Toro 04054 Greensmaster 800, 04055 Greensmaster 1000, 04056 Greensmaster 1600 Operator's Manual

Page 1

FormNo.3380-159RevC

Greensmaster

®

800,1000,and

1600Mower

ModelNo.04054—SerialNo.314000001andUp

ModelNo.04055—SerialNo.314000001andUp

ModelNo.04056—SerialNo.314000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3380-159*C

Page 2

ThisproductcomplieswithallrelevantEuropeandirectives,

fordetailspleaseseetheseparateproductspecicDeclaration

ofConformity(DOC)sheet.

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

ThissparkignitionsystemcomplieswithCanadianICES-002.

Becauseinsomeareastherearelocal,state,orfederal

regulationsrequiringthatasparkarresterbeusedonthe

engineofthismachine,asparkarresterisincorporatedwith

themuferassembly.

GenuineT orosparkarrestersareapprovedbytheUSDA

ForestryService.

Important:Thisengineisequippedwithaspark

arrestermufer.ItisaviolationofCaliforniaPublic

ResourceCodeSection4442touseoroperatetheengine

onanyforest-covered,brush-covered,orgrass-covered

landwithoutasparkarrestermufermaintainedin

workingorder,ortheengineconstricted,equipped,and

maintainedforthepreventionofre.Otherstatesor

federalareasmayhavesimilarlaws.

CustomerServiceandhavethemodelandserialnumbers

ofyourproductready .Themodelandserialnumbersare

locatedonaplateontherearframe.Writethenumbersin

thespaceprovided.

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure1),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure1

1.Safetyalertsymbol.

Thismanualusestwootherwordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Introduction

Thismachineisawalkbehind,reel-bladelawnmower

intendedtobeusedbyprofessional,hiredoperatorsin

commercialapplications.Itisprimarilydesignedforcutting

grassonwell-maintainedlawnsinparks,golfcourses,sports

elds,andoncommercialgrounds.Itisnotdesignedfor

cuttingbrush,mowinggrassandothergrowthalongside

highways,orforagriculturaluses.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

©2014—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

Contents

Safety...........................................................................4

SafeOperatingPractices...........................................4

ToroMowerSafety..................................................6

ForModel04054.....................................................6

ForModel04055.....................................................6

ForModel04056.....................................................7

SafetyandInstructionalDecals.................................8

Setup...........................................................................10

1InstallingandAdjustingtheHandle........................10

2InstallingtheKickstand(ForGR800and

GR1600)...........................................................11

3InstallingtheTransportWheelShafts(For

GR1000andGR1600).........................................12

4InstallingtheTransportWheels(Optional)..............12

5AdjustingtheCuttingUnit....................................13

6InstallingtheGrassBasket....................................13

7InstallingtheHigh-AltitudeKit(Optional)...............13

ProductOverview.........................................................14

Controls...............................................................14

Specications........................................................15

Attachments/Accessories........................................16

Operation....................................................................16

ThinkSafetyFirst...................................................16

CheckingtheEngineOilLevel.................................16

FillingtheFuelTank...............................................16

Break-inPeriod......................................................17

CheckingtheInterlockSwitchOperation...................18

DailyAdjustmentsoftheCuttingUnit.......................18

StartingandStoppingtheEngine..............................18

DrivingtheMachineinTransport.............................19

PreparingtoMow...................................................19

Mowing................................................................19

OperatingTips......................................................19

Maintenance.................................................................20

RecommendedMaintenanceSchedule(s)......................20

DailyMaintenanceChecklist....................................21

Lubrication...............................................................22

GreasingtheMachine.............................................22

EngineMaintenance..................................................23

ServicingtheEngineOil..........................................23

ServicingtheAirCleaner.........................................24

ReplacingtheSparkPlug.........................................24

FuelSystemMaintenance...........................................25

CleaningtheFuelFilter...........................................25

ElectricalSystemMaintenance....................................26

ServicingtheInterlockSwitch.................................26

BrakeMaintenance....................................................26

AdjustingtheService/ParkingBrake.........................26

BeltMaintenance......................................................28

AdjustingtheBelts.................................................28

ReplacingtheDifferentialBelt..................................30

ControlsSystemMaintenance.....................................31

AdjustingtheTractionControl.................................31

CuttingUnitMaintenance...........................................31

LevelingtheRearDrumtotheReel...........................31

AdjustingtheBedknifetotheReel............................32

AdjustingtheHeightofCut.....................................33

AdjustingtheGrassShieldHeight.............................34

AdjustingtheCut-OffBar.......................................34

BedbarIdentication..............................................35

SettingtheMachinetoMatchTurfConditions............36

ServicingtheBedbar...............................................37

BacklappingtheReel...............................................38

Storage........................................................................38

3

Page 4

Safety

–Storefuelincontainersspecicallydesignedforthis

purpose.

ThismachinemeetsorexceedsCENstandardEN836:1997,

ISOstandard5395:1990,andANSIB71.4-2004specications

ineffectatthetimeofproductionwhentheOperator

PresenceKit,PartNo.112-9282isinstalled.

Improperuseormaintenancebytheoperatororownercan

resultininjury.Toreducethepotentialforinjury,comply

withthesesafetyinstructionsandalwayspayattentiontothe

safetyalertsymbol,whichmeansCaution,Warning,or

Danger—personalsafetyinstruction.Failuretocomplywith

theinstructionmayresultinpersonalinjuryordeath.

SafeOperatingPractices

ThefollowinginstructionsareadaptedfromtheCEN

standardEN836:1997,ISOstandard5395:1990,andANSI

B71.4-2012.

Training

•ReadtheOperator'sManualandothertrainingmaterial

carefully.Befamiliarwiththecontrols,safetysigns,and

theproperuseoftheequipment.

•Iftheoperatorormechaniccannotreadthelanguage

oftheOperator'sManualitistheowner’ sresponsibilityto

explainthismaterialtothem.

•Neverallowchildrenorpeopleunfamiliarwiththese

instructionstouseorservicethemower.Local

regulationsmayrestricttheageoftheoperator.

•Nevermowwhilepeople,especiallychildren,orpetsare

nearby.

•Keepinmindthattheoperatororuserisresponsiblefor

accidentsorhazardsoccurringtootherpeopleortheir

property.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtohimselforherself,other

people,orproperty.

•Alloperatorsormechanicsmustbetrained.Itisthe

owner’sresponsibilityfortrainingusers.

Preparation

•Whilemowing,alwayswearsubstantialfootwear,long

trousers,hardhat,safetyglasses,andhearingprotection.

Longhair,looseclothing,orjewelrymaygettangled

inmovingparts.Donotoperatetheequipmentwhen

barefootorwearingopensandals.

–Refueloutdoorsonlyanddonotsmokewhile

refuelling.

–Addfuelbeforestartingtheengine.Neverremove

thecapofthefueltankoraddfuelwhiletheengineis

runningorwhentheengineishot.

–Iffuelisspilled,donotattempttostarttheengine

butmovethemachineawayfromtheareaofspillage

andavoidcreatinganysourceofignitionuntilfuel

vaporshavedissipated.

–Secureallfueltanksandcontainercaps.

•Replacefaultysilencers.

•Evaluatetheterraintodeterminewhataccessoriesand

attachmentsareneededtoproperlyandsafelyperform

thejob.Onlyuseaccessoriesandattachmentsapproved

bythemanufacturer.

•Checkthatoperator'spresencecontrols,safetyswitches

andshieldsareattachedandfunctioningproperly.Donot

operateunlesstheyarefunctioningproperly.

Operation

•Donotoperatetheengineinaconnedspacewhere

dangerouscarbonmonoxidefumescancollect.

•Mowonlyindaylightoringoodarticiallight.

•Beforeattemptingtostarttheengine,disengageallblade

attachmentclutches,shiftintoneutral,andengagethe

parkingbrake.

•Stayalertforholesintheterrainandotherhiddenhazards.

•Watchoutfortrafcwhencrossingornearroadways.

•Stopthebladesrotatingbeforecrossingsurfacesother

thangrass.

•Whenusinganyattachments,neverdirectdischargeof

materialtowardbystandersnorallowanyonenearthe

machinewhileinoperation.

•Neveroperatethemachinewithdamagedguards,shields,

orwithoutsafetyprotectivedevicesinplace.Besureall

interlocksareattached,adjustedproperly ,andfunctioning

properly.

•Donotchangetheenginegovernorsettingsoroverspeed

theengine.Operatingtheengineatexcessivespeedmay

increasethehazardofpersonalinjury.

•Thoroughlyinspecttheareawheretheequipmentisto

beusedandremoveallobjectswhichmaybethrownby

themachine.

•Warning—Fuelishighlyammable.Takethefollowing

precautions:

4

Page 5

•Beforeleavingtheoperator'sposition:

–stoponlevelground;

–disengagethecuttingunitandtractiondrive;

–settheparkingbrake;

–stoptheengine.

•Disengagedrivetoattachmentswhentransportingornot

inuse.

•Stoptheengineanddisengagedrivetoattachment:

–beforerefuelling;

–beforeremovingthegrasscatcher;

–beforemakingheightadjustments;

–beforeclearingblockages;

–beforechecking,cleaningorworkingonthemower;

–afterstrikingaforeignobjectorifanabnormal

vibrationoccurs.Inspectthemowerfordamage

andmakerepairsbeforerestartingandoperatingthe

equipment.

•Reducethethrottlesettingbeforestoppingengineand,if

theengineisprovidedwithafuelshut-offvalve,turnthe

valveoffattheconclusionofmowing.

•Keephandsandfeetawayfromthecuttingunit.

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalks.Stopreelsifnotmowing.

•Donotoperatethemowerundertheinuenceofalcohol

ordrugs

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

•Usecarewhenloadingorunloadingthemachineinto

atrailerortruck

•Usecarewhenapproachingblindcorners,shrubs,trees,

orotherobjectsthatmayobscurevision.

SafeHandlingofFuels

•Toavoidpersonalinjuryorpropertydamage,use

extremecareinhandlinggasoline.Gasolineisextremely

ammableandthevaporsareexplosive.

•Extinguishallcigarettes,cigars,pipes,andothersources

ofignition.

•Useonlyanapprovedfuelcontainer.

•Neverremovefuelcaporaddfuelwiththeengine

running.

•Allowenginetocoolbeforerefueling.

•Neverrefuelthemachineindoors.

•Neverstorethemachineorfuelcontainerwherethereis

anopename,spark,orpilotlightsuchasonawater

heateroronotherappliances.

•Neverllcontainersinsideavehicleoronatruckor

trailerbedwithaplasticliner.Alwaysplacecontainerson

thegroundawayfromyourvehiclebeforelling.

•Removeequipmentfromthetruckortrailerandrefuelit

ontheground.Ifthisisnotpossible,thenrefuelsuch

equipmentwithaportablecontainer,ratherthanfroma

fueldispensernozzle.

•Keepthenozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilfuelingiscomplete.

•Donotuseanozzlelockopendevice.

•Iffuelisspilledonclothing,changeclothingimmediately.

•Neveroverllfueltank.Replacefuelcapandtighten

securely.

MaintenanceandStorage

•Keepallnuts,boltsandscrewstighttobesurethe

equipmentisinsafeworkingcondition.

•Neverstoretheequipmentwithfuelinthetankinsidea

buildingwherefumesmayreachanopenameorspark.

•Allowtheenginetocoolbeforestoringinanyenclosure.

•Toreducetherehazard,keeptheengine,silencer,and

fuelstorageareafreeofgrass,leaves,orexcessivegrease.

•Checkthegrasscatcherfrequentlyforwearor

deterioration.

•Keepallpartsingoodworkingconditionandallhardware

andhydraulicttingstightened.Replaceallwornor

damagedpartsanddecals.

•Ifthefueltankhastobedrained,dothisoutdoors.

•Becarefulduringadjustmentofthemachinetoprevent

entrapmentofthengersbetweenmovingbladesand

xedpartsofthemachine.

•Disengagedrives,disengagethecuttingunit,setparking

brake,stopengineanddisconnectsparkplugwire.Wait

forallmovementtostopbeforeadjusting,cleaningor

repairing.

•Cleangrassanddebrisfromcuttingunit,drives,mufers,

andenginetohelppreventres.Cleanupoilorfuel

spillage.

•Carefullyreleasepressurefromcomponentswithstored

energy.

•Removethesparkplugwirebeforemakinganyrepairs.

•Usecarewhencheckingthereel.W earglovesanduse

cautionwhenservicingthem.

•Keephandsandfeetawayfrommovingparts.Ifpossible,

donotmakeadjustmentswiththeenginerunning.

Hauling

1.Usecarewhenloadingorunloadingthemachineintoa

trailerortruck.

2.Usefullwidthrampsforloadingmachineintotrailer

ortruck.

3.Tiethemachinedownsecurelyusingstraps,chains,

cable,orropes.Bothfrontandrearstrapsshouldbe

directeddownandoutwardfromthemachine.

5

Page 6

ToroMowerSafety

ThefollowinglistcontainssafetyinformationspecictoToro

productsorothersafetyinformationthatyoumustknowthat

isnotincludedintheCEN,ISO,orANSIstandard.

Thisproductiscapableofamputatinghandsandfeetand

throwingobjects.Alwaysfollowallsafetyinstructionsto

avoidseriousinjuryordeath.

•Ifmajorrepairsareeverneededorifassistanceisdesired,

contactanAuthorizedToroDistributor.

•UseonlyToro-approvedattachmentsandreplacement

parts.Thewarrantymaybevoidedifusedwith

unapprovedattachments.

ForModel04054

Useofthisproductforpurposesotherthanitsintendeduse

couldprovedangeroustouserandbystanders.

•Knowhowtostoptheenginequickly.

•Donotoperatethemachinewhilewearingtennisshoes

orsneakers.

•Wearingsafetyshoesandlongpantsisadvisableand

requiredbysomelocalordinancesandinsurance

regulations.

•Handlegasolinecarefully.Wipeupanyspills.

•Checkthesafetyinterlockswitchesdailyforproper

operation.Ifaswitchshouldfail,replacetheswitch

beforeoperatingthemachine.

•Usingthemachinedemandsattention.Topreventloss

ofcontrol:

–Donotoperateclosetosandtraps,ditches,creeks,or

otherhazards.

–Reducespeedwhenmakingsharpturns.Avoid

suddenstopsandstarts.

–Whennearorcrossingroads,alwaysyieldthe

right-of-way.

–Reduceenginespeedandapplytheservicebrakes

whengoingdownhilltokeepforwardspeedslowand

tomaintaincontrolofthemachine.

SoundPowerLevel

Thisunithasaguaranteedsoundpowerlevelof95dBA,

whichincludesanUncertaintyValue(K)of1dBA.

Soundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinISO11094.

SoundPressureLevel

Thisunithasasoundpressurelevelattheoperator’searof85

dBA,whichincludesanUncertaintyValue(K)of1dBA.

Soundpressurelevelwasdeterminedaccordingtothe

proceduresoutlinedinEN836.

VibrationLevel

Hand-Arm

Measuredvibrationlevelforlefthand=4.00m/s

Measuredvibrationlevelforrighthand=2.87m/s

UncertaintyValue(K)=0.5m/s

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinEN836.

2

2

2

ForModel04055

•Donottouchtheengine,mufer,orexhaustpipewhile

theengineisrunningorsoonafterithasstoppedbecause

theseareascouldbehotenoughtocauseburns.

•Whenapersonorpetappearsunexpectedlyinornear

themowingarea,stopmowing.Carelessoperation,

combinedwithterrainangles,ricochets,orimproperly

positionedguardscanleadtothrownobjectinjuries.Do

notresumemowinguntiltheareaiscleared.

MaintenanceandStorage

•Checkallfuellinesfortightnessandwearonaregular

basis.Tightenorrepairthemasneeded.

•Iftheenginemustberunningtoperformamaintenance

adjustment,keephands,feet,clothing,andanypartsof

thebodyawayfromthecuttingunit,attachments,andany

movingparts.Keepeveryoneaway.

•Toensuresafetyandaccuracy,haveanAuthorizedToro

Distributorcheckthemaximumenginespeedwitha

tachometer.Maximumgovernedenginespeedshould

be3600±100RPM.

SoundPowerLevel

Thisunithasaguaranteedsoundpowerlevelof95dBA,

whichincludesanUncertaintyValue(K)of1dBA.

Soundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinISO11094.

SoundPressureLevel

Thisunithasasoundpressurelevelattheoperator’searof84

dBA,whichincludesanUncertaintyValue(K)of1dBA.

Soundpressurelevelwasdeterminedaccordingtothe

proceduresoutlinedinEN836.

VibrationLevel

Hand-Arm

Measuredvibrationlevelforrighthand=2.52m/s

Measuredvibrationlevelforlefthand=2.39m/s

UncertaintyValue(K)=1.3m/s

2

2

2

6

Page 7

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinEN836.

ForModel04056

SoundPowerLevel

Thisunithasaguaranteedsoundpowerlevelof95dBA,

whichincludesanUncertaintyValue(K)of1dBA.

Soundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinISO11094.

SoundPressureLevel

Thisunithasasoundpressurelevelattheoperator’searof85

dBA,whichincludesanUncertaintyValue(K)of1dBA.

Soundpressurelevelwasdeterminedaccordingtothe

proceduresoutlinedinEN836.

VibrationLevel

Hand-Arm

Measuredvibrationlevelforrighthand=3.35m/s

Measuredvibrationlevelforlefthand=2.59m/s

UncertaintyValue(K)=1.7m/s

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinEN836.

2

2

2

7

Page 8

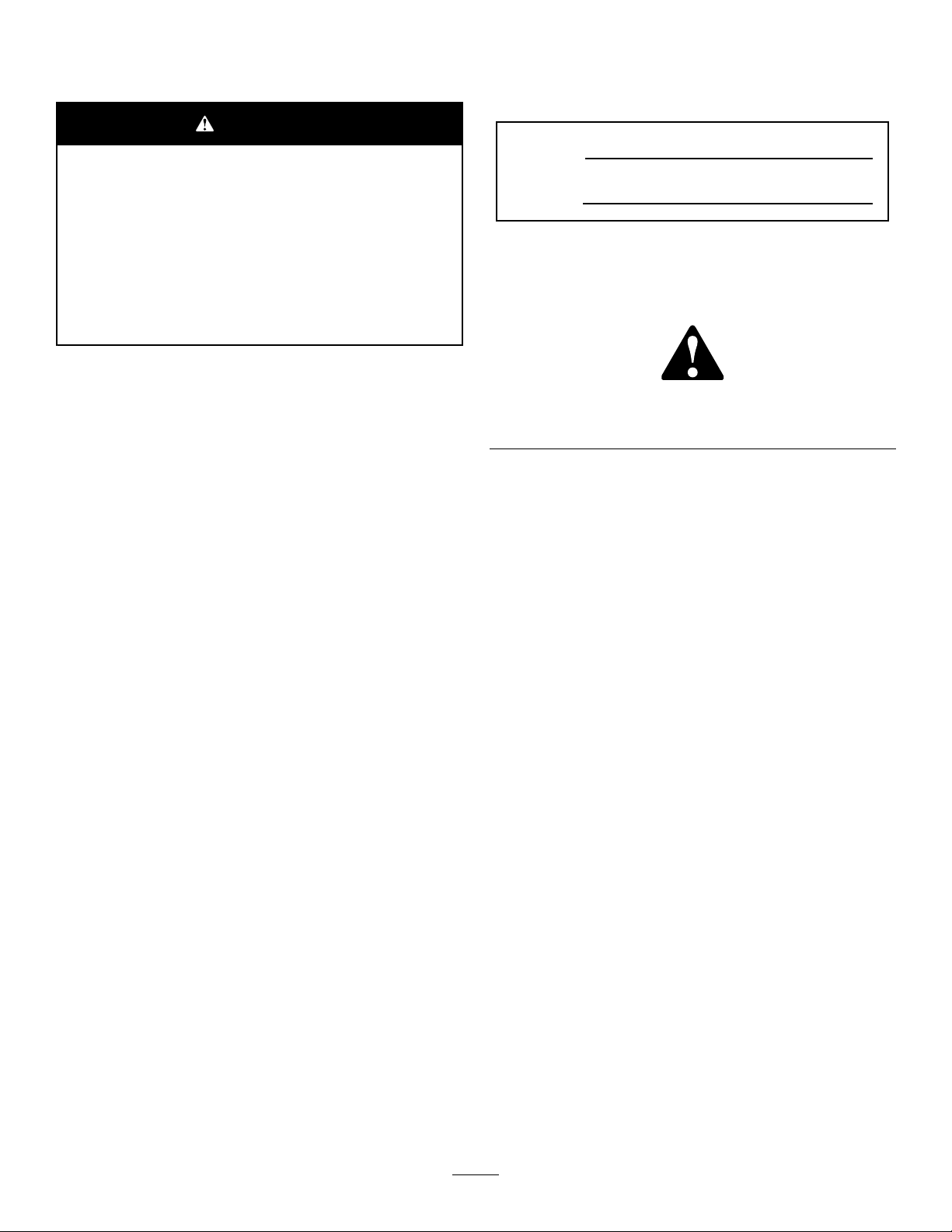

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

115-7355

1.Warning—toxicgas

inhalationhazard;do

notusethemachine

indoors.

2.Explosionhazard;stopthe

engineandextinguishall

ameswhenfueling.

3.Warning;stoptheengine

andturnofftheignition

beforeleavingthemachine

orfueling.

4.Warning;disconnectthe

sparkplugwireandread

theinstructionsbefore

servicingorperforming

maintenance.

5.Hotsurface;donottouch.

93-9356

1.Entanglementhazard—stayawayfrommovingparts.

93-6085

1.Fast

2.Continuousvariable

setting

3.Slow

93-8064

1.Warning—readtheinstructionsbeforeservicingor

performingmaintenance.

2.Cuttinghazardoffootorhand—stoptheengineandwait

formovingpartstostop.

1.Reeldrive3.Disengage

2.Engage

93-7346

8

Page 9

115-1614

1.Warning—readtheOperator'sManual.3.Thrownobjecthazard—keepbystandersasafedistancefrom

2.Warning—donotoperatethemachineunlessyouaretrained.

themachine.

4.Warning—stayawayfrommovingparts;keepallguardsin

place.

115-1720

1.Forward3.Neutral

2.Drivewheel

117–2718

120-2727

1.Brake—toengage,pullthe

levertowardthehandle;

todisengage,releasethe

lever.

2.Parkingbrake—tolock,

pullthelevertowardthe

handle,pressthebutton

inandreleasethelever

againstthelockingbutton;

torelease,pullthelever

towardthehandleuntil

thebuttonreleasesand

releasethelever ..

106-8120

1.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine.

2.Cuttinghazardofhandandfoot—stayawayfrommoving

parts.

9

Page 10

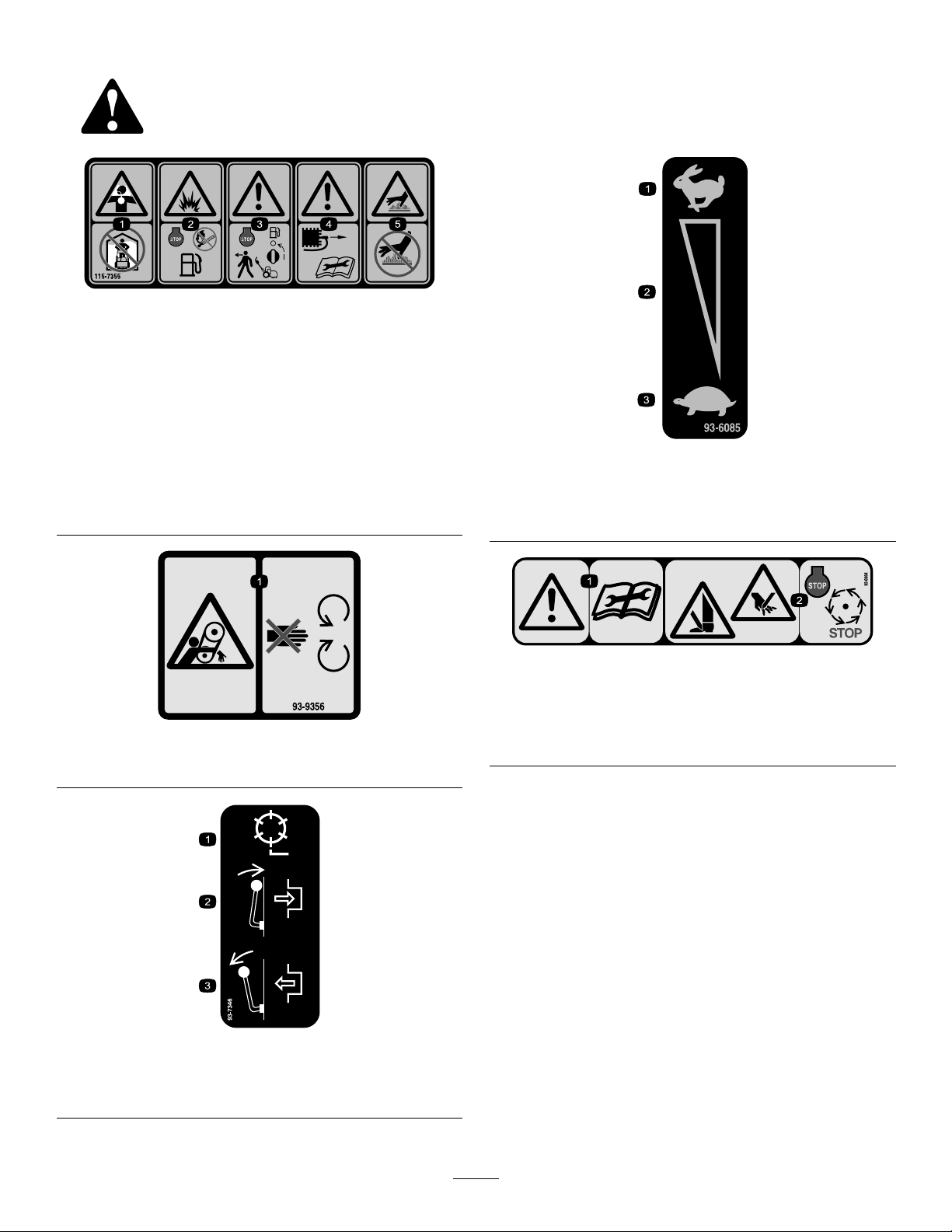

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

6

7

MediaandAdditionalParts

Description

Operator'sManual

EngineOperator'sManual

PartsCatalog

OperatorTrainingMaterial

CerticateofCompliance

Handle1

Cabletie

Kickstandassembly1

Spring

Wheelshaft,right

Wheelshaft,left

Transportwheels(optional)

Nopartsrequired

Grassbasket

High-altitudekit,partnumber117-0073

(acquireseparatelyasneeded)

Qty.

1

1

1

1

1

Readorviewbeforeoperatingthemachine

Qty.

2

1

1

1

2

–

1Installthegrassbasket.

1

Installthehandle.

Installthekickstand.

Installthetransportwheelshafts.

Installthetransportwheels(optional).

Adjustthecuttingunit.

Installthehigh-altitudekit(optional).

Use

Use

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

1

InstallingandAdjustingthe Handle

Partsneededforthisprocedure:

1Handle

2

Cabletie

InstallingtheHandle

1.Removetheboltsandlocknutssecuringthebottomof

thehandlearmstoeachsideofthemower(Figure2).

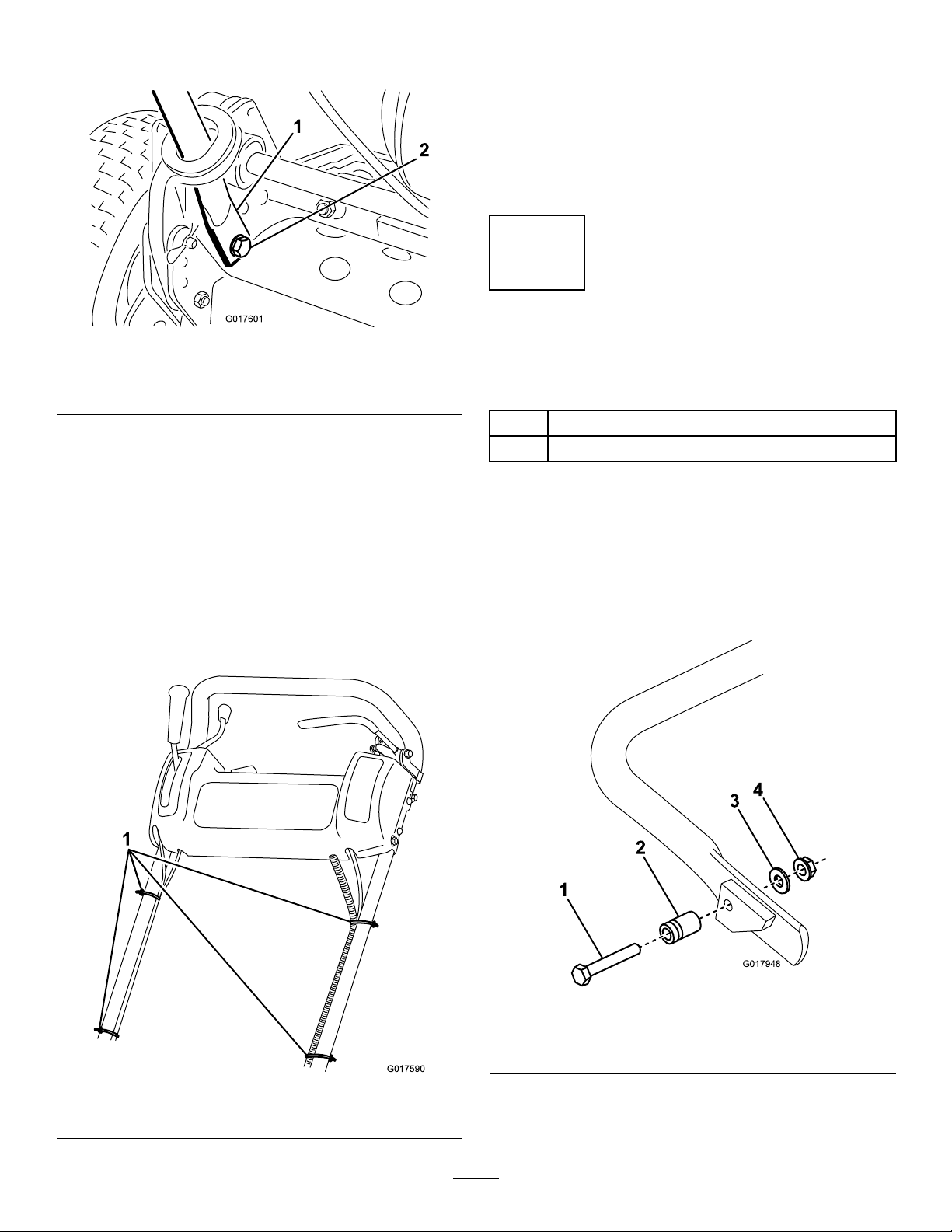

Figure2

1.Mountingpins3.Boltandlocknut

2.Handlearms4.Hairpincotterandringpin

2.Removethehairpincottersandringpinssecuringthe

handlearmstotherearoftheframe(Figure2).

3.Insertthehandleendsthroughtheholesinthehandle

armsandaligntheholeswiththemountingpins

(Figure2).

10

Page 11

4.Squeezethehandleendsinwardandinstallthemonthe

2

G017601

G017590

1

G017948

1

2

3

4

mountingpins(Figure3).

Figure3

1.Handleend

2.Bolt,washer,andlockwasher

AdjustingtheHandle

1.Removethehairpincottersfromtheringpinsoneach

sideofthemower(Figure2).

2.Whilesupportingthehandle,removetheringpins

fromeachsideandraiseorlowerthehandletothe

desiredoperatingposition(Figure2).

3.Installtheringpinsandhairpincotters.

2

InstallingtheKickstand(For GR800andGR1600)

Partsneededforthisprocedure:

5.Securethehandleendstothemountingpinswiththe

bolts,washers,andlockwashersprovided(Figure3).

6.Securethebottomofthehandlearmstoeachside

ofthemowerwiththeboltsandlocknutspreviously

removed(Figure3).Ensurethatyouinstallthe

bushingsinthehandlearmmountingholes.

7.Securethehandlearmstotherearoftheframewith

thehairpincottersandringpinspreviouslyremoved

(Figure3).

8.Securethecablesandwireharnesstothehandlewith

cableties(Figure4).

1Kickstandassembly

1

Spring

Procedure

Note:Thefastenersareshippedlooselyinstalledonthe

kickstandassembly .

1.OntheGR1600only,connectthespringstudtothe

righthandsideofthekickstand(Figure5)usingthe

bolt,washer,andange-headnutprovided.

1.Cableties

Figure4

1.Bolt3.Washer

2.Springstud

2.Hookthespringintotheholeinthespringbracketand

ontothespringstudwhilealigningthekickstandwith

themountingholesintherearframe(Figure6).

11

Figure5

4.Flange-headnut

Page 12

Figure6

Figure7

1.Kickstand

2.Springbracket4.Spring

3.Mountthekickstandtoeachsideoftheframewitha

bolt,lockwasher,spacer,atwasherandlocknut(Figure

6).Positionthespacerinthekickstandmountinghole.

3.Springstud

3

InstallingtheTransportWheel Shafts(ForGR1000and GR1600)

Partsneededforthisprocedure:

1

Wheelshaft,right

1

Wheelshaft,left

Procedure

1.Pushthekickstanddownwithyourfootandpullup

onthehandletosupportthemoweronthekickstand.

1.Rightwheelshaft

4.Torquetheshaftto88to101N-m(65to75ft-lb).

5.Repeatontheleftside.

4

InstallingtheTransport Wheels(Optional)

Partsneededforthisprocedure:

2

Transportwheels(optional)

Procedure

1.Slidethewheelontotheaxle(Figure8).

2.Pivotthewheellockingclipawayfromcenterofthe

wheelallowingittoslidefartherontotheaxle(Figure

8).

2.Apply#242Loctitetothethreadsofthewheelshafts.

3.Threadtherightwheelshaftintothedrivepulleyon

therightsideofthemachine(Figure7).

Note:Therightwheelshafthaslefthandthreads.

12

Page 13

G017591

Figure8

1.Lockingclip

3.Rotatethewheelbackandforthuntilitslides

completelyontotheaxleandthelockingclipissecured

inthegrooveontheaxleshaft.

4.Repeattheprocedureontheoppositesideofthe

machine.

5.Inatethetiresto574to718Pa(12to15psi.).

6

InstallingtheGrassBasket

Partsneededforthisprocedure:

1

Grassbasket

Procedure

Graspthebasketbythetoplipandslideitontothebasket

mountingrods(Figure9).

Figure9

1.Grassbasket

2.Basketmountingrod

5

AdjustingtheCuttingUnit

NoPartsRequired

Procedure

Beforeoperatingthemachine,completethefollowing

adjustments:

•LevelingtheRearDrumtotheReel(page31).

•AdjustingtheBedknifetotheReel(page32).

•AdjustingtheHeightofCut(page33).

•AdjustingtheGrassShieldHeight(page34).

•AdjustingtheCut-OffBar(page34).

RefertotheCuttingUnitMaintenancesectioninMaintenance

forinstructionsonperformingtheseprocedures.

Note:Model04056only—Whencuttinginhigher

heights-of-cut,thebasketmaybeloweredbyremovingeach

basketmountingrodandinstallingeachontheoppositeside

ofthemachine.

7

InstallingtheHigh-AltitudeKit (Optional)

Partsneededforthisprocedure:

High-altitudekit,partnumber117-0073(acquire

1

separatelyasneeded)

Procedure

Ifyouwillbeusingthemachineataltitudesabove1500

m(5000ft),obtainandinstalltheHigh-AltitudeKit,part

number117-0073.

13

Page 14

ProductOverview

1

2

3

4

5

6

7

G017592

G016976

G016977

Controls

Figure11

ParkingBrake

Figure10

1.Tractiondrivelever

2.Throttlecontrol6.Parkingbrake

3.On/offswitch7.Operatorpresencecontrol

4.Hourmeter

5.Servicebrake

(optional)

ThrottleControl

Thethrottlecontrol(Figure10)islocatedontherearright

sideofthecontrolpanel.Theleverconnectstoandoperates

thethrottlelinkagetothecarburetor.SeeSpecications(page

15)forenginespeed.

TractionDriveLever

Thetractiondrivelever(Figure10)islocatedonthefront

rightsideofthecontrolpanel.Ithastwopositions:Neutral

andForward.Pushingtheleverforwardengagesthetraction

drive.

Theparkingbrake(Figure12)islocatedatthebaseofthe

servicebrake.Fullyengagetheservicebrakeandpushthe

parkingbrakeknobtoallowtheservicebraketorestonthe

parkingbrakepin.Engagetheservicebraketoreleasethe

parkingbrake.Youmustreleasethebrakebeforethetraction

driveisengaged.

Figure12

ServiceBrake

Theservicebrake(Figure11)islocatedonthetopleftfront

sideofthecontrolpanel.Youcanusethebraketoslowor

stopthemachine.

On/OffSwitch

Theon/offswitch(Figure10)islocatedonthetopofthe

controlpanel.MovetheswitchtotheOnpositiontostartthe

engineandtheOffpositiontostoptheengine.

OperatorPresenceControl(Optional)

Ifequipped,theoperatorpresencecontrol(Figure10)is

locatedontherearofthehandle.Pushtheoperatorpresence

controlagainstthehandle.Ifequipped,theoperatorpresence

controlmustbeengagedbeforemovingthetractiondrive

leverortheenginewillstop.

14

Page 15

ReelDriveLever

G016978

1

1

g024364

2

RecoilStarter

Thereeldrivelever(Figure13)islocatedontherightfront

cornerofthemachine.Theleverhastwopositions:Engage

andDisengage.Movetheleverforwardtoengagethereelor

rearwardtodisengagethereel.

Figure13

1.Reeldrivelever

ChokeLever

Pulltherecoilstarterhandle(Figure15)tostarttheengine.

Figure15

1.Recoilstarter2.Kickstand

Kickstand

Thekickstand(Figure15)ismountedtotherearofthe

machineandisusedtoraisetherearofthemachinefor

installationorremovalofthetransportwheels.

Thechokelever(Figure14)islocatedontheleftfrontofthe

engine.Theleverhastwopositions:RunandChoke.Move

thelevertotheChokepositionwhenstartingacoldengine.

Aftertheenginestarts,movethelevertotheRunposition.

Figure14

1.Chokelever2.Fuelshut-offvalve

FuelShut-OffValve

Thefuelshut-offvalve(Figure14)islocatedontheleft

frontoftheenginenearthechokelever.Thevalvehastwo

Specications

Width

Height

Lengthwith

basket

Dryweight

(withbasket

andWiehle

roller;without

wheelsor

grooming

reel)

Widthofcut46cm(18

Heightofcut

Clip3.3mm(0.13

EnginespeedLowidle

Model04054Model04055Model04056

84cm(33

inches)

114cm(45

inches)

122cm(48

inches)

97kg(216lb)100kg(220

inches)

1.6mmto

31.8mm

(0.063to1.25

inches)

inches)

–1565±150

RPM,High

idle–3375

±100RPM

91cm(36

inches)

114cm(45

inches)

122cm(48

inches)

lb)

53cm(21

inches)

1.6mmto

31.8mm

(0.063to1.25

inches)

4.3mm(0.17

inch)

Lowidle

–1565±150

RPM,High

idle–3375

±100RPM

104cm(41

inches)

122cm(48

inches)

150cm(59

inches)

105kg(232

lb)

66cm(26

inches)

3.1mmto

31.7mm

(0.125to1.25

inches)

5.8mm(0.23

inch)

Lowidle

–1565±150

RPM,High

idle–3375

±100RPM

positions:ClosedandOpen.Movetheleveruptotheclosed

positionwhenstoringortransportingthemachine.Openthe

valvebeforestartingtheenginebyrotatingtheleverdown.

15

Page 16

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesis

availableforusewiththemachinetoenhanceandexpand

itscapabilities.ContactyourAuthorizedServiceDealeror

Distributororgotowww .Toro.comforalistofallapproved

attachmentsandaccessories.

Operation

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

ThinkSafetyFirst

Pleasecarefullyreadallofthesafetyinstructionsanddecals

inthesafetysection.Knowingthisinformationcouldhelp

youorbystandersavoidinjury.

CheckingtheEngineOilLevel

Checktheengineoillevelbeforeeachuseorevery8operating

hours,refertoCheckingtheEngineOilLevel(page23)in

EngineMaintenance(page23).

FillingtheFuelTank

Note:Thefueltankcapacityis2.7liters(2-3/4quarts).

•Forbestresults,useonlyclean,fresh(lessthan30days

old),unleadedgasolinewithanoctaneratingof87or

higher((R+M)/2ratingmethod).

•Ethanol:Gasolinewithupto10%ethanol(gasohol)

or15%MTBE(methyltertiarybutylether)byvolume

isacceptable.EthanolandMTBEarenotthesame.

Gasolinewith15%ethanol(E15)byvolumeisnot

approvedforuse.Neverusegasolinethatcontains

morethan10%ethanolbyvolume,suchasE15

(contains15%ethanol),E20(contains20%ethanol),or

E85(containsupto85%ethanol).Usingunapproved

gasolinemaycauseperformanceproblemsand/orengine

damagewhichmaynotbecoveredunderwarranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuelcontainers

overthewinterunlessafuelstabilizerisused.

•Donotaddoiltogasoline.

16

Page 17

DANGER

G017594

1

WARNING

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupanygasoline

thatspills.

•Neverllthefueltankinsideanenclosedtrailer.

•Donotllthefueltankcompletelyfull.Add

gasolinetothefueltankuntilthelevelis6to13

mm(1/4to1/2inch)belowthebottomofthe

llerneck.Thisemptyspaceinthetankallows

gasolinetoexpand.

•Neversmokewhenhandlinggasoline,andstay

awayfromanopenameorwheregasoline

fumesmaybeignitedbyaspark.

•Storegasolineinanapprovedcontainerand

keepitoutofthereachofchildren.Neverbuy

morethana30-daysupplyofgasoline.

•Donotoperatewithoutentireexhaustsystemin

placeandinproperworkingcondition.

Gasolineisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgastankor

conditionerbottleopening.

•Avoidcontactwithskin;washoffspillagewith

soapandwater.

1.Cleanaroundthefueltankcapandremovethecap

fromthetank(Figure16).

Figure16

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingasparkwhich

canignitethegasolinevapors.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Alwaysplacegasolinecontainersontheground

awayfromyourvehiclebeforelling.

•Donotllgasolinecontainersinsideavehicleor

onatruckortrailerbedbecauseinteriorcarpets

orplastictruckbedlinersmayinsulatethe

containerandslowthelossofanystaticcharge.

•Whenpractical,removegas-poweredequipment

fromthetruckortrailerandrefueltheequipment

withitswheelsontheground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfromaportable

container,ratherthanfromagasolinedispenser

nozzle.

•Ifagasolinedispensernozzlemustbeused,

keepthenozzleincontactwiththerimofthe

fueltankorcontaineropeningatalltimesuntil

fuelingiscomplete.

1.Fueltankcap

2.Usingunleadedgasoline,llthefueltanknohigher

thanthebottomofthelterscreen.Thisspaceallows

thegasolinetoexpand.Donotllthefueltank

completelyfull.

3.Installfueltankcapandwipeupanyspilledgasoline.

Break-inPeriod

RefertotheEngineManualsuppliedwiththemachineforoil

changeandmaintenanceproceduresrecommendedduring

thebreak-inperiod.

Only8hoursofmowingoperationisrequiredforthebreak-in

period.

Sincethersthoursofoperationarecriticaltofuture

dependabilityofthemachine,monitoritsfunctionsand

performancecloselysothatminordifculties,whichcould

leadtomajorproblems,arenotedandcanbecorrected.

Inspectthemachinefrequentlyduringbreak-inforsignsof

oilleakage,loosefasteners,oranyothermalfunction.

Toensureoptimumperformanceofthebrakesystem,burnish

(break-in)thebrakesbeforeusingthemachine.Toburnish

thebrakes,rmlyapplythebrakesanddrivethemachineat

mowingspeeduntilthebrakesarehot,asindicatedbytheir

smell.Anadjustmenttothebrakesmayberequiredafter

17

Page 18

break-in;refertoAdjustingtheService/ParkingBrake(page

26).

CheckingtheInterlockSwitch Operation

CAUTION

Ifsafetyinterlockswitchesaredisconnectedor

damagedthemachinecouldoperateunexpectedly

causingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlockswitches

dailyandreplaceanydamagedswitchesbefore

operatingthemachine.

1.Pushthekickstanddownwithyourfootandpullup

andbackonthehandletoraisethewheelsoffofthe

ground.

2.PlacethetractionleverintotheEngagepositionand

theenginecontrolsinthestartingposition.

3.Attempttostarttheengine.

Theengineshouldnotstart.Iftheenginestarts,the

interlockswitchneedsservice.Correcttheproblem

beforeoperating.RefertoServicingtheInterlock

Switch(page26).

4.Carefullyliftuponthehandletoreleasethekickstand.

DailyAdjustmentsofthe

Figure17

Note:Ifexcessivecontact/reeldragisevidentitwill

beeithernecessarytobacklap,refacethefrontofthe

bedknife,orregrindthecuttingunittoachievethe

sharpedgesneededforprecisioncutting(Refertothe

ToroManualforSharpeningReelandRotaryMowers,

FormNo.09168SL).

Important:Lightcontactispreferredatalltimes.If

youdonotmaintainlightcontact,thebedknifeandreel

edgeswillnotsufcientlyself-sharpenandwilldullafter

aperiodofoperation.Ifyoumaintainexcessivecontact,

thebedknifeandreelwillwearquicker,wearunevenly,

andthequalityofcutmaybeadverselyaffected.

Note:Afterextendedrunning,aridgewilleventually

developatbothendsofthebedknife.Roundofforlethese

notchesushwiththecuttingedgeofthebedknifetoensure

smoothoperation.

CuttingUnit

Priortomowingeachday,orasrequired,checkeachcutting

unittoverifyproperbedknife-to-reelcontact.Thismustbe

performedeventhoughqualityofcutisacceptable.

1.Lowerthecuttingunitsontoahardsurface,shutoff

theengine,andremovetheignitionkey .

2.Slowlyrotatethereelinareversedirection,listening

forreel-to-bedknifecontact.

Note:Theadjustmentknobshavedetents

correspondingto0.018mm(0.0007inch)bedknife

movementforeachindexedposition.Referto

AdjustingtheBedknifetotheReel.

3.Testthecuttingperformancebyinsertingalongstrip

ofcuttingperformancepaper(T oropartnumber

125-5610)betweenreelandbedknife,perpendicular

tothebedknife(Figure17).Slowlyrotatethereel

forward;itshouldcutthepaper.

StartingandStoppingthe Engine

Note:Forillustrationsanddescriptionsofthecontrols

referencedinthissection,refertotheControls(page14)

sectioninProductOverview(page14).

StartingtheEngine

Note:Ensurethatthesparkplugwireisinstalledonthe

sparkplug.

1.Ensurethatthetractionandreeldriveleversareinthe

Disengagedposition.

Note:Theenginewillnotstartifthetractionleveris

intheEngagedposition.

2.Openthefuelshut-offvalveontheengine.

3.Movetheon/offswitchtotheOnposition.

4.MovethethrottlecontroltotheFastposition.

18

Page 19

5.MovethechokeleverhalfwaybetweentheOnandOff

positionswhenstartingacoldengine.Thechokemay

notberequiredwhenstartingawarmengine.

6.Pulltherecoilstarterhandleoutuntilpositive

engagementresults,thenpullitvigorouslytostartthe

engine.

Important:Donotpullrecoilropetoitslimitor

letgoofstarterhandlewhenropeispulledout

becauseropemaybreakorrecoilassemblymay

bedamaged.

7.MovethechoketotheOffpositionastheengine

warmsup.

3.Slidethewheelsoffoftheshafts.

4.Movetheunitoffofthekickstand.

Mowing

Properuseofthemachineprovidesthesmoothestturf

cuttingavailable.ReferalsotoOperatingTips(page19)for

fundamentalsuggestionstoobtaintheutmostperformance

fromyourmower.

Important:Excessiveoperationofthecuttingunitwith

theabsenceofgrassclippings(lubricant)candamage

thecuttingunit.

StoppingtheEngine

1.Movethetractionandreeldrivecontrolstothe

Disengagedposition,thethrottlecontroltotheSlow

position,andtheOn/OffswitchtotheOffposition.

2.Pullthesparkplugwireoffofthesparkplugtoprevent

thepossibilityofaccidentalstartingbeforestoringthe

machine.

3.Closethefuelshut-offvalvebeforestoringor

transportingthemowerinavehicle.

DrivingtheMachinein Transport

1.Ifthemachineisequippedwiththeoptionaltransport

wheels,pushthekickstanddownwithyourfootand

pulluponthehandletoraisetherearofthemower

andinstallthetransportwheels.

2.Toreleasethekickstand,pulluponthehandle,push

themowerforward,andthenlowertherearofthe

mowerontothetransportwheels.

3.Ensurethatthetractionandreeldrivecontrolsarein

theDisengagedpositionandstarttheengine.

4.SetthethrottlecontroltoSlow ,raisethefrontofthe

machineupslightly ,graduallyengagethetractiondrive

andslowlyincreasetheenginespeed.

5.Adjustthethrottletooperatethemoweratthedesired

groundspeedandtransportthemowertothedesired

destination.

6.ReturnthetractioncontrollevertotheDisengage

position,thethrottletotheSlowposition,andstop

theengine.

1.Starttheengine,setthethrottleatareducedspeed,

pushdownonthehandletoraisethecuttingunit,

movethetractionlevertotheEngagedposition,and

transportthemowerontothecollarofthegreen.

2.MovethetractionlevertotheDisengagedpositionand

movethereeldrivelevertotheEngagedposition.

3.MovethetractionlevertotheEngagedposition,

increasethethrottlespeeduntilthemoweristraveling

atthedesiredgroundspeed,drivethemowerontothe

green,lowerthefrontofthemower,andcommence

operation.

4.Whennishedmowing,driveoffofthegreen,move

thetractioncontrollevertotheDisengageposition,

stoptheengineandpushthereeldriveleverintothe

Disengageposition.

5.Emptythegrassbasketofclippings,installthegrass

basket,andcommencetransportoperation.

OperatingTips

BeforeMowing

•Ensurethatthemoweriscarefullyadjustedandisset

evenlyonbothsidesofthereel.Impropermower

adjustmentismagniedmanytimesoverinthe

appearanceoftheclippedturf.

•Removeallforeignobjectsfromtheturfpriortomowing.

•Ensurethateveryone,especiallychildrenandpets,are

clearoftheworkarea.

MowingTechniques

PreparingtoMow

1.Ifthemachineisequippedwiththeoptionaltransport

wheels,pushthekickstanddownwithyourfootand

pullupandbackonthehandletoraisethewheelsoff

oftheground.

2.Pushthelockingclipsonthewheelsoutofthegrooves

intheshafts.

•Mowagreeninastraightbackandforthdirection,across

thegreen.

•Avoidcircularmowingorturningthemoweronagreen

becausescufngmayoccur.Turnthemoweroffofthe

greenbyraisingthecuttingreel(pushingthehandle

down)andturningonthetractiondrum.

•Mowatanormalwalkingpace.Fastspeedsavesvery

littletimeandwillresultinaninferiormowingjob.

19

Page 20

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

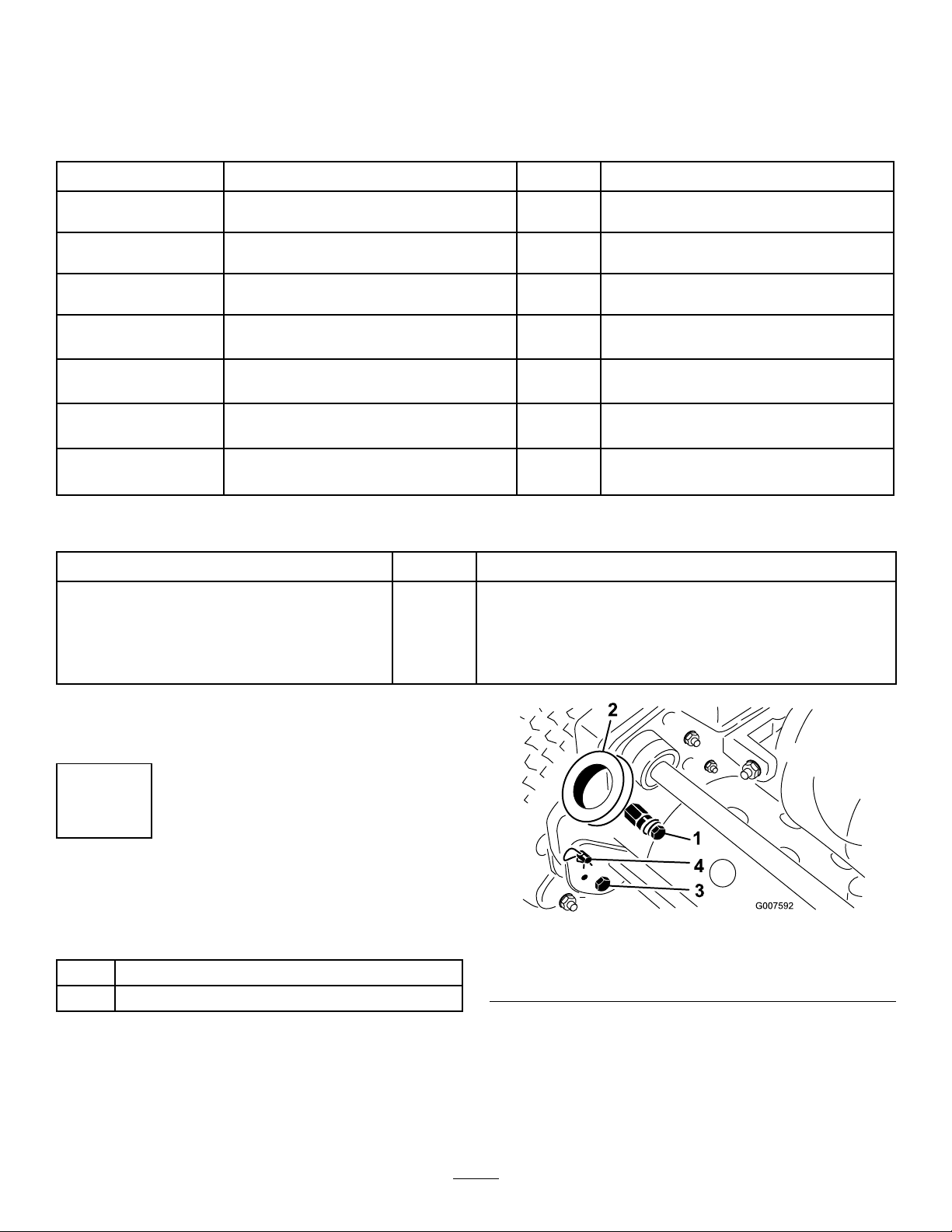

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst20hours

Beforeeachuseordaily

Every25hours

Every50hours

Every100hours

Every500hours

Every1,000hours

Important:Refertoyour

MaintenanceProcedure

•Changetheengineoil.

•Cleanthefuellterandcup.

•Checktheinterlockswitchoperation.

•Checktheengineoillevel.

•Greasethemachine.(Greasethettingsimmediatelyaftereverywashing

regardlessoftheintervallisted.)

•Changetheengineoil.(Morefrequentlyindustyordirtyconditions)

•Cleanandoiltheaircleanerfoamelement.(Moreoftenindirtyordustyconditions)

•Replacethepaperairlterelement.(Moreoftenindirtyordustyconditions)

•Checkthesparkplug.

•Cleanthefuellterandcup.

•Checkintakeandexhaustvalves.Adjustasnecessary.

•Cleanthecarburetor.

•replacethefuelline.

•Checkthetransmissiondrivebelts.

•Checkthetransmissionbearings.

Engine Operator's Man ual

foradditionalmaintenanceprocedures.

20

Page 21

DailyMaintenanceChecklist

Important:Duplicatethispageforroutineuse.

Maintenance

CheckItem

Checkthe

safetyinterlock

operation.

Checkthe

parkingbrake

operation.

Checkthefuel

level.

Checktheengine

oillevel.

Checktheair

lter.

Cleantheengine

coolingns.

Checkfor

unusualengine

noises.

Checkfor

unusual

operatingnoises.

Checkthe

reel-to-bedknife

adjustment.

Checkthe

height-of-cut

adjustment.

Greaseall

ttings.

Touchup

damagedpaint.

Fortheweekof:

Mon.Tues.Wed.Thurs.Fri.

Sat.Sun.

NotationforAreasofConcern

Inspectionperformedby:

ItemDate

Information

21

Page 22

Lubrication

G016993

G016981

G016982

GreasingtheMachine

ServiceInterval:Every25hours

Lubricatethe13greasettingsonthemowerusingaNo.2

multipurposelithiumbasegrease.Ahandoperatedgrease

gunisrecommendedforbestresults.

Thegreasettinglocationsareasfollows:

•2onthefrontroller(Figure18)

•2onthereelbearings(Figure18)

•2onthedrumaxles(Figure19)

•3onthedifferential(Figure19)

•2onthereelcountershaftbearings(Figure20)

•2onthebeltidlerpivots(Figure21).

1.Wipeeachgreasettingwithacleanrag.

2.Pumpgreaseintoeachttinguntilitbeginstoget

difculttopumpthegun.

Important:Donotapplytoomuchpressureor

greasesealswillbecomepermanentlydamaged.

3.Wipeoffanyexcessgrease.

Figure20

Figure21

Figure18

Figure19

22

Page 23

EngineMaintenance

G016983

1

ServicingtheEngineOil

ServiceInterval:Aftertherst20hours—Changethe

engineoil.

Beforeeachuseordaily—Checktheengineoillevel.

Every50hours—Changetheengineoil.(More

frequentlyindustyordirtyconditions)

Thecrankcasemustbelledwithapproximately21uid

ouncesofproperviscosityoilbeforestaring.Theengine

usesanyhigh-qualityoilhavingtheAmericanPetroleum

Institute-APl-“serviceclassication"SF,SG,SHorSJ.Oil

viscosity-weight-mustbeselectedaccordingtoambient

temperature.Figure22illustratesthetemperature/viscosity

recommendations.

Figure23

1.Oillevelgauge

2.Removetheoillevelgaugebyrotatingit

counterclockwise.

3.Wipetheoillevelgaugecleanandinsertitintotheller

port.Donotscrewitintotheport.

2.Drainplug

Figure22

Note:Usingmulti-gradeoils(5W-20,10W -30,and10W -40)

willincreaseoilconsumption.Checktheoillevelmore

frequentlywhenusingthem.

CheckingtheEngineOilLevel

1.Positionthemowersothattheengineislevelandclean

aroundtheoillevelgauge(Figure23).

4.Removethegaugeandchecktheleveloftheoil.

5.Ifthelevelislow,addonlyenoughoiltoraisethelevel

untilitisbetweenthehatchmarksonthegauge(Figure

24).Donotoverll.

Figure24

1.Hatchmarks

6.Installtheoillevelgaugeandwipeupanyspilledoil.

ChangingtheEngineOil

1.Startandruntheengineforafewminutestowarm

theengineoil.

2.Placeadrainpanattherearofmachine,underthe

drainplug(Figure23).

3.Removethedrainplug.

4.Pushdownonthehandletotipthemowerandthe

enginebackward,allowingmoreoiltorunintothe

drainpan.

23

Page 24

5.Installthedrainplugandrellthecrankcasewiththe

1

G016984

G016985

1

2

3

4

5

G016986

1

properoil;refertoCheckingtheEngineOilLevel

(page16).

ServicingtheAirCleaner

ServiceInterval:Every50hours—Cleanandoiltheair

cleanerfoamelement.(Moreoftenin

dirtyordustyconditions)

Every100hours—Replacethepaperairlterelement.

(Moreoftenindirtyordustyconditions)

Important:Servicetheaircleanermoreoftenindirty

ordustyconditions

1.Makesurethewireisoffofthesparkplug.

2.Removethewingnutsecuringtheaircleanercoverand

removethecover(Figure25).

Figure26

1.Wingnut4.Foamelement

2.Aircleanercover5.Paperelement

3.Plasticwingnut

5.Checktheconditionofthepaperelement.Cleanitby

gentlytappingorreplaceitasrequired.

Important:Donotusecompressedairtoclean

thepaperelement.

6.Installthefoamelement,paperelement,andaircleaner

cover.

Figure25

1.Aircleanercover

Important:Donotoperatetheenginewithoutthe

aircleanerelementbecauseextremeenginewear

anddamagewilllikelyresult.

3.Cleanthecoverthoroughly.

4.Ifthefoamelementisdirty ,removeitfromthepaper

element(Figure26)andcleanitthoroughly,asfollows:

A.Washthefoamelementinasolutionofliquid

soapandwarmwater.Squeezeittoremovedirt,

ReplacingtheSparkPlug

ServiceInterval:Every100hours

UseanNGKBR6HSsparkplugorequivalent.Thecorrect

airgapis0.6-0.7mm(0.024-0.028inches).

butdonottwistitbecausethefoammaytear.

1.Pullthemoldedwireoffofthesparkplug(Figure27).

B.Drythefoamelementbywrappingitinaclean

rag.Squeezetheragandfoamelementtodryit,

butdonottwistit.

C.Saturatethefoamelementwithcleanengineoil.

Squeezetheelementtoremoveexcessoilandto

distributetheoilthoroughly.Anoildampelement

isdesirable.

1.Sparkplugwire

Figure27

24

Page 25

2.Cleanaroundthesparkplugandremoveitfromthe

4

G016987

G016988

1

2

cylinderhead.

FuelSystem

Important:Replaceacracked,fouled,ordirty

sparkplug.Donotsandblast,scrape,orclean

electrodesbecauseenginedamagecouldresult

fromgritenteringthecylinder.

3.Ensurethattheairgapiscorrect(Figure28).

Figure28

4.Installthecorrectlygappedsparkplugandtightenitto

23N-m(17ft.-lb).

5.Installthesparkplugwireonthesparkplug.

Maintenance

CleaningtheFuelFilter

ServiceInterval:Aftertherst20hours

Every100hours

1.Closethefuelshut–offvalveandunscrewthebowl

fromthelterbody(Figure29).

Figure29

1.Bowl

2.Cleanthebowlandlterincleangasolineandinstallit.

2.Fuelshut–offvalve

25

Page 26

ElectricalSystem

G016989

1

2

3

4

G016990

Maintenance

BrakeMaintenance

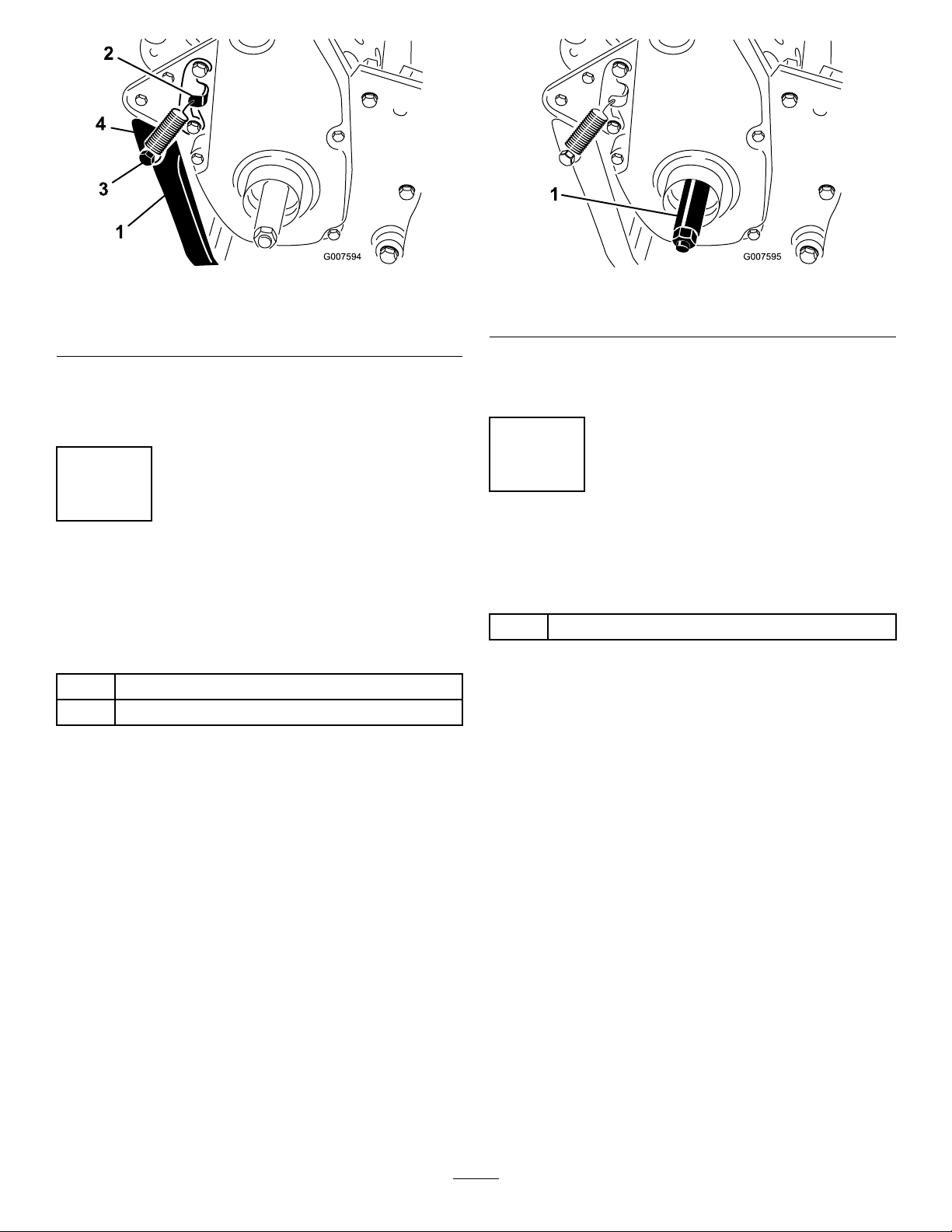

AdjustingtheService/Parking

ServicingtheInterlockSwitch

Usethefollowingprocedureiftheswitchneedsadjustment

orreplacement.

1.Makesuretheengineisoffandthetractionleveris

disengagedandrestingagainsttheneutralstop(Figure

30).

Brake

Iftheservice/parkingbrakeslipswhenoperated,an

adjustmentisrequired.

1.Engagetheservicebrake,pushinontheparkingbrake

knobandallowtheservicebraketorestontheparking

brakepin(Figure31)

Figure30

1.Tractionlever3.Interlockswitch

2.Neutralstop

2.Loosentheinterlockswitchmountingfasteners(Figure

30).

3.Placea.032"thickshimbetweenthetractionleverand

theinterlockswitch(Figure30).

4.Tightentheinterlockswitchmountingfasteners.

Recheckthegap.Thetractionlevermustnotcontact

theswitch.

5.Engagethetractionleverandverifythattheswitch

losescontinuity.Replaceifrequired.

4..032"Gap

Figure31

2.Usingaspringscale,pressrearwardontheservice

brakelever(Figure32).Theparkingbrakeshould

releasewhenaforceof13.5to18kg(30to40lbs)is

attained.Iftheparkingbrakereleasesbefore13.5to18

kg(30to40lbs)offorceisattained,anadjustmentto

thebrakecableisrequired.Proceedtostep3.

26

Page 27

G016991

1

2

Figure34

Figure32

1.Rearpressureonservicebrakelever

3.LoosentheretainersecuringtheV-beltcoverandpivot

thecoveropen(Figure33).

Figure33

1.V–beltcover2.Retainer

1.Service/Parkingbrake

cable

2.Frontjamnut

5.Closethecoverandsecuretheretainer.

4.Toadjustthebrakecabletension,proceedasfollows.

•Todecreasethecabletension,loosenthefront

cablejamnutandtightentherearjamnut(Figure

34).Repeatsteps1and2andreadjustifrequired.

•Toincreasethecabletension,tightenthefront

cablejamnutandloosentherearjamnut(Figure

34).Repeatsteps1and2andreadjustifrequired.

Note:Theadjustmentcanbeperformedonthe

cableatthejamnutbracketsbythecontrolpanel

oratthebracketatthebaseoftheengine.

27

Page 28

BeltMaintenance

AdjustingtheBelts

Ensurethatthebeltsareproperlytensionedtoensureproper

operationofthemachineandunnecessarywear.Checkthe

beltsfrequently.

5.Whilemaintainingaslightgapbetweenthecoverseal

andthesideplate,installeachmountingboltuntilthe

threadsengageintheinsert.Thegapallowsvisual

alignmentoftheboltstothethreadedinserts.

6.Afterallboltsareinstalled,tightenthemuntilthe

stand-offsinsidethecovercontactthesideplate.Do

notovertighten.

AdjustingtheReelDriveBelt

1.Removethebeltcovermountingfastenersandbelt

covertoexposethebelt(Figure35).

Figure35

1.Beltcover

2.Checkthetensionbypressingthebeltatmidspanof

thepulleys(Figure36)with18–22N(4to5lbs)of

force.Thebeltshoulddeect6mm(1/4inch).

AdjustingtheTractionDriveBelt

1.Removethebeltcovermountingfastenersandthebelt

covertoexposethebelt(Figure37).

Figure37

1.Tractiondrivebeltcover

2.Checkthetensionbypressingthebeltatmidspanof

thepulleys(Figure38)with18–22N(4to5lbs)of

force.Thebeltshoulddeect6mm(1/4inch).

Figure36

1.Reeldrivebelt2.Idlerpulley

3.Completethefollowingtoadjustthebelttension:

A.Loosentheidlerpulleymountingnutandpivot

theidlerpulleyclockwiseagainstthebacksideof

thebeltuntilyouattainthedesiredbelttension

(Figure36).

Important:Donotovertensionthebelt.

B.Tightenthenuttolocktheadjustment.

4.Installthebeltcoverbyplacingitinposition.

Figure38

1.Tractiondrivebelt2.Idlerpulley

3.Completethefollowingtoadjustthebelttension:

A.Loosentheidlerpulleymountingnutandpivot

theidlerpulleyclockwiseagainstthebacksideof

thebeltuntilthedesiredbelttensionisattained

(Figure38).

Important:Donotovertensionthebelt.

B.Tightenthenuttolocktheadjustment.

4.Installthebeltcoverbyplacingitinposition.

28

Page 29

5.Whilemaintainingaslightgapbetweenthecoverseal

G016991

1

2

G016992

1

2

3

4

andthesideplate,installeachmountingboltuntilthe

threadsengageintheinsert.Thegapallowsvisual

alignmentoftheboltstothethreadedinserts.

6.Afterallboltsareinstalled,tightenthemuntilthe

stand-offsinsidethecovercontactthesideplate.Do

notovertighten.

AdjustingtheDifferentialBelt

1.Removetheboltssecuringthefrontandrearsections

ofthedifferentialcovertothedifferentialhousingand

slidethecoversectionsawaytoexposethebelt.

2.Checkthetensionbypressingthebeltatmidspan

ofthepulleys(Figure39)with22–26N(5to6lb)of

force.Thebeltshoulddeect6mm(1/4inch).

2.LoosentheretainersecuringtheV-beltcoverandpivot

thecoveropen(Figure40).

Figure40

1.V-beltcover2.Retainer

3.Toincreasebelttension,loosentheenginemounting

boltsandmovetheenginebackwardsintheslots.

Important:Donotovertensionthebelt.

4.Tightenthemountingbolts.

Note:Thedistancebetweenthecentersofthedriver

andthedrivenpulleysshouldbeapproximately12.85

cm(5.06inches)afternewV -beltsareinstalled.

5.AftertensioningtheprimaryV -belts,checkthe

alignmentoftheengineoutputshaftpulleyandthe

countershaftpulleywithastraightedge.

1.Differentialbelt

Figure39

2.Idlerpulley

6.Ifthepulleysaremisaligned,loosenthescrewssecuring

3.Completethefollowingtoadjustthebelttension:

A.Loosentheidlerpulleymountingnutandpivot

theidlerpulleyclockwiseagainstthebacksideof

theenginemountingbasetothemowerframeand

slidetheenginefromsidetosideuntilthepulleysare

alignedwithin0.07cm(0.030inch).

thebeltuntilthedesiredbelttensionisattained

(Figure39).

Important:Donotovertensionthebelt.

B.Tightenthenuttolocktheadjustment.

4.Installthebeltcoverbyplacingitinposition.

5.Whilemaintainingaslightgapbetweenthecoverseal

andthesideplate,installeachmountingboltuntilthe

threadsengageintheinsert.Thegapallowsvisual

alignmentoftheboltstothethreadedinserts.

6.Afterallboltsareinstalled,tightenthemuntilthe

stand-offsinsidethecovercontactthesideplate.Do

notovertighten.

AdjustingthePrimaryV-Belts

1.ToadjustthebelttensiononprimaryV -belts,rst

checktheadjustmentofthetractioncontrol.Referto

AdjustingtheTractionControl(page31).Ifyouare

unabletoattainthe18–22N(4to5lb)forcerequiredin

adjustingthetractioncontrol,proceedtothenextstep.

Figure41

1.Locknut3.Idlerpulley

2.Beltguide4.Idlerarm

7.Tightenthemountingscrewsandcheckthealignment.

29

Page 30

8.Topushorpullthemachineeasierwithoutstarting

theengine,adjustthebeltguide(Figure41,inset)as

follows:

A.Engagetheclutch.

B.Loosenthelocknutsecuringtheidlerpulleyand

beltguidetotheidlerarm.

C.Rotatethebeltguideclockwiseuntilagapof

approximately0.15cm(0.06inch)isobtained

betweentheguidengerandthebacksideofthe

drivebelts.

D.Tightenthelocknutsecuringtheidlerpulleyand

beltguidetotheidlerarm.

9.Closethecoverandsecuretheretainer.

ReplacingtheDifferentialBelt

1.Removetheboltssecuringthetractiondriveandreel

drivebeltcoverstotherightsideplateandremovethe

beltcovers.

2.Loosentheidlerpulleymountingnutoneachidler

pulleyandpivoteachidlerpulleycounterclockwise

awayfromthebacksideofeachbelttoreleasethebelt

tension.

3.Removethebelts.

4.Removetheboltssecuringthefrontandrearsections

ofthedifferentialcovertothedifferentialhousingand

slidethecoversectionsawaytoexposethebelt(Figure

42).

8.Removethe2boltsandlocknutssecuringtherightrear

bearinghousingtothesideplate(Figure42).

9.Rotatethehousing180°sothebottomofthehousing

pointsupward.Removetheoldbelt.

10.Slidethenewbeltovertherotatedhousingcovers,the

differentialcoversections,andontothedifferential

pulleys.

11.Ensurethattheidlerpulleyispositionedagainstthe

backsideofthebelt.

12.Rotatebothhousingsbackintotheuprightposition

andsecurethemtothesideplatewiththeboltsand

nutspreviouslyremoved.

13.Adjustthedifferentialbelttension;refertoAdjusting

theDifferentialBelt(page29).

14.Adjustthebelttensiononthetractiondriveandreel

drivebelts;refertoAdjustingtheTractionDriveBelt

(page28),andAdjustingtheReelDriveBelt(page28).

15.Installthedifferential,tractiondrive,andreeldrive

covers.

Figure42

1.Differentialcoversections

2.Frontclutchhousing

3.Rightrearbearinghousing

5.Loosentheidlerpulleymountingnutonthedifferential

idlerpulleyandpivottheidlerpulleycounterclockwise

awayfromthebacksideofthebelttoreleasethebelt

tension.

6.Removethe2boltsandlocknutssecuringthefront

clutchhousingtothesideplate(Figure42).

7.Rotatethehousing180°sothebottomofthehousing

pointsupward.

30

Page 31

ControlsSystem

Maintenance

CuttingUnitMaintenance

LevelingtheRearDrumtothe

AdjustingtheTractionControl

Ifthetractioncontroldoesnotengageoritslipsduring

operation,anadjustmentisrequired.

1.MovethetractioncontroltotheDisengagedposition.

2.LoosentheretainersecuringtheV-beltcoverandpivot

thecoveropen(Figure40).

3.Toincreasethecabletension,loosenthefrontcable

jamnutandtightenthebackcablejamnut(Figure

43)untilaforceof3to4kg(7to9lbs)isrequiredto

engagethetractioncontrol.Measuretheforceatthe

controlknob.

Reel

1.Positionthemachineonaat,levelsurface,preferably

aprecisionsteelworkplate.

2.Placea0.6x2.5cm(1/4x1inch)atsteelstrip,

approximately73.6cm(29inches)long,underthereel

bladesandagainstthefrontedgeofthebedknifeto

preventthebedbarfromrestingontheworksurface.

3.Raisethefrontrollersoonlythereardrumandreelare

onthesurface.

4.Firmlypressdownonthemachineabovethereelso

allreelbladescontactthesteelstrip.

5.Whilepressingdownonthereel,slideafeelergauge

underoneendofthedrum,thenchecktheotherend

ofthedrum.

Ifthereisagapbetweenthedrumandtheworksurface,

greaterthan.025cm(0.010inch),oneitherend,adjust

thedrum(proceedtostep6).Ifthegapislessthan

.025cm(0.010inch)noadjustmentisrequired.

6.Removetherearbeltcoverfromtherightsideofthe

machine(Figure44).

Figure43

1.Tractioncable2.Frontjamnut

4.Tightenthefrontcablejamnut.

5.Closethecoverandsecuretheretainer.

6.Checkthetractioncontroloperation.

Figure44

1.Tractiondrivebeltcover

7.Rotatethedrivenpulleyuntiltheholesalignwiththe4

rollerbearingangescrews(Figure45).

31

Page 32

Figure45

g026076

1

2

1.Drivenpulley3.IdlerPulley

2.4holes

Figure46

8.Loosenthe4rollerbearingscrewsandthescrew

securingtheidlerpulley.

9.Raiseorlowertherightsideoftherollerassemblyuntil

thegapislessthan.025cm(0.010inch).

10.Tightentherollerbearingscrews.

11.Adjustthebelttensionandtightentheidlerpulley

mountingscrew(Figure45).

AdjustingtheBedknifetothe Reel

Note:Usethisprocedureaftergrinding,backlapping,or

disassembly.Itisnotintendedasadailyadjustment.

1.Positionthecuttingunitonaat,levelworksurface.

2.Tiltthemowerbackonthehandletoexposethe

bedknifeandreel.

Note:Donottiltthemachinebackfurtherthan60

degreestopreventfuelleakage.

3.Rotatethereelsothatabladecrossesthebedknifeedge

betweentherstandsecondbedknifescrewheadson

therightsideofthecuttingunit.

4.Putanidentifyingmarkonthebladewhereit

crossesthebedknifeedge;thiswillmakesubsequent

adjustmentseasier.

1.Bedbaradjustingscrew2.Nut

7.Fortheleftsideofthecuttingunit,slowlyrotatethe

reelsothattheclosestbladecrossesthebedknifeedge

betweentherstandsecondscrewheads.

8.Repeatsteps4through6fortheleftsideofthecutting

unitandleftbedbaradjustingscrew.

9.Repeatsteps5and6untillightdragisachievedon

boththerightandleftsidesofthecuttingunitutilizing

thesamecontactpoints.

Thebedknifeisnowparalleltothereel.

10.Toobtainlightcontactbetweenthereelandbedknife,

turneachbedbaradjustingscrewclockwise3clicks.

Note:Eachclickturnedonthebedbaradjusting

screwmovesthebedknife0.018mm(0.0007inches).

Clockwiserotationmovesthebedknifeedgecloser

tothereelandcounterclockwiserotationmovethe

bedknifeedgeawayfromthereel.Donotovertighten

theadjustingscrews.

11.Testthecuttingperformancebyinsertingalongstrip

ofcuttingperformancepaper(T oropartnumber

125-5610)betweenthereelandbedknife,perpendicular

tothebedknife(Figure47).Slowlyrotatethereel

forward;itshouldcutpaper

5.Insertthe0.05mm(0.002inch)shimbetweenthe

markedbladeandthebedknifeedgeatthepointwhere

themarkedbladecrossesthebedknifeedge.

6.Turntherightbedbaradjustingscrewuntilyoufeel

lightpressure(i.e.drag)ontheshimbyslidingit

side-to-side.Removetheshim.

32

Page 33

Figure49

Figure47

Note:Ifexcessivecontact/reeldragisevidentitwill

beeithernecessarytobacklap,refacethefrontofthe

bedknife,orregrindthecuttingunittoachievethe

sharpedgesneededforprecisioncutting(Refertothe

ToroManualforSharpeningReelandRotaryMowers,

FormNo.09168SL).

AdjustingtheHeightofCut

1.Verifythattherearrollerislevelandthatthebedknife

toreelcontactiscorrect.Tipthemowerbackonthe

handletoexposethefrontandrearrollersandthe

bedknife.

2.Loosenthelocknutssecuringtheheight-of-cutarmsto

theheight-of-cutbrackets(Figure48).

1.Gaugebar

2.Heightadjustingscrew

3.Nut

4.Hookthescrewheadonthecuttingedgeofthe

bedknifeandresttherearendofthebarontherear

roller(Figure50).

Figure50

5.Rotatetheadjustingscrewuntiltherollercontactsthe

frontofthegaugebar.

Figure48

1.Height-of-cutarm

2.Height-of-cutbracket

3.Locknut

4.Adjustingscrew

3.Loosenthenutonthegaugebar(Figure49)andset

theadjustingscrewtothedesiredheight-of-cut.The

distancebetweenthebottomofthescrewheadandthe

faceofthebaristheheight-of-cut.

6.Adjustbothendsoftherolleruntiltheentirerolleris

paralleltothebedknife.

Important:Whensetproperly,therearandfront

rollerswillcontactthegaugebarandthescrew

willbesnugagainstthebedknife.Thisensures

theheight-of-cutisidenticalatbothendsofthe

bedknife.

7.Tightennutstolocktheadjustment.

Important:Toavoidscalpingonundulatingturf,

ensurethattherollersupportsarepositioned

rearward(therollerclosertothereel).

Note:Thefrontrollercanbeputinthreedifferent

positions(Figure51),dependingontheapplicationand

needsoftheuser.

•Usethefrontpositionwhenagroomerisinstalled.

•Usethemiddlepositionwithoutagroomer.

•Usethethirdpositioninextremelyundulatingturf

conditions.

33

Page 34

Figure51

AdjustingtheGrassShield

Figure53

1.Cut-offbar

2.Inserta0.15cm(0.060inch)feelergaugebetweenthe

topofthereelandthebarandtightenthescrews.

3.Ensurethatthebarandreelareequaldistancesapart

acrosstheentirereel.

Height

Adjusttheshieldtoensurepropergrassclippingdischarge

intothebasket.

1.Measurethedistancefromthetopofthefrontsupport

rodtothefrontlipoftheshieldateachendofthe

cuttingunit(Figure52).

Figure52

1.Supportrod2.Shield

2.Theheightoftheshieldfromthesupportrodfor

normalcuttingconditionsshouldbe10cm(4inches).

Loosentheboltsandnutssecuringeachendofthe

shieldtothesideplateandadjusttheshieldtothe

correctheight.

Note:Thebarisadjustabletocompensateforchanges

inturfconditions.Adjustthebarclosertothereel

whentheturfisextremelywet.Bycontrast,adjustthe

barfurtherawayfromthereelwhenturfconditionsare

dry.Thebarshouldbeparalleltothereeltoensure

optimumperformance.Adjustthebarwheneverthe

shieldheightisadjustedorwhenthereelissharpened

onareelgrinder.

3.Tightenthefasteners.

Note:Theshieldcanbeloweredfordrierconditions

(clippingsyovertopofthebasket)orraisedtoallow

forheavywetgrassconditions(clippingsbuildupon

therearofthebasket).

AdjustingtheCut-OffBar

Adjustthecut-offbartoensurethattheclippingsarecleanly

dischargedfromthereelarea.

1.Loosenthescrewssecuringthetopbar(Figure53)to

thecuttingunit.

34

Page 35

BedbarIdentication

Todetermineifthebedbarisstandardoraggressive,check

theleftbedbarmountingears.Ifthemountingearsare

roundeditisastandardbedbar.Ifthemountingearshavea

notchinthem,itisanaggressivebedbar(Figure54).

Figure54

1.Standardbedbar

2.Aggressivebedbar

35

Page 36

SettingtheMachinetoMatch TurfConditions

Usethefollowingtabletosetthemachinetomatchturf

conditions.

GreensmowerCuttingUnitSet-upMatrix

Bedbars:StandardandOptional

PartNumberDescriptionMowerAggressiveness

120-2682-03

112-9281-01

112-9279-03Aggressive

112-9280-01

110-9278-03Aggressive

Bedknives:StandardandOptional

PartNumberDescriptionMower

98-7261Microcut

117-1530EdgeMaxMicrocut

98-7260T ournament

117-1532EdgeMaxT ournament

110-2300ExtendedMicrocut

110-2301

93-4262Microcut

115-1880EdgeMaxMicrocut

93-4263T ournament

115-1881EdgeMaxT ournament

93-4264

112-9275Microcut

94-5885T ournament

104-2646

93-9015

107-8181

StandardGreensmaster800

StandardGreensmaster

StandardGreensmaster

Greensmaster8001.57–4.78mm(0.062–0.188

Greensmaster8001.57–4.78mm(0.062–0.188

Greensmaster8003.18–12.70mm(0.125–0.500

Greensmaster8003.18–12.70mm(0.125–0.500

Greensmaster8001.57–4.78mm(0.062–0.188

LowCutGreensmaster8004.78–25.40mm(0.188–1.000

LowCutGreensmaster

HighCutGreensmaster

LowCutGreensmaster

FairwayCutGreensmaster

Comments

Less

1000

Greensmaster

1000

1600

Greensmaster

1600

HeightofCutRangeComments

Greensmaster

1000

Greensmaster

1000

Greensmaster

1000

Greensmaster

1000

1000

Greensmaster

1600

Greensmaster

1600

1600

1600

1600

1.57–4.78mm(0.062–0.188

1.57–4.78mm(0.062–0.188

3.1–6mm(0.125–0.250

3.1–6mm(0.125–0.250

4.78–25.40mm(0.188–1.000

1.57–4.78mm(0.062–0.188

3.18–12.70mm(0.125–0.500

7.94–25.40mm(0.313–1.000

4.78–25.40mm(0.188–1.000

9.53–25.40mm(0.375–1.000

Less

More

Less

More

inches)

inches)

inches)

inches)

inches)

inches)

inches)

inches)

inches)

inches)

inches)

inches)

inches)

inches)

inches)

inches)

StandardGreensmaster800

StandardGreensmaster1000

StandardGreensmaster1600

StandardGreensmaster800

LongerWearing

LessAggressive

StandardGreensmaster1000

LongerWearing

Tees

StandardGreensmaster1600

36

Page 37

Rollers:StandardandOptional

g014780

1

2

PartNumberDescriptionMower

99-6240NarrowWiehle

99-6241NarrowWiehle

88-6790WideWiehle

104-2642FullRoller

71-1550WiehleRoller

93-9045WiehleRoller

52-3590

93-9039NarrowWiehle

95-0930FullRoller

ClipKit

PartNumberDescriptionMower

65-9000

SwagedRollerGreensmaster

ClipKitGreensmaster1000

Diameter/MaterialComments

Greensmaster80050.8mm(2.0inches)

Greensmaster

1000

Greensmaster

1000

Greensmaster

1000

Greensmaster

1000

Greensmaster

1000

1000

Greensmaster

1600

Greensmaster

1600

&Greensmaster

1600

50.8mm(2.0inches)

50.8mm(2.0inches)

50.8mm(2.0inches)Steel

50.8mm(2.0inches)CastIron

63.5mm(2.5inches)

63.5mm(2.5inches)

63.5mm(2.5inches)

63.5mm(2.5inches)Steel

Greensmaster1000:Decreasesclipfrom4.06mm(0.16inch)

to6.35mm(0.25inch)forstandard11bladereel.

Greensmaster1600:Decreasesclipfrom5.84mm(0.23inch)

to8.64mm(0.34inch)forstandard8bladereel.

Aluminum

Aluminum

Aluminum

Aluminum

Aluminum

Aluminum

Standard,0.20inchSpacing

Standard,0.20inchSpacing

MorePenetration,0.43inch

Spacing

LeastPenetration

MorePenetration,0.43inch

Spacing

24inchesWideforEdge

Support

Standard

LeastPenetration

Comments

ServicingtheBedbar

RemovingtheBedbar

1.Turnthebedbaradjusterscrewcounterclockwiseto

backthebedknifeawayfromthereel(Figure55).

Figure55

1.Bedbaradjustingscrew3.Bedbar

2.Springtensionnut

2.Backoutthespringtensionnutuntilthewasherisno

longertensionedagainstthebedbar(Figure55).

3.Oneachsideofthemachineloosenthejamnut

securingthebedbarbolt(Figure56).

Figure56

1.Jamnut2.Bedbarbolt

4.Removeeachbedbarboltallowingthebedbartobe

pulleddownwardandremovedfromthemachine.Save

the2nylonand2stampedsteelwashersoneachend

ofthebedbar(Figure56).

InstallingtheBedbar

1.Installthebedbar,positioningthemountingears

betweenthewasherandthebedbaradjuster.

2.Securethebedbartoeachsideplatewiththebedbar

bolts(jamnutsonthebolts)and8washers.Positiona

37

Page 38

nylonwasheroneachsideofthesideplateboss.Place

asteelwasheroutsideeachofthenylonwashers.

Storage

3.Torquetheboltsto27to36N-m(240to320inch-lb).

4.Tightenthejamnutsuntiltheoutsidethrustwashers

justrotatefreely.

5.Tightenthespringtensionnutuntilthespringis

collapsed,thenbackitoff1/2turn.

6.Adjustthebedbar;refertoAdjustingtheBedknifeto

theReel(page32).

BacklappingtheReel

1.Removetheplugintherightreeldrivecover(Figure

57).

1.Removegrassclippings,dirt,andgrimefromthe

externalpartsoftheentiremachine,especiallythe

engine.Cleandirtandchafffromtheoutsideofthe

engine'scylinderheadnsandblowerhousing.

Important:Youcanwashthemachinewithmild

detergentandwater.Donotpressurewashthe

machine.Avoidexcessiveuseofwater,especially

neartheshiftleverplateandengine.

2.Forlong-termstorage(morethan90days)add

stabilizer/conditioneradditivetothefuelinthetank.

A.Runtheenginetodistributeconditionedfuel

throughthefuelsystem(5minutes).

B.Eitherstoptheengine,allowittocool,anddrain

thefueltank,oroperatetheengineuntilitstops.

C.Restarttheengineandrunituntilitstops.Repeat,

onChoke,untiltheenginewillnotrestart.

D.Disposeofthefuelproperly.Recycleasperlocal

codes.

Note:Donotstorestabilizer/conditioned

gasolineover90days.

Figure57

1.Coverplug

2.Inserta1/2inchsocketextension,connectedtothe

backlappingmachine,intothesquareholeinthecenter

ofthereelpulley.

3.BacklapaccordingtotheprocedureintheToro

SharpeningReelandRotaryMowersManual,FormNo.

80-300PT.

DANGER

Contactwiththereelorothermovingparts

canresultinpersonalinjury.

•Stayawayfromthereelwhilebacklapping.

•Neveruseashorthandledpaintbrushfor

backlapping.PartNo.29-9100Handle

assemblycompleteorindividualpartsare

availablefromyourlocalAuthorizedT oro

Distributor.

3.Checkandtightenallbolts,nuts,andscrews.Repairor

replaceanypartthatisdamagedordefective.

4.Paintallscratchedorbaremetalsurfaces.Paintis

availablefromyourAuthorizedServiceDealer.

5.Storethemachineinaclean,drygarageorstoragearea.

Coverthemachinetoprotectitandkeepitclean.

Note:Forabettercuttingedge,runaleacrossthe

frontfaceofthebedknifewhenthelappingoperation

iscompleted.Thiswillremoveanyburrsorrough

edgesthatmayhavebuiltuponthecuttingedge.

4.Installthepluginthecoverwhennished.

38

Page 39

Notes:

39

Page 40

TheToroTotalCoverageGuarantee

ALimitedWarranty

ConditionsandProductsCovered

TheToroCompanyanditsafliate,T oroWarrantyCompany,pursuant

toanagreementbetweenthem,jointlywarrantyourT oroCommercial

product(“Product”)tobefreefromdefectsinmaterialsorworkmanship

fortwoyearsor1500operationalhours*,whicheveroccursrst.This

warrantyisapplicabletoallproductswiththeexceptionofAerators

(refertoseparatewarrantystatementsfortheseproducts).Wherea

warrantableconditionexists,wewillrepairtheProductatnocosttoyou

includingdiagnostics,labor,parts,andtransportation.Thiswarranty

beginsonthedatetheProductisdeliveredtotheoriginalretailpurchaser.

*Productequippedwithanhourmeter.

InstructionsforObtainingWarrantyService

YouareresponsiblefornotifyingtheCommercialProductsDistributoror

AuthorizedCommercialProductsDealerfromwhomyoupurchasedthe

Productassoonasyoubelieveawarrantableconditionexists.Ifyouneed

helplocatingaCommercialProductsDistributororAuthorizedDealer,or

ifyouhavequestionsregardingyourwarrantyrightsorresponsibilities,

youmaycontactusat:

ToroCommercialProductsServiceDepartment

ToroWarrantyCompany

811 1LyndaleAvenueSouth

Bloomington,MN55420-1196

952–888–8801or800–952–2740

E-mail:commercial.warranty@toro.com

OwnerResponsibilities

AstheProductowner,youareresponsibleforrequiredmaintenanceand

adjustmentsstatedinyourOperator'sManual.Failuretoperformrequired

maintenanceandadjustmentscanbegroundsfordisallowingawarranty

claim.