Page 1

FormNo.3385-965RevA

g014597

Greensmaster

®

3320TriFlex

TractionUnit

ModelNo.04530—SerialNo.314004001andUp

™

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3385-965*A

Page 2

ThisproductcomplieswithallrelevantEuropeandirectives;

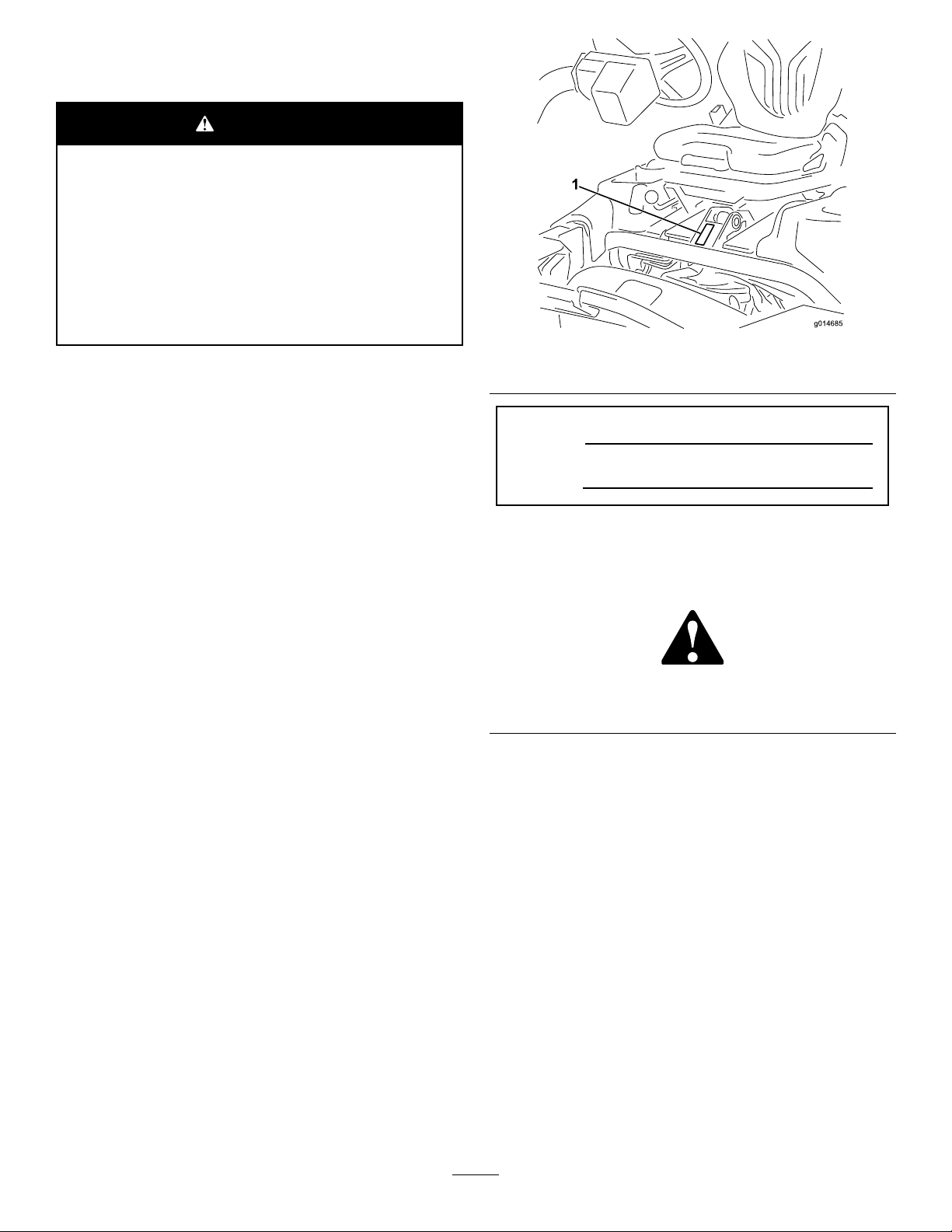

g014685

1

fordetails,pleaseseetheseparateproductspecicDeclaration

ofConformity(DOC)sheet.

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Figure1

Important:Thisengineisnotequippedwithaspark

arrestermufer.ItisaviolationofCaliforniaPublic

ResourceCodeSection4442touseoroperatetheengine

onanyforest-covered,brush-covered,orgrass-covered

land.Otherstatesorfederalareasmayhavesimilarlaws.

Introduction

Thismachineisaride-on,reel-bladelawnmowerintended

tobeusedbyprofessional,hiredoperatorsincommercial

applications.Itisprimarilydesignedforcuttinggrasson

well-maintainedlawnsinparks,golfcourses,sportselds,

andoncommercialgrounds.Itisnotdesignedforcutting

brush,mowinggrassandothergrowthalongsidehighways,

orforagriculturaluses.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure2

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready.Figure1identiesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

©2014—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Contents

Introduction..................................................................2

Safety...........................................................................4

SafeOperatingPractices...........................................4

ToroMowerSafety..................................................6

SoundPowerLevel..................................................7

SoundPressureLevel...............................................7

VibrationLevel......................................................7

SafetyandInstructionalDecals.................................8

Setup...........................................................................11

1InstallingtheRollBar...........................................12

2InstallingtheSeat.................................................12

3InstallingtheSteeringWheel..................................13

4ActivatingandChargingtheBattery........................13

5InstallingtheOptionalOilCooler...........................14

6InstallingtheGrassBasketHooks..........................15

7InstallingtheCuttingUnits...................................15

8AddingRearWeight.............................................17

9InstallingEUDecals.............................................17

ProductOverview.........................................................18

Controls...............................................................18

Specications........................................................25

Attachments/Accessories........................................25

Operation....................................................................26

ThinkSafetyFirst...................................................26

CheckingtheEngineOil..........................................26

FillingtheFuelTank...............................................26

CheckingtheHydraulicFluidLevel...........................27

CheckingtheReel-to-BedknifeContact.....................28

CheckingtheTirePressure......................................28

CheckingtheTorqueoftheWheelNuts.....................28

Breaking-intheMachine..........................................28

StartingtheEngine.................................................29

CheckingtheSafetyInterlockSystem........................29

InstallingandRemovingtheCuttingUnits.................30

TrainingPeriod......................................................32

Mowing................................................................32

TransportingtheMachine........................................33

InspectingandCleaningAfterMowing......................33

TowingtheMachine...............................................33

Maintenance.................................................................34

RecommendedMaintenanceSchedule(s)......................34

DailyMaintenanceChecklist....................................35

Lubrication...............................................................36

GreasingtheMachine.............................................36

EngineMaintenance..................................................36

ServicingtheAirCleaner.........................................36

ChangingtheEngineOilandFilter...........................37

ReplacingtheSparkPlugs........................................37

FuelSystemMaintenance...........................................38

ReplacingtheFuelFilter..........................................38

InspectingtheFuelLinesandConnections.................38

ElectricalSystemMaintenance....................................38

ServicingtheBattery...............................................38

ServicingtheFuses.................................................39

DriveSystemMaintenance.........................................39

AdjustingtheTransmissionforNeutral.....................39

AdjustingtheTransportSpeed.................................40

AdjustingtheMowingSpeed....................................40

BrakeMaintenance....................................................41

AdjustingtheBrakes...............................................41

HydraulicSystemMaintenance....................................41

ChangingtheHydraulicOilandFilter........................41

CheckingtheHydraulicLinesandHoses....................42

CuttingUnitMaintenance...........................................42

BacklappingtheReels.............................................42

Storage........................................................................43

3

Page 4

Safety

ThismachinemeetsorexceedsCENstandardEN

836:1997,ISOstandard5395:1990,andANSIB71.4-2012

specicationsineffectatthetimeofproductionwhen54

kg(119lb)ofweightisaddedtotherearwheel.

Note:Theadditionofattachmentsmadebyother

manufacturersthatdonotmeetAmericanNationalStandards

Institutecerticationwillcausenoncomplianceofthis

machine.

Improperuseormaintenancebytheoperatororowner

canresultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandalwayspay

attentiontothesafetyalertsymbol(Figure2),which

meansCaution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeinstructionmay

resultinpersonalinjuryordeath.

SafeOperatingPractices

ThefollowinginstructionsareadaptedfromCENstandard

EN836:1997,ISOstandard5395:1990,andANSI

B71.4-2012.

Training

•ReadtheOperator’sManualandothertrainingmaterial

carefully.Befamiliarwiththecontrols,safetysigns,and

theproperuseoftheequipment.

•Iftheoperatorormechaniccannotreadthelanguage

ofthismanual,itistheowner’sresponsibilitytoexplain

thismaterialtothem.

•Neverallowchildrenorpeopleunfamiliarwiththese

instructionstouseorservicethemower.Local

regulationsmayrestricttheageoftheoperator.

•Nevermowwhilepeople,especiallychildren,orpetsare

nearby.

•Keepinmindthattheoperatororuserisresponsiblefor

accidentsorhazardsoccurringtootherpeopleortheir

property.

•Donotcarrypassengers.

•Alldriversandmechanicsshouldseekandobtain

professionalandpracticalinstruction.Theowneris

responsiblefortrainingtheusers.Suchinstructionshould

emphasize:

–theneedforcareandconcentrationwhenworking

withride-onmachines;

–controlofaride-onmachineslidingonaslopewill

notberegainedbytheapplicationofthebrake.The

mainreasonsforlossofcontrolare:

◊insufcientwheelgrip;

◊beingdriventoofast;

◊inadequatebraking;

◊thetypeofmachineisunsuitableforthetask;

◊lackofawarenessoftheeffectofground

conditions,especiallyslopes.

◊Theowner/usercanpreventandisresponsible

foraccidentsorinjuriesoccurringtopeople,or

damagetoproperty.

Preparation

•Whilemowing,alwayswearsubstantialfootwear,long

trousers,hardhat,safetyglasses,andhearingprotection.

Longhair,looseclothing,orjewelrymaygettangled

inmovingparts.Donotoperatetheequipmentwhen

barefootorwearingopensandals.

•Thoroughlyinspecttheareawheretheequipmentisto

beusedandremoveallobjectswhichmaybethrownby

themachine.

•Replacefaultysilencers/mufers.

•Evaluatetheterraintodeterminewhataccessoriesand

attachmentsareneededtoproperlyandsafelyperform

thejob.Onlyuseaccessoriesandattachmentsapproved

bythemanufacturer.

•Checkthatoperator’spresencecontrols,safetyswitches

andshieldsareattachedandfunctioningproperly.Donot

operateunlesstheyarefunctioningproperly.

Operation

•Donotoperatetheengineinaconnedspacewhere

dangerouscarbonmonoxidefumescancollect.

•Mowonlyindaylightoringoodarticiallight.

•Beforeattemptingtostarttheengine,disengageallblade

attachmentclutches,shiftintoneutral,andengagethe

parkingbrake.

•Rememberthereisnosuchthingasasafeslope.Travel

ongrassslopesrequiresparticularcare.T oguardagainst

overturning:

–donotstoporstartsuddenlywhengoingupor

downhill;

–machinespeedsshouldbekeptlowonslopesand

duringtightturns;

–stayalertforhumpsandhollowsandotherhidden

hazards;

–nevermowacrossthefaceoftheslope,unlessthe

mowerisdesignedforthispurpose.

•Stayalertforholesintheterrainandotherhiddenhazards.

•Watchoutfortrafcwhencrossingornearroadways.

•Stopthebladesfromrotatingbeforecrossingsurfaces

otherthangrass.

•Whenusinganyattachments,neverdirectdischargeof

materialtowardbystandersnorallowanyonenearthe

machinewhileinoperation.

•Neveroperatethemachinewithdamagedguards,shields,

orwithoutsafetyprotectivedevicesinplace.Besureall

4

Page 5

interlocksareattached,adjustedproperly ,andfunctioning

properly.

•Donotchangetheenginegovernorsettingsoroverspeed

theengine.Operatingtheengineatexcessivespeedmay

increasethehazardofpersonalinjury.

•Beforeleavingtheoperator’ sposition:

–stoponlevelground;

–disengagethepowertake-offandlowerthe

attachments;

–changeintoneutralandsettheparkingbrake;

–stoptheengineandremovethekey.

•Disengagedrivetoattachmentswhentransportingornot

inuse.

•Stoptheengineanddisengagedrivetoattachment:

–beforerefuelling;

–beforeremovingthegrasscatcher/catchers;

–beforemakingheightadjustmentunlessadjustment

canbemadefromtheoperator’sposition.

–beforeclearingblockages;

–beforechecking,cleaningorworkingonthemower;

–afterstrikingaforeignobjectorifanabnormal

vibrationoccurs.Inspectthemowerfordamage

andmakerepairsbeforerestartingandoperatingthe

equipment.

•Reducethethrottlesettingbeforestoppingtheengine

and,iftheengineisprovidedwithafuelshut-offvalve,

turnthefueloffattheconclusionofmowing.

•Keephandsandfeetawayfromthecuttingunits.

•Lookbehindanddownbeforebackinguptobesureof

aclearpath.

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalks.Stopthereelswhennot

mowing.

•Donotoperatethemowerundertheinuenceofalcohol

ordrugs.

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

•Usecarewhenloadingorunloadingthemachineintoa

trailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,trees,

orotherobjectsthatmayobscurevision.

•Becertainthattheseatbeltcanbereleasedquicklyin

theeventofanemergency.

•Checktheareatobemowedandneverfolddowna

foldingROPSinareaswherethereareslopes,dropoffs

orwater.

•Checkcarefullyforoverheadclearances(i.e.branches,

doorways,electricalwires)beforedrivingunderany

objectsanddonotcontactthem.

•KeeptheROPSinsafeoperatingconditionby

periodicallythoroughlyinspectingfordamageand

keepingallmountingfastenerstight.

•ReplaceadamagedROPS.Donotrepairorrevise.

•DonotremovetheROPS.

•AnyalterationstoaROPSmustbeapprovedbythe

manufacturer.

SafeHandlingofFuels

•Toavoidpersonalinjuryorpropertydamage,use

extremecareinhandlinggasoline.Gasolineisextremely

ammableandthevaporsareexplosive.

•Extinguishallcigarettes,cigars,pipes,andothersources

ofignition.

•Useonlyanapprovedfuelcontainer.

•Neverremovefuelcaporaddfuelwiththeengine

running.

•Allowenginetocoolbeforerefueling.

•Neverrefuelthemachineindoors.

•Neverstorethemachineorfuelcontainerwherethereis

anopename,spark,orpilotlightsuchasonawater

heateroronotherappliances.

•Neverllcontainersinsideavehicleoronatruckor

trailerbedwithaplasticliner.Alwaysplacecontainerson

thegroundawayfromyourvehiclebeforelling.

•Removeequipmentfromthetruckortrailerandrefuelit

ontheground.Ifthisisnotpossible,thenrefuelsuch

equipmentwithaportablecontainer,ratherthanfroma

fueldispensernozzle.

•Keepthenozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilfuelingiscomplete.

•Donotuseanozzlelockopendevice.

RolloverProtectionSystem(ROPS)UseandMaintenance

•TheROPSisanintegralandeffectivesafetydevice.Keep

afoldingROPSintheraisedandlockedpositionanduse

theseatbeltwhenoperatingthemachine.

•LowerafoldingROPStemporarilyonlywhenabsolutely

necessary.Donotweartheseatbeltwhenfoldeddown.

•Beawarethereisnorolloverprotectionwhenafolded

ROPSisinthedownposition.

•Iffuelisspilledonclothing,changeclothingimmediately.

•Neveroverllfueltank.Replacefuelcapandtighten

securely.

MaintenanceandStorage

•Keepallnuts,boltsandscrewstighttobesurethe

equipmentisinsafeworkingcondition.

•Neverstoretheequipmentwithfuelinthetankinsidea

buildingwherefumesmayreachanopenameorspark.

5

Page 6

•Allowtheenginetocoolbeforestoringinanyenclosure.

•Toreducetheriskofrehazard,keeptheengine,

silencer/mufer,batterycompartment,andfuelstorage

areafreeofgrass,leaves,orexcessivegrease.

•Replacewornordamagedpartsforsafety.

•Checkthegrasscatcherfrequentlyforwearor

deterioration.

•Keepallpartsingoodworkingconditionandallhardware

andhydraulicttingstightened.Replaceallwornor

damagedpartsanddecals.

•Ifthefueltankhastobedrained,dothisoutdoors.

•Becarefulduringadjustmentofthemachinetoprevent

entrapmentofthengersbetweenmovingbladesand

xedpartsofthemachine.

•Onmulti-reelmachines,takecareasrotatingonereelcan

causeotherreelstorotate.

•Disengagedrives,lowerthecuttingunits,setparking

brake,stopengineandremovekey .Waitforallmovement

tostopbeforeadjusting,cleaningorrepairing.

•Cleangrassanddebrisfromcuttingunits,drives,mufers,

andenginetohelppreventres.Cleanupoilorfuel

spillage.

•Usejackstandstosupportcomponentswhenrequired.

•Carefullyreleasepressurefromcomponentswithstored

energy.

•Disconnectbatterybeforemakinganyrepairs.Disconnect

thenegativeterminalrstandthepositivelast.Reconnect

positiverstandnegativelast.

•Usecarewhencheckingthereels.Wrapthereelsorwear

gloves,andusecautionwhenservicingthem.

•Keephandsandfeetawayfrommovingparts.Ifpossible,

donotmakeadjustmentswiththeenginerunning.

•Chargebatteriesinanopenwellventilatedarea,away

fromsparkandames.Unplugchargerbeforeconnecting

ordisconnectingfrombattery.W earprotectiveclothing

anduseinsulatedtools.

•Neverstorethemachineorfuelcontainerwherethereis

anopename,spark,orpilotlightsuchasonawater

heateroronotherappliances.

ToroMowerSafety

ThefollowinglistcontainssafetyinformationspecictoToro

productsorothersafetyinformationthatyoumustknowthat

isnotincludedintheANSIstandards.

Thisproductiscapableofamputatinghandsandfeetand

throwingobjects.Alwaysfollowallsafetyinstructionsto

avoidseriousinjuryordeath.

Useofthisproductforpurposesotherthanitsintendeduse

couldprovedangeroustouserandbystanders.

Operation

•Knowhowtostoptheenginequickly.

•Alwayswearsubstantialshoes.Donotoperatethe

machinewhilewearingsandals,tennisshoes,orsneakers.

Wearingsafetyshoesandlongpantsisadvisableand

requiredbysomelocalordinancesandinsurance

regulations.

•Handlefuelcarefully.Wipeupanyspills.

•Checkthesafetyinterlockswitchesdailyforproper

operation.Ifaswitchhasfailed,replacetheswitchbefore

operatingthemachine.

•Beforeattemptingtostarttheengine,sitontheseat,pull

ontheraise/lowermowcontroltoensurethatthecutting

unitsaredisengaged,ensurethatthetractionpedalisin

neutral,andengagetheparkingbrake.

•Usingthemachinedemandsattention.Topreventloss

ofcontrol:

–Donotdriveclosetosandtraps,ditches,creeks,or

otherhazards.

–Reducespeedwhenmakingsharpturns.Avoid

suddenstopsandstarts.

–Thismachineisnotdesignedorequippedforon-road

useandisa“slow-movingvehicle.”Ifyoumustcross

ortravelonapublicroad,youshouldbeawareofand

complywithlocalregulations,suchasrequiredlights,

slowmovingvehiclesigns,andreectors.

–Watchoutfortrafcwhennearorcrossingroads.

Alwaysyieldtheright-of-way.

–Applytheservicebrakeswhengoingdownhillto

keepforwardspeedslowandtomaintaincontrolof

themachine.

•Shuttheengineoffbeforeemptyingthebaskets.

•Raisethecuttingunitswhendrivingfromoneworkarea

toanother.

•Donottouchtheengine,mufer,orexhaustpipewhile

theengineisrunningorsoonafterithasstoppedbecause

theseareascouldbehotenoughtocauseburns.

•Stayclearoftherotatingscreenatthesideoftheengine

topreventdirectcontactwithyourbodyorclothing.

•Ifacuttingunitstrikesasolidobjectorvibrates

abnormally,stopimmediately,turntheengineoff,waitfor

allmotiontostop,andinspectthemachinefordamage.

Adamagedreelorbedknifemustberepairedorreplaced

beforeoperationiscontinued.

•Beforegettingoffoftheseat,movethefunctionalcontrol

levertoneutral(N),raisethecuttingunitsandwaitfor

thereelstostopspinning.Settheparkingbrake.Stopthe

engineandremovethekeyfromtheignitionswitch.

•Traverseslopescarefully.Donotstartorstopsuddenly

whentravelinguphillordownhill.

•Theoperatormustbeskilledandtrainedinhowtodrive

onhillsides.Failuretousecautiononslopesorhillsmay

causelossofcontrolandcausethemachinetotiporroll,

possiblyresultinginpersonalinjuryordeath.

6

Page 7

•Iftheenginestallsorlosesheadwayandcannotmakeit

tothetopofaslope,donotturnthemachinearound.

Alwaysbackslowly,straightdowntheslope.

•Whenapersonorpetappearsunexpectedlyinornear

themowingarea,stopmowing.Carelessoperation,

combinedwithterrainangles,ricochets,orimproperly

positionedguardscanleadtothrownobjectinjuries.Do

notresumemowinguntiltheareaiscleared.

•Wheneverthemachineisleftunattended,makesurethe

cuttingunitsarefullyraised,thereelsarenotspinning,

thekeyisremovedfromtheignitionswitch,andthe

parkingbrakeisset.

•AlwaysusetheseatbeltwiththeROPSwhenoperating

themachine.

•Donotoperatethismachineonslopesexceeding15

degrees.

SoundPowerLevel

Thisunithasaguaranteedsoundpowerlevelof97dBA,

whichincludesanUncertaintyValue(K)of1dBA.

Soundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinISO11094.

SoundPressureLevel

Thisunithasasoundpressurelevelattheoperator’searof81

dBA,whichincludesanUncertaintyValue(K)of1dBA.

Soundpressurelevelwasdeterminedaccordingtothe

proceduresoutlinedinEN836.

VibrationLevel

MaintenanceandStorage

•Makesureallhydrauliclineconnectorsaretightandall

hydraulichosesandlinesareingoodconditionbefore

applyingpressuretothesystem.

•Keepyourbodyandhandsawayfrompinholeleaksor

nozzlesthatejecthydraulicuidunderhighpressure.

Usepaperorcardboard,notyourhands,tosearchfor

leaks.Hydraulicuidescapingunderpressurecanhave

sufcientforcetopenetratetheskinandcauseserious

injury.

•Beforedisconnectingorperforminganyworkonthe

hydraulicsystem,allpressureinthesystemmustbe

relievedbystoppingtheengineandloweringthecutting

unitsandattachmentstotheground.

•Checkallfuellinesfortightnessandwearonaregular

basis.Tightenorrepairthemasneeded.

•Iftheenginemustberunningtoperformamaintenance

adjustment,keephands,feet,clothing,andanypartsof

thebodyawayfromthecuttingunits,attachments,and

anymovingparts,especiallythescreenatthesideofthe

engine.Keepeveryoneaway.

•Donotoverspeedtheenginebychanginggovernor

settings.Toensuresafetyandaccuracy,havean

AuthorizedToroDistributorcheckthemaximumengine

speedwithatachometer..

•Theenginemustbeshutoffbeforecheckingtheoilor

addingoiltothecrankcase.

•Ifmajorrepairsareeverneededorifassistanceisdesired,

contactanAuthorizedToroDistributor.

•Toassureoptimumperformanceandcontinuedsafety

certicationofthemachine,useonlygenuineToro

replacementpartsandaccessories.Replacementparts

andaccessoriesmadebyothermanufacturerscouldbe

dangerous,andsuchusecouldvoidtheproductwarranty.

•Disconnectthecuttingunitsfromthepowersupply ,

usingthecuttingunitpowerdisconnectcouplers,before

performinganyworkonthecuttingunits.

Hand-Arm

Measuredvibrationlevelforrighthand=0.20m/s

Measuredvibrationlevelforlefthand=0.31m/s

UncertaintyValue(K)=0.15m/s

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinEN836.

WholeBody

Measuredvibrationlevel=0.14m/s

UncertaintyValue(K)=0.07m/s

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinEN836.

2

2

2

2

2

7

Page 8

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

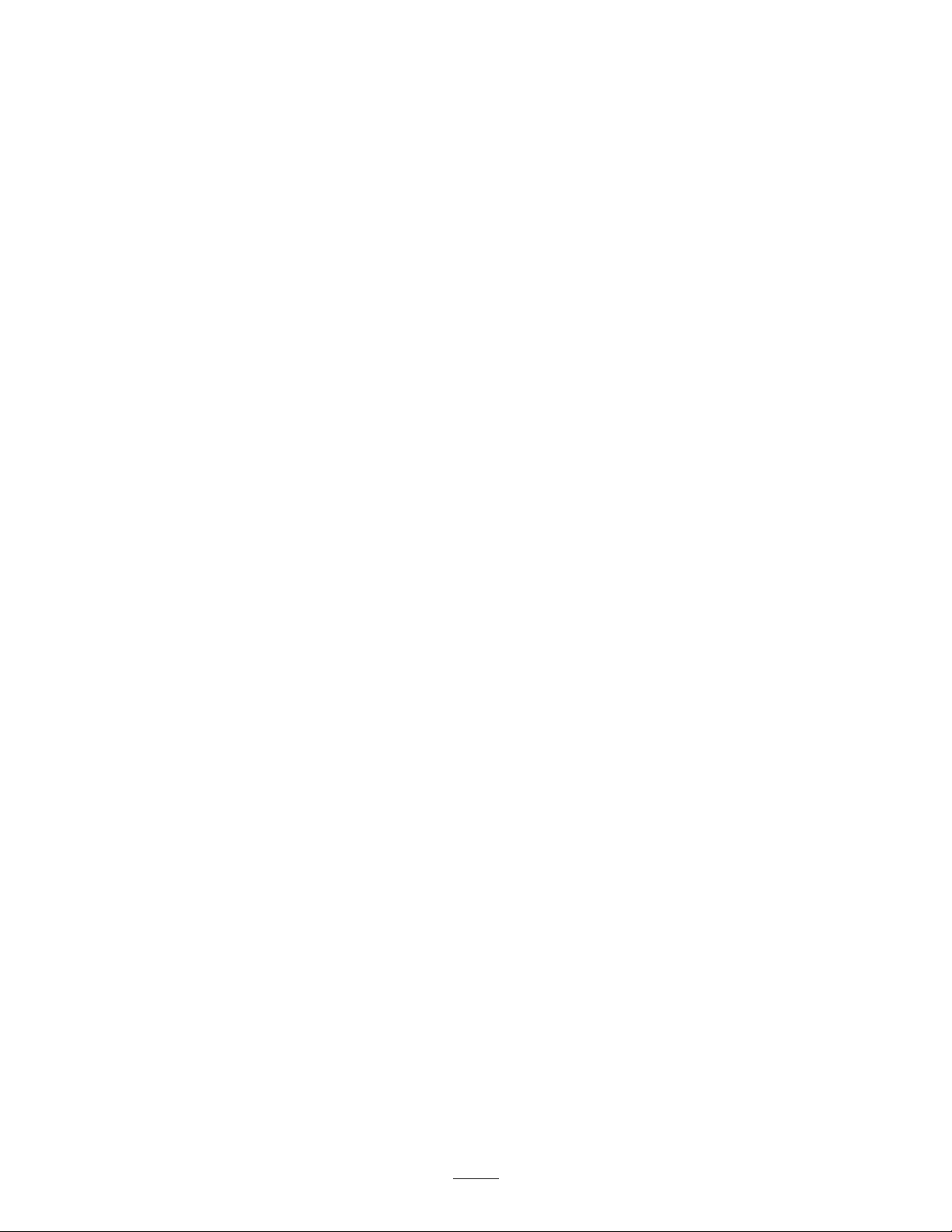

119-9345

115-8156

1.Reelheight3.8Bladecuttingunit5.14Bladecuttingunit7.Fast

2.5Bladecuttingunit4.11Bladecuttingunit6.Reelspeed

8.Slow

8

Page 9

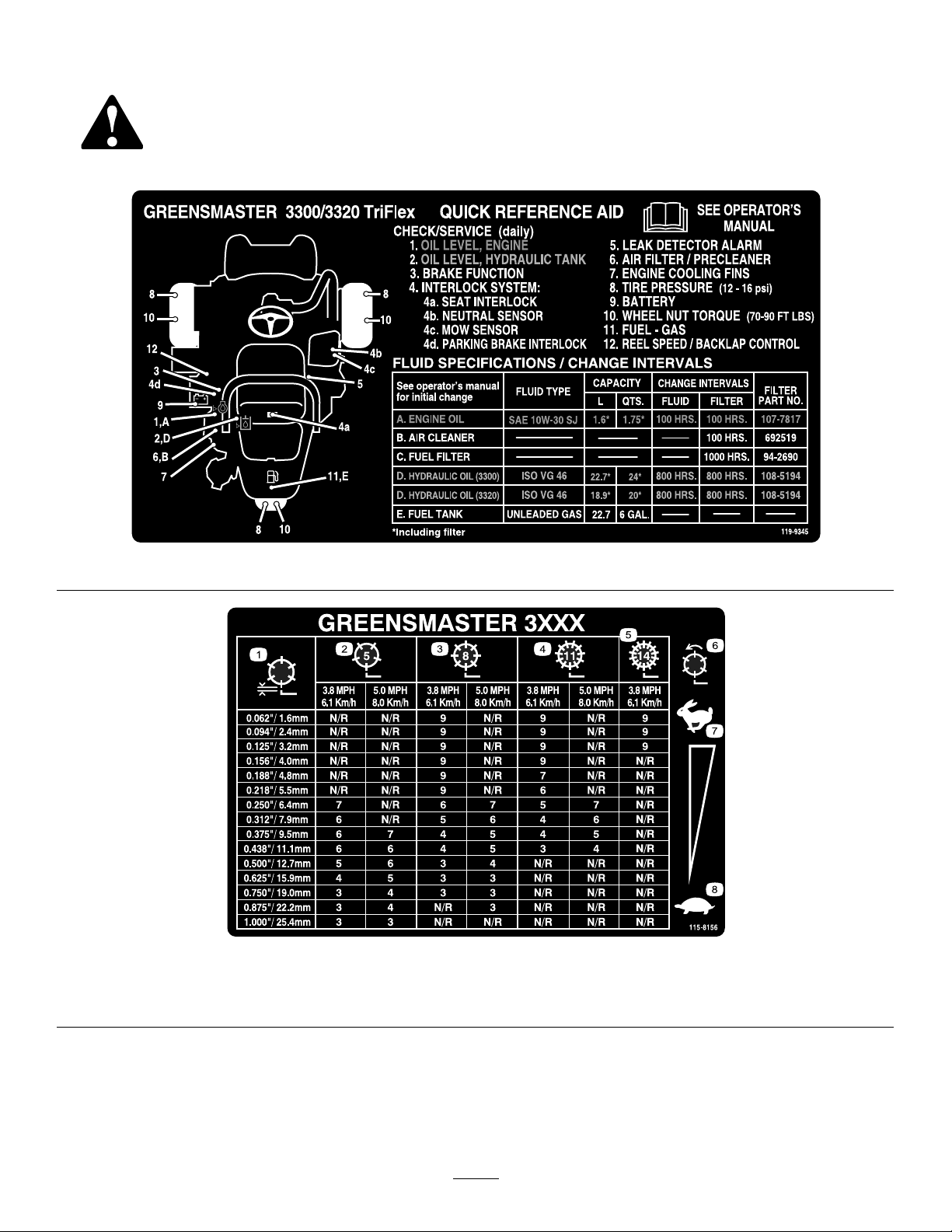

121–6670

1.Engagethereels.2.Disengagethereels.

121–5171

1.Presspedaltounlock

1.Choke

2.Engine—start4.Engine—stop

3.Enginerun

117–2718

119-9346

2.ReadtheOperator's

Manualformore

information.

1.Off3.On

2.Headlights

121–5172

1.Slow

2.Continuous

variable

setting

3.Fast6.Lower

4.Raisethe

reels

5.Reel

position

setting

and

engage

thereels

121–5169

7.Reel—backlapping 10.Fast—use

8.Neutral—use

for

backlapping

9.Slow—use

for

mowing

BatterySymbols

Someorallofthesesymbolsareonyourbattery

1.Explosionhazard

2.Nore,opename,or

smoking.

for

transport

11.Functional

control

lever

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

6.Keepbystandersasafe

distancefromthebattery.

7.Weareyeprotection;

explosivegasescan

causeblindnessandother

injuries

8.Batteryacidcancause

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

10.Containslead;donot

discard.

9

Page 10

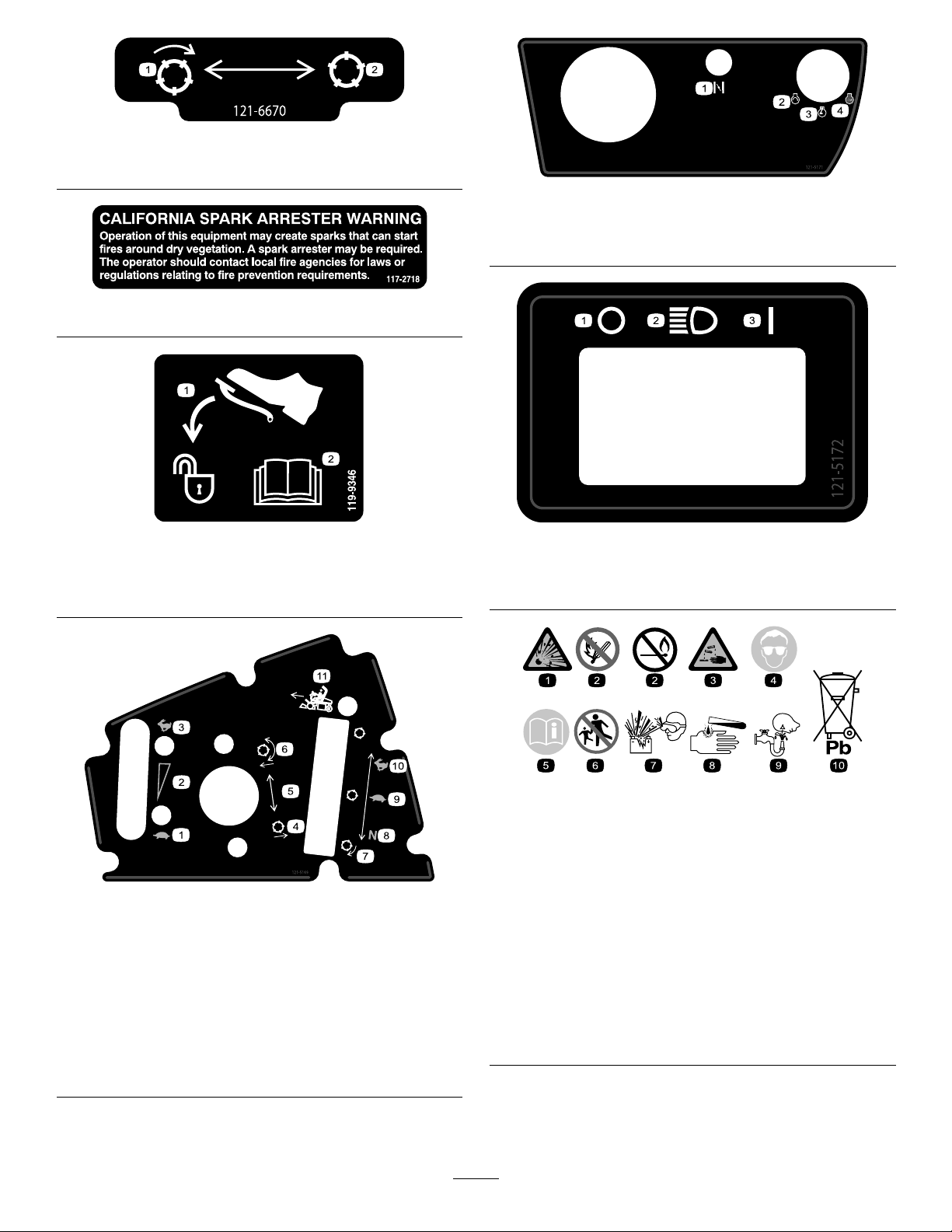

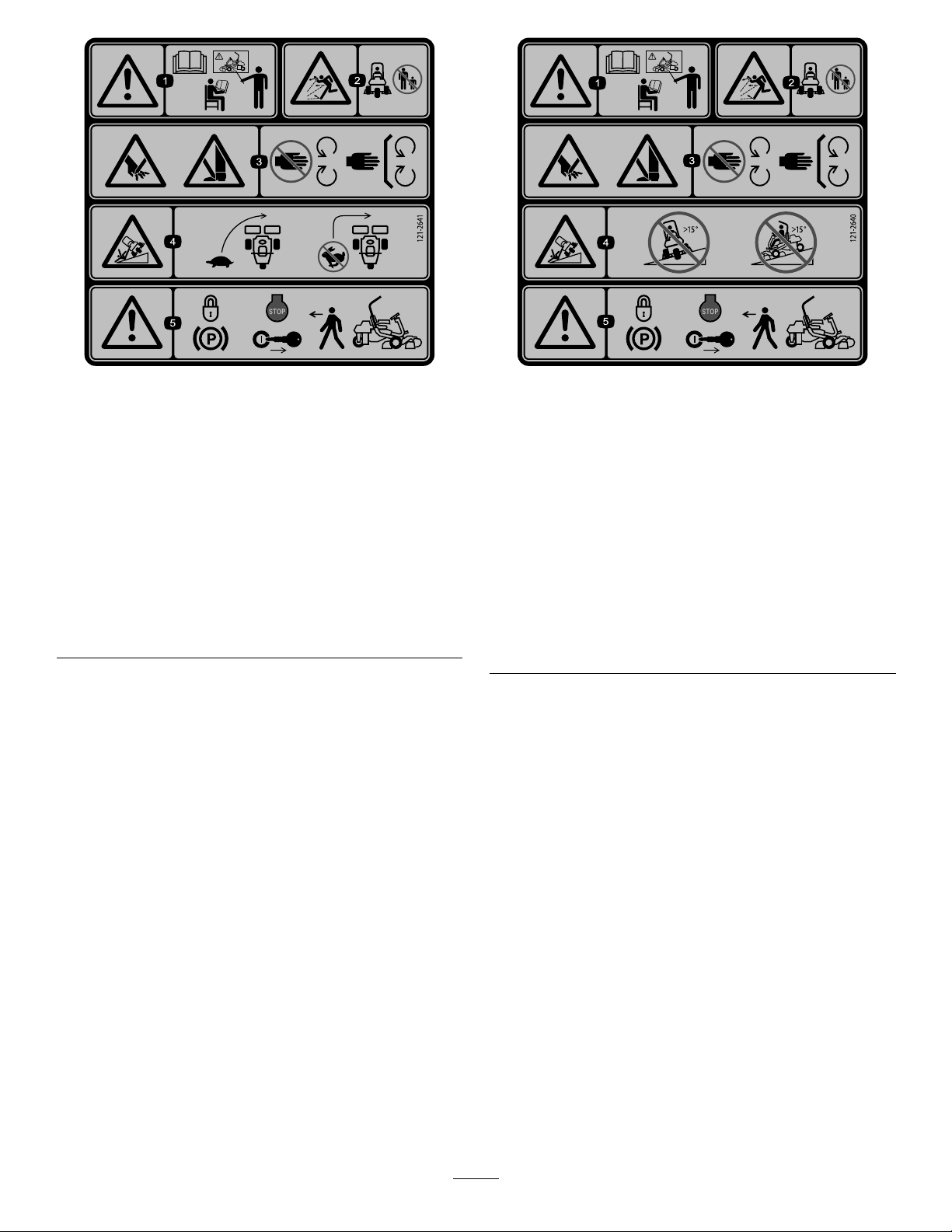

121–2641

121–2640

1.Warning—readthe

Operator’sManual,do

notoperatethismachine

unlessyouaretrained.

2.Thrownobject

hazard—keepbystanders

asafedistancefromthe

machine.

3.Cutting/dismemberment

hazardofhandorfoot,

mowerblade—stayaway

frommovingparts;keep

allguardsandshieldsin

place.

4.Tippinghazard—slow

machinebeforeturning,

donotturnathighspeeds.

5.Warning—locktheparking

brake,stoptheengine

andremovetheignition

keybeforeleavingthe

machine.

1.Warning—readthe

Operator’sManual,do

notoperatethismachine

unlessyouaretrained.

2.Thrownobject

hazard—keepbystanders

asafedistancefromthe

machine

3.Cutting/dismemberment

hazardofhandorfoot,

mowerblade—stayaway

frommovingparts;keep

allguardsandshieldsin

place.

4.Tippinghazard—donot

driveacrossslopesgreater

than15degreesordown

slopesgreaterthan15

degrees.

5.Warning—locktheparking

brake,stoptheengine

andremovetheignition

keybeforeleavingthe

machine.

10

Page 11

Setup

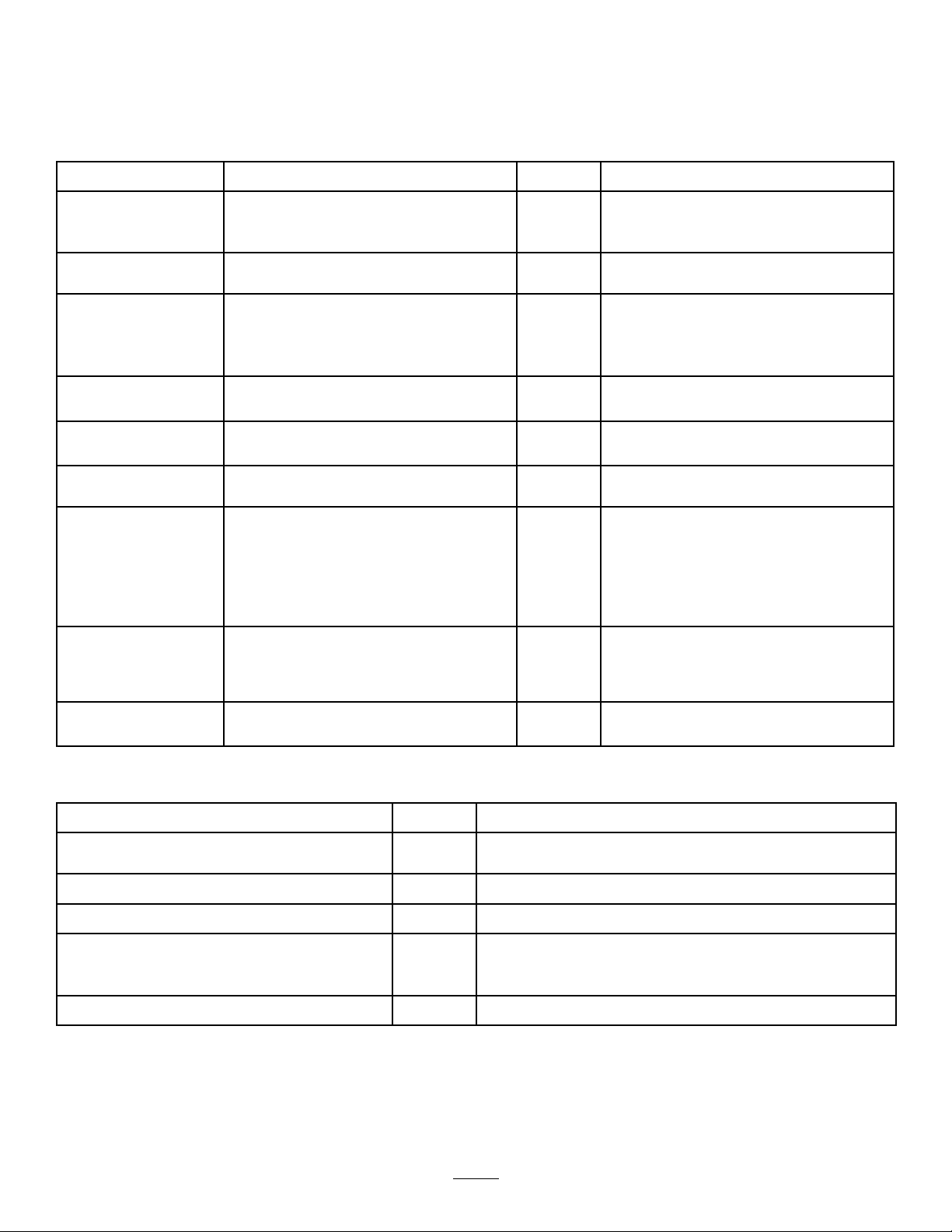

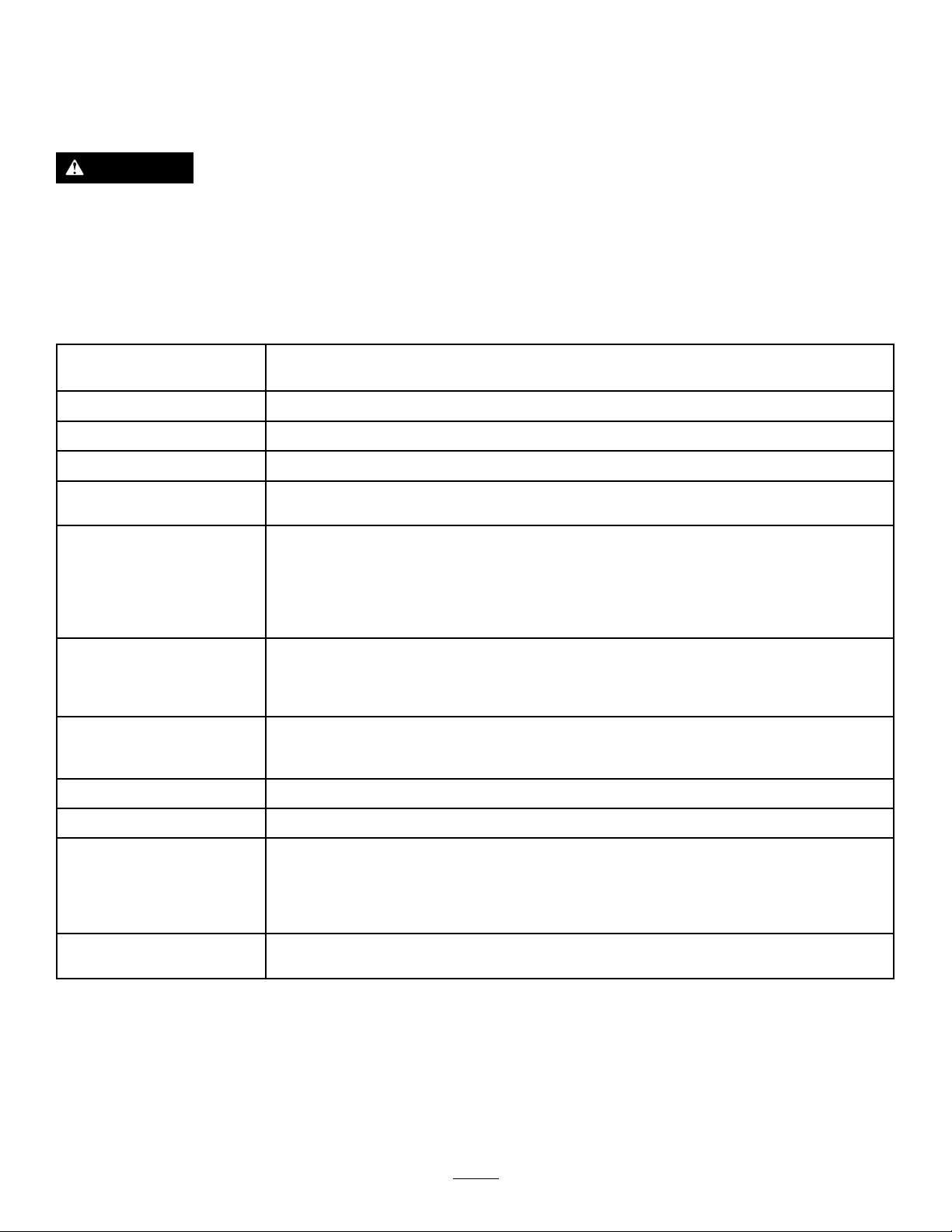

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

6

7

8

Rollbar1

Bolt(1/2x3-3/4inches)

Flange-nut(1/2inch)

Seat

Seatwiringharness

Steeringwheel

Locknut(1-1/2inches)

Washer1

Steeringwheelcap

Nopartsrequired

Nopartsrequired

Grassbaskethook

Flangebolts12

Gaugebar

Cuttingunit(model04613,04614,or

04615)

Cuttingunitupperweight

Hexheadscrews6

GrassBasket

Weightkit,119-7129(for2-wheeldrive

units)

Weightkit,120-5750(forunitswiththe

3-wheeldrivekitinstalled)

Qty.

Use

4

4

1

1

1

1

1

–

–

6

1

3

3

3

1

1

Installtherollbar.

Installtheseattothebase.

Installthesteeringwheel.

Activateandchargethebattery.

Installtheoptionaloilcooler.

Installthegrassbaskethooks.

Installthecuttingunits

Addrearweight.

9

Warningdecal121–26401

MediaandAdditionalParts

Description

Operator'sManual(machine)

EngineOperator'sManual(engine)

PartsCatalog

OperatorTrainingMaterials

Pre-deliveryInspectionSheet

Noiseratingcerticate

Certicateofcompliance

Ignitionkeys2

Qty.

InstallEUdecals,ifrequired.

Use

1

1

1

1

1

1

1

Readbeforeoperatingthemachine.

Saveforfuturepartsordering.

Viewbeforeoperatingthemachine.

Saveforfuturereference.

Starttheengine.

11

Page 12

1

g014601

1

2

3

g016317

1

2

3

4

5

2

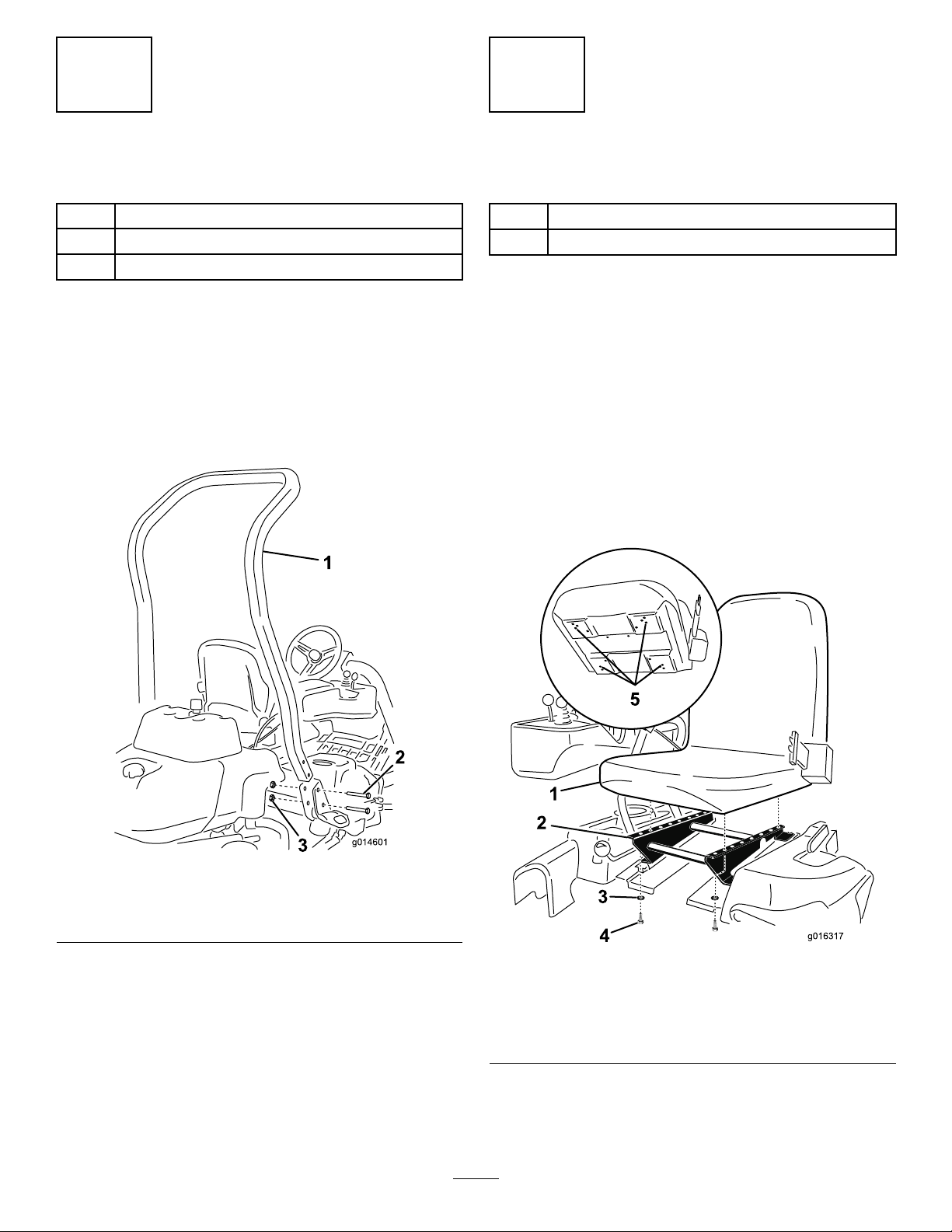

InstallingtheRollBar

Partsneededforthisprocedure:

1Rollbar

4

Bolt(1/2x3-3/4inches)

4

Flange-nut(1/2inch)

Procedure

1.Removethetopcratesupportfromthecrate.

2.Removetherollbarfromthecrate.

3.Installtherollbarintothepocketsoneachsideof

themachine,using4bolts(1/2x3-3/4inches)and4

ange-nuts(1/2inch)(Figure3)

InstallingtheSeat

Partsneededforthisprocedure:

1

Seat

1

Seatwiringharness

Procedure

Note:Mounttheseatinthefrontsetofmountingholesto

gainanadditional7.6cm(3inches)intheforwardadjustment,

orintherearmountingholesforanadditional7.6cm(3

inches)intherearwardadjustment.

1.Removeanddiscardthelagboltssecuringtheseat

slidesandcuttheshippingstraps.

2.Removethe4bolts(5/16x3/4inch)andwashers

fromtheshippingbracketanddiscardthebracket.

3.Securetheseattotheseatbasewith4boltsandwashers

removedpreviously(Figure4).

Figure3

1.Rollbar

2.Bolt(1/2x3-3/4inches)

4.Torquethefastenersto136to149N-m(100to110

ft-lb).

3.Flange-nut(1/2inch)

Figure4

1.Seat4.Bolt(5/16x3/4inch)

2.Seatbase

3.Washer

12

5.Installtheseatusingthese

holes.

Page 13

4.Locatetheopenconnectoronthemainwiringharness

totherightoftheseatandconnectittothewiring

harnessthatcamewiththeseat.

5.Routetheseatwiringharnessaroundtheseatslides,

ensuringthatitwillnotbepinchedwhentheseat

moves,andconnectittotheportonthebottomof

theseat.

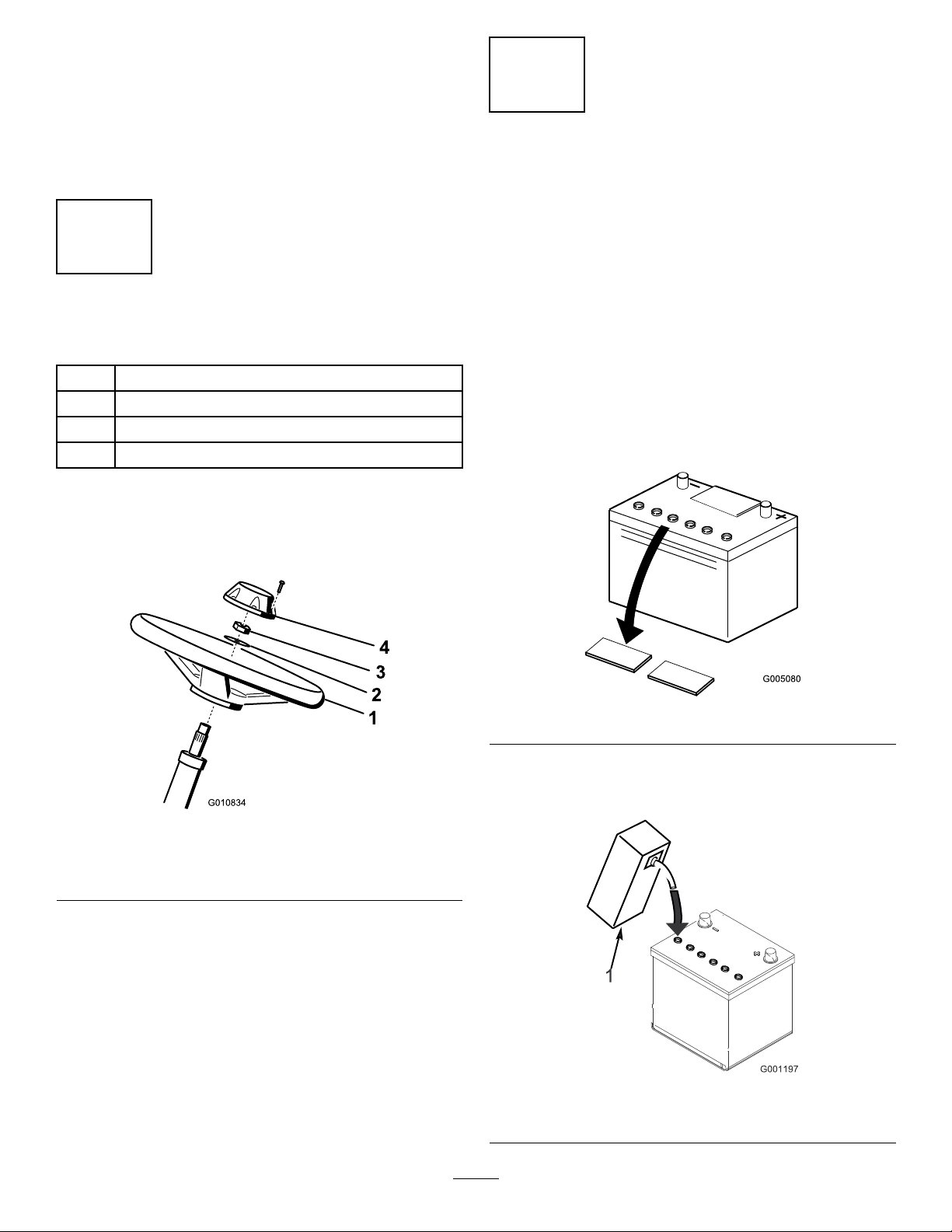

4

ActivatingandChargingthe Battery

NoPartsRequired

3

InstallingtheSteeringWheel

Partsneededforthisprocedure:

1

Steeringwheel

1

Locknut(1-1/2inches)

1Washer

1

Steeringwheelcap

Procedure

1.Slidethesteeringwheelontothesteeringshaft(Figure

5).

Procedure

Useonlyelectrolyte(1.265specicgravity)tollbattery

initially.

1.Removethefastenersandbatteryclampandliftout

thebattery.

Important:Donotaddelectrolytewhilethe

batteryisinthemachine.Y oucouldspillit,

causingcorrosion.

2.Cleanthetopofthebatteryandremovetheventcaps

(Figure6).

Figure5

1.Steeringwheel

2.Washer

2.Slidethewasherontothesteeringshaft(Figure5).

3.Securethesteeringwheeltotheshaftwithajamnut

andtightenitto27to35N-m(20to26ft-lb)(Figure5).

4.Installthecaptothesteeringwheelandsecureitwitha

screw(Figure5).

3.Jamnut

4.Cap

Figure6

3.Carefullylleachcellwithelectrolyteuntiltheplates

arecoveredwithabout6mm(1/4inch)ofuid(Figure

7).

Figure7

1.Electrolyte

13

Page 14

4.Allowapproximately20to30minutesforthe

1 2

g016293

3

4

5

6

7

electrolytetosoakintotheplates.Fillasnecessaryto

bringtheelectrolytetowithinabout6mm(1/4inch)

ofthebottomofthellwell(Figure7).

WARNING

Chargingthebatteryproducesgassesthatcan

explode.

Neversmokenearthebatteryandkeepsparks

andamesawayfrombattery.

5.Connecta2to4ampbatterychargertothebattery

posts.Chargethebatteryfor2hoursat4ampsorfor

4hoursat2ampsuntilthespecicgravityis1.250or

higherandthetemperatureisatleast16°C(60°F)

withallcellsgassingfreely .

6.Whenthebatteryischarged,disconnectthecharger

fromtheelectricaloutletandbatteryposts.

Note:Afterthebatteryhasbeenactivated,add

onlydistilledwatertoreplacenormalloss,although

maintenance-freebatteriesshouldnotrequirewater

undernormaloperatingconditions.

7.Placethebatteryonthebatterytrayandsecureitwith

thebatteryclampandfastenersremovedpreviously

(Figure8).

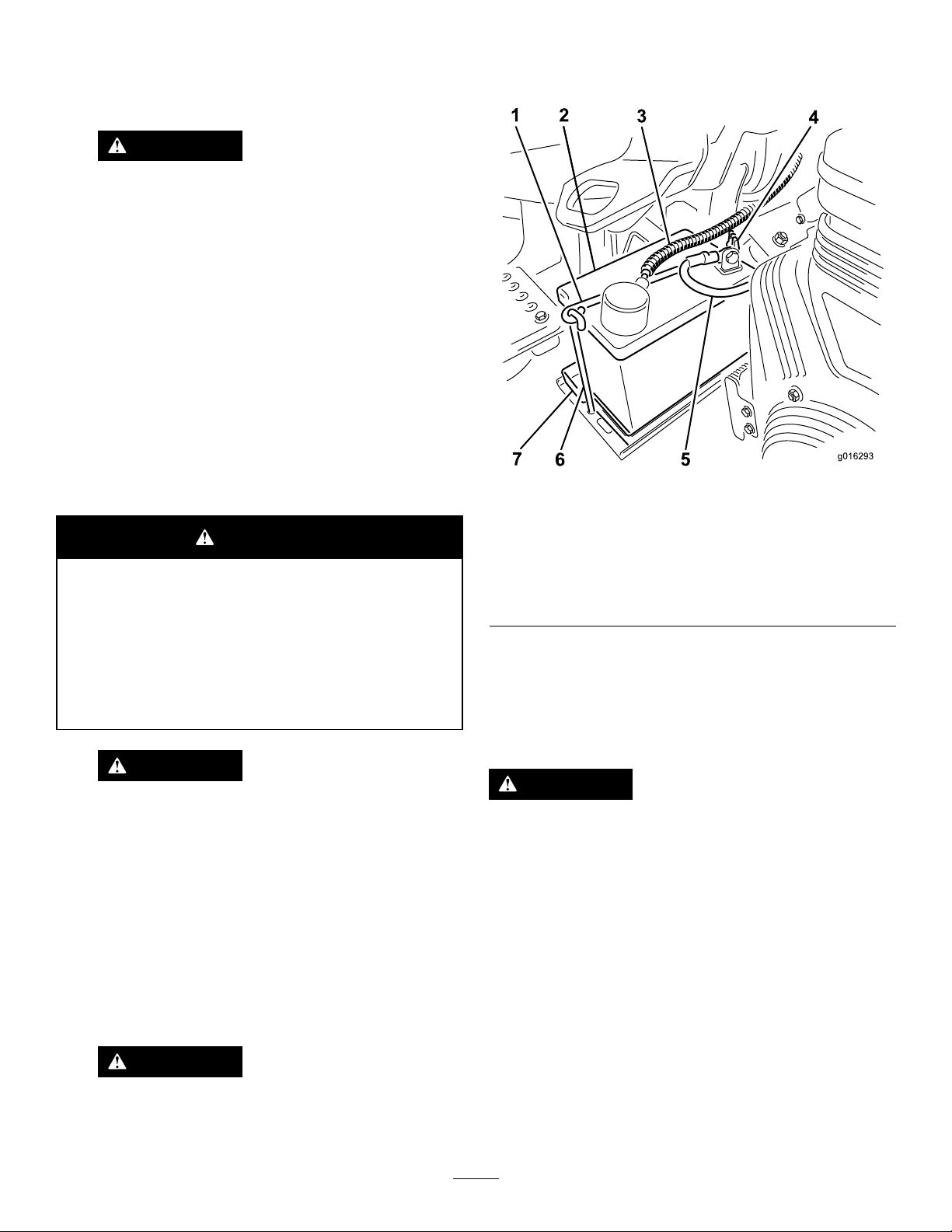

Figure8

Gasolinemodelshown,yourmodelmayvary .

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

Washhandsafterhandling.

WARNING

Batteryterminalsormetaltoolscouldshort

againstmetaltractorcomponentscausing

sparks.Sparkscancausethebatterygassesto

explode,resultinginpersonalinjury.

•Whenremovingorinstallingthebattery,

donotallowthebatteryterminalstotouch

anymetalpartsofthetractor.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsof

thetractor.

1.Batteryclamp

2.Battery6.Batteryclamphook

3.Positive(+)batterycable

4.Batteryclampwingnut

8.Installthepositivecable(red)tothepositive(+)

terminalandthenthenegativecable(black)tothe

negative(–)terminalofthebatteryandsecurethem

withtheboltsandnuts(Figure8).Slidetherubber

bootoverthepositiveterminaltopreventapossible

shortfromoccurring.

5.Negative(-)batterycable

7.Batterytray

WARNING

Incorrectbatterycableroutingcoulddamagethe

tractorandcablescausingsparks.Sparkscancause

thebatterygassestoexplode,resultinginpersonal

injury.

•Alwaysdisconnectthenegative(black)battery

cablebeforedisconnectingthepositive(red)

cable.

•Alwaysconnectthepositive(red)batterycable

beforeconnectingthenegative(black)cable.

WARNING

Failuretocorrectlyactivatethebatterymay

resultinbatterygassingand/orpremature

batteryfailure.

14

Page 15

5

g014596

1

2

2

7

InstallingtheOptionalOil

Cooler

NoPartsRequired

Procedure

Ifyouareoperatingthemachineinhotclimates,wherethe

ambienttemperatureisabove29°C(85°F),orusingitfor

heavy-dutyuse(mowingotherthangreens,suchasfairways

orverticutting),installaHydraulicOilCoolerKit,PartNo.

119-1691,tothemachine.

6

InstallingtheGrassBasket Hooks

Partsneededforthisprocedure:

6

Grassbaskethook

12Flangebolts

InstallingtheCuttingUnits

Partsneededforthisprocedure:

1

Gaugebar

3

Cuttingunit(model04613,04614,or04615)

3

Cuttingunitupperweight

6Hexheadscrews

3

GrassBasket

Procedure

Note:Whensharpening,settingtheheight-of-cut,or

performingothermaintenanceproceduresonthecutting

units,storethecuttingunitreelmotorsinthestoragelocation

onthefrontofthesuspensionarmstopreventdamageto

them.

Important:Donotraisethesuspensiontothetransport

positionwhenthereelmotorsareintheholdersinthe

machineframe.Damagetothemotorsorhosescould

result.

Important:Wheneverthecuttingunithastobetipped

toexposebedknife/reel,propuprearofcuttingunitto

makesurenutsonbackendofbedbaradjustingscrews

arenotrestingonworksurface(Figure10).

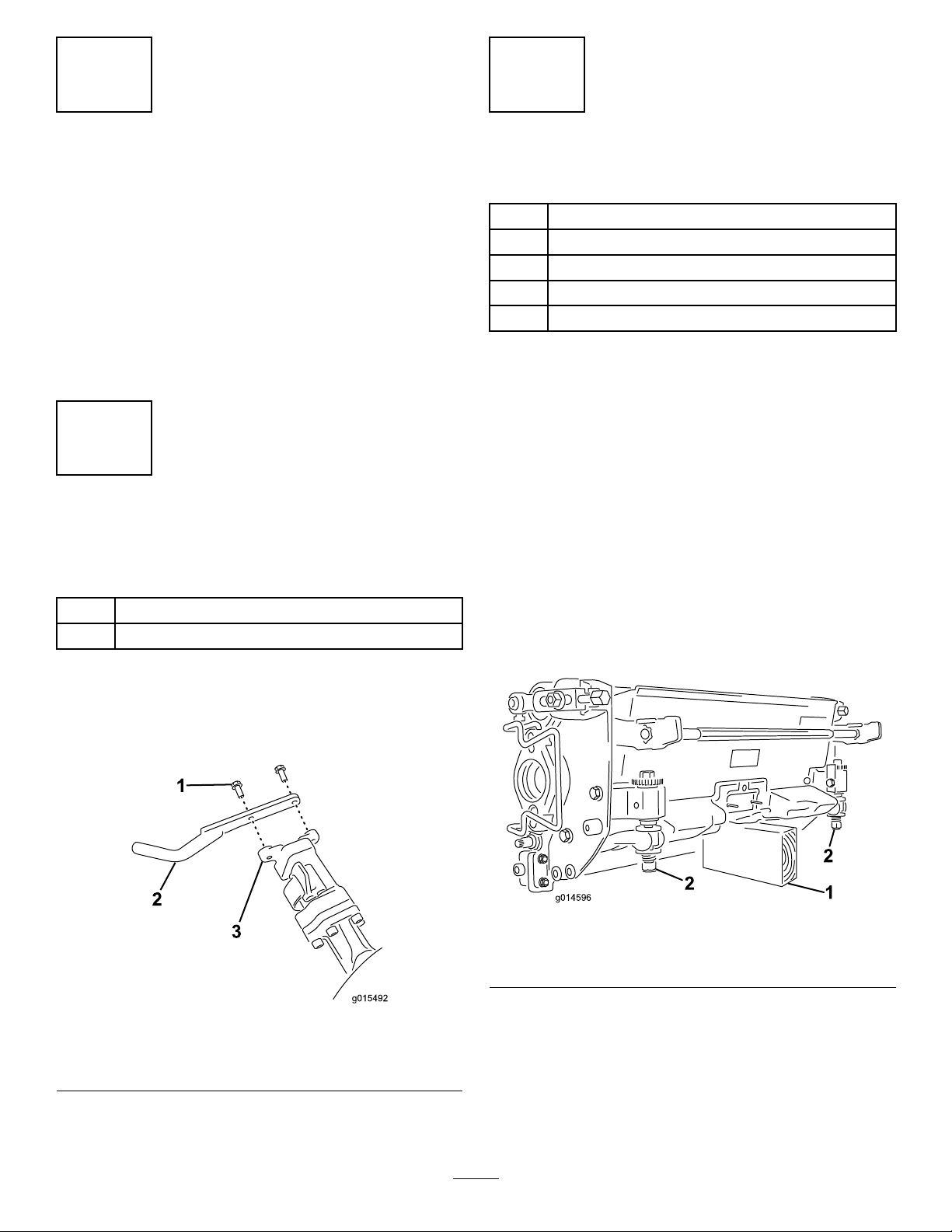

Procedure

Installthe6grassbaskethooksontotheendsofthe

suspensionarmbarsusing12angebolts(Figure9).

Figure9

1.Flangebolt

2.Grassbaskethook

3.Suspensionarmbar

Figure10

1.Prop(notprovided)2.Bedknifeadjustingscrew

nut(2)

Note:Allcuttingunitsareshippedwiththecounterweight

mountedtotherightendandthemotormountanddrive

couplermountedtotheleftendofthecuttingunit.

1.Disconnectthecuttingunitpowerdisconnectcouplers;

refertoCuttingUnitPowerDisconnect(page25).

15

Page 16

CAUTION

1

2

g016294

3

g014602

1

2

g014609

1

2

3

CAUTION

Ifyoudonotdisconnectthepowertothe

cuttingunits,someonecouldaccidentally

startthecuttingunit,causingseriousinjury

tohandsandfeet.

Alwaysseparatethecuttingunitpower

disconnectcouplersbeforeworkingonthe

cuttingunits.

2.Applygreasetotheinsidediameterofthedrivecoupler.

3.Thecuttingunitisshippedwithoutafrontroller.

Obtainaroller(ModelNo.04625,04626or04627)

fromyourlocalToroDistributor.Installtheroller

usingtheloosepartssuppliedwiththecuttingunitand

installationinstructionsincludedwiththeroller.

4.Removethe2boltssecuringtheweighttothesideof

thecuttingunit(Figure11).

Thefootrestcanpinchngersifitfallsinto

theclosedposition.

Keepyourngersclearoftheareawherethe

footrestseatswhileitisopen.

Figure12

1.Footrest—closed2.Footrest—open

8.Positionthecuttingunitunderthesuspensionarm.

9.Withthelatchesonthesuspension-armbarpointing

up(i.e.,open)(Figure13),pushthesuspensionarm

downsothatthebartsoverthebaracrossthetopof

thecuttingunit(Figure14).

Figure11

1.Cuttinguntilweight(ip

over)

2.Upperweight

3.Hexheadscrews

5.Rotatetheweight180degreessothattheopenscrew

holesthatwereontheundersideoftheweightarenow

ontop.Installtheweighttothecuttingunitusingthe

boltsremovedpreviously.

6.Installanupperweighttothecuttingunitweightusing

2hexheadscrews(Figure11).

7.Ifinstallingthecentercuttingunit,liftuponthefoot

restandswingitup,allowingaccesstothecenter

cuttingunitposition(Figure12).

Figure13

1.Latch—closedposition3.Latch—openposition

2.Suspension-armbar

16

Page 17

g01461 1

1

2

Figure14

1.Suspension-armbar2.Cutting-unitbar

10.Closethelatchesdownandaroundthecutting-unitbar

andlocktheminplace(Figure13).

Note:A“click”canbeheardandfeltwhenthelatches

areproperlylockedinplace.

11.Coatthesplineshaftofthecuttingunitmotorwith

cleangrease(Figure15).

12.Insertthemotorintotheleftsideofthecuttingunit

(asviewedfromtheoperator'sposition)andpullthe

motorretainingbaronthecuttingunittowardthe

motoruntilyouhearanaudible“click”frombothsides

ofthemotor(Figure15).

Figure15

1.Reelmotor

2.Splineshaft

13.Mountagrassbasketontothebaskethooksonthe

suspensionarm.

14.Repeatthisprocedurefortheothercuttingunits.

15.Connectthecuttingunitpowerdisconnectcouplers;

refertoCuttingUnitPowerDisconnect(page25).

3.Cavity

4.Motorretainingbar

8

AddingRearWeight

Partsneededforthisprocedure:

1

Weightkit,119-7129(for2-wheeldriveunits)

Weightkit,120-5750(forunitswiththe3-wheeldrive

1

kitinstalled)

Procedure

ThisunitcomplieswiththeANSIB71.4-2004andEN836

Standardswhenequippedwithweightkit119-7129(2-wheel

driveunits)or120-5750(3-wheeldriveunits).

17

Page 18

9

g014674

1

2

3

4

5

6

7

8

InstallingEUDecals

Partsneededforthisprocedure:

1Warningdecal121–2640

Procedure

IfthismachinewillbeusedintheEU,afxthewarningdecal

121–2640overwarningdecal121–2641.

ProductOverview

Figure16

1.Engine

2.Rollbar6.Tractionpedal

3.Controlpanel

4.Seat8.Cuttingunits

5.Steeringwheel

7.Footrest

Controls

TractionPedal

Thetractionpedal(Figure17)hasthreefunctions:tomake

themachinemoveforward,tomoveitbackward,andtostop

themachine.Pressthetopofthepedaltomoveforward

andthebottomofthepedaltomovebackwardortoassist

instoppingwhenmovingforward.Also,allowthepedal

tomovetotheNeutralpositiontostopthemachine.For

operatorcomfort,donotresttheheelofyourfootonreverse

whenoperatingforward(Figure18).

18

Page 19

g014603

1

2

3

Figure17

G017945

1

3

2

4

5

6

1.Tractionpedal—forward3.Steeringarmlockingpedal

2.Tactionpedal—reverse

Figure19

1.Ignitionswitch

2.Choke

3.Functionalcontrollever

4.Raise/LowerMowControl

5.Throttlecontrol

6.InfoCenter

Choke

Tostartacoldengine,closethecarburetorchokebypulling

thechokecontrol(Figure19)outtotheClosedposition.

Aftertheenginestarts,regulatethechoketokeeptheengine

runningsmoothly.Assoonaspossible,openthechokeby

pushingitintotheOpenposition.Awarmenginerequires

littleornochoking.

Figure18

SteeringArmLockingPedal

Pressthepedal(Figure17)andraiseorlowerthesteering

armforoperatorcomfort,then,releasethepedaltolockthe

arminplace.

Note:Movethesteeringarmfullyforwardbeforelifting

theseat.

ThrottleControl

Thethrottlecontrol(Figure19)givestheoperatortheability

tocontrolthespeedoftheengine.Movingthethrottle

controltowardtheFastpositionincreasestheenginerpm;

movingthethrottlecontroltowardSlowwilldecreasethe

enginerpm.Groundspeedsareasfollows:

•3.2to8km/h(2to5mph)forwardmowingspeed

•16km/h(10mph)maximumtransportspeed

•4.0km/h(2.5mph)reversespeed

Note:Theenginecannotbestoppedbytheuseofthe

throttlecontrol.

Raise/LowerMowControl

Movingthecontrol(Figure19)forwardduringoperation

lowersthecuttingunitsandstartsthereels.Pullbackonthe

controltostopthereelsandraisethecuttingunits.During

operationthereelscanbestoppedbypullingbackonthe

controlmomentarilyandreleasingit.Thisfeatureisknownas

Tap-offandisadjustableintheInfoCenter.Restartthereels

bymovingthecontrolforward.

FunctionalControlLever

Thefunctionalcontrollever(Figure19)providestwotraction

selectionsplusaNeutralposition.Itispermissibletoshift

frommowtotransportortransporttomow(nottoneutral)

whilethemachineisinmotion.Nodamagewillresult.

•RearPosition—neutralandbacklapping

•MiddlePosition—usedformowingoperation

•FrontPosition—usedfortransportoperation

19

Page 20

IgnitionSwitch

G017943

2

2

7.5

7.5

7.5

7.5

7.5

7.5

10

10

15

15

C2

C2

1

2

1

G017973

2

3

4

5

6

7

8

9

TORO

13.2

10,000.0

STOP

n/min

52.2V

10,000.0

n/min

52.2V

1200

1600

n/min

G017974

2

1

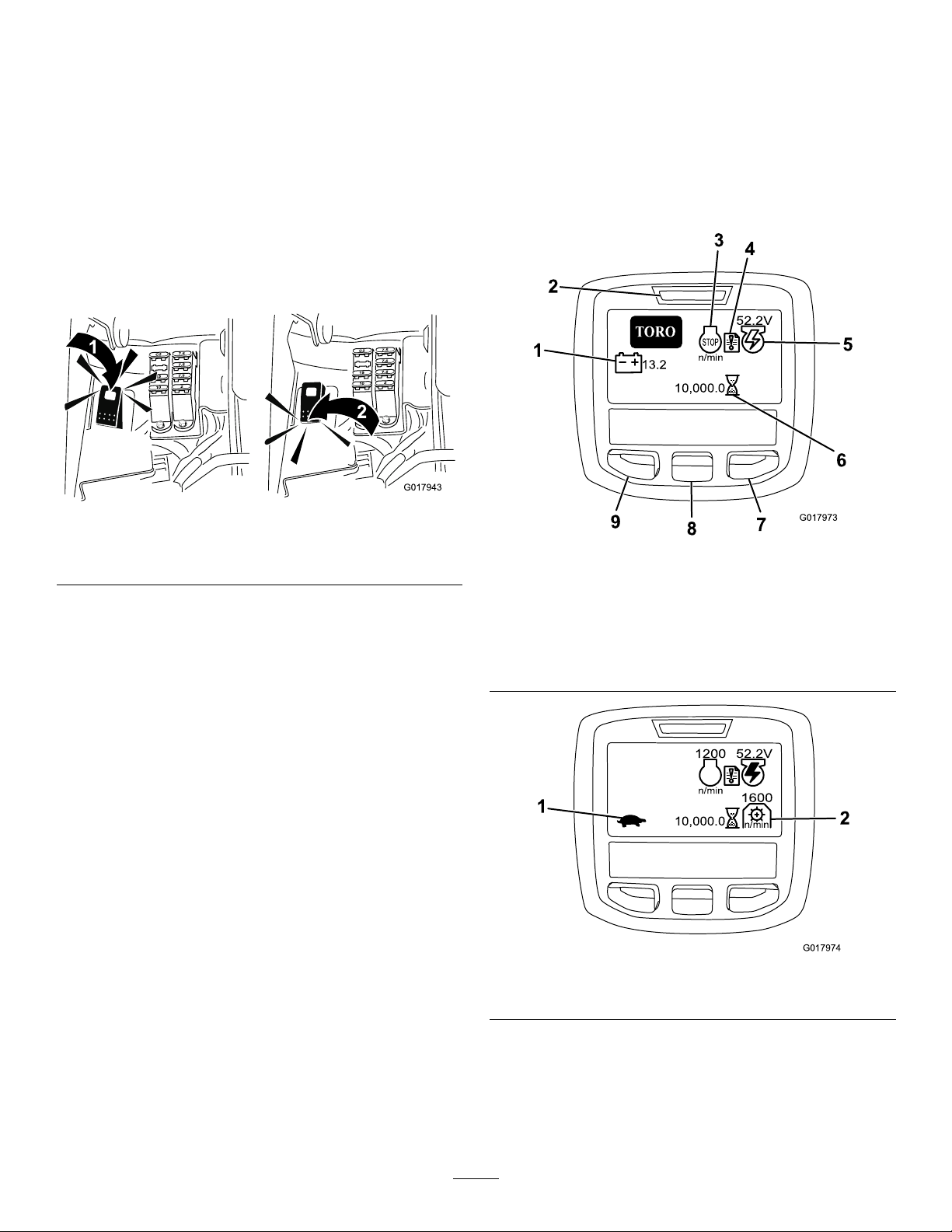

UsingtheInfoCenterLCDDisplay

Insertthekeyintotheswitch(Figure19)andturnitclockwise

asfaraspossibletotheStartpositiontostarttheengine.

Releasethekeyassoonastheenginestarts;thekeywillmove

totheOnposition.TurnthekeycounterclockwisetotheOff

positiontostoptheengine.

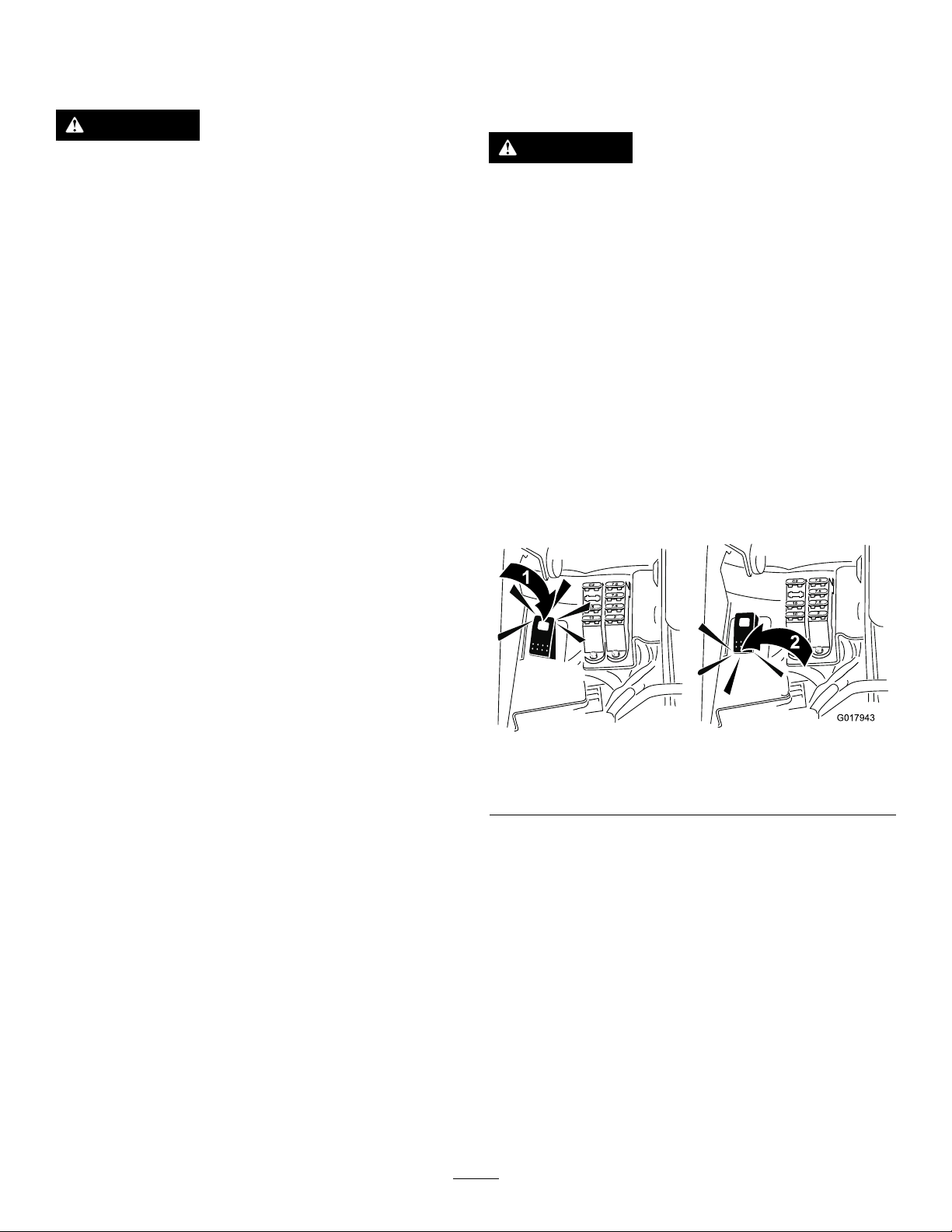

BacklapSwitch

Thebacklapswitchislocatedundertheplasticcoverto

theleftoftheseat.Usethebacklapswitch(Figure20)in

conjunctionwiththeraise/lowermowcontrolleverandthe

reelspeedcontrolforbacklappingthereels.

Figure20

TheInfoCenterLCDdisplayshowsinformationaboutyour

machinesuchasthegeneratorstatus,thespeed,andvarious

diagnosticsandotherinformationaboutthemachineandthe

batterypack.Figure21andFigure22illustratethesplash

screenandmaininformationscreenoftheInfoCenter.You

canswitchbetweenthesplashscreenandmaininformation

screenatanytimebypressinganyoftheInfoCenterbuttons

andthenselectingtheappropriatedirectionalarrow.

1.Backlapswitch—backlap

position

2.Backlapswitch—mow

position

Figure21

1.Batteryvoltage6.Hourmeter

2.Powerlight/faultindicator

3.EngineRPM/status

4.Faultlog

7.Rightbutton

8.Downbutton

9.Menuaccess/backbutton

5.Generatorvoltage/status

Figure22

1.Functionalcontrolstatus

2.PTOspeed

•Enginerpm/status—indicatestheenginerpm.

•Faultlog—indicatesthatthereisacurrentfaultlogto

review.

•Generatorvoltage/status—indicatesthegenerator

voltage.

20

Page 21

•Hourmeter—indicatesthetotalhoursthemachinehas

operated.Itstartstofunctionwheneverthekeyswitch

isrotatedtoOn.

•PTOspeed—indicatesthePTOspeed.

•Glowplug—indicatesthattheglowplugisactive.

•Batteryvoltage—indicatesthebatterypotentialinVolts.

•Coolanttemperature—indicatestheenginecoolant

temperatureineither°Cor°F .

•Functionalcontrolstatus—transportmodeisindicated

byarabbitandmowmodeisindicatedbyaturtle.

•Engineoilpressurelight—thisiconappearsiftheengine

oilpressuredropsbelowasafelevel.

•Menuaccess/backbutton—pressthisbuttontoaccess

theInfoCentermenus.Youcanuseittobackoutofany

menuyouarecurrentlyusing.

•Downbutton—usethisbuttontoscrolldownmenus.

•Rightbutton—usethisbuttontoopenamenuwherea

rightarrowindicatesadditionalcontent.

Note:Thepurposeofeachbuttonmaychangedepending

onwhatisrequiredatthetime.Eachbuttonwillbelabeled

withanicondisplayingitscurrentfunction.

21

Page 22

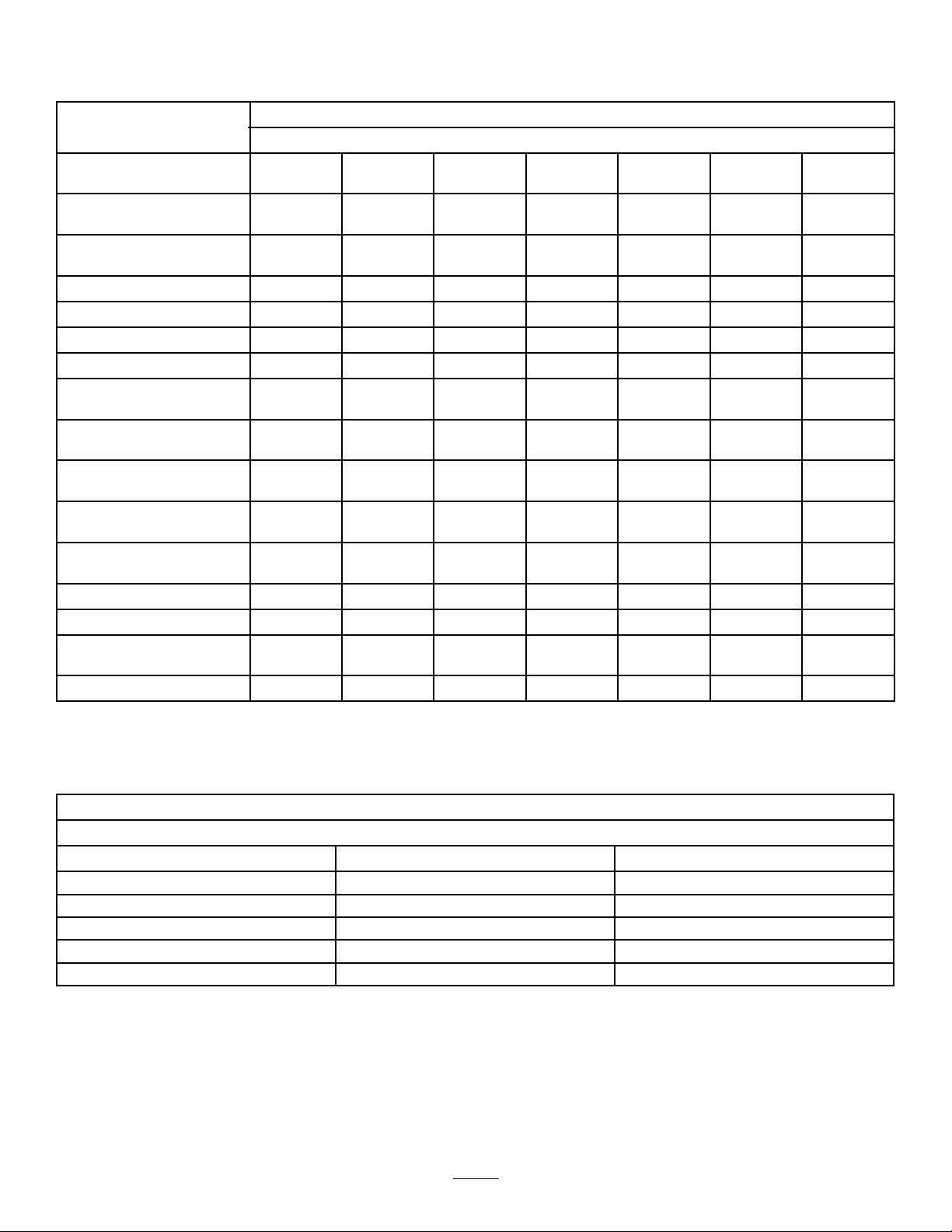

UsingtheMenus

ToaccesstheInfoCentermenusystem,pressthemenuaccess

buttonwhileatthemainscreen.Thiswillbringyoutothe

mainmenu.Refertothefollowingtablesforasynopsisof

theoptionsavailablefromthemenus:

MainMenu

MenuItemDescription

FaultsTheFaultsmenucontains

ServiceTheServicemenucontains

DiagnosticsTheDiagnosticsmenu

SettingsTheSettingsmenuallows

AboutTheAboutmenuliststhe

Service

MenuItemDescription

Hours

CountsListsthenumberofpreheats

Diagnostics

MenuItemDescription

EngineRun

alistoftherecentmachine

faults.RefertotheService

ManualoryourAuthorized

ToroDistributorformore

informationontheFaults

menuandtheinformation

containedthere.

informationonthemachine

suchashoursofuseandother

similarnumbers.

listsvariousstatesthatthe

machinecurrentlyhas.You

canusethistotroubleshoot

certainissuesasitwillquickly

tellyouwhichmachine

controlsareonandwhichare

off.

youtocustomizeandmodify

congurationvariablesonthe

InfoCenterdisplay.

modelnumber,serialnumber,

andsoftwareversionofyour

machine.

Liststhetotalnumberofhours

thatthemachine,engine,

reels,backlap,andfanhave

beenon,aswellasthe

numberofhoursthemachine

hasbeentransportedand

overheated.

andstartsthemachinehas

experienced.

Indicatesifthefollowingitems

areactive:Keystart,keyrun,

joysticklower,joystickraise,

neutral,seatorparkingbrake,

OKrun,andRTRorETR.

S1–S4Controlstheraisingand

ReelsEnable

Settings

MenuItemDescription

Units

Language

LCDBacklightControlsthebrightnessofthe

LCDContrastControlsthecontrastofthe

ProtectedMenus

ProtectionSettingsControlstheprotectedmenus.

ResetDefaultsResetstheInfoCenterto

RaiseDelay

LowerDelay

TapoffDelayControlsthetap-offdelay.

ReelSpeedControlsthereelspeed.

Backlaprpm

About

MenuItemDescription

Model

SNListstheserialnumberofthe

TEC5001Liststhesoftwarerevisionof

InfoCenterListsthesoftwarerevisionof

CU1Liststhesoftwarerevisionof

CU2Liststhesoftwarerevisionof

CU3Listthesoftwarerevisionof

GeneratorListstheserialnumberofthe

CANBus

loweringofthesolenoids.

IndicatesiftheeReelis

enabled.

Controlstheunitsusedonthe

InfoCenter.Themenuchoices

areEnglishorMetric.

Controlsthelanguageused

ontheInfoCenter.

LCDdisplay.

LCDdisplay.

Allowsthedistributor/engineer

toaccessprotectedmenusby

inputtingapasscode.

defaultsettings.

Controlstheraisedelaytime

forthecentercuttingunit.

Controlsthelowerdelayfor

thecentercuttingunit.

Controlsthebacklaprpm

speed.

Liststhemodelnumberofthe

machine.

machine.

themastercontroller .

theInfoCenter.

therstcuttingunit.

thesecondcuttingunit.

thethirdcuttingunit.

generator.

Liststhemachine

communicationbusstatus.

22

Page 23

CenterCuttingUnitRaise/LowerDelay

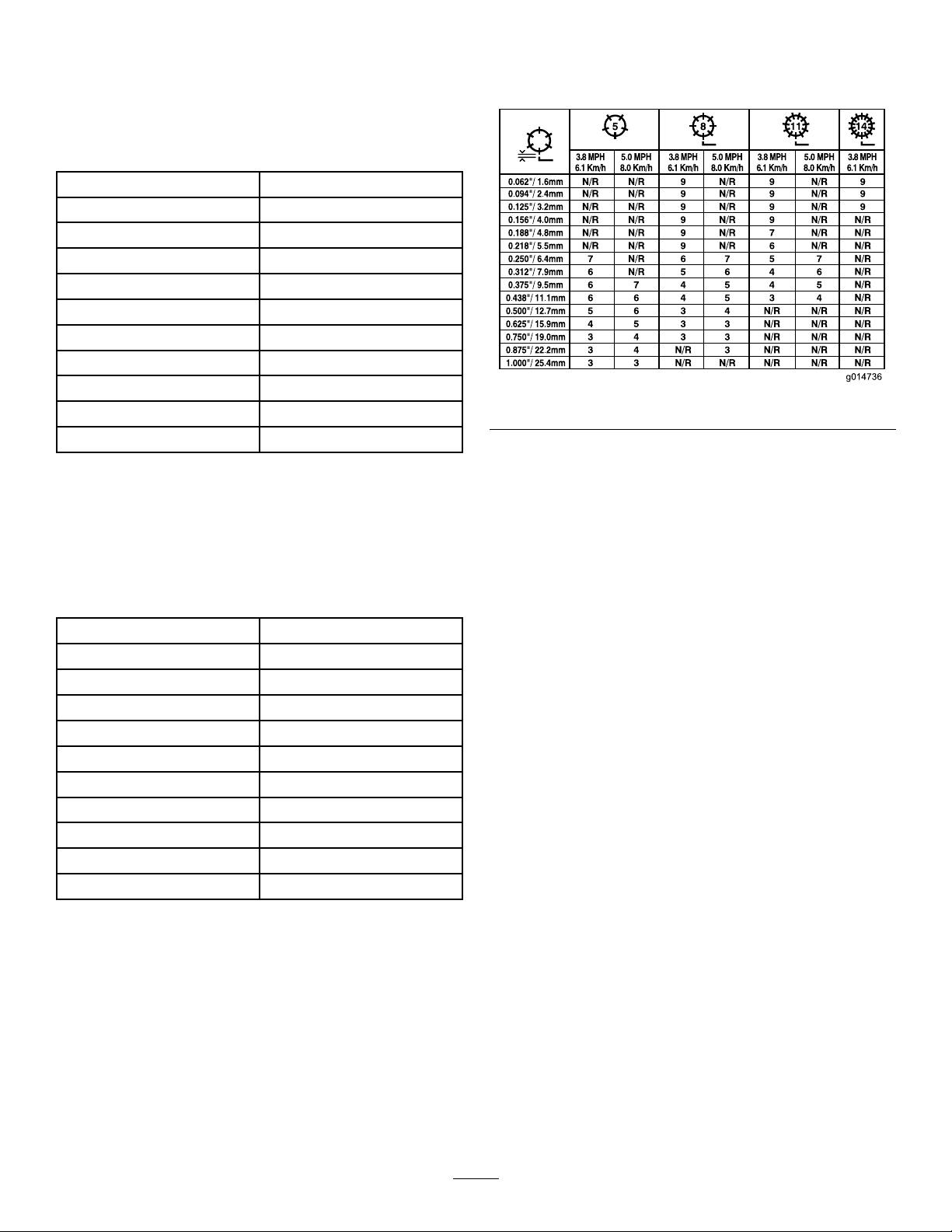

g014736

Theraiseandlowerdelaytimeforthecentercuttingmaybe

adjustedindependentlywiththeInfoCenter.Eachsetting

maybeadjustedfrom1to9accordingtothetablebelow .

Thefactorydefaultsettingis6(375ms)andisoptimizedfor

a3.8mphmowspeed.

3.Usingtheappropriategraph(SeeFigure23)for5,8,

11,or14bladecuttingunits,determinetheproperreel

speedsetting.

IncrementNumber

10.100

20.150

30.200

40.250

5

60.375

7

80.600

90.750

100.925

DelayTime(Seconds)

0.300

0.475

Tap-offDelay

Thetap-offdelayfeatureallowsthecuttingunitstoturnoff

withoutraising,andmaybeadjustedwiththeInfoCenter.The

delaysettingrepresentsthemaximumtimefortheraise/lower

joysticktoremainintheraisepositiontoactivatethisfeature.

Thefactorydefaultsettingis1whichdisablesthisfeature.

IncrementNumber

1

20.050

30.100

40.150

5

60.250

7

80.350

90.400

100.450

DelayTime(Seconds)

Off

0.200

0.300

Figure23

4.Tosetthereelspeed,ontheInfoCenteropentheMain

MenuandscrolldowntoSettings.

5.IntheSettingsmenuscrolldowntoReelSpeedand

usethe±buttontosetthereelspeedtothedesired

number.

MachineCongurationPasscode

Thereare5operatingcongurationsettingsthatare

adjustablewithinthesettingmenuoftheInfoCenter:Raise

andlowerdelay,tap-offdelay,reelspeed,andbacklapspeed.

Thesesettingcanbeprotectedbyauserdenedpasscodeby

openingtheMainmenuandscrollingdowntotheSettings

menu.FindProtectSettingsandselectOn.

WhenprotectsettingOnisselectedtheuserisprompted

toenterafourdigitpasscode.Afterthepasscodeisset,the

keyswitchmustbeturnedoffandbackontoenableand

savethisfeature.Afterenablingtheprotectsettingsoption,

thecongurationsettingsarehiddenuntiltheuserdened

passcodeisentered.

Note:Iftheuserdenedpasscodeisforgotten,atemporary

passcodecanbeobtainedthroughyourauthorizedT oro

distributor.

SettingtheReelSpeed

Toachieveaconsistent,highquality–of–cutandauniform

aftercutappearance,itisimportantthatthereelspeedcontrol

becorrectlyset.

Adjustthereelspeedcontrolasfollows:

1.Selecttheheight-of-cutatwhichthecuttingunitsare

set.

2.Choosethedesiredgroundspeedbestsuitedfor

conditions.

DiagnosingtheFaultLogIndicator

Thefaultlogindicatoriconappearsonthemainscreeninthe

eventofafaultinthemachine(Figure21).Whenthisiconis

presentthereisanewlogentryintheFaultsmenuthatyou

oryourdistributorcanusetoidentifytheproblem.

Foralistoffaults,refertoyourAuthorizedDistributoror

theServiceManual.

23

Page 24

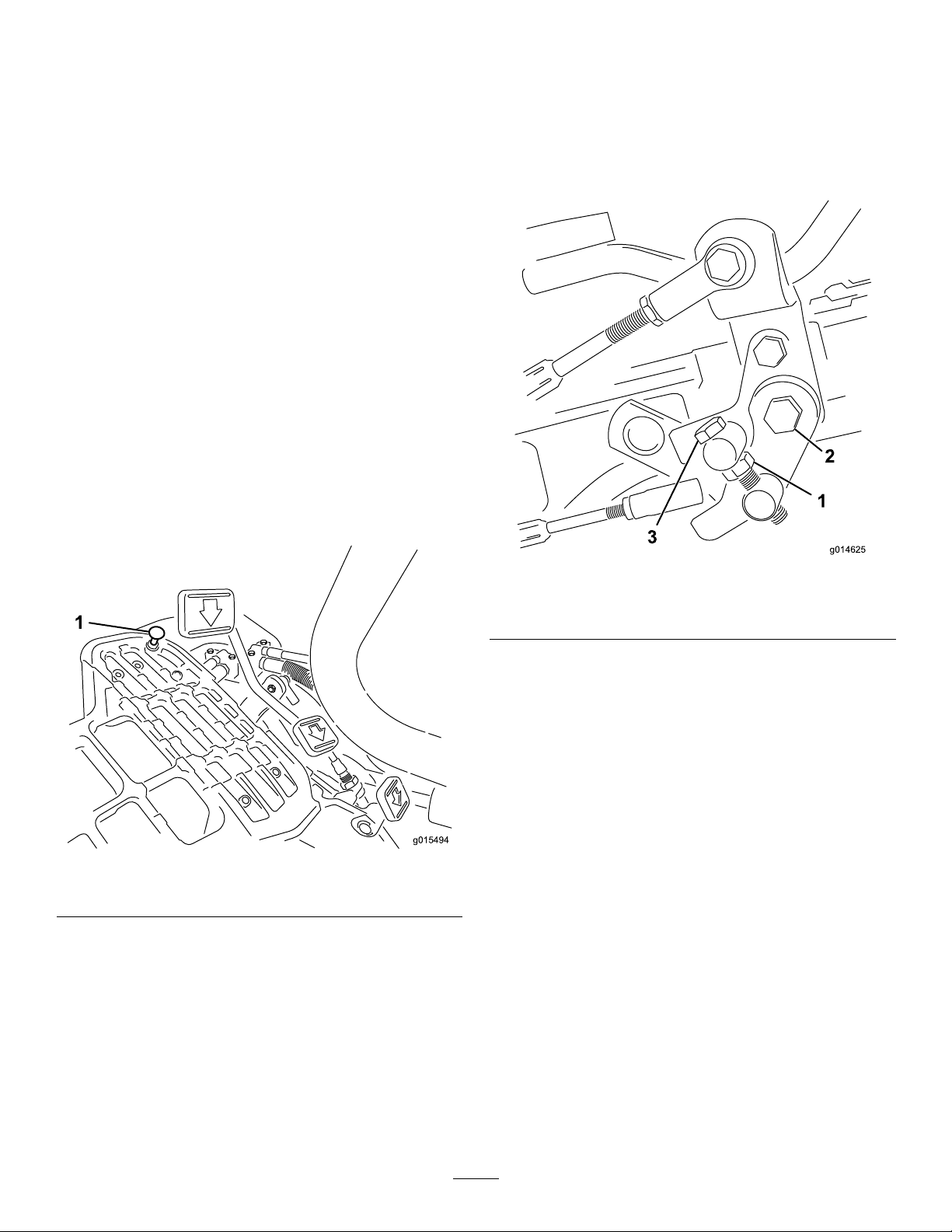

ParkingBrakeLever

g01461 0

g014628

1

g01462 6

1

Pulluponthebrakelever(Figure24)tosettheparkingbrake.

Disengageitbypushingitforwardanddown.Settheparking

brakeanytimeyouleavethemachine.Aniconwillappearon

theInfoCenterscreenwhentheparkingbrakeisset.

Figure25

1.Seatadjustinglever

Figure24

SeatAdjustingLever

Theseatadjustingleverislocatedonthefront,rightcorner

oftheseat(Figure25),allowingyoutoadjusttheseatfore

andaft.Pushthelevertotheleft(towardsthecenter),to

releasethelockandslidetheseat.

Note:Ifyouneedadditionaladjustmentontheseat,youcan

removethefourboltssecuringtheseattothebaseandmove

theseattothesecondsetofmountingholesprovided.

Note:Beforeliftingtheseat,slideittothefurthestback

positionandmovethesteeringarmfullyforward.

FuelShutoffValve

Closethefuelshutoffvalve(Figure26),behindtheseatand

underthefueltank,whenstoringortransportingthemachine

onatruckortrailer.

1.Fuelshutoff(underthefueltank)

24

Figure26

Page 25

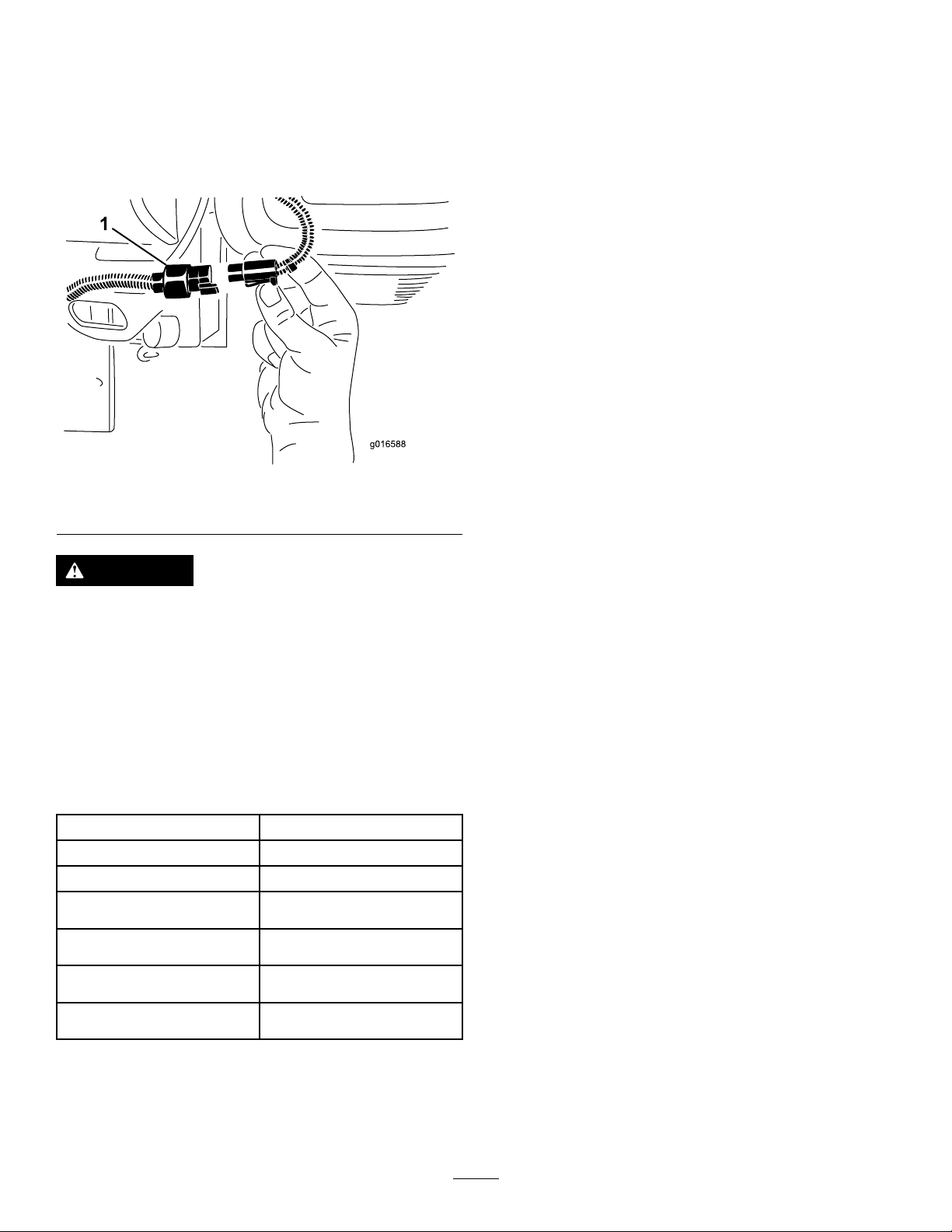

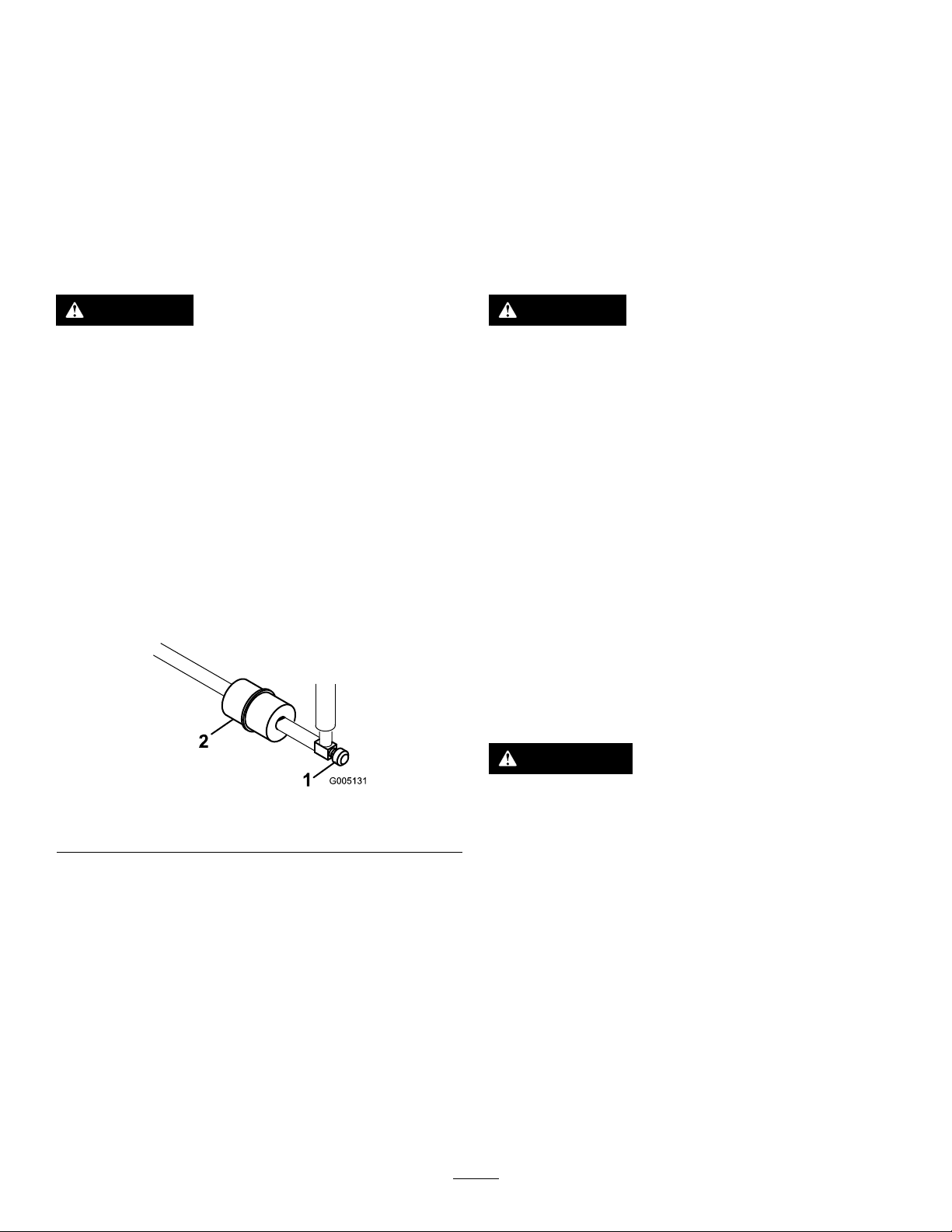

CuttingUnitPowerDisconnect

Beforeinstalling,removing,orworkingonthecutting

units,disconnectthecuttingunitsfromthepowersupply

byseparatingthecuttingunitpowerdisconnectconnector

(Figure27),locatedatthebaseoftherolloverbarontheleft

sideofthemachine.Plugtheconnectorstogetherbefore

operatingthemachine.

Figure27

itscapabilities.ContactyourAuthorizedServiceDealeror

Distributororgotowww .Toro.comforalistofallapproved

attachmentsandaccessories.

1.Cuttingunitpowerdisconnectconnector

CAUTION

Ifyoudonotdisconnectthepowertothecutting

units,someonecouldaccidentallystartthecutting

unit,causingseriousinjurytohandsandfeet.

Alwaysseparatethecuttingunitpowerdisconnect

connectorsbeforeworkingonthecuttingunits.

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

Widthofcut151cm(59.5inches)

Wheeltread

Wheelbase

Overalllength(w/baskets)249cm(98.0inches)

Overallwidth179cm(70.62inches)

128cm(50.5inches)

119cm(46.9inches)

Overallheight205cm(80.83inches)

Weight

Refertothemachineserial

tag(Figure1).

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesis

availableforusewiththemachinetoenhanceandexpand

25

Page 26

Operation

1

2

g016292

Important:Checktheoillevelevery8operating

hoursordaily .

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

ThinkSafetyFirst

Pleasecarefullyreadallofthesafetyinstructionsandsymbols

inthesafetysection.Knowingthisinformationcouldhelp

youorbystandersavoidinjury.

Theuseofprotectiveequipment,suchasbutnotlimitedto,

foreyes,ears,feet,andheadisrecommended.

CheckingtheEngineOil

Theengineisshippedwith1.65liters(1-3/4quarts)(w/lter)

ofoilinthecrankcase;however,theoillevelmustbechecked

beforeandaftertheengineisrststarted.

Theengineusesanyhigh-qualitydetergentoilhavingthe

AmericanPetroleumInstitute(API)serviceclassicationof

SG,SH,orSJorhigher.Therecommendedviscosity(weight)

isSAE30.

1.Positionthemachineonalevelsurface.

2.Unscrewthedipstickandwipeitwithacleanrag.

Screwthedipstickintothetubeandmakesureitis

seatedfully(Figure28).

5.Installthellercapanddipstickrmlyinplace.

FillingtheFuelTank

•Forbestresults,useonlyclean,fresh(lessthan30days

old),unleadedgasolinewithanoctaneratingof87or

higher((R+M)/2ratingmethod).

•Ethanol:Gasolinewithupto10%ethanol(gasohol)

or15%MTBE(methyltertiarybutylether)byvolume

isacceptable.EthanolandMTBEarenotthesame.

Gasolinewith15%ethanol(E15)byvolumeisnot

approvedforuse.Neverusegasolinethatcontainsmore

than10%ethanolbyvolume,suchasE15(contains15%

ethanol),E20(contains20%ethanol),orE85(contains

85%ethanol).Usingunapprovedgasolinemaycause

performanceproblemsand/orenginedamagewhichmay

notbecoveredunderwarranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuelcontainers

overthewinterunlessafuelstabilizerisused.

•Donotaddoiltogasoline.

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

1.Dipstick2.Fillercap

3.Unscrewthedipstickoutofthetubeandcheckthe

oillevel.

4.Iftheoillevelislow,removethellercapfromthe

valvecoverandpouroilintotheopeninginthevalve

coveruntiltheoillevelisuptotheFullmarkonthe

dipstick.Addtheoilslowlyandchecktheleveloften

duringthisprocess.Donotoverll.

Figure28

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupanygasoline

thatspills.

•Neverllthefueltankinsideanenclosedtrailer.

•Donotllthefueltankcompletelyfull.Add

gasolinetothefueltankuntilthelevelis1inch

(25mm)belowthebottomofthellerneck.

Thisemptyspaceinthetankallowsgasolineto

expand.

•Neversmokewhenhandlinggasoline,andstay

awayfromanopenameorwheregasoline

fumesmaybeignitedbyaspark.

•Storegasolineinanapprovedcontainerand

keepitoutofthereachofchildren.Neverbuy

morethana30-daysupplyofgasoline.

•Donotoperatewithoutentireexhaustsystemin

placeandinproperworkingcondition.

26

Page 27

DANGER

CheckingtheHydraulicFluid

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingasparkwhich

canignitethegasolinevapors.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Alwaysplacegasolinecontainersontheground

awayfromyourvehiclebeforelling.

•Donotllgasolinecontainersinsideavehicleor

onatruckortrailerbedbecauseinteriorcarpets

orplastictruckbedlinersmayinsulatethe

containerandslowthelossofanystaticcharge.

•Whenpractical,removegas-poweredequipment

fromthetruckortrailerandrefueltheequipment

withitswheelsontheground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfromaportable

container,ratherthanfromagasolinedispenser

nozzle.

•Ifagasolinedispensernozzlemustbeused,

keepthenozzleincontactwiththerimofthe

fueltankorcontaineropeningatalltimesuntil

fuelingiscomplete.

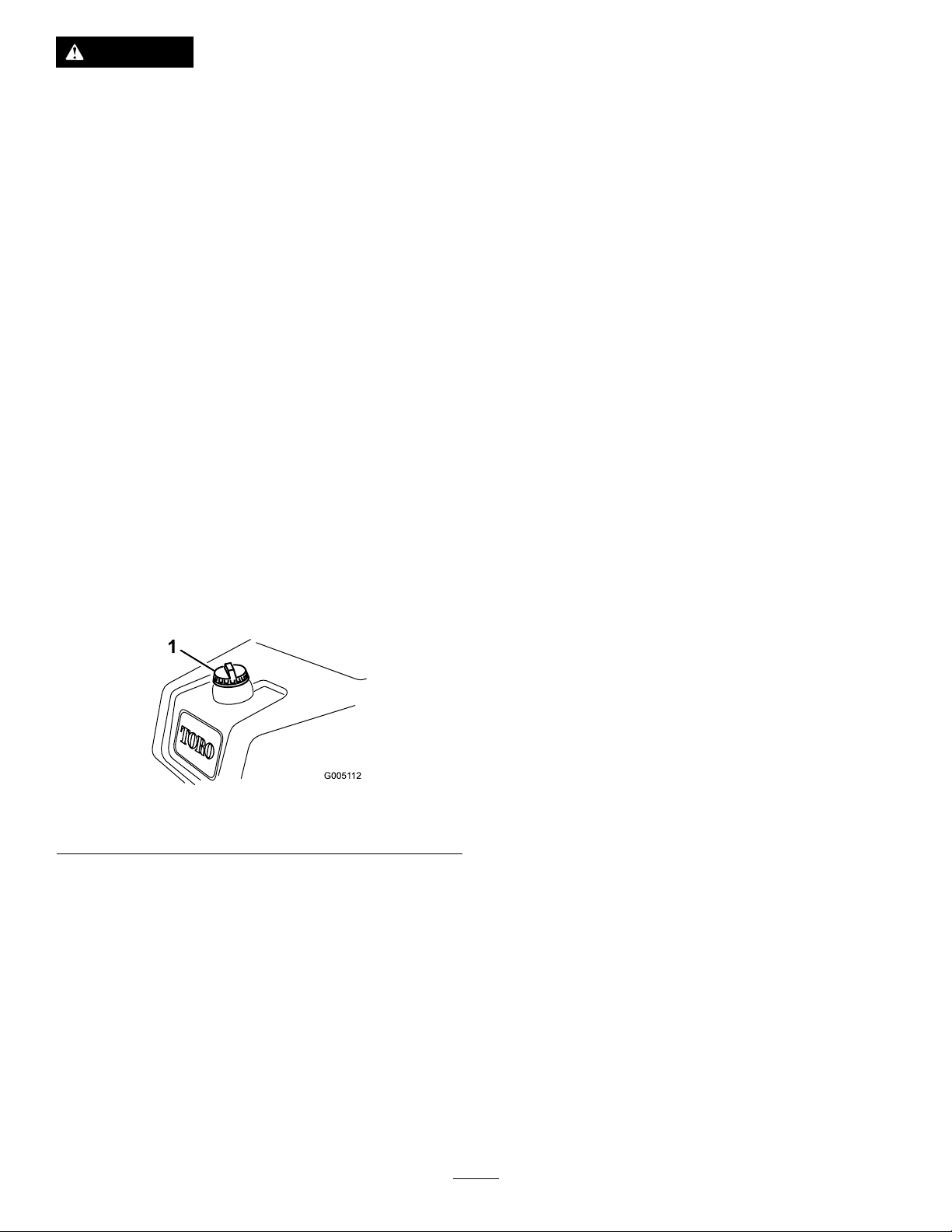

1.Cleanaroundthefueltankcapandremoveit(Figure

29).

Level

Thehydraulicuidreservoirislledatthefactorywith

approximately18.9L(5USgallons)ofhighqualityhydraulic

uid.Beforeoperatingthemachineeachday,checklevelof

thehydraulicuidinthewhiteplasticwindowonthefrontof

thehydraulicuidreservoir(behindtheseatontheleftside).

Theuidshouldbebetweenthelinesinthewindow;ifnot,

addanappropriateuidasdescribedinthefollowingsections:

Therecommendedreplacementuidisasfollows:

ToroPremiumAllSeasonHydraulicFluid(Availablein5

gallonpailsor55gallondrums.SeepartscatalogorToro

distributorforpartnumbers.)

Alternateuids:IftheTorouidisnotavailable,otheruids

maybeusedprovidedtheymeetallthefollowingmaterial

propertiesandindustryspecications.W edonotrecommend

theuseofsyntheticuid.Consultwithyourlubricant

distributortoidentifyasatisfactoryproduct

Note:Torowillnotassumeresponsibilityfordamage

causedbyimpropersubstitutions,souseonlyproducts

fromreputablemanufacturerswhowillstandbehindtheir

recommendation.

HighViscosityIndex/LowPourPointAnti-wearHydraulic

Fluid,ISOVG46

MaterialProperties:

Viscosity,ASTMD445cSt@40°C44to48

ViscosityIndexASTM

D2270

PourPoint,ASTMD97-34°Fto-49°F

IndustrySpecications:

VickersI-286-S(QualityLevel),VickersM-2950-S

(QualityLevel),DenisonHF-0,Vickers35VQ(Eaton

ATS373-C)

cSt@100°C7.9to8.5

140to160

Figure29

1.Fueltankcap

2.Addunleadedregulargasolinetothefueltankuntilthe

levelis25mm(1inch)belowthebottomoftheller

neck.

Thisspaceinthetankallowsgasolinetoexpand.Do

notllthefueltankcompletelyfull.

Note:Thefueltankcapacityis22.7L(6USgallons).

3.Installthefueltankcapsecurely.Wipeupanygasoline

thatmayhavespilled.

Important:TheISOVG46Multigradeuidhasbeen

foundtoofferoptimalperformanceinawiderangeof

temperatureconditions.Foroperationinconsistently

highambienttemperatures,18°C(65°F)to49°C

(120°F),ISOVG68hydraulicuidmayofferimproved

performance.

PremiumBiodegradableHydraulicFluid-MobilEAL

EnviroSyn46H

Important:MobilEALEnviroSyn46Histheonly

syntheticbiodegradableuidapprovedbyT oro.This

uidiscompatiblewiththeelastomersusedinToro

hydraulicsystemsandissuitableforawide-range

oftemperatureconditions.Thisuidiscompatible

withconventionalmineraloils,butformaximum

biodegradabilityandperformancethehydraulicsystem

shouldbethoroughlyushedofconventionaluid.The

oilisavailablein19L(5gallon)containersor55gallon

drumsfromyourMobilDistributor.

Note:Manyhydraulicuidsarealmostcolorless,makingit

difculttospotleaks.Areddyeadditiveforthehydraulic

27

Page 28

systemoilisavailablein20ml(2/3oz)bottles.Onebottle

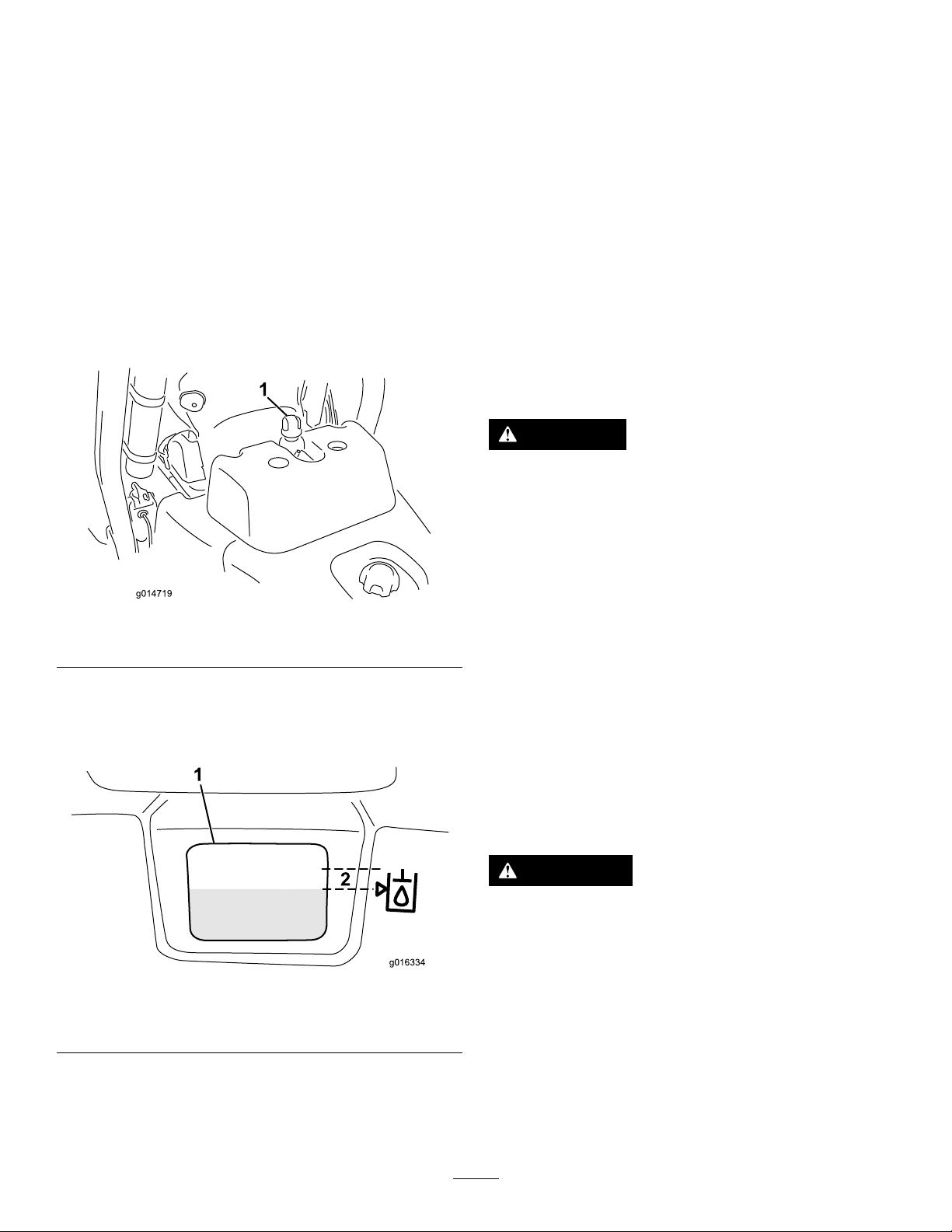

g014719

1

1

2

g016334

issufcientfor15-22L(4-6gallons)ofhydraulicoil.Order

partno.44-2500fromyourauthorizedTorodistributor.This

reddyeisnotrecommendedforusewithbiodegradable

uids.Usefoodcoloring .

Important:Regardlessofthehydraulicuidtypeused,

anymachineusedforoffgreenapplications,verticutting

orusedduringambienttemperaturesabove29°C(85°F)

shouldhaveOilCoolerKitinstalled;referto5Installing

theOptionalOilCooler(page14).

FillingtheHydraulicTank

1.Positionthemachineonalevelsurface.Makesurethe

machinehascooleddownsotheoiliscold.

2.Removethecapfromthereservoir(Figure30).

4.Installthereservoircap.Wipeupanyuidthatmay

havespilled.

Important:Checklevelofhydraulicuidbefore

engineisrststartedanddailythereafter.

CheckingtheReel-to-Bedknife Contact

Eachdaybeforeoperatingthemachine,checkthe

reel-to-bedknifecontact,regardlessifthequalityofcuthad

previouslybeenacceptable.Theremustbelightcontact

acrossthefulllengthofthereelandbedknife;referto

AdjustingtheReeltoBedknifeintheCuttingUnitOperator’s

Manual.

Beforecheckingthereels,disconnectthecuttingunitpower

disconnectcouplers;refertoCuttingUnitPowerDisconnect

(page25).Connectthemwhennished.

CAUTION

Ifyoudonotdisconnectthepowertothecutting

units,someonecouldaccidentallystartthecutting

unit,causingseriousinjurytohandsandfeet.

Figure30

1.Hydraulictankcap

3.Slowlyllthereservoirwiththeappropriatehydraulic

uiduntilthelevelisatorwithin6mm(1/4inch)of

thearrowinthesymbolnexttothewhitewindowin

thefrontofthereservoir(Figure31).Donotoverll.

Figure31

1.Whitewindowonthefront

ofthehydraulicreservoir

2.Filltowithinthisarea.

Alwaysseparatethecuttingunitpowerdisconnect

couplersbeforeworkingonthecuttingunits.

CheckingtheTirePressure

Thetiresareover-inatedatthefactoryforshipping

purposes.Reducethepressuretotheproperlevelsbefore

startingtheunit.

Varythetirepressureforall3wheels,dependinguponyour

turfconditions,fromaminimumof83toamaximumof110

kPa(12psito16psi).

CheckingtheTorqueofthe WheelNuts

WARNING

Failuretomaintainpropertorqueofthewheelnuts

couldresultinpersonalinjury.

Torquethewheelnutsto95to122N-m(70to90

ft-lb)after1-4hoursofoperationandagainafter

10hoursofoperation.T orqueevery200hours

thereafter.

Important:Topreventsystemcontamination,

cleanthetopofthehydraulicuidcontainers

beforepuncturing.Ensurethepourspoutand

funnelareclean.

Breaking-intheMachine

RefertotheEngineManualsuppliedwiththemachineforoil

changeandmaintenanceproceduresrecommendedduring

thebreak-inperiod.

28

Page 29

Only8hoursofmowingoperationisrequiredforthebreak-in

period.

ToroDistributorforassistanceand,ifnecessary,

replacementparts.

Sincethersthoursofoperationarecriticaltofuture

dependabilityofthemachine,monitoritsfunctionsand

performancecloselysothatminordifculties,whichcould

leadtomajorproblems,arenotedandcanbecorrected.

Inspectthemachinefrequentlyduringbreak-inforsignsof

oilleakage,loosefasteners,oranyothermalfunction.

Toensureoptimumperformanceofthebrakesystem,burnish

(break-in)thebrakesbeforeusingthemachine.Toburnish

thebrakes,rmlyapplythebrakesanddrivethemachineat

mowingspeeduntilthebrakesarehot,asindicatedbytheir

smell.Anadjustmenttothebrakesmayberequiredafter

break-in;refertoAdjustingtheBrakes.

StartingtheEngine

Note:Inspecttheareabeneaththemowerstobecertain

theyareclearofdebris.

1.Sitontheseat,locktheparkingbrake,disengagethe

raise/lowermowcontrolandmovethefunctional

controllevertoNeutral.

2.Removeyourfootfromthetractionpedalandmake

surethepedalisintheNeutralposition.

3.Movethechokelevertotheclosedposition(onlywhen

startingacoldengine)andthethrottlelevertothehalf

throttleposition.

4.Insertandrotatetheignitionkeyclockwiseuntilthe

enginestarts.Aftertheenginestarts,regulatethe

choketokeeptheenginerunningsmoothly.Assoon

aspossible,openthechokebypushingitintotheOff

position.Awarmenginerequireslittleornochoking.

5.Checkthemachineoutwiththefollowingprocedures

aftertheenginehasstarted:

A.MovethefunctionalcontrollevertotheMow

positionandreleasetheparkingbrake.Move

thethrottlecontroltotheFastpositionand

momentarilyengagethereelsbymovingthe

raise/lowermowcontrolleverforward.The

cuttingunitsshoulddropandallthereelsshould

turn.

B.Movetheraise/lowermowcontrolleverrearward.

Thecuttingreelsshouldstopandthecuttingunits

shouldraisetothefulltransportposition.

C.Setthebraketokeepthemachinefrommoving,

andoperatethetractionpedalthroughthe

forwardandreversepositions.

D.Continuetheaboveprocedurefor1-2minutes.

Neutralizethefunctionalcontrollever,lockthe

parkingbrake,andturntheengineoff.

Important:Atraceofoilonthemotoror

wheelsealsisnormal.Sealsrequireasmall

amountoflubricationtoperformproperly.

Note:Whenthemachineisnewandthebearings

andreelsaretight,itisnecessarytousetheFast

throttlecontrolpositionforthischeck.Afast

throttlesettingmaynotberequiredafterthe

break-inperiod.

CheckingtheSafetyInterlock System

CAUTION

Ifthesafetyinterlockswitchesaredisconnectedor

damagedthemachinecouldoperateunexpectedly

causingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlockswitches

dailyandreplaceanydamagedswitchesbefore

operatingthemachine.

Thepurposeofthesafetyinterlocksystemistoprevent

operationofthemachinewherethereispossibleinjuryto

theoperatororthemachine.

Thesafetyinterlocksystempreventstheenginefromstarting

unless:

•Thetractionpedalisinneutral.

•Thefunctionalcontrolleverisinneutral.

Thesafetyinterlocksystempreventsthemachinefrom

movingunless:

•Theparkingbrakeisoff.

•Theoperatorisseated.

•ThefunctionalcontrolleverisinMoworTransport.

Thesafetyinterlocksystempreventsthereelsfromoperating

unlessthefunctionalcontrolleverisintheMowposition.

Performthefollowingsystemchecksdailytobesurethe

interlocksystemisoperatingcorrectly:

1.Sitontheseat,movethetractionpedaltoNeutral,

movethefunctionalcontrollevertoNeutral,and

engagetheparkingbrake.Trytodepressthetraction

pedal.Thepedalshouldnotdepress,whichmeansthat

theinterlocksystemisoperatingcorrectly.Correctthe

problemifitisnotoperatingproperly.

E.Checkforoilleaks.Ifoilleaksappear,check

thetightnessofthehydraulicttings.Ifoil

leakscontinuetoappear,contactyourlocal

2.Sitontheseat,movethetractionpedaltoNeutral,

movethefunctionalcontrollevertoNeutral,and

engagetheparkingbrake.Movethefunctionalcontrol

29

Page 30

levertomowortransportandtrytostarttheengine.

g014602

1

2

g014609

1

2

3

g01461 1

1

2

Theengineshouldnotcrank,whichmeansthatthe

interlocksystemisoperatingcorrectly.Correctthe

problemifitisnotoperatingproperly.

3.Sitontheseat,movethetractionpedaltoNeutral,

movethefunctionalcontrollevertoNeutral,and

engagetheparkingbrake.Starttheengineandmove

thefunctionalcontrollevertomowortransport.The

engineshouldkill,whichmeansthattheinterlock

systemisoperatingcorrectly.Correcttheproblemifit

isnotoperatingproperly.

4.Sitontheseat,movethetractionpedaltoNeutral,

movethefunctionalcontrollevertoNeutral,and

engagetheparkingbrake.Starttheengine.Release

theparkingbrake,movethefunctionalcontrollever

tomow ,andrisefromtheseat.Theengineshould

kill,whichmeansthattheinterlocksystemisoperating

correctly.Correcttheproblemifitisnotoperating

properly.

5.Sitontheseat,movethetractionpedaltoNeutral,

movethefunctionalcontrollevertoNeutral,and

engagetheparkingbrake.Starttheengine.Movethe

raise/lowermowcontrolforwardtolowerthecutting

units.Thecuttingunitsshouldnotstartrotating.If

theydo,theinterlocksystemisnotoperatingcorrectly.

Correcttheproblem.

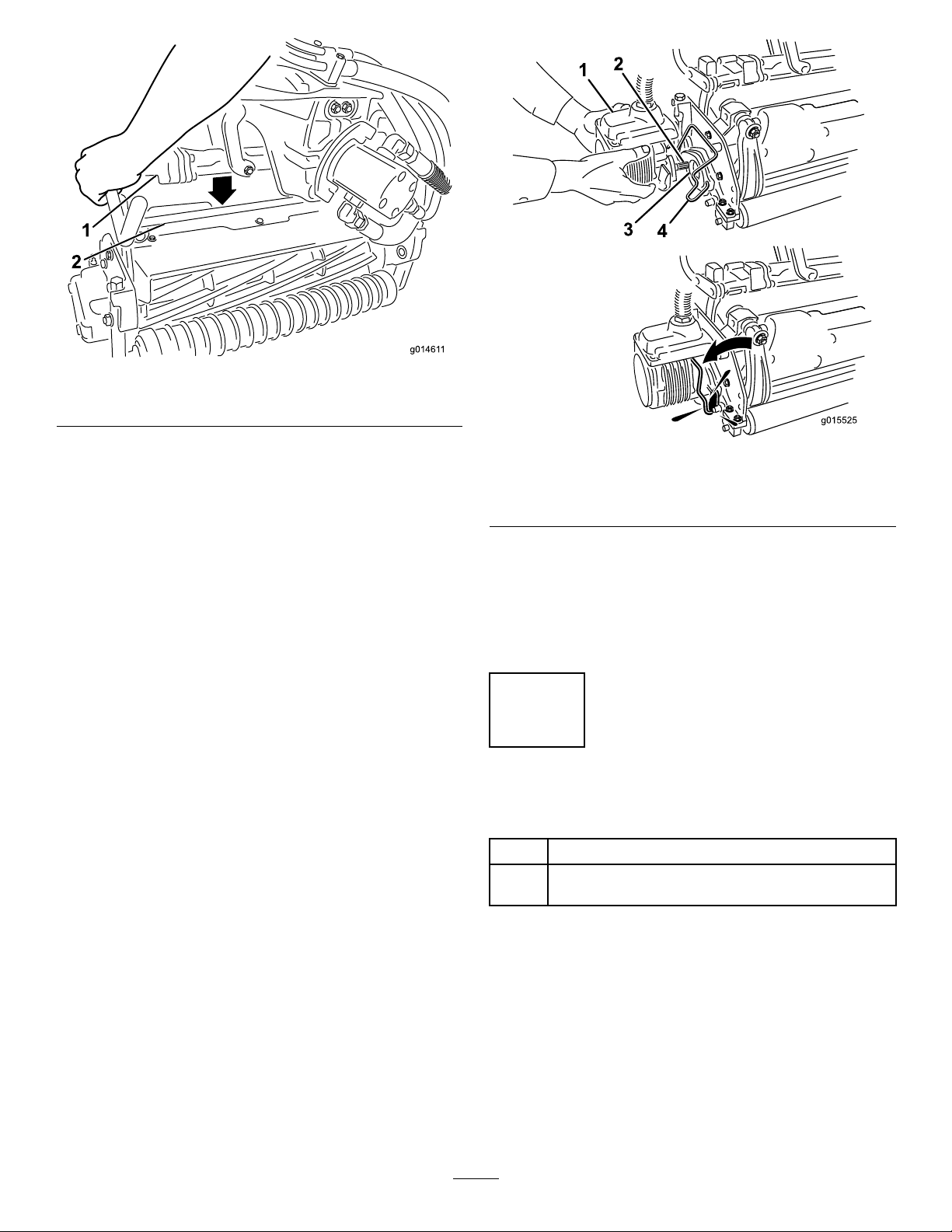

Figure32

1.Footrest—closed2.Footrest—open

3.Positionthecuttingunitunderthecentersuspension

arm.

4.Withthelatchesonthesuspension-armbarpointing

up(i.e.,open)(Figure33),pushthesuspensionarm

downsothatthebartsoverthebaracrossthetopof

thecuttingunit(Figure34).

InstallingandRemovingthe CuttingUnits

1.Latch—closedposition3.Latch—openposition

InstallingtheCuttingUnits

1.Disconnectthecuttingunitpowerdisconnectcouplers;

refertoCuttingUnitPowerDisconnect(page25).

CAUTION

Ifyoudonotdisconnectthepowertothe

cuttingunits,someonecouldaccidentally

startthecuttingunit,causingseriousinjury

tohandsandfeet.

Alwaysseparatethecuttingunitpower

disconnectcouplersbeforeworkingonthe

cuttingunits.

2.Liftuponthefootrestandswingitopen,allowing

accesstothecentercuttingunitposition(Figure32).

CAUTION

Thefootrestcanpinchngersifitfallsinto

theclosedposition.

Keepyourngersclearoftheareawherethe

footrestseatswhileitisopen.

2.Suspension-armbar

1.Suspension-armbar2.Cutting-unitbar

5.Closethelatchesdownandaroundthecutting-unitbar

andlocktheminplace(Figure33).

Figure33

Figure34

30

Page 31

Note:A“click”canbeheardandfeltwhenthelatches

areproperlylockedinplace.

6.Coatthesplineshaftofthecuttingunitmotorwith

cleangrease(Figure35).

7.Insertthemotorintotheleftsideofthecuttingunit

(asviewedfromtheoperator'sposition)andpullthe

motorretainingbaronthecuttingunittowardthe

motoruntilyouhearanaudible“click”frombothsides

ofthemotor(Figure35).

2.Parkthemachineonacleanlevelsurface,lower

thecuttingunitstothegrounduntilthesuspension

hydraulicsarefullyextended,stoptheengine,andset

theparkingbrake.

3.Pushthemotorretainingbaroutoftheslotsonthe

motortowardsthecuttingunitandremovethemotor

fromthecuttingunit.

Figure36

1.Reelmotor2.Motorretainingbar

4.Movethemotortothestoragelocationonthefrontof

thesuspensionarm(Figure37).

Figure35

1.Reelmotor

2.Splineshaft

3.Cavity

4.Motorretainingbar

8.Mountagrassbasketontothebaskethooksonthe

suspensionarm.

9.Repeatthisprocedurefortheothercuttingunits.

10.Connectthecuttingunitpowerdisconnectcouplers;

refertoCuttingUnitPowerDisconnect(page25).

RemovingtheCuttingUnits

1.Disconnectthecuttingunitpowerdisconnectcouplers;

refertoCuttingUnitPowerDisconnect(page25).

CAUTION

Ifyoudonotdisconnectthepowertothe

cuttingunits,someonecouldaccidentally

startthecuttingunit,causingseriousinjury

tohandsandfeet.

Alwaysseparatethecuttingunitpower

disconnectcouplersbeforeworkingonthe

cuttingunits.

Figure37

Note:Whensharpening,settingtheheight-of-cut,

orperformingothermaintenanceproceduresonthe

cuttingunits,storethecuttingunitreelmotorsinthe

storagelocationonthefrontofthesuspensionarmsto

preventdamagetothem.

Important:Donotraisethesuspensiontothe

transportpositionwhenthereelmotorsareinthe

holdersinthemachineframe.Damagetothe

31

Page 32

motorsorhosescouldresult.Ifyoumustmovethe

G017821

1

3

2

machinewithoutthecuttingunitsinstalled,secure

themtothesuspensionarmsusingcableties.

5.Openthelatchesonthesuspension-armbarofthe

cuttingunityouareremoving(Figure33).

6.Disconnectthelatchesfromthecutting-unitbar.

7.Rollthecuttingunitoutfromunderthesuspension

arm.

8.Repeatsteps3through7fortheothercuttingunits

asrequired.

9.Connectthecuttingunitpowerdisconnectcouplers;

refertoCuttingUnitPowerDisconnect(page25).

TrainingPeriod

Beforemowinggreenswiththemachine,itisrecommended

thatyoundaclearareaandpracticestartingandstopping,

raisingandloweringthecuttingunits,turning,etc.This

trainingperiodwillbebenecialtotheoperatoringaining

condenceintheperformanceofthemachine.

withapointthatisalwayskeptthesamedistanceaway

fromthefrontofthemachine(Figure38).

5.Asthefrontofthebasketscrosstheedgeofthegreen,

movetheraise/lowermowleverrearward.Thiswill

stopthereelsandliftthecuttingunits.Timingofthis

procedureisimportant,sothemowersdonotcutinto

thefringearea.However,asmuchofthegreenas

possibleshouldbecuttominimizetheamountofgrass

lefttomowaroundtheouterperiphery.

6.Cutdownonoperatingtimeandeaselineupforthe

nextpassbymomentarilyturningthemachineinthe

oppositedirection,thenturninginthedirectionof

theuncutportion;i.e.,ifintendingtoturnright,rst

swingslightlyleft,thenright.Thiswillassistingetting

themachinemorequicklyalignedforthenextpass.

Followthesameprocedureforturningintheopposite

direction.Itisagoodpracticetotrytomakeasshort

ofaturnaspossible.However,turninawiderarc

duringwarmerweathertominimizethepossibilityof

bruisingtheturf.

Mowing

1.Inspectthegreenfordebris,removetheagfromthe

cup,anddeterminethebestdirectiontomow .Basethe

directiontomowonthepreviousmowingdirection.

Alwaysmowinanalternatepatternfromtheprevious

mowingsothatthegrassbladeswillbelessapttolay

downandthereforebedifculttotrapbetweenthe

reelbladesandbedknife.

2.Approachthegreenwiththefunctionalcontrolleverin

theMowpositionandthethrottleatfullspeed.Start

ononeedgeofthegreensotheribbonprocedure

ofcuttingmaybeused.Thisholdscompactiontoa

minimumandleavesaneat,attractivepatternonthe

greens.

3.Actuatetheraise/lowermowleverasthefrontedge

ofthegrassbasketscrosstheouteredgeofthegreen.

1.Alignmentmarker

Thisproceduredropsthecuttingunitstotheturfand

startsthereels.

2.Cutgrassonleft

Important:Familiarizeyourselfwiththefactthat

theNo.1cuttingunitreelisdelayedandtherefore,

youshouldpracticetotrytogaintherequired

timingnecessarytominimizethecleanupmowing

operation.

4.Overlapaminimalamountwiththepreviouscut

onreturnpasses.Toassistinmaintainingastraight

lineacrossthegreenandkeepthemachineanequal

distancefromtheedgeofthepreviouscut,establish

animaginarysightlineapproximately1.8to3m(6to

10ft)aheadofthemachinetotheedgeoftheuncut

portionofthegreen(Figure38).Somenditusefulto

includetheouteredgeofthesteeringwheelaspartof

thesightline;i.e.keepthesteeringwheeledgealigned

Note:Duetothenatureofthepowersteeringsystem,

thesteeringwheelwillnotreturntoitsoriginalposition

afteraturnhasbeencompleted.

Important:Themachineshouldneverbestopped

onagreenwiththecuttingunitreelsoperating

asdamagetotheturfmayresult.Stoppingona

wetgreenwiththemachinemayleavemarksor

indentationsfromthewheels.

7.Iftheleakdetectoralarmsoundswhilecuttingona

green,immediatelyraisethecuttingunits,drivedirectly

offofthegreenandstopthemachineinanareaaway

Figure38

3.Keepfocalspot1.8-3

m(6-10ft)aheadofthe

machine.

32

Page 33

fromthegreen.Determinethecauseofthealarmand

g014627

1

correcttheproblem.

8.Finishcuttingthegreenbymowingtheouterperiphery.

Besuretochangethedirectionofcuttingfromthe

previousmowing.Alwayskeepweatherandturf

conditionsinmindandbesuretochangethedirection

ofmowingfromthepreviouscutting.Replacetheag.

9.Attheendoftheperipherycut,momentarilypull

backontheRaise/LowerMowControllevertoshut

thereelsoffwithoutraisingthem.Continuemoving

forwarduntilthereelsstoprotating,thendriveoff

thegreenandraisethereels.Thiswillhelpprevent

dribblinggrassontothegreenwhileraisingthereels.

10.Emptythegrassbasketsofallclippingsbefore

transportingtothenextgreen.Heavywetclippings

placeanunduestrainonthebasketsandwilladd

unnecessaryweighttothemachine,therebyincreasing

theloadontheengine,hydraulicsystem,brakes,etc.

TransportingtheMachine

Makesurethecuttingunitsareinthefullupposition.Move

thefunctionalcontrollevertothetransportposition.Usethe

tractionpedaltoslowthemachinewhilegoingdownsteep

hillstoavoidlossofcontrol.Alwaysapproachroughareas

atareducedspeedandcrosssevereundulationscarefully.

Familiarizeyourselfwiththewidthofthemachine.Donot

attempttopassbetweenobjectsthatareclosetogetherso

thatcostlydamageanddowntimecanbeprevented.

InspectingandCleaningAfter Mowing

Atthecompletionofthemowingoperation,thoroughly

washthemachinewithagardenhosewithoutanozzleso

excessivewaterpressurewillnotcausecontaminationand

damagetothesealsandbearings.Aftercleaning,inspectthe

machineforpossiblehydraulicuidleaks,damageorwear

tohydraulicandmechanicalcomponents,andthecutting

unitsforsharpness.Also,lubricatethemowandliftpedal

andbrakeshaftassemblywithSAE30oilorspraylubricant

todetercorrosionandhelpkeepthemachineperforming

satisfactorilyduringthenextmowingoperation.