Page 1

FormNo.3382-400RevB

G015454

Workman

ModelNo.07299—SerialNo.314000001andUp

ModelNo.07299TC—SerialNo.314000001andUp

®

MDEUtilityMachine

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3382-400*B

Page 2

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Thismachineisautilitymachineintendedtobeusedby

professional,hiredoperatorsincommercialapplications.It

isprimarilydesignedforthetransportofimplementsusedin

suchapplications.Thismachineallowsforthesafetransport

ofanoperatorandonepassengerintheidentiedseats.The

bedofthismachineisnotsuitableforanyriders.

ThisproductcomplieswithallrelevantEuropeandirectives;

fordetails,pleaseseetheseparateproductspecicDeclaration

ofConformity(DOC)sheet.

Introduction

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

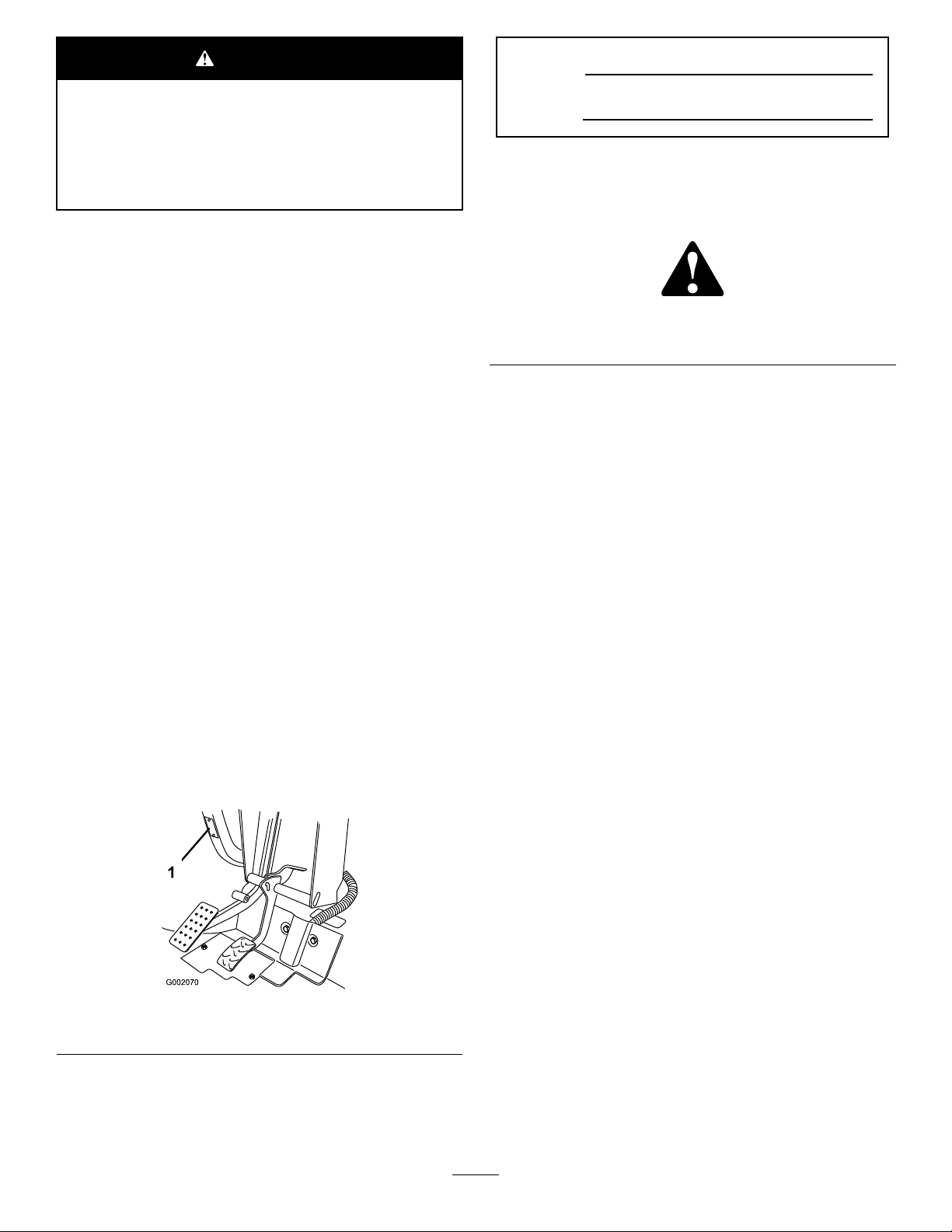

Figure2

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready.Figure1identiesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

1.Modelandserialnumberlocation

©2014—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Figure1

Contactusatwww.Toro.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

Contents

Introduction..................................................................2

Safety...........................................................................4

SafeOperatingPractices...........................................4

BeforeOperating....................................................4

Operation...............................................................4

HandlingandServicingBatteries...............................6

Maintenance...........................................................7

SoundPressure.......................................................7

Hand-armVibration................................................7

Whole-bodyVibration.............................................7

SafetyandInstructionalDecals.................................8

Setup...........................................................................11

1InstallingtheSteeringWheel..................................11

2InstallingtheBatteries..........................................11

3CheckingtheTirePressure....................................13

4SettingtheChargerVoltage(model07299TC

only).................................................................14

5ReadingtheManualandViewingtheSafety

Video................................................................14

ProductOverview.........................................................15

Controls...............................................................15

Specications........................................................17

Attachments/Accessories........................................17

Operation....................................................................18

ThinkSafetyFirst...................................................18

PreformingPre-startingChecks................................18

CheckingtheTirePressure......................................18

OperatingtheMachine............................................18

StoppingtheMachine.............................................18

ParkingtheMachine...............................................18

UnderstandingandUsingtheBatterySystem..............18

OperatingtheCargoBox.........................................20

BreakinginaNewMachine......................................22

TransportingtheMachine........................................22

TowingtheMachine...............................................22

TowingaMachine..................................................23

Maintenance.................................................................24

RecommendedMaintenanceSchedule(s)......................24

DailyMaintenanceChecklist....................................24

PremaintenanceProcedures........................................25

MaintainingtheMachineunderSpecialOperating

Conditions.........................................................25

LiftingtheMachine................................................25

AccessingtheHood................................................26

Lubrication...............................................................26

AddingGrease.......................................................26

ElectricalSystemMaintenance....................................27

MaintainingtheBatteries.........................................27

ReplacingtheFuses................................................29

ReplacingtheHeadlights.........................................29

DriveSystemMaintenance.........................................30

InspectingtheTires................................................30

AdjustingtheFrontWheelToe-inand

Camber.............................................................30

CheckingtheTransaxle-oilLevel..............................32

ChangingtheTransaxleOil......................................32

BrakeMaintenance....................................................33

CheckingtheBrake-uidLevel.................................33

InspectingtheBrakes..............................................33

AdjustingtheParkingBrake.....................................33

Cleaning...................................................................34

WashingtheMachine..............................................34

Storage........................................................................34

Troubleshooting...........................................................35

3

Page 4

Safety

Improperuseormaintenancebytheoperatororownercan

resultininjury.Toreducepotentialinjury,complywith

thesesafetyinstructionsandalwayspayattentiontothe

safetyalertsymbol,whichmeansCaution,Warning,or

Danger—“personalsafetyinstruction.”Failuretocomply

withtheinstructionmayresultinpersonalinjuryordeath.

Supervisors,operators,andservicepersonsshouldbefamiliar

withthefollowingstandardsandpublications(thematerial

maybeobtainedfromtheaddressshown):

SAEJ2258LightUtilitymachine

SAEInternational,400CommonwealthDrive,Warrendale,

PA15096-0001U .S.A.

SafeOperatingPractices

WARNING

Themachineisanoff-highwayvehicleonly,andis

notdesigned,equipped,ormanufacturedforuseon

publicroads.Usingitonapublicroadmayresult

inanaccident,whichcouldseriouslyinjureorkill

youorothers.

Donotusethismachineonpublicroads.

Supervisor'sResponsibilities

•Makesurethatoperatorsarethoroughlytrainedand

familiarwiththeOperator'sManualandalllabelsonthe

machine.

•Besuretoestablishyourownspecialproceduresand

workrulesforunusualoperatingconditions(e.g.slopes

toosteepformachineoperation).

Note:Thismachinehasasupervisorspeedlimitswitchto

allowyoutolimitthemaximumspeedthattheoperatorcan

drivethemachine.

BeforeOperating

•Operatethemachineonlyafterreadingandunderstanding

thecontentsofthismanual.

•Neverallowchildrentooperatethemachine.Anyone

whooperatesthemachineshouldhaveamotorvehicle

license.

•Neverallowotheradultstooperatethemachinewithout

rstreadingandunderstandingtheOperator'sManual.

Onlytrainedandauthorizedpersonsshouldoperatethis

machine.Makesurethatalloperatorsarephysicallyand

mentallycapableofoperatingthemachine.

•Thismachineisdesignedtocarryonlyyou,the

operator,andonepassengerintheseatprovidedbythe

manufacturer.Nevercarryanyotherpassengersonthe

machine.

•Neveroperatethemachinewhenundertheinuence

ofdrugsoralcohol.Evenprescriptiondrugsandcold

medicinescancausedrowsiness.

•Donotdrivethemachinewhenyouaretired.Besureto

takeoccasionalbreaks.Itisveryimportantthatyoustay

alertatalltimes.

•Becomefamiliarwiththecontrolsandknowhowtostop

themachinequickly.

•Keepallshields,safetydevices,anddecalsinplace.Ifa

shield,safetydevice,ordecalismalfunctioning,illegible,

ordamaged,repairorreplaceitbeforeoperatingthe

machine.

•Alwayswearsubstantialshoes.Donotoperatethe

machinewhilewearingsandals,tennisshoesorsneakers.

Donotwearloosettingclothingorjewelrywhichcould

getcaughtinmovingpartsandcausepersonalinjury.

•Wearingsafetyglasses,safetyshoes,longpants,anda

helmetisadvisableandrequiredbysomelocalsafetyand

insuranceregulations.

•Avoiddrivingwhenitisdark,especiallyinunfamiliar

areas.Ifyoumustdrivewhenitisdark,besuretodrive

cautiously,usetheheadlights,andevenconsideradding

additionallights.

•Beextremelycarefulwhenoperatingaroundpeople.

Alwaysbeawareofwherebystandersmightbe.

•Beforeoperatingthemachine,alwayscheckthedesignated

areasofthemachinethatarestatedinthepre-starting

sectionofthismanual.Ifsomethingiswrong,donotuse

themachine.Makesurethattheproblemiscorrected

beforethemachineorattachmentisoperated.

Operation

•Theoperatorandpassengershouldremainseated

wheneverthemachineisinmotion.Theoperatorshould

keepbothhandsonthesteeringwheelwheneverpossible,

andthepassengershouldusethehandholdsprovided.

Keepyourarmsandlegswithinthemachinebodyatall

times.

•Driveslowerandturnlesssharplywhenyouarecarrying

apassenger.Rememberyourpassengermaynotbe

expectingyoutobrakeorturnandmaynotbeready.

•Alwayswatchoutforandavoidlowoverhangssuchas

treelimbs,doorjambs,andoverheadwalkways.Make

surethereisenoughroomoverheadtoeasilyclearthe

machineandyourhead.

•Failuretooperatethemachinesafelymayresultinan

accident,tipoverofthemachine,andseriousinjuryor

death.Drivecarefully.Topreventtippingorlossof

control:

–Useextremecaution,reducespeed,andmaintain

asafedistancearoundsandtraps,ditches,creeks,

ramps,unfamiliarareas,oranyareasthathaveabrupt

changesingroundconditionsorelevation.

4

Page 5

–Watchforholesorotherhiddenhazards.

–Useextracautionwhenoperatingthemachineon

wetsurfaces,inadverseweatherconditions,athigher

speeds,orwithafullload.Stoppingtimeanddistance

willincreasewithafullload.

–Avoidsuddenstopsandstarts.Donotgofrom

reversetoforwardorforwardtoreversewithoutrst

comingtoacompletestop.

–Slowdownbeforeturning.Donotattemptsharp

turnsorabruptmaneuversorotherunsafedriving

actionsthatmaycausealossofmachinecontrol.

–Whendumping,donotletanyonestandbehindthe

machineanddonotdumptheloadonanyone'sfeet.

Releasethetailgatelatchesfromthesideofthebox,

notfrombehind.

–Onlyoperatethemachinewhenthecargoboxis

downandlatched.

–Beforebackingup,looktotherearandensurethat

nooneisbehindyou.Backupslowly.

–Watchoutfortrafcwhenyouarenearorcrossing

roads.Alwaysyieldtherightofwaytopedestrians

andothermachines.Thismachineisnotdesignedfor

useonstreetsorhighways.Alwayssignalyourturns

orstopearlyenoughsothatotherpeopleknowwhat

youplantodo.Obeyalltrafcrulesandregulations.

–Theelectricalsystemofthemachinecanproduce

sparkscapableofignitingexplosivematerials.Never

operatethemachineinornearanareawherethereis

dustorfumesintheairwhichareexplosive.

–Ifyouareeverunsureaboutsafeoperation,stopwork

andaskyoursupervisor.

•Ifthemachineevervibratesabnormally,stopimmediately,

waitforallmotiontostop,andinspectthemachinefor

damage.Repairalldamagebeforecommencingoperation.

•Beforegettingofftheseat:

1.Stopthemovementofthemachine.

2.Settheparkingbrake.

3.TurnthekeytotheOffposition.

4.Removethekey.

Note:Ifthemachineisonanincline,blockthe

wheelsaftergettingoffofthemachine.

5.Lightningcancausesevereinjuryordeath.If

lightningisseenorthunderisheardinthearea,do

notoperatethemachine;seekshelter.

Braking

•Slowdownbeforeyouapproachanobstacle.This

givesyouextratimetostoporturnaway.Hittingan

obstaclecandamagethemachineanditscontents.More

important,itcaninjureyouandyourpassenger.

•Grossmachineweight(GVW)hasamajorimpactonyour

abilitytostopand/orturn.Heavyloadsandattachments

makeamachinehardertostoporturn.Theheavierthe

load,thelongerittakestostop.RefertoLoadingthe

CargoBox(page21)formoreinformation.

•Decreasethemachinespeedifthecargoboxhasbeen

removedandthereisnoattachmentonthemachine.The

brakingcharacteristicschangeandfaststopsmaycause

therearwheelstolockup,whichmayaffectthecontrol

ofthemachine.

•Turfandpavementaremuchmoreslipperywhenthey

arewet.Itcantake2to4timesaslongtostoponwet

surfacesasondrysurfaces.Ifyoudrivethroughstanding

waterdeepenoughtogetthebrakeswet,theywillnot

workwelluntiltheyaredry.Afterdrivingthroughwater,

youshouldtestthebrakestomakesuretheywork

properly.Iftheydonot,driveslowlywhileputtinglight

pressureonthebrakepedal.Thiswilldrythebrakesout.

OperatingonHills

WARNING

Operatingthemachineonahillmaycausetipping

orrollingofthemachine,orthebatteriesmayrun

lowandyoucouldloseheadwayonthehill.This

couldresultinpersonalinjury.

•Donotoperatethemachineonexcessivelysteep

slopes.

•Donotacceleratequicklyorslamonthebrakes

whenbackingdownahill,especiallywithaload.

•Ifthebatteriesrunloworyoubegintolose

headwaywhileclimbingahill,graduallyapply

thebrakesandslowlybackstraightdownthe

hill.

•Operatethemachineslowlyonahillanduse

caution.

•Avoidturningonahill.

•Reduceyourloadandthespeedofthemachine.

•Avoidstoppingonhills,especiallywithaload.

Theseextracautionsneedtobetakenwhenoperatingthe

machineonahillbyperformingthefollowing:

•Slowdownbeforestartingupordownahill.

•Ifthebatteriesrunloworyoubegintoloseheadway

whileclimbingahill,graduallyapplythebrakesandslowly

backstraightdownthehill.

•Turningwhiletravelingupordownhillscanbedangerous.

Ifyouhavetoturnwhileonahill,doitslowlyand

cautiously.Nevermakesharporfastturns.

•Heavyloadsaffectstability.Reducetheweightoftheload

andyourspeedwhenoperatingonhillsoriftheloadhas

ahighcenterofgravity.Securetheloadtopreventitfrom

shiftingandtakeextracarewhenhaulingloadsthatshift

easily(liquid,rock,sand,etc.).

•Avoidstoppingonhills,especiallywithaload.Stopping

whilegoingdownahillwilltakelongerthanstopping

5

Page 6

onlevelground.Ifthemachinemustbestopped,avoid

suddenspeedchanges,whichmayinitiatetippingor

rollingofthemachine.Donotslamonthebrakes

whenrollingbackward,asthismaycausethemachine

tooverturn.

•YoucaninstallanoptionalROPSkitforoperationon

hillyterrain.

OperatingonRoughTerrain

Reduceyourspeedandloadwhenoperatingonroughterrain,

unevenground,nearcurbs,holes,andothersuddenchanges

interrain.Loadsmayshift,causingthemachinetobecome

unstable.

YoucaninstallaoptionalROPSkitforoperationinrough

terrain.

WARNING

Suddenchangesinterrainmaycauseabrupt

steeringwheelmovement,possiblyresultingin

handandarminjuries.

•Reduceyourspeedwhenoperatingonrough

terrainandnearcurbs.

•Gripthesteeringwheellooselyaroundthe

perimeterkeepingthumbsupandoutoftheway

ofthesteering-wheelspokes.

LoadingandDumping

Theweightandpositionofthecargoandpassengercan

changethemachinecenterofgravityandmachinehandling.

Toavoidlossofcontrolandpersonalinjury,followthese

guidelines:

•Donotcarryloadswhichexceedtheloadlimitsdescribed

onthemachineweightlabel;refertoLoadingtheCargo

Box(page21)forthemachineweightlimits.Theload

ratingisforlevelsurfacesonly .

•Reducetheweightoftheloadwhenoperatingonhills

androughterraintoavoidtippingoroverturningofthe

machine.

•Reducetheweightoftheloadifthecenterofgravityis

high.Itemssuchasbricks,fertilizer,orlandscapetimbers

stackhigherinthebox.Thehigheraloadisstacked,the

morelikelythemachineistotipover.Distributetheload

aslowaspossible,makingsurethattheloaddoesnot

affectrearvisibility.

•Positiontheweightoftheloadevenlyfromsidetoside.

Ifyoupositiontheloadtowardoneofthesides,the

machineismorelikelytotipoverwhileturning.

•Positiontheweightofaloadevenlyfromfronttoback.

Ifyoupositiontheloadbehindtherearaxle,itwillreduce

theweightonthefrontwheels.Thismayresultinaloss

ofsteeringcontrolorcausethemachinetotipoveron

hillsorbumpyterrain.

•Useextracautioniftheloadexceedsthedimensionsof

theboxandwhenhandlingoff-centerloadsthatcannot

becentered.Keeploadsbalancedandsecuretoprevent

themfromshifting.

•Alwayssecureloadssothattheydonotshift.Ifaloadis

notsecured,oryouaretransportingaliquidinalarge

containersuchasasprayer,theloadcanshift.This

shiftinghappensmostoftenwhileturning,goingupor

downhills,suddenlychangingspeeds,orwhiledriving

overroughsurfaces.Shiftingloadscancausethemachine

totipover.

WARNING

Theweightoftheboxmaybeheavy.Handsor

otherbodypartscouldbecrushed.

–Keephandsandotherbodypartsclearwhen

loweringthebox.

–Donotdumpmaterialsonbystanders.

•Neverdumpaloadedcargoboxwhilethemachineis

sidewaysonahill.Thechangeinweightdistributionmay

causethemachinetooverturn.

•Whenoperatingwithaheavyloadinthecargobox,

reduceyourspeedandallowforsufcientbraking

distance.Donotsuddenlyapplythebrakes.Useextra

cautiononslopes.

•Beawarethatheavyloadsincreaseyourstoppingdistance

andreduceyourabilitytoturnquicklywithouttipping

over.

•Therearcargospaceisintendedforloadcarrying

purposesonly,notforpassengers.

•Neveroverloadyourmachine.Thedecal(locatedonthe

rearframe)showsloadlimitsforthemachine.Never

overloadtheattachmentsorexceedthegrossmachine

weight(GVW).

HandlingandServicing Batteries

•Toreducethepotentialforre,keepthebatteriesand

motorareafreeofexcessivegrease,grass,leaves,and

accumulationofdirt.

•Alwaysdisconnectandremoveabatterycablebefore

servicinganyelectricalcomponents.

•Disconnectinganybatterycablewillinhibitoperationof

theelectricalsystem.

•Batteryelectrolytecontainssulfuricacid.Sulfuricacid

produceshydrogengaswhich,intherightproportions,

isexplosive.

–Alwaysservice,store,andchargethemachineina

well-ventilatedarea.

–Keepsparksandopenamesawayfromthebatteries.

6

Page 7

–Donotsmokenearthebatteries.

–Neveruseanopenametocheckthelevelorleakage

ofbatteryelectrolyte.

•Usecautionwhenhandlingandworkingaround

electrolyte.Thesulfuricacidinelectrolytecanburnskin

anddamageclothing.Furthermore,itcanbeemittedasa

gasthatcandamageyourlungs.

–Wearpropereye,hand,andfaceprotection.

–Donotleanoverthebatteriesatanytime.

–Avoidbreathinginbatteryfumes.

–Fillthebatterieswherecleanwaterisalwaysavailable

forushingtheskin.

–Ifyougetelectrolyteonyourskinoreyes,ush

theaffectedareafor20minuteswithcleanwater.

Removeacid-soakedclothing.Seekmedicalattention

immediately.

–Keepchildrenandpetsawayfromthebatteriesand

electrolyte.

•Electrolyteisverypoisonous.

–Donotdrinkelectrolyte.

–Ifelectrolyteisswallowed,donotinducevomiting;

instead,drinklargeamountsofwaterormilkfollowed

bymilkofmagnesia,beatenraweggs,orvegetable

oil.Getmedicalattentionimmediately.

–Keepchildrenandpetsawayfromthebatteriesand

electrolyte.

•Whennotllingthebatteries,keepthebatteryventcaps

tightonthebatteries.Neveroperatethemachineifany

oftheventcapsaremissingordamaged.

•Whenremovingorinstallingthebatteries,donotallow

thebatteryterminalstotouchanymetalpartsofthe

machine.

•Donotallowmetaltoolstoshortbetweenthebattery

terminalsandmetalpartsofthemachine.Removeall

jewelryandwatchesbeforeservicingthebatteries.

•Donotcheckabatterychargebyplacingametalobject

acrosstheposts.Thiswillcausesparkswhichcancause

anexplosion.

•Alwayskeepthebatteryretainersinplacetoprotectand

securethebatteries.

•Readandunderstandthecharginginstructionsbefore

chargingthebatteries;refertoChargingtheBatteries

(page27).Also,takethefollowingprecautionsand

actionswhenchargingthebatteries:

–TurnthemachineOn/OffswitchtoOffbefore

connectingthechargertoapowersource.

–Useonlythebatterychargersuppliedwiththe

machinetochargethebatteries.

–Donotchargeadamagedorfrozenbattery.

–AlwaysunplugtheACpowercordfromthepower

outletbeforeunpluggingitfromthemachinecharging

receptacletoavoidsparks.

–Ifduringchargingabatterygetshot,beginsemitting

largeamountsofgasses,orspewselectrolyte,

immediatelydisconnectthechargerpowercordfrom

thepoweroutlet.Havethemachineservicedbyan

AuthorizedServiceDealerbeforeusingitagain.

Maintenance

•Onlyqualiedandauthorizedpersonnelshallbe

permittedtomaintain,repair,adjust,orinspectthe

machine.

•Beforeservicingormakingadjustmentstothemachine,

stopthemachine,settheparkingbrake,andremovethe

keytopreventsomeonefromaccidentallystartingthe

motor.

•Tomakesurethattheentiremachineisingoodcondition,

keepallnuts,bolts,andscrewsproperlytightened.

•Donotuseopenpansoffuelorammablecleaning

uidsforcleaningparts.

•Ifmajorrepairsareeverneededorassistanceisrequired,

contactanAuthorizedToroDistributor.

•Tobesureofoptimumperformanceandsafety,always

purchasegenuineTororeplacementpartsandaccessories.

Replacementpartsandaccessoriesmadebyother

manufacturerscouldbedangerous.Alteringthismachine

inanymannerthatmayaffectmachineoperation,

performance,durability ,oritsuse,mayresultininjuryor

death.Suchusecouldvoidtheproductwarranty.

SoundPressure

Thisunithasasoundpressurelevelattheoperator’searof68

dBA,whichincludestheUncertaintyValue(K)of1dBA.

Hand-armVibration

Measuredvibrationlevelforrighthand=0.43m/s²

Measuredvibrationlevelforlefthand=0.38m/s²

UncertaintyValue(K)=0.5m/s²

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinEN1032.

Whole-bodyVibration

Measuredvibrationlevel=0.2m/s²

UncertaintyValue(K)=0.5m/s²

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinEN1032.

7

Page 8

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

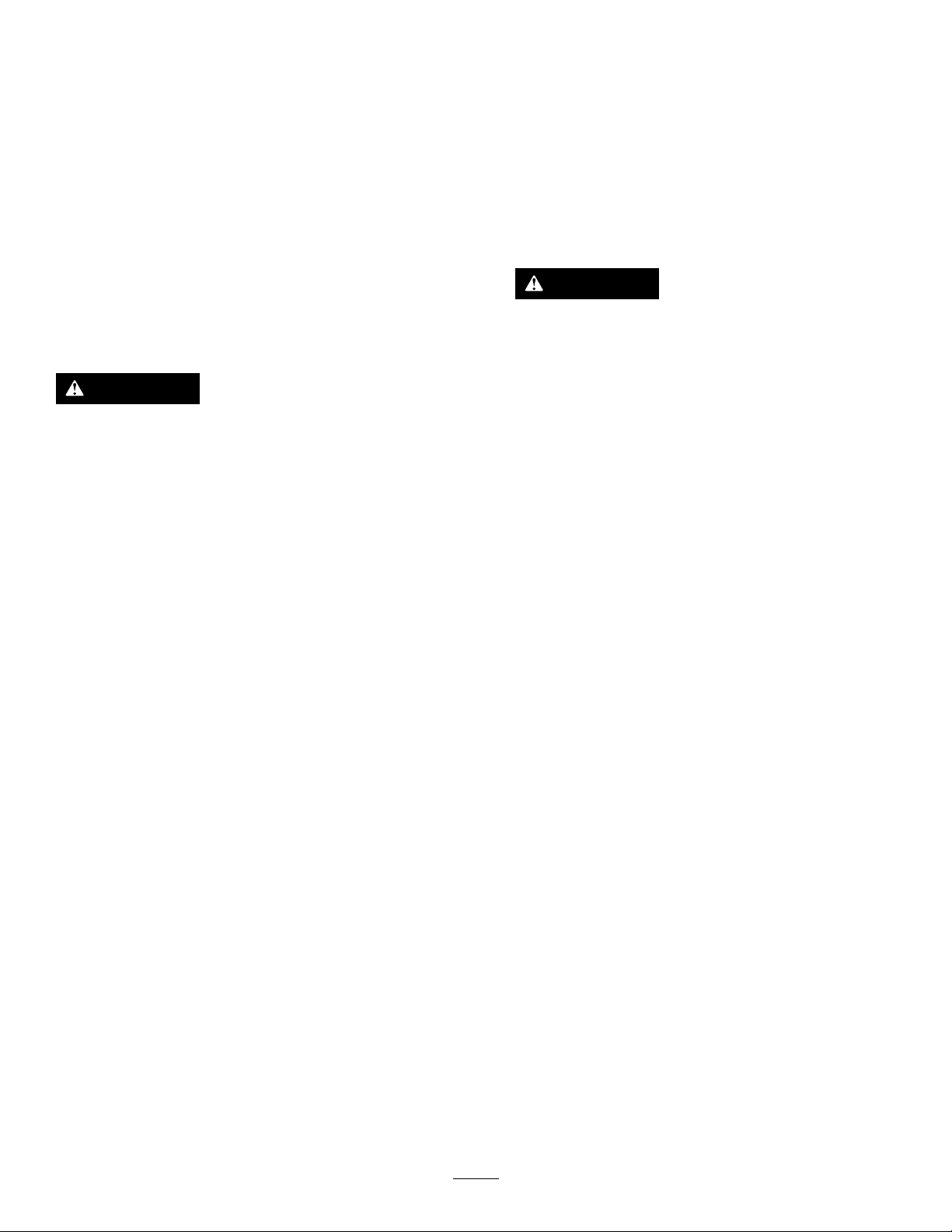

112-3310

1.Warning—readtheOperator'sManual.10.Lighton,OK

2.Collisionhazard—donotoperatethevehicleonpublicstreets,

roads,orhighways.

3.Fallinghazard—donotcarrypassengersinthecargobed.

4.Fallinghazard—donotallowchildrentooperatethevehicle.

5.Tostartthemotor,sitontheoperator'sseat,releasethe

parkingbrake,turnthepowerkeyon,pullthechokeleverout

(ifneeded),andpresstheacceleratorpedal.

6.Tostopthemotor,releasetheacceleratorpedal,setthe

parkingbrake,turnthepowerkeyoff,andremovethepower

key.

7.Horn

8.Headlights

9.Battery/hourmeter

11.Lightblinking,readtheOperator'sManual.

12.Cargobedlift

13.Rearlift

14.Forward

15.Reverse

16.Power—Off

17.Power—On

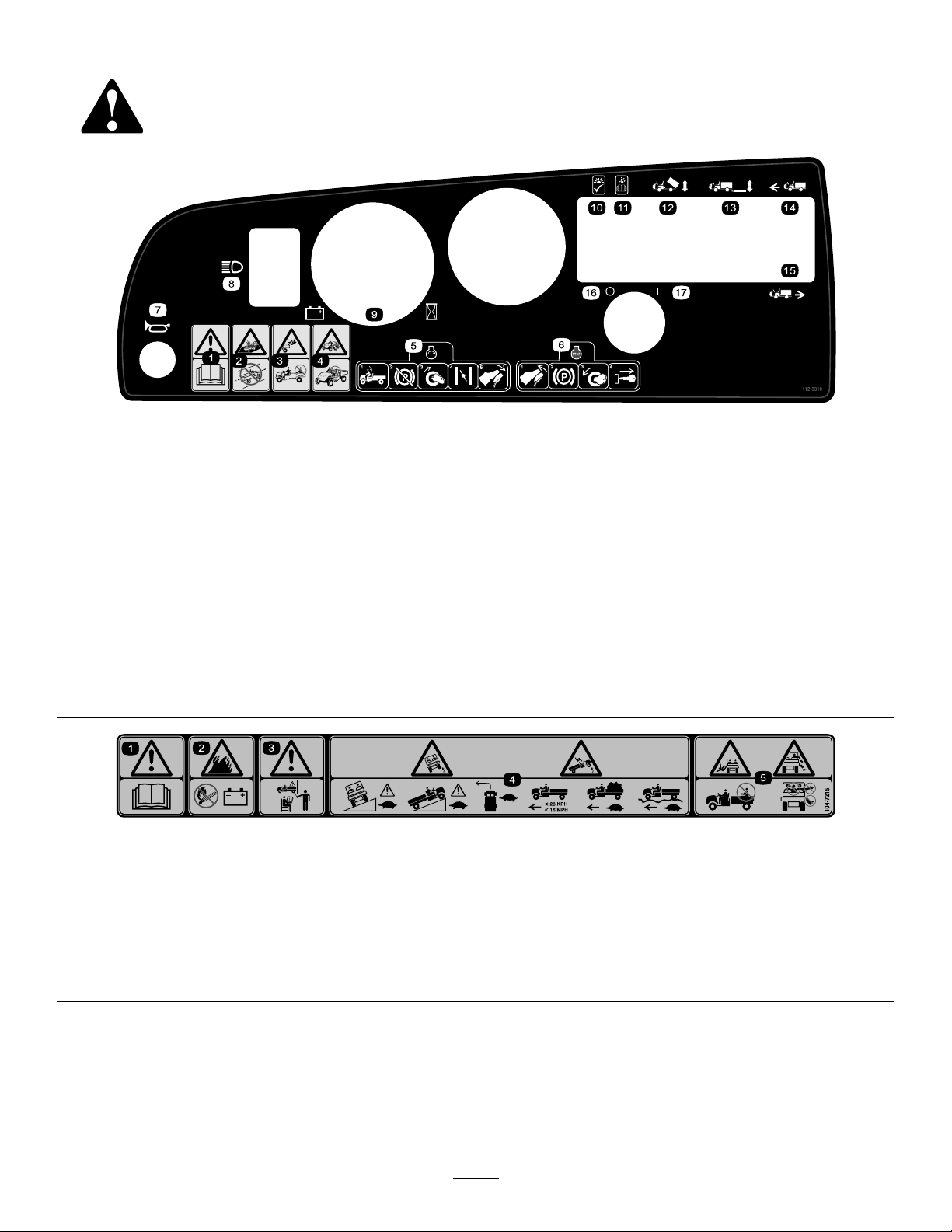

104-7215

1.Warning—readtheOperator'sManual.

2.Explosionhazard—nore,openames,orsmokingaroundbatteries.

3.Warning—donotoperatethismachineunlessyouaretrained.

4.Tippinghazard—usecautionanddriveslowlywhileonslopes;driveslowlywhenturning,keepthevehiclespeedunder16mph

(26km/h)whencarryingafullorheavyloadandwhendrivingonroughterrain.

5.Fallingandarm/leginjuryhazards—donotcarrypassengersinthecargobedandkeeparmsandlegsinsideofthevehicleatall

times.

8

Page 9

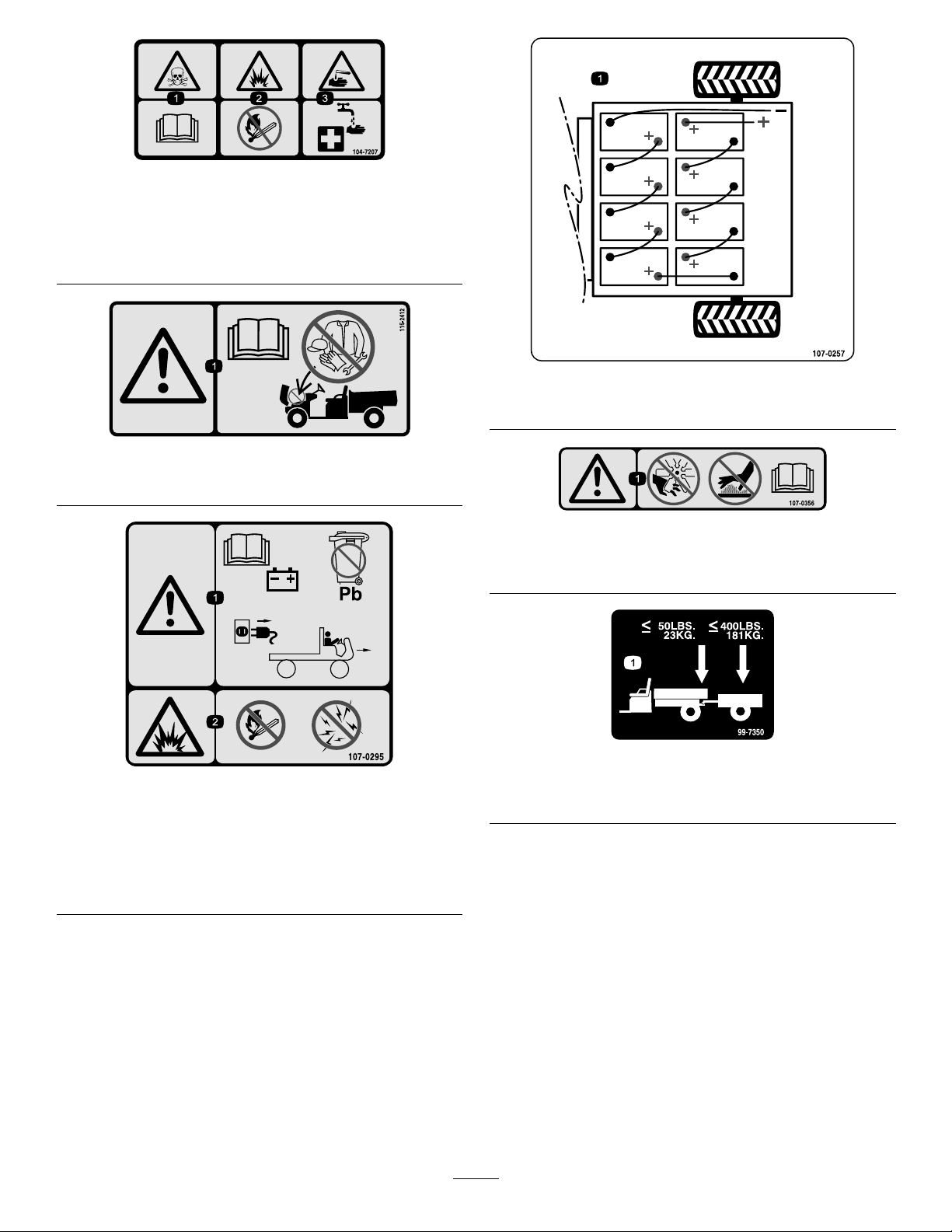

104-7207

1.Poisonhazard—readtheOperator'sManual.

2.Explosionhazard—nore,openames,orsmoking.

3.Causticliquid/chemicalburnhazard—toperformrstaid,

ushwithwater.

115-2412

1.Warning—readtheOperator'sManual;nostorage.

107-0257

1.Batteryschematic

107-0356

1.Warning—donottouchmovingobjects,fan;donottouch

thehotsurfaces;readtheOperator'sManual.

107-0295

1.Warning—readtheOperator'sManualformoreinformation

onbatteries;batteriescontainlead,donotdiscard;

disconnectthepowercordfrompowersourcebeforedriving

vehicle.

2.Explosionhazard—nore,openames,orsmoking;avoid

sparks.

99-7350

1.Maximumtongueweightis50lb(23kg);maximumtrailer

weightis400lb(181kg).

9

Page 10

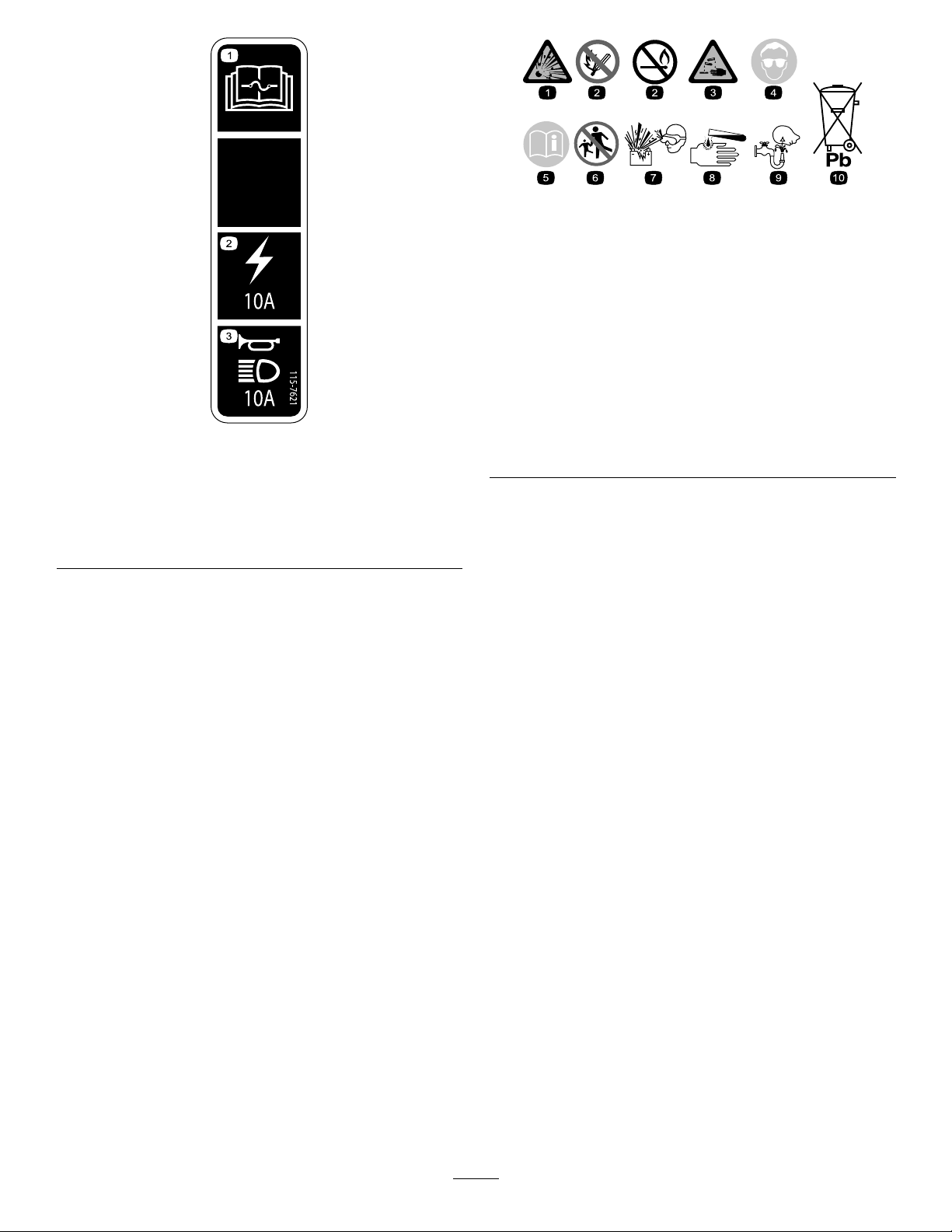

BatterySymbols

Someorallofthesesymbolsareonyourbattery

1.ReadtheOperator’s

Manualforinformationon

fuses.

2.Electrical

power/accessories—

10A

115–7621

3.Hornandlights—10A

1.Explosionhazard

2.Nore,opename,or

smoking.

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

6.Keepbystandersasafe

7.Weareyeprotection;

8.Batteryacidcancause

10.Containslead;donot

distancefromthebattery.

explosivegasescan

causeblindnessandother

injuries

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

discard.

10

Page 11

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

Steeringwheel

Batteryholddown2

Batteryhold-downrod2

Batterycables

Battery-traypads4

Batterypad1

Flangenut(3/8inch)

Battery-terminal-protectorspray1

Nopartsrequired

Nopartsrequired

Operator'sManual

PartsCatalog

Safetytrainingmaterial

Registrationcard1

PredeliveryInspectionForm1

CerticateofQuality

Key2

Qty.

Use

1

7

2

–

–

1

1

1

1

Installthesteeringwheel(model

07299TConly).

Installthebatteries(model07299TC

only).

Checkthetirepressure.

Setthechargervoltage(model07299TC

only).

ReadtheOperator'sManualandview

thetrainingmaterialbeforeoperating

themachine.

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

1

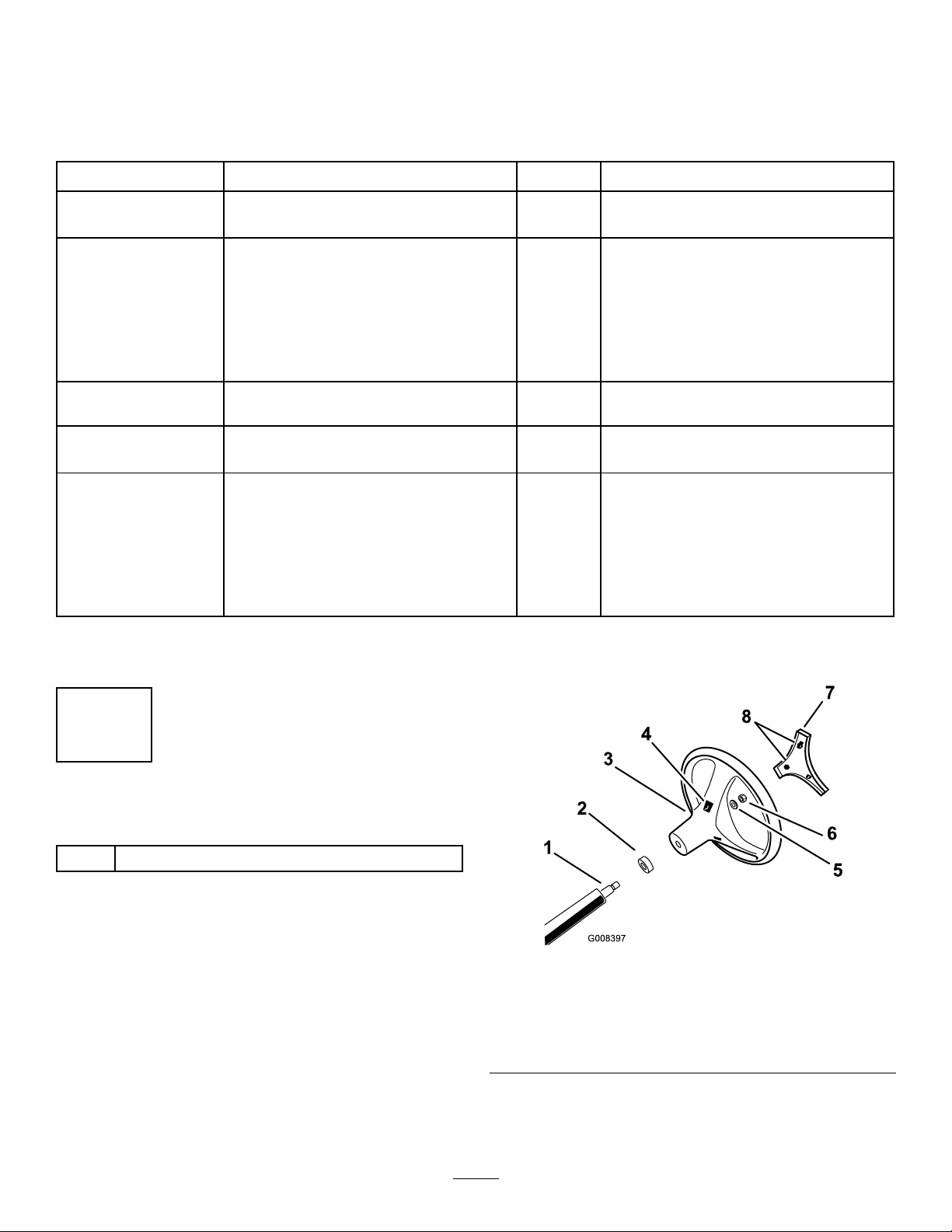

InstallingtheSteeringWheel

Partsneededforthisprocedure:

1

Steeringwheel

Procedure

Note:ThisprocedureisonlyneededforModelNo.

07299TC.

1.Releasethetabsonthebackofthesteeringwheelthat

holdthecentercoverinplace,andremovethecover.

2.Removethenutandwasherfromthesteeringshaft.

3.Slidethesteeringwheelandwasherontotheshaft.

4.Positionthesteeringwheelontheshaft,sothatthe

crossbeamishorizontalwhenthetiresarepointed

straightaheadandthethickerspokeofthesteering

wheelisdownward.

5.Securethesteeringwheeltotheshaftwiththenut

(Figure3).

Figure3

1.Steeringshaft

2.Dustcover6.Nut

3.Steeringwheel7.Cover

4.Tabslotsinthewheel8.Tabsinthecover

6.Torquethenutto24to29N-m(18to22ft-lbs).

7.Snapthecentercoverintoplace.

5.Washer

11

Page 12

2

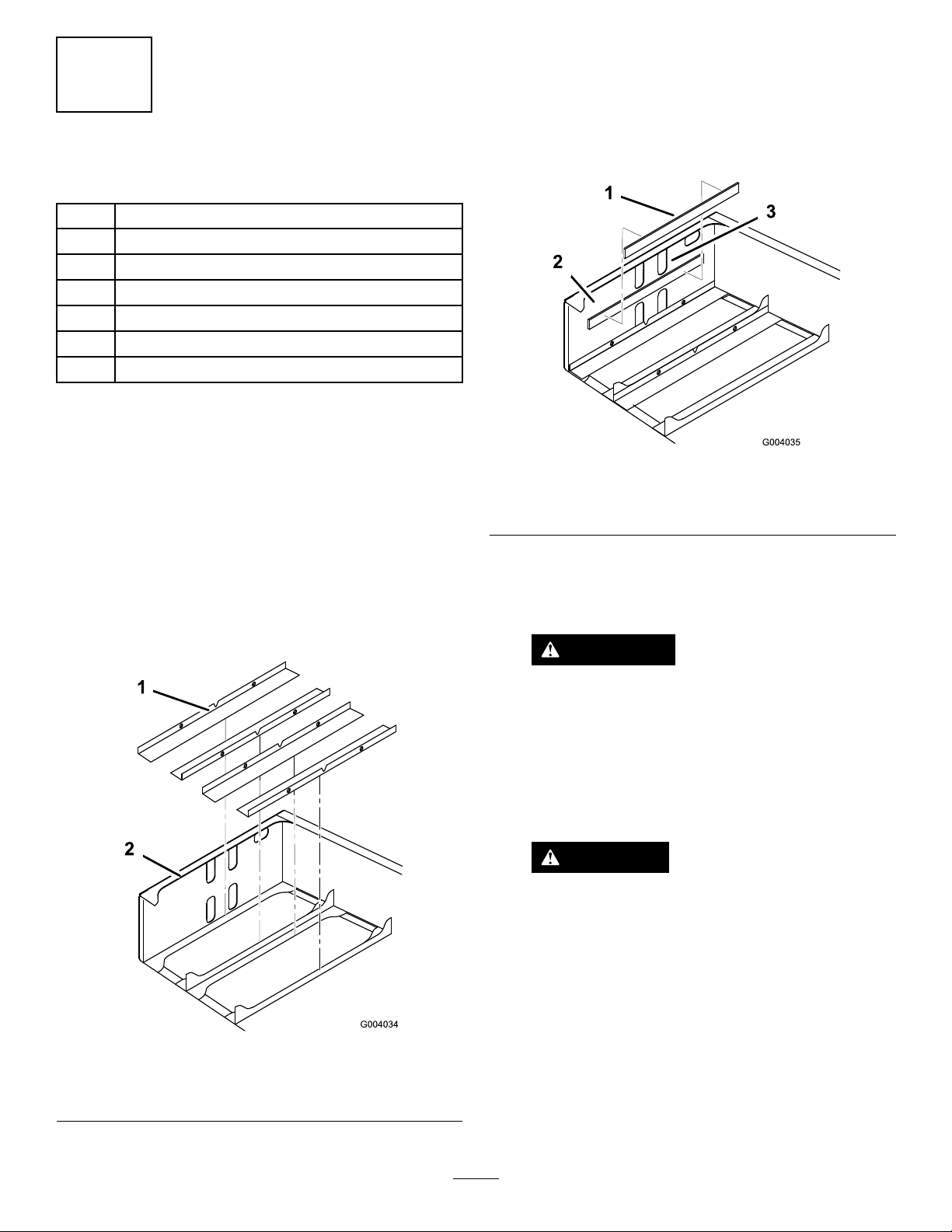

InstallingtheBatteries

Partsneededforthisprocedure:

2Batteryholddown

2Batteryhold-downrod

7

Batterycables

4Battery-traypads

1Batterypad

2

Flangenut(3/8inch)

1Battery-terminal-protectorspray

Procedure

3.Removetheadhesivestripfromthebackofthebattery

padandinstallitontothefrontinsidefaceoftherear

frame(Figure5).

Note:Thepadshouldbeapproximately6mm(1/4

inch)belowthebottomedgeoftheuppersetofcutout

holes(Figure5).

UseeitherTrojanT105orT145,orUSBatteryUS2200or

US145.

BatterySpecication:6V225AH@20hrrate

Dimensions:(LxWxH)26.4x18.1x26.5cm(10-3/8x

7-1/8x10-7/16inches)

1.TurnthekeyswitchtotheOffpositionandremove

thekey.

2.Installthebattery-traypadsintotherear-frame

assembly(Figure4).

Figure5

1.Batterypad3.Uppercutoutholes

2.Frontinsideface

4.Installthebatteries(Figure6).

Note:Payattentiontothebatterypolaritywhen

installingthenewbatteries(Figure6).

WARNING

Incorrectbatterycableroutingcoulddamage

themachineandcables,causingsparks.

Sparkscancausethebatterygassesto

explode,resultinginpersonalinjury.

Alwaysensurethebatterypolaritywhen

makingconnections.

CAUTION

Batteriescangiveyouapowerfulelectrical

shock.

1.Battery-traypads

2.Rear-frameassembly

•Usetoolswithplastichandlesorwrapthe

handlesofmetaltoolswithelectricaltape.

•Becarefulnottocontactbothapositive

terminalandanegativeterminalatthe

sametime.

Figure4

12

Page 13

3

CheckingtheTirePressure

NoPartsRequired

Procedure

Checkthetirepressureevery8hoursordailytoensure

properlevels.

Theairpressurerangeinthefrontandreartiresis55to152

kPa(8to22psi).

Figure6

5.Installthebatteryretainersandtorquethenutsto17to

22N-m(150to200in-lbs).

6.Connectthebatteriestogetherwiththebatterycables

includedinlooseparts(Figure6).

Important:Checkallhigh-currentbattery

connectionstoensurethattheyhavebeenproperly

secured.

Note:Ensurethatthecableroutingdoesnotallow

cablestocontactanysharpedges.

7.Tightentheboltandsecuretheothersideoftheclip

withanewbolt(5/16x3/4inch)andaangenut

(5/16inch)(Figure6).

8.Connectthelong,red,mainpositiveleadbetweenthe

bankofbatteriesandthemachine(Figure6).

9.Connectthelong,black,mainnegativeleadbetween

thebankofbatteriesandthemachine(Figure6).

Theairpressureneededisdeterminedbythepayloadcarried.

Lowerairpressurewillprovidelesscompaction,asmoother

ride,andfewertiremarks.Lowerpressureshouldnotbeused

forheavypayloadsathighspeeds.

Higherpressuresshouldbeusedforheavierpayloadsandat

higherspeeds.Donotexceedthemaximumpressure.

WARNING

Looseorimproperlysecuredbattery

connectionscoulddamagethemachineand

cables,causingsparks.Sparkscancause

thebatterygassestoexplode,resultingin

personalinjury.

Alwaysensurethebatterypolaritywhen

makingconnections.

10.Torquethenutssecuringallbatterycablesto13.5to21

N-m(120to180in-lbs).

11.CoatthebatteryterminalswithTorobattery-terminal

protector.

12.Ensurethattherubbercoversoneachbatterycableare

securelyseatedoverthebatteryterminals.

13

Page 14

4

220

200

100

120

G005241

5

SettingtheChargerVoltage (model07299TConly)

NoPartsRequired

Procedure

Important:Theincorrectvoltagesettingonthebattery

chargercanimpairfunctionanddamagethecharger.

Alwaysmakesurethatthechargervoltagesettingmatchesthe

voltageusedtopowerthecharger.

1.Locatethevoltageselectorontherearofthecharger

(Figure7).

2.Adjustthevoltagesettingbymovingtheswitchonthe

voltageselectorupwardordownwardtochangethe

voltagesetting(Figure7).

ReadingtheManualand ViewingtheSafetyVideo

Partsneededforthisprocedure:

1

Operator'sManual

1

PartsCatalog

1

Safetytrainingmaterial

1Registrationcard

1PredeliveryInspectionForm

1

CerticateofQuality

2Key

Procedure

•ReadtheOperator'sManual.

•Viewthesafetytrainingmaterial.

•Fillouttheregistrationcard.

•CompletethePre-deliveryInspectionForm.

Figure7

1.Voltageselector

2.Voltage-settingwindow4.Voltagesbyswitchposition

Note:Alwaysusetheappropriatepowercordforthepower

outletofthecountryorregionwherechargingwilloccur.

ContactyourAuthorizedToroDealertoobtainthecorrect

powercordifnecessary.

3.Switch

14

Page 15

ProductOverview

G015455

1

2

3

4

5

6

Figure8

1.Hoodstrap

2.Parkingbrake

Controls

Figure9

1.Brakepedal5.Passengerhandhold

2.Parkingbrake/center

console

3.Steeringwheel

4.Cupholder

6.Operator'sManualtube

7.Acceleratorpedal

3.Cargobox5.Chargingreceptacle

4.Cargoboxreleaselever

enginerpmandgroundspeed.Releasingthepedaldecreases

theenginespeedandgroundspeedofthemachine.

6.Towingtongue

BrakePedal

Thebrakepedalisusedtoapplyservicebrakestostopor

slowthemachine(Figure9).

CAUTION

Brakescanbecomewornorcanbeincorrectly

adjustedresultinginpersonalinjury.

Ifthebrakepedaltravelstowithin25mm(1inch)

ofthemachineoorboard,thebrakesmustbe

adjustedorrepaired.

ParkingBrake

Theparkingbrakeisbetweentheseats(Figure9).Whenever

youshutoffthemachine,settheparkingbraketoprevent

themachinefromaccidentalmovement.Tosettheparking

brake,pullbackthelever.Toreleasetheparkingbrake,push

theleverforward.Ifthemachineisparkedonasteepgrade,

makesurethatyousettheparkingbrake.

AcceleratorPedal

Theacceleratorpedal(Figure9)givestheoperatortheability

tovarytheengineandgroundspeedofthemachinewhen

thetransmissionisingear.Pressingthepedalincreasesthe

On/OffSwitch

TheOn/Offswitch(Figure10),usedtoactivatetheelectrical

systemsofthemachine,has2positions:OnandOff.Rotate

15

Page 16

thekeyclockwisetotheOnpositiontooperatethemachine

G009236

1

andaccessories.Afterstoppingthemachine,rotatethekey

counterclockwisetotheOffposition.Removethekeywhen

leavingthemachine.

Figure10

1.On/Offswitch

2.Hornbutton(TCModels

only)

3.Lightswitch

4.Battery/hourmeter

5.Machine-statuslight

6.Power-cargo-bedswitch

(optional)

7.Rearliftswitch(optional)

8.Machine-directionswitch

Machine-statusLight

Themachinecontainsacomputerthatmonitorsthestateof

themachineelectricalsystems.Thiscomputercommunicates

thestatusofthemachinetoyouthroughthemachine-status

light.AlwayscheckthislightwhenyouturntheOn/Off

switchtotheOnposition(Figure14)Whenthereareno

problemsandthemachineisoperational,thelightison.

Whenthereisaproblem,thelightashes.Thelightashes

atvariousintervalsfordifferentproblemsandevents.Ifthe

lightblinks,refertoUnderstandingandUsingtheBattery

System(page18)foradescriptionoftheashcodes.

LightSwitch

Usethisswitchtoturntheheadlightsonandoff(Figure10).

CargoBedLiftSwitch(Optional)

Usethisswitchtoraiseandlowerthecargobed(Figure10).

RearLiftSwitch(Optional)

HornButton(TCModelsonly)

Pressthehornbuttontosoundthehorn(Figure10).

Battery-dischargeIndicator

Thebattery/hourmeterprovidesyouwithanindicationof

howmuchchargeiscontainedinthebatteries(Figure10

andFigure14)andthenumberofoperatinghoursonthe

machine.ThebatterymeterislocatedatthetopoftheLCD

screen.Whenthemachinebatteriesarefullycharged,ten

barsextendfromthe0tothe1position.Asthechargeis

used,barsdisappearstartingontherightside.Fordetailed

informationonthebatterymeter,refertoUnderstandingand

UsingtheBatterySystem(page18).

ThehourmeterislocatedatthebottomoftheLCDscreen.

ItlogsoperatinghourswheneverthekeyisintheOnposition

andthemachineisinmotion.

Machine-directionSwitch

Usethisswitch(Figure10)totogglebetweenforwardand

reverseoperation.

Usethisswitchtoraiseandlowertherearlift(Figure10).

SupervisorSpeed-limitSwitch

Thesupervisorspeed-limitswitch,locatedunderthecup

holder(Figure11)has2positions:OnandOff.Rotatethe

keyclockwisetotheOnpositiontolimitthemaximum

machinespeedtoafactorysettingof19kph(12mph).Rotate

thekeycounterclockwisetotheOffpositiontorestorethe

maximumspeedofthemachine.

Figure11

Note:Ifthemachine-directionalswitchismovedtothe

ReversepositionwhentheOn/OffswitchisintheOn

position,abuzzerwillsoundtowarntheoperatorthatthe

machineissettomoveinthereversedirection.

1.Supervisorspeed-limitswitch

16

Page 17

PassengerHandHolds

G009193

1

2

Thepassengerhandholdsarelocatedontherightsideofthe

dashpanelandattheoutsideofeachseat(Figure12).

1.Hiprestraint2.Passengerhandhold

Specications

Note:Specicationsanddesignaresubjecttochangewithoutnotice.

Figure12

Baseweight

BaseweightwithoutBatteries

Ratedcapacity

(onlevelground)

Maximumgrossmachine

weight(GMW)(onlevelground)

Maximumcargocapacity(on

levelground)

Towcapacity:

StandardhitchTongueweight23kg(50lbs),Maximumtrailerweight182kg(400lbs)

Heavy-dutyhitch

Overallwidth150cm(59inches)

Overalllength304cm(120inches)

Groundclearance

Wheelbase

Wheeltread

(centerlinetocenterline)

Cargoboxlength117cm(46inches)inside,133cm(52inches)outside

Cargoboxwidth125cm(49inches)inside,150cm(59inches)attheoutsideofthemoldedfenders

Cargoboxheight

726kg(1600lbs)

765kg(1025lbs)

545kg(1200lbs)total—includinga90.7kg(200lbs)operatoranda90.7kg(200lbs)passenger ,

load,trailertongueweight,grosstrailerweight,accessories,andattachments

1270kg(2800lbs)total—includingalloftheweightslistedabove

362kg(800lbs)*total—includingtrailertongueweightandgrosstrailerweight

Tongueweight45kg(100lbs),Maximumtrailerweight363kg(800lbs)

25cm(10inches)atthefrontwithnoloadoroperator,18cm(7inches)attherearwithno

loadoroperator

211cm(83inches)

125cm(49inches)inthefront,1 18cm(46inches)intherear

25cm(10inches)inside

*SpecicationslistedarewithTrojanT145batteries.

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesisavailableforusewiththemachinetoenhanceandexpand

itscapabilities.ContactyourAuthorizedServiceDealerorDistributororgotowww.Toro.comforalistofallapproved

attachmentsandaccessories.

17

Page 18

Operation

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

ThinkSafetyFirst

Pleasecarefullyreadallofthesafetyinstructionsanddecals

inthesafetysection.Knowingthisinformationcouldhelp

youorbystandersavoidinjury.

PreformingPre-starting Checks

OperatingtheMachine

1.Disconnectthebatterycharger.

2.Sitintheoperator'sseat,insertthekeyintotheOn/Off

switch,androtatethekeyclockwisetotheOnposition.

3.Movethemachine-directionswitchtothedesired

position.

Note:Ifyoumovethedirectionalswitchtothe

ReversepositionwhiletheOn/OffswitchisintheOn

position,abuzzersoundstowarnyouthatthemachine

issettomoveinthereversedirection.

4.Releasetheparkingbrake.

5.Slowlystepontheacceleratorpedaltodrivethe

machine.

Checkthefollowingitemseachtimeyoubeginusingthe

machinefortheday:

•Checkthetirepressure.

•Checkthebrakepedaloperation.

•Checktoseethatthelightsareworking.

•Turnthesteeringwheeltotheleftandrighttocheck

steeringresponse.

•Checkforloosepartsandanyothernoticeable

malfunctions.Makesurethatthemachineisoffandall

movingpartshavestoppedbeforecheckingforloose

partsandothermalfunctions.

Ifanyoftheaboveitemsarenotcorrect,notifyyourmechanic

orcheckwithyoursupervisorbeforetakingthemachineout

fortheday.Yoursupervisormaywantyoutocheckother

itemsonadailybasis,soaskwhatyourresponsibilitiesare.

CheckingtheTirePressure

ServiceInterval:Beforeeachuseordaily

Checkthetirepressureevery8hoursordailytoensure

properlevels.

Theair-pressurerangeinthefrontandreartiresis55to

103kPa(8to22psi).

Note:Inatingthetiresatalowerpressurereduces

compaction,createsasmootherride,andminimizestire

marks.Donotinatethetiresatalowerpressurewhen

operatingthemachinewithheavypayloadsathighspeeds.

Inatethetiresathigherpressureswhenoperatingthe

machinewithheavierpayloadsathighspeeds.

StoppingtheMachine

Important:Whenstoppingthemachineonanincline,

usethebraketostopthemachine,andtheparking

braketoholditinplace.Usingtheacceleratortostall

themachinecandamagethemachine.

Tostopthemachine,removeyourfootfromtheaccelerator

pedalandslowlypressthebrakepedal.

Note:Thestoppingdistancemayvarydependingonthe

machineloadandspeed.

ParkingtheMachine

1.SettheparkingbrakeandrotatetheOn/Offkeyto

theOffpositon.

2.Removethekeyfromtheswitchtopreventaccidental

starting.

UnderstandingandUsingthe BatterySystem

UnderstandingDeep-cycleBatteries

Themachinecontains8deepcycle,lead-acidbatterieswhich

supplypowertothemotorandaccessories.Adeep-cycle

batteryisnotthesameasanautomobilebattery.An

automobilebatteryisdesignedtoprovideasurgeofpowerto

startthemachineandmoderatepowertorunthelightsand

accessorieswhenthemotorifofforidling.Thealternator

thencontinuouslychargesastheautomobileruns.Assuch,

anautomobilebatteryseldomdropsbelow90%ofthe

maximumchargelevel.

Adeep-cyclebatteryisdesignedtobeaprimarypower

sourcetoprovideasustainedoutput.Deep-cyclebatteriesare

typicallydischargedaslowas20to30%ofthemaximum

chargelevel.Adischargethislowisconsideredadeep

discharge.

Lead-acidbatteriesproduceelectricitythroughachemical

reactionbetweencoatedleadplatesandsulfuricacid.

18

Page 19

Chargingabatteryreversesthechemicalreaction,allowing

thebatterytoonceagainproduceelectricity.

Abatteryisaperishableitemthathasalimitedlifetime

(Figure13).Whenabatteryisnew ,itrequiresabreak-in

periodtoestablishefcientelectricalproduction.Thisbreak

inperiodusuallyrequires20to50discharge/chargecycles.

UsingtheBatterySystem

Whenyourbatteriesarefullycharged,thebatterymeterwill

have10barsshowingfromlefttoright(Figure14).

Figure13

Battery-lifetimetable

1.Batterycapacity

2.Discharge/chargecycles5.Endofthebatterylife

3.Break-inperiod(20to50

cycles)

4.Primebatterylife

Afterthebreak-inperiod,thebatterywillmaintainahigh

capacityformanycycles.Thenumberofcyclesabatterywill

performisdependantonthefollowing:

•Batterymaintenance—impropermaintenancewill

severelyreducethelifeofthebatteries.

•Depthofdischargebetweenchargecycles—thedeeper

thebatteriesaredischargedonaregularbasis

betweencharges,thelesslifetheywillhave.

•Chargefrequency—chargethebatterieswheneverthey

arenotinuse.Fullydischargingthebatterieswill

damagethemandreducetheirlife.

Attheendofthebatterylife,thecoatingontheleadplates

beginstodeteriorate,causingthebatteriestorapidlylose

electriccapacity.

Figure14

1.Battery/hourmeter2.Charge-indicatorbars

Asyouusethemachine,thebarswilldisappearasthe

electricalcapacityofthebatteriesisused.

Whenonly2barsareleft,theredwarninglightonthemeter

willilluminate,andthebatteryiconwillbeginashingonthe

screen(Figure15).Thisindicatesthatthebatterycapacityis

nearlydrainedandyoushouldchargethebatteriesassoonas

possibletopreventbatterydamage.

Figure15

1.Batteryicon

2.Warninglight—On

Whenonlyonebarisleft,thewarninglightwillash,andthe

machinewillgointoanenergy-savingmode(Figure16).In

thismode,themachinewillonlydriveat3mph.Chargethe

batteriesimmediatelytopreventseriousdamagetothem.

Ifthebatteriesbecomefullydischarged,themachinewill

shutdown.Donotallowthebatteriestobecomefully

discharged.

Important:Toobtainmaximumbatterylife,always

chargethebatterieswhenthereare2ormorebarsvisible

onthescreen.Depletingthebatteriestolowerthan2

19

Page 20

bars,especiallyonaregularbasis,willreducethelife

g014860

1

2

3

ofthebatteries.

Figure16

1.Batteryicon

2.Warninglight—ashing

Figure17

1.Latchlever3.Detentslot

2.Proprod

OperatingtheCargoBox

RaisingtheCargoBox

WARNING

Drivingthemachinewiththecargoboxraisedmay

causethemachinetotiporrolleasier.Thebox

structuremaybecomedamagedifyouoperatethe

machinewiththeboxraised.

•Onlyoperatethemachinewhenthecargobox

isdown.

•Afteremptyingthecargobox,lowerit.

CAUTION

Ifaloadisconcentratednearthebackofthecargo

boxwhenyoureleasethelatches,theboxmay

unexpectedlytipopeninjuringyouorbystanders.

•Centerloadsinthecargoboxifpossible.

•Holdthecargoboxdownandensurethatno

oneisleaningovertheboxorstandingbehindit

whenreleasingthelatches.

LoweringtheCargoBox

WARNING

Theweightoftheboxmaybeheavy.Handsor

otherbodypartscouldbecrushed.

Keephandsandotherbodypartsclearwhen

loweringthebox.

1.Raisethecargoboxslightlybyliftinguponthelatch

lever(Figure17).

2.Pulltheproprodoutofthedetentslot(Figure17).

3.Lowertheboxuntilitlatchesintosecurely(Figure17).

•Removeallcargofromtheboxbeforeliftingthe

boxuptoservicethemachine.

1.Liftthelatchleverthatisattheeithersidenearthe

forwardcornerofthecargobox,andlifttheboxup

(Figure17).

2.Securethecargoboxbypullingtheproprodintothe

reardetentatendoftheslotthatisintheleftframeof

themachine(Figure17).

20

Page 21

OpeningtheTailgate

1.Ensurethatthecargoboxisdownandlatched.

2.Liftuponthengerpullsatthebackpanelofthetail

gate(Figure18).

Figure18

1.Tailgateange(cargobox)3.Liftup(ngerpull)

2.Lockange(tailgate)

4.Rotaterearwardanddown

Figure19

3.Usingashort,shakingmotiontorotatethetailgate

backandforthseveraltimes(Figure19).

Note:Thisactionwillhelpmovematerialawayfrom

thehingearea

4.Lowerthetailgateandcheckthehingeareasfor

remainingmaterialthatisinthehingearea.

5.Repeatsteps1through4untilthematerialisremoved

fromthehingearea.

6.Rotatethetailgateupandforwarduntilthelockanges

ofthetailgateareushwiththetailgatepocketinthe

cargobox(Figure18).

Note:Raiseorlowerthetailgateinordertoalignthe

lockangesofthetailgatewiththeverticalopenings

betweenthetailgateangesofthecargobox.

3.Alignthelockangesofthetailgatewiththeopenings

betweenthetailgateangesofthecargobox(Figure

18).

4.Rotatethetailgaterearwardanddown(Figure18).

ClosingtheTailgate

Ifyouunloadedloosematerialsuchassand,landscapingrock,

orwoodchipsfromthecargoboxofthemachine,somethe

materialthatyouunloadedmayhavelodgedinthehinge

areaofthetailgate.Performthefollowingbeforeclosingthe

tailgate.

1.Useyourhandstoremoveasmuchofthematerial

fromthehingeareaaspossible.

2.Rotatethetailgatetoapproximately45°position

(Figure19).

7.Lowerthetailgateuntilitisseatedinthebackofthe

cargobox(Figure18).

Note:Thelockangesofthetailgatewillbefully

securedbythetailgateangesofthecargobox.

LoadingtheCargoBox

Maximumcargobox

capacity(onlevel

3

3

3

3

3

(13ft3).The

ground)

1/2Full

1/3Full

1/2Full

1/3Full

Thecapacityofthecargoboxis0.37m

amount(volume)ofmaterialthatcanbeplacedinthebox

withoutexceedingthemachine-loadratingscanvarygreatly

dependingonthedensityofthematerial.Forexample,a

levelboxofwetsandweighs680kg(1500lbs),whichgreatly

exceedstheloadrating.

Seethetablebelowforloadvolumelimitswithvarious

materials:

MaterialDensity

Gravel,dry1522kg/m

Gravel,wet1922kg/m

Sand,dry1442kg/m

Sand,wet1922kg/m

3

(95lb/ft

(120lb/ft

(90lb/ft

(120lb/ft

)

3

)

3

)

3

)

21

Page 22

Wood

Bark

Earth,packed

721kg/m

(45lb/ft

721kg/m

(45lb/ft

1602kg/m

(100lb/ft

3

3

)

3

3

)

3

3

)

Full

Full

1/2Full

AdjustingtheBoxLatches

Iftheboxlatchdoesnotlatchtightly,vibratingupanddown

asyoudrivethemachine,youcanadjustthelatchpoststo

makethelatchestsnugly.

1.Loosenthenutontheendofthelatchpost(Figure20).

CAUTION

Looseseatsmayfalloffofthevehicleandtrailer

whentransportingthemachine,andtheseatsmay

landonanothervehicleorobstructtheroadway.

Removetheseatsormakesurethattheseatsare

securelyfastenedtothecouplingintheseatshroud.

Figure21

1.Tie-downpoints

TowingtheMachine

Incaseofanemergency ,themachinecanbetowedfora

shortdistance.However,wedonotrecommendthisasa

standardprocedure.

Figure20

1.Latch3.Latchpost

2.Nut

2.Turnthelatchpostclockwiseuntilitissnugagainstthe

latchandthentightenthenut(Figure20).

3.Repeatthisprocedureforthelatchontheotherside

ofthemachine.

BreakinginaNewMachine

ServiceInterval:Aftertherst100hours

•Avoidhard-brakingsituationsfortherstseveralhoursof

newmachinebreak-inoperation.Newbrakeliningsmay

notbeatoptimumperformanceuntilseveralhoursofuse

hascausedthebrakestobecomeburnished(broken-in).

•RefertoMaintenance(page24)foranyspeciallow-hour

checks.

•Checkthefrontsuspensionpositioningandadjustitif

necessary.

WARNING

Towingatexcessivespeedscouldcausealossof

steeringcontrol,resultinginpersonalinjury.

Nevertowthemachineatfasterthan8km/h

(5mph).

Towingthemachineisa2-personjob.Ifthemachinemust

bemovedaconsiderabledistance,transportitonatruckor

trailer;refertoTransportingtheMachine(page22).

1.TurnofftheOn/Offswitchandremovethekey.

Important:Ifyoutowthemachinewiththekey

intheOnposition,theelectricalsystemmaybe

damaged.

2.Afxatowlinetothetongueonthefrontoftheframe

(Figure22).

3.Releasetheparkingbrake.

TransportingtheMachine

Formovingthemachinelongdistances,atrailershouldbe

used.Makesurethatthemachineissecuredtothetrailer.

RefertoFigure21andFigure22forthelocationofthe

tie-downpoints.

Figure22

1.Towingtongueandtie-downpoint

22

Page 23

TowingaMachine

Themachineiscapableofpullingtrailers.2typesoftow

hitchesareavailableforthemachine,dependingonyour

application.ContactyourAuthorizedToroDistributorfor

details.

Whenhaulingcargoortowingatrailer,donotoverloadyour

machineortrailer.Overloadingcancausepoorperformance

ordamagetothebrakes,axle,motor,transaxle,steering,

suspension,bodystructure,ortires.Alwaysloadatrailerwith

60%ofthecargoweightinthefrontofthetrailer.Thisplaces

approximately10%oftheGrossTrailerWeight(GTW)on

thetowhitchofthemachine.

Themaximumcargoloadshallnotexceed362kg(800lb),

includingtheGTW .Forexample,iftheGTWis90kg(200

lb)thenthemaximumcargoloadis272kg(600lb).

Toprovideadequatebrakingandtraction,alwaysloadthe

cargoboxwhentrailering.DonotexceedtheGTWorGVW

limits.

Avoidparkingamachinewithatraileronahill.Ifyoumust

parkonahill,settheparkingbrakeandblockthetrailertires.

23

Page 24

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst100hours

Beforeeachuseordaily

Every25hours

Every100hours

Every200hours

Every800hours

DailyMaintenanceChecklist

Duplicatethispageforroutineuse.

Fortheweekof: MaintenanceCheckItem

MondayTuesdayWednesdayThursdayFriday

Checkthebrakeand

parkingbrakeandadjust

asneeded.

Checkunusualoperating

noises.

Checkthetirepressure.

Checkforuidleaks.

Checktheinstrument

operation.

Checktheaccelerator

operation.

Lubricateallgrease

ttings.

Touchupanydamaged

paint.

MaintenanceProcedure

•Performtheguidelinesforbreakinginanewmachineguidelines.

•Checkthetirepressure.

•Chargethebatteries.

•Checkthebrake-uidlevel.

•Cleanthebatteries.

•Checkthebatteryelectrolytelevel.

•Greasethebearingsandbushings.

•Inspecttheconditionandwearofthetires.

•T orquethewheellugnuts.

•Checkthefrontwheeltoe-inandcamber.

•Checkthetransaxle-oillevel.

•Inspectthebrakes.

•Adjusttheparkingbrakeifneeded.

•Changethetransaxleoil.

SaturdaySunday

WARNING

Thebedmustberaisedtoperformsomeroutinemaintenance.

Araisedbedcanfallandinjurepersonsthatareunderneathit.

•Alwaysusetheproprodtoholdthebedupbeforeworkingunderit.

•Removeanyloadmaterialfromthebedbeforeworkingunderit.

24

Page 25

CAUTION

IfyouleavethekeyintheOn/Offswitch,someonecouldaccidentlystartthemachineandseriously

injureyouorotherbystanders.

RemovethekeyfromtheOn/Offswitchanddisconnectabatterycablebeforeyoudoanymaintenance.

Premaintenance

Procedures

MaintainingtheMachineunder SpecialOperatingConditions

Ifthemachineissubjectedtoanyoftheconditionslisted

below,maintenanceshouldbeperformedtwiceasfrequently.

•Desertoperation

•Coldclimateoperation—below10°C(50°F)

•Trailertowing

•Afterextendedoperationinmud,sand,water,orsimilar

dirtyconditions,haveyourbrakesinspectedandcleaned

assoonaspossible.Thiswillpreventanyabrasive

materialfromcausingexcessivewear.

1.Frontjackingpoint

Figure23

Figure24

LiftingtheMachine

Wheneverthemachineisrunforroutinemaintenanceand/or

motordiagnostics,therearwheelsofthemachineshouldbe

25mm(1inch)offthegroundwiththerearaxlesupported

onjackstands.

DANGER

Themachinemaybeunstablewhenusingajack.It

couldslipoffthejack,injuringanyonebeneathit.

•Donotstartthemachinewhilethemachineis

onajack.

•AlwaysremovethekeyfromtheOn/Offswitch

beforegettingoffofthemachine.

•Blockthetireswhenthemachineisonajack.

Thejackingpointatthefrontofthemachineisonthefront

oftheframebehindthetowingtongue(Figure23).

Thejackingpointattherearofthemachineisundertheaxle

tubes(Figure24).

1.Rearjackingpoints

25

Page 26

AccessingtheHood

1.Releasetherubberstrapsonbothsidesofthehood

(Figure25).

Figure25

Lubrication

Lubricateallofthebearingsandbushingsevery100hours

oronceayear,whicheveroccursrst.Greasethemmore

frequentlywhenusingthemachineforheavy-dutyoperations.

GreaseType:Number2GeneralPurposeLithium-Base

Grease

AddingGrease

ServiceInterval:Every100hours

1.Wipethegreasettingcleansoforeignmattercannot

beforcedintothebearingorthebushing.

2.Pumpgreaseintothebearingorbushing.

3.Wipeoffanyexcessgrease.

Thegreasettingsarelocatedatthe4tie-rodends(Figure

26)andthe2kingpins(Figure27).

2.Raisethehood.

3.Lowerthehoodtocloseanduserubberretaining

strapstosecurethehood.

1.Greasetting

Figure26

Leftsideshown

2.Tierod

Figure27

26

Page 27

ElectricalSystem

Maintenance

MaintainingtheBatteries

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

Washhandsafterhandling.

ChargingtheBatteries

ServiceInterval:Beforeeachuseordaily

Achargerissuppliedwiththemachine.Alwayskeepthe

chargerinadrylocation.Formaximumbatterylife,charge

thebatterieswheneveryouarenotusingthemachine.

Dependingonhowdischargedthebatteriesare,itmaytake

upto16hourstochargethebatteriestofullcapacity .

Important:Lead-acidbatteriesdonotdevelopa

chargememoryanddonotneedtobefullydischarged

beforechargingthem.

may dama ge them.

machineisnotinuse.

Full y discharging the batteries

Chargethebatteriesanytimethe

WARNING

Chargingthebatteryproducesgassesthatcan

explode.

WARNING

Batteryterminalsormetaltoolscouldshortagainst

metalcomponentscausingsparks.Sparkscan

causethebatterygassestoexplode,resultingin

personalinjury.

•Whenremovingorinstallingthebattery,donot

allowthebatteryterminalstotouchanymetal

partsofthemachine.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsofthe

machine.

•Alwayskeepthebatteryretainersinplaceto

protectandsecurethebatteries.

CleaningtheBatteries

ServiceInterval:Every25hours

1.Ensurethatallofthebatterycapsaretight.

2.Useapapertoweltocleanthebatteries.

3.Ifthebatteryterminalsarecorroded,cleanthemwith

asolutionof4partswaterandonepartbakingsoda.

Also,cleanthepostsandcableclampswithapostand

clampcleaner.

Note:Thepostsandclampsshouldhaveabright

metallicshine.

4.ApplyalightcoatingofTorobattery-terminal

protector.

Neversmokenearthebatteriesandkeepsparks

andamesawayfromthem.

1.Positionthemachineinawell-ventilatedareaneara

suitablepoweroutlet.

2.Connectthechargercordtothechargingreceptacleon

themachine(locatedonthepanelbetweentheseats).

Note:Ensurethatthechargervoltagesettingmatches

thevoltageatthepoweroutletbeingused.

3.Plugthechargerpowercordintothepoweroutlet.

Note:Whilethebatteriesarecharging,thegreenlight

onthechargerwillblinkonandoff.Whenthebatteries

arefullycharged,thegreenlightstopsblinkingand

stayson.

4.Disconnectthecordfromthepoweroutlet.

5.Disconnectthechargerfromthemachine.

Important:Donotcarrythechargeronthemachine.

Excessiveorprolongedjarringmaydamageit.

AddingWatertotheBatteries

ServiceInterval:Every25hours/Monthly(whichever

comesrst)

Useonlyclean,distilledwatertollthebatteries.

1.Raisethecargobed,turnthekeyoff,andremoveit.

2.Removethellercapsfromeachbattery.

3.Iftheelectrolyteisnotoverthetopoftheplatesin

eachbatterycell,addjustenoughdistilledwaterto

covertheplates.

4.Replacethellercapsonallbatteries.

5.Chargethebatteriesuntilafullchargeisachieved;refer

toChargingtheBatteries(page27).

6.Oncethebatteriesarefullycharged,removetheller

capsfromeachbattery.

27

Page 28

7.Addjustenoughdistilledwatertobringtheelectrolyte

levelto3mm(1/8inch)belowthebottomofeach

llwell(Figure28).

Figure28

Figure29

1.Batteryplates3.Electrolytelevel

2.Fillercap4.Batteryterminal

Important:Donotoverllthebattery.Electrolyte

willoverowontootherpartsofthemachineand

severecorrosionanddeteriorationmayresult.

Also,overllingthebatterywillreducethelifeof

thebattery.

8.Replacethellercapsonallbatteries.

ReplacingUsedBatteries

Whenthemachinebeginstoshowalossofrangeorwhenthe

lengthofthedischarge/chargecycleissignicantlyreduced,

thebatteriesareprobablygettingoldandlosingtheirability

toholdacharge.TakethemachinetoanAuthorizedService

Dealerandhavethemtestthebatteriestodeterminewhether

thebatteriesneedtobereplaced.Thedealercanthenreplace

thebatteriesforyou.Ifyouwishtoreplacethebatteries

yourself,usethefollowingprocedure:

1.Raisethecargobed,turnthekeyoff,andremoveit.

2.Disconnectthelong,black,mainnegativeleadrunning

fromthebankofbatteriestothemachinefromthe

batterypost(Figure29).

3.Removethelong,red,mainpositiveleadrunningfrom

thebankofbatteriestothemachinefromthebattery

post(Figure29).

4.Disconnectallofthebatteryleadsfromthebatteries.

5.Removethebatteryretainerslocatedbetweenthe

batteries.

6.Removeallofthebatteriesandrecyclethemaccording

toyourlocalcodes.

7.Installnewbatteriesintheplacesvacatedbytheold

batteries

Note:Payattentiontothebatterypolaritywhen

installingthenewbatteries(Figure29).

8.Installthebatteryretainersandtorquethenutsto17to

22N-m(150to200in-lb).

9.Connectthebatteriestogetherwiththebatterycables

removedpreviously,asshowninFigure29.

10.Connectthelong,red,mainpositiveleadbetweenthe

bankofbatteriesandthemachine(Figure29).

11.Connectthelong,black,mainnegativeleadbetween

thebankofbatteriesandthemachine(Figure29).

12.Torquethenutssecuringallofthebatterycablesto

13.5to21N-m(120to180in-lb).

13.CoatthebatteryterminalswithTorobattery-terminal

protector.

14.Ensurethattherubberbootsoneachbatterycableare

securelyseatedoverthebatteryterminals.

28

Page 29

StoringtheBatteries

G021810

1

2

Chargethebatteriesfullybeforeplacingthemachineinto

storage.Plugthechargerintoawalloutletwhilethemachine

andbatteriesareinstorage.Leavethechargerpluggedintoa

walloutletandchargingreceptacleduringstoragetoensure

thatthebatteriesstaychargedanddonotfreeze;otherwise,

chargethebatteriesatleastonceevery3months.

CAUTION

Anysurfacecontaminationcandamagethe

headlightbulbandleadingtoitsfailureorexplosion

creatingaserioussafetyhazard.

Headlightlampsshouldbehandledwithout

touchingtheclearquartz,eitherbyusingaclean

papertowelorcarefullyholdingthebase.

ReplacingtheFuses

Thereare2fusesintheelectricalsystem.Theyarelocated

beneaththedashonthedriver'sside(Figure30).

Open

PowerPoint10A

LightsandHorn10A

Figure30

1.Machinefuseholder

2.Relay

10A

Specication:SeeyourPartsCatalog.

1.Disconnecttheelectricalharnessfromthebulb

housingonthebackofthelamp.

2.Removetheprotectiverubberboot(Figure31).

Figure31

1.Headlight4.Retainingring

2.Speedclipandatwasher

3.Headlightbulb6.Headlightbulbharness

3.Releasetheplasticretainingringbyturningit1/4turn

counterclockwise.

4.Removethering.

5.Rubberboot

connection

ReplacingtheHeadlights

Beforeperforminganymaintenancesettheparkingbrake,

turntheOn/OffswitchtoOff,andremovethekey.

Releasetheretainingstrapsonthehoodandraisethehoodto

accesstheheadlights.

ReplacingtheBulbs

CAUTION

Thehalogenbulbsbecomeextremelyhotwhenin

operation.Handlingahotbulbcancausesevere

burnsandpersonalinjury.

Alwaysallowenoughtimetoforthebulbstocool

beforereplacingthem.Usecarewheneverhandling

thebulb.

5.Removethebulbassemblybymovingitrearward,out

ofthelamphousing.

6.Installanewbulbintothelamphousing.

Note:Useapapertoweltograspthenewbulbwith

handlingittoavoidcontaminatingthesurface.

7.Securethebulbinplacebyinstallingtheretainingring.

Note:Turnthering1/4turnclockwisetolockitin

place.

8.Installtherubberbootovertheringandbulb.

9.Connectthebulbtotheelectricalharness.

29

Page 30

ReplacingtheHeadlight

Whenremovingorreplacingtheheadlightassembly,

disconnectthewiringharnesstothebulbassemblyifthebulb

istoberemovedwiththelamp.

DriveSystem

Maintenance

1.Removethespeedclipsandwasherssecuringthe

headlightinplace.

Note:Retainalloftheparts.

2.Removetheheadlightassemblybymovingitforward

throughtheopeninginthefrontbumper(Figure31).

3.Installthenewheadlightthroughtheopeninginthe

bumper(Figure31).

4.Ensurethattheadjustmentpostsarelinedupwiththe

holesinthemountingbracketinthebumper.

5.Securetheheadlightassemblywiththewashersand

speedclipsremovedpreviously.

6.Attachtheheadlighttothewireharnessremoved

previously.

7.Adjusttheheadlightstodirectthebeamstothedesired

position.

AdjustingtheHeadlights

Usethefollowingproceduretoadjusttheheadlightbeam

positionwheneveraheadlightassemblyisreplacedor

removed.

1.TurnthekeytotheOnpositionandturnonthe

headlights.

2.Attheheadlightassembly,usethefastenerstopivotthe

headlightassemblyandaffectthecast-beamposition.

InspectingtheTires

ServiceInterval:Every100hours

Every100hours

Checkthetireconditionatleastevery100hoursofoperation.

Operatingaccidents,suchashittingcurbs,candamagea

tireorrimandalsodisruptwheelalignment,soinspecttire

conditionafteranaccident.

Checkthewheelstoensurethattheyaremountedsecurely.

Torquethelugnutsto61to88N-m(45to65ft-lb).

AdjustingtheFrontWheel Toe-inandCamber

ServiceInterval:Every100hours/Yearly(whichevercomes

rst)—Checkthefrontwheeltoe-inand

camber.

Important:Youwillneedtoobtaintoolnumber

TORO6010fromyourToroDistributortoperformthis

procedure.

Thetoe-inshouldbe0to6mm(0to1/4inch)andthe

cambershouldbe0+1/2degree,i.e.,thebottomofthewheel

rimsangledin2.3mm(0.09inch)morethanthetop,withthe

followingparameters:

•Checkthetirepressuretoensurethatthefronttiresare

inatedto82kPa(12psi).

•Either,addweighttothedriver'sseatequaltotheaverage

operatorwhowillrunthemachine,orhaveanoperator

sitontheseat.Theweightoroperatormustremainon

theseatforthedurationoftheprocedure.

•Onalevelsurface,rollthemachinestraightback2to3

m(6to10ft)andthenstraightforwardtotheoriginal

startingposition.Thiswillallowthesuspensiontosettle

intotheoperatingposition.

•Measurethetoe-inwiththewheelsfacingstraightahead.

1.Tocheckthecamber,placea90degreesquareonthe

groundwiththeverticaledgetouchingthefaceofthe

tire(Figure32).

30

Page 31

g014968

1

2

Figure32

G014994

1

2

3

G009235

1

2

3

Left,frontwheelshownfromthefront;theangleis

exaggeratedforillustrativepurposes

1.Measurehere

2.Measurehere—shouldbe2.3mm(0.09inch)largerthan

themeasurementat1

2.Measurefromthesamepartoftherimonthetopand

bottomofthetiretothesquare(Figure32).

Note:Thedistanceofthebottommeasurement

shouldbe2.3mm(0.09inch)largerthanthetop

measurement.Completethemeasurementonboth

fronttiresbeforeadjusting.

Completethefollowingprocedureforeachtirethat

needsadjusting:

3.UsingtoolTORO6010,rotatethecollarontheshock

absorbertochangethelengthofthespring(Figure33).

Figure33

1.Shock-absorberspring3.Springlength

2.Collar

4.Onalevelsurface,rollthemachinestraightback2to3

m(6to10ft)andthenstraightforwardtotheoriginal

startingposition.

5.Repeatthisprocedure,startingwithstep1untilthe

camberissetcorrectlyforbothfrontwheels.

6.Measurethedistancebetweenbothofthefronttiresat

theaxleheightatboththefrontandrearofthefront

tires(Figure34).

•Ifthebottommeasurementwastooshort,reduce

thelengthofthespring.

•Ifthebottommeasurementwastoolong,increase

thelengthofthespring.

1.Tirecenterline—back3.Axlecenterline

2.Tirecenterline—front

7.Ifthemeasurementdoesnotfallwithin0to6mm(0

to1/4inch),loosenthejamnutsatbothendsofthe

tierods(Figure35).

Figure34

31

Page 32

ChangingtheTransaxleOil

ServiceInterval:Every800hours

Oiltype:10W30(SAESJorhigher)

Oilcapacity:1.9L(2USqt)

1.Alignadrainpanunderthedrainplug(Figure36).

Figure35

1.Jamnut2.Tierod

8.Rotatebothtierodstomovethefrontofthetire

inwardoroutward.

9.Tightenthetierodjamnutswhentheadjustmentis

correct.

10.Ensurethatthereisfulltravelofthesteeringwheelin

bothdirections.

CheckingtheTransaxle-oil Level

ServiceInterval:Every100hours

Oiltype:10W30(SAESJorhigher)

1.Parkthemachineonalevelsurface,settheparking

brake,andturnoffandremovethekey .

2.Removethellplugonthetransaxle(Figure36).

2.Removethellplugandtheseal(Figure36).

Note:Retainthellplugandsealforinstallationin

step6.

3.Removethedrainplugandtheseal,andallowtheoilto

draincompletely(Figure36).

Note:Retainthedrainplugandsealforinstallation

instep4.

4.Installthedrainplugandseal,andtorqueitto20to27

N-m(15to20ft-lb).

5.Fillthetransaxlewiththespeciedoiluntilitrunsout

ofthellhole.

6.Installthellplugandseal,andtorqueitto20to27

N-m(15to20ft-lb).

Note:Theoillevelshouldbeevenwiththebottom

ofthellplug.

Figure36

1.Fillplug2.Drainplug

3.Iftheoillevelislow,removethellplugandaddthe

speciedoiluntilitrunsoutofthehole(Figure36).

4.Replacethellplugandtorqueitto20to27N-m(15

to20ft-lb).

32

Page 33

BrakeMaintenance

AdjustingtheParkingBrake

ServiceInterval:Every200hours

CheckingtheBrake-uidLevel

ServiceInterval:Beforeeachuseordaily

Thebrake-uidreservoirislledandshippedfromthe

factorywithDOT3brakeuid.Checkthelevelbeforethe

machineisrststartedandevery8hoursordaily,thereafter.

1.Parkthemachineonalevelsurface,settheparking

brake,turntheOn/OffswitchtoOff,andremovethe

key.

2.Removetherubberpluginthecenterandontopof

thedashtogainaccesstothemasterbrakecylinder

andreservoir.

3.Lookatthesideofthereservoir,andensurethatthe

uidlevelisabovetheMinimumline(Figure37).

4.Iftheuidlevelislow,cleantheareaaroundthecap,

removethecap,andllthereservoirtoabovethe

Minimumline.Donotoverll.

1.Prytherubbercoverofftheparkingbrake.

2.Loosenthesetscrewsecuringtheknobtothe

parking-brakelever(Figure38).

Figure38

1.Parking-brakelever

2.Knob

3.Rotatetheknobuntilaforceof133to156N-m(30to

35ft-lb)isrequiredtoactuatethelever.

4.Tightenthesetscrewandinstalltherubbercover.

3.Setscrew

Figure37

1.Brake-uidreservoir

2.Minimumline

InspectingtheBrakes

ServiceInterval:Every100hours

Brakesareacriticalsafetycomponentofthemachine.As

withallsafetycomponents,theyshouldbecloselyinspectedat

regularintervalstoensureoptimumperformanceandsafety.

Thefollowinginspectionsshouldbedoneevery100hours:

•Inspectthebrakeshoesforwearordamage.Ifthelining

(brakepad)thicknessislessthan1.6mm(1/16inch),the

brakeshoesshouldbereplaced.

•Inspectthebackingplateandothercomponentsforsigns

ofexcessivewearordeformation.Ifanydeformationis

found,theappropriatecomponentsmustbereplaced.

•Checkthebrakeuidlevel;refertoCheckingthe

Brake-uidLevel(page33).

33

Page 34

Cleaning

WashingtheMachine

Storage

1.Positionthemachineonalevelsurface,settheparking

brake,stopthemachine,andremovethekey.

Washthemachineasneeded.Usewateraloneorwithamild

detergent.Aragmaybeused,howeverthehoodwillloose

someofitsluster.

Important:Pressurizedwaterisnotrecommended

whenwashingthemachine.Itmaydamagetheelectrical

system,loosenimportantdecals,orwashawaynecessary

greaseatfrictionpoints.Avoidexcessiveuseofwater,

especiallynearthecontrolpanel,motor,andbatteries.

2.Cleandirtandgrimefromtheentiremachine,including

theoutsideofthemotorhousing.

Important:Youcanwashthemachinewithmild

detergentandwater.Donotusehighpressure

watertowashthemachine.Pressurewashing

maydamagetheelectricalsystemorwashaway

necessarygreaseatfrictionpoints.Avoidexcessive

useofwater,especiallynearthecontrolpanel,

lights,motor,andthebattery.

3.Inspectthebrakes;refertoInspectingtheBrakes(page

33).

4.Greasethemachine;refertoAddingGrease(page26).

5.Checkthetirepressure;referto.

6.Chargethebatteriesfullybeforeplacingthemachine

intostorage;refertoChargingtheBatteries(page27).

Plugthechargerintoawalloutletwhilethemachine

andbatteriesareinstorage.Leavethechargerplugged

intoawalloutletandchargingreceptacleduringstorage

toensurethatthebatteriesstaychargedanddonot

freeze;otherwise,chargethebatteriesatleastonce

every3months.

7.Checkandtightenallbolts,nuts,andscrews.Repairor

replaceanypartthatisdamaged.

8.Paintallscratchedorbaremetalsurfaces.

PaintisavailablefromyourAuthorizedServiceDealer.

9.Storethemachineinaclean,drygarageorstoragearea.

10.Removethekeyandputitinasafeplaceoutofthe

reachofchildren.

11.Coverthemachinetoprotectitandkeepitclean.

34

Page 35

Troubleshooting

MachineStatusLightFlashPattern

Alwayson

1ash

2ashes

3ashes

4ashes

Problem

1.Thesystemisfunctioningproperly.

1.Thecomputerprogrammingpersonality

isoutofrange.

1.Theacceleratorpedalwaspressed

whentheOn/Offkeywasturned.

1.Thepowerblockhasashortcircuit

(MOSFETS/C).

2.Thereisapoorbatterorpowercable

connection.

1.Thelinecontactorisnotrespondingto

commands.

PossibleCauseCorrectiveAction

1.None

1.TurntheOn/OffkeytotheOffposition,

waitafewseconds,andturntheOn/Off

keytotheOnposition.Ifthecondition

continues,refertoyourAuthorized

ServiceDealer.

1.TurntheOn/OffkeytotheOffposition,

releasetheacceleratorpedal,andturn

theOn/OffkeytotheOnposition.

1.TurntheOn/OffkeytotheOffposition,

waitafewseconds,andturnthe

On/OffkeytotheOnposition.Check

allbatteriesandhighcurrentcontroller

connectionsIftheconditioncontinues,

refertoyourAuthorizedService

Dealer.

2.TurntheOn/OffkeytotheOffposition,

waitafewseconds,andturnthe

On/OffkeytotheOnposition.Check

allbatteriesandhighcurrentcontroller

connectionsIftheconditioncontinues,

refertoyourAuthorizedService

Dealer.

1.TurntheOn/OffkeytotheOffposition,

waitafewseconds,andturntheOn/Off

keytotheOnposition.Ifthecondition

continues,refertoyourAuthorized

ServiceDealer.

5ashes

6ashes1.Acceleratorpotentiometerisoutof

7ashes

8ashes

9ashes

Off

1.Thechargerinterlockswitchisactive.

adjustment.

1.Thebatteryvoltageisoutofrange.1.RefertoyourAuthorizedService

2.Thereisanovervoltageerrorcode

causedbyoverspeedingwhen

travelingdownasteephill.

1.Thecontrollerisoverheated.1.Themachinewillcontinuetorun,but

1.Themotorisoverheatedorthebattery

isnearlydischarged(themachinewill

gointotheenergy-savingmode).

1.Thereiseithernopowertothe

controllerorthecontrollerhasfailed.

1.TurntheOn/OffkeytotheOffposition,

disconnectthecharger,andturnthe

On/OffkeytotheOnposition.

1.RefertoyourAuthorizedService

Dealer.

Dealer.

2.Cyclethepedaltoclearfault,ifit

doesnotclearthefault,refertoyour

AuthorizedServiceDealertohave

thebatteriestestedandreplacedif

necessary.

atareducedpoweruntilthecontroller

coolsdown.

1.Ifthebattermeterdisplaysmorethan

onebar,stopthemachine,andallow

themotortocoolbeforeoperatingit

again.Ifthebatterymeterdisplays

onlyonebar,chargethemachine

immediately.

1.RefertoyourAuthorizedService

Dealer.

35

Page 36

Notes:

36

Page 37

Notes:

37

Page 38

Notes:

38

Page 39

InternationalDistributorList

Distributor:

AgrolancKft

BalamaPrimaEngineeringEquip.HongKong85221552163

B-RayCorporation

CascoSalesCompany

CeresS.A.CostaRica

CSSCTurfEquipment(pvt)Ltd.SriLanka

CyrilJohnston&Co.

CyrilJohnston&Co.RepublicofIreland

EquiverMexico525553995444ParklandProductsLtd.NewZealand6433493760

FemcoS.A.Guatemala

ForGarderOU

G.Y .K.CompanyLtd.

GeomechanikiofAthensGreece

GolfinternationalTurizm

GuandongGoldenStarChina

HakoGroundandGardenSweden

HakoGroundandGarden

HayterLimited(U.K.)

HydroturfInt.CoDubai

HydroturfEgyptLLC

IrrimacPortugal351212388260T oroEuropeNVBelgium3214562960

IrrigationProductsInt'lPvtLtd.India0091442449

JeanHeybroekb.v.Netherlands3130639461 1VictusEmakPoland48618238369

Country:

Hungary3627539640

Korea82325512076

PuertoRico7877888383