Page 1

66” Rake–O–Vac Sweeper

PTO and Engine Driven

Model No. 07050–220000001 and up

Model No. 07052–220000001 and up

Form No. 3329–240

Operator ’s Manual

Domestic English (EN)

Page 2

Warning

CALIFORNIA

Proposition 65 Warning

The engine exhaust from this product contains

chemicals known to the State of California to cause

cancer, birth defects, or other reproductive harm.

Important The engine in this product is not equipped

with a spark arrester muffler. It is a violation of California

Public Resource Code Section 4442 to use or operate this

engine on any forest-covered, brush-covered, or

grass-covered land as defined in CPRC 4126. Other states

or federal areas may have similar laws.

This spark ignition system complies with Canadian

ICES-002.

Ce système d’allumage par étincelle de véhicule est

conforme à la norme NMB-002 du Canada.

Contents

Page

Introduction 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety and Instruction Decals 5. . . . . . . . . . . . . . . .

Specifications 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dimensions and Weights (approx.) 7. . . . . . . . . . .

Optional Equipment 7. . . . . . . . . . . . . . . . . . . . . . .

Setup 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remove, Activate And Charge Battery 8. . . . . . . .

Install Battery 8. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mount Sweeper To Prime Mover 9. . . . . . . . . . . . .

Connecting Drive Shaft to Prime Mover PTO Shaft 10

Removing Sweeper From Prime Mover 10. . . . . . . .

Before Operating 11. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Check Engine Oil 11. . . . . . . . . . . . . . . . . . . . . . . . .

Check Clutch Housing Oil 11. . . . . . . . . . . . . . . . . .

Fill Fuel Tank 12. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Check Tire Pressure 12. . . . . . . . . . . . . . . . . . . . . . .

Transport Hooks 13. . . . . . . . . . . . . . . . . . . . . . . . . .

Adjust Reel Support Arm 13. . . . . . . . . . . . . . . . . . .

Adjust Rake Depth 13. . . . . . . . . . . . . . . . . . . . . . . .

Adjust Rubber Flap 14. . . . . . . . . . . . . . . . . . . . . . .

Page

Operation 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Controls 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Starting Instructions (Engine Driven) 15. . . . . . . . .

Stopping Instructions 16. . . . . . . . . . . . . . . . . . . . . .

Starting Instructions (PTO Driven) 16. . . . . . . . . . .

Operating Tips 16. . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection And Cleanup After Operation 16. . . . . . .

Maintenance 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lubrication 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Oil Drive Chain 18. . . . . . . . . . . . . . . . . . . . . . . . . .

Oil Sweeper Jack 18. . . . . . . . . . . . . . . . . . . . . . . . .

Changing Engine Oil and Filter 18. . . . . . . . . . . . . .

General Air Cleaner Maintenance 19. . . . . . . . . . . .

Servicing Air Cleaner 19. . . . . . . . . . . . . . . . . . . . . .

Replacing Spark Plugs 19. . . . . . . . . . . . . . . . . . . . .

Removing Debris From Engine 20. . . . . . . . . . . . . .

Replace Fuel Filter 20. . . . . . . . . . . . . . . . . . . . . . . .

Changing Clutch Housing Oil 20. . . . . . . . . . . . . . .

Adjusting Clutch 20. . . . . . . . . . . . . . . . . . . . . . . . . .

Changing Rubber Flap 21. . . . . . . . . . . . . . . . . . . . .

Cleaning Blower Housing 21. . . . . . . . . . . . . . . . . .

Adjusting Belts 22. . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjusting Drive Chain 24. . . . . . . . . . . . . . . . . . . . .

Changing Gear Box Oil 25. . . . . . . . . . . . . . . . . . . .

Gear Box Removal 25. . . . . . . . . . . . . . . . . . . . . . . .

Locking Collar Removal 26. . . . . . . . . . . . . . . . . . .

Pulley Removal 26. . . . . . . . . . . . . . . . . . . . . . . . . .

Flex Tip Reel Removal 26. . . . . . . . . . . . . . . . . . . . .

Thatcher Installation 27. . . . . . . . . . . . . . . . . . . . . . .

Flex Tip Rake Rod Or Finger Plate Replacement 27

Flex Tip Rake Tine Replacement 28. . . . . . . . . . . . .

Brush Half Replacement 28. . . . . . . . . . . . . . . . . . . .

Changing Tires 29. . . . . . . . . . . . . . . . . . . . . . . . . . .

Battery Care 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The Toro General Commercial Products Warranty 32. .

2002 by The Toro Company

8111 Lyndale Avenue South

Bloomington, MN 55420-1196

All Rights Reserved

Printed in the USA

2

Page 3

Introduction

Safety

Read this manual carefully to learn how to operate and

maintain your product properly. The information in this

manual can help you and others avoid injury and product

damage. Although Toro designs and produces safe

products, you are responsible for operating the product

properly and safely.

Whenever you need service, genuine Toro parts, or

additional information, contact an Authorized Service

Dealer or Toro Customer Service and have the model and

serial numbers of your product ready. Figure 1 illustrates

the location of the model and serial numbers on the

product.

1

Figure 1

1. Model & serial number plate

Write the product model and serial numbers in the space

below:

Model No.

Serial No.

The RAKE–O–VAC was designed and tested to offer

safe service when operated and maintained properly.

Although hazard control and accident prevention

partially are dependent upon the design and

configuration of the machine, these factors are also

dependent upon the awareness, concern, and proper

training of the personnel involved in the operation,

transport, maintenance, and storage of the machine.

Improper use or maintenance of the machine can result

in injury or death. To reduce the potential for injury or

death, comply with the following safety instructions.

Since the Rake–O–Vac must be towed to operate, it is

extremely important that the tow tractor be carefully

selected to assure the best performance and safe operation.

The tow tractor must have the proper wheel base and tread

width and equipped with a roll bar and seat belt to operate

safely on hilly terrain. The normal operating speed is 6 mph

but will vary with terrain and debris being picked up. The

maximum transport speed is 20 mph with slower speeds

required on hilly terrain. Refer to tractor Operator’s Manual

for information or tractor service agency if you have any

question on safe operation.

The brakes of the tow tractor must have the capacity to stop

the Rake–O–Vac with hopper fully loaded and traveling at

the maximum recommended transport speed.

The power take–off drive of the Rake–O–Vac requires a

tractor with operating speeds of 540 rpm and output power

of 20 hp or higher. Do not exceed the 540 rpm speed.

The Rake–O–Vac must comply with local road

requirements, if transported on public roads. A

Slow–moving vehicle sign has been provided. Signal lights

and brakes are not provided and may be required in some

areas.

This manual identifies potential hazards and has special

safety messages that help you and others avoid personal

injury and even death. Danger, Warning, and Caution are

signal words used to identify the level of hazard. However,

regardless of the hazard, be extremely careful.

Danger signals an extreme hazard that will cause serious

injury or death if you do not follow the recommended

precautions.

Warning signals a hazard that may cause serious injury or

death if you do not follow the recommended precautions.

Caution signals a hazard that may cause minor or moderate

injury if you do not follow the recommended precautions.

This manual uses two other words to highlight information.

Important calls attention to special mechanical

information and Note: emphasizes general information

worthy of special attention.

Before Operating

• Operate the machine only after reading and

understanding the contents of this manual. A

replacement manual is available by sending complete

model and serial number to:

The Toro Company

8111 Lyndale Avenue South

Bloomington, Minnesota 55420–1196.

• Never allow children to operate the machine or adults to

operate it without proper instructions.

• Become familiar with the controls and know how to

stop the engine/sweeper quickly.

• Keep all shields, safety devices and decals in place. If a

shield, safety device or decal is malfunctioning,

illegible, or damaged, repair or replace it before

operating the machine.

3

Page 4

• Always wear substantial shoes. Do not operate machine

while wearing sandals, tennis shoes or sneakers. Do not

wear loose fitting clothing which could get caught in

moving parts and cause personal injury.

– Shut engine off and wait for all movement to stop.

The impeller may momentarily turn after other

components have stopped. Use extreme caution

when removing cover from blower housing.

• Wearing safety glasses, safety shoes, long pants and a

helmet is advisable and required by some local safety

and insurance regulations.

• Keep everyone, especially children and pets away from

the areas of operation.

• Since gasoline is highly flammable, handle it carefully.

– Use an approved gasoline container.

– Do not remove cap from fuel tank when engine is

hot or running.

– Do not smoke while handling gasoline.

– Fill fuel tank outdoors and to about one inch below

top of tank, (bottom of filler neck). Do not overfill.

– Wipe up any spilled gasoline.

While Operating

• Exhaust fumes are hazardous and could be deadly, so do

not run the engine in a confined area without adequate

ventilation.

• This product may exceed noise levels of 85 dB(A) at

the operator position. Ear protectors are recommended,

for prolonged exposure, to reduce the potential of

permanent hearing damage.

• Never carry passengers on prime mover or allow

anyone to ride on sweeper.

• Disengage clutch before starting sweeper engine.

• Using the machine demands attention. To prevent

tipping or loss of control:

– Use extreme caution around ditches, creeks or other

hazards.

– Watch for holes or other hidden hazards.

– Use caution when operating machine on a steep

slope. Reduce speed when making sharp turns or

when turning on hillsides.

– Avoid sudden stops and starts.

– Before backing up, look to the rear and assure no

one is behind the machine.

– Watch out for traffic when near or crossing roads.

Always yield the right of way.

• Before leaving operator position:

– Shift into neutral, stop prime mover and engage

parking brake.

– Disengage and lower sweeper implement.

– Shut sweeper engine off.

– Disengage P.T.O.

– Take precautions to prevent accidental starts, rolling

away, etc.

• Do not step over P.T.O. shaft to get to other side of

machine. Walk around sweeper.

• Never get on or off prime mover with P.T.O. shaft

engaged.

• If prime mover or sweeper ever vibrate abnormally,

stop immediately, turn engine off, wait for all motion to

stop and inspect for damage. Repair all damage before

commencing operation.

• Whenever machine is left unattended, be sure engine is

stopped, implement is lowered and key is removed from

ignition switch.

• Shut sweeper blower off when dumping contents of

hopper. Always stand to extreme right or left side of

hopper when opening tailgate.

• Park on a level surface, empty hopper and block wheels

before removing sweeper from prime mover.

Maintenance

• Disengage power to sweeper implement and stop engine

before servicing or making adjustments.

• Disengage power to sweeper implement and stop engine

when transporting or not in use.

• To make sure entire machine is in good condition, keep

all nuts, bolts and screws properly tightened.

• If major repairs are ever needed or assistance is

required, contact an Authorized TORO Distributor.

• To reduce potential fire hazard, keep the engine area

free of excessive grease, grass, leaves and accumulation

of dirt.

• If the engine must be running to perform a maintenance

adjustment, keep hands, feet, clothing, and any parts of

the body away from the engine and any moving parts.

Keep everyone away.

• Do not overspeed engine by changing governor settings.

To assure safety and accuracy, have an Authorized Toro

Distributor check maximum engine speed with a

tachometer. P.T.O. driven machines must not exceed

540 R.P.M.

4

Page 5

• Engine must be shut off before checking oil or adding

oil to the crankcase.

• Check prime mover brakes periodically to be sure

brakes, when applied, will hold firmly. Also, check to

make sure all safety equipment is functioning properly.

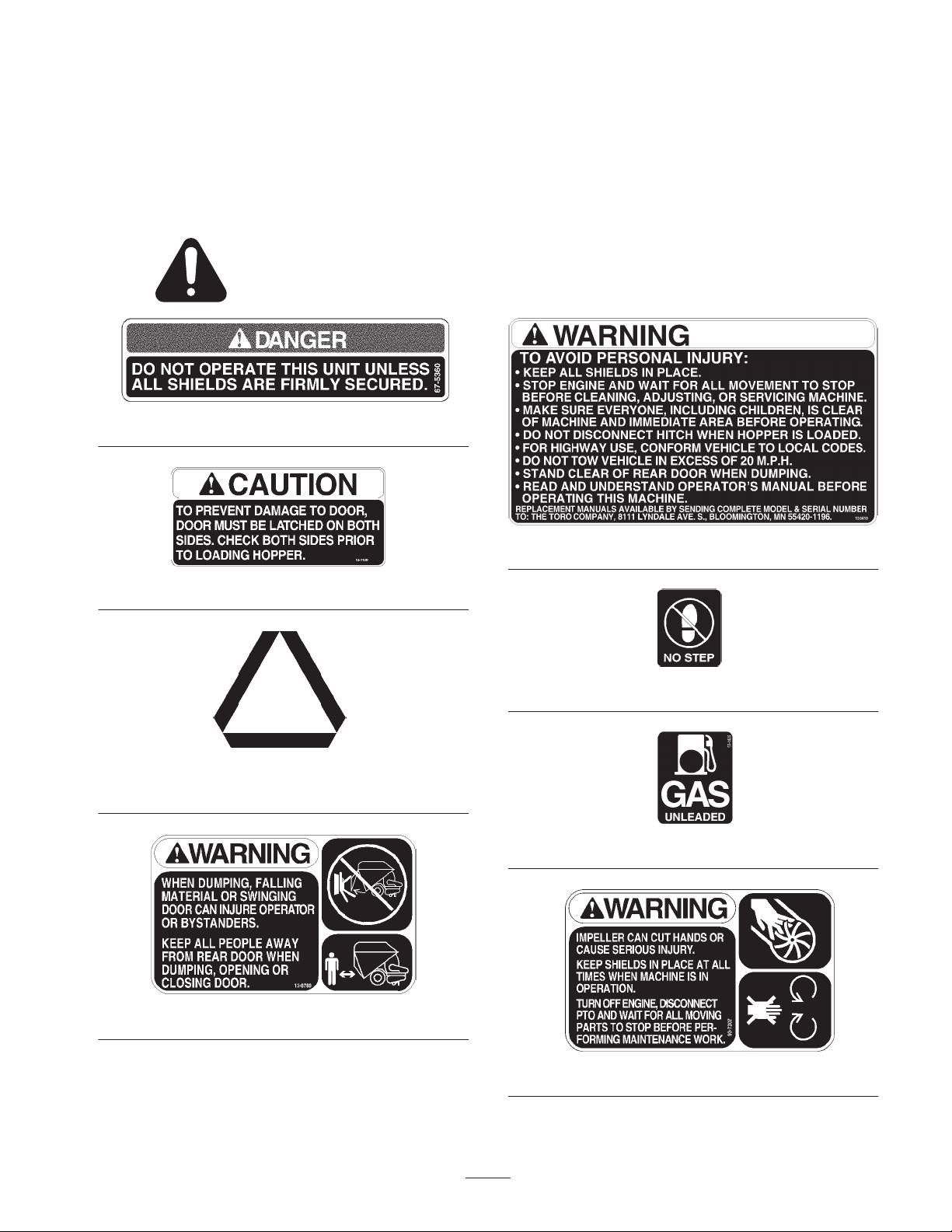

Safety and Instruction Decals

Safety decals and instructions are easily visible to the operator and are located near any area

of potential danger. Replace any decal that is damaged or lost.

67-5360

• To be sure of optimum performance and safety, always

purchase genuine TORO replacement parts and

accessories. Replacement parts and accessories made by

other manufacturers could be dangerous. Such use

could void the product warranty of The Toro Company.

1. Slow moving vehicle

13-6410

13-7430

61-5950

13-2930

53-4420

13-6760

93-7307

5

Page 6

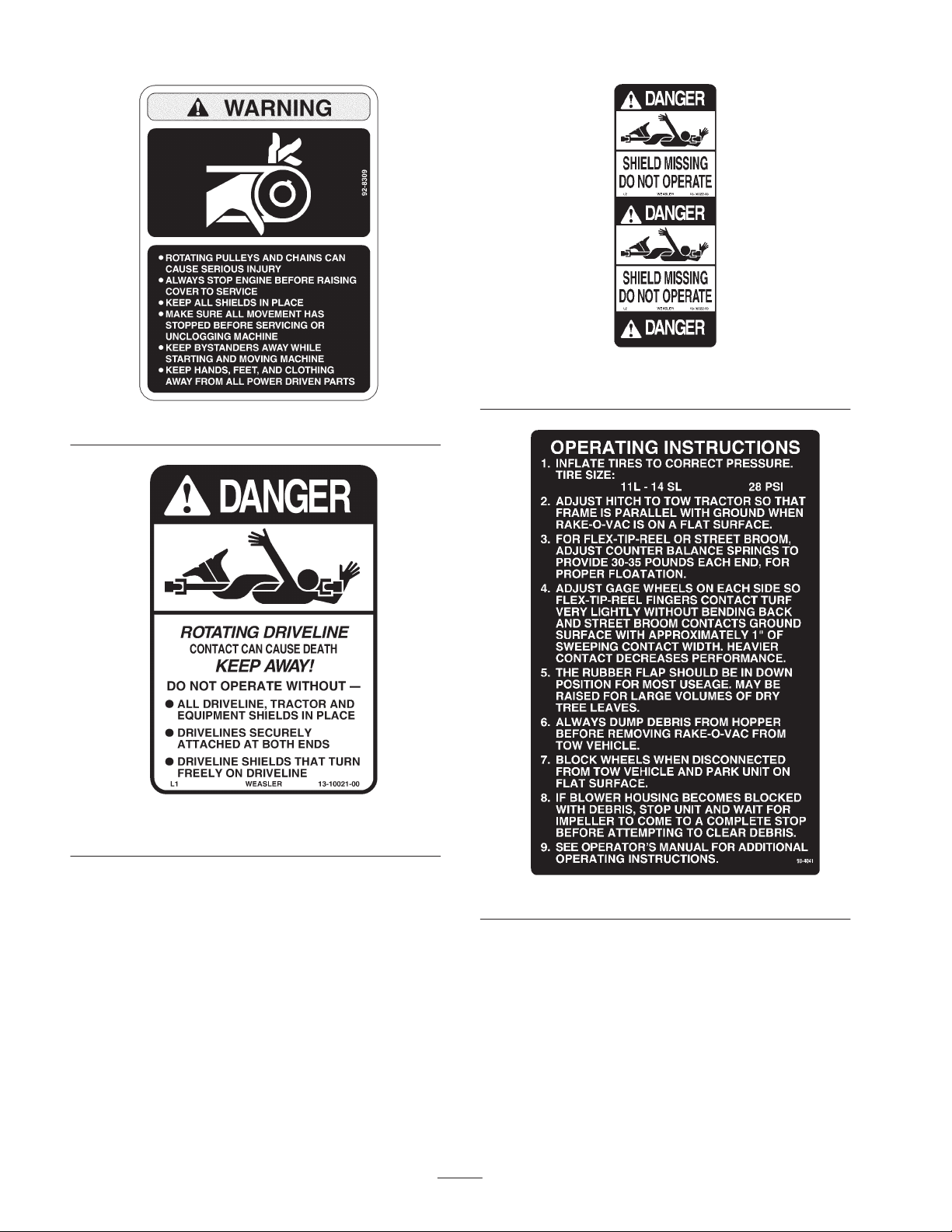

92-8309

92-1581

(Model 07052)

92-1582

(Model 07052)

93-4041

6

Page 7

Specifications

Note: Specifications and design are subject to change without notice.

(Model 07050): Kohler, 4 cycle air cooled 22 H.P. engine @ 3600 rpm, 41.1 cu. in.

Machine Drive

Frame All welded structural rectangular 11 ga. tubing.

Hitch (Model 07050) Pin–type, 3/4” dia. vertically adjustable in 1” increments.

(674 cc) displacement. Oil capacity is 4 pints w/filter. Mechanical fuel pump. Gas

tank capacity is 4 gallons.

(Model 07052): Powered by Power Take Off drive from prime mover–540 RPM.

Hitch (Model 07052)

Fan

Fan Drive (Model 07050)

Fan Drive (Model 07052)

Hopper

Flex Tip Reel

Flex Tip Reel Drive

(Model 07050)

Pin–type, 3/4” dia. three vertical positions for tractor hitches ranging from 7–1/4” to

17–1/4” in height.

Centrifugal type–double inlet; 4 blade, 16” wide, 23–14” diameter, 3/16” thick, high

tensile steel. Shaft mounted in self–aligning, sealed ball bearings. Blower inlet area

is 286 sq. in., blower discharge area is 255 sq. in. Twin fan hood construction for

uniform air distribution: 4–1/2” deep x 63” wide (inlet area–283 sq. in.); variable

position from weighted rubber flap.

Banded double drive belt direct from drive shaft to fan impeller drive shaft with

driver pulley, fan with driven pulley. Fan impeller runs at 1580 R.P.M. (tip speed

9100 ft./min.) at 3250 engine R.P.M.

Banded double drive belt direct from drive shaft to fan impeller drive shaft with

driver pulley, fan with driven pulley. Fan impeller runs at 1490 R.P.M. (tip speed

9100 ft./min.) with 540 PTO R.P.M.

5–3/4 cu. yd. volume; 18 gauge top section with 16 gauge bottom section–rib

reinforced; full width self cleaning semi–automatic dumping.

Forward spinning with 6 rows of teeth. All steel construction with replaceable nylon

teeth; each row containing 11 individually spring–loaded flexible sets, 552 teeth

total; shaft set in self–aligning sealed bearings. Reel supported by adjustable

counter balance springs and adjustable gauge wheels. Gauge wheels are steel

construction with non–scuffing rubber tires and sealed ball bearings; infinitely

adjustable vertically.

Banded double drive belt from engine pulley to jackshaft pulley; belt from jack shaft

(driver) pulley to flex tip reel (driven) pulley. Flex tip runs at 275 R.P.M. (tip speed

1355 ft./min.) at 3250 engine R.P.M.

Flex Tip Reel Drive

(Model 07052)

#60 roller chain from 40 tooth side shaft sprocket to 29 tooth jackshaft sprocket.

Belt jack shaft (driver) pulley flex tip reel (driven) pulley. Flex tip runs at 260 R.P.M.

(tip speed 1,230 ft./min.) with 540 R.P.M.

Dimensions and Weights

(approx.)

Width 85–1/2”

Height 79–1/2”

Length 13’ 3” (Model 07050)

14’ (Model 07052)

Empty Weight 2160 lb. (Model 07050)

1980 lb. (Model 07052)

Optional Equipment

Hard Surface Brush Kit Model No. 07162

Thatching Reel Kit Model No. 07178

Flex Tip Reel Model No. 07164

Spark Arrester Muffler* Kohler No 1218902

* Contact Your Local Kohler Dealer

7

Page 8

Setup

Note: Determine the left and right side of the machine from the normal operating position.

Description Qty. Use

Clutch Adjusting Plates

Bolt

Nut

Operator’s Manual

Engine Operator’s Manual

Parts Catalog 1

Registration Card 1 Fill out and return to Toro.

Remove, Activate And Charge

Battery

(Model 07050 only)

1. If Battery is not filled with electrolyte or activated, bulk

electrolyte with 1.260 specific gravity must be

purchased from a local battery supply outlet and added

to battery.

Danger

Battery electrolyte contains sulfuric acid which is a

deadly poison and causes severe burns.

• Do not drink electrolyte and avoid contact with

skin, eyes or clothing. Wear safety glasses to

shield your eyes and rubber gloves to protect

your hands.

• Fill the battery where clean water is always

available for flushing the skin.

2

4

4

1

1

Use to torque clutch

Read before operating the machine.

2. When battery is charged, disconnect charger from

electrical outlet and battery posts. Allow battery to sit

for 5 to 10 minutes before proceeding to next step.

3. Unhook springs from battery cover, remove cover and

lift battery out of battery box.

4. Remove filler caps from battery and slowly fill each

cell until electrolyte is up to fill line.

5. Replace filler caps and connect a 3 to 4 amp battery

charger to the battery posts. Charge the battery at a rate

of 3 to 4 amperes for 4 to 8 hours.

Warning

Charging the battery produces gasses that can

explode.

Never smoke near the battery and keep sparks and

flames away from battery.

6. Remove filler caps and slowly add electrolyte to each

cell until level is up fill line. Install filler caps.

Warning

CALIFORNIA

Proposition 65 Warning

Battery posts, terminals, and related accessories

contain lead and lead compounds, chemicals

known to the State of California to cause cancer

and reproductive harm. Wash hands after

handling.

Important Do not overfill battery. Electrolyte will

overflow onto other parts of the machine and severe

corrosion and deterioration will result.

Install Battery

(Model 07050 only)

1. Slide the battery into battery box with the terminals to

the inside.

8

Page 9

Warning

5. Adjust sweeper hitch tongue to same level as hitch of

prime mover as follows:

Battery terminals or metal tools could short

against metal tractor components causing sparks.

Sparks can cause the battery gasses to explode,

resulting in personal injury.

• When removing or installing the battery, do not

allow the battery terminals to touch any metal

parts of the tractor.

• Do not allow metal tools to short between the

battery terminals and metal parts of the tractor.

2. Attach the negative cable (wire from engine block) to

the negative (–) terminal of the battery.

Warning

Incorrect battery cable routing could damage the

tractor and cables causing sparks. Sparks can

cause the battery gasses to explode, resulting in

personal injury.

• Always disconnect the negative (black) battery

cable before disconnecting the positive (red)

cable.

• Always connect the positive (red) battery cable

before connecting the negative (black) cable.

Model 07050

• Remove capscrews and locknuts securing hitch tongue

to frame (Fig. 2).

• Raise or lower hitch tongue to position approximately

level with prime move hitch and secure with (2)

capscrews and locknuts.

1

3

23–1/2”

3. Attach the positive cable (wire from ignition switch) to

the positive (+) terminal.

4. Coat the terminals and mounting fasteners with

petroleum jelly to prevent corrosion.

5. Install battery cover and secure with springs.

Mount Sweeper To Prime

Mover

To assure proper debris pickup, make sure sweeper frame is

parallel with the ground.

1. Position sweeper on a flat, level surface.

2. Insert sweeper jack caster wheel onto sweeper end of

jack tube.

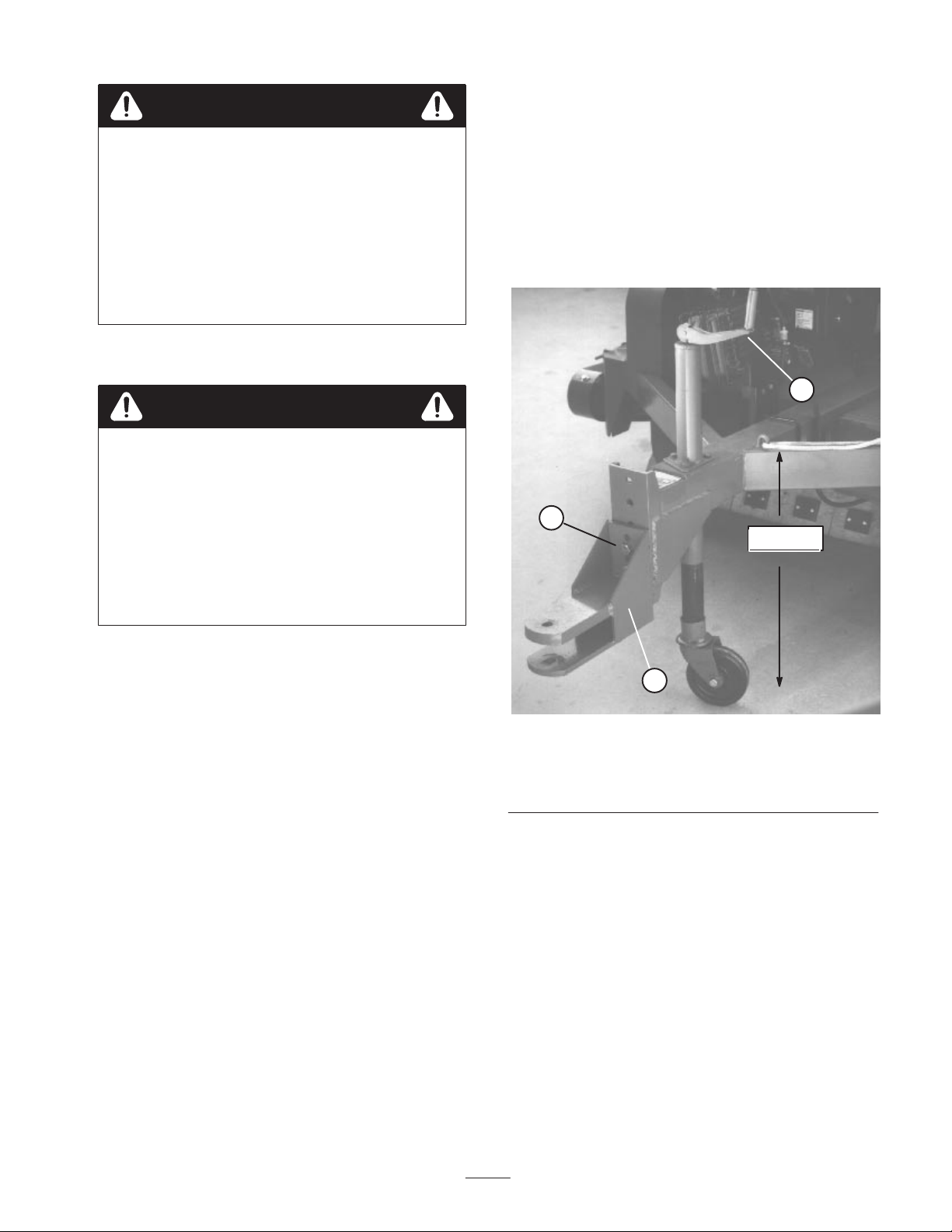

3. Adjust sweeper jack so distance from top of frame to

ground is approximately 23–1/2” (Fig. 2).

4. Back prime mover up to sweeper.

2

Figure 2

1. Sweeper jack

2. Hitch tongue

(Model 07050)

3. Adjusting screws

Model 07052

• Remove front and rear capscrews and locknuts securing

hitch tongue to frame (Fig. 3).

• Raise or lower hitch tongue to position it approximately

level with prime move hitch and secure with (2)

capscrews and locknuts. The main frame should be

parallel with the ground surface about 23–1/2” when

attached to tractor.

9

Page 10

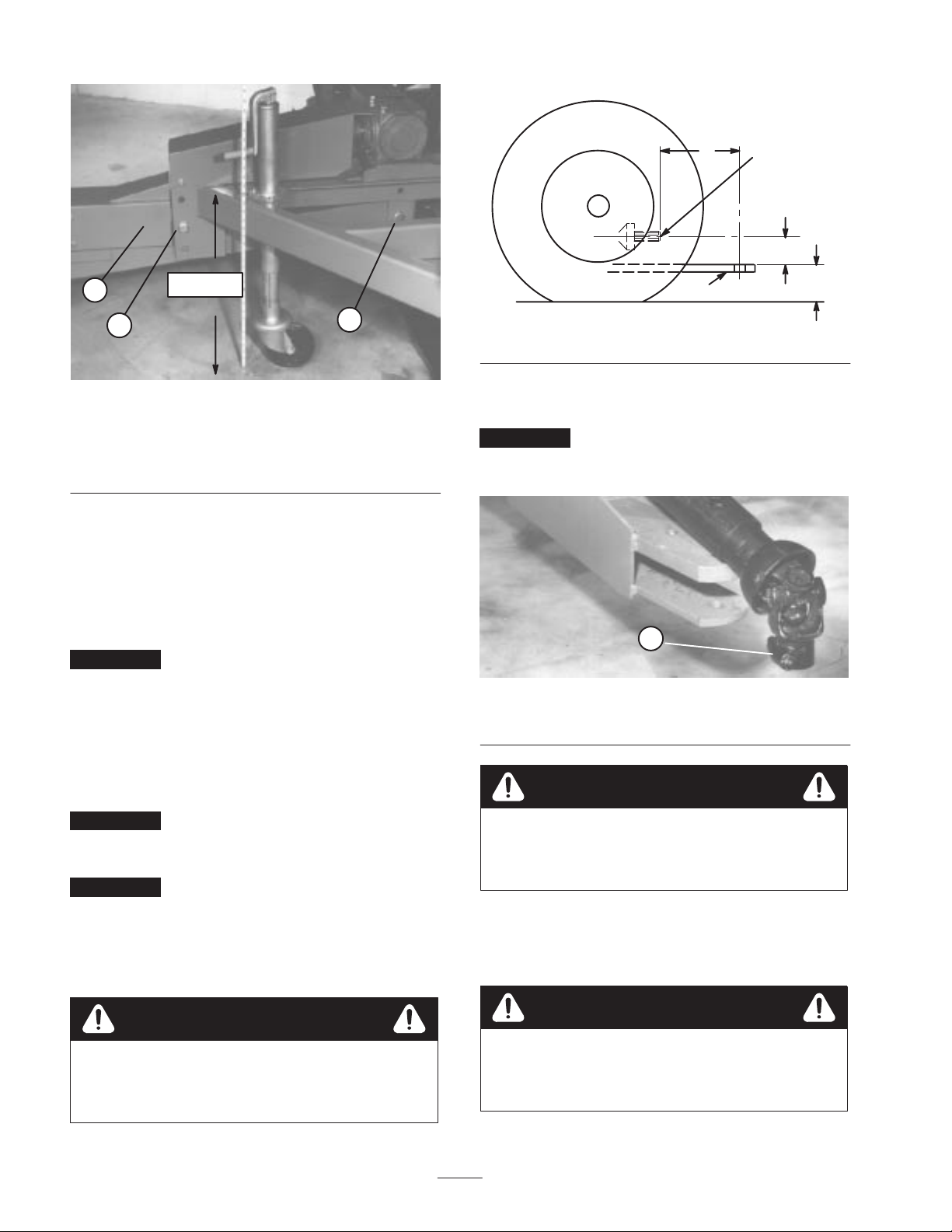

A = 13–1/2” TO 14–l/2”

B = 2–3/4” TO 11–1/2’’

C = 7–1/4” TO 17–1/4”

A

P.T.O. SHAFT

(540 RPM)

B

1

2

1. Hitch tongue

(Model 07052)

2. Front adjustment

capscrew

6. Secure sweeper hitch tongue to prime mover hitch with

hitch pin and hair pin cotter.

7. Raise sweeper jack caster wheel tube up to frame and

fold handle down.

8. Store caster wheel in compartment on left side of

machine in front of hopper.

Important After first ten hours of operation, re–tighten

capscrews and locknuts securing hitch tongue to sweeper.

23–1/2”

3

Figure 3

3. Rear adjustment

capscrew

Connecting Drive Shaft to

DRAW BAR

Figure 4

1. Attach drive shaft quick disconnect to P.T.O. shaft of

prime mover.

Important A shield should be provided on tractor to

cover drive shaft universal joint. Do not operate drive shaft

without this shield in place.

1

Figure 5

1. Drive shaft quick coupler

C

Prime Mover PTO Shaft

(Model 07052 only)

Important Mating tractor must have the dimensions

shown in figure 4. Do not operate sweeper with tractor of

different dimensions.

Important The distance (“A” Figure 4) between the

hole in the tractor hitch and the point where the drive shaft

coupler attaches to the prime mover, P.T.O. shaft must be

14’’ plus or minus 1/2”. If 14” is not attained, an

adjustment to the tractor hitch must be made before

operating sweeper.

Warning

If ”B” dimension (Fig. 4) is less than 3”, extreme

caution must be used when tractor and sweeper

unit crests tops of steep hills.

Warning

This sweeper is designed for a 540 RPM P.T.O.

shaft only. Do not operate with a 1000 RPM P.T.O.

tractor.

Removing Sweeper From

Prime Mover

Warning

Always empty sweeper hopper before

disconnecting hopper from prime mover or

sweeper may tip backwards and cause injury.

1. Park sweeper on a level surface and block wheels.

10

Page 11

2. On Model 07052 only, disconnect drive shaft quick

coupler from prime mover PTO shaft.

3. Insert castor wheel onto jack tube.

4. Raise sweeper jack handle and lower caster wheel to

ground.

5. Continue to raise sweeper with jack until hair pin cotter

and hitch pin can be removed from hitch.

Before Operating

Caution

1

Figure 7

1. Filler cap

Before servicing or making adjustments to the

machine, stop engine(s), disengage clutch and

disconnect PTO (If so equipped) from prime

mover.

Check Engine Oil

(Model 07050 only)

The engine is shipped with approximately 2 quarts

(w/filter) of oil in the crankcase; however, level of oil must

be checked before and after the engine is first started.

1. Position machine on a level surface.

2. Remove dipstick and wipe it with a clean rag. Insert

dipstick into tube and make sure it is seated fully.

Remove dipstick from tube and check level of oil. If oil

level is low, remove filler cap and add enough oil to

raise level to “FULL” mark on dipstick.

1

3. The engine uses any high-quality detergent oil having

the American Petroleum Institute -API- “service

classification” SG, SH or SJ. Oil viscosity (weight) is

selected according to the anticipated ambient

temperature.

Temperature / viscosity recommendations are:

• Above 0F (–20C) – Use 10W–30 or 10W–40.

• Below 32F (0C) – Use 5W–20 or 5W–30.

4. Pour oil into fill opening until the oil level is up to the

“FULL” mark on the dipstick. Add the oil slowly and

check the level often during this process. DO NOT

OVERFILL

Important Check level of oil every 8 operating hours

or daily. Initially, change oil after the first 5 hours of

operation; thereafter, under normal conditions, change oil

every 100 hours and filter every 200 hours. However,

change oil more frequently when engine is operated in

extremely dusty or dirty conditions.

5. Install the dipstick firmly in place.

Check Clutch Housing Oil

1. Dipstick

Figure 6

(Model 07050 only)

The clutch housing uses any high-quality detergent oil

having the American Petroleum Institute -API- “service

classification” SE, SF, SG or SH. Recommended viscosity

(weight) is SAE 30.

1. Position machine on a level surface.

2. Remove oil level plug on side of clutch housing.

11

Page 12

2

1

3

Figure 8

1. Oil level plug

2. Filler/breather plug

3. If oil drips from hole, there is enough oil in clutch

housing. Replace plug.

4. If oil does not drip from hole, oil must be added to

clutch housing. Do not replace plug.

5. Remove filler plug from top of clutch housing.

6. Add enough oil to clutch housing until it drips out oil

level hole.

7. Reinstall plugs.

3. Drain plug

Fill Fuel Tank

(Model 07050 only)

Fuel tank capacity is approximately 4 gallons.

Use unleaded regular gasoline suitable for automotive use

(85 pump octane minimum). Leaded regular gasoline may

be used if unleaded regular is not available.

Important Never use methanol, gasoline containing

methanol, or gasohol containing more than 10% ethanol

because the fuel system could be damaged. Do not mix oil

with gasoline.

Danger

In certain conditions, gasoline is extremely

flammable and highly explosive. A fire or

explosion from gasoline can burn you and others

and can damage property.

• Fill the fuel tank outdoors, in an open area,

when the engine is cold. Wipe up any gasoline

that spills.

• Do not fill the fuel tank completely full. Add

gasoline to the fuel tank until the level is 1 in.

(25 mm) below the bottom of the filler neck.

This empty space in the tank allows gasoline to

expand.

• Never smoke when handling gasoline, and stay

away from an open flame or where gasoline

fumes may be ignited by a spark.

• Store gasoline in an approved container and

keep it out of the reach of children. Never buy

more than a 30-day supply of gasoline.

• Always place gasoline containers on the ground

away from your vehicle before filling.

• Do not fill gasoline containers inside a vehicle or

on a truck or trailer bed because interior

carpets or plastic truck bed liners may insulate

the container and slow the loss of any static

charge.

• When practical, remove gas-powered equipment

from the truck or trailer and refuel the

equipment with its wheels on the ground.

• If this is not possible, then refuel such

equipment on a truck or trailer from a portable

container, rather than from a gasoline dispenser

nozzle.

• If a gasoline dispenser nozzle must be used, keep

the nozzle in contact with the rim of the fuel

tank or container opening at all times until

fueling is complete.

Check Tire Pressure

Check tire pressure daily to assure proper level.

Correct tire pressure is 28 psi.

1. Clean area around fuel tank cap.

2. Remove fuel tank cap.

3. Fill tank to about one inch below top of tank, (bottom of

filler neck). DO NOT OVERFILL. Then install cap.

4. Wipe up any fuel that may have spilled to prevent a fire

hazard.

12

Page 13

Transport Hooks

1. Lift each end of reel and remove transport hooks before

operating machine.

2. Position a spring scale on transport hook and lift up.

Tension necessary to lift gauge wheel off ground should

be 30–50 lbs.

3. If tension is not 30–50 lbs., adjustment is made by

tightening or loosening adjustment screw on

counterbalance spring.

1

Figure 9

1. Transport hook

2. When transporting sweeper from one location to

another, support flex tip reel, broom or thatching reel.

with transport hooks.

Adjust Reel Support Arm

When machine is operated, gauge wheel should ride over

the turf evenly. If reel support arm has a tendency to

bounce, spring setting is too tight. If gauge wheel scars turf,

spring setting is too light.

To adjust reel support arm:

4. Perform this procedure on both sides of sweeper.

Note: Because of added weight of drive components, the

R.H. spring will require a tighter setting than the L.H.

spring.

Adjust Rake Depth

Flex tip reel should be adjusted so rake tips slightly touch

surface but do not penetrate turf. If rake tips penetrate turf,

improper debris pickup could result.

1. Position sweeper on a level surface.

2. Loosen locknut on depth adjustment bolt so it can be

turned.

1

1. Pull rake lever rearward to lower flex tip reel or broom.

1

3

1. Spring scale

2. Counterbalance spring

2

Figure 10

3. Adjustment screw

Figure 11

1. Locknut

3. Turn depth adjustment bolt until rake slightly contacts

top of turf grass. If a broom is installed, slight contact

should be made with surface. When broom is operating,

the contact width surface should be about 1” wide

across entire length of broom.

1

Figure 12

1. Depth adjusting bolt

13

Page 14

4. Repeat procedure on opposite side of machine.

5. Retighten adjustment lock nut.

Adjust Rubber Flap

Operation

Note: Determine the left and right sides of the machine

from the normal operating position.

For best debris pick up results, metal portion of front flap

should be vertical to ground.

1. Move flat lever forward to lower flat.

2

1

Figure 13

1. Rubber flap 2. Metal edge

2. Loosen jam nut on top of stop and rotate adjustment

bolt up or down until flap is vertical to ground.

Controls

Flap Lever

Move flap lever (Fig. 15) downward to engaged position

and upward for disengaged position. Move lever to upward

position when transporting machine.

Reel Lever

Push reel lever (Fig. 15) forward to raise flex tip reel. To

lower flex reel, push lever forward until catch releases, then

push to rear until lever hits STOP. Move lever to raised

position when sweeper is not in operation, when storing

machine or when transporting machine.

1

2

1

2

Figure 14

1. Adjustment bolt 2. Stop

3. Tighten jam nut to secure adjustment.

Note: Flap may be positioned in raised position when

picking up large amounts of leaves.

Figure 15

1. Flap lever 2. Reel lever

Clutch Handle

The clutch handle (Fig. 16) is located on the clutch

housing. Push outward on clutch handle to engage and

inward to disengage (Model 07050 only).

Important Move sweeper as quickly as possible after

lowering reel lever and engaging clutch lever to prevent

turf damage.

14

Page 15

Throttle Control

1

Figure 16

1. Clutch handle

Choke Control

To start a cold engine, close carburetor choke by moving

choke control lever (Fig. 17) to the “ON” position. After

engine starts, regulate choke to keep engine running

smoothly. As soon as possible, open the choke by moving

lever to the “OFF” position. Starting a warm engine

requires little or no choking (Model 07050 only).

Throttle (Fig. 17) is used to operate engine at various

speeds. Moving throttle lever to FAST position increases

engine speed. To decrease engine speed, move lever to

SLOW position (Model 07050 only).

Tailgate Latch Rope

Pull tailgate latch rope (Fig. 18) to unlatch tailgate when

emptying hopper.

2

1

Figure 18

1. Tailgate latch rope 2. Jack handle

1

2

Figure 17

1. Choke control

2. Ignition switch

3

3. Throttle control

Ignition Switch

The ignition switch (Fig. 17), which is used to start and

stop the engine, has three positions: OFF, RUN and

START. Rotate key clockwise — START position — to

engage starter motor. Release key when engine starts. The

key will move automatically to the ON position. To shut

engine off, rotate key counterclockwise to the OFF position

(Model 07050 only).

Starting Instructions

(Engine Driven)

1. Place all controls in disengaged or off position.

2. Move throttle lever midway between SLOW and FAST

position.

3. Move choke lever to ON position.

Note: Choke not required when starting a warm engine.

4. Insert key into ignition switch and rotate it clockwise to

start the engine. Release key when engine starts.

Regulate the choke to keep engine running smoothly.

Important To prevent overheating of the starter motor,

do not engage starter longer than 10 seconds. After 10

seconds of continuous cranking, wait 60 seconds before

engaging starter motor again.

5. Move throttle lever to desired engine speed.

6. Pull flap lever as far forward as possible.

7. Push rake lever to the rear as far as possible.

8. Engage rake by engaging clutch handle.

Note: Do not allow sweeper to stand still with rake

engaged as turf damage may occur.

15

Page 16

Stopping Instructions

1. Disengage power to rake by disengaging clutch lever.

2. Move throttle lever to “SLOW” position.

3. Move ignition switch to “OFF” position. Remove key

from switch to prevent accidental starting.

Important To stop sweeper in an emergency, move

ignition switch to “OFF”position.

Important Do not operate sweeper while reel is turning

and in the raised position. Damage to the rake and tires may

result if teeth come in contact with tires.

Caution

This product may exceed noise levels of 85 dB(A)

at the operator position. Ear protectors are

recommended, for prolonged exposure, to reduce

the potential of permanent hearing damage.

Starting Instructions

(PTO Driven)

1. Read and understand all operating procedures in tow

tractor operator’s manual. Contact tow tractor dealer or

manufacturer regarding any questions you have about

safety or operation.

2. Make sure all P.T.O. guards are installed and operating

properly.

3. Know how to stop tow tractor and sweeper in an

emergency.

4. Pull flap lever as far forward as possible.

5. Push rake lever to the rear as far as possible.

6. Engage rake by engaging clutch handle.

Note: Do not allow sweeper to stand still with rake

engaged as turf damage may occur.

Operating Tips

• Before starting to sweep, survey area to determine the

best direction to sweep.

• To empty hopper, pull tailgate latch rope.

Inspection And Cleanup After

Operation

• When sweeping has been completed, thoroughly clean

and wash the machine. Air dry hopper. After cleaning, it

is recommended that the machine be inspected for

possible damage to mechanical components and blower.

These procedures will assure that the machine will

perform satisfactorily during next sweeping operation.

Important When towing sweeper for long distances,

fasten gauge wheel arm securely to sweeper frame with

transport hooks. Should gauge wheel arm fall to ground,

damage to sweeper may occur.

Note: To maintain a straight line when sweeping, sight of

an object in the foreground.

• Always try to make a long, continuous run with a slight

overlap on the return run.

• On turf areas, the flex tip reel will pick up twigs,

clippings, leaves, pine needles and cones, small debris

(beverage cans, small bottles, paper plates, etc.).

• The rake teeth are made of flexible nylon and easily

changed. To prevent damage, the rake is protected from

solid obstructions by spring action. The nylon teeth will

not mar bronze, stone markers, sidewalks or pavement.

• Because of its unique design, the sweeper also grooms

the turf. The flex tip reel combs through and lifts grass

for a uniform cut when mowed. As it cleans, the light

scarifying action increase water and pesticide

penetration, thus reducing the need for renovation.

Important Do not make sharp turns when using the

thatching reel as damage to turf may occur.

16

Page 17

Maintenance

Note: Determine the left and right sides of the machine

from the normal operating position.

Important Refer to your engine operator’s manual for

additional maintenance procedures.

Lubrication

The Rake–O–Vac has grease fittings that must be lubricated

regularly with No. 2 General Purpose Lithium Base Grease.

Lubricate bearings after every 30 hours of operation or

whenever machine is washed with water. Bearings and

bushings must be lubricated daily when operating

conditions are extremely dusty and dirty. Dusty and dirty

operating conditions could cause dirt to get into the

bearings and bushings, resulting in accelerated wear. The

grease fittings that must be lubricated are the gauge wheel

bearings (2) (Fig. 19); reel shaft bearings (2) (Fig. 19);

impeller shaft bearings (2) (Fig. 20); Jackshaft bearings (2)

(Fig. 21) left and right trailing arms (1 ea.) (Fig. 21) front

and rear drive shafts (6) (Model 07052 only)

(Fig. 22 & 23).

1. Wipe grease fittings clean so foreign matter cannot be

forced into the bearing or bushing.

Figure 20

2. Pump grease into the bearing or bushing.

3. Wipe up excess grease.

Figure 19

Figure 21

To lubricate drive shafts:

1. Disconnect sweeper from P.T.O. shaft on prime mover.

2. Rotate shafts by hand until you can see the grease

fittings through the three holes in sides of shields.

17

Figure 22

Page 18

Changing Engine Oil and Filter

(Model 07050 only)

Change oil initially after the first 5 hours of operation,

thereafter change oil every 100 hours and filter every 200

hours.

1. Park the machine on a level surface and turn the engine

off.

2. Remove drain plug and let oil flow into drain pan.

When oil stops, install drain plug.

Note: Warm oil flows better and carries more contaminants

than cold oil.

3. Remove oil filter. Apply a light coat of clean oil to the

new filter gasket.

Figure 23

Oil Drive Chain

(Model 07052)

Oil entire length of all chains every 30 hours of operation

with SAE 30 oil.

Figure 24

Oil Sweeper Jack

Sweeper jack must be oiled after every 50 hours of

operation.

2

1

Figure 26

1. Drain plug 2. Oil filter

4. Screw filter on by hand until gasket contacts mounting

plate, then tighten 1/2 turn further. DO NOT

OVER–TIGHTEN.

5. Add oil to crankcase, refer to Check Engine Oil.

Figure 25

6. Dispose of used oil properly.

18

Page 19

General Air Cleaner

Maintenance

4. Blow compressed air from inside to the outside of dry

filter element. Do not exceed 100 psi to prevent damage

to the element.

(Model 07050 only)

• Check air cleaner body for damage which could

possibly cause an air leak. Replace a damaged air

cleaner body.

• Service the air cleaner filters every 400 hours (more

frequently in extreme dusty or dirty conditions). Do not

over service air filter.

• Be sure cover is sealing around air cleaner body.

Servicing Air Cleaner

1. Release latches securing air cleaner cover to air cleaner

body. Separate cover from body. Clean inside of air

cleaner cover.

4

2

5. Keep air hose nozzle at least 2” from filter and move

nozzle up and down while rotating the filter element.

Inspect for holes and tears by looking through the filter

toward a bright light.

6. Inspect new filter for shipping damage. Check sealing

end of filter. Do not install a damaged filter.

7. Insert new filter properly into air cleaner body. Make

sure filter is sealed properly by applying pressure to

outer rim of filter when installing. Do not press on

flexible center of filter.

8. Reinstall cover and secure latches. Make sure cover is

positioned with TOP side up.

Replacing Spark Plugs

(Model 07050 only)

Replace spark plugs or reset gap after every 200 operating

hours to assure proper engine performance and reduce

exhaust emission level.

Correct spark plug to use is a Champion RC 12YC or

equivalent.

Recommended air gap is .040”.

3

1

Figure 27

1. Air cleaner latches

2. Dust cup

2. Gently slide primary filter out of air cleaner body to

reduce the amount of dust dislodged. Avoid knocking

filter against air cleaner body. Do not remove safety

filter.

3. Inspect primary filter and discard if damaged. Do not

wash or reuse a damaged filter.

Important Never attempt to clean a safety filter.

Replace the safety filter with a new one after every

three primary filter services.

3. Primary filter

4. Safety filter

Note: The spark plug usually lasts a long time; however,

the plug should be removed and checked whenever the

engine malfunctions.

1. Clean area around spark plugs so foreign matter cannot

fall into cylinder when spark plug is removed.

2. Pull spark plug wires off spark plugs and remove plugs

from cylinder head.

3. Check condition of side electrode, center electrode, and

center electrode insulator to assure there is no damage.

.040”

Figure 28

19

Page 20

Important A cracked, fouled, dirty or otherwise

malfunctioning spark plug must be replaced. Do not sand

blast, scrape, or clean electrodes by using a wire brush

because grit may eventually release from the plug and fall

into the cylinder. The result is usually a damaged engine.

Changing Clutch Housing Oil

(Model 07050 only)

Clutch housing oil should be changed annually, or every

800 hours of operation, whichever comes first.

Removing Debris From Engine

(Model 07050 only)

To ensure proper cooling, make sure the grass screen,

cooling fins and other external surfaces of the engine are

kept clean at all times.

Every 100 hours of operation (more often under extremely

dusty, dirty conditions) remove the blower housing and

other cooling shrouds and clean the cooling fins and

external surfaces as necessary. Make sure cooling shrouds

are reinstalled.

Note: Operating the engine with a blocked grass screen,

dirty or plugged cooling fins or cooling shrouds removed,

will cause engine damage due to overheating.

Replace Fuel Filter

(Model 07050 only)

Replace fuel filter after every 600 hours of operation.

1. Place a clean container under fuel filter.

2. Remove clamps securing fuel filter to fuel lines.

1. Place a drain pan under drain plug at bottom of housing.

2. Remove drain plug at bottom of housing and remove

filler plug.

Note: Warm oil flows better and carries more contaminants

than cold oil.

3. Allow all oil to drain out.

4. Replace drain plug.

5. Remove filler/breather plug from top of clutch housing.

6. Remove oil level plug on side of clutch housing.

7. Add enough oil to clutch housing until it drips out

overflow hole.

2

1

1

Figure 29

1. Fuel filter

3. Install new fuel filter to fuel lines with clamps

previously removed. Filter to be mounted so arrow

points toward carburetor.

3

Figure 30

1. Oil level plug

2. Filler/breather plug

8. Reinstall plugs.

3. Drain plug

Adjusting Clutch

(Model 07050 only)

If clutch slips, an adjustment is required. A properly

adjusted clutch will require 45–50 pounds of force applied

to clutch lever, 12 inches above clutch lever pivot shaft.

To check clutch adjustment proceed as follows:

1. Loosely assembly clutch adjusting plates together with

(4) bolts and nuts (Fig. 31).

20

Page 21

2. Insert clutch adjusting plates onto clutch handle.

3. Position adjusting plates on clutch handle so distance

between center of square hole in plates and center of

clutch lever pivot shaft is 12 inches. Tighten fasteners

securing adjusting plates to clutch lever.

Warning

Do not operate P.T.O. with clutch cover plate

removed as rotating parts can cause injury.

3

1

4

2

1. Clutch lever

2. Clutch lever pivot shaft

Figure 31

3. Clutch adjusting plates

4. Clutch cover plate

Changing Rubber Flap

Replace rubber flap when it becomes worn or damaged.

Caution

12.00”

Change rubber flap on a flat, level surface and

block wheels to prevent sweeper from rolling.

Failure to do so may result in personal injury.

1. Remove (10) capscrews, washers, and nuts mounting

flap and flap retainer.

2

1

4. Insert torque wrench into square holes in adjusting

plates and check to make sure torque is 45–50 pounds.

5. Remove adjusting plates and store in a memorable

place.

To adjust clutch proceed as follows:

1. Remove clutch cover plate.

2. Loosen clutch locking tab.

3. Turn adjusting ring clockwise until proper adjustment is

attained.

4. Tighten clutch locking tab.

5. Insert torque wrench into square holes in adjusting

plates and check to make sure torque is 45–50 pounds.

6. Install cover plate.

Figure 32

1. Rubber flap 2. Flap retainer

2. Replace with new rubber flap and fasten securely.

Cleaning Blower Housing

Warning

Before removing any debris from blower housing,

disengage clutch, disengage P.T.O. drive, stop

engine(s) and make certain all moving parts have

stopped or personal injury may occur.

21

Page 22

1. Make sure impeller has stopped rotating before

removing access plates.

2. Loosen (2) wing nuts securing access plate.

1

Figure 33

1. Access plate (2)

3. Swing access plate to one side allowing removal of

debris.

4. After debris has been removed, lower access plate and

secure with wing nuts. Repeat procedure on other

access plate.

Adjusting Belts

1

3

2

Figure 34

1. Impeller belt

2. Jackshaft belt

3. Idler pulley

Note: It is not necessary to remove upper belt guard

(Fig. 35) to check belt tension. If for some reason belt

guard must be removed, remove (4) capscrews, washers

and nuts securing guard to frame. Never operate sweeper

without guards in place.

Check condition and tension of belts after first day of

operation and every 200 operating hours thereafter.

Impeller Drive Belt

(Model 07050 only)

1. Check tension by depressing belt at mid span of

impeller and clutch pulleys with 4 to 5 lbs. of force.

Belt should deflect .5 in. If deflection is incorrect,

proceed to next step. If correct, continue operation.

1

Figure 35

1. Upper belt guard

22

Page 23

2. To adjust belt tension:

• Loosen (4) engine mounting bolts.

Impeller Drive Belt

(Model 07052 only)

1. Check tension by depressing belt at mid span of

impeller and reel gear case pulleys with 5–7 lbs. of

force. Belt should deflect .5 in. If deflection is incorrect,

proceed to next step. If correct, continue operation.

2. To adjust belt tension:

• Loosen drive chain idler sprocket (Fig. 41) and back it

off completely.

• Loosen (4) capscrews on gear box base and (2)

1

capscrews on gear box shields.

Figure 36

1. Engine mounting bolts

• Turn belt adjusting (Fig. 37) bolt until desired belt

tension is obtained. Retighten engine mounting bolts.

Reorient engine to make sure engine is parallel with

frame. Retighten engine mounting bolts.

1

Figure 37

1. Adjusting bolt

3

1

4

2

Figure 38

1. Drive belt

2. Gear box base

3. Gear box shield

4. Adjustment bolt

• Turn adjustment bolt on back on gear box base until

proper belt tension is attained.

• Square up gear box base parallel to frame by moving

L.H. end (gear box end) to required position.

• Tighten all capscrews.

3. Whenever impeller belt is adjusted it is necessary to

readjust jackshaft belt (engine drive) or chain (PTO

drive).

Note: Make sure gear box base is square on frame and not

set on an angle when adjusting belt tension.

• Readjust and tighten idler sprocket on drive chain.

23

Page 24

Jackshaft Belt

(Model 07050 only)

1. Check tension by depressing belt at mid span of

jackshaft and clutch pulleys with 4 to 5 lbs. of force.

Belt should deflect .25 in. If deflection is incorrect,

proceed to next step. If correct, continue operation.

2. To adjust belt tension:

• Remove (4) capscrews, washers and nuts securing

upper shroud to frame (Fig. 35).

• If belt has too much slack, loosen idler pulley nut, press

forward on idler pulley until desired tension is obtained

and retighten idler pulley nut.

• If belt is too tight, loosen idler pulley nut, pull rearward

on idler pulley until desired tension is obtained and

retighten idler pulley nut.

Reel Drive Belt

1. Check tension by depressing belt at mid span of idler

pulley and reel driver pulley with 25–29 lbs. of force.

Belt should deflect .25 in. If deflection is incorrect,

proceed to next step. If correct, continue operation.

2. To adjust belt tension:

• Remove (2) capscrews, nut, retaining nut and washer

securing lower belt guard to frame (Fig. 39). Remove

guard.

2

1

Figure 40

1. Reel drive belt 2. Idler pulley

Adjusting Drive Chain

(Model 07052 only)

1. Check tension by pressing side of chain at mid span of

upper and lower drive sprockets with 10 lbs. of force.

Chain should deflect .10 in. in each direction from

center (.20 total deflection from side to side). If

deflection is incorrect, proceed to next step. If correct,

continue operation.

2. To adjust drive chain tension:

1

Figure 39

1. Lower belt guard

• If belt has too much slack, loosen idler pulley nut

(Fig. 40), press down on idler pulley until desired

tension is obtained and retighten idler pulley nut.

• If belt is too tight, loosen idler pulley nut (Fig. 40), pull

upward on idler pulley until desired tension is obtained

and retighten idler pulley nut.

• Reinstall guard. Make sure there is clearance between

belt and belt guard.

• Remove idler sprocket mounting capscrew.

• Add or delete spacers behind idler sprocket until upper

drive sprocket and lower drive sprocket properly

aligned.

3

2

1

1. Drive chain

2. Idler sprocket

4

Figure 41

3. Upper drive sprocket

4. Lower driven sprocket

24

Page 25

• To increase chain tension push idler sprocket toward

chain. To decrease chain tension push idler sprocket

away from chain.

Note: Make sure all sprockets are in alignment. Failure to

do this could result in throwing of chains, plugging sweeper

and may result in personal injury.

Changing Gear Box Oil

(Model 07052 only)

Change gear box oil every 800 hours of operation .

1. Remove capscrews securing shield to gear box and

frame.

Warning

Gear Box Removal

(Model 07052 only)

1. Remove capscrews securing shield to gear box and

frame.

2. Remove (4) capscrews securing bottom of gear box to

gear box base plate.

2

DO NOT OPERATE SWEEPER WITH SAFETY

SHIELDS REMOVED. If safety shields are

removed from sweeper and maintenance is being

performed, make sure universal coupler is

disconnected from prime mover P.T.O. shaft.

2. Place a pan on the ground beneath gear box.

3. Remove oil drain plug from bottom of gear box and

allow all oil to drain out.

1

2

Figure 42

1. Fill plug/breather 2. Drain plug

4. When all oil has drained out of gear box secure oil drain

5. Remove oil fill plug/breather from top of gear box.

1

1. Gear box base plate

2. Coupler sprockets

3. Disconnect double coupler chain by removing clip and

pin and remove from coupler sprockets.

4. Pull gear box to the rear of sweeper until universal shaft

pulls out of its housing.

5. Lift gear box from sweeper and perform maintenance.

To mount gear box back on sweeper reverse procedure.

Note: When gear box is set back on gear box base make

sure it is squared up as close as possible.

3

4

Figure 43

3. Double coupler chain

4. Universal shaft

Warning

If the side coupler sprocket and the front universal

joint are removed from gear box make sure they

are replaced in the same orientation on the gear

box. (Note there is an end plate cover on the

opposite side of the coupler sprocket, but there is

no end plate cover on opposite side of universal

joint) Failure to do this will cause extreme high

speed operation of the sweeper and may cause

personal injury.

6. Fill gear box with 2 pints of 80 or 90 weight oil.

7. Insert plug into hole and secure.

25

Page 26

1

6. Install all shields.

Pulley Removal

To remove any pulley secured by a taper lock bushing,

proceed as follows:

1. Remove capscrews and lockwashers one at a time and

screw into adjoining holes.

1. Side coupler sprocket

2. Front universal joint

2

Figure 44

3. End plate cover

3

Locking Collar Removal

(Model 07052 only)

If it becomes necessary to replace the bearings or shaft, the

eccentric locking collars must be removed, proceed as

follows:

1. Remove shields over drive shafts.

2. To loosen eccentric locking collar, place a punch in

cutout on collar. Using a hammer, drive collar in

opposite direction of the shafts rotation.

3

2

1

Figure 46

1. Capscrews & lockwasher

2. Taper lock bushing

2. Turn each capscrew the same number of times until

lock separates. Pulley will now slide off shaft.

3. Taper lock release hole

1

Figure 45

1. Eccentric locking collar

3. Slide collar off shaft and replace necessary parts.

4. Slide collar back onto shaft and snug it up tight against

bearing.

5. With the hammer and punch, drive eccentric locking

collar in the direction of the shafts rotation. This will

tighten collar.

Flex Tip Reel Removal

Removal of flex tip reel should be done on a hard and level

surface.

1. Raise front of sweeper as high as possible by lowering

jack.

2. Raise reel to highest position.

3. Remove lower belt guard (Fig. 39) and reel drive belt

(Fig. 40).

4. Remove (2) capscrews, lockwashers and nuts securing

reel shaft bearings to reel support arms on each side of

sweeper. Lower flex tip reel to the ground.

5. Lift reel support arms to the highest position.

6. Slide end of rake rearward and pull out from under

machine.

26

Page 27

Thatcher Installation

A 32 tooth jackshaft sprocket, a 19 tooth idler sprocket and

a No. 60 chain make up the Thatcher Kit Drive

Components.

1. Remove lower belt guard (Fig. 39) and reel drive belt

(Fig. 40).

2. Remove capscrew and washer securing jackshaft pulley

to jackshaft and remove pulley.

2

11. Put reel support arms in a lowered position.

12.Remove jam nut and adjusting screw. Slide spacer off

adjusting screw.

3

4

2

5

1

4

1

5

3

Figure 47

1. Thatcher reel

2. Reel support arm

3. Jackshaft sprocket

4. Idler sprocket

5. Chain

3. Slide 16 Tooth Jackshaft sprocket onto jackshaft.

4. Secure by tightening two (2) set screws and lock nuts

on sprocket hub.

5. Remove idler pulley presently on machine and replace

it with 19 tooth (#60) idler sprocket supplied with

Thatcher Kit.

6. Slide Thatcher into position and secure to reel support

arms.

7. Align idler sprocket with jackshaft sprocket and

thatcher sprocket.

8. Install No. 60 chain, included in kit. Lubricate with

SAE 30 oil.

9. Push down on idler sprocket until desired chain tension

is obtained.

10.Fasten idler sprocket securely.

Note: Spacers mounted on lift mechanism adjusting screws

must be removed when thatcher is installed on machine.

Figure 48

1. Spacer

2. Adjusting screw

3. Jam nut

4. Pivot block

5. Clevis

13.Reassemble jam nut and adjusting screw with spacer

positioned on adjusting screw between pivot block and

clevis. This is the storage position for spacer during

thatcher operation.

14.Repeat procedure on other side of sweeper.

Note: Spacers should be re–installed whenever the thatcher

is removed and either the brush or flex tip reel is mounted

to sweeper.

Flex Tip Rake Rod Or Finger

Plate Replacement

1. Remove capscrew and locknut from one end of reel.

2. Remove locknut only, from opposite end of reel.

3. Drive rod from end plate. Drive rod from end without

the tab welded to it.

4. Remove finger plates or rods as required and replace.

5. Line up finger plate with rod and drive rod back

through end plate.

6. Attach capscrew and locknuts and hook up springs.

27

Page 28

1

Figure 49

1. Capscrew and locknut 2. Locknut

Brush Half Replacement

2

1. Remove brush from sweeper.

2. Loosen clamps with a allen wrench and remove from

brush halves.

1

Flex Tip Rake Tine

Replacement

1. Remove tine retainer and slide damaged tine out.

2

1

Figure 51

1. Clamp

3. Separate brush halves and discard damaged section(s).

Figure 52

4. Install new brush section(s) by pushing together and

3

secure both ends with brush clamps. When ends have

been secured, fasten brush with remaining clamps.

Figure 50

1. Finger plate

2. Tine retainer

2. Bend new tine in half and slide into position.

3. Place tine bracket over curved end of tine and fasten

securely with capscrew and lockwasher.

3. Tine

28

Page 29

Changing Tires

1. Park machine on a flat, level surface. Block other tire to

prevent accidental rolling or injury.

2. Place jack under frame or axle shaft behind wheel and

jack up wheel until it just contacts floor.

Warning

A 2000 lb. capacity hydraulic jack should be used

when changing a tire.

3. Loosen all lug bolts and continue to jack up until tire

can be removed.

4. Reverse above procedure to install tire. Torque lug bolts

to 70 to 90 ft.–lbs.

Warning

CALIFORNIA

Proposition 65 Warning

Battery posts, terminals, and related accessories

contain lead and lead compounds, chemicals

known to the State of California to cause cancer

and reproductive harm. Wash hands after

handling.

• If corrosion occurs at terminals, disconnect cables,

negative (–) cable first and scrape clamps and terminals

separately. Reconnect cables, positive (+) cable first and

coat terminals with petroleum jelly.

• Check the electrolyte level every 25 operating hours or,

if machine is in storage, every 30 days.

Battery Care

(Model 07050 only)

• Battery electrolyte level must be properly maintained

and the top of the battery kept clean. lf the machine is

stored in a location where temperatures are extremely

high, the battery will run down more rapidly than if the

machine is stored in a location where temperatures are

cool.

Danger

Battery electrolyte contains sulfuric acid which is a

deadly poison and causes severe burns.

• Do not drink electrolyte and avoid contact with

skin, eyes or clothing. Wear safety glasses to

shield your eyes and rubber gloves to protect

your hands.

• Fill the battery where clean water is always

available for flushing the skin.

• Keep top of battery clean by washing periodically with

a brush dipped in ammonia or bicarbonate of soda

solution. Flush the top surface with water after cleaning.

Do not remove the fill cap while cleaning.

• Battery cables must be tight on terminals to provide

good electrical contact.

• Maintain cell level with distilled or demineralized

water. Do not fill cells above fill line.

• If machine will be stored for more than 30 days, remove

the battery and charge it fully. Either store it on the

shelf on the machine. Leave the cables disconnected if

stored on the machine. Store the battery in a cool

atmosphere to avoid quick deterioration of the charge in

the battery. To prevent battery from freezing, make sure

it is fully charged. The specific gravity of a fully

charged battery is 1.250.

Warning

Charging the battery produces gasses that can

explode.

Never smoke near the battery and keep sparks and

flames away from battery.

Warning

Battery terminals or metal tools could short

against metal tractor components causing sparks.

Sparks can cause the battery gasses to explode,

resulting in personal injury.

• When removing or installing the battery, do not

allow the battery terminals to touch any metal

parts of the tractor.

• Do not allow metal tools to short between the

battery terminals and metal parts of the tractor.

29

Page 30

30

Page 31

31

Page 32

The Toro General Commercial Products Warranty

A Two-Year Limited Warranty

Conditions and Products Covered

The Toro Company and its affiliate, Toro Warranty Company,

pursuant to an agreement between them, jointly warrant your 1996

or newer Toro Commercial Product (“Product”) purchased after

January 1, 1997, to be free from defects in materials or

workmanship for two years or 1500 operational hours*, whichever

occurs first. Where a warrantable condition exists, we will repair

the Product at no cost to you including diagnosis, labor, parts, and

transportation. This warranty begins on the date the Product is

delivered to the original retail purchaser.

* Product equipped with hour meter

Instructions for Obtaining Warranty Service

You are responsible for notifying the Commercial Products

Distributor or Authorized Commercial Products Dealer from whom

you purchased the Product as soon as you believe a warrantable

condition exists.

If you need help locating a Commercial Products Distributor or

Authorized Dealer, or if you have questions regarding your

warranty rights or responsibilities, you may contact us at:

Toro Commercial Products Service Department

Toro Warranty Company

8111 Lyndale Avenue South

Bloomington, MN 55420-1196

952-888-8801 or 800-982-2740

E-mail: commercial.service@toro.com

Owner Responsibilities

As the Product owner, you are responsible for required maintenance and adjustments stated in your operator’s manual. Failure

to perform required maintenance and adjustments can be grounds

for disallowing a warranty claim.

Items and Conditions Not Covered

Not all product failures or malfunctions that occur during the

warranty period are defects in materials or workmanship. This

express warranty does not cover the following:

• Product failures which result from the use of non-Toro

replacement parts, or from installation and use of add-on,

modified, or unapproved accessories

• Product failures which result from failure to perform required

maintenance and/or adjustments

• Product failures which result from operating the Product in an

abusive, negligent or reckless manner

• Parts subject to consumption through use unless found to be

defective. Examples of parts which are consumed, or used up,

during normal Product operation include, but are not limited to,

blades, reels, bedknives, tines, spark plugs, castor wheels,

tires, filters, belts, etc.

• Failures caused by outside influence. Items considered to be

outside influence include, but are not limited to, weather,

storage practices, contamination, use of unapproved coolants,

lubricants, additives, or chemicals, etc.

• Normal “wear and tear” items. Normal “wear and tear”

includes, but is not limited to, damage to seats due to wear or

abrasion, worn painted surfaces, scratched decals or windows, etc.

Parts

Parts scheduled for replacement as required maintenance are

warranted for the period of time up to the scheduled replacement

time for that part.

Parts replaced under this warranty become the property of Toro.

T oro will make the final decision whether to repair any existing part

or assembly or replace it. Toro may use factory remanufactured

parts rather than new parts for some warranty repairs.

General Conditions

Repair by an Authorized Toro Distributor or Dealer is your sole

remedy under this warranty.

Neither The Toro Company nor Toro Warranty Company is

liable for indirect, incidental or consequential damages in

connection with the use of the T oro Products covered by this

warranty, including any cost or expense of providing substitute equipment or service during reasonable periods of

malfunction or non-use pending completion of repairs under

this warranty. Except for the Emissions warranty referenced

below, if applicable, there is no other express warranty. All

implied warranties of merchantability and fitness for use are

limited to the duration of this express warranty.

Some states do not allow exclusions of incidental or consequential

damages, or limitations on how long an implied warranty lasts, so

the above exclusions and limitations may not apply to you.

This warranty gives you specific legal rights, and you may also

have other rights which vary from state to state.

Note regarding engine warranty: The Emissions Control

System on your Product may be covered by a separate warranty

meeting requirements established by the U.S. Environmental

Protection Agency (EPA) and/or the California Air Resources

Board (CARB). The hour limitations set forth above do not apply to

the Emissions Control System Warranty. Refer to the Engine

Emission Control Warranty Statement printed in your operator’s

manual or contained in the engine manufacturer’s documentation

for details.

Countries Other than the United States or Canada

Customers who have purchased Toro products exported from the United States or Canada should contact their Toro Distributor (Dealer)

to obtain guarantee policies for your country, province, or state. If for any reason you are dissatisfied with your Distributor’s service or

have difficulty obtaining guarantee information, contact the Toro importer. If all other remedies fail, you may contact us at Toro Warranty

Company.

Part No. 374-0031 Rev. –

Loading...

Loading...