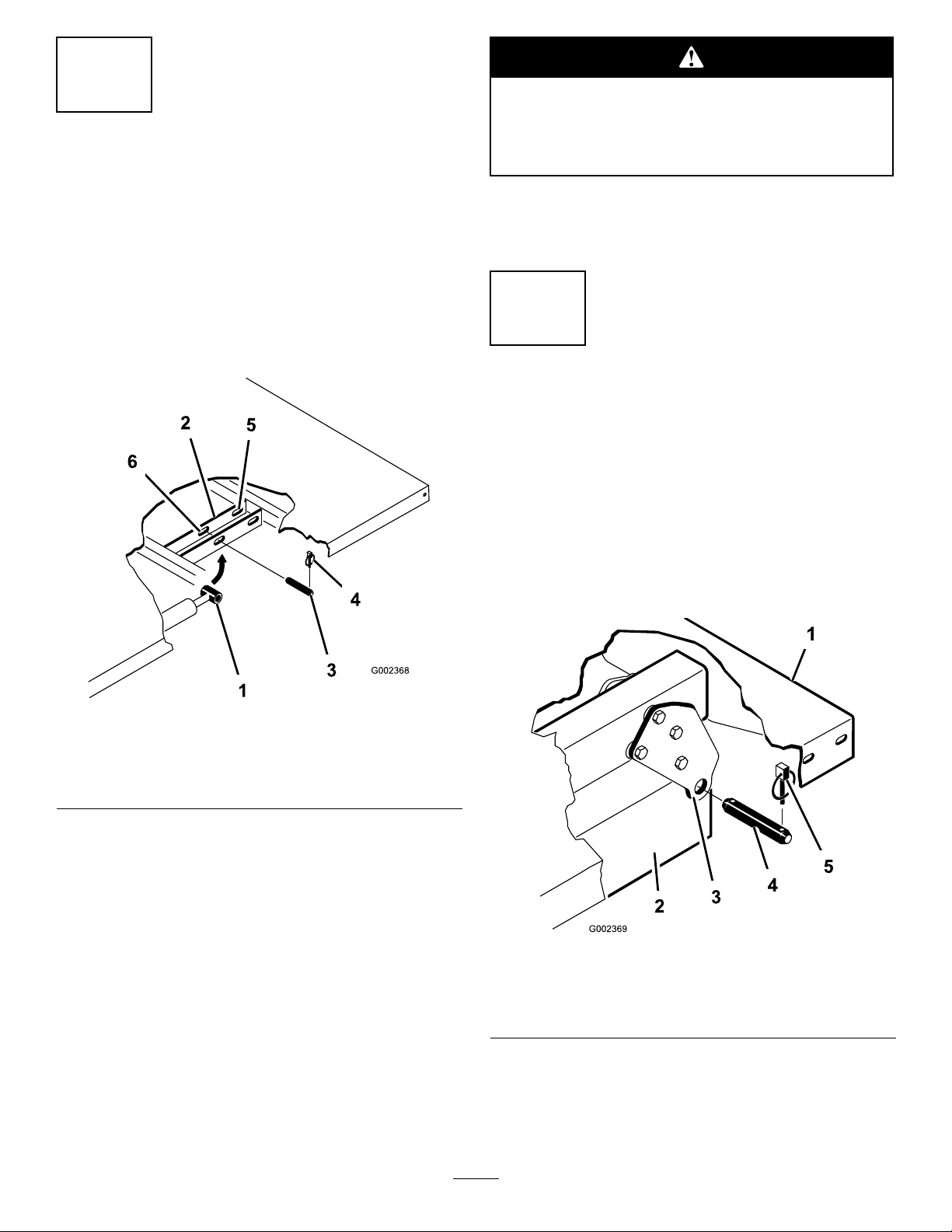

2.Removelynchpinsfromouterendsofcylinderrod

clevispins(Figure11).

6.Storecylindersinstorageclips.Engagehydrauliclift

lockleveronvehicletopreventaccidentalextension

ofliftcylinders.

8

Re-InstalltheFullBed

NoPartsRequired

Procedure

Note:Ifbedsideswillbeinstalledonatbed,itis

easiertoinstallthembeforebedisinstalledonvehicle.

Note:Assurerearpivotplatesareboltedtothebed

frame/channelsothatlowerendanglestotherear

(Figure12).

Figure11

1.Bedmountingplate4.Lynchpin

2.Cylinderrodend5.Rearslots(Fullbed)

3.Clevispin6.Frontslots(2/3bed)

3.Removeclevispinssecuringcylinderrodendsto

bedmountingplatesbypushingpinstowardsinside

(Figure12).

4.Removelynchpinsandclevispinssecuringpivot

bracketstoframechannels(Figure12).

5.Liftbedoffvehicle.

Figure12

1.Leftrearcornerofbed4.Clevispin

2.Vehicleframechannel

3.Pivotplate

Note:Makesurespacerbracketsandwearblocks

(Figure13)areinstalledorradiatorcovermaybe

damaged.Carriageboltsheadstobepositionedinside

themachine.

5.Lynchpin

18

Page 19

ProductOverview

Thefullbedweighsapproximately325pounds,

sodonottrytoinstallorremoveitbyyourself.

Useanoverheadhoistorgetthehelpoftwoor

threeotherpeople.

Figure13

1.Spacerbracket3.Carriagebolt

2.Wearblock

Controls

Note:Determinetheleftandrightsideofthemachine

fromthenormaloperatingposition.

AcceleratorPedal

Theacceleratorpedal(Figure14)givestheoperatorthe

abilitytovaryengineandgroundspeedofthevehicle,

whenthetransmissionisingear.Depressingthepedal

increasesengineRPMandgroundspeed.Releasing

pedalwilldecreaseengineRPMandgroundspeedof

themachine.

1.Assureliftcylindersarefullyretracted.

2.Carefullysetbedontovehicleframealigningrearbed

pivotplateholeswithholesinrearframechannel

andinstall(2)clevispinsandlynchpins(Figure12).

3.Withbedlowered,secureeachcylinderrodend,to

appropriateslotsinbedmountingplateswithclevis

pinandlynchpin.Insertclevispinfromoutsideof

bedwithlynchpintowardoutside(Figure12).Rear

slotsareforfullbedinstallationandfrontslotsare

for2/3bedinstallation.

Note:Enginemayneedtobestartedtoextend

orretractcylindersforalignmentwithholes.Keep

ngersout!

Note:Unusedslotcanbepluggedwithaboltand

nuttopreventassemblyerrors.

4.Startengineandengagehydraulicliftlevertoraise

bed.Releaseliftleverandturnoffengine.Installthe

bedsafetysupporttopreventaccidentalloweringof

thebed.RefertoUsingBedSafetySupport.

5.Installlynchpinstoinsideendsofclevispins.

Figure14

1.Acceleratorpedal3.Brakepedal

2.Clutchpedal

ClutchPedal

Theclutchpedal(Figure14)mustbefullydepressed

todisengageclutchwhenstartingengineorshifting

transmissiongears.Releasepedalsmoothlywhen

transmissionisingeartopreventunnecessarywearon

transmissionandotherrelatedparts.

Important:Donotrideclutchpedalduring

operation.Clutchpedalmustbefullyoutorclutch

willslipcausingheatandwear.Neverholdthe

vehiclestoppedonahillusingtheclutchpedal.

Damagetotheclutchmayoccur.

BrakePedal

Thebrakepedal(Figure14)isusedtoapplyservice

brakestostoporslowvehicle.

Note:Ifautomatictailgatereleasehasbeen

installedonbed,makesurefrontdumplinkrodhas

beenplacedoninsideofleftsideclevispinbefore

lynchpinisinstalled.

19

Page 20

Wornormisadjustedbrakesmayresultin

personalinjury.Ifbrakepedaltravelstowithin

1–1/2”ofthevehicleoorboard,thebrakes

mustbeadjustedorrepaired.

GearShiftLever

Fullydepressclutchpedalandmoveshiftlever(@@@5)

intodesiredgearselection.Adiagramoftheshift

patternisindicatedbelow .

Important:Donotshiftthetransaxletothereverse

orforwardgearunlessthevehicleisstandingstill.

Damagetotransaxlemayoccur.

Downshiftingfromtoohighaspeedcan

causetherearwheelstoskidresultinginloss

ofvehiclecontrolaswellasclutchand/or

transmissiondamage.Shiftsmoothlytoavoid

grindinggears.

DifferentialLock

Allowsrearaxletobelockedforincreasedtraction.

Differentiallock(Figure16)maybeengagedwith

vehicleinmotion.Moveleverforwardandtotheright

toengagelock.

Figure16

1.Gearshiftlever4.Hydraulicliftlock

2.Parkingbrake

3.Hydraulicbedlift6.High–lowrangeshifter

5.Differentiallock

ParkingBrake

Whenevertheengineisshutoff,theparkingbrake

(Figure16)mustbeengagedtopreventaccidental

movementofthevehicle.Toengagetheparkingbrake,

pullbackonlever.Todisengage,pushleverforward.

Makesureparkingbrakeisreleasedbeforemoving

vehicle.Ifvehicleisparkedonasteepgrade,makesure

parkingbrakeisapplied.Also,shiftthetransmission

into1stgearonauphillgradeorreverseonadownhill

grade.Placechocksatthedownhillsideofwheels.

HydraulicLift

Raisesandlowersbed.Moverearwardtoraise,forward

tolower(Figure16).

Important:Whenloweringbed,holdleverin

forwardpositionfor1or2secondsafterbed

contactsframetosecureitinloweredposition.

Donotholdthehydraulicliftineithertheraiseor

lowerposition,formorethan5seconds,oncethe

cylindershavereachedtheendoftheirtravel.

HydraulicLiftLock

Note:Vehiclemotionplusaslightturnisrequiredto

engageordisengagedifferentiallock.

Turningwiththedifferentiallockoncanresult

inlossofvehiclecontrol.Donotoperatewith

differentiallockonwhenmakingsharpturnsor

athighspeeds.Refertousingthedifferential

lock.

Locksliftleversohydrauliccylindersdonotoperate

whenvehicleisnotequippedwithabed(Figure16).

ItalsolocksliftleverinONpositionwhenusingthe

hydraulicsforattachments.

High–LowRangeShifter

Addsthreeadditionalspeedsforprecisespeedcontrol

(Figure16).

•Vehiclemustbecompletelystoppedbeforeshifting

betweenHighandLowrange.

•Shiftonlyonlevelground.

20

Page 21

•Depressclutchpedalfully.

•MoveleverfullyforwardforHighandfullyrearward

forLow .

HIGHisforhigherspeeddrivingonlevel,drysurfaces

withlightloads.

LOWisforlowspeeddriving.Usethisrangewhen

greaterthannormalpowerorcontrolisrequired.For

example,steepgrades,difcultterrain,heavyloads,slow

speedbuthighenginespeed(spraying).

Important:ThereisalocationbetweenHIGHand

LOWinwhichthetransaxleisinneitherrange.

Thisshouldnotbeusedasaneutralposition

becausethevehiclecouldmoveunexpectedlyifthe

HIGH–LOWshifterisbumpedandthegearshift

leverisingear.

CoolantTemperatureGaugeandLight

Registerscoolanttemperatureinengine.Operatesonly

whenignitionswitchisinOnposition(Figure17).

Indicatorlightwillilluminateifengineoverheats.

ChargeIndicator

Illuminateswhenbatteryisbeingdischarged.Iflight

illuminatesduringoperation,stopvehicle,turnoff

engineandcheckforpossiblecauses,suchasalternator

belt(Figure17).

starts.ThekeywillmoveautomaticallytotheON

position.Toshutengineoff,rotatekeycounterclockwise

toOFFposition.

Figure17

1.Chargeindicator

2.Coolanttemperature

gauge&light

3.Hourmeter

4.Ignitionswitch

5.3rdhighlockoutswitch

Important:Ifalternatorbeltislooseorbroken,do

notoperatevehicleuntiladjustmentorrepairis

complete.Failuretoobservethisprecautionmay

resultindamagetotheengine.

Tocheckoperationofwarninglights:

•Applyparkingbrake.

•Turnignitionkeyto“ON”,butdonotstartengine.

Thecoolanttemperature,chargeindicatorandoil

pressurelightsshouldglow.Ifanylightdoesnot

function,eitherabulbisburnedoutorthereisa

malfunctioninthesystemwhichmustberepaired.

HourMeter

Indicatesthetotalhoursofmachineoperation.The

hourmeter(Figure17)startstofunctionwheneverthe

keyswitchisrotatedto“ON”positionorifengineis

running.

IgnitionSwitch

Theignitionswitch(Figure17),usedtostartandstop

theengine,hasthreepositions:OFF ,RUN(GLOW)

andSTART .Rotatekeyclockwise—STARTposition

—toengagestartermotor.Releasekeywhenengine

3rdHighLockoutSwitch

Movingswitch(Figure17)toslowpositionand

removingkeywillpreventuseofthirdgearwheninthe

Highrange.Enginewillshutoffifshiftleverismoved

tothirdgearwheninHighrange.Keyisinstalledwith

teethpointingdownward.Pushkeyintoturn.Keyis

removableineitherposition.

GlowPlugIndicator

Glowplugindicator(Figure18)willglowredwhenthe

glowplugsareactivated.

Important:Theglowplugindicatorwillturn

on,foranadditional15seconds,whentheswitch

returnstotheSTARTposition.

LightSwitch

Toggleswitch(Figure18)toactivateheadlights.Push

toturnlights“ON”.

OilPressureWarningLight

Lightglows(Figure18)ifengineoilpressuredrops

belowasafelevelwhileengineisrunning.Iflight

21

Page 22

ickersorremainsON,stopvehicle,turnoffengineand

checkoillevel.Ifoillevelwaslow ,butaddingoildoes

notcauselighttogooutwhenengineisrestarted,turn

engineoffimmediatelyandcontactyourlocalTORO

distributorforassistance.

Tocheckoperationofwarninglights:

1.Applyparkingbrake.

2.Turnignitionkeyto“ON”,butdonotstartengine.

Theoilpressurelightshouldglowred.Iflightdoes

notfunction,eitherabulbisburnedoutorthereisa

malfunctioninthesystemwhichmustberepaired.

Note:Ifenginewasjustturnedoff,itmaytake1to2

minutesforlighttocomeon.

1.Passengerhandhold

SeatAdjustingLever

Figure19

2.Storagecompartment

FuelGauge

Showsamountoffuelintank.Operatesonlywhen

ignitionswitchisin“ON”position(Figure18).

Figure18

1.Lightswitch

2.Oilpressurewarninglight5.Tachometer(Optional)

3.Fuelgauge6.Horn

4.Glowplugindicatorlight

HornButton

Pressingbuttonactivateshorn(Figure18).

Tachometer

Optional(Figure18).

PassengerHandHold

Ondashboard(Figure19).

Theseatscanbeadjustedforeandaftforoperator

comfort(Figure20).

Figure20

1.Seatadjustinglever

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

Dimensions

OverallWidth

OverallLength

BaseWeight(Dry

w/oatbed)

RatedCapacity

(includes200lb.

operator,200lb.

passengerandloaded

attachment).

Maximum.Gross

VehicleWeight

TowCapacity

63”

128.25”w/obed

130.38”w/fullbed

136.38”w/2/3bedinrearmounting

location

Model07362–1929lbs.

Model07364–2029lbs.

Model07362–2321lbs.

Model07364–2221lbs.

4,250lbs.

Tongueweight200lbs.

Maximumtrailerweight1,500lbs.

22

Page 23

Dimensions(cont'd.)

GroundClearance7”w/noload

WheelBase70”

WheelTread(center

linetocenterline)

Height

Front46”

Rear47.7”

75”totopofROPS

Attachments/Accessories

AselectionofToroapprovedattachmentsand

accessoriesareavailableforusewiththemachineto

enhanceandexpanditscapabilities.Contactyour

AuthorizedServiceDealerorDistributororgoto

www.Toro.comforalistofallapprovedattachments

andaccessories.

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

Beforeservicingormakingadjustmentstothe

machine,stopengine,setparkingbrakeand

removekeyfromtheswitch.Anyloadmaterial

mustberemovedfrombedorotherattachment

beforeworkingunderraisedbed.Neverwork

underaraisedbedwithoutpositioningsafety

supportonafullyinstalledcylinderrod.

CheckCrankcaseOil

ServiceInterval:Beforeeachuseordaily

Aftertherst50hours

Every150hours

Theengineisshippedwithapproximately3.5quarts

(w/lter)ofoilinthecrankcase;however,levelofoil

mustbecheckedbeforeandaftertheengineisrst

started.

Note:Thebesttimetochecktheengineoiliswhen

theengineiscoolbeforeithasbeenstartedforthe

day.Ifithasalreadybeenrun,allowtheoiltodrain

backdowntothesumpforatleast10minutesbefore

checking.Iftheoillevelisatorbelowthe“add”mark

onthedipstick,addoiltobringtheoilleveltothe“full”

mark.DONOTOVERFILL.Iftheoillevelisbetween

the“full”and“add”marks,nooiladditionisrequired.

1.Positionmachineonalevelsurface.

2.Removedipstickandwipeitwithacleanrag.Insert

dipstickintotubeandmakesureitisseatedfully .

Removedipstickandchecklevelofoil.

23

Page 24

Figure21

1.Dipstick

3.Theengineusesanyhigh-quality10W30detergent

oilhavingtheAmericanPetroleumInstitute-API“serviceclassication”CForhigher.Choosea

viscosityaccordingtothetableinFigure22.

Note:Whenaddingoil,removedipsticktoallow

properventing,pouroilslowlyandcheckthelevel

oftenduringthisprocess.DONOTOVERFILL.

Important:Whenaddingengineoilorlling

oil,theremustbeclearancebetweentheoilll

deviceandtheoilllholeinthevalvecoveras

showninFigure24.Thisclearanceisnecessary

topermitventingwhenlling,whichprevents

oilfromoverrunningintobreather.

Figure22

4.Ifoillevelislow,removellercapandaddenough

oiltoraiseleveltoFULLmarkondipstick.

Figure23

1.Fillercap

Figure24

5.Installthedipstickrmlyinplace.

Important:Checklevelofoilevery8operating

hoursordaily.Changeoilandlterinitiallyafter

therst50hoursofoperation,thereafter,change

oilandlterevery150hours.However,change

oilmorefrequentlywhenengineisoperatedin

extremelydustyordirtyconditions.

Note:Afterllingorchangingoil,startandrunthe

engineatidlefor30seconds.Shutengineoff.W ait30

secondsandcheckoillevel.Addenoughoiltoraise

leveltoFULLmarkondipstick.

FillFuelTank

Fueltankcapacityisapproximately7gallons.

TheenginerunsonNo.2–Dor1–Dautomotivetype

dieselfuelwithaminimumcetaneratingof40.

Note:Highercetaneratedfuelmayberequired

ifmachineistobeusedathighaltitudesand

low-atmospherictemperatures.

1.Cleanareaaroundfueltankcap.

2.Removefueltankcap.

24

Page 25

Undercertainconditions,dieselfuelandfuel

vaporsarehighlyammableandexplosive.A

reorexplosionfromfuelcanburnyouand

othersandcancausepropertydamage.

•Useafunnelandllthefueltankoutdoors,

inanopenarea,whentheengineisoffand

iscold.Wipeupanyfuelthatspills.

•Donotllthefueltankcompletelyfull.Add

fueltothefueltankuntilthelevelis1in.

(25mm)belowthebottomofthellerneck.

Thisemptyspaceinthetankallowsthefuel

toexpand.

•Neversmokewhenhandlingfuel,andstay

awayfromanopenameorwherefuel

fumesmaybeignitedbyaspark.

•Storefuelinaclean,safety-approved

containerandkeepthecapinplace.

3.Filltanktoaboutoneinchbelowtopoftank,

(bottomofllerneck).DONOTOVERFILL.

Theninstallcap.

Iftheenginehasbeenrunning,thepressurized,

hotcoolantcanescapeandcauseburns.

•Donotopentheradiatorcapwhenthe

engineisrunning.

•Allowenginetocoolatleast15minutes

oruntiltheradiatorcapiscoolenoughto

touchwithoutburninghand.

•Usearagwhenopeningtheradiatorcap,

andopenthecapslowlytoallowsteamto

escape.

2.Checkcoolantlevel.Coolantshouldbeupto

COLDlineonreservetank,whenengineiscold.

4.Wipeupanyfuelthatmayhavespilledtopreventa

rehazard.

Figure25

1.Fueltankcap

CheckCoolingSystem

ServiceInterval:Beforeeachuseordaily

Capacityofcoolingsystemisapproximately4qts.

Thecoolingsystemislledwitha50/50solutionof

waterandpermanentethyleneglycolanti–freeze.

1.Parkmachineonalevelsurface.

Figure26

1.Reservetank

2.Hotline

3.Coldline

3.Ifcoolantislow,removereservetankcapandadd

a50/50mixtureofwaterandpermanentethylene

glycolanti–freeze.DONOTOVERFILL.

4.Installreservetankcap.

CheckTransaxle/Hydraulic

Fluid

ServiceInterval:Beforeeachuseordaily

ThetransaxlereservoirislledwithDexronIIlATF .

Checklevelbeforeengineisrststartedandevery8

hoursordaily ,thereafter.Capacityofsystemis7.5qt.

1.Positionthevehicleonalevelsurface.

2.Cleanareaarounddipstick.

3.Unscrewdipstickfromtopoftransaxleandwipe

itwithacleanrag.

25

Page 26

CheckTorqueOfWheelNuts

ServiceInterval:Aftertherst2hours

Aftertherst10hours

Every200hours

Failuretomaintainpropertorqueofthewheel

nutscouldresultinfailureorlossofwheeland

mayresultinpersonalinjury.

Torquethefrontandrearwheelnutsto45–65

Figure27

1.Dipstick

ft.-lb.

4.Screwdipstickintotransaxleandmakesureitis

seatedfully.Unscrewdipstickandcheckuidlevel.

Fluidshouldbeuptotopofatportionofdipstick.

Iflevelislow ,addenoughuidtoachievethe

properlevel.

CheckFrontDifferentialOil

Fourwheeldriveonly

ServiceInterval:Every100hours/Monthly

(whichevercomesrst)

Thedifferentialislledwith10W30oil.Capacityof

systemis1qt.

1.Positionthevehicleonalevelsurface.

2.Cleanareaaroundll/checkplugonsideof

differential.

3.Removell/checkplugandchecklevelofoil.Oil

shouldbeuptohole.Ifoilislow,add10W30oil.

4.Re–installll/checkplug.

CheckTirePressure

ServiceInterval:Beforeeachuseordaily

Maximumairpressureinfronttiresis20psiandrear

(24”)tiresis18psi.

1.Theairpressureneededisdeterminedbythe

payloadcarried.

2.Thelowertheairpressure,thelessthecompaction

andtiremarksareminimized.Lowerpressure

shouldnotbeusedforheavypayloadsathigh

speeds.Tiredamagemayresult.

3.Higherpressuresshouldbeusedforheavier

payloadsathigherspeeds.Donotexceedthe

maximumpressure.

CheckBrakeFluid

ServiceInterval:Beforeeachuseordaily

Every1,000hours/Every2years

(whichevercomesrst)

Thebrakeuidreservoirisshippedfromthefactory

lledwith“DOT3”brakeuid.Checklevelbefore

engineisrststartedandevery8hoursordaily ,

thereafter.

1.Frontdifferential

2.Fill/checkplug

1.Parkmachineonalevelsurface.

2.Loosenknobsecuringcupholdertodash

(Figure29).Removecupholderfromdash.

Figure28

3.Drainplug

26

Page 27

Figure29

1.Cupholder

3.FluidlevelshouldbeuptoFULLlineonreservoir.

2.Knob

Pre–startingChecks

Safeoperationbeginsbeforetakingthevehicleoutfor

aday’swork.Youshouldchecktheseitemseachtime:

•Checktirepressure.

Note:Thesetiresaredifferentthancartires,they

requirelesspressuretominimizeturfcompaction

anddamage.

•Checkalluidlevelsandaddtheappropriate

amountofTorospecieduids,ifanyarefound

tobelow .

•Checkthefrontoftheradiator.Removeanydebris

andcleantheradiatorscreen.

•Checkbrakepedaloperation.

•Checktoseethatthelightsandhornareworking.

•Turnsteeringwheeltotheleftandrighttocheck

steeringresponse.

•Checkforoilleaks,loosepartsandanyother

noticeablemalfunctions.Makesureengineisoff

andallmovingpartshavestoppedbeforechecking

foroilleaks,loosepartsandothermalfunctions.

Figure30

1.Brakeuidreservoir

4.Ifuidlevelislow,cleanareaaroundcap,remove

reservoircapandlltoproperlevel.DONOT

OVERFILL.

5.Reinstallcupholdertodash.

CheckFanBeltTension

Checkallbeltsforwear,crackingorimpropertension.

Checktensionbydepressingbeltatmidspanoffan

anddriveshaftpulleyswith22lbs.offorce.Anew

beltshoulddeect.48–.58in.Ausedbeltshould

deect.55–.65in.Ifdeectionisincorrect,proceedto

page45fortensioningprocedure.Ifcorrect,continue

operation.

Important:Improperbelttensionmayresultin

increasedsteeringeffort.

Ifanyoftheaboveitemsarenotcorrect,notifyyour

mechanicorcheckwithyoursupervisorbeforetaking

thevehicleoutfortheday .Yoursupervisormaywant

youtocheckotheritemsonadailybasis,soaskwhat

yourresponsibilitiesare.

StartingEngine

•Initialstartupofanewmachine.

•Enginehasceasedrunningduetolackoffuel.

•Maintenancehasbeenperformeduponfuelsystem

components;i.e.,lterreplaced,separatorserviced,

etc.

RefertoBleedingTheFuelSystem.

1.Sitonoperator’sseatandengageparkingbrake.

2.DisengagePTO(ifsoequipped)andreturnhand

throttlelevertoOFFposition(ifsoequipped).

3.MoveshiftlevertoNEUTRALpositionand

depressclutchpedal.

4.Makesurethehydraulicliftleverisinthecenter

position.

5.Keepfootoffacceleratorpedal.

6.TurnignitionswitchtoONposition.Whenglow

plugindicatorlightgoesoff,engineisreadyto

START.

7.RotateignitionkeyswitchtoSTARTposition

Releasekeyimmediatelywhenenginestartsand

allowittoreturntoRUNposition.

27

Page 28

Note:Theglowplugindicatorwillturnon,foran

additional15seconds,whentheswitchreturnstothe

STARTposition.

Note:Donotrunstartermotormorethan10seconds

atatimeorprematurestarterfailuremayresult.If

enginefailstostartafter10seconds,turnkeytoOFF

position.Recheckcontrolsandprocedures,wait10

additionalsecondsandrepeatstartingoperation

DrivingVehicle

1.Releaseparkingbrake.

2.Fullydepressclutchpedal.

3.Movegearshiftleverto1stgear.

4.Releaseclutchpedalsmoothlywhiledepressing

acceleratorpedal.

5.Whenvehiclegainsenoughspeed,removefoot

fromacceleratorpedal,fullydepressclutchpedal,

movegearshiftlevertonextgearandreleaseclutch

pedalwhiledepressingacceleratorpedal.Repeat

procedureuntildesiredspeedisattained.

Note:Alwaysstopvehiclebeforeshiftingto

reverseorforward.

Usethechartbelowtodeterminethegroundspeed

ofthevehicleat3600RPM.

Gear

1L82.83:12.94.7

2L54.52:14.57.2

3L31.56:1

1H32.31:17.612.2

2H21.27:111.518.5

3H12.31:119.831.9

RL86.94:12.84.5

RH33.91:17.111.6

RangeRatio

Speed

(mph)

7.7

Speed

(kmh)

12.5

StoppingEngine

Tostopengine,rotateignitionkeytoOFFandengage

parkingbrake.Removekeyfromswitchtoprevent

accidentalstarting.

NewVehicleBreak–in

YourW orkmanisreadyforwork.T oprovideproper

performanceandlongvehiclelife,followthese

guidelinesfortherst100operatinghours.

•Checktheuidandengineoillevelsregularly

andbealertforindicationsofoverheatinginany

componentofthevehicle.

•Afterstartingacoldengine,letitwarmupforabout

15secondsbeforeshiftingintogear.

•Avoidracingtheengine.

•Toassureoptimumperformanceofthebrake

system,burnish(break–in)thebrakesbeforeuse.

Toburnishbrakes:Operatethevehicleatfullspeed

for3minutes,applythebrakesfor30secondswhile

drivingin1stgear.Repeatthesesteps20to30

times.T overifythebrakesarecompletelyburnished

removeareartireandinspectthebrakedrumfor

residue.Theresiduecolorshouldbelightgreyto

almostwhitecolor.

•Varyvehiclespeedsduringoperation.Avoid

excessiveidling.Avoidfaststartsandquickstops.

•Abreak–inoilfortheengineisnotrequired.

Originalengineoilisthesametypespeciedfor

regularoilchanges.

•RefertoMaintenancesectionofOperator’sManual

foranyspeciallowhourchecks.

CheckInterlockSystem

Thepurposeoftheinterlocksystemistopreventthe

enginefromcrankingorstartingunlesstheclutchpedal

isdepressed.

Note:Avoidlongperiodsofengineidling.

Important:Donotholdfrontwheelsturned

againsttherightorleftstopsforlongerthan

5seconds.

6.Donotattempttopushortowvehicletogetit

started.Damagetodrivetraincouldresult.

StoppingVehicle

Tostopmachine,removefootfromacceleratorpedal,

depressclutchpedal,thendepressbrakepedal.

Toverifyclutchinterlockswitchoperation:

1.Sitonoperator’sseatandengageparkingbrake.

MoveshiftlevertoNEUTRALposition.

Note:Enginewillnotcrankifhydraulicliftlever

islockedintheforwardposition.

2.Withoutdepressingclutchpedal,rotatekey

clockwisetostartposition.

3.Ifenginecranksorstarts,thereisamalfunctionin

theinterlocksystemthatmustberepairedbefore

operatingvehicle.

Toverifyhydraulicliftleverinterlock:

28

Page 29

1.Sitonoperator’sseatandengageparkingbrake.

MoveshiftlevertoNEUTRALposition.Makesure

thehydraulicliftleverisinthecenterposition.

2.Depressclutchpedal.

3.Movethehydraulicliftleverforwardandrotatekey

clockwisetostartposition.

4.Ifenginecranksorstarts,thereisamalfunctionin

theinterlocksystemthatmustberepairedbefore

operatingvehicle.

Ifsafetyinterlockswitchesaredisconnected

ordamagedthemachinecouldoperate

unexpectedlycausingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlock

switchesdailyandreplaceanydamaged

switchesbeforeoperatingthemachine.

RefertoAttachmentOperator’sManualforprocedure

oncheckingattachmentinterlocksystem.

OperatingCharacteristics

Driverandpassengershouldalwaysusetheseatbelts.

Ifyouarenotexperiencedatdrivingthevehicle,

practicedrivingitinasafeareaawayfromother

people.Besureyouarefamiliarwithallthevehicle’s

controls,particularlythoseusedforbraking,steering

andtransmissionshifting.Learnhowyourvehicle

handlesondifferentsurfaces.Youroperatingskills

willimprovewithexperience,butasinoperatingany

vehicle,takeiteasyasyoubegin.Besureyouknow

howtostopquicklyinanemergency.Ifyouneedhelp,

askyoursupervisorforassistance.

Manyfactorscontributetoaccidents.Youhavecontrol

overseveralofthemostimportant.Youractions,

suchasdrivingtoofastforconditions,brakingtoo

fast,turningtoosharp,andcombinationsofthese,are

frequentcauseofaccidents.

Oneofthemajorcausesofaccidentsisfatigue.Besure

totakeoccasionalbreaks.Itisveryimportantthatyou

stayalertatalltimes.

Neveroperatethevehicle,oranyequipment,ifyou

areundertheinuenceofalcoholorotherdrugs.

Evenprescriptiondrugsandcoldmedicinescancause

drowsiness.Readthelabelonthemedicineorcheck

withyourdoctororpharmacistifyouareunsureabout

acertainmedication.

Thevehicleisdesignedwithsafetyinmind.Ithasfour

wheelsforaddedstability.Itusesfamiliarautomotive

stylecontrols,includingthesteeringwheel,brakepedal,

clutchpedal,acceleratorpedal,andgearshifter.Itis

importanttoremember,however,thatthisvehicleis

notapassengercar.Itisaworkvehicleandisdesigned

foroffroaduseonly.

TheWORKMANisanoff–highwayvehicle

only,andisnotdesigned,equipped,or

manufacturedforuseonpublicstreets,roads

orhighways.

Thevehiclehasspecialtires,lowgearratios,alocking

differential,andotherfeaturesthatgiveitextratraction.

Thesefeaturesaddtotheversatilityofthevehiclebut,

theycanalsogetyouintodangeroussituations.You

mustkeepinmindthatthevehicleisnotarecreation

vehicle.Itisnotanallterrainvehicle.And,itis

denitelynotmeantfor“stuntdriving”or“horsing

around”.Itisaworkvehicle,notaplayvehicle.

Childrenshouldnotbeallowedtooperatethevehicle.

Anyonewhooperatesthevehicleshouldhaveamotor

vehiclelicense.

Oneofthemostimportantrulestofollowistogo

slowerinunfamiliarareas.Itissurprisinghowmuch

damageandinjurycommonthingscancause.Tree

branches,fences,wires,othervehicles,treestumps,

ditches,sandtraps,streams,andotherthingsfoundin

mostparksandgolfcoursescanbehazardoustothe

operatorandpassenger.

Avoiddrivingwhenitisdark,especiallyinunfamiliar

areas.Ifyoumustdrivewhenitisdark,besuretodrive

cautiously,usetheheadlights,andevenconsideradding

additionallights.

Passengers

Wheneveryouhaveapassengerridinginthevehicle

makesureheorsheiswearingtheseatbeltandholding

onsecurely.Driveslowerandturnlesssharplybecause

yourpassengerdoesnotknowwhatyouaregoingto

donextandmaynotbepreparedforturning,stopping,

accelerating,andbumps.

Youandyourpassengershouldremainseatedatall

times,keepingarmsandlegsinsidethevehicle.The

operatorshouldkeepbothhandsonsteeringwheel,

wheneverpossibleandpassengershouldusehand

holdsprovided(Figure31&Figure32).

29

Page 30

1.Passengerhandhold

Figure31

Turning

Turningisanotherimportantvariableleadingto

accidents.Turningtoosharplyfortheconditionscan

causethevehicletolosetractionandskid,oreventip

over.

Wet,sandyandslipperysurfacesmaketurningmore

difcultandrisky.Thefasteryouaregoing,theworse

thissituationbecomesso,slowdownbeforeturning.

Duringasharpturnathigherspeeds,theinsiderear

wheelmayliftoffoftheground.Thisisnotaawin

thedesign,ithappenswithmostfourwheelvehicles

includingpassengercars.Ifthishappens,youare

turningtoosharplyforthespeedatwhichyouare

traveling.Slowdown!

Braking

Itisgoodpracticetoslowdownbeforeyougetnear

anobstacle.Thisgivesyouextratimetostoporturn

away.Hittinganobstaclecandamagethevehicleand

itscontents.Moreimportant,itcaninjureyouandyour

passenger.Grossvehicleweighthasamajorimpact

onyourabilitytostopand/orturn.Heavierloadsand

heavierattachmentsmakeavehiclehardertostopor

turn.Theheaviertheload,thelongerittakestostop

Figure32

1.Handhold&hiprestraint

Thereshouldneverbepassengersinthedumpboxor

onanyattachments.Thevehicleismeanttohaveone

driverandonlyonepassenger–nomore.

Speed

Speedisoneofthemostimportantvariablesleadingto

accidents.Drivingtoofastfortheconditionscancause

youtolosecontrolandhaveanaccident.Speedcan

alsomakeaminoraccidentworse.Drivinghead–on

intoatreeatslowspeedcancauseinjuryanddamage,

but,drivingintoatreeathighspeedcandestroythe

vehicleandkillyouandyourpassenger.

Neverdrivetoofastfortheconditions.Ifthereisany

doubtabouthowfasttodrive,slowdown.

Whenusingheavyattachments(morethan1000

pounds),suchassprayers,topdressers,orspreaders,

etc.,operatingspeedsshouldberestrictedbymoving

3rdhighlockoutswitchtoslow––position.

Thebrakingcharacteristicsalsochangewithnobedor

attachmentonthevehicle.Faststopsmaycausethe

rearwheelstolockupbeforethefrontwheelslock

up,whichmayaffectthecontrolofthevehicle.Itis

agoodideatodecreasevehiclespeedwithnobedor

attachment.

Turfandpavementaremuchslipperierwhentheyare

wet.Itcantake2to4timesaslongtostoponwet

surfacesasondrysurfaces.

Ifyoudrivethroughstandingwaterdeepenoughtoget

thebrakeswet,theywillnotworkwelluntiltheyare

dry.Afterdrivingthroughwater,youshouldtestthe

brakestomakesuretheyworkproperly.Iftheydonot,

driveslowlyinrstgearwhileputtinglightpressureon

thebrakepedal.Thiswilldrythebrakesout.

Donotdownshiftforbrakingonicyorslippery

surfaces(wetgrass)orwhilegoingdownahillbecause

enginebrakingmaycauseskiddingandlossofcontrol.

Shifttoalowergearbeforestartingdownahill.

Tipovers

TheTOROWORKMANisequippedwitharollbar,

hiprestraints,seatbeltsandhandhold.TheROPS

system(RolloverProtectionSystem)usedonthevehicle

30

Page 31

willreducetheriskofseriousorfatalinjuryinthe

unlikelyeventofatipover,althoughthesystemcannot

protecttheoperatorfromallpossibleinjuries.

ReplaceadamagedROPS,donotrepairorrevise.Any

alterationofROPSmustbeapprovedbymanufacturer.

Thebestwaytopreventaccidentsinvolvingutility

vehiclesisthroughcontinuoussupervisionandtraining

ofoperatorsandpayingconstantattentiontothearea

inwhichvehicleisbeingoperated.

Thebestwayforoperatorstopreventseriousinjury

ordeathtothemselvesorothers,istofamiliarize

themselveswiththeproperoperationoftheutility

vehicle,tostayalertandtoavoidactionsorconditions

whichcouldresultinaaccident.Intheeventofatip

over,theriskofseriousinjuryordeathwillbereduced

iftheoperatorisusingtheROPSsystemandseatbelts

andisfollowingtheinstructionsprovided.

Hills

Slowdownandshiftintoalowergearbeforestarting

upordownahill.Ifyouhavetoturnwhileonahill,

doitasslowlyandcautiouslyaspossible.Nevermake

sharporfastturnsonahill.

Ifyoustallorbegintoloseheadwaywhileclimbing

asteephill,quicklyapplythebrakes,shifttoneutral,

restarttheengineandshifttoreverse.Atidlespeed,

engineandtransaxledragwillaidthebrakesin

controllingthevehicleonthehillandhelpyouback

downthehillmoresafely.

Reducetheweightoftheloadifitisasteephillorifthe

loadhashighcenterofgravity.Remember,loadscan

shift.Securethem.

Note:TheWorkmanhasexcellenthillclimbingability.

Thedifferentiallockwillincreasethisability .Hill

climbingtractioncanalsobeincreasedbyaddingweight

totherearofthevehicleinoneofthefollowingways:

•Addingweighttoinsideofbox,makingsureitis

secured.

•Mountingwheelweightstorearwheels.

Tippingorrollingthevehicleonahillwillcause

seriouspersonalinjury.

•Donotoperatethevehicleonsteepslopes.

•Ifenginestallsoryouloseheadwayonahill,

neverattempttoturnvehiclearound.

•Alwaysbackstraightdownahillinreverse

gear.

•Neverbackdowninneutralorwiththe

clutchdepressed,usingonlythebrakes.

•Neverdriveacrossasteephill,alwaysdrive

straightupordown.

•Avoidturningonahill.

•Don’t“droptheclutch”orslamonthe

brakes.Suddenspeedchangecaninitiate

tipover.

Useextracarewhenonhills.Nevergoonhillsthatare

extremelysteep.Stoppingwhilegoingdownahillwill

takelongerthanonlevelground.Turningwhilegoing

upordownahillismoredangerousthanturningon

thelevel.Turnswhilegoingdownhill,especiallywith

thebrakeson,and,turninguphillwhiletraversinga

hillareparticularlydangerous.Evenataslowspeed

andwithoutaload,tipoversaremorelikelyifyouturn

onahill.

•Addingliquidballast(calciumchloride)toreartires.

•Tractionwillincreasewithnopassengerinfront

seat.

LoadingAndDumping

Theweightandpositionofthecargoandpassenger

canchangethevehiclecenterofgravityandvehicle

handling.Toavoidlossofcontrolresultinginpersonal

injury,followtheseguidelines.

Donotcarryloadswhichexceedtheloadlimits

describedonthevehicleweightlabel.

Thebedwilllowerwheneverthedumplever

ispusheddown,evenwhentheengineisoff.

TurningofftheenginewillNOTpreventthe

boxfromlowering.Alwaysplacethesafety

supportonextendedliftcylindertoholdboxup

ifyouarenotgoingtoloweritrightaway.

31

Page 32

Thebedwilllowerwheneverthedumplever

ispusheddown,evenwhentheengineisoff.

TurningofftheenginewillNOTpreventthe

boxfromlowering.Alwaysplacethesafety

supportonextendedliftcylindertoholdboxup

ifyouarenotgoingtoloweritrightaway.

Thevehiclehasseveralcombinationsofboxes,

platforms,andattachmentsavailable.Thesecanbe

usedinvariouscombinationsthatallowformaximum

capacityandversatility .Thefullsizedboxis55inches

wideby65incheslongandcanholdupto2000pounds

ofevenlydistributedcargo.

Loadsvaryinhowtheyaredistributed.Sandspreads

outevenlyandquitelow .Otheritems,suchasbricks,

fertilizerorlandscapetimbers,stackhigherinthebox.

Theheightandweightoftheloadhasasignicant

inuenceontipovers.Thehigheraloadisstacked,

themorelikelythevehicleistotipover.Youmaynd

that2000poundsstackstoohighforsafeoperation.

Reducingthetotalweightisonewaytoreducetherisk

ofatipover.Distributingtheloadaslowaspossibleis

anotherwaytoreducetheriskofatipover.

Iftheloadispositionedtowardoneofthesides,itwill

makethevehiclemuchmorelikelytotipoveronthat

side.Thisisespeciallytruewhenturningiftheloadis

ontheoutsideoftheturn.

Neverpositionheavyloadsbehindtherearaxle.Ifthe

loadispositionedsofartotherearthatitisbehindthe

rearaxle,itwillreducetheweightonthefrontwheels

andthiswillreducesteeringtraction.Withtheloadall

thewaytotheback,thefrontwheelscanevencome

offofthegroundwhengoingoverbumpsorupahill.

Thiswillresultinalossofsteeringandmayleadtothe

vehicletippingover.

Therearcargospaceisintendedforloadcarrying

purposesonly ,notforpassengers.

UsingTheDifferentialLock

Thedifferentiallockincreasesthevehicle’stractionby

lockingtherearwheelssoonewheelwillnotspinout.

Thiscanhelpwhenyouhaveheavyloadstohaulon

wetturforslipperyareas,goinguphillsandonsandy

surfaces.Itisimportanttorememberhowever,thatthis

extratractionisonlyfortemporarylimiteduse.Itsuse

doesnotreplacethesafeoperation,alreadydiscussed

concerningsteephillsandheavyloads.

Thedifferentiallockcausestherearwheelstospinat

thesamespeed.Whenusingdifferentiallockyour

abilitytomakesharpturnsissomewhatrestrictedand

mayscufftheturf.Usethedifferentiallockonlywhen

needed,atslowerspeedsandonlyinrstorsecond

gear.

Tippingorrollingthevehicleonahillwillcause

seriousinjury.

•Theextratractionavailablewiththe

differentiallockcanbeenoughtogetyou

intodangeroussituationssuchasclimbing

slopesthataretoosteeptoturnaround.

Beextracarefulwhenoperatingwiththe

differentiallockon,especiallyonsteeper

slopes.

•Ifthedifferentiallockisonwhenmakinga

sharpturnatahigherspeedandinsiderear

wheelliftsofftheground,theremaybea

lossofcontrolwhichcouldcausevehicleto

skid(RefertosectiononDifferentialLock

Operation).Usethedifferentiallockonly

atslowerspeeds.

Asageneralrule,positiontheweightoftheload

evenlyfromfronttorearandevenlyfromsideto

side.

Ifaloadisnotsecured,oryouaretransportingaliquid

inalargecontainersuchasasprayer,itcanshift.This

shiftinghappensmostoftenwhileturning,goingupor

downhills,suddenlychangingspeedsorwhiledriving

overroughsurfaces.Shiftingloadscanleadtotipovers.

Alwayssecureloadssothattheydonotshift.Never

dumptheloadwhilethevehicleissidewaysonthehill.

Heavyloadsincreasestoppingdistanceandreduceyour

abilitytoturnquicklywithouttippingover.

FourWheelDrive

FourWheelDriveOnly

The“ AutomaticonDemand”fourwheeldrivefeature,

onthisvehicledoesnotrequireoperatoractivation.

Thefrontwheeldriveisnotengaged(nopower

deliveredtofrontwheels)untiltherearwheelsbegin

tolosetraction.Thebi–directionalclutchsensesthe

rearwheelsslipping,engagesthefrontwheeldriveand

deliverspowertothefrontwheels.Thefourwheel

32

Page 33

drivesystemcontinuestodeliverpowertothefront

wheelsuntiltherearwheelshaveenoughtractionto

movethevehiclewithoutslipping.Oncethisoccurs,

thesystemstopsdeliveringpowertothefrontwheels

andthehandlingcharacteristicsbecomesimilartothat

ofatwowheeldrivevehicle.Thefourwheeldrive

systemfunctionsinbothfrowardandreverse,however,

whenturningtherearwheelswillslipslightlymore

beforepowerisdeliveredtothefrontwheels.

Tippingorrollingthevehicleonahillwillcause

seriousinjury.

•Theextratractionavailablewiththefour

wheeldrivefeaturecanbeenoughtogetyou

intodangeroussituationssuchasclimbing

slopesthataretoosteeptoturnaround.

Becarefulwhenoperating,especiallyon

steeperslopes.

Figure33

1.Eyeholesinframe

Figure34

1.Axletube2.Hitchplate

TransportingVehicle

Formovingthevehiclelongdistances,atrailershould

beused.Makesurethevehicleissecuredtothetrailer.

RefertoFigure33andFigure34forlocationoftie

downpoints.

TowingVehicle

Incaseofemergency,thevehiclecanbetowedfora

shortdistance.However,Torodoesnotrecommend

thisasastandardprocedure.

Towingatexcessivespeedscouldcausevehicle

tolosesteeringcontrol.Nevertowvehiclefaster

than5MPH.

Towingthevehicleisatwopersonjob.Afxatow

linetoholesinfrontframemember.Moveshifterto

Neutralandreleaseparkingbrake.Ifmachinemustbe

movedaconsiderabledistance,transportitonatruck

ortrailer.

Note:Thepowersteeringwillnotfunction,

makingitdifcult(increaseeffort)tosteer.

TrailerTowing

TheWorkmaniscapableofpullingtrailersand

attachmentsofgreaterweightthanthevehicleitself.

Severaltypesoftowhitchesareavailableforthe

Workman,dependingonyourapplication.Contact

yourAuthorizedTORODistributorfordetails.

Whenequippedwithatowhitchboltedontorearaxle

tube,yourWorkmancantowtrailersorattachments

withaGrossTrailerWeight(GTW)upto1500lbs.

Alwaysloadatrailerwith60%ofthecargoweightin

thefrontofthetrailer.Thisplacesapproximately10%

(200lbs.max.)oftheGrossTrailerWeight(GTW)on

thetowhitchofthevehicle.

Whentowingeitherstandardtongueor5thwheel

trailershavingaGrossTrailerWeight(GTW)inexcess

of1500lbs.,useeitherachassismounteddrawbarhitch

(ratedfor3500lb.GTW)or5thwheelkitwithbrakes.

Trailerbrakesarerequiredwheneveratrailerover1500

lbs.GTWistowedbehindaWorkmanvehicle.

Whenhaulingcargoortowingatrailer(attachment),do

notoverloadyourvehicleortrailer.Overloadingcan

causepoorperformanceordamagetothebrakes,axle,

engine,transaxle,steering,suspension,bodystructure

ortires.

Important:T oreducepotentialfordriveline

damage,uselowrange.

33

Page 34

Whentowing5thwheelattachments,likeafairway

aerator,alwaysinstallthe”wheelybar”(included

withthe5thwheelkit)topreventthefrontwheels

fromliftingoffthegroundifthetowedattachments

movementissuddenlyimpaired.

HydraulicControl

Thehydrauliccontrolsupplies“live”hydraulicpower

fromthevehiclepumpwhenevertheengineisrunning.

Thepowercanbeusedthroughthequickcouplersat

therearofthevehicle.

Important:Ifmultiplevehiclesusethe

sameattachment,crosscontaminationofthe

transmissionuidmayoccur.Changethe

transmissionuidmorefrequently

ControlLeverPositions

OffPosition

Thisisthenormalpositionforthecontrolvalvewhen

itisnotbeingused.Inthispositiontheworkportsof

thecontrolvalveareblockedandanyloadwillbeheld

bythecheckvalvesinbothdirections.

Raise(QuickCoupler“A”Position)

Thisisthepositionwhichwillliftthebed,rearhitch

attachmentorapplypressuretoquickcoupler”A ”.

ThisalsoallowsreturnoilfromQuickcoupler”B”to

owbackintothevalveandthenouttothereservoir.

Thisisamomentarypositionandwhentheleveris

releaseditspringreturnstothecenteroffposition.

Lower(QuickCoupler“B”Position)

Thispositionwilllowerthebed,rearhitchattachment

orapplypressuretoquickcoupler”B”.Thisalso

allowsreturnoilfromquickcoupler”A”toowback

intothevalveandthenouttothereservoir.Thisisa

momentarypositionandwhentheleverisreleasedit

springreturnstothecenteroffposition.Momentarily

holdingandthenreleasingthecontrolleverinthis

positionwillprovideowtoquickcoupler”B”which

providespowerdownontherearhitch.Whenreleased,

itwillholdthedownpressureonthehitch.

Figure35

1.Quickcoupler“A”position2.Quickcoupler“B”position

OnPosition

ThispositionissimilartoLower(quickcoupler”B”

position).Italsodirectsoiltoquickcoupler”B”except

thattheleverisheldinthispositionbyadetentleverin

thecontrolpanel.Thisallowsoiltoowcontinuously

toequipmentthatusesahydraulicmotor.Thisposition

mustonlybeusedonattachmentswithahydraulic

motorattached.

Important:Ifusedwithahydrauliccylinderor

noattachment,theOnpositioncausestheoil

owtogooverareliefvalvewhichcandamage

thehydraulicsystem.Usethispositiononly

momentarilyorwithamotorattached.

Important:Checkhydraulicoillevelafter

installationofattachment.Checkoperationof

attachmentbycyclingattachmentseveraltimes

topurgeairfromsystem,thenrecheckhydraulic

oillevel.Attachmentcylinderwillslightlyaffect

transaxleoillevel.Operationofvehiclewithlowoil

levelcandamagepump,remotehydraulics,power

steeringandvehicletransaxle.

Important:Ifusedwithahydrauliccylinder,

holdingthecontrolleverinthelowerposition

causestheoilowtogooverareliefvalvewhich

candamagethehydraulicsystem.

34

Page 35

Hydraulicuidescapingunderpressurecan

havesufcientforcetopenetrateskinanddo

seriousdamage.Caremustbeusedwhen

connectingordisconnectinghydraulicquick

couplers.Stopengine,applyparkingbrake,

lowerattachmentandplaceremotehydraulic

valveinoatdetentpositiontorelievehydraulic

pressurebeforeconnectingordisconnecting

quickcouplers.

–Fittingsloose.

–Fittingmissingo–ring.

•Attachmentdoesnotfunction.

–Quickcouplersnotfullyengaged.

–Quickcouplersareinterchanged.

•Squealingnoise.

–RemotevalveleftinONdetentpositioncausing

hydraulicoiltoowoverreliefvalve.

•Enginewillnotstart.

QuickCouplerOperation

Connection

Important:Cleandirtfromquickcouplers

beforeconnecting.Dirtycouplerscanintroduce

contaminationtohydraulicsystem

Pullbacklockingringoncoupler.

Inserthosenippleintocoupleruntilitsnapsinto