Page 1

8-Blade,11-Blade,and14-Blade

DPAReelMower

FormNo.3397-897RevA

Greensmaster

®

3120,3150,or3250-DSeries

TractionUnit

ModelNo.04652—SerialNo.316000001andUp

ModelNo.04654—SerialNo.316000001andUp

ModelNo.04656—SerialNo.316000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3397-897*A

Page 2

ThisproductcomplieswithallrelevantEuropeandirectives.

G020063

Fordetails,pleaseseetheDeclarationofIncorporation(DOI)

atthebackofthispublication.

WARNING

CALIFORNIA

Proposition65W arning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Useofthisproductmaycauseexposureto

chemicalsknowntotheStateofCalifornia

tocausecancer,birthdefects,orother

reproductiveharm.

Introduction

Thiscuttingunitisdesignedforcuttingturfongreensand

smallfairwaysofgolfcourses.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

Figure1

1.Locationofthemodelandserialnumbers

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafety-alertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready.Figure1identiesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

Figure2

1.Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

©2015—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Contents

Safety

Safety...........................................................................3

Hauling..................................................................4

SafetyandInstructionalDecals.................................4

Setup............................................................................5

InstallingtheRoller..................................................5

InstallingtheBallStuds............................................5

InstallingtheHoopLink,OffsetLink,orChain

Link...................................................................5

RepositioningtheCounterWeights............................6

AdjustingtheCuttingUnit........................................7

ProductOverview..........................................................8

Specications.........................................................8

Attachments/Accessories.........................................8

Operation.....................................................................8

Maintenance..................................................................9

SupportingtheCuttingUnit......................................9

AdjustingtheBedknife-to-ReelContact......................9

AdjustingtheRear-RollerHeight..............................10

AdjustingtheHeightofCut.....................................11

AdjustingtheCut-OffBar.......................................12

ServicingtheBedbar...............................................12

BedknifeSpecications...........................................14

BacklappingtheCuttingUnit...................................14

ThismachinehasbeendesignedinaccordancewithENISO

5395:2013andANSIB71.1-2012.

Hazardcontrolandaccidentpreventionaredependent

upontheawareness,concern,andpropertraining

ofthepersonnelinvolvedintheoperation,transport,

maintenance,andstorageofthemachine.Improper

useormaintenanceofthemachinecanresultininjury

ordeath.T oreducethepotentialforinjuryordeath,

complywiththefollowingsafetyinstructions.

•Read,understand,andfollowallinstructionsinthe

traction-unitandcutting-unitoperator’smanualsbefore

operatingthemachine.

•Neverallowchildrentooperatethemachine.Donot

allowadultstooperatethemachinewithoutproper

instruction.Onlytrainedoperatorswhohavereadthis

manualshouldoperatethemachine.

•Neveroperatethemachinewhenundertheinuenceof

drugsoralcohol.

•Keepallshieldsandsafetydevicesinplace.Ifashield,

safetydeviceordecalisillegibleordamaged,repairor

replaceitbeforecommencingoperation.Alsotighten

anyloosenuts,bolts,andscrewstoensurecuttingunitis

insafeoperatingcondition.

•Wearappropriateclothingincludingsubstantial,

slip-resistantfootwear,safetyglasses,andhearing

protection.Tiebacklonghair.Donotwearjewelry.

•Removealldebrisorotherobjectsthatthecutting-unit

bladesmightpickupandthrow.Keepallbystandersaway

fromtheworkingarea.

•Ifthecuttingbladesstrikeasolidobjectortheunit

vibratesabnormally,stopandshuttheengineoff.Check

thecuttingunitfordamagedparts.Repairanydamage

beforestartingthecuttingunit.

•Lowerthecuttingunitstothegroundandremovethekey

fromtheignitionswitchwheneveryouleavethemachine.

•Ensurethatthemachineisinsafeoperatingconditionby

keepingnuts,bolts,andscrewstight.

•Removethekeyfromignitionswitchtopreventaccidental

startingoftheenginewhenservicing,adjusting,orstoring

themachine.

•Performonlythosemaintenanceinstructionsdescribed

inthismanual.Ifthemachineneedsmajorrepairsoryou

needassistance,contactanAuthorizedToroDistributor.

•Toensureoptimumperformanceandcontinuedsafety

certicationofthemachine,useonlygenuineToro

replacementpartsandaccessories.Replacementparts

andaccessoriesmadebyothermanufacturerscouldbe

dangerous,andsuchusecouldvoidtheproductwarranty.

3

Page 4

Hauling

•Usecarewhenloadingorunloadingthemachineintoa

traileroratruck.

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

104–7729

•Usefull-widthrampsforloadingthemachineintoa

traileroratruck.

•Tiethemachinedownsecurelyusingstraps,chains,cable,

orropes.Boththefrontandtherearstrapsshouldbe

directeddownandoutwardfromthemachine.

1.Warning—readthe

instructionsbefore

servicingorperforming

maintenance.

2.Cutting/dismemberment

hazard;handorfoot—stop

theengineandwaitfor

movingpartstostop.

4

Page 5

Setup

G016936

1

2

4

5

6

3

G020075

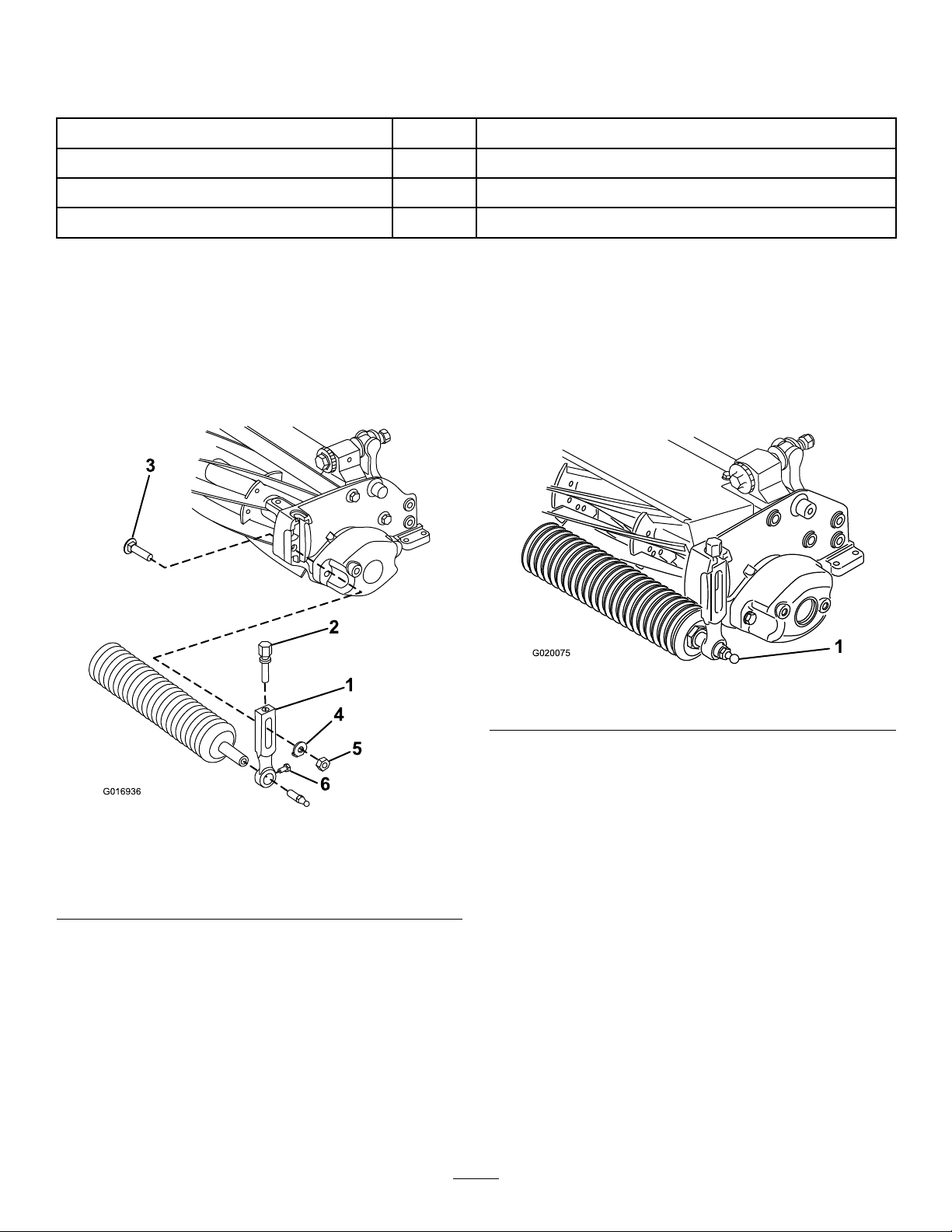

MediaandAdditionalParts

Description

Ballstud2Mountthistotheroller.

Operator'sManual

Partscatalog1

InstallingtheRoller

Thecuttingunitisshippedwithoutafrontroller.Obtain

arollerfromyourdealerandinstallitonthecuttingunit,

asfollows:

1.Removetheplowbolt,washer,andangenutsecuring

oneoftheheight-of-cutarmstothecuttingunitside

plate(Figure3).

Qty.

1

Readbeforeinstallingandoperatingthecuttingunit.

Usethistoreferencepartnumbers.

7.Tightentheroller-mountingscrews(Figure3).

8.Adjusttothedesiredheight-of-cutandtightenthe

height-of-cutarmmountingfasteners.

InstallingtheBallStuds

Installaballstudoneachendofthefrontroller(Figure4).

Use

Figure3

1.Height-of-cutarm

2.Adjustingscrew5.Flangenut

3.Plowbolt6.Roller-mountingscrew

2.Loosentheroller-mountingscrewsintheheight-of-cut

arms(Figure3).

3.Slidetherollershaftintotheheight-of-cutarmonthe

oppositeendofthecuttingunit(Figure3).

4.Slidetheheight-of-cutarmontotherollershaft(Figure

3).

5.Looselysecuretherollertothecuttingunitwiththe

height-of-cutarmandfastenerspreviouslyremoved

(Figure3).

6.Centertherollerbetweentheheight-of-cutarms.

4.Washer

Figure4

1.Ballstud

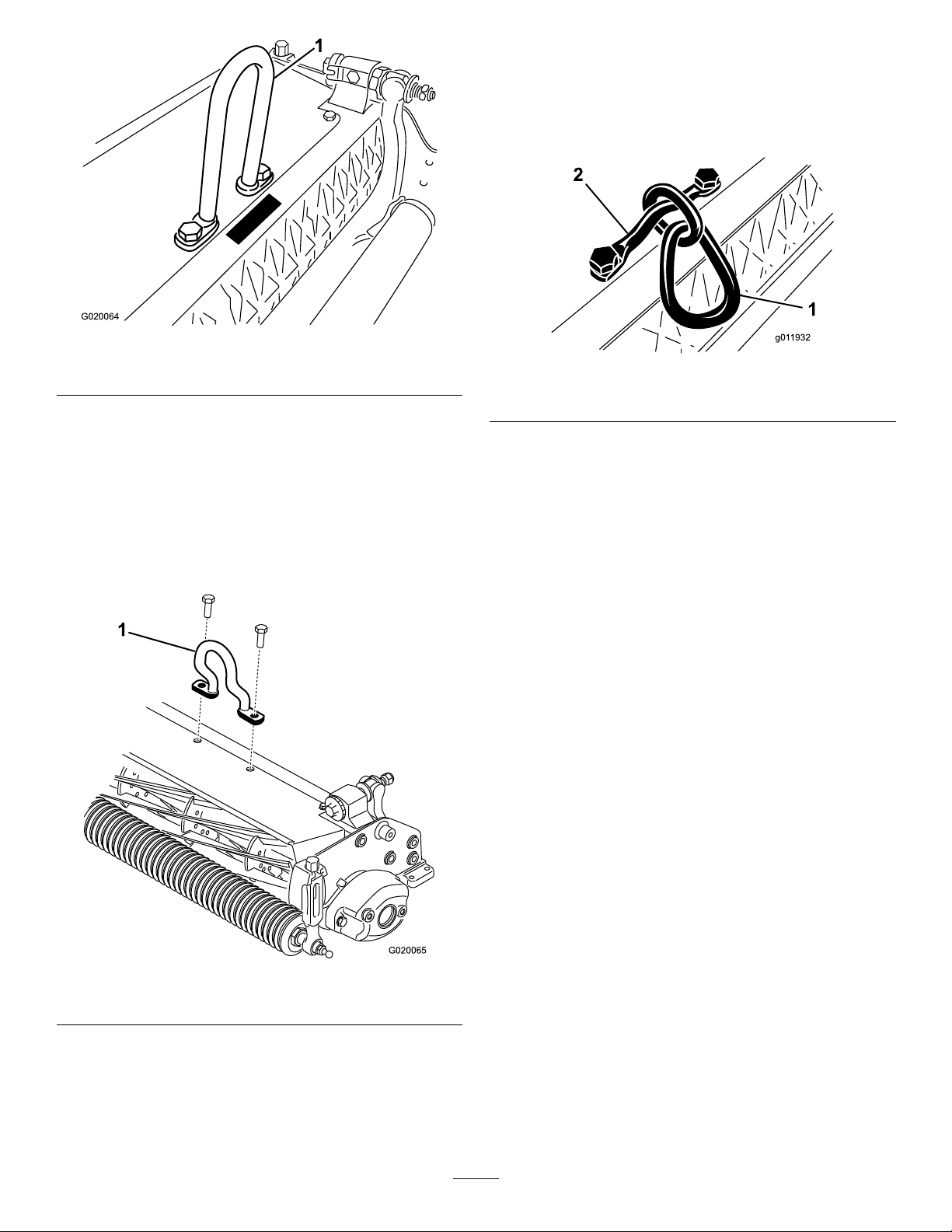

InstallingtheHoopLink,Offset

Link,orChainLink

Forcuttingunitsmountingonatractionunitwithaserial

numberpriorto240000001,obtainandinstalltheproper

liftlinkasfollows:

Note:The2boltsusedtomounttheliftlinkareshipped

installedonthecuttingunit.

•ForGreensmaster3120and3150tractionunits,install

thehooplink(PartNo.105-5740)suppliedwiththe

tractionunit.

Installthehooplinktothetopofthecuttingunitwith2

bolts.Torquetheboltsto34to40N∙m(25to30ft-lb)

(Figure5).

5

Page 6

G020064

Figure5

G020065

g011932

1

2

Installthechainlink(Figure7)tothetopofthecutting

unitwiththemountingbracketand2bolts.Torquethe

boltsto34to40N∙m(25to30ft-lb).

Note:Whenmountingthecuttingunittothetraction

unit,hookthewiderendofthechainlinktotheliftarm.

1.Hooplink

•FortheGreensmaster3250-Dtractionunits,installthe

offsetlink(PartNo.110-2397)suppliedwiththetraction

unit.

Installtheoffsetlink(Figure6)tothetopofthecutting

unitwith2bolts.Torquetheboltsto34to40N∙m(25

to30ft-lb).

Important:Positionthelifthookoffsettowardsthe

frontofthecuttingunit.

Figure7

1.Chainlink

2.Mountingbracket

RepositioningtheCounter

Weights

Thecuttingunitsareshippedwiththecounterweight

mountedtotheleftendandthemotormounttotherightend

ofthecuttingunit.T ochangethecuttingunittodifferent

positions,proceedasfollows:

Important:Wheneveryouneedtotipthecuttingunit

onitsside,ensurethatyoupropituptoavoiddamaging

thebedbar-adjustingscrews;refertoSupportingthe

CuttingUnit(page9)

1.Removethe2boltssecuringthecounterweighttothe

leftendofthecuttingunit.Removethecounterweight

(Figure9).

2.Removethe2Allenheadscrewssecuringthemotor

mounttotheleftendofthecuttingunit.Removethe

motormount(Figure8).

Figure6

1.Offsetlifthook

•OptionallyfortheGreensmaster3250-Dtractionunits,

youcaninstallthechainLink(PartNo.106-2601)and

mountingbracket(PartNo.105-5738)availablefrom

yourT oroDistributor.

3.Applygreasetotheinsidediameterofthedrivespline

(Figure8).

4.Ontheleftendofthecuttingunit,applyalightcoating

ofoiltotheO-ringandinstallthemotormountwith

the2Allenheadscrewspreviouslyremoved(Figure8).

Torquethescrewsto16to20N∙m(12to15ft-lb).

6

Page 7

Figure8

1.Drivespline3.Allenheadscrew

2.Motormount

5.Ontherightendofthecuttingunit,applyalight

coatingofoiltotheO-ringandinstallthecounter

weightwiththeboltspreviouslyremoved(Figure9).

Torquethescrewsto16to20N∙m(12to15ft-lb).

Figure9

1.Counterweight

AdjustingtheCuttingUnit

1.Supportthecuttingunit;refertoSupportingthe

CuttingUnit(page9).

2.Adjustthebedknifetothereel;refertoAdjustingthe

BedknifetotheReel(page9).

3.Adjusttherearrollerheight;refertoAdjustingthe

Rear-RollerHeight(page10).

4.Adjusttheheightofcut;refertoAdjustingtheHeight

ofCut(page11).

5.Adjustthecut-offbar;refertoAdjustingtheCut-Off

Bar(page12).

7

Page 8

ProductOverview

Specications

Tractors

HeightofCutAdjustonthefrontrollerusing2verticalscrewsandheld2lockingscrews.

Height-of-CutRangeStandardbenchheight-of-cutrangeis1.6mm(0.062inch)to12.7mm(0.500inch).Bench

CuttingWidth53cm(21inches)

ReelBearingsT wosealedstainlesssteel,deepgrooveballbearings

Rollers

BedknifeReplaceablesingleedged,highcarbonsteelbedknifeisfastenedtoamachinedcastiron

BedknifeAdjustmentDual-screwadjustmenttothereel;detentscorrespondingto0.018mm(0.0007inch)

GrassShieldNon-adjustableshieldwithadjustablecut-offbartoimprovegrassdischargefromreelin

Counterweight

NetWeight

Greensmaster3120,3150,3250-D,and3150-QTractionUnits.

height-of-cutrangewiththeHighHeightofCutKitinstalledis7mm(0.285inch)to25mm

(1.00inch).Effectiveheightofcutmayvarydependingonturfconditions,typeofbedknife,

rollers,andattachmentsinstalled.

Therearrollerisa5.1cm(2inch)diametersteelfullroller.

bedbarwith13screws

bedknifemovementforeachindexedposition

wetconditions

Acastironweightmountedoppositetothedrivemotorbalancesthecuttingunit.

8Blade—30kg(65lb),11Blade—31kg(68lb),14Blade—32kg(71lb)

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesisavailableforusewiththemachinetoenhanceandexpand

itscapabilities.ContactyourAuthorizedServiceDealerorDistributororgotowww.Toro.comforalistofallapproved

attachmentsandaccessories.

TobestprotectyourinvestmentandmaintainoptimalperformanceofyourToroequipment,countonTorogenuineparts.

Whenitcomestoreliability,Torodeliversreplacementpartsdesignedtotheexactengineeringspecicationofourequipment.

Forpeaceofmind,insistonT orogenuineparts.

Operation

RefertoyourtractionunitOperator’sManualfordetailedoperationinstructions.Beforeusingthecuttinguniteachday,adjustthe

bedknife;refertoAdjustingtheBedknifeDaily(page9).Testthequalityofcutbycuttingatestswathbeforeusingthecutting

unitonagreentoensurethatthenishedcutiscorrect.

8

Page 9

Maintenance

g026076

1

2

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

SupportingtheCuttingUnit

Wheneveryouneedtotipthecuttingunittoexposethe

bedknife/reel,propuptherearofthecuttingunittoensure

thatthenutsonthebackendofthebedbar-adjustingscrews

arenotrestingontheworksurface(Figure10).

Figure10

1.Prop(notprovided)

AdjustingtheBedknife-to-Reel Contact

AdjustingtheBedknifeDaily

Priortomowingeachday,orasrequired,verifyproper

bedknife-to-reelcontact.Performthisprocedureeven

thoughqualityofcutisacceptable.

1.Lowerthecuttingunitsontoahardsurface,shutoff

theengine,andremovetheignitionkey.

2.Slowlyrotatethereelinareversedirection,listening

forreel-to-bedknifecontact.

•Ifnocontactisevident,adjustthebedknifeas

follows

A.Turnthebedbaradjustingscrewsclockwise

(Figure11),1clickatatime,untilyoufeeland

hearlightcontact.

Note:Thebedbaradjustingscrewshave

detentscorrespondingto0.018mm(0.0007

inch)bedknifemovementforeachindexed

position.

2.Bedbar-adjusting-screw

nut(2)

Figure11

1.Bedbaradjustingscrew

B.Insertalongstripofcuttingperformance

paper(ToroPartNo.125-5610)between

thereelandbedknife,perpendiculartothe

bedknife(Figure12),thenslowlyrotatethe

reelforward;itshouldcutthepaper;ifnot,

repeatstepsAandBuntilitdoes.

•Ifexcessivecontact/reeldragisevident,backlap,

refacethefrontofthebedknife,orgrindthecutting

unittoachievethesharpedgesneededforprecision

cutting(RefertotheToroManualforSharpeningReel

andRotaryMowers,FormNo.09168SL).

Important:Lightcontactispreferredatall

times.Ifyoudonotmaintainlightcontact,

thebedknife/reeledgeswillnotsufciently

self-sharpen,anddullcuttingedgeswillresultafter

aperiodofoperation.Ifyoumaintainexcessive

contact,bedknife/reelwearwillbeaccelerated,

unevenwearcanresult,andthequalityofcutmay

decline.

Note:Asthereelbladescontinuetorunagainstthe

bedknife,aslightburrwillappearonthefrontcutting

edgesurfacealongthefulllengthofthebedknife.

Occasionallyrunaleacrossthefrontedgetoremove

thisburrtoimprovecutting.

Afterextendedrunning,aridgewilleventuallydevelop

atbothendsofthebedknife.Roundoffthesenotches

orlethemushwiththecuttingedgeofthebedknife

toensuresmoothoperation.

AdjustingtheBedknifetotheReel

Usethisprocedureduringinitialcutting-unitsetupandafter

grinding,backlapping,ordisassemblingthereel.Thisisnota

dailyadjustment.

1.Positionthecuttingunitonaat,levelworksurface.

2.Tipthecuttingunittoexposethebedknifeandreel.

9

Page 10

Note:Ensurethatthenutsonthebackofthebedbar

adjustingscrewsarenotrestingontheworksurface

(Figure10).

3.Rotatethereelsothat1ofthebladescrossesthe

bedknifeedgebetweentherstandsecondbedknife

screwheadslocatedontherightsideofthecuttingunit.

4.Makeanidentifyingmarkonthebladewhereitcrosses

thebedknifeedge.

Note:Thiswillmakelateradjustmentseasier.

5.Inserta0.05mm(0.002inch)shimbetweentheblade

andthebedknifeedgeatthepointmarkedinstep4.

6.Turntherightbedbaradjustingscrew(Figure11)until

youfeellightpressureontheshimwhenslidingit

side-to-side.Removetheshim.

7.Fortheleftsideofthecuttingunit,slowlyrotatethe

reelsothattheclosestbladecrossesthebedknifeedge

betweentherstandsecondscrewheads.

8.Repeatsteps4through6fortheleftsideofthecutting

unitandleftbedbaradjustingscrew.

9.Repeatsteps5and6untilthereislightpressureatthe

contactpointsonboththeleftandrightsidesofthe

cuttingunit.

10.Toobtainlightcontactbetweenthereelandbedknife,

turneachbedbaradjustingscrewclockwise3clicks.

Note:Ifexcessivecontact/reeldragisevident,backlap,

refacethefrontofthebedknife,orgrindthecuttingunitto

achievethesharpedgesneededforprecisioncutting(Refer

totheToroManualforSharpeningReelandRotaryMowers,Form

No.09168SL).

AdjustingtheRear-Roller Height

Dependingonyourdesiredheight-of-cutrange,youneedto

adjusttherear-rollerbrackets(Figure13orFigure14)tothe

loworhighposition:

•Positionthespacerabovethesideplate-mountingange

(factorysetting)whentheheight-of-cutsettingsrange

from1.5mmto6mm(1/16inchto1/4inch)asshown

inFigure13.

Note:Eachclickonthebedbaradjustingscrewmoves

thebedknife0.018mm(0.0007inches).Donotover

tightentheadjustingscrews.

Turningtheadjustingscrewclockwisemovesthe

bedknifeedgeclosertothereel.Turningtheadjusting

screwcounterclockwisemovesthebedknifeedgeaway

fromthereel.

11.Insertalongstripofcuttingperformancepaper(Toro

PartNo.125-5610)betweenthereelandbedknife,

perpendiculartothebedknife(Figure12),thenslowly

rotatethereelforward;itshouldcutthepaper;ifnot,

turneachbedbaradjustingscrewclockwise1clicksand

repeatthisstepuntilitcutsthepaper.

Figure13

1.Spacer

2.Sideplate-mountingange

3.Rollerbracket

•Positionthespacerbelowthesideplate-mountingange

whentheheight-of-cutsettingsrangefrom3mmto25

mm(1/8inchto1inch)asshowninFigure14.

Figure14

1.Sideplate-mountingange

2.Spacer

3.Rollerbracket

Figure12

1.Raisetherearofthecuttingunitandplaceablock

underthebedknife.

2.Removethe2nutssecuringeachrollerbracketand

spacertoeachsideplatemountingange.

3.Lowertherollerandscrewsfromthesideplate

mountingangesandspacers.

10

Page 11

4.Placethespacersontothescrewsaboveorbelowthe

G020074

rollerbrackets,asrequired(Figure13orFigure14).

5.Securetherollerbracketandspacerstotheunderside

ofthemountingangeswiththenutspreviously

removed.

Note:Thepositionoftherearrollertothereeliscontrolled

bythemachiningtolerancesoftheassembledcomponents

andparallelingisnotrequired.

Figure15

AdjustingtheHeightofCut

Usethefollowingcharttodeterminewhichbedknifeisbest

suitedforthedesiredheightofcut.

Bedknife

Edgemax

Micro-cut

(Standard)

Edgemax

Tournament

(Optional)

Micro-cut

(Optional)

Tournament

(Optional)

Extended

Micro-cut

(Optional)

Extended

Tournament

(Optional)

Low-cut

(Optional)

High-cut

(Optional)

Fairway

(Optional)

Fairway

EdgeMax

(optional)

PartNo.

115-1880

115-1881

93-4262

93-4263

108-4303

108-4302

93-4264

94-6392

63-8600

112–7475

Height-of-Cut

1.5to4.7mm(0.062to

0.188inch)

3.1to12.7mm(0.125to

0.500inch)

1.5to4.7mm(0.062to

0.188inch)

3.1to12.7mm(0.125to

0.500inch)

1.5to4.7mm(0.062to

0.188inch)

3.1to12.7mm(0.125to

0.500inch)

4.7to25.4mm(0.188to

1.00inch)

7.9to25.4mm(0.312to

1.00inch)

9.5to25.4mm(0.375to

1.00inch)

9.5to25.4mm(0.375to

1.00inch)

1.Gaugebar

2.Height-adjustingscrew

3.Nut

2.Tightenthenut.

AdjustingtheHeightofCut

1.Loosenthelocknutssecuringtheheight-of-cutarmsto

thecutting-unitsideplates(Figure16).

Figure16

1.Height-of-cutarm

2.Locknut

3.Adjustingscrew

Note:Forheightsofcutgreaterthan9.5mm(0.375inch),

installthehigh-height-of-cutkit.

AdjustingtheHeight-of-CutGauge

Beforeadjustingtheheightofcut,settheheight-of-cutgauge

asfollows:

1.Loosenthenutonthegaugebarandsettheadjusting

screwtothedesiredheightofcut(Figure15).

Note:Thedistancebetweenthebottomofthescrew

headandthefaceofbaristheheightofcut.

2.Hookthescrewheadoftheheight-of-cutgaugeonto

therightsideofthecuttingedgeofthebedknifeand

resttherearendofthebarontotherearoftheroller

(Figure17).

11

Page 12

1

g014643

Figure18

Figure17

1.Gaugebar

3.Rotatetheadjustingscrewuntiltherollercontactsthe

frontofthegaugebar.

4.Repeatsteps2and3fortheleftside.

5.Adjustbothendsoftherolleruntiltheentirerolleris

paralleltothebedknife.

Important:Whensetproperly,therearandfront

rollerswillcontactthegaugebarandthescrew

willbesnugagainstthebedknife.Thisensures

thattheheightofcutisidenticalatbothendsof

thebedknife.

6.Tightenthenutstosecuretheadjustmentenoughto

removeplayfromthewasher.

7.Verifythattheheight-of-cutsettingiscorrect;repeat

thisprocedureifnecessary.

AdjustingtheCut-OffBar

Adjustthecut-offbartoensurethattheclippingsarecleanly

dischargedfromthereelarea,asfollows:

Note:Thebarisadjustabletocompensateforchangesin

turfconditions.Adjustthebarclosertothereelwhentheturf

isextremelydry.Bycontrast,adjustthebarfurtherawayfrom

thereelwhentheturfconditionsarewet.Thebarshouldbe

paralleltothereeltoensureoptimumperformance.Adjustit

afterthereelissharpenedonareelgrinder.

1.Cut-offbar

2.Inserta1.5mm(0.060inch)feelergaugebetweenthe

topofthereelandthebarthentightenthescrews.

Important:Ensurethatthebarandreelareequal

distanceapartacrossthecompletereel.

Note:Adjustthegapasneededforyourturf

conditions.

ServicingtheBedbar

Onlyaproperlytrainedmechanicshouldservicethebedbar

andbedknifetopreventdamagetothereel,bedbar,or

bedknife.Ideally,takethecuttingunittoyourAuthorized

ToroDistributorforservice.RefertotheServiceManualfor

yourtractionunitforcompleteinstructions,specialtools,

anddiagramsforservicingthebedknife.Shouldyouever

needtoremoveorassemblethebedbaryourself,instructions

areprovidedbelow ,asarethespecicationsforservicingthe

bedknife.

Important:Alwaysfollowthebedknifeprocedures

detailedinyour

bedknife.Failuretoinstallandgrindthebedknife

correctlycanleadtodamagetothereel,bedbar,or

bedknife.

RemovingtheBedbar

1.Turnthebedbaradjustingscrew ,counterclockwise,to

backthebedknifeawayfromthereel(Figure19).

Ser vice Man ual

whenservicingthe

1.Loosenthescrewssecuringthetopbar(Figure18)to

thecuttingunit.

12

Page 13

Figure19

g020056

Figure21

1.Bedbarbolt3.Nylonwasher

2.Nut

4.Steelwasher

1.Bedbar-adjustingscrew3.Bedbar

2.Spring-tensionnut

4.Washer

2.Backoutthespring-tensionnutuntilthewasherisno

longertensionedagainstthebedbar(Figure19).

3.Oneachsideofthemachine,loosenthelocknut

securingthebedbarbolt(Figure20).

Figure20

1.Bedbarbolt2.Locknut

4.Removeeachbedbarboltallowingthebedbartobe

pulleddownwardandremovedfromthecuttingunit

(Figure21).

AssemblingtheBedbar

1.Installthebedbar,positioningthemountingears

betweenthewashersandthebedbar-adjustingscrew

(Figure22).

2.Securethebedbartoeachsideplatewiththebedbar

bolts(nutsonbolts)and3washers(6total).

3.Positionanylonwasheroneachsideoftheside-plate

boss.Placeasteelwasheroutsideeachofthenylon

washers(Figure21).

4.Torquethebedbarboltsto27to36N∙m(240to320

inch-lb).

5.Tightenthelocknutsuntilyouremovetheendplay

fromsteelwashers,butyouareabletorotatethemby

hand.Thewashersontheinsidemayhaveagap.

Important:Donotovertightenthelocknutsor

theywilldeectthesideplates.

6.Tightenthespringtensionnutuntilthespringis

collapsed,thenbackitoff1/2turn(Figure22).

Accountforthe2nylonwashersand1steelwasheron

eachendofthebedbar(Figure21).

Figure22

1.Spring-tensionnut2.Spring

13

Page 14

7.Adjustthebedknifetothereel;refertoAdjustingthe

BedknifetotheReel(page9).

BedknifeSpecications

BedknifeTypes

Figure23

1.Standardbedknife:42.9

mm(1.689inches)

BedknifeScrews

Torque:23to28N∙m(200to250in-lb)

Installationtool:TOR510880

Installationorder:

BedknifeGrindingSpecications

2.Extendedbedknife:47.7

mm(1.876inches)

Figure24

BacklappingtheCuttingUnit

DANGER

Contactwiththereelorothermovingpartscan

resultinpersonalinjury.

Keepngers,hands,andclothingawayfromthe

reelsorothermovingparts.

•Stayawayfromthereelwhilebacklapping.

•Neveruseashorthandledpaintbrushfor

backlapping.PartNo.29-9100Handleassembly

completeorindividualpartsareavailablefrom

yourlocalAuthorizedT oroDistributor.

1.Positionthemachineonaclean,levelsurface,lower

thecuttingunits,stoptheengine,engagetheparking

brake,andremovetheignitionkey.

2.Removethereelmotorsfromthecuttingunitsand

disconnectandremovethecuttingunitsfromthelift

arms.

3.Connectthebacklappingmachinetothecuttingunit

byinsertingapieceof3/8inchsquarestockintothe

splinedcouplingintheendofthecuttingunit.

Note:Additionalinstructionsandprocedureson

BacklappingareavailableinyourtractionunitOperator’ s

ManualandtheToroSharpeningReelandRotaryMowers

Manual,FormNumber80-300PT.

Note:Forabettercuttingedge,runaleacrossthe

frontfaceofthebedknifeandreelwhenthelapping

operationiscompleted.Thiswillremoveanyburrsor

roughedgesthatmayhavebuiltuponthecuttingedge.

Figure25

1.Reliefangle4.Frontface

2.Topface

3.Removeburr

Standardbedknifereliefangle3°

Extendedbedknifereliefangle7°

FrontAngle(allbedknife

types)

FrontAngleRange

5.Frontangle

13°

13°to17°

14

Page 15

Notes:

15

Page 16

Notes:

16

Page 17

Notes:

17

Page 18

DeclarationofIncorporation

TheT oroCompany,811 1LyndaleAve.South,Bloomington,MN,USAdeclaresthatthefollowingunit(s)

conform(s)tothedirectiveslisted,wheninstalledinaccordancewiththeaccompanyinginstructionsontocertain

ToromodelsasindicatedontherelevantDeclarationsofConformity.

ModelNo.

04652316000001andUp8-BladeDPAReelMower

04654316000001andUp11-BladeDP AReelMower

04656316000001andUp14-BladeDP AReelMower

SerialNo.

ProductDescriptionInvoiceDescription

8BLADECUTTINGUNIT

NGDPA

11BLADECUTTING

UNITNGDPA

14BLADECUTTING

UNITNGDPA

GeneralDescription

8-BladeDPAReelMower

11-BladeDP AReelMower

14-BladeDPAReelMower

Directive

2006/42/EC,

2000/14/EC

2006/42/EC,

2000/14/EC

2006/42/EC,

2000/14/EC

RelevanttechnicaldocumentationhasbeencompiledasrequiredperPartBofAnnexVIIof2006/42/EC.

Wewillundertaketotransmit,inresponsetorequestsbynationalauthorities,relevantinformationonthispartly

completedmachinery.Themethodoftransmissionshallbeelectronictransmittal.

ThismachineryshallnotbeputintoserviceuntilincorporatedintoapprovedToromodelsasindicatedonthe

associatedDeclarationofConformityandinaccordancewithallinstructions,wherebyitcanbedeclaredin

conformitywithallrelevantDirectives.

Certied:EUTechnicalContact:

MarcVermeiren

ToroEuropeNV

B-2260Oevel-Westerloo

Belgium

DavidKlisTel.003214562960

Sr.EngineeringManager

811 1LyndaleAve.South

Bloomington,MN55420,USA

October9,2015

Fax003214581911

18

Page 19

InternationalDistributorList

Distributor:

AgrolancKft

AsianAmericanIndustrial(AAI)

B-RayCorporation

BrisaGoodsLLC

CascoSalesCompany

CeresS.A.CostaRica

CSSCTurfEquipment(pvt)Ltd.SriLanka

CyrilJohnston&Co.

CyrilJohnston&Co.RepublicofIreland

FatDragon

FemcoS.A.Guatemala

FIVEMANSNew-T echCo.,LtdChina

ForGarderOU

G.Y .K.CompanyLtd.

GeomechanikiofAthensGreece

GolfinternationalTurizm

HakoGroundandGardenSweden

HakoGroundandGarden

HayterLimited(U.K.)

HydroturfInt.CoDubai

HydroturfEgyptLLC

IrrimacPortugal351212388260T oroEuropeNVBelgium3214562960

IrrigationProductsInt'lPvtLtd.India00914424494387ValtechMorocco212537663636

JeanHeybroekb.v.Netherlands31306394611VictusEmakPoland48618238369

Country:

Hungary3627539640

HongKong85224977804

Korea82325512076

Mexico12104952417

PuertoRico7877888383

NorthernIreland442890813121

China

Estonia3723846060

Japan81726325861Riversa

Turkey902163365993

Norway4722907760

UnitedKingdom441279723444

UnitedArabEmirates97143479479T-MarktLogisticsLtd.Hungary3626525500

Egypt2025194308ToroAustraliaAustralia61395807355

PhoneNumber:Distributor:

MaquiverS.A.Colombia

MaruyamaMfg.Co.Inc.

Mountelda.s.CzechRepublic

Mountelda.s.Slovakia

5062391138

94112746100

442890813121ParklandProductsLtd.NewZealand6433493760

8861080841322

5024423277

86-10-63816136

30109350054

4635100000

MunditolS.A.

NormaGarden

OslingerTurfEquipmentSA

OyHakoGroundandGardenAb

Perfetto

PratoverdeSRL.

Prochaska&Cie

RTCohen2004Ltd.

LelyTurfcare

Lely(U.K.)Limited

SolvertS.A.S.

SpyprosStavrinidesLimitedCyprus

SurgeSystemsIndiaLimited

Country:

Japan81332522285

Argentina541 148219999

Russia749541 16120

Ecuador59342396970

Finland35898700733

Poland48618208416

Italy390499128128

Austria4312785100

Israel97298617979

Spain

Denmark4566109200

UnitedKingdom441480226800

France33130817700

India911292299901

PhoneNumber:

5712364079

420255704220

420255704220

34952837500

35722434131

EuropeanPrivacyNotice

TheInformationToroCollects

ToroWarrantyCompany(Toro)respectsyourprivacy.Inordertoprocessyourwarrantyclaimandcontactyouintheeventofaproductrecall,weaskyou

tosharecertainpersonalinformationwithus,eitherdirectlyorthroughyourlocalT orocompanyordealer.

TheT orowarrantysystemishostedonserverslocatedwithintheUnitedStateswhereprivacylawmaynotprovidethesameprotectionasapplies

inyourcountry.

BYSHARINGYOURPERSONALINFORMATIONWITHUS,YOUARECONSENTINGTOTHEPROCESSINGOFYOURPERSONALINFORMATION

ASDESCRIBEDINTHISPRIV ACYNOTICE.

TheWayT oroUsesInformation

Toromayuseyourpersonalinformationtoprocesswarrantyclaims,tocontactyouintheeventofaproductrecallandforanyotherpurposewhichwetell

youabout.ToromayshareyourinformationwithT oro'safliates,dealersorotherbusinesspartnersinconnectionwithanyoftheseactivities.Wewillnot

sellyourpersonalinformationtoanyothercompany.Wereservetherighttodisclosepersonalinformationinordertocomplywithapplicablelawsand

withrequestsbytheappropriateauthorities,tooperateoursystemsproperlyorforourownprotectionorthatofotherusers.

RetentionofyourPersonalInformation

Wewillkeepyourpersonalinformationaslongasweneeditforthepurposesforwhichitwasoriginallycollectedorforotherlegitimatepurposes

(suchasregulatorycompliance),orasrequiredbyapplicablelaw .

Toro'sCommitmenttoSecurityofYourPersonalInformation

Wetakereasonableprecautionsinordertoprotectthesecurityofyourpersonalinformation.Wealsotakestepstomaintaintheaccuracyandcurrent

statusofpersonalinformation.

AccessandCorrectionofyourPersonalInformation

Ifyouwouldliketorevieworcorrectyourpersonalinformation,pleasecontactusbyemailatlegal@toro.com.

AustralianConsumerLaw

AustraliancustomerswillnddetailsrelatingtotheAustralianConsumerLaweitherinsidetheboxoratyourlocalToroDealer.

374-0269RevK

Page 20

TheT oroWarranty

ATwo-YearLimitedWarranty

ConditionsandProductsCovered

TheToroCompanyanditsafliate,T oroWarrantyCompany,pursuant

toanagreementbetweenthem,jointlywarrantyourT oroCommercial

product(“Product”)tobefreefromdefectsinmaterialsorworkmanship

fortwoyearsor1500operationalhours*,whicheveroccursrst.This

warrantyisapplicabletoallproductswiththeexceptionofAerators

(refertoseparatewarrantystatementsfortheseproducts).Wherea

warrantableconditionexists,wewillrepairtheProductatnocosttoyou

includingdiagnostics,labor,parts,andtransportation.Thiswarranty

beginsonthedatetheProductisdeliveredtotheoriginalretailpurchaser .

*Productequippedwithanhourmeter.

InstructionsforObtainingWarrantyService

YouareresponsiblefornotifyingtheCommercialProductsDistributoror

AuthorizedCommercialProductsDealerfromwhomyoupurchasedthe

Productassoonasyoubelieveawarrantableconditionexists.Ifyouneed

helplocatingaCommercialProductsDistributororAuthorizedDealer,or

ifyouhavequestionsregardingyourwarrantyrightsorresponsibilities,

youmaycontactusat:

ToroCommercialProductsServiceDepartment

ToroWarrantyCompany

811 1LyndaleAvenueSouth

Bloomington,MN55420-1196

952–888–8801or800–952–2740

E-mail:commercial.warranty@toro.com

OwnerResponsibilities

AstheProductowner,youareresponsibleforrequiredmaintenanceand

adjustmentsstatedinyourOperator'sManual.Failuretoperformrequired

maintenanceandadjustmentscanbegroundsfordisallowingawarranty

claim.

ItemsandConditionsNotCovered

Notallproductfailuresormalfunctionsthatoccurduringthewarranty

periodaredefectsinmaterialsorworkmanship.Thiswarrantydoesnot

coverthefollowing:

•Productfailureswhichresultfromtheuseofnon-T ororeplacement

parts,orfrominstallationanduseofadd-on,ormodiednon-Toro

brandedaccessoriesandproducts.Aseparatewarrantymaybe

providedbythemanufactureroftheseitems.

•Productfailureswhichresultfromfailuretoperformrecommended

maintenanceand/oradjustments.Failuretoproperlymaintainyour

ToroproductpertheRecommendedMaintenancelistedinthe

Operator’sManualcanresultinclaimsforwarrantybeingdenied.

•ProductfailureswhichresultfromoperatingtheProductinanabusive,

negligent,orrecklessmanner.

•Partssubjecttoconsumptionthroughuseunlessfoundtobedefective.

Examplesofpartswhichareconsumed,orusedup,duringnormal

Productoperationinclude,butarenotlimitedto,brakepadsand

linings,clutchlinings,blades,reels,rollersandbearings(sealedor

greasable),bedknives,sparkplugs,castorwheelsandbearings,tires,

lters,belts,andcertainsprayercomponentssuchasdiaphragms,

nozzles,andcheckvalves,etc.

•Failurescausedbyoutsideinuence.Conditionsconsideredtobe

outsideinuenceinclude,butarenotlimitedto,weather,storage

practices,contamination,useofunapprovedfuels,coolants,lubricants,

additives,fertilizers,water,orchemicals,etc.

•Failureorperformanceissuesduetotheuseoffuels(e.g.gasoline,

diesel,orbiodiesel)thatdonotconformtotheirrespectiveindustry

standards.

•Normalnoise,vibration,wearandtear ,anddeterioration.

•Normal“wearandtear”includes,butisnotlimitedto,damagetoseats

duetowearorabrasion,wornpaintedsurfaces,scratcheddecalsor

windows,etc.

Parts

Partsscheduledforreplacementasrequiredmaintenancearewarranted

fortheperiodoftimeuptothescheduledreplacementtimeforthatpart.

Partsreplacedunderthiswarrantyarecoveredforthedurationofthe

originalproductwarrantyandbecomethepropertyofT oro.T orowillmake

thenaldecisionwhethertorepairanyexistingpartorassemblyorreplace

it.T oromayuseremanufacturedpartsforwarrantyrepairs.

DeepCycleandLithium-IonBatteryWarranty:

DeepcycleandLithium-Ionbatterieshaveaspeciedtotalnumberof

kilowatt-hourstheycandeliverduringtheirlifetime.Operating,recharging,

andmaintenancetechniquescanextendorreducetotalbatterylife.Asthe

batteriesinthisproductareconsumed,theamountofusefulworkbetween

chargingintervalswillslowlydecreaseuntilthebatteryiscompletelyworn

out.Replacementofwornoutbatteries,duetonormalconsumption,

istheresponsibilityoftheproductowner.Batteryreplacementmaybe

requiredduringthenormalproductwarrantyperiodatowner’sexpense.

Note:(Lithium-Ionbatteryonly):ALithium-Ionbatteryhasapartonly

proratedwarrantybeginningyear3throughyear5basedonthetime

inserviceandkilowatthoursused.RefertotheOperator'sManualfor

additionalinformation.

MaintenanceisatOwner’sExpense

Enginetune-up,lubrication,cleaningandpolishing,replacementoflters,

coolant,andcompletingrecommendedmaintenancearesomeofthe

normalservicesT oroproductsrequirethatareattheowner’sexpense.

GeneralConditions

RepairbyanAuthorizedToroDistributororDealerisyoursoleremedy

underthiswarranty.

NeitherTheToroCompanynorToroWarrantyCompanyisliablefor

indirect,incidentalorconsequentialdamagesinconnectionwiththe

useoftheToroProductscoveredbythiswarranty,includingany

costorexpenseofprovidingsubstituteequipmentorserviceduring

reasonableperiodsofmalfunctionornon-usependingcompletion

ofrepairsunderthiswarranty.ExceptfortheEmissionswarranty

referencedbelow,ifapplicable,thereisnootherexpresswarranty.All

impliedwarrantiesofmerchantabilityandtnessforusearelimitedto

thedurationofthisexpresswarranty.

Somestatesdonotallowexclusionsofincidentalorconsequential

damages,orlimitationsonhowlonganimpliedwarrantylasts,sotheabove

exclusionsandlimitationsmaynotapplytoyou.Thiswarrantygivesyou

speciclegalrights,andyoumayalsohaveotherrightswhichvaryfrom

statetostate.

Noteregardingenginewarranty:

TheEmissionsControlSystemonyourProductmaybecoveredby

aseparatewarrantymeetingrequirementsestablishedbytheU.S.

EnvironmentalProtectionAgency(EP A)and/ortheCaliforniaAirResources

Board(CARB).Thehourlimitationssetforthabovedonotapplytothe

EmissionsControlSystemWarranty.RefertotheEngineEmissionControl

WarrantyStatementsuppliedwithyourproductorcontainedintheengine

manufacturer’sdocumentationfordetails

CountriesOtherthantheUnitedStatesorCanada

CustomerswhohavepurchasedT oroproductsexportedfromtheUnitedStatesorCanadashouldcontacttheirT oroDistributor(Dealer)toobtain

guaranteepoliciesforyourcountry ,province,orstate.IfforanyreasonyouaredissatisedwithyourDistributor'sserviceorhavedifcultyobtaining

guaranteeinformation,contacttheT oroimporter.

374-0253RevD

Loading...

Loading...