FormNo.3395-469RevA

ProSweepTurfSweeper

ModelNo.07068—SerialNo.315000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3395-469*A

ThisproductcomplieswithallrelevantEuropeandirectives.

FordetailspleaseseetheseparateproductspecicDeclaration

ofConformity(DOC)sheet.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

ElectromagneticCompatibility

Domestic:ThisdevicecomplieswithFCCrulesPart15.

Operationissubjecttothefollowingtwoconditions:(1)This

devicemaynotcauseharmfulinterferenceand(2)thisdevice

mustacceptanyinterferencethatmaybereceived,including

interferencethatmaycauseundesirableoperation.

Thisequipmentgeneratesandusesradiofrequencyenergyand

ifnotinstalledandusedproperly,thatis,instrictaccordance

withthemanufacturer'sinstructions,maycauseinterferenceto

radioandtelevisionreception.Ithasbeentypetestedandfound

tocomplywiththelimitsforaFCCClassBcomputingdevice

inaccordancewiththespecicationsinSubpartJofPart15of

FCCRules,whicharedesignedtoprovidereasonableprotection

againstsuchinterferenceinaresidentialinstallation.However,

thereisnoguaranteethatinterferencewillnotoccurina

particularinstallation.Ifthisequipmentdoescauseinterference

toradioortelevisionreception,whichcanbedeterminedby

turningtheequipmentoffandon,theuserisencouragedto

trytocorrecttheinterferencebyoneormoreofthefollowing

measures:Reorientthereceivingantenna,relocatetheremote

controlreceiverwithrespecttotheradio/TVantennaorplug

thecontrollerintoadifferentoutletsothatthecontrollerand

radio/TVareondifferentbranchcircuits.Ifnecessary,theuser

shouldconsultthedealeroranexperiencedradio/television

technicianforadditionalsuggestions.Theusermayndthe

followingbookletpreparedbytheFederalCommunications

Commissionhelpful:"HowtoIdentifyandResolveRadio-TV

InterferenceProblems".ThisbookletisavailablefromtheU.S.

GovernmentPrintingOfce,Washington,DC20402.StockNo.

004-000-00345-4.

FCCID:OA3MRF24J40MC-BASE,

OA3MRF24J40MA-HANDHELD

IC:7693A-24J40MC-BASE,7693A-24J40MA-HANDHELD

Operationissubjecttothefollowingtwoconditions:(1)this

devicemaynotcauseinterference,and(2)thisdevicemust

acceptanyinterference,includinginterferencethatmaycause

undesiredoperationofthedevice.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready.Figure1identiesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

CAUTION

Ifausermakeschangesormodicationsnot

expresslyapprovedbythepartyresponsiblefor

compliance,theycouldvoidtheuser'sauthorityto

operatetheequipment.

Introduction

Thismachineisintendedtobeusedbyprofessional,hired

operatorsincommercialapplications.Theprimaryfunction

ofthemachineistoremovedebrisfromlargeturfareas.The

movabletongueprovidesanoffsetpositionforsweeping.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

©2015—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Figure2

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Contactusatwww.Toro.com.

2

PrintedintheUSA.

AllRightsReserved

Contents

Safety

Safety...........................................................................3

SafeOperatingPractices...........................................3

SafetyandInstructionalDecals.................................5

Setup............................................................................8

1RequirementsBeforeUsingtheV ehicle....................9

2RemovingtheHitchTongueandHydraulic

CylinderfromtheShippingPosition.......................9

3InstallingtheHitchT ongue....................................9

4InstallingtheHydraulicCylinder............................11

5InstallingthePowerWiringHarness.......................12

6MountingtheSweepertotheTowVehicle................12

7RoutingandSecuringtheHydraulicHosesand

WiringHarness..................................................13

8ConnectingtheHydraulicHoses............................13

9ConnectingtheHarness........................................14

10MountingtheWindrowBlades.............................14

11AssemblingtheHandheldRemote........................16

ProductOverview.........................................................17

Controls...............................................................17

Specications........................................................18

DimensionsandW eights.........................................18

Attachments/Accessories........................................18

Operation....................................................................19

OperatingtheSweeper............................................19

AdjustingtheBrushHeight.....................................20

AdjustingtheRollerScraper.....................................21

AdjustingtheFrontFlapHeight..............................22

CheckingtheTirePressure......................................22

CheckingtheWheelLugNutTorque.........................22

ActivatingtheController.........................................22

UsingtheControllerTimeOut.................................23

UsingtheHopperSafetySupport.............................23

CheckingtheInterlockSystem.................................23

OperatingTips.......................................................23

DumpingtheHopper.............................................24

LoweringtheHopper..............................................24

InspectingandCleaningtheMachine........................25

TransportingtheSweeper........................................25

OperatingtheMachineinColdWeather.....................25

SwitchingtheSweeper-UpMode..............................25

Maintenance.................................................................26

RecommendedMaintenanceSchedule(s)......................26

DailyMaintenanceChecklist....................................27

Lubrication............................................................28

AssociatetheRemoteControlandtheBaseUnit

........................................................................29

ReplacingtheRemoteBatteries................................29

Storage........................................................................30

Troubleshooting...........................................................31

CheckingFaultCodes.............................................31

EnteringDiagnosticModeandCheckingthe

Codes................................................................32

ResettingtheFaultCodes........................................33

ExitingDiagnosticMode.........................................33

Hazardcontrolandaccidentpreventionaredependent

upontheawareness,concern,andpropertraining

ofthepersonnelinvolvedintheoperation,transport,

maintenance,andstorageofthemachine.Improper

useormaintenanceofthemachinecanresultininjury

ordeath.T oreducethepotentialforinjuryordeath,

complywiththefollowingsafetyinstructions.

ThefollowinginstructionsarefromANSIstandard

B71.4-2012.

SafeOperatingPractices

Supervisor'sResponsibilities

•Ensuretheoperatorsarethoroughlytrainedandfamiliar

withtheOperator'sManualandalldecalsonthemachine.

•Establishyourownspecialproceduresandworkrulesfor

unusualoperatingconditions(e.g.,slopestoosteepfor

machineoperation,adverseweatherconditions,etc.).

BeforeOperating

•Read,understandandfollowtheinstructionsinthe

Operator'sManualandonthemachinebeforestarting.

Becomefamiliarwithallcontrolsandknowhowto

stopquickly.Afreereplacementmanualisavailableby

contactingT orodirectlyatwww .Toro.com.

•Neverallowchildrentooperatethemachine.Neverallow

adultstooperatethemachinewithoutproperinstruction.

Onlytrainedoperatorswhohavereadthismanualshould

operatethismachine.

•Neveroperatethemachinewhileundertheinuenceof

drugsoralcohol.

•Becomefamiliarwiththecontrolsandknowhowtostop

thetowvehicleenginequickly.

•Keepallshields,safetydevices,anddecalsinplace.

Ifashield,safetydevice,ordecalbecomesdamaged,

malfunctioning,orillegible,repairorreplaceitbefore

operationiscommenced.Alsotightenloosenutsand

boltstoensuremachineisinsafeoperatingcondition.

•Alwayswearsubstantialshoes.Donotoperatemachine

whilewearingsandals,tennisshoes,orsneakersorwhen

barefoot.Donotwearloose-ttingclothingthatcould

getcaughtinmovingpartsandpossiblycauseinjury.

Wearingsafetyglasses,safetyshoes,longpants,anda

helmetisadvisableandrequiredbysomelocalordinances

andinsuranceregulations.

•Donotalterthisequipmentinanymannerwhichmay

causehazardousconditions.

•Safetyinterlockswitchesarefortheoperatorsprotection.

Disconnectedormalfunctioningsafetyinterlockswitches

couldallowthemachinetooperateinanunsafemanner

andmaycausepersonalinjury

–Donotdisconnectthesafetyinterlockswitches.

3

–Checktheoperationoftheswitchesdailytobesure

theinterlocksystemisoperatingcorrectly.

–Ifaswitchismalfunctioning,replaceitbefore

operatingthemachine.

–Watchforholesorotherhazards.

–Usecarewhenbackingmachine.

–Donotdriveclosetoasandtrap,ditch,tallcurb,

creek,orotherhazard.

WhileOperating

•Rotatingpartscancauseseriouspersonalinjury.Keep

handsandfeetawayfromsweeperreelwhilemachineis

running.Keephands,feet,hair,andclothingawayfrom

allmovingpartstopreventinjury.Neveroperatethe

machinewithcovers,shrouds,orguardsremoved.

•Don'ttakeaninjuryrisk!Whenapersonorpet

appearsunexpectedlyinornearthesweepingarea,stop

sweeping.Carelessoperation,combinedwithterrain

angles,ricochets,ormissingordamagedguards,canlead

tothrownobjectinjuries.Donotresumesweepinguntil

areaiscleared.

•Nevercarrypassengers.

•Alwayslooktotherearofmachinebeforebackingupand

assurenooneisbehindthemachine.

•Operatormustbeskilledandtrainedinhowtodriveon

hillsides.Failuretousecautiononslopesorhillsmay

causelossofcontrol,possiblyresultinginpersonalinjury

ordeath.

•WhenusingaWorkmanasatowvehicle,itis

recommendedtoput500poundsofweightintothe

vehiclebedwhenoperatingonanyslopes.

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

•Tipovercancauseseriousinjuryordeath.

–Neveroperateonsteepslopes.

–Sweepslopesupanddown,neveracrosstheface.

–Whengoinguphillordownhill,donotstoporstart

suddenly.

–Stayalertforholesintheterrainorotherhidden

hazards.T oavoidtippingorlossofcontrol,donot

driveclosetoaditch,creek,ordropoff.

–Nevertransportthesweeperwhenthetransport

alarmisactivated.

–Nevertransportthesweeperwhenitisintheoffset

position.

–Ifenginestallsormachinelosesheadwayandcannot

makeittothetopofaslope,donotturnmachine

around.Alwaysbackslowlystraightdowntheslope.

•Usingthemachinedemandsattention.Failuretooperate

machinesafetymayresultinanaccident,tipoverofthe

machine,andpossibleseriousinjuryordeath.Drive

carefully.T opreventtippingorlossofcontrol:

–Operateonlyindaylightorwhenthereisgood

articiallight.

–Driveslowly.

–Reducespeedwhenmakingsharpturns.

–Avoidturningthesweeperonahillsideor

embankment.

–Avoidsuddenstopsandstarts.

–Donotgofromreversetoforwardorforwardto

reversewithoutrstcomingtoacompletestop.

–Donotattemptsharpturnsorabruptmaneuversor

otherunsafedrivingactionsthatmaycauselossof

control.

–Watchoutfortrafcwhennearorcrossingroads.

Alwaysyieldtheright-of-way.

WhileDumping

•Thesweepermustbeinthetransportposition(directly

behindtowvehicle)beforeactivatingdumpcycle.

•Dumpingdebriscancauseseriousinjury.Stayclearof

hopperwhilemachineisbackingupordumping.

•Underrarecircumstanceswet,compressedgrassclippings

maygenerateheat.Alwaysemptythehopperbefore

storingtheunit.

•Raisingandloweringofhopperdoorcouldcauseinjury

tobystandersorpets.Keepbystandersandpetsasafe

distancefromhopperwhenoperatingtodumpdebrisor

whenopeningandclosinghopperdoor.

•Toavoidtheriskofelectricalshock,dumphopperonlyin

areaclearofoverheadwiresandotherobstructions.

•Neverdumphopperonaslope.Alwaysdumphopper

onlevelground.

•Parkmachineonalevelsurface,emptyhopper,lower

hooperuntilrollerisonthegroundandblockwheels

beforeremovingsweeperfromtowvehicle.

Maintenance

•Hydraulicuidescapingunderpressurecanpenetrate

skinanddoseriousdamage.Keepbodyandhandsaway

frompinholeleaksornozzlesthatejecthighpressure

hydraulicuid.Usecardboardorpapertondhydraulic

leaks.Fluidaccidentallyinjectedintotheskinmustbe

surgicallyremovedwithinafewhoursbyadoctorfamiliar

withthisformofinjuryorgangrenemayresult.

•Performonlythosemaintenanceinstructionsdescribedin

thismanual.Ifmajorrepairsareeverneededorassistance

desired,contactanAuthorizedToroDistributor.

•Makesureallhydrauliclineconnectorsaretight,andall

hydraulichosesandlinesareingoodconditionbefore

applyingpressuretothesystem.

4

•Performingmaintenanceonmachinenotproperly

93-9899

supportedwithjackstandsmaycausemachinetofalland

couldcauseinjury.

•Tobesureofoptimumperformanceandsafety ,always

purchasegenuineTororeplacementpartsandaccessories.

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

Replacementpartsandaccessoriesmadebyother

manufacturerscouldbedangerous.Alteringthismachine

inanymannermayaffectthemachine'soperation,

performance,ordurability,oritsusemayresultininjury

ordeath.SuchusecouldvoidproductwarrantyofThe

ToroCompany.

108–0872

1.Crushinghazardofhand—keephandsawayfrompinch

points.

93-9899

1.Crushinghazard—installthecylinderlock.

58-6520

1.Grease

108–0868

1.Warning—keephandsandfeetoutofthesweeperbrush.

2.Tippinghazard—donotoperatewiththesweeperinthe

raisedpositiononslopesgreaterthan5degrees.

108–0870

1.Entanglementhazard,belts—stayawayfrommovingparts,

keepallguardsandshieldsinplace;donotoperatewith

coversremoved.

5

93-9852

1.Warning—readtheOperator’sManual.2.Crushinghazard—installthecylinderlock.

108–0862

1.Warning—readtheOperator'sManual,donotoperatethismachineunlessyouaretrained;keepbystandersasafedistancefrom

themachine.

2.Entanglementhazard,belts—stayawayfrommovingparts,keepallguardsandshieldsinplace;donotoperatewithcovers

removed.

108–0873

1.Thrownobjecthazard—keepbystandersasafedistance

away.

1.Warning—keepbystandersasafedistancefromthe

machinewhendumpingsweeper.

108–0865

108–0861

1.Warning—readtheOperator'sManual,donotoperatethismachineunlessyouaretrained.

2.Crushing/dismembermenthazardofbystanders—donotcarrypassengers.

3.Electricalshockhazard,overheadpowerlines—watchforoverheadpowerlines.

4.Lossofcontrolhazard—themaximumloadatthesweeperis1590kg(3500lb),atthehitchis114kg(250lb),donotdrive

downslopes.

5.Warning—keepspeedsbelow24kmh(15mph).

6.Storedenergyhazard,trailer—lowerthesweeper,placeitonblocksorjackstands,disconnectthesweeper,disconnectthe

hydraulicsandwiringharness;donotdrivethesweeperintheraisedposition.

6

108–0863

1.Crushinghazard,fallingobjecthazard—keepbystanders

andvehiclesasafedistancefromthemachinewhenthe

sweeperisraised.

110-7999

1.Warning3.Themachinemustbe

2.Tippinghazard—Whenthe

attachmentisinthesweep

positiondonotraisethe

attachmenttodump.

parkedwiththeattachment

inthetowpositionbefore

raisingthesweeperto

dump.

131-6766

1.7.5A3.Electricalaccessory—15A

2.7.5A

4.TEC-2403—2A

7

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

6

7

Nopartsrequired

Nopartsrequired

Hitchtongue1

Hitchpin1

Bolt(3/8x1-1/4inch)

Nut(3/8-16)

Largewasher1

Largenut1

Square-headsetscrew

Rear-actuatortab1

Bolt(1/2x2inch)

Flatwasher(.531x.063)

Locknut(1/2inch)

Bolt(3/8x1–1/4inch)

Pinassembly2

Flangenut(3/8inch)

Powerwiringharness1

Cabletie

Hitchpin1

Hairpincotter1

Cabletie

Qty.

Use

–

–

1

1

1

4

8

4

2

2

2

8

Requirementsbeforeusingthevehicle.

Removethetongueandhydraulic

cylinderfromtheshippingposition.

Installthehitchtongue

Installthehydrauliccylinder.

Installthepowerwiringharness.

Mountthesweepertothetowvehicle.

Routeandsecurethehydraulichoses

andwiringharness.

8

9

10

11

Nopartsrequired

Nopartsrequired

Blade-mountingassembly1

Bolt(7/16x3-3/4inch)

Bolt(7/16x3-1/4inch)

Smallwasher(1/2inch)

Largewasher1

Spacer

Locknut(7/16inch)

Chain

Bolt(3/8x1-1/4inch)

Flangenut(3/8inch)

Snaplink

Handheldremote1

Battery(AAA)

Screws,small

–

–

1

1

4

1

2

1

1

1

1

4

6

Connectthehydraulichoses.

Connecttheharness.

Mountthewindrowblades.

Assemblethehandheldremote.

8

MediaandAdditionalParts

Description

Operator'sManual

PartsCatalog

CECerticate

RemoteControl

1

RequirementsBeforeUsing theVehicle

NoPartsRequired

Procedure

•TheToroProSweepcanbetowedbymostutilitytractors

equippedwithhydraulicsproducing7to8GPM@2000

p.s.i.andotationtiresforoperationovergolfgreens.

Ensurethetractorhasadequatebrakesandadrawbar

hitchcapacitytohandlea3500lb.(1587kg.)trailer.

RefertothetowvehicleOperator'sManualfortowing

instructionsandprecautions.

•TheWorkmanvehiclemustbeequippedwiththe

High-FlowHydraulicsKit.Workmanvehicleswithserial

numberspriorto900000001,needtheHeavyDuty

Drawbar(Model44212or44213)installed.

Note:The4WDW orkmanmodelisthebestforhillyor

bermedapproachestogreens.

Important:ForoldermodelWorkmanvehicles,do

notattempttopullthesweeperwhenloadedwith

material,withthestandardWorkmanhitch.Itisonly

ratedto1500lbs.andmaybendordamagethecross

tubeaxlesupportorrearspringshackles.Alwaysuse

theH.D.DrawbarKitModel44212orH.D.Frame

DrawbarModel44213.

Important:Donotattempttowingaloadedsweeper

withalightutilityvehicleorrun-about.These

machinesdonothaveadequatebrakes,suspension,

orframestrengthtohandletheweightofthesweeper.

Qty.

1

1

1

1Usetooperatethesweeper

Readbeforeoperatingthesweeper

Usetoreferencepartnumbers

2

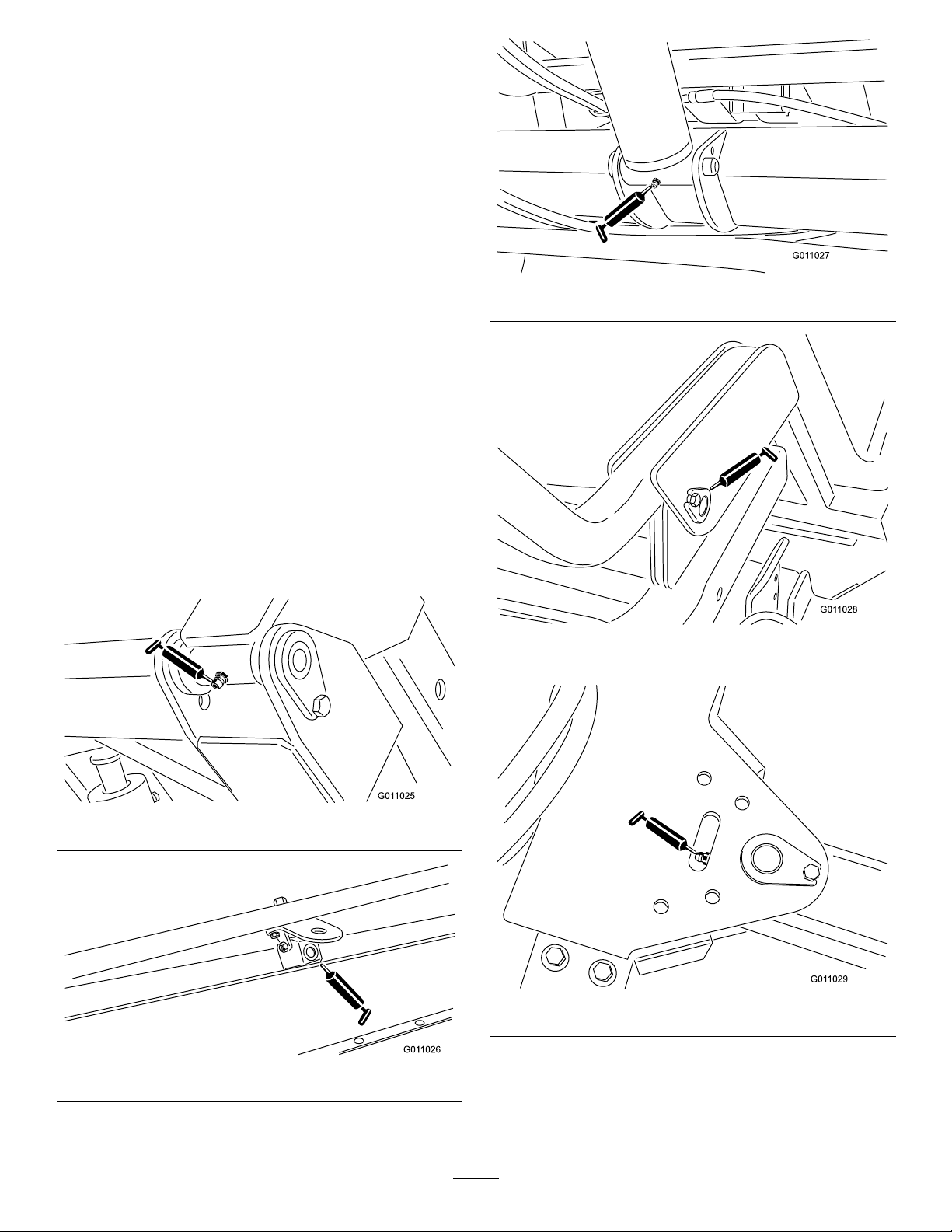

RemovingtheHitchTongue andHydraulicCylinderfrom theShippingPosition

NoPartsRequired

Procedure

Note:Have2peopleremovethehitchassembly.

1.Removethepinassembly ,boltandnutsecuringthe

2.Removethehairpincotterandhitchpinsecuringthe

3.Pivotatthelowershippingpinandpivotthetounge

4.Removethepinassembly ,boltandnutsecuringthe

5.Removethefastenerssecuringtheshippingbracketsto

Use

hydrauliccylinderandhosestothehitchtonguefor

shipping.Also,cutthecabletie.Carefullylowerthe

cylinderandhosesfromthetongue.Retainthepin

assemblyandfastenersforre-use.

hitchtonguetotheuppershippingbracket.Thehitch

tongueisveryheavy,usecautionwhenremovingthe

tonguefromtheshippingbrackets.

down.

hitchtonguetothelowershippingbracket.

Note:Themachinewillshiftupwardatthelowerpin

shippingbracket.

thesweeper.Removeanddiscardtheshippingbrackets.

•Trailerbrakesarerecommendedwhenusingthesweeper

inhillyterrain.Whenfullyloaded,thesweepermayweigh

asmuchas1,588kg(3,500lb)(GVW).Thisweightisover

therecommendedtowingandbrakinglimitofmostutility

vehicles.Aspecialtrailerbrakekitisavailablefordirect

installationwiththeWorkmanvehicle.

Note:Thetrailerbrakekitcanbeadaptedtoother

vehicleswitha12voltbrakelightsource.

9

3

InstallingtheHitchTongue

Partsneededforthisprocedure:

1Hitchtongue

1Hitchpin

1

Bolt(3/8x1-1/4inch)

1

Nut(3/8-16)

1Largewasher

1Largenut

1

Square-headsetscrew

Procedure

Note:Thisprocedurerequires2people.

1.Inserttherearendofthehitchtonguebetweenthe

mountingplatesonthesweeperwhilealigningthe

mountingholes(Figure3).

Note:Thehoseguidesaretobepositionedontop

ofhitchtongue.

2.Insertthehitchpinthroughthemountingplatesand

thehitchtongue(Figure3).

3.Securethetopofthehitchpintothemountingplate

withabolt(3/8x1-1/4inch)andalocknut(3/8inch)

(Figure3).

4.Securethebottomofthehitchpinwithalargewasher,

largenutandsquare-headsetscrew(Figure3).

Figure3

1.Hitchtongue4.Largenutandsquare-headsetscrew

2.Hitchpin5.Largewasher

3.Bolt(3/8x1–1/4inch)andlocknut(3/8inch)

10

5.Loosenthejamnutssecuringtheproximityswitchto

G011587

1

2

3

4

5

2

theframeandlowertheswitchuntilitis2.6to4.0mm

(0.10to0.16inch)fromthesensingplateonthehitch

tongue(Figure4).Tightenthejamnutstosecurethe

adjustment.

Figure5

Figure4

1.Proximityswitch

2.Jamnut5.Hitchtongue

3.2.6to4.0mm(0.10to0.16

inch)

4

InstallingtheHydraulic Cylinder

4.Sensingplate

1.Rearactuatortab

2.Secureeachendofthehydrauliccylindertoanactuator

tabwithapinassembly ,abolt(3/8x1-1/4inch),and

aangenut(3/8inch)Figure6).

Note:Makesurethattherodend(workingend)of

thecylinderisattachedtothefrontactuatortab.

1.Frontactuatortab3.Hydrauliccylinder

2.Rearactuatortab4.Pinassembly

2.Sweeperframe

Figure6

Partsneededforthisprocedure:

1Rear-actuatortab

4

Bolt(1/2x2inch)

8

Flatwasher(.531x.063)

4

Locknut(1/2inch)

2

2Pinassembly

2

Bolt(3/8x1–1/4inch)

Flangenut(3/8inch)

Procedure

1.Mounttherearactuatortabtothesweeperframewith

4bolts(1/2x2inch),8atwashers(.531x.063),and

4locknuts(1/2inch).Positionthecomponentsas

showninFigure5.

11

5

6

InstallingthePowerWiring Harness

Partsneededforthisprocedure:

1Powerwiringharness

2

Cabletie

Procedure

1.Disconnectthebatteryfromthevehicle.

2.Attachthepowerwiringharnessringterminaltothe

groundboltnearthevehiclefuseblock.

3.Plugtheharnesswireintotheredwireonthebackof

thefuseblock.

Note:IftheW orkmanvehicledoesnothaveanopen

fuseslot,obtainandinstallaToroaccessoryfuseblock,

Partno.92–2641.

4.Routethewiringharnessalongsidethemainvehicle

wiringharnesstotherearofthevehicle(Figure7).

MountingtheSweepertothe TowVehicle

Partsneededforthisprocedure:

1Hitchpin

1Hairpincotter

Procedure

Toensureproperdebrispickup,makesurethatthesweeper

frameisparallelwiththeground.

1.Positionthesweeperonaat,levelsurface.

2.Backthetowvehicleuptothesweeper.

3.Removethespringpin,rotatethejackdownandinstall

thespringpin(Figure8).

Figure7

1.Powerwiringharness

5.Securethewiringharnesstothevehicleinseveral

placeswithcableties.Keeptheharnessawayfromany

hotorrotatingcomponents.

Note:Theharnessisequippedwithaconnectorfor

theoptionalbrakecontrolkit.

6.Connectthevehiclebattery.

Figure8

1.Jack

4.Jackupthehitchtongueuntilitisparalleltotheground.

5.Adjustthesweeperhitchclevistothesamelevelastow

vehiclehitchasfollows:

•Removetheboltsandlocknutssecuringthehitch

clevis(Figure9)tothehitchtongue.

12

2.Springpin

Figure10

Figure9

1.Hitchpin3.Hairpincotter

2.Clevis

•Raiseorlowerthehitchclevistotheposition

approximatelylevelwiththetowvehiclehitch.

•Securetheclevistothehitchwiththeboltsand

locknutspreviouslyremoved.

Note:Makesurethatthesweeperisparallelwith

theground.

6.Connectthesweeperclevishitchtothetowvehicle

hitchwiththehitchpinandhairpincotter.

7.Removethespringpin,rotatethejackanduptothe

storagepositionandinstallthespringpin.

1.Hydraulichosesandwiring

harness

2.Securethehydraulichosesandwiringharnessasshown

inFigure11andFigure12.

1.Cabletie(6)

2.Hoseguide

Figure11

FrontView

7

RoutingandSecuringthe HydraulicHosesandWiring Harness

Partsneededforthisprocedure:

8

Cabletie

Procedure

1.Routethehydraulichosesandwiringharnessthrough

thehoseguidestothefrontofthehitchtongue(Figure

10).

Figure12

RearView

1.Cabletie(2)

13

8

g03051 1

9

ConnectingtheHydraulic

Hoses

NoPartsRequired

Procedure

Connectthehydraulichosesfromthesweepertothequick

couplersonthetowvehicle(Figure13).

Figure13

1.Hydraulichoses2.Harness'

Important:Makesurethatthebrushrotatesinthe

properdirection(whenviewedfromthemotorend,

thebrushshouldrotateclockwise).Ifthebrushis

rotatingcounterclockwise,reversethehydraulichose

connections.

Note:Markthehigh-pressurehosewithacabletieto

identifythecorrecthoseinstallation(Figure14).

ConnectingtheHarness

NoPartsRequired

Procedure

Connecttheharnessfromthesweepertothepowerharness

onthetowvehicle(Figure13).

Note:Ensuretheharnesscannotgetpinchedinthehitch

andensuretheharnessisnotontopoforaroundthehitch

pin.

10

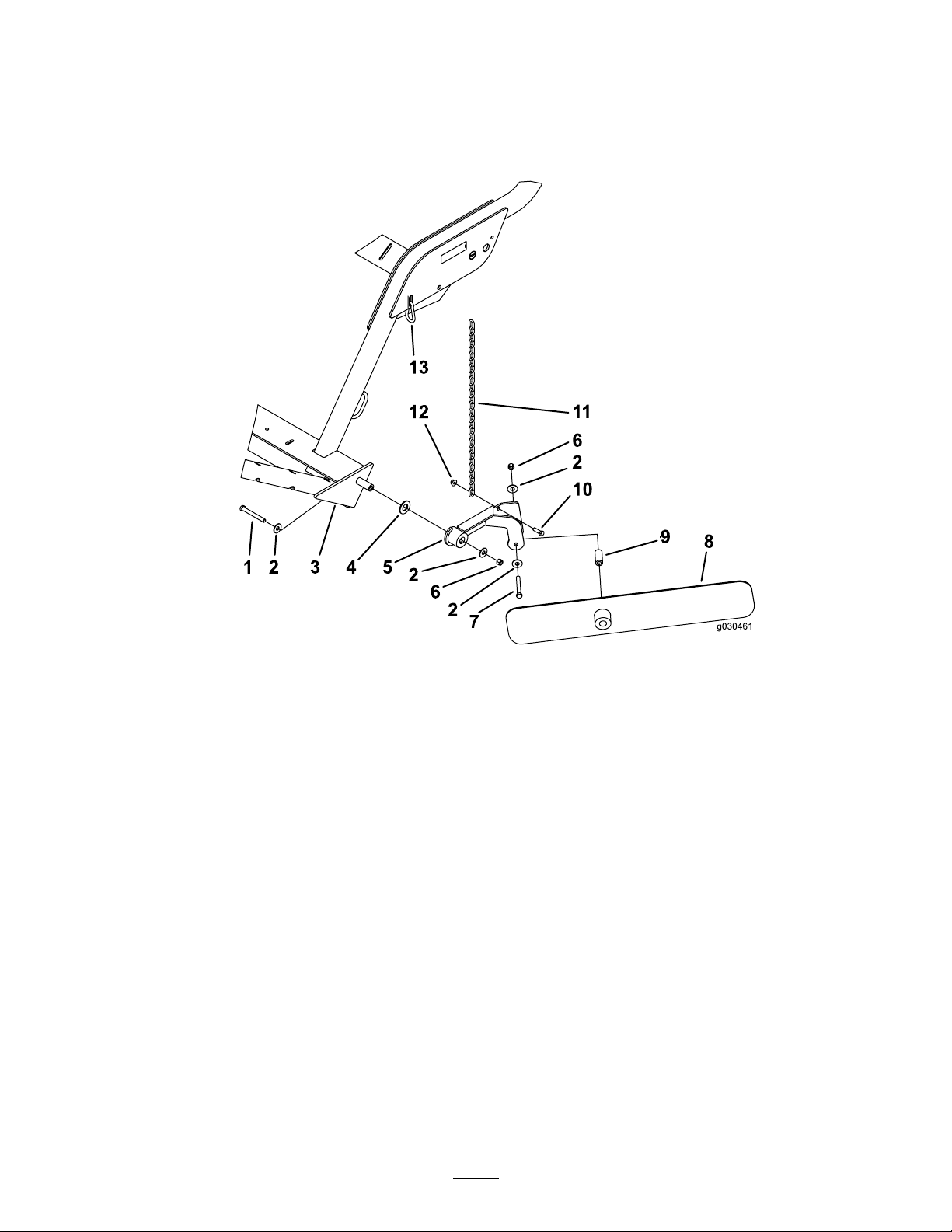

MountingtheWindrowBlades

Partsneededforthisprocedure:

1Blade-mountingassembly

1

Bolt(7/16x3-3/4inch)

1

Bolt(7/16x3-1/4inch)

4

Smallwasher(1/2inch)

1Largewasher

1

Spacer

2

Locknut(7/16inch)

1

Chain

1

Bolt(3/8x1-1/4inch)

1

Flangenut(3/8inch)

1

Snaplink

Procedure

1.Securetheblademountingassemblytotheleftend

ofthesweeperframewithabolt(7/16x3-1/4inch)

bolt,2smallwashers,alargewasher,andalocknut

(7/16inch).

1.Highpressurehose

Figure14

2.Cabletie

Note:PositioncomponentsasshowninFigure15.

2.Securethewindrowbladetothemountingassembly

withabolt(7/16x3-1/4inch),2atwashers,aspacer

andalocknut(7/16inch).Assemblethecomponents

asshowninFigure15.

Note:Positionthelongerendofthebladeawayfrom

thesweeper.

3.Securethechaintotheblademountingassemblywith

abolt(3/8x1-1/4inch)andaangenut(3/8inch)

(Figure15).

14

4.Securetheotherendofthechaintotheslotinthe

framewiththesnaplink(Figure15).

Note:Thereshouldbesomeslackinthechainwhen

connected.

5.Greasethettingontheblademountingassemblyand

onthewindrowbladehubwithNo.2lithiumgrease.

Note:Whenthewindrowisnotrequired,unhookthe

chainfromthesnaplink,pivotthewindrowassembly

upward,andhookthechainattheraisedlevel.

Figure15

1.Bolt(7/16x3-3/4inches)

2.Smallwasher(1/2inch)9.Spacer

3.Sweeperframe10.Bolt(3/8x1-1/4inches)

4.Largewasher

5.Blade-mountassembly

6.Locknut(7/16inch)13.Snaplink

7.Bolt(7/16x3-1/4inches)

8.Windrowblade

11.Chain

12.Flangenut(3/8inch)

15

11

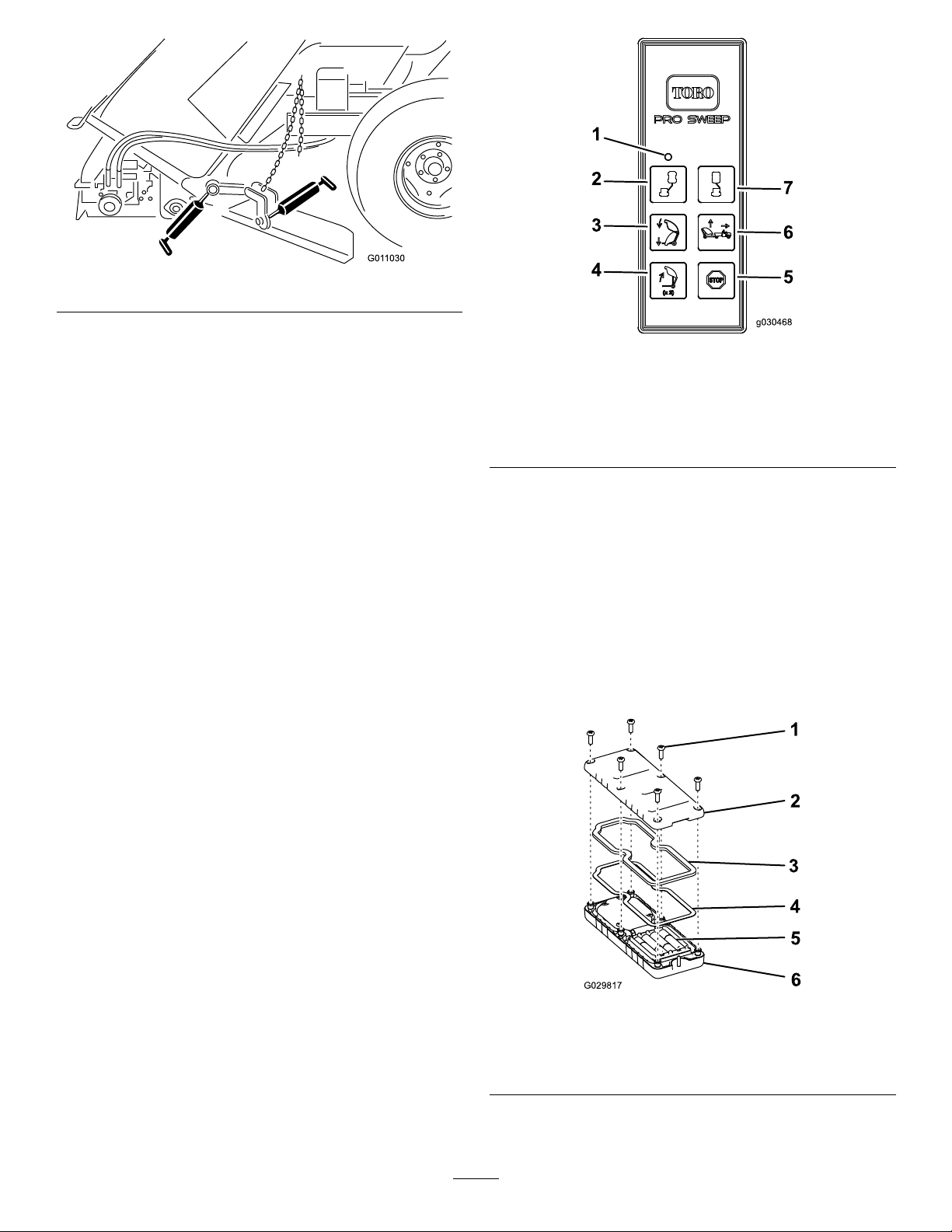

AssemblingtheHandheld Remote

Partsneededforthisprocedure:

1Handheldremote

4

Battery(AAA)

6

Screws,small

Procedure

1.Removetherubberbandssecuringtheremotehalves

together,andremovethebackcover.

2.Plugeachbatteryintoaterminalcradleobserving

properpolarity(Figure16).

Note:Ifthebatteriesareimproperlyinstalled,theunit

willnotbedamaged,butitwillfailtooperate.The

cradleisembossedwithpolaritymarkingsforeach

terminal.

Figure16

1.Screw4.Steelgasket

2.Cover

3.Seal

3.Ensurethatthesteelgasketandrubbersealareseated

inthechannelintheremoteandsetthebackcover

inplace(Figure16).

4.Securethecoverwith6screws(Figure16)andtorque

themto1.5to1.7N-m(13to15in-lb).

Note:Donotovertightenthescrews.

5.Batteries

6.Handheldremote

16

ProductOverview

•Transportheight(homeposition)is13–1/4to15–1/4

inches.

Controls

HopperDumpButton

Todumpthehopper,pressthehopperdumpbutton2times

(Figure17).

Important:Thesweepermustbedirectlybehindthe

towvehicleandintransportheightbeforethedump

sequencecanbeactivated.

•Turnaroundheight(off-setposition)is8–1/2to10–1/2

inches.

SweeperUpButton—OptionalMode

Thismodeallowstheoperatortoadjustthesweepertoany

desiredheightanditstopsatthepre-denedheights.

Note:RefertoSwitchingtheSweeper-UpMode(page25)to

switchtotheoptionalmode.

Toraisethesweeperinoptionalmode,pressandholdthe

sweeper-upbuttonuntilthehopperreachesthedesiredheight

orstopsatthepre-denedheight(Figure17).

•Transportheight(homeposition)is13–1/4to15–1/4

inches.

•Turnaroundheight(off-setposition)is8–1/2to10–1/2

inches.

Off-SetLeftButton

Tooff-setthesweepertotheleft,pressandholdtheoff-set

leftbutton(Figure17).Releasingthebuttonwillstopthe

movementtotheleft.

Figure17

1.LEDlight

2.Off-setleft6.Sweeperup

3.Sweeperdown7.Off-setright

4.Hopperdump

5.Stop

SweeperDownButton

Tolowerthehopper,pressthesweeperdownbutton(Figure

17).Thehoppercanbeloweredwhenitisatanyofthe

followingpositions:

•Hopperdumpheight

•Transportheight

•Turnaroundheight

Note:Whenloweringthehopperfromthedump

position,thelowerhopperfunctioncanbestoppedatany

timebyreleasingthesweeper-downbutton.

Note:Withthesweeperinthetransportorturn-around

positions,thelowerhopperfunctioncanbestoppedat

anytimebypressingthesweeperupbutton.

Off-SetRightButton

Tooff-setthesweepertotheright,pressandholdtheoff-set

rightbutton(Figure17).Releasingthebuttonwillstopthe

movementtotheright.

StopButton

Pressingthestopbuttonwilldisableanyactivefunction.

Note:Thereisapproximatelya3seconddelay.

SweeperUpButton—StandardMode

Toraisethesweeperinstandardmode,pressthesweeper-up

button.Thehopperwillstopatthepre-denedheight

(Figure17).

17

DiagnosticLight

Thediagnosticlight(Figure18)islocatedonthefrontcover

andindicatesmachinefaultcodes.Afteryouturnthekey

totheRUNposition,thediagnosticlightwillilluminatefor

5seconds,turnofffor5seconds,andthenbeginashing

3timesaseconduntilyoupushabuttononthehandheld

remote.Ifthelightturnsonfor5secondsandthenstarts

blinking10timesasecond(withorwithouta5secondpause)

thereisafaultwiththemachine;refertoCheckingFault

Codes(page31).

Note:Thediagnosticlightilluminateswhenabuttonis

pushedonthehandheldremote.

Note:Ifyouhaveabuttondepressedonthehandheld

remotewhenyoustartthemachine,thelightwillnotash3

timesasecondafteritturnsofffor5seconds.

Figure18

1.Diagnosticlight

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

DimensionsandWeights

Width

Height

Dumpheightclearance

LengthHopperlowered-

Emptyweight

Grossvehicleweight(GVW)1588kg(3500lb)

221cm(87inches)

202cm(79-1/2inches)

173cm(68inches)

173cm(68inches)

Hopperraised-229-249

cm(90-98inches)

680kg(1500lb)

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesis

availableforusewiththemachinetoenhanceandexpand

itscapabilities.ContactyourAuthorizedServiceDealeror

Distributororgotowww .Toro.comforalistofallapproved

attachmentsandaccessories.

18

Operation

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

OperatingtheSweeper

Theprimaryfunctionofthemachineistosweepupdebris

fromlargeturfareas.

Thesweeperisoperatedbyusingtheremotecontrol.Referto

Controls(page17)fortheproperuseofthecontrolbuttons.

Positonthesweeperinthefollowingheightswhen

transportingandturning:

•Transportheight(homeposition)is33.7to38.7cm

(13–1/4to15–1/4inches).

•Turnaroundheight(offsetposition)is21.6to26.7cm

(8–1/2to10–1/2inches).

WARNING

Rotatingpartscancauseseriouspersonalinjury.

•Keephandsandfeetawayfromthesweeperreel

whilethemachineisrunning.

•Keephands,feet,hair,andclothingawayfrom

allmovingpartstopreventinjury.

•Neveroperatethemachinewithcovers,shrouds,

orguardsremoved.

19

AdjustingtheBrushHeight

Adjustthesweepersothebrushtipsslightlytouchthesurfacebutdonotpenetratetheturf.Ifthebrushtipsdopenetrate

theturf,improperdebrispickupcouldresult.

Refertothechartsbelowfortherecommendedsweepersettings.

ConditionRoller/BrushAdjustment

Greens/TeeBoxes2to4notchesfrombottom6to13mm(1/4to1/2inch)

Fairways

Sportselds5to7notchesfrombottom25to76mm(1to3inches)

Leaves

AB

OpenSlots

0

1

2

3

4

5

6

7

8

9

10

11

12

13

3to5notchesfrombottom13to25mm(1/2to1inch)from

5to9notchesfrombottomRemovefrontpanel

TabUp

5.5006.000

5.7506.250

6.0006.500

6.2506.750

6.5007.000

6.7507.250

7.0007.500

7.2507.750

7.5008.000

7.7508.250

8.0008.500

8.2508.750

8.5009.000

8.7509.250

FrontFlapAdjustmentNotes

fromground

ground

fromground

TabDown

5.6256.125

5.8756.375

6.1256.625

6.3756.875

6.6257.125

6.8757.375

7.1257.625

7.3757.875

7.6258.125

7.8758.375

8.1258.625

8.3758.875

8.6259.125

8.8759.375

Brushshouldbeslightly

engagedintheturf

Brushshouldbeengagedinto

thetop1/3ofthegrassheight

Brushshouldbeengagedinto

thetop1/3ofthegrassheight

Brushshouldbeengagedinto

thetop1/3ofthegrassheight

C

20

Figure19

1.“A”4.6to13mm(1/4to1/2inch)

2.“B”

3.“C”

5.Brushdirection

1.Positionthesweeperonalevelsurface.

2.Raisethehopperandinstallthehoppersafetysupport.RefertoUsingtheHopperSafetySupport(page23).

3.Loosenthelocknutontheheightadjustmentkey(Figure20)soitcanbepulledoutapproximately13mm(1/2inch).

Figure20

1.Locknut4.Roller-heightadjustingplat

2.Height-adjustingkey5.Roller-scraperadjustingnuts

3.Roller-heightadjustingnuts

4.Loosentheroller-heightadjustmentlocknuts(Figure20).

5.Pullouttheheight-adjustorkeyandmovetherearrollerupordownbyslidingtheroller-heightadjustingplatetothe

desiredheight(Figure20).

6.Tightenthelocknutssecuringtheadjustment.

7.Repeattheprocedureontheoppositeendofthebrush.Makesurethattheadjustmentsarethesame.

AdjustingtheRollerScraper

Checkandensuretherollerscraper(Figure20)isadjusted

theroller.Loosentherollerscraperadjustingnuts,position

rollerasdesiredandtightenthenuts.

witha2mm(1/16inch)clearancebetweenthescraperand

21

AdjustingtheFrontFlap

CheckingtheWheelLugNut

Height

Forbestdebrispickupresults,adjustthefrontap(Figure

21)witha6mmto13mm(1/4inchto1/2inch)clearance

betweenthebottomoftheapandsurface.

Note:Raisingthefrontapallthewayorremovingthe

frontapmayberequiredwhenpickinguplargerdebrisorif

debrisistobepickedupinlonggrass.

Figure21

1.Frontap

Torque

WARNING

Failuretomaintainpropertorquecouldresultin

failureorlossofwheelandcouldresultinpersonal

injury.

Checkandtorquethewheellugnutsto95-122N-m(70-90

ft-lb).

1.Loosenthenutssecuringthemetalstrapandthefront

aptothebrushhousing(Figure22).

Figure22

1.Frontap

2.Adjustthefrontaptothedesiredoperatingheight

andtightenthenuts.

2.Metalstrap

CheckingtheTirePressure

Figure23

1.Lugnut

ActivatingtheController

Thecontroller(Figure24)isactivatedassoonasyouplugthe

sweeperharnessintothevehiclepowerharness.

•OnWorkmanmodelswithserialnumberspriorto

899999999,theharnesswillhavepower.

•OnWorkmanmodelswithserialnumbers900000001and

up,turntheignitionkeytotheRUNpositiontopower

theharness.

Checkthetirepressuredailytoensuretheyareinated

properly.

Correcttireairpressure:86.2kPa(12-1/2psi.)

Maximumtireairpresssure:of124kPa(18psi)

Note:Thevalvestemislocatedonthebacksideoftherim.

Figure24

1.Controller

22

UsingtheControllerTimeOut

Thesweeperisequippedwithatime-outfeatureforthe

controlmodule.Thetime-outfeatureisactivatedafter2-1/2

hoursofcontinuousremotetransmitterinactivity.

•Wheninthetime-outmodetheremotetransmitterwill

notcontrolanyfunction.

•Towakethecontrollerintime-outmode:

–OnW orkmanmodelswithserialnumberspriorto

899999999,unplugandplugthesweeperharnessinto

thevehiclepowerharness.

–OnWorkmanmodelswithserialnumbers900000001

andup,turntheignitionkeytotheOFFpositionand

backtotheRUNposition.

•Toavoidcontrollertime-outduringoperation,usethe

remotetransmittertooff-setthesweeperatleastevery

2-1/2hours.

Figure26

1.Safetysupport

UsingtheHopperSafety Support

Wheneveryouworkundertheraisedhopper,ensurethat

thehoppersafetysupportisinstalledontotheextendedlift

cylinder.

1.Raisethehopperuntiltheliftcylinderisextended.

2.Removethehairpincotterandpinsecuringthesafety

supporttothestoragebracketonthesweeperframe

(Figure25).Removethesafetysupport.

4.Tostorethesafetysupport,removethesafetysupport

fromthecylinderandsecureittothestoragebracket

onthesweeperframe.

5.Alwaysinstallorremovethesafetysupportfrom

behindthehopper.

6.Donottrytolowerthehopperwiththesafetysupport

onthecylinder.

CheckingtheInterlockSystem

CAUTION

Safetyinterlockswitchesarefortheoperator's

protection.Disconnectedormalfunctioning

safetyinterlockswitchescouldallowthemachine

tooperateinanunsafemannerandmaycause

personalinjury.

•Donotdisconnectthesafetyinterlockswitches.

•Checkoperationoftheswitchesdailytobesure

theinterlocksystemisoperatingcorrectly.

•Ifaswitchismalfunctioning,replaceitbefore

operatingthemachine.

Figure25

1.Hopper-safetysupport

2.Storagebracket

3.Insertthehopper-safetysupportontothecylinderrod,

makingsurethesupportendrestsagainstthecylinder

barrelandthecylinderrodend(Figure26).

Note:Securethehoppersafetysupporttothecylinder

rodwiththehairpincotterandpin.

3.Pin

Thepurposeofthesafetyinterlocksystemisasfollows:

•Preventsthebrushfromrotatingwhenthehopperisin

theraisedposition.

•Preventsthehopperfrombeingdumpedwhenthe

sweeperisintheoffsetposition.

•Audiblealarmwillsoundwhendumpingthehopper.Do

notmovethetowvehiclewhendumpingthehopper.

OperatingTips

•Beforestartingtosweep,surveytheareatodetermine

thebestdirectiontosweep.

23

Note:Tomaintainastraightlinewhensweeping,sight

g030465

anobjectintheforeground.

1.Placethemachineonalevelsurfaceandmakesurethat

itisinthetransportpositionbeforedumping.

•Alwaystrytomakealong,continuousrunwithaslight

overlaponthereturnrun.

•Onturfareas,thebrushwillpickupturfcores,twigs,

clippings,leaves,pineneedlesandcones,andsmalldebris.

•Thesweeperalsogroomstheturf.Thebrushcombs

throughandliftsthegrassforauniformcutwhen

mowed.Asitcleans,thelightscarifyingactionincreases

waterandpesticidepenetration,thusreducingtheneed

forrenovation.

Important:Donotmakesharpturnswhenusing

thesweeperasdamagetotheturfmayoccur.

•Whenthehopperisfull,thesweeperwillnolonger

pickupasefciently,leavingorthrowingmaterialback

ontotheground.

DANGER

Tipovercancauseseriousinjuryordeath.

•Neveroperatethemachineonsteepslopes.

•Sweepslopesupanddown,neveracrossthe

face.

•Whengoinguphillordownhill,donotstopor

startsuddenly .

•Stayalertforholesintheterrainorotherhidden

hazards.Toavoidtippingorlossofcontrol,do

notdriveclosetoaditch,creekordropoff.

2.Pressthehopper-dumpbuttonforonesecond,release

thebuttonforonesecond,andpressthehopper-dump

buttonagain(Figure27).

Note:Thesweeperwillnotrespondifthe

hopper-dumpbuttonispressedtooquickly .

Figure27

1.LEDlight

2.Offsetleft6.Sweeperup

3.Sweeperdown7.Offsetright

4.Hopperdump

5.Stop

•Ifmachinestopsgoinguphill,disengagereels

andbackslowlydownhill.Donotattemptto

turn.

DumpingtheHopper

DANGER

Tipoverorelectricalshockcouldcauseserious

injuryordeath.

•Neverdumpthehopperonaslope.Always

dumpthehopperonlevelground.

•Dumponlyinanareaclearofoverheadwires

andotherobstructions.

Important:Makesurethatthesweeperissecuredto

thetowvehiclehitchwiththehitchpinandtheclevis

pinduringthedumpingoperation.

Important:Ensurethatthesweeperisdirectlybehind

thetowvehicleandintransportheightbeforethedump

sequencecanbeactivated.

Toactivatethedumpsequence:

Figure28

CAUTION

Dumpingthehoppercancauseinjuryto

bystandersorpets.

Keepbystandersandpetsasafedistancefrom

thehopperwhendumpingthehopper.

LoweringtheHopper

Tolowerthehopper,pressthesweeperdownbutton.

Note:Ensurethehopperisinthedownpositionbefore

startingtousethesweeper.

24

InspectingandCleaningthe

g030597

SwitchingtheSweeper-Up

Machine

Whensweepinghasbeencompleted,thoroughlycleanand

washthemachine.Airdrythehopper.Aftercleaning,inspect

themachineforpossibledamagetomechanicalcomponents.

Performingtheseproceduresensuresthatthemachinewill

performsatisfactorilyduringthenextsweepingoperation.

TransportingtheSweeper

•Nevertransportthesweeperwhenthetransportalarm

andthelightareactivated.

•Whentransportingthesweeper,usethetie-downsto

securethefrontofthemachine(Figure29)andtheaxle

(Figure30)tosecuretherearofthemachinetothetrailer.

Note:Transportingthesweeperwithoutusingthe

tie-downscoulddamagethemachine.

Mode

Thesweeper-upbuttonhas2possiblemodes;standardand

optional.

Thestandardmodeallowstheoperatortoraisethesweeper

tothepre-denedheightswithasinglebuttonpush.Referto

SweeperUpButton—StandardMode(page17)

Theoptionalmodeallowstheoperatortoadjustthesweeper

toanydesiredheightanditstopsatthepre-denedheights.

RefertoSweeperUpButton—OptionalMode(page17).

Usethefollowingtoswitchthesweepertotheoptionalmode:

1.Removethecoveroffthecontrolmodule.

2.Unplugthe2wireconnectionsfromthepigtail

connectorshowinFigure31.

3.Plugthe2wireconnectionsintotheexistingpigtail

connectortetheredtothewiringharness.

4.Installthecoverontothecontrolmodule.

Figure29

1.Fronttie-downs

Figure30

1.Reartie-downlocations

OperatingtheMachineinCold Weather

TheWorkmanhighowhydraulicsoilmustreachaoperating

temperatureof82degreesC(180degreesF)forproper

operationoftheoatingsweeperhead.

Figure31

1.Locationofpigtails3.Standard-modepigtail

2.Optional-mode

pigtail—tetheredtothe

wiringhareness

Note:Toreturntostandardmode,installtheoriginal

pigtailconnector.

25

Maintenance

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst10hours

Every25hours

Every50hours

Every100hours

Every200hours

Every600hours

MaintenanceProcedure

•T orquethewheellugnuts

•Cleanthereeldrivearea.

•Greasethesweeper.

•Inspecttheconditionofthetires.

•Replacethebrush.

•T orquethewheellugnuts

•Replacethefrontap.

•Inspectthehopperfordamage.

26

DailyMaintenanceChecklist

Duplicatethispageforroutineuse.

Fortheweekof:

MaintenanceCheckItem

Checkthesafetyinterlock

operation.

Checkforunusualoperating

noises.

Checkthetirepressure

Checkhydraulichosesfor

damage

Checkforuidleaks

Checkcontroloperation.

Checkhopper.

Cleanwrappedmaterial

frombrush.

Checkbrushwear .

Lubricateallthegrease

2

ttings

Touch-upanydamaged

paint

1

=.Replaceifmissingorbroken

2

=Immediatelyaftereverywashing,regardlessoftheintervallisted

1

Mon.Tues.Wed.Thurs.Fri.

Sat.Sun.

NotationforAreasofConcern

Inspectionperformedby:

ItemDate

Information

27

Lubrication

ServiceInterval:Every50hours

Thesweeperhas11greasettingsthatrequirelubrication

withNo.2lithiumgrease.Ifthemachineisoperated

undernormalconditions,lubricateallbearingsandbushings

immediatelyaftereverywashing.Lubricatethebearings

andbushingsdailywhenoperatingconditionsareextremely

dustyanddirty.Dustyanddirtyoperatingconditionscould

causedirttogetintothebearingsandbushings,resultingin

acceleratedwear.

1.Lubricatethefollowinggreasettings:

•Hopperpivot(upper)(2)(Figure32).

•Brushpivot(2)(Figure33).

•Liftcylinder(2)(Figure34).

•Hopperpivot(lower)(2)(Figure35).

•Hitchtonguepivot(1)(Figure36).

•Windrowblademount(Figure37).

•Windrowbladehub(Figure37).

2.Wipegreasettingscleansothatforeignmattercannot

beforcedintothebearingorbushing.

3.Pumpgreaseintothebearingorbushing.

4.Wipeupexcessgrease.

Figure34

Figure35

Figure32

Figure33

Figure36

28

Figure37

AssociatetheRemoteControl andtheBaseUnit

Important:Makesuretoreadtheentireprocedure

beforeattemptingtheassociationprocess.

Theremotecontrolmustestablishcommunicationswith

thebaseunitbeforethesystemcanbeused.Theremote

controlisassociatedtothesystembaseunitbeforeleaving

thefactory.Thisisdoneusingtheassociateprocedure.

Insituationswhereitisnecessarytore-establishremote

control-to-baseunitcommunications(example:introducing

aneworspareremotecontroltoanexistingbaseunit),the

followingassociateproceduremustbeperformed.

Note:Associatingtheremotecontroltoadifferentbase

unitwilldisassociatethatremotecontrolfromtheoriginal

baseunit.

1.Removepowerfromthebaseunit.

2.Standnearthebaseunitinunobstructed,clear

line-of-sightwiththeremotecontrolinhand.

3.SimultaneouslypressandholdtheOFF-SETLEFTand

OFF-SETRIGHTbuttons.TheLEDwillblinkabout

oncepersecond.

Figure38

1.LEDlight

2.Off-setleft6.Sweeperup

3.Sweeperdown7.Off-setright

4.Hopperdump

5.Stop

ReplacingtheRemote Batteries

Thehandheldremoteispoweredby4AAAbatteries.When

installingbatteries,observeproperpolarityasmarkedonthe

insideofthecompartmenttoavoiddamagingtheunit.

1.Removethe6screwsfromthebackoftheremoteand

removethecover(Figure39).

Note:Ifpossible,leavetherubbersealandsteelgasket

inthechannelwhenremovingthecoverandbatteries.

4.ContinuetoholdbothbuttonsuntiltheLEDbegins

blinkingabouttwicepersecond.

5.Releasethebuttons.

6.PressandholdtheOFF-SETLEFTbutton.TheLED

willblinkabouttwicepersecond.

7.ContinueholdingtheOFF-SETLEFTbuttonandturn

thekeystarttotheRUNposition.TheLEDwillturn

solidiftheprocedureissuccessful.

Note:Thiscouldtakeupto20seconds.

8.ReleasetheOFF-SETLEFTbutton.

Thesystemisreadyforusewiththatparticularremote

control.

Figure39

1.Screw4.Steelgasket

2.Cover

3.Seal

2.Removethedischargedbatteriesandproperlydispose

inaccordancewithlocalregulations.

29

5.Batteries

6.Handheldremote

3.Plugeachfreshbatteryintoaterminalcradleobserving

properpolarity.

Storage

Note:Ifthebatteriesareimproperlyinstalled,theunit

willnotbedamaged,butitwillfailtooperate.

4.Ifyouaccidentallyremovedtherubbersealandthe

steelgasket,replacethemcarefullyintothechannelin

thehandheldremote.

5.Replacethecoverandsecureitwiththe6screws

removedpreviously(Figure39)andtorquethemto1.5

to1.7N-m(13to15in-lb).

Note:Donotover-tightenthescrews.

1.Thoroughlycleanthesweepersoitisfreeofdirt,leaves

anddebris.

2.Checkthetirepressure.RefertoCheckingtheTire

Pressure(page22).

3.Checkallfasteners.Tightenasnecessary.

4.Greaseallgreasettings.Wipeoffexcesslubricant.

5.Checktheconditionofthebrush.Replaceasrequired.

30

Troubleshooting

ConditionPossibleCausesCorrectiveAction

Thesweeperisnot

pickingupdebris.

Thebrushisdamaged.

Thebrushheightistoohigh.

Replacebrush.

Adjustbrushheight.SeeBrushHeightAdjustment.

Thesweeperhas

excessivevibration.

Thediagnosticlighton

thesweeperdoesnot

illuminatewhenpressing

aremotebutton.

TheFrontapheightistoolowortoohigh.

Checkthebearingsonthebrushshaft.Iftheyare

excessivelyhot,checkthebearingsfordamage.

Foreignmaterialsarewrappedaroundbrush.

Thereisfrequencyinterference.Associatetheremotecontroltothebaseunit.Refer

Adjustfrontapheight.SeeFrontFlapAdjustment

Replaceanydamagedbearings.

Cleanoffanyforeignobjects.

toAssociatetheRemoteControlandtheBaseUnit

(page29).

CheckingFaultCodes

Ifthediagnosticlightindicatesthatthereisasystemfault(referto(page)),checkthefaultcodestodetermine

whatiswrongwiththemachine.

31

EnteringDiagnosticModeandCheckingtheCodes

1.TurnthekeytotheRUNposition.

2.Disconnectthepowerbyseparatingthevehicleharnessfromthesweeperharness.

3.Removethefrontcover.

4.Pullthetetheredcapoffthe2diagnostic,shuntconnectors(Figure40,A).

5.Connectthediagnostic,shuntconnectorstogether(Figure40,B).

Figure40

6.Connectthevehicleandsweeperwireharnesstogethertopowerthesweeper.

7.Countthenumberofashestodeterminethefaultcode,thenconsultthefollowingtable:

Note:Iftherearemultiplefaults,bothfaultswillash,thenalongpause,thentheashsequenceswillrepeat.

Code

11Blinkonce,pause,blinkonce,

12Blinkonce,pause,blinktwice,

13Blinkonce,pause,blink3

LEDFlashPatternBehaviorDetails

MachineSpecicFaults

longpause,thenrepeat

longpause,thenrepeat

times,longpause,thenrepeat

Lostcommunicationwith

BASE.

Versionincompatibilityofthe

BASEand/orHH

WrongHH—notimplemented

onRevA

8.Installthefrontcover.

Connectornotplugged

in;locatethelooseor

disconnectedharness

connectorandconnectit.

Somethingwronginthewiring;

contactyourToroDistributor.

BASEisbad;contactyourToro

Distributor.

Wrongsoftware(install

thecorrectsoftwarefrom

TORODIAG);contactyourToro

Distributor.

Wrongproductassociation

(i.e.tryingtoupdatesoftware

onaMH–400withaProPass

handheld)

32

ResettingtheFaultCodes

Aftersolvingtheproblem,disconnectandreconnectthediagnosticconnectors.Thediagnosticlightwillash

continuouslyoncepersecond.

ExitingDiagnosticMode

1.TurnthekeytotheRUNposition.

2.Disconnectthepowerbyseparatingthevehicleharnessfromthesweeperharness.

3.Disconnectthediagnostic,shuntconnectors.

4.Pushthetetheredcapontothe2diagnostic,shuntconnectors.

5.Connectthevehicleandsweeperwiringharnesstogethertopowerthesweeper.

33

Notes:

34

InternationalDistributorList

Distributor:

AgrolancKft

BalamaPrimaEngineeringEquip.HongKong85221552163

B-RayCorporation

CascoSalesCompany

CeresS.A.CostaRica

CSSCTurfEquipment(pvt)Ltd.SriLanka

CyrilJohnston&Co.

CyrilJohnston&Co.RepublicofIreland

EquiverMexico525553995444ParklandProductsLtd.NewZealand6433493760

FemcoS.A.Guatemala

ForGarderOU

G.Y .K.CompanyLtd.

GeomechanikiofAthensGreece

GolfinternationalTurizm

GuandongGoldenStarChina

HakoGroundandGardenSweden

HakoGroundandGarden

HayterLimited(U.K.)

HydroturfInt.CoDubai

HydroturfEgyptLLC

IrrimacPortugal351212388260ToroEuropeNVBelgium3214562960

IrrigationProductsInt'lPvtLtd.India0091442449

JeanHeybroekb.v.Netherlands3130639461 1VictusEmakPoland48618238369

Country:

Hungary3627539640

Korea82325512076

PuertoRico7877888383

NorthernIreland442890813121

Estonia3723846060

Japan81726325861

Turkey902163365993Riversa

Norway4722907760

UnitedKingdom441279723444

UnitedArabEmirates97143479479T-MarktLogisticsLtd.Hungary3626525500

Egypt2025194308ToroAustraliaAustralia61395807355

PhoneNumber:Distributor:

5062391138

94112746100

442890813121

5024423277

30109350054

862087651338

4635100000

4387

Country:

MaquiverS.A.Colombia

MaruyamaMfg.Co.Inc.

Mountelda.s.CzechRepublic

Mountelda.s.Slovakia

MunditolS.A.

NormaGarden

OslingerTurfEquipmentSA

OyHakoGroundandGarden

Ab

Perfetto

PratoverdeSRL.

Prochaska&Cie

RTCohen2004Ltd.

LelyTurfcare

SolvertS.A.S.

SpyprosStavrinidesLimitedCyprus

SurgeSystemsIndiaLimited

ValtechMorocco21253766

Japan81332522285

Argentina54114821

Russia749541 16120

Ecuador59342396970

Finland35898700733

Poland48618208416

Italy390499128

Austria4312785100

Israel97298617979

Spain

Denmark4566109200

France331308177

India911292299901

Phone

Number:

5712364079

420255704

220

420255704

220

9999

128

34952837500

00

35722434131

3636

EuropeanPrivacyNotice

TheInformationToroCollects

ToroWarrantyCompany(T oro)respectsyourprivacy .Inordertoprocessyourwarrantyclaimandcontactyouintheeventofaproductrecall,weaskyou

tosharecertainpersonalinformationwithus,eitherdirectlyorthroughyourlocalT orocompanyordealer.

TheT orowarrantysystemishostedonserverslocatedwithintheUnitedStateswhereprivacylawmaynotprovidethesameprotectionasapplies

inyourcountry.

BYSHARINGYOURPERSONALINFORMATIONWITHUS,YOUARECONSENTINGTOTHEPROCESSINGOFYOURPERSONALINFORMATION

ASDESCRIBEDINTHISPRIV ACYNOTICE.

TheWayT oroUsesInformation

Toromayuseyourpersonalinformationtoprocesswarrantyclaims,tocontactyouintheeventofaproductrecallandforanyotherpurposewhichwetell

youabout.ToromayshareyourinformationwithT oro'safliates,dealersorotherbusinesspartnersinconnectionwithanyoftheseactivities.Wewillnot

sellyourpersonalinformationtoanyothercompany.Wereservetherighttodisclosepersonalinformationinordertocomplywithapplicablelawsand

withrequestsbytheappropriateauthorities,tooperateoursystemsproperlyorforourownprotectionorthatofotherusers.

RetentionofyourPersonalInformation

Wewillkeepyourpersonalinformationaslongasweneeditforthepurposesforwhichitwasoriginallycollectedorforotherlegitimatepurposes

(suchasregulatorycompliance),orasrequiredbyapplicablelaw .

Toro'sCommitmenttoSecurityofY ourPersonalInformation

Wetakereasonableprecautionsinordertoprotectthesecurityofyourpersonalinformation.Wealsotakestepstomaintaintheaccuracyandcurrent

statusofpersonalinformation.

AccessandCorrectionofyourPersonalInformation

Ifyouwouldliketorevieworcorrectyourpersonalinformation,pleasecontactusbyemailatlegal@toro.com.

AustralianConsumerLaw

AustraliancustomerswillnddetailsrelatingtotheAustralianConsumerLaweitherinsidetheboxoratyourlocalT oroDealer.

374-0269RevH

ToroGeneralCommercialProductWarranty

ATwo-YearLimitedWarranty

ConditionsandProductsCovered

TheToroCompanyanditsafliate,ToroWarrantyCompany,pursuant

toanagreementbetweenthem,jointlywarrantyourT oroCommercial

product(“Product”)tobefreefromdefectsinmaterialsorworkmanship

fortwoyearsor1500operationalhours*,whicheveroccursrst.This

warrantyisapplicabletoallproductswiththeexceptionofAerators

(refertoseparatewarrantystatementsfortheseproducts).Wherea

warrantableconditionexists,wewillrepairtheProductatnocosttoyou

includingdiagnostics,labor,parts,andtransportation.Thiswarranty

beginsonthedatetheProductisdeliveredtotheoriginalretailpurchaser.

*Productequippedwithanhourmeter.

InstructionsforObtainingWarrantyService

YouareresponsiblefornotifyingtheCommercialProductsDistributoror

AuthorizedCommercialProductsDealerfromwhomyoupurchasedthe

Productassoonasyoubelieveawarrantableconditionexists.Ifyouneed

helplocatingaCommercialProductsDistributororAuthorizedDealer,or

ifyouhavequestionsregardingyourwarrantyrightsorresponsibilities,

youmaycontactusat:

ToroCommercialProductsServiceDepartment

ToroWarrantyCompany

811 1LyndaleAvenueSouth

Bloomington,MN55420-1196

952–888–8801or800–952–2740

E-mail:commercial.warranty@toro.com

OwnerResponsibilities

AstheProductowner,youareresponsibleforrequiredmaintenanceand

adjustmentsstatedinyourOperator'sManual.Failuretoperformrequired

maintenanceandadjustmentscanbegroundsfordisallowingawarranty

claim.

ItemsandConditionsNotCovered

Notallproductfailuresormalfunctionsthatoccurduringthewarranty

periodaredefectsinmaterialsorworkmanship.Thiswarrantydoesnot

coverthefollowing:

•Productfailureswhichresultfromtheuseofnon-T ororeplacement

parts,orfrominstallationanduseofadd-on,ormodiednon-Toro

brandedaccessoriesandproducts.Aseparatewarrantymaybe

providedbythemanufactureroftheseitems.

•Productfailureswhichresultfromfailuretoperformrecommended

maintenanceand/oradjustments.Failuretoproperlymaintainyour

ToroproductpertheRecommendedMaintenancelistedinthe

Operator’sManualcanresultinclaimsforwarrantybeingdenied.

•ProductfailureswhichresultfromoperatingtheProductinanabusive,

negligent,orrecklessmanner.

•Partssubjecttoconsumptionthroughuseunlessfoundtobedefective.

Examplesofpartswhichareconsumed,orusedup,duringnormal

Productoperationinclude,butarenotlimitedto,brakepadsand

linings,clutchlinings,blades,reels,rollersandbearings(sealedor

greasable),bedknives,sparkplugs,castorwheelsandbearings,tires,

lters,belts,andcertainsprayercomponentssuchasdiaphragms,

nozzles,andcheckvalves,etc.

•Failurescausedbyoutsideinuence.Conditionsconsideredtobe

outsideinuenceinclude,butarenotlimitedto,weather,storage

practices,contamination,useofunapprovedfuels,coolants,lubricants,

additives,fertilizers,water,orchemicals,etc.

•Failureorperformanceissuesduetotheuseoffuels(e.g.gasoline,

diesel,orbiodiesel)thatdonotconformtotheirrespectiveindustry

standards.

•Normalnoise,vibration,wearandtear ,anddeterioration.

•Normal“wearandtear”includes,butisnotlimitedto,damagetoseats

duetowearorabrasion,wornpaintedsurfaces,scratcheddecalsor

windows,etc.

Parts

Partsscheduledforreplacementasrequiredmaintenancearewarranted

fortheperiodoftimeuptothescheduledreplacementtimeforthatpart.

Partsreplacedunderthiswarrantyarecoveredforthedurationofthe

originalproductwarrantyandbecomethepropertyofT oro.T orowillmake

thenaldecisionwhethertorepairanyexistingpartorassemblyorreplace

it.T oromayuseremanufacturedpartsforwarrantyrepairs.

DeepCycleandLithium-IonBatteryWarranty:

DeepcycleandLithium-Ionbatterieshaveaspeciedtotalnumberof

kilowatt-hourstheycandeliverduringtheirlifetime.Operating,recharging,

andmaintenancetechniquescanextendorreducetotalbatterylife.Asthe

batteriesinthisproductareconsumed,theamountofusefulworkbetween

chargingintervalswillslowlydecreaseuntilthebatteryiscompletelyworn

out.Replacementofwornoutbatteries,duetonormalconsumption,

istheresponsibilityoftheproductowner.Batteryreplacementmaybe

requiredduringthenormalproductwarrantyperiodatowner’sexpense.

Note:(Lithium-Ionbatteryonly):ALithium-Ionbatteryhasapartonly

proratedwarrantybeginningyear3throughyear5basedonthetime

inserviceandkilowatthoursused.RefertotheOperator'sManualfor

additionalinformation.

MaintenanceisatOwner’sExpense

Enginetune-up,lubrication,cleaningandpolishing,replacementoflters,

coolant,andcompletingrecommendedmaintenancearesomeofthe

normalservicesT oroproductsrequirethatareattheowner’sexpense.

GeneralConditions

RepairbyanAuthorizedToroDistributororDealerisyoursoleremedy

underthiswarranty.

NeitherTheToroCompanynorToroWarrantyCompanyisliablefor

indirect,incidentalorconsequentialdamagesinconnectionwiththe

useoftheToroProductscoveredbythiswarranty,includingany

costorexpenseofprovidingsubstituteequipmentorserviceduring

reasonableperiodsofmalfunctionornon-usependingcompletion

ofrepairsunderthiswarranty.ExceptfortheEmissionswarranty

referencedbelow,ifapplicable,thereisnootherexpresswarranty.All

impliedwarrantiesofmerchantabilityandtnessforusearelimitedto

thedurationofthisexpresswarranty.

Somestatesdonotallowexclusionsofincidentalorconsequential

damages,orlimitationsonhowlonganimpliedwarrantylasts,sotheabove

exclusionsandlimitationsmaynotapplytoyou.Thiswarrantygivesyou

speciclegalrights,andyoumayalsohaveotherrightswhichvaryfrom

statetostate.

Noteregardingenginewarranty:

TheEmissionsControlSystemonyourProductmaybecoveredby

aseparatewarrantymeetingrequirementsestablishedbytheU.S.

EnvironmentalProtectionAgency(EP A)and/ortheCaliforniaAirResources

Board(CARB).Thehourlimitationssetforthabovedonotapplytothe

EmissionsControlSystemWarranty.RefertotheEngineEmissionControl

WarrantyStatementsuppliedwithyourproductorcontainedintheengine

manufacturer’sdocumentationfordetails

CountriesOtherthantheUnitedStatesorCanada

CustomerswhohavepurchasedT oroproductsexportedfromtheUnitedStatesorCanadashouldcontacttheirT oroDistributor(Dealer)toobtain

guaranteepoliciesforyourcountry ,province,orstate.IfforanyreasonyouaredissatisedwithyourDistributor'sserviceorhavedifcultyobtaining

guaranteeinformation,contacttheT oroimporter.

374-0253RevC

Loading...

Loading...