Page 1

Form No. 3326-890

8 and 11 Blade SPA Reel Mowers

Greensmaster 3250-D

Model No. 04472—Serial No. 220000001 and Up

Model No. 04473—Serial No. 220000001 and Up

Operator ’s Manual

English (EN, GB)

Page 2

Contents

Page

Introduction 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional Equipment 2. . . . . . . . . . . . . . . . . . . . . . . . . .

Adjustments 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjusting the Bedknife to the Reel 3. . . . . . . . . . . .

Choosing Cutting Unit Attitude 3. . . . . . . . . . . . . .

Leveling the Front Roller to the Reel 4. . . . . . . . . .

Adjusting the Top Shield Height 5. . . . . . . . . . . . .

Adjusting the Top Bar 5. . . . . . . . . . . . . . . . . . . . .

Adjusting the Height of Cut 5. . . . . . . . . . . . . . . . .

Operation 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cutting Unit Characteristics 5. . . . . . . . . . . . . . . . .

Daily Adjustments of Cutting Unit 6. . . . . . . . . . . .

Maintenance 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Greasing the Bearings and Bushings 6. . . . . . . . . .

Backlapping the Cutting Units 7. . . . . . . . . . . . . . .

The Toro General Commercial Products Warranty 8. .

Introduction

Read this manual carefully to learn how to operate and

maintain your product properly. The information in this

manual can help you and others avoid injury and product

damage. Although Toro designs and produces safe

products, you are responsible for operating the product

properly and safely.

Whenever you need service, genuine Toro parts, or

additional information, contact an Authorized Service

Dealer or Toro Customer Service and have the model and

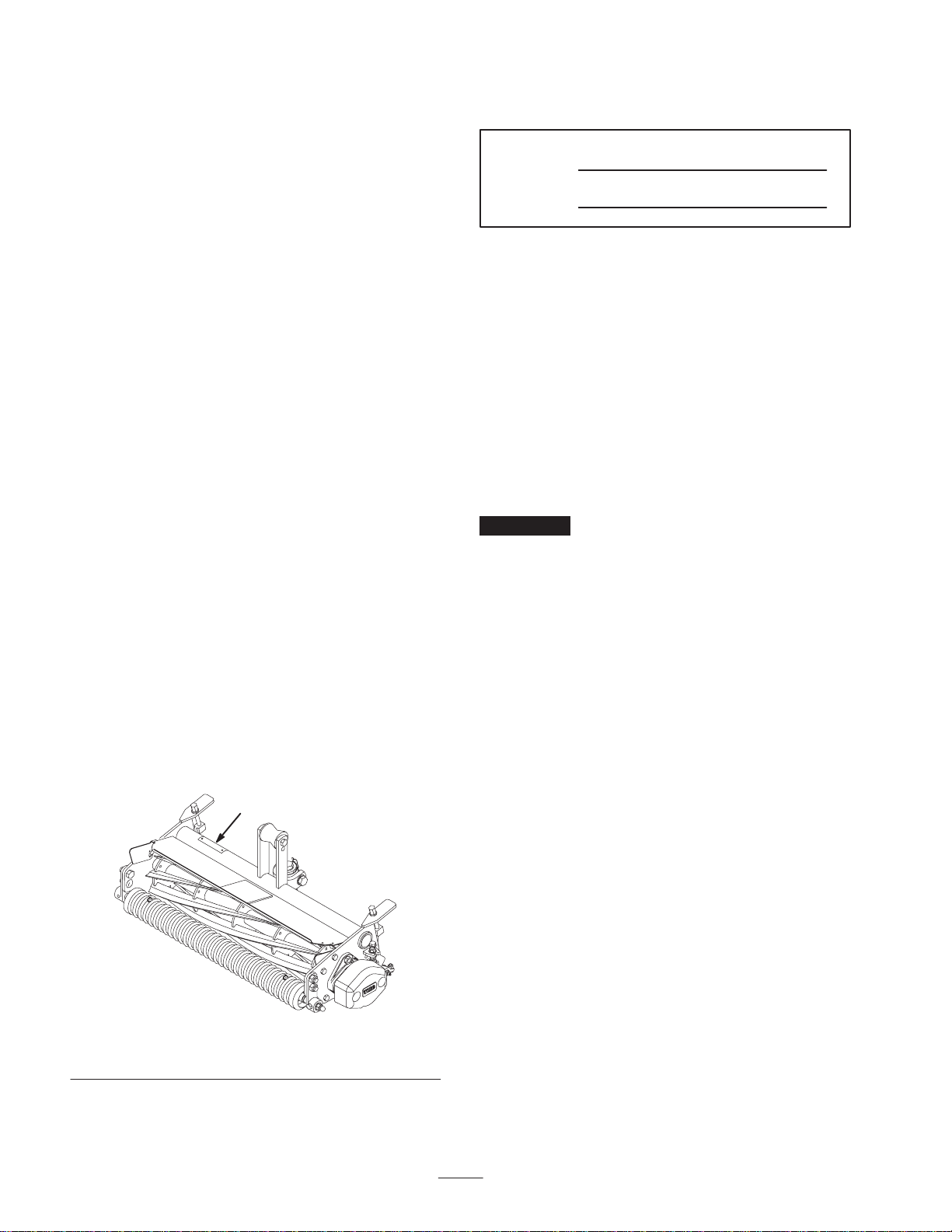

serial numbers of your product ready. Figure 1 illustrates

the location of the model and serial numbers on the

product.

1

Write the product model and serial numbers in the space

below:

Model No.

Serial No.

This manual identifies potential hazards and has special

safety messages that help you and others avoid personal

injury and even death. Danger, Warning, and Caution are

signal words used to identify the level of hazard. However,

regardless of the hazard, be extremely careful.

Danger signals an extreme hazard that will cause serious

injury or death if you do not follow the recommended

precautions.

Warning signals a hazard that may cause serious injury or

death if you do not follow the recommended precautions.

Caution signals a hazard that may cause minor or moderate

injury if you do not follow the recommended precautions.

This manual uses two other words to highlight information.

Important calls attention to special mechanical

information and Note: emphasizes general information

worthy of special attention.

Optional Equipment

Extended Micro Cut Bedknife Part No. 104-7720

Lo Cut Bedknife Part No. 93-4264

High Cut Bedknife Part No. 94-6392

Fairway Bedknife Part No. 94-6393

5 Blade Heavy Duty Reel Part No. 98-2181

8 Blade Heavy Duty Reel Part No. 98-2182

High Height-of-Cut Kit Part No. 99-1496

Wiehle Rear Roller Model No. 04488

Rear Roller Scraper Kit Part No. 95-1600

Groomer Model No. 04485

Rear Roller Brush Kit (for use with

Groomer Model No. 04485)

Rear Roller Brush Kit Model No. 04489

Front Roller Scraper/Brush Part No. 104-7731

Full Roller Assembly Part No. 104-2642

Model No. 04491

Figure 1

1. Location of the model and serial numbers

2001 by The Toro Company

8111 Lyndale Avenue South

Bloomington, MN 55420-1196

Note: Specifications and design subject to change without

notice.

All Rights Reserved

Printed in the USA

2

Page 3

Adjustments

4. Loosen locknuts retaining the left-hand bedbar pivot

housing (Fig. 2).

Note: Determine the left and right sides of the machine

from the normal operating position.

After the cutting unit is unboxed, use the following

procedures to ensure that the cutting units are adjusted

properly.

1. Check each end of the reel for grease. Grease should be

visibly evident in the reel bearings.

2. Ensure that all nuts and bolts are securely fastened.

3. Position the lift roller to match the suspension.

• Upper position for standard transport height

• Lower position for increased transport height

4. Check to make sure that the bedknife and reel are

parallel; refer to Adjusting the Bedknife to the Reel,

page 3.

Adjusting the Bedknife to the

Reel

1. Remove cutting units from traction unit and position on

a level work surface.

5. Rotate flange nuts (Fig. 2, inset), on top and bottom of

frame tab, clockwise or counterclockwise to raise or

lower end of bedbar, as required. Do not loosen bottom

flange nut. Tighten flangenuts against frame tab when

desired adjustment is attained.

6. Check adjustments by repeating steps 2 and 3.

7. When light contact on paper is evident at each end of

bedknife, tighten locknuts retaining pivot housing

securely.

2. Make sure reel contact is removed by turning bedknife

adjustment knob counterclockwise (Fig. 2).

1

Figure 2

1. Bedknife adjustment knob

2. Left-hand bedbar pivot

housing

3. On either end of front side of reel, insert a long strip of

newspaper between the reel and bedknife (Fig. 3).

While slowly rotating the reel forward, turn the

bedknife adjusting knob clockwise, one click at a time,

until the paper is pinched lightly on one end of the reel,

which results in a slight drag when the paper is pulled.

3. Flange nuts

4. Frame tab

3

4

3

2

Figure 3

Choosing Cutting Unit Attitude

There are four positions for the front roller brackets.

Position 1

Least aggressive; use for very soft and tender turf.

HOC Range: 0.094 (3/32)–0.84 (27/32) in. (2.4–21.3 mm)

Frame

Bracket

down

Position 1

3

Page 4

Position 2

Standard position; use for most conditions (factory setting).

HOC Range: 0.094 (3/32)–0.72 (23/32) in. (2.4–18.3 mm)

Note: A more aggressive setting may be required to

compensate for reel wear. (As the reel wears, the cutting

unit becomes less aggressive).

Note: The top frame hole and top bracket hole will yield

Position 2 (standard position).

Frame

Bracket

down

Position 2

Position 3

More aggressive; use on firm turf or higher height-of-cuts.

HOC Range: 0.094 (3/32)–0.62 (5/8) in. (2.4–15.7 mm)

Bracket

Frame

down

Leveling the Front Roller to the

Reel

1. Position the cutting unit on a flat, level surface.

2. Place a 1/4 inch or thicker plate under the reel blades

and against the front face of the bedknife.

Note: Be sure that the plate covers the full length of the

reel blades and three blades contact the plate.

3. Loosen the locknuts retaining the right front roller

bracket (Fig. 4).

2

1

Figure 4

1. Right front roller bracket 2. Upper right roller

mounting bolt

Position 3

Position 4

Most aggressive; use only on very firm greens or at the

higher height-of-cuts.

HOC Range: 0.094 (3/32)–0.50 (1/2) in. (2.4–12.7 mm)

Bracket

Frame

Position 4

Note: A more aggressive setting will increase grass

removal and provide a cleaner cut, but may cause increased

scalping and marking.

down

4. While holding the reel securely on the plate and

maintaining pressure on the front roller, rotate the upper

right roller mounting bolt (Fig. 4). This mounting bolt

has an offset, which when rotated, acts as an eccentric

(cam) to raise or lower the roller. On the bolt head there

is an I.D. dot which denotes the offset of the bolt. The

dot indicates in which direction the right end of the

roller moves when the bolt is turned.

Note: If additional adjustment is required, replace one

screw on the left-hand bracket with another eccentric bolt,

Part No. 93-2573. Ensure that both front roller brackets are

in the same hole.

5. To verify if the roller is level, try inserting a piece of

paper under each end of the roller.

6. When the roller is level, tighten the nuts securely.

4

Page 5

Adjusting the Top Shield

Height

1. Loosen bolts and nuts securing the shield to each side

plate.

2. Adjust the shield to the desired position and secure the

fasteners.

3. Repeat this procedure on the remaining cutting units

and adjust the top bar.

Note: The shield can be raised for extremely wet

conditions.

Adjusting the Top Bar

Adjust the top bar, under the rear shield, to ensure that

clippings are cleanly discharged from the reel area.

1. Loosen the screws securing the top bar. Insert a 0.06 in.

(1.5 mm) feeler gauge between the top of the reel and

bar and tighten the screws. Ensure that the bar and reel

are an equal distance apart across the complete reel.

2. Repeat the settings on the remaining cutting units.

Note: The bar is adjustable to compensate for changes in

turf conditions. The bar should be adjusted closer to the

reel when the turf is extremely wet. By contrast, adjust the

bar further away from the reel when turf conditions are dry.

The bar should be adjusted whenever the top shield height

is changed, the reel wears, or the reel is sharpened by

grinding.

profile. Therefore, benchsetting a cutting unit does not

equal the effective (actual) height of cut you achieve. You

need to determine how to adjust your cutter on the bench to

achieve a comparable height of cut to a cutting unit of a

different configuration, model, or brand.

3

1

2

Figure 5

1. Gauge bar

2. Roller bracket bolt

3. Height-of-cut knob

Adjusting the Height of Cut

1. Verify that the front roller is level and the

bedknife-to-reel contact is correct.

2. Turn the cutting unit over (90°) and rest it on the rear

roller and top rear tabs. Loosen the locknuts on the bolts

retaining the rear roller brackets (Fig. 5).

3. On the gauge bar (Part No. 13-8199), set the head of the

screw to the desired height of cut (Fig. 5). This

measurement is from the bar face to the underside of the

screw head.

4. Place the bar across the front and rear rollers and adjust

the height-of-cut knob (Fig. 5) until the underside of the

screw head engages the bedknife cutting edge.

Important Repeat this procedure on each end of the

bedknife and tighten the locknuts retaining the rear roller

brackets on each end.

Note: The cutting units will deliver differing effective

height of cuts depending on their configuration. Effective

cutting height may be influenced by the following factors:

turf conditions, roller profiles, cutting unit attitude, cutting

unit accessories, weight of cutting units, and bedknife

Operation

Note: Determine the left and right sides of the machine

from the normal operating position.

Cutting Unit Characteristics

The single knob bedknife-to-reel adjustment system

incorporated in this cutting unit simplifies the adjustment

procedure needed to deliver optimum mowing

performance. The precise adjustment possible with the

single knob/bedbar design gives the necessary control to

provide a continual self-sharpening action—thus

maintaining sharp cutting edges, ensuring good

quality-of-cut, and greatly reducing the need for routine

backlapping.

5

Page 6

Daily Adjustments of Cutting

Unit

Prior to mowing each day, or as required, each cutting unit

must be checked to verify proper bedknife-to-reel contact.

This must be performed even though quality of cut is

acceptable.

1. Lower the cutting units onto a hard surface, shut off the

engine, and remove the ignition key.

2. Slowly rotate the reel in a reverse direction, listening

for reel-to-bedknife contact. If no contact is evident,

turn the bedknife adjusting knob clockwise, one click at

a time, until light contact is felt and heard.

Note: The adjustment knob has detents corresponding to

0.0007 in. (0.018 mm) bedknife movement for each

indexed position.

3. If excessive contact is felt, turn the bedknife adjusting

knob counterclockwise, one click at a time until no

contact is evident. Then turn the bedknife adjusting

knob one click at a time clockwise, until light contact is

felt and heard.

Maintenance

Note: Determine the left and right sides of the machine

from the normal operating position.

Greasing the Bearings and

Bushings

Each cutting unit has 7 grease fittings that must be

lubricated regularly with No. 2 General Purpose Lithium

Base Grease.

The grease fitting locations and quantities are:

• Adjusting knob pivot point (Fig. 6)

• Reel bearings (2) (Fig. 6)

• Front and rear rollers (2 ea.) (Fig. 6)

Important Lubricating the cutting units immediately

after washing helps purge water out of the bearings and

increases bearing life.

1. Wipe each grease fitting with a clean rag.

Important Light contact is preferred at all times. If

light contact is not maintained, the bedknife/reel edges will

not sufficiently self-sharpen and dull cutting edges will

result after a period of operation. If excessive contact is

maintained, bedknife/reel wear will be accelerated, uneven

wear can result, and quality of cut may be adversely

affected.

Note: As the reel blades continue to run against the

bedknife, a slight burr will appear on the front cutting edge

surface along the full length of the bedknife. If a file is

occasionally run across the front edge to remove this burr,

improved cutting can be obtained.

After extended running, a ridge will eventually develop at

both ends of the bedknife. These notches must be rounded

off or filed flush with the cutting edge of the bedknife to

ensure smooth operation.

2. Grease the reel bearings (Fig. 6) until grease comes out

of the pressure relief.

3. Grease the front and rear roller bearings (Fig. 6) until

grease begins to show around the seal lips.

4. Grease the adjusting pivot point (Fig. 6).

Important Do not apply too much pressure or the

grease seals will be permanently damaged.

1

Figure 6

1. Pressure relief

5. Wipe excess grease away.

6

Page 7

Backlapping the Cutting Units

Caution

Contact with the reels or other moving parts can

result in personal injury.

Keep fingers, hands, and clothing away from the

reels or other moving parts.

1. Position the machine on a clean, level surface, lower the

cutting units, stop the engine, engage the parking brake,

and remove the ignition key.

2. Remove the reel motors from the cutting units and

disconnect and remove the cutting units from the lift

arms.

3. Connect the backlapping machine to the cutting unit by

inserting a piece of 3/8 in. square stock into the splined

coupling at the right end of the cutting unit.

Note: Additional instructions and procedures on

Backlapping are available in the Toro Sharpening Reel &

Rotary Mowers Manual, Form No. 80-300PT.

Note: For a better cutting edge, run a file across the front

face of the bedknife when the lapping operation is

completed. This will remove any burrs or rough edges that

may have built up on the cutting edge.

7

Page 8

The Toro General Commercial Products Warranty

A Two-Year Limited Warranty

Conditions and Products Covered

The Toro Company and its affiliate, Toro Warranty Company,

pursuant to an agreement between them, jointly warrant your 1996

or newer Toro Commercial Product (“Product”) purchased after

January 1, 1997, to be free from defects in materials or

workmanship for two years or 1500 operational hours*, whichever

occurs first. Where a warrantable condition exists, we will repair

the Product at no cost to you including diagnosis, labor, parts, and

transportation. This warranty begins on the date the Product is

delivered to the original retail purchaser.

* Product equipped with hour meter

Instructions for Obtaining Warranty Service

You are responsible for notifying the Commercial Products

Distributor or Authorized Commercial Products Dealer from whom

you purchased the Product as soon as you believe a warrantable

condition exists.

If you need help locating a Commercial Products Distributor or

Authorized Dealer, or if you have questions regarding your

warranty rights or responsibilities, you may contact us at:

Toro Commercial Products Service Department

Toro Warranty Company

8111 Lyndale Avenue South

Bloomington, MN 55420-1196

952-888-8801 or 800-982-2740

E-mail: commercial.service@toro.com

Owner Responsibilities

As the Product owner, you are responsible for required maintenance and adjustments stated in your operator’s manual. Failure

to perform required maintenance and adjustments can be grounds

for disallowing a warranty claim.

Items and Conditions Not Covered

Not all product failures or malfunctions that occur during the

warranty period are defects in materials or workmanship. This

express warranty does not cover the following:

• Product failures which result from the use of non-Toro

replacement parts, or from installation and use of add-on,

modified, or unapproved accessories

• Product failures which result from failure to perform required

maintenance and/or adjustments

• Product failures which result from operating the Product in an

abusive, negligent or reckless manner

• Parts subject to consumption through use unless found to be

defective. Examples of parts which are consumed, or used up,

during normal Product operation include, but are not limited to,

blades, reels, bedknives, tines, spark plugs, castor wheels,

tires, filters, belts, etc.

• Failures caused by outside influence. Items considered to be

outside influence include, but are not limited to, weather,

storage practices, contamination, use of unapproved coolants,

lubricants, additives, or chemicals, etc.

• Normal “wear and tear” items. Normal “wear and tear”

includes, but is not limited to, damage to seats due to wear or

abrasion, worn painted surfaces, scratched decals or windows, etc.

Parts

Parts scheduled for replacement as required maintenance are

warranted for the period of time up to the scheduled replacement

time for that part.

Parts replaced under this warranty become the property of Toro.

T oro will make the final decision whether to repair any existing part

or assembly or replace it. Toro may use factory remanufactured

parts rather than new parts for some warranty repairs.

General Conditions

Repair by an Authorized Toro Distributor or Dealer is your sole

remedy under this warranty.

Neither The Toro Company nor Toro Warranty Company is

liable for indirect, incidental or consequential damages in

connection with the use of the T oro Products covered by this

warranty, including any cost or expense of providing substitute equipment or service during reasonable periods of

malfunction or non-use pending completion of repairs under

this warranty. Except for the Emissions warranty referenced

below, if applicable, there is no other express warranty. All

implied warranties of merchantability and fitness for use are

limited to the duration of this express warranty.

Some states do not allow exclusions of incidental or consequential

damages, or limitations on how long an implied warranty lasts, so

the above exclusions and limitations may not apply to you.

This warranty gives you specific legal rights, and you may also

have other rights which vary from state to state.

Note regarding engine warranty: The Emissions Control

System on your Product may be covered by a separate warranty

meeting requirements established by the U.S. Environmental

Protection Agency (EPA) and/or the California Air Resources

Board (CARB). The hour limitations set forth above do not apply to

the Emissions Control System Warranty. Refer to the Engine

Emission Control Warranty Statement printed in your operator’s

manual or contained in the engine manufacturer’s documentation

for details.

Countries Other than the United States or Canada

Customers who have purchased Toro products exported from the United States or Canada should contact their Toro Distributor (Dealer)

to obtain guarantee policies for your country, province, or state. If for any reason you are dissatisfied with your Distributor’s service or

have difficulty obtaining guarantee information, contact the Toro importer. If all other remedies fail, you may contact us at Toro Warranty

Company.

Part No. 374-0031 Rev. –

Loading...

Loading...