Page 1

FormNo.3356-924RevC

Workman

ModelNo.07277—SerialNo.270000001andUp

ModelNo.07277TC—SerialNo.270000001andUp

®

2110UtilityVehicle

Registeratwww.T oro.com.OriginalInstructions(EN)

Page 2

Warning

CALIFORNIA

Proposition65Warning

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Important:Thisengineisnotequippedwitha

sparkarrestermufer.ItisaviolationofCalifornia

PublicResourceCodeSection4442touseoroperate

theengineonanyforest-covered,brush-covered,or

grass-coveredland.Otherstatesorfederalareas

mayhavesimilarlaws.

ThissparkignitionsystemcomplieswithCanadian

ICES-002.

Theenclosed

Engine Owner’ s Man ual

issupplied

forinformationregardingtheUSEnvironmental

ProtectionAgency(EPA)andtheCalifornia

EmissionControlRegulationofemissionsystems,

maintenance,andwarranty.Replacementsmaybe

orderedthroughtheenginemanufacturer.

Introduction

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoidinjury

andproductdamage.Youareresponsibleforoperating

theproductproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comfor

productandaccessoryinformation,helpndinga

dealer,ortoregisteryourproduct.

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafetyalertsymbol

(Figure2),whichsignalsahazardthatmaycauseserious

injuryordeathifyoudonotfollowtherecommended

precautions.

Figure2

1.Safetyalertsymbol

Thismanualuses2otherwordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Wheneveryouneedservice,genuineToroparts,

oradditionalinformation,contactanAuthorized

ServiceDealerorToroCustomerServiceandhave

themodelandserialnumbersofyourproductready .

Figure1identiesthelocationofthemodelandserial

numbersontheproduct.Writethenumbersinthe

spaceprovided.

©2007—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

Contents

Introduction.................................................................2

Safety...........................................................................4

SafeOperatingPractices.......................................4

BeforeOperating.................................................4

Operation.............................................................5

Maintenance.........................................................7

SoundPressure.....................................................7

Vibration..............................................................7

SafetyandInstructionalDecals.............................8

Setup..........................................................................10

1InstallingtheWheels........................................10

2InstallingtheSteeringWheel............................11

3InstallingtheBumper.......................................11

4InstallingtheSeats...........................................11

5InstallingtheHitch..........................................12

6InstallingtheCargoBox...................................12

7ActivatingtheBattery......................................13

8AdjustingtheFrontWheelToe-in.....................14

9ReadingtheManualandViewingtheSafety

Video.............................................................14

ProductOverview......................................................16

Controls.............................................................16

Specications.....................................................19

Attachments/Accessories...................................19

Operation...................................................................19

ThinkSafetyFirst...............................................19

Pre-StartingChecks............................................19

CheckingtheEngineOil.....................................19

CheckingtheBrakeFluidLevel...........................20

CheckingtheTirePressure.................................20

AddingFuel.......................................................20

CheckingtheTransmissionOilLevel..................21

StartingtheEngine.............................................21

StoppingtheVehicle...........................................21

ParkingtheV ehicle.............................................21

OperatingtheCargoBox....................................22

BreakinginaNewVehicle..................................23

LoadingtheCargoBox.......................................23

TransportingtheVehicle.....................................23

TowingtheVehicle.............................................23

TowingaTrailer..................................................24

Maintenance...............................................................25

RecommendedMaintenanceSchedule(s)................25

DailyMaintenanceChecklist...............................25

PremaintenanceProcedures....................................27

MaintainingtheVehicleunderSpecial

OperatingConditions.....................................27

JackingtheVehicle..............................................27

Lubrication.............................................................28

AddingGrease...................................................28

EngineMaintenance...............................................28

ServicingtheAirCleaner....................................28

ServicingtheEngineOil.....................................29

ServicingtheSparkPlugs....................................30

FuelSystemMaintenance.......................................31

InspectingFuelLinesandConnections...............31

ReplacingtheFuelFilter.....................................31

ElectricalSystemMaintenance................................31

ReplacingtheFuses............................................31

ReplacingtheHeadlights....................................31

ServicingtheBattery...........................................32

DriveSystemMaintenance.....................................34

CheckingandAdjustingNeutral.........................34

InspectingtheTires............................................34

AdjustingtheFrontSuspension..........................34

AdjustingFrontWheelToe-In............................35

MaintainingthePrimaryDriveClutch.................36

ChangingtheTransaxleFluid..............................37

CoolingSystemMaintenance..................................38

CleaningtheEngineCoolingAreas.....................38

BrakeMaintenance.................................................38

InspectingtheBrakes.........................................38

CheckingtheBrakeFluidLevel...........................38

AdjustingtheParkingBrake................................38

BeltMaintenance....................................................39

ServicingtheDriveBelt......................................39

AdjustingtheStarterGeneratorBelt...................39

Cleaning.................................................................40

WashingtheV ehicle............................................40

Storage.......................................................................41

Schematics.................................................................42

3

Page 4

Safety

Improperuseormaintenancebytheoperatororowner

canresultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandalwayspay

attentiontothesafetyalertsymbol,whichmeans

Caution,Warning,orDanger—“personalsafety

instruction.”Failuretocomplywiththeinstructionmay

resultinpersonalinjuryordeath.

Supervisors,operators,andservicepersonsshouldbe

familiarwiththefollowingstandardsandpublications

(thematerialmaybeobtainedfromtheaddressshown):

•FlammableandCombustibleLiquidsCode:

ANSI/NFPA30

•NationalFireProtectionAssociation:

ANSI/NFPA#505;PoweredIndustrialTrucks,

NationalFirePreventionAssociation,Barrymarch

Park,Quincy ,Massachusetts02269U.S.A.

•ANSI/ASMEB56.8PersonalBurdenCarriers

AmericanNationalStandardsInstitute,Inc.,1430

Broadway,NewYork,NewYork10018U.S.A.

•SAEJ2258LightUtilityVehicle

SAEInternational,400CommonwealthDrive,

Warrendale,PA15096-0001U .S.A.

•ANSI/UL558;InternalCombustionEngine

PoweredIndustrialTrucks

AmericanNationalStandardsInstitute,Inc.,1430

Broadway,NewYork,NewYork10018U.S.A.

or

UnderwritersLaboratories,333PngstenRoad,

Northbrook,Illinois60062U .S.A.

BeforeOperating

•Operatethemachineonlyafterreadingand

understandingthecontentsofthismanual.

•Neverallowchildrentooperatethevehicle.Anyone

whooperatesthevehicleshouldhaveamotor

vehiclelicense.

•Neverallowotheradultstooperatethevehicle

withoutrstreadingandunderstandingtheOperator’ s

Manual.Onlytrainedandauthorizedpersonsshould

operatethisvehicle.Makesurethatalloperators

arephysicallyandmentallycapableofoperatingthe

vehicle.

•Thisvehicleisdesignedtocarryonlyyou,the

operator,andonepassengerintheseatprovidedby

themanufacturer.Nevercarryanyotherpassengers

onthevehicle.

•Neveroperatethevehiclewhenundertheinuence

ofdrugsoralcohol.Evenprescriptiondrugsand

coldmedicinescancausedrowsiness.

•Donotdrivethevehiclewhenyouaretired.Besure

totakeoccasionalbreaks.Itisveryimportantthat

youstayalertatalltimes.

•Becomefamiliarwiththecontrolsandknowhowto

stoptheenginequickly.

•Keepallshields,safetydevices,anddecalsinplace.

Ifashield,safetydevice,ordecalismalfunctioning,

illegible,ordamaged,repairorreplaceitbefore

operatingthemachine.

•Alwayswearsubstantialshoes.Donotoperate

themachinewhilewearingsandals,tennisshoes

orsneakers.Donotwearloosettingclothingor

jewelrywhichcouldgetcaughtinmovingpartsand

causepersonalinjury.

SafeOperatingPractices

TheWorkmanisanoff-highwayvehicleonly

andisnotdesigned,equipped,ormanufactured

foruseonpublicstreets,roads,orhighways.

Supervisor’sResponsibilities

•Makesurethatoperatorsarethoroughlytrainedand

familiarwiththeOperator’sManualandalllabelson

thevehicle.

•Besuretoestablishyourownspecialproceduresand

workrulesforunusualoperatingconditions(e.g.

slopestoosteepforvehicleoperation).

•Wearingsafetyglasses,safetyshoes,longpantsanda

helmetisadvisableandrequiredbysomelocalsafety

andinsuranceregulations.

•Avoiddrivingwhenitisdark,especiallyinunfamiliar

areas.Ifyoumustdrivewhenitisdark,besure

todrivecautiously,usetheheadlights,andeven

consideraddingadditionallights.

•Beextremelycarefulwhenoperatingaroundpeople.

Alwaysbeawareofwherebystandersmightbe.

•Beforeoperatingthevehicle,alwayscheckthe

designatedareasofthevehiclethatarestatedinthe

pre-startingsectionofthismanual.Ifsomething

iswrong,donotusethevehicle.Makesurethat

theproblemiscorrectedbeforethevehicleor

attachmentisoperated.

•Sincegasolineishighlyammable,handleitcarefully.

4

Page 5

–Useanapprovedgasolinecontainer.

–Donotremovethecapfromthefueltankwhen

theengineishotorrunning.

–Donotsmokewhilehandlinggasoline.

–Fillthefueltankoutdoors,andllittoabout

1inch(25mm)belowthetopofthetank(the

bottomofthellerneck).Donotoverllit.

–Wipeupanyspilledgasoline.

Operation

Engineexhaustcontainscarbonmonoxide,

whichisanodorless,deadlypoisonthatcan

killyou.

Donotrunengineindoorsorinanenclosed

area.

•Theoperatorandpassengershouldremainseated

wheneverthevehicleisinmotion.Theoperator

shouldkeepbothhandsonthesteeringwheel

wheneverpossible,andthepassengershoulduse

thehandholdsprovided.Keepyourarmsandlegs

withinthevehiclebodyatalltimes.

•Driveslowerandturnlesssharplywhenyouare

carryingapassenger.Rememberyourpassengermay

notbeexpectingyoutobrakeorturnandmaynot

beready .

•Alwayswatchoutforandavoidlowoverhangssuch

astreelimbs,doorjambs,andover-headwalkways.

Makesurethereisenoughroomoverheadtoeasily

clearthevehicleandyourhead.

•Failuretooperatethevehiclesafelymayresultinan

accident,tipoverofthevehicle,andseriousinjury

ordeath.Drivecarefully .Topreventtippingorloss

ofcontrol:

–Useextremecaution,reducespeed,andmaintain

asafedistancearoundsandtraps,ditches,creeks,

ramps,unfamiliarareas,oranyareasthathave

abruptchangesingroundconditionsorelevation.

–Watchforholesorotherhiddenhazards.

–Useextracautionwhenoperatingthevehicleon

wetsurfaces,inadverseweatherconditions,at

higherspeeds,orwithafullload.Stoppingtime

anddistancewillincreasewithafullload.

–Avoidsuddenstopsandstarts.Donotgofrom

reversetoforwardorforwardtoreversewithout

rstcomingtoacompletestop.

–Slowdownbeforeturning.Donotattempt

sharpturnsorabruptmaneuversorotherunsafe

drivingactionsthatmaycausealossofvehicle

control.

–Whendumping,donotletanyonestandbehind

thevehicleanddonotdumptheloadonanyone’s

feet.Releasethetailgatelatchesfromthesideof

thebox,notfrombehind.

–Onlyoperatethevehiclewhenthecargoboxis

downandlatched.

–Beforebackingup,looktotherearandensure

thatnooneisbehindyou.Backupslowly.

–Watchoutfortrafcwhenyouarenearor

crossingroads.Alwaysyieldtherightofway

topedestriansandothervehicles.Thisvehicle

isnotdesignedforuseonstreetsorhighways.

Alwayssignalyourturnsorstopearlyenough

sothatotherpeopleknowwhatyouplantodo.

Obeyalltrafcrulesandregulations.

–Theelectricalandexhaustsystemsofthevehicle

canproducesparkscapableofignitingexplosive

materials.Neveroperatethevehicleinornearan

areawherethereisdustorfumesintheairwhich

areexplosive.

–Ifyouareeverunsureaboutsafeoperation,stop

workandaskyoursupervisor.

•Donottouchtheengineormuferwhiletheengine

isrunningorsoonafterithasstopped.Theseareas

maybehotenoughtocauseburns.

•Ifthemachineevervibratesabnormally,stop

immediately,waitforallmotiontostop,andinspect

thevehiclefordamage.Repairalldamagebefore

commencingoperation.

•Beforegettingoffoftheseat:

1.Stopthemovementofthemachine.

2.Settheparkingbrake.

3.TurntheignitionkeytoOff.

4.Removetheignitionkey.

Note:Ifthevehicleisonanincline,blockthe

wheelsaftergettingoffofthevehicle.

Braking

•Slowdownbeforeyouapproachanobstacle.This

givesyouextratimetostoporturnaway.Hitting

anobstaclecandamagethevehicleanditscontents.

Moreimportant,itcaninjureyouandyourpassenger.

•GrossVehicleWeight(GVW)hasamajorimpacton

yourabilitytostopand/orturn.Heavyloadsand

attachmentsmakeavehiclehardertostoporturn.

Theheaviertheload,thelongerittakestostop.

5

Page 6

•Decreasethevehiclespeedifthecargoboxhasbeen

removedandthereisnoattachmentonthevehicle.

Thebrakingcharacteristicschangeandfaststops

maycausetherearwheelstolockup,whichmay

affectthecontrolofthevehicle.

•Turfandpavementaremuchmoreslipperywhen

theyarewet.Itcantake2to4timesaslongtostop

onwetsurfacesasondrysurfaces.Ifyoudrive

throughstandingwaterdeepenoughtogetthe

brakeswet,theywillnotworkwelluntiltheyare

dry.Afterdrivingthroughwater,youshouldtestthe

brakestomakesuretheyworkproperly .Iftheydo

not,driveslowlywhileputtinglightpressureonthe

brakepedal.Thiswilldrythebrakesout.

topreventitfromshiftingandtakeextracarewhen

haulingloadsthatshifteasily(liquid,rock,sand,etc.).

•Avoidstoppingonhills,especiallywithaload.

Stoppingwhilegoingdownahillwilltakelonger

thanstoppingonlevelground.Ifthevehiclemust

bestopped,avoidsuddenspeedchanges,whichmay

initiatetippingorrollingofthevehicle.Donotslam

onthebrakeswhenrollingbackward,asthismay

causethevehicletooverturn.

•Westronglyrecommendinstallingtheoptional

ROPSKitwhenoperatingonhillyterrain.

OperatingonRoughTerrain

OperatingonHills

Operatingthevehicleonahillmaycause

tippingorrollingofthevehicle,ortheengine

maystallandyoucouldloseheadwayonthe

hill.Thiscouldresultinpersonalinjury.

•Donotacceleratequicklyorslamonthe

brakeswhenbackingdownahill,especially

withaload.

•Iftheenginestallsoryouloseheadwayon

ahill,slowlybackstraightdownthehill.

Neverattempttoturnthevehiclearound.

•Operatethevehicleslowlyonahillanduse

caution.

•Avoidturningonahill.

•Reduceyourloadandthespeedofthe

vehicle.

•Avoidstoppingonhills,especiallywitha

load.

Theseextracautionsneedtobetakenwhenoperating

thevehicleonahill:

•Slowdownbeforestartingupordownahill.

•Iftheenginestallsoryoubegintoloseheadway

whileclimbingahill,graduallyapplythebrakesand

slowlybackstraightdownthehill.

•Turningwhiletravelingupordownhillscanbe

dangerous.Ifyouhavetoturnwhileonahill,do

itslowlyandcautiously.Nevermakesharporfast

turns.

•Heavyloadsaffectstability.Reducetheweightofthe

loadandyourspeedwhenoperatingonhillsorif

theloadhasahighcenterofgravity.Securetheload

Reducespeedandloadwhenoperatingonroughterrain,

unevenground,andnearcurbs,holes,andothersudden

changesinterrain.Loadsmayshift,causingthevehicle

tobecomeunstable.

WestronglyrecommendinstallingtheoptionalROPS

Kitwhenoperatingonroughterrain.

Suddenchangesinterrainmaycauseabrupt

steeringwheelmovement,possiblyresultingin

handandarminjuries.

•Reduceyourspeedwhenoperatingonrough

terrainandnearcurbs.

•Gripthesteeringwheellooselyaroundthe

perimeter.Keepyourhandsclearofthe

steeringwheelspokes.

LoadingandDumping

Theweightandpositionofthecargoandpassenger

canchangethevehiclecenterofgravityandvehicle

handling.T oavoidlossofcontrolandpersonalinjury,

followtheseguidelines:

•Donotcarryloadswhichexceedtheloadlimits

describedonthevehicleweightlabel;referto

SpecicationsinProductOverview,page16,for

vehicleweightlimits.Theloadratingisforlevel

surfacesonly .

•Reducetheweightoftheloadwhenoperating

onhillsandroughterraintoavoidtippingor

overturningofthevehicle.

•Reducetheweightoftheloadifthecenterofgravity

ishigh.Itemssuchasbricks,fertilizer,orlandscape

timbersstackhigherinthebox.Thehigheraload

isstacked,themorelikelythevehicleistotipover.

6

Page 7

Distributetheloadaslowaspossible,makingsure

thattheloaddoesnotaffectrearvisibility.

•Positiontheweightoftheloadevenlyfromsideto

side.Ifyoupositiontheloadtowardoneofthesides,

thevehicleismorelikelytotipoverwhileturning.

•Positiontheweightofaloadevenlyfromfrontto

back.Ifyoupositiontheloadbehindtherearaxle,

itwillreducetheweightonthefrontwheels.This

mayresultinalossofsteeringcontrolorcausethe

vehicletotipoveronhillsorbumpyterrain.

•Useextracautioniftheloadexceedsthedimensions

oftheboxandwhenhandlingoff-centerloadsthat

cannotbecentered.Keeploadsbalancedandsecure

topreventthemfromshifting.

•Alwayssecureloadssothattheydonotshift.Ifa

loadisnotsecured,oryouaretransportingaliquidin

alargecontainersuchasasprayer,theloadcanshift.

Thisshiftinghappensmostoftenwhileturning,

goingupordownhills,suddenlychangingspeeds,or

whiledrivingoverroughsurfaces.Shiftingloadscan

causethevehicletotipover.

Maintenance

•Onlyqualiedandauthorizedpersonnelshallbe

permittedtomaintain,repair,adjust,orinspectthe

vehicle.

•Beforeservicingormakingadjustmentstothe

machine,stoptheengine,settheparkingbrake,

andremovethekeyfromtheignitiontoprevent

someonefromaccidentallystartingtheengine.

•Tomakesurethattheentiremachineisingood

condition,keepallnuts,bolts,andscrewsproperly

tightened.

•Toreducethepotentialforre,keeptheengine

areafreeofexcessivegrease,grass,leaves,and

accumulationofdirt.

•Neveruseanopenametocheckthelevelor

leakageoffuelorbatteryelectrolyte.

•Iftheenginemustberunningtoperforma

maintenanceadjustment,keepyourhands,feet,

clothing,andanypartsofyourbodyawayfromthe

engineandanymovingparts.Keepeveryoneaway.

Theweightoftheboxmaybeheavy.Handsor

otherbodypartscouldbecrushed.

–Keephandsandotherbodypartsclearwhen

loweringthebox.

–Donotdumpmaterialsonbystanders.

•Neverdumpaloadedcargoboxwhilethevehicleis

sidewaysonahill.Thechangeinweightdistribution

maycausethevehicletooverturn.

•Whenoperatingwithaheavyloadinthecargobox,

reduceyourspeedandallowforsufcientbraking

distance.Donotsuddenlyapplythebrakes.Use

extracautiononslopes.

•Beawarethatheavyloadsincreaseyourstopping

distanceandreduceyourabilitytoturnquickly

withouttippingover.

•Therearcargospaceisintendedforloadcarrying

purposesonly ,notforpassengers.

•Neveroverloadyourvehicle.Thedecal(locatedon

therearframe)showsloadlimitsforthevehicle.

NeveroverloadtheattachmentsorexceedtheGross

VehicleWeight(GVW).

•Donotuseopenpansoffuelorammablecleaning

uidsforcleaningparts.

•Ifmajorrepairsareeverneededorassistanceis

required,contactanAuthorizedToroDistributor.

•Tobesureofoptimumperformanceandsafety,

alwayspurchasegenuineTororeplacementpartsand

accessories.Replacementpartsandaccessoriesmade

byothermanufacturerscouldbedangerous.Altering

thisvehicleinanymannerthatmayaffectvehicle

operation,performance,durability,oritsuse,may

resultininjuryordeath.Suchusecouldvoidthe

productwarranty.

SoundPressure

Thisunithasamaximumsoundpressurelevelatthe

operator’searof80dBA,basedonmeasurementsof

identicalmachinesperEN11094.

Vibration

Thisunitdoesnotexceedahand/armvibrationlevelof

2.5m/s

perEN1033.

Thisunitdoesnotexceedawholebodyvibration

levelof0.5m/s

machinesperEN1032.

2

,basedonmeasurementsofidenticalmachines

2

,basedonmeasurementsofidentical

7

Page 8

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaof

potentialdanger.Replaceanydecalthatisdamagedorlost.

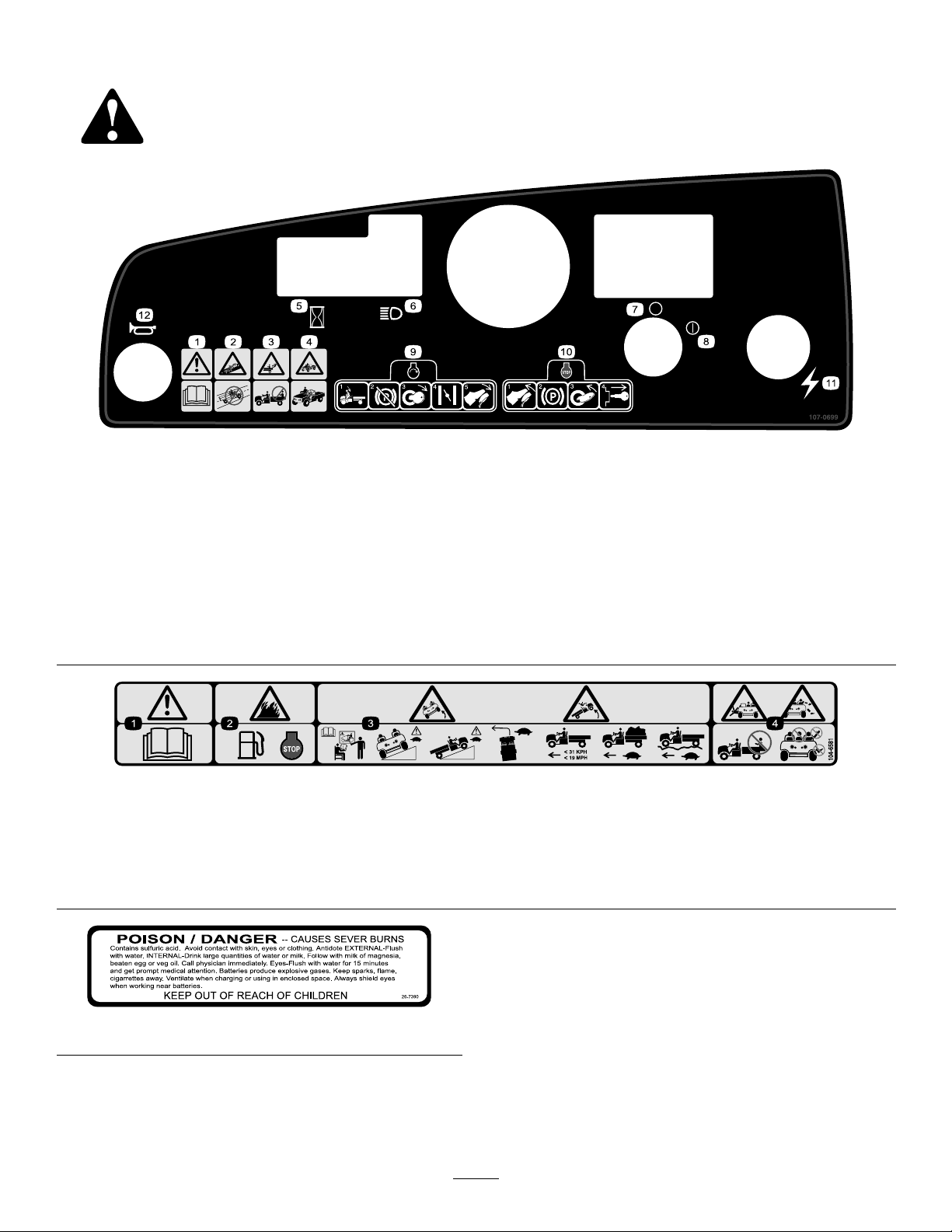

107-0699

1.Warning—readtheOperator’sManual.7.Ignition—Off

2.Collisionhazard—donotoperatethevehicleonpublicstreets,

roads,orhighways.

3.Fallinghazard—donotcarrypassengersinthecargobed.9.Tostarttheengine,sitontheoperator’sseat,releasethe

4.Fallinghazard—donotallowchildrentooperatethevehicle.10.Tostoptheengine,releasetheacceleratorpedal,setthe

5.Hourmeter

6.Headlights12.Horn

8.Ignition—On

parkingbrake,turntheignitionkeyon,pullthechokeleverout

(ifneeded),andpresstheacceleratorpedal.

parkingbrake,turntheignitionkeyoff,andremovethe

ignitionkey.

11.Electricalpower(powerpoint)

104-6581

1.Warning—readtheOperator’sManual.

2.Firehazard—beforefueling,stoptheengine.

3.Tippinghazard—receivetrainingbeforeoperatingthemachine,usecautionanddriveslowlywhileonslopes;driveslowlywhen

turning,keepthevehiclespeedunder19MPH(31km/h)whencarryingafullorheavyloadandwhendrivingonroughterrain.

4.Fallingandarm/leginjuryhazards—donotcarrypassengersinthecargobedandkeeparmsandlegsinsideofthevehicleatall

times.

26-7390

8

Page 9

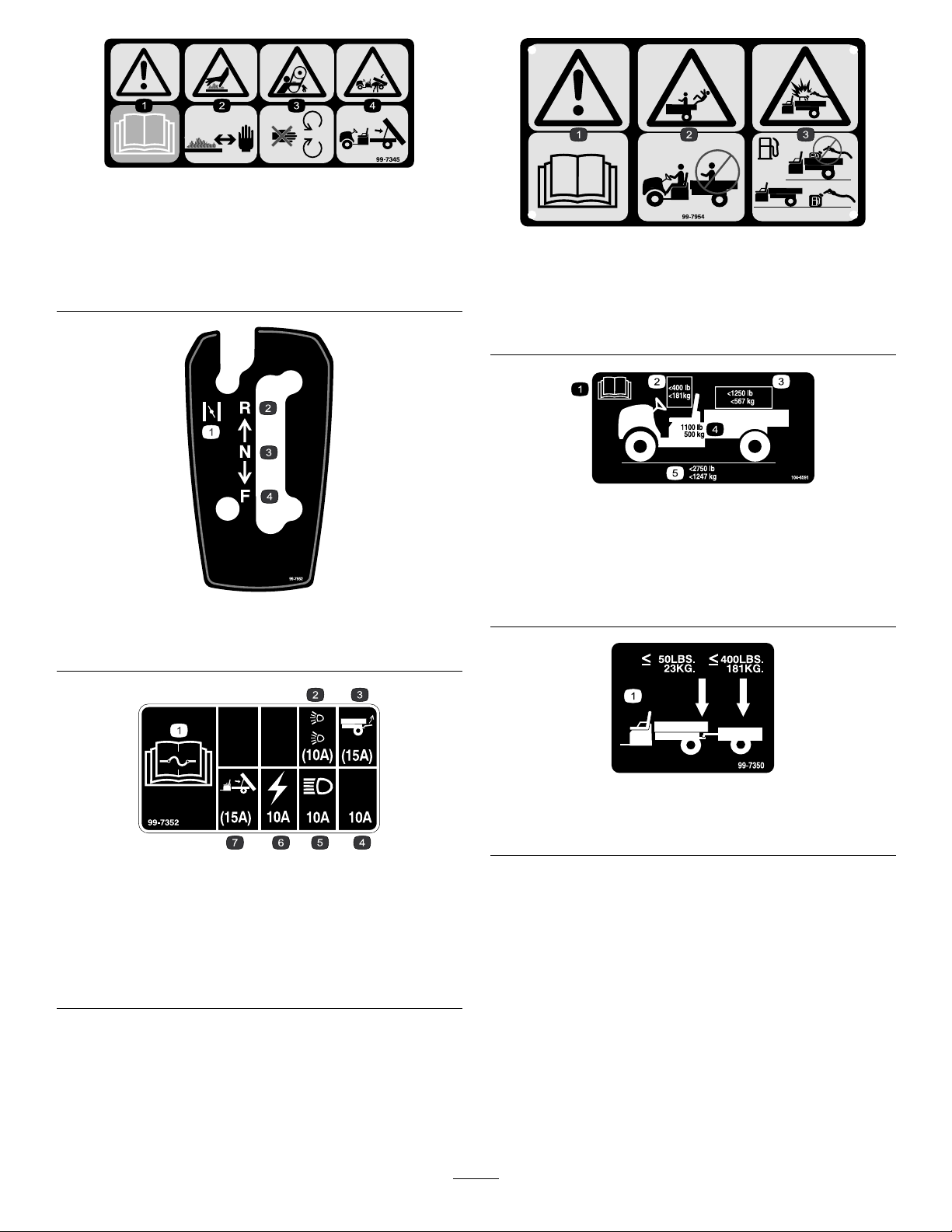

99-7345

1.Warning—readtheOperator’sManual.

2.Hotsurface/burnhazard—stayasafedistancefromthe

hotsurface.

3.Entanglementhazard,belt—stayawayfrommovingparts

4.Crushinghazard,cargobox—usetheproprodtosupport

thecargobed

99-7952

1.Choke

2.Reverse4.Forward

3.Neutral

99-7954

1.Warning—readtheOperator’sManual.

2.Fallinghazard—donotcarrypassengersinthecargobed.

3.Explosionhazard,staticdischargeintofuelcontainer—do

notllfuelcontainersinthecargobed;placefuelcontainers

onthegroundbeforelling.

104–6591

1.ReadtheOperator’sManual.

2.Themaximumcombinedoperatorandpassengerweightis

400lb.(181kg).

3.Themaximumcargoweightis1250lb.(567kg).

4.Thebaseweightofthevehicleis1 100lb.(500kg).

5.Themaximumgrossvehicleweightis2750lb.(1247kg).

99-7352

1.ReadtheOperator’sManualforinformationonfuses.

2.10amp.fusefortheoptionalRoadLightKit

3.15amp.fusefortheoptionalRearLiftKit

4.10amp.fuse—open

5.10amp.fusefortheheadlights

6.10amp.fusefortheignitionsystem

7.15amp.fusefortheoptionalElectricBedLiftKit

99-7350

1.Maximumtongueweightis50lb(23kg);maximumtrailer

weightis400lb(181kg).

9

Page 10

Setup

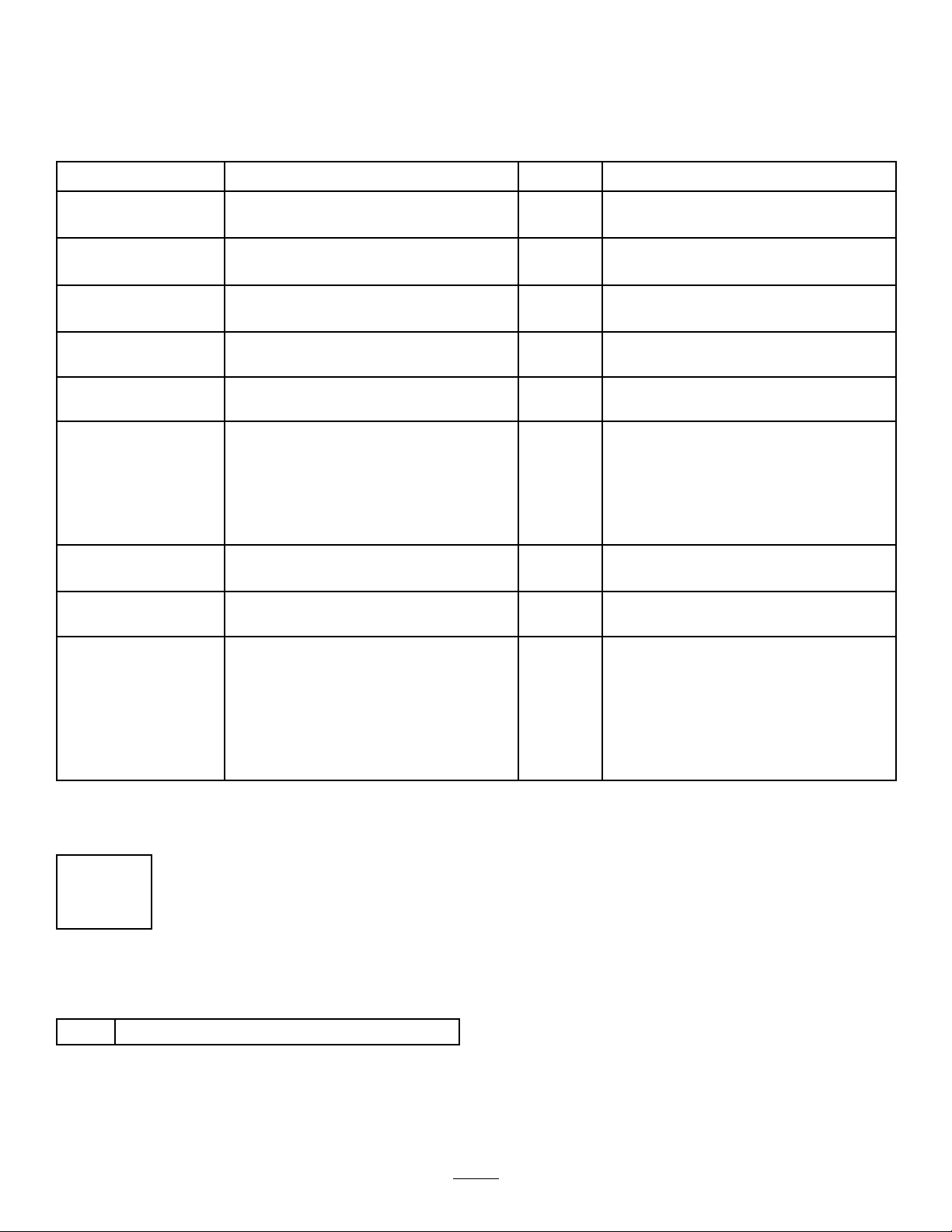

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

6

7

8

9

Wheelassembly4

Steeringwheel

Bumper1

Seat

Hitch1

Cargobox

Right-handpivotbracket1

Left-handpivotbracket

Flangeheadscrew(3/8x1inch)

Bolt(5/16x3/4inch)

Flangenut(5/16inch)

Nopartsrequired

Nopartsrequired

Operator’sManual

EngineOperator’sManual

PartsCatalog

SafetyVideo

RegistrationCard

PredeliveryInspectionForm1

Key2

Qty.

Use

Installthewheels(Model07277TC

only).

1

2

1

1

4

1

1

–

–

1

1

1

1

1

Installthesteeringwheel(Model

07277TConly).

Installthebumper(Model07277TC

only).

Installtheseats(Model07277TConly).

Installthehitch(Model07277TConly).

Installthecargobox(Model07277TC

only).

Activatethebattery(Model07277TC

only).

Adjustthefrontwheeltoe-in.

ReadtheOperator’sManualandwatch

thevideobeforeoperatingthemachine.

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

1

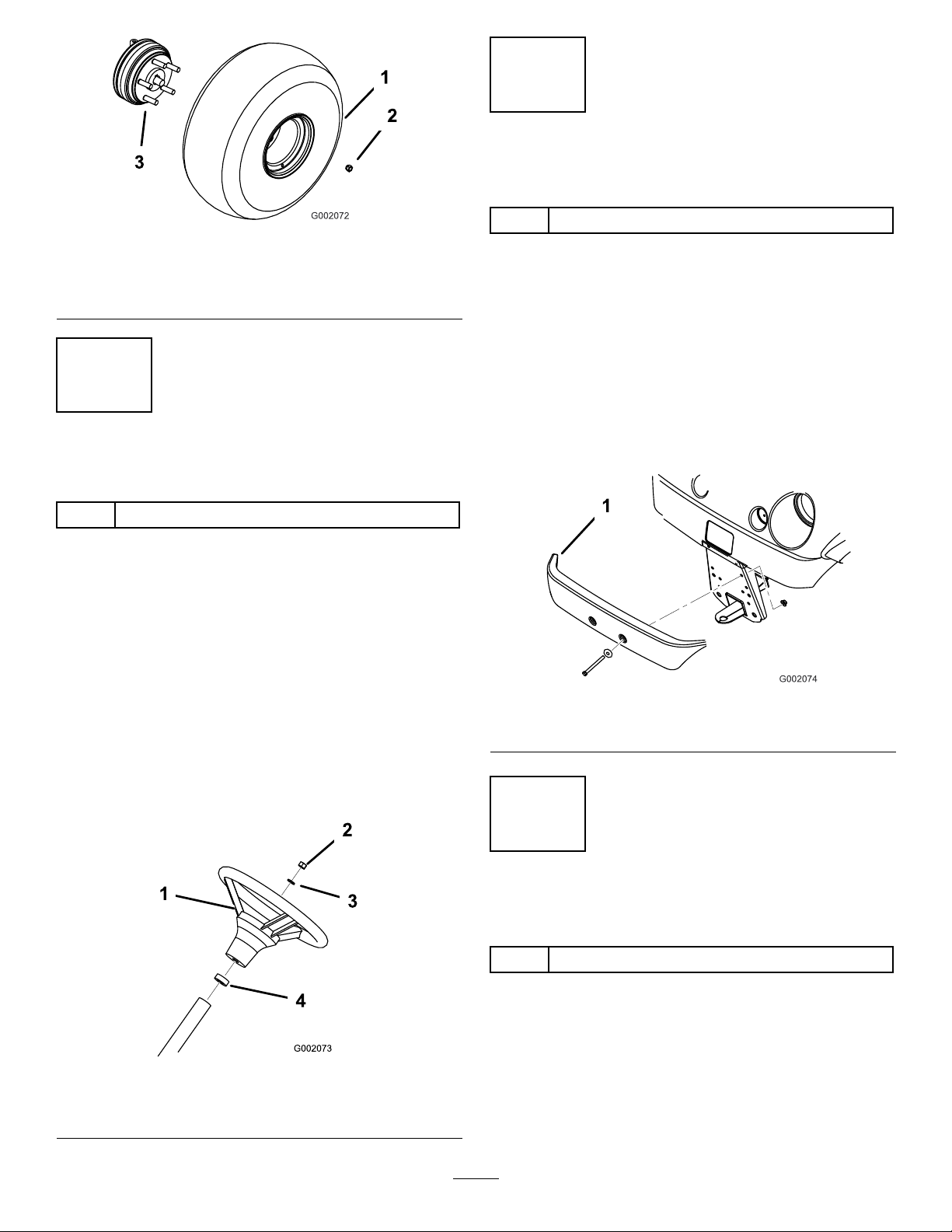

InstallingtheWheels

Partsneededforthisprocedure:

4Wheelassembly

Procedure

Note:ThisprocedureisonlyneededforModelNo.

07277TC.

1.Removethefastenerssecuringthewheels.

2.Removetheshippingbracketsecuredtothewheel

studs.

3.Mountthewheelswiththepreviouslyremoved

fasteners(Figure3)andtorqueto45-65ft-lb

(61-88N-m).

10

Page 11

3

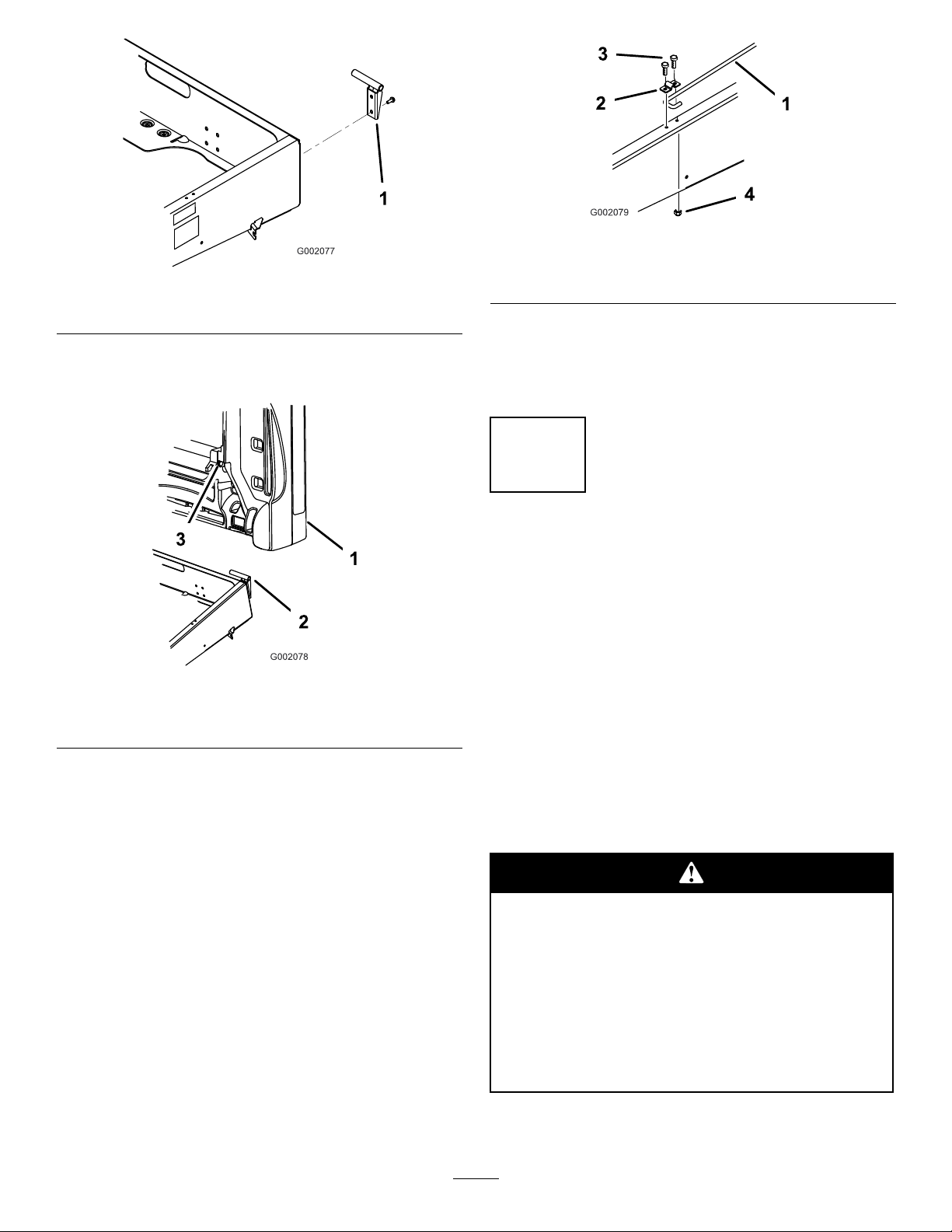

InstallingtheBumper

Partsneededforthisprocedure:

Figure3

1.Wheelassembly

2.Wheelnut

3.Wheelstud(rearwheel

hubshown)

2

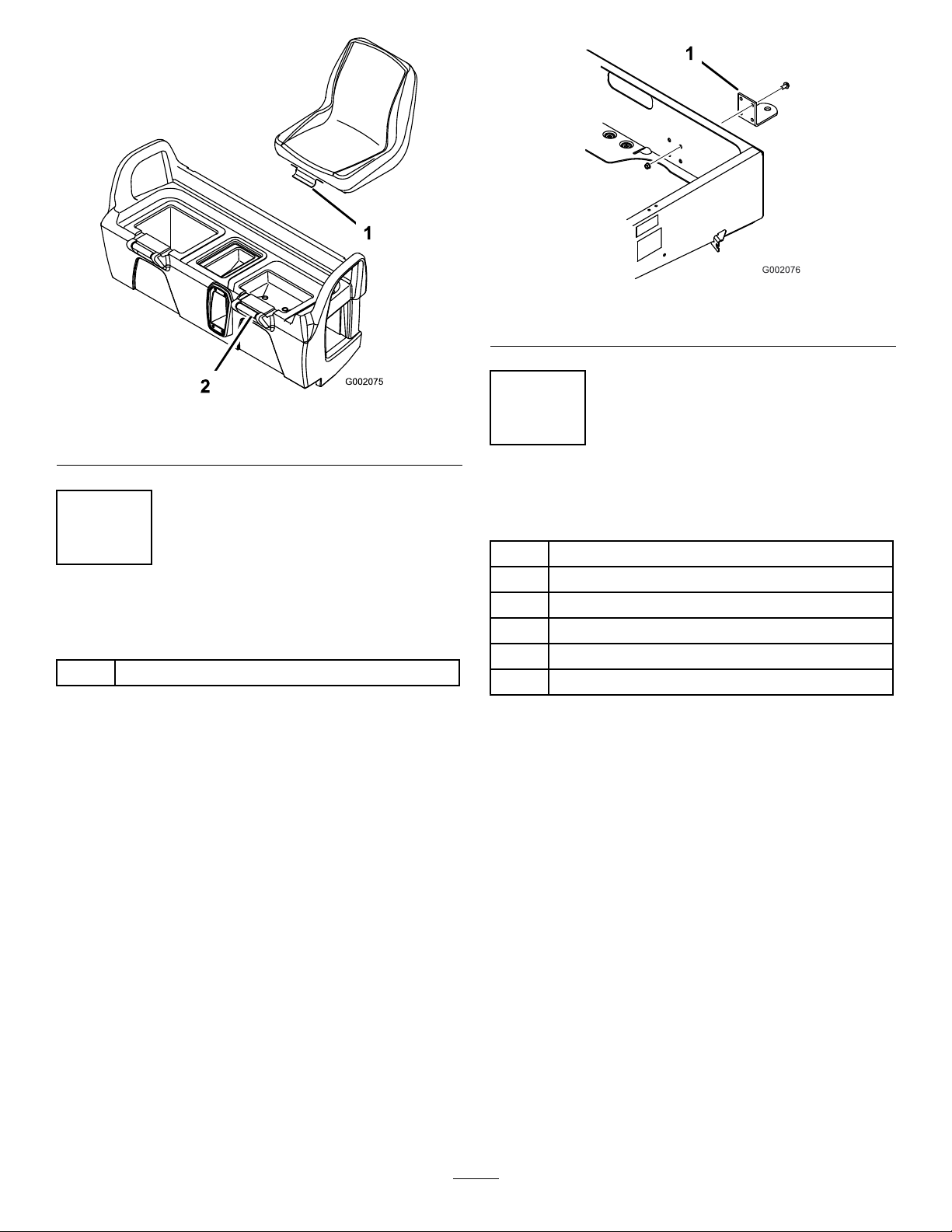

InstallingtheSteeringWheel

Partsneededforthisprocedure:

1

Steeringwheel

Procedure

Note:ThisprocedureisonlyneededforModelNo.

07277TC.

1.Removethenutandwasherfromthesteeringshaft.

2.Slidethesteeringwheelandwasherontotheshaft.

Positionthesteeringwheelontheshaftsothatthe

crossbeamishorizontalwhenthetiresarepointed

straightaheadandthethickerspokeofthesteering

wheelisdownward.

3.Securethesteeringwheeltotheshaftwiththenut

(Figure4).Torquethenutto18-22ft-lb(24-29N-m)

1Bumper

Procedure

Note:ThisprocedureisonlyneededforModelNo.

07277TC.

1.Removethe2bolts,washers,andnutssecuredtothe

frontoftheframe.

2.Alignthemountingholesandsecurethebumper

totheframewiththefastenerspreviouslyremoved

(Figure5).

Figure5

1.Bumper

Figure4

1.Steeringwheel

2.Nut4.Foamseal

3.Washer

4

InstallingtheSeats

Partsneededforthisprocedure:

2

Seat

Procedure

Note:ThisprocedureisonlyneededforModel

No.07277TC.

Inserttheseatbracketintotheseatbaseopeningand

pivottheseatdownward(Figure6).

11

Page 12

Figure6

1.Seatbracket2.Seatbase

Figure7

1.Hitch

6

InstallingtheCargoBox

Partsneededforthisprocedure:

5

InstallingtheHitch

Partsneededforthisprocedure:

1Hitch

Procedure

Note:ThisprocedureisonlyneededforModelNo.

07277TC.

1.Removethe4boltsandnutsfromtheinsiderear

oftheframe.

2.Alignthehitchwiththemountingholesonthe

frame.Securethehitchwiththescrewsandnuts

(Figure7).

1

Cargobox

1Right-handpivotbracket

1

Left-handpivotbracket

4

Flangeheadscrew(3/8x1inch)

1

Bolt(5/16x3/4inch)

1

Flangenut(5/16inch)

Procedure

Note:ThisprocedureisonlyneededforModel

No.07277TC.

1.Positionthecargoboxontotheframe.Thecargo

boxmustlayatandbecentered.

2.Mountthelefthandpivotbrackettotheleftrear

corneroftheframewith2angeheadscrews(3/8x

1inch).PositionthebracketasshowninFigure8.

12

Page 13

Figure8

1.Pivotbracket

3.Slidethecargoboxmountingholeontothepivot

bracket(Figure9).

Figure10

1.Proprod

2.Proprodclip

7.Tightentheboltandsecuretheothersideoftheclip

withanewbolt(5/16x3/4inch)andangenut

(5/16inch)(Figure10).

8.Lowerthecargobox.

3.Bolt(5/16x3/4inch)

4.Flangenut(5/16inch)

7

ActivatingtheBattery

NoPartsRequired

Procedure

None

Figure9

1.Cargobox3.Cargoboxmountinghole

2.Pivotbracket

4.Inserttherighthandpivotbracketintothemounting

holeinthecargoboxandthenmountittotheframe.

5.Haveanotherpersonhelptoraisethecargobox.

6.Loosentheboltsecuringtheproprodcliptothe

frameuntilyoucanslidetheJ-hookendoftheprop

rodundertheclip(Figure10).

Note:ThisprocedureisonlyneededforModelNo.

07277TC.

Ifthebatteryisnotlledwithelectrolyteoractivated,it

mustberemovedfromthevehicle,lledwithelectrolyte,

andcharged.Bulkelectrolytewith1.260specicgravity

mustbepurchasedfromalocalbatterysupplyoutlet.

1.Removethebatteryhold-downandliftthebattery

outofthebatterybase.

Batteryelectrolytecontainssulfuricacidwhich

isadeadlypoisonandcausessevereburns.

•Donotdrinkelectrolyteorallowittocontact

yourskin,eyesorclothing.Wearsafety

glassestoshieldyoureyesandrubbergloves

toprotectyourhands.

•Fillthebatterywherecleanwaterisalways

availableforushingtheskin.

2.Removethellercapsfromthebatteryandslowly

lleachcelluntilelectrolyteisjustabovetheplates.

13

Page 14

3.Replacethellercapsandconnecta3to4amp.

batterychargertothebatteryposts.Chargethe

batteryatarateof3to4amperesfor4to8hours

(12volts).Donotoverchargethebattery.

Chargingthebatteryproducesgassesthatcan

explode.

Neversmokenearthebatteryandkeepsparks

andamesawayfrombattery.

4.Whenthebatteryischarged,disconnectthecharger

fromtheelectricaloutletandbatteryposts.

5.Removethellercaps.Slowlyaddelectrolyteto

eachcelluntilelectrolyteisuptothellline.Install

thellercaps.

Important:Donotoverllthebattery.

Electrolytewilloverowontootherpartsofthe

vehicleandseverecorrosionanddeterioration

willresult.

Ifthevehiclewillberunwithmediumtoheavyloads

mostofthetime,setthetoe-inonthehighsideof

therecommendedamount.Ifitisgoingtoberun

withalightloadmostofthetime,setthetoe-inon

thelowsideoftherecommendedamount.

1.Measurethedistancebetweenbothofthefronttires

attheaxleheightatboththefrontandrearofthe

fronttires(Figure11).Axtureoralignmentgauge

isneededfortherearmeasurementofthefronttires

ataxleheight.Usethesamextureoralignment

gaugetoaccuratelymeasurethefrontofthefront

tiresataxleheight(Figure11).

6.Installthebattery;refertoInstallingtheBattery,

ElectricalSystemMaintenance,page31.

8

AdjustingtheFrontWheel

Toe-in

NoPartsRequired

Procedure

Thetoe-inshouldbe1/8-5/8inch(3-16mm)withthe

followingparameters:

•Thetirepressureshouldbeat12psi(83kPa).

•Therideheightshouldbecorrectbeforesettingthe

toe-in;refertotheAdjustingtheFrontSuspension

procedureinMaintenance,page25.

•Thevehicleshouldbedrivenbackandforthafew

timestorelaxtheA-arms.

•Measurethetoe-inwiththewheelsfacingstraight

aheadanda175-225lb(79-102kg)operatorinthe

driver’sseat.

Note:Thedrivershoulddriveuptothe

measurementareaandstayseatedinthevehicle

whilethemeasurementisbeingtaken.

Figure11

1.Tirecenterline-back4.Fixture

2.Tirecenterline-front

3.Axlecenterline

2.Ifthemeasurementdoesnotfallwithinthespecied

range(refertothedimensionsandparametersatthe

beginningofthisprocedure),loosenthejamnutsat

bothendsofthetierods(Figure12).

1.Jamnut2.Tierod

3.Rotatebothtierodstomovethefrontofthetire

inwardoroutward.

4.Tightenthetierodjamnutswhentheadjustmentis

correct.

5.Ensurethatthereisfulltravelofthesteeringwheel

inbothdirections.

5.Axlecenterlinedistance

6.6inches(15cm)ruler

Figure12

14

Page 15

9

ReadingtheManualand

ViewingtheSafetyVideo

Partsneededforthisprocedure:

1

Operator’sManual

1

EngineOperator’sManual

1

PartsCatalog

1

SafetyVideo

1

RegistrationCard

1PredeliveryInspectionForm

2Key

Procedure

•ReadtheOperator’ sManualandEngineOperator’s

Manual.

•Viewthesafetyvideo.

•Fillouttheregistrationcard.

•CompletethePredeliveryInspectionForm.

15

Page 16

ProductOverview

1.Steeringwheel

2.Gearshiftselector

Figure13

3.Parkingbrake

4.Fuelcap6.T owingtongue

5.Cargobox7.Cargoboxreleaselever

Controls

AcceleratorPedal

Theacceleratorpedal(Figure14)givestheoperatorthe

abilitytovarygroundspeedofthevehicle.Pressing

thepedalstartstheengine.Pressingthepedalfarther

increasesgroundspeed.Releasingthepedalwillslow

thevehicleandtheenginewillstoprunning.Maximum

forwardspeedis16mph(26km/h).

Figure14

1.Acceleratorpedal2.Brakepedal

BrakePedal

Thebrakepedalisusedtostoporslowthevehicle

(Figure14).

Brakescanbecomewornorcanbemisadjusted

resultinginpersonalinjury.

Ifbrakepedaltravelstowithin1inch(25mm)

ofthevehicleoorboard,thebrakesmustbe

adjustedorrepaired.

ParkingBrake

Theparkingbrakeisbetweentheseats(Figure15).

Whenevertheengineisshutoff,theparkingbrake

mustbeengagedtopreventaccidentalmovementof

thevehicle.T oengagetheparkingbrake,pullbackon

thelever.Todisengage,pushtheleverforward.Ifthe

vehicleisparkedonasteepgrade,makesurethatthe

parkingbrakeisapplied.Placeblocksatthedownhill

sideofthewheels.

16

Page 17

Figure15

1.Parkingbrakelever

ChokeControl

Thechokecontrolislocatedbelowandtotherightof

theoperator’sseat.Tostartacoldengine,pullthechoke

controloutward(Figure16).Aftertheenginestarts,

regulatethechoketokeeptheenginerunningsmoothly.

Assoonaspossible,pushthecontrolintotheOff

position.Awarmenginerequireslittleornochoking.

Figure16

1.Choke2.Gearshiftselector

Figure17

1.Ignitionswitch

2.Hourmeter5.PowerPoint

3.Lightswitch6.HornButton

4.Oillight

HourMeter

Thehourmeter(Figure17)indicatesthetotalnumber

ofhourstheenginehasrun.Thehourmeterstartsto

functionwhenevertheacceleratorispressed.

OilLight

Theoillightwarnstheoperatoriftheengineoillevel

dropsbelowasafelevel(Figure17).Ifthelightcomes

onandremainslit,theoillevelshouldbecheckedand

oiladdedifnecessary;refertoCheckingtheEngineOil

inOperation,page19.

Note:Theoillightmayicker.Thisisnormalandno

actionneedstobetaken.

GearShiftSelector

Thegearshiftselectorhasthreepositions:forward,

reverse,andneutral(Figure16).Theenginewillstart

andruninanyofthethreepositions.

Note:IfthegearshiftselectorisinReversewhenthe

ignitionisturnedon,abuzzerwillsoundtowarnthe

operator.

Important:Alwaysstopthevehiclebefore

changinggears.

IgnitionSwitch

Theignitionswitch(Figure17),usedtostartandstopthe

engine,hastwopositions:OffandOn.Rotatethekey

clockwisetotheOnpositiontoallowoperation.When

thevehicleisstopped,rotatethekeycounterclockwise

totheOffposition.Removethekeyfromtheignition.

LightSwitch

Toggletheswitchtoactivatetheheadlights.Pushto

turnthelightson(Figure17).

PowerPoint

Usethepowerpointtopower12voltoptionalelectrical

accessories(Figure17).

HornButton

Pressthehornbuttontosoundthehorn(Figure17).

FuelGauge

Thefuelgauge(Figure18)showstheamountoffuel

inthetank.

17

Page 18

Figure18

1.Fuelgauge

PassengerHandHolds

Thepassengerhandholdsarelocatedontherightsideof

thedashpanelandattheoutsideofeachseat(Figure19).

Figure19

1.Passengerhandhold2.Hiprestraint

18

Page 19

Specications

Note:Specicationsanddesignaresubjecttochangewithoutnotice.

Baseweight

Ratedcapacity(onlevelground)1650lb(749kg)total,including200lb(90.7kg)operatorand200lb(90.7kg)passenger ,load,

Maximumgrossvehicleweight

(GVW)(onlevelground)

Maximumcargocapacity(onlevel

ground)

Towcapacity:

StandardHitchTongueweight50lb(23kg)Maximumtrailerweight400lb(182kg)

HeavyDutyHitch

Overallwidth59inches(150cm)

Overalllength115inches(292cm)

Groundclearance9-1/4inches(23.5cm)atthefrontwithnoloadoroperator,7inches(18cm)attherearwith

Wheelbase

Wheeltread(centerlinetocenter

line)

Cargoboxlength46inches(1 16.8cm)inside,51inches(129.5cm)outside

Cargoboxwidth49inches(124.5cm)inside,54inches(137.2cm)outside

Cargoboxheight10inches(25.4cm)inside

Dry1050lb(476kg)

trailertongueweight,grosstrailerweight,accessories,andattachments

2700lb(1225kg)total,includingalloftheweightslistedabove

1250lb(567kg)total,includingtrailertongueweightandgrosstrailerweight

Tongueweight100lb(45kg)Maximumtrailerweight800lb(363kg)

noloadoroperator

79inches(200.7cm)

49inches(124.5cm)inthefront,48-1/4inches(122.6cm)intherear

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesareavailableforusewiththemachinetoenhanceand

expanditscapabilities.ContactyourAuthorizedServiceDealerorDistributororgotowww .Toro.comforalistof

allapprovedattachmentsandaccessories.

Operation

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

ThinkSafetyFirst

Pleasecarefullyreadallofthesafetyinstructionsand

decalsinthesafetysection.Knowingthisinformation

couldhelpyouorbystandersavoidinjury.

Pre-StartingChecks

Checkthefollowingitemseachtimeyoubeginusingthe

vehiclefortheday:

•Checkthetirepressure.

Note:Thesetiresaredifferentthancartires;they

requirelesspressuretominimizeturfcompaction

anddamage.

•Checkalluidlevelsandaddtheappropriateamount

ofspecieduids,ifanyarefoundtobelow .

•Checkthebrakepedaloperation.

•Ensurethatthelightsareworking.

•Turnthesteeringwheeltotheleftandrighttocheck

steeringresponse.

•Checkforoilleaks,looseparts,andanyother

noticeablemalfunctions.Makesuretheengineisoff

andallmovingpartshavestoppedbeforechecking

foroilleaks,looseparts,andothermalfunctions.

Ifanyoftheaboveitemsarenotcorrect,notify

yourmechanicorcheckwithyoursupervisorbefore

takingthevehicleoutfortheday.Yoursupervisor

maywantyoutocheckotheritemsonadailybasis,

soaskwhatyourresponsibilitiesare.

CheckingtheEngineOil

Note:Theengineisshippedwithoilinthecrankcase;

however,theleveloftheoilmustbecheckedbeforeand

aftertheengineisrststarted.

19

Page 20

Checktheengineoillevelbeforestartingtheengine

eachday.

1.Positionthemachineonalevelsurface.

2.Cleanaroundtheoildipstick(Figure20)sodirt

cannotfallintotheholeanddamagetheengine.

Figure20

1.Oildipstick

3.Removetheoildipstickandwipetheendclean.

4.Slidetheoildipstickintothellertubefullyseating

it.Pullthedipstickoutandlookattheend.

AddingFuel

Usefresh,clean,unleadedregulargasolinesuitablefor

automotiveuse(87pumpoctaneminimum).Leaded

gasolinemaybeusedifunleadedregularisnotavailable.

Important:Neverusegasolinecontaining

methanol,gasolinecontainingmorethan10%

ethanol,gasolineadditives,orwhitegasbecause

enginefuelsystemdamagecouldresult.

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areor

explosionfromgasolinecanburnyouand

othersandcandamageproperty.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupany

gasolinethatspills.

•Neverllthefueltankinsideanenclosed

trailer.

Iftheoillevelislow ,removethellercapandaddoil

ofthepropertypetoraisethelevelto,butnotover,

theFullmarkonthedipstick.RefertoServicingthe

EngineOilinEngineMaintenance,page28,forthe

properoiltypeandviscosity.Addtheoilslowlyand

checktheleveloftenduringthisprocess.Donot

overll.

5.Installtheoildipstickrmlyinplace.

CheckingtheBrakeFluid

Level

Checkthebrakeuidlevelbeforetheengineisrst

started;refertoCheckingtheBrakeFluidLevelinBrake

Maintenance,page38.

CheckingtheTirePressure

Checkthetirepressureevery8hoursordailytoensure

properlevels.

Theairpressurerangeinthefrontandreartiresis

8–22psi(55–103kPa).

•Donotllthefueltankcompletelyfull.Add

gasolinetothefueltankuntilthelevelis1/4

to1/2inch(6to13mm)belowthebottomof

thellerneck.Thisemptyspaceinthetank

allowsgasolinetoexpand.

•Neversmokewhenhandlinggasoline,and

stayawayfromanopenameorwhere

gasolinefumesmaybeignitedbyaspark.

•Storegasolineinanapprovedcontainerand

keepitoutofthereachofchildren.Never

buymorethana30-daysupplyofgasoline.

•Donotoperatewithoutentireexhaust

systeminplaceandinproperworking

condition.

Theairpressureneededisdeterminedbythepayload

carried.Thelowertheairpressure,thelessthe

compaction,smoothertheride,andtiremarksare

minimized.Lowerpressureshouldnotbeusedfor

heavypayloadsathighspeeds.

Higherpressuresshouldbeusedforheavierpayloadsat

higherspeeds.Donotexceedthemaximumpressure.

20

Page 21

CheckingtheTransmissionOil

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingaspark

whichcanignitethegasolinevapors.Are

orexplosionfromgasolinecanburnyouand

othersandcandamageproperty.

•Alwaysplacegasolinecontainersonthe

groundawayfromyourvehiclebeforelling.

•Donotllgasolinecontainersinsidea

vehicleoronatruckortrailerbedbecause

interiorcarpetsorplastictruckbedliners

mayinsulatethecontainerandslowtheloss

ofanystaticcharge.

•Whenpractical,removegas-powered

equipmentfromthetruckortrailerand

refueltheequipmentwithitswheelsonthe

ground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfroma

portablecontainer,ratherthanfroma

gasolinedispensernozzle.

•Ifagasolinedispensernozzlemustbeused,

keepthenozzleincontactwiththerimof

thefueltankorcontaineropeningatall

timesuntilfuelingiscomplete.

Level

Thetransaxleuidlevelshouldbeatthebottomof

thelevelindicatorhole(Figure22).Ifitisnot,llthe

reservoirwiththeappropriateuid;refertoChanging

theTransaxleFluidinDriveSystemMaintenance,

page34.

Figure22

1.Levelindicatorhole

StartingtheEngine

1.Sitintheoperator’sseat,insertthekeyintothe

ignitionswitch,androtatethekeyclockwisetothe

Onposition.

Note:IfthegearshiftselectorisinReverse,the

buzzerwillsoundtowarntheoperator.

2.Movethegearshiftselectortothedesiredposition.

FillingtheFuelTank

Thefueltankcapacityisapproximately7gallons(26.5l).

1.Shuttheengineoffandsettheparkingbrake.

2.Cleantheareaaroundthefueltankcap(Figure21).

Figure21

1.Fueltankcap

3.Removethefueltankcap.

4.Fillthetanktoabout1inch(25mm)belowthetop

oftank,(bottomofthellerneck).Thisspaceinthe

tankallowsgasolinetoexpand.Donotoverll.

5.Installthefueltankcapsecurely .Wipeupanyfuel

thatmayhavespilled.

3.Releasetheparkingbrake.

4.Slowlystepontheacceleratorpedal.

Note:Iftheengineiscold,pressandholdthe

acceleratorpedalabouthalf-waydown,andpullthe

chokeknobouttotheOnposition.Returnthe

chokeknobtoOffaftertheenginewarmsup.

Important:Donotattempttopushortowthe

vehicletogetitstarted.

StoppingtheVehicle

Tostopthevehicle,removeyourfootfromthe

acceleratorpedalandslowlypressthebrakepedal.

Note:Stoppingdistancemayvarydependingonthe

vehicleloadandspeed.

ParkingtheVehicle

1.Engagetheparkingbrakeandrotatetheignition

keytoOff.

2.Removethekeyfromtheignitionswitchtoprevent

accidentalstarting.

21

Page 22

OperatingtheCargoBox

RaisingtheBox

LoweringtheBox

Theweightoftheboxmaybeheavy.Handsor

otherbodypartscouldbecrushed.

Drivingthevehiclewiththecargoboxraised

maycausethevehicletotiporrolleasier.The

boxstructuremaybecomedamagedifyou

operatethevehiclewiththeboxraised.

•Onlyoperatethevehiclewhenthecargobox

isdown.

•Afterdumpingaload,lowerthecargobox.

1.Lifttheleveroneithersideoftheboxandliftthe

boxup(Figure23).

Figure23

1.Lever

Keephandsandotherbodypartsclearwhen

loweringthebox.

Pulltheproprodoutofthedetentslotandlowerthe

boxuntilitlatchesintoplace.

AdjustingtheBoxLatches

Iftheboxlatchdoesnotlatchtightly,vibratingupand

downasyoudrivethevehicle,youcanadjustthelatch

poststomakethelatchestsnugly.

1.Loosenthenutontheendofthelatchpost

(Figure25).

2.Pulltheproprodintothedetentslot,securingthe

box(Figure24).

Figure24

1.Proprod

Figure25

1.Latch3.Latchpost

2.Nut

2.Turnthelatchpostclockwiseuntilitissnugagainst

thelatchandthentightenthenut(Figure25).

3.Repeatthisprocedureforthelatchontheotherside

ofthevehicle.

OperatingtheTailgateLatches

1.Toopenthetailgatelatches,liftthelatchhandlesup

(Figure26).Thelatcheswillspringouttowardthe

centerofthetailgate.Slowlylowerthetailgate.

Note:Youmayneedtopushtheendofthetailgate

in(especiallyifthereisaloadagainstthetailgate)

beforethelatcheswillspringtowardthecenterof

thetailgateandrelease.

22

Page 23

Seethetablebelowforloadvolumelimitswithvarious

materials:

Figure26

1.Tailgatelatch

2.Toclosethetailgatelatches,liftthehandlesupward

andslidethemtowardtheoutsideofthevehicle.

3.Pushthelatchhandlesdownwardtosecurethelatch

andtailgate.

BreakinginaNewVehicle

Toprovideproperperformanceandlongvehiclelife,

followtheseguidelinesfortherst100operatinghours:

•Checktheuidandengineoillevelsregularlyandbe

alertforindicationsofoverheatinginanycomponent

ofthevehicle.

•Afterstartingacoldengine,letitwarmupforabout

15secondsbeforeaccelerating.

•Avoidhardbrakingsituationsfortherstseveral

hoursofnewvehiclebreak-inoperation.Newbrake

liningsmaynotbeatoptimumperformanceuntil

severalhoursofusehascausedthebrakestobecome

burnished(broken-in).

MaterialMax.cargoboxcapacity

Gravel,dry3/4full(approx.)

Gravel,wet1/2full(approx.)

Sand,dry3/4full

Sand,wet1/2full

WoodFull

BarkFull

Earth,packed

(onlevelground)

3/4full(approx.)

TransportingtheVehicle

Formovingthevehiclelongdistances,atrailershould

beused.Makesurethatthevehicleissecuredtothe

trailer.RefertoFigure27andFigure28forthelocation

ofthetie-downpoints.

Looseseatsmayfalloffofthevehicleandtrailer

whentransportingandlandonanothervehicle

orbecomeanobstructionontheroad.

Removetheseatsormakesurethattheseats

aresecurelyfastenedinthedetents.

•Varythevehiclespeedduringoperation.Avoidfast

startsandquickstops.

•Abreak-inoilforengineisnotrequired.Original

engineoilisthesametypespeciedforregularoil

changes.

•RefertotheMaintenancesectionforanyspeciallow

hourchecks.

•Checkthefrontsuspensionpositioningandadjustit

ifnecessary;refertoAdjustingtheFrontSuspension

inDriveSystemMaintenance,page34.

LoadingtheCargoBox

Thecapacityofthecargoboxis13ft

3

(0.37m

amount(volume)ofmaterialthatcanbeplacedinthe

boxwithoutexceedingthevehicleloadratingscanvary

greatlydependingonthedensityofthematerial.For

example,alevelboxofwetsandweighs1500lb(680kg),

whichexceedstheloadratingby250lb(113kg).But

alevelboxofwoodweighs650lb(295kg),whichis

undertheloadrating.

3

).The

Figure27

1.Tiedownpoints

TowingtheVehicle

Incaseofanemergency,thevehiclecanbetowedfora

shortdistance.However,wedonotrecommendthisas

astandardprocedure.

23

Page 24

weight=50lb(23kg),thenthemaximumcargoload=

800lb(363kg)

Towingatexcessivespeedscouldcausealoss

ofsteeringcontrol,resultinginpersonalinjury.

Nevertowthevehiclefasterthan5mph

(8km/h).

Towingthevehicleisatwopersonjob.Ifthemachine

mustbemovedaconsiderabledistance,transportitona

truckortrailer;refertoTransportingtheVehicle.

1.Removethedrivebelt;refertoReplacingtheDrive

BeltinBeltMaintenance,page39.

2.Afxatowlinetothetongueonthefrontofthe

frame(Figure28).

3.Putthevehicleinneutralandreleasetheparking

brake.

Toprovideadequatebrakingandtraction,alwaysload

thecargoboxwhentrailering.DonotexceedtheGTW

limits.

Avoidparkingavehiclewithatraileronahill.Ifyou

mustparkonahill,engagetheparkingbrakeandblock

thetrailertires.

Figure28

1.Towingtongueandtiedownpoint

TowingaTrailer

Thevehicleiscapableofpullingtrailers.Twotypes

oftowhitchesareavailableforthevehicle,depending

onyourapplication.ContactyourAuthorizedToro

Distributorfordetails.

Whenhaulingcargoortowingatrailer,donotoverload

yourvehicleortrailer.Overloadingcancausepoor

performanceordamagetothebrakes,axle,engine,

transaxle,steering,suspension,bodystructure,ortires.

Alwaysloadatrailerwith60%ofthecargoweightin

thefrontofthetrailer.Thisplacesapproximately10%

oftheGrossTrailerWeight(GTW)onthetowhitchof

thevehicle.

Themaximumcargoloadshallnotexceed1250lb

(567kg),includingtheGTWandtongueweight.For

example,iftheGTW=400lb(181.5kg)andtongue

24

Page 25

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst8operating

hours

Aftertherst25operating

hours

Beforeeachuseordaily

Every50hours

Every100hours

MaintenanceProcedure

•Changetheengineoil.

•Checktheconditionandtensionofthedrivebelt.

•Checkthetensionofthestartergeneratorbelt.

•Checkthefrontwheeltoe-inandfrontsuspension.

•Checktheengineoil.

•Checkthetirepressure.

•Checkthetransmissionoillevel.

•Checkthebrakeuidlevel.

•Changetheengineoil(twiceasofteninspecialoperatingconditions;referto

MaintainingtheVehicleunderSpecialOperatingConditions).

•Checkthebatterycableconnectionsforwearordamage.

•Checkthebatteryelectrolytelevel.

•Greasethebearingsandbushings.

•Inspectandcleantheairlterelement(twiceasofteninspecialoperatingconditions;

refertoMaintainingtheVehicleunderSpecialOperatingConditions).

•Changetheoillter(twiceasofteninspecialoperatingconditions;referto

MaintainingtheVehicleunderSpecialOperatingConditions).

•ChecktheoperationoftheNeutralgearshiftposition.

•Inspecttheconditionandwearofthetires.

•T orquethewheellugnutsto45-65ft-lb(61-88N-m).

•Checkthefrontwheeltoe-inandfrontsuspension.

•Cleantheenginecoolingareas(twiceasofteninspecialoperatingconditions;refer

toMaintainingtheVehicleunderSpecialOperatingConditions).

•Inspectthebrakes.

•Replacetheairlterelement.

Every200hours

Every400hours

Every800hours

Yearly

Important:Refertoyour

•Adjusttheparkingbrake.

•Checktheconditionandtensionofthedrivebelt.

•Checkthetensionofthestartergeneratorbelt.

•Inspectthefuellinesandconnections.

•Cleanandlubricatetheprimarydriveclutch.

•Replacethesparkplugs.

•Replacethefuellter.

•Changethetransaxleuid.

•CompleteallyearlymaintenanceproceduresspeciedintheEngineOperator’s

Engine Operator’ s Man ual

DailyMaintenanceChecklist

Duplicatethispageforroutineuse.

Manual.

foradditionalmaintenanceprocedures.

25

Page 26

Checkbrakeandparking

brakeoperation.

Checkgearshift/neutral

operation.

Checkfuellevel.

Checkengineoillevel.

Checktransaxleoillevel.

Inspectairlter.

Inspectenginecoolingns.

Checkunusualengine

noises.

Checkunusualoperating

noises.

Checktirepressure.

Checkuidleaks.

Checkinstrument

operation.

Checkaccelerator

operation.

Checkrideheightand

toe-in.

Lubricateallgrease

ttings.

Touchupdamagedpaint.

Fortheweekof: MaintenanceCheckItem

Mon.Tues.Wed.Thurs.Fri.

Sat.Sun.

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriously

injureyouorotherbystanders.

Removethekeyfromtheignitionanddisconnectthewirefromthesparkplugbeforeyoudoany

maintenance.Setthewireasidesothatitdoesnotaccidentallycontactthesparkplug.

Thebedmustberaisedtoperformsomeroutinemaintenance.

Araisedbedcanfallandinjurepersonsthatareunderneathit.

•Alwaysusetheproprodtoholdthebedupbeforeworkingunderit.

•Removeanyloadmaterialfromthebedbeforeworkingunderit.

26

Page 27

Premaintenance

G002092

1 1

Procedures

MaintainingtheVehicleunder

SpecialOperatingConditions

Ifthevehicleissubjectedtoanyoftheconditions

listedbelow,maintenanceshouldbeperformedtwice

asfrequently .

•Desertoperation

•Coldclimateoperation(below50°F[10°C])

•Trailertowing

•Drivingtimetypicallylessthan5minutes

•Frequentoperationindustyconditions

•Constructionwork

•Afterextendedoperationinmud,sand,water,or

similardirtyconditions,haveyourbrakesinspected

andcleanedassoonaspossible.Thiswillprevent

anyabrasivematerialfromcausingexcessivewear.

•Underfrequentheavydutyoperatingconditions,

lubricateallgreasettingsandinspectaircleaner

dailytopreventexcessivewear.

JackingtheVehicle

Whenevertheengineisrunforroutinemaintenance

and/orenginediagnostics,therearwheelsofthevehicle

shouldbe1inch(25mm)offthegroundwiththerear

axlesupportedonjackstands.

Figure29

1.Frontjackingpoint

Figure30

1.Rearjackingpoints

Thevehiclemaybeunstablewhenusinga

jack.Itcouldslipoffthejack,injuringanyone

beneathit.

•Donotstarttheenginewhilethevehicleis

onajack.

•Alwaysremovethekeyfromtheignition

beforegettingoffofthevehicle.

•Blockthetireswhenthevehicleisonajack.

Thejackingpointatthefrontofthevehicleisonthe

frontoftheframebehindthetowingtongue(Figure29)

Thejackingpointattherearofthevehicleisunderthe

axletubes(Figure30).

27

Page 28

Lubrication

Lubricateallofthebearingsandbushingsevery100

hoursoronceayear,whicheveroccursrst.Grease

themmorefrequentlywhenusingthevehiclefor

heavy-dutyoperations.

GreaseType:Number2GeneralPurposeLithiumBase

Grease

AddingGrease

1.Wipethegreasettingcleansoforeignmatter

cannotbeforcedintothebearingorbushing.

2.Pumpgreaseintothebearingorbushing.

3.Wipeoffexcessgrease.

Thegreasettingsarelocatedatthefourtierodends

Figure31)andthetwokingpins(Figure32).

(

Figure31

EngineMaintenance

ServicingtheAirCleaner

Checktheaircleanerbodyfordamagewhichcould

possiblycauseanairleak.Replaceadamagedaircleaner

body.

Ensurethecoverissealingaroundtheaircleanerbody.

AirCleanerFilter:Inspectafterevery100operating

hours;replaceafterevery200hoursorsoonerifdirty

ordamaged.

Note:Servicetheaircleanermorefrequently(every

fewhours)ifoperatingconditionsareextremelydusty

orsandy .

RemovingtheFilterElement

1.Parkthemachineonalevelsurface,settheparking

brake,turntheignitionoff,andremovethekey.

2.Raisethebedandsecureitwiththeproprod.

3.Releasethelatchessecuringtheaircleanercover

totheaircleanerbody.Separatethecoverfrom

thebody.Cleantheinsideoftheaircleanercover

(Figure33).

4.Gentlyslidethelteroutoftheaircleanerbodyto

reducetheamountofdustdislodged(Figure33).

Avoidknockingthelteragainsttheaircleanerbody.

Figure32

Figure33

1.Aircleanerlatches3.Filter

2.Cover

5.Inspectthelteranddiscarditifitisdamaged.

CleaningtheFilterElement

Important:Donotwashorreuseadamagedlter.

•Washingmethod:

1.Prepareasolutionofltercleanerandwater

andsoakthelterelementforabout15minutes.

28

Page 29

Refertothedirectionsontheltercleanercarton

forcompleteinformation.

Note:Changetheoilandoilltermorefrequently

whenoperatingconditionsareextremelydustyorsandy .

2.Aftersoakingthelterfor15minutes,rinseit

withclearwater.Rinsethelterfromtheclean

sidetothedirtyside.

Important:T opreventdamagetothelter

element,themaximumwaterpressuremust

notexceed40psi.(276kPa).

3.Drythelterelementusingwarm,owingairat

160°F(71°C)maximum,orallowtheelement

toair-dry.

Important:Donotusealightbulbtodrythe

lterelementbecausedamagecouldresult.

•Compressedairmethod:

1.Blowcompressedairfromtheinsidetothe

outsideofthedrylterelement.Keeptheair

hosenozzleatleast2inches(51mm)fromthe

lterandmovethenozzleupanddownwhile

rotatingthelterelement.

Important:T opreventdamagetothelter

element,donotexceed100psi(689kPa)air

pressure.

2.Inspectthelterelementforholesandtearsby

lookingthroughtheltertowardabrightlight.

InstallingtheFilterElement

Important:T opreventenginedamage,always

operatetheenginewiththecompleteaircleaner

assemblyinstalled.

1.Inspectthenewlterforshippingdamage.Check

thesealingendofthelter.

OilType:Detergentoil(APIserviceSF,SG,SH,SJ,or

higher)

CrankcaseCapacity:48oz./1-1/2qt.(1.4liters)when

thelterischanged

Viscosity:Seethetablebelow

Figure34

CheckingtheOilLevel

Tochecktheoillevel,refertoCheckingtheEngineOil

inOperation,page19.

ChangingtheOil

1.Startthevehicleandletitrunforafewminutesto

warmtheoil.

2.Parkthemachineonalevelsurface,settheparking

brake,turntheignitionoff,andremovethekey.

Important:Donotinstalladamagedlter.

2.Insertthenewlterintoaircleanerbody .Ensure

thelterissealedproperlybyapplyingpressureto

theouterrimofthelterwheninstallingit.Donot

pressontheexiblecenterofthelter.

3.Installthecoverandsecurethelatches.

ServicingtheEngineOil

Checktheoillevelbeforeeachuse.

Changetheoilaftertherst8operatinghoursandevery

50hoursthereafter.Changetheoiltwiceasoftenin

specialoperatingconditions;refertoMaintainingthe

VehicleunderSpecialOperatingConditions.

Replacetheoillterevery100hours.

3.Raisethebedandsecureitwiththeproprod.

4.Disconnectthesparkplugwiresandbatterycables.

5.Removethedrainplug(Figure35)andlettheoil

owintoadrainpan.Whentheoilstops,installthe

drainplug.

Note:Disposeoftheusedoilatacertiedrecycling

center.

29

Page 30

Figure35

1.Engineoildrainplug

2.Engineoillter

6.Pouroilintothellopeninguntiltheoillevelisup

totheFullmarkonthedipstick.Addtheoilslowly

andchecktheleveloftenduringthisprocess.Do

notoverll.

7.Installtheoilllcapanddipstickrmlyinplace.

ChangingtheOilFilter

Replacetheoillterevery100operatinghoursoryearly ,

whicheveroccursrst.

1.Draintheoilfromtheengine;refertoChanging

theOil.

2.Removetheexistingoillter(Figure35).

2.Pullthesparkplugwiresoffofthesparkplugsand

removetheplugsfromthecylinderhead.

3.Checktheconditionofthesideelectrode,center

electrode,andcenterelectrodeinsulatortoensure

thatthereisnodamage(Figure36).

Figure36

1.Centerelectrodeinsulator3.Airgap(nottoscale)

2.Sideelectrode

Important:Acracked,fouled,dirty,or

malfunctioningsparkplugmustbereplaced.Do

notsand-blast,scrape,orcleantheelectrodesby

usingawirebrushbecausegritmayeventually

releasefromtheplugandfallintothecylinder.

Theresultisusuallyadamagedengine.

3.Applyalightcoatofcleanoiltothenewltergasket.

4.Screwthenewlteronuntilthegasketcontactsthe

mountingplate,thentightenthelteranadditional

1/2to3/4turnfurther.Donotovertighten.

5.Fillthecrankcasewiththepropertypeofnewoil.

6.Startandruntheenginetocheckforleaks.

7.Stoptheengineandchecktheoillevel.Addoilif

necessary.

ServicingtheSparkPlugs

Replacethesparkplugsafterevery800operatinghours

oryearly,whicheveroccursrst,toensureproperengine

performanceandreducetheexhaustemissionlevel.

Type:ChampionRC14YC(orequivalent)

AirGap:0.030inch(0.762mm)

Note:Thesparkplugsusuallylastalongtime;however,

theplugsshouldberemovedandcheckedwheneverthe

enginemalfunctions.

4.Settheairgapbetweenthecenterandsideelectrodes

at0.030inch(0.762mm)(Figure36).

5.Installthecorrectlygappedsparkplugandtighten

theplugto18-22ft-lb(24-30N-m).Ifatorque

wrenchisnotused,tightentheplugrmly.

6.Installthesparkplugwires.

1.Cleantheareaaroundthesparkplugssothatforeign

mattercannotfallintothecylinderwhenthespark

plugisremoved.

30

Page 31

FuelSystem

ElectricalSystem

Maintenance

InspectingFuelLinesand

Connections

Checkthefuellinesandconnectionsevery400operating

hoursoryearly ,whicheveroccursrst.Inspectthemfor

deterioration,damage,orlooseconnections.

ReplacingtheFuelFilter

Replacethefuellterevery800operatinghoursor

yearly,whicheveroccursrst.

1.Raisetheboxandsupportitwiththeproprod.

2.Placeacleancontainerunderthefuellter.

3.Removetheclampssecuringthefuelltertothefuel

lines(Figure37).

Maintenance

ReplacingtheFuses

Thereare3fusesintheelectricalsystem.Theyare

locatedbeneaththebedinaboxontherighthandside

oftheframe(Figure38).

IgnitionSystem

Lights10amp.

PowerPoint

Figure38

1.Ignitionsystem3.Powerpoint

2.Lights

10amp.(15amp.max.)

10amp.

Figure37

1.Fuellter

4.Installthereplacementltertothefuellineswiththe

clampspreviouslyremoved.

Mounttheltersothatthearrowpointstowardthe

carburetor.

ReplacingtheHeadlights

Specication:GEHeadlight#H7610

1.Settheparkingbrake,turntheignitionoff,and

removethekey.

2.Reachbeneaththedashandpushtheheadlightout

ofthehood.

3.Removethescrewsattachingthewireharnessto

theheadlight.

4.Removetherubbersealfromaroundtheheadlight

(Figure39).Discardtheheadlight.

31

Page 32

RemovingtheBattery

1.Positionthevehicleonalevelsurface,settheparking

brake,turntheignitionoff,andremovethekey.

2.Raisethebedandsecureitwiththeproprod.

3.Removethebatteryhold-down.

4.Disconnectthenegative(black)groundcablefrom

thebatterypost.

Figure39

1.Rubberseal

2.Insidenotch-alignwiththe

notchontheheadlight

3.Outsidenotch-alignwith

notchinhood

4.Headlight

5.Alignthenotchontheinsideofthesealwiththe

notchonthenewheadlight(Figure39).Slidetheseal

ontotheheadlightuntilthesealisrmlyinplace.

6.Attachtheheadlighttothewireharnessusingthe

previouslyremovedscrews.

7.Alignthenotchontheoutsideofthesealwiththe

notchinthehood.Pushtheheadlightandsealinto

thehooduntilitisrmlyinplace.

Note:Applyingsoapywatertotheoutsideofthe

sealmayaidinslidingthesealintothehood.

ServicingtheBattery

Warning

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

Washhandsafterhandling.

Incorrectbatterycableroutingcoulddamage

thevehicleandcables,causingsparks.Sparks

cancausethebatterygassestoexplode,

resultinginpersonalinjury.

•Alwaysdisconnectthenegative(black)

batterycablebeforedisconnectingthe

positive(red)cable.

•Alwaysreconnectthepositive(red)battery

cablebeforereconnectingthenegative

(black)cable.

•Alwayskeepthebatterystrapinplaceto

protectandsecurethebattery.

Batteryterminalsormetaltoolscouldshort

againstmetalvehiclecomponents,causing

sparks.Sparkscancausethebatterygassesto

explode,resultinginpersonalinjury.

•Whenremovingorinstallingthebattery,do

notallowthebatteryterminalstotouchany

metalpartsofthevehicle.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsofthe

vehicle.

5.Disconnectthepositive(red)cablefromthebattery

post.

Important:Donotjumpstartthevehicle.

Alwayskeepthebatterycleanandfullycharged.Use

apapertoweltocleanthebatteryandbatterybox.If

thebatteryterminalsarecorroded,cleanthemwitha

solutionoffourpartswaterandonepartbakingsoda.

Applyalightcoatingofgreasetothebatteryterminals

topreventcorrosion.

Voltage:12voltwith280coldcrankingAmps@0°F

(-18°C).

6.Removethebatteryfromthechassis.

InstallingtheBattery

1.Setthebatteryonthebatterybasesothebattery

postsaretowardtherearofthevehicle.

2.Connectthepositive(red)cabletothepositive(+)

batterypostandthenegative(black)cabletothe

negative(-)batterypostusingtheboltsandwing

32

Page 33

nuts.Slidetherubberbootoverthepositivebattery

post.

3.Replacethebatteryhold-downtosecurethebattery

tothebase.

Important:Alwayskeepthebatteryhold-down

inplacetoprotectandsecurethebattery.

CheckingtheElectrolyteLevel

2.Connecta3to4ampbatterychargertothebattery

posts.Chargethebatteryatarateof3to4amperes

for4to8hours(12volts).Donotoverchargethe

battery.

Chargingthebatteryproducesgassesthatcan

explode.

Checktheelectrolytelevelevery50operatinghoursor,

ifthemachineisinstorage,every30days.

1.Raisethebedandsecureitwiththeproprod.

2.Removethellercaps.Iftheelectrolyteisnotup

tothellline,addtherequiredamountofdistilled

water;refertoAddingWatertotheBattery.

Batteryelectrolytecontainssulfuricacidwhich

isadeadlypoisonandcausessevereburns.

•Donotdrinkelectrolyteorallowittocontact

yourskin,eyesorclothing.Wearsafety

glassestoshieldyoureyesandrubbergloves

toprotectyourhands.

•Fillthebatterywherecleanwaterisalways

availableforushingtheskin.

AddingWatertotheBattery

Neversmokenearthebatteryandkeepsparks

andamesawayfrombattery.

3.Installthebatteryinthechassis;refertoInstalling

theBattery.

StoringtheBattery

Ifthemachinewillbestoredformorethan30days,

removethebatteryandchargeitfully.Eitherstore

itontheshelforonthemachine.Leavethecables

disconnectedifitisstoredonthemachine.Storethe

batteryinacoolatmospheretoavoidquickdeterioration

ofthechargeinthebattery.Topreventthebatteryfrom

freezing,makesureitisfullycharged.

Thebesttimetoadddistilledwatertothebatteryisjust

beforeyouoperatethemachine.Thisletsthewatermix

thoroughlywiththeelectrolytesolution.

1.Cleanthetopofthebatterywithapapertowel.

2.Removethellercapsfromthebatteryandslowly

lleachcellwithdistilledwateruntilthelevelisup

tothellline.Replacethellercaps.

Important:Donotoverllthebattery.

Electrolytewilloverowontootherpartsofthe

vehicleandseverecorrosionanddeterioration

willresult.

ChargingtheBattery

Important:Alwayskeepthebatteryfullycharged

(1.260specicgravity).Thisisespeciallyimportant

topreventbatterydamagewhenthetemperatureis

below32°F(0°C).

1.Removethebatteryfromthechassis;referto

RemovingtheBattery.

33

Page 34

DriveSystem

G002093

1

2

Maintenance

CheckingandAdjusting

Neutral

Whenperformingroutinemaintenanceand/orengine

diagnostics,thetransaxlemustbeshiftedintoneutral

(Figure40).Thevehiclehasaneutralpositiononthe

shiftlever,whichcontrolstheneutralinthetransaxle.

Thefollowingstepsshouldbetakentomakesurethat

theneutralshiftleveroperatesthetransaxleneutral

correctly:

Figure41

1.Neutralbracket4.Wrong,musttightenthe

2.Pullup

3.Cableboot

nut

5.Correctadjustment

1.SettheshiftleverintotheNeutralposition.

2.Ensurethattheneutralbracketisintheneutral

position(level)byturningthedriveclutch

(Figure40).Thevehicleshouldnotrollbackand

forth.Ifitdoes,manuallymovetheneutralbracket

totheneutralposition.

Figure40

1.Neutralbracket2.Locknuts

3.Tightenoneofthelocknuts(Figure40)justenough

totaketheslackoutoftheshiftcable.

Note:Youmustholdthethreadedshaftbelowthe

brackettotightenthelocknutontop.

4.Tightentheotherlocknutjustenoughtotakethe

slackoutoftheothershiftcable.

5.Pulluponeachshiftcableanensurethatthereisno

gapbetweenthenut/washerandtheneutralbracket

(Figure41).Ifthereisagap,tightenthenut.

6.StarttheengineandshiftintoForward,Reverse,

andNeutralseveraltimestoensurethattheneutral

bracketisoperatingproperly.

InspectingtheTires

Checkthetireconditionatleastevery100hours

ofoperation.Operatingaccidents,suchashitting

curbs,candamageatireorrimandalsodisruptwheel

alignment,soinspecttireconditionafteranaccident.

Checkthewheelstoensurethattheyaremounted

securely.Torquethelugnutsto45-65ft-lb(61-88N-m).

AdjustingtheFront

Suspension

Therideheightofeachsideofthevehiclecanbe

adjustedseparately .Therideheightshouldbe8-3/4

to9-1/2inches(22.2to24cm)withthefollowing

parameters:

•Thetirepressureshouldbeat12psi(83kPa).

•Thevehicleshouldbedrivenbackandforthafew

timestorelaxtheA-arms.

•Measuretherideheightwiththewheelsfacing

straightaheadanda175-225lb(79-102kg)operator

inthedriver’sseat.

Note:Thedrivershoulddriveuptothe

measurementareaandstayseatedinthevehicle

whilethemeasurementisbeingtaken.

•Measuretherideheightonaatsurface,fromthe

bottomofthefronttonguetotheground.

1.Jackthefrontendofthevehicleoffoftheground;

refertoJackingtheV ehicleinPremaintenance

Procedures,page27.

2.Removethetravellimitingbolt(Figure42).

34

Page 35

3.LoosenthecenteringboltsinthefrontA-arm

(Figure42).

4.Removetherideheightadjustmentbolt(Figure42).

Figure42

1.Travellimitingbolt3.Rideheightadjustment

bolt

2.Centeringbolt

Figure43

1.Left-handA-arm

6.Torquetherideheightadjustmentboltto

135-165ft-lb(183-224N-m).

7.Replacethetravellimitingbolt(Figure42).

5.RotatethefrontA-armtothedesiredposition

(refertothenotebelow)andreplacetherideheight

adjustmentbolt(Figure42).

Note:TheA-armsaremadewithrubberandhave

differentspringrates.Becauseofthedifferentspring

rates,theA-armscomeadjustedfromthefactory

basedonthatspringrate.Generallytheadjustment

boltswillbeinstalledinholenumber2,3,or4

(Figure43)anditmaybedifferentfromtheleftside

(driverside)totherightside(passengerside).Ifthe

A-armslookliketheyaresagging,thentheyshould

beadjustedtothenexthighernumber(Figure43).

Eachholeequalsabout3/4inch(19mm)of

adjustmentatthewheel.Youwillalsoneedtodo

thisifyouareaddingheavyattachmentsorcarrying

heavyloadsoften.

Note:Thevehiclemayneedtobeloweredtothe

groundonthatsidetoinstallthebolt.

8.Tightenandtorquethecenteringboltsto

240-290ft-lb(325-393N-m).

9.Checktherideheightatthefronttongueperthe

dimensionsandparametersgivenatthebeginningof

thisprocedure.

AdjustingFrontWheelToe-In

Checkthefrontwheeltoe-inafterevery100operating

hours,orannually,whicheveroccursrst.

Thetoe-inshouldbe1/8-5/8inch(3-16mm)withthe

followingparameters:

•Thetirepressureshouldbeat12psi(83kPa).

•Therideheightshouldbecorrectbeforesettingthe

toe-in;refertoAdjustingtheFrontSuspension.

•Thevehicleshouldbedrivenbackandforthafew

timestorelaxtheA-arms.

•Measurethetoe-inwiththewheelsfacingstraight

aheadanda175-225lb(79-102kg)operatorinthe

driver’sseat.

Note:Thedrivershoulddriveuptothe

measurementareaandstayseatedinthevehicle

whilethemeasurementisbeingtaken.

Ifthevehiclewillberunwithmediumtoheavyloads

mostofthetime,setthetoe-inonthehighsideof

therecommendedamount.Ifitisgoingtoberun

35

Page 36

withalightloadmostofthetime,setthetoe-inon

thelowsideoftherecommendedamount.

1.Ensurethatthefrontsuspensionisadjusted

properly;refertoAdjustingtheFrontSuspension.

Adjustifnecessary.

MaintainingthePrimaryDrive

Clutch

Afterevery400operatinghoursoryearly,cleanand

lubricatetheclutchasfollows:

2.Measurethedistancebetweenbothofthefronttires

attheaxleheightatboththefrontandrearofthe

fronttires(Figure44).Axtureoralignmentgauge

isneededfortherearmeasurementofthefronttires

ataxleheight.Usethesamextureoralignment

gaugetoaccuratelymeasurethefrontofthefront

tiresataxleheight(Figure44).

Figure44

1.Tirecenterline-back4.Fixture

2.Tirecenterline-front

3.Axlecenterline

5.Axlecenterlinedistance

6.6inches(15cm)ruler

3.Ifthemeasurementdoesnotfallwithinthespecied

range(refertothedimensionsandparametersatthe

beginningofthisprocedure),loosenthejamnutsat

bothendsofthetierods(Figure45).

1.Stoptheengine,removethekey,andsettheparking

brake.

2.Raiseandlatchthecargobox.

3.Removethe3boltssecuringthecovertotheclutch

andremovethecover(Figure46).

Figure46

1.Cover

2.Bolts

4.Thoroughlycleantheinsideofthecoverandthe

innerworkingsoftheclutchusingcompressedair.

Thedustintheclutchwillbecomeairborneand

coulddamageyoureyesoryoucouldinhaleit

causingbreathingdifculties.

Wearsafetygogglesandadustmaskorother

eyeandrespiratoryprotectionwhenperforming

thisprocedure.

Figure45

1.Jamnut2.Tierod

4.Rotatebothtierodstomovethefrontofthetire

inwardoroutward.

5.Tightenthetierodjamnutswhentheadjustmentis

correct.

6.Ensurethatthereisfulltravelofthesteeringwheel

inbothdirections.

5.Lubricatethemovingpartsintheareascircledin

Figure47usingT oroDryLubricantSpray ,available

throughyourAuthorizedToroDealerorDistributor.

36

Page 37

Figure47

6.Installtheclutchcoverandsecureitwiththe3bolts

removedpreviously.

ChangingtheTransaxleFluid

Changethetransaxleuidevery800operatinghoursor

yearly,whicheveroccursrst.

1.Positionthevehicleonalevelsurface,settheparking

brake,turntheignitionoff,andremovethekey.

2.Removethedrainplugfromtherightsideofthe

reservoir(Figure48)andlettheuidowintoa

drainpan.Installandtightentheplugwhentheuid

stopsdraining.

Note:Disposeoftheusedoilatacertiedrecycling

center.

Figure49

1.Oilll

4.Starttheengineandoperateittollthesystem.

Rechecktheoillevelandreplenishit,ifrequired.

Figure48

1.Drainplug2.Levelindicatorhole

3.Fillthereservoir(Figure49)withapproximately

1-1/2qt.(1.4liters)ofSAE10W30motoroil

oruntiltheoillevelisatthebottomofthelevel

indicatorhole(Figure48).

37

Page 38

CoolingSystem

BrakeMaintenance

Maintenance