Page 1

Part No. 12187SL

Service Manual

(Models 04510 and 04520)

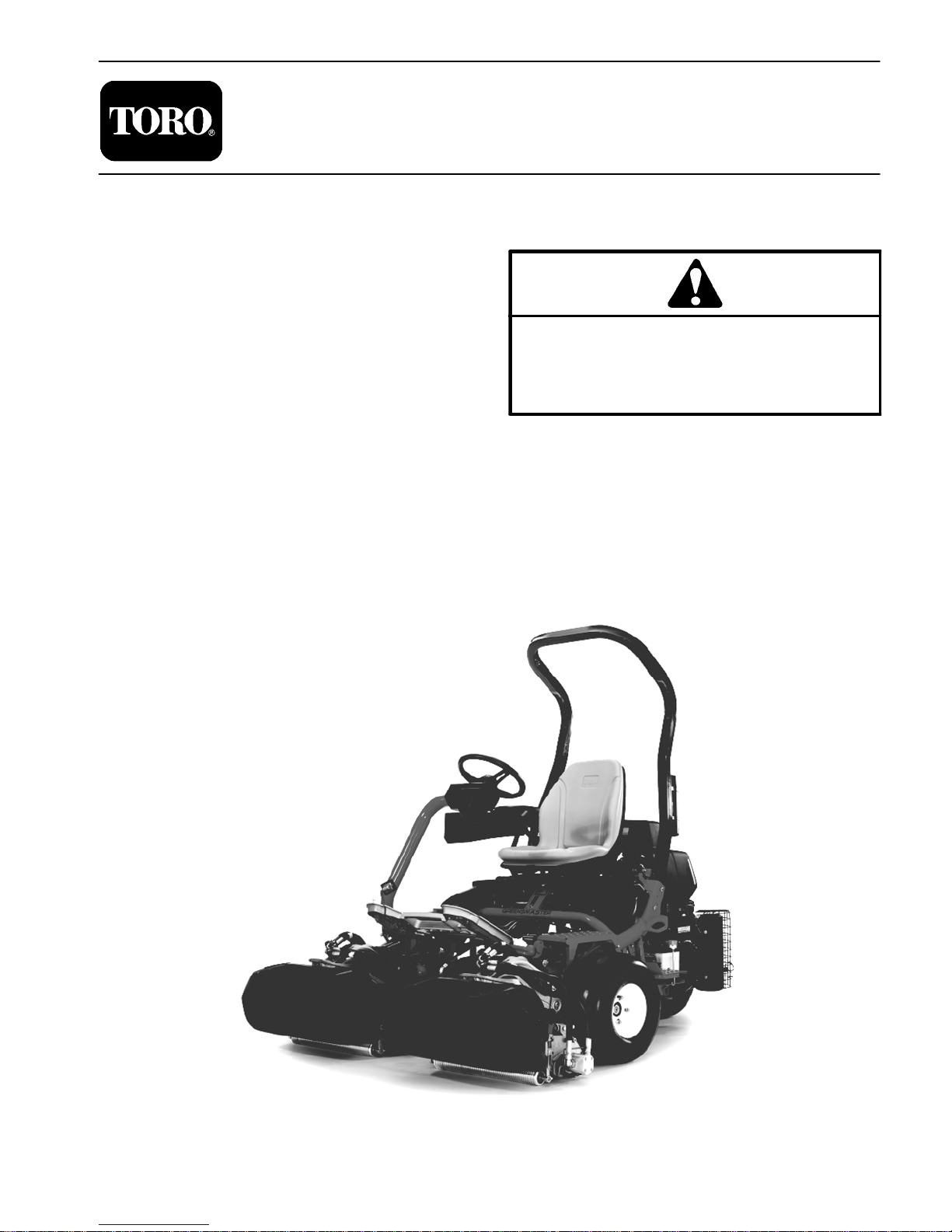

Greensmaster

Preface

The purpose of this publication is to provide the service

technician with information for troubleshooting, testing

and repair of major systems and components on the

Greensmaster TriFlex 3300 and 3400.

REFER TO THE TRACTION UNIT AND CUTTING

UNIT OPERATOR’S MANUALS FOR OPERATING,

MAINTENANCE AND ADJUSTMENT INSTRUCTIONS. For reference, insert a copy of the Operator’s

Manuals and Parts Catalogs for your machine into

Chapter 2 of this service manual. Additional copies of

theOperator’s ManualsandParts Catalogare available

on the internet at www.T oro.com.

TheT oroCompany reservesthe right tochangeproduct

specifications or this publication without notice.

R

TriFlex

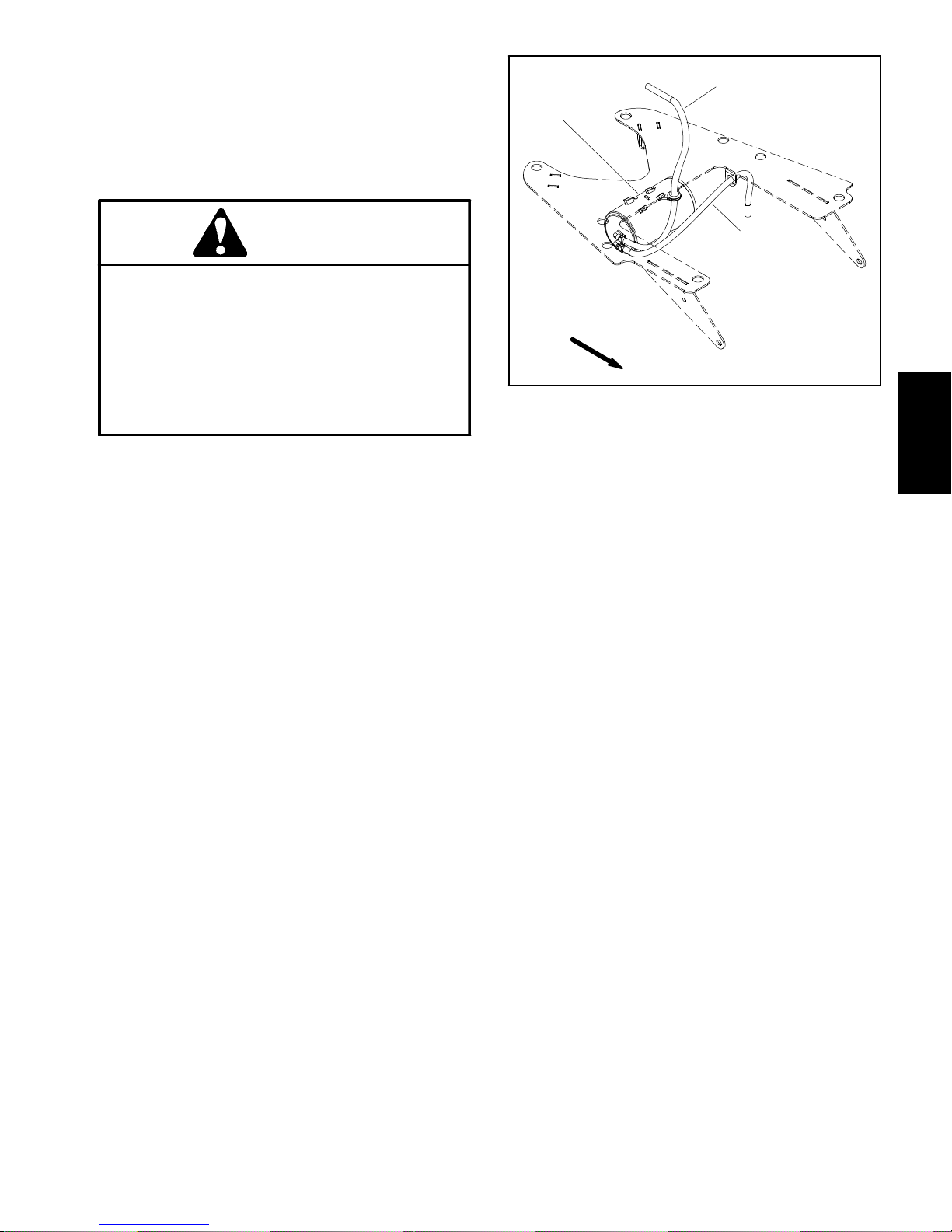

This safety symbol means DANGER, WARNING

or CAUTION, PERSONAL SAFETY INSTRUCTION. When you see this symbol, carefully read

the instructions that follow. Failure to obey the

instructions may result in personal injury.

NOTE: ANOTE will give general information about the

correct operation, maintenance, service, testing or repair of the machine.

IMPORTANT: The IMPORTANT notice will give importantinstructionswhichmustbefollowedtoprevent damage to systems or components on the

machine.

TM

3300/3400

Greensmaster3300

E The Toro Company -- 2012

Page 2

This page is intentionally blank.

Greensmaster 3300/3400

Page 3

Table Of Contents

Chapter 1 -- Safety

General Safety Instructions 1 -- 2..................

Jacking Instructions 1 -- 5.........................

Safety and Instruction Decals 1 -- 6................

Chapter 2 -- Product Records and Maintenance

Product Records 2 -- 1...........................

Maintenance 2 -- 1...............................

Equivalents and Conversions 2 -- 2................

Torque Specifications 2 -- 3.......................

Chapter 3 -- Gasoline Engine

Specifications 3 -- 2..............................

General Information 3 -- 3........................

Fuel Evaporative Control System 3 -- 4.............

Adjustments 3 -- 7...............................

Service and Repairs 3 -- 8........................

BRIGGS & STRATTON REPAIR MANUAL FOR

4-CYCLE V-TWIN CYLINDER OHV HEAD

ENGINES

Chapter 4 -- Diesel Engine

Specifications 4 -- 2..............................

General Information 4 -- 3........................

Adjustments 4 -- 5...............................

Service and Repairs 4 -- 6........................

KUBOTA WORKSHOP MANUAL, DIESEL ENGINE,

02--E3B SERIES

Chapter 5 -- Hydraulic System

Chapter 6 -- Electrical System

General Information 6 -- 3........................

Turf Guardian Leak Detector

System Operation 6 -- 4........................

Special Tools 6 -- 6..............................

Troubleshooting 6 -- 8............................

Electrical System Quick Checks 6 -- 23.............

Adjustments 6 -- 24..............................

Component Testing 6 -- 26........................

Service and Repairs 6 -- 54.......................

Chapter 7 -- Chassis

Specifications 7 -- 2..............................

General Information 7 -- 3........................

Special Tools 7 -- 4..............................

Adjustments 7 -- 5...............................

Service and Repairs 7 -- 6........................

Chapter 8 -- DPA Cutting Units

Specifications 8 -- 2..............................

General Information 8 -- 3........................

Special Tools 8 -- 4..............................

Factors That Can Affect Cutting Performance 8 -- 6..

Set Up and Adjustments 8 -- 10....................

Service and Repairs 8 -- 12.......................

Safety

Product Records

GasolineElectricalChassis

Diesel

Hydraulic

and Maintenance

Engine

Engine

System

Specifications 5 -- 3..............................

General Information 5 -- 4........................

Hydraulic Schematic 5 -- 10.......................

Hydraulic Flow Diagrams 5 -- 12...................

Special Tools 5 -- 22.............................

Troubleshooting 5 -- 26...........................

Testing 5 - - 32...................................

Adjustments 5 -- 54..............................

Service and Repairs 5 -- 56.......................

EATON, MEDIUM DUTY PISTON PUMP, REPAIR

INFORMATION, MODEL 70160 VARIABLE

DISPLACEMENT PISTON PUMP

PARKER TORQMOTOR

(TC, TB, TE, TJ, TF, TG, TH AND TL SERIES)

SAUER/DANFOSS STEERING UNIT TYPE OSPM

SERVICE MANUAL

Greensmaster 3300/3400

TM

SERVICE PROCEDURE

System

Units

DPA Cutting

Page 4

This page is intentionally blank.

Greensmaster 3300/3400

Page 5

Table Of Contents (Continued)

Chapter 9 -- Groomer

Specifications 9 -- 2..............................

General Information 9 -- 3........................

Troubleshooting 9 -- 4............................

Adjustments 9 -- 6...............................

Service and Repairs 9 -- 7........................

Chapter 10 -- Foldout Drawings

Groomer

Hydraulic Schematic 10 -- 3.......................

Electrical Schematics 10 -- 4......................

Wire Harness Drawings 10 -- 8....................

Foldout

Drawings

Greensmaster 3300/3400

Page 6

This page is intentionally blank.

Greensmaster 3300/3400

Page 7

Table of Contents

GENERAL SAFETY INSTRUCTIONS 2............

Before Operating 2............................

While Operating 3.............................

Maintenance and Service 4....................

JACKING INSTRUCTIONS 5.....................

SAFETY AND INSTRUCTION DECALS 6..........

Chapter 1

Safety

Safety

Greensmaster 3300/3400 Page 1 -- 1 Safety

Page 8

General Safety Instructions

Greensmaster TriFlex 3300 and 3400 machines have

been tested and certified by TORO for compliance with

existing safety standards and specifications. Although

hazardcontrol and accident prevention partiallyare dependent upon the design and configuration of the machine, these factors are also dependent upon the

awareness, concern and proper training of the personnel involved in the operation, transport, maintenance

and storage of the machine. Improper use or maintenanceofthemachinecan result in injury or death. Toreduce the potential for injury or death, comply with the

following safety instructions.

Before Operating

WARNING

To reduce the potential for injury or death,

comply with the following safety instructions.

1. Review and understand the contents of the Operator’s Manuals and Operator’s DVD before starting and

operatingthe vehicle. Becomefamiliar with thecontrols

and know how to stop the vehicle and engine quickly.

AdditionalcopiesoftheOperator’sManualareavailable

on the internet at www.Toro.com.

2. Keep all shields, safety devices and decalsin place.

Ifashield,safetydevice or decal is defective,illegibleor

damaged, repair or replace it before operating the machine.Alsotightenanyloosenuts,boltsorscrewstoensure machine is in safe operating condition.

3. Assure interlock switches are adjusted correctly so

engine cannot be started unless traction pedal is in

NEUTRAL and cutting units are DISENGAGED.

4. Since fuel is flammable, handle it carefully:

A. Use an approved fuel container.

B. Donotremovefuel tank capwhileengineishotor

running.

C. Do not smoke while handling fuel.

D. Fillfueltankoutdoorsandonlytowithinaninchof

the top of the tank, not the filler neck. Do not overfill

the fuel tank.

E. Wipe up any spilled fuel.

Greensmaster 3300/3400Page 1 -- 2Safety

Page 9

While Operating

1. Sit on the seat when starting and operating the machine.

2. Before starting the engine:

A. Sitontheseat,makesurecuttingunitsaredisen-

gaged.

B. Verify that functional control lever is in neutral.

C. Verify that parking brake is applied.

D. Proceed to start engine.

E. Afterengineisstarted, releaseparkingbrakeand

keepfootofftractionpedal.Machine must not move.

If movement is evident, the traction pedal linkage is

adjusted incorrectly; therefore, shut engine off and

adjust traction pedal linkage until machine does not

move when traction pedal is released.

3. Do not run engine in a confined area without ade-

quate ventilation. Exhaust fumes are hazardous and

could possibly be deadly.

4. Donottouchengine,exhaustsystemcomponentsor

radiator(ifequipped)while engine is running orsoonafter it is stopped. These areas could be hot enough to

cause burns.

Safety

5. Before getting off the seat:

A. Make sure cutting units are disengaged.

B. Verify that functional control lever is in neutral.

C. Apply the parking brake.

D. Stop the engine and remove key from ignition

switch.

E. Toro recommends that anytime the machine is

parked (short or long term), the cutting units should

be lowered to the ground. This relieves pressure

fromthehydraulicliftcircuitandeliminatestheriskof

cutting units accidentally lowering to the ground.

F. Donotparkthemachineonslopesunlesswheels

are chocked or blocked.

Greensmaster 3300/3400 Page 1 -- 3 Safety

Page 10

Maintenance and Service

1. TheTractionUnitandCuttingUnitOperator’s Manualsprovideinformationregardingtheoperation,general

maintenance and maintenance intervals for your

Greensmaster machine. Refer to these publications for

additional information when servicing the machine.

2. Before servicing or making adjustments, lower cuttingunits, stop engine, applyparking brake and remove

key from the ignition switch.

3. Make sure machine is in safe operatingcondition by

keeping all nuts, bolts and screws tight.

4. Never store the machine or fuel container inside

wherethereis anopenflame,such asnearawaterheater or furnace.

5. Make sure all hydraulic line connectorsare tight and

all hydraulic hoses and lines are in good condition before applying pressure to the hydraulic system.

6. Keepbodyandhandsawayfrompinholeleaksinhydrauliclinesthatejecthighpressurehydraulic fluid. Use

cardboard or paper to find hydraulic leaks. Hydraulic

fluid escaping under pressure can penetrate skin and

cause injury. Fluid accidentally injected into the skin

mustbesurgicallyremovedwithin a few hours by adoctor familiar with this form of injury or gangrene may result.

7. Before disconnecting or performing any work on the

hydraulic system, all pressure in system must be relieved by stopping engine and lowering cutting units to

the ground.

8. If major repairsare ever neededor assistance is desired, contact an Authorized Toro Distributor.

9. To reduce potential fire hazard, keep engine area

free of excessive grease, grass, leaves and dirt. Clean

protective screen on machine frequently.

10.If engine must be running to perform maintenance or

an adjustment, keep hands, feet, clothing and other

partsofthebodyawayfromcuttingunitsandothermoving parts. Keep bystanders away.

12.Shut engine off before checking or adding oil to the

engine crankcase.

13.Disconnect battery before servicing the machine.

Disconnect negative battery cable first and positive

cablelast.Ifbatteryvoltage is required for troubleshooting or test procedures, temporarily connect the battery.

Reconnect positive battery cable first and negative

cable last.

14.Battery acid is poisonous and can cause burns.

Avoidcontact with skin, eyes and clothing. Protect your

face, eyes and clothing when working with a battery.

15.Battery gases can explode. Keep cigarettes, sparks

and flames away from the battery.

16.When welding on machine, disconnect both battery

cables to prevent damage to machine electronic equipment. Disconnect negative battery cable first and positive cable last. Also, disconnect the wire harness

connector from the TEC controller and the alternator

connector(s). This will prevent damage to the electrical

system of your Greensmaster.

17.At the time of manufacture, the machine conformed

tothe safety standards forriding mowers. Toassure optimumperformanceandcontinuedsafetycertificationof

the machine, use genuine Toro replacement parts and

accessories.Replacementpartsandaccessoriesmade

by other manufacturers may result in non-conformance

with the safety standards and the warranty may be

voided.

18.When changing attachments, tires or performing

other service, use correct blocks, hoists and jacks.

Make sure machine is parked on a solid level surface

suchasaconcrete floor.Priorto raising themachine,remove any attachments that may interfere with the safe

and proper raising of the machine. Always chock or

block wheels. Use appropriate jack stands to support

the raised machine. If the machine is not properly supported by jack stands, the machine may move or fall,

whichmayresultinpersonal injury (seeJackingInstructions in this chapter).

11.Do not overspeed the engine by changing governor

setting.Toassuresafetyandaccuracy,checkmaximum

engine speed.

Greensmaster 3300/3400Page 1 -- 4Safety

Page 11

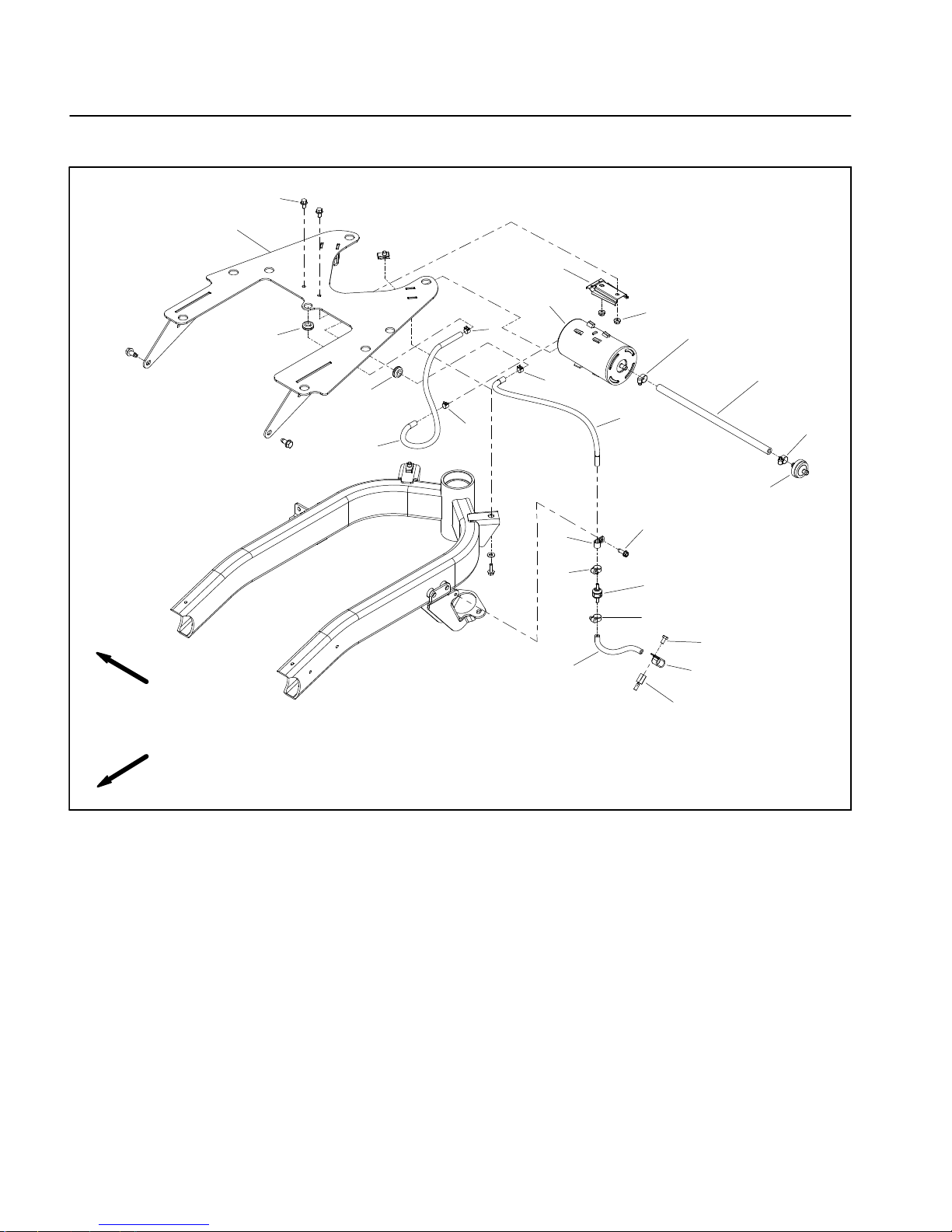

Jacking Instructions

CAUTION

When changing attachments, tires or performing other service, use correct jacks and supports. Make sure machine is parked on a solid,

level surface such as a concrete floor. Prior to

raising machine, remove any attachments that

may interfere with the safe and properraising of

themachine.Always chockorblockwheels. Use

jackstands to support the raised machine. If the

machine is not properly supported by jack

stands, the machine may move or fall, which

may result in personal injury.

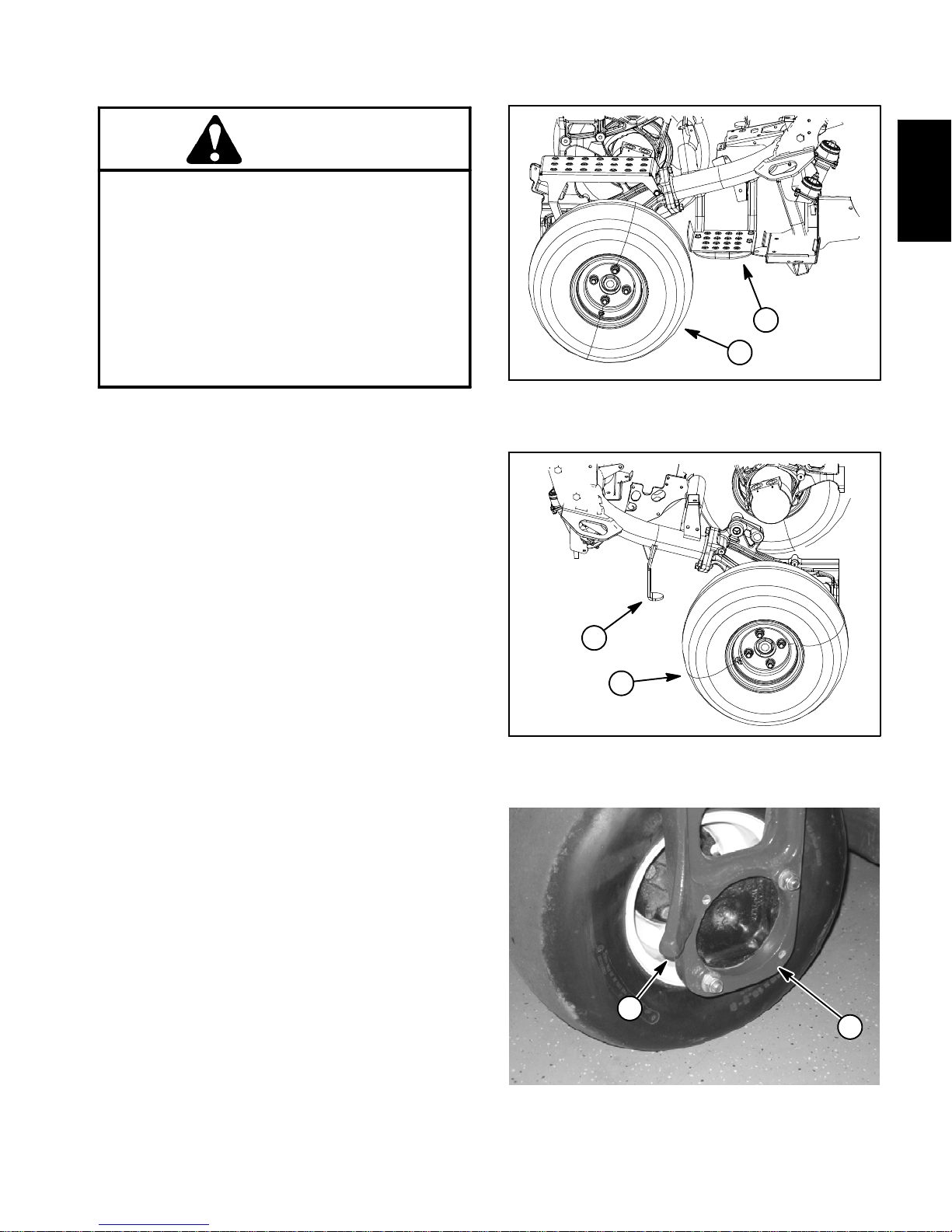

Front End Jacking

1. Apply parking brake and chock rear tire to prevent

the machine from moving.

2. Position jack securely underthe frame jacking point:

A. The left side jacking point is the frame channel

under the step behind the LH front wheel (Fig. 1).

B. The right side jacking point is the frame bracket

behind the RH front wheel (Fig. 2).

3. Jack front of machine off the ground.

Safety

2

1

Figure 1

1. LH front wheel 2. Jacking point

2

4. Position appropriate jack stands under the frame as

close to the wheel as possible to support the machine.

Rear End Jacking

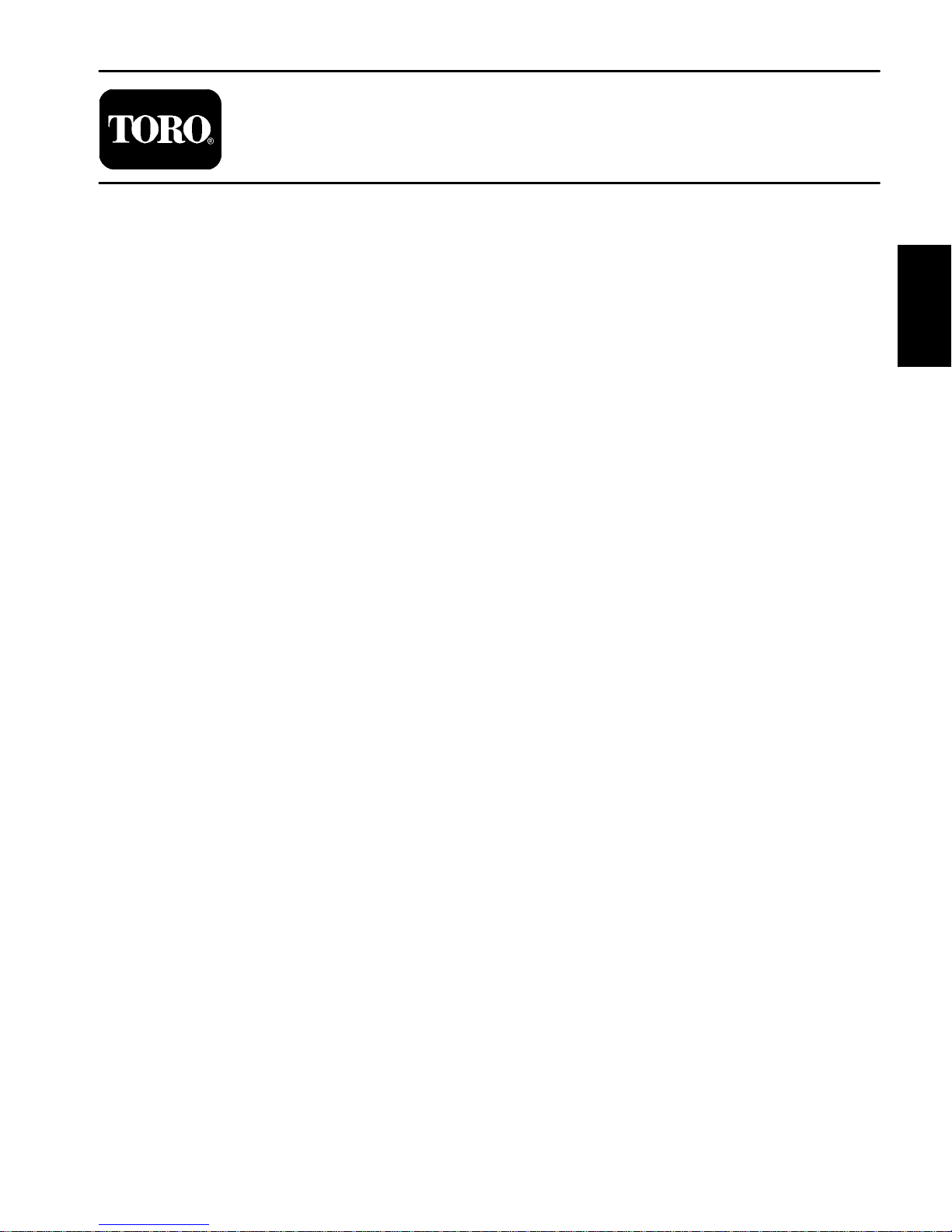

1. Applyparkingbrakeandchock both fronttirestopre-

vent the machine from moving.

2. Place jack securely under the rear jacking point on

the rear steering fork (Fig. 3).

3. Jack rear of machine off the ground.

4. Position appropriate jack stands under the frame to

support the machine.

1

Figure 2

1. RH front wheel 2. Jacking point

2

1

Figure 3

1. Rear steering fork 2. Rear jacking point

Greensmaster 3300/3400 Page 1 -- 5 Safety

Page 12

Safety and Instruction Decals

Numerous safety and instruction decals are affixed to

the traction unit and the cutting units of Greensmaster

TriFlex3300and 3400 machines.Ifany decal becomes

illegible or damaged, install a new decal. Part numbers

are listed in your Parts Catalog and Operator’s Manual.

Order replacement decals from your Authorized Toro

Distributor.

Greensmaster 3300/3400Page 1 -- 6Safety

Page 13

Product Records and Maintenance

Table of Contents

PRODUCT RECORDS 1.........................

MAINTENANCE 1...............................

EQUIVALENTS AND CONVERSIONS 2...........

Decimal and Millimeter Equivalents 2............

U.S. to Metric Conversions 2...................

TORQUE SPECIFICATIONS 3....................

Fastener Identification 3.......................

Using a Torque Wrench with an Offset Wrench 3..

Standard Torque for Dry, Zinc Plated and

Steel Fasteners (Inch Series). 4...............

Standard Torque for Dry, Zinc Plated and

Steel Fasteners (Metric Fasteners). 5..........

Other Torque Specifications 6..................

Conversion Factors 6..........................

Chapter 2

Product Records

and Maintenance

Product Records

Inserta copy ofthe TractionUnit and CuttingUnit Operator’s Manuals and Parts Catalog for your Greensmasterat the endof this chapter.Additionally,ifanyoptional

equipment or accessories have been installed to your

machine, insert the Installation Instructions, Operator’s

ManualsandPartsCatalogsforthoseoptions at theend

of this chapter.

Maintenance

Maintenanceproceduresandrecommendedserviceintervals for your Greensmaster are covered in the Traction Unit Operator’s Manual. Maintenance procedures

andrecommendedserviceintervalsfortheGreensmaster Cutting Units are covered in the Cutting Unit Operator’s Manual. Refer to these publications when

performing regular equipment maintenance. Refer to

theEngineOperator’sManualforadditionalenginespecific maintenance procedures.

Greensmaster 3300/3400 Page 2 -- 1 Product Records and Maintenance

Page 14

Equivalents and Conversions

0.09375

Greensmaster 3300/3400Page 2 -- 2Product Records and Maintenance

Page 15

Torque Specifications

Recommended fastener torque values are listed in the

followingtables.For critical applications, as determined

byToro, either the recommended torque or a torquethat

is unique to the application is clearly identifiedand specified in this Service Manual.

These Torque Specifications for the installation and

tightening of fastenersshall apply to all fasteners which

donot have aspecific requirement identifiedin this Service Manual. The following factors shall be considered

when applying torque: cleanliness of the fastener, use

of a thread sealant (e.g. Loctite), degree of lubrication

onthe fastener,presenceof a prevailing torquefeature,

hardnessofthesurfaceunderneaththefastener’s head

or similar condition which affects the installation.

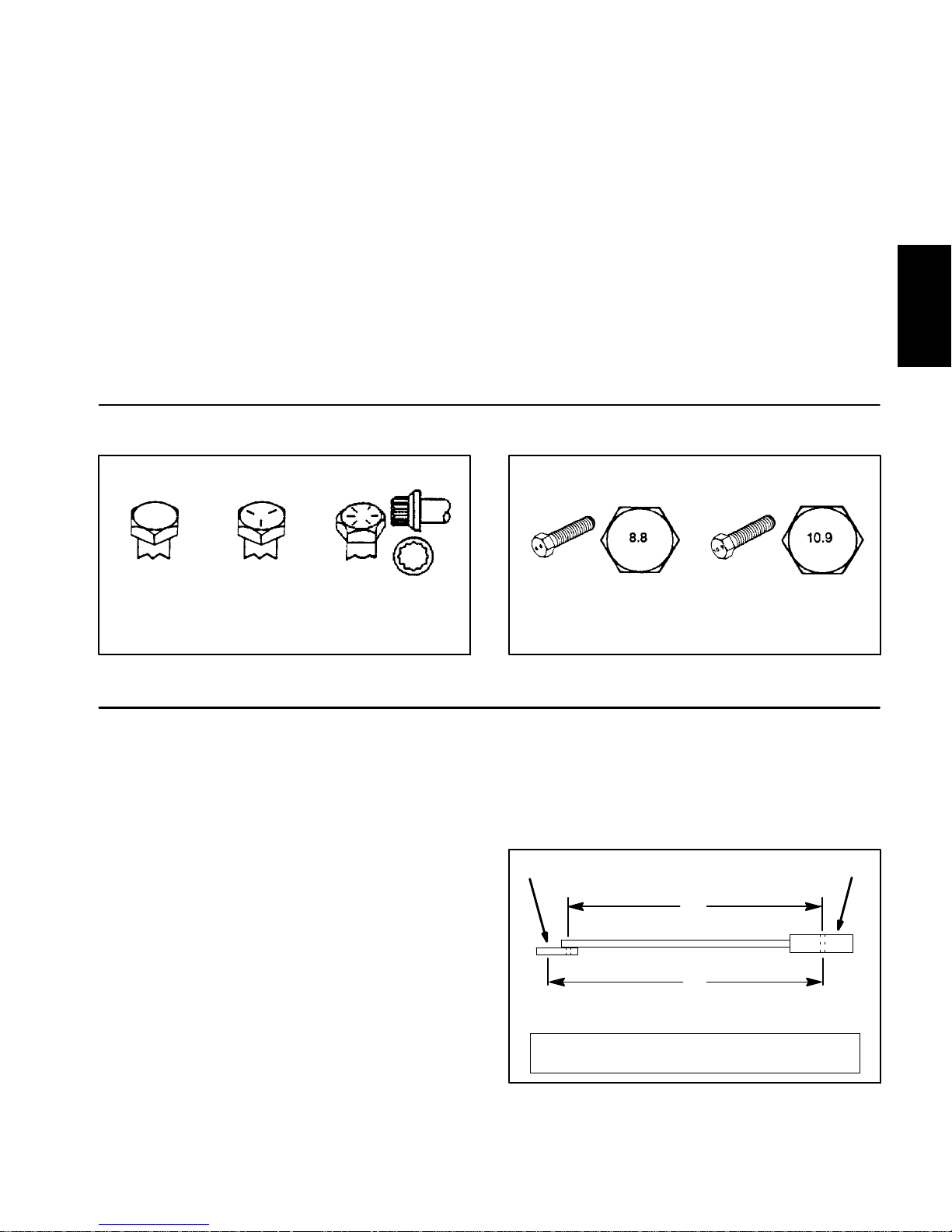

Fastener Identification

Asnotedinthe following tables,torquevaluesshouldbe

reduced by 25% for lubricated fasteners to achieve

the similar stress as a dry fastener.Torque values may

also have to be reduced when the fastener is threaded

into aluminum or brass. The specific torque value

should be determined based on the aluminum or brass

material strength, fastener size, length of thread engagement, etc.

The standard method of verifying torque shall be performed by marking a line on the fastener (head or nut)

and mating part, then back off fastener 1/4 of a turn.

Measurethetorquerequiredtotighten the fastener until

the lines match up.

Product Records

and Maintenance

Grade 1 Grade 5 Grade 8

Inch Series Bolts and Screws

Figure 1

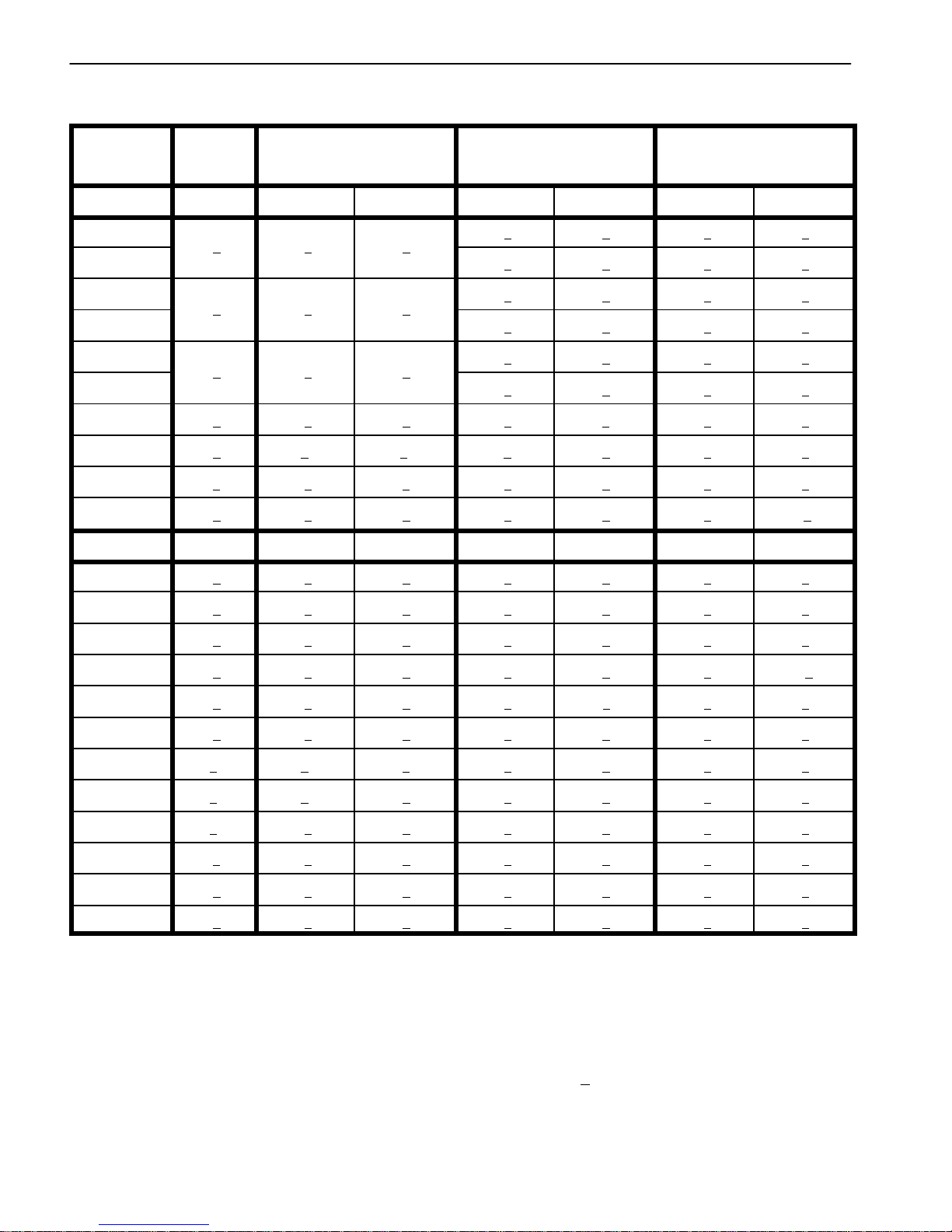

Using a Torque Wrench with an Offset Wrench

Useofanoffsetwrench(e.g. crowfootwrench)willaffect

torquewrench calibration dueto the effective change of

torquewrenchlength.Whenusingatorque wrench with

an offset wrench, multiply the listed torque recommendation by the calculated torque conversion factor (Fig.

3) to determine proper tightening torque. Tightening

torque when using a torque wrench with an offset

wrench will be lower than the listed torque recommendation.

Example: The measured effective length of the torque

wrench (distance from the center of the handle to the

center of the square drive) is 18”.

Themeasuredeffectivelengthofthetorquewrenchwith

the offset wrench installed (distance from the center of

the handle to the center of the offset wrench) is 19”.

Class 8.8 Class 10.9

Metric Bolts and Screws

Figure 2

If the listed torque recommendation for a fastener is

from 76 to 94 ft--lb, the proper torque when using this

torque wrench with an offset wrench would be from 72

to 89 ft--lb.

(effective length of

torque wrench)

A

B

(effective length of torque

wrench + offset wrench)

TORQUE CONVERSION FACTOR = A / B

Torque wrenchOffset wrench

The calculated torque conversion factor for this torque

wrenchwiththis offset wrench would be18/ 19 = 0.947.

Greensmaster 3300/3400 Page 2 -- 3 Product Records and Maintenance

Figure 3

Page 16

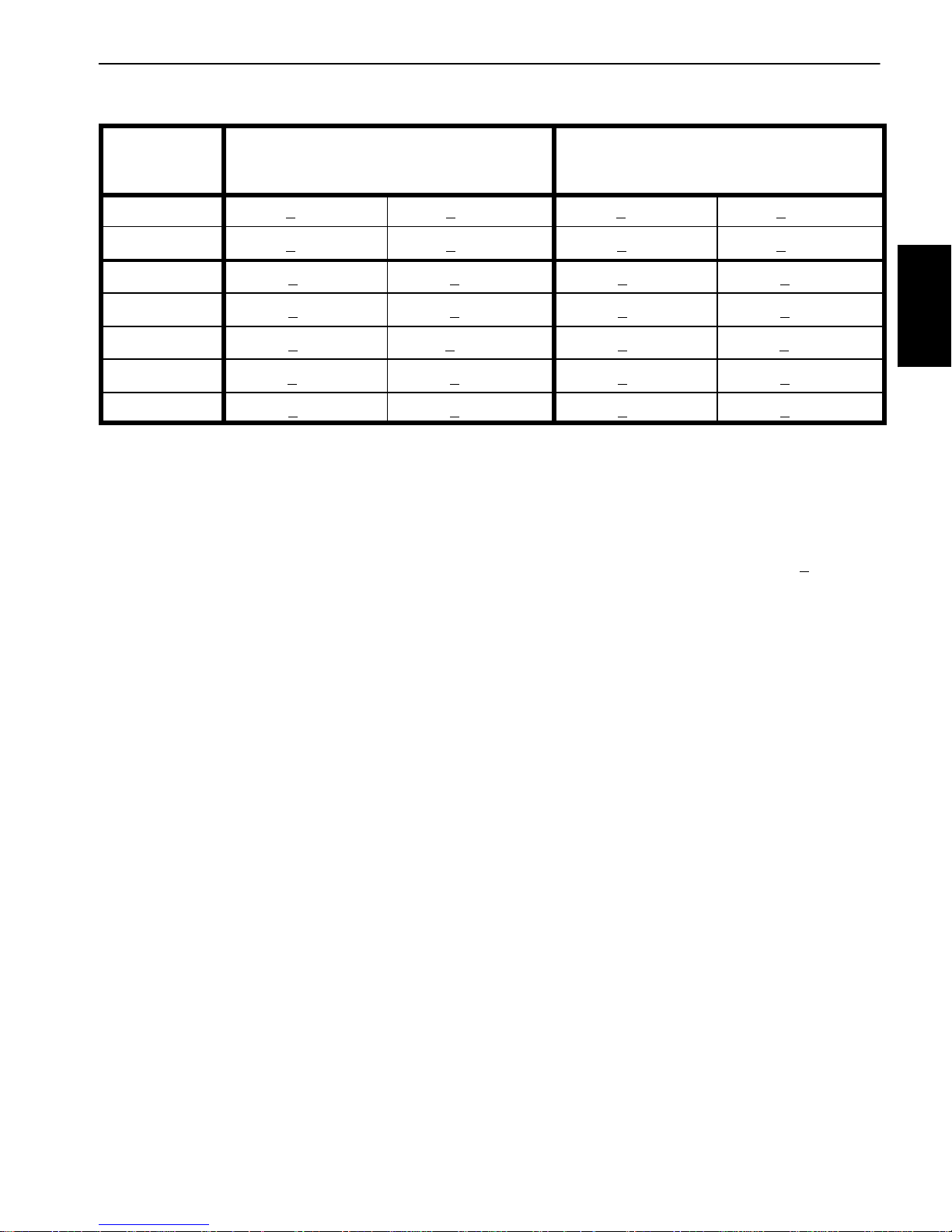

Standard Torque for Dry, Zinc Plated and Steel Fasteners (Inch Series)

Thread Size

# 6 -- 32 UNC

# 6 -- 40 UNF

# 8 -- 32 UNC

# 8 -- 36 UNF

#10--24UNC

#10--32UNF

1/4 -- 20 UNC 48 + 7 53 + 7 599 + 79 100 + 10 1125+ 100 140 + 15 1580 + 170

1/4 -- 28 UNF 53 + 7 65+ 10 734 + 113 115 + 10 1300 + 100 160 + 15 1800 + 170

5/16 -- 18 UNC 115 + 15 105 + 17 1186 + 169 200 + 25 2250 + 280 300+ 30 3390 + 340

5/16 -- 24 UNF 138 + 17 128 + 17 1446 + 192 225 + 25 2540 + 280 325 + 30 3670 + 340

3/8 -- 16 UNC 16 + 2 16 + 2 22 + 3 30 + 3 41 + 4 43 + 4 58 + 5

Grade 1, 5 &

8withThin

Height Nuts

in--lb in--lb N--cm in--lb N--cm in--lb N--cm

10 + 2 13 + 2 147 + 23

13 + 2 25 + 5 282 + 30

18 + 2 30 + 5 339 + 56

ft--lb ft--lb N--m ft--lb N--m ft--lb N--m

SAE Grade 1 Bolts, Screws, Studs &

Sems with Regular Height Nuts

(SAE J995 Grade 2 or Stronger Nuts)

SAE Grade 5 Bolts, Screws, Studs &

Sems with Regular Height Nuts

(SAE J995 Grade 2 or Stronger Nuts)

15 + 2 170 + 20 23 + 2 260 + 20

17 + 2 190 + 20 25 + 2 280 + 20

29 + 3 330 + 30 41 + 4 460 + 45

31 + 3 350 + 30 43 + 4 485 + 45

42 + 4 475 + 45 60 + 6 675 + 70

48 + 4 540 + 45 68 + 6 765 + 70

SAE Grade 8 Bolts, Screws, Studs &

Sems with Regular Height Nuts

(SAE J995 Grade 5 or Stronger Nuts)

3/8 -- 24 UNF 17 + 2 18 + 2 24 + 3 35 + 3 47 + 4 50 + 4 68 + 5

7/16 -- 14 UNC 27 + 3 27 + 3 37 + 4 50 + 5 68 + 7 70 + 7 95 + 9

7/16 -- 20 UNF 29 + 3 29 + 3 39 + 4 55 + 5 75 + 7 77 + 7 104 + 9

1/2 -- 13 UNC 30 + 3 48 + 7 65 + 9 75 + 8 102 + 11 105 + 10 142 + 14

1/2 -- 20 UNF 32 + 3 53 + 7 72 + 9 85 + 8 115 + 11 120 + 10 163 + 14

5/8 -- 11UNC 65 + 10 88 + 12 119 + 16 150 + 15 203 + 20 210 + 20 285+ 27

5/8 -- 18 UNF 75 + 10 95 + 15 129 + 20 170 + 15 230 + 20 240 + 20 325 + 27

3/4 -- 10 UNC 93 + 12 140 + 20 190 + 27 265 + 25 359 + 34 375 + 35 508 + 47

3/4 -- 16 UNF 115 + 15 165 + 25 224 + 34 300 + 25 407 + 34 420 + 35 569 + 47

7/8 -- 9 UNC 140 + 20 225 + 25 305 + 34 430 + 45 583 + 61 600 + 60 813 + 81

7/8 -- 14 UNF 155 + 25 260 + 30 353 + 41 475 + 45 644 + 61 660 + 60 895 + 81

NOTE: Reduce torque values listed in the table above

by 25% for lubricated fasteners. Lubricated fasteners

on the fastener size, the aluminum or base material

strength, length of thread engagement, etc.

are defined as threads coated with a lubricant such as

oil, graphite or thread sealant such as Loctite.

NOTE: The nominal torque values listed above for

Grade 5 and 8 fasteners are based on 75% of the miniNOTE: Torque values may have to be reduced when

installing fasteners into threaded aluminum or brass.

The specific torque value should be determined based

mumproof load specifiedin SAE J429.Thetolerance is

approximately +

10% of the nominal torque value. Thin

height nuts include jam nuts.

Greensmaster 3300/3400Page 2 -- 4Product Records and Maintenance

Page 17

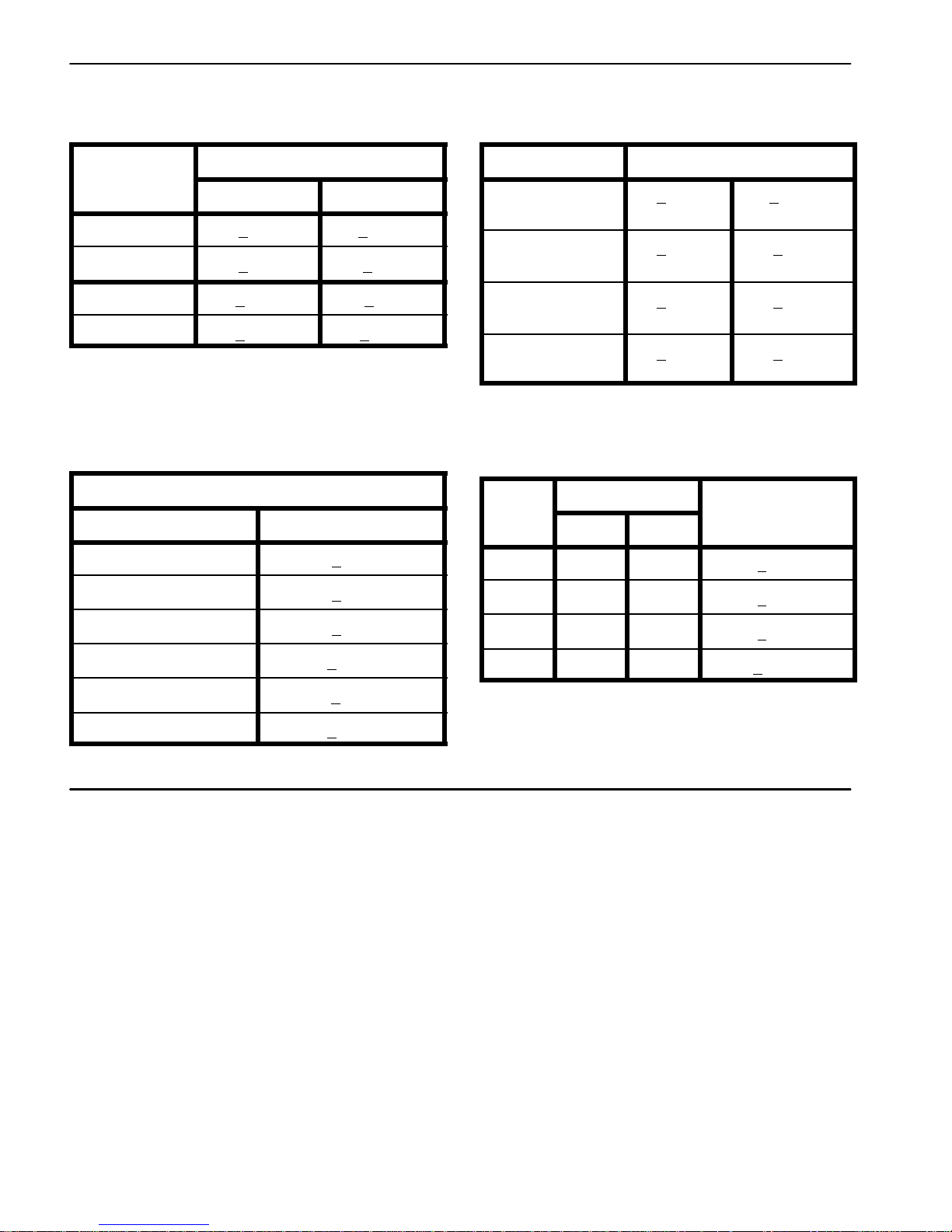

Standard Torque for Dry, Zinc Plated and Steel Fasteners (Metric Fasteners)

Class 8.8 Bolts, Screws and Studs with

Thread Size Regular Height Nuts

(Class 8 or Stronger Nuts)

Class 10.9 Bolts, Screws and Studs with

Regular Height Nuts

(Class 10 or Stronger Nuts)

M5 X 0.8 57 + 5in--lb 640 + 60 N--cm 78 + 7in--lb 885 + 80 N--cm

M6 X 1.0 96 + 9in--lb 1018 + 100 N--cm 133 + 13 in--lb 1500 + 150 N--cm

M8 X 1.25 19 + 2ft--lb 26 + 3N--m 27 + 2ft--lb 36 + 3N--m

M10 X 1.5 38 + 4ft--lb 52 + 5N--m 53 + 5ft--lb 72 + 7N--m

M12 X 1.75 66 + 7ft--lb 90 + 10 N--m 92 + 9ft--lb 125+ 12 N--m

M16 X 2.0 166 + 15 ft--lb 225 + 20 N-- m 229 + 22 ft--lb 310 + 30 N--m

M20 X 2.5 325 + 33 ft--lb 440 + 45 N--m 450 + 37 ft--lb 610 + 50 N--m

NOTE: Reduce torque values listed in the table above

by 25% for lubricated fasteners. Lubricated fasteners

on the fastener size, the aluminum or base material

strength, length of thread engagement, etc.

are defined as threads coated with a lubricant such as

oil, graphite or thread sealant such as Loctite.

NOTE: The nominal torque values listed above are

NOTE: Torque values may have to be reduced when

installing fasteners into threaded aluminum or brass.

The specific torque value should be determined based

based on 75% of the minimum proof load specified in

SAEJ1199.Thetoleranceisapproximately+

nominal torque value.

10%ofthe

Product Records

and Maintenance

Greensmaster 3300/3400 Page 2 -- 5 Product Records and Maintenance

Page 18

Other Torque Specifications

*

SAE Grade 8 Steel Set Screws

Recommended Torque

Thread Size

Square Head Hex Socket

1/4 -- 20 UNC 140 + 20 in--lb 73 + 12 in--lb

5/16 -- 18 UNC 215 + 35 in--lb 145 + 20 in--lb

3/8 -- 16 UNC 35 + 10 ft--lb 18 + 3ft--lb

1/2 -- 13 UNC 75 + 15 ft--lb 50 + 10 ft--lb

Thread Cutting Screws

(Zinc Plated Steel)

Type 1, Type 23 or Type F

Thread Size Baseline Torque*

No. 6 -- 32 UNC 20 + 5in--lb

Wheel Bolts and Lug Nuts

Thread Size

7/16 -- 20 UNF

Grade 5

1/2 -- 20 UNF

Grade 5

M12 X 1.25

Class 8.8

M12 X 1.5

Class 8.8

** For steel wheels and non--lubricated fasteners.

Thread Cutting Screws

(Zinc Plated Steel)

Thread

Size

No. 6 18 20 20 + 5in--lb

Threads per Inch

Type A Type B

Recommended Torque**

65 + 10 ft--lb 88 + 14 N--m

80 + 10 ft--lb 108 + 14 N--m

80 + 10 ft--lb 108 + 14 N--m

80 + 10 ft--lb 108 + 14 N--m

Baseline Torque

No. 8 -- 32 UNC 30 + 5in--lb

No. 10 -- 24 UNC 38 + 7in--lb

1/4 -- 20 UNC 85 + 15 in--lb

5/16 -- 18 UNC 110 + 20 in--lb

3/8 -- 16 UNC 200 + 100 in--lb

Conversion Factors

in--lb X 11.2985 = N--cm N--cm X 0.08851 = in--lb

ft--lb X 1.3558 = N--m N--m X 0.7376 = ft--lb

No. 8 15 18 30 + 5in--lb

No. 10 12 16 38 + 7in--lb

No. 12 11 14 85 + 15 in--lb

*Holesize,materialstrength,material thicknessandfinish must be considered when determining specific

torquevalues.Alltorque values are based onnon--lubricated fasteners.

Greensmaster 3300/3400Page 2 -- 6Product Records and Maintenance

Page 19

Table of Contents

SPECIFICATIONS 2.............................

GENERAL INFORMATION 3.....................

Operator’s Manual 3..........................

FUEL EVAPORATIVE CONTROL SYSTEM 4.......

ADJUSTMENTS 7..............................

Choke Cable Adjustment 7.....................

Throttle Cable Adjustment 7....................

SERVICE AND REPAIRS 8......................

Fuel Evaporative Control System (Serial Number

Below 312000000) 8.........................

Fuel Evaporative Control System (Serial Number

Above 312000000) 10.......................

Fuel Tank 12.................................

Engine 14....................................

Engine Removal 14..........................

Engine Installation 16........................

BRIGGS & STRATTON VANGUARD V--TWIN OHV

REPAIR MANUAL

Chapter 3

Gasoline Engine

Engine

Gasoline

Greensmaster 3300 Page 3 -- 1 Gasoline Engine

Page 20

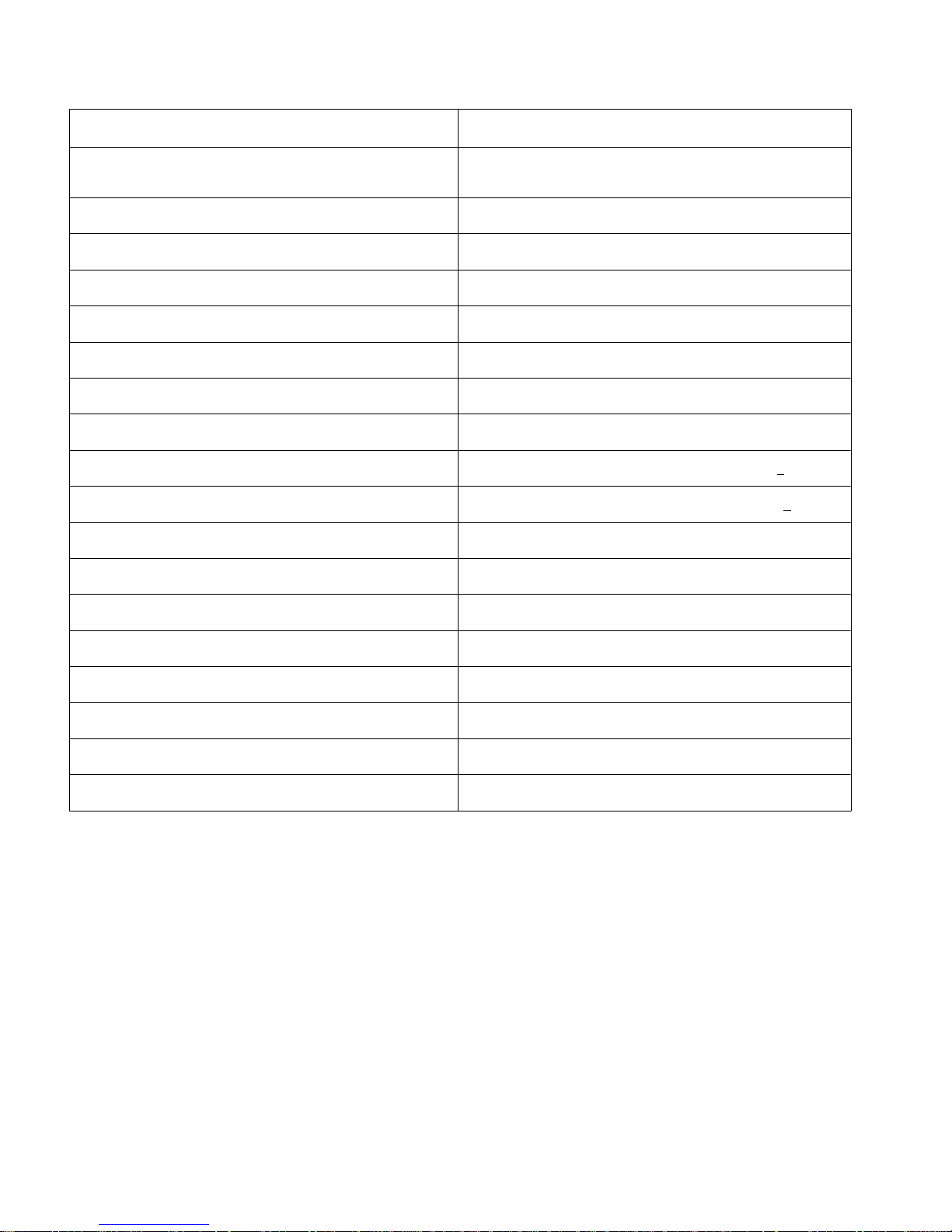

Specifications

Item Description

Make / Designation Briggs and Stratton, 4--cycle, V--Twin Cylinder,

Bore x Stroke 2.97” x 2.76” (75.5 mm x 70 mm)

Total Displacement 38.3 in3(627 cc)

Governor Mechanical Governor

Carburetor Float Feed, Two Barrel

Fuel Pump Pulsating Crankcase Vacuum

Fuel Unleaded, regular grade gasoline

Fuel Tank Capacity 6.0 U.S. gallons (22.7 liters)

Low Idle (no load) 1650 + 100 RPM

High Idle (no load) 2920 + 50 RPM

Lubrication System Pressure Lubrication, Gear Driven Geroter Oil Pump

Engine Oil See Operator’s Manual

Crankcase Oil Capacity 1.75 U.S. quarts (1.65 liters) with new filter

OHV, Air Cooled, Gasoline Engine -- Model 385447

Ignition System Flywheel magneto, twin electronic armatures

Spark Plugs Champion RC 14YC (or equivalent)

Spark Plug Gap 0.030” (0.76 mm)

Alternator 20/50 Amp

Dry Weight (approximate) 85 lb (39 kg)

Greensmaster 3300Page 3 -- 2Gasoline Engine

Page 21

General Information

Informationaboutspecifications, maintenance, troubleshooting,testing and repair ofthegasoline engine used

in the Greensmaster TriFlex 3300 is included in this

chapter and the Briggs & Stratton Vanguard V--Twin

OHV Repair Manual.

Most engine repairs and adjustments require tools

which are commonly available in many service shops.

Special tools are described in the Briggs & Stratton Repair Manual. The use of some specialized test equipment is explained. However, the cost of the test

equipment and the specialized nature of some repairs

may dictate that the work be done at an engine repair

facility.

Operator’s Manual

The Traction Unit Operator’s Manual provides information regarding the operation, general maintenance and

maintenanceintervals for your Greensmastermachine.

Refer to the Operator’s Manual for additional information when servicing the machine.

Service and repair parts for Briggs &Stratton Vanguard

V-Twin OHV enginesare supplied through yourlocal localToro distributor.If noparts list is available,besure to

provide your distributor with the Toro model and serial

numberalongwith the engine modelandserialnumber.

Engine

Gasoline

Greensmaster 3300 Page 3 -- 3 Gasoline Engine

Page 22

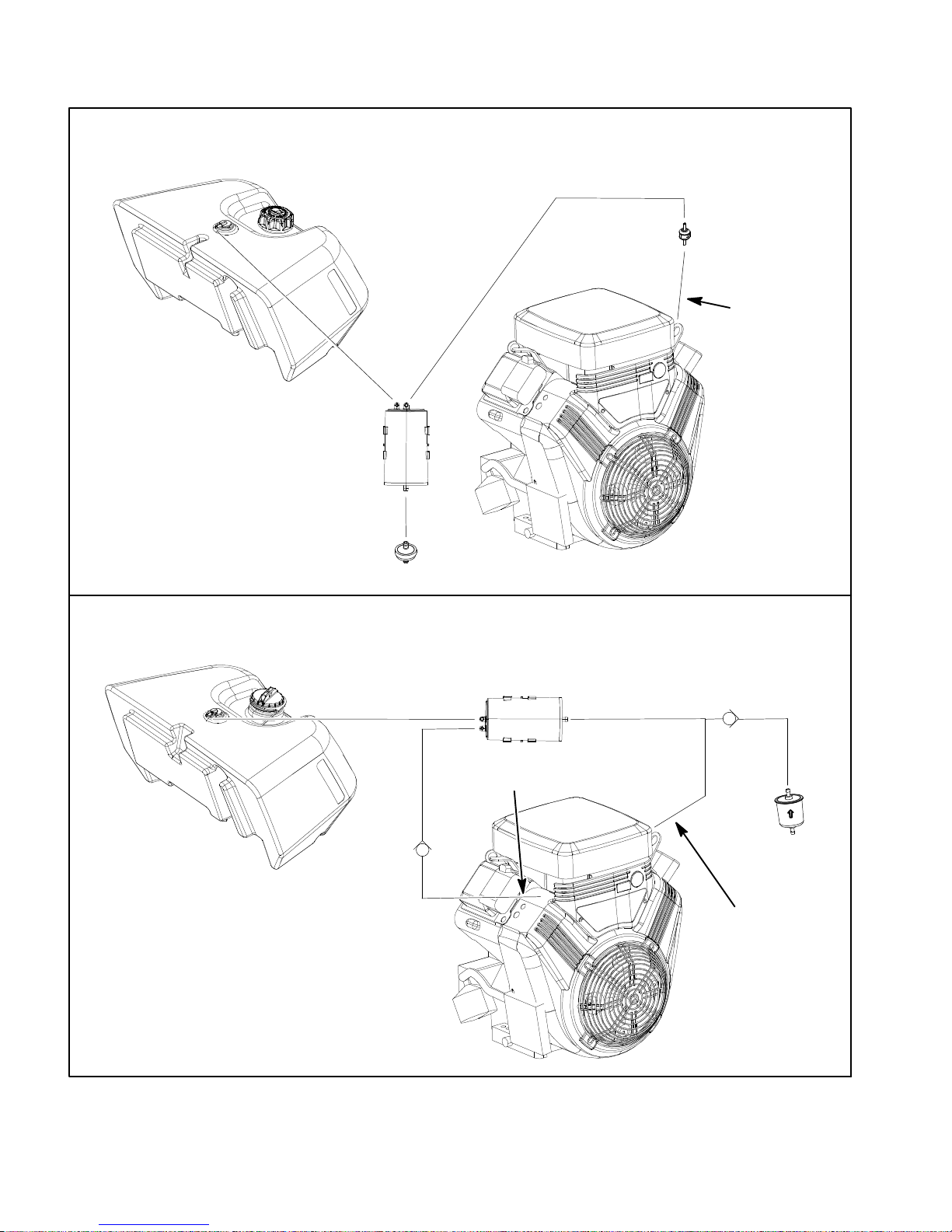

Fuel Evaporative Control System

SERIAL NUMBER BELOW 312000000

FUEL

TANK

CARBON

CANNISTER

CHECK

VALVE

TO INTAKE

MANIFOLD

ENGINE

FUEL

TANK

FRESH AIR

FILTER

SERIAL NUMBER ABOVE 312000000

CARBON

CANNISTER

TO INTAKE

MANIFOLD

CHECK

VALVE

CHECK

VALVE

FRESH AIR

FILTER

TO AIR

CLEANER

ENGINE

Figure 1

Greensmaster 3300Page 3 -- 4Gasoline Engine

Page 23

The function of the fuel evaporative control system is to

collect and store evaporative emissions from the fuel

tankandengine.Theevaporatecontrolsystem used on

Greensmaster 3300 machines uses a carbon cannister

to collect these evaporative emissions. Fuel vapors

fromthefueltankareventedtothecanisterwhentheengine is not running. Vapors from the canister are consumed when the engine is running.

Machines With Serial Number Below 312000000

Onmachines with serial number below 312000000, the

carbon canister is mounted under the fuel tank mount

plate. One fitting at the engine intake manifold is used

toconnect the evaporative systemtothe engine. These

machinesuseaninlinecheckvalvebetweenthecarbon

cannister and the engine intake manifold fitting.

The fuel tank on Greensmaster 3300 machines uses a

non--vented fuel cap. To connect the tank to the evaporative control system, a fuel vent valve is positioned in

the top of the tank that allows tank venting through the

carbon cannister.

NOTE: Ifthereisrestrictioninthefreshairfilter,thecarbon cannister or the fuel vent valve, the fuel tank may

distortduetoventing issues.Ifthefueltank returns toit’s

normal shape when the fuel cap is removed, restriction

in the evaporative control system is likely.

Components used in the evaporative controlsystem on

Greensmaster 3300 machines changed at serial number 312000000. Figure 1 illustrates the components

used in the evaporative control system.

Machines With Serial Number Above 312000000

Onmachines with serial numberabove312000000, the

carbon canister is mounted between the hydraulic reservoir and leak detector tank. The evaporative system

includestwo(2)connectionsto theengine:onetotheintake manifold and the second to the air cleaner base.

Venting hose assemblies include a check valve in two

(2) locations as shown in Figure 1.

NOTE: Thecheckvalves used onmachines with serial

numberabove312000000areincludedasacomponent

of the hose assembly and are not available as a separatepart.Toensureproperoperationofcheckvalves,do

not attempt to remove them from the hose assembly. If

either of these hose assemblies are removed, make

surethattheyare correctlyinstalledtoinsurecorrectoperation of the evaporative control system.

Engine

Gasoline

Greensmaster 3300 Page 3 -- 5 Gasoline Engine

Page 24

This page is intentionally blank.

Greensmaster 3300Page 3 -- 6Gasoline Engine

Page 25

Adjustments

Choke Cable Adjustment

1. Parkmachineonalevelsurface,disengageand lower cutting units, move functional control lever to neutral

(N),engage parking brake, stoptheengine and remove

the key from the ignition switch. Wait for all machine

movement to stop.

2. Remove air cleaner cover and air filter from engine.

3. Move choke control on control panel while watching

choke plate in carburetor.

A. Choke plate should be fully open when choke

control is pushed in.

B. Choke plate should be fully closed when choke

control is pulled out.

Throttle Cable Adjustment

1. Parkmachineonalevelsurface,disengageand lower cutting units, move functional control lever to neutral

(N),engage parking brake, stoptheengine and remove

the key from the ignition switch. Wait for all machine

movement to stop.

4. Ifcableadjustmentis needed, loosen cap screw and

nut that secure choke cable clamp. Reposition cable to

allow correct choke operation. Secure choke cable

clamp.

5. After adjustment, move choke control several times

to make sure that choke operation is correct.

6. Assemble air cleaner.

Engine

Gasoline

2. Adjustthrottle control onconsoleto the fast position.

Inspectgovernorlever onenginetomakesure thatlever

is fully rotated and against stop on governor control.

3. If throttle cable adjustment is needed (Fig. 2):

A. Loosen cap screw that secures throttle cable

clamp on engine bracket.

B. Reposition cable to allow correct governor rota-

tion.

C. Tighten screw to secure throttle cable clamp.

4. After adjustment, move throttle control on console

from low idle to high idle to make sure that cable travel

is correct.

1

1. Throttle cable

2. Cable clamp

2

Figure 2

3. Governor control lever

3

Greensmaster 3300 Page 3 -- 7 Gasoline Engine

Page 26

Service and Repairs

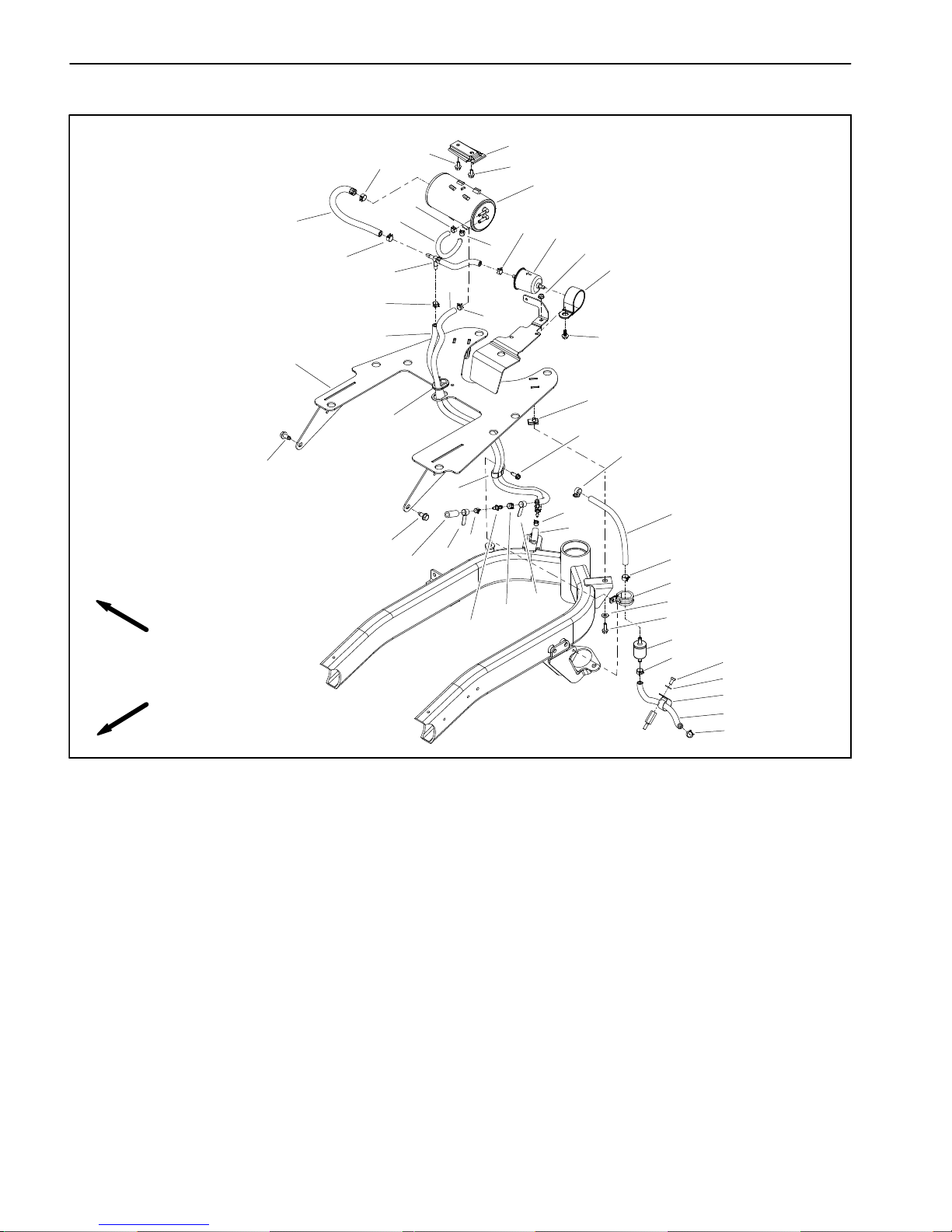

Fuel Evaporative Control System (Serial Number Below 312000000)

1

2

8

RIGHT

FRONT

7

4

4

6

6

9

19

11

10

6

19

5

12

14

13

19

15

19

16

3

17

18

1. Flange head screw (2 used)

2. Tank mount plate

3. Fuel hose (to engine intake manifold)

4. Grommet (2 used)

5. Fuel hose (cannister to tank vent)

6. Hose clamp (3 used)

7. Carbon canister

Figure 3

8. Bracket

9. Flange nut (2 used)

10. Fuel hose (cannister to check valve)

11. Fuel hose

12. Fresh air filter

13. R--clamp

14. Washer head screw

15. Check valve

16. Cap screw

17. R--clamp

18. Spacer screw (attached to engine)

19. Worm clamp (4 used)

Greensmaster 3300Page 3 -- 8Gasoline Engine

Page 27

Removal (Fig. 3)

1. Parkmachineonalevelsurface,disengageand low-

er cutting units, move functional control lever to neutral

(N),engage parking brake, stoptheengine and remove

the key from the ignition switch. Wait for all machine

movement to stop.

2

1

DANGER

Gasolineisflammable. Use cautionwhenstoring

or handling it. Do not smoke while filling the fuel

tank. Do not fill fuel tank while engine is running

or in an enclosed area. Always fill fuel tank out side and wipe up any spilled fuel before starting

the engine. Store fuel in a clean, safety--approved container and keep the cap in place. Use

gasoline for the engine only; not for any other

purpose.

2. Access the carboncannister under thefuel tank and

betweentherearframesections. Ifnecessary,raiseand

supporttankmountplateassembly(hydraulicreservoir,

fuel tank and tank mount plate) to reach the cannister

(seeTank Mount PlateAssemblyinthe Service and Repairs section of Chapter 7 -- Chassis).

3. Inspect carbon cannister and attached for damage

or obvious leaks. A damaged or leaking cannister

should be replaced.

4. Remove components as needed using Figure 3 as

a guide.

FRONT

1. Carbon cannister

2. Hose to tank vent

Figure 4

3. Hose to engine

3

Engine

Gasoline

A. Ifcheckvalve (item15)isremoved,notedirection

of arrow on valve body for assembly purposes.

Installation (Fig. 3)

1. Install all removed components using Figure 3 as a

guide.

A. Ifcheckvalve(item 15) was removed,makesure

that arrow on valve body points toward engine.

B. Make sure that fuel hoses are not kinked after

installation.Also,secureallhoseswithhoseclamps.

2. If tank mount plate assembly (hydraulic reservoir,

fueltankandtankmountplate)wasraisedtoaccessthe

cannister,lowerand secure tank mount plate assembly

(seeTank Mount PlateAssemblyinthe Service and Repairs section of Chapter 7 -- Chassis).

Greensmaster 3300 Page 3 -- 9 Gasoline Engine

Page 28

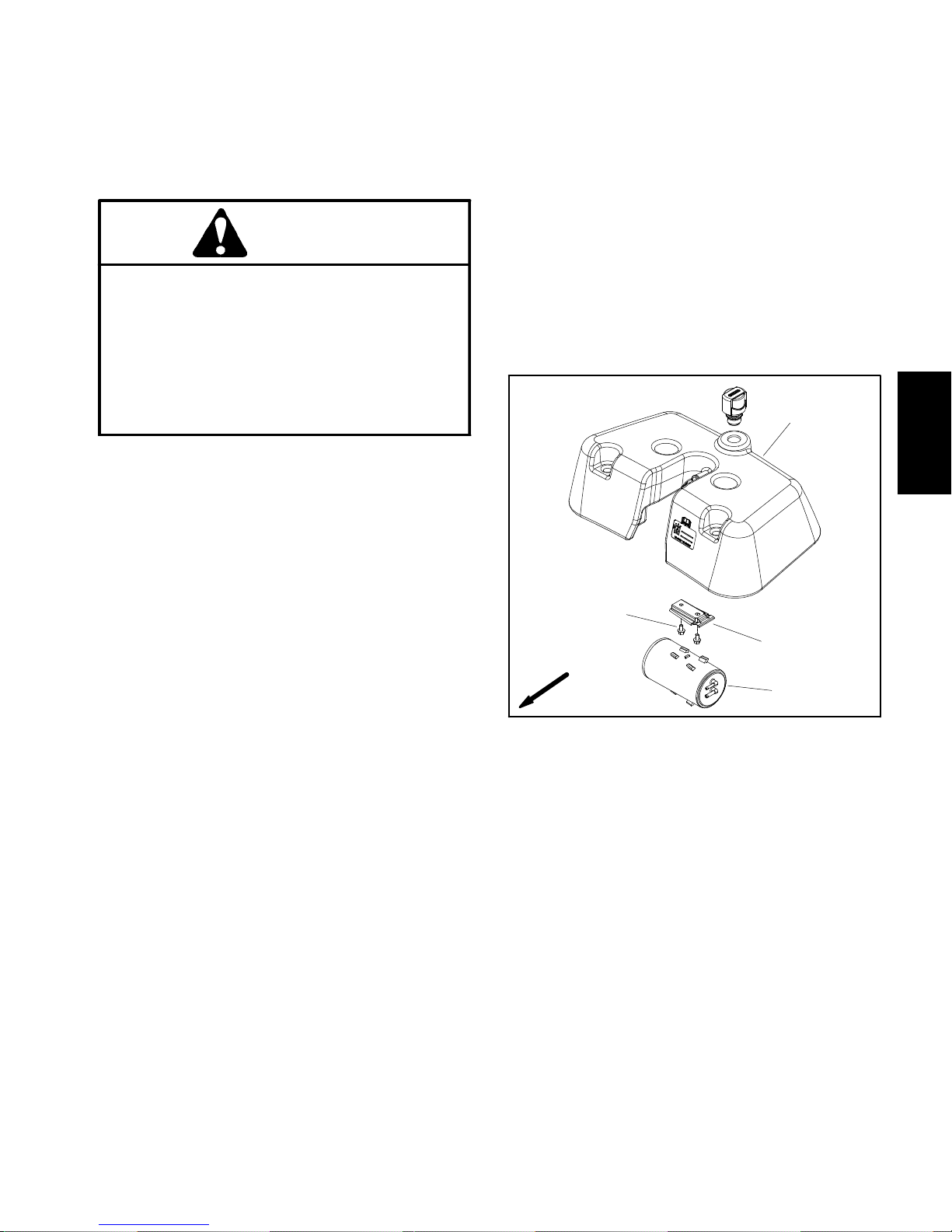

Fuel Evaporative Control System (Serial Number Above 312000000)

RIGHT

FRONT

14

1

8

1

7

6

31

14

29

32

28

21

27

29

29

30

6

9

12

11

2

24

4

5

10

3

22

20

13

35

3

34

18

20

14

15

25

26

16

14

23

33

29

18

25

19

17

14

1. Flange head screw (2 used)

2. Tank mount plate

3. Washer head screw (2 used)

4. Grommet (2 used)

5. Washer head screw

6. Hose clamp (2 used)

7. Carbon cannister

8. Cannister bracket

9. Flange nut

10. Worm clamp

11. Cap screw

12. R--clamp

The function of the fuel evaporative control system is to

collect and store evaporative emissions from the fuel

tankandengine.Onmachineswithserialnumberabove

312000000, a carbon canister mounted above the hydraulicreservoirisused tocollectcollecttheseevaporative emissions. Fuel vapors from the engine and fuel

tank are vented to the canister when the engine is not

running. Vaporsfrom the canister are consumed when

the engine is running.

Figure 5

13. Fuel hose (fuel supply)

14. Hose clamp (5 used)

15. R--clamp

16. Fuel filter (fuel supply)

17. Fuel hose (fuel supply)

18. Label (air cleaner)

19. R--clamp

20. Hose clamp (2 used)

21. Fuel hose (to vent valve on fuel tank)

22. R--clamp

23. Cap screw

24. Clip (2 used)

NOTE: The purge hose assembly (item 27) and tee

hose assembly (item 28) both include a check valve as

a component of the assembly. The check valve is not

available as a separate part. If either of these hose assembliesareremoved,makesurethattheyarecorrectly

installed to insure correct operation of the evaporative

control system.

25. Flat washer (3 used)

26. Flange head screw (2 used)

27. Purge hose assembly (see NOTE)

28. Tee hose assembly (see NOTE)

29. Hose clamp (4 used)

30. Fresh air filter

31. Fuel hose

32. Fuel hose

33. Barbed fitting

34. Engine hose (to air cleaner)

35. Engine hose (to intake manifold)

Greensmaster 3300Page 3 -- 10Gasoline Engine

Page 29

Removal (Fig. 5)

Installation (Fig. 5)

1. Parkmachineonalevelsurface,disengageand low-

er cutting units, move functional control lever to neutral

(N),engage parking brake, stoptheengine and remove

the key from the ignition switch. Wait for all machine

movement to stop.

DANGER

Gasolineisflammable. Use cautionwhenstoring

or handling it. Do not smoke while filling the fuel

tank. Do not fill fuel tank while engine is running

or in an enclosed area. Always fill fuel tank out side and wipe up any spilled fuel before starting

the engine. Store fuel in a clean, safety--approved container and keep the cap in place. Use

gasoline for the engine only; not for any other

purpose.

2. Remove leak detector tank (machines with Turf

Guardian

voircover(machineswithoutTurfGuardian

tector System) to gain access to carbon cannister (see

Service and Repairs section of Chapter 5 -- Hydraulic

System).

TM

Leak Detector System) or hydraulic reser-

TM

LeakDe-

1. Install all removed components using Figure 5 as a

guide.

A. If either purge hose assembly (item 27) or tee

hose assembly (item 28) was removed, make sure

that installation is correct.

B. Make sure that fuel hoses are not kinked after

installation.Also,secureallhoseswithhoseclamps.

2. Install leak detector tank (machines with Turf Guar-

TM

dian

cover (machines without Turf Guardian

Leak Detector System) or hydraulic reservoir

TM

Leak Detector System) (see Service and Repairs section of Chapter 5 -- Hydraulic System).

4

Engine

Gasoline

3. Inspect carbon cannister and attached hoses for

damageorobvious leaks.Adamagedorleakingcannister should be replaced.

4. Remove components as needed using Figure 5 as

a guide.

A. If either purge hose assembly (item 27) or tee

hoseassembly(item28)istoberemoved,labelends

of hose for assembly purposes. Both of these assembliesincludea check valve sodirectionofinstallation is important for correct operation of the

evaporative control system. The check valve is not

available as a separate part so hose assembly replacement is necessary if the check valve or hose is

faulty. To ensure proper operation of check valves,

donotattempttoremovethemfromthehose assembly.

2

FRONT

1. Carbon cannister

2. Screw (2 used)

3

1

Figure 6

3. Cannister bracket

4. Leak detector tank

Greensmaster 3300 Page 3 -- 11 Gasoline Engine

Page 30

Fuel Tank

Illustration from machine with serial

number below 312000000 shown

5

2

3

33

34

35

Antiseize

Lubricant

30 to 50 in--lb

(3.4 to 5.6 N--m)

3

RIGHT

FRONT

31

32

27

28

23

22

30

29

1

24

8

6

9

7

10

6

10

4

5

13

14

5

18

11

10

12

15

19

25

26

14

16

10

20

10

21

1. Flange head screw (2 used)

2. Tank mount plate

3. Washer head screw (2 used)

4. Grommet (2 used)

5. Fuel hose (2 used)

6. Hose clamp (3 used)

7. Carbon cannister

8. Bracket

9. Flange nut (2 used)

10. Worm clamp (5 used)

11. Fuel hose

12. Fresh air filter

Figure 7

13. Fuel supply hose

14. Hose clamp (3 used)

15. R--clamp

16. Fuel filter

17. Fuel hose

18. Clamp

19. Washer head screw

20. Check valve

21. Fuel hose

22. Fuel tank

23. Fuel tank cap

24. Clip (2 used)

17

14

25. Flat washer (2 used)

26. Flange head screw (2 used)

27. Fitting (LH thread)

28. O--ring

29. Shut--off valve

30. Nut (LH thread)

31. Fuel vent valve

32. Grommet

33. Flange bushing (4 used)

34. Washer (4 used)

35. Cap screw (4 used)

Greensmaster 3300Page 3 -- 12Gasoline Engine

Page 31

Fuel Tank Removal (Fig. 7)

Fuel Tank Installation (Fig. 7)

1. Parkmachineonalevelsurface,disengageand lower cutting units, move functional control lever to neutral

(N),engage parking brake, stoptheengine and remove

the key from the ignition switch. Wait for all machine

movement to stop.

CAUTION

The muffler and exhaust manifold may be hot.

Avoid possible burns, allow exhaust system to

cool before working on the engine.

DANGER

Gasolineisflammable. Use cautionwhenstoring

or handling it. Do not smoke while filling the fuel

tank. Do not fill fuel tank while engine is running

or in an enclosed area. Always fill fuel tank out side and wipe up any spilled fuel before starting

the engine. Store fuel in a clean, safety--approved container and keep the cap in place. Use

gasoline for the engine only; not for any other

purpose.

2. Drain fuel tank:

1. Install fitting assembly and shut--off valve into fuel

tankiftheywere removedfromtank(Fig.8). Thenutand

fitting have left hand threads.

2. Position fuel tank on the tank mount plate.

3. Secure fuel tank to tank mount plate:

A. Applyantiseizelubricantto the threadsofthefour

(4) cap screws (item 35).

B. Securefuel tank tothe tank mountplate with four

(4) cap screws (item 35), flat washers (item 34) and

flange bushings (item 33).

C. Torque cap screws from 30 to 50in--lb(3.4to5.6

N--m).

4. Install fuel supply hose (item 13) to fuel shut--off

valve and fuel filter. Secure supply hose with hose

clamps.

5. Connectfuelhose(item5)tofuelventvalve(item31)

and secure with hose clamp.

6. Fill fuel tank with fuel.

7. Open fuel shut--off valve. Check all fuel hoses and

fuel tank for leaks.

Engine

Gasoline

A. Close fuel shut--off valve (item 29).

B. Disconnect fuel supply hose (item 13) at the fuel

filter (item 16) and drain any fuel trapped in the fuel

filter and fuel hose into a suitable container.

C. Placeendoffuel hoseintoasuitablecontainerfor

draining the tank.

D. Drain fuel tank by opening the fuel shutoff valve.

3. Remove fuel hose (item 5) from fuel vent valve (item

31).

4. Remove four (4) cap screws (item 35), flat washers

(item 34) and flange bushings (item 33) that secure the

fuel tank to the tank mount plate (item 2). Remove the

fuel tank from the machine.

5. Ifnecessary,remove fuel supplyhose(item13) from

fuel shut--off valve.

6. If necessary, remove shut--off valve and fitting assembly from fuel tank (Fig. 8). The nut and fitting have

left hand threads.

1. Shut--off valve

2. Nut (LH thread)

3

2

1

4

Figure 8

3. Fitting (LH thread)

4. O--ring

Greensmaster 3300 Page 3 -- 13 Gasoline Engine

Page 32

Engine

20 to 25 in--lb

(2.3 to 2.8 N--m)

7

90 to 110 in--lb

1

Antiseize

Lubricant

2

3

10

6

25

20

22

4

8

9

8

11

26

5

12

(10.2 to 12.4 N--m)

21

23

24

14

25 to 38 ft--lb

(34to51N--m)

170 to 200 in--lb

(19.3 to 22.6 N--m)

19

13

15

16

FRONT

RIGHT

1. Engine assembly

2. Spacer screw

3. Muffler

4. Muffler mount

5. Cap screw (4 used)

6. Flange nut (4 used)

7. Muffler shield

8. Hardened washer (8 used)

9. Cap screw (4 used)

10. Muffler clamp

11. Lock nut (4 used)

12. Pump mount

13. Cap screw (4 used)

14. Exhaust manifold

15. Gasket (2 used)

16. Flange head screw (4 used)

17. Engine frame

18. Flange head screw (3 used)

Engine Removal (Fig. 9)

1. Parkmachineonalevelsurface,disengageand lower cutting units, move functional control lever to neutral

(N),engage parking brake, stoptheengine and remove

the key from the ignition switch. Wait for all machine

movement to stop.

CAUTION

The engine and exhaust system may be hot.

Avoid possible burns, allow engine and exhaust

system to cool before working on the engine.

Figure 9

17

19. Square key

20. Engine hub

21. Square head screw (2 used)

22. Rubber coupling

23. Coupling spacer (2 used)

24. Flange head screw (2 used)

25. Lock washer

26. Flat washer (4 used)

18

DANGER

Gasolineisflammable. Use cautionwhenstoring

or handling it. Do not smoke while filling the fuel

tank. Do not fill fuel tank while engine is running

or in an enclosed area. Always fill fuel tank out side and wipe up any spilled fuel before starting

the engine. Store fuel in a clean, safety--approved container and keep the cap in place. Use

gasoline for the engine only; not for any other

purpose.

Greensmaster 3300Page 3 -- 14Gasoline Engine

Page 33

2. Disconnect the negative (--) battery cable at the battery.

3. Close fuel shut--off valve on fuel tank.

4. Disconnect fuel hoses from the fuel filter outlet and

thecheckvalve nearrearenginecylinderhead (Fig.10).

Drainany fuel trappedin the fuel filterand fuel hoseinto

a suitable container.

3

2

5. Disconnect choke and throttle control cables from

engine.

6. Loosen and remove cap screw (item 5), flat washer

(item 26), lock washer (item 25) and flange nut (item 6)

that secure wire harness ground connectors to engine

assembly (Fig. 11).

7. Disconnect wire harness connectors from engine

components:

NOTE: Beforedisconnectingwireharnessconnectors,

label all electrical leads for assembly purposes.

A. Alternator (from regulator/rectifier) (Fig. 11)

B. Fuel solenoid (Fig. 11)

C. Magneto (Fig. 11)

D. Oil pressure switch (next to oil filter)

E. Starter motor (Fig. 11)

F. Ground wire at rear muffler mount screw

4

1. Fuel filter

2. Check valve

3

1

4

Figure 10

3. Rear cylinder head

4. Fuel pump

1

Engine

Gasoline

2

8. Loosen the two (2) square head screws (item 21)

thatsecuretheenginehub(item20)totheenginecrankshaft.

9. Supportthe engine assembly topreventit from shifting or falling.

10.Remove four (4) cap screws (item 13) that secure

engine assembly to pump mount (item 12).

IMPORTANT: Make sure to not damage the engine,

fuel lines, hydraulic hoses, electrical harness, controlcablesorother parts whileremovingtheengine.

11.Carefully move the engine assembly away from the

pumpmounttoslidetheengine crankshaft out oftheenginehub(item 20). Once thecrankshafthas cleared the

hub, remove the engine from the machine.

12.Locateandretrievesquare key(item19)fromengine

crankshaft.

13.If necessary, remove exhaust system components

from engine using Figure 9 as a guide.

1. Ground connectors

2. Alternator wire

3. Fuel solenoid wire

1. Piston (traction) pump

2. Pump mount

Figure 11

4. Magneto wire

5. Starter motor cable

1

Figure 12

3. Engine hub

4. Rubber coupling

5

3

4

2

Greensmaster 3300 Page 3 -- 15 Gasoline Engine

Page 34

Engine Installation (Fig. 9)

1. Make sure that all removed engine components are

correctly installed to the engine.

2. If exhaust system components were removed from

engine, attach removed components using Figure 9 as

a guide.

3. Apply antiseize lubricantto engine crankshaft. Position square key (item 19) to crankshaft.

IMPORTANT: Make sure to not damage the engine,

fuel hose, hydraulic hoses, electrical harness, controlcablesorotherpartswhileinstallingtheengine.

4. Aligntheenginehub(item20)withtheenginecrankshaft and square key.

5. While supporting the engine to prevent damaging

thepump coupling, carefullymove the engineso crankshaftslidesintotheenginehub(item20)and toward the

pump mount. Once the engine contacts the pump

mount,alignmounting holesandsecureengineto pump

mount with four (4) cap screws (item 13). Torque cap

screws from 25 to 38 ft--lb (34 to 51 N--m).

7. Securewireharnessgroundconnectortoengine assembly with cap screw (item 5), flat washer (item 26),

lock washer (item 25) and flange nut (item 6) (Fig. 11).

Make sure that lock washer is positioned between

ground connector and engine flange to ensure ground

connection to engine.

8. Connect all wire harness connectors to correct engine components.

9. Connectandadjustthechoke control cable (see Adjusting the Choke Control in the Adjustments section of

this chapter).

10.Connect and adjust the throttle control cable (see

Adjusting the Throttle Control in the Adjustments section of this chapter).

11.Connect fuel hoses to the fuel filter outlet and check

valve near rear engine cylinder head (Fig. 10). Secure

hoses with hose clamps.

12.Openfueltankshut--offvalveandcheck fuelhosefor

leaks.

13.Check engine oil level and adjust if necessary.

6. Make sure that rubber coupling (item 22) is not distorted.Secureenginehubto engine crankshaft with two

(2) square head screws (item 21). Torque screws from

90 to 110 in--lb (10.2 to 12.4 N--m).

14.Start the engine and check for proper operation.

Greensmaster 3300Page 3 -- 16Gasoline Engine

Page 35

Table of Contents

SPECIFICATIONS 2.............................

GENERAL INFORMATION 3.....................

Operator’s Manual 3..........................

ADJUSTMENTS 5..............................

Adjust Throttle Control 5.......................

SERVICE AND REPAIRS 6......................

Air Cleaner Assembly 6........................

Exhaust System 8............................

Fuel Tank 10.................................

Radiator 12..................................

Engine 14....................................

Engine Removal 14..........................

Engine Installation 16........................

Engine Bell Housing 18........................

KUBOTA WORKSHOP MANUAL, DIESEL ENGINE,

SM--E3B SERIES

Chapter 4

Diesel Engine

Diesel

Engine

Greensmaster 3400 Page 4 -- 1 Diesel Engine

Page 36

Specifications

Item Description

Make / Designation Kubota water--cooled, Diesel,

Number of Cylinders 3

Bore x Stroke 2.83” x 2.9” (72mm x 73.6mm)

Total Displacement 54.8 in3(898 cc)

Compression Ratio 24.0:1

Firing Order 1 (closest to gear case end) -- 2 -- 3 (closest to flywheel end)

Direction of Rotation Counterclockwise (viewed from flywheel)

Fuel Diesel or Biodiesel (up to B20) Fuel with

Low or Ultra Low Sulfur Content

Fuel Injector Pump Bosch MD Type Mini

Fuel Injection Nozzle Bosch Throttle Type

Fuel Capacity 6.0 U.S. gallons (22.7 liters)

Governor Centrifugal Mechanical

Model D902--E3B

Low Idle (no load) 1500+150/--100 RPM

High Idle (no load) 2880 + 50 RPM

Engine Oil API CH--4, CI--4 or higher

Engine Oil Viscosity See Operator’s Manual

Oil Pump Gear Driven Trochoid Type

Crankcase Oil Capacity 3.9 U.S. quarts (3.7 liters) with filter

Cooling System Capacity (including reserve tank) 4.9 U.S. quarts (4.6 liters)

Starter 12 VDC 1.2 KW

Alternator/Regulator 12 VDC 60 AMP

Dry Weight (approximate) 159 lbs (72 kg)

Greensmaster 3400Page 4 -- 2Diesel Engine

Page 37

General Information

Informationaboutspecifications, maintenance, troubleshooting, testing andrepair ofthe diesel engine used in

theGreensmaster TriFlex 3400 is included in this chapter and the Kubota Workshop Manual, Diesel Engine,

SM--E3B Series.

Most engine repairs and adjustments require tools

which are commonly available in many service shops.

Special tools are described in the Kubota Workshop

Manual. The use of some specialized test equipment is

explained. However, the cost of the test equipment and

the specialized nature of some repairs may dictate that

the work be done at an engine repair facility.

Operator’s Manual

The Traction Unit Operator’s Manual provides information regarding the operation, general maintenance and

maintenanceintervals for your Greensmastermachine.

Refer to the Operator’s Manual for additional information when servicing the machine.

Service and repair parts for Kubota engines are supplied through yourlocal localToro distributor.Ifno parts

list is available, be sure to provide your distributor with

the Toro model and serial number.

Diesel

Engine

Greensmaster 3400 Page 4 -- 3 Diesel Engine

Page 38

This page is intentionally blank.

Greensmaster 3400Page 4 -- 4Diesel Engine

Page 39

Adjustments

Adjust Throttle Control

Proper throttle operation is dependent upon proper adjustment of throttle control. Make sure throttle control is

operating properly.

NOTE: The throttle cable swivel should be positioned

in the lowest hole in the speed control lever.

1. Move throttle control lever on control console to

FAST position.

2. Check position of the engine speed control lever on

fuel injection pump (Fig. 1). The speed control lever

should be contacting the high speed screw when the

throttle control lever is in the FAST position.

3. Ifnecessary,throttlecontrolcanbeadjustedbylooseningcablejamnutsandrepositioningcontrolcableuntil speed control lever contacts high speed screw when

the throttle control lever is in the FAST position (Fig. 2).

Tightencable jam nuts after adjustment has been completed.

3

1

1. High speed screw

2. Speed control lever

1

1. Throttle cable

2. Speed control lever

Figure 1

3

Figure 2

2

3. Fuel solenoid

2

3. Cable jam nut

4. Throttle cable swivel

Diesel

Engine

4

Greensmaster 3400 Page 4 -- 5 Diesel Engine

Page 40

Service and Repairs

Air Cleaner Assembly

RIGHT

FRONT

1

7

2

3

4

6

8

1. Air inlet hood

2. Flat washer (2 used)

3. Cap screw (2 used)

5

6

9

Figure 3

4. Mounting bracket

5. Air cleaner assembly

6. Hose clamp (2 used)

7. Flange nut (2 used)

8. Air intake hose

9. R--clamp

Greensmaster 3400Page 4 -- 6Diesel Engine

Page 41

Air Cleaner Removal (Fig. 3)

1. Park machine on a level surface, lower the cutting

units, stop the engine, engage parking brake and remove the key from the ignition switch.

2. Remove air cleaner components as needed using

Figure 3 as a guide.

3. Check air intake hose (item 8) for damage or wear.

Replace hose if damage is found.

5

4. Disassemble air cleaner as necessary (Fig. 4).

5. Checkaircleaner housingandcoverfordamagethat

could cause possible air leaks.

Air Cleaner Installation (Fig. 3)

IMPORTANT: Any leaks in the air cleaner system

will allow dirt into engine and will cause serious engine damage. Make sure that all air cleaner components are in good condition and are properly

secured during assembly.

1. Assemble air cleaner system using Figures 3 and 4

as guides.

A. Ifplugwasremoved from aircleanerhousing,apply sealant to threads of plug before assembly.

B. Make sure that vacuator valve on air cleaner assembly is pointed down after assembly.

C. Make sure thatair intake hose(item 8) has clearance around it at all points after air cleaner installation is completed.

1

1. Housing

2. Filter element

3. Cover

2

3

Figure 4

4. Vacuator valve

5. Plug

4

Diesel

Engine

Greensmaster 3400 Page 4 -- 7 Diesel Engine

Page 42

Exhaust System

FRONT

RIGHT

3

13

15

11

5

9

7

8

17

4

13

14

6

16

10

16

13

3

2

6

12

1

18

1. Engine assembly

2. Muffler assembly

3. Lock nut (4 used)

4. Exhaust pipe

5. Flange head screw

6. Flange nut (4 used)

Figure 5

7. Lock washer (3 used)

8. Exhaust plate

9. Exhaust gasket

10. Flange nut

11. Flange nut

12. Brace

13. Flat washer (8 used)

14. Cap screw (4 used)

15. Brace

16. Spring (4 used)

17. Muffler shield

18. Flange head screw

Greensmaster 3400Page 4 -- 8Diesel Engine

Page 43

Exhaust System Removal (Fig. 5)

Exhaust System Installation (Fig. 5)

1. Park machine on a level surface, lower the cutting

units, stop the engine, engage parking brake and remove the key from the ignition switch.

CAUTION

The muffler and exhaust pipe may be hot. To

avoid possible burns, allow the engine and exhaust system to cool before workingon the muffler.

2. Removeexhaustsystemcomponentsasneededusing Figure 5 as a guide.

NOTE: Mufflerassemblyis secured tobrackets on piston(traction)pumpwith lock nuts (item 3)andflatwashers (item 13).

1. Make sure the engine is off.

IMPORTANT: If exhaust studs were removed from

engine cylinder head, thoroughly clean threads in

head and apply Loctite #277 (or equivalent) to stud

threads before installing studs into head.

NOTE: Make sure exhaust plate and engine exhaust

manifold sealing surfaces are free of debris or damage

that may prevent a tight seal.

2. If exhaust gasket (item 9) was removed, place new

exhaust gasket on the engine exhaust manifold.

NOTE: To ensure proper exhaust system sealing,

mount all exhaust system components loosely before

fully tightening any fastener.

3. Assemble all removed exhaust system components

using Figure 5 as a guide.

4. Afterallexhaustcomponentshavebeenassembled,

make sure that all fasteners are properly tightened.

Diesel

Engine

Greensmaster 3400 Page 4 -- 9 Diesel Engine

Page 44

Fuel Tank

5

6

7

11

10

1

8

RIGHT

FRONT

1. Fuel tank

2. Tank mount plate

3. Flange head screw (4 used)

4. Clip (2 used)

5. Fuel cap

6. Fuel vent valve

2

3

4

9

11

12

13

14

3

15

Antiseize

Lubricant

30 to 50 in--lb

(3.4 to 5.6 N--m)

16

17

Figure 6

7. Grommet

8. Bushing

9. Elbow fitting

10. Vent hose

11. Hose clamp

12. Flange bushing (4 used)

13. Flat washer (4 used)

14. Cap screw (4 used)

15. Return hose

16. Hose clamp

17. Fuel supply hose

Fuel Tank Removal (Fig. 6)

1. Parkmachineonalevelsurface,disengageand lower cutting units, move functional control lever to neutral

(N),engage parking brake, stoptheengine and remove

the key from the ignition switch. Wait for all machine

movement to stop.

CAUTION

The muffler and exhaust manifold may be hot.

Avoid possible burns, allow exhaust system to

cool before working on the engine.

Greensmaster 3400Page 4 -- 10Diesel Engine

Page 45

2. Position fuel tank on the tank mount plate.

DANGER

Diesel fuel is flammable. Use caution when storing or handling it. Do not smoke while filling the

fuel tank. Do not fill fuel tank while engine is running or in an enclosed area. Always fill fuel tank

outsideand wipe up any spilledfuel before starting the engine. Store fuel in a clean, safety--approved container and keep the cap in place.

2. Drain fuel tank:

A. Close fuel shut--off valve on bottom of fuel tank.

B. Disconnect fuel supply hose (item 17) at the fuel

filter and drain any fuel trapped in the fuel filter and

fuel hose into a suitable container.

C. Placeendoffuel hoseintoasuitablecontainerfor

draining the tank.

D. Drain fuel tank by opening the fuel shutoff valve.

3. To allow easier access to fasteners that secure fuel

tank, raise and support tank mount plate assembly (hydraulic reservoir, fuel tank and tank mount plate) (see

Tank Mount Plate Assembly in the Service andRepairs

section of Chapter 7 -- Chassis).

3. Move fuel tank towards the rear of the machine and

install return hose (item 15) to elbow fitting on front of

tank. Secure hose with hose clamp.

4. Secure fuel tank to tank mount plate:

A. Applyantiseizelubricantto the threadsofthefour

(4) cap screws (item 14).

B. Securefuel tank tothe tank mountplate with four

(4) cap screws (item 14), flat washers (item 13) and

flange bushings (item 12).

C. Torque cap screws from 30 to 50in--lb(3.4to5.6

N--m).

5. Lower and secure tank mount plate assembly (hy-

draulic reservoir, fuel tank and tank mount plate) (see

Tank Mount Plate Assembly in the Service andRepairs

section of Chapter 7 -- Chassis).

6. Connect fuel supply hose (item 17) to the fuel shut--

off valve and fuel filter. Secure supply hose with hose

clamps.

7. Connect vent hose (item 10) to fuel vent valve (item

6) and secure with hose clamp.

8. Fill fuel tank with fuel.

Diesel

Engine

4. Remove vent hose (item 10) from fuel vent valve

(item 6).

5. Remove four (4) cap screws (item 14), flat washers

(item 13) and flange bushings (item 12) that secure the

fuel tank to the tank mount plate (item 2).

6. Move fuel tank towards the rear of the machine to

gainaccessto fuelreturnhose(item15). Removereturn

hose from elbow fitting on front of tank.

7. Remove the fuel tank from the machine.

8. If necessary, remove fuel supply hose from shut--off

valve.

9. If necessary, remove shut--off valve and fitting assembly from fuel tank (Fig. 7). The nut and fitting have

left hand threads.

Fuel Tank Installation (Fig. 6)

1. Install fitting assembly and shut--off valve into fuel

tankiftheywere removedfromtank(Fig.7). Thenutand

fitting have left hand threads.

9. Open fuel shut--off valve. Check all fuel hoses and

fuel tank for leaks.

3

2

1

4

Figure 7

1. Shut--off valve

2. Nut (LH thread)

3. Fitting (LH thread)

4. O--ring

Greensmaster 3400 Page 4 -- 11 Diesel Engine

Page 46

Radiator

22

18

25

20

23

24

7

20

16

8

5

3

6

20

1

16

16

6

2

17

19

21

4

16

20

14

RIGHT

FRONT

1. Seal panel

2. Radiator shroud

3. Trim seal

4. Fan assembly

5. Radiator assembly

6. Hose clamp (2 used)

7. R--clamp (2 used)

8. Clip (8 used)

9. Stud (2 used)

16

8

13

12

Figure 8

10. Stud retainer (2 used)

11. Receptacle (2 used)

12. Cap screw (4 used)

13. Flat washer (4 used)

14. R--clamp

15. Screen

16. Flange head screw (12 used)

17. Lock nut (4 used)

11

18. Flange head screw (4 used)

19. Front shroud

20. Flange nut (12 used)

21. Lower radiator hose

22. Upper radiator hose

23. Breather hose (to thermostat)

24. Overflow hose (to overflow tank)

25. Fuel pump assembly

9

10

15

Greensmaster 3400Page 4 -- 12Diesel Engine

Page 47

Radiator Removal (Fig. 8)

1. Park machine on a level surface, lower the cutting

units, stop the engine, engage parking brake and remove the key from the ignition switch.

10.Disconnect fan wire connector from machine wire

harness.

11.Support radiator assembly to prevent it from falling.

12.Remove four (4) flangenutsthatsecurefrontshroud

to machine. Remove radiator assembly from machine.

CAUTION

DO NOT open radiator cap or drain coolant if the

engineorradiatorishot. Pressurized hot coolant

can escape and cause burns.

Ethylene--gycol antifreeze is poisonous. Disposeofitproperlyorstoreitinaproperlylabeled

container away from children and pets.

2. Remove the radiator cap.

3. Drain radiator into a suitable container by disconnecting lower radiator hose from the radiator.

4. Remove screen (item 15) from radiator shroud.

5. Remove four (4) flange head screws (item 16) that

secure radiator shroud (item 2) to radiator assembly.

Remove radiator shroud.

6. Remove flange head screw that secures R--clamp

(item 14) to bottom of front shroud (item 19).

7. Remove the following hoses from the radiator:

A. Loosen hose clamps and disconnect breather

hose (item 23) and overflow hose (item 24) from radiator filler neck.

13.Removecomponentsfromr adiator asnecessaryusing Figure 8 as a guide.

Radiator Installation (Fig. 8)

1. Assembleall removed components toradiatorusing

Figure 8 as a guide.

2. Position radiator assembly to machine.Secure front

shroud to machine with four (4) flange nuts.

3. Position fuel pump assembly to radiator assembly

and secure with flange head screw and flange nut.

4. Connect fan wire connector to machine wire harness.

5. Slidefuelreturnhosethroughbothr--clamps(item7)

onfront shroud (item19). Connect return hose sections

at splice fitting and secure with hose clamp.

6. Connect the following hoses to the radiator and secure with hose clamps:

A. Upper and lower radiator hoses (items 22 and

21).

B. Breather hose (item 23) and overflow hose (item

24) to radiator filler neck.

Diesel

Engine

B. Loosenhose clamps (item6) and disconnectupper and lower radiator hoses (items 22 and 21).

8. Locate splice fitting in fuel return hose near fuel

pump. Disconnect one of the return hose sections from

splicefittingandremovereturnhose frombothr--clamps

(item 7) on front shroud (item 19).

9. Remove flange head screw and flange nut that se-

cure fuel pump assembly to front shroud. Position fuel

pump assembly away from radiator assembly.

Greensmaster 3400 Page 4 -- 13 Diesel Engine

7. Secure R--clamp (item 14) to bottom of front shroud

(item 19).

8. Secureradiatorshroud (item 2) to radiatorassembly

with four (4) flange head screws (item 16).

9. Install screen (item 15) to radiator shroud.

10.Fill radiator with coolant. Check radiator and hoses

for leaks.

Page 48

Engine

FRONT

18

26

RIGHT

28

24

21

22

27

3

13

15

17

22

11

4

5

9

7

8

13

14

6

23

16

25

10

16

13

3

2

6

1

20

12

18

19

1. Engine assembly

2. Muffler assembly

3. Lock nut (4 used)

4. Exhaust pipe

5. Flange head screw

6. Flange nut (4 used)

7. Lock washer (3 used)

8. Exhaust plate

9. Exhaust gasket

10. Flange nut

11. Flange nut

12. Brace

13. Flat washer (8 used)

14. Cap screw (4 used)

15. Brace

16. Spring (4 used)

17. Muffler shield

18. Flange head screw

19. Alternator assembly

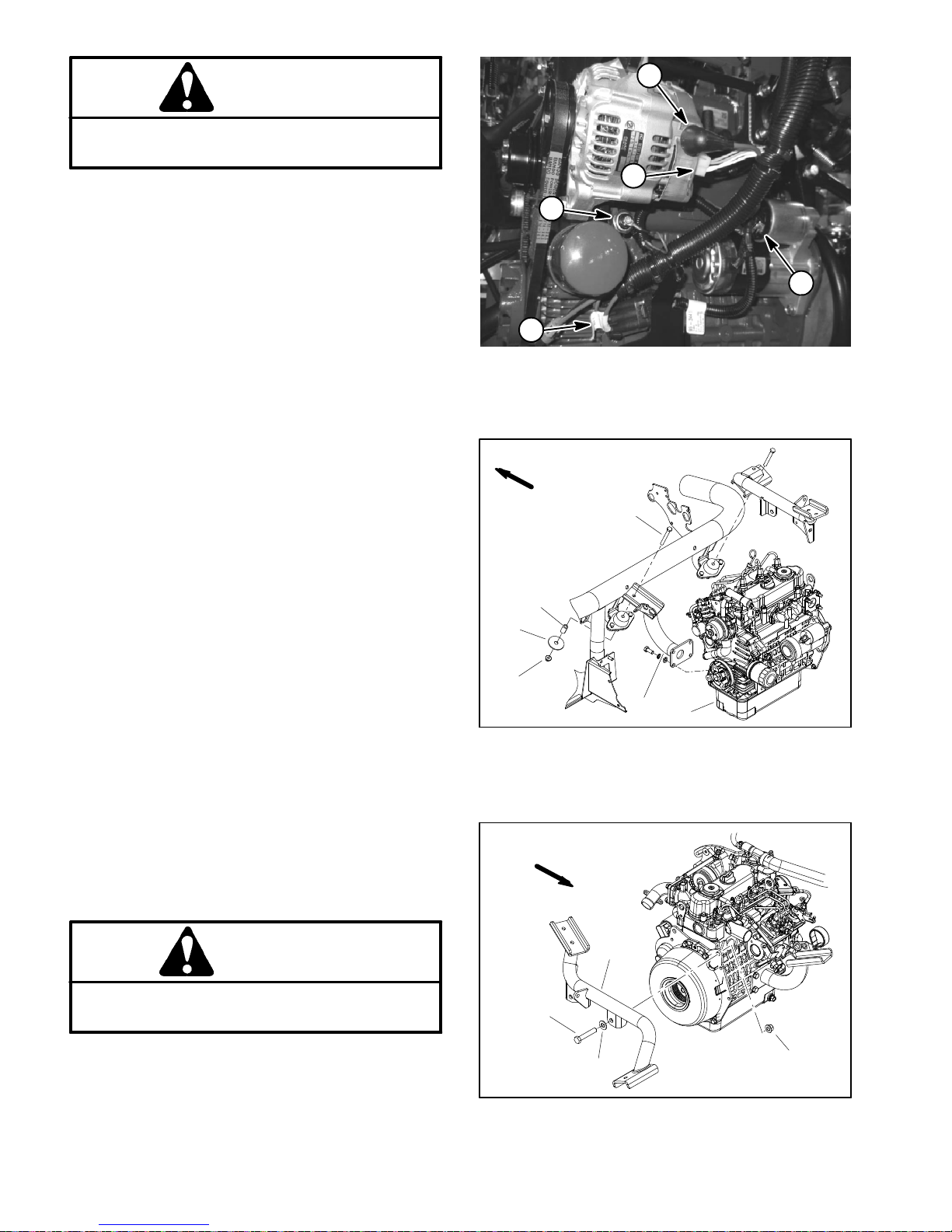

Engine Removal (Fig. 9)

1. Parkmachineonalevelsurface,disengageand lower cutting units, move functional control lever to neutral

(N),engage parking brake, stoptheengine and remove

the key from the ignition switch. Wait for all machine

movement to stop.

Figure 9

20. V--belt

21. Fuel/water separator

22. Cap screw (2 used)

23. Engine support

24. Cap screw (4 used)

25. Lock washer (4 used)

26. Lock washer (ground connection)

27. Rear engine mount

28. R--clamp (air intake hose)

CAUTION

The engine, radiator, exhaust system and hydraulic system may be hot. T oavoid possible injury,allowmachinetocoolbefore working on the

engine.

Greensmaster 3400Page 4 -- 14Diesel Engine

Page 49

2. Close fuel shut--off valve on fuel tank.

3. Remove air cleaner and air intake hose from ma-

chine (see Air Cleaner Removal in this section).

3

4. Remove radiator from machine (see Radiator Re-

moval in this section).

5. Remove exhaust system from machine (see Ex-

haust System Removal in this section).

6. Disconnect fuel supply hose from the injector pump

and fuel return hose from the #3 injector. Drain any fuel

trapped in the hoses into a suitable container.Remove

hoses from grommets in engine support on front of engine. Plug hoses and position them away from engine

assembly.

7. Loosenscrewthat secures the throttle cable to swiv-

el on injector pump speed control lever. Disconnect

cable from swivel and cable bracket (Fig. 10). Position

cable away from engine.

8. Disconnect wire harness connectors from engine

components:

NOTE: Beforedisconnectingwireharnessconnectors,

label all electrical leads for assembly purposes.

A. Negative battery cable and wire harness ground

from lower engine mount fastener (Fig. 11).

1

1. Throttle cable

2. Speed control lever

1

Figure 10

3. Cable jam nut

4. Throttle cable swivel

3

2

4

2

Diesel

Engine

B. Fuel stop solenoid (Fig. 12).

C. Glow plug bus (Fig. 12).

D. Temperature sender (Fig. 12).

E. Alternator connector and stud (Fig. 13).

F. Starter motor solenoid and fusible link harness

(Fig. 13).

G. Oil pressure switch (near oil filter) (Fig. 13).

CAUTION

Support the hydraulic pump assembly when removing its supporting fasteners to prevent it

from falling and causing damage or personal injury.

9. Support hydraulic pump assembly to prevent it from

moving during engine removal.

10.Removetwo(2)capscrewsandflat washersthatse-

cure hydraulic pump assembly to bell housing on engine.

1. Engine mount

2. Negative cable

1

1. Fuel return hose

2. Throttle cable swivel

3. Fuel stop solenoid

Figure 11

3. Wire harness ground

4

Figure 12

4. Glow plug bus

5. Temperature sender

5

3

2

Greensmaster 3400 Page 4 -- 15 Diesel Engine

Page 50

CAUTION

When removing engine assembly, make sure lift

or hoist can safely support 190 lbs (86 kg).

11.Attach a suitable lift or hoist to engine. Support engine with lift or hoist to prevent engine from shifting or

moving.

1

2

5

12.Remove fasteners that secure engine to machine:

A. Remove cap screw, spacer, snubbing washer

and flange nut that secure engine support to engine

mount (Fig. 14).

B. Remove two (2) cap screws, washers and lock

nuts that secure rear engine plate to rear engine

mount (Fig. 15).