Toro 04613, 04614, 04615, Greensmaster 3300 Series, Greensmaster 3400 Series Operator's Manual

Page 1

FormNo.3376-576RevB

8,11,and14-BladeDPAReel

Mower

Greensmaster

®

3300/3400SeriesTraction

Unit

ModelNo.04613—SerialNo.313000001andUp

ModelNo.04614—SerialNo.313000001andUp

ModelNo.04615—SerialNo.313000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3376-576*B

Page 2

Figure2

Introduction

Thiscuttingunitisdesignedforcuttingturfongreensand

smallfairwaysofgolfcourses.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready.Figure1identiesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Contents

Introduction..................................................................2

Safety...........................................................................3

SafetyandInstructionalDecals.................................3

Setup............................................................................4

InstallingtheFrontRoller.........................................4

UsingtheCuttingUnitProp......................................4

AdjustingtheBedknifetotheReel.............................4

AdjustingtheRearRoller..........................................5

AdjustingtheHeightofCut......................................5

AdjustingtheCut-OffBar........................................7

ProductOverview..........................................................8

Specications.........................................................8

Attachments/Accessories.........................................8

Operation.....................................................................9

CuttingUnitCharacteristics......................................9

DailyAdjustmentsoftheCuttingUnit........................9

Maintenance.................................................................10

ServicingtheBedbar...............................................10

BacklappingtheReel...............................................11

Figure1

1.Locationofthemodelandserialnumbers

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

©2014—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

Safety

Hazardcontrolandaccidentpreventionaredependent

upontheawareness,concern,andpropertraining

ofthepersonnelinvolvedintheoperation,transport,

maintenance,andstorageofthemachine.Improper

useormaintenanceofthemachinecanresultininjury

ordeath.Toreducethepotentialforinjuryordeath,

complywiththefollowingsafetyinstructions.

•Read,understand,andfollowallinstructionsinthe

tractionunitandcuttingunitOperator’sManualsbefore

operatingthecuttingunit.

•Neverallowchildrentooperatethetractionunitor

cuttingunits.Donotallowadultstooperatetractionunit

orcuttingunitswithoutproperinstruction.Onlytrained

operatorswhohavereadthismanualshouldoperatethe

tractionunitorcuttingunits.

•Neveroperatethecuttingunitswhenundertheinuence

ofdrugsoralcohol.

•Keepallshieldsandsafetydevicesinplace.Ifashield,

safetydeviceordecalisillegibleordamaged,repairor

replaceitbeforeoperationiscommenced.Alsotighten

anyloosenuts,bolts,andscrewstoensurecuttingunitis

insafeoperatingcondition.

•Alwayswearsubstantialshoes.Donotoperatecutting

unitswhilewearingsandals,tennisshoes,sneakers,or

shorts.Also,donotwearloosettingclothingwhich

couldgetcaughtinmovingparts.Alwayswearlongpants

andsubstantialshoes.Wearingsafetyglasses,safetyshoes,

andahelmetisadvisableandrequiredbysomelocal

ordinancesandinsuranceregulations.

•Removealldebrisorotherobjectsthatmightbepicked

upandthrownbythecuttingunitreelblades.Keepall

bystandersawayfromtheworkingarea.

•Ifthecuttingbladesstrikeasolidobjectortheunit

vibratesabnormally,stopandshuttheengineoff.Check

thecuttingunitsfordamagedparts.Repairanydamage

beforerestartingandoperatingthecuttingunits.

•Lowerthecuttingunitstothegroundandremovekey

fromignitionswitchwhenevermachineisleftunattended.

•Ensurethatthecuttingunitsareinsafeoperating

conditionbykeepingnuts,bolts,andscrewstight.

•Removethekeyfromtheignitionswitchtoprevent

accidentalstartingoftheenginewhenservicing,adjusting,

orstoringthemachine.

•Performonlythosemaintenanceinstructionsdescribedin

thismanual.Ifmajorrepairsareeverneededorassistance

isdesired,contactanAuthorizedT oroDistributor.

•Toensureoptimumperformanceandsafety ,always

purchasegenuineTororeplacementpartsandaccessories.

Neveruse"will-t"replacementpartsand

accessoriesmadebyothermanufacturers.Lookfor

theTorologotoensuregenuineness.Usingunapproved

replacementpartsandaccessoriescouldvoidthewarranty

ofTheToroCompany.

SafetyandInstructionalDecals.

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

104–7729

1.Warning—readthe

instructionsbefore

servicingorperforming

maintenance.

2.Cutting/dismemberment

hazard;handorfoot—stop

theengineandwaitfor

movingpartstostop.

3

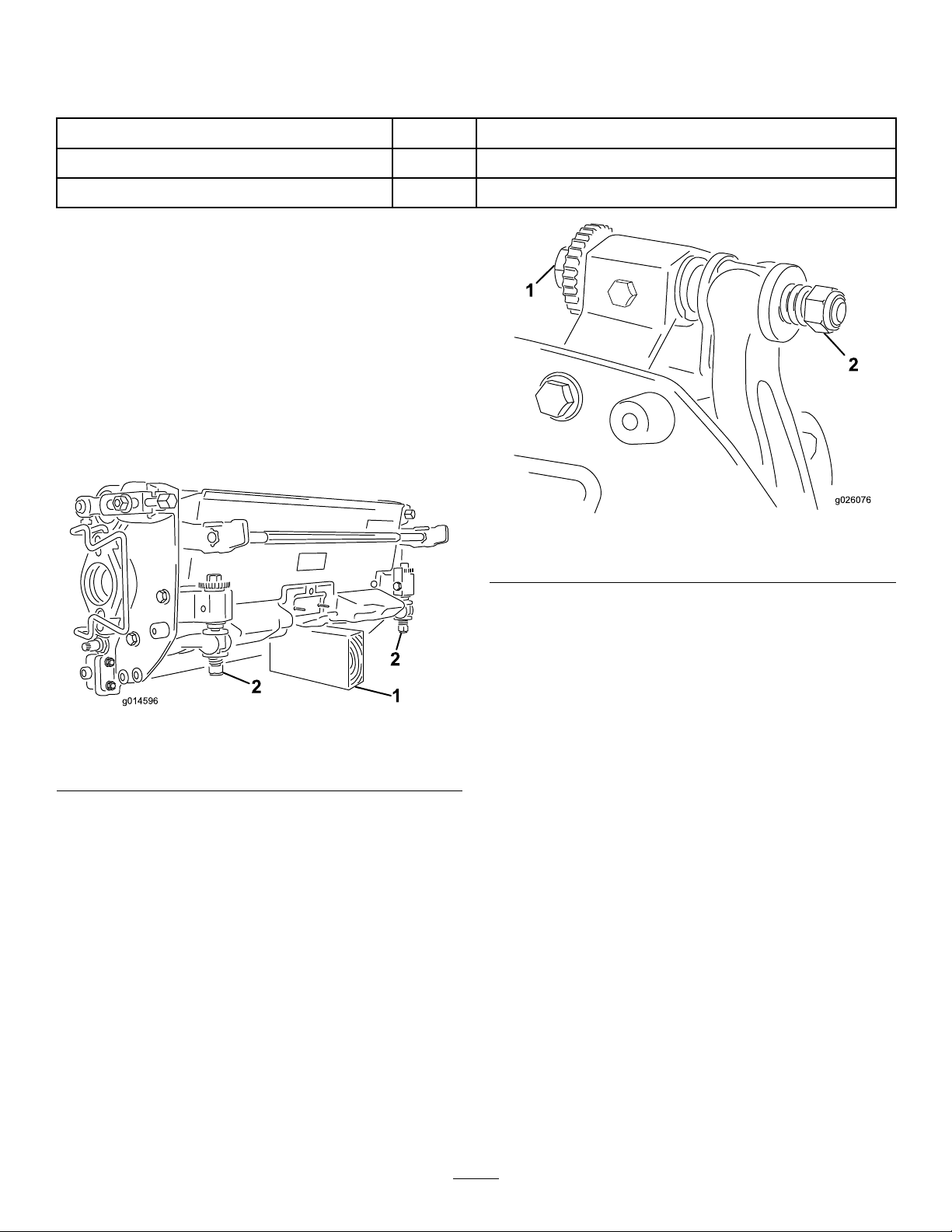

Page 4

Setup

g014596

1

2

2

g026076

1

2

MediaandAdditionalParts

Description

Operator'sManual

Partscatalog1

InstallingtheFrontRoller

Thecuttingunitisshippedwithoutafrontroller.Installthe

rollerusingtheloosepartssuppliedwiththecuttingunitand

installationinstructionsincludedwiththeroller.

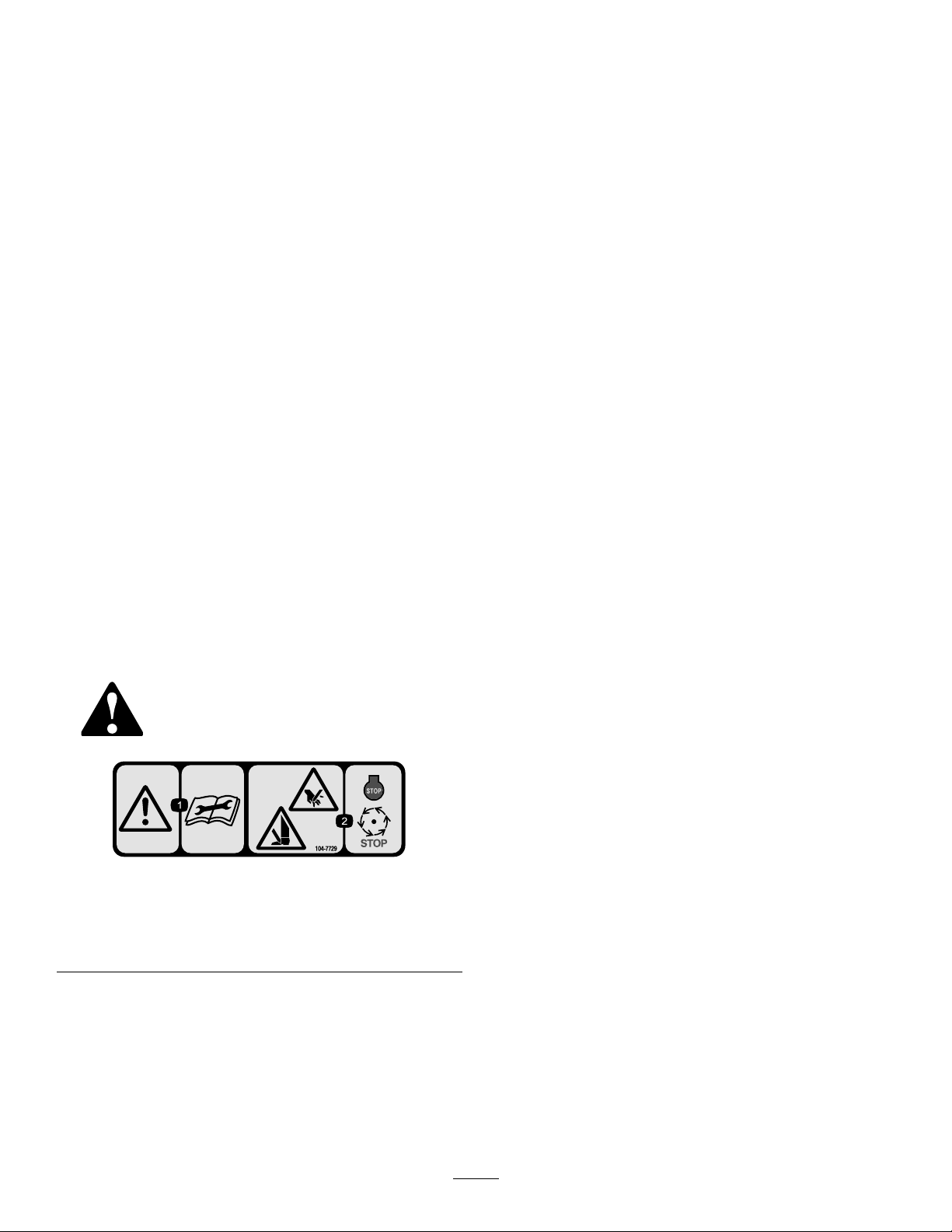

UsingtheCuttingUnitProp

Wheneverthecuttingunithastobetippedtoexposethe

bedknife/reel,propuptherearofthecuttingunittomake

surethenutsonthebackendofthebedbaradjustingscrews

arenotrestingontheworksurface(Figure3).

Qty.

Use

1

Readbeforeinstallingandoperatingcuttingunit

Usetoreferencepartnumbers

Figure4

1.Bedknifeadjustingscrew

2.Nut

Figure3

1.Prop(notprovided)2.Bedknifeadjustingscrew

nut(2)

AdjustingtheBedknifetothe

Reel

Note:Usethisprocedureaftergrinding,backlapping,or

disassembly.Itisnotintendedasadailyadjustment.

1.Positionthecuttingunitonaat,levelworksurface.

2.Tipthecuttingunittoexposethebedknifeandthe

reel.Makesurethenutsorthebackofthebedbar

adjustingscrewsarenotrestingonthework

surface(Figure4).

3.Rotatethereelsothatabladecrossesthebedknifeedge

betweentherstandsecondbedknifescrewheadson

therightsideofthecuttingunit.

4.Putanidentifyingmarkonthebladewhereit

crossesthebedknifeedge;thiswillmakesubsequent

adjustmentseasier.

5.Insertthe.05mm(0.002inch)shimbetweenthe

markedbladeandthebedknifeedgeatthepointwhere

themarkedbladecrossesthebedknifeedge.

6.Turntherightbedbaradjustingscrewuntilyoufeel

lightpressure(i.e.drag)ontheshimbyslidingit

side-to-side.Removetheshim.

7.Fortheleftsideofthecuttingunit,slowlyrotatethe

reelsothattheclosestbladecrossesthebedknifeedge

betweentherstandsecondscrewheads.

8.Repeatsteps4through6fortheleftsideofthecutting

unitandleftbedbaradjustingscrew.

9.Repeatsteps5and6untillightdragisachievedon

boththerightandleftsidesofthecuttingunitutilizing

thesamecontactpoints.

Thebedknifeisnowparalleltothereel.

10.Toobtainlightcontactbetweenthereelandbedknife,

turneachbedbaradjustingscrewclockwise3clicks.

Note:Eachclickturnedonthebedbaradjusting

screwmovesthebedknife0.018mm(0.0007inches).

Clockwiserotationmovesthebedknifeedgecloser

4

Page 5

tothereelandcounterclockwiserotationmovethe

bedknifeedgeawayfromthereel.Donotovertighten

theadjustingscrews.

11.Testthecuttingperformancebyinsertingalongstrip

ofcuttingperformancepaper(T oropartnumber

125-5610)betweenthereelandbedknife,perpendicular

tothebedknife(Figure5).Slowlyrotatethereel

forward;itshouldcutpaper

Positionthespacerbelowthesideplatemounting

angewhenheightofcutsettingsrangefrom3to25

mm(1/8to1inch)(Figure7).

Figure7

1.Spacer3.Sideplatemountingange

2.Rollerbracket

2.Toadjustrearrollerproceedasfollows:

A.Raisetherearofthecuttingunitandplaceablock

underthebedknife.

Figure5

Note:Ifexcessivecontact/reeldragisevidentitwill

beeithernecessarytobacklap,refacethefrontofthe

bedknife,orregrindthecuttingunittoachievethe

sharpedgesneededforprecisioncutting(Refertothe

ToroManualforSharpeningReelandRotaryMowers,

FormNo.09168SL).

AdjustingtheRearRoller

1.Adjusttherearrollerbrackets(Figure6orFigure7)

totheloworhighpositiondependingonthedesired

heightofcutrange.

Positionthespacerabovethesideplatemountingange

(factorysetting)whenheightofcutsettingsrangefrom

1.6to6mm(1/16to1/4inch)(Figure6).

B.Removethe2nutssecuringeachrollerbracket

andspacertoeachsideplatemountingange.

C.Lowertherollerandscrewsfromthesideplate

mountingangesandspacers.

D.Placethespacersontothescrewsontheroller

brackets.

E.Securetherollerbracketandspacerstothe

undersideofthemountingangeswiththenuts

previouslyremoved.

Note:Thepositionoftherearrollertothereel

iscontrolledbythemachiningtolerancesofthe

assembledcomponentsandparallelingisnotrequired.

AdjustingtheHeightofCut

Note:Forheightsofcutgreaterthan1.270cm(0.500inch),

youmustinstallthehighheightofcutkit.

Important:Wheneverthecuttingunithastobetipped

toexposethebedknife/reel,propuptherearofthe

cuttingunittomakesurethenutsonthebackendof

thebedbaradjustingscrewsarenotrestingonthework

surface(Figure3).

Figure6

1.Spacer3.Sideplatemountingange

2.Rollerbracket

1.Loosenthelocknutssecuringtheheight-of-cutarmsto

thecuttingunitsideplates(Figure8).

5

Page 6

G020095

1.Gaugebar

Figure10

Figure8

1.Height-of-cutarm

2.Locknut

3.Adjustingbolt

2.Loosenthenutonthegaugebarandsettheheight

adjustingbolttothedesiredheight-of-cut(Figure9).

Thedistancebetweenthebottomoftheboltheadand

thefaceofthebaristheheight-of-cut.

Figure9

1.Gaugebar

2.Heightadjustingbolt

3.Nut

3.Hooktheboltheadontothecuttingedgeofthe

bedknifeandresttherearendofthebarontotherear

oftheroller(Figure10).

4.Rotatetheadjustingboltontheheight-of-cutarms

untilthefrontrollercontactsthegaugebar.Adjust

bothendsoftherolleruntiltheentirerollerisparallel

tothebedknife.

Important:Whensetproperly,therearandfront

rollerswillcontactthegaugebarandthebolthead

willbesnugagainstthebedknife.Thisensures

thattheheight-of-cutisidenticalatbothendsof

thebedknife.

5.Tightenthenutstosecuretheadjustment.Donot

overtightenthenuts.Tightenthemenoughtoremove

playfromthewasher.

Note:Usethefollowingcharttodeterminewhich

bedknifeisbestsuitedforthedesiredheightofcut.

RecommendedBedknife/HeightofCutChart

Bedknife

Edgemax

Micro-cut

(Standard)

Edgemax

Tournament

(Optional)

Micro-cut

(Optional)

Tournament

(Optional)

Extended

Micro-cut

(Optional)

Extended

Tournament

(Optional)

Low-cut

(Optional)

High-cut

(Optional)

Fairway

(Optional)

PartNumber

115-18801.5–4.7mm

(0.062–0.188inch)

115-18813.1–12.7mm

(0.125–0.500inch)

93-42621.5–4.7mm

(0.062–0.188inch)

93-42633.1–12.7mm

(0.125–0.500inch)

108-43031.5–4.7mm

(0.062–0.188inch)

108-43023.1–12.7mm

(0.125–0.500inch)

93-42644.7–25.4mm

(0.188–1.00inch)

94-63927.9–25.4mm

(0.312–1.00inch)

63-86009.5–25.4mm

(0.375–1.00inch)

HeightofCut

6

Page 7

AdjustingtheCut-OffBar

1

g014643

Adjustthecut-offbartoensurethattheclippingsarecleanly

dischargedfromthereelarea:

1.Loosenthescrewssecuringthetopbar(Figure11)to

thecuttingunit.

Figure11

1.Cut-offbar

2.Inserta0.060inchfeelergaugebetweenthetopofthe

reelandthebarandtightenthescrews.Ensurethebar

andreelareequaldistanceapartacrossthecomplete

reelforoptimumperformance.

Note:Thebarisadjustabletocompensateforchanges

inturfconditions.Adjustthebarclosertothereel

whentheturfisextremelydry.Bycontrast,adjustthe

barfurtherawayfromthereelwhentheturfconditions

arewet.Adjustthebarwheneveryousharpenthereel

onareelgrinder.

7

Page 8

ProductOverview

Specications.

Tractors

HeightofCutCuttingheightisadjustedonthefrontrollerbytwoverticalscrewsandheldbytwolocking

HeightOfCutRangeStandardbenchheight-of-cutrangeis1.6mm(0.062inch)to12.7mm(0.500inch).Bench

ReelBearingsT wosealedstainlesssteel,deepgrooveballbearings.

Rollers

BedknifeReplaceablesingleedged,highcarbonsteelbedknifeisfastenedtoamachinedcastiron

BedknifeAdjustmentDualscrewadjustmenttothereel;detentscorrespondingto0.018mm(0.0007inch)

GrassShieldNon-adjustableshieldwithadjustablecut-offbartoimprovegrassdischargefromreelin

Counterweight

NetWeight

ThesecuttingunitswillmountontheGreensmaster3300and3400TractionUnits.

capscrews

height-of-cutrangewiththeHighHeightofCutKitinstalledis7mm(0.285inch)to25mm

(1.00inch).Effectiveheightofcutmayvarydependingonturfconditions,typeofbedknife,

rollers,andattachmentsinstalled

Therearrollerisa5.1cm(2inch)diametersteelfullroller

bedbarwith13screws.

bedknifemovementforeachindexedposition.

wetconditions.

Acastironweightmountedoppositetothedrivemotorbalancesthecuttingunit.

8Blade—32kg(71lb),11Blade—34kg(74lb),14Blade—35kg(77lb)

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesis

availableforusewiththemachinetoenhanceandexpand

itscapabilities.ContactyourAuthorizedServiceDealeror

Distributororgotowww .Toro.comforalistofallapproved

attachmentsandaccessories.

8

Page 9

Operation

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

CuttingUnitCharacteristics

Thedualknobbedknife-to-reeladjustmentsystem

incorporatedinthiscuttingunitsimpliestheadjustment

procedureneededtodeliveroptimummowingperformance.

Thepreciseadjustmentpossiblewiththedualknob/bedbar

designgivesthenecessarycontroltoprovideacontinual

self-sharpeningaction-thusmaintainingsharpcuttingedges,

ensuringgoodquality-of-cut,andgreatlyreducingtheneed

forroutinebacklapping.

DailyAdjustmentsofthe CuttingUnit

Priortomowingeachday,orasrequired,checkeachcutting

unittoverifyproperbedknife-to-reelcontact.Thismustbe

performedeventhoughqualityofcutisacceptable.

bedknife,orregrindthecuttingunittoachievethe

sharpedgesneededforprecisioncutting(Refertothe

ToroManualforSharpeningReelandRotaryMowers,

FormNo.09168SL).

Important:Lightcontactispreferredatalltimes.If

youdonotmaintainlightcontact,thebedknifeandreel

edgeswillnotsufcientlyself-sharpenandwilldullafter

aperiodofoperation.Ifyoumaintainexcessivecontact,

thebedknifeandreelwillwearquicker,wearunevenly,

andthequalityofcutmaybeadverselyaffected.

Note:Afterextendedrunning,aridgewilleventually

developatbothendsofthebedknife.Roundofforlethese

notchesushwiththecuttingedgeofthebedknifetoensure

smoothoperation.

1.Lowerthecuttingunitsontoahardsurface,shutoff

theengine,andremovetheignitionkey.

2.Slowlyrotatethereelinareversedirection,listening

forreel-to-bedknifecontact.

Note:Theadjustmentknobshavedetents

correspondingto0.018mm(0.0007inch)bedknife

movementforeachindexedposition.Referto

AdjustingtheBedknifetotheReel.

3.Testthecuttingperformancebyinsertingalongstrip

ofcuttingperformancepaper(T oropartnumber

125-5610)betweenreelandbedknife,perpendicular

tothebedknife(Figure12).Slowlyrotatethereel

forward;itshouldcutthepaper.

Figure12

Note:Ifexcessivecontact/reeldragisevidentitwill

beeithernecessarytobacklap,refacethefrontofthe

9

Page 10

Maintenance

1

G020096

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

ServicingtheBedbar

RemovingtheBedbar

1.Turnthebedbaradjusterscrewcounterclockwise,to

backthebedknifeawayfromthereel(Figure13).

Figure15

Figure13

1.Bedbaradjustingscrew3.Bedbar

2.Springtensionnut

2.Backoutthespringtensionnut,untilthewasherisno

longertensionedagainstthebedbar(Figure13).

3.Oneachsideofthemachine,loosenthelocknut

securingthebedbarbolt(Figure14).

4.Washer

Figure14

1.Bedbarbolt

2.Locknut4.Nylonwasher

3.Steelwasher

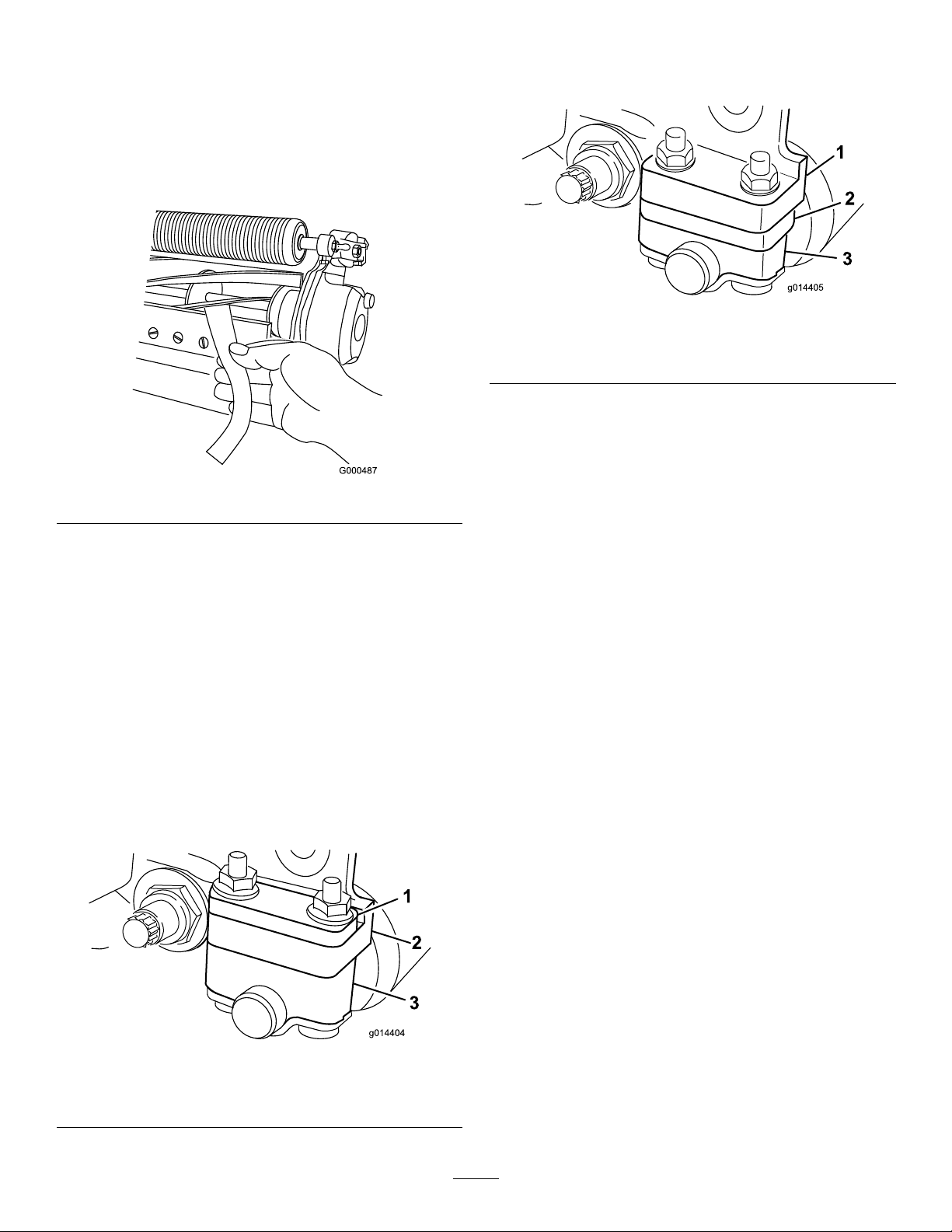

AssemblingtheBedbar

1.Installthebedbar,positioningthemountingears

betweenthewasherandbedbaradjuster.

2.Securethebedbartoeachsideplatewith2bedbar

bolts,locknuts(nutsonbolts),and6washers.Position

anylonwasheroneachsideofthesideplateboss.

Placeasteelwasheroutsideoftheouternylonwasher

(Figure15).

3.Torquethebedbarboltsto27-36N-m(240-320

inch-lb).

4.Tightenthelocknutsequallyoneachsideuntilyou

cannotrotatethesteelwashersbyhand().

5.Loosenthelocknutsjustuntilyoucanrotatethesteel

washersbyhandandyetthereisnoendplayinthe

bedbar.

Important:Ifyouovertightenthelocknuts,you

maydeectthesideplateswhichcouldinterfere

withthebedknifetoreelcontact.

1.Bedbarbolt2.Locknut

4.Removeeachbedbarboltallowingthebedbartobe

pulleddownwardandremovedfromthemachine

bolt(Figure14).Accountforthetwonylonandone

stampedsteelwashersoneachendofthebedbar

(Figure15).

Note:Thewashersontheinsidemayhaveagap.

6.Tightenthespringtensionnutuntilthespringis

collapsed,thenbackitoff1/2turn(Figure16).

10

Page 11

g014642

1

2

Figure16

1.Springtensionnut2.Spring

7.Adjustthebedknifetothereel;refertoAdjustingthe

BedknifetotheReel.

BacklappingtheReel

DANGER

Contactwiththereelorothermovingpartscan

resultinpersonalinjury.

Keepngers,hands,andclothingawayfromthe

reelsorothermovingparts.

•Stayawayfromthereelwhilebacklapping.

•Neveruseashorthandledpaintbrushfor

backlapping.PartNo.29-9100Handleassembly

completeorindividualpartsareavailablefrom

yourlocalAuthorizedT oroDistributor.

1.Positionthemachineonaclean,levelsurface,lower

thecuttingunits,stoptheengine,engagetheparking

brake,andremovetheignitionkey.

2.Removethereelmotorsfromthecuttingunitsand

disconnectandremovethecuttingunitsfromthelift

arms.

3.Connectthebacklappingmachinetothecuttingunit

byinsertingapieceof3/8inchsquarestockintothe

splinedcouplingintheendofthecuttingunit.

Note:Additionalinstructionsandprocedureson

BacklappingareavailableintheToroSharpeningReeland

RotaryMowersManual,FormNumber80-300PT.

Note:Forabettercuttingedge,runaleacrossthe

frontfaceofthebedknifeandreelwhenthelapping

operationiscompleted.Thiswillremoveanyburrsor

roughedgesthatmayhavebuiltuponthecuttingedge.

11

Page 12

Notes:

12

Page 13

Notes:

13

Page 14

Notes:

14

Page 15

DeclarationofIncorporation

TheT oroCompany,81 11LyndaleAve.South,Bloomington,MN,USAdeclaresthatthefollowingunit(s)

conform(s)tothedirectiveslisted,wheninstalledinaccordancewiththeaccompanyinginstructionsontocertain

ToromodelsasindicatedontherelevantDeclarationsofConformity.

ModelNo.

04613313000001andUp8-BladeDPAReelMower8BLADEDPA-TRIFLEX8-BladeDPAReelMower

04614313000001andUp11-BladeDP AReelMower11BLADEDPA-TRIFLEX11-BladeDP AReelMower

04615313000001andUp14-BladeDP AReelMower14BLADEDPA-TRIFLEX14-BladeDP AReelMower

SerialNo.

ProductDescriptionInvoiceDescription

GeneralDescription

Directive

2006/42/EC,

2000/14/EC

2006/42/EC,

2000/14/EC

2006/42/EC,

2000/14/EC

RelevanttechnicaldocumentationhasbeencompiledasrequiredperPartBofAnnexVIIof2006/42/EC.

Wewillundertaketotransmit,inresponsetorequestsbynationalauthorities,relevantinformationonthispartly

completedmachinery.Themethodoftransmissionshallbeelectronictransmittal.

ThismachineryshallnotbeputintoserviceuntilincorporatedintoapprovedToromodelsasindicatedonthe

associatedDeclarationofConformityandinaccordancewithallinstructions,wherebyitcanbedeclaredin

conformitywithallrelevantDirectives.

Certied:EUTechnicalContact:

PeterT etteroo

ToroEuropeNV

B-2260Oevel-Westerloo

Belgium

DavidKlisTel.003214562960

Sr.EngineeringManager

811 1LyndaleAve.South

Bloomington,MN55420,USA

September26,2013

Fax003214581911

15

Page 16

TheToroTotalCoverageGuarantee

ALimitedWarranty

ConditionsandProductsCovered

TheToroCompanyanditsafliate,T oroWarrantyCompany,pursuant

toanagreementbetweenthem,jointlywarrantyourT oroCommercial

product(“Product”)tobefreefromdefectsinmaterialsorworkmanship

fortwoyearsor1500operationalhours*,whicheveroccursrst.This

warrantyisapplicabletoallproductswiththeexceptionofAerators

(refertoseparatewarrantystatementsfortheseproducts).Wherea

warrantableconditionexists,wewillrepairtheProductatnocosttoyou

includingdiagnostics,labor,parts,andtransportation.Thiswarranty

beginsonthedatetheProductisdeliveredtotheoriginalretailpurchaser.

*Productequippedwithanhourmeter.

InstructionsforObtainingWarrantyService

YouareresponsiblefornotifyingtheCommercialProductsDistributoror

AuthorizedCommercialProductsDealerfromwhomyoupurchasedthe

Productassoonasyoubelieveawarrantableconditionexists.Ifyouneed

helplocatingaCommercialProductsDistributororAuthorizedDealer,or

ifyouhavequestionsregardingyourwarrantyrightsorresponsibilities,

youmaycontactusat:

ToroCommercialProductsServiceDepartment

ToroWarrantyCompany

811 1LyndaleAvenueSouth

Bloomington,MN55420-1196

952–888–8801or800–952–2740

E-mail:commercial.warranty@toro.com

OwnerResponsibilities

AstheProductowner,youareresponsibleforrequiredmaintenanceand

adjustmentsstatedinyourOperator'sManual.Failuretoperformrequired

maintenanceandadjustmentscanbegroundsfordisallowingawarranty

claim.

ItemsandConditionsNotCovered

Notallproductfailuresormalfunctionsthatoccurduringthewarranty

periodaredefectsinmaterialsorworkmanship.Thiswarrantydoesnot

coverthefollowing:

•Productfailureswhichresultfromtheuseofnon-T ororeplacement

parts,orfrominstallationanduseofadd-on,ormodiednon-Toro

brandedaccessoriesandproducts.Aseparatewarrantymaybe

providedbythemanufactureroftheseitems.

•Productfailureswhichresultfromfailuretoperformrecommended

maintenanceand/oradjustments.Failuretoproperlymaintainyour

ToroproductpertheRecommendedMaintenancelistedinthe

Operator’sManualcanresultinclaimsforwarrantybeingdenied.

•ProductfailureswhichresultfromoperatingtheProductinanabusive,

negligent,orrecklessmanner.

•Partssubjecttoconsumptionthroughuseunlessfoundtobedefective.

Examplesofpartswhichareconsumed,orusedup,duringnormal

Productoperationinclude,butarenotlimitedto,brakepadsand

linings,clutchlinings,blades,reels,rollersandbearings(sealedor

greasable),bedknives,sparkplugs,castorwheelsandbearings,tires,

lters,belts,andcertainsprayercomponentssuchasdiaphragms,

nozzles,andcheckvalves,etc.

•Failurescausedbyoutsideinuence.Conditionsconsideredtobe

outsideinuenceinclude,butarenotlimitedto,weather,storage

practices,contamination,useofunapprovedfuels,coolants,lubricants,

additives,fertilizers,water,orchemicals,etc.

•Failureorperformanceissuesduetotheuseoffuels(e.g.gasoline,

diesel,orbiodiesel)thatdonotconformtotheirrespectiveindustry

standards.

•Normalnoise,vibration,wearandtear ,anddeterioration.

•Normal“wearandtear”includes,butisnotlimitedto,damagetoseats

duetowearorabrasion,wornpaintedsurfaces,scratcheddecalsor

windows,etc.

Parts

Partsscheduledforreplacementasrequiredmaintenancearewarranted

fortheperiodoftimeuptothescheduledreplacementtimeforthatpart.

Partsreplacedunderthiswarrantyarecoveredforthedurationofthe

originalproductwarrantyandbecomethepropertyofT oro.T orowillmake

thenaldecisionwhethertorepairanyexistingpartorassemblyorreplace

it.T oromayuseremanufacturedpartsforwarrantyrepairs.

DeepCycleandLithium-IonBatteryWarranty:

DeepcycleandLithium-Ionbatterieshaveaspeciedtotalnumberof

kilowatt-hourstheycandeliverduringtheirlifetime.Operating,recharging,

andmaintenancetechniquescanextendorreducetotalbatterylife.Asthe

batteriesinthisproductareconsumed,theamountofusefulworkbetween

chargingintervalswillslowlydecreaseuntilthebatteryiscompletelyworn

out.Replacementofwornoutbatteries,duetonormalconsumption,

istheresponsibilityoftheproductowner.Batteryreplacementmaybe

requiredduringthenormalproductwarrantyperiodatowner’sexpense.

Note:(Lithium-Ionbatteryonly):ALithium-Ionbatteryhasapartonly

proratedwarrantybeginningyear3throughyear5basedonthetime

inserviceandkilowatthoursused.RefertotheOperator'sManualfor

additionalinformation.

MaintenanceisatOwner’sExpense

Enginetune-up,lubrication,cleaningandpolishing,replacementoflters,

coolant,andcompletingrecommendedmaintenancearesomeofthe

normalservicesT oroproductsrequirethatareattheowner’sexpense.

GeneralConditions

RepairbyanAuthorizedToroDistributororDealerisyoursoleremedy

underthiswarranty.

NeitherTheToroCompanynorToroWarrantyCompanyisliablefor

indirect,incidentalorconsequentialdamagesinconnectionwiththe

useoftheToroProductscoveredbythiswarranty,includingany

costorexpenseofprovidingsubstituteequipmentorserviceduring

reasonableperiodsofmalfunctionornon-usependingcompletion

ofrepairsunderthiswarranty.ExceptfortheEmissionswarranty

referencedbelow,ifapplicable,thereisnootherexpresswarranty.All

impliedwarrantiesofmerchantabilityandtnessforusearelimitedto

thedurationofthisexpresswarranty.

Somestatesdonotallowexclusionsofincidentalorconsequential

damages,orlimitationsonhowlonganimpliedwarrantylasts,sotheabove

exclusionsandlimitationsmaynotapplytoyou.Thiswarrantygivesyou

speciclegalrights,andyoumayalsohaveotherrightswhichvaryfrom

statetostate.

Noteregardingenginewarranty:

TheEmissionsControlSystemonyourProductmaybecoveredby

aseparatewarrantymeetingrequirementsestablishedbytheU.S.

EnvironmentalProtectionAgency(EP A)and/ortheCaliforniaAirResources

Board(CARB).Thehourlimitationssetforthabovedonotapplytothe

EmissionsControlSystemWarranty.RefertotheEngineEmissionControl

WarrantyStatementsuppliedwithyourproductorcontainedintheengine

manufacturer’sdocumentationfordetails

CountriesOtherthantheUnitedStatesorCanada

CustomerswhohavepurchasedT oroproductsexportedfromtheUnitedStatesorCanadashouldcontacttheirT oroDistributor(Dealer)toobtain

guaranteepoliciesforyourcountry ,province,orstate.IfforanyreasonyouaredissatisedwithyourDistributor'sserviceorhavedifcultyobtaining

guaranteeinformation,contacttheT oroimporter.

374-0253RevB

Loading...

Loading...