Page 1

Form No. 3325-997

Operator’s Manual

®

Workman®2100

Air-Cooled Gasoline Utility Vehicle

07253TC—210000501 and Up

English (GB)

Page 2

The engine in this product is not equipped with a

spark arrester muffler. It is a violation of California

Public Resource Code Section 4442 to use or operate

this engine on any forest-covered, brush-covered, or

grass-covered land as defined in CPRC 4126. Other

states or federal areas may have similar laws.

This spark ignition system complies with Canadian

ICES-002.

Ce système d’allumage par étincelle de véhicule est

conforme à la norme NMB-002 du Canada

Contents

Contents 2

Introduction 3

Safety 3

Safe Operating Practices 4

Slope Chart 9

Specifications 12

Checking the Crankcase Oil 13

Checking the Tire Pressure 13

Fuel Tank 13

Before Operating 13

Operation 14

Think Safety First 14

Controls 14

Pre-Starting Checks 16

Starting the Engine 17

Stopping the Vehicle 17

Parking the Vehicle 17

Cargo Bed 17

Tailgate Latches 18

New Vehicle Break-in 18

Transporting the Vehicle 19

Towing the Vehicle 19

Towing a Trailer 19

Maintenance 20

Daily Maintenance Checklist 21

Heavy-Duty Operation 22

Jacking the Vehicle 22

Neutral Lock Assembly 23

Servicing the Engine Oil 23

Cleaning the Engine Cooling Areas 24

Servicing the Air Cleaner 24

Greasing the Machine 26

Servicing the Brakes 26

Inspecting Tires 27

Adjusting the Front Suspension 27

Servicing the Drive Belt 27

Adjusting the Starter Generator Belt 28

Adjusting Front Wheel Toe-in 28

Servicing the Fuel System 29

Spark Plugs 29

Changing Transaxle Fluid 30

Fuses 31

Replacing the Headlights 31

Servicing the Battery 31

Washing the Vehicle 33

2

@2001 by The Toro Company

8111 Lyndale Avenue South

Bloomington, MN 55420-1196

All Rights Reserved

The engine exhaust from this product contains

chemicals known to the State of California to cause

cancer, birth defects, or other reproductive harm.

WARNING

Page 3

Introduction

Read this manual carefully to learn how to operate

and maintain your product correctly. The information

in this manual can help you and others avoid injury

and product damage. Although Toro designs and

produces safe products, you are responsible for

operating the product properly and safely.

Whenever you need service, genuine Toro parts, or

additional information, contact an Authorized Service

Dealer or Toro Customer Service and have the model

and serial numbers of your product ready. Figure 1

illustrates the location of the model and serial

numbers on the product.

Figure 1

1. Location of the model and serial number plate

Write the product model and serial numbers in the

space below.

This manual identifies potential hazards and has

special safety messages that help you and others avoid

personal injury, even death. Danger, Warning and

Caution are signal words used to identify the level of

hazard. However, regardless of the hazard, be

extremely careful.

Danger signals an extreme hazard that will cause

serious injury or death if you do not follow the

recommended precautions.

Warning signals a hazard that may cause serious

injury or death if the recommended precautions are

not followed.

Caution signals a hazard that may cause minor or

moderate injury if the recommended precautions are

not followed.

The manual uses two other words to highlight

information. calls attention to special

mechanical information and Note: emphasizes general

information worthy of special attention.

Safety

Improper use or maintenance by the operator or owner

can result in injury. To reduce the potential for injury,

comply with these safety instructions and always pay

attention to the safety alert symbol, which means

CAUTION, WARNING, or DANGER—“personal

safety instruction.” Failure to comply with the

instruction may result in personal injury or death.

Supervisors, operators, and service persons should be

familiar with the following standards and

publications: (The material may be obtained from the

address shown).

• Flammable and Combustible Liquids Code:

ANSI/NFPA 30

• National Fire Protection Association: ANSI/NFPA

# 505; Powered Industrial Trucks

National Fire Prevention Association

Barrymarch Park

Quincy, Massachusetts 02269 U. S. A.

• ANSI/ASME B56.8 Personal Burden Carriers

American National Standards Institute, Inc. 1430

Broadway New York, New York 10018 U.S.A.

• ANSI/UL 558; Internal Combustion Engine

Powered Industrial Trucks

American National Standards Institute, Inc.

1430 Broadway

Important

3

Model No: ________________________

Serial No.: ________________________

Page 4

4

New York, New York 10018 U. S. A.

or

Underwriters Laboratories

333 Pfingsten Road

Northbrook, Illinois 60062 U.S.A.

Safe Operating Practices

Supervisor’s Responsibilities

• Make sure that operators are thoroughly trained

and familiar with the operator’s manual and all

labels on the vehicle.

• Be sure to establish your own special procedures

and work rules for unusual operating conditions

(e.g., slopes too steep for vehicle operation).

Before Operating

• Operate the machine only after reading and

understanding the contents of this manual.

• Never allow children to operate the vehicle.

Anyone who operates the vehicle should have a

motor vehicle license.

• Never allow other adults to operate the vehicle

without first reading and understanding the

Operator’s Manual. Only trained and authorized

persons should operate this vehicle. Make sure

that all operators are physically and mentally

capable of operating the vehicle.

• This vehicle is designed to carry only you, the

operator, and one passenger in the seat provided

by the manufacturer. Never carry any other

passengers on the vehicle.

• Never operate the vehicle when under the

influence of drugs or alcohol. Even prescription

drugs and cold medicines can cause drowsiness.

• Do not drive the vehicle when you are tired. Be

sure to take occasional breaks. It is very important

that you stay alert at all times.

• Become familiar with the controls and know how

to stop the engine quickly.

• Keep all shields, safety devices, and decals in

place. If a shield, safety device, or decal is

malfunctioning, illegible, or damaged, repair or

replace it before operating the machine.

• Always wear substantial shoes. Do not operate the

machine while wearing sandals, tennis shoes or

sneakers. Do not wear loose fitting clothing or

jewelry which could get caught in moving parts

and cause personal injury.

• Wearing safety glasses, safety shoes, long pants

and a helmet is advisable and required by some

local safety and insurance regulations.

• Avoid driving when it is dark, especially in

unfamiliar areas. If you must drive when it is

dark, be sure to drive cautiously, use the

headlights, and even consider adding additional

lights.

• Be extremely careful when operating around

people. Always be aware of where bystanders

might be.

• Before operating the vehicle, always check the

designated areas of the vehicle that are stated in

the pre-starting section of this manual. If

something is wrong, do not use the vehicle. Make

sure that the problem is corrected before the

vehicle or attachment is operated.

• Since gasoline is highly flammable, handle it

carefully.

– Use an approved gasoline container.

– Do not remove the cap from the fuel tank

when the engine is hot or running.

– Do not smoke while handling gasoline.

– Fill the fuel tank outdoors, and fill it to about

1 in. (25 mm) below the top of the tank ( the

The Workman is an off-highway vehicle only and is

not designed, equipped, or manufactured for use on

public streets, roads, or highways.

WARNING

Page 5

bottom of the filler neck). Do not overfill it.

–Wipe up any spilled gasoline.

While Operating

• The operator and passenger should remain seated

whenever the vehicle is in motion. The operator

should keep both hands on the steering wheel

whenever possible, and the passenger should use

the hand holds provided. Keep your arms and legs

within the vehicle body at all times.

• Drive slower and turn less sharply when you are

carrying a passenger. Remember your passenger

may not be expecting you to brake or turn and

may not be ready.

• Always watch out for and avoid low overhangs

such as tree limbs, door jambs, and over- head

walkways. Make sure there is enough room over

head to easily clear the vehicle and your head.

• Always shift into neutral and apply the parking

brake before leaving an idling vehicle, or else the

vehicle may creep.

• Failure to operate the vehicle safely may result in

an accident, tip over of the vehicle, and serious

injury or death. Drive carefully. To prevent tipping

or loss of control:

– Use extreme caution, reduce speed, and

maintain a safe distance around sand traps,

ditches, creeks, ramps, unfamiliar areas, or

any areas that have abrupt changes in ground

conditions or elevation.

– Watch for holes or other hidden hazards.

– Use extra caution when operating the vehicle

on wet surfaces, in adverse weather

conditions, at higher speeds, or with a full

load. Stopping time and distance will increase

with a full load.

– Avoid sudden stops and starts. Do not go from

reverse to forward or forward to reverse

without first coming to a complete stop.

– Slow down before turning. Do not attempt

sharp turns or abrupt maneuvers or other

unsafe driving actions that may cause a loss of

vehicle control.

– When dumping, do not let anyone stand

behind the vehicle and do not dump the load

on anyone’s feet. Release the tailgate latches

from the side of the box, not from behind.

– Only operate the vehicle when the cargo box

is down and latched.

– Before backing up, look to the rear and ensure

that no one is behind you. Back up slowly.

– Watch out for traffic when you are near or

crossing roads. Always yield the right of way

to pedestrians and other vehicles. This vehicle

is not designed for use on streets or highways.

Always signal your turns or stop early enough

so that other people know what you plan to

do. Obey all traffic rules and regulations.

– The electrical and exhaust systems of the

vehicle can produce sparks capable of igniting

explosive materials. Never operate the vehicle

in or near an area where there is dust or fumes

in the air which are explosive.

– If you are ever unsure about safe operation,

stop work and ask your supervisor.

• Do not touch the engine or muffler while the

engine is running or soon after it has stopped.

These areas may be hot enough to cause burns.

• If the machine ever vibrates abnormally, stop

immediately, wait for all motion to stop, and

inspect the vehicle for damage. Repair all damage

before commencing operation.

• Before getting off of the seat:

A. Stop the movement of the machine.

B. Set the parking brake.

C. Turn the ignition key to Off.

D. Remove the ignition key.

5

Engine exhaust contains carbon monoxide, which is

an odorless, deadly poison that can kill you.

Do not run engine indoors or in an enclosed area.

WARNING

Page 6

Note: If the vehicle is on an incline, block the

wheels after getting off of the vehicle.

Braking

• Slow down before you approach an obstacle. This

gives you extra time to stop or turn away. Hitting

an obstacle can damage the vehicle and its

contents. More important, it can injure you and

your passenger.

• Gross Vehicle Weight (GVW) has a major impact

on your ability to stop and/ or turn. Heavy loads

and attachments make a vehicle harder to stop or

turn. The heavier the load, the longer it takes to

stop.

• Decrease the vehicle speed if the cargo box has

been removed and there is no attachment on the

vehicle. The braking characteristics change and

fast stops may cause the rear wheels to lock up,

which may affect the control of the vehicle.

• Turf and pavement are much slipperier when they

are wet. It can take 2 to 4 times as long to stop on

wet surfaces as on dry surfaces. If you drive

through standing water deep enough to get the

brakes wet, they will not work well until they are

dry. After driving through water, you should test

the brakes to make sure they work properly. If

they do not, drive slowly while putting light

pressure on the brake pedal. This will dry the

brakes out.

Operating on Hills

These extra cautions need to be taken when operating

the vehicle on a hill:

• Slow down before starting up or down a hill.

• If the engine stalls or you begin to lose headway

while climbing a hill, gradually apply the brakes

and slowly back straight down the hill.

• Turning while traveling up or down hills can be

dangerous. If you have to turn while on a hill, do

it slowly and cautiously. Never make sharp or fast

turns.

• Heavy loads affect stability. Reduce the weight of

the load and your speed when operating on hills or

if the load has a high center of gravity. Secure the

load to prevent it from shifting.

• Avoid stopping on hills, especially with a load.

Stopping while going down a hill will take longer

than stopping on level ground. If the vehicle must

be stopped, avoid sudden speed changes, which

may initiate tipping or rolling of the vehicle. Do

6

Operating the vehicle on a hill may cause tipping or

rolling of the vehicle, or the engine may stall and

you could lose headway on the hill. This could

result in personal injury.

• Do not exceed slopes greater than 12°.

• Do not accelerate quickly or slam on the brakes

when backing down a hill, especially with a

load.

• If the engine stalls or you lose headway on a

hill, slowly back straight down the hill. Never

attempt to turn the vehicle around.

• Never drive across a steep hill; always drive

straight up or down or go around the hill.

• Avoid turning on a hill.

• Reduce your load and the speed of the vehicle.

• Avoid stopping on hills, especially with a load.

WARNING

Page 7

not slam on the brakes when rolling backward, as

this may cause the vehicle to overturn.

• Travel straight up and down slopes whenever

possible.

• We strongly recommend installing the optional

roll-over protection kit when operating on hilly

terrain.

Operating on Rough Terrain

Reduce speed and load when operating on rough

terrain, uneven ground, and near curbs, holes, and

other sudden changes in terrain. Loads may shift,

causing the vehicle to become unstable.

We strongly recommend installing the optional rollover protection kit when operating on rough terrain.

Loading and Dumping

The weight and position of the cargo and passenger

can change the vehicle center of gravity and vehicle

handling. To avoid loss of control and personal injury,

follow these guidelines:

• Do not carry loads which exceed the load limits

described on the vehicle weight label; refer to

Specifications, page 12, for vehicle weight limits.

The load rating is for level surfaces only.

• Reduce the weight of the load when operating on

hills and rough terrain to avoid tipping or

overturning of the vehicle.

• Reduce the weight of the load if the center of

gravity is high. Items such as bricks, fertilizer, or

landscape timbers stack higher in the box. The

higher a load is stacked, the more likely the

vehicle is to tip over. Distribute the load as low as

possible, making sure that the load does not affect

rear visibility.

• Position the weight of the load evenly from side to

side. If you position the load toward one of the

sides, the vehicle is more likely to tip over while

turning.

• Position the weight of a load evenly from front to

back. If you position the load behind the rear

axle, it will reduce the weight on the front wheels.

This may result in a loss of steering control or

cause the vehicle to tip over on hills or bumpy

terrain.

• Use extra caution if the load exceeds the

dimensions of the box and when handling offcenter loads that cannot be centered. Keep loads

balanced and secure to prevent them from

shifting.

• Never dump a loaded cargo box while the vehicle

is sideways on a hill. The change in weight

distribution may cause the vehicle to overturn.

• When operating with a heavy load in the cargo

box, reduce your speed and allow for sufficient

braking distance. Do not suddenly apply the

brakes. Use extra caution on slopes.

• Be aware that heavy loads increase your stopping

distance and reduce your ability to turn quickly

without tipping over.

• The rear cargo space is intended for load carrying

7

The weight of the box may be heavy. Hands or

other body parts could be crushed.

• Keep hands and other body parts clear

when lowering the box.

• Do not dump materials on bystanders.

WARNING

Sudden changes in terrain may cause abrupt

steering wheel movement, possibly resulting in

hand and arm injuries.

• Reduce your speed when operating on rough

terrain and near curbs.

• Grip the steering wheel loosely around the

perimeter. Keep your hands clear of the

steering wheel spokes.

WARNING

Page 8

purposes only, not for passengers.

• Never overload your vehicle. The name plate

(located under dash on center column) shows load

limits for the vehicle. Never overload the

attachments or exceed the gross vehicle weight.

Maintenance

• Only qualified and authorized personnel shall be

permitted to maintain, repair, adjust, or inspect the

vehicle.

• Before servicing or making adjustments to the

machine, stop the engine, set the parking brake,

and remove the key from the ignition to prevent

someone from accidentally starting the engine.

• To make sure that the entire machine is in good

condition, keep all nuts, bolts, and screws

properly tightened.

• To reduce the potential for fire, keep the engine

area free of excessive grease, grass, leaves, and

accumulation of dirt.

• Never use an open flame to check the level or

leakage of fuel or battery electrolyte.

• If the engine must be running to perform a

maintenance adjustment, keep your hands, feet,

clothing, and any parts of your body away from

the engine and any moving parts. Keep everyone

away.

• Do not use open pans of fuel or flammable

cleaning fluids for cleaning parts.

• Do not adjust the ground speed governor. To

ensure safety and accuracy, have an authorized

Toro distributor check the ground speed.

• If major repairs are ever needed or assistance is

required, contact an authorized Toro distributor.

• To be sure of optimum performance and safety,

always purchase genuine Toro replacement parts

and accessories. Replacement parts and

accessories made by other manufacturers could be

dangerous. Altering this vehicle in any manner

that may affect vehicle operation, performance,

durability, or its use, may result in injury or death.

Such use could void the product warranty.

Sound Pressure Level

This unit has an equivalent continuous A-weighted

sound pressure at the operator ear of: 80 dB(A) based

on measurements of identical machines per J1174MAR 85 procedures.

Vibration Level

This unit does not exceed a vibration level of 2.5 m/s

2

at the hands based on measurements of identical

machines per ISO 5349 procedures.

This unit does not exceed a vibration level of 2.5 m/s

2

at the posterior based on measurements of identical

machines per ISO 2631 procedures.

8

Page 9

9

This is a 5° Slope

Fold along appropriate line

Example:

Compare slope

with folded

edge.

Align this edge with a vertical surface (tree, building, fence post, pole, etc.

This is a 10° Slope

This is a 12° Slope

This is a 15° Slope

Slope Chart

Page 10

10

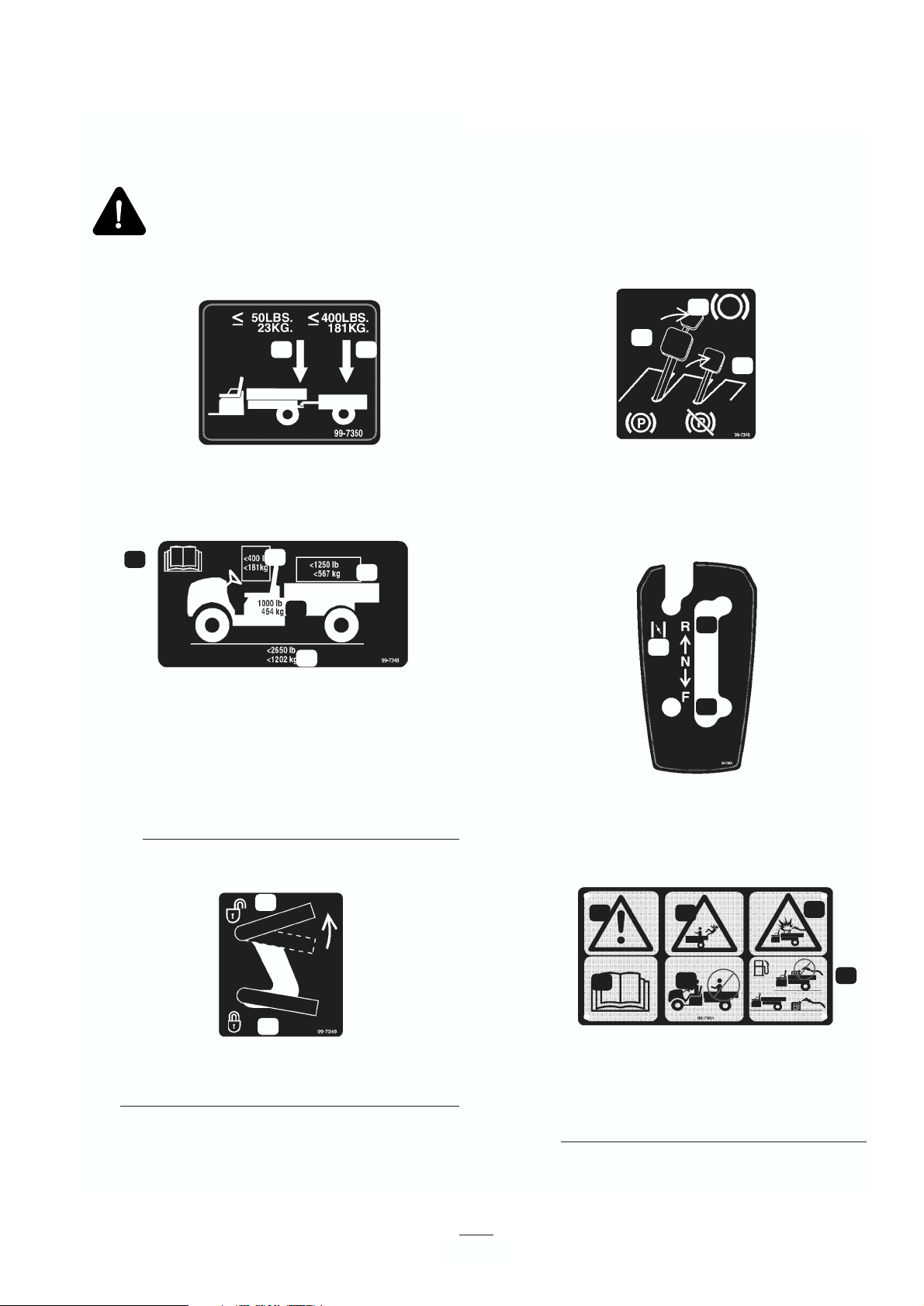

Safety decals and instructions are easily visible to the operator and are located near any area of

potential danger. Replace any decal that is damaged or lost.

Safety and Instruction Decals

1

2

3

1

4

2

3

5

1

2

1

2

2

3

1

99-7350

1. Maximum tongue weight is 23 kg (50 lbs.)

2. Maximum trailer weight is 181 kg (400 lbs.)

99-7349

1. Unlock cargo bed

2. Lock cargo bed

99-7346

1 Parking brake

2. Parking brake on

3. Parking brake off

99-7952

1. Choke

2. Reverse

3. Forward

99-7954

1. Danger—read the operator’s manual

2. Do not carry passengers in the cargo bed. They

may fall out.

3. Explosive hazard—remove fuel containers from the

cargo bed before filling

99-7348

1. Read the operator’s manual for further instructions.

2. The maximum combined operator and passenger

weight should not exceed 181 kg (400 lbs.).

3. The maximum cargo weight should not exceed 567

kg. (1250 lbs.).

4. The base weight of the vehicle is 454 kg (1000 lbs.).

5. The maximum gross vehicle weight should not

exceed 1202 kg (2650 lbs.).

2

2

3

3

1

1

Page 11

11

11

5

6

7

8

9

10

99-7343

1. Warning—read the operator’s manual.

2. Only drive this vehicle off- highway. This vehicle is not made for use on public streets, roads, or highways.

3. Do not carry passengers in the cargo bed. They may fall out of the vehicle.

4. Do not allow children to operate this vehicle.

5. Hour meter

6. Headlights

7. Ignition off

8. Ignition on

9. To start the vehicle, sit in the operator’s seat. Release the parking brake. Turn the ignition on. Pull the choke lever out (if needed).

Depress the accelerator.

10. To stop the vehicle, disengage the accelerator and engage the parking brake. Turn the ignition off and remove the key.

11. Power point

1 2 3

4

99-7344

1. Danger—read the operator’s manual.

2. Fuel is flammable. Stop the engine before adding fuel.

3. Tipping hazard—do not drive across slopes that are greater than 15 degrees or up slopes greater than 12 degrees. Reduce speed

when turning, carrying heavy loads, or driving on rough terrain. Keep the engine speed under 26kmh (16 MPH).

4. Passengers are at risk of falling from the vehicle. Do not carry passengers in the cargo bed. Keep arms and legs inside of the

vehicle at all times.

1

1

2

2

3

3

4

4

1

2

3

4

4

3

2

1

26-7390

99-7345

1. Danger—read the operator’s manual.

2. Hot surface hazard—keep hands away.

3. Entanglement hazard—stay away from moving parts.

4. Crushing hazard—use the prop rod to support the

cargo bed.

Page 12

12

2

7

6 5 4

3

1

99-7352

1. Read the operator’s manual for information on fuses.

2. 10-amp. fuse for optional road light kit

3. 15-amp. fuse for optional rear lift kit

4. 10-amp. fuse—open

5. 10-amp. fuse for headlights

6. 10-amp. fuse for ignition system

7. 15-amp. fuse for optional electric bed lift kit

Specifications

Note: specifications and design are subject to change without notice.

Base weight

Rated capacity (on level ground)

Maximum gross vehicle weight (on

level ground)

Maximum cargo capacity (on level

ground)

Tow capacity:

Standard Hitch

Heavy Duty Hitch

Overall width

Overall length

Ground clearance

Wheel base

Wheel tread (center line to center

line)

Cargo box length

Cargo box width

Cargo box height

Dry 454kg (1000 lbs.)

749 kg (1650 lbs.) total, including 90.7 kg (200 lbs.) operator and 90.7 kg

passenger, load, trailer tongue weight, gross trailer weight, accessories,

and attachments

1203 kg (2650 lbs.) total, including all the weights listed above

567 kg (1250 lbs.)total, including trailer tongue weight and gross trailer

weight

Tongue weight 23 kg. Maximum trailer weight 182 kg.

Tongue weight 45 kg. Maximum trailer weight 363 kg.

152.4 cm (60 in.)

297.2 cm (117 in.)

23.5 cm at the front with no load or operator

16.5 cm at the rear with no load or operator

200.7 cm

124.5 cm in the front

122.6 cm in the rear

116.8 cm inside, 129.5 cm outside

124.5 cm inside, 137.2 cm outside

25.4 cm inside

Page 13

Checking the Crankcase Oil

The engine is shipped with oil in the crankcase;

however, the oil level must be checked before and

after the engine is first started.

1. Position the machine on a level surface.

2. Remove the dipstick and wipe it with a clean cloth

(Fig. 2). Insert the dipstick into the tube and make

sure it is seated fully. Remove the dipstick and

check the level of oil.

Figure 2

1. Dipstick

2. Filler cap

3. If the oil level is low, remove the filler cap from

the valve cover (next to the dipstick) and pour oil

into the opening until the oil level is up to the

“FULL” mark on the dipstick; refer to Engine Oil,

page 23 Add the oil slowly and check the level

often during this process. Do not overfill.

4. Install the dipstick firmly in place.

Checking the Tire Pressure

Check tire pressure every 8 hours or daily to assure

proper levels. Air pressure range in front and rear

tires is 55–152 kPa (8–22 psi).

The needed air pressure is determined by the payload

carried. The lower the air pressure, the less the

compaction and tire marks are minimized. Lower

pressure should not be used for heavy payloads at

high speeds.

Higher pressures should be used for heavier payloads

at higher speeds. Do not exceed the maximum

pressure.

Fuel Tank

Recommended Gasoline

Use fresh, clean, unleaded regular grade gasoline

13

Before Operating

In certain conditions, gasoline is extremely

flammable and highly explosive. A fire or explosion

from gasoline can burn you and others and can

damage property.

• Fill the fuel tank outdoors, in an open area,

when the engine is cold. Wipe up any gasoline

that spills.

• Do not fill the fuel tank completely full. Add

gasoline to the fuel tank until the level is 25 mm

(1 in.) below the bottom of the filler neck. This

empty space in the tank allows gasoline to

expand.

• Never smoke when handling gasoline, and stay

away from an open flame or where gasoline

fumes may be ignited by a spark.

• Store gasoline in an approved container and

keep it out of the reach of children. Never buy

more than a 30-day supply of gasoline.

• Always place gasoline containers on the ground

away from your vehicle before filling.

• Do not fill gasoline containers inside a vehicle

or on a truck or trailer bed because interior

carpets or plastic truck bed liners may insulate

the container and slow the loss of any static

charge.

• When practical, remove gas- powered

equipment from the truck or trailer and refuel

the equipment with its wheels on the ground.

• If this is not possible, then refuel such

equipment on a truck or trailer from a portable

container, rather than from a gasoline dispenser

nozzle.

• If a gasoline dispenser nozzle must be used,

keep the nozzle in contact with the rim of the

fuel tank or container opening at all times until

fueling is complete.

DANGER

1

2

Page 14

suitable for automotive use (85 pump octan

minimum). Leaded gasoline may be used if unleaded

regular is not available.

Never use gasoline containing

methanol, gasoline containing more than 10%

ethanol, gasoline additives, or white gas because

engine fuel system damage could result.

Filling the Fuel Tank

Fuel tank capacity is approximately 26.5 L (7

gallons).

1. Shut the engine off and set the parking brake.

2. Clean the area around the fuel tank cap (Fig. 3).

Figure 3

1. Fuel tank cap

3. Remove the fuel tank cap.

4. Fill the tank to about one inch below the top of the

tank, (bottom of the filler neck). This space in the

tank allows gasoline to expand. Do not overfill.

5. Install the fuel tank cap securely. Wipe up any fuel

that may have spilled.

Operation

Note: Determine the left and right sides of the

machine from the normal operating position.

Think Safety First

Please carefully read all the safety instructions and

symbols in the safety section. Knowing this

information could help you or bystanders avoid injury.

Controls

Accelerator Pedal

The accelerator pedal (Fig. 4) gives the operator the

ability to vary ground speed of the vehicle.

Depressing the pedal starts the engine. Depressing the

pedal farther increases ground speed. Releasing the

pedal will slow the vehicle and the engine will stop

running. Maximum forward speed is 26 kmh (16

MPH)

Brake Pedal

The brake pedal is used to stop or slow the vehicle

(Fig. 4).

Parking Brake

The parking brake is a small plate at the top of the

brake pedal (Fig. 4). Whenever the engine is shut off,

the parking brake must be engaged to prevent

accidental movement of the vehicle. To engage the

parking brake, step on the brake pedal firmly and roll

forward with the top of your foot. To disengage,

depress the accelerator pedal. If the vehicle is parked

Important

14

Brakes can become worn or can be misadjusted,

resulting in personal injury.

If the brake pedal travels within 2.5cm (1”) of the

vehicle floor board, the brakes must be adjusted or

repaired.

CAUTION

Page 15

on a steep grade, make sure the parking brake is

applied. Place blocks at the downhill side of the

wheels.

Figure 4

1. Accelerator pedal

2. Brake pedal

3. Parking brake

Choke Control

The choke control is located below and to the right of

the operator’s seat. To start a cold engine, close the

carburetor choke (Fig. 5) by pulling the choke control

outward to ON position. After the engine starts,

regulate the choke to keep the engine running

smoothly. As soon as possible, open the choke by

pushing the control in to the OFF position. A warm

engine requires little or no choking.

Figure 5

1. Choke

2. Gear shift selector

Gear Shift Selector

The gear shift selector moves the vehicle in the

desired direction forward or reverse (Fig. 5). The

vehicle will start in either direction.

Note: If the gear shift selector is in reverse when the

ignition is turned on, a buzzer will sound to warn the

operator.the

: The vehicle should always be stopped

before changing the gear selection and direction.

Ignition Switch

The ignition switch (Fig. 6), used to start and stop the

engine, has two positions: OFF and ON. Turn the key

clockwise-ON position-to allow operation. When the

vehicle is stopped, turn the key counterclockwise to

THE OFF position. Remove the key from the ignition.

Hour Meter

The hour meter (Fig. 6) indicates the total number of

hours the engine is running. The hour meter starts to

function whenever the accelerator is depressed.

Oil Light

The oil light warns the operator if the engine oil

pressure drops below a safe level (Fig. 6). If the light

comes on and remains lit, the oil level should be

checked and oil added if necessary; see Engine Oil,

page 23.

Note: The oil light may flicker. This is normal and no

action needs to be taken.

Light Switch

Toggle switch to activate headlights. Push to turn

lights “ON” (Fig. 6).

Power Point

The power point is used to power optional electrical

accessories (Fig. 6).

Important

15

1

2

Page 16

Figure 6

1. Ignition switch

2. Hour meter

3. Light switch

4. Oil light

5. Power point

Fuel Gauge

The fuel gauge (Fig. 7) shows amount of fuel in the

tank.

Figure 7

1. Fuel gauge

Passenger Hand Holds

The passenger hand holds are located on the right side

of the dash panel and at the outside of each seat

(Fig. 8).

Figure 8

1. Passenger hand hold

2. Hip restraint

Pre-Starting Checks

Safe operation begins before taking the vehicle out for

a day’s work. You should check these items each time:

• Check tire pressure.

Note: These tires are different than car tires, they

require less pressure to minimize turf compaction

and damage.

• Check all fluid levels and add the appropriate

amount of Toro specified fluids, if any are found

to be low.

• Check brake pedal operation.

• Check to see that the lights are working.

•Turn the steering wheel to the left and right to

check steering response.

• Check for oil leaks, loose parts and any other

noticeable malfunctions. Make sure the engine is

off and all moving parts have stopped before

checking for oil leaks, loose parts and other

malfunctions

If any of the above items are not correct, notify your

mechanic or check with your supervisor before taking

the vehicle out for the day. Your supervisor may want

you to check other items on a daily basis, so ask what

your responsibilities are.

16

Page 17

Starting the Engine

1. Sit in the operator’s seat, insert the key into the

ignition switch, and turn the key clockwise to the

On position.

Note: If the gear shift selector is in reverse, the

buzzer will sound to warn the operator.

2. Move gear shift selector to the desired position.

4. Slowly step on the accelerator pedal.

Note:The parking brake will automatically

disengage when the accelerator pedal is

depressed.

Note: If the engine is cold, depress and hold the

accelerator pedal about half way down and pull

the choke knob out to the ON position.

Do not attempt to push or tow the

vehicle to get it started.

Stopping the Vehicle

To stop the machine, remove your foot from the

accelerator pedal and slowly depress the brake pedal.

Parking the Vehicle

1. Engage the parking brake and turn the ignition

key to OFF.

2. Remove the key from switch to prevent accidental

starting.

Cargo Bed

Raising the Bed

1. Slide the latch upward toward the top of the

cutout in the bed frame (Fig. 9).

Figure 9

1. Latch

2. Lift up on the latch with one hand while raising

the bed with your other hand.

3. Raise the bed to its full height; then lower it

slightly to engage the prop rod (Fig. 10).

Figure 10

1. Prop rod

Lowering the Bed

1. Lift up the bed slightly with one hand while

pressing down on the prop rod.

2. Lower the bed until the latch engages.

3. To secure the bed tightly to the bed frame, move

the latch to the lower section of the cutout.

Important

17

Page 18

Tailgate Latches

1. To open the tailgate latches, lift the latch handles

up (Fig. 11). The latches will spring out toward

the center of the tailgate. Slowly lower the

tailgate.

Note: You may need to push the end of the

tailgate in (especially if there is a load against the

tailgate) before the latches will spring toward the

center of the tailgate and release.

Figure 11

1. Tailgate latch

2. To close the tailgate latches, lift the handles

upward and slide them toward the outside of the

vehicle.

3. Push the latch handles downward to secure the

latch and tailgate.

New Vehicle Break-in

To provide proper performance and long vehicle life,

follow these guidelines for the first 100 operating

hours.

• Check the fluid and engine oil levels regularly and

be alert for indications of overheating in any

component of the vehicle.

• After starting a cold engine, let it warm up for

about 15 seconds before accelerating.

•Avoid hard braking situations for the first several

hours of new vehicle brake-in operation. New

brake linings may not be at optimum performance

until several hours of use has caused the brakes to

become burnished (broke-in).

•Vary vehicle speeds during operation. Avoid fast

starts and quick stops.

•Abreak-in oil for the engine is not required.

Original engine oil is the same type specified for

regular oil changes.

• Refer to the Maintenance section of the operator’s

manual for any special low hour checks.

• Check front suspension positioning and adjust if

necessary; refer to Adjusting the Front

Suspension, page 27

Loading the Cargo Box

The capacity of the cargo box is 13 ft.3(0.37 m 3). The

amount (volume) of material that can be placed in the

box without exceeding the vehicle load ratings can

vary greatly depending on the density of the material.

For example, a level box of wet sand weighs 680 kg

(1500 lbs.), which exceeds the load rating by 295 kg

(650 lbs.). But a level box of wood weighs 295 kg

(650 lbs.), which is under the load rating.

See the able below for load volume limits with

various materials:

Gravel

Dry 95

3

⁄4 full (approx.)

Wet 120

1

⁄

2 full (approx.)

Sand

Dry 90

3

⁄

4 full

Wet 120

1

⁄2 full

Wood 45 Full

Bark <45 Full

Earth, packed 100

3

⁄4 full (approx.)

18

Material

Density

(lbs./ft.3)

Max. cargo box

capacity (on level

ground)

Page 19

Transporting the Vehicle

For moving the vehicle long distances, a trailer should

be used. Make sure the vehicle is secured to the trailer.

Refer to Figures 12 and 13 for location of tie down

points.

Figure 12

1. Tie-down points

Towing the Vehicle

In case of emergency, the vehicle can be towed for a

short distance. However, Toro does not recommend

this as a standard procedure.

Towing the vehicle is a two-person job. If the

machine must be moved a considerable distance,

transport it on a truck or trailer; refer to Transporting

the Vehicle, page 19

1. Remove the drive belt; refer to Servicing the

Drive Belt, page 27, steps 1 and 2.

2. Affix a tow line to tongue on front frame member

(Fig. 13).

3. Put the vehicle in neutral (see Neutral Lock

Assembly, page 23) and release the parking brake.

Figure 13

1. Towing tongue and tie-down point

Towing a Trailer

The vehicle is capable of pulling trailers. Two types of

tow hitches are available for the vehicle, depending on

your application. Contact your authorized Toro

distributor for details.

When hauling cargo or towing a trailer, do not

overload your vehicle or trailer. Overloading can

cause poor performance or damage to the brakes, axle,

engine, transaxle, steering, suspension, body structure,

or tires. Always load a trailer with 60% of the cargo

weight in the front of the trailer. This places

approximately 10% of the gross trailer weight on the

tow hitch of the vehicle.

The maximum cargo load shall not exceed 567 kg

(1250 lbs.), including the gross trailer weight and

tongue weight.

To provide adequate braking and traction, always load

the cargo box when trailering. Do not exceed the gross

trailer weight limits.

Avoid parking a vehicle with a trailer on a hill. If you

must park on a hill, engage the parking brake and

block the trailer tires.

19

Loose seats may fall off of the vehicle and trailer

when transporting and land on another vehicle or

become an obstruction on the road.

Remove the seats or make sure that the seats are

securely fastened in the detents.

CAUTION

Towing at excessive speeds could cause a loss of

steering control, resulting in personal injury.

Never tow the vehicle faster than 8 kmh.

WARNING

Page 20

20

• Replace the fuel filter.

• Change the transaxle oil.

• Replace the spark plugs.

Maintenance Procedure

After First 8 hours

• Check the engine oil.

• Check the drive belt tension.

• Check the starter belt tension.

• Check the engine oil.

• Check the tire pressure.

Every 8 Hours

After First 20 Hours

• Check the front wheel toe-in at the proper ride

height.

Every 50 Hours

• Check the battery fluid level.

• Check the battery cable connections.

• Change the engine oil (includes synthetic oil).

1

Every 100 Hours

• Lubricate all grease fittings.

• Clean the engine rotating screen.

2

• Inspect the air cleaner filter.

2

• Replace the engine oil filter.

Inspect the brake and parking brake.

• Inspect the condition and wear of the tires.

•Torque the wheel lug nuts.

• Check the front suspension adjustment toe-in

and ride height.

Maintenance Service Interval

Every 200 Hours

• Replace the air cleaner filter.

• Check the brake cable adjustments.

• Inspect the drive belt.

• Inspect and adjust the starter belt.

Every 400 Hours or Yearly • Inspect the fuel lines.

Every 800 Hours or Yearly

Maintenance

Note: Determine the left and right sides of the machine from the normal operating position.

Recommended Maintenance Schedule

1

More often when operating under heavy load or high temperatures

2

More often in dusty, dirty conditions

Refer to your engine operator’s manual for additional maintenance procedures.

Important

Page 21

21

SunSatFriThursWedTu esMon

Daily Maintenance check for Week of __________________________

Brake & Parking Brake Operation

Gear Shift Operation

Fuel Level

Engine Oil Level

Transaxle Oil Level

Inspect the Air Filter

Inspect Engine Cooling Fins

Unusual Engine Noises

Unusual Operating Noises

Tire Pressure

Fluid Leaks

Instrument Operation

Accelerator Operation

Lubricate All Grease Fittings

1

Touch-up Damaged Paint

1

= Immediately after every washing, regardless of the interval listed.

Maintenance Check Item

Notation for areas of concern:

Inspection performed by:____________________________________________________________________

Date Information

Daily Maintenance Checklist

Duplicate this page for routine use.

Note: Check proper section of the operator’s manual for fluid specifications.

Page 22

Heavy-Duty Operation

If the vehicle is subjected to conditions

listed below, maintenance should be performed twice

as frequently.

• Desert operation

• Cold climate operation (below 0°C)

•Trailer towing

• Frequent operation on dusty roads

• Construction work

• After extended operation in mud, sand, water, or

similar dirty conditions, have your brakes

inspected and cleaned as soon as possible. This

will prevent any abrasive material from causing

excessive wear.

• Under frequent heavy-duty operating conditions,

lubricate all grease fittings and inspect the air

cleaner daily to prevent excessive wear.

Jacking the Vehicle

Whenever the engine is run for routine maintenance

and/or engine diagnostics, the rear wheels of the

vehicle should be 25mm (1”) off the ground with the

rear axle supported on jack stands.

The jacking point at the front of the vehicle is on the

front of the frame behind the towing tongue (Fig. 14).

The jacking point at the rear of the vehicle is under

the axle tubes (Fig. 15).

Figure 14

1. Front jacking point

Important

22

If you leave the key in the ignition switch, someone could accidentally start the engine and seriously injure

you or other bystanders.

Remove the key from the ignition and disconnect the wire(s) from the spark plug(s) before you do any

maintenance. Set the wire(s) aside so it does not accidentally contact the spark plug(s).

CAUTION

The bed must be raised to perform some routine

maintenance. The bed could fall and injure persons

that are underneath a raised bed.

• Always use prop rod to hold bed up before

working under raised bed.

• Remove any load material from the bed before

working under raised bed.

WARNING

A vehicle on a jack may be unstable and slip off the

jack, injuring anyone beneath it.

• Do not start the engine while the vehicle is on a

jack.

• Always remove the key from the ignition before

getting off the vehicle.

• Block the tires when the vehicle is on a jack.

DANGER

1

Page 23

Figure 15

1. Rear jacking points

Neutral Lock Assembly

When performing routine maintenance and/or engine

diagnostics, the transaxle must be shifted into a

neutral position. The vehicle does not have a neutral

position on the shift lever, so the following steps must

be performed:

1. To lock the transaxle in neutral, rotate the locking

pin 180 degrees on the shift block (Fig. 16).

Figure 16

1. Locking pin

2. Shift the gear selector into REVERSE and then

into FORWARD. Leave the gear shift selector in

the FORWARD position.

3. Ensure that the transaxle is locked in neutral by

rotating the secondary clutch (Fig. 17). No tire

rotation should occur.

Figure 17

1. Secondary clutch

Servicing the Engine Oil

Service Interval/Specification

Check the oil level before each use.

Change oil:

• After the first 8 operating hours.

• After every 50 operating hours.

Replace the oil filter every 100 hours.

Note: Change oil and oil filter more frequently when

operating conditions are extremely dusty or sandy.

Oil Type: Detergent oil (API service SF, SG, SH,

SJ,or higher)

Crankcase Capacity: 1.4 liters (48 oz./1-

1

⁄2 qt.) when

the filter is changed

Viscosity: See table below

1. SAE 30

2. SW-30, 10W-30

3. Synthetic Sw-20, 5W-30

23

1

1

1

1

1

2

3

Page 24

Checking the Oil Level

To check the oil level, refer to Checking the

Crankcase Oil, page 13.

Changing and Draining the Oil

1. Start the vehicle and let it run for a few minutes to

warm the oil.

2. Park the machine on a level surface, set the

parking brake, turn the ignition off, and remove

the key.

3. Raise the bed and secure it with the prop rod.

4. Disconnect the spark plug wires and battery

cables.

5. Remove the drain plug (Fig. 18) and let the oil

flow into a drain pan. When the oil stops, install

the drain plug.

Note: Dispose of the used oil at a certified

recycling center.

Figure 18

1. Engine oil drain plug

2. Engine oil filter

6. Pour oil into the fill opening until the oil level is

up to the Full mark on the dipstick. Add the oil

slowly and check the level often during this

process. Do not overfill.

7. Install the oil fill cap and dipstick firmly in place.

Changing the Oil Filter

Replace the oil filter every 100 operating hours or

yearly, whichever occurs first.

1. Drain the oil from the engine; refer to Changing

and Draining the Oil, page 24.

2. Remove the existing oil filter ( Fig. 27). Apply a

light coat of clean oil to the new filter gasket.

3. Screw the new filter on until the gasket contacts

the mounting plate, then tighten the filter an

additional

1

⁄

2- to

3

⁄

4-turn further. Do not

overtighten.

4. Fill the crankcase with the proper type of new oil;

refer to Engine Oil, page 23.

5. Start and run the engine to check for leaks.

6. Stop the engine and check the oil level. Add oil if

necessary.

Cleaning the Engine Cooling

Areas

Clean the rotating screen, cooling fins, and external

surfaces of the engine every 100 hours of operation or

more often under extremely dusty and dirty

conditions.

Operating the engine with a blocked

rotating screen, dirty or plugged cooling fins, or

cooling shrouds removed, will cause engine damage

due to overheating.

Never clean the engine with pressurized

water because water could contaminate the fuel

system.

Servicing the Air Cleaner

Service Interval/Specification

Check the air cleaner body for damage that could

possibly cause an air leak. Replace a damaged air

cleaner body.

Important

Important

24

Page 25

Ensure the cover is sealing around the air cleaner

body.

Air Cleaner Filter: Inspect after every 100 operating

hours; replace after every 200 hours or sooner if dirty

or damaged.

Note: Service the air cleaner more frequently (every

few hours) if operating are extremely dusty or sandy.

Removing the Filter Element

1. Park the machine on a level surface and turn the

engine off.

2. Raise the bed and secure it with a prop rod.

3. Release the latches securing the air cleaner cover

to the air cleaner body. Separate the cover from

the body. Clean the inside of the air cleaner cover

(Fig. 19).

Figure 19

1. Air cleaner latches

2. Cover

3. Filter

4. Gently slide the filter out of the air cleaner body

to reduce the amount of dust dislodged (Fig. 19).

Avoid knocking the filter against the air cleaner

body.

5. Inspect the filter and discard if damaged.

Cleaning the Filter Element

Do not wash or reuse a damaged filter.

1. Washing method:

A. Prepare a solution of filter cleaner and water

and soak the filter element about 15 minutes.

Refer to directions of the filter cleaner carton

for complete information.

B. After soaking the filter for 15 minutes, rinse it

with clear water. Rinse the filter from clean

side to dirty side.

To prevent damage to the filter

element, maximum water pressure must not

exceed 276 kPa (40 psi).

C. Dry the filter element using warm, flowing air

(71°C, 160°F max.), or allow element to air

dry.

Do not use a light bulb to dry

the filter element because damage could

result.

2. Compressed air method:

A. Blow compressed air from inside to the

outside of dry filter element. Keep the air

hose nozzle at least 5cm (2 inches) from the

filter and move the nozzle up and down while

rotating the filter element.

To prevent damage to the filter

element, do not exceed 689 kPa (100 psi) air

pressure.

B. Inspect for holes and tears by looking through

the filter toward a bright light.

Installing the Filter Element

To prevent engine damage, always

operate the engine with the complete air cleaner

assembly installed.

1. Inspect new filter for shipping damage. Check the

sealing end of the filter.

Do not install a damaged filter.

Important

Important

Important

Important

Important

Important

25

Page 26

2. Insert the new filter properly into the air cleaner

body. Ensure the filter is sealed properly by

applying pressure to outer rim of the filter when

installing. Do not press on the flexible center of

the filter.

3. Reinstall the cover and secure the latches.

Greasing the Machine

Service Interval/Specification

Lubricate all bearings and bushings after every 100

hours or once a year, whichever occurs first. Grease

them more frequently when using for heavy-duty

vehicle operations.

Grease Type: No. 2 General Purpose Lithium Base

Grease

Where to Add Grease

The grease fitting locations and quantities are: tie rod

ends (4) (Fig. 20), king pins (2) (Fig. 21), and throttle

and brake pedal pivots (2) (Fig. 22).

1. Wipe grease fitting clean so foreign matter cannot

be forced into the bearing or bushing.

2. Pump grease into the bearing or bushing.

3. Wipe off excess grease.

Figure 20

Figure 21

Figure 22

Servicing the Brakes

Inspecting Brakes

Brakes are a critical safety component of the vehicle.

As with all safety components, they should be closely

inspected at regular intervals to ensure optimum

performance and safety. The following inspections

should be done every 100 hours:

• Inspect the brake shoes for wear or damage. If the

lining (brake pad) thickness is less than

1

⁄16 in. (1.6

mm), the brake shoes should be replaced.

• Inspect the backing plate and other components

for signs of excessive wear or deformation. If any

deformation is found, the appropriate components

must be replaced.

Adjusting the Brake Pedal

Adjust the brake if the parking brake does not hold,

brake pedal travel is excessive, or braking power is

not sufficient when the brake pedal is depressed.

Check adjustment every 200 hours.

26

Page 27

1. Turn the ignition to OFF and remove the key.

2. Raise the vehicle off the ground; see Jacking the

Vehicle page 22.

3. Tighten the cable adjusting screw, located beneath

the floor panel, until the cables are snug in the

brake equalizer (Fig. 23).

Figure 23

1. Cable adjusting screw

2. Brake equalizer

Inspecting Tires

Check tire condition at least every 100 hours of

operation. Operating accidents, such as hitting curbs,

can damage a tire or rim and also disrupt wheel

alignment, so inspect tire condition after an accident.

Check the wheels to ensure that they are mounted

securely. Torque the front bolts to 183–224 N•m (135

–165 ft.-lbs.) and the rear lug nuts to 61–88 N•m

(45–65 ft.-lbs.).

Adjusting the Front Suspension

The ride height of each side of the vehicle can be

adjusted.

1. Jack the front end of the vehicle off the ground;

refer to Jacking the Vehicle, page 22.

2. Remove the travel limiting bolt (Fig. 24).

3. Loosen the centering bolts in the front “A” frame

(Fig. 24).

4. Remove the ride height adjustment bolt

(Fig. 24).

5. Rotate the front “A” frame to desired position

(Fig. 24). The distance from the bottom side of

the front hitch to the ground should be 9 to 9-

3

⁄

4 in.

(22.9 to 24.8 cm) with the tires inflated to 12 psi

(83 kPa).

6. Replace the ride height adjustment bolt and the

travel limiting bolt (Fig. 24).

7. Tighten and torque the centering bolts to 359 ±34

N•m (265 ±25 ft-lbs.).

8. Tighten and torque the ride height adjustment bolt

to 203 ±20 N•m (150 ±15 ft-lbs.).

9. Repeat procedure on opposite side of the vehicle.

Figure 24

1. Travel limiting bolt

2. Centering bolt

3. Ride height adjustment bolt

Servicing the Drive Belt

Service Interval/Specification

Check condition and tension of drive belt after first

day of operation and every 200 operating hours

thereafter.

1. Park the machine on a level surface, set the

parking brake, and turn the engine off.

2. Raise the bed and secure it with a prop rod.

3. Put the vehicle in neutral; refer to Neutral Lock

27

1

2

3

Page 28

Assembly, page 23.

4. Rotate and inspect the belt for excessive wear or

damage. Replace as necessary.

Figure 25

1. Drive belt

2. Primary clutch

3. Secondary clutch

Replacing the Drive Belt

1. Rotate and route the belt over the secondary

clutch (Fig. 25).

2. Remove the belt from the primary clutch

(Fig. 25).

3. To replace the belt, reverse the procedure.

Adjusting the Starter Generator

Belt

Check the tension of the starter generator belt after the

first day of operation and every 200 operating hours

thereafter.

1. Park the machine on a level surface, set the

parking brake, turn the ignition off, and remove

the key.

2. Loosen the starter generator pivot bolt (Fig. 26).

Figure 26

1. Generator pivot bolt

2. Jam nut

3. 14 N•m

4. 6mm (1⁄4 in.)

3. Adjust the jam nut on the starter rod (Fig. 26)

until the belt flexes 6mm (

1

⁄

4 in.) with 14 N•m (10

lbs..) of force.

4. Tighten the starter generator pivot bolt (Fig. 26).

Adjusting Front Wheel Toe-in

Check the front wheel toe-in after every 100 operating

hours or annually, whichever occurs first.

1. Ensure that the distance from the bottom of the

tongue to the ground is 22.9 to 24.8 cm (9 to 9-

3

⁄4

in.) when the tires are inflated to 83 kPa (12 psi).

Adjust if necessary; refer to Adjusting the Front

Suspension, page 27.

2. Measure the distance between both of the front

tires at axle height (at the front and rear of the

wheels) (Fig. 27). The front measurement must be

equal to the rear measurement ±

1

⁄4 in. (6.4 mm).

28

1

2

3

3

4

Page 29

Figure 27

1. Center-to-center distance (rear of tires)

2. Forward

3. Center-to-center distance (front of tires)

3. If the measurement is greater than 1⁄4 in. (6.4 mm),

loosen the jam nuts at both ends of the tie rods

(Fig. 28).

4. Rotate both tie rods to move the front of the tire

inward or outward.

Figure 28

1. Jam nut

2. Tie rod8

5. Tighten tie rod jam nuts when the adjustment is

correct.

6. Ensure that there is full travel of the steering

wheel in both directions.

Servicing the Fuel System

Fuel Lines and Connections

Check lines and connections every 400 hours or

yearly, whichever occurs first. Inspect for

deterioration, damage, or loose connections.

Replacing the Fuel Filter

Replace the fuel filter after every 800 operating hours

or yearly, whichever occurs first.

1. Raise the bed and support it with the prop rod.

2. Place a clean container under the fuel filter.

3. Remove the clamps securing the fuel filter to the

fuel lines.

Figure 29

1. Fuel filter

4. Install the new fuel filter to the fuel lines with the

clamps previously removed. The filter to be

mounted so arrow points toward the carburetor.

Spark Plugs

Service Interval/Specification

Replace spark plugs after every 800 operating hours

or yearly, whichever occurs first, to assure proper

engine performance and reduce exhaust emission

level.

Type: Champion RC 12YC (or equivalent)

Air Gap: 0.76 mm (0.03”)

Note: The spark plug usually lasts a long time;

however, the plug should be removed and checked

whenever the engine malfunctions.

29

1

2

3

1

Page 30

Replacing the Spark Plug

1. Clean the area around the spark plugs so foreign

matter cannot fall into the cylinder when the spark

plug is removed.

2. Pull the spark plug wires off the spark plugs and

remove the plugs from the cylinder head.

3. Check the condition of the side electrode, center

electrode, and center electrode insulator to assure

there is no damage.

Figure 30

1. 0.76mm (0.03”)

A cracked, fouled, dirty or otherwise

malfunctioning spark plug must be replaced. Do

not sand blast, scrape, or clean electrodes by using

a wire brush because grit may eventually release

from the plug and fall into the cylinder. The result

is usually a damaged engine.

4. Set the air gap between center and side of

electrodes at 0.76mm (0.03”). Install a correctly

gapped spark plug and tighten the plug to 24–30

Nm (18–22 ft-lbs..). If a torque wrench is not

used, tighten the plug firmly.

5. Install the spark plug wires.

Changing Transaxle Fluid

Change transaxle fluid every 800 operating hours or

yearly, whichever occurs first.

1. Position the vehicle on a level surface, stop the

engine, engage the parking brake and remove the

key from the ignition switch.

2. Remove drain plug from right side of reservoir

(Fig. 31) and let fluid flow into drain pan.

Reinstall and tighten the plug when fluid stops

draining.

Figure 31

1. Drain plug

3. Fill the reservoir (Fig 32) with approximately 1.4

liters (1-

1

⁄2 qt.) of 10W30 motor oil or until the oil

level is at the bottom of the level indicator hole

(Fig. 32).

Figure 32

1. Oil fill

4. Start the engine and operate to fill system.

Recheck the oil level and replenish, if required.

Important

30

0.76mm

3

Page 31

Fuses

There are three fuses in the machine’s electrical

system. They are located beneath the bed in a box on

the right hand side of the frame (Fig. 33).

Fuses: Ignition System—10 amp.

Lights—10 amp.

Power Point—10 amp. (15 amp. max.)

Figure 33

1. Ignition system

2. Lights

3. Power point

4. Open

Replacing the Headlights

Specification: GE Headlight # H7610

1. Set the parking brake, turn the ignition off, and

remove the key.

2. Reach beneath the dash and push the headlight out

of the hood.

3. Remove the screws attaching the wire harness to

the headlight.

4. Remove the rubber seal from around the headlight

(Fig. 34). Discard the headlight.

5. Align the notch on the inside of the seal with the

notch on the new headlight (Fig. 34). Slide the

seal onto the headlight until the seal is firmly in

place.

Figure 34

1. Rubber seal

2. Inside notch—align with notch on headlight

3. Outside notch align with notch in hood

4. Headlight

6. Attach the headlight to the wire harness using the

previously removed screws.

7. Align the notch on the outside of the seal with the

notch in the hood. Push the headlight and seal into

the hood until it is firmly in place.

Note: Applying soapy water to the outside of the

seal may aid in sliding the seal into the hood.

Servicing the Battery

Do not jump start the vehicle.

Service Interval/Specification

Always keep the battery clean and fully charged. Use

a paper towel to clean the battery and battery box. If

the battery terminals are corroded, clean them with a

solution of four parts water and one part baking soda.

Apply a light coating of grease to the battery terminals

to prevent corrosion.

Important

31

2

3

Battery posts, terminals, and related accessories

contain lead and lead compounds, chemicals known

to the State of California to cause cancer and

reproductive harm. Wash hands after handling.

WARNING

2

Page 32

Voltage: 12 volts with 280 cold-cranking Amps @

–17.8°C (0°F).

Removing the Battery

1. Position the vehicle on a level surface, set the

parking brake, turn the ignition off and remove

the key.

2. Raise the bed and secure it with the prop rod.

3. Unhook the battery strap.

4. Disconnect the negative (black) ground cable

from the battery post.

5. Disconnect the positive (red) cable from the

battery post.

6. Remove the battery from the chassis.

Installing the Battery

1. Set the battery on the battery base so the battery

posts are toward the rear of the vehicle.

2. Connect the positive (red) cable to the positive (+)

battery post and the negative (black) cable to the

negative (–) battery post using the bolts and wing

nuts. Slide the rubber boot over the positive

battery post.

3. Replace the rubber strap to secure the battery to

the base.

Always keep the battery strap in

place to protect and secure the battery.

Checking Electrolyte Level

Check the electrolyte level every 50 operating hours

or, if the machine is in storage, every 30 days.

1. Raise the bed and secure with the prop rod.

2. Remove the filler caps. If the electrolyte is not up

to the fill line, add the required amount of distilled

water; refer to Adding Water to the Battery, page

32.

Adding Water to the Battery

The best time to add distilled water to the battery is

just before you operate the machine. This lets the

water mix thoroughly with the electrolyte solution.

1. Clean the top of the battery with a paper towel.

2. Remove the filler caps from the battery and

slowly fill each cell with distilled water until the

level is up to the fill line. Replace the filler caps.

Do not overfill the battery.

Electrolyte will overflow onto other parts of the

vehicle and severe corrosion and deterioration

will result.

Important

Important

32

Incorrect battery cable routing could damage

the vehicle and cables causing sparks. Sparks

can cause the battery gasses to explode,

resulting in personal injury.

• Always disconnect the negative (black)

battery cable before disconnecting the

positive (red) cable.

• Always reconnect the positive (red)

battery cable before reconnecting the

negative (black) cable.

WARNING

Battery terminals or metal tools could short

against metal vehicle components causing

sparks. Sparks can cause the battery gasses to

explode, resulting in personal injury.

• When removing or installing the battery,

do not allow the battery terminals to touch

any metal parts of the vehicle.

• Do not allow metal tools to short between

the battery terminals and metal parts of the

vehicle.

• Always keep the battery strap in place to

protect and secure the battery.

WARNING

Page 33

Charging the Battery

Always keep the battery fully charged

(1.260 specific gravity). This is especially important

to prevent battery damage when the temperature is

below 0°C (32°F).

1. Remove the battery from the chassis; refer to

Removing the Battery, page 32.

2. Connect a 3- to 4-amp battery charger to the

battery posts. Charge the battery at a rate of 3 to 4

amperes for 4 to 8 hours (12 volts). Do not

overcharge the battery.

3. Install the battery in the chassis; refer to Installing

the Battery, page 32.

Storing the Battery

If the machine will be stored for more than 30 days,

remove the battery and charge it fully. Either store it

on the shelf or on the machine. Leave the cables

disconnected if it is stored on the machine. Store the

battery in a cool atmosphere to avoid quick

deterioration of the charge in the battery. To prevent

the battery from freezing, make sure it is fully

charged.

Washing the Vehicle

The vehicle should be washed as needed. Use water

alone or with a mild detergent. A rag may be used,

however, the hood will loose some of its luster.

Pressurized water is not recommended

when washing the machine. It may damage the

electrical system, loosen important decals, or wash

away necessary grease at friction points. Avoid

excessive use of water, especially near the control

panel, engine, and battery.

Important

Important

33

Charging the battery produces gasses that can

explode.

Never smoke near the battery and keep sparks

and flames away from the battery.

WARNING

Loading...

Loading...