Page 1

FormNo.3416-503RevC

Workman

®

GTXElectricUtility

Vehicle

ModelNo.07041—SerialNo.401061654andUp

ModelNo.07043—SerialNo.401160341andUp

ModelNo.07131TC—SerialNo.400000000andUp

ModelNo.07139—SerialNo.400000000andUp

ModelNo.07139TC—SerialNo.400000000andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3416-503*C

Page 2

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemical

orchemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orreproductiveharm.

Useofthisproductmaycauseexposure

tochemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

ThisproductcomplieswithallrelevantEuropean

directives;fordetails,pleaseseetheseparateproduct

specicDeclarationofConformity(DOC)sheet.

Introduction

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

g000502

Figure2

Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely .

YoumaycontactT orodirectlyatwww.Toro.comfor

productandaccessoryinformation,helpndinga

dealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

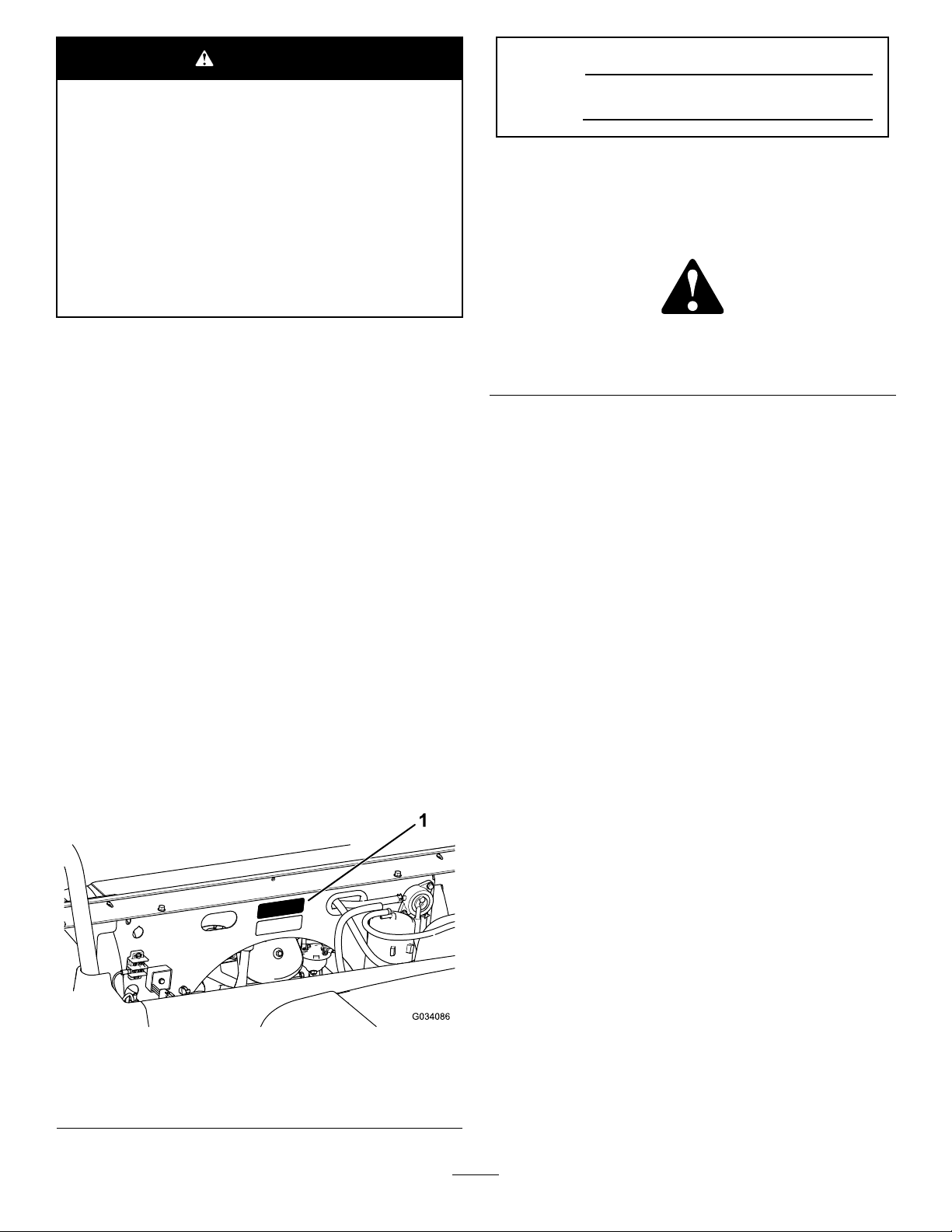

andserialnumbersofyourproductready.Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

BottomofSeatAssemblyShown

1.Modelandserial-numberlocation

©2017—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Figure1

g034086

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Contents

Safety.......................................................................4

GeneralSafety...................................................4

BeforeOperationSafety.....................................4

DuringOperationSafety.....................................4

Multi-PassengerSafety......................................5

SlopeSafety.......................................................5

LoadingandDumpingSafety..............................6

AfterOperationSafety........................................6

SafetyandInstructionalDecals..........................7

Setup......................................................................10

1InstallingtheSteeringWheel(International

ModelsOnly).................................................10

2CheckingtheFluidLevelsandTire

Pressure.......................................................10

3BurnishingtheBrakes.....................................11

4ReadingtheManualandViewingthe

SetupMaterial................................................11

ProductOverview...................................................12

Controls...........................................................13

Specications..................................................16

Attachments/Accessories.................................16

Operation................................................................17

ThinkSafetyFirst..............................................17

OperatingtheCargoBed..................................17

UsingtheRearCargoBedAccessory

Mount............................................................20

PerformingDailyMaintenance..........................20

CheckingtheTirePressure...............................20

UnderstandingandUsingtheBattery

System..........................................................21

StoppingtheMachine.......................................23

BreakinginaNewMachine..............................23

LoadingtheCargoBed.....................................23

TransportingtheMachine.................................24

TowingtheMachine..........................................25

TowingaTrailer................................................25

Maintenance...........................................................26

RecommendedMaintenanceSchedule(s)...........26

DailyMaintenanceChecklist.............................27

MaintainingtheMachineunderSpecial

OperatingConditions....................................27

Pre-MaintenanceProcedures..............................28

MaintenanceSafety..........................................28

PreparingtheMachineforMaintenance............28

LiftingtheMachine...........................................29

AccessingtheHood..........................................30

RaisingandLoweringtheSeat

Assembly......................................................30

RemovingtheSeatAssembly...........................31

InstallingtheSeatAssembly.............................31

Lubrication..........................................................31

GreasingtheMachine.......................................31

GreasingtheFrontWheelBearings..................32

ElectricalSystemMaintenance...........................35

ElectricalSystemSafety...................................35

BatterySafety...................................................35

MaintainingtheBatteries..................................36

ReplacingtheFuses.........................................40

MaintainingtheHeadlights...............................40

DriveSystemMaintenance..................................42

MaintainingtheTires........................................42

AdjustingtheFrontWheelAlignment................42

CheckingtheTransaxle-FluidLevel..................43

ChangingtheTransaxleFluid...........................43

BrakeMaintenance.............................................44

CheckingtheParkingBrake.............................44

AdjustingtheParkingBrake..............................44

CheckingtheBrake-FluidLevel........................44

InspectingtheBrakes.......................................45

ReplacingtheServiceandParking-Brake

Pads..............................................................45

ChangingtheBrakeFluid.................................45

ChassisMaintenance...........................................46

AdjustingtheCargo-BedLatches.....................46

Cleaning..............................................................46

WashingtheMachine.......................................46

Storage...................................................................47

BatteryStorage................................................47

Troubleshooting......................................................48

3

Page 4

Safety

motorquickly.

•Knowhowtostopthemachineandshutoffthe

Improperuseormaintenancebytheoperatoror

ownercanresultininjury.T oreducethepotential

forinjury,complywiththesesafetyinstructions

andalwayspayattentiontothesafety-alert

symbol(Figure2),whichmeansCaution,Warning,

orDanger—personalsafetyinstruction.Failureto

complywiththeinstructionmayresultinpersonal

injuryordeath.

ThismachinemeetstherequirementsofSAEJ2258.

GeneralSafety

Thisproductiscapableofcausingpersonalinjury.

Alwaysfollowallsafetyinstructionstoavoidserious

personalinjury.

Usingthisproductforpurposesotherthanitsintended

usecouldprovedangeroustoyouandbystanders.

•Readandunderstandthecontentsofthis

Operator’sManualbeforeyoustarttheengine.

Ensurethateveryoneusingthisproductknows

howtouseitandunderstandsthewarnings.

•Donotputyourhandsorfeetnearmoving

componentsofthemachine.

•Donotoperatethemachinewithoutallguards

andothersafetyprotectivedevicesinplaceand

workingonthemachine.

•Keepthemachineasafedistanceawayfrom

bystanderswhileitismoving.

•Keepchildrenoutoftheoperatingarea.Never

allowchildrentooperatethemachine.

•Stopthemachineandshutofftheenginebefore

servicing,fueling,oruncloggingthemachine.

Improperlyusingormaintainingthismachinecan

resultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandalwayspay

attentiontothesafety-alertsymbol,whichmeans

Caution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeseinstructions

mayresultinpersonalinjuryordeath.

Youcanndadditionalsafetyinformationwhere

neededthroughoutthismanual.

•Checkthatallsafetydevicesanddecalsarein

place.Repairorreplaceallsafetydevicesand

replaceallillegibleormissingdecals.Donot

operatethemachineunlesstheyarepresentand

functioningproperly.

DuringOperationSafety

•Theowner/operatorcanpreventandisresponsible

foraccidentsthatmaycausepersonalinjuryor

propertydamage.

•Passengersshouldsitinthedesignatedseating

positionsonly.Donotcarrypassengersinthe

cargobed.Keepbystandersandpetsawayfrom

themachineduringoperation.

•Wearappropriateclothing,includingeye

protection;longpants;substantial,slip-resistant

footwear;andhearingprotection.Tiebacklong

hairanddonotwearjewelry.

•Donotoperatethemachinewhileill,tired,or

undertheinuenceofalcoholordrugs.

•Operatethemachineoutdoorsorina

well-ventilatedareaonly.

•Donotexceedthemaximumgrossvehicleweight

(GVW)ofthemachine.

•Useextracautionwhenoperatingthemachine

withaheavyloadinthecargobed.Theheavier

theload,themoredifcultitistoturnorstop.

•Carryingoversizedloadsinthecargobedreduces

thestabilityofthemachine.

•Carryingmaterialthatcannotbeboundtothe

machine,suchasalargetankofliquid,adversely

affectsthesteering,braking,andstabilityofthe

machine.

•Beforeyoustartthemotor,ensurethatthe

transmissionisinneutral,theparkingbrakeis

engaged,andyouareintheoperatingposition.

•Youandyourpassengersshouldremainseated

wheneverthemachineismoving.Keepyour

handsonthesteeringwheel;yourpassengers

shouldusethehandholdsprovided.Keepyour

armsandlegswithinthemachinebodyatalltimes.

BeforeOperationSafety

•Neverallowchildrenoruntrainedpeopleto

operateorservicethemachine.Localregulations

mayrestricttheageoftheoperator.Theowner

isresponsiblefortrainingalloperatorsand

mechanics.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Operatethemachineonlyingoodvisibility.

Watchforholes,ruts,bumps,rocks,orother

hiddenobjects.Uneventerraincouldoverturnthe

machine.Tallgrasscanhideobstacles.Usecare

whenapproachingblindcorners,shrubs,trees,or

otherobjectsthatmayobscureyourvision.

•Alwayswatchoutforandavoidlowoverhangs

suchastreelimbs,doorjambs,overhead

walkways,etc.

4

Page 5

•Lookbehindanddownbeforereversingthe

machinetobesureofaclearpath.

•Donotdrivethemachineneardrop-offs,ditches,

orembankments.Themachinecouldsuddenly

rolloverifawheelgoesovertheedgeorifthe

edgegivesway.

•Whenusingthemachineonpublicroads,follow

alltrafcregulationsanduseanyadditional

accessoriesthatmayberequiredbylaw,suchas

lights,turnsignals,slow-movingvehicle(SMV)

signs,andothersasrequired.

•Ifthemachineevervibratesabnormally,stopthe

machineimmediately,shutoffthemotor,waitfor

allmovementtostop,andinspectfordamage.

Repairalldamagetothemachinebeforeresuming

operation.

Multi-PassengerSafety

•Youmustaccountfortheextrapassengers

contributingtotheoverallgrossvehicleweight

(GVW)ofthemachine.

•Ifyouhavealoadinthecargobed,ensurethat

youdonotexceedthecapacityofthemachineby

havingtoomanypassengers.

•Passengersshouldsitinthedesignatedseating

positionsonly.Donotallowpassengerstositin

thecargobed.

•Youandyourpassengersshouldremainseated

wheneverthemachineisinmotion.

•Theadditionalmachinelengthresultsinalarger

turnradius,soallowmorespacetomaneuverthe

machine.

•Carryareducedloadandreducetheground

speedofthemachinewhenoperatingonrough,

uneventerrain,andnearcurbs,holes,andother

suddenchangesinterrain.Loadsmayshift,

causingthemachinetobecomeunstable.

•Itcantakelongertostopthemachineonwet

surfacesthanondrysurfaces.T odryoutwet

brakes,driveslowlyonlevelgroundwhileputting

lightpressureonthebrakepedal.

•Suddenchangesinterrainmaymovethesteering

wheelunexpectedly,whichcouldresultinhand

andarminjuries.Reduceyourspeedandgrip

thesteeringwheellooselyaroundtheperimeter,

keepingyourthumbsoutofthewayofthesteering

wheelspokes.

•Reducethespeedwhenyouoperatethemachine

withthecargobedremoved.Operatingthe

machineathighspeedandthenquicklystopping

maycausetherearwheelstolockup,which

impairsyourcontrolofthemachine.

•Donottouchthemotor,transmission,mufer,or

mufermanifoldwhilethemotorisrunning,or

soonafteryouturnoffthemotor,becausethese

areasmaybehotenoughtocauseburns.

•Donotleavearunningmachineunattended.

•Beforeleavingtheoperatingposition,dothe

following:

–Parkthemachineonlevelground.

–Engagetheparkingbrake.

–Lowerthecargobed.

–Shutoffthemotorandremovethekey .

•Donotoperatethemachinewhenthereistherisk

oflightning.

•Useaccessoriesandattachmentsapprovedby

TheT oro®Companyonly.

SlopeSafety

Note:A2-postRolloverProtectionSystem(ROPS)

isavailableforthismachineasanaccessory.Usea

ROPSifyouwillworknexttodrop-offs,nearwater,

inroughterrain,oronaslope,whichcouldresultin

arollover.ContactanauthorizedTorodistributorfor

moreinformation.

Slopesareamajorfactorrelatedtoloss-of-control

andtip-overaccidents,whichcanresultinsevere

injuryordeath.

•Surveythesitetodeterminewhichslopesare

safeforoperatingthemachineandestablishyour

ownproceduresandrulesforoperatingonthose

slopes.Alwaysusecommonsenseandgood

judgmentwhenperformingthissurvey.

•Ifyoufeeluneasyoperatingthemachineona

slope,donotdoit.

•Keepallmovementonslopesslowandgradual.

Donotsuddenlychangethespeedordirectionof

themachine.

•Avoidoperatingthemachineonwetterrain.Tires

maylosetractionregardlessifthebrakesare

availableandfunctioning.Arollovercanoccur

beforethetireslosetraction.

•Avoidstarting,stopping,orturningthemachine

onaslope.

•Travelstraightupanddownaslope.

•Ifyoubegintolosemomentumwhileclimbinga

slope,graduallyengagethebrakesandslowly

reversethemachinestraightdowntheslope.

•Turningwhilegoingupordownaslopecanbe

dangerous.Ifyoumustturnonaslope,doitslowly

andcautiously.

•Heavyloadsaffectstabilityonaslope.Carrya

reducedloadandreduceyourgroundspeedwhen

operatingonaslopeoriftheloadhasahigh

centerofgravity.Securetheloadtothecargobed

5

Page 6

ofthemachinetopreventtheloadfromshifting.

Takeextracarewhenhaulingloadsthatshifteasily

(e.g.,liquids,rock,sand,etc.).

•Avoidstoppingonaslope,especiallywitha

load.Stoppingwhilegoingdownaslopetakes

longerthanstoppingonlevelground.Ifyoumust

stopthemachine,avoidsuddenspeedchanges,

whichcancausethemachinetotiporrollover.

Donotengagethebrakessuddenlywhenrolling

rearward,asthismaycausethemachineto

overturn.

LoadingandDumping Safety

•Donotexceedthegrossvehicleweight(GVW)

ofthemachinewhenoperatingitwithaloadin

thecargobedand/ortowingatrailer;referto

Specications(page16).

•Distributetheloadinthecargobedevenlyto

improvethestabilityandcontrolofthemachine.

•Beforedumping,ensurethatthereisnoone

behindthemachine.

•Donotdumpaloadedcargobedwhilethe

machineissidewaysonaslope.Thechange

inweightdistributionmaycausethemachineto

overturn.

AfterOperationSafety

•Allowtheenginetocoolbeforestoringthemachine

inanyenclosure.

•Shutoffthefuelbeforestoringortransportingthe

machine.

•Donotstorethemachineorfuelcontainerwhere

thereisanopename,spark,orpilotlight,such

asonawaterheaterorotherappliance.

•Keepallpartsofthemachineingoodworking

conditionandallhardwaretightened.

•Replaceallworn,damaged,ormissingdecals.

•Usecarewhenloadingorunloadingthemachine

intoatraileroratruck.

•Usefull-widthrampsforloadingthemachineinto

atraileroratruck.

•Tiethemachinedownsecurely.

6

Page 7

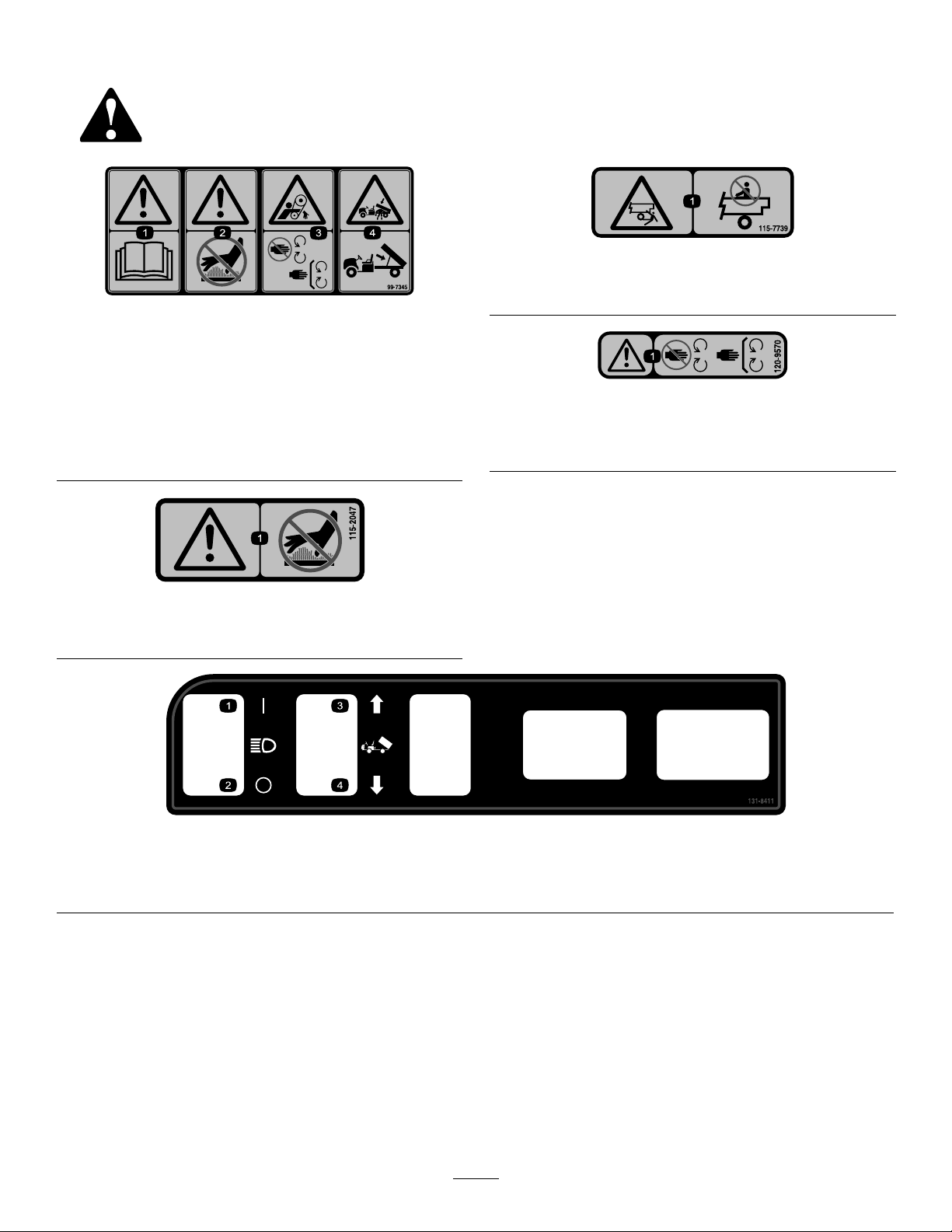

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

decal115-7739

115-7739

99-7345

1.Warning—readtheOperator'sManual.

2.Hotsurface/burnhazard—stayasafedistanceawayfrom

thehotsurface.

3.Entanglementhazard,belt—stayawayfrommovingparts;

keepallguardsinplace.

4.Crushinghazard,cargobed—usetheproprodtosupport

thecargobed.

115-2047

1.Warning—donottouchthehotsurface.

decal99-7345

1.Falling,crushinghazard,bystanders—noridersonmachine

decal120-9570

120-9570

1.Warning—stayawayfrommovingparts;keepallguards

andshieldsinplace.

decal115-2047

131-8411

1.Headlight—on3.Raisethebed.

2.Headlight—off

4.Lowerthebed.

7

decal131-8411

Page 8

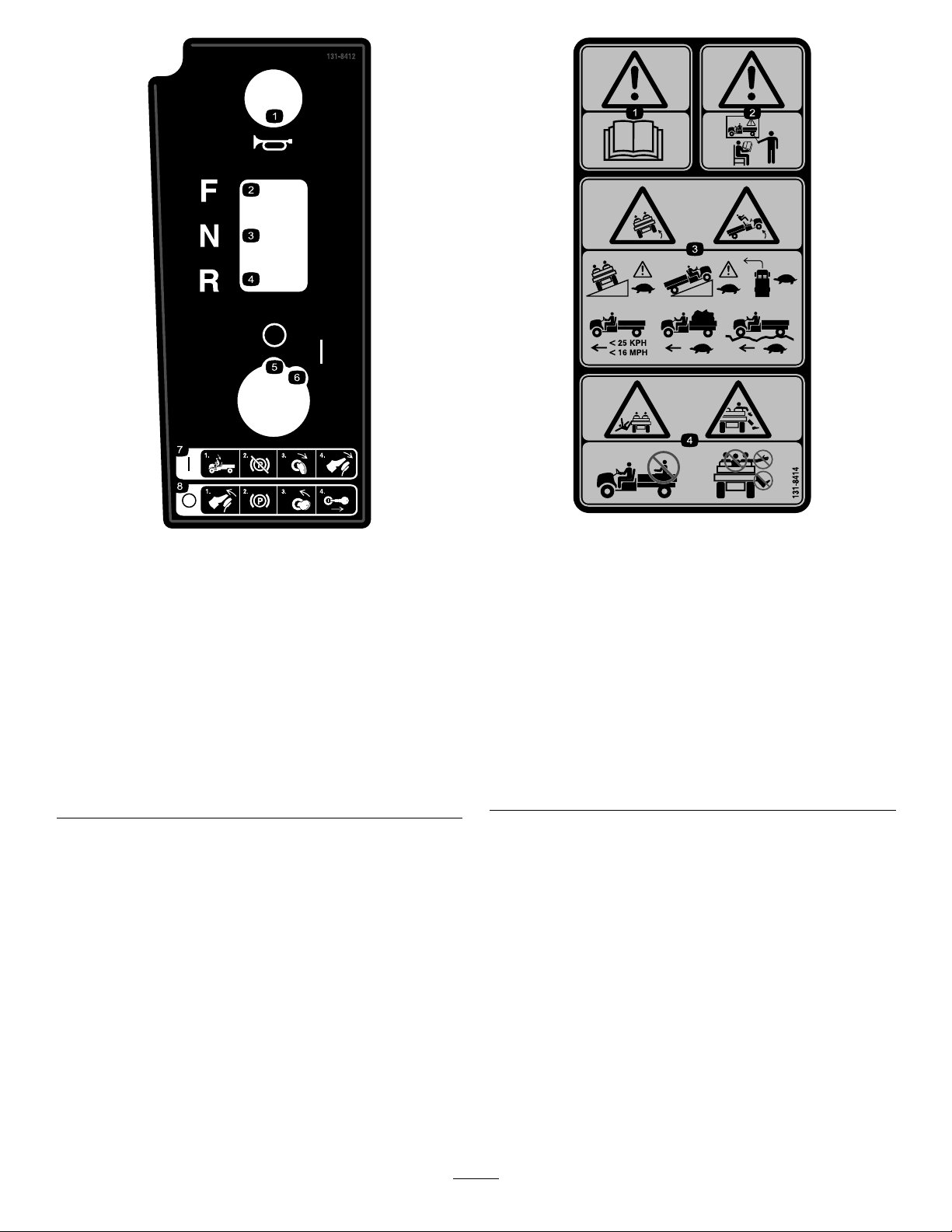

decal131-8412

131-8414

decal131-8414

131-8412

1.Warning—readthe

1.Horn

2.Forward

3.Neutral

5.Off

6.On

7.Turningon—1)Sitinthe

Operator'sManual.

driver'sseat;2)Disengage

theparkingbrake;3)Turn

thekeyswitchtothestart

position;4)Pushdownon

thepedal.

4.Reverse

8.Turningoff—1)Release

2.Warning—receiveproper

trainingbeforeoperating

themachine.

thepedal;2)Engagethe

parkingbrake;3)Turn

thekeyswitchtothestop

position;4)Removethe

keyfromthekeyswitch.

3.Tippinghazard—drive

slowlyacrossorupslopes;

taketurnsslowly;donot

exceedspeedsof25kph

(16mph);driveslowly

whenhaulingcargo;drive

slowlyonuneventerrain.

4.Fallinghazard;severing

hazardoflimbs—donot

carrypassengersinthe

bed;donotcarryextra

passengersinbetween

theseats;donotputyour

armsorlegsoutsideofthe

machinewhileoperating.

8

Page 9

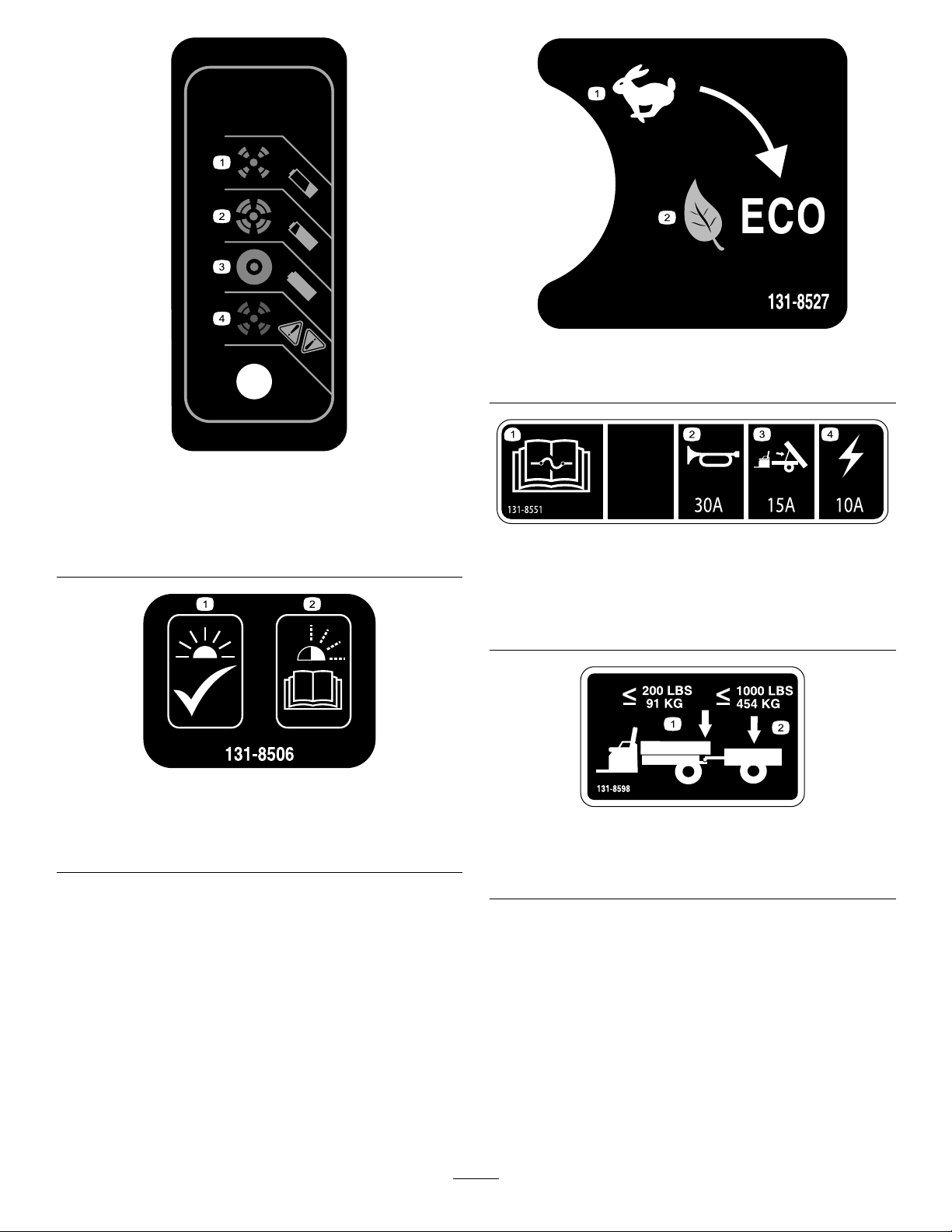

decal131-8527

131-8527

131-8495

1.Thebatteryisempty .3.Thebatteryischarged.

2.Thebatteryisalmost

charged.

4.Chargerfault;refertothe

chargermanualforthe

faultcodes.

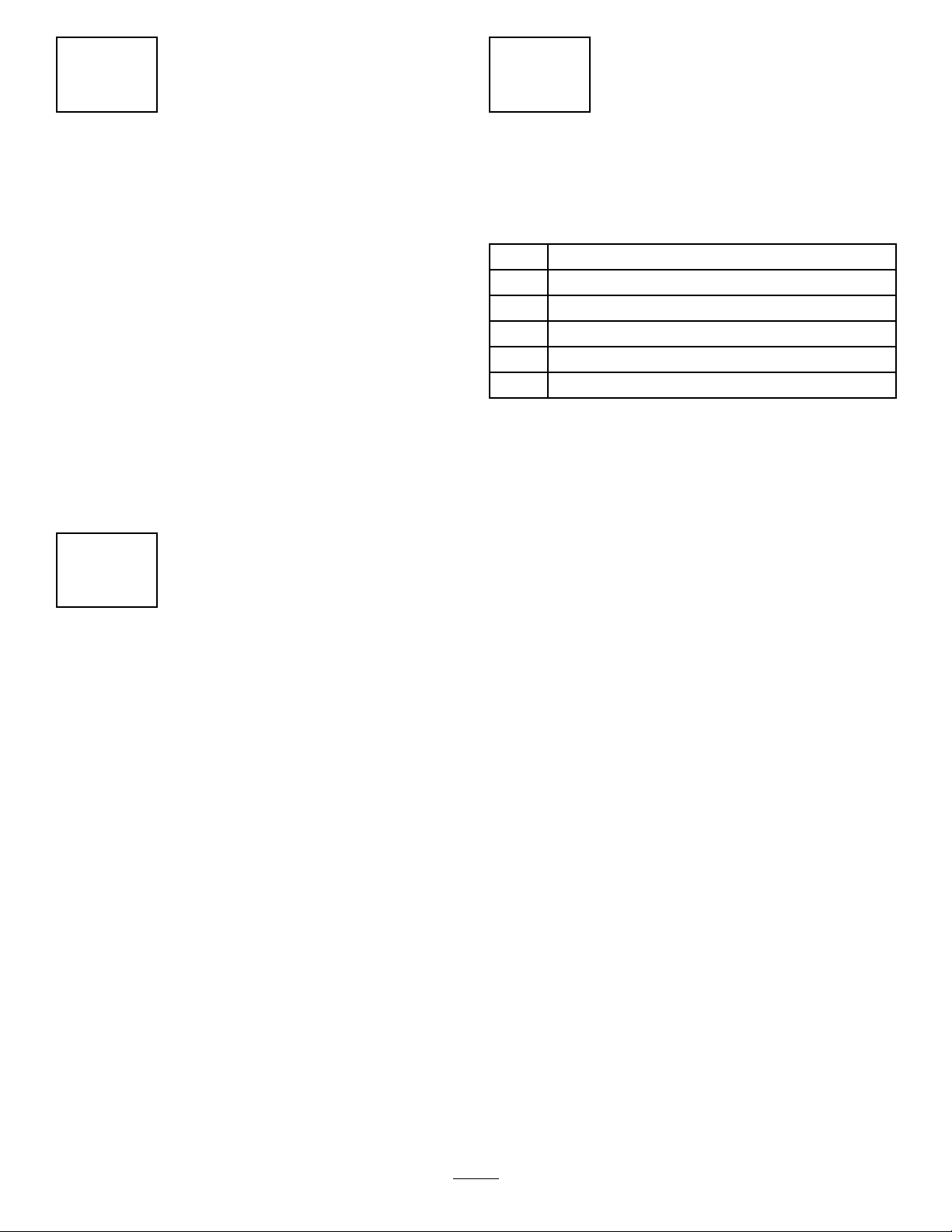

131-8506

1.Solidlight—unitis

preparedforoperation.

2.Flashinglight—refertothe

chargermanualforthe

faultcodes.

1.Performancemode

decal131-8495

2.Ecomode

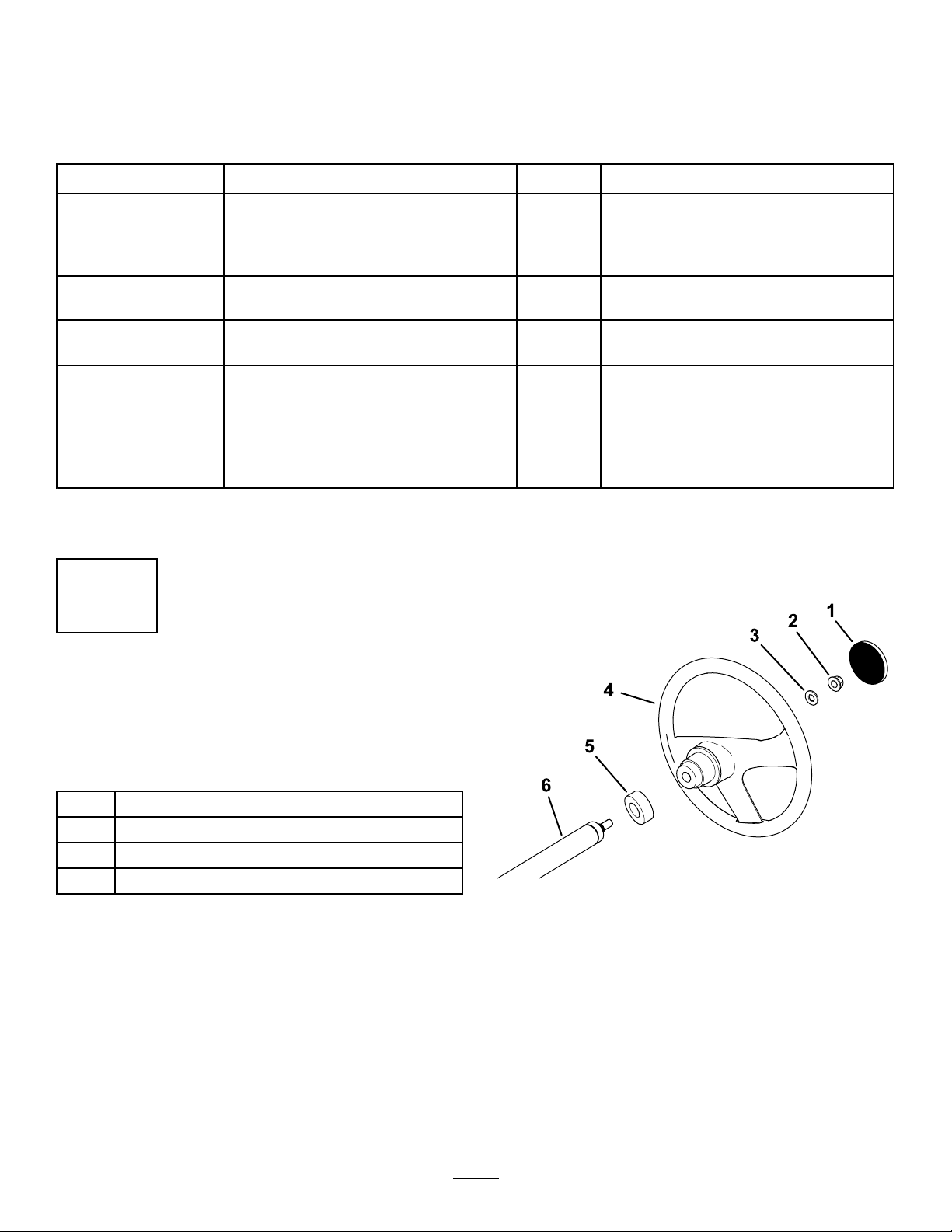

decal131-8551

131-8551

1.ReadtheOperator’s

Manualforfuse

information.

2.Horn(30A)4.Mainpower(10A)

decal131-8506

3.Optionalliftkit(15A)

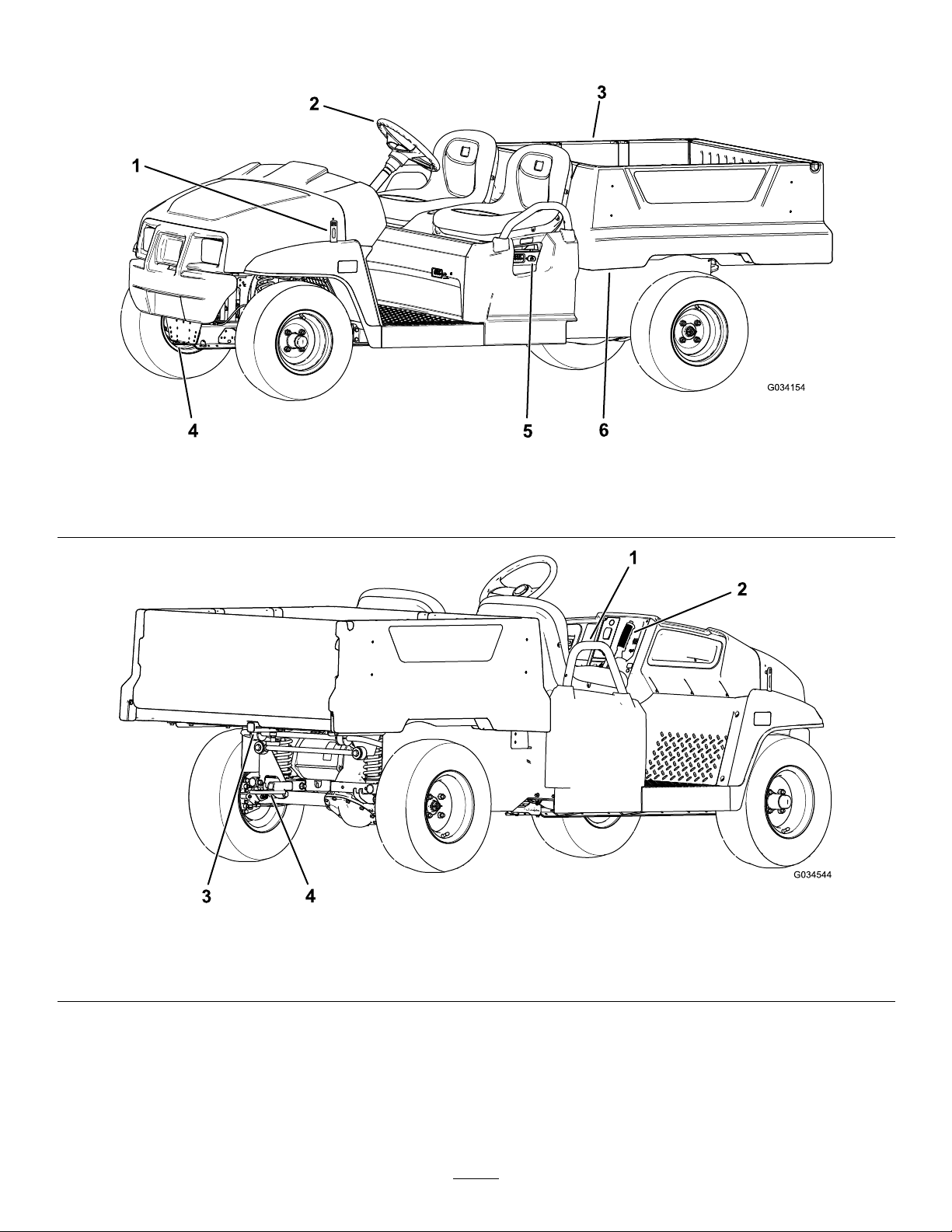

decal131-8598

131-8598

1.Maximumbedweight91

kg(200lb)

2.Maximumtrailerweight

454kg(1,000lb)

9

Page 10

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

Steeringwheel

Steeringwheelcover

1

2

3

4

Washer(1/2inch)

Dustcover1

Nopartsrequired

Nopartsrequired

Operator'sManual

Engineowner'smanual1

Registrationcard1

PredeliveryInspectionForm1

CerticateofQuality

Key2

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

1

Qty.

1

1

1

–

–

1

1

4.Securethesteeringwheeltotheshaftwiththe

locknut(1/2inch)andtightenitto18to30N∙m

(13to22ft-lb).

5.Installthecoveronthesteeringwheel(Figure3).

Installthesteeringwheel(International

modelsonly).

Checktheuidlevelsandtirepressure.

Burnish(break-in)thebrakes.

ReadtheOperator'sManualandview

thesetupmaterialbeforeoperatingthe

machine.

Use

InstallingtheSteering Wheel(InternationalModels Only)

Partsneededforthisprocedure:

1

Steeringwheel

1

Steeringwheelcover

1

Washer(1/2inch)

1Dustcover

Procedure

1.Ifthecoverisinstalled,removeitfromthehub

ofthesteeringwheel(Figure3).

2.Removethelocknut(1/2inch)fromthesteering

shaft(Figure3).

3.Slidethesteeringwheel,dustcover,andwasher

(1/2inch)ontothesteeringshaft(Figure3).

Note:Withthefrontwheelsstraight,orientthe

steeringwheelsothatthesmallerspokeonthe

steeringwheelisvertical.

Figure3

1.Steeringwheelcover4.Steeringwheel

2.Locknut(1/2inch)

3.Washer(1/2inch)6.Steeringshaft

5.Dustcover

g198932

10

Page 11

2

4

CheckingtheFluidLevels

andTirePressure

NoPartsRequired

Procedure

1.Checkthewaterlevelinthebatteriesbefore

youoperatethemachine;refertoCheckingthe

WaterLeveloftheBatteries(page38).

2.Ensurethatthebatteriesarecharged;referto

ChargingtheBatteries(page36).

3.Checkthebrake-uidlevelbeforeyouoperate

themachine;refertoCheckingtheBrake-Fluid

Level(page44).

4.Checktheairpressureinthetires;referto

CheckingtheTirePressure(page20).

3

ReadingtheManualand ViewingtheSetupMaterial

Partsneededforthisprocedure:

1

Operator'sManual

1Engineowner'smanual

1Registrationcard

1PredeliveryInspectionForm

1

CerticateofQuality

2Key

Procedure

•ReadtheOperator'sManualandtheengine

owners'smanual.

•Fillouttheregistrationcard.

•CompletethePredeliveryInspectionForm.

•ReviewtheCerticateofQuality.

BurnishingtheBrakes

NoPartsRequired

Procedure

Toensureoptimumperformanceofthebrakesystem,

burnish(break-in)thebrakesbeforeuse.

1.Bringthemachineuptofullspeed,applythe

brakestorapidlystopthemachinewithout

lockingupthetires.

2.Repeatthisprocedure10times,waiting1minute

betweenstops,toavoidoverheatingthebrakes.

Important:Thisprocedureismosteffective

ifthemachineisloadedwith227kg(500lb).

11

Page 12

ProductOverview

g034154

Figure4

1.Hoodlatch

2.Steeringwheel

3.Cargobed

4.Towingtongue

5.Batterycharger

6.Cargo-bedlever

g034544

Figure5

1.Passengerhandhold3.Rearcargo-bed-accessorymount

2.Parking-brakelever4.Trailerhitch

12

Page 13

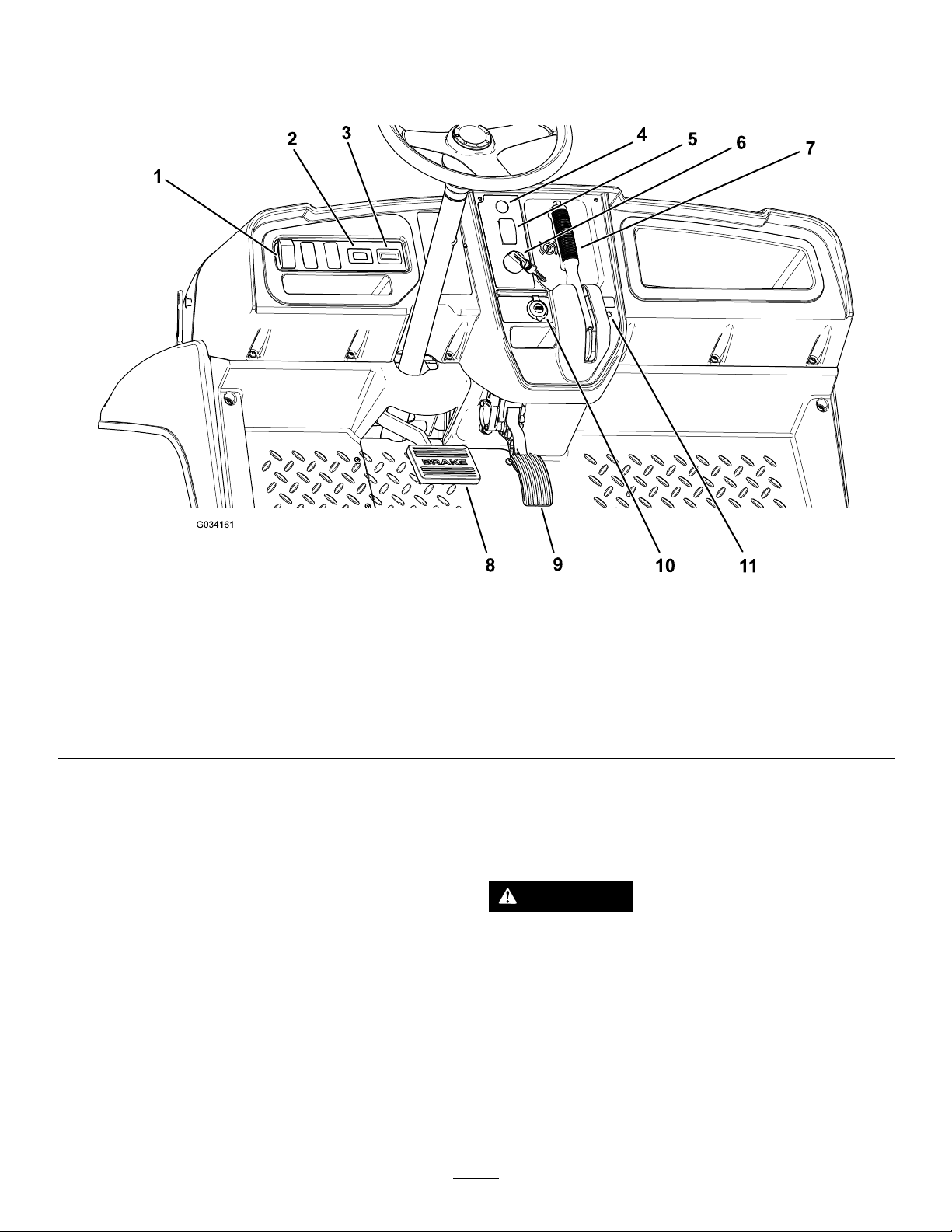

Controls

ControlPanel

Figure6

1.Lightswitch7.Parking-brakelever

2.Hourmeter8.Brakepedal

3.Battery-dischargeindicator9.Acceleratorpedal

4.Hornbutton(Internationalmodelsonly)10.USBpowerpoint

5.Gear-shiftselector11.Status-indicatorlight

6.Keyswitch

AcceleratorPedal

Usetheacceleratorpedal(Figure6)tovaryground

speedofthemachine.Pressingdowntheaccelerator

pedalstartsthemachine.Pressingthepedalfarther

increasesgroundspeed.Releasingthepedalslows

themachine,andthemachineshutsoff.

BrakePedal

Usethebrakepedaltostoporslowthemachine

(Figure6).

CAUTION

Operatingamachinewithwornorincorrectly

Themaximumforwardspeedinperformancemodeis

26km/h(16mph)asshowninFigure9.

Themaximumforwardspeedineconomymodeis19

km/h(12mph)asshowninFigure9.

adjustedbrakescanmayresultinpersonal

injury.

Ifthebrakepedaltravelstowithin25mm(1

inch)ofthemachineoorboard,adjustor

repairthebrakes.

g034161

13

Page 14

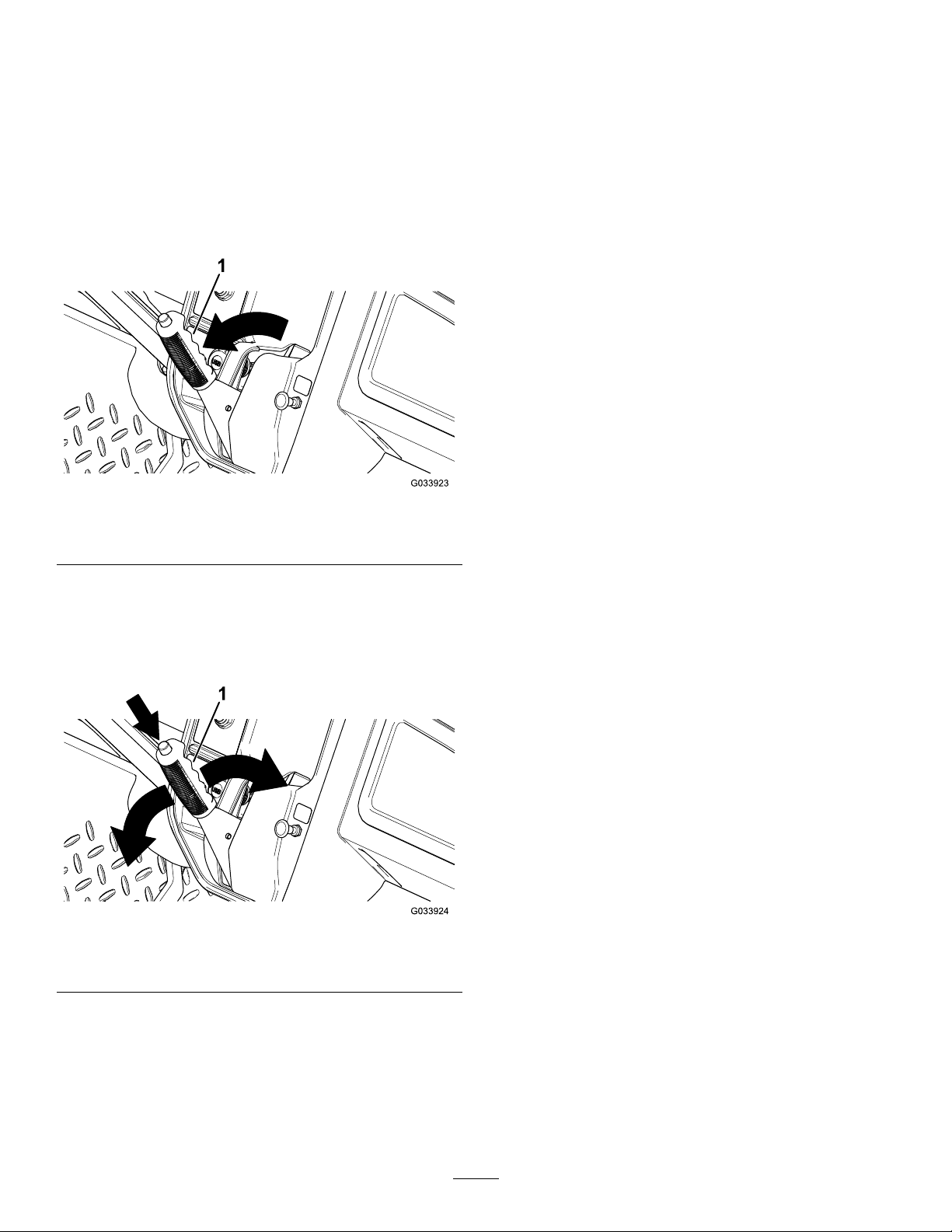

Parking-BrakeLever

DirectionSelector

Theparking-brakeleverislocatedonthecontrol

panel(Figure7).

Wheneveryoushutofftheengine,engagetheparking

braketopreventthemachinefromaccidentally

moving.Ifthemachineisparkedonasteepgrade,

ensurethatyouengagetheparkingbrake.

Toengagetheparkingbrake,pulltheparking-brake

levertowardyou(Figure7).

Figure7

Thedirectionselectorislocatedtotheleftofthe

parking-brakelever.Thedirectionselectorhas3

positions:FORWARD,REVERSE,andNEUTRAL(Figure

6).

Note:Themachinecanbeoninanyofthe3

positions,butonlymovesintheFORWARDand

REVERSEpositions.

Important:Alwaysstopthemachinebefore

changingdirection.

HornButton

InternationalModelsOnly

Thehornbuttonislocatedonthecontrolpanel(Figure

6).Pressthehornbuttontosoundthehorn.

LightSwitch

Usethelightswitch(Figure6)toilluminatethe

headlights.Pushthelightswitchuptoturnonthe

g033923

headlights.Pushthelightswitchdowntoturnoffthe

lights.

1.Parking-brakelever

Todisengagetheparkingbrake,pushdownthe

buttonontopoftheparking-brakelever,pullthe

parking-brakelevertowardyoutoreleasepressure,

andthenpushtheparking-brakeleverforward(Figure

8).

Figure8

1.Parking-brakelever

Battery-DischargeIndicator

Thebattery-dischargeindicatorislocatedto

theleftofthesteeringcolumn(Figure6).The

battery-dischargeindicatorindicatestheremaining

chargeinthebatteries.Whenthebatteriesarefully

charged,10indicatorbarsextendfromthe0tothe1

position.Asyouusethecharge,theindicatorbars

disappear,startingattherightsideofthemeter.For

detailedinformationonthebatterymeter,referto

UnderstandingandUsingtheBatterySystem(page

21).

HourMeter

Thehourmeterislocatedtotherightofthelight

switch(Figure6).Usethehourmetertondoutthe

totalnumberofoperatinghours.Thehourmeter

startstofunctionwheneveryouturnthekeyswitchto

theONpositionorifthemachineisrunning.

g033924

Note:Whenthemachineisrunning,thehourmeter

blinkscontinuously,recordingusage.

USBPowerPoint

TheUSBpowerpointislocatedtotheleftofthe

parking-brakelever(Figure6).Usethepowerpoint

topowermobiledevices.

Important:WhenyouarenotusingtheUSB

powerpoint,inserttherubberplugtoprevent

damagetothepowerpoint.

14

Page 15

KeySwitch

Status-IndicatorLight

Usethekeyswitch(Figure6),torunandshutoffthe

machine.

Thekeyswitchhas2positions:ONandOFF.Rotate

thekeyclockwisetotheONpositiontooperatethe

machine.Whenyoustopthemachine,rotatethekey

counterclockwisetotheOFFpositiontoshutoffthe

machine.Removethekeywheneveryouleavethe

machine.

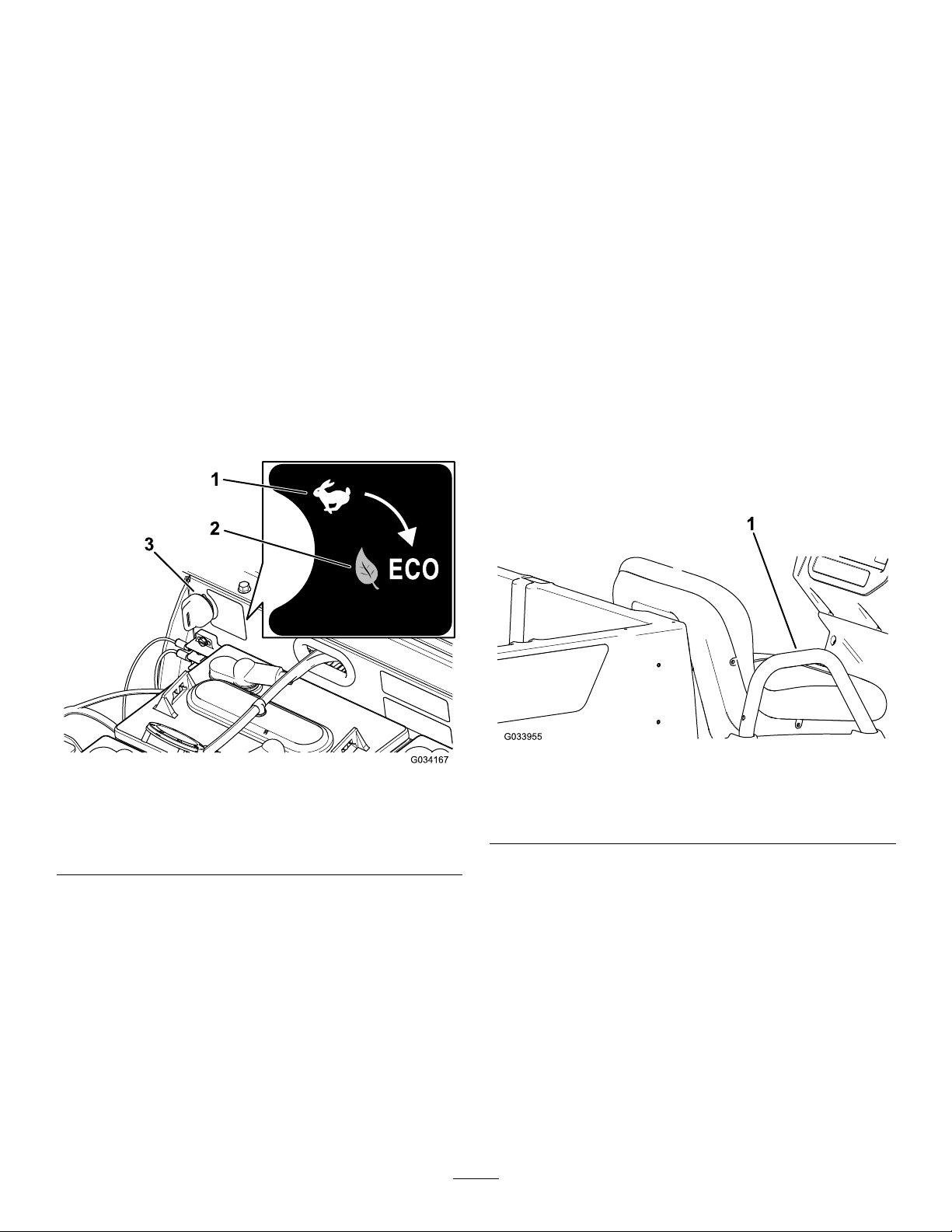

SupervisorSpeed-LimitSwitch

Thesupervisorspeed-limitswitch,locatedunder

theseatassembly,has2positions:PERFORMANCE

andECONOMY.Rotatetheswitchclockwisetothe

ECONOMYpositiontolimitthemaximummachine

speedto19km/h(12mph).Rotatetheswitch

counterclockwisetothePERFORMANCEpositionto

restorethemaximumspeedofthemachineto26km/h

(16mph)asshowninFigure9.

Thestatus-indicatorlightislocatedtotherightofthe

parking-brakeleveronthecontrolpanel(Figure6).

Whenthemachineisturnedon,thegreen

status-indicatorlightilluminateseithersolidorblinking.

Ifthelightissolid,thisindicatesthatthemachineis

readyfornormaloperation.Ifthelightisblinking,

thereisanissuethatneedstoberesolvedbefore

continuingwithnormaloperationofthemachine.

Ifthestatus-indicatorlightblinks2times,this

indicatesthattheparkingbrakeisengagedwhilein

theFORWARDorREVERSEpositiononthedirection

selector.Disengagetheparkingbraketoshutoffthe

status-indicatorlight.

RefertoTroubleshooting(page48)ifthe

status-indicatorlightblinksmorethan2times.

PassengerHandholds

Thepassengerhandholdsarelocatedontheoutside

ofeachseat(Figure10).

1.PERFORMANCEposition

2.ECONOMYposition

Figure9

3.Supervisorspeed-limit

g033955

g034167

switch

1.Passengerhandhold

15

Figure10

PassengerSideShown

Page 16

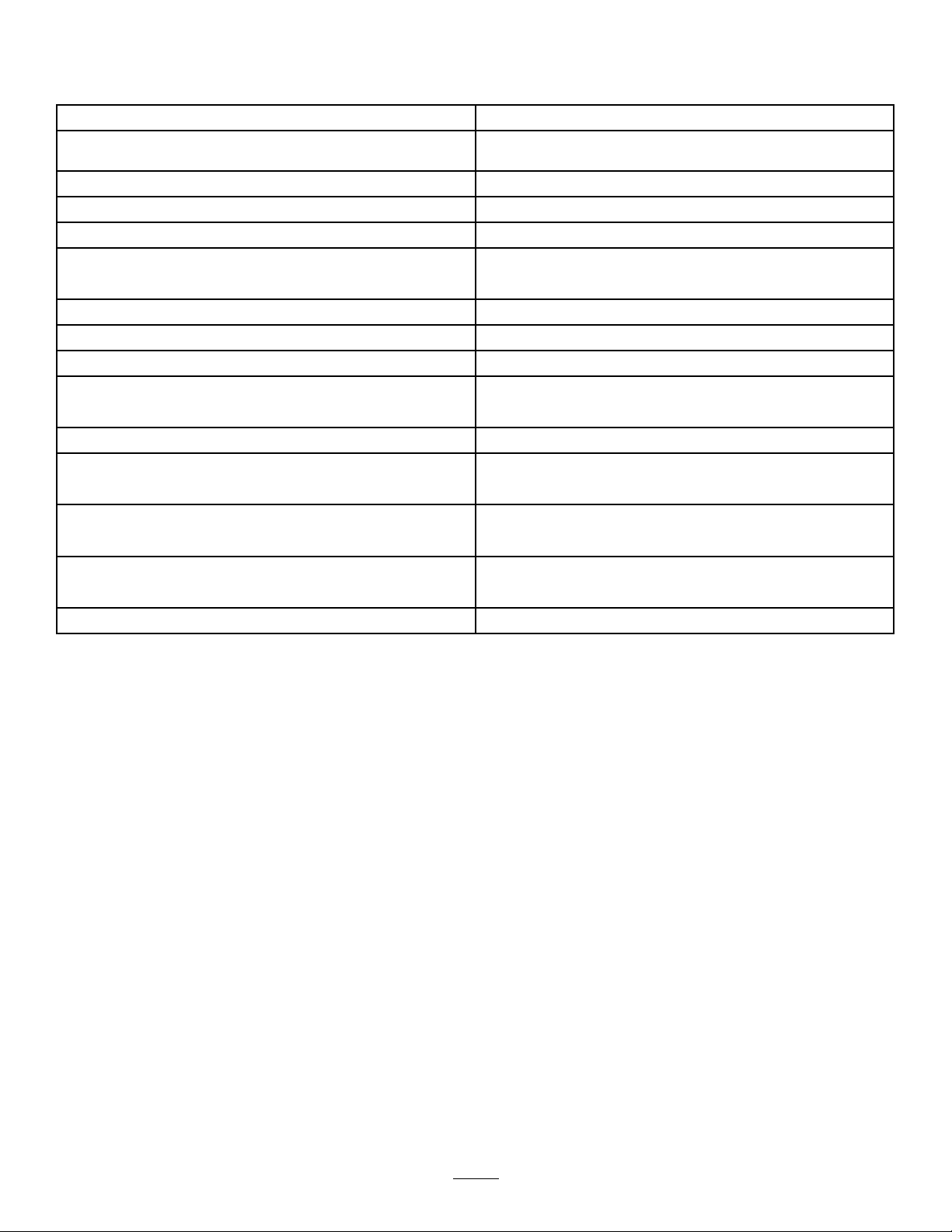

Specications

Note:Specicationsanddesignaresubjecttochangewithoutnotice.

Baseweight

Ratedcapacity(onlevelground)

Maximumgrossvehicleweight(GVW)—onlevelground1177kg(2,595lb)total,includingalloftheweightslistedabove

Maximumcargocapacity(onlevelground)363kg(800lb)total,includingrear-mountedaccessories

Maximumrearcargobedaccessorymountcapacity

Towcapacity

Overallwidth119cm(47inches)

Overalllength302cm(119inches)

Overallheight127.5cm(50.2inches)

Groundclearance

Wheelbase

Wheeltread(centerlinetocenterline)

Cargobedlength

Cargobedwidth

Cargobedheight28cm(11inches)inside

Dry633kg(1,395lb)

544kg(1,200lb)total,including91kg(200lb)operatorand91kg

(200lb)passenger,load,accessories,andattachments

45kg(100lb)total

Tongueweight:91kg(200lb)

Maximumtrailerweight:454kg(1,000lb)

21.6cm(8.5inches)atthefrontwithnoloadoroperator

14cm(5.5inch)attherearwithnoloadoroperator

220cm(86.6inches)

Front:119cm(47inches)

Rear:119cm(47inches)

Inside:102cm(40inches)

Outside:1 14.3cm(45inches)

Inside:98cm(38.5inches)

Outsideofthemoldedfenders:107.3cm(42.3inches)

*SpecicationslistedarewithTrojanT-125batteries.**Installingnon-standardbatteriesmayreducethe

cargo-bedcapacity.

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesisavailableforusewiththemachinetoenhance

andexpanditscapabilities.ContactyourAuthorizedServiceDealerorDistributororgotowww.Toro.comfora

listofallapprovedattachmentsandaccessories.

16

Page 17

Operation

OperatingtheCargoBed

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

CAUTION

Araisedbedfullofmaterialwithouttheproper

safetysupportmaylowerunexpectedly.

Workingunderanunsupportedraisedbed

couldinjureyouorothers.

•Beforeservicingormakingadjustmentsto

themachine,parkthemachineonalevel

surface,engagetheparkingbrake,shutoff

theengine,andremovethekey.

•Removeanyloadmaterialfromthebed

orotherattachment,andinsertthesafety

supportonafully-extendedcylinderrod

beforeworkingunderaraisedbed.

ThinkSafetyFirst

Carefullyreadallthesafetyinstructionsandsymbols

inthesafetysection.Knowingthisinformationcould

helpyouorbystandersavoidinjury.

DANGER

RaisingtheCargoBedtothe DumpPosition

WARNING

Araisedbedcouldfallandinjurepersonsthat

areworkingbeneathit.

•Alwaysusetheproprodtoholdthebedup

beforeworkingunderthebed.

•Removeanyloadmaterialfromthebed

beforeraisingit.

WARNING

Drivingthemachinewiththecargobedraised

couldcausethemachinetotiporrolleasier.

Youcoulddamagethestructureofthecargo

bedifyouoperatethemachinewiththebed

raised.

•Operatethemachinewhenthecargobed

isdown.

•Afteremptyingthecargobed,lowerit.

Operatingonwetgrassorslopescancause

slidingandlossofcontrol.

Wheelsdroppingoveredgescancause

rollovers,whichmayresultinseriousinjury,

death,ordrowning.

Toavoidlossofcontrolandpossibilityof

rollover:

•Donotoperateneardropoffsornearwater.

•Reducespeedanduseextremecautionon

slopes.

•Avoidsuddenturnsorrapidspeed

changes.

CAUTION

Ifaloadisconcentratednearthebackofthe

cargobedwhenyoureleasethelatches,the

bedmayunexpectedlytipopen,injuringyou

orbystanders.

•Centerloadsinthecargobed,ifpossible.

•Holdthecargobeddownandensurethat

nooneisleaningoverthebedorstanding

behinditwhenreleasingthelatches.

•Removeallcargofromthebedbefore

liftingthebeduptoservicethemachine.

1.Pulltheleveronleft,insideofthecargobed

towardyouandliftthecargobedup(Figure11).

17

Page 18

RaisingtheCargoBedtothe ServicePosition

1.Pulltheleveronleft,insideofthecargobed

towardyouandliftthecargobedup(Figure11).

2.Pullproprodintotheservicepositiondetentslot

tosecurethebedformaintenance(Figure12).

LoweringtheCargoBed

Figure11

1.Cargo-bedlever

2.Pulltheproprodintothedumppositiondetent

slottosecurethebedfordumping(Figure12).

Figure12

1.Servicepositiondetent

slot

2.Proprod

3.Dumppositiondetentslot

g034019

WARNING

Theweightofthebedmaybeheavy.Hands

orotherbodypartscouldbecrushed.

Keepyourhandsandotherbodypartsaway

whenloweringthebed.

1.Raisethecargobedslightlybyliftinguponthe

latchlever(Figure11).

2.Pulltheproprodoutofthedetentslot(Figure

12).

3.Lowerthebeduntilitlatchessecurely.

g034021

18

Page 19

OpeningtheTailgate

ClosingtheTailgate

1.Ensurethatthecargobedisdownandlatched.

2.Usingbothhands,raisethetailgateusingthe

ridgenearthetopofthetailgate(Figure13).

3.Lowerthetailgateuntilitisushwiththebottom

ofthecargobed(Figure13).

Ifyouunloadedloosematerialsuchassand,

landscapingrock,orwoodchipsfromthecargobedof

themachine,someofthematerialthatyouunloaded

mayhavelodgedinthehingeareaofthetailgate.

Performthefollowingstepsbeforeclosingthetailgate.

1.Useyourhandstoremoveasmuchofthe

materialfromthehingeareaaspossible.

2.Rotatethetailgatetoapproximatelythe45°

position(Figure14).

g034023

Figure14

Figure13

1.Rotatethetailgateback

andforthseveraltimes.

2.Rotatethetailgateto

g034022

approximatelythe45°

position.

3.Hingearea

3.Useashort,shakingmotiontorotatethetailgate

backandforthseveraltimes(Figure14).

Note:Thisactionhelpsmovematerialaway

fromthehingearea.

4.Lowerthetailgateandcheckformaterial

remaininginthehingearea.

5.Repeatsteps1through4untilthematerialis

removedfromthehingearea.

6.Rotatethetailgateupandliftthetailgateintothe

notchesinthecargobed.

19

Page 20

UsingtheRearCargoBed

PerformingDaily

AccessoryMount

Usetherearcargobedaccessorymounttoattach

accessoriestotherearofthemachine.

Capacity:45kg(100lb)

1.Loosenthe“T”handlebyrotatingitclockwise

(Figure15).

Figure15

1.Receiver

2.Insertyouraccessoryintothereceiveruntilthe

holesalign(Figure15).

3.Securetheassembledaccessorytothereceiver

tubeusingtheclevispinandhairpincotter

suppliedwiththeaccessory .

2.“T”handle

Maintenance

Beforestartingthemachineeachday,perform

theEachUse/DailyprocedureslistedinDaily

MaintenanceChecklist(page27).

CheckingtheTirePressure

ServiceInterval:Beforeeachuseordaily

Frontandreartiresairpressurespecication:165

to207kPa(24to30psi)

Important:Donotexceedthemaximumair

pressureindicatedonthesidewallofthetire.

Note:Theairpressureneededinthetiresis

determinedbythepayloadthatyouintendtocarry.

1.Checktheairpressureinthetires.

g034545

•Uselowerairpressureinthetiresforlighter

payloads,forlesssoilcompaction,fora

smootherride,andtominimizetiremarkson

theground.

•Usehigherairpressureinthetiresfor

carryingheavierpayloadsathigherspeeds.

2.Ifnecessary ,adjusttheairpressureinthetires

byaddingorremovingairinthetires.

4.Tightenthe“T”handlebyrotatingit

counterclockwise(Figure16).

Figure16

1.“T”handle

g001055

Figure17

g034546

20

Page 21

UnderstandingandUsing theBatterySystem

UnderstandingDeep-Cycle Batteries

Themachinecontains8deep-cycle,lead-acid

batteriesthatsupplypowertothemotorand

accessories.Adeep-cyclebatteryisnotthesame

asanautomobilebattery .Anautomobilebattery

isdesignedtoprovideasurgeofpowertostart

themachineandmoderatepowertorunthelights

andaccessorieswhenthemotorifofforidling.

Thealternatorthencontinuouslychargesasthe

automobileruns.Assuch,anautomobilebattery

seldomdropsbelow90%ofthemaximumcharge

level.

Adeep-cyclebatteryisdesignedtobeaprimarypower

sourcetoprovideasustainedoutput.Deep-cycle

batteriesaretypicallydischargedaslowas20to30%

ofthemaximumchargelevel.Adischargethislowis

consideredadeepdischarge.

Important:Repeateddeep-dischargecycles

reducesthebatterylife.

Lead-acidbatteriesproduceelectricitythrougha

chemicalreactionbetweenleadplatesandsulfuric

acid.Chargingabatteryreversesthechemical

reaction,allowingthebatterytoonceagainproduce

electricity.

Abatteryisaperishableitemthathasalimited

lifetime(Figure18).Whenabatteryisnew,itrequires

abreak-inperiodtoestablishefcientelectrical

production.Thisbreakinperiodusuallyrequires100

to150discharge/chargecycles.

Afterthebreak-inperiod,thebatterymaintainsahigh

capacityformanycycles.Thenumberofcyclesthata

batteryperformsdependsonthefollowing:

•Batterymaintenance—impropermaintenance

severelyreducesthelifeofthebatteries.

•Depthofdischargebetweenchargecycles—the

deeperthebatteriesaredischargedona

regularbasisbetweencharges,theshorterthe

servicelifethebatterieswillhave.

•Chargefrequency—fullychargethebatteries

wheneverpossible.

Important:Fullydischargingthebatteries

damagesthemandreducestheirlife.

•Lowwaterlevels—iftheleadplatesbecome

exposed,itmaypermanentlydamagethe

batteries.Performthefollowingtomaintainthe

electrolytelevel:

Afterfullychargingthebatteries,llthe

batterieswithdistilledordeionizedwater;referto

CheckingtheWaterLeveloftheBatteries(page

38)andAddingDistilledorDeionizedWatertothe

Batteries(page38).

Important:Fullychargethebatteriesbefore

addingthewatertothebatteries.While

charging,theelectrolyteincreasesinvolume,

andllingalowbatterybeforefullycharging

thebatteriescancausetheelectrolyteto

overowandleakoutofthevent.

Attheendofthebatterylife,thebatteriesgradually

loseelectriccapacity.

Figure18

Battery-LifetimeT able

1.Batterycapacity

2.Discharge/chargecycles5.Endofthebatterylife

3.Break-inperiod(100to

150cycles)

4.Primebatterylife

g004049

21

Page 22

UsingtheBatterySystem

Whenyourbatteriesarefullycharged,thetenth

bar(farright)illuminatesonthebattery-discharge

indicator(Figure19).

Figure19

Ifyoucontinuetousethemachinewithonly2bars

remaining,bars1and2alternatelyash.

Important:Whenonlythesecondbarfromthe

leftremainsonthebattery-dischargeindicator,

themachinemayenterareduced-speedmode;

thismodeaidsinprotectingthebatteries,but

prolongedoperationinthismodecandamage

thebatteriesand/orthemachine.Avoiddraining

yourbatteriesdowntothesecondbarfromthe

lefttopreventthisissue.Chargethebatteries

immediately.

Ifthebatteriesbecomefullydischarged,the

machineshutsdown.Donotallowthebatteriesto

becomefullydischarged.

Important:Toobtainmaximumbatterylife,

alwayschargethebatteriesbeforethecharge

reachesthesecondbarfromtheleftonthe

screen.Regularlydepletingthebatteriestolower

thanthesecondbarfromtheleftreducesthelife

g192308

ofthebatteries.

1.Battery-discharge

indicator

2.Charge-indicatorbars

Asyouusethemachine,thebarsdisappearasthe

electricalcapacityofthebatteriesisused.

Whenonlythesecondbarfromtheleftremainson

thebattery-dischargeindicator,itisagoodtimeto

charge(Figure20).

Figure20

1.The2leftbarsalternatelyblinkuntilyouchargethe

batteries.

g192309

22

Page 23

StoppingtheMachine

LoadingtheCargoBed

Important:Whenstoppingthemachineon

anincline,usetheservicebrakestostopthe

machineandengagetheparkingbraketoholdthe

machineinplace.Usingtheacceleratortostall

themachineonthehillcanoverheatthemotoror

drainthebatteries.

1.Removeyourfootfromtheacceleratorpedal.

2.Slowlypressthebrakepedaltoapplytheservice

brakesuntilthemachinecomestoacomplete

stop.

Note:Thestoppingdistancemayvary

dependingonthemachineloadandspeed.

BreakinginaNewMachine

ServiceInterval:Aftertherst100hours—Perform

thebreakinginanewmachine

guidelines.

Performthebreakinginanewmachineguidelines

toprovideproperperformanceandlonglifeforthe

machine.

•Checkthebrakeuidandthewaterlevelinthe

batteriesregularly.

•Avoidhardbrakingsituationsfortherstseveral

hoursofnewmachinebreak-inoperation.New

brakeliningsmaynotbeatoptimumperformance

untilseveralhoursofusehascausedthebrakes

tobecomeburnished(broken-in).

•RefertoMaintenance(page26)foranyspecial

lowhourchecks.

•Checkthefrontsuspensionpositioningandadjust

itifnecessary.

Usethefollowingguidelineswhenloadingthecargo

bedandoperatingthemachine:

•Observetheweightcapacityofthemachineand

limittheweightoftheloadthatyoucarryinthe

cargobedasdescribedinSpecications(page

16)andonthegrossvehicleweighttagofthe

machine.

Note:Theloadratingisspeciedformachine

operationonalevelsurfaceonly.

•Reducetheweightoftheloadthatyoucarryinthe

cargobedwhenoperatingthemachineonhills

androughterrain.

•Reducetheweightoftheloadthatyoucarrywhen

thematerialsaretall(andhaveahighcenterof

gravity),suchasastackofbricks,landscaping

timbers,orfertilizerbags.Distributetheloadas

lowaspossibletoensurethattheloaddoesnot

reduceyourabilitytoseebehindthemachine

whenoperatingit.

•Keeploadscenteredbyloadingthecargobedas

follows:

–Evenlypositiontheweightinthecargobed

fromsidetoside.

Important:Tippingoverismorelikelyto

occurifthecargobedisloadedto1side.

–Evenlypositiontheweightinthecargobed

fromfronttoback.

Important:Lossofsteeringcontrolorthe

machinemaytipoverifyoupositionthe

loadbehindtherearaxleandthetraction

onthefronttiresisreduced.

•Useextracautionwhentransportingoversized

loadsinthecargobed,particularlywhenyou

cannotcenterthewightoftheoversizeloadtothe

cargobed.

•Wheneverpossible,securetheloadbybindingit

tothecargobedsothatitdoesnotshift.

•Whentransportingliquidinalargetank(such

asasprayertank),usecautionwhendriving

themachineuphillordownhill,whensuddenly

changingspeedorstopping,orwhendrivingover

toughsurfaces.

Thecapacityofthecargobedis0.28m

Theamount(volume)ofmaterialthatyoucanplace

inthebedwithoutexceedingtheloadratingsofthe

machinecanvarygreatlydependingonthedensity

ofthematerial.

23

3

(10ft3).

Page 24

Refertothefollowingtableforloadvolumelimitswith

variousmaterials:

MaterialDensity

Gravel,dry1522kg/m

Gravel,wet1922kg/m

Sand,dry1442kg/m

Sand,wet1922kg/m

Wood

Bark

Earth,packed

721kg/m

3

(95

3

lb/ft

)

3

(120

3

lb/ft

)

3

(90

3

lb/ft

)

3

(120

3

lb/ft

)

3

(45lb/ft

<721kg/m

1602kg/m

3

(<45

3

lb/ft

)

3

(100

3

lb/ft

)

MaximumCargo

BedCapacity

(onlevelground)

Full

3/4Full

Full

3/4full

3

)

Full

Full

3/4Full

(approximately)

TransportingtheMachine

Useatrailerwithfull-widthrampstomovethe

machinealongdistance.Ensurethatyousecurethe

machinetothetrailer.RefertoFigure21andFigure

22forthetie-downlocationsonthemachine.

g034029

Figure21

1.Towingtongueandtie-downpoint(frontofthemachine)

Note:Loadthemachineonthetrailerwiththefront

ofthemachinefacingforward.Ifthatisnotpossible,

securethemachinehoodtotheframewithastrap,

orremovethehoodandtransportandsecureit

separatelyorthehoodmayblowoffduringtransport.

CAUTION

Looseseatsmayfalloffthemachineand

trailerwhentransportingthemachine,and

theseatsmaylandonanothermachineor

obstructtheroadway.

Removetheseatsormakesurethattheseats

aresecurelyfastenedtothecouplinginthe

seatshroud.

g034273

Figure22

1.Reartie-downpoints

24

Page 25

TowingtheMachine

TowingaTrailer

Incaseofanemergency,youcantowthemachine

forashortdistance;however,thisshouldnotbea

standardoperatingprocedure.

WARNING

Towingatexcessivespeedscouldcausea

lossofsteeringcontrol,resultinginpersonal

injury.

Nevertowthemachineatfasterthan8km/h

(5mph).

Towingthemachineisa2-personjob.Ifyoumust

movethemachineaconsiderabledistance,transport

itonatruckortrailer;refertoT owingaTrailer(page

25).

1.Shutoffthemachineandremovethekey.

Important:Ifyoutowthemachinewiththe

keyintheONposition,theelectricalsystem

maybedamaged.

2.Afxatowlinetothetongueatthefrontofthe

machine’sframe(Figure21).

3.Disengagetheparkingbrake.

Themachineiscapableofpullingtrailers.2typesof

towhitchesareavailableforthemachine,depending

onyourapplication.ContactyourAuthorizedT oro

Distributorfordetails.

Whenhaulingcargoortowingatrailer,donot

overloadyourmachineortrailer.Overloadingeither

themachineorthetrailercancausepoorperformance

ordamagetothebrakes,axle,motor,transaxle,

steering,suspension,bodystructure,ortires.

Alwaysloadatrailerwith60%ofthecargoweightin

thefrontofthetrailer.Thisplacesapproximately10%

ofthegrosstrailerweight(GTW)onthetowhitchof

themachine.

Themaximumcargoloadshouldnotexceed454kg

(1,000lb),includingtheGTW.Forexample,ifthe

GTWis181.5kg(400lb)thenthemaximumcargo

loadis544kg(1,200lb)includingoperator(s).

Toprovideadequatebrakingandtraction,alwaysload

thecargobedwhenusingatrailer.Donotexceed

theGTWorGVWlimits.

Avoidparkingamachinewithatraileronahill.Ifyou

mustparkonahill,engagetheparkingbrakeand

blockthetiresofthetrailer.

25

Page 26

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

Note:Downloadacopyoftheelectricalschematicbyvisitingwww.T oro.comandsearchingforyourmachine

fromtheManualslink.

WARNING

Failuretoproperlymaintainthemachinecouldresultinprematurefailureofmachinesystems

causingpossibleharmtoyouorbystanders.

Keepthemachinewellmaintainedandingoodworkingorderasindicatedintheseinstructions.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst100hours

Beforeeachuseordaily

Every25hours

Every100hours

Every300hours

Every400hours

Every800hours

Every1,000hours

MaintenanceProcedure

•Performthebreakinginanewmachineguidelines.

•Checkthetirepressure.

•Chargethebatteries.

•Checkthewaterlevelofthebatteries.

•Checkthebrake-uidlevel.

•Cleanthebatteries.

•Checkthewaterlevelofthebatteriesandadddistilledordeionizedwatertothe

batteries(ifnecessary).

•Greasethebearingsandbushings.

•Checktheconditionofthetiresandrims.

•Torquethewheel-lugnuts.

•Checkthefrontwheelcamberandtoe-in.

•Checkthetransaxle-uidlevel.

•Checkthetransaxleforleaks.

•Inspectthebrakes.

•Greasethefrontwheelbearings.

•Replacetheserviceandparking-brakepads.

•Changethetransaxleuid.

•Changethebrakeuid.

26

Page 27

DailyMaintenanceChecklist

Duplicatethispageforroutineuse.

Fortheweekof: MaintenanceCheckItem

Checkbrakeandparking

brakeoperation.

Checkgearshift/neutral

operation.

Checkthewaterlevelof

thebatteries.

Checkbrake-uidlevel.

Checkunusualoperating

noises.

Checktirepressure.

Checkuidleaks.

Checkinstrument

operation.

Checkaccelerator

operation.

Lubricateallgrease

ttings.

Touchupanydamaged

paint.

MondayTuesdayWednesdayThursdayFriday

SaturdaySunday

MaintainingtheMachineunderSpecialOperating Conditions

Important:Ifthemachineissubjectedtoanyoftheconditionslistedbelow,performmaintenance

twiceasfrequently:

•Desertoperation

•Coldclimateoperation—below10°C(50°F)

•Trailertowing

•Frequentoperationindustyconditions

•Constructionwork

•Afterextendedoperationinmud,sand,water,orsimilardirtyconditions,haveyourbrakesinspectedand

cleanedassoonaspossible.Thispreventsanyabrasivematerialfromcausingexcessivewear.

27

Page 28

Pre-Maintenance

Procedures

WARNING

Raisethecargobedbeforeperforming

maintenance.Araisedcargobedcanfalland

injurepersonsthatareunderneathit.

•Alwaysusetheproprodtoholdthecargo

bedupbeforeworkingunderneathit.

•Removeanyloadmaterialfromthecargo

bedbeforeworkingunderneathit.

MaintenanceSafety

•Donotallowuntrainedpersonneltoservicethe

machine.

•Beforeservicingormakinganyadjustmentstothe

machine,parkthemachineonalevelsurface,

engagetheparkingbrake,shutoffthemotor,and

removethekeytopreventaccidentalstartingof

themachine.

•Usejackstandstosupportthemachineor

componentswhenrequired.

•Donotworkunderaraisedbedwithouttheproper

bedsafetysupportinplace.

•Ensurethatallhydraulic-lineconnectorsaretight

andthatallthehydraulichosesandlinesarein

goodconditionbeforeapplyingpressuretothe

system.

•Beforedisconnectingorperforminganyworkon

thehydraulicsystem,relieveallpressureinthe

systembyshuttingoffthemotor,cyclingthedump

valvefromraisetolower,and/orloweringthecargo

bedandattachments.Placetheremotehydraulics

leverintheoatposition.Ifthebedmustbein

raisedposition,secureitwiththesafetysupport.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

•Toensurethattheentiremachineisingood

condition,keepallthenuts,bolts,andscrews

properlytightened.

•Toreducethepotentialrehazard,keepthemotor

areafreeofexcessivegrease,grass,leaves,and

accumulationofdirt.

•Ifpossible,donotperformmaintenancewhilethe

motorisrunning.Keepawayfrommovingparts.

•Ifyoumustrunthemotortoperformamaintenance

adjustment,keepyourhands,feet,clothing,and

anypartsofthebodyawayfromthemotorand

anymovingparts.Keepbystandersawayfrom

themachine.

•Checktheparkingbrakeoperationfrequently.

Adjustandserviceasrequired.

•Keepallpartsingoodworkingconditionandall

hardwaretightened.Replaceallwornordamaged

decals.

•Neverinterferewiththeintendedfunctionofa

safetydeviceorreducetheprotectionprovided

byasafetydevice.Checktheirproperoperation

regularly.

•Ifmajorrepairsareevernecessaryorassistance

isrequired,contactanauthorizedT orodistributor.

•Toensureoptimumperformanceandsafety,

alwayspurchasegenuineTororeplacement

partsandaccessories.Replacementpartsand

accessoriesmadebyothermanufacturerscould

bedangerous.Alteringthismachineinany

mannermayaffecttheoperationofthemachine,

performance,durability,oritsusemayresultin

injuryordeath.Suchusecouldvoidtheproduct

warrantyofTheToro®Company.

PreparingtheMachineforMaintenance

1.Parkthemachineonalevelsurface.

2.Engagetheparkingbrake.

3.Shutofftheengineandremovethekey .

g038447

Figure23

28

Page 29

LiftingtheMachine

DANGER

Themachinemaybeunstablewhenusing

ajack.Themachinecouldslipoffthejack,

injuringanyonebeneathit.

•Donotstartthemachinewhilethemachine

isonajack.

•Alwaysremovethekeyfromthekeyswitch

beforegettingoffthemachine.

•Blockthetireswhenthemachineis

supportedbyliftingequipment.

•Usejackstandstosupportthemachine

onceyouhaveliftedit.

Important:Wheneveryourunthemachinefor

routinemaintenanceand/ordiagnostics,ensure

thattherearwheelsofthemachineare25mm(1

inch)offtheground,withtherearaxlesupported

onjackstands.

g034407

Figure25

1.Rearliftingpoints

•Theliftingpointatthefrontofthemachineis

locatedatthefrontoftheframe,behindthetowing

tongue(Figure24).

Figure24

1.Frontliftingpoint

•Theliftingpointattherearofthemachineis

locatedundertheaxletubes(Figure25).

g034043

29

Page 30

AccessingtheHood

RaisingtheHood

1.Liftupthehandleoftherubberlatchesoneach

sideofthehood(Figure26).

Figure26

RaisingandLoweringthe SeatAssembly

Toraisetheseatassembly,pushtheseatassembly

forwarduntilitrestsonthesteeringwheel(Figure27).

Tolowertheseatassembly,pushtheseatassembly

rearwarduntilitseatsbackintotheoriginalposition

(Figure27).

g008402

2.Raisethehood.

ClosingtheHood

1.Gentlylowerthehood.

2.Securethehoodbyaligningtherubberlatches

ontothelatchanchorsoneachsideofthehood

(Figure26).

g190066

Figure27

30

Page 31

RemovingtheSeat Assembly

Lubrication

1.Pushtheseatassemblyforwardtotheraised

position(Figure27).

2.Slidetheseatassemblytothesideoutofthe

pins,andlifttheseatassemblyupward(Figure

28).

Figure28

1.Pins

GreasingtheMachine

ServiceInterval:Every100hours/Yearly(whichever

comesrst)—Greasethebearings

andbushings.Greasethemachine

morefrequentlywhenusingitfor

heavy-dutyoperations.

GreaseType:No.2lithiumgrease

1.Usearagtowipethegreasettingcleansothat

foreignmattercannotbeforcedintothebearing

orbushing.

2.Withagreasegun,apply1or2pumpsofgrease

intothegreasettingsonthemachine.

3.Wipetheexcessgreaseoffthemachine.

Thegreasettingsarelocatedattheinnerendofthe

controlarms,thetie-rodballjoint,andtheouterend

ofthecontrolarms(Figure30andFigure31).

g190187

InstallingtheSeat Assembly

Slidetheseatassemblyontothepinsandlowerthe

seatassembly(Figure29).

Figure29

1.Pins

g034057

Figure30

g034058

Figure31

g190186

31

Page 32

GreasingtheFrontWheel Bearings

ServiceInterval:Every300hours

Greasespecication:MobilgreaseXHP™-222

RemovingtheHubandRotor

1.Liftthefrontofthemachineandsupportitwith

jackstands.

2.Removethe4lugnutsthatsecurethewheel

tothehub(Figure32).

g033047

Figure33

Figure32

1.Hub3.Lugnut

2.Wheel

3.Removetheange-headbolts(3/8x3/4inch)

thatsecurethebracketforthebrakeassembly

tothespindleandseparatethebrakefromthe

spindle(Figure33).

Note:Supportthebrakeassemblybefore

proceedingtothenextstep.

1.Flange-headbolts(3/8x

3/4inch)

2.Spindle

3.Caliperbracket(brake

assembly)

4.Removethedustcapfromthehub(Figure34).

g033046

g192346

Figure34

1.Cotterpin4.Spindlenut

2.Spindle

3.Tabwasher6.Dustcap

5.Nutretainer

5.Removethecotterpinandnutretainerfromthe

spindleandspindlenut(Figure34).

6.Removethespindlenutfromthespindle,and

separatethehubandrotorassemblyfromthe

spindle(Figure34andFigure35).

32

Page 33

Figure35

GreasingtheWheelBearings

1.Removetheoutboardbearingandbearingrace

fromthehub(Figure36).

g192347

1.Spindle

2.Hubandrotorassembly

7.Wipecleanthespindlewitharag.

8.Repeatsteps1through7tothehubandrotorat

theothersideofthemachine.

Figure36

1.Seal4.Bearingcavity(hub)

2.Inboardbearing

3.Inboard-bearingrace

5.Outboard-bearingrace

6.Outboardbearing

2.Removetheseal,inboardbearingfromthehub

(Figure36).

3.Wipecleanthesealandcheckforwearand

damage.

Note:Donotusecleaningsolventtocleanthe

seal.Replacethesealifitiswornordamaged.

4.Cleanthebearingsandraces,andcheckthese

partsforwearanddamage.

Note:Replaceallwornordamagedparts.

Ensurethatthebearingsandracesareclean

anddry.

5.Cleanthecavityofthehubofallgrease,dirt,

anddebris(Figure36).

g033050

6.Packthebearingswiththespeciedgrease.

7.Fillthecavityofhub50to80%fullofthe

speciedgrease(Figure36).

8.Assembletheinboardbearingontotheraceat

theinboardsideofthehubandinstalltheseal

(Figure36).

9.Repeatsteps1through8tothebearingsforthe

otherhub.

33

Page 34

InstallingtheHubandRotor

1.Applyalightcoatofthespeciedgreasetothe

spindle(Figure37).

Figure37

1.Nutretainer

2.Spindlenut

3.Tabwasher

2.Assemblethehubandrotorontothespindle

withtherotorinboard(Figure37).

3.Assembletheoutboardbearingontothespindle

andseatthebearingtotheoutboardrace

(Figure37).

4.Assemblethetabwasherontothespindle

(Figure37).

5.Threadthespindlenutontothespindleand

tightenthenutwhilerotatingthehub(Figure37).

Note:Tightenthenutandrotatethespindle

untilthebearingsarefullyseatedandthehub

hasnolinear-endmovement.

6.Loosenthespindlenutuntilthehubrotates

freely.

7.Torquethespindlenutto170N∙cm(15in-lb)

whilerotatingthehub.

8.Installtheretaineroverthenutandcheckthe

alignmentoftheslotintheretainerandthehole

inthespindleforthecotterpin(Figure38).

Note:Iftheslotintheretainerandtheholein

thespindlearenotaligned,tightenthespindle

nuttoaligntheslotandholetoamaximum

torqueof226N∙cm(20in-lb)onthenut.

4.Outerbearing

5.Hub,rotor,innerbearing,

race,andseal

6.Spindle

g192345

g192344

1.Cotterpin

2.Nutretainer

Figure38

3.Dustcap

9.Installthecotterpinandbendeachlegsaround

theretainer(Figure38).

10.Installthedustcapontothehub(Figure38).

11.Repeatsteps1through10forthehubandrotor

attheothersideofthemachine.

InstallingtheBrakesandWheels

1.Cleanthe2ange-headbolts(3/8x3/4inch)

andapplyacoatofanti-seizecompoundtothe

threadsofthebolts.

2.Alignthebrakepadstoeithersideoftherotor

(Figure33)andtheholesinthecaliperbracket

withtheholesinthebrakemountofthespindle

frame(Figure36).

3.Assemblethecaliperbrackettothespindle

frame(Figure33)withthe2ange-headbolts

(3/8x3/4inch),andtorquetheboltsto47to54

N∙m(35to40ft-lb).

4.Aligntheholesinthewheeltothestudsofthe

hubandassemblethewheeltothehubwiththe

valvestemoutward(Figure32).

Note:Ensurethatthemountingsurfaceofthe

wheelisushwiththehub.

5.Securethewheeltothehubwiththelugnuts

(Figure32),andtorquethenutsto108to122

N∙m(80to90ft-lb).

6.Repeatsteps1through5forthebrakeand

wheelattheothersideofthemachine.

34

Page 35

ElectricalSystem

–Donotuseanopenametocheckthelevelor

leakageofbatteryelectrolyte.

Maintenance

ElectricalSystemSafety

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandlead

compounds,chemicalsknownto

theStateofCaliforniatocause

cancerandreproductiveharm.Wash

handsafterhandling.

•Disconnectthebatterybeforerepairingthe

machine.Disconnectthenegativeterminalrst

andthepositivelast.Connectthepositiveterminal

rstandthenegativelast.

•Chargethebatteryinanopen,well-ventilated

area,awayfromsparksandames.Unplugthe

chargerbeforeconnectingordisconnectingthe

battery.Wearprotectiveclothinganduseinsulated

tools.

–Wearpropereye,hand,andfaceprotection.

–Donotleanoverthebatteriesatanytime.

–Avoidbreathinginbatteryfumes.

–Fillthebatterieswherecleanwaterisalways

availableforushingtheskin.

–Ifyougetelectrolyteonyourskinoreyes,

ushtheaffectedareafor20minuteswith

cleanwater.Removeaffectedclothing.Seek

medicalattentionimmediately .

–Keepchildrenandpetsawayfromthebatteries

andelectrolyte.

•Electrolyteispoisonous.

–Donotdrinktheelectrolyte.

–Ifelectrolytehasbeenswallowed,havethem

drinklargequantitiesofwaterimmediatelyto

dilutetheelectrolyte,ifpossible.

–Donotattempttomakethemvomit.

–Callapoisoncontrolcenterandgetmedical

attentionimmediately.

•Whennotllingthebatteries,keepthebattery

ventcapstightonthebatteries.Donotoperate

themachineifanyoftheventcapsaremissingor

damaged.

BatterySafety

•Toreducethepotentialforre,keepthebatteries

andmotorareafreeofexcessivegrease,grass,

leaves,andaccumulationofdirt.

•Removealljewelryandwatchesbeforeservicing

thebatteries.

•Donotchargethebatterieswhileservicingthe

machine.

•Alwaysdisconnectallthebatterycablesbefore

servicinganyelectricalcomponents;referto

DisconnectingtheBatteries(page39).

Note:Disconnectingallthebatterycables

isolatespowerfromtheelectricalsystem.

•Batteryelectrolytecontainssulfuricacid,which

produceshydrogen,agasthatisexplosivein

certainconditions.Sulfuricacidcanburnskinand

damageclothing;whenemittedingasform,itcan

damageyourlungs.

–Alwaysservice,store,andchargethemachine

inawell-ventilatedarea.

–Keepsparksandopenamesawayfromthe

batteries.

–Donotsmokenearthebatteries.

•Whenremovingorinstallingthebatteries,donot

allowthebatteryterminalstotouchanymetal

partsofthemachine.

•Donotallowmetaltoolstoshortbetweenthe

batteryterminalsandmetalpartsofthemachine.

•Donotcheckabatterychargebyplacingametal

objectacrosstheposts.Thiscausessparks,

whichcancauseanexplosion.

•Alwayskeepthebatteryretainersinplaceto

protectandsecurethebatteries.

•Readandunderstandthecharginginstructions

beforechargingthebatteries;refertoCharging

theBatteries(page36).Also,takethefollowing

precautionswhenchargingthebatteries:

–TurnthemachinekeyswitchtoOFFbefore

connectingthechargertoapowersource.

–Useonlythebatterychargersuppliedwiththe

machinetochargethebatteries.

–Donotchargeadamagedorfrozenbattery.

–AlwaysunplugtheACpowercordfromthe

poweroutletbeforeunpluggingitfromthe

machinechargingreceptacletoavoidsparks.

–Ifabatterygetshotwhilecharging,begins

emittinglargeamountsofgasses,orspews

35

Page 36

electrolyte,immediatelydisconnectthecharger

powercordfromthepoweroutlet.Have

themachineservicedbyanauthorizedToro

distributorbeforeusingitagain.

MaintainingtheBatteries

Raisetheseatassemblyandraisethecargobed

beforemaintainingthebatteries;refertoRaisingand

LoweringtheSeatAssembly(page30)andRaising

theCargoBedtotheDumpPosition(page17).

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandlead

compounds,chemicalsknownto

theStateofCaliforniatocause

cancerandreproductiveharm.Wash

handsafterhandling.

WARNING

Batteryterminalsormetaltoolscouldshort

againstmetalcomponentscausingsparks.

Sparkscancausethebatterygasesto

explode,resultinginpersonalinjury.

•Whenremovingorinstallingthebattery,

donotallowthebatteryterminalstotouch

anymetalpartsofthemachine.

CleaningtheBatteries

ServiceInterval:Every25hours

1.Ensurethatallthebatterycapsaretight.

2.Useapapertoweltocleanthebatteries.

3.Ifthebatteryterminalsarecorroded,cleanthem

withasolutionof4partswaterand1partbaking

soda.Also,cleanthepostsandcableclamps

withapostandclampcleaner.

Note:Thepostsandclampsshouldhavea

bright,metallicshine.

4.ApplyalightcoatingofT orobattery-terminal

protector.

ChargingtheBatteries

ServiceInterval:Beforeeachuseordaily

Thechargerforthismachineislocatedinsidethe

machineundertheoperator’sseat.Formaximum

batterylife,chargethebatterieswheneveryouarenot

usingthemachine.Dependingonhowdischarged

thebatteriesareandtheambienttemperatureofthe

batteries,itmaytakeupto16hourstochargethe

batteriestofullcapacity.

Note:Normalchargetimeisapproximately8to10

hours.

Important:Lead-acidbatteriesdonotdevelop

achargememoryanddonotneedtobe

fullydischargedbeforechargingthem.Fully

dischargingthebatteriesmaydamagethem.

Chargethebatteriesanytimethemachineisnot

inuse.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsofthe

machine.

•Useinsulatedtoolswhenmaintainingthe

batteries.

•Alwayskeepthebatteryretainersinplace

toprotectandsecurethebatteries.

DANGER

Donottouchanyelectricalcomponentsor

contactsonthemotor.

Touchinganyofthesecomponentsor

contactscouldseriouslyinjureyouorcause

death.

WARNING

Chargingthebatteryproducesgasesthatcan

explode.

Neversmokenearthebatteriesandkeep

sparksandamesawayfromthem.

1.Positionthemachineinawell-ventilatedarea

nearasuitablepoweroutlet.

2.Checktheelectrolytelevelofthebatteries.

Note:Afterfullychargingthebatteries,ll

thebatterieswithdistilledordeionizedwater;

refertoAddingDistilledorDeionizedWaterto

theBatteries(page38).

Important:Fullychargethebatteries

beforeaddingthewatertothebatteries.

Whilecharging,theelectrolyteincreases

involume,andllingalowbatterybefore

fullychargingthebatteriescancausethe

electrolytetooverowandleakoutofthe

vent.

36

Page 37

3.Connecta16gauge(orlargerdiameter),

2.5m(8.2ft)orshorterchargercordtothe

chargingreceptacleonthemachine(Figure39).

RefertothefollowingtableandFigure39for

informationonthemeaningsofthevaryingcolorsof

thecharger-statuslight.

Note:Ensurethatthecharger-voltagesetting

matchesthevoltageatthepoweroutletbeing

used.

Note:Inhigh-ambienttemperature

environments,removetheseatassemblyfor

optimalchargingtime;refertoRemovingthe

SeatAssembly(page31).Ifthebatterycharger

istoohot,itmaynotchargeproperly.Incold

temperatures,itmaytakealongerforthe

batteriestocharge.

Charger-StatusLightT able

Charger-Status

LightColor

GreenSolidChargingcomplete

Green

AmberFlashingReduced-power

RedFlashing

Solid/Flashing

Flashing

Meaning

Shortash—less

than80%charge

Long

ash—greaterthan

80%charge

mode—lowAC

voltageorhigh

internalcharger

temperature;

chargeimmediately

Charger

error—resetthe

chargerpower

Ifthiserrorpersists,

refertotheblink

codesinthe

chargermanual

Figure39

1.Charger-statuslight

2.Chargingreceptacle

3.Thebatteryisnearempty.

4.Thebatteryisalmost

charged.

5.Thebatteryischarged.

6.Chargerfault;refertothe

chargermanualforthe

faultcodes.

4.Plugthechargerpowercordintothepower

outlet.

Note:Whilethebatteriesarecharging,the

greenlightonthechargerblinksonandoff.

Whenthebatteriesarefullycharged,thegreen

lightstopsblinkingandstayson.

5.Disconnectthecordfromthepoweroutlet.

6.Disconnectthechargerfromthemachine.

g034217

37

Page 38

CheckingtheWaterLevelofthe Batteries

ServiceInterval:Beforeeachuseordaily

1.Parkthemachineonalevelsurface,engagethe

parkingbrake,shutoffthemachine,removethe

key,andraisecargobed;RaisingtheCargoBed

totheDumpPosition(page17).

2.Raisetheseatassemblytoaccessthebatteries;

refertoRaisingandLoweringtheSeatAssembly

(page30).

3.Checktheeyeletsoneachofthebatteriesto

seeiftheyareeitherblackorwhite(Figure40).

Note:Blackeyeletsindicatethatthebatteries

arefullofwater.Whiteeyeletsindicatethat

waterisneededforthebatteries.

key,andraisecargobed;RaisingtheCargoBed

totheDumpPosition(page17).

2.Chargethebatteriesuntilafullchargeis

achieved;refertoChargingtheBatteries(page

36).

3.Raisetheseatassemblytoaccessthebatteries;

refertoRaisingandLoweringtheSeatAssembly

(page30).

4.ConnectyourT orowaterhandpumptothe

water-llport(Figure41).

Figure40

1.Batteryeyelet

4.Iftheeyeletsarewhite,youmustadddistilledor

deionizedwatertothebatteries;refertoAdding

DistilledorDeionizedWatertotheBatteries

(page38).

AddingDistilledorDeionized WatertotheBatteries

ServiceInterval:Every25hours/Every2weeks

(whichevercomesrst)

Important:Fullychargethebatteriesbefore

addingthewatertothebatteries.Whilecharging,

theelectrolyteincreasesinvolume,andllinga

lowbatterybeforefullychargingthebatteriescan

causetheelectrolytetooverowandleakoutof

thevent.

Important:Useonlyclean,distilledordeionized

watertollthebatteries.Usingtapwatermay

damageandreducethelifeofthebatteries.

1.Parkthemachineonalevelsurface,engagethe

parkingbrake,shutoffthemachine,removethe

g034218

Figure41

1.Water-llport

2.Hand-pumpconnector

5.Pumpwaterintothewaterintobatteriesuntilall

oftheeyeletsontopofthebatteriesareblack,

indicatingthattheyarelledwithwater.

3.Waterhandpump

g034255

Important:Donotoverllthebattery.

Electrolytewilloverowontootherparts

ofthemachineandseverecorrosionand

deteriorationmayresult.Also,overllingthe

batterymayreducethelifeofthebattery.

ChangingtheBatteries

Whenthemachinebeginstoloseoperatingrange

orwhenthelengthoftimetodischargeorcharge

thebatteryissignicantlyreduced,thebatteriesare

probablywearingandlosingtheirabilitytoholda

charge.T akethemachinetoanAuthorizedService

Dealerandhavethemtestthebatteriestodetermine

whetherthebatteriesneedtobereplaced.Thedealer

canthenreplacethebatteriesforyou.Ifyouwish

toreplacethebatteriesyourself,usethefollowing

procedures:

38

Page 39

DisconnectingtheBatteries

ConnectingtheBatteries

1.Raisethecargobed,turnthekeyswitchtothe

OFFposition,andremovethekey.

2.Disconnectthemainnegative-batterycable

(black)thatconnectsthebankofbatteriestothe

groundpointofthemachine(Figure42).

Note:Themainbatterycablesarelongwhen

comparedtobattery-interconnectcables.

1.Ensurethatthebatteryterminalsarecleanand

freeofoxidation.

2.Connectthemainpositive-batterycable(red)

betweenthebankofbatteriesandthemachine

(Figure42).

3.Connectthemainnegative-batterycable(black)

betweenthebankofbatteriesandthemachine

(Figure42).

4.T orquethenutssecuringallofthebatterycables

untiltheretainersecurelygripsthebattery.

5.CoatthebatteryterminalswithT oro

battery-terminalprotector.

6.Ensurethattherubberbootsoneachbattery

cablearesecurelyseatedoverthebattery

terminals.

7.Insertthekeyintothekeyswitchandrotatethe

switchtotheONposition.

8.Lowerthecargobed,rotatethekeyswitchto

theOFFposition,andremovethekey.

Figure42

3.Disconnectthemainpositive-batterycable(red)

thatconnectsthebankofbatteriestothemain

contactorofthemachine(Figure42).

ReplacingtheBatteries

1.Removeallofthebattery-interconnectcables

fromthebatteries.

2.Removethebatteryretainerslocatedbetween

thebatteries.

3.Removeallofthebatteriesandrecyclethem

accordingtoyourlocalcodes.

4.Assemblenewbatteriesintothemachineatthe

locationsfromwhereyouremovedbatteriesin

step3.

Note:Payattentiontothebatterypolaritywhen

installingthenewbatteries(Figure42).

StoringtheBatteries

g034412

Chargethebatteriesfullybeforeplacingthemachine

intostorage.Plugthechargerintoawalloutletwhile

themachineandbatteriesareinstorage.Leave

thechargerpluggedintoawalloutletandcharging

receptacleduringstoragetoensurethatthebatteries

staychargedanddonotfreeze;otherwise,chargethe

batteriesatleastonceamonth.

Important:Ifthemachinecannotbeplugged

induringstorage,fullychargethebatteriesat

leastonceamonth.Thebatteriesself-discharge

overlongperiodsoftime,whichmaydamagethe

batteriestothepointofbeingunusable,evenif

thebatteriesarenew.

5.Installthebatteryretainersandtightenthenuts

untiltheretainersecurelygripsthebatteries.

6.Connectthebatteriestogetherasshownin

Figure42withthebattery-interconnectcables

thatyouremovedinstep1.

39

Page 40

ReplacingtheFuses

Thereis1fuseintheelectricalsystem;theotherslots

areopenforoptions.Theyarelocatedundertheseat

assemblybehindabatteryontherightsideofthe

machine(Figure43).

MaintainingtheHeadlights

ReplacingtheBulbs

CAUTION

Optionalliftkit—open

Mainpower10A

Horn—optional(standardon

Internationalmodelsonly)

Figure43

1.Fuseblock

15A

30A

Ifyouinstallahigherwattagebulbthanthe

systemisdesignedfor,youmaydamagethe

12Vpowersupply,orataminimum,blowthe

fuse.

AlwaysusethespeciedToroLEDbulbto

preventthisissue.

CAUTION

Thebulbsbecomeextremelyhotwhenin

operation.Handlingahotbulbcancause

severeburnsandpersonalinjury.

Alwaysallowenoughtimeforthebulbs

tocoolbeforereplacingthem.Usecare

wheneverhandlingthebulb.

Specication:SeeyourPartsCatalog.

1.Disconnectthebatteries;refertoDisconnecting

theBatteries(page39).

2.Openthehood;refertoRaisingtheHood(page

g036964

30).

3.Disconnecttheelectricalconnectorforthe

harnessfromtheconnectorofthelamp

assemblyatthebackoftheheadlighthousing

(Figure44).

Figure44

1.Headlighthousing3.Harness-electrical

2.Lampassembly

4.Rotatethelampassembly1/4turn

counterclockwiseandmovingitrearward,

outoftheheadlighthousing(Figure44).

5.Insertthenewlampassemblyandheadlight

housingandalignthetabsinthelampassembly

40

g035852

connector

Page 41

withtheslotsintheheadlighthousing(Figure

44).

6.Securelampassemblybyturningit1/4turn

clockwise(Figure44).

7.Connecttheelectricalconnectorfortheharness

totheconnectorofthenewlampassembly

(Figure44).

8.Connectthebatteriesandclosethehood;refer

toClosingtheHood(page30).

ReplacingtheHeadlight

Note:Ensuretheadjustmentpostsarelinedup

withtheholesinthemountingbracketbehind

thebumper.

7.Securetheheadlightassemblywiththespeed

clipsthatyouremovedinstep4.

8.Connecttheelectricalconnectorfortheharness

totheconnectorofthelampassembly(Figure

45).

9.Adjusttheheadlightstodirectthebeamsto

thedesiredposition,refertoAdjustingthe

Headlights(page41).

1.Disconnectthebatteries;refertoDisconnecting

theBatteries(page39).

2.Openthehood;refertoRaisingtheHood(page

30).

3.Disconnecttheelectricalconnectorforthe

harnessfromtheconnectorofthelamp

assembly(Figure45).

AdjustingtheHeadlights

Usethefollowingproceduretoadjusttheheadlight

beampositionwheneveraheadlightassemblyis

replacedorremoved.

1.TurnthekeyswitchtotheONposition,andturn

ontheheadlights.

2.Atthebackoftheheadlightassembly,rotate

adjustmentscrews(Figure45)topivotthe

headlightassemblyandalignthepositionofthe

castbeam.

3.Connectthebatteryandclosethehood;referto

ClosingtheHood(page30).

Figure45

1.Speedclip

2.Openinginthebumper

3.Adjustmentscrew6.Harness-electrical

4.Headlight

5.Lampassembly

connector

4.Removethespeedclipsthatsecurethe

headlighttotheheadlightbracket(Figure45).

Note:Retainallpartsforinstallationofthenew

headlight.

5.Removetheheadlightassemblybymovingit

forwardthroughtheopeninginthefrontbumper

(Figure45).

6.Installthenewheadlightthroughtheopeningin

thebumper(Figure45).

g035853

41

Page 42

DriveSystem

Maintenance

MaintainingtheTires

ServiceInterval:Every100hours—Checkthe

conditionofthetiresandrims.

Every100hours—Torquethewheel-lugnuts.

1.Inspectthetiresanrimsforsignsofwearand

damage.

Note:Operatingaccidents,suchashitting

curbs,candamageatireorrimandalsodisrupt

wheelalignment,soinspecttireconditionafter

anaccident.