Page 1

FormNo.3362-974RevA

Greensmaster

®

30502-Wheel

DriveTractionUnit

ModelNo.04351—SerialNo.290000001andUp

ToregisteryourproductordownloadanOperator'sManualorPartsCatalogatnocharge,gotowww.T oro.com.OriginalInstructions(EN)

Page 2

WARNING

G011182

1

CALIFORNIA

Proposition65Warning

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Important:Thisengineisnotequippedwitha

sparkarrestermufer.ItisaviolationofCalifornia

PublicResourceCodeSection4442touseoroperate

theengineonanyforest-covered,brush-covered,or

grass-coveredland.Otherstatesorfederalareas

mayhavesimilarlaws.

ThissparkignitionsystemcomplieswithCanadian

ICES-002.

Theenclosed

Engine Owner’ s Man ual

issupplied

forinformationregardingtheUSEnvironmental

ProtectionAgency(EPA)andtheCalifornia

EmissionControlRegulationofemissionsystems,

maintenance,andwarranty.Replacementsmaybe

orderedthroughtheenginemanufacturer.

Introduction

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoidinjury

andproductdamage.Youareresponsibleforoperating

theproductproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comfor

productandaccessoryinformation,helpndinga

dealer,ortoregisteryourproduct.

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafetyalertsymbol

(Figure2),whichsignalsahazardthatmaycauseserious

injuryordeathifyoudonotfollowtherecommended

precautions.

Figure2

1.Safetyalertsymbol

Thismanualalsouses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.

Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

©2009—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

Contents

Introduction.................................................................2

Safety...........................................................................4

SafeOperatingPractices.......................................4

ToroMowerSafety...............................................5

SoundPressure.....................................................6

SoundPower........................................................6

Vibration..............................................................6

SafetyandInstructionalDecals.............................7

Setup..........................................................................10

1ActivatingandChargingtheBattery..................11

2MountingtheSeat............................................12

3SecuringtheSteeringArm................................12

4InstallingtheCover..........................................12

5InstallingtheBattery........................................13

6InstallingtheCuttingUnits(ForCutting

UnitModels04610and04611Only)...............14

7AddingRearBallast..........................................15

8InstallCEDecals.............................................15

ProductOverview......................................................16

Controls.............................................................16

Specications.....................................................17

Attachments/Accessories...................................18

Operation...................................................................18

ThinkSafetyFirst...............................................18

CheckingtheEngineOil.....................................18

FillingtheFuelTank...........................................19

CheckingtheHydraulicFluidLevel.....................20

CheckingtheTirePressure.................................20

CheckingtheTorqueoftheWheel

Nuts...............................................................21

Break-inPeriod..................................................21

StartingtheEngine.............................................21

CheckingtheSafetyInterlockSystem..................22

PreparingtheMachineforMowing.....................23

TrainingPeriod...................................................23

BeforeMowing..................................................23

Mowing..............................................................23

TransportOperation..........................................24

InspectionandCleanupAfterMowing................24

Maintenance...............................................................25

RecommendedMaintenanceSchedule(s)................25

DailyMaintenanceChecklist...............................26

Lubrication.............................................................27

GreasingtheMachine.........................................27

EngineMaintenance...............................................28

ServicingtheAirCleaner....................................28

ChangingtheEngineOilandFilter.....................29

AdjustingtheThrottleControl............................29

AdjustingtheChokeControl..............................29

AdjustingtheCarburetorandSpeed

Control..........................................................30

ReplacingtheSparkPlugs...................................30

FuelSystemMaintenance.......................................31

ReplacingtheFuelFilter.....................................31

FuelLinesandConnections................................31

ElectricalSystemMaintenance................................31

ServicingtheBattery...........................................31

BrakeMaintenance.................................................32

AdjustingtheBrakes...........................................32

ControlsSystemMaintenance.................................33

AdjustingtheRearCamshaft...............................33

AdjustingtheLiftandMowPedalHeight............33

LevelingtheLiftandMowPedals........................33

AdjustingtheTractionPedal...............................34

AdjustingCuttingUnitLiftandDrop..................34

AdjustingtheLiftCylinders................................35

ReplacingtheSeatSwitch...................................35

ReplacingtheTractionSwitch.............................35

ReplacingtheMow/LiftSwitch..........................36

AdjustingtheTractionReturnLinkage................36

ServicingtheSteeringAssembly..........................36

HydraulicSystemMaintenance...............................37

ChangingtheHydraulicOilandFilter.................37

CheckingtheHydraulicLinesandHoses.............38

Storage.......................................................................39

Troubleshooting.........................................................40

Schematics.................................................................44

ConditionsandProductsCovered.......................48

InstructionsforObtainingWarranty

Service...........................................................48

OwnerResponsibilities.......................................48

ItemsandConditionsNotCovered.....................48

Parts...................................................................48

NoteRegardingDeepCycleBattery

Warranty:.......................................................48

MaintenanceisatOwner’sExpense.....................48

GeneralConditions............................................48

Noteregardingenginewarranty:.........................48

CountriesOtherthantheUnitedStatesor

Canada...........................................................48

3

Page 4

Safety

ThismachinemeetsorexceedsCENstandard

EN836:1997,ISOstandard5395:1990,andANSI

B71.4-2004specicationsineffectatthetimeof

productionwhen40lb.ofballastisaddedtothe

rearwheel.

Note:Theadditionofattachmentsmadeby

othermanufacturersthatdonotmeetAmerican

NationalStandardsInstitutecerticationwillcause

noncomplianceofthismachine.

Improperuseormaintenancebytheoperatoror

ownercanresultininjury.Toreducethepotential

forinjury,complywiththesesafetyinstructions

andalwayspayattentiontothesafetyalertsymbol

Figure2),whichmeansCaution,Warning,or

(

Danger—personalsafetyinstruction.Failureto

complywiththeinstructionmayresultinpersonal

injuryordeath.

SafeOperatingPractices

ThefollowinginstructionsarefromCENstandard

EN836:1997,ISOstandard5395:1990,andANSI

B71.4-2004.

Training

•ReadtheOperator’sManualandothertraining

material.Iftheoperator(s)ormechanic(s)cannot

readthemanualitistheowner’sresponsibilityto

explainthismaterialtothem.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateor

servicetheequipment.Localregulationsmayrestrict

theageoftheoperator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtohimselforherself,

otherpeopleorproperty.

Preparation

•Evaluatetheterraintodeterminewhataccessories

andattachmentsareneededtoproperlyand

safelyperformthejob.Onlyuseaccessoriesand

attachmentsapprovedbythemanufacturer.

•Wearappropriateclothingincludingsubstantial

footwear,hardhat,safetyglassesandearprotection.

Longhair,looseclothingorjewelrymaygettangled

inmovingparts.

•Inspecttheareawheretheequipmentistobeused

andremoveallobjectssuchasrocks,toysandwire

whichcanbethrownbythemachine.

•Useextracarewhenhandlinggasolineandother

fuels.Theyareammableandvaporsareexplosive.

–Useonlyanapprovedcontainer.

–Neverremovethegascaporaddfuelwithengine

running.Allowenginetocoolbeforerefueling.

–Neversmokewhenhandlinggasoline,andstay

awayfromanopenameorwheregasoline

fumesmaybeignitedbyaspark.

–Neverrefuelordrainthemachineindoors.

•Checkthatoperator’spresencecontrols,safety

switchesandshieldsareattachedandfunctioning

properly.Donotoperateunlesstheyarefunctioning

properly.

Operation

•Neverrunanengineinanenclosedarea.

•Onlyoperateingoodlight,keepingawayfromholes

andhiddenhazards.

•Besurealldrivesareinneutralandparkingbrakeis

engagedbeforestartingengine.Onlystartengine

fromtheoperator’sposition.Useseatbeltsif

provided.

•Slowdownanduseextracareonhillsides.Besure

totravelintherecommendeddirectiononhillsides.

Turfconditionscanaffectthemachine’sstability.

Usecautionwhileoperatingneardrop-offs.

•Slowdownandusecautionwhenmakingturnsand

whenchangingdirectionsonslopes.

•Neveroperatewithguardsnotsecurelyinplace.Be

sureallinterlocksareattached,adjustedproperly,

andfunctioningproperty.

•Donotchangetheenginegovernorsettingor

overspeedtheengine.

•Stoponlevelground,lowerthecuttingunits,

disengagedrives,engageparkingbrake(ifprovided),

shutoffenginebeforeleavingtheoperator’sposition

foranyreasonincludingemptyingthegrassbaskets.

•Stopequipmentandinspectthemachineafter

strikingobjectsorifanabnormalvibrationoccurs.

Makenecessaryrepairsbeforeresumingoperations.

•Keephandsandfeetawayfromthecuttingunits.

•Lookbehindanddownbeforebackinguptobesure

ofaclearpath.

•Nevercarrypassengersandkeeppetsandbystanders

away.

4

Page 5

•Slowdownandusecautionwhenmakingturns

andcrossingroadsandsidewalks.Stopreelsifnot

mowing.

•Donotoperatethemowerundertheinuenceof

alcoholordrugs

•Usecarewhenloadingorunloadingthemachine

intoatrailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscurevision.

ToroMowerSafety

Thefollowinglistcontainssafetyinformationspecicto

Toroproductsorothersafetyinformationthatyoumust

knowthatisnotincludedintheANSIstandards.

Thisproductiscapableofamputatinghandsand

feetandthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriousinjuryordeath.

Useofthisproductforpurposesotherthanitsintended

usecouldprovedangeroustouserandbystanders.

MaintenanceandStorage

•Disengagedrives,lowerthecuttingunits,setthe

parkingbrake,stoptheengine,removethekey,and

disconnectsparkplugwire(s).Waitforallmovement

tostopbeforeadjusting,cleaning,orrepairing.

•Cleangrassanddebrisfromcuttingunits,drives,

mufers,andenginetohelppreventres.Cleanup

oilorfuelspillage.

•Lettheenginecoolbeforestoringanddonotstore

nearame.

•Shutofffuelwhilestoringortransporting.Donot

storefuelnearamesordrainindoors.

•Parkthemachineonlevelground.

•Neverallowuntrainedpersonneltoservicethe

machine.

•Usejackstandstosupportcomponentswhen

required.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

•Disconnectthebatteryandremovethesparkplug

wire(s)beforemakinganyrepairs.Disconnect

thenegativeterminalrstandthepositivelast.

Reconnectpositiverstandnegativelast.

•Usecarewhencheckingthereels.Wearglovesand

usecautionwhencheckingthereels.

•Keephandsandfeetawayfrommovingparts.If

possible,donotmakeadjustmentswiththeengine

running.

•Chargebatteriesinanopen,wellventilatedarea,away

fromsparkandames.Unplugthechargerbefore

connectingordisconnectingitfromthebattery.

Wearprotectiveclothinganduseinsulatedtools.

•Keepallpartsingoodworkingconditionandall

hardwareandhydraulicttingstightened.Replaceall

wornordamageddecals.

Operation

•Knowhowtostoptheenginequickly.

•Alwayswearsubstantialshoes.Donotoperatethe

machinewhilewearingsandals,tennisshoes,or

sneakers.Wearingsafetyshoesandlongpantsis

advisableandrequiredbysomelocalordinancesand

insuranceregulations.

•Handlefuelcarefully.Wipeupanyspills.

•Checkthesafetyinterlockswitchesdailyforproper

operation.

•Beforeattemptingtostarttheengine,disengageall

bladeattachmentclutches,shiftintoneutral,and

engagetheparkingbrake.

•Usingthemachinedemandsattention.Toprevent

lossofcontrol:

–Donotdriveclosetosandtraps,ditches,creeks,

orotherhazards.

–Reducespeedwhenmakingsharpturns.Avoid

suddenstopsandstarts.

–Thismachineisnotdesignedorequippedfor

on-roaduseandisa“slow-movingvehicle.”

Ifyoumustcrossortravelonapublicroad,

youshouldbeawareofandcomplywithlocal

regulations,suchasrequiredlights,slowmoving

vehiclesigns,andreectors.

–Watchoutfortrafcwhennearorcrossing

roads.Alwaysyieldtheright-of-way.

–Applytheservicebrakeswhengoingdownhillto

keepforwardspeedslowandtomaintaincontrol

ofthemachine.

•Thegrassbasketsmustbeinplaceduringoperation

ofthereelsorthatchersformaximumsafety .Shut

theengineoffbeforeemptyingthebaskets.

•Raisethecuttingunitswhendrivingfromonework

areatoanother.

•Donottouchtheengine,mufer,orexhaustpipe

whiletheengineisrunningorsoonafterithas

stoppedbecausetheseareascouldbehotenough

tocauseburns.

5

Page 6

•Stayclearoftherotatingscreenatthesideofthe

enginetopreventdirectcontactwithyourbodyor

clothing.

•Ifacuttingunitstrikesasolidobjectorvibrates

abnormally,stopimmediately ,turntheengineoff,

waitforallmotiontostop,andinspectthemachine

fordamage.Adamagedreelorbedknifemustbe

repairedorreplacedbeforeoperationiscontinued.

•Beforegettingoffoftheseat,movethefunctional

controllevertoneutral(N),raisethecuttingunits

andwaitforthereelstostopspinning.Setthe

parkingbrake.Stoptheengineandremovethekey

fromtheignitionswitch.

•Traverseslopescarefully.Donotstartorstop

suddenlywhentravelinguphillordownhill.

•Theoperatormustbeskilledandtrainedinhowto

driveonhillsides.Failuretousecautiononslopesor

hillsmaycauselossofcontrolandcausethemachine

totiporroll,possiblyresultinginpersonalinjury

ordeath.

•Iftheenginestallsorlosesheadwayandcannotmake

ittothetopofaslope,donotturnthemachine

around.Alwaysbackslowly ,straightdowntheslope.

•Iftheenginemustberunningtoperforma

maintenanceadjustment,keephands,feet,clothing,

andanypartsofthebodyawayfromthecutting

units,attachments,andanymovingparts,especially

thescreenatthesideoftheengine.Keepeveryone

away.

•Donotoverspeedtheenginebychanginggovernor

settings.T oensuresafetyandaccuracy,havean

AuthorizedToroDistributorcheckthemaximum

enginespeedwithatachometer..

•Theenginemustbeshutoffbeforecheckingtheoil

oraddingoiltothecrankcase.

•Ifmajorrepairsareeverneededorifassistanceis

desired,contactanAuthorizedToroDistributor.

•Toassureoptimumperformanceandcontinued

safetycerticationofthemachine,useonly

genuineTororeplacementpartsandaccessories.

Replacementpartsandaccessoriesmadebyother

manufacturerscouldbedangerous,andsuchuse

couldvoidtheproductwarranty.

SoundPressure

•Whenapersonorpetappearsunexpectedlyinor

nearthemowingarea,stopmowing.Careless

operation,combinedwithterrainangles,ricochets,

orimproperlypositionedguardscanleadtothrown

objectinjuries.Donotresumemowinguntilthe

areaiscleared.

•Wheneverthemachineisleftunattended,make

surethecuttingunitsarefullyraised,thereelsare

notspinning,thekeyisremovedfromtheignition

switch,andtheparkingbrakeisset.

MaintenanceandStorage

•Makesureallhydrauliclineconnectorsaretightand

allhydraulichosesandlinesareingoodcondition

beforeapplyingpressuretothesystem.

•Keepyourbodyandhandsawayfrompinhole

leaksornozzlesthatejecthydraulicuidunderhigh

pressure.Usepaperorcardboard,notyourhands,

tosearchforleaks.Hydraulicuidescapingunder

pressurecanhavesufcientforcetopenetratethe

skinandcauseseriousinjury.

Thisunithasamaximumsoundpressurelevelatthe

operator’searof82dBA,basedonmeasurementsof

identicalmachinesperISO11094andEN836.

SoundPower

Thisunithasaguaranteedsoundpowerlevelof105

dBA,basedonmeasurementsofidenticalmachinesper

ISO11094.

Vibration

Thisunitdoesnotexceedahand/armvibrationlevelof

2.5m/s

perEN1033.

Thisunitdoesnotexceedawholebodyvibration

levelof0.5m/s

machinesperEN1032.

2

,basedonmeasurementsofidenticalmachines

2

,basedonmeasurementsofidentical

•Beforedisconnectingorperforminganyworkon

thehydraulicsystem,allpressureinthesystemmust

berelievedbystoppingtheengineandloweringthe

cuttingunitsandattachmentstotheground.

•Checkallfuellinesfortightnessandwearona

regularbasis.Tightenorrepairthemasneeded.

6

Page 7

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaof

potentialdanger.Replaceanydecalthatisdamagedorlost.

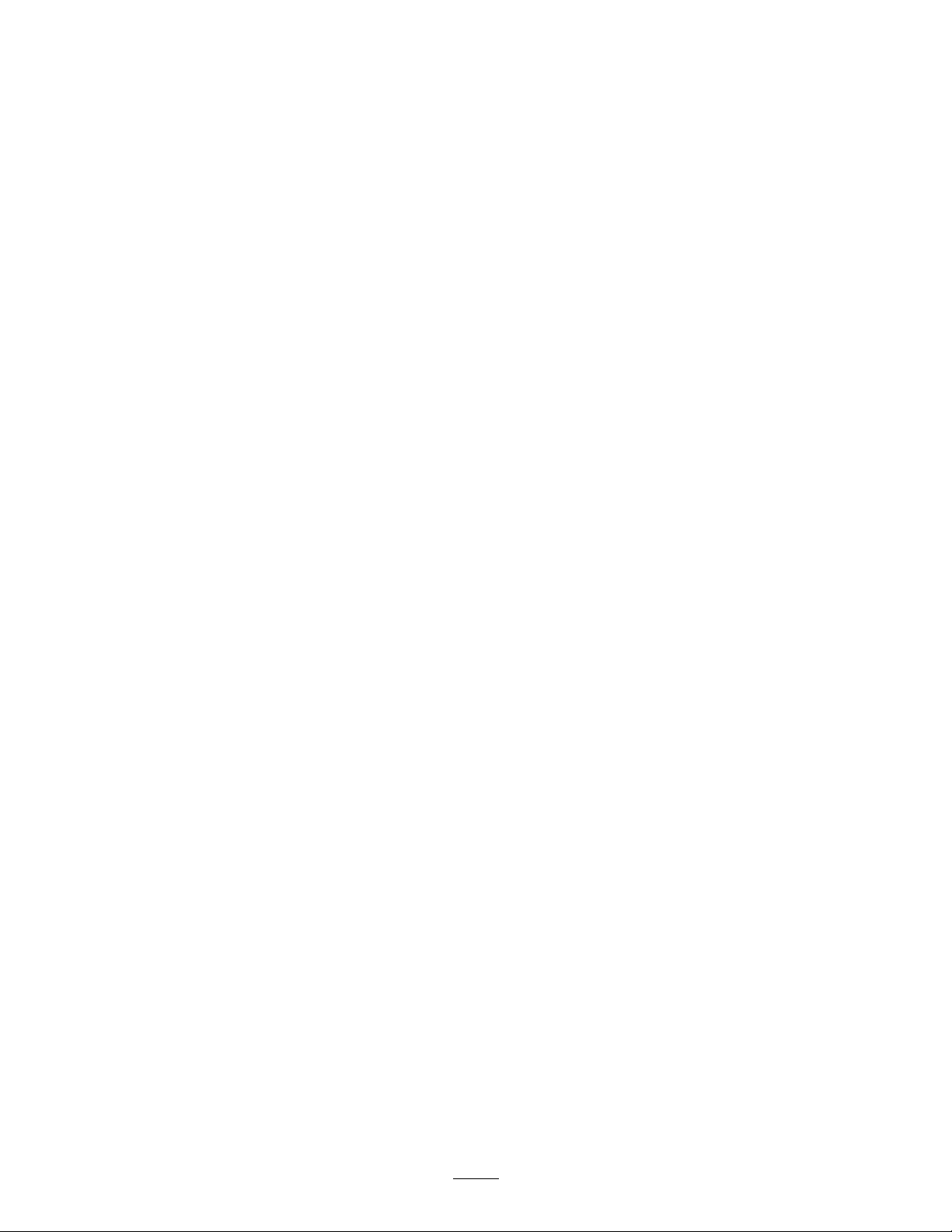

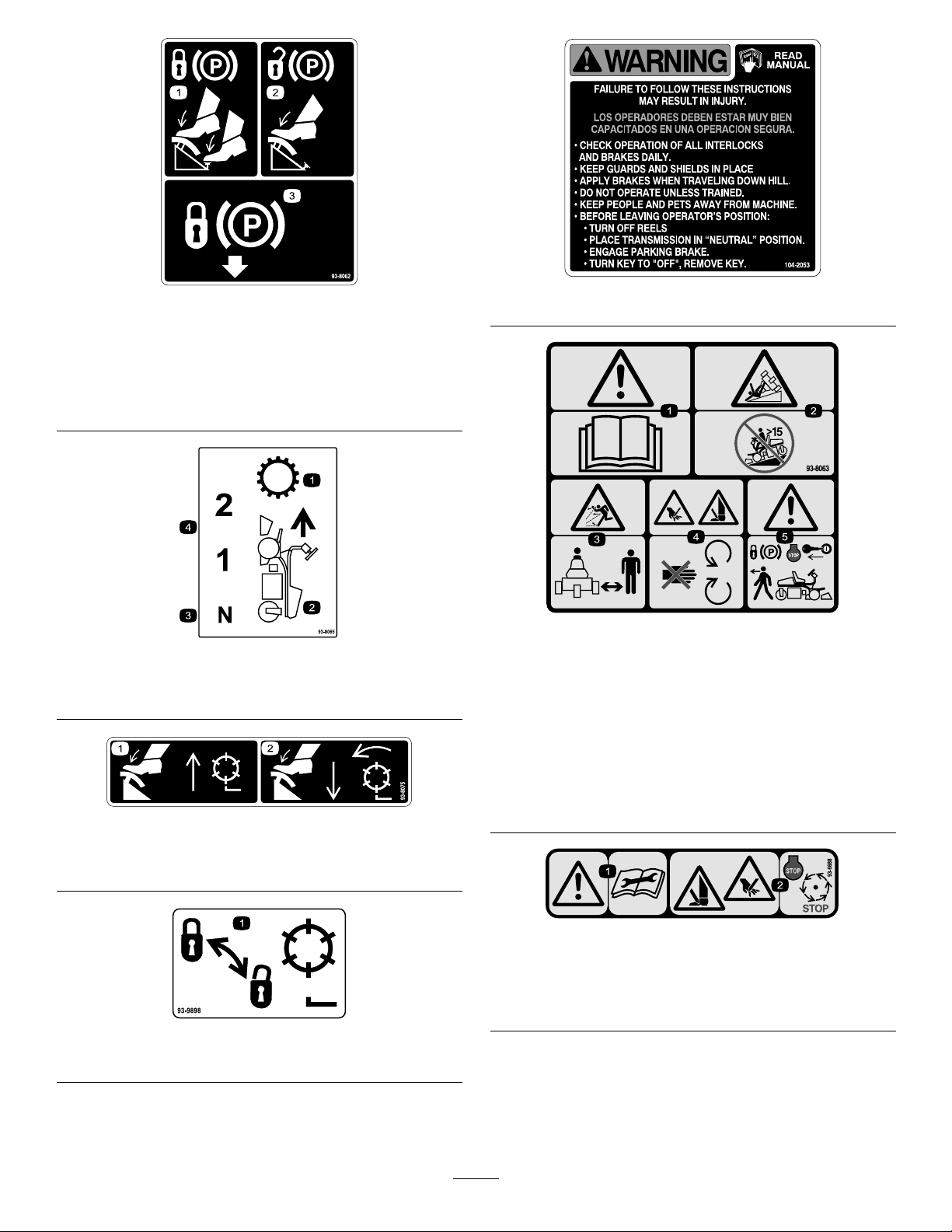

106–9071

107-2554

1.ReadtheOperator’s

Manual.

2.Off5.Slow8.Failure/malfunction(Leak

3.Choke6.Continuousvariablesetting

4.On

7.Fast10.Engine—stop

detectoralarmtest)

9.Headlights

11.Engine—start

1.Hydraulicoil

2.ReadtheOperator’sManual.

93-6691

93-6686

1.ReadtheOperator’sManual.

7

Page 8

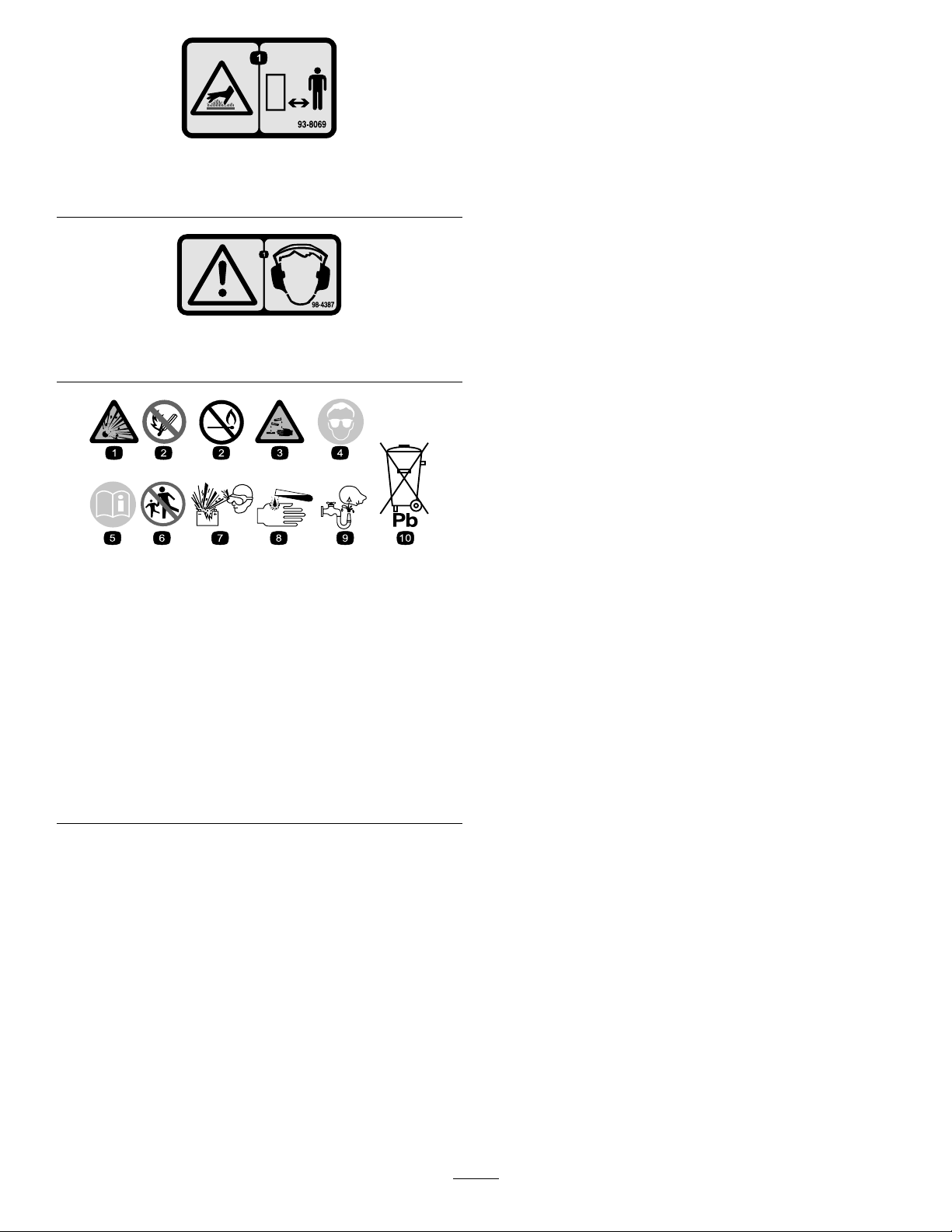

93-8062

1.Tolocktheparkingbrake,

pressthebrakepedaland

theparkingbrakelock.

2.Tounlocktheparking

brake,pressthebrake

pedal.

3.Parkingbrakelock

93-8065

1.Transmission3.Neutral

2.Forwardmotion4.Forwardspeeds

93-8075

1.Presstheliftpedaltoraiseandstopthereels.

2.Pressthemowpedaltolowerandstartthereels.

104–2053

93-8063

CEmodelonly ,replaces104-2053

1.Warning—readtheOperator’sManual.

2.Tippinghazard—donotusethemachineonaslopegreater

than15degrees.

3.Thrownobjecthazard—stayasafedistancefromthe

machine.

4.Cuttinghazardofhandorfoot—stayawayfrommoving

parts.

5.Warning—locktheparkingbrake,stoptheengine,and

removetheignitionkeybeforeleavingthemachine.

1.Lockandunlockthereels

93-6688

1.Warning—readthe

instructionsbefore

servicingorperforming

maintenance.

2.Cuttinghazardofhandor

foot—stoptheengineand

waitformovingpartsto

stop.

93-9898

8

Page 9

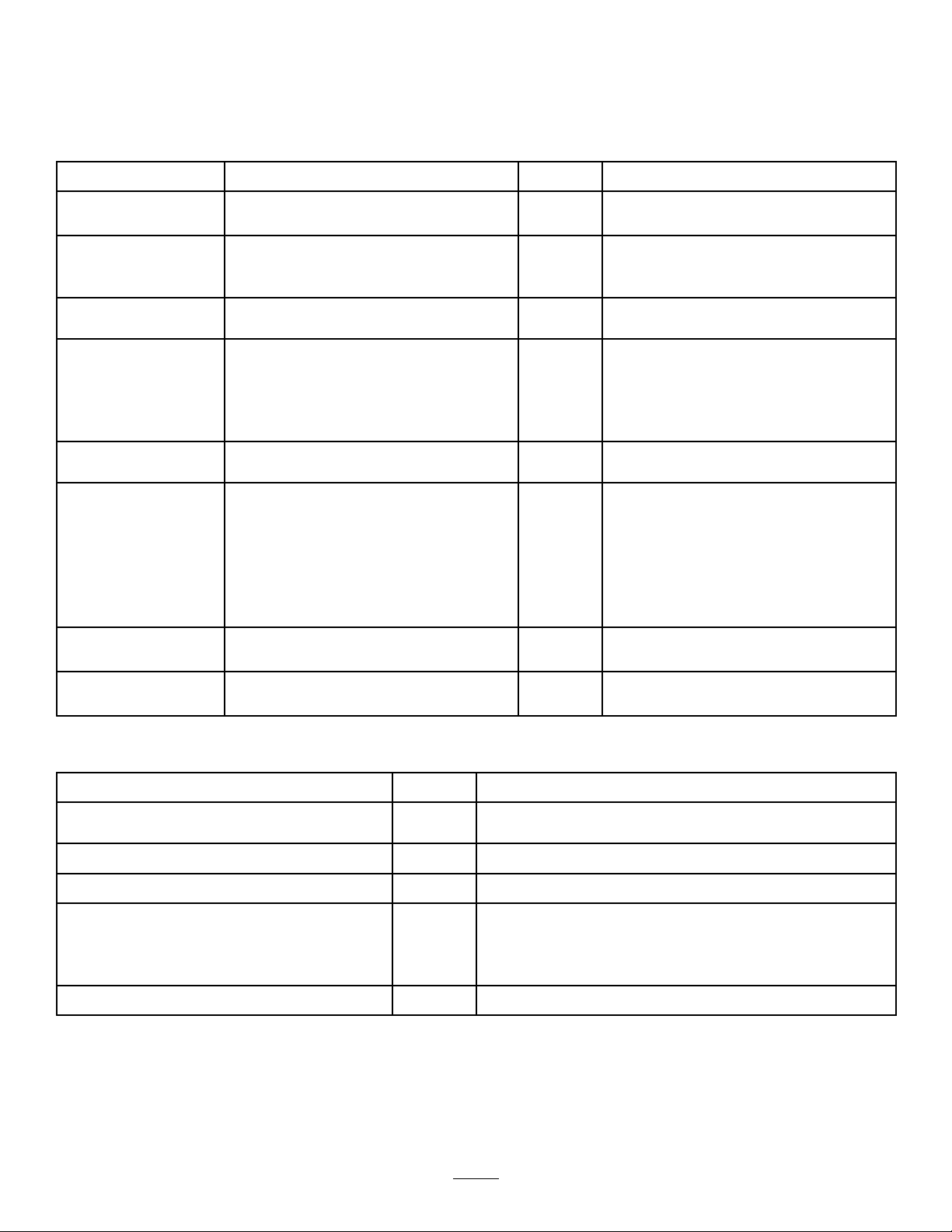

93–8069

1.Hotsurface/burnhazard-stayasafedistancefromthehot

surface.

98-4387

1.Warning—wearhearingprotection.

BatterySymbols

Someorallofthesesymbolsareonyourbattery

1.Explosionhazard

2.Nore,opename,or

smoking.

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection9.Flusheyesimmediately

5.ReadtheOperator’s

Manual.

6.Keepbystandersasafe

distancefromthebattery .

7.Weareyeprotection;

explosivegasescan

causeblindnessandother

injuries

8.Batteryacidcancause

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

10.Containslead;donot

discard.

9

Page 10

Setup

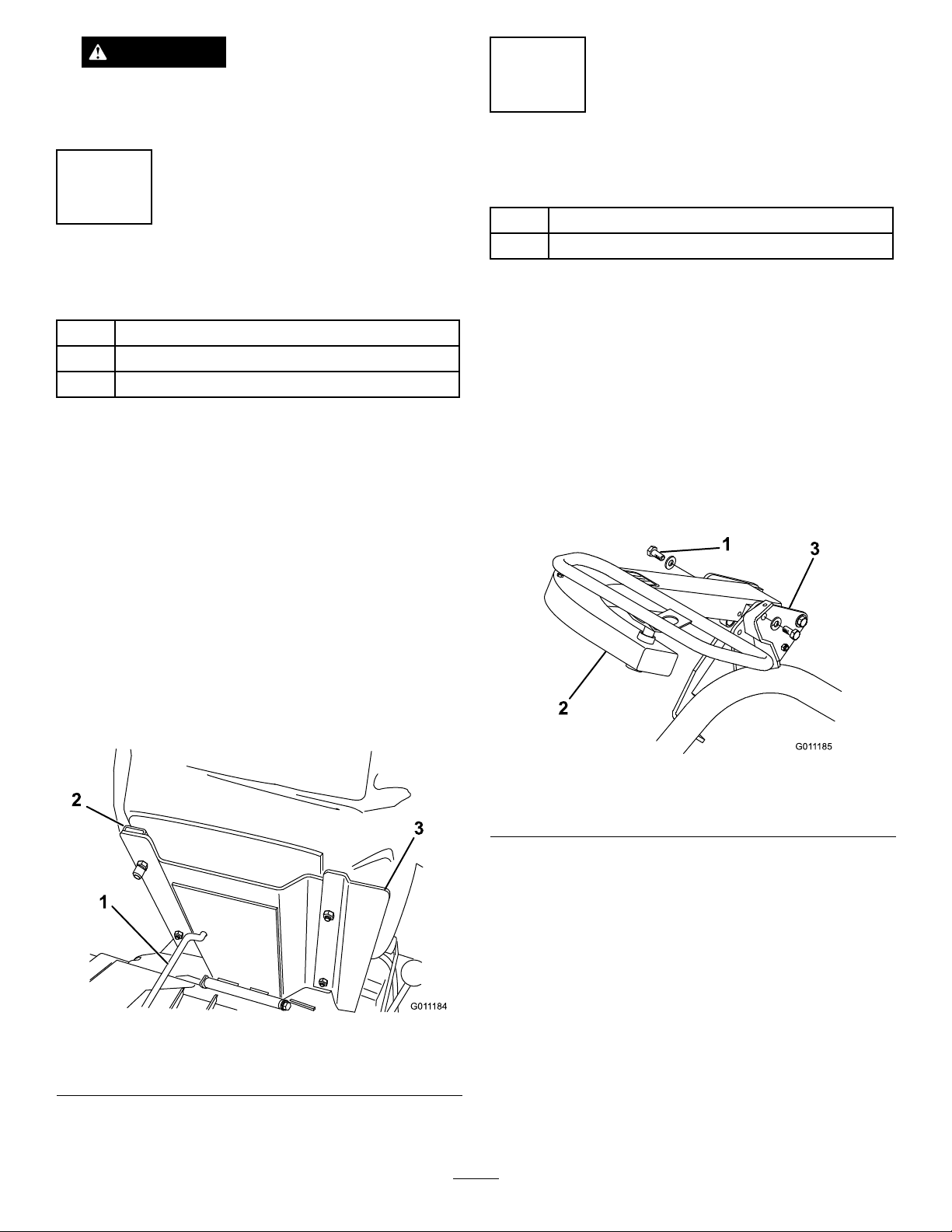

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

6

Nopartsrequired

Seat

Nute(5/16inch)

Seatcover

Bolt(1/2x3/4inch)

Washer(1/2inch)

Cover

Socketheadscrew(1/4x3/4inch)

Locknut(1/4inch)

Washer(1/4inch)

Self-tappingscrew

Bolt(1/4x5/8inch)

Nut(1/4inch)

Gaugebar

Bolt(#10x5/8inch)

Jamnut(#10)

Cuttingunit

Washer6

Ballstud6

Grassbasket

Qty.

Use

–

1

4

1

1

1

1

1

1

1

2

2

2

1

1

1

3

3

Activateandchargethebattery.

Mounttheseat.

Securethesteeringarm.

Installthecover.

Installthebattery .

Installthecuttingunits.

7

8

Nopartsrequired

Warningdecal(93-8063)

MediaandAdditionalParts

Description

Operator’sManual

EngineOperator’sManual

OperatorVideo

PartsCatalog

Pre-deliveryInspectionSheet

Noiseratingcerticate

Certicateofcompliance

Emissionswarranty1

Ignitionkeys2

Qty.

1

1

1

1Usetoorderparts.

1

1

1

Readbeforeoperating.

Watchbeforeoperating.

Fileforfuturereference.

Useforstartingtheengine.

–

1

Addrearballast.

InstallCEdecals,ifrequired.

Use

10

Page 11

1

ActivatingandChargingthe

Battery

NoPartsRequired

Procedure

Useonlyelectrolyte(1.265SpecicGravity)toll

batteryinitially.

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

Washhandsafterhandling.

1.Removethewingnuts,washers,andbatteryclamp

andliftoutthebattery.

Important:Donotaddelectrolytewhilethe

batteryisinthemachine.Youcouldspillit,

causingcorrosion.

2.Cleanthetopofthebatteryandremovethevent

Figure3).

caps(

Figure4

1.Electrolyte

4.Allowapproximately20to30minutesforthe

electrolytetosoakintotheplates.Fillasnecessary

tobringtheelectrolytetowithinabout1/4inch(6

mm)ofthebottomofthellwell(

5.Connecta2to4ampbatterychargertothebattery

posts.Chargethebatteryfor2hoursat4ampsor

for4hoursat2ampsuntilthespecicgravityis

1.250orhigherandthetemperatureisatleast60°F

(16°C)withallcellsgassingfreely.

Figure4).

WARNING

Chargingthebatteryproducesgassesthatcan

explode.

Neversmokenearthebatteryandkeepsparks

andamesawayfrombattery.

6.Whenthebatteryischarged,disconnectthecharger

fromtheelectricaloutletandbatteryposts.

Figure3

3.Carefullylleachcellwithelectrolyteuntiltheplates

arecoveredwithabout1/4inch(6mm)ofuid

(Figure4).

Note:Afterthebatteryhasbeenactivated,add

onlydistilledwatertoreplacenormalloss,although

maintenance-freebatteriesshouldnotrequirewater

undernormaloperatingconditions.

WARNING

Batteryterminalsormetaltoolscouldshort

againstmetaltractorcomponentscausing

sparks.Sparkscancausethebatterygassesto

explode,resultinginpersonalinjury.

•Whenremovingorinstallingthebattery,do

notallowthebatteryterminalstotouchany

metalpartsofthetractor.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsofthe

tractor.

11

Page 12

WARNING

G011184

1

2

3

G011185

1

2

3

Failuretocorrectlyactivatethebatterymay

resultinbatterygassingand/orpremature

batteryfailure.

2

MountingtheSeat

3

SecuringtheSteeringArm

Partsneededforthisprocedure:

1

Bolt(1/2x3/4inch)

1

Washer(1/2inch)

Partsneededforthisprocedure:

1

Seat

4

Nute(5/16inch)

1

Seatcover

Procedure

Note:Mounttheseatslidesinthefrontsetofmounting

holestogainanadditional3inches(7.6cm)inthe

forwardadjustment,orintherearmountingholesforan

additional3inches(7.6cm)intherearwardadjustment.

1.Supporttheseatbaseintheuppositionwiththeseat

supportrod.

2.Removethelocknutssecuringtheseatslidestothe

plywoodshippingbase.Discardthelocknuts.

3.Securetheseat,seatpanel,andseatslidestotheseat

supportwiththelocknuts(5/16inch)(

suppliedinthelooseparts.Mounttheseatpanelon

therightside,positionedasshowninFigure5.

Figure5)

Procedure

1.Removethebolt(1/2x3/4inch)andwasher(1/2

inch)mountedtotheoutsideofthesteeringarm

framebracket.

2.Pivotthesteeringarmupward,aligningthemounting

holesinthearmwiththeholesintheframebracket.

3.Selectthedesiredmountingholeforoperator

comfortandsecurethearmwith2bolts(1/2x3/4

inch)andwashers(1/2inch)(oneeachinloose

parts)(

Figure6).

Figure6

1.Boltandwasher3.Framebracket

2.Steeringarm

1.Seatsupportrod3.Seatpanel

2.Seatslide

Figure5

12

Page 13

4

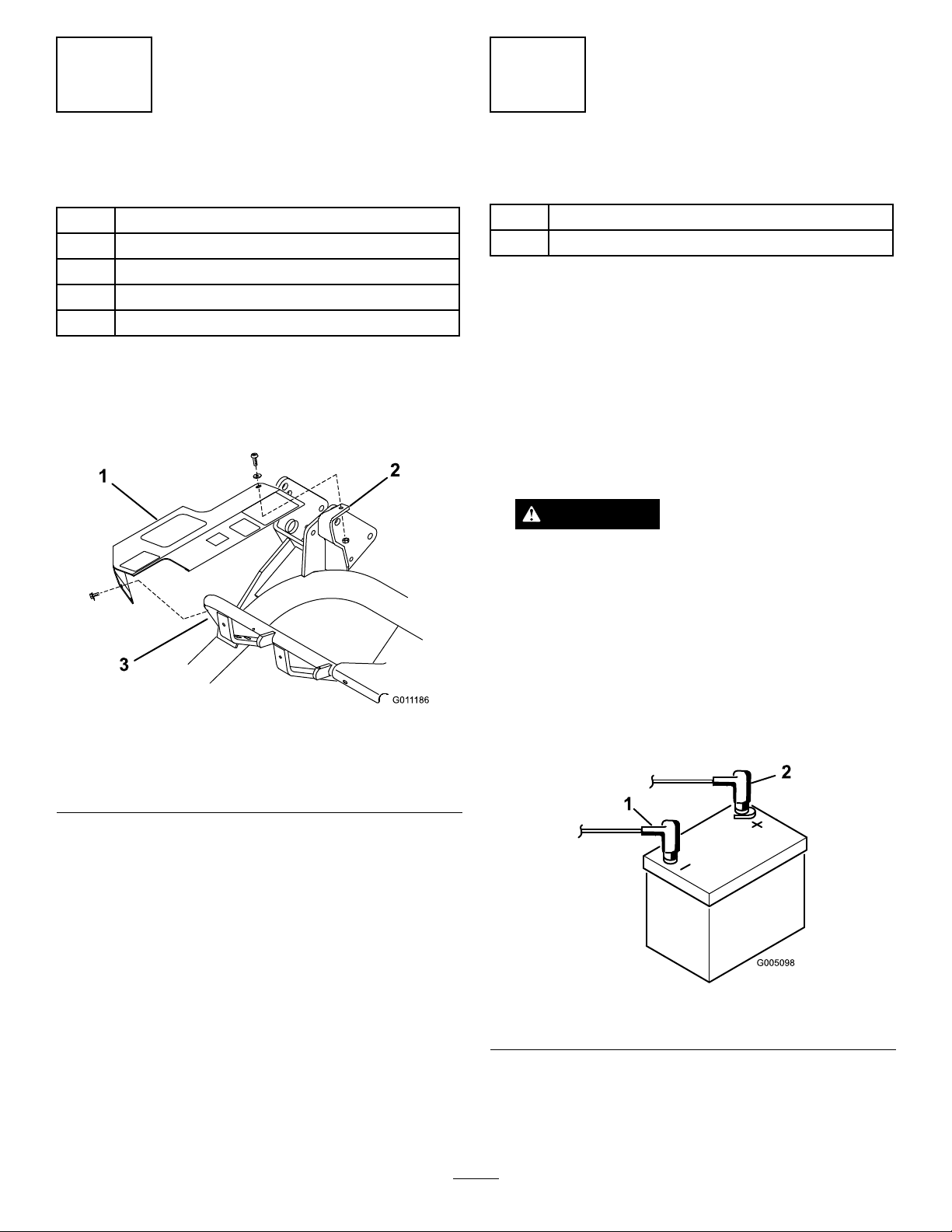

G011186

1

2

3

5

InstallingtheCover

Partsneededforthisprocedure:

1

Cover

1

Socketheadscrew(1/4x3/4inch)

1

Locknut(1/4inch)

1

Washer(1/4inch)

2

Self-tappingscrew

Procedure

1.Alignthecovermountingholeswiththeholesinthe

frametubeandmountingbracket(Figure7).

InstallingtheBattery

Partsneededforthisprocedure:

2

Bolt(1/4x5/8inch)

2

Nut(1/4inch)

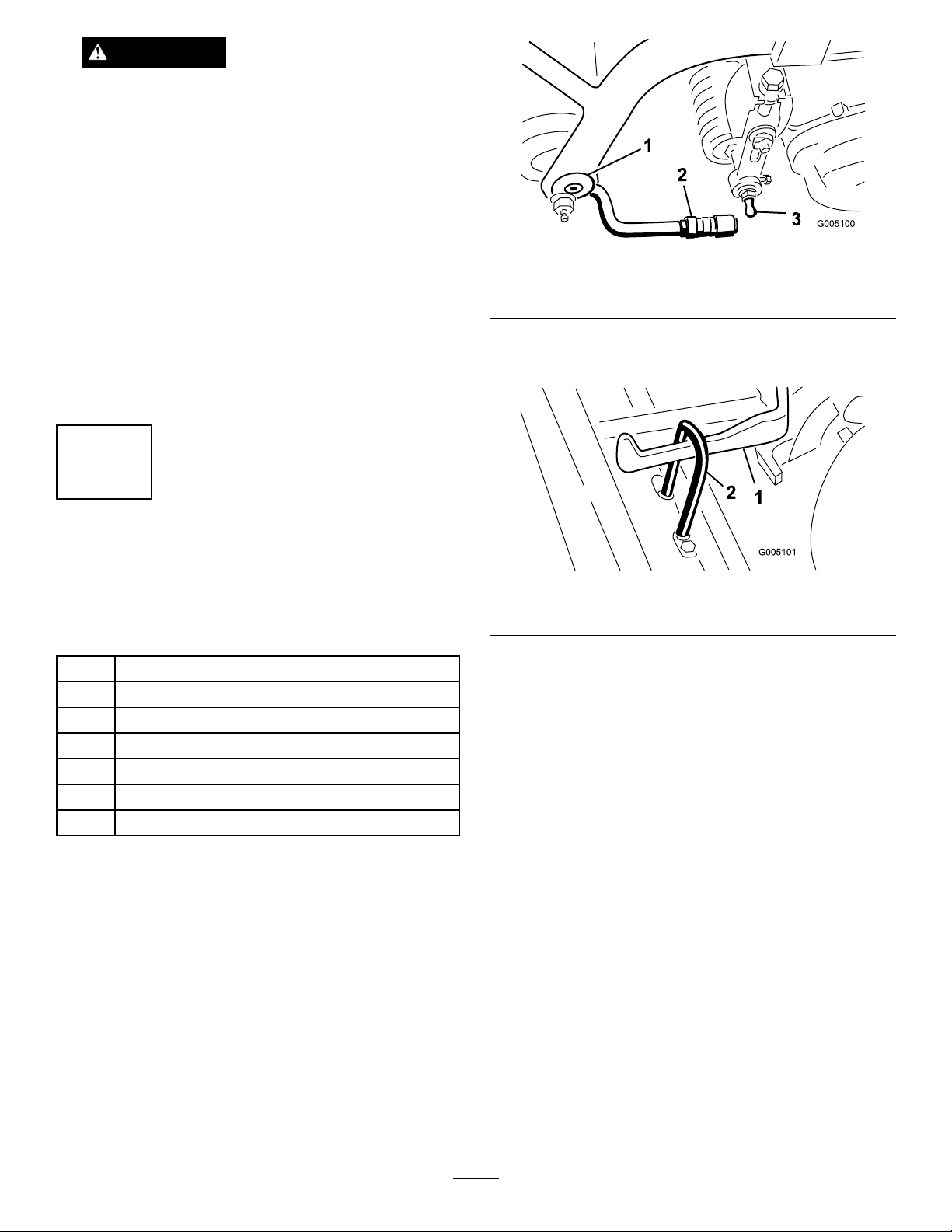

Procedure

1.Mountthebatterywiththebatteryterminalstoward

thehydraulictankonthemachine.

2.Connectthepositivebatterycable(red)fromthe

startersolenoidtothepositivepost(+)ofthebattery

(Figure8).Secureitwithawrenchandcoatthe

terminalwithpetroleumjelly .Makesurethecable

willcleartheseat,intherear-mostposition,which

couldcausewearordamagetothecable.

WARNING

Batteryterminalsormetaltoolscouldshort

againstmetaltractorcomponentscausing

sparks.Sparkscancausethebatterygassesto

explode,resultinginpersonalinjury.

•Whenremovingorinstallingthebattery,do

notallowthebatteryterminalstotouchany

metalpartsofthetractor.

Figure7

Shownwithsteeringarmremoved

1.Cover

2.Mountingbracket

2.Looselysecuretherearofthecovertothetopof

themountingbracketwithasocketheadscrew(1/4

x3/4inch),washer(1/4inch),andalocknut(1/4

inch)(Figure7).

3.Looselysecurethefrontofthecovertotheframe

tubewithtwoselftappingscrews(Figure7).Tighten

allofthecovermountingfasteners.

3.Frametube

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsofthe

tractor.

Figure8

1.Negative(-)2.Positive(+)

3.Connecttheblackgroundcable(fromtheengine

base)tothenegative(-)postofthebattery.Secureit

withawrenchandcoattheterminalwithpetroleum

jelly.

13

Page 14

WARNING

Incorrectbatterycableroutingcoulddamage

thetractorandcablescausingsparks.Sparks

cancausethebatterygassestoexplode,

resultinginpersonalinjury.

•Alwaysdisconnectthenegative(black)

batterycablebeforedisconnectingthe

positive(red)cable.

•Alwaysconnectthepositive(red)battery

cablebeforeconnectingthenegative(black)

cable.

4.Installthebatteryclampandwashersandsecure

themwiththewingnuts.

5.Placetheterminalcoveroverthepositive(+)battery

post.

6

InstallingtheCuttingUnits

(ForCuttingUnitModels04610

and04611Only)

Partsneededforthisprocedure:

1

Gaugebar

1

Bolt(#10x5/8inch)

1

Jamnut(#10)

3

Cuttingunit

6Washer

6Ballstud

3

Grassbasket

Figure9

1.Pullframe

2.Pullarm

3.Slidethecuttingunitunderthepullframewhile

hookingthelifthookontotheliftarm(Figure10).

1.Liftarm2.Lifthook

4.Slidethesleevebackontheballjointandrotatethe

pullarmdownsothesockettsovertheballstud.

Releasethesleevesoitslidesoverthestudandlocks

theassembliestogether(

5.Mountthebasketsonthepullframes,loosenthe

jamnutsonthepullarms,andadjusttheballsockets

untilthereis1/4to1/2inch(6to13mm)clearance

betweenthelipofthebasketandthereelbladesor

thefrontshield.

3.Ballstud

Figure10

Figure9).

Procedure

Note:Whensharpening,settingtheheight-of-cut

orperformingothermaintenanceproceduresonthe

cuttingunits,storethecuttingunitreelmotorsinthe

supporttubesonthefrontoftheframetoprevent

damagetothehoses.

1.Removethecuttingunitsfromthecartons.Assemble

andadjustthemaslistedinthecuttingunitOperator’s

Manual.Usethegaugebarfromtheloosepartskit

toadjusttheheightofcut.

2.Mountawasherandballstudtoeachendofthe

frontrolleronthecuttingunits(

Figure9).

Note:Thispreventsthebasketfromtippingthe

cuttingunitforward,causingtheliftrollertocome

offoftheliftarmwhileinthemowingoperation.

Besurethebasketlipisequidistantfromthereel

bladesallacrosseachreel.Ifthebasketistooclose

tothereel,itispossibleforthereeltocontactthe

basketwhenthecuttingunitisraisedoffofthe

ground.

6.Alignthesocketsintheballjointssotheopenside

ofthesocketiscenteredtowardstheballstud.

Tightenthejamnutstosecurethesocketsinposition

(Figure11).

14

Page 15

Figure11

1.Pullarm3.Balljoint

2.Jamnut

7.Assemblethemountingboltsforthereeldrive

motortoeachcuttingunit.Leaveapproximately1/2

inch(13mm)ofthreadsexposedoneachmounting

bolt(Figure12).

7

AddingRearBallast

NoPartsRequired

Procedure

ThisunitcomplieswiththeANSIB71.4-2004Standard

when40lbofcalciumchlorideballastisaddedtothe

rearwheel.

Important:Ifapunctureoccursinatirewith

calciumchloride,removetheunitfromtheturfarea

asquicklyaspossible.Topreventpossibledamage

totheturf,immediatelysoaktheaffectedareawith

water.

8

Figure12

1.Bolts2.Drivemotor

8.Removetheprotectivecoversfromthecuttingunits

andthereeldrivemotorshafts.

Note:Retaintheprotectivecoversforthecutting

units.Installthemwheneverthereeldrivemotors

areremovedtoprotectthecuttingunitbearings

fromcontamination.

9.Usingahandpumpgreasegun,llthecavityatthe

endofthecuttingunitwith#2generalpurpose

grease.

10.Coatthesplineshaftofthemotorwithcleangrease

andinstallthemotorbyrotatingthemotorclockwise

sothatthemotorangesclearthestuds.Rotate

themotorcounterclockwiseuntiltheangesare

encirclingthestuds.

InstallCEDecals

Partsneededforthisprocedure:

1

Warningdecal(93-8063)

Procedure

IfthismachinewillbeusedintheCE,afxthewarning

decal(93-8063)overEnglishwarningdecal(104-2053).

11.Tightenthemountingbolts(

Figure12).

15

Page 16

ProductOverview

1

2

3

4

5

G011189

1

2

3

4

5

6

7

Controls

Figure13

1.Mowpedal4.Brakepedal

2.Liftpedal

3.Tractionpedal

5.Parkingbrakebutton

TractionandStoppingPedal

Thetractionpedal(Figure13)hasthreefunctions:to

makethemachinemoveforward,tomoveitbackward,

andtostopthemachine.Pressthetopofthepedalto

moveforwardandthebottomofthepedaltomove

backwardortoassistinstoppingwhenmovingforward.

Also,allowthepedaltomovetotheneutralpositionto

stopthemachine.Foroperatorcomfort,donotrestthe

heelofyourfootonreversewhenoperatingforward

Figure14).

(

Figure14

MowPedal

Pressingthemowpedal(Figure13)fullyduring

operationlowersthecuttingunitsandstartsthereels.

Themowpedalwillstaypressedduetodetentactionof

thevalvebankduringoperation.Theoperatordoesnot

needtoholdthepedaldown.

ThrottleControl

Thethrottlecontrol(Figure15)givestheoperatorthe

abilitytocontrolthespeedoftheengine.Movingthe

throttlecontroltowardtheFastpositionincreasesthe

engineRPM;movingthethrottlecontroltowardSlow

willdecreasetheengineRPM.

Note:Theenginecannotbestoppedbytheuseofthe

BrakePedal

throttlecontrol.

Thebrakepedal(Figure13)actuatesanautomotive

drum-typemechanicalbrakelocatedateachtraction

wheel.

LiftPedal

Pressingtheliftpedal(Figure13)duringoperationstops

thereelsfromturningandliftsthecuttingunits.Thelift

pedalmustbefullypresseduntilthecuttingunitsare

fullyraisedandhavestoppedrotating.

ParkingBrakeButton

Pressingthebrakepedaltoactuatethebrakeassembly,

thenpressingthesmallbuttonindicated(Figure13)will

keepthebrakesactuatedforparking.Disengageitby

pressingthebrakepedal.Locktheparkingbrakebefore

youleavethemachine.

Figure15

1.Chokecontrol

2.Throttlecontrol

3.Ignitionswitch

4.Voltmeter

5.Hourmeter

6.Fuse(10amp)

7.Seatadjustinglever

16

Page 17

Choke

G011190

1

G011191

1

G011192

1

ShiftSelector

Tostartacoldengine,closethecarburetorchokeby

movingthechokecontrol(Figure15)forwardtothe

Closedposition.Aftertheenginestarts,regulatethe

choketokeeptheenginerunningsmoothly.Assoon

aspossible,openthechokebypullingitrearwardto

theOpenposition.Awarmenginerequireslittleorno

choking.

HourMeter

Thehourmeter(Figure15)indicatesthetotalhoursthe

machinehasoperated.Itstartstofunctionwheneverthe

keyswitchisrotatedtoOn.

SeatAdjustingLever

Thislever,ontheleftsideoftheseat(Figure15),allows

a4inchforeandaftadjustmentoftheseat.

IgnitionSwitch

Insertthekeyintotheswitch(Figure15)andturnit

clockwiseasfaraspossibletotheStartpositiontostart

theengine.Releasethekeyassoonastheenginestarts;

thekeywillmovetotheOnposition.Turnthekey

counterclockwisetotheOffpositiontostoptheengine.

Theshiftselectorislocatedonthetopoftherighthand

panel(

Figure17).Itprovidestwotractionselections

plusaNeutralposition.Itispermissibletoshiftfrom

oneselectiontoanotherwhilethemachineisinmotion.

Nodamagewillresult.

•Neutral—usedforstartingtheengine

•No.1Position—usedforgreensmowingoperation

•No.2Position—usedfortransportoperation

Important:Ifthemachineisoperatedinreverse

withthecuttingunitsdown,thecuttingunitswill

bepulledoffoftheliftarms.

Figure17

1.Shiftselector

FuelShut-OffValve

Voltmeter

Thevoltmeter(Figure15)indicatestheelectricalsystem

voltage.

Fuse

Thefuse(Figure15)ispartoftheelectricalcircuit.It

containsa10ampfuse(15ampmaximum).

MowLockoutLever

Thelockoutleverlocksthemowpedalpreventing

accidentalstartingofthecuttingunits.Tounlockit,

pullthemowlockoutpinoutward(

clockwise,andinserttheendintotherearholeinthe

bracket.

Figure16

1.Mowlockoutlever

Figure16),rotateit

Closethefuelshut-offvalve(Figure18),underthefuel

tank,whenstoringortransportingthemachineona

truckortrailer.

Figure18

1.Fuelshut-off(underthefueltank)

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

OverallWidthw/reels69–3/4inches(177cm)

OverallLength90inches(228.6cm)

OverallHeight48-1/2inches(123.2cm)

OverallWeightwithReels1256lb(570kg)

NetWeight(wet)930lb(422kg)

17

Page 18

WidthofCut59inches(149.9cm)

Operation

WheelTread

WheelBase

1stGearSpeed

2ndGearSpeed

ReverseSpeed1.9MPH(3.1km/h)

ReelSpeed

49-1/2inches(125.7cm)

46-7/8inches(119.1cm)

3.8MPHapproximately

(6.1km/h)

8.1MPHapproximately

(13km/h)

1975RPMapproximately

Attachments/Accessories

AselectionofToroapprovedattachmentsand

accessoriesareavailableforusewiththemachineto

enhanceandexpanditscapabilities.Contactyour

AuthorizedServiceDealerorDistributororgoto

www.Toro.comforalistofallapprovedattachments

andaccessories.

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

ThinkSafetyFirst

Pleasecarefullyreadallofthesafetyinstructions

andsymbolsinthesafetysection.Knowingthis

informationcouldhelpyouorbystandersavoidinjury.

Theuseofprotectiveequipment,suchasbutnot

limitedto,foreyes,ears,feet,andheadisrecommended.

CAUTION

Thismachineproducessoundlevelsinexcessof

85dBAattheoperator’searandcancausehearing

lossthroughextendedperiodsofexposure.

Wearhearingprotectionwhenoperatingthis

machine.

CheckingtheEngineOil

Theengineisshippedwith1-3/4quarts(1.65liters)

(w/lter)ofoilinthecrankcase;however,theoillevel

mustbecheckedbeforeandaftertheengineisrst

started.

Theengineusesanyhigh-qualitydetergentoilhaving

theAmericanPetroleumInstitute(API)service

classicationofSG,SH,orSJorhigher.The

recommendedviscosity(weight)isSAE30.

1.Positionthemachineonalevelsurface.

2.Unscrewthedipstickandwipeitwithacleanrag.

Screwthedipstickintothetubeandmakesureitis

seatedfully(

1.Dipstick2.Fillercap

Figure19).

Figure19

3.Unscrewthedipstickoutofthetubeandcheckthe

oillevel.

18

Page 19

4.Iftheoillevelislow,removethellercapfromthe

valvecoverandpouroilintotheopeninginthe

valvecoveruntiltheoillevelisuptotheFullmark

onthedipstick.Addtheoilslowlyandcheckthe

leveloftenduringthisprocess.Donotoverll.

Important:Checktheoillevelevery8

operatinghoursordaily .

5.Installthellercapanddipstickrmlyinplace.

FillingtheFuelTank

Useunleadedregulargasolinesuitableforautomotive

use(85pumpoctaneminimum).Leadedregular

gasolinemaybeusedifunleadedregularisnotavailable.

Important:Neverusemethanol,gasoline

containingmethanol,orgasoholcontainingmore

than10%ethanolbecausethefuelsystemcouldbe

damaged.Donotmixoilwithgasoline.

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupanygasoline

thatspills.

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingasparkwhich

canignitethegasolinevapors.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Alwaysplacegasolinecontainersontheground

awayfromyourvehiclebeforelling.

•Donotllgasolinecontainersinsideavehicle

oronatruckortrailerbedbecauseinterior

carpetsorplastictruckbedlinersmayinsulate

thecontainerandslowthelossofanystatic

charge.

•Whenpractical,removegas-powered

equipmentfromthetruckortrailerandrefuel

theequipmentwithitswheelsontheground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfromaportable

container,ratherthanfromagasolinedispenser

nozzle.

•Ifagasolinedispensernozzlemustbeused,

keepthenozzleincontactwiththerimofthe

fueltankorcontaineropeningatalltimesuntil

fuelingiscomplete.

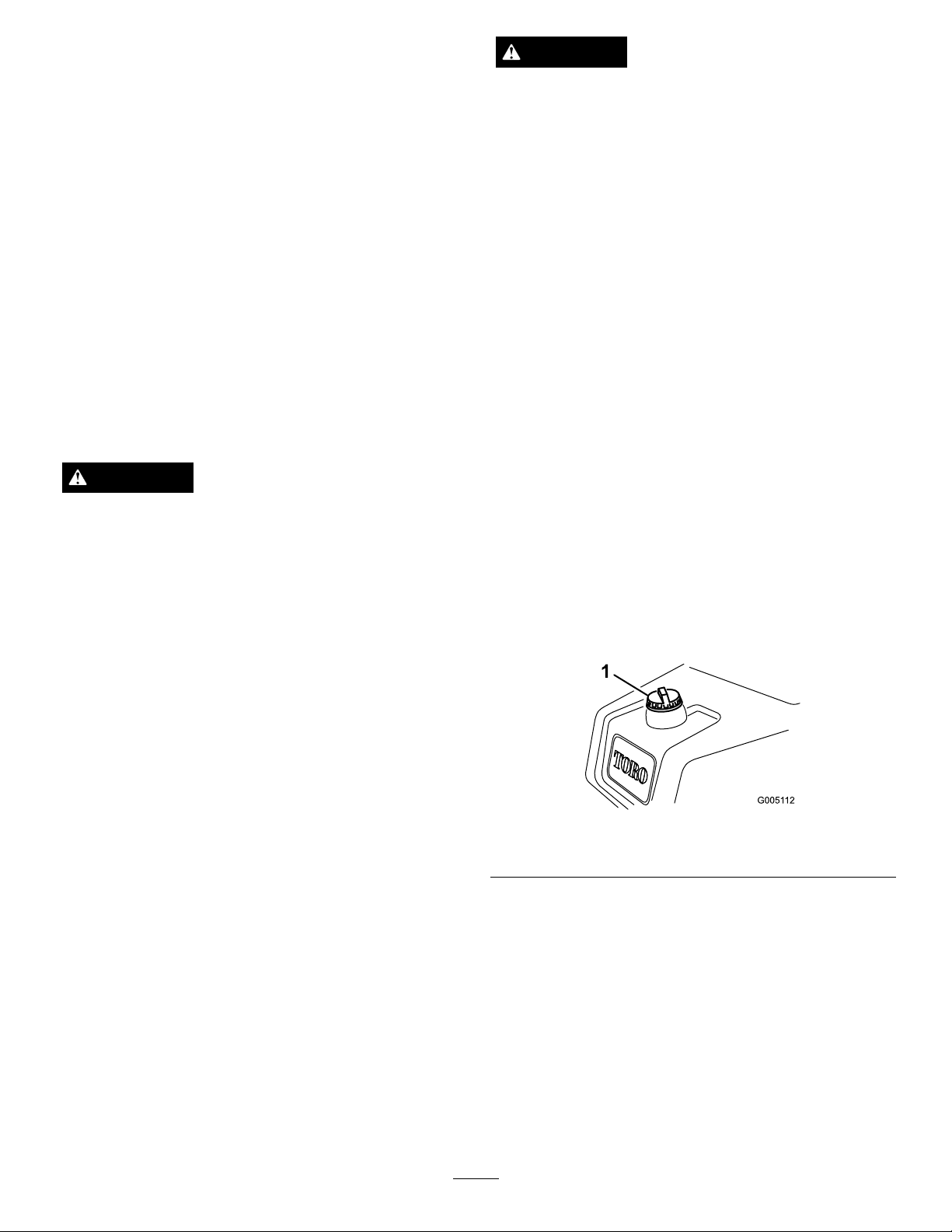

1.Cleanaroundthefueltankcapandremoveit

(Figure20).

•Neverllthefueltankinsideanenclosedtrailer.

•Donotllthefueltankcompletelyfull.Add

gasolinetothefueltankuntilthelevelis1inch

(25mm)belowthebottomofthellerneck.

Thisemptyspaceinthetankallowsgasoline

toexpand.

•Neversmokewhenhandlinggasoline,andstay

awayfromanopenameorwheregasoline

fumesmaybeignitedbyaspark.

•Storegasolineinanapprovedcontainerand

keepitoutofthereachofchildren.Neverbuy

morethana30-daysupplyofgasoline.

•Donotoperatewithoutentireexhaustsystem

inplaceandinproperworkingcondition.

Figure20

1.Fueltankcap

2.Addunleadedregulargasolinetothefueltankuntil

thelevelis1inch(25mm)belowthebottomofthe

llerneck.

Thisspaceinthetankallowsgasolinetoexpand.

Donotllthefueltankcompletelyfull.

Note:Fueltankcapacityis7U .S.gallons(26.6

liters)

3.Installthefueltankcapsecurely .Wipeupany

gasolinethatmayhavespilled.

19

Page 20

CheckingtheHydraulicFluid

Level

Thehydraulicuidreservoirislledatthefactorywith

approximately4.5U.S.gallons(17l)ofhighquality

hydraulicuid.Checkthelevelofthehydraulicuid

beforetheengineisrststartedanddailythereafter.

Therecommendedreplacementuidisasfollows:

ToroPremiumAllSeasonHydraulicFluid(Availablein5

gallonpailsor55gallondrums.SeepartscatalogorT oro

distributorforpartnumbers.)

Alternateuids:IftheT orouidisnotavailable,other

uidsmaybeusedprovidedtheymeetallthefollowing

materialpropertiesandindustryspecications.Wedo

notrecommendtheuseofsyntheticuid.Consult

withyourlubricantdistributortoidentifyasatisfactory

product

Note:Torowillnotassumeresponsibilityfordamage

causedbyimpropersubstitutions,souseonlyproducts

fromreputablemanufacturerswhowillstandbehind

theirrecommendation.

HighViscosityIndex/LowPourPointAnti-wearHydraulic

Fluid,ISOVG46

MaterialProperties:

Viscosity,ASTMD445cSt@40°C44to48

ViscosityIndexASTM

D2270

PourPoint,ASTMD97-34°Fto-49°F

IndustrySpecications:

VickersI-286-S(QualityLevel),VickersM-2950-S

(QualityLevel),DenisonHF-0

cSt@100°C7.9to8.5

140to160

Note:Manyhydraulicuidsarealmostcolorless,

makingitdifculttospotleaks.Areddyeadditive

forthehydraulicsystemoilisavailablein2/3oz.(20

ml)bottles.Onebottleissufcientfor4-6gal(15-22

1)ofhydraulicoil.Orderpartno.44-2500fromyour

authorizedTorodistributor.Thisreddyeisnot

recommendedforusewithbiodegradableuids.

Usefoodcoloring.

1.Positionthemachineonalevelsurface.Makesure

themachinehascooleddownsotheoiliscold.

2.Removethecapfromthetopofthereservoir

andchecktheuidlevel.Theuidshouldbe

approximately3-1/2in.(89mm)belowthetopof

thellhole(

Figure21).

Important:Topreventsystemcontamination,

cleanthetopofthehydraulicoilcontainers

beforepuncturingthem.Ensurethatthepour

spoutandfunnelareclean.

Note:Makeaclosevisualinspectionofthe

hydrauliccomponents.Inspectthemforleaks,loose

fasteners,missingparts,improperlyroutedlines,etc.

Makeanycorrectionsnecessary.

Important:TheISOVG46Multigradeuidhas

beenfoundtoofferoptimalperformanceinawide

rangeoftemperatureconditions.Foroperationin

consistentlyhighambienttemperatures,65°F(18°

C)to120°F(49°C),ISOVG68hydraulicuidmay

offerimprovedperformance.

PremiumBiodegradableHydraulicFluid-Mobil

EALEnviroSyn46H

Important:MobilEALEnviroSyn46Histheonly

syntheticbiodegradableuidapprovedbyT oro.

Thisuidiscompatiblewiththeelastomersused

inT orohydraulicsystemsandissuitablefora

wide-rangeoftemperatureconditions.Thisuidis

compatiblewithconventionalmineraloils,butfor

maximumbiodegradabilityandperformancethe

hydraulicsystemshouldbethoroughlyushedof

conventionaluid.Theoilisavailablein5gallon

(19l)containersor55gallondrumsfromyour

MobilDistributor.

Figure21

1.Hydraulicreservoir

2.Screen

3.Fluidlevel3-1/2in.from

topofllhole

3.Iftheoillevelislow ,slowlyllthereservoirwith

ISOVG46orequivalenthydraulicoiluntilthelevel

isuptothecorrectlevel.Donotmixoils.

4.Installthecap.

CheckingtheTirePressure

Thetiresareover-inatedatthefactoryforshipping

purposes.Reducethepressuretotheproperlevels

beforestartingtheunit.

Varythetirepressureforthefrontwheels,depending

uponyourturfconditions,fromaminimumof8psito

amaximumof12psi(55to83kPa).

20

Page 21

Varythetirepressurefortherearwheelfroma

minimumof8psitoamaximumof15psi(55to103

kPa).

CheckingtheTorqueofthe

WheelNuts

WARNING

Failuretomaintainpropertorqueofthewheelnuts

couldresultinpersonalinjury.

4.MovethechokelevertotheOnposition(only

whenstartingacoldengine)andthethrottlelever

tothehalfthrottleposition.

5.Insertandrotatetheignitionkeyclockwiseuntil

theenginestarts.Aftertheenginestarts,regulate

thechoketokeeptheenginerunningsmoothly.

Assoonaspossible,openthechokebypulling

itrearwardtotheOffposition.Awarmengine

requireslittleornochoking.

6.Checkthemachineoutwiththefollowing

proceduresaftertheenginehasstarted:

Torquethewheelnutsto70-90ft-lbafter1-4hours

ofoperationandagainafter10hoursofoperation.

Torqueevery200hoursthereafter.

Break-inPeriod

RefertotheEngineManualsuppliedwiththe

machineforoilchangeandmaintenanceprocedures

recommendedduringthebreak-inperiod.

Only8hoursofmowingoperationisrequiredforthe

break-inperiod.

Sincethersthoursofoperationarecriticaltofuture

dependabilityofthemachine,monitoritsfunctions

andperformancecloselysothatminordifculties,

whichcouldleadtomajorproblems,arenotedandcan

becorrected.Inspectthemachinefrequentlyduring

break-inforsignsofoilleakage,loosefasteners,orany

othermalfunction.

Toensureoptimumperformanceofthebrakesystem,

burnish(break-in)thebrakesbeforeusingthemachine.

Toburnishthebrakes,rmlyapplythebrakesand

drivethemachineatmowingspeeduntilthebrakes

arehot,asindicatedbytheirsmell.Anadjustment

tothebrakesmayberequiredafterbreak-in;referto

AdjustingtheBrakes(page32).

StartingtheEngine

Note:Inspecttheareabeneaththemowerstobe

certaintheyareclearofdebris.

1.Unlockthemowlockoutleverbypullingthepin

outward,rotatingitclockwise,andinsertingtheend

intotherearholeinthebracket.

2.Sitontheseat,placetheshiftselectorinNeutral,

andcheckthemowandliftpedalstobesurethey

arelevelwithoneanother.

A.MovethethrottlecontroltotheFastposition

andmomentarilyengagethereelsbypressing

themowpedal.Thecuttingunitsshoulddrop

andallthereelsshouldturn.

B.Operatetheliftpedal.Thecuttingreelsshould

stopandthecuttingunitsshouldraisetothefull

transportposition.

Important:Stoptheengine.Checkthelip

ofeachbaskettobesureitisnotincontact

withthereelduringoperation.Adjust

thepullarmsifcontactisnoted;referto

InstallingtheCuttingUnits.

C.Pressthebrakepedaltokeepthemachinefrom

moving,andoperatethetractionpedalthrough

theforwardandreversepositions.

D.Continuetheaboveprocedurefor1–2minutes.

Neutralizethetractionleverandmowandlift

pedals,locktheparkingbrake,andturnthe

engineoff.

E.Checkforoilleaks.Ifoilleaksappear,check

thetightnessofthehydraulicttings.Ifoil

leakscontinuetoappear,contactyourlocal

ToroDistributorforassistanceand,ifnecessary,

replacementparts.

Important:Themotororwheelsealsmay

showsometraceofoilforashortperiodof

timeuntilthemachinebreak-inperiodhas

transpired.

Note:Sincethemachineisnewandthe

bearingsandreelsaretight,itisnecessarytouse

theFastthrottlecontrolpositionforthischeck.

Afastthrottlesettingmaynotberequiredafter

thebreak-inperiod.

3.Removeyourfootfromthetractionpedalandmake

surethepedalisintheNeutralposition.

21

Page 22

CheckingtheSafetyInterlock

System

CAUTION

Ifthesafetyinterlockswitchesaredisconnectedor

damagedthemachinecouldoperateunexpectedly

causingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlockswitches

dailyandreplaceanydamagedswitchesbefore

operatingthemachine.

Thepurposeoftheinterlocksystem(Figure22)isto

preventtheenginefromcrankingorstartingunlessthe

tractionshiftselectorisinNeutralandthecuttingunits

aredisengaged.Inaddition,theenginewillstopwhen:

•Thecuttingunitsareengagedwiththeoperatoroff

oftheseat.

•ThetractionshiftselectorisintheNo.1orNo.2

positionwiththeoperatoroffoftheseat.

switchonthevalvebankisoperatingcorrectly.If

theenginedidnotcrank,proceedtostep3.Ifthe

enginecranked,contactyourlocalToroDistributor

forassistance

3.Sitontheseatandengagetheparkingbrake.Fully

presstheliftpedalandreleaseit.Movethetraction

shiftselectortoneutralandtrytostarttheengine.

Theengineshouldstartandcontinuetorun,which

meansthetractionswitchandmow/liftswitchon

thevalvebankareoperatingcorrectly;proceedto

4..Iftheenginecrankedbutdidnotstart,the

step

problemisnotintheinterlocksystem.Ifengine

didnotcrank,contactyourlocalToroDistributor

forassistance.

4.Sitontheseat,engagetheparkingbrake,andmove

thetractionshiftselectortoneutral.Pressthemow

pedalandtrytostarttheengine.Theengineshould

notcrank,whichmeansthemow/liftswitchis

operatingcorrectly.Iftheenginedidnotcrank,

proceedtostep

yourlocalT oroDistributorforassistance.

5.Sitontheseatandmovethetractionshiftselector

toneutral.Fullypresstheliftpedalandrelease

it.Starttheengineanddepressthemowpedal.

Carefullyrisefromtheseat;theengineshouldstop.

Iftheenginestops,theinterlocksystemisoperating

correctly.Iftheenginedoesnotstop,stopthe

engineandndtheproblembeforeoperatingthe

machineagain.Ifassistanceisrequired,contact

yourlocalToroDistributor

5.Iftheenginecranked,contact

Figure22

1.Tractionswitch

2.Seatswitch

Performthefollowingsystemchecksdailytobesure

theinterlocksystemisoperatingcorrectly:

1.Sitontheseat,engagetheparkingbrake,andmove

theshiftselectortoneutral.Removeyourfoot

fromthetractionpedalandmakesurethepedalis

inneutral.Fullydepresstheliftpedalandrelease

it.Trytostarttheengine.Theengineshould

crankandrun,whichmeanstheinterlocksystemis

operatingcorrectly.Iftheenginedidcrank,proceed

tostep

localToroDistributorforassistance.

2.Sitontheseatandengagetheparkingbrake.Press

theliftpedalfullyandreleaseit.Movethetraction

shiftselectortothe#1and#2positionswhile

tryingtostarttheengineineachposition.The

engineshouldnotcrank,whichmeansthetraction

2.Iftheenginedidnotcrank,contactyour

3.Mow/liftswitch

6.Sitontheseatandmovethetractionshiftselector

toNeutral.Fullypresstheliftpedalandreleaseit.

Starttheengineanddrivetoanopenareathatis

freeofdebrisandforeignobjects.Keepallpeople,

especiallychildren,awayfromthefrontofthe

machineandoutoftheareaofoperation.Movethe

shiftselectortoNeutral,makesurethemowpedal

isdisengaged,setthethrottlecontrolathalfspeed,

anddepressthebrakepedal(donotengagethe

parkingbrakebutton).Whileholdingthesteering

wheel,braceyourfeetonthefootdeckandbrake

pedalandmovetheshiftselectortothe#1position.

Carefullyrisefromtheseat;theengineshouldstop.

Iftheenginestops,theinterlocksystemisoperating

correctly.

7.Repeatstep6withtheshiftselectorinthe#2

position.Iftheenginedoesnotstop,stopthe

engineandndtheproblembeforeoperatingthe

machineagain.Ifassistanceisrequired,contact

yourlocalToroDistributor.

Note:Themachineisequippedwithaninterlock

switchontheparkingbrake.Theenginewillstopifthe

22

Page 23

tractionshiftselectorisinthe#1and#2positionswith

theparkingbrakeengaged.

PreparingtheMachinefor

Mowing

Toassistinaligningthemachineforsuccessivecutting

passes,itissuggestedthefollowingbedonetotheNo.

2andNo.3cuttingunitbaskets:

BeforeMowing

Inspectthegreenfordebris,removetheagfromthe

cup,anddeterminethebestdirectiontomow .Basethe

directiontomowonthepreviousmowingdirection.

Alwaysmowinanalternatepatternfromtheprevious

mowingsothatthegrassbladeswillbelessapttolay

downandthereforebedifculttotrapbetweenthereel

bladesandbedknife.

1.Measureinapproximately5inches(12.7cm)from

theouteredgeofeachbasket.

2.Eitherplaceastripofwhitetapeorpaintaline

ontoeachbasketparallelingtheouteredgeofeach

basket(

1.Alignmentstrip

2.Approximately5inches

(12.7cm)

Figure23).

Figure23

3.Cutgrassonright

4.Keepfocalspot6-10ft

(1.8-3m)aheadofthe

machine.

TrainingPeriod

Beforemowinggreenswiththemachine,itis

recommendedthatyoundaclearareaandpractice

startingandstopping,raisingandloweringthecutting

units,turning,etc.Thistrainingperiodwillbe

benecialtotheoperatoringainingcondenceinthe

performanceofthemachine.

Important:IfyoushifttotheNo.2position

whilecuttinggreens,noincreaseinspeedwill

result.However,asuddenincreaseinspeedwill

developwhenyouactuatetheliftpedal.Forsafety

purposes,itisrecommendedthatyouuseonlythe

No.1positionforcuttinggreensandtheNo.2

positionfortransport.

Mowing

1.Approachthegreenwiththeshiftselectorinthe

No.1position.Startononeedgeofthegreenso

thattheribbonprocedureofcuttingmaybeused.

Thisholdscompactiontoaminimumandleavesa

neat,attractivepatternonthegreens.

Important:ShifttotheNo.1positionwhen

approachingagreenbecausethemachine

speedwillautomaticallybereducedwhenthe

cuttingunitsareengaged.Higherspeedwill

resumewhenthecuttingunitsaredisengaged.

2.Actuatethemowpedalasthefrontedgeofthe

grassbasketscrosstheouteredgeofthegreen.

Thisproceduredropsthecuttingunitstotheturf

andstartsthereels.

Note:TheNo.1(rear)cuttingunitreelwillnot

startuntilallthecuttingunitsareonthegroundand

theNo.2andNo.3cuttingunitsarecutting.

Important:Familiarizeyourselfwiththefact

thattheNo.1cuttingunitreelisdelayedand

therefore,youshouldpracticetotrytogain

therequiredtimingnecessarytominimizethe

cleanupmowingoperation.

3.Overlapaminimalamountwiththepreviouscut

onreturnpasses.Toassistinmaintainingastraight

lineacrossthegreenandkeepthemachinean

equaldistancefromtheedgeofthepreviouscut,

establishanimaginarysightlineapproximately6to

10ft(1.8to3m)aheadofthemachinetotheedge

oftheuncutportionofthegreen(

Figure24).Somenditusefultoincludetheouter

edgeofthesteeringwheelaspartofthesightline;

i.e.keepthesteeringwheeledgealignedwithapoint

thatisalwayskeptthesamedistanceawayfromthe

frontofthemachine(

Figure23andFigure24).

Figure23and

23

Page 24

Figure24

1.Alignmentstrip

2.Approximately5inches

(12.7cm)

3.Cutgrassonleft

4.Keepfocalspot6-10ft

(1.8-3m)aheadofthe

machine.

4.Asthefrontofthebasketscrosstheedgeofthe

green,presstheliftpedal.Thiswillstopthereels

andliftthecuttingunits.Timingofthisprocedureis

important,sothemowersdonotcutintothefringe

area.However,asmuchofthegreenaspossible

shouldbecuttominimizetheamountofgrassleft

tomowaroundtheouterperiphery.

5.Cutdownonoperatingtimeandeaselineupforthe

nextpassbymomentarilyturningthemachinein

theoppositedirection,thenturninginthedirection

oftheuncutportion;i.e.,ifintendingtoturnright,

rstswingslightlyleft,thenright.Thiswillassistin

gettingthemachinemorequicklyalignedforthe

nextpass.Followthesameprocedureforturningin

theoppositedirection.Itisagoodpracticetotryto

makeasshortofaturnaspossible.However,turn

inawiderarcduringwarmerweathertominimize

thepossibilityofbruisingtheturf.

thedirectionofmowingfromthepreviouscutting.

Replacetheag.

7.Raisethecuttingunitsandemptythegrassbaskets

ofallclippingsbeforetransportingtothenext

green.Heavywetclippingsplaceanunduestrainon

thebasketsandwilladdunnecessaryweighttothe

machine,therebyincreasingtheloadontheengine,

hydraulicsystem,brakes,etc.

TransportOperation

Makesurethecuttingunitsareinthefullupposition.

SettheshiftselectorinNo.2ifconditionswillpermit

fastergroundspeed.ShifttoNo.1andoperateat

slowergroundspeedsinroughorhillyareas.Usethe

brakestoslowthemachinewhilegoingdownsteep

hillstoavoidlossofcontrol.Alwaysapproachrough

areasatareducedspeed(shiftselectorinNo.1),and

crosssevereundulationscarefully.Familiarizeyourself

withthewidthofthemachine.Donotattempttopass

betweenobjectsthatareclosetogethersothatcostly

damageanddowntimecanbeprevented.

InspectionandCleanupAfter

Mowing

Atthecompletionofthemowingoperation,thoroughly

washthemachinewithagardenhosewithoutanozzle

soexcessivewaterpressurewillnotcausecontamination

anddamagetothesealsandbearings.Aftercleaning,

inspectthemachineforpossiblehydraulicuid

leaks,damageorweartohydraulicandmechanical

components,andthecuttingunitsforsharpness.

Also,lubricatethemowandliftpedalandbrakeshaft

assemblywithSAE30oilorspraylubricanttodeter

corrosionandhelpkeepthemachineperforming

satisfactorilyduringthenextmowingoperation.

Important:Themachineshouldneverbe

stoppedonagreenwiththecuttingunitreels

operatingasdamagetotheturfmayresult.

Stoppingonawetgreenwiththemachinemay

leavemarksorindentationsfromthewheels.

6.Finishcuttingthegreenbymowingtheouter

periphery.Besuretochangethedirectionofcutting

fromthepreviousmowing.Alwayskeepweather

andturfconditionsinmindandbesuretochange

24

Page 25

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Afterthersthour

Aftertherst8hours

Aftertherst10hours

Beforeeachuseordaily

Every50hours

Every100hours

Every200hours

Every800hours

MaintenanceProcedure

•Checkthetorqueofthewheelnuts.

•Changetheengineoilandlter.

•Checkthetorqueofthewheelnuts.

•Checktheengineoil.

•Checkthehydraulicuidlevel.

•Checkthesafetyinterlocksystem.

•Inspectandcleanupaftermowing.

•Checkthehydrauliclinesandhoses.

•Greasethemachine(immediatelyaftereverywashing).

•Servicetheaircleanerfoampre-cleaner(morefrequentlywhenoperatingconditions

aredustyordirty).

•Changetheengineoil.

•Checkthebatteryelectrolytelevel.

•Checkthebatterycableconnections.

•Servicetheaircleanercartridge(morefrequentlywhenoperatingconditionsare

dustyordirty).

•Changetheengineoillter.

•Checkthetorqueofthewheelnuts.

•Checkthereelbearingpreloadadjustment.

•Replacethesparkplugs.

•Replacethefuellter.

•ChecktheengineRPM(atidleandfullthrottle).

•Checkthevalveclearance.

Every2,000hours

•Checkthefuellinesandconnections.

•Drainandushthefueltank.

•Changethehydraulicoilandlter.

•Drainandushthehydraulictank.

•Replacemovinghoses.

25

Page 26

DailyMaintenanceChecklist

Duplicatethispageforroutineuse.

Fortheweekof: MaintenanceCheckItem

Mon.Tues.Wed.Thurs.Fri.

Checkthesafetyinterlock

operation.

Checktheinstrument

operation

Checkthebrakeoperation.

Checkthefuellevel.

Checktheengineoillevel.

Cleantheengineaircooling

ns.

Inspecttheairlter

pre-cleaner.

Checkanyunusualengine

noises.

Checkthereel-to-bedknife

adjustment.

Checkthehydraulichoses

fordamage.

Checkforuidleaks.

Checkthetirepressure.

Checktheheight-of-cut

adjustment.

Lubricateallgreasettings.

Lubricatethemow,lift,and

brakelinkage.

Touch-updamagedpaint.

1.Immediatelyaftereverywashing,regardlessoftheintervallisted.

1

Sat.Sun.

NotationforAreasofConcern

Inspectionperformedby:

ItemDate

Information

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriouslyinjure

youorotherbystanders.

Removethekeyfromtheignitionanddisconnectthewirefromthesparkplugbeforeyoudoany

maintenance.Setthewireasidesothatitdoesnotaccidentallycontactthesparkplug.

26

Page 27

Lubrication

G011194

GreasingtheMachine

LubricatethegreasettingsregularlywithNo.2General

PurposeLithium-BaseGrease.Iftheyouoperatethe

machineundernormalconditions,lubricateallbearings

andbushingsafterevery50hoursofoperation.

Locatethegreasettingasfollows:

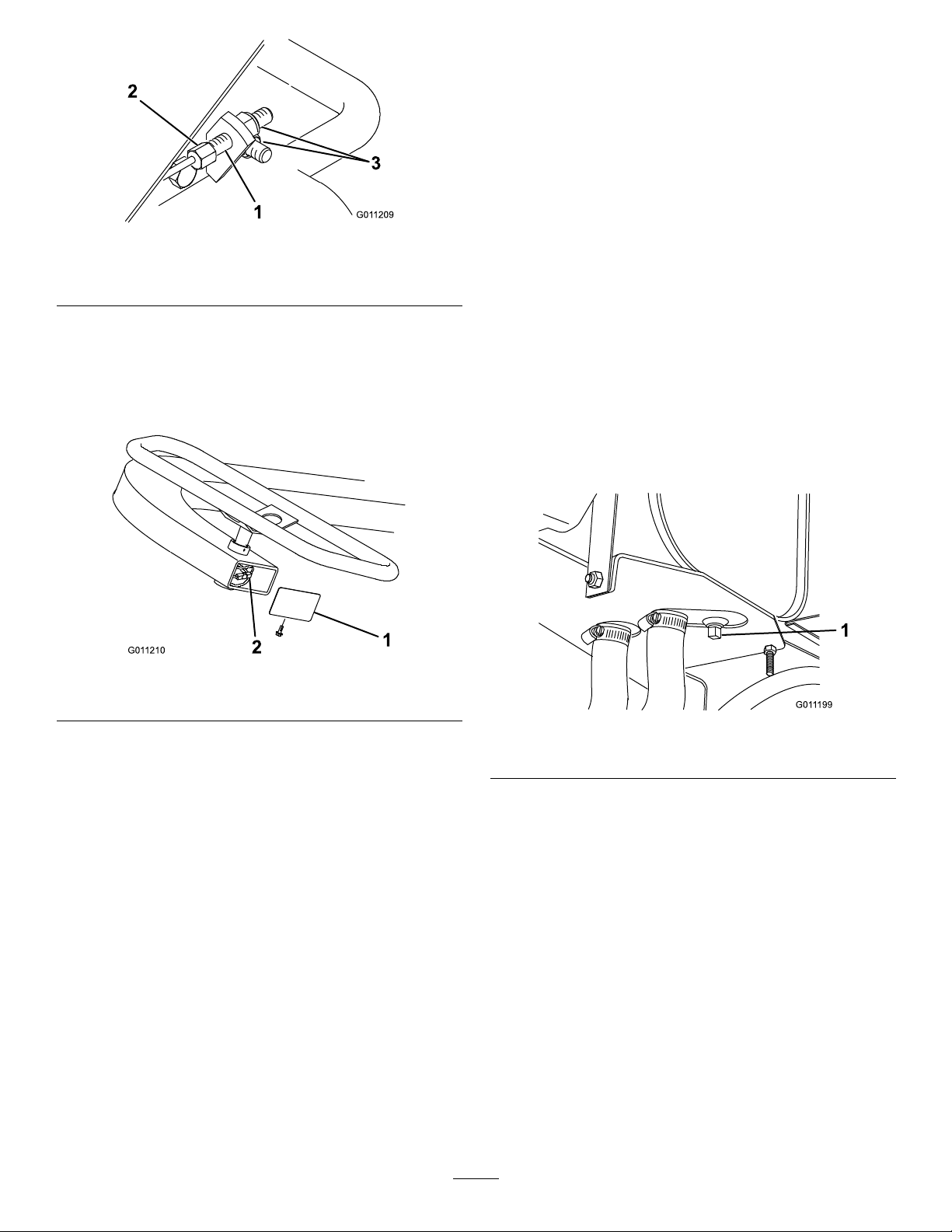

•Rearwheelbearings(1)(

Figure25)

Figure25

•Pullframeshaftandroller(12)(Figure28)

Figure28

•Mowliftpivot(Figure29).

•Steeringforkshaft(1)(Figure26)

Figure26

•Liftarmpivot(3)andpivothinge(3)(Figure27)

Figure29

•Liftcylinders(3)(Figure30)

Figure30

•Mowlockoutlever(Figure31).

Figure27

27

Page 28

G011197

Figure31

Togreasethemachine,completethefollowing

procedure:

1.Wipethegreasettingcleansoforeignmatter

cannotbeforcedintothebearingorbushing.

2.Pumpgreaseintothebearingorbushinguntilthe

greaseisvisible.Wipeupexcessgrease.

3.Applygreasetothereelmotorsplineshaftandonto

theliftarmwhenthecuttingunitisremovedfor

service.

4.ApplyafewdropsofSAE30engineoilorspray

lubricant(WD40)toallpivotpointsdailyafter

cleaning.

EngineMaintenance

ServicingtheAirCleaner

Servicetheaircleanerfoampre-cleanerafterevery50

operatinghoursandtheaircleanercartridgeafterevery

100operatinghours(morefrequentlywhenoperating

conditionsaredustyordirty).

1.Releasethelockingclipsandremovetheaircleaner

cover(

1.Aircleanercover

Figure32).Cleanthecoverthoroughly .

Figure32

2.Removethewingnutsecuringtheelementstothe

aircleanerbody .

3.Ifthefoamelementisdirty,removeitfromthepaper

element(Figure33).Cleanitthoroughly,asfollows:

A.Washthefoamelementinasolutionofliquid

soapandwarmwater.Squeezeittoremovedirt,

butdonottwistitbecausethefoammaytear.

B.Dryitbywrappingitinacleanrag.Squeezethe

ragandfoamelementdry.

Figure33

1.Foamelement2.Paperelement

28

Page 29

4.Whenservicingthefoamelement,checkthe

conditionofthepaperelement.Cleanitbygently

tappingitonaatsurfaceorreplaceitifneeded.

5.Installthefoamelement,paperelement,andair

cleanercover.

Important:Donotoperatetheenginewithout

theaircleanerelementbecauseextremeengine

wearanddamagewilllikelyresult.

ChangingtheEngineOiland

Filter

Changetheoilandlteraftertherst8hoursof

operation.Thereafter,changetheoilevery50hoursand

thelterevery100hours.

AdjustingtheThrottleControl

Properthrottleoperationisdependentuponproper

adjustmentofthethrottlecontrol.Beforeadjustingthe

carburetor,ensurethatthethrottlecontrolisoperating

properly.

1.Loosenthecableclampscrewsecuringthecableto

theengine(Figure35).

1.Removethedrainplug(

Figure34)andletoilow

intoadrainpan.Whentheoilstops,installthedrain

plug.

Figure34

1.Drainplug

2.Oillter

2.Removetheoillter(Figure34).Applyalightcoat

ofcleanoiltothenewltergasket.

Figure35

1.Throttlecasingclamp

screw

2.Throttlecable

3.Swivel7.Chokebuttery

4.Stop

5.Chokecasingclampscrew

6.Chokecable

2.Movetheremotethrottlecontrolleverforwardto

theFastposition.

3.Pullrmlyonthethrottlecableuntilthebackofthe

swivelcontactsthestop(

Figure35).

4.Tightenthecableclampscrewandchecktheengine

RPMsetting.

•HighIdle:2850±50RPM

•LowIdle:1650±100RPM

3.Screwthelteronbyhanduntilthegasketcontacts

thelteradapter,thentighten1/2to3/4turn

further.Donotovertighten.

4.Addoiltothecrankcase;referto

CheckingtheEngineOil(page18).

5.Disposeoftheusedoilproperly.

AdjustingtheChokeControl

1.Loosenthecableclampscrewsecuringthecableto

theengine(Figure35).

2.Movetheremotechokecontrolleverforwardtothe

Closedposition.

3.Pullrmlyonthechokecableuntilthechoke

butteryiscompletelyclosed,thentightenthecable

clampscrew(Figure35).

29

Page 30

AdjustingtheCarburetorand

ReplacingtheSparkPlugs

SpeedControl

Important:Beforethecarburetorandspeed

controlareadjusted,thethrottleandchokecontrols

mustbeadjustedproperly.

WARNING

Theenginemustberunningduringadjustment

ofthecarburetorandspeedcontrol.Contactwith

movingpartsorhotsurfacesmaycausepersonal

injury.

•Shiftintoneutralandengagetheparkingbrake

beforeperformingthisprocedure.

•Keephands,feet,clothing,andotherbodyparts

awayfromthecuttingblades,rotatingparts,the

mufer,andotherhotsurfaces.

1.Starttheengineandletitrunathalfthrottlefor

approximatelyveminutestowarmup.

2.MovethethrottlecontroltotheSlowsetting.Adjust

theidlestopscrewcounterclockwiseuntilitno

longercontactsthethrottlelever.

3.Bendthegovernedidlespringanchortang

(Figure36)toattainanidlespeedof1650±100

RPM.Checkthespeedwithatachometer.

Replacethesparkplugsafterevery800operatinghours.

Therecommendedairgapis0.030inch(0.76mm)

ThecorrectsparkplugtouseisaChampionRC14YC.

Note:Thesparkplugusuallylastsalongtime;however,

theplugshouldberemovedandcheckedwheneverthe

enginemalfunctions.

1.Cleantheareaaroundthesparkplugssoforeign

mattercannotfallintothecylinderwhenthespark

plugisremoved.

2.Pullthesparkplugwiresoffofthesparkplugsand

removetheplugsfromthecylinderhead.

3.Checktheconditionofthesideelectrode,center

electrode,andcenterelectrodeinsulatortoensure

thatthereisnodamage.

Important:Replaceacracked,fouled,dirty,or

otherwisemalfunctioningsparkplug.Donot

sandblast,scrape,orcleanelectrodesbyusinga

wirebrushbecausegritmayeventuallyrelease

fromtheplug,fallintothecylinder,anddamage

theengine.

4.Settheairgapbetweenthecenterandsideofthe

electrodesat0.030in.(0.76mm)(

Figure37).

Figure36

ShownwithAirCleanerRemoved

1.Governedidlespring

anchortang

2.Highspeedspringanchor

tang

4.Adjusttheidlestopscrewclockwiseuntiltheidle

speedisanadditional25to50RPMovertheidle

speedsetinstep3

5.MovethethrottlecontroltotheFastposition.Bend

thehighspeedspringanchortang(Figure36)to

attainahighspeedof2850±50RPM.

Figure37

5.Installthecorrectlygappedsparkplugwithgasket

seal,andtightentheplugto200in-lb(23N-m).Ifa

torquewrenchisnotused,tightentheplugrmly.

30

Page 31

FuelSystem

G011198

1

2

ElectricalSystem

Maintenance

ReplacingtheFuelFilter

Anin-linelterisincorporatedintothefuellinebetween

thefueltankandcarburetor(Figure38).Replacethe

lterevery800hoursorsoonerifthefuelowis

restricted.Besurethearrowonthelterispointing

awayfromthefueltank.

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Draingasolinefromthefueltankwhenthe

engineiscold.Dothisoutdoorsinanopenarea.

Wipeupanygasolinethatspills.

•Neversmokewhendraininggasoline,andstay

awayfromanopenameorwhereasparkmay

ignitethegasolinefumes.

1.Closethefuelshutoffvalve,loosenthehoseclamp

onthecarburetorsideoflter,andremovethefuel

linefromthelter(Figure38).

Maintenance

ServicingtheBattery

Properlymaintainthebatteryelectrolyteandkeepthe

topofthebatteryclean.Storethemachineinacool

placetopreventthebatteryfromrunningdown.

Checktheelectrolytelevelevery50operatinghoursor,

ifmachineisinstorage,every30days.

DANGER

Batteryelectrolytecontainssulfuricacidwhichisa

deadlypoisonandcausessevereburns.

•Donotdrinkelectrolyteandavoidcontactwith

skin,eyesorclothing .Wearsafetyglassesto

shieldyoureyesandrubberglovestoprotect

yourhands.

•Fillthebatterywherecleanwaterisalways

availableforushingtheskin.

Maintainthecelllevelwithdistilledordemineralized

water.Donotllthecellsabovethebottomofthesplit

ringinsideeachcell.

Keepthetopofthebatterycleanbywashingit

periodicallywithabrushdippedinammoniaor

bicarbonateofsodasolution.Flushthetopsurfacewith

wateraftercleaningit.Donotremovethellcapswhile

cleaningthebattery.

Thebatterycablesmustbetightontheterminalsto

Figure38

1.Fuelshutoffvalve2.Fuellter

providegoodelectricalcontact.

WARNING

2.Placeadrainpanunderthelter,loosenthe

remaininghoseclampandremovethelter

(Figure38).

3.Installthenewlterwiththearrowonthelterbody

pointingawayfromthefueltank.

Incorrectbatterycableroutingcoulddamagethe

tractorandcablescausingsparks.Sparkscancause

thebatterygassestoexplode,resultinginpersonal

injury.

•Alwaysdisconnectthenegative(black)battery

cablebeforedisconnectingthepositive(red)

cable.

FuelLinesandConnections

•Alwaysconnectthepositive(red)batterycable

ServiceInterval:Every2,000hours/Every2years

(whichevercomesrst)

Every2,000hours/Every2years

(whichevercomesrst)

Inspectthefuellinesfordeterioration,damage,orloose

connections.

31

beforeconnectingthenegative(black)cable.

Ifcorrosionoccursattheterminals,disconnectthe

cables,negative(-)cablerst,andscrapetheclampsand

terminalsseparately.Reconnectthecables,positive(+)

cablerst,andcoattheterminalswithpetroleumjelly.

Page 32

WARNING

CALIFORNIA

Proposition65Warning

BrakeMaintenance

AdjustingtheBrakes

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

Washhandsafterhandling.

Abrakeadjustmentrodislocatedoneachsideofthe

machinesothatthebrakescanbeequallyadjusted.

Adjustthebrakesasfollows:

1.Whilemovingforwardintransportspeed,pressthe

brakepedal;bothwheelsshouldlockequally.

CAUTION

Testingthebrakesinaconnedareawhere

othersarepresentcouldcauseinjury.

Alwayscheckthebrakesinawide,open-spaced,

atareawhichisfreeofotherpersonsand

obstructionsbeforeandafteradjustment.

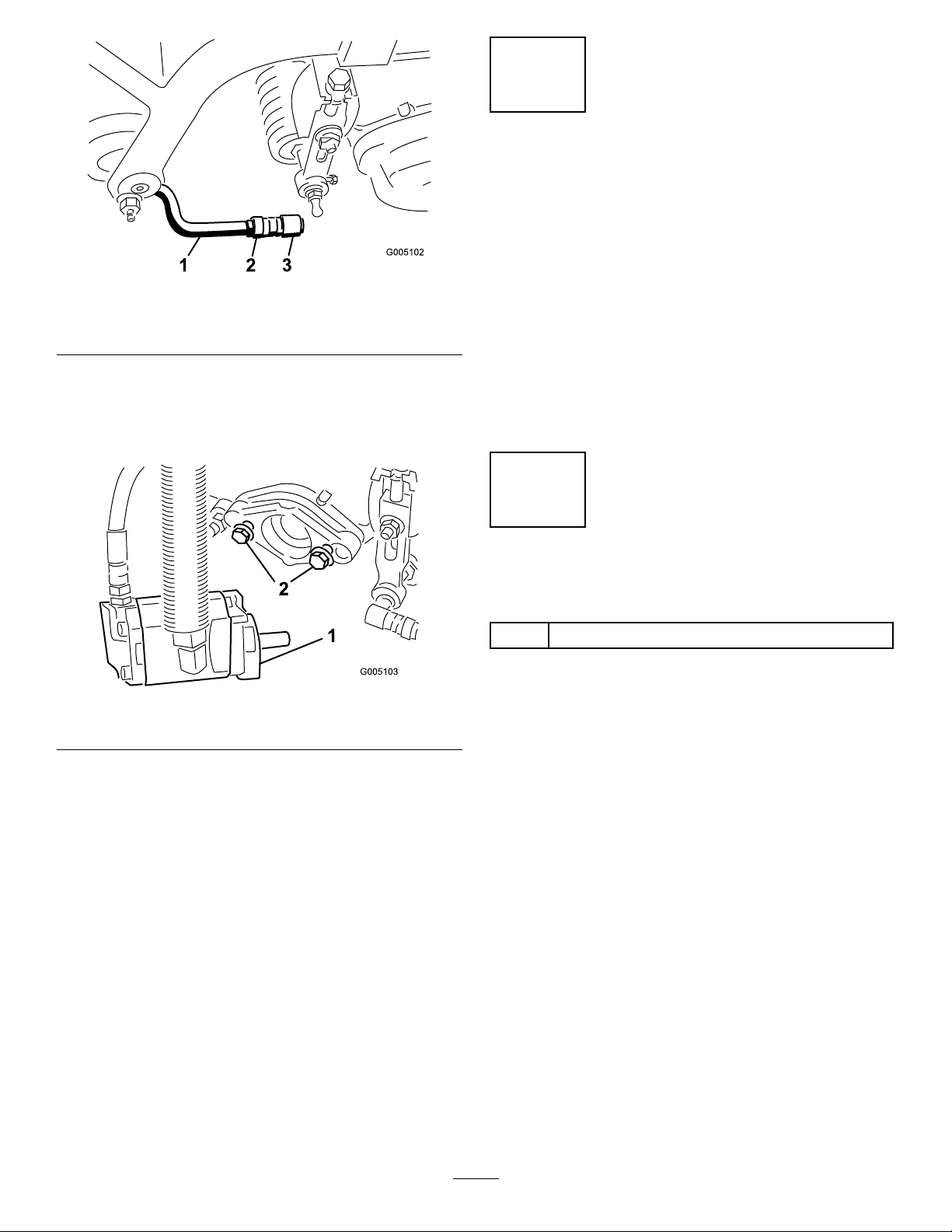

2.Ifthebrakesdonotlockequally,disconnectthe

brakerodsbyremovingthecotterpinandclevispin

Figure39).

(

Figure39

1.Clevispinandcotterpin3.Clevis

2.Jamnut

3.Loosenthejamnutandadjusttheclevisaccordingly

(Figure39).

4.Assembletheclevistothebrakeshaft(Figure39).

5.Checktheamountoffreetravelofthebrakepedal

whentheadjustmentiscompleted.Thereshouldbe

1/2to1inch(13to26mm)travelbeforethebrake

shoesmakecontactwiththebrakedrums.Adjust,if

necessary,toachievethissetting.

6.Whilemovingforwardintransportspeed,pressthe

brakepedal;bothbrakesshouldlockequally .Adjust,

ifnecessary.

7.Itisrecommendedthatthebrakesbeburnished

annually;refertotheBreak-InPeriodsection.

32

4.Brakeshaft

Page 33

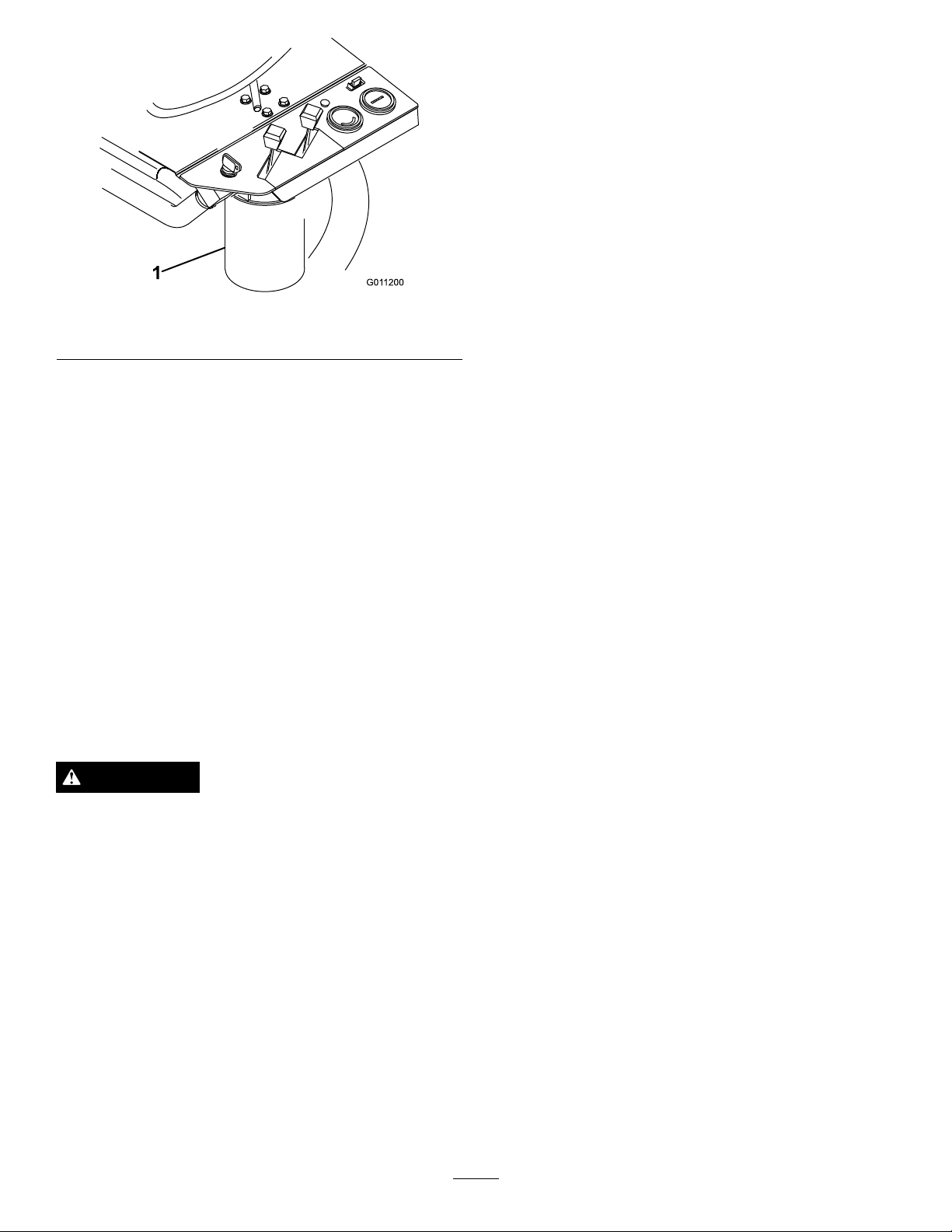

ControlsSystem

G011201

1

2

G011202

1

G011203

1

2

3

4

Maintenance

AdjustingtheRearCamshaft

Acamshaftmisalignedwiththevalvebankmaycause

thefollowing:

•NoincreaseingroundspeedintheNo.2(transport)

tractionselection

•Themowpedalwillnotstaydepressed(indetent)

withoutfootpressure.

•Slowliftofthecuttingunits

•Slowornodrivetothecuttingunits

Ifoneormoremalfunctionsoccur,loosentherear

camshaftmountingbolts(

camshaftuntiltheconditioniscorrected.Retightenthe

bolts.

Important:Readjustthemow/liftswitchand

theliftandmowpedalheightwhenthecamshaft

adjustmentiscompleted.

Figure40)andrelocatethe

Figure41

1.Transferrodguard

2.Loosenthejamnutsecuringtheyokeonthefront

ofthelongcontrolrod.Removethecotterpinand

clevispin.

3.Movetheadjustmentleverbyhandtolevelthemow

andliftpedalsandadjusttheyokeonthecontrol

roduntiltheholeintheyokelinesupwiththe

adjustmentleverhole(

Figure42).

Figure40

1.Mountingbolts

2.Camblocks

AdjustingtheLiftandMow

PedalHeight

Togainproperspooltravelinthevalvebank,adjustthe

liftandmowpedalstoequalheightsasfollows:

1.Place1,2,and3spoolsinneutral(centeroftravel)

andremovethetransferrodguardfromthefoot

panel(

Figure41).

Figure42

1.Jamnut

2.Yoke4.Adjustmentlever

3.Controlrod

LevelingtheLiftandMow

Pedals

Iftheliftandmowpedalsarenotlevelwhentheyare

intheneutralposition,anadjustmenttotheliftpivot

isrequired.

1.Loosenthenutonthebacksideoftheliftpivot

(Figure43).

33

Page 34

Figure43

G011206

2.Rotatetheeccentricscrew(Figure43)toraiseor

lowertheliftpivotspring,levelingtheliftpivotand

pedals.

3.Whileholdingthescrew ,tightenthenutlockingthe

adjustment.

AdjustingtheTractionPedal

AdjustingReverse

1.Pressdownontherearofthetractionpedal(reverse)

untiltheNo.5sectionspoolvalveiscompletely

pushedin.2.A.B.

2.Checkthedistancebetweenthebottomofthepedal

andfootrestasshownin

shouldbeapproximately3/16inch(5mm).Ifthe

distanceisgreaterorlessthan3/16inch(5mm),an

adjustmenttothetractioncontrolrodisrequired.

Proceedasfollows:

A.Removethejamnutandballjointsecuringthe

controlrod(

Figure44)tothetractionshaftpivot.

B.Loosenthejamnutssecuringtheballjoints

tothecontrolrodandadjusttheballjoints

andcontrolrodtoattainthe3/16inch(5mm)

dimensionwhenreinstalled.

Figure44.Thedistance

Tochecktheforwardandreverseoperationofthe

tractionpedal,proceedasfollows:

AdjustingForward

1.PressthetractionpedalfullyforwarduntiltheNo.

5sectionvalvespooliscompletelypulledout.The

pedalshouldcontactthepedalstop(Figure44).

AdjustingCuttingUnitLiftand

Drop

Thecuttingunitlift/dropcircuitisequippedwitha

owcontrolvalve.Thisvalveispresetatthefactoryat

approximately3-1/2turnsopen,butanadjustmentmay

berequiredtocompensatefordifferencesinhydraulic

oiltemperatures,mowingspeeds,etc.Ifanadjustment

isrequired,proceedasfollows:

Note:Allowthehydraulicoiltoreachfulloperating

temperaturebeforeadjustingtheowcontrolvalve.

1.Raisetheseatandlocatetheowcontrolvalve

mountedtothemaincontrolvalve(

Figure45).

Figure44

1.Fullyforward

2.Pedalstop

3.Reverse

4.Controlrod

Ifthepedalcontactsthestopbeforethespoolis

completelyout,orifthepedaldoesnotmakecontact

withthestop,anadjustmenttothestopisnecessary.

Proceedasfollows:

2.Loosenthehexnutsecuringthethreadedrodto