Page 1

MODEL. 04353—60001 AND UP

MODEL. 04354—60001 AND UP

FORM NO. 3318-251 GB

OPERATOR'S

MANUAL

®

GREENSMASTER

®

3100

© The T oro Company—1996

Page 2

This operator's manual has instructions on safety, operation, and maintenance.

This manual emphasizes safety, mechanical and general product information. DANGER, WARNING and CAUTION

identify safety messages. Whenever the triangular safety alert symbol appears, understand the safety message that follows. “IMPORTANT” highlights special mechanical information and “NOTE” emphasizes general product information

worthy of special attention.

IDENTIFICATION AND ORDERING

MODEL AND SERIAL NUMBER

The model and serial number for the traction unit is on a plate that is mounted on the left front frame member. The

model and serial number for the cutting unit is on a plate that is mounted on the top front of the center cutting unit. Use

model and serial number in all correspondence and when ordering parts.

To order replacement parts from an authorized TORO Distributor, supply the following information:

1. Model and serial numbers of the machine.

2. Part number, description and quantity of parts desired.

NOTE: Do not order by reference number if a parts catalog is being used; use the part number.

Table of Contents

Safety 3

Specifications 9

Before Operating 10

Controls 13

First-Time Operation 15

Operating 19

Maintenance 22

Page

2

Page 3

Safety

Training

1. Read the instructions carefully. Be familiar with

the controls and the proper use of the equipment.

2. Never allow children or people unfamiliar with

these instructions to use the lawn mower. Local

regulations may restrict the age of the operator.

3. Never mow while people, especially children, or

pets are nearby.

4. Keep in mind that the operator or user is responsi-

ble for accidents or hazards occurring to other people or their property.

5. Do not carry passengers.

6. All drivers should seek and obtain professional and

practical instruction. Such instruction should

emphasize:

2. Thoroughly inspect the area where the equipment is

to be used and remove all objects which may be

thrown by the machine.

3. WARNING—Petrol is highly flammable.

• Store fuel in containers specifically designed for

this purpose.

• Refuel outdoors only and do not smoke while

refueling.

• Add fuel before starting the engine. Never

remove the cap of the fuel tank or add petrol

while the engine is running or when the engine

is hot.

• If petrol is spilled, do not attempt to start the

engine but move the machine away from the are

of spillage and avoid creating any source of ignition until petrol vapors have dissipated.

• Replace all fuel tanks and container caps

securely.

• the need for care and concentration when

working with ride-on machines;

• control of a ride-on machine sliding on a slope

will not be regained by the application of the

brake. The main reasons for loss of control

are:

– insufficient wheel grip;

– being driven too fast;

– inadequate braking;

– the type of machine is unsuitable for its

task;

– lack of awareness of the effects of ground

conditions, especially slopes;

– incorrect hitching and load distribution.

Preparation

1. While mowing, always wear substantial footwear

and long trousers. Do not operate the equipment

when barefoot or wearing open sandals.

4. Replace faulty silencers.

Operation

1. Do not operate the engine in a confined space where

dangerous carbon monoxide fumes can collect.

2. Mow only in daylight or in good artificial light.

3. Before attempting to start the engine, disengage all

blade attachment clutches and shift into neutral.

4. Do not use on slopes of more than:

• Never mow side hills over 5°

• Never mow uphill over 10°

• Never mow downhill over 15°

5. Remember there is no such thing as a “safe” slope.

Travel on grass slopes requires particular care. To

guard against overturning:

• do not stop or start suddenly when going up or

downhill;

3

Page 4

• engage the clutch slowly, and always keep the

machine in gear, especially when travailing

downhill;

• machine speeds should be kept low on slopes

and during tight turns;

• stay alert for bumps and hollows and other

hidden hazards;

• never mow across the face of the slope, unless

the lawn mower is designed for this purpose.

6. Use care when pulling loads or using heavy equip-

ment.

• Use only approved drawbar hitch points.

• Limit loads to those you can safely control.

14. Stop the engine and disengage the drive to the attach-

ment

• before refueling;

• before removing the grass catcher;

• before making height adjustments unless the

adjustment can be made from the operator’s position.

• before clearing blockages;

• before checking, cleaning or working on the

lawnmower;

• after striking a foreign object. Inspect the lawnmower for damage and make repairs before

restarting and operating the equipment.

• Do not turn sharply. Use care when reversing.

• Use counterweight(s) or wheel weights when

suggested in the instruction handbook.

7. Watch out for traffic when crossing or near road-

ways.

8. Stop the blades rotating before crossing surfaces

other than grass.

9. When using any attachments, never direct dis-

charge of material toward bystanders nor allow

anyone near the machine while in operation .

10. Never operate the lawn mower with defective

guards, shields or without safety protective devices

in place.

11. Do not change the engine governor settings or

overspeed the engine. Operating the engine at

excessive speeds may increase the hazard of personal injury.

15. Reduce the throttle setting during engine runout and, if

the engine is provided with a shutoff valve, turn the

fuel off at the conclusion of mowing.

Maintenance and Storage

1. Keep all nuts, bolts and screws tight to be sure the

equipment is in safe working condition.

2. Never store the equipment with petrol in the tank

inside a building where fumes may reach an open

flame or spark.

3. Allow the engine to cool before storing in any enclo-

sure.

4. To reduce the fire hazard, keep the engine, silencer,

battery compartment and petrol storage area free of

grass, leaves, or excessive grease.

5. Check the grass catcher frequently for wear or deterio-

ration.

12. Before leaving the operator’s position:

• disengage the power take-off and lower the

attachments;

• change into neutral and set the parking brake;

• stop the engine and remove the key.

13. Disengage the drive to attachments when transport-

ing or not in use.

6. Replace worn or damaged parts for safety.

7. If the fuel tank has to be drained, this should be done

outdoors.

8. Be careful during adjustment of the machine to prevent

entrapment of the fingers between moving blades and

fixed parts of the machine.

9. On multi-bladed machines, take care as rotating one

4

Page 5

blade can cause other blades to rotate.

10. When the machine is to be parked, stored or left

unattended, lower the cutting means unless a positive mechanical lock is used.

Sound & Vibration Levels

Sound Levels

This unit has an equivalent continuous A-weighted

sound pressure at the operator ear of: 86 dB(A), based

on measurements of identical machines per

84/538/EEC.

This unit has a sound power level of 100 dB(A)/1pW,

based on measurements of identical machines per procedures outlined in Directive 79/113/EEC and amendments.

Vibration Levels

This unit has a vibration level of 2.5 m/s2at the posterior, based on measurements of identical machines per

ISO 2631 procedures.

This unit does not exceed a vibration level of 0.5 m/s

at the posterior based on measurements of identical

machines per ISO 2631 procedures.

2

5

Page 6

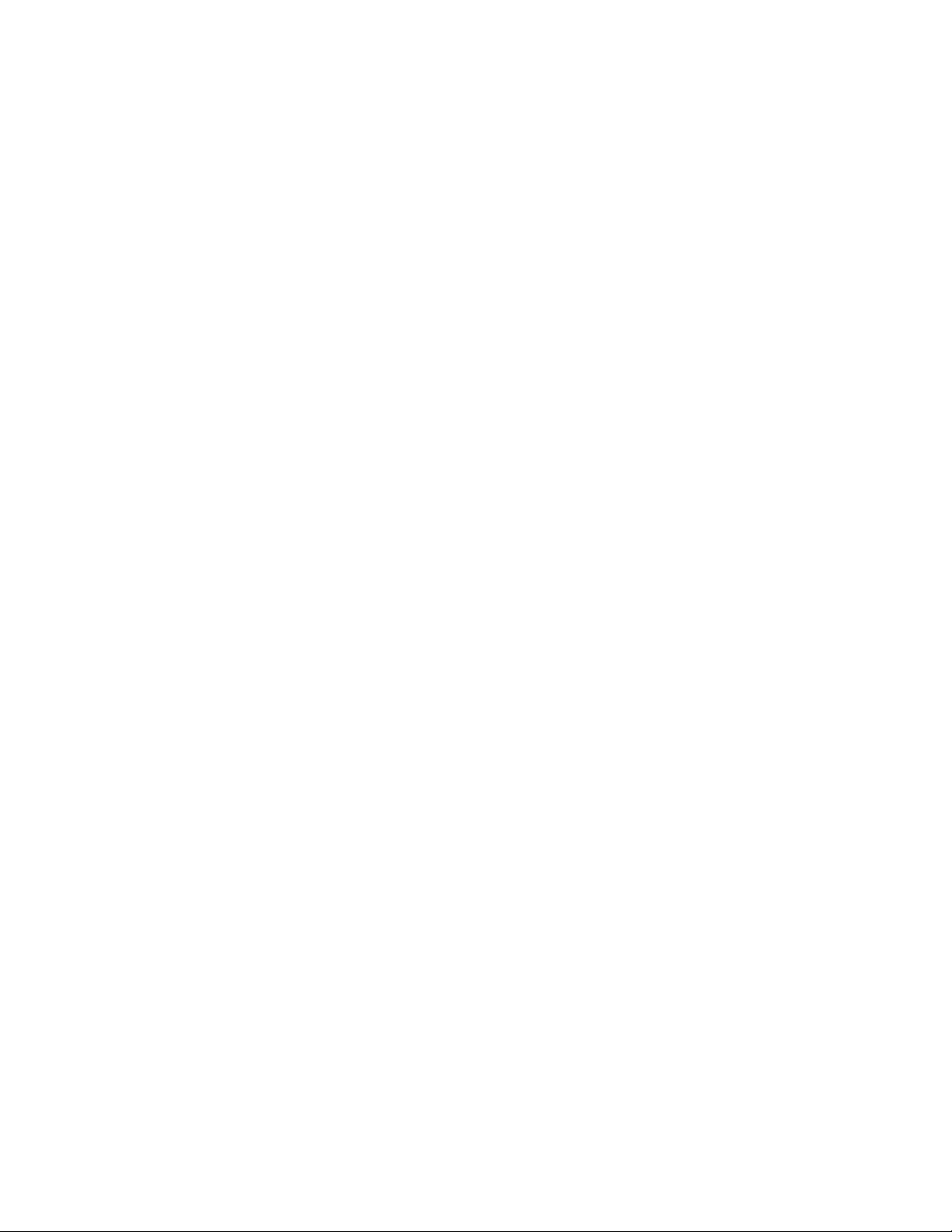

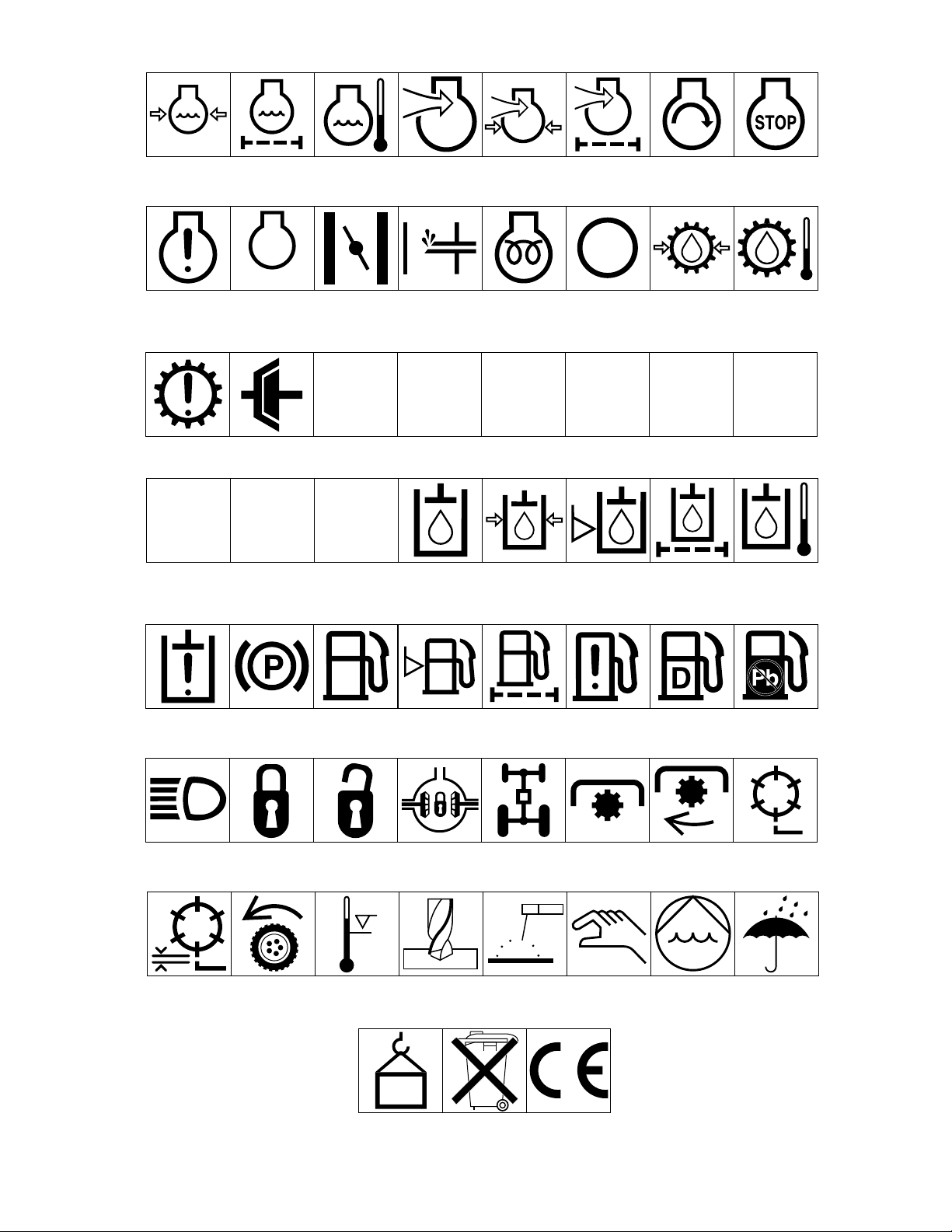

Symbol Glossary

Caustic liquids,

chemical burns to

fingers or hand

Crushing of

whole body,

applied from

above

Cutting or

entanglement of

foot, rotating auger

Poisonous

fumes or toxic

gases, asphyxiation

Crushing of

torso, force

applied from side

Severing of

foot, rotating

knives

Electrical shock,

electrocution

Crushing of fingers

or hand/, force

applied from side

Severing of

fingers or hand,

impeller blade

High pressure

fluid, injection

into body

force applied

from side

Wait until all

machine

components have

completely stopped

before touching them

High pressure

spray, erosion of

flesh

Crushing of

whole body

Severing of

fingers or hand,

engine fan

High pressure

spray, erosion of

flesh

Crushing of

head, torso and

arms

Whole body entanglement,

implement input drive line

Crushing of

fingers

or hand,

force

applied from

above

Cutting of

fingers or hand

Crushing of

toes or foot, force

applied from above

Cutting of footCrushing of leg,

Fingers or

hand entangle-

ment, chain drive

Hand & arm

entanglement,

belt drive

Explosion Fire or open

Shut off engine

& remove key before

performing mainten-

ance or repair work

Thrown or fly-

ing objects, whole

body exposure

flame

Riding on this

machine is allowed

only on a passen-

ger seat & only if the

driver’s view is not

hindered

Thrown or

flying objects,

face exposure

Secure lifting

cylinder with locking

device before getting

in hazardous area

Consult

technical manual

for proper service

procedures

Runover/back-

over, (relevant

machine to appear

in dashed box)

Stay a safe

distance from

the machine

Fasten seat belts Safety alert

Machine tipping,

riding mower

Stay clear of

articulation area

while engine is

running

6

Machine rollover,

ROPS (relevant

machine to appear

in dashed box)

Do not open

or remove safety

shields while

engine is

running

triangle

Stored energy

hazard, kickback

or upward motion

Do not step on

loading platform if

PTO is connected to tractor

& engine is running

outline safety

alert symbol

Hot surfaces,

burns to fingers

or hands

Do not step

Read operator’s

manual

Page 7

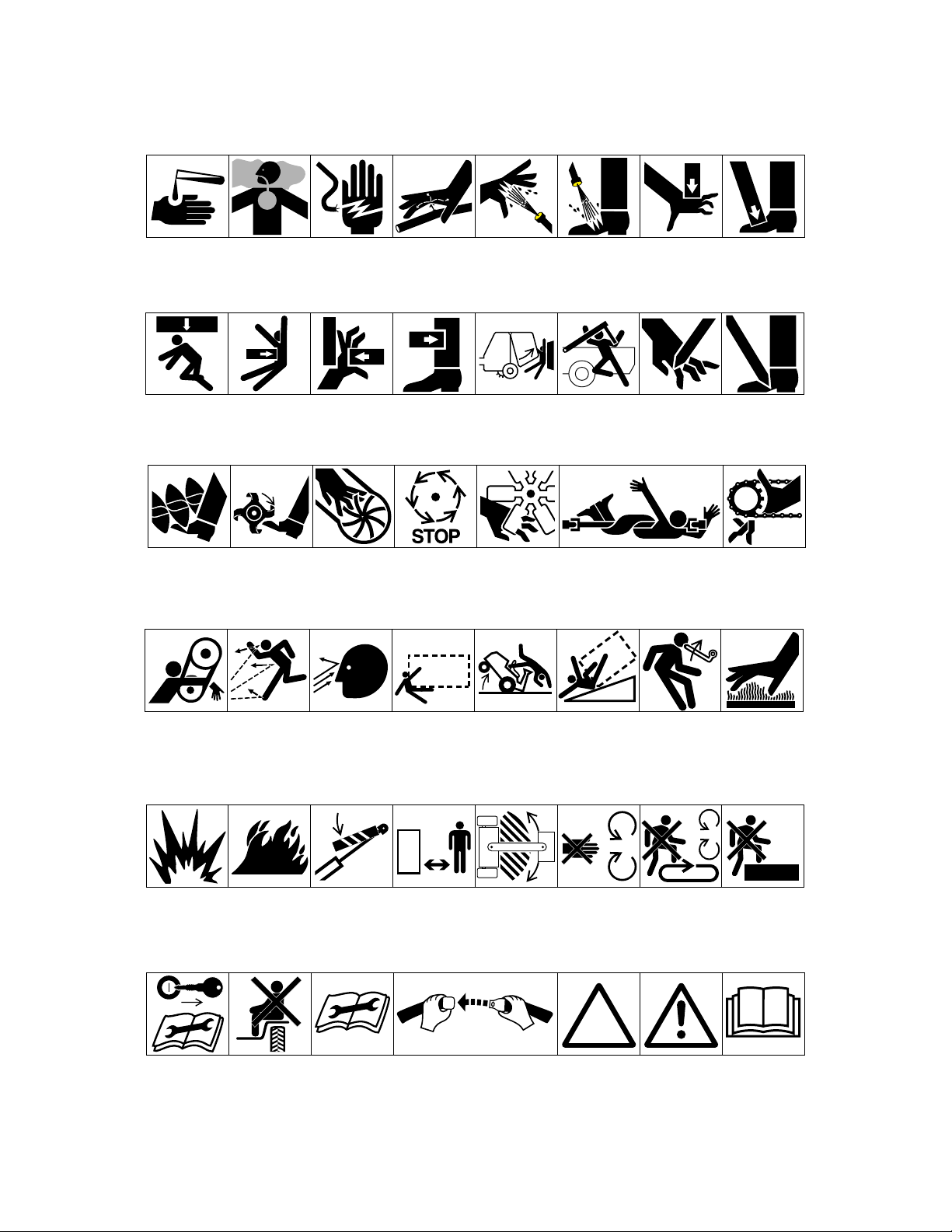

Eye protection

must be worn

Head protection

must be worn

Hearing

protection must

be worn

Caution, toxic

risk

First aid

Flush with water Engine Transmission

Fire, open light

& smoking

prohibited

Level

indicator

Engage Disengage

Horn Battery charging

Hydraulic

system

Liquid level Filter Temperature Failure/

Attachment

lower

condition

Hourmeter/elapsed

operating hours

Brake system

Oil Coolant (water) Intake air Exhaust gas Pressure

Malfunction

Attachment

raise

Fast Slow Continuous

Spacing distance Snow thrower,

Start switch/

mechanism

collector auger

variable, linear

On/start Off/stop

Plus/increase/

positive polarity

Volume empty Volume full

Minus/decrease/

negative polarity

Machine travel

direction,

forward/rearward

Jack or

support point

Control lever

operating

direction, dual

direction

Draining/

emptying

Control lever

operating

direction, multiple

direction

Engine lubricating oil

Clockwise

rotation

Engine lubricating

oil pressure

Counter-clockwise rotation

Engine lubricating

oil level

Grease

lubrication

point

Engine lubricating

oil filter

7

Oil lubrication

point

Engine

lubricating oil

temperature

Lift point

Engine coolant

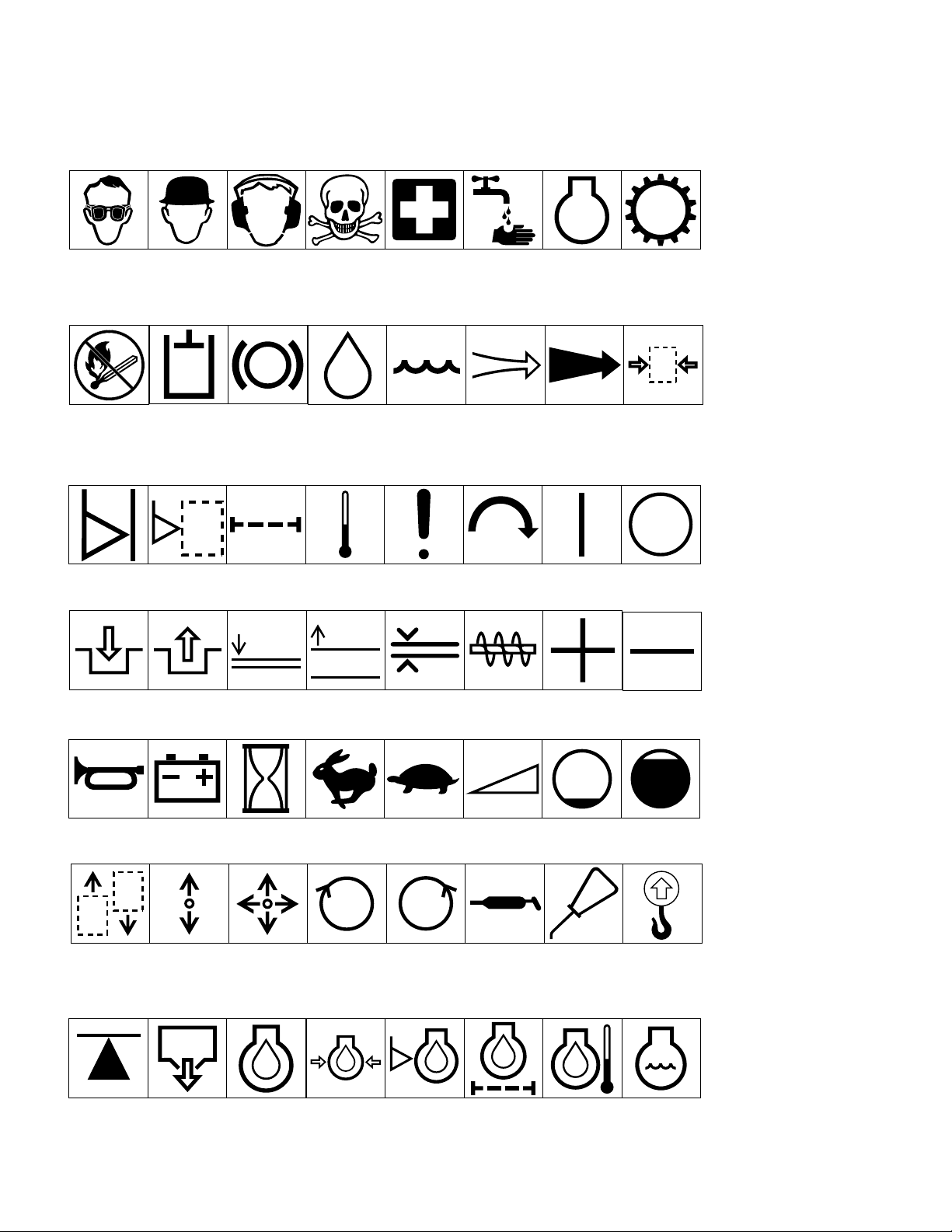

Page 8

Engine coolant

pressure

Engine coolant f

ilter

n/min

Engine failure/

malfunction

Transmission

failure/malfunction

Engine rotational

speed/frequency

Clutch Neutral High Low Forward Reverse Park

231

First gear Second gear

Engine

lubricating oil

pressure

Choke Primer (start aid) Electrical preheat

Engine intake/

combustion air

Engine intake/

combustion air

pressure

(low temperature

start aid)

Engine intake/

air filter

Transmission oil Transmission oil

Engine start Engine stop

pressure

Transmission oil

temperature

NHLFRP

Third gear (other #'s

may be used until

the maximum # of forward gears is reached.)

Hydraulic oil Hydraulic oil

Hydraulic oil

pressure

Hydraulic oil level Hydraulic oil filter

temperature

Hydraulic oil

failure/malfunction

Headlights Lock Unlock Differential lock 4-Wheel drive Power Take-Off Power Take-Off,

Reel cutting

element, height

adjustment

Parking brake Fuel Fuel level Fuel filter Fuel system

Traction Above working

temperature range

Drilling Manual metal arc

0430 weight Do not dispose

welding

in the garbage

failure/malfunction

Manual 0356 Water pump

CE logo

Diesel fuel Unleaded fuel

rotational speed

8

Reel cutting

element

0626 Keep dry

Page 9

Specifications

Power: 4-cycle gasoline engine, electric start, with

output of 11.9 kW @3,600 rpm. Maximum no-load

governed engine speed is 2,850 rpm.

Traction: All-hydraulic drive.

Cutting Units: All-hydraulic drive.

Hydraulic Valve: Five spool sections: the first 3

spool sections control the lowering, mowing and lift

functions of the cutting units. The spools moved

out provide lowering and MOW operation, moved

in they provide LIFT operation. The number 4

spool section controls the traction functions, N

(Neutral), 1 (Mow), and 2 (transport). The number

5 spool section controls forward and reverse traction.

Tire Pressure :

• 55–83 kPa—front

• 55–103 kPa—rear

Brakes: 15 cm drum-type mechanical with rack and

pawl lock for parking.

Hydraulic Filter: 10-micron, cartridge type.

test switch if attachment of headlights is desired.

Battery: 12-Volt, Lead Acid, 32-Amp. Hour.

General Specifications:

Width of Cut: 140 cm

Wheel Tread: 125 cm

Wheel Base: 119 cm

Overall Length: 229 cm

Overall Width: 177 cm

Overall Height: 123 cm

Net Weight (Wet): 373 kg

Shipping Weight (In carton):429 kg

Speeds:

1st —6.1 kmh

2nd—11.9 kmh

Rev.—13.1 kmh

Reels: 1,975 rpm (approximately)

Clip:

0.46 cm (11-Blade Cutting Unit)

0.64 cm (8-Blade Cutting Unit)

1.00 cm (5-Blade Cutting Unit)

Hydraulic Oil Reservoir: 32 liter capacity with inter-

nal baffle. Type fluid: Mobil DTE 26. Red dye is

added at the factory.

Gas Tank: 28 liter capacity.

Fuel Filter: In-line type.

Fuel Pump: Vacuum pulse type.

Seat Adjustment: 17.8 cm (forward and rearward).

Wheel Bearings:

Drive Wheels: Needle provided in wheel motors.

Rear Caster Wheel: Timken tapered roller.

Electrical & Instrumentation: The engine contains a

15-amp alternator; the circuit is fused at 20 amps.

Instruments include ammeter and hour meter. An

accessory terminal is available at the leak detector

Accessories:

Thatching Reels, Model No. 04416.

Powered Spikers, Model No. 04420.

Individual Reel Shut-Off Kit, Model No. 28-2150 Basket

Reinforcement Kit, Model No. 26-0900. Variable

Traction Speed Kit, Model No. 04422.

Specifications and design subject to change without

.

notice

9

Page 10

Before Operating

CHECK THE ENGINE OIL

The engine is shipped with 1.7 liter (with filter) of oil in the

crankcase; however, the level of oil must be checked before and

after you first start the engine.

1. Position the machine on a level surface.

2. Unscrew the dipstick and wipe it with a clean cloth.

Screw the dipstick into the filler neck and make sure it is

seated fully. Unscrew the dipstick and check the oil level.

If it is low, add enough oil to raise the level to the FULL

mark on the dipstick.

3. The engine uses any high-quality detergent oil having the

American Petroleum Institute —API—service classification SC, SD, SE, SF or SG. Recommended viscosity

(weight) is SAE 30.

1

4. Pour the oil into the filler neck until the oil level is up to

the FULL mark on the dipstick. Add the oil slowly and

check the level often during this process. DO NOT OVERFILL.

IMPORTANT: Check the oil level every 8 operating

hours or daily. Initially change the oil after the first 8

hours of operation; after that—under normal conditions—change the oil after every 50 hours and the filter

after every 100 hours. However, change the oil more

often when you operate the engine in extremely dusty

or dirty conditions.

5. Install the dipstick firmly in place.

FILLING THE GAS T ANK

THE TORO COMPANY STRONGLY RECOMMENDS THE

USE OF CLEAN, FRESH UNLEADED REGULAR GASOLINE IN TORO GASOLINE-POWERED PRODUCTS.

UNLEADED GASOLINE BURNS CLEANER, EXTENDS

ENGINE LIFE, AND PROMOTES GOOD STARTING BY

REDUCING THE BUILD-UP OF COMBUSTION CHAMBER

DEPOSITS. LEADED GASOLINE CAN BE USED IF

UNLEADED IS NOT AVAILABLE.

Figure 1

1. Dipstick

NOTE: Never use methanol, gasoline containing methanol,

gasohol containing more than 10% ethanol, gasoline additives,

10

Page 11

premium gasoline, or white gas because the engine fuel system

damage could result.

1. Fill the gasoline tank to the bottom of the filler neck. DO

NOT OVERFILL. Install the cap and tighten it securely in

place.

DANGER

Because gasoline is flammable, use caution when storing or

handling lt. Do not fill the fuel tank while the engine is

running, or hot, or when the machine is in an enclosed

area. Vapors may build up and be ignited by a spark or

flame source many feet away. DO NOT SMOKE while filling the fuel tank to prevent the possibility of an explosion.

Always fill the fuel tank outside and wipe up any spilled

gasoline before starting the engine. Use a funnel or spout

to prevent spilling gasoline before starting the engine and

fill the tank to about 1 inch from the top of the tank, not

the filler neck. Store gasoline in a clean safety-approved

container and keep the cap in place on the container. Keep

gasoline in a cool, well-ventilated place—never in an

enclosed area such as a hot storage shed. To assure volatility, do not buy more than a 30-day supply of gasoline.

Gasoline is a fuel for internal combustion engines; therefore, do not use it for any other purpose. Since many children like the smell of gas, keep it out of their reach because

the fumes are explosive and dangerous to inhale.

1

Figure 2

1. Fuel tank cap

CHECK THE HYDRAULIC SYSTEM

The hydraulic system is designed to operate on Mobil DTE 26

or equivalent anti-wear hydraulic fluid. The machine’s large

hydraulic oil tank and smaller auxiliary oil tank are filled at the

factory with 32 liters of fluid. However, check the level of

hydraulic fluid before first starting the engine and daily thereafter.

Hydraulic Oil (Recommended brands):

Mobil DTE 26

Shell Tellus 68

Amoco Rykon Oil #68

Conoco Super Hydraulic Oil 68

Exxon Nuto 68

11

Page 12

Kendall Kenoil R&O AW 68

Pennzoil Penreco 68

Phillips Magnus A 68

Standard Energol HLP 68

Sun Sunvis 831 WR

Union Unax AW 68

Chevron AW Hydraulic Oil 68

NOTE: All are interchangeable.

2

3

IMPORTANT. Use only the hydraulic oils specified. Other

fluids could cause system damage.

NOTE: A red dye additive for the hydraulic system oil is avail-

able in 20.7 gram bottles. One bottle is sufficient for 15–22

liters of hydraulic oil. Order Part No. 44-2500 from your authorized Toro dealer.

1. Park the machine on a level surface. Make sure it has

cooled down so the oil is cold. Check the level of oil by

viewing the sight gauge on the side of auxiliary oil tank.

2. If the oil level is below FULL mark on auxiliary tank,

remove cap from the hydraulic oil tank and slowly fill with

Mobil DTE 26 or equivalent hydraulic oil until the level is

up to the mark next to the sight gauge. Install the cap.

IMPORTANT To prevent system contamination, clean the

top of the hydraulic oil containers before puncturing. Make

sure the pour spout and funnel are clean.

NOTE: Make a close visual inspection of the hydraulic compo-

nents. Inspect for leaks, loose fasteners, missing parts, improperly routed lines, etc. Make any corrections necessary.

1

Figure 3

1. Sight gauge

2. Hydraulic tank cap

3. Auxiliary tank breather

TIRE PRESSURE

The tires are over-inflated at the factory for shipping. Reduce

the tire pressure to the proper levels before starting the unit.

Vary the tire pressure for the drive wheels, depending on your

turf conditions, from a minimum of 55 KPa to a maximum of

83 KPa

Vary the tire pressure for the rear wheel from a minimum of 55

KPa to a maximum of 103 KPa. Traction improves with lower

tire pressure.

12

Page 13

Controls

MOW PEDAL (Fig. 4)—Depressing the mow pedal FULLY

during operation lowers the cutting units and starts the reels.

BRAKE PEDAL (Fig. 4)—The brake pedal actuates an automotive drum-type mechanical brake.

LIFT PEDAL (Fig. 4)—Depressing the lift pedal during operation stops the reels from turning and lifts the cutting units. The

lift pedal must be FULLY depressed until the cutting units are

fully raised and have stopped rotating.

PARKING BRAKE BUTTON (Fig. 4)—Depressing the brake

pedal to actuate the brake assembly, then depressing the parking

brake button will keep the brakes engaged for parking.

Disengage by depressing the brake pedal. Form the habit of

locking the parking brake before you leave the machine.

TRACTION PEDAL (Fig. 4)—The traction pedal makes the

machine move forward or backward. Depress the top of the

pedal to move forward and the bottom of the pedal to move

backward. Do not rest your heel on reverse when operating forward (Fig. 5).

2

4

1

Figure 4

1. Mow pedal 4. Brake pedal

2. Lift pedal 5. Parking brake button

3. Traction pedal

5

Forward

3

THROTTLE CONTROL (Fig. 6)—The throttle controls the

engine speed. Moving the throttle control toward FAST increases engine rpm; moving the throttle toward SLOW decreases

engine rpm.

NOTE: You cannot stop the engine using the throttle control.

CHOKE (Fig. 6) —To start a cold engine, close the carburetor

choke by moving the choke control forward to the CLOSED

position. After the engine starts, regulate the choke to keep the

engine running smoothly. As soon as possible, open the choke

by pulling it rearward to OPEN. A warm engine requires little

or no choking.

IGNITION SWITCH (Fig. 6)—Insert the key into the switch

and turn it clockwise to the START position to start the engine.

Release the key as soon as the engine starts. Turn the key

counter-clockwise to OFF to stop the engine.

AMMETER (Fig. 6)—The ammeter shows the rate of battery

charge and discharge.

NOTE: During normal operation there will be little or no movement of the ammeter needle.

Rev

Figure 5

3

2

1

5

7

4

6

Figure 6

1. Choke control 5. Leak detector test / light switch

2. Throttle control 6. Hour meter

3. Igniti on switch 7. Fuse (20 amp)

4. Ammeter

13

Page 14

FUSE (Fig. 6)—The 20-amp fuse is part of the electrical circuit.

LEAK DETECTOR TEST/LIGHT SWITCH (Fig. 6) From

the middle operating position, move the switch rearward to

check the operation of the leak detector alarm and time delay.

Move the switch forward to operate optional headlights.

HOUR METER (Fig. 6)—Shows the total hours of machine

operation. The hour meter starts whenever the key switch is

turned to ON.

SEAT ADJUSTING HANDLE (Fig. 6)

SHIFT SELECTOR (Fig. 7)—Provides two traction selec-

tions, plus a NEUTRAL position. It is permissible to shift from

one selection to another while the machine is in motion. No

damage will result.

1. Neutral—Used for starting the engine.

2. No. 1 Position—Used for greens mowing operation.

3. No. 2 Position—Used for transport operation.

NOTE: If you operate the machine in reverse with the cutting

units down, they will be pulled off the lift arms.

STEERING ARM LOCKING LEVER (Fig. 7)—Rotate the

lever rearward to loosen, then raise or lower the steering arm for

comfort. Then rotate the lever forward to tighten.

To adjust the locking lever:

1. Rotate the lever rearward to loosen adjustment and move

the steering arm to its lowest position.

2. Loosen the lever set screw.

3. Rotate the adjusting bolt (left-hand thread) counter-clock-

wise to tighten, or clockwise to loosen the adjustment.

4. Tighten the set screw to lock the adjustment.

1

3

2

4

Figure 7

1. Shift selector

2. Steering arm locking lever

3. Set screw

4. Adjusting bolt

14

Page 15

First-Time Operation

BREAK-IN PERIOD

1. Refer to the Engine Manual supplied with the

Greensmaster 3100 for oil change and maintenance

procedures recommended during break-in.

2. Only 8 hours of mowing operation is required for

the Greensmaster 3100 break-in period.

3. The first hours of operation are critical to future

dependability. Monitor performance closely so

that minor difficulties that could lead to major

problems can be corrected. Inspect the machine

often during break-in for signs of oil leakage, loose

fasteners, or any other malfunction.

STARTING INSTRUCTIONS

Note: Inspect the areas beneath the mowers to make

sure they are clear of debris.

1. Sit on the seat, place the shift selector in NEU-

TRAL, and check the mow and lift pedals to make

sure they are level with one another.

B. Operate the lift pedal; the cutting reels should

stop and the cutting units raise to full transport

position.

NOTE: Stop the engine. Check the lip of each

basket to be sure it doesn’t contact the reel dur

ing operation. Re-adjust if the basket does make

contact.

C. Depress the brake pedal to keep the machine

from moving and operate the traction pedal

through the forward and reverse positions.

Continue the above procedure for 1–2 minutes.

D. Neutralize the traction lever and the mow and

lift pedals, lock the parking brake, and turn the

engine off. Check for oil leaks; if oil leaks

appear, check the tightness of the hydraulic fittings. If oil leaks continue to appear, contact

your local TORO dealer for assistance and, if

necessary, replacement parts.

IMPORTANT: The motor or wheel seals may show

some trace of oil for a short period of time until the

break-in period is completed.

2. Remove your foot from the traction pedal and

make sure the pedal is in neutral.

3. Move the choke lever to ON—when starting a cold

engine—and the throttle lever to the half-throttle

position.

4. Insert and turn the ignition key clockwise until the

engine starts. After the engine starts, regulate the

choke to keep the engine running smoothly. As

soon as possible, open the choke by pulling it rearward to the OFF position. A warm engine requires

little or no choking.

5. Check the machine out with the following proce-

dures after the engine has started:

A. Move the throttle control to FAST and

momentarily engage the reels by depressing

the mow pedal (the cutting units should drop

and all reels should turn).

NOTE: When the Greensmaster 3100 is new and the

bearings and reels are tight, it is necessary to use the

FAST throttle control position for this check. A fast

throttle setting may not be required after break-in.

CHECK THE INTERLOCK

SYSTEM OPERATION

The interlock system prevents the engine from cranking

or starting unless the operator is on the seat, the shift

selector is in NEUTRAL and the cutting units are DISENGAGED. Also, the engine will stop when the cutting

units are engaged or if the shift selector is in the No. 1 or

No. 2 position with operator off the seat. Do the following system checks daily to make sure the interlock system operates correctly.

15

Page 16

CAUTION

The interlock switches are for the operator’s protection, so

do not disconnect them. Check switch operation daily to

assure the interlock system is operating. If a switch is

defective, replace it before operating. Regardless of

whether the switches are operating properly, replace them

every two years to assure maximum safety. Do not rely

entirely on safety switches—use common sense!

1. Engage the parking brake, move the shift selector to neu-

tral, remove your foot from the traction pedal and make

sure the pedal is in neutral, and depress the lift pedal and

release it. Rise off the seat and try to start the engine. The

engine should not crank, which means the interlock system

is operating correctly. If the engine did not crank, go to

step 2. If the engine cranked, contact your local TORO

dealer for assistance.

2. Sit on the seat, engage the parking brake and depress the

lift pedal fully and release it. Move the shift selector to the

#1 and #2 positions while trying to start the engine in each

position. The engine should not crank, which means the

traction switch on the valve bank is operating correctly. If

the engine did not crank, go to step 3. If the engine

cranked, contact your local TORO dealer for assistance.

3. Sit on the seat, engage the parking brake, depress the lift

pedal and release it. Move the shift selector to Neutral and

try to start the engine. The engine should start and continue to run, which means the traction switch and the mow/lift

switch on valve bank are operating correctly—go to step 4.

If the engine cranked but did not start, the problem is not in

the interlock system. If the engine did not crank, contact

your local TORO dealer for assistance.

4. Sit on the seat, engage the parking brake and move the shift

selector to neutral. Depress the mow pedal and try to start

the engine. The engine should not crank, which means the

mow-lift switch is operating correctly. If the engine did not

crank, go to step 5. If the engine cranked, ask your local

TORO dealer for assistance.

5. Sit on the seat, move the shift selector to Neutral, depress

the lift pedal and release it. Start the engine and drive to an

open area that is free of debris and foreign objects. Keep

all people, especially children, away from the front of the

16

3

Figure 8

1. Traction switch 3. Mow/lift switch

2. Seat switch

1

2

Page 17

machine and out of the area of operation. Move the shift

selector to Neutral, make sure the mow pedal is disengaged, set the throttle control at half speed and engage the

parking brake. Hold the steering wheel, brace your feet on

the foot deck and brake pedal, and move the shift selector

to the #1 position. Carefully rise off the seat; the engine

should stop. If the engine stops, the interlock system is

operating correctly. Repeat this check with the shift selector in the #2 position. If the engine does not stop, stop the

engine and find the problem before operating the machine.

If you need assistance, contact your local TORO dealer.

CHECK THE LEAK DETECTOR’S

OPERATION

The TURF GUARDIAN™ leak detector detects hydraulic oil

system leaks. If the oil level in the main hydraulic reservoir is

lowered by 4 to 6 ounces, the float switch in the tank will close.

After a 1-second delay, the alarm will sound. Expansion of oil,

due to normal heating during machine operation, will cause oil

to transfer into the auxiliary oil reservoir. The oil is allowed to

return to the main tank when the ignition switch is turned off.

3

1

2

8

Figure 9

BEFORE START (cold oil)

1. Sight window

2. Solenoid return valve open

3. Filler cap

4. Filler neck

5 Overflow tube

6. Fluid level (cold)

7. No sound

8. Float raised, switch open

9. Hydraulic oil tank

4

5

6

7

9

To check system operation

1. With the ignition switch in the ON position, move the leak

detector switch rearward and hold. After the one-second

time delay elapses, the alarm should sound.

2. Release leak detector switch.

To check leak detector system operation

1. Move the ignition switch to ON. DO NOT START THE

ENGINE.

2. Remove the hydraulic tank cap and strainer from the neck

of the tank.

3. Insert a clean rod or screw driver into the tank neck and

gently push down on the switch float (Fig. 12). The alarm

should sound after a one-second delay.

4. Release the float; the alarm should stop.

5. Install the strainer screen and the hydraulic tank cap.

Move the ignition switch to OFF.

2

1

3

4

Figure 10

NORMAL OPERATION (oil warm)

1. Solenoid return valve closed

2. Fluid level (warm)

3. No sound

4. Float raised, switch open

17

Page 18

PREPARING THE MACHINE FOR MOWING

To help align the machine for successive cutting passes, do the

following to the No. 2 and No. 3 cutting-unit baskets:

1. Measure in approximately 12 cm from the outer edge of

each basket.

2. Either place a strip of white tape or paint a line onto each

basket paralleling the outer edge of each basket (Fig. 13).

TRAINING PERIOD

Before mowing greens with the GREENSMASTER 3100, we

suggest that you find a clear area and practice starting and stopping, raising and lowering the cutting units, turning, etc. This

will help you gain confidence in the performance of the

GREENSMASTER 3100.

IMPORTANT. If you shift to the No. 2 position while cutting greens, no increase in speed will result. However, a sudden Increase In speed will develop when you actuate the lift

pedal. For safety, use only the No. 1 position for cutting

greens and the No. 2 position for transport.

1

2

3

Figure 11

LEAK ALERT!

1. Fluid level (warm)

2. Warning buzzer

3. Float down, switch closed

1

2

3

Figure 12

1. Clean the rod or screwdriver

2. Warning buzzer

3. Press down on the switch float

4

2

1

Figure 13

1. Alignment strip 3. Cut grass on right

2. Approx. 12 cm 4. Keep focal spot 2–3 meters

ahead of the machine

3

18

Page 19

Operating

BEFORE MOWING

Inspect the green for debris, remove the flag from the cup,

and determine the best direction in which to mow.

Always mow in an alternate pattern from the previous

mowing, so that the grass blades will be less apt to lay

down and become difficult to cut.

MOWING PROCEDURES

1. Approach the green with the shift selector in the

number 1 position. Start on one edge of the green so

the ribbon procedure of cutting may be used. This

holds compaction to a minimum and leaves a neat,

attractive pattern on the greens.

IMPORTANT: Shift to the No. 1 position when

approaching a green because machine speed will

automatically be reduced when the cutting units are

engaged. Higher speed will resume when the cutting

units are disengaged.

2. Actuate the mow pedal as the front edge of the grass

baskets cross the outer edge of the green. This procedure drops the cutting units to the turf and starts

the reels.

NOTE: The No. 1 (rear) cutting unit reel will not

start until all the cutting units are on the ground and

No. 2 and No. 3 cutting units are cutting.

IMPORTANT Remember that the No. 1 cutting

unit reel is delayed and therefore, you should

practice to gain the timing necessary to minimize

the clean-up mowing operation.

3. Overlap a minimal amount with the previous cut on

return passes. To maintain a straight line across the

green and keep the machine an equal distance from

the edge of the previous cut, establish an imaginary

sight line 2 to 3 meters ahead of the machine to the

edge of the uncut portion of the green (Fig. 13 & 14).

Some people find it useful to include the outer edge

of the steering wheel as part of the sight line; i.e.,

keep the steering wheel edge aligned with a point

that is always kept the same distance away from the

front of the machine (Fig. 13 & 14).

4. As the front of the baskets cross the edge of the

green, depress the lift pedal. This will stop the reels

and lift the cutting units. Timing of this procedure

is important, so the mowers do not cut into the

fringe area. However, as much of the green as possible should be cut to minimize the amount of grass

left to mow around the outer periphery.

5. Cut down on operating time and ease line-up for the

next pass by momentarily turning the machine in

the opposite direction, then turning in the direction

of the uncut portion; i.e., if intending to turn right,

first swing slightly left, then right. This will help

get the machine more quickly aligned for the next

pass. Follow the same procedure for turning in the

opposite direction. It’s good practice to try to make

as short a turn as possible. However, turn in a

wider arc during warmer weather to avoid bruising

the turf.

NOTE: Due to the nature of the power steering system, the steering wheel will not return to its original

position after a turn has been completed.

IMPORTANT: Never stop on a green with the

cutting unit reels operating because you may

damage the turf. Stopping on a wet green with

the Greens–master 3100 may leave marks or

indentations from the wheels.

6. If the leak detector alarm sounds while cutting on a

green, immediately raise the cutting units, drive

directly off the green and stop the machine in a area

away from the green. Find out what caused the

alarm and correct the problem.

IMPORTANT: Prolonged idling of the machine

after heavy use may cause a false alarm in the

leak detector system, due to oil contraction as it

cools. If this occurs, turn the engine off for a

minute while the main hydraulic tank is refilled

from the auxiliary tank.

7. Finish cutting the green by mowing the outer

periphery. Be sure to change the direction of cutting from the previous mowing. Always keep

weather and turf conditions in mind and be sure to

change the direction of mowing from the previous

19

Page 20

cutting. Replace the flag.

4

8. Empty the grass baskets of all clippings before transporting

to the next green. Heavy wet clippings place an undue

strain on the baskets and will add unnecessary weight to

the machine, thereby increasing the load on the engine,

hydraulic system, brakes, etc.

LEAK DETECTOR OPERATION

The leak detector alarm may sound for one of the

following reasons:

1. A leak has occurred.

2. The oil level in the main reservoir is reduced by 4 to 6

ounces due to oil contraction from cooling.

If the alarm sounds, turn it off as quickly as possible and

inspect for leaks. If the alarm sounds while operating on a

green, drive off the green first. Determine the source of the leak

and repair it before continuing operation. If a leak is not found

and a false leak is suspected, move the ignition switch to OFF

and let the machine stand for 1–2 minutes to allow the oil levels

to stabilize. Then start the machine and operate in a non-sensitive area to confirm that no leak exists.

False alarms due to oil contraction may be caused by extended

idling after normal operation. A false alarm may also occur if

the machine is worked at a reduced work load after an extended

period of heavier work. To avoid false alarms, turn the machine

off rather than letting it idle for extended periods.

2

3

Figure 14

1. Alignment strip 3. Cut grass on right

2. Approx. 12 cm 4. Keep local spot 2

3 meters ahead of the

machine

1

INSPECTION AND CLEAN-UP

AFTER MOWING

After mowing, thoroughly wash the machine. Use a

garden hose without a nozzle so excessive water

pressure doesn’t contaminate and damage seals and

bearings. After cleaning, inspect the machine for

possible hydraulic fluid leaks, damage or wear to the

hydraulic and mechanical components. Also check

the cutting units for sharpness. Lubricate the mow

and lift pedal and the brake shaft assembly with

SAE 30 oil or spray lubricant to deter corrosion and

keep the machine performing well during the next

mowing operation.

TRANSPORT OPERATION

Make sure the cutting units are in the highest UP position. Set

the shift selector in No. 2 if conditions will permit faster ground

speed. In rough or hilly areas, shift to No. 1 and operate at

slower ground speeds. Use the brakes to slow the machine

while going down steep hills to avoid loss of control. Always

approach rough areas at a reduced speed (shift selector in No.

1), and cross severe undulations carefully. Familiarize yourself

with the width of the machine. Do not attempt to pass between

objects that are close together so that you can prevent costly

damage and down time.

20

LUBRICATION

Figure 15

Page 21

Figure 16

Figure 19

Figure 17

Figure 18

Figure 20

Figure 21

21

Page 22

Maintenance

22

Page 23

0.8 mm

2

1

Figure 22

1. Drain plug 2. Oil filter

Figure 23

1. Air cleaner cover

Figure 25

1

1

2

Figure 26

1. Fuel filter 2. Hose clamps

Figure 24

1. Foam element 2. Paper element

2

1

1

Figure 27

1. Hydraulic reservoir drain plug

23

Page 24

1. Hydraulic filter

1

Figure 28

24

Loading...

Loading...