Page 1

FormNo.3389-299RevB

G014966

Workman

ModelNo.07359—SerialNo.315000001andUp

ModelNo.07359TC—SerialNo.315000001andUp

®

MDX-DUtilityVehicle

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3389-299*B

Page 2

ThisproductcomplieswithallrelevantEuropeandirectives;

fordetails,pleaseseetheseparateproductspecicDeclaration

ofConformity(DOC)sheet.

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Dieselengineexhaustandsomeofits

constituentsareknowntotheStateof

Californiatocausecancer,birthdefects,

andotherreproductiveharm.

Important:Thisengineisnotequippedwithaspark

arrestermufer.ItisaviolationofCaliforniaPublic

ResourceCodeSection4442touseoroperatetheengine

onanyforest-covered,brush-covered,orgrass-covered

land.Otherstatesorfederalareasmayhavesimilarlaws.

CustomerServiceandhavethemodelandserialnumbersof

yourproductready.Figure1identiesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

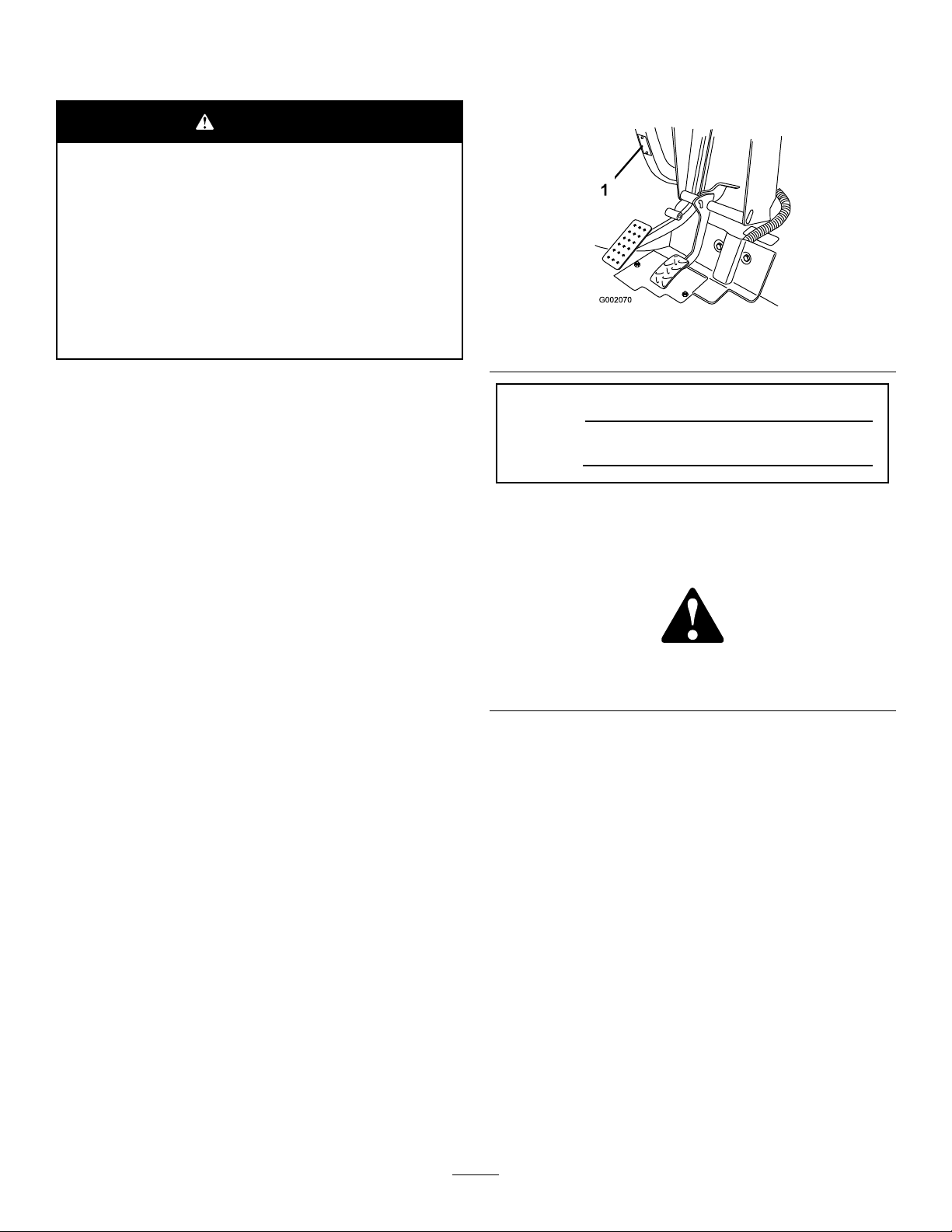

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Theenclosed

Engine Owner's Man ual

issuppliedfor

informationregardingtheUSEnvironmentalProtection

Agency(EPA)andtheCaliforniaEmissionControl

Regulationofemissionsystems,maintenance,and

warranty.Replacementsmaybeorderedthroughthe

enginemanufacturer.

Introduction

Themachineisdesignedprimarilyasanoff-roadvehicleand

isnotintendedforextensiveuseonpublicroads.Whenusing

themachineonpublicroads,followalltrafcregulationsand

useanyadditionalaccessoriesthatmayberequiredbylaw,

suchaslights,turnsignals,slowmovingvehicle(SMV)sign,

andothersasrequired.

Thismachineisautilityvehicleintendedtobeusedby

professional,hiredoperatorsincommercialapplications.It

isprimarilydesignedforthetransportofimplementsusedin

suchapplications.Thisvehicleallowsforthesafetransport

ofanoperatorandonepassengerintheidentiedseats.The

bedofthisvehicleisnotsuitableforanyriders.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure2

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

©2015—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Contents

Safety...........................................................................4

SafeOperatingPractices...........................................4

BeforeOperating....................................................4

Supervisor’sResponsibilities.....................................5

SafeHandlingofFuels.............................................5

Operation...............................................................5

Maintenance...........................................................7

Hauling..................................................................7

SoundPower..........................................................8

SoundPressure.......................................................8

Hand-ArmVibration...............................................8

WholeBodyVibration.............................................8

SafetyandInstructionalDecals.................................9

Setup...........................................................................11

1InstallingtheSteeringWheel..................................12

2CheckingtheFluidLevelsandTireAir

Pressure............................................................12

3ReadingtheManualandViewingtheSafety

TrainingMaterial................................................12

ProductOverview.........................................................13

Controls...............................................................13

Specications........................................................16

Attachments/Accessories........................................16

Operation....................................................................17

ThinkSafetyFirst...................................................17

OperatingtheCargoBox.........................................17

PreformingPre-StartingChecks...............................18

CheckingtheBrakeFluidLevel................................19

CheckingtheEngine-OilLevel.................................19

CheckingtheTireAirPressure.................................20

AddingFuel...........................................................20

StartingtheEngine.................................................21

StoppingtheMachine.............................................21

ParkingtheMachine...............................................21

BreakinginaNewMachine......................................22

LoadingtheCargoBox...........................................22

TransportingtheVehicle.........................................23

TowingtheMachine...............................................23

TowingaTrailer.....................................................23

Maintenance.................................................................24

RecommendedMaintenanceSchedule(s)......................24

DailyMaintenanceChecklist....................................25

PremaintenanceProcedures........................................26

MaintainingtheVehicleunderSpecialOperating

Conditions.........................................................26

LiftingtheMachine................................................26

AccessingtheHood................................................26

Lubrication...............................................................27

GreasingtheMachine.............................................27

GreasingtheFrontWheelBearings...........................28

EngineMaintenance..................................................30

ServicingtheAirCleaner.........................................30

ServicingtheEngineOil..........................................31

FuelSystemMaintenance...........................................33

InspectingFuelLinesandConnections......................33

ReplacingtheFuelFilter..........................................33

ElectricalSystemMaintenance....................................33

ServicingtheBattery...............................................33

ReplacingtheFuses................................................35

MaintainingtheHeadlights......................................35

DriveSystemMaintenance.........................................37

MaintainingtheTires..............................................37

AdjustingtheFrontWheelToe-inand

Camber.............................................................37

CheckingtheTransaxleOilLevel..............................38

ChangingtheTransaxleOil......................................39

CheckingandAdjustingtheNeutralPosition..............39

InspectingthePrimaryDriveClutch.........................40

MaintainingthePrimaryDriveClutch.......................40

CoolingSystemMaintenance......................................41

CleaningtheEngineCoolingAreas...........................41

FillingtheRadiator.................................................41

BrakeMaintenance....................................................42

InspectingtheBrakes..............................................42

AdjustingtheParking-BrakeHandle..........................42

AdjustingtheBrakeCables......................................43

ChangingtheBrakeFluid........................................43

BeltMaintenance......................................................44

ServicingtheDriveBelt...........................................44

ReplacingtheDriveBelt..........................................44

CheckingtheBelt-pullBumper.................................44

ChassisMaintenance..................................................45

AdjustingtheCargo-boxLatches..............................45

Cleaning...................................................................45

WashingtheVehicle................................................45

Storage........................................................................46

3

Page 4

Safety

Improperuseormaintenancebytheoperatororownercan

resultininjury.Toreducethepotentialforinjury,comply

withthesesafetyinstructionsandalwayspayattentionto

thesafetyalertsymbol,whichmeansCaution,Warning,or

Danger—“personalsafetyinstruction.”Failuretocomply

withtheinstructionmayresultinpersonalinjuryordeath.

ThemachinemeetstherequirementsofSAEJ2258.

SafeOperatingPractices

Important:Themachineisdesignedprimarilyasan

off-roadvehicleandisnotintendedforextensiveuseon

publicroads.Whenusingthemachineonpublicroads,

followalltrafcregulationsanduseanyadditional

accessoriesthatmayberequiredbylaw,suchaslights,

turnsignals,slowmovingvehicle(SMV)sign,and

othersasrequired.

TheW orkmanwasdesignedandtestedtooffersafeservice

whenoperatedandmaintainedproperly.Althoughhazard

controlandaccidentpreventionpartiallyaredependent

uponthedesignandcongurationofthemachine,these

factorsarealsodependentupontheawareness,concern,and

propertrainingofthepersonnelinvolvedintheoperation,

maintenanceandstorageofthemachine.Improperuseor

maintenanceofthemachinecanresultininjuryordeath.

•Thismachineisdesignedtocarryonlyyou,the

operator,andonepassengerintheseatprovidedbythe

manufacturer.Nevercarryanyotherpassengersonthe

vehicle.

•Becomefamiliarwiththecontrolsandknowhowtostop

theenginequickly.

•Neveroperatethemachinewhenundertheinuence

ofdrugsoralcohol.Evenprescriptiondrugsandcold

medicinescancausedrowsiness.

•Donotdrivethemachinewhenyouaretired.Besureto

takeoccasionalbreaks.Itisveryimportantthatyoustay

alertatalltimes.

•Alwayswearsubstantialshoes.Donotoperatethe

machinewhilewearingsandals,tennisshoes,orsneakers.

Donotwearloosettingclothingorjewelrywhichcould

getcaughtinmovingpartsandcausepersonalinjury.

•Wearingsafetyglasses,safetyshoes,longpants,anda

helmetisadvisableandrequiredbysomelocalsafetyand

insuranceregulations.

•Neverallowchildrentooperatethemachine.Never

allowadultstooperateitwithoutproperinstructions.

Onlytrainedandauthorizedpersonsshouldoperate

thismachine.Makesurealloperatorsarephysicallyand

mentallycapableofoperatingthemachine.

•Keepeveryone,especiallychildrenandpets,awayfrom

theareasofoperation.

Thisisaspecializedutilityvehicledesignedforoff–roaduse

only.Itsrideandhandlingwillhaveadifferentfeelthanwhat

driversexperiencewithpassengercarsortrucks.Sotaketime

tobecomefamiliarwithyourWorkman.

NotalloftheattachmentsthatadapttotheWorkman

arecoveredinthismanual.SeethespecicOperator’s

Manualprovidedwitheachattachmentforadditionalsafety

instructions.Readthesemanuals.

Toreducethepotentialforinjuryordeath,complywith

thefollowingsafetyinstructions:

BeforeOperating

•Operatethemachineonlyafterreadingandunderstanding

thecontentsofthismanual.Areplacementmanualis

availablebysendingcompletemodelandserialnumber

to:TheToro®Company,8111LyndaleAvenueSouth,

Minneapolis,Minnesota55420.

•Neverallowchildrentooperatethemachine.Anyone

whooperatesthemachineshouldhaveamotorvehicle

license.

•Neverallowotheradultstooperatethemachinewithout

rstreadingandunderstandingtheOperator'sManual.

Onlytrainedandauthorizedpersonsshouldoperatethis

machine.Makesurethatalloperatorsarephysicallyand

mentallycapableofoperatingthemachine.

•Checkthesafetyinterlocksystemdailyforproper

operation.Ifaswitchshouldmalfunction,replacethe

switchbeforeoperatingmachine.

•Keepallshields,safetydevicesanddecalsinplace.Ifa

shield,safetydeviceordecalismalfunctioning,illegible,

ordamaged,repairorreplaceitbeforeoperatingthe

machine.

•Avoiddrivingwhenitisdark,especiallyinunfamiliar

areas.Ifyoumustdrivewhenitisdark,besuretodrive

cautiously,usetheheadlights,andevenconsideradding

additionallights.

•Beforeoperatingthevehicle,alwayscheckallpartsof

thevehicleandanyattachments.Ifsomethingiswrong,

stopusingvehicle.Makesuretheproblemiscorrected

beforevehicleorattachmentisoperatedagain.

•Useonlyanapprovednonmetal,portablefuelcontainer.

Staticelectricdischargecanignitefuelvaporsinafuel

containerthatisnotgrounded.Removethefuelcontainer

fromthebedofthemachineandplaceitontheground

andawayfromthevehiclebeforelling.Keepthe

nozzleincontactwiththecontainerwhilellingthefuel

container.Removeequipmentfrombedofthemachine

beforefuelingit.

•Operatethemachineonlyoutdoorsorinawellventilated

area.

4

Page 5

Supervisor’sResponsibilities

•Makesureoperatorsarethoroughlytrainedandfamiliar

withtheOperator’ sManualandalllabelsonthevehicle.

•Besuretoestablishyourownspecialproceduresand

workrulesforunusualoperatingconditions(e.g.slopes

toosteepforthesafeoperationofthemachine).

SafeHandlingofFuels

•Toavoidpersonalinjuryorpropertydamage,useextreme

careinhandlingfuel.Dieselfuelisextremelyammable

andthevaporsareexplosive.

•Extinguishallcigarettes,cigars,pipes,andothersources

ofignition.

•Useonlyanapprovedfuelcontainer.

•Neverremovefuelcaporaddfuelwiththeengine

running.

•Allowenginetocoolbeforerefueling.

•Neverrefuelthemachineindoors.

•Neverstorethemachineorfuelcontainerwherethereis

anopename,spark,orpilotlightsuchasonawater

heateroronotherappliances.

•Neverllcontainersinsideavehicleoronatruckor

trailerbedwithaplasticliner.Alwaysplacecontainerson

thegroundawayfromyourvehiclebeforelling.

•Removeequipmentfromthetruckortrailerandrefuelit

ontheground.Ifthisisnotpossible,thenrefuelsuch

equipmentwithaportablecontainer,ratherthanfroma

fueldispensernozzle.

•Keepthenozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilfuelingiscomplete.

Donotuseanozzlelockopendevice.

•Iffuelisspilledonclothing,changeclothingimmediately.

•Neveroverllfueltank.Replacefuelcapandtighten

securely.

Operation

•Theoperatorandpassengershouldremainseatedand

usetheseatbeltswheneverthevehicleisinmotion.The

operatorshouldkeepbothhandsonthesteeringwheel,

wheneverpossible,andthepassengershouldusethehand

holdsprovided.Keeparmsandlegswithinthevehicle

bodyatalltimes.Nevercarrypassengersintheboxor

onattachments.Rememberyourpassengermaynotbe

expectingyoutobrakeorturnandmaynotbeready.

•Neveroverloadyourvehicle.Thenameplate(located

underthemiddleofthedash)showstheloadlimitsfor

thevehicle.Neveroverllattachmentsorexceedthe

vehiclemaximumgrossvehicleweight(GVW).

•Whenstartingtheengine:

–Sitonoperator’sseatandensurethattheparking

brakeisengaged.

–Keepyourfootonthebrake.

–TurnignitionswitchtotheOnposition.Whenthe

glowplugindicatorgoesoff,theengineisreadyto

start.

–TurntheignitionkeytotheStartposition.

•Usingthemachinedemandsattention.Failuretooperate

machinesafelymayresultinanaccident,tipoverofthe

machine,andseriousinjuryordeath.Drivecarefully.

Topreventtippingorlossofcontrol,takethefollowing

precautions:

–Useextremecaution,reducespeed,andmaintain

asafedistancearoundsandtraps,ditches,creeks,

ramps,anyunfamiliarareas,orotherhazards.

–Watchforholesorotherhiddenhazards.

–Usecautionwhenoperatingthevehicleonasteep

slope.Normally,travelstraightupanddownslopes.

Reducespeedwhenmakingsharpturnsorwhen

turningonhillsides.Avoidturningonhillsides

wheneverpossible.

–Useextracautionwhenoperatingthemachineon

wetsurfaces,athigherspeeds,orwithafullload.

Stoppingtimewillincreasewithafullload.

–Whenloadingthebed,distributetheloadevenly.

Useextracautioniftheloadexceedsthedimensions

ofthevehicle/bed.Operatethemachinewithextra

cautionwhenhandlingoff-centerloadsthatcannot

becentered.Keeploadsbalancedandsecureto

preventthemfromshifting.

–Avoidsuddenstopsandstarts.Donotgofrom

reversetoforwardorforwardtoreversewithoutrst

comingtoacompletestop.

–Donotattemptsharpturnsorabruptmaneuversor

otherunsafedrivingactionsthatmaycausealossof

controlofthemachine.

–Donotpassanothermachinetravelinginthesame

directionatintersections,blindspots,oratother

dangerouslocations.

–Whendumping,donotletanyonestandbehind

machineanddonotdumptheloadonanyone’sfeet.

Releasethetailgatelatchesfromthesideofbox,not

frombehind.

–Keepallbystandersaway .Beforebackingup,lookto

therearandensurethatnooneisbehindthevehicle.

Backupslowly.

–Watchoutfortrafcwhennearorcrossingroads.

Alwaysyieldtherightofwaytopedestriansand

othervehicles.Alwayssignalyourturnsorstopearly

enoughsootherpersonsknowwhatyouplantodo.

Obeyalltrafcrulesandregulations.

–Neveroperatethemachineinornearanareawhere

thereisdustorfumesintheairwhichareexplosive.

Theelectricalandexhaustsystemsofthemachinecan

producesparkscapableofignitingexplosivematerials.

–Alwayswatchoutforandavoidlowoverhangssuch

astreelimbs,doorjambs,overheadwalkways,etc.

5

Page 6

Makesurethereisenoughroomoverheadtoeasily

clearthemachineandyourhead.

OperatingonHills

–Ifyouareeverunsureaboutthesafeoperationofthe

machine,stopyourworkandaskyoursupervisor.

•Beforegettingofftheseat:

–Stopmovementofthemachine.

–Lowerbed.

–Shutengineoffandwaitforallmovementtostop.

–Setparkingbrake.

–Removekeyfromignition.

•Donottouchengine,transmission,radiator,muferor

mufermanifoldwhileengineisrunningorsoonafter

ithasstoppedbecausetheseareasmaybehotenough

tocauseburns.

•Ifthemachineevervibratesabnormally,stopthemachine

immediately,turnengineoff,waitforallmotionto

stopandinspectfordamage.Repairalldamagebefore

resumingoperation.

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

Braking

•Slowdownbeforeyouapproachanobstacle.Thisgives

youextratimetostoporturnaway.Hittinganobstacle

caninjureyouandyourpassenger.Inaddition,itcan

damagethemachineanditscontents.

•Grossvehicleweight(GVW)hasamajorimpactonyour

abilitytostopand/orturn.Heavyloadsandattachments

makethemachinehardertostoporturn.Theheavier

theload,thelongerittakestostop.RefertoLoadingthe

CargoBox(page22)formoreinformation.

•Decreasethespeedofthemachineifthecargoboxhas

beenremovedandthereisnoattachmentinstalledon

themachine.Thebrakingcharacteristicschangeandfast

stopsmaycausetherearwheelstolockup,whichwill

affectthecontrolofthemachine.

•Turfandpavementaremuchmoreslipperywhentheyare

wet.Itcantake2to4timeslongertostopthemachine

onwetsurfacesasondrysurfaces.Ifyoudrivethrough

deep-standingwaterandgetthebrakeswet,theywill

notworkwelluntiltheyaredry.Afterdrivingthrough

water,youshouldtestthebrakestomakesuretheywork

properly.Iftheydonot,driveslowlyonalevelground

whileputtinglightpressureonthebrakepedal.Thiswill

drythebrakesout.

WARNING

Operatingthemachineonahillmaycausetipping

orrollingofthemachine,ortheenginemaystall

andyoucouldloseheadwayonthehill.Thiscould

resultinpersonalinjury.

•Donotoperatemachineonexcessivelysteep

slopes.

•Donotacceleratequicklyorslamonthebrakes

whenbackingdownahill,especiallywithaload.

•Iftheenginestallsoryouloseheadwayona

hill,slowlybackstraightdownthehill.Never

attempttoturnthemachinearound.

•Operatethemachineslowlyonahillanduse

caution.

•Avoidturningonahill.

•Reduceyourloadandthespeedofthemachine.

•Avoidstoppingonhills,especiallywithaload.

Theseextracautionsneedtobetakenwhenoperatingthe

machineonahill:

•Slowthemachinedownbeforestartingupordownahill.

•Iftheenginestallsoryoubegintolosemomentumwhile

climbingahill,graduallyapplythebrakesandslowlyback

themachinestraightdownthehill.

•Turningwhiletravelingupordownhillscanbedangerous.

Ifyouhavetoturnwhileonahill,doitslowlyand

cautiously.Nevermakesharporfastturns.

•Heavyloadsaffectstability.Reducetheweightofthe

loadandyourgroundspeedwhenoperatingonhillsorif

theloadhasahighcenterofgravity.Securetheloadto

thecargoboxofthemachinetopreventtheloadfrom

shifting.Takeextracarewhenhaulingloadsthatshift

easily(liquid,rock,sand,etc.).

•Avoidstoppingonhills,especiallywithaload.Stopping

whilegoingdownahillwilltakelongerthanstopping

onlevelground.Ifthemachinemustbestopped,avoid

suddenspeedchanges,whichmayinitiatetippingor

rollingofthemachine.Donotslamonthebrakes

whenrollingbackward,asthismaycausethemachine

tooverturn.

•Ifyouwillbeusingthemachineonhillyterrain,youcan

installtheoptionalROPSKit.

6

Page 7

OperatingonRoughTerrain

WARNING

Suddenchangesinterrainmaycauseabrupt

steeringwheelmovement,possiblyresultingin

handandarminjuries.

•Reduceyourspeedwhenoperatingonrough

terrainandnearcurbs.

•Gripthesteeringwheellooselyaroundthe

perimeterkeepingthumbsupandoutoftheway

ofthesteeringwheelspokes.

Reducethegroundspeedofthemachineandloadcarriedin

themachinewhenoperatingonroughterrain,unevenground,

andnearcurbs,holes,andothersuddenchangesinterrain.

Loadsmayshift,causingthemachinetobecomeunstable.

Ifyouwillbeusingthemachineonroughterrain,youcan

installtheoptionalROPSKit.

LoadingandDumping

WARNING

Theweightoftheboxmaybeheavy.Handsor

otherbodypartscouldbecrushed.

•Keephandsandotherbodypartsclearwhen

loweringthebox.

•Donotdumpmaterialsonbystanders.

•Donotexceedtheratedweightcapacityofthemachine

whenoperatingitwithaloadinthecargobox,when

towingatrailer,orboth;refertoSpecications(page16).

•Usecautionwhenoperatingthemachineonahillsideor

onroughterrain,particularlywithaloadinthecargobox

orwhentowingatrailerorboth.

•Usecautionwhencarryingtallloadsinthecargobox.

•Beawarethatthestabilityandcontrolofthemachine

arereducedwhentheloadinthecargoboxispoorly

distributed.

•Carryingoversizedloadsinthecargoboxchangesthe

stabilityofthemachine.

•Thesteering,braking,andstabilityofthemachineare

affectedwhencarryingaloadwheretheweightofthe

materialcannotbeboundtothemachinesuchasthe

liquidinalargetank.

•Neverdumpaloadedcargoboxwhilethemachineis

sidewaysonahill.Thechangeinweightdistributionmay

causethemachinetooverturn.

•Whenoperatingwithaheavyloadinthecargobox,

reduceyourspeedandallowforsufcientbraking

distance.Donotsuddenlyapplythebrakes.Useextra

cautiononslopes.

•Beawarethatheavyloadsincreaseyourstoppingdistance

andreduceyourabilitytoturnquicklywithouttipping

over.

•Therearcargospaceisintendedforloadcarrying

purposesonly,notforpassengers.

•Neveroverloadyourmachine.Thenameplate(located

underthemiddleofthedash)showstheloadlimitsfor

themachine.Neveroverllattachmentsorexceedthe

machinemaximumgrossmachineweight(GVW);refer

toLoadingtheCargoBox(page22).

Maintenance

•Beforeservicingormakingadjustmentstothemachine,

movethemachinetoalevelsurface,stoptheengine,set

theparkingbrake,andremovethekeyfromignitionto

preventaccidentalstartingoftheengine.

•Tomakesuretheentiremachineisingoodcondition,

keepallnuts,bolts,andscrewsproperlytightened.

•Toreducethepotentialrehazard,keeptheenginearea

freeofexcessivegrease,grass,leaves,andaccumulation

ofdirt.

•Iftheenginemustberunningtoperformamaintenance

adjustment,keephands,feet,clothing,andanypartsof

thebodyawayfromtheengineandanymovingparts.

Keepeveryoneaway.

•Donotoverspeedtheenginebychangingthegovernor

settings.Themaximumenginespeedis3650rpm.To

ensuresafetyandaccuracy,haveanAuthorizedToro

Distributorcheckthemaximumenginespeedwitha

tachometer.

•Ifmajorrepairsareeverneededorassistanceisrequired,

contactanAuthorizedToroDistributor.

•Tobesureofoptimumperformanceandsafety,always

purchasegenuineTororeplacementpartsandaccessories.

Replacementpartsandaccessoriesmadebyother

manufacturerscouldbedangerous.Alteringthismachine

inanymannermayaffecttheoperation,performance,

durabilityofthemachine,oritsusemayresultininjury

ordeath.Suchusecouldvoidtheproductwarrantyof

TheToro®Company.

•Thismachineshouldnotbemodiedwithout

authorizationfromTheToro®Company.Directany

inquiriestoTheToro®Company,CommercialDivision,

VehicleEngineeringDept.,8111LyndaleAve.So.,

Bloomington,Minnesota55420–1196USA.

Hauling

•Usecarewhenloadingorunloadingthemachineintoa

trailerortruck.

•Usefullwidthrampsforloadingmachineintotraileror

truck.

•Tiethemachinedownsecurelyusingstraps,chains,cable,

orropes.Bothfrontandrearstrapsshouldbedirected

downandoutwardfromthemachine.

7

Page 8

SoundPower

Thisunithasaguaranteedsoundpowerlevelof98dBA,

whichincludesanUncertaintyValue(K)of1dBA.

Soundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinENISO11094.

SoundPressure

Thisunithasasoundpressurelevelattheoperator’searof85

dBA,whichincludesanUncertaintyValue(K)of1dBA.

Soundpressurelevelwasdeterminedaccordingtothe

proceduresoutlinedinENISO11201.

Hand-ArmVibration

Measuredvibrationlevelforrighthand=1.25m/s

Measuredvibrationlevelforlefthand=1.36m/s

UncertaintyValue(K)=0.68m/s2

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinEN1032.

WholeBodyVibration

Measuredvibrationlevel=0.35m/s

UncertaintyValue(K)=0.17m/s

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinEN1032.

2

2

2

2

8

Page 9

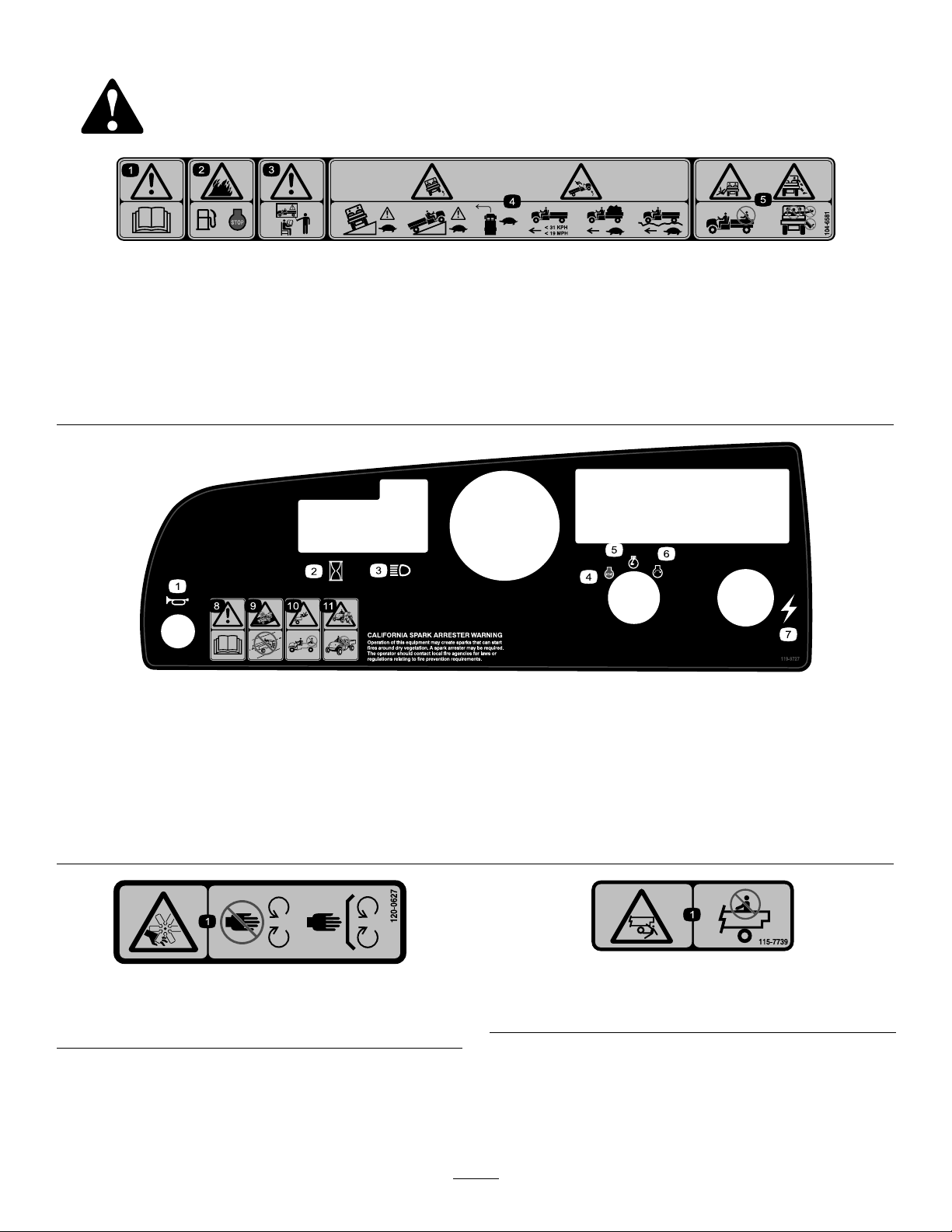

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

104-6581

1.Warning—readtheOperator'sManual.

2.Firehazard—beforefueling,stoptheengine.

3.Warning—donotoperatethismachineunlessyouaretrained.

4.Tippinghazard—usecautionanddriveslowlywhileonslopes;driveslowlywhenturning,keepthevehiclespeedunder16MPH

(26km/h)whencarryingafullorheavyloadandwhendrivingonroughterrain.

5.Fallingandarm/leginjuryhazards—donotcarrypassengersinthecargobedandkeeparmsandlegsinsideofthevehicleatall

times.

119-9727

1.Horn7.Powerpoint

2.Hourmeter

3.Headlights

4.Engine—stop10.Fallinghazard—donotcarrypassengersinthecargobed.

5.Engine—on11.Fallinghazard—donotallowchildrentooperatethevehicle.

6.Engine—start

120-0627

1.Cutting/dismembermenthazard,fan—stayawayfrom

movingparts,keepallguardsandshieldsinplace.

8.Warning—readtheOperator'sManual.

9.Collisionhazard—donotoperatethevehicleonpublicstreets,

roads,orhighways.

115-7739

1.Falling,crushinghazard,bystanders—noriderson

machine.

9

Page 10

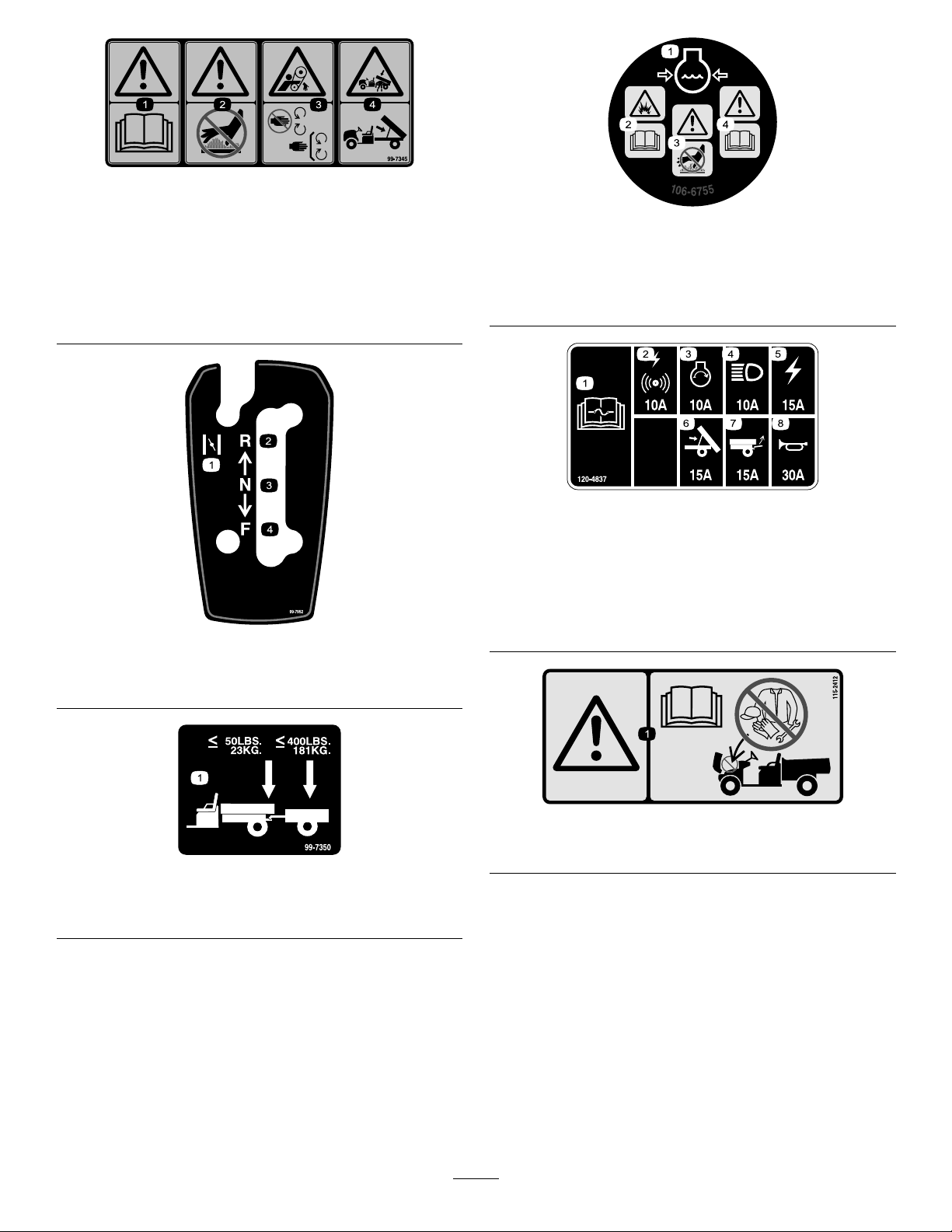

99-7345

1.Warning—readtheOperator'sManual.

2.Hotsurface/burnhazard—stayasafedistancefromthe

hotsurface.

3.Entanglementhazard,belt—stayawayfrommovingparts;

keepallguardsinplace.

4.Crushinghazard,cargobox—usetheproprodtosupport

thecargobed

99-7952

106-6755

1.Enginecoolantunder

pressure.

2.Explosionhazard—read

theOperator'sManual.

3.Warning—donottouchthe

hotsurface.

4.Warning—readthe

Operator'sManual.

120-4837

1.ReadtheOperator's

Manualforinformationon

fuses.

2.Alarm/powerpoint,10A6.Lift,15A

3.Engine,10A

4.Headlights,10A8.Horn,30A

5.Machinefuse,15A

7.Rearlift,15A

1.Choke

2.Reverse4.Forward

3.Neutral

99-7350

1.Maximumtongueweightis50lb(23kg);maximumtrailer

weightis400lb(181kg).

115-2412

1.Warning—readtheOperator'sManual;nostorage.

10

Page 11

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

Steeringwheel

Nopartsrequired

Operator'sManual

Engineowner’smanual1

PartsCatalog

SafetyTrainingmaterial

RegistrationCard

PredeliveryInspectionForm1

CerticateofQuality

Key2

Qty.

Use

1

–

1

1

1

1

1

Installthesteeringwheel(Model

07359TConly).

Checktheuidlevelsandtireair

pressure.

ReadtheOperator'sManualandview

thetrainingmaterialbeforeoperating

themachine.

11

Page 12

1

2

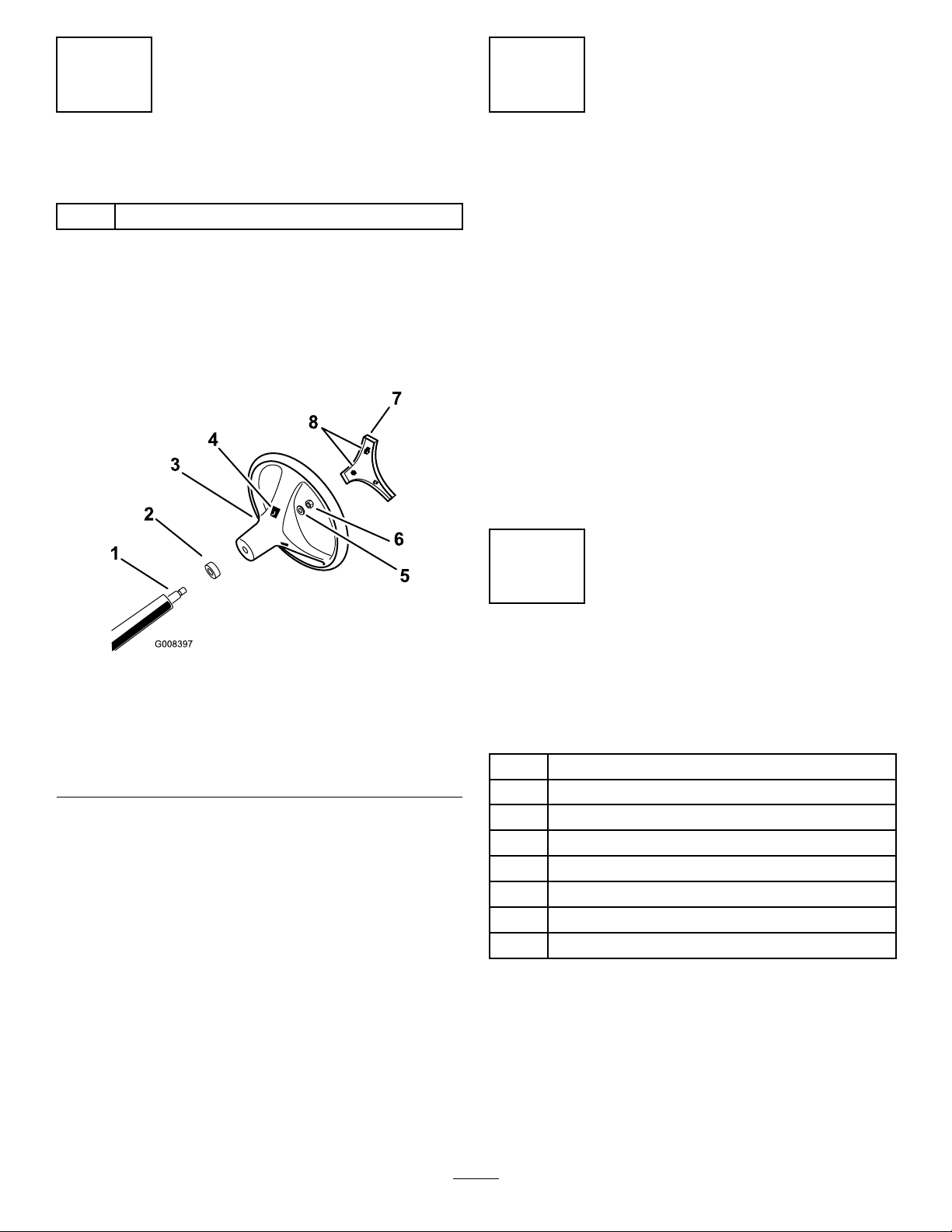

InstallingtheSteeringWheel

Partsneededforthisprocedure:

1

Steeringwheel

Procedure

Note:ThisprocedureisonlyneededforModel07359TC.

1.Throughtheopeningsinthebackofthesteering

wheel,releasethelocktabsofthecentercoverand

removethecoverfromthewheel(Figure3).

CheckingtheFluidLevelsand TireAirPressure

NoPartsRequired

Procedure

1.Checktheengineoillevelbeforeandaftertheengineis

rstoperated;refertoCheckingtheEngine-OilLevel

(page19).

2.Checkthebrakeuidlevelbeforetheengineisrst

operated;refertoCheckingtheBrakeFluidLevel(page

19).

3.Checkthetransaxle-oillevelbeforetheengineisrst

operated;refertoCheckingtheTransaxleOilLevel

(page38).

4.Checktheairpressureinthetires;refertoChecking

theTireAirPressure(page20)

Figure3

1.Steeringshaft

2.Dustcover6.Locknut

3.Steeringwheel7.Centercover

4.Tabslotsinwheel

2.Removethelocknutandwasherfromthesteering

shaft(Figure3).

3.Alignthesteeringwheelontothesplinesofthesteering

shaft(Figure3).

Note:Positionthesteeringwheelontheshaft

sothatwhenthetiresofthemachinearepointed

straightahead,thecrossbeamofthesteeringwheelis

horizontalandthethickerspokeofthesteeringwheel

ispointingdown.

4.Assemblethewasherandlocknutthreadsofthe

steeringshaft(Figure3).

5.Torquethenutto24-29N-m(18-22ft-lb).

6.Alignthelocktabsofthecentercovertotheopenings

inthesteeringwheelandpressthecoverintothewheel

untilthelockstabssnapintoplace(Figure3).

5.Washer

8.Opening(foraccesstothe

steeringwheeltabs)

3

ReadingtheManualand ViewingtheSafetyTraining Material

Partsneededforthisprocedure:

1

Operator'sManual

1Engineowner’smanual

1

PartsCatalog

1

SafetyTrainingmaterial

1

RegistrationCard

1PredeliveryInspectionForm

1

CerticateofQuality

2Key

Procedure

•ReadtheOperator'sManualandEngineowner'smanual.

•Viewthesafetytrainingmaterial.

•Fillouttheregistrationcard.

•CompletethePredeliveryInspectionForm.

•ReviewtheCerticateofQuality.

12

Page 13

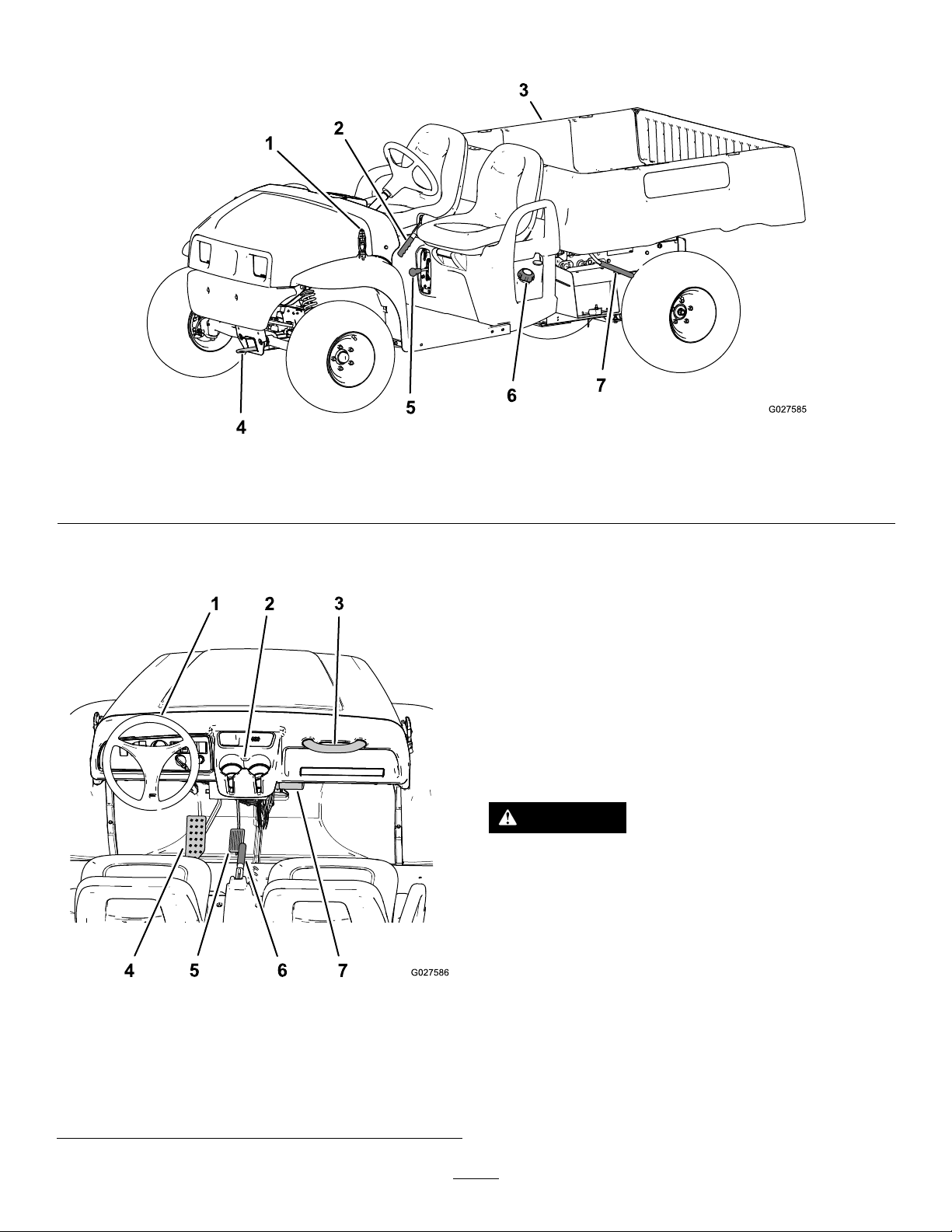

ProductOverview

Figure4

1.Hoodlatch

2.Parkingbrakehandle4.Towingtongue6.Fuelcap

3.Cargobox5.Gearshiftselector7.Cargoboxlever

Controls

AcceleratorPedal

Usetheacceleratorpedal(Figure5)tovarygroundspeed

ofthemachine.Pressingdownthepedalincreasesground

speed.Releasingthepedalwillslowthemachine.

Note:Themaximumforwardspeedis26km/h(16mph).

BrakePedal

Usethebrakepedalisusedtostoporslowthemachine

(Figure5).

CAUTION

Operatingamachinewithwornorincorrectly

adjustedbrakescanmayresultinpersonalinjury.

Ifbrakepedaltravelstowithin25mm(1inch)of

thevehicleoorboard,thebrakesmustbeadjusted

orrepaired.

1.Steeringwheel

2.Cupholder

3.Passengerhandhold

4.Brakepedal

Figure5

5.Acceleratorpedal

6.Parkingbrakehandle

7.Operator'sManualstorage

ParkingBrakeLever

Theparkingbrakeleverislocatedbetweentheseats(Figure

4andFigure5).Whenevertheengineisshutoff,setthe

(centerconsole)

tube

parkingbraketopreventthemachinefromaccidentalmoving.

Tosettheparkingbrake,pullupontheparkingbrakelever.

Toreleasetheparkingbrake,pushtheleverdown.Ifthe

machineisparkedonasteepgrade,makesurethatthe

parkingbrakeisset.

13

Page 14

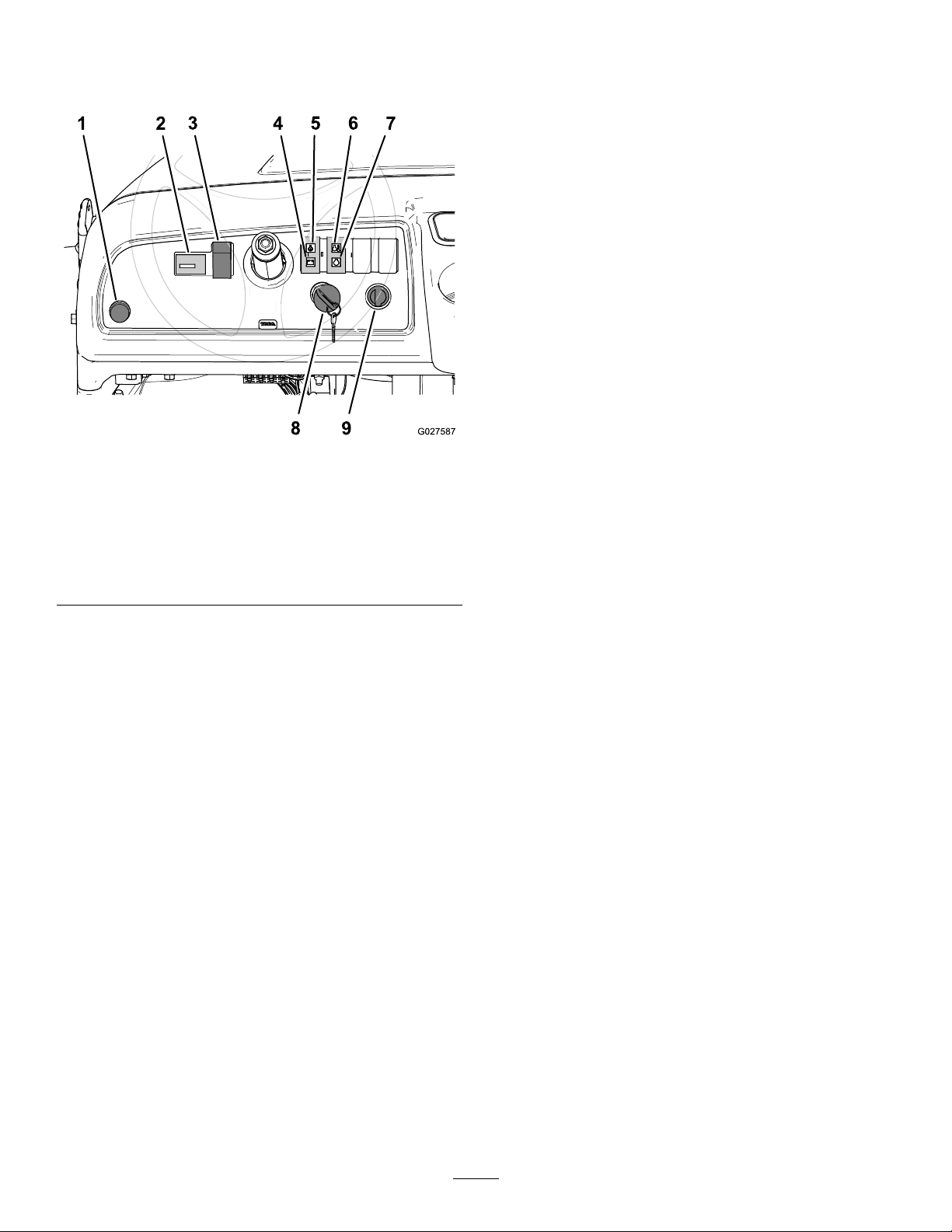

HornButton(TCModelonly)

Thehornbuttonislocatedatthelowerleftcornerofthedash

panel(Figure6).Pressthehornbuttontosoundthehorn.

oillightwarnstheoperatoriftheengineoilpressuredrops

belowasafeleveltooperatetheengine.Ifthelightcomeson

andremainslit,shutofftheengineandchecktheengineoil

level.Addoiltotheengineifnecessary;refertoCheckingthe

Engine-OilLevel(page19).

Note:Theoillightmayicker.Thisisnormalandnoaction

needstobetaken.

EngineCoolant-temperatureLight

Theenginecoolant-temperaturelightislocatedtothe

rightofthebatteryandtheengineoilpressurelights,and

abovetheglowplugindicatorlight(Figure6).Theengine

coolant-temperaturelightwarnstheoperatorthatthecoolant

temperatureoftheengineistoohottocontinueoperating

theengine(theengineisoverheating).Stoptheengineand

allowthemachinetocooldown.Checkthecoolantleveland

thebeltstothefanandwaterpump.Fillthecoolantreservoir

withcoolantasneededandreplaceanyworn,damaged,or

slippingbelts.

Figure6

1.Hornbutton(TCModels

Only)

2.Hourmeter

3.Lightswitch

4.Batterylight9.Powerpoint

5.Engineoilpressurelight

6.Engine

coolant-temperaturelight

7.Glow-plugIndicatorlight

8.Starterswitch

LightSwitch

Thelightswitchislocatedtotheleftofthesteeringcolumn

(Figure6).Usethelightswitchtoilluminatetheheadlights.

Pushupthelightswitchturnontheheadlightsorpushdown

theswitchtoturnoffthelights.

HourMeter

Thehourmeterislocatedtotheleftofthelightswitch

(Figure6).Usethehourmetertondoutthetotalnumberof

hourstheenginehasrun.Thehourmeterstartstofunction

wheneveryouturnthekeyswitchtotheOnpositionorif

theengineisrunning.

BatteryLight

Thebatterylightislocatedtotherightofthesteeringcolumn

andabovetheoillight(Figure6).Thebatterylightwillturn

onforseveralsecondswhenyourststarttheengine,and

thenturnoffoncetheengineisrunning.Ifthelightremains

onwhiletheengineisrunning,thealternator,battery,or

electricalsystemisdamaged.

EngineOilPressureLight

Important:Iftheengineoverheatingproblempersists,

contactyourAuthorizedT oroDealerfordiagnosticsand

repair.

Glow-plugIndicatorLight

Theglow-plugindicatorlightislocatedtotherightofthe

batteryandtheengineoilpressurelights,andbelowthe

enginecoolant-temperaturelight(Figure6).Theglow-plug

indicatorlightwillilluminateredwhenyourotatetheignition

switchtotheOnpositionandtheengineiscold.Thelight

indicatesthattheglowplugsareoperating.

StarterSwitch

Theignitionswitchislocatedtotherightofthesteering

columnandbelowtheindicatorlightsforthebattery,engine

oilpressure,enginecoolanttemperature,glowplugs(Figure

6).Usetheignitionswitchtostartandstoptheengine.The

switchhas3positions:Off,On,andStart.Rotatethekey

clockwisetotheOnpositiontoactivatetheglowplugs.

Whentheglowplugindicatorlightturnsoff,rotatethekey

counterclockwisetotheStartpositiontostarttheengine.

Toshutofftheengine,rotatethekeycounterclockwiseto

theOffposition.

Note:Removethekeyfromtheignitionwhenleavingthe

machine.

PowerPoint

Thepowerpointislocatedtotherightofthestarterswitch

(Figure6).Usethepowerpointtopower12voltoptional

electricalaccessories.

Theengineoilpressurelightislocatedtotherightofthe

steeringcolumnandbelowthebatterylight(Figure6).The

14

Page 15

Gear-ShiftSelector

G009193

1

2

PassengerHandHolds

Thegearshiftselectorislocatedbetweentheseatsandbelow

theparkingbrakelever.Thegearshiftselectorhasthree

positions:Forward,Reverse,andNeutral(Figure7).

Note:Theenginewillstartandruninanyofthethree

positions.

Important:Alwaysstopthevehiclebeforechanging

gears.

Thepassengerhandholdsarelocatedontherightsideofthe

dashpanelandattheoutsideofeachseat(Figure9).

Figure9

1.Handhold—hiprestraint2.Passengerhandhold

Figure7

1.Gearshiftselector

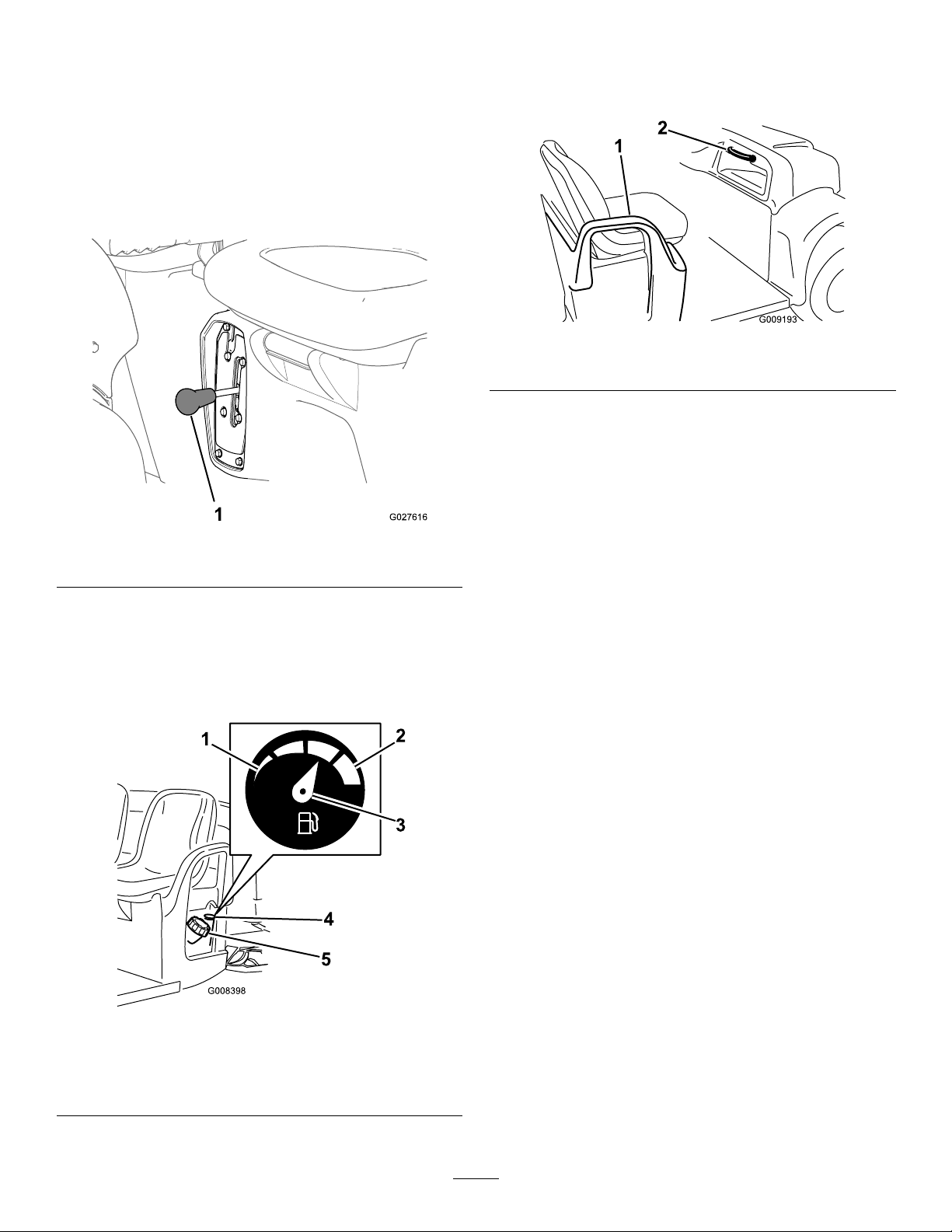

FuelGauge

Thefuelgauge(Figure8)islocatedonthefueltank,nextto

thellercapattheoperator'ssideofthemachine.Thegauge

displaystheamountoffuelinthetank.

Figure8

1.Empty4.Fuelgauge

2.Full5.Fuel-tankcap

3.Needle

15

Page 16

Specications

Note:Specicationsanddesignaresubjecttochangewithoutnotice.

Baseweight

Ratedcapacity(onlevelground)749kg(1650lb)total,including90.7kg(200lb)operatorand90.7kg(200lb)passenger,load,

Maximumgrossvehicleweight

(GVW)(onlevelground)

Maximumcargocapacity(onlevel

ground)

Towcapacity:

StandardhitchTongueweight23kg(50lb)Maximumtrailerweight182kg(400lb)

Heavy-dutyhitch

Overallwidth150cm(59inches)

Overalllength299cm(117.75inches)

Groundclearance25.4cm(10inches)atthefrontwithnoloadoroperator,18cm(7inches)attherearwith

Wheelbase

Wheeltread(centerlinetocenter

line)

Cargoboxlength116.8cm(46inches)inside,132.7cm(52-1/4inches)outside

Cargoboxwidth124.5cm(49inches)inside,150cm(59inches)atoutsideofthemoldedfenders

Cargoboxheight25.4cm(10inches)inside

Maximumspeed

Enginespeed(non-adjustable)

Dry590kg(1300lb)

trailertongueweight,grosstrailerweight,accessories,andattachments

1341kg(2950lb)total,includingalloftheweightslistedabove

567kg(1250lb)total,includingtrailertongueweightandgrosstrailerweight

Tongueweight45kg(100lb)Maximumtrailerweight363kg(800lb)

noloadoroperator

205.7cm(81inches)

124.5cm(49inches)inthefront,120cm(47-1/4inches)intherear

26km/h(16mph)

Lowidle–1250±50rpm,Highidle–3470±50rpm

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesisavailableforusewiththemachinetoenhanceandexpand

itscapabilities.ContactyourAuthorizedServiceDealerorDistributororgotowww.Toro.comforalistofallapproved

attachmentsandaccessories.

16

Page 17

Operation

g014860

1

2

3

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

ThinkSafetyFirst

Pleasecarefullyreadallofthesafetyinstructionsanddecals

inthesafetysection.Knowingthisinformationcouldhelp

youorbystandersavoidinjury.

OperatingtheCargoBox

RaisingtheCargoBox

WARNING

Drivingthemachinewiththecargoboxraisedmay

causethemachinetotiporrolleasier.Thebox

structuremaybecomedamagedifyouoperatethe

machinewiththeboxraised.

•Onlyoperatethemachinewhenthecargobox

isdown.

•Afteremptyingthecargobox,lowerit.

CAUTION

Ifaloadisconcentratednearthebackofthecargo

boxwhenyoureleasethelatches,theboxmay

unexpectedlytipopeninjuringyouorbystanders.

•Centerloadsinthecargoboxifpossible.

•Holdthecargoboxdownandensurethatno

oneisleaningovertheboxorstandingbehindit

whenreleasingthelatches.

Figure10

1.Latchlever3.Detentslot

2.Proprod

LoweringtheCargoBox

WARNING

Theweightoftheboxmaybeheavy.Handsor

otherbodypartscouldbecrushed.

Keephandsandotherbodypartsclearwhen

loweringthebox.

1.Raisethecargoboxslightlybyliftinguponthelatch

lever(Figure10).

2.Pulltheproprodoutofthedetentslot(Figure10).

3.Lowertheboxuntilitlatchesintosecurely(Figure10).

•Removeallcargofromtheboxbeforeliftingthe

boxuptoservicethemachine.

1.Liftthelatchleverthatisattheeithersidenearthe

forwardcornerofthecargobox,andlifttheboxup

(Figure10).

2.Securethecargoboxbypullingtheproprodintothe

reardetentatendoftheslotthatisintheleftframeof

themachine(Figure10).

17

Page 18

OpeningtheTailgate

1.Ensurethatthecargoboxisdownandlatched.

2.Liftuponthengerpullsatthebackpanelofthetail

gate(Figure11).

Figure11

1.Tailgateange(cargobox)3.Liftup(ngerpull)

2.Lockange(tailgate)

4.Rotaterearwardanddown

Figure12

3.Useashort,shakingmotiontorotatethetailgateback

andforthseveraltimes(Figure12).

Note:Thisactionwillhelpmovematerialawayfrom

thehingearea

4.Lowerthetailgateandcheckformaterialremainingin

thehingearea.

5.Repeatsteps1through4untilthematerialisremoved

fromthehingearea.

6.Rotatethetailgateupandforwarduntilthelockanges

ofthetailgateareushwiththetailgatepocketinthe

cargobox(Figure11).

Note:Raiseorlowerthetailgateinordertoalignthe

lockangesofthetailgatewiththeverticalopenings

betweenthetailgateangesofthecargobox.

3.Alignthelockangesofthetailgatewiththeopenings

betweenthetailgateangesofthecargobox(Figure

11).

4.Rotatethetailgaterearwardanddown(Figure11).

ClosingtheTailgate

Ifyouunloadedloosematerialsuchassand,landscapingrock,

orwoodchipsfromthecargoboxofthemachine,somethe

materialthatyouunloadedmayhavelodgedinthehinge

areaofthetailgate.Performthefollowingbeforeclosingthe

tailgate.

1.Useyourhandstoremoveasmuchofthematerial

fromthehingeareaaspossible.

2.Rotatethetailgatetoapproximately45°position

(Figure12).

7.Lowerthetailgateuntilitisseatedinthebackofthe

cargobox(Figure11).

Note:Thelockangesofthetailgatewillbefully

securedbythetailgateangesofthecargobox.

PreformingPre-Starting Checks

ServiceInterval:BeforeeachuseordailyCheckthe

followingitemseachtimeyoubegin

usingthemachinefortheday:

•Checkbrakeuidlevels,andaddthespeciedbrake

uidsasneeded;refertoCheckingtheBrakeFluidLevel

(page19).

•Checkengineoil,andaddthespeciedoilasneeded;

refertoCheckingtheEngine-OilLevel(page19).

•Checktheairpressureinthetires;refertoCheckingthe

TireAirPressure(page20).

•Checkthebrakepedaloperation.

•Checktoseethatthelightsareworking.

•Turnthesteeringwheeltotheleftandrighttocheck

steeringresponse.

•Checkforoilleaks,looseparts,andanyothernoticeable

malfunctions.

18

Page 19

Note:Shutofftheengineandallowallmovingpartsto

F

-30

C

-34

-10

-23

10

-12

32

0

50

10

70

21

90

32

110

43

STARTING TEMPERA TURE RANGE ANTICIPATED BEFORE NEXT OIL CHANGE

*A synthetic 5W -30 oil may be used.

15W -40

10W -30

5W-30

G017503

stopbeforecheckingforoilleaks,looseparts,andother

wearanddamage.

Ifanyoftheaboveitemsarenotcorrect,notifyyour

mechanicorcheckwithyoursupervisorbeforetakingthe

machineoutfortheday.Yoursupervisormaywantyouto

checkotheritemsonadailybasis,soaskhimorherabout

additionaloperator’ sresponsibilities.

CheckingtheBrakeFluid Level

ServiceInterval:BeforeeachuseordailyCheckthe

brake-uidlevelbeforethemotorisrst

used.

BrakeFluidType:DOT3

1.Parkthemachineonalevelsurface,settheparking

brake,rotatetheOn/OffswitchtotheOffposition,

andremovethekey..

2.Removetherubberpluginthecenterandontopof

thedashtogainaccesstothemasterbrakecylinder

andreservoir(Figure13).

Figure14

1.Brake-uidreservoir

2.Minimumline

4.Iftheuidlevelislow,preformthefollowing:

A.Cleantheareaaroundthereservoircap,and

removethecap(Figure13).

B.AddDOT3brakeuidtothereservoiruntilthe

uidlevelisabovetheMinimumline(Figure14).

Note:Donotoverllthereservoirwithbrake

uid.

C.Installthereservoircap(Figure13).

5.Installtherubberplugintopofthedash(Figure14).

CheckingtheEngine-OilLevel

ServiceInterval:BeforeeachuseordailyChecktheoillevel

intheenginebeforetheengineisrst

started.

Note:Themachineisshippedwithoilinthecrankcase;

however,checktheoilbeforeandafteryoustarttheengine.

Figure13

1.Rubberplug

2.Reservoircap

3.Fillerneck(reservoir)

4.DOT3brakeuid

3.Lookattheoutlineoftheuidlevelatthesideofthe

reservoir.(Figure14).

Note:ThelevelshouldbeabovetheMinimumline

OilType:Detergentoil(APIserviceCH-4,CI-4,CJ-4,or

higher)

Viscosity:Seethetablebelow

Figure15

1.Movethemachinetoalevelsurface.

2.Raisethecargobox;refertoRaisingtheCargoBox

(page17).

3.Usearagtocleanaroundtheoildipstick(Figure16)so

thatdirtcannotfallintothedipsticktubeanddamage

theengine.

19

Page 20

G016858

1

2

2.Ifneeded,adjusttheairpressureinthetiresbyadding

orremovingairinthetires.

AddingFuel

Theenginerunsonclean,freshdieselfuelwithaminimum

cetaneratingof40.Purchasefuelinquantitiesthatcanbe

usedwithin30daystoensurefuelfreshness.

Usesummergradedieselfuel(No.2-D)attemperatures

above20F(–7C)andwintergradedieselfuel(No.1-D

orNo.1-D/2-Dblend)below20F(–7C).Useofwinter

gradedieselfuelatlowertemperaturesprovideslowerash

pointandpourpointcharacteristics,allowingeasierstartsand

lesseningthechancesofchemicalseparationofthefueldue

tolowertemperatures.

Useofsummergradedieselfuelabove20F(–7C)will

contributetowardlongerlifeofthefuelpumpcomponents.

Figure16

1.Fillcap

4.Removetheoildipstickandwipetheendclean.

5.Slidetheoildipstickintothedipsticktubefullyseating

it(Figure16).

6.Pullthedipstickoutandlookattheend(Figure16).

Note:Iftheoillevelislow,removethellercapfrom

theengineandaddthespeciedoiltoraisethelevelup

to,butnotover,theFullmarkonthedipstick.Addthe

oilslowlyandchecktheleveloftenduringthisprocess.

Donotoverlltheenginewithoil..

7.Installtheoildipstickandrmlyseatit(Figure16).

8.Lowerthecargobox;refertoLoweringtheCargoBox

(page17).

2.Oildipstick

CheckingtheTireAirPressure

ServiceInterval:Beforeeachuseordaily

TireAirPressureRange:55to103kPa(8to22psi)

Important:Donotexceedthemaximumairpressure

indicatedonthesidewallofthetire.

Note:Theairpressureneededinthetiresisdeterminedby

thepayloadthatyouintendtocarry.

1.Checktheairpressureinthetires.

Important:Neverusekeroseneorgasolineinplaceof

dieselfuel.Failuretoobservethiscautionwilldamage

theengine.

DANGER

Incertainconditions,fuelisextremelyammable

andhighlyexplosive.Areorexplosionfromfuel

canburnyouandothersandcandamageproperty.

•Fillthefueltankoutdoors,inanopenarea,when

theengineiscold.Wipeupanyfuelthatspills.

•Neverllthefueltankinsideanenclosedtrailer.

•Donotllthefueltankcompletelyfull.Addfuel

tothefueltankuntilthelevelis1inch(25mm)

belowthebottomofthellerneck.Thisempty

spaceinthetankallowsfueltoexpand.

•Neversmokewhenhandlingfuel,andstayaway

fromanopenameorwherefuelfumesmaybe

ignitedbyaspark.

•Storefuelinanapprovedcontainerandkeepit

outofthereachofchildren.Neverbuymore

thana30-daysupplyoffuel.

•Donotoperatethemachinewithouttheentire

intakeandexhaustsysteminplaceandinproper

workingcondition.

Note:Theairpressurerangeinthefrontandreartires

is55to103kPa(8to22psi).

•Uselowerairpressureinthetiresforlighter

payloads,forlessthesoilcompaction,fora

smoothertheride,andtominimizetiremarksin

theground.

•Usehigherairpressureinthetiresforcarrying

heavierpayloadsathigherspeeds.

20

Page 21

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingasparkwhich

canignitethefuelvapors.Areorexplosionfrom

fuelcanburnyouandothersandcandamage

property.

•Alwaysplacefuelcontainersonthegroundaway

fromyourvehiclebeforelling.

•Donotllfuelcontainersinsideavehicleoron

atruckortrailerbedbecauseinteriorcarpets

orplastictruckbedlinersmayinsulatethe

containerandslowthelossofanystaticcharge.

•Whenpractical,removefuel-poweredequipment

fromthetruckortrailerandrefueltheequipment

withitswheelsontheground.

•Ifthisisnotpossible,thenrefuelsuchequipment

onatruckortrailerfromaportablecontainer,

ratherthanfromafueldispensernozzle.

•Ifafueldispensernozzlemustbeused,keepthe

nozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilfuelingis

complete.

FillingtheFuelTank

Thefueltankcapacityisapproximately26.5L(7USgallons).

1.Shutofftheengineandsettheparkingbrake.

2.Cleantheareaaroundthefuel-tankcap(Figure17).

Note:Thisspaceinthetankallowsfueltoexpand.

Donotoverllthefueltank..

5.Installthefueltankcapsecurely.

6.Wipeupanyfuelthatmayhavespilled.

StartingtheEngine

Important:Donotattempttopushortowthevehicle

togetitstarted.

1.Sitintheoperator'sseat,insertthekeyintothestarter

switch,pressdownonthebrake,androtatethekey

clockwisetotheOnposition.

Note:Ifthebackupalarmisinstalledandthegear

shiftselectorisinReverse,thebuzzerwillsoundto

warntheoperator.

2.Oncetheglowplugindicatorlightturnsoff,rotatethe

keycounterclockwisetotheStartposition.

3.Releasetheparkingbrake.

StoppingtheMachine

Important:Whenstoppingthemachineonanincline,

usetheservicebrakestostopthemachineandsetthe

parkingbraketoholdthemachineinplace.Usingthe

acceleratortostallthemachineonthehillcandamage

themachine.

1.Removeyourfootfromtheacceleratorpedal;referto

AcceleratorPedal(page13)).

2.Slowlypressthebrakepedaltoapplytheservicebrakes

untilthemachinecomestoacompletestop;referto

BrakePedal(page13).

Figure17

1.Empty4.Fuelgauge

2.Full5.Fuel-tankcap

3.Needle

3.Removethefuel-tankcap.

4.Fillthetanktoabout25mm(1inch)belowthetopof

tank,(bottomofthellerneck).

Note:Thestoppingdistancemayvarydependingon

themachineloadandspeed.

ParkingtheMachine

1.Stopthemachineusingtheservicebrakesbypressing

andholdingthebrakepedal;refertoBrakePedal(page

13).

2.Settheparkingbrakebypullinguptheparking-brake

lever;refertoParkingBrakeLever(page13).

3.Rotatethekeyforthestarterswitchcounterclockwise

totheOffposition;refertoStarterSwitch(page14).

4.Removethekeyfromthestarterswitch.

21

Page 22

BreakinginaNewMachine

ServiceInterval:Aftertherst100hours—Performthe

breakinginanewmachineguidelines.

Performthebreakinginanewmachineguidelinestoprovide

properperformanceandlonglifeforthemachine.

•Checktheuidandengineoillevelsregularly.Remain

alertforsignsthatthemachineoritscomponentsare

overheating.

•Afterstartingacoldengine,letitwarmupforabout15

secondsbeforeusingthemachine.

•Avoidhardbrakingsituationsfortherstseveralhoursof

newmachinebreak-inoperation.Newbrakeliningsmay

notbeatoptimumperformanceuntilseveralhoursofuse

hascausedthebrakestobecomeburnished(broken-in).

•Varythemachinespeedduringoperation.Avoidfast

startsandquickstops.

•Abreak-inoilforengineisnotrequired.Originalengine

oilisthesametypespeciedforregularoilchanges.

•RefertoMaintainingtheVehicleunderSpecialOperating

Conditions(page26)foranyspeciallowhourchecks.

•Checkthefrontsuspensionpositioningandadjustitif

necessary;refertoAdjustingtheFrontWheelT oe-inand

Camber(page37).

LoadingtheCargoBox

Usethefollowingguidelineswhenloadingthecargoboxand

operatingthemachine:

•Observetheweightcapacityofthemachineandlimit

theweightoftheloadthatyoucarryinthecargoboxas

describedinSpecications(page16)andonthegross

vehicleweighttagofthemachine(Figure18).

Note:Note:Theloadratingisspeciedformachine

operationonalevelsurfaceonly .

•Reducetheweightoftheloadthatyoucarrywhenthe

materialsaretall(andhaveahighcenterofgravity)such

asastackofbricks,landscapingtimbers,orfertilizerbags.

Distributetheloadaslowaspossible,makingsurethat

theloaddoesnotreduceyourabilitytoseebehindthe

machinewhenoperatingit.

•Keeploadscenteredbyloadingthecargoboxasfollows:

–Evenlypositiontheweightinthecargoboxfrom

sidetoside.

Important:Tippingoverismorelikelytooccur

ifthecargoboxisloadedtooneside.

–Evenlypositiontheweightinthecargoboxfrom

fronttoback.

Important:Lossofsteeringcontrolorthe

machinemaytipoverifyoupositiontheload

behindtherearaxleandthetractiononthefront

tiresisreduced.

•Useextracautionwhentransportingoversizedloadsin

thecargobox,particularlywhenyoucannotcenterthe

wightoftheoversizeloadtothecargobox

•Wheneverpossible,securetheloadbybindingittothe

cargoboxsoitdoesnotshift.

•Whentransportingliquidinalargetank(suchasasprayer

tank),usecautionwhendrivingthemachineuphillor

downhill,whensuddenlychangingspeedorstopping,or

whendrivingovertoughsurfaces.

Thecapacityofthecargoboxis0.37m

(volume)ofmaterialthatcanbeplacedintheboxwithout

exceedingthevehicleloadratingscanvarygreatlydepending

onthedensityofthematerial.Forexample,alevelboxofwet

sandweighs680kg(1500lb),whichexceedstheloadrating

by113kg(250lb).Butalevelboxofwoodweighs295kg

(650lb),whichisundertheloadrating.

Seethetablebelowforloadvolumelimitswithvarious

materials:

3

(13ft3).Theamount

Figure18

1.Grossmachineweightdecal

•Reducetheweightoftheloadthatyoucarryinthecargo

boxwhenoperatingthemachineonhillsandrough

terrain.

MaterialDensityMax.cargobox

Gravel,dry1521.7kg/m

Gravel,wet1922.2kg/m

Sand,dry1441.6kg/m

Sand,wet1922.2kg/m

Wood

Bark

Earth,packed

22

<720.8kg/m

720.8kg/m

1601.8kg/m

capacity(onlevel

ground)

3

(95lb/ft

(120lb/ft

(90lb/ft

(120lb/ft

(100lb/ft

3

)

3

)

3

)

3

)

3

(45

3

lb/ft

)

3

(<45

3

lb/ft

)

3

)

3/4full(approx.)

3

1/2full(approx.)

3

3

3

3/4full

1/2full

Full

Full

3/4full(approx.)

Page 23

TransportingtheVehicle

TowingtheMachine

Formovingthevehiclelongdistances,atrailershouldbe

used.Makesurethatthevehicleissecuredtothetrailer.Refer

toFigure19andFigure20forthelocationofthetie-down

points.

CAUTION

Looseseatsmayfalloffofthevehicleandtrailer

whentransportingandlandonanothervehicleor

becomeanobstructionontheroad.

Removetheseatsormakesurethattheseatsare

securelyfastenedinthedetents.

Figure19

1.Towingtongueandtiedownpoint(frontofthemachine)

Incaseofanemergency ,themachinecanbetowedfora

shortdistance.However,wedonotrecommendthisasa

standardoperatingprocedure.

WARNING

Towingatexcessivespeedscouldcausealossof

steeringcontrol,resultinginpersonalinjury.

Nevertowthemachinefasterthan8km/h(5mph).

Towingthemachineisa2-personjob.Ifthemachinemust

bemovedaconsiderabledistance,transportitonatruckor

trailer;refertoTransportingtheVehicle(page23).

1.Removethedrivebeltfromthemachine;referto

ReplacingtheDriveBelt(page44).

2.Afxatowlinetothetongueatthefrontofthe

machine’sframe(Figure19).

3.Putthetransmissionofthemachineinneutraland

releasetheparkingbrake;refertoGear-ShiftSelector

(page15)andParkingBrakeLever(page13).

TowingaTrailer

Figure20

1.Rearaxletie-downpoints(backofthemachine)

Themachineiscapableofpullingtrailers.2typesoftow

hitchesareavailableforthemachine,dependingonyour

application.ContactyourAuthorizedToroDistributorfor

details.

Whenhaulingcargoortowingatrailer,donotoverloadyour

vehicleortrailer.Overloadingcancausepoorperformance

ordamagetothebrakes,axle,engine,transaxle,steering,

suspension,bodystructure,ortires.Alwaysloadatrailerwith

60%ofthecargoweightinthefrontofthetrailer.Thisplaces

approximately10%oftheGrossTrailerWeight(GTW)on

thetowhitchofthevehicle.

Themaximumcargoloadshallnotexceed567kg(1250lb),

includingtheGTW.Forexample,iftheGTW=181.5kg

(400lb)thenthemaximumcargoload=386kg(850lb)

Toprovideadequatebrakingandtraction,alwaysloadthe

cargoboxwhentrailering.DonotexceedtheGTWorGVW

limits.

Avoidparkingavehiclewithatraileronahill.Ifyoumust

parkonahill,engagetheparkingbrakeandblockthetrailer

tires.

23

Page 24

Maintenance

Note:LookingforanElectricalSchematicorHydraulicSchematicforyourmachine?Downloadafreecopyoftheschematicby

visitingwww .T oro.comandsearchingforyourmachinefromtheManualslinkonthehomepage.

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst8hours

Aftertherst50hours

Aftertherst100hours

Beforeeachuseordaily

Every100hours

MaintenanceProcedure

•Checktheconditionofthedrivebelt.

•Changetheengineoil.

•Performthebreakinginanewmachineguidelines.

•Preformthepre-staringchecks.Checkthefollowingitemseachtimeyoubegin

usingthemachinefortheday:

•Checkthebrake-uidlevel.

•Checktheengineoil.Checktheoillevelintheenginebeforetheengineisrst

started.

•Checkthetirepressure.

•Checkgearshiftoperation.

•Inspecttheprimarydriveclutch.

•Checktheradiatorcoolantlevel.

•Greasethebearingsandbushings.

•Air-cleanerlter:Inspectafterevery100operatinghoursReplacetheairlter

elementsoonerifitdirtyordamaged.

•Checktheconditionofthetiresandrims.

•T orquethewheel-lugnuts.

•Checkthefrontwheeltoe-inandcamber.

•Checkthetransaxleoillevel.

•ChecktheoperationoftheNeutralgearshiftposition.

•Cleantheenginecoolingareas(twiceasofteninspecialoperatingconditions;refer

toMaintainingtheVehicleunderSpecialOperatingConditions).

•Inspectthebrakes.

Every150hours

Every200hours

Every300hours

Every400hours

Every800hours

Every1,000hours

Yearly

Important:Refertoyour

•Changetheengineoil(twiceasofteninspecialoperatingconditions;referto

MaintainingtheVehicleunderSpecialOperatingConditions).

•Changetheoillter.Changetheoiltwiceasoftenduringspecialoperating

conditions;refertoMaintainingtheVehicleunderSpecialOperatingConditions.

•Replacetheairlterelement.

•Cleantheprimarydriveclutch(moreoftenindustyormuddyconditions).

•Adjusttheparkingbrakeifneeded.

•Checktheconditionandtensionofthedrivebelt.

•Greasethefrontwheelbearings.

•Inspectthefuellinesandconnections.

•Replacethefuellter.

•Changethetransaxleuid.

•Changetheradiatorcoolant.

•Changethebrakeuid.

•Completeallyearlymaintenanceproceduresspeciedintheengineowner'smanual.

engine operator's man ual

foradditionalmaintenanceprocedures.

24

Page 25

DailyMaintenanceChecklist

Duplicatethispageforroutineuse.

Fortheweekof: MaintenanceCheckItem

Mon.Tues.Wed.Thurs.Fri.

Checkbrakeandparking

brakeoperation.

Checkgearshift/neutral

operation.

Checkfuellevel.

Checkengineoillevel.

Checktransaxleoillevel.

Inspectairlter .

Inspectenginecooling

ns.

Checkunusualengine

noises.

Checkunusualoperating

noises.

Checkclutchoperation.

Checktirepressure.

Checkuidleaks.

Checkinstrument

operation.

Checkaccelerator

operation.

Lubricateallgrease

ttings.

Touchupdamagedpaint.

Sat.Sun.

WARNING

Thebedmustberaisedtoperformsomeroutinemaintenance.

Araisedbedcanfallandinjurepersonsthatareunderneathit.

•Alwaysusetheproprodtoholdthebedupbeforeworkingunderit.

•Removeanyloadmaterialfromthebedbeforeworkingunderit.

CAUTION

Ifyouleavethekeyinthestarterswitch,someonecouldaccidentlystarttheengineandseriouslyinjure

youorotherbystanders.

Removethekeyfromthestarterswitchbeforeyoudoanymaintenance.

25

Page 26

Premaintenance

Procedures

MaintainingtheVehicleunder SpecialOperatingConditions

Ifthevehicleissubjectedtoanyoftheconditionslisted

below,maintenanceshouldbeperformedtwiceasfrequently.

•Desertoperation

•Coldclimateoperation(below50°F[10degreesC])

•Trailertowing

•Drivingtimetypicallylessthan5minutes

•Frequentoperationindustyconditions

•Constructionwork

•Afterextendedoperationinmud,sand,water,orsimilar

dirtyconditions,haveyourbrakesinspectedandcleaned

assoonaspossible.Thiswillpreventanyabrasive

materialfromcausingexcessivewear.

•Underfrequentheavydutyoperatingconditions,lubricate

allgreasettingsandinspectaircleanerdailytoprevent

excessivewear.

LiftingtheMachine

DANGER

Themachinemaybeunstablewhenusingajack.It

couldslipoffthejack,injuringanyonebeneathit.

•Donotstarttheenginewhilethemachineis

onajack.

Figure21

1.Frontliftingpoint

•Theliftingpointattherearofthemachineisunderthe

axletubes(Figure22).

Figure22

1.Rearliftingpoints

AccessingtheHood

Raisingthehood

1.Liftupthehandleoftherubberlatchesateachside

ofthehood(Figure23).

•Alwaysremovethekeyfromthestarterswitch

beforegettingoffofthemachine.

•Blockthetireswhenthemachineissupported

byliftingequipment.

•Usejackstandstosupportthemachineonce

youhaveliftedtheit.

Important:Whenevertheengineisrunforroutine

maintenanceand/orenginediagnostics,therearwheels

ofthemachineshouldbe25mm(1inch)offtheground,

withtherearaxlesupportedonjackstands.

•Theliftingpointatthefrontofthemachineisatthefront

oftheframebehindthetowingtongue(Figure21).

Figure23

2.Raisethehood.

26

Page 27

ClosingtheHood

1.Gentlylowerthehoodontothechassis.

Lubrication

2.Securethehoodbyaligningtherubberlatchesontothe

latchanchorsateachsideofthehood(Figure23).

GreasingtheMachine

ServiceInterval:Every100hours/Yearly(whichevercomes

rst)—Greasethebearingsandbushings.

Greasethemachinemorefrequently

whenusingitforheavy-dutyoperations.

GreaseType:Number2general-purpose,lithium-base

grease

1.Usearagtowipethegreasettingcleansothatforeign

mattercannotbeforcedintothebearingorbushing.

2.Withagreasegun,apply1or2pumpsofgreaseinto

thegreasettingsonthemachine.

3.Wipetheexcessgreaseoffthemachine.

Thegreasettingsarelocatedatthe4tie-rodends(Figure

24)andthe2kingpins(Figure25).

1.Greasetting

1.Greasetting(kingpin)

Figure24

Leftsideshown

2.Tierod

Figure25

Leftsideshown

27

Page 28

GreasingtheFrontWheel Bearings

ServiceInterval:Every300hours

Greasespecication:MobilgreaseXHP™-222

RemovingtheHubandRotor

1.Liftthefrontofthemachineandsupportitwithjack

stands.

2.Removethe5lugnutsthatsecurethewheeltothehub

(Figure26).

Figure27

Figure26

1.Lugnut3.Hub

2.Wheel

3.Removetheange-headbolts(3/8x1inch)thatsecure

thebracketforthebrakeassemblytothespindleand

separatethebrakefromthespindle(Figure27).

Note:Supportthebrakeassemblybeforeproceeding

tothenextstep.

1.Caliperbracket(brake

assembly)

2.Spindle

3.Flange-headbolts(3/8x

1inch)

4.Removethedustcapfromthehub(Figure28).

Figure28

1.Dustcap4.Tabwasher

2.Nutretainer

3.Spindlenut6.Cotterpin

5.Spindle

5.Removethecotterpinandhutretainerfromthe

spindleandspindlenut(Figure28).

6.Removethespindlenutfromthespindle,andseparate

thehubandrotorassemblyfromthespindle(Figure

28andFigure29).

28

Page 29

Figure29

8.Fillthecavityofhub50to80%fullofthespecied

grease(Figure30).

9.Assembletheinboardbearingontotheraceatthe

inboardsideofthehubandinstalltheseal(Figure30).

10.Repeatsteps1through9tothebearingsfortheother

hub.

InstallingtheHubandRotor

1.Applyalightcoatofthespeciedgreasetothespindle

(Figure31).

1.Hubandrotorassembly

2.Spindle

7.Wipecleanthespindlewitharag.

8.Repeatsteps1through7tothehubandrotoratthe

othersideofthemachine.

GreasingtheWheelBearings

1.Removetheoutboardbearingandbearingracefrom

thehub(Figure30).

Figure30

1.Outboardbearing

2.Outboard-bearingrace

3.Bearingcavity(hub)6.Seal

4.Inboard-bearingrace

5.Inboardbearing

Figure31

1.Retainer5.Hub,rotor,innerbearing,

2.Spindlenut6.Spindle

3.Tabwasher

4.Outerbearing

race,andseal

7.Holes(brakemountofthe

spindleframe)

2.Assemblethehubandrotorontothespindlewiththe

rotorinboard(Figure31).

3.Assembletheoutboardbearingontothespindleand

seatthebearingtotheoutboardrace(Figure31).

2.Removetheseal,inboardbearingandbearingrace

fromthehub(Figure30).

3.Wipecleanthesealandcheckforwearanddamage.

Note:Donotusecleaningsolventtocleantheseal.

Replacethesealifitiswornordamaged.

4.Cleanthebearingsandraces,andcheckthesepartsfor

wearanddamage.

Note:Replaceallwornordamagedparts.Ensurethat

thebearingsandracesarecleananddry.

5.Cleanthecavityofthehubofallgrease,dirt,anddebris

(Figure30).

6.Packthebearingswiththespeciedgrease.

7.Installtheinboardandoutboardbearingracesintothe

hub(Figure30).

Note:Ensurethattheracesarefullyseatedinthe

boresofthehub.

4.Assemblethetabwasherontothespindle(Figure31).

5.Threadthespindlenutontothespindleandtightenthe

nutwhilerotatingthehub(Figure31).

Note:Tightenthenutandrotatethespindleuntilthe

bearingsarefullyseatedandthehubhasnolinear-end

movement.

6.Loosenthespindlenutuntilthehubrotatesfreely.

7.Torquethespindlenutto170N-cm(15in-lb)while

rotatingthehub.

8.Installtheretaineroverthenutandcheckthealignment

oftheslotintheretainerandtheholeinthespindlefor

thecotterpin(Figure32).

Note:Iftheslotintheretainerandtheholeinthe

spindlearenotaligned,tightenthespindlenuttoalign

theslotandholetoamaximumtorqueof226N-cm

(20in-lb)onthenut.

29

Page 30

1.Dustcap

2.Nutretainer

Figure32

3.Cotterpin

EngineMaintenance

ServicingtheAirCleaner

ServiceInterval:Every100hoursReplacetheairlter

elementsoonerifitdirtyordamaged.

Every200hours

Note:Servicetheaircleanermorefrequently(everyfew

hours)ifoperatingconditionsareextremelydustyorsandy.

CheckingtheFilter

1.Raisethecargoboxandsecureitwiththeproprod;

refertoRaisingtheCargoBox(page17).

9.Installthecotterpinandbendeachlegsaroundthe

retainer(Figure32).

10.Installthedustcapontothehub(Figure32).

11.Repeatsteps1through10forthehubandrotoratthe

othersideofthemachine.

InstallingtheBrakesandWheels

1.Cleanthe2ange-headbolts(3/8x1inch)andapply

acoatforanti-seizecompoundtothethreadsofthe

bolts.

2.Alignthebrakepadstoeithersideoftherotor(Figure

27)andtheholesinthecaliperbracketwiththeholes

inthebrakemountofthespindleframe(Figure31).

3.Assemblecaliperbrackettothespindleframe(Figure

27)withthe2ange-headbolts(3/8x1inch),and

torquethebolts47to54N-cm(35to40ft-lb).

4.Aligntheholesinthewheeltothestudsofthehub

andassemblethewheeltothehubwiththevalvestem

outward(Figure26).

Note:Ensurethemountingsurfaceofthewheelis

ushwiththehub.

5.Securethewheeltothehubwiththelugnuts(Figure

26),andtorquethenutsto108to122N-m(80to90

ft-lb).

6.Repeatsteps1through5forthebrakeandwheelatthe

othersideofthemachine.

2.Checktheaircleanerbodyfordamagewhichcould

possiblycauseanairleak.Ensuretheair-ltercoveris

sealingaroundtheaircleanerhousing(Figure33).

Note:Replaceadamagedaircleanercoverorhousing.

Figure33

1.Dirt-ejectionport

2.Latch

3.Air-ltercover6.Backofthemachine

3.Pullthelatchoutwardandrotatetheaircleanercover

counterclockwise(Figure33).

4.Removethecoverfromtheaircleanerbody .

5.Gentlyslidetheair-lterelementoutoftheair-lter

housing(Figure33)toreducetheamountofdust

dislodged.

Note:Avoidknockingthelteragainsttheair-lter

housing.

4.Air-lterelement

5.Air-lterhousing

6.Inspecttheair-lterelement.

30

•Iftheair-lterelementisclean,installthelter

element,refertoInstallingtheFilter(page31).

•Iftheair-lterelementisdamaged,replacethe

lterelement;referto.

Page 31

ReplacingtheAirFilter

F

-30

C

-34

-10

-23

10

-12

32

0

50

10

70

21

90

32

110

43

STARTING TEMPERA TURE RANGE ANTICIPATED BEFORE NEXT OIL CHANGE

*A synthetic 5W -30 oil may be used.

15W -40

10W -30

5W-30

G017503

1.Removetheair-lterelement;refertosteps1through

5inCheckingtheFilter(page30).

2.Inspectthenewlterforshippingdamage.

Note:Checkthesealingendofthelter.

ServicingtheEngineOil

Note:Changetheoilandoilltermorefrequentlywhen

operatingconditionsareextremelydustyorsandy.

OilType:Detergentoil(APIserviceCH-4,CI-4,CJ-4,or

higher)

Important:Donotinstalladamagedlter.

3.Installthenewairlter;refertoInstallingtheFilter

(page31).

InstallingtheFilter

Important:Topreventenginedamage,alwaysoperate

theenginewiththecompleteaircleanerassembly

installed.

Note:Donotuseadamagedelement.

Note:Cleaningoftheusedair-lterelementisnot

recommendedduetothepossibilityofdamagetothelter

media.

1.Cleanthedirtejectionportlocatedontheair-lter

cover(Figure33).

2.Removetherubberoutletvalvefromthecover,clean

thecavity,andreplacetheoutletvalve(Figure33).

3.Inserttheair-lterelementintoair-lterhousingby

applyingpressuretotheouterrimoftheelementto

seatitintotheair-lterhousing(Figure33).

Note:Ensurethatthelterissealedproperlyby

applyingpressuretotheouterrimofthelterwhen

installingit.Donotpressontheexiblecenterofthe

lter.

4.Aligntheair-cleanercoverwiththeair-cleanerhousing

withthetherubberoutletvalveinadownward

position—betweenapproximately5:00to7:00O’clock

whenviewedfromtheend(Figure33).

5.Securethecovertothehousingwiththelatches(Figure

33).

6.Lowerthecargobox;refertoLoweringtheCargoBox

(page17).

Viscosity:Seethetablebelow

CrankcaseCapacity:1.4liters.(48oz.or1.5qt)whenthe

lterischanged

Figure34

ChangingtheOil

ServiceInterval:Aftertherst50hours

Every150hours(twiceasofteninspecialoperating

conditions;refertoMaintainingtheV ehicleunder

SpecialOperatingConditions).

1.Startthevehicleandletitrunforafewminutesto

warmtheoil.

2.Parkthemachineonalevelsurface,settheparking

brake,turntheignitionoff,andremovethekey.

3.Raisethecargoboxandsecureitwiththeproprod;

refertoRaisingtheCargoBox(page17).

4.Disconnectthepositivebatterycable;referto

DisconnectingtheBattery(page33).

5.Alignadrainpanwitha1.6L(1.7qt)capacityunder

thedrainplug(Figure35).

31

Page 32

G016858

1

2

10.Addtheoilslowlyandchecktheleveloftenduringthis

process.

Note:Donotoverlltheenginewithoil.

11.Installtheoil-llcapanddipstickrmlyinplace.

ChangingtheOilFilter

ServiceInterval:Every150hours/Yearly(whichevercomes

rst)Changetheoiltwiceasoftenduring

specialoperatingconditions;referto

MaintainingtheVehicleunderSpecial

OperatingConditions.

1.Draintheoilfromtheengine;refertosteps1through

7inChangingtheOil(page31).

Figure35

1.Engineoillter

2.Engineoildrainplug

6.Removethedrainplug(Figure35).

Note:Allowtheoiltocompletelydrainfromthe

engine.

Note:Disposeoftheusedoilatacertiedrecycling

center.

7.Installthedrainplugandseal(Figure35),andtorque

theplugto45to53N-m(33to39ft-lb).

8.Cleanaroundtheoildipstickandllcap,andremove

thedipstick(Figure36).

2.Removetheexistingoillter(Figure35).

3.Applyalightcoatofcleanoiltothenewltergasket.

4.Threadthenewlterontothelteradapteruntilthe

gasketcontactsthemountingplate,thentightenthe

lteranadditional1/2to3/4turnfurther(Figure35).

Note:Donotovertightentheoillter.

5.Fillthecrankcasewiththespeciedoil;refertoFigure

34.

6.Startandruntheenginetocheckforleaks.

7.Stoptheengineandchecktheoillevel.

Note:Ifnecessary,addthespeciedoilintotheengine

untiltheoillevelisattheFullmarkonthedipstick.

Figure36

1.Fillcap2.Dipstick

9.Pouroilintothellopeninguntiltheoillevelisupto

theFullmarkonthedipstick.

32

Page 33

FuelSystem

G017504

1

ElectricalSystem

Maintenance

InspectingFuelLinesand Connections

ServiceInterval:Every400hours/Yearly(whichevercomes

rst)

Inspectthefuellines,ttings,andclampsforsignsofleaking,

deterioration,damage,orlooseconnections.

Note:Repairanydamagedorleakingfuelsystemcomponent

beforeusingthemachine.

ReplacingtheFuelFilter

ServiceInterval:Every800hours/Yearly(whichevercomes

rst)

1.Raisetheboxandsupportitwiththeproprod.

2.Placeacleancontainerunderthefuellter.

3.Unscrewthefuellterfromthebracket(Figure37).

Maintenance

ServicingtheBattery

Batteryvoltage:12voltwith540coldcrankingampsat-18°

C(0°F).

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

Washhandsafterhandling.

DANGER

Batteryelectrolytecontainssulfuricacidwhichisa

deadlypoisonandcausessevereburns.

•Donotdrinkelectrolyteorallowittocontact

yourskin,eyesorclothing.Wearsafetyglasses

toshieldyoureyesandrubberglovestoprotect

yourhands.

•Fillthebatterywherecleanwaterisalways

availableforushingtheskin.

Figure37

1.Fuellter

4.Installthereplacementlterbyturningituntilthe

ltercontactsthetopofthebracket,thentightenitan

additional3/4ofaturn.

•Alwayskeepthebatterycleanandfullycharged.

•Alwayskeepthebatterycleanandfullycharged.

•Ifthebatteryterminalsarecorroded,cleanthemwitha

solutionof4partswaterand1partbakingsoda.

•Applyalightcoatingofgreasetothebatteryterminals

topreventcorrosion.

DisconnectingtheBattery

WARNING

Incorrectbatterycableroutingcoulddamagethe

vehicleandcables,causingsparks.Sparkscan

causethebatterygassestoexplode,resultingin

personalinjury.

•Alwaysdisconnectthenegative(black)battery

cablebeforedisconnectingthepositive(red)

cable.

•Alwaysreconnectthepositive(red)batterycable

beforereconnectingthenegative(black)cable.

•Alwayskeepthebatterystrapinplacetoprotect

andsecurethebattery.

33

Page 34

WARNING

Batteryterminalsormetaltoolscouldshortagainst

metalvehiclecomponents,causingsparks.Sparks

cancausethebatterygassestoexplode,resulting

inpersonalinjury.

InstallingtheBattery

1.Alignthebatterytothebatterytrayofthemachine