Page 1

FormNo.3398-694RevA

g014597

Greensmaster

®

3400TriFlex

TractionUnit

ModelNo.04520—SerialNo.316000001andUp

®

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3398-694*A

Page 2

ThisproductcomplieswithallrelevantEuropeandirectives;

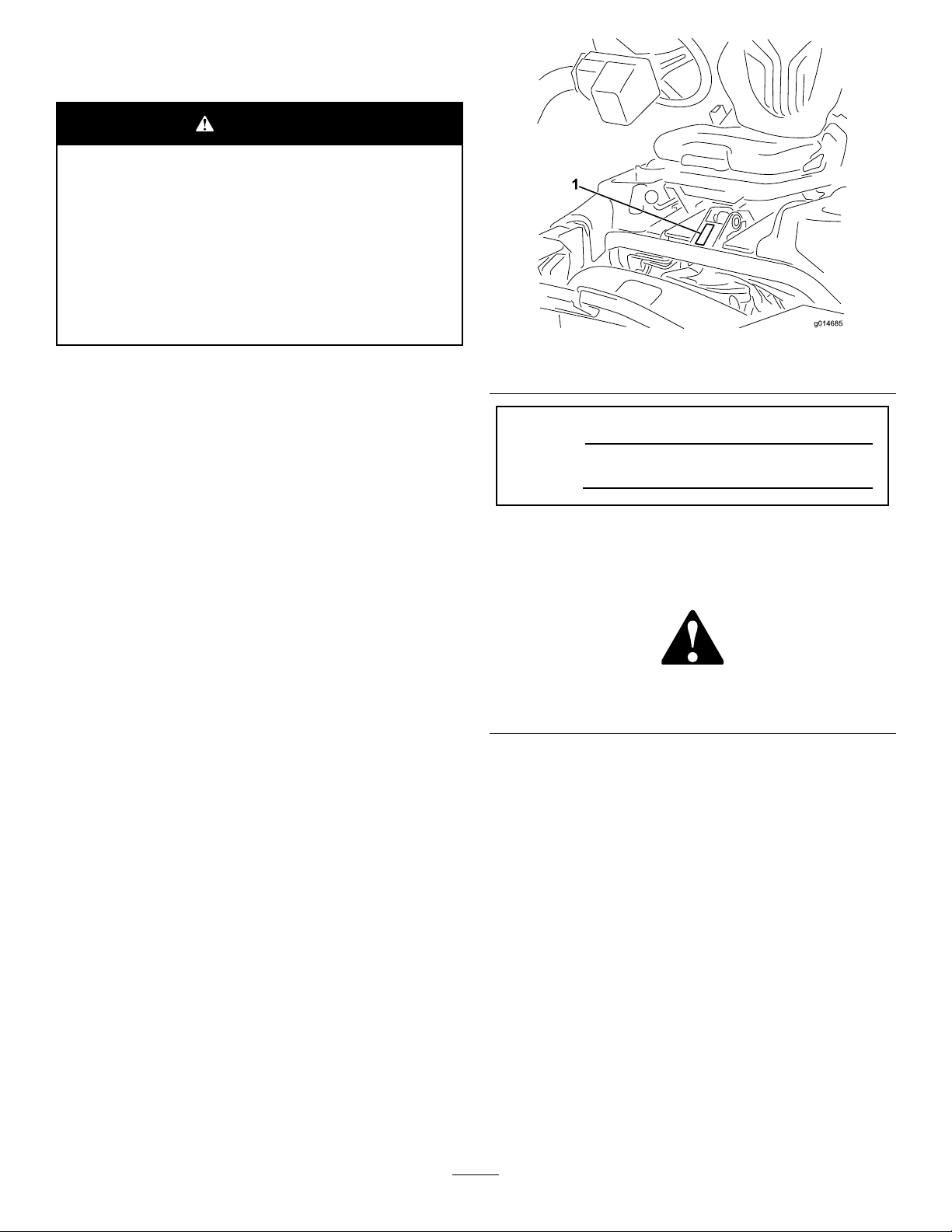

g014685

1

fordetails,pleaseseetheseparateproductspecicDeclaration

ofConformity(DOC)sheet.

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Figure1

ThissparkignitionsystemcomplieswithCanadianICES-002.

ItisaviolationofCaliforniaPublicResourceCode

Section4442or4443touseoroperatetheengineonany

forest-covered,brush-covered,orgrass-coveredlandunless

theengineisequippedwithasparkarrester,asdenedin

Section4442,maintainedineffectiveworkingorderorthe

engineisconstructed,equipped,andmaintainedforthe

preventionofre.

Introduction

Thismachineisaride-on,reel-bladelawnmowerintended

tobeusedbyprofessional,hiredoperatorsincommercial

applications.Itisprimarilydesignedforcuttinggrasson

well-maintainedlawnsinparks,golfcourses,sportselds,

andoncommercialgrounds.Itisnotdesignedforcutting

brush,mowinggrassandothergrowthalongsidehighways,

orforagriculturaluses.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafety-alertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure2

1.Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready.Figure1identiesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

©2015—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Contents

Safety...........................................................................4

SafeOperatingPractices...........................................4

ToroMowerSafety..................................................5

SoundPowerLevel..................................................6

SoundPressureLevel...............................................6

Hand-ArmVibrationLevel......................................6

WholeBodyVibrationLevel....................................6

SafetyandInstructionalDecals.................................7

Setup...........................................................................11

1InstallingtheRollBar...........................................12

2InstallingtheSeat.................................................12

3InstallingtheSteeringWheel..................................12

4ActivatingandChargingtheBattery........................12

5InstallingtheOilCooler(optional).........................14

6InstallingtheGrass-BasketHooks..........................14

7InstallingtheCuttingUnits...................................15

8AddingRearWeight.............................................15

9InstallingEUDecals.............................................15

10ReducingtheTirePressure..................................15

11BurnishingtheBrakes.........................................15

ProductOverview.........................................................16

Controls...............................................................16

Specications........................................................19

Attachments/Accessories........................................19

Operation....................................................................20

ThinkSafetyFirst...................................................20

CheckingtheEngineOil..........................................20

FillingtheFuelTank...............................................21

UsingBiodieselFuel...............................................22

CheckingtheCoolingSystem...................................23

CheckingtheHydraulic-FluidLevel..........................23

DrainingWaterfromtheFuelFilter...........................24

CheckingtheReel-to-BedknifeContact.....................25

CheckingtheTirePressure......................................25

CheckingtheTorqueoftheWheelNuts.....................25

BreakingintheMachine..........................................25

StartingandStoppingtheEngine..............................25

CheckingtheSafetyInterlockSystem........................26

InstallingandRemovingtheCuttingUnits.................26

SettingtheReelSpeed.............................................29

Mowing................................................................29

InspectingandCleaningafterMowing.......................30

DrivingtheMachinewithoutMowing.......................30

TransportingtheMachine........................................30

TowingtheMachine...............................................31

Maintenance.................................................................33

RecommendedMaintenanceSchedule(s)......................33

DailyMaintenanceChecklist....................................34

EngineMaintenance..................................................35

ServicingtheAirCleaner.........................................35

ChangingtheEngineOilandFilter...........................35

FuelSystemMaintenance...........................................36

ReplacingtheFuelFilter/WaterSeparator..................36

InspectingtheFuelLinesandConnections.................37

ElectricalSystemMaintenance....................................37

ServicingtheBattery...............................................37

StoringtheBattery..................................................38

LocatingtheFuses..................................................38

Jump-StartingtheMachine......................................39

DriveSystemMaintenance.........................................39

AdjustingtheTransmissionforNeutral.....................39

AdjustingtheTransportSpeed.................................40

AdjustingtheMowingSpeed....................................41

CoolingSystemMaintenance......................................41

CleaningtheRadiatorScreen....................................41

BrakeMaintenance....................................................42

AdjustingtheBrakes...............................................42

BeltMaintenance......................................................42

AdjustingtheAlternatorBelt...................................42

HydraulicSystemMaintenance....................................43

ChangingtheHydraulicFluidandFilter.....................43

CheckingtheHydraulicLinesandHoses....................43

CuttingUnitMaintenance...........................................44

BacklappingtheReels.............................................44

DiagnosticsSystem....................................................45

DiagnosingtheServiceIndicatorLight......................45

Storage........................................................................45

3

Page 4

Safety

Thismachinehasbeendesignedinaccordancewith

ENISO5395:2013andANSIB71.4-2012andmeetsthese

standardswhentheappropriateweightkitisadded.

Improperuseormaintenancebytheoperatororowner

canresultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandalwayspay

attentiontothesafetyalertsymbol(Figure2),which

meansCaution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeinstructionmay

resultinpersonalinjuryordeath.

SafeOperatingPractices

Training

•ReadtheOperator'sManualandothertrainingmaterial.If

theoperator(s)ormechanic(s)cannotreadthemanualitis

theowner'sresponsibilitytoexplainthismaterialtothem.

•Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateorservice

theequipment.Localregulationsmayrestricttheageof

theoperator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtopeopleorproperty.

Preparation

•Evaluatetheterraintodeterminewhataccessoriesand

attachmentsareneededtoproperlyandsafelyperform

thejob.Useonlyaccessoriesandattachmentsapproved

bythemanufacturer.

•Wearappropriateclothingincludingsubstantial,

slip-resistantfootwear,safetyglasses,andhearing

protection.Tiebacklonghair.Donotwearjewelry.

•Inspecttheareawhereyouwillusetheequipmentand

removeallobjectsthatcouldbethrownbythemachine,

suchasrocks,toys,andwire.

•Checkthatoperatorpresencecontrols,safetyswitches,

andguardsareattachedandfunctioningproperly .Donot

operatethemachineunlesstheyarefunctioningproperly.

Operation

•Donotoperatetheengineinaconnedspacewhere

dangerouscarbonmonoxideandotherexhaustgasses

cancollect.

•Operatethemachineonlyingoodlight,keepingaway

fromholesandhiddenhazards.

•Besurealldrivesareinneutralandparkingbrakeis

engagedbeforestartingengine.Startengineonlyfrom

theoperator'sposition.

•Slowdownanduseextracareonhillsides.Turfconditions

canaffectthemachine'sstability.Usecautionwhile

operatingneardrop-offs.

•Slowdownandusecautionwhenmakingturnsandwhen

changingdirectionsonslopes.

•Neveroperatewithoutguardssecurelyinplace.Besure

allinterlocksareattached,adjusted,andfunctioning

properly.

•Donotchangetheenginegovernorsettingoroverspeed

theengine.

•Stopthemachineonlevelground,lowerthecuttingunits,

disengagethedrives,engagetheparkingbrake,andshut

offtheenginebeforeleavingtheoperator'spositionfor

anyreason,includingemptyingthegrassbaskets.

•Stopandinspectthemachineafterstrikingobjectsorif

anabnormalvibrationoccurs.Makenecessaryrepairs

beforeresumingoperations.

•Keephandsandfeetawayfromthecuttingunits.

•Lookbehindanddownbeforebackinguptobesureof

aclearpath.

•Nevercarrypassengersandkeeppetsandbystanders

away.

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalks.Stopthereelsifnot

mowing.

•Donotoperatethemachinewhentired,ill,orunderthe

inuenceofalcoholordrugs.

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

•Usecarewhenloadingorunloadingthemachineintoa

trailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,trees,

orotherobjectsthatmayobscurevision.

RolloverProtectionSystem

(ROPS)—UseandMaintenance

•TheROPSisanintegralandeffectivesafetydevice.Use

theseatbeltwhenoperatingthemachine.

•Ensurethatyoucanreleasetheseatbeltquicklyinthe

eventofanemergency.

•Checkcarefullyforoverheadclearances(i.e.branches,

doorways,electricalwires)beforedrivingunderany

objectsanddonotcontactthem.

•KeeptheROPSinsafeoperatingconditionby

periodicallythoroughlyinspectingfordamageand

keepingallmountingfastenerstight.

•ReplaceadamagedROPS.Donotrepairorrevise.

•DonotremovetheROPS.

•AnyalterationstoaROPSmustbeapprovedbythe

manufacturer.

4

Page 5

MaintenanceandStorage

•Parkthemachineonlevelground,disengagethedrives,

lowerthecuttingunits,settheparkingbrake,stopthe

engine,removethekey,anddisconnectsparkplugwire(s).

Waitforallmovementtostopbeforeadjusting,cleaning,

orrepairingthemachine.

•Cleangrassanddebrisfromcuttingunits,drives,mufers,

andtheenginetohelppreventres.Cleanupoilorfuel

spills.

•Lettheenginecoolbeforestoringanddonotstorethe

machinenearames.

•Shutoffthefuelwhilestoringortransportingthe

machine.Donotstorefuelnearamesordrainthefuel

tankindoors.

•Neverallowuntrainedpersonneltoservicethemachine.

•Usejackstandstosupportcomponentswhenrequired.

•Carefullyreleasepressurefromcomponentswithstored

energy.

•Disconnectthebatteryandremovethesparkplugwire(s)

beforemakinganyrepairs.Disconnectthenegative

terminalrstandthepositivelast.Connectthepositive

terminalrstandthenegativeterminallast.

•Usecareandweargloveswhencheckingthereels.

•Keephandsandfeetawayfrommovingparts.Ifpossible,

donotmakeadjustmentswiththeenginerunning.

•Chargebatteriesinanopen,well-ventilatedarea,away

fromsparkandames.Unplugthechargerbefore

connectingordisconnectingitfromthebattery.Wear

protectiveclothinganduseinsulatedtools.

•Keepallpartsingoodworkingconditionandallhardware

andhydraulicttingstightened.Replaceallwornor

damageddecals.

ToroMowerSafety

ThefollowinglistcontainssafetyinformationspecictoToro

productsorothersafetyinformationthatyoumustknowthat

isnotincludedintheANSIstandards.

Thisproductiscapableofamputatinghandsandfeetand

ofthrowingobjects.Alwaysfollowallsafetyinstructionsto

avoidseriousinjuryordeath.

Useofthisproductforpurposesotherthanitsintendeduse

couldprovedangeroustouserandbystanders.

Operation

•Knowhowtostoptheenginequickly.

•Checkthesafetyinterlockswitchesdailyforproper

operation.

•Beforeattemptingtostarttheengine,disengageallblade

attachmentclutches,shiftintoneutral,andengagethe

parkingbrake.

•Usingthemachinedemandsattention.Topreventloss

ofcontrol:

–Donotdriveclosetosandtraps,ditches,creeks,or

otherhazards.

–Reducespeedwhenmakingsharpturns.Avoid

suddenstopsandstarts.

–Thismachineisnotdesignedorequippedforon-road

useandisa“slow-movingvehicle.”Ifyoumustcross

ortravelonapublicroad,youshouldbeawareofand

complywithlocalregulations,suchasrequiredlights,

slow-movingvehiclesigns,andreectors.

–Watchoutfortrafcwhennearorcrossingroads.

Alwaysyieldtheright-of-way.

–Applytheservicebrakeswhengoingdownhillto

keepforwardspeedslowandtomaintaincontrolof

themachine.

•Thegrassbasketsmustbeinplaceduringoperation

ofthereelsorthatchersformaximumsafety.Shutthe

engineoffbeforeemptyingthebaskets.

•Raisethecuttingunitswhendrivingfromoneworkarea

toanother.

•Donottouchtheengine,mufer,orexhaustpipewhile

theengineisrunningorsoonafterithasstoppedbecause

theseareascouldbehotenoughtocauseburns.

•Stayclearoftherotatingscreenatthesideoftheengine

topreventdirectcontactwithyourbodyorclothing.

•Ifacuttingunitstrikesasolidobjectorvibrates

abnormally,stopimmediately,turntheengineoff,waitfor

allmotiontostop,andinspectthemachinefordamage.

Repairorreplaceadamagedreelorbedknifebefore

continuingoperation.

•Beforegettingofftheseat,movethefunctionalcontrol

levertoNEUTRAL,raisethecuttingunits,andwaitforthe

reelstostopspinning.Settheparkingbrake.Stopthe

engineandremovethekeyfromtheignitionswitch.

•Traverseslopescarefully.Donotstartorstopsuddenly

whentravelinguphillordownhill.

•Theoperatormustbeskilledandtrainedinhowtodrive

onhillsides.Failuretousecautiononslopesorhillsmay

causelossofcontrolandcausethemachinetotiporroll,

possiblyresultinginpersonalinjuryordeath.

•Iftheenginestallsorlosesheadwayandcannotmakeit

tothetopofaslope,donotturnthemachinearound.

Alwaysbackslowly,straightdowntheslope.

•Whenapersonoranimalappearsunexpectedlyinor

nearthemowingarea,stopmowing.Carelessoperation,

combinedwithterrainangles,ricochets,orimproperly

positionedguardscanleadtothrown-objectinjuries.Do

notresumemowinguntiltheareaiscleared.

MaintenanceandStorage

•Ensurethatallhydrauliclineconnectorsaretightandthat

allhydraulichosesandlinesareingoodconditionbefore

applyingpressuretothesystem.

•Keepyourbodyandhandsawayfrompin-holeleaksor

nozzlesthatejecthydraulicuidunderhighpressure.

5

Page 6

Usepaperorcardboard,notyourhands,tosearchfor

leaks.Hydraulicuidescapingunderpressurecanhave

sufcientforcetopenetratetheskinandcauseserious

injury.

SoundPowerLevel

Thisunithasaguaranteedsoundpowerlevelof98dBA,

whichincludesanUncertaintyValue(K)of1dBA.

•Beforedisconnectingorperforminganyworkonthe

hydraulicsystem,allpressureinthesystemmustbe

relievedbystoppingtheengineandloweringthecutting

unitsandattachmentstotheground.

•Checkallfuellinesfortightnessandwearonaregular

basis.Tightenorrepairthemasneeded.

•Iftheenginemustberunningtoperformamaintenance

adjustment,keephands,feet,clothing,andanypartsof

thebodyawayfromthecuttingunits,attachments,and

anymovingparts,especiallythescreenatthesideofthe

engine.Keepeveryoneaway.

•Donotoverspeedtheenginebychanginggovernor

settings.Toensuresafetyandaccuracy,havean

AuthorizedToroDistributorcheckthemaximumengine

speedwithatachometer..

•Theenginemustbeshutoffbeforecheckingtheoilor

addingoiltothecrankcase.

•Ifmajorrepairsareeverneededorifassistanceisdesired,

contactanAuthorizedToroDistributor.

•Toensureoptimumperformanceandcontinuedsafety

certicationofthemachine,useonlygenuineToro

replacementpartsandaccessories.Replacementparts

andaccessoriesmadebyothermanufacturerscouldbe

dangerous,andsuchusecouldvoidtheproductwarranty.

Soundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinISO11094.

SoundPressureLevel

Thisunithasasoundpressurelevelattheoperator’searof84

dBA,whichincludesanUncertaintyValue(K)of1dBA.

Soundpressurelevelwasdeterminedaccordingtothe

proceduresoutlinedinENISO5395:2013.

Hand-ArmVibrationLevel

Measuredvibrationlevelforrighthand=0.22m/s

Measuredvibrationlevelforlefthand=0.24m/s

UncertaintyValue(K)=0.24m/s

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinENISO5395:2013.

2

2

2

WholeBodyVibrationLevel

Measuredvibrationlevel=0.41m/s

UncertaintyValue(K)=0.21m/s

2

2

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinENISO5395:2013.

6

Page 7

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

119-9343

115-8156

1.Reelheight3.8Bladecuttingunit5.14Bladecuttingunit7.Fast

2.5Bladecuttingunit4.11Bladecuttingunit6.Reelspeed

8.Slow

7

Page 8

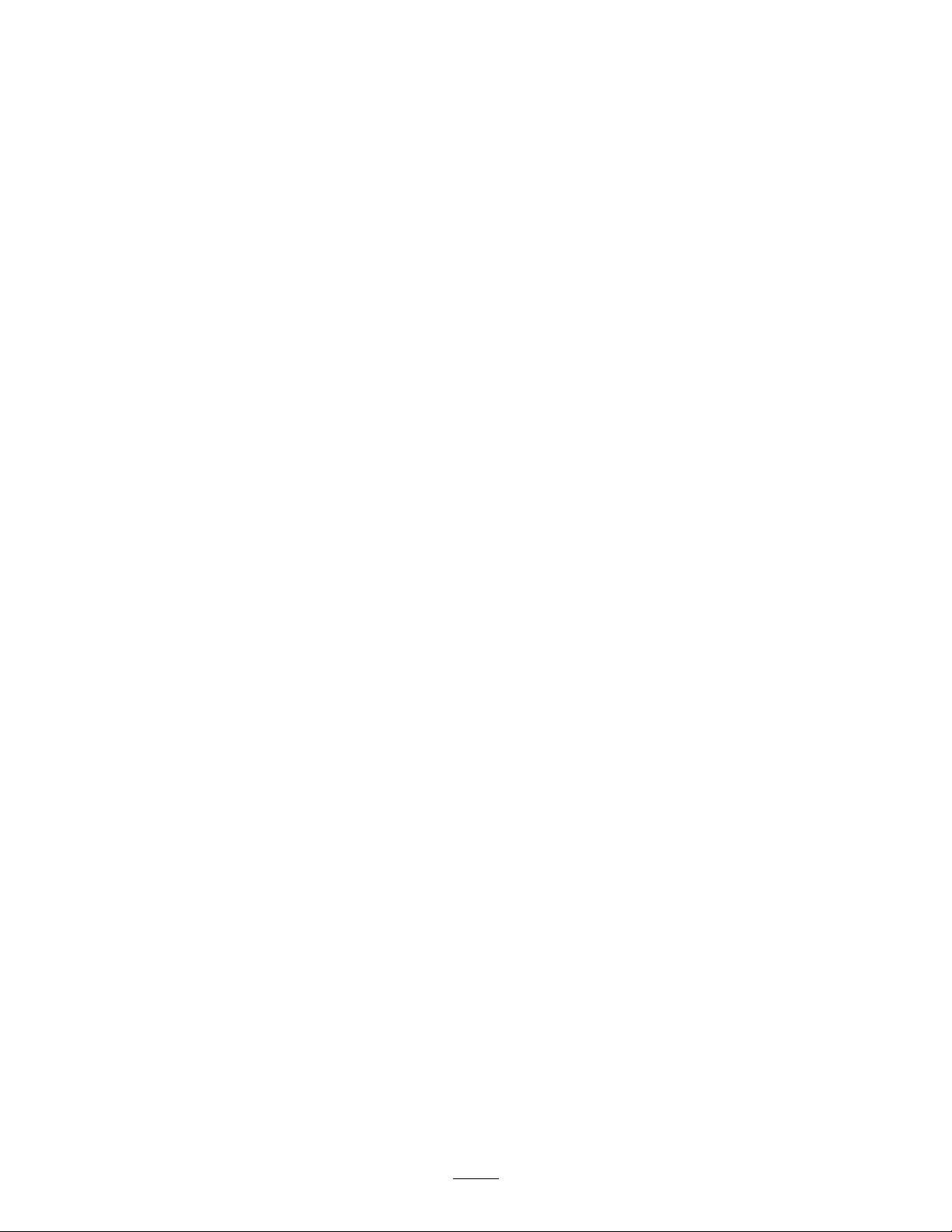

115-8155

1.Warning—readtheOperator'sManual,donotprimeoruse

startinguid.

117–2718

131-2046

1.ReadtheOperator's

manualforfuse

information.

115-8203

2.Radiatorfan—50Amp

1.Doublelights

2.Singlelight

1.Presspedaltounlock

3.Off

119-9346

2.ReadtheOperator's

Manualformore

information.

115-8226

1.Tippinghazard—readtheOperator'smanual;alwayswear

aseatbeltwhenoperating;donotremovetherollover

protectionsystem(ROPS).

8

Page 9

BatterySymbols

Someorallofthesesymbolsareonyourbattery .

1.Explosionhazard

2.Nore,openames,or

smoking.

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection.9.Flusheyesimmediately

5.ReadtheOperator’s

Manual.

6.Keepbystandersasafe

7.Weareyeprotection;

8.Batteryacidcancause

10.Containslead;donot

distancefromthebattery.

explosivegasescan

causeblindnessandother

injuries.

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

discard.

132-9548

1.Enginespeed—fast

2.Enginespeed—slow8.Reel—transport

3.Lowerandengagethereels9.Reel—mow

4.Raiseanddisengagethereels10.Reel—backlaping

5.Reelspeed—fast11.Moveforward

6.Reelspeed—slow

7.Reelspeed—neutral

9

Page 10

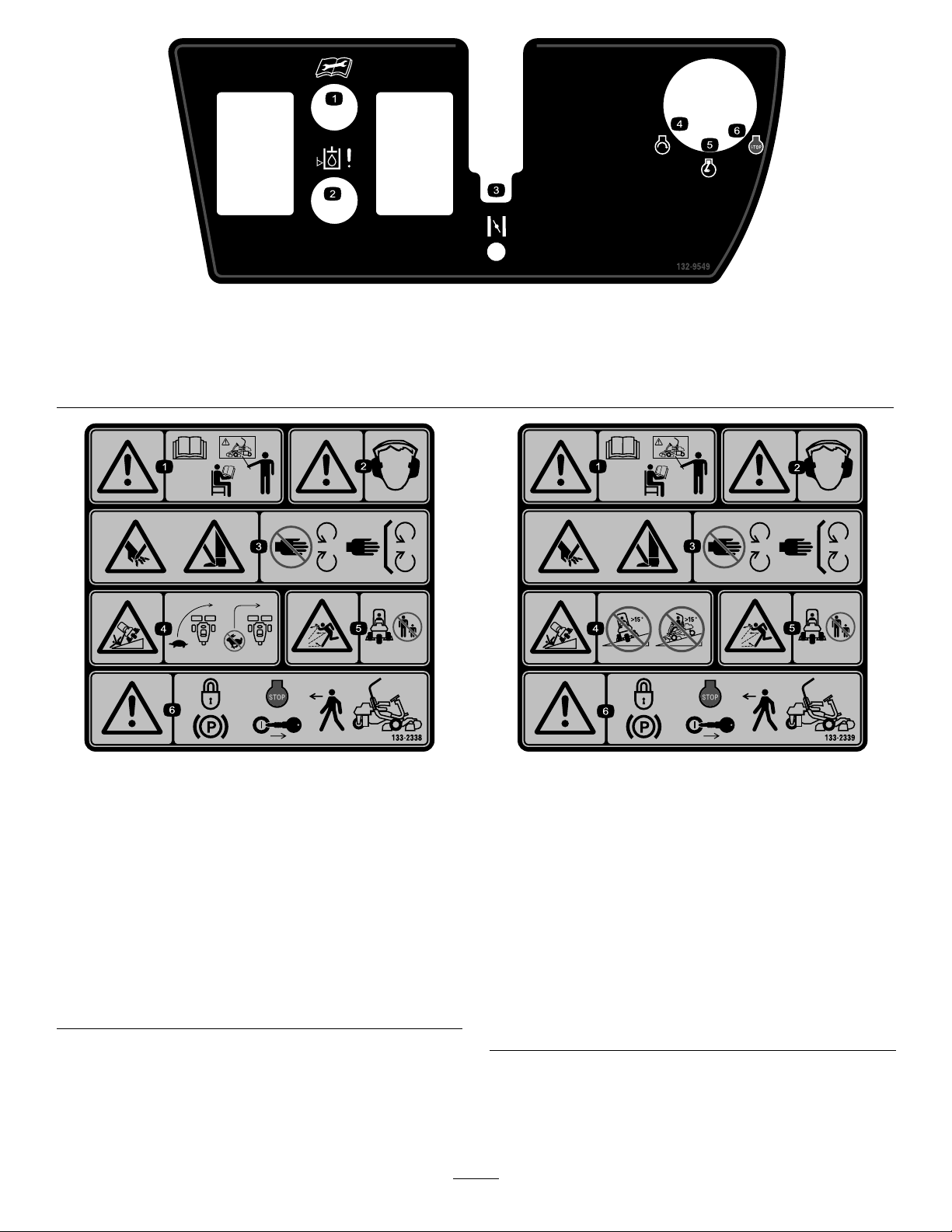

132-9549

1.ReadtheOperator'sManualbeforeservicingorperforming

maintenance.

2.Hydraulicuidlevel

3.Choke

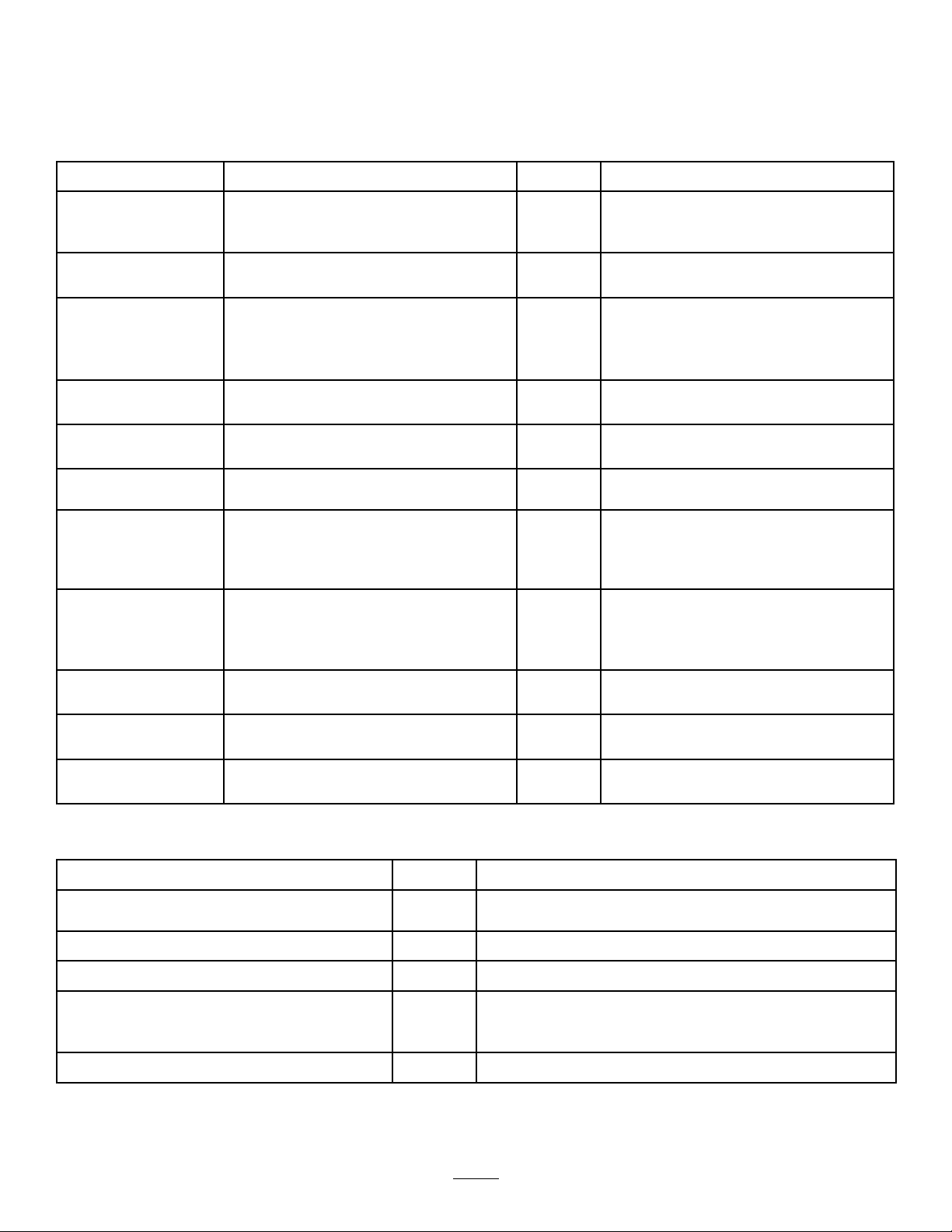

133-2338

1.Warning—readthe

Operator’sManual,do

notoperatethismachine

unlessyouaretrained.

2.Warning—wearhearing

protection.

3.Cutting/dismemberment

hazardofhandorfoot,

mowerblade—stayaway

frommovingparts;keep

allguardsandshieldsin

place.

4.Tippinghazard—slow

machinebeforeturning,

donotturnathighspeeds.

5.Thrownobject

hazard—keepbystanders

asafedistancefromthe

machine.

6.Warning—locktheparking

brake,stoptheengine

andremovetheignition

keybeforeleavingthe

machine.

4.Engine—start

5.Engine—run

6.Engine—stop

ReplacesDecal133-2338forCEMachines

1.Warning—readthe

Operator’sManual,do

notoperatethismachine

unlessyouaretrained.

2.Warning—wearhearing

protection.

3.Cutting/dismemberment

hazardofhandorfoot,

mowerblade—stayaway

frommovingparts;keep

allguardsandshieldsin

place.

133-2339

4.Tippinghazard—donot

driveacrossordown

slopesgreaterthan15

degrees.

5.Thrownobject

hazard—keepbystanders

asafedistancefromthe

machine.

6.Warning—locktheparking

brake,stoptheengine

andremovetheignition

keybeforeleavingthe

machine.

10

Page 11

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

6

7

8

Rollbar1

Bolt(1/2x3-3/4inches)

Flange-nut(1/2inch)

Seat-completionkit

Steeringwheel

Locknut(1-1/2inches)

Washer1

Steering-wheelcap

Nopartsrequired

Nopartsrequired

Grass-baskethook

Flangebolts12

Gaugebar

Cuttingunit(obtainfromyourT oro

Distributor)

Grassbasket

WeightKit,121-6665(purchase

separately)Note:Thiskitisnotrequired

forunitswiththe3wheeldrivekit

installed.

Qty.

4

4

1Installtheseattothebase.

1

1

1

–

–

6

1

3

3

1Addrearweight.

Installtherollbar.

Installthesteeringwheel.

Activateandchargethebattery.

Installtheoptionaloilcooler.

Installthegrass-baskethooks.

Installthecuttingunits.

Use

9

10

11

Warningdecal,133-23381

Nopartsrequired

Nopartsrequired

MediaandAdditionalParts

Description

Operator'sManual(machine)

Engineoperator'smanual(engine)

PartsCatalog

Operatortrainingmaterials

Pre-deliveryInspectionSheet

Noiseratingcerticate

Certicateofcompliance

Ignitionkeys2

Qty.

InstallEUdecals,ifrequired.

–

–

1

1

1

1

1

1

1

Readbeforeoperatingthemachine

Saveforfuturepartsordering

Viewbeforeoperatingthemachine

Saveforfuturereference

Starttheengine

Reducethetirepressure.

Burnishthebrakes.

Use

11

Page 12

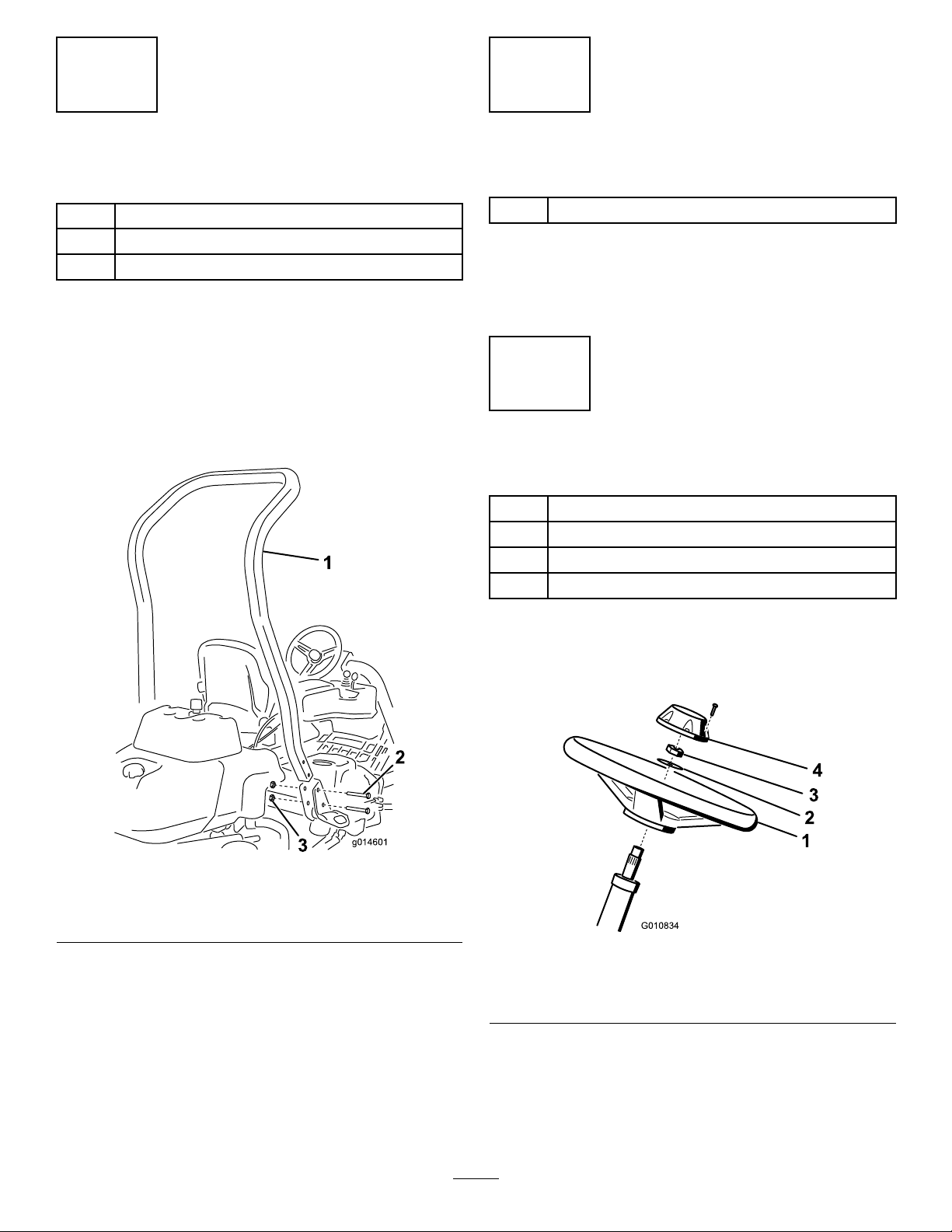

1

g014601

1

2

3

2

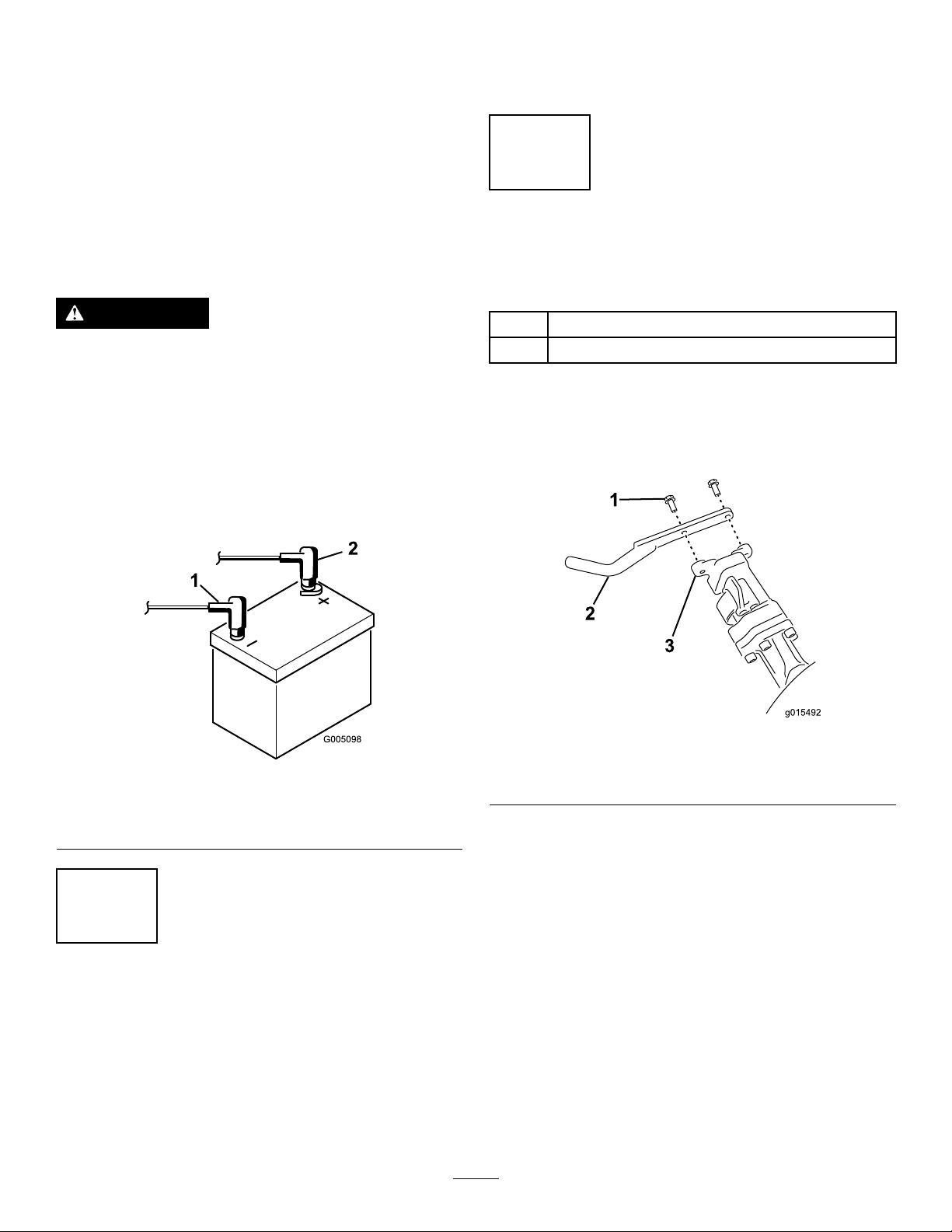

InstallingtheRollBar

Partsneededforthisprocedure:

1Rollbar

4

Bolt(1/2x3-3/4inches)

4

Flange-nut(1/2inch)

Procedure

1.Removethetopcratesupportfromthecrate.

2.Removetherollbarfromthecrate.

3.Installtherollbarintothepocketsoneachsideof

themachine,using4bolts(1/2x3-3/4inches)and4

ange-nuts(1/2inch)(Figure3).

InstallingtheSeat

Partsneededforthisprocedure:

1

Seat-completionkit

Procedure

Acquireyourdesiredseatkitfromyourdistributorandinstall

itasdirectedintheinstructionincludedwiththekit.

3

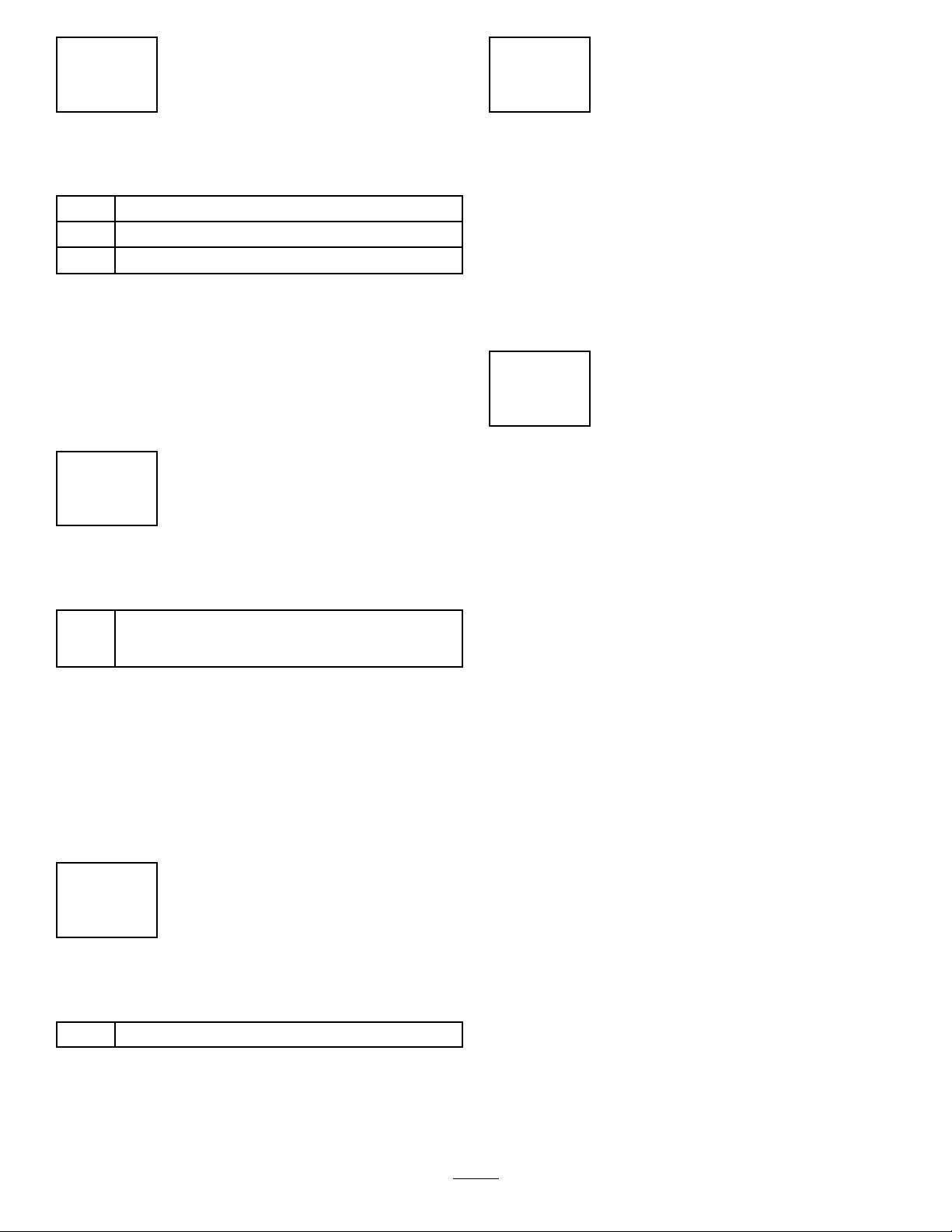

InstallingtheSteeringWheel

Partsneededforthisprocedure:

1

Steeringwheel

1

Locknut(1-1/2inches)

1Washer

1

Steering-wheelcap

Figure3

1.Rollbar

2.Bolt(1/2x3-3/4inches)

4.Torquethefastenersto136to149N∙m(100to110

ft-lb).

3.Flange-nut(1/2inch)

Procedure

1.Slidethesteeringwheelontothesteeringshaft(Figure

4).

Figure4

1.Steeringwheel

2.Washer

2.Slidethewasherontothesteeringshaft(Figure4).

3.Securethesteeringwheeltotheshaftwithalocknut

andtightenitto27to35N∙m(20to26ft-lb)(Figure4).

4.Installthecaptothesteeringwheelandsecureitwith6

bolts(Figure4).

3.Locknut

4.Cap

12

Page 13

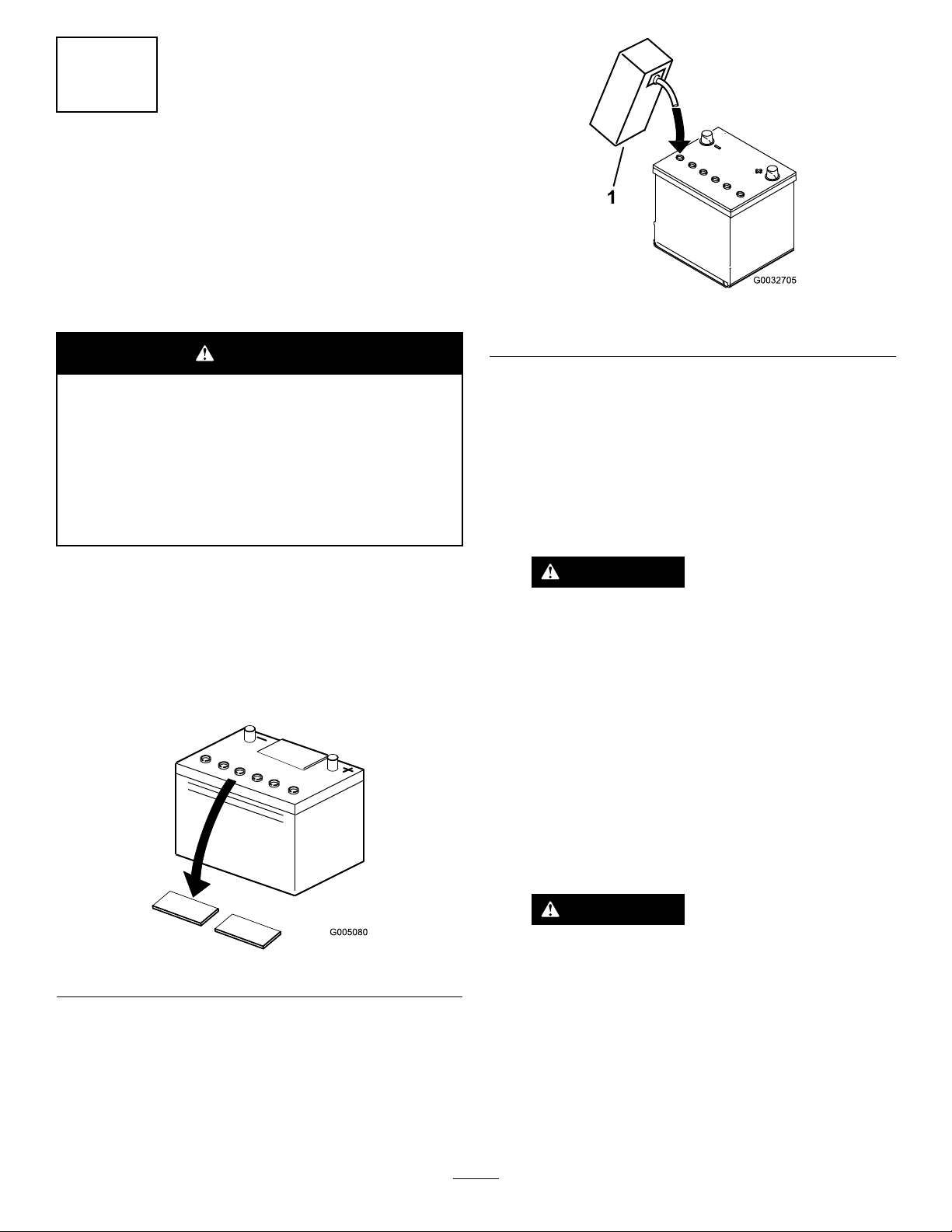

4

ActivatingandChargingthe

Battery

NoPartsRequired

Procedure

Useonlyelectrolyte(1.265specicgravity)tollthebattery

initially.

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

Washhandsafterhandling.

1.Removethefastenersandbatteryclampandliftout

thebattery.

Important:Donotaddelectrolytewhilethe

batteryisinthemachine.Y oucouldspillit,

causingcorrosion.

2.Cleanthetopofthebatteryandremovetheventcaps

(Figure5).

Figure6

1.Electrolyte

4.Allowapproximately20to30minutesforthe

electrolytetosoakintotheplates.Fillasnecessaryto

bringtheelectrolytetowithinabout6mm(1/4inch)

ofthebottomofthellwell(Figure6).

5.Connecta2to4Abatterychargertothebatteryposts.

Chargethebatteryforatleast2hoursat4Aorforat

least4hoursat2Auntilthespecicgravityis1.250

orhigherandthetemperatureisatleast16°C(60°F)

withallcellsgassingfreely .

WARNING

Chargingthebatteryproducesgassesthatcan

explode.

Neversmokenearthebatteryandkeepsparks

andamesawayfromthebattery.

Important:Ifyoudonotchargethebatteryforat

leastthetimespeciedabove,youmayreducethe

lifeofthebattery.

6.Whenthebatteryischarged,disconnectthecharger

fromtheelectricaloutletandbatteryposts.

Figure5

3.Carefullylleachcellwithelectrolyteuntiltheplates

arecoveredwithabout6mm(1/4inch)ofuid(Figure

6).

Note:Afterthebatteryhasbeenactivated,add

onlydistilledwatertoreplacenormalloss,although

maintenance-freebatteriesshouldnotrequirewater

undernormaloperatingconditions.

WARNING

Batteryterminalsormetaltoolscouldshort

againstmetaltractorcomponentscausing

sparks.Sparkscancausethebatterygassesto

explode,resultinginpersonalinjury.

•Whenremovingorinstallingthebattery,

donotallowthebatteryterminalstotouch

anymetalpartsofthetractor.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsof

thetractor.

13

Page 14

Important:Failuretocorrectlyactivatethe

batterymayresultinbatterygassingand/or

prematurebatteryfailure.

7.Installtheventcaps.

8.Placethebatteryonthebatterytrayandsecureitwith

thebatteryclampandfastenersremovedpreviously.

9.Installthepositivecable(red)tothepositive(+)

terminalandthenthenegativecable(black)tothe

negative(–)terminalofthebatteryandsecurethem

withtheboltsandnuts(Figure7).Slidetherubber

bootoverthepositiveterminaltopreventapossible

shortfromoccurring.

WARNING

Incorrectbatterycableroutingcoulddamagethe

tractorandcablescausingsparks.Sparkscancause

thebatterygassestoexplode,resultinginpersonal

injury.

•Alwaysdisconnectthenegative(black)battery

cablebeforedisconnectingthepositive(red)

cable.

•Alwaysconnectthepositive(red)batterycable

beforeconnectingthenegative(black)cable.

heavy-dutyuse(mowingotherthangreens,suchasfairways

orverticutting),installaHydraulicOilCoolerKit,PartNo.

119-1691.

6

InstallingtheGrass-Basket Hooks

Partsneededforthisprocedure:

6

Grass-baskethook

12Flangebolts

Procedure

Installthe6grass-baskethooksontotheendsofthe

suspension-armbarsusingthe12angebolts(Figure8).

Figure7

1.Negative(-)

2.Positive(+)

5

InstallingtheOilCooler (optional)

NoPartsRequired

Procedure

Ifyouareoperatingthemachineinhotclimates,wherethe

ambienttemperatureisabove29°C(85°F),orusingitfor

1.Flangebolt

2.Grass-baskethook

Figure8

3.Suspension-armbar

14

Page 15

7

10

InstallingtheCuttingUnits

Partsneededforthisprocedure:

1

Gaugebar

3

Cuttingunit(obtainfromyourT oroDistributor)

3

Grassbasket

Procedure

1.Setupthecuttingunitsasdescribedinthecuttingunit

Operator’sManual.

2.Applygreasetotheinsidediameterofthedrivecoupler.

3.InstallthecuttingunitsasdescribedinInstallingthe

CuttingUnits(page27).

8

AddingRearWeight

Partsneededforthisprocedure:

WeightKit,121-6665(purchaseseparately)Note:

1

Thiskitisnotrequiredforunitswiththe3wheeldrive

kitinstalled.

ReducingtheTirePressure

NoPartsRequired

Procedure

Thetiresareover-inatedatthefactoryforshipping

purposes.Reducethepressuretotheproperlevelsbefore

startingthemachine.RefertoCheckingtheTirePressure

(page25).

11

BurnishingtheBrakes

NoPartsRequired

Procedure

Firmlyapplythebrakesanddrivethemachineatmowing

speeduntilthebrakesarehot,asindicatedbytheirsmell.Y ou

mayneedtoadjustthebrakesafterthebreak-inperiod;refer

toAdjustingtheBrakes(page42).

Procedure

ThisunitcomplieswithENISO5395:2013andANSI

B71.4-2012whenequippedwithWeightKit,PartNo.

121-6665.

Note:Iftheunitisequippedwitha3-WheelDriveKit,

additionalweightisnotrequiredtomeetENISO5395:2013

andANSIB71.4-2012.

9

InstallingEUDecals

Partsneededforthisprocedure:

1Warningdecal,133-2338

Procedure

IfthismachinewillbeusedintheEU ,afxthewarning-decal

133-2338overEnglishwarning-decal133-2339.

15

Page 16

ProductOverview

g014674

1

2

3

4

5

6

7

8

g014603

1

2

3

Figure10

Figure9

1.Engine

2.Rollbar6.Tractionpedal

3.Controlpanel

4.Seat

5.Steeringwheel

7.Footrest

8.Reelswithgrassbaskets

1.Tractionpedal—forward3.Steering-arm-locking

2.Tactionpedal—reverse

pedal

Controls

TractionPedal

Thetractionpedal(Figure10)has3functions:tomakethe

machinemoveforward,tomoveitbackward,andtostopthe

machine.Pressthetopofthepedaltomoveforwardandthe

bottomofthepedaltomovebackwardortoassistinstopping

whenmovingforward.Also,allowthepedaltomovetothe

neutralpositiontostopthemachine.Foroperatorcomfort,

donotresttheheelofyourfootonreversewhenoperating

forward(Figure11).

Groundspeedsareasfollows:

•3.2to8km/h(2to5mph)forwardmowingspeed

•16km/h(10mph)maximumtransportspeed

•4.0km/h(2.5mph)reversespeed

Steering-Arm-LockingPedal

Pressthepedal(Figure10)andraiseorlowerthesteering

armforoperatorcomfort,then,releasethepedaltolockthe

arminplace.

Figure11

ThrottleLever

Thethrottlelever(Figure12)allowsyoutocontrolthespeed

oftheengine.MovethethrottlelevertowardtheFAST

positiontoincreasestheenginespeed;moveittowardthe

SLOWpositiontodecreasetheenginespeed.

Note:Youcannotstoptheenginecannotusingthethrottle

lever.

16

Page 17

Engine-Oil-PressureLight

g014600

1

Thelight(Figure12)glowsiftheengineoilpressuredrops

belowasafelevel.

Water-TemperatureLight

Thelight(Figure12)glowsandtheengineautomaticallyshuts

downwhentheengine-coolanttemperaturegetstoohigh.If

theengineshutsdown,youcanstarttheengineanddrive

themachinefor10secondsbeforeitwillshutdownagain,

allowingyoutomovethemachinetoalocationwhereyou

canallowittocooldown.

Service-IndicatorLight

Figure12

1.Throttlelever6.Battery-warninglight

2.Raise/Lowermowcontrol7.Service-indicatorlight

3.Functional-controllever

4.Ignitionswitch9.Water-temperaturelight

5.Engine-oil-pressurelight

8.Glow-plug-indicatorlight

Raise/LowerMowControl

Movingthecontrol(Figure12)forwardduringoperation

lowersthecuttingunitsandstartsthereels.Pullbackonthe

controltostopthereelsandraisethecuttingunits.During

operationthereelscanbestoppedbypullingbackonthe

controlmomentarilyandreleasingit.Startthereelsby

movingthecontrolforward.

FunctionalControlLever

Thefunctionalcontrollever(Figure12)provides2traction

selectionsplusaNEUTRALposition.Itispermissibletoshift

frommowtotransportortransporttomow(nottoneutral)

whilethemachineisinmotion.Nodamagewillresult.

Theservice-indicatorlight(Figure12)illuminateswhenthe

machinesensorsdetectanissuewithoneofthesystems

ofthemachine.Ifthislightilluminates,stopwhatyouare

doinganddrivetoasafelocationwhereyouoraservice

techniciancandiagnosetheproblem.Formoreinformation

ondiagnosingsystemissuesusingtheservice-indicatorlight,

refertoDiagnosingtheServiceIndicatorLight(page45).

Glow-Plug-IndicatorLight

Whentheglow-plug-indicatorlight(Figure12)islit,it

indicatestheglowplugsareon.

Note:Theglow-plug-indicatorlightmayilluminatefora

shorttimeaftertheenginehasstarted;thisisnormal.

HourMeter

Thehourmeter(Figure13)indicatesthetotalhoursthe

machinehasoperated.Itstartstofunctionwheneveryou

rotatetheignitionswitchtotheONposition.

•REARPosition—neutralandbacklapping

•MIDDLEPosition—usedformowingoperation

•FRONTPosition—usedfortransportoperation

IgnitionSwitch

Insertthekeyintotheswitch(Figure12)andturnitclockwise

asfaraspossibletotheSTARTpositiontostarttheengine.

Releasethekeyassoonastheenginestarts;thekeywillmove

totheONposition.Turnthekeycounterclockwisetothe

OFFpositiontostoptheengine.

Battery-WarningLight

Thelight(Figure12)glowsifthebatterychargeislow .

Figure13

1.Hourmeter

17

Page 18

Parking-BrakeLever

g014620

1

2

g014623

1

g014628

1

Pulluponthebrakelever(Figure14)tosettheparkingbrake.

Disengageitbypullinguponthereleaselatchandlowering

thebrakehandle.Locktheparkingbrakeanytimeyouleave

themachine.

Figure16

1.Reel-speedcontrol

Figure14

1.Parking-brakelever2.Releaselatch

BacklapLever

Thebacklapleverislocatedundertheplasticcovertotheleft

oftheseat.Usethebacklaplever(Figure15)inconjunction

withtheraise/lowermowcontrolleverandthereelspeed

controlforbacklappingthereels.

Figure15

Seat-AdjustingLever

Theseat-adjustingleverislocatedonthefront,rightcorner

oftheseat(Figure17),allowingyoutoadjusttheseatfore

andaft.

Note:Ifyouneedadditionaladjustmentontheseat,youcan

removethefourboltssecuringtheseattothebaseandmove

theseattothesecondsetofmountingholesprovided.

1.Backlaplever—mow

position

2.Backlaplever—backlap

position

Reel-SpeedControl

Thereel–speedcontrolislocatedundertheplasticcoverto

theleftoftheseat.Usethereel-speedcontrol(Figure16)to

adjusttherpmofthereels.

Figure17

1.Seat-adjustinghandle

18

Page 19

Fuel-ShutoffValve

g01462 6

1

Specications

Closethefuel-shutoffvalve(Figure18),behindtheseatand

underthefueltank,whenstoringortransportingthemachine

onatruckortrailer.

Figure18

1.Fuelshutoff(underthefueltank)

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

Widthofcut151cm(59.5inches)

Wheeltread

Wheelbase

Overalllength(w/baskets)249cm(98inches)

Overallwidth179cm(70.5inches)

Overallheight205cm(81inches)

NetWeightw/reels(11Blade)696kg(1,535lb)

128cm(50.5inches)

123cm(48.5inches)

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesis

availableforusewiththemachinetoenhanceandexpand

itscapabilities.ContactyourAuthorizedServiceDealeror

Distributororgotowww .Toro.comforalistofallapproved

attachmentsandaccessories.

Tobestprotectyourinvestmentandmaintainoptimal

performanceofyourToroequipment,countonTorogenuine

parts.Whenitcomestoreliability ,Torodeliversreplacement

partsdesignedtotheexactengineeringspecicationofour

equipment.Forpeaceofmind,insistonT orogenuineparts.

19

Page 20

Operation

G009027

1

2

Usehigh-qualityengineoilthatmeetsthefollowing

specications:

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

ThinkSafetyFirst

Carefullyreadallsafetyinstructionsandsymbolsinthe

safetysection.Knowingthisinformationcouldhelpyouor

bystandersavoidinjury.

DANGER

Operatingthemachineonwetgrassorsteepslopes

cancauseslidingandlossofcontrol.

•Reducespeedanduseextremecautionon

slopes.

•Donotoperatethemachinenearwater.

DANGER

Wheelsdroppingoveredgescancauserollovers,

whichmayresultinseriousinjury,death,or

drowning.

Donotoperatethemachineneardrop-offs.

•APIClassicationLevelRequired:CH–4,CI–4orhigher.

•Preferredoil:SAE10W–30

•Alternateoil:SAE15W–40

ToroPremiumEngineoilisavailablefromyourdistributorin

the10W–30viscosity .Seethepartscatalogforpartnumbers.

Note:Thebesttimetochecktheengineoiliswhenthe

engineiscoolbeforeithasbeenstartedfortheday.Ifithas

alreadybeenrun,allowtheoiltodrainbackdowntothe

sumpforatleast10minutesbeforechecking.Iftheoillevel

isatorbelowtheAddmarkonthedipstick,addoiltobring

theoilleveltotheFULLmark.Donotoverll.

Important:Keeptheengineoillevelbetweentheupper

andlowerlimitsontheoilgauge;theenginemayfailif

yourunitwithtoomuchortoolittleoil.

1.Positionthemachineonalevelsurface.

2.Removethedipstickandwipeitwithacleanrag

(Figure21).

Important:Removethedipstickwhilellingthe

enginewithoil.Whenaddingengineoilorlling

oil,there

deviceandtheoilllholeinthevalvecoveras

showninFigure20.Thisclearanceisnecessary

topermitventingwhenlling,whichpreventsoil

fromoverrunningintobreather.

must be

clearancebetweentheoilll

CAUTION

Thismachineproducessoundlevelsthatcancause

hearinglossthroughextendedperiodsofexposure.

Wearhearingprotectionwhenoperatingthis

machine.

Useprotectiveequipmentforeyes,ears,hands,feet,andhead.

Figure19

1.Weareyeprotection.2.Wearhearingprotection.

CheckingtheEngineOil

ServiceInterval:Beforeeachuseordaily

Figure20

1.Noteclearance

Theengineisshippedwith3.7L(3.9USqt)(w/lter)ofoil

inthecrankcase;however,youmustchecktheoillevelbefore

andafterstartingtheenginethersttime.

20

Page 21

g014618

1

2

Figure21

1.Fillercap2.Dipstick

DANGER

Undercertainconditions,dieselfuelandfuel

vaporsarehighlyammableandexplosive.Are

orexplosionfromfuelcanburnyouandothersand

cancausepropertydamage.

•Useafunnelandllthefueltankoutdoors,in

anopenarea,whentheengineisoffandiscold.

Wipeupanyfuelthatspills.

•Donotllthefueltankcompletelyfull.Add

fueltothefueltankuntilthelevelis6to13mm

(1/4to1/2inch)belowthebottomoftheller

neck.Thisemptyspaceinthetankallowsthe

fueltoexpand.

•Neversmokewhenhandlingfuel,andstayaway

fromanopenameorwherefuelfumesmaybe

ignitedbyaspark.

3.Pushthedipstickintothetubeandmakesureitis

seatedfully.

4.Removethedipstickfromthetubeandcheckthelevel

ofoil.

Note:Iftheoillevelislow,removethellercapfrom

thevalvecoverandslowlyaddenoughoiltoraisethe

leveltotheFULLmarkonthedipstick.

Addtheoilslowlyandchecktheleveloftenduringthis

process.Donotoverll.

5.Replacethedipstick.

6.Startandruntheengineatidlefor30seconds,then

shuttheengineoff.Wait30seconds,thenrepeatsteps

2through5.

7.Installthellercapanddipstickrmlyinplace.

FillingtheFuelTank

Useonlyclean,freshdieselfuelorbiodieselfuelswithlow

(<500ppm)orultralow(<15ppm)sulfurcontent.The

minimumcetaneratingshouldbe40.Purchasefuelin

quantitiesthatcanbeusedwithin180daystoensurefuel

freshness.

•Storefuelinaclean,sealed,safety-approved

container.

Fueltankcapacity:22.7L(6U.S.gallons)

Usesummergradedieselfuel(No.2-D)attemperatures

above-7°C(20°F)andwintergrade(No.1-DorNo.

1-D/2-Dblend)belowthattemperature.Useofwintergrade

fuelatlowertemperaturesprovideslowerashpointand

coldowcharacteristicswhichwilleasestartingandreduce

fuellterplugging.

Useofsummergradefuelabove-7°C(20°F)willcontribute

towardlongerfuelpumplifeandincreasedpowercompared

towintergradefuel.

21

Page 22

DANGER

g014612

1

Incertainconditions,fuelisextremelyammable

andhighlyexplosive.Areorexplosionfromfuel

canburnyouandothersandcandamageproperty.

•Fillthefueltankoutdoors,inanopenarea,when

theengineiscold.Wipeupanyfuelthatspills.

•Donotllthefueltankcompletelyfull.Addfuel

tothefueltankuntilthelevelis25mm(1inch)

belowthebottomofthellerneck.Thisempty

spaceinthetankallowsfueltoexpand.

•Neversmokewhenhandlingfuel,andstayaway

fromanopenameorwherefuelfumesmaybe

ignitedbyaspark.

•Storefuelinanapprovedcontainerandkeepit

outofthereachofchildren.Neverbuymore

thana30-daysupplyoffuel.

•Alwaysplacefuelcontainersonthegroundaway

fromyourvehiclebeforelling

•Donotllfuelcontainersinsideavehicleoron

atruckortrailerbedbecauseinteriorcarpets

orplastictruckbedlinersmayinsulatethe

containerandslowthelossofanystaticcharge.

•Whenpractical,removethemachinefromthe

truckortrailerandrefuelitwithitswheelson

theground.

•Ifthisisnotpossible,thenrefuelsuchequipment

onatruckortrailerfromaportablecontainer,

ratherthanfromafueldispensernozzle.

•Ifafueldispensernozzlemustbeused,keepthe

nozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilfuelingis

complete.

1.Cleanaroundthefuel-tankcap(Figure22).

Figure22

1.Fuel-tankcap

2.Removethefuel-tankcap.

3.Fillthetankuntilthelevelis6to13mm(1/4to1/2

inch)belowthebottomofthellerneck.

Important:Donotoverll.

4.Installthecap.

5.Wipeupanyfuelthatmayhavespilled.

UsingBiodieselFuel

Thismachinecanalsouseabiodieselblendedfuelofup

toB20(20%biodiesel,80%petrodiesel).Thepetrodiesel

portionshouldbeloworultralowsulfur.Observethe

followingprecautions:

•Thebiodieselportionofthefuelmustmeetspecication

ASTMD6751orEN14214.

•TheblendedfuelcompositionshouldmeetASTMD975

orEN590.

•Paintedsurfacesmaybedamagedbybiodieselblends.

•UseB5(biodieselcontentof5%)orlesserblendsincold

weather

•Monitorseals,hoses,gasketsincontactwithfuelasthey

maybedegradedovertime.

•Fuellterpluggingmaybeexpectedforatimeafter

convertingtobiodieselblends.

•Contactyourdistributorifyouwishformoreinformation

onbiodiesel

22

Page 23

CheckingtheCoolingSystem

g01461 3

1

2

3

4

Thecapacityofthecoolingsystemisapproximately4.6L

(4.9USqt).Keeptheradiatorscreenclean;refertoCleaning

theRadiatorScreen(page41).

Figure24

1.Reservetank

3.Ifthecoolantislow,removethereservetankcapand

adda50/50mixtureofwaterandpermanentethylene

glycolantifreeze.Donotoverll.

Figure23

1.Wingbolts3.Reservetank

2.Radiatorscreen

Fillthecoolingsystemwitha50/50solutionofwaterand

permanentethyleneglycolantifreeze.Checkthelevelof

thecoolantatthebeginningofeachdaybeforestartingthe

engine.

4.Radiatorllcap

CAUTION

Iftheenginehasbeenrunning,thepressurized,hot

coolantcanescapeandcauseburns.

•Donotopentheradiatorcapwhentheengine

isrunning.

•Usearagwhenopeningtheradiatorcap,and

openthecapslowlytoallowsteamtoescape.

1.Parkthemachineonalevelsurface.

2.Checkthecoolantlevel(Figure24).

4.Installthereserve-tankcap.

CheckingtheHydraulic-Fluid Level

Thehydraulic-uidreservoirislledatthefactorywith

approximately20.8L(5.5USgallons)ofhighqualityhydraulic

uid.Beforeoperatingthemachineeachday,checklevelof

thehydraulicuidinthewhiteplasticwindowonthefrontof

thehydraulic-uidreservoir(behindtheseatontheleftside).

Theuidshouldbebetweenthelinesinthewindow;ifnot,

addanappropriateuidasdescribedinthefollowingsections:

Therecommendedreplacementuidisasfollows:

ToroPremiumAllSeasonHydraulicFluid(Availablein

5-gallonpailsor55-gallondrums.Seepartscatalogor

Torodistributorforpartnumbers.)

Alternateuids:IftheTorouidisnotavailable,otheruids

maybeusedprovidedtheymeetallthefollowingmaterial

propertiesandindustryspecications.W edonotrecommend

theuseofsyntheticuid.Consultwithyourlubricant

distributortoidentifyasatisfactoryproduct

Note:Itshouldbebetweenthelinesonthereserve

tankwhentheengineiscold.

Note:Torowillnotassumeresponsibilityfordamage

causedbyimpropersubstitutions,souseonlyproducts

fromreputablemanufacturerswhowillstandbehindtheir

recommendation.

23

Page 24

HighViscosityIndex/LowPourPointAnti-wearHydraulic

g014719

1

g014720

1

2

Fluid,ISOVG46

MaterialProperties:

Viscosity,ASTMD445cSt@40°C44to48

ViscosityIndexASTMD2270

PourPoint,ASTMD97-34°Fto-49°F

IndustrySpecications:

VickersI-286-S(QualityLevel),VickersM-2950-S

(QualityLevel),DenisonHF-0

cSt@100°C7.9to8.5

140to160

Important:TheISOVG46Multigradeuidhasbeen

foundtoofferoptimalperformanceinawiderangeof

temperatureconditions.Foroperationinconsistently

highambienttemperatures,18°C(65°F)to49°C

(120°F),ISOVG68hydraulicuidmayofferimproved

performance.

PremiumBiodegradableHydraulicFluid-MobilEAL

EnviroSyn46H

Important:MobilEALEnviroSyn46Histheonly

syntheticbiodegradableuidapprovedbyT oro.This

uidiscompatiblewiththeelastomersusedinToro

hydraulicsystemsandissuitableforawide-range

oftemperatureconditions.Thisuidiscompatible

withconventionalmineraloils,butformaximum

biodegradabilityandperformancethehydraulicsystem

shouldbethoroughlyushedofconventionaluid.The

oilisavailablein19L(5gallon)containersor55gallon

drumsfromyourMobilDistributor.

Important:Manyhydraulicuidsarealmostcolorless,

makingitdifculttospotleaks.Areddyeadditive

forthehydraulicsystemoilisavailablein20ml(2/3

oz)bottles.Onebottleissufcientfor15-22L(4-6

gallons)ofhydraulicuid.OrderPartNo.44-2500from

yourauthorizedTorodistributor.

T his r ed dy e is not

r ecommended f or use with biodeg rada ble uids.

Important:Regardlessofhydraulicuidtypeused,any

machineusedformowingfairways,verticuttingorused

duringambienttemperaturesabove29°C(85°F)should

haveOilCoolerKit,PartNo.117-9314,installed.

Figure25

1.Hydraulic-reservoircap

3.Slowlyllthereservoirwiththeappropriatehydraulic

uiduntilthelevelreachestheFullmarkinthewhite

windowinthefrontofthereservoir.Donotoverll.

Important:Topreventsystemcontamination,

cleanthetopofthehydraulicuidcontainers

beforepuncturing .Ensurethatthepourspoutand

funnelareclean.

4.Installthereservoircapandwipeupanyuidthatmay

havespilled.

Important:Checklevelofhydraulicuidbefore

engineisrststartedanddailythereafter.

DrainingWaterfromtheFuel Filter

ServiceInterval:Beforeeachuseordaily

1.Positionthemachineonalevelsurfaceandshutoff

theengine.

2.Placeadrainpanunderthefuellter.

3.Openthedrainplugonthefuellterapproximately

oneturnanddrainanyaccumulatedwater(Figure26).

FillingtheHydraulicTank

1.Positionthemachineonalevelsurface.

Note:Makesurethemachinehascooleddownso

theoiliscold.

2.Removethecapfromthereservoir(Figure25).

Figure26

1.Fuellter

24

2.Drainplug

Page 25

4.Tightentheplugafterdraining.

Note:Becausetheaccumulatedwaterwillbemixed

withdieselfuel,drainthefuellterintoasuitable

containeranddisposeofitproperly.

StartingandStoppingthe Engine

Note:Inspecttheareasbeneaththemowerstobecertain

theyareclearofdebris.

CheckingtheReel-to-Bedknife Contact

Eachdaybeforeoperatingthemachine,checkthe

reel-to-bedknifecontact,regardlessifthequalityofcuthad

previouslybeenacceptable.Theremustbelightcontact

acrossthefulllengthofthereelandbedknife;refertothe

CuttingUnitOperator’sManual.

CheckingtheTirePressure

Varythetirepressureforthefrontwheels,dependingupon

yourturfconditions,fromaminimumof83toamaximum

of110kPa(12psito16psi).

Varythetirepressurefortherearwheelfromaminimumof

83toamaximumof110kPa(12psito16psi).

CheckingtheTorqueofthe WheelNuts

WARNING

Failuretomaintainpropertorqueofthewheelnuts

couldresultinpersonalinjury.

StartingtheEngine

Important:Donotuseetherorothertypesofstarting

uid.

1.Sitontheseat,locktheparkingbrake,disengage

theraise/lowermowcontrolandmovethe

functional-controllevertotheNEUTRALposition.

2.Removeyourfootfromthetractionpedalandmake

surethepedalisintheNEUTRALposition.

3.MovethethrottlelevertotheSLOWposition.

4.Insertthekeyintotheswitchandrotateittothe

ONposition.HolditintheONpositionuntilthe

glow-plug-indicatorlightgoesoff(approximately6

seconds).

5.TurntheignitionkeytotheSTARTposition.

Important:Topreventoverheatingofthestarter

motor,donotengagethestarterlongerthan10

seconds.After10secondsofcontinuouscranking,

wait60secondsbeforeengagingthestartermotor

again.

6.Releasethekeywhentheenginestartsandallowitto

movetotheONposition.

7.MovethethrottlecontroltotheSLOWposition.

Torquethewheelnutsto95to122N∙m(70-90ft-lb)

after1-4hoursofoperationandagainafter10hours

ofoperation.Torqueevery200hoursthereafter.

Toensureevendistribution,torquethebrakesinastar

pattern.

BreakingintheMachine

Refertotheenginemanualsuppliedwiththemachineforoil

changeandmaintenanceproceduresrecommendedduring

thebreak-inperiod.

Only8hoursofmowingoperationisrequiredforthebreak-in

period.

Sincethersthoursofoperationarecriticaltofuture

dependabilityofthemachine,monitoritsfunctionsand

performancecloselysothatminordifculties,whichcould

leadtomajorproblems,arenotedandcanbecorrected.

Inspectthemachinefrequentlyduringbreak-inforsignsof

oilleakage,loosefasteners,oranyothermalfunction.

8.Allowtheenginetowarmupforafewminutesbefore

operating.

Important:Whenstartingtheenginefortherst

timeorafteranoverhauloftheengine,operate

themachineinforwardandreverseforoneto

twominutes.Turnthesteeringwheeltotheleft

andrighttocheckthesteeringresponse.Then

shuttheengineoff(seeStoppinginStartingand

StoppingtheEngine)andwaitforallmovingparts

tostop.Checkforoilleaks,loosepartsandany

othernoticeablemalfunctions.

StoppingtheEngine

1.MovethethrottlelevertotheSLOWposition,

disengagetheraise/lowermowcontrol,andmovethe

functional-controllevertotheNEUTRALposition.

2.RotatethestarterkeytotheOFFpositiontoshutthe

engineoff.Removethekeyfromtheswitchtoprevent

accidentalstarting.

3.Closethefuelshut-offvalvesbeforestoringthe

machine.

25

Page 26

CheckingtheSafetyInterlock

g014596

1

2

2

System

7.Sitontheseat,movethetractionpedaltotheNEUTRAL

position,movethefunctionalcontrollevertothe

NEUTRALposition,andengagetheparkingbrake.

CAUTION

Ifthesafetyinterlockswitchesaredisconnectedor

damagedthemachinecouldoperateunexpectedly

causingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlockswitches

dailyandreplaceanydamagedswitchesbefore

operatingthemachine.

Thepurposeofthesafety-interlocksystemistoprevent

operationofthemachinewherethereispossibleinjurytothe

operatorordamagetothemachine.

•ThetractionpedalisintheNEUTRALposition.

•Thefunctional-controlleverisintheNEUTRALposition.

Thesafety-interlocksystempreventsthemachinefrom

movingunless:

•Theparkingbrakeisoff.

•Theoperatorisseated.

•Thefunctional-controlleverisintheMOWpositionor

theTRANSPORTposition.

Thesafety-interlocksystempreventsthereelsfromoperating

unlessthefunctional-controlleverisintheMOWposition.

Performthefollowingsystemchecksdailytoensurethatthe

interlocksystemisoperatingcorrectly:

1.Sitontheseat,movethetractionpedaltotheNEUTRAL

position,movethefunctional-controllevertothe

NEUTRALposition,andengagetheparkingbrake.

2.Trytopressthetractionpedal.

Thepedalshouldnotpress,whichmeansthatthe

interlocksystemisoperatingcorrectly.Correctthe

problemifitisnotoperatingproperly.

3.Sitontheseat,movethetractionpedaltotheNEUTRAL

position,movethefunctional-controllevertothe

NEUTRALposition,andengagetheparkingbrake.

4.Movethefunctional-controllevertotheMOWposition

ortheTRANSPORTpositionandtrytostarttheengine.

8.Starttheengine.

9.Releasetheparkingbrake,movethefunctionalcontrol

levertotheMOWposition,andrisefromtheseat.

Theengineshouldshutoff,whichmeansthatthe

interlocksystemisoperatingcorrectly.Correctthe

problemifitisnotoperatingproperly.

10.Sitontheseat,movethetractionpedaltotheNEUTRAL

position,movethefunctionalcontrollevertothe

NEUTRALposition,andengagetheparkingbrake.

11.Starttheengine.

12.Movetheraise/lowermowcontrolforwardtolower

thecuttingunits.Thecuttingunitsshouldlowerbut

notstartrotating.

Iftheystartrotating,theinterlocksystemisnot

operatingcorrectly;correcttheproblembefore

operatingthemachine.

InstallingandRemovingthe CuttingUnits

Note:Whensharpening,settingtheheight-of-cut,or

performingothermaintenanceproceduresonthecutting

units,storethecuttingunitreelmotorsinthestoragelocation

onthefrontofthesuspensionarmstopreventdamageto

them.

Important:Donotraisethesuspensiontothetransport

positionwhenthereelmotorsareintheholdersinthe

machineframe.Damagetothemotorsorhosescould

result.

Important:Wheneveryouneedtotipthecuttingunit,

propuprearofcuttingunittoensurethatthenutson

thebedbaradjustingscrewsarenotrestingonwork

surface(Figure27).

Theengineshouldnotturn-overorstart,whichmeans

thattheinterlocksystemisoperatingcorrectly.Correct

theproblemifitisnotoperatingproperly.

5.Sitontheseat,movethetractionpedaltotheNEUTRAL

position,movethefunctional-controllevertothe

NEUTRALposition,andengagetheparkingbrake.

6.Starttheengineandmovethefunctional-controllever

totheMOWpositionortheTRANSPORTposition.

Theengineshouldkill,whichmeansthattheinterlock

systemisoperatingcorrectly.

Correcttheproblemifitisnotoperatingproperly.

Figure27

1.Prop(notprovided)

26

2.Bedbar-adjusting-screw

nut(2)

Page 27

InstallingtheCuttingUnits

g014602

1

2

g014609

1

2

3

g01461 1

1

2

1.Liftuponthefootrestandswingitopen,allowing

accesstothecentercuttingunitposition(Figure28).

CAUTION

Thefootrestcanpinchngersifitfallsinto

theclosedposition.

Keepyourngersclearoftheareawherethe

footrestseatswhileitisopen.

Figure30

1.Suspension-armbar2.Cutting-unitbar

Figure28

1.Footrest—closed2.Footrest—open

2.Positionthecuttingunitunderthecentersuspension

arm.

3.Withthelatchesonthesuspension-armbarpointing

up(i.e.,open)(Figure29),pushthesuspensionarm

downsothatthebartsoverthebaracrossthetopof

thecuttingunit(Figure30).

Figure29

1.Latch—closedposition3.Latch—openposition

2.Suspension-armbar

4.Closethelatchesdownandaroundthecutting-unitbar

andlocktheminplace(Figure29).

Note:A“click”canbeheardandfeltwhenthelatches

areproperlylockedinplace.

5.Coatthesplineshaftofthecuttingunitmotorwith

cleangrease(Figure31).

6.Insertthemotorintotheleftsideofthecuttingunit

(asviewedfromtheoperator'sposition)andpullthe

motorretainingbaronthecuttingunittowardthe

motoruntilyouhearanaudible“click”frombothsides

ofthemotor(Figure31).

27

Page 28

g014690

1

2

3

4

g014605

1

2

Figure32

g014608

1.Reelmotor2.Motor-retainingbar

3.Movethemotortothestoragelocationonthefrontof

thesuspensionarm(Figure33).

Figure31

1.Reelmotor

2.Splineshaft

3.Cavity

4.Motor-retainingbar

7.Mountagrassbasketontothebaskethooksonthe

suspensionarm.

8.Repeatthisprocedurefortheothercuttingunits.

RemovingtheCuttingUnits

1.Parkthemachineonacleanlevelsurface,lower

thecuttingunitstothegrounduntilthesuspension

hydraulicsarefullyextended,stoptheengine,andset

theparkingbrake.

2.Pushthemotorretainingbaroutoftheslotsonthe

motortowardsthecuttingunitandremovethemotor

fromthecuttingunit.

Figure33

Note:Whensharpening,settingtheheight-of-cut,

orperformingothermaintenanceproceduresonthe

cuttingunits,storethecuttingunitreelmotorsinthe

storagelocationonthefrontofthesuspensionarmsto

preventdamagetothem.

Important:Donotraisethesuspensiontothe

transportpositionwhenthereelmotorsareinthe

holdersinthemachineframe.Damagetothe

motorsorhosescouldresult.Ifyoumustmovethe

tractionunitwithoutthecuttingunitsinstalled,

securethemtothesuspensionarmsusingcable

ties.

4.Openthelatchesonthesuspension-armbarofthe

cuttingunityouareremoving(Figure29).

5.Disconnectthelatchesfromthecutting-unitbar.

6.Rollthecuttingunitoutfromunderthesuspension

arm.

7.Repeatsteps2through6fortheothercuttingunits

asrequired.

28

Page 29

SettingtheReelSpeed

g014736

g014623

1

Mowing

Toachieveaconsistent,high-qualitycutandauniform,

after-cutappearance,youmustcorrectlysetthereelspeed

control(locatedonthemanifoldblockunderthecovertothe

leftoftheseat).Adjustthereelspeedcontrolasfollows:

1.Selecttheheight-of-cutatwhichthecuttingunitsare

set.

2.Choosethedesiredgroundspeedbestsuitedfor

conditions.

3.Usingtheappropriategraph(SeeFigure34)for5,8,

11,or14bladecuttingunits,determinetheproperreel

speedsetting.

Beforemowinggreens,ndaclearareaandpracticestarting

andstoppingthemachine,raisingandloweringthecutting

units,turning,etc.

Inspectthegreenfordebris,removetheagfromthecup,

anddeterminethebestdirectiontomow .Basethedirection

tomowonthepreviousmowingdirection.Alwaysmowinan

alternatepatternfromthepreviousmowingsothatthegrass

bladeswillbelessapttolaydownandthereforebedifcult

totrapbetweenthereelbladesandthebedknife.

1.Approachthegreenwiththefunctional-controllever

intheMOWpositionandthethrottleatfullspeed.

2.Startononeedgeofthegreensothatyoucanusethe

ribbonprocedureofcutting.

Note:Thisholdscompactiontoaminimumand

leavesaneat,attractivepatternonthegreens.

3.Actuatetheraise/lowermowleverasthefrontedges

ofthegrassbasketscrosstheouteredgeofthegreen.

Note:Thisproceduredropsthecuttingunitstothe

turfandstartsthereels.

Important:TheNo.1cuttingunitreelisdelayed;

therefore,youshouldpracticetogaintherequired

timingnecessarytominimizethecleanupmowing

operation.

Figure34

4.Tosetthereelspeed,rotatetheknob(Figure35)

untiltheindicatorarrowsareinlinewiththenumber

designatingdesiredsetting.

Figure35

1.Reel-speedcontrol

4.Overlapaminimalamountwiththepreviouscuton

returnpasses.

Note:Toassistinmaintainingastraightlineacross

thegreenandkeepthemachineanequaldistancefrom

theedgeofthepreviouscut,establishanimaginary

sightlineapproximately1.8to3m(6to10ft)ahead

ofthemachinetotheedgeoftheuncutportionofthe

green(Figure36).Somenditusefultoincludethe

outeredgeofthesteeringwheelaspartofthesight

line;i.e.keepthesteeringwheeledgealignedwitha

pointthatisalwayskeptthesamedistanceawayfrom

thefrontofthemachine.

5.Asthefrontedgesofthebasketscrosstheedgeofthe

green,movetheraise/lowermowleverrearwardand

holdituntilallthecuttingunitshaverisen.Thiswill

stopthereelsandliftthecuttingunits.

Note:Itisimportanttotimethisstepcorrectlyso

thatyoudonotcutintothefringeareayetcutasmuch

ofthegreenaspossibletominimizetheamountof

grasslefttomowaroundtheouterperiphery.

6.Tocutdownonoperatingtimeandeaselineupfor

thenextpass,momentarilyturnthemachineinthe

oppositedirection,thenturnitinthedirectionofthe

uncutportion;i.e.,ifintendingtoturnright,rstswing

slightlyleft,thenright.

Note:Youcanincreaseordecreasethereelspeedto

compensateforturfconditions.

Note:Thiswillassistingettingthemachinemore

quicklyalignedforthenextpass.Trytomakeasshort

29

Page 30

ofaturnaspossibleexceptduringwarmerweather

whenawiderarcwillminimizetheturfbruising.

Figure36

Note:Heavywetclippingsplaceanunduestrainon

thebasketsandwilladdunnecessaryweighttothe

machine,therebyincreasingtheloadontheengine,

hydraulicsystem,brakes,etc.

InspectingandCleaningafter Mowing

Atthecompletionofthemowingoperation,thoroughlywash

themachinewithagardenhosewithoutanozzlesoexcessive

waterpressurewillnotcausecontaminationanddamageto

sealsandbearings.Neverwashawarmengineorelectrical

connectionswithwater.

Aftercleaning,inspectthemachineforpossiblehydraulic

uidleaks,damageorweartohydraulicandmechanical

components,andthecuttingunitsforsharpness.Also,

lubricatebrakeshaftassemblywithSAE30oilorspray

lubricanttodetercorrosionandhelpkeepthemachine

performingsatisfactorilyduringthenextmowingoperation.

1.Alignmentstrip

2.Approximately12.7cm(5

inches)

Note:Duetothenatureofthepowersteeringsystem,

thesteeringwheelwillnotreturntoitsoriginalposition

afteraturnhasbeencompleted.

Important:Neverstoponagreenwiththecutting

unitreelsoperatingasdamagetotheturfmay

result.Stoppingonawetgreenwiththemachine

mayleavemarksorindentationsfromthewheels.

7.Iftheleakdetectoralarmsoundswhilecuttingona

green,immediatelyraisethecuttingunits,drivedirectly

offthegreenandstopthemachineinanareaaway

fromthegreen.Determinethecauseofthealarmand

correcttheproblem.

8.Finishcuttingthegreenbymowingtheouterperiphery.

Besuretochangethedirectionofcuttingfromthe

previousmowing.

Note:Alwayskeepweatherandturfconditionsin

mindandbesuretochangethedirectionofmowing

fromthepreviouscutting.

9.Whennishedmowingtheouterperiphery,tapthe

raise/lowermowleverrearwardtostopthereels,then

driveoffthegreen.Whenallofthecuttingunitsare

offofthegreen,raisethem.

Note:Thiswillminimizegrassclumpsleftonthe

green.

10.Replacetheag.

11.Emptythegrassbasketsofallclippingsbefore

transportingtothenextgreen.

3.Cutgrassontheleft

4.Keepafocalspot2to3

m(6to10ft)aheadofthe

machine.

DrivingtheMachinewithout Mowing

Ensurethatthecuttingunitsarefullyraised.Movethe

functional-controllevertotheTRANSPORTposition.Use

thebrakestoslowthemachinewhilegoingdownsteep

hillstoavoidlossofcontrol.Alwaysapproachroughareas

atareducedspeedandcrosssevereundulationscarefully.

Familiarizeyourselfwiththewidthofthemachine.Donot

attempttopassbetweenobjectsthatareclosetogetherso

thatcostlydamageanddowntimecanbeprevented.

TransportingtheMachine

Useaheavy-dutytrailerortrucktotransportthemachine.

Ensurethatthetrailerortruckhasallnecessarybrakes,

lighting,andmarkingasrequiredbylaw .Readallthesafety

instructions.Knowingthisinformationcouldhelpyou,your

family,pets,orbystandersavoidinjury.

WARNING

Drivingonthestreetorroadwaywithoutturn

signals,lights,reectivemarkings,oraslow

movingvehicleemblemisdangerousandcanlead

toaccidentscausingpersonalinjury.

Donotdrivethemachineonapublicstreetor

roadway.

Useextremecautionwhenloadingthemachineontoatrailer

oratruck.Onefull-widthrampthatiswideenoughtoextend

beyondthereartiresisrequired(Figure37).

Therampshouldbelongenoughsothattheanglesdonot

exceed15degrees(Figure37).Asteeperanglemaycause

mowercomponentstogetcaughtastheunitmovesfromthe

ramptothetrailerortruck.Steeperanglesmayalsocause

30

Page 31

themachinetotipbackward.Ifloadingonornearaslope,

positionthetrailerortrucksothatitisonthedownside

oftheslopeandtherampextendsuptheslope.Thiswill

minimizetherampangle.Thetrailerortruckshouldbeas

levelaspossible.

Important:Donotattempttoturnthemachinewhile

ontheramp;youmaylosecontrolanddriveofftheside.

Avoidsuddenaccelerationwhendrivinguparampand

suddendecelerationwhenbackingdownaramp.Both

maneuverscancausethemachinetotipbackward.

WARNING

Loadingamachineontoatrailerortruckincreases

thepossibilityofbackwardtip-overandcouldcause

seriousinjuryordeath.

•Useextremecautionwhenoperatingamachine

onaramp.

Figure37

•Usetheseatbeltwhenloadingthemachine.

EnsurethattheROPSwillclearthetopofan

enclosedtrailer.

•Useonlyasingle,full-widthramp;donotuse

individualrampsforeachsideofthemachine.

•Ifindividualrampsmustbeused,useenough

rampstocreateanunbrokenrampsurfacewider

thanthemachine.

•Donotexceeda15-degreeanglebetweenthe

rampandthegroundorbetweentherampand

thetrailerortruck.

•Avoidsuddenaccelerationwhiledrivingthe

machineuparamp,toavoidtippingbackward.

•Avoidsuddendecelerationwhilebacking

themachinedownaramp,toavoidtipping

backward.

1.Trailer3.Notgreaterthan15

degrees

2.Full-widthramp4.Full-widthramp—side

view

1.Ifusingatrailer,connectittothetowingvehicleand

connectthesafetychains.

2.Ifapplicable,connectthetrailerbrakes.

3.Loadthemachineontothetrailerortruck.

4.Stoptheengine,removethekey ,settheparkingbrake,

andclosethefuelvalve.

5.Usethemetaltie-downloopsonthemachineto

securelyfastenthemachinetothetrailerortruckwith

straps,chains,cable,orropes.

TowingtheMachine

Incaseofanemergencythemachinecanbetowedforashort

distance(lessthan0.4km(1/4mile)).However,T orodoes

notrecommendthisasstandardprocedure.

Important:Donottowthemachinefasterthan3-5

km/h(2-3mph)becausethedrivesystemmaybe

damaged.Ifthemachinemustbemovedaconsiderable

distance,transportitonatruckortrailer.

1.Locatethebypassvalveonthepumpandrotateitso

thattheslotisvertical(Figure38).

31

Page 32

g014627

1

Figure38

1.Bypassvalve—slotshowninclosed(horizontal)position

2.Beforestartingtheengine,closethebypassvalveby

rotatingitsothattheslotishorizontal(Figure38).Do

notstarttheenginewhenthevalveisopen.

32

Page 33

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

Note:Downloadafreecopyoftheelectricalorhydraulicschematicbyvisitingwww .Toro.comandsearchingforyour

machinefromtheManualslinkonthehomepage.

Important:Refertoyourengineoperator’smanualforadditionalmaintenanceprocedures.

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriouslyinjure

youorotherbystanders.

Removethekeyfromtheignition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Afterthersthour

Aftertherst8hours

Aftertherst10hours

Aftertherst50hours

Beforeeachuseordaily

Every25hours

Every50hours

Every150hours

Every200hours

MaintenanceProcedure

•Checkthetorqueofthewheelnuts.

•Checkthetensiononthealternatorbelt.

•Checkthetorqueofthewheelnuts.

•Changetheengineoilandlter.

•Changethehydraulic-oillter.

•Checktheenginerpm(atidleandfullthrottle).

•Checktheengineoil.

•Cleandebrisoffoftheradiatorscreenandradiator.Cleanhourlyifconditionsare

extremelydustyanddirty.

•Checkthehydraulic-uidlevel.

•Drainwaterfromthefuellter.

•Checkthereel-to-bedknifecontact.

•Checkthehydrauliclinesandhoses.

•Checkthebatteryelectrolytelevel.(Ifthemachineisinstorage,checkevery30

days.)

•Checkthebatterycableconnections.

•Changetheengineoilandlter.

•Checkthetorqueofthewheelnuts.

•Servicetheair-cleanerlter(morefrequentlywhenoperatingconditionsaredusty

ordirty).

Every800hours

Every2years

•Replacethefuellter.

•Changethehydraulicuid,lter,andtankbreather.

•Checktheenginerpm(atidleandfullthrottle).

•Checkthevalveclearance.

•Checkthefuellinesandconnections.

•Replacemovinghoses.

•Drainandushthecoolingsystem.

33

Page 34

DailyMaintenanceChecklist

Duplicatethispageforroutineuse.

Fortheweekof: MaintenanceCheckItem

Checkthesafetyinterlock

operation.

Checktheinstrument

operation

Checkthebrakeoperation.

Checkthefuellter/water

separator.

Checkthefuellevel.

Checktheengineoillevel.

Cleanthescreenand

radiator.

Inspecttheairlter.

Checkanyunusualengine

noises.

Checkthereel-to-bedknife

adjustment.

Checkthehydraulichoses

fordamage.

Checkforuidleaks.

Checkthetirepressure.

Checktheheight-of-cut

adjustment.

Lubricatethetractionand

brakelinkage.

Touch-updamagedpaint.

Mon.Tues.Wed.Thurs.Fri.

Sat.Sun.

NotationforAreasofConcern

Inspectionperformedby:

ItemDate

Information

34

Page 35

EngineMaintenance

g014614

1

2

3

g014754

1

B.Carefullypulltheoldlteroutofthelterbody

anddiscardit.

ServicingtheAirCleaner

ServiceInterval:Every200hours

•Checktheair-cleanerbodyfordamagewhichcouldcause

anairleak;replaceitifitisdamaged.Checkthewhole

intakesystemforleaks,damage,orloosehoseclamps.

•Servicetheair-cleanerlterbefore200hoursifthe

engineperformancesuffersduetoextremelydusty,dirty

conditions.Changingtheairlterbeforeitisnecessary

onlyincreasesthechanceofdirtenteringtheenginewhen

thelterisremoved.

•Ensurethatthecoverisseatedcorrectlyandsealswith

theaircleanerbody.

1.Releasethelatchessecuringtheair-cleanercovertothe

air-cleanerbody(Figure39).

C.Insertthenewlterbyapplyingpressuretothe

outerrimoftheelementtoseatitinthecanister,

checkingthesealingendofthelterandthebody.

Important:Donotapplypressuretothe

exiblecenterofthelter.

5.Cleanthedirtejectionportlocatedintheremovable

cover.Removetherubberoutletvalvefromthecover,

cleanthecavityandreplacetheoutletvalve.

6.Installthecoverorientingtherubberoutletvalveina

downwardposition—betweenapproximately5:00to

7:00whenviewedfromtheend.

7.Securethelatches(Figure39).

ChangingtheEngineOiland Filter

ServiceInterval:Aftertherst50hours

Every150hours

1.Removethedrainplugandletoilowintoadrainpan.

Whentheoilstops,installthedrainplug(Figure40).

Figure39

1.Air-cleanerbody3.Air-cleanercover

2.Airlter

2.Removethecoverfromtheair-cleanerbody.

3.Beforeremovingthelter,uselowpressureair(40psi,

cleananddry)tohelpremovelargeaccumulationsof

debrispackedbetweentheoutsideoftheprimarylter

andthecanister.Thiscleaningprocesspreventsdebris

gettingintotheintakewhenyouremovetheprimary

lter.

Important:Avoidusinghighpressureairwhich

couldforcedirtthroughthelterintotheintake

tract.

4.Removeandreplacetheprimarylter,asfollows:.

Important:Donotcleantheusedelement.

A.Inspectthenewlterforshippingdamage;do

notuseadamagedelement.

Figure40

1.Drainplug

2.Removetheoillter(Figure41).Applyalightcoatof

cleanoiltothenewltergasket.

35

Page 36

g014615

1

Figure41

g01462 6

1

1.Oillter

3.Screwthelteronbyhanduntilthegasketcontacts

thelteradapter,thentighten1/2to3/4turnfurther.

Donotovertighten.

4.Addoiltothecrankcase;refertoCheckingtheEngine

Oil(page20).

FuelSystem

Maintenance

ReplacingtheFuelFilter/Water Separator

ServiceInterval:Every800hours

1.Closethefuel-shutoffvalve(Figure42)belowthefuel

tank.

5.Disposeoftheusedoilproperly.

Figure42

1.Fuel-shutoffvalve

2.Cleantheareawheretheltercanistermounts(Figure

43).

3.Placeadrainpanunderthefuellter.

4.Openthelterdrainplug(Figure43).

36

Page 37

g014720

1

2

1.Fuellter/waterseparator

canister

Figure43

2.Filter-drainplug

ElectricalSystem

Maintenance

ServicingtheBattery

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

Washhandsafterhandling.

5.Unscrewtheltercanisteranddisposeofitaccording

tolocalregulations.

6.Screwthelteronbyhanduntilthegasketcontactsthe

lteradapter,thentighten1/2to3/4turnfurther.

7.Ensurethatthelter-drainplugisclosed.Openthe

fuel-shutoffvalve.

InspectingtheFuelLinesand Connections

ServiceInterval:Every2years

Inspectthefuellinesfordeterioration,damage,orloose

connections.

Voltage:12v,530ColdCrankingAmps

Thebatteryelectrolytelevelmustbeproperlymaintainedand

thetopofthebatterykeptclean.lfthemachineisstoredina

locationwheretemperaturesareextremelyhigh,thebattery

willrundownmorerapidlythanifthemachineisstoredin

alocationwheretemperaturesarecool.

Maintainthecelllevelwithdistilledordemineralizedwater.

Donotllthecellsabovethebottomofthesplitringinside

eachcell.

DANGER

Batteryelectrolytecontainssulfuricacidwhichisa

deadlypoisonandcausessevereburns.

•Donotdrinkelectrolyteandavoidcontactwith

skin,eyesorclothing.Wearsafetyglassesto

shieldyoureyesandrubberglovestoprotect

yourhands.

•Fillthebatterywherecleanwaterisalways

availableforushingtheskin.

Keepthetopofthebatterycleanbywashingitperiodically

withabrushdippedinammoniaorbicarbonateofsoda

solution.Flushthetopsurfacewithwateraftercleaningit.

Donotremovethellcapswhilecleaningthebattery.

Thebatterycablesmustbetightontheterminalstoprovide

goodelectricalcontact.

37

Page 38

WARNING

g014617

1

2

LocatingtheFuses

Batteryterminalsormetaltoolscouldshortagainst

metaltractorcomponentscausingsparks.Sparks

cancausethebatterygassestoexplode,resulting

inpersonalinjury.

•Whenremovingorinstallingthebattery,donot

allowthebatteryterminalstotouchanymetal

partsofthetractor.

•Donotallowmetaltoolstoshortbetweenthe

batteryterminalsandmetalpartsofthetractor.

WARNING

Incorrectbatterycableroutingcoulddamagethe

tractorandcablescausingsparks.Sparkscancause

thebatterygassestoexplode,resultinginpersonal

injury.