Page 1

Form No. 3356-911 Rev B

Workman® 1110 Utility Vehicle

Model No. 07264 —Serial No. 270000001 and Up

Model No. 07264TC —Serial No. 270000001 and Up

Register your product at www.Toro.com Original Instructions (EN)

Page 2

Warning

CALIFORNIA

Pr oposition 65 W ar ning

T he engine exhaust fr om this pr oduct

contains chemicals kno wn to the State of

Calif or nia to cause cancer , bir th defects, or

other r epr oducti v e har m.

Important: T his engine is not equipped

with a spar k ar r ester muf fler . It is a

violation of Calif or nia Public R esource Code

Section 4442 to use or operate the engine

on an y f or est-co v er ed, br ush-co v er ed, or

g rass-co v er ed land. Other states or federal

ar eas may ha v e similar la ws.

T his spark ignition system complies with Canadian

ICES-002

T he enclosed Engine Owner’ s Man ual is

supplied f or inf or mation r egarding the US

En vir onmental Pr otection Agency (EP A) and

the Calif or nia Emission Contr ol R egulation of

emission systems, maintenance, and w ar ranty .

R eplacements may be order ed thr ough the

engine man uf actur er .

Introduction

R ead this infor mation carefully to lear n ho w to

operate and maintain y our product properly and

to a v oid injur y and product damag e . Y ou are

responsible for operating the product properly

and safely .

Figure 1

1. Model and serial number location

Model No.

Serial No.

T his man ual identifies potential hazards and has

safety messag es identified b y the safety aler t

symbol ( Figure 2 ), whic h signals a hazard that ma y

cause serious injur y or death if y ou do not follo w

the recommended precautions .

Figure 2

1. Safety alert symbol

T his man ual uses 2 other w ords to highlight

infor mation. Impor tant calls attention to special

mec hanical infor mation and Note emphasizes

g eneral infor mation w or th y of special attention.

Y ou ma y contact T oro directly at www .T oro .com

for product and accessor y infor mation, help

finding a dealer , or to register y our product.

W henev er y ou need ser vice , g en uine T oro par ts ,

or additional infor mation, contact an A uthorized

Ser vice Dealer or T oro Customer Ser vice and ha v e

the model and serial n umbers of y our product

ready . Figure 1 identifies the location of the model

and serial n umbers on the product. W rite the

n umbers in the space pro vided.

© 2005—The Toro® Company

8111 Lyndale Avenue South

Bloomington, MN 55420

Contact us at www.Toro.com.

2

Printed in the USA.

All Rights Reserved

Page 3

Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Safe Operating Practices . . . . . . . . . . . . . . . . . . . . . . 4

Before Operating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Sound Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Vibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Safety and Instr uctional Decals . . . . . . . . . . . . 9

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1 Installing the W heels . . . . . . . . . . . . . . . . . . . . . . . 11

2 Installing the Steering W heel . . . . . . . . . . . 12

3 Installing the Bumper . . . . . . . . . . . . . . . . . . . . . . 12

4 Installing the Seats . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5 Installing the Hitc h . . . . . . . . . . . . . . . . . . . . . . . . . 13

6 Installing the Carg o Bo x . . . . . . . . . . . . . . . . . . 14

7 Acti v ating the Batter y . . . . . . . . . . . . . . . . . . . . . . 15

8 Adjusting the F ront W heel

T oe-in . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

9 R eading the Man ual and Viewing

the Safety Video . . . . . . . . . . . . . . . . . 16

Product Ov er view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

T hink Safety First . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Pre-Star ting Chec ks . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Chec king the Engine Oil . . . . . . . . . . . . . . . . . . . . 22

Chec king the Brak e Fluid

Lev el . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Chec king the Tire Pressure . . . . . . . . . . . . . . . . . 22

Adding Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Chec king the T ransmission Oil

Lev el . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Star ting the Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Stopping the V ehicle . . . . . . . . . . . . . . . . . . . . . . . . . . 24

P arking the V ehicle . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Operating the Carg o Bo x . . . . . . . . . . . . . . . . . . . 24

Breaking in a New V ehicle . . . . . . . . . . . . . . . . . . 25

Loading the Carg o Bo x . . . . . . . . . . . . . . . . . . . . . . 26

T ranspor ting the V ehicle . . . . . . . . . . . . . . . . . . . . 26

T o wing the V ehicle . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

T o wing a T railer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

R ecommended Maintenance

Sc hedule(s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Daily Maintenance Chec klist . . . . . . . . . . . . . . 29

Premaintenance Procedures . . . . . . . . . . . . . . . . . . . . . . . 30

Maintaining the V ehicle under

Special Operating

Conditions . . . . . . . . . . . . . . . . . . . . . . . . 30

J ac king the V ehicle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Adding Grease . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Engine Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Ser vicing the Air Cleaner . . . . . . . . . . . . . . . . . . . 31

Ser vicing the Engine Oil . . . . . . . . . . . . . . . . . . . . 32

Ser vicing the Spark Plug . . . . . . . . . . . . . . . . . . . . 33

Fuel System Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Inspecting Fuel Lines and

Connections . . . . . . . . . . . . . . . . . . . . . . 33

R e placing the Fuel Filter . . . . . . . . . . . . . . . . . . . . 33

Electrical System Maintenance . . . . . . . . . . . . . . . . . . . 34

R e placing the Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

R e placing the Headlights . . . . . . . . . . . . . . . . . . . 34

Ser vicing the Batter y . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Dri v e System Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . 36

Chec king and Adjusting

Neutral . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Inspecting the Tires . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Adjusting the F ront

Suspension . . . . . . . . . . . . . . . . . . . . . . . . 37

Adjusting F ront W heel T oe-In . . . . . . . . . . . 38

Maintaining the Primar y Dri v e

Clutc h . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Changing the T ransaxle Fluid . . . . . . . . . . . . . 40

Cooling System Maintenance . . . . . . . . . . . . . . . . . . . . . 40

Cleaning the Engine Cooling

Areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Brak e Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Inspecting the Brak es . . . . . . . . . . . . . . . . . . . . . . . . . 41

Chec king the Brak e Fluid

Lev el . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Adjusting the P arking Brak e . . . . . . . . . . . . . . . 41

Belt Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Ser vicing the Dri v e Belt . . . . . . . . . . . . . . . . . . . . . 41

Adjusting the Star ter Generator

Belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

W ashing the V ehicle . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Storag e . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Sc hematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

3

Page 4

Safety

Improper use or maintenance b y the operator

or o wner can result in injur y . T o reduce the

potential for injur y , comply with these safety

instr uctions and alw a ys pa y attention to the safety

aler t symbol, whic h means Caution , W ar ning , or

Danger —“personal safety instr uction. ” F ailure to

comply with the instr uction ma y result in personal

injur y or death.

Super visors , operators , and ser vice persons should

be familiar with the follo wing standards and

publications (the material ma y be obtained from

the address sho wn):

• Flammable and Combustible Liquids Code:

ANSI/NFP A 30

• National Fire Protection Association:

ANSI/NFP A #505; P o w ered Industrial

T r uc ks , National Fire Prev ention Association,

Bar r ymarc h P ark, Quincy , Massac husetts

02269 U .S .A.

• ANSI/ASME B56.8 P ersonal Burden Car riers

American National Standards Institute , Inc .,

1430 Broadw a y , New Y ork, New Y ork 10018

U .S .A.

Supervisor’s Responsibilities

• Mak e sure that operators are thoroughly

trained and familiar with the Operator’ s Manual

and all labels on the v ehicle .

• Be sure to establish y our o wn special

procedures and w ork r ules for un usual

operating conditions (e .g . slopes too stee p for

v ehicle operation).

Before Operating

• Operate the mac hine only after reading and

understanding the contents of this man ual.

• Nev er allo w c hildren to operate the v ehicle .

Any one who operates the v ehicle should ha v e

a motor v ehicle license .

• Nev er allo w other adults to operate the v ehicle

without first reading and understanding the

Operator’ s Manual . Only trained and authorized

persons should operate this v ehicle . Mak e sure

that all operators are ph ysically and mentally

capable of operating the v ehicle .

• T his v ehicle is designed to car r y only y ou,

the operator , and one passeng er in the seat

pro vided b y the man ufacturer . Nev er car r y any

other passeng ers on the v ehicle .

• SAE J2258 Light Utility V ehicle

SAE Inter national, 400 Commonw ealth Dri v e ,

W ar rendale , P A 15096-0001 U .S .A.

• ANSI/UL 558; Inter nal Combustion Engine

P o w ered Industrial T r uc ks

American National Standards Institute , Inc .,

1430 Broadw a y , New Y ork, New Y ork 10018

U .S .A.

or

Underwriters Laboratories , 333 Pfingsten

R oad, Nor thbrook, Illinois 60062 U .S .A.

Safe Operating Practices

T he W or kman is an of f-highw ay v ehicle

onl y and is not designed, equipped, or

man uf actur ed f or use on public str eets,

r oads, or highw ays.

• Nev er operate the v ehicle when under

the influence of dr ugs or alcohol. Ev en

prescription dr ugs and cold medicines can

cause dro wsiness .

• Do not dri v e the v ehicle when y ou are tired.

Be sure to tak e occasional breaks . It is v er y

impor tant that y ou sta y aler t at all times .

• Become familiar with the controls and kno w

ho w to stop the engine quic kly .

• K ee p all shields , safety devices , and decals in

place . If a shield, safety device , or decal is

malfunctioning, illegible , or damag ed, re pair or

re place it before operating the mac hine .

• Alw a ys w ear substantial shoes . Do not operate

the mac hine while w earing sandals , tennis

shoes or sneak ers . Do not w ear loose fitting

clothing or jew elr y whic h could g et caught in

mo ving par ts and cause personal injur y .

• W earing safety glasses , safety shoes , long pants

and a helmet is advisable and required b y some

local safety and insurance regulations .

4

Page 5

• A v oid dri ving when it is dark, especially in

unfamiliar areas . If y ou m ust dri v e when it

is dark, be sure to dri v e cautiously , use the

headlights , and ev en consider adding additional

lights .

• Be extremely careful when operating around

people . Alw a ys be a w are of where b ystanders

might be .

• Before operating the v ehicle , alw a ys c hec k the

designated areas of the v ehicle that are stated

in the pre-star ting section of this man ual. If

something is wrong, do not use the v ehicle .

Mak e sure that the problem is cor rected before

the v ehicle or attac hment is operated.

• Since g asoline is highly flammable , handle it

carefully .

– Use an appro v ed g asoline container .

– Do not remo v e the cap from the fuel tank

when the engine is hot or r unning .

– Do not smok e while handling g asoline .

– Fill the fuel tank outdoors , and fill it to

about 1 inc h (25 mm) belo w the top of the

tank (the bottom of the filler nec k). Do

not o v erfill it.

– Wipe up any spilled g asoline .

Operation

Engine exhaust contains carbon mono xide,

which is an odor less, deadl y poison that can

kill y ou.

Do not r un engine indoor s or in an enclosed

ar ea.

• T he operator and passeng er should remain

seated whenev er the v ehicle is in motion.

T he operator should k ee p both hands on the

steering wheel whenev er possible , and the

passeng er should use the hand holds pro vided.

K ee p y our ar ms and legs within the v ehicle

body at all times .

• Dri v e slo w er and tur n less shar ply when y ou

are car r ying a passeng er . R emember y our

passeng er ma y not be expecting y ou to brak e

or tur n and ma y not be ready .

• Alw a ys w atc h out for and a v oid lo w o v erhangs

suc h as tree limbs , door jambs , and o v er -head

w alkw a ys . Mak e sure there is enough room

o v er head to easily clear the v ehicle and y our

head.

• Alw a ys shift into neutral and apply the parking

brak e before lea ving an idling v ehicle , or else

the v ehicle ma y cree p .

• F ailure to operate the v ehicle safely ma y result

in an accident, tip o v er of the v ehicle , and

serious injur y or death. Dri v e carefully . T o

prev ent tipping or loss of control:

– Use extreme caution, reduce speed, and

maintain a safe distance around sand traps ,

ditc hes , creeks , ramps , unfamiliar areas ,

or any areas that ha v e abr upt c hang es in

g round conditions or elev ation.

– W atc h for holes or other hidden hazards .

– Use extra caution when operating the

v ehicle on w et surfaces , in adv erse w eather

conditions , at higher speeds , or with a

full load. Stopping time and distance will

increase with a full load.

– A v oid sudden stops and star ts . Do not

g o from rev erse to forw ard or forw ard to

rev erse without first coming to a complete

stop .

– Slo w do wn before tur ning . Do not attempt

shar p tur ns or abr upt maneuv ers or other

unsafe dri ving actions that ma y cause a loss

of v ehicle control.

– W hen dumping, do not let any one stand

behind the v ehicle and do not dump the

load on any one’ s feet. R elease the tailg ate

latc hes from the side of the bo x, not from

behind.

– Only operate the v ehicle when the carg o

bo x is do wn and latc hed.

– Before bac king up , look to the rear and

ensure that no one is behind y ou. Bac k up

slo wly .

– W atc h out for traffic when y ou are near or

crossing roads . Alw a ys yield the right of

w a y to pedestrians and other v ehicles . T his

v ehicle is not designed for use on streets or

highw a ys . Alw a ys signal y our tur ns or stop

early enough so that other people kno w

what y ou plan to do . Obey all traffic r ules

and regulations .

– T he electrical and exhaust systems of the

v ehicle can produce sparks capable of

5

Page 6

igniting explosi v e materials . Nev er operate

the v ehicle in or near an area where there is

dust or fumes in the air whic h are explosi v e .

Operating on Hills

– If y ou are ev er unsure about safe operation,

stop w ork and ask y our super visor .

• Do not touc h the engine or m uffler while the

engine is r unning or soon after it has stopped.

T hese areas ma y be hot enough to cause bur ns .

• If the mac hine ev er vibrates abnor mally , stop

immediately , w ait for all motion to stop , and

inspect the v ehicle for damag e . R e pair all

damag e before commencing operation.

• Before g etting off of the seat:

1. Stop the mo v ement of the mac hine .

2. Set the parking brak e .

3. T ur n the ignition k ey to Off .

4. R emo v e the ignition k ey .

Note: If the v ehicle is on an incline , bloc k

the wheels after g etting off of the v ehicle .

Braking

• Slo w do wn before y ou approac h an obstacle .

T his gi v es y ou extra time to stop or tur n a w a y .

Hitting an obstacle can damag e the v ehicle and

its contents . More impor tant, it can injure y ou

and y our passeng er .

• Gross V ehicle W eight (GVW) has a major

impact on y our ability to stop and/or tur n.

Hea vy loads and attac hments mak e a v ehicle

harder to stop or tur n. T he hea vier the load,

the long er it tak es to stop .

• Decrease the v ehicle speed if the carg o bo x has

been remo v ed and there is no attac hment on

the v ehicle . T he braking c haracteristics c hang e

and fast stops ma y cause the rear wheels to loc k

up , whic h ma y affect the control of the v ehicle .

• T urf and pa v ement are m uc h more slipper y

when they are w et. It can tak e 2 to 4 times

as long to stop on w et surfaces as on dr y

surfaces . If y ou dri v e through standing w ater

dee p enough to g et the brak es w et, they will

not w ork w ell until they are dr y . After dri ving

through w ater , y ou should test the brak es to

mak e sure they w ork properly . If they do not,

dri v e slo wly while putting light pressure on the

brak e pedal. T his will dr y the brak es out.

Operating the v ehicle on a hill may cause

tipping or r olling of the v ehicle, or the engine

may stall and y ou could lose head w ay on the

hill. T his could r esult in per sonal injur y .

• Do not accelerate quickl y or slam on

the brak es when backing do wn a hill,

especiall y with a load.

• If the engine stalls or y ou lose head w ay

on a hill, slo wl y back straight do wn the

hill. Nev er attempt to tur n the v ehicle

ar ound.

• Operate the v ehicle slo wl y on a hill and

use caution.

• A v oid tur ning on a hill.

• R educe y our load and the speed of the

v ehicle.

• A v oid stopping on hills, especiall y with

a load.

T hese extra cautions need to be tak en when

operating the v ehicle on a hill:

• Slo w do wn before star ting up or do wn a hill.

• If the engine stalls or y ou begin to lose headw a y

while climbing a hill, g radually apply the brak es

and slo wly bac k straight do wn the hill.

• T ur ning while tra v eling up or do wn hills can

be dang erous . If y ou ha v e to tur n while on a

hill, do it slo wly and cautiously . Nev er mak e

shar p or fast tur ns .

• Hea vy loads affect stability . R educe the w eight

of the load and y our speed when operating on

hills or if the load has a high center of g ra vity .

Secure the load to prev ent it from shifting and

tak e extra care when hauling loads that shift

easily (liquid, roc k, sand, etc .).

• A v oid stopping on hills , especially with a load.

Stopping while g oing do wn a hill will tak e

long er than stopping on lev el g round. If the

v ehicle m ust be stopped, a v oid sudden speed

c hang es , whic h ma y initiate tipping or rolling

of the v ehicle . Do not slam on the brak es

6

Page 7

when rolling bac kw ard, as this ma y cause the

v ehicle to o v er tur n.

• W e strongly recommend installing the optional

R OPS Kit when operating on hilly ter rain.

Operating on Rough Terrain

R educe speed and load when operating on rough

ter rain, unev en g round, and near curbs , holes , and

other sudden c hang es in ter rain. Loads ma y shift,

causing the v ehicle to become unstable .

W e strongly recommend installing the optional

R OPS Kit when operating on rough ter rain.

Sudden changes in ter rain may cause a br upt

steering wheel mo v ement, possibl y r esulting

in hand and ar m injuries.

• R educe y our speed when operating on

r ough ter rain and near curbs.

• Grip the steering wheel loosel y ar ound

the perimeter . K eep y our hands clear of

the steering wheel spok es.

• P osition the w eight of a load ev enly from front

to bac k. If y ou position the load behind the

rear axle , it will reduce the w eight on the front

wheels . T his ma y result in a loss of steering

control or cause the v ehicle to tip o v er on hills

or bumpy ter rain.

• Use extra caution if the load ex ceeds the

dimensions of the bo x and when handling

off-center loads that cannot be centered. K ee p

loads balanced and secure to prev ent them

from shifting .

• Alw a ys secure loads so that they do not shift.

If a load is not secured, or y ou are transpor ting

a liquid in a larg e container suc h as a spra yer ,

the load can shift. T his shifting happens most

often while tur ning, g oing up or do wn hills ,

suddenly c hanging speeds , or while dri ving

o v er rough surfaces . Shifting loads can cause

the v ehicle to tip o v er .

T he w eight of the bo x may be hea vy .

Hands or other body par ts could be

cr ushed.

Loading and Dumping

T he w eight and position of the carg o and

passeng er can c hang e the v ehicle center of g ra vity

and v ehicle handling . T o a v oid loss of control and

personal injur y , follo w these guidelines:

• Do not car r y loads whic h ex ceed the load

limits described on the v ehicle w eight label;

refer to Specifications in Product Ov er view ,

pag e 18 , for v ehicle w eight limits . T he load

rating is for lev el surfaces only .

• R educe the w eight of the load when operating

on hills and rough ter rain to a v oid tipping or

o v er tur ning of the v ehicle .

• R educe the w eight of the load if the center of

g ra vity is high. Items suc h as bric ks , fer tilizer ,

or landscape timbers stac k higher in the bo x.

T he higher a load is stac k ed, the more lik ely

the v ehicle is to tip o v er . Distribute the load as

lo w as possible , making sure that the load does

not affect rear visibility .

• P osition the w eight of the load ev enly from

side to side . If y ou position the load to w ard

one of the sides , the v ehicle is more lik ely to

tip o v er while tur ning .

– K eep hands and other body par ts

clear when lo w ering the bo x.

– Do not dump materials on bystander s.

• Nev er dump a loaded carg o bo x while the

v ehicle is sidew a ys on a hill. T he c hang e in

w eight distribution ma y cause the v ehicle to

o v er tur n.

• W hen operating with a hea vy load in the carg o

bo x, reduce y our speed and allo w for sufficient

braking distance . Do not suddenly apply the

brak es . Use extra caution on slopes .

• Be a w are that hea vy loads increase y our

stopping distance and reduce y our ability to

tur n quic kly without tipping o v er .

• T he rear carg o space is intended for load

car r ying pur poses only , not for passeng ers .

• Nev er o v erload y our v ehicle . T he decal

(located on the rear frame) sho ws load limits

for the v ehicle . Nev er o v erload the attac hments

or ex ceed the Gross V ehicle W eight (GVW).

7

Page 8

Maintenance

Vibration

• Only qualified and authorized personnel shall

be per mitted to maintain, re pair , adjust, or

inspect the v ehicle .

• Before ser vicing or making adjustments to

the mac hine , stop the engine , set the parking

brak e , and remo v e the k ey from the ignition

to prev ent someone from accidentally star ting

the engine .

• T o mak e sure that the entire mac hine is in

g ood condition, k ee p all n uts , bolts , and screws

properly tightened.

• T o reduce the potential for fire , k ee p the engine

area free of ex cessi v e g rease , g rass , lea v es , and

accum ulation of dir t.

• Nev er use an open flame to c hec k the lev el or

leakag e of fuel or batter y electrolyte .

• If the engine m ust be r unning to perfor m a

maintenance adjustment, k ee p y our hands ,

feet, clothing, and any par ts of y our body a w a y

from the engine and any mo ving par ts . K ee p

ev er y one a w a y .

T his unit does not ex ceed a hand/ar m vibration

lev el of 2.5 m/s

identical mac hines per EN 1033.

T his unit does not ex ceed a whole body vibration

lev el of 0.5 m/s

identical mac hines per EN 1032.

2

, based on measurements of

2

, based on measurements of

• Do not use open pans of fuel or flammable

cleaning fluids for cleaning par ts .

• Do not adjust the g round speed g o v er nor . T o

ensure safety and accuracy , ha v e an A uthorized

T oro Distributor c hec k the g round speed.

• If major re pairs are ev er needed or assistance

is required, contact an A uthorized T oro

Distributor .

• T o be sure of optim um perfor mance and safety ,

alw a ys purc hase g en uine T oro re placement

par ts and accessories . R e placement par ts and

accessories made b y other man ufacturers

could be dang erous . Altering this v ehicle in

any manner that ma y affect v ehicle operation,

perfor mance , durability , or its use , ma y result

in injur y or death. Suc h use could v oid the

product w ar ranty .

Sound Pressure

T his unit has a maxim um sound pressure lev el

at the operator’ s ear of 78 dB A, based on

measurements of identical mac hines per EN

11094.

8

Page 9

Safety and Instructional

Decals

Safety decals and instr uctions are easily visible to the operator and are located near any

area of potential dang er . R e place any decal that is damag ed or lost.

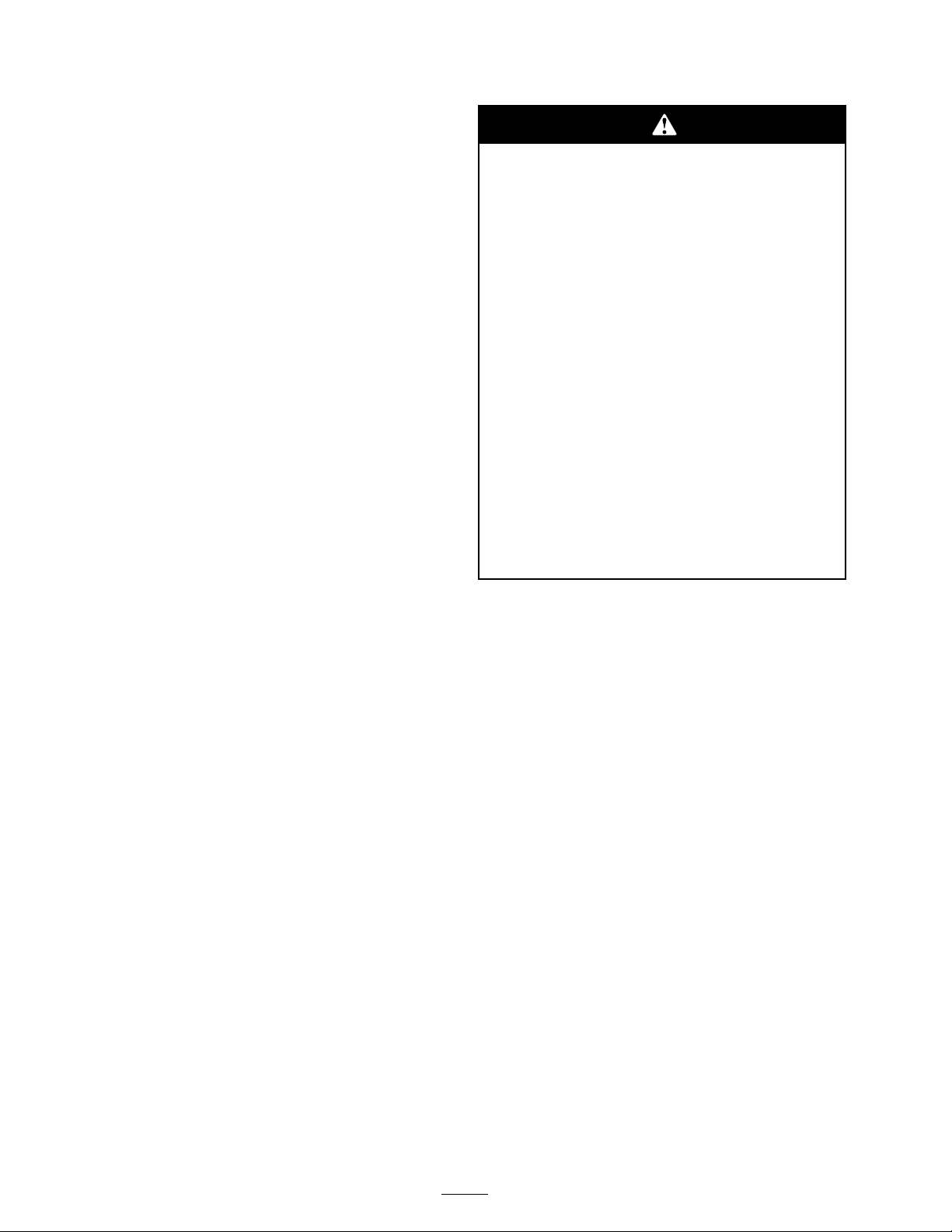

107–0699

1. Warning—read the Operator’s Manual .

2. Collision hazard—do not operate the vehicle on public streets,

roads, or highways.

3. Falling hazard—do not carry passengers in the cargo bed.

4. Falling hazard—do not allow children to operate the vehicle. 10. To stop the engine, release the accelerator pedal, set the

5. Hour meter

6. Headlights

7. Ignition—Off

8. Ignition—On

9. To start the engine, sit on the operator’s seat, release the

parking brake, turn the ignition key on, pull the choke lever

out (if needed), and press the accelerator pedal.

parking brake, turn the ignition key off, and remove the

ignition key.

11. Electrical power (power point)

12. Horn

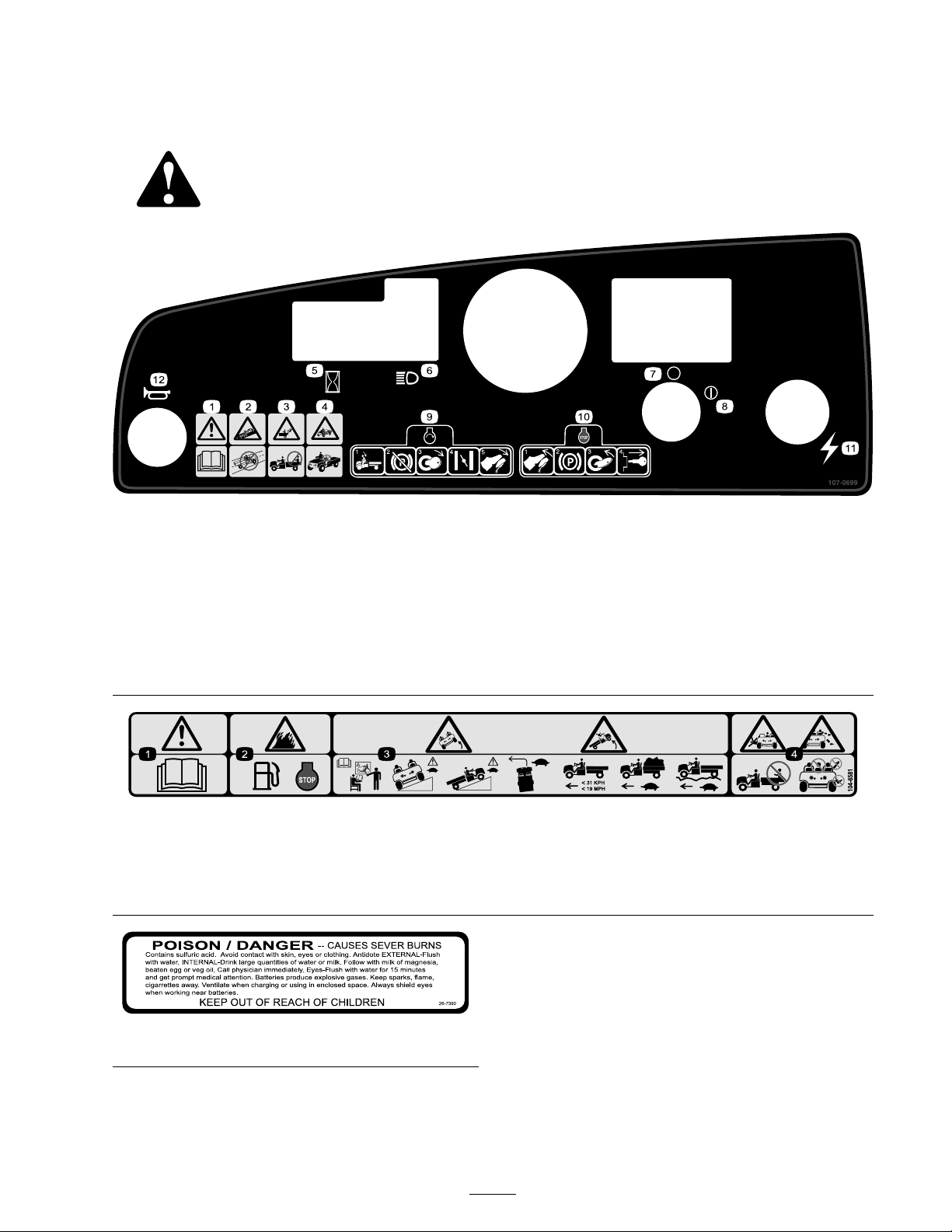

104–6581

1. Warning—read the Operator’s Manual .

2. Fire hazard—before fueling, stop the engine.

3. Tipping hazard—receive training before operating the machine, use caution and drive slowly while on slopes; drive slowly when

turning, keep the vehicle speed under 19 MPH (31 km/h) when carrying a full or heavy load and when driving on rough terrain .

4. Falling and arm/leg injury hazards—do not carry passengers in the cargo bed and keep arms and legs inside of the vehicle at all times.

26-7390

9

Page 10

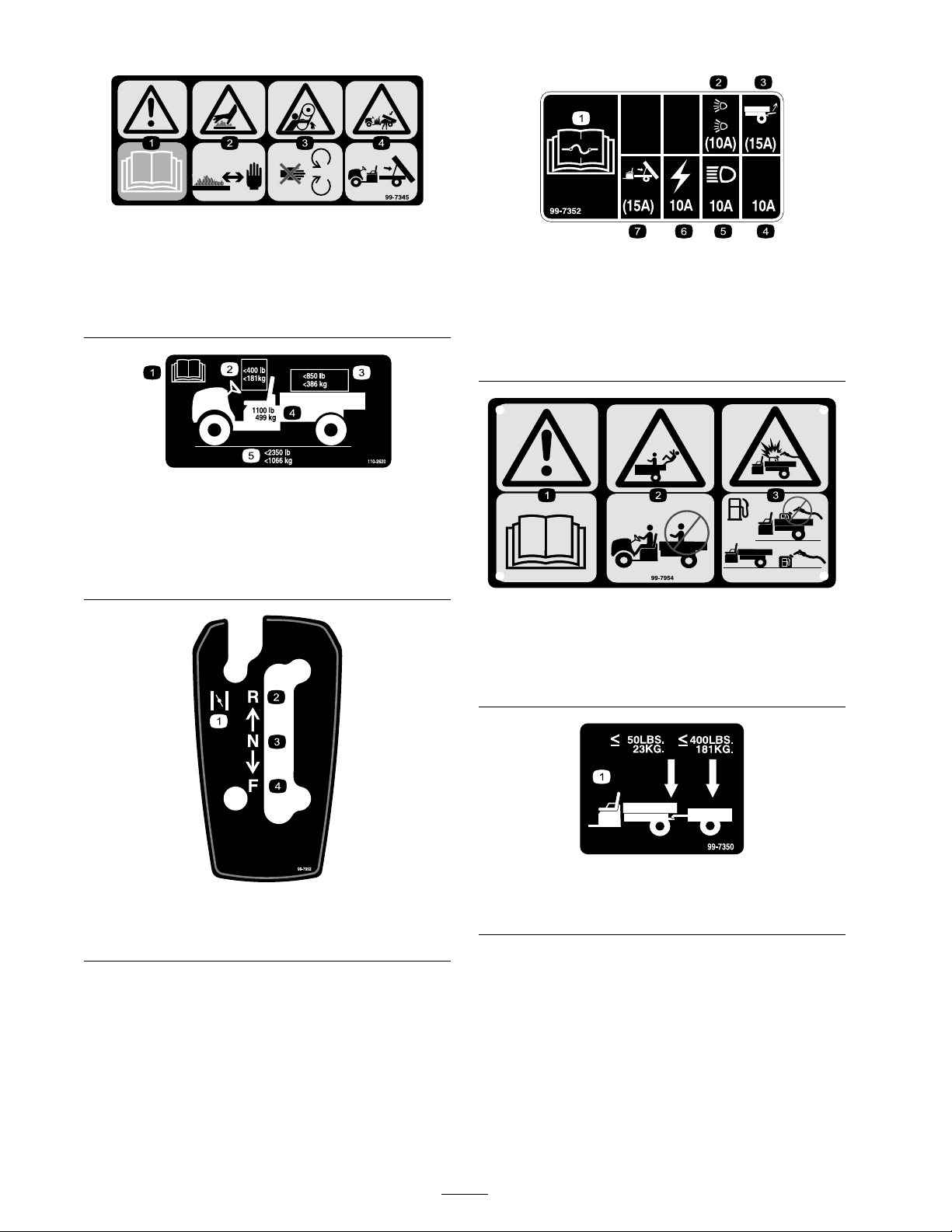

99–7345

1. Warning—read the Operator’s Manual .

2. Hot surface/burn hazard—stay a safe distance from the hot

surface.

3. Entanglement hazard, belt—stay away from moving parts

4. Crushing hazard, cargo box—use the prop rod to support

the cargo bed

110–2620

1. Read the Operator’s Manual .

2. The maximum combined operator and passenger weight is

400 lb (181 kg).

3. The maximum cargo weight is 850 lb (386 kg).

4. The base weight of the vehicle is 1100 lb (499 kg).

5. The maximum gross vehicle weight is 2350 lb (1066 kg).

99–7352

1. Read the Operator’s Manual for information on fuses.

2. 10 amp. fuse for the optional Road Light Kit

3. 15 amp. fuse for the optional Rear Lift Kit

4. 10 amp. fuse—open

5. 10 amp. fuse for the headlights

6. 10 amp. fuse for the ignition system

7. 15 amp. fuse for the optional Electric Bed Lift Kit

99–7954

1. Warning—read the Operator’s Manual .

2. Falling hazard—do not carry passengers in the cargo bed.

3. Explosion hazard, static discharge into fuel container—do

not ll fuel containers in the cargo bed; place fuel containers

on the ground before lling.

99–7952

1. Choke 3. Neutral

2. Reverse

99–7350

1. Maximum tongue weight is 50 lb (23 kg); maximum trailer

weight is 400 lb (181 kg).

4. Forward

10

Page 11

Setup

Loose Parts

Use the chart below to verify that all parts have been shipped.

Step

1

2

3

4

5

6

7

8

9

Wheel assembly

Steering wheel

Bumper 1

Seat 2

Hitch

Cargo box

Right-hand pivot bracket

Left-hand pivot bracket

Flange head screw (3/8 x 1 inch)

Bolt (5/16 x 3/4 inch)

Flange nut (5/16 inch)

No parts required

No parts required

Operator’s Manual

Engine Operator’s Manual

Parts Catalog

Safety Video

Registration Card

Predelivery Inspection Form

Key 2

Description

Qty.

4

1

1

1

1

1

4

1

1

–

–

1

1

1

1

1

1

Install the wheels (Model 07264TC

only).

Install the steering wheel (Model

07264TC only).

Install the bumper (Model 07264TC

only).

Install the seats (Model 07264TC

only).

Install the hitch (Model 07264TC

only).

Install the cargo box (Model

07264TC only).

Activate the battery (Model

07264TC only).

Adjust the front wheel toe-in.

Read the Operator’s Manual and

watch the video before operating

the machine.

Use

Note: Deter mine the left and right sides of the

mac hine from the nor mal operating position.

11

Page 12

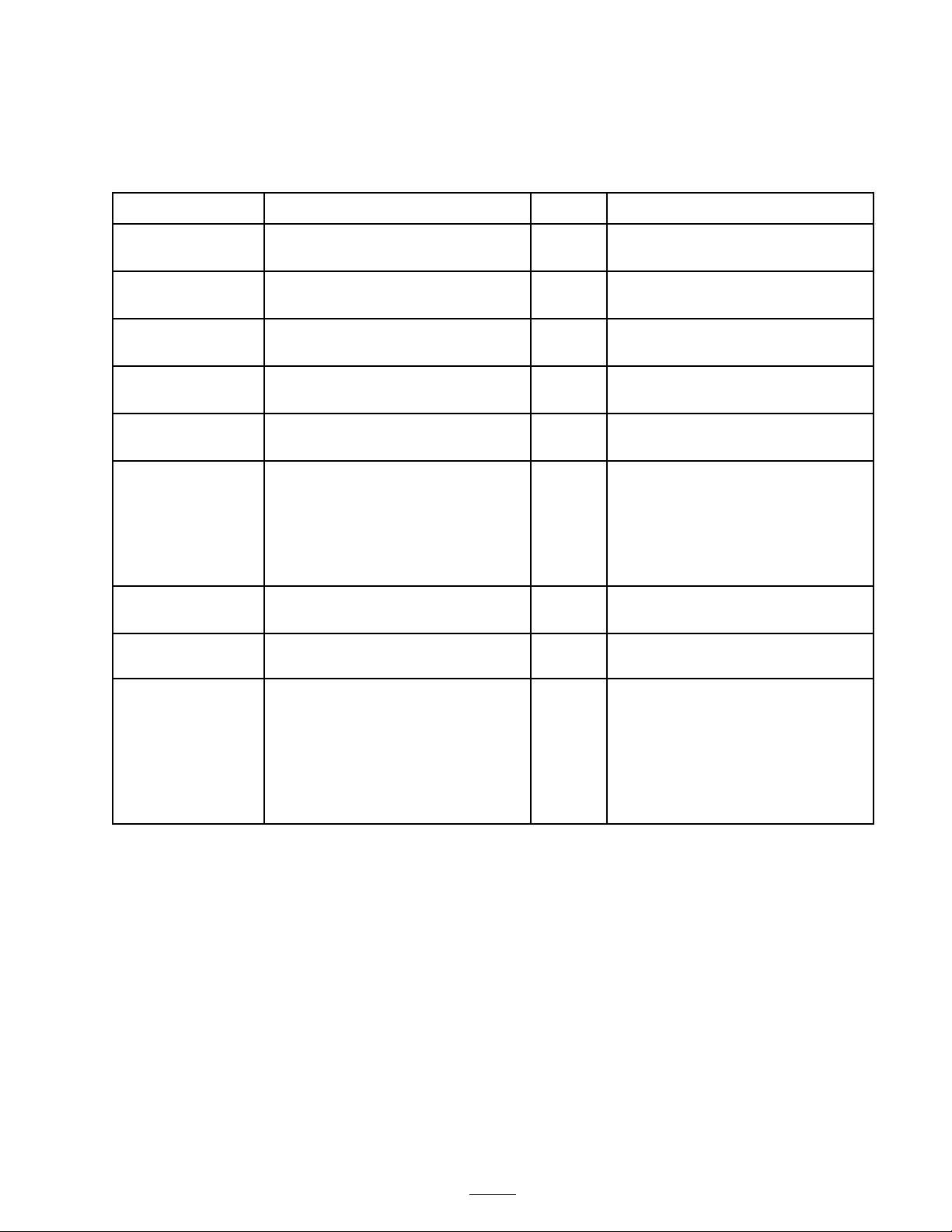

Step

Step

1

Installing the Wheels

Parts needed for this step:

4

Wheel assembly

Procedure

Note: T his procedure is only needed for Model

No . 07264TC .

1. R emo v e the fasteners securing the wheels .

2. R emo v e the shipping brac k et secured to the

wheel studs .

3. Mount the wheels with the previously remo v ed

fasteners ( Figure 3 ) and tor que to 45-65 ft-lb

(61-88 N ⋅ m).

2

Installing the Steering

Wheel

Parts needed for this step:

1

Steering wheel

Procedure

Note: T his procedure is only needed for Model

No . 07264TC .

1. R emo v e the n ut and w asher from the steering

shaft.

2. Slide the steering wheel and w asher onto the

shaft. P osition the steering wheel on the shaft

so that the cross beam is horizontal when the

tires are pointed straight ahead and the thic k er

spok e of the steering wheel is do wnw ard.

3. Secure the steering wheel to the shaft with the

n ut ( Figure 4 ). T or que the n ut to 18-22 ft-lb

(24-29 N ⋅ m)

1. Wheel assembly

2. Wheel nut

Figure 3

3. Wheel stud (rear wheel hub

shown)

1. Steering wheel 3. Washer

2. Nut

12

Figure 4

4. Foam seal

Page 13

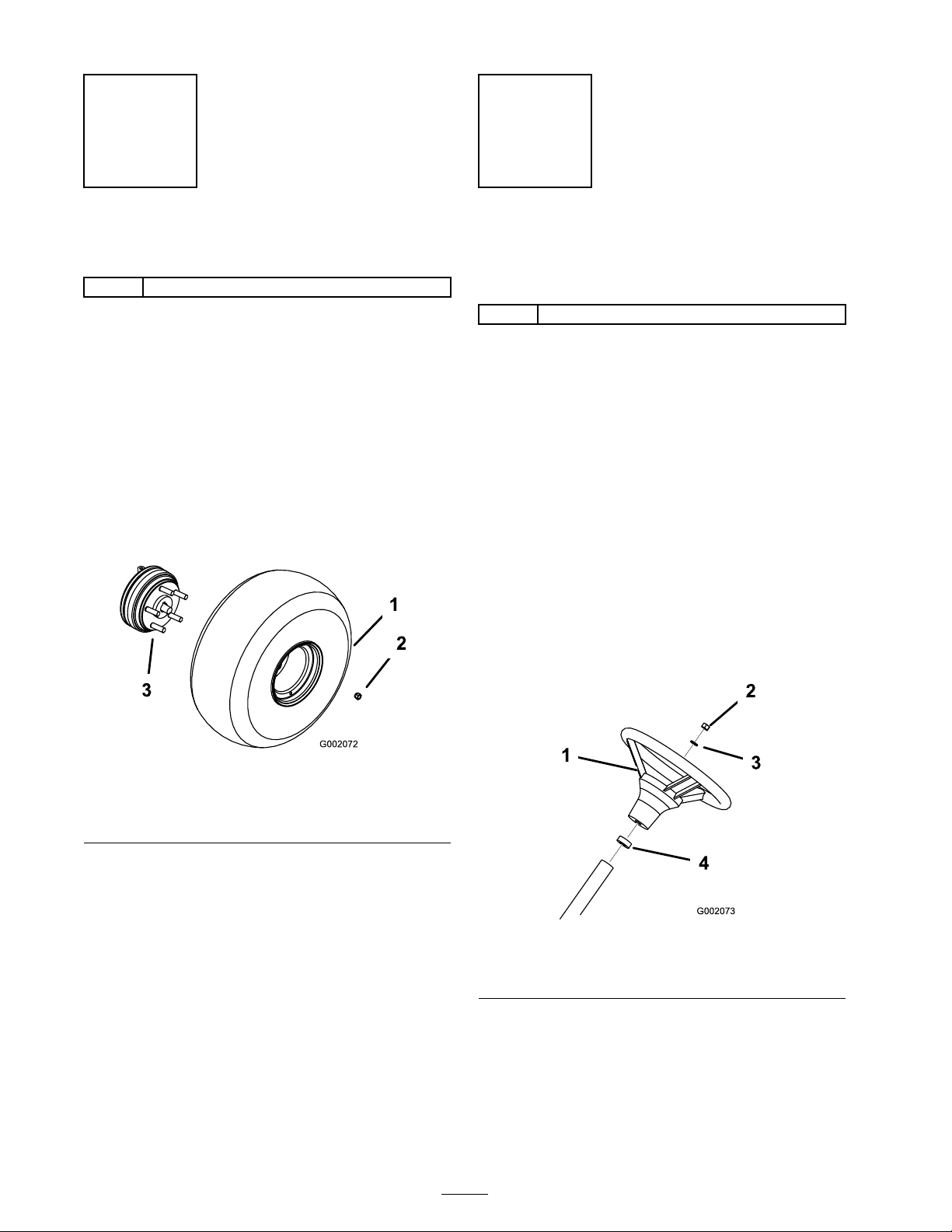

Step

3

Installing the Bumper

Parts needed for this step:

1 Bumper

Procedure

Note: T his procedure is only needed for Model

No . 07264TC .

1. R emo v e the 2 bolts , w ashers , and n uts secured

to the front of the frame .

2. Align the mounting holes and secure the

bumper to the frame with the fasteners

previously remo v ed ( Figure 5 ).

Inser t the seat brac k et into the seat base opening

and pi v ot the seat do wnw ard ( Figure 6 ).

Figure 6

1. Seat bracket 2. Seat base

1. Bumper

Step

4

Installing the Seats

Parts needed for this step:

2 Seat

Figure 5

Step

5

Installing the Hitch

Parts needed for this step:

1

Hitch

Procedure

Note: T his procedure is only needed for Model

No . 07264TC .

1. R emo v e the 4 bolts and n uts from the inside

rear of the frame .

2. Align the hitc h with the mounting holes on the

frame . Secure the hitc h with the screws and

n uts ( Figure 7 ).

Procedure

Note: T his procedure is only needed for Model

No . 07264TC .

13

Page 14

Figure 7

1. Hitch

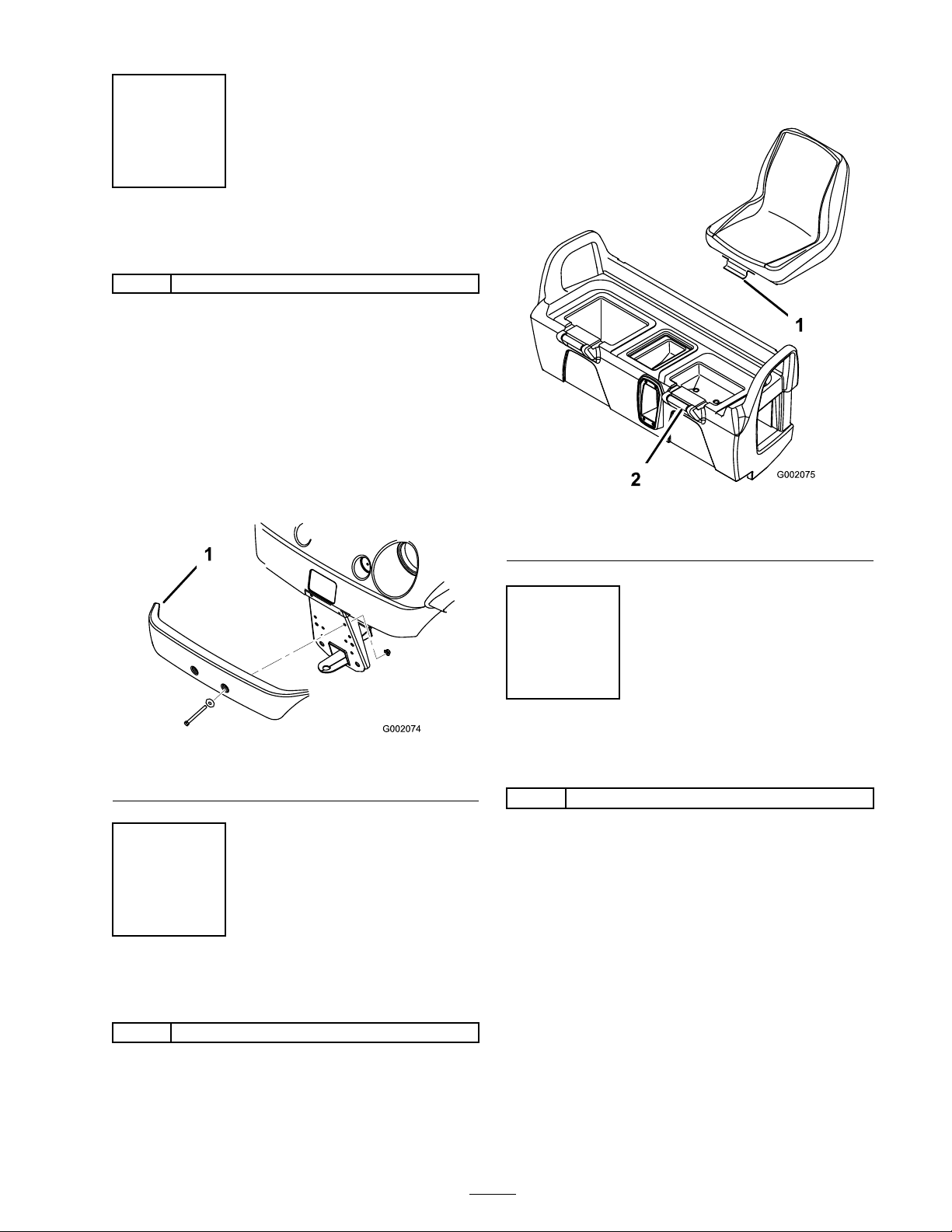

Step

6

Installing the Cargo Box

Parts needed for this step:

1

Cargo box

1

Right-hand pivot bracket

1

Left-hand pivot bracket

4

Flange head screw (3/8 x 1 inch)

1

Bolt (5/16 x 3/4 inch)

1

Flange nut (5/16 inch)

Procedure

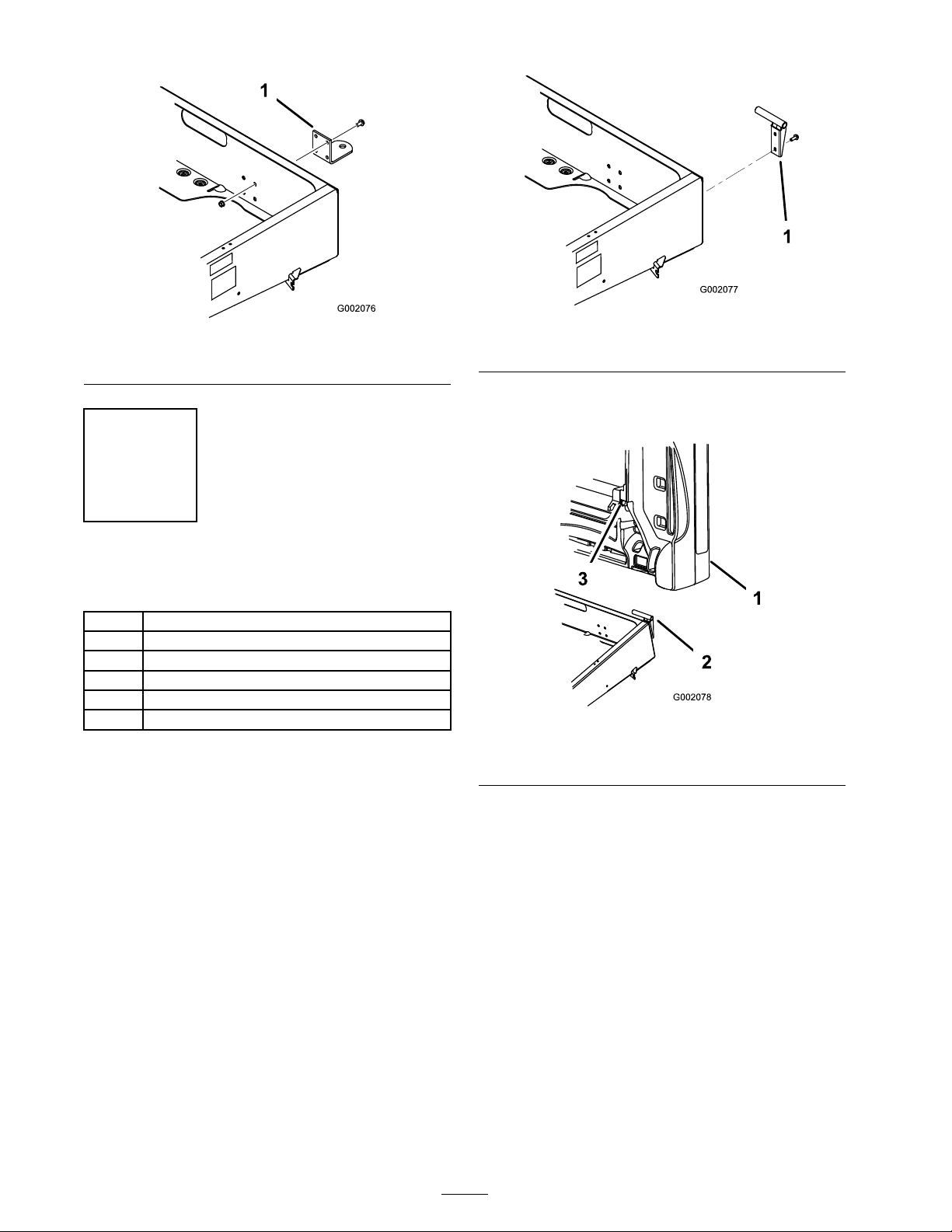

Figure 8

1. Pivot bracket

3. Slide the carg o bo x mounting hole onto the

pi v ot brac k et ( Figure 9 ).

Figure 9

1. Cargo box 3. Cargo box mounting hole

2. Pivot bracket

Note: T his procedure is only needed for Model

No . 07264TC .

1. P osition the carg o bo x onto the frame . T he

carg o bo x m ust la y flat and be centered.

2. Mount the left hand pi v ot brac k et to the left

rear cor ner of the frame with 2 flang e head

screws (3/8 x 1 inc h). P osition the brac k et as

sho wn in Figure 8 .

4. Inser t the right hand pi v ot brac k et into the

mounting hole in the carg o bo x and then

mount it to the frame .

5. Ha v e another person help to raise the carg o

bo x.

6. Loosen the bolt securing the prop rod clip to

the frame until y ou can slide the J-hook end of

the prop rod under the clip ( Figure 10 ).

14

Page 15

1. Prop rod

2. Prop rod clip

Figure 10

3. Bolt (5/16 x 3/4 inch)

4. Flange nut (5/16 inch)

Batter y electr ol yte contains sulfuric acid

which is a deadl y poison and causes

sev er e bur ns.

• Do not drink electr ol yte or allo w it to

contact y our skin, ey es or clothing .

W ear safety g lasses to shield y our

ey es and r ub ber g lo v es to pr otect y our

hands.

• Fill the batter y wher e clean w ater is

al w ays a v aila ble f or flushing the skin.

7. Tighten the bolt and secure the other side of

the clip with a new bolt (5/16 x 3/4 inc h) and

flang e n ut (5/16 inc h) ( Figure 10 ).

8. Lo w er the carg o bo x.

Step

7

Activating the Battery

No Parts Required

Procedure

None

Note: T his procedure is only needed for Model

No . 07264TC .

If the batter y is not filled with electrolyte or

acti v ated, it m ust be remo v ed from the v ehicle ,

filled with electrolyte , and c harg ed. Bulk electrolyte

with 1.260 specific g ra vity m ust be purc hased from

a local batter y supply outlet.

1. R emo v e the batter y hold-do wn and lift the

batter y out of the batter y base .

2. R emo v e the filler caps from the batter y and

slo wly fill eac h cell until electrolyte is just abo v e

the plates .

3. R e place the filler caps and connect a 3 to

4 amp . batter y c harg er to the batter y posts .

Charg e the batter y at a rate of 3 to 4 amperes

for 4 to 8 hours (12 v olts). Do not o v erc harg e

the batter y .

Charging the batter y pr oduces gasses

that can explode.

Nev er smok e near the batter y and k eep

spar ks and flames a w ay fr om batter y .

4. W hen the batter y is c harg ed, disconnect the

c harg er from the electrical outlet and batter y

posts .

5. R emo v e the filler caps . Slo wly add electrolyte

to eac h cell until electrolyte is up to the fill line .

Install the filler caps .

Important: Do not o v erfill the batter y .

Electr ol yte will o v erflo w onto other par ts

of the v ehicle and sev er e cor r osion and

deterioration will r esult.

6. Install the batter y; refer to Installing the

Batter y , Electrical System Maintenance ,

pag e 34 .

15

Page 16

Step

8

Adjusting the Front Wheel

Toe-in

No Parts Required

Procedure

T he toe-in should be 1/8-5/8 inc h (3-16 mm) with

the follo wing parameters:

• T he tire pressure should be at 12 psi (83 kP a).

Figure 11

1. Tire center line-back

2. Tire center line-front 5. Axle center line distance

3. Axle center line

4. Fixture

6. 6 inches (15 cm) ruler

• T he ride height should be cor rect before

setting the toe-in; refer to the Adjusting the

F ront Suspension procedure in Maintenance ,

pag e 28 .

• T he v ehicle should be dri v en bac k and for th a

few times to relax the A-ar ms .

• Measure the toe-in with the wheels facing

straight ahead and a 175-225 lb (79-102 kg)

operator in the dri v er’ s seat.

Note: T he dri v er should dri v e up to the

measurement area and sta y seated in the v ehicle

while the measurement is being tak en.

If the v ehicle will be r un with medium to hea vy

loads most of the time , set the toe-in on the

high side of the recommended amount. If it

is g oing to be r un with a light load most of

the time , set the toe-in on the lo w side of the

recommended amount.

1. Measure the distance betw een both of the

front tires at the axle height at both the front

and rear of the front tires ( Figure 11 ). A fixture

or alignment g aug e is needed for the rear

measurement of the front tires at axle height.

Use the same fixture or alignment g aug e to

accurately measure the front of the front tires

at axle height ( Figure 11 ).

2. If the measurement does not fall within the

specified rang e (refer to the dimensions and

parameters at the beginning of this procedure),

loosen the jam n uts at both ends of the tie

rods ( Figure 12 ).

Figure 12

1. Jam nut

3. R otate both tie rods to mo v e the front of the

tire inw ard or outw ard.

4. Tighten the tie rod jam n uts when the

adjustment is cor rect.

5. Ensure that there is full tra v el of the steering

wheel in both directions .

2. Tie rod

16

Page 17

Step

9

Reading the Manual and

Viewing the Safety Video

Parts needed for this step:

1

Operator’s Manual

1

Engine Operator’s Manual

1

Parts Catalog

1

Safety Video

1

Registration Card

1

Predelivery Inspection Form

2 Key

Procedure

• R ead the Operator’ s Manual and Engine Operator’ s

Manual .

• View the safety video .

• Fill out the registration card.

• Complete the Pr edeli ver y Inspection F or m and file

it in y our customer histor y por tfolio .

17

Page 18

Product Overview

Figure 13

1. Steering wheel 3. Parking brake 5. Cargo box 7. Cargo box release lever

2. Gear shift selector 4. Fuel cap

6. Towing tongue

Controls

Accelerator Pedal

T he accelerator pedal ( Figure 14 ) gi v es the

operator the ability to v ar y g round speed of the

v ehicle . Pressing the pedal star ts the engine .

Pressing the pedal far ther increases g round speed.

R eleasing the pedal will slo w the v ehicle and the

engine will stop r unning . Maxim um forw ard speed

is 14 mph (22 km/h).

Figure 14

1. Accelerator pedal 2. Brake pedal

Brake Pedal

T he brak e pedal is used to stop or slo w the v ehicle

( Figure 14 ).

Brak es can become w or n or can be

misadjusted r esulting in per sonal injur y .

If brak e pedal tra v els to within 1 inch

(25 mm) of the v ehicle floor board, the

brak es must be adjusted or r epair ed.

Parking Brake

T he parking brak e is betw een the seats ( Figure 15 ).

W henev er the engine is shut off , the parking brak e

m ust be eng ag ed to prev ent accidental mo v ement

of the v ehicle . T o eng ag e the parking brak e , pull

bac k on the lev er . T o diseng ag e , push the lev er

forw ard. If the v ehicle is park ed on a stee p g rade ,

mak e sure that the parking brak e is applied. Place

bloc ks at the do wnhill side of the wheels .

18

Page 19

Figure 15

1. Parking brake lever

Choke Control

T he c hok e control is located belo w and to the

right of the operator’ s seat. T o star t a cold engine ,

pull the c hok e control outw ard ( Figure 16 ). After

the engine star ts , regulate the c hok e to k ee p the

engine r unning smoothly . As soon as possible ,

push the control in to the Off position. A w ar m

engine requires little or no c hoking .

stopped, rotate the k ey countercloc kwise to the

Off position. R emo v e the k ey from the ignition.

Figure 17

1. Ignition switch 4. Oil light

2. Hour meter

3. Light switch

5. Power Point

6. Horn Button

Hour Meter

T he hour meter ( Figure 17 ) indicates the total

n umber of hours the engine has r un. T he hour

meter star ts to function whenev er the accelerator

is pressed.

Figure 16

1. Choke 2. Gear shift selector

Gear Shift Selector

T he g ear shift selector has three positions:

forw ard, rev erse , and neutral ( Figure 16 ). T he

engine will star t and r un in any of the three

positions .

Note: If the g ear shift selector is in R ev erse when

the ignition is tur ned on, a buzzer will sound to

w ar n the operator .

Important: Al w ays stop the v ehicle bef or e

changing gear s.

Ignition Switch

Oil Light

T he oil light w ar ns the operator if the engine oil

lev el drops belo w a safe lev el ( Figure 17 ). If the

light comes on and remains lit, the oil lev el should

be c hec k ed and oil added if necessar y; refer to

Chec king the Engine Oil in Operation , pag e 22 .

Note: T he oil light ma y flic k er . T his is nor mal

and no action needs to be tak en.

Light Switch

T og gle the switc h to acti v ate the headlights . Push

to tur n the lights on ( Figure 17 ).

Power Point

Use the po w er point to po w er 12 v olt optional

electrical accessories ( Figure 17 ).

Horn Button

Press the hor n button to sound the hor n

( Figure 17 ).

T he ignition switc h ( Figure 17 ), used to star t

and stop the engine , has tw o positions: Off

and On. R otate the k ey cloc kwise to the On

position to allo w operation. W hen the v ehicle is

Fuel Gauge

T he fuel g aug e ( Figure 18 ) sho ws the amount of

fuel in the tank.

19

Page 20

Figure 18

1. Fuel gauge

Passenger Hand Holds

T he passeng er hand holds are located on the right

side of the dash panel and at the outside of eac h

seat ( Figure 19 ).

Figure 19

1. Passenger hand hold

2. Hip restraint

20

Page 21

Specications

Note: Specifications and design are subject to c hang e without notice .

Base weight

Rated capacity (on level ground) 1250 lb (567 kg) total, including 200 lb (90.7 kg) operator and 200 lb (90.7 kg)

Maximum gross vehicle weight

(GVW) (on level ground)

Maximum cargo capacity (on

level ground)

Tow capacity:

Standard Hitch

Heavy Duty Hitch

Overall width

Overall length

Ground clearance

Wheel base

Wheel tread (center line to center

line)

Cargo box length

Cargo box width

Cargo box height

Dry 1050 lb (476 kg)

passenger, load, trailer tongue weight, gross trailer weight, accessories, and

attachments

2350 lb (1066 kg) total, including all of the weights listed above

850 lb (386 kg) total, including trailer tongue weight and gross trailer weight

Tongue weight 50 lb (23 kg) Maximum trailer weight 400 lb (182 kg)

Tongue weight 100 lb (45 kg) Maximum trailer weight 800 lb (363 kg)

60 inches (152.4 cm)

117 inches (297.2 cm)

9-1/4 inches (23.5 cm) at the front with no load or operator, 6-1/2 inches (19.7 cm)

at the rear with no load or operator

79 inches (200.7 cm)

49 inches (124.5 cm) in the front, 48-1/4 inches (122.6 cm) in the rear

46 inches (116.8 cm) inside, 51 inches (129.5 cm) outside

49 inches (124.5 cm) inside, 54 inches (137.2 cm) outside

10 inches (25.4 cm) inside

Attachments/Accessories

A selection of T oro appro v ed attac hments and accessories are a v ailable for use with the mac hine to

enhance and expand its capabilities . Contact y our A uthorized Ser vice Dealer or Distributor or g o to

www .T oro .com for a list of all appro v ed attac hments and accessories .

21

Page 22

Operation

Note: Deter mine the left and right sides of the

mac hine from the nor mal operating position.

Think Safety First

Please carefully read all of the safety instr uctions

and decals in the safety section. Kno wing this

infor mation could help y ou or b ystanders a v oid

injur y .

Pre-Starting Checks

Chec k the follo wing items eac h time y ou begin

using the v ehicle for the da y:

2. Clean around the oil dipstic k ( Figure 20 ) so

dir t cannot fall into the hole and damag e the

engine .

• Chec k the tire pressure .

Note: T hese tires are different than car tires;

they require less pressure to minimize turf

compaction and damag e .

• Chec k all fluid lev els and add the appropriate

amount of specified fluids , if any are found to

be lo w .

• Chec k the brak e pedal operation.

• Ensure that the lights are w orking .

• T ur n the steering wheel to the left and right to

c hec k steering response .

• Chec k for oil leaks , loose par ts , and any other

noticeable malfunctions . Mak e sure the engine

is off and all mo ving par ts ha v e stopped before

c hec king for oil leaks , loose par ts , and other

malfunctions .

If any of the abo v e items are not cor rect,

notify y our mec hanic or c hec k with y our

super visor before taking the v ehicle out for the

da y . Y our super visor ma y w ant y ou to c hec k

other items on a daily basis , so ask what y our

responsibilities are .

Figure 20

1. Oil dipstick

3. R emo v e the oil dipstic k and wipe the metal

end clean.

4. Slide the oil dipstic k fully into the filler tube .

Pull the dipstic k out and look at the metal end.

If the oil lev el is lo w , add oil of the proper

type to raise the lev el to , but not o v er , the F

mark on the dipstic k. R efer to Ser vicing the

Engine Oil in Engine Maintenance , pag e 31 ,

for the proper oil type and viscosity . Add the

oil slo wly and c hec k the lev el often during this

process . Do not o v erfill.

5. Install the oil dipstic k.

Checking the Brake Fluid

Level

Chec k the brak e fluid lev el before the engine is

first star ted; refer to Chec king the Brak e Fluid

Lev el in Brak e Maintenance , pag e 41 .

Checking the Engine Oil

Note: T he engine is shipped with oil in the

crankcase; ho w ev er , the lev el of the oil m ust be

c hec k ed before and after the engine is first star ted.

Chec k the engine oil lev el before star ting the

engine eac h da y .

1. P osition the mac hine on a lev el surface .

Checking the Tire Pressure

Chec k the tire pressure ev er y 8 hours or daily to

ensure proper lev els .

T he air pressure rang e in the front and rear tires is

8–22 psi (55–103 kP a).

T he air pressure needed is deter mined b y the

pa yload car ried. T he lo w er the air pressure , the

22

Page 23

less the compaction, smoother the ride , and tire

marks are minimized. Lo w er pressure should not

be used for hea vy pa yloads at high speeds .

Higher pressures should be used for hea vier

pa yloads at higher speeds . Do not ex ceed the

maxim um pressure .

In cer tain conditions during fueling , static

electricity can be r eleased causing a spar k

which can ignite the gasoline v apor s. A fir e

or explosion fr om gasoline can bur n y ou and

other s and can dama ge pr oper ty .

Adding Fuel

Use fresh, clean, unleaded regular g asoline suitable

for automoti v e use (87 pump octane minim um).

Leaded g asoline ma y be used if unleaded regular is

not a v ailable .

Important: Nev er use gasoline containing

methanol, gasoline containing mor e than

10% ethanol, gasoline additi v es, or white gas

because engine fuel system dama ge could

r esult.

In cer tain conditions, gasoline is extr emel y

flamma ble and highl y explosi v e. A fir e or

explosion fr om gasoline can bur n y ou and

other s and can dama ge pr oper ty .

• Fill the fuel tank outdoor s, in an open

ar ea, when the engine is cold. W ipe up

an y gasoline that spills.

• Al w ays place gasoline container s on the

g r ound a w ay fr om y our v ehicle bef or e

filling .

• Do not fill gasoline container s inside

a v ehicle or on a tr uck or trailer bed

because interior car pets or plastic tr uck

bed liner s may insulate the container and

slo w the loss of an y static charge.

• W hen practical, r emo v e gas-po w er ed

equipment fr om the tr uck or trailer and

r efuel the equipment with its wheels on

the g r ound.

• If this is not possible, then r efuel such

equipment on a tr uck or trailer fr om a

por ta ble container , rather than fr om a

gasoline dispenser nozzle.

• If a gasoline dispenser nozzle must be

used, k eep the nozzle in contact with the

rim of the fuel tank or container opening

at all times until fueling is complete.

• Nev er fill the fuel tank inside an enclosed

trailer .

• Do not fill the fuel tank completel y full.

Add gasoline to the fuel tank until the

lev el is 1/4 to 1/2 inch (6 to 13 mm)

belo w the bottom of the filler neck. T his

empty space in the tank allo ws gasoline

to expand.

• Nev er smok e when handling gasoline,

and stay a w ay fr om an open flame or

wher e gasoline fumes may be ignited by

a spar k.

• Stor e gasoline in an appr o v ed container

and k eep it out of the r each of childr en.

Nev er buy mor e than a 30-day suppl y of

gasoline.

• Do not operate without entir e exhaust

system in place and in pr oper w or king

condition.

Filling the Fuel Tank

T he fuel tank capacity is appro ximately 7 g allons

(26.5 l).

1. Shut the engine off and set the parking brak e .

2. Clean the area around the fuel tank cap

( Figure 21 ).

Figure 21

1. Fuel tank cap

3. R emo v e the fuel tank cap .

4. Fill the tank to about 1 inc h (25 mm) belo w the

top of tank, (bottom of the filler nec k). T his

23

Page 24

space in the tank allo ws g asoline to expand.

Do not o v erfill.

5. Install the fuel tank cap securely . Wipe up any

fuel that ma y ha v e spilled.

Checking the Transmission

Oil Level

T he transaxle fluid lev el should be at the bottom

of the lev el indicator hole ( Figure 22 ). If it

is not, fill the reser v oir with the appropriate

fluid; refer to Changing the T ransaxle Fluid in

Dri v e System Maintenance , pag e 36 .

Note: Stopping distance ma y v ar y de pending on

the v ehicle load and speed.

Parking the Vehicle

1. Eng ag e the parking brak e and rotate the

ignition k ey to Off .

2. R emo v e the k ey from the ignition switc h to

prev ent accidental star ting .

Operating the Cargo Box

Raising the Box

Dri ving the v ehicle with the cargo bo x raised

may cause the v ehicle to tip or r oll easier .

T he bo x str uctur e may become dama ged if

y ou operate the v ehicle with the bo x raised.

Figure 22

1. Level indicator hole

Starting the Engine

1. Sit in the operator’ s seat, inser t the k ey into the

ignition switc h, and rotate the k ey cloc kwise to

the On position.

Note: If the g ear shift selector is in R ev erse ,

the buzzer will sound to w ar n the operator .

2. Mo v e the g ear shift selector to the desired

position.

3. R elease the parking brak e .

4. Slo wly ste p on the accelerator pedal.

Note: If the engine is cold, press and hold

the accelerator pedal about half-w a y do wn, and

pull the c hok e knob out to the On position.

R etur n the c hok e knob to Off after the engine

w ar ms up .

Important: Do not attempt to push or

to w the v ehicle to get it star ted.

• Onl y operate the v ehicle when the cargo

bo x is do wn.

• After dumping a load, lo w er the cargo

bo x.

1. Lift the lev er on either side of the bo x and lift

the bo x up ( Figure 23 ).

Figure 23

1. Lever

2. Pull the prop rod into the detent slot, securing

the bo x ( Figure 24 ).

Stopping the Vehicle

T o stop the v ehicle , remo v e y our foot from the

accelerator pedal and slo wly press the brak e pedal.

24

Page 25

Figure 24

1. Prop rod

Lowering the Box

T he w eight of the bo x may be hea vy . Hands

or other body par ts could be cr ushed.

K eep hands and other body par ts clear when

lo w ering the bo x.

Operating the Tailgate Latches

1. T o open the tailg ate latc hes , lift the latc h

handles up ( Figure 26 ). T he latc hes will spring

out to w ard the center of the tailg ate . Slo wly

lo w er the tailg ate .

Note: Y ou ma y need to push the end of the

tailg ate in (especially if there is a load ag ainst

the tailg ate) before the latc hes will spring

to w ard the center of the tailg ate and release .

Figure 26

1. Tailgate latch

Pull the prop rod out of the detent slot and lo w er

the bo x until it latc hes into place .

Adjusting the Box Latches

If the bo x latc h does not latc h tightly , vibrating up

and do wn as y ou dri v e the v ehicle , y ou can adjust

the latc h posts to mak e the latc hes fit sn ugly .

1. Loosen the n ut on the end of the latc h post

( Figure 25 ).

Figure 25

1. Latch 3. Latch post

2. Nut

2. T o close the tailg ate latc hes , lift the handles

upw ard and slide them to w ard the outside of

the v ehicle .

3. Push the latc h handles do wnw ard to secure the

latc h and tailg ate .

Breaking in a New Vehicle

T o pro vide proper perfor mance and long

v ehicle life , follo w these guidelines for the first

100 operating hours:

• Chec k the fluid and engine oil lev els regularly

and be aler t for indications of o v erheating in

any component of the v ehicle .

• After star ting a cold engine , let it w ar m up for

about 15 seconds before accelerating .

• A v oid hard braking situations for the first

sev eral hours of new v ehicle break-in

operation. New brak e linings ma y not be at

optim um perfor mance until sev eral hours of

use has caused the brak es to become bur nished

(brok en-in).

2. T ur n the latc h post cloc kwise until it is sn ug

ag ainst the latc h and then tighten the n ut

( Figure 25 ).

3. R e peat this procedure for the latc h on the

other side of the v ehicle .

• V ar y the v ehicle speed during operation. A v oid

fast star ts and quic k stops .

• A break-in oil for engine is not required.

Original engine oil is the same type specified

for regular oil c hang es .

25

Page 26

• R efer to the Maintenance section for any

special lo w hour c hec ks .

• Chec k the front suspension positioning

and adjust it if necessar y; refer to

Adjusting the F ront Suspension in

Dri v e System Maintenance , pag e 36 .

Loading the Cargo Box

T he capacity of the carg o bo x is 13 ft

3

(0.37 m

T he amount (v olume) of material that can be

placed in the bo x without ex ceeding the v ehicle

load ratings can v ar y g reatly de pending on the

density of the material. F or example , a lev el bo x of

w et sand w eighs 1500 lb (680 kg), whic h ex ceeds

the load rating b y 650 lb (295 kg). But a lev el bo x

of w ood w eighs 650 lb (295 kg), whic h is under

the load rating .

See the table belo w for load v olume limits with

v arious materials:

3

Max. cargo box

)

capacity (on

level ground)

95

90

45

2/3 full (approx.)

1/2 full (approx.)

2/3 full

1/2 full

Full

Full

2/3 full (approx.)

Gravel, dry

Gravel, wet

Sand, dry

Sand, wet

Wood

Bark

Earth, packed

Material

Density (lb/ft

120

120

<45

100

3

).

Figure 27

1. Tie down points

Towing the Vehicle

In case of an emerg ency , the v ehicle can be

to w ed for a shor t distance . Ho w ev er , w e do not

recommend this as a standard procedure .

T o wing at ex cessi v e speeds could cause a

loss of steering contr ol, r esulting in per sonal

injur y .

Nev er to w the v ehicle f aster than 5 mph

(8 km/h).

T o wing the v ehicle is a tw o person job . If

the mac hine m ust be mo v ed a considerable

distance , transpor t it on a tr uc k or trailer; refer to

T ranspor ting the V ehicle .

Transporting the Vehicle

F or mo ving the v ehicle long distances , a trailer

should be used. Mak e sure that the v ehicle is

secured to the trailer . R efer to Figure 27 and

Figure 28 for the location of the tie-do wn points .

Loose seats may f all of f of the v ehicle

and trailer when transpor ting and land on

another v ehicle or become an obstr uction

on the r oad.

R emo v e the seats or mak e sur e that the seats

ar e secur el y f astened in the detents.

1. R emo v e the dri v e belt; refer to R e placing the

Dri v e Belt in Belt Maintenance , pag e 41 .

2. Affix a to w line to the tongue on the front of

the frame ( Figure 28 ).

3. Put the v ehicle in neutral and release the

parking brak e .

26

Page 27

Figure 28

1. Towing tongue and tie down point

Towing a Trailer

T he v ehicle is capable of pulling trailers . T w o

types of to w hitc hes are a v ailable for the v ehicle ,

de pending on y our application. Contact y our

A uthorized T oro Distributor for details .

W hen hauling carg o or to wing a trailer , do not

o v erload y our v ehicle or trailer . Ov erloading can

cause poor perfor mance or damag e to the brak es ,

axle , engine , transaxle , steering, suspension, body

str ucture , or tires . Alw a ys load a trailer with 60%

of the carg o w eight in the front of the trailer . T his

places appro ximately 10% of the Gross T railer

W eight (GTW) on the to w hitc h of the v ehicle .

T he maxim um carg o load shall not ex ceed 850 lb

(386 kg), including the GTW and tongue w eight.

F or example , if the GTW = 400 lb (181.5 kg) and

tongue w eight = 50 lb (23 kg), then the maxim um

carg o load = 400 lb (181.5 kg)

T o pro vide adequate braking and traction, alw a ys

load the carg o bo x when trailering . Do not ex ceed

the GTW limits .

A v oid parking a v ehicle with a trailer on a hill. If

y ou m ust park on a hill, eng ag e the parking brak e

and bloc k the trailer tires .

27

Page 28

Maintenance

Note: Deter mine the left and right sides of the mac hine from the nor mal operating position.

Recommended Maintenance Schedule(s)

Maintenance Service

Interval

After the rst 8 operating

hours

After the rst 25

operating hours

Before each use or daily

Every 50 hours

Every 100 hours

Maintenance Procedure

• Check the engine oil.

• Check the condition and tension of the drive belt.

• Check the tension of the starter generator belt.

• Change the engine oil.

• Check the front wheel toe-in and front suspension.

• Check the engine oil.

• Check the tire pressure.

• Check the transmission oil level.

• Check the brake uid level.

• Check the battery cable connections for wear or damage.

• Check the battery electrolyte level.

• Grease the bearings and bushings.

• Inspect and clean the air lter element (twice as often in special operating

conditions; refer to Maintaining the Vehicle under Special Operating

Conditions).

• Change the engine oil (twice as often in special operating conditions; refer

to Maintaining the Vehicle under Special Operating Conditions).

• Check the spark plug.

• Check the operation of the Neutral gear shift position.

• Inspect the condition and wear of the tires.

•

Torque the wheel lug nuts to 45-65 ft-lb (61-88 N ⋅ m).

• Check the front wheel toe-in and front suspension.

• Clean the engine cooling areas (twice as often in special operating

conditions; refer to Maintaining the Vehicle under Special Operating

Conditions).

• Inspect the brakes.

• Replace the air lter element.

Every 200 hours

Every 400 hours

Every 800 hours

Yearly

• Adjust the parking brake.

• Check the condition and tension of the drive belt.

• Check the tension of the starter generator belt.

• Inspect the fuel lines and connections.

• Clean and lubricate the primary drive clutch.

• Replace the fuel lter.

• Change the transaxle uid.

• Complete all yearly maintenance procedures specied in the Engine

Operator’s Manual.

Important: R efer to y our Engine Operator’ s Man ual f or additional maintenance pr ocedur es.

28

Page 29

Daily Maintenance Checklist

Duplicate this page for routine use.

Maintenance Check

Item

Check brake and parking

brake operation.

Check gear shift/neutral

operation.

Check fuel level.

Check engine oil level.

Check transaxle oil level.

Inspect air lter.

Inspect engine cooling

ns.

Check unusual engine

noises.

Check unusual operating

noises.

Check tire pressure.

Check uid leaks.

Check instrument

operation.

Check accelerator

operation.

Check ride height and

toe-in.

Lubricate all grease

ttings.

Touch up damaged

paint.

For the week of:

Mon. Tues.

Wed. Thurs.

Fri.

Sat. Sun.

If y ou lea v e the k ey in the ignition s witch, someone could accidentl y star t the engine and

seriousl y injur e y ou or other bystander s.

R emo v e the k ey fr om the ignition and disconnect the wir e fr om the spar k plug bef or e y ou do

an y maintenance. Set the wir e aside so that it does not accidentall y contact the spar k plug .

T he bed must be raised to perf or m some r outine maintenance.

A raised bed can f all and injur e per sons that ar e under neath it.

• Al w ays use the pr op r od to hold the bed up bef or e w or king under it.

• R emo v e an y load material fr om the bed bef or e w or king under it.

29

Page 30

Premaintenance

Procedures

Maintaining the Vehicle

under Special Operating

Conditions

If the v ehicle is subjected to any of the conditions

listed belo w , maintenance should be perfor med

twice as frequently .

• Deser t operation

• Cold climate operation (belo w 50 deg rees F

[10 deg rees C])

• T railer to wing

• Dri ving time typically less than 5 min utes

• F requent operation in dusty conditions

• Constr uction w ork

• After extended operation in m ud, sand, w ater ,

or similar dir ty conditions , ha v e y our brak es

inspected and cleaned as soon as possible . T his

will prev ent any abrasi v e material from causing

ex cessi v e w ear .

T he jac king point at the front of the v ehicle is on

the front of the frame behind the to wing tongue

( Figure 29 ) T he jac king point at the rear of the

v ehicle is under the axle tubes ( Figure 30 ).

Figure 29

1. Front jacking point

• Under frequent hea vy duty operating

conditions , lubricate all g rease fittings and

inspect air cleaner daily to prev ent ex cessi v e

w ear .

Jacking the Vehicle

W henev er the engine is r un for routine

maintenance and/or engine diagnostics , the rear

wheels of the v ehicle should be 1 inc h (25 mm)

off the g round with the rear axle suppor ted on

jac k stands .

T he v ehicle may be unsta ble when using

a jack. It could slip of f the jack, injuring

an y one beneath it.

• Do not star t the engine while the v ehicle

is on a jack.

• Al w ays r emo v e the k ey fr om the ignition

bef or e getting of f of the v ehicle.

• Block the tir es when the v ehicle is on a

jack.

Figure 30

1. Rear jacking points

Lubrication

Lubricate all of the bearings and bushings ev er y

100 hours or once a year , whic hev er occurs first.

Grease them more frequently when using the

v ehicle for hea vy-duty operations .

Grease T ype: Number 2 General Pur pose Lithium

Base Grease

Adding Grease

1. Wipe the g rease fitting clean so foreign matter

cannot be forced into the bearing or bushing .

2. Pump g rease into the bearing or bushing .

3. Wipe off ex cess g rease .

30

Page 31

T he g rease fittings are located at the four tie rod

ends ( Figure 31 and the tw o king pins ( Figure 32 ).

Figure 31

Figure 32

co v er from the body . Clean the inside of the

air cleaner co v er ( Figure 33 ).

4. Gently slide the filter out of the air cleaner

body to reduce the amount of dust dislodg ed

( Figure 33 ). A v oid knoc king the filter ag ainst

the air cleaner body .

Figure 33

1. Air cleaner latches 3. Filter

2. Cover

Engine Maintenance

Servicing the Air Cleaner

Chec k the air cleaner body for damag e whic h could

possibly cause an air leak. R e place a damag ed air

cleaner body .

Ensure the co v er is sealing around the air cleaner

body .

Air Cleaner Filter : Inspect after ev er y

100 operating hours; re place after ev er y 200 hours

or sooner if dir ty or damag ed.

Note: Ser vice the air cleaner more frequently

(ev er y few hours) if operating conditions are

extremely dusty or sandy .

Removing the Filter Element

1. P ark the mac hine on a lev el surface , set the

parking brak e , tur n the ignition off , and

remo v e the k ey .

2. Raise the bed and secure it with the prop rod.

3. R elease the latc hes securing the air cleaner

co v er to the air cleaner body . Se parate the

5. Inspect the filter and discard it if it is damag ed.

Cleaning the Filter Element

Important: Do not w ash or r euse a dama ged

filter .

• W ashing method:

1. Pre pare a solution of filter cleaner and

w ater and soak the filter element for about

15 min utes . R efer to the directions on

the filter cleaner car ton for complete

infor mation.

2. After soaking the filter for 15 min utes , rinse

it with clear w ater . Rinse the filter from the

clean side to the dir ty side .

Important: T o pr ev ent dama ge

to the filter element, the maximum

w ater pr essur e must not ex ceed 40 psi.

(276 kP a).

3. Dr y the filter element using w ar m, flo wing

air at 160 deg rees F (71 deg rees C)

maxim um, or allo w the element to air -dr y .

Important: Do not use a light bulb to

dr y the filter element because dama ge

could r esult.

• Compr essed air method:

31

Page 32

1. Blo w compressed air from the inside to the

outside of the dr y filter element. K ee p the

air hose nozzle at least 2 inc hes (51 mm)

from the filter and mo v e the nozzle up and

do wn while rotating the filter element.

Important: T o pr ev ent dama ge to

the filter element, do not ex ceed 100 psi

(689 kP a) air pr essur e.

2. Inspect the filter element for holes and

tears b y looking through the filter to w ard a

bright light.

Installing the Filter Element

Important: T o pr ev ent engine dama ge,

al w ays operate the engine with the complete

air cleaner assembl y installed.

1. Inspect the new filter for shipping damag e .

Chec k the sealing end of the filter .

Important: Do not install a dama ged

filter .

2. Inser t the new filter into air cleaner body .

Ensure the filter is sealed properly b y applying

pressure to the outer rim of the filter when

installing it. Do not press on the flexible center

of the filter .

3. Install the co v er and secure the latc hes .

Servicing the Engine Oil

Chec k the oil lev el before eac h use .

Chang e the oil after the first 25 operating

hours and ev er y 100 operating hours thereafter .

Chang e the oil twice as often in special operating

conditions; refer to Maintaining the V ehicle under

Special Operating Conditions .

Figure 34

Checking the Oil Level

T o c hec k the oil lev el, refer to Chec king the Engine

Oil in Operation , pag e 22 .

Changing the Oil

1. Star t the v ehicle and let it r un for a few min utes

to w ar m the oil.

2. P ark the mac hine on a lev el surface , set the

parking brak e , tur n the ignition off , and

remo v e the k ey .

3. Raise the bed and secure it with the prop rod.

4. Disconnect the spark plug wires and batter y

cables .

5. R emo v e the drain plug ( Figure 35 ) and let the

oil flo w into a drain pan. W hen the oil has

drained completely , install the drain plug and

tor que it to 13 ft-lb (17.6 N ⋅ m).

Note: Chang e the oil more frequently when

operating conditions are extremely dusty or sandy .

Oil T ype: Deterg ent oil (API ser vice SG , SH, SJ ,

or higher)

Viscosity: See the table belo w .

32

Page 33

Figure 35

1. Engine oil drain plug

Note: Dispose of the used oil at a cer tified

recycling center .

6. Clean around the oil dipstic k and unscrew the

cap .

7. Slo wly pour appro ximately 80% of the

specified amount of oil into the filler tube

and c hec k the oil lev el; refer to Chec king the

Crankcase Oil in Operation , pag e 22 . Slo wly

add oil to bring the lev el to the F mark on the

dipstic k.

8. Install the dipstic k.

3. Chec k the condition of the side electrode ,

center electrode , and center electrode insulator

to ensure that there is no damag e ( Figure 36 ).

Important: A crack ed, f ouled, dir ty ,

or malfunctioning spar k plug must be

r eplaced. Do not sand-blast, scrape, or

clean electr odes by using a wir e br ush

because g rit may ev entuall y r elease fr om

the plug and f all into the cylinder . T he

r esult is usuall y a dama ged engine.

Figure 36

1. Center electrode insulator

2. Side electrode

4. Set the air g ap betw een the center and side

of the electrodes at 0.030 inc h (0.762 mm)

( Figure 36 ). Install the cor rectly g apped spark

plug and tighten the plug to 14 ft-lb (20 N ⋅ m).

3. Air gap (not to scale)

Servicing the Spark Plug

Chec k the spark plug after ev er y 100 operating

hours or yearly , whic hev er occurs first. R e place

if necessar y .

T ype: Champion RN14Y C (or equi v alent)

Air Gap: 0.030 inc h (0.762 mm)

Checking and Replacing the Spark

Plug

Note: T he spark plug usually lasts a long time;

ho w ev er , the plug should be remo v ed and c hec k ed

whenev er the engine malfunctions .

1. Clean the area around the spark plugs so that

foreign matter cannot fall into the cylinder

when the spark plug is remo v ed.

2. Pull the wires off of the spark plugs and

remo v e the plugs from the cylinder head.

5. Install the spark plug wires .

Fuel System

Maintenance

Inspecting Fuel Lines and

Connections

Chec k the fuel lines and connections ev er y 400

operating hours or yearly , whic hev er occurs first.

Inspect them for deterioration, damag e , or loose

connections .

Replacing the Fuel Filter

R e place the fuel filter ev er y 800 operating hours

or yearly , whic hev er occurs first.

1. Raise the bo x and suppor t it with the prop rod.

33

Page 34

2. Place a clean container under the fuel filter .

3. R emo v e the clamps securing the fuel filter to

the fuel lines ( Figure 37 ).

Figure 37

1. Fuel lter

4. Install the re placement filter to the fuel lines

with the clamps previously remo v ed.

Mount the filter so that the ar ro w points