Page 1

FormNo.3370-794RevA

66inRake-O-Vac

ModelNo.07050—SerialNo.312000001andUp

®

Sweeper

ToregisteryourproductordownloadanOperator'sManualorPartsCatalogatnocharge,gotowww.T oro.com.OriginalInstructions(EN)

Page 2

ThisproductcomplieswithallrelevantEuropean

g015255

1

directives,fordetailspleaseseetheseparateproduct

specicDeclarationofConformity(DOC)sheet.

WARNING

CALIFORNIA

Proposition65Warning

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

ThissparkignitionsystemcomplieswithCanadian

ICES-002.

Important:Thisengineisnotequippedwitha

sparkarrestermufer.ItisaviolationofCalifornia

PublicResourceCodeSection4442touseoroperate

theengineonanyforest-covered,brush-covered,or

grass-coveredland.Otherstatesorfederalareas

mayhavesimilarlaws.

Introduction

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoidinjury

andproductdamage.Youareresponsibleforoperating

theproductproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comfor

productandaccessoryinformation,helpndingadealer,

ortoregisteryourproduct.

Figure1

1.Locationofthemodelandserialnumbers

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjury

ordeathifyoudonotfollowtherecommended

precautions.

Figure2

1.Safetyalertsymbol

Thismanualuses2otherwordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Wheneveryouneedservice,genuineToroparts,

oradditionalinformation,contactanAuthorized

ServiceDealerorToroCustomerServiceandhave

themodelandserialnumbersofyourproductready.

Figure1illustratesthelocationofthemodelandserial

numbersontheproduct.Writethenumbersinthe

spaceprovided.

©2012—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

Contents

Introduction.................................................................2

Safety...........................................................................4

SafeOperatingPractices.......................................4

SafetyandInstructionalDecals.............................6

Setup...........................................................................8

1ActivatingandChargingtheBattery....................8

2MounttheSweepertothePrime

Mover..............................................................9

3RemovingSweeperfromthePrime

Mover............................................................10

ProductOverview......................................................11

Controls.............................................................11

Specications.....................................................12

Operation...................................................................12

AddingFuel.......................................................12

CheckingtheEngineOilLevel............................13

StartingandStoppingtheEngine........................13

TransportingtheMachine...................................14

AdjustingtheRakeDepth...................................14

AdjusttheRubberFlap.......................................14

InspectandCleanupafterOperation...................15

OperatingTips...................................................15

Maintenance...............................................................16

RecommendedMaintenanceSchedule(s)................16

Lubrication.............................................................17

Lubrication.........................................................17

OiltheSweeperJack...........................................17

EngineMaintenance...............................................18

ServicingtheAirCleaner....................................18

ChangingtheEngineOilandFilter.....................18

ServicingtheSparkPlugs....................................19

RemoveDebrisfromtheEngine.........................19

FuelSystemMaintenance.......................................20

ReplacingtheFuelFilter.....................................20

ElectricalSystemMaintenance................................20

ServicingtheBattery...........................................20

DriveSystemMaintenance.....................................21

TireMaintenance................................................21

BeltMaintenance....................................................22

InspectingtheBelts............................................22

AdjustingtheBelts.............................................23

ChangingtheRubberFlap......................................24

PulleyRemoval.......................................................24

FlexTipReelRemoval............................................25

FlexTipRakeRodOrFingerPlate

Replacement...................................................25

FlexTipRakeTineReplacement.............................26

BrushHalfReplacement.........................................26

Cleaning.................................................................27

CleaningtheBlowerHousing..............................27

Storage.......................................................................27

3

Page 4

Safety

Improperuseormaintenancebytheoperator

orownercanresultininjury.Toreducethe

potentialforinjury,complywiththesesafety

instructionsandalwayspayattentiontothesafety

alertsymbol,whichmeans

Danger

complywiththeinstructionmayresultinpersonal

injuryordeath.

—personalsafetyinstruction.Failureto

SafeOperatingPractices

Caution

,

W ar ning

Preparation

•Evaluatetheterraintodeterminewhataccessories

andattachmentsareneededtoproperlyand

safelyperformthejob.Onlyuseaccessoriesand

attachmentsapprovedbythemanufacturer.

,or

•Weartheappropriateclothingincludingahardhat,

safetyglasses,andhearingprotection.Longhair,

looseclothing,orjewelrymaygettangledinmoving

parts.

•Useextracarewhenhandlinggasolineandother

fuels.Theyareammableandthevaporsare

explosive.

Training

•ReadtheOperator’sManualandothertraining

material.Iftheoperator(s)ormechanic(s)cannot

readEnglishitistheowner’sresponsibilitytoexplain

thismaterialtothem.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateor

servicetheequipment.Localregulationsmayrestrict

theageoftheoperator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtohimselforherself,

otherpeopleorproperty.

•Themachinemustbetowedtooperate,itis

extremelyimportantthatthetowtractorbecarefully

selectedtoassurethebestperformanceandsafe

operation.

•Thetowtractormusthavetheproperwheelbase,

treadwidth,workingseatbelt,andmustbeequipped

witharollbartooperatesafelyonhillyterrain.

Thenormaloperatingspeedis6MPH(9km/h)

butwillvarywithterrainanddebrisbeingpicked

up.Themaximumtransportspeedis20MPH(32

km/h)withslowerspeedsrequiredonhillyterrain.

RefertotractorOperator’sManualforinformationor

tractorserviceagencyifyouhaveanyquestionon

safeoperation.

•Thebrakesofthetowtractormusthavethecapacity

tostopthemachinewithhopperfullyloadedand

travelingatthemaximumrecommendedtransport

speed.

•Ensurethatthemachinecomplieswithlocalroad

requirementswhenbeingtransportedonpublic

roads.Aslowmovingvehiclesignhasbeenprovided.

Signallightsandbrakesarenotprovidedandmay

berequiredinsomeareas.

–Useonlyanapprovedcontainer.

–Neverremovethegascaporaddfuelwiththe

enginerunning.

–Allowtheenginetocoolbeforerefueling.

–Donotsmokewhenhandlinggasolineandother

fuels.

–Neverrefuelordrainthemachineindoors.

•Checkthattheoperatorpresencecontrols,safety

switches,andshieldsareattachedandfunctioning

properly.Donotoperateunlesstheyarefunctioning

properly.

•Keepallshields,safetydevices,anddecalsinplace.

Ifashield,safetydevice,ordecalismalfunctioning,

illegible,ordamaged,replaceitbeforeoperatingthe

machine.

Operation

•Neverrunanengineinanenclosedarea.

•Onlyoperateingoodlight,keepingawayfromholes

andhiddenhazards.

•Besurealldrivesareinneutralandparkingbrakeis

engagedbeforestartingengine.Starttheengineonly

fromtheoperator’sposition.

•Neveroperatewithouttheshields,covers,orother

guardssecurelyinplace.Besureallinterlocksare

functioningproperly .

•Stoponalevelground,emptythehopper,andblock

thewheelsbeforeremovingthesweeperfromthe

primemover.

•Shuttheengineoffandwaitforallmovementto

stop.Theimpellermaymomentarilyturnafterother

componentshavestopped.Useextremecaution

whenremovingthecoverfromtheblowerhousing.

•Keephandsandfeetawayfromthesweeperarea.

•Nevercarrypassengers.Keeppetsandbystanders

away.

4

Page 5

•Bealert,slowdown,andusecautionwhenmaking

turns.Lookbehindandtothesideofthemachine

beforechangingdirections.

•Beforebackingup,looktotherearofthemachine

andensurethatnooneisbehindthemachine.

•Slowdownandusecautionwhencrossingroads

andsidewalks.

MaintenanceandStorage

•Disengagethepowertothemachine,stopthe

engine,andwaitforallmovementtostopbefore

adjusting,cleaning,repairing,ortransporting.

•Cleanthegrassanddebrisfromtheraketines,drives,

mufers,andenginetohelppreventres.Cleanup

anyoilorfuelspillage.

•Donotoperatethemachineundertheinuenceof

alcoholordrugs.

•Lightningcancausesevereinjuryordeath.If

lightningisseen,orthunderisheardinthearea,do

notoperatethemachine;seekshelter.

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscurevision.

•Useextremecautionaroundditches,creeks,orother

hazards.

•Avoidsuddenstopsandstarts.

•Ifthemachinevibratesabnormally,stopimmediately ,

turntheengineoff,waitforallmotiontostop,and

inspectfordamage.Repairallofthedamagebefore

operation.

•Shutthesweeperbloweroffwhendumpingthe

contentsofthehopper.Alwaysstandtotheextreme

rightorleftsideofthehopperwhenopeningthe

tailgate.

SlopeOperation

•Donotoperateneardrop-offs,ditches,steepbanks,

orwater.Wheelsdroppingoveredgescancause

rollovers,whichmayresultinseriousinjuryordeath.

•Donotoperateonslopeswhengrassiswet.Slippery

conditionsreducetractionandcouldcausesliding

andlossofcontrol.

•Donotmakesuddenturnsorrapidspeedchanges.

•Reducespeedanduseextremecautiononslopes.

•Removeormarkobstaclessuchasrocks,treelimbs,

etc.fromtheoperatingarea.Tallgrasscanhide

obstacles.

•Lettheenginecoolbeforestoringanddonotstore

nearame.

•Shutoffthefuelwhilestoringortransportingon

trailers.Donotstorethefuelnearamesordrain

indoors.

•Disconnectthebatteryorremovethesparkplug

wiresbeforemakinganyrepairs.Disconnectthe

negativeterminalrstandthepositiveterminallast.

Reconnectthepositiveterminalrstandthenegative

terminallast.

•Keephandsandfeetawayfromanymovingparts.If

possible,donotmakeadjustmentswiththeengine

running.

•Donotoverspeedtheenginebychangingthe

governorsettings.Toensuresafetyandaccuracy,

haveanauthorizedT orodistributorcheckthe

maximumenginespeedwithatachometer.

•Lettheenginecoolbeforecheckingtheoiloradding

oiltothecrankcase.

•Checktheprimemoverbrakesandallsafety

equipmentperiodically .

•Chargethebatteryinanopen,wellventilatedarea,

awayfromsparkandames.Unplugthecharger

beforeconnectingordisconnectingitfromthe

battery.Wearprotectiveclothinganduseinsulated

tools.

•Keepallofthepartsingoodworkingconditionand

allhardwaretightened.Replaceallofthewornor

damageddecals.

•UseonlyToro-approvedattachments.The

warrantymaybevoidedifthemachineisusedwith

unapprovedattachments.

•Watchforditches,holes,rocks,dips,andrisesthat

changetheoperatingangle,asroughterraincould

overturntheaerator.

•Alwaysavoidsuddenstartingorstoppingonaslope.

Iftireslosetraction,disengagethetinesandproceed

slowlyofftheslope.

•Followtherecommendationsforwheelweightsor

counterweightstoimprovestability.

5

Page 6

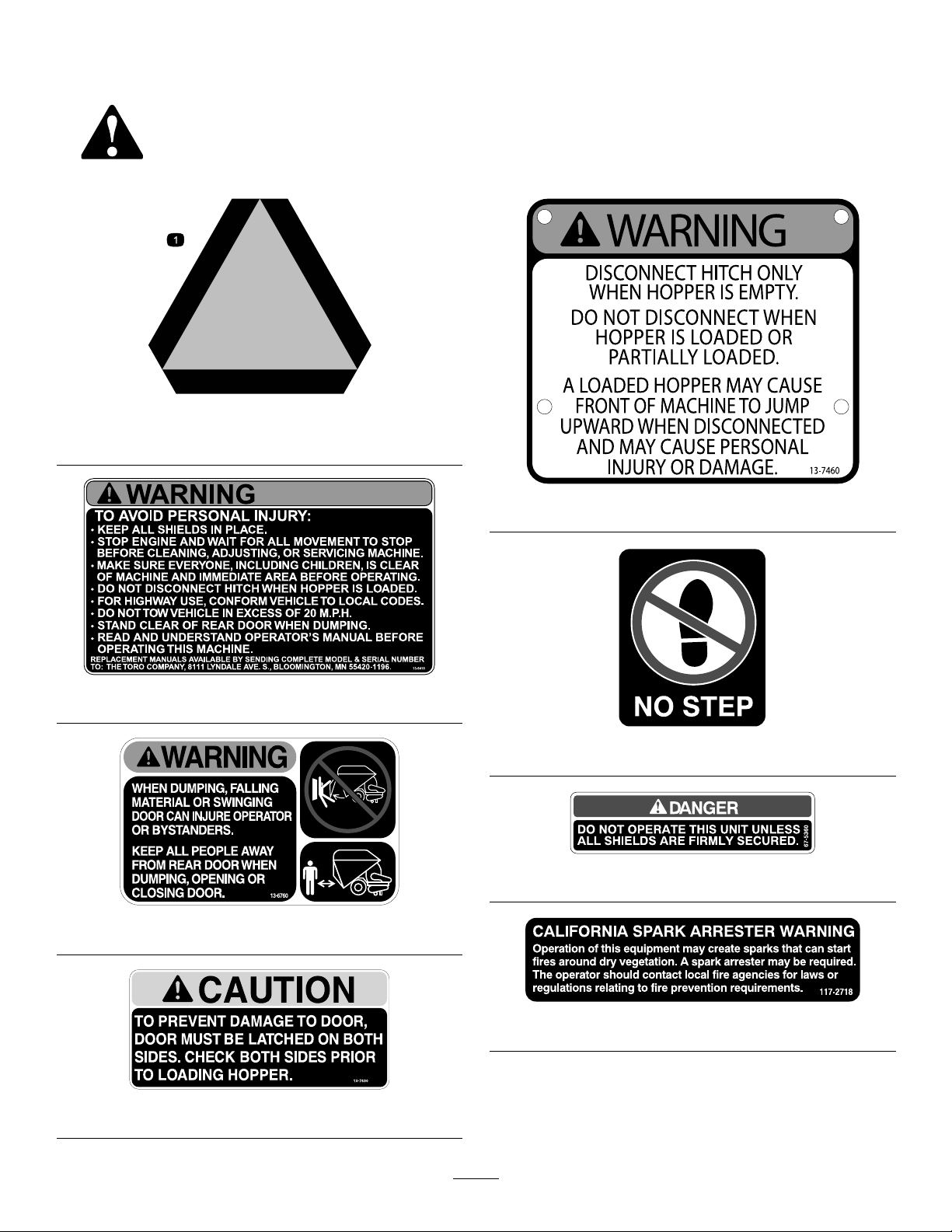

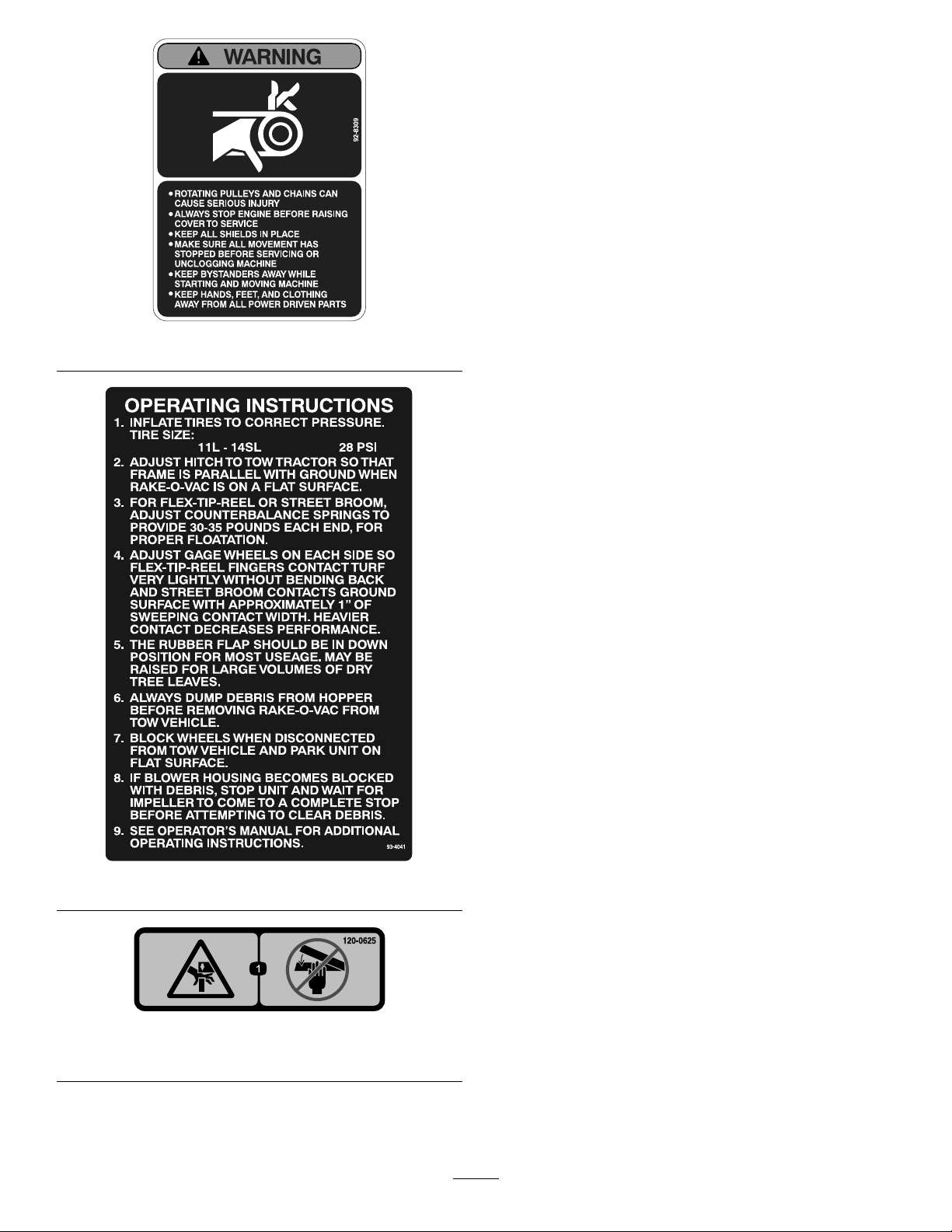

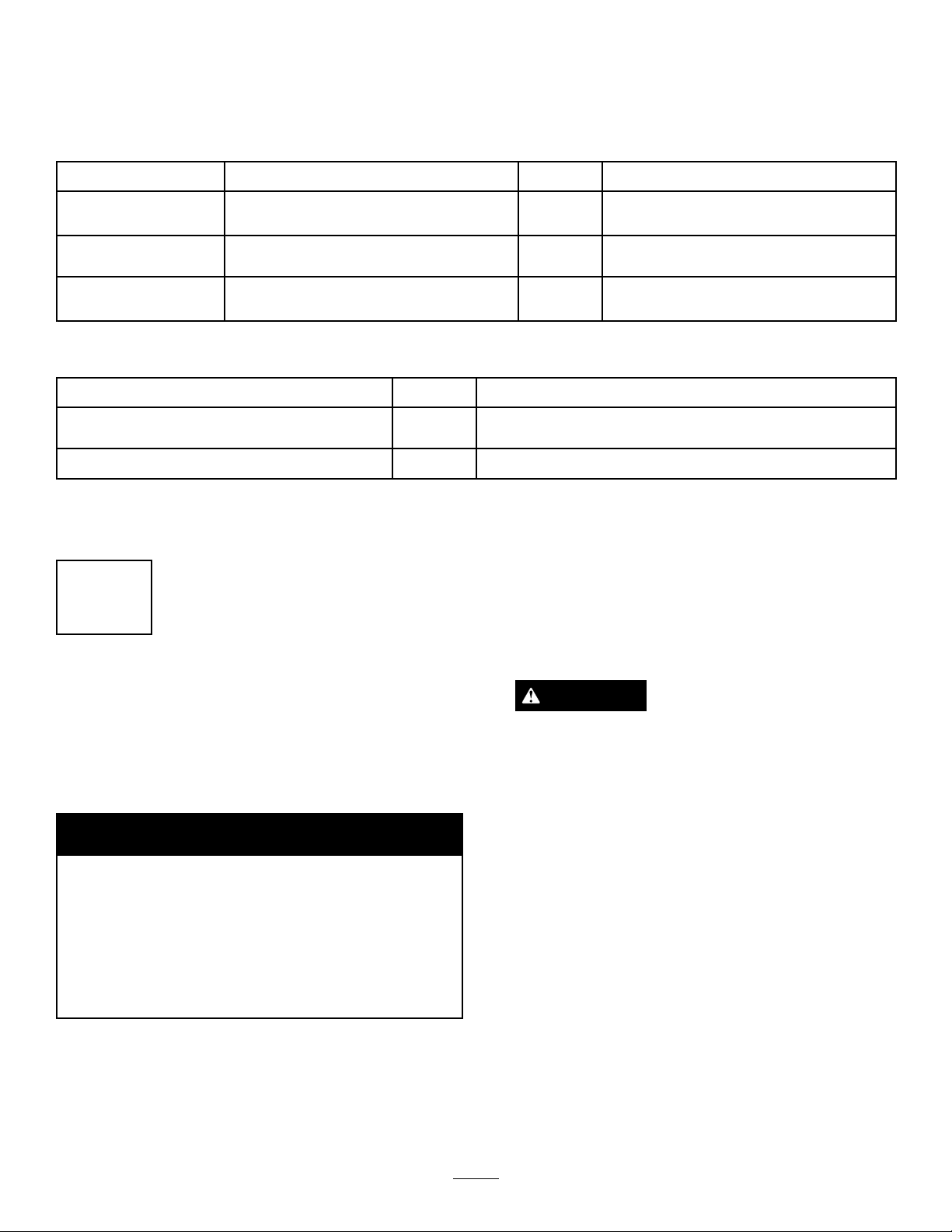

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaof

potentialdanger.Replaceanydecalthatisdamagedorlost.

13-2930

1.Slowmovingvehiclesymbol

13–7460

13–6410

61-5950

67-5360

13-6760

117–2718

13-7430

6

Page 7

92-8309

93-4041

120-0625

1.Pinchpoint,hand—keephandsaway .

7

Page 8

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

Nopartsrequired

Bolts2

Locknuts2

Nopartsrequired

MediaandAdditionalParts

Description

Operator'sManual

EngineOperator'sManual

PartsCatalog

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

1

ActivatingandChargingthe

Qty.

1

1

1Viewandorderparts.

Readbeforeoperatingthemachine.

4.Carefullylleachcellwithelectrolyteuntilthe

electrolyteisuptothellline.

Useonlyelectrolyte(1.260SpecicGravity)toll

thebatteryinitially.

Important:Donotaddelectrolytewhilethe

batteryisinthemachine.Y oucouldspillit,

causingcorrosion.

Qty.

Use

–

–

Activateandchargethebattery.

Mountsweepertoprimemover.

Removingsweeperfromprimemover.

Use

Battery

NoPartsRequired

Procedure

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

Washhandsafterhandling.

1.Unlatchandopenthebatterycompartmentcover.

2.Removethebatteryfromthebatterycompartment.

3.Cleanthetopofthebatteryandremovethevent

caps.

DANGER

Batteryelectrolytecontainssulfuricacidwhich

isadeadlypoisonandcausessevereburns.

•Donotdrinkelectrolyteandavoidcontact

withskin,eyes,orclothing.Wearsafety

glassestoshieldyoureyesandrubbergloves

toprotectyourhands.

•Fillthebatterywherecleanwaterisalways

availableforushingtheskin.

5.Connecta3to4ampbatterychargertothebattery

posts.Chargethebatteryatarateof3to4amps

for4to8hours.

6.Removethellercapsandslowlyaddelectrolyteto

eachcelluntilthelevelisuptothellline.Install

thellercaps.

Important:Donotoverllthebattery.

Electrolytewilloverowontootherpartsofthe

machineandseverecorrosionanddeterioration

willresult.

8

Page 9

WARNING

Chargingthebatteryproducesgassesthatcan

explode.

Neversmokenearthebatteryandkeepsparks

andamesawayfromthebattery.

7.Whenthebatteryischarged,disconnectthecharger

fromtheelectricaloutletandbatteryposts.Allowthe

batterytositfor5to10minutesbeforeproceeding

tothenextstep.

Note:Afterthebatteryhasbeenactivated,add

onlydistilledwatertoreplacenormalloss,although

maintenance-freebatteriesshouldnotrequirewater

undernormaloperatingconditions.

8.Insertthebatteryintothetrayinthebattery

compartment.Positionthebatterysothatthe

terminalsaretotheinside.

WARNING

Batteryterminalsormetaltoolscouldshort

againstmetalmachinecomponentscausing

sparks.Sparkscancausethebatterygassesto

explode,resultinginpersonalinjury.

Important:Makesurethereisclearance

betweenthebatterycablesandthespeed

selectorlever.V erifythatthespeedselectorlever

doesnotcomewithin1inch(2.5cm)ofeither

batterycablewhenitismovedthroughitsentire

rangeofmotion.Donotwiretieortapethe

negativeandpositivebatterycablestogether.

WARNING

Incorrectbatterycableroutingcoulddamage

themachineandcablescausingsparks.Sparks

cancausethebatterygassestoexplode,

resultinginpersonalinjury.

•Always

batterycablebeforedisconnectingthe

positive(red)cable.

•Always

cablebeforeconnectingthenegative(black)

cable.

11.Coattheterminalsandmountingfastenerswith

petroleumjellytopreventcorrosion.

12.Installthebatterycoverandsecureitwiththe

springs.

disconnect

connect

thenegative(black)

thepositive(red)battery

•Whenremovingorinstallingthebattery,do

notallowthebatteryterminalstotouchany

metalpartsofthemachine.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsofthe

machine.

WARNING

Batteryterminalsormetaltoolscouldshort

againstmetaltractorcomponentscausing

sparks.Sparkscancausethebatterygassesto

explode,resultinginpersonalinjury.

•Whenremovingorinstallingthebattery,do

notallowthebatteryterminalstotouchany

metalpartsofthetractor.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsofthe

tractor.

9.Attachthepositivecable(redcablefromtheignition

switch)tothepositive(+)terminal.

10.Attachthenegativecable(blackcablefromthe

engineblock)tothenegative(–)terminalofthe

battery.

2

MounttheSweepertothe

PrimeMover

Partsneededforthisprocedure:

2Bolts

2Locknuts

Procedure

Toensureproperdebrispickup,makesurethesweeper

frameisparallelwiththeground.

1.Positionthemachineonaat,levelsurface.

2.Insertthesweeperjackcasterwheelontothe

sweeperendofthejacktube.

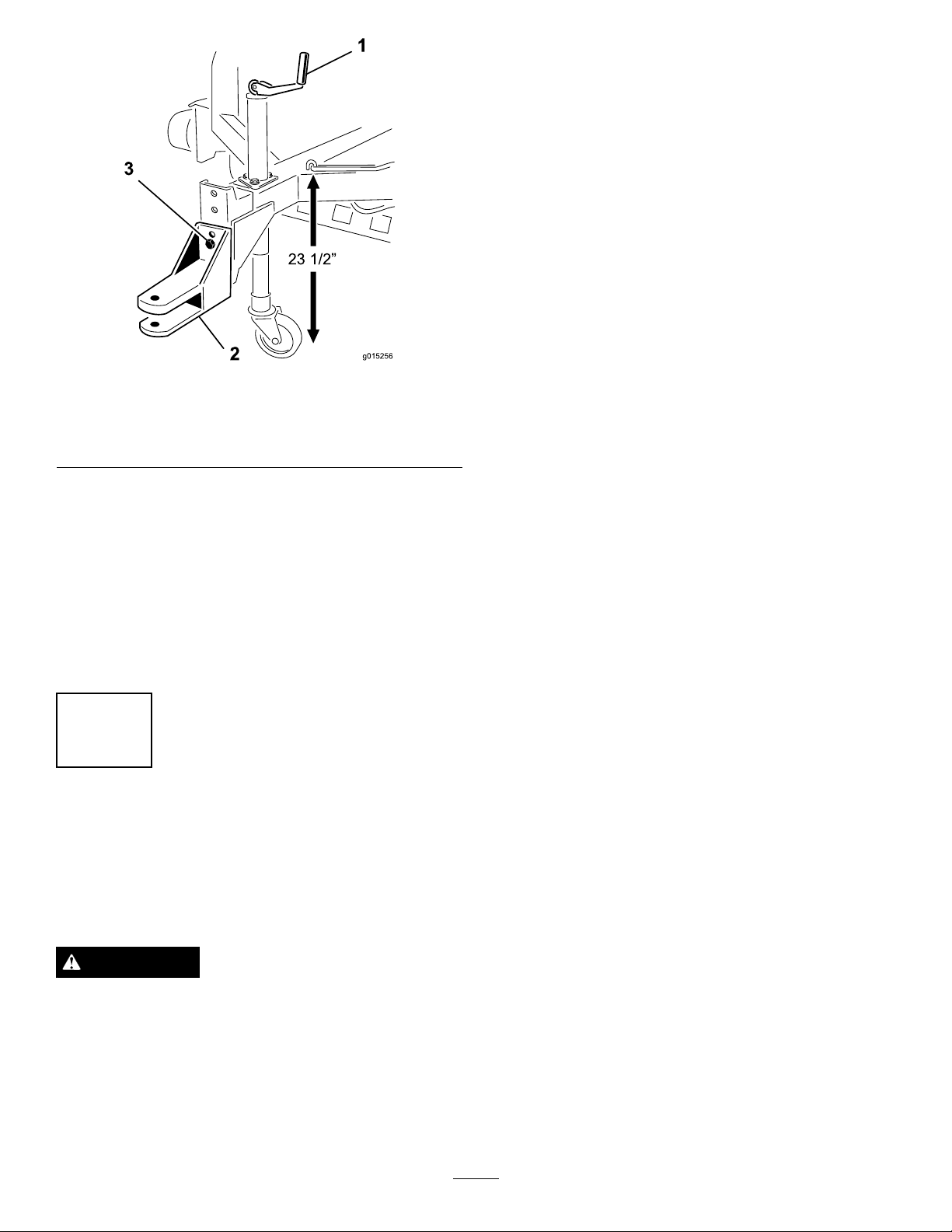

3.Adjustthesweeperjacksothatthedistancefrom

thetopoftheframetothegroundisapproximately

23–1/2inches(59.69cm)(

Figure3).

9

Page 10

3

2

1

g01525 6

23 1/2 ”

Figure3

3.Raisethesweeperjackhandleandlowerthecaster

wheeltoground.

4.Continuetoraisethesweeperwithajackuntilthe

hairpincotterandhitchpincanberemovedfrom

thehitch.

1.Sweeperjack

2.Hitchtongue(Model

07050)

4.Backtheprimemoveruptothesweeper.

5.Adjustthesweeperhitchtonguetothesamelevelas

thehitchoftheprimemoverasfollows:

•Removetheboltsandlocknutssecuringthehitch

tonguetotheframe.

•Raiseorlowerthehitchtonguetotheposition

approximatelylevelwiththeprimemovehitch

andsecureitwiththe2boltsandlocknuts.

3.Adjustingscrews

3

RemovingSweeperfromthe

PrimeMover

NoPartsRequired

Procedure

WARNING

Alwaysemptythesweeperhopperbefore

disconnectingthehopperfromtheprimemoveror

thesweepermaytipbackwardsandcauseinjury.

1.Parkthesweeperonalevelsurfaceandblockthe

wheels.

2.Insertthecastorwheelontothejacktube.

10

Page 11

ProductOverview

2

1

g015265

3

2

1

g015266

2

1

g015267

Controls

FlapLever

Movetheapleverdownwardtotheengagedposition

andupwardforthedisengagedposition.Movethelever

totheupwardpositionwhentransportingthemachine.

ReelLever

Pushthereelleverforwardtoraisetheextipreel.To

lowertheexreel,pushtheleverforwarduntilthecatch

releases,thenpushtotherearuntiltheleverhitsStop.

Movethelevertotheraisedpositionwhenthemachine

isnotinoperation,whenstoringthemachine,orwhen

transportingthemachine(

Figure4).

Figure5

1.Chokecontrol

2.Ignitionswitch

3.Throttlecontrol

IgnitionSwitch

Theignitionswitch,whichisusedtostartandstopthe

engine,hasthreepositions:Off,Run,andStart.Rotate

thekeyclockwisetotheStartpositiontoengagethe

startermotor.Releasethekeywhentheenginestarts.

ThekeywillmoveautomaticallytotheRunposition.

Toshuttheengineoff,rotatethekeycounterclockwise

totheOffposition.

Figure4

1.Flaplever2.Reellever

ChokeControl

Tostartacoldengine,closethecarburetorchokeby

movingthechokecontrollevertotheOnposition.

Aftertheenginestarts,regulatethechoketokeepthe

enginerunningsmoothly .Openthechokebymoving

thelevertotheOffposition.Startingawarmengine

requireslittleornochoking(

Figure5).

ThrottleControl

Thethrottleisusedtooperatetheengineatvarious

speeds.MovingthethrottlelevertotheFastposition

increasestheenginespeed.Todecreasetheengine

speed,movethelevertotheSlowposition.

TailgateLatchRope

Pullthetailgatelatchropetounlatchthetailgatewhen

emptyingthehopper(Figure6).

Figure6

1.Tailgatelatchrope2.Jackhandle

11

Page 12

Specications

Note:Specicationsanddesignaresubjecttochangewithoutnotice.

Width

Length

Height

EmptyWeight

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

AddingFuel

Useunleadedgasoline(87pumpoctaneminimum).

Leaded,regulargasolinemaybeusedifunleadedisnot

available.

Important:Donotusemethanol,gasoline

containingmethanol,orgasoholcontainingmore

than10%ethanolbecausethefuelsystemcouldbe

damaged.Donotmixoilwithgasoline.

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupanygasoline

thatspills.

•Donotllthefueltankcompletelyfull.Add

gasolinetothefueltankuntilthelevelis1inch

(25mm)belowthebottomofthellerneck.

Thisemptyspaceinthetankallowsgasoline

toexpand.

•Neversmokewhenhandlinggasoline,andstay

awayfromanopenameorwheregasoline

fumesmaybeignitedbyaspark.

•Storegasolineinanapprovedcontainerand

keepitoutofthereachofchildren.Neverbuy

morethana30-daysupplyofgasoline.

85.5inches(217.17cm)

159inches(403.86cm)

79.5inches(201.93cm)

2160lbs(979.76kg)

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingasparkwhich

canignitethegasolinevapors.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Alwaysplacegasolinecontainersontheground

awayfromyourvehiclebeforelling.

•Donotllgasolinecontainersinsideavehicle

oronatruckortrailerbedbecauseinterior

carpetsorplastictruckbedlinersmayinsulate

thecontainerandslowthelossofanystatic

charge.

•Whenpractical,removegas-powered

equipmentfromthetruckortrailerandrefuel

theequipmentwithitswheelsontheground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfromaportable

container,ratherthanfromagasolinedispenser

nozzle.

•Ifagasolinedispensernozzlemustbeused,

keepthenozzleincontactwiththerimofthe

fueltankorcontaineropeningatalltimesuntil

fuelingiscomplete.

WARNING

Gasolineisharmfulorfatalifswallowed.

Long–termexposuretovaporscancauseserious

injuryandillness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgastankor

conditioneropening .

•Keepgasawayfromeyesandskin.

•Donotoperatewithouttheentireexhaust

systeminplaceandinproperworking

condition.

FillingtheFuelTank

Thefueltankcapacityisapproximately4gal(15.14l).

1.Cleanaroundthefueltankcapandremoveit.

2.Fillthetanktoapproximately1inchbelowthetop

ofthetank(thebottomofthellerneck).

12

Page 13

Important:Thisspaceinthetankallows

1

g015257

1

g015258

gasolinetoexpand.Donotllthefueltank

completelyfull.

3.Installthefueltankcapsecurely.

4.Wipeupanygasolinethatmayhavespilled.

CheckingtheEngineOilLevel

ServiceInterval:Beforeeachuseordaily(Checkthe

oilwhentheengineiscold.)

Theengineisshippedwithoilinthecrankcase;

however,theoillevelmustbecheckedbeforeandafter

theengineisrststarted.

Crankcasecapacityisapproximately2qt.(1.9l)with

thelter.

Usehigh-qualityengineoilasdescribedin

ChangingtheEngineOilandFilter(page18).

5.IftheoillevelisbelowtheFullmark,removethe

llertubecapandaddoiluntilthelevelreaches

theFullmarkonthedipstick(

Figure8).Donot

overll.

Figure8

1.Fillercap

Note:Thebesttimetochecktheengineoiliswhen

theengineiscoolbeforeithasbeenstartedforthe

day.Ifithasalreadybeenrun,allowtheoiltodrain

backdowntothesumpforatleast10minutesbefore

checking.Iftheoillevelisatorbelowtheaddmark

onthedipstick,addoiltobringtheoilleveltothefull

mark.Donotoverll.Iftheoillevelisbetweenthefull

andaddmarks,nooiladditionisrequired.

1.Parkthemachineonalevelsurface,stoptheengine,

removethekey,andwaitforallmovingpartsto

stopbeforeleavingtheoperatingposition.

2.Cleanaroundtheoildipsticksothatdirtcannotfall

intothellerholeanddamagetheengine(

Figure7

1.Dipstick

Figure7).

3.Removethedipstick,wipeitclean,andinstallit

untilitisfullyseated.

4.Removethedipstickandchecktheoillevelonthe

dipstick.

TheoillevelshouldbeuptotheFullmarkonthe

metalendofthedipstick.

Important:Donotoverllthecrankcasewith

oilbecausethismaycauseenginedamage.Do

notruntheenginewithoilbelowthelowmark

becausetheenginemaybedamagedasaresult.

6.Installthellertubecapanddipstick.

StartingandStoppingthe

Engine

StartingtheEngine

1.PlaceallofthecontrolsintheOfforDisengaged

position.

2.MovethethrottlelevermidwaybetweentheSlow

andFastposition.

3.MovethechokelevertotheOnposition.

Note:Chokeisnotrequiredwhenstartingawarm

engine.

4.Insertthekeyintotheignitionswitchandrotateit

clockwisetostarttheengine.Releasethekeywhen

theenginestarts.Regulatethechoketokeepthe

enginerunningsmoothly.

Important:Topreventoverheatingofthe

startermotor,donotengagethestarterlonger

than10seconds.After10secondsofcontinuous

cranking,wait60secondsbeforeengagingthe

startermotoragain.

5.Movethethrottlelevertothedesiredenginespeed.

6.Pulltheapleverasfarforwardaspossible.

7.Pushthereelleverforwarduntilthecatchreleases,

thenpushittotherearuntiltheleverhitsStop.

13

Page 14

Note:Donotallowthesweepertostandstillwith

1

g015259

1

g015261

1

g015262

therakeengagedasturfdamagemayoccur.

StoppingtheEngine

1.MovethethrottlelevertotheSlowposition.

2.Lettheengineidlefor60seconds.

3.TurntheignitionkeytotheOffpositionand

removethekey.

Note:Tostopthemachineinanemergency,move

theignitionswitchtotheOffposition.

Figure10

1.Locknut

TransportingtheMachine

1.Lifteachendofthereelandremovethetransport

hooksbeforeoperatingthemachine(Figure9).

Figure9

1.Transporthook

2.Supporttheextipreel,broom,orthatchingreel

withthetransporthooks.

3.Turnthedepthadjustmentboltuntiltherake

slightlycontactsthetopoftheturfgrass.Ifa

broomisinstalled,slightcontactshouldbemade

withthesurface.Whenthebroomisoperating,the

contactwidthsurfaceshouldbeabout1inch(25.4

mm)wideacrosstheentirelengthofthebroom

Figure11).

(

Figure11

1.Depthadjustingbolt

4.Repeattheprocedureontheoppositesideofthe

machine.

AdjustingtheRakeDepth

Theextipreelshouldbeadjustedtoensurethatthe

raketipsslightlytouchsurfacebutdonotpenetratethe

turf.Iftheraketipspenetratetheturf,improperdebris

pickupcouldresult.

1.Positionthemachineonalevelsurface.

2.Loosenthelocknutonthedepthadjustmentboltso

thatitcanbeturned(Figure10).

5.Tightentheadjustmentlocknut.

AdjusttheRubberFlap

Forthebestdebrispickupresults,themetalportionof

thefrontapshouldbeverticaltotheground.

1.Movetheatleverforwardtolowertheat

(Figure12).

14

Page 15

2

1

g015263

Figure12

2

1

g015264

1.Rubberap

2.Metaledge

2.Loosenthejamnutontopofthestopandrotate

theadjustmentboltupordownuntiltheapis

verticaltotheground(Figure13).

tothesweeperframewiththetransporthooks.

Shouldthegaugewheelarmfalltotheground,

damagetothesweepermayoccur.

OperatingTips

General

•Beforestartingtosweep,surveyareatodetermine

thebestdirectiontosweep.

Note:Tomaintainastraightlinewhensweeping,

sightofanobjectintheforeground.

•Alwaystrytomakealong,continuousrunwitha

slightoverlaponthereturnrun.

•Onturfareas,theextipreelwillpickuptwigs,

clippings,leaves,pineneedlesandcones,small

debris(beveragecans,smallbottles,paperplates,

etc.).

•Theraketeetharemadeofexiblenylonandeasily

changed.Topreventdamage,therakeisprotected

fromsolidobstructionsbyspringaction.Thenylon

teethwillnotmarbronze,stonemarkers,sidewalks

orpavement.

Figure13

1.Adjustmentbolt

2.Stop

3.Tightenthejamnuttosecuretheadjustment.

Note:Theapmaybepositionedinraisedposition

whenpickinguplargeamountsofleaves.

InspectandCleanupafter

Operation

Whenthesweepinghasbeencompleted,thoroughly

cleanandwashthemachine.Airoutthedryhopper.

Aftercleaning,itisrecommendedthatthemachine

beinspectedforpossibledamagetothemechanical

componentsandblower.Theseprocedureswillensure

thatthemachinewillperformsatisfactorilyduringthe

nextsweepingoperation.

•Becauseofitsuniquedesign,thesweeperalso

groomstheturf.Theextipreelcombsthrough

andliftsgrassforauniformcutwhenmowed.As

itcleans,thelightscarifyingactionincreasewater

andpesticidepenetration,thusreducingtheneed

forrenovation.

Important:Donotmakesharpturnswhen

usingthethatchingreelasdamagetoturfmay

occur.

Important:Donotoperatesweeperwhilereel

isturningandintheraisedposition.Damage

totherakeandtiresmayresultifteethcomein

contactwithtires.

•Toemptyhopper,pulltailgatelatchrope.

CAUTION

Thisproductmayexceednoiselevelsof85

dB(A)attheoperatorposition.Earprotectors

arerecommended,forprolongedexposure,

toreducethepotentialofpermanenthearing

damage.

Important:Whentowingthesweeperforlong

distances,fastenthegaugewheelarmsecurely

15

Page 16

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

Important:Refertoyourengine

Man ual

foradditionalmaintenanceprocedures.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst50hours

Beforeeachuseordaily

Every25hours

Every50hours

Every100hours

Every200hours

Every600hours

MaintenanceProcedure

•Changetheengineoilandlter.

•Checktheengineoillevel.(Checktheoilwhentheengineiscold.)

•Checkthetirepressure.

•Lubricatethebearings.

•ServicetheAirCleaner.

•Checktheelectrolytelevelandcleanthebattery .

•Checkthebatterycableconnections.

•OiltheSweeperJack.

•Changetheengineoilandlter.

•Removedebrisfromengine.

•Checkthesparkplugs.

•Replacethefuellter.

Operator's

Beforestorage

•RefertotheStoragesectionforproceduresnecessarytoperformbeforestoringthe

machineformorethan30days.

16

Page 17

Lubrication

g015268

g015269

g015270

g015271

Lubrication

ServiceInterval:Every25hours

TheRake–O–Vachasgreasettingsthatmustbe

lubricatedregularlywithNo.2GeneralPurposeLithium

BaseGrease.Lubricatethebearingsafterevery30

hoursofoperationorwhenevermachineiswashed

withwater.Bearingsandbushingsmustbelubricated

dailywhenoperatingconditionsareextremelydusty

anddirty.Dustyanddirtyoperatingconditionscould

causedirttogetintothebearingsandbushings,resulting

inacceleratedwear.Thegreasettingsthatmustbe

lubricatedare:thegaugewheelbearings,thereelshaft

bearings,theimpellershaftbearings,thejackshaft

bearings,andtheleftandrighttrailingarms.

1.Wipethegreasettingscleantoensurethatforeign

mattercannotbeforcedintothebearingorbushing.

Figure15

2.Pumpgreaseintothebearingorbushing(

Figure15,andFigure16).

Figure14

Figure14,

Figure16

3.Wipeupanyexcessgrease.

OiltheSweeperJack

ServiceInterval:Every50hours—OiltheSweeper

Jack.

OiltheSweeperjackafterevery50hoursofoperation

(Figure17).

Figure17

17

Page 18

EngineMaintenance

3

4

2

1

g015273

2

1

g015272

ServicingtheAirCleaner

ServiceInterval:Every25hours

1.Releasethelatchessecuringtheaircleanercoverto

theaircleanerbody.Separatethecoveroftheair

cleanerfromthebodyoftheunit.Cleantheinside

oftheaircleanercover(Figure18).

7.Insertthenewlterproperlyintotheaircleaner

body.Makesurethelterissealedproperlyby

applyingpressuretotheouterrimofthelterwhen

installing.Donotpressontheexiblecenterofthe

lter.

8.Reinstallthecoverandsecurethelatches.Makesure

thecoverispositionedwiththetopsideup.

ChangingtheEngineOiland

Filter

ServiceInterval:Aftertherst50hours

Every100hours—Changetheengine

oilandlter.

Note:Changetheoilandltermorefrequentlywhen

operatingconditionsareextremelydustyorsandy.

OilType:Detergentoil(APIserviceSJ,SK,SL,or

higher)

CrankcaseCapacity:w/lter,2.0qt.(1.9l)

Figure18

1.Aircleanerlatches

2.Dustcup

3.Primarylter

4.Safetylter

2.Gentlyslidetheprimarylteroutoftheaircleaner

bodytoreducetheamountofdustdislodged.Avoid

knockingthelteragainsttheaircleanerbody.Do

notremovethesafetylter.

3.Inspecttheprimarylterandreplaceitifthereis

damage.Donotwashorreuseadamagedlter.

Important:Donotattempttocleanthesafety

lter.Replacethesafetylterwithanewone

afterevery3primarylterservices.

4.Blowcompressedairfromtheinsidetotheoutside

ofthedrylterelement.Donotexceed100psito

preventdamagetotheelement.

1.Starttheengineandletitrunforveminutes.This

warmstheoilsoitdrainsbetter.

2.Parkthemachinesothatthedrainsideisslightly

lowerthantheoppositesidetoensurethattheoil

drainscompletely .

3.Settheparkingbrake,stoptheengine,andremove

thekey .

4.Placeapanbelowtheoildrain.Removetheoildrain

plugtoallowtheoiltodrain(

Figure19).

5.Keeptheairhosenozzleatleast2inchesfrom

thelterandmovethenozzleupanddownwhile

rotatingthelterelement.Inspectthelterfor

holesandtearsbylookingthroughtheltertowarda

brightlight.

6.Inspectthenewlterforanyshippingdamages.

Checkthesealingendofthelter.Donotinstalla

damagedlter.

Figure19

1.Drainplug

18

2.Oillter

Page 19

5.Whentheoilhasdrainedcompletely,replacethe

plug.

engineisoperatingproperly.Ablackcoatingonthe

insulatorusuallymeanstheaircleanerisdirty.

Note:Disposeoftheusedoilatacertiedrecycling

center.

6.Placeashallowpanorragundertheltertocatchoil.

7.Removetheoldlterandwipethesurfaceofthe

lteradaptergasket.

8.Pourthenewoilofthepropertypethroughthe

centerholeofthelter.Stoppouringwhentheoil

reachesthebottomofthethreads.

9.Allowaminuteortwofortheoiltobeabsorbedby

ltermaterial,thenpourofftheexcessoil.

10.Applyathincoatofnewoiltotherubbergasket

onthereplacementlter.

11.Installthereplacementoilltertothelteradapter.

Turntheoillterclockwiseuntiltherubbergasket

contactsthelteradapter,thentightenthelteran

additional1/2turn.Donotovertighten.

12.Checktheoillevel;referto

CheckingtheEngineOilLevel(page13).

13.Slowlyaddadditionaloiltobringtheleveltothefull

markonthedipstick.

Important:Nevercleanthesparkplugs.Always

replacethesparkplugswhentheyhaveablack

coating,wornelectrodes,anoilylm,orcracks.

Figure20

1.Centerelectrodeinsulator3.Airgap(nottoscale)

2.Sideelectrode

2.Checkthegapbetweenthecenterandsideelectrodes

(Figure20).

3.Bendthesideelectrode(

correct.

Figure20)ifthegapisnot

14.Replacethellcap.

ServicingtheSparkPlugs

ServiceInterval:Every200hours—Checkthespark

plugs.

Ensurethattheairgapbetweenthecenterandside

electrodesiscorrectbeforeinstallingeachsparkplug.

Useasparkplugwrenchforremovingandinstallingthe

sparkplugsandagappingtool/feelergaugetocheckand

adjusttheairgap.Installnewsparkplugsifnecessary.

Type:ChampionRC12YCorequivalent.AirGap:0.03

inch(0.75mm)

RemovingtheSparkPlugs

1.Stoptheengine,settheparkingbrake,andremove

thekey .

2.Pullthewiresoffofthesparkplugs.

3.Cleanaroundthesparkplugs.

4.Removebothsparkplugsandmetalwashers.

CheckingtheSparkPlugs

InstallingtheSparkPlugs

1.Threadthesparkplugsintothesparkplugholes.

2.Tightenthesparkplugsto20ft-lb(27N-m).

3.Pushthewiresontothesparkplugs.

RemoveDebrisfromthe

Engine

ServiceInterval:Every100hours

Toensurepropercooling,keepthegrassscreen,cooling

ns,andotherexternalsurfacesoftheenginecleanat

alltimes.

Every100hoursofoperation(moreoftenunder

extremelydusty,dirtyconditions)removetheblower

housingandothercoolingshrouds.Cleanthecooling

nsandexternalsurfacesasnecessary.Makesurethe

coolingshroudsarereinstalled.

Note:Operatingtheenginewithablockedgrass

screen,dirtyorpluggedcoolingns,orcoolingshrouds

removed,willcauseenginedamageduetooverheating.

1.Lookatthecenterofbothsparkplugs(Figure20).

Ifyouseelightbrownorgrayontheinsulator,the

19

Page 20

FuelSystem

1

g015274

ElectricalSystem

Maintenance

ReplacingtheFuelFilter

ServiceInterval:Every600hours/Yearly(whichever

comesrst)

Important:Neverinstalladirtylterifitis

removedfromthefuelline.

1.Allowthemachinetocooldown.

2.Placeacleancontainerunderthefuellter

Figure21).

(

Maintenance

ServicingtheBattery

ServiceInterval:Every25hours—Checktheelectrolyte

levelandcleanthebattery.

Every25hours—Checkthebattery

cableconnections.

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

Washhandsafterhandling.

DANGER

Figure21

1.Fuellter

3.Removetheclampssecuringthefuelltertothefuel

lines.

4.Installanewltertothefuellineswiththeclamps

previouslyremoved.Filteristobemountedsothat

thearrowpointstowardthecarburetor.

5.Wipeupanyspilledfuel.

Batteryelectrolytecontainssulfuricacidwhichisa

deadlypoisonandcausessevereburns.

•Donotdrinkelectrolyteandavoidcontactwith

skin,eyes,orclothing.Wearsafetyglassesto

shieldyoureyesandrubberglovestoprotect

yourhands.

•Fillthebatterywherecleanwaterisalways

availableforushingtheskin.

Thebatteryelectrolytelevelmustbeproperlymaintained

andthetopofthebatterykeptclean.Ifthemachineis

storedinalocationwheretemperaturesareextremely

high,thebatterywillrundownmorerapidlythanifthe

machineisstoredinalocationwheretemperaturesare

cool.

Checktheelectrolytelevelevery25operatinghoursor,

ifmachineisinstorage,every30days.

Maintainthecelllevelwithdistilledordemineralized

water.Donotllthecellsabovethebottomofthesplit

ringinsideeachcell.

Keepthetopofthebatterycleanbywashingit

periodicallywithabrushdippedinammoniaor

bicarbonateofsodasolution.Flushthetopsurfacewith

wateraftercleaning.Donotremovethellcapswhile

cleaning.

Thebatterycablesmustbetightontheterminalsto

providegoodelectricalcontact.

20

Page 21

WARNING

Incorrectbatterycableroutingcoulddamagethe

machineandcablescausingsparks.Sparkscan

causethebatterygassestoexplode,resultingin

personalinjury.

•Always

cablebeforedisconnectingthepositive(red)

cable.

•Always

beforeconnectingthenegative(black)cable.

Ifcorrosionoccursattheterminals,disconnectthe

cables(negative(–)cablerst)andscrapeclampsand

terminalsseparately.Reconnectthecables(positive(+)

cablerst)andcoattheterminalswithpetroleumjelly.

disconnect

connect

thenegative(black)battery

thepositive(red)batterycable

WARNING

Batteryterminalsormetaltoolscouldshortagainst

metaltractorcomponentscausingsparks.Sparks

cancausethebatterygassestoexplode,resulting

inpersonalinjury.

DriveSystem

Maintenance

TireMaintenance

CheckingtheTirePressure

ServiceInterval:Beforeeachuseordaily

Maintaintheairpressureinthefrontandreartiresat

28psi(193kPa).Checkthepressureatthevalvestem

(Figure22)beforeeachuse.

Figure22

1.Valvestem

•Whenremovingorinstallingthebattery,donot

allowthebatteryterminalstotouchanymetal

partsofthemachine.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsofthe

machine.

ChangingtheTires

1.Parkthemachineonaat,levelsurface.Blockthe

othertiretopreventaccidentalrollingorinjury.

2.Placethejackundertheframeoraxleshaftbehind

thewheelandjackupthewheeluntilitjustcontacts

theoor.

WARNING

A2000lb.capacityhydraulicjackshouldbe

usedwhenchangingatire.

3.Loosenalllugboltsandcontinuetojackupuntil

thetirecanberemoved.

4.Reversetheaboveproceduretoinstallatire.Torque

thelugboltsto70–90ft-lb(95–122N-m).

21

Page 22

BeltMaintenance

1

g015278

3

2

1

g015277

InspectingtheBelts

Note:Itisnotnecessarytoremovetheupperbelt

guard(Figure23)tocheckthebelttension.Ifforsome

reasonthebeltguardmustberemoved,removethe4

bolts,washers,andnutssecuringtheguardtotheframe.

Neveroperatethemachinewithouttheguardsinplace.

Figure24

1.Impellerbelt3.Idlerpulley

2.Jackshaftbelt

1.Upperbeltguard

Figure23

InspectingtheImpellerDriveBelt

Checkthetensionbydepressingthebeltatthemid

spanoftheimpellerandclutchpulleyswith4–5lbs

(18–22N)offorce.Thebeltshoulddeect.5inches

(1.27cm).Ifthedeectionisincorrect,proceed

AdjustingtheImpellerDriveBelt(page23).If

to

thedeectioniscorrect,continuenormaloperation

(Figure23).

InspectingtheJackshaftBelt

Checkthetensionbydepressingthebeltatmid

spanofthejackshaftandclutchpulleyswith4–5lbs

(18–22N)offorce.Thebeltshoulddeect.25inches

(6.35mm).Ifthedeectionisincorrect,proceedto

AdjustingtheJackshaftBelt(page23).Ifthedeection

iscorrect,continuenormaloperation(Figure23).

InspectingtheReelDriveBelt

Checkthetensionbydepressingthebeltatmidspanof

theidlerpulleyandthereeldriverpulleywith25–29lbs

(111–129N)offorce.Thebeltshoulddeect.25inches

(6.35mm).Ifthedeectionisincorrect,proceedto

AdjustingtheReelDriveBelt(page23).Ifthedeection

iscorrect,continuenormaloperation.

22

Page 23

AdjustingtheBelts

1

g015279

1

g015280

g015281

1

2

1

g015282

AdjustingtheImpellerDriveBelt

1.Loosentheenginemountingbolts(Figure25).

Figure25

2.Ifthebelthastoomuchslack,loosentheidlerpulley

nut,pressforwardontheidlerpulleyuntilthedesired

tensionisobtainedandretightentheidlerpulleynut.

3.Ifthebeltistootight,loosentheidlerpulleynut,

pullrearwardontheidlerpulleyuntilthedesired

tensionisobtainedandtightentheidlerpulleynut.

AdjustingtheReelDriveBelt

1.Removethe2bolts,nut,retainingnut,andwasher

securingthelowerbeltguardtotheframe.Remove

theguard(

Figure27).

1.Enginemountingbolts

2.Turnthebeltadjustingboltuntilthedesiredbelt

tensionisobtained.Slightlytightentheengine

mountingbolts.Adjusttheenginesothatitis

parallelwithframe.Continuetighteningtheengine

mountingbolts(

Figure26).

Figure26

Figure27

1.Lowerbeltguard

2.Ifthebelthastoomuchslack,loosentheidlerpulley

nut,pressdownontheidlerpulleyuntilthedesired

tensionisobtainedandtightentheidlerpulleynut

(Figure28).

1.Adjustingbolt

3.Whenevertheimpellerbeltisadjusteditisnecessary

toreadjustthejackshaftbelt(enginedrive)orchain

(PTOdrive).

AdjustingtheJackshaftBelt

1.Removethe4bolts,washersandnutssecuringthe

uppershroudtotheframe(

Figure23).

Figure28

1.Reeldrivebelt2.Idlerpulley

3.Ifthebeltistootight,loosentheidlerpulleynut,pull

upwardontheidlerpulleyuntilthedesiredtensionis

obtainedandtightentheidlerpulleynut.

4.Installthebeltguard.Ensurethatthereisclearance

betweenthebeltandthebeltguard.

23

Page 24

ChangingtheRubber

2

1

g015275

1

3

2 g015283

PulleyRemoval

Flap

Replacetherubberapwhenitbecomeswornor

damaged.

CAUTION

Changerubberaponaat,levelsurfaceandblock

wheelstopreventsweeperfromrolling.Failureto

dosomayresultinpersonalinjury.

1.Removethe10bolts,washers,andnutsonthe

mountingapandapretainer(Figure29).

1.Removetheboltsandlockwashersoneatatimeand

screwthemintotheadjoiningholes(Figure30).

Figure30

1.Bolts&locknuts

2.Taperlockbushing

3.Taperlockreleasehole

Figure29

1.Rubberap

2.Replacewiththenewrubberapandfastenit

securely.

2.Flapretainer

2.Turneachboltthesamenumberoftimesuntilthe

lockseparates.Thepulleywillnowslideoffofthe

shaft.

24

Page 25

FlexTipReelRemoval

1

2

g015286

FlexTipRakeRod

1.Placethemachineonahardandlevelsurface.

2.Raisethefrontofthesweeperashighaspossible

byloweringthejack.

3.Raisethereeltothehighestposition.

4.Removethelowerbeltguardandreeldrivebelt

Figure27andFigure28).

(

5.Removethe2bolts,lockwashers,andnutssecuring

thereelshaftbearingstothereelsupportarmson

eachsideofthesweeper.Lowertheextipreelto

theground.

6.Liftthereelsupportarmstothehighestposition.

7.Slidetheendoftherakerearwardandpullitout

fromunderthemachine.

OrFingerPlate

Replacement

1.Removetheboltandlocknutfromoneendofthe

reel(Figure31).

Figure31

1.boltandlocknut2.Locknut

2.Removethelocknutonlyfromtheoppositeendof

thereel.

3.Drivetherodfromtheendplate.Drivetherodfrom

theendwithoutthetabweldedtoit.

4.Removethengerplatesorrodsasrequiredand

replace.

5.Lineupthengerplatewiththerodanddrivethe

rodbackthroughtheendplate.

6.Attachthebolt,locknuts,andhookupthesprings.

25

Page 26

FlexTipRakeTine

3

2

1

g015287

1

g015288

g015289

BrushHalfReplacement

Replacement

1.Removethetineretainerandslidethedamagedtine

out(Figure32).

1.Removethebrushfromthesweeper.

2.Loosentheclampswithanallenwrenchandremove

itfromthebrushhalves(

1.Clamp

Figure33).

Figure33

Figure32

1.Fingerplate3.Tine

2.Tineretainer

3.Separatethebrushhalvesanddiscardthedamaged

section(s)(Figure34).

2.Bendthenewtineinhalfandslideitintoposition.

3.Placethetinebracketoverthecurvedendofthetine

andfastenitsecurelywiththeboltandlockwasher.

Figure34

4.Installthenewbrushsectionbypushingthem

togetherandsecuringbothendswiththebrush

clamps.Whentheendshavebeensecured,fasten

thebrushwiththeremainingclamps.

26

Page 27

Cleaning

g015276

CleaningtheBlowerHousing

WARNING

Beforeremovinganydebrisfromblowerhousing,

disengageP .T.O.drive,stopengine(s)andmake

certainallmovingpartshavestoppedorpersonal

injurymayoccur.

1.Makesuretheimpellerhasstoppedrotatingbefore

removingtheaccessplates.

2.Loosenthe2wingnutssecuringtheaccessplate

Figure35).

(

Storage

1.Settheparkingbrakeandturntheignitionkeytooff.

Removethesparkplugwireandthekey.

2.Removegrass,dirt,andgrimefromtheexternal

partsoftheentiremachine,especiallytheengine.

Cleandirtandchafffromtheoutsideoftheengine’ s

cylinderheadnsandblowerhousing.

3.Servicetheaircleaner;referto

ServicingtheAirCleaner(page18).

4.Changethecrankcaseoil;referto

ChangingtheEngineOilandFilter(page18).

5.Checkthetirepressure;referto

CheckingtheTirePressure(page21).

6.Checktheconditionofthetines.

7.Ifyouwillbestoringthemachineformorethan30

days,prepareitasfollows:

A.Removethebatteryterminalsfromthebattery

postsandremovethebatteryfromthemachine.

B.Cleanthebattery,terminals,andpostswithawire

brushandbakingsodasolution.

C.Coatthecableterminalsandbatterypostswith

Grafo112Xskin-overgrease(ToroPartNo.

505-47)orpetroleumjellytopreventcorrosion.

D.Slowlyrechargethebatteryevery60daysfor24

hourstopreventleadsulfationofthebattery.To

preventthebatteryfromfreezing,makesureit

isfullycharged.Thespecicgravityofafully

chargedbatteryis1.265to1.299.

Figure35

AccessPlate

3.Swingtheaccessplatetoonesideallowingthe

removalofdebris.

4.Afterthedebrishasbeenremoved,lowertheaccess

plateandsecurewiththewingnuts.Repeatthe

procedureontheotheraccessplate.

WARNING

Chargingthebatteryproducesgassesthat

canexplode.

Neversmokenearthebatteryandkeep

sparksandamesawayfromit.

E.Eitherstorethebatteryontheshelforonthe

machine.Leavethecablesdisconnectedifit

isstoredonthemachine.Storeitinacool

atmospheretoavoidquickdeteriorationofthe

chargeinthebattery.

F.Addapetroleumbasedstabilizer/conditionerto

fuelinthetank.Followmixinginstructionsfrom

stabilizermanufacture.Donotuseanalcohol

basedstabilizer(ethanolormethanol).

Note:Afuelstabilizer/conditionerismost

effectivewhenmixedwithfreshgasolineand

usedatalltimes.

G.Runtheenginetodistributeconditionedfuel

throughthefuelsystem(5minutes).

27

Page 28

H.Stoptheengine,allowittocoolanddrainthe

fueltank.

I.Restarttheengineandrunituntilitstops.

J.Choketheengine.Startandruntheengineuntil

itwillnotstart.

K.Disposeofthefuelproperly.Recycleasperlocal

codes.

Important:Donotstore

stabilizer/conditionedgasolineover90

days.

8.Removethesparkplugsandcheckthecondition;

referto

ServicingtheSparkPlugs(page19).With

thesparkplugsremovedfromtheengine,pour

twotablespoonsofengineoilintoeachsparkplug

hole.Nowusethestartertocranktheengineand

distributetheoilinsidethecylinders.Installthespark

plugs.Donotinstallthewiresonthesparkplugs.

9.Checkandtightenallbolts,nuts,andscrews.Repair

orreplaceanypartthatisdamagedordefective.

10.Washanddrytheentireunit.Removethetines,clean

andoilthem.Spraylightoilmistonthecoringhead

bearings(crank&damperlinks).

Important:Youcanwashthemachinewith

milddetergentandwater.Donotpressurewash

themachine.Avoidexcessiveuseofwater,

especiallyneartheengine.

Note:Runthemachinewiththeengineathighidle

for2to5minutesafterwashing.

11.Paintallscratchedorbaremetalsurfaces.Paintis

availablefromyourAuthorizedServiceDistributor.

12.Secureservicelatchiftheaeratoristobestoredfor

morethanacoupledays.

13.Storethemachineinaclean,drygarageorstorage

area.Removethekeyfromtheignitionswitchand

keepitoutofreachofchildrenorotherunauthorized

users.

14.Coverthemachinetoprotectitandkeepitclean.

28

Page 29

Notes:

29

Page 30

Notes:

30

Page 31

Notes:

31

Page 32

TheT oroTotalCoverageGuarantee

ALimitedWarranty

ConditionsandProductsCovered

TheT oroCompanyanditsafliate,T oroWarrantyCompany ,pursuant

toanagreementbetweenthem,jointlywarrantyourT oroCommercial

product(“Product”)tobefreefromdefectsinmaterialsorworkmanship

fortwoyearsor1500operationalhours*,whicheveroccursrst.This

warrantyisapplicabletoallproductswiththeexceptionofAerators

(refertoseparatewarrantystatementsfortheseproducts).Wherea

warrantableconditionexists,wewillrepairtheProductatnocosttoyou

includingdiagnostics,labor,parts,andtransportation.Thiswarranty

beginsonthedatetheProductisdeliveredtotheoriginalretailpurchaser.

*Productequippedwithanhourmeter.

InstructionsforObtainingWarrantyService

YouareresponsiblefornotifyingtheCommercialProductsDistributoror

AuthorizedCommercialProductsDealerfromwhomyoupurchasedthe

Productassoonasyoubelieveawarrantableconditionexists.Ifyouneed

helplocatingaCommercialProductsDistributororAuthorizedDealer,or

ifyouhavequestionsregardingyourwarrantyrightsorresponsibilities,

youmaycontactusat:

ToroCommercialProductsServiceDepartment

ToroWarrantyCompany

811 1LyndaleAvenueSouth

Bloomington,MN55420-1196

952–888–8801or800–952–2740

E-mail:commercial.warranty@toro.com

OwnerResponsibilities

AstheProductowner,youareresponsibleforrequiredmaintenance

andadjustmentsstatedinyourOperator'sManual.Failuretoperform

requiredmaintenanceandadjustmentscanbegroundsfordisallowinga

warrantyclaim.

ItemsandConditionsNotCovered

Notallproductfailuresormalfunctionsthatoccurduringthewarranty

periodaredefectsinmaterialsorworkmanship.Thiswarrantydoesnot

coverthefollowing:

•Productfailureswhichresultfromtheuseofnon-T ororeplacement

parts,orfrominstallationanduseofadd-on,ormodiednon-T oro

brandedaccessoriesandproducts.Aseparatewarrantymaybe

providedbythemanufactureroftheseitems.

•Productfailureswhichresultfromfailuretoperformrecommended

maintenanceand/oradjustments.Failuretoproperlymaintainyour

ToroproductpertheRecommendedMaintenancelistedinthe

Operator’sManualcanresultinclaimsforwarrantybeingdenied.

•ProductfailureswhichresultfromoperatingtheProductinan

abusive,negligent,orrecklessmanner.

•Partssubjecttoconsumptionthroughuseunlessfoundtobe

defective.Examplesofpartswhichareconsumed,orusedup,

duringnormalProductoperationinclude,butarenotlimitedto,brake

padsandlinings,clutchlinings,blades,reels,rollersandbearings

(sealedorgreasable),bedknives,sparkplugs,castorwheelsand

bearings,tires,lters,belts,andcertainsprayercomponentssuchas

diaphragms,nozzles,andcheckvalves,etc.

•Failurescausedbyoutsideinuence.Conditionsconsideredtobe

outsideinuenceinclude,butarenotlimitedto,weather,storage

practices,contamination,useofunapprovedfuels,coolants,

lubricants,additives,fertilizers,water,orchemicals,etc.

•Failureorperformanceissuesduetotheuseoffuels(e.g.gasoline,

diesel,orbiodiesel)thatdonotconformtotheirrespectiveindustry

standards.

•Normalnoise,vibration,wearandtear,anddeterioration.

•Normal“wearandtear”includes,butisnotlimitedto,damageto

seatsduetowearorabrasion,wornpaintedsurfaces,scratched

decalsorwindows,etc.

Parts

Partsscheduledforreplacementasrequiredmaintenancearewarranted

fortheperiodoftimeuptothescheduledreplacementtimeforthatpart.

Partsreplacedunderthiswarrantyarecoveredforthedurationofthe

originalproductwarrantyandbecomethepropertyofT oro.T orowill

makethenaldecisionwhethertorepairanyexistingpartorassemblyor

replaceit.T oromayuseremanufacturedpartsforwarrantyrepairs.

DeepCycleandLithium-IonBatteryWarranty:

DeepcycleandLithium-Ionbatterieshaveaspeciedtotalnumberof

kilowatt-hourstheycandeliverduringtheirlifetime.Operating,recharging,

andmaintenancetechniquescanextendorreducetotalbatterylife.Asthe

batteriesinthisproductareconsumed,theamountofusefulworkbetween

chargingintervalswillslowlydecreaseuntilthebatteryiscompletelyworn

out.Replacementofwornoutbatteries,duetonormalconsumption,

istheresponsibilityoftheproductowner .Batteryreplacementmaybe

requiredduringthenormalproductwarrantyperiodatowner’sexpense.

Note:(Lithium-Ionbatteryonly):ALithium-Ionbatteryhasapartonly

proratedwarrantybeginningyear3throughyear5basedonthetime

inserviceandkilowatthoursused.RefertotheOperator'sManualfor

additionalinformation.

MaintenanceisatOwner’sExpense

Enginetune-up,lubrication,cleaningandpolishing,replacementoflters,

coolant,andcompletingrecommendedmaintenancearesomeofthe

normalservicesToroproductsrequirethatareattheowner’sexpense.

GeneralConditions

RepairbyanAuthorizedT oroDistributororDealerisyoursoleremedy

underthiswarranty.

NeitherTheToroCompanynorToroWarrantyCompanyisliablefor

indirect,incidentalorconsequentialdamagesinconnectionwiththe

useoftheT oroProductscoveredbythiswarranty,includingany

costorexpenseofprovidingsubstituteequipmentorserviceduring

reasonableperiodsofmalfunctionornon-usependingcompletion

ofrepairsunderthiswarranty.ExceptfortheEmissionswarranty

referencedbelow,ifapplicable,thereisnootherexpresswarranty .

Allimpliedwarrantiesofmerchantabilityandtnessforuseare

limitedtothedurationofthisexpresswarranty .

Somestatesdonotallowexclusionsofincidentalorconsequential

damages,orlimitationsonhowlonganimpliedwarrantylasts,sothe

aboveexclusionsandlimitationsmaynotapplytoyou.Thiswarranty

givesyouspeciclegalrights,andyoumayalsohaveotherrightswhich

varyfromstatetostate.

Noteregardingenginewarranty:

TheEmissionsControlSystemonyourProductmaybecoveredby

aseparatewarrantymeetingrequirementsestablishedbytheU.S.

EnvironmentalProtectionAgency(EP A)and/ortheCaliforniaAir

ResourcesBoard(CARB).Thehourlimitationssetforthabovedonot

applytotheEmissionsControlSystemWarranty .RefertotheEngine

EmissionControlWarrantyStatementsuppliedwithyourproductor

containedintheenginemanufacturer’sdocumentationfordetails

CountriesOtherthantheUnitedStatesorCanada

CustomerswhohavepurchasedT oroproductsexportedfromtheUnitedStatesorCanadashouldcontacttheirToroDistributor(Dealer)toobtain

guaranteepoliciesforyourcountry ,province,orstate.IfforanyreasonyouaredissatisedwithyourDistributor'sserviceorhavedifcultyobtaining

guaranteeinformation,contacttheT oroimporter.

374-0253RevB

Loading...

Loading...