Page 1

Electric Bed Lift Kit

For Workman 1100/2100 and Twister Utility Vehicle

Model No. 07259, 07259R

Installation

Loose Parts

Use the c

hart below to verify that all parts have been shipped.

Form No. 3353-886 Rev A

Installation Instructions

Step

1

2

3

None

Lift bracket, upper

Flange

inch)

Lift cy

Lift ac tuator

U-bolts

Flange nut (3/4 inch)

Carria

Clevis pin

Cotter pin

Nylon washer

Steel

Switch

Fuse, 15 amp 1

Clevi

Cotte

Description

head screws (5/16 x 3/4

linder support

ge bolts (3/8 x 3/4 inch)

washer

spin

rpin

Note: If this kit is used on Model No. 07253

with a serial number of 210000243 and prior or

Model No. 07253TC with a serial number of

210000393 and prior, you will need to order an

Upper Lift Bracket, Part No. 99-7710-03.

Qty.

Step

1

Use

Prepare the machine

1

4

1

1

2

6

2

1

1

1

3

1

1

1

Install the bed lift

Install the switch

© 2005—The Toro® Company

8111 Lyndale Avenue South

Bloomington, MN 55420

Preparing the Machine

Parts needed for this step:

Procedure

1. Position the machine on a level surface. Set

the parking brake, turn the ignition off, and

remove the key.

Register at www.Toro.com.

None

Original Instructions (EN)

Printed in the USA.

All Rights Reserved

Page 2

If you leave the

switch, someo

theengineand

other bystand

key in t he ignition

ne could accidently start

seriously injure you or

ers.

Remove the key from the ignition switch

before you do any maintenance.

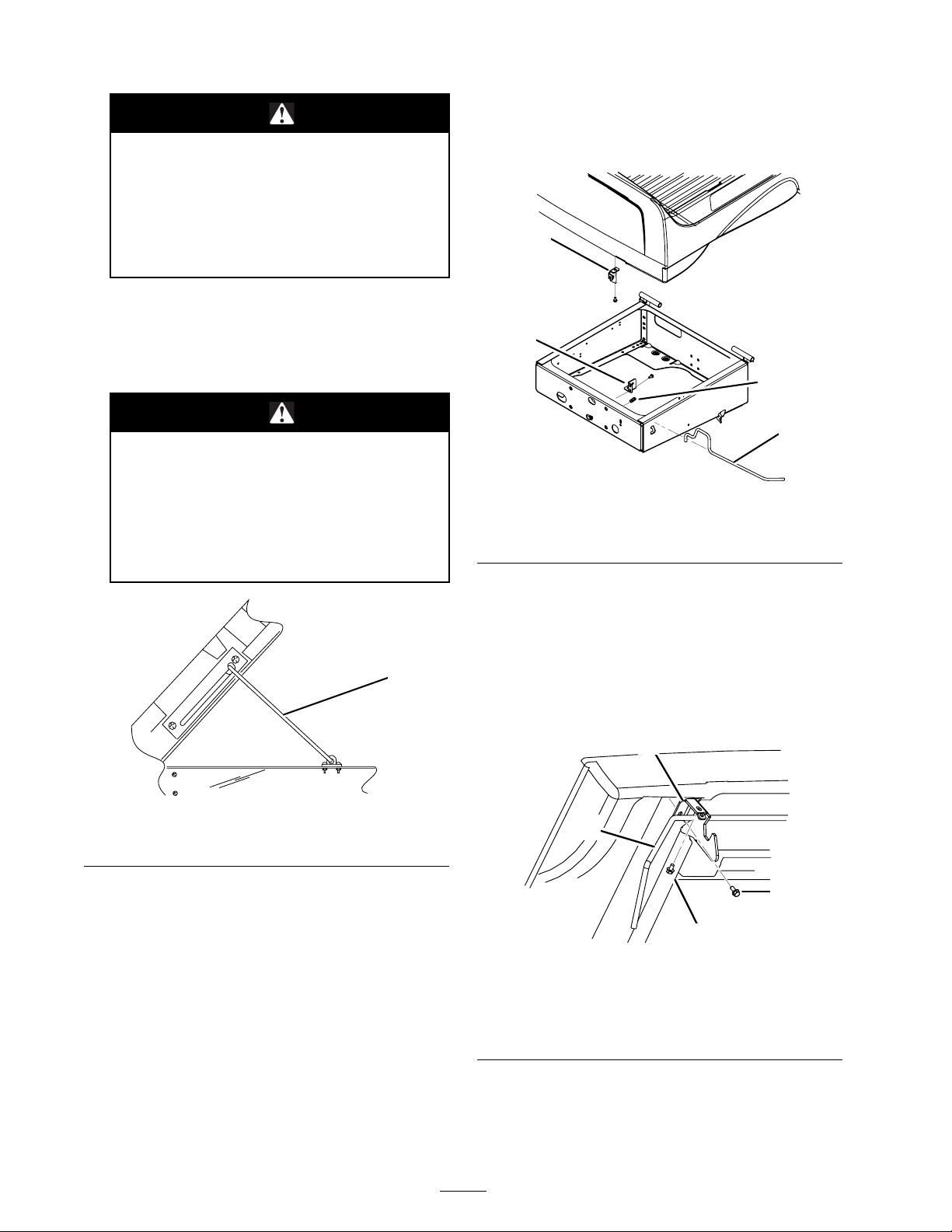

2. Raise the bed. Rotate the latch rod upward and

raise the box with the other hand.

3. Raise the box to its full height; then lower it

slightly to engage the prop rod (Figure 1).

Araisedboxcouldfallandinjurepersons

that are working beneath it.

Remove the 2 flange head screws securing each

side of the latch rod bracket to the front of the

rear frame ( Figure 2).

2

1

4

3

G001319

• Always use the prop rod to hold the

box up before working under the box.

• Remove any load material from the

box before raising it.

1

G001318

Figure 1

1. Prop rod

4. Disconnect the battery cables from the batter y.

5. Remove the rubber strap securing the battery

to the battery base. Lift the battery out of the

battery base.

For machines with Serial numbers 259999999 and

lower:

Figure 2

1. Latch rod b

2. Latch hook

racket

3. Latch rod

4. Spring

For machines with Serial numbers 260000001 and

up:

Remove the 2 flange head screws securing each

side of the latch rod bracket to the underside and

front face of the box (Figure 3). Retain all parts

for future use.

1

2

4

G001320

Figure 3

1. Latch rod bracket 3. Flange head screw, inside

2. Latch rod 4. Flange head screw,

3

front face of box

underside of box

2

Page 3

Step

2

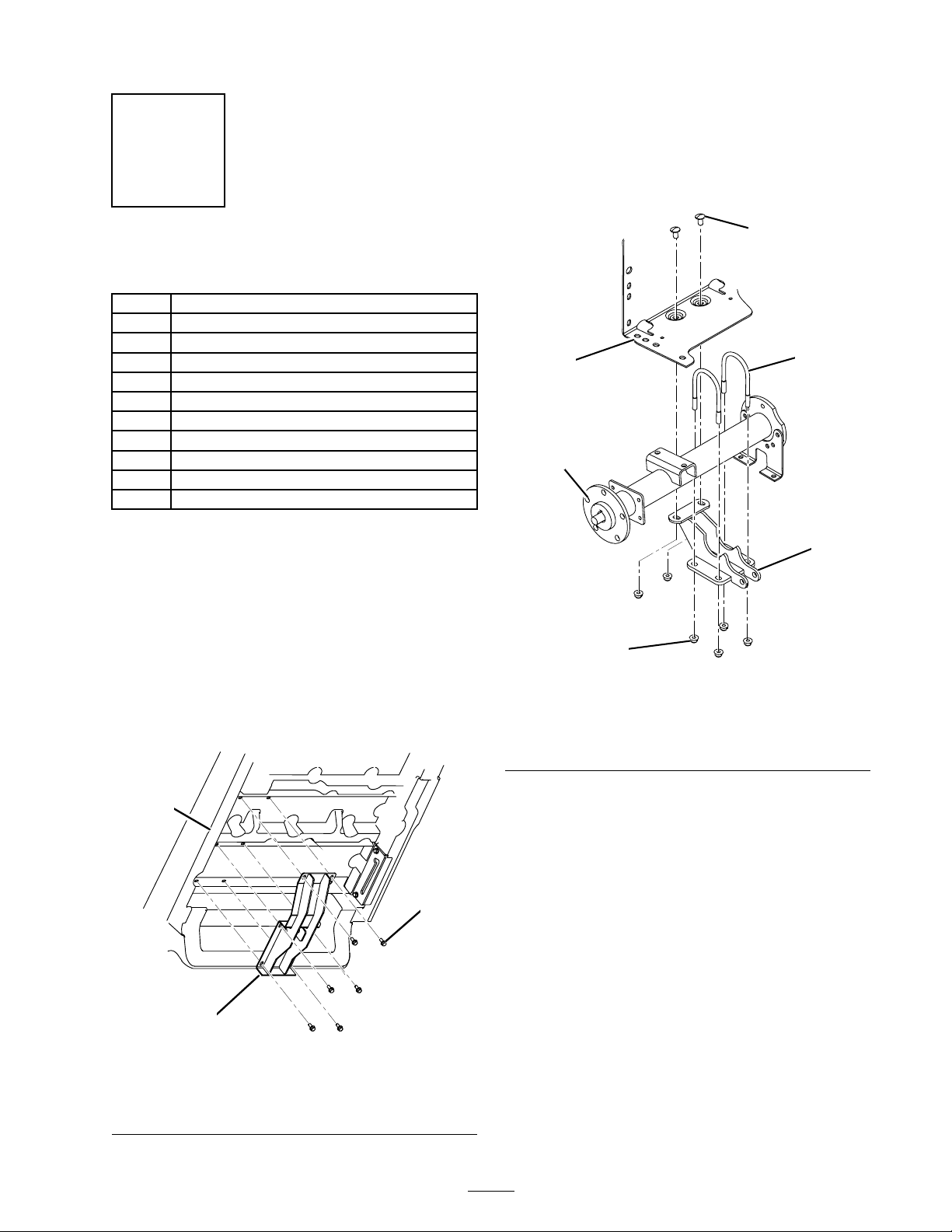

3. Loosely mount the lift cylinder support to

the right end of the rear axle with 2 U-bolts

and 4 flange nuts (3/4 inch) while aligning the

mounting holes with the holes in the battery

tray (Figure 5).

Installing th

eBedLift

Parts needed for this step:

1

Lift bracket, upper

4

Flange head screws (5/16 x 3/4 inch)

1

Lift cylinder support

1

Lift actuator

2

U-bolts

6

Flange nut (3/4 inch)

2

Carriage bolts (3/8 x 3/4 inch)

1

Clevis pin

1

Cotter pin

1

Nylon washer

3

Steel washer

Procedure

1. Remove the screws from the braces on the

underside of the box in the positions shown

in (Figure 4).

2. Mount the upper lift bracket to the underside

of the box with 6 flange head screws (5/16

x 3/4 inch) from loose parts and removed

previously. Position the bracket as shown in

Figure 4.

G001322

5

3

2

6

Figure

1. Lift cy

2. Right end of the axle 5. Carriage bolt, 3/8 x 3/4

3. Rear frame battery tray 6. Flange nut, 3/4 inch

linder support

5

4. U-bolt

inch

4

1

1

3

G001321

2

Figure 4

1. Bed 3. Flange head screw, 5/16 x

3/4 inch

2. Upper lift bracket

4. Secure the lift cylinder support to the rear

frame with 2 carriage bolts (3/8 x 3/4 inch)

and 2 flange nuts (3/4 inch). Tighten the 4

flange nuts on the U-bolts equally to make sure

the bracket is aligned to the axle. Tighten the

two nuts securing the rear of the bracket to the

rear frame (Figure 5).

5. Mount the bottom end of the lift actuator to

the lift cylinder support with a clevis pin and

3

Page 4

cotter pin. Position the components as shown

in Figure 6.

6

5

Step

3

2

G001323

3

Figure 6

1. Actuator

2. Lift cylinder support 5. Nylon washer

3. Clevis pi

n

4. Cotter pin

6. Steel w as

hers

Installing th

eSwitch

Parts needed for this step:

1

1

Switch

1Fuse,15amp

1

Clevis pin

1

Cotter pin

Procedure

1. Remove the plug from the hole in the right

side of the dash (Figure 7).

4

Note: If the hole in the dash is in use,

measure over 1/2 inch (13 mm) and cut

another 0.835 inch x 1.46 inch (21 mm x 35

mm) rectangular hole in t he dash. Make sure

not to damag e any existing components behind

the dash when cutting the hole.

3

6. Slide a nylon washer onto the actuator rod,

then slide on one steel washer.

Note: Additional steel washers are provided

and can be used to adjust the lower stop of the

actuator rod.

1

2

G001324

Figure 7

1. Plugged hole

2. Switch

3. Cut new hole (if required)

2. Plug the switch into the harness connector in

the dash. Insert the switch into the hole in the

dash (Figure 7).

3. Remove the cover to expose the fuse block.

Install a new fuse (15 amp) into the open slot

in the fuse block. Install the cover.

4

Page 5

4. Plug the actuator harness into the vehicle

harness connector, located near the fuse block.

5. Install the battery and connect the cables.

6. Press the switch upward to extend the actuator

rod until it is aligned with the mounting holes

in the upper lift bracket. Secure the rod to the

bracket with the clevis pin and cotter pin.

7. Remove the screws and clip securing the prop

rod to the frame rail (Figure 8).

3

1

2

G001325

Figure 8

1. Prop rod 3. Prop rod bracket

2. Prop rod clip

8. Remove the screws securing the prop rod

bracket to the underside of the box. Remove

the retainer securing the rod t o the bracket and

remove the rod (Figure 8). Retain the prop rod

components for future use.

Note: If the electric box lift is ever removed,

install the prop rod, prop rod clip, and prop

rod bracket.

5

Page 6

Operation

Raising the Bed

Driving the ve

may cause the

The box struc

the box is rai

time while o

• Only operat

box is down.

•Afteraload

cargo box.

1. Turn the ignition key to the On position.

2. Push the top of the switch to raise the box.

Important: When a ratcheting noise is

heard, the box lift is completely extended

or retracted. Do not continue pressing the

switch.

hicle with the cargo box raised

vehicle to tip or roll easier.

ture may become damaged if

sed for an extended period of

perating the vehicle.

e the vehicle when the cargo

has been dumped, lower the

Lowering the Bed

The weight of the box may be heavy. Hands

or other body parts could be crushed.

Keep hands and other body parts clear when

lowering the box.

1. Push the bottom of the switch to lower the

box.

Note: The bed will deform slightly before

the actuator clutch begins to engage. If the

bed floor deforms more than 1/4 inch add

additional steel washers to the raise the lower

stop of the actuator rod. When bed is pulled

tight to the vehicle frame, but the bed floor

does not deform more than 1/4 inch the lift

has been adjusted correctly.

2. Turn the ignition key to the Off position and

remove the key.

6

Page 7

Page 8

Loading...

Loading...