Page 1

FormNo.3377-374RevB

Greensmaster

®

31502-Wheel

DriveTractionUnit

ModelNo.04358—SerialNo.313000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3377-374*B

Page 2

ThisproductcomplieswithallrelevantEuropeandirectives,

fordetailspleaseseetheseparateproductspecicDeclaration

ofConformity(DOC)sheet.

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Figure1

1.Modelandserialnumberlocation

ModelNo.

Important:Thisengineisnotequippedwithaspark

arrestermufer.ItisaviolationofCaliforniaPublic

ResourceCodeSection4442touseoroperatetheengine

onanyforest-covered,brush-covered,orgrass-covered

land.Otherstatesorfederalareasmayhavesimilarlaws.

ThissparkignitionsystemcomplieswithCanadianICES-002.

Introduction

Thismachineisaride-on,reel-bladelawnmowerintended

tobeusedbyprofessional,hiredoperatorsincommercial

applications.Itisprimarilydesignedforcuttinggrasson

well-maintainedlawnsinparks,golfcourses,sportselds,

andoncommercialgrounds.Itisnotdesignedforcutting

brush,mowinggrassandothergrowthalongsidehighways,

orforagriculturaluses.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely .

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure2

1.Safetyalertsymbol

Thismanualalsouses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

Wheneveryouneedservice,genuineToroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready .Figure1identiesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

©2013—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.T oro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Contents

Introduction..................................................................2

Safety...........................................................................4

SafeOperatingPractices...........................................4

ToroMowerSafety..................................................5

SoundPowerLevel..................................................6

SoundPressureLevel...............................................6

VibrationLevel......................................................6

SafetyandInstructionalDecals.................................7

Setup...........................................................................11

1ActivatingandChargingtheBattery........................12

2InstallingtheBattery............................................13

3InstallingtheRollOverProtectionSystem

(ROPS).............................................................13

4InstallingtheCuttingUnits(Forcuttingunit

models04610,04611,04616,04618,04619,and

04624only)........................................................14

5AddingRearBallastandW eightKit........................15

6InstallingCEDecals.............................................15

ProductOverview.........................................................16

Controls...............................................................16

Specications........................................................19

Attachments/Accessories........................................19

Operation....................................................................19

ThinkSafetyFirst...................................................19

CheckingtheEngineOil..........................................19

FillingtheFuelTank...............................................20

CheckingtheHydraulicFluidLevel...........................20

CheckingtheTirePressure......................................21

CheckingtheTorqueoftheWheelNuts.....................22

Break-inPeriod......................................................22

StartingtheEngine.................................................22

CheckingtheSafetyInterlockSystem........................23

CheckingtheLeakDetector.....................................23

SettingtheReelSpeed.............................................24

PreparingtheMachineforMowing...........................25

TrainingPeriod......................................................25

BeforeMowing......................................................25

Mowing................................................................25

LeakDetectorOperation.........................................27

TransportOperation...............................................27

InspectionandCleanupAfterMowing......................27

TowingtheTractionUnit.........................................27

Maintenance.................................................................28

RecommendedMaintenanceSchedule(s)......................28

DailyMaintenanceChecklist....................................29

ServiceIntervalChart.............................................30

PremaintenanceProcedures........................................30

RemovingtheSeat..................................................30

JackingtheMachine................................................30

Lubrication...............................................................31

GreasingtheMachine.............................................31

EngineMaintenance..................................................33

ServicingtheAirCleaner.........................................33

ChangingtheEngineOilandFilter...........................33

AdjustingtheThrottleControl.................................34

AdjustingtheChokeControl....................................34

AdjustingtheEngineSpeed.....................................34

ReplacingtheSparkPlugs........................................35

FuelSystemMaintenance...........................................35

ReplacingtheFuelFilter..........................................35

FuelLinesandConnections.....................................35

ElectricalSystemMaintenance....................................36

ServicingtheBattery...............................................36

ServicingtheFuses.................................................36

DriveSystemMaintenance.........................................37

AdjustingtheTransmissionforNeutral.....................37

AdjustingtheTransportSpeed.................................37

AdjustingtheMowingSpeed....................................38

BrakeMaintenance....................................................38

AdjustingtheBrakes...............................................38

ControlsSystemMaintenance.....................................39

AdjustingtheCuttingUnitLift/Drop........................39

AdjustingtheLiftCylinders.....................................39

HydraulicSystemMaintenance....................................40

ChangingtheHydraulicOilandFilter........................40

CheckingtheHydraulicLinesandHoses....................40

CuttingUnitMaintenance...........................................41

Backlapping...........................................................41

Storage........................................................................42

Schematics...................................................................43

3

Page 4

Safety

ThismachinemeetsorexceedsCENstandardEN

836:1997,ISOstandard5395:1990,andANSIB71.4-2004

specicationsineffectatthetimeofproductionwhen

40lb.ofballastandtheappropriatewheelweightkit

isaddedtotherearwheel.

Note:Theadditionofattachmentsmadebyother

manufacturersthatdonotmeetAmericanNationalStandards

Institutecerticationwillcausenoncomplianceofthis

machine.

Improperuseormaintenancebytheoperatororowner

canresultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandalwayspay

attentiontothesafetyalertsymbol(Figure2),which

meansCaution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeinstructionmay

resultinpersonalinjuryordeath.

SafeOperatingPractices

ThefollowinginstructionsarefromCENstandardEN

836:1997,ISOstandard5395:1990,andANSIB71.4-2004.

Training

•ReadtheOperator'sManualandothertrainingmaterial.If

theoperator(s)ormechanic(s)cannotreadthemanual

itistheowner'sresponsibilitytoexplainthismaterialto

them.

•Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateorservice

theequipment.Localregulationsmayrestricttheageof

theoperator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtohimselforherself,other

peopleorproperty.

Preparation

•Evaluatetheterraintodeterminewhataccessoriesand

attachmentsareneededtoproperlyandsafelyperform

thejob.Onlyuseaccessoriesandattachmentsapproved

bythemanufacturer.

•Wearappropriateclothingincludingsubstantialfootwear,

hardhat,safetyglassesandearprotection.Longhair,

looseclothingorjewelrymaygettangledinmovingparts.

•Inspecttheareawheretheequipmentistobeusedand

removeallobjectssuchasrocks,toysandwirewhichcan

bethrownbythemachine.

•Useextracarewhenhandlinggasolineandotherfuels.

Theyareammableandvaporsareexplosive.

–Useonlyanapprovedcontainer.

–Neverremovethegascaporaddfuelwithengine

running.Allowenginetocoolbeforerefueling.

–Neversmokewhenhandlinggasoline,andstayaway

fromanopenameorwheregasolinefumesmaybe

ignitedbyaspark.

–Neverrefuelordrainthemachineindoors.

•Checkthatoperator'spresencecontrols,safetyswitches

andshieldsareattachedandfunctioningproperly .Donot

operateunlesstheyarefunctioningproperly.

Operation

•Neverrunanengineinanenclosedarea.

•Onlyoperateingoodlight,keepingawayfromholesand

hiddenhazards.

•Besurealldrivesareinneutralandparkingbrakeis

engagedbeforestartingengine.Onlystartenginefrom

theoperator'sposition.Useseatbeltsifprovided.

•Slowdownanduseextracareonhillsides.Besureto

travelintherecommendeddirectiononhillsides.Turf

conditionscanaffectthemachine'sstability.Usecaution

whileoperatingneardrop-offs.

•Slowdownandusecautionwhenmakingturnsandwhen

changingdirectionsonslopes.

•Neveroperatewithoutguardssecurelyinplace.Besure

allinterlocksareattached,adjusted,andfunctioning

properly.

•Donotchangetheenginegovernorsettingoroverspeed

theengine.

•Stoponlevelground,lowerthecuttingunits,disengage

drives,engageparkingbrake(ifprovided),shutoffengine

beforeleavingtheoperator'spositionforanyreason

includingemptyingthegrassbaskets.

•Stopequipmentandinspectthemachineafterstriking

objectsorifanabnormalvibrationoccurs.Make

necessaryrepairsbeforeresumingoperations.

•Keephandsandfeetawayfromthecuttingunits.

•Lookbehindanddownbeforebackinguptobesureof

aclearpath.

•Nevercarrypassengersandkeeppetsandbystanders

away.

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalks.Stopreelsifnotmowing.

•Donotoperatethemowerundertheinuenceofalcohol

ordrugs.

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

•Usecarewhenloadingorunloadingthemachineintoa

trailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,trees,

orotherobjectsthatmayobscurevision.

4

Page 5

MaintenanceandStorage

•Disengagedrives,lowerthecuttingunits,settheparking

brake,stoptheengine,removethekey,anddisconnect

sparkplugwire(s).Waitforallmovementtostopbefore

adjusting,cleaning,orrepairing.

•Cleangrassanddebrisfromcuttingunits,drives,mufers,

andenginetohelppreventres.Cleanupoilorfuel

spillage.

•Lettheenginecoolbeforestoringanddonotstorenear

ame.

•Shutofffuelwhilestoringortransporting.Donotstore

fuelnearamesordrainindoors.

•Parkthemachineonlevelground.

•Neverallowuntrainedpersonneltoservicethemachine.

•Usejackstandstosupportcomponentswhenrequired.

•Carefullyreleasepressurefromcomponentswithstored

energy.

•Disconnectthebatteryandremovethesparkplugwire(s)

beforemakinganyrepairs.Disconnectthenegative

terminalrstandthepositivelast.Reconnectpositive

rstandnegativelast.

•Usecareandweargloveswhencheckingthereels.

•Keephandsandfeetawayfrommovingparts.Ifpossible,

donotmakeadjustmentswiththeenginerunning.

•Chargebatteriesinanopen,wellventilatedarea,away

fromsparkandames.Unplugthechargerbefore

connectingordisconnectingitfromthebattery.Wear

protectiveclothinganduseinsulatedtools.

•Keepallpartsingoodworkingconditionandallhardware

andhydraulicttingstightened.Replaceallwornor

damageddecals.

ToroMowerSafety

ThefollowinglistcontainssafetyinformationspecictoToro

productsorothersafetyinformationthatyoumustknowthat

isnotincludedintheANSIstandards.

Thisproductiscapableofamputatinghandsandfeetand

throwingobjects.Alwaysfollowallsafetyinstructionsto

avoidseriousinjuryordeath.

Useofthisproductforpurposesotherthanitsintendeduse

couldprovedangeroustouserandbystanders.

Operation

•Knowhowtostoptheenginequickly.

•Alwayswearsubstantialshoes.Donotoperatethe

machinewhilewearingsandals,tennisshoes,orsneakers.

Wearingsafetyshoesandlongpantsisadvisableand

requiredbysomelocalordinancesandinsurance

regulations.

•Handlefuelcarefully.Wipeupanyspills.

•Checkthesafetyinterlockswitchesdailyforproper

operation.

•Beforeattemptingtostarttheengine,disengageallblade

attachmentclutches,shiftintoneutral,andengagethe

parkingbrake.

•Usingthemachinedemandsattention.Topreventloss

ofcontrol:

–Donotdriveclosetosandtraps,ditches,creeks,or

otherhazards.

–Reducespeedwhenmakingsharpturns.Avoid

suddenstopsandstarts.

–Thismachineisnotdesignedorequippedforon-road

useandisa“slow-movingvehicle.”Ifyoumustcross

ortravelonapublicroad,youshouldbeawareofand

complywithlocalregulations,suchasrequiredlights,

slowmovingvehiclesigns,andreectors.

–Watchoutfortrafcwhennearorcrossingroads.

Alwaysyieldtheright-of-way .

–Applytheservicebrakeswhengoingdownhillto

keepforwardspeedslowandtomaintaincontrolof

themachine.

•Thegrassbasketsmustbeinplaceduringoperation

ofthereelsorthatchersformaximumsafety.Shutthe

engineoffbeforeemptyingthebaskets.

•Raisethecuttingunitswhendrivingfromoneworkarea

toanother.

•Donottouchtheengine,mufer,orexhaustpipewhile

theengineisrunningorsoonafterithasstoppedbecause

theseareascouldbehotenoughtocauseburns.

•Stayclearoftherotatingscreenatthesideoftheengine

topreventdirectcontactwithyourbodyorclothing.

•Ifacuttingunitstrikesasolidobjectorvibrates

abnormally,stopimmediately ,turntheengineoff,waitfor

allmotiontostop,andinspectthemachinefordamage.

Adamagedreelorbedknifemustberepairedorreplaced

beforeoperationiscontinued.

•Beforegettingoffoftheseat,movethefunctionalcontrol

levertoneutral(N),raisethecuttingunitsandwaitfor

thereelstostopspinning.Settheparkingbrake.Stopthe

engineandremovethekeyfromtheignitionswitch.

•Traverseslopescarefully.Donotstartorstopsuddenly

whentravelinguphillordownhill.

•Theoperatormustbeskilledandtrainedinhowtodrive

onhillsides.Failuretousecautiononslopesorhillsmay

causelossofcontrolandcausethemachinetotiporroll,

possiblyresultinginpersonalinjuryordeath.

•Iftheenginestallsorlosesheadwayandcannotmakeit

tothetopofaslope,donotturnthemachinearound.

Alwaysbackslowly,straightdowntheslope.

•Whenapersonoranimalappearsunexpectedlyinor

nearthemowingarea,stopmowing.Carelessoperation,

combinedwithterrainangles,ricochets,orimproperly

positionedguardscanleadtothrownobjectinjuries.Do

notresumemowinguntiltheareaiscleared.

•Wheneverthemachineisleftunattended,makesurethe

cuttingunitsarefullyraised,thereelsarenotspinning,

5

Page 6

thekeyisremovedfromtheignitionswitch,andthe

parkingbrakeisset.

VibrationLevel

Hand-Arm

MaintenanceandStorage

•Makesureallhydrauliclineconnectorsaretightandall

hydraulichosesandlinesareingoodconditionbefore

applyingpressuretothesystem.

•Keepyourbodyandhandsawayfrompinholeleaksor

nozzlesthatejecthydraulicuidunderhighpressure.

Usepaperorcardboard,notyourhands,tosearchfor

leaks.Hydraulicuidescapingunderpressurecanhave

sufcientforcetopenetratetheskinandcauseserious

injury.

•Beforedisconnectingorperforminganyworkonthe

hydraulicsystem,allpressureinthesystemmustbe

relievedbystoppingtheengineandloweringthecutting

unitsandattachmentstotheground.

•Checkallfuellinesfortightnessandwearonaregular

basis.Tightenorrepairthemasneeded.

•Iftheenginemustberunningtoperformamaintenance

adjustment,keephands,feet,clothing,andanypartsof

thebodyawayfromthecuttingunits,attachments,and

anymovingparts,especiallythescreenatthesideofthe

engine.Keepeveryoneaway.

Measuredvibrationlevelforrighthand=0.97m/s

Measuredvibrationlevelforlefthand=1.11m/s

UncertaintyValue(K)=0.5m/s

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinEN836.

WholeBody

Measuredvibrationlevel=0.40m/s

UncertaintyValue(K)=0.5m/s

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinEN836.

2

2

2

2

2

•Donotoverspeedtheenginebychanginggovernor

settings.Toensuresafetyandaccuracy ,havean

AuthorizedT oroDistributorcheckthemaximumengine

speedwithatachometer..

•Theenginemustbeshutoffbeforecheckingtheoilor

addingoiltothecrankcase.

•Ifmajorrepairsareeverneededorifassistanceisdesired,

contactanAuthorizedToroDistributor.

•Toassureoptimumperformanceandcontinuedsafety

certicationofthemachine,useonlygenuineToro

replacementpartsandaccessories.Replacementparts

andaccessoriesmadebyothermanufacturerscouldbe

dangerous,andsuchusecouldvoidtheproductwarranty.

SoundPowerLevel

Thisunithasaguaranteedsoundpowerlevelof95dBA,

whichincludesanUncertaintyValue(K)of1dBA.

Soundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinISO11094.

SoundPressureLevel

Thisunithasasoundpressurelevelattheoperator’searof82

dBA,whichincludesanUncertaintyValue(K)of1dBA.

Soundpressurelevelwasdeterminedaccordingtothe

proceduresoutlinedinEN836.

6

Page 7

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

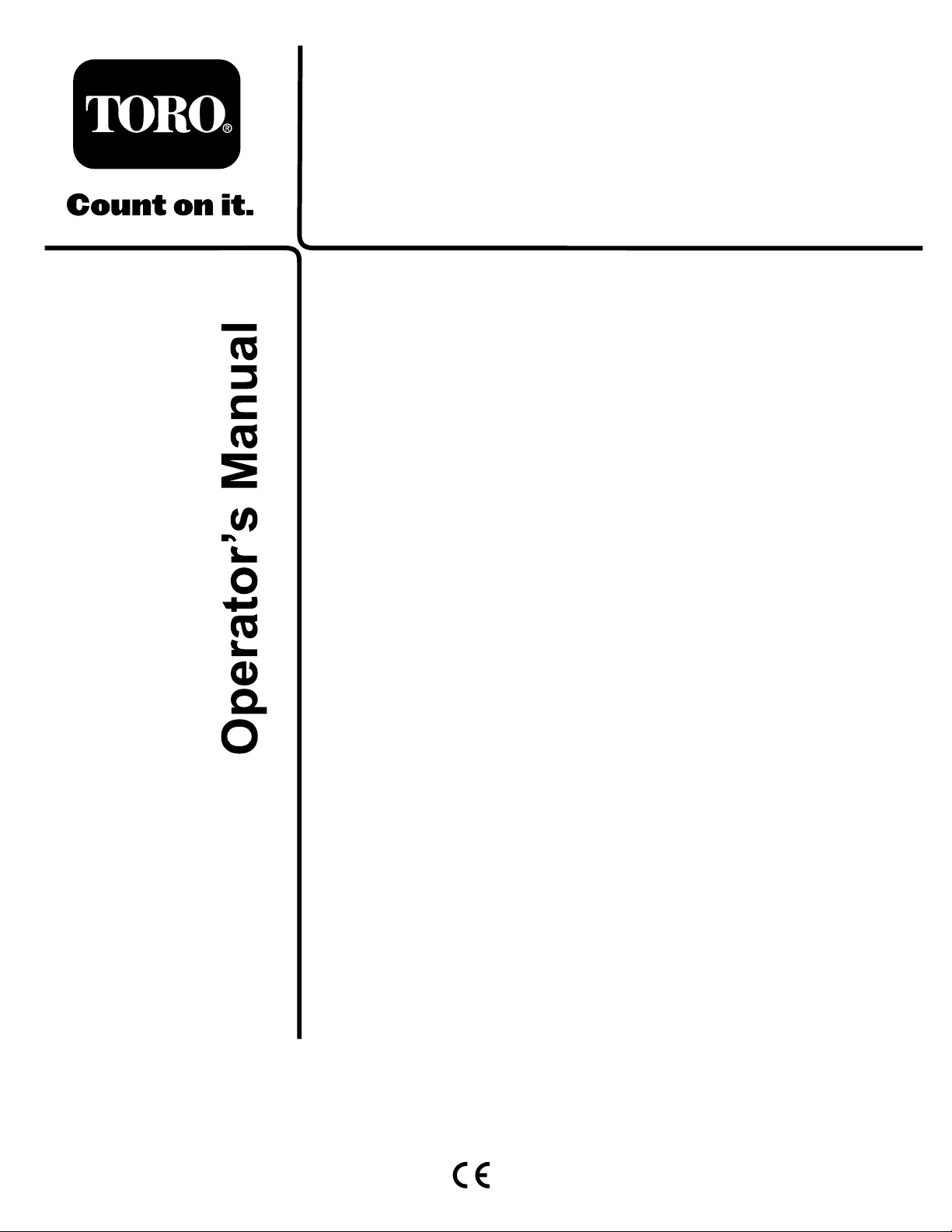

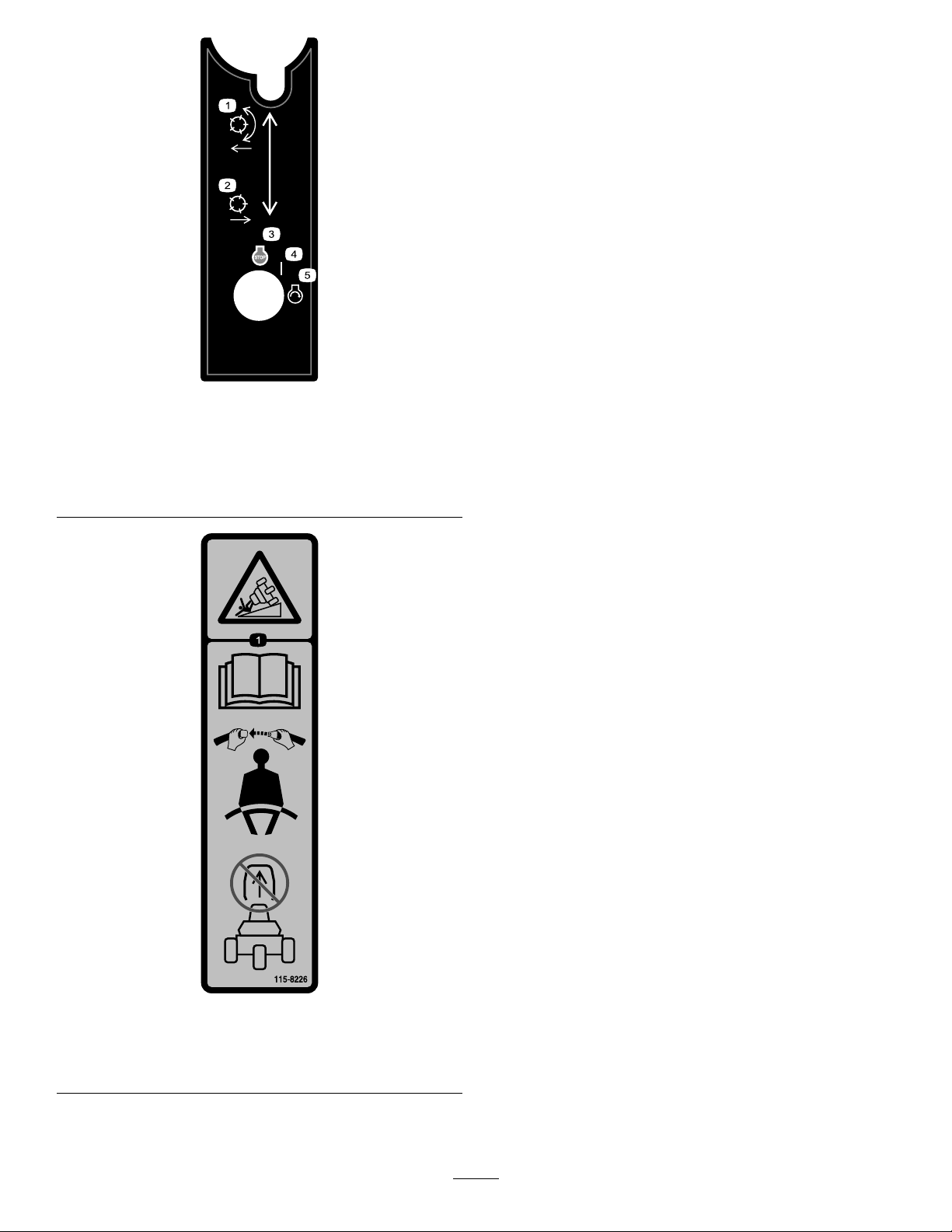

121–9566

105–5471

1.ReadtheOperator'sManual.6.Continuousvariablesetting

2.Off

3.Choke8.Failure/malfunction(Lealdetectoralarmtest)

4.On

5.Slow

7.Fast

9.Headlights

1.Hydraulicoil

2.ReadtheOperator'sManual.

93-6686

7

117–2718

Page 8

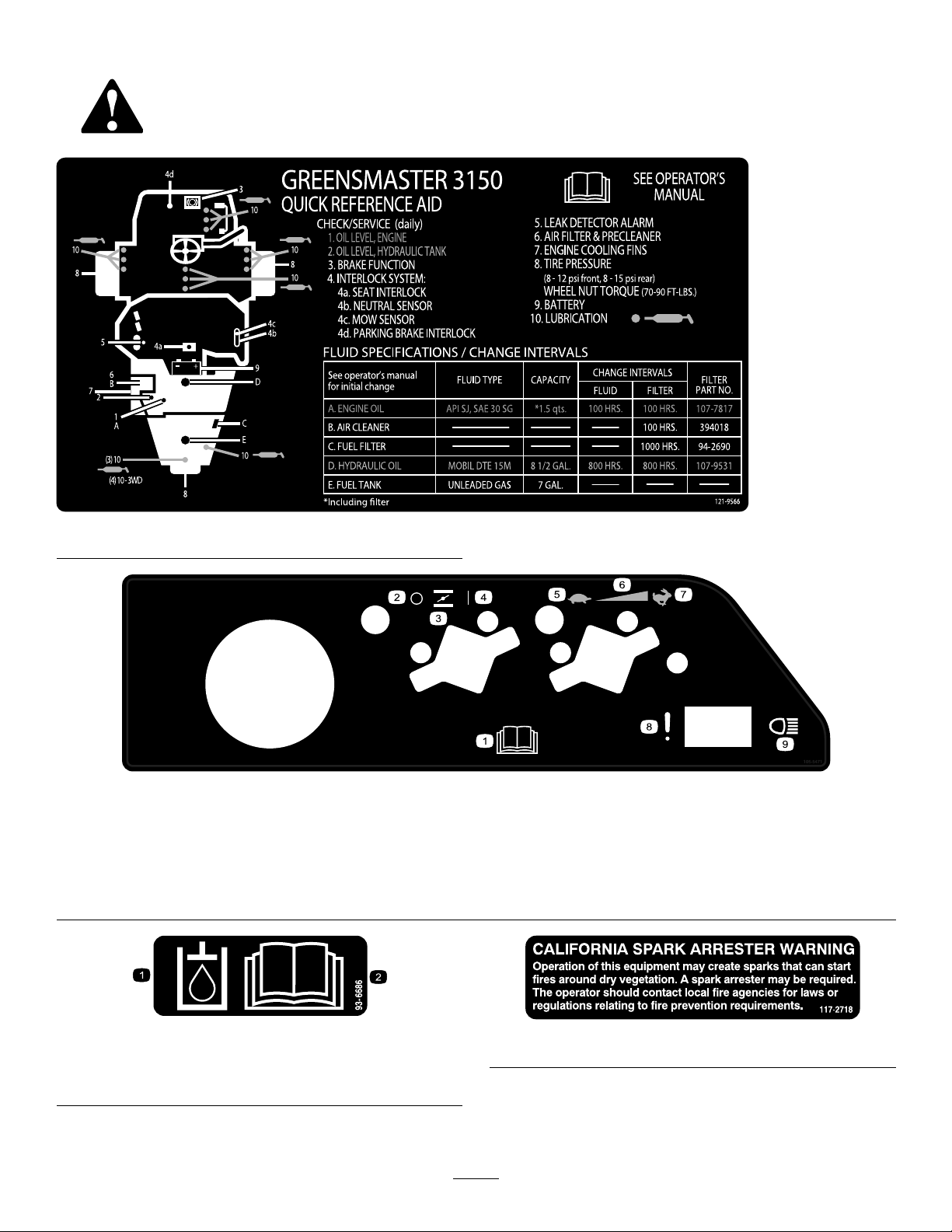

1.ReadtheOperator'sManual.

93–9051

121–2641

105–8306

1.Forwardmachinespeeds

2.Fast-usefortransport4.Neutral-usefor

3.Slow-useformowing

backlapping.

93-8062

1.Tolocktheparkingbrake,

pressthebrakepedaland

theparkingbrakelock.

2.Tounlocktheparking

brake,pressthebrake

pedal.

3.Parkingbrakelock

1.Warning—readthe

Operator’sManual,do

notoperatethismachine

unlessyouaretrained.

2.Thrownobject

hazard—keepbystanders

asafedistancefromthe

machine.

3.Cutting/dismemberment

hazardofhandorfoot,

mowerblade—stayaway

frommovingparts;keep

allguardsandshieldsin

place.

4.Tippinghazard—slow

machinebeforeturning,

donotturnathighspeeds.

5.Warning—locktheparking

brake,stoptheengine

andremovetheignition

keybeforeleavingthe

machine.

8

Page 9

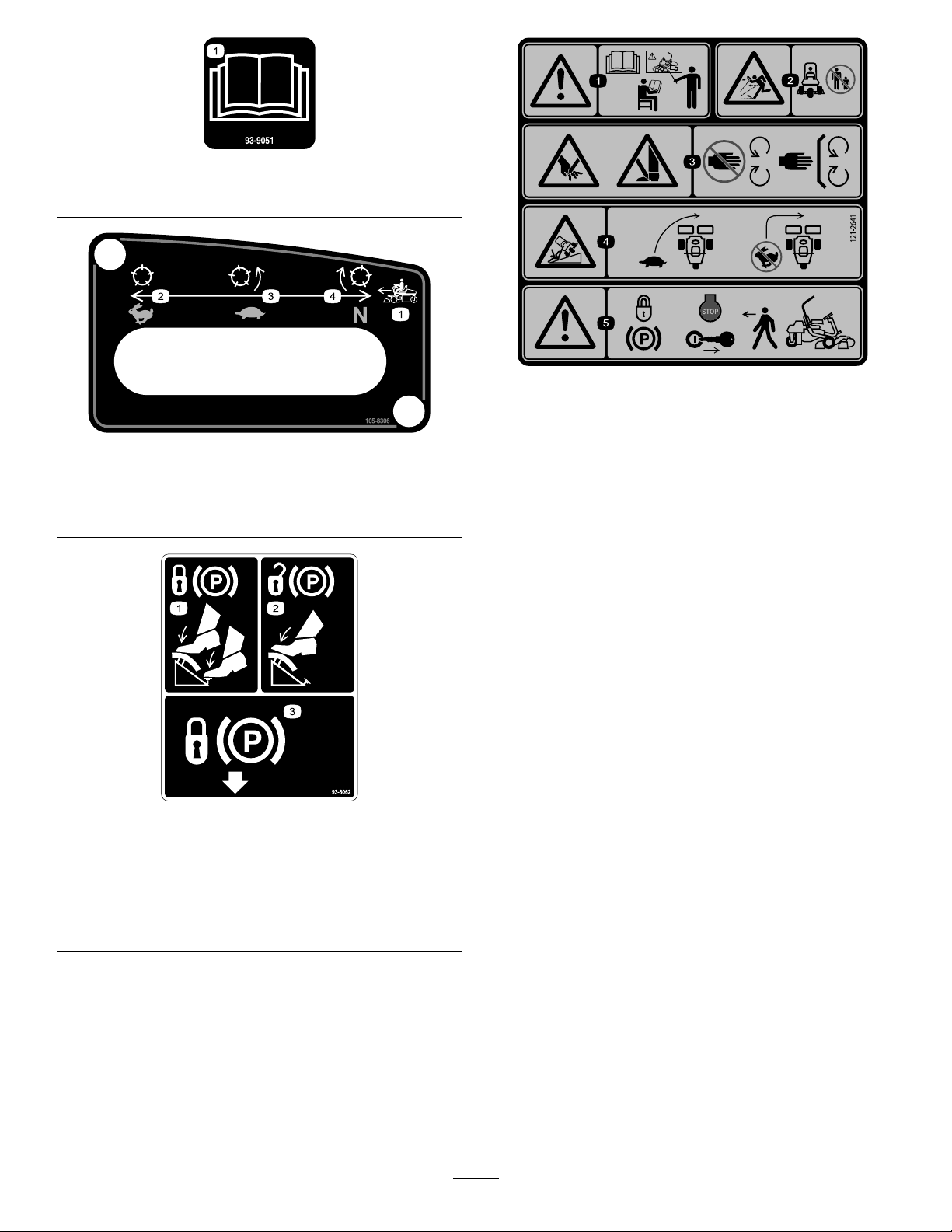

104–7729

Replaces121–2641forCE.

1.Warning—readthe

Operator’sManual,do

notoperatethismachine

unlessyouaretrained.

2.Thrownobject

hazard—keepbystanders

asafedistancefromthe

machine

3.Cutting/dismemberment

hazardofhandorfoot,

mowerblade—stayaway

frommovingparts;keep

allguardsandshieldsin

place.

121–2640

4.Tippinghazard—donot

driveacrossslopesgreater

than15degreesordown

slopesgreaterthan15

degrees.

5.Warning—locktheparking

brake,stoptheengine

andremovetheignition

keybeforeleavingthe

machine.

1.Warning—readthe

instructionsbefore

servicingorperforming

maintenance.

2.Cutting/dismemberment

BatterySymbols

Someorallofthesesymbolsareonyourbattery

1.Explosionhazard

2.Nore,opename,or

smoking.

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

6.Keepbystandersasafe

7.Weareyeprotection;

8.Batteryacidcancause

10.Containslead;donot

hazard;handorfoot—stop

theengineandwaitfor

movingpartstostop.

distancefromthebattery .

explosivegasescan

causeblindnessandother

injuries

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

discard.

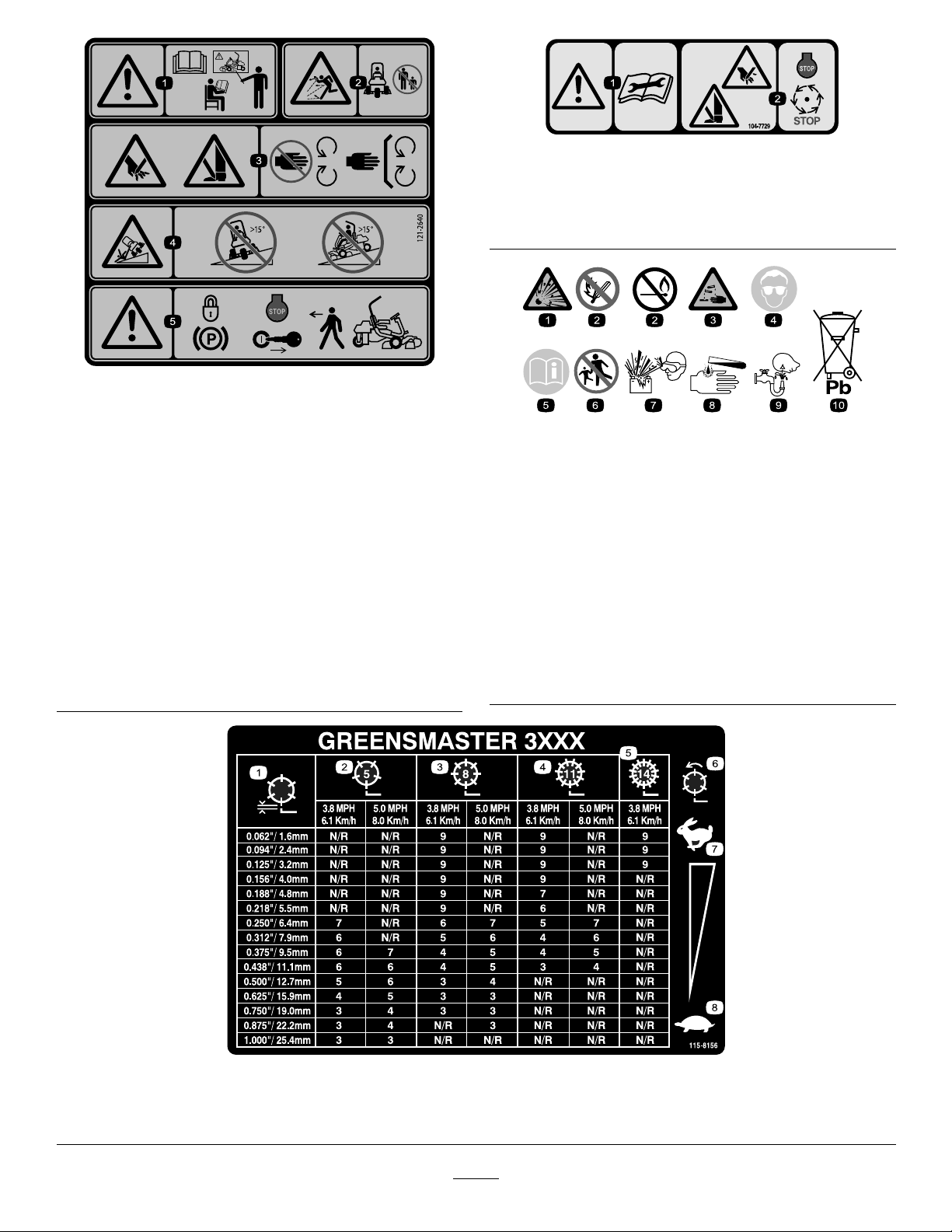

115-8156

1.Reelheight3.8Bladecuttingunit5.14Bladecuttingunit7.Fast

2.5Bladecuttingunit4.11Bladecuttingunit6.Reelspeed

9

8.Slow

Page 10

105–8305

1.Lowerandengagethe

reels.

2.Raiseanddisengagethe

reels.

3.Engine-stop

4.On

5.Engine-start

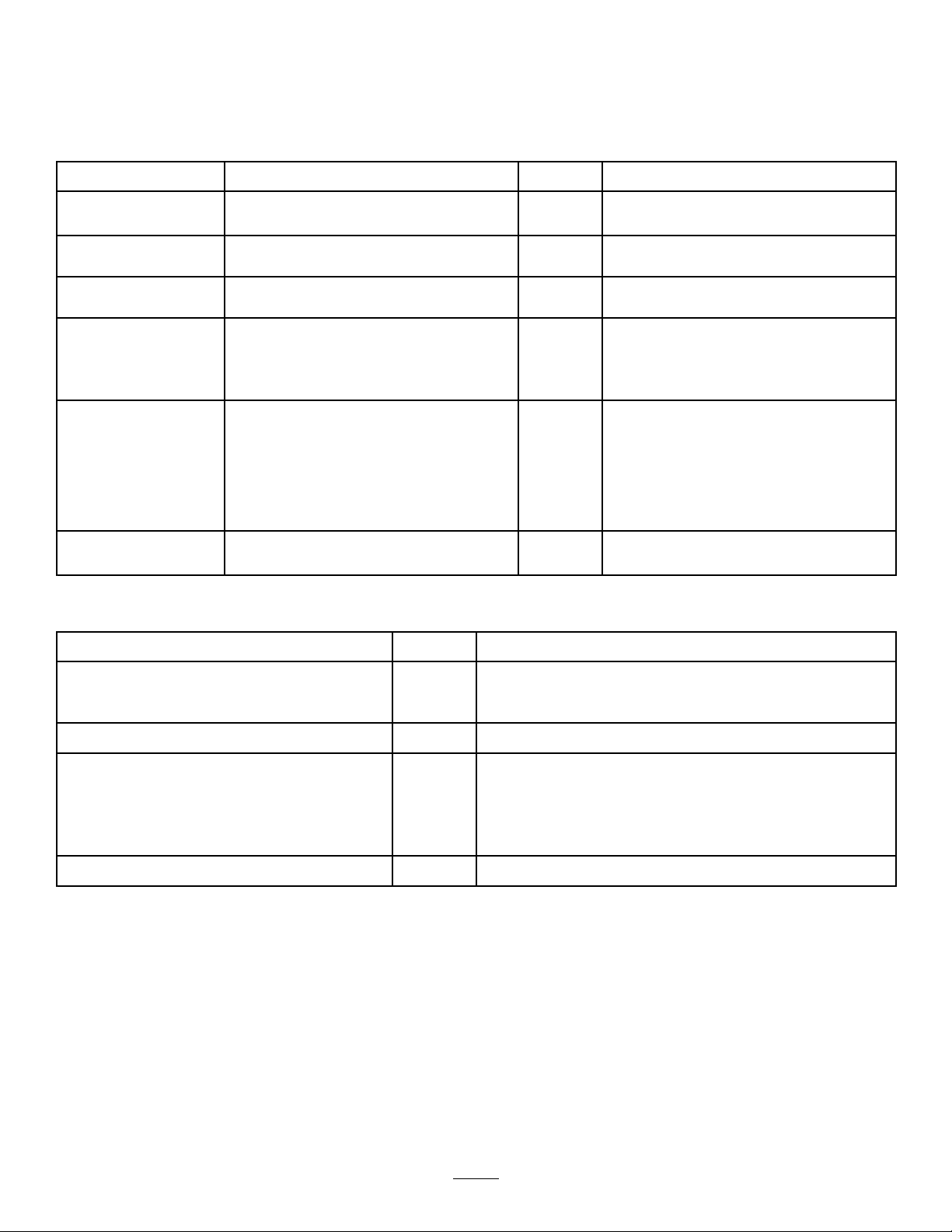

115-8226

1.Tippinghazard—readtheOperator'smanual;alwayswear

aseatbeltwhenoperating,donotremovetherollover

protectionsystem(ROPS).

10

Page 11

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

6

MediaandAdditionalParts

Nopartsrequired

Bolt(1/4x5/8inch)

Nut(1/4inch)

Bolt(1/2x1.75inch)

Nut(1/2inch)

Bolt(#10x5/8inch)

Jamnut(#10)

Cuttingunit

Grassbasket

Rearweightkit,100-6441(purchase

separately)

Calciumchloride(purchaseseparately)

Rearweightkit,99-1645(purchase

separatelyifyouhavea3-wheeldrive

kitinstalled)

Warningdecal(121–2641)

18kg(40

Qty.

lb)

Use

–

2

2

8

8

1

1

3

3

1

1

1

Activateandchargethebattery .

Installthebattery.

Installtherolloverprotectionsystem

(ROPS).

Installthecuttingunits.

Addrearballastandweightkit.

InstallEUdecals,ifrequired.

Description

Operator’sManual

EngineOperator’sManual

OperatorTrainingMaterial

PartsCatalog

Pre-deliveryInspectionSheet

Noiseratingcerticate

CerticateofQuality

DeclarationofConformity

Emissionswarranty1

Ignitionkeys2

Qty.

Use

1

1

1

1

1

1

1

1

Readthisinformationbeforeoperatingthemachine.

Identifyandorderserviceparts.

Readthiscomplianceinformation.

Startthemachine.

11

Page 12

1

ActivatingandChargingthe Battery

NoPartsRequired

Procedure

Useonlyelectrolyte(1.265SpecicGravity)tollbattery

initially.

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

Washhandsafterhandling.

1.Removethewingnuts,washers,andbatteryclampand

liftoutthebattery.

Important:Donotaddelectrolytewhilethe

batteryisinthemachine.Youcouldspillit,

causingcorrosion.

2.Cleanthetopofthebatteryandremovetheventcaps

(Figure3).

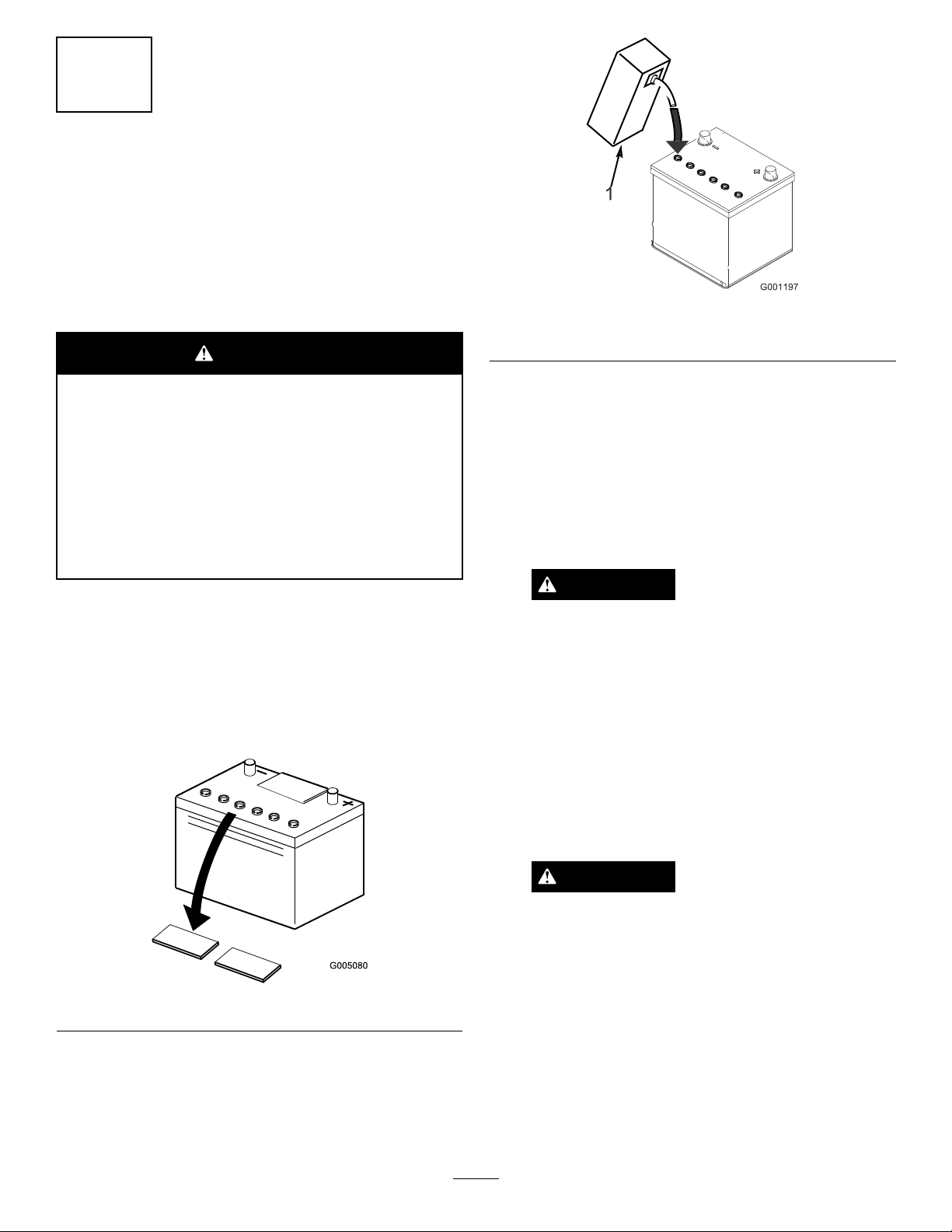

Figure4

1.Electrolyte

4.Allowapproximately20to30minutesforthe

electrolytetosoakintotheplates.Fillasnecessaryto

bringtheelectrolytetowithinabout6mm(1/4inch)

ofthebottomofthellwell(Figure4).

5.Connecta2to4ampbatterychargertothebattery

posts.Chargethebatteryfor2hoursat4ampsorfor

4hoursat2ampsuntilthespecicgravityis1.250or

higherandthetemperatureisatleast16°C(60°F)

withallcellsgassingfreely .

WARNING

Chargingthebatteryproducesgassesthatcan

explode.

Neversmokenearthebatteryandkeepsparks

andamesawayfrombattery.

6.Whenthebatteryischarged,disconnectthecharger

fromtheelectricaloutletandbatteryposts.

Figure3

3.Carefullylleachcellwithelectrolyteuntiltheplates

arecoveredwithabout6mm(1/4inch)ofuid

(Figure4).

Note:Afterthebatteryhasbeenactivated,add

onlydistilledwatertoreplacenormalloss,although

maintenance-freebatteriesshouldnotrequirewater

undernormaloperatingconditions.

WARNING

Batteryterminalsormetaltoolscouldshort

againstmetaltractorcomponentscausing

sparks.Sparkscancausethebatterygassesto

explode,resultinginpersonalinjury.

•Whenremovingorinstallingthebattery,

donotallowthebatteryterminalstotouch

anymetalpartsofthetractor.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsof

thetractor.

12

Page 13

WARNING

Failuretocorrectlyactivatethebatterymay

resultinbatterygassingand/orpremature

batteryfailure.

7.Installtheventcaps.

2

InstallingtheBattery

Partsneededforthisprocedure:

2

Bolt(1/4x5/8inch)

2

Nut(1/4inch)

Procedure

1.Mountthebatterywiththebatteryterminalstoward

thefrontofthemachine.

2.Connectthepositivebatterycable(red)fromthe

startersolenoidtothepositivepost(+)ofthebattery

(Figure5).Secureitwithawrenchandcoatthe

terminalwithpetroleumjelly.Makesurethecablewill

cleartheseat,intherear-mostposition,whichcould

causewearordamagetothecable.

WARNING

Batteryterminalsormetaltoolscouldshort

againstmetaltractorcomponentscausing

sparks.Sparkscancausethebatterygassesto

explode,resultinginpersonalinjury.

•Whenremovingorinstallingthebattery,

donotallowthebatteryterminalstotouch

anymetalpartsofthetractor.

Figure5

1.Negative(-)2.Positive(+)

3.Connecttheblackgroundcable(fromtheenginebase)

tothenegative(-)postofthebattery.Secureitwitha

wrenchandcoattheterminalwithpetroleumjelly .

WARNING

Incorrectbatterycableroutingcoulddamage

thetractorandcablescausingsparks.Sparks

cancausethebatterygassestoexplode,

resultinginpersonalinjury.

•Alwaysdisconnectthenegative(black)

batterycablebeforedisconnectingthe

positive(red)cable.

•Alwaysconnectthepositive(red)battery

cablebeforeconnectingthenegative

(black)cable.

4.Installthebatteryclampandwashersandsecurethem

withthewingnuts.

5.Placetheterminalcoveroverthepositive(+)battery

post.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsof

thetractor.

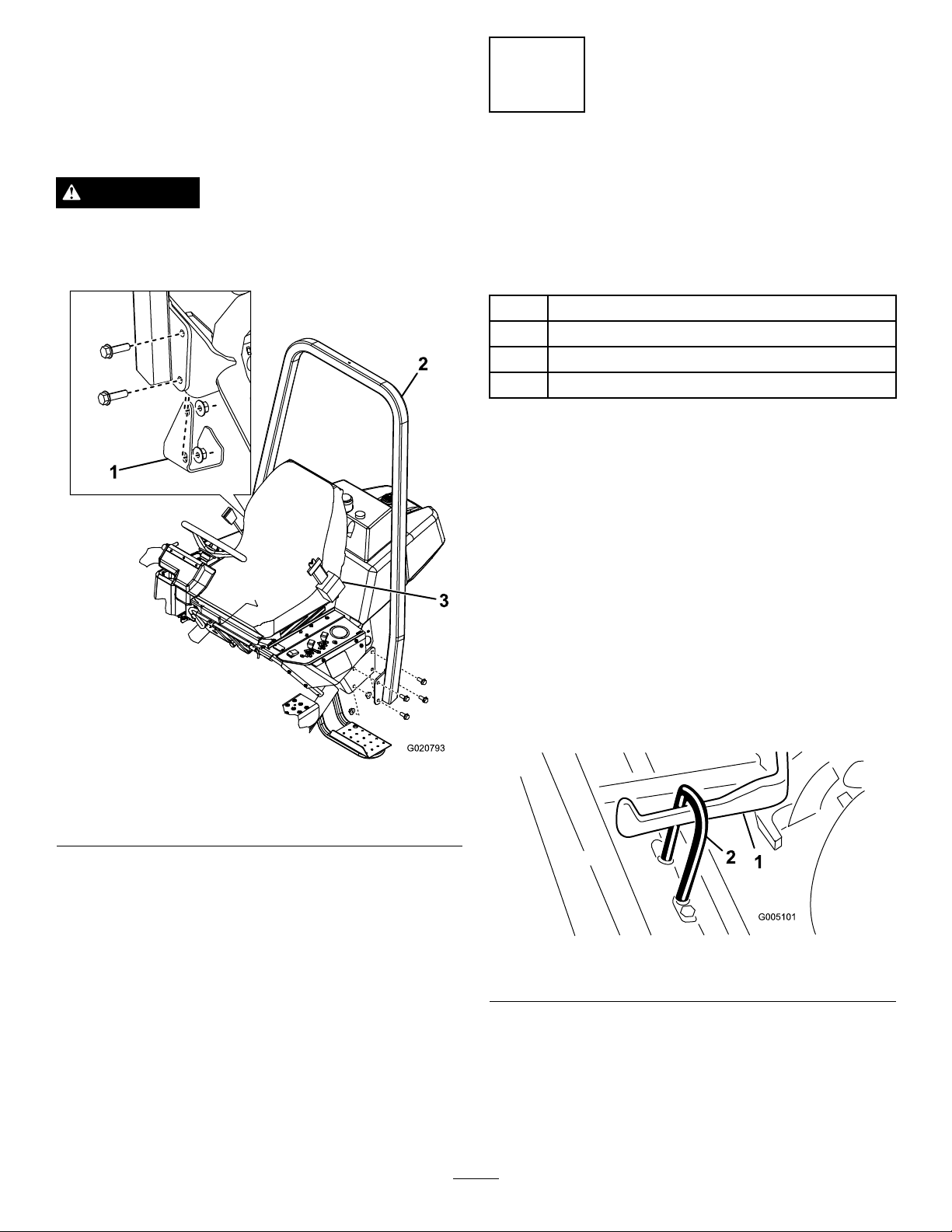

3

InstallingtheRollOver ProtectionSystem(ROPS)

Partsneededforthisprocedure:

8

Bolt(1/2x1.75inch)

8

Nut(1/2inch)

Procedure

1.Removethescrewsandnutssupportingthejackpad

ontherightsideofthemachine.

13

Page 14

2.LowertheROPSframe(Figure6)ontothemounting

3

G020793

brackets,aligningthemountingholes.

3.Secureeachsideoftherollbarandthepreviously

removedjackpadtothemountingbracketswith8

screws(1/2-13x1.75inch)andlocknuts.Torquethe

fastenersto91to115N-m(67to85ft-lb).

WARNING

TheRolloverProtectionSystem(ROPS)isan

integralandeffectivesafetydevice.Alwaysusethe

seatbeltwiththerollbar.

4

InstallingtheCuttingUnits

(Forcuttingunitmodels04610,

04611,04616,04618,04619,

and04624only)

Partsneededforthisprocedure:

1

Bolt(#10x5/8inch)

1

Jamnut(#10)

3

Cuttingunit

3

Grassbasket

Procedure

Important:Don’traisethesuspensiontothetransport

positionwhenthereelmotorsareintheholdersonthe

machineframe.Damagetothemotorsorhosescould

result.

1.Jackpad

2.ROPS

Note:Whensharpening,settingtheheight-of-cutor

performingothermaintenanceproceduresonthecutting

units,storethecuttingunitreelmotorsinthesupporttubes

onthefrontoftheframetopreventdamagetothehoses.

1.Removethecuttingunitsfromthecartons.Assemble

andadjustthemaslistedinthecuttingunitOperator's

Manual.

2.Slidethecuttingunitunderthepullframewhile

hookingthelifthookontotheliftarm(Figure7).

Figure6

3.Seatbelt

Figure7

1.Liftarm2.Lifthook

3.Slidethesleevebackontheballjointreceiverandhook

thereceiverontothecuttingunitballstud.Releasethe

14

sleevesoitslidesoverthestudandlockstheassemblies

together(

Figure8).

Page 15

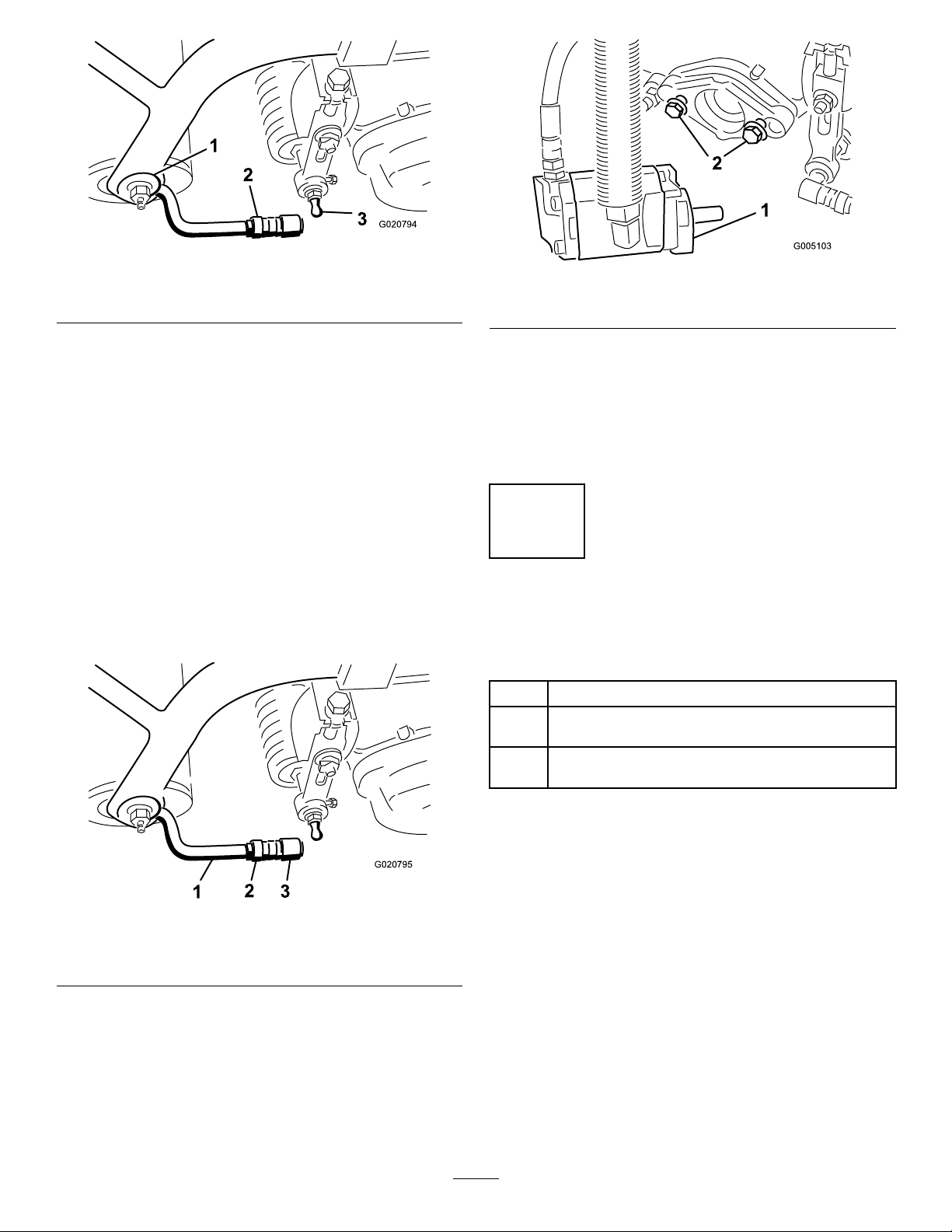

G020794

1.Pullframe

G020795

2.Pullarm

Figure8

3.Ballstud

Figure10

1.Mountingbolts2.Drivemotor

4.Mountthebasketsonthepullframes,loosenthe

jamnutsonthepullarms,andadjusttheballsockets

untilthereis6to13mm(1/4to1/2inch)clearance

betweenthelipofthebasketandthereelbladesorthe

frontshield.

Note:Thispreventsthebasketfromtippingthe

cuttingunitforward,causingtheliftrollertocomeoff

oftheliftarmwhileinthemowingoperation.

Besurethebasketlipisequidistantfromthereelblades

allacrosseachreel.Ifthebasketistooclosetothereel,

itispossibleforthereeltocontactthebasketwhenthe

cuttingunitisraisedoffoftheground.

5.Alignthesocketsintheballjointssotheopensideof

thesocketiscenteredtowardstheballstud.Tightenthe

jamnutstosecurethesocketsinposition(Figure9).

7.Coatthesplineshaftofthemotorwithcleangrease

andinstallthemotorbyrotatingthemotorclockwise

sothatthemotorangesclearthestuds.Rotatethe

motorcounterclockwiseuntiltheangesareencircling

thestuds.

8.Tightenthemountingbolts(Figure10).

5

AddingRearBallastand WeightKit

Partsneededforthisprocedure:

1

Rearweightkit,100-6441(purchaseseparately)

18kg

(40lb)

Calciumchloride(purchaseseparately)

Rearweightkit,99-1645(purchaseseparatelyifyou

1

havea3-wheeldrivekitinstalled)

Figure9

1.Pullarm3.Balljoint

2.Jamnut

6.Ensurethatthereisapproximately13mm(1/2inch)

ofthreadsexposedoneachreeldrivemotormounting

bolt(Figure10).

Procedure

ThisunitcomplieswiththeANSIB71.4-2004andEN836

Standardswhenyouequipitwithrearweightkit100-6441

and18kg(40lb)ofcalciumchlorideballastisaddedtothe

rearwheel.Ifyouinstalla3-WheelDrivekit,userearweight

kit99-1645insteadof100-6441.

Important:Ifapunctureoccursinatirewithcalcium

chloride,removetheunitfromtheturfareaasquickly

aspossible.Topreventpossibledamagetotheturf,

immediatelysoaktheaffectedareawithwater.

15

Page 16

ProductOverview

6

InstallingCEDecals

Partsneededforthisprocedure:

1

Warningdecal(121–2641)

Procedure

IfthismachinewillbeusedintheEU,afxthewarningdecal

121–2641overwarningdecal(121–2640).

Controls

BrakePedal

Thebrakepedal(Figure11)actuatesanautomotivedrum-type

mechanicalbrakelocatedateachtractionwheel.

ParkingBrakeButton

Pressingthebrakepedaltoactuatethebrakeassembly,then

pressingthesmallbuttonindicated(Figure11)willkeepthe

brakesactuatedforparking.Disengageitbypressingthe

brakepedal.Locktheparkingbrakebeforeyouleavethe

machine.

Figure11

1.Tractionpedal3.Parkingbrakebutton

2.Brakepedal

TractionandStoppingPedal

Thetractionpedal(Figure11)hasthreefunctions:tomake

themachinemoveforward,tomoveitbackward,andtostop

themachine.Pressthetopofthepedaltomoveforward

andthebottomofthepedaltomovebackwardortoassist

instoppingwhenmovingforward.Also,allowthepedal

tomovetotheneutralpositiontostopthemachine.For

operatorcomfort,donotresttheheelofyourfootonreverse

whenoperatingforward(Figure12).

Figure12

16

Page 17

ThrottleControl

Thethrottlecontrol(Figure13)givestheoperatortheability

tocontrolthespeedoftheengine.Movingthethrottle

controltowardtheFastpositionincreasestheenginerpm;

movingthethrottlecontroltowardSlowwilldecreasethe

enginerpm.

Note:Theenginecannotbestoppedbytheuseofthe

throttlecontrol.

Figure13

1.Throttlecontrol

2.Chokecontrol

3.Leakdetectortest/light

switch

Figure14

1.Seatadjustmentlever

Raise/LowerMowControl

Movingthecontrol(Figure15)forwardduringoperation

lowersthecuttingunitsandstartsthereels.Pullbackonthe

controltostopthereelsandraisethecuttingunits.During

operationthereelscanbestoppedbypullingbackonthe

controlmomentarilyandreleasingit.Restartthereelsby

movingthecontrolforward.

Choke

Tostartacoldengine,closethecarburetorchokebymoving

thechokecontrol(

Aftertheenginestarts,regulatethechoketokeeptheengine

runningsmoothly.Assoonaspossible,openthechokeby

pullingitrearwardtotheOpenposition.Awarmengine

requireslittleornochoking.

Figure13)forwardtotheClosedposition.

Leakdetectortest/lightswitch

Fromthemiddleoperatingposition,movetheswitch

(Figure13)rearwardtochecktheoperationoftheleak

detectoralarmandtimedelay.Movetheswitchforwardto

operatetheoptionallights.

HourMeter

Thehourmeter(locatedontheleftcontrolpanel)indicates

thetotalhoursthemachinehasoperated.Itstartstofunction

wheneverthekeyswitchisrotatedtoOn.

SeatAdjustingLever

Figure15

1.Functionalcontrollever

2.Ignitionswitch

3.Raise/lowermowcontrol

FunctionalControlLever

Thefunctionalcontrollever(Figure15)providestwotraction

selectionsplusaNeutralposition.Itispermissibletoshift

frommowtotransportortransporttomow(nottoneutral)

whilethemachineisinmotion.Nodamagewillresult.

•RearPosition-neutralandbacklapping

•MiddlePosition-usedformowingoperation

•FrontPosition-usedfortransportoperation

Thislever,ontheleftsideoftheseat(Figure14),allowsa10

cm(4inch)foreandaftadjustmentoftheseat.

IgnitionSwitch

Insertthekeyintotheswitch(Figure15)andturnitclockwise

asfaraspossibletotheStartpositiontostarttheengine.

Releasethekeyassoonastheenginestarts;thekeywillmove

totheOnposition.TurnthekeycounterclockwisetotheOff

positiontostoptheengine.

17

Page 18

SteeringWheelLockingLever

Rotatethelever(Figure16)forwardtoloosentheadjustment,

raiseorlowersteeringwheelforoperatorcomfort,then,

rotatetheleverrearwardtotightentheadjustment.

Figure16

1.Steeringwheellockinglever

SteeringArmLockingKnob

Loosenknob(Figure17)untilshoulderonknobclearsthe

notchesinsteeringarm.Raiseorlowersteeringarmto

desiredheightwhilealigningshoulderofknobwithnotchin

steeringarm.Tightenknobtolockadjustment.

Figure18

1.Fuelshut-off(underthefueltank)

BacklapLever

Usethebacklaplever(Figure19)inconjunctionwiththe

lowermow/raisecontrolleverforbacklappingthereels.

Figure19

Figure17

1.Steeringarmlockingknob

FuelShut-OffValve

Closethefuelshut-offvalve(Figure18),underthefueltank,

whenstoringortransportingthemachineonatruckortrailer.

1.Backlaplever2.Reelspeedcontrol

ReelSpeedControl

Usethereelspeedcontrol(Figure19)toadjusttherpmof

thereel.

18

Page 19

Specications

G017134

1

2

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

OverallWidthw/reels177cm(69–3/4inches)

OverallLength228.6cm(90inches)

OverallHeight189cm(74-1/2inches)

OverallWeightw/1 1–blade

cuttingunits

NetWeight(dry)493kg(1,087lb)

WidthofCut149.9cm(59inches)

583kg(1,374lb)

Operation

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

ThinkSafetyFirst

Pleasecarefullyreadallofthesafetyinstructionsandsymbols

inthesafetysection.Knowingthisinformationcouldhelp

youorbystandersavoidinjury.

Theuseofprotectiveequipment,suchasbutnotlimitedto,

foreyes,ears,feet,andheadisrecommended.

WheelTread

WheelBase

MowSpeed(adjustable)3.2–8km/h(2–5mph)

TransportSpeed12.9km/h(8.0mph)

ReverseSpeed4km/h(2.5mph)

ReelSpeed(at2,850RPM

enginespeed)

125.7cm(49-1/2inches)

119.1cm(46-7/8inches)

approximately

approximately

1,845rpmapproximately

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesis

availableforusewiththemachinetoenhanceandexpand

itscapabilities.ContactyourAuthorizedServiceDealeror

Distributororgotowww .T oro.comforalistofallapproved

attachmentsandaccessories.

CAUTION

Useyourseatbeltwhileoperatingthismachine.

CheckingtheEngineOil

Theengineisshippedwith1.4liters(1.5quarts)(w/lter)of

oilinthecrankcase;however,theoillevelmustbechecked

beforeandaftertheengineisrststarted.

Theengineusesanyhigh-qualitydetergentoilhavingthe

AmericanPetroleumInstitute(API)serviceclassicationof

SG,SH,orSJorhigher.Therecommendedviscosity(weight)

isSAE30.

1.Positionthemachineonalevelsurface.

2.Pullthedipstickoutandwipeitwithacleanrag.Push

thedipstickintothetubeandmakesureitisseated

fully(

Figure20).

Figure20

1.Dipstick2.Fillercap

3.Pullthedipstickoutofthetubeandchecktheoillevel.

4.Iftheoillevelislow,removethellercapfromthe

valvecoverandpouroilintotheopeninginthevalve

coveruntiltheoillevelisuptotheFullmarkonthe

dipstick.Addtheoilslowlyandchecktheleveloften

duringthisprocess.Donotoverll.

Important:Checktheoillevelevery8operating

hoursordaily.

19

Page 20

5.Installthellercapanddipstickrmlyinplace.

FillingtheFuelTank

Useunleadedregulargasolinesuitableforautomotiveuse

(87pumpoctaneminimum).Leadedregulargasolinemaybe

usedifunleadedregularisnotavailable.

Important:Neverusemethanol,gasolinecontaining

methanol,orgasoholcontainingmorethan10%ethanol

becausethefuelsystemcouldbedamaged.Donotmix

oilwithgasoline.

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupanygasoline

thatspills.

•Neverllthefueltankinsideanenclosedtrailer.

•Donotllthefueltankcompletelyfull.Add

gasolinetothefueltankuntilthelevelis1inch

(25mm)belowthebottomofthellerneck.

Thisemptyspaceinthetankallowsgasolineto

expand.

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingasparkwhich

canignitethegasolinevapors.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Alwaysplacegasolinecontainersontheground

awayfromyourvehiclebeforelling.

•Donotllgasolinecontainersinsideavehicleor

onatruckortrailerbedbecauseinteriorcarpets

orplastictruckbedlinersmayinsulatethe

containerandslowthelossofanystaticcharge.

•Whenpractical,removegas-poweredequipment

fromthetruckortrailerandrefueltheequipment

withitswheelsontheground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfromaportable

container,ratherthanfromagasolinedispenser

nozzle.

•Ifagasolinedispensernozzlemustbeused,

keepthenozzleincontactwiththerimofthe

fueltankorcontaineropeningatalltimesuntil

fuelingiscomplete.

1.Cleanaroundthefueltankcapandremoveit

(Figure21).

•Neversmokewhenhandlinggasoline,andstay

awayfromanopenameorwheregasoline

fumesmaybeignitedbyaspark.

•Storegasolineinanapprovedcontainerand

keepitoutofthereachofchildren.Neverbuy

morethana30-daysupplyofgasoline.

•Donotoperatewithoutentireexhaustsystemin

placeandinproperworkingcondition.

Figure21

1.Fueltankcap

2.Addunleadedregulargasolinetothefueltankuntilthe

levelis25mm(1inch)belowthebottomoftheller

neck.

Thisspaceinthetankallowsgasolinetoexpand.Do

notllthefueltankcompletelyfull.

Note:Fueltankcapacityis26.6liters(7U.S.gallons)

3.Installthefueltankcapsecurely.Wipeupanygasoline

thatmayhavespilled.

CheckingtheHydraulicFluid Level

Thehydraulicuidreservoirislledatthefactorywith

approximately32.2l(8.5U .S.gallons)ofhighqualityhydraulic

20

Page 21

uid.Checkthelevelofthehydraulicuidbeforethe

G017136

1

2

engineisrststartedanddailythereafter.Therecommended

replacementuidisasfollows:

ToroPremiumAllSeasonHydraulicFluid(Availablein5

gallonpailsor55gallondrums.SeepartscatalogorT oro

distributorforpartnumbers.)

Alternateuids:IftheTorouidisnotavailable,otheruids

maybeusedprovidedtheymeetallthefollowingmaterial

propertiesandindustryspecications.Wedonotrecommend

theuseofsyntheticuid.Consultwithyourlubricant

distributortoidentifyasatisfactoryproduct

Note:Torowillnotassumeresponsibilityfordamage

causedbyimpropersubstitutions,souseonlyproducts

fromreputablemanufacturerswhowillstandbehindtheir

recommendation.

HighViscosityIndex/LowPourPointAnti-wearHydraulic

Fluid,ISOVG46

MaterialProperties:

Viscosity,ASTMD445cSt@40°C44to48

ViscosityIndexASTM

D2270

PourPoint,ASTMD97-34°Fto-49°F

IndustrySpecications:

VickersI-286-S(QualityLevel),VickersM-2950-S

(QualityLevel),DenisonHF-0

cSt@100°C7.9to8.5

140to160

29°C(85°F)shouldhaveOilCoolerKit,PartNo.

105-8339,installed.

1.Positionthemachineonalevelsurface.Makesurethe

machinehascooleddownsotheoiliscold.Check

theoillevelbyviewingthesightwindowontheside

oftheauxiliaryoiltank(

Figure22).Iftheoillevelis

betweenthetwomarksonthesightwindow,theoil

levelissufcient.

2.Iftheoillevelisbelowthebottommarkinthesight

window,removethecapfromthehydraulicoiltank

andslowlyllthetankwiththeappropriatehighquality

hydraulicuiduntilthelevelisbetweenthetwomarks

onthesightwindow.Donotmixoils.Installthecap.

Important:Topreventsystemcontamination,

cleanthetopofthehydraulicoilcontainersbefore

puncturingthem.Ensurethatthepourspoutand

funnelareclean.

Note:Makeaclosevisualinspectionofthehydraulic

components.Inspectthemforleaks,loosefasteners,

missingparts,improperlyroutedlines,etc.Makeany

correctionsnecessary.

Important:TheISOVG46Multigradeuidhasbeen

foundtoofferoptimalperformanceinawiderangeof

temperatureconditions.Foroperationinconsistently

highambienttemperatures,18°C(65°F)to49°C

(120°F),ISOVG68hydraulicuidmayofferimproved

performance.

PremiumBiodegradableHydraulicFluid-MobilEAL

EnviroSyn46H

Important:MobilEALEnviroSyn46Histheonly

syntheticbiodegradableuidapprovedbyToro.This

uidiscompatiblewiththeelastomersusedinToro

hydraulicsystemsandissuitableforawide-range

oftemperatureconditions.Thisuidiscompatible

withconventionalmineraloils,butformaximum

biodegradabilityandperformancethehydraulicsystem

shouldbethoroughlyushedofconventionaluid.The

oilisavailablein19l(5gallon)containersor55gallon

drumsfromyourMobilDistributor.

Note:Manyhydraulicuidsarealmostcolorless,makingit

difculttospotleaks.Areddyeadditiveforthehydraulic

systemoilisavailablein20ml(2/3oz)bottles.Onebottle

issufcientfor15-221(4-6gallons)ofhydraulicoil.Order

partno.44-2500fromyourauthorizedTorodistributor.This

reddyeisnotrecommendedforusewithbiodegradable

uids.Usefoodcoloring.

Figure22

1.Sightwindow

2.Hydraulictankcap

CheckingtheTirePressure

Thetiresareover-inatedatthefactoryforshipping

purposes.Reducethepressuretotheproperlevelsbefore

startingtheunit.

Varythetirepressureforthefrontwheels,depending

uponyourturfconditions,fromaminimumof55kPatoa

maximumof83kPa(8to12psi).

Varythetirepressurefortherearwheelfromaminimumof

55kPatoamaximumof103kPa(8to15psi).

Important:Regardlessofthehydraulicuidtype

used,anytractionunitusedforoffgreenapplications,

verticuttingorusedduringambienttemperaturesabove

21

Page 22

CheckingtheTorqueofthe

StartingtheEngine

WheelNuts

WARNING

Failuretomaintainpropertorqueofthewheelnuts

couldresultinpersonalinjury.

Torquethewheelnutsto95to122N-m(70-90ft-lb)

after1-4hoursofoperationandagainafter10hours

ofoperation.Torqueevery200hoursthereafter.

Break-inPeriod

RefertotheEngineManualsuppliedwiththemachineforoil

changeandmaintenanceproceduresrecommendedduring

thebreak-inperiod.

Only8hoursofmowingoperationisrequiredforthebreak-in

period.

Sincethersthoursofoperationarecriticaltofuture

dependabilityofthemachine,monitoritsfunctionsand

performancecloselysothatminordifculties,whichcould

leadtomajorproblems,arenotedandcanbecorrected.

Inspectthemachinefrequentlyduringbreak-inforsignsof

oilleakage,loosefasteners,oranyothermalfunction.

Toensureoptimumperformanceofthebrakesystem,burnish

(break-in)thebrakesbeforeusingthemachine.Toburnish

thebrakes,rmlyapplythebrakesanddrivethemachineat

mowingspeeduntilthebrakesarehot,asindicatedbytheir

smell.Anadjustmenttothebrakesmayberequiredafter

break-in;refertoAdjustingtheBrakes(page38).

Note:Inspecttheareabeneaththemowerstobecertain

theyareclearofdebris.

1.Sitontheseat,locktheparkingbrake,disengagethe

raise/lowermowcontrolandmovethefunctional

controllevertoNeutral.

2.Removeyourfootfromthetractionpedalandmake

surethepedalisintheNeutralposition.

3.Movethechokelevertotheclosedposition(onlywhen

startingacoldengine)andthethrottlelevertothehalf

throttleposition.

4.Insertandrotatetheignitionkeyclockwiseuntilthe

enginestarts.Aftertheenginestarts,regulatethe

choketokeeptheenginerunningsmoothly.Assoon

aspossible,openthechokebypullingitrearwardto

theOffposition.Awarmenginerequireslittleorno

choking.

5.Checkthemachineoutwiththefollowingprocedures

aftertheenginehasstarted:

A.MovethethrottlecontroltotheFastposition

andmomentarilyengagethereelsbymoving

theraise/lowermowcontrolleverforward.The

cuttingunitsshoulddropandallthereelsshould

turn.

B.Movetheraise/lowermowcontrolleverrearward.

Thecuttingreelsshouldstopandthecuttingunits

shouldraisetothefulltransportposition.

Important:Stoptheengine.Checkthelipof

eachbaskettobesureitisnotincontactwith

thereelduringoperation.Adjustthe

pullarmsifcontactisnoted;referto

4InstallingtheCuttingUnits(Forcuttingunitmodels04610,04611,04616,04618,04619,and04624only)(page14).

C.Depressthebrakepedaltokeepthemachinefrom

moving,andoperatethetractionpedalthrough

theforwardandreversepositions.

D.Continuetheaboveprocedurefor1-2minutes.

Neutralizethefunctionalcontrollever,lockthe

parkingbrake,andturntheengineoff.

E.Checkforoilleaks.Ifoilleaksappear,check

thetightnessofthehydraulicttings.Ifoil

leakscontinuetoappear,contactyourlocal

ToroDistributorforassistanceand,ifnecessary,

replacementparts.

Important:Atraceofoilonthemotoror

wheelsealsisnormal.Sealsrequireasmall

amountoflubricationtoperformproperly.

Note:Sincethemachineisnewandthebearings

andreelsaretight,itisnecessarytousetheFast

throttlecontrolpositionforthischeck.Afast

throttlesettingmaynotberequiredafterthe

break-inperiod.

22

Page 23

CheckingtheSafetyInterlock System

CAUTION

Ifthesafetyinterlockswitchesaredisconnectedor

damagedthemachinecouldoperateunexpectedly

causingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlockswitches

dailyandreplaceanydamagedswitchesbefore

operatingthemachine.

engagetheparkingbrake.Starttheengine.Release

theparkingbrake,movethefunctionalcontrollever

tomow ,andrisefromtheseat.Theengineshould

kill,whichmeansthattheinterlocksystemisoperating

correctly.Correcttheproblemifitisnotoperating

properly.

5.Sitontheseat,movethetractionpedaltoNeutral,

movethefunctionalcontrollevertoNeutral,and

engagetheparkingbrake.Starttheengine.Movethe

raise/lowermowcontrolforwardtolowerthecutting

units.Thecuttingunitsshouldnotstartrotating.If

theydo,theinterlocksystemisnotoperatingcorrectly.

Correcttheproblem.

Thepurposeofthesafetyinterlocksystemistoprevent

operationofthemachinewherethereispossibleinjuryto

theoperatororthemachine.

Thesafetyinterlocksystempreventstheenginefromstarting

unless:

•Thetractionpedalisinneutral.

•Thefunctionalcontrolleverisinneutral.

Thesafetyinterlocksystempreventsthemachinefrom

movingunless:

•Theparkingbrakeisoff.

•Theoperatorisseated.

•ThefunctionalcontrolleverisinMoworTransport.

Thesafetyinterlocksystempreventsthereelsfromoperating

unlessthefunctionalcontrolleverisintheMowposition.

Performthefollowingsystemchecksdailytobesurethe

interlocksystemisoperatingcorrectly:

1.Sitontheseat,movethetractionpedaltoNeutral,

movethefunctionalcontrollevertoNeutral,and

engagetheparkingbrake.Trytodepressthetraction

pedal.Thepedalshouldnotdepress,whichmeansthat

theinterlocksystemisoperatingcorrectly.Correctthe

problemifitisnotoperatingproperly.

2.Sitontheseat,movethetractionpedaltoNeutral,

movethefunctionalcontrollevertoNeutral,and

engagetheparkingbrake.Movethefunctionalcontrol

levertomowortransportandtrytostarttheengine.

Theengineshouldnotcrank,whichmeansthatthe

interlocksystemisoperatingcorrectly.Correctthe

problemifitisnotoperatingproperly.

3.Sitontheseat,movethetractionpedaltoNeutral,

movethefunctionalcontrollevertoNeutral,and

engagetheparkingbrake.Starttheengineandmove

thefunctionalcontrollevertomowortransport.The

engineshouldkill,whichmeansthattheinterlock

systemisoperatingcorrectly.Correcttheproblemifit

isnotoperatingproperly .

CheckingtheLeakDetector

Theleakdetectorsystemisdesignedtoassistinearly

detectionofhydraulicoilsystemleaks.Iftheoillevelinthe

mainhydraulicreservoir,isloweredby118-177ml(4to6

ounces),theoatswitchinthetankwillclose.Afteraone

seconddelay,thealarmwillsound,alertingtheoperator

(Figure25).Expansionofoil,duetonormalheatingduring

machineoperation,willcausetheoiltotransferintothe

auxiliaryoilreservoir.Theoilisallowedtoreturntothemain

tankwhentheignitionswitchisturnedoff.

Figure23

BeforeStarting(oilcold)

1.Fillercap

2.Fillerneck6.Floatraisedswitchopen

3.Overowtube

4.Sightwindow8.Fluidlevel(cold)

5.Solenoidreturnvalveopen

7.Nosound

4.Sitontheseat,movethetractionpedaltoNeutral,

movethefunctionalcontrollevertoNeutral,and

23

Page 24

Figure24

NormalOperation(oilwarm)

3.Insertacleanrodorscrewdriverintothetankneckand

gentlypushdownontheswitchoat(Figure26).The

alarmshouldsoundaftertheone-seconddelay.

1.Solenoidreturnvalve

closed

2.Floatraisedswitchopen

LeakAlert!

1.Floatdownswitchclosed

Fluidleveldown118–177

ml(4to6ounces)

2.Warningbuzzer

3.Warningbuzzer

4.Fluidlevel(warm)

Figure25

3.Fluidlevel(warm)

CheckingtheSystemOperation

1.WithignitionswitchintheOnposition,movethe

leakdetectorswitchrearwardandhold.Afterthe

one-secondtimedelayelapsesthealarmshouldsound.

2.Releasetheleakdetectorswitch.

Figure26

1.Cleanrodorscrewdriver

2.Pressdownonswitch

3.Warningbuzzer

4.Releasetheoat.Thealarmshouldstopsounding.

5.Installthestrainerscreenandhydraulictankcap.Move

theignitionswitchtotheOffposition.

SettingtheReelSpeed

Toachieveaconsistent,highquality-of-cutandauniform

aftercutappearance,itisimportantthatthereelspeedcontrol

(locatedonthemanifoldblockunderseat)becorrectlyset.

Adjustthereelspeedcontrolasfollows:

1.Selecttheheight-of-cutatwhichthecuttingunitsare

set.

2.Choosethedesiredgroundspeedbestsuitedfor

conditions.

3.Usingtheappropriategraph(SeeFigure27)for8,11

or14bladecuttingunits,determinetheproperreel

speedsetting.

CheckingtheLeakDetectorSystem

Operation

1.MovetheignitionswitchtotheOnposition.Donot

starttheengine.

2.Removethehydraulictankcapandstrainerfromthe

neckofthetank.

24

Page 25

Figure27

1.Reelheight5.14Bladecuttingunit

2.5Bladecuttingunit6.Reelspeed

3.8Bladecuttingunit7.Fast

4.11Bladecuttingunit

4.Tosetthereelspeed,rotatetheknob(Figure28)

untiltheindicatorarrowsareinlinewiththenumber

designatingdesiredsetting.

8.Slow

Figure29

1.Alignmentstrip

2.Approximately12.7cm(5

inches)

3.Cutgrassonright

4.Keepfocalspot1.8-3

m(6-10ft)aheadofthe

machine.

TrainingPeriod

Beforemowinggreenswiththemachine,itisrecommended

thatyoundaclearareaandpracticestartingandstopping,

raisingandloweringthecuttingunits,turning,etc.This

trainingperiodwillbebenecialtotheoperatoringaining

condenceintheperformanceofthemachine.

BeforeMowing

Figure28

1.Backlaplever2.Reelspeedcontrol

Note:Reelspeedcanbeincreasedordecreasedto

compensateforturfconditions.

PreparingtheMachinefor Mowing

Toassistinaligningthemachineforsuccessivecuttingpasses,

itissuggestedthefollowingbedonetotheNo.2andNo.

3cuttingunitbaskets:

1.Measureinapproximately12.7cm(5inches)fromthe

outeredgeofeachbasket.

2.Eitherplaceastripofwhitetapeorpaintalineonto

eachbasketparallelingtheouteredgeofeachbasket

(

Figure29).

Inspectthegreenfordebris,removetheagfromthecup,

anddeterminethebestdirectiontomow .Basethedirection

tomowonthepreviousmowingdirection.Alwaysmowinan

alternatepatternfromthepreviousmowingsothatthegrass

bladeswillbelessapttolaydownandthereforebedifcult

totrapbetweenthereelbladesandbedknife.

Mowing

1.Approachthegreenwiththefunctionalcontrolleverin

theMowpositionandthethrottleatfullspeed.Start

ononeedgeofthegreensotheribbonprocedure

ofcuttingmaybeused.Thisholdscompactiontoa

minimumandleavesaneat,attractivepatternonthe

greens.

2.Actuatetheraise/lowermowleverasthefrontedge

ofthegrassbasketscrosstheouteredgeofthegreen.

Thisproceduredropsthecuttingunitstotheturfand

startsthereels.

Important:Familiarizeyourselfwiththefactthat

theNo.1cuttingunitreelisdelayedandtherefore,

youshouldpracticetotrytogaintherequired

25

Page 26

timingnecessarytominimizethecleanupmowing

operation.

3.Overlapaminimalamountwiththepreviouscut

onreturnpasses.Toassistinmaintainingastraight

lineacrossthegreenandkeepthemachineanequal

distancefromtheedgeofthepreviouscut,establish

animaginarysightlineapproximately1.8to3m(6to

10ft)aheadofthemachinetotheedgeoftheuncut

portionofthegreen(Figure29andFigure30).Some

nditusefultoincludetheouteredgeofthesteering

wheelaspartofthesightline;i.e.keepthesteering

wheeledgealignedwithapointthatisalwayskeptthe

samedistanceawayfromthefrontofthemachine

(Figure29andFigure30).

4.Asthefrontofthebasketscrosstheedgeofthegreen,

movetheraise/lowermowleverrearward.Thiswill

stopthereelsandliftthecuttingunits.Timingofthis

procedureisimportant,sothemowersdonotcutinto

thefringearea.However,asmuchofthegreenas

possibleshouldbecuttominimizetheamountofgrass

lefttomowaroundtheouterperiphery.

5.Cutdownonoperatingtimeandeaselineupforthe

nextpassbymomentarilyturningthemachineinthe

oppositedirection,thenturninginthedirectionof

theuncutportion;i.e.,ifintendingtoturnright,rst

swingslightlyleft,thenright.Thiswillassistingetting

themachinemorequicklyalignedforthenextpass.

Followthesameprocedureforturningintheopposite

direction.Itisagoodpracticetotrytomakeasshort

ofaturnaspossible.However,turninawiderarc

duringwarmerweathertominimizethepossibilityof

bruisingtheturf.

Note:Duetothenatureofthepowersteeringsystem,

thesteeringwheelwillnotreturntoitsoriginalposition

afteraturnhasbeencompleted.

Important:Themachineshouldneverbestopped

onagreenwiththecuttingunitreelsoperating

asdamagetotheturfmayresult.Stoppingona

wetgreenwiththemachinemayleavemarksor

indentationsfromthewheels.

6.Iftheleakdetectoralarmsoundswhilecuttingona

green,immediatelyraisethecuttingunits,drivedirectly

offofthegreenandstopthemachineinanareaaway

fromthegreen.Determinethecauseofthealarmand

correcttheproblem.

7.Finishcuttingthegreenbymowingtheouterperiphery.

Besuretochangethedirectionofcuttingfromthe

previousmowing.Alwayskeepweatherandturf

conditionsinmindandbesuretochangethedirection

ofmowingfromthepreviouscutting.Replacetheag.

8.Emptythegrassbasketsofallclippingsbefore

transportingtothenextgreen.Heavywetclippings

placeanunduestrainonthebasketsandwilladd

unnecessaryweighttothemachine,therebyincreasing

theloadontheengine,hydraulicsystem,brakes,etc.

1.Alignmentstrip

2.Approximately12.7cm(5

inches)

Figure30

3.Cutgrassonleft

4.Keepfocalspot1.8-3

m(6-10ft)aheadofthe

machine.

26

Page 27

LeakDetectorOperation

G017135

1

Theleakdetectoralarmmaysoundforoneofthefollowing

reasons:

•Aleakof118-177ml(4to6ounces)hasoccurred.

•Theoillevelinthemainreservoirisreducedby118–177

ml(4to6ounces)duetocontractionoftheoilbycooling.

Ifthealarmsounds,itshouldbeturnedoffasquicklyas

possibleandinspectedforleaks.Ifthealarmsoundswhile

operatingonagreenitmaybeappropriatetodriveoffthe

greenrst.Thesourceoftheleakshouldbedeterminedand

repairedbeforecontinuingoperation.Ifaleakisnotfound,

andafalseleakissuspected,movetheignitionswitchtothe

Offpositionandallowthemachinetostandfor1-2minutes

toallowtheoillevelstostabilize.Thenstartthemachineand

operateinanon-sensitiveareatoconrmnoleakexists.

Falsealarms,duetooilcontraction,maybecausedby

extendedidlingofthemachineafternormaloperation.A

falsealarmmayalsooccur,ifthemachineisworkedata

reducedworkloadafteranextendedperiodofaheavier

workload.Toavoidfalsealarms,turnthemachineoffrather

thanidlingforextendedperiods.

TransportOperation

damaged.Ifthemachinemustbemovedaconsiderable

distance,transportitonatruckortrailer.

1.Locatethebypassvalveonthepumpandrotateitso

thattheslotisvertical(Figure31).

Figure31

1.Bypassvalve-slotshowninclosed(horizontal)position

2.Beforestartingtheengine,closethebypassvalveby

rotatingitsothattheslotishorizontal(Figure31).Do

notstarttheenginewhenthevalveisopen.

Makesurethecuttingunitsareinthefullupposition.Setthe

shiftselectorinNo.2ifconditionswillpermitfasterground

speed.ShifttoNo.1andoperateatslowergroundspeeds

inroughorhillyareas.Usethebrakestoslowthemachine

whilegoingdownsteephillstoavoidlossofcontrol.Always

approachroughareasatareducedspeed(shiftselectorin

No.1),andcrosssevereundulationscarefully.Familiarize

yourselfwiththewidthofthemachine.Donotattemptto

passbetweenobjectsthatareclosetogethersothatcostly

damageanddowntimecanbeprevented.

InspectionandCleanupAfter Mowing

Atthecompletionofthemowingoperation,thoroughlywash

themachinewithagardenhosewithoutanozzlesoexcessive

waterpressurewillnotcausecontaminationanddamageto

thesealsandbearings.Aftercleaning,inspectthemachinefor

possiblehydraulicuidleaks,damageorweartohydraulicand

mechanicalcomponents,andthecuttingunitsforsharpness.

Also,lubricatebrakeshaftassemblywithSAE30oilorspray

lubricanttodetercorrosionandhelpkeepthemachine

performingsatisfactorilyduringthenextmowingoperation.

TowingtheTractionUnit

Incaseofanemergencythemachinecanbetowedforashort

distance(lessthan0.4km(1/4mile)).However,Torodoes

notrecommendthisasstandardprocedure.

Important:Donottowthemachinefasterthan3-5

km/h(2-3mph)becausethedrivesystemmaybe

27

Page 28

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

Important:Refertoyourengine

Operator's Man ual

foradditionalmaintenanceprocedures.

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriouslyinjure

youorotherbystanders.

Removethekeyfromtheignitionanddisconnectthewirefromthesparkplugbeforeyoudoany

maintenance.Setthewireasidesothatitdoesnotaccidentallycontactthesparkplug.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Afterthersthour

Aftertherst10hours

Aftertherst25hours

Aftertherst50hours

Beforeeachuseordaily

MaintenanceProcedure

•Checkthetorqueofthewheelnuts.

•Checkthetorqueofthewheelnuts.

•Changetheengineoilandlter .

•Changethehydrauliclter.

•Checktheenginerpm(atidleandfullthrottle).

•Checktheengineoil.

•Checkthehydraulicuidlevel.

•Checkthesafetyinterlocksystem.

•Inspectandcleanupaftermowing.

•Checkthehydrauliclinesandhoses.

Every50hours

Every100hours

Every200hours

Every800hours

Every2years

•Greasethemachine(immediatelyaftereverywashing).

•Servicetheaircleanerfoampre-cleaner(morefrequentlywhenoperatingconditions

aredustyordirty).

•Checkthebatteryelectrolytelevel.

•Checkthebatterycableconnections.

•Servicetheaircleanercartridge(morefrequentlywhenoperatingconditionsare

dustyordirty).

•Changetheengineoilandlter .

•Checkthetorqueofthewheelnuts.

•Checkthereelbearingpreloadadjustment.

•Replacethesparkplugs.

•Replacethefuellter.

•Changethehydraulicoil.

•Changethehydrauliclter.

•Checktheenginerpm(atidleandfullthrottle).

•Checkthevalveclearance.

•Checkthefuellinesandconnections.

•Replacemovinghoses.

28

Page 29

DailyMaintenanceChecklist

Duplicatethispageforroutineuse.

Fortheweekof: MaintenanceCheckItem

Mon.Tues.Wed.Thurs.Fri.

Checkthesafetyinterlock

operation.

Checktheinstrument

operation

Checktheleakdetector

alarm.

Checkthebrakeoperation.

Checkthefuellevel.

Checkthehydraulicoillevel.

Checktheengineoillevel.

Cleantheengineaircooling

ns.

Inspecttheairlter

pre-cleaner.

Checkanyunusualengine

noises.

Checkthereel-to-bedknife

adjustment.

Checkthehydraulichoses

fordamage.

Checkforuidleaks.

Checkthetirepressure.

Checktheheight-of-cut

adjustment.

Lubricateallgreasettings.

Lubricatethemow,lift,and

brakelinkage.

Touch-updamagedpaint.

1.Immediatelyaftereverywashing,regardlessoftheintervallisted.

1

Sat.Sun.

NotationforAreasofConcern

Inspectionperformedby:

ItemDate

Information

29

Page 30

ServiceIntervalChart

Figure32

Premaintenance

Procedures

RemovingtheSeat

Theseatmayberemovedtoeaseperformingmaintenancein

thevalveblockareaofthemachine.

1.Unlatchandraisetheseat.Securewithproprod.

2.Disconnectthe2wireharnessconnectorsunderthe

seat.

3.Lowertheseatandremovethecotterpinsecuringthe

seatpivotrodtotheframe(Figure33).

JackingtheMachine

CAUTION

Beforeservicing,supportthemachinewithjacks

standsorblocksofwood.

Beforejackingthemachine,lowerthecuttingunits.The

jackingpointsareasfollows:

•Rightside-underthejackpadandadjacenttotheROPS

(RollOverProtectionSystem)supportbracket(Figure34)

•Leftside-underthestep

•Rear-atthecastorfork

Figure34

Figure33

1.Cotterpin2.Seatpivotrod

4.Slidetheseatpivotrodtotheleftside,slidetheseat

forward,andlifttheseatout.

5.Reversetheproceduretoinstalltheseat.

1.Jackpad

30

Page 31

Lubrication

G017144

GreasingtheMachine

LubricatethegreasettingsregularlywithNo.2General

PurposeLithium-BaseGrease.Iftheyouoperatethemachine

undernormalconditions,lubricateallbearingsandbushings

afterevery50hoursofoperation.

Locatethegreasettingasfollows:

•Rearrollerhubassemblyor,ifequippedwitha3-wheel

drivekits,rearwheelrollerclutchesandexternalball

bearing(1)(Figure35)

•Liftarmpivot(3)andpivothinge(3)(Figure37)

Figure37

•Pullframeshaftandroller(12)(Figure38)

Figure35

•Steeringforkshaft(1)(Figure36)

•Steeringcylinderrodend(Figure36)

Figure36

Figure38

•Steeringcylinderend(Figure39)

Figure39

31

Page 32

•Liftcylinders(3)(Figure40)

G017145

Figure40

Figure43

Togreasethemachine,completethefollowingprocedure:

•Tractionpedal(Figure41)

Figure41

•Speedselectorlinkage(Figure42andFigure43)

1.Wipethegreasettingcleansoforeignmattercannot

beforcedintothebearingorbushing.

2.Pumpgreaseintothebearingorbushinguntilthe

greaseisvisible.Wipeupexcessgrease.

3.Applygreasetothereelmotorsplineshaftandontothe

liftarmwhenthecuttingunitisremovedforservice.

4.ApplyafewdropsofSAE30engineoilorspray

lubricant(WD40)toallpivotpointsdailyafter

cleaning.

Figure42

32

Page 33

EngineMaintenance

4.Whenservicingthefoamelement,checkthecondition

ofthepaperelement.Cleanitbygentlytappingitona

atsurfaceorreplaceitifneeded.

ServicingtheAirCleaner

Servicetheaircleanerfoampre-cleanerafterevery50

operatinghoursandtheaircleanercartridgeafterevery100

operatinghours(morefrequentlywhenoperatingconditions

aredustyordirty).

1.Releasethelockingclipsandremovetheaircleaner

cover(

Figure44).Cleanthecoverthoroughly.

Figure44

1.Aircleanercover

5.Installthefoamelement,paperelement,andaircleaner

cover.

Important:Donotoperatetheenginewithoutthe

aircleanerelementbecauseextremeenginewear

anddamagewilllikelyresult.

ChangingtheEngineOiland Filter

Changetheoilandlteraftertherst25hoursofoperation.

Thereafter,changethemevery100hours.

1.Removethedrainplug(Figure46)andletoilowinto

adrainpan.Whentheoilstops,installthedrainplug.

2.Removethewingnutsecuringtheelementstotheair

cleanerbody.

3.Ifthefoamelementisdirty,removeitfromthepaper

element(

A.Washthefoamelementinasolutionofliquid

B.Dryitbywrappingitinacleanrag.Squeezethe

Figure45).Cleanitthoroughly,asfollows:

soapandwarmwater.Squeezeittoremovedirt,

butdonottwistitbecausethefoammaytear.

ragandfoamelementdry.

Figure46

1.Drainplug

2.Removetheoillter(Figure46).Applyalightcoatof

cleanoiltothenewltergasket.

3.Screwthelteronbyhanduntilthegasketcontacts

thelteradapter,thentighten3/4to1turnfurther.

Donotovertighten.

4.Addoiltothecrankcase;referto

CheckingtheEngineOil(page19).

5.Disposeoftheusedoilproperly.

2.Oillter

Figure45

1.Foamelement2.Paperelement

33

Page 34

AdjustingtheThrottleControl

AdjustingtheEngineSpeed

Properthrottleoperationisdependentuponproper

adjustmentofthethrottlecontrol.Beforeadjustingthe

carburetor,ensurethatthethrottlecontrolisoperating

properly.

1.Loosenthecableclampscrewsecuringthecabletothe

engine(

1.Throttlecasingclamp

screw

2.Throttlecable

3.Swivel7.Chokebuttery

4.Stop

Figure47).

Figure47

5.Chokecasingclampscrew

6.Chokecable

Important:Beforethecarburetorandspeedcontrol

areadjusted,thethrottleandchokecontrolsmustbe

adjustedproperly.

WARNING

Theenginemustberunningduringadjustment

ofthecarburetorandspeedcontrol.Contactwith

movingpartsorhotsurfacesmaycausepersonal

injury.

•Shiftintoneutralandengagetheparkingbrake

beforeperformingthisprocedure.

•Keephands,feet,clothing,andotherbodyparts

awayfromthecuttingblades,rotatingparts,the

mufer,andotherhotsurfaces.

1.Starttheengineandletitrunathalfthrottlefor

approximatelyveminutestowarmup.

2.MovethethrottlecontroltotheSlowsetting.Adjust

theidlestopscrewcounterclockwiseuntilitnolonger

contactsthethrottlelever.

3.Bendthegovernedidlespringanchortang(Figure48)

toattainanidlespeedof1650±100rpm.Checkthe

speedwithatachometer.

2.Movetheremotethrottlecontrolleverforwardtothe

Fastposition.

3.Pullrmlyonthethrottlecableuntilthebackofthe

swivelcontactsthestop(Figure47).

4.Tightenthecableclampscrewandchecktheengine

rpmsetting.

•HighIdle:2850±50rpm

•LowIdle:1650±100rpm

AdjustingtheChokeControl

1.Loosenthecableclampscrewsecuringthecabletothe

engine(Figure47).

2.Movetheremotechokecontrolleverforwardtothe

Closedposition.

3.Pullrmlyonthechokecableuntilthechokebuttery

iscompletelyclosed,thentightenthecableclamp

screw(

Figure47).

Figure48

ShownwithAirCleanerRemoved

1.Governedidlespring

anchortang

4.Adjusttheidlestopscrewclockwiseuntiltheidlespeed

isanadditional25to50rpmovertheidlespeedset

instep

5.MovethethrottlecontroltotheFastposition.Bend

thehighspeedspringanchortang(Figure48)toattain

ahighspeedof2850±50rpm.

3

2.Highspeedspringanchor

tang

34

Page 35

ReplacingtheSparkPlugs

FuelSystem

Replacethesparkplugsafterevery800operatinghours.

Therecommendedairgapis0.76mm(0.030inch)

ThecorrectsparkplugtouseisaChampionRC14YC.

Note:Thesparkplugusuallylastsalongtime;however,the

plugshouldberemovedandcheckedwhenevertheengine

malfunctions.

1.Cleantheareaaroundthesparkplugssoforeignmatter

cannotfallintothecylinderwhenthesparkplugis

removed.

2.Pullthesparkplugwiresoffofthesparkplugsand

removetheplugsfromthecylinderhead.

3.Checktheconditionofthesideelectrode,center

electrode,andcenterelectrodeinsulatortoensurethat

thereisnodamage.

Important:Replaceacracked,fouled,dirty,or

otherwisemalfunctioningsparkplug .Donotsand

blast,scrape,orcleanelectrodesbyusingawire

brushbecausegritmayeventuallyreleasefromthe

plug,fallintothecylinder,anddamagetheengine.

4.Settheairgapbetweenthecenterandsideofthe

electrodesat0.76mm(0.030inch)(Figure49).

Maintenance

ReplacingtheFuelFilter

Anin-linelterisincorporatedintothefuellinebetweenthe

fueltankandcarburetor(Figure50).Replacethelterevery

800hoursorsoonerifthefuelowisrestricted.Besurethe

arrowonthelterispointingawayfromthefueltank.

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Draingasolinefromthefueltankwhenthe

engineiscold.Dothisoutdoorsinanopenarea.

Wipeupanygasolinethatspills.

•Neversmokewhendraininggasoline,andstay

awayfromanopenameorwhereasparkmay

ignitethegasolinefumes.

1.Closethefuelshutoffvalve,loosenthehoseclampon

thecarburetorsideoflter,andremovethefuelline

fromthelter(Figure50).

Figure49

5.Installthecorrectlygappedsparkplugwithgasketseal,

andtightentheplugto23Nm(200in-lb).Ifatorque

wrenchisnotused,tightentheplugrmly.

Figure50

1.Fuelshutoffvalve2.Fuellter

2.Placeadrainpanunderthelter,loosentheremaining

hoseclampandremovethelter(Figure50).

3.Installthenewlterwiththearrowonthelterbody

pointingawayfromthefueltank.

FuelLinesandConnections

ServiceInterval:Every2years

Inspectthefuellinesfordeterioration,damage,orloose

connections.

35

Page 36

ElectricalSystem

WARNING

Maintenance

ServicingtheBattery

Properlymaintainthebatteryelectrolyteandkeepthetopof

thebatteryclean.Storethemachineinacoolplacetoprevent

thebatteryfromrunningdown.

Checktheelectrolytelevelevery50operatinghoursor,if

machineisinstorage,every30days.

DANGER

Batteryelectrolytecontainssulfuricacidwhichisa

deadlypoisonandcausessevereburns.

•Donotdrinkelectrolyteandavoidcontactwith

skin,eyesorclothing.Wearsafetyglassesto

shieldyoureyesandrubberglovestoprotect

yourhands.

•Fillthebatterywherecleanwaterisalways

availableforushingtheskin.

Maintainthecelllevelwithdistilledordemineralizedwater.

Donotllthecellsabovethebottomofthesplitringinside

eachcell.

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

Washhandsafterhandling.

ServicingtheFuses

Thefusesinthemachine'selectricalsystemarelocatedunder

theseat(

Figure51).

Keepthetopofthebatterycleanbywashingitperiodically

withabrushdippedinammoniaorbicarbonateofsoda

solution.Flushthetopsurfacewithwateraftercleaningit.

Donotremovethellcapswhilecleaningthebattery.

Thebatterycablesmustbetightontheterminalstoprovide

goodelectricalcontact.

WARNING

Incorrectbatterycableroutingcoulddamagethe

tractorandcablescausingsparks.Sparkscancause

thebatterygassestoexplode,resultinginpersonal

injury.

•Alwaysdisconnectthenegative(black)battery

cablebeforedisconnectingthepositive(red)

cable.

•Alwaysconnectthepositive(red)batterycable

beforeconnectingthenegative(black)cable.

Ifcorrosionoccursattheterminals,disconnectthecables,

negative(-)cablerst,andscrapetheclampsandterminals

separately.Reconnectthecables,positive(+)cablerst,and

coattheterminalswithpetroleumjelly.

Figure51

1.Fuses

36

Page 37

DriveSystem

Maintenance

AdjustingtheTransmission forNeutral

Ifthemachinecreepswhenthetractioncontrolpedalisin

theneutralposition,theneutralreturnmechanismmustbe

adjusted.

D.Fromeachsideofthebulkhead,tightenthe

locknutsevenly,securingthetractioncabletothe

bulkhead(Figure52)Donottwistthecable.

Note:Ifcabletensionexistswhenthefunctional

controlleverisinneutral,themachinemaycreep

whentheleverismovedtotheMoworTransport

position.

AdjustingtheTransportSpeed

1.Blockupundertheframesothatoneofthefront

wheelsisoffoftheoor.

Note:Ifmachineisequippedwitha3wheeldrivekit,

therearwheelmustberaisedofftheoorandblocked.

2.Starttheengine,movethethrottletoSlow ,andcheck

thefrontwheelthatisoffoftheoor;itmustnotbe

rotating.

3.Ifthewheelisrotating,stoptheengineandproceed

asfollows:

A.Loosenbothjamnutssecuringthetraction

controlcabletothebulkheadonthehydrostat

Figure52).Makesurethejamnutsareloosened

(