Page 1

FormNo.3362-385RevA

IndustrialWorkman

®

HDX-D

UtilityVehiclewithBed

ModelNo.07354—SerialNo.311000001andUp

ToregisteryourproductordownloadanOperator'sManualorPartsCatalogatnocharge,gotowww.T oro.com.OriginalInstructions(EN)

Page 2

Thismachineisautilityvehicleintendedtobeusedby

professional,hiredoperatorsincommercialapplications.

Itisprimarilydesignedforthetransportofimplements

usedinsuchapplications.Thisvehicleallowsforthe

safetransportofanoperatorandonepassengerinthe

identiedseats.Thebedofthisvehicleisnotsuitable

foranyriders.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafetyalertsymbol

(Figure2),whichsignalsahazardthatmaycauseserious

injuryordeathifyoudonotfollowtherecommended

precautions.

Introduction

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoidinjury

andproductdamage.Youareresponsibleforoperating

theproductproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comfor

productandaccessoryinformation,helpndinga

dealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

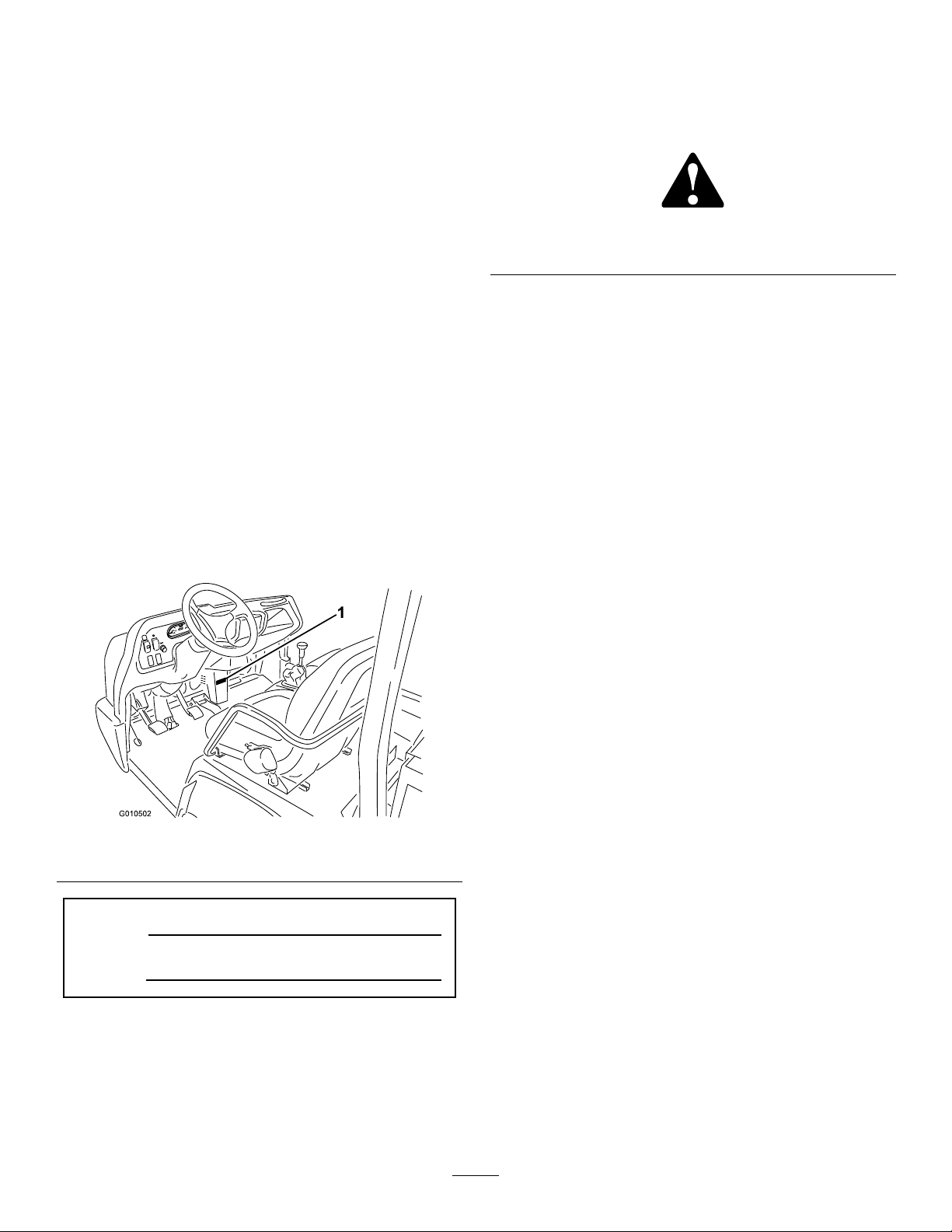

Figure1

Figure2

1.Safetyalertsymbol

Thismanualuses2otherwordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

©2011—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Figure1

Contactusatwww.Toro.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

Contents

Introduction.................................................................2

Safety...........................................................................4

SafeOperatingPractices.......................................4

Supervisor’sResponsibilities.................................4

BeforeOperating.................................................4

Operation.............................................................5

Maintenance.........................................................6

SoundPressure.....................................................6

Vibration..............................................................6

SoundLevelCertication.....................................7

SafetyandInstructionalDecals.............................8

Setup..........................................................................13

1CheckingtheFluidLevels................................13

ProductOverview......................................................14

Controls.............................................................14

Specications.....................................................17

Attachments/Accessories...................................17

Operation...................................................................18

CheckingtheEngineOilLevel............................18

AddingFuel.......................................................19

CheckingtheCoolantLevel................................20

CheckingtheTransaxle/HydraulicFluid

Level..............................................................20

CheckingtheHighFlowHydraulicFluid(If

soequipped)...................................................21

CheckingtheFrontDifferentialOilLevel

(FourWheelDriveModelsOnly)....................21

CheckingtheTorqueoftheWheel

Nuts...............................................................22

CheckingtheTirePressure.................................22

CheckingtheBrakeFluid....................................22

Pre–startingChecks............................................23

StartingtheEngine.............................................23

DrivingtheV ehicle.............................................23

StoppingtheVehicle...........................................24

StoppingtheEngine...........................................24

NewVehicleBreak–in........................................24

CheckingtheInterlockSystem............................24

OperatingCharacteristics...................................25

Passengers..........................................................25

Speed.................................................................26

Turning..............................................................26

Braking..............................................................26

TipOvers...........................................................26

Hills...................................................................27

LoadingandDumping........................................27

FourWheelDrive(FourWheelDriveModels

Only)..............................................................28

TransportingtheVehicle.....................................28

TowingtheVehicle.............................................28

TowingaTrailerwiththeVehicle.........................29

Maintenance...............................................................30

RecommendedMaintenanceSchedule(s)................30

ServiceIntervalChart.........................................31

HeavyDutyOperation.......................................32

PremaintenanceProcedures....................................32

RemovingtheFullBed.......................................32

InstallingtheFullBed.........................................32

JackingtheVehicle..............................................33

RemovingtheHood...........................................33

Lubrication.............................................................34

GreasingBearingsandBushings.........................34

EngineMaintenance...............................................37

ServicingtheAirCleaner....................................37

ChangingtheEngineOilAndFilter....................37

FuelSystemMaintenance.......................................38

FuelLinesandConnections................................38

ServicingtheWaterSeparator/Fuel

Filter..............................................................38

ElectricalSystemMaintenance................................39

Fuses..................................................................39

JumpStartingtheVehicle....................................40

ServicingtheBattery...........................................40

DriveSystemMaintenance.....................................41

ChangingtheFrontDifferentialOil(Four

WheelDriveModelsOnly).............................41

InspectingtheConstantVelocityBoot(Four

WheelDriveModelsOnly).............................41

AdjustingtheShiftCables...................................42

AdjustingtheHigh–LowCable...........................42

InspectingtheTires............................................42

CheckingtheFrontWheelAlignment.................42

CoolingSystemMaintenance..................................43

RemovingDebrisfromtheCooling

System............................................................43

ChangingEngineCoolant...................................44

BrakeMaintenance.................................................45

AdjustingtheParkingBrake................................45

AdjustingtheBrakePedal...................................45

BeltMaintenance....................................................46

AdjustingBelts...................................................46

ControlsSystemMaintenance.................................46

AdjustingtheAcceleratorPedal..........................46

AdjustingtheClutchPedal..................................47

ConvertingtheSpeedometer..............................47

HydraulicSystemMaintenance...............................48

ChangingtheHydraulicFluidandCleaning

theStrainer.....................................................48

ReplacingtheHydraulicFilter.............................48

ChangingtheHighFlowHydraulicOiland

Filter(Ifsoequipped).....................................49

Storage.......................................................................50

Schematics.................................................................51

3

Page 4

Safety

ThemachinemeetstherequirementsofSAEJ2258.

Supervisors,operatorsandservicepersonsshouldbe

familiarwiththefollowingstandardsandpublications:

(Thematerialmaybeobtainedfromtheaddressshown).

•FlammableandCombustibleLiquidsCode:

ANSI/NFPA30

•NationalFireProtectionAssociation:

feelthanwhatdriversexperiencewithpassengercars

ortrucks.Sotaketimetobecomefamiliarwithyour

Workman.

NotalloftheattachmentsthatadapttotheW orkman

arecoveredinthismanual.SeethespecicOperator’s

Manualprovidedwitheachattachmentforadditional

safetyinstructions.Readthesemanuals.

Toreducethepotentialforinjuryordeath,comply

withthefollowingsafetyinstructions:

ANSI/NFPA#505;PoweredIndustrialTrucks

ADDRESS:

NationalFirePreventionAssociation

BarrymarchPark

Quincy,Massachusetts02269U.S.A

•ANSI/ASMEB56.8PersonalBurdenCarriers

ADDRESS:

AmericanNationalStandardsInstitute,Inc.

1430Broadway

NewYork,NewYork10018U.S.A.

•ANSI/UL558;InternalCombustionEngine

PoweredIndustrialTrucks

ADDRESS:

AmericanNationalStandardsInstitute,Inc.

1430Broadway

NewYork,NewYork10018U.S.A.

or

UnderwritersLaboratories333PngstenRoad

Northbrook,Illinois60062U.S.A.

SafeOperatingPractices

WARNING

TheWorkmanisanoff–highwayvehicleonly ,and

isnotdesigned,equipped,ormanufacturedforuse

onpublicstreets,roadsorhighways.

TheWorkmanwasdesignedandtestedtooffersafe

servicewhenoperatedandmaintainedproperly.

Althoughhazardcontrolandaccidentprevention

partiallyaredependentuponthedesignand

congurationofthemachine,thesefactorsarealso

dependentupontheawareness,concern,andproper

trainingofthepersonnelinvolvedintheoperation,

maintenanceandstorageofthemachine.Improperuse

ormaintenanceofthemachinecanresultininjuryor

death.

Thisisaspecializedutilityvehicledesignedforoff–road

useonly .Itsrideandhandlingwillhaveadifferent

Supervisor’sResponsibilities

•Makesureoperatorsarethoroughlytrainedand

familiarwiththeOperator’sManualandalllabelson

thevehicle.

•Besuretoestablishyourownspecialproceduresand

workrulesforunusualoperatingconditions(e.g.

slopestoosteepforvehicleoperation).Usethe3rd

HighLockoutswitchifhighspeedcouldresultina

safetyorvehicleabusesituation.

BeforeOperating

•Operatethemachineonlyafterreadingand

understandingthecontentsofthismanual.A

replacementmanualisavailablebysendingcomplete

modelandserialnumberto:TheToroCompany,

8111LyndaleAvenueSouth,Minneapolis,Minnesota

55420.

•Neverallowchildrentooperatethevehicle.Never

allowadultstooperateitwithoutproperinstructions.

Onlytrainedandauthorizedpersonsshouldoperate

thisvehicle.Makesurealloperatorsarephysically

andmentallycapableofoperatingthevehicle.

•Thisvehicleisdesignedtocarryonlyyou,the

operator,andonepassengerintheseatprovidedby

themanufacturer.Nevercarryanyotherpassengers

onthevehicle.

•Neveroperatethevehiclewhenundertheinuence

ofdrugsoralcohol.

•Becomefamiliarwiththecontrolsandknowhowto

stoptheenginequickly.

•Keepallshields,safetydevicesanddecalsinplace.

Ifashield,safetydeviceordecalismalfunctioning,

illegible,ordamaged,repairorreplaceitbefore

operatingthemachine.

•Alwayswearsubstantialshoes.Donotoperate

themachinewhilewearingsandals,tennisshoes,

orsneakers.Donotwearloosettingclothingor

jewelrywhichcouldgetcaughtinmovingpartsand

causepersonalinjury.

4

Page 5

•Wearingsafetyglasses,safetyshoes,longpants,anda

helmetisadvisableandrequiredbysomelocalsafety

andinsuranceregulations.

•Keepeveryone,especiallychildrenandpets,away

fromtheareasofoperation.

•Beforeoperatingthevehicle,alwayscheckallparts

ofthevehicleandanyattachments.Ifsomethingis

wrong,stopusingvehicle.Makesuretheproblem

iscorrectedbeforevehicleorattachmentisoperated

again.

•Sincedieselfuelishighlyammable,handleit

carefully.

–Useanapprovedfuelcontainer.

–Donotremovethecapfromthefueltankwhen

theengineishotorrunning.

–Donotsmokewhilehandlingfuel.

–Fillthefueltankoutdoorsandtoaboutoneinch

belowthetopoftank(bottomofllerneck).Do

notoverll.

–Wipeupanyspilledfuel.

•Operatethevehicleonlyoutdoorsorinawell

ventilatedarea.

•Useonlyanapprovednonmetal,portablefuel

container.Staticelectricdischargecanignitefuel

vaporsinaungroundedfuelcontainer.Removethe

fuelcontainerfromthebedofthevehicleandplace

itonthegroundawayfromthevehiclebeforelling.

Keepthenozzleincontactwiththecontainerwhile

lling.Removeequipmentfromvehiclebedbefore

lling.

•Checkthesafetyinterlocksystemdailyforproper

operation.Ifaswitchmalfunctions,replacethe

switchbeforeoperatingmachine.

Operation

•Theoperatorandpassengershoulduseseatbelts

andremainseatedwheneverthevehicleisinmotion.

Theoperatorshouldkeepbothhandsonthesteering

wheel,wheneverpossible,andthepassengershould

usethehandholdsprovided.Keeparmsandlegs

withinthevehiclebodyatalltimes.Nevercarry

passengersintheboxoronattachments.Remember

yourpassengermaynotbeexpectingyoutobrakeor

turnandmaynotbeready.

•Neveroverloadyourvehicle.Thenameplate

(locatedunderthemiddleofthedash)showsthe

loadlimitsforthevehicle.Neveroverllattachments

orexceedthevehiclemaximumgrossvehicleweight

(GVW).

•Whenstartingtheengine:

–Sitonoperator’sseatandensurethattheparking

brakeisengaged.

–DisengagePTO(ifsoequipped)andreturnthe

handthrottlelevertotheOffposition(ifso

equipped).

–MoveshiftlevertoNeutralandpresstheclutch

pedal.

–Keepyourfootoffoftheacceleratorpedal.

–TurnignitionswitchtotheOnposition.When

theglowplugindicatorgoesoff,theengineis

readytostart.

–TurntheignitionkeytotheStartposition.

Note:Theglowplugindicatorwillturnon,foran

additional15seconds,whentheswitchreturnsto

theOnposition.

•Usingthemachinedemandsattention.Failureto

operatevehiclesafelymayresultinanaccident,tip

overofthevehicle,andseriousinjuryordeath.

Drivecarefully.Topreventtippingorlossofcontrol,

takethefollowingprecautions:

–Useextremecaution,reducespeed,andmaintain

asafedistancearoundsandtraps,ditches,creeks,

ramps,anyunfamiliarareas,orotherhazards.

–Watchforholesorotherhiddenhazards.

–Usecautionwhenoperatingthevehicleona

steepslope.Normally,travelstraightupand

downslopes.Reducespeedwhenmakingsharp

turnsorwhenturningonhillsides.Avoidturning

onhillsideswheneverpossible.

–Useextracautionwhenoperatingthevehicleon

wetsurfaces,athigherspeeds,orwithafullload.

Stoppingtimewillincreasewithafullload.Shift

intoalowergearbeforestartingupordowna

hill.

–Whenloadingthebed,distributetheload

evenly.Useextracautioniftheloadexceeds

thedimensionsofthevehicle/bed.Operate

thevehiclewithextracautionwhenhandling

off-centerloadsthatcannotbecentered.Keep

loadsbalancedandsecuretopreventthemfrom

shifting.

–Avoidsuddenstopsandstarts.Donotgofrom

reversetoforwardorforwardtoreversewithout

rstcomingtoacompletestop.

–Donotattemptsharpturnsorabruptmaneuvers

orotherunsafedrivingactionsthatmaycausea

lossofvehiclecontrol.

–Donotpassanothervehicletravelinginthesame

directionatintersections,blindspots,oratother

dangerouslocations.

5

Page 6

–Keepallbystandersaway.Beforebackingup,

looktotherearandensurethatnooneisbehind

thevehicle.Backupslowly.

–Watchoutfortrafcwhennearorcrossingroads.

Alwaysyieldtherightofwaytopedestriansand

othervehicles.Thisvehicleisnotdesignedfor

useonstreetsorhighways.Alwayssignalyour

turnsorstopearlyenoughsootherpersons

knowwhatyouplantodo.Obeyalltrafcrules

andregulations.

–Neveroperatethevehicleinornearanarea

wherethereisdustorfumesintheairwhichare

explosive.Theelectricalandexhaustsystems

ofthevehiclecanproducesparkscapableof

ignitingexplosivematerials.

–Alwayswatchoutforandavoidlowoverhangs

suchastreelimbs,doorjambs,overhead

walkways,etc.Makesurethereisenoughroom

overheadtoeasilyclearthevehicleandyour

head.

–Ifeverunsureaboutsafeoperation,stopwork

andaskyoursupervisor.

•Donottouchengine,transaxle,radiator,muferor

mufermanifoldwhileengineisrunningorsoon

afterithasstoppedbecausetheseareasmaybehot

enoughtocauseburns.

•Ifthemachineevervibratesabnormally,stop

immediately,turnengineoff,waitforallmotion

tostopandinspectfordamage.Repairalldamage

beforeresumingoperation.

•Beforegettingofftheseat:

–Stopmovementofthemachine.

–Shutengineoffandwaitforallmovementto

stop.

–Setparkingbrake.

–Removekeyfromignition.

•Lightningcancausesevereinjuryordeath.If

lightningisseenorthunderisheardinthearea,do

notoperatethemachine;seekshelter.

highpressure.Usepaperorcardboard,nothands,

tosearchforleaks.Hydraulicuidescapingunder

pressurecanhavesufcientforcetopenetrateskin

anddoseriousdamage.Ifuidisinjectedintothe

skinitmustbesurgicallyremovedwithinafew

hoursbyadoctorfamiliarwiththisformofinjury

organgrenemayresult.

•Tomakesuretheentiremachineisingoodcondition,

keepallnuts,bolts,andscrewsproperlytightened.

•Toreducethepotentialrehazard,keeptheengine

areafreeofexcessivegrease,grass,leaves,and

accumulationofdirt.

•Iftheenginemustberunningtoperforma

maintenanceadjustment,keephands,feet,clothing,

andanypartsofthebodyawayfromtheengineand

anymovingparts.Keepeveryoneaway.

•Donotoverspeedtheenginebychangingthe

governorsettings.Themaximumenginespeedis

3650RPM.Toensuresafetyandaccuracy,havean

AuthorizedToroDistributorcheckthemaximum

enginespeedwithatachometer.

•Ifmajorrepairsareeverneededorassistanceis

required,contactanAuthorizedToroDistributor.

•Tobesureofoptimumperformanceandsafety,

alwayspurchasegenuineTororeplacementpartsand

accessories.Replacementpartsandaccessoriesmade

byothermanufacturerscouldbedangerous.Altering

thisvehicleinanymannermayaffectthevehicle’s

operation,performance,durabilityoritsusemay

resultininjuryordeath.Suchusecouldvoidthe

productwarrantyofTheToro®Company.

•Thisvehicleshouldnotbemodiedwithout

TheToro®Company’sauthorization.Directany

inquiriestoTheToro®Company ,Commercial

Division,VehicleEngineeringDept.,8111Lyndale

Ave.So.,Bloomington,Minnesota55420–1196.

USA

SoundPressure

Maintenance

•Beforeservicingormakingadjustmentstothe

machine,stoptheengine,settheparkingbrake,and

removethekeyfromignitiontopreventaccidental

startingoftheengine.

•Makesureallhydrauliclineconnectorsaretight,and

allhydraulichosesandlinesareingoodcondition

beforeapplyingpressuretothesystem.

•Keepyourbodyandhandsawayfrompinhole

leaksornozzlesthatejecthydraulicuidunder

Thisunithasasoundpressurelevelattheoperator’ s

earof82dBA,whichincludesanUncertaintyValue(K)

of1dBA.

Thesoundpressurelevelwasdeterminedaccordingto

theproceduresoutlinedinENISO11201.

Vibration

Hand-Arm

•Measuredvibrationlevelforrighthand=0.41m/s

6

2

Page 7

•Measuredvibrationlevelforlefthand=0.2m/s

•UncertaintyValue(K)=0.5m/s

2

Measuredvaluesweredeterminedaccordingtothe

proceduresoutlinedinEN1032.

WholeBody

•Measuredvibrationlevel=0.3m/s

•UncertaintyValue(K)=0.5m/s

Measuredvaluesweredeterminedaccordingtothe

proceduresoutlinedinEN1032.

2

2

SoundLevelCertication

WhentestedperITSDFB56-11-5-2005thevehicle

meetsAlcoa30.3.2Section4.1.2aforenginespeedsup

to:

•3650withoutcab@80dBA

•2850withcab@80dBA

2

7

Page 8

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaof

potentialdanger.Replaceanydecalthatisdamagedorlost.

93-9852

1.Warning—readtheOperator’sManual.2.Crushinghazard—installthecylinderlock.

115-7739

1.Falling,crushinghazard,bystanders—noriderson

machine.

1.Warning—donottouchthehotsurface.

1.Liftpoint

115-2047

93-9084

115-7723

1.Warning—thehydraulicoilpressureis124bar(1800PSI).

2.CouplerA

3.CouplerB

2.Tie-downpoint

115-7740

1.Warning—maximumtrailerweightis1500lb(680kg),

maximumtongueweightis200lb(90kg).

2.Warning—trailerbrakesarerequiredwhentowinggreater

than1500lb(680kg),maximumtrailerweightwithtrailer

brakesis3500lb(1591kg),maximumtongueweightwith

trailerbrakesis600lb(273kg).

8

Page 9

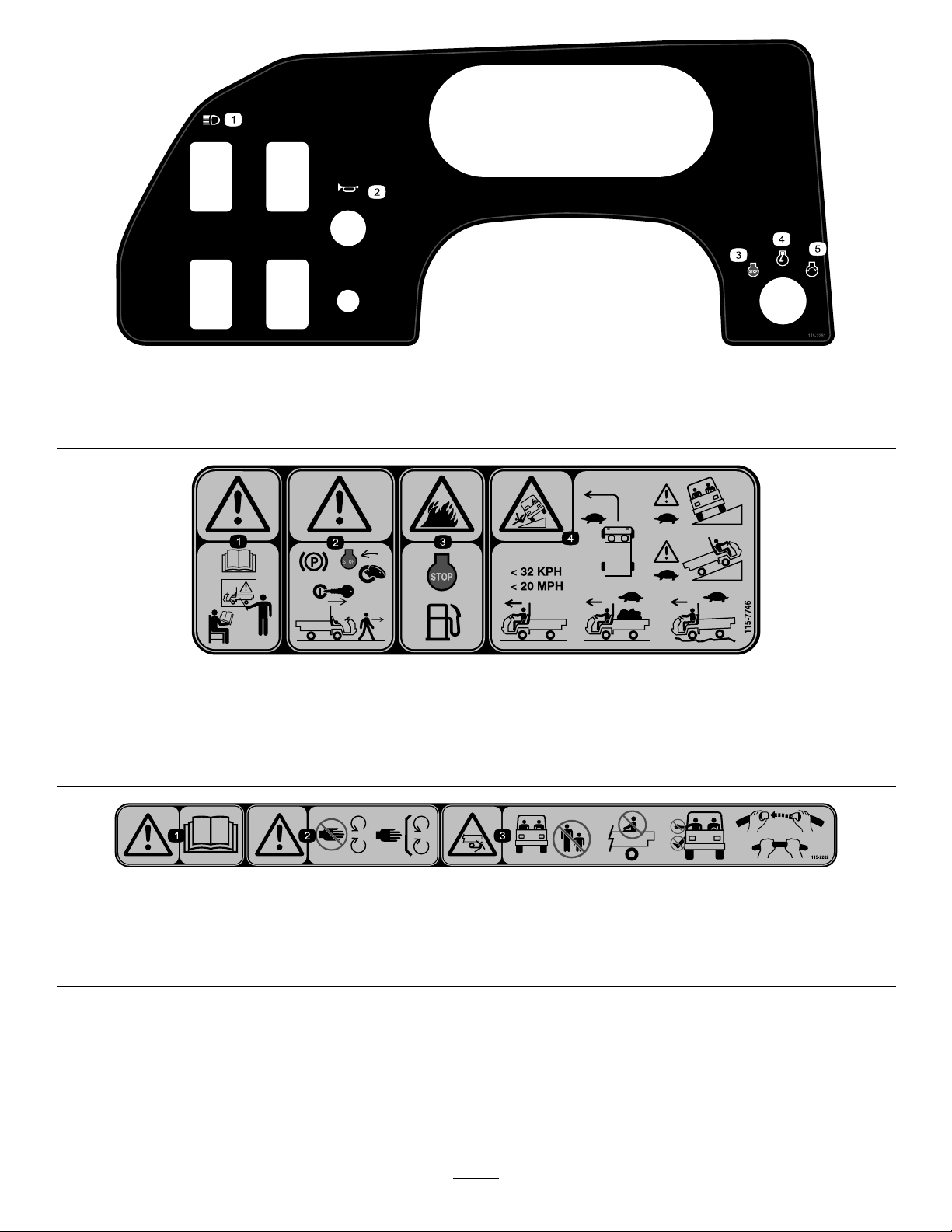

1.Headlights4.Engine—run

2.Horn5.Engine—start

3.Engine—stop

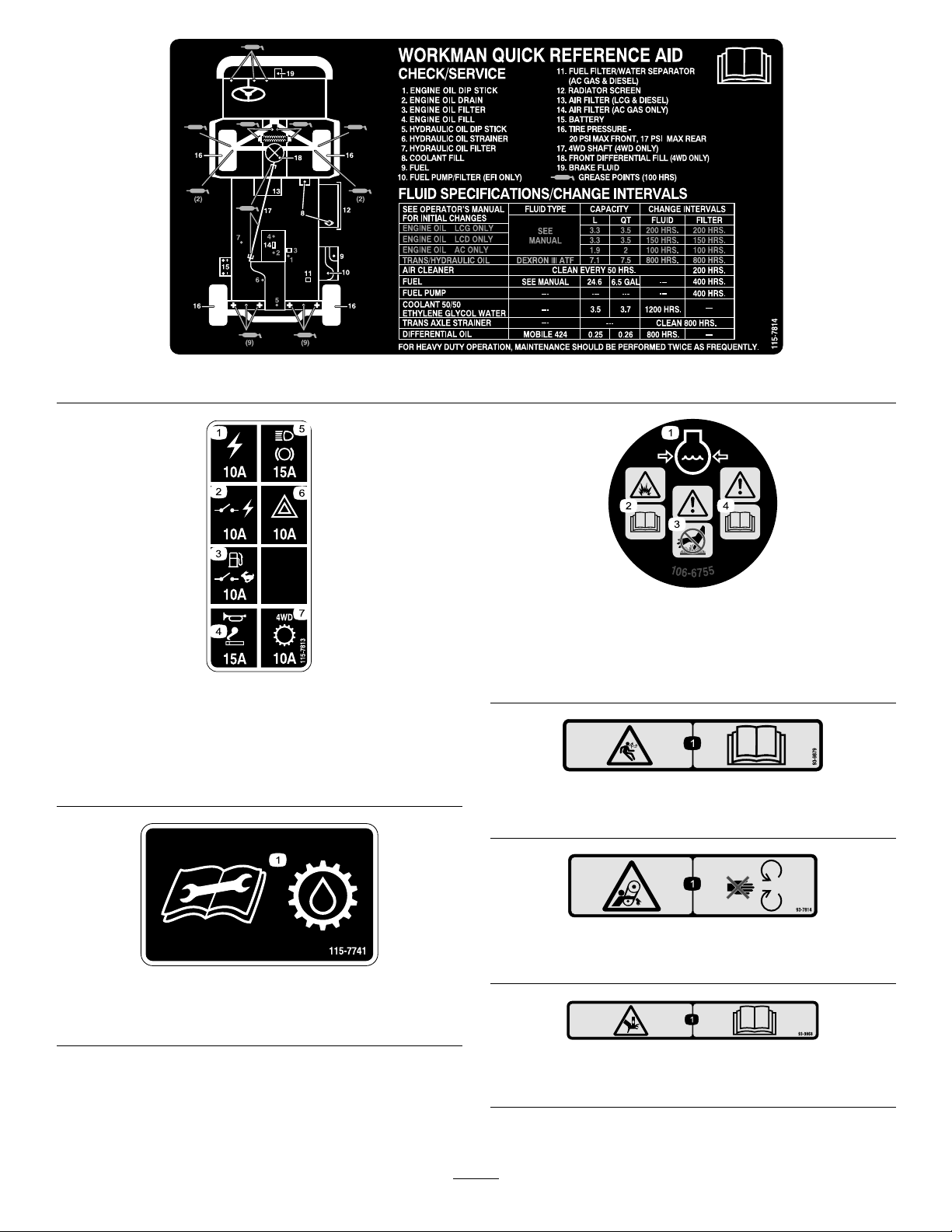

1.Warning—donotoperatethismachineunlessyouaretrained.

2.Warning—locktheparkingbrake,stoptheengine,and

removetheignitionkeybeforeleavingthemachine.

115-2281

115-7746

3.Firehazard—stoptheenginebeforefueling.

4.Tippinghazard—slowdownandturngradually ,usecaution

anddriveslowlywhendrivingonslopes,donotexceed20

mph(32kph),anddriveslowlyoverroughterrainorwhen

carryingafullorheavyload.

115-2282

1.Warning—readtheOperator’sManual.

2.Warning—stayawayfrommovingparts,keepallguardsandshieldsinplace.

3.Crushing/dismembermenthazardofbystanders—keepbystandersasafedistancefromthevehicle,donotcarrypassengersin

thecargobed,keeparmsandlegsinsideofthevehicleatalltimes,anduseseatbeltsandhandholds.

9

Page 10

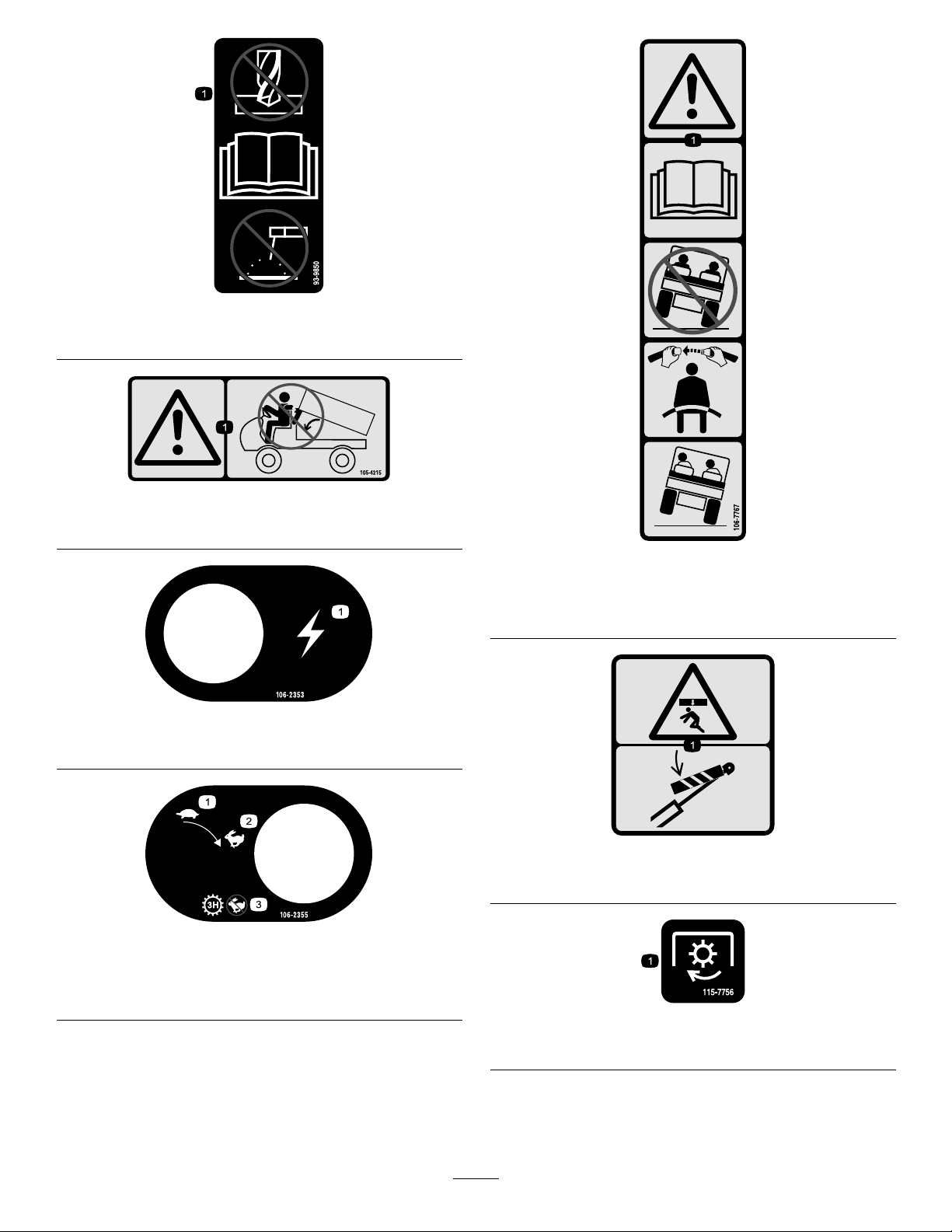

115-7813

1.Poweroutlet10A5.Lights,brake15A

2.Switchedpower10A

3.Fuelpump,supervisor

switch10A

4.Horn,powerpoint15A

6.Hazard10A

7.4WD,Transmission10A

115-7814

106-6755

1.Enginecoolantunder

pressure.

2.Explosionhazard—read

theOperator’sManual.

3.Warning—donottouch

thehotsurface.

4.Warning—readthe

Operator’sManual.

93-9879

1.Storedenergyhazard—readtheOperator’sManual.

115-7741

1.ReadtheOperator’sManualbeforeservicingtransmission

uid.

93-7814

1.Entanglementhazard,belt—stayawayfrommovingparts.

93–9868

1.Crushinghazardofhand—readtheOperator’sManual.

10

Page 11

93-9850

93-9899

1.Donotrepairorrevise—readtheOperator’sManual.

105-4215

1.Warning—avoidpinchpoints.

106-2353

1.Electricalpowerpoint

106-7767

1.Warning—readtheOperator’sManual;avoidtippingthe

machine;weartheseatbelt;leanawayfromthedirection

themachineistipping.

93-9899

1.Crushinghazard—installthecylinderlock.

106-2355

1.Slow

2.Fast

3.Transmission—thirdhigh;

nofastspeed

115-7756

1.Highowhydraulics—engaged

11

Page 12

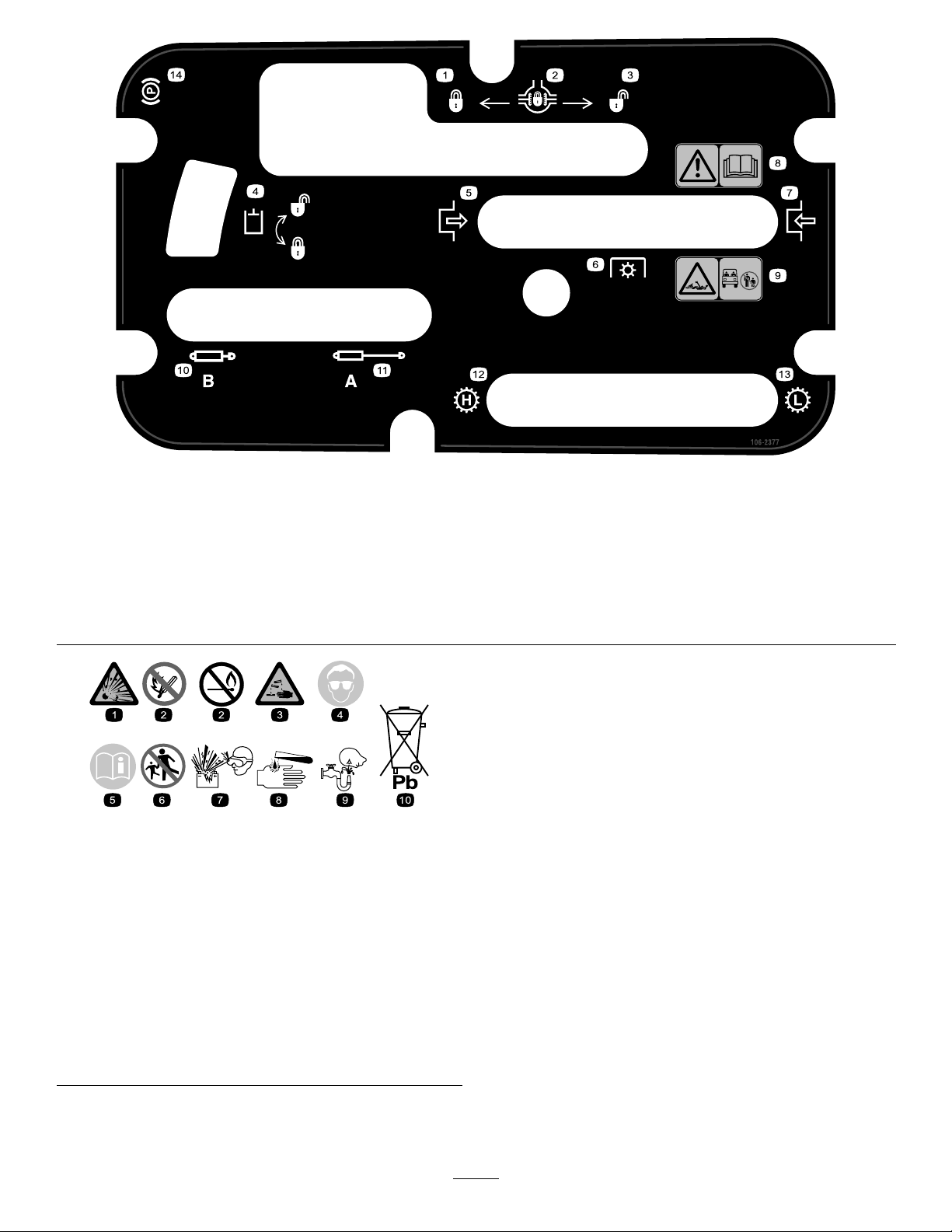

106-2377

1.Locked

2.Differentiallock9.Entanglementhazard,shaft—keepbystander’sasafe

3.Unlocked10.Retracthydraulics

4.Hydrauliclock11.Extendhydraulics

5.Engage12.Transmission—highspeed

6.Powertake-off(PTO)

7.Disengage14.Parkingbrake

8.Warning—readtheOperator’sManual.

distancefromthevehicle.

13.Transmission—lowspeed

BatterySymbols

Someorallofthesesymbolsareonyourbattery

1.Explosionhazard

2.Nore,opename,or

smoking.

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection9.Flusheyesimmediately

5.ReadtheOperator’s

Manual.

6.Keepbystandersasafe

distancefromthebattery .

7.Weareyeprotection;

explosivegasescan

causeblindnessandother

injuries

8.Batteryacidcancause

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

10.Containslead;donot

discard.

12

Page 13

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

Nopartsrequired

MediaandAdditionalParts

Description

Operator’sManual

PartsManual1

OperatorTrainingMaterial

Note:Determinetheleftandrightsideofthemachine

fromthenormaloperatingposition.

1

CheckingtheFluidLevels

Qty.

Qty.

–

1

1

Readbeforeoperatingthevehicle

Usetoreferencepartnumbers

Viewbeforeoperatingmachine

Checktheengineoil,transaxle/hydraulic

uid,andbrakeuidlevels

Use

Use

NoPartsRequired

Procedure

1.Checktheengineoillevelbeforeandaftertheengine

isrststarted,refertoCheckingtheEngineOil

LevelinOperation.

2.Checkthetransaxle/hydraulicuidlevelbefore

theengineisrststarted,refertoCheckingthe

Transaxle/HydraulicFluidLevelinOperation.

3.Checkthebrakeuidlevelbeforetheengineisrst

started,refertoCheckingtheBrakeFluidLevelin

Operation.

13

Page 14

ProductOverview

Controls

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

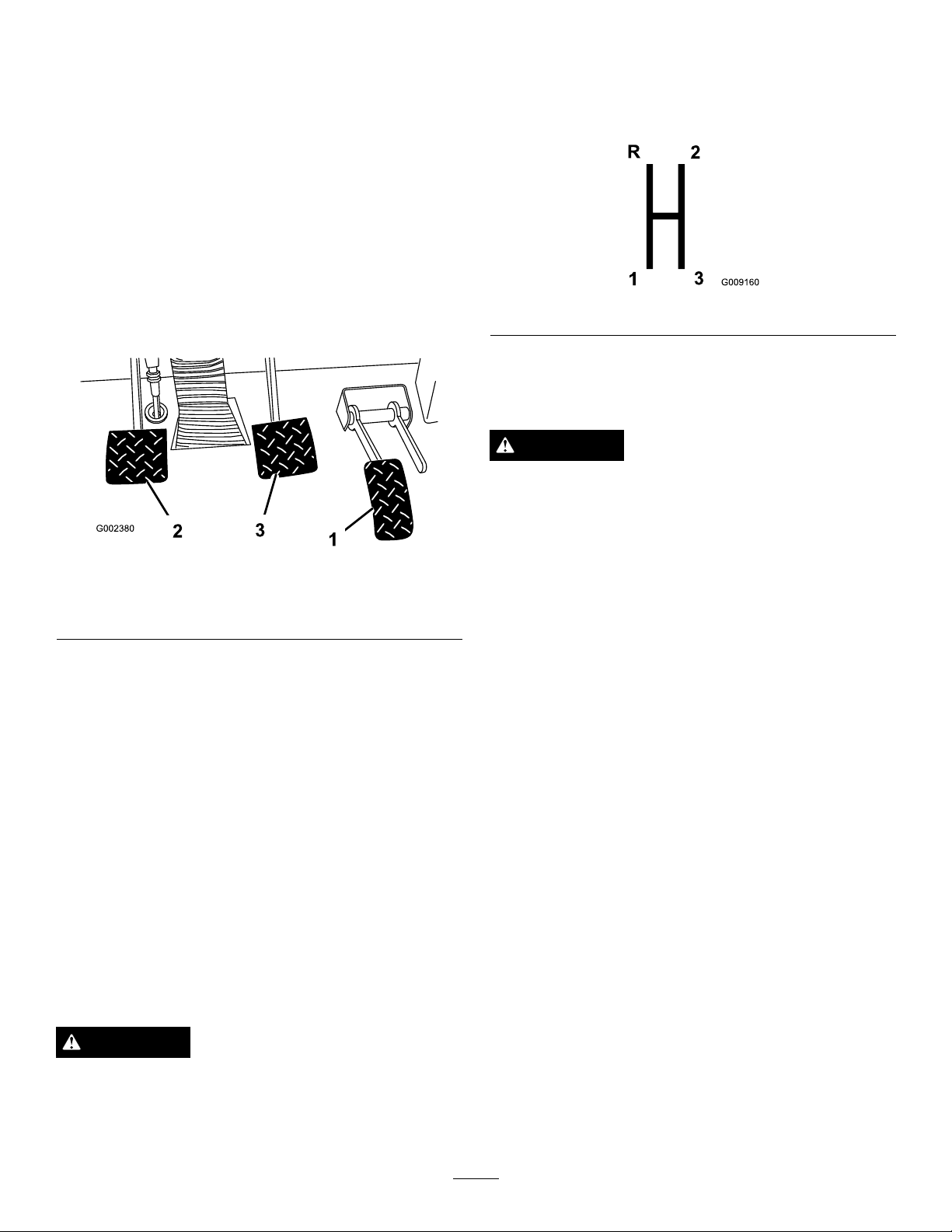

AcceleratorPedal

Theacceleratorpedal(Figure3)givestheoperator

theabilitytovarytheengineandgroundspeedofthe

vehicle,whenthetransmissionisingear.Pressing

thepedalincreasesengineRPMandgroundspeed.

ReleasingthepedalwilldecreaseengineRPMand

groundspeedofthemachine.

GearShiftLever

Fullypresstheclutchpedalandmovetheshiftlever

Figure4)intothedesiredgearselection.Adiagramof

(

theshiftpatternisindicatedbelow .

Figure4

Important:Donotshiftthetransaxletothereverse

orforwardgearunlessthevehicleisstandingstill.

Damagetothetransaxlemayoccur.

CAUTION

Downshiftingfromtoohighaspeedcancause

therearwheelstoskidresultinginlossofvehicle

controlaswellasclutchand/ortransmission

damage.Shiftsmoothlytoavoidgrindinggears.

Figure3

1.Acceleratorpedal3.Brakepedal

2.Clutchpedal

ClutchPedal

Theclutchpedal(Figure3)mustbefullypressedto

disengageclutchwhenstartingtheengineorshifting

transmissiongears.Releasethepedalsmoothlywhenthe

transmissionisingeartopreventunnecessarywearon

thetransmissionandotherrelatedparts.

Important:Donotridetheclutchpedalduring

operation.Theclutchpedalmustbefullyoutorthe

clutchwillslipcausingheatandwear.Neverhold

thevehiclestoppedonahillusingtheclutchpedal.

Damagetotheclutchmayoccur.

BrakePedal

Thebrakepedal(Figure3)isusedtoapplyservice

brakestostoporslowvehicle.

ParkingBrake

Whenevertheengineisshutoff,theparkingbrake

(Figure5)mustbeengagedtopreventaccidental

movementofthevehicle.Toengagetheparkingbrake,

pullbackonthelever.Todisengage,pushthelever

forward.Releasetheparkingbrakebeforemovingthe

vehicle.Ifyouparkthevehicleonasteepgrade,apply

theparkingbrake.Also,shiftthetransmissioninto1st

gearonauphillgradeorreverseonadownhillgrade.

Placechocksatthedownhillsideofthewheels.

CAUTION

Wornormaladjustedbrakesmayresultinpersonal

injury.Ifthebrakepedaltravelstowithin1-1/2

inches(3.8cm)ofthevehicleoorboard,thebrakes

mustbeadjustedorrepaired.

14

Page 15

Figure5

1.Gearshiftlever3.High–lowrangeshifter

2.Parkingbrake

High–LowRangeShifter

Thehigh–lowrangeshifteraddsthreeadditionalspeeds

forprecisespeedcontrol(Figure5).

•Thevehiclemustbecompletelystoppedbefore

shiftingbetweenHighandLowrange.

•Shiftonlyonlevelground.

•Pressclutchpedalfully.

•MovetheleverfullyforwardforHighandfully

rearwardforLow.

Figure6

1.Highow

hydraulicsswitch

(Optional)

2.Horn9.Powerpoint

3.Tachometer10.3rdhighlockoutswitch

4.Hourmeter

5.Speedometer12.Glowplugindicator

6.Coolanttemperature

gaugeandlight

7.Fuelgauge

8.Ignitionswitch

11.Oilpressurewarninglight

13.Chargeindicator

HourMeter

Highisforhigherspeeddrivingonlevel,drysurfaces

withlightloads.

Lowisforlowspeeddriving.Usethisrangewhen

greaterthannormalpowerorcontrolisrequired.For

example,steepgrades,difcultterrain,heavyloads,slow

speedbuthighenginespeed(spraying).

Important:ThereisalocationbetweenHighand

Lowinwhichthetransaxleisinneitherrange.

Donotusethispositionasaneutralposition

becausethevehiclecouldmoveunexpectedlyif

theHigh–Lowshifterisbumpedandthegearshift

leverisingear.

IgnitionSwitch

Usetheignitionswitch(Figure6)tostartandstopthe

engine.Ithasthreepositions:Off,On/Preheat,and

Start.RotatethekeyclockwisetotheStartpositionto

engagethestartermotor.Releasethekeywhenthe

enginestarts.Thekeywillmoveautomaticallytothe

Onposition.Toshuttheengineoff,rotatethekey

counterclockwisetotheOffposition.

Indicatesthetotalhoursofmachineoperation.The

hourmeter(Figure6)startstofunctionwheneverthe

keyswitchisrotatedtotheOnpositionoriftheengine

isrunning.

3rdHighLockoutSwitch

Movethe3rdhighlockoutswitch(Figure6)totheslow

positionandremovethekeytopreventtheuseofthird

gearwhenintheHighrange.Theenginewillshutoff

iftheshiftleverismovedtothirdgearwheninHigh

range.Thekeyisremovableineitherposition.

OilPressureWarningLight

Theoilpressurewarninglightglows(Figure6)ifthe

engineoilpressuredropsbelowasafelevelwhilethe

engineisrunning.Ifthelightickersorremainson,

stopthevehicle,turnofftheengine,andchecktheoil

level.Iftheoillevelwaslow ,butaddingoildoesnot

causethelighttogooutwhentheengineisrestarted,

turntheengineoffimmediatelyandcontactyourlocal

Torodistributorforassistance.

Checktheoperationofwarninglightsasfollows:

1.Applytheparkingbrake.

2.TurntheignitionkeytotheOn/Preheatposition,

butdonotstarttheengine.Theoilpressurelight

shouldglowred.Ifthelightdoesnotfunction,

15

Page 16

eitherabulbisburnedoutorthereisamalfunction

inthesystemwhichmustberepaired.

HighFlowHydraulicsSwitch(Ifso

equipped)

Note:Ifenginewasjustturnedoff,itmaytake1to2

minutesforthelighttocomeon.

LowOilPressureShutDown

Iftheengineoilpressuredropsbelowasafelevel,

formorethan10seconds,theenginewillshutdown.

ContactyourlocalTorodistributorforassistance.

GlowPlugIndicator

Glowplugindicator(Figure6)willglowredwhenthe

glowplugsareactivated.

Important:Theglowplugindicatorwillturn

on,foranadditional15seconds,whentheswitch

returnstotheOnposition.

CoolantTemperatureGaugeandLight

Registersthecoolanttemperatureintheengine.

OperatesonlywhentheignitionswitchisinOnposition

(Figure6).Theindicatorlightwillilluminateblinking

rediftheengineoverheats.

Turnontheswitchtoactivatethehighowhydraulics

(Figure6).

HornButton

Pressingthehornbuttonactivatesthehorn(Figure6).

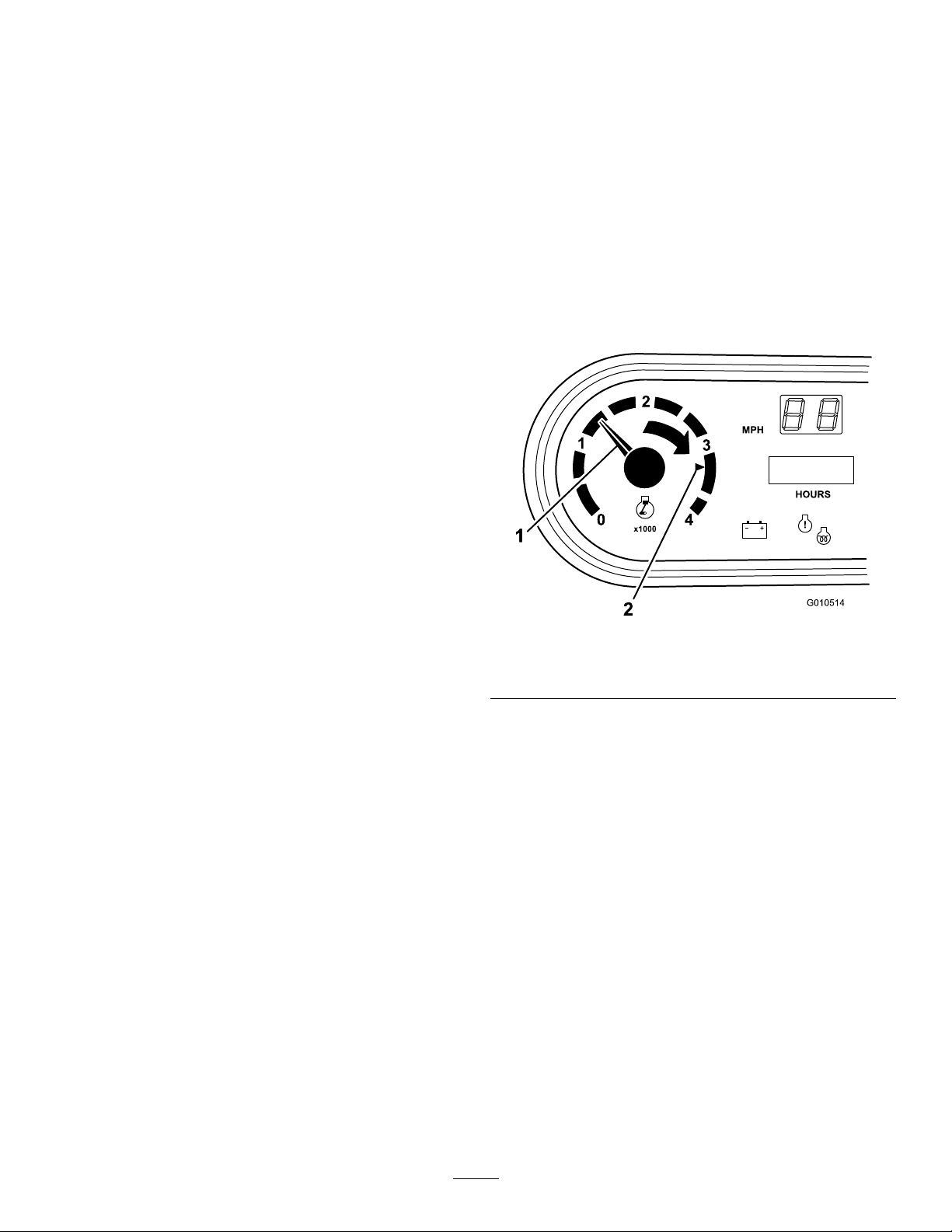

Tachometer

RegisterstheRPMoftheengine(Figure6&Figure7).

WhitetriangleindicatesdesiredRPMforPTOoperation

(Figure7).

ChargeIndicator

Illuminateswhenbatteryisbeingdischarged.Iflight

illuminatesduringoperation,stopvehicle,turnoff

engineandcheckforpossiblecauses,suchasalternator

Figure6).

belt(

Important:Ifalternatorbeltislooseorbroken,do

notoperatethevehicleuntiladjustmentorrepairis

complete.Failuretoobservethisprecautionmay

resultindamagetotheengine.

Checktheoperationofwarninglightsasfollows:

•Applyparkingbrake.

•TurntheignitionkeytotheOn/Preheatposition,

butdonotstarttheengine.Thecoolanttemperature,

chargeindicator,andoilpressurelightsshouldglow .

Ifanylightdoesnotfunction,eitherabulbisburned

outorthereisamalfunctioninthesystemwhich

mustberepaired.

FuelGauge

Figure7

1.RPMoftheengine2.3300RPMfor540RPM

PTOoperation

Speedometer

Registersthegroundspeedofthevehicle(Figure6).

ThespeedometerisinMPHbutcaneasilyconvertedto

KPH.RefertoConvertingtheSpeedometerinControls

Maintenance.

PowerPoint

Usethepowerpoint(Figure6)topoweroptional12

voltelectricalaccessories.

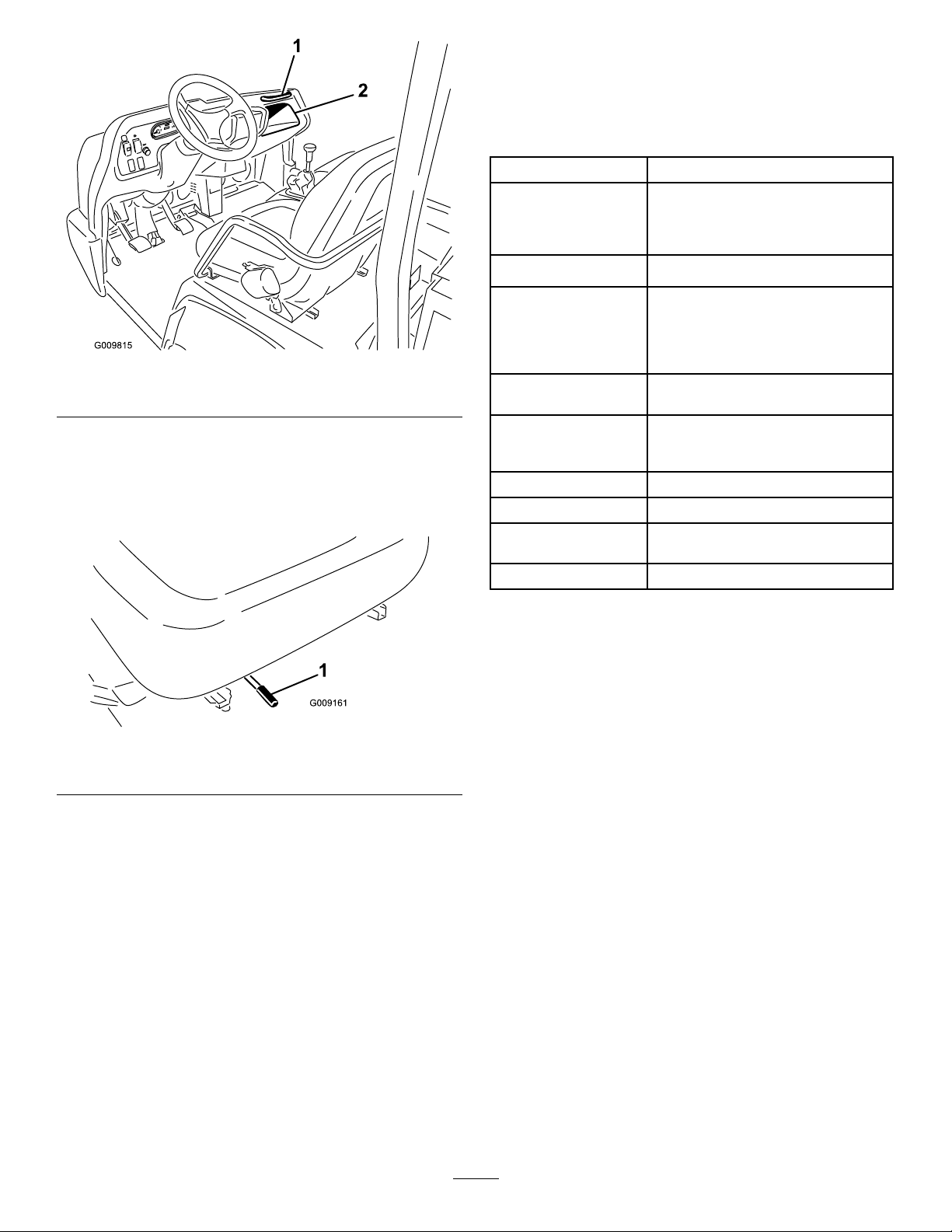

PassengerHandHold

Thepassengerhandholdislocatedonthedashboard

(Figure8).

Thefuelgaugeshowstheamountoffuelinthetank.It

operatesonlywhenignitionswitchisintheOn/Preheat

position(

blinkingredindicatesnearempty.

Figure6).Redindicateslowfuelleveland

16

Page 17

Figure8

1.Passengerhandhold

2.Storagecompartment

SeatAdjustingLever

Theseatscanbeadjustedforeandaftforoperator

comfort(

Figure9).

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

Dimensions

OverallWidth63inches(160cm)

w/obed:128.25inches(326cm)

OverallLength

BaseWeight(Dry)1806lb(819kg)

RatedCapacity

(includes200lb.

operator,200lb.

passengerandloaded

attachment).

Maximum.Gross

VehicleWeight

TowCapacityT ongueweight600lb(272kg)

GroundClearance7inches(18cm)w/noload

WheelBase

WheelTread(center

linetocenterline)

Height

w/fullbed:130.38inches(331cm)

w/2/3bedinrearmountinglocation:

136.38inches(346cm)

3044lb(1381kg)

4,850lb(2200kg)

Maximumtrailerweight3,500lb(1587

kg)

70inches(1 18cm)

Front:46inches(117cm)

Rear:47.7inches(121cm)

75inches(190.5cm)totopofROPS

1.Seatadjustinglever

Figure9

Attachments/Accessories

AselectionofToroapprovedattachmentsand

accessoriesareavailableforusewiththemachineto

enhanceandexpanditscapabilities.Contactyour

AuthorizedServiceDealerorDistributororgoto

www.Toro.comforalistofallapprovedattachments

andaccessories.

17

Page 18

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

CAUTION

Beforeservicingormakingadjustmentstothe

machine,stoptheengine,settheparkingbrake,

andremovethekeyfromtheswitch.

CheckingtheEngineOilLevel

ServiceInterval:Beforeeachuseordaily

Theengineisshippedwithapproximately3.5quarts

(3.3l)(w/lter)ofoilinthecrankcase;however,you

shouldchecktheoillevelbeforeandaftertheengine

isrststarted.

Note:Thebesttimetochecktheengineoiliswhen

theengineiscoolbeforeithasbeenstartedforthe

day.Ifithasalreadybeenrun,allowtheoiltodrain

backdowntothesumpforatleast10minutesbefore

checking.IftheoillevelisatorbelowtheAddmark

onthedipstick,addoiltobringtheoilleveltotheFull

mark.Donotoverll.Iftheoillevelisbetweenthe

FullandAddmarks,noadditionaloilisrequired.

Theengineusesanyhigh-quality10W-30detergent

oilhavingtheAmericanPetroleumInstitute(API)

serviceclassicationCForhigher.Chooseaviscosity

accordingtothetablein

Figure10.

Figure11

1.Dipstick

3.Iftheoillevelislow,removethellercap

Figure12)andaddenoughoiltoraisethelevelto

(

theFullmarkonthedipstick.

Figure12

1.Fillercap

Figure10

1.Positionthemachineonalevelsurface.

2.Removethedipstickandwipeitwithacleanrag.

Insertthedipstickintothetubeandmakesureitis

seatedfully.Removedipstickandcheckthelevel

oftheoil.

Note:Whenaddingoil,removedipsticktoallow

properventing.Pouroilslowlyandcheckthelevel

oftenduringthisprocess.Donotoverll.

Important:Whenaddingengineoilorlling

oil,theremustbeclearancebetweentheoilll

deviceandtheoilllholeinthevalvecoveras

showninFigure13.Thisclearanceisnecessary

topermitventingwhenlling,whichprevents

oilfromoverrunningintothebreather.

18

Page 19

Figure13

1.Noteclearance

4.Installthedipstickrmlyinplace.

DANGER

Undercertainconditions,dieselfuelandfuel

vaporsarehighlyammableandexplosive.Are

orexplosionfromfuelcanburnyouandothersand

cancausepropertydamage.

•Beforeremovingthefueltankcap,makesure

thevehicleispositionedonalevelsurface.

Openfueltankcapslowly.

•Useafunnelandllthefueltankoutdoors,

inanopenarea,whentheengineisoffandis

cold.Wipeupanyfuelthatspills.

•Donotllthefueltankcompletelyfull.Add

fueltothefueltankuntilthelevelis1in.(25

mm)belowthebottomofthellerneck.This

emptyspaceinthetankallowsthefuelto

expand.

•Neversmokewhenhandlingfuel,andstay

awayfromanopenameorwherefuelfumes

maybeignitedbyaspark.

AddingFuel

Useonlyclean,freshdieselfuelorbiodieselfuelswith

low(<500ppm)orultralow(<15ppm)sulfurcontent.

Theminimumcetaneratingshouldbe40.Purchase

fuelinquantitiesthatcanbeusedwithin180daysto

ensurefuelfreshness.

Fueltankcapacity:6.5USgallons(25l).

Usesummergradedieselfuel(No.2-D)attemperatures

above20°F(-7°C)andwintergrade(No.1-Dor

No.1-D/2-Dblend)belowthattemperature.Useof

wintergradefuelatlowertemperaturesprovideslower

ashpointandcoldowcharacteristicswhichwillease

startingandreducefuellterplugging.

Useofsummergradefuelabove20°F(-7°C)will

contributetowardlongerfuelpumplifeandincreased

powercomparedtowintergradefuel.

Important:Donotusekeroseneorgasoline

insteadofdieselfuel.Failuretoobservethis

cautionwilldamagetheengine.

WARNING

Fuelisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

•Avoidprolongedbreathingofvapors.

•Keepyourfaceawayfromthenozzleandgas

tankorconditioneropening.

•Keepfuelawayfromyoureyesandskin.

•Storefuelinaclean,safety-approvedcontainer

andkeepthecapinplace.

BiodieselReady

Thismachinecanalsouseabiodieselblendedfuel

ofuptoB20(20%biodiesel,80%petrodiesel).The

petrodieselportionshouldbeloworultralowsulfur.

Observethefollowingprecautions:

•Thebiodieselportionofthefuelmustmeet

specicationASTMD6751orEN14214.

•TheblendedfuelcompositionshouldmeetASTM

D975orEN590.

•Paintedsurfacesmaybedamagedbybiodiesel

blends.

•UseB5(biodieselcontentof5%)orlesserblends

incoldweather.

•Monitorseals,hoses,gasketsincontactwithfuelas

theymaybedegradedovertime.

•Fuellterpluggingmaybeexpectedforatimeafter

convertingtobiodieselblends.

•Contactyourdistributorifyouwishformore

informationonbiodiesel.

1.Cleantheareaaroundthefueltankcap.

2.Removethefueltankcap(

shieldremoved).

Figure14,shownwith

19

Page 20

Figure14

1.Fueltankcap

3.Fillthetanktoaboutoneinchbelowthetopofthe

tank,(bottomofthellerneck),theninstallthecap.

Donotoverll.

Figure15

1.Reservetank

2.Hotline

3.Ifcoolantislow ,removethereservetankcap

andadda50/50mixtureofwaterandpermanent

ethyleneglycolantifreeze.Donotoverll.

4.Installthereservetankcap.

3.Coldline

4.Wipeupanyfuelthatmayhavespilledtopreventa

rehazard.

CheckingtheCoolantLevel

ServiceInterval:Beforeeachuseordaily

Coolingsystemcapacity:4qt(3.7l)

Thecoolingsystemislledwitha50/50solutionof

waterandpermanentethyleneglycolantifreeze.

1.Parkthemachineonalevelsurface.

CAUTION

Iftheenginehasbeenrunning,thepressurized,

hotcoolantcanescapeandcauseburns.

•Donotopentheradiatorcapwhenthe

engineisrunning.

•Allowtheenginetocoolatleast15minutes

oruntiltheradiatorcapiscoolenoughto

touchwithoutburningyourhand.

Checkingthe

Transaxle/HydraulicFluid

Level

ServiceInterval:Beforeeachuseordaily

ThetransaxlereservoirislledwithDexronIIIATF.

Checkthelevelbeforetheengineisrststartedand

every8hoursordaily,thereafter.Capacityofsystemis.

Transaxlereservoircapacity:7.5qt(7l).

1.Positionthevehicleonalevelsurface.

2.Cleantheareaaroundthedipstick(

Figure16).

•Usearagwhenopeningtheradiatorcap,

andopenthecapslowlytoallowsteamto

escape.

2.Checkthecoolantlevelonthesideofthereserve

tank(Figure15).Thecoolantshouldbeuptothe

Coldline,whenengineiscold.

Figure16

1.Dipstick

20

Page 21

3.Unscrewthedipstickfromthetopofthetransaxle

andwipeitwithacleanrag.

4.Screwthedipstickintothetransaxleandensurethat

itisfullyseated.

5.Unscrewthedipstickandchecktheuidlevel.

Theuidshouldbeuptotopoftheatportion

ofthedipstick.

6.Ifthelevelislow,addenoughuidtoachievethe

properlevel.

CheckingtheHighFlow

HydraulicFluid(Ifso

equipped)

ServiceInterval:Beforeeachuseordaily

Thehighowhydraulicsreservoirislledwith

approximately4USgallons(15l)ofhighquality

hydraulicuid.Checkthelevelofhydraulic

uidbeforetheengineisrststartedanddaily

thereafter.

1.Cleantheareaaroundthellerneckandthecap

ofthehydraulictank(Figure17).Removethecap

fromthellerneck.

WARNING

Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjury.

•Makesureallhydraulicuidhosesand

linesareingoodconditionandallhydraulic

connectionsandttingsaretightbefore

applyingpressuretothehydraulicsystem.

•Keepyourbodyandhandsawayfrompin

holeleaksornozzlesthatejecthighpressure

hydraulicuid.

•Usecardboardorpapertondhydraulic

leaks.

•Safelyrelieveallpressureinthehydraulic

systembeforeperforminganyworkonthe

hydraulicsystem.

•Seekimmediatemedicalattentionifuidis

injectedintoyourskin.

CheckingtheFront

DifferentialOilLevel(Four

WheelDriveModelsOnly)

ServiceInterval:Every100hours/Monthly

(whichevercomesrst)

Figure17

1.Cap

2.Removethedipstick(Figure17)fromthellerneck

andwipeitwithacleanrag.Insertthedipstickinto

thellerneck;thenremoveitandchecktheuid

level.Theuidlevelshouldbebetweenthetwo

marksonthedipstick.

3.Ifthelevelislow ,addtheappropriateuidtoraise

theleveltotheuppermark.RefertoChangingthe

HighFlowHydraulicFluid

4.Installthedipstickandcapontothellerneck.

5.Starttheengineandturnontheattachment.Let

themrunforabouttwominutestopurgeairfrom

thesystem.Stoptheengineandattachmentand

checkforleaks.

Important:Thevehiclemustberunning

beforestartingthehighowhydraulics.

ThedifferentialislledwithMobil424hydraulicoil.

1.Positionthevehicleonalevelsurface.

2.Cleantheareaaroundthell/checkplugonsideof

thedifferential(Figure18).

Figure18

1.Fill/checkplug

3.Removethell/checkplugandcheckthelevelof

theoil.Theoilshouldbeuptohole.Iftheoilis

low,addMobil424hydraulicoil.

4.Installthell/checkplug.

2.Drainplug

21

Page 22

CheckingtheTorqueofthe

WheelNuts

ServiceInterval:Aftertherst2hours

Aftertherst10hours

Every200hours

WARNING

Failuretomaintainpropertorqueofthewheelnuts

couldresultinfailureorlossofawheelandmay

resultinpersonalinjury.

Torquethefrontandrearwheelnutsto80to90

ft-lb(109to122N-m)after1to4hoursofoperation

andagainafter10hoursofoperation.T orqueevery

200hoursthereafter.

CheckingtheTirePressure

ServiceInterval:Beforeeachuseordaily

Themaximumairpressureinthefronttiresis32psi

(220kPa)andthereartiresis20psi(138kPa).

Checkthetirepressurefrequentlytoensureproper

ination.Ifthetiresarenotinatedtothecorrect

pressure,thetireswillwearprematurely.

Figure19isanexampleoftirewearcausedbyunder

ination.

Figure20

1.Overinatedtire

CheckingtheBrakeFluid

ServiceInterval:Beforeeachuseordaily—Checkthe

brakeuidlevel.

Every1,000hours/Every2years

(whichevercomesrst)—Change

thebrakeuid.

Thebrakeuidreservoirisshippedfromthefactory

lledwithDOT3brakeuid.Checkthelevelbefore

theengineisrststartedandevery8hoursordaily,

thereafter.

Thebrakeuidreservoirislocatedunderthedash.

1.Parkthemachineonalevelsurface.

2.TheuidlevelshouldbeuptotheFulllineonthe

reservoir(

Figure21).

Figure19

1.Underinatedtire

Figure20isanexampleoftirewearcausedbyover

ination.

Figure21

1.Brakeuidreservoir

3.Iftheuidlevelislow ,cleantheareaaroundthe

cap,removethereservoircap,andllthereservoir

totheproperlevel.Donotoverll.

Note:Youcanremovethehoodaccesstothereservoir

fromthefrontofthemachine(

22

Figure22).

Page 23

Figure22

1.Brakeuidreservoir

Pre–startingChecks

Safeoperationbeginsbeforetakingthevehicleoutfor

aday’swork.Y oushouldchecktheseitemseachtime:

•Checkthetirepressure.

•Checkalluidlevelsandaddtheappropriate

amountofTorospecieduids,ifanyarefound

tobelow .

•Initialstartupofanewmachine.

•Theenginehasceasedrunningduetolackoffuel.

•Youhaveperformedmaintenanceuponthefuel

systemcomponents;i.e.,lterreplaced,separator

serviced,etc.

1.Sitontheoperator’sseatandengagetheparking

brake.

2.DisengagethePTOandhighowhydraulics(ifso

equipped)andmovethehandthrottlelevertothe

Offposition(ifsoequipped).

3.MovetheshiftlevertotheNeutralpositionand

presstheclutchpedal.

4.Keepyourfootoffoftheacceleratorpedal.

5.TurntheignitionswitchtotheOnposition.When

theglowplugindicatorlightgoesoff,theengineis

readytostart.

6.RotatetheignitionkeyswitchtotheStartposition.

Releasethekeyimmediatelywhentheenginestarts

andallowittoreturntotheOnposition.

Note:Theglowplugindicatorwillturnonforan

additional15seconds,whentheswitchreturnstothe

Onposition.

Note:Donotrunthestartermotormorethan10

secondsatatimeorprematurestarterfailuremay

result.Ifenginefailstostartafter10seconds,turnthe

keytotheOffposition.Checkthecontrolsandstarting

procedure,wait10additionalseconds,andrepeatthe

startingoperation.

•Checktheradiator.Removeanydebrisandclean

theradiatorscreen.

•Checkthebrakepedaloperation.

•Checktoseethatthelightsandhornareworking.

•Turnthesteeringwheeltotheleftandrightto

checkthesteeringresponse.

•Stoptheengineandwaitformovingpartstostop,

thencheckforoilleaks,looseparts,andanyother

noticeablemalfunctions.

Ifanyoftheaboveitemsarenotcorrect,notifyyour

mechanicorcheckwithyoursupervisorbeforetaking

thevehicleoutfortheday .Yoursupervisormaywant

youtocheckotheritemsonadailybasis,soaskwhat

yourresponsibilitiesare.

StartingtheEngine

Ifanyofthefollowingconditionsexist,youneedto

bleedthefuelsystembeforestartingtheengine;refer

toBleedingTheFuelSystem:

DrivingtheVehicle

1.Releasetheparkingbrake.

2.Fullypresstheclutchpedal.

3.Movethegearshiftleverto1stgear.

4.Releasetheclutchpedalsmoothlywhilepressing

theacceleratorpedal.

5.Whenthevehiclegainsenoughspeed,removeyour

footfromtheacceleratorpedal,fullypressthe

clutchpedal,movethegearshiftlevertothenext

gearandreleasetheclutchpedalwhilepressingthe

acceleratorpedal.Repeattheprocedureuntilthe

desiredspeedisattained.

Important:Alwaysstopthevehiclebefore

shiftingtoreversefromaforwardgearortoa

forwardgearfromreverse.

Note:Avoidlongperiodsofengineidling.

Important:Donotattempttopushortow

vehicletogetitstarted.Damagetothedrive

traincouldresult.

23

Page 24

Usethechartbelowtodeterminethegroundspeed

ofthevehicle.

Gear

StoppingtheVehicle

Tostopthevehicle,removeyourfootfromthe

acceleratorpedal,presstheclutchpedal,thenpressthe

brakepedal.

RangeRatio

1L82.83:12.94.71.93.0

2L54.52:14.57.22.94.6

3L31.56:1

1H32.31:17.612.24.97.8

2H21.27:111.518.57.311.8

3H12.31:119.831.912.720.4

RL86.94:12.84.51.82.9

RH33.91:17.111.44.57.3

Speed(mph)@3600Speed(kmh)@3600Speed(mph)@2300Speed(kmh)@2300

7.7

12.44.97.9

•Abreak–inoilfortheengineisnotrequired.The

originalengineoilisthesametypespeciedfor

regularoilchanges.

•RefertotheMaintenancesectionforanyspecial

lowhourchecks.

StoppingtheEngine

CheckingtheInterlockSystem

Tostoptheengine,rotatetheignitionkeytotheOff

positionandengagetheparkingbrake.Removethekey

fromtheswitchtopreventaccidentalstarting.

NewVehicleBreak–in

ServiceInterval:Beforeeachuseordaily

Thepurposeoftheinterlocksystemistopreventthe

enginefromcrankingorstartingunlesstheclutchpedal

ispressed.

YourWorkmanisreadyforwork.Toprovideproper

performanceandlongvehiclelife,followthese

guidelinesfortherst100operatinghours.

•Checktheuidandengineoillevelsregularly

andbealertforindicationsofoverheatinginany

componentofthevehicle.

•Afterstartingacoldengine,letitwarmupforabout

15secondsbeforeshiftingintogear.

•Avoidracingtheengine.

•Toensureoptimumperformanceofthebrake

system,burnish(break–in)thebrakesbeforeuse.

Toburnishthebrakes,bringthevehicleuptofull

speed,applythebrakestorapidlystopthevehicle

withoutlockingupthetires.Repeatthis10times,

waiting1minutebetweenstopstoavoidoverheating

thebrakes.Thisismosteffectiveifthevehicleis

loadedwith1000lb(454kg).

•Varyvehiclespeedsduringoperation.Avoid

excessiveidling.Avoidfaststartsandquickstops.

CAUTION

Ifsafetyinterlockswitchesaredisconnectedor

damagedthemachinecouldoperateunexpectedly

causingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlockswitches

dailyandreplaceanydamagedswitchesbefore

operatingthemachine.

Note:RefertoAttachmentOperator’ sManualfor

proceduresoncheckingtheattachmentinterlock

system.

VerifyingtheClutchInterlockSwitch

1.Sitontheoperator’sseatandengagetheparking

brake.MovetheshiftlevertotheNeutralposition.

2.Withoutpressingtheclutchpedal,rotatethe

ignitionkeyclockwisetotheStartposition.

Iftheenginecranksorstarts,thereisamalfunction

intheinterlocksystemthatmustberepairedbefore

operatingthevehicle.

24

Page 25

OperatingCharacteristics

Thevehicleisdesignedwithsafetyinmind.Ithasfour

wheelsforaddedstability.Itusesfamiliarautomotive

stylecontrols,includingthesteeringwheel,brakepedal,

clutchpedal,acceleratorpedal,andgearshifter.Itis

importanttoremember,however,thatthisvehicleis

notapassengercar.Itisaworkvehicleandisdesigned

foroffroaduseonly.

WARNING

TheWorkmanvehicleisanoff–highway

vehicleonly,andisnotdesigned,equipped,or

manufacturedforuseonpublicstreets,roadsor

highways.

Thevehiclehasspecialtires,lowgearratiosandother

featuresthatgiveitextratraction.Thesefeaturesadd

totheversatilityofthevehiclebut,theycanalsoget

youintodangeroussituations.Youmustkeepinmind

thatthevehicleisnotarecreationvehicle,itisnotanall

terrainvehicle,and,itisdenitelynotmeantforstunt

drivingorhorsingaround.Itisaworkvehicle,nota

playvehicle.Childrenshouldnotbeallowedtooperate

thevehicle.Anyonewhooperatesthevehicleshould

haveamotorvehiclelicense.

Thedriverandpassengershouldalwaysusetheseat

belts.

Oneofthemostimportantrulestofollowistogo

slowerinunfamiliarareas.Itissurprisinghowmuch

damageandinjurycommonthingscancause.Tree

branches,fences,wires,othervehicles,treestumps,

ditches,sandtraps,streams,andotherthingsfoundin

mostparksandgolfcoursescanbehazardoustothe

operatorandpassenger.

Avoiddrivingwhenitisdark,especiallyinunfamiliar

areas.Ifyoumustdrivewhenitisdark,besuretodrive

cautiously,usetheheadlights,andevenconsideradding

additionallights.

Passengers

Wheneveryouhaveapassengerridinginthevehicle

makesureheorsheiswearingtheseatbeltandholding

onsecurely.Driveslowerandturnlesssharplybecause

yourpassengerdoesnotknowwhatyouaregoingto

donextandmaynotbepreparedforturning,stopping,

accelerating,andbumps.

Youandyourpassengershouldremainseatedatall

times,keepingarmsandlegsinsidethevehicle.The

operatorshouldkeepbothhandsonsteeringwheel,

wheneverpossible,andthepassengershouldusethe

handholdsprovided(

Figure23&Figure24).

Ifyouarenotexperiencedatdrivingthevehicle,

practicedrivingitinasafeareaawayfromotherpeople.

Besureyouarefamiliarwithallthevehicle’scontrols,

particularlythoseusedforbraking,steering,and

transmissionshifting.Learnhowyourvehiclehandles

ondifferentsurfaces.Youroperatingskillswillimprove

withexperience,butasinoperatinganyvehicle,take

iteasyasyoubegin.Besureyouknowhowtostop

quicklyinanemergency.Ifyouneedhelp,askyour

supervisorforassistance.

Manyfactorscontributetoaccidents.Youhavecontrol

overseveralofthemostimportant.Y ouractions,

suchasdrivingtoofastforconditions,brakingtoo

fast,turningtoosharp,andcombinationsofthese,are

frequentcauseofaccidents.

Oneofthemajorcausesofaccidentsisfatigue.Besure

totakeoccasionalbreaks.Itisveryimportantthatyou

stayalertatalltimes.

Neveroperatethevehicle,oranyequipment,ifyou

areundertheinuenceofalcoholorotherdrugs.

Evenprescriptiondrugsandcoldmedicinescancause

drowsiness.Readthelabelonthemedicineorcheck

withyourdoctororpharmacistifyouareunsureabout

acertainmedication.

1.Passengerhandhold

Figure23

2.Storagecompartment

25

Page 26

Figure24

1.Handhold&hiprestraint

Neveralowpassengersinthedumpboxoronany

attachments.Thevehicleismeanttohaveonedriver

andonlyonepassenger—nomore.

Speed

Speedisoneofthemostimportantvariablesleadingto

accidents.Drivingtoofastfortheconditionscancause

youtolosecontrolandhaveanaccident.Speedcan

alsomakeaminoraccidentworse.Drivinghead-on

intoatreeatslowspeedcancauseinjuryanddamage,

but,drivingintoatreeathighspeedcandestroythe

vehicleandkillyouandyourpassenger.

Neverdrivetoofastfortheconditions.Ifthereisany

doubtabouthowfasttodrive,slowdown.

Whenusingheavyattachments,morethan1000lb(454

kg),suchassprayers,topdressers,orspreaders,etc.,

restrictyouroperatingspeedbymovingthe3rdhigh

lockoutswitchtotheslowposition.

Turning

Braking

Itisgoodpracticetoslowdownbeforeyougetnear

anobstacle.Thisgivesyouextratimetostoporturn

away.Hittinganobstaclecandamagethevehicleand

itscontents.Moreimportant,itcaninjureyouandyour

passenger.Grossvehicleweighthasamajorimpact

onyourabilitytostopand/orturn.Heavierloadsand

heavierattachmentsmakeavehiclehardertostopor

turn.Theheaviertheload,thelongerittakestostop

Thebrakingcharacteristicsalsochangewithnobedor

attachmentonthevehicle.Faststopsmaycausethe

rearwheelstolockupbeforethefrontwheelslock

up,whichmayaffectthecontrolofthevehicle.Itis

agoodideatodecreasevehiclespeedwithnobedor

attachment.

Turfandpavementaremuchslipperierwhentheyare

wet.Itcantake2to4timesaslongtostoponwet

surfacesasondrysurfaces.

Ifyoudrivethroughstandingwaterdeepenoughtoget

thebrakeswet,theywillnotworkwelluntiltheyare

dry.Afterdrivingthroughwater,youshouldtestthe

brakestomakesuretheyworkproperly .Iftheydonot,

driveslowlyinrstgearwhileputtinglightpressureon

thebrakepedal.Thiswilldrythebrakesout.

Donotdownshiftforbrakingonicyorslippery

surfaces(wetgrass)orwhilegoingdownahillbecause

enginebrakingmaycauseskiddingandlossofcontrol.

Shifttoalowergearbeforestartingdownahill.

TipOvers

Thevehicleisequippedwitharollbar,hiprestraints,

seatbelts,andhandhold.TheROPSsystem(Rollover

ProtectionSystem)usedonthevehiclewillreduce

theriskofseriousorfatalinjuryintheunlikelyevent

ofatipover,althoughthesystemcannotprotectthe

operatorfromallpossibleinjuries.

Turningisanotherimportantvariableleadingto

accidents.Turningtoosharplyfortheconditionscan

causethevehicletolosetractionandskid,oreventip

over.

Wet,sandy,andslipperysurfacesmaketurningmore

difcultandrisky.Thefasteryouaregoing,theworse

thissituationbecomesso,slowdownbeforeturning.

Duringasharpturnathigherspeeds,theinsiderear

wheelmayliftoffoftheground.Thisisnotaawin

thedesign,ithappenswithmostfourwheelvehicles

includingpassengercars.Ifthishappens,youare

turningtoosharplyforthespeedatwhichyouare

traveling.Slowdown!

ReplaceadamagedROPS,donotrepairorrevise.

AnyalterationoftheROPSmustbeapprovedbythe

manufacturer.

Thebestwaytopreventaccidentsinvolvingutility

vehiclesisthroughcontinuoussupervisionandtraining

ofoperatorsandpayingconstantattentiontothearea

inwhichvehicleisbeingoperated.

Thebestwayforoperatorstopreventseriousinjury

ordeathtothemselvesorothers,istofamiliarize

themselveswiththeproperoperationoftheutility

vehicle,tostayalertandtoavoidactionsorconditions

whichcouldresultinaaccident.Intheeventofatip

over,theriskofseriousinjuryordeathwillbereduced

26

Page 27

iftheoperatorisusingtheROPSsystemandseatbelts

andisfollowingtheinstructionsprovided.

Hills

WARNING

Tippingorrollingthevehicleonahillwillcause

seriouspersonalinjury.

•Donotoperatethevehicleonsteepslopes.

•Addingliquidballast(calciumchloride)toreartires.

•Tractionwillincreasewithnopassengerinfront

seat.

LoadingandDumping

Theweightandpositionofthecargoandpassenger

canchangethevehiclecenterofgravityandvehicle

handling.Toavoidlossofcontrolresultinginpersonal

injury,followtheseguidelines.

•Ifenginestallsoryouloseheadwayonahill,

neverattempttoturnvehiclearound.

•Alwaysbackstraightdownahillinreversegear.

•Neverbackdowninneutralorwiththeclutch

depressed,usingonlythebrakes.

•Neverdriveacrossasteephill,alwaysdrive

straightupordown.

•Avoidturningonahill.

•Don’t“droptheclutch”orslamonthebrakes.

Suddenspeedchangecaninitiateatipover.

Useextracarewhenonhills.Nevergoonhillsthatare

extremelysteep.Stoppingwhilegoingdownahillwill

takelongerthanonlevelground.Turningwhilegoing

upordownahillismoredangerousthanturningon

thelevel.Turnswhilegoingdownhill,especiallywith

thebrakeson,and,turninguphillwhiletraversinga

hillareparticularlydangerous.Evenataslowspeed

andwithoutaload,tipoversaremorelikelyifyouturn

onahill.

Slowdownandshiftintoalowergearbeforestarting

upordownahill.Ifyouhavetoturnwhileonahill,

doitasslowlyandcautiouslyaspossible.Nevermake

sharporfastturnsonahill.

Ifyoustallorbegintoloseheadwaywhileclimbing

asteephill,quicklyapplythebrakes,shifttoneutral,

restarttheengineandshifttoreverse.Atidlespeed,

theengineandtransaxledragwillaidthebrakesin

controllingthevehicleonthehillandhelpyouback

downthehillmoresafely.

Reducetheweightoftheloadifitisasteephillorif

theloadhashighcenterofgravity.Remember,loads

canshift,securethem.

Note:Thevehiclehasexcellenthillclimbingability .

Hillclimbingtractioncanalsobeincreasedbyadding

weighttotherearofthevehicleinoneofthefollowing

ways:

•Addingweighttobed,makingsureitissecured.

•Mountingwheelweightstorearwheels.

Donotcarryloadswhichexceedtheloadlimits

describedonthevehicleweightlabel.

Thevehiclehasseveralcombinationsofboxes,

platforms,andattachmentsavailable.Thesecanbe

usedinvariouscombinationsthatallowformaximum

capacityandversatility .Thefullsizedboxis55inches

(140cm)wideby65inches(165cm)longandcanhold

upto3044lb(1381kg)ofevenlydistributedcargo.

Loadsvaryinhowtheyaredistributed.Sandspreads

outevenlyandquitelow .Otheritems,suchasbricks,

fertilizerorlandscapetimbers,stackhigherinthebox.

Theheightandweightoftheloadhasasignicant

inuenceontipovers.Thehigheraloadisstacked,the

morelikelythevehicleistotipover.Youmayndthat

3044lb(1381kg)stackstoohighforsafeoperation.

Reducingthetotalweightisonewaytoreducetherisk

ofatipover.Distributingtheloadaslowaspossibleis

anotherwaytoreducetheriskofatipover.

Iftheloadispositionedtowardoneofthesides,itwill

makethevehiclemuchmorelikelytotipoveronthat

side.Thisisespeciallytruewhenturningiftheloadis

ontheoutsideoftheturn.

Neverpositionheavyloadsbehindtherearaxle.Ifthe

loadispositionedsofartotherearthatitisbehindthe

rearaxle,itwillreducetheweightonthefrontwheels

andthiswillreducesteeringtraction.Withtheloadall

thewaytotheback,thefrontwheelscanevencome

offofthegroundwhengoingoverbumpsorupahill.

Thiswillresultinalossofsteeringandmayleadtothe

vehicletippingover.

Asageneralrule,positiontheweightoftheload

evenlyfromfronttorearandevenlyfromsideto

side.

Ifaloadisnotsecured,oryouaretransportingaliquid

inalargecontainersuchasasprayer,itcanshift.This

shiftinghappensmostoftenwhileturning,goingupor

downhills,suddenlychangingspeeds,orwhiledriving

overroughsurfaces.Shiftingloadscanleadtotipovers.

Alwayssecureloadssothattheydonotshift.Never

dumptheloadwhilethevehicleissidewaysonthehill.

27

Page 28

Heavyloadsincreasestoppingdistanceandreduceyour

abilitytoturnquicklywithouttippingover.

Therearcargospaceisintendedforloadcarrying

purposesonly ,notforpassengers.

FourWheelDrive(FourWheel

DriveModelsOnly)

TheAutomaticonDemandfourwheeldrivefeature,on

thisvehicledoesnotrequireoperatoractivation.The

frontwheeldriveisnotengaged(nopowerdelivered

tofrontwheels)untiltherearwheelsbegintolose

traction.Thebidirectionalclutchsensestherearwheels

slipping,engagesthefrontwheeldrive,anddelivers

powertothefrontwheels.Thefourwheeldrivesystem

continuestodeliverpowertothefrontwheelsuntilthe

rearwheelshaveenoughtractiontomovethevehicle

withoutslipping.Oncethisoccurs,thesystemstops

deliveringpowertothefrontwheelsandthehandling

characteristicsbecomesimilartothatofatwowheel

drivevehicle.Thefourwheeldrivesystemfunctions

inbothfrowardandreverse,however,whenturning

therearwheelswillslipslightlymorebeforepoweris

deliveredtothefrontwheels.

Figure25

1.Eyeholeinframe(eachside)

WARNING

Tippingorrollingthevehicleonahillwillcause

seriousinjury.

Theextratractionavailablewiththefourwheel

drivefeaturecanbeenoughtogetyouinto

dangeroussituationssuchasclimbingslopesthat

aretoosteeptoturnaround.Becarefulwhen

operating,especiallyonsteeperslopes.

TransportingtheVehicle

Formovingthevehiclelongdistances,useatrailer.

Makesurethevehicleissecuredtothetrailer.Referto

Figure25&Figure26forthelocationofthetiedown

points.

Important:Trailersweighingover1500lb(680kg)

arerequiredtobeequippedwithtrailerbrakes.

Note:Loadthevehicleonthetrailerwiththefront

ofthevehiclefacingforward.Ifthatisnotpossible,

securethevehiclehoodtotheframewithastrap,or

removethehoodandtransportandsecureitseparately

orthehoodmayblowoffduringtransport.

Figure26

1.Axle2.Hitchplate

TowingtheVehicle

Incaseofanemergency,thevehiclecanbetowedfor

ashortdistance.However,Torodoesnotrecommend

thisasastandardprocedure.

WARNING

Towingatexcessivespeedscouldcausevehicleto

losesteeringcontrol.Nevertowvehiclefasterthan

5mph(8kph).

Towingthevehicleisatwopersonjob.Afxatowline

toholesinthefrontframemember.Movetheshifterto

Neutralandreleasetheparkingbrake.Ifthemachine

mustbemovedaconsiderabledistance,transportiton

atruckortrailer.

Note:Thepowersteeringwillnotfunction,

makingitdifcult(increasedeffort)tosteer.

28

Page 29

TowingaTrailerwiththe

Vehicle

TheWorkmaniscapableofpullingtrailersand

attachmentsofgreaterweightthanthevehicleitself.

Severaltypesoftowhitchesareavailableforthe

Workman,dependingonyourapplication.Contact

yourAuthorizedToroDistributorfordetails.

Whenequippedwithatowhitchboltedontothe

rearaxletube,yourWorkmancantowtrailersor

attachmentswithaGrossTrailerW eight(GTW)upto

3500lb(1587kg).Alwaysloadatrailerwith60%of

thecargoweightinthefrontofthetrailer.Thisplaces

approximately10%(600lb(272kg)max.)oftheGross

TrailerWeight(GTW)onthetowhitchofthevehicle.

Trailerbrakesarerequiredwheneveryoutowatrailer

over1500lb(680kg)GTWistowedbehindaWorkman

vehicle.

Whenhaulingcargoortowingatrailer(attachment),do

notoverloadyourvehicleortrailer.Overloadingcan

causepoorperformanceordamagetothebrakes,axle,

engine,transaxle,steering,suspension,bodystructure,

ortires.

Important:T oreducepotentialfordriveline

damage,uselowrange.

Whentowing5thwheelattachments,alwaysinstallthe

wheelybar(includedwiththe5thwheelkit)toprevent

thefrontwheelsfromliftingoffthegroundifthe

towedattachmentsmovementissuddenlyimpaired.

29

Page 30

Maintenance

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst2hours

Aftertherst8hours

Aftertherst10hours

Aftertherst50hours

Beforeeachuseordaily

Every50hours

MaintenanceProcedure

•T orquethefrontandrearwheelnuts.

•Checkconditionandtensionofthealternatorbelt.

•T orquethefrontandrearwheelnuts.

•Checktheadjustmentoftheshiftcables.

•Checktheadjustmentoftheparkingbrake.

•Replacethehydrauliclter.

•Changethehighowhydraulicoillter(ifsoequipped).

•Changeengineoilandlter.

•Adjusttheenginevalveclearance.

•Checkengineoillevel.

•Checkthelevelofcoolant.

•Checkthetransaxle/hydraulicuidlevel.

•Checkthehighowhydraulicuidlevel(ifsoequipped).

•Checkthetirepressure.

•Checkthebrakeuidlevel.

•Checktheoperationoftheinterlocksystem.

•Drainwaterorothercontaminantsfromthewaterseparator.

•Removedebrisfromtheengineareaandradiator.(Cleanmorefrequentlyindirty

conditions.)

•Checkthebatteryuidlevel.(Every30daysifinstorage)

•Checkthebatterycableconnections.

Every100hours

Every150hours

Every200hours

Every400hours

Every600hours

•Checktheleveloffrontdifferentialoil(fourwheeldrivemodelsonly).

•Greaseallbearingsandbushings.(Lubricatemorefrequentlyinheavyduty

applications)

•Checktheconditionofthetires.

•Changeengineoilandlter.

•T orquethefrontandrearwheelnuts

•Changetheaircleanerlter.(morefrequentlyindustyordirtyconditions)

•Inspecttheconstantvelocitybootforcracks,holes,oralooseclamp.

•Checktheadjustmentoftheshiftcables.

•Checktheadjustmentofthehigh–lowcable.

•Checktheadjustmentoftheparkingbrake.

•Checktheadjustmentofthebrakepedal.

•Checkconditionandtensionofthealternatorbelt.

•Checktheadjustmentoftheclutchpedal.

•Inspecttheserviceandparkingbrakes.

•Checkthefuellinesandconnections.

•Replacethefuelltercanister.

•Checkthefrontwheelalignment.

•Visuallyinspectthebrakesforwornbrakeshoes.

•Adjusttheenginevalveclearance.

30

Page 31

MaintenanceService

Interval

Every800hours

Every1,000hours

MaintenanceProcedure

•Changethefrontdifferentialoil.

•Changethehydraulicuidandcleanthestrainer.

•Replacethehydrauliclter.

•Changethehighowhydraulicoilandlter(ifsoequipped).

•Changethebrakeuid.

•Drain/ushthefueltank.

•Flush/replacethecoolantsystemuid.

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

DANGER

Onlyqualiedandauthorizedpersonnelshallbepermittedtomaintain,repair,adjust,orinspectthe

vehicle.

Avoidrehazardsandhavereprotectionequipmentpresentintheworkarea.Donotuseanopename

tochecklevelorleakageoffuel,batteryelectrolyte,orcoolant.Donotuseopenpansoffuelorammable

cleaninguidsforcleaningparts.

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriouslyinjure

youorotherbystanders.

Removethekeyfromtheignitionbeforeyoudoanymaintenance.

ServiceIntervalChart

Figure27

31

Page 32

HeavyDutyOperation

Important:Ifthevehicleissubjectedtoanyoftheconditionslistedbelow,maintenanceshouldbe

performedtwiceasfrequently:

•Desertoperation

•Coldclimateoperationbelow32degreesF(0degreesC)

•Trailertowing

•Frequentoperationondustyroads

•Constructionwork

•Afterextendedoperationinmud,sand,water,orsimilardirtyconditions,haveyourbrakesinspectedandcleaned

assoonaspossible.Thiswillpreventanyabrasivematerialfromcausingexcessivewear.

Premaintenance

Procedures

RemovingtheFullBed

1.Oneachsideofthemachine,removetheange

headboltandangenutsecuringthebedmounting

brackettotheframebracket(

Figure28).

Figure28

1.Bedmountingbracket

2.Removethelynchpinsandclevispinssecuringthe

pivotbracketstotheframechannels(Figure29).

Figure29

1.Leftrearcornerofbed4.Clevispin

2.Vehicleframechannel

3.Pivotplate

3.Liftthebedoffofthevehicle.

5.Lynchpin

CAUTION

Thefullbedweighsapproximately325lb(147.5

kg),sodonottrytoinstallorremoveitby

yourself.Useanoverheadhoistorgetthehelp

oftwoorthreeotherpeople.

InstallingtheFullBed

Note:Ifthebedsideswillbeinstalledontheatbed,

itiseasiertoinstallthembeforeinstallingthebedon

thevehicle.

CAUTION

Thefullbedweighsapproximately325lb(147.5

kg),sodonottrytoinstallorremoveitbyyourself.

Useanoverheadhoistorgetthehelpoftwoor

threeotherpeople.

32

Page 33

1.Carefullysetthebedontothevehicleframealigning

therearbedpivotplateholeswiththeholesinthe

rearframechannelandinstall2clevispinsandlynch

Figure29).

pins(

2.Oneachsideofthemachine,securethebed

mountingbrackettotheframebracketwiththe

angeheadboltandangenutpreviouslyremoved

(Figure28)

JackingtheVehicle

DANGER

Avehicleonajackmaybeunstableandslipoffof

thejack,injuringanyonebeneathit.

•Donotstartthevehiclewhilethevehicleisona

jack.

•Alwaysremovethekeyfromtheswitchbefore

gettingoffofthevehicle.

•Blockthetireswhenthevehicleisonajack.

•Donotstarttheenginewhilethevehicleisonajack,

becausetheenginevibrationorwheelmovement

couldcausethevehicletoslipoffofthejack.

•Donotworkunderthevehiclewithoutjackstands

supportingit.Thevehiclecouldslipoffajack,

injuringanyonebeneathit.

•Whenjackingupthefrontofthevehicle,always

placea2x4block(orsimilarmaterial)betweenthe

jackandthevehicleframe.

•Thejackingpointatthefrontofthevehicleisunder

thefrontcenterframesupport(

rearitisundertheaxle(Figure31).

Figure30)andatthe

Figure31

1.Rearjackingpoints

RemovingtheHood

1.Whilegraspingthehoodintheheadlightopenings,

liftuponthehoodtoreleasethelowermounting

tabsfromtheframeslots(Figure32).

1.Frontjackingpoints

Figure30

Figure32

1.Hood

2.Pivotthebottomofthehoodupwarduntilthetop

mountingtabscanbepulledfromtheframeslots

(Figure32).

3.Pivotthetopofhoodforwardandunplugthewire

connectorsfromtheheadlights(Figure32).

4.Removethehood.

33

Page 34

Toinstallthehood,completethefollowing:

1.Connectthelights.

Lubrication

2.Insertthetopmountingtabsintotheframeslots.

3.Insertthelowermountingtabsintotheframeslots.

4.Ensurethatthehoodisfullyengagedinthetop,

sidesandbottomgrooves.

GreasingBearingsand

Bushings

ServiceInterval:Every100hours(Lubricatemore

frequentlyinheavydutyapplications)

Thevehiclehasgreasettingsthatmustbelubricated

regularlywithNo.2GeneralPurposeLithiumBase

Grease.

Thegreasettinglocationsandquantitiesareasfollows:

•Balljoints(4),tierods(2),pivotmounts(2)and

steeringcylinder(2)(

•Springtower(2)(Figure34)

•Clutch(1),accelerator(1),brake(qty .1)(Figure35)

•Acceleratorarm(1)(Figure36)

•U-joint(18)and4wheeldriveshaft(3)(

Important:Whengreasingthedriveshaftuniversal

shaftbearingcrosses,pumpgreaseuntilitcomes

outofall4cupsateachcross.

Figure33)

Figure37)

1.Wipeeachgreasettingcleansoforeignmatter

cannotbeforcedintothebearingorbushing.

2.Pumpgreaseintoeachbearingorbushing.

3.Wipeoffexcessgrease.

Figure33

34

Page 35

Figure34

Figure35

Figure36

35

Page 36

Figure37

36

Page 37

EngineMaintenance

5.Insertthenewlterbyapplyingpressuretotheouter

rimoftheelementtoseatitinthecanister.

ServicingtheAirCleaner

ServiceInterval:Every200hours—Changetheair

cleanerlter.(morefrequentlyin

dustyordirtyconditions)

Inspecttheaircleanerandhosesperiodicallytomaintain

maximumengineprotectionandtoensuremaximum

servicelife.Checktheaircleanerbodyfordamage

whichcouldpossiblycauseanairleak.Replacea

damagedaircleanerbody.

Inspectandchangetheaircleanerlterasdescribedin

thefollowingprocedure:

1.Pullthelatchoutwardandrotatetheaircleaner

covercounterclockwise.

6.Cleanthedirtejectionportlocatedintheremovable

cover.Removetherubberoutletvalvefromthe

cover,cleanthecavity,andreplacetheoutletvalve.

7.Installthecoverorientingtherubberoutletvalvein

adownwardposition—betweenapproximately5:00

to7:00whenviewedfromtheend.

8.Securethecoverlatches.Resettheindicatorifitis

showingred(ifsoequipped).

ChangingtheEngineOilAnd

Filter

ServiceInterval:Aftertherst50hours

Every150hours

1.Removethedrainplugandletoilowintoadrain

pan(Figure39).Whentheoilstops,installthedrain

plug.

Figure38

1.Aircleanercover2.Filter

2.Beforeremovingthelter,uselowpressure

air(40psi,cleananddry)tohelpremovelarge

accumulationsofdebrispackedbetweentheoutside

oftheprimarylterandthecanister.

Important:Avoidusinghighpressureairwhich

couldforcedirtthroughthelterintotheintake

tract.Thiscleaningprocesspreventsdebris

frommigratingintotheintakewhentheprimary

lterisremoved.

3.Removeandreplacetheprimarylter.

Note:Cleaningoftheusedelementisnot

recommendedduetothepossibilityofdamageto

theltermedia.

4.Inspectthenewlterforshippingdamage,checking

thesealingendofthelterandthebody.

Important:Donotuseadamagedelement.

Figure39

1.Engineoildrainplug

2.Removetheoillter(Figure40).

Figure40

1.Engineoillter

3.Applyalightcoatofcleanoiltothenewlterseal

beforescrewingiton.

37

Page 38

4.Screwthelteronuntilthegasketcontactsthe

mountingplate,thentightenthelter1/2to2/3of

aturn.Donotovertighten.

5.Addoiltothecrankcase;refertoCheckingthe

EngineOilLevel.

FuelSystem

Maintenance

FuelLinesandConnections

ServiceInterval:Every400hours/Yearly(whichever

comesrst)

Every1,000hours/Every2years

(whichevercomesrst)

Inspectthefuellinesandconnectionsfordeterioration,

damage,orlooseconnections.

ServicingtheWater

Separator/FuelFilter

DrainingtheWaterSeparator

ServiceInterval:Beforeeachuseordaily—Drainwater

orothercontaminantsfromthewater

separator.

1.Placeacleancontainerunderthefuellter

Figure41).

(

2.Loosenthedrainplugonthebottomofthelter

canister.

Figure41

1.Waterseparatorltercanister

3.Tightenthedrainplugonthebottomofthelter

canister.

ChangingtheFuelFilterCanister

ServiceInterval:Every400hours—Replacethefuel

ltercanister.

1.Drainthewaterfromthewaterseparator;referto

DrainingtheWaterSeparator.

2.Cleantheareawheretheltercanistermounts

(Figure41).

38

Page 39

3.Removetheltercanisterandcleanthemounting

surface.

4.Lubricatethegasketontheltercanisterwithclean

oil.

5.Installtheltercanisterbyhanduntilthegasket