Page 1

FormNo.3414-906RevA

GroomerDriveSystem

forGreensmaster

®

800/1000/1010/1600/1610Mower

ModelNo.04134

InstallationInstructions

WARNING

CALIFORNIA

Proposition65Warning

ThisproductcontainsachemicalorchemicalsknowntotheStateofCalifornia

tocausecancer,birthdefects,orreproductiveharm.

Important:Readtheseinstructionsthoroughlybeforesettinguporoperatingthegroomer.Failure

tofollowthesetuporoperatinginstructionsinthismanualmayresultindamagetothemachine,

groomer,andtheturf.

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

Qty.

Use

1

Nopartsrequired

–

Preparethemachine.

2

Nopartsrequired

–

Movethefrontroller.

Groomer-housingassembly

1

Flat-headscrew(3/8x2inches)

2

Locknut(3/8inch)

2

Bearingadapter1

Spacer

2

O-ring

1

Syntheticgrease

-

Slotcover

1

3

Adapterring1

Installthegroomerhousing.

Shaftassembly

1

Drivegear1

4

Syntheticgrease

–

Installthedrivegear.

5

ForwardRotationKit-obtainseparately1

Setthegroomerforforwardrotation

(optional).

Groomer-housingcoverassembly

1

Gasket

1

Flange-headbolt(1/4x3/4inch)

5

6

Syntheticgrease(3.0oz)

1

Installthegroomer-housingcover.

©2017—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.T oro.com.

OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved

*3414-906*A

Page 2

ProcedureDescription

Qty.

Use

BearingAdapter1

Spacer

2

Groomer-plateassembly

1

Adapterring1

Bolt(1/4x3-3/4inches)

2

Starwasher

2

Fastenerretainer2

7

Weight1

Installthegroomerontherightsideof

themachine.

Groomer-shaftclamp

4

Socket-headscrew(1/4x1-1/4inches)

4

8

Groomerreel(obtainseparately)

1

Installthegroomingreel.

1

PreparingtheMachine

NoPartsRequired

Procedure

1.Parkthemachineonalevelsurface.

2.Engagetheparkingbrake.

3.Shutofftheengineandremovethekeyfrom

theswitch.

2

MovingtheFrontRoller

NoPartsRequired

Procedure

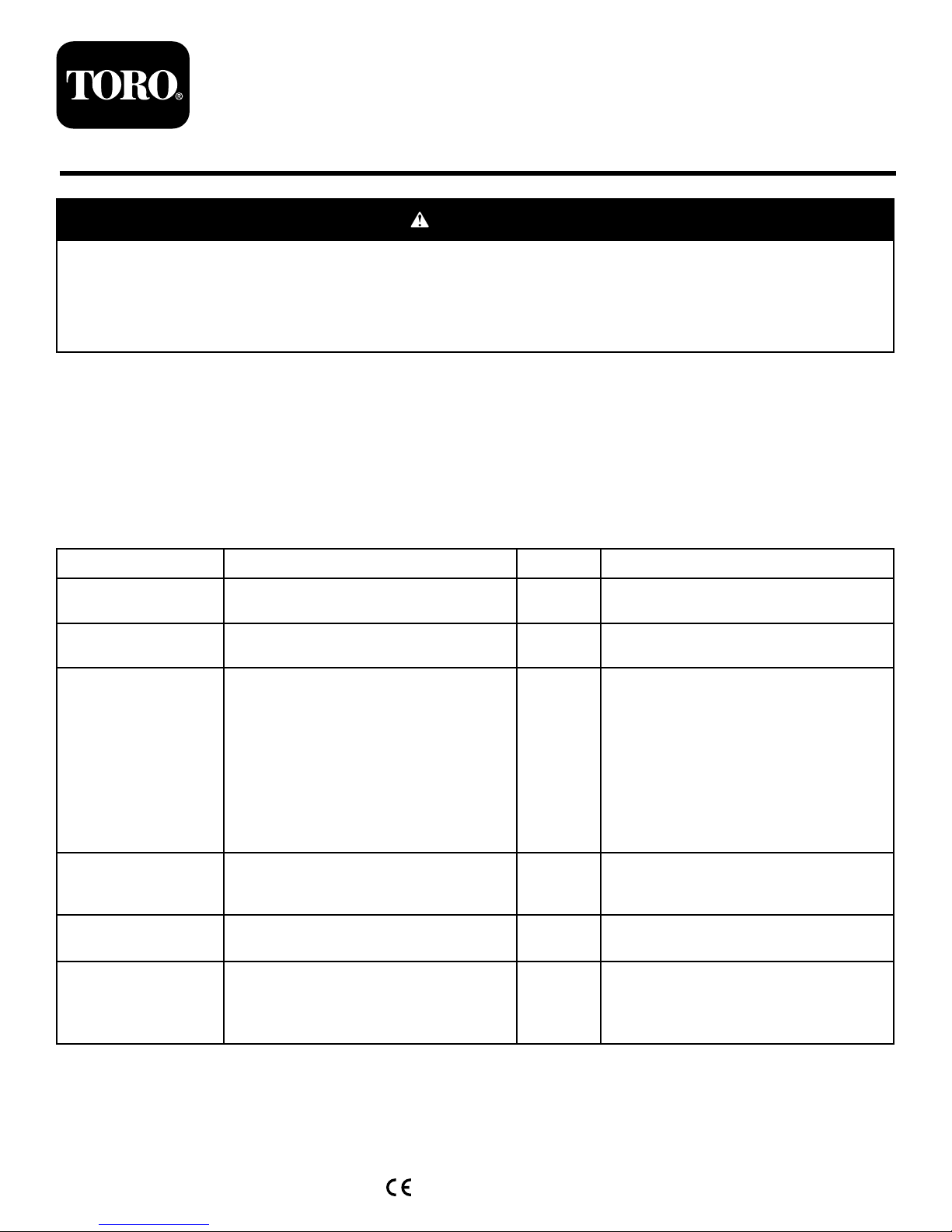

1.Loosenthejamnutsandsetscrewssecuring

eachendofthefrontrollertotheheight-of-cut

arms(Figure1).

g017178

1

2

3

4

5

6

g017178

Figure1

1.Height-of-cutarm4.Height-of-cutadjusting

screw

2.Jamnutandsetscrew

5.Height-of-cutbracket

3.Carriagebolt,washer,and

locknut

6.Taper-facebolt(bolthead

ontheothersideofthe

sideplate)

2.Removethecarriageboltsandlocknutssecuring

theheight-of-cutarmstotheadjustingbrackets

(Figure1).

3.Removetheheight-of-cutarmsfromtheside

platesandrollerassembly.

4.Removetheheight-of-cuthardwareasfollows:

•Greensmaster1600mowers—removethe

height-of-cutadjustingscrews,jamnuts,

andsetscrewsfromtheheight-of-cutarms

(Figure1).

•Greensmaster800and1000

mowers—removethe2taper-face

boltssecuringtherightandleftheight-of-cut

bracketstothesideplates(Figure1).Install

theheight-of-cutbracketstotheopposite

2

Page 3

sidesofthemachinewiththe2taper-face

bolts,usingtherearsetsofmountingholes

inthesideplates.

5.Installtheheight-of-cutarmsasfollows:

•Greensmaster1600mowers—obtain2new

height-of-cutarmsfromyourAuthorizedToro

Distributorandinstallthemontotheroller

assemblyandsideplateswiththefasteners

removedpreviously(Figure2).

•Greensmaster800and1000mowers—rotate

theheight-of-cutarmsyouremoved

previouslytotheforwardpositionandinstall

themontotherollerassemblyandside

plateswiththefastenersremovedpreviously

(Figure2).

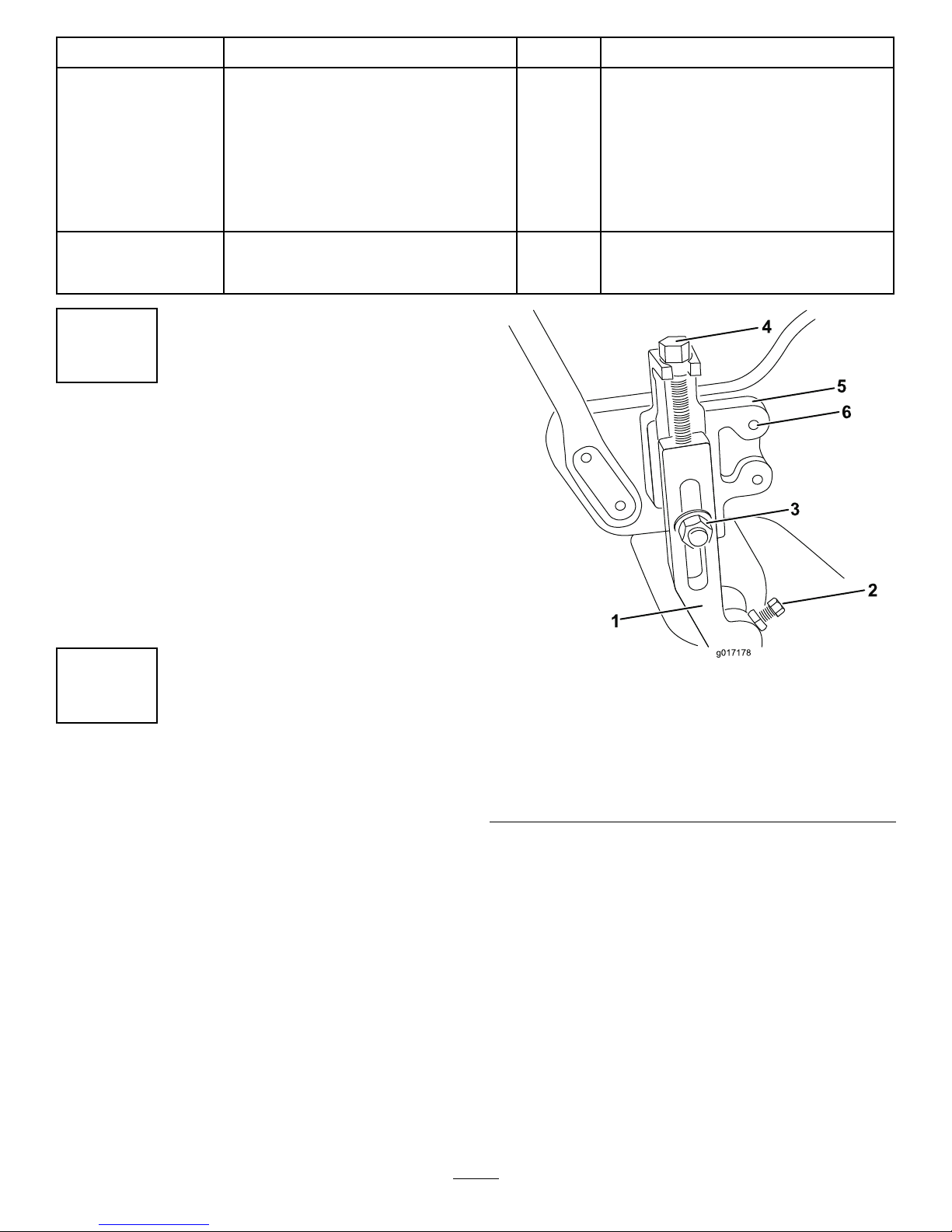

g017179

1

g017179

Figure2

1.Height-of-cutarmintheforwardposition

3

InstallingtheGroomer

Housing

Partsneededforthisprocedure:

1

Groomer-housingassembly

2

Flat-headscrew(3/8x2inches)

2

Locknut(3/8inch)

1Bearingadapter

2

Spacer

1

O-ring

-

Syntheticgrease

1

Slotcover

1Adapterring

Procedure

1.Removethe2boltsandlocknutssecuringthe

endcaptotheleft,reel-bearinghousingandthe

sideplate.

2.Removeandretaintheendcapandfasteners

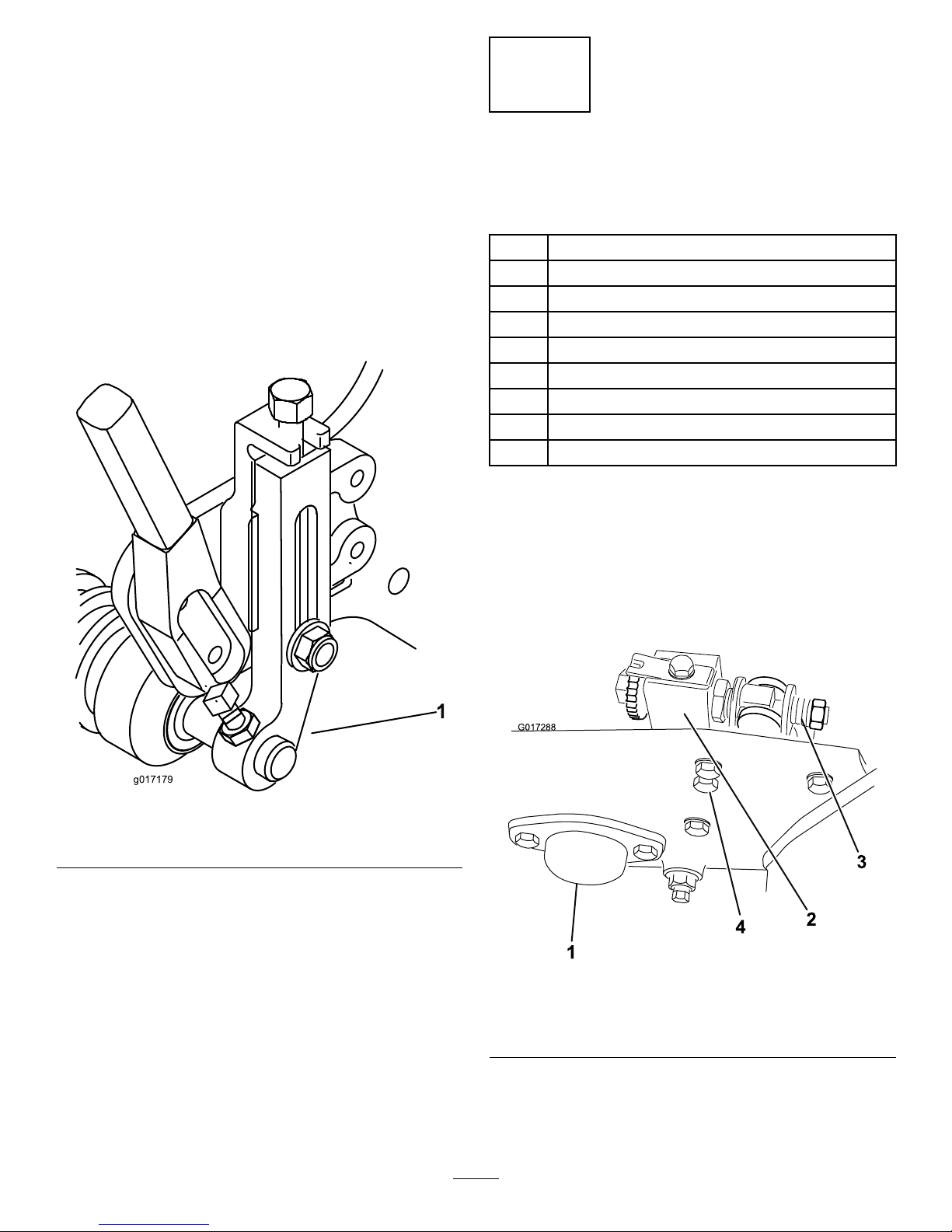

foruseifyoueverremovethegroomer(Figure

3).

1

4

2

3

G017288

g017288

Figure3

1.Endcap

3.Springtensionscrew

2.Bedbar-adjusterframe

4.Boltsandwashers

3.IfyouareinstallingthiskitonaGreensmaster

800mowerwithaserialnumberpriorto

230999999,aGreensmaster1000mower

withaserialnumberpriorto229999999,or

3

Page 4

aGreensmaster1600mowerwithaserial

numberpriorto260001401,completethe

following:

A.Usinga7/8inchstandardwrench,loosen

thespringtensionscrewsontherightand

leftbedbaradjusters(Figure4).

1

2

g020979

g020979

Figure4

1.Springtension

screw—loosen

2.Boltsand

washers—remove

B.Backoutthescrewsuntilthethrustwashers

arenolongertensionedagainstthebedbar.

C.Removethe2boltsandwasherssecuring

left,bedbar-adjusterframetothesideplate

(Figure4).

4.Removethe40toothidlergear.

g022023

1

g022023

Figure5

1.40toothidlergear.

5.Removethecurvedwasherandthebolt(3/8x

5/8inch)fromtheadjustment-knobmounting

block(Figure6).

g020842

Figure6

1.Locknut4.Mountingblock7.Bearingadapter

10.O-ring

2.Bolt(3/8x5/8inch)

5.Adjustmentknobassembly8.Flat-headscrew

11.Slotcover(atedge

orienteddown)

3.Curvedwasher6.Spacer9.Groomerhousing

12.Adapterring

4

Page 5

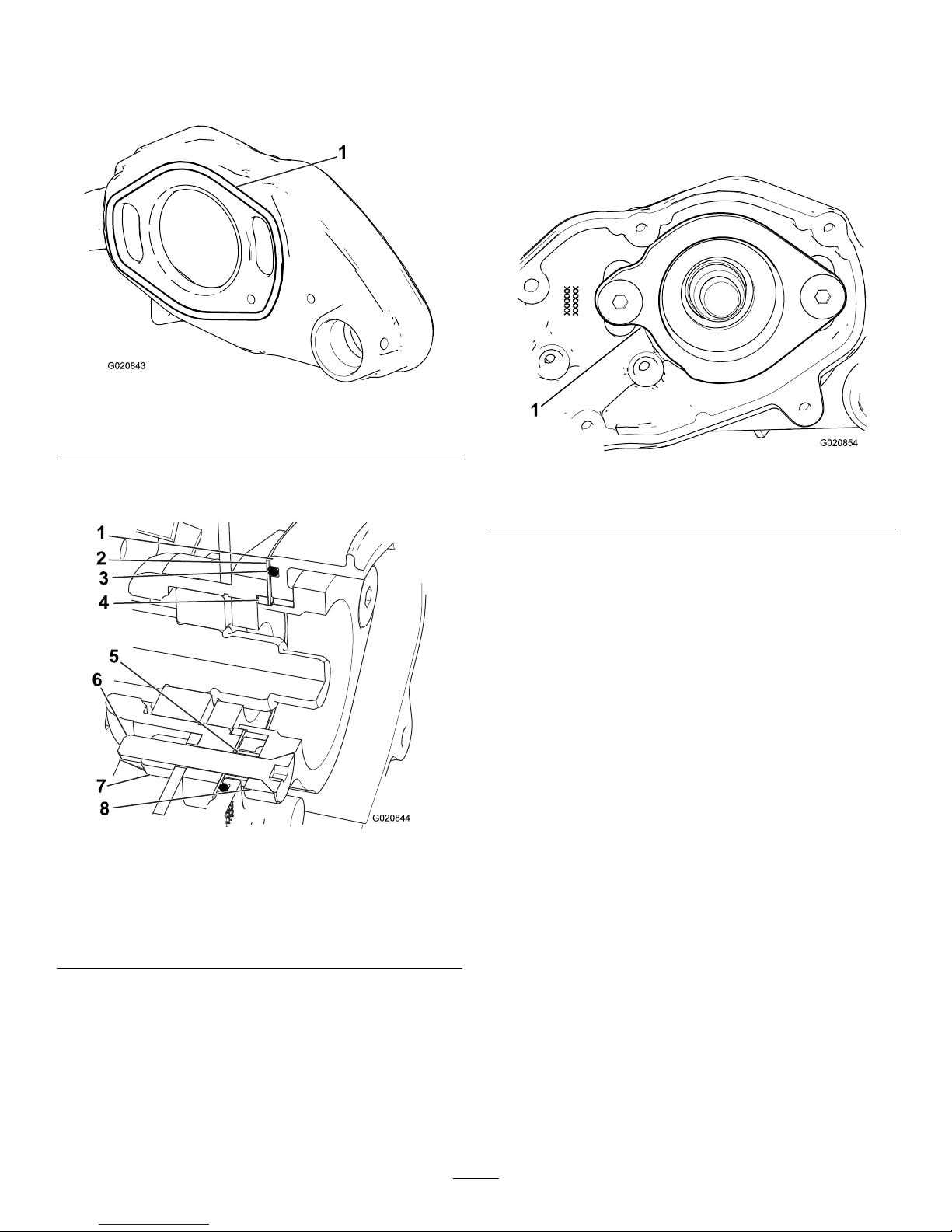

6.InstalltheO-ringintothebackofthegroomer

housing(Figure6andFigure7)andlightly

lubricatetheexposedsurfacesoftheO-ringwith

syntheticgrease(suppliedwiththekit).

g020843

Figure7

1.O-ring

7.Inserttheadapterringintothereelbearing

housing(Figure6andFigure8).

g020844

Figure8

1.Groomerhousing5.Spacer

2.Slotcover

6.Flat-headscrew

3.O-ring

7.Locknut

4.Adapterring8.Bearingadapter

8.Insertthe2at-headscrews(3/8x2inch)

throughthebearingadapterandpositionthe

spacersontheendsofthescrews(Figure6and

Figure8).

9.Alignthebearingadapter,spacers,andscrews

withthebronzebushingandtheslotsinthe

groomerhousing.

10.Slidethebearingadapterthroughthebronze

bushingandthescrewsthroughtheslotsinthe

groomerhousingassembly(Figure6andFigure

8).

Important:Ensurethatthebearingadapter

isorientedasshowninFigure9.

g020854

Figure9

1.Bearingadapter

11.Placetheslotcoveroverthescrewsandup

againstthelubricatedO-ring(Figure6).

12.Ensurethattheatedgeoftheslotcoveris

orientedatthebottom.

13.Inserttheat-headscrewsthroughthe

reel-bearinghousingandsecurethemwith

locknuts.

14.Torquethelocknutsto31to37N∙m(23to27

ft-lb)(Figure6andFigure8).

Note:T ogainaccesstothelocknutsyoumay

needtomoveorremovethebedbar.

15.Mounttheadjustmentknobmountingblockto

theleftsideplatewiththebolt(3/8x5/8inch)

andcurvedwasheryouremovedpreviously

(Figure6).

16.IfyouareinstallingthiskitonaGreensmaster

800mowerwithaserialnumberpriorto

230999999,aGreensmaster1000mower

withaserialnumberpriorto229999999,or

aGreensmaster1600mowerwithaserial

numberpriorto260001401,installtheleft,

bedbar-adjusterframetothesideplatewith

theboltsandwashersyouremovedpreviously

(Figure4).

5

Page 6

4

InstallingtheDriveGear

Partsneededforthisprocedure:

1

Shaftassembly

1Drivegear

–

Syntheticgrease

Procedure

1.Removethereel-bearinglocknutfromthereel

shaft(Figure10).

Note:Thereel-bearinglocknuthas

right-handedthreads.

g022029

g022029

Figure10

1.Reel-bearinglocknut

2.Securethereelfromturningwithawoodblock.

3.Threadtheshaftassemblyontothereel-shaft

extension(Figure1 1).

4

1

2

3

g022024

g022024

Figure11

1.Shaftassembly3.Groove

2.Drivegear4.40toothidlergear

4.Securethereelfromturningwithawoodblock

andtorquetheshaftassemblyto54to81N∙m

(40to60ft-lb).

5.Applysyntheticgrease(suppliedwiththekit)to

themalesplineoftheshaftassembly(Figure

11).

6.Slidethedrivegearwiththegrooveoriented

outwardontotheshaftassembly(Figure11).

7.Installthe40toothidlergear(Figure11).

5

SettingtheGroomerfor

ForwardRotation(Optional)

Partsneededforthisprocedure:

1ForwardRotationKit-obtainseparately

Procedure

Thegroomercomesdesignedtorotateintheopposite

directionofthereel.Optionally,youcansetittorotate

inthesamedirectionasthereelbyobtainingthe

ForwardRotationKitusingthefollowingprocedure:

1.Removethe2socket-headboltsandlocknuts

fromthecover(Figure12).

g020880

Figure12

1.Socket-headbolts—keep

one

2.Locknuts—discard

2.Keeponeoftheboltsanddiscardtherestofthe

fasteners.

3.Removethecentergearassembly,savingthe

gearanddiscardingthebushingandbolt(Figure

13).

6

Page 7

g020881

Figure13

1.Bushing—discard3.Bolt—discard

2.Centergear—keep

4.Installthesocket-headboltyouremovedfrom

thecoverintotheholewherethecentergear

wasinstalled(Figure14).

g020882

Figure14

1.Socket-headboltpreviouslyremovedfromthecover

5.Presstthecentergearremovedpreviously

ontothehub(Figure15).

Important:Supporttheinnerraceofthe

gearbearingwhilepressingitontothehub.

g020883

Figure15

1.Gearassembly—fromthe

forwardrotationkit

3.Gearhub—fromthe

forwardrotationkit

2.Flange-headbolt—from

theforwardrotationkit

4.Centergearassembly

6.Installthecentergearandhubassemblyand

thegearassembly,fromtheforwardrotationkit,

tothecoverwith2ange-headboltsasshown

inFigure15.

6

Installingthe

Groomer-HousingCover

Partsneededforthisprocedure:

1

Groomer-housingcoverassembly

1

Gasket

5

Flange-headbolt(1/4x3/4inch)

1

Syntheticgrease(3.0oz)

Procedure

1.Coattheteethofthegearswiththesynthetic

greasesuppliedwiththekit.Usetheremaining

greasetollintheareaaroundthegears.

2.Placethegasketoverthedowelpinsonthe

groomerhousing(Figure16).

7

Page 8

g020848

Figure16

1.Actuatorpininthegroove

onthedrivegear

3.Flange-headbolt

2.Clutchassembly4.Gasket

3.Installthecoverontothegroomerhousing,

insertingtheactuatorpinoftheclutchassembly

intothegrooveofthedrivegear(Figure16).

4.Securethecoverwith5ange-headbolts

(Figure16)andtorquethemto9.6to10.5N∙m

(85to95in-lb).

7

InstallingtheGroomer

ontheRightSideofthe

Machine

Partsneededforthisprocedure:

1BearingAdapter

2

Spacer

1

Groomer-plateassembly

1Adapterring

2

Bolt(1/4x3-3/4inches)

2

Starwasher

2Fastenerretainer

1Weight

Procedure

1.Removethe4boltssecuringthereel-drive-belt

covertotheright,sideplateandremovethe

cover(Figure17).

g017184

1

g017184

Figure17

1.Reel-drive-beltcover

2.Loosentheidlerpulleytorelievethebelttension

andremovethereel-drivebeltfromthepulleys

(Figure18).

8

Page 9

g017185

1

2

3

4

g017185

Figure18

1.Reeldrivebelt3.Drivepulley

2.Idlerpulley4.Flat-headscrew

3.Usinga1/2inchdriveratchetandextension,

removethedrivepulleyfromthereelshaft

(Figure18).

Note:Thedrivepulleyhasright-handthreads.

4.Securethereelfromturningwithawoodblock.

5.Removethe2at-headscrewsandnuts

securingthegroomerarmcovertothebearing

housingandsideplate(Figure18).

6.Removethegroomerarmcover(Figure19);

retaintheat-headscrewsanddiscardthe

spacersunderthecover.

7.IfyouareinstallingthiskitonaGreensmaster

800mowerwithaserialnumberpriorto

230999999,aGreensmaster1000mower

withaserialnumberpriorto229999999,or

aGreensmaster1600mowerwithaserial

numberpriorto260001401,removethe2bolts

andwasherssecuringtherightbedbaradjuster

frametothesideplate.

8.Removethecurvedwasherandthebolt(3/8x

5/8inch)fromtheadjustment-knob,mounting

block(Figure19).

9.Insertanadapterringintothereel-bearing

housing(Figure19).

g020847

Figure19

1.Flat-headscrew

4.Spacer

7.Bolt

2.Groomerarmcover

5.Adjustment-knob,mountingblock8.Adapterring

3.Bearingadapter

6.Curvedwasher9.Groomer-plateassembly

10.Insertthe2at-headscrews(3/8x2inch)

throughthegroomerarmcoverandthebearing

adapterandputaspacerovereachscrew

(Figure19).

11.Installthegroomerarmcover,bearingadapter,

spacers,andgroomer-plateassemblyto

thereel-bearinghousing,slidingtheadapter

throughthebronzebushinginthegroomerplate

assemblyandintothereelbearinghousing

(Figure19).

12.Installthelocknutsontheat-headscrewsand

torquethemto31to37N∙m(23to27ft-lb).

13.Securethemountingblockofthegroomer

adjustmentknobassemblytotherightsideplate

withthebolt(3/8x5/8inch)andcurvedwasher

removedpreviously(Figure19).

9

Page 10

14.IfyouareinstallingthiskitonaGreensmaster

800mowerwithaserialnumberpriorto

230999999,aGreensmaster1000mower

withaserialnumberpriorto229999999,or

aGreensmaster1600mowerwithaserial

numberpriorto260001401,installtheright,

bedbar-adjusterframetothesideplatewiththe

boltsandwashersyouremovedpreviously.

15.Usinga1/2inchdriveratchetandextension,

installthedrivepulley(right-handthreads)tothe

reelshaft(Figure20).

g017188

1

2

3

4

g017188

Figure20

1.Drivepulley

3.Quick-uplever

2.Idlerpulley4.Microadjustmentknob

16.Securethereelfromturningwithawoodblock.

17.Torquethepulleyto54to81N∙m(40to60ft-lb).

18.Installreeldrivebeltandcheckthebelttension

bypressingthebeltatthemidspanofthe

pulleyswith1.5to2.5kg(3to5lb)offorce.

Thebeltshoulddeect6mm(1/4inch).

Repositiontheidlerpulleytoadjustthebelt

tension.Tightenthescrewsonceyouachieve

thepropertension.

19.Installthereel-drive-beltcovertothesideplate

asfollows:

•Greensmaster800mowers—installthereel

drivecovertothesideplatewiththe4bolts

youremovedpreviously.

•Greensmaster1000/1600mowers—install

thecoverusingtheupperandlowerbolts

removedpreviouslyandtheweightandnew

fastenersasshowninFigure21.Usethe

fastenerretainersasrequiredbyyourlocal

codes.

g020853

Figure21

1.Bolt3.Weight

2.Starwasher

4.Fastenerretainer

8

InstallingtheGrooming

Reel

Partsneededforthisprocedure:

4

Groomer-shaftclamp

4

Socket-headscrew(1/4x1-1/4inches)

1

Groomerreel(obtainseparately)

Procedure

1.Obtainagroomerreelappropriateforyour

needsandcuttingunit;refertothefollowing

tableforalistofgroomerreels:

ModelNumber

Groomer

0428018inchgroomer,springsteel

0428118inchgroomer,carbide

0428218inchgroomer ,brush

0428321inchgroomer,springsteel

0428421inchgroomer,carbide

0428521inchgroomer ,brush

0428626inchgroomer,springsteel

0428726inchgroomer,carbide

0428826inchgroomer ,brush

04268

18inchsoftgroomingbrush

04269

18inchstiffgroomingbrush

04270

21inchsoftgroomingbrush

04271

21inchstiffgroomingbrush

04276

26inchstiffgroomingbrush

10

Page 11

2.Looselyinstallthe2halvesofagroomer-shaft

clamptothedrivenshaftontherightsideofthe

machine(Figure22andFigure23).

g020851

Figure22

1.Socket-headscrew

2.Socket-headscrew—looselyinstalledintheclamp

g020850

Figure23

1.Groomerreel3.Socket-headscrew

2.Groomer-shaftclamp

3.Slidethegroomer-reelshaftintotheclampon

therightsideandswingituptothedriveshaft

ontheleft(Figure22).

Important:Ifinstallingacarbide-toothed

groomer,ensurethattheteethpointin

thedirectionthegroomerwillrotatewhen

installed.

4.Securethegroomerreelwiththeclampsas

showninFigure22andFigure23,torquingthe

socketheadscrewsto9.6to10.5N∙m(85to

95in-lb).

5.Checktheassemblyofthegroomer.

6.Rotatebothquick-upleverstoraisethe

groomingreelintothetransportposition(Figure

20).

7.Correctanyproblemsandrechecktheassembly.

8.Usingahand-pumpgreasegun,lubricatethe2

groomer-shaftbearings(oneoneachend).

Note:Pumponly2to3pumpsmaximumto

avoidpermanentlydamagingthegreaseseals.

9.Centertherollerbetweentheheight-of-cutarms

andtightenthesetscrewsandjamnuts.

Operation

Grooming

Groomingisperformedintheturfcanopyabovethe

soillevel.Groomingpromotesverticalgrowthofgrass

plants,reducesgrain,andseversstolonsproducing

adenserturf.Groomingproducesamoreuniform

andtighterplayingsurfaceforfasterandtrueraction

ofthegolfball.

Verticuttingisamoreaggressivecultivationtechnique

designedtoremovethatchbycuttingthrough

theturfcanopyandintothethatch/matlayer.

Groomingshouldnotbeconsideredareplacementfor

verticutting.Verticuttingisgenerallyamorerigorous

andperiodictreatmentthatcantemporarilydamage

theplayingsurface,whilegroomingisaroutineand

gentlertreatmentdesignedtomanicuretheturf.

g006671

Figure24

1.Grassrunners

2.Thatch

Groomingbrushesareamorerecentdevelopment

whicharedesignedtobelessintrusivethan

conventionalgroomingbladeswhenadjustedto

lightlycontacttheturfcanopy.Brushingmaybemore

benecialfortheultra–dwarfcultivars,sincethese

grasstypeshavemoreofauprightgrowthpattern

anddonotllinthatwellthroughhorizontalgrowth.

Brushes,however,caninjureleaftissueiftheyareset

topenetratetoodeeplyintothecanopy.

Groomingissimilartoverticuttinginitsrunnercutting

action.Groomingbladeshowever,shouldnever

penetratethesoillikeverticuttingordethatching.

Groomerbladesarespacedclosertogetherandare

usedmoreoftenthanverticutterssothattheyare

moreeffectiveincuttingrunnersandremovingthatch.

Becausegroominginjuresleaftissuetosomedegree

itshouldbeavoidedduringperiodsofhighstress.

11

Page 12

Coolseasonspeciessuchascreepingbentgrass

andannualbluegrassshouldnotbegroomedduring

hightemperature(andhighhumidity)periodsin

midsummer.

Itisdifculttomakepreciserecommendationsonuse

ofgroomingreelsbecausesomanyvariablesaffect

theperformanceofgrooming,including:

•Thetimeoftheyear(i.e.,thegrowingseason)and

weatherpattern

•Thegeneralconditionofeachgreen

•Thefrequencyofgrooming/cutting—bothhow

manycuttingsperweekandhowmanypasses

percutting

•Theheight-of-cutsettingonthemainreel

•Theheight/depthsettingonthegroomingreel

•Howlongthegroomingreelhasbeeninuseon

thisgreen

•Thetypeofgrassonthegreen

•Theoverallgreensmanagementprogram(i.e.

irrigation,fertilizing,spraying,coring,overseeding,

etc.)

•Trafc

•Stressperiods(i.e.,hightemperatures,high

humidity,unusuallyhightrafc)

Thesefactorscanvaryfromgolfcoursetogolfcourse

andfromgreentogreen.Inspectthegreensfrequently

andvarythegroomingpracticeinaccordancewith

theneed.

Thegroomerissetatthefactorywith13mm(1/2

inch)bladespacing.Byremovingspacersandadding

bladesoraddingspacersandremovingbladesthe

groomercanbechangedto6mm(1/4inch)or19mm

(3/4inch)spacing.

Groomingwith6mm(1/4inch)bladespacingis

recommendedforfastgrowthperiods(springthrough

earlysummer).Groomingwith19mm(3/4inch)blade

spacingisrecommendedforslowergrowthperiods

(latesummerthroughfallandwinter).Donotusethe

groomingreelduringhighstressperiods.

Note:Groomingwith6mm(1/4inch)bladespacing

removesmoregrassbladesandthatchandcutsmore

runnersthangroomingwith13mm(1/2inch)or19

mm(3/4inch)bladespacing.Ifgroomingwith6mm

(1/4inch)bladespacing,oneortwogroomingsper

weekshouldbesufcientexceptduringmaximum

growthperiods.

Note:Thepracticeofchangingthedirectionofcut

eachtimethegreeniscutshouldbecontinuedwhen

agroomerisused.Thisrotationwillenhancethe

effectsofthegrooming.

TestingtheGroomer

Performance

Important:Improperorover-aggressiveuseof

thegroomingreel(i.e.,toodeeportoofrequent

grooming)maycauseunnecessarystressonthe

turf,leadingtoseveregreensdamage.Usethe

groomercautiously.

Itisimportanttodeterminetheperformanceofthe

groomerbeforeputtingitintoregularuseongreens.

Westronglysuggeststhataformaltestprocedurebe

used.Thefollowingisapracticalwayofdetermining

theproperheight/depthsetting:

1.Placethecuttingunitonaatlevelsurface.

2.Setthecuttingreeltotheheightofcutthatwould

normallybeusedwithoutthegroomingreel.Use

aWiehlerollerandscraperforthefrontroller.

3.Setthegroomingreel1/2theheight-of-cut

settingabovetheground(e.g.for3.2mm(1/8

inch)height-of-cutsetting,setthegroomerat

1.6mm(1/16inch)abovetheground).

Note:Ifusingthegroomerbrush,setitatthe

height-of-cutsettingabovetheground(e.g.for

3.2mm(1/8inch)height-of-cutsetting,setthe

groomerat3.2mm(1/8inch)abovetheground).

4.Makeapassoverthetestgreen,thenlowerthe

groomerushwiththegroundlevelandmake

anotherpassoverthetestgreen.

Note:Ifusingthegroomerbrush,loweritto1/2

theheight-of-cutsettingabovetherollerlevel

(e.g.for3.2mm(1/8inch)height-of-cutsetting,

setthegroomerat1.6mm(1/16inch)abovethe

ground).

5.Comparetheresults.Therstgroomedarea

whenthesettingwas1/2theheight-of-cut

settingabovetherollerlevelwillhaveremoved

signicantlylessgrassandthatchthanthe

secondsetting.

Checkthetestgreen2or3daysaftertherst

groomingforgeneralcondition/damage.Ifthe

groomedareasareturningyellow/brown,and

thenon-groomedareasaregreen,thenthe

groomingwastooaggressive.

Note:Thecolorofthegrasswillchange

whenyouusethegroomingreel.Youcan

observethiswiththerstgroominganditwill

continueovertime.Experiencewillallowthe

greenssuperintendenttojudgebythecolorof

theturf(alongwithcloseexamination)ifthe

currentgroomingpracticeisappropriateforthe

particulargreen.Becausethegroomingreel

standsupmoregrassandremovesthatch,the

12

Page 13

qualityofthecutwillnotbethesameaswithout

thegroomer.Y ouwillnoticethiseffectmostthe

rstfewtimesagroomerisusedonagreen.

Note:Onmultiplepasses(i.e.,doubleandtriple

cutting),thegroomerwillcontinuetopenetrate

deeperoneachsuccessivepass.Multiple

passesarenotrecommended.

6.Afteryoutesttheperformanceofthegroomeron

atestgreenandobtainsatisfactoryresults,you

canbegingroomingontheplayinggreens.Itis

importanttorealize,however,thateachgreen

mayresponddifferentlytogrooming.Inaddition,

growingconditionsareconstantlychanging.

Inspectthegroomedgreensfrequentlyand

makeadjustmentstothegroomingprocedure

asoftenasnecessary .

SettingtheHeight/Depthof

theGroomer

Setthegroomerbladeheight/depthusingthefollowing

procedure:

1.Makesurethattherollersarecleanandthe

mainreelissettothedesiredheightofcut.Park

themachineonaat,levelworksurface.

2.Usethequick-uplevers(bothsides)tolowerthe

groomingreelintothegroomingposition(Figure

25).

g017189

1

2

g017189

Figure25

1.Quick-uplever

2.Microadjustmentknob

3.Ononeendofthegroomershaft,measurethe

distancefromthelowesttipofagroomerblade

totheworksurface(Figure26).

1 2 3 4 5 6 7 8 9 10 1

1 12

g017190

g017190

Figure26

4.Liftandturnthemicroadjustmentknob(Figure

25)toraiseorlowerbladetip.

Note:Eachnotchonthemicroadjustment

knobisapproximatelyequalto0.17mm(0.007

inch)ofgroomerdepth.

5.Repeatthisprocedureontheoppositeendof

thegroomer,thenrecheckthesettingontherst

side.

6.Putthegroomingreelintothetransportposition.

TurningtheGroomerOn

andOff

Youcanturnthegroomeronoroffbyrotatingthe

groomer-driveclutchasshowninFigure27.

13

Page 14

g020855

Figure27

1.Groomer-driveclutch3.Off

2.On

TransportingtheGroomer

Whentransportingmachinebesuretoraisethe

groomingreelintoitstransport(raised)position.

Toraisethegroomingreel,rotatetherightandleft

quick-upleverssotheyfacetotherear(Figure25).

Tolowerthegroomingreel,turnthequick-uplevers

forward.

Maintenance

Cleaning

Hoseoffthegroomingreelafteruse.Donotdirectthe

waterstreamdirectlyatthegroomerbearingseals.

Donotpermitthegroomingreeltostandinwaterso

thatthecomponentsrust.

Lubrication

Usingahand-pumpgreasegun,lubricatethe2

groomer-shaftbearings(oneoneachend).Pump

only2to3pumpsmaximumtoavoidpermanently

damagingthegreaseseals.

Note:Whenlubricatingthemainreelbearings,do

notovergreasebecauseexcessgreasecanworkits

wayintothegroomer-driveboxordripontotheturf.

Every500operatinghours,removethecoverfrom

thegroomer-drivebox.Cleanoutalloftheoldgrease

andpackitwith85g(3.0oz)ofsyntheticgrease(T oro

partnumber125-3511orequivalentsyntheticgrease

meetingISOVG220,NLGI2standards).

InspectingtheBlades

Inspectthegrooming-reelbladesfrequentlyfor

damageandwear.Straightenbentbladeswitha

pliers.Replacewornblades.Wheninspectingthe

blades,checktoseethattherightandleftbladeshaft

endnutsaretight.

Note:Ifusingspringsteelblades,whenonesideof

thebladesbecomeworn,removethegroomingreel,

rotateit180degrees,andinstallitsothattheunworn

sideisfacingthedirectionofrotation.

Note:Becausethegroomermayintroducemore

debris(i.e.,dirtandsand)intothecuttingunitthan

whatthereelwouldnormallybeexposedto,the

bedknifeandmainreelshouldbecheckedforwear

morefrequently.Thisisespeciallyimportantinsandy

soiland/orwhenthegroomerissetforpenetration.

ReplacingtheGrooming

Reel

Removeandreplacethegroomingreelusingthe

followingprocedure:

1.Removebothsocket-headscrewsandshaft

clampsfromonesideofthegroomerreel(Figure

23).

2.Removetheinnersocket-headscrewfromthe

clampontheothersideandloosentheouter

screw.

g020852

Figure28

1.Socket-headscrew

2.Socket-headscrew—looselyinstalledintheclamp

3.Slidethereelassemblyoutoftheclamp.

4.Referto8InstallingtheGroomingReel(page

10)toinstallthereelasneeded.

5.Checkthegroomingreelheight/depthsetting.

14

Page 15

Notes:

Page 16

DeclarationofIncorporation

TheToroCompany,8111LyndaleAve.South,Bloomington,MN,USAdeclaresthatthefollowingunit(s)

conform(s)tothedirectiveslisted,wheninstalledinaccordancewiththeaccompanyinginstructionsontocertain

ToromodelsasindicatedontherelevantDeclarationsofConformity.

ModelNo.

SerialNo.

ProductDescriptionInvoiceDescription

GeneralDescription

Directive

04134

—

GroomerDrive

System,Greensmaster

800/1000/1010/1600/1610

Mower

GROOMERDRIVE,

FIXEDHEAD

LawnMower

2006/42/EC,

2000/14/EC

RelevanttechnicaldocumentationhasbeencompiledasrequiredperPartBofAnnexVIIof2006/42/EC.

Wewillundertaketotransmit,inresponsetorequestsbynationalauthorities,relevantinformationonthispartly

completedmachinery.Themethodoftransmissionshallbeelectronictransmittal.

ThismachineryshallnotbeputintoserviceuntilincorporatedintoapprovedT oromodelsasindicatedonthe

associatedDeclarationofConformityandinaccordancewithallinstructions,wherebyitcanbedeclaredin

conformitywithallrelevantDirectives.

Certied:

AuthorizedRepresentative:

MarcelDutrieux

ManagerEuropeanProductIntegrity

ToroEuropeNV

Nijverheidsstraat5

2260Oevel

Belgium

JohnHeckel

Sr.EngineeringManager

Tel.+3216386659

811 1LyndaleAve.South

Bloomington,MN55420,USA

March7,2017

Loading...

Loading...