Page 1

FormNo.3393-398RevB

g014597

Greensmaster

®

3420TriFlex

TractionUnit

ModelNo.04540—SerialNo.315000001andUp

™

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3393-398*B

Page 2

ThisproductcomplieswithallrelevantEuropeandirectives;

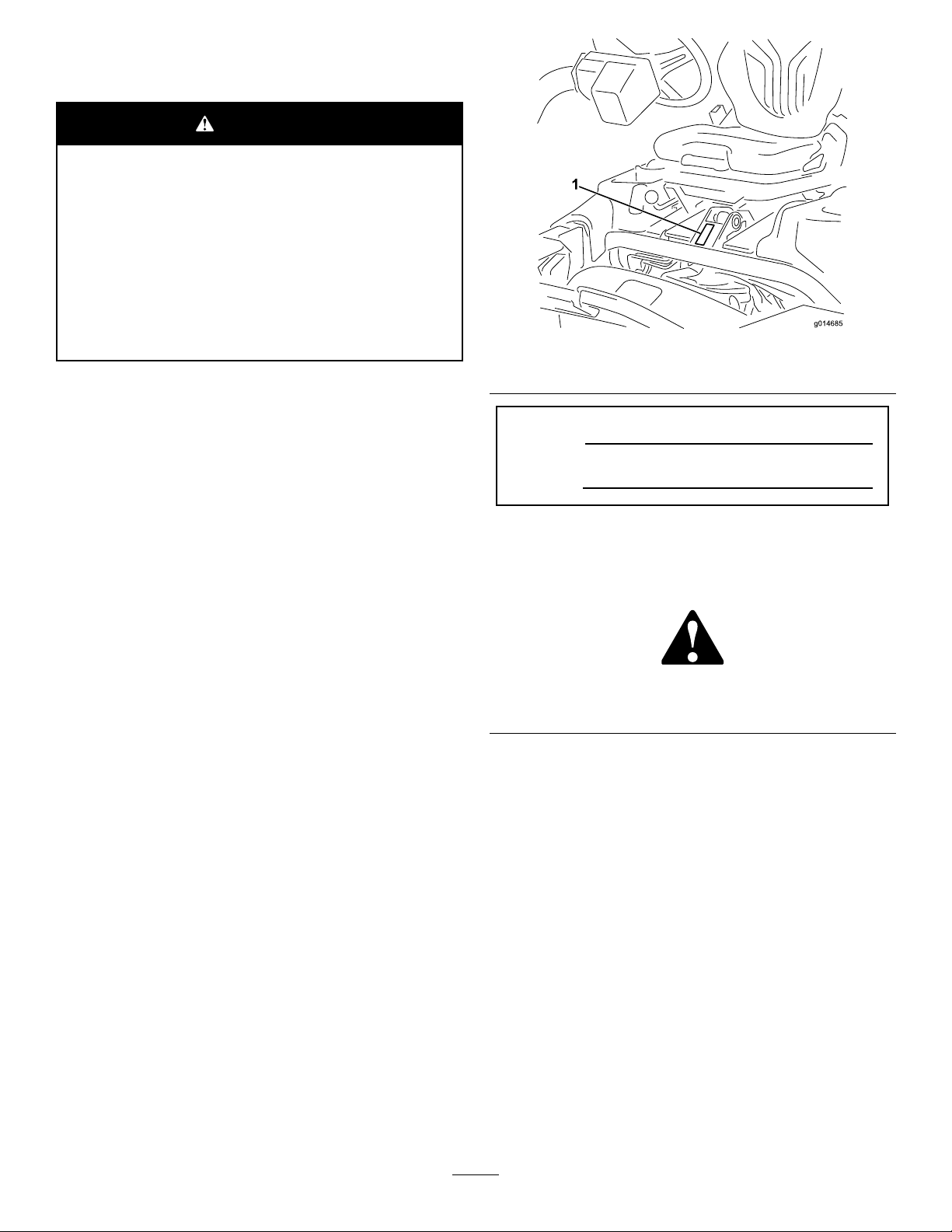

g014685

1

fordetails,pleaseseetheseparateproductspecicDeclaration

ofConformity(DOC)sheet.

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Dieselengineexhaustandsomeofits

constituentsareknowntotheStateof

Californiatocausecancer,birthdefects,

andotherreproductiveharm.

Important:Thisengineisnotequippedwithaspark

arrestermufer.ItisaviolationofCaliforniaPublic

ResourceCodeSection4442touseoroperatetheengine

onanyforest-covered,brush-covered,orgrass-covered

land.Otherstatesorfederalareasmayhavesimilarlaws.

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Introduction

Thismachineisaride-on,reel-bladelawnmowerintended

tobeusedbyprofessional,hiredoperatorsincommercial

applications.Itisprimarilydesignedforcuttinggrasson

well-maintainedlawnsinparks,golfcourses,sportselds,

andoncommercialgrounds.Itisnotdesignedforcutting

brush,mowinggrassandothergrowthalongsidehighways,

orforagriculturaluses.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready.Figure1identiesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure2

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

©2015—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Contents

Safety...........................................................................4

SafeOperatingPractices...........................................4

ToroMowerSafety..................................................6

SoundPowerLevel..................................................7

SoundPressureLevel...............................................7

VibrationLevel......................................................7

SafetyandInstructionalDecals.................................8

Setup...........................................................................12

1InstallingtheRollBar...........................................13

2InstallingtheSeat.................................................13

3InstallingtheSteeringWheel..................................13

4ActivatingandChargingtheBattery........................13

5InstallingtheGrass-BasketHooks..........................15

6InstallingtheCuttingUnits...................................15

7AddingRearWeight.............................................17

8InstallingEUDecals.............................................17

ProductOverview.........................................................18

Controls...............................................................18

Specications........................................................24

Attachments/Accessories........................................24

Operation....................................................................25

ThinkSafetyFirst...................................................25

CheckingtheEngineOil..........................................25

FillingtheFuelTank...............................................26

CheckingtheCoolingSystem...................................27

CheckingtheHydraulic-FluidLevel..........................27

DrainingWaterfromtheFuelFilter...........................29

CheckingtheTirePressure......................................29

CheckingtheTorqueoftheWheelNuts.....................29

CheckingtheReel-to-BedknifeContact.....................29

Breaking-intheMachine..........................................29

StartingandStoppingtheMachine............................30

InstallingandRemovingtheCuttingUnits.................30

Mowing................................................................32

DrivingtheMachinewithoutMowing.......................33

TransportingtheMachine........................................33

LoadingtheMachine..............................................34

InspectingandCleaningtheMachineafter

Mowing.............................................................34

TowingtheMachine...............................................34

Maintenance.................................................................36

RecommendedMaintenanceSchedule(s)......................36

DailyMaintenanceChecklist....................................37

Lubrication...............................................................38

GreasingtheGeneratorBeltTensioner......................38

EngineMaintenance..................................................38

ServicingtheAirCleaner.........................................38

ChangingtheEngineOilandFilter...........................39

FuelSystemMaintenance...........................................40

ServicingtheFuelFilter/WaterSeparator...................40

InspectingtheFuelLinesandConnections.................40

ElectricalSystemMaintenance....................................41

ServicingtheBattery...............................................41

StoringtheBattery..................................................41

LocatingtheFuses..................................................42

JumpStartingtheMachine.......................................42

DriveSystemMaintenance.........................................43

AdjustingtheTransmissionforNeutral.....................43

AdjustingtheTransportSpeed.................................43

AdjustingtheMowingSpeed....................................44

CoolingSystemMaintenance......................................44

CleaningtheRadiatorScreen....................................44

BrakeMaintenance....................................................45

AdjustingtheBrakes...............................................45

BeltMaintenance......................................................45

AdjustingtheAlternatorBelt...................................45

HydraulicSystemMaintenance....................................46

ChangingtheHydraulicOilandFilter........................46

CheckingtheHydraulicLinesandHoses....................46

CuttingUnitMaintenance...........................................47

BacklappingtheReels.............................................47

Storage........................................................................48

3

Page 4

Safety

Thismachinehasbeendesignedinaccordancewith

ENISO5395:2013andANSIB71.4-2012specications

ineffectatthetimeofproductionwhen16.8kg(37lb)

ofweightisaddedtotherearwheel.

Improperuseormaintenancebytheoperatororowner

canresultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandalwayspay

attentiontothesafetyalertsymbol(Figure2),which

meansCaution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeinstructionmay

resultinpersonalinjuryordeath.

SafeOperatingPractices

Training

•ReadtheOperator’sManualandothertrainingmaterial

carefully.Befamiliarwiththecontrols,safetysigns,and

theproperuseoftheequipment.

•Iftheoperatorormechaniccannotreadthelanguage

ofthismanual,itistheowner’sresponsibilitytoexplain

thismaterialtothem.

•Neverallowchildrenorpeopleunfamiliarwiththese

instructionstouseorservicethemower.Local

regulationsmayrestricttheageoftheoperator.

•Nevermowwhilepeople,especiallychildren,orpetsare

nearby.

•Keepinmindthattheoperatororuserisresponsiblefor

accidentsorhazardsoccurringtootherpeopleortheir

property.

•Donotcarrypassengers.

•Alldriversandmechanicsshouldseekandobtain

professionalandpracticalinstruction.Theowneris

responsiblefortrainingtheusers.Suchinstructionshould

emphasize:

–theneedforcareandconcentrationwhenworking

withride-onmachines;

–controlofaride-onmachineslidingonaslopewill

notberegainedbytheapplicationofthebrake.The

mainreasonsforlossofcontrolare:

◊insufcientwheelgrip;

◊beingdriventoofast;

◊inadequatebraking;

◊thetypeofmachineisunsuitableforthetask;

◊lackofawarenessoftheeffectofground

conditions,especiallyslopes.

◊Theowner/usercanpreventandisresponsible

foraccidentsorinjuriesoccurringtopeople,or

property.

Preparation

•Whilemowing,alwayswearsubstantial,slip-resistant

footwear,longtrousers,safetyglasses,andhearing

protection.Longhair,looseclothing,orjewelrymayget

tangledinmovingparts.Donotoperatetheequipment

whenbarefootorwearingopensandals.

•Thoroughlyinspecttheareawheretheequipmentisto

beusedandremoveallobjectswhichmaybethrownby

themachine.

•Replacefaultysilencers/mufers.

•Evaluatetheterraintodeterminewhataccessoriesand

attachmentsareneededtoproperlyandsafelyperform

thejob.Onlyuseaccessoriesandattachmentsapproved

bythemanufacturer.

•Checkthatoperator’spresencecontrols,safetyswitches

andshieldsareattachedandfunctioningproperly.Donot

operateunlesstheyarefunctioningproperly.

Operation

•Donotoperatetheengineinaconnedspacewhere

dangerouscarbonmonoxideandotherexhaustgasses

cancollect.

•Mowonlyindaylightoringoodarticiallight.

•Beforeattemptingtostarttheengine,disengageallblade

attachmentclutches,shiftintoneutral,andengagethe

parkingbrake.

•Rememberthereisnosuchthingasasafeslope.Travel

ongrassslopesrequiresparticularcare.T oguardagainst

overturning:

–donotstoporstartsuddenlywhengoingupor

downhill;

–machinespeedsshouldbekeptlowonslopesand

duringtightturns;

–stayalertforhumpsandhollowsandotherhidden

hazards;

–nevermowacrossthefaceoftheslope,unlessthe

mowerisdesignedforthispurpose.

•Stayalertforholesintheterrainandotherhiddenhazards.

•Watchoutfortrafcwhencrossingornearroadways.

•Stopthebladesfromrotatingbeforecrossingsurfaces

otherthangrass.

•Whenusinganyattachments,neverdirectdischargeof

materialtowardbystandersnorallowanyonenearthe

machinewhileinoperation.

•Neveroperatethemachinewithdamagedguards,shields,

orwithoutsafetyprotectivedevicesinplace.Besureall

interlocksareattached,adjustedproperly ,andfunctioning

properly.

•Donotchangetheenginegovernorsettingsoroverspeed

theengine.Operatingtheengineatexcessivespeedmay

increasethehazardofpersonalinjury.

•Beforeleavingtheoperator’ sposition:

–stoponlevelground;

4

Page 5

–disengagethepowertake-offandlowerthe

attachments;

–changeintoneutralandsettheparkingbrake;

–stoptheengineandremovethekey.

•Disengagedrivetoattachmentswhentransportingornot

inuse.

•Stoptheengineanddisengagedrivetoattachment:

–beforerefuelling;

–beforeremovingthegrasscatcher/catchers;

–beforemakingheightadjustmentunlessadjustment

canbemadefromtheoperator’sposition.

–beforeclearingblockages;

–beforechecking,cleaningorworkingonthemower;

–afterstrikingaforeignobjectorifanabnormal

vibrationoccurs.Inspectthemowerfordamage

andmakerepairsbeforerestartingandoperatingthe

equipment.

•Reducethethrottlesettingbeforestoppingtheengine

and,iftheengineisprovidedwithafuelshut-offvalve,

turnthefueloffattheconclusionofmowing.

•Keephandsandfeetawayfromthecuttingunits.

•Lookbehindanddownbeforebackinguptobesureof

aclearpath.

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalks.Stopthereelswhennot

mowing.

•Donotoperatethemowerundertheinuenceofalcohol

ordrugs.

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

•Usecarewhenloadingorunloadingthemachineintoa

trailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,trees,

orotherobjectsthatmayobscurevision.

RolloverProtectionSystem(ROPS)UseandMaintenance

•TheROPSisanintegralandeffectivesafetydevice.Keep

afoldingROPSintheraisedandlockedpositionanduse

theseatbeltwhenoperatingthemachine.

•LowerafoldingROPStemporarilyonlywhenabsolutely

necessary.Donotweartheseatbeltwhenfoldeddown.

•Beawarethereisnorolloverprotectionwhenafolded

ROPSisinthedownposition.

•Becertainthattheseatbeltcanbereleasedquicklyin

theeventofanemergency.

•Checktheareatobemowedandneverfolddowna

foldingROPSinareaswherethereareslopes,dropoffs

orwater.

•Checkcarefullyforoverheadclearances(i.e.branches,

doorways,electricalwires)beforedrivingunderany

objectsanddonotcontactthem.

•KeeptheROPSinsafeoperatingconditionby

periodicallythoroughlyinspectingfordamageand

keepingallmountingfastenerstight.

•ReplaceadamagedROPS.Donotrepairorrevise.

•DonotremovetheROPS.

•AnyalterationstoaROPSmustbeapprovedbythe

manufacturer.

SafeHandlingofFuels

•Toavoidpersonalinjuryorpropertydamage,use

extremecareinhandlinggasoline.Gasolineisextremely

ammableandthevaporsareexplosive.

•Extinguishallcigarettes,cigars,pipes,andothersources

ofignition.

•Useonlyanapprovedfuelcontainer.

•Neverremovefuelcaporaddfuelwiththeengine

running.

•Allowenginetocoolbeforerefueling.

•Neverrefuelthemachineindoors.

•Neverstorethemachineorfuelcontainerwherethereis

anopename,spark,orpilotlightsuchasonawater

heateroronotherappliances.

•Neverllcontainersinsideavehicleoronatruckor

trailerbedwithaplasticliner.Alwaysplacecontainerson

thegroundawayfromyourvehiclebeforelling.

•Removeequipmentfromthetruckortrailerandrefuelit

ontheground.Ifthisisnotpossible,thenrefuelsuch

equipmentwithaportablecontainer,ratherthanfroma

fueldispensernozzle.

•Keepthenozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilfuelingiscomplete.

•Donotuseanozzlelockopendevice.

•Iffuelisspilledonclothing,changeclothingimmediately.

•Neveroverllfueltank.Replacefuelcapandtighten

securely.

MaintenanceandStorage

•Keepallnuts,boltsandscrewstighttobesurethe

equipmentisinsafeworkingcondition.

•Neverstoretheequipmentwithfuelinthetankinsidea

buildingwherefumesmayreachanopenameorspark.

•Allowtheenginetocoolbeforestoringinanyenclosure.

•Toreducetheriskofrehazard,keeptheengine,

silencer/mufer,batterycompartment,andfuelstorage

areafreeofgrass,leaves,orexcessivegrease.

•Replacewornordamagedpartsforsafety.

5

Page 6

•Checkthegrasscatcherfrequentlyforwearor

deterioration.

•Keepallpartsingoodworkingconditionandallhardware

andhydraulicttingstightened.Replaceallwornor

damagedpartsanddecals.

•Ifthefueltankhastobedrained,dothisoutdoors.

•Becarefulduringadjustmentofthemachinetoprevent

entrapmentofthengersbetweenmovingbladesand

xedpartsofthemachine.

•Onmulti-reelmachines,takecareasrotatingonereelcan

causeotherreelstorotate.

•Disengagedrives,lowerthecuttingunits,setparking

brake,stopengineandremovekey .Waitforallmovement

tostopbeforeadjusting,cleaningorrepairing.

•Cleangrassanddebrisfromcuttingunits,drives,mufers,

andenginetohelppreventres.Cleanupoilorfuel

spillage.

•Usejackstandstosupportcomponentswhenrequired.

•Carefullyreleasepressurefromcomponentswithstored

energy.

•Disconnectbatterybeforemakinganyrepairs.Disconnect

thenegativeterminalrstandthepositivelast.Reconnect

positiverstandnegativelast.

•Usecarewhencheckingthereels.Wrapthereelsorwear

gloves,andusecautionwhenservicingthem.

•Keephandsandfeetawayfrommovingparts.Ifpossible,

donotmakeadjustmentswiththeenginerunning.

•Chargebatteriesinanopenwellventilatedarea,away

fromsparkandames.Unplugchargerbeforeconnecting

ordisconnectingfrombattery.W earprotectiveclothing

anduseinsulatedtools.

Operation

•Knowhowtostoptheenginequickly.

•Alwayswearsubstantial,slip-resistantshoes.Donot

operatethemachinewhilewearingsandals,tennisshoes,

orsneakers.Wearingsafetyshoesandlongpantsis

advisableandrequiredbysomelocalordinancesand

insuranceregulations.

•Theoperatormustbeskilledandtrainedinhowtodrive

onhillsides.Failuretousecautiononslopesorhillsmay

causelossofcontrolandcausethevehicletotiporroll,

possiblyresultinginpersonalinjuryordeath.

•Handlefuelcarefully.Wipeupanyspills.

•Checkthesafetyinterlockswitchesdailyforproper

operation.Ifaswitchhasfailed,replacetheswitchbefore

operatingthemachine

•Beforeattemptingtostarttheengine,sitontheseat,pull

theliftleverbackandreleaseittoensurethecutting

unitsaredisengaged.V erifythatthetractionsystemisin

neutralandtheparkingbrakeisset.

•Usingthemachinedemandsattention.Topreventloss

ofcontrol:

–Donotdriveclosetosandtraps,ditches,creeks,or

otherhazards.

–Reducespeedwhenmakingsharpturns.Avoid

suddenstopsandstarts.

–Watchoutfortrafcwhennearorcrossingroads.

Alwaysyieldtheright-of-way.

–Applytheservicebrakeswhengoingdownhillto

keepforwardspeedslowandtomaintaincontrolof

themachine.

•Shuttheengineoffbeforeemptyingthebaskets.

Hauling

•Usecarewhenloadingorunloadingthemachineintoa

trailerortruck.

•Usefullwidthrampsforloadingmachineintotraileror

truck.

•Tiethemachinedownsecurelyusingstraps,chains,cable,

orropes.Bothfrontandrearstrapsshouldbedirected

downandoutwardfromthemachine.

ToroMowerSafety

ThefollowinglistcontainssafetyinformationspecictoToro

productsorothersafetyinformationthatyoumustknowthat

isnotincludedintheANSIstandards.

Thisproductiscapableofamputatinghandsandfeetand

throwingobjects.Alwaysfollowallsafetyinstructionsto

avoidseriousinjuryordeath.

Useofthisproductforpurposesotherthanitsintendeduse

couldprovedangeroustouserandbystanders.

•Raisethecuttingunitswhendrivingfromoneworkarea

toanother.

•Donottouchtheengine,mufer,orexhaustpipewhile

theengineisrunningorsoonafterithasstoppedbecause

theseareascouldbehotenoughtocauseburns.

•Beforegettingoffoftheseat,movethefunctionalcontrol

levertoneutral(N),raisethecuttingunitsandwaitfor

thereelstostopspinning.Settheparkingbrake.Stopthe

engineandremovethekeyfromtheignitionswitch.

•Traverseslopescarefully.Donotstartorstopsuddenly

whentravelinguphillordownhill.

•Theoperatormustbeskilledandtrainedinhowtodrive

onhillsides.Failuretousecautiononslopesorhillsmay

causelossofcontrolandcausethemachinetotiporroll,

possiblyresultinginpersonalinjuryordeath.

•Iftheenginestallsorlosesheadwayandcannotmakeit

tothetopofaslope,donotturnthemachinearound.

Alwaysbackslowly,straightdowntheslope.

•Whenapersonorpetappearsunexpectedlyinornear

themowingarea,stopmowing.Carelessoperation,

6

Page 7

combinedwithterrainangles,ricochets,orimproperly

positionedguardscanleadtothrownobjectinjuries.Do

notresumemowinguntiltheareaiscleared.

•AlwaysusetheseatbeltwiththeROPSwhenoperating

themachine.

•Wheneverthemachineisleftunattended,makesurethe

cuttingunitsarefullyraised,thereelsarenotspinning,

thekeyisremovedfromtheignitionswitch,andthe

parkingbrakeisset.

MaintenanceandStorage

•Makesureallhydrauliclineconnectorsaretightandall

hydraulichosesandlinesareingoodconditionbefore

applyingpressuretothesystem.

SoundPowerLevel

Thisunithasaguaranteedsoundpowerlevelof98dBA,

whichincludesanUncertaintyValue(K)of1dBA.

Soundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinISO11094.

SoundPressureLevel

Thisunithasasoundpressurelevelattheoperator’searof84

dBA,whichincludesanUncertaintyValue(K)of1dBA.

Soundpressurelevelwasdeterminedaccordingtothe

proceduresoutlinedinENISO5395:2013.

•Keepyourbodyandhandsawayfrompinholeleaksor

nozzlesthatejecthydraulicuidunderhighpressure.

Usepaperorcardboard,notyourhands,tosearchfor

leaks.Hydraulicuidescapingunderpressurecanhave

sufcientforcetopenetratetheskinandcauseserious

injury.

•Beforedisconnectingorperforminganyworkonthe

hydraulicsystem,allpressureinthesystemmustbe

relievedbystoppingtheengineandloweringthecutting

unitsandattachmentstotheground.

•Checkallfuellinesfortightnessandwearonaregular

basis.Tightenorrepairthemasneeded.

•Iftheenginemustberunningtoperformamaintenance

adjustment,keephands,feet,clothing,andanypartsof

thebodyawayfromthecuttingunits,attachments,and

anymovingparts,especiallythescreenatthesideofthe

engine.Keepeveryoneaway.

•Toensuresafetyandaccuracy,haveanAuthorizedToro

Distributorcheckthemaximumenginespeedwitha

tachometer.Maximumgovernedenginespeedshould

be2900rpm.

•Theenginemustbeshutoffbeforecheckingtheoilor

addingoiltothecrankcase.

VibrationLevel

Hand-Arm

Measuredvibrationlevelforrighthand=0.33m/s

Measuredvibrationlevelforlefthand=0.52m/s

UncertaintyValue(K)=0.26m/s

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinENISO5395:2013.

WholeBody

Measuredvibrationlevel=0.12m/s

UncertaintyValue(K)=0.06m/s

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinENISO5395:2013.

2

2

2

2

2

•Ifmajorrepairsareeverneededorifassistanceisdesired,

contactanAuthorizedToroDistributor.

•Toensureoptimumperformanceandcontinuedsafety

certicationofthemachine,useonlygenuineToro

replacementpartsandaccessories.Replacementparts

andaccessoriesmadebyothermanufacturerscouldbe

dangerous,andsuchusecouldvoidtheproductwarranty.

•Disconnectthecuttingunitsfromthepowersupply ,

usingthecuttingunitpowerdisconnectcouplers,before

performinganyworkonthecuttingunits.

7

Page 8

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

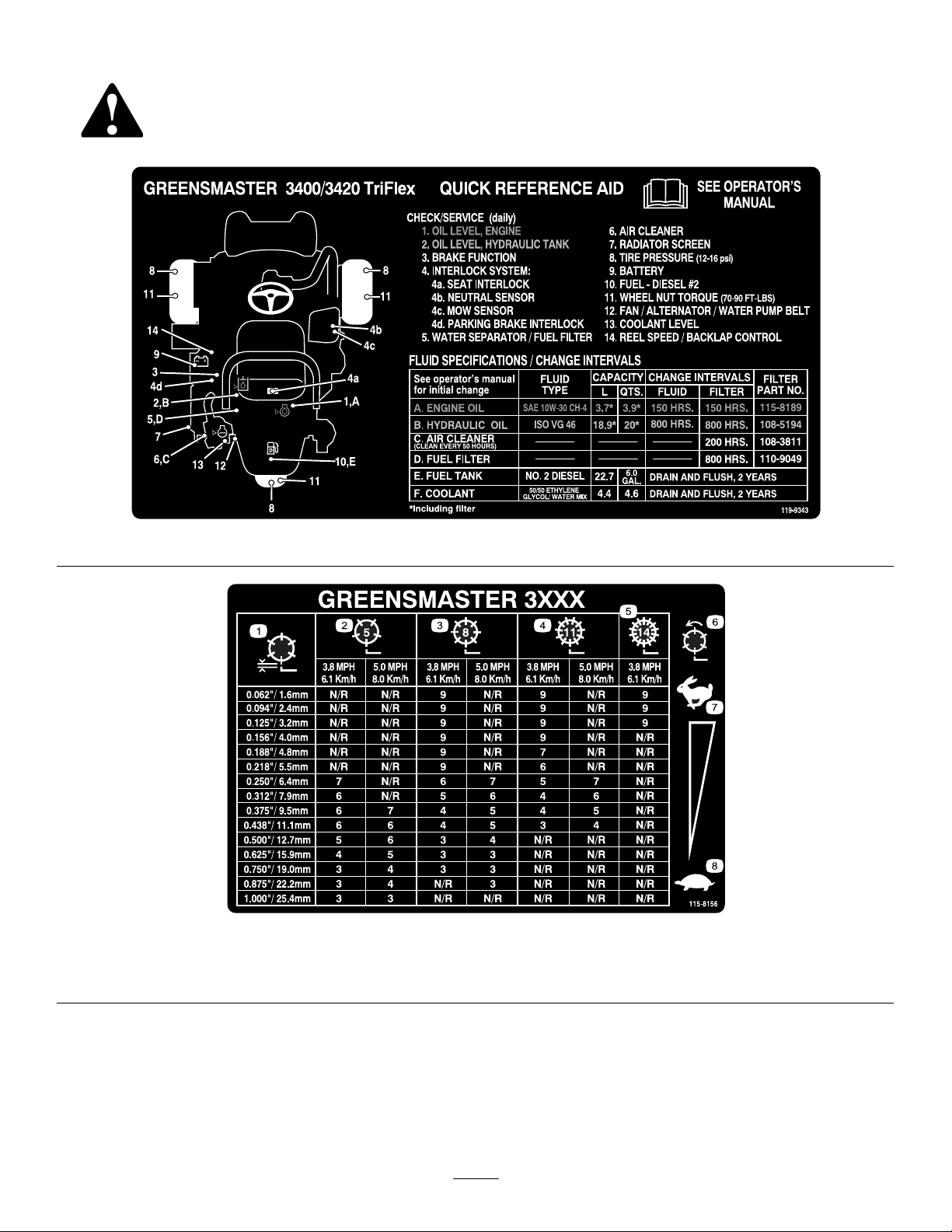

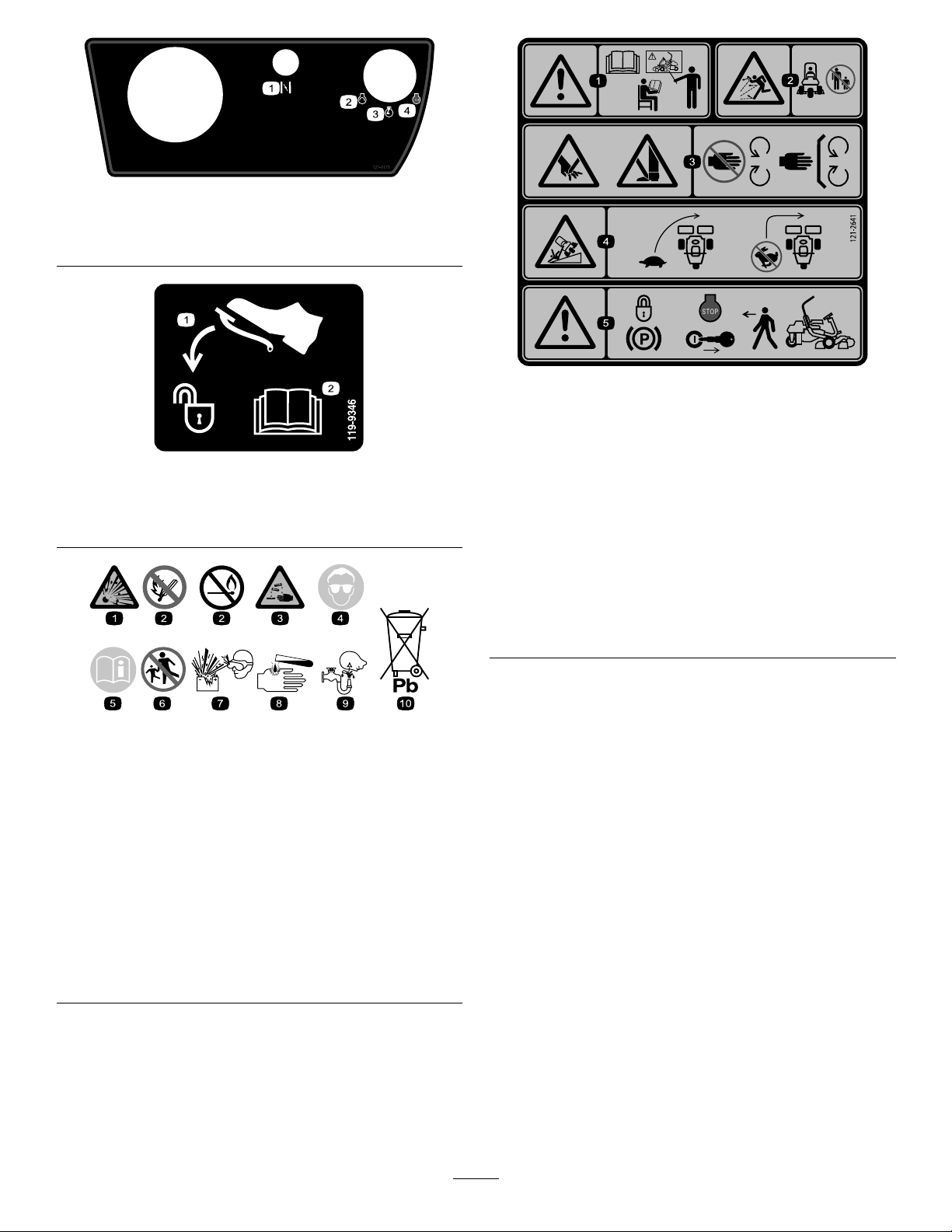

119-9343

115-8156

1.Reelheight3.8Bladecuttingunit5.14Bladecuttingunit7.Fast

2.5Bladecuttingunit4.11Bladecuttingunit6.Reelspeed

8.Slow

8

Page 9

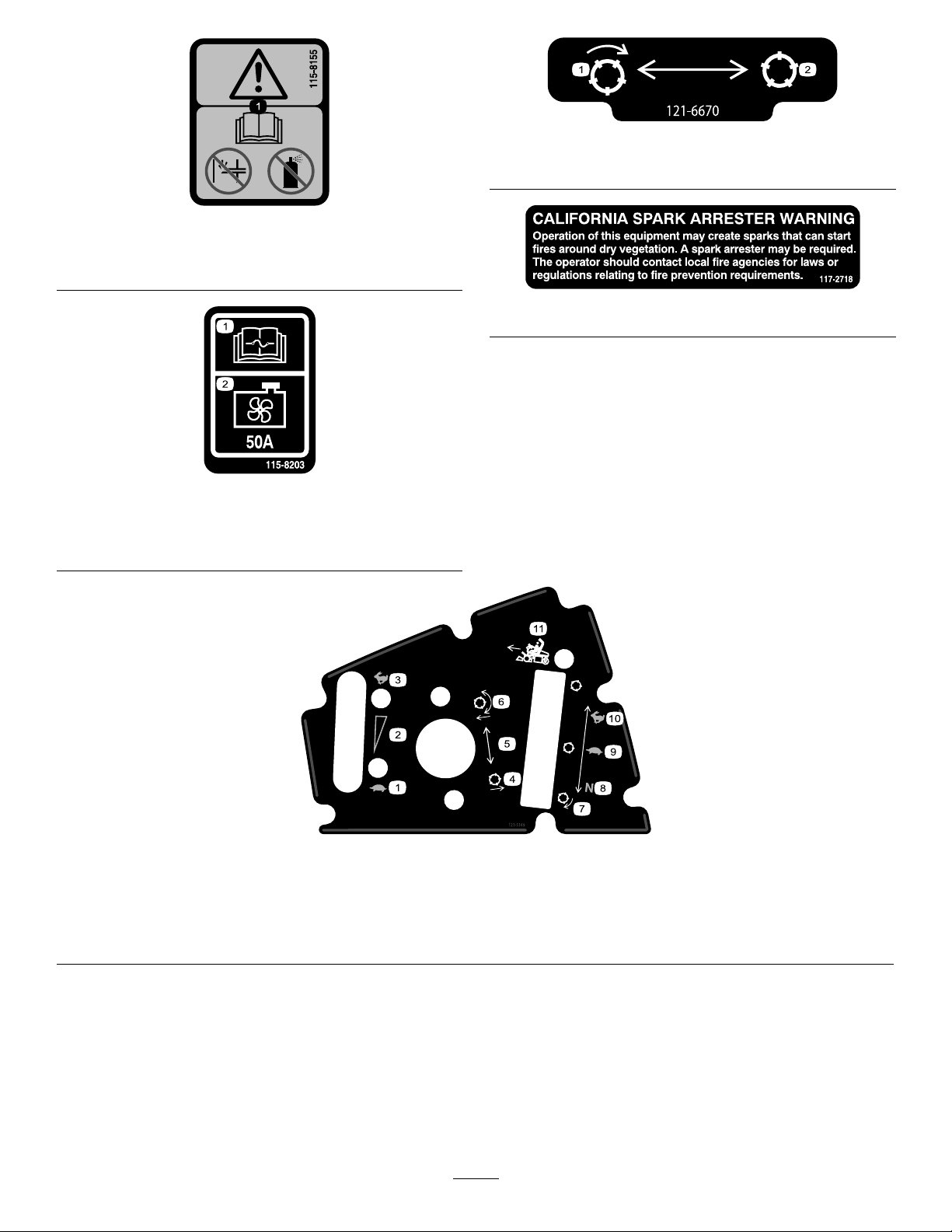

115-8155

1.Warning—readtheOperator'sManual,donotprimeoruse

startinguid.

115-8203

121–6670

1.Engagethereels.2.Disengagethereels.

117–2718

1.ReadtheOperator's

manualforfuse

information.

2.Radiatorfan—50Amp

121–5169

1.Throttle—slow5.Functionalcontrollever

2.Throttle—continuousvariablesetting6.Lowerthereelsandengage.

3.Throttle—fast7.Useforbacklappingreels

4.Raisethereels8.Neutral

9.Useformowing

10.Usefortransport

9

Page 10

121–5171

1.Choke

2.Engine—start4.Engine—stop

1.Presspedaltounlock

3.Enginerun

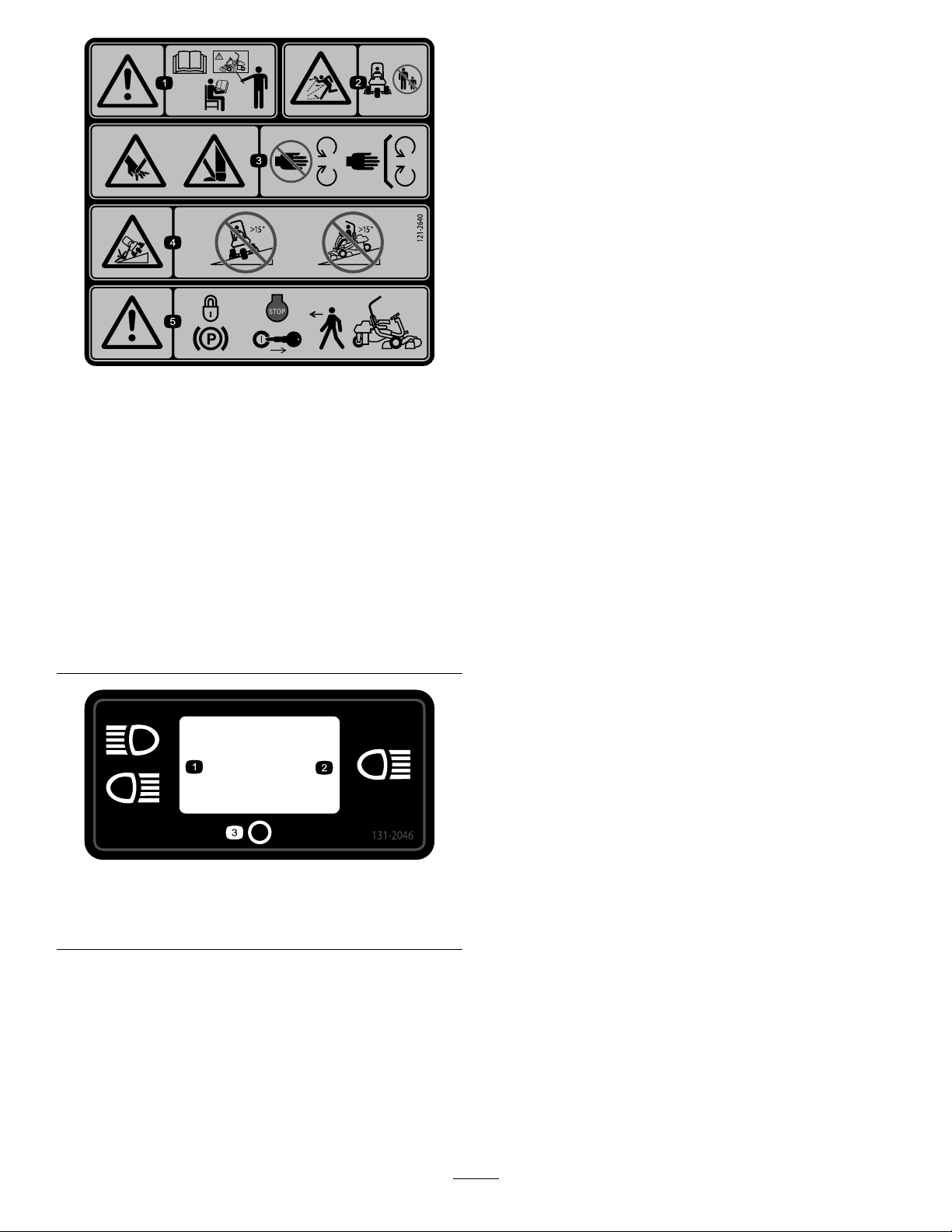

121–2641

1.Warning—readthe

Operator’sManual,do

notoperatethismachine

119-9346

2.ReadtheOperator's

Manualformore

information.

unlessyouaretrained.

2.Thrownobject

hazard—keepbystanders

asafedistancefromthe

machine.

3.Cutting/dismemberment

hazardofhandorfoot,

mowerblade—stayaway

frommovingparts;keep

allguardsandshieldsin

place.

4.Tippinghazard—slow

machinebeforeturning,

donotturnathighspeeds.

5.Warning—locktheparking

brake,stoptheengine

andremovetheignition

keybeforeleavingthe

machine.

BatterySymbols

Someorallofthesesymbolsareonyourbattery .

1.Explosionhazard

2.Nore,openames,or

smoking.

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection.9.Flusheyesimmediately

5.ReadtheOperator’s

Manual.

6.Keepbystandersasafe

distancefromthebattery.

7.Weareyeprotection;

explosivegasescan

causeblindnessandother

injuries.

8.Batteryacidcancause

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

10.Containslead;donot

discard.

10

Page 11

121–2640

1.Warning—readthe

Operator’sManual,do

notoperatethismachine

unlessyouaretrained.

2.Thrownobject

hazard—keepbystanders

asafedistancefromthe

machine

3.Cutting/dismemberment

hazardofhandorfoot,

mowerblade—stayaway

frommovingparts;keep

allguardsandshieldsin

place.

4.Tippinghazard—donot

driveacrossslopesgreater

than15degreesordown

slopesgreaterthan15

degrees.

5.Warning—locktheparking

brake,stoptheengine

andremovetheignition

keybeforeleavingthe

machine.

1.Doublelights

2.Singlelight

131-2046

3.Off

11

Page 12

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

6

7

Rollbar1

Bolt(1/2x3-3/4inches)

Flange-nut(1/2inch)

Seat-completionkit

Steeringwheel

Locknut(1-1/2inches)

Washer1

Steeringwheelcap

Nopartsrequired

Grass-baskethook

Flangebolts12

Gaugebar

Cuttingunit(model04613,04614,or

04615)

Cutting-unitupperweight

Hex-headbolts6

GrassBasket

Weightkit,121–6665(purchase

seperately)Note:notrequiredforunits

withthe3wheeldrivekitinstalled.

Qty.

4

4

1Installtheseattothebase.

1

1

1

–

6

1

3

3

3

1Addrearweight.

Installtherollbar.

Installthesteeringwheel.

Activateandchargethebattery.

Installthegrass-baskethooks.

Installthecuttingunits.

Use

8

Warningdecal121–26401

MediaandAdditionalParts

Description

Operator'sManual(machine)

EngineOperator'sManual(engine)

PartsCatalog

OperatorTrainingMaterials

Pre-deliveryInspectionSheet

Noiseratingcerticate

Certicateofcompliance

Ignitionkeys2

Qty.

InstallEUdecals,ifrequired.

Use

1

1

1

1

1

1

1

Readbeforeoperatingthemachine

Saveforfuturepartsordering

Viewbeforeoperatingthemachine

Saveforfuturereference

Starttheengine

12

Page 13

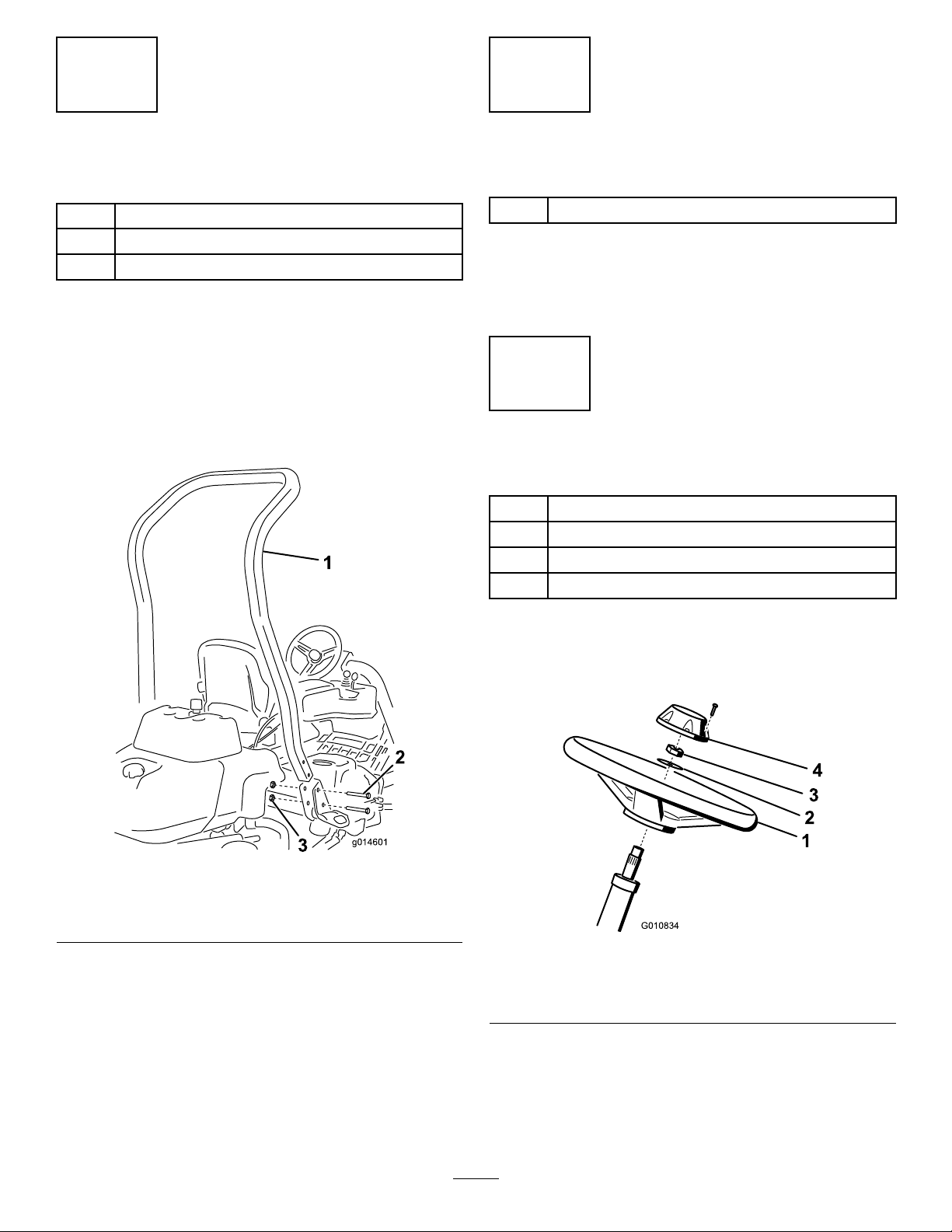

1

g014601

1

2

3

2

InstallingtheRollBar

Partsneededforthisprocedure:

1Rollbar

4

Bolt(1/2x3-3/4inches)

4

Flange-nut(1/2inch)

Procedure

1.Removethetopcratesupportfromthecrate.

2.Removetherollbarfromthecrate.

3.Installtherollbarintothepocketsoneachsideof

themachine,using4bolts(1/2x3-3/4inches)and4

ange-nuts(1/2inch)(Figure3).

InstallingtheSeat

Partsneededforthisprocedure:

1

Seat-completionkit

Procedure

Acquireyourdesiredseatkitfromyourdistributorandinstall

itasdirectedintheinstructionincludedwiththekit.

3

InstallingtheSteeringWheel

Partsneededforthisprocedure:

1

Steeringwheel

1

Locknut(1-1/2inches)

1Washer

1

Steeringwheelcap

Figure3

1.Rollbar

2.Bolt(1/2x3-3/4inches)

4.Torquethefastenersto136to149N-m(100to110

ft-lb).

3.Flange-nut(1/2inch)

Procedure

1.Slidethesteeringwheelontothesteeringshaft(Figure

4).

Figure4

1.Steeringwheel

2.Washer

2.Slidethewasherontothesteeringshaft(Figure4).

3.Securethesteeringwheeltotheshaftwithalocknut

andtightenitto27to35N-m(20to26ft-lb)(Figure4).

4.Installthecaptothesteeringwheelandsecureitwith6

bolts(Figure4).

3.Locknut

4.Cap

13

Page 14

4

ActivatingandChargingthe

Battery

NoPartsRequired

Procedure

Useonlyelectrolyte(1.265specicgravity)tollbattery

initially.

1.Removethefastenersandbatteryclampandliftout

thebattery.

Important:Donotaddelectrolytewhilethe

batteryisinthemachine.Y oucouldspillit,

causingcorrosion.

2.Cleanthetopofthebatteryandremovetheventcaps

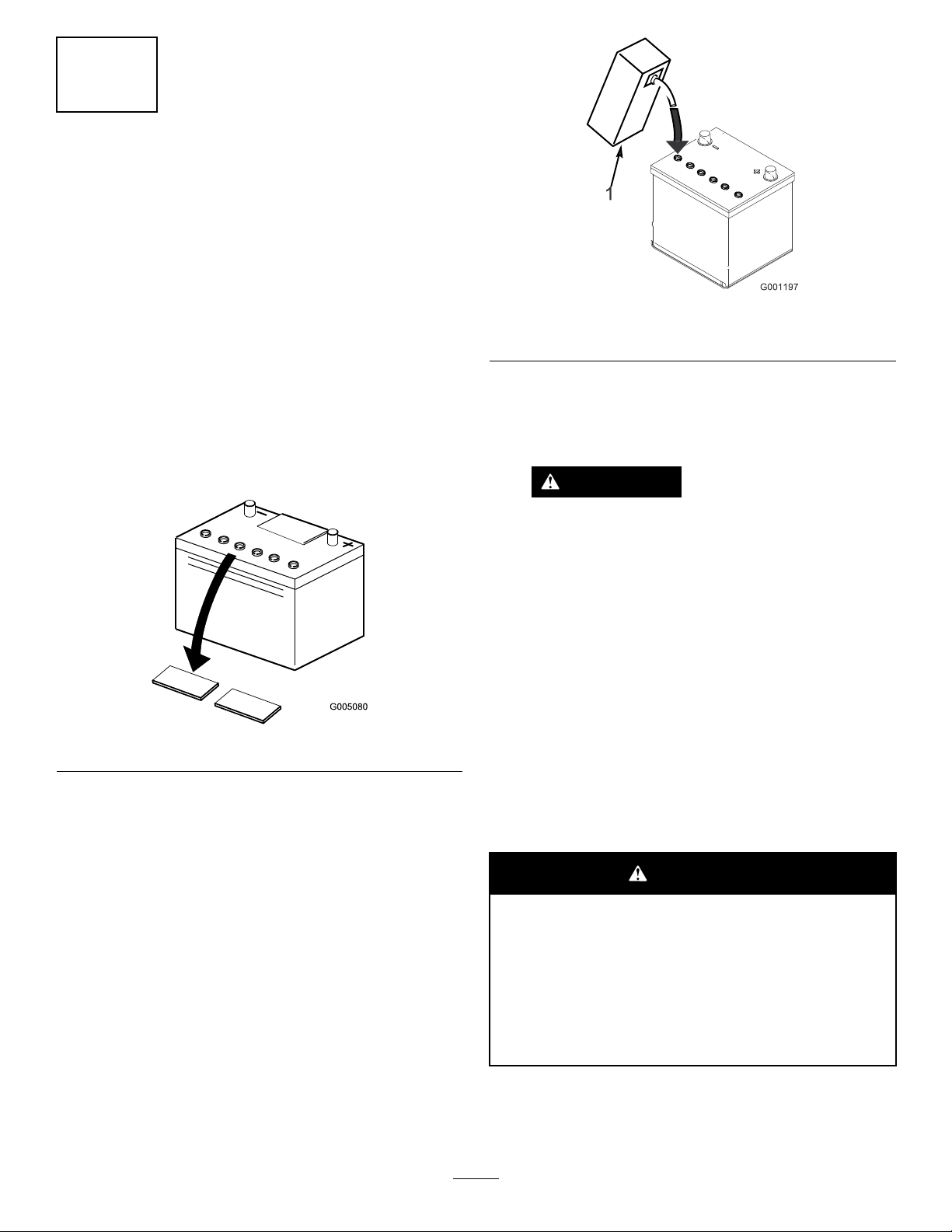

(Figure5).

Figure5

Figure6

1.Electrolyte

4.Allowapproximately20to30minutesforthe

electrolytetosoakintotheplates.Fillasnecessaryto

bringtheelectrolytetowithinabout6mm(1/4inch)

ofthebottomofthellwell(Figure6).

WARNING

Chargingthebatteryproducesgassesthatcan

explode.

Neversmokenearthebatteryandkeepsparks

andamesawayfrombattery.

5.Connecta2to4ampbatterychargertothebattery

posts.Chargethebatteryfor2hoursat4ampsorfor

4hoursat2ampsuntilthespecicgravityis1.250or

higherandthetemperatureisatleast60°F(16°C)with

allcellsgassingfreely.

6.Whenthebatteryischarged,disconnectthecharger

fromtheelectricaloutletandbatteryposts.

3.Carefullylleachcellwithelectrolyteuntiltheplates

arecoveredwithabout6mm(1/4inch)ofuid(Figure

6).

Note:Afterthebatteryhasbeenactivated,add

onlydistilledwatertoreplacenormalloss,although

maintenance-freebatteriesshouldnotrequirewater

undernormaloperatingconditions.

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

Washhandsafterhandling.

14

Page 15

WARNING

Batteryterminalsormetaltoolscouldshort

againstmetaltractorcomponentscausing

sparks.Sparkscancausethebatterygassesto

explode,resultinginpersonalinjury.

•Whenremovingorinstallingthebattery,

donotallowthebatteryterminalstotouch

anymetalpartsofthetractor.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsof

thetractor.

5

InstallingtheGrass-Basket Hooks

Partsneededforthisprocedure:

6

Grass-baskethook

12Flangebolts

WARNING

Failuretocorrectlyactivatethebatterymay

resultinbatterygassingand/orpremature

batteryfailure.

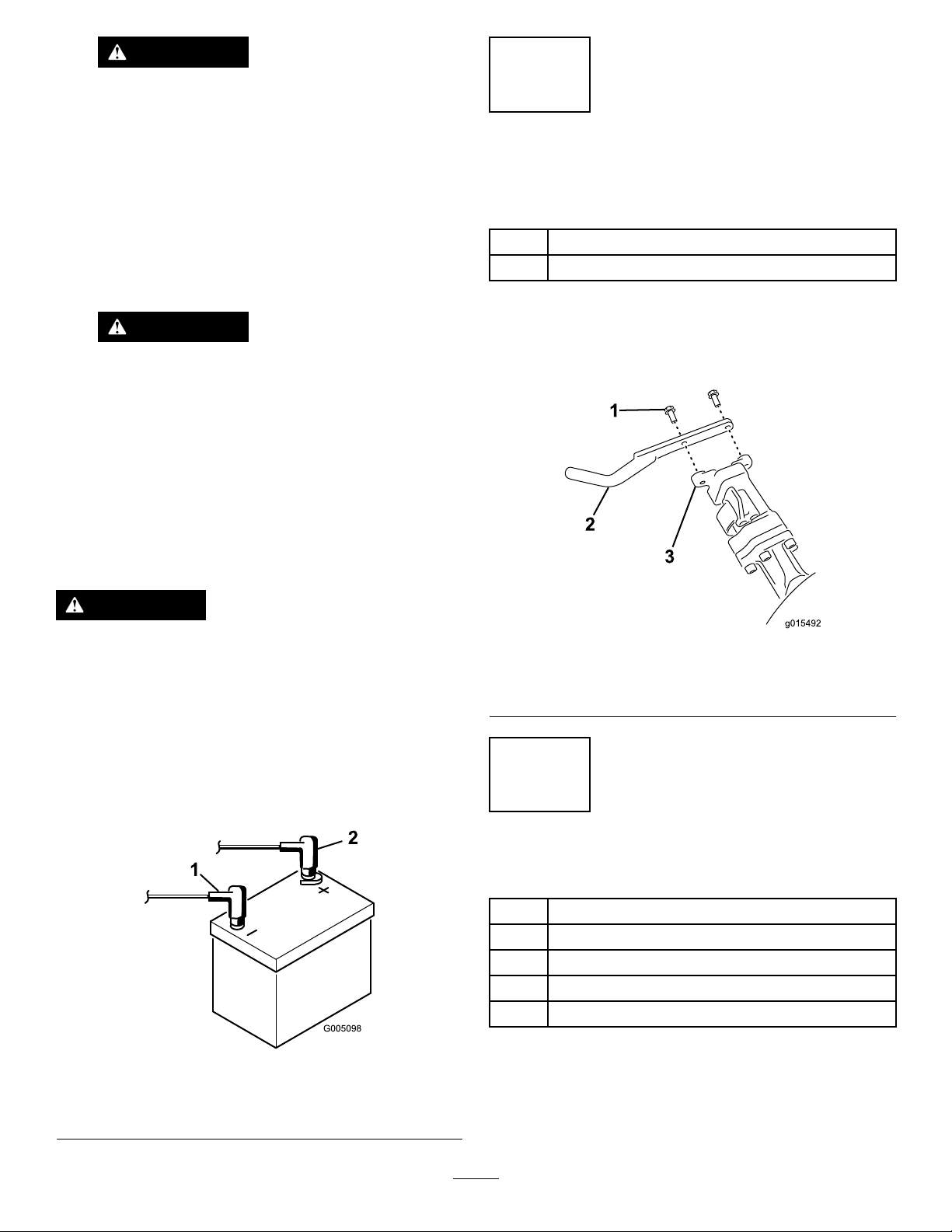

7.Placethebatteryonthebatterytrayandsecureitwith

thebatteryclampandfasternersremovedpreviously.

8.Installthepositivecable(red)tothepositive(+)

terminalandthenthenegativecable(black)tothe

negative(–)terminalofthebatteryandsecurethem

withtheboltsandnuts(Figure7).Slidetherubber

bootoverthepositiveterminaltopreventapossible

shortfromoccurring.

WARNING

Incorrectbatterycableroutingcoulddamagethe

tractorandcablescausingsparks.Sparkscancause

thebatterygassestoexplode,resultinginpersonal

injury.

•Alwaysdisconnectthenegative(black)battery

cablebeforedisconnectingthepositive(red)

cable.

•Alwaysconnectthepositive(red)batterycable

beforeconnectingthenegative(black)cable.

Procedure

Installthe6grass-baskethooksontotheendsofthe

suspension-armbarsusingthe12angebolts(Figure8).

Figure8

1.Flangebolt

2.Grass-baskethook

3.Suspension-armbar

6

1.Negative(-)

2.Positive(+)

Figure7

InstallingtheCuttingUnits

Partsneededforthisprocedure:

1

Gaugebar

3

Cuttingunit(model04613,04614,or04615)

3

Cutting-unitupperweight

6Hex-headbolts

3

GrassBasket

Procedure

Note:Whensharpening,settingtheheight-of-cut,or

performingothermaintenanceproceduresonthecutting

units,storethecuttingunitreelmotorsinthestoragelocation

15

Page 16

onthefrontofthesuspensionarmstopreventdamageto

g014596

1

2

2

1

2

g016294

3

g014602

1

2

them.

Important:Donotraisethesuspensiontothetransport

positionwhenthereelmotorsareintheholdersinthe

machineframe.Damagetothemotorsorhosescould

result.

Important:Wheneverthecuttingunithastobetipped

toexposebedknife/reel,propuprearofcuttingunitto

makesurenutsonbackendofbedbaradjustingscrews

arenotrestingonworksurface(Figure9).

Figure10

Figure9

1.Prop(notprovided)2.Bedknifeadjustingnut(2)

Note:Allcuttingunitsareshippedwiththecounterweight

mountedtotherightendandthemotormountanddrive

couplermountedtotheleftendofthecuttingunit.

1.Disconnectthecuttingunitpowerdisconnectcouplers;

refertoCuttingUnitPowerDisconnectConnectors

(page24).

CAUTION

Ifyoudonotdisconnectthepowertothe

cuttingunits,someonecouldaccidentally

startthecuttingunit,causingseriousinjury

tohandsandfeet.

Alwaysseparatethecuttingunitpower

disconnectcouplersbeforeworkingonthe

cuttingunits.

1.Cutting-untilweight(ip

over)

2.Upperweight

3.Hex-headbolts

5.Rotatetheweight180degreessothattheopenscrew

holesthatwereontheundersideoftheweightarenow

ontop.Installtheweighttothecuttingunitusingthe

boltsremovedpreviously.

6.Installanupperweighttothecuttingunitweightusing

2hexheadscrews(Figure10).

7.Ifinstallingthecentercuttingunit,liftuponthefoot

restandswingitup,allowingaccesstothecenter

cuttingunitposition(Figure11).

CAUTION

Thefootrestcanpinchngersifitfallsinto

theclosedposition.

Keepyourngersclearoftheareawherethe

footrestseatswhileitisopen.

2.Applygreasetotheinsidediameterofthedrivecoupler.

3.Thecuttingunitisshippedwithoutafrontroller.

Obtainaroller(Models04625,04626,or04627)from

yourlocalToroDistributor.Installtherollerusing

theloosepartssuppliedwiththecuttingunitand

installationinstructionsincludedwiththeroller.

4.Removethe2boltssecuringtheweighttothesideof

thecuttingunit(Figure10).

Figure11

1.Footrest—closed2.Footrest—open

8.Positionthecuttingunitunderthesuspensionarm.

16

Page 17

9.Withthelatchesonthesuspension-armbarpointing

g014609

1

2

3

g01461 1

1

2

up(i.e.,open)(Figure12),pushthesuspensionarm

downsothatthebartsoverthebaracrossthetopof

thecuttingunit(Figure13).

Figure12

1.Latch—closedposition3.Latch—openposition

2.Suspension-armbar

Figure14

Figure13

1.Suspension-armbar2.Cutting-unitbar

10.Closethelatchesdownandaroundthecutting-unitbar

andlocktheminplace(Figure12).

Note:A“click”canbeheardandfeltwhenthelatches

areproperlylockedinplace.

11.Coatthesplineshaftofthecutting-unitmotorwith

cleangrease(Figure14).

12.Insertthemotorintotheleftsideofthecuttingunit

(asviewedfromtheoperator'sposition)andpullthe

motor-retainingbaronthecuttingunittowardthe

motoruntilyouhearanaudible“click”frombothsides

ofthemotor(Figure14).

1.Reelmotor

2.Splineshaft

13.Mountagrassbasketontothebaskethooksonthe

suspensionarm.

14.Repeatthisprocedurefortheothercuttingunits.

15.Connectthecutting-unitpower-disconnectcouplers;

refertoCuttingUnitPowerDisconnectConnectors

(page24).

3.Cavity

4.Motor-retainingbar

7

AddingRearWeight

Partsneededforthisprocedure:

Weightkit,121–6665(purchaseseperately)Note:not

1

requiredforunitswiththe3wheeldrivekitinstalled.

Procedure

ThisunitcomplieswiththeANSIB71.4-2004andEN836

Standardswhenequippedwithweightkit121–6665.

Note:Iftheunitisequippedwithathreewheeldrivekit

additionalweightisnotrequiredtomeetANSIB71.4-2004

andEN836standards.

17

Page 18

8

g014674

1

2

3

4

5

6

7

8

InstallingEUDecals

Partsneededforthisprocedure:

1Warningdecal121–2640

Procedure

IfthismachinewillbeusedintheEU,afxthewarningdecal

121–2640overwarningdecal121–2641.

ProductOverview

Figure15

1.Engine

2.Rollbar6.Tractionpedal

3.Controlpanel

4.Seat

5.Steeringwheel

7.Footrest

8.Reelswithgrassbaskets

Controls

TractionPedal

Thetractionpedal(Figure16)has3functions:tomakethe

machinemoveforward,tomoveitbackward,andtostopthe

machine.Pressthetopofthepedaltomoveforwardandthe

bottomofthepedaltomovebackwardortoassistinstopping

whenmovingforward.Also,allowthepedaltomovetothe

Neutralpositiontostopthemachine.Foroperatorcomfort,

donotresttheheelofyourfootonreversewhenoperating

forward(Figure17).

18

Page 19

g014603

1

2

3

Figure16

G017975

1

3

2

4

5

1.Tractionpedal—forward3.Steeringarmlockingpedal

2.Tractionpedal—reverse

Figure17

Figure18

1.Ignitionswitch4.Throttle

2.Functional-controllever

3.Raise/LowerMowControl

5.InfoCenter

Raise/LowerMowControl

Movingthecontrol(Figure18)forwardduringoperation

lowersthecuttingunitsandstartsthereels.Pullbackonthe

controltostopthereelsandraisethecuttingunits.During

operationthereelscanbestoppedbypullingbackonthe

controlmomentarilyandreleasingit.Thisfeatureisknownas

Tap-offandisadjustableintheInfoCenter.Startthereelsby

movingthecontrolforward.

Functional-ControlLever

Groundspeedsareasfollows:

•3.2to8km/h(2to5mph)forwardmowingspeed

•16km/h(10mph)maximumtransportspeed

•4.0km/h(2.5mph)reversespeed

Steering-Arm-LockingPedal

Pressthepedal(Figure16)andraiseorlowerthesteering

armforoperatorcomfort,then,releasethepedaltolockthe

arminplace.

Note:Movethesteeringarmfullyforwardbeforelifting

theseat.

ThrottleControl

Thethrottlecontrol(Figure18)givestheoperatortheability

tocontrolthespeedoftheengine.Movingthethrottle

controltowardtheFastpositionincreasestheenginerpm;

movingthethrottlecontroltowardSlowwilldecreasethe

enginerpm.

Note:Thethrottlecontrolwillnotstoptheengine.

Thefunctionalcontrollever(Figure18)provides2traction

selectionsplusaNeutralposition.Itispermissibletoshift

frommowtotransportortransporttomow(nottoneutral)

whilethemachineisinmotion.Nodamagewillresult.

•RearPosition—neutralandbacklapping

•MiddlePosition—usedformowingoperation

•FrontPosition—usedfortransportoperation

IgnitionSwitch

Insertthekeyintotheswitch(Figure18)andturnitclockwise

asfaraspossibletotheStartpositiontostarttheengine.

Releasethekeyassoonastheenginestarts;thekeywillmove

totheOnposition.TurnthekeycounterclockwisetotheOff

positiontostoptheengine.

BacklapSwitch

Thebacklapswitchislocatedundertheplasticcoverto

theleftoftheseat.Usethebacklapswitch(Figure19)in

conjunctionwiththeraise/lowermowcontrolleverandthe

reelspeedcontrolforbacklappingthereels.

19

Page 20

G017943

2

2

7.5

7.5

7.5

7.5

7.5

7.5

10

10

15

15

C2

C2

1

2

Figure19

1

G017946

2

3

4

5

6

7

8

9

10

TORO

13.2

10,000.0

STOP

n/min

52.2V

10,000.0

n/min

52.2V

1200

100

170

240

1600

n/min

G017947

2

3

1

1.Backlapswitch—backlap

position

2.Backlapswitch—mow

position

UsingtheInfoCenterLCDDisplay

TheInfoCenterLCDdisplayshowsinformationaboutyour

machinesuchasthegeneratorstatus,thespeed,andvarious

diagnosticsandotherinformationaboutthemachineandthe

batterypack.Figure20andFigure21illustratethesplash

screenandmaininformationscreenoftheInfoCenter.You

canswitchbetweenthesplashscreenandmaininformation

screenatanytimebypressinganyoftheInfoCenterbuttons

andthenselectingtheappropriatedirectionalarrow.

Figure21

1.Functionalcontrolstatus

2.Functionalcontrolstatus

3.PTOspeed

•Enginerpm/status—indicatestheenginerpm.

•Faultlog—indicatesthatthereisacurrentfaultlogto

review.

•Generatorvoltage/status—indicatesthegenerator

voltage.

•Hourmeter—indicatesthetotalhoursthemachinehas

operated.Itstartstofunctionwheneverthekeyswitch

isrotatedtoOn.

•PTOspeed—indicatesthePTOspeed.

•Glowplug—indicatesthattheglowplugisactive.

•Batteryvoltage—indicatesthebatterypotentialinVolts.

•Coolanttemperature—indicatestheenginecoolant

temperatureineither°Cor°F .

•Functionalcontrolstatus—transportmodeisindicated

byarabbitandmowmodeisindicatedbyaturtle.

•Engineoilpressurelight—thisiconappearsiftheengine

oilpressuredropsbelowasafelevel.

•Menuaccess/backbutton—pressthisbuttontoaccess

theInfoCentermenus.Youcanuseittobackoutofany

Figure20

1.Batteryvoltage

2.Powerlight/faultindicator

3.Enginerpm/status

4.Faultlog9.Downbutton

5.Generatorvoltage/status10.Menuaccess/backbutton

6.GlowPlug

7.Hourmeter

8.Rightbutton

20

menuyouarecurrentlyusing.

•Downbutton—usethisbuttontoscrolldownmenus.

•Rightbutton—usethisbuttontoopenamenuwherea

rightarrowindicatesadditionalcontent.

Note:Thepurposeofeachbuttonmaychangedepending

onwhatisrequiredatthetime.Eachbuttonwillbelabeled

withanicondisplayingitscurrentfunction.

UsingtheMenus

ToaccesstheInfoCentermenusystem,pressthemenuaccess

buttonwhileatthemainscreen.Thiswillbringyoutothe

mainmenu.Refertothefollowingtablesforasynopsisof

theoptionsavailablefromthemenus:

Page 21

MainMenu

MenuItemDescription

FaultsTheFaultsmenucontains

ServiceTheServicemenucontains

DiagnosticsTheDiagnosticsmenu

SettingsTheSettingsmenuallows

AboutTheAboutmenuliststhe

Service

MenuItemDescription

Hours

CountsListsthenumberofpreheats

Diagnostics

MenuItemDescription

EngineRun

GlowplugsIndicatesifthefollowingitems

Fan

alistoftherecentmachine

faults.RefertotheService

ManualoryourAuthorized

ToroDistributorformore

informationontheFaults

menuandtheinformation

containedthere.

informationonthemachine

suchashoursofuseandother

similarnumbers.

listsvariousstatesthatthe

machinecurrentlyhas.You

canusethistotroubleshoot

certainissuesasitwillquickly

tellyouwhichmachine

controlsareonandwhichare

off.

youtocustomizeandmodify

congurationvariablesonthe

InfoCenterdisplay.

modelnumber,serialnumber,

andsoftwareversionofyour

machine.

Liststhetotalnumberofhours

thatthemachine,engine,

reels,backlap,andfanhave

beenon,aswellasthe

numberofhoursthemachine

hasbeentransportedand

overheated.

andstartsthemachinehas

experienced.

Indicatesifthefollowingitems

areactive:Keystart,keyrun,

joysticklower,joystickraise,

neutral,seatorparkingbrake,

OKrun,andRTRorETR.

areactive:Keystart,timeout

limited,andglowplugs.

Indicatesifthefanisactive

inthefollowinginstances:

Enginehightemp,oilhigh

temp,engineorhydraulichigh

temp,andfanon.

S1–S4Controlstheraisingand

ReelsEnable

Settings

MenuItemDescription

Units

Language

LCDBacklightControlsthebrightnessofthe

LCDContrastControlsthecontrastofthe

ProtectedMenus

ProtectionSettingsControlstheprotectedmenus.

ResetDefaultsResetstheInfoCenterto

RaiseDelay

LowerDelay

TapoffDelayControlsthetap-offdelay.

ReelSpeedControlsthereelspeed.

Backlaprpm

About

MenuItemDescription

Model

SNListstheserialnumberofthe

TEC5001Liststhesoftwarerevisionof

InfoCenterListsthesoftwarerevisionof

CU1Liststhesoftwarerevisionof

CU2Liststhesoftwarerevisionof

CU3Listthesoftwarerevisionof

GeneratorListstheserialnumberofthe

CANBus

loweringofthesolenoids.

IndicatesiftheeReelis

enabled.

Controlstheunitsusedonthe

InfoCenter.Themenuchoices

areEnglishorMetric.

Controlsthelanguageused

ontheInfoCenter.

LCDdisplay.

LCDdisplay.

Allowsthedistributor/engineer

toaccessprotectedmenusby

inputtingapasscode.

defaultsettings.

Controlstheraisedelaytime

forthecentercuttingunit.

Controlsthelowerdelayfor

thecentercuttingunit.

Controlsthebacklaprpm

speed.

Liststhemodelnumberofthe

machine.

machine.

themastercontroller .

theInfoCenter.

therstcuttingunit.

thesecondcuttingunit.

thethirdcuttingunit.

generator.

Liststhemachine

communicationbusstatus.

21

Page 22

CenterCuttingUnitRaise/LowerDelay

g014736

Theraiseandlowerdelaytimeforthecentercuttingmaybe

adjustedindependentlywiththeInfoCenter.Eachsetting

maybeadjustedfrom1to10accordingtothetablebelow .

Thefactorydefaultsettingis6(375ms)andisoptimizedfor

a3.8mphmowspeed.

3.Usingtheappropriategraph(SeeFigure22)for5,8,

11,or14bladecuttingunits,determinetheproperreel

speedsetting.

IncrementNumber

10.100

20.150

30.200

40.250

5

60.375

7

80.600

90.750

100.925

DelayTime(Seconds)

0.300

0.475

Tap-offDelay

Thetap-offdelayfeatureallowsthecuttingunitstoturnoff

withoutraising,andmaybeadjustedwiththeInfoCenter.The

delaysettingrepresentsthemaximumtimefortheraise/lower

joysticktoremainintheraisepositiontoactivatethisfeature.

Thefactorydefaultsettingis1whichdisablesthisfeature.

IncrementNumber

1

20.050

30.100

40.150

5

60.250

7

80.350

90.400

100.450

DelayTime(Seconds)

Off

0.200

0.300

Figure22

4.Tosetthereelspeed,ontheInfoCenteropentheMain

MenuandscrolldowntoSettings.

5.IntheSettingsmenu,scrolldowntoReelSpeedand

usethe±buttontosetthereelspeedtothedesired

number.

MachineCongurationPasscode

Thereare5operatingcongurationsettingsthatare

adjustablewithinthesettingmenuoftheInfoCenter:Raise

andlowerdelay,tap-offdelay,reelspeed,andbacklapspeed.

Thesesettingcanbeprotectedbyauserdenedpasscodeby

openingtheMainmenuandscrollingdowntotheSettings

menu.FindProtectSettingsandselectOn.

WhenprotectsettingOnisselectedtheuserisprompted

toentera4digitpasscode.Afterthepasscodeisset,the

keyswitchmustbeturnedoffandbackontoenableand

savethisfeature.Afterenablingtheprotectsettingsoption,

thecongurationsettingsarehiddenuntiltheuserdened

passcodeisentered.

Note:Iftheuserdenedpasscodeisforgotten,atemporary

passcodecanbeobtainedthroughyourauthorizedT oro

distributor.

SettingtheReelSpeed

Toachieveaconsistent,highquality–of–cutandauniform

aftercutappearance,itisimportantthatthereelspeedcontrol

becorrectlyset.

Adjustthereelspeedcontrolasfollows:

1.Selecttheheight-of-cutatwhichthecuttingunitsare

set.

2.Choosethedesiredgroundspeedbestsuitedfor

conditions.

DiagnosingtheFault-LogIndicator

Thefault-logindicatoriconappearsonthemainscreeninthe

eventofafaultinthemachine.Whenthisiconispresent

thereisanewlogentryintheFaultsmenuthatyouoryour

distributorcanusetoidentifytheproblem.

Foralistoffaults,refertoyourAuthorizedToroDistributor

ortheServiceManual.

22

Page 23

Seat-AdjustingLever

g014628

1

g01462 6

1

Theseat-adjustingleverislocatedonthefront,rightcorner

oftheseat(Figure23),allowingyoutoadjusttheseatfore

andaft.Pushthelevertotheleft(towardsthecenter),to

releasethelockandslidetheseat.

Note:Ifyouneedadditionaladjustmentontheseat,youcan

removethefourboltssecuringtheseattothebaseandmove

theseattothesecondsetofmountingholesprovided.

Figure24

1.Fuelshutoff(underthefueltank)

Figure23

1.Seat-adjustinglever

Note:Beforeliftingtheseat,slideittothefurthestback

positionandmovethesteeringarmfullyforward.

Fuel-ShutoffValve

Closethefuel-shutoffvalve(Figure24)behindtheseatand

underthefueltankwhenstoringortransportingthemachine

onatruckortrailer.

Parking-BrakeLever

Pulluponthebrakelever(Figure25)tosettheparkingbrake.

Disengageitbypullinguponthereleaselatchandlowering

thebrakehandle.Locktheparkingbrakeanytimeyouleave

themachine.

Figure25

1.Parking-brakelever2.Releaselatch

23

Page 24

CuttingUnitPowerDisconnect

Connectors

Beforeinstalling,removing,orworkingonthecutting

units,disconnectthecuttingunitsfromthepowersupply

byseparatingthecuttingunitpowerdisconnectconnectors

(Figure26),locatedatthebaseoftherolloverbarontheleft

sideofthetractionunit.Plugtheconnectorstogetherbefore

operatingthemachine.

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

Widthofcut151cm(59.5inches)

Wheeltread

Wheelbase

Overalllength(w/baskets)249cm(98.0inches)

Overallwidth179cm(70.62inches)

Overallheight205cm(80.83inches)

128cm(50.5inches)

123cm(48.6inches)

Figure26

1.Cuttingunitpowerdisconnectconnector

CAUTION

Ifyoudonotdisconnectthepowertothecutting

units,someonecouldaccidentallystartthecutting

unit,causingseriousinjurytohandsandfeet.

Alwaysseparatethecuttingunitpowerdisconnect

connectorsbeforeworkingonthecuttingunits.

NetWeightw/reels(11Blade)Refertothetractionunit

serialtag(Figure1).

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesis

availableforusewiththemachinetoenhanceandexpand

itscapabilities.ContactyourAuthorizedServiceDealeror

Distributororgotowww .Toro.comforalistofallapproved

attachmentsandaccessories.

24

Page 25

Operation

g014618

1

2

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

ThinkSafetyFirst

Pleasecarefullyreadallofthesafetyinstructionsandsymbols

inthesafetysection.Knowingthisinformationcouldhelp

youorbystandersavoidinjury.

Theuseofprotectiveequipment,suchasbutnotlimitedto,

foreyes,ears,feet,andheadisrecommended.

CheckingtheEngineOil

Theengineisshippedwithoilinthecrankcase;however,the

oillevelmustbecheckedbeforeandaftertheengineisrst

started.

Crankcasecapacityisapproximately3.7l(3.9quarts)with

thelter.

isnecessarytopermitventingwhenlling,which

preventsoilfromoverrunningintobreather.

Figure27

Usehigh-qualityengineoilthatmeetsthefollowing

specications:

•APIClassicationLevelRequired:CH–4,CI–4orhigher.

•Preferredoil:SAE10W–30

•Alternateoil:SAE15W–40

ToroPremiumEngineoilisavailablefromyourdistributorin

the10W–30viscosity .Seethepartscatalogforpartnumbers.

Note:Thebesttimetochecktheengineoiliswhenthe

engineiscoolbeforeithasbeenstartedfortheday.Ifithas

alreadybeenrun,allowtheoiltodrainbackdowntothe

sumpforatleast10minutesbeforechecking.Iftheoillevel

isatorbelowthe“add”markonthedipstick,addoiltobring

theoilleveltothe“full”mark.Donotoverll.Iftheoil

levelisbetweenthe“full”and“add”marks,nooiladdition

isrequired.

Important:Besuretokeeptheengineoillevelbetween

theupperandlowerlimitsontheoilgauge.Engine

failuremayoccurasaresultofoverllingorunder

llingtheengineoil.

1.Positionthemachineonalevelsurface.

2.Removethedipstickandwipeitwithacleanrag(Figure

28).Pushthedipstickintothetubeandmakesureit

isseatedfully.Removethedipstickfromthetubeand

checkthelevelofoil.Iftheoillevelislow,removethe

llercapfromthevalvecoverandslowlyaddenough

oiltoraisetheleveltotheFullmarkonthedipstick.

Addtheoilslowlyandchecktheleveloftenduringthis

process.Donotoverll.

Important:Makesurethatthedipstickisremoved

whilellingtheenginewithoil.Whenadding

engineoilorllingoil,there

betweentheoillldeviceandtheoilllholeinthe

valvecoverasshowninFigure27.Thisclearance

must be

clearance

1.Noteclearance

Figure28

1.Fillercap2.Dipstick

3.Replacethedipstick.

4.Startandruntheengineatidlefor30seconds,then

shuttheengineoff.Wait30seconds,thenrepeatsteps

2–3.

Important:Checkthelevelofoilevery8operating

hoursordaily.Changetheoilandlterinitially

aftertherst50hoursofoperation,thereafter

changetheoilandthelterevery150hours.

However,changetheoilmorefrequentlywhen

theengineisoperatedinextremelydustyordirty

conditions.

5.Installthellercapanddipstickrmlyinplace.

25

Page 26

FillingtheFuelTank

Useonlyclean,freshdieselfuelorbiodieselfuelswithlow

(<500ppm)orultralow(<15ppm)sulfurcontent.The

minimumcetaneratingshouldbe40.Purchasefuelin

quantitiesthatcanbeusedwithin180daystoensurefuel

freshness.

•Fuellterpluggingmaybeexpectedforatimeafter

convertingtobiodieselblends.

•Contactyourdistributorifyouwishformoreinformation

onbiodiesel

DANGER

Fueltankcapacity:22.7L(6USgallons)

Usesummergradedieselfuel(No.2-D)attemperatures

above-7°C(20°F)andwintergrade(No.1-DorNo.

1-D/2-Dblend)belowthattemperature.Useofwintergrade

fuelatlowertemperaturesprovideslowerashpointand

coldowcharacteristicswhichwilleasestartingandreduce

fuellterplugging.

Useofsummergradefuelabove-7°C(20°F)willcontribute

towardlongerfuelpumplifeandincreasedpowercompared

towintergradefuel.

DANGER

Undercertainconditions,dieselfuelandfuel

vaporsarehighlyammableandexplosive.Are

orexplosionfromfuelcanburnyouandothersand

cancausepropertydamage.

•Useafunnelandllthefueltankoutdoors,in

anopenarea,whentheengineisoffandiscold.

Wipeupanyfuelthatspills.

•Donotllthefueltankcompletelyfull.Add

fueltothefueltankuntilthelevelis6to13mm

(1/4to1/2inch)belowthebottomoftheller

neck.Thisemptyspaceinthetankallowsthe

fueltoexpand.

•Neversmokewhenhandlingfuel,andstayaway

fromanopenameorwherefuelfumesmaybe

ignitedbyaspark.

•Storefuelinaclean,sealed,safety-approved

container.

BiodieselReady

Thismachinecanalsouseabiodieselblendedfuelofup

toB20(20%biodiesel,80%petrodiesel).Thepetrodiesel

portionshouldbeloworultralowsulfur.Observethe

followingprecautions:

•Thebiodieselportionofthefuelmustmeetspecication

ASTMD6751orEN14214.

•TheblendedfuelcompositionshouldmeetASTMD975

orEN590.

•Paintedsurfacesmaybedamagedbybiodieselblends.

•UseB5(biodieselcontentof5%)orlesserblendsincold

weather.

•Monitorseals,hoses,gasketsincontactwithfuelasthey

maybedegradedovertime.

Incertainconditions,fuelisextremelyammable

andhighlyexplosive.Areorexplosionfromfuel

canburnyouandothersandcandamageproperty.

•Fillthefueltankoutdoors,inanopenarea,when

theengineiscold.Wipeupanyfuelthatspills.

•Donotllthefueltankcompletelyfull.Addfuel

tothefueltankuntilthelevelis25mm(1inch)

belowthebottomofthellerneck.Thisempty

spaceinthetankallowsfueltoexpand.

•Neversmokewhenhandlingfuel,andstayaway

fromanopenameorwherefuelfumesmaybe

ignitedbyaspark.

•Storefuelinanapprovedcontainerandkeepit

outofthereachofchildren.Neverbuymore

thana30-daysupplyoffuel.

•Alwaysplacefuelcontainersonthegroundaway

fromyourvehiclebeforelling

•Donotllfuelcontainersinsideavehicleoron

atruckortrailerbedbecauseinteriorcarpets

orplastictruckbedlinersmayinsulatethe

containerandslowthelossofanystaticcharge.

•Whenpractical,removegas-poweredequipment

fromthetruckortrailerandrefueltheequipment

withitswheelsontheground.

•Ifthisisnotpossible,thenrefuelsuchequipment

onatruckortrailerfromaportablecontainer

ratherthanfromafuel-dispensernozzle.

•Whenusingafuel-dispensernozzle,keepthe

nozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilfuelingis

complete.

1.Cleanaroundthefuel-tankcap(Figure29).

26

Page 27

g014612

1

Figure29

g01461 3

1

2

3

4

1.Fuel-tankcap

2.Removethefuel-tankcap.

3.Fillthetankuntilthelevelis6to13mm(1/4to1/2

inch)belowthebottomofthellerneck.Donot

overll.Installthecap.

thecoolantatthebeginningofeachdaybeforestartingthe

engine.

CAUTION

Iftheenginehasbeenrunning,thepressurized,hot

coolantcanescapeandcauseburns.

•Donotopentheradiatorcapwhentheengine

isrunning.

•Usearagwhenopeningtheradiatorcap,and

openthecapslowlytoallowsteamtoescape.

1.Parkthemachineonalevelsurface.

2.Checkthecoolantlevel(Figure31).

Note:Itshouldbebetweenthelinesonthereserve

tankwhentheengineiscold.

4.Wipeupanyfuelthatmayhavespilled.

CheckingtheCoolingSystem

Thecapacityofthecoolingsystemisapproximately4.6L(4.9

quarts).RefertoCleaningtheRadiatorScreen(page44).

Figure30

Figure31

1.Reservetank

3.Ifthecoolantislow,removethereservetankcapand

adda50/50mixtureofwaterandpermanentethylene

glycolantifreeze.Donotoverll.

4.Installthereserve-tankcap.

CheckingtheHydraulic-Fluid Level

Beforeoperatingthemachineeachday ,checklevelofthe

hydraulicuidinthewhiteplasticwindowonthefrontofthe

hydraulic-uidreservoir(behindtheseatontheleftside).The

uidshouldbebetweenthelinesinthewindow;ifnot,add

anappropriateuidasdescribedinthefollowingsections:

1.Wingbolts3.Reservetank

2.Radiatorscreen

Thecoolingsystemislledwitha50/50solutionofwater

andpermanentethyleneglycolantifreeze.Checkthelevelof

4.Radiator-llcap

Themachinesreservoirislledatthefactorywith

approximately20.8L(5.5gallons)ofhighqualityhydraulic

uid.Checkthelevelofthehydraulicuidbefore

theengineisrststartedanddailythereafter.The

recommendedreplacementuidisasfollows:

27

Page 28

ToroPremiumAllSeasonHydraulicFluid(Availablein5

g014719

1

1

2

g016334

gallonpailsor55gallondrums.SeepartscatalogorToro

distributorforpartnumbers.)

Alternateuids:IftheTorouidisnotavailable,otheruids

maybeusedprovidedtheymeetallthefollowingmaterial

propertiesandindustryspecications.W edonotrecommend

theuseofsyntheticuid.Consultwithyourlubricant

distributortoidentifyasatisfactoryproduct

Note:Torowillnotassumeresponsibilityfordamage

causedbyimpropersubstitutions,souseonlyproducts

fromreputablemanufacturerswhowillstandbehindtheir

recommendation.

HighViscosityIndex/LowPourPointAnti-wearHydraulic

Fluid,ISOVG46

MaterialProperties:

Viscosity,ASTMD445cSt@40°C44to48

ViscosityIndexASTM

D2270

PourPoint,ASTMD97-34°Fto-49°F

IndustrySpecications:

VickersI-286-S(QualityLevel),VickersM-2950-S

(QualityLevel),DenisonHF-0,Vickers35VQ25(Eaton

ATS373-C)

cSt@100°C7.9to8.5

140to160

Important:TheISOVG46Multigradeuidhasbeen

foundtoofferoptimalperformanceinawiderangeof

temperatureconditions.Foroperationinconsistently

highambienttemperatures,65°F(18°C)to120°F

(49°C),ISOVG68hydraulicuidmayofferimproved

performance.

FillingtheHydraulicTank

1.Positionthemachineonalevelsurface.Makesurethe

machinehascooleddownsotheoiliscold.

2.Removethecapfromthereservoir(Figure32).

Figure32

1.Hydraulic-tankcap

3.Slowlyllthereservoirwiththeappropriatehydraulic

uiduntilthelevelisatorwithin6mm(0.25inch)of

thearrowinthesymbolnexttothewhitewindowin

thefrontofthereservoir(Figure33).Donotoverll.

PremiumBiodegradableHydraulicFluid-MobilEAL

EnviroSyn46H

Important:MobilEALEnviroSyn46Histheonly

syntheticbiodegradableuidapprovedbyT oro.This

uidiscompatiblewiththeelastomersusedinToro

hydraulicsystemsandissuitableforawide-range

oftemperatureconditions.Thisuidiscompatible

withconventionalmineraloils,butformaximum

biodegradabilityandperformancethehydraulicsystem

shouldbethoroughlyushedofconventionaluid.The

oilisavailablein19L(5-gallon)containersor55-gallon

drumsfromyourMobilDistributor.

Note:Manyhydraulicuidsarealmostcolorless,makingit

difculttospotleaks.Areddyeadditiveforthehydraulic

systemoilisavailablein20ml(2/3oz)bottles.Onebottle

issufcientfor15-22L(4-6gallons)ofhydraulicoil.Order

partno.44-2500fromyourauthorizedTorodistributor.This

reddyeisnotrecommendedforusewithbiodegradable

uids.

Important:Regardlessofhydraulicuidtypeused,any

machineusedformowingfairways,verticuttingorused

duringambienttemperaturesabove85°F(29°C)should

haveOilCoolerKit,PartNo.117-9314,installed.

Figure33

1.Whitewindowonthefront

ofthehydraulicreservoir

2.Filltowithinthisarea.

Important:Topreventsystemcontamination,

cleanthetopofthehydraulicuidcontainers

beforepuncturing.Ensurethepourspoutand

funnelareclean.

4.Installthereservoircap.Wipeupanyuidthatmay

havespilled.

Important:Checklevelofhydraulicuidbefore

engineisrststartedanddailythereafter.

28

Page 29

DrainingWaterfromtheFuel

g014720

1

2

CheckingtheReel-to-Bedknife

Filter

ServiceInterval:Beforeeachuseordaily

1.Positionthemachineonalevelsurfaceandstopthe

engine.

2.Placeadrainpanunderthefuellter.

3.Openthedrainplugonthefuellterapproximately

oneturnanddrainanyaccumulatedwater(Figure34).

Tightentheplugafterdraining.

Note:Becausetheaccumulatedwaterwillbemixed

withdieselfuel,drainthefuellterintoasuitable

containeranddisposeofitproperly.

Contact

Eachdaybeforeoperatingthemachine,checkthe

reel-to-bedknifecontact,regardlessifthequalityofcuthad

previouslybeenacceptable.Theremustbelightcontact

acrossthefulllengthofthereelandbedknife;referto

AdjustingtheReeltoBedknifeinthecuttingunitOperator’s

Manual.

Beforecheckingthereels,disconnectthecuttingunitpower

disconnectcouplers;refertoCuttingUnitPowerDisconnect

Connectors(page24).Connectthemwhennished.

CAUTION

Ifyoudonotdisconnectthepowertothecutting

units,someonecouldaccidentallystartthecutting

unit,causingseriousinjurytohandsandfeet.

Alwaysseparatethecuttingunitpowerdisconnect

couplersbeforeworkingonthecuttingunits.

Breaking-intheMachine

RefertotheEngineManualsuppliedwiththemachineforoil

changeandmaintenanceproceduresrecommendedduring

thebreak-inperiod.

Figure34

1.Fuellter

2.Drainplug

CheckingtheTirePressure

Thetiresareover-inatedatthefactoryforshipping

purposes.Reducethepressuretotheproperlevelsbefore

startingtheunit.

Varythetirepressureforall3wheels,dependinguponyour

turfconditions,fromaminimumof83toamaximumof110

kPa(12psito16psi).

CheckingtheTorqueofthe WheelNuts

WARNING

Failuretomaintainpropertorqueofthewheelnuts

couldresultinpersonalinjury.

Only8hoursofmowingoperationisrequiredforthebreak-in

period.

Sincethersthoursofoperationarecriticaltofuture

dependabilityofthemachine,monitoritsfunctionsand

performancecloselysothatminordifculties,whichcould

leadtomajorproblems,arenotedandcanbecorrected.

Inspectthemachinefrequentlyduringbreak-inforsignsof

oilleakage,loosefasteners,oranyothermalfunction.

Toensureoptimumperformanceofthebrakesystem,burnish

(break-in)thebrakesbeforeusingthemachine.Toburnish

thebrakes,rmlyapplythebrakesanddrivethemachineat

mowingspeeduntilthebrakesarehot,asindicatedbytheir

smell.Anadjustmenttothebrakesmayberequiredafter

break-in;refertoAdjustingtheBrakes.

Torquethewheelnutsto95to122N-m(70to90

ft-lb)after1-4hoursofoperationandagainafter

10hoursofoperation.Torquethenutsevery200

hoursthereafter.

29

Page 30

StartingandStoppingthe

g014602

1

2

InstallingandRemovingthe

Machine

Note:Inspecttheareasbeneaththemowerstobecertain

theyareclearofdebris.

StartingtheMachine

Important:Donotuseetherorothertypesofstarting

uid.

1.Besuretheparkingbrakeisset,theraise/lowermow

controlisdisengaged,andthefunctionalcontrolisin

theneutralposition.

2.Removeyourfootfromthetractionpedalandmake

surethepedalisintheneutralposition.

3.MovethethrottlelevertotheSlowposition.

4.InsertthekeyintotheswitchandrotateittoOn.Hold

itintheOnpositionuntiltheglowplugindicatorlight

goesoff(approximately6seconds).

5.ImmediatelyturntheignitionkeytotheStartposition.

Releasethekeywhentheenginestartsandallowitto

movetotheOnposition.Movethethrottlecontrol

toSlow .

Important:Topreventoverheatingofthestarter

motor,donotengagethestarterlongerthan10

seconds.After10secondsofcontinuouscranking,

wait60secondsbeforeengagingthestartermotor

again.

CuttingUnits

InstallingtheCuttingUnits

1.Disconnectthecuttingunitpowerdisconnectcouplers;

refertoCuttingUnitPowerDisconnectConnectors

(page24).

CAUTION

Ifyoudonotdisconnectthepowertothe

cuttingunits,someonecouldaccidentally

startthecuttingunit,causingseriousinjury

tohandsandfeet.

Alwaysseparatethecuttingunitpower

disconnectcouplersbeforeworkingonthe

cuttingunits.

2.Liftuponthefootrestandswingitopen,allowing

accesstothecentercuttingunitposition(Figure35).

CAUTION

Thefootrestcanpinchngersifitfallsinto

theclosedposition.

Keepyourngersclearoftheareawherethe

footrestseatswhileitisopen.

6.Allowtheenginetowarmupforafewminutesbefore

operating.

Important:Whentheengineisstartedfortherst

time,orafteranoverhauloftheengine,operate

themachineinforwardandreverseforoneto

twominutes.Turnthesteeringwheeltotheleft

andrighttocheckthesteeringresponse.Then

shuttheengineoff(seeStoppinginStartingand

StoppingtheEngine)andwaitforallmovingparts

tostop.Checkforoilleaks,loosepartsandany

othernoticeablemalfunctions.

StoppingtheMachine

1.MovethethrottlecontroltoSlow,disengagethe

raise/lowermowcontrol,andmovethefunctional

controltoneutral.

2.RotatethestarterkeytoOfftoshuttheengineoff.

Removethekeyfromtheswitchtopreventaccidental

starting.

3.Closethefuelshut-offvalvesbeforestoringthe

machine.

Figure35

1.Footrest—closed2.Footrest—open

3.Positionthecuttingunitunderthecentersuspension

arm.

4.Withthelatchesonthesuspension-armbarpointing

up(i.e.,open)(Figure36),pushthesuspensionarm

downsothatthebartsoverthebaracrossthetopof

thecuttingunit(Figure37).

30

Page 31

g014609

1

2

3

Figure36

g01461 1

1

2

1.Latch—closedposition3.Latch—openposition

2.Suspension-armbar

Figure38

Figure37

1.Suspension-armbar2.Cutting-unitbar

5.Closethelatchesdownandaroundthecutting-unitbar

andlocktheminplace(Figure36).

Note:A“click”canbeheardandfeltwhenthelatches

areproperlylockedinplace.

6.Coatthesplineshaftofthecuttingunitmotorwith

cleangrease(Figure38).

7.Insertthemotorintotheleftsideofthecuttingunit

(asviewedfromtheoperator'sposition)andpullthe

motorretainingbaronthecuttingunittowardthe

motoruntilyouhearanaudible“click”frombothsides

ofthemotor(Figure38).

1.Reelmotor

2.Splineshaft

3.Cavity

4.Motor-retainingbar

8.Mountagrassbasketontothebaskethooksonthe

suspensionarm.

9.Repeatthisprocedurefortheothercuttingunits.

10.Connectthecuttingunitpowerdisconnectcouplers;

refertoCuttingUnitPowerDisconnectConnectors

(page24).

RemovingtheCuttingUnits

1.Disconnectthecuttingunitpowerdisconnectcouplers;

refertoCuttingUnitPowerDisconnectConnectors

(page24).

CAUTION

Ifyoudonotdisconnectthepowertothe

cuttingunits,someonecouldaccidentally

startthecuttingunit,causingseriousinjury

tohandsandfeet.

Alwaysseparatethecuttingunitpower

disconnectcouplersbeforeworkingonthe

cuttingunits.

2.Parkthemachineonacleanlevelsurface,lower

thecuttingunitstothegrounduntilthesuspension

hydraulicsarefullyextended,stoptheengine,andset

31

theparkingbrake.

3.Pushthemotorretainingbaroutoftheslotsonthe

motortowardsthecuttingunitandremovethemotor

fromthecuttingunit.

Page 32

Figure39

1.Reelmotor2.Motor-retainingbar

4.Movethemotortothestoragelocationonthefrontof

thesuspensionarm(Figure40).

7.Rollthecuttingunitoutfromunderthesuspension

arm.

8.Repeatsteps3through7fortheothercuttingunits

asrequired.

9.Connectthecuttingunitpowerdisconnectcouplers;

refertoCuttingUnitPowerDisconnectConnectors

(page24).

Mowing

Note:Beforemowinggreenswiththemachine,nda

clearareaandpracticestartingandstopping,raisingand

loweringthecuttingunits,turning,etc.Thistrainingperiod

willbebenecialtotheoperatoringainingcondenceinthe

performanceofthemachine.

Note:Beforemowing,inspectthegreenfordebris,remove

theagfromthecup,anddeterminethebestdirectionto

mow .Basethedirectiontomowonthepreviousmowing

direction.Alwaysmowinanalternatepatternfromthe

previousmowingsothatthegrassbladeswillbelessaptto

laydownandthereforebedifculttotrapbetweenthereel

bladesandbedknife.

Figure40

Note:Whensharpening,settingtheheight-of-cut,

orperformingothermaintenanceproceduresonthe

cuttingunits,storethecuttingunitreelmotorsinthe

storagelocationonthefrontofthesuspensionarmsto

preventdamagetothem.

Important:Donotraisethesuspensiontothe

transportpositionwhenthereelmotorsareinthe

holdersinthemachineframe.Damagetothe

motorsorhosescouldresult.Ifyoumustmovethe

tractionunitwithoutthecuttingunitsinstalled,

securethemtothesuspensionarmsusingcable

ties.

5.Openthelatchesonthesuspension-armbarofthe

cuttingunityouareremoving(Figure36).

6.Disconnectthelatchesfromthecutting-unitbar.

1.ApproachthegreenwiththeshiftselectorintheNo.

1position.Startononeedgeofthegreensothatthe

ribbonprocedureofcuttingmaybeused.

Note:Thisholdscompactiontoaminimumand

leavesaneat,attractivepatternonthegreens.

2.Actuatethemowpedalasthefrontedgeofthegrass

basketscrosstheouteredgeofthegreen.

Note:Thisproceduredropsthecuttingunitstothe

turfandstartsthereels.

Important:Familiarizeyourselfwiththefactthat

theNo.1cuttingunitreelisdelayedandtherefore,

youshouldpracticetotrytogaintherequired

timingnecessarytominimizethecleanupmowing

operation.

3.Overlapaminimalamountwiththepreviouscuton

returnpasses.

Note:Toassistinmaintainingastraightlineacross

thegreenandkeepthemachineanequaldistancefrom

theedgeofthepreviouscut,establishanimaginary

sightlineapproximately1.8to3m(6to10ft)ahead

ofthemachinetotheedgeoftheuncutportionofthe

green(Figure41).

Somenditusefultoincludetheouteredgeofthe

steeringwheelaspartofthesightline;i.e.keepthe

steeringwheeledgealignedwithapointthatisalways

keptthesamedistanceawayfromthefrontofthe

machine(Figure41).

32

Page 33

G017821

1

3

2

Figure41

1.Alignmentmarker

2.Cutgrassonleft

4.Asthefrontofthebasketscrosstheedgeofthegreen,

depresstheliftpedal.

3.Keepfocalspot1.8-3

m(6-10ft)aheadofthe

machine.

Note:Attheendoftheperipherycut,momentarily

pullbackontheraise/lowermowlevertoshutthereels

offwithoutraisingthem.Continuemovingforward

untilthereelstopsrotating,then,driveoffthegreen

andraisethereels(Thiswillhelppreventdribbling

grassontothegreenwhileraisingthereels).

7.Emptythegrassbasketsofallclippingsbefore

transportingtothenextgreen.

Note:Heavywetclippingsplaceanunduestrainon

thebasketsandwilladdunnecessaryweighttothe

machine,therebyincreasingtheloadontheengine,

hydraulicsystem,brakes,etc.

DrivingtheMachinewithout Mowing

Makesurethecuttingunitsareinthefullupposition.Move

thefunctionalcontrollevertothetransportposition.Use

thebrakestoslowthemachinewhilegoingdownsteep

hillstoavoidlossofcontrol.Alwaysapproachroughareas

atareducedspeedandcrosssevereundulationscarefully.

Familiarizeyourselfwiththewidthofthemachine.Donot

attempttopassbetweenobjectsthatareclosetogetherso

thatcostlydamageanddowntimecanbeprevented.

Note:Thiswillstopthereelsandliftthecuttingunits.

Timingofthisprocedureisimportant,sothemowers

donotcutintothefringearea.However,asmuchof

thegreenaspossibleshouldbecuttominimizethe

amountofgrasslefttomowaroundtheouterperiphery

5.Cutdownonoperatingtimeandeaselineupforthe

nextpassbymomentarilyturningthemachineinthe

oppositedirection,thenturninginthedirectionofthe

uncutportion;i.e.,ifintendingtoturnright,rstswing

slightlyleft,thenright.

Note:Thiswillassistingettingthemachinemore

quicklyalignedforthenextpass.

Followthesameprocedureforturningintheopposite

direction.Itisagoodpracticetotrytomakeasshort

ofaturnaspossible.However,turninawiderarc

duringwarmerweathertominimizethepossibilityof

bruisingtheturf.

Important:Themachineshouldneverbestopped

onagreenwiththecuttingunitreelsoperating

asdamagetotheturfmayresult.Stoppingona

wetgreenwiththemachinemayleavemarksor

indentationsfromthewheels.

6.Finishcuttingthegreenbymowingtheouterperiphery

andreplacetheags.

TransportingtheMachine

Useaheavy-dutytrailerortrucktotransportthemachine.

Ensurethatthetrailerortruckhasallnecessarybrakes,

lighting,andmarkingasrequiredbylaw .Pleasecarefullyread

allthesafetyinstructions.Knowingthisinformationcould

helpyou,yourfamily,pets,orbystandersavoidinjury.

WARNING

Drivingonthestreetorroadwaywithoutturn

signals,lights,reectivemarkings,oraslow

movingvehicleemblemisdangerousandcanlead

toaccidentscausingpersonalinjury.

Donotdrivemachineonapublicstreetorroadway.

Totransportthemachine:

1.Ifusingatrailer,connectittothetowingvehicleand

connectthesafetychains.

2.Ifapplicable,connectthetrailerbrakes.

3.Loadthemachineontothetrailerortruck.

4.Stoptheengine,removethekey,setthebrake,and

closethefuelvalve.

Note:Besuretochangethedirectionofcuttingfrom

thepreviousmowing.Alwayskeepweatherandturf

conditionsinmindandbesuretochangethedirection

ofmowingfromthepreviouscutting.

5.Usethemetaltiedownloopsonthemachineto

securelyfastenthemachinetothetrailerortruckwith

straps,chains,cable,orropes.

33

Page 34

LoadingtheMachine

Useextremecautionwhenloadingthemachineontoatrailer

oratruck.Onefull-widthrampthatiswideenoughtoextend

beyondthereartiresisrecommendedinsteadofindividual

rampsforeachsideofthemachine(Figure42).Thelower

rearsectionofthemachineframeextendsbackbetweenthe

rearwheelsandservesasastopfortippingbackward.Having

afull-widthrampprovidesasurfacefortheframemembers

tocontactifthemachinestartstotipbackward.Ifitisnot

possibletouseonefull-widthramp,useenoughindividual

rampstosimulateafull-widthcontinuousramp.