Page 1

FormNo.3367-393RevA

11and14BladeCuttingUnits

Greensmaster

®

Flex18andFlex21Traction

Units

ModelNo.04202—SerialNo.311000001andUp

ModelNo.04206—SerialNo.311000001andUp

ModelNo.04207—SerialNo.311000001andUp

ModelNo.04208—SerialNo.311000001andUp

ToregisteryourproductordownloadanOperator'sManualorPartsCatalogatnocharge,gotowww.T oro.com.OriginalInstructions(EN)

Page 2

ThisproductcomplieswithallrelevantEuropean

directives,fordetailspleaseseetheseparateproduct

specicDeclarationofConformity(DOC)sheet.

injuryordeathifyoudonotfollowtherecommended

precautions.

Introduction

Thisreel-bladelawnmowerismountedtoawalkbehind

machineandisintendedtobeusedbyprofessional,hired

operatorsincommercialapplications.Itisprimarily

designedforcuttinggrassonwell-maintainedlawnsin

parks,golfcourses,sportselds,andoncommercial

grounds.Itisnotdesignedforcuttingbrush,mowing

grassandothergrowthalongsidehighways,orfor

agriculturaluses.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoidinjury

andproductdamage.Youareresponsibleforoperating

theproductproperlyandsafely .

YoumaycontactTorodirectlyatwww.Toro.comfor

productandaccessoryinformation,helpndinga

dealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

Figure1

Figure2

1.Safetyalertsymbol

Thismanualuses2otherwordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Contents

Introduction.................................................................2

Safety...........................................................................3

SafetyandInstructionalDecals.............................3

Operation.....................................................................4

AdjustingtheRearRoller......................................4

AdjustingtheBedknifetotheReel........................4

AdjustingtheHeightofCut..................................5

AdjustingtheCut-OffBar....................................6

SettingtheMachinetoMatchTurf

Conditions.......................................................7

Maintenance.................................................................9

SeparatingtheCuttingUnitfromtheTraction

Unit..................................................................9

ServicingtheBedbar...........................................10

BacklappingtheReel..........................................10

Figure1

1.Locationofthemodelandserialnumbers

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafetyalertsymbol

(Figure2),whichsignalsahazardthatmaycauseserious

©2010—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

Safety

Hazardcontrolandaccidentpreventionare

dependentupontheawareness,concern,and

propertrainingofthepersonnelinvolvedinthe

operation,transport,maintenance,andstorageof

themachine.Improperuseormaintenanceofthe

machinecanresultininjuryordeath.Toreduce

thepotentialforinjuryordeath,complywiththe

followingsafetyinstructions.

•Read,understand,andfollowallinstructionsinthe

tractionunitandcuttingunitoperatorsmanual’s

beforeoperatingthecuttingunit.

•Neverallowchildrentooperatethetractionunitor

cuttingunits.Donotallowadultstooperatetraction

unitorcuttingunitswithoutproperinstruction.

Onlytrainedoperatorswhohavereadthismanual

shouldoperatethetractionunitorcuttingunits.

•Neveroperatethecuttingunitswhenunderthe

inuenceofdrugsoralcohol.

sneakersorshorts.Also,donotwearloosetting

clothingwhichcouldgetcaughtinmovingparts.

Alwayswearlongpantsandsubstantialshoes.

Wearingsafetyglasses,safetyshoesandahelmetis

advisableandrequiredbysomelocalordinancesand

insuranceregulations.

•Removealldebrisorotherobjectsthatmightbe

pickedupandthrownbythecuttingunitreelblades.

Keepallbystandersawayfromtheworkingarea.

•Ifthecuttingbladesstrikeasolidobjectortheunit

vibratesabnormally,stopandshuttheengineoff.

Checkcuttingunitfordamagedparts.Repairany

damagebeforerestartingandoperatingthecutting

unit.

•Besurecuttingunitsareinsafeoperatingcondition

bykeepingnuts,boltsandscrewstight.

•Performonlythosemaintenanceinstructions

describedinthismanual.Ifmajorrepairsare

everneededorassistanceisdesired,contactan

AuthorizedToroDistributor.

•Lightningcancausesevereinjuryordeath.If

lightningisseenorthunderisheardinthearea,do

notoperatethemachine;seekshelter.

•Keepallshieldsandsafetydevicesinplace.Ifa

shield,safetydeviceordecalisillegibleordamaged,

repairorreplaceitbeforeoperationiscommenced.

Alsotightenanyloosenuts,bolts,andscrewsto

ensurecuttingunitisinsafeoperatingcondition.

•Alwayswearsubstantialshoes.Donotoperate

cuttingunitswhilewearingsandals,tennisshoes,

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaof

potentialdanger.Replaceanydecalthatisdamagedorlost.

•Toensureoptimumperformanceandsafety,always

purchasegenuineTororeplacementpartsand

accessoriestokeeptheToroallTORO.Neveruse

"will-t"replacementpartsandaccessories

madebyothermanufacturers.Lookforthe

Torologotoassuregenuineness.Usingunapproved

replacementpartsandaccessoriescouldvoidthe

warrantyofTheToroCompany.

93-8064

1.Warning—readtheinstructionsbeforeservicingor

performingmaintenance.

2.Cuttinghazardoffootorhand—stoptheengineandwait

formovingpartstostop.

3

Page 4

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

AdjustingtheRearRoller

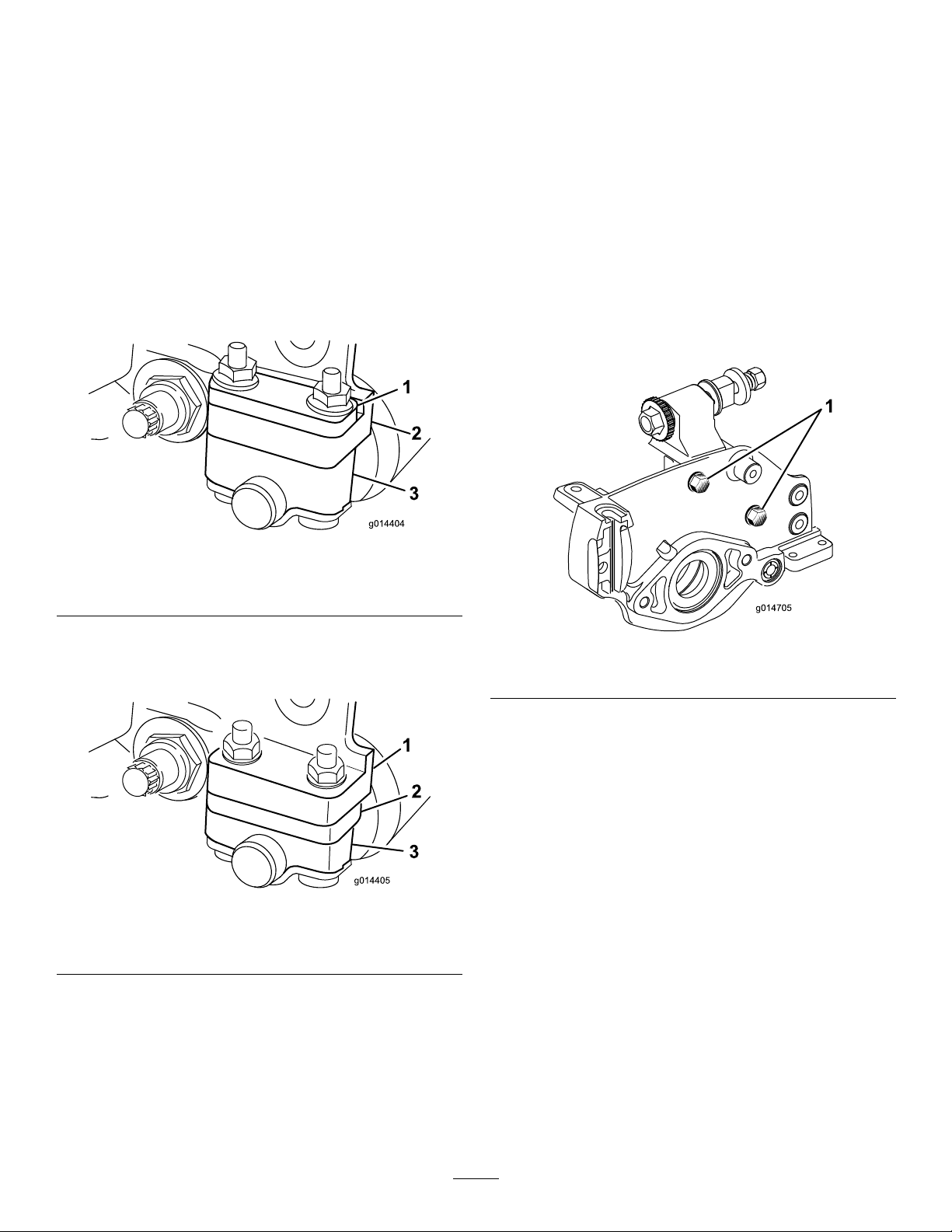

1.Adjusttherearrollerbracketstotheloworhigh

positiondependingondesiredheightofcutrange

Figure3andFigure4).

(

•Positionthespacerabovethesideplate

mountingange(factorysetting)whenheight

ofcutsettingsrangefrom1/16to1/4inch(1.5

to6.3mm)(Figure3).

•Placespacersontoscrewsonrollerbrackets.

•Re-securerollerbracketandspacersto

undersideofsideplatemountingangeswith

nutspreviouslyremoved.

3.Verifythatthebedknifetoreelcontactiscorrect.

Tipmowertoexposefrontandrearrollersand

bedknife.

Note:Thepositionoftherearrollertothe

reeliscontrolledbythemachiningtolerances

oftheassembledcomponentsandparallelingis

notrequired.Alimitedamountofadjustmentis

possiblebysettingthecuttingunitonasurface

plateandlooseningthesideplatemountingbolts

Figure5).Adjustandre-tightenbolts.

(

Figure3

1.Spacer

2.Sideplatemountingange

•Positionthespacerbelowthesideplate

mountingangewhenheightofcutsettings

rangefrom1/8"to1"(

1.Sideplatemountingange

2.Spacer

3.Rollerbracket

Figure4

3.Rollerbracket

Figure4).

Figure5

1.Sideplatemountingbolts

Important:Wheneverthecuttingunithasto

betippedtoexposebedknife/reel,propuprear

ofcuttingunittomakesurenutsonbackend

ofbedbaradjustingscrewsarenotrestingon

worksurface.

AdjustingtheBedknifetothe

Reel

Bedknifetoreeladjustmentisaccomplishedby

looseningortighteningbedbaradjustingscrews,located

ontopofmower.

2.Toadjustrearrollerproceedasfollows:

•Raiserearofcuttingunitandplaceablock

underbedknife.

•Remove(2)nutssecuringeachrollerbracket

andspacertoeachsideplatemountingange.

•Lowerrollerandscrewsfromsideplate

mountingangesandspacers.

1.Positionmachineonaat,levelworksurface.

2.Makesurereelcontactisremovedbyturningbedbar

adjustingscrewscounterclockwise(Figure6).

4

Page 5

tothebedknife(Figure7).Itshouldbepossible

tocutpaperwithminimumcontactbetweenthe

bedknifeandthereelblades.Shouldexcessivereel

dragbeevidentitwillbeeithernecessarytobacklap

orregrindthecuttingunittoachievethesharp

edgesneededforprecisioncutting(seeTororeel

sharpeningmanual).

Figure6

1.Bedbaradjustingscrew

3.Tiltmoweronbacktoexposebedknifeandreel.

Note:Whentiltingthecuttingunitback,make

surethecenterofthecuttingunitisblockedupso

thebedbaradjusterscrewsarenotsupportingthe

cuttingunit.Restingthecuttingunitonthebedbar

adjustingscrewswillgiveafalsereel-to-bedknife

contactwhenthecuttingunitisloweredbackto

level.

4.Atoneendofreel,insertalongstripofnewspaper

betweenreelandbedknife(

Figure7).Whileslowly

rotatingreelforward,turnbedbaradjustingscrew

clockwise(onsameendofreel)(Figure6),one

clickatatime,untilpaperispinchedlightly ,when

insertedfromthefront,paralleltothebedknife.A

slightdragwillbenotedasthepaperispulled.

AdjustingtheHeightofCut

Forheightsofcutgreaterthan.500inch(12.7mm),the

highheightofcutkitmustbeinstalled.

1.Loosenlocknutssecuringheight-of-cutarmsto

cuttingunitsideplates(

Figure8).

Figure7

Note:Eachtimeadjustingscrewisrotatedone

clickclockwise,thebedknifemoves.0007inch

(.017mm)closertoreel.Donotovertightenthe

adjustingscrews.

5.Checkforlightcontactatotherendofreelusing

paperandadjustasrequired.

6.Afteradjustmentisaccomplished,checktosee

ifreelcanpinchpaperwheninsertedfromthe

frontandcutpaperwheninsertedatarightangle

Figure8

1.Rearrollerbracket3.Locknut

2.Height-of-cutarm

4.Adjustingscrew

2.Loosennutongaugebar(Figure9)andset

adjustingscrewtodesiredheight-of-cut.Distance

betweenbottomofscrewheadandfaceofbaris

height-of-cut.

Figure9

1.Gaugebar

2.Heightadjustingscrew

3.Nut

5

Page 6

3.Hookscrewheadoncuttingedgeofbedknifeand

restrearendofbaronrearroller(Figure10).

4.Rotateadjustingscrewuntilrollercontactsfrontof

gaugebar.Adjustbothendsofrolleruntilentire

rollerisparalleltothebedknife.

Important:Whensetproperly,therearand

frontrollerswillcontactthegaugebarandthe

screwwillbesnugagainstthebedknife.This

ensuresthattheheight-of-cutisidenticalat

bothendsofthebedknife.

Figure10

1.Gaugebar

Figure11

1.Cut-offbar

2.Insert.060inch(1.5mm)feelergaugebetweentop

ofreelandbarandtightenscrews.Ensurebarand

reelareequaldistanceapartacrosscompletereel.

Note:Thebarisadjustabletocompensatefor

changesinturfconditions.Thebarshouldbe

adjustedclosertoreelwhenturfisextremelydry.

Bycontrast,adjustbarfurtherawayfromreelwhen

turfconditionsarewet.Thebarshouldbeparallel

toreeltoensureoptimumperformanceandshould

beadjustedwheneverreelissharpenedonareel

grinder.

5.Tightennutstosecureadjustment.Donot

overtightennut.Tightenenoughtoremoveplay

fromwasher.

Note:Usethefollowingcharttodeterminewhich

bedknifeisbestsuitedforthedesiredheightofcut.

AdjustingtheCut-OffBar

Adjustcut-offbartoassureclippingsarecleanly

dischargedfromthereelarea:

1.Loosenscrewssecuringtopbar(Figure11)to

cuttingunit.

6

Page 7

SettingtheMachinetoMatchTurfConditions

Usethefollowingtabletosetthemachinetomatchturfconditions.

FlexGreensmowerCuttingUnitSet-upMatrix

Bedbars:StandardandOptional

PartNumberDescriptionMowerAggressiveness

106-2468-01

99-3794-03AggressiveFlex21More

110-2282-01

110-2281-03AggressiveFlex18More

Bedknives:StandardandOptional

PartNumberDescriptionMower

93-4262MicrocutFlex210.062-0.125inches

115–1880EdgeMaxMicrocutFlex210.062-0.125inches

93-4263TournamentFlex210.125-0.250inches

115–1881EdgeMaxT ournamentFlex210.125-0.250inches

93-4264

108-4303ExtendedMicrocutFlex210.062-0.125inches

98-7261MicrocutFlex180.062-0.125inches

117–1530‘

98-7260TournamentFlex180.125-0.250inches

117–1532‘

110-2300ExtendedMicrocutFlex180.062-0.125inches

110-2301

Standard

Standard

LowCut

EdgeMaxMicrocutFlex180.062-0.125inches

EdgeMaxT ournamentFlex180.125-0.250inches

LowCut

Flex21Less

Flex18Less

HeightofCutRangeComments

Flex21

Flex18

0.250inches(6mm)andup

0.250inches(6mm)andup

(1.57-3.1mm)

(1.57-3.1mm)

(1.57-3.1mm)

(1.57-3.1mm)

(1.57-3.1mm)

(1.57-3.1mm)

Comments

Standard

Standard

Standard(11Blade)

Standard(14Blade)

(3.1-6mm)

LongerWearing

(3.1-6mm)

LessAggressive

Standard(11Blade)

Standard(14Blade)

(3.1-6mm)

LongerWearing

(3.1-6mm)

LessAggressive

Rollers:StandardandOptional

PartNumberDescriptionMower

107-9037NarrowWiehleFlex21

107-9038WideWiehleFlex21

107-9039FullRollerFlex21

107-9036RearRollerFlex21

106-6945RearRollerFlex21

93–9045

AntiScalpWiehle

Flex21

Diameter/MaterialComments

2.5inches(63.5mm)

Aluminum

2.5inches(63.5mm)

Aluminum

2.5inches(63.5mm)Steel

2.0inches(50.8mm)

Aluminum

2.0inches(50.8mm)SteelSteelRear

2.5inches(63.5mm)

Aluminum1–7/8inches

(47.4mm)longer

7

StandardFront

MorePenetration

LeastPenetration

StandardRear

Moreedgesupport

Page 8

110-2304NarrowWiehleFlex18

110-2305WideWiehleFlex18

110-2306FullRollerFlex18

110-2303RearRollerFlex18

2.5inches(63.5mm)

Aluminum

2.5inches(63.5mm)

Aluminum

2.5(63.5mm)inchesSteel

2.0inches(50.8mm)

Aluminum

StandardFront

MorePenetration

LeastPenetration

StandardRear

UsethefollowingtableandFigure12tosettherateofclip.

Clip(RefertoFigure12forpulleylocations.)

Drivepulleynumber

ofteeth

27(standard)22(standard)0.112(2.9)0.143(3.6)0.197(5.0)

2222

2227

Drivenpulleynumber

ofteeth

14BladeClipinch(mm)11BladeClipinch(mm)8BladeClipinch(mm)

0.138(3.5)0.176(4.5)0.241(6.1)

0.172(4.4)0.219(5.6)0.301(7.7)

Thereelisshippedwithone27toothandone22toothpulley .Togeta.16inch(4mm)clip,youmustpurchase

a22toothpulley.Theclipcanonlybechangedonthereeldrive(Figure12).Donotchangethedriveratio

onthegearboxpulleys.

Figure12

1.Reeldrivebelt3.Drivenpulley

2.Drivepulley

8

Page 9

Maintenance

SeparatingtheCuttingUnit

fromtheTractionUnit

1.Placethemoweronitsdrumsonalevelsurface.

2.Lowerkickstand.Inserta1/4inch(6mm)diameter

pinorequivalentintoframeholeabovekickstand

mountingbolt(

Figure13).

Figure15

1.Transmissioncoupling

7.Reverseproceduretoinstallcuttingunit.

Note:Whentighteningthepivotarmmounting

fasteners,useanadjustableendwrenchtoholdthe

pivotarmparalleltothesideplate(

Figure16).

Figure13

1.1/4"Pin

2.Handle

3.Kickstand

3.Removegrassbasket.

4.Remove(2)boltssecuringcuttingunitpivotarmsto

tractionunitframetube(Figure14).

Figure14

1.Cuttingunitpivotarms

2.Tractionunitframetube

3.Bolts

Figure16

5.Rotatepivotarmsforward(Figure14)andrest

tractionunitonrestrainedkickstand.

6.Pullcuttingunitforwardabout2inch(51mm)

andthentotherighttodisengagethetransmission

coupling(Figure15).

9

Page 10

ServicingtheBedbar

RemovingtheBedbar

1.Turnthebedbaradjusterscrew,counterclockwise,to

backthebedknifeawayfromreel(Figure17).

Figure17

1.Bedbaradjustingscrew4.Jamnut

2.Springtensionnut

3.Bedbar

2.Backoutthespringtensionnut,untilthewasheris

nolongertensionedagainstthebedbar(Figure18).

3.Oneachsideofthemachine,loosenthejamnut

securingthebedbarbolt(

5.Bedbarbolt

Figure18).

Figure19

1.Bedbarbolt3.Nut

2.Steelwasher

4.Nylonwasher

AssemblingtheBedbar

1.Installbedbar,positioningmountingearsbetween

washerandbedbaradjuster.

2.Securebedbartoeachsideplatewithbedbarbolts

(jamnutsonbolts)and8washers.Anylonwasher

istobepositionedoneachsideofsideplateboss.

Placeasteelwasheroutsideeachofthenylon

washers.Torqueboltsto240-320in.-lb(27-36N-m).

Figure18

1.Bedbarbolt2.Nut

4.Removeeachbedbarboltallowingbedbartobe

pulleddownwardandremovedfrommachine.

Accountfor2nylonand2stampedsteelwasherson

eachendofbedbar(

Figure19).

3.Tightenthejamnutuntiltheendplayisremoved

fromtheoutsidethrustwashers.Donotovertighten.

Note:Itisacceptablethattheinsidethrustwashers

onthecuttingunitmayremainloose.

4.Tightenspringtensionnutuntilspringiscollapsed,

thenbackoff1/2turn.

5.Adjustbedbar;refertoAdjustingtheBedknifeto

theReel.

BacklappingtheReel

1.Removeplugfromthereeldrivecoverontheleft

sideofreelassembly(

Figure20)

10

Page 11

Figure20

1.Reeldrivecoverplug

2.Inserta18mmsocketontohexangenutonleft

endofreelshaft.

3.BacklapaccordingtotheprocedureintheToro

SharpeningReelandRotaryMowersManual,Form

No.80-300PT.

DANGER

Contactwiththereelorothermovingpartscan

resultinpersonalinjury.

•Stayawayfromthereelwhilebacklapping.

•Neveruseashorthandledpaintbrushfor

backlapping.PartNo.29-9100Handle

assemblycompleteorindividualpartsare

availablefromyourlocalAuthorizedToro

Distributor.

Note:Forabettercuttingedge,runaleacross

thefrontfaceofthebedknifewhenthelapping

operationiscompleted.Thiswillremoveanyburrs

orroughedgesthatmayhavebuiltuponthecutting

edge.

4.Reinstallplugwhenbacklapoperationiscompleted.

11

Page 12

TheToroTotalCoverageGuarantee

ALimitedWarranty

ConditionsandProductsCovered

TheT oro

toanagreementbetweenthem,jointlywarrantyourT oroCommercial

product(“Product”)tobefreefromdefectsinmaterialsorworkmanship

fortwoyearsor1500operationalhours*,whicheveroccursrst.This

warrantyisapplicabletoallproductswiththeexceptionofAerators

(refertoseparatewarrantystatementsfortheseproducts).Wherea

warrantableconditionexists,wewillrepairtheProductatnocosttoyou

includingdiagnostics,labor,parts,andtransportation.Thiswarranty

beginsonthedatetheProductisdeliveredtotheoriginalretailpurchaser.

*Productequippedwithanhourmeter.

®

Companyanditsafliate,T oroWarrantyCompany,pursuant

InstructionsforObtainingWarrantyService

YouareresponsiblefornotifyingtheCommercialProductsDistributoror

AuthorizedCommercialProductsDealerfromwhomyoupurchasedthe

Productassoonasyoubelieveawarrantableconditionexists.Ifyouneed

helplocatingaCommercialProductsDistributororAuthorizedDealer,or

ifyouhavequestionsregardingyourwarrantyrightsorresponsibilities,

youmaycontactusat:

CommercialProductsServiceDepartment

ToroWarrantyCompany

811 1LyndaleAvenueSouth

Bloomington,MN55420-1196

E-mail:commercial.warranty@toro.com

OwnerResponsibilities

AstheProductowner,youareresponsibleforrequiredmaintenance

andadjustmentsstatedinyourOperator’sManual.Failuretoperform

requiredmaintenanceandadjustmentscanbegroundsfordisallowinga

warrantyclaim.

ItemsandConditionsNotCovered

Notallproductfailuresormalfunctionsthatoccurduringthewarranty

periodaredefectsinmaterialsorworkmanship.Thiswarrantydoesnot

coverthefollowing:

•Productfailureswhichresultfromtheuseofnon-T ororeplacement

parts,orfrominstallationanduseofadd-on,ormodiednon-Toro

brandedaccessoriesandproducts.Aseparatewarrantymaybe

providedbythemanufactureroftheseitems.

•Productfailureswhichresultfromfailuretoperformrecommended

maintenanceand/oradjustments.Failuretoproperlymaintainyour

ToroproductpertheRecommendedMaintenancelistedinthe

Operator’sManualcanresultinclaimsforwarrantybeingdenied.

•ProductfailureswhichresultfromoperatingtheProductinan

abusive,negligentorrecklessmanner.

•Partssubjecttoconsumptionthroughuseunlessfoundtobe

defective.Examplesofpartswhichareconsumed,orusedup,during

normalProductoperationinclude,butarenotlimitedto,brakes

padsandlinings,clutchlinings,blades,reels,bedknives,tines,

sparkplugs,castorwheels,tires,lters,belts,andcertainsprayer

componentssuchasdiaphragms,nozzles,andcheckvalves,etc.

•Failurescausedbyoutsideinuence.Itemsconsideredtobeoutside

inuenceinclude,butarenotlimitedto,weather,storagepractices,

contamination,useofunapprovedcoolants,lubricants,additives,

fertilizers,water,orchemicals,etc.

•Normalnoise,vibration,wearandtear,anddeterioration.

•Normal“wearandtear”includes,butisnotlimitedto,damageto

seatsduetowearorabrasion,wornpaintedsurfaces,scratched

decalsorwindows,etc.

Parts

Partsscheduledforreplacementasrequiredmaintenancearewarranted

fortheperiodoftimeuptothescheduledreplacementtimeforthatpart.

Partsreplacedunderthiswarrantyarecoveredforthedurationofthe

originalproductwarrantyandbecomethepropertyofT oro.T orowill

makethenaldecisionwhethertorepairanyexistingpartorassemblyor

replaceit.Toromayuseremanufacturedpartsforwarrantyrepairs.

NoteRegardingDeepCycleBatteryWarranty:

Deepcyclebatterieshaveaspeciedtotalnumberofkilowatt-hoursthey

candeliverduringtheirlifetime.Operating,recharging,andmaintenance

techniquescanextendorreducetotalbatterylife.Asthebatteriesinthis

productareconsumed,theamountofusefulworkbetweencharging

intervalswillslowlydecreaseuntilthebatteryiscompletelywornout.

Replacementofwornoutbatteries,duetonormalconsumption,isthe

responsibilityoftheproductowner.Batteryreplacementmayberequired

duringthenormalproductwarrantyperiodatowner’sexpense.

MaintenanceisatOwner’sExpense

Enginetune-up,lubricationcleaningandpolishing,replacementof

ItemsandConditionsNotCoveredlters,coolant,andcompleting

RecommendedMaintenancearesomeofthenormalservicesT oro

productsrequirethatareattheowner’sexpense.

GeneralConditions

RepairbyanAuthorizedT oroDistributororDealerisyoursoleremedy

underthiswarranty.

NeitherTheToroCompanynorToroWarrantyCompanyisliablefor

indirect,incidentalorconsequentialdamagesinconnectionwiththe

useoftheT oroProductscoveredbythiswarranty,includingany

costorexpenseofprovidingsubstituteequipmentorserviceduring

reasonableperiodsofmalfunctionornon-usependingcompletion

ofrepairsunderthiswarranty.ExceptfortheEmissionswarranty

referencedbelow,ifapplicable,thereisnootherexpresswarranty.

Allimpliedwarrantiesofmerchantabilityandtnessforusearelimitedto

thedurationofthisexpresswarranty.Somestatesdonotallowexclusions

ofincidentalorconsequentialdamages,orlimitationsonhowlongan

impliedwarrantylasts,sotheaboveexclusionsandlimitationsmaynot

applytoyou.

Thiswarrantygivesyouspeciclegalrights,andyoumayalsohaveother

rightswhichvaryfromstatetostate.

Noteregardingenginewarranty:

TheEmissionsControlSystemonyourProductmaybecoveredby

aseparatewarrantymeetingrequirementsestablishedbytheU.S.

EnvironmentalProtectionAgency(EP A)and/ortheCaliforniaAir

ResourcesBoard(CARB).Thehourlimitationssetforthabovedonot

applytotheEmissionsControlSystemWarranty .RefertotheEngine

EmissionControlW arrantyStatementprintedinyourOperator’sManual

orcontainedintheenginemanufacturer’sdocumentationfordetails

CountriesOtherthantheUnitedStatesorCanada

CustomerswhohavepurchasedT oroproductsexportedfromtheUnitedStatesorCanadashouldcontacttheirToroDistributor(Dealer)toobtain

guaranteepoliciesforyourcountry ,province,orstate.IfforanyreasonyouaredissatisedwithyourDistributor’sserviceorhavedifcultyobtaining

guaranteeinformation,contacttheT oroimporter.Ifallotherremediesfail,youmaycontactusatT oroWarrantyCompany .

374-0253RevA

Loading...

Loading...